Patents

Literature

250 results about "Nickel-zinc ferrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferrite composite magnetic powder core and preparing method thereof

InactiveCN103426584AOvercome the disadvantage of reduced magnetic performanceImprove permeabilityInorganic material magnetismInductances/transformers/magnets manufactureAdhesivePhosphoric acid

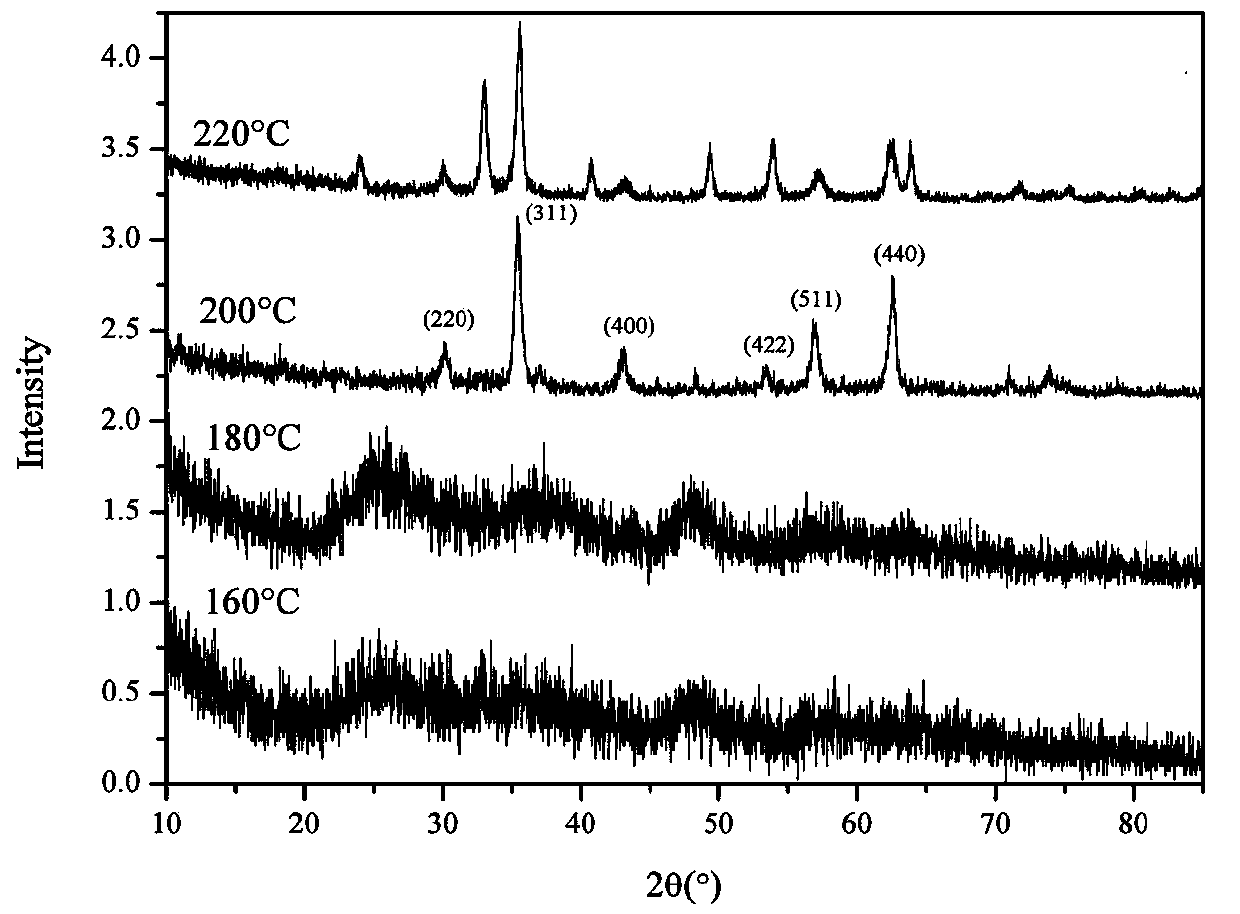

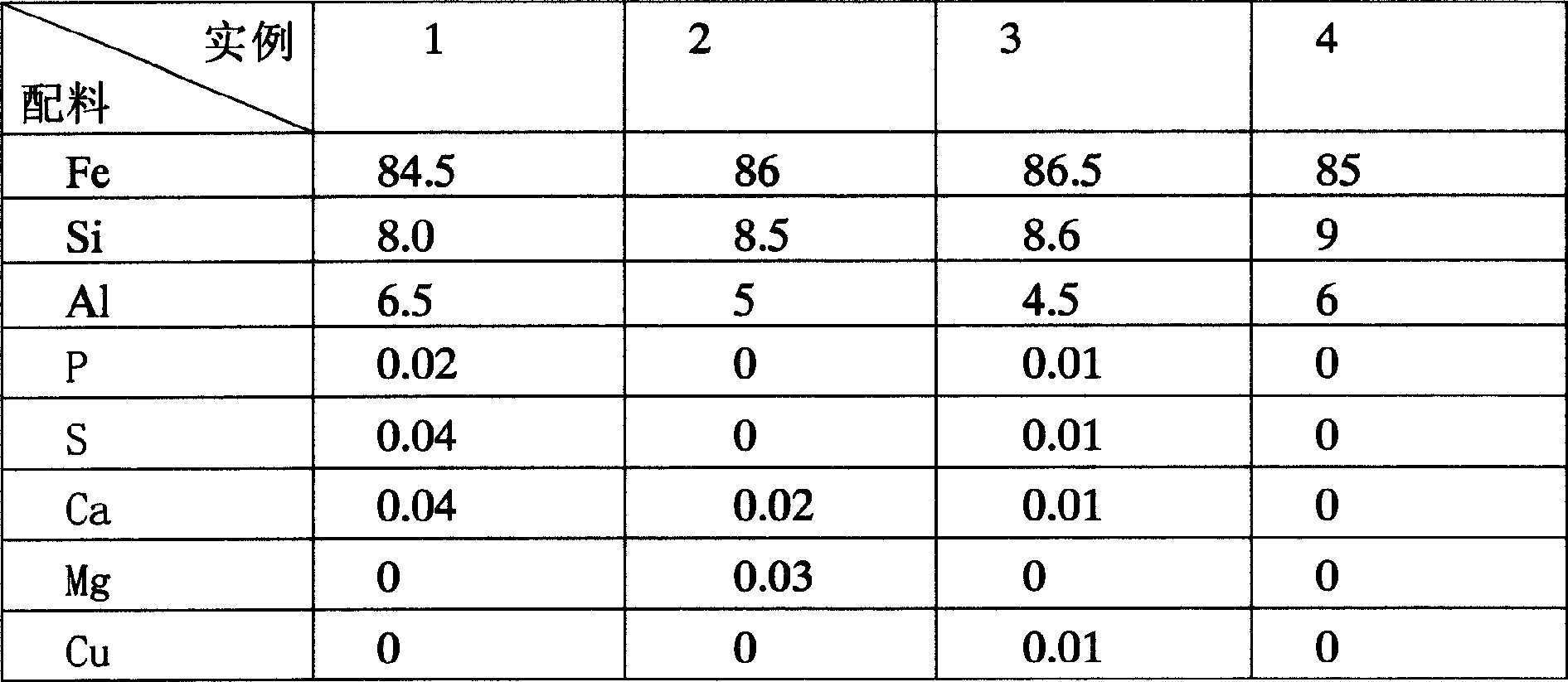

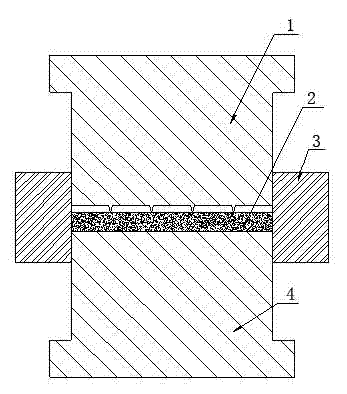

The invention relates to a ferrite composite magnetic powder core and a preparing method thereof. According to the technical scheme, a hydrothermal method is used for preparing nano nickel zinc ferrite particles with even particle sizes, the nano nickel zinc ferrite particles are used as insulation media to coat magnetically soft alloy powder which is passivated by phosphoric acid, an inorganic adhesive is added, and a novel nickel zinc ferrite composite magnetic powder core is prepared after compression and heat treatment. The ferrite composite magnetic powder core and the preparing method thereof have the advantages that first, due to the fact that the ferrite is used as the insulation coating agent of the magnetically soft alloy powder, the defect that the magnetic performance of a substrate is lowered due to the fact that traditional nonmagnetic substances are used as the coating agent is overcome, and high magnetic conductivity and saturation magnetization can be achieved; second, the hydrothermal method is used for preparing the ferrite, and controllable nano particles with even sizes can be prepared conveniently; third, inorganic materials are used as the coating agent, and magnetic powder devices can be prevented from losing efficacy when being used at a high temperature.

Owner:CHINA JILIANG UNIV

Composition for mobile phone case and method of manufacturing mobile phone case using the same

InactiveUS20100171234A1Low absorption rateReduce lossesCeramic shaping apparatusSolid electrolyte fuel cellsPolytetramethylene terephthalateAcrylic resin

There are provided a composition for mobile phone cases and a method of manufacturing a mobile phone case using the same. The composition comprises 70 to 97% by weight of a thermoplastic resin selected from the group consisting of polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS), polybutyrene terephtalate (PBT), acrylic resin and combinations thereof; and 3 to 30% by weight of ferrite selected from the group consisting of nickel-zinc ferrite, manganese-magnesium ferrite, manganese-zinc ferrite, copper-zinc ferrite, manganese-magnesium-aluminum ferrite, yttrium iron garnet (YIG) ferrite and combinations thereof, wherein the composition is a pellet resin formed by extruding the thermoplastic resin and the ferrite at a high temperature of 160 to 290° C.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for preparing graphene doped polyaniline-based carbon coated nickel zinc ferrite mesoporous material

InactiveCN103641488AImprove conductivityGood environmental stabilityCeramicwareConductive polymerIn situ polymerization

The invention discloses a method for preparing a graphene doped polyaniline-based carbon coated nickel zinc ferrite mesoporous material, which combines conductive polymer polyaniline, ferrite and graphene material. The method comprises steps of firstly preparing a nickel zinc ferrite magnetic matrix through a self-propagating combustion method, then preparing graphene doped polyaniline coated nickel zinc ferrite magnetic nanoparticle through an in site polymerization method by taking graphene as the dopant, finally, carbonizing at high temperature and reducing so as to obtain the carbon coated graphene or nickel zinc ferrite nanometer mesoporous material. The graphene doped polyaniline-based carbon coated nickel zinc ferrite mesoporous material prepared by the method can be used as both an electromagnetic wave absorbing material and an environment adsorbing material for adsorbing pollutants such as heave metals, POPs (persistent organic pollutants) and the like in the environment, and has very important value in fields such as military stealth materials, electromagnetic shielding materials and environment adsorbing materials.

Owner:江西瑞祥化工有限公司

Composite magnetic powder core and preparation method thereof

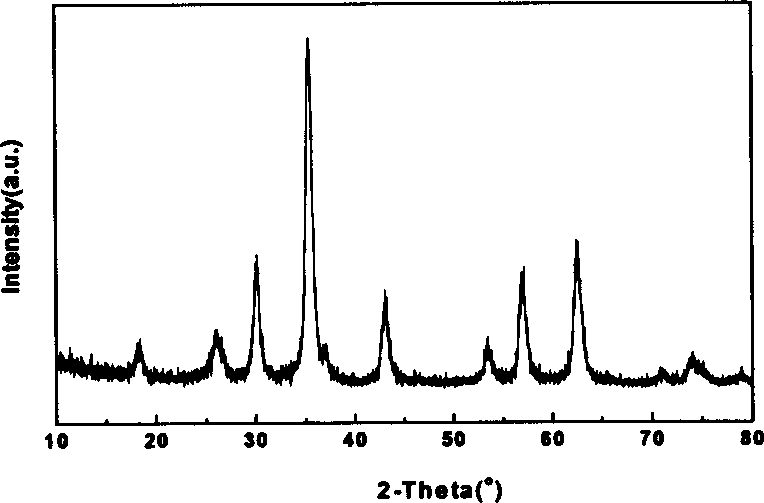

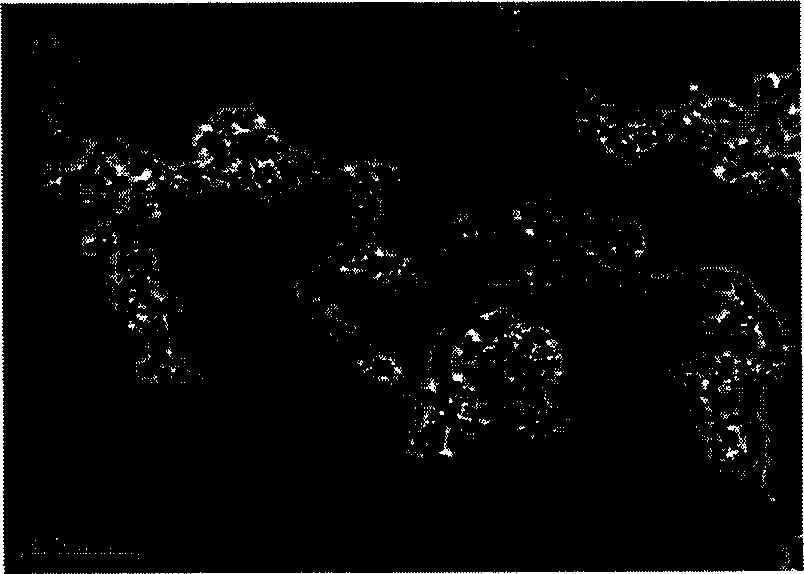

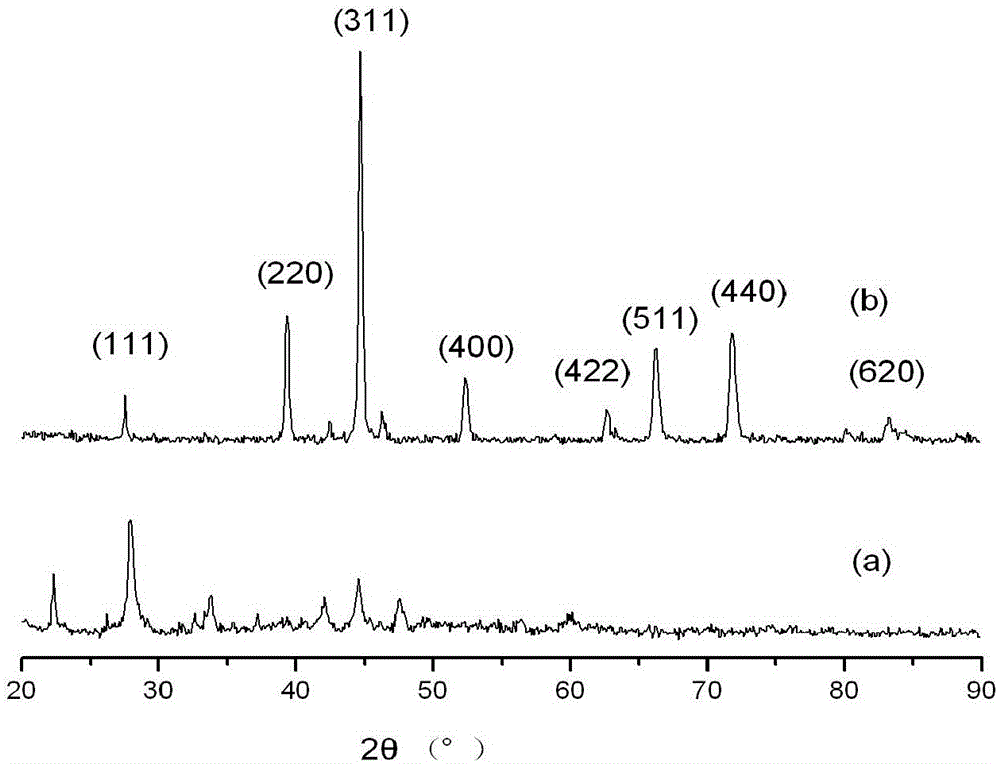

InactiveCN103426580AEasy to manufactureUniform sizeInductances/transformers/magnets manufactureMagnetic materialsNanoparticleNickel-zinc ferrite

The invention relates to a composite magnetic powder core and a preparation method of the composite magnetic powder core. According to the technical scheme, nanometer ferrite particles with even size are prepared on the surface of soft magnetic alloy powder through a hydrothermal method in a root-positioning mode, and a novel ferrite composite magnetic powder core is prepared through the pressing and thermal processing technology. The composite magnetic powder core and the manufacturing method of the composite magnetic powder core have the advantages that due to the fact that manganese zinc ferrite and nickel zinc ferrite are prepared through a hydrothermal method and a root position method, nanometer particles with controllable and even size can be prepared conveniently; the ferrite can be used as an insulated coating agent of the soft magnetic alloy powder, the defect that magnetic performance of a substrate is reduced when traditional nonmagnetic substances are used as the coating agent are overcome, and high magnetic conductivity and saturation magnetization strength can be obtained.

