Patents

Literature

403results about How to "Eliminate losses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

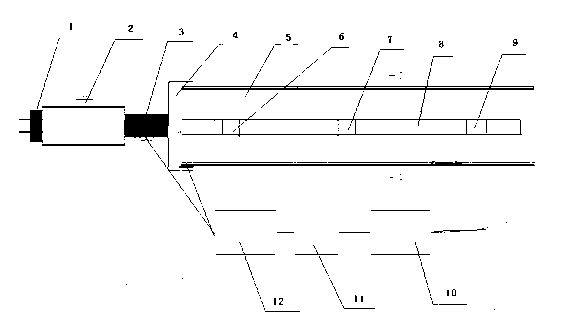

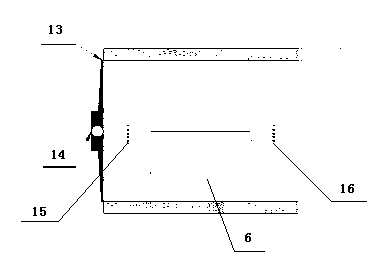

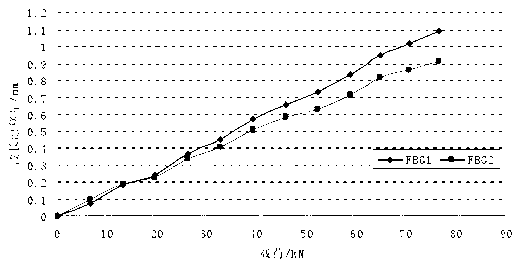

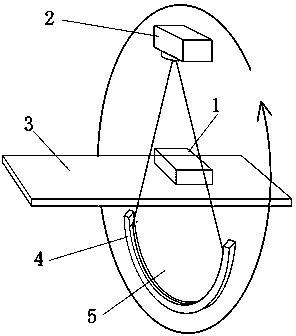

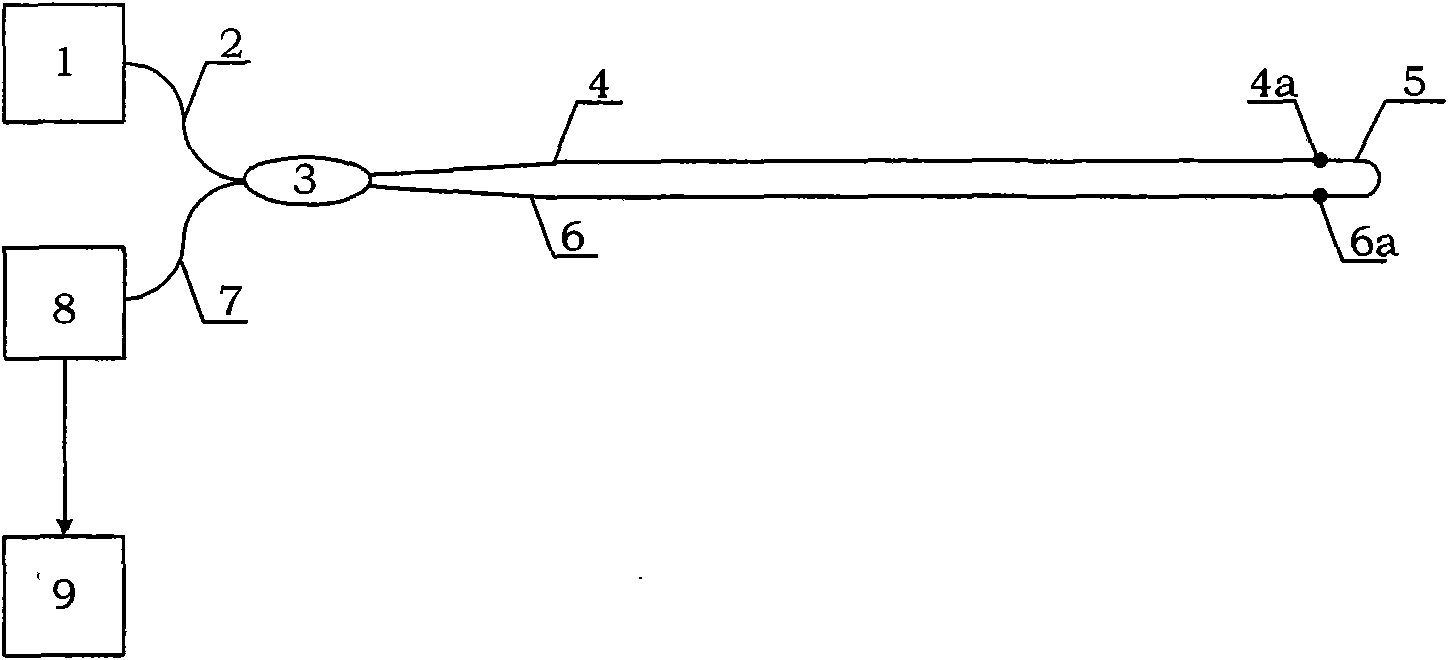

Fiber bragg grating detection system device and method for detecting anchoring force of anchor rod

InactiveCN102798492AEliminate strain effectsHigh precisionForce measurement by measuring optical property variationSensor arrayFiber

The invention discloses a fiber bragg grating detection system device and method for detecting an anchoring force of an anchor rod. The fiber bragg grating detection system device consists of a fiber bragg grating sensor array, a fiber bragg grating anchor rod dynamometer, a fiber bragg grating demodulator, an optical cable and a computer, wherein the fiber bragg grating anchor rod dynamometer mainly comprises a plurality of fiber bragg grating sensors which are uniformly arranged on an annular elastic body arm and is arranged at the end part of the anchoring end of the anchor rod; meanwhile, the fiber bragg grating sensor array is distributed on a rod body of the anchor rod; the fiber bragg grating sensor array and the fiber bragg grating anchor rod dynamometer are respectively connected with the fiber bragg grating demodulator through the optical cable; and the fiber bragg grating demodulator is connected with the computer. According to the fiber bragg grating detection system device, the real-time detection on the stress of the anchor rod can be realized and the distributed measurement can be realized. The fiber bragg grating detection system device has the advantages of simple structure, convenience in mounting, high detection speed, long-distance monitoring, repeated use and easiness in protection and maintenance, and is widely applied to tunnels and slopes dug for coal mines, metallurgical mines, water conservancy, railways, roads and defense.

Owner:XIAN UNIV OF SCI & TECH

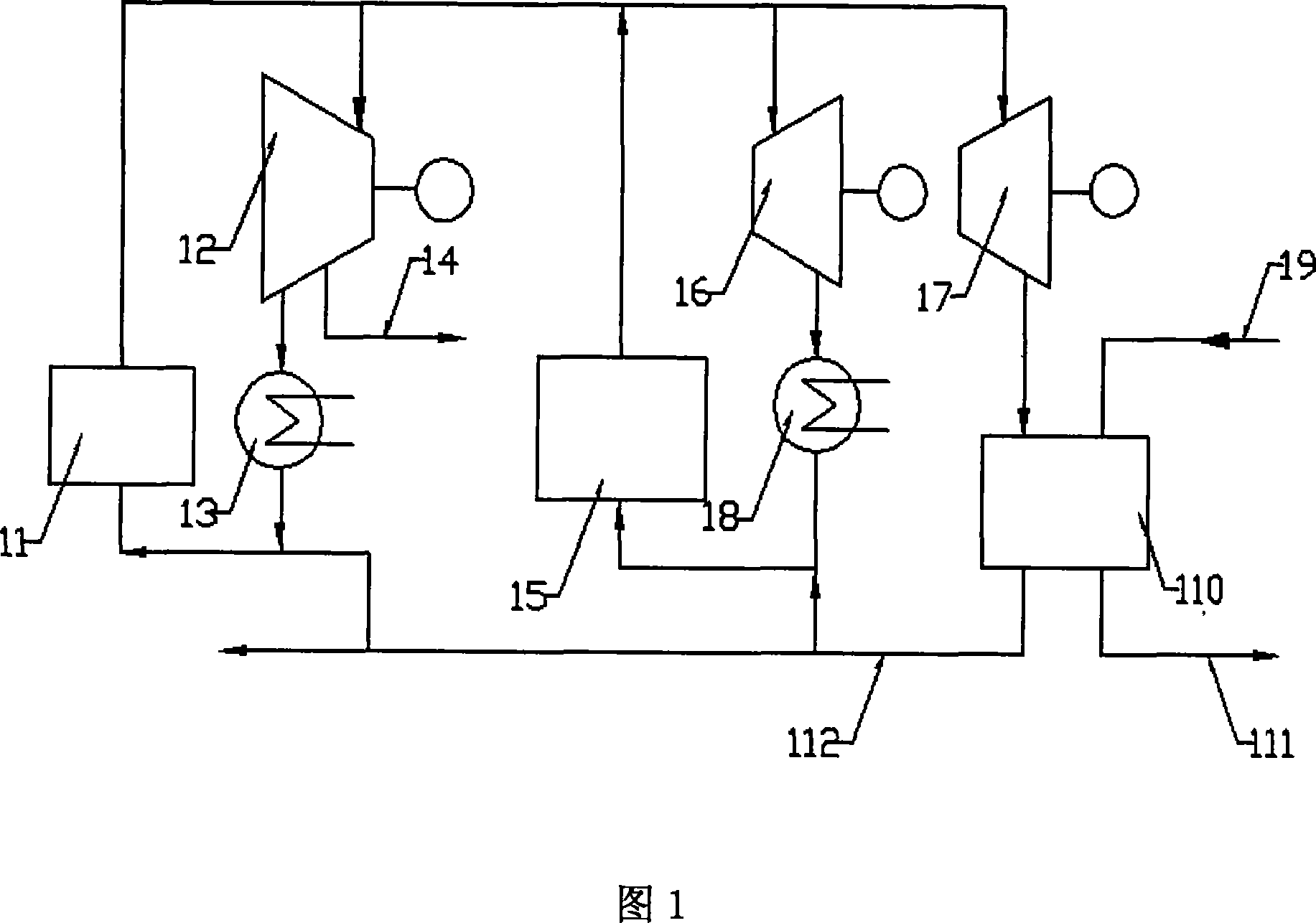

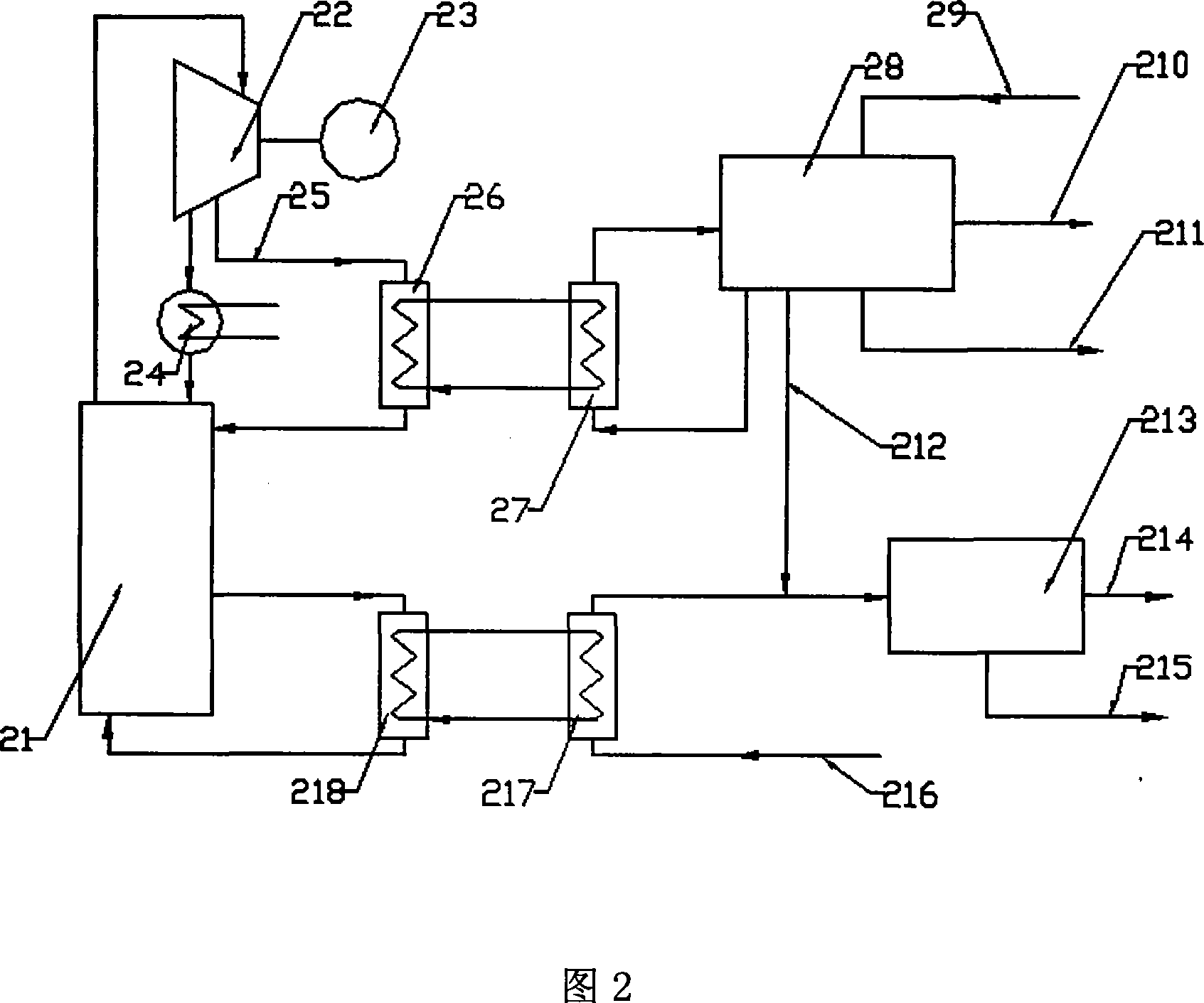

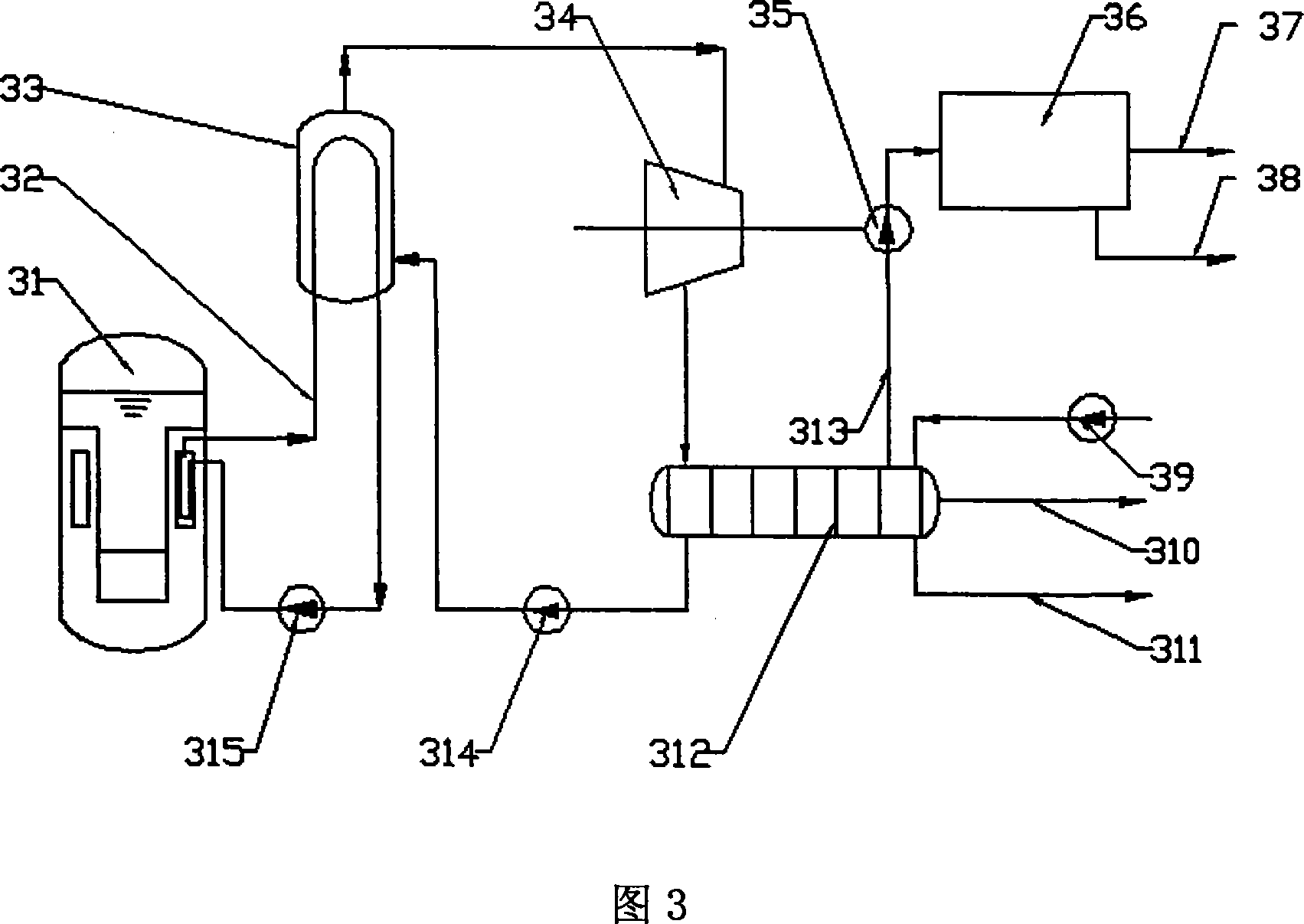

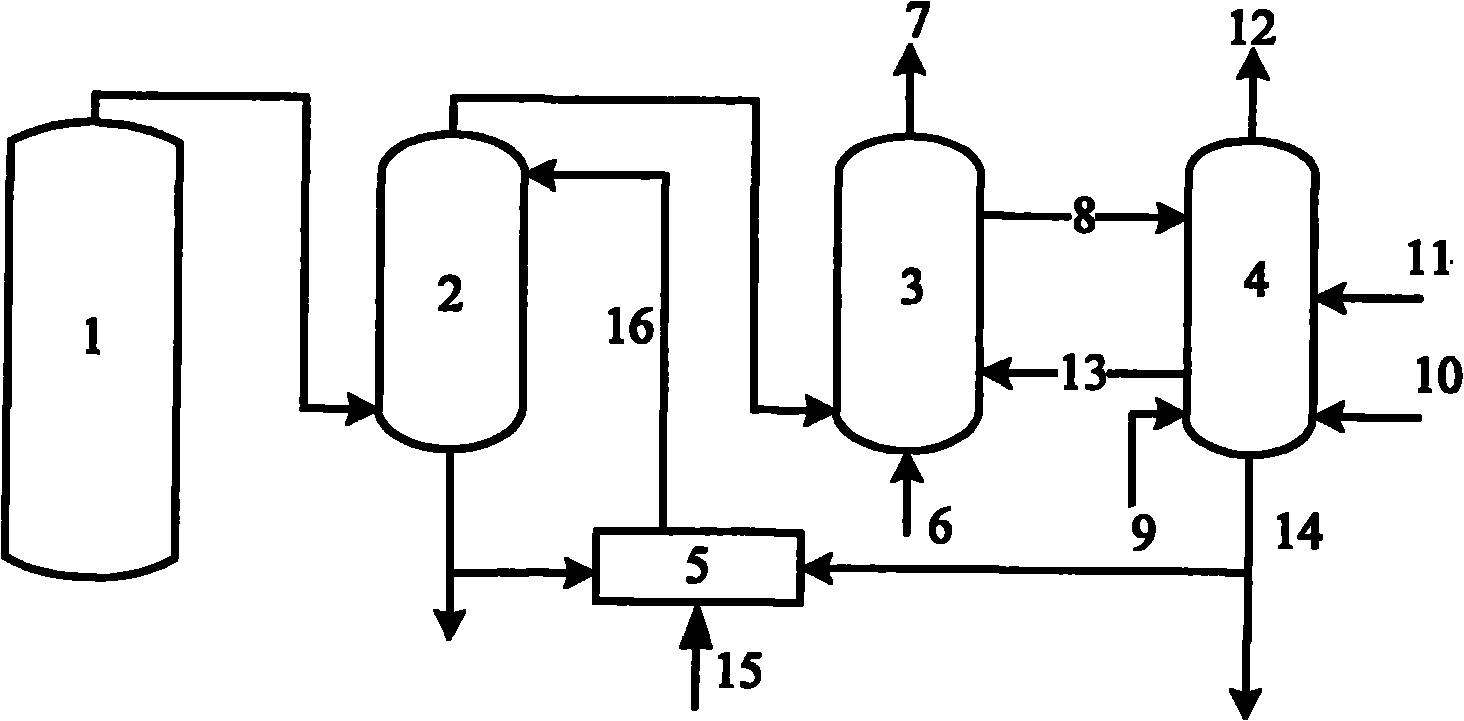

Coupling devices of using nuclear energy for sea water desalination, and method

ActiveCN101049999AEliminate lossesIncrease profitGeneral water supply conservationSeawater treatmentWater desalinationDistillation

This invention relates to coupling apparatus and method for desalting seawater by using nuclear energy. The apparatus comprises: a small-scale nuclear thermal reactor, a reverse osmosis seawater desalting system, a distillation seawater desalting system, and auxiliary apparatus. The method comprises: (1) transferring the heat generated from the small-scale nuclear thermal reactor to the steam generator, and driving the reverse osmosis high-pressure pump with the generated saturated steam in the turbine for seawater desalting; (2) introducing the saturated steam exhausted from the end stage of the turbine to the distillation seawater desalting system for seawater desalting; (3) returning the condensed water to the steam generator; (4) introducing seawater into the distillation seawater desalting system, cooling at the heat discharge section, sending to the reverse osmosis high-pressure pump, pressurizing, sending to the reverse osmosis seawater desalting system, storing the product water in a desalted water tank, and utilizing the condensed seawater or discharging into sea. The method has such advantages as advanced technology, high heat utility, high water productivity and high water quality.

Owner:CHINERGY CO LTD +1

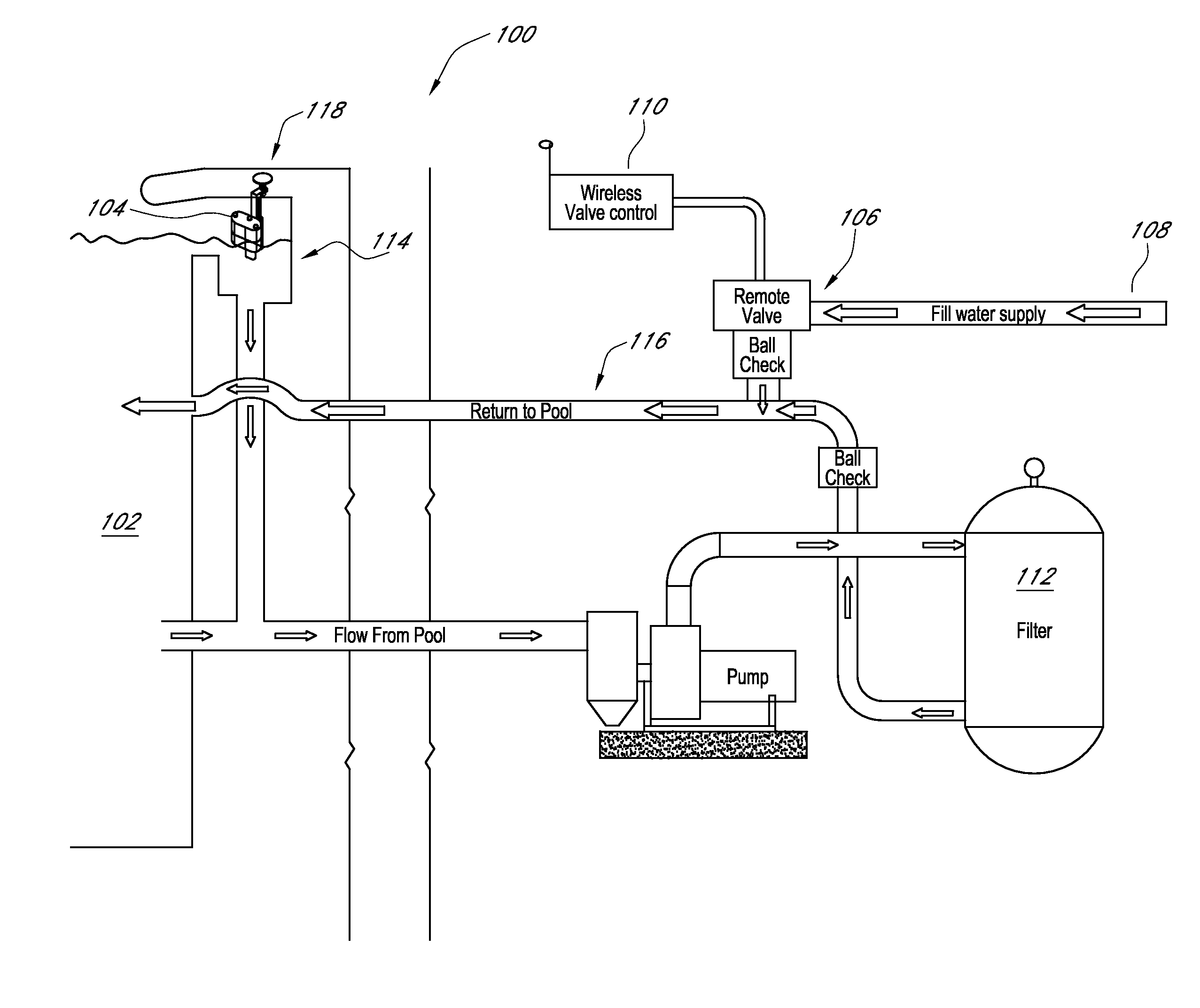

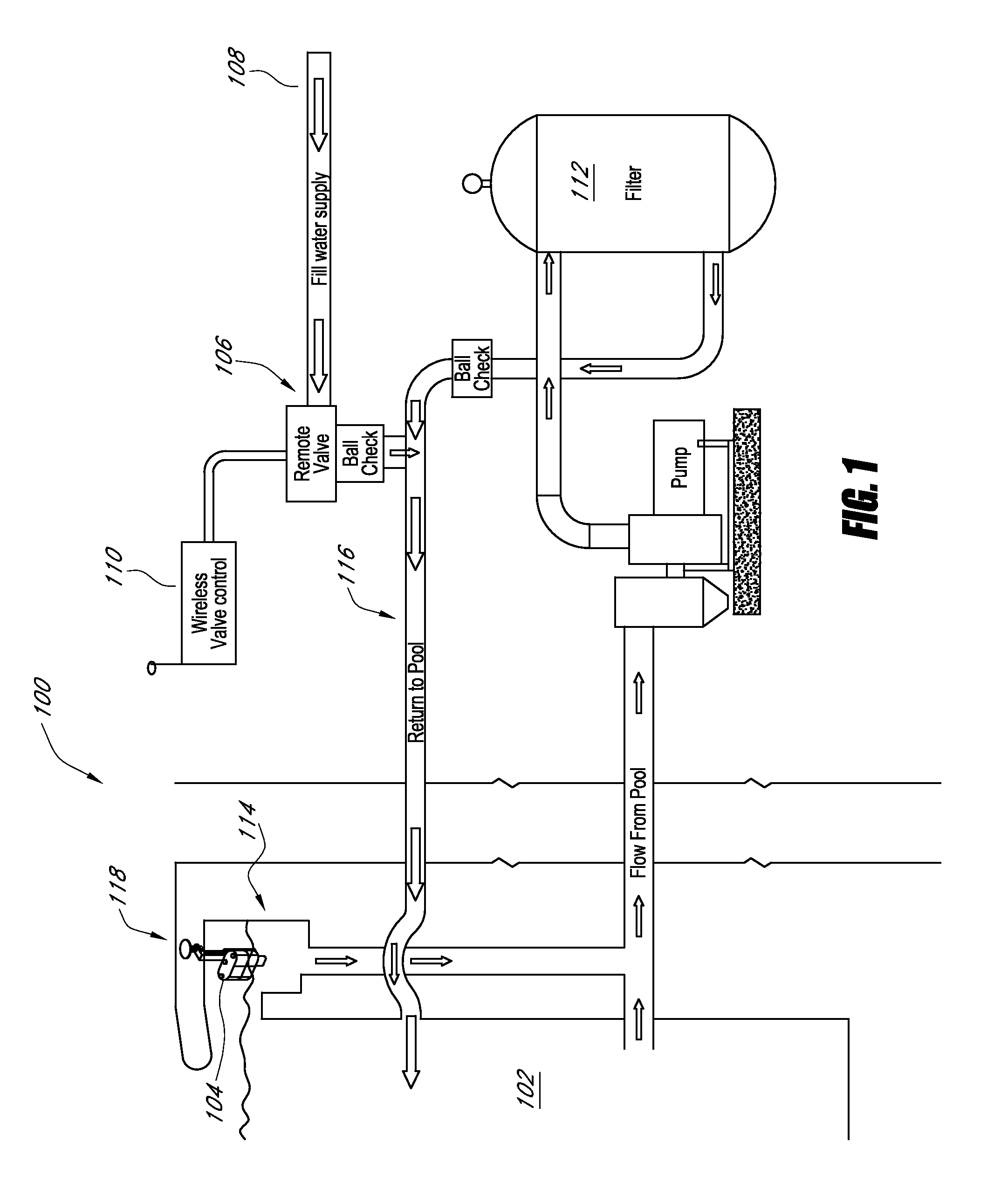

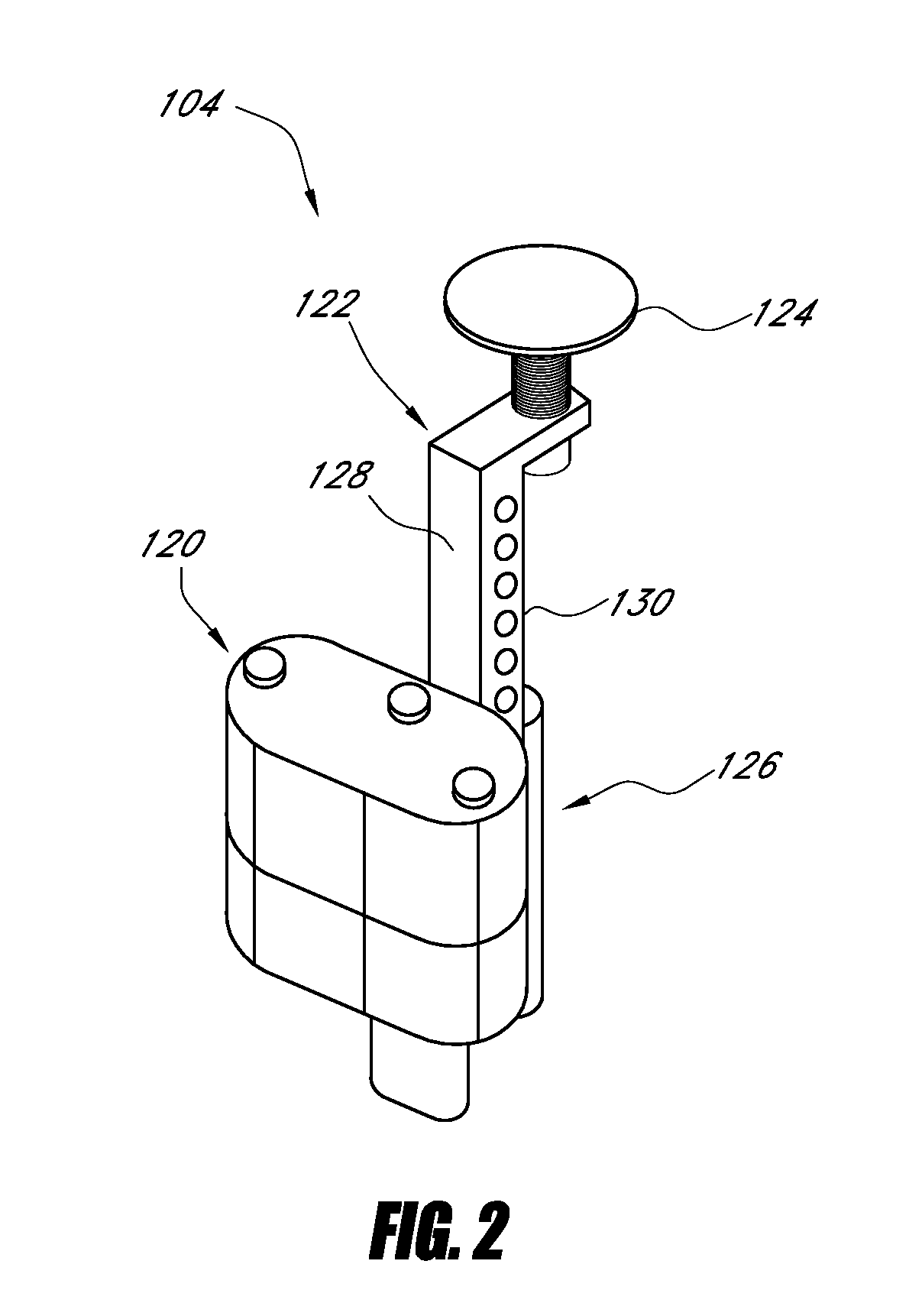

Automated system for monitoring and maintenance of fluid level in swimming pools and other contained bodies of water

ActiveUS20100300548A1Rapid assessmentRapid and accurate monitoring and maintenancePipeline systemsFluid-delivery valvesProximity sensorMarine engineering

An automated system for monitoring and maintaining fluid level in a swimming pool, spa, or other environment containing water is provided. The system includes a sensor assembly having a microprocessor and a proximity sensor encapsulated in a non-conductive material. A lower section of the sensor assembly has a flat profile and at least a portion of the proximity sensor is positioned in the lower section. The sensor assembly transmits a signal to a remote controller when the water level measured is above or below a predetermined target value. The remote controller in turn causes a remote water valve to turn on or off. In certain implementations, the sensor assembly incorporates a precision mounting system and algorithm, which work together to provide the end user with a means to mount the sensor easily and maintain precise operational level of the water. The combination of the physical mounting system and the range and resolution of the proximity sensor allow for precise maintenance of water level at the preferred level.

