High-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy and preparation method thereof

An iron-based nanocrystalline and soft magnetic alloy technology, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of performance influence, uneven heating, etc., achieve high thermal stability, good high-frequency characteristics, and reduce precious metals. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

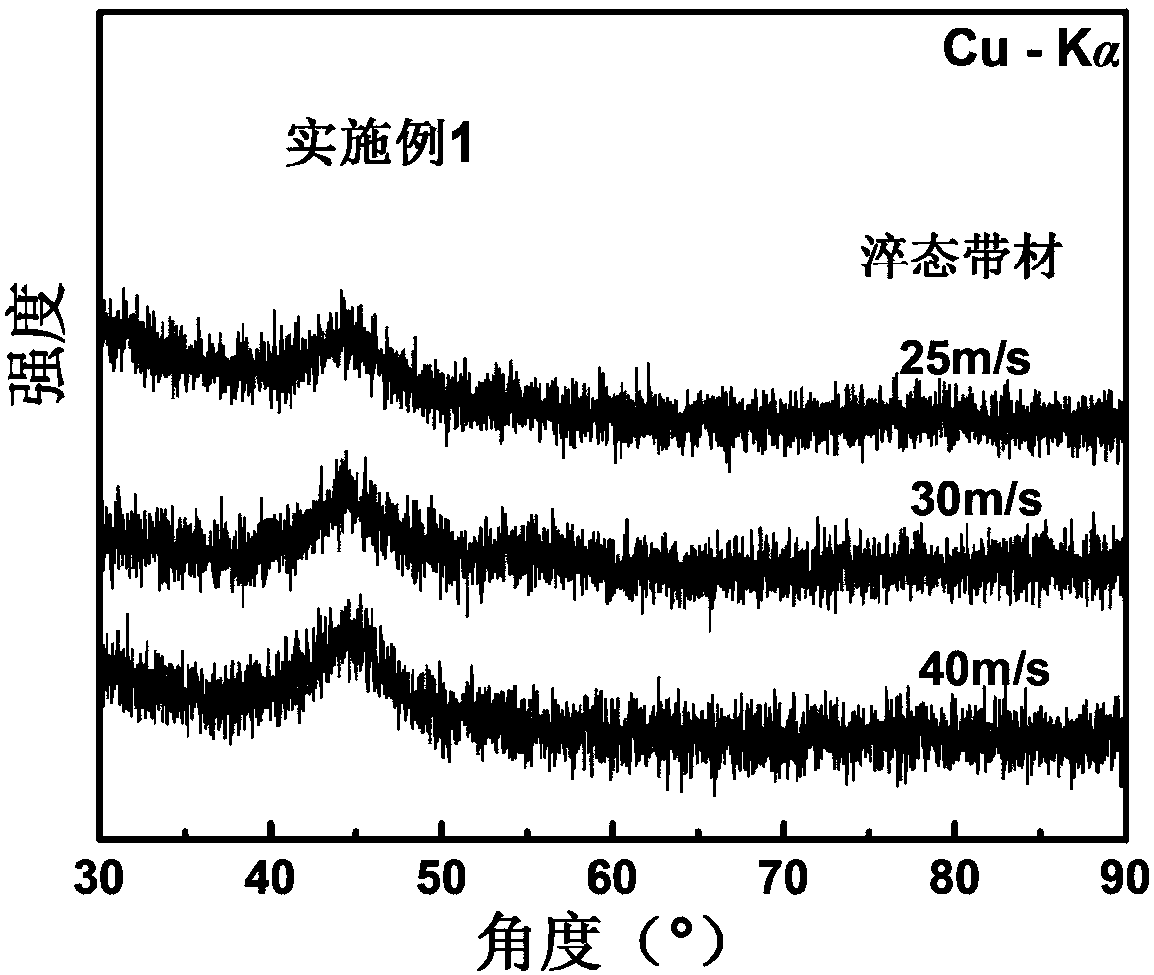

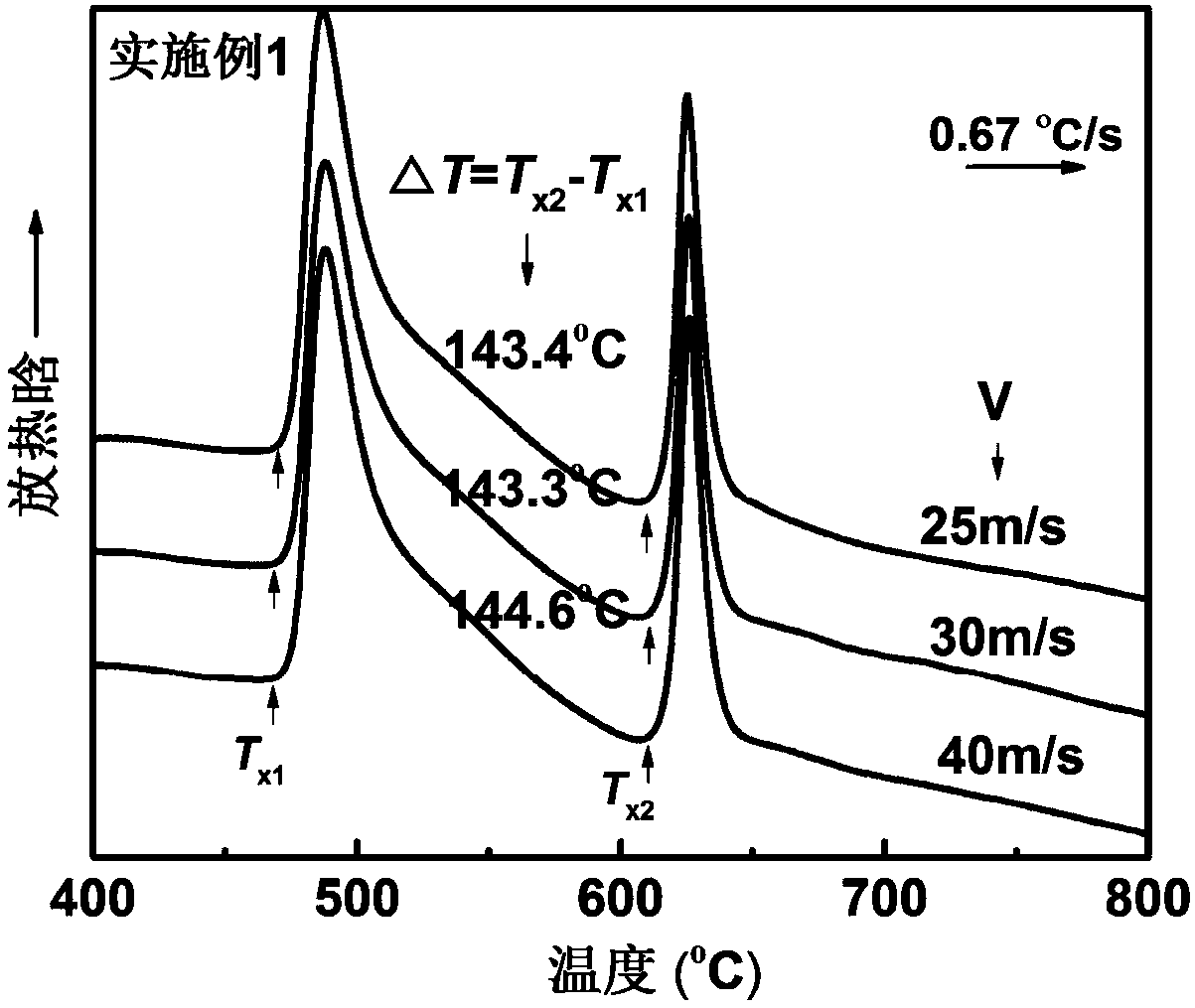

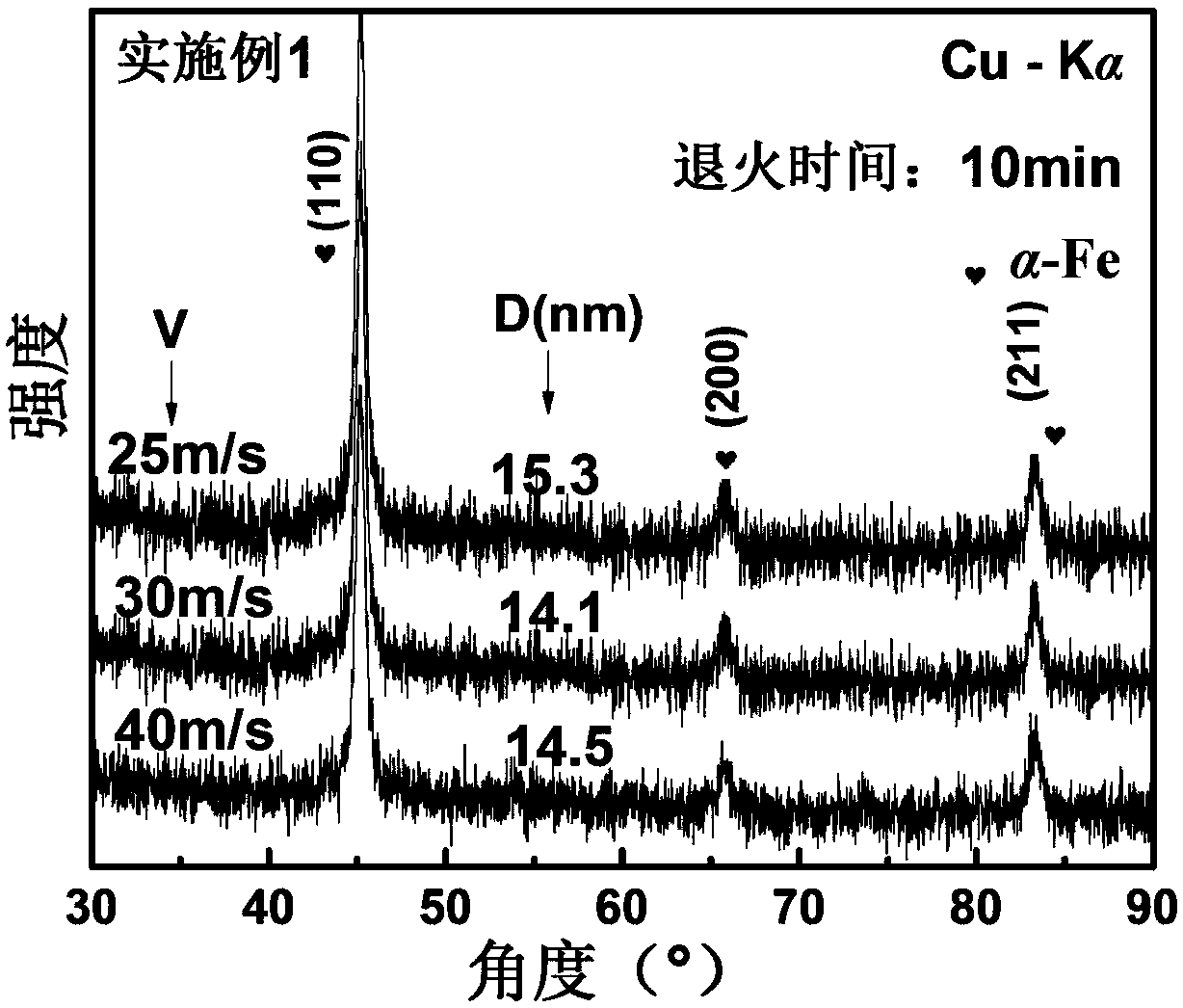

[0048] In this embodiment, the chemical molecular formula of the iron-based nanocrystalline soft magnetic alloy material is: Fe 76 Si 12 B 8.5 P 0.5 Nb 1.4 V 0.1 Mo 0.5 Cu 1 .

[0049] The concrete preparation method of this iron-based nanocrystalline alloy is as follows:

[0050] Step 1: Raw materials Fe, Si, B, Fe3P, Nb, FeV, Mo, Cu with a purity greater than 99.8% are formulated according to the compositional formula Fe 76 Si 12 B 8.5 P 0.5 Nb 1.4 V 0.1 Mo 0.5 Cu 1 carry out ingredients;

