Patents

Literature

279results about How to "Good high frequency characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing solid sheet type electrolytic capacitor

InactiveCN1649053AGood high frequency characteristicsLower equivalent series resistanceSolid electrolytic capacitorsCapacitor electrodesEpoxyAlloy

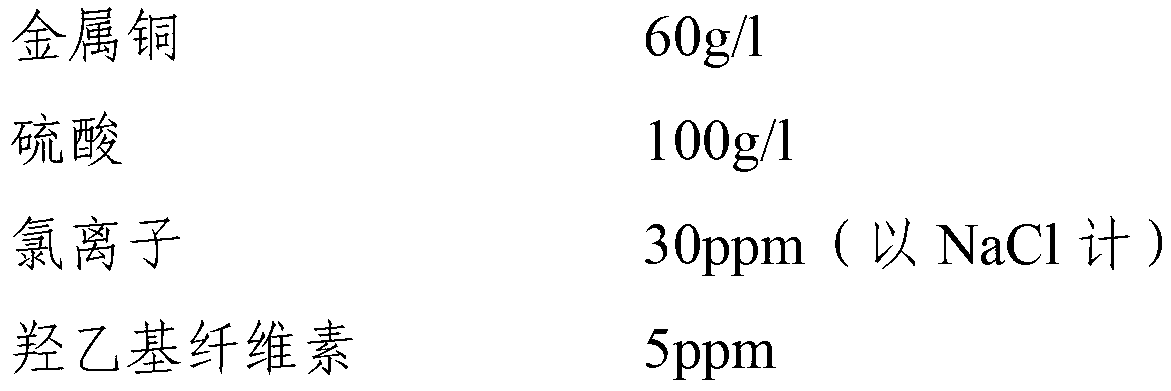

A manufacturing method for a solid plate electrolytic capacitor is to weld a strip Al foil to a stainless steel technical bar, the Al foil is coated with silicon resin or F resin to be divided into cathode and anode. The cathode part is immersed into a solution containing oxalamine and ammonium biphosphate plus 6-35v voltage, then again immersed in KMno4 solution to be dipped in a solution with Py and sulfosalt to form a pre-conductive layer on its surface as the anode, a stainless steel as the cathode to carry out constant current electrolyte in a mixed solution with Py and sulfosalt. The Al foil cathode is immersed in a solution containing oxalamine, ammonium biphosphate and sulfosalt plus 5-25v voltage to be coated with graphite and Ag to get single chip cores to be laminated, the anode is welded at that of an alloy lead frame, the cathode to the cathode to form a capacitor core to be molded and packaged with epoxy resin.

Owner:XI AN JIAOTONG UNIV

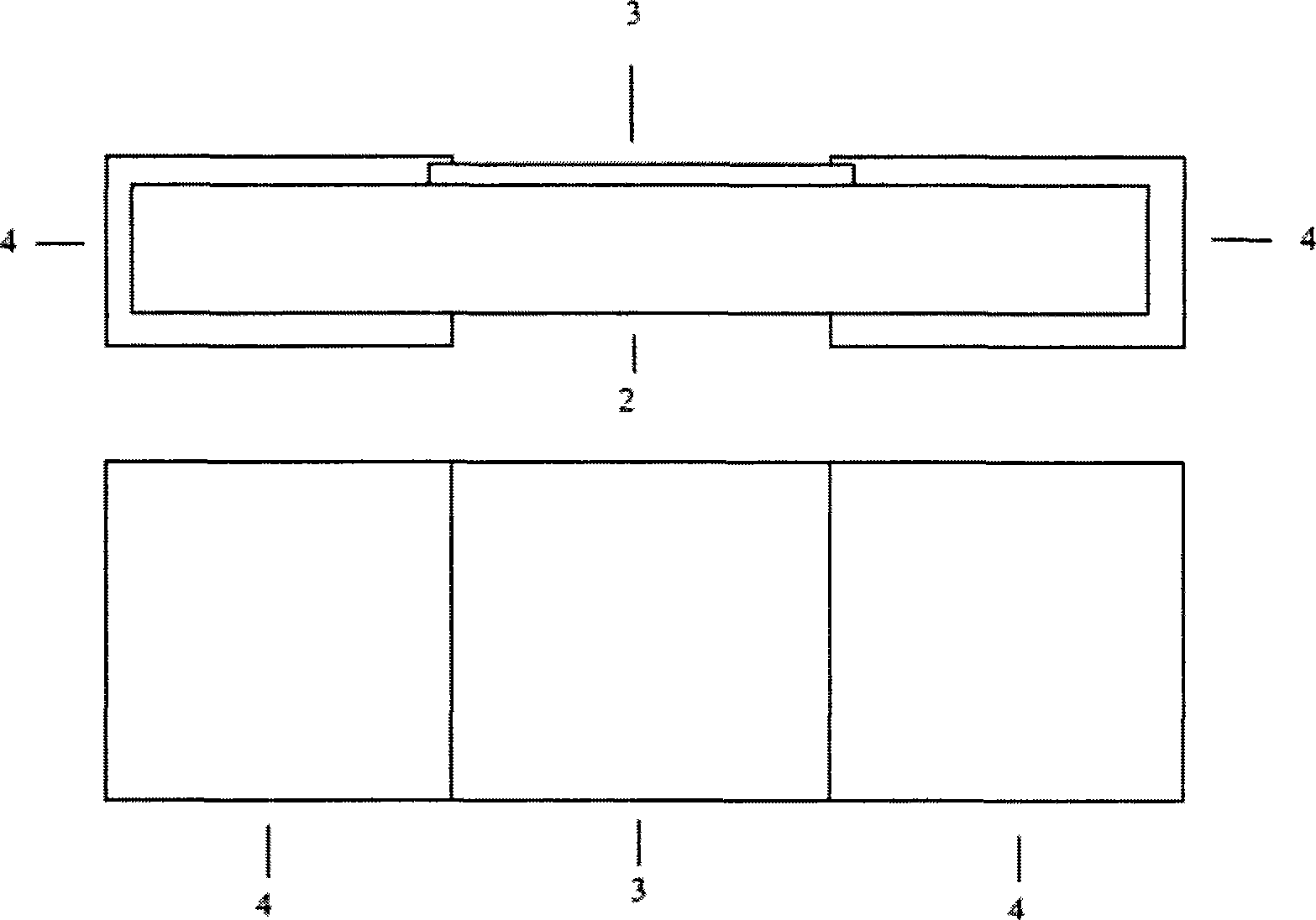

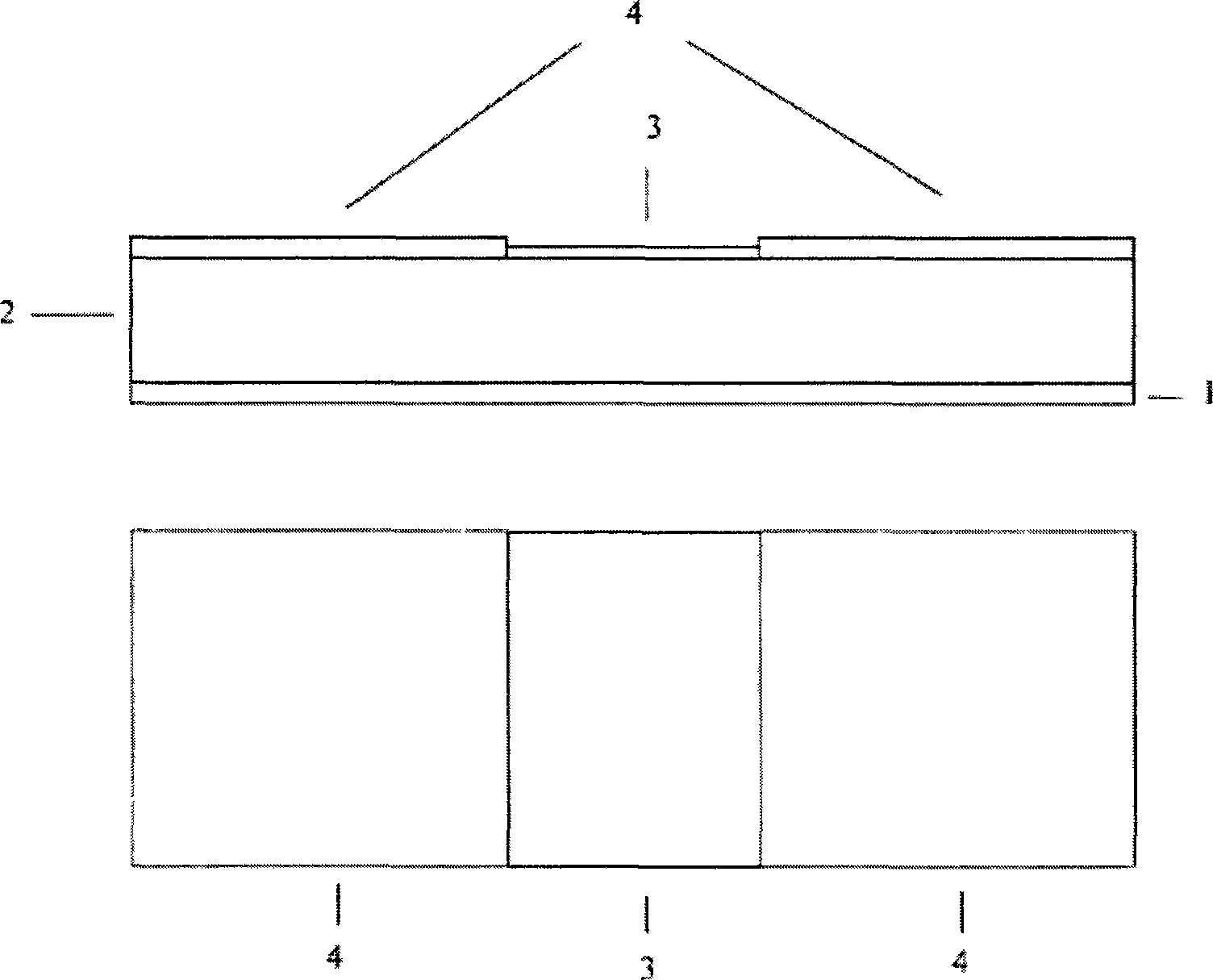

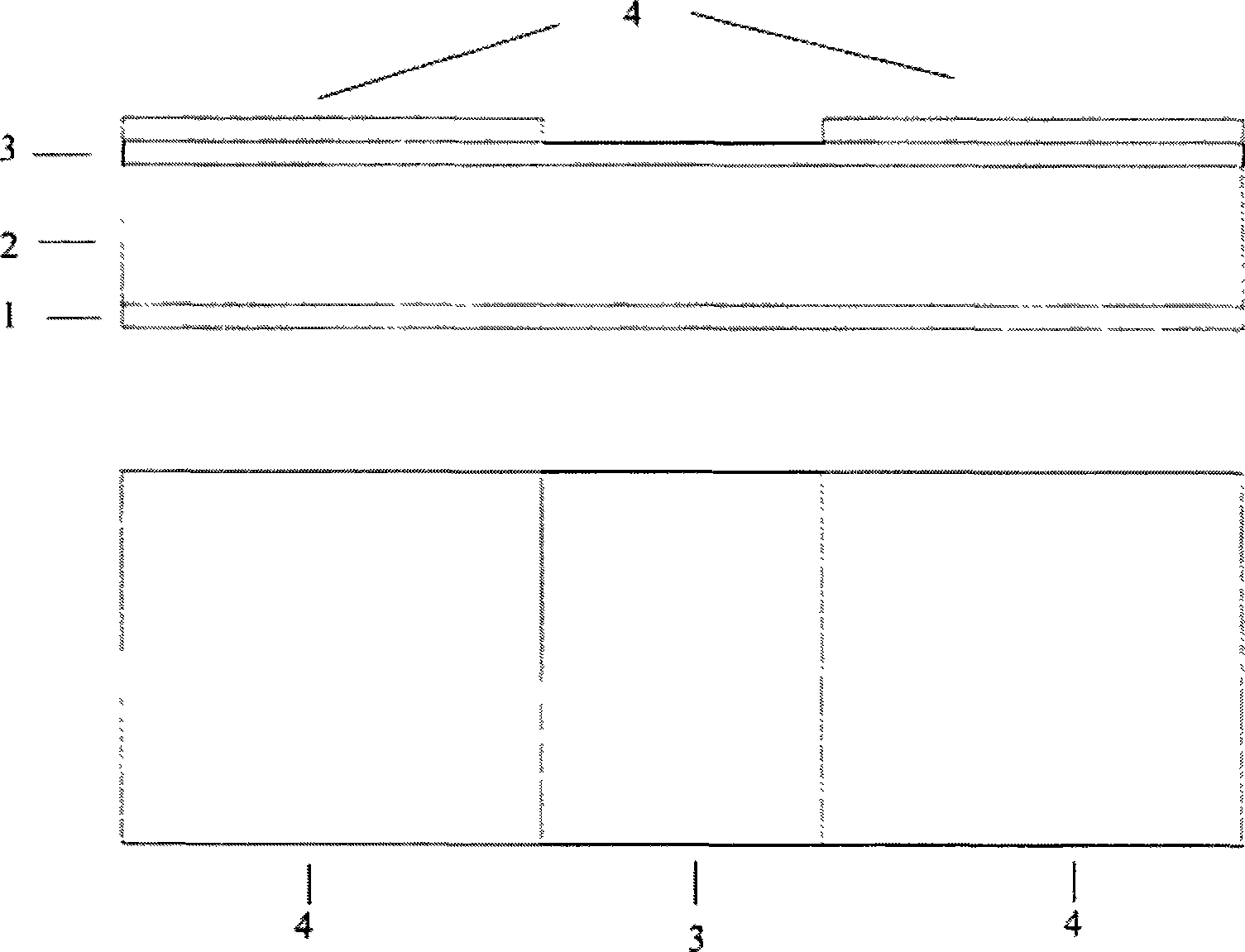

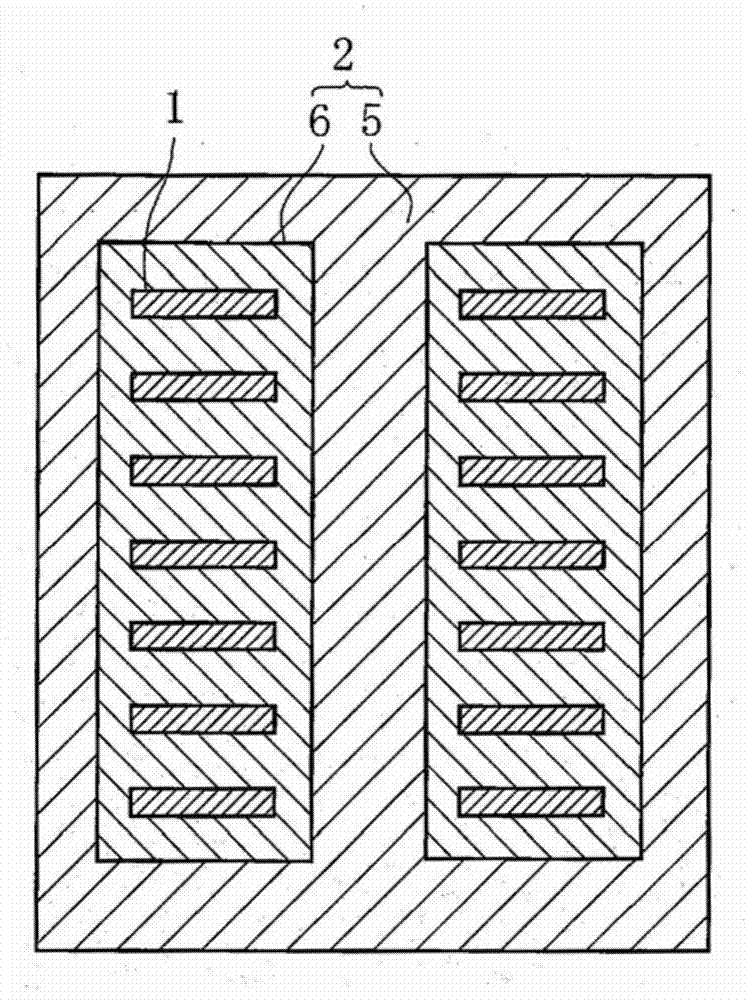

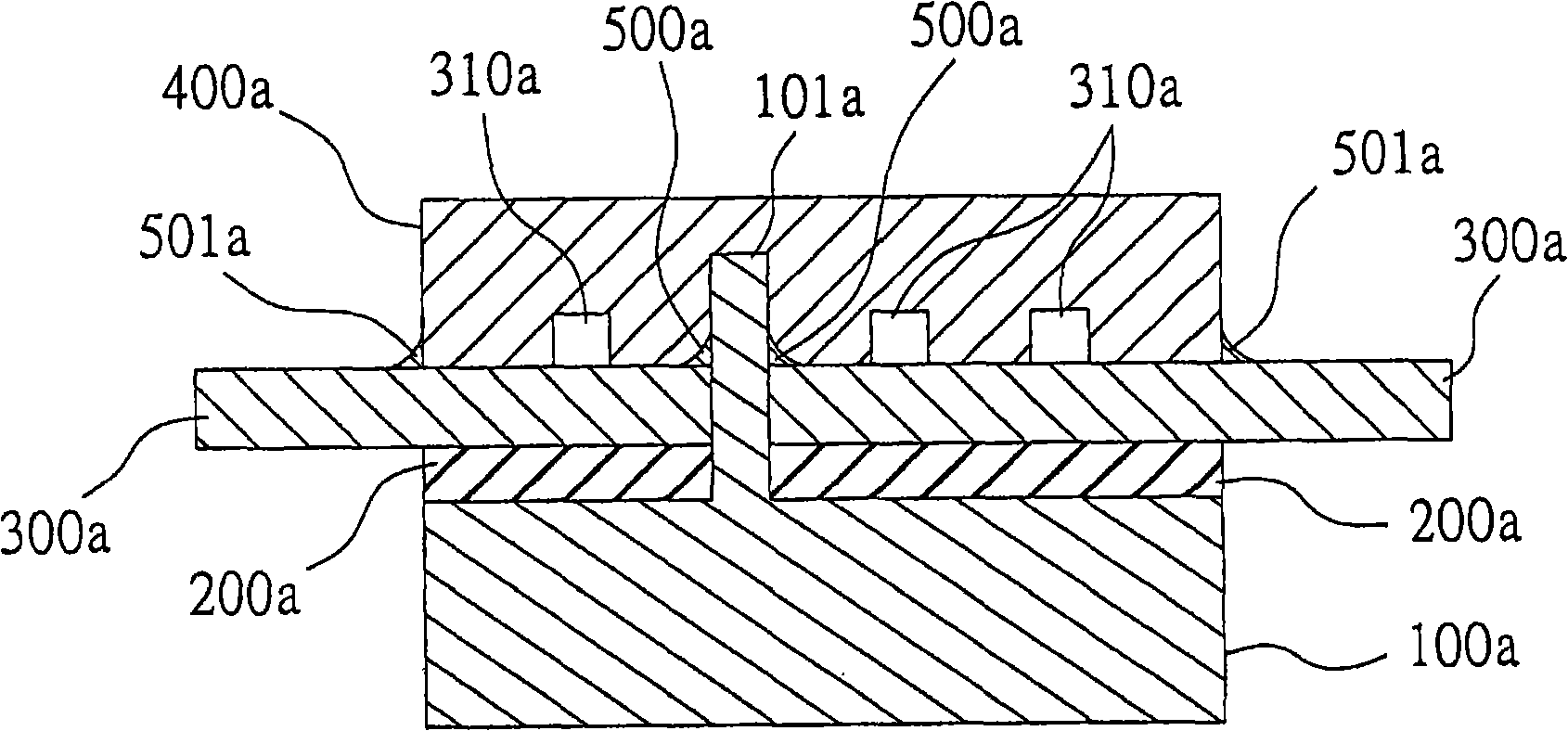

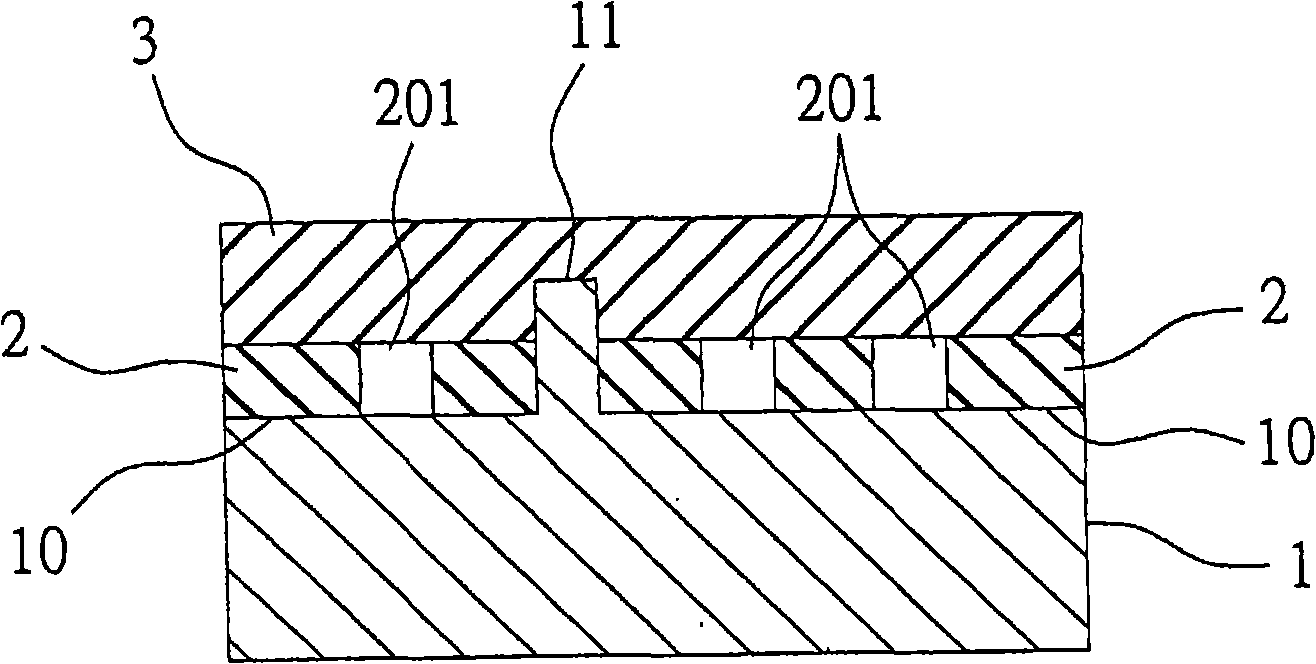

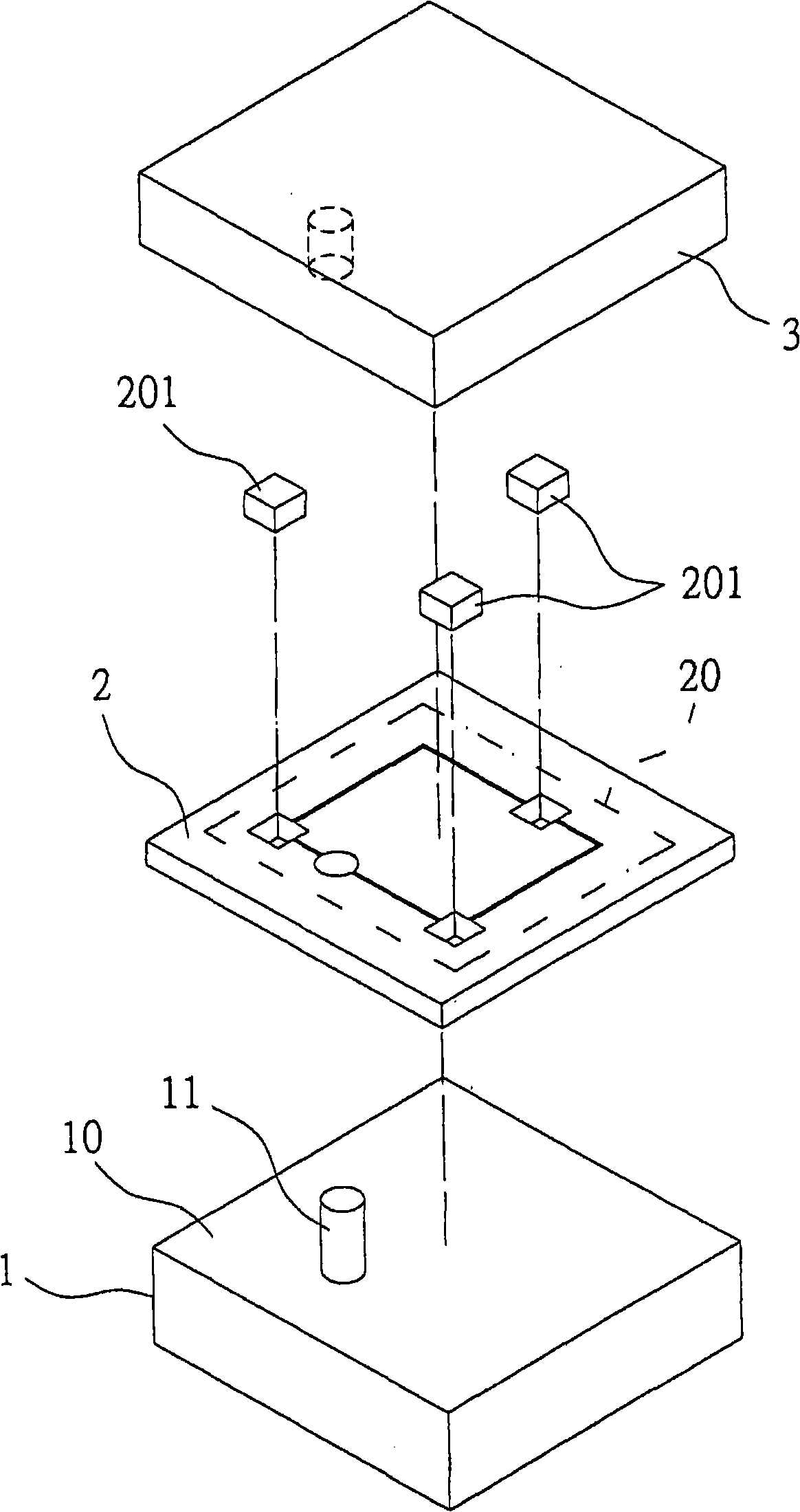

Microwave film resistor, microwave film resistor network module and manufacturing method thereof

InactiveCN101533693AReduce microwave lossReduce areaOther resistor networksResistors adapted for applying terminalsFilm resistanceHigh resistance

The invention discloses a microwave film resistor and a manufacturing method thereof, and belongs to the field of circuit elements. The microwave film resistor comprises a ceramic substrate, a film resistance layer which is adhered to the upper surface of the ceramic substrate and an electrode layer which is adhered to the film resistance layer. The film resistor has the advantages of high precision, high using frequency and high resistance stability. In addition, the invention also discloses a microwave film resistor network module and a manufacturing method thereof, wherein the microwave film resistor network module is formed by integrating three or more microwave film resistors on one module.

