Method for correcting online monitoring data of flue gas desulfurization device

A technology for monitoring data and desulfurization devices, which is applied in the field of flue gas desulfurization online monitoring data correction, can solve problems affecting desulfurization efficiency, emission concentration and emission volume, desulfurization efficiency of units, desulfurization electricity price subsidies and energy-saving scheduling, etc., to eliminate measurement deviations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

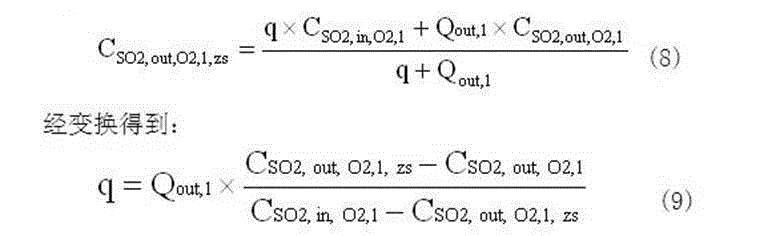

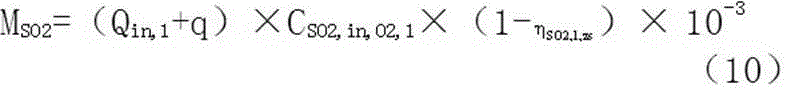

[0012] Embodiment 1: the data modification of the present invention is completed according to the following steps

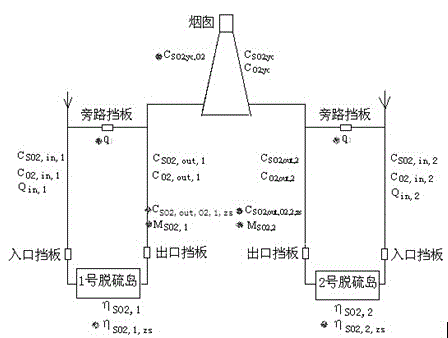

[0013] (1) Take the chimney flue gas monitoring point as the reference point

[0014] The reasons are: ①. The monitoring data of chimney flue gas monitoring points are the main basis for environmental protection authorities to manage pollution sources and control the total discharge of local pollutants. The monitoring point data has legal effect; ②. Chimney flue gas monitoring points are generally installed At the height of 80 meters, compared with the original flue and clean flue at the inlet and outlet of the desulfurization device, the internal flue gas flow field of this measuring point is more uniform, and the SO 2 The concentration distribution is more uniform, and the measurement results are more representative. Therefore, the SO on the chimney can be viewed 2 The monitoring value of the emission concentration is the standard value, and the standard da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com