Owner:CHINA JILIANG UNIV

Ni-Zn soft magnetic ferrite material and preparation method thereof

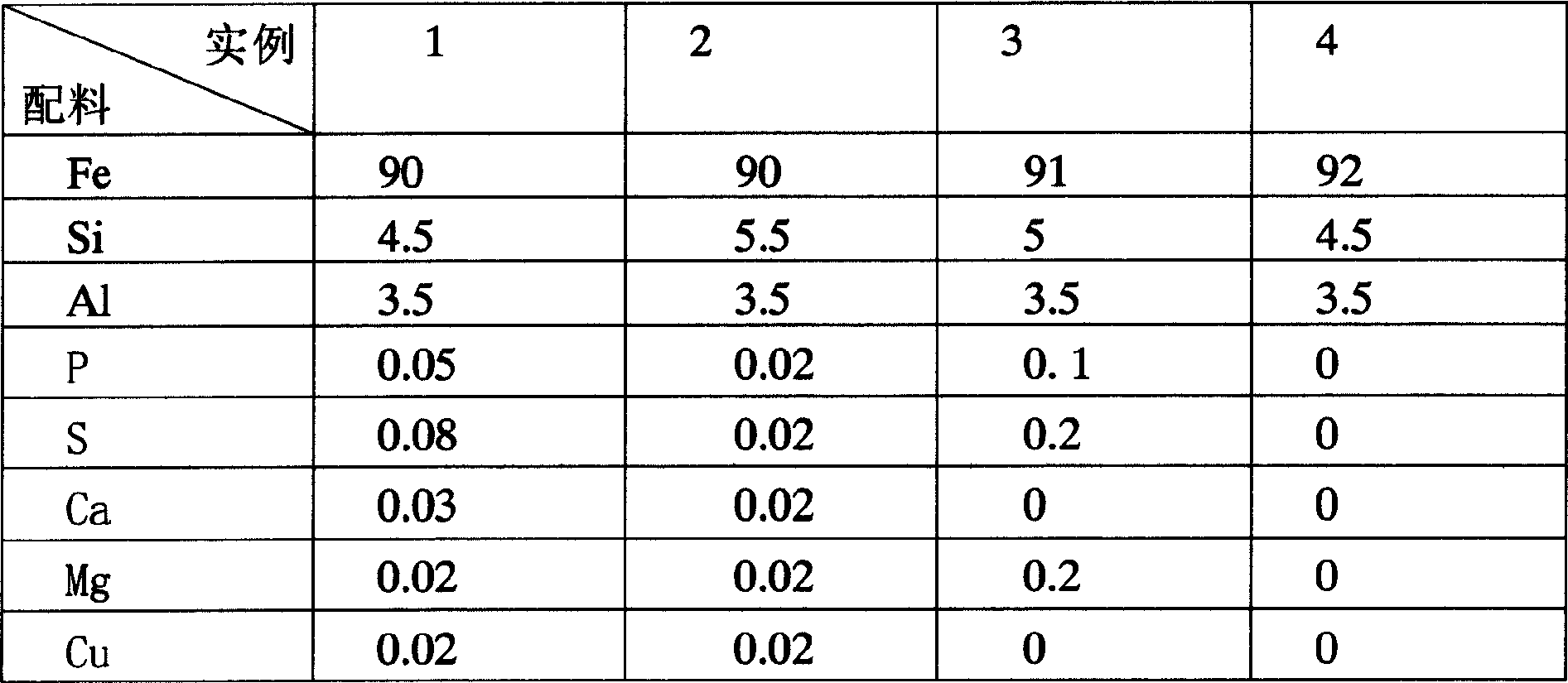

The invention discloses a nickel-zinc soft magnetic ferrite material and a preparation method thereof. The material comprises the following compositions in mol percentage: 45 to 50 mol percent of ferric oxide Fe2O3, 20 to 26 mol percent of zinc oxide ZnO, 12 to 17 mol percent of nickel protoxide NiO, 5 to 10 mol percent of copper oxide CuO, and 3 to 10 mol percent of magnesium oxide MgO. The preparation method comprises the following steps: treating raw materials, proportioning, primary ball milling, drying, powdering or screening, preburning, secondary proportioning, secondary ball milling, secondary drying and secondary powdering or screening; the preburning condition is to carry out pre-synthesis in an air furnace at a temperature of between 900 and 980 DEG C, and the sintering temperature is between 1,050 and 1,100 DEG C. The nickel-zinc soft magnetic ferrite material has the characteristics of property of high Q, high frequency, high TC, high Bm and low cost.

Owner:广东肇庆微硕电子有限公司 +1

Electromagnetic wave interference preventive material and production thereof

InactiveCN1646000AHigh specific surface areaIncrease reflectionMagnetic/electric field screeningIron powderSendust

The anti electromagnetic interference material is composed of several layers: the impedance matching layer is made of absorbing type sendust powder, manganese-zinc ferrite and resin; the absorbing layer is made of absorbing type sendust powder, nickel zinc ferrite and resin; the reflecting layer is made of reflection type sendust powder, iron powder and resin.

Owner:横店集团东磁有限公司

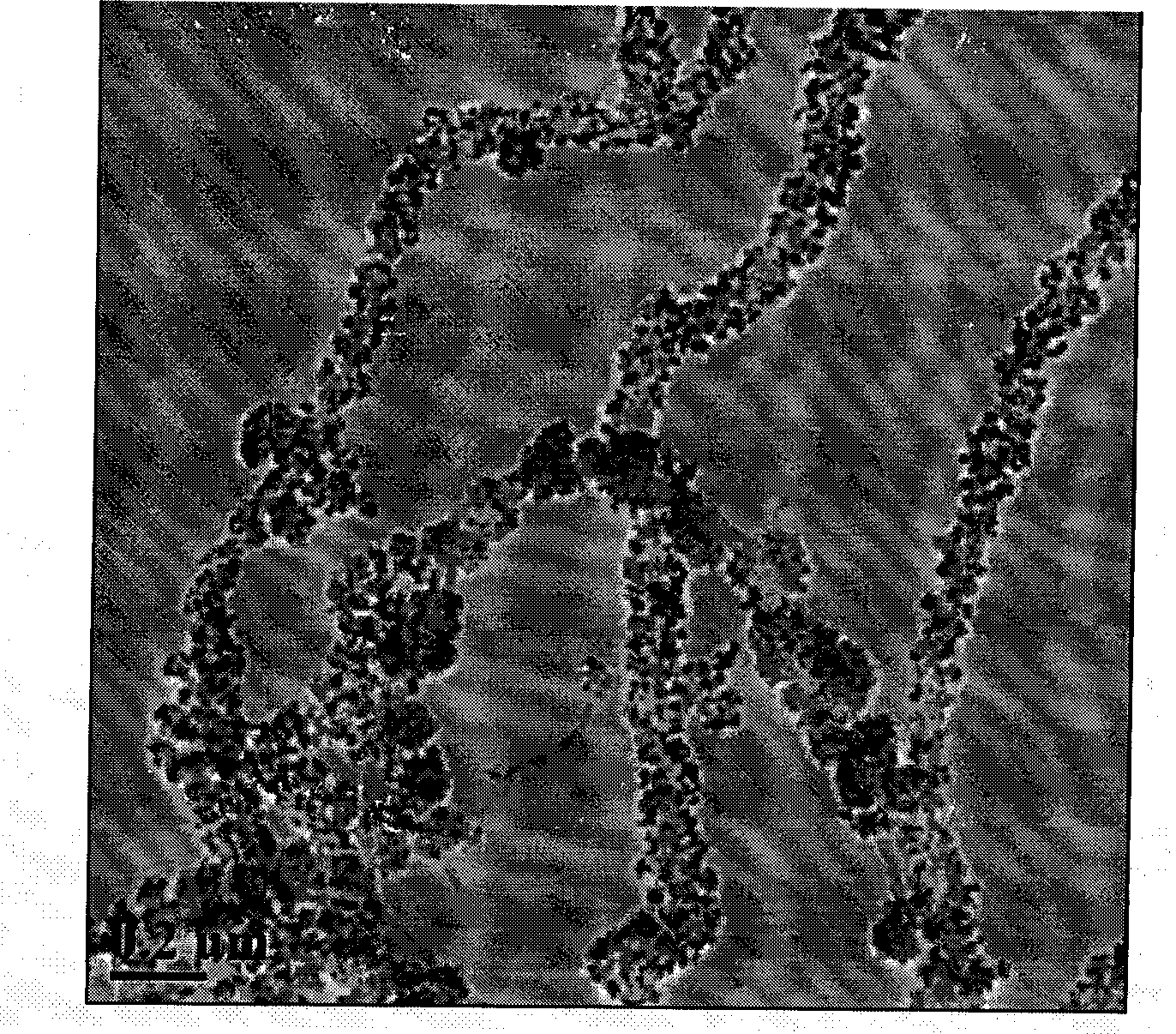

Process for preparing composite material of carbon nano tube/NiZn ferrite

InactiveCN1793421AStrong magnetismExcellent dielectric propertiesLiquid/solution decomposition chemical coatingMagnetic materialsSolubilityMass ratio

The invention discloses a carbon nanometer tube / nickel zinc ferrite composite material manufacturing method. It includes the following steps: manufacturing modified carbon nanometer tube by the backflow of the mixture of carbon nanometer tube and aqua fortis in oil bath; weighing solubility Ni2+, Zn2+, Fe3+ salt with curtain quantity relative ratio to add to distilled water to do ultra sonic dispersion at room temperature; adding to modified carbon nanometer tube with 1:10-15 mass ratio to Fe3+ to do ultra sonic dispersion again; using 4-8mol / l strongly alkaline solution to make the pH value bigger than 8; reacting for 3-24h in hot kettle; cooling to room temperature after full reaction; filtering; washing by distilled water until the pH value reaches 7; washing by alcohol; drying at 60-100 centigrade degree for 5-12h. The formed material has good magnetic, dielectric and electrical properties, and has extensive application prospect in high density magnetic recording material field, and son.

Owner:DONGHUA UNIV

Nickel-zinc ferrite material for wireless signal sensing, sheet core and preparation method thereof

ActiveCN102807361AImprove frequency characteristicsHigh resistivityInorganic material magnetismTransformers/inductances detailsSurface mountingNano sio2

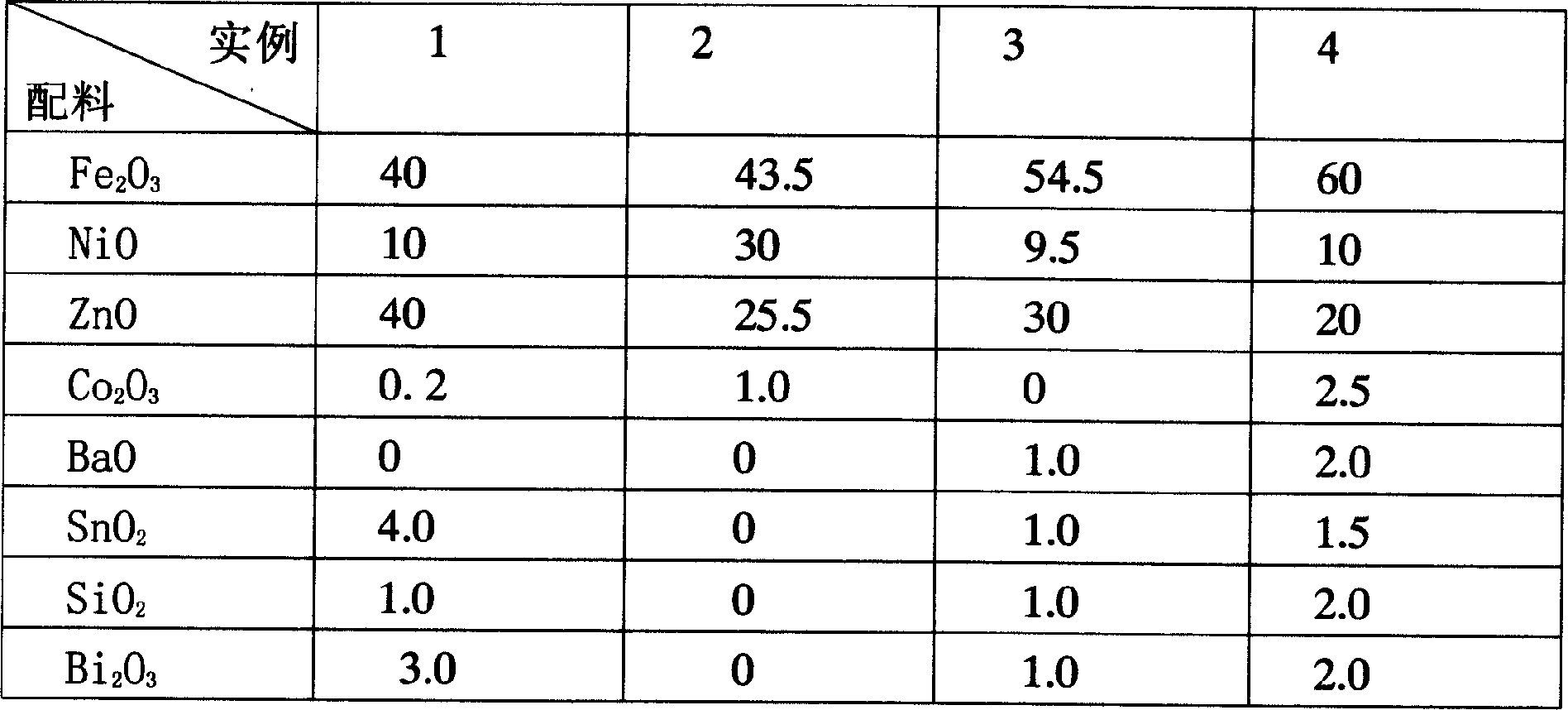

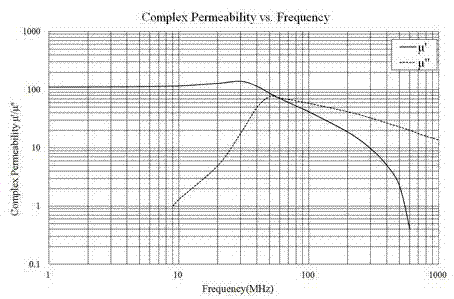

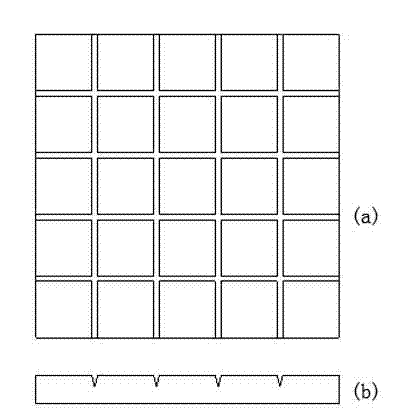

The invention relates to a nickel-zinc ferrite material for wireless signal sensing, a sheet core and a preparation method thereof. The nickel-zinc ferrite material comprises main components which are calculated by the following oxides in mole percent: 48.0-62.5mol% of Fe2O3, 15.3-25.5mol% of NiO, 18.5-23.5mol% of ZnO and 3-10mol% of CuO; and the nickel-zinc ferrite material additionally comprises auxiliary components which are calculated by the following standard substances in weight percent relative to the total weight of the main components: 0.05-0.10wt% of nano CaCO3, 0.30-0.85wt% of nano SiO2, 1.50-2.50wt% of Mn3O4, 0.05-0.35wt% of Co2O3 and 1.00-1.50wt% of Bi2O3. The nickel-zinc ferrite material is prepared by adopting an oxidation method. The sheet core is a reticular sheet, the length is 45-250mm, the width is 45-250mm, the thickness is 0.05-0.3mm, the sheet core is formed by small sheets in a connecting way, the gaps among the small sheets are less than 50mum, and the sheet core is directly molded and then is sintered, or a magnetic bar is molded and then is sliced into small sheets which form the sheet core through an SMT (surface mount device) technology. At frequency of 13.56MHz, the material has the electromagnetic performance that mu' is equal to 125 plus or minus 20% and the mu'' is less than or equal to 4. Therefore, the material can satisfy the requirement of high-frequency low consumption on the ferrite material for wireless signal sensing.

Owner:TDG HLDG CO LTD

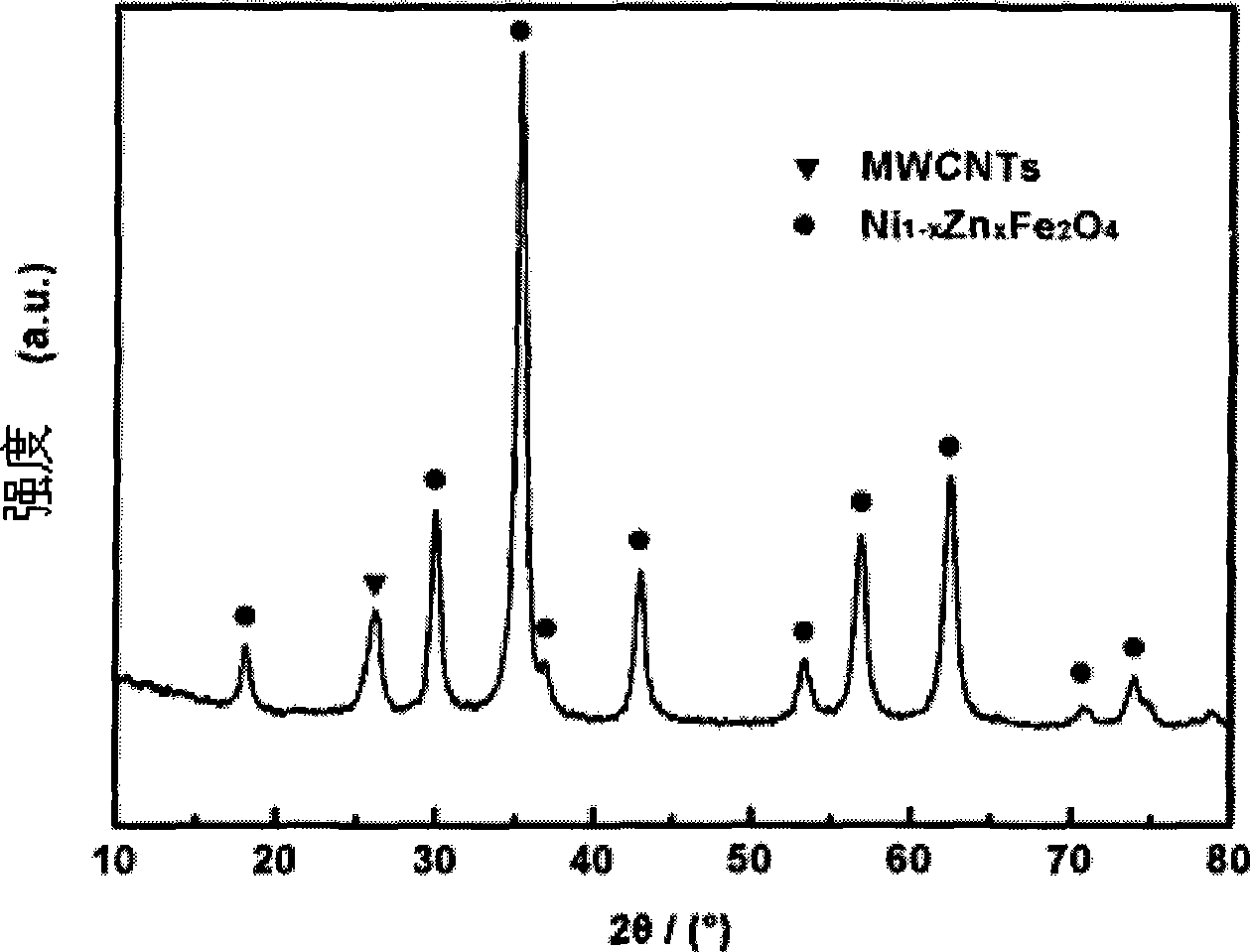

Preparation of nickel-zine ferrite (Ni1-xZnxFe2O4) coated carbon nano-tube magnetic nano composite material

InactiveCN101481107ASimple preparation processProduction equipment requirements are simpleSodium acetateNickel salt

The invention relates to a method for preparing magnetic nanometer composite material of a nickel-zinc ferrite (Ni1-xZnxFe2O4) wrapping carbon nano tube, which comprises the following steps: (1) weighing the carbon nano tube to put into a three-necked flask, adding strong oxidizing property acid, and performing ultrasonic dispersion; and (2) dispersing the carbon nano tube after the acidizing process inside glycol solution at a room temperature, weighing malysite, zinc salt and nickel salt to dissolve inside the solution, adding polyethyleneglycol after the mixture dissolves completely and sodium acetate anhydrous to be stirred mechanically, putting the mixture after complete dissolution inside a high pressure reaction kettle, cooling the kettle to the room temperature, washing and collecting products, and drying the products. The method has simple preparation technique, low requirement on the production equipment, and easy industrial production. The prepared magnetic nanometer composite material has pure crystalling phase, good dispersibility, poor agglomeration, high intensity of magnetization and high magnetic induction sensitivity.

