Sendust alloy magnetic powder core preparation method

A technology of magnetic powder core and alloy powder, applied in the field of preparing Sendaiste alloy magnetic powder core, can solve the problems of increasing oxygen content, poor magnetic loss performance, increasing stress, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

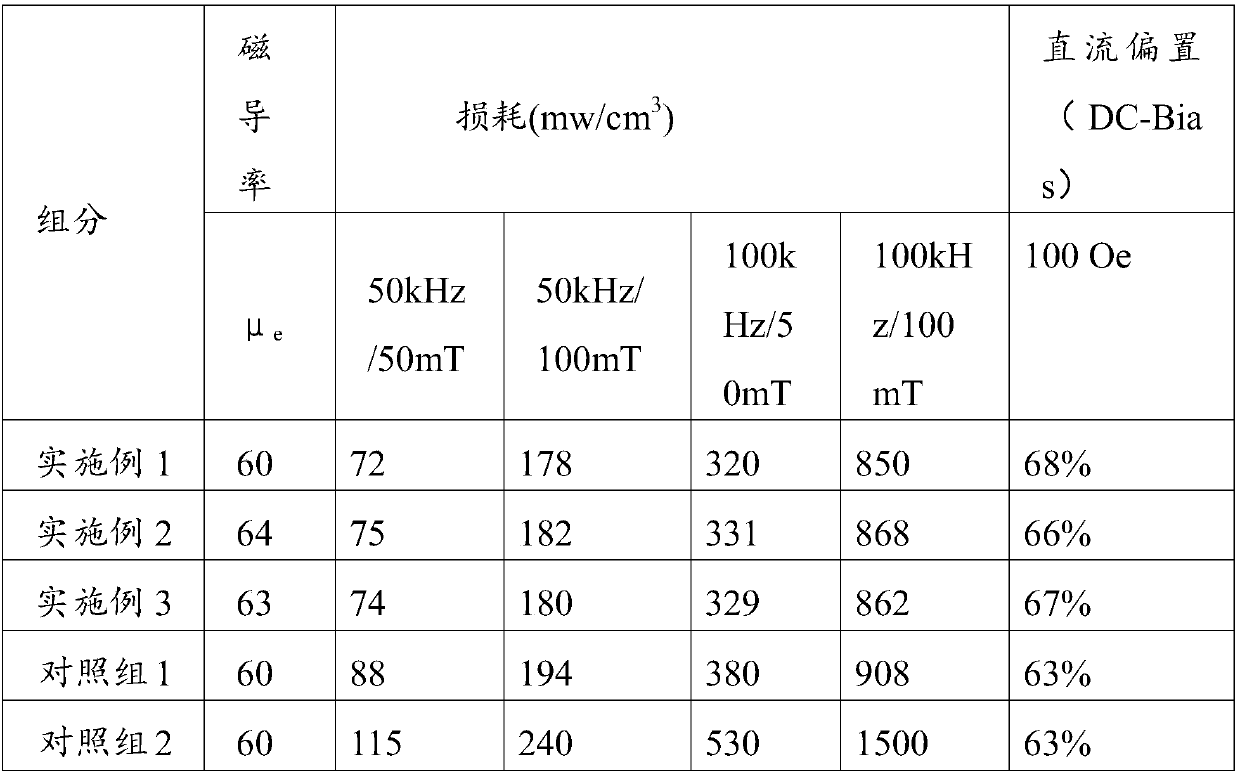

Examples

Embodiment 1

[0047] A method for preparing a Sendaiste alloy magnetic powder core, comprising the following steps:

[0048] Step 1: Preparation of alloy powder: take the following metal raw materials in mass percentages: 4% aluminum, 6% silicon, 3.27% nickel, and the rest are iron, and the alloy melt is obtained after metal smelting at a temperature of 1650 ° C. Said alloy melt adopts liquid nitrogen as protective gas, adjusts the pressure of the spray plate to be 45bar, and the spraying flow rate is 15Kg / min for gas atomization to obtain alloy powder;

[0049] Step 2: Alloy powder insulation coating treatment: after the alloy powder is sieved, add a phosphoric acid solution accounting for 0.5% by weight of the alloy powder for passivation, and after drying, add 0.5% by weight of the alloy powder The percentage is 0.5% low-melting point glass powder, stir evenly, then add the silicone resin that accounts for 1% by weight of the alloy powder, stir evenly, and finally add zinc stearate accou...

Embodiment 2

[0052] A method for preparing a Sendaiste alloy magnetic powder core, comprising the following steps:

[0053] Step 1: Preparation of alloy powder: take the following metal raw materials in mass percentages: 4% aluminum, 6% silicon, 3.27% nickel, and the rest are iron. After metal smelting at a temperature of 1400 ° C, an alloy melt is obtained. Said alloy melt adopts liquid nitrogen as a protective gas, adjusts the pressure of the spray plate to 50bar, and sprays the powder at a flow rate of 7Kg / min for gas atomization to obtain alloy powder;

[0054] Step 2: Alloy powder insulation coating treatment: After the alloy powder is sieved, add a phosphoric acid solution accounting for 0.1% by weight of the alloy powder for passivation, and after drying, add 0.1% by weight of the alloy powder The percentage is 0.5% low-melting point glass powder, stir evenly, then add silicone resin that accounts for 2.5% by weight of the alloy powder, stir evenly, and finally add zinc stearate acc...

Embodiment 3

[0057] A method for preparing a Sendaiste alloy magnetic powder core, comprising the following steps:

[0058] Step 1: Prepare alloy powder: take the following metal raw materials in mass percentages: 4% aluminum, 6% silicon, 3.27% nickel, and the rest are iron. After metal smelting at a temperature of 1800 ° C, an alloy melt is obtained. Said alloy melt adopts liquid nitrogen as the protective gas, adjusts the pressure of the spray plate to 5bar, and sprays the powder at a flow rate of 30Kg / min for gas atomization to obtain the alloy powder;

[0059] Step 2: Alloy powder insulation coating treatment: after the alloy powder is sieved, add a phosphoric acid solution accounting for 5% by weight of the alloy powder for passivation, and after drying, add The percentage is 0.5% low-melting point glass powder, stir evenly, then add the silicone resin that accounts for 0.5% by weight of the alloy powder, stir evenly, finally add zinc stearate accounting for 0.5% by weight of the allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com