Owner:广州翔宇微电子有限公司

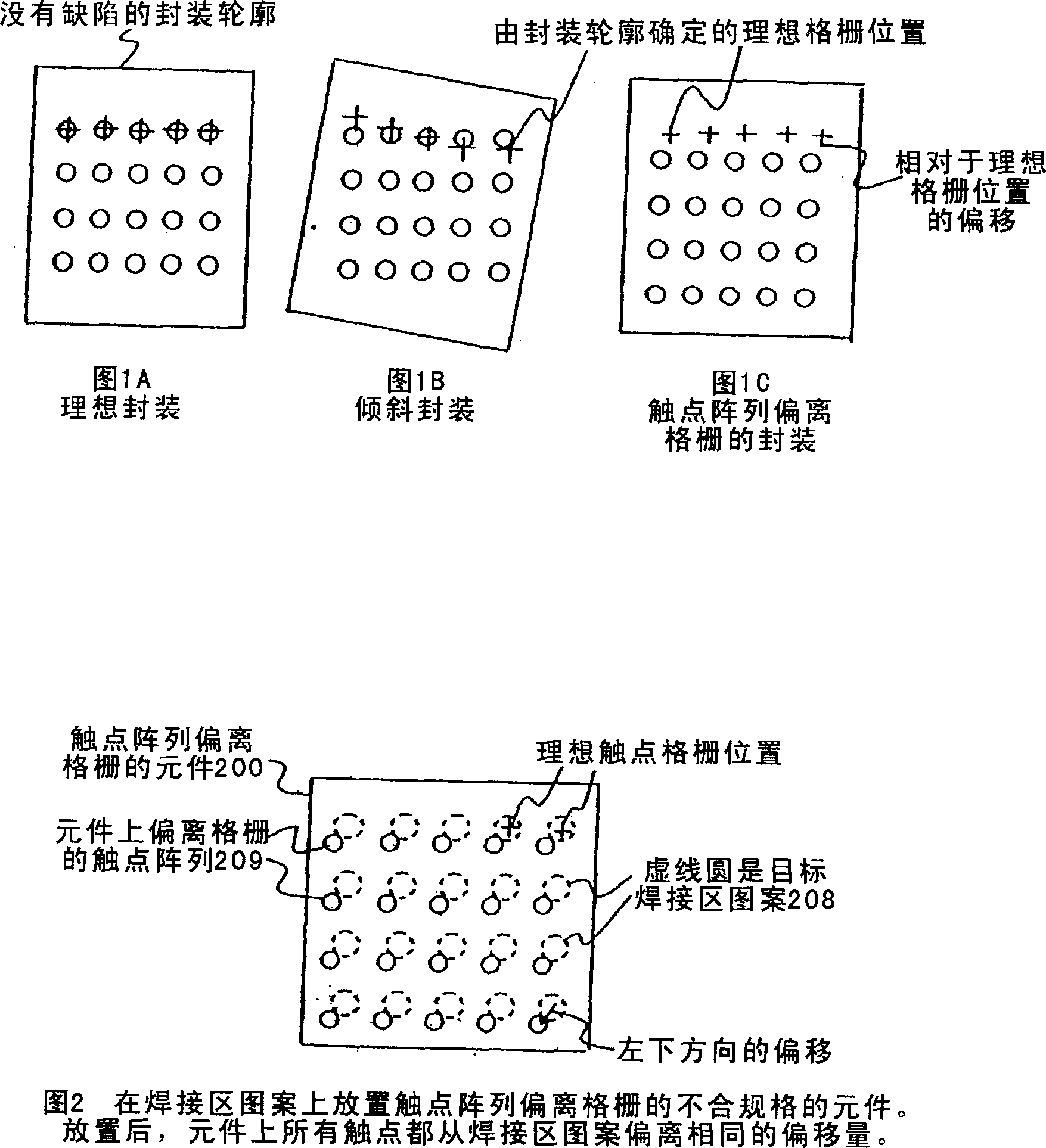

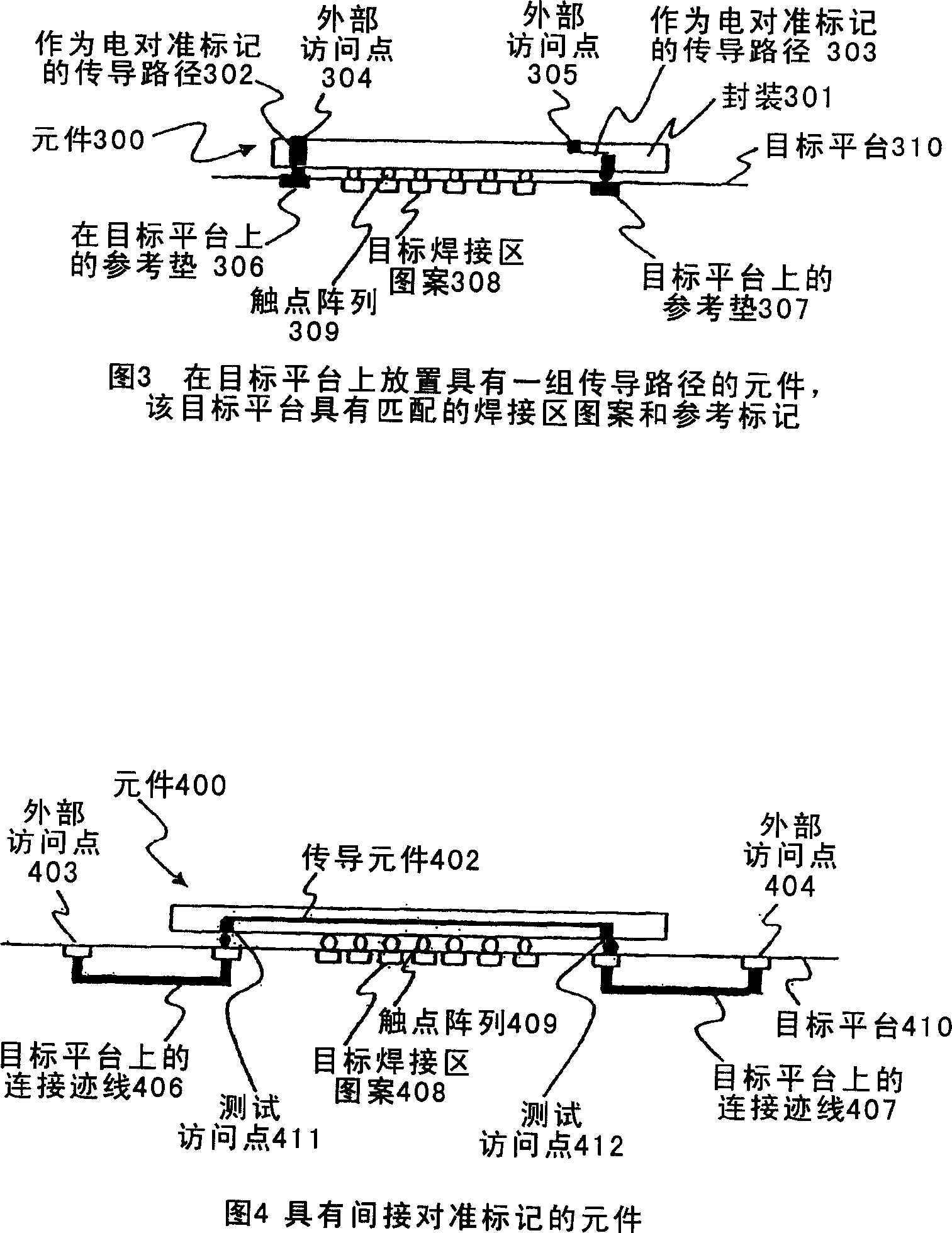

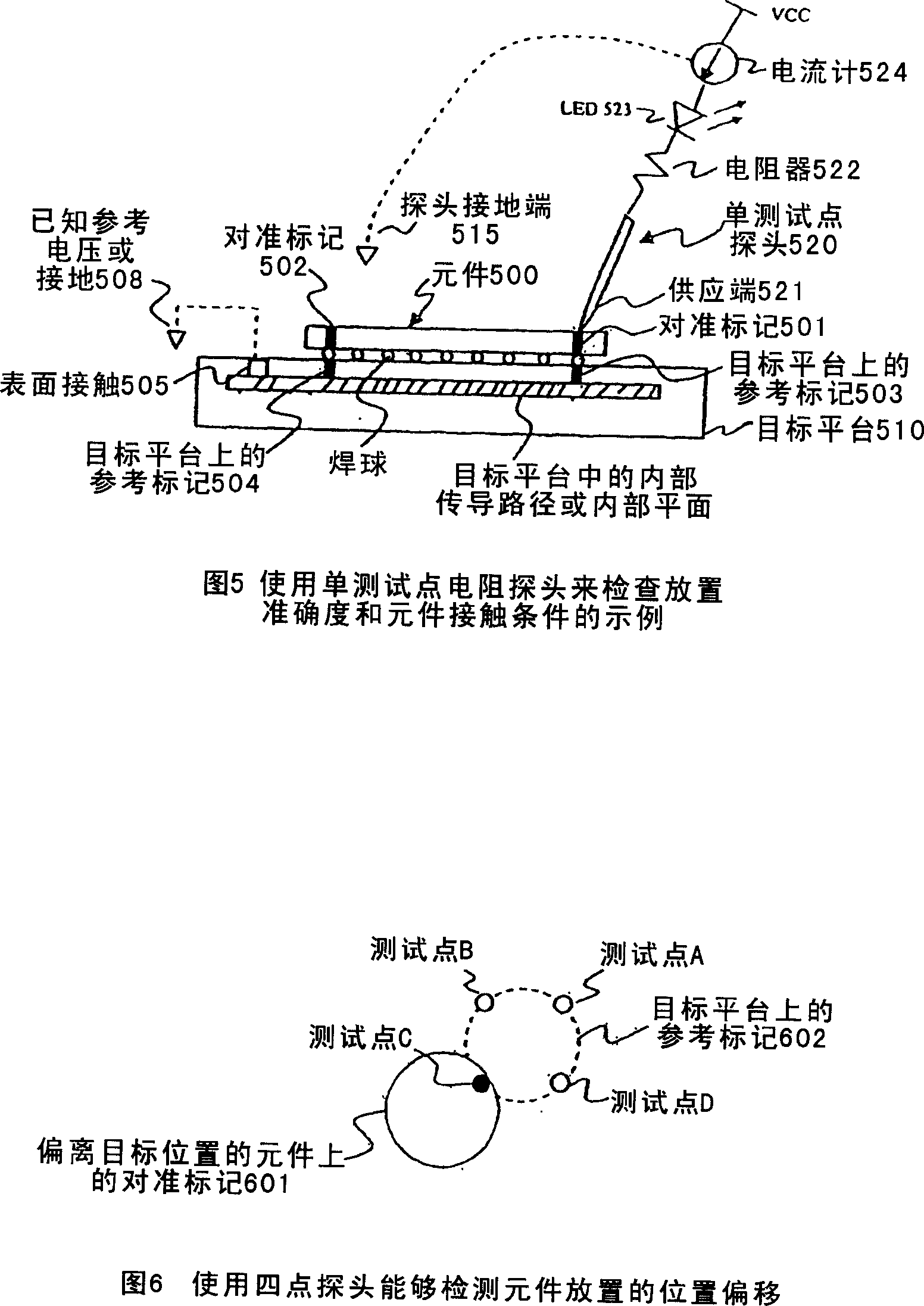

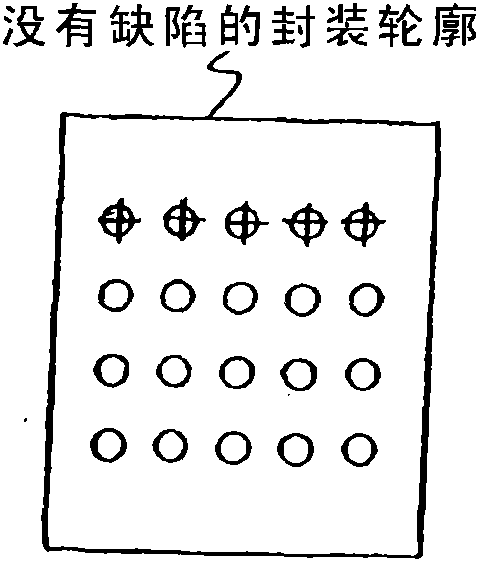

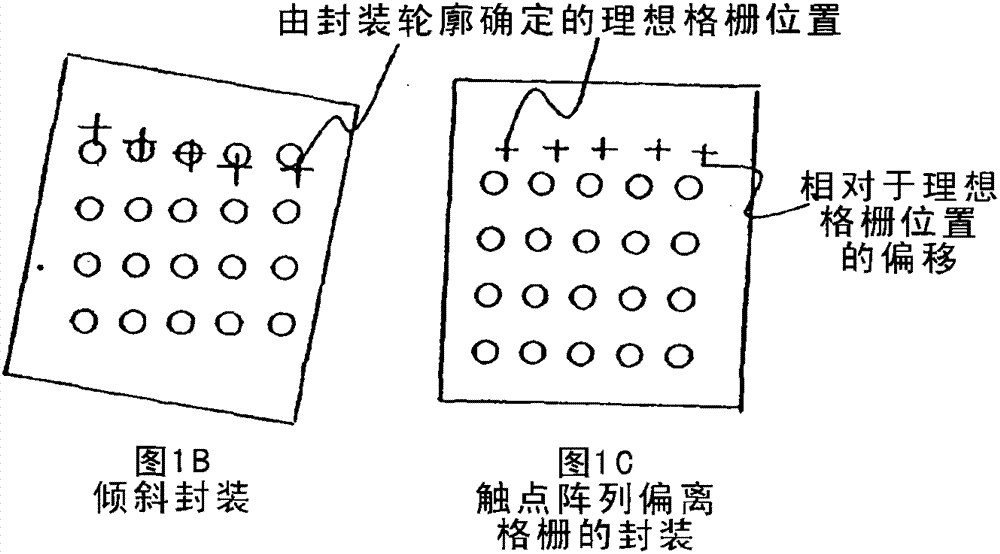

Apparatus and method for arranging predetermined element on target platform

ActiveCN101118899AHigh yieldReduce reworkSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineering

Owner:温泰克工业有限公司

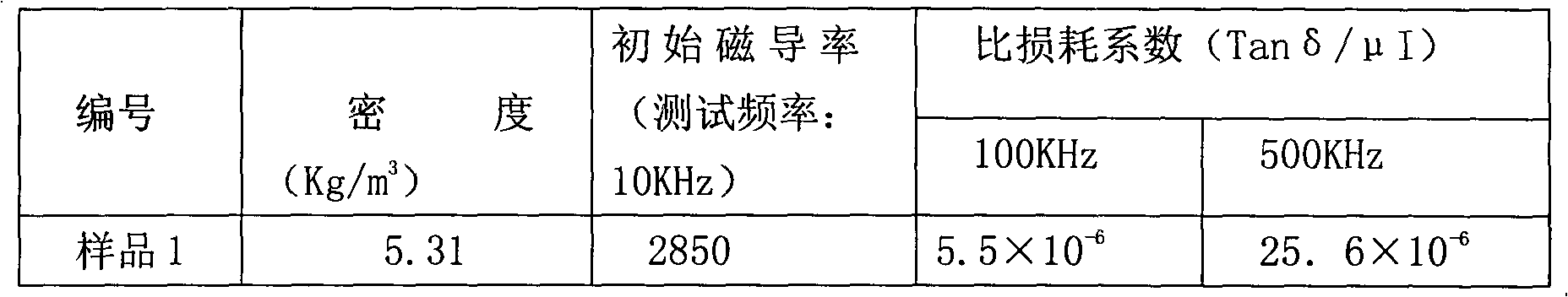

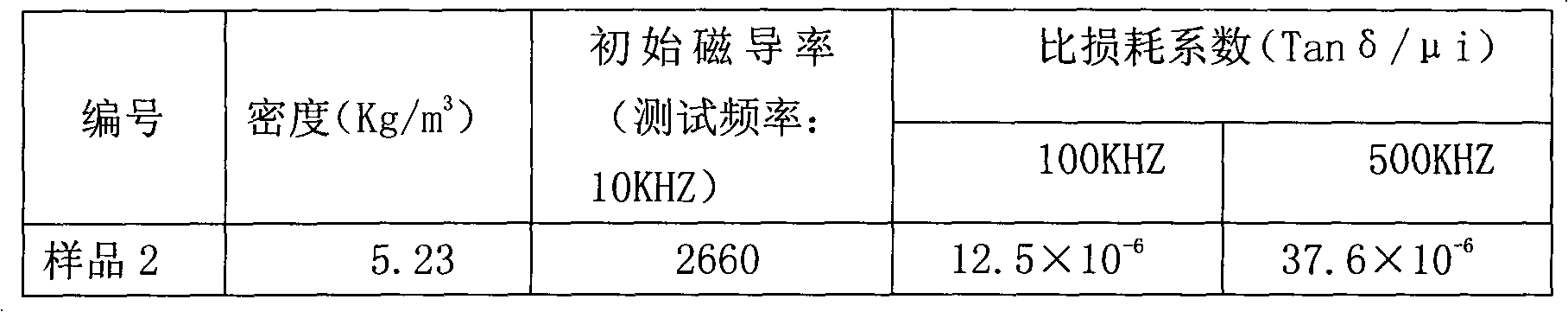

Low-temperature sintered high-permeability NiCuZn ferrite material

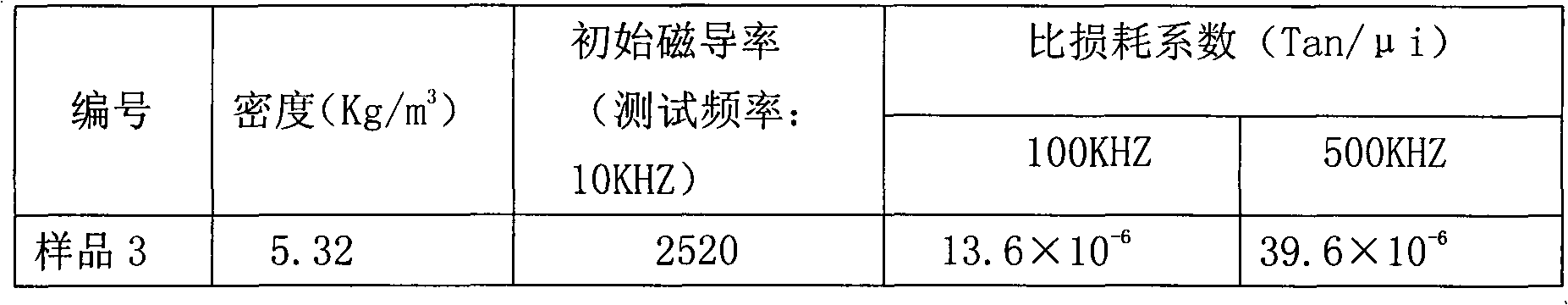

The invention discloses a low-temperature sintered high-permeability NiCuZn ferrite material for a wire wound chip inductor and a preparation method of the ferrite material. The ferrite material comprises the following main components based on oxide content: 40.5 to 49.6 moles percent of Fe2O3, 30 to 47 moles percent of ZnO, 5 to 20 moles percent of CuO and the balance of NiO. The preparation method comprises the following steps of: (1) mixing raw materials, (2) performing primary sanding, (3) performing primary spray drying and granulation, (4) pre-sintering, (5) adding trace elements, (6) performing secondary sanding, (7) performing secondary spray drying and granulation, (8) molding and (9) sintering. By adding auxiliary components such as NaCO3, B2O3, Ta2O5 and the like, the sintering temperature is greatly reduced, the sintering temperature is below 900 DEG C, the high-frequency electromagnetic performance of the material is greatly improved, the sintering density of the material is improved, the mechanical strength of the material is improved, and the manufacturing process requirement of the wire wound chip inductor is met; and on the other hand, energy is saved, and the producing and manufacturing costs are greatly reduced. The initial permeability of the material is 2,850; the specific loss coefficient of the material is less than 5.5*10<-6> under the test conditions of 100 kHz and 0.25mT; and the specific loss coefficient of the material is less than 25.6*10<-6> under the test conditions of 500 kHz and 0.25mT.