Owner:DONGHUA UNIV

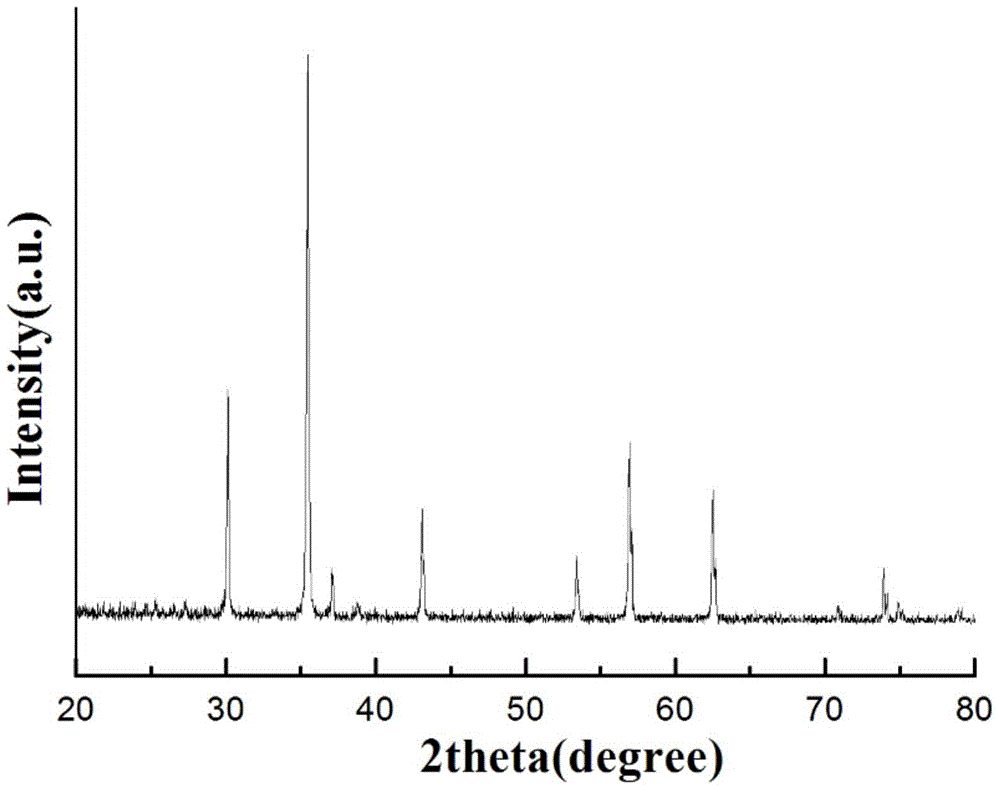

Nickel zinc ferrite powder and preparation method thereof

The invention belongs to a material preparation technology, and relates to nickel zinc ferrite powder and a preparation method thereof. The expression of the nickel zinc ferrite powder is NixZn1-xFe2O4, wherein x is equal to 0.5-0.7. The preparation method comprises the following steps of: taking analytically pure iron nitrate, zinc nitrate and nickel nitrate according to a stoichiometric ratio of NixZn1-xFe2O4, simultaneously dissolving in de-ionized water, adding a certain amount of citric acid, and uniformly dispersing by using equipment such as a magnetic stirrer to obtain brown yellow mixed solution; heating the mixed solution under a certain temperature condition until a solvent is evaporated to dryness to form a brown ash-shaped material; filling the brown ash-shaped material in a muffle furnace and sintering under a certain temperature condition to obtain black sinter; and finally crushing the black sinter in a ball mill or other grinding equipment to certain particle size and sieving. The preparation process is simple and is easy to realize; and the prepared nickel zinc ferrite powder has better magnetic permeability and lower dielectric constant at the frequency band of 2GHz-4GHz and has lower density.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

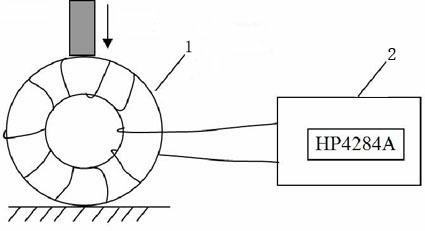

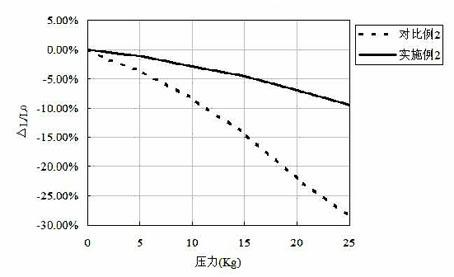

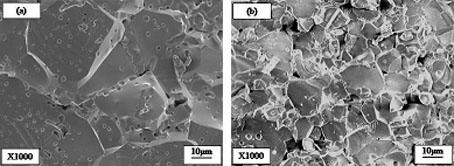

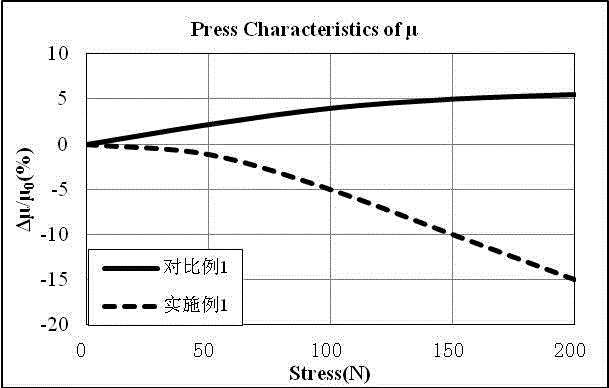

Stress-resistant nickel zinc ferrite with initial permeability of 120, and preparation method of stress-resistant nickel zinc ferrite

The invention relates to a stress-resistant nickel zinc ferrite which has the initial permeability of 120 and is applicable to a power inductor and a preparation method of the stress-resistant nickel zinc ferrite. The stress-resistant nickel zinc ferrite comprises the main components based on respective reference substance: 46.5-50mol% of ferric oxide (Fe2O3), 20-25mol% of nickel oxide (NiO), 20-25mol% of zinc oxide (ZnO) and 9-12mol% of copper oxide (CuO); and the nickel zinc ferrite comprises the accessory ingredient by respective reference substance: 0.1-0.3wt% of calcium carbonate (CaCO3), 0.035-0.10wt% of cobalt oxide (Co2O3), 0.05-0.45wt% of bismuth oxide (Bi2O3), 0.1-1.0wt% of talcum powder and 0.1-1.0wt% of mica powder. The stress-resistant nickel zinc ferrite is prepared by an oxide method and is sintered under a certain condition. After sintering, the product has the crystallized grain size of 20-30mu m, has obvious crystal boundary, and has the characteristic of less inductance change under the stress action, thus meeting the requirement of the power inductor needed to be packaged by resin on the stress resistance of the ferrite material.

Owner:TDG HLDG CO LTD

A kind of nickel-zinc-copper soft ferrite and preparation method thereof

InactiveCN102262950AHigh initial permeabilityHigh densityInorganic material magnetismInitial permeabilitySecondary component

The invention provides a nickel-zinc-copper soft ferrite and a preparation method thereof. The nickel-zinc-copper soft ferrite includes main components and auxiliary components, and the main components are iron oxide, nickelous oxide, zinc oxide, oxide Copper, characterized in that the content of the main components is as follows: iron oxide 65.05wt-66.35wt%; zinc oxide 20.66wt-22.20wt%; nickelous oxide 9.55wt-10.06wt%; copper oxide 2.91wt-3.17wt% ; The secondary component includes tungsten trioxide, and the content of the tungsten trioxide is 0.003wt-0.03wt%. The electromagnetic properties of the material in the invention reduce the loss performance of the product under the premise of maintaining high initial magnetic permeability and saturation magnetic flux density.

Owner:BYD CO LTD

Power type nickel-zinc ferrite material and preparation method thereof

ActiveCN106587977AThe preparation method is simple and easyEasy to operateInorganic material magnetismNickel-zinc ferriteZinc

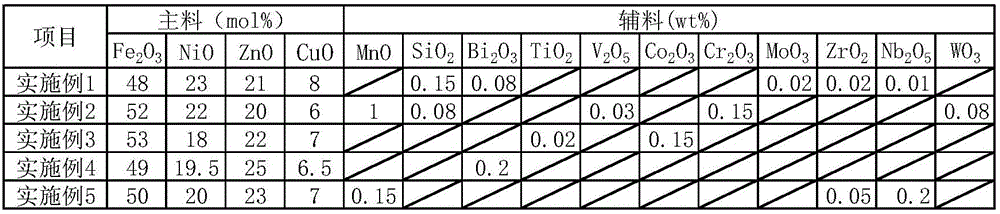

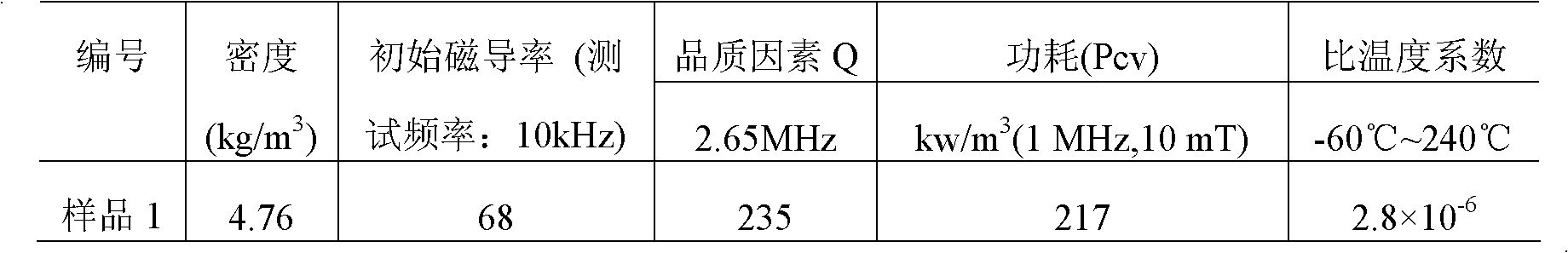

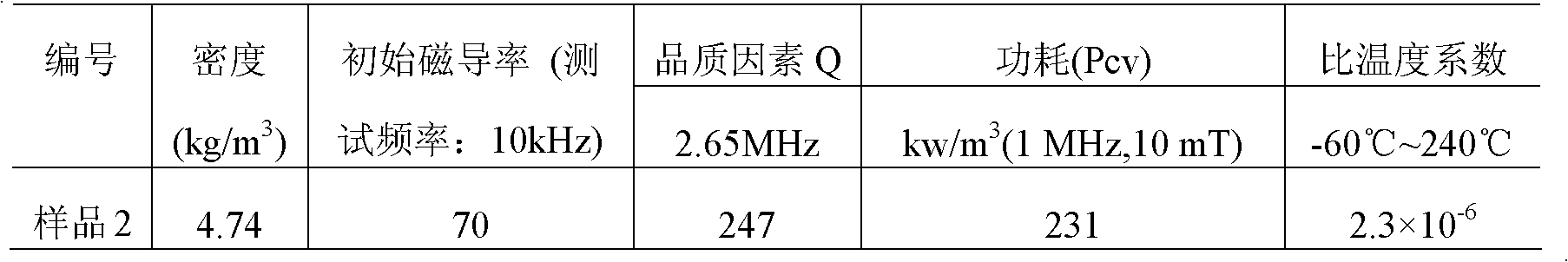

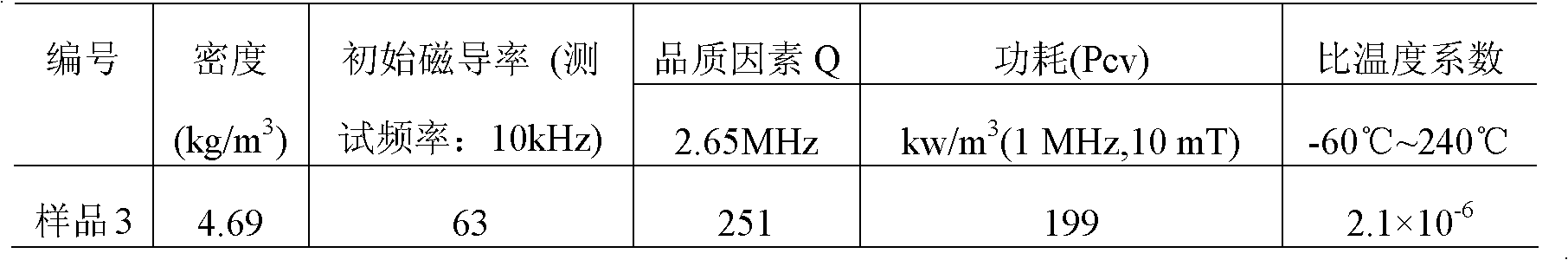

The invention discloses a power type nickel-zinc ferrite material. The power type nickel-zinc ferrite material is prepared from a main material and an auxiliary material. The main material is prepared from, by molar percentage, 48-53 mol% of Fe2O3, 18-23 mol% of NiO, 20-25 mol% of ZnO and 6-8 mol% of CuO. The auxiliary material is selected from at least one of MnO, SiO2, Bi2O3, TiO2, V2O5, Co2O3, Cr2O3, MoO3, ZrO2, Nb2O5 and WO3. The power type nickel-zinc ferrite material has high magnetic conductivity, ultrahigh saturation flux density, ultralow power loss and high high-temperature-resisting soldering tin temperature, and the application range of the nickel-zinc ferrite material can be widened. The invention further provides a preparation method of the power type nickel-zinc ferrite material. The preparation method is simple in step, high in operability and suitable for industrial production.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Special nickel-zinc ferrite material for integrated high frequency electrodeless discharge lamp inductive coupler and preparation method

The invention discloses a special nickel-zinc ferrite material for integrated high frequency electrodeless discharge lamp inductive coupler and a preparation method. The principal phase of the nickel-zinc ferrite material is spinel structure comprising Fe2O3, ZnO, NiO and Co2O3, wherein the composing and content are calculated in oxides comprising: Fe2O3 48mol%-56mol%, ZnO 15mol%-22mol%, NiO 20mol%-33mol%, Co2O3 0.001mol%-0.004. The invention can prepare a novel nickel-zinc soft magnetic ferrite with ultra wide temperature, high stability and low electromagnetic loss in high frequency and high current by using suitable formula and appropriate technological parameter, and the nickel-zinc ferrite material can do normal work in high temperature. The invention is contribute to reduce the electromagnetic loss and heat of the high frequency electronic discharge lamp inductive coupler, so as to guarantee the normal and stable work and is good for miniaturizing of device, therefore the material has very wide market prospect in novel electrodeless discharge lamp lighting system.

