Patents

Literature

488 results about "Manganese-zinc ferrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferrite Materials: Ferrite Cores. Magnetics® soft ferrite cores are an oxide made from Iron (Fe), Manganese (Mn), and Zinc (Zn) which are commonly referred to as manganese zinc ferrites.

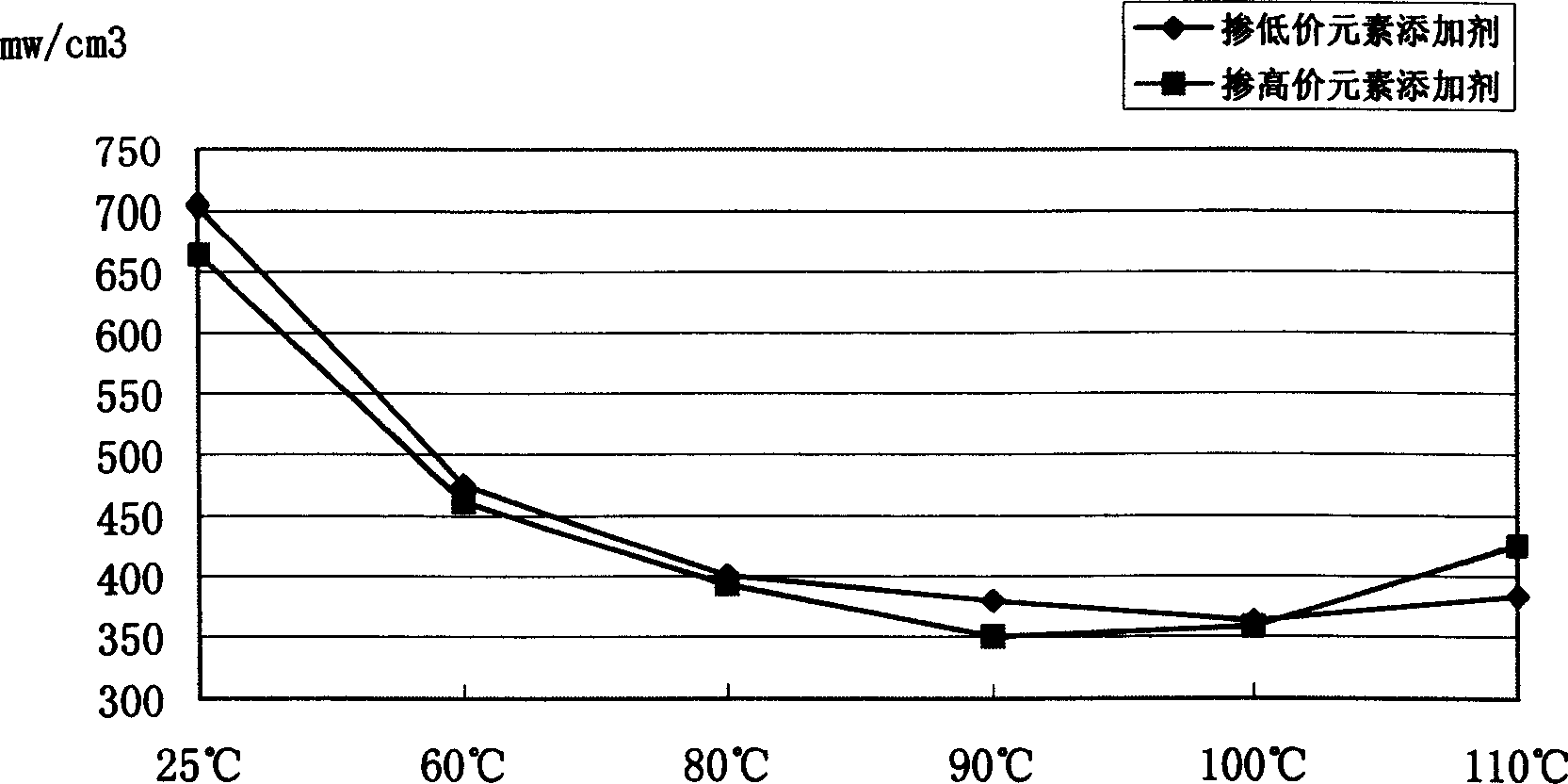

High performant low consumption manganese zine ferrite material and preparation process thereof

The invention relates to a high capacity low power consumption manganese-zinc ferrite material manufacturing method. The constituents includes 69.1-72.5wt% Fe2 O3, 22-24wt% Mn3O4, and ZnO. In the process of grinding and sintering, two or more from TiO2, Gd2 O3, SnO2, Co2O3, Ta2O5, Nb2O5, CaCO 3 could be added into the raw material. After grinding, pressure molding, sintering following certain temperature curve, the manganese-zinc ferrite material would be gained. The invention is simple and cost low. It has the feature of wide bandwidth and wide temperature.

Owner:SHANGHAI JIAO TONG UNIV

High saturated magnetic flux density and low loss manganese-zinc ferrite material and its preparing method

ActiveCN1749209ASimple manufacturing methodLower sintering temperatureInorganic material magnetismVolumetric Mass DensityNanometre

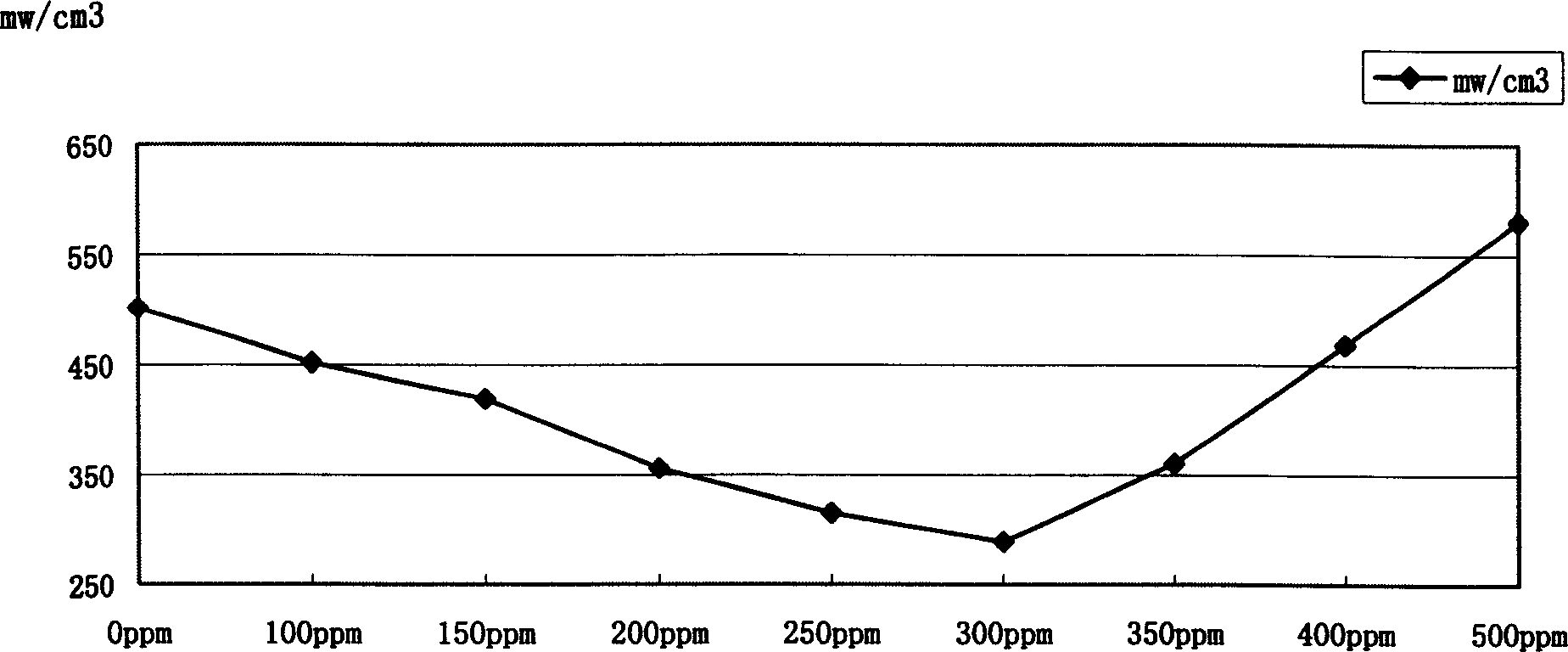

The present invention discloses high saturated magnetic flux density and low loss manganese manganese-zinc ferrite material and its preparation process. The manganese-zinc ferrite material contains: Fe2O3 52-54 mol%, MnO 33-40 mol%, ZnO 8-13 mol%, supplementary components CaCO3 100-600 ppm, SiO2 50-300 ppm and other metal oxides. The preparation process includes the steps of: mixing material, pre-sintering, adding supplementary components, secondary ball milling, forming and sintering. The supplementary components are common oxide grains, and this result in easy adding and low cost. The preparation process of the manganese-zinc ferrite material has relatively low pre-sintering and sintering temperature and relaxed requirement on sintering apparatus, may be completed in common vacuum sintering furnace, and easily realized in industrial production.

Owner:ZHEJIANG UNIV +1

Ferrite magnetic core for network communication and method for producing the same

The invention relates to a manganese-zinc ferrite magnetic core for network communication and a method for preparing the same. The magnetic core comprises the following compositions in terms of mol ratio: 51 to 58 mol percent of Fe2O3, 23 to 38 mol percent of MnO, 6 to 14 mol percent of ZnO, 0.01 to 5 mol percent of NiO, and 0.01 to 3 mol percent of CuO. The method for preparing the magnetic core comprises the following steps sequentially: first time of material blending and ball milling, presintering, second time of material blending and ball milling, spraying granulation to obtain granule materials, pressing the materials into biscuits, and biscuit sintering. The sintering is performed in push board kiln in an N2 protective atmosphere, experiences different sintering temperature stages, and finally keeps the temperature for 3 to 8 hours in the N2 atmosphere until the temperature is cooled to room temperature. The magnetic core has the performances of high MU i, high superposition, broad band and low loss. The magnetic core is widely used in the fields of network communication and electronic power, in particular in an ADSL technical separator.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +2

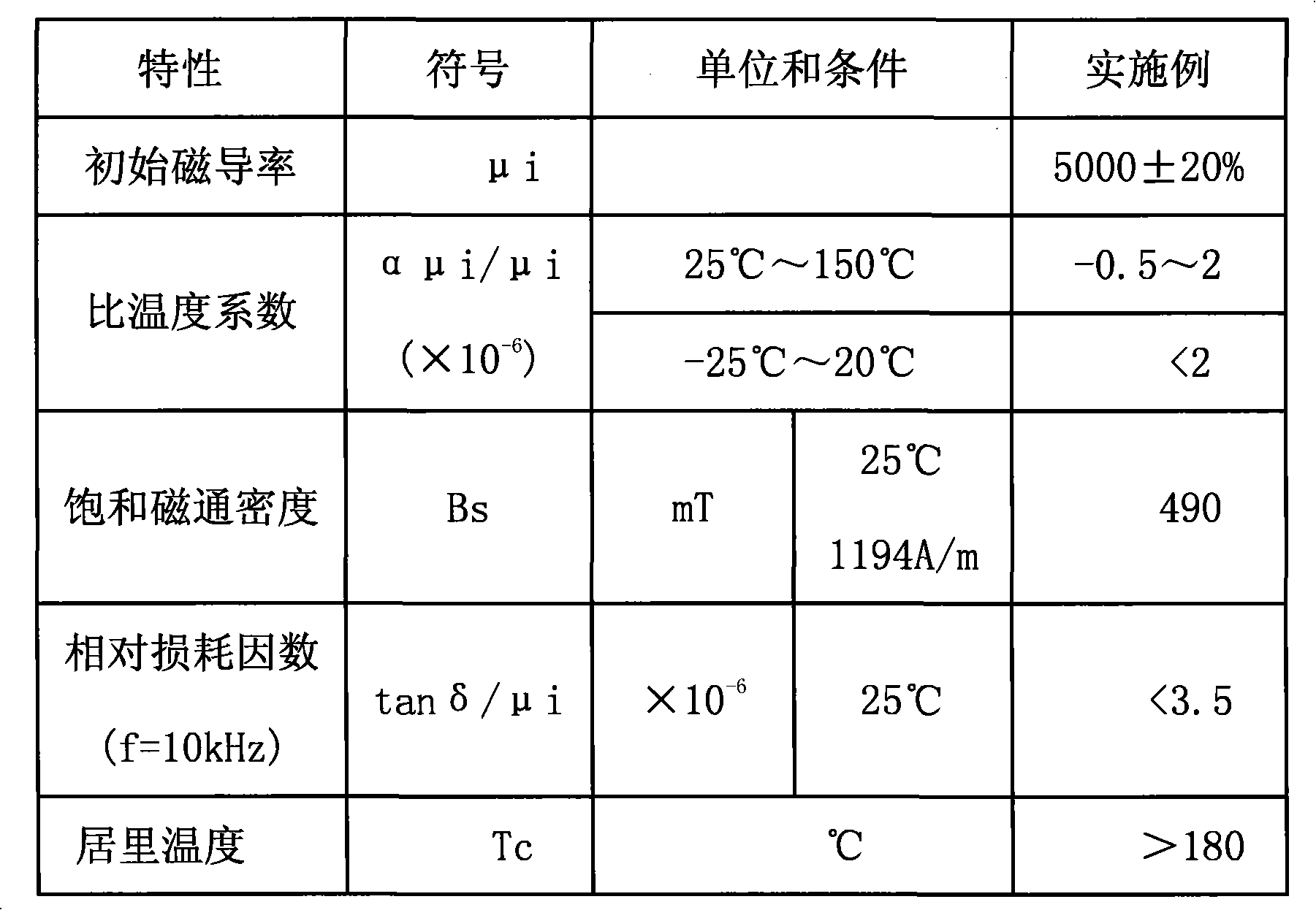

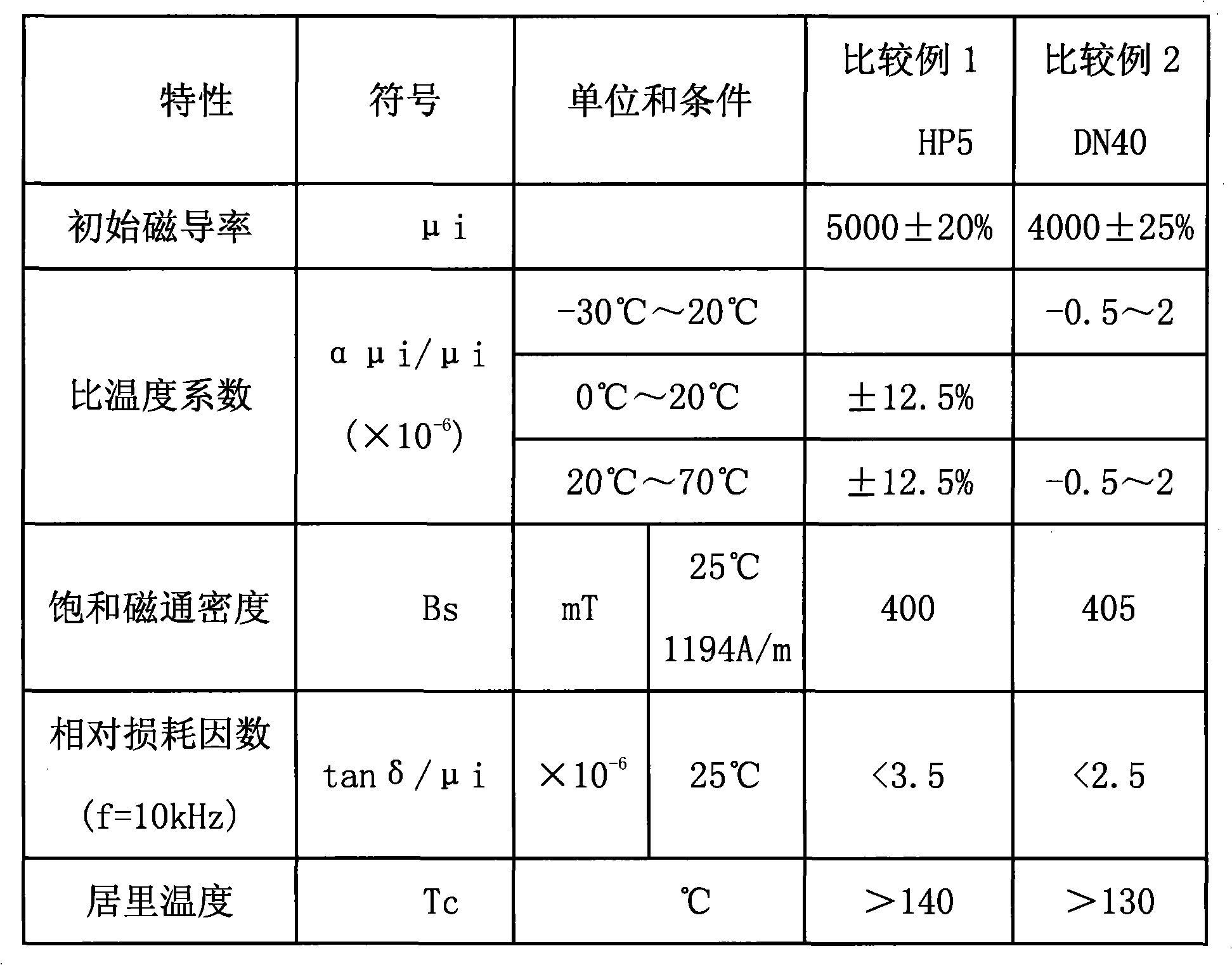

Manganese-zinc ferrite material and preparation method thereof

The invention discloses manganese-zinc ferrite material. The material consists of main components and additives. The main components comprise the following raw materials according to the mol percentage: 52.5 to 55 of Fe2O3 powder, 10 to 18 of ZnO powder, and the balance of MnO powder. The additives comprise the following raw materials according to the weight percentage in the main components: 0.01 to 0.2 of CaO powder, 0.01 to 0.5 of TiO2 powder, and 0.01 to 0.5 of Co2O3 powder. The additives also comprise one or more of V2O5 powder, Bi2O3 powder and MoO3 powder. The invention also provides a preparation method for the manganese-zinc ferrite material. The manganese-zinc ferrite material has comprehensive performances of wide temperature range, low temperature coefficient and high Curie temperature; in the wide temperature range from 25 DEG C below zero to 150 DEG C, the magnetic conductivity of the material has lower temperature coefficient and the Curie temperature reaches as high as above 180 DEG C.