Owner:DEVERSE RICHARD

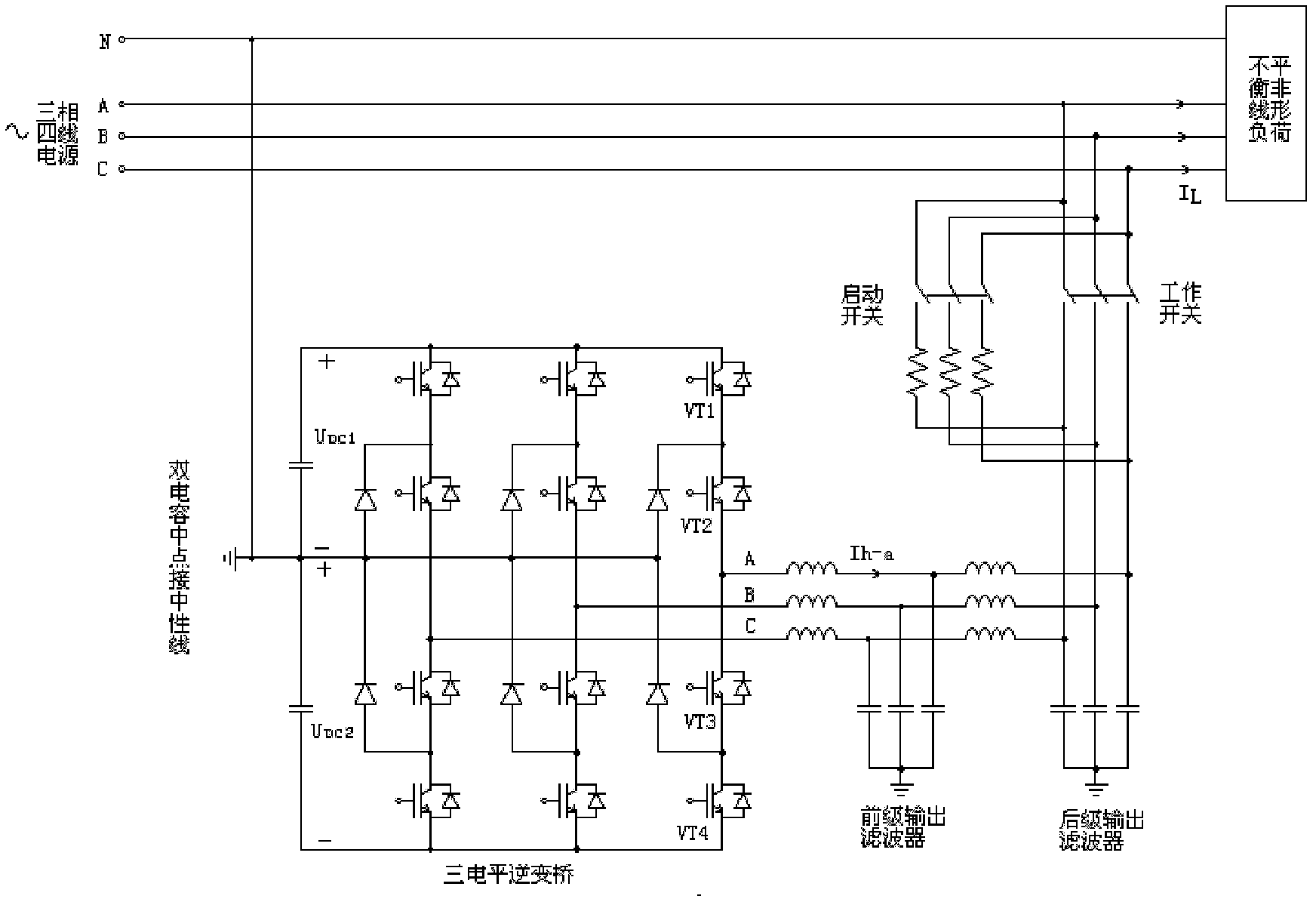

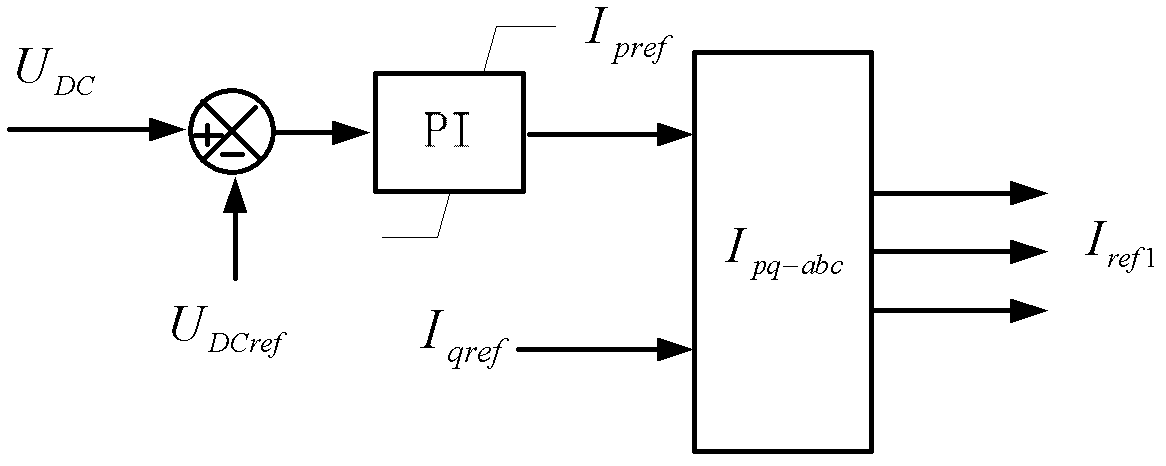

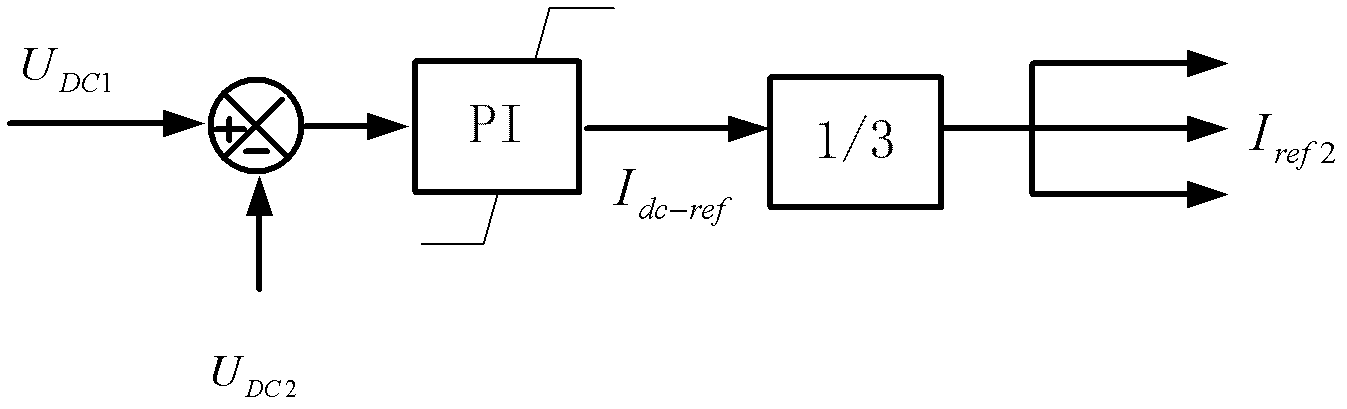

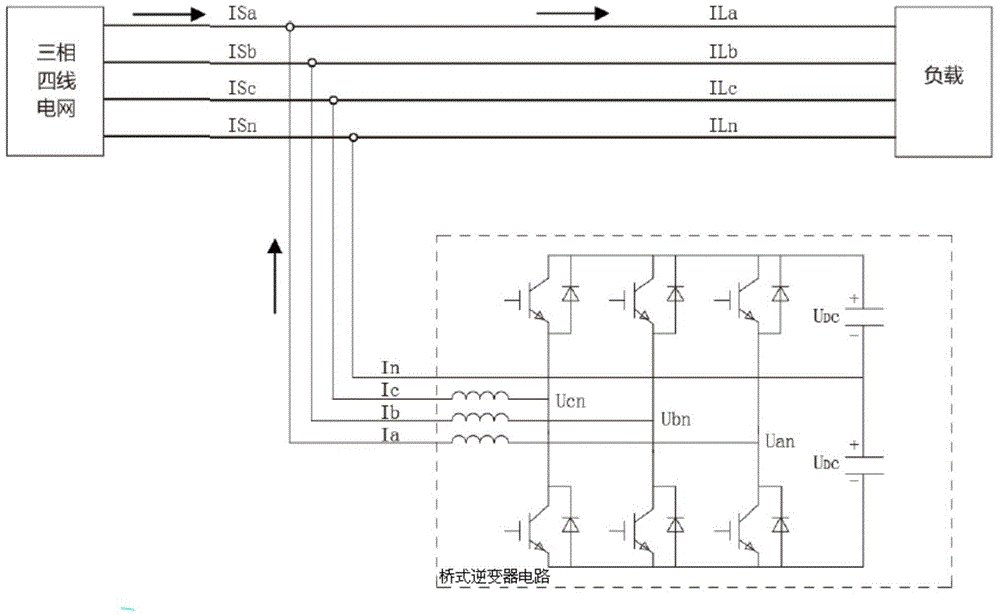

Three-level three-phase four-wire active power filter and control method thereof

InactiveCN102611108AImprove performanceEffective filteringActive power filteringHarmonic reduction arrangementCapacitanceThree level

The invention discloses a three-level three-phase four-wire active power filter and a control method thereof. The filter comprises two capacitors, a three-level inverter bridge, a previous LC (inductance and capacitance) output filter, a posterior LC output filter and a grid-connected switch, middle points of the two capacitors are directly connected with a neutral wire of a power grid, the two capacitors are connected with three bridge arms of the three-level inverter bridge in parallel after being serially connected with each other, the three-level inverter bridge is a three-level diode-clamped type three-level inverter bridge, and an output end of the three-level inverter bridge is connected into a three-phase power source in a three-phase four-wire power source by the previous LC output filter, the posterior LC output filter and the grid-connected switch sequentially. The control method includes controlling the three-level three-phase four-wire active power filter by the aid of control of three control loops and a hysteresis comparator.

Owner:HUNAN UNIV

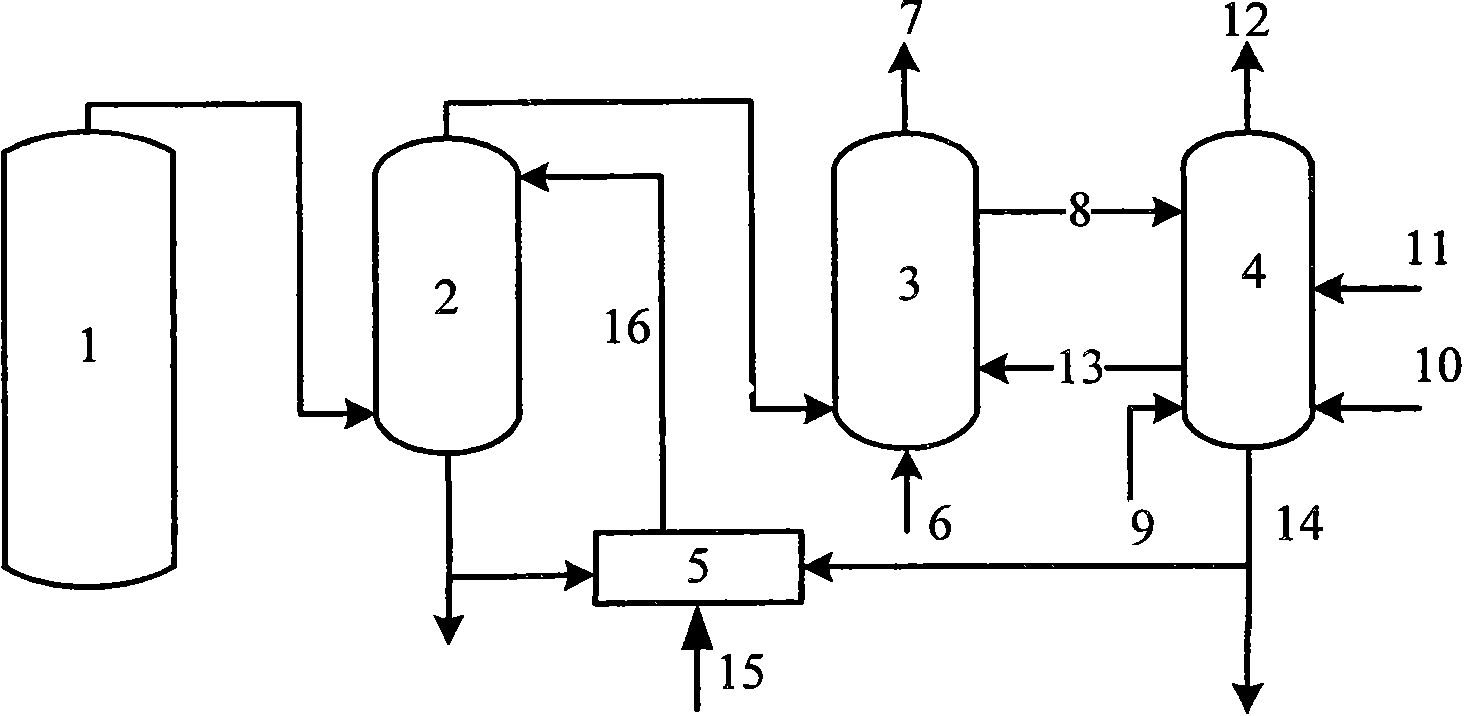

Method for circularly trapping SO2 and CO2 by using calcium-based absorbent

InactiveCN101797470AGood technical economyAvoid inputGas treatmentDispersed particle separationCarbonationCarbon dioxide

The invention provides a method for trapping SO2 and CO2 on a large scale aiming at a pulverized coal furnace of a power plant. Fume generated by the pulverized coal furnace of the power plant is desulfurized by a desulfurizing tower and then enters a fluidized bed carbonation reactor; CaO in the reactor generates solid Ca(OH)2 under the action of water vapor; Ca(OH)2 particles are subjected to a carbonation reaction to trap CO2; a product CaCO3 enters a fluidized bed calcining furnace; the CaCO3 is decomposed into CaO and CO2 by using the heat generated by oxygen enriched combustion of a biomass fuel; and the CaO is introduced into the carbonation reactor for trapping the CO2 to realize the recycling. The inactive CaO is discharged from the lower part of the fluidized bed calcining furnace, and meanwhile, the calcium-based absorbent is supplemented. Part of inactive CaO discharged from the calcining furnace is introduced into a digestion reaction to form a Ca(OH)2 solution and then enters the desulfurizing tower for desulfurization, so that the respective removal of the SO2 and the CO2 can be realized and the energy consumption of the system can be reduced.

Owner:SHANDONG UNIV

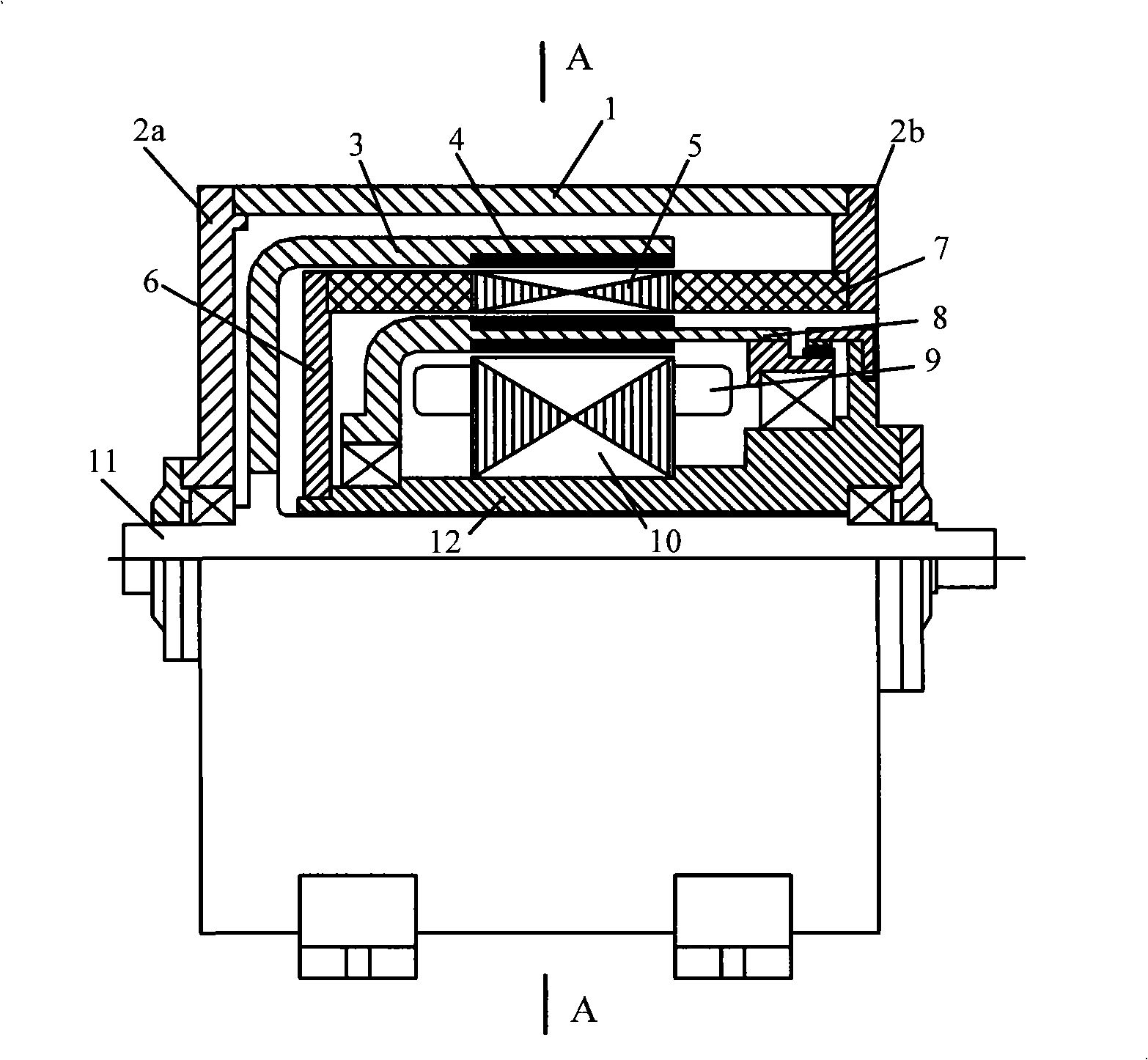

Direct-drive composite type permanent magnet motor

InactiveCN101330234ACancel noiseEliminate vibrationMagnetic circuit rotating partsDynamo-electric gearsLow speedElectric machine

The invention relates to a direct-drive combined motor which comprises a self-control permanent-magnet motor and a concentric magnetic gear. The permanent-magnet motor and the magnetic gear are integrated by adopting the sleeve-type structure or the axial series connection structure. The combined permanent-magnet motor can automatically realize the high-speed low-torque power transfer and the low-speed high-torque power transfer therein without a mechanical gear case. The motor can serve as an electric motor and a power generator.

