Electromagnetic wave interference preventive material and production thereof

A technology of anti-electromagnetic wave and manufacturing method, which is applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of poor reflection and absorption ability, poor combination, and small specific surface area of materials, etc., and achieve light weight and processing Ease of use and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

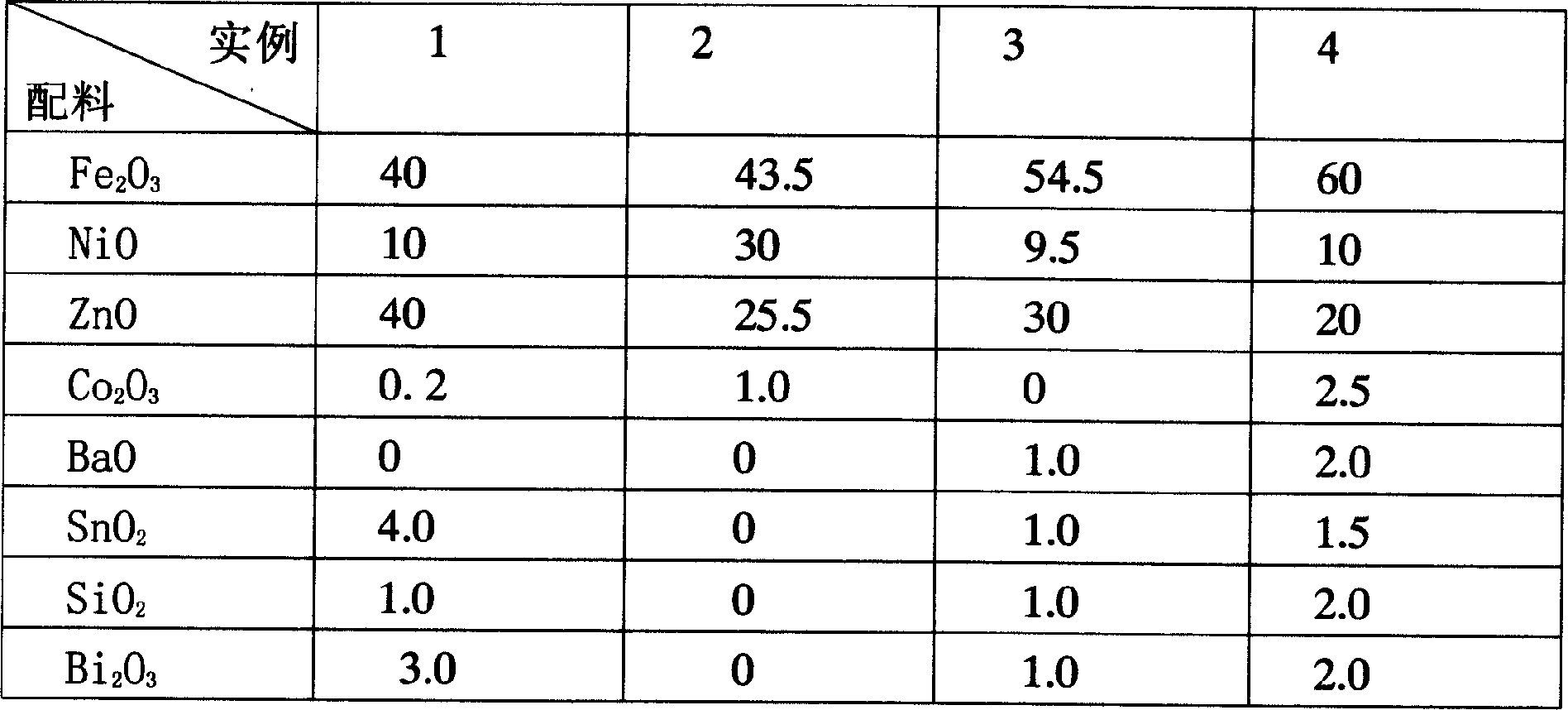

[0027]Embodiment: The anti-electromagnetic wave interference material is composed of an impedance matching layer, an absorbing layer, and a reflecting layer; the impedance matching layer is made of materials including absorbing sendust powder, manganese-zinc ferrite and resin; the The absorption layer is made of materials including absorption type sendust powder, nickel zinc ferrite and resin; the reflection layer is made of materials including reflection type sendust powder, iron powder and resin.

