Fiber bragg grating detection system device and method for detecting anchoring force of anchor rod

A fiber grating and detection system technology, which is applied in the direction of measuring the changing force of optical properties of materials when they are stressed, can solve the problem that the sensor has poor moisture-proof, waterproof and anti-interference performance, cannot well meet the needs of real-time engineering detection, and cannot be Long-term effective detection and other problems, to eliminate the influence of light source power fluctuation and system loss, easy protection and maintenance, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

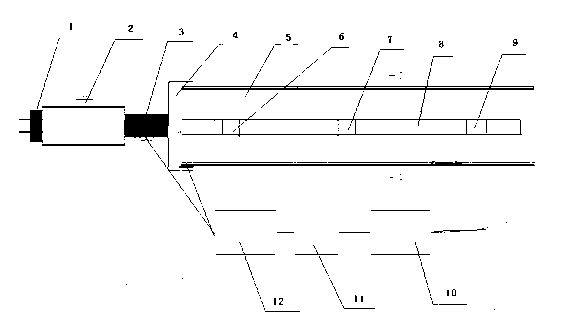

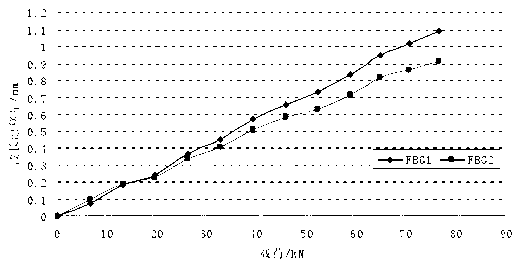

[0042] After connecting the fiber grating anchor detection device with the anchor, the anchoring process of the anchor is detected. Through the fiber grating demodulator software, the data acquisition frequency is set to 2Hz, that is, two groups of fiber grating sensor wavelength data are collected every second, and the average value is taken as the instantaneous wavelength value of the fiber grating at the end of each recording.

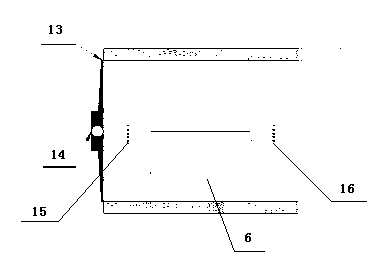

[0043] In a coal mine roadway, the fiber grating sensing method is used to detect the force of the bolt on-line, and the bolt pulling machine is used to carry out the pull test on the bolt. First, install 3 FBG sensors on the anchor rod. A fiber grating anchor dynamometer is installed at the end of the anchor to detect the axial force of the anchor; the anchor specimen and similar materials are put into the prepared steel pipe for anchoring, and after the anchoring is sufficient, the bolt at the free end The anchor head is equipped with a bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com