Owner:许晓华

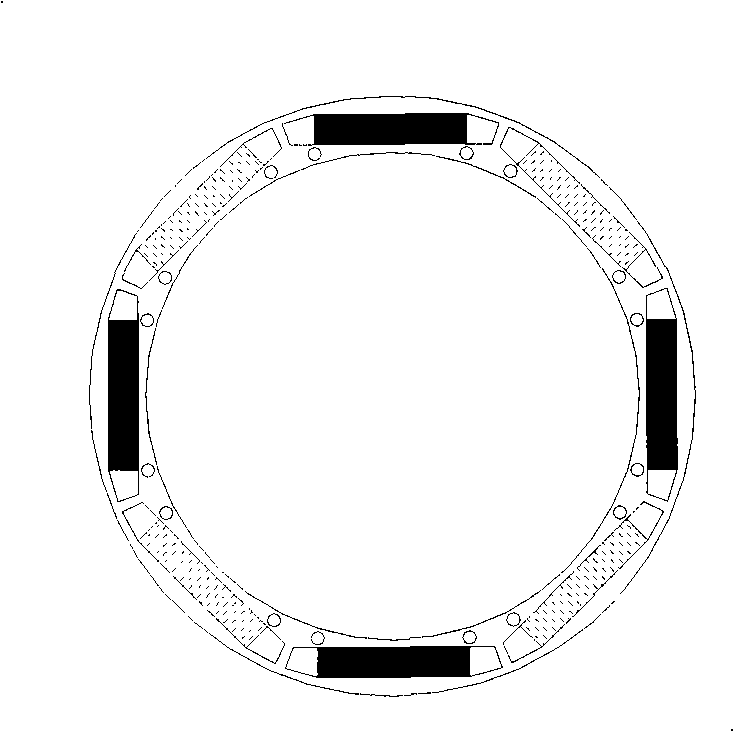

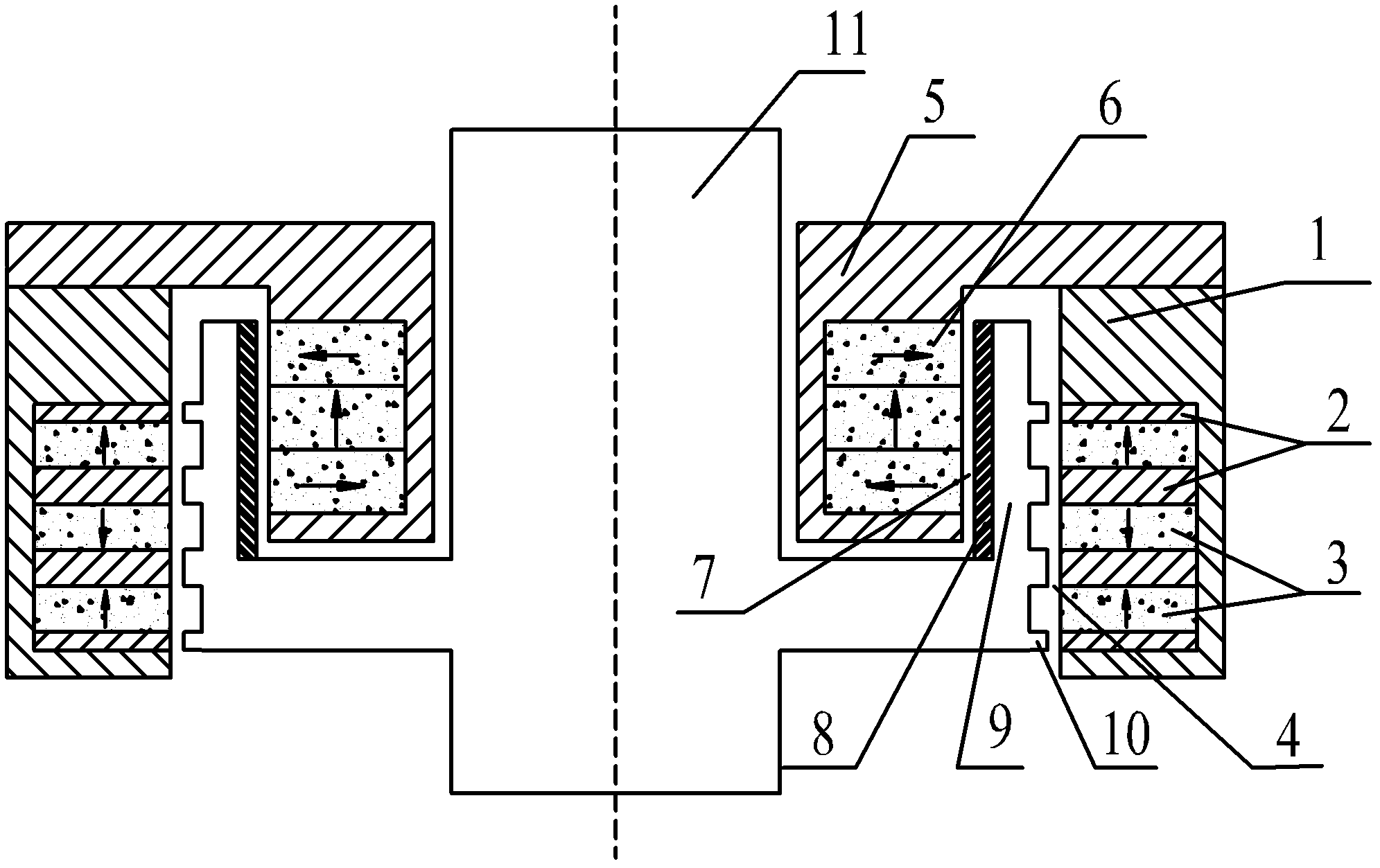

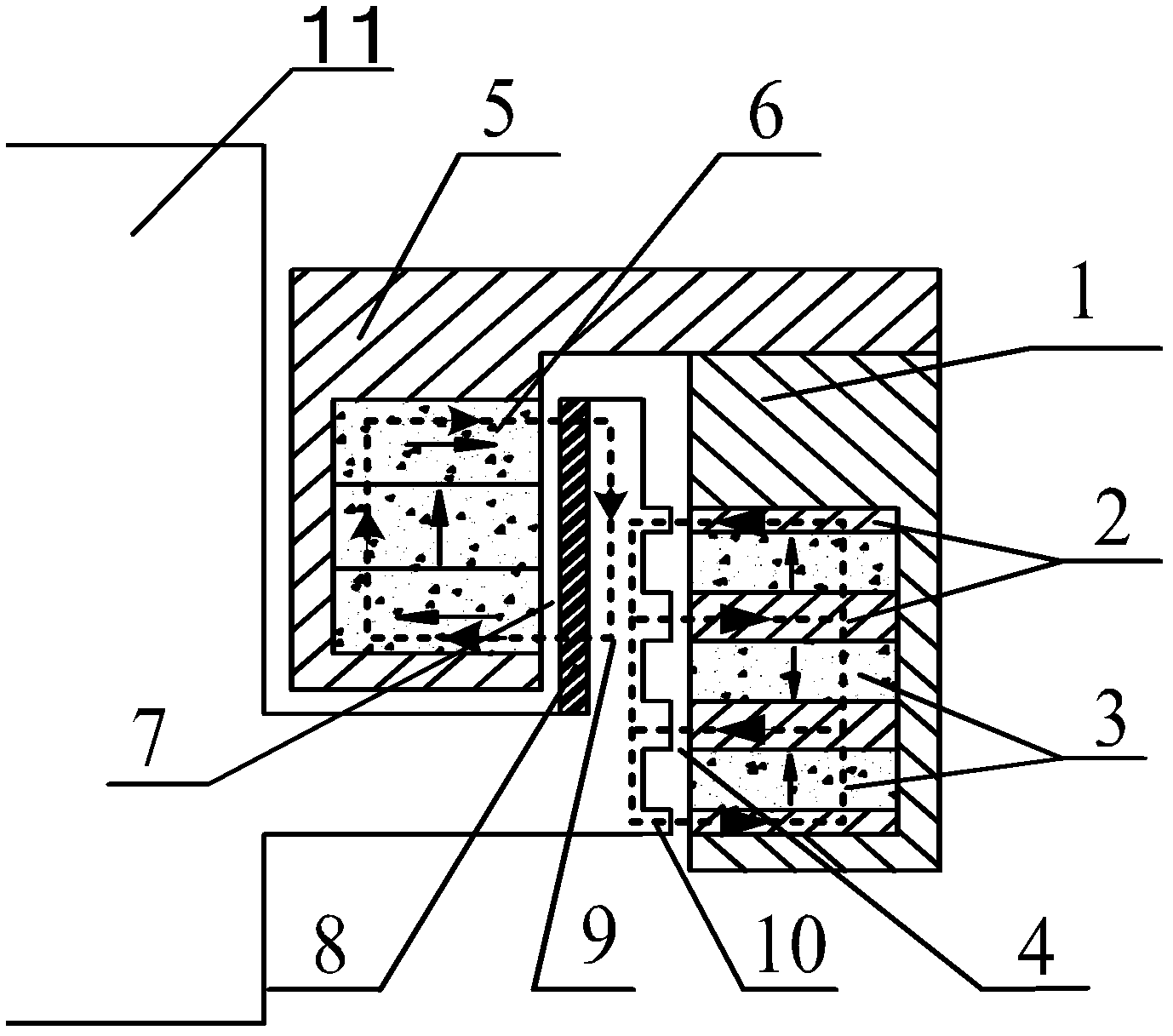

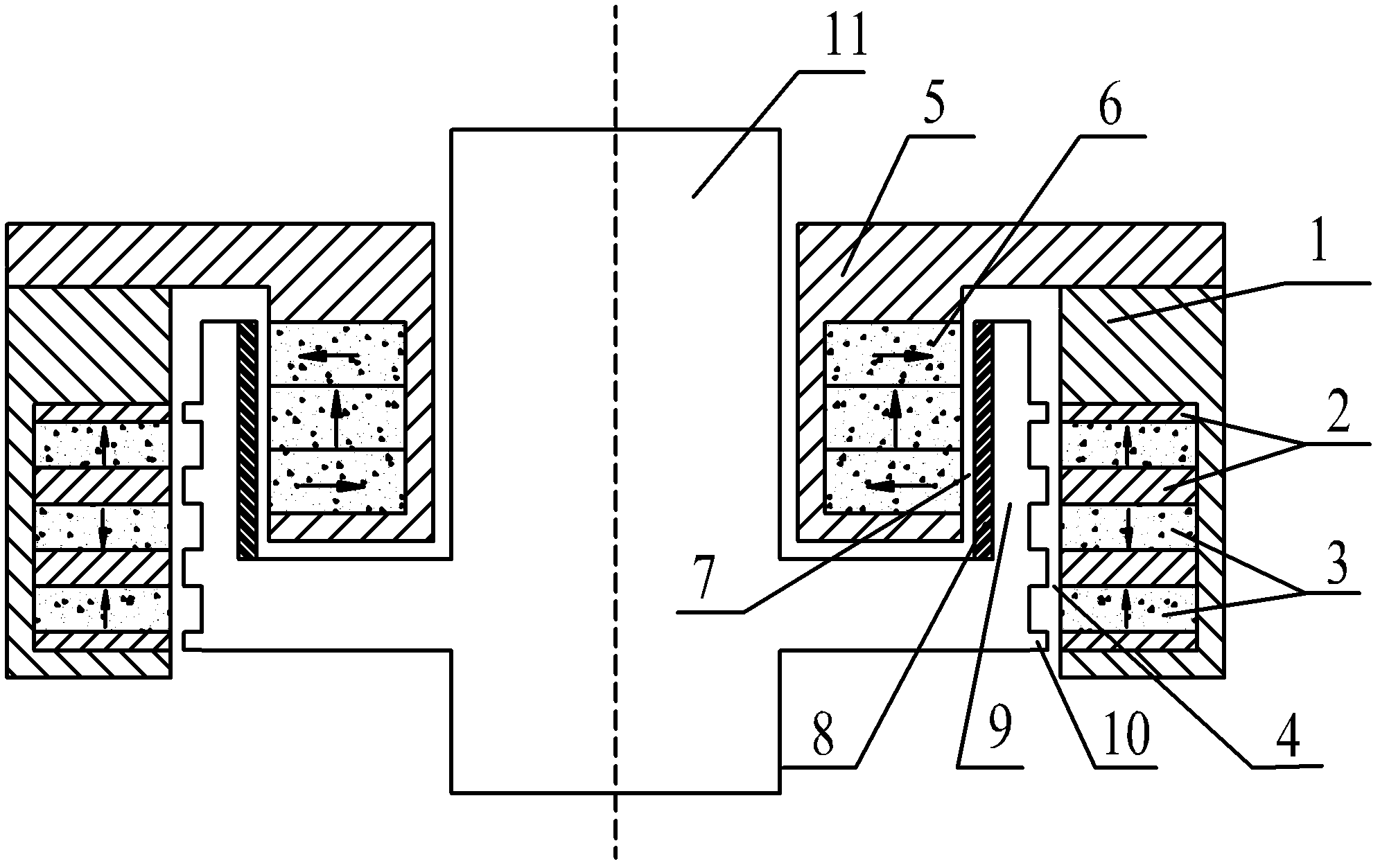

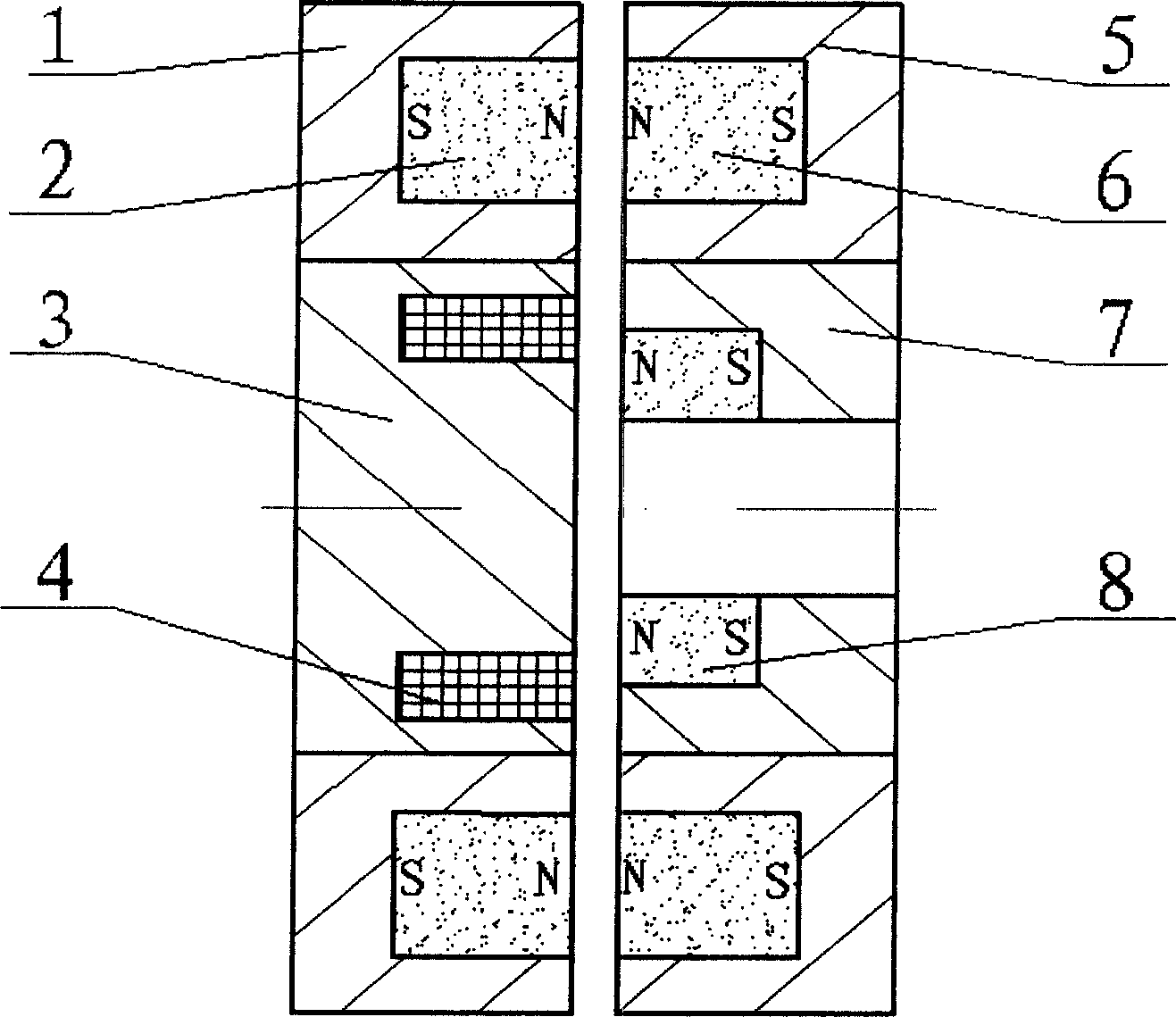

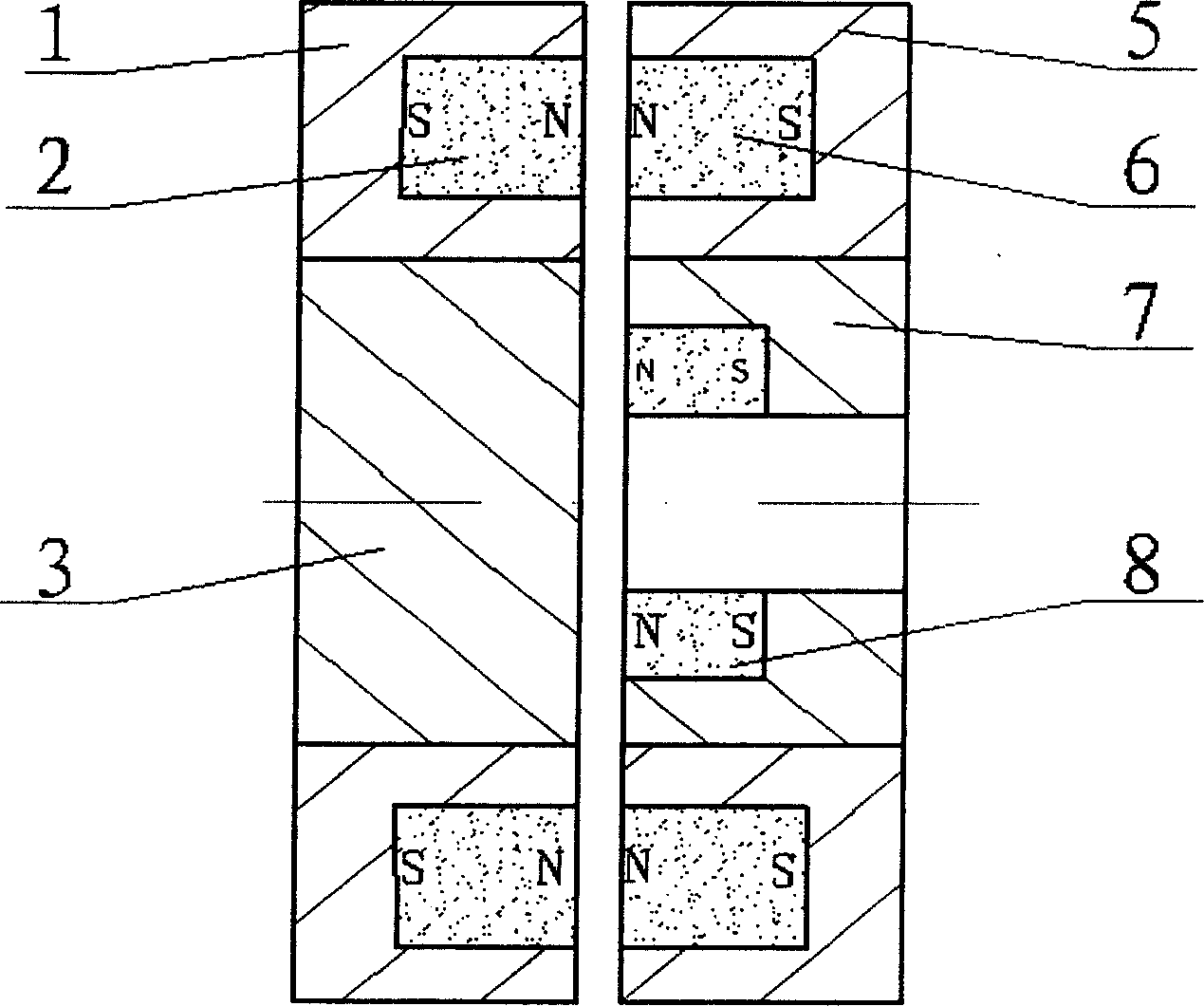

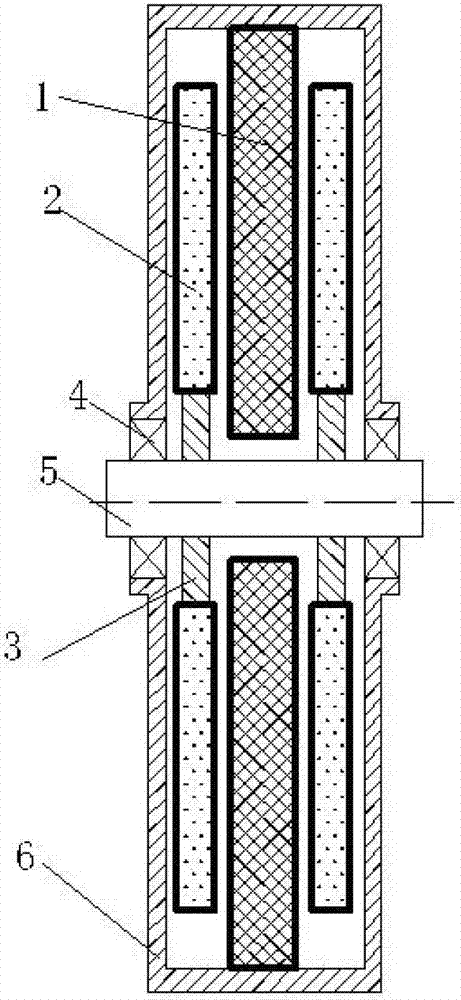

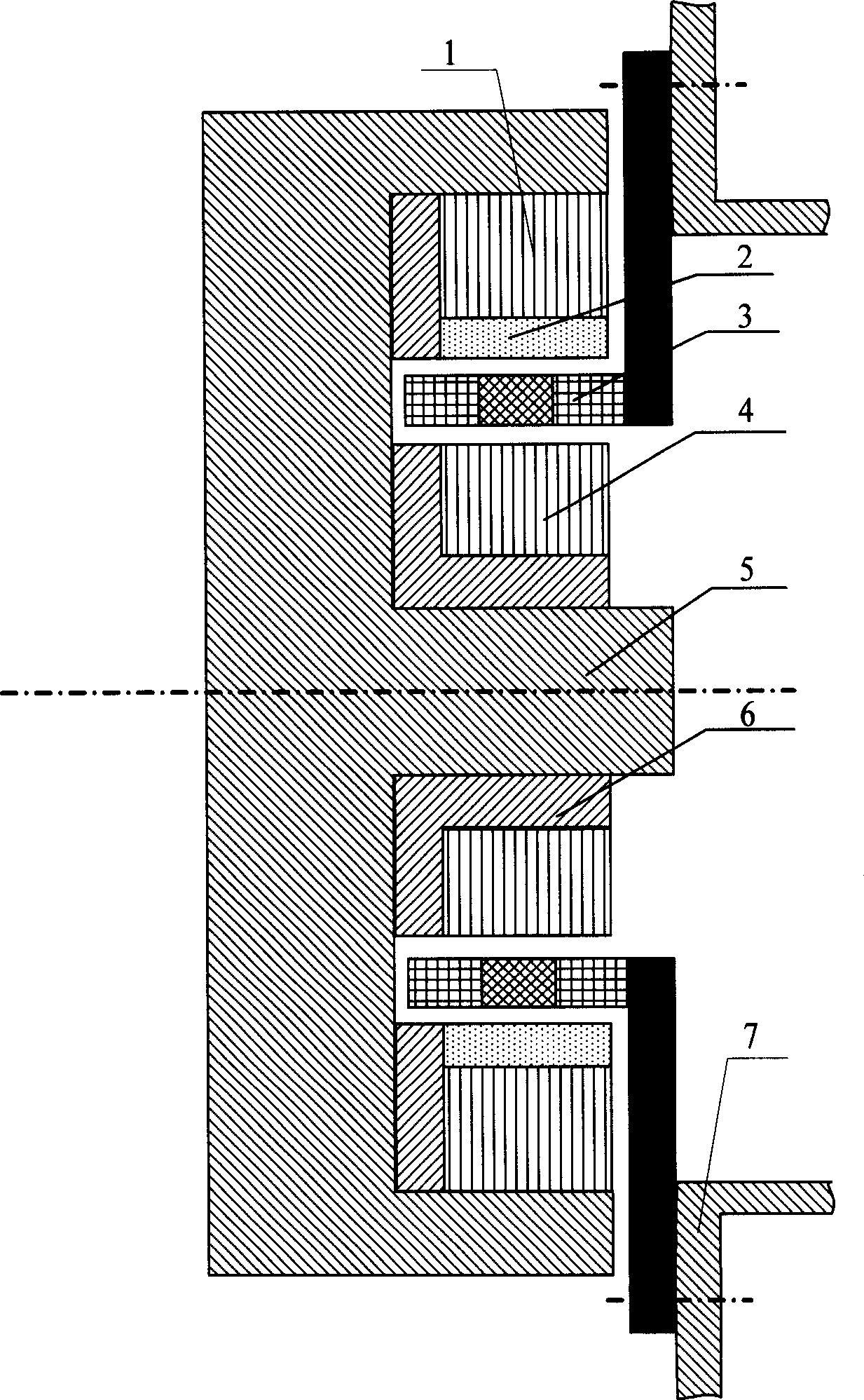

Permanent-magnetic passive axial magnetic suspension bearing with passive damping effect

The invention discloses a permanent-magnetic passive axial magnetic suspension bearing with passive damping effect. The magnetic bearing is split, and consists of a static part and a movable part. The static part comprises a stator bearing mounting sleeve, a stator damping mounting sleeve, stator magnetic rings, stator permanent magnets and a stator damping permanent magnet; and the movable part has hollow cup structure, and comprises a rotor shaft, a hollow cup rotor, rotor teeth and a damping copper bush. In the static part, three stator permanent magnets and four stator magnetic rings are sequentially arranged across in the axial direction, arranged on the stator bearing mounting sleeve together and used for providing rigidity for a system. The stator damping permanent magnet consists of three permanent magnets in a Halbach magnetizing mode, arranged on the stator damping mounting sleeve and used for providing damping for the system. According to the magnetic suspension bearing, anaxial sensor and a control system are saved, the volume is reduced, the weight is lightened, and the loss is eliminated. Through the passive damping structure of the magnetic suspension bearing, the oscillation of a rotor can be quickly attenuated, and the reliability of the system is improved.

Owner:BEIHANG UNIV

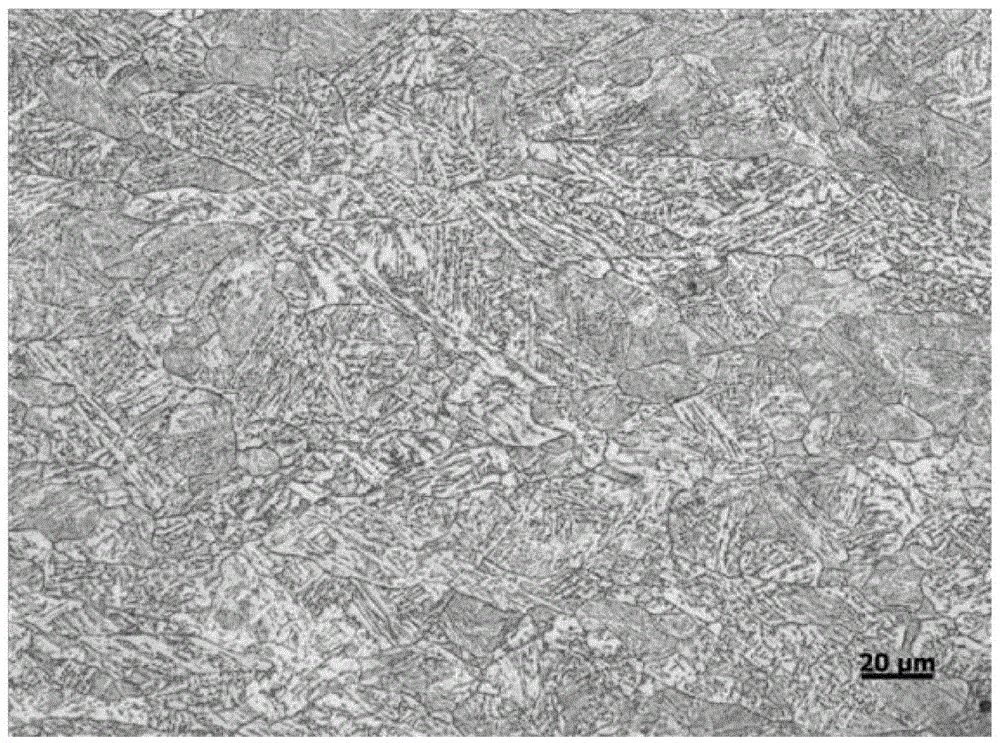

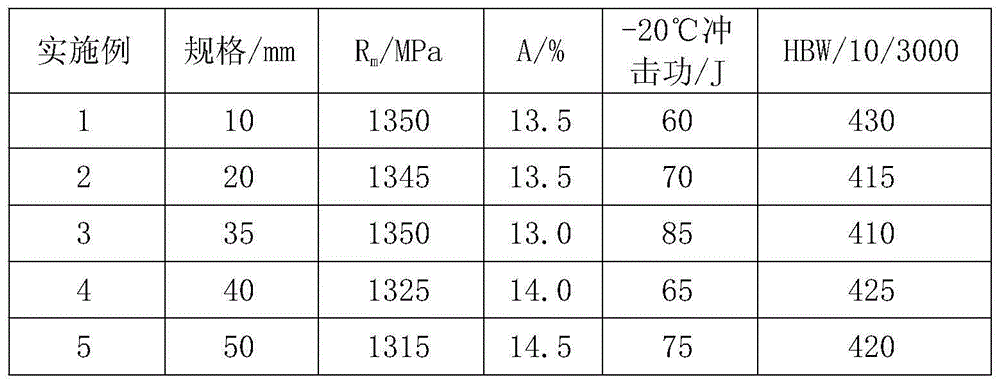

Low-cost HB400-grade wear-resisting steel and production method thereof

The invention discloses low-cost HB400-grade wear-resisting steel and a production method thereof. The low-cost HB400-grade wear-resisting steel comprises the following chemical components in percentage by weight: 0.08-0.19 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, smaller than or equal to 0.015 percent of P, smaller than or equal to 0.015 percent of S, 0.30-0.65 percent of Cr, 0.02-0.05 percent of Nb, 0.005-0.025 percent of Ti, 0.001-0.005 percent of B, 0.010-0.040 percent of Als and the balance of Fe and a trace amount of impurity elements. According to a steel plate, the thickness specification range is 10mm to 50mm; Rm is larger than or equal to 1300MPa; the percentage elongation is larger than or equal to 15%; the Akv is larger than or equal to 47J at -20 DEG C; the HBW / 10 / 3000 is larger than or equal to 400. The low-cost HB400-grade wear-resisting steel has the advantages that the manufacturing cost is greatly lowered, the problems of high strength and poor plasticity of wear-resisting martensite steel are solved, and the steel plate can be delivered directly. Therefore, the low-cost HB400-grade wear-resisting steel has quite high market competitiveness, wide application prospect and obvious economic benefits and social benefits.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Millimetre wave planar antenna and array thereof

InactiveCN101982898ASmall dielectric lossUniform radiation patternAntenna arraysRadiating elements structural formsPhysicsRadiation