Owner:TAIXING ZHONGHENG BUILDING DECORATION ENGCO

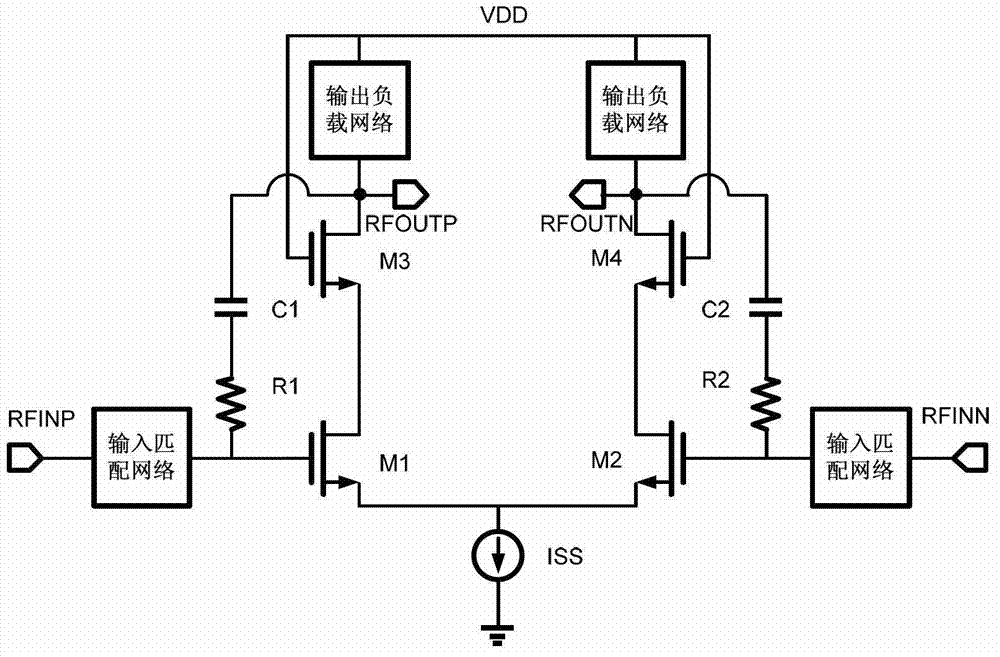

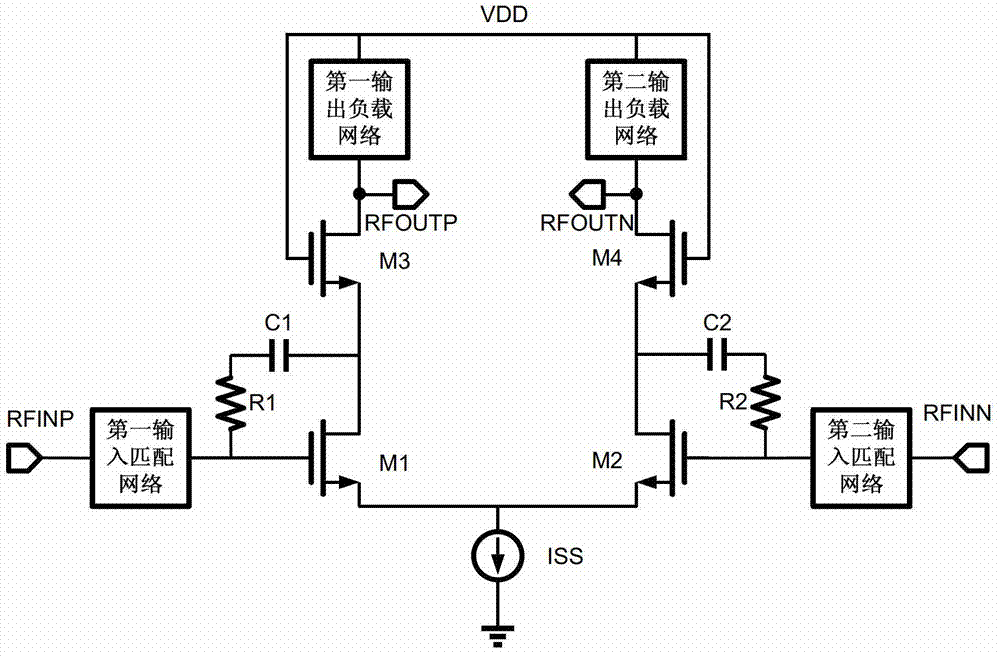

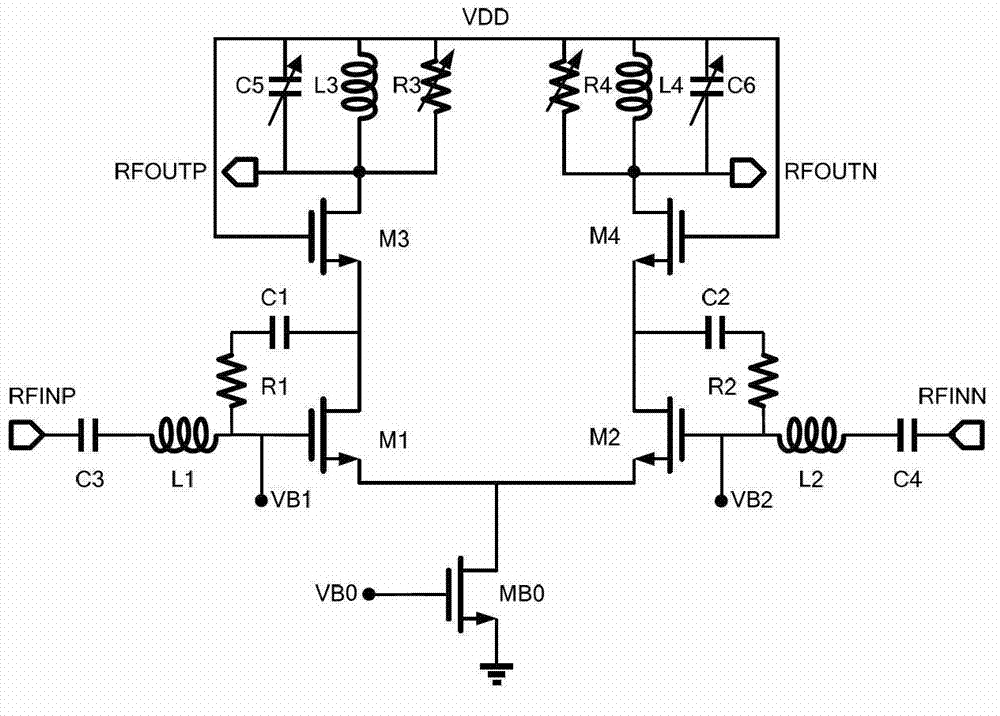

Parallel-resistance feedback differential low-noise amplifier

InactiveCN102790593AReduce parasitic capacitanceGood high frequency characteristicsNegative-feedback-circuit arrangementsDifferential amplifiersOxide semiconductorEngineering

The invention relates to a parallel-resistance feedback differential low-noise amplifier, which comprises a main amplification circuit. The main amplification circuit comprises a first MOS (metal oxide semiconductor) tube, a second MOS tube, a third MOS tube and a fourth MOS tube, a grid end of the first MOS tube is connected with a first differential input end through a first input matching network, the second MOS tube is connected with a second differential input end through a second input matching network, a drain end of the first MOS tube M1 is connected with the grid end of the first MOS tube through a first parallel-resistance feedback branch, and a drain end of the second MOS tube is connected with a grid end of the second MOS tube through a second parallel-resistance feedback branch; the first parallel-resistance feedback branch comprises a first resistor and a first capacitor connected with the first resistor in series; and the second parallel-resistance feedback branch comprises a second resistor and a second capacitor connected with the second resistor in series. The parasitic capacitance of the output end of the amplifier can be reduced, the isolation between the output end and the input end of the amplifier can be improved, good high-frequency characteristics can be achieved, and the circuit stability can be enhanced.

Owner:JIANGSU CAS JUNSHINE TECH

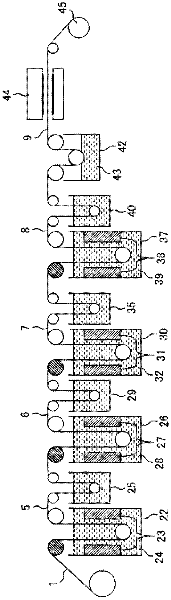

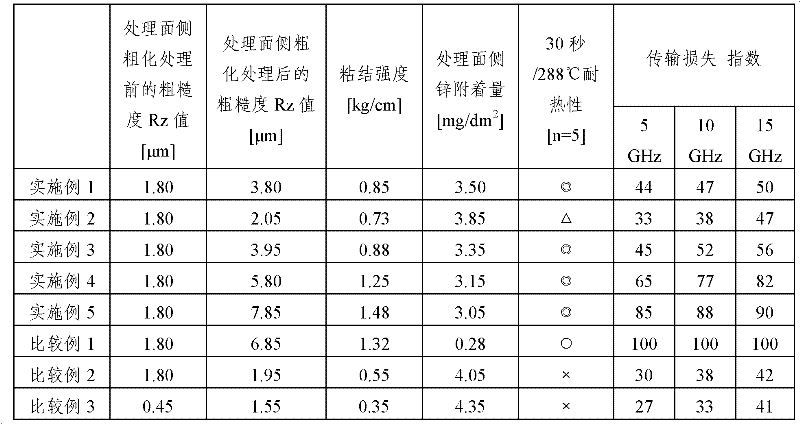

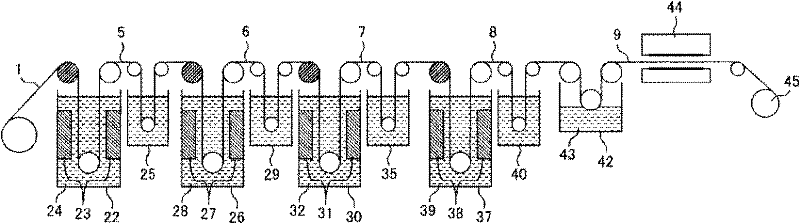

Heat-resistant copper foil and method for producing same, circuit board, and copper-clad laminate board and method for manufacturing same

ActiveCN102482795AHigh peel strengthImprove heat resistanceChromatisationPrinted circuit aspectsSurface layerZinc metal

Disclosed is a copper foil which has excellent high frequency characteristics and heat resistance, while achieving high heat-resistant adhesion to a resin substrate at the same time. Specifically disclosed is a heat-resistant copper foil which has a configuration wherein a primary roughened surface layer which has been subjected to a primary roughening process by copper metal, a secondary roughened surface layer which has been subjected to a secondary roughening process by copper metal, and a tertiary processed surface layer which has been subjected to a tertiary processing process by zinc metal are sequentially provided on one surface of an unprocessed copper foil. Also specifically disclosed are: a circuit board which is obtained by laminating the heat-resistant copper foil on a flexible resin substrate or a rigid resin substrate; and a method for manufacturing a copper-clad laminate board wherein the heat-resistant copper foil and a heat-resistant resin substrate are thermally pressure-bonded and the tertiary processed surface layer, which is composed of the roughened copper metal and the zinc metal, is alloyed.

Owner:FURUKAWA ELECTRIC CO LTD

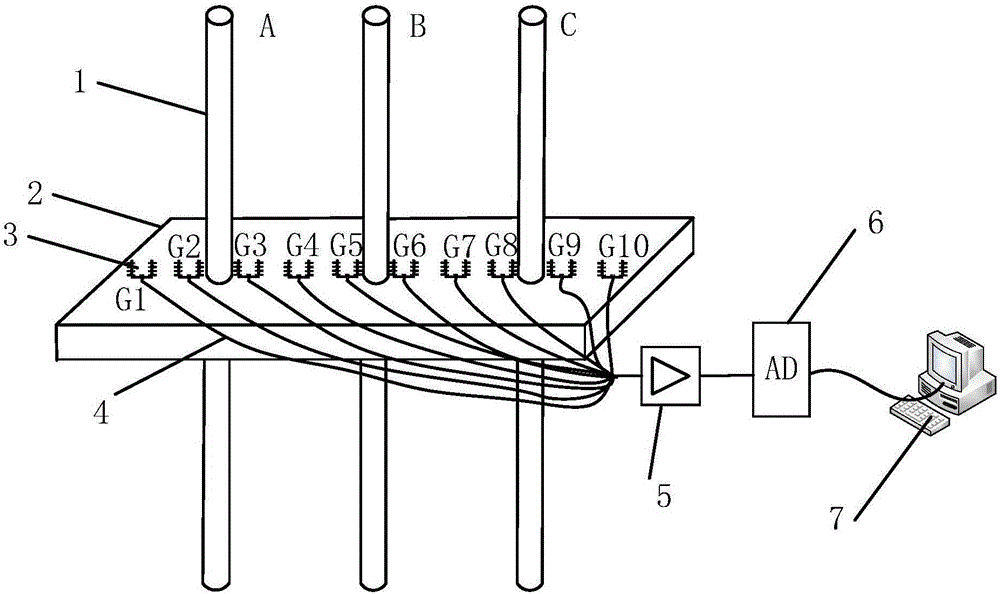

Current sensor array used for measuring three-phase current and measuring method thereof

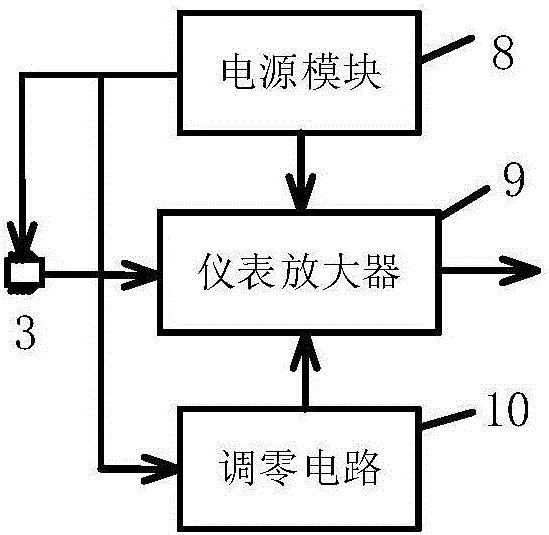

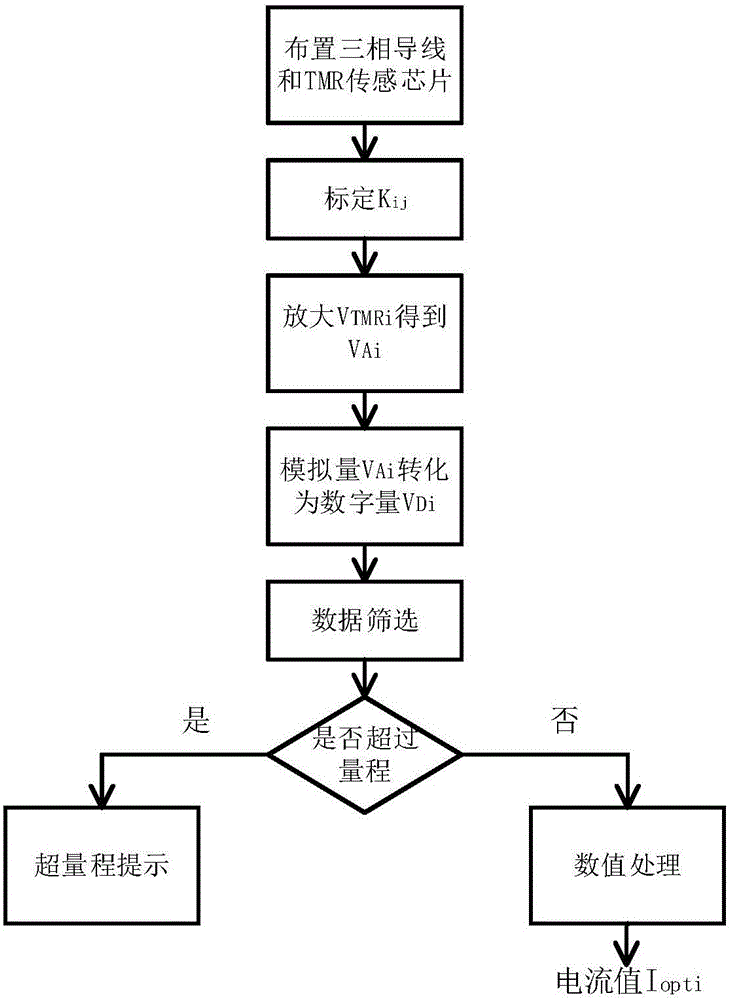

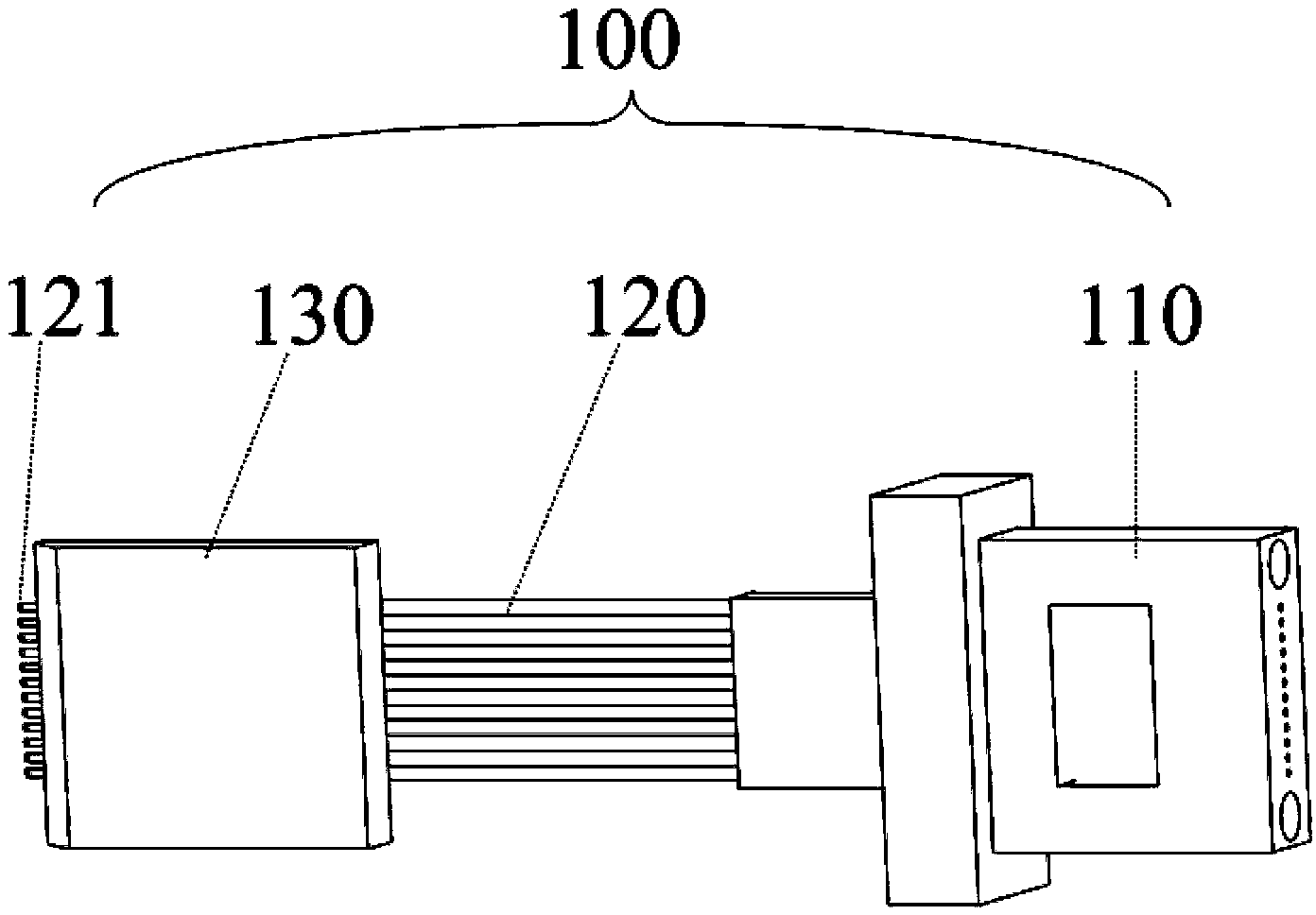

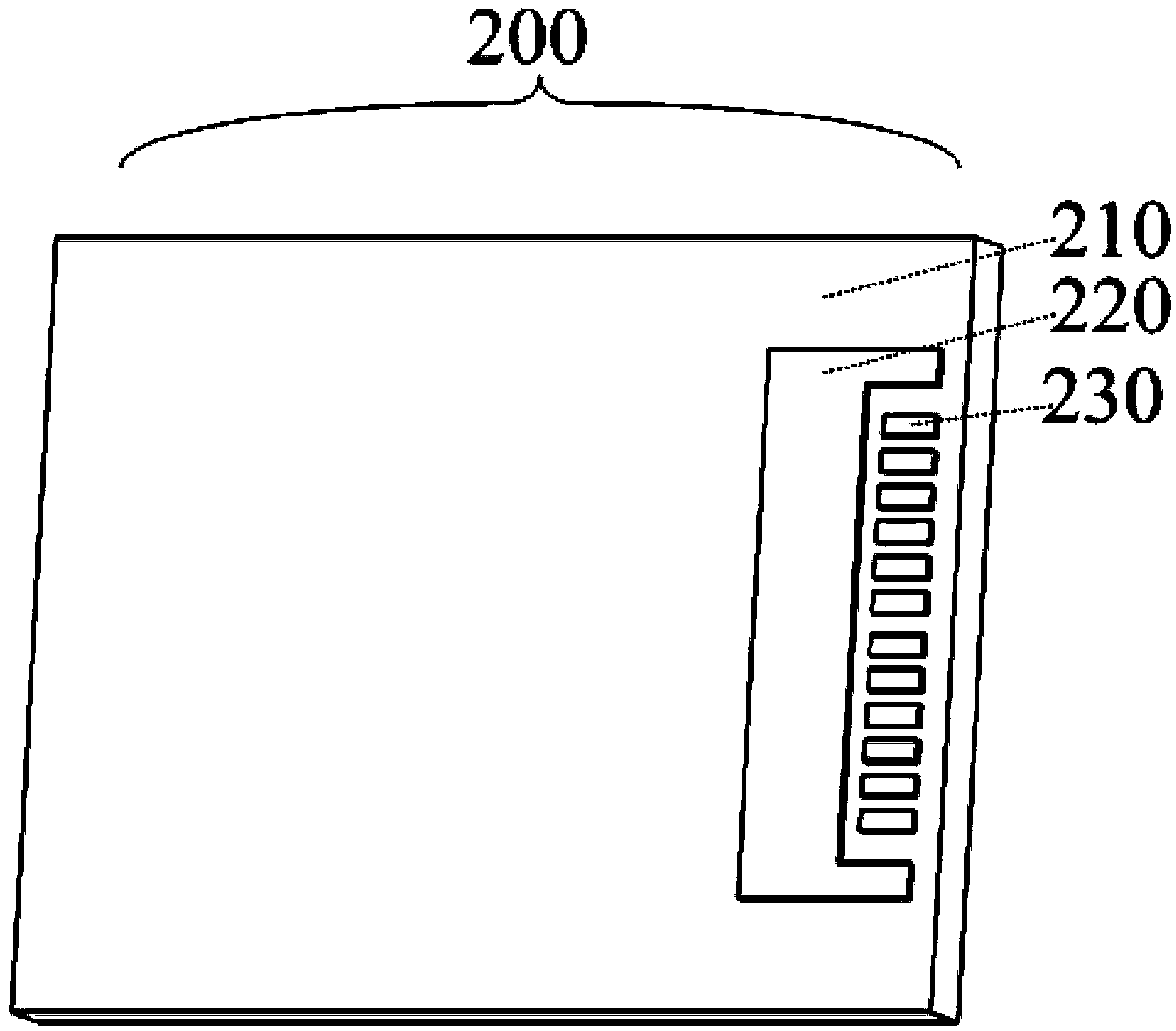

ActiveCN106018942ALarge rangeExpand the measurable current rangeMeasurement using digital techniquesSignal conditioning circuitsCurrent sensor

The invention relates to a current sensor array used for measuring three-phase current and a measuring method thereof, and belongs to the technical field of sensing measurement. The device comprises three-phase current carrying leads, an operating platform, N sensing chips, a signal transmission line, a signal conditioning circuit, an analog-to-digital conversion device and a data processing device. The current sensor array formed by the three-phase current carrying leads and the N sensing chips is fixed on the operating platform in measurement. The three-phase current carrying leads are equal in distance. The N sensing chips are arranged according to different distance to the three-phase current carrying leads. Each sensing chip is connected with the signal conditioning circuit through the signal transmission line. The signal conditioning circuit, the analog-to-digital conversion device and the data processing device are connected in turn. The data processing device performs numerical processing on output data so as to obtain the current values of the three-phase current carrying leads. The current sensor array used for measuring three-phase current is large in measuring range, high in precision, low in cost, easy to prepare, safe and reliable, convenient to install and maintain without invasion and suitable for mass application.