[0051] Step 2: Put the proportioned raw materials into the cleaned alumina crucible in the induction melting furnace, evacuate to lower than -0.002Pa, and then fill in argon until the pressure is -0.05Pa for melting, and the melting temperature is 1300°C, keep warm for 5 minutes after melting, then pour the molten alloy ingot into a copper mold and cool for 20 minutes to obtain an alloy ingot with uniform composition;

[0052] Step 3: Put the alloy ingot obtained in step ...

Embodiment 2

[0061] In this embodiment, the chemical molecular formula of the iron-based nanocrystalline soft magnetic alloy material is: Fe 76 Si 12 B 8.5 P 0.5 Nb 1.6 V 0.2 Mo 0.2 Cu 1 .

[0062] The specific preparation method of this iron-based nanocrystalline alloy is basically the same as the steps of Example 1 as follows, and it is also necessary to pay attention to the accuracy of the quality when weighing, and to carry out under an inert atmosphere (Ar) during induction smelting and rapid quenching. Carry out various magnetic properties and microstructure observation afterwards, and the place different from embodiment 1 step is that the selected melting temperature selection is 1400 ℃ during smelting, and the selection of inner and outer pressure difference of quartz tube is 250Pa when throwing belt, and the heating rate during annealing is 2°C / min.

[0063] The XRD pattern of the quenched alloy strip and the alloy strip after heat treatment was tested by D8 Advance polycr...

Embodiment 3

[0068] In this embodiment, the chemical molecular formula of the iron-based nanocrystalline soft magnetic alloy material is: Fe 76 Si 12 B 8.2 P 0.8 Nb 1.2 V 0.2 Mo 0.6 Cu 1 .

[0069] The concrete preparation method of this iron-based nanocrystalline alloy is as follows the same as the step of embodiment 1, need to pay attention to the accuracy of quality when weighing equally, and carry out under inert atmosphere (Ar) when induction smelting and quick quenching strip, after that Carry out each magnetic property and microscopic structure observation and embodiment 1 and 2 steps difference place is that the melting temperature selected during smelting is selected as 1500 ℃, and the pressure difference inside and outside the quartz tube is selected as 350Pa when the band is thrown, and the heating rate during annealing is 4°C / min.

[0070] The XRD pattern of the quenched alloy strip and the alloy strip after heat treatment was tested by D8 Advance polycrystalline X-ray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com