Soft-magnetic manganese-zinc ferrite in low wastage

A manganese-zinc ferrite, low-loss technology, applied in the field of manganese-zinc soft ferrite, high-performance soft ferrite, can solve the problems of difficult uniform dispersion of nano-scale materials, high production cost, easy agglomeration, etc., to achieve Conducive to mass production, high saturation magnetic flux density, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

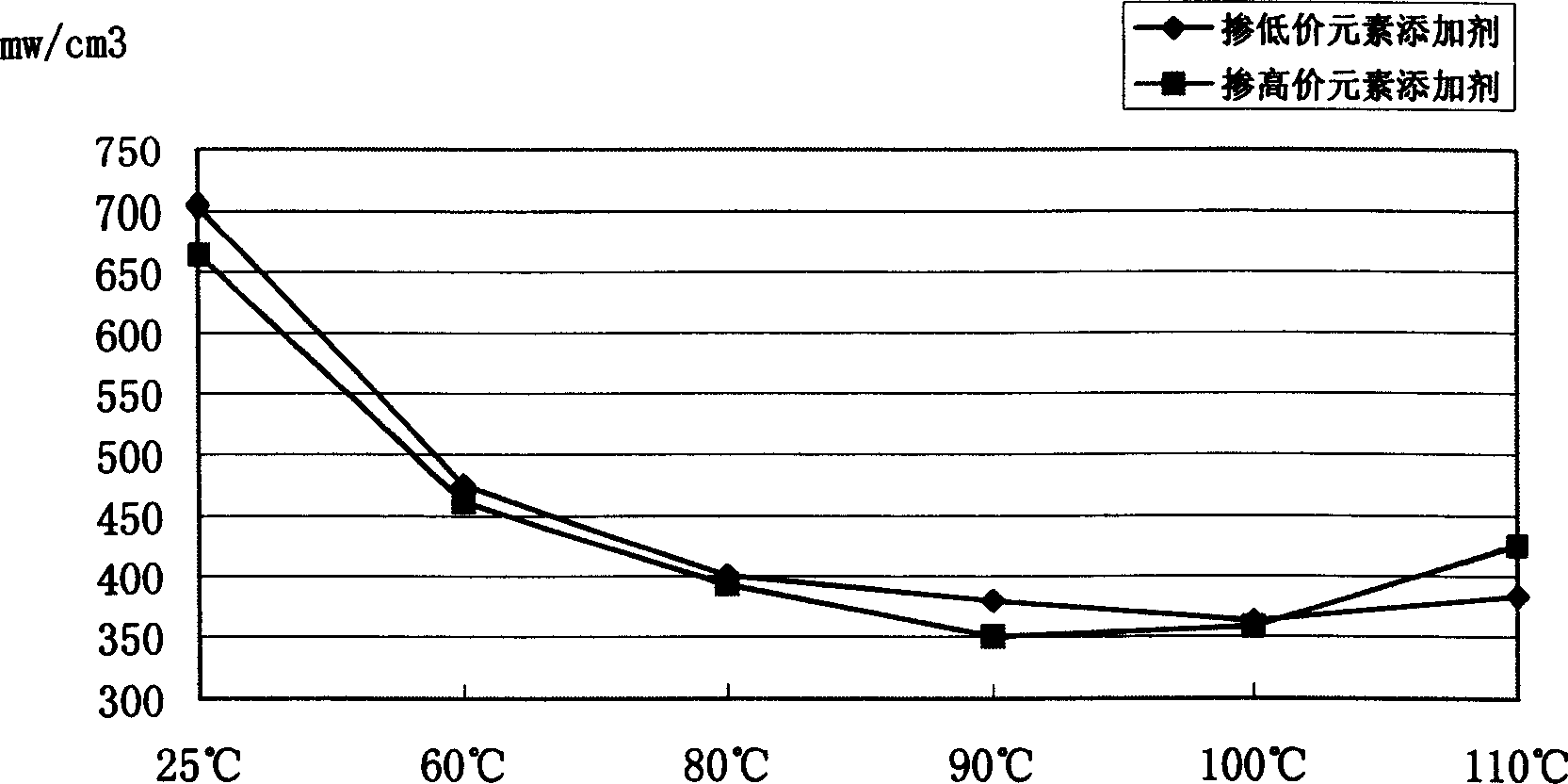

[0023] As shown in Figure 1, the main component formula of MnZn ferrite material is 53.2mol% Fe 2 o 3 , 35.8mol% of MnO, 11mol% of ZnO, low-valent oxide CaCO in the main component 3 (1000ppm) doping makes the temperature of the lowest loss point move to the high temperature direction, and the