Owner:成都清蓉深瞳科技有限责任公司

Parallel optical emission assembly based on 45-degree fiber array and manufacturing method thereof

InactiveCN103383483AEasy to integrateImprove thermal conductivityCoupling light guidesElectromagnetic transmittersOptical reflectionFiber array

The invention relates to a parallel optical emission assembly based on a 45-degree fiber array and a manufacturing method thereof. The parallel optical emission assembly comprises the 45-degree fiber array with an MT connector, a ceramic substrate and a VCSEL laser device array, wherein an electrode and a bonding pad are arranged on the ceramic substrate, the VCSEL laser device array is fixedly bonded on the electrode of the ceramic substrate, a bonding pad of a chip of the VCSEL laser device array is connected with the bonding pad of the ceramic substrate in a gold wire bonding mode, the 45-degree optical reflection surface of the 45-degree fiber array with the MT connector is in one-to-one aligned coupling with the VCSEL laser device array, and the 45-degree fiber array with the MT connector is fixed on the ceramic substrate. During usage, a user only needs to bond the ceramic substrate on a printed circuit board (PCB) of the user, driving signals of the VCSEL laser device array are connected with the bonding pad on the ceramic substrate in a routing mode, high-speed signals can demodulate and drive the VCSEL laser device array, parallel electric signals can be converted into parallel optical signals, and the parallel optical signals can be output to the standard MT connector through direct coupling of the 45-degree fiber array to be connected with the outside.

Owner:WUHAN POWERISE OPTOELECTRONICSAL TECH

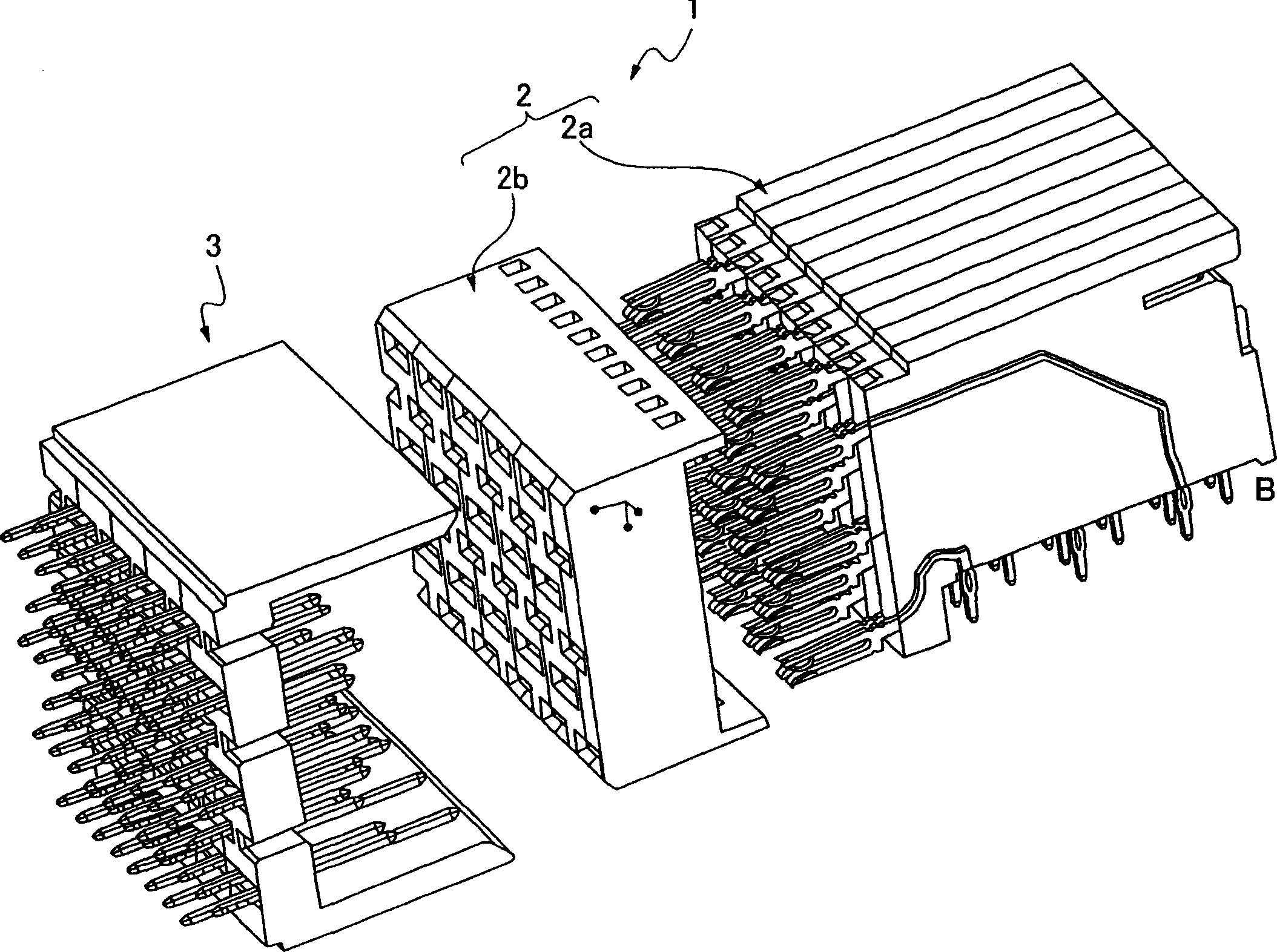

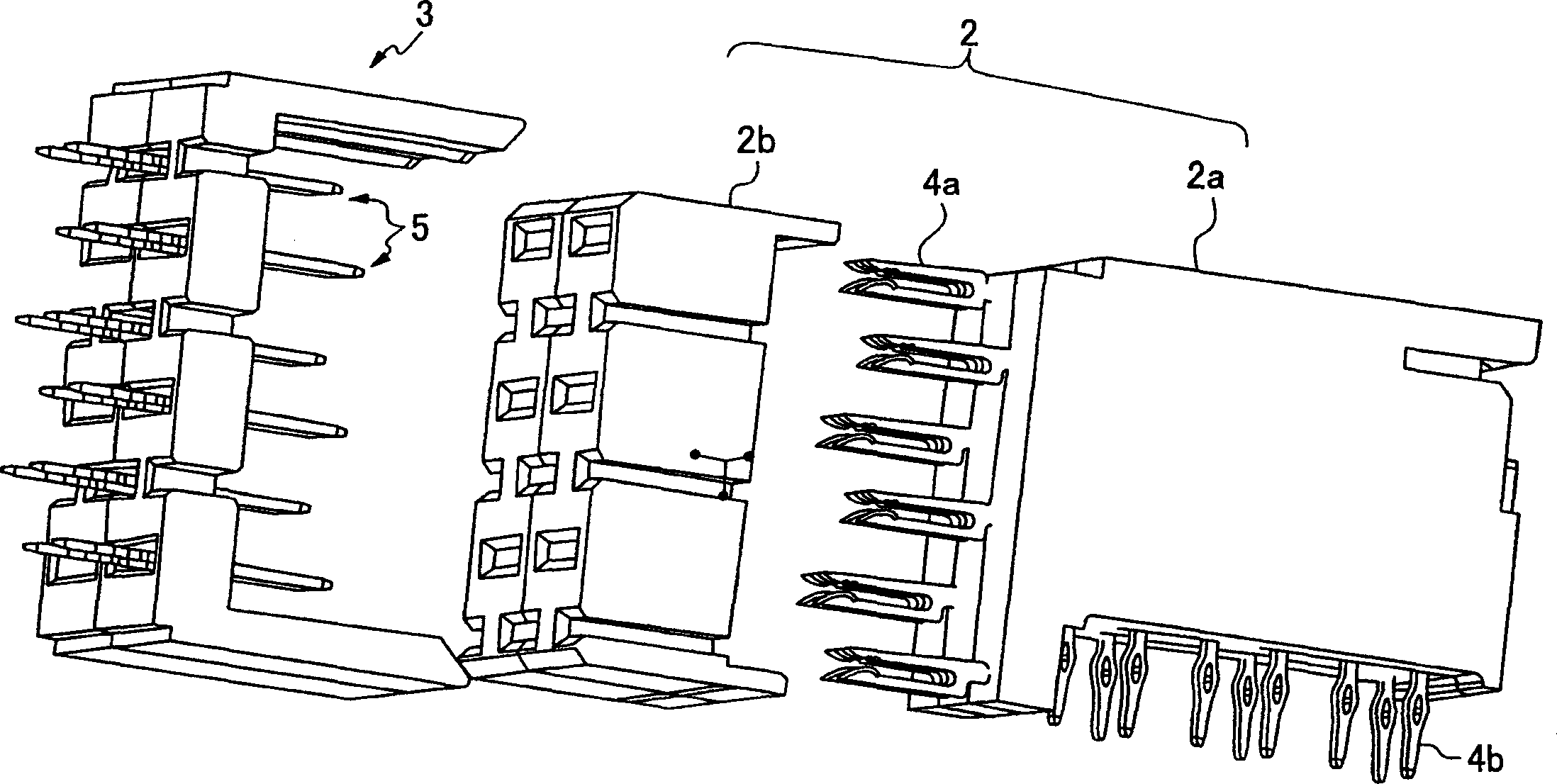

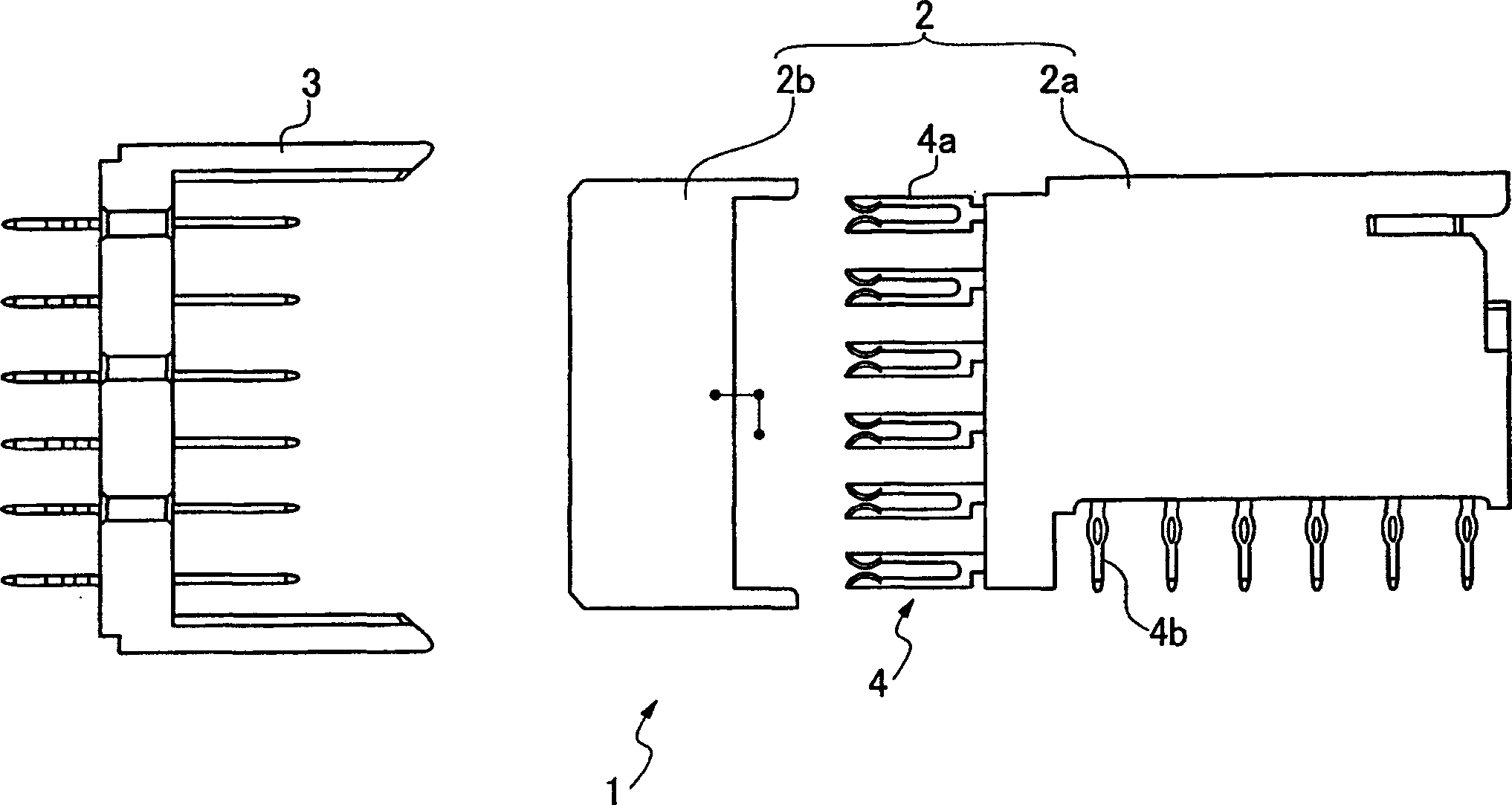

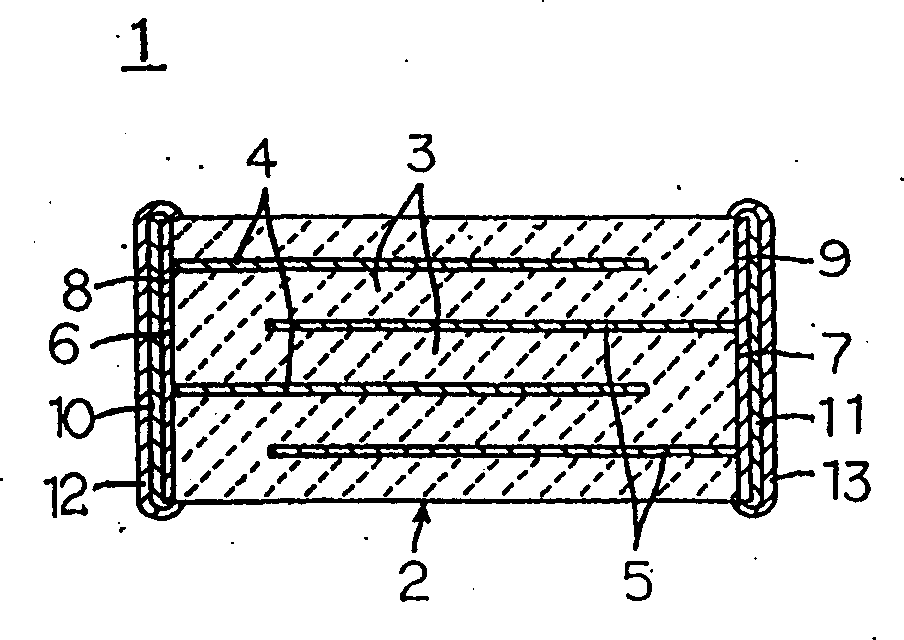

Electric connector and paired contact

InactiveCN1714482ALow insertion lossAvoid noiseCoupling contact membersCoupling protective earth/shielding arrangementsLeft directionEngineering

There is provided a connector used for connection between a printed circuit board and a device or between printed circuit boards such as between a computer, a server, or a backboard-package and in particular a high-speed transmission connector for transmitting a high-frequency electric signal. The high-speed transmission connector (1) includes a plurality of signal terminals and an insulation housing having a plurality of containing holes for containing the signal terminals arranged in right-left direction in multiple stages arranged in vertical direction. In one containing hole (2c), a paired terminal (4, 4) for transmitting one electric signal is contained in such a manner that the terminals are located near to each other in the right-left direction. This increases the high-speed transmission characteristic and reduces the number of parts required.

Owner:HONDA TSUSHIN IND

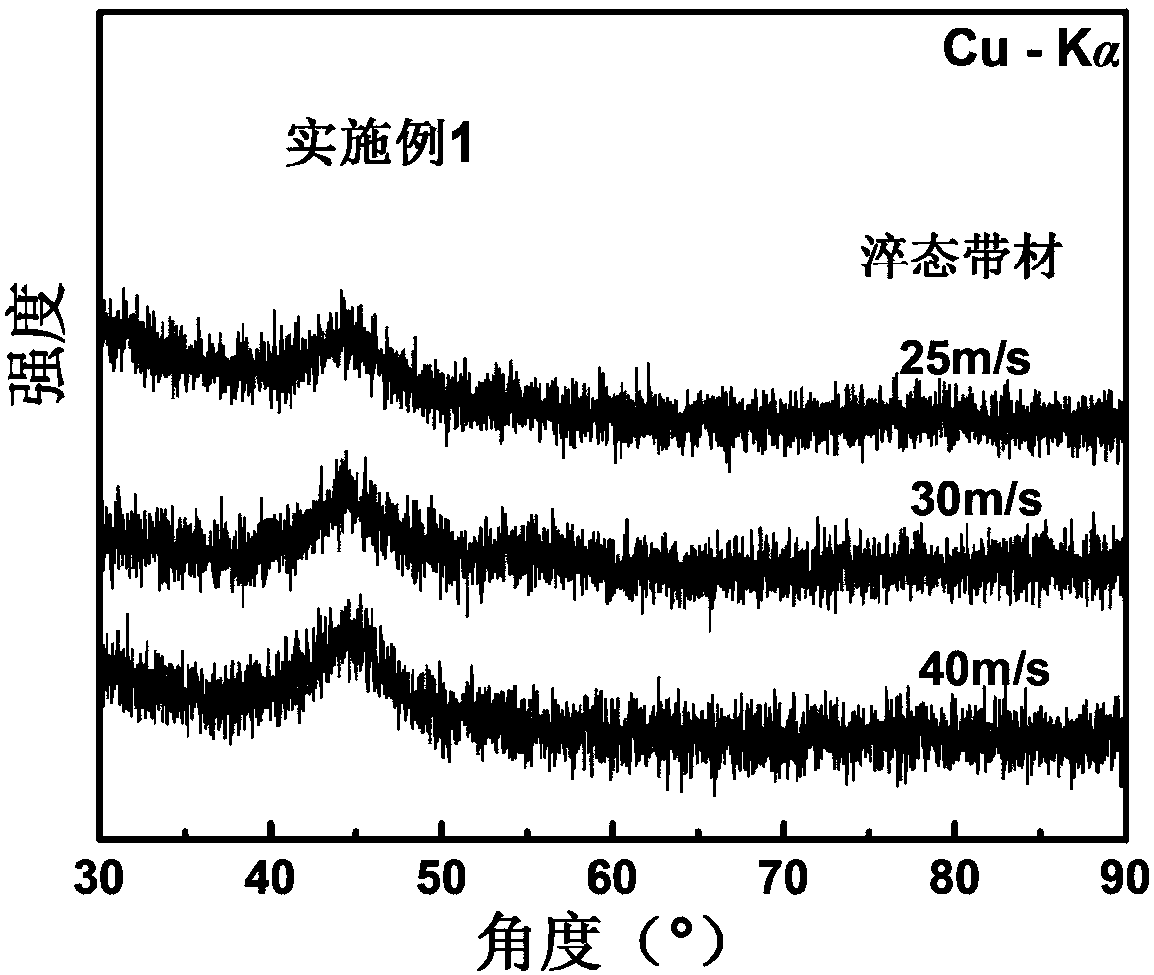

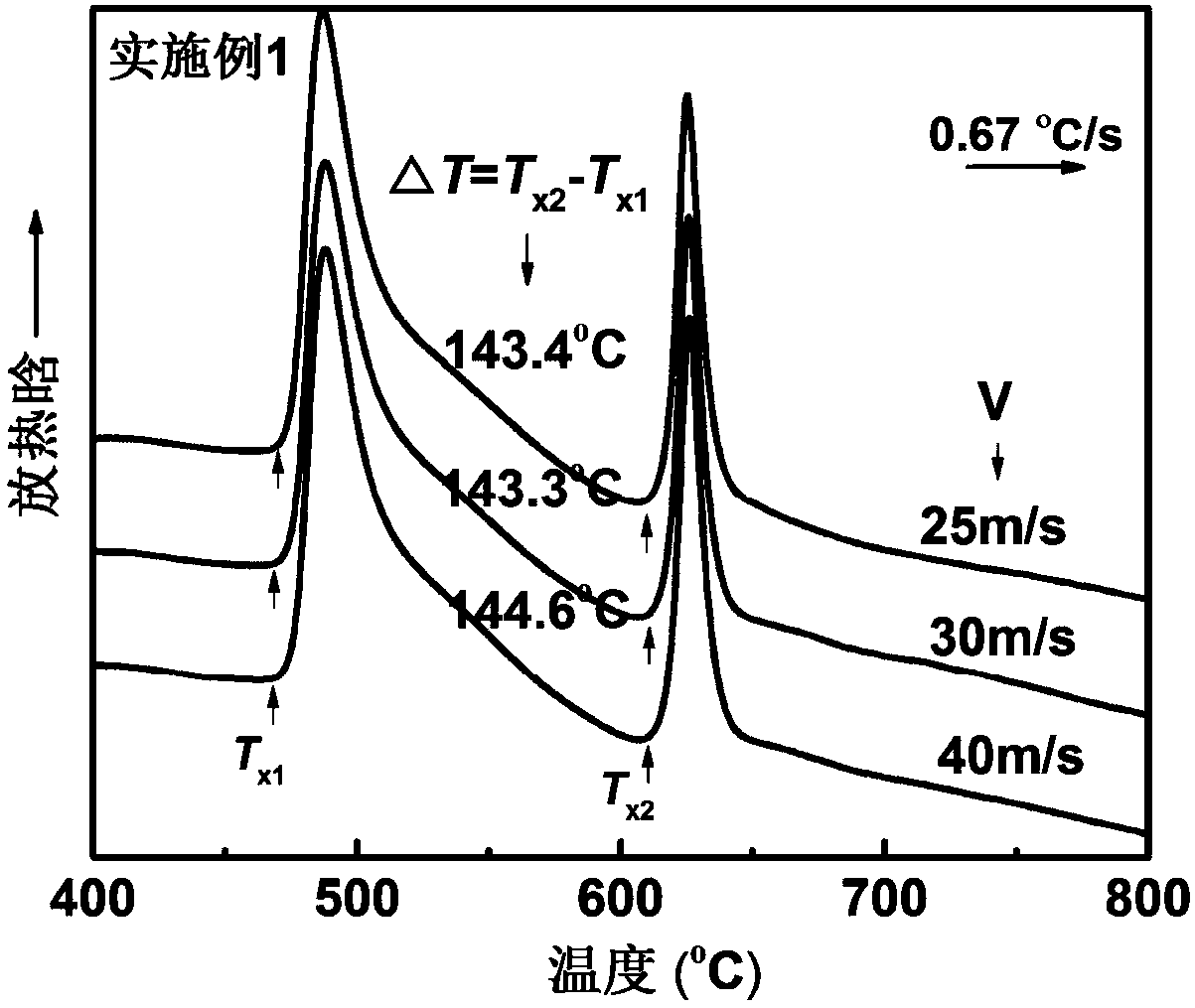

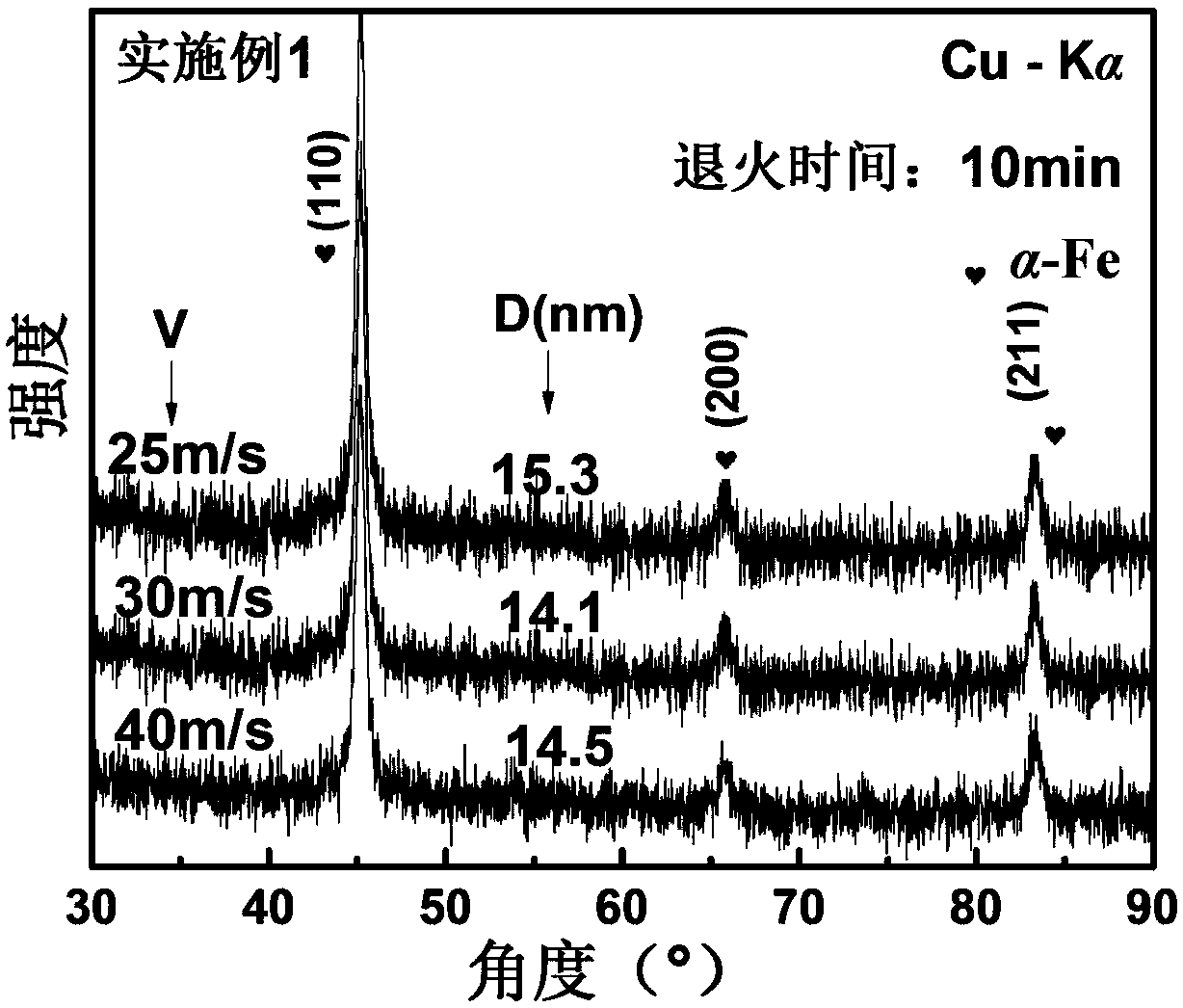

High-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy and preparation method thereof

