Patents

Literature

56 results about "Sendust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sendust is a magnetic metal powder that was invented by Hakaru Masumoto at Tohoku Imperial University in Sendai, Japan, about 1936 as an alternative to permalloy in inductor applications for telephone networks. Sendust composition is typically 85% iron, 9% silicon and 6% aluminum. The powder is sintered into cores to manufacture inductors. Sendust cores have high magnetic permeability (up to 140 000), low loss, low coercivity (5 A/m) good temperature stability and saturation flux density up to 1 T.

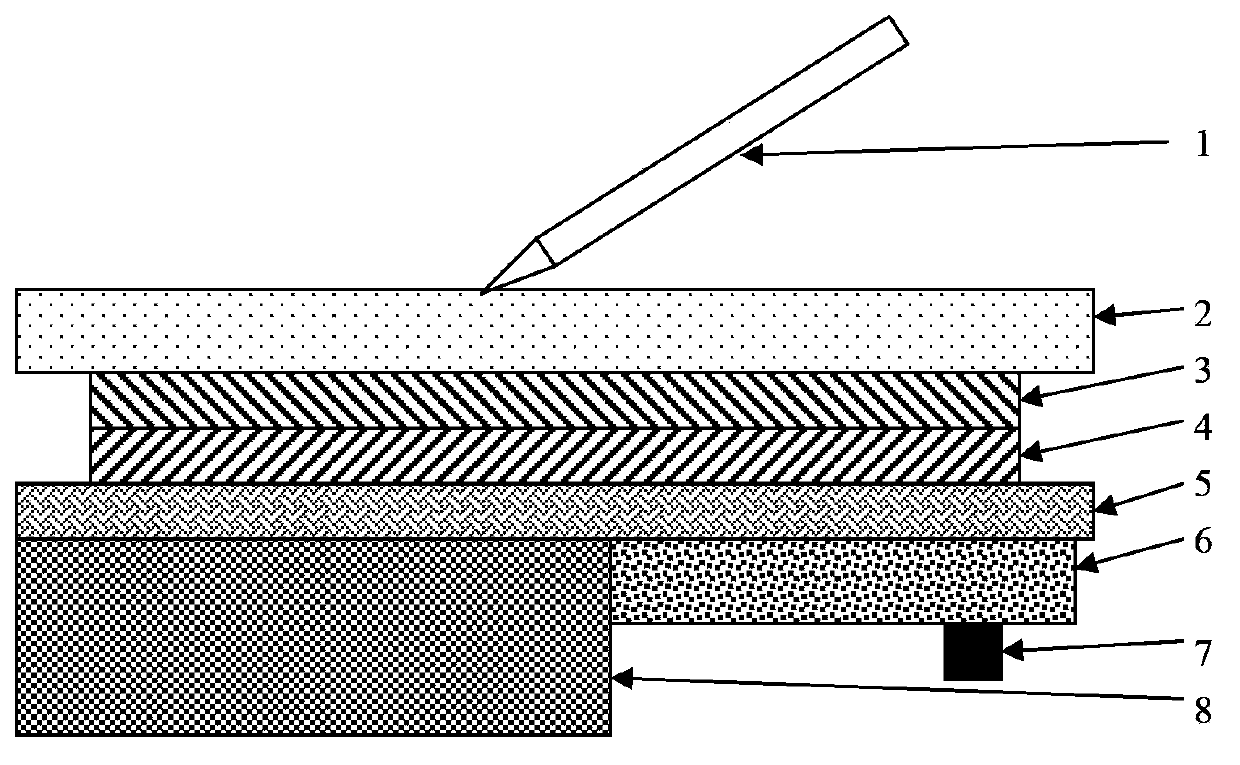

Electromagnetic wave interference preventive material and production thereof

InactiveCN1646000AHigh specific surface areaIncrease reflectionMagnetic/electric field screeningIron powderSendust

The anti electromagnetic interference material is composed of several layers: the impedance matching layer is made of absorbing type sendust powder, manganese-zinc ferrite and resin; the absorbing layer is made of absorbing type sendust powder, nickel zinc ferrite and resin; the reflecting layer is made of reflection type sendust powder, iron powder and resin.

Owner:横店集团东磁有限公司

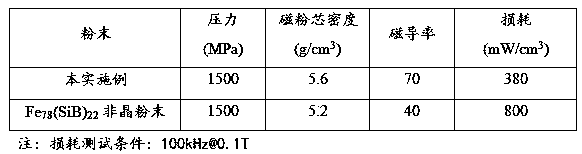

Sendust/ferrite composite magnetic powder and preparation method of magnetic powder core adopting same

InactiveCN106356177AImprove permeabilityHigh resistivityInorganic material magnetismInductances/transformers/magnets manufactureMaterials preparationSendust

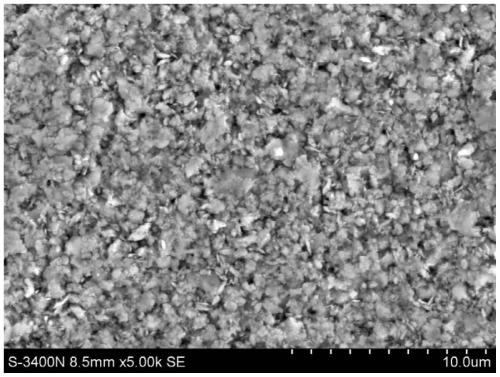

The invention relates to the field of material preparation, in particular to sendust / ferrite composite magnetic powder and a preparation method of a magnetic powder core adopting the same. The preparation method comprises the following steps: firstly, flat sendust magnetic powder is prepared, then, the sendust magnetic powder is put in a Fe-Zn-Mn mixed nitrate solution, a ferrite coating is synthesized in situ on the surface of the flat sendust magnetic powder through a hydrothermal reaction, the ferrite coating is washed, dried and mixed with a binder and a lubricant, the magnetic powder core is prepared from the sendust / ferrite composite magnetic powder through cold pressing, and then stress relief annealing is performed. The sendust / ferrite composite magnetic powder and magnetic powder core have high magnetic conductivity and low high-frequency loss, and can be applied to telecommunications and radar as well as fields of microwave absorption and electromagnetic shielding.