Owner:HAINING LIANFENG MAGNET IND

High magnetic conductivity and low loss factor manganese-zinc ferrite material and manufacture process thereof

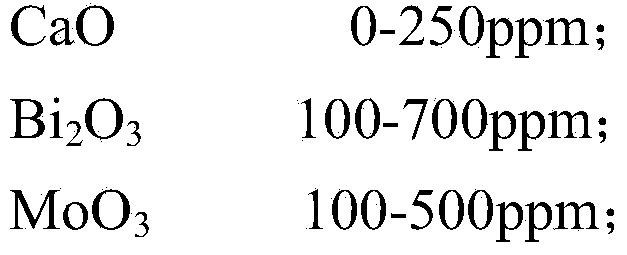

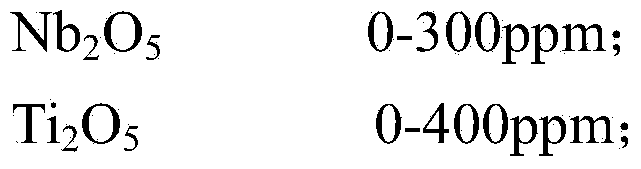

InactiveCN101905970AImprove permeabilityLow Permeability Temperature FactorLoss factorManganese-zinc ferrite

The invention discloses a high magnetic conductivity and low loss factor manganese-zinc ferrite material and a manufacture process thereof. The high magnetic conductivity and low loss factor manganese-zinc ferrite material mainly comprises the main components in percent by mole (calculated by oxide) of 51-56 mol percent of Fe2O3, 22-29 percent of MnO and 20-25 mol percent of ZnO and the auxiliarymaterials including P2O5, CaO, SiO2, Bi2O3 and the like. The manganese-zinc ferrite material with high magnetic conductivity, low magnetic conductivity temperature factor and low relevant loss factoris prepared by the steps of mixing, pre-roasting, sanding, pelleting, forming and sintering. The invention has the advantages of simple and proper formulation and advanced and reasonable manufacture process. The prepared manganese-zinc ferrite material has property exceeding CL11F-brand property and superior to the H5C2-brand material property of a TDK company in Japan.

Owner:TIANCHANG CITY ZHAOTIAN MAGNETOELECTRICITY TECH

Composition for mobile phone case and method of manufacturing mobile phone case using the same

InactiveUS20100171234A1Low absorption rateReduce lossesCeramic shaping apparatusSolid electrolyte fuel cellsPolytetramethylene terephthalateAcrylic resin

There are provided a composition for mobile phone cases and a method of manufacturing a mobile phone case using the same. The composition comprises 70 to 97% by weight of a thermoplastic resin selected from the group consisting of polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS), polybutyrene terephtalate (PBT), acrylic resin and combinations thereof; and 3 to 30% by weight of ferrite selected from the group consisting of nickel-zinc ferrite, manganese-magnesium ferrite, manganese-zinc ferrite, copper-zinc ferrite, manganese-magnesium-aluminum ferrite, yttrium iron garnet (YIG) ferrite and combinations thereof, wherein the composition is a pellet resin formed by extruding the thermoplastic resin and the ferrite at a high temperature of 160 to 290° C.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

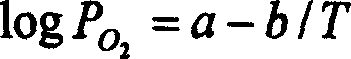

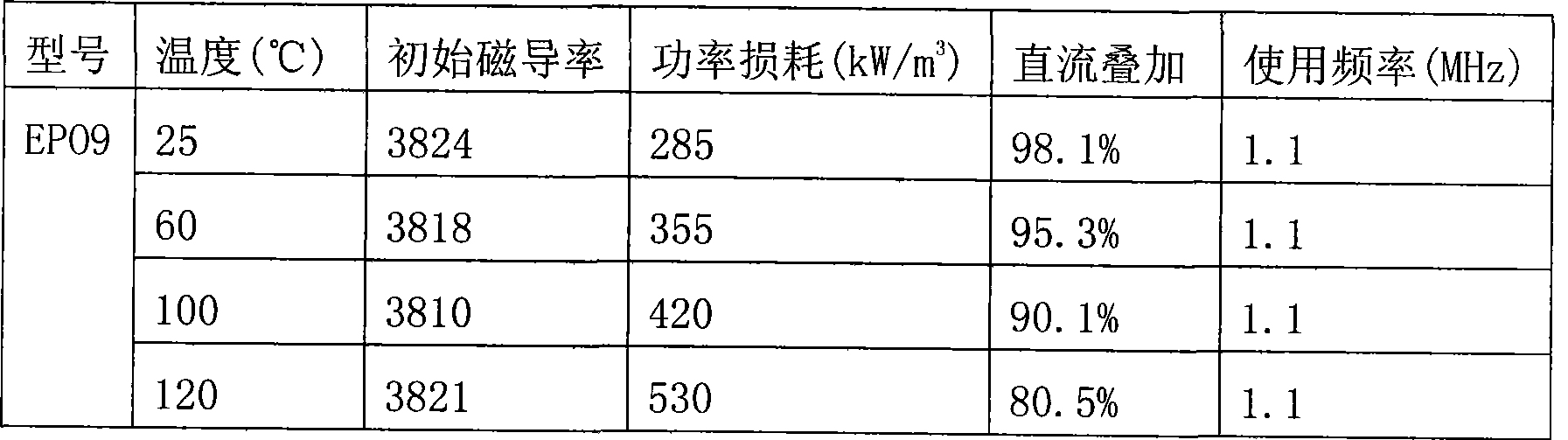

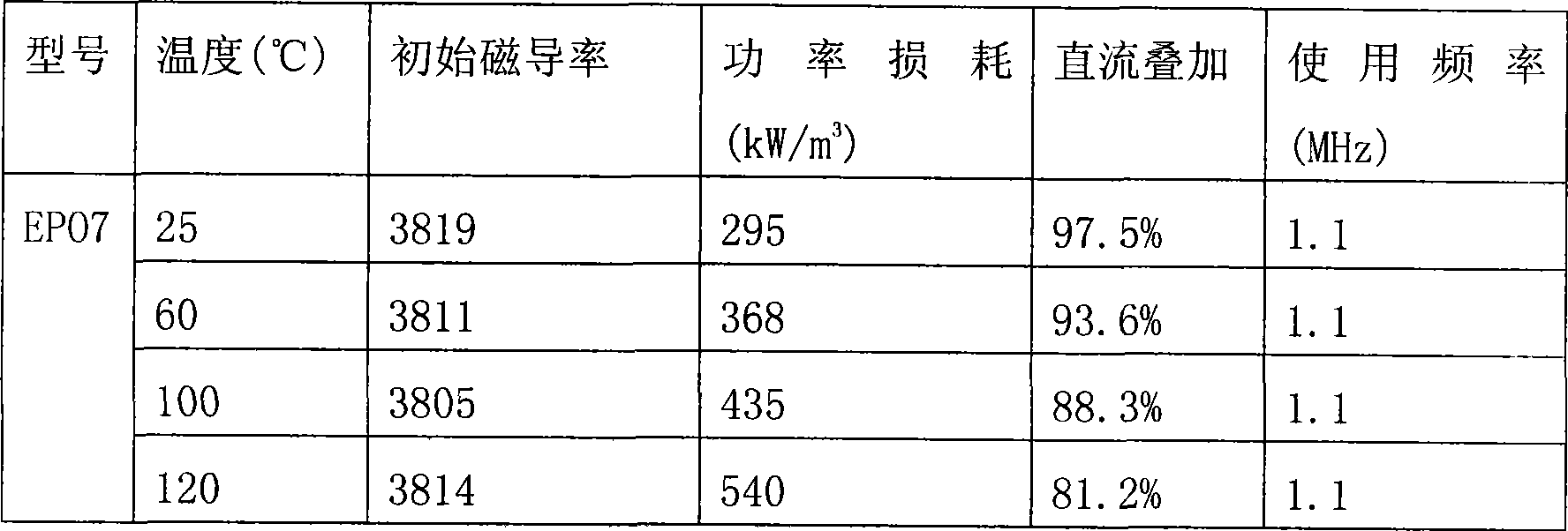

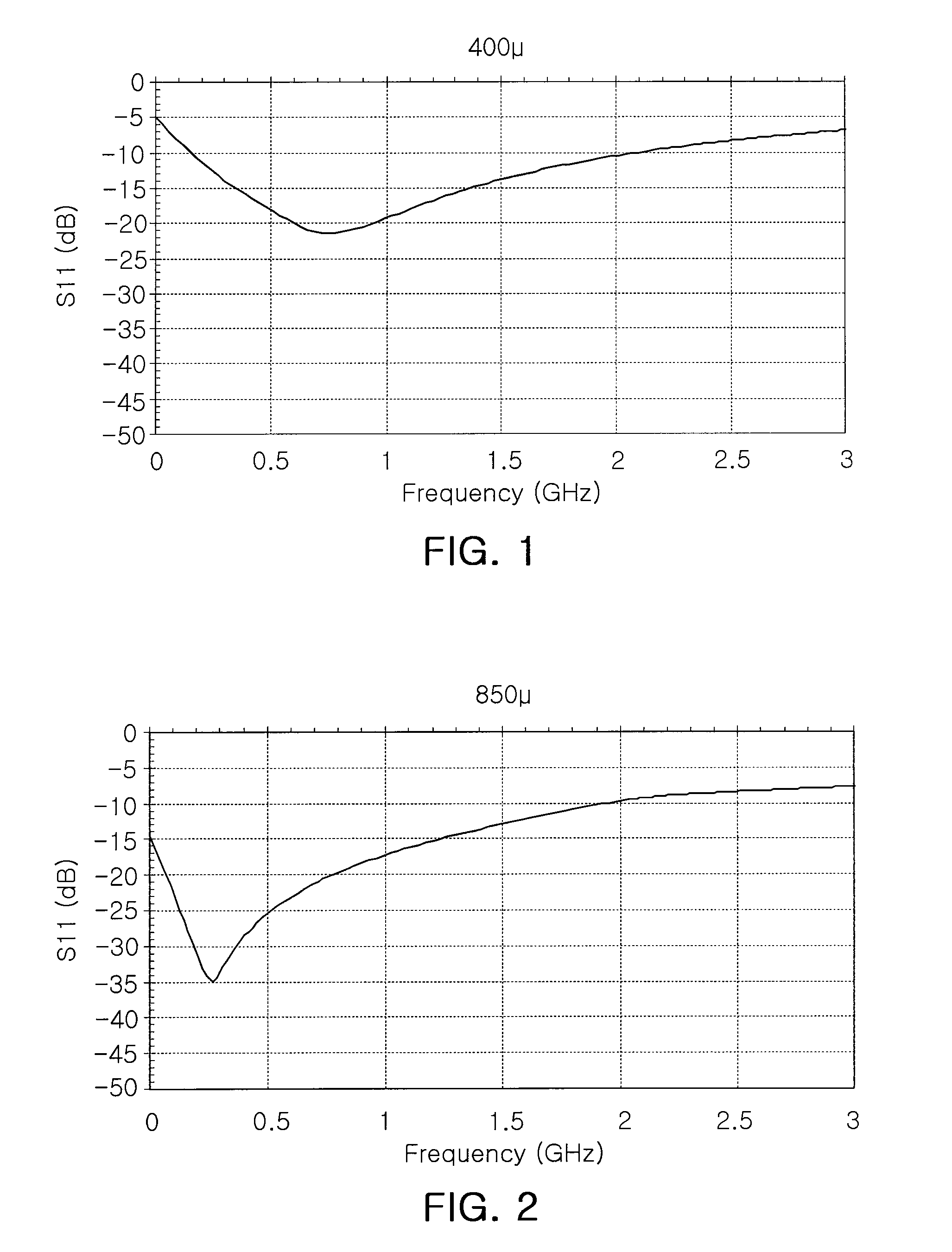

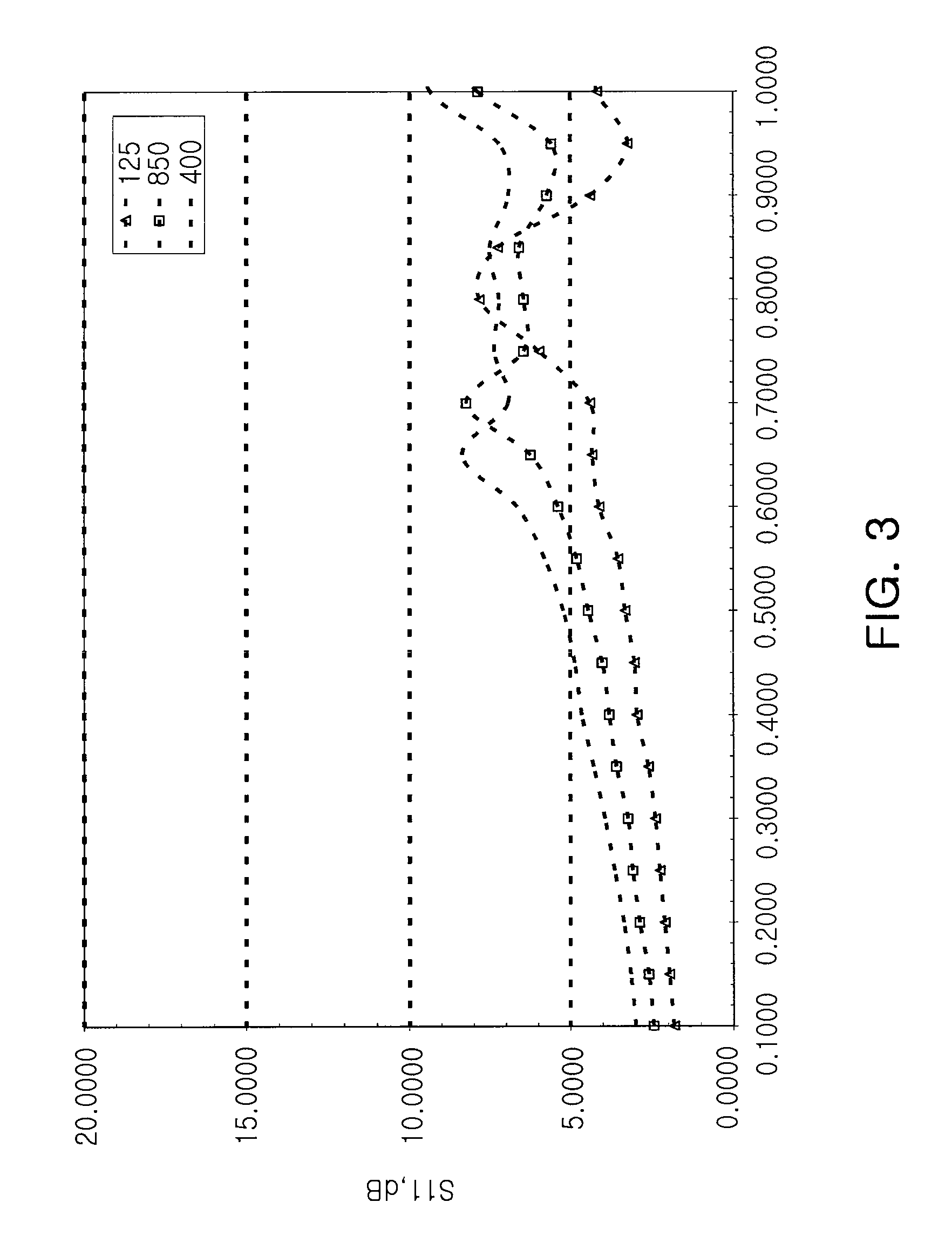

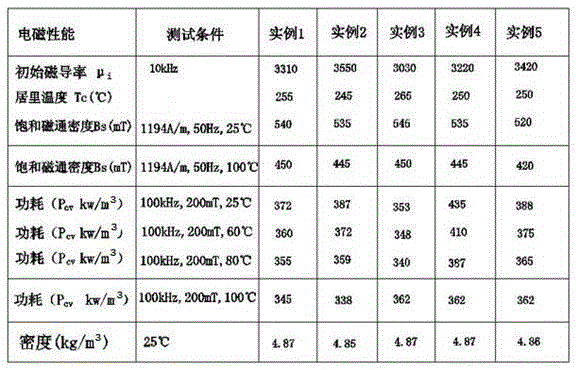

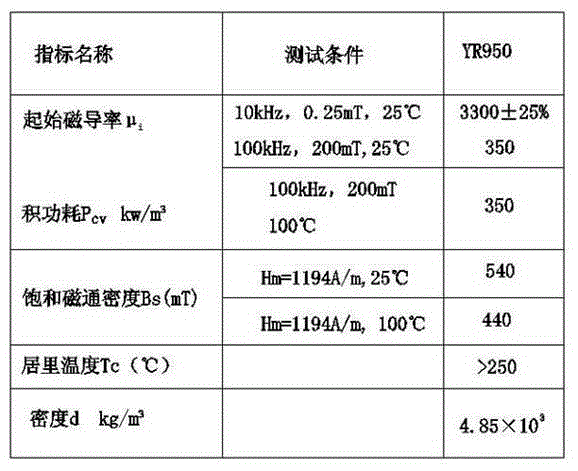

YR950 wide-temperature high-direct-current-superposition low-power-consumption manganese-zinc ferrite material and preparation method thereof

ActiveCN105565790AWith wide temperature and high DC superposition characteristicsReduce wide temperature and high DC superposition characteristicsManganeseZinc

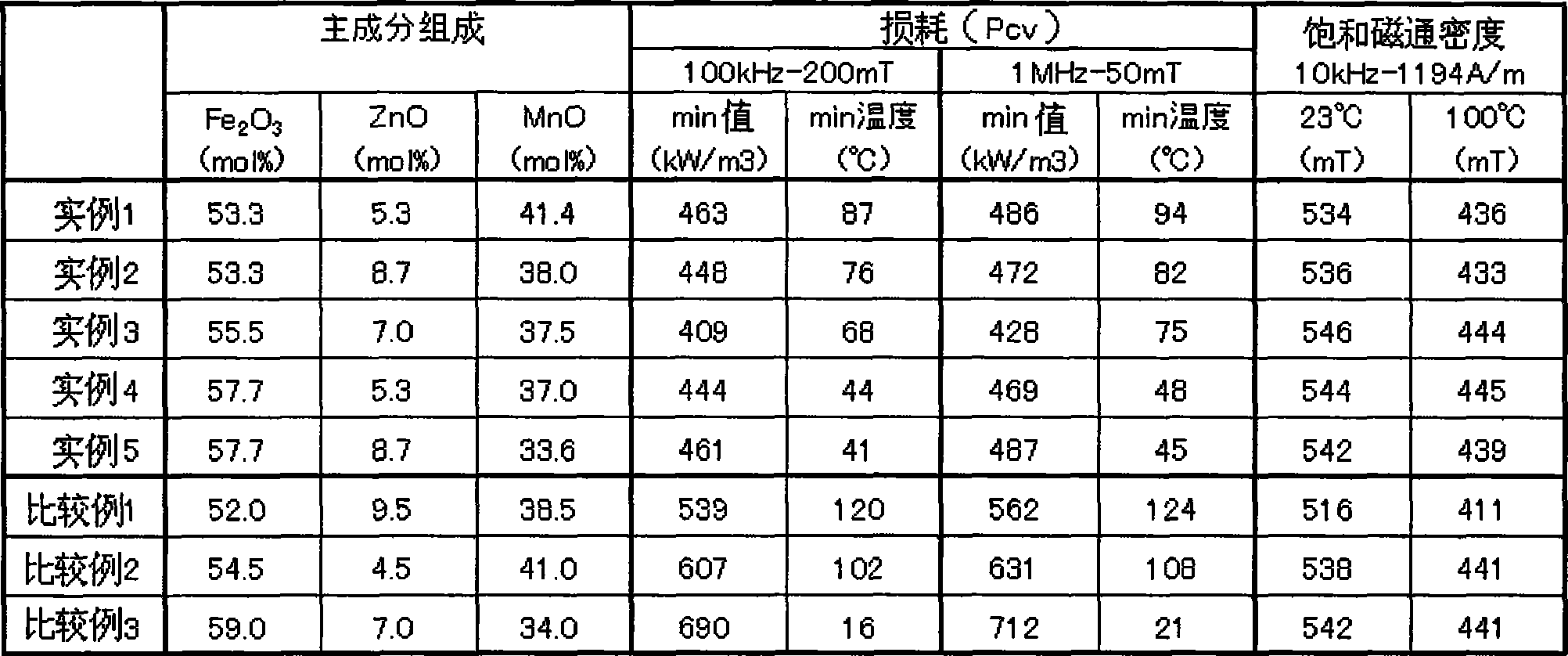

The present invention relates to an YR950 wide-temperature high-direct-current-superposition low-power-consumption manganese-zinc ferrite material and a preparation method thereof, wherein the main material components comprise 53-56 mol% of Fe2O3, 3-9 mol% of ZnO and 38-41 mol% of MnO, the added first auxiliary component is 0.02-0.1 wt% (calculated as CaCO3) and 0.005-0.02 wt% (calculated as SiO2), the added second auxiliary component is about 0-0.2 wt% (calculated as V2O5, Nb2O5, Ta2O5, ZrO2, K2CO3 and Li2CO3), and the added third auxiliary component is about 0.05-1.5 wt% (calculated as TiO2, NiO and Co2O3). The preparation method sequentially comprises raw material selection, component design and weighing, raw material mixing, pre-firing, impurity adding, secondary ball milling, and molding sintering. According to the present invention, the manganese-zinc ferrite material has characteristics of stable performance, high magnetic permeability, low and balanced power consumption within a wide use temperature range, and good comprehensive performance.