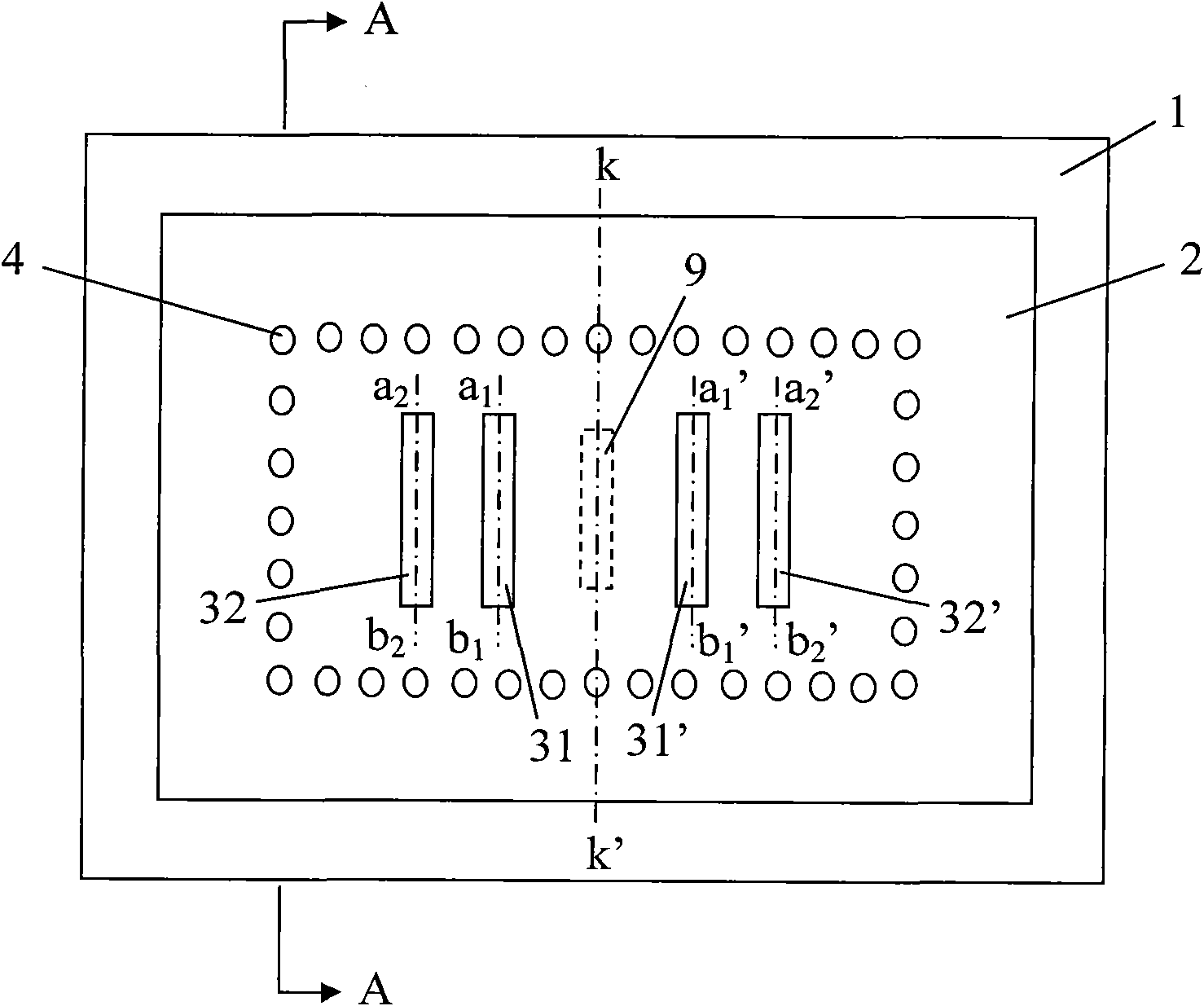

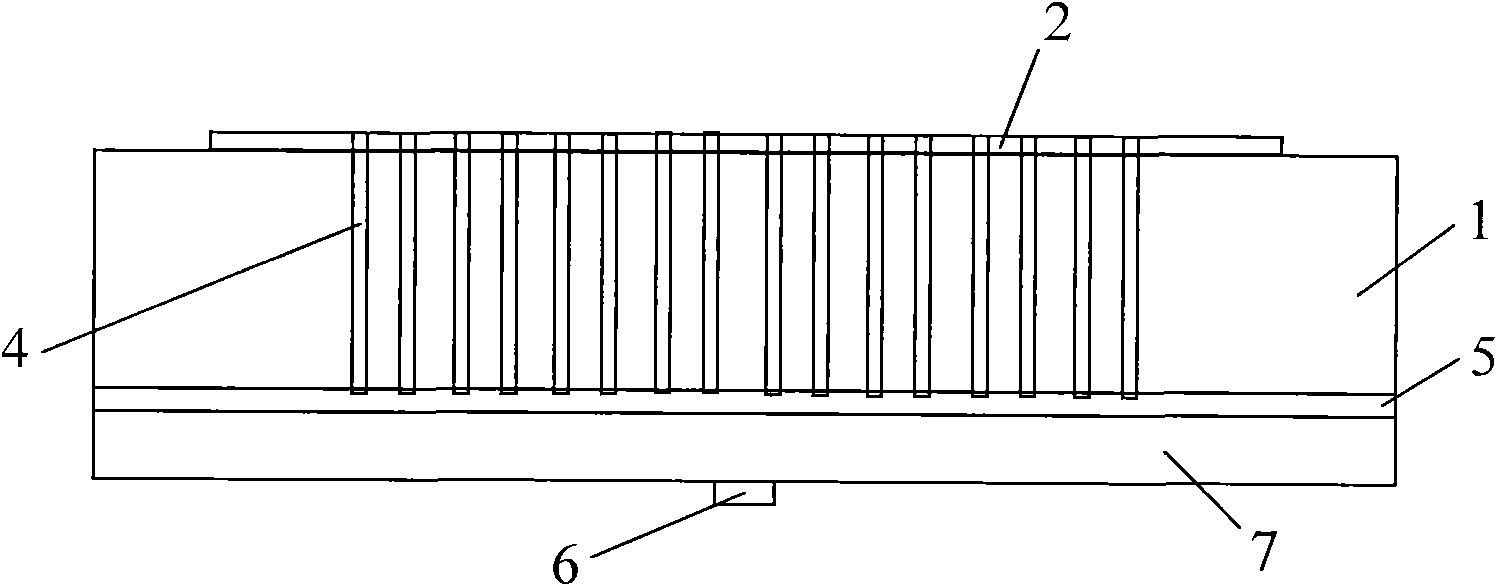

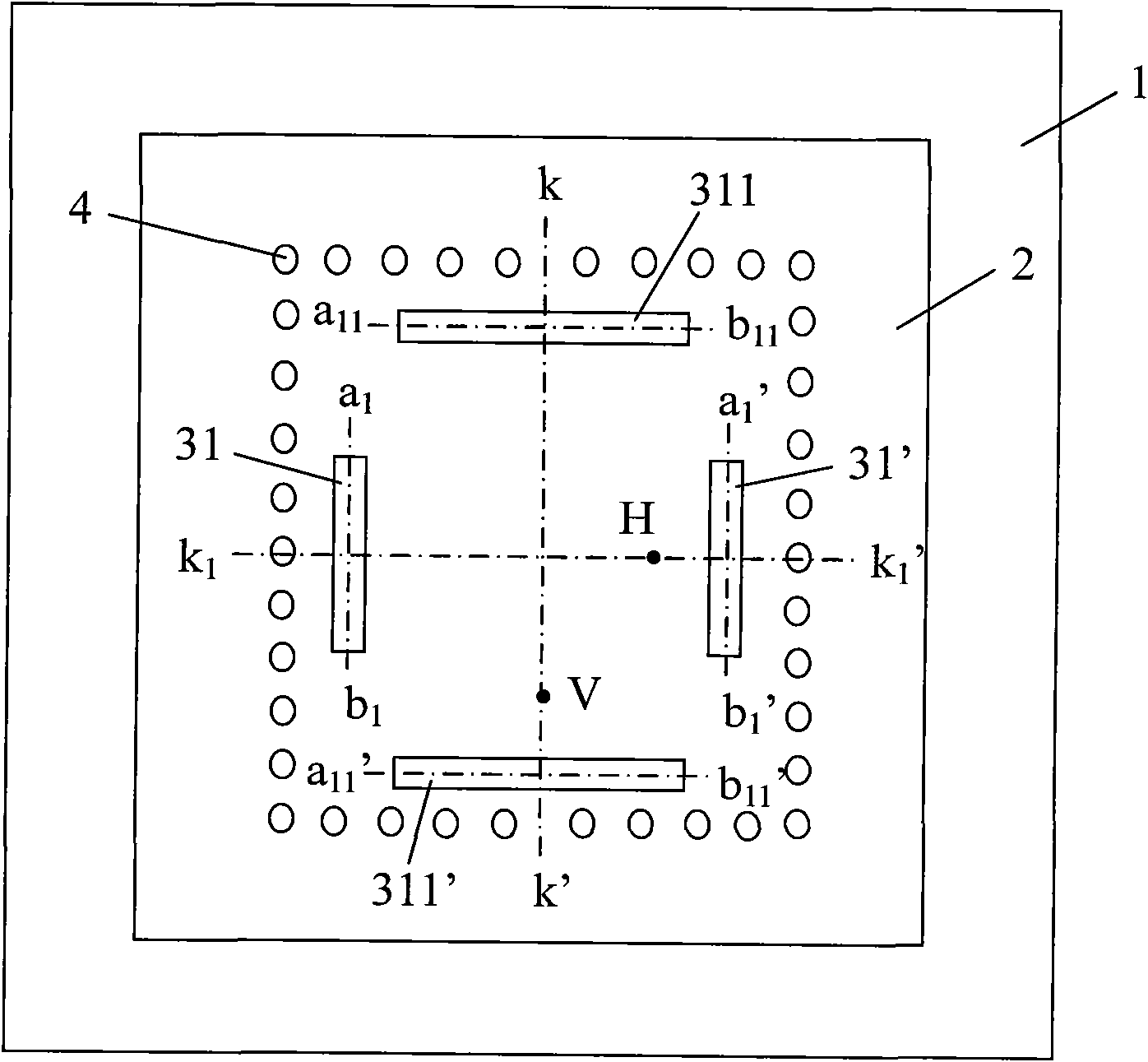

The invention discloses a millimetre wave planar antenna and an array thereof, wherein the millimetre wave planar antenna includes a metal patch, a medium substrate, a metal floor board and ground poles, the metal patch is placed on an upper surface of the medium substrate, and a lower surface of the medium substrate is fixed with an upper surface of the metal floor board; the metal patch is parallel to the upper surface of the metal floor board; the metal patch is provided with at least one pair of same first bar-shaped channels, each pair of first bar-shaped channels are distributed in bilateral symmetry form, symmetrical centre lines of each pair of bar-shaped channels are superposed, a centre line in a length direction of each first bar-shaped channel is parallel to each other, and length of each first bar-shaped channel is 1 / 2 of an operating wavelength; the ground poles vertically penetrate through the medium substrate, the ground poles are circularly distributed at intervals at the periphery of a region where the first bar-shaped channels are distributed, and two ends of each ground pole are respectively contacted with the metal patch and the metal floor board. The invention can reduce loss of a millimetre wave antenna, improve radiation efficiency of the millimetre wave antenna, simultaneously, guarantee work bandwidth of the antenna, and improve antenna gain.

Owner:ZHEJIANG UNIV

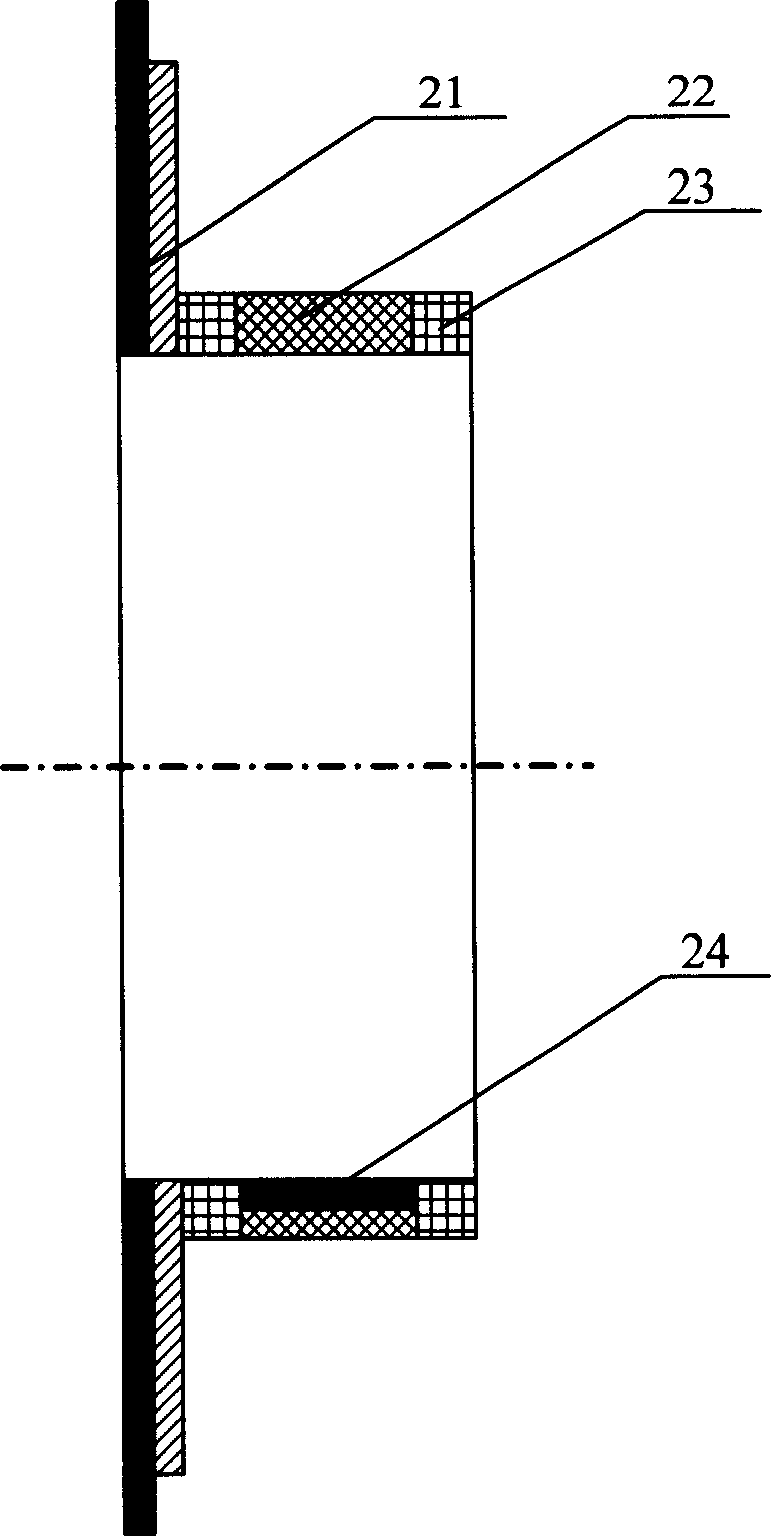

Passive type axial magnetic suspension bearing of possessing damping action

InactiveCN1687606AReduce volumeReduce weightMechanical energy handlingElastic bearingsEngineeringMagnetic levitation

The invention relates to the passive axial magnetic suspension bearing with the damp action, which comprises the static part and the movable part. The static part includes the static outside bearing body, the static repulsion permanent magnet, the magnetic conductor and the damp coil; the movable part is composed of the movable outside bearing body, the movable repulsion permanent magnet, the inside bearing body, the suction permanent magnet. The movable part and the static part are justified. In the static part, the magnetic conductor is equipped in the static outside bearing, the static repulsion permanent magnet is equipped on the static outside bearing, the damp coil on the magnetic conductor; in the movable part, the inside bearing is equipped in the movable outside bearing, the movable repulsion permanent magnet on the movable outside bearing, and the suction permanent magnet on the inside bearing. The polarity of the static repulsion permanent magnet is opposite to that of the movable repulsion permanent magnet and form the repulsion state.

Owner:BEIHANG UNIV

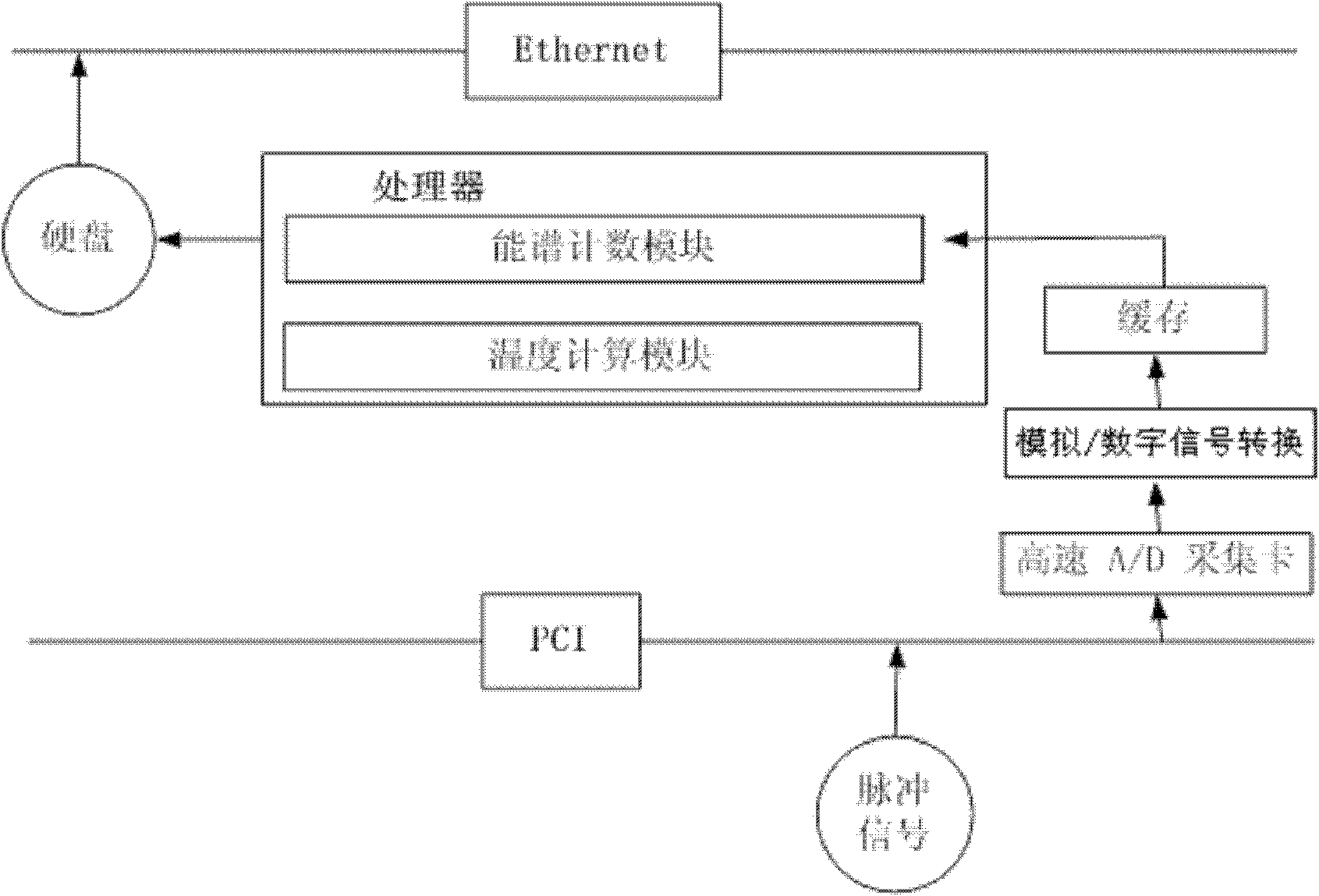

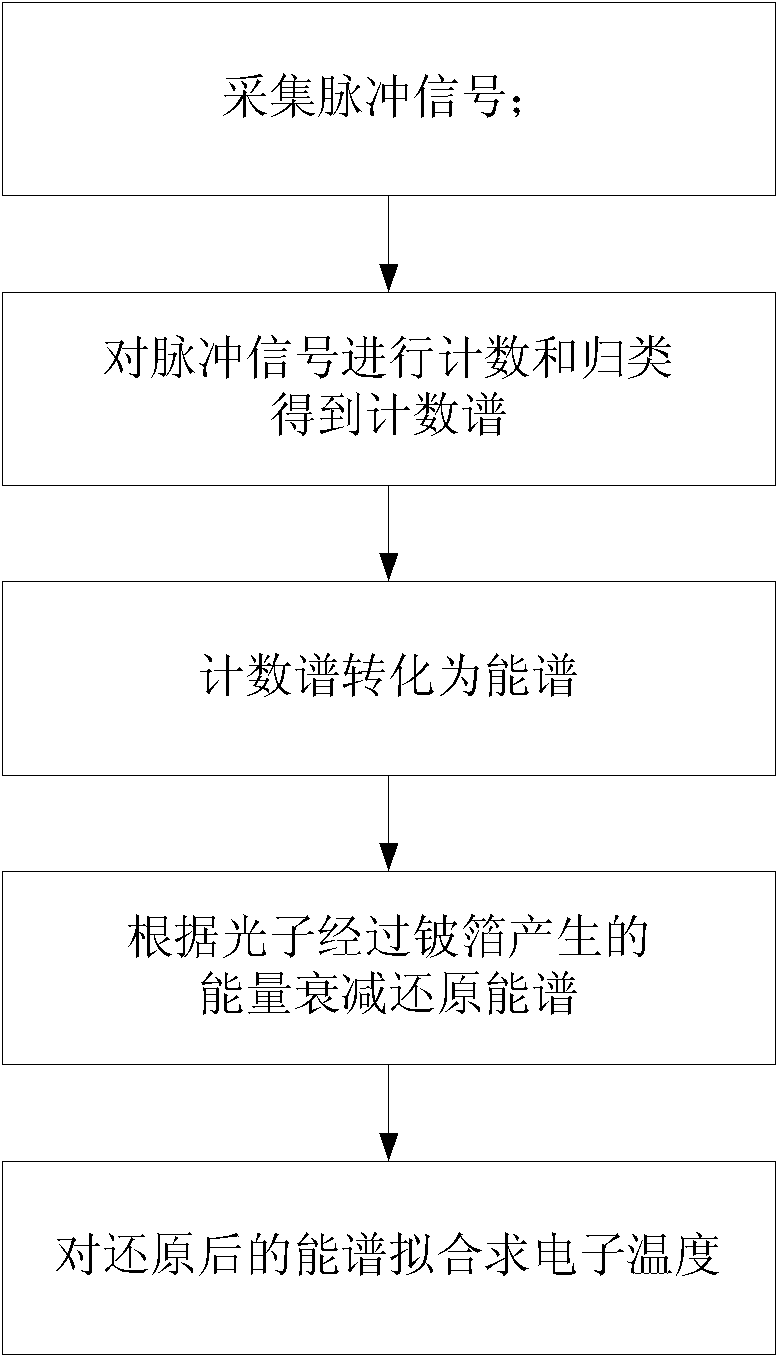

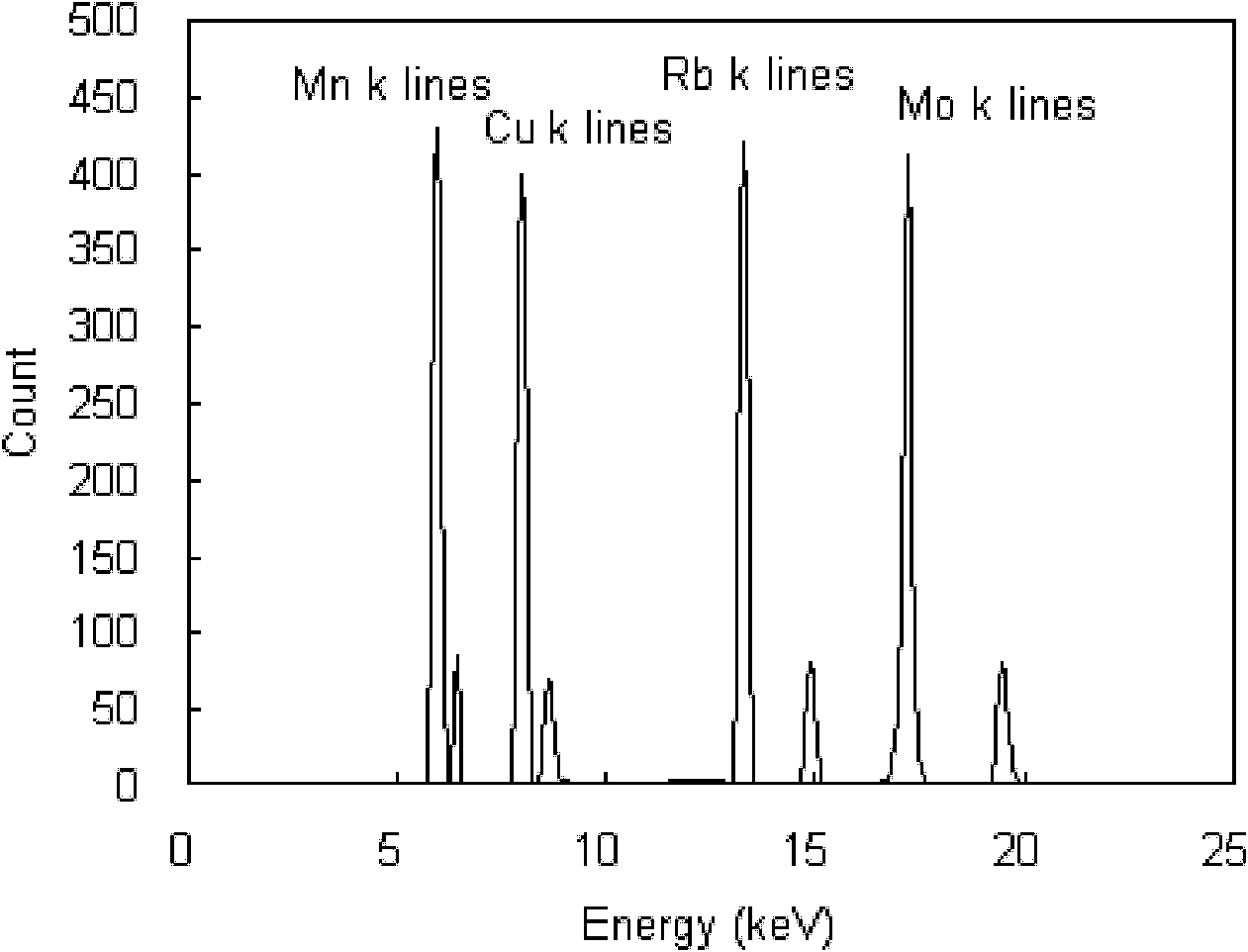

Processing method and device for multi-channel energy spectrum measurement

InactiveCN102279408AEliminate lossesEliminate stacking effectsX-ray spectral distribution measurementPhotonicsDigitization

The invention belongs to the field of plasma diagnosis computer processing, in particular to a processing method and device for multi-channel energy spectrum measurement. The processing method includes the following steps: collecting a pulse signal sent by a probe and converting it into a digital pulse signal; counting and classifying the digitized pulse signal to obtain a count spectrum; converting the count spectrum into an energy spectrum; The energy attenuation produced by the beryllium foil is reduced, and the energy spectrum obtained in the third step is restored; the energy spectrum after reduction is smoothed and peaked and fitted to obtain the electron temperature. The processing device includes a pulse signal generation module, a high-speed acquisition card, an analog / digital signal conversion module, a high-speed cache module, and a processor unit with an energy counting module and a temperature calculation module. The problems of common multi-channel energy spectrum measurement and processing methods, such as high hardware cost, strong equipment specificity, limited number of energy channels, low spatial and temporal resolution, and inability to save original signals, are solved.

