X-ray source array based real-time online industrial CT (computed tomography) detecting system

A detection system, X-ray technology, applied in radiological diagnostic instruments, material analysis using radiation, medical science, etc., can solve the problems of bulky machines, slow scanning time, etc., to simplify the process, increase the speed, extend the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

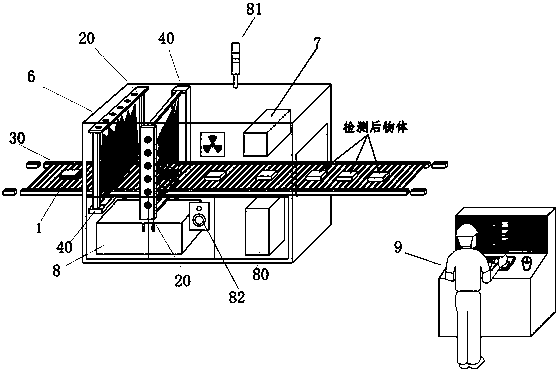

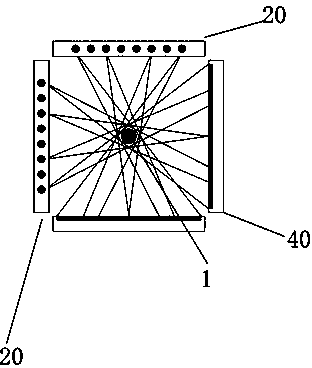

[0046] Such as figure 2 , the real-time online industrial CT detection system based on the carbon nanotube cathode X-ray source array, including a conveyor belt for transporting the object to be detected 1, the X-ray source array 20 of the carbon nanotube cathode and the carbon nanotube cathode are arranged on the outside of the conveyor belt The X-ray source array of the cathode cooperates with the detector array 40 for CT detection of the object 1 to be detected, and the system also includes a control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com