Owner:GUANGDONG UNIV OF TECH

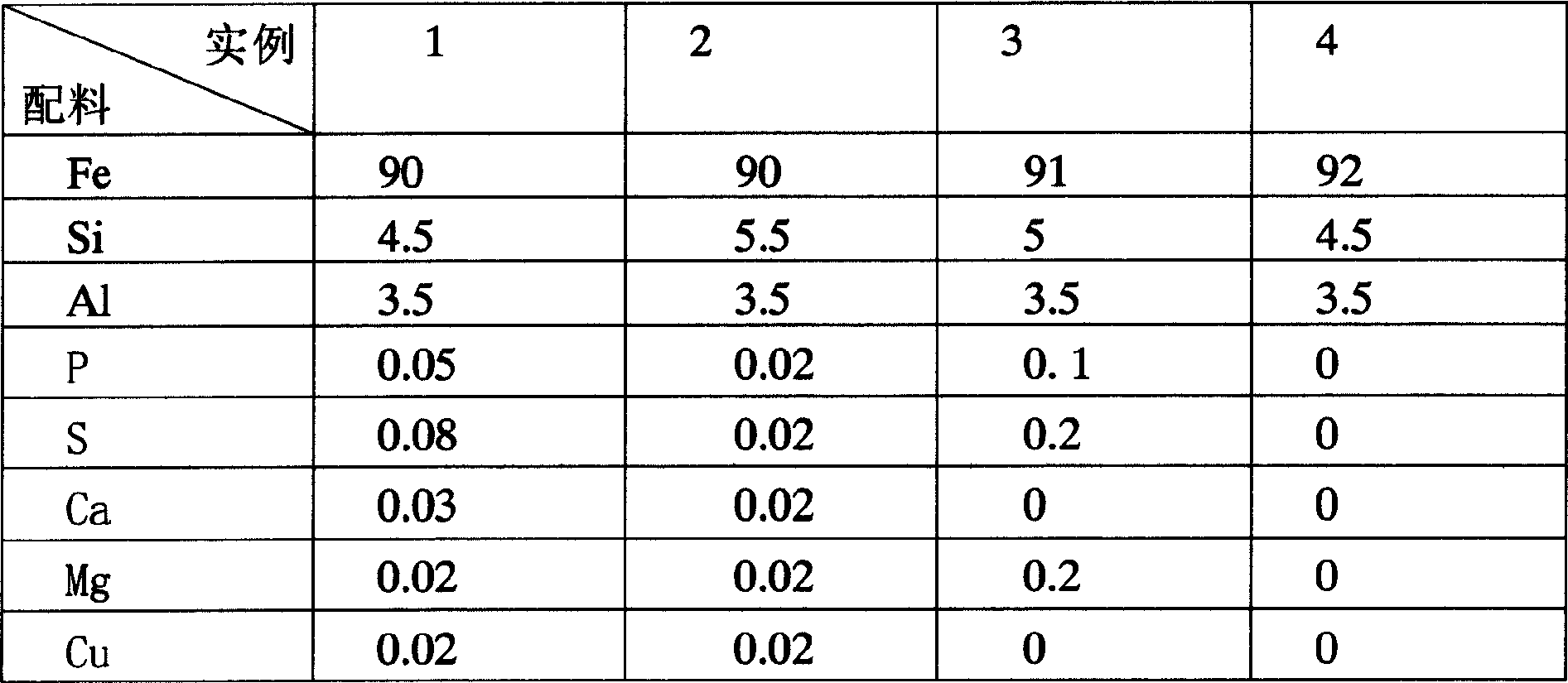

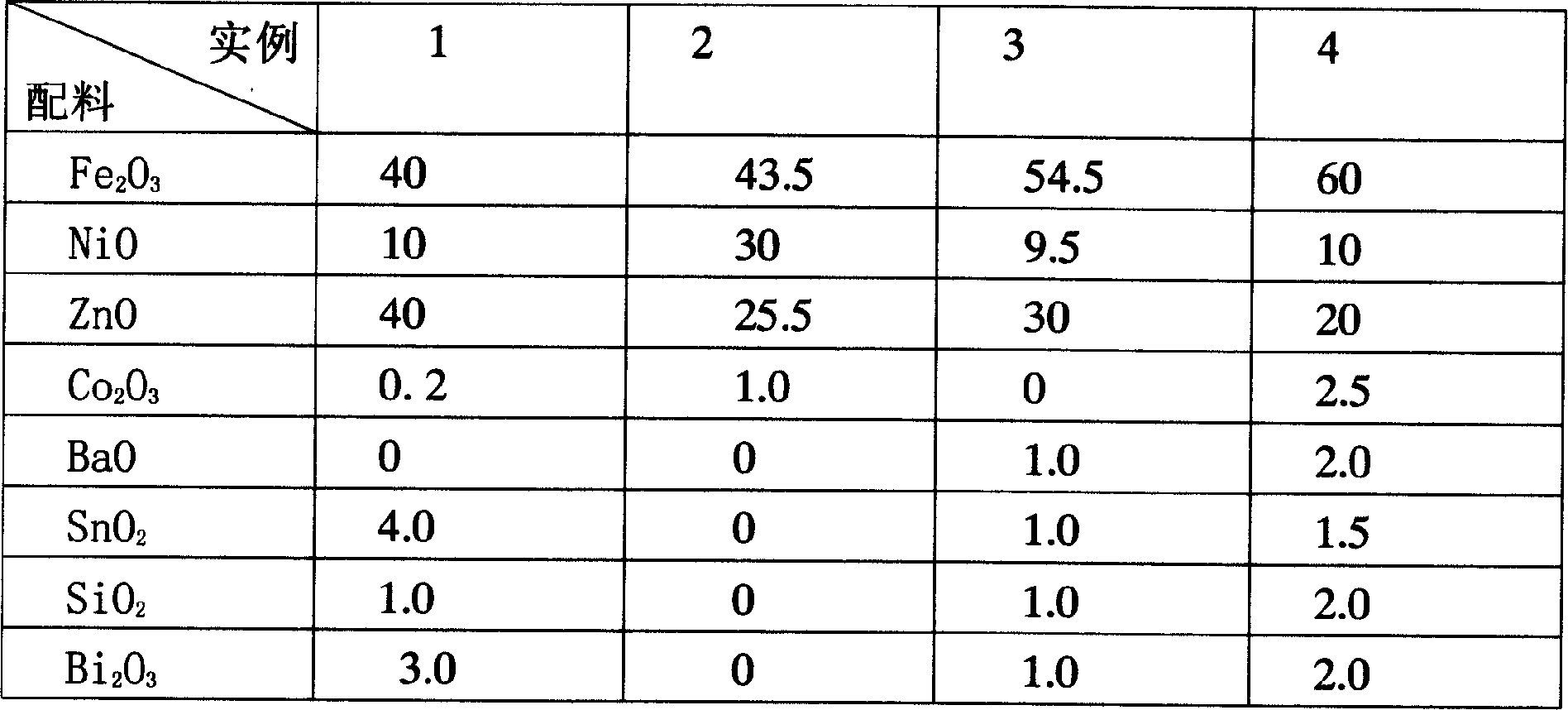

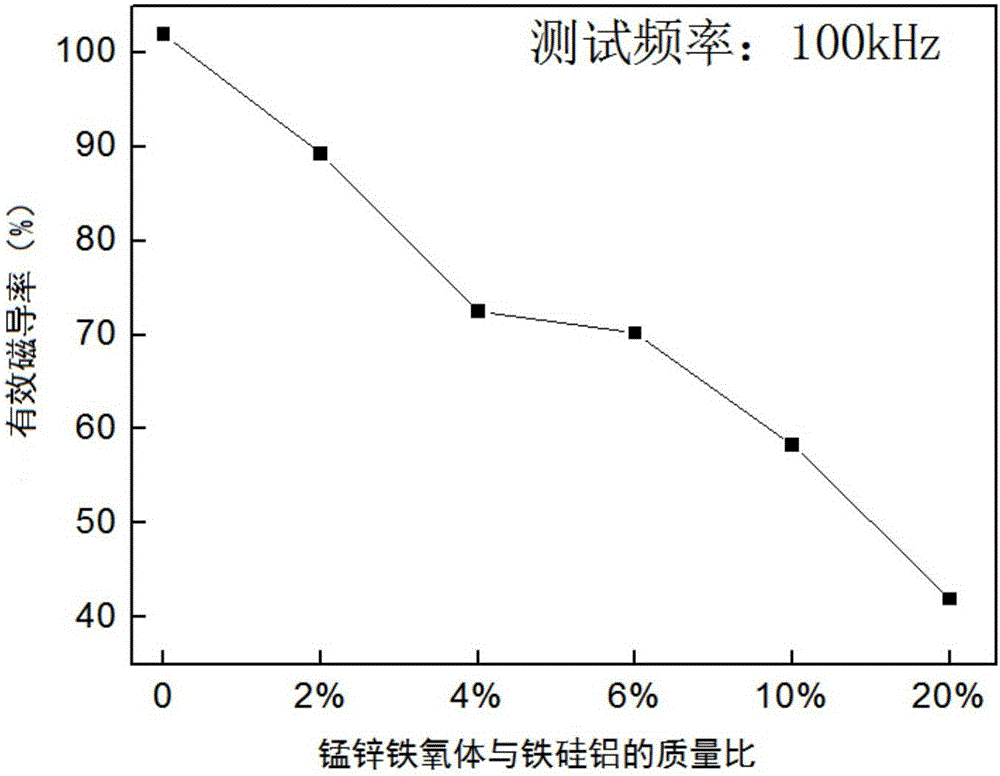

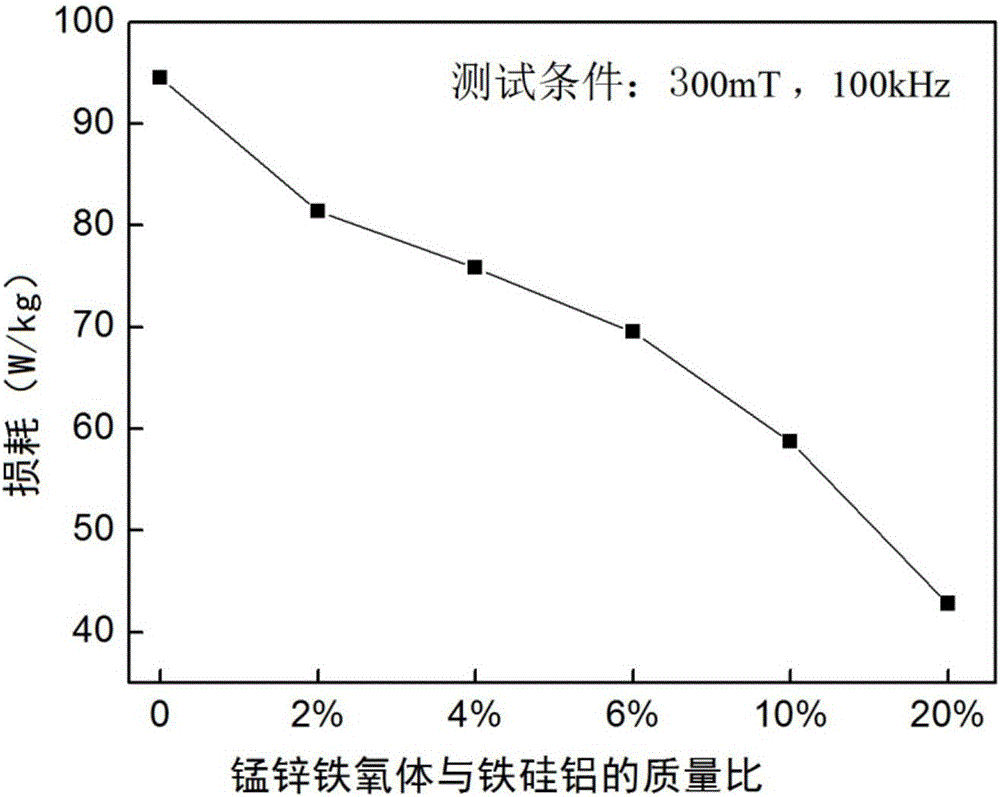

Composite magnetic powder and preparation method therefor

InactiveCN106531388AImprove permeabilityReduce the impactInorganic material magnetismInductances/transformers/magnets manufactureSendustFerrite powder

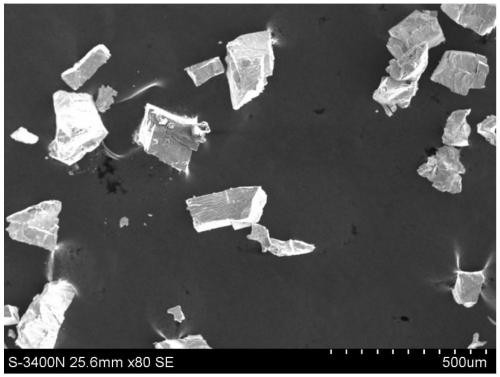

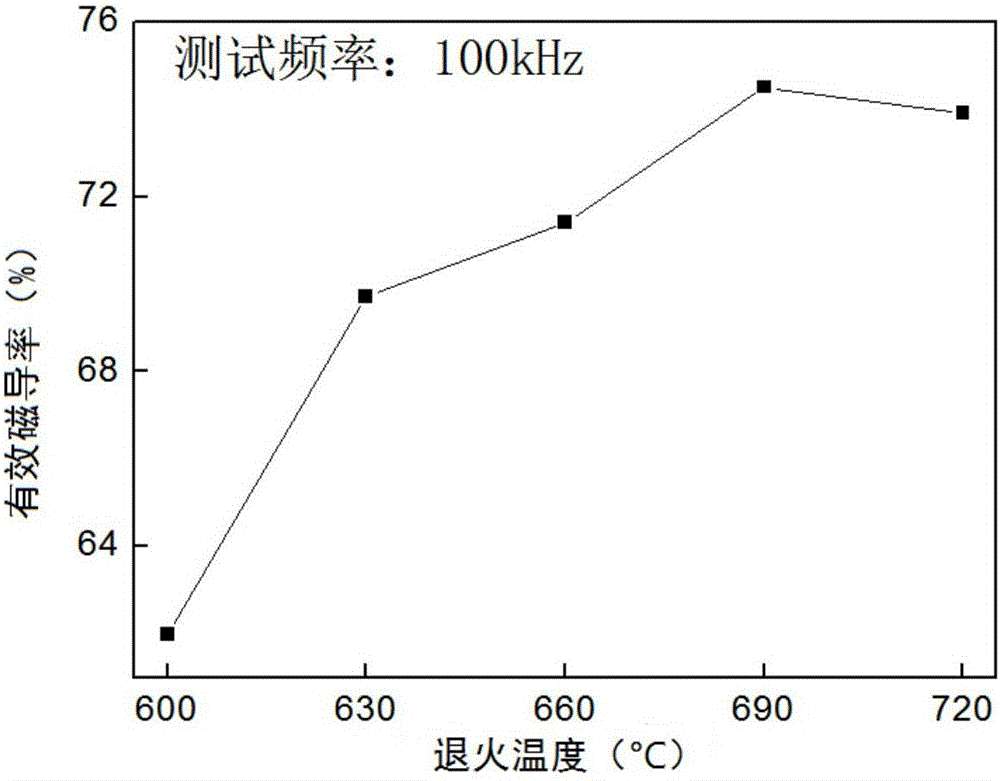

The invention belongs to the preparation field of a magnetic material, and particularly relates to composite magnetic powder and a preparation method therefor. The preparation method comprises the following steps of a), preparing an iron-silicon-aluminum alloy (which also can be called as sendust in the specification) thin belt by a melt rapid quenching method; in the preparation process, applying a directional magnetic field in belt-spinning; and performing crushing on the prepared iron-silicon-aluminum alloy thin belt to obtain an iron-silicon-aluminum alloy fragment; b), enabling the iron-silicon-aluminum alloy fragment and ferrite powder to be mixed and ball grinded to obtain composite magnetic powder; and c), enabling a binder, a lubricating agent and the composite magnetic powder to be mixed and pressed in sequence to obtain a composite magnetic powder core. Experiment results prove that the effective magnetic conductivity of the magnetic powder core prepared by the method can be higher than 40 at the test frequency of 100kHz; and the loss is lower than 83W / kg in the test conditions of 100kHz when Bm is equal to 300mT.

Owner:GUANGDONG UNIV OF TECH

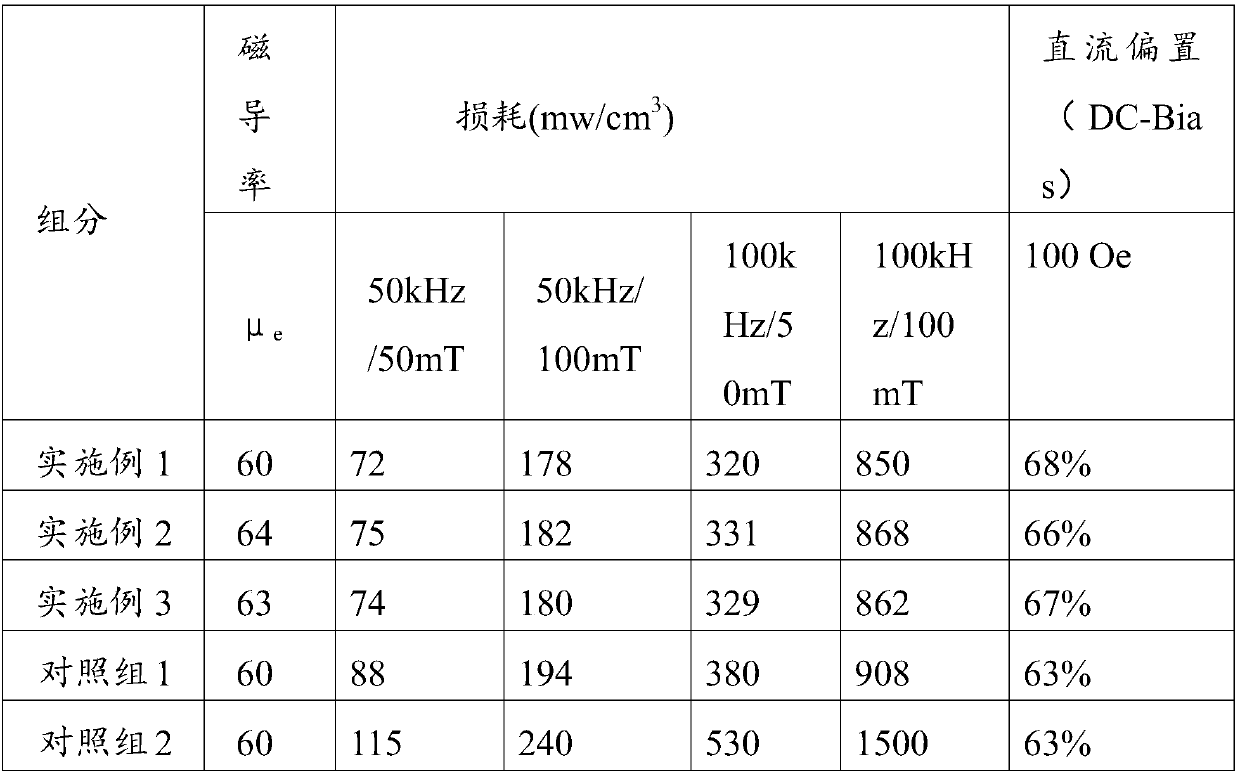

Preparation method of sendust core with high direct current bias characteristic

ActiveCN102945720AReduce stress concentrationHigh densityInorganic material magnetismInductances/transformers/magnets manufactureSendustMetal powder

The invention discloses a preparation method of a sendust core with a high direct current bias characteristic. The preparation method comprises the following steps of (1) core powder preparation, (2) passivating treatment, (3) compression moulding and (4) heat treatment, wherein low-hardness plastic metal powder is mixed into sendust in Step (1); a passivant is added to the prepared core powder for the passivating treatment in Step (2); an adhesive agent, an insulating agent and a lubricant are successively added to the mixed metal powder subjected to the passivating treatment, and then the compression moulding is conducted in Step (3); and annealing treatment is conducted on the sendust core subjected to compression moulding at 600-700 DEGC for 0.5-2h in Step (4). The preparation method has the benefits that the core powder formula is improved, the density of the sendust core is increased and the uniformity of air gap distribution is improved, so that the direct current bias characteristic of the sendust core is improved, and the problem that the conventional sendust core cannot work under the condition of low loss and high direct current bias characteristics is solved.

Owner:GUANGZHOU DELOOP ELECTRONICS DEVICES

Metallic magnetic material for magnetic element of a choke coil and SMD choke coil

InactiveUS20090095380A1Good” DC-biasImprove insulation performanceInorganic material magnetismFixed inductancesGraphic cardHigh frequency power

A metallic magnetic material for magnetic element for magnetic element of a choke coil and an SMD choke power coil for accommodating low voltage and high current in a personal computer, graphic card, high frequency power supply, etc, is prepared by baking a powder of Fe—Si—Al alloy sendust, obtained by an atomization process and having an average particle diameter of 10 to 70 μm, at 600° C. to 1000° C. in air or in an oxidizing atmosphere and mixing the baked sendust with 3 to 45 wt % of a carbonyl iron powder with an average particle diameter of 1 to 10 μm. The metallic magnetic material for magnetic element according to the present invention is used in a coil-embedded SMD power choke coil having a square or rectangular shape with a height of 1 mm to 7 mm and with a length of one side being 3 mm to 13 mm.

Owner:SEKISHIN IND

Method for manufacturing mu-90 sendust magnetic powder cores

ActiveCN102610349AStress reliefPromote environmental protectionInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingSendust

The invention provides a method for manufacturing mu-90 sendust magnetic powder cores, which comprises the steps of smelting, coarse crushing, heat treatment, fine crushing, annealing treatment, powder grading, powder insulation, compression molding, secondary heat treatment and coating treatment. The mu-90 sendust magnetic powder cores comprise binary iron-silicon alloy with added aluminum, wherein the silicon content accounts for 9-10%, the aluminum content accounts for 5-6%, and the balance is iron. The smelting temperature is 1600 DEG C. The compression molding pressure is 1900 MPa. The heat treatment temperature is 600-800 DEG C, the holding time is 1 hour, and the nitrogen-oxygen mixed atmosphere is adopted. When f=10 kHz and B=1 mT, mu=90+ / -7.2; when f=50 kHz and B=50 mT, the volume ratio loss Pcv<=100mW / cm3. When an additional direct current bias magnetic field is 100 Oe, the change rate of the magnetic conductivity is not greater than 75%. The method for manufacturing the mu-90 sendust cores has the advantages that an added bonding agent is a solid inorganic bonding agent, the heat treatment after the molding is performed in the nitrogen-oxygen mixed atmosphere environment and subjected to heat preservation for 1 hour. Prepared magnetic powder cores are not prone to pulverize, high in strength and stable in performance and have good direct current biasing characteristic, frequency stabilization characteristic and low loss.

Owner:TDG HLDG CO LTD

Method for manufacturing sendust material and mu173 sendust magnetic powder core

InactiveCN103594219AReduce multiple drying processesEasy to produceInorganic material magnetismInductances/transformers/magnets manufactureEpoxySendust

The invention discloses a method for manufacturing a sendust material and a mu173 sendust magnetic powder core. The specific method includes the steps of a, conducting alloy smelting, wherein the smelting temperature is more than 1400 DEG C, and the time for alloy smelting is more than 50 minutes; b, preparing powder, namely, directly conducting nitrogen spraying to manufacture powder after the alloy smelting is conducted; c, conducting powder reduction, namely, conducting reduction through nitrogen; d, conducting power material inactivation, namely, adding an analysis pure grade phosphoric acid solution to the sendust powder, and conducting uniform mixing, wherein the analysis pure grade phosphoric acid solution accounts for, by weight, 3% to 5% of the sendust powder; e, conducting annealing, namely, placing powder into a nitrogen protection furnace at the temperature of 360+ / -30 DEG C; f, conducting insulation coating, namely, adding silicon resin adhesives and powder lubricants, wherein the silicon resin adhesives account for, by weight, 1.5% to 3.5% of the powder, and the powder lubricants account for, by weight, 0.5% to 1% of the powder; g, conducting die pressing forming; h, conducting thermal treatment, namely, placing a formed product into the nitrogen protection furnace at the temperature of 700+ / -30 DEG C, and conducting annealing for about one hour; i, conducting surface coating, namely, evenly spray painting a layer of epoxy resin paint on the outer surface of the product.