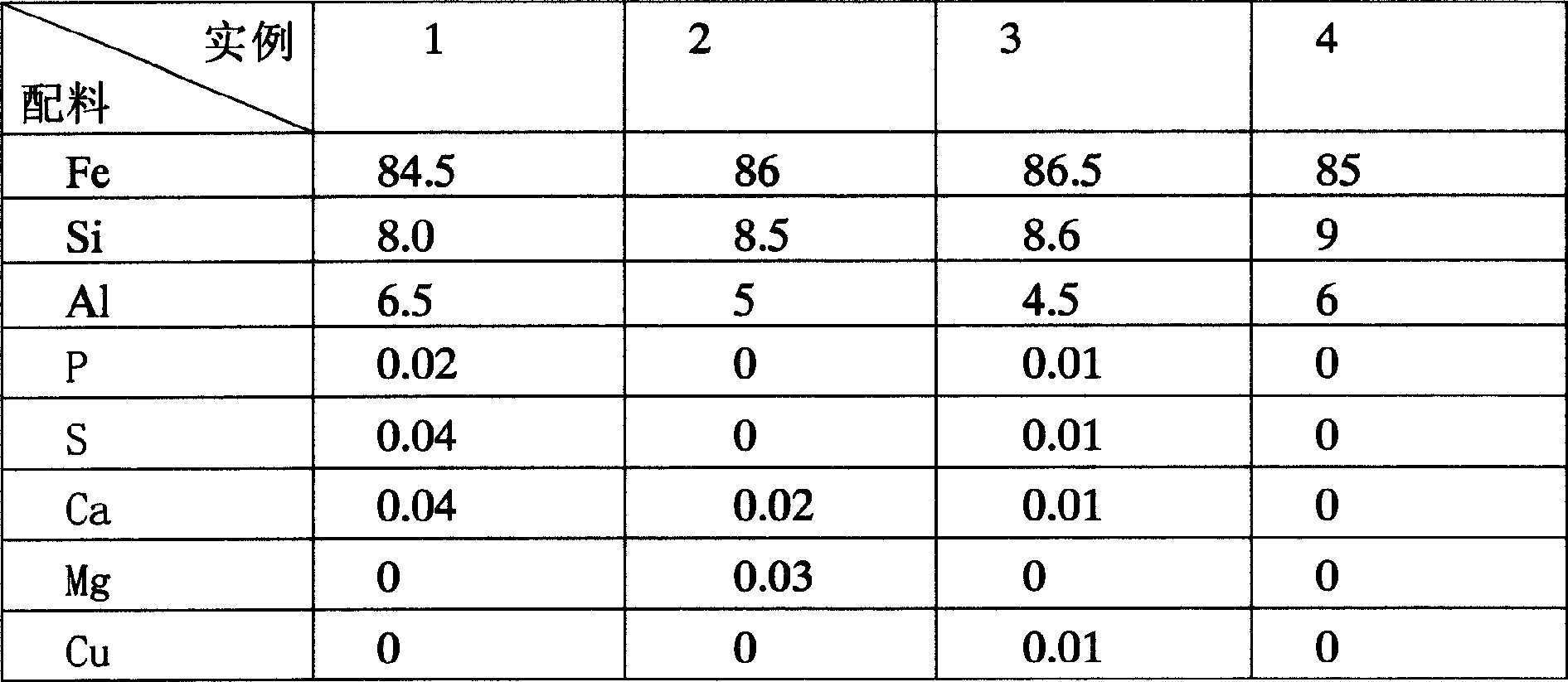

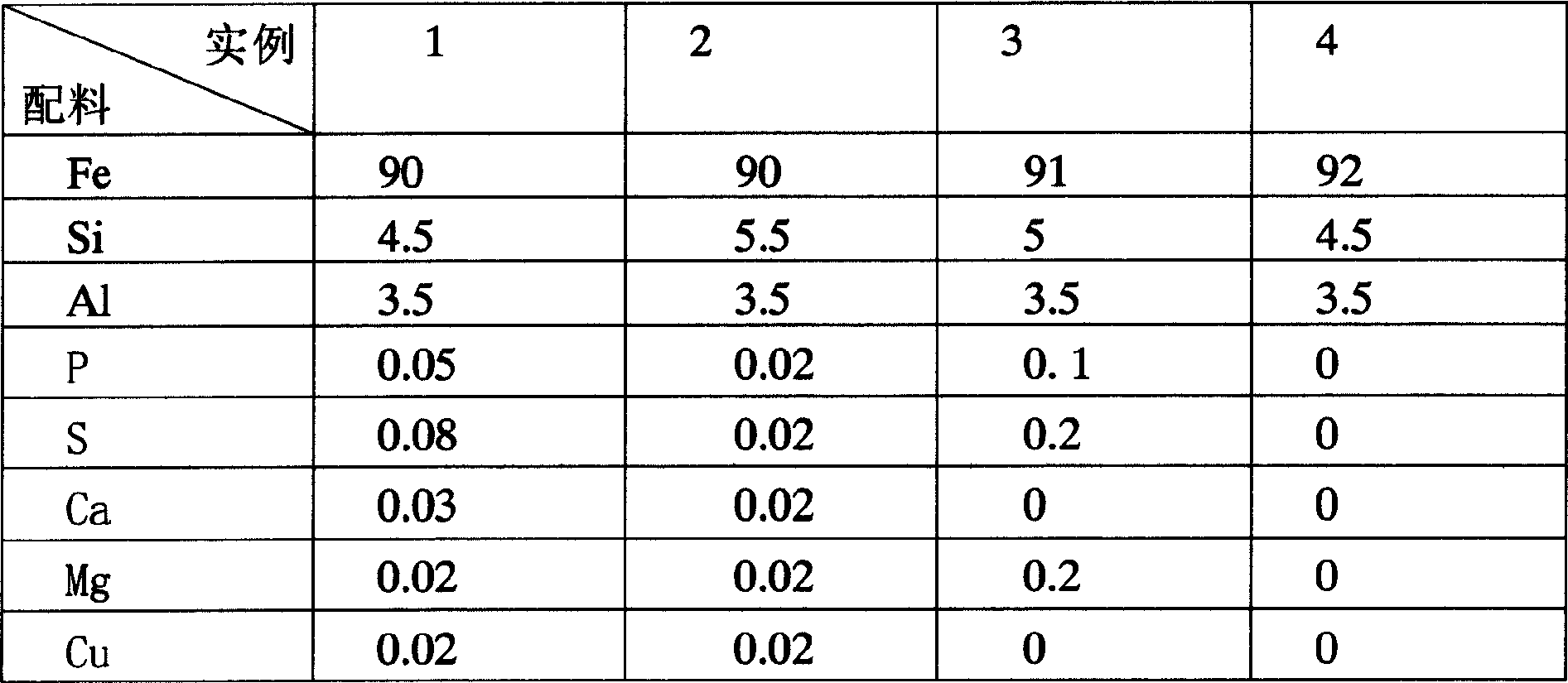

[0028] Table 1 Component distribution ratio of absorption sendust powder

[0029]

[0030] The preparation process of absorption-type sendust powder is as follows: First, weigh various raw materials according to the formula; put them into a ball mill and mix them for 2.5 hours; then melt them at 1800°C for 8 hours; water pressure atomize them into 150-mesh particles; put them into a ball mill Medium ball milling for 3 hours; then carry out vacuum insulation at 700°C for 4 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com