Owner:SOUTHWESTERN INST OF PHYSICS

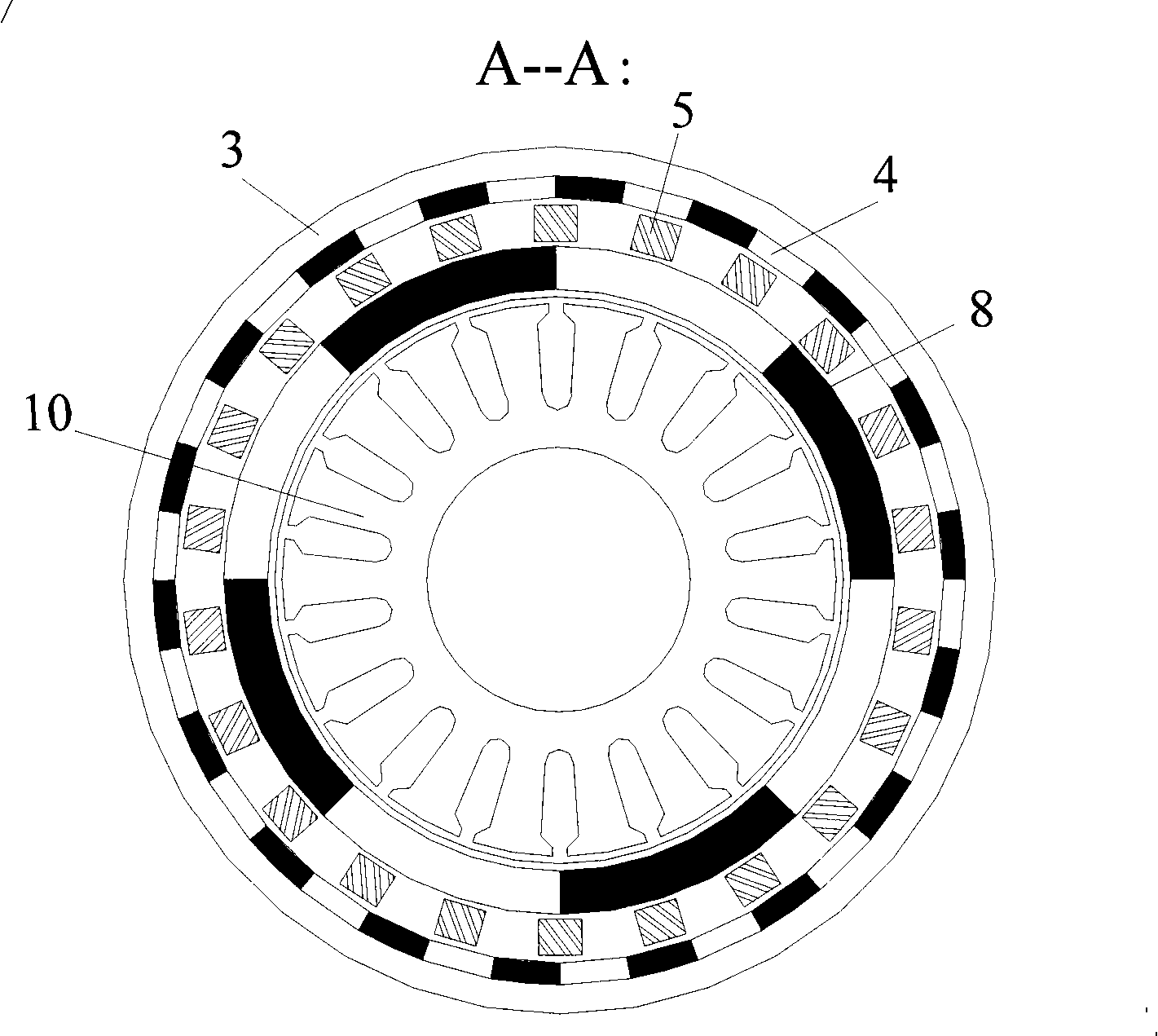

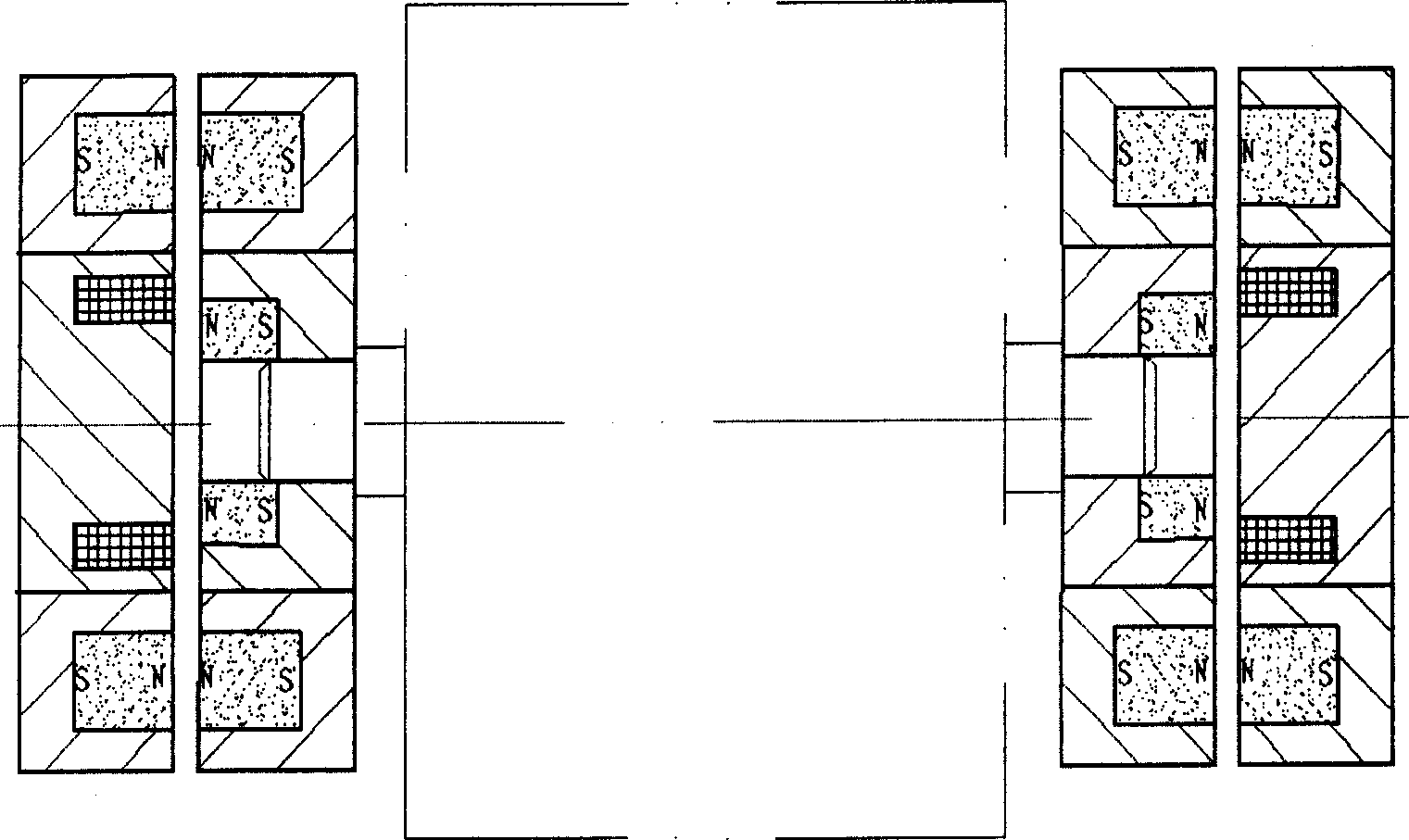

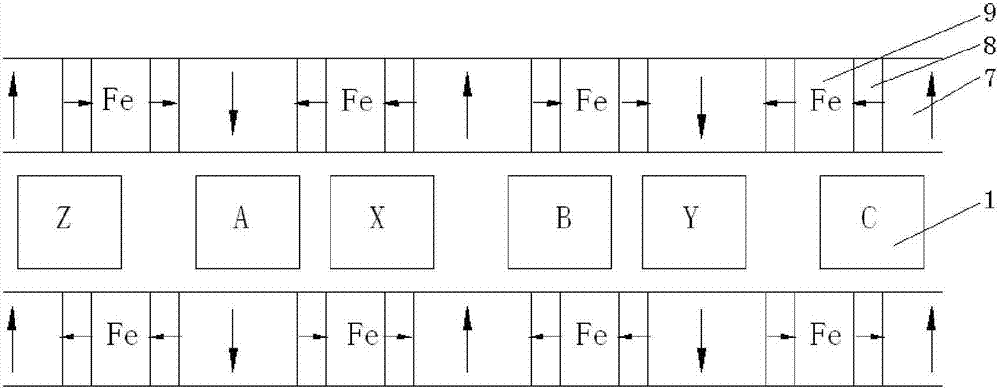

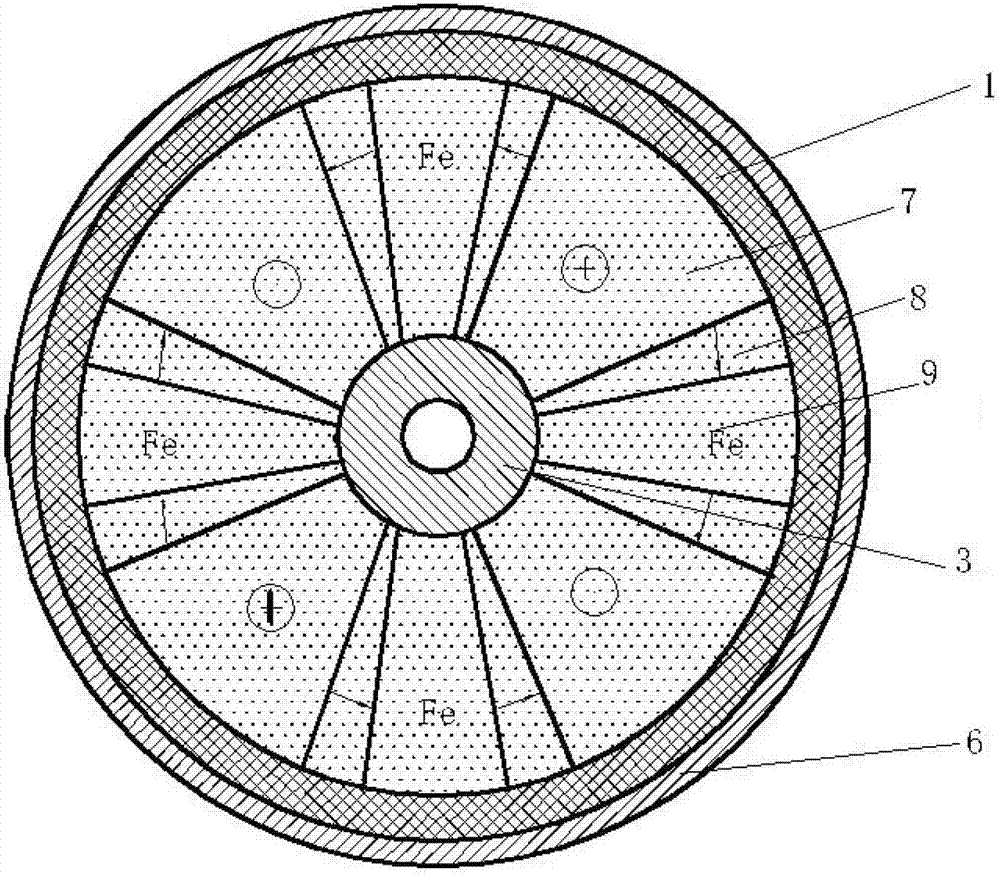

Halbach-structure-based iron-core-free axial magnetic field brushless direct-current electromotor

InactiveCN102904404AEliminate cogging torque and core lossEliminate axial magnetic forceMagnetic circuit rotating partsElectric machinesPhysicsTorque density

The invention discloses a Halbach-structure-based iron-core-free axial magnetic field brushless direct-current electromotor which comprises a stator iron-core-free armature disc, a permanent magnet, a rotor disc, a shaft, a bearing and a rotor outer shell, wherein two symmetrical rotor discs are arranged at two sides of the stator iron-core-free armature disc; the stator iron-core-free armature disc and the rotor disc are installed on the shaft; the shaft is installed in the rotor outer shell through the bearing; the permanent magnet is pasted on the rotor disc, and is pasted on the inner surface of the rotor outer shell; a Halbach magnet structure with axial magnetizing and tangential magnetizing is adopted for the permanent magnet, and an enclosed magnetic circuit is formed automatically; and a soft magnetic material is placed at the middle of the permanent magnet with tangential magnetizing. According to the invention, on the basis that more permanent magnets are not used, flux density with great air clearance can be obtained, and are is in sine distribution; the output torque is high; the torque density is large; the efficiency is high; the structure is simple; the assembly is simple; and the Halbach-structure-based iron-core-free axial magnetic field brushless direct-current electromotor is suitable for relevant driving occasions with compact structures for electric automobile hub motors and the like.

Owner:SOUTHEAST UNIV

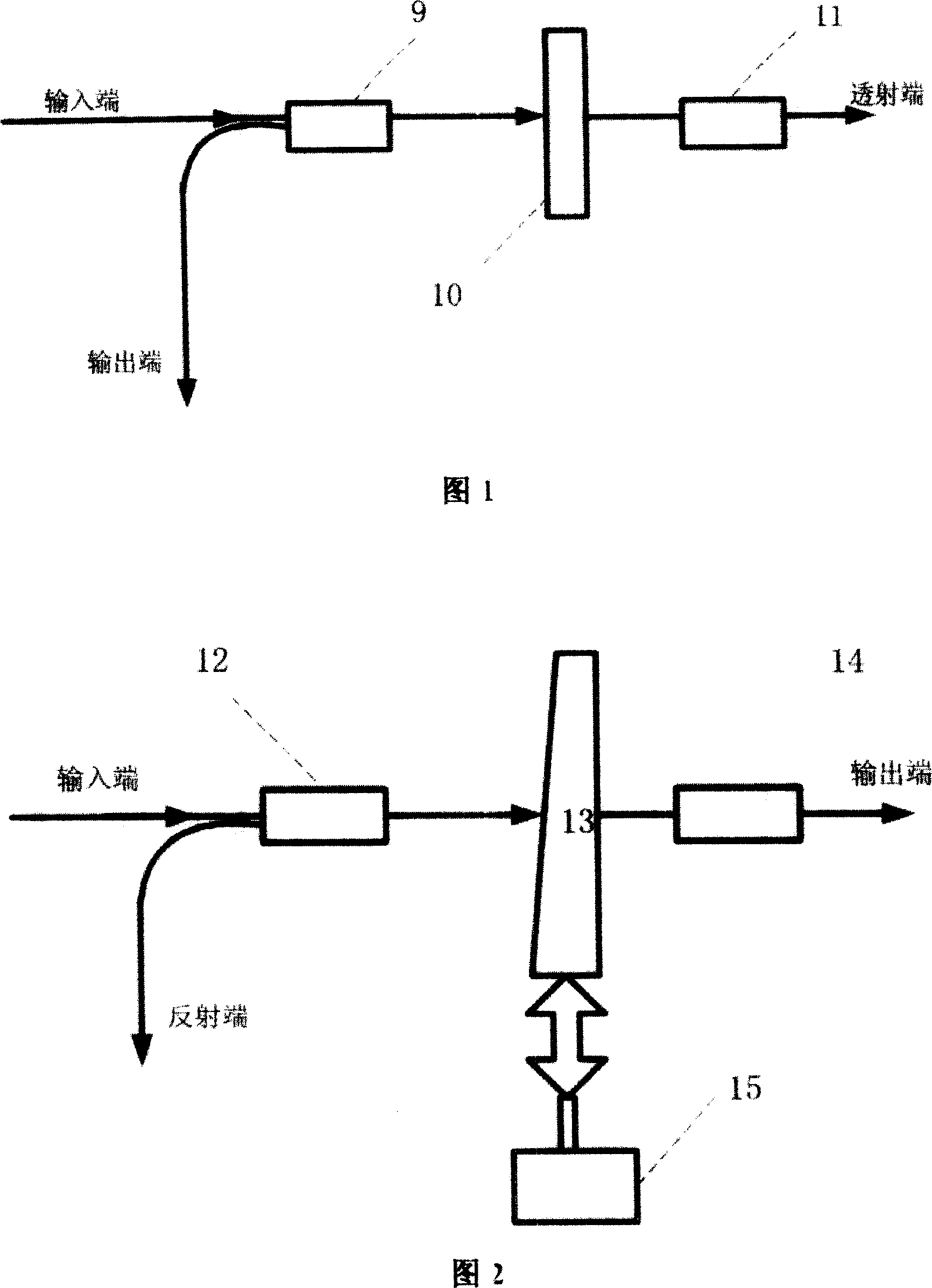

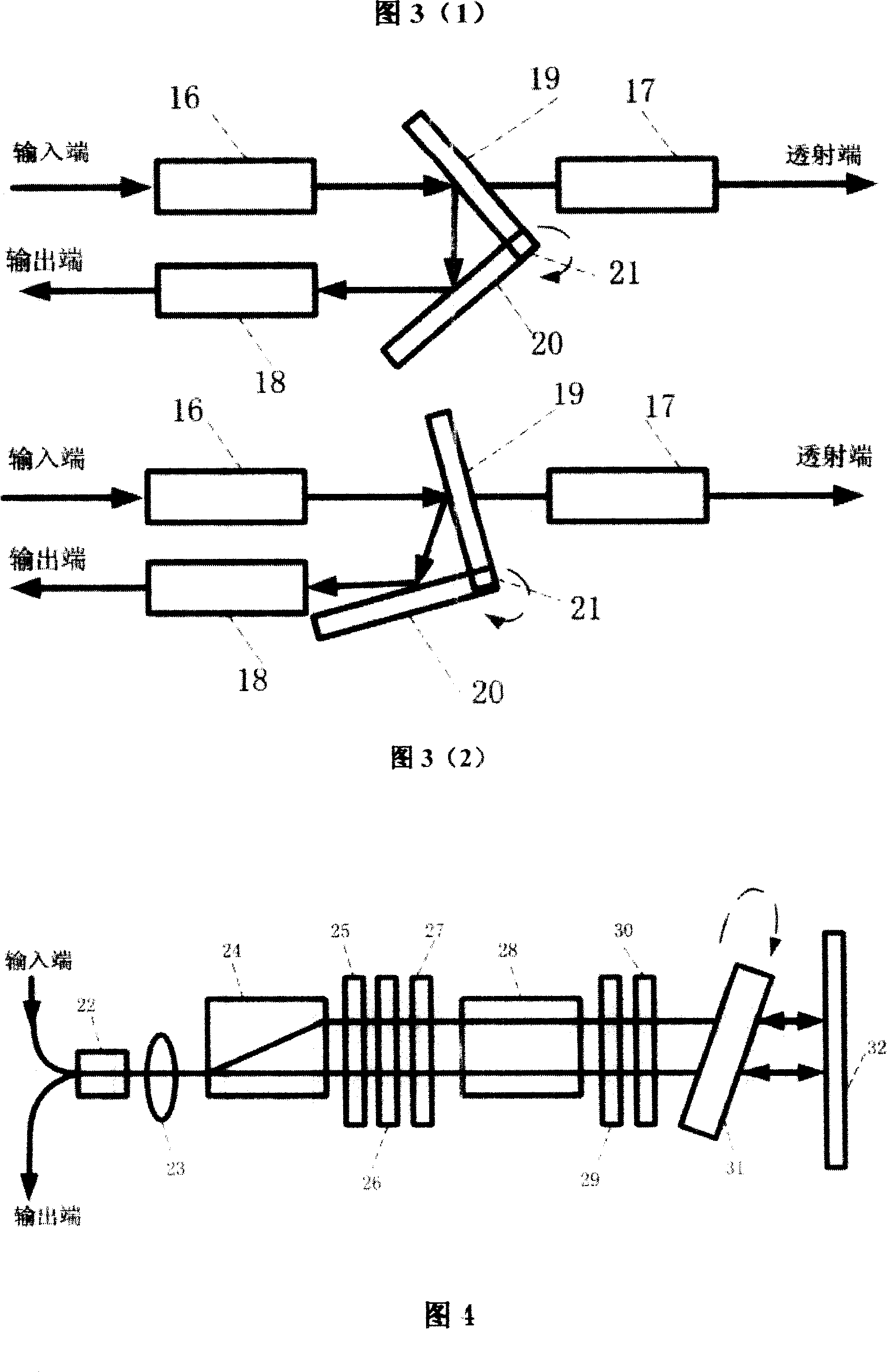

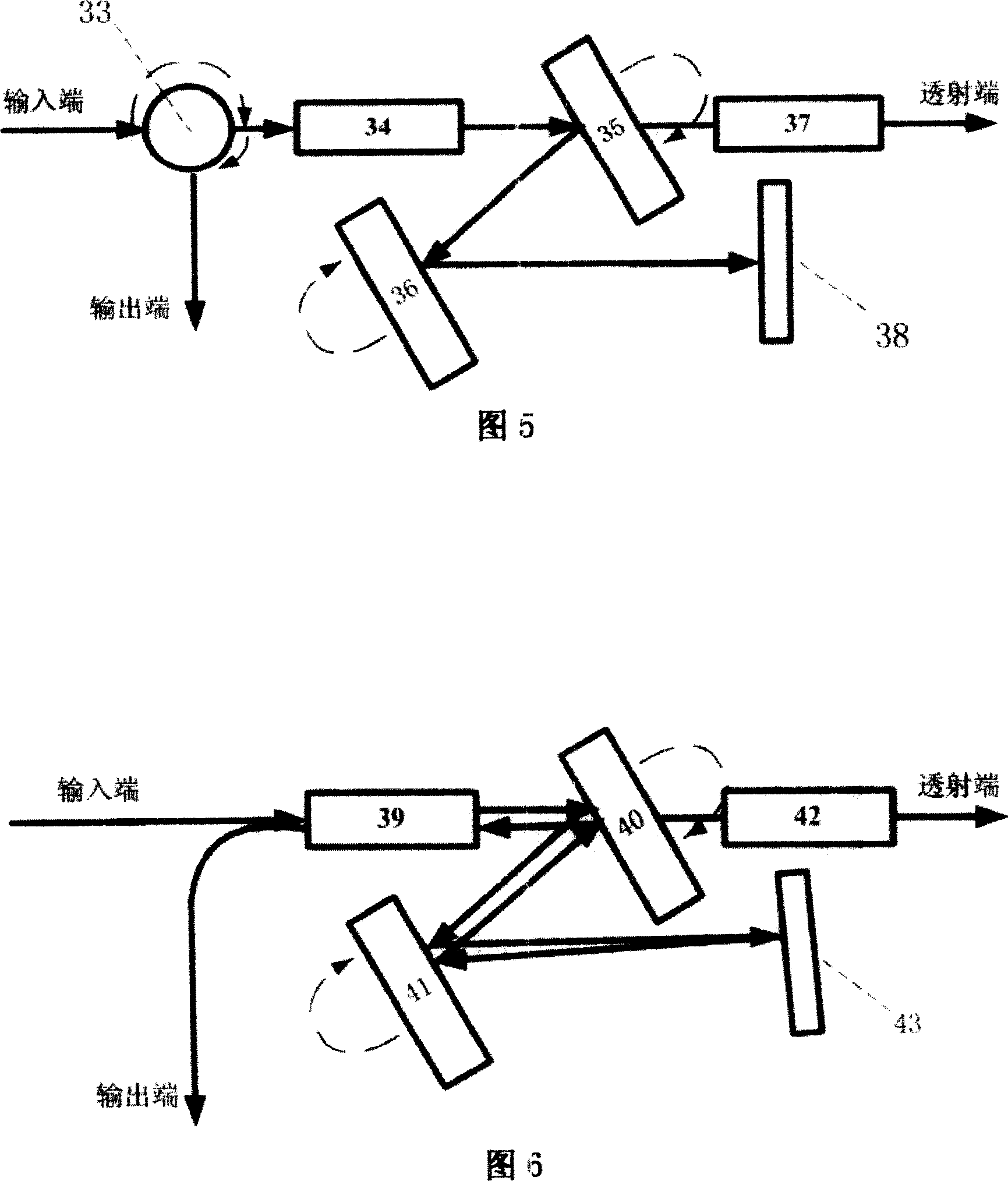

Tri-port depolarizing tunable optical filter based on TFF

The three-port polarizing offset tunable optical filter based on TFF comprises a set or more tunable filter unit with one composed of optical ring connected to the multi channel optical signal input end, a thin film filter, the polarized beam divider A & B on the same light path on the back and forth of the thin film filter plate, featuring in the polarized beam divider A dividing input signal light dividing into P and S parallel lights, with P having half wave plate C rotating P into P-S, two parallel S lights reaching thin film filter plate whose normal line slants on the two parallel S light paths, half wave plate D rotating S into S-P, polarized beam divider B synthesizing P and S into ordinary light signal to output, reflective mirror E paralleling laid with thin film filter plate with reflective mirror F setting behind reflective mirror E with F vertically set with two parallel light paths. It is simple in structure, easy for realization, being able to eliminate polarized relative consumption and polarized light dividing.

Owner:GUANGXUN SCI & TECH WUHAN +1

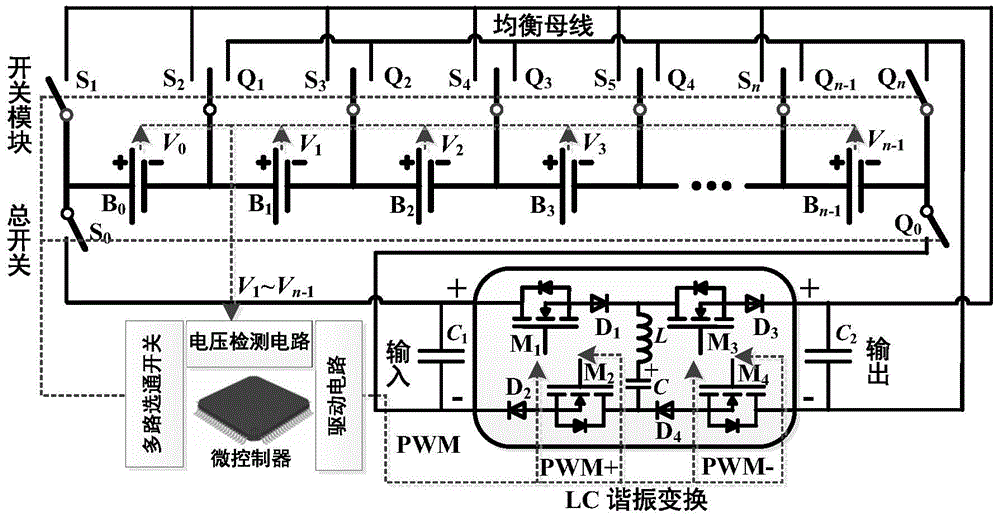

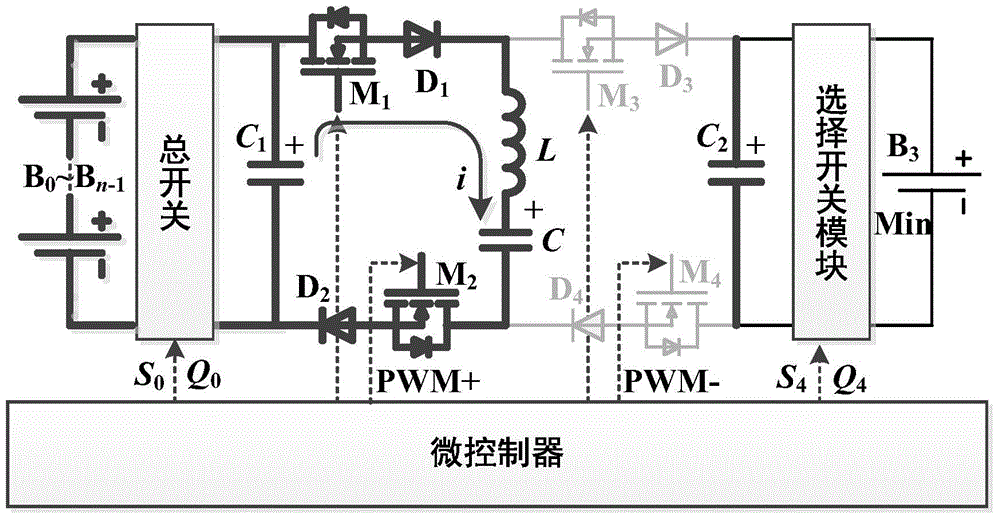

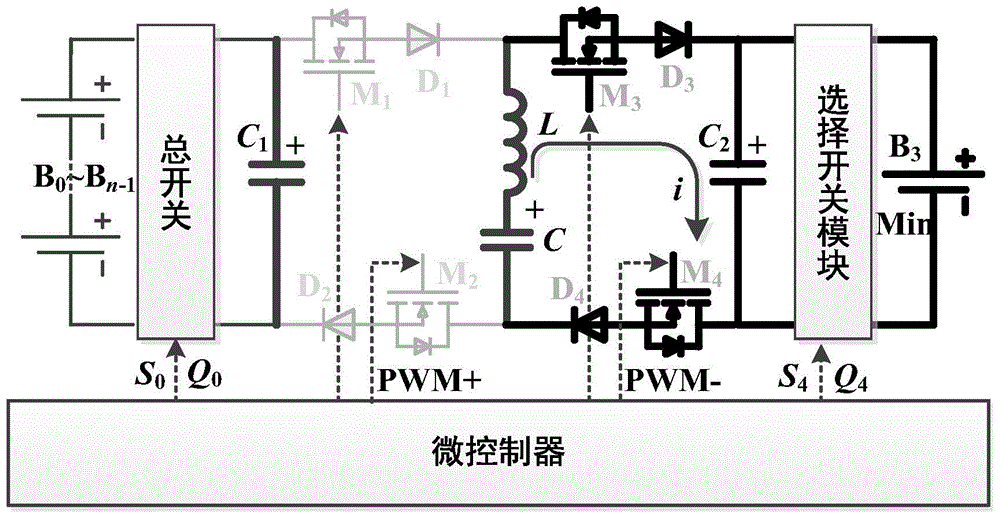

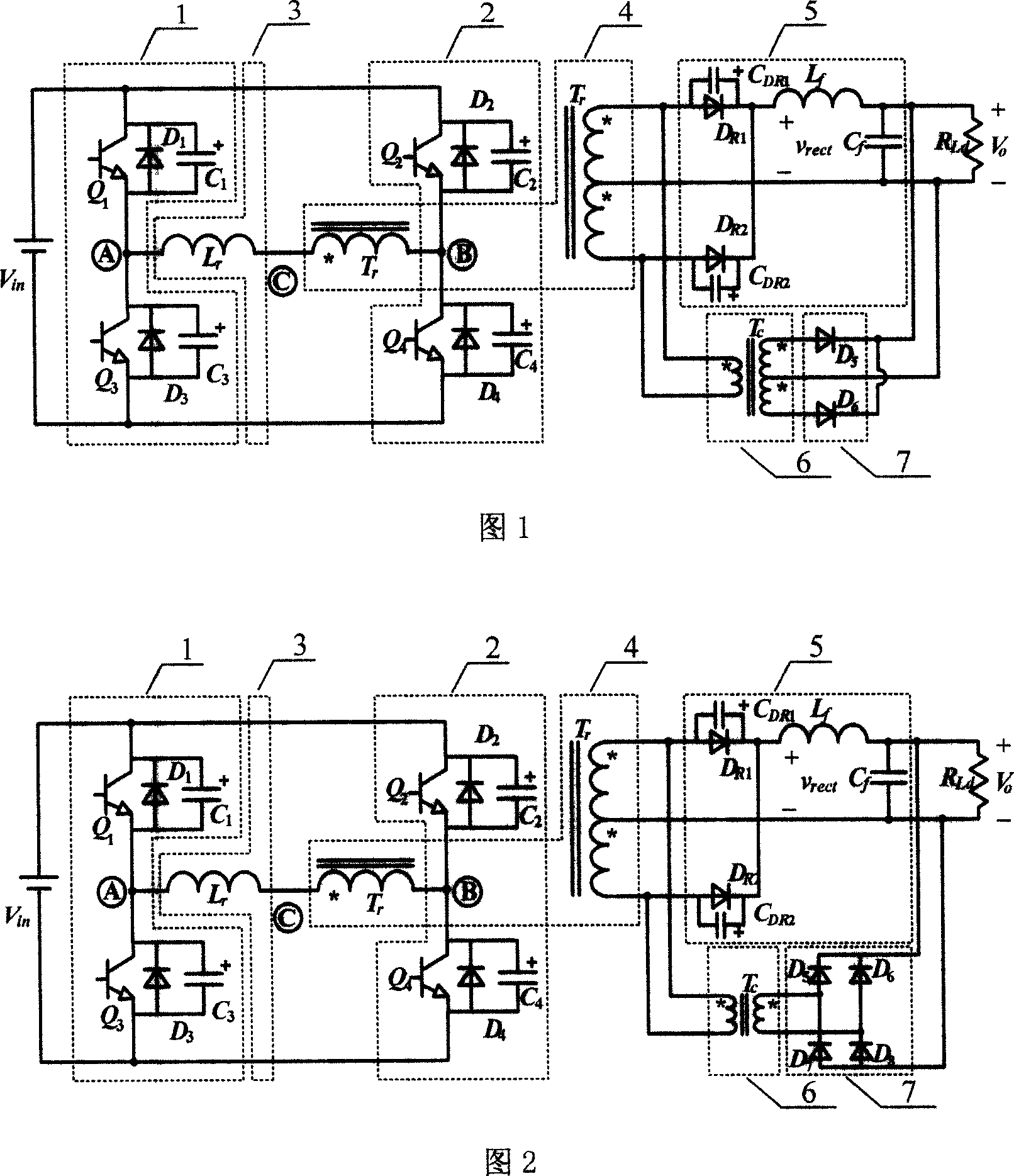

Pack to Cell equalization circuit based on LC resonant converter and implementation method thereof

ActiveCN103956801AEliminate lossesBalance switchBatteries circuit arrangementsElectric powerMicrocontrollerLow voltage

The invention discloses a Pack to Cell equalization circuit based on an LC resonant converter and an implementation method of the Pack to Cell equalization circuit based on the LC resonant converter. The equalization circuit mainly comprises a microcontroller, a selective switch module, a master switch, an equalization bus-bar, the LC resonant converter and filter capacitors. A battery single body with the lowest voltage is strobed into the equalization bus-bar by the microcontroller and is connected with the output of the LC resonant converter, and the positive electrode and the negative electrode of a battery set is connected with the input of the LC resonant converter by controlling opening and closing of the master switch. Meanwhile, the microcontroller sends a pair of PWM signals which are complementary in state to control the LC resonant converter to alternately work in a charging state or in a discharging state so as to achieve equalization of zero current switching. The Pack to Cell equalization circuit based on the LC resonant converter and the implementation method of the Pack to Cell equalization circuit based on the LC resonant converter effectively improve inconsistency among the battery signal bodies, enhance equalization efficiency, increase equalization currents, shorten equalization time, achieve equalization of zero current switching, reduce energy dissipation, reduce the number of switches and reduce the circuit size and cost.