Owner:SICHUAN DONGGE TECH

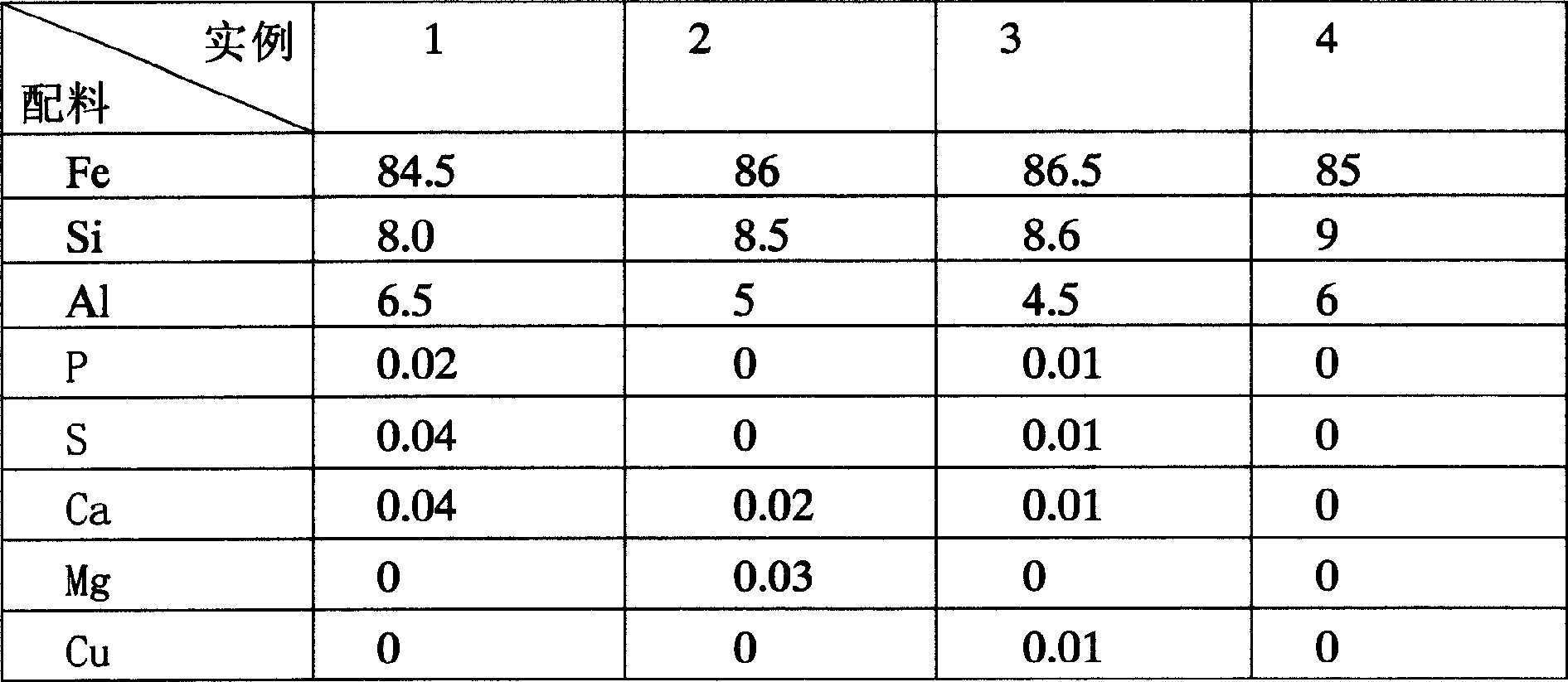

Method for manufacturing [mu]90 composite magnetic powder core

InactiveCN107369514AImprove power densitySuitable for low voltage and high currentTransportation and packagingMetal-working apparatusSendustLow voltage

The invention discloses a method for manufacturing a [mu]90 composite magnetic powder core. The [mu]90 composite magnetic powder core is made by compounding two or more alloy powders. The alloy powders comprise the following components: mechanically crushed sendust, aerosolized sendust, aerosolized iron-silicon, aerosolized iron-nickel and aerosolized iron-nickel-molybdenum. The manufacturing method comprises the steps of powder compounding, passivation, insulation coating, press molding, heat treatment and surface coating. The alloy powders complement each other in terms of performance so that the performance of the prepared composite powder core is close to that of a commercially available amorphous magnetic powder core. The alloy powders used in the method have the advantages of mature technology, stable performance and relatively low cost so that the prepared magnetic powder core has quite high cost performance and stable characteristics. The composite magnetic powder core with magnetic permeability of [mu]90 has excellent physical properties and magnetic properties. By use of the magnetic powder core prepared by the invention, the development requirements of an existing electronic industry for low-voltage high current, high power density and high frequency are greatly satisfied.

Owner:天通(六安)新材料有限公司

Preparation method of low-loss high-superposition sendust material with magnetic conductivity mu equal to 26

InactiveCN104505208AReduce lossImprove overlay effectInductances/transformers/magnets manufactureMagnetic materialsCompression moldingSendust

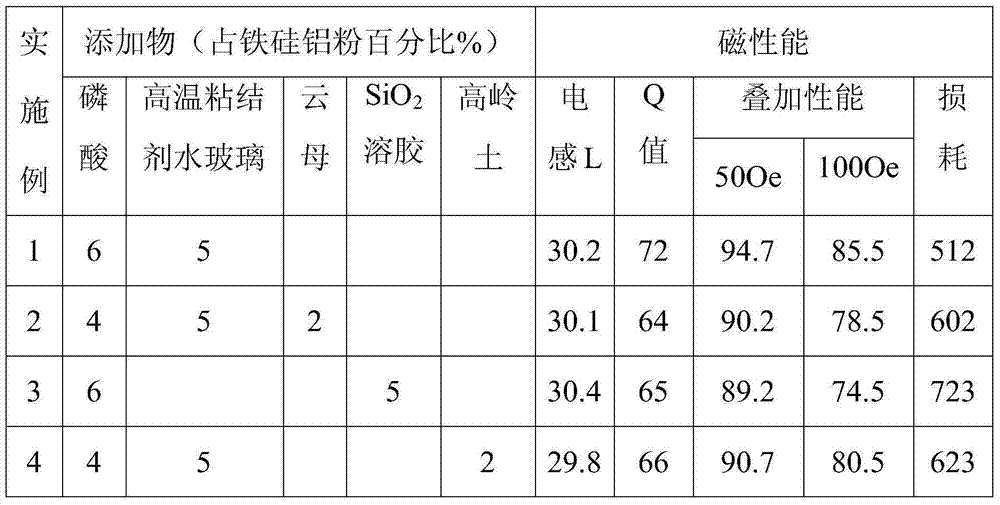

The invention discloses a preparation method of a low-loss high-superposition sendust material with magnetic conductivity mu equal to 26. The method comprises the steps of performing batching, phosphatization and primary annealing, adding an appropriate high-temperature resistant insulating material, performing compression molding and secondary annealing, and then performing appropriate insulating coating. According to the method, the loss of a magnetic core prepared from the sendust material with the magnetic conductivity mu equal to 26 is 500mW / cm3 at 100K / 100mT; and the superposition property is 100Oe:85% and 50Oe:95%. The method has the benefits that the loss of the sendust material is reduced by 100-300mW / cm3 compared with that of other sendust materials of the same kind; and the superposition property is improved by 10% compared with that of the sendust materials of the same kind, reaches an iron silicon level and is approximate to the level of high-flux iron nickel.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

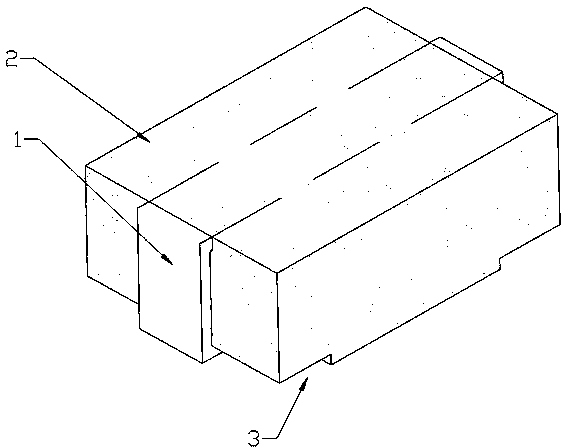

Method for manufacturing [mu]26 composite magnetic powder core

InactiveCN107369515AGood value for moneyImprove stabilityTransportation and packagingMetal-working apparatusSendustPhosphoric acid

The invention discloses a method for manufacturing a [mu]26 composite magnetic powder core. The technical scheme is as follows: after two or more alloy powders from mechanically crushed sendust, aerosolized sendust, aerosolized iron-silicon, aerosolized iron-nickel and aerosolized iron-nickel-molybdenum are selected and are fully mixed, phosphoric acid passivation treatment and drying are performed, then one or more from silicon oxide, aluminum oxide, calcium oxide and magnesia calcinata, sodium silicate, and deionized water are successively added to the alloy powders subjected to the passivation processing and drying for insulation coating, and afterwards, the [mu]26 composite magnetic powder core is prepared after press molding, heat treatment and surface coating. The alloy powders used in the method have the advantages of mature technology, stable performance and relatively low cost so that the prepared magnetic powder core has quite high cost performance and stability. Such oxides as the silicon oxide, the aluminum oxide, the magnesia calcinata and the like and such inorganic materials as the sodium silicate and the like are used for coating adhesion so that the obtained composite magnetic powder core has the advantages of high stability, high reliability, low cost, high safety and facilitated production.

Owner:天通(六安)新材料有限公司

Method for manufacturing mu 125 sendust cores

ActiveCN102623123AIncrease heat treatment temperaturePromote environmental protectionInorganic material magnetismInductances/transformers/magnets manufactureSendustInsulation layer

The invention relates to a method for manufacturing mu 125 sendust cores. The method comprises the steps of alloy smelting, coarse crushing, heat treatment, fine crushing, annealing treatment, powder classification, powder insulation, compression moulding, secondary heat treatment and coating treatment. The mu 125 sendust cores comprise the following compositions: 9.10 percent of silicon, 5.95 percent of aluminum and the balance of iron; the sendust cores are smelted at 1,600DEG C, molded under the pressure of between 1,950 and 2,150MPa, subjected to heat treatment at the temperature of between 600 and 800DEG C, kept at the temperature for 30min, and subjected to heat treatment under the protection of nitrogen. The magnetic permeability mu of the sendust cores is equal to 125+ / -10 (10kHz / 1mT); the mu change rate in 1 MHz is less than 5%; Pcv is less than or equal to 190 mW / cm<3> (100kHz / 50mT); and the applied direct current bias field H is not less than 390e when the mu is 50%. A passivating solution does not contain chromium ions, which is environment-friendly; and an insulation layer between powder of the sendust cores has a glass phase structure containing P, which has high temperature for heat treatment and contributes to eliminating internal stress and reducing iron loss. A solid inorganic binder is adopted, so the adhesive strength is high, the performance is stable, and the process is simplified.

Owner:TDG HLDG CO LTD

Metallic magnetic material for magnetic element of a choke coil and SMD choke coil

InactiveUS7767035B2Excellent DC biasImprove insulation performanceInorganic material magnetismFixed inductancesGraphic cardHigh frequency power

A metallic magnetic material for magnetic element for magnetic element of a choke coil and an SMD choke power coil for accommodating low voltage and high current in a personal computer, graphic card, high frequency power supply, etc, is prepared by baking a powder of Fe—Si—Al alloy sendust, obtained by an atomization process and having an average particle diameter of 10 to 70 μm, at 600° C. to 1000° C. in air or in an oxidizing atmosphere and mixing the baked sendust with 3 to 45 wt % of a carbonyl iron powder with an average particle diameter of 1 to 10 μm. The metallic magnetic material for magnetic element according to the present invention is used in a coil-embedded SMD power choke coil having a square or rectangular shape with a height of 1 mm to 7 mm and with a length of one side being 3 mm to 13 mm.

Owner:SEKISHIN IND

Surface insulation treating method adopting boric acid as reactant to reduce sendust core loss

InactiveCN105336492AAchieve flatPrevent escapeInductances/transformers/magnets manufactureEpoxySendust

The invention relates to a surface insulation treating method adopting boric acid as a reactant to reduce sendust core loss and belongs to the technical field of magnetic material preparation. The method comprises the following steps that 1, sendust is placed into a boric acid water solution to carry out high-energy ball milling so that the surface of the sendust can be fully moistened by the boric acid water solution; 2, the moistened sendust is dried for 1 h in a vacuum drying box with the temperature of 120 DEG C to be dehydrated; 3, the dehydrated sendust is placed into a reaction furnace with the temperature of 900 DEG C for 10-minute heat preserving, and cooled along with the furnace, and a multiphase insulating coating layer containing Al2O3, SiO2 and the like is synthesized on the surface of the sendust through a one-step reaction; 4, deionized water is used for cleaning the sendust having subjected to the boric reaction, and drying is carried out after cleaning; 5, 1wt% of epoxy resin and 0.8wt% of magnesium stearate are added to enable the sendust to be pressed into a magnetic powder core in a cold mode under 2000 Mpa; 6, the sendust core is annealed for 1 h at the temperature of 660 DEG C. The method is simple in process and low in cost; the prepared product is high in magnetic conductivity, low in loss and wide in application range.

Owner:GUANGDONG UNIV OF TECH

Method of preparing iron silicon aluminum magnetic powder core with magnetic-conductivity [Mu] of 26

InactiveCN101226806AImprove frequency characteristicsExcellent inductive performanceInorganic material magnetismInductances/transformers/magnets manufacturePowder mixtureSendust

The invention provides a process for preparing sendust cores with magnetic permeability of Mu=26, which comprises steps of a) taking proper sendust for disintegrating at high speed, b) adding passivant when roasting to a temperature of 30DEG C-80DEG C, adding silicone grease and insulating compound when roasting to a temperature of 200DEG C-400DEG C, then continuing roasting till being dried, c) granulating, namely adding binder of 1-12% in powder mixture prepared via step b), screening after grinding up to obtain grain size of 60-150 meshes, d) adding lubricating agent, e) press-forming, f) heat processing to obtain targeted products. The invent has the advantages that 1 production cost is largely reduced by employing sendust with low price, 2 the method of disintegrating at high speed is employed, which enables the powder after being press-formed has perfect frequency characteristic, inductance property and high quality factor, and 3) the prepared magnetic powder cores with magnetic permeability of 26 Mu has lower iron core loss and perfect direct current bias field performance.