ActiveCN110387500AExcellent soft magnetic propertiesImprove thermal stabilityMagnetic materialsTransformerThermal stability

The invention discloses a high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy and a preparation method thereof. The molecular formula of the iron-based nanocrystalline soft magnetic alloy is FeaSibBcPdNbeVfMogCuh, the a, the b, the c, the d, the e, the f, the g and the h in the molecular formula correspondingly represent the atomic percentage contents of all thecorresponding alloy elements, and satisfy the following conditions that the a is greater than or equal to 75.5 and less than or equal to 77.5, the b is greater than or equal to 8.5 and less than or equal to 13.5, the c is greater than or equal to 7 and less than or equal to 10, the d is greater than or equal to 0.2 and less than or equal to 1, the e is greater than or equal to 1.0 and less than orequal to 1.7, the f is greater than or equal to 0.05 and less than or equal to 0.4, the g is greater than or equal to 0.1 and less than or equal to 1.5, the h is greater than or equal to 0.8 and lessthan or equal to 1.2, and the sum of the a, the b, the c, the d, the e, the f, the g and the h is 100. The high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy material has the advantages of excellent comprehensive soft magnetic performance, low cost, high thermal stability and the like, particularly, the high-frequency performance is good, the magnetic conductivity under the condition of 10 kHz can reach 28000 or above, a good application prospect is achieved, and the high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy material can be applied to the technical fields of high-frequency transformers, common mode chokes, wireless charging and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

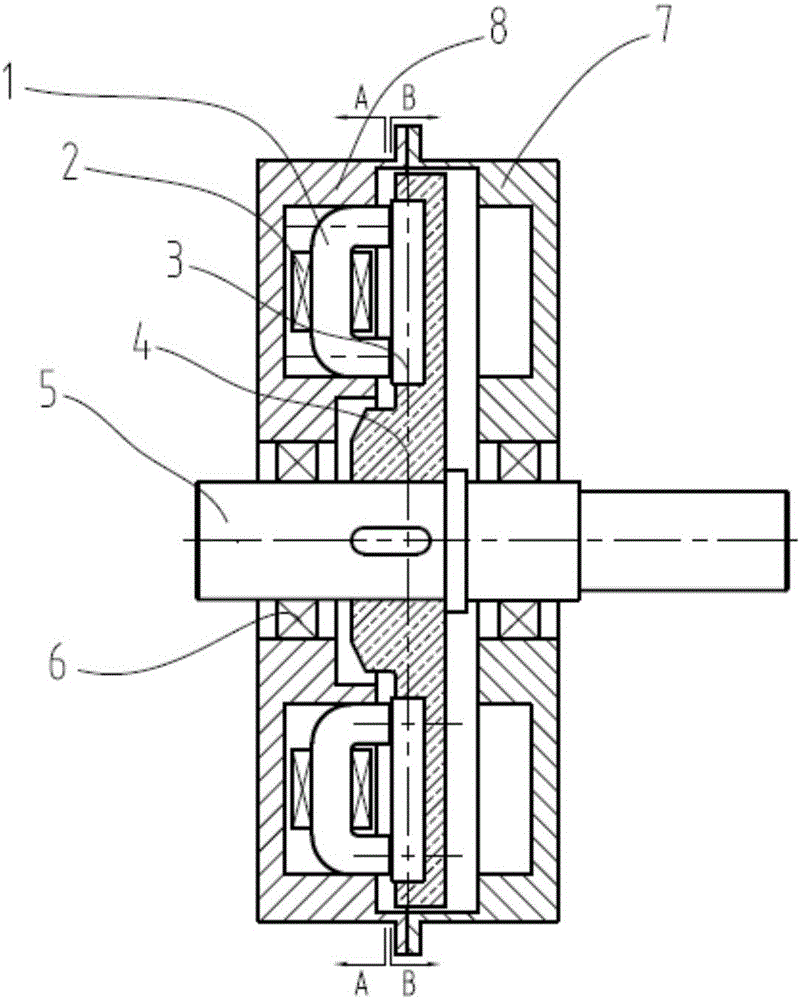

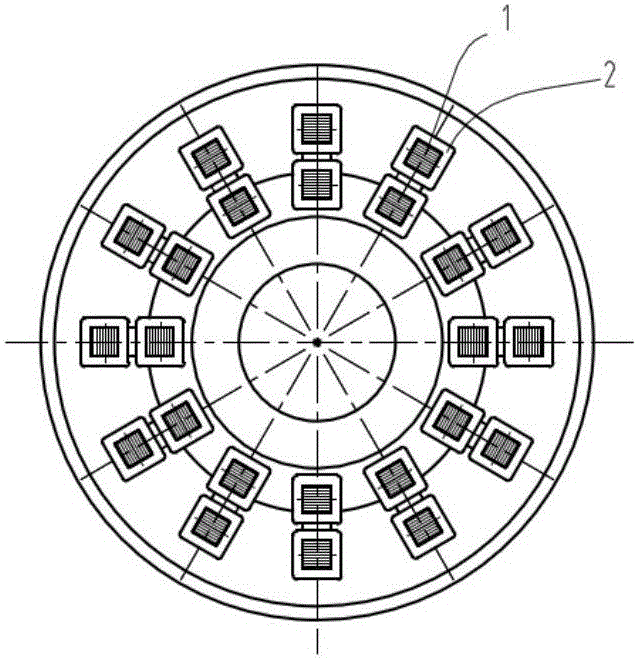

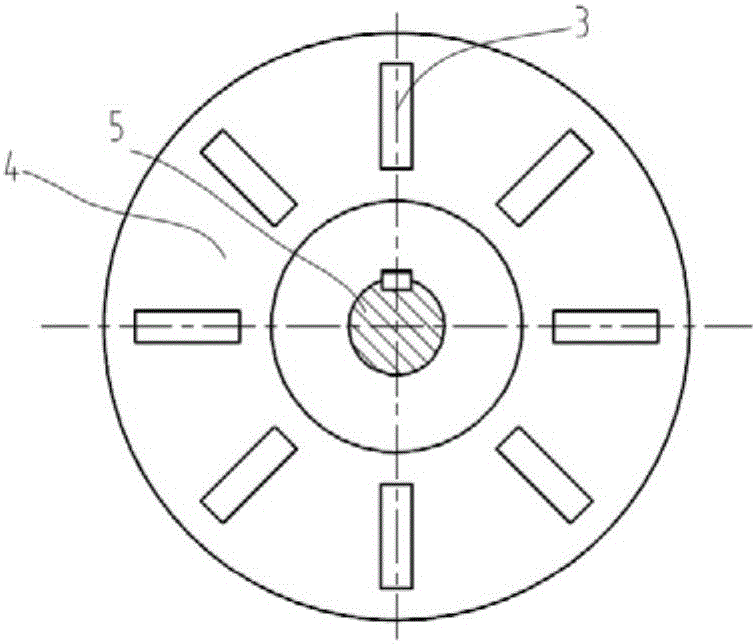

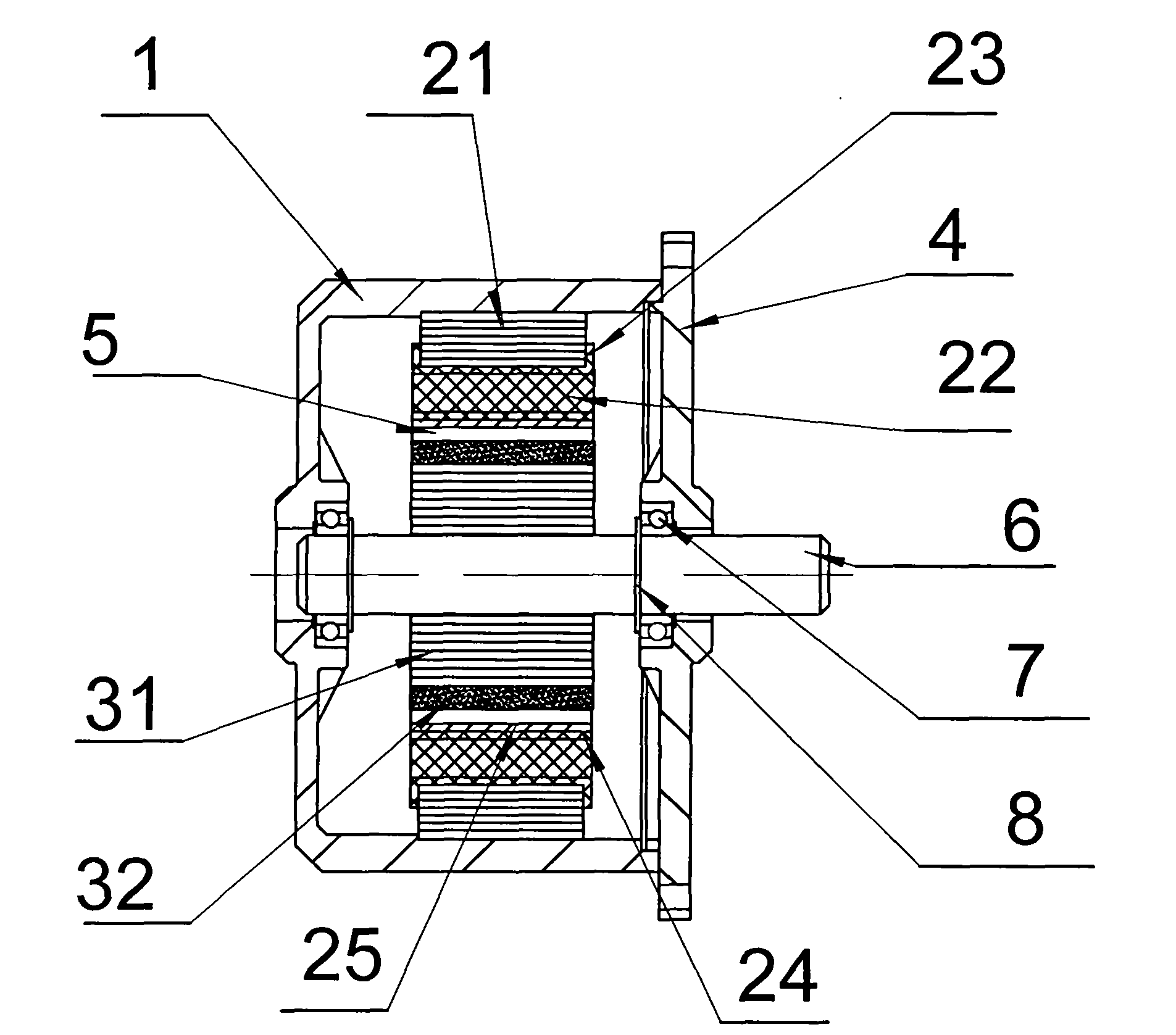

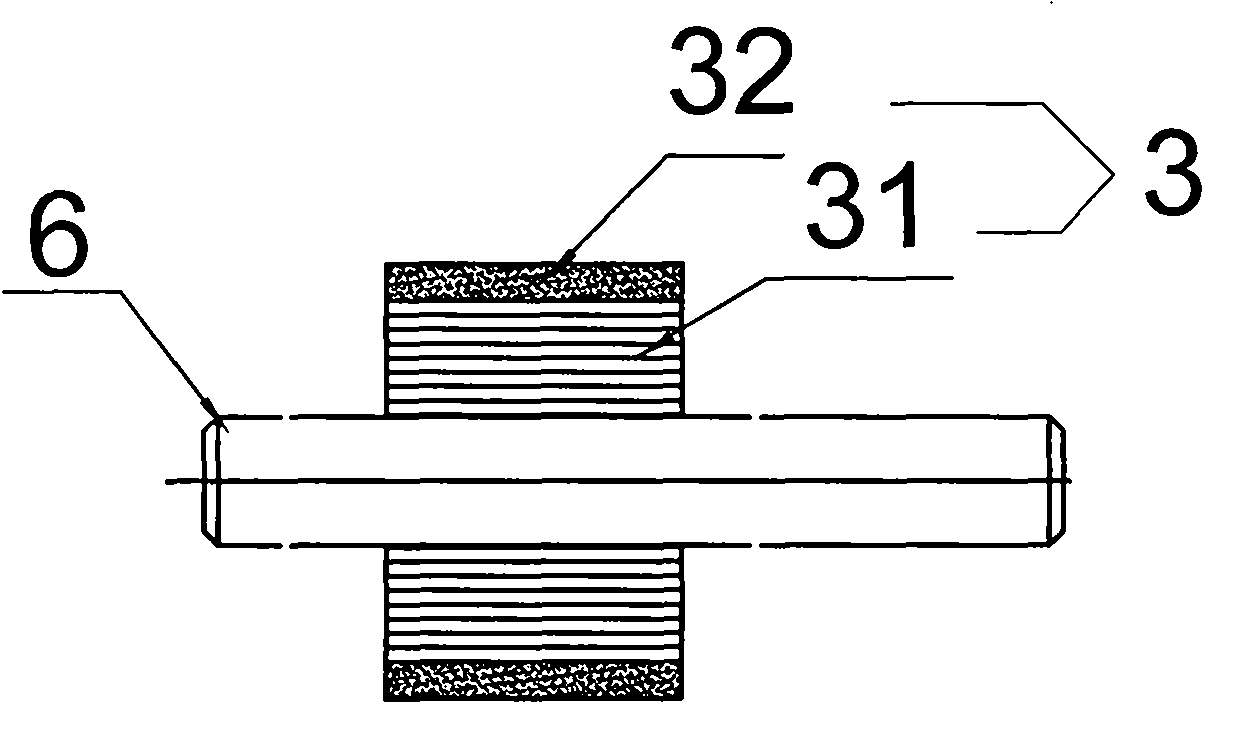

Axial air gap switch reluctance motor and preparation method thereof

ActiveCN105827027AReduce eddy current lossGood high frequency characteristicsWindings insulation shape/form/constructionMagnetic circuit rotating partsConductor CoilControl theory

The invention provides an axial air gap switch reluctance motor and a preparation method thereof. The axial air gap switch reluctance motor includes stators, rotor iron cores, a motor rotation shaft, a rotor disc and a shell; the motor rotation shaft is fixed in the shell; the rotor disc is assembled on the motor rotation shaft; the rotor iron cores are fixed on the rotor disc; the stators are fixed in the shell; the stators are corresponding to the rotor iron cores; and axial air gaps exist between the stators and the rotor iron cores. The axial air gap switch reluctance motor of the invention is convenient to assemble, and spatial layout and wire winding mode of the axial air gap switch reluctance motor can be flexibly adjusted according to different application conditions, the number of the phases, the size and the power of the motor can be expanded through adjusting the number of the stator iron cores or rotor iron cores, so that the requirements of the use of motors of various kinds of power in various kinds of conditions can be satisfied, and the application range of the axial air gap switch reluctance motor can be extended.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

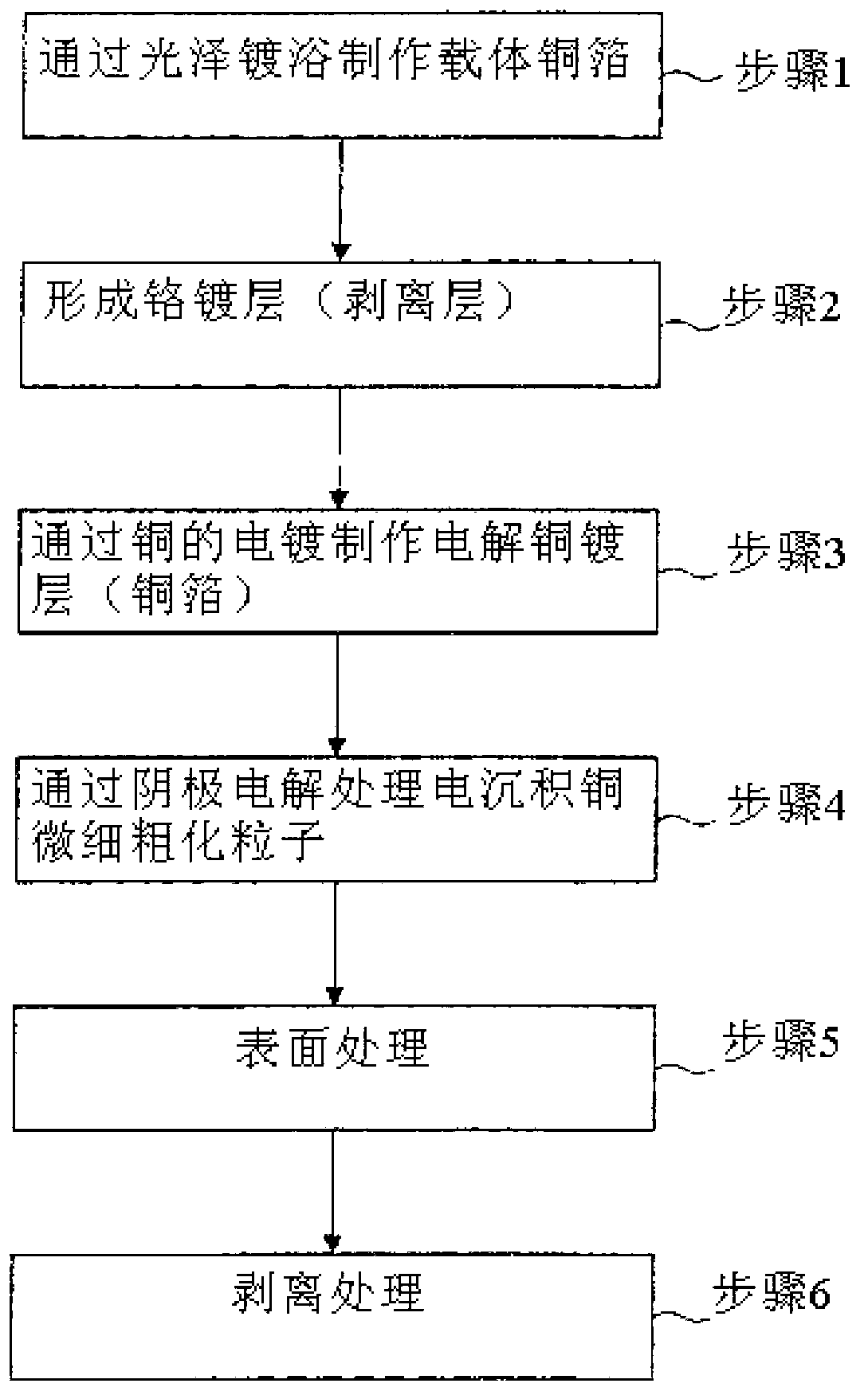

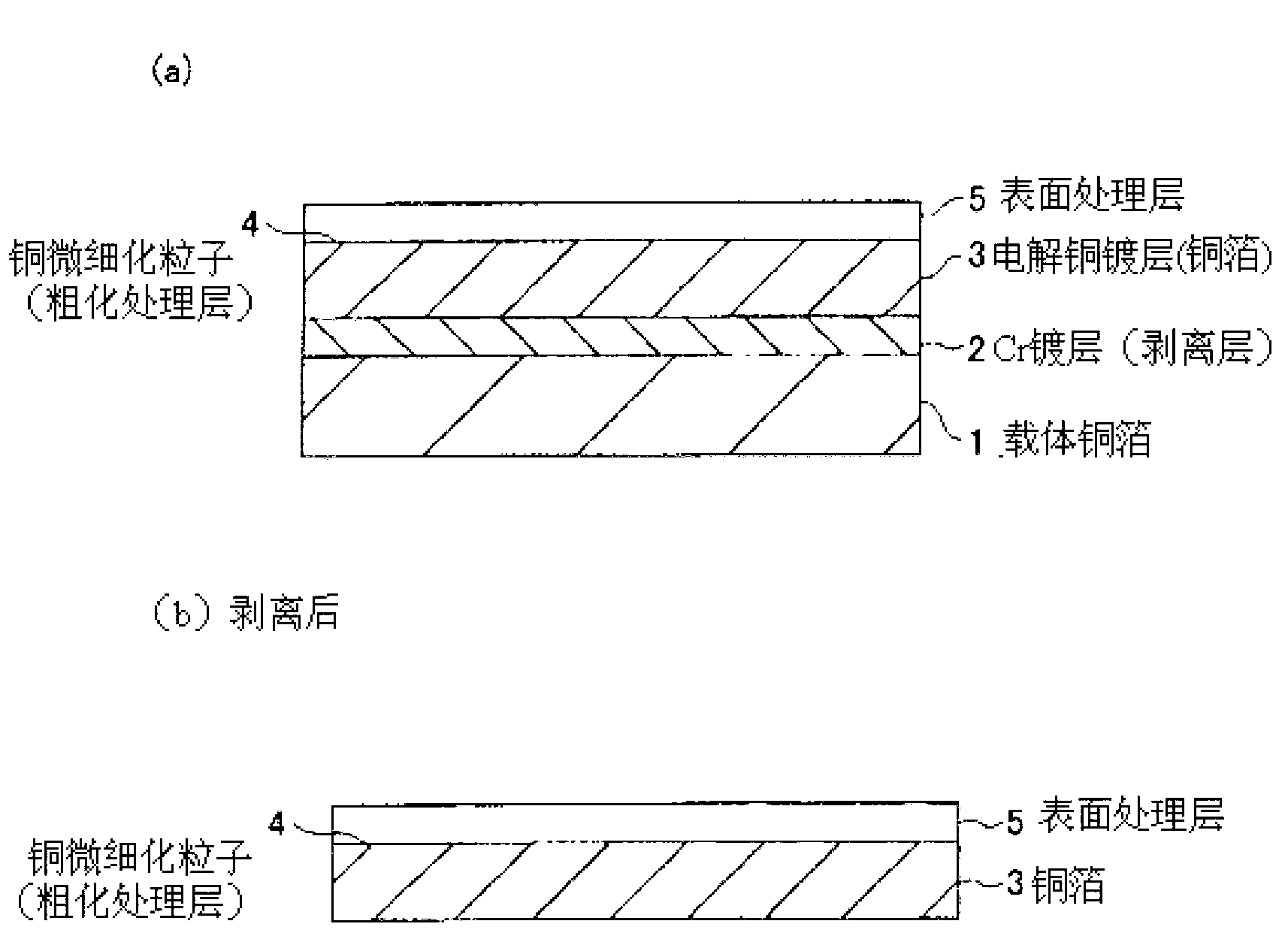

Copper foil and manufacturing method therefor, copper foil with carrier and manufacturing method therefor, printed circuit board, and multilayer printed circuit board

InactiveCN103154327AHigh Density Fine WiringHigh wiringThin material handlingCircuit precursor manufactureCopper foilEngineering

Provided is a copper foil with carrier capable of providing wirings of line / space=15 [mu] m / 15 [mu] m or less on a printed circuit board on which copper foils are laminated. Also provided are a printed circuit board and a multilayer printed circuit board capable of providing wirings with fine patterns of line / space=15 [mu] m / 15 [mu] m or less using the copper foil. A copper foil with carrier obtained by laminating a release layer and a copper foil in this order on a carrier foil having an average interval Sm of 25 [mu] m or more between irregularities of a substrate crest on the surface, the Sm being defined in JIS-B-06012-1994, and by laminating a release layer and a copper foil in this order on a carrier foil which is a copper foil obtained by peeling the former copper foil from the former carrier foil, wherein the interval between irregularities of a substrate crest on the surface of the carrier foil on which copper foils are laminated is 25 [mu]m or more as the average interval Sm defined in JIS-B-06012-1994. A roughening process layer and a surface treatment layer are laminated in this order on the surface of the copper foil as needed.