Owner:重庆耀润电子科技有限公司

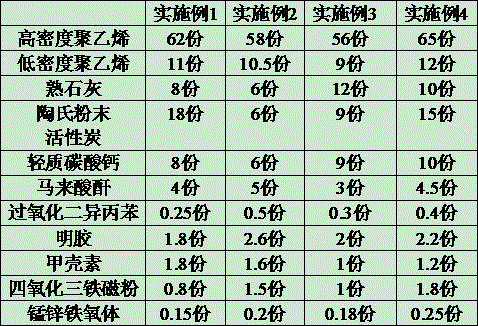

Hydrophilic carrier for microbial biofilm formation

InactiveCN105621595ANot easy to fall offPromote sheddingTreatment with microorganism supports/carriersLow-density polyethyleneMicrobial Biofilms

The invention discloses a hydrophilic carrier for microbial biofilm formation. The hydrophilic carrier comprises a hollow short tube, and a first concentric ring and a second concentric ring which are sequentially concentrically arranged outside the hollow short tube, wherein the surface of the outermost second concentric ring is toothed; and the microbial filler is composed of the following components in parts by weight: high-density polyethylene, low-density polyethylene, white lime, Dow powder activated carbon, light calcium carbonate, maleic anhydride, dicumyl peroxide, gelatin, chitin, ferroferric oxide magnetic powder and manganese-zinc ferrite. The density of the microbial filler is 0.96-0.98 g / cm<3>. The hydrophilic carrier for microbial biofilm formation prolongs the contact time between microbes and organic matters, so that the organic matters are degraded quickly and thoroughly; and the biological oxidation can restore the surface adsorption capacity of the activated carbon.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

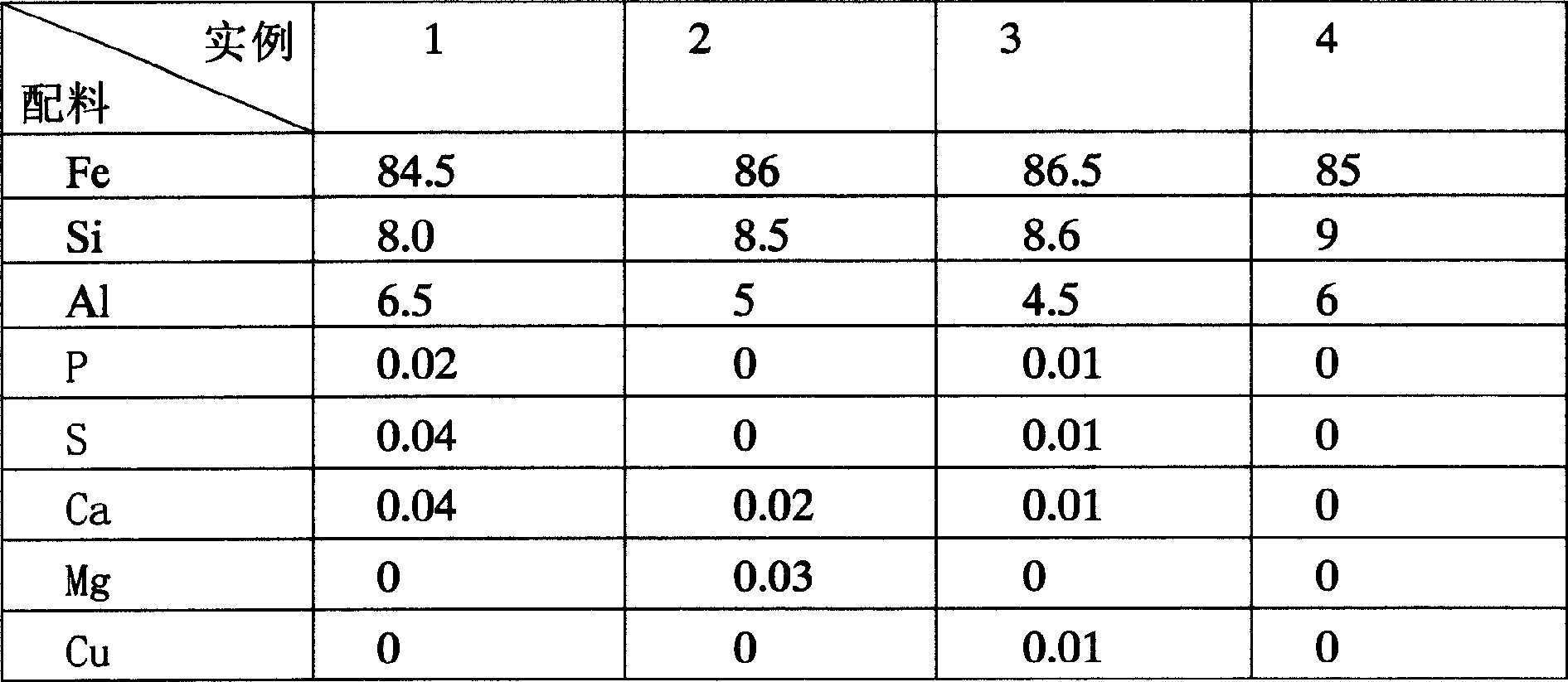

Composite magnetic powder core and preparation method thereof

InactiveCN103426580AEasy to manufactureUniform sizeInductances/transformers/magnets manufactureMagnetic materialsNanoparticleNickel-zinc ferrite

The invention relates to a composite magnetic powder core and a preparation method of the composite magnetic powder core. According to the technical scheme, nanometer ferrite particles with even size are prepared on the surface of soft magnetic alloy powder through a hydrothermal method in a root-positioning mode, and a novel ferrite composite magnetic powder core is prepared through the pressing and thermal processing technology. The composite magnetic powder core and the manufacturing method of the composite magnetic powder core have the advantages that due to the fact that manganese zinc ferrite and nickel zinc ferrite are prepared through a hydrothermal method and a root position method, nanometer particles with controllable and even size can be prepared conveniently; the ferrite can be used as an insulated coating agent of the soft magnetic alloy powder, the defect that magnetic performance of a substrate is reduced when traditional nonmagnetic substances are used as the coating agent are overcome, and high magnetic conductivity and saturation magnetization strength can be obtained.

Owner:CHINA JILIANG UNIV

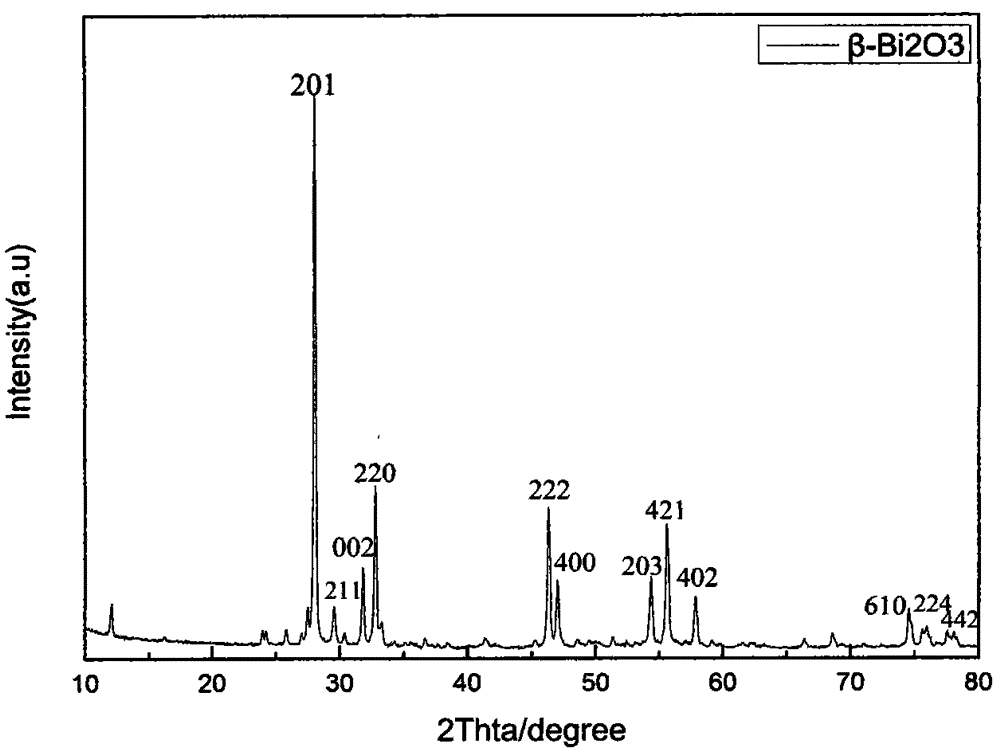

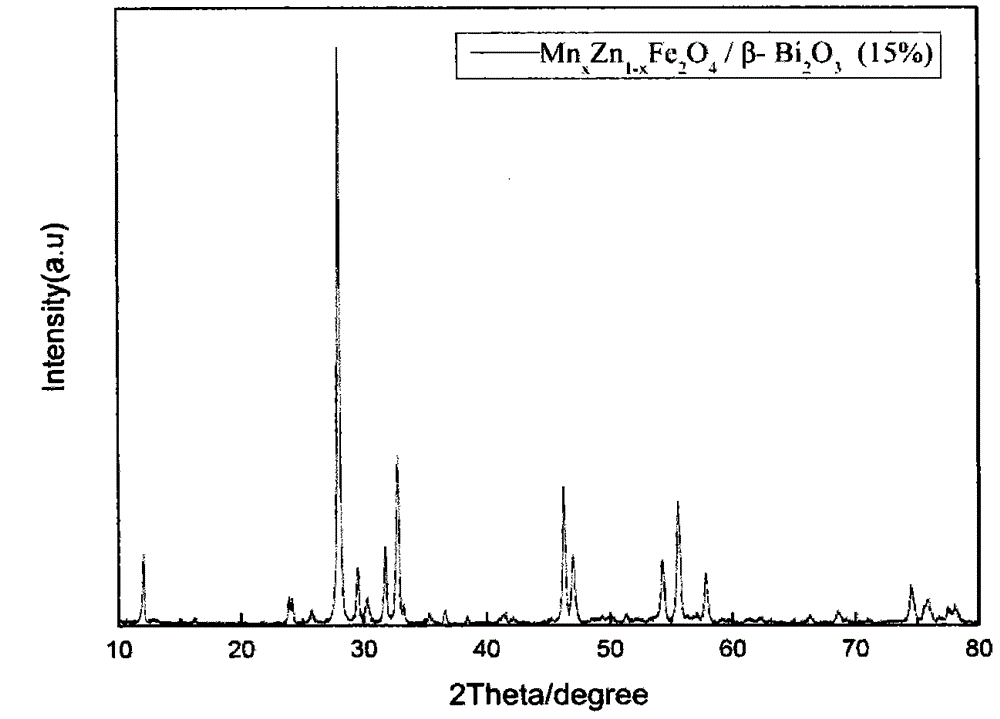

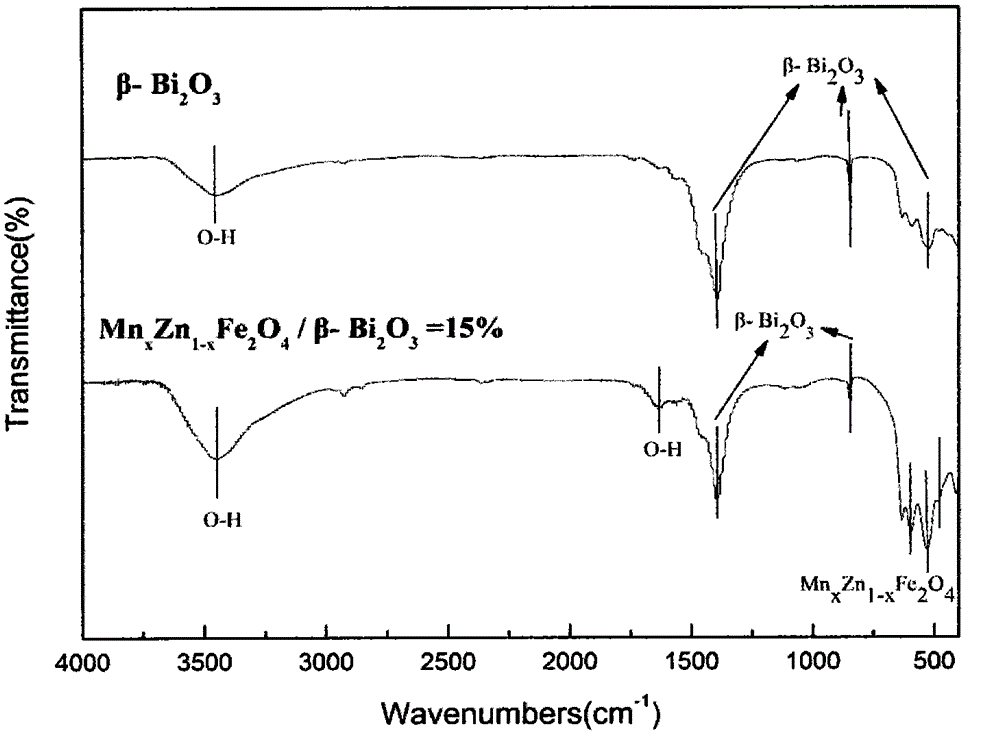

Preparation method of manganese zinc ferrite/bismuth oxide magnetic photocatalyst

InactiveCN104437536AImprove degradation rateHigh recovery rateWater/sewage treatment by irradiationInorganic material magnetismManganeseOxide composite

The invention discloses a preparation method of a manganese zinc ferrite / bismuth oxide magnetic photocatalyst, and belongs to the field of inorganic catalytic materials. The preparation method comprises the following steps of firstly, preparing a bismuth oxide precursor, then preparing a precursor of the manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst, and finally, filtering, washing, drying and roasting to obtain the manganese zinc ferrite / bismuth oxide magnetic photocatalyst. According to the method, the preparation technology is simple; the used equipment is few; the preparation cycle is short; the production cost is low. The prepared magnetic composite photocatalyst is high in photocatalytic activity; the degradation rate of a 10mg / L rhodamine B solution for 2.5 hours reaches 99.1% under simulated sunlight, and the recovery rate reaches 89.3%; the manganese zinc ferrite / bismuth oxide composite magnetic photocatalyst which is recycled for three times has the degradation rate of 85% to rhodamine B within 2.5 hours. The manganese zinc ferrite / bismuth oxide magnetic photocatalyst prepared by the invention can be widely applied to the field of photo-catalyzed degradation of organic pollutants.

Owner:CHONGQING UNIV

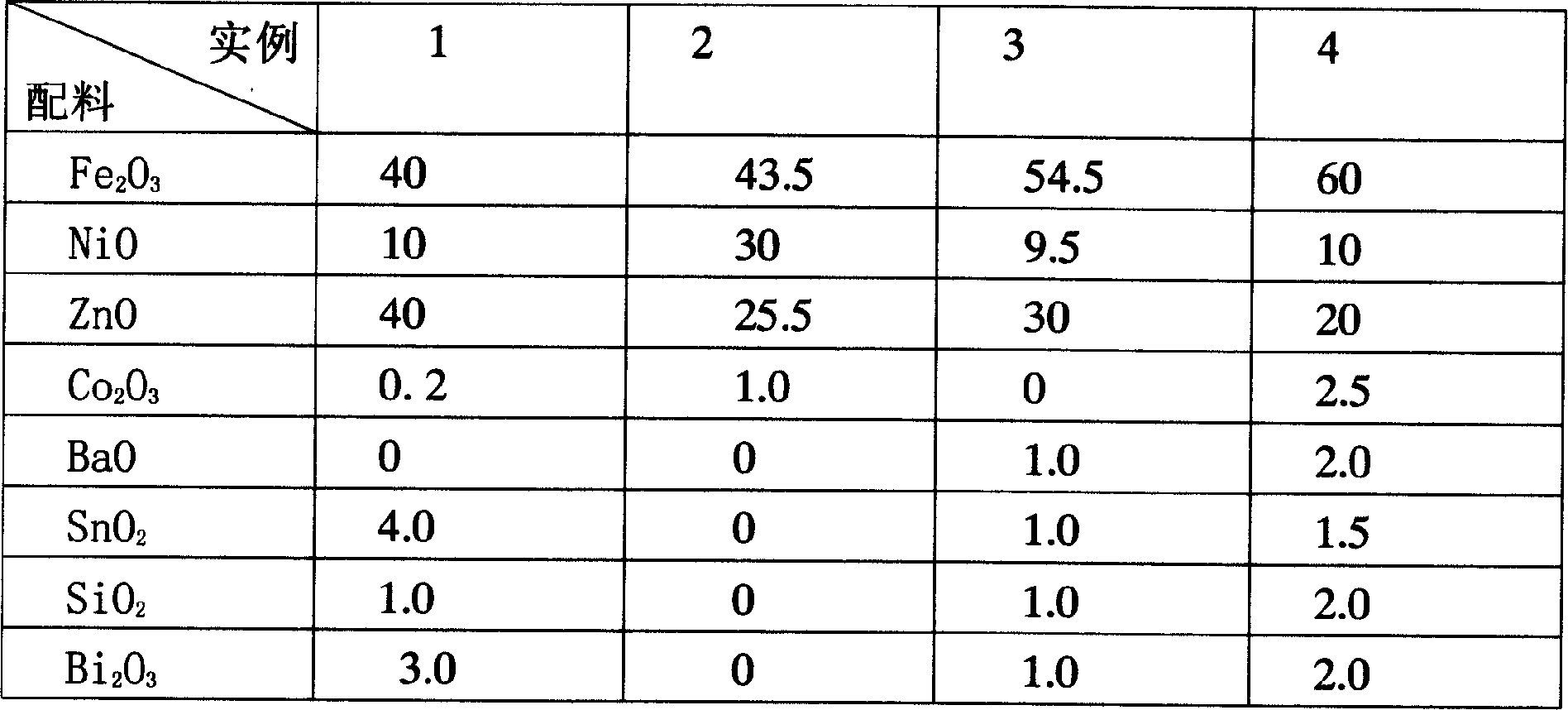

Electromagnetic wave interference preventive material and production thereof

InactiveCN1646000AHigh specific surface areaIncrease reflectionMagnetic/electric field screeningIron powderSendust

The anti electromagnetic interference material is composed of several layers: the impedance matching layer is made of absorbing type sendust powder, manganese-zinc ferrite and resin; the absorbing layer is made of absorbing type sendust powder, nickel zinc ferrite and resin; the reflecting layer is made of reflection type sendust powder, iron powder and resin.