Owner:祁峰

Sendust alloy magnetic powder core preparation method

InactiveCN107564655AReduce lossReduce oxygen contentInorganic material magnetismSendustOxygen content

The invention provides a sendust alloy magnetic powder core preparation method. The method includes: step one, preparing alloy powder, to be more specific, subjecting metal raw materials including aluminum, silicon, nickel and iron to metal smelting to obtain alloy melt, and preparing the alloy melt into alloy powder according to a gas atomization method; step two, insulation coating treatment ofthe alloy powder; step three, magnetic powder core spraying insulating treatment. By direct preparation of the super sendust alloy powder according to the gas atomization method, production proceduresare reduced, stress caused by shaping processes including crushing, ball milling and the like is eliminated, the oxygen content of a prepared sendust alloy magnetic powder core is reduced, and magnetic performances of the sendust alloy magnetic powder core are improved. In addition, by insulation coating treatment of the alloy powder, a super sendust alloy powder core appropriate in magnetic conductivity and low in loss can be obtained.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

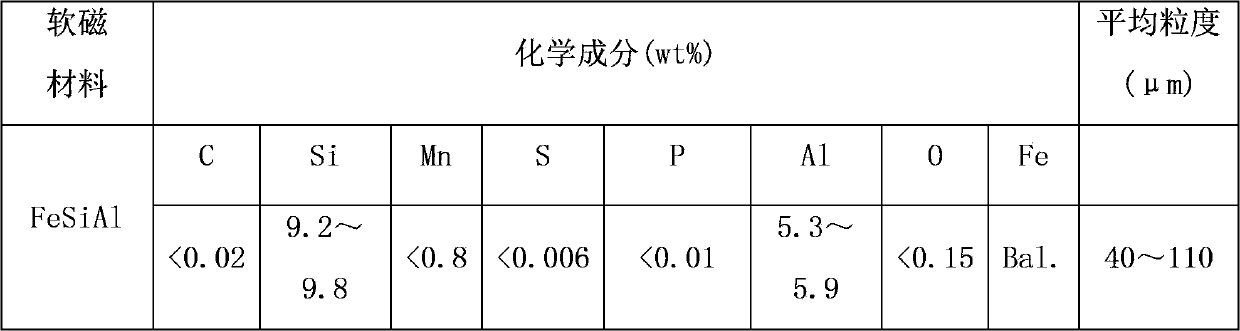

Electromagnetic screen mobile phone and soft magnetic material piece applied to same

ActiveCN103871706ARF index will not degradeIncrease powerPermanent magnetsInorganic material magnetismSendustManganese

The invention relates to an electromagnetic screen mobile phone and a soft magnetic material piece applied to the same. The soft magnetic material piece is made of Sendust magnetic powders. The Sendust magnetic powders comprise components of, by weight, 9.2%-9.8% of silicon, 5.3%-5.9% of aluminum, less than 0.02% of carbon, less than 0.8% of manganese, less than 0.006% of sulphur, less than 0.01% of phosphorus and less than 1.15% of oxygen, with the balance being iron. The thickness of the soft magnetic material piece is 0.9-1.5 mm. A user can apply the soft magnetic material piece to the electromagnetic screen mobile phone to solve the problem of soft magnetic compatibility in the prior art and to ensure that an electromagnetic screen causes no interference in neighboring magneto-sensitive elements such as an electronic compass, namely, a geomagnetic sensor, and meanwhile to guarantee that the radio frequency index of the electromagnetic screen cannot reduce. Besides, a GSM (Global System for Mobile Communications) interference problem can be solved, the electromagnetic screen is free from influences of GSM radiant power and movement track signals of an electromagnetic pen can be sensitively and accurately received.

Owner:深圳市经纬科技有限公司

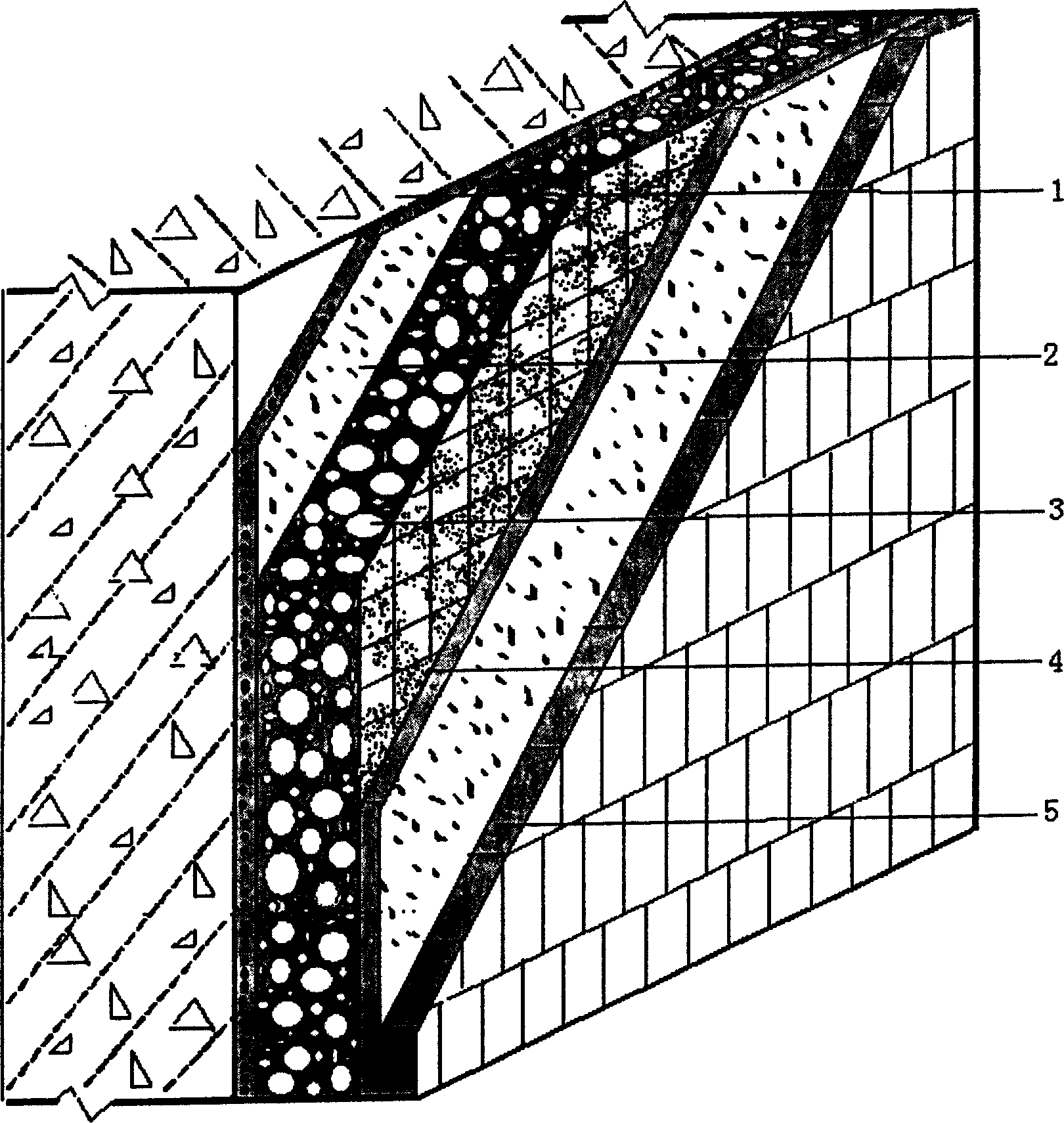

Novel thermal insulation and heat preservation structure for complex building and construction technique

InactiveCN1594774ASave raw materialsImprove ergonomicsCovering/liningsWallsSendustThermal insulation

The present invention provides a novel complex thermal insulation and heat preservation structure, the structure has from inside to outside a subbase, a thermal insulation and heat preservation layer, a strengthening and crack-resistant layer, a thermal reflecting decorative layer. The thermal insulation and heat preservation layer is formed with complex powder material A and polystyrene bubble particle B, the complex powder material A has 50-80% concrete, 10-40% sendust glass hollow ball material having specific surface area of 400-5000 m[2] / kg, air entraining agent 0.005-0.05%, modifying agent 1-5%, water reducing agent 0.2-1.2%, fiber 0.1-5%, tackifier 0.5-2%, the strengthening and crack-resistant layer is coagulated with thermal galvanization steel wire net and modifying crack-resistant base body of fiber strengthening polymer, the wire net is hung and fixed on the thermal insulation and heat preservation layer with plastic expanding bolt, the thermal reflecting decorative layer is made of tint glazed ceramic wall tile or glass, aluminium alloy, stainless steel curtain wall material. The structure apparently improves the thermal insulation and heat preservation ability, and effectively resolves the problem of crack, gaul, and drop of the tile, also greatly improves the wear ability and construction efficiency.

Owner:奥捷科技股份有限公司

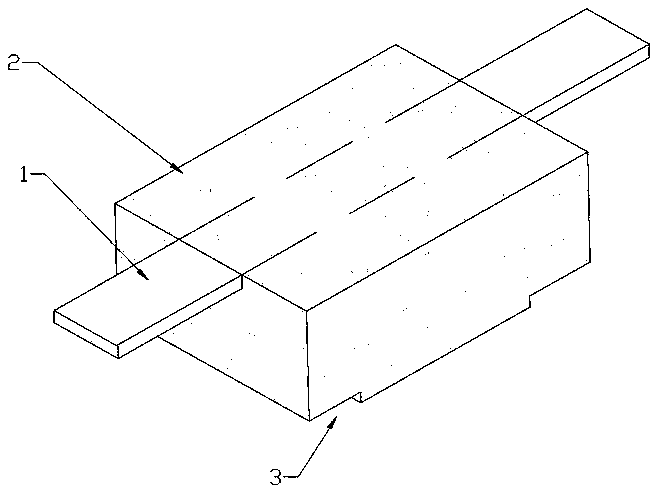

Sendust powder integrated pressing inductor and production process thereof

ActiveCN104183359AHigh mechanical strength of compactGood molding effectCoils manufactureInductance with magnetic coreSendustEngineering

The invention relates to a sendust powder integrated pressing inductor and a production process thereof and belongs to the technical field of the production of inductors. According to the sendust powder integrated suppression inductor and the production process thereof, a red copper band is used as a coil, the middle portion of the red copper band is wrapped in a sendust block, the exposed portions at both ends are bent downwards along the side of the sendust block and bent inwards at the bottom of the sendust block, and a cover sheet is connected with the upper surface of the sendust block through gelatinous materials. The production process includes the steps of forming a blank through pressing, sintering heat treatment, electro plating nickel and tin, cutting and bending, adhering cover sheet and obtaining sendust powder integrated pressing inductor. The sendust powder integrated pressing inductor and the production process thereof have the advantages of being less in iron loss and good in formability, saving space, reducing noise and having stable and reliable electromagnetic performance, and meanwhile improve the production efficiency and reduce the production costs.