Owner:SHANDONG UNIV

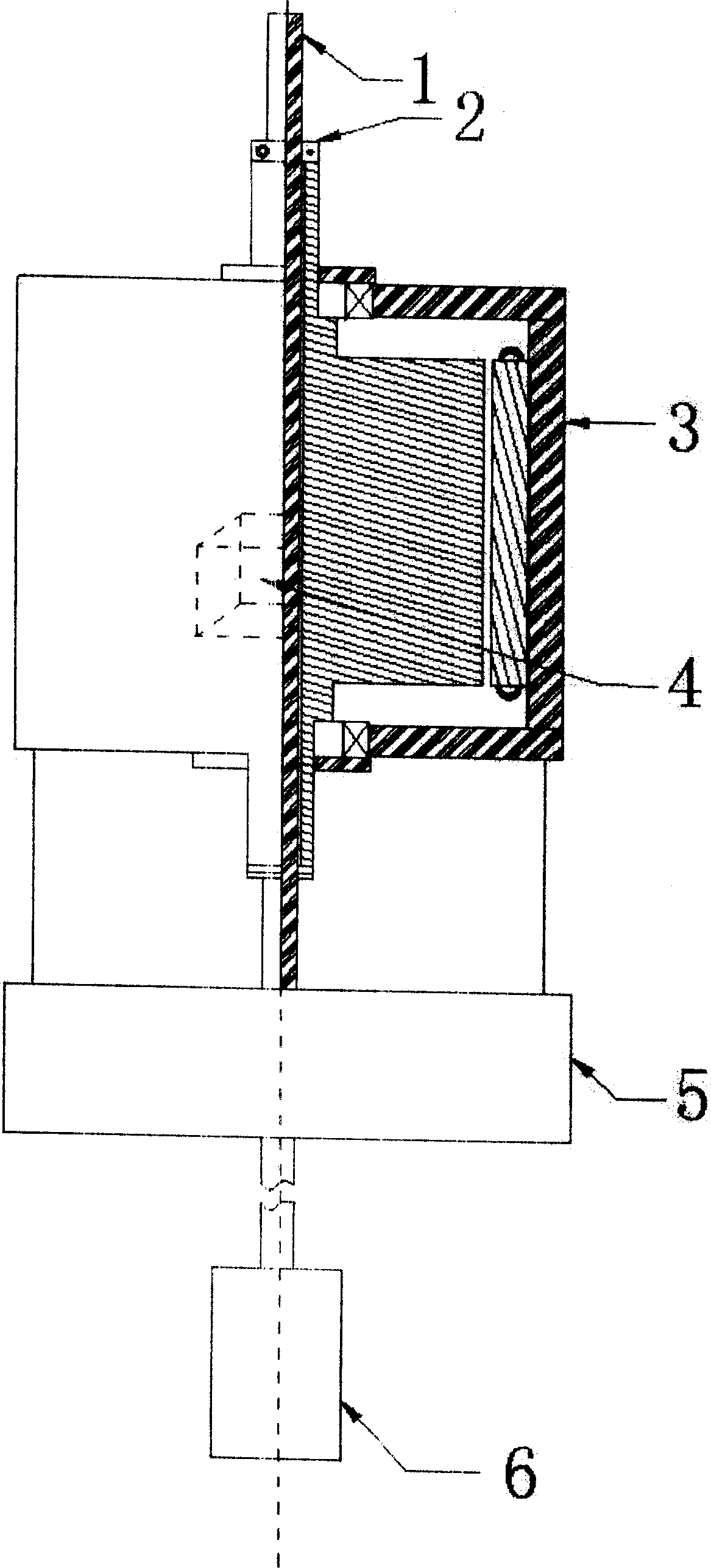

Directly driving screw pump device

InactiveCN1683791AEliminate Oil Spill ProblemsEliminate lossesFlexible member pumpsFluid removalLow speedEngineering

The directly driven screw pump device consists of polished rod, shaft coupler, low speed motor, motor controller, fixing seat and screw pump body. It features the hollow low speed motor shaft penetrating through the polished rod to connect integrally with the polished rod; the polished rod penetrating through the central hole in the fixing seat to connect to the shaft of screw pump in well; the low speed motor fixed on the fixing seat; the fixing seat fixed on the well head through support; and coaxiality of the polished rod, the low speed motor and the fixing seat with the well head.

Owner:胜利油田胜利电器有限责任公司

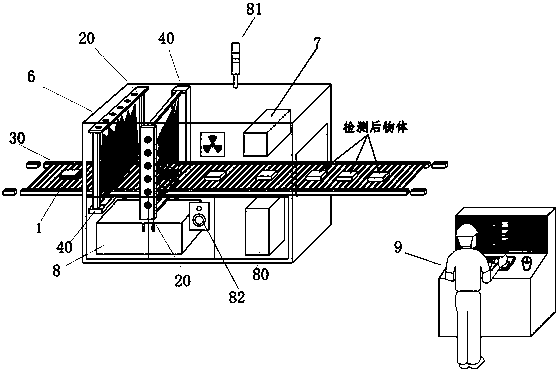

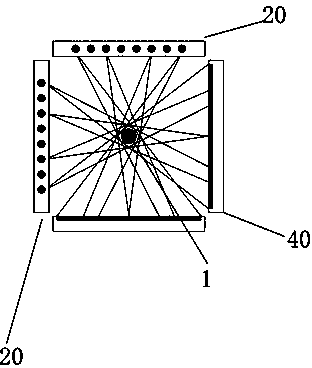

X-ray source array based real-time online industrial CT (computed tomography) detecting system

ActiveCN103760180AIncrease productivityFast scanningMaterial analysis by transmitting radiationRadiation diagnosticsImaging processingX-ray

The invention discloses an X-ray source array based real-time online industrial CT (computed tomography)detecting system. The system comprises a conveyor belt for conveying a to-be-detected object, wherein an X-ray source array of a carbon nanotube cathode and a detector array matched with the X-ray source array of the carbon nanotube cathode to conduct CT detection on the to-be-detected object are arranged on the outer side of the conveyor belt, and the system further comprises a control device for rapidly switching an X-ray source and reading a detector synchronously, and an image processing device used for acquiring a CT image detected by the detector array and storing and processing the CT image. The system greatly increases the scanning speed, rapidly finishes product detection, improves the production efficiency of a factory, and reduces economic cost.

Owner:SOUTHEAST UNIV

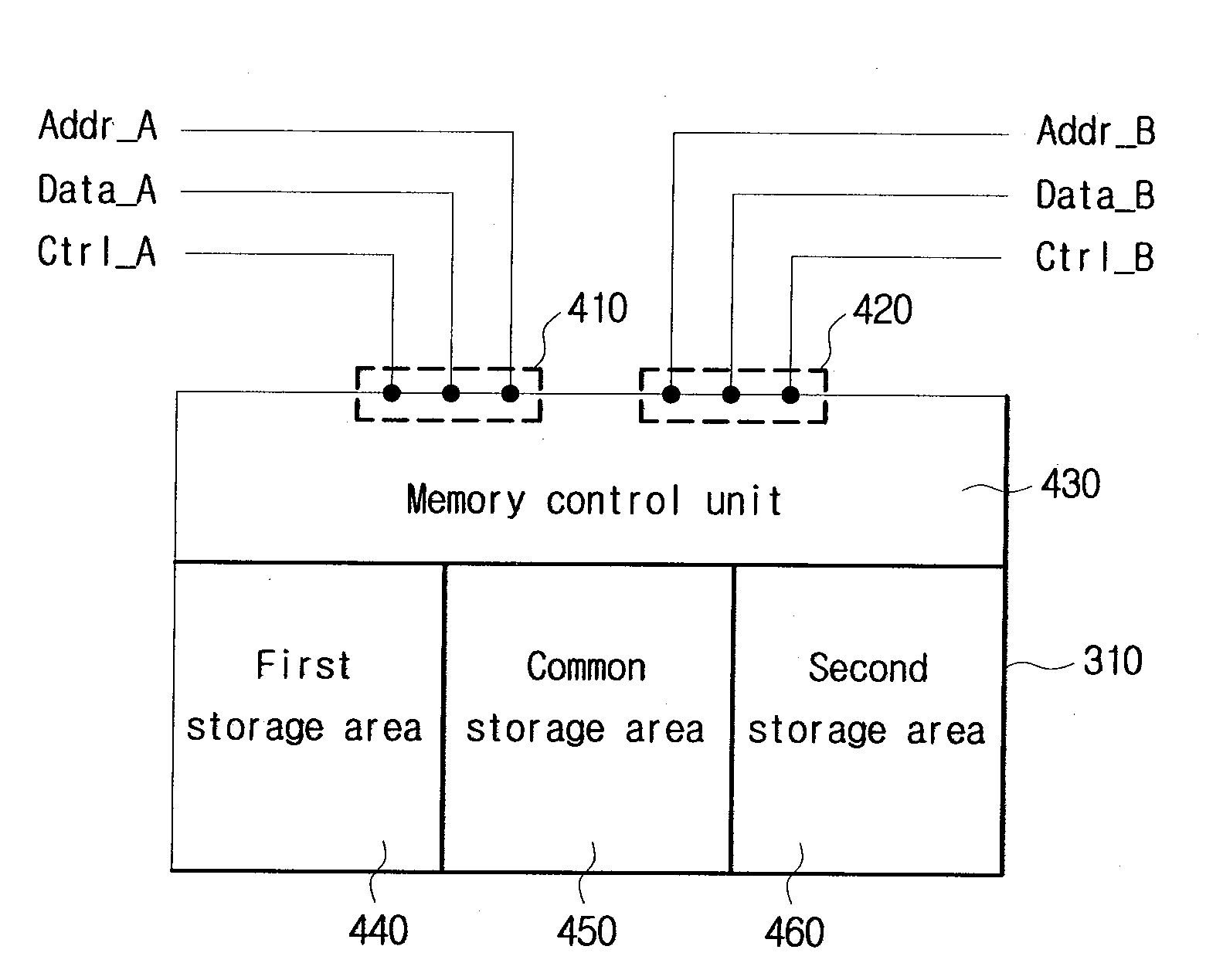

Operation Control of Shared Memory

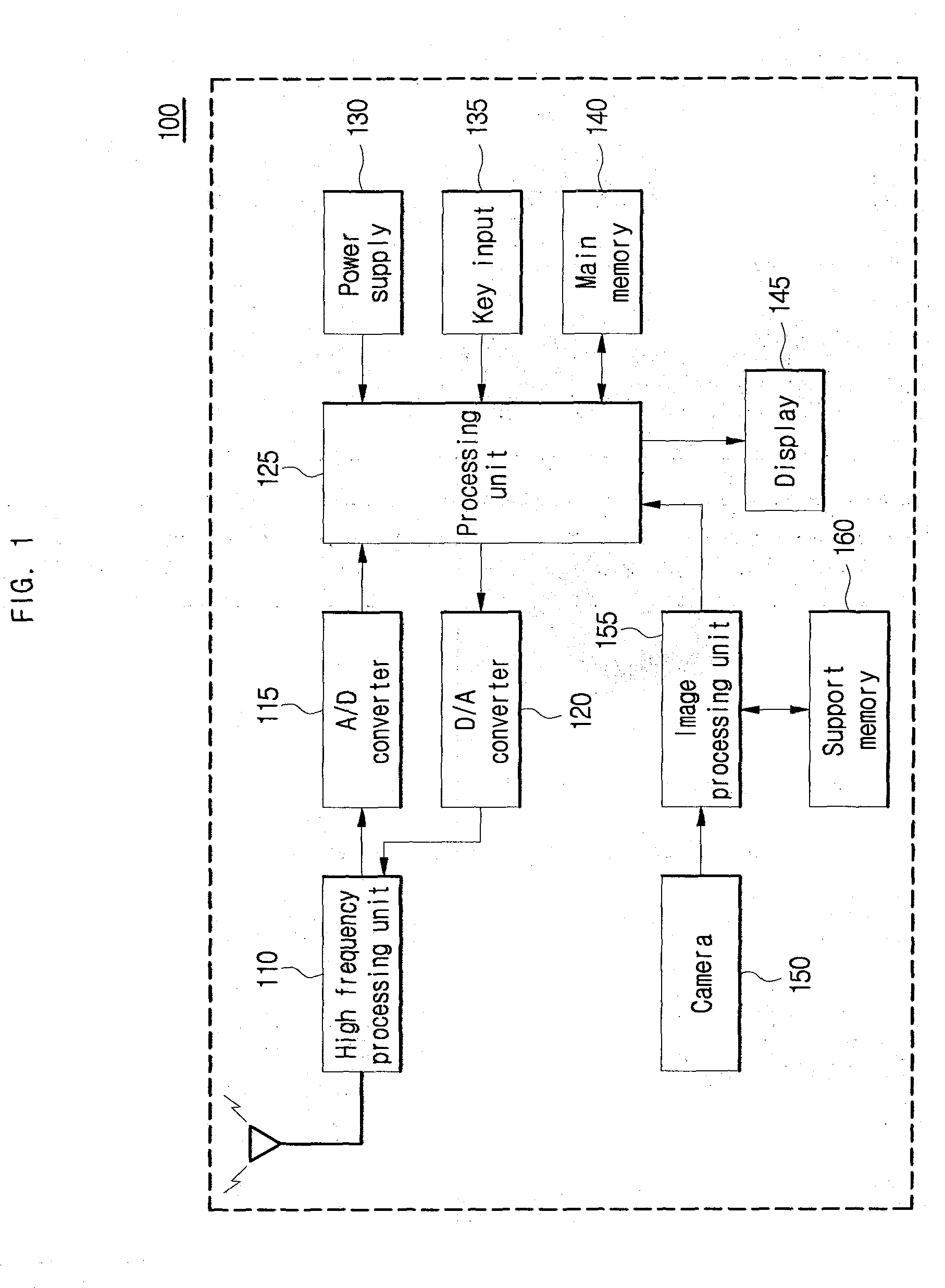

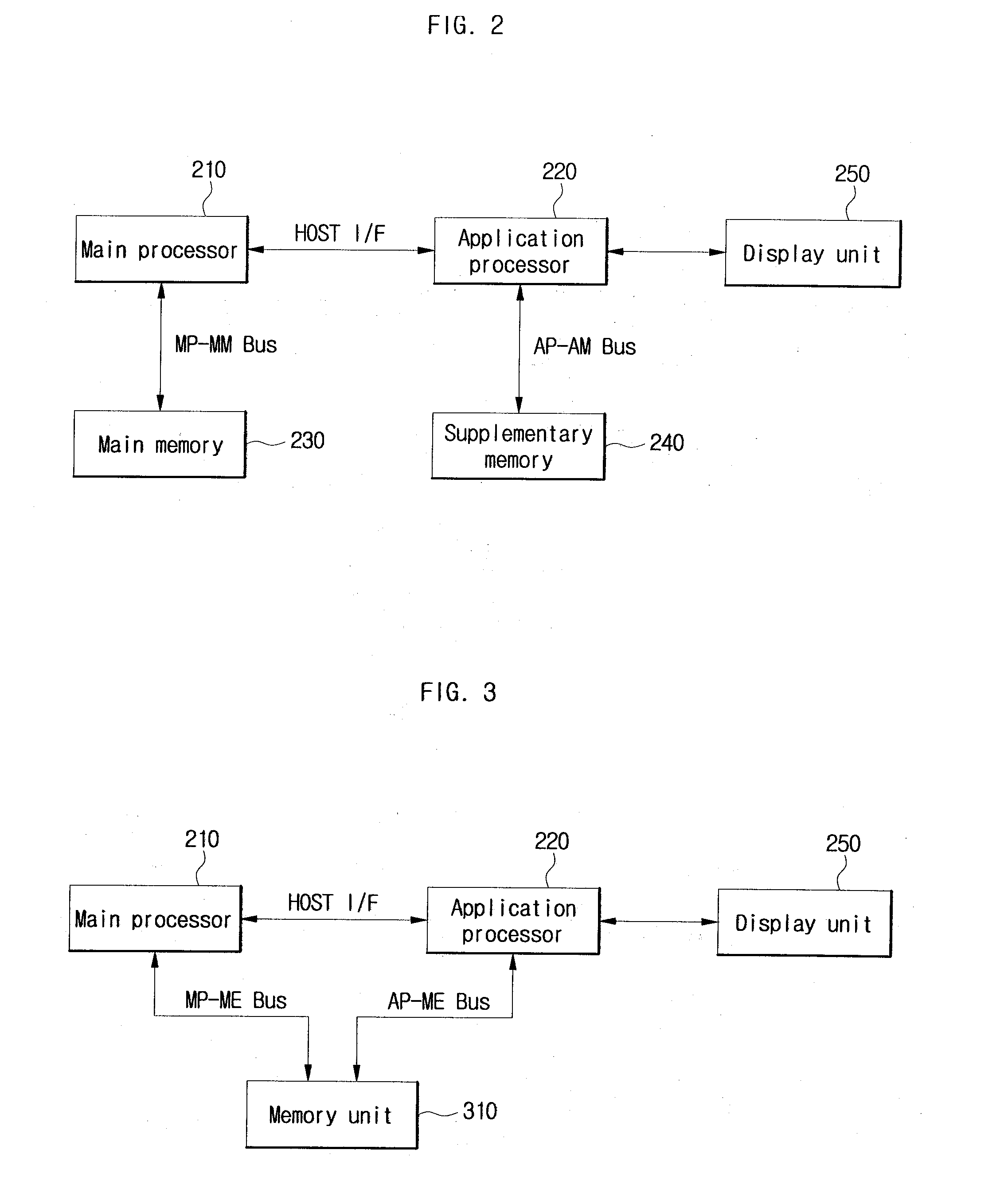

ActiveUS20080263286A1Minimize timeOptimize operation speed and efficiencyDigital computer detailsUnauthorized memory use protectionData transmission timeData storing

A method of controlling a shared memory and a user terminal controlling the operation of the shared memory are disclosed. The portable terminal according to an embodiment of the present invention has a memory unit with a storage area partitioned to blocks in a quantity of n and a plurality of processors reading or writing data by accessing a partitioned block. At least one of the partitioned blocks is assigned as a common storage area, accessible by a processor having an access privilege, and the processor having the access privilege performs an operation of maintaining the data stored in the common storage area. With the present invention, the common storage area can be accessed by a plurality of processors, and thus the data transmission time between the processors can be minimized.

Owner:MILA CO LTD

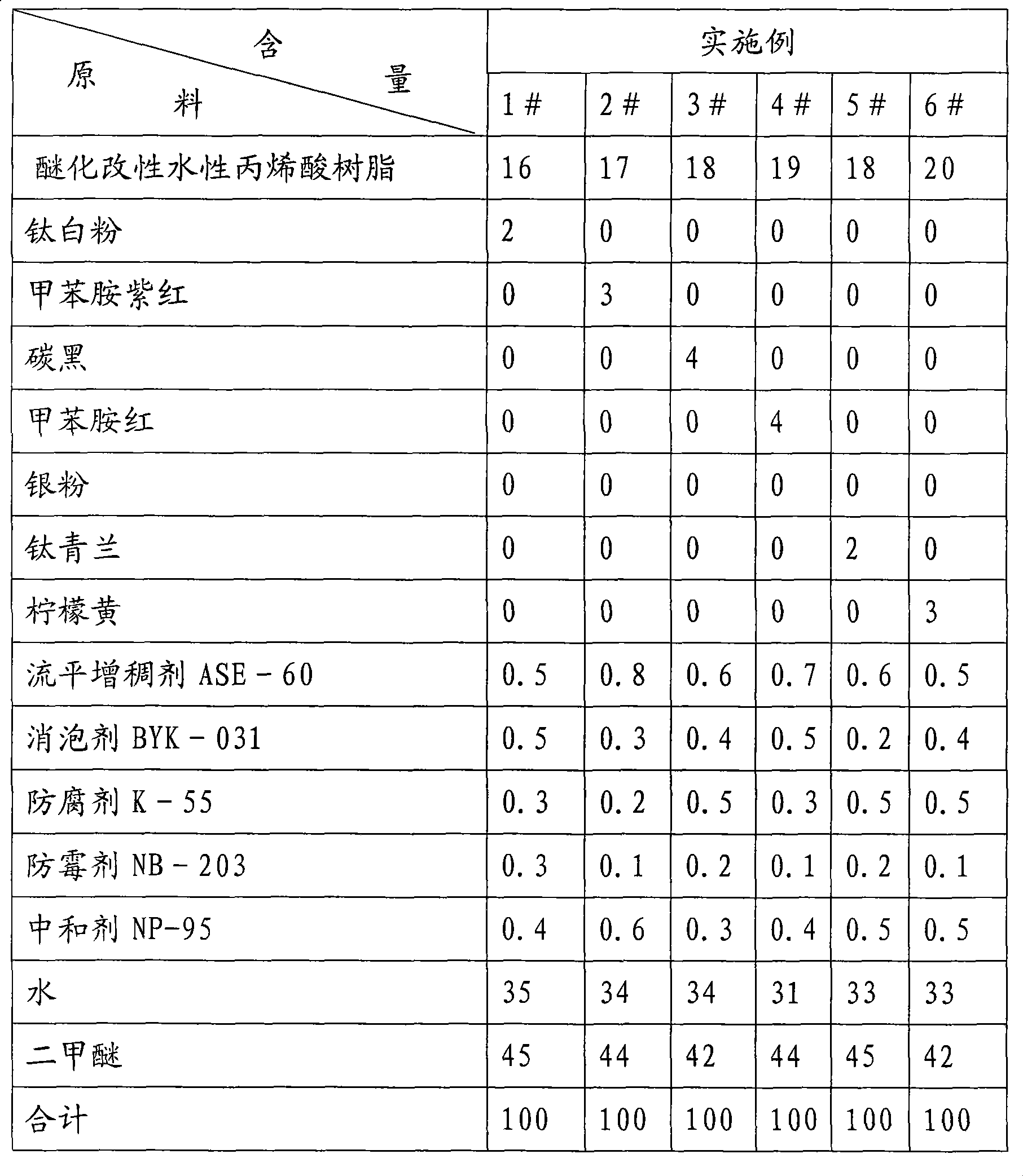

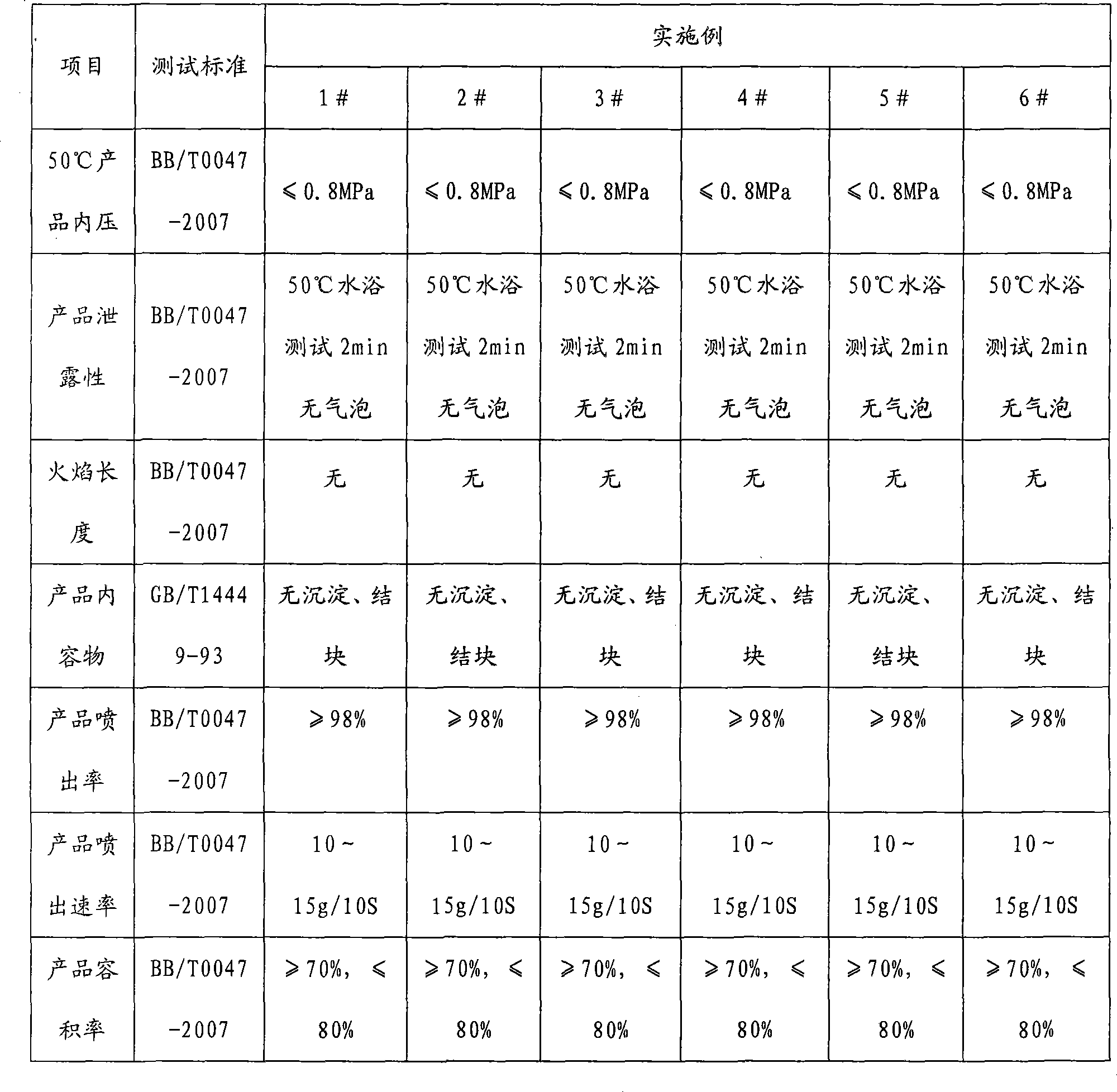

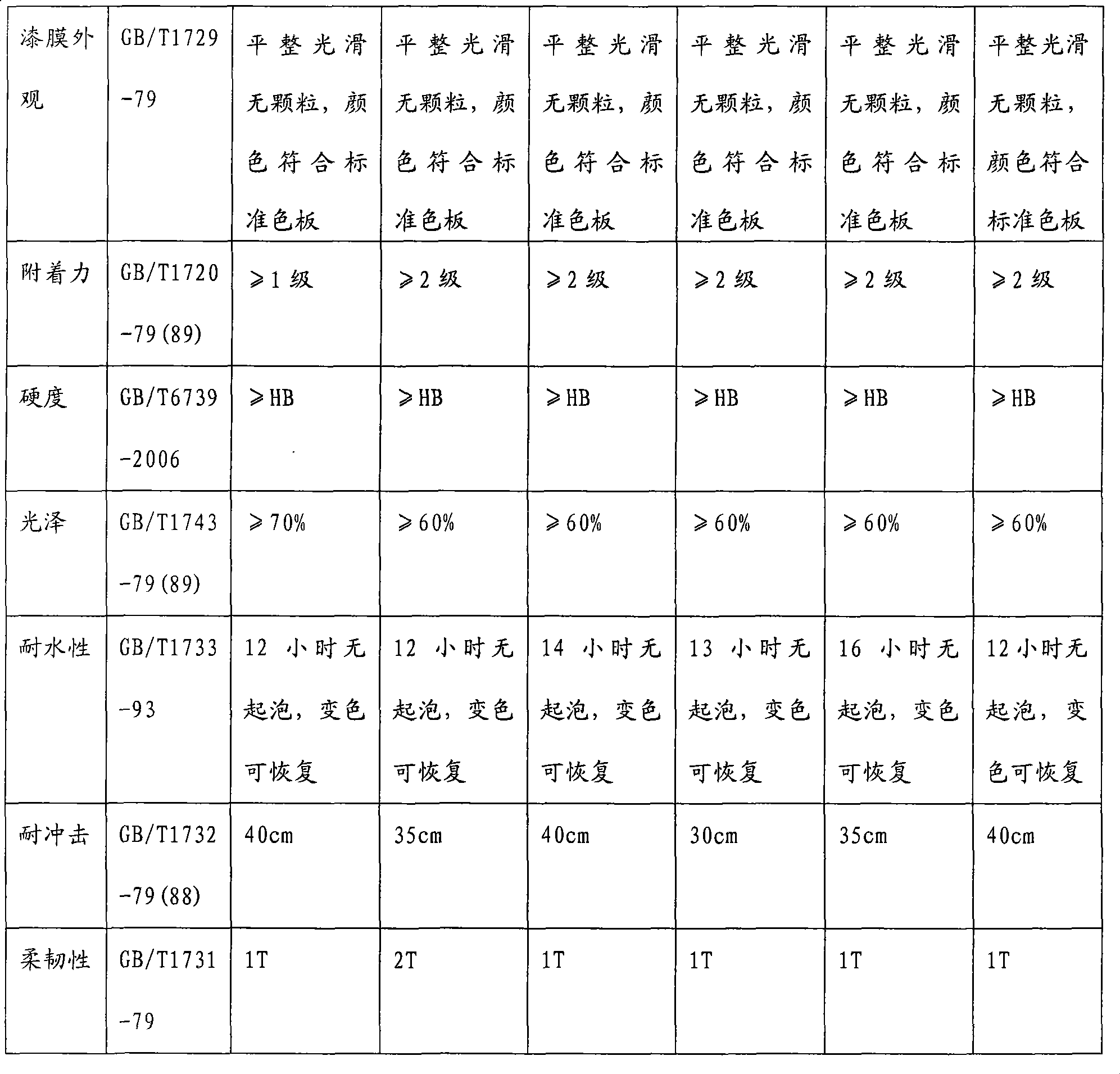

Water-soluble acroleic acid aerosol paint and preparation method thereof

InactiveCN101362873AFix compatibility issuesEliminate lossesCoatingsChemical compositionAtmospheric ozone

The invention relates to acrylics, in particular to aqueous acrylic acid aerosol paint. The aqueous acrylic acid aerosol paint includes the chemical components (counted in weight percentage) as follows: 15 to 20wt percent of etherified-modified aqueous acrylic acid resin, 2 to 5wt percent of coloring dye, 0.1 to 1.0wt percent of flatting thickening agent, 0.1 to 0.5wt percent of foam killer, 2 to 15wt percent of latent solvents, 20 to 35wt percent of water, 40 to 45wt percent of dimethyl ether as well as 0.5 to 1.0wt percent of addition agent. The invention also provides a preparation method of the aqueous acrylic acid aerosol paint, solves the compatibility problem between a propellant and the material of an aqueous aerosol, eliminates the loss of an atmospheric ozone layer, greatly reduces the content of VOC, lightens the pollution to the environment, also eliminates the problem of the flame length for product burning, leads the whole production process to be more environment-friendly and safer as well as is beneficial to the body health of a worker.

Owner:广州保赐利化工有限公司

Non-stator iron core brushless DC motor

The brush-less DC motor without stator iron core includes mainly outer rotor iron core, hollow cup stator, permanent magnet, inner rotor iron core and rotor shaft. Both the outer rotor iron core and the inner rotor iron core are connected to the rotor shaft for synchronous rotation; the permanent magnet is installed onto the outer rotor iron core or the inner rotor iron core; and the hollow cup stator is fixed to the casing. The permanent magnetic path is one closed loop comprising the outer rotor iron core, the inner rotor iron core and the air gap in between. Unlike traditional brush-less DC motor, the present invention has no stator iron core and rotor iron core divided into two parts including the outer rotor iron core and the inner rotor iron core, and has no stator iron loss radically and lowered total motor loss.