Owner:JIAXING LONG KINGS LIGHTING SCI & TECH

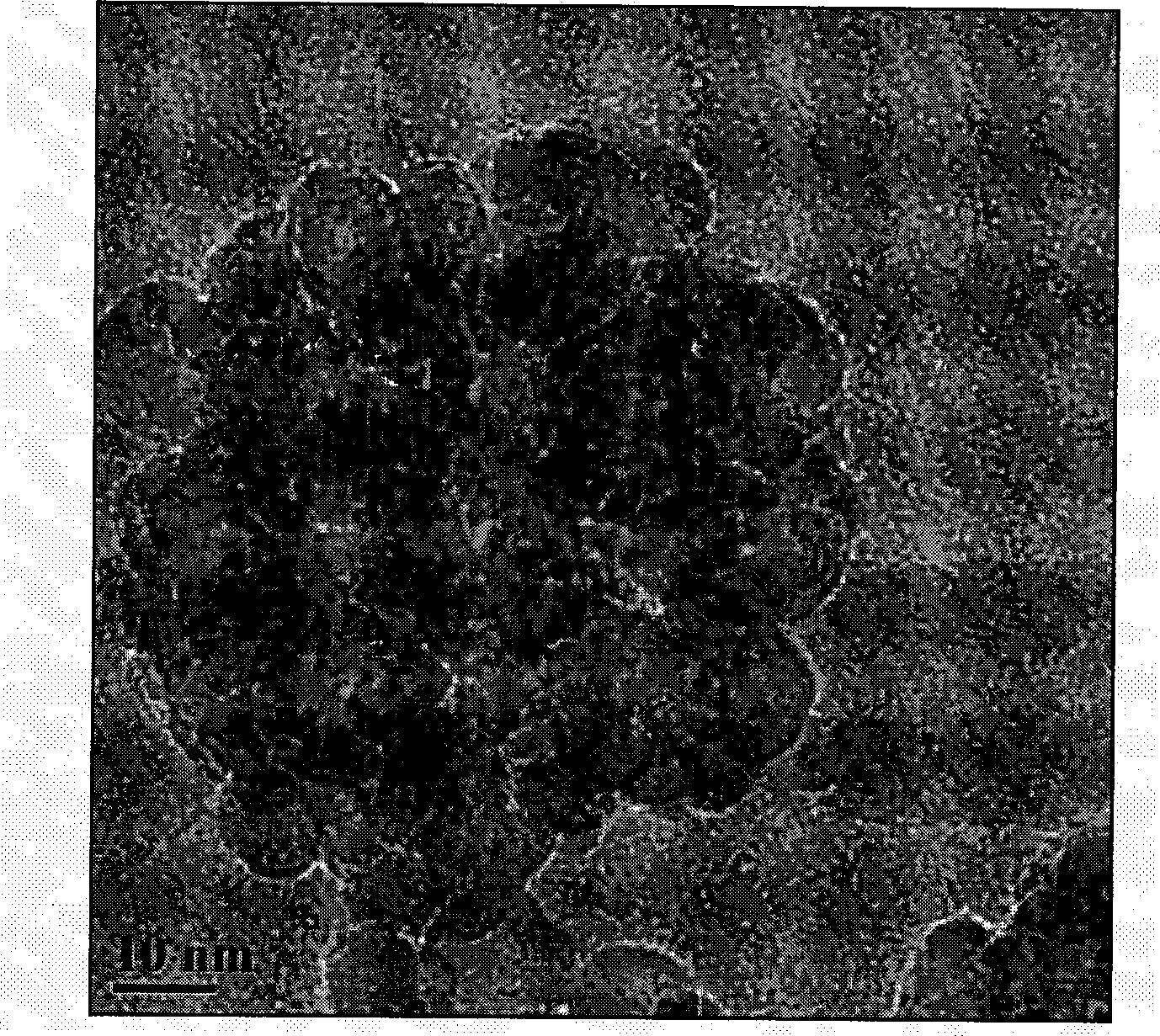

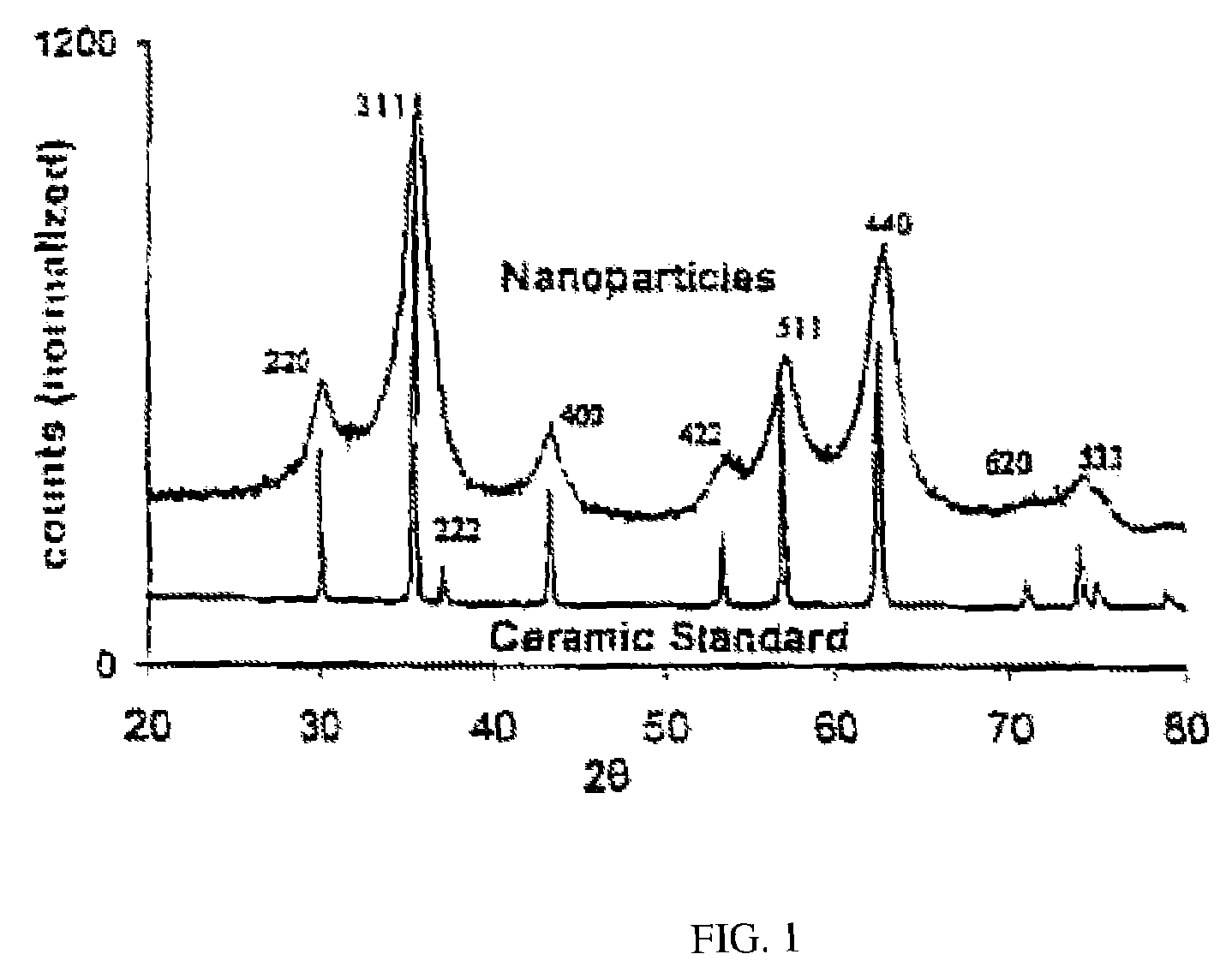

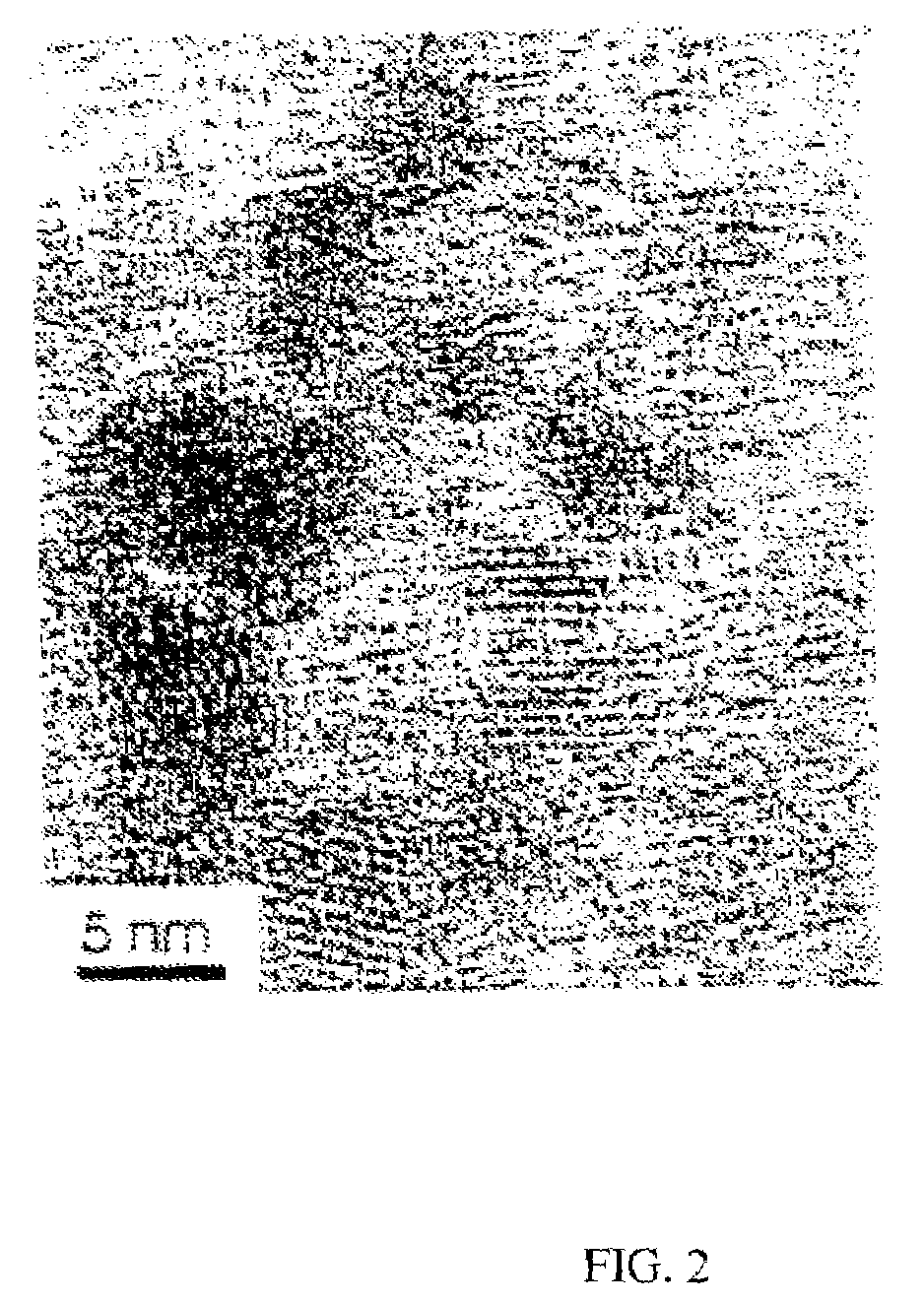

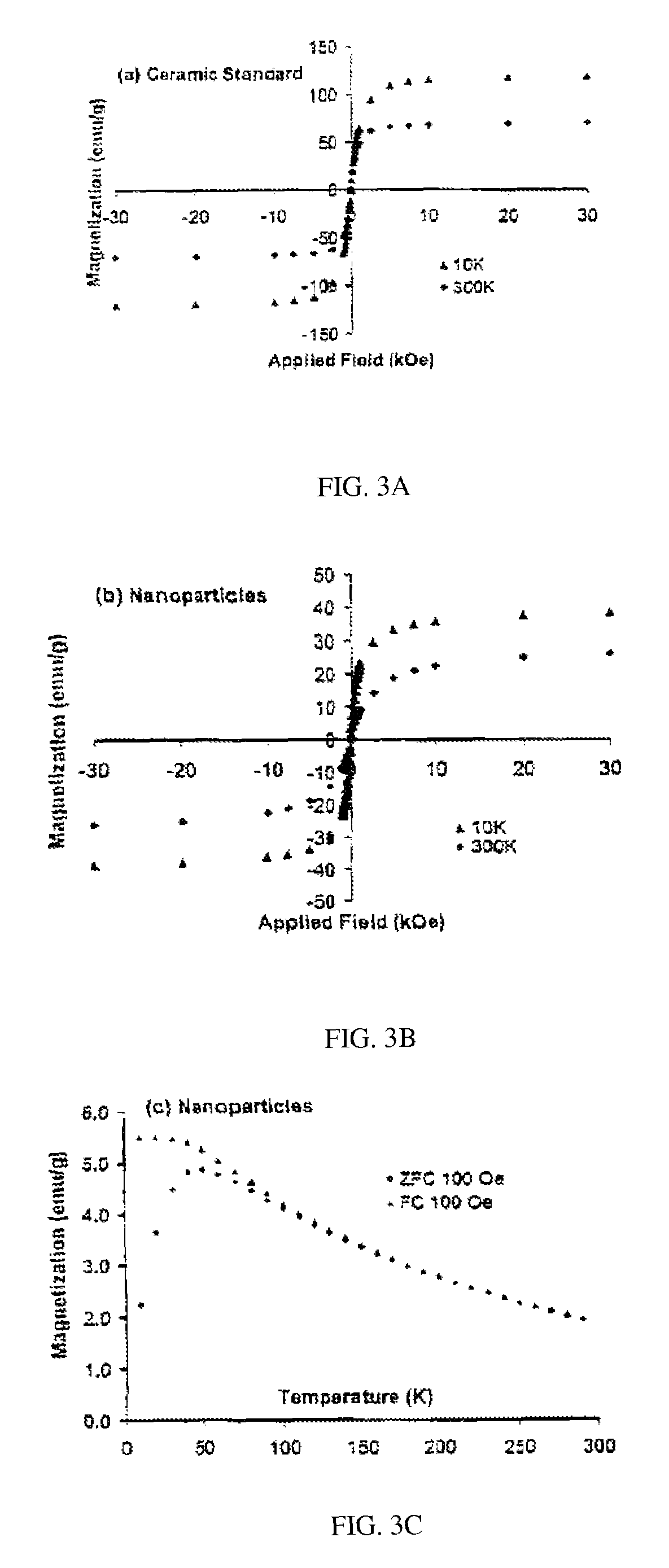

Nanoparticle nickel zinc ferrites synthesized using reverse micelles

InactiveUS7547400B1Small sizeEasy to packMaterial nanotechnologyIron compoundsNickel-zinc ferriteMagnetite Nanoparticles

A method for making monodispersed magnetic nanoparticles of nickel zinc ferrite (NZFO) at room temperature by mixing together two micelle solutions. The first micelle solution comprises zinc, nickel, and iron metal salts; a surfactant; and a hydrocarbon. The second micelle solution comprises an aqueous hydroxide, a surfactant, and a hydrocarbon. After mixing the two micelle solutions, the ferrite precipitates.