Owner:资兴市弘电电子科技有限公司

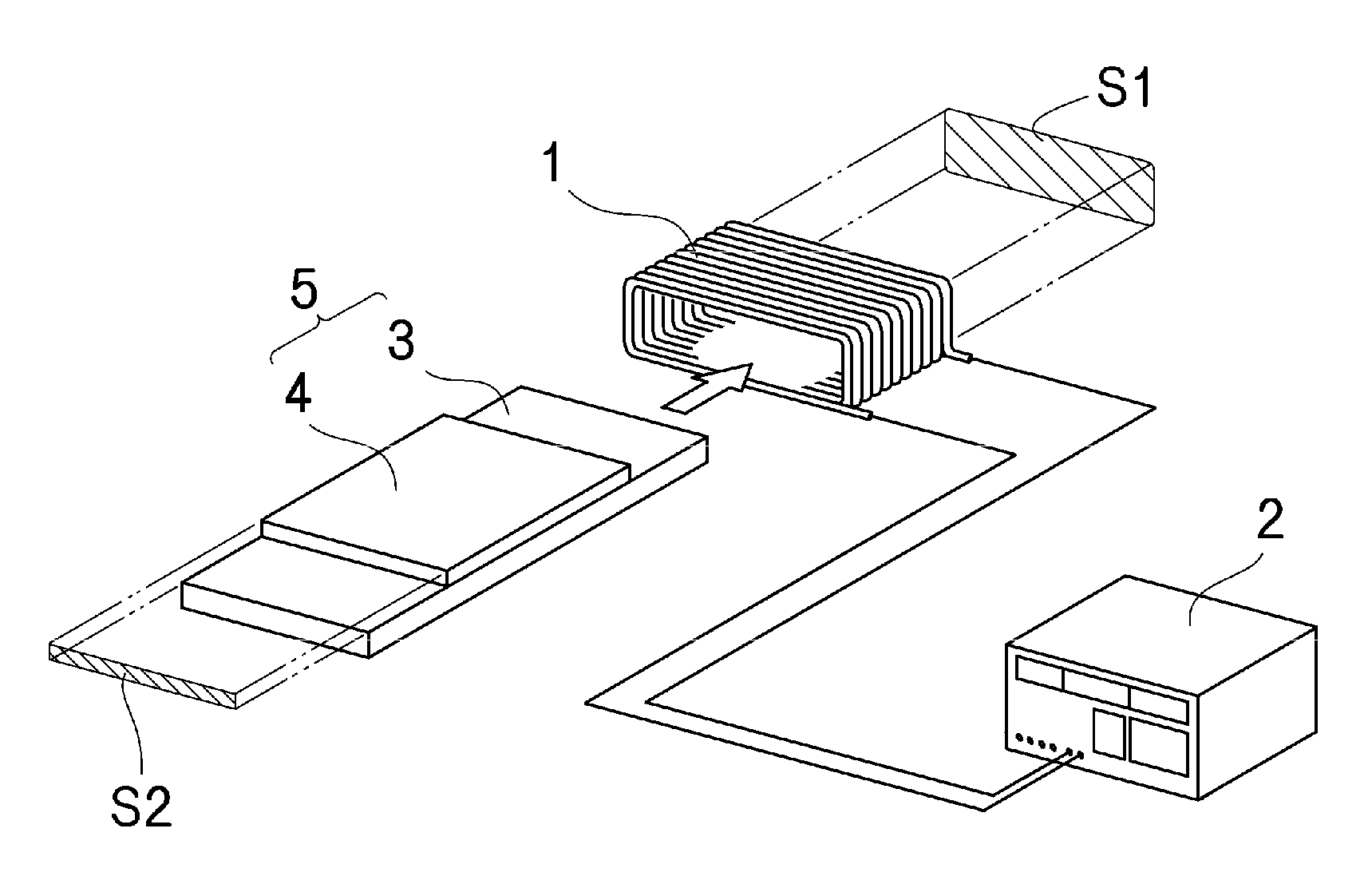

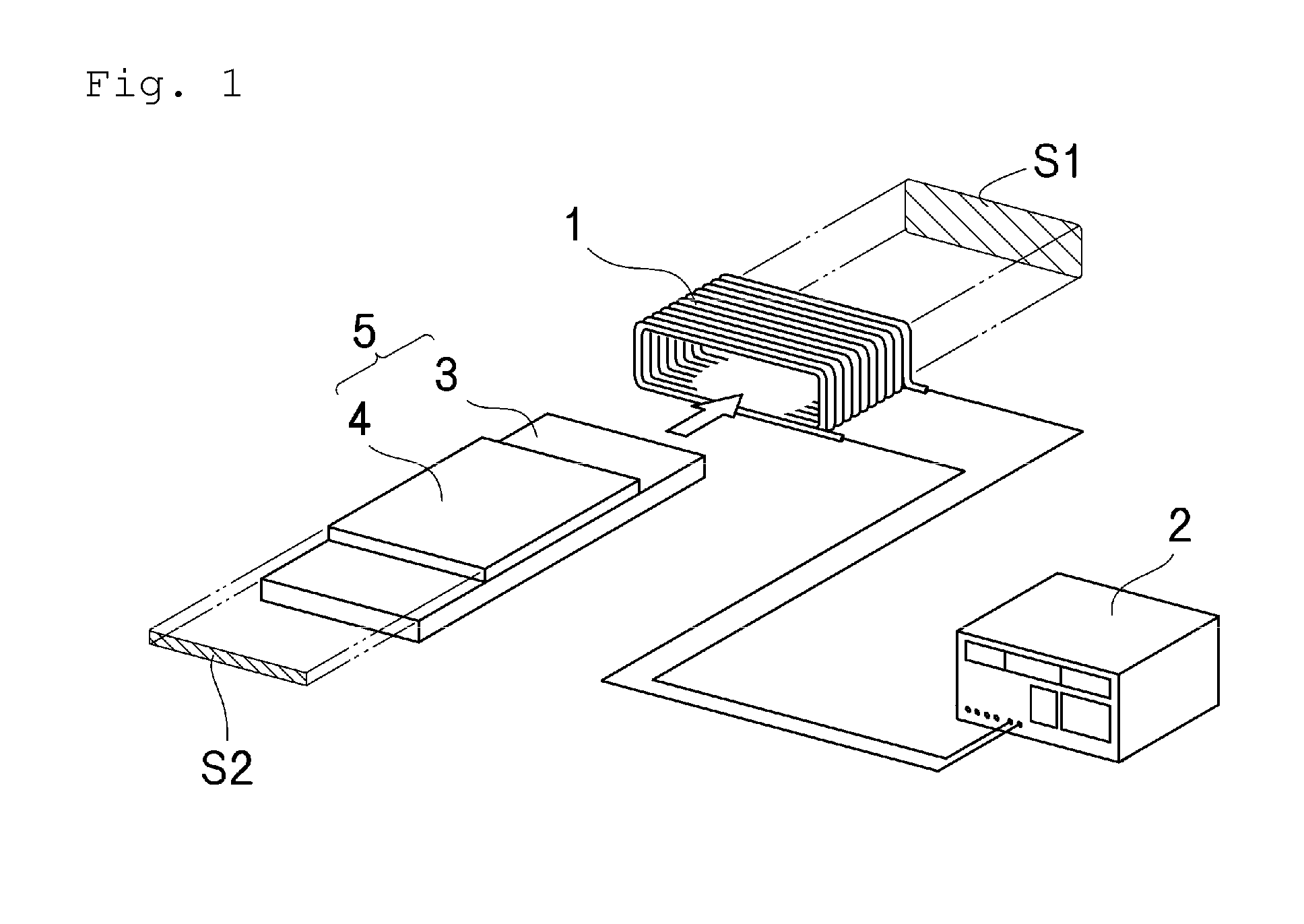

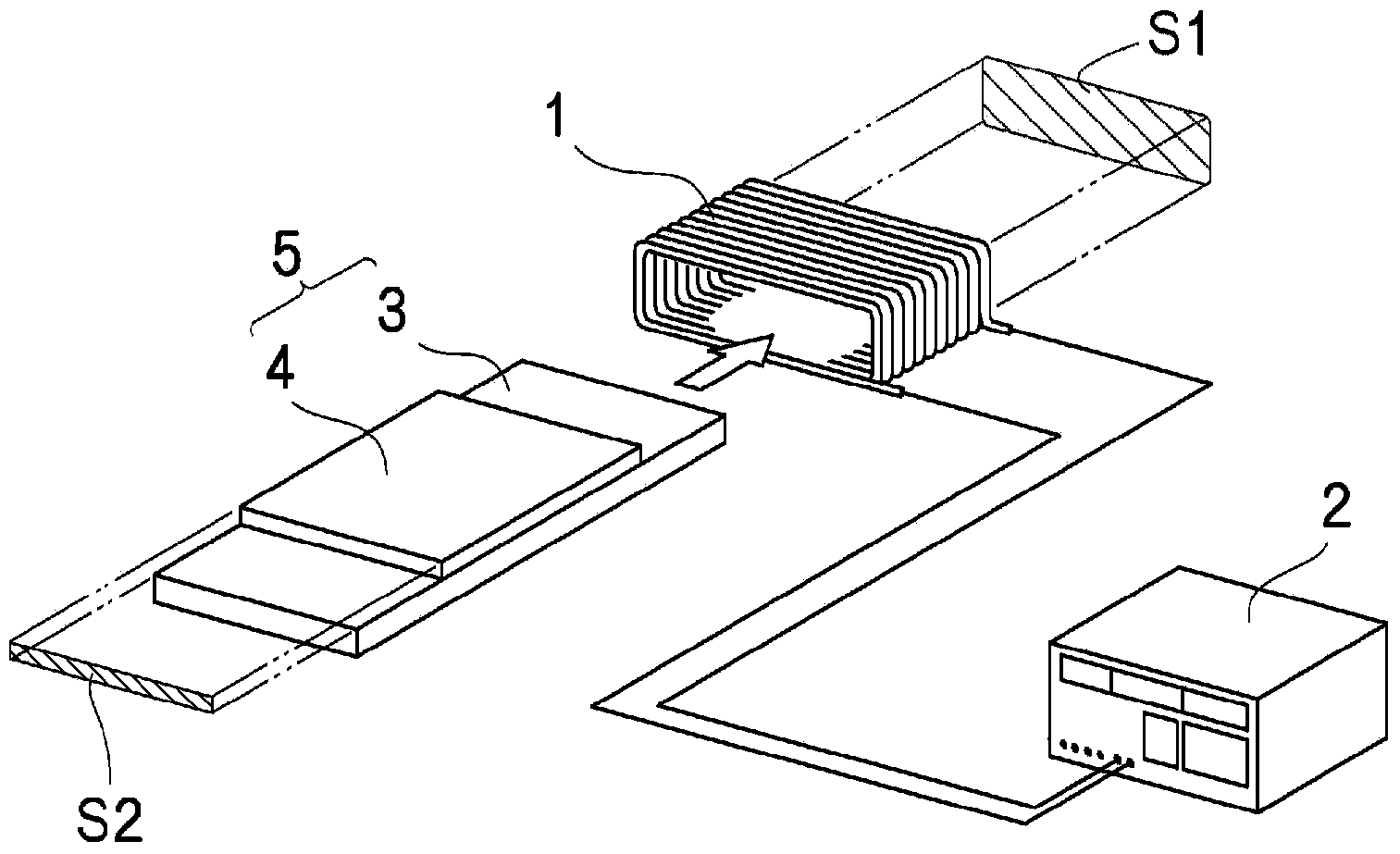

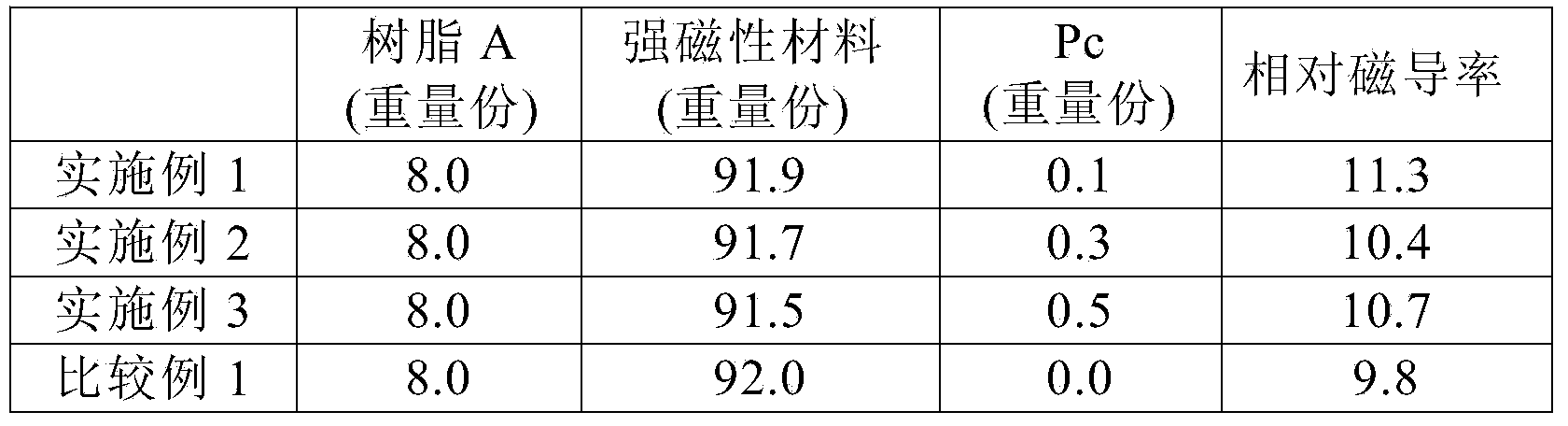

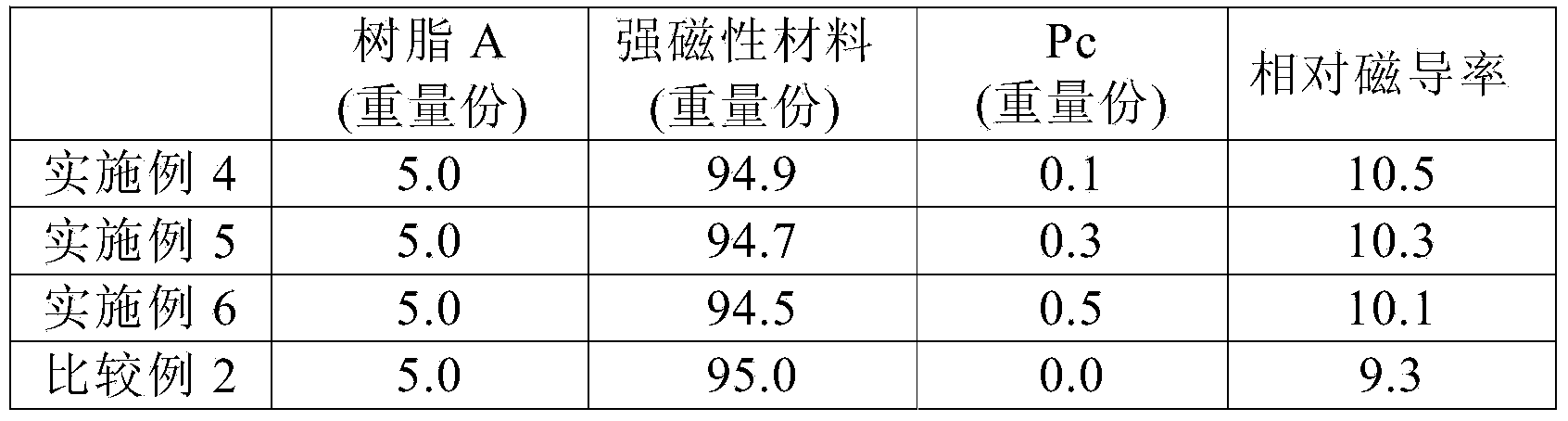

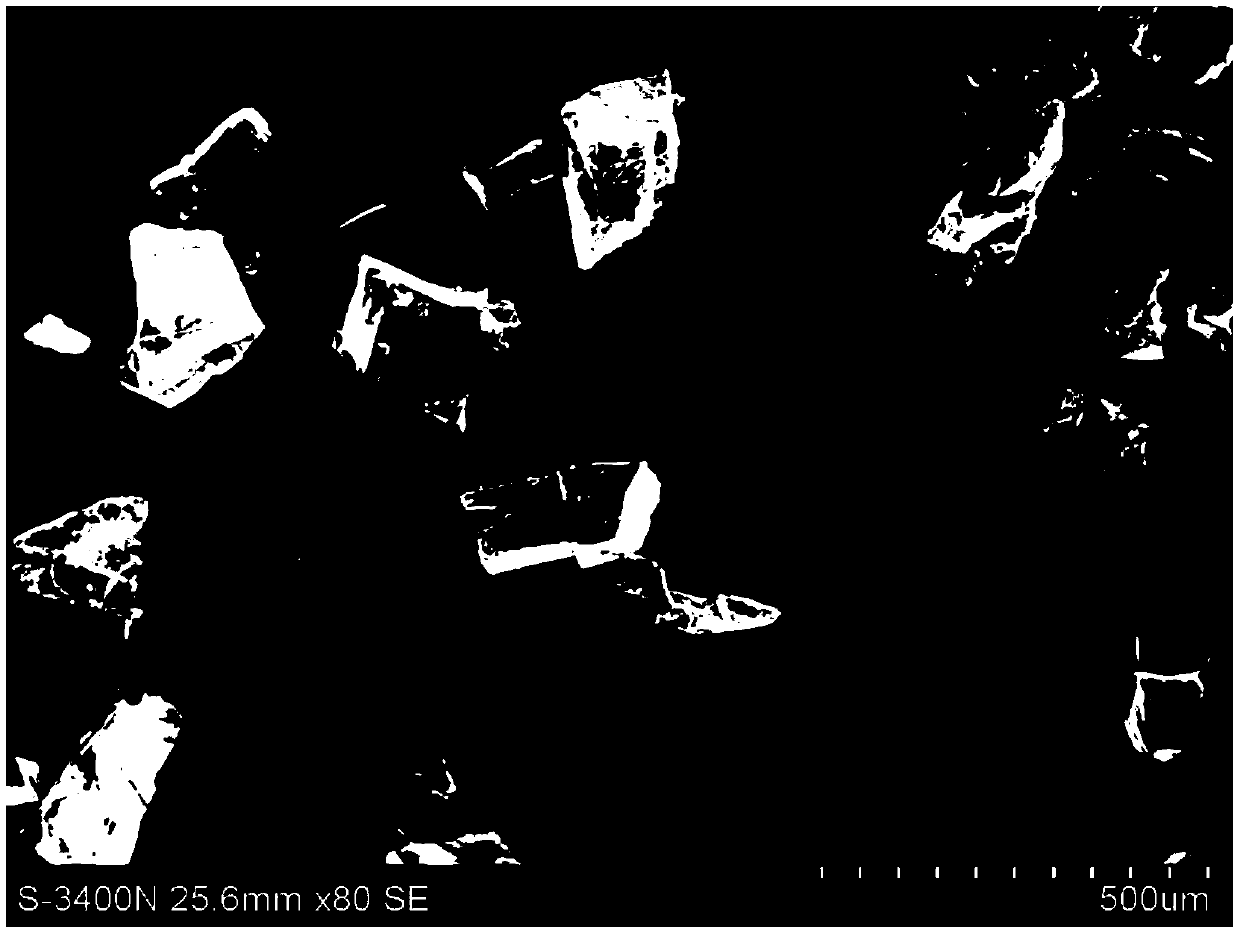

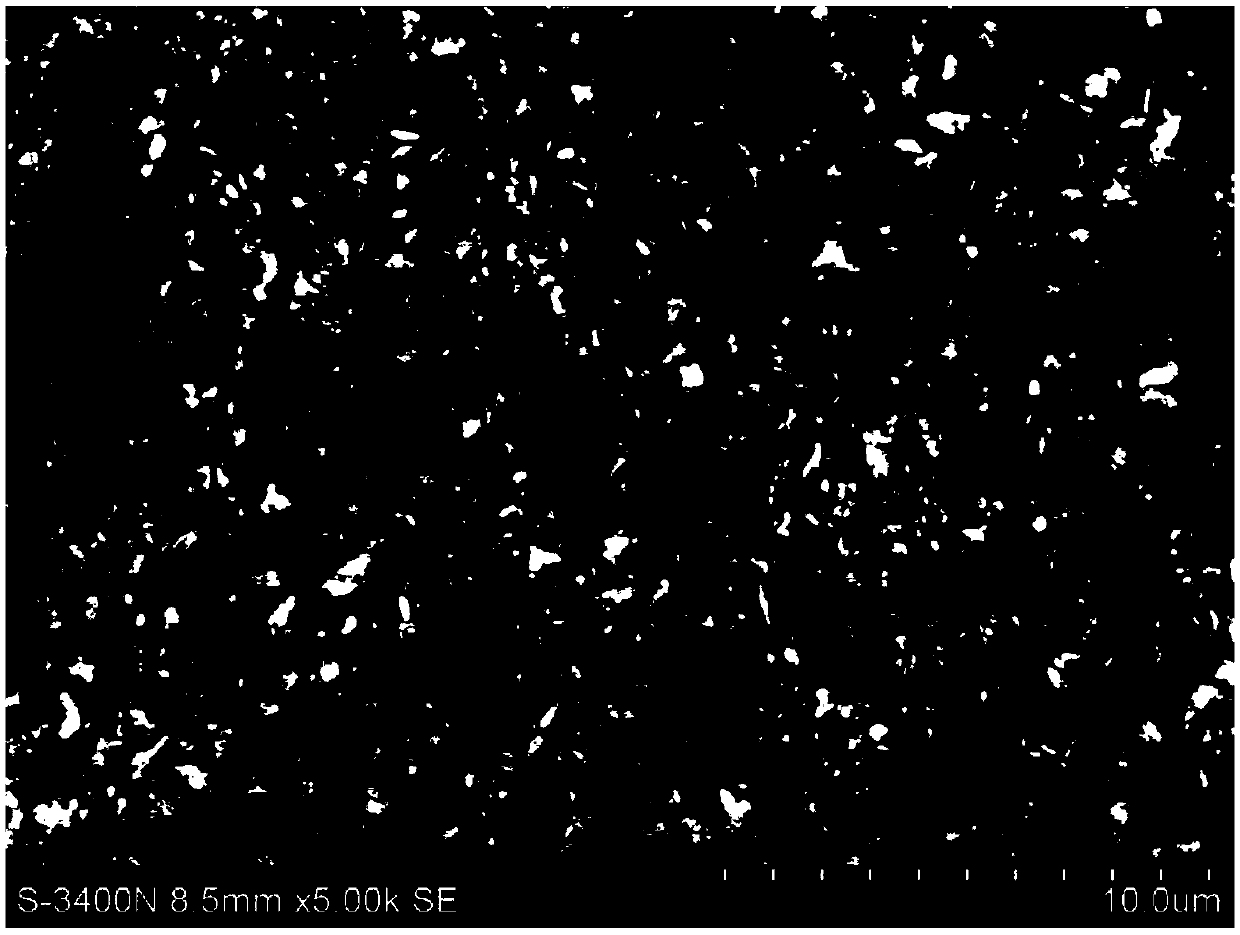

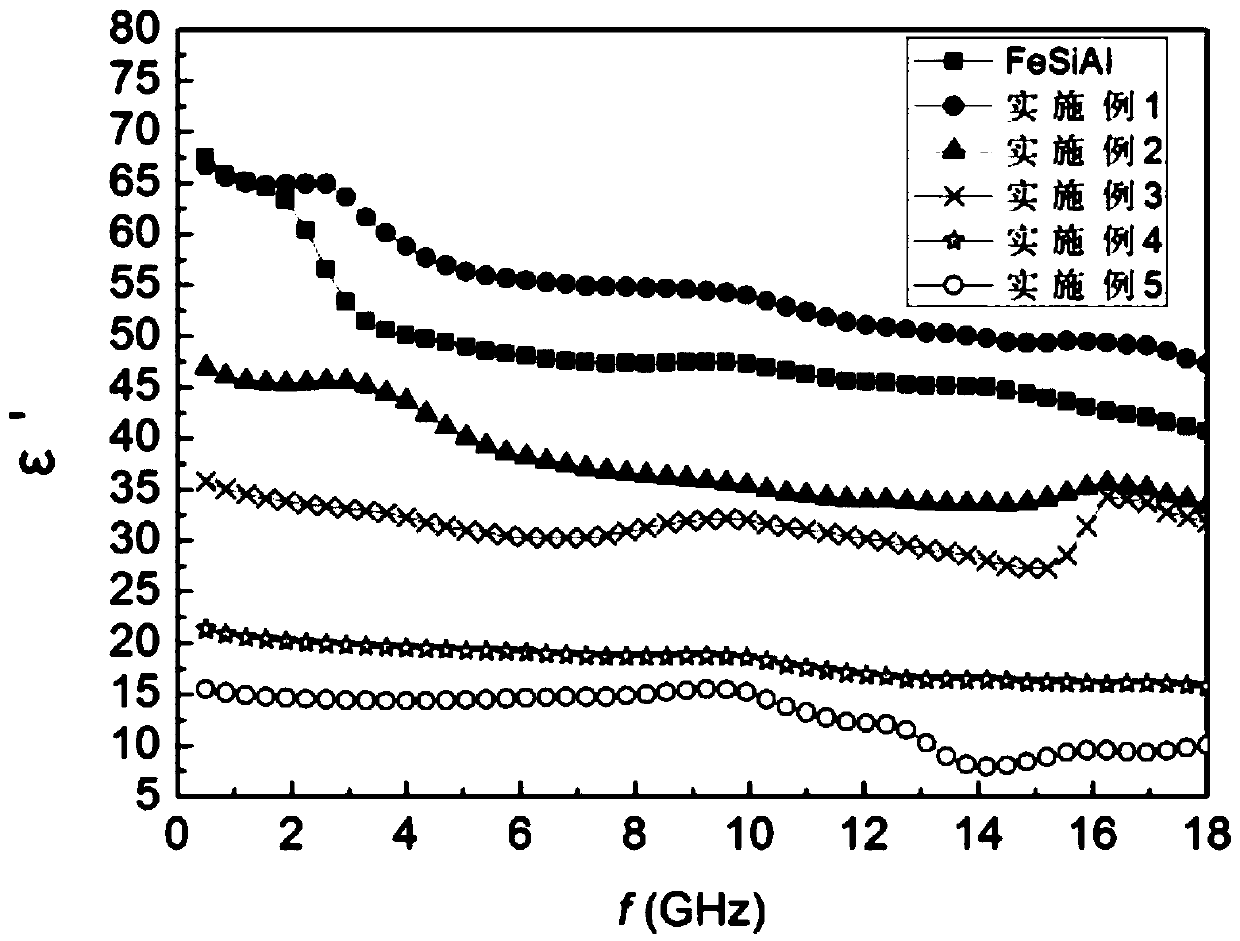

Magnetically Enhanced Resin

InactiveUS20140077120A1Improve magnetic efficiencyImprove permeabilityMagnetic paintsInorganic material magnetismEpoxySendust

A major objective of the present invention is to provide a magnetically enhanced resin and the like having an improved magnetic permeability. The magnetically enhanced resin contains a ferromagnetic material, a compound having a macrocyclic π electronic structure, and an adhesive resin. The ferromagnetic material is preferably a powder of a Fe—Ni alloy, a Fe—Ni—Mo alloy, a Fe—Ni—Cu alloy, or a Fe—Al—Si alloy. The ferromagnetic material is preferably a powder of permalloy, supermalloy, sendust, or ferrite. The compound having a macrocyclic π electronic structure is preferably phthalocyanine, porphyrin, or polycyanine, a substitution product thereof, or a metal coordination complex thereof. The adhesive resin is preferably an epoxy resin, a melamine resin, a polyimide resin, a polycarbonate resin, a phenol resin, or a fluorosilicone resin. The average particle size of the powder of the ferromagnetic material is preferably 0.1 to 100 μm.

Owner:TANAKA SEIMITSU IND

Magnetically enhanced resin

InactiveCN103608409AImprove permeabilityImprove magnetic efficiencyMagnetic paintsInorganic material magnetismEpoxySendust

The main purpose of the present invention is to provide a magnetically enhanced resin or the like having increased magnetic permeability. The magnetically enhanced resin is characterized by containing a ferromagnetic substance, a compound having a macrocyclic p electronic structure, and an adhesive resin. The ferromagnetic substance is preferably a powder of a Fe-Ni alloy, a Fe-Ni-Mo alloy, a Fe-Ni-Cu alloy, or a Fe-Al-Si alloy. The ferromagnetic substance is also preferably a powder of Permalloy, Supermalloy, Sendust, or a ferrite. The compound having a macrocyclic p electronic structure is preferably phthalocyanine, porphyrin, polycyanine, or substitution products thereof, or ligands thereof with a metal. The adhesive resin is preferably an epoxy resin, a melamine resin, a polyimide resin, a polycarbonate resin, a phenolic resin, or a fluorosilicone resin. The average particle size of the ferromagnetic powder is preferably 0.1-100 µm.

Owner:TANAKA SEIMITSU IND

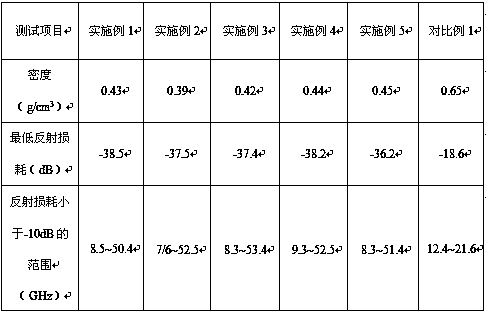

Sendust electromagnetic wave absorbent and preparation method thereof

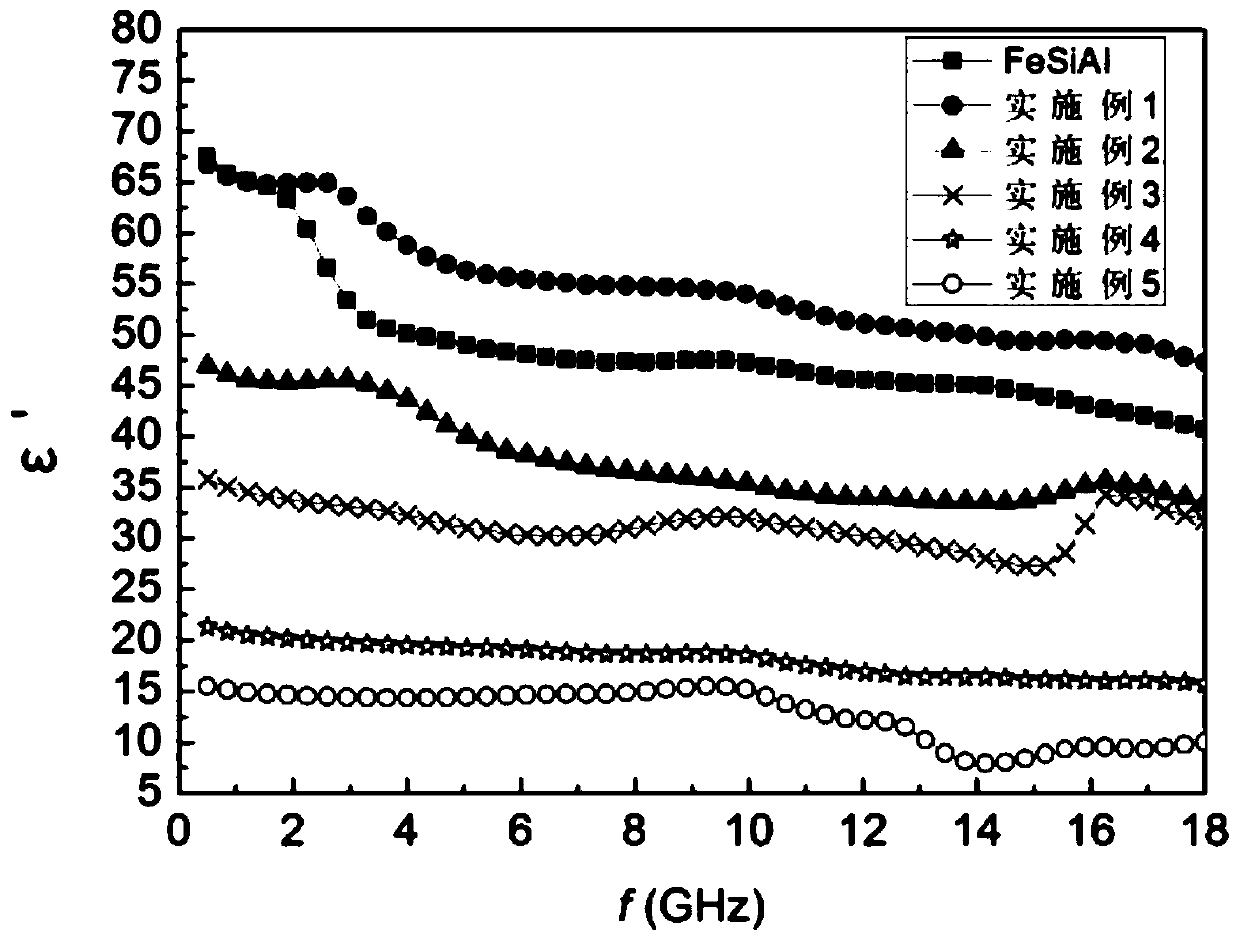