Owner:横店集团东磁有限公司

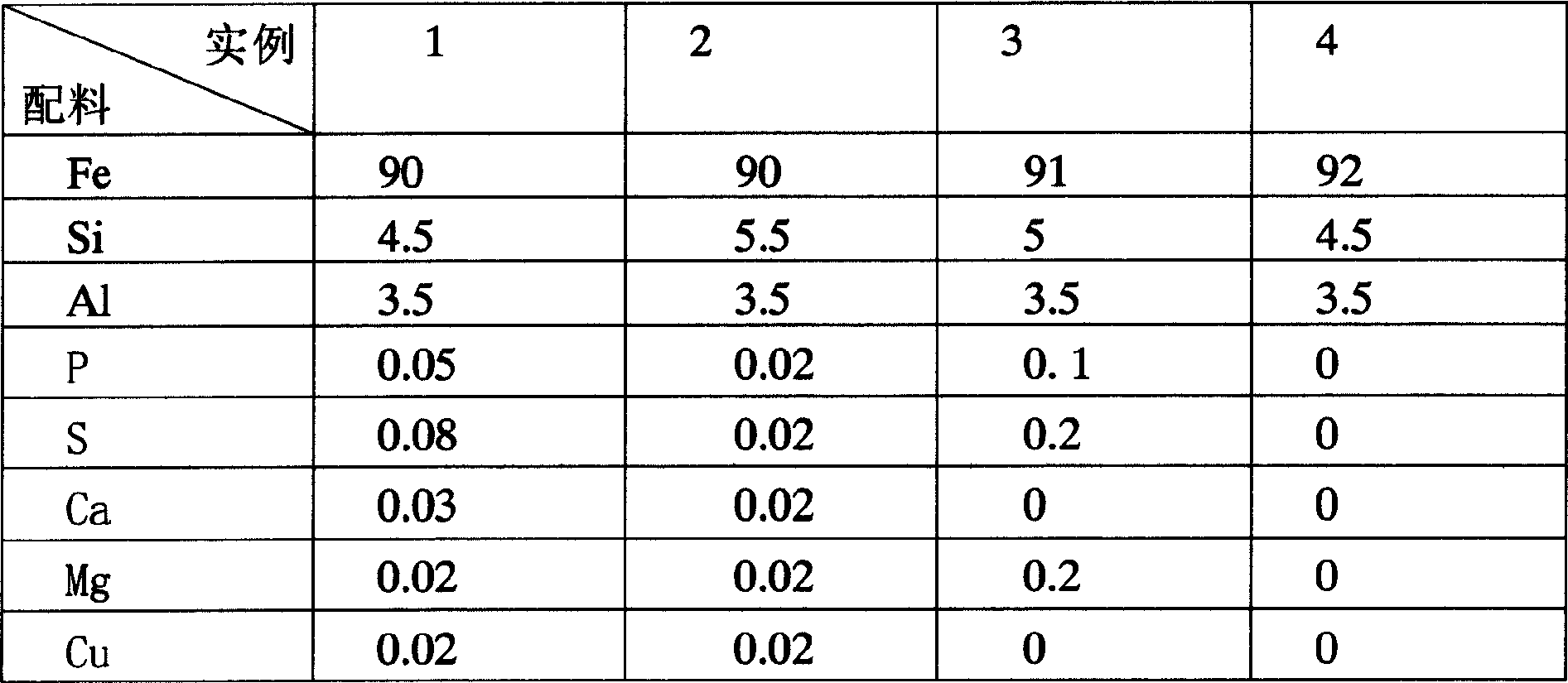

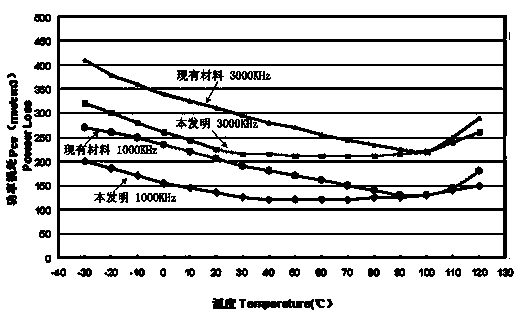

High-frequency wide-temperature low-loss manganese-zinc ferrite and manufacturing technique thereof

The invention discloses a high-frequency wide-temperature low-loss manganese-zinc ferrite which is composed of a main ingredient and a micro ingredient, wherein the main ingredient is composed of 52-55 mol% of Fe2O3, 38-43 mol% of Mn3O4 and 5-9 mol% of ZnO; the micro ingredient is divided into a micro ingredient A and a micro ingredient B; the micro ingredient A is at least one of TiO2, Ni2O3, Co3O4 and SnO2, and the total mass content of the micro ingredient A in the high-frequency wide-temperature low-loss manganese-zinc ferrite is 1000-5000 ppm; and the micro ingredient B is composed of at least two of Nb2O5, ZrO2, CaCO3, Ta2O5, SiO2 and V2O5. Compared with the existing 3F4, the material disclosed by the invention has lower power loss and is more energy-saving under the conditions of 1000-3000 KHz and -30-120 DEG C.

Owner:JIANGSUSR MAGNETIC MATERIAL & DEVICE ENG TECH RES

Low dissipative ferrite material of manganese and zinc in broad frequency, and high magnetic permeability, and preparation method

This invention provides a wide-frequency low-loss manganese-zinc ferrite material with high magnetic conductivity. The major components comprise: MnO 21.5-26.5 mol. %, ZnO 20.5-25.5 mol. %, and Fe2O3 as balance. The auxiliary components comprise: one or two of Na2O (measured by Na2CO3) 0.01-0.05 wt.%, and K2O (measured by K2CO3) 0.01-0.04 wt.%, Bi2O3 0-0.04 wt.%, MoO3 0-0.04 wt.%, and V2O5 0-0.05 wt.%. This invention also provides a method for preparing the wide-frequency low-loss manganese-zinc ferrite material.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Manganese zinc ferrite material and preparation method thereof

The invention relates to a manganese zinc ferrite material and a preparation method thereof. The manganese zinc ferrite material comprises main components in mole percentage: 54-56 percent of ferric oxide, 38-42 percent of trimanganese tetraoxide and 4-6 percent of zinc oxide, and auxiliary components selected from at least five of CaCO3, SiO2, K2CO3, Y2O3, NiO, Co3O4 and Al2O3. The manganese zinc ferrite material is low in self-power loss in a (0.1-1) MHz wide frequency range.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

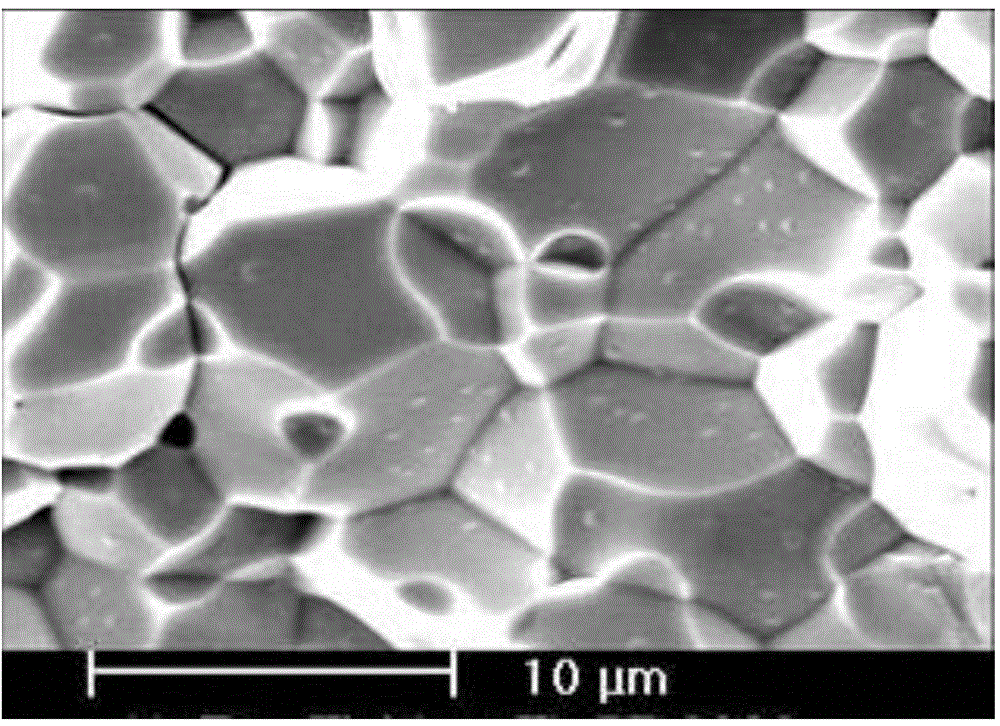

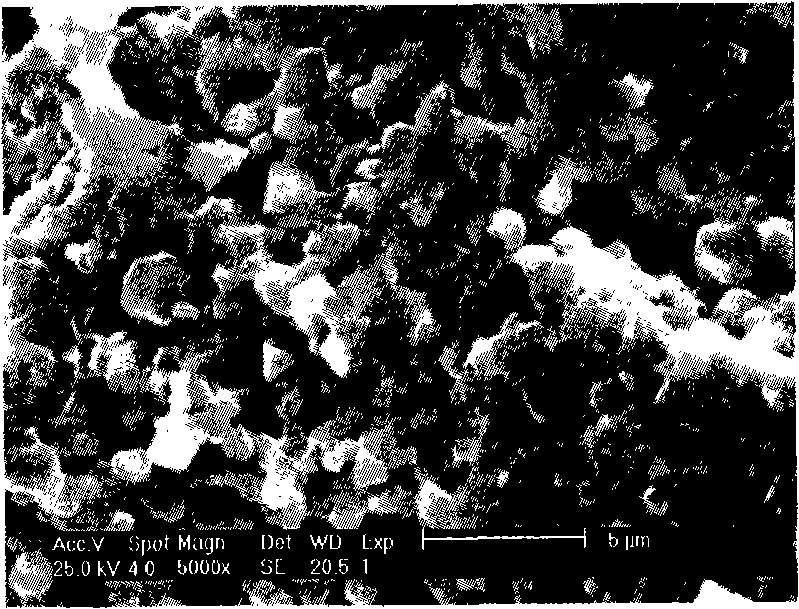

Method for preparing low-power loss manganese-zinc ferrite based on core-shell structure grains

The invention provides a method for preparing low-power loss manganese-zinc ferrite based on core-shell structure grains. Through adding of high-resistance low-melting point oxide, the core-shell structure grains are formed, so that the power loss of the manganese-zinc ferrite is reduced. The innovativeness of the invention is that the higher pre-sintering temperature is adopted, so that pre-sintered powder obtains a higher ferrite percentage; through ball milling, the size of ferrite powder is reduced below the single domain size; and then, the low-melting point oxide is added, and an additive is molten on the ferrite particle surface during sintering, so that the grains with high-resistivity shells are formed, and the hysteresis loss and the eddy current loss of the manganese-zinc ferrite are simultaneously and greatly reduced.

Owner:ZHEJIANG UNIV

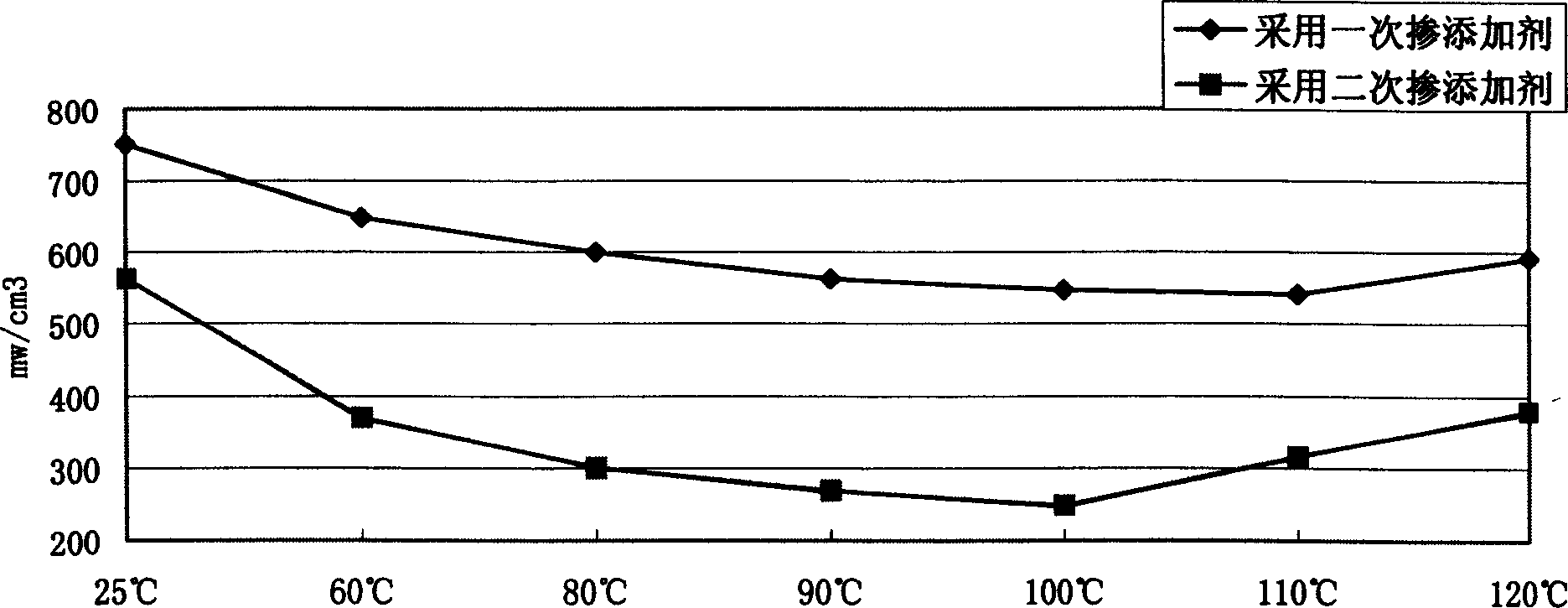

Soft-magnetic manganese-zinc ferrite in low wastage

InactiveCN1627454AReduce manufacturing costEase of mass productionInorganic material magnetismMaterials scienceManganese-zinc ferrite

Major converted components of soft-magnetic manganese-zinc ferrite in low wastage are as follows: 52.7-53.6 mol% Fe2O3, 8.5-11.8 mol% ZnO and MnO as the rest. At least one of following component: 1000-8000ppm SnO2, 500-2000ppm CaCO3, 300-1500ppm V2O5 is added into the major components. After major components and additive are mixed and preburning, second adulteration is carried out in pulverizing operation. Admixing additive includes at least two kinds of materials from Nb2O5, K2O, CaCO3, Ta2O5, SnO2, and V2O5. Total add on is between 800-1200ppm. Features of the disclosed ferrite are higher operation frequency, low loss, and higher saturation flux density.