Owner:BEIHANG UNIV

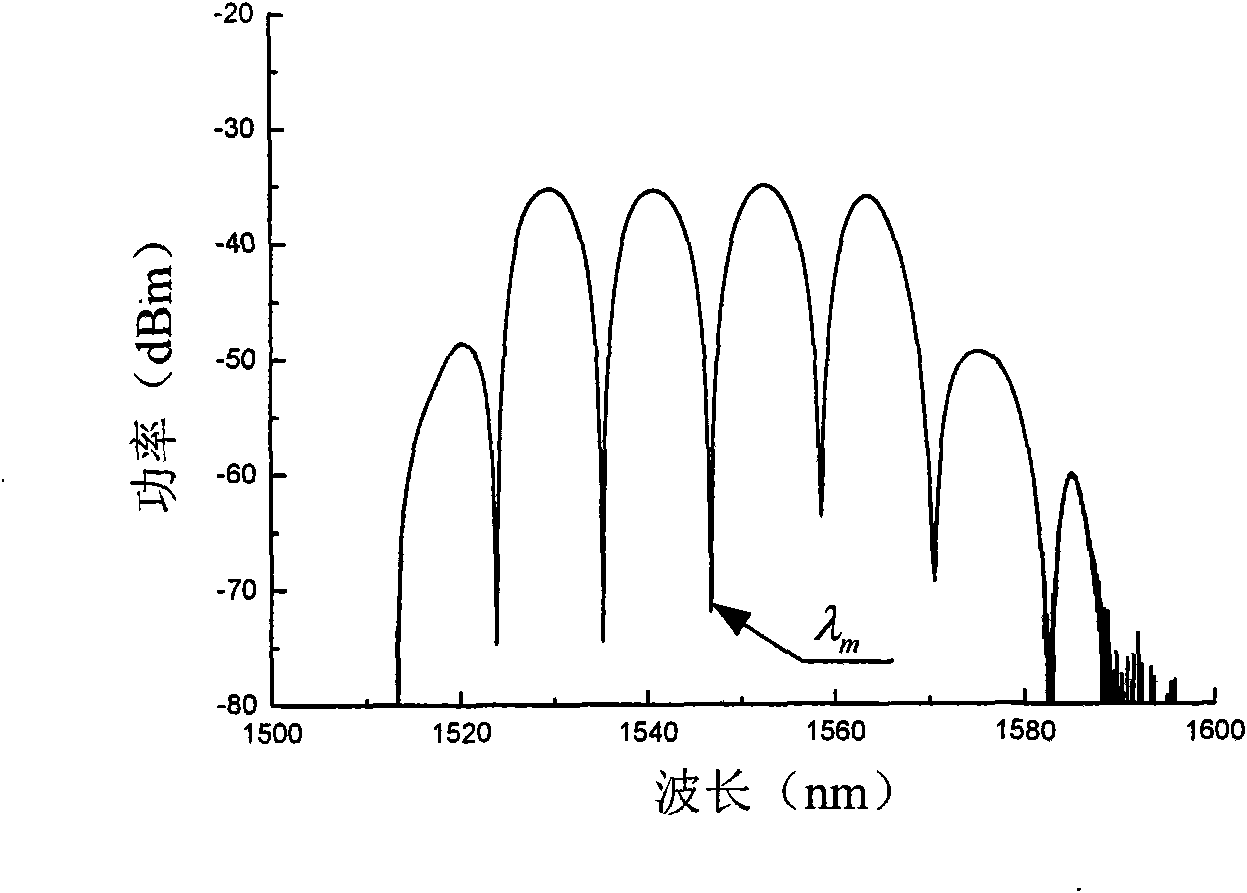

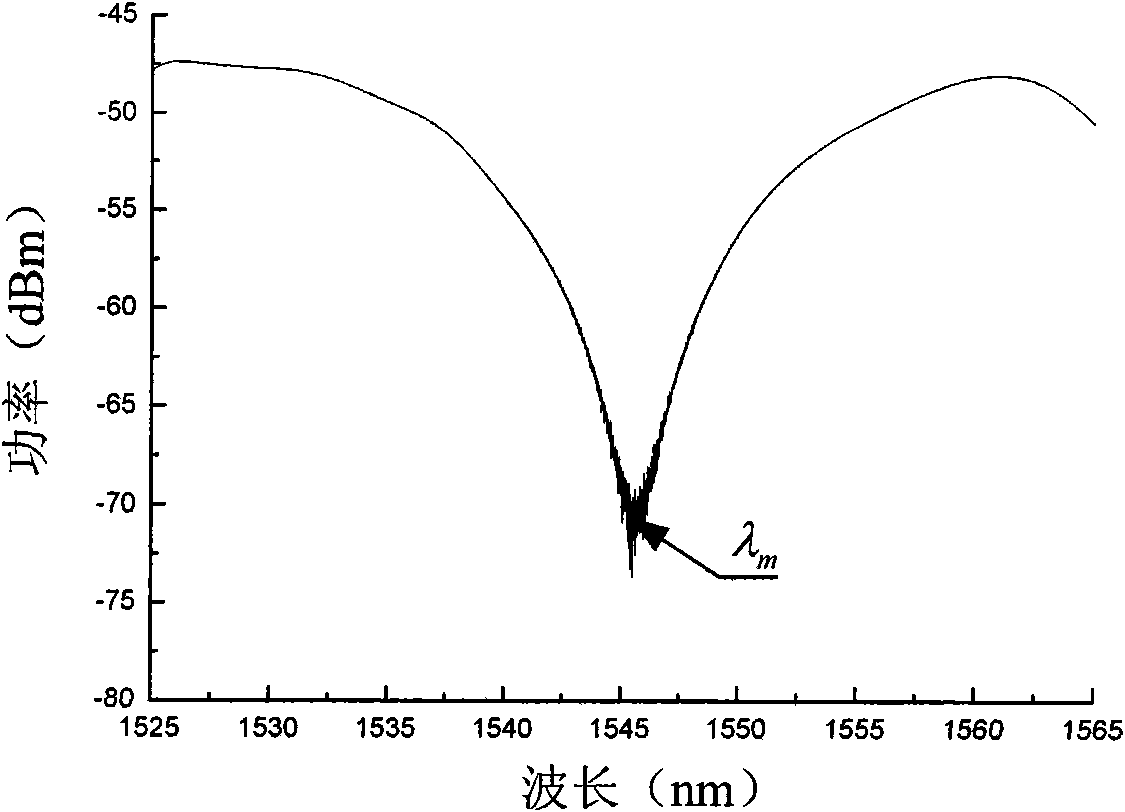

Optical fiber temperature sensor for detection based on wavelength corresponding to extreme value and temperature sensing method

InactiveCN101639387AEasy to implementImprove anti-interference abilityThermometers using physical/chemical changesFiber couplerPolarization-maintaining optical fiber

The invention discloses an optical fiber temperature sensor for detection based on wavelength corresponding to an extreme value. The optical fiber temperature sensor determines length of a polarization maintaining fiber sensing head by calculation so that a transmitted spectrum at a transmission port of a hybrid fiber Sagnac interferometer which consists of the polarization maintaining fiber sensing head, a fiber coupler and a broadband light source has single extremum property. The wavelength corresponding to an extreme value of the transmitted spectrum also changes with ambient temperature variation, and the wavelength and the temperature acting on the fiber sensing head form a linear proportional relation T=(m / aL) Lambada m-b / a. The optical fiber temperature sensor realizes temperaturemeasurement by detecting the wavelength change corresponding to the extreme value of the transmitted spectrum. The optical fiber temperature sensor can realize temperature measurement by detecting thewavelength change corresponding to the extreme value of the transmitted spectrum, can eliminate the influence such as light source floating, light path loss and the like, and can improve the sensingsensitivity. The optical fiber temperature sensor is an all-fiber structure, and has the advantages of a small quantity of devices, easy realization, low cost, strong adaptability and strong anti-interference capability.

Owner:BEIHANG UNIV

Making method for fracture model of artificial bone

InactiveCN102522039ASimple and fast operationImprove performanceEducational modelsDICOMBone specimen

The invention discloses a making method for a fracture model of artificial bone, which comprises the following steps: carrying out continuous spiral CT (computed tomography) scanning on affected bone along the cross section to obtain a multi-layer image, storing according to a Dicom 3.0 standard and making out a three-dimensional reconstruction model of the bone and a fractured section by utilizing Mimics software; fractioning the model to be processed by UG (Unigraphics) software and making an appearance mold of the bone and a mark groove for the position of a fracture line of the archetypalbone by numerically-controlled mill processing; and carrying out three-dimensional printing to obtain a fractured section model, also placing at the position of the mark groove of the corresponding bone appearance mold, jointing an upper mold and a lower mold, filling polymethyl methacrylate, standing at room temperature, solidifying and taking out the fractured section model so as to obtain a specimen of the fracture model of the artificial bone. In this way, the prepared fracture model is made in one step, and the complicated processes of obtaining a bone specimen and afterwards making fracture artificially, the consumption of equipment and the worry of enhancing the cost are omitted. The condition of stress between fractured sections is comprehensively and truly reflected by an obtained fracture interface, and the assistance is provided to the treatment of clinical fracture.

Owner:TIANJIN HOSPITAL

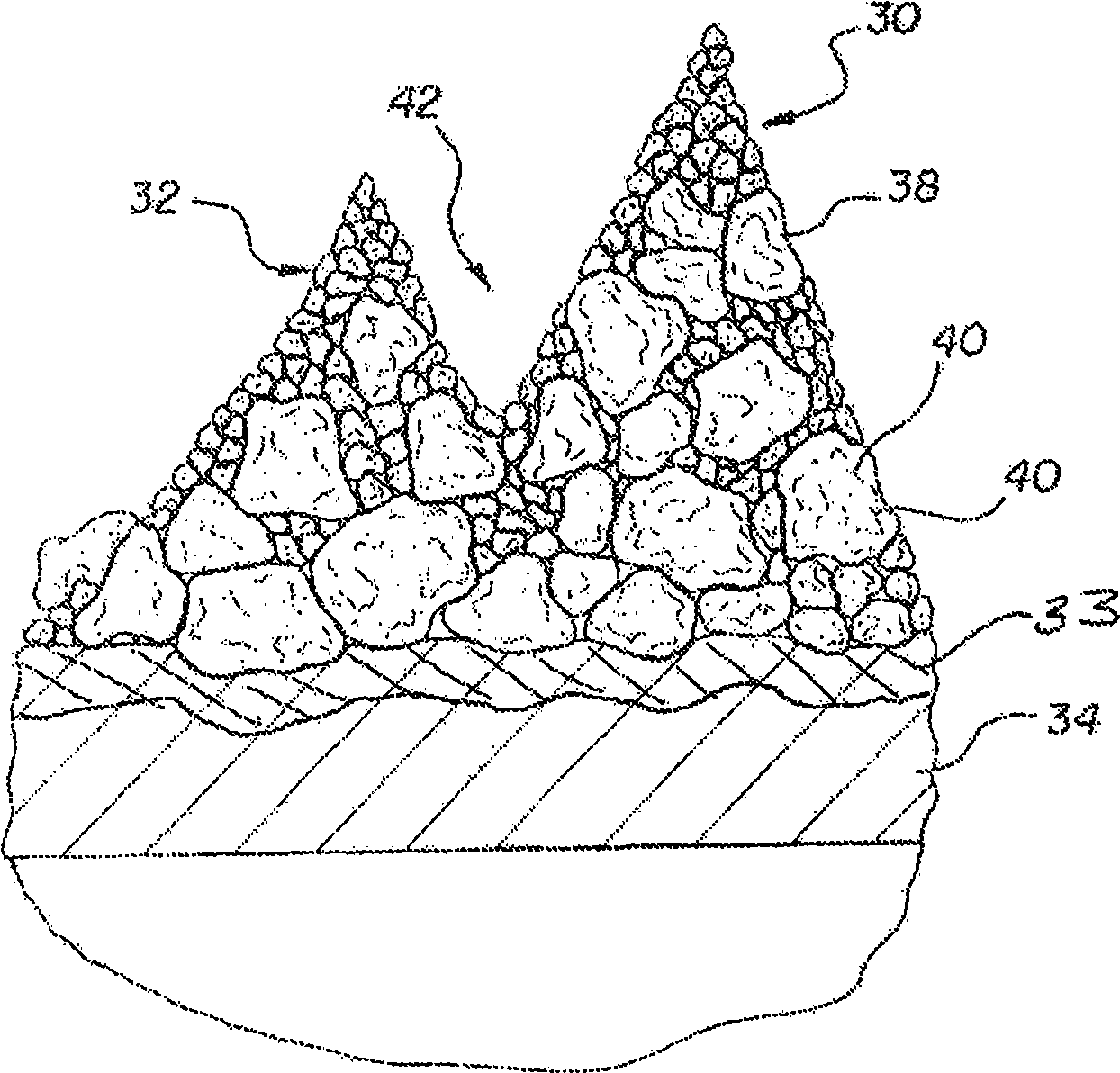

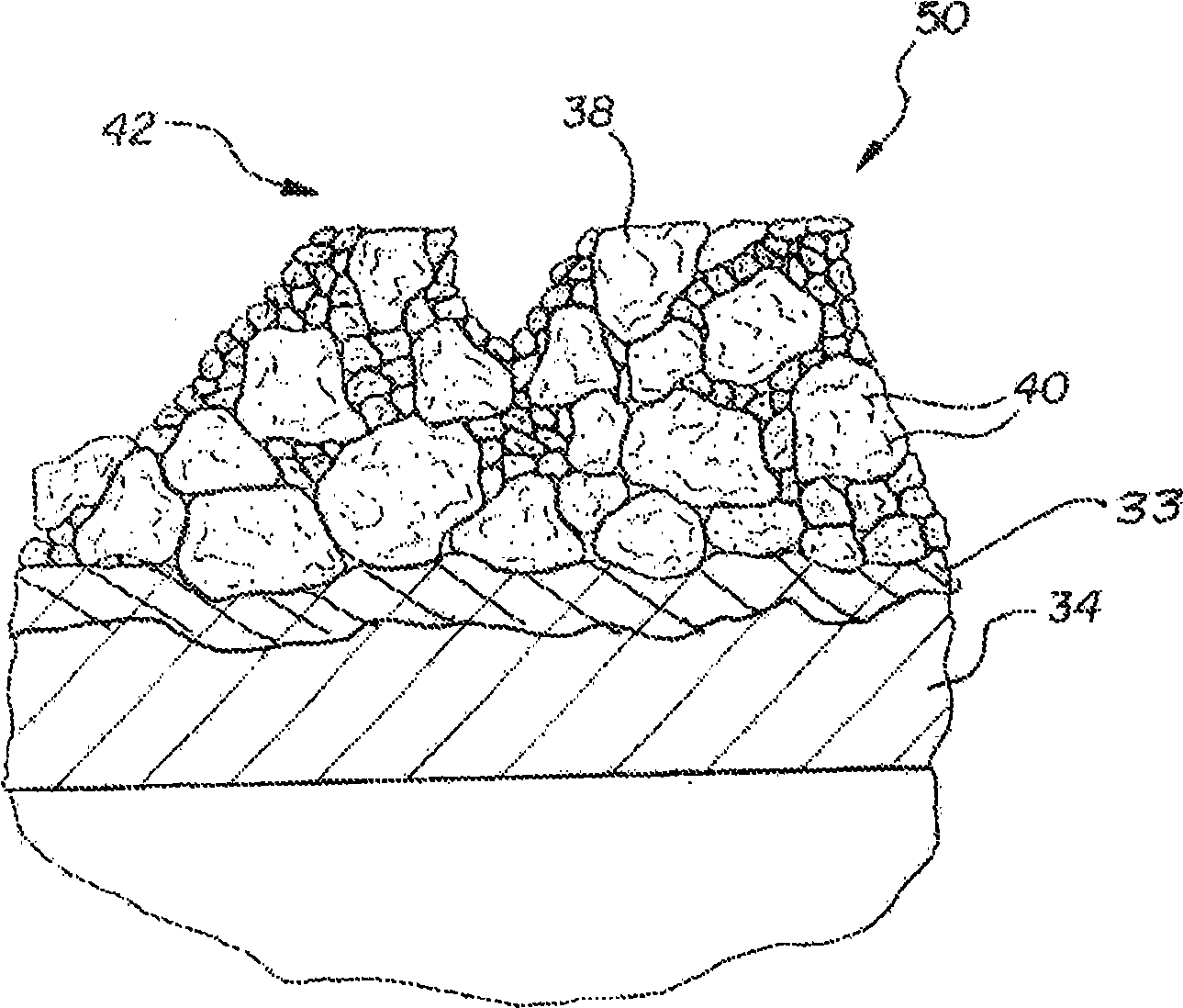

Abradable dry film lubricant and the method for applying same and article made therefrom

InactiveCN101535420AEasy meshReduce contact stressShaftsBearing componentsSubstrate surfaceLubricant

An article with an abradable dry powder coating thereon comprises an abradably coated article with a substrate surface and having at least one coating of a liquid primer on the substrate surface and then coating with at least one abradable dry powder coating on the surface of the liquid primer. The sequence of layers may also be reversed, or additional layers may be useful. The abradable dry powder coating is formed of a dry powder coating composition including a thermoset resin having a cure temperature combined with at least one filler material, wherein the filler is formed of a material which does not melt substantially at or below the cure temperature of the resin, whereby an abradable coating results employing a filler to make the coating. A method of making a composition for coating an article with a coating curable into an abradable coating is also disclosed, comprising melt- mixing an evaporative carrier-free mixture of a dry powder thermoset resin having a cure temperature, to form a mass composite, wherein the filler is formed of a material which does not substantially melt at or below the cure temperature of the resin, cooling the mass composite, and breaking the cooled mass composite into powder particles, thereby forming the composite powder composition.

Owner:安德鲁·W·苏曼

Sendust magnetic powder core

InactiveCN104795195AImproves uniformity and coordinationReduce lattice distortion and internal stressInorganic material magnetismSendustMagnetic powder

The invention discloses a sendust magnetic powder core. Magnetic powder adopted for the sendust magnetic powder core comprises, by weight, 9-10% of Si, 5-6% of Al, and the balance Fe. Based on the ratio, the sendust magnetic powder core is prepared through powder pre-annealing, screening, passivation, insulation coating, compression moulding forming and heat treatment. According to the sendust magnetic powder core, the sendust magnetic powder core preparing technology is optimized, each preparation step is controlled, and excellent comprehensive performance is realized through the cooperation of all the steps.

Owner:ANHUI HUALIN MAGNETIC TECH

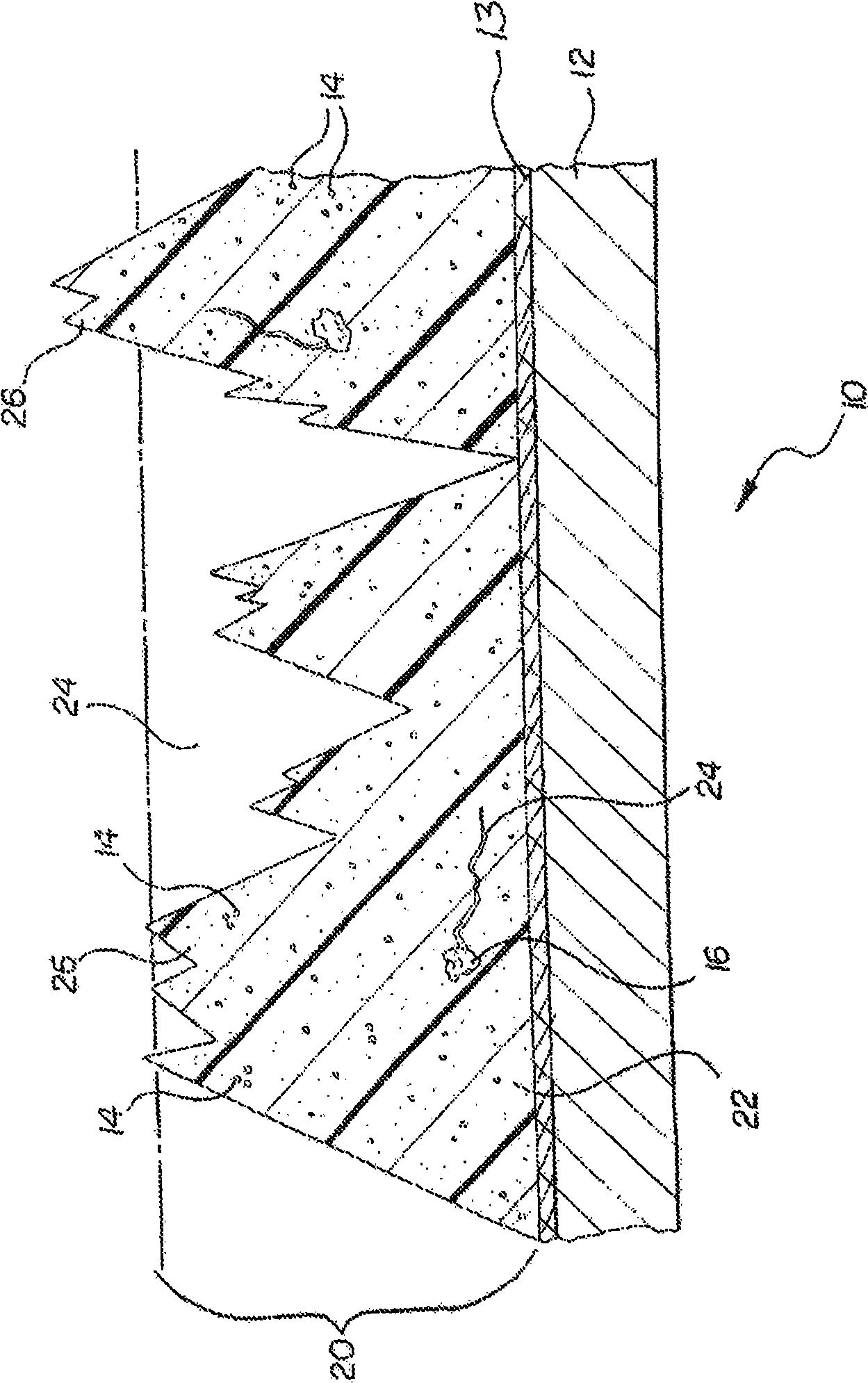

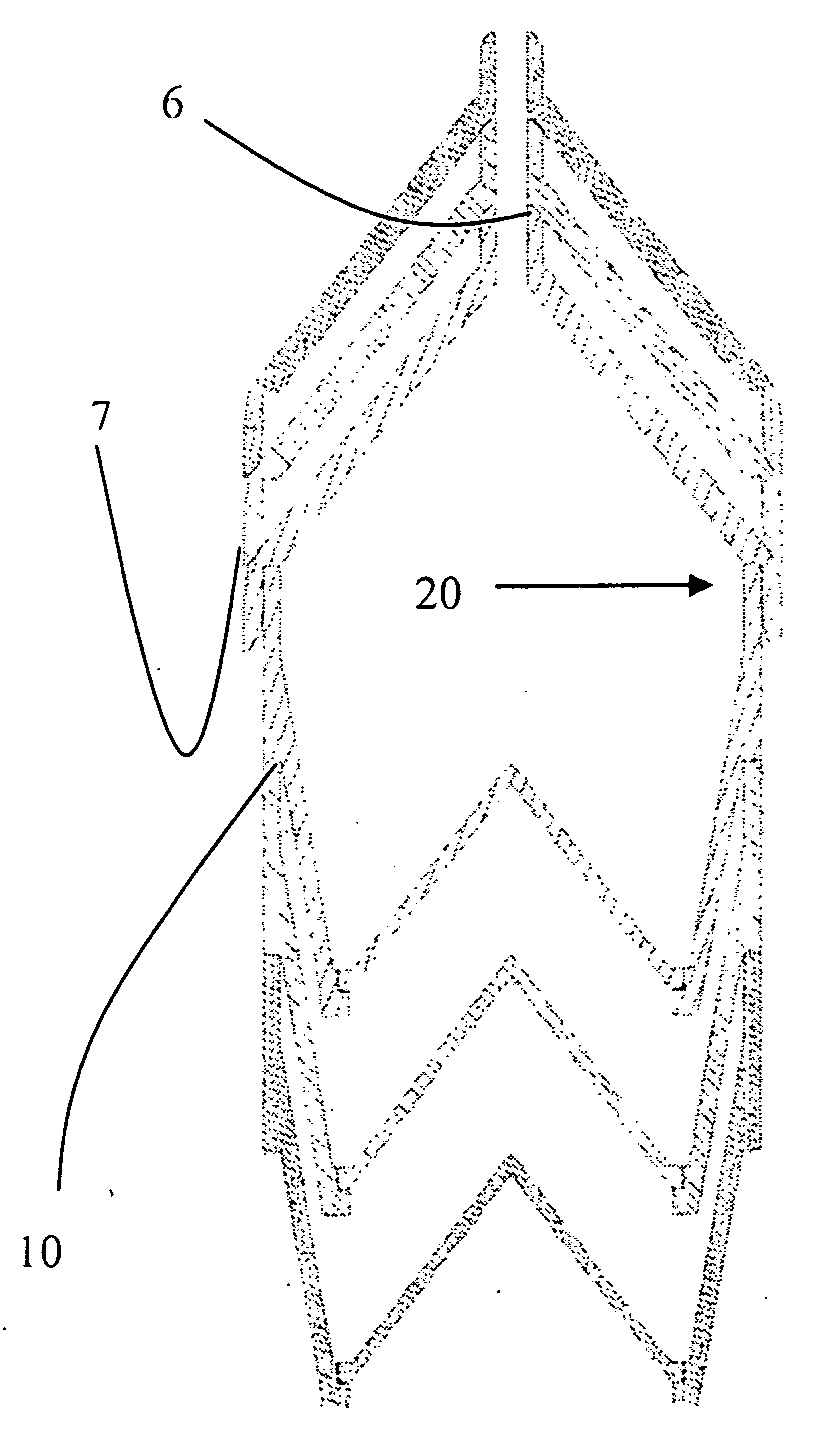

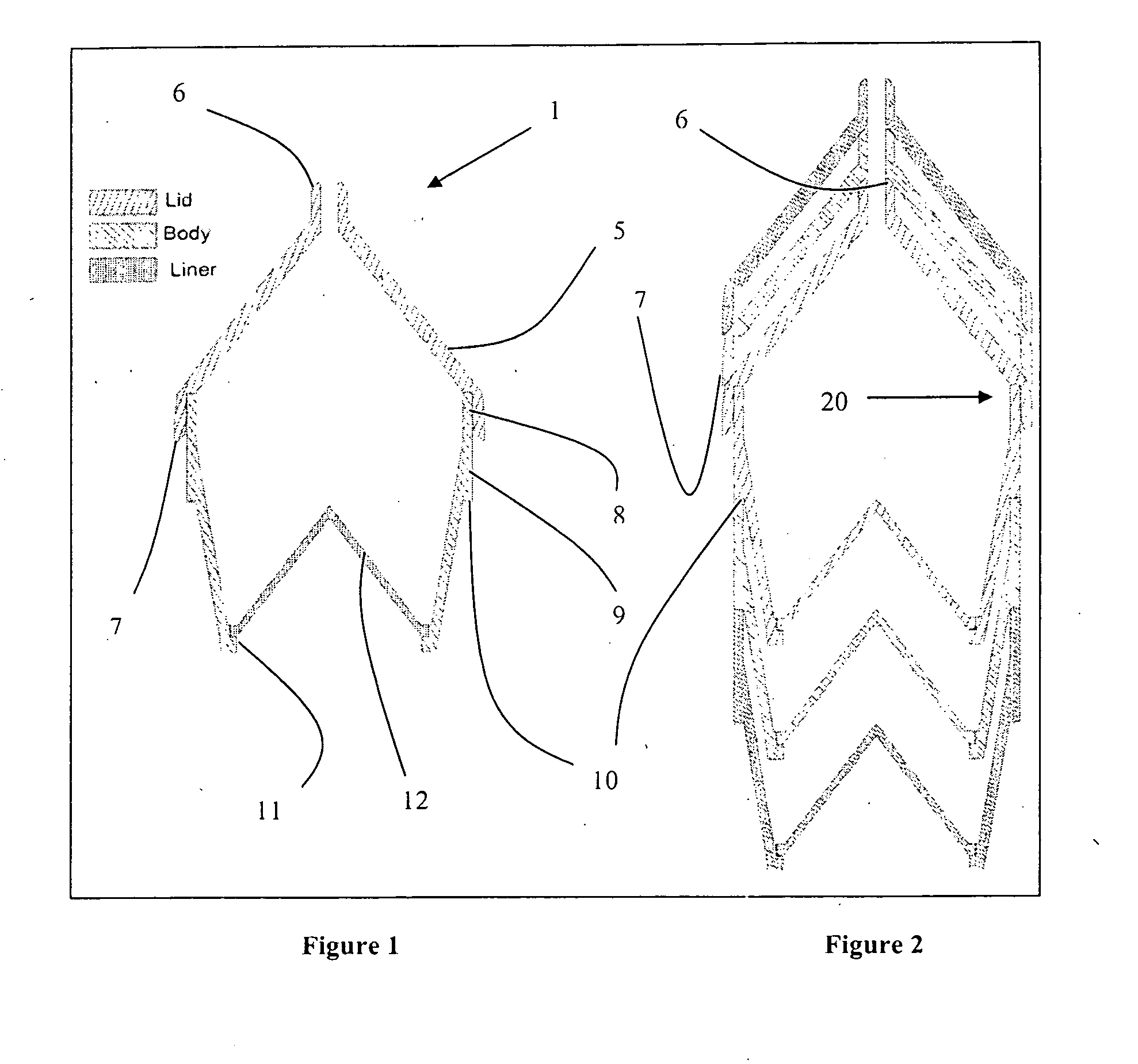

Shaped Charge Casing

ActiveUS20140060369A1Save volumeConvenient nestingAmmunition projectilesExplosive chargesShaped chargeEngineering

A shaped charge casing 1 designed to be nested to reduce overall volume, which benefits storage or carriage. A lid portion 5 is connected at 8 to a body portion 9 by means of a screw thread. A shaped charge liner 12 can be positioned onto lip 11. The lid portion 5 and body portion 9 can be separated to allow filling or unpacking of explosive material.

