Nickel-zinc ferrite material and preparation method thereof

A technology of nickel-zinc ferrite and raw materials, applied in the field of nickel-zinc ferrite soft magnetic materials for magnetic isolation sheets and their preparation, can solve the problems of small mutual inductance, loose coupling, large leakage inductance, etc., and reduce power loss , the effect of high saturation magnetic induction and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

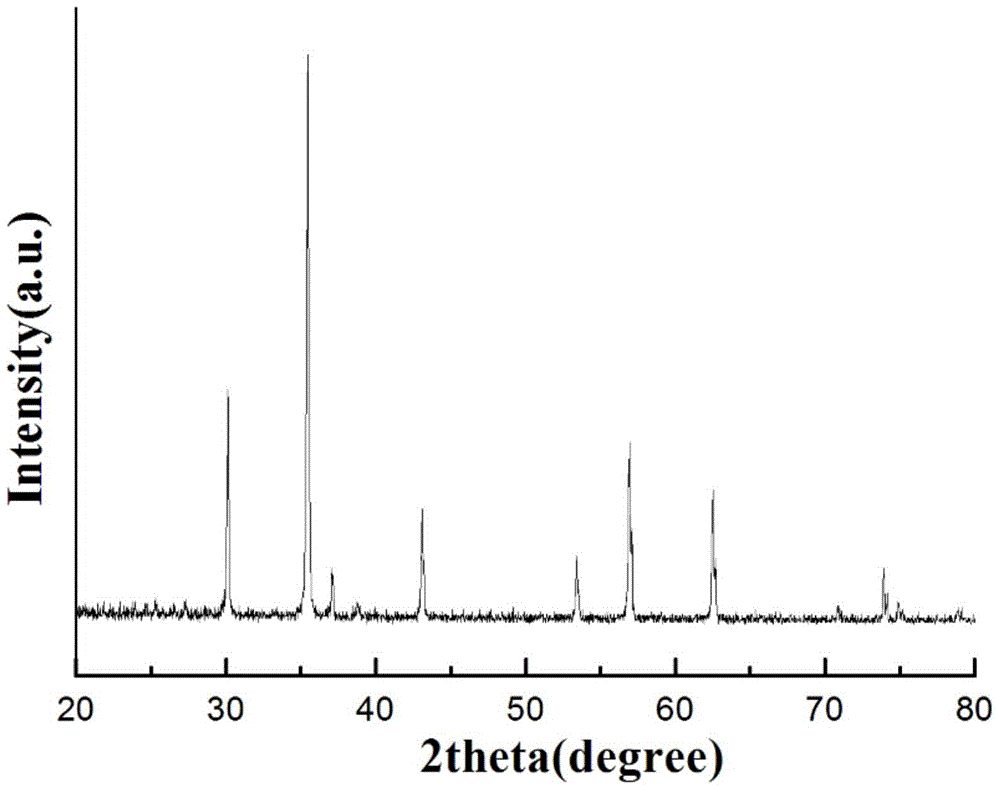

Image

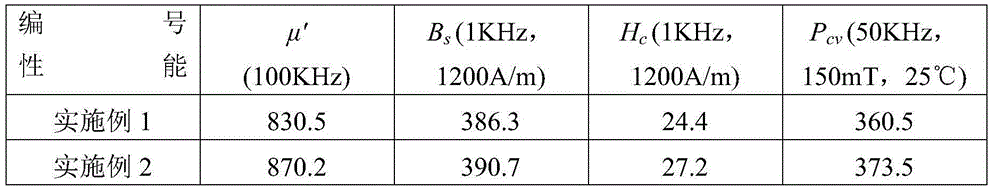

Examples

Embodiment 1

[0023] Step 1, ingredients: according to Fe 2 o 3 49.6 mol%, NiO 13.1 mol%, ZnO 29.2 mol%, CuO 8.1 mol% composition ratio preparation of raw materials.

[0024] Step 2, primary ball milling: mill the raw materials prepared in step 1 in a star ball mill for 2 hours at a speed of 250 r / min, and the mass ratio of raw materials, water and steel balls is 1:1:3.

[0025] Step 3, primary drying: put the powder obtained by ball milling in step 2 into an oven, and dry at 80°C.

[0026] Step 4, pre-calcination: Grind and pulverize the material obtained in step 3, put it into a sintering container for pre-calcination, the temperature is 850°C, and the holding time is 3 hours.

[0027] Step 5, secondary ball milling: 0.05wt% MoO of the total mass of the main component is mixed into the material obtained by pre-calcining in step 4 3 and 0.02wt% Nd 2 o 3 , and then ball milled in a planetary ball mill for 3 hours, the rotating speed is 250r / min, and the ratio of raw material, water and...

Embodiment 2

[0032] Step 1, ingredients: according to Fe 2 o 3 49.6 mol%, NiO 13.1 mol%, ZnO 29.2 mol%, CuO 8.1 mol% composition ratio and weigh raw materials.

[0033] Step 2, primary ball milling: ball milling in a star ball mill for 2 hours, the rotating speed is 250r / min, and the mass ratio of raw materials, water and steel balls is 1:1:3.

[0034] Step 3, primary drying: put the powder obtained by ball milling in step 2 into an oven, and dry at 80°C.

[0035] Step 4, pre-calcination: Grind and pulverize the material obtained in step 3, put it into a sintering container for pre-calcination, the temperature is 850°C, and the holding time is 3 hours.

[0036] Step 5, secondary ball milling: 0.1wt% MoO of the total mass of the main component is mixed in the material obtained by pre-calcining in step 4 3 and 0.01wt% Nd 2 o 3 , and then ball milled in a planetary ball mill for 3 hours, the rotating speed is 250r / min, and the ratio of raw material, water and steel ball mass is 0.75:1:3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com