Owner:NAVY USA AS REPRESENTED BY THE SEC OF THE THE

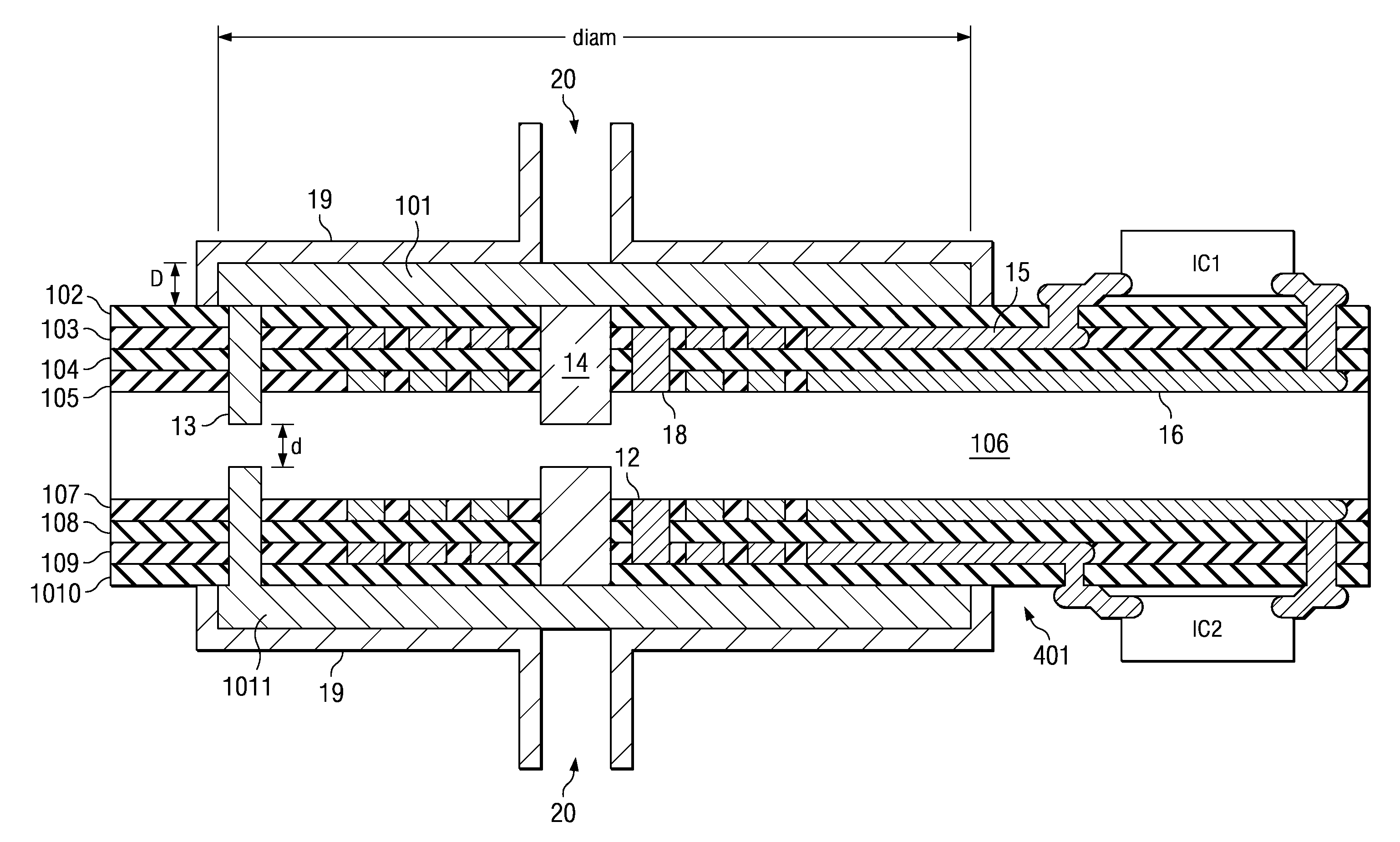

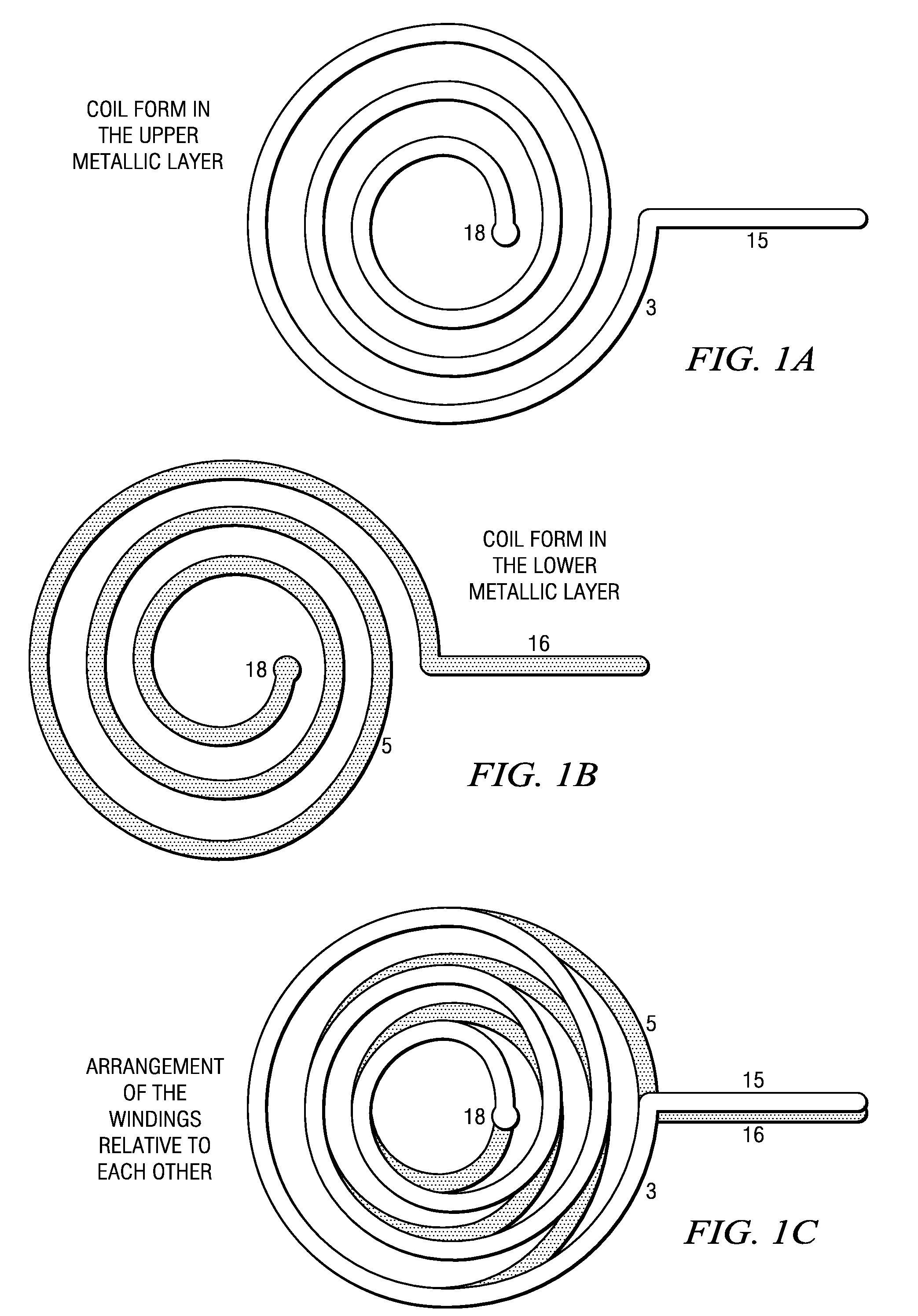

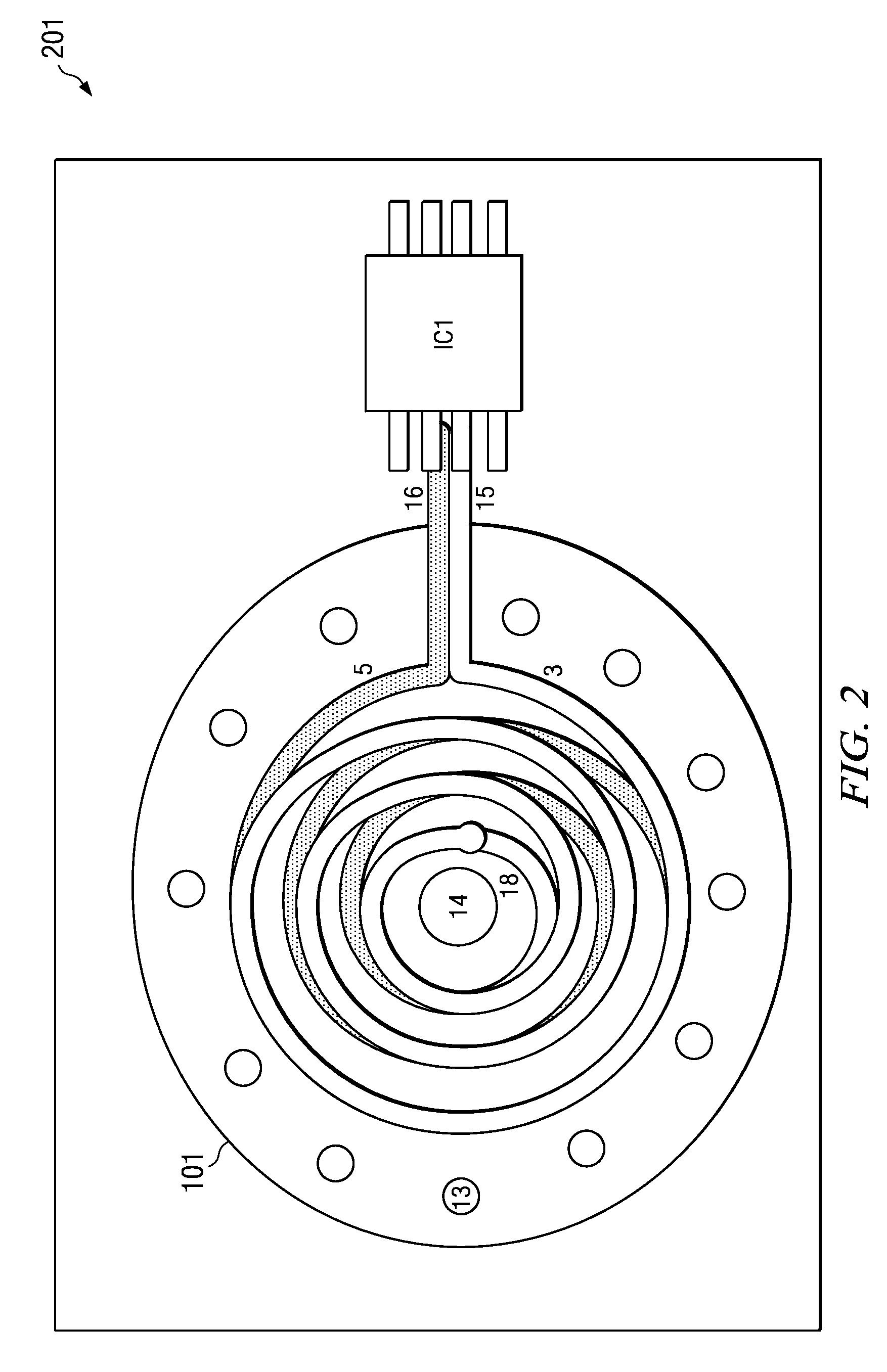

Method of constructing inductors and transformers

An embodiment of the invention relates to an apparatus including a magnetic device and a related method. A multilayer substrate is constructed with a winding formed in a metallic layer, an electrically insulating layer above the metallic layer, and a via formed in the electrically insulating layer to couple the winding to a circuit element positioned on the multilayer substrate. A depression is formed in the multilayer substrate, and a polymer solution, preferably an epoxy, containing a ferromagnetic component such as nanocrystaline nickel zinc ferrite is deposited within a mold positioned on a surface of the multilayer substrate above the winding and in the depression. An integrated circuit electrically coupled to the winding may be located on the multilayer substrate. The multilayer substrate may be a semiconductor substrate or a printed wiring board, and the circuit element may be an integrated circuit formed on the multilayer substrate.

Owner:INFINEON TECH AUSTRIA AG

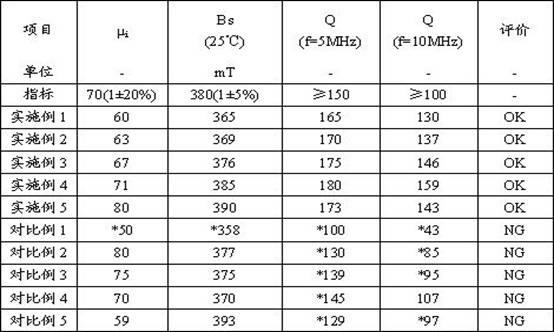

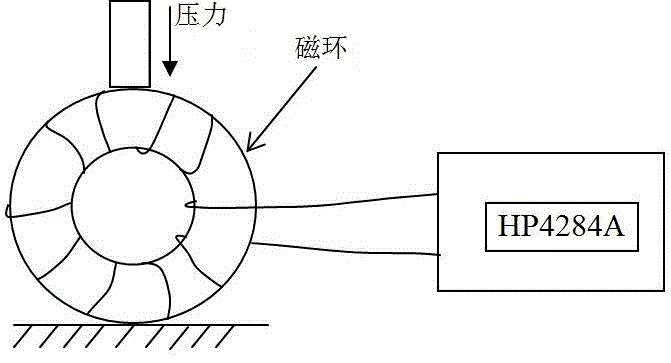

High-Q value nickel and zinc ferrite with initial permeability of 70 and preparation method thereof

The invention relates to high-Q value nickel and zinc ferrite with the initial permeability of 70 and a preparation method thereof, which are suitable for a power inductor. The nickel and zinc ferrite comprises the following main ingredients calculated by the oxide: 47.0-49.0mol% of Fe2O3, 25.1-28.5mol% of NiO, 16.3-20.5mol% of ZnO, 4.3-7.5mol% of CuO, and also comprises the following auxiliary components: 0.1-0.2wt% of CaCO3, 0.8-1.3wt% of SiO2, 2-7wt% of LiFe5O8, 0.3-0.6wt% of Co2O3 and 0.8-1.3wt% of Bi2O3. The high-Q value nickel and zinc ferrite is prepared with an oxide method and is sintered under certain condition. The sintered product has the characteristics of high Q value within the high-frequency range of 5-10MHz, and is suitable for the requirement of high frequency and low loss of the ferrite material by the power inductor.

Owner:TDG HLDG CO LTD

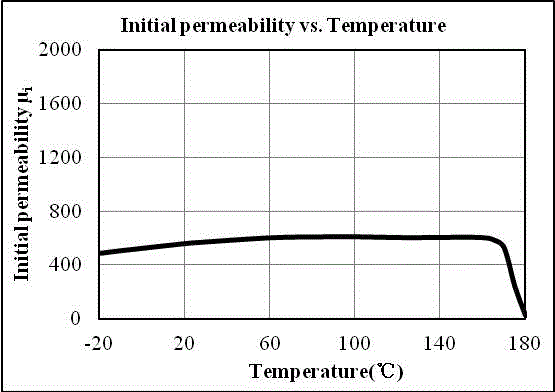

Low-temperature-factor anti-stress nickel zinc ferrite and preparation method thereof

The invention relates to low-temperature-factor anti-stress nickel zinc ferrite with initial permeability for a power inductor being 500 and a preparation method of nickel zinc ferrite. Principal components of the nickel zinc ferrite are calculated in oxides as follows: 43.8 to 48.2 percent by mol of Fe2O3, 15.3 to 20.2 percent by mol of NiO, 28.8 to 31.2 percent by mol of ZnO, and 4.3 to 6.1 percent by mol of CuO; auxiliary components of the nickel zinc ferrite are: 0.90 to 1.3 percent by weight of nano SiO2, 0.13 to 0.25 percent by weight of nano Bi2O3, 0.05 to 0.08 percent by weight of Co3O4, 0.10 to 0.25 percent by weight of TiO2 and 0.1 to 0.45 percent by weight of talcum powder. The nickel zinc ferrite is prepared in an oxide method and sintered under certain conditions. The average size of crystal grains of a sintered product is 25 to 35 micrometers, the sintered product has an obvious crystal interface, the product has characteristics that the magnetic permeability is relatively small in variation in the temperature range of -40DEG C to 125 DEG C under the stress effect, and the requirement of the power inductor needing the resin encapsulation for the stress resistance of the ferrite material can be met.

Owner:TDG HLDG CO LTD

Magnetic powder core in-situ preparation method

InactiveCN103440950AEasy to manufactureUniform sizeInorganic material magnetismNanoparticleMagnetization

The invention relates to a magnetic powder core in-situ preparation method. Nanometer ferrite particles with uniform particle sizes are prepared on the surface of a magnetically soft alloy powder surface with a sol-gel method in an in-situ manner, and the pressing and heat treatment processes are adopted to prepare a novel ferrite composited magnetic powder core. The magnetic powder core in-situ preparation method has the advantages that: (1) the sol-gel method is adopted to prepare the Mn-Zn and Ni-Zn ferrite in an in-situ manner, so as to prepare the nanometer particles with uniform and controllable sizes conveniently; (2) the ferrite used as the insulation cladding agent of the magnetically soft alloy powder can overcome the disadvantage that the magnetic property of the base body is reduced when being clad by the traditional non-magnetic substances as the cladding agent, thereby acquiring high magnetic conductivity and saturation magnetization.

Owner:CHINA JILIANG UNIV

Preparation method of nickel-zinc ferrite/polyaniline composite material

The invention discloses a preparation method of a nickel-zinc ferrite / polyaniline composite material. The preparation method comprises the following steps: respectively weighing nickel nitrate, zinc nitrate and ferric nitrate in a stoichiometric ratio of 3:2:10 of Ni<2+>:Zn<2+>:Fe<3> in Ni0.6Zn0.4Fe2O4, adding distilled water, and mixing and dissolving under a magnetic stirring condition; dropwise adding a NaOH solution to an obtained mixing solution, regulating pH to 9-11, reacting under a water bath condition until the solution is in a colloidal form; repeatedly centrifuging and washing through distilled water and absolute ethyl alcohol to obtain a brown precipitate; drying the precipitate in an oven at 80-100 DEG C to obtain a ferrite precursor; calcining in a muffle for 2-2.5 hours at 900-1100 DEG C and naturally cooling to obtain the required nickel-zinc ferrite. Processability, stability and electric performance of the material disclosed by the invention are better improved.

Owner:NANJING UNIV

Preparation method for carbon-coated Ni-Zn-Fe magnetic nanometer material taking chitosan as carbon source

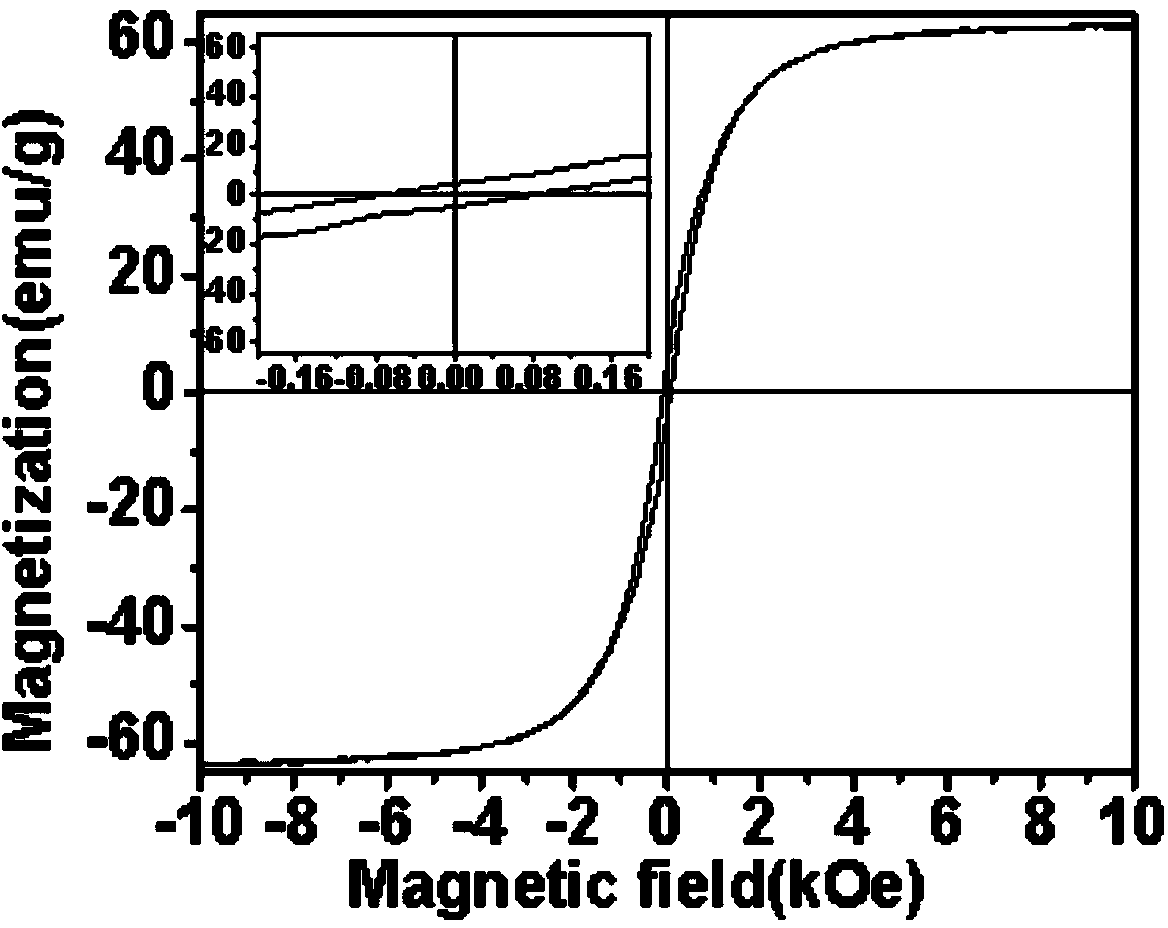

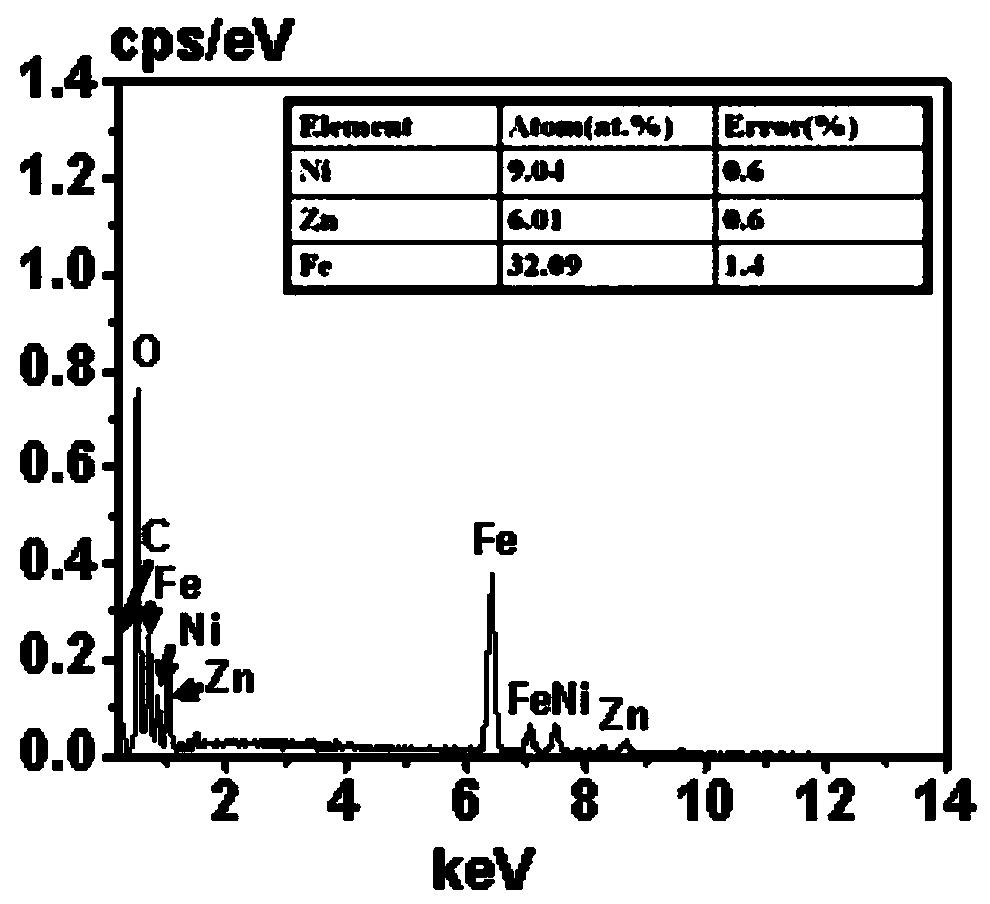

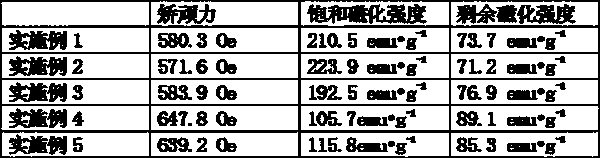

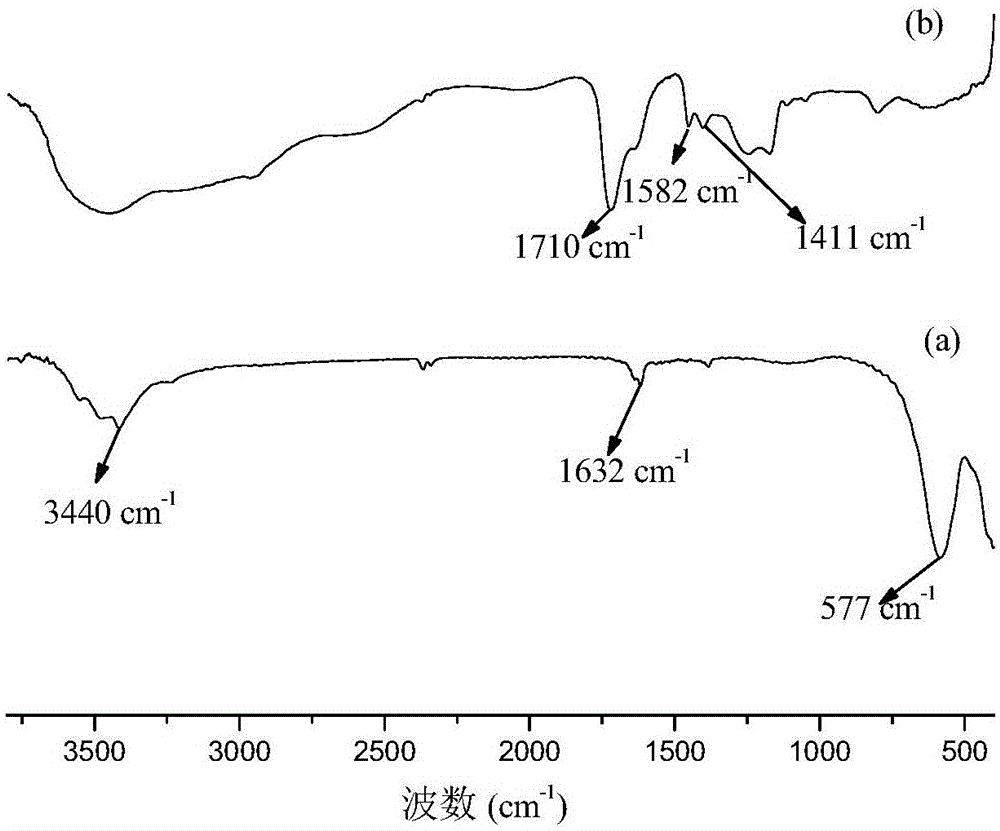

InactiveCN103632793AHigh saturation magnetizationSimple and fast operationMagnetic materialsNickel-zinc ferriteMagnetite Nanoparticles