Owner:FURUKAWA ELECTRIC CO LTD

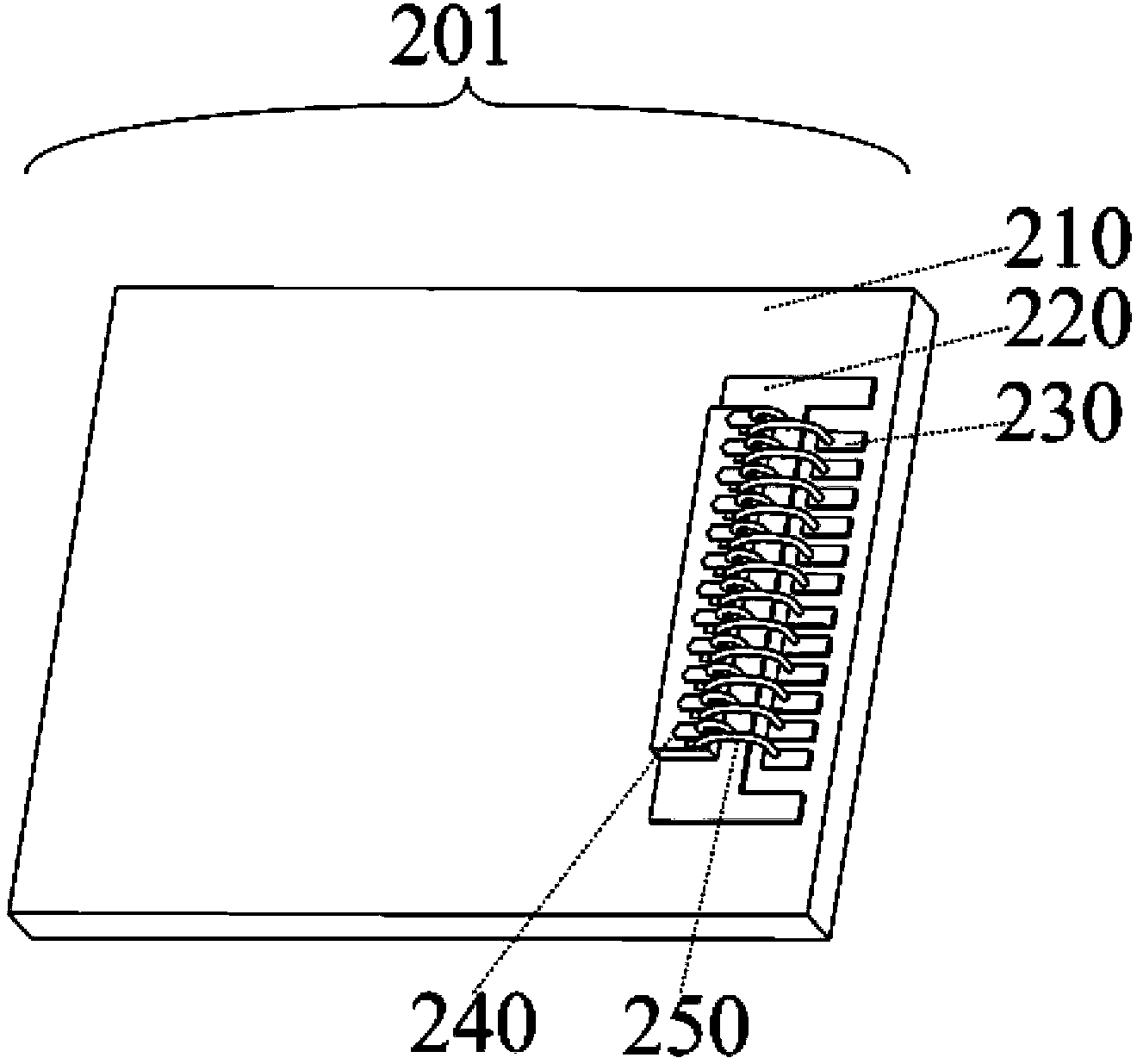

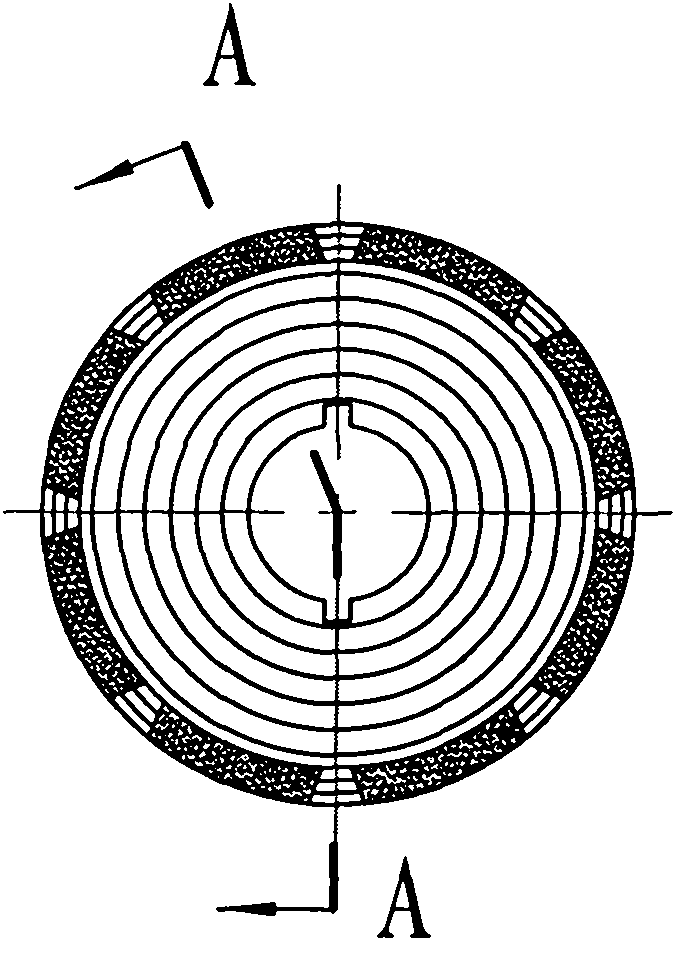

Motor with slotless amorphous iron alloy radial magnetic circuit and process method thereof

InactiveCN101976895AReduce volumeEliminate coggingWindingsMagnetic circuit rotating partsAlloyProcessing cost

The invention discloses a motor with a slotless amorphous iron alloy radial magnetic circuit. A stator core (21) is wound into a cylinder by an amorphous iron alloy strip; a stator winding (22) is wholly cylindrical and is fixed on a cylindrical surface in the stator core (21); a metal reinforced bushing (25) is fixed on an inner wall of the stator winding (22); and a radial air gap (5) is formed between an inner hole of the stator winding (22) and an outer surface of a rotor (3). A rotor core (31) is made of an amorphous iron alloy material to form a hollow columnar structure; a key slot (312) which is connected with a motor shaft (6) is formed on an inner hole wall; a radial outer surface of the key slot (312) is matched with a permanent magnet (32); and the permanent magnet (32) is embedded in or sleeved on an outer surface of the rotor core (31) for fixation. The motor effectively reduces the volume, reduces the loss, improves the efficiency, simultaneously avoids processing difficulty of slots, saves working hours, greatly reduces the processing cost, eliminates motor slot effect, reduces electromagnetic noise, has the advantages of low eddy-current loss, excellent high-frequency characteristics and high power density, and is a high-efficiency and energy-saving motor.

Owner:SHENZHEN DONG MING MOTOR ELECTRIC CO LTD +2

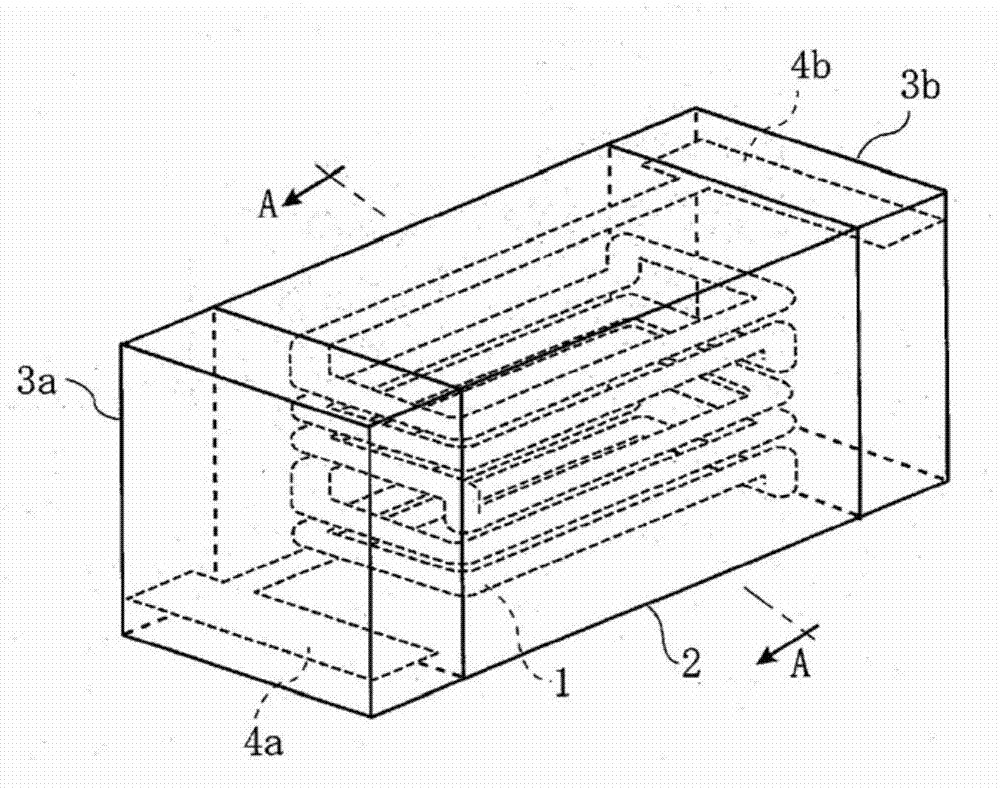

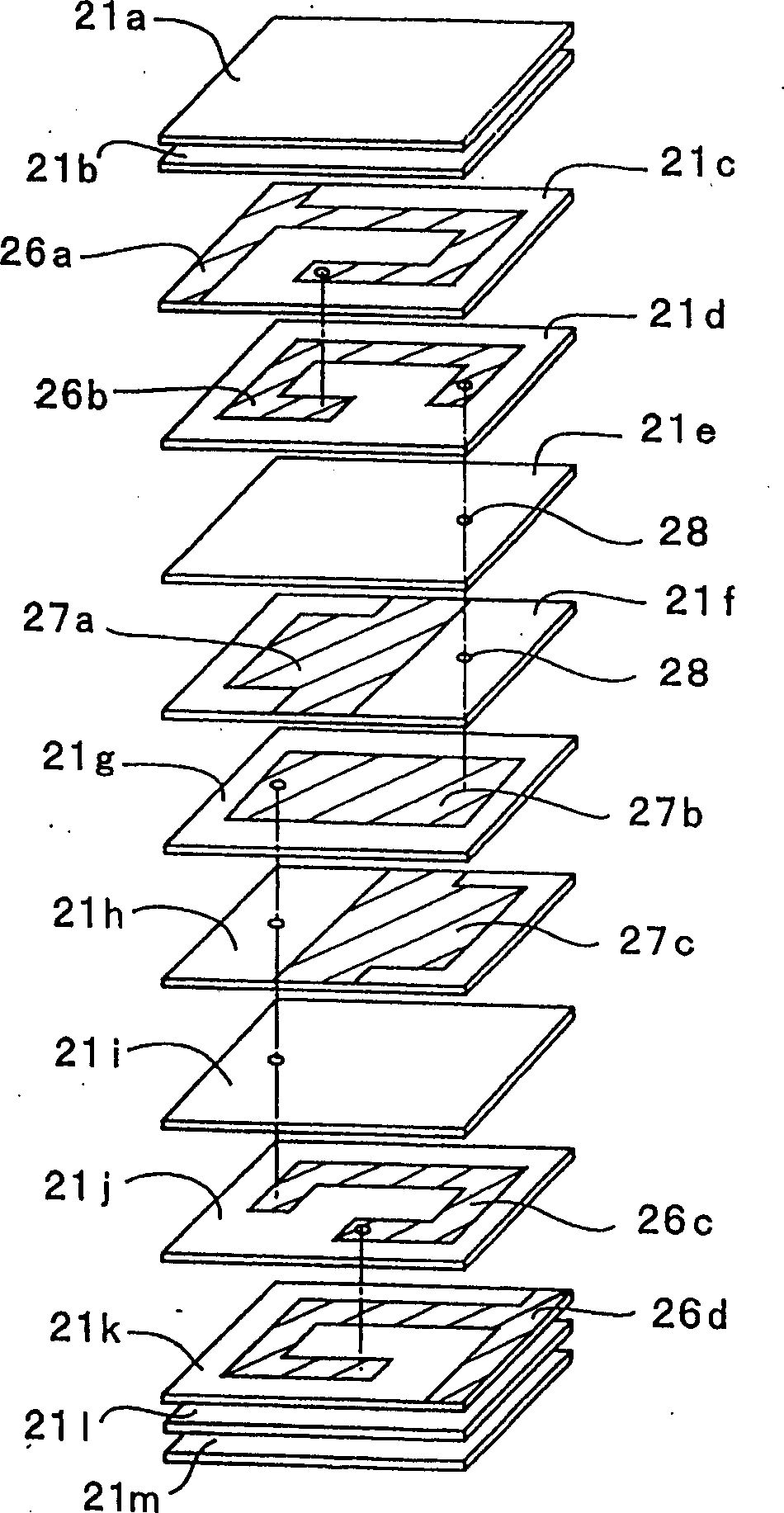

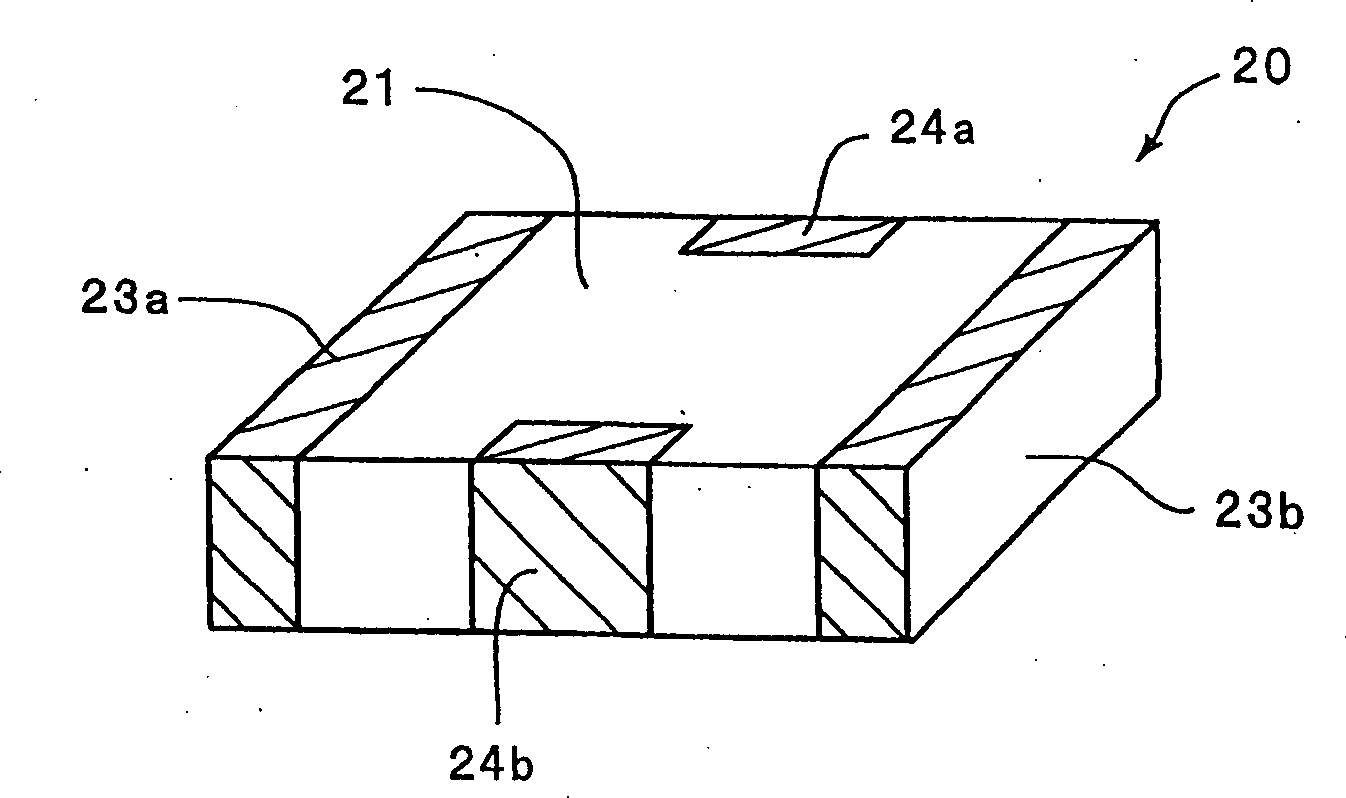

Laminated coil device and manufacturing method therefor

ActiveCN104737245AImprove reliabilitySuppression of stray capacitance riseInorganic material magnetismTransformers/inductances detailsElectrical conductorMagnetic characteristic

A laminated coil device includes a magnetic part (5) that includes a metallic magnetic material and a first glass component, and a non-magnetic part (6) that includes a ceramic material and a second glass component, and a coil conductor (1) is formed such that at least a main surface of the coil pattern contacts the non-magnetic part (6). The magnetic part (5) is formed such that the volume content of the first glass component in the total of the metallic magnetic material and the first glass component is 46 to 60 volume%. The non-magnetic part (6) is formed such that the volume content of the second glass component in the total of the ceramic material and the second glass component is 69 to 79 volume%. As a result, it is possible to achieve a highly reliable laminated coil device and manufacturing method therefor which can provide good high-frequency characteristics and good magnetic characteristics without impairing insulation, and can reduce the occurrence of structural defects such as cracks or peeling.

