Water-soluble acroleic acid aerosol paint and preparation method thereof

A technology of water-based acrylic and aerosol paint, which is applied in coatings and other directions, can solve the problems of poor physical properties of coatings, high VOC content, and damage to users, and achieve the effects of easy portability, reduced VOC content, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

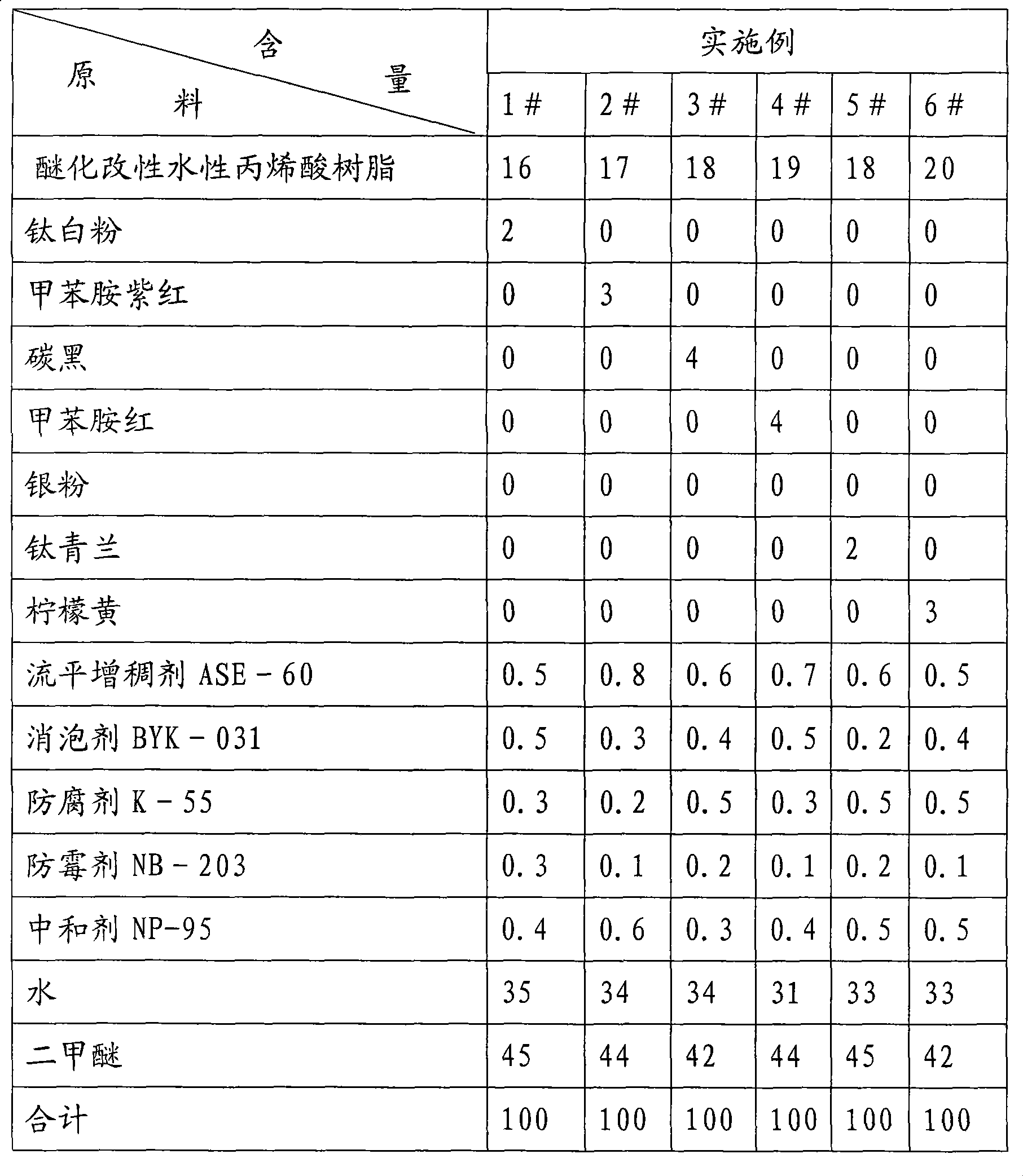

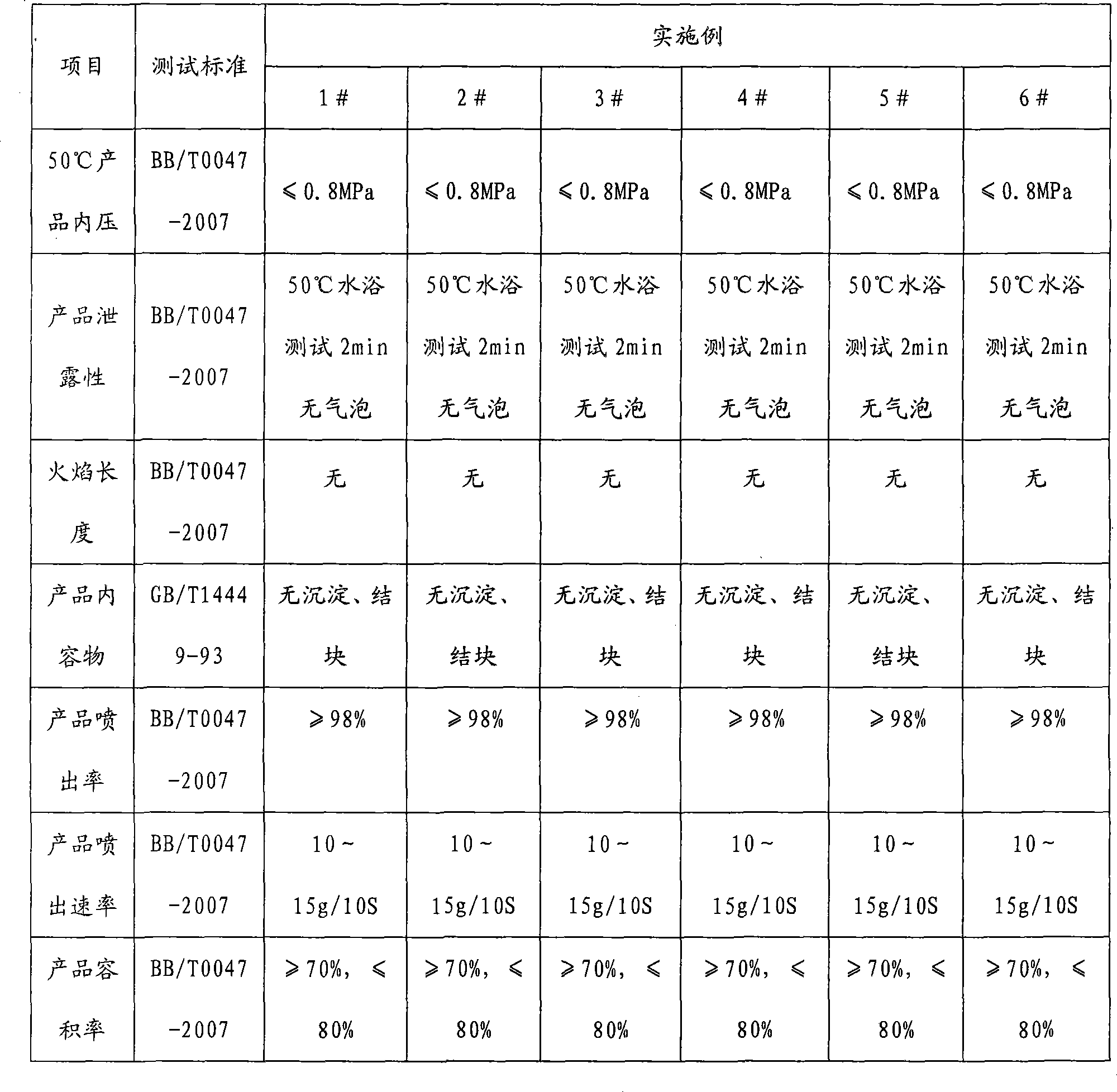

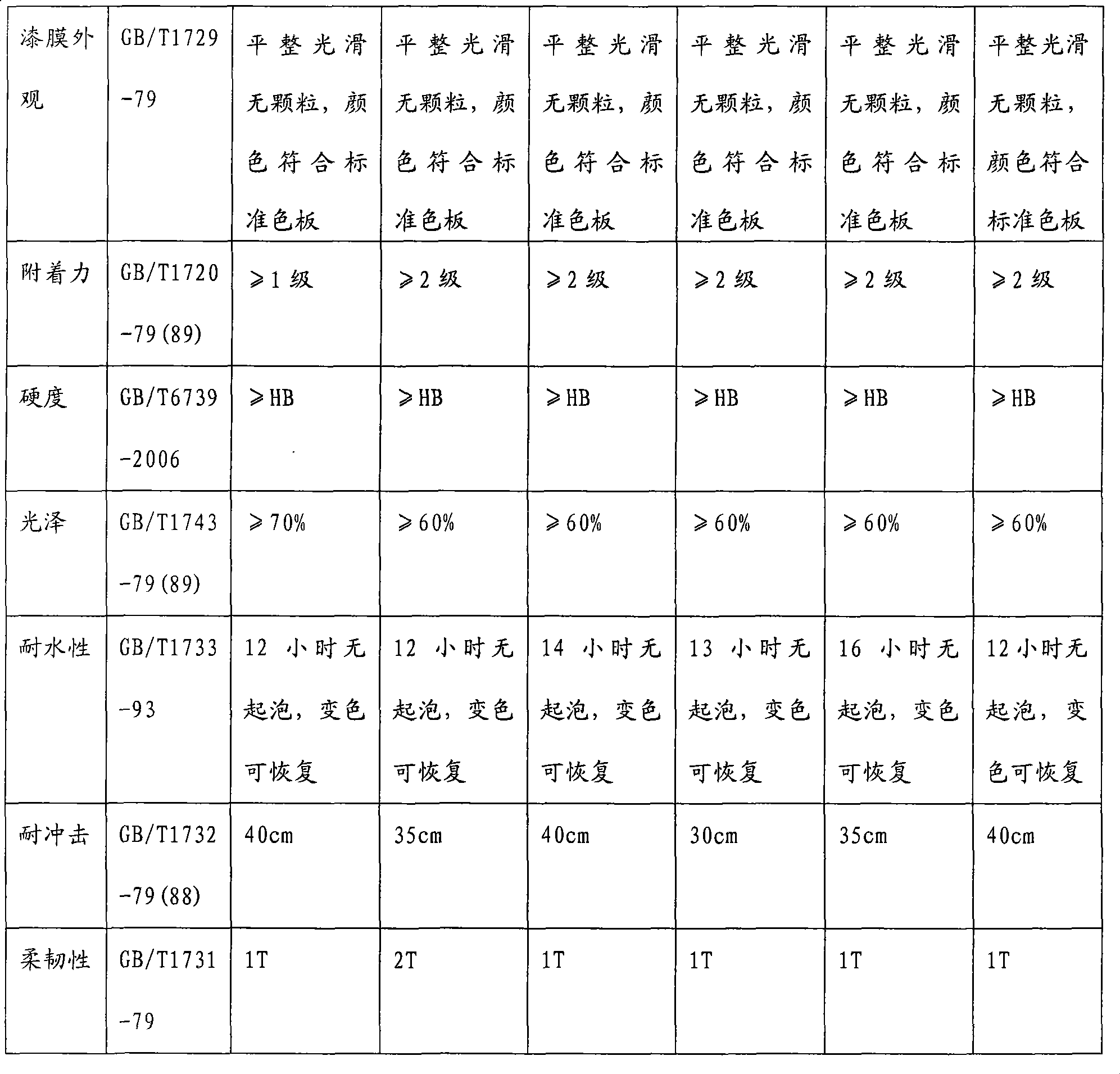

[0027] The formula of the water-based acrylic aerosol paint of the present invention is as follows: etherified modified water-based acrylic resin 15-20wt%, colored pigment 2-5wt%, leveling thickener 0.1-1.0wt%, defoamer 0.1-0.5wt%, The auxiliary solvent is 2-15wt%, the water is 20-35wt%, the dimethyl ether is 40-45wt%, and the auxiliary agent is 0.5-1.0wt%.

[0028] Wherein the etherification modifier of the etherification modified water-based acrylic resin is propylene glycol methyl ether acetate. The solid content of the etherified modified water-based acrylic resin is 40-50%. DME is processed through molecular sieve dehydration and molecular sieve desulfurization. The leveling thickener is an alkali-soluble thickener. The defoamer is a water-soluble defoamer. The auxiliary solvent is one or more of n-butanol, ethylene glycol ether and ethanol. The coloring pigment is one or more mixtures of titanium dioxide, toluidine purple, carbon black, toluidine red, titanium blue a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com