Iron-based amorphous nanocrystalline magnetically soft alloy and preparation method thereof

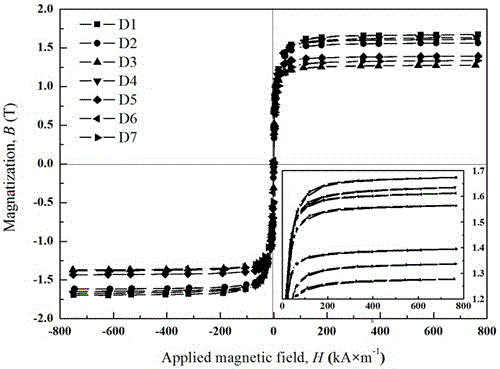

A nanocrystalline soft magnetic and amorphous nanocrystalline technology, which is applied in the field of nanocrystalline alloys, can solve the problems of increased coercive force and decreased magnetic permeability of iron-based nanocrystalline soft magnetic alloys, and achieves low coercive force and excellent preparation process. The effect of relaxed conditions and high magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

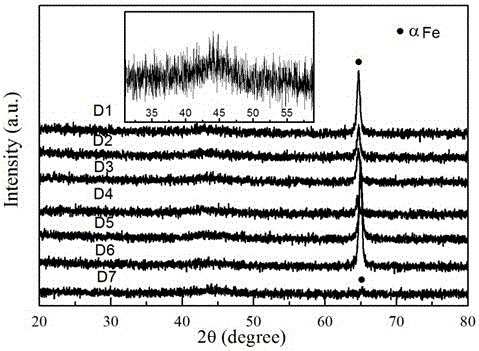

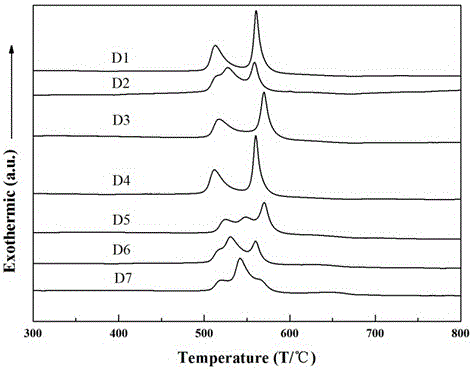

[0050] An iron-based amorphous nanocrystalline soft magnetic alloy Fe 78.32 Si 9.41 B 11.5 C 0.12 mn 0.49 P 0.13 Cu 0.02 Mo 0.01 (at%), denoted as D1, and its preparation method includes the following steps:

[0051] 1) Ingredients: Fe, Si, Mn, Cu, Mo and pre-alloyed FeB with a mass fraction of not less than 99.9% (Fe content and B content are 79.51wt% and 19.62wt% respectively, the same below), FeP (Fe content The amount of Fe and P are 75wt%, 24.98wt%, the same below), and FeC (the content of Fe and C are 95.7wt%, 4.3wt%, the same below) is proportioned according to the element ratio required by the alloy;

[0052] 2) Melting the master alloy: place the prepared raw materials in a non-consumable vacuum electric arc furnace, add Ti ingots for deoxidation, and evacuate to a vacuum degree of 5.0×10 -3 After Pa, argon gas is introduced, the purity is 99.99%, and the raw material is refined into a master alloy ingot by arc melting, and the master alloy ingot is repeated...

Embodiment 2

[0056] An iron-based amorphous nanocrystalline soft magnetic alloy Fe 77.36 Si 9.3 B 11.36 C 0.11 mn 0.49 P 0.12 Ni 1.23 Cu 0.02 Mo 0.01(at%), denoted as D2, its preparation method comprises the following steps:

[0057] 1) Ingredients: Fe, Si, Mn, Cu, Mo with a mass fraction not less than 99.9% and pre-alloyed FeB, FeP, FeC are proportioned according to the element ratio required by the alloy;

[0058] 2) Melting the master alloy: place the prepared raw materials in a non-consumable vacuum electric arc furnace, add Ti ingots for deoxidation, and evacuate to a vacuum degree of 5.2×10 -3 After Pa, argon gas with a purity of 99.99% is introduced, and the raw material is refined into a master alloy ingot by arc melting, and the master alloy ingot is repeatedly smelted 6 times to ensure the uniformity of the master alloy composition;

[0059] 3) Spray tape: After cutting the smelted master alloy, put it into a quartz tube with a nozzle at the bottom, when the vacuum deg...

Embodiment 3

[0062] An iron-based amorphous nanocrystalline soft magnetic alloy Fe 75.94 Si 9.13 B 11.15 C 0.11 mn 0.48 P 0.12 Cr 3.04 Cu 0.02 Mo 0.01 (at%), denoted as D3, its preparation method comprises the following steps:

[0063] 1) Ingredients: Fe, Si, Mn, Cu, Mo with a mass fraction not less than 99.9% and pre-alloyed FeB, FeP, FeC are proportioned according to the element ratio required by the alloy;

[0064] 2) Melting master alloy: place the prepared raw materials in a non-consumable vacuum electric arc furnace, add Ti ingots for deoxidation, and evacuate to a vacuum degree of 5.4×10 -3 After Pa, argon gas with a purity of 99.99% is introduced, and the raw material is refined into a master alloy ingot by arc melting, and the master alloy ingot is repeatedly smelted 6 times to ensure the uniformity of the master alloy composition;

[0065] 3) Spray tape: After cutting the smelted master alloy, put it into a quartz tube with a nozzle at the bottom, when the vacuum degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com