high-valent oxide SnO 2 The doping of (1000ppm) makes the temperature of the lowest point of loss move to the low temperature direction, and it also shows that the doping of low-valent oxides can make Fe 2+ Reduction, the incorporation of high-valent oxides can make Fe 2+ Increase.

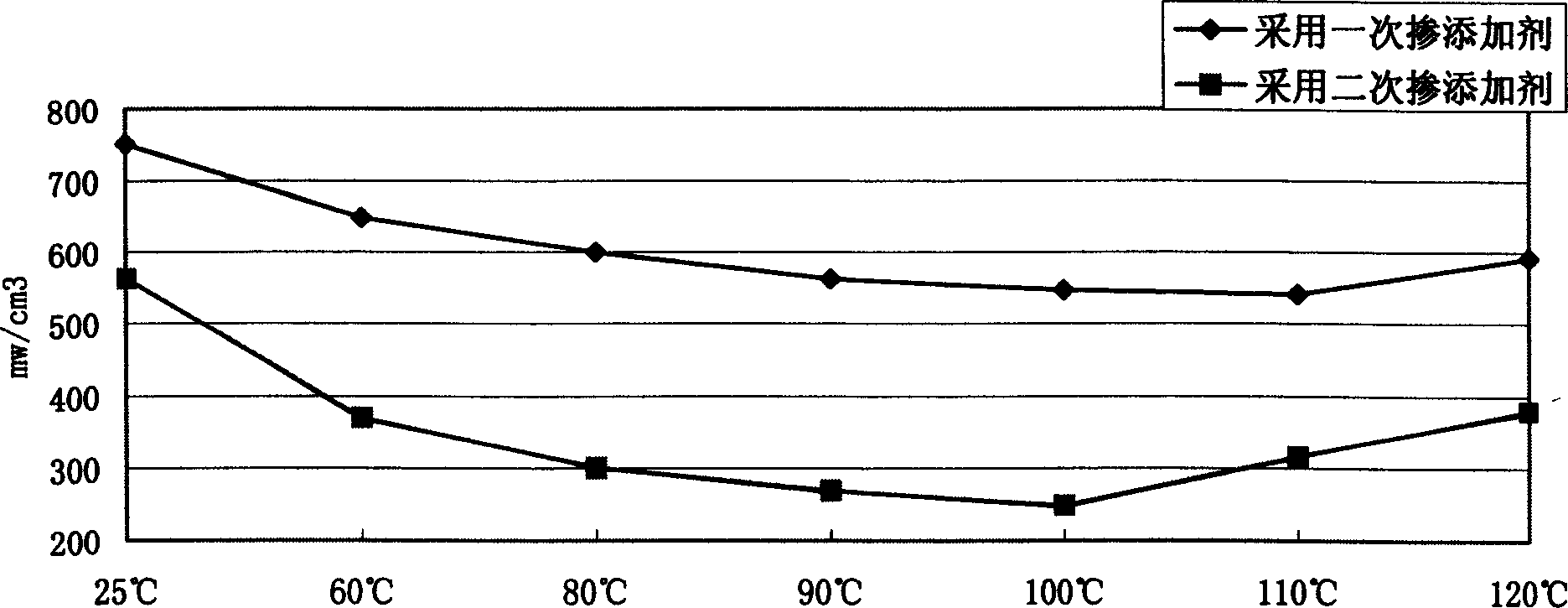

[0024] As shown in Figure 2, the main ingredient formula is Fe 2 o 3 --53.0mol%, MnO--37.0mol%, ZnO--10.0mol%. The lower curve represents the use of secondary doping technology, that is, in the main component Fe 2 o 3 , MnO, ZnO once sanding, doped with SnO 2 3000ppm. And pre-fired at 950°C after drying and granulating, and then added 300ppm of Nb when it was finely ground by the second sand mill af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com