Owner:MURATA MFG CO LTD

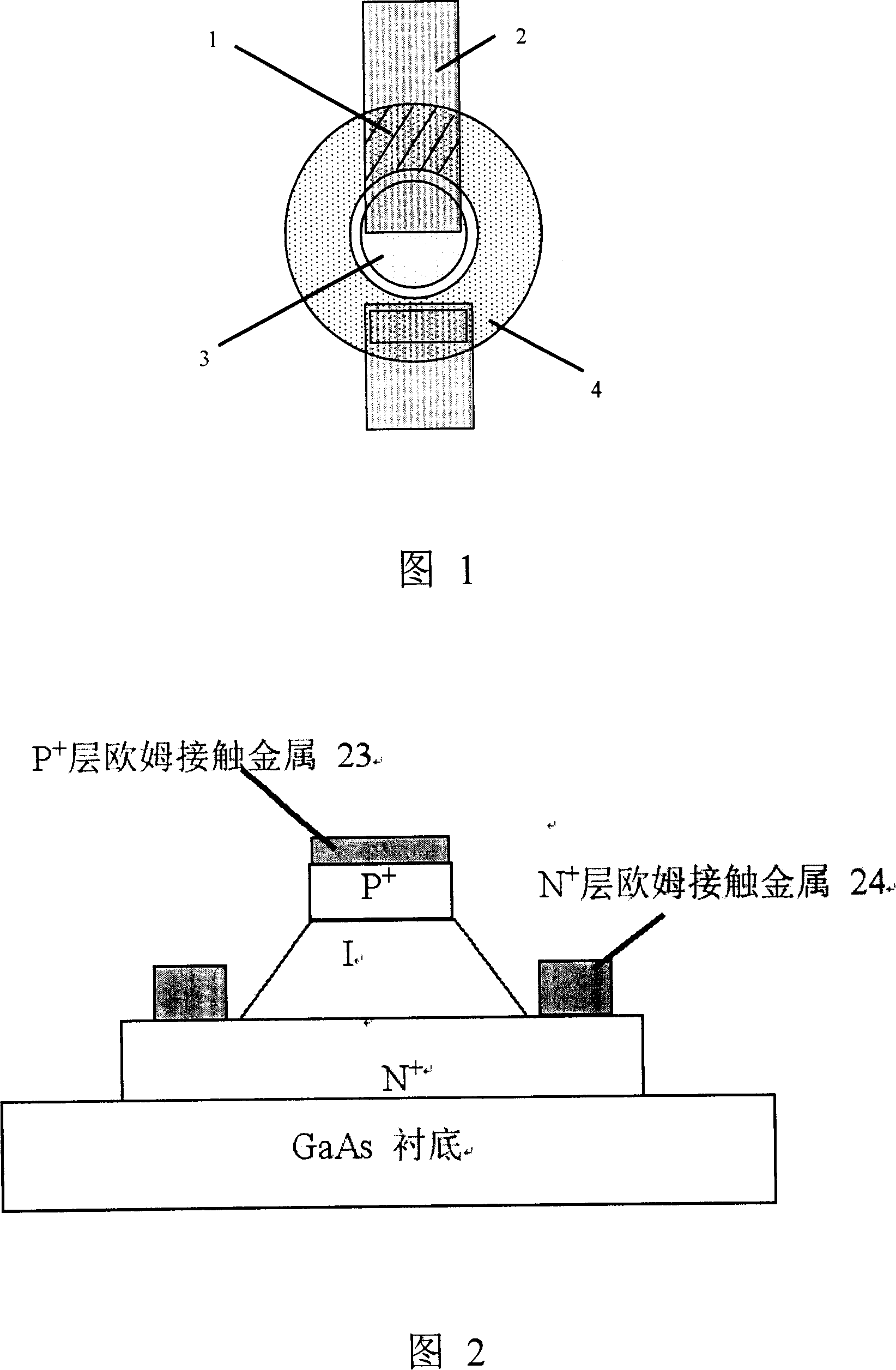

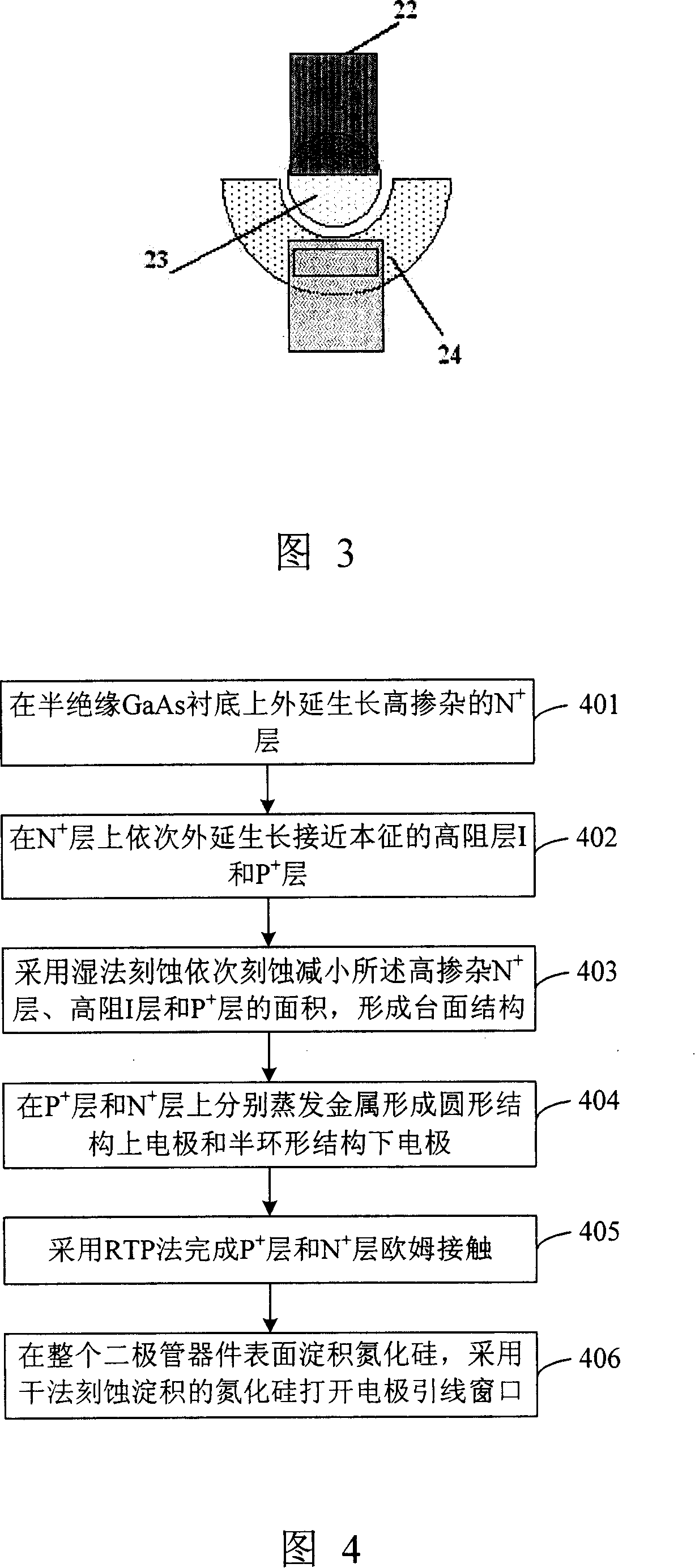

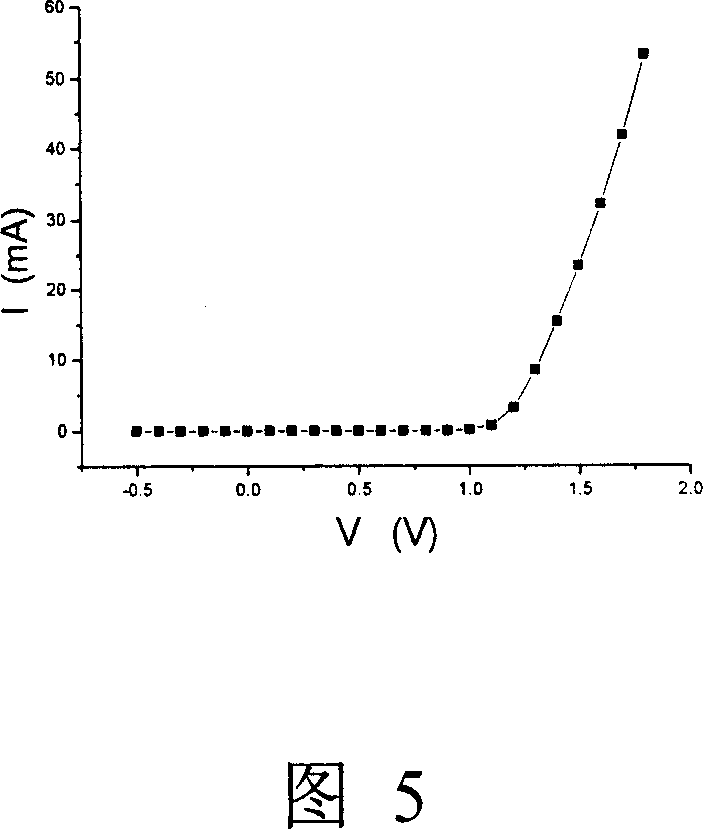

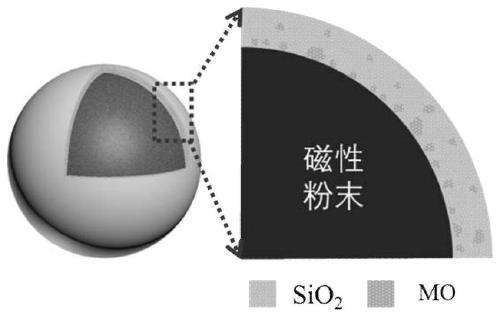

Gallium arsenide PIN diode and preparation method thereof

ActiveCN101140955AReduce parasitic capacitanceRealize the process is simpleSemiconductor/solid-state device manufacturingSemiconductor devicesMaterials scienceAir bridge

The invention discloses a GaAs PIN diode, which comprises: a semi-insulating GaAs underlay for supporting the whole GaAs diode; a high doped layer N growing in extension on the semi-insulating GaAs underlay, resistive formations I and P close to eigen growing in extension in turn on the high doped layer N; By wet process and etching, the areas of the said high doped layer N, resistive formations I and P reduced in turn to form a mesa structure; a top electrode of the round structure formed by metal evaporator on layer P; a semi-orbicular bottom electrode formed by metal evaporator on layer N. The invention also discloses a manufacturing method of GaAs PIN diode. The invention efficiently lowers the parasitic capacitance of the PIN diode without increasing the difficulty of the process and simultaneously greatly shortens the microstrip line connected with the top electrode. The spurious inductance brought by the invention can be greatly reduced or even omitted without using the air-bridge process. The invention has the advantages of easy making, better high frequency characteristic, which is easy to realize the single scale integration.

Owner:北京中科微投资管理有限责任公司

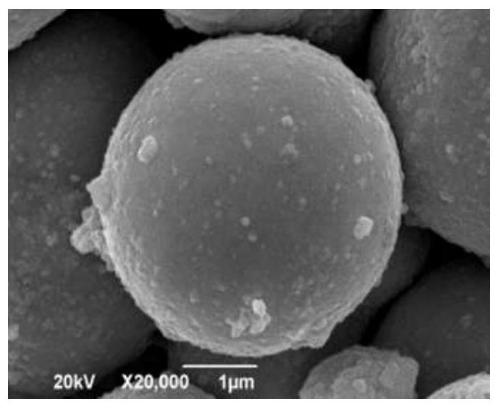

Magnetic powder surface gradient coating structure and coating method and soft magnetic composite

ActiveCN110405201ACoated evenlyCover tightlyTransportation and packagingMetal-working apparatusHigh resistivityThermal expansion

The invention relates to a magnetic powder surface gradient coating structure and coating method and a soft magnetic composite. The gradient coating structure is prepared from a coating layer which isformed on the surface of ferromagnetic powder by silicon dioxide and other coated components, and the contents of the silicon dioxide and other coated components in the coating layer are gradiently distributed. The coating method comprises the step of depositing the silicon dioxide and other coated components on the surface of the ferromagnetic powder in one step by adopting a chemical coprecipitation method, wherein the pH value of the system is adjusted in the deposition process. The soft magnetic composite is obtained by sectionally annealing the ferromagnetic powder with the coating layeron the surface after being pressed and formed. The coefficient of thermal expansion of the coating layer prepared by using the method can be controlled, the prepared soft magnetic composite has the advantages of low eddy current loss, high magnetic conductivity, high resistivity and high saturation magnetization, and the defects of low resistivity, mismatching of the coefficient of thermal expansion between coating layers and the like of the material in the prior art are overcome; in order to solve the problems of the reduction of the medium-high frequency magnetic conductivity, high eddy current loss, serious heating and the like of an existing magnetic powder core, a good method is provided.

Owner:CENT SOUTH UNIV

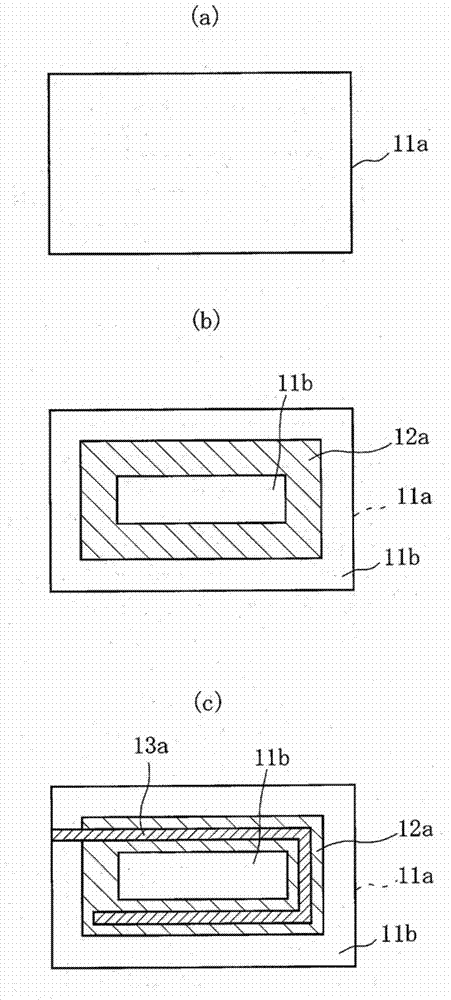

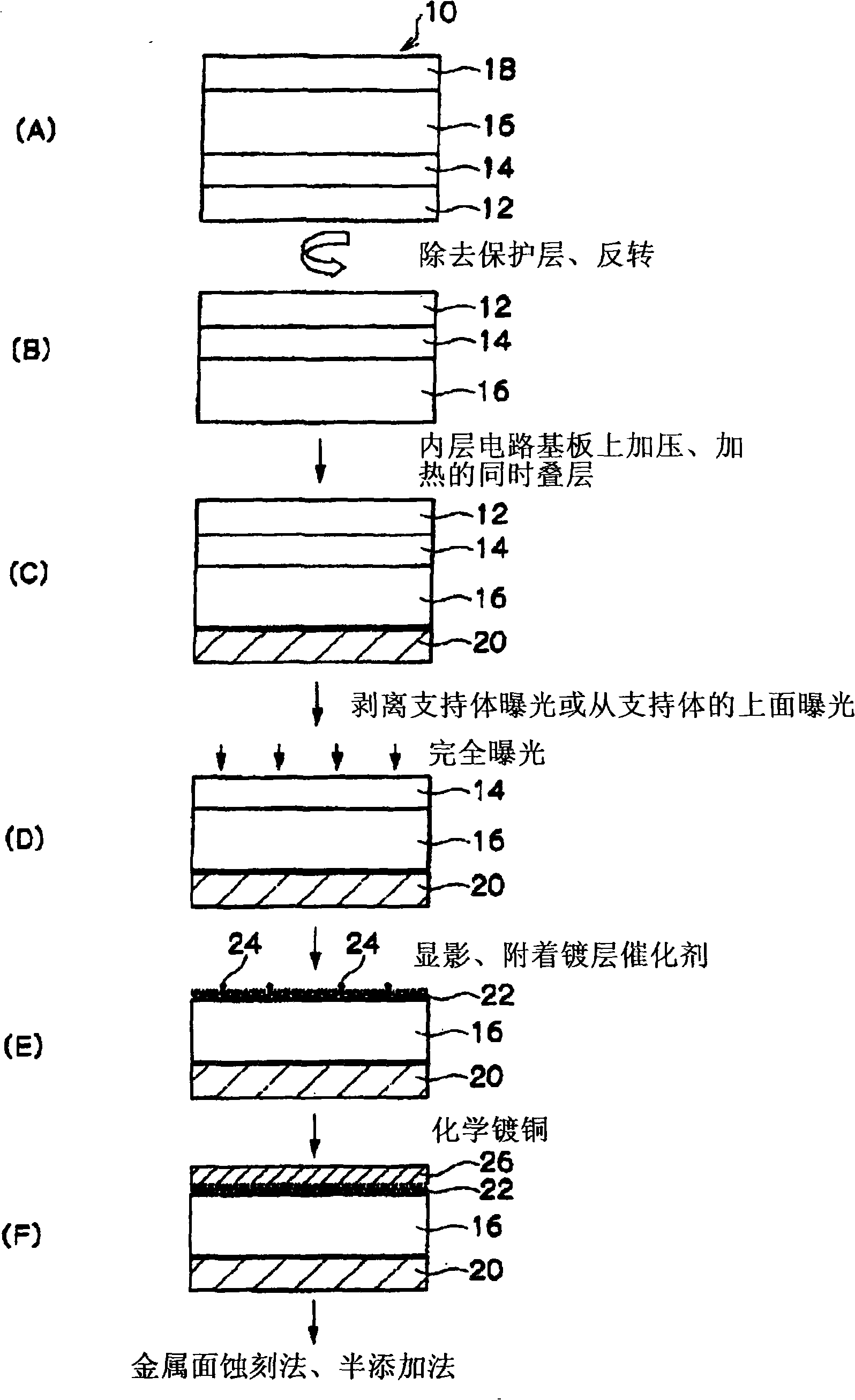

Laminated body used to produce printed wiring board, and method of producing printed wiring board using the same

InactiveCN101166393AGood high frequency characteristicsInsulating substrate metal adhesion improvementPrinted circuit detailsEngineeringPolymer

The present invention provides a laminated body for producing a printed wiring board, which includes an adhesive layer that is provided between an insulating film for a printed wiring board and a metal film for forming wiring. The adhesive layer includes an active species generating composition that is capable of generating an active species having reactivity by energy application, and a polymer precursor composition that includes a compound capable of forming a polymer compound by reaction with the active species generating composition. The invention also provides a method of producing a printed wiring board.

Owner:FUJIFILM CORP

Ceramic packaging structure and pressure sensitive apparatus shell of ceramic packaging structure

InactiveCN103759864ALow dielectric constantReasonable stress distributionForce measurementFluid pressure measurementTransition layerCeramic

The invention provides a ceramic packaging structure and a pressure sensitive apparatus shell of the ceramic packaging structure, and relates to a packaging structure of the pressure sensitive apparatus shell, in particular to the pressure sensitive apparatus shell of the ceramic packaging structure. Accordingly, the problem that in the prior art, the pressure sensitive apparatus shell is prone to corrosion and oxidation when used at a high temperature or the pressure sensitive apparatus shell is influenced by thermal mechanical stress is solved. Ceramic is adopted to serve as an insulating material of the ceramic packaging structure, a metallization layer is sintered on the surface of the ceramic at a high temperature, and the metallization layer and a metal shell are sintered through solder, such as nickel or gold or Ag-Cu, serving as a transition material to form a sealing structure. The pressure sensitive apparatus shell comprises a lead, the metallization layer, a seal ring, the solder, a ceramic body, a transition layer and a tube base, wherein the metallization layer is arranged on the junction surface of the ceramic body and the tube base, the ceramic body and the metallization layer are sintered to form a whole under a high temperature, the transition layer is formed between the metallization layer and the tube base through the sintering effect of the solder, and the lead and the surface of an inner hole of the seal ring are sintered to form a whole through the solder.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

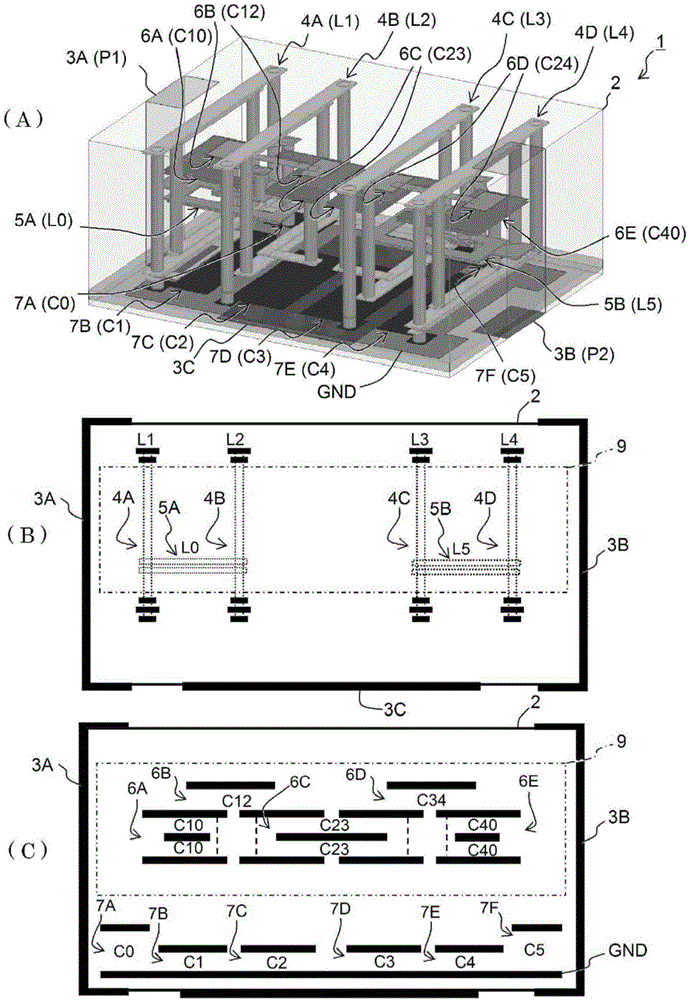

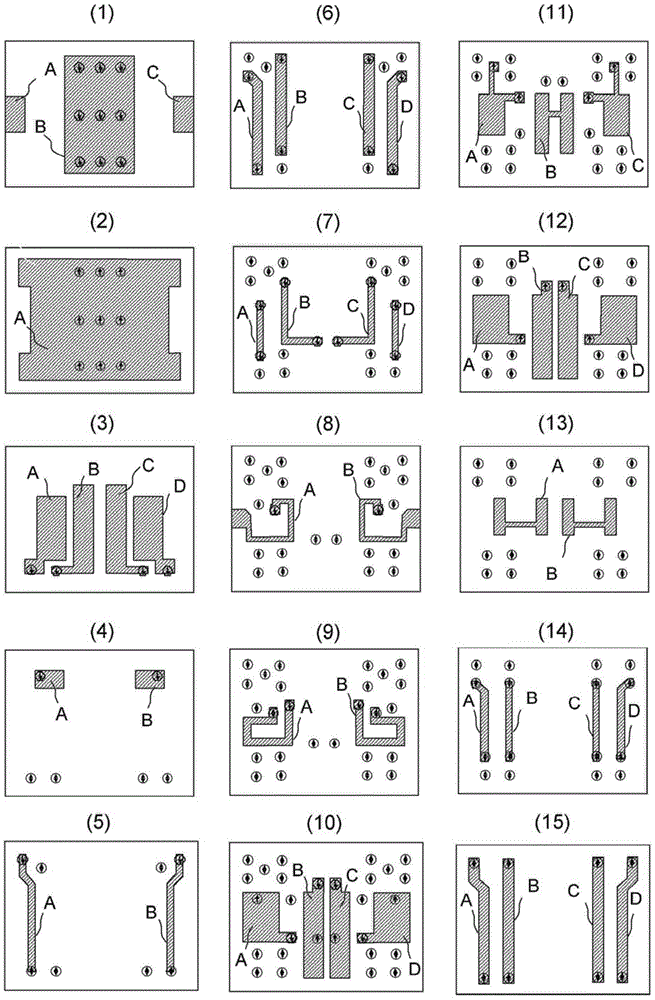

High frequency component and filter component

ActiveCN104348440AReduce the number of layersReduce areaMultiple-port networksFixed signal inductancesElectrical conductorEngineering

Owner:MURATA MFG CO LTD

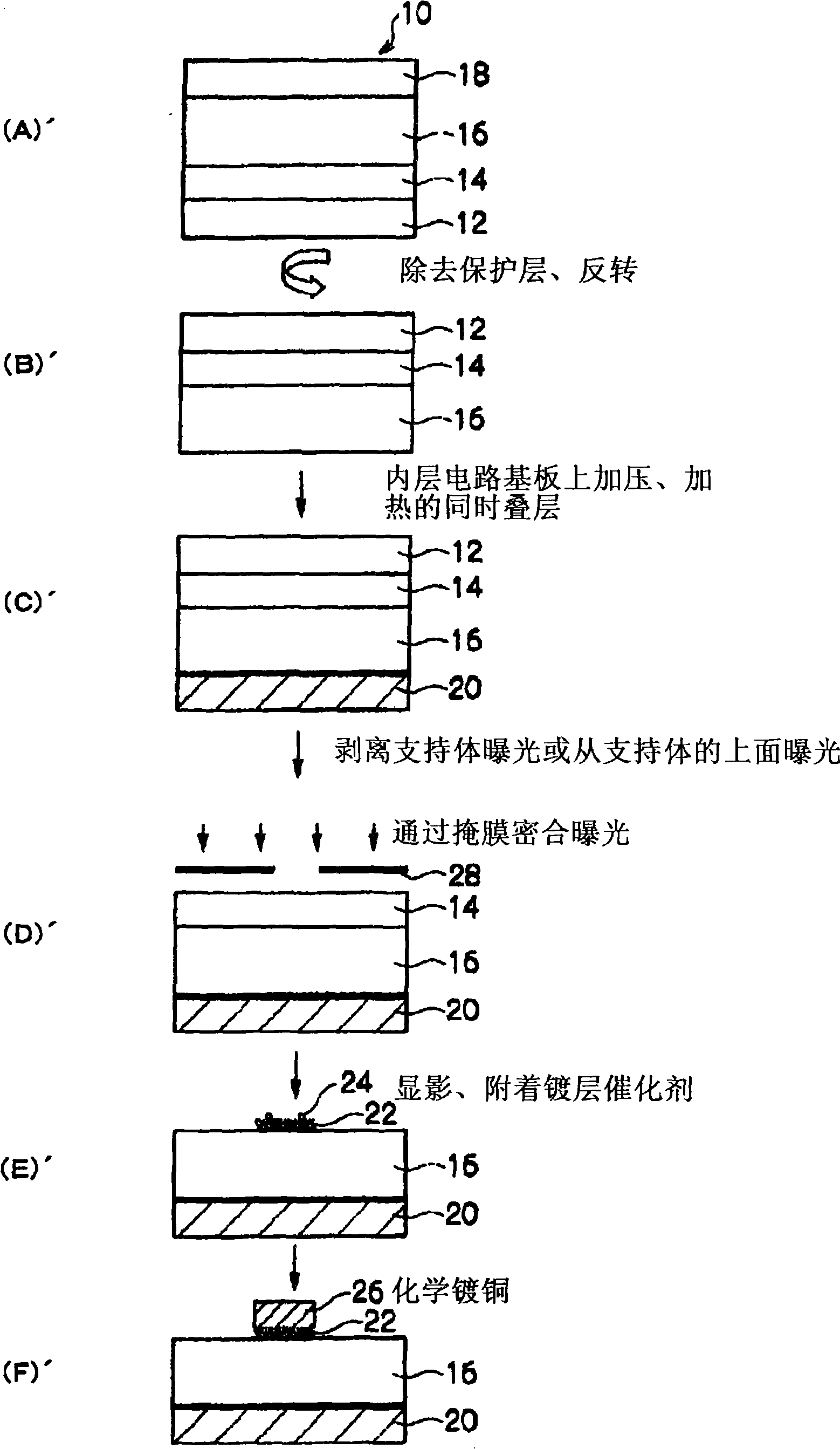

Laminate for printed wiring board, printed wiring board using same, method for manufacturing printed wiring board, electrical component, electronic component, and electrical device

InactiveCN101300134AExcellent adhesionWell formedSynthetic resin layered productsPrinted circuit aspectsPolymer scienceEngineering

Disclosed is a laminate characterized by having, on a supporting body, an insulating resin composition layer which is capable of producing a reactive active species when provided with energy and a reactive polymer precursor layer containing a compound which is capable of forming a polymer compound by reacting with the insulating resin composition layer.