The invention discloses a preparation method for carbon-coated Ni-Zn-Fe magnetic nanometer material taking chitosan as a carbon source. The method comprises the steps that Ni0.6Zn0.4Fe2O4 magnetic nanometer particles are prepared by adopting co-precipitation method, sodium dodecyl benzene sulfonate is used as surfactant to modify the surface of the nickel zinc ferrite, the Ni0.6Zn0.4Fe2O4 magnetic nanometer particles are subjected to in-situ coating by chitosan, meanwhile the emulsion cross-linking method is adopted for carrying out surface modification on the magnetic nanometer particles, and finally, the chitosan-coated nickel zinc ferrite is subjected to high-temperature hydrogen gas reduction, so that the carbon-coated Ni-Zn-Fe magnetic nanometer material is obtained. The magnetic nanometer material has higher saturation magnetization, lower coercive force and residual magnetization, and has important scientific significance and good application value on the further modified preparation of materials such as magnetic resonance imaging contrast agent, bioanalysis and drug carrier, hyperthermia medium, catalyst, magnetic recording and magnetic separation medium.

Owner:NANCHANG HANGKONG UNIVERSITY +1

Nickel-zinc ferrite/polyacrylic acid nano-composite material and preparation method thereof

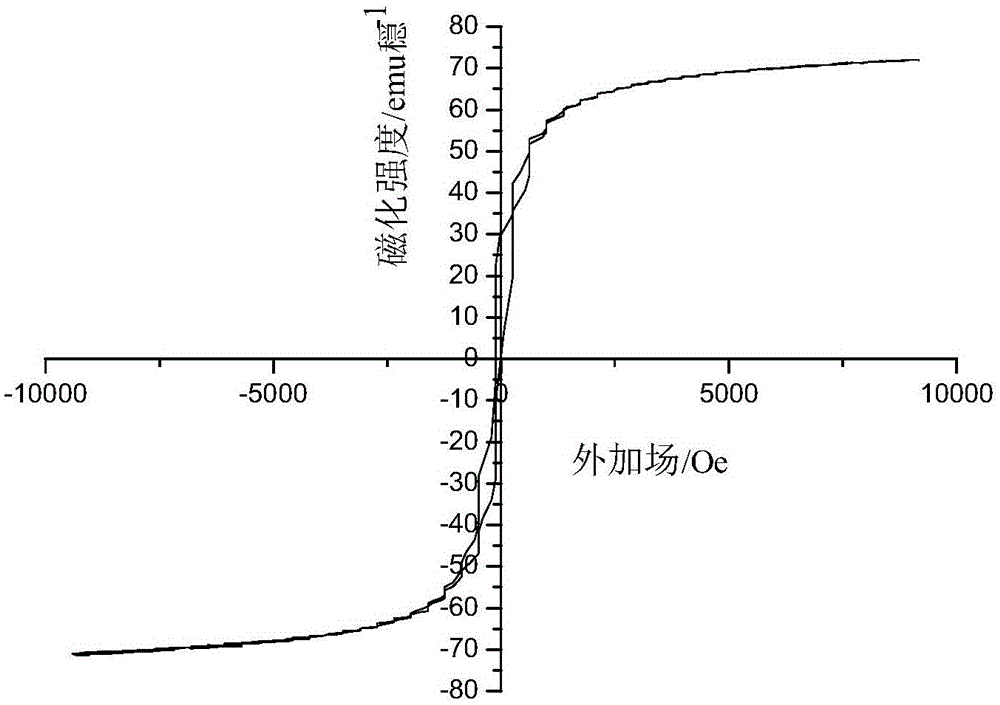

ActiveCN105161246ACore-shell structureObvious hysteresisInorganic material magnetismOrganic/organic-metallic materials magnetismNano compositesNickel-zinc ferrite

The invention discloses a nickel-zinc ferrite / polyacrylic acid nano-composite material and a preparation method thereof. The nano-composite material is in a core-shell structure and comprises core nickel-zinc ferrite and shell polyacrylic acid; the shell polyacrylic acid coats the nickel-zinc ferrite; and the nano-composite material is represented by Ni0.1-1Zn0.1-1Fe1-3O2-6 / PAA. The preparation method of the nano-composite material mainly comprises the following steps: (1) weighing zinc sulfate, ferrous sulfate and nickel sulfate to prepare a metal salt solution, adding the metal salt solution into an ammonium oxalate solution; (2) adjusting the pH of the mixed solution, and separating and drying the mixed solution to obtain a ferrite precursor; (3) burning the ferrite precursor to obtain the nickel-zinc ferrite; and (4) mixing and reacting the nickel-zinc ferrite and acrylic acid, and separating and drying the mixture to obtain the nickel-zinc ferrite / polyacrylic acid nano-composite material. The nickel-zinc ferrite / polyacrylic acid nano-composite material has the advantages of low specific saturated magnetic field intensity, relatively low coercive force and relatively high soft magnetic property; and the preparation method disclosed by the invention is simple, feasible and low in cost.

Owner:YANCHENG INST OF TECH

Composite fireboard with electromagnetic shielding function and preparation method thereof

ActiveCN105082314AWith electromagnetic shielding functionLight in massWood working apparatusDomestic articlesFiberAdhesive

The invention provides a composite fireboard with the electromagnetic shielding function and a preparation method of the composite fireboard. The composite fireboard is mainly prepared by compositing nickel zinc ferrite expanded graphite and wood fibers in mass ratio of 2-7: 3; the composite fiberboard is 2-5mm in thickness, and 0.7-1.0g / cm<3> in density. The preparation method comprises the following steps: respectively weighing the wood fibers and nickel zinc ferrite expanded graphite, and uniformly mixing to obtain a first mixture; adding a certain amount of isocyanate adhesives to the first mixture, and uniformly stirring to obtain raw materials for being pressed to prepare the board, wherein the dosage of the isocyanate adhesives is 8 to 16% of the total mass of the wood fibers and nickel zinc ferrite expanded graphite; uniformly paving the obtained raw materials for being pressed to prepare the board, and then prepressing and thermally pressing to obtain the composite fireboard with the electromagnetic shielding function. According to the composite fireboard, the electromagnetic shielding effect can be more than 50dB averagely within the range from 0.3 to 1500MHz, and the bandwidth is 11-17GHz when the electromagnetic wave reflection coefficient reaches -5dB within the range from 2 to 18GHz.

Owner:GUANGXI UNIV

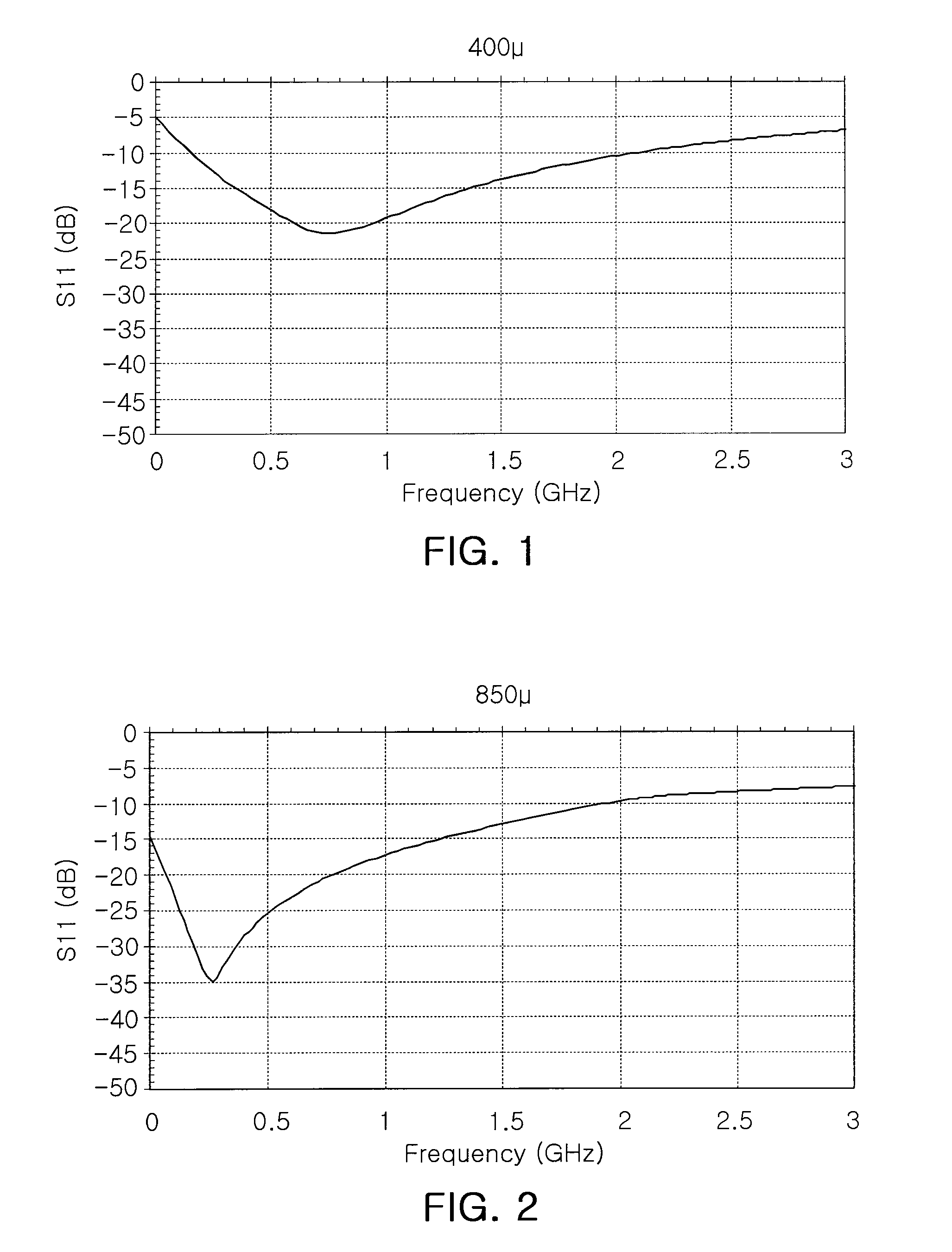

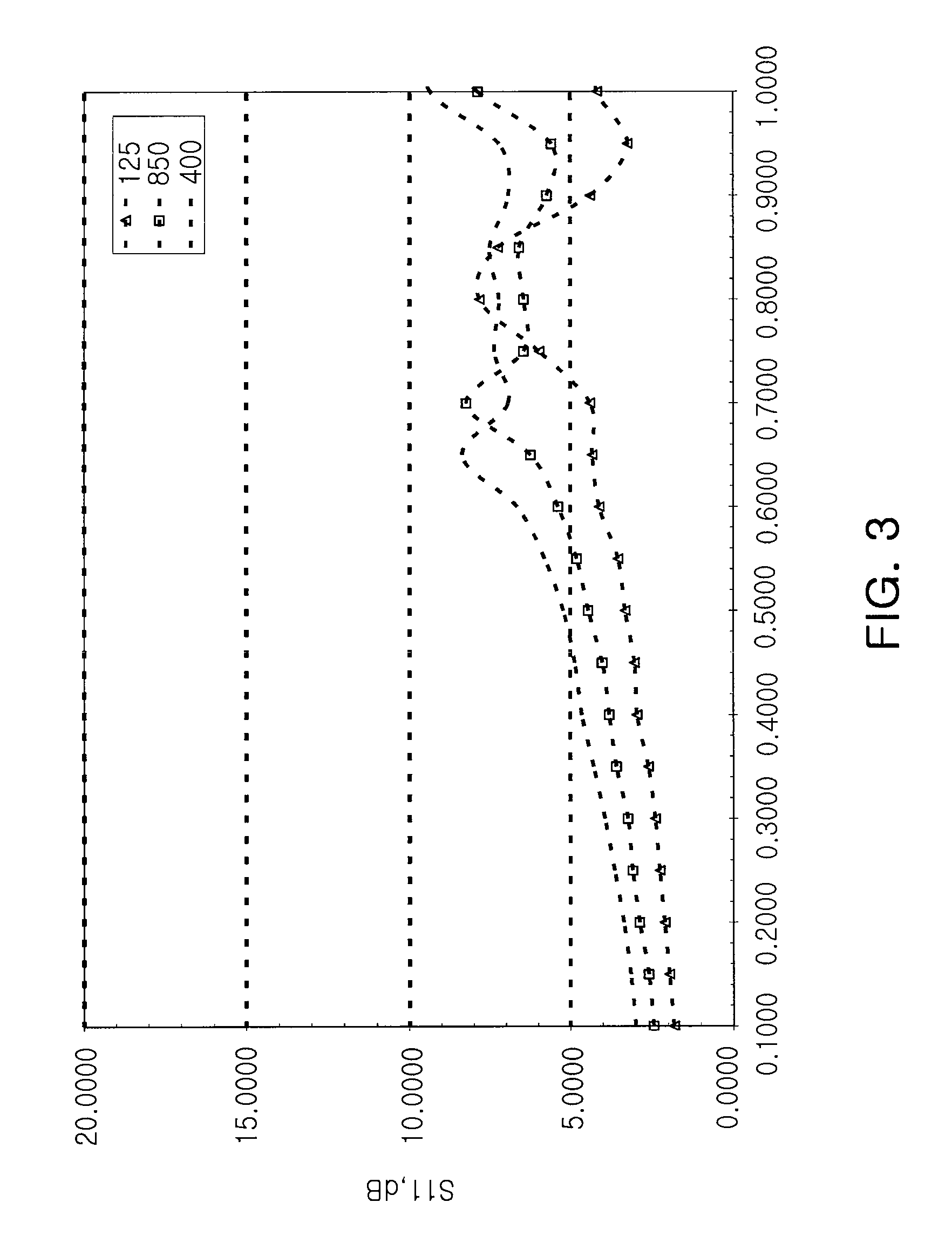

Compositions and materials for electronic applications

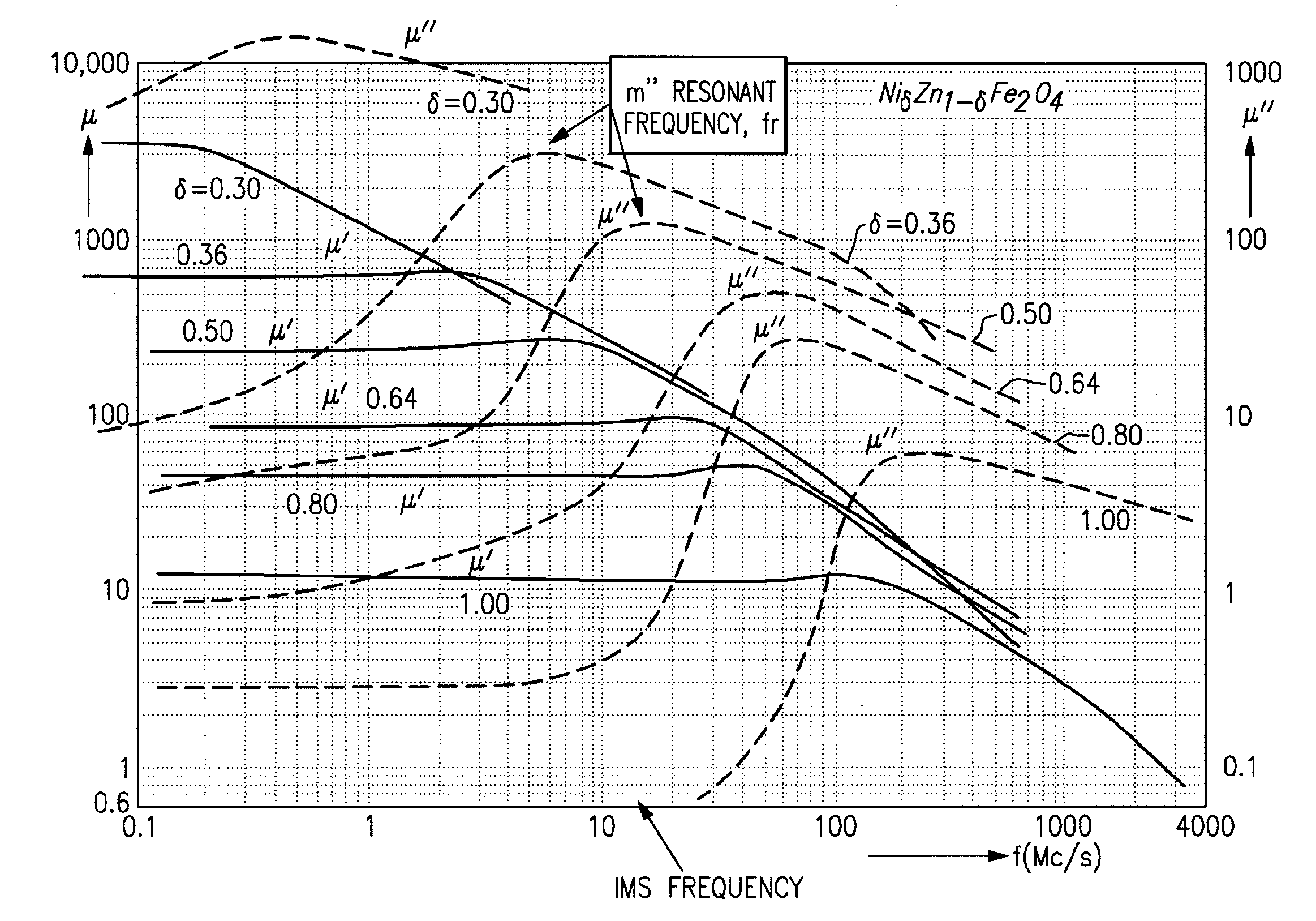

InactiveUS20120068103A1Improve material performanceFavorable Q factorInorganic material magnetismIron compoundsISM bandNickel-zinc ferrite