The invention relates to the technical field of electromagnetic wave absorption, and provides a preparation method of a sendust electromagnetic wave absorbent. The preparation method comprises the steps: manganese zinc ferrite and sendust alloy powder are mixed to be ball-milled, wherein the ratio of milled materials to milling media is 1:(14 to 16), and ball milling is conducted for 5-50 h; and then drying is conducted to obtain the sendust electromagnetic wave absorbent, wherein the manganese zinc ferrite accounts for 0.5-5at% of the sendust electromagnetic wave absorbent, and the manganesezinc ferrite is prepared from the components in percentage by atom: 52-55% of Fe2O3, 33-36% of MnO and 10-14% of ZnO. According to the preparation method, the manganese zinc ferrite is doped in the sendust alloy powder with the reasonable content, and the reasonable ball milling time is selected in the mixed ball milling process of the manganese zinc ferrite and the sendust alloy powder, so that the prepared sendust electromagnetic wave absorbent has a good absorption effect on electromagnetic waves. The invention further provides the sendust electromagnetic wave absorbent prepared through thepreparation method. The sendust electromagnetic wave absorbent has good absorption performance on the electromagnetic waves.

Owner:XIHUA UNIV

A kind of sendust electromagnetic wave absorber and preparation method thereof

InactiveCN109688780BPromote absorptionMagnetic/electric field screeningElectromagnetic wave absorberSendust

The invention relates to the technical field of electromagnetic wave absorption, and provides a preparation method of a sendust electromagnetic wave absorbent. The preparation method comprises the steps: manganese zinc ferrite and sendust alloy powder are mixed to be ball-milled, wherein the ratio of milled materials to milling media is 1:(14 to 16), and ball milling is conducted for 5-50 h; and then drying is conducted to obtain the sendust electromagnetic wave absorbent, wherein the manganese zinc ferrite accounts for 0.5-5at% of the sendust electromagnetic wave absorbent, and the manganesezinc ferrite is prepared from the components in percentage by atom: 52-55% of Fe2O3, 33-36% of MnO and 10-14% of ZnO. According to the preparation method, the manganese zinc ferrite is doped in the sendust alloy powder with the reasonable content, and the reasonable ball milling time is selected in the mixed ball milling process of the manganese zinc ferrite and the sendust alloy powder, so that the prepared sendust electromagnetic wave absorbent has a good absorption effect on electromagnetic waves. The invention further provides the sendust electromagnetic wave absorbent prepared through thepreparation method. The sendust electromagnetic wave absorbent has good absorption performance on the electromagnetic waves.

