Preparation of magnetic molecularly imprinted polymer and application in complex sample pre-processing

A magnetic molecular imprinting and complex sample technology, applied in the field of separation and analysis, can solve problems such as large consumption of organic solvents, low analysis efficiency, and time-consuming, achieving wide applicability, broad application prospects, and removal of matrix interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Applying the contents of the present invention, ciprofloxacin is used as template molecule to prepare magnetic molecularly imprinted polymer. 1. The preparation of a magnetic molecularly imprinted polymer using ciprofloxacin as a template molecule comprises the following steps:

[0035] a. Preparation of Fe by chemical co-precipitation method 3 o 4 ferrofluid. 10mmol FeCl 2 4H 2 O and 20 mmol FeCl 3 ·6H 2 O was placed in a 250ml three-necked flask, and then 100ml of deionized water was added to dissolve it, mechanically stirred, nitrogen deoxidized, heated to 80°C, and 80mmol of NaOH solution was added at one time to react for 1.0h; after the reaction, the magnetic field was separated, and the magnet was placed At the bottom of the outer side of the three-necked bottle, attract Fe 3 o 4 , and then the waste liquid was poured out, and the Fe was washed with deionized water 3 o 4 until neutral, the resulting Fe 3 o 4 The mass of the magnetic fluid is 2.3g;

...

Embodiment 2

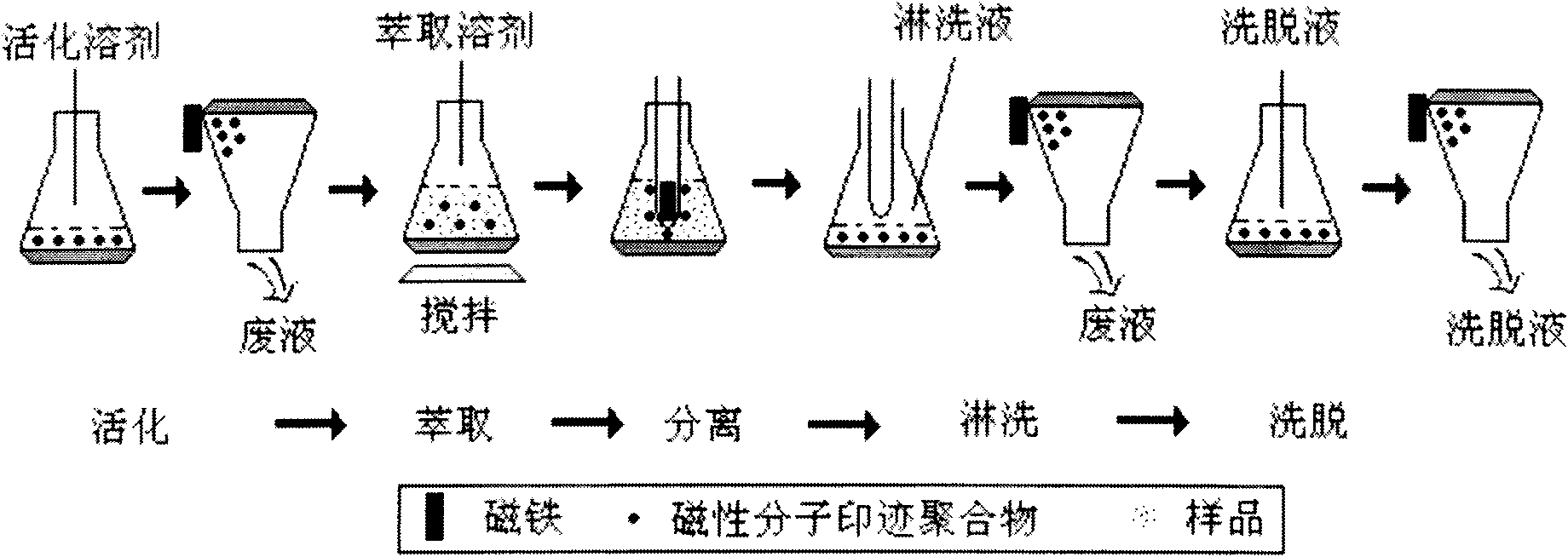

[0041] The establishment of a three-phase extraction system based on magnetic molecularly imprinted polymers with ciprofloxacin as a template molecule and its application in the extraction and separation of quinolone antibiotics in chicken samples (Note: Ciprofloxacin was used as a template molecule to prepare The magnetic molecularly imprinted polymer can simultaneously extract ciprofloxacin and its analogues such as levofloxacin, lomefloxacin, fleroxacin, enrofloxacin and sparfloxacin). like figure 1 shown, including the following steps:

[0042] a. Activation: Add 80 mg of the magnetic molecularly imprinted polymer with ciprofloxacin as the template molecule prepared in Example 1 into the Erlenmeyer flask, activate with 3.0 mL of methanol, separate by magnetic field, and pour off the waste liquid; Wash with mL deionized water to remove the methanol on the surface of the magnetic molecularly imprinted polymer with ciprofloxacin as the template molecule, separate with the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com