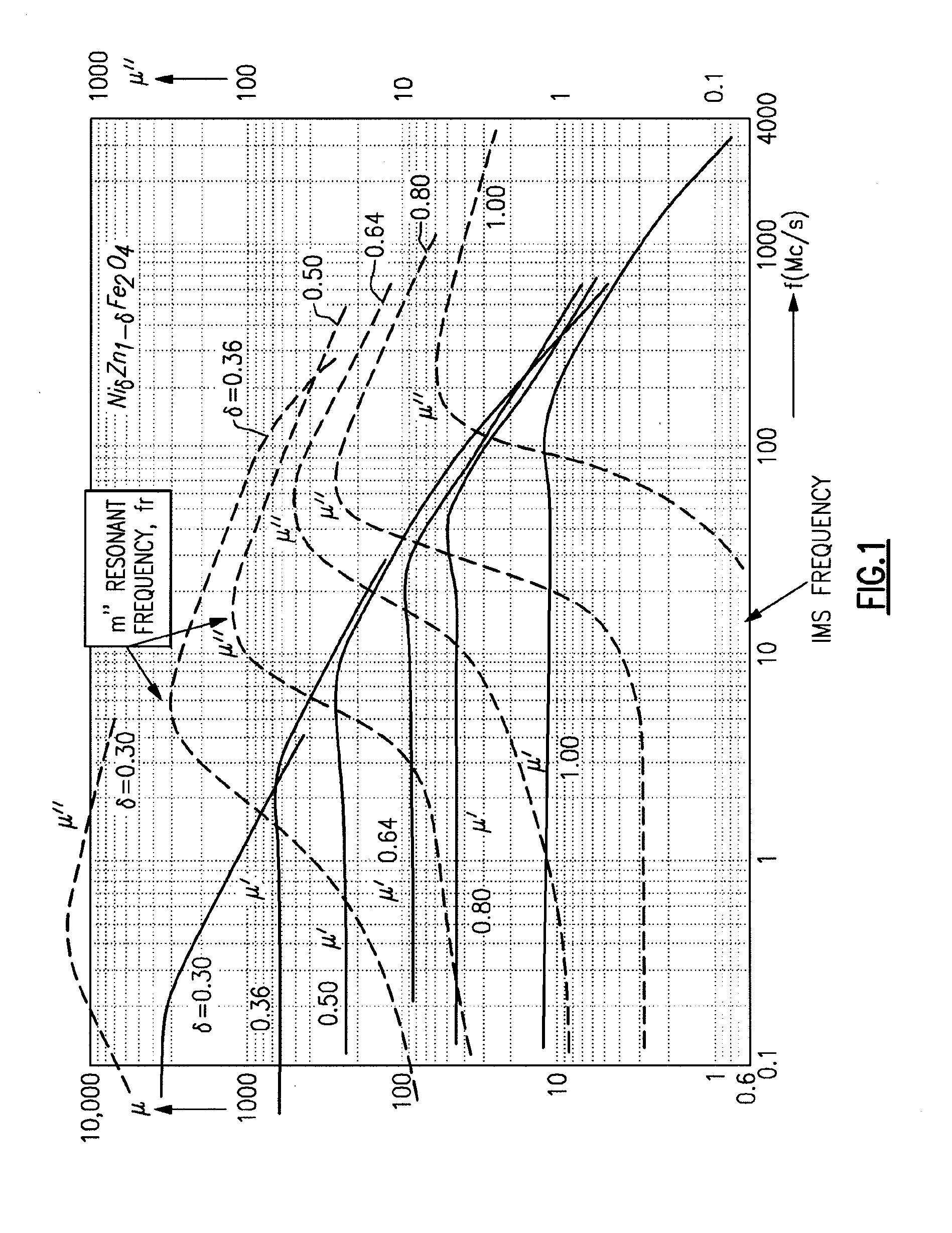

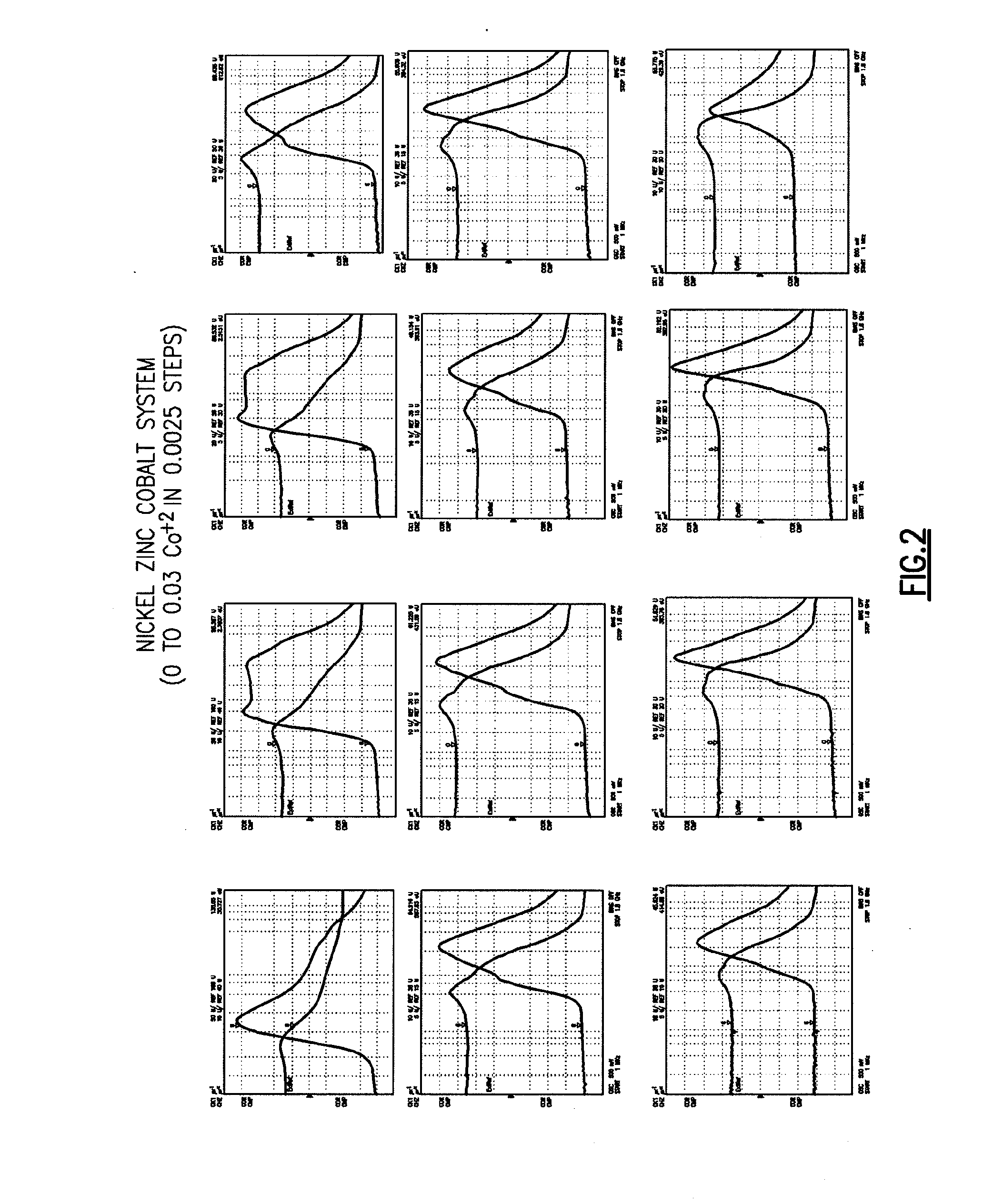

Embodiments disclosed herein relate to using cobalt (Co) to fine tune the magnetic properties, such as permeability and magnetic loss, of nickel-zinc ferrites to improve the material performance in electronic applications. The method comprises replacing nickel (Ni) with sufficient Co+2 such that the relaxation peak associated with the Co+2 substitution and the relaxation peak associated with the nickel to zinc (Ni / Zn) ratio are into near coincidence. When the relaxation peaks overlap, the material permeability can be substantially maximized and magnetic loss substantially minimized. The resulting materials are useful and provide superior performance particularly for devices operating at the 13.56 MHz ISM band.

Owner:ALLUMAX TTI LLC

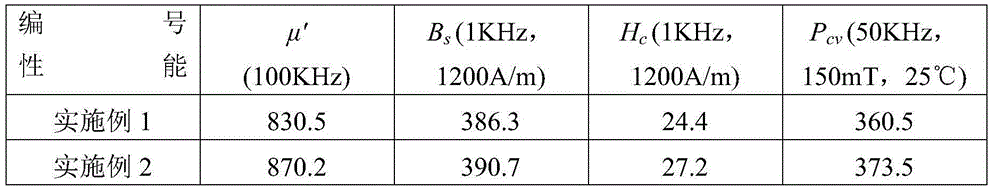

Nickel-zinc ferrite material and preparation method thereof

InactiveCN104909736AHigh saturation magnetic inductionImprove permeabilityNickel-zinc ferriteEngineering

The invention relates to a nickel-zinc ferrite soft-magnetic material for separating magnetic pieces of wireless charging transmitting terminal and receiving terminal coils, and a preparation method thereof. Raw materials of the nickel-zinc ferrite soft-magnetic material comprise a main component and an auxiliary component, and the main component comprises, by respective reference substances, 49.6-50.5mol% of Fe2O3, 12.5-13.5mol% of NiO, 29.2-32mol% of ZnO, and 7-9mol% of CuO. The auxiliary component comprises, by respective reference substances, 0.01-0.1wt% of MoO3 and 0.01-0.05wt% of Nd2O3. The nickel-zinc ferrite is prepared through a traditional oxide method; in a frequency region of 100-200KHz, the saturated magnetic induction intensity Bs is not smaller than 380mT, the coercive force Hc is not greater than 30A / m, and the magnetic permeability [mu]' is not smaller than 700 and not greater than 900; and the power loss Pcv of the material at normal temperature under 50KHz and 150mT is not smaller than 330mW / cc and not greater than 380Mw / cc.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

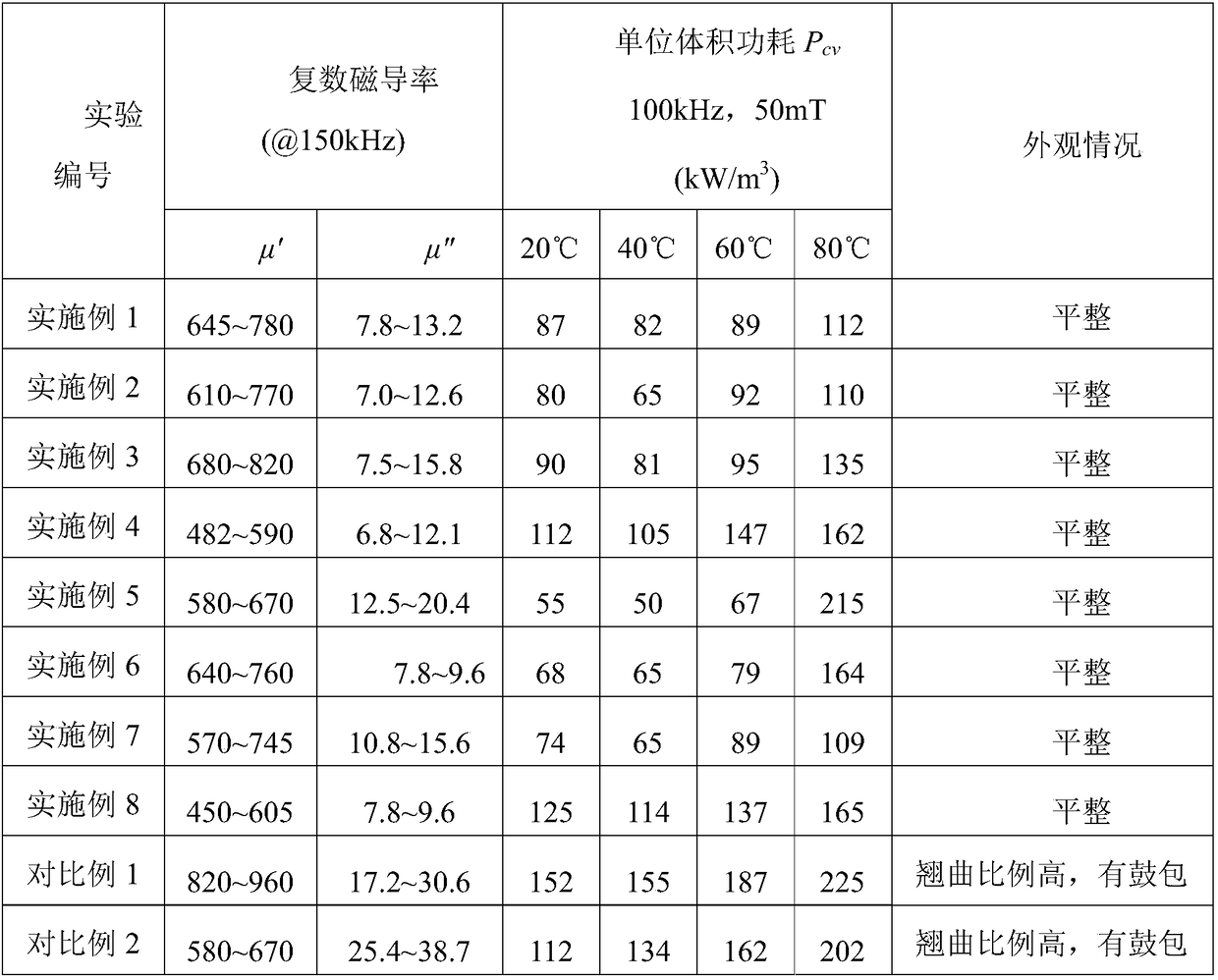

Nickel-zinc soft ferrite for wireless charging and preparation method and application thereof

ActiveCN108164260AImprove the sintering temperature rangeImprove magnetic propertiesInorganic material magnetismShrinkage rateNickel-zinc ferrite

The invention belongs to the field of soft ferrite, and discloses nickel-zinc soft ferrite for wireless charging and a preparation method and application thereof. The ferrite comprises a main component and a doping component, wherein the main component comprises Fe2O3, NiO, ZnO and CuO; the doping component at least comprises one of Nd2O3, Pr6O11, Gd2O3, Dy2O3, Tb2O3, Ho2O3 and Sm2O3; in terms ofthe weight of the main component, the Fe2O3 content of the main component is 64-67wt%, the NiO content thereof is 4-10wt%, the ZnO content thereof is 18-24wt% and the CuO content thereof is 3-9wt%; interms of the weight of the main component, the content of each doping component is 0.02-0.2wt%, and the total addition amount is smaller than or equal to 0.5wt%. Through improvement on the doping component of the nickel-zinc soft ferrite, a thin ferrite magnetic sheet product is sintered densely when T is equal to 0.05-0.2mm, the sintering temperature width is increased, the shrinkage rate is slow during sintering temperature rise, and the appearance is smooth; meanwhile, the power loss per unit volume of the magnetic sheet (power consumption) can be also effectively reduced, the working temperature rise of a wireless charging component can be reduced, and the transmission efficiency can be improved.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

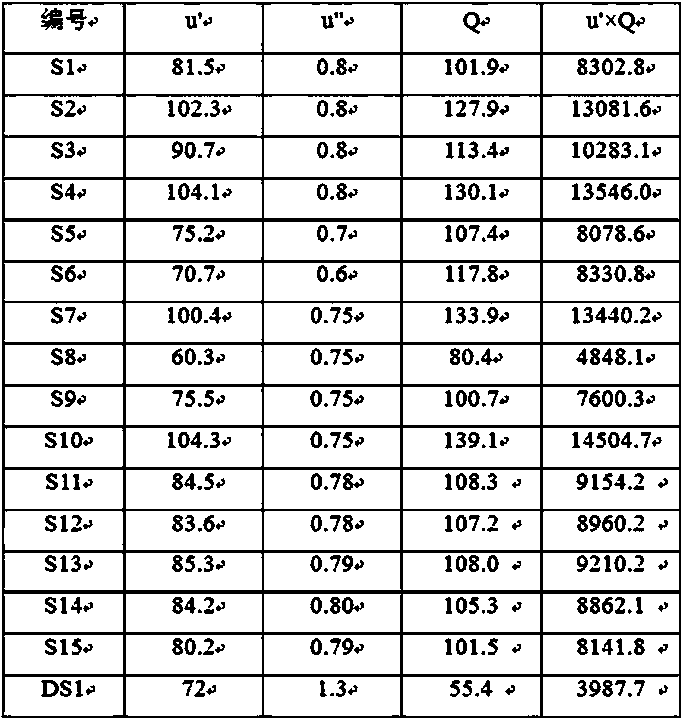

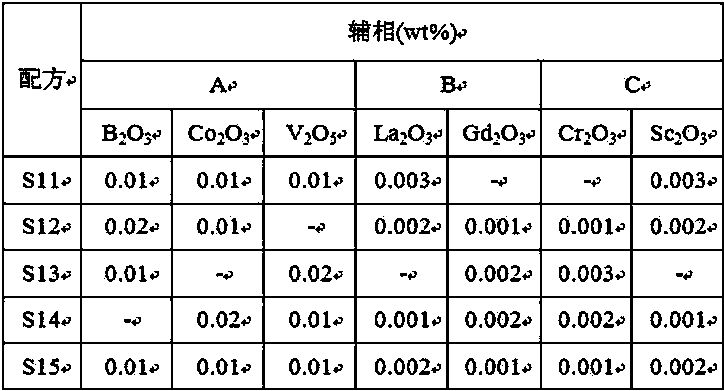

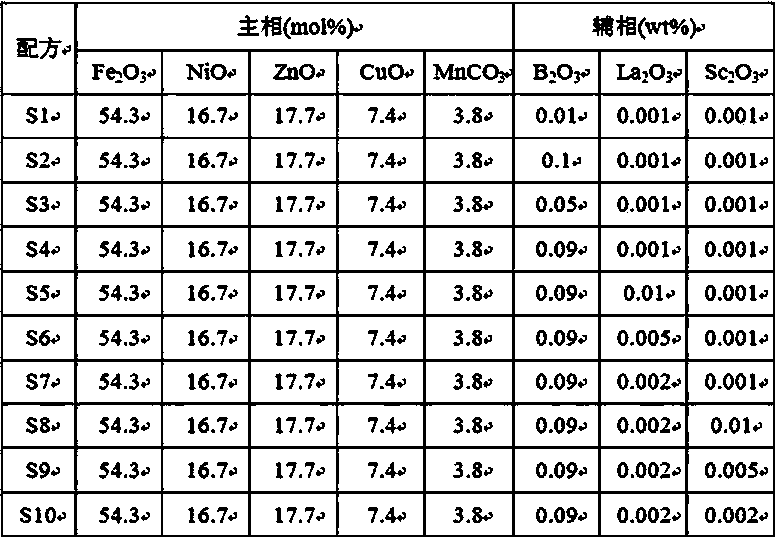

Nickel zinc ferrite soft magnetic material and preparation method thereof

The invention provides a nickel zinc ferrite soft magnetic material and a preparation method thereof. The nickel zinc ferrite soft magnetic material contains a main phase and an auxiliary phase, wherein based on the total molar weight of the nickel zinc ferrite soft magnetic material, the main phase contains the following components: 50-55mol% of Fe2O3, 15-25mol% of NiO, 15-25mol% of ZnO, 5-15mol% of CuO and 3-10mol% of MnCO3; based on the total mass of the nickel zinc ferrite soft magnetic material, the auxiliary phase contains the following components: 0.01-0.1wt% of A, 0.001-0.01wt% of B and 0.001-0.01wt% of C; A is one or more of Co2O3,B2O3 and V2O5; B is one or two of La2O3 and Gd2O3; C is one or two of Cr2O3 and Sc2O3. The nickel zinc ferrite soft magnetic material provided by the invention simultaneously has higher magnetic permeability, quality factors and mu'*Q value in the frequency interval of 10-100MHZ and meets the application requirements of NFC (near field communication) and FRID (radio frequency identification).