Owner:TDG HLDG CO LTD

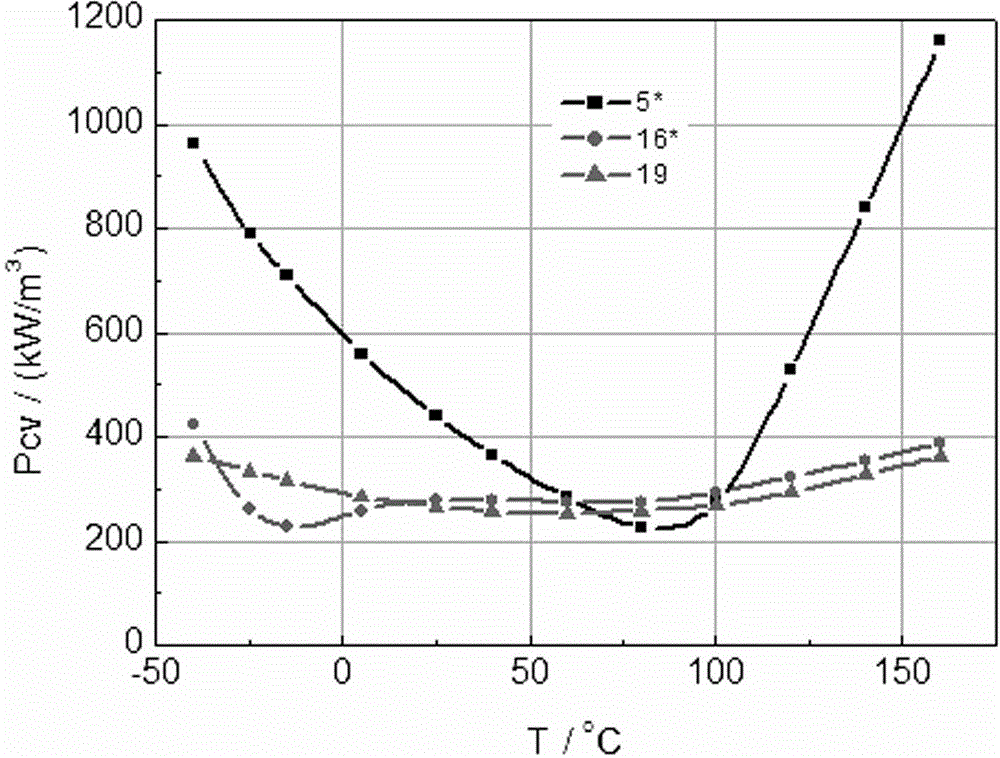

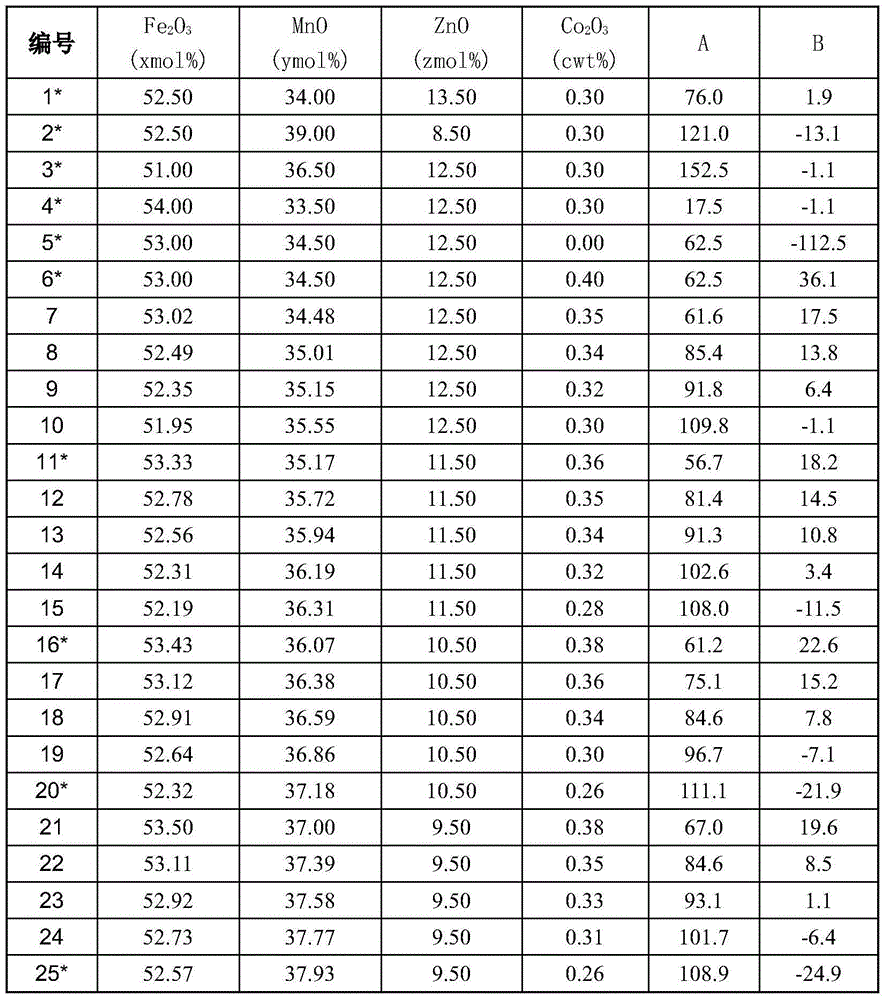

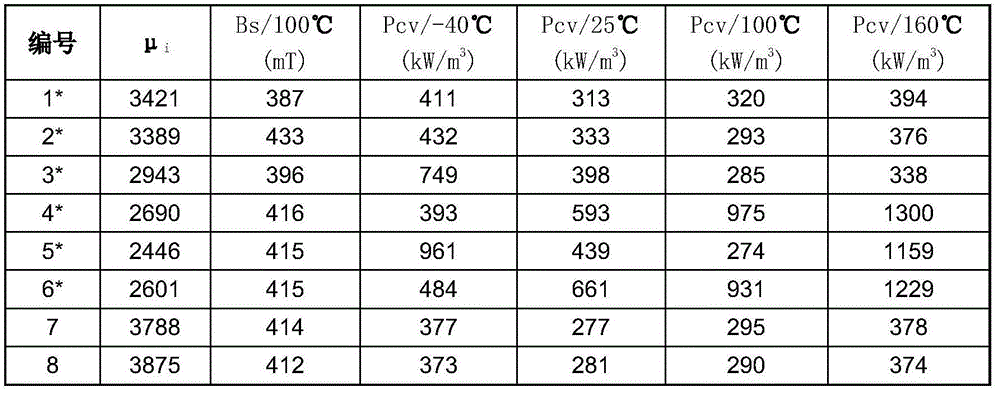

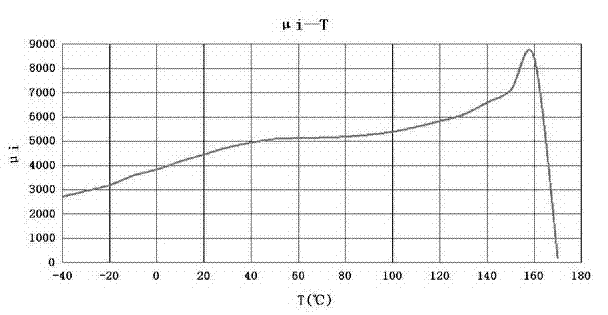

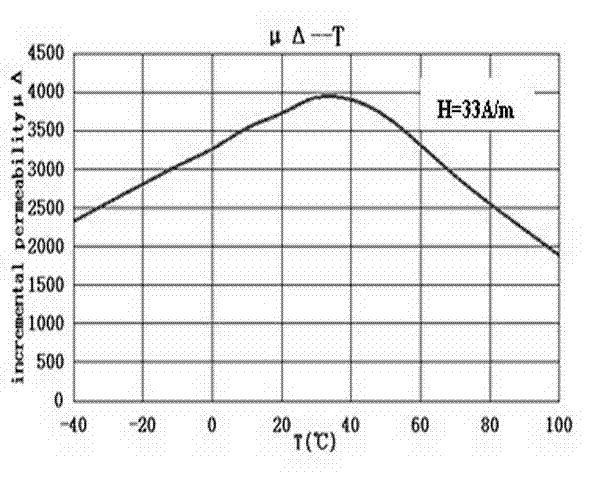

Low-loss manganese zinc ferrite material for temperature of 40 DEG C below zero to 160 DEG C and manufacturing method thereof

The invention provides a low-loss manganese zinc ferrite material for temperature of 40 DEG C below zero to 160 DEG C and a manufacturing method thereof. The ferrite material comprises main components and an auxiliary component, wherein the main components refer to x mol% of Fe2O3, y mol% of MnO and z mol% of ZnO; the auxiliary component comprises c wt% of Co2O3 based on the total weight of main components; the ratios of the components are that x is equal to 51.5-53.5, z is equal to 9.5-12.5, y is equal to 100-x-z and c is equal to 0.26-0.38; A being 2560-45x-9z is more than or equal to 60 and less than or equal to 110; and B being 150-3x-3y+371c is more than or equal to -20 and less than or equal to 20. The manganese zinc ferrite material is prepared by the process steps of batching, mixing, pre-sintering, performing secondary grinding, granulating, molding and sintering.

Owner:江门安磁电子有限公司

Manganese zinc ferrite material for resisting EMI and preparation method thereof

The present invention discloses a manganese zinc ferrite material for resisting EMI and a preparation method thereof The specific operation steps are as follows: (1) mixing: weighing the main ingredients in accordance with the corresponding percentage, mixing by ball milling, and spray-drying a slurry to obtain a powder; (2) pre-calcining: pre-calcining the powder in a box electric resistance furnace; (3) weighing of accessories: weighing accessories in accordance with the percentage of the accessories in the total weight of the pre-calcined materials; (4) a secondary ball milling: subjecting the pre-calcined material supplemented with the accessories to a secondary ball milling; (5) granulation: conducting spray granulation on the slurry after the secondary milling; (6) molding: subjecting the powder after spray granulation to press-molding; and (7) sintering: conducting sintering treatment in sintering equipment of a bell-type furnace with strictly controlled atmosphere. The invention has the beneficial effects that the prepared manganese zinc ferrite material has high impedance characteristic, high magnetic permeability, high Curie temperature Tc, high saturation magnetic induction intensity Bs, and excellent integrated magnetic properties and can be well applied to the anti-EMI components.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

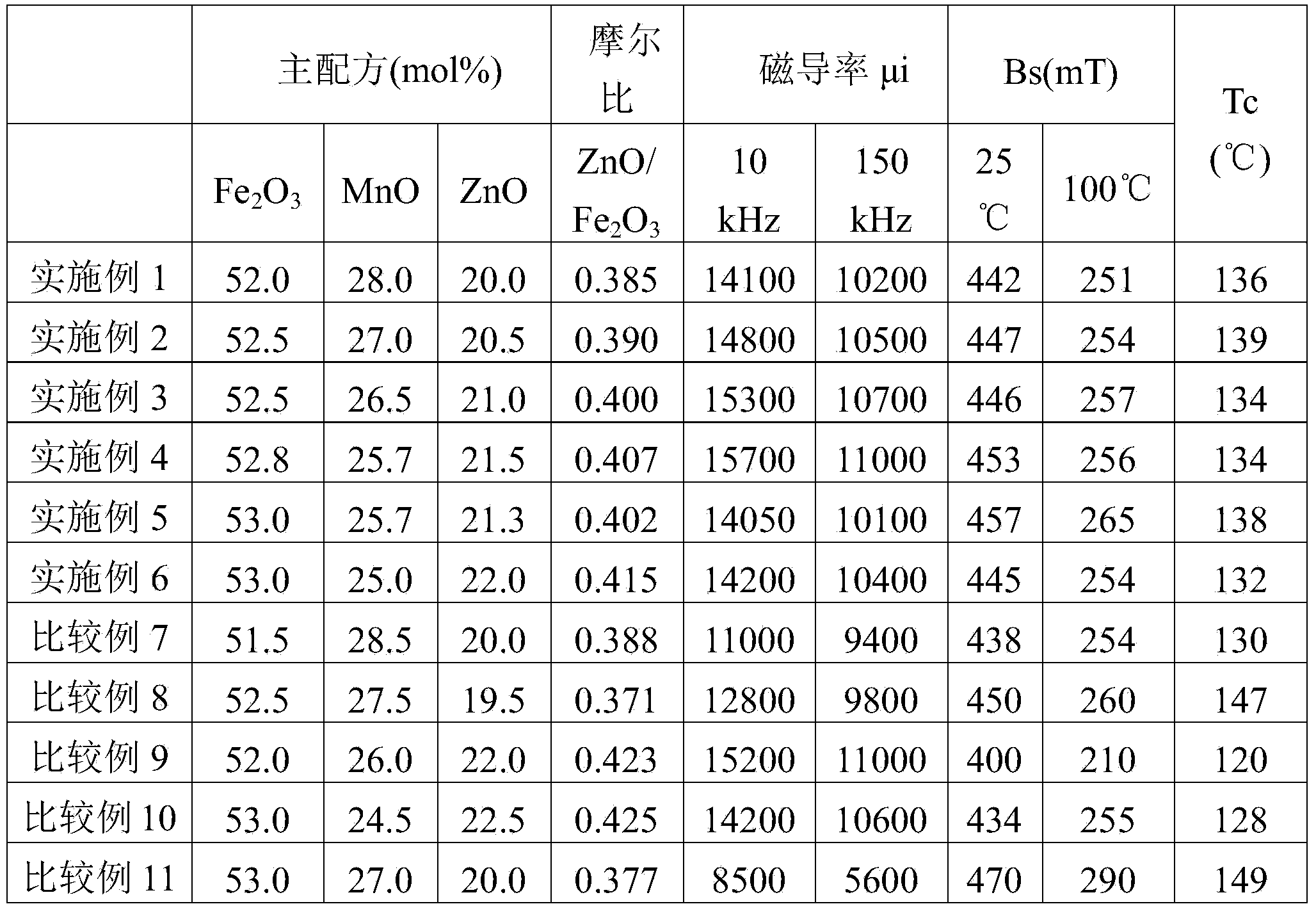

High-magnetic-permeability manganese-zinc series ferrite and preparation method thereof

The invention discloses high-magnetic-permeability manganese-zinc series ferrite and a preparation method thereof, belonging to the field of high-magnetic-permeability manganese-zinc series ferrite. The high-magnetic-permeability manganese-zinc series ferrite is prepared from a ferrite pre-sintering material, an auxiliary component, an adhesive, a dispersing agent and a defoaming agent, wherein the ferrite pre-sintering material comprises the following components: 52.0-53.0mol% of Fe2O3, 20.0-22.0mol% of ZnO and 25.0-28.0mol% of MnO. The high-magnetic-permeability manganese-zinc series ferrite can be used for producing a manganese-zinc ferrite magnetic ring of a specification of phi 25* phi 15*10, and the following excellent effects are achieved: B is less than 0.25mT at 25 DEG C, mu(i) is greater than or equal to 14000 under the condition of 10kHz, mu(i) is greater than or equal to 10000 under the condition of 150kHz, the Curie temperature Tc is greater than or equal to 130 DEG C, Bs is greater than or equal to 440mT under the conditions of 50Hz and 1194A / m at 25 DEG C, and Bs is greater than or equal to 250mT at 100 DEG C.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Manganese-zinc ferrite material of high performance and power, and manufacturing method therefor

