A kind of sendust electromagnetic wave absorber and preparation method thereof

An electromagnetic wave and absorber technology, which is applied in the field of sendust electromagnetic wave absorber and its preparation, can solve problems such as improvement, unfavorable absorbing performance, difficulty in satisfying free space impedance matching conditions, etc., and achieve good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of sendust electromagnetic wave absorber, comprising:

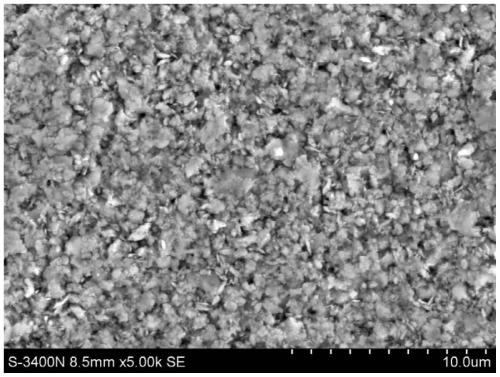

[0023] Doping manganese-zinc ferrite into sendust powder, then ball-milling the doped mixture according to the material-ball ratio of 1:14-16, ball-milling for 5-50 hours, and drying to obtain sendust electromagnetic wave absorber. Manganese-zinc ferrite accounts for 0.5-5 at% of the iron-silicon-aluminum electromagnetic wave absorber, and the ratio of manganese-zinc ferrite is: 52-55 at% Fe 2 o 3 , 33-36at% MnO, 10-14at% ZnO.

[0024] specifically:

[0025] S1. Vacuum melting iron, silicon and aluminum into alloy ingots.

[0026] High-purity iron rods, silicon particles and aluminum ingots with a purity greater than 99.9% are used to prepare raw materials according to the proportions of 72.5-75.5at% Fe, 15-17.5at% Si, and 9.5-11.5at% Al, respectively, in a vacuum induction melting furnace Smelting alloys. The vacuum degree before smelting is less than 0.1Pa, and the vacuum degree is contr...

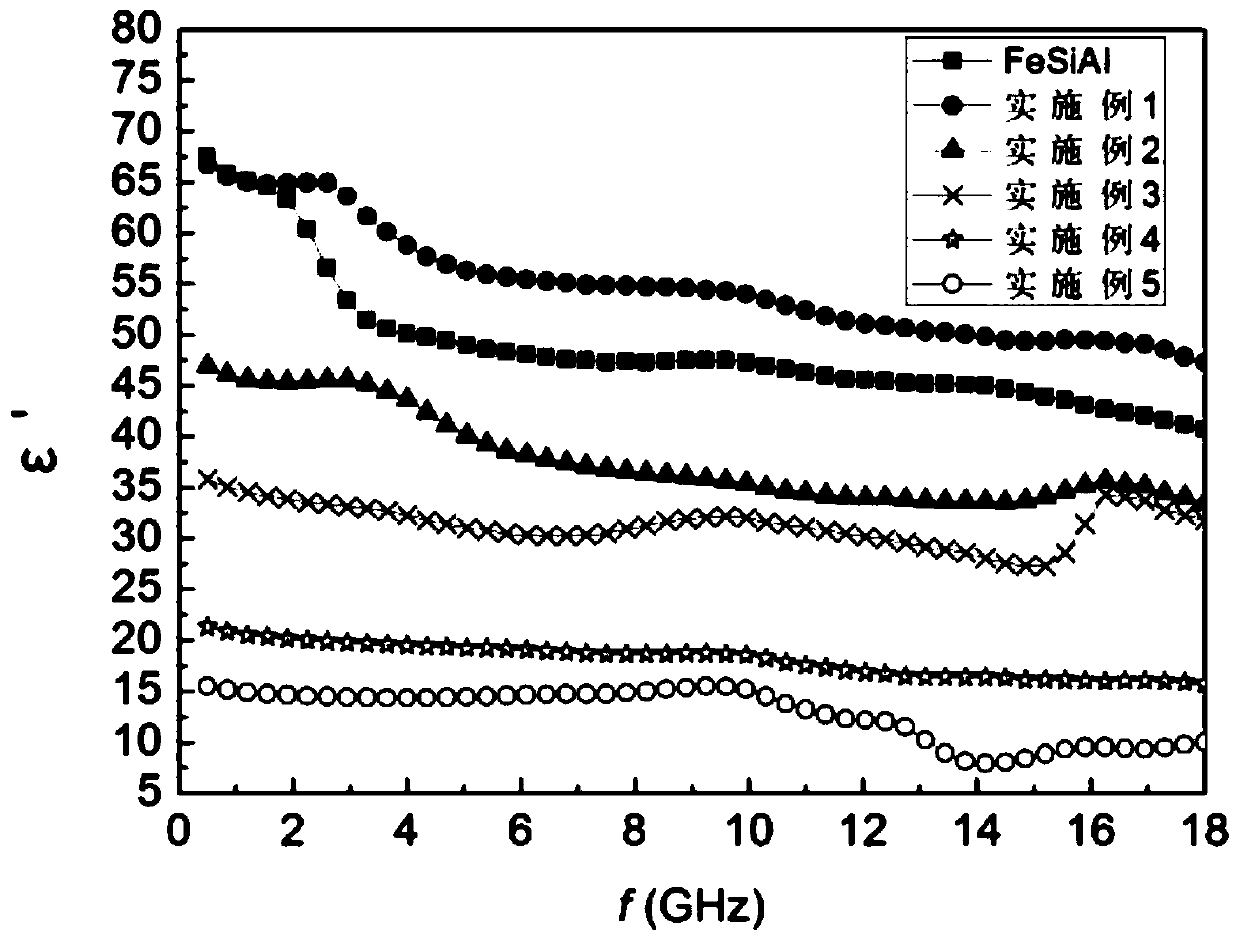

Embodiment 1

[0040] This embodiment provides a sendust electromagnetic wave absorber and a preparation method thereof.

[0041] A preparation method of sendust electromagnetic wave absorber, comprising:

[0042] High-purity iron rods, silicon particles and aluminum ingots with a purity greater than 99.9% are used to prepare raw materials at the ratio of 72.5at% Fe, 17.5at% Si, and 10at% Al respectively, and the alloy is melted in a vacuum induction melting furnace. The vacuum degree before smelting is less than 0.1Pa, and the vacuum degree is controlled to 1Pa during the capacity process to ensure that the vacuum requirement for raw materials in smelting is met. After smelting to obtain the melt, melt the melt for 2 minutes and pour it into ingots for crushing.

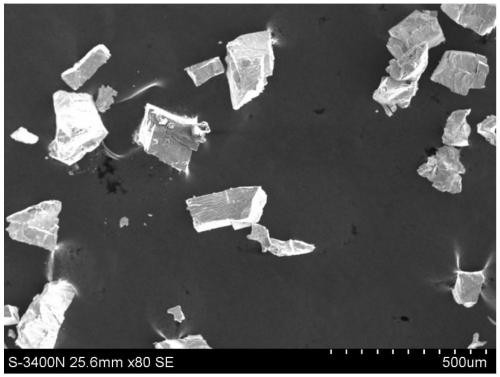

[0043] The alloy ingot obtained in S1 is preliminarily broken into particles with a particle size of about 100 μm in a crusher.

[0044] use and Three kinds of stainless steel balls are mixed, the alloy particles are place...

Embodiment 2- Embodiment 5

[0049] Example 2-Example 5 are basically the same as Example 1, except that the milling time of the manganese-zinc-ferrite and the sendust powder made by S5 in the ball mill is 15h, 25h, 35h, and 45h, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com