Owner:BYD CO LTD

Preparation method of core-shell soft magnetic composite

InactiveCN108597717AReduce lossImprove adhesionInorganic material magnetismInductances/transformers/magnets manufactureNickel-zinc ferriteRoom temperature

The invention discloses a preparation method of a core-shell soft magnetic composite. The preparation method comprises the following steps of S1. preparing quantitative magnetic metal powder; S2. determining corresponding molar mass of a required metal element Mn or Ni, Fe and Zn according to a wrapping amount of a required Mn-Zn ferrite or Ni-Zn ferrite, and preparing a metal salt solution of thecorresponding molar mass; S3. adding deionized water to the magnetic metal powder of S1 and stirring, and heating to 30-80DEG C; S4. slowly dripping the metal salt solution of S2, stirring and dripping a precipitant at the same time, controlling pH at 9-11, reacting for 30-60 minutes to obtain alloy magnetic powder; S5. washing and drying the alloy magnetic powder; S6. sintering the dried alloy magnetic powder for 1-3 hours at 500-700DEG C, so as to obtain core-shell particles; and S7. pressing the core-shell particles at 1400Mpa at room temperature so as to obtain magnetic cores, and sintering for 1 hour at 600DEG C so as to obtain the core-shell soft magnetic composite. The prepared core-shell soft magnetic composite has good performance.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV +2

High-conductive nickel-zinc ferrite and preparing process thereof

InactiveCN1420101AImprove permeabilityIngredient Design ScienceInorganic material magnetismManganeseNickel-zinc ferrite

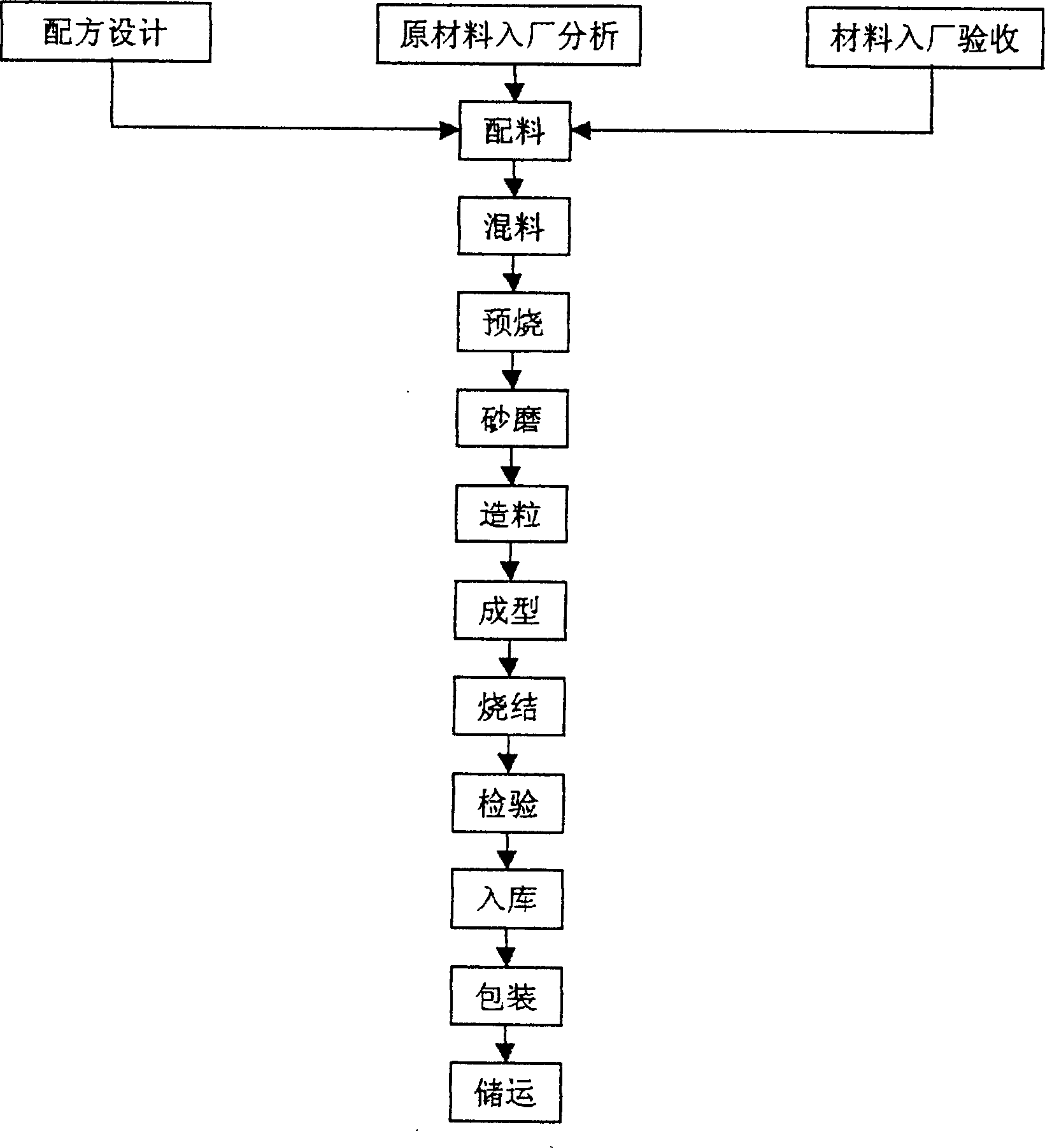

A high-conductivity Ni-Zn ferrite is prepared from iron oxide, neckelous oxide, zinc oxide, copper oxide, and manganese carbonate through proportional mixing, precalcining, sand grinding, granulating, shaping and sintering. Its advantages are high magnetic conductivity up to R3K, broad spectrum, high gain and reflection loss, and low insertion loss.

Owner:邓廷成

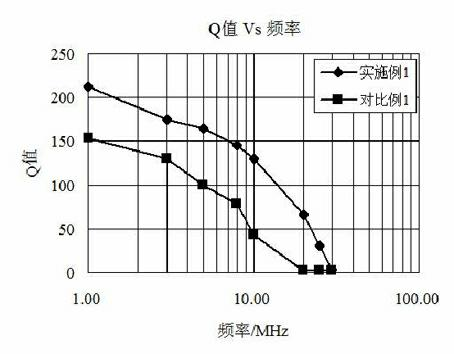

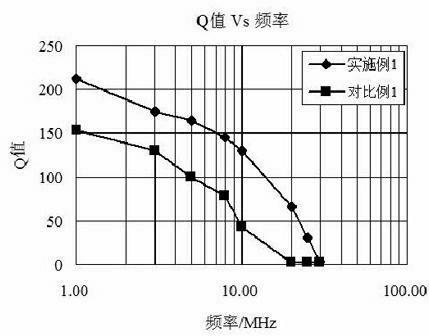

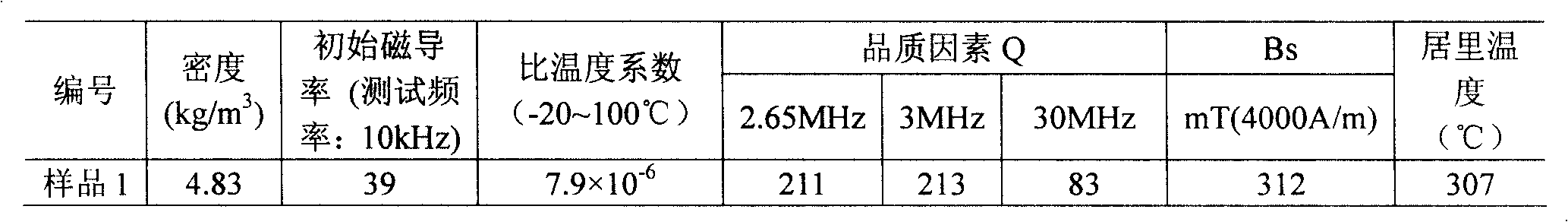

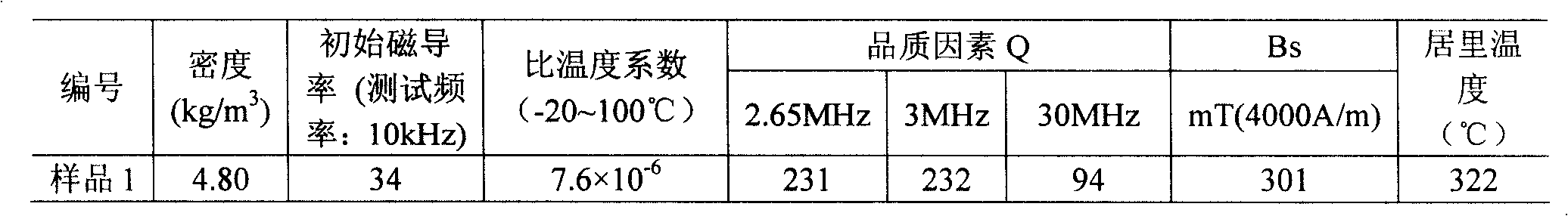

Initial magnetic-inductive capacity 40 (-8) (+8) nickel-zinc ferrite material and preparation method

InactiveCN101286397AReduce electromagnetic lossesReduce lossInorganic material magnetismNickel-zinc ferriteOxygen

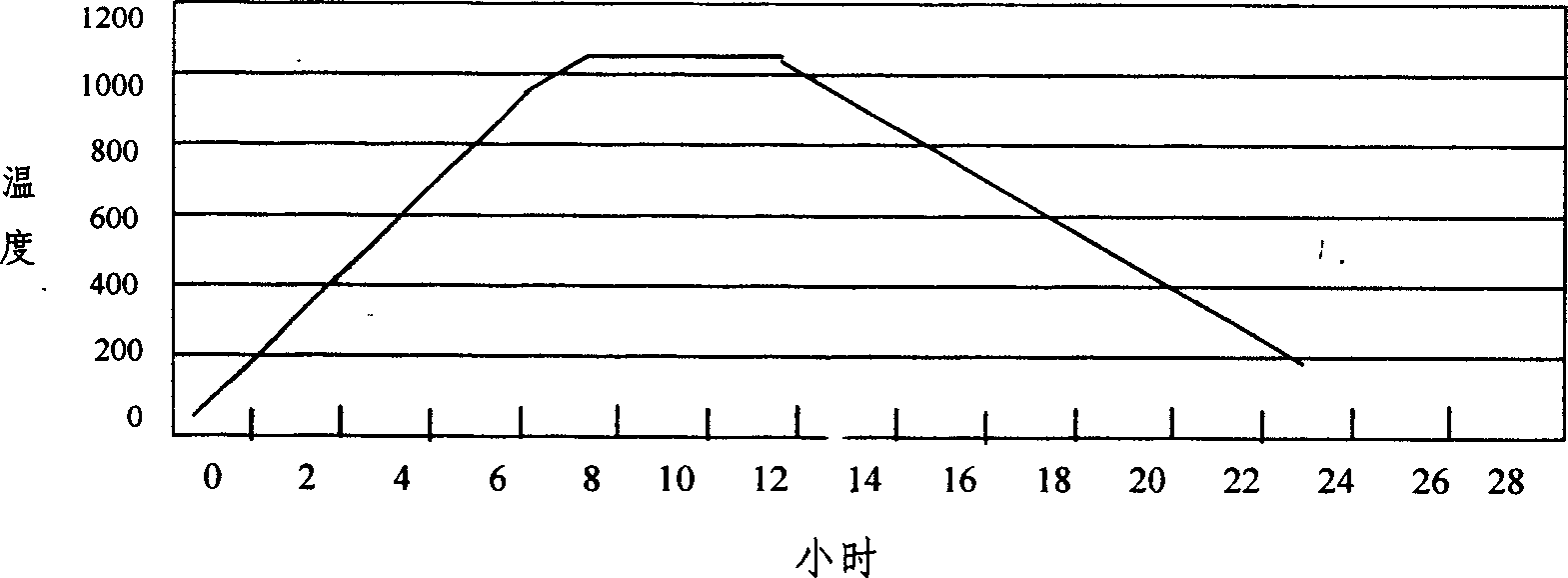

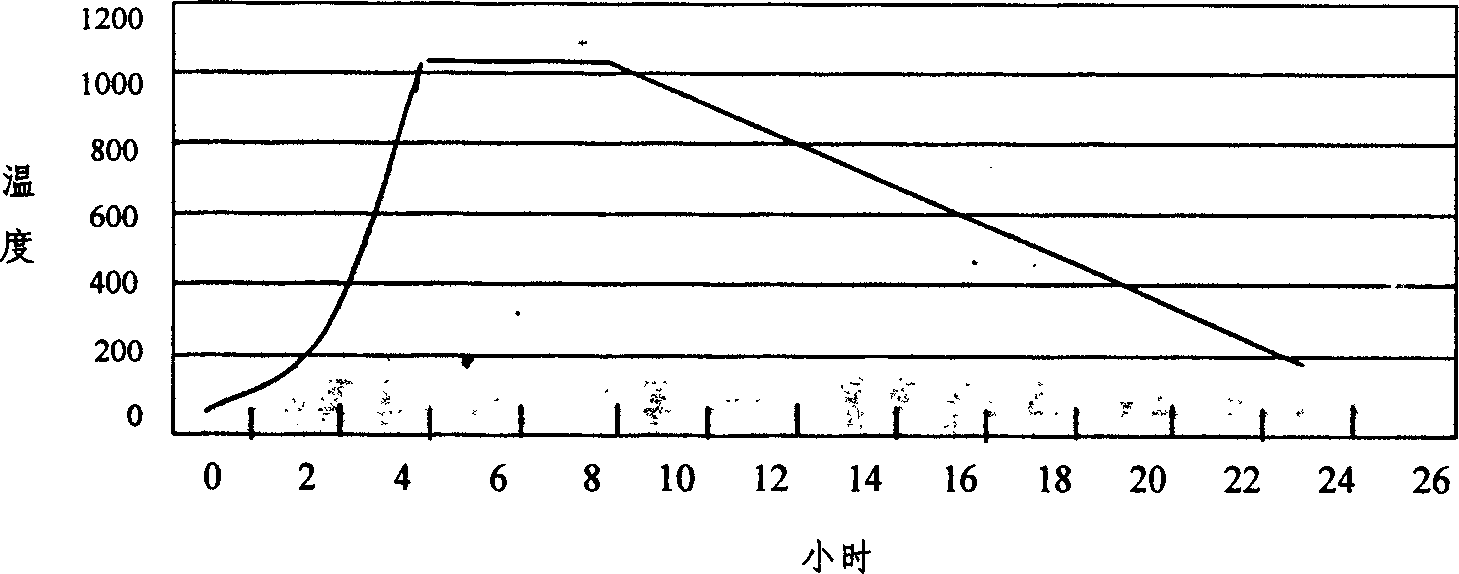

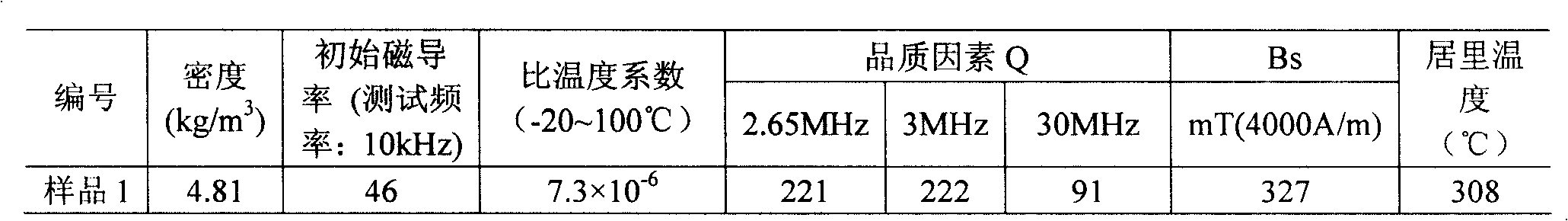

The invention discloses an oxygen body material of nickel, zinc and ferrum with initial permeability being 40<-8><+8> and a preparation method thereof. The main phase of the material is spinel structure, and the material essentially consists of Fe2O3, ZnO, MnO, NiO and CoO, and the contents of composition calculated by oxide are: 46mol percent to 49mol percent of Fe2O3, 2mol percent to 8mol percent of ZnO, 0.1mol percent to 1.0mol percent of MnO, 41.7mol percent to 48mol percent of NiO and 0.3mol percent to 1.5mol percent of CoO; the oxygen body material of nickel, zinc and ferrum with initial permeability being 40<-8><+8> has broadband, low electromagnetic consumption and good stability in larger working current and can be used for producing various power couplers of high-frequency electrodeless lamps with the working frequency in 30MHz; the material has extremely low electromagnetic consumption in high frequency ranging from 2MHz to 30MHz; when the frequency is in the range of 2.5MHz to 3MHz, the quality factor Q is more than 200; when the frequency is 30MHz, the quality factor Q is more than 80; due to good electromagnetic consumption characteristic in such wide frequency range, the oxygen body material can be applied to any electrodeless lamp with the working frequency in 30MHz.

Owner:TONGXIANG TELIYOU ELECTRONICS SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com