Owner:XIHUA UNIV

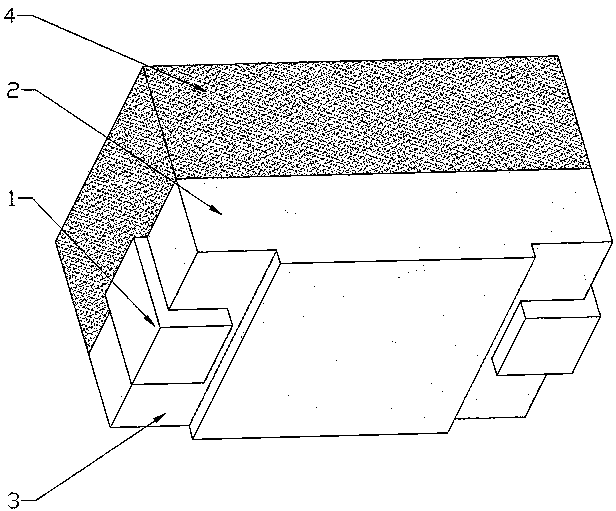

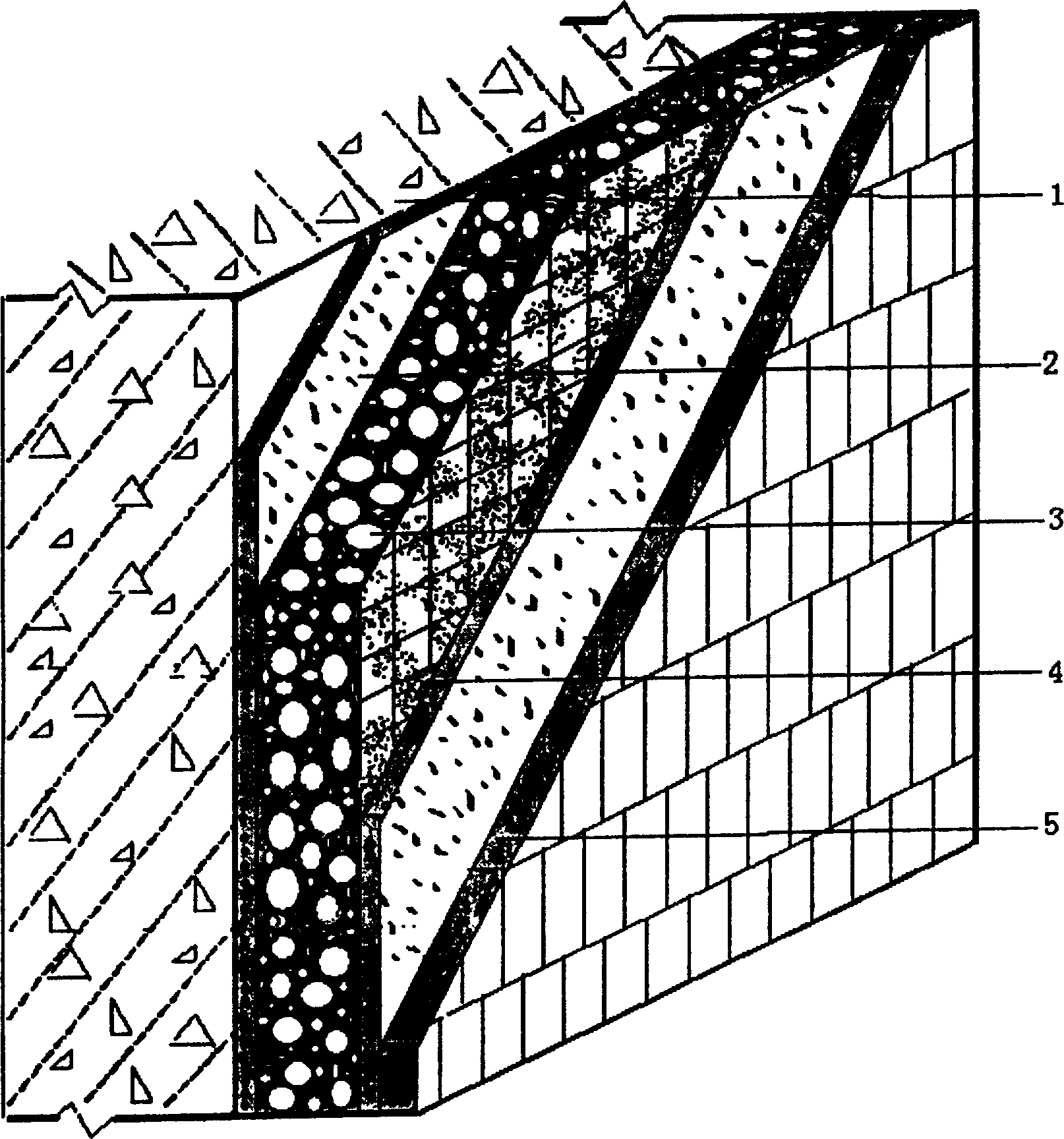

Unit block used in manufacturing core with soft magnetic metal powder, and method for manufacturing core with high current DC bias characteristics using the unit block

InactiveCN1871670AReduce lossReduce heat and noiseInductances/transformers/magnets manufactureThin material handlingSendustFire resistance

Owner:CHANG SUNG CO LTD

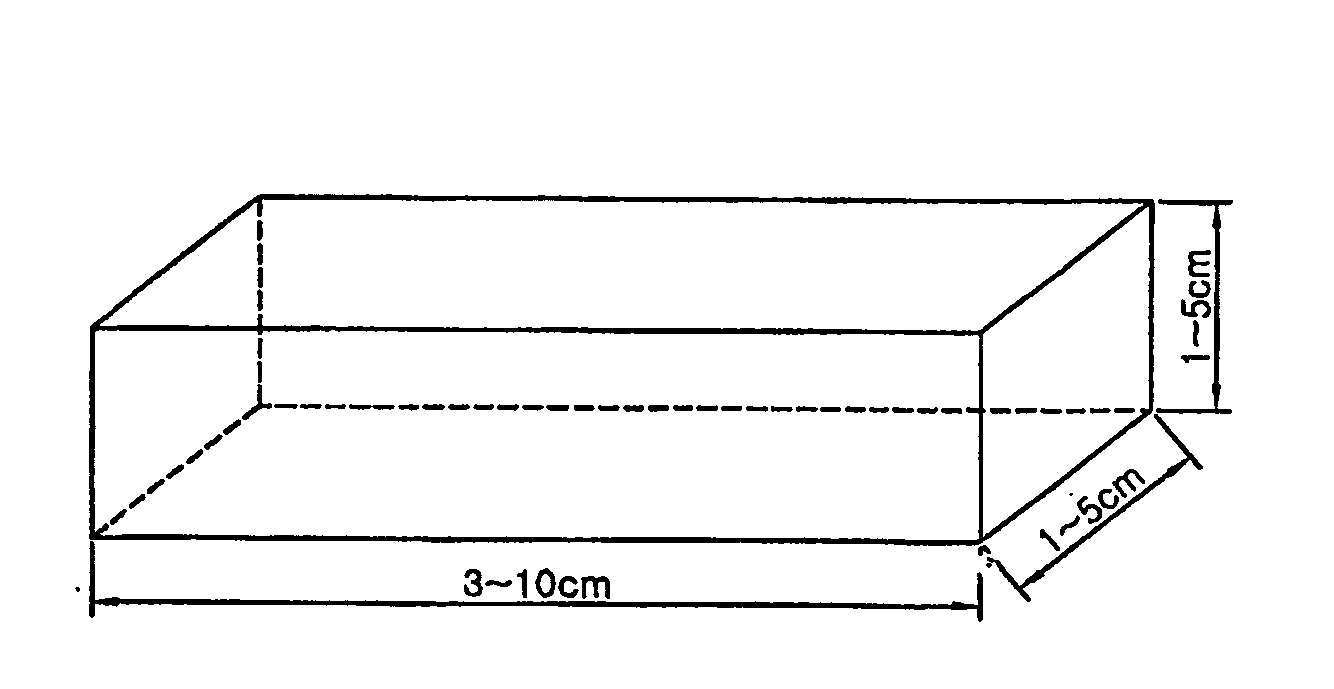

Unit Block Used in Manufacturing Core with Soft Magnetic Metal Powder, and Method for Manufacturing Core with High Current Dc Bias Characteristics Using the Unit Block

InactiveUS20070237975A1Reduce noiseReduce occurrenceLamination ancillary operationsLaminationSendustAdhesive

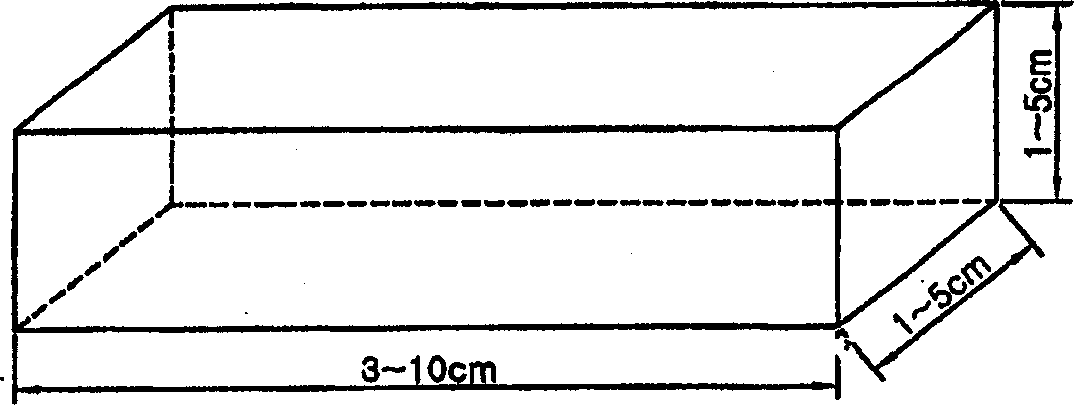

A unit block for a core using soft magnetic metal powder, a core having excellent high-current DC bias characteristics using the unit block, and a method of producing the core are disclosed. The unit block is used to produce cores applied to an active filter for PFC, a three-phase line reactor, or an inductor for automotive electronics. A method of producing the core comprises mixing sendust alloy, High Flux, MPP, or silicon steel powders, which have an average particle size of 175 gm or less, with a solid lubricant; compacting a mixture at a pressure of 10-18 tons per unit area; heat-treating the compacted mixture at 600-800° C. for 1-2 hours to form the unit blocks each having a length of 3-10 cm, a width of 1-5 cm, and a height of 1-5 cm; and attaching the unit blocks using a heat- and fire-resistant adhesive.

Owner:CHANG SUNG CO LTD

Novel thermal insulation and heat preservation structure for complex building and construction technique

InactiveCN1274926CSave raw materialsImprove ergonomicsCovering/liningsWallsSendustThermal insulation

The present invention provides a novel complex thermal insulation and heat preservation structure, the structure has from inside to outside a subbase, a thermal insulation and heat preservation layer, a strengthening and crack-resistant layer, a thermal reflecting decorative layer. The thermal insulation and heat preservation layer is formed with complex powder material A and polystyrene bubble particle B, the complex powder material A has 50-80% concrete, 10-40% sendust glass hollow ball material having specific surface area of 400-5000 m[2] / kg, air entraining agent 0.005-0.05%, modifying agent 1-5%, water reducing agent 0.2-1.2%, fiber 0.1-5%, tackifier 0.5-2%, the strengthening and crack-resistant layer is coagulated with thermal galvanization steel wire net and modifying crack-resistant base body of fiber strengthening polymer, the wire net is hung and fixed on the thermal insulation and heat preservation layer with plastic expanding bolt, the thermal reflecting decorative layer is made of tint glazed ceramic wall tile or glass, aluminium alloy, stainless steel curtain wall material. The structure apparently improves the thermal insulation and heat preservation ability, and effectively resolves the problem of crack, gaul, and drop of the tile, also greatly improves the wear ability and construction efficiency.

Owner:奥捷科技股份有限公司

Graphene-containing lightweight anti-electromagnetic pollution composite material plate and preparation method

InactiveCN108790348AIncrease the interfacial bonding areaImprove polarization performanceSynthetic resin layered productsSendustProcedure Agents

The invention discloses a graphene-containing lightweight anti-electromagnetic pollution composite material plate and a preparation method thereof. The lightweight wave absorbing multi-layered composite plate is prepared through the following steps that a, graphene, nanosized ferrite, sendust and a foaming agent are mixed and added into a thermosensitive bag material and subjected to spray drying,and three kinds of microcapsules are obtained; b, the three kinds of microcapsules are mixed with polyolefin and a processing assistant, and three kinds of first polyolefin compositions are obtained;and c, the compositions are added into a three-layer co-extrusion machine, extrusion and overlaying are conducted, and the lightweight wave absorbing composite plate with the three-layer structure isprepared. The method has the following beneficial effects that the gas generated in the extrusion and foaming processes of each layer is subjected to secondary dispersion, so that a microwave absorbent is uniformly dispersed in a polymer, and the obtained lightweight composite plate with the three-layer structure has the excellent wave absorbing capability, and the outstanding damping propertiessuch as damping and wave absorbing.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

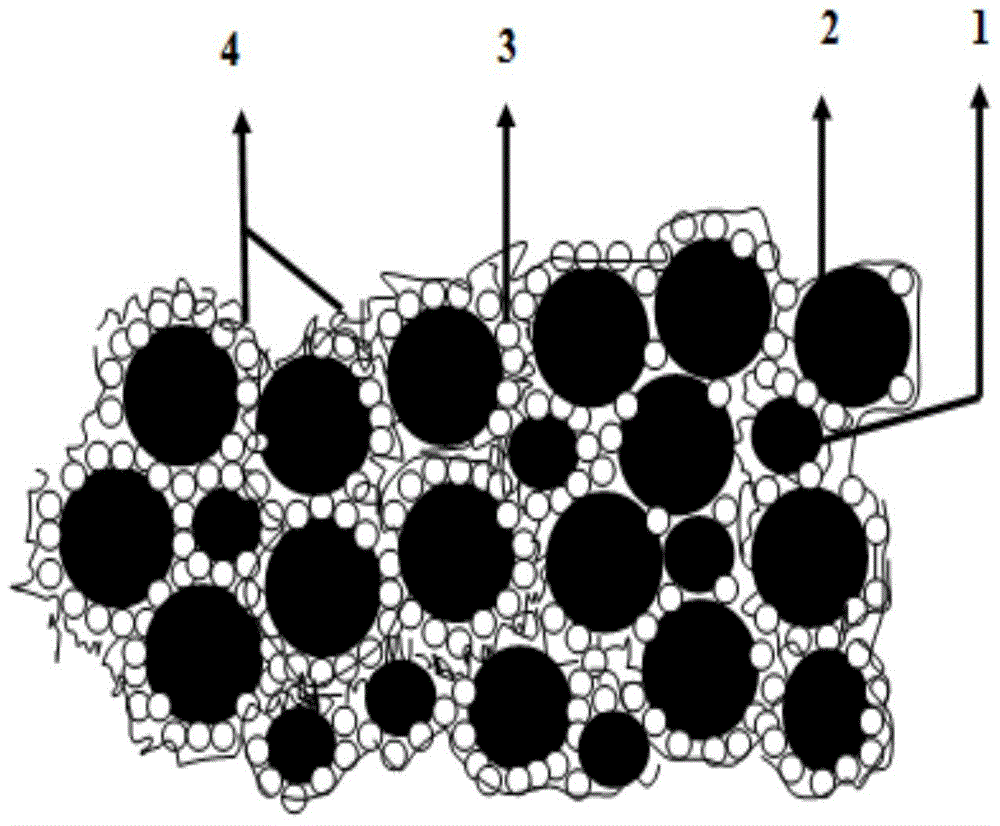

Magnetic metal powder with high forming density, low molding pressure and surface insulation

The invention provides a magnetic metal powder with high forming density, low molding pressure and surface insulation. The powder manufactured through the method has three layers of structures from inside to outside. An innermost material is magnetic metal or an alloy powder with Vickers hardness which is greater than or equal to 800 and is a source of a magnetic property of a metal powder core; asecond layer material is a relatively soft metal or an alloy film with the Vickers hardness which is less than or equal to 400 and achieves the effect of reducing a stress during a powder molding process; and an outermost layer material is an insulating layer formed by an inorganic non-metal material. In addition, the metal powder core manufactured through using the powder has a small residual stress, high powder core density and small molding pressure so that the metal powder core has low losses and high magnetic permeability. The composite structure magnetic powder is suitable for manufacturing the metal powder of the magnetic metal powder which has high hardness and is difficult to deform, such as a Sendust alloy powder, an amorphous soft magnetic metal powder, a nanocrystalline alloypowder and the like. The molding pressure and the residual stress can be significantly reduced during a molding process. Powder core density is increased and finally the performance of the metal powder core is improved.