Owner:THE SEC OF STATE FOR DEFENCE IN HER BRITANNIC MAJESTYS GOVERNMENT OF THE UK OF GREAT BRITAIN & NORTHERN IRELAND

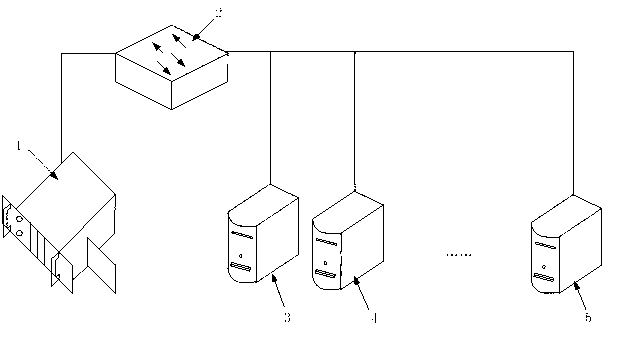

Rapid and unattended operation system

InactiveCN102710788AEliminate lossesAvoid inconsistenciesProgram loading/initiatingTransmissionSystem configurationNetwork interface controller

The invention provides a rapid and unattended operation system, which comprises a head node and a plurality of child nodes, wherein the head node is connected with the child nodes through a switchboard; the head node is provided with a terminal service device; and each child node is provided with a server, and each server is provided with a network card which has a preboot execution environment read only memory (PXEROM) chip. In a limit range which can be born by the servers, an operating system can be installed in a plurality of servers simultaneously, so that the system is high in concentration degree, the installation speed is greatly increased, the phenomenon of different system configuration because the operating system is installed by different personnel is prevented, and the inconsistency of files is effectively prevented.

Owner:AMAX INFORMATION TECH (SUZHOU) CO LTD

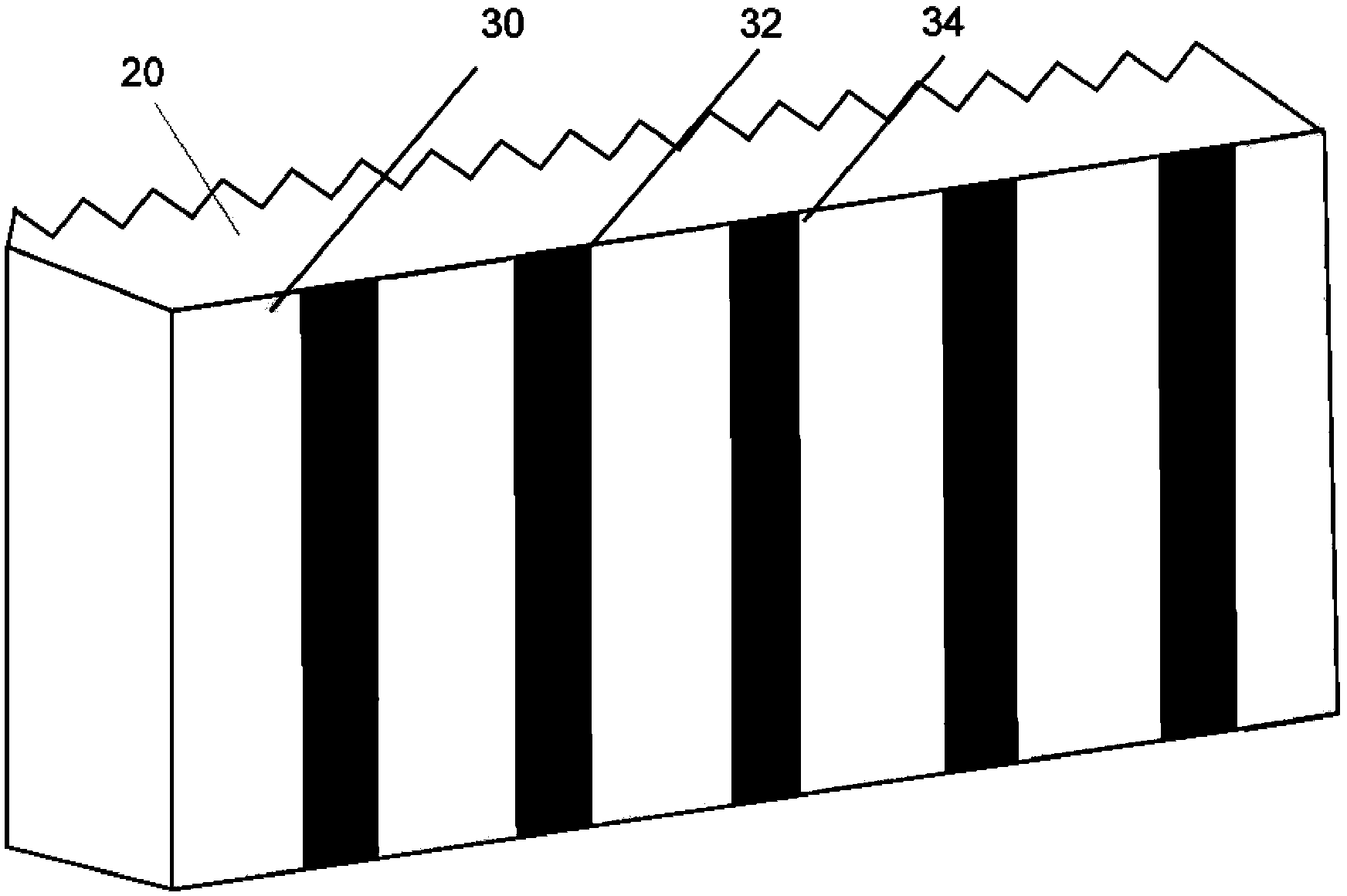

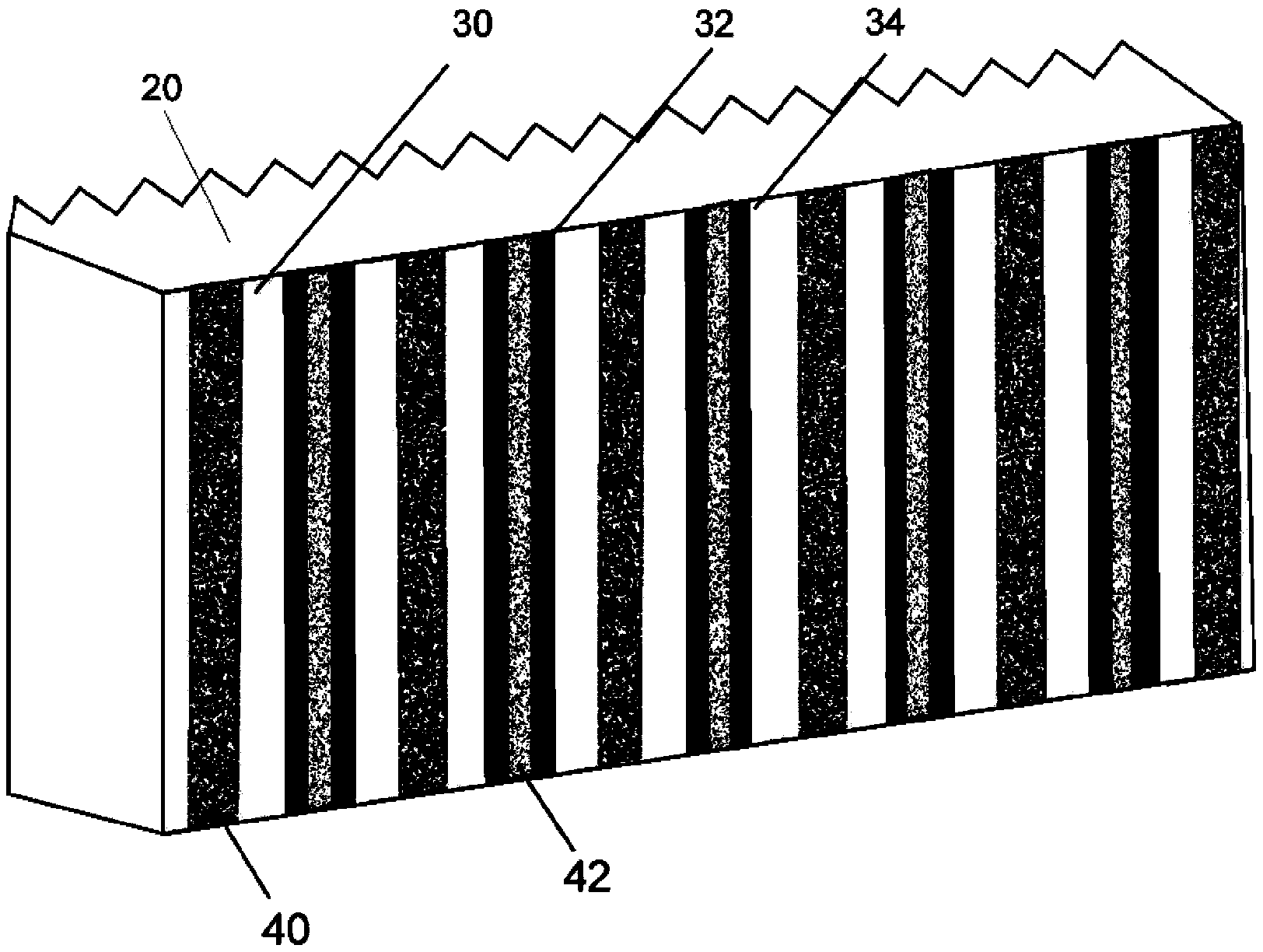

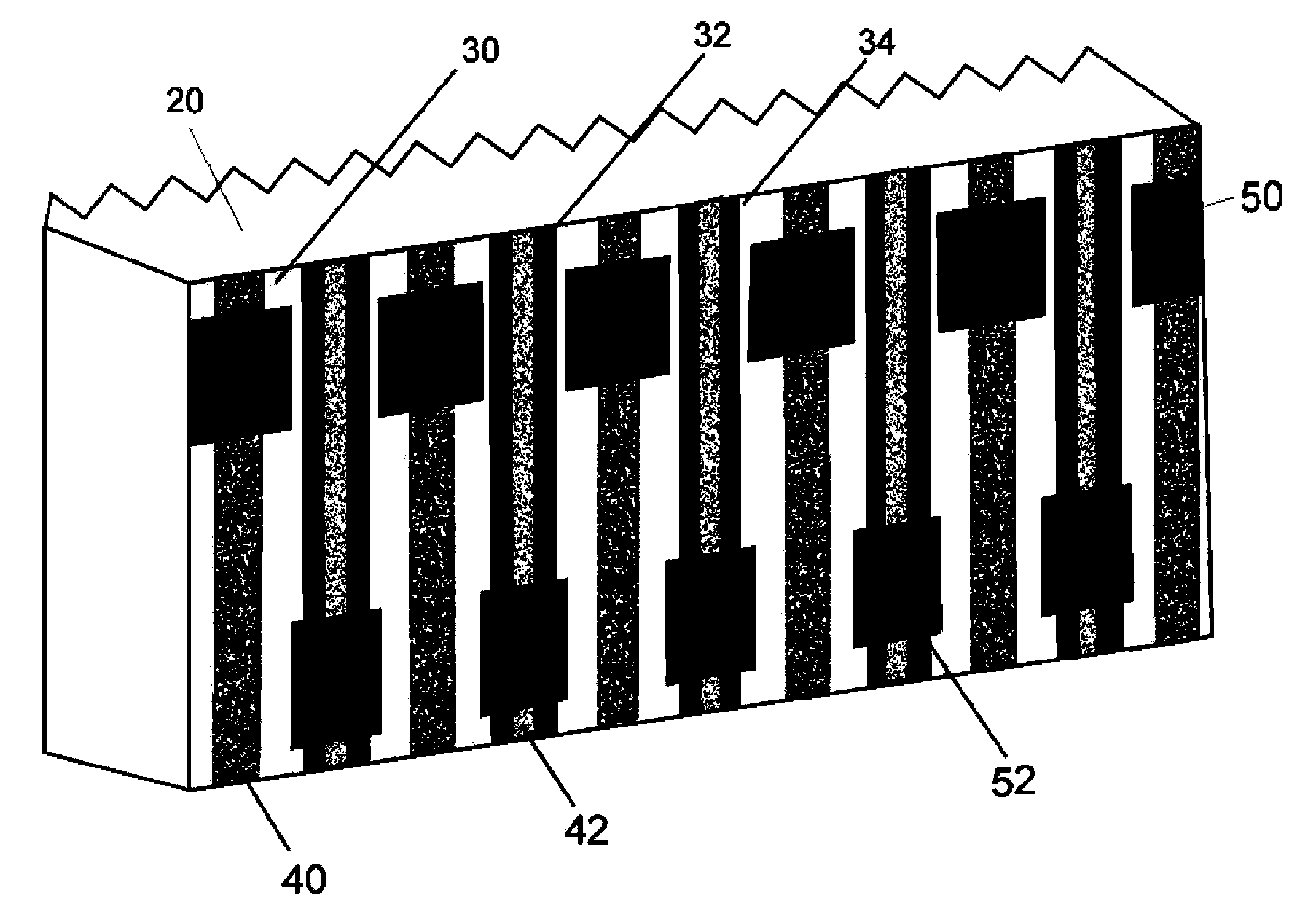

Back-contact solar battery and manufacturing method thereof

InactiveCN103762253AEliminate lossesEliminate electrode shadowing effectsFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention discloses a back-contact solar battery. The back-contact solar battery comprises a silicon substrate, wherein p+ doping areas and n+ doping areas are mutually alternately distributed on the back surface of the silicon substrate, each p+ doping area is provided with a positive-electrode contact fine grid, each n+ doping area is provided with a negative-electrode contact fine grid, the back surface of the silicon substrate is further provided with a positive-electrode main grid and a negative-electrode main grid, the positions, making contact with the negative-electrode contact fine grids, of the positive-electrode main grid are provided with insulation blocking layers, and the positive-electrode main grid is located on the insulation blocking layers and connected with the positive-electrode contact fine grids. The positions, making contact with the positive-electrode contact fine grids, of the negative-electrode main grid are provided with insulation blocking layers, and the negative-electrode main grid is located on the insulation blocking layers and connected with the negative-electrode contact fine grids. The invention further discloses a manufacturing method of the back-contact solar battery. The back-contact solar battery can eliminate carrier transverse transmission loss caused by a common main grid of a back-contact solar battery in the prior art and the electrode shadowing effect of the common main grid, and the number of fill factors and the number of short-circuit currents of the back-contact solar battery are increased.

Owner:JA SOLAR TECH YANGZHOU +1

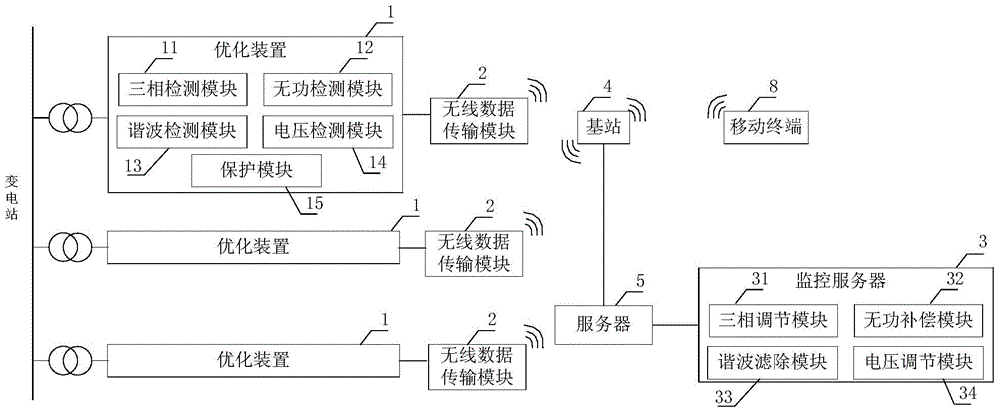

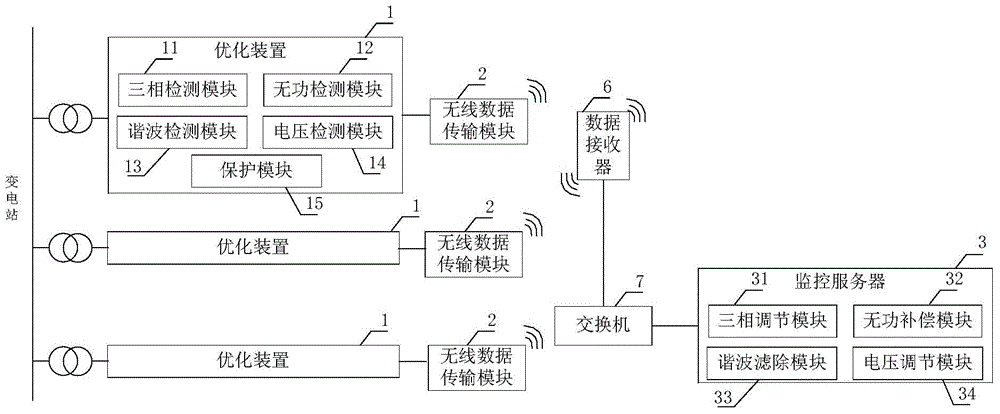

Integrated optimization system of electric energy quality of power distribution network

ActiveCN105186518AAddressing deficiencies in compensationImprove power qualityPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationVoltage regulator moduleEngineering

Disclosed in the invention is an integrated optimization system of an electric energy quality of a power distribution network. The system is composed of a monitoring server, optimizing devices, and wireless data transmission modules. The optimizing devices consist of three-phase detection modules, reactive power detection modules, harmonic detection modules, and voltage detection modules. The monitoring server includes a three-phase adjustment module, a reactive power compensation module, a harmonic filtering module, and a voltage regulation module. With the system, defects of compensation of the traditional capacitor can be overcome; the electric energy quality and energy conversion application requirements of the power distribution network can be met; and the electric energy quality can be improved substantially. On the basis of the modular design, reactive compensation, harmonic wave filtering, and three-phase unbalance inhibition of all modules can be realized independently or simultaneously; and non-capacity attenuation is realized and the service life is long.

Owner:江苏振光电力设备制造有限公司

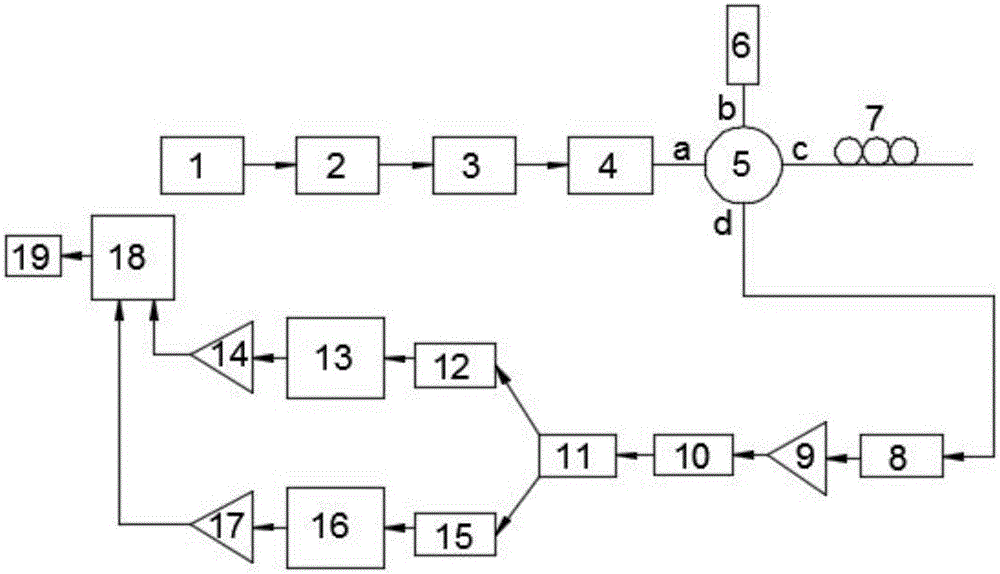

Distributed optical fiber sensing system

InactiveCN106153089ARealize dynamic measurementEliminate instabilityThermometers using physical/chemical changesUsing optical meansPhase cancellationGrating

The invention discloses a distributed optical fiber sensing system, which comprises a narrow linewidth laser, a modulator, an optical isolator, an erbium-doped optical fiber amplifier, a circulator, an optical fiber grating, a sensing optical fiber, an optical detector, a microwave amplifier, a high pass filter, a power distributor, a first filter module, a first microwave detection module, a first low-frequency amplifier, a second filter module, a second microwave detection module, a second low-frequency amplifier, a data acquisition card and a computer. Distributed optical fiber vibration or sound signal measurement is realized, dynamic large-phase signal measurement is effectively realized, a phase cancellation and fading problem can be eliminated, a high-speed data acquisition device with a GS / s sampling rate is not needed, the cost is reduced, the response time is not influenced, the strength and the frequency shift changes of Brillouin scattering light can be measured respectively on the premise of eliminating instability of a laser source and line loss, and temperature changes and the strain are further obtained.

Owner:YANSHAN UNIV

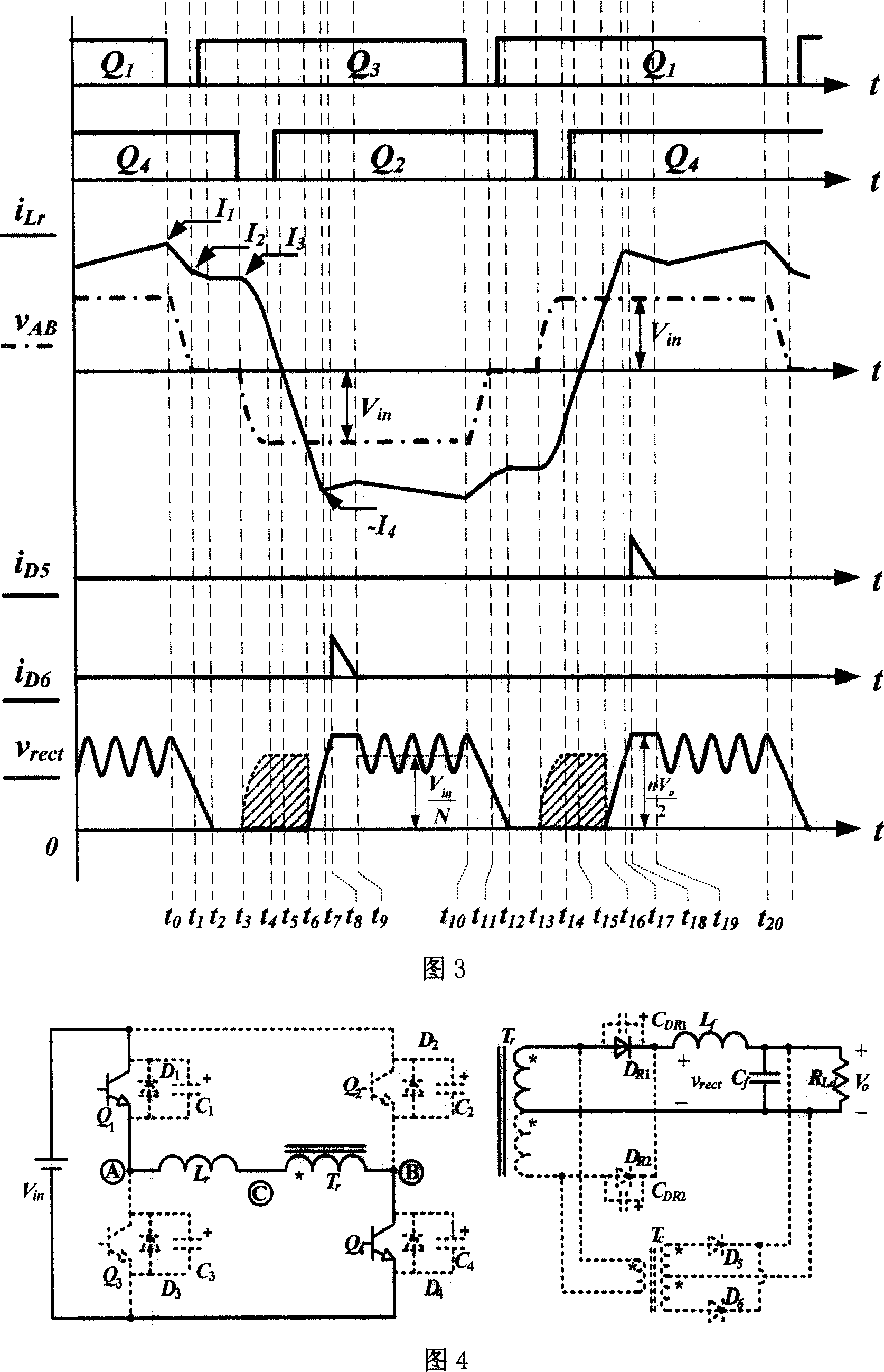

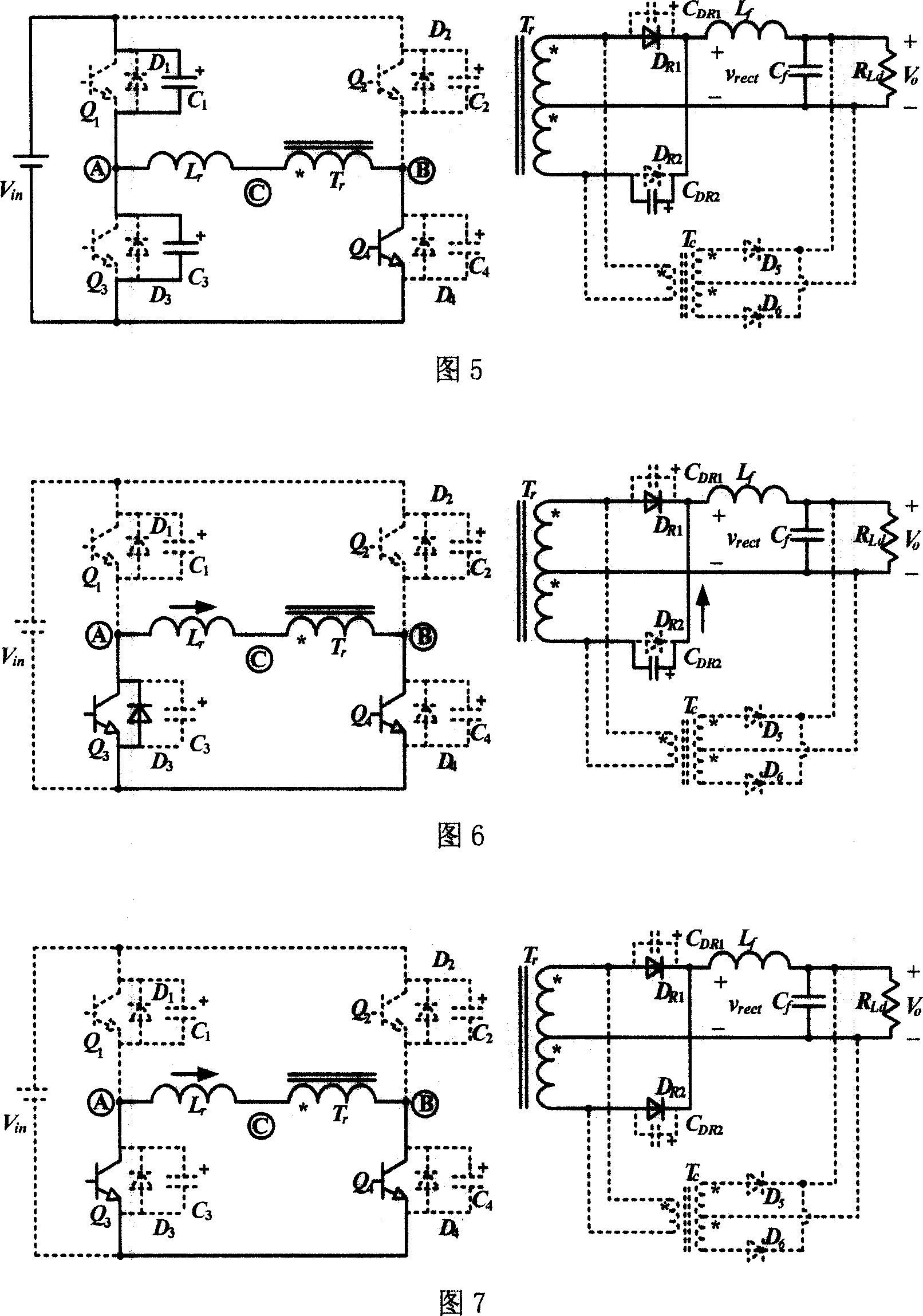

Isolated DC transducer of side edge clamp

InactiveCN101005240AEliminate the effects ofEliminate lossesAc-dc conversionApparatus with intermediate ac conversionRectifier diodesTransducer

The DC convertor is composed of DC power supply, first inversion bridge arm, second bridge arm, resonant inductance, isolating transformer, rectifying and filtering circuit, current transformer, and clipper circuit. The added current transformer and clipper circuit eliminates voltage surge and voltage pike caused by backward recovery of rectifying tube, reduces voltage stress of rectifying tube, and eliminates waste caused by backward recovery of rectifying tube. Since voltage stress of clamp diode is smaller, tube with good capability can be selected to eliminate influence on circuit caused by stray parameter of clamp diode. Moreover, Comparing with mode that a clamp diode is placed at primary side of transformer to clip voltage at primary side, the clipper circuit clips voltage at secondary side of transformer in the invention can eliminate voltage surge and voltage pike of rectifier diode caused by leakage inductance of transformer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com