Owner:FUJIFILM CORP

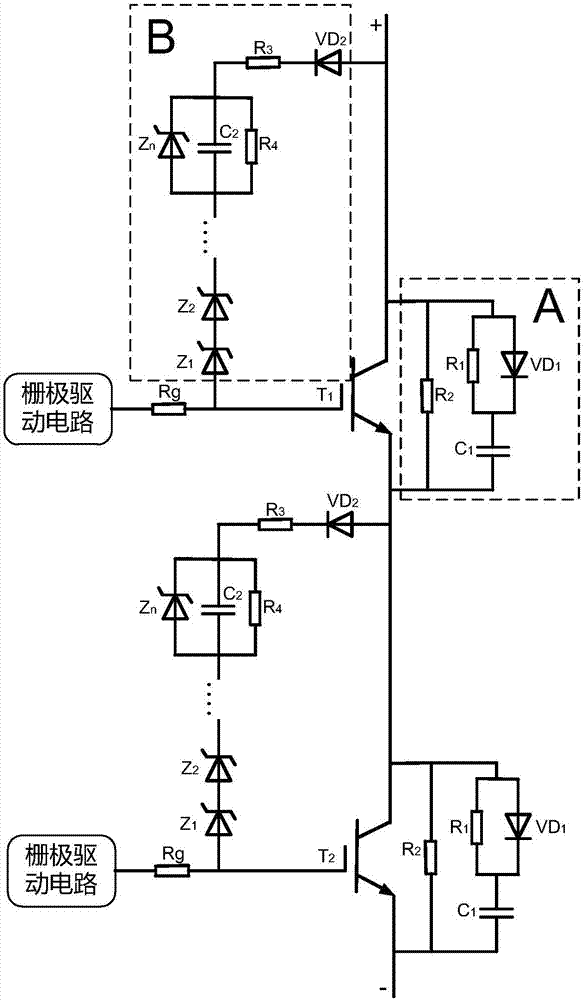

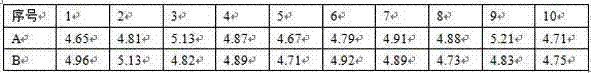

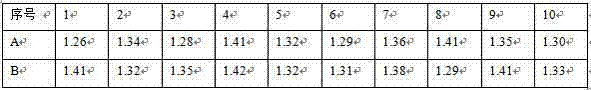

IGBT serial-connected composite voltage balancing circuit with grid-side and load-side control

InactiveCN107248857ASmall parasitic resistanceSmall lead inductanceTransistorElectronic switchingCapacitanceEngineering

The invention discloses an IGBT serial-connected composite voltage balancing circuit with grid-side and load-side control. The composite voltage balancing circuit comprises load-side and grid-side control voltage sharing circuits; the load-side voltage sharing circuit is connected in parallel between collectors and emitters of IGBTs, is composed of a resistor, a diode and a capacitor, and realizes static and dynamic voltage balancing in the load side; and the grid clamping voltage sharing circuit is connected in parallel between collectors and grids of IGBTs, is composed of a diode, a capacitor and a resistor, and can realize dynamic voltage balancing of the grids. The composite voltage balancing circuit realizes composite voltage balancing in the load side and the grid side via discrete passive devices, solves the problem of voltage imbalance due to characteristic difference of the devices and asynchronous driving signals in the IGBT switching on / off process, and ensures the working stability of the IGBT serial-connected circuit.

Owner:ZHEJIANG UNIV

Magnetism, copper and zinc-iron soft magnetic ferrite material and preparation method thereof

InactiveCN102531560ATo completely replaceGood high frequency characteristicsNickel-zinc ferriteCopper oxide

The invention discloses a magnetism, copper and zinc-iron soft magnetic ferrite material and a preparation method thereof. Formula of main components by mole percentage comprises ferric oxide, zinc oxide, magnesium oxide and copper oxide. First assistant components of doping agents comprise one of or mixture of several of components of calcium carbonate or cobalt oxide or silicon dioxide. Second assistant components of the doping agents comprise one of or mixture of any two or three of components of vanadium pentoxide or bismuth oxide or lithium carbonate. The preparation method includes primary ball-milling, presintering, secondary ball-milling, forming and sintering. Then a blank part is placed in a sintering furnace for sintering, four-hour heat preservation at temperature of 1250 DEG C is carried out, and a finished magnetic core is obtained. Technical performance of the magnetism, copper and zinc-iron soft magnetic ferrite material is the same as that of nickel zinc ferrite, and rod-shaped, I-shaped and annular-shaped magnetic cores manufactured by the preparation method have large cost advantages.

Owner:南通鼎源电子磁材有限公司

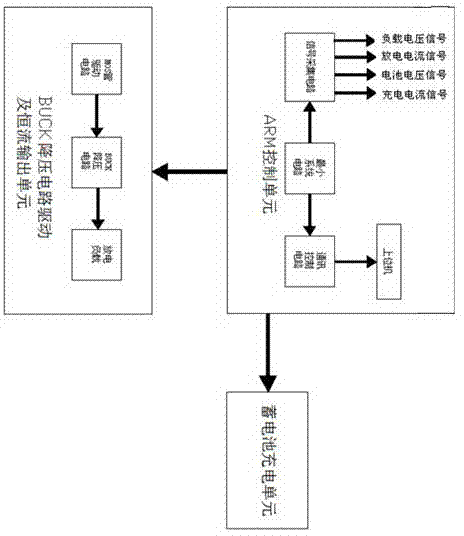

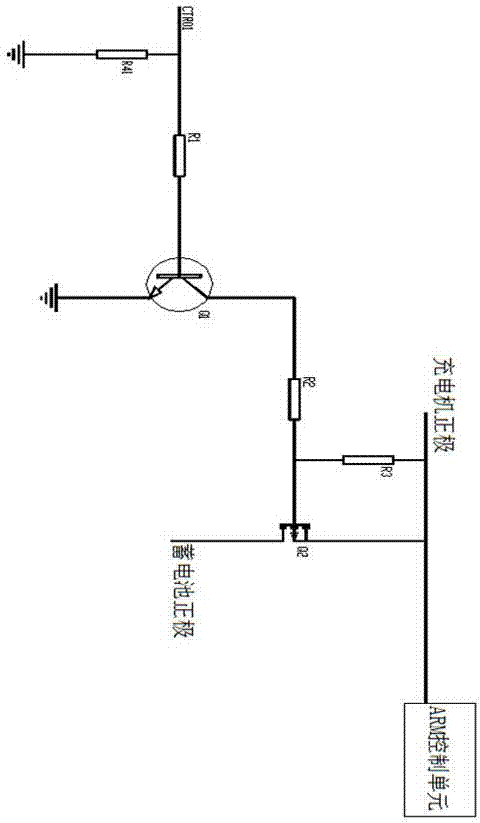

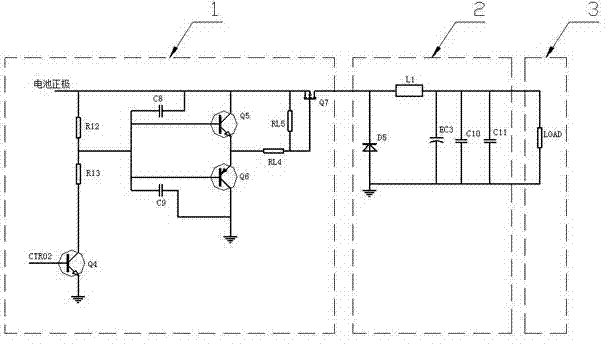

Automatic storage battery charging-discharging and capacity detection device

The invention discloses an automatic storage battery charging-discharging and capacity detection device which comprises an ARM control unit, a storage battery charging unit and a BUCK step-down circuit drive and constant current output unit. The output end of the ARM control unit is connected with the storage battery charging unit and the BUCK step-down circuit drive and constant current output unit; the ARM control unit is formed by a signal acquisition circuit, an ARM minimum system circuit, a communication control circuit and an upper computer, and the signal acquisition circuit, the ARM minimum system circuit, the communication control circuit and the upper computer are connected in sequence; the storage battery charging unit comprises a charger, a storage battery and a corresponding charging control circuit, the positive electrode of the charger is connected with the power supply positive electrode of the ARM control unit, and power supply to the ARM control unit is achieved; the BUCK step-down circuit drive and constant current output unit comprises an MOS drive circuit, a BUCK step-down circuit and a discharging load resistor. The automatic storage battery charging-discharging and capacity detection device is simple in structure and high in anti-jamming capability and has application and popularization value, and the storage battery is automatically charged and discharged without manual operation.

Owner:JIANGSU YINJIA GROUP

Method for producing laminate

InactiveCN1798647AImprove adhesionHeat resistance with high adhesionPrinted circuit manufactureFlat articlesLiquid crystallineMetal foil

A method for producing a laminate, wherein a film comprised of a liquid-crystalline polymer film forming an optically anisotropic molten phase and a metal foil are piled and are passed between pressing rolls, to adhere said film to said metal foil by pressing with heating, which comprises using, as at least one roll of said pressing rolls, a coated roll having a metal roll and, provided on the surface thereof, a coating layer of a resin such as a fluororubber or a polyimide having a thickness of 0.02 to 5 mm, or comprises passing the above polymer film and metal foil between metal pressing rolls together with a heat-resistant film piled on the surface contacting with the metal roll of the polymer film or the metal foil. The method allows the production of a laminate of a liquid-crystalline film and a metal foil exhibiting satisfactory adhesion between them and being excellent in heat resistance, with good productivity.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

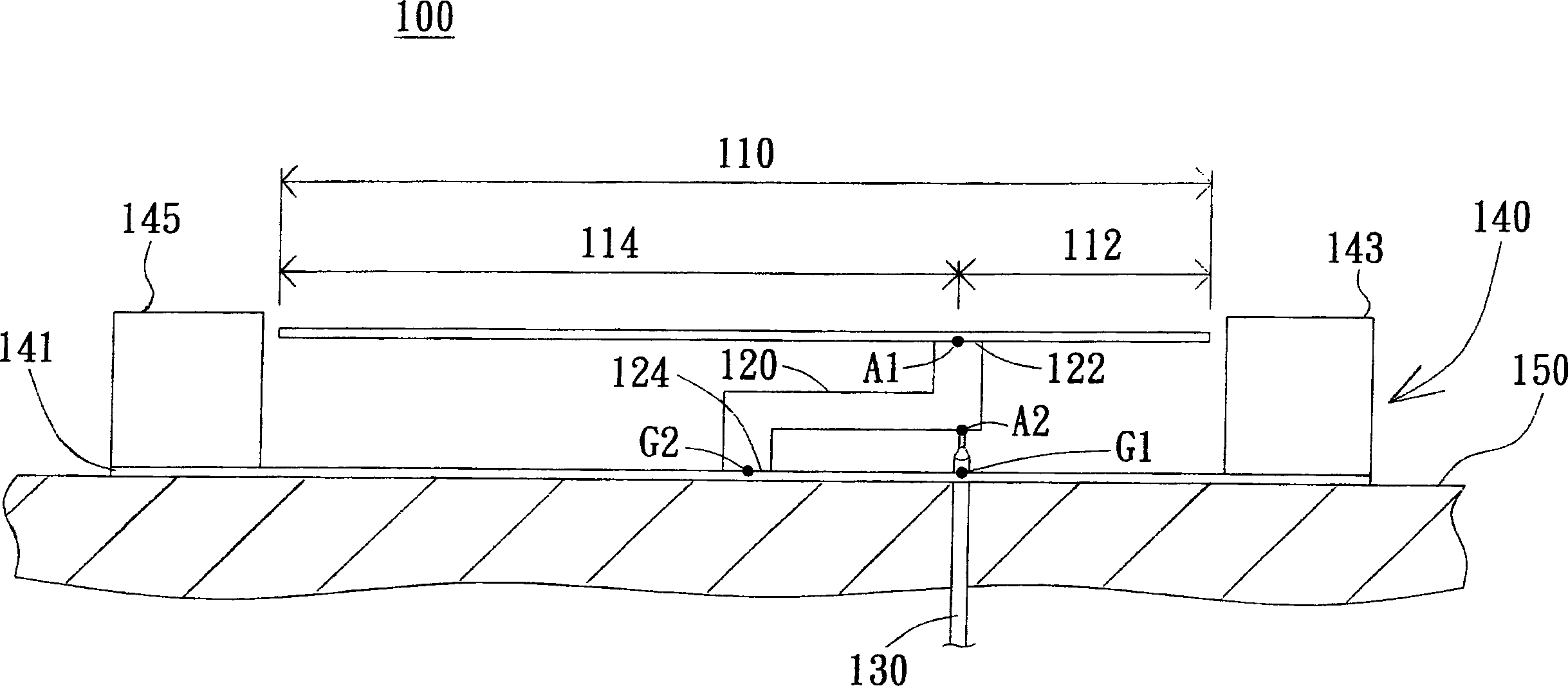

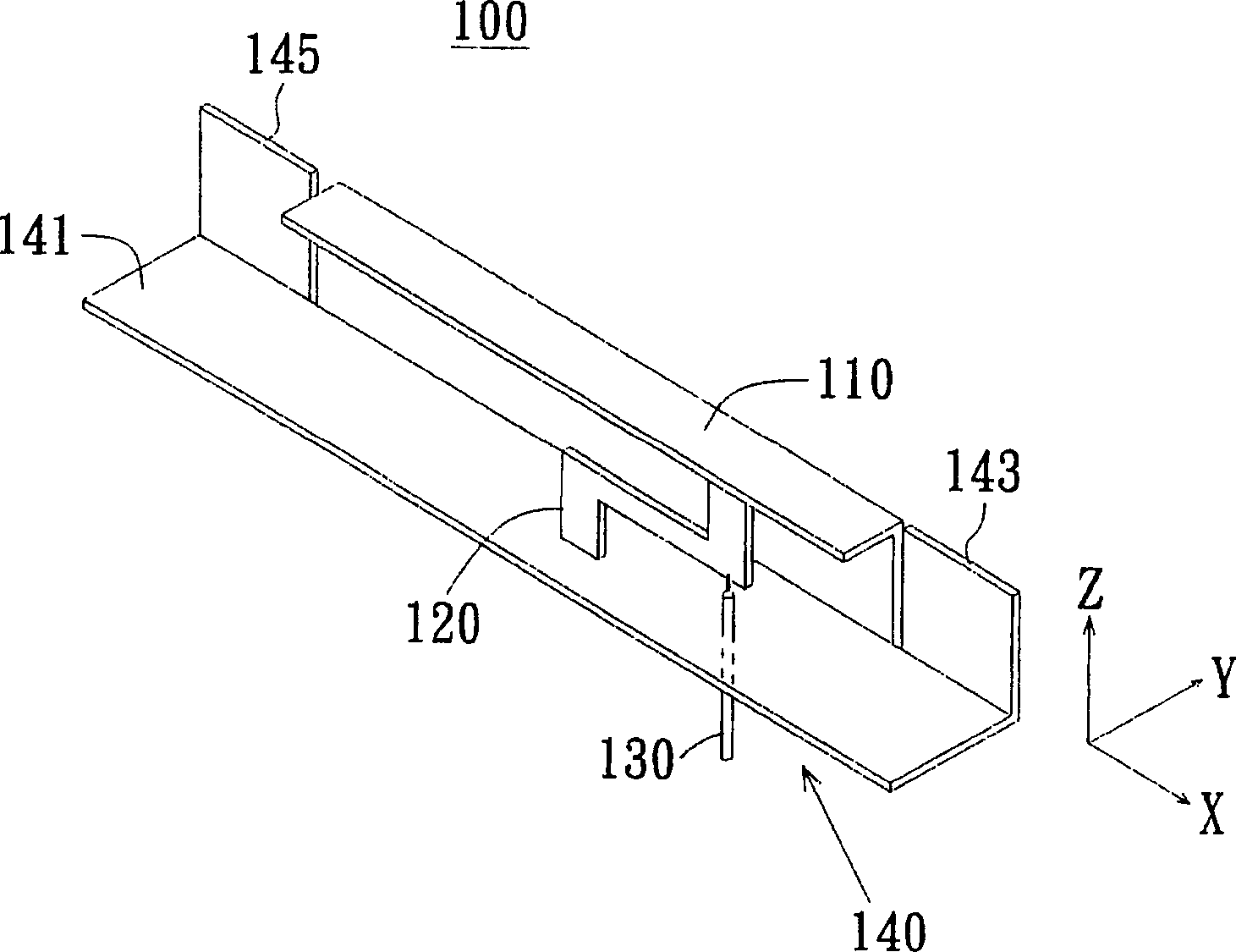

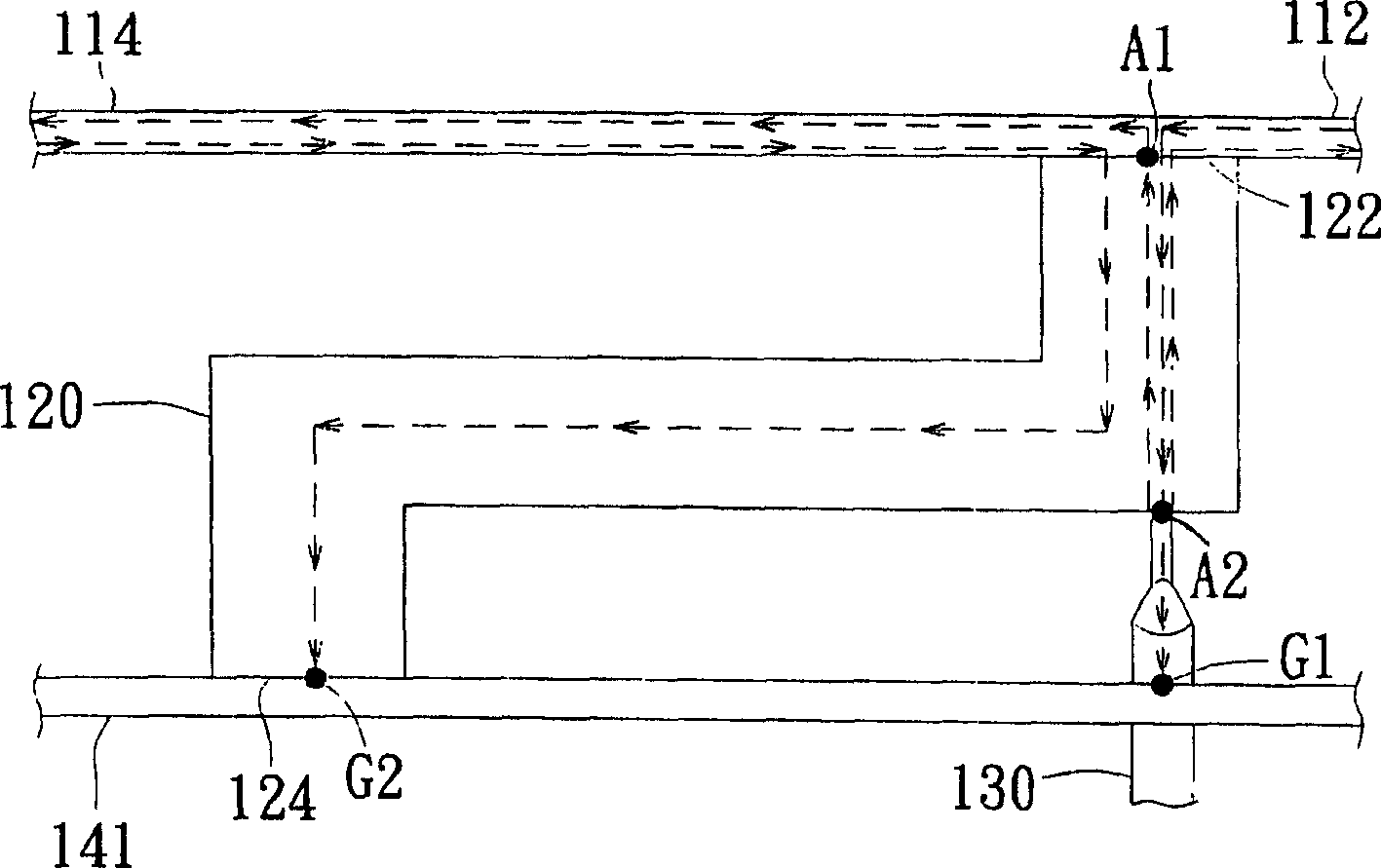

Antenna module of global position system and manufacturing method therefor

InactiveCN101286588AReduce volumeGood high frequency characteristicsRadiating elements structural formsPrinted circuit manufactureInsulation layerEngineering

The invention relates to an antenna module of a global positioning system, comprising a substrate, a first insulation layer and a second insulation layer; wherein, the substrate refers to the lower surface of a patch antenna; the first insulation layer is coated on the substrate and forms a wiring circuit to further integrate a variety of electronic elements on the substrate according to the wiring circuit. Moreover, the second insulation layer is coated on the first insulation layer in order to completely shield the electronic elements integrated on the substrate, therefore, the antenna module of the global positioning system can shorten the distances between the electronic elements and the antenna to realize best high-frequency characteristics, and save spaces occupied by printed circuit boards and shielding caps to effectively reduce the volumes of the antenna modules, simplify the manufacturing process and reduce production cost.

Owner:INPAQ TECH

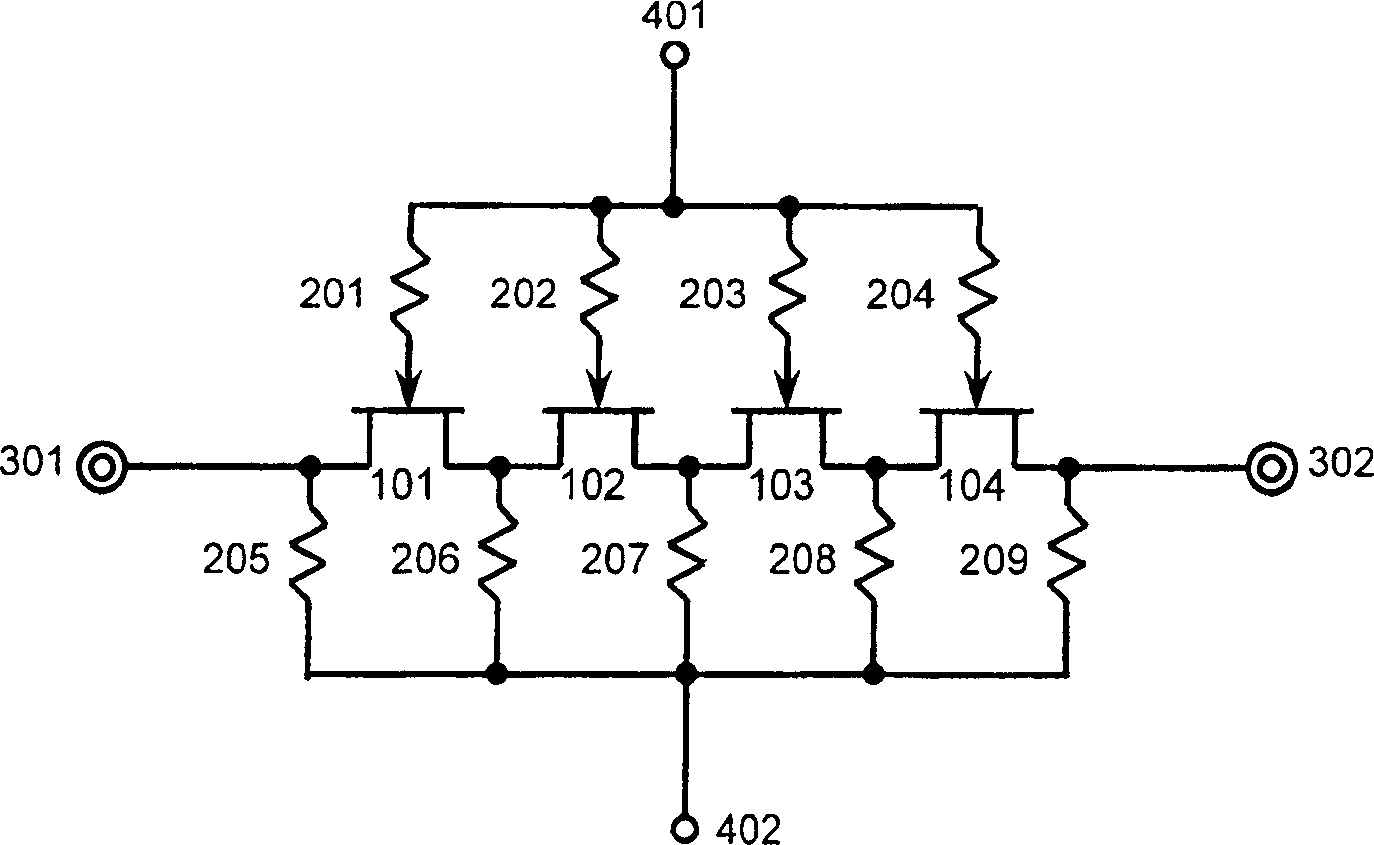