Owner:KUNSHAN CITONG NEW MATERIAL TECH CO LTD

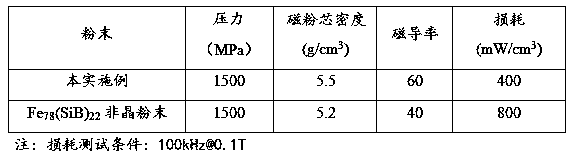

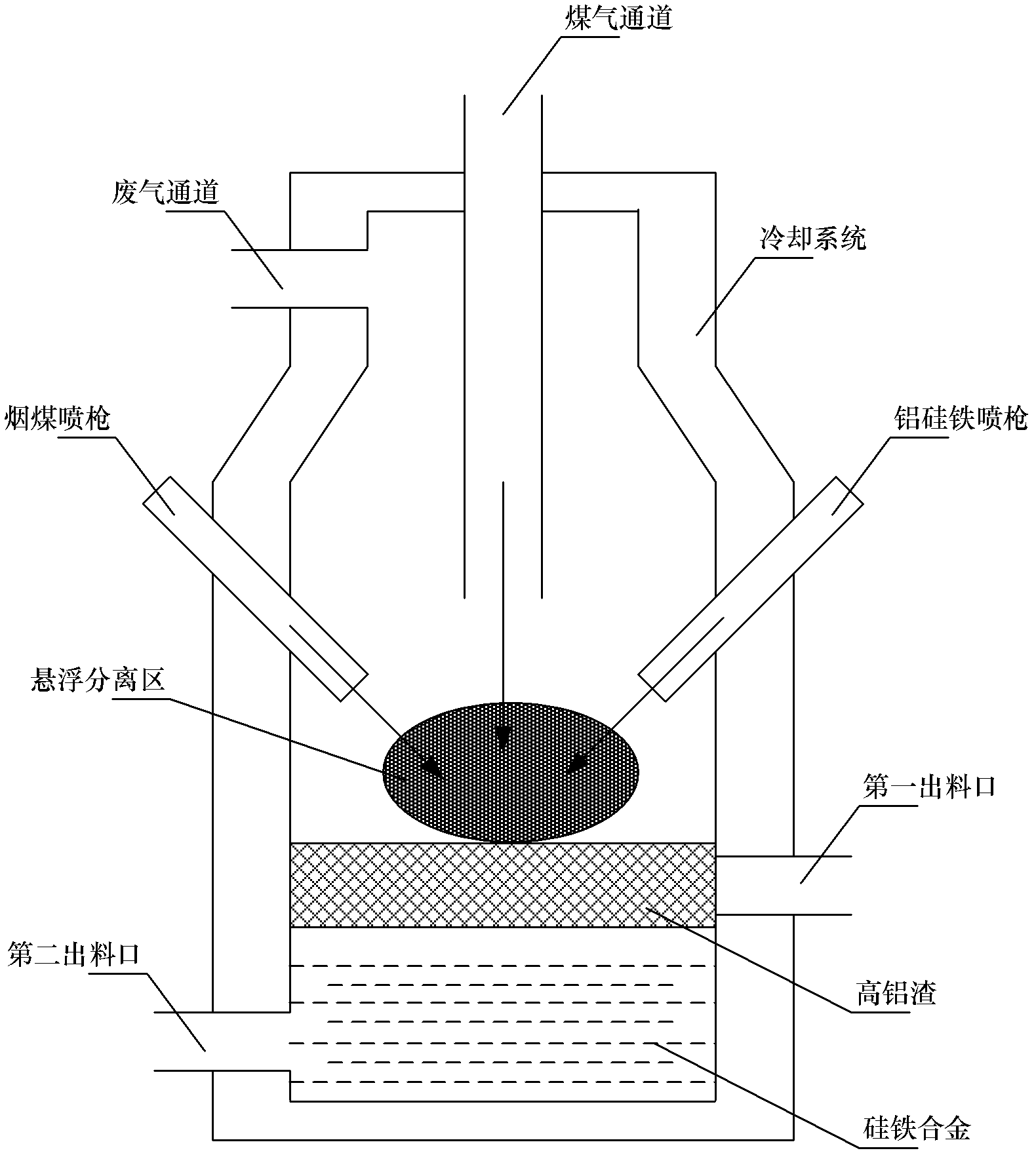

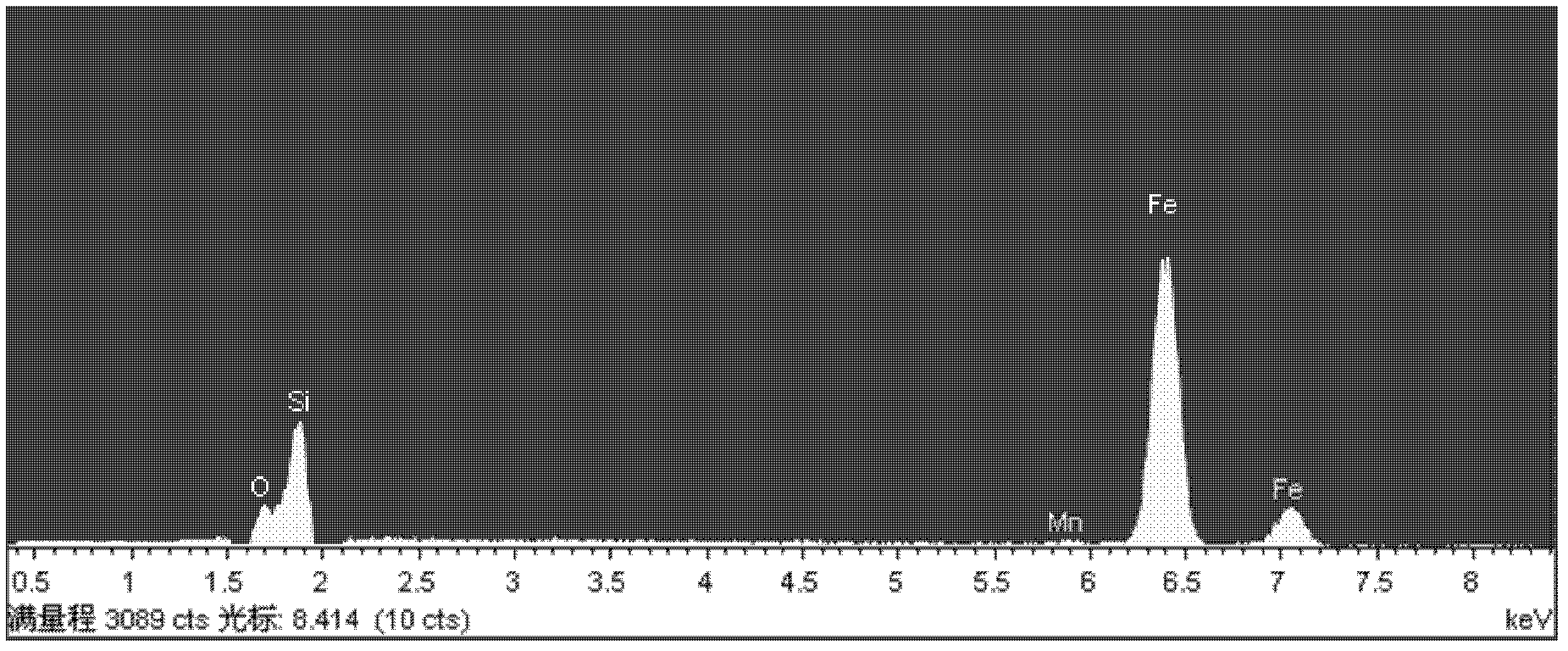

Method for Industrialized Production of Ferrosilicon Alloy by Carbon Reduction from Senustin Mixed Ore

The invention discloses a method for producing ferrosilicon alloy by carbon reduction from aluminum-silicon-iron mixed ore. The method utilizes the continuous supply of powdery raw materials and the continuous supply of reducing gas to reduce the need for multiple equipment to cooperate in industrial production. To complete the production, while reducing production costs. The present invention adopts the combination of pulverizer and flash suspension furnace on production equipment, and the whole processing time from raw material entering to ferrosilicon alloy production is 20 minutes to 40 minutes, which improves production efficiency and recovery rate.

Owner:陕西延长石油中陕金属矿业有限公司 +1

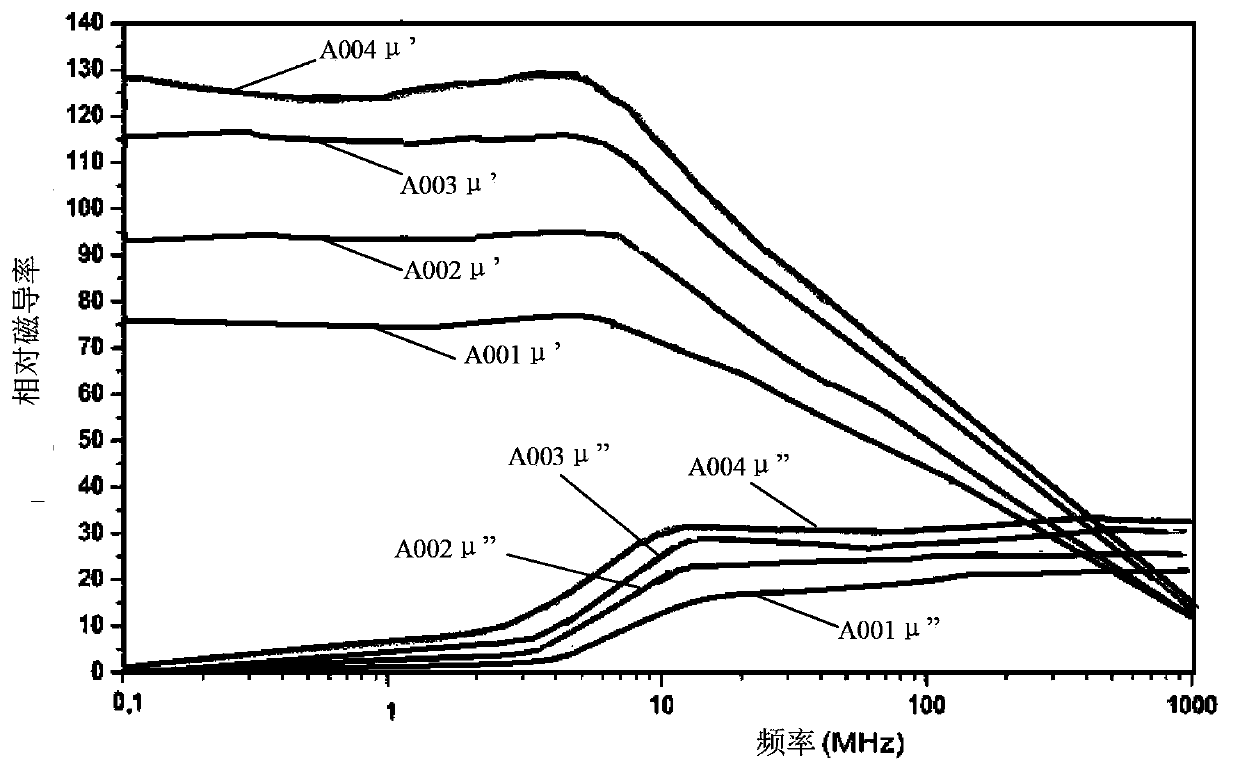

Composite soft magnetic material thin film based on sendust soft magnetic material and preparation method thereof

InactiveCN103824672BLow costSimple processInorganic material magnetismMagnetic film to substrate applicationSendustAdhesive

The invention provides a composite soft magnetic material thin film based on Fe-Si-Al soft magnetic materials and a manufacturing method of the composite soft magnetic material thin film. The thin film comprises Fe-Si-Al soft magnetic powder particles, a silicon dioxide hardened network structure formed by dehydrating water glass and manganese zinc ferrite soft magnetic powder particles, the Fe-Si-Al soft magnetic powder particles are coated with the manganese zinc ferrite soft magnetic powder particles, the particles are bonded through the silicon dioxide hardened network structure formed by dehydrating the water glass, and mechanical strength is formed. The manufacturing method of the thin film comprises the steps of pretreatment on Fe-Si-Al soft magnetic powder of thin film base materials, insulation coating on the thin film base materials with manganese zinc ferrite soft magnetic powder and low-temperature solidification forming with adhesives of the water glass. Manganese zinc ferrite is used as insulating agents, the high-frequency magnetic performance of the composite soft magnetic material thin film can be regulated, and the upper limit of working frequency is improved; good bonding power is achieved. The thin film saves energy, and is environmentally friendly and good in process compatibility, and the composite soft magnetic material thin film with excellent comprehensive magnetic performance can be obtained.

Owner:SHANGHAI JIAO TONG UNIV

Magnetic ring core raw material and preparation method of magnetic ring core

InactiveCN110098023AImprove heat resistanceImprove flame retardant performanceInductances/transformers/magnets manufactureMagnetic materialsSendustAlcohol

A magnetic ring core raw material includes a raw material A and a raw material B. The raw material A is composed of 50% of ferrosilicon, 35% of sendust and 15% of crushed powder, and the total amountof the raw material A is 100%. The raw material B is composed of phosphoric acid, resin, lubricating powder and alcohol. The weight ratio of the raw material A to the phosphoric acid is 100:(0.1-0.3).The weight ratio of the raw material A to the resin is 100:(0.3-0.8). The weight ratio of the raw material A to the lubricating powder is 100:(0.1-0.5). The weight ratio of the raw material A to thealcohol is 100:(1-4.5).

Owner:SICHUAN DONGGE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for manufacturing [mu]26 composite magnetic powder core Method for manufacturing [mu]26 composite magnetic powder core](https://images-eureka.patsnap.com/patent_img/a9a52e52-c44a-4432-9340-750296d5c074/170720100023.png)