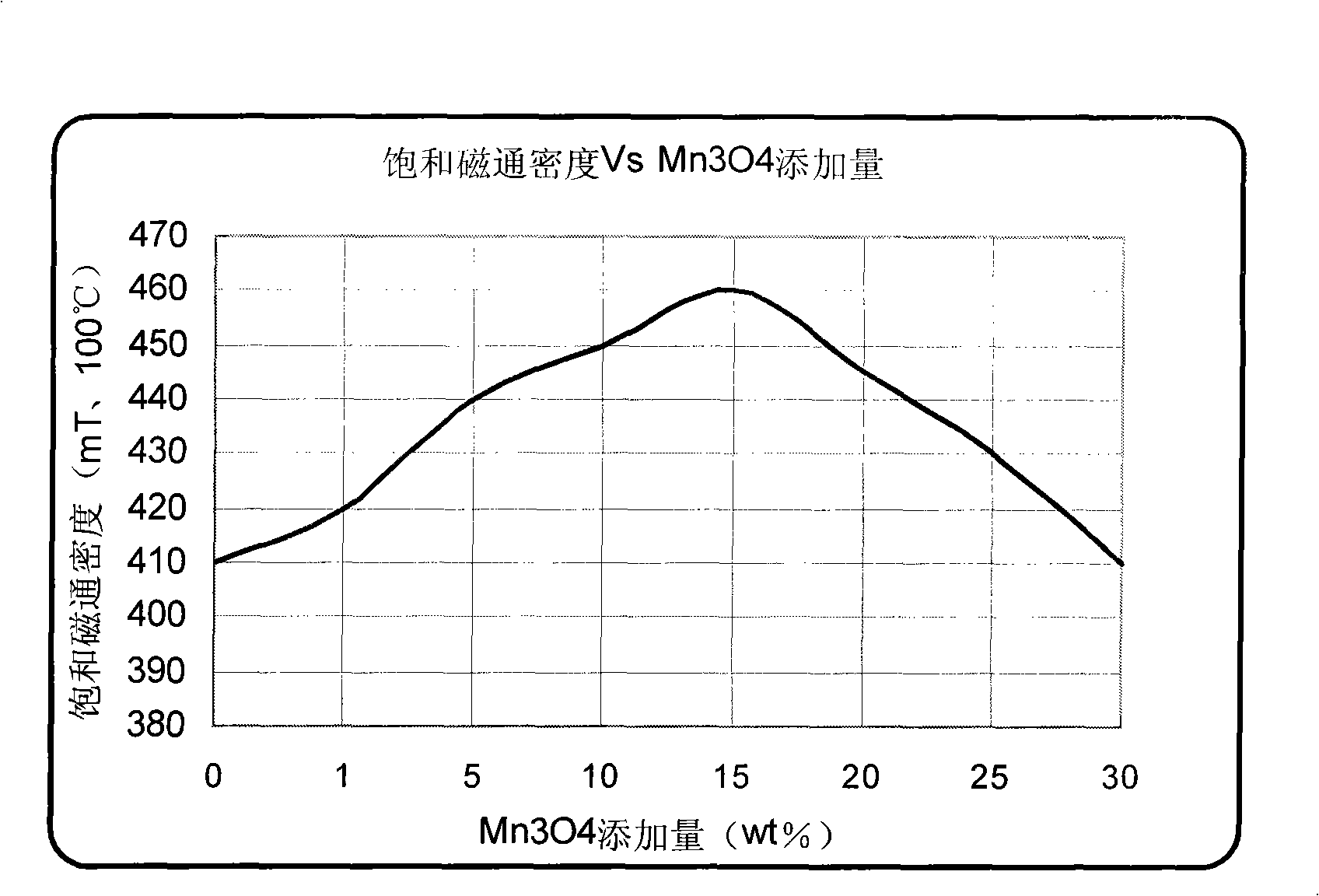

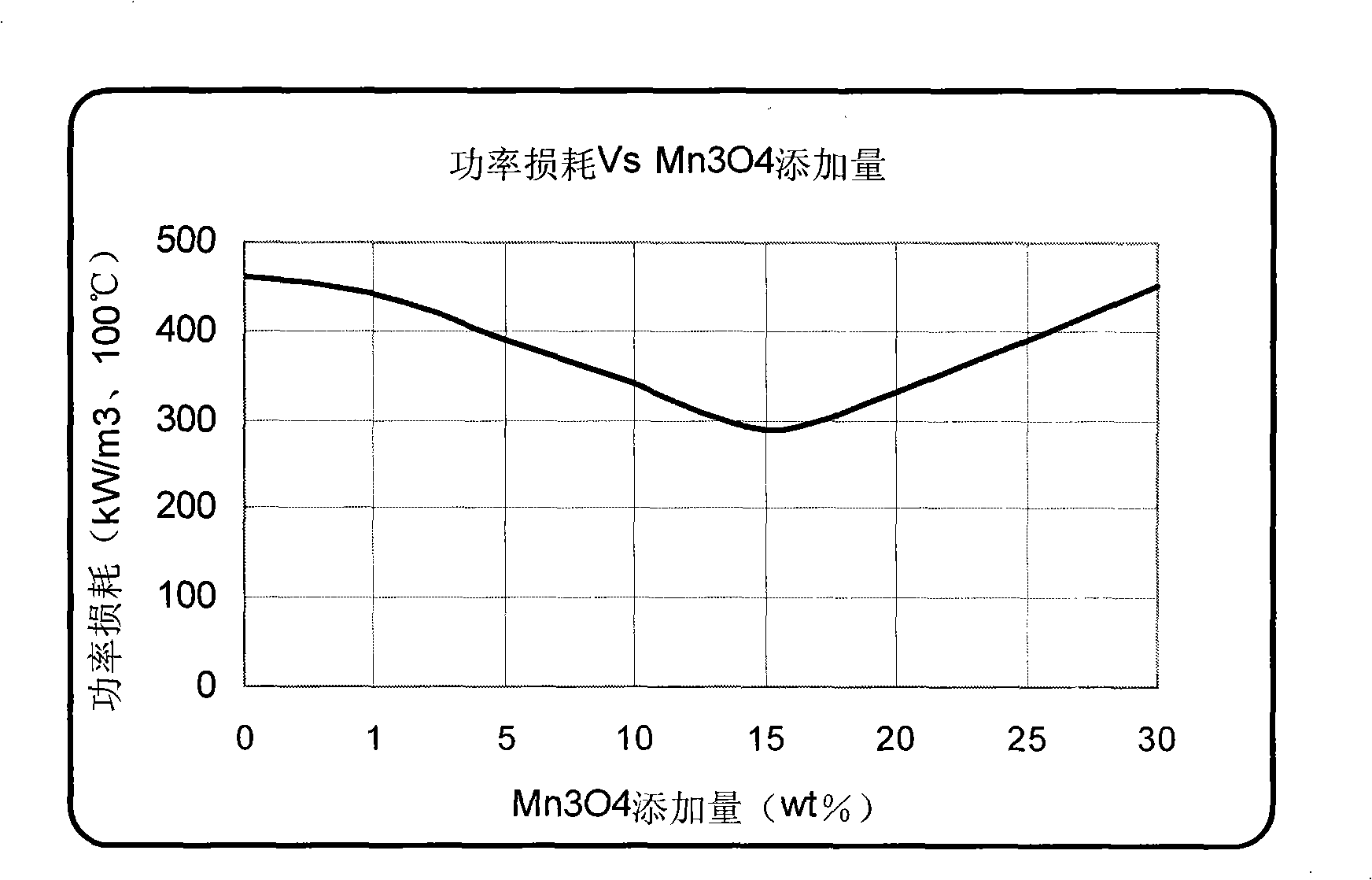

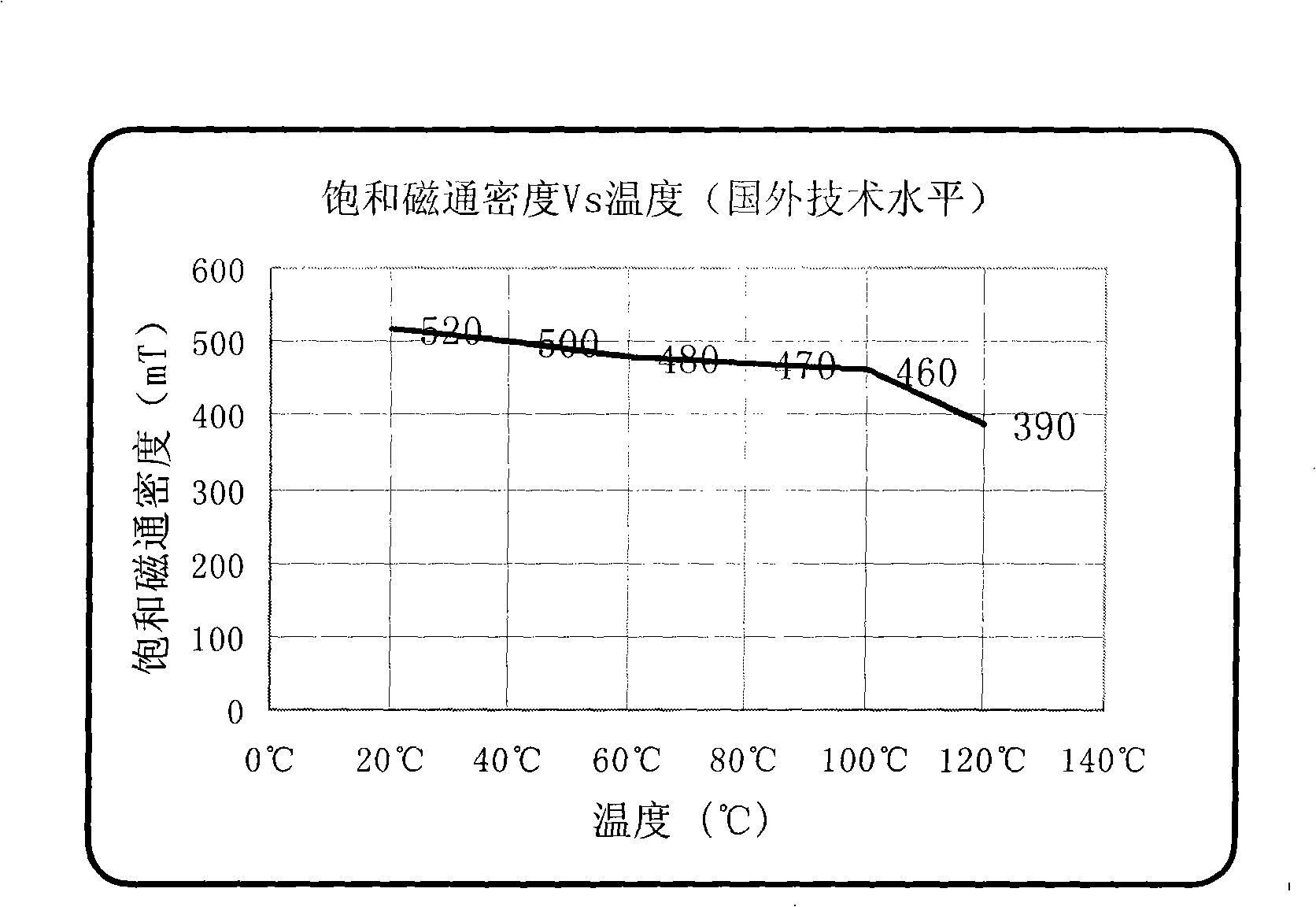

ActiveCN101290827AGrain refinementReduce power lossInorganic material magnetismManganeseCurie temperature

The invention discloses a manganese-zinc ferrite material and a manufacturing method thereof. The material synchronously has high saturation flux density (Bs), lower power consumption (Pcv) and high Curie temperature (Tc) under the state of lower temperature and high temperature; the method solves the technical problem that three performances, namely the high saturation flux density, the high Curie temperature and the lower power consumption of the prior soft magnetic power ferrite material fail to be consistently realized in one material. The main compositions adopted by the invention are Fe2O3, Mn3O4 and ZnO; the manufacturing process successively has stages such as material mixing of the main compositions, initial crushing, preburning, additive adding, secondary crushing, pelleting and so on; and the main innovation of the method is that: additive added in the four stage contains a large quantity of Mn3O4, the preferred amount of the Mn3O4 is between 1 and 20wt percent, and the best amount is between 13 and 18wt percent. The material is applied in electronic assemblies and whole machines, and can improve direct current bias ability of the electronic assemblies and reduce power consumption of the whole machines.

Owner:TDG HLDG CO LTD

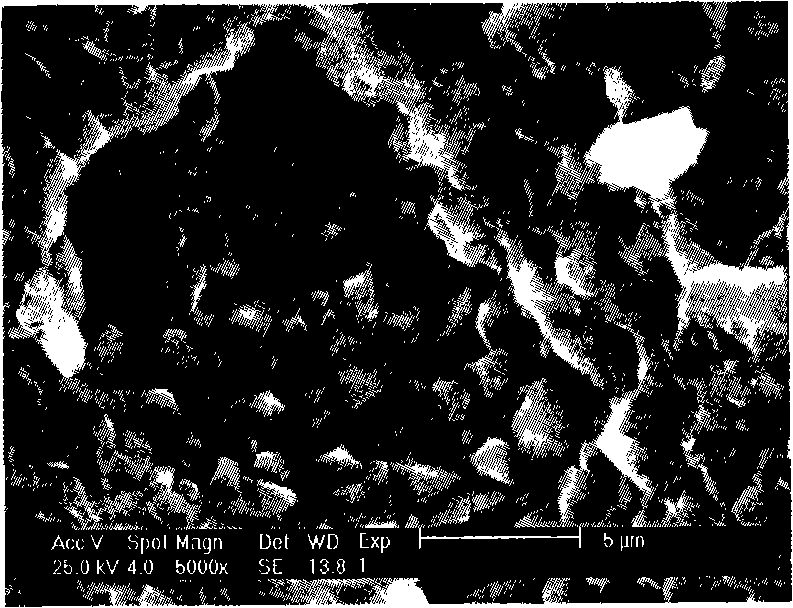

Low-temperature-coefficient high-impedance high-magnetic-permeability manganese zinc ferrite material and preparation method thereof

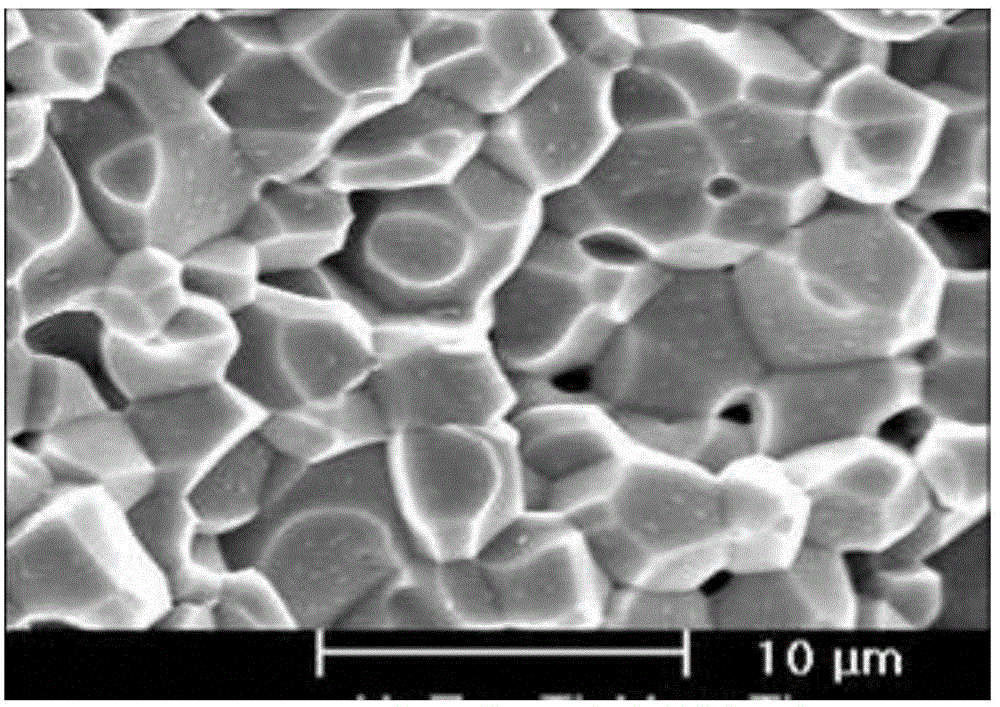

The invention discloses low-temperature-coefficient high-impedance high-magnetic-permeability manganese zinc ferrite material and a preparation method thereof, and belongs to the technical field of ferrite material preparation. The material comprises the components as follows: main components and at least two additives, wherein the main components comprise the following ingredients: 52.0 to 54.0 mol% of Fe2O3, 19.0 to 24.0 mol% of ZnO, 0.01 to 0.05 mol% of NiO, and the balance of MnO; the additives comprises the following ingredients: 0.01 to 0.08 wt% of CaCO3, 0.01 to 0.10 wt% of MoO3, 0.01 to 0.08 wt% of nano TiO2, 0.01 to 0.04 wt% of Bi2O3, 0.005 to 0.02 wt% of SiO2, 0.01 to 0.12 wt% of V2O5, 0.005 to 0.04 wt% of Nb2O5 and 0.005 to 0.04 wt% of B2O3. According to the invention, the material is uniform in size, obvious in grain boundary, and fewer in gas pores.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

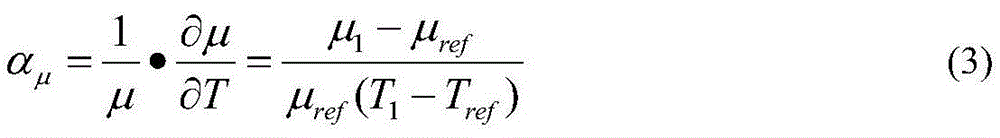

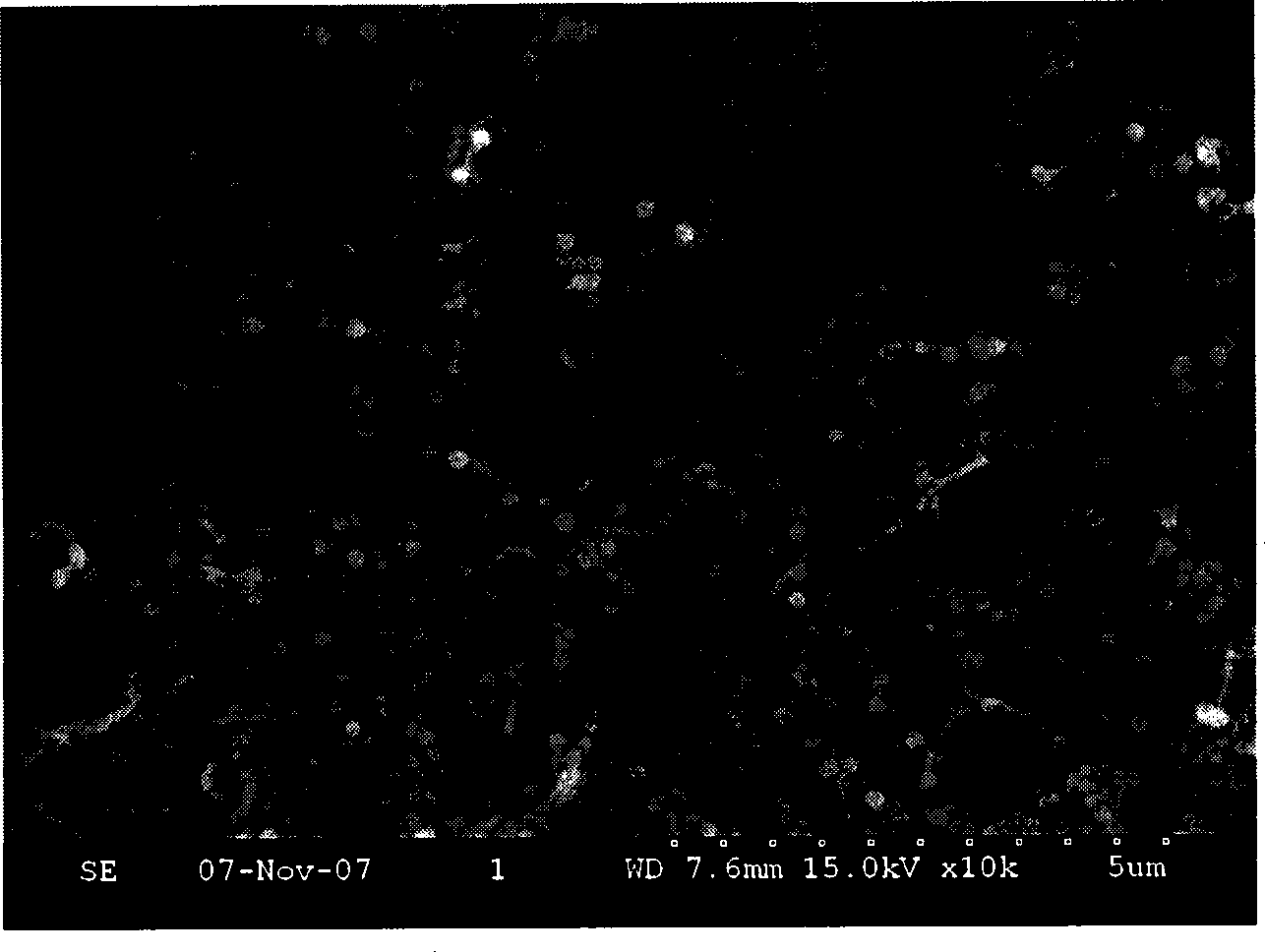

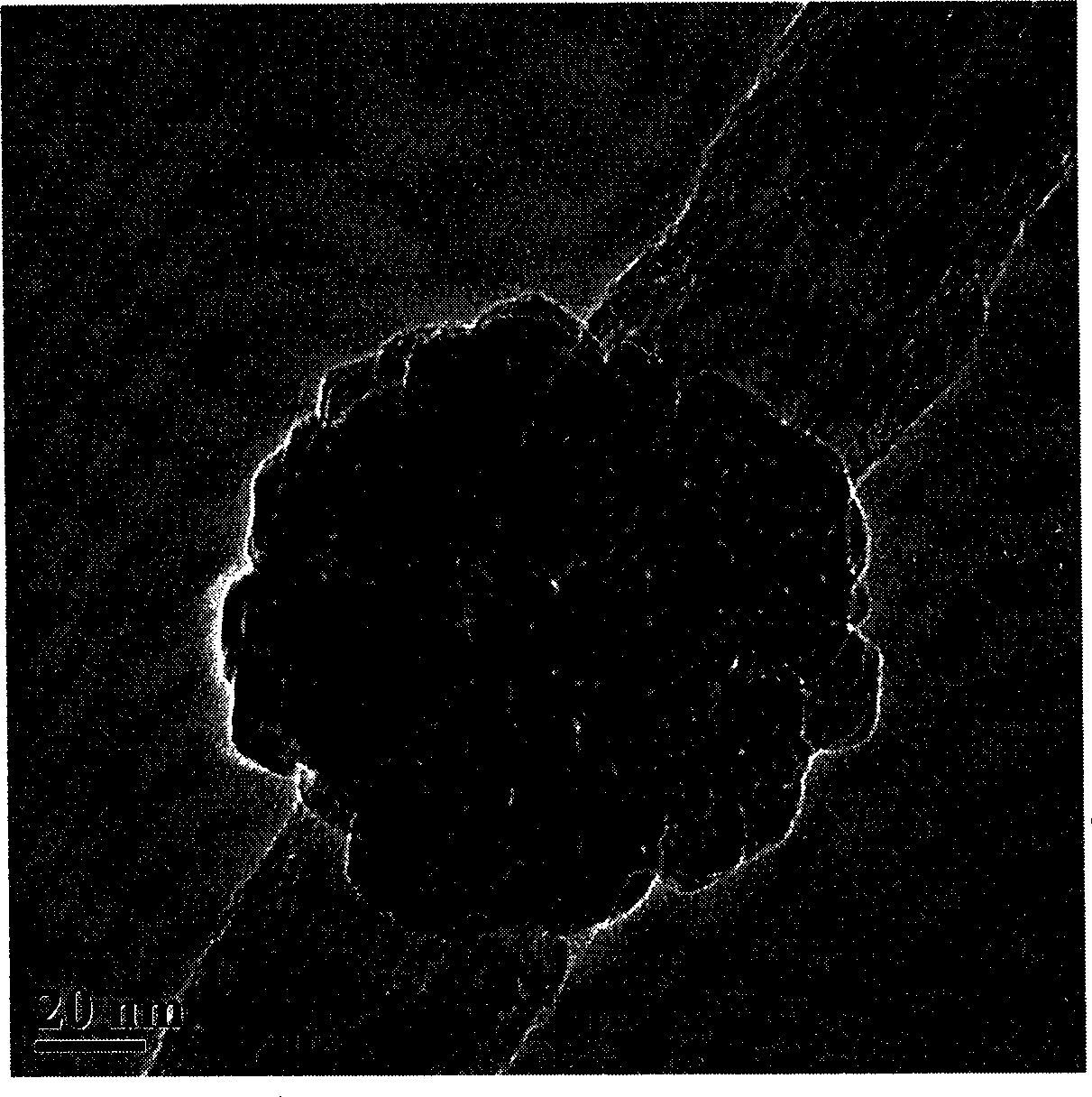

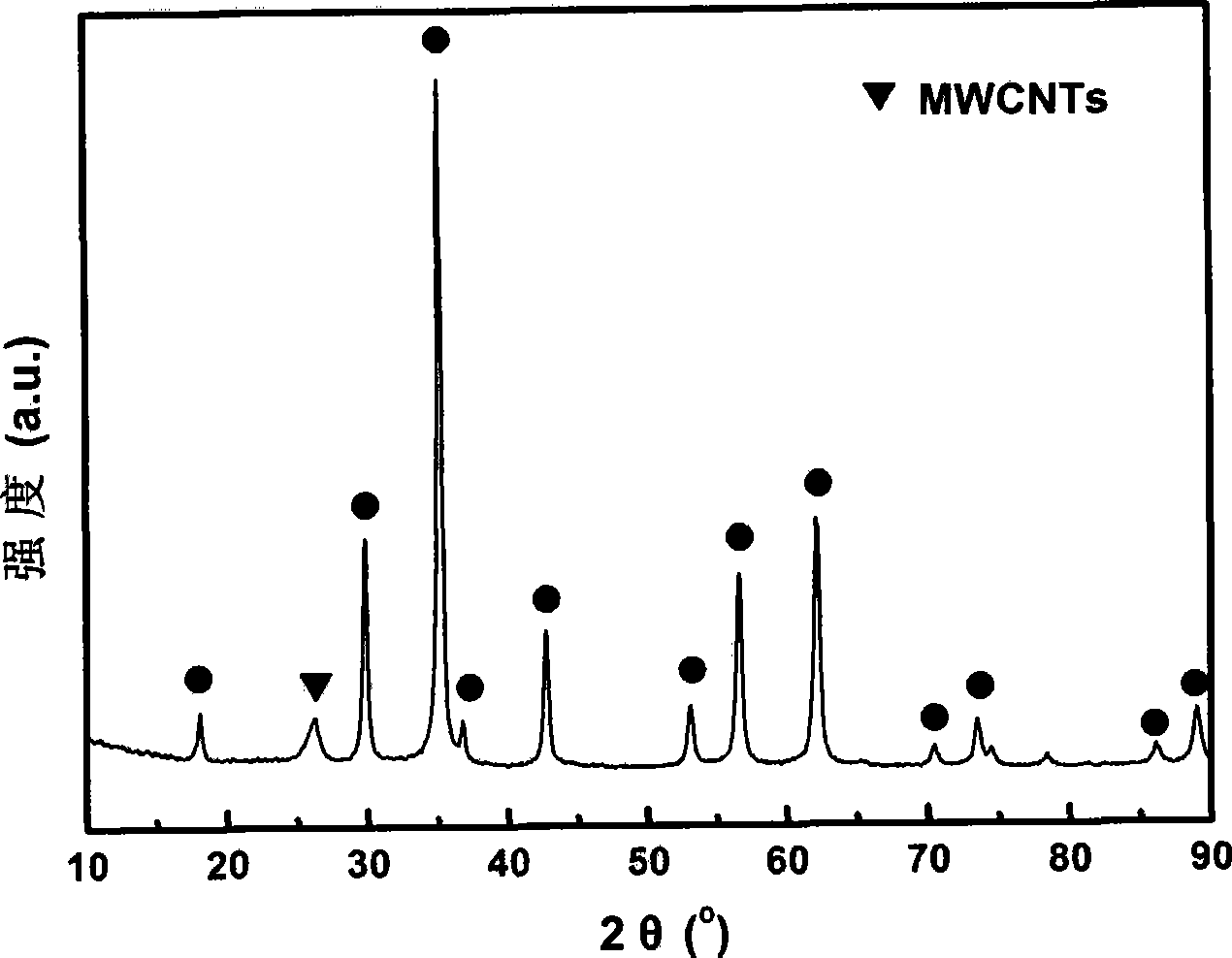

Preparation of carbon nano-tube(MWCNTs)/manganese-zinc ferrite(Mn1-xZnxFe2O4) magnetic nano material by alcohol-thermal method

InactiveCN101499341ACrystal phase pureGood dispersionInorganic material magnetismMagnetizationCarbon nanotube

The invention relates to an alcohol-thermal method for preparing a carbon nano tube (MWCNTs) / manganese-zinc ferrite (Mn1-xZnxFe2O4) magnetic nano-material. The method is mainly characterized in that the carbon nano tube, soluble malysite, zinc salt and manganese salt are taken as initial raw materials, and acid with strong oxidizing property is firstly used for acidizing the surface of the MWCNTs,; the acidized MWCNTs is dispersed into glycol solution, and then the malysite, the zinc salt, the manganese salt, anhydrous sodium acetate and dispersant polyethylene glycol are added in; and the lcohol-thermal method is adopted for preparing the (MWCNTs) / Mn1-xZnxFe2O4 magnetic nano composite material. The prepared (MWCNTs) / Mn1-xZnxFe2O4 magnetic nano composite material has pure crystalling phase, good dispersivity, high magnetization, strong magnetic induction sensitivity and simple preparing technique, and is not easy to agglomerate, thus being simple in the requirements for the production equipment and easy for commercial process.

Owner:DONGHUA UNIV

Manganese zinc ferrite soft magnet and its manufacturing method

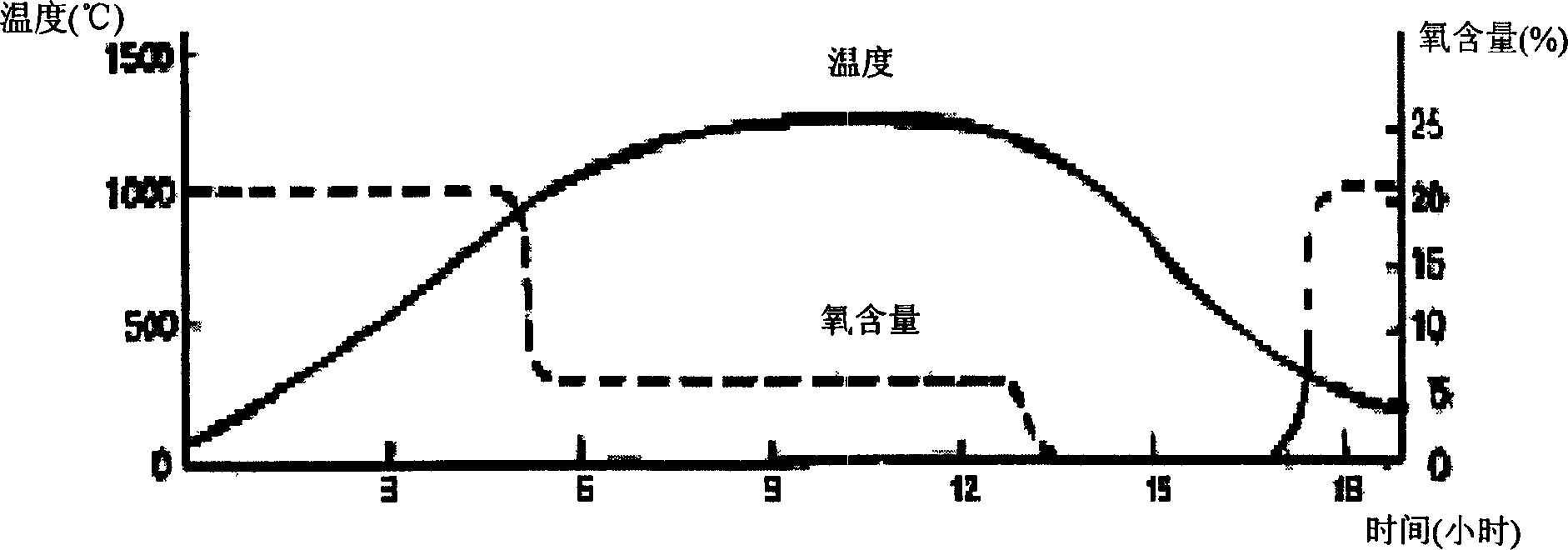

ActiveCN1619719AReduce power consumptionMinimum power consumption and easy temperature adjustmentInorganic material magnetismInductances/transformers/magnets manufactureSoft magnetOxygen content

This invention discloses a method for making manganese-zinc ferrite soft-magnet, which comprises at least one constant temperature insulation in temperature reducing period of sintering process wherein the temperature of constant temperature insulation is lower at least 50 deg.C centigrade than that in temperature reducing period, the optimal is lower at least 10 deg.C, the oxygen content keeps no change in this period. Said invention also discloses a manganese-zinc ferrite made by said method. Said invention has advantages of low power consumption and simple lowest temperature adjustment.

Owner:TDG HLDG CO LTD

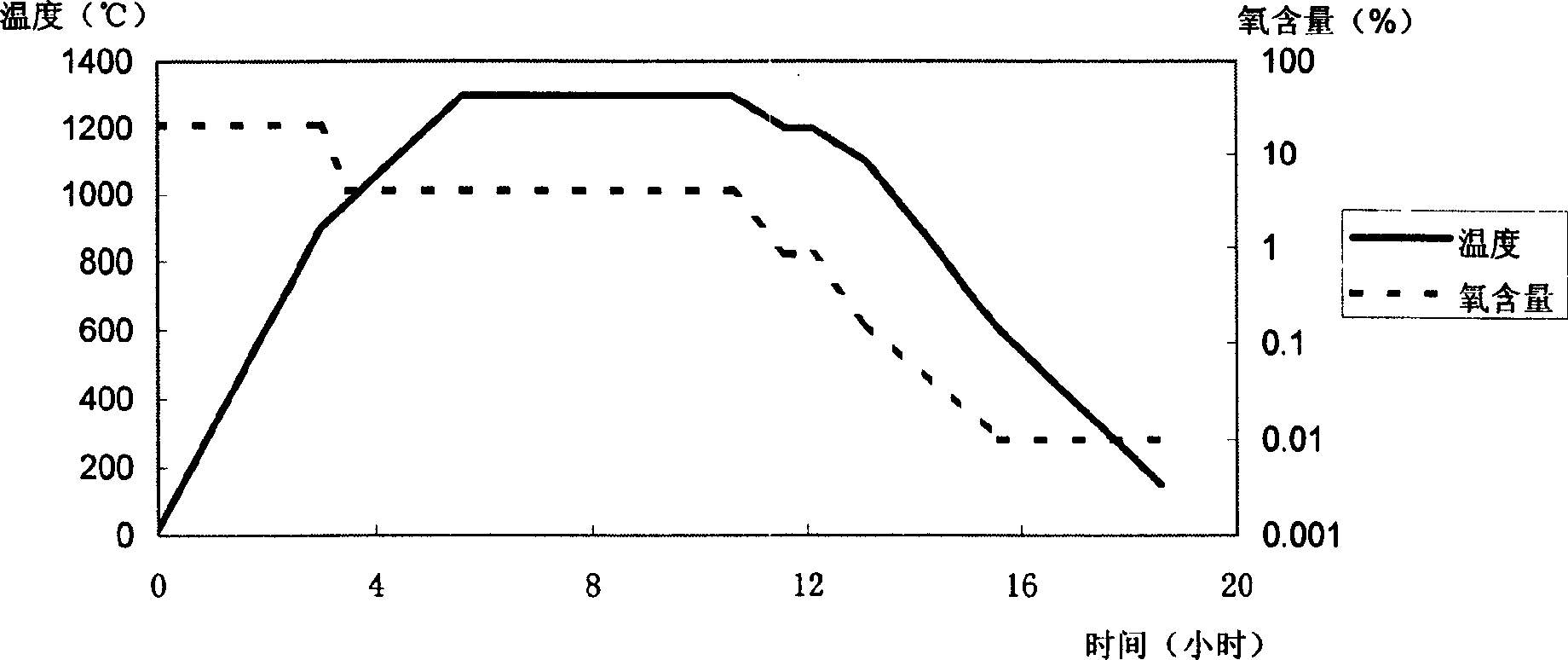

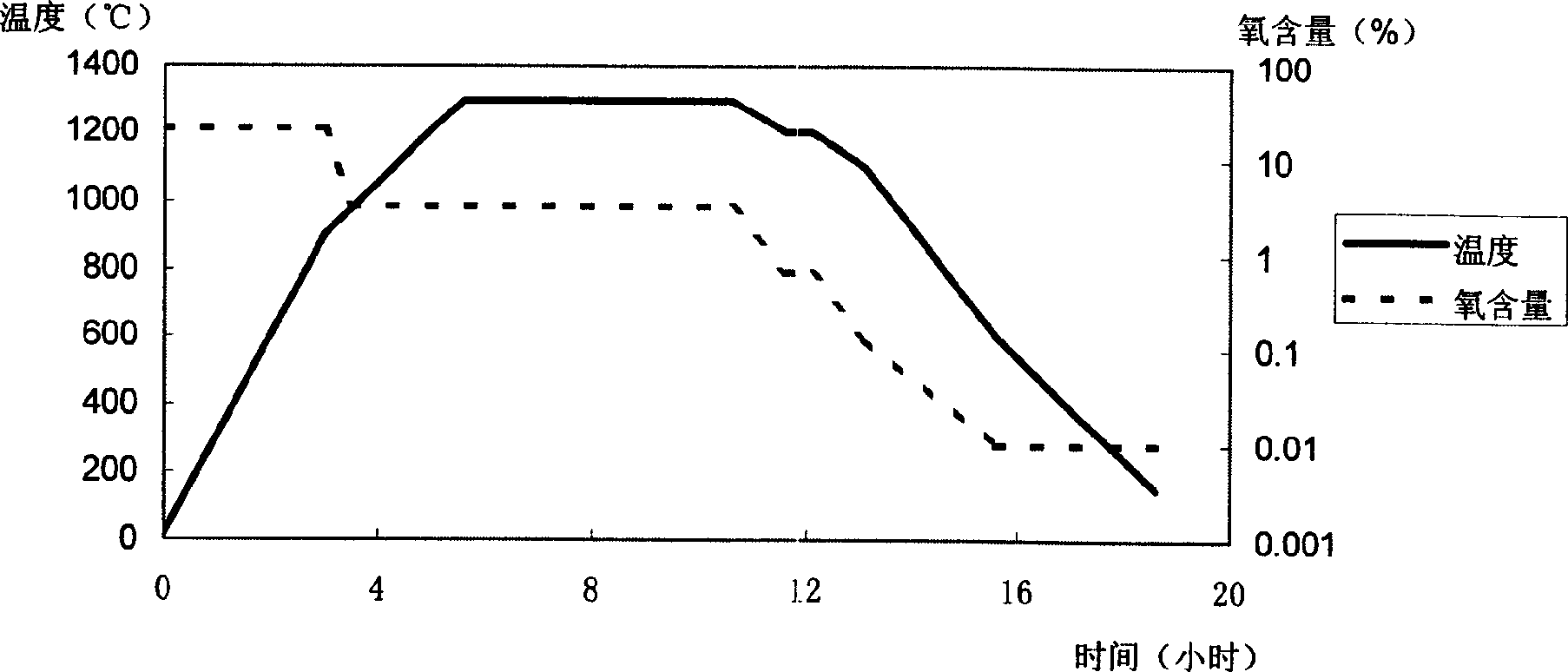

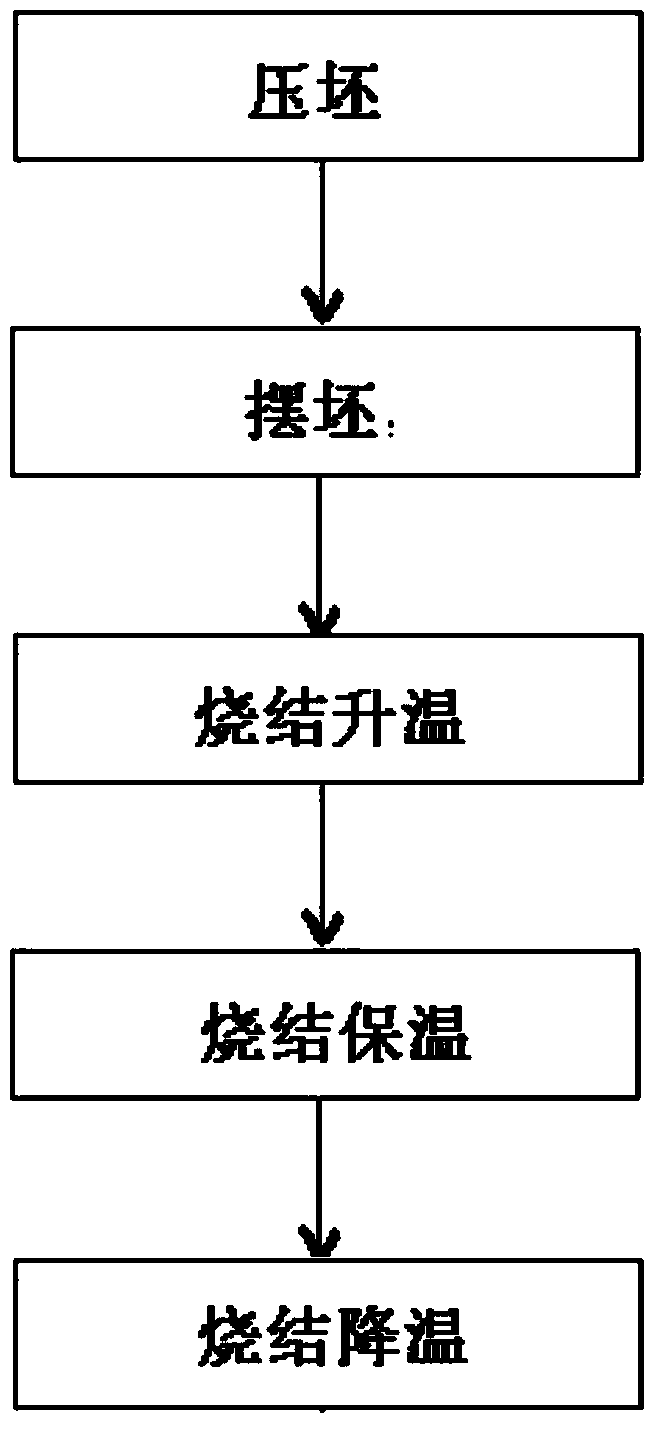

Production method of manganese-zinc ferrite magnetic core

ActiveCN104392837ASimple structureCompact structureInorganic material magnetismInductances/transformers/magnets manufactureRoom temperatureMagnetic core

The invention provides a production method of a manganese-zinc ferrite magnetic core. The production method comprises the following steps: blank pressing, blank placement, sintering heating, sintering heat preservation and sintering cooling, wherein during blank placement, pressed blanks are automatically stacked in a sintering plate by virtue of an automatic blank placement machine; sintering heating is performed stepwise, and is performed respectively at temperature of minus 700 DEG C, 700-1100 DEG C and 1100-1350 DEG C; during sintering heat preservation, heat preservation is performed on the blanks at a temperature of 1350 for 2-6 hours; sintering cooling is performed stepwise and is performed respectively at the temperature of 1350-900 DEG C, 900-200 DEG C and 200-room temperature. The invention also discloses an automatic blank placement machine capable of realizing blank placement. The production method of the manganese-zinc ferrite magnetic core is scientific and reasonable in step, and is capable of improving the production efficiency and also lowering the manufacturing cost. The manganese-zinc ferrite magnetic core prepared by the method is stable in performance.

Owner:NANTONG HUAXING MAGNETIC MATERIAL

Method for preparing nano soft magnetic manganese-zinc ferrite

InactiveCN101276668AImprove magnetic propertiesEasy to controlInorganic material magnetismChemical reactionFree cooling

The invention discloses a preparation method of a nanometer soft magnetic manganese zinc ferrite preparation method, belonging to the ferrite magnetic material technology field. The method comprises: a first step of preparing manganese zinc ferrite nanometer power; a second step of pressing to form a circular blank; a third step of sintering the prepared product, i.e., putting the formed blank in the second step into a tube electric resistance furnace, rising the temperature from the room temperature to 900-1100 DEG C at a speed of 5 DEG C / minute under nitrogen protection, free-cooling the temperature to 850 DEG C, insulating heat under the temperature in two hours, then free-cooling to the room temperature, and finally obtaining the soft magnetic manganese zinc ferrite sinter, i.e., the nanometer soft magnetic manganese zinc ferrite product. The method of the invention adopts a low-temperature two-step sintering process, has low sintering temperature, short sintering time and no high-temperature solid-phase chemical reaction process, thereby realizing energy-saving, consumption reduction, low production cost and high yield.

Owner:HEBEI UNIV OF TECH

Manganese zinc ferrite with characteristics of high temperature, low power consumption and high overlaying, and preparation method thereof

ActiveCN103680796AEasy to prepareReduce temperature riseInorganic material magnetismTransformerSilicon oxide

The invention discloses a manganese zinc ferrite with characteristics of high temperature, low power consumption and high overlaying, and a preparation method of the manganese zinc ferrite. The manganese zinc ferrite comprises ferric oxide, manganese oxide, zinc oxide, calcium carbonate, titanium oxide, cobaltous oxide, silicon oxide, chromic oxide, niobium oxide and vanadium oxide. The manganese zinc ferrite is prepared through the steps of material blending, preburning and crashing, sanding, preparation of granulation slurry, spray granulation, manufacturing of blanks, sintering and the like, and under the test condition of 100KHz 200mT, the power loss at the temperature of 100 DEG C is smaller than 260kw / m<3>, and the Bs at the temperature of 100 DEG C is larger than 420mT; a filter, a switch power source and a transformer application electronic product are partially made of magnetic materials, partial energy is consumed, and an electronic device which is wider in use field, smaller in size, more efficient and saving in energy can be provided for users, the use frequency of the materials is expanded, the loss is reduced, performance of components with magnetic cores applied can be improved largely, electronic products are made to be smaller and more efficient, and effective help is provided for adjustment of the national industrial structure, energy conservation and emission reduction.

Owner:SUZHOU GUANDA MAGNET

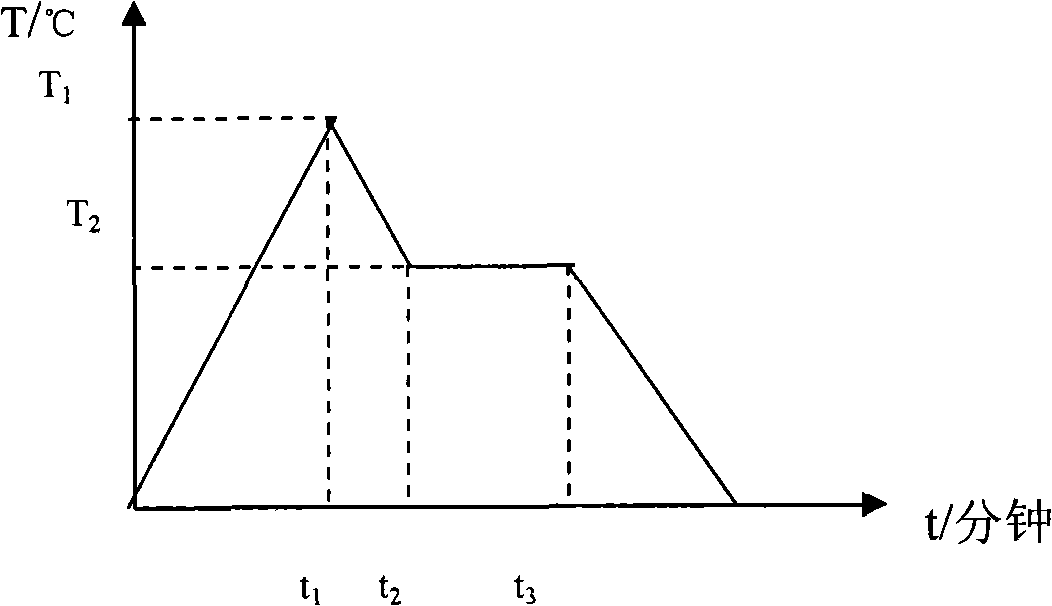

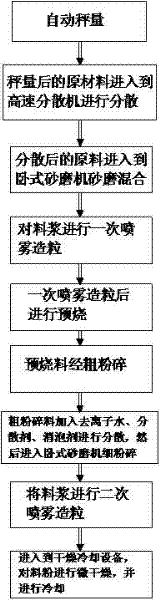

Preparation method for high-performance manganese zinc ferrite powder

The invention relates to a preparation method for high-performance manganese zinc ferrite powder and belongs to the field of preparation of manganese zinc ferrite. The preparation method for the high-performance manganese zinc ferrite powder comprises the following steps of: automatically weighing; dispersing; allowing raw materials to enter a horizontal sand mill, sanding and mixing; performing primary spray granulation; pre-sintering; coarsely crushing; allowing the dispersed coarse crushed materials to enter the horizontal sand mill and finely crushing; performing secondary spray granulation; drying; cooling; and adjusting the water content of the powder. The raw materials are sanded and mixed by the high-efficiency horizontal sand mill, so that the grain sizes of all the raw materials tend to be consistent; the grain size and the grain size distribution of the mixture is controlled strictly in the preparation process, so the microstructures of the raw materials are highly homogenized; and drying and cooling are performed after the secondary spray granulation, so that the high water content consistency of the powder is achieved, and the water stability of the powder before the powder is packaged is maintained.

Owner:SHANGHAI BAOSTEEL MAGNETICS

Manganese zinc ferrite material for eddy current type approach switch, film-coated magnetic core and preparing method of manganese zinc ferrite material

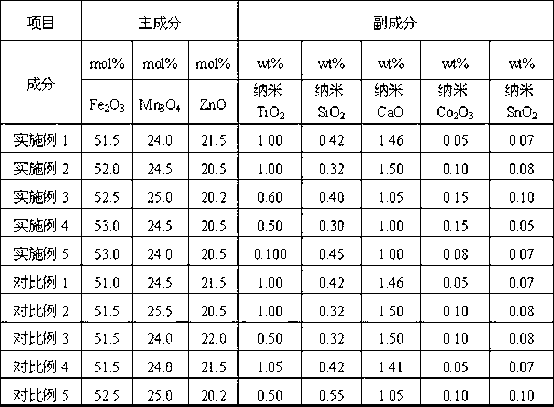

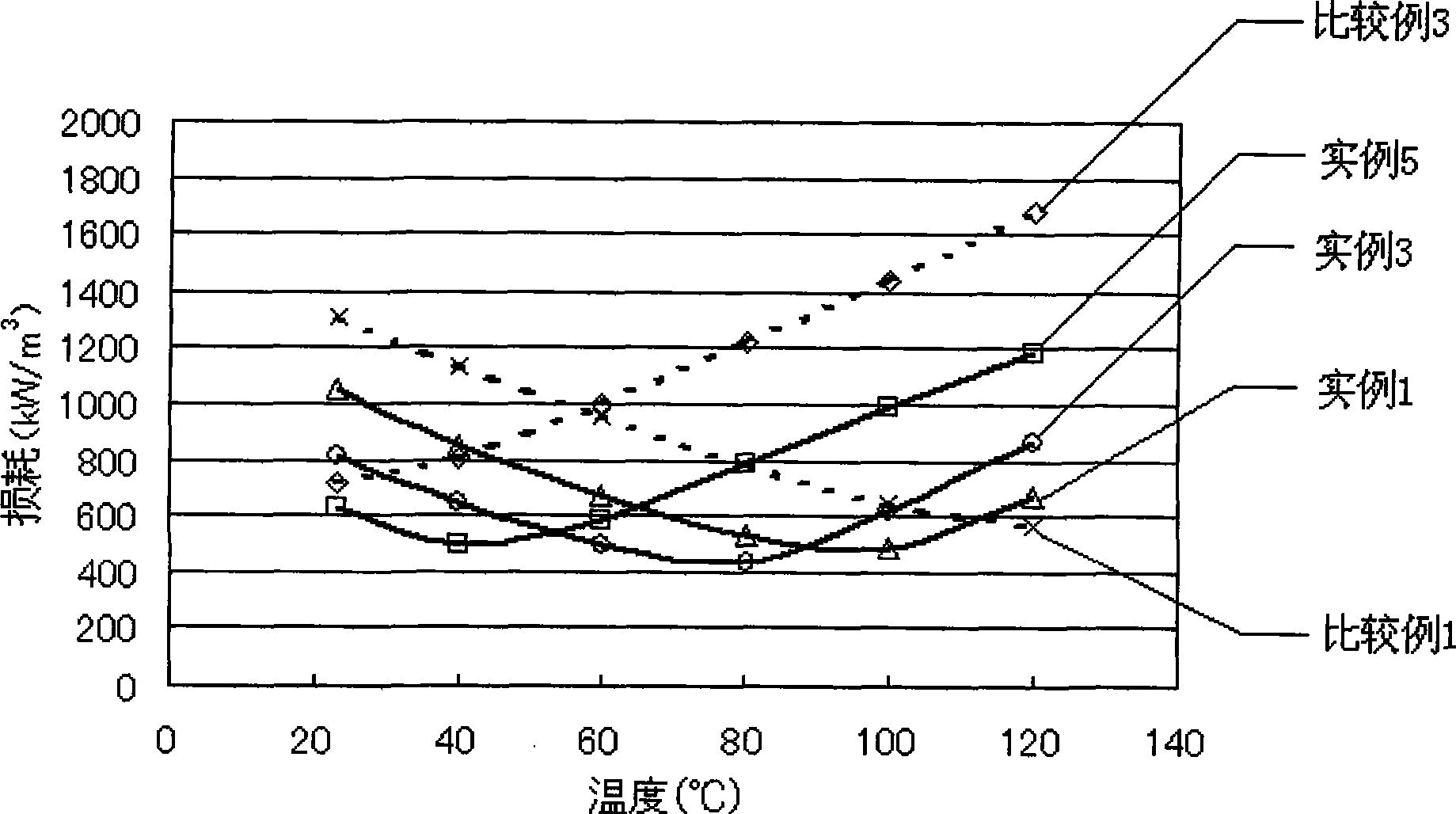

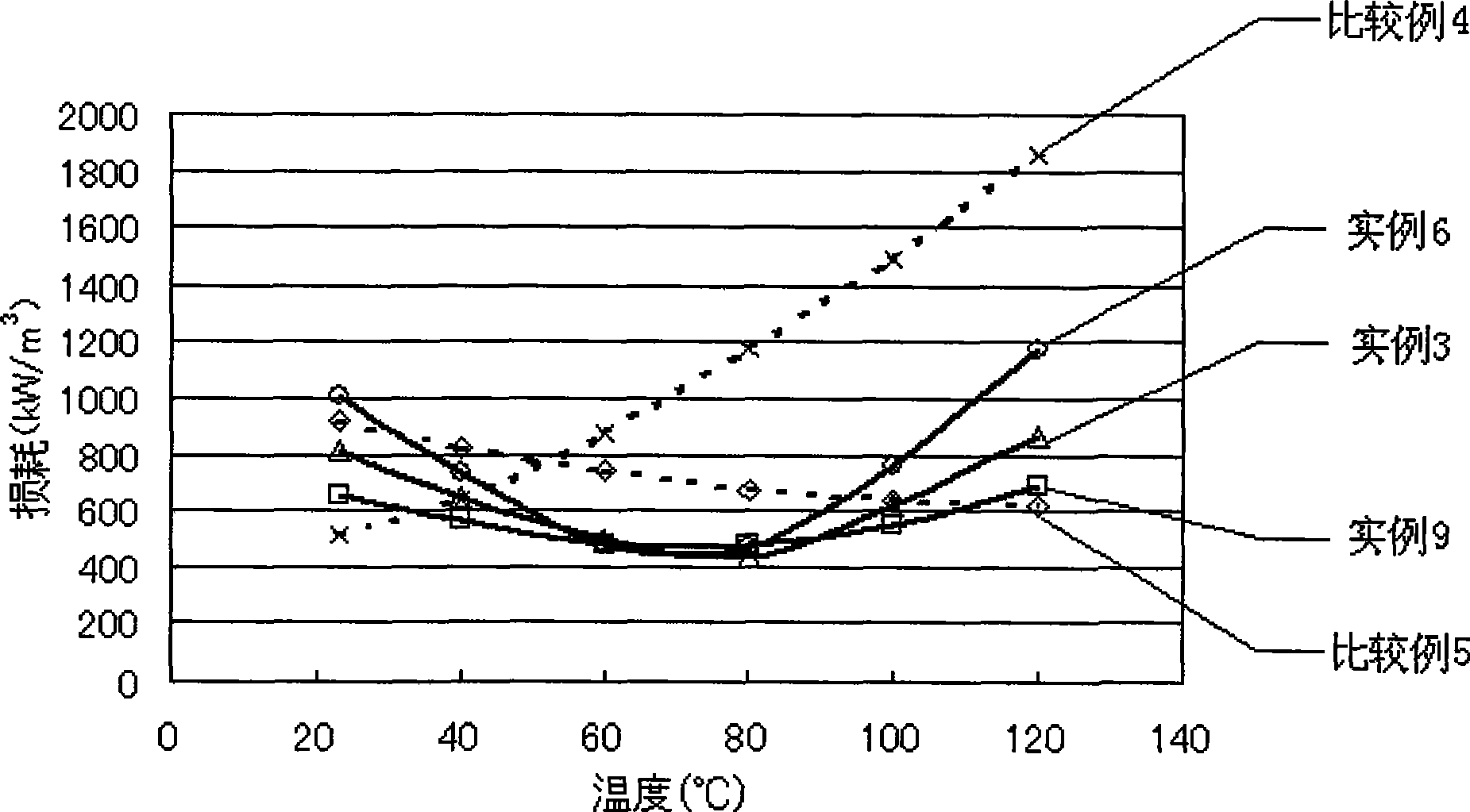

The invention relates to a manganese zinc ferrite material for an eddy current type approach switch, a film-coated magnetic core and a preparing method of the manganese zinc ferrite material. The principal component of the manganese zinc ferrite material contains: 51.5-53 mol% of Fe2O3, 24.0-25.0 mol% of Mn3O4 and 20.50-22.5 mol% of ZnO; and the accessory component of the manganese zinc ferrite material contains:0.50-1.00 wt% of nanometer TiO2, 0.30-0.50 wt% of nanometer SiO2, 1.00-1.50 wt% of nanometer CaO, 0.05-0.35 wt% of nanometer Co2O3 and 0.05-0.10 wt% of nanometer SnO2. The manganese zinc ferrite material is made in the oxide method, formed in mold pressing mode, sintered and grinded and then subjected to film coating on the outer surface of the magnetic core, a transition layer is made of chrome, and a target layer is made of palladium. Resistivity of the manganese zinc ferrite material in 1 MHz is that rho>=10 ohmm, relative temperature thermal index of the manganese zinc ferrite material in the temperature range of -55 DEG C to 25 DEG C is that alpha muir<=(0.3-1.2)*10-6 / DEG C, and relative temperature thermal index of the manganese zinc ferrite material in the temperature range of 25 DEG C to 100 DEG C is that alpha muir<=(0.4-1.6)*10-6 / DEG C. The magnetic core with the film-coated outer surface has excellent electromagnetic shielding performance, and meets requirements of the eddy current type approach switch for the ferrite material of being high in resistivity, small in specific temperature coefficient and strong in anti-jamming capability.

Owner:TDG HLDG CO LTD

Manganese-zinc ferrite

The invention relates to mangan-zinc ferrite, which is characterized in comprising primary components and secondary components, wherein the primary components comprise 52.0 to 59.0 mol percent of Fe2O3, 4.0 to 10 mol percent of ZnO, and the balance of MnO, the secondary components comprise 0.02 to 0.04 weight percent of SiO2, 0.01 to 0.4 weight percent of CaO, 0.01 to 0.2 weight percent of Nb2O5, 0.03 to 1.5 weight percent of MgO, and 0.1 to 0.8 weight percent of CoO. The mangan-zinc ferrite is applicable to magnetic cores of power transformers, achieves low loss and high saturation magnetic flux density and high permeability in a wide frequency range, can be widely used and can be held in other moulds for mass production.

Owner:KUSN NICERA ELECTRICAL APPLIANCE

Suspended filler for quick biofilm culturing of microorganisms

InactiveCN105461083AFast film formationImprove processing efficiencyWater contaminantsSustainable biological treatmentBiocompatibility TestingBiology

The invention discloses a suspended filler for quick biofilm culturing of microorganisms. The suspended filler is prepared from, by weight, 65-75 parts of high-density polyethylene, 5-15 parts of slaked lime, 5-20 parts of Dow powdered activated carbon, 6-10 parts of light calcium carbonate, 3-5 parts of maleic anhydride, 0.2-0.6 part of dicumyl peroxide, 1.5-3 parts of gelatin, 1-2 parts of chitin, 0.8-2 parts of ferroferric oxide magnetic powder and 0.1-0.3 part of manganese zinc ferrite. The density of the suspended filler for quick biofilm culturing of microorganisms is 0.96-0.98 g / cm3. The biofilm culturing speed is high, disengagement does not occur easily, treatment efficiency is high, and the suspended filler is suitable for treating low-concentration organic matter and ammonia nitrogen in sewage and low-concentration organic waste water. The suspended filler has extremely high hydrophilia and biocompatibility, the filler has high adsorption strength on biological films, biofilm culturing time is remarkably shortened, and the COD and ammonia nitrogen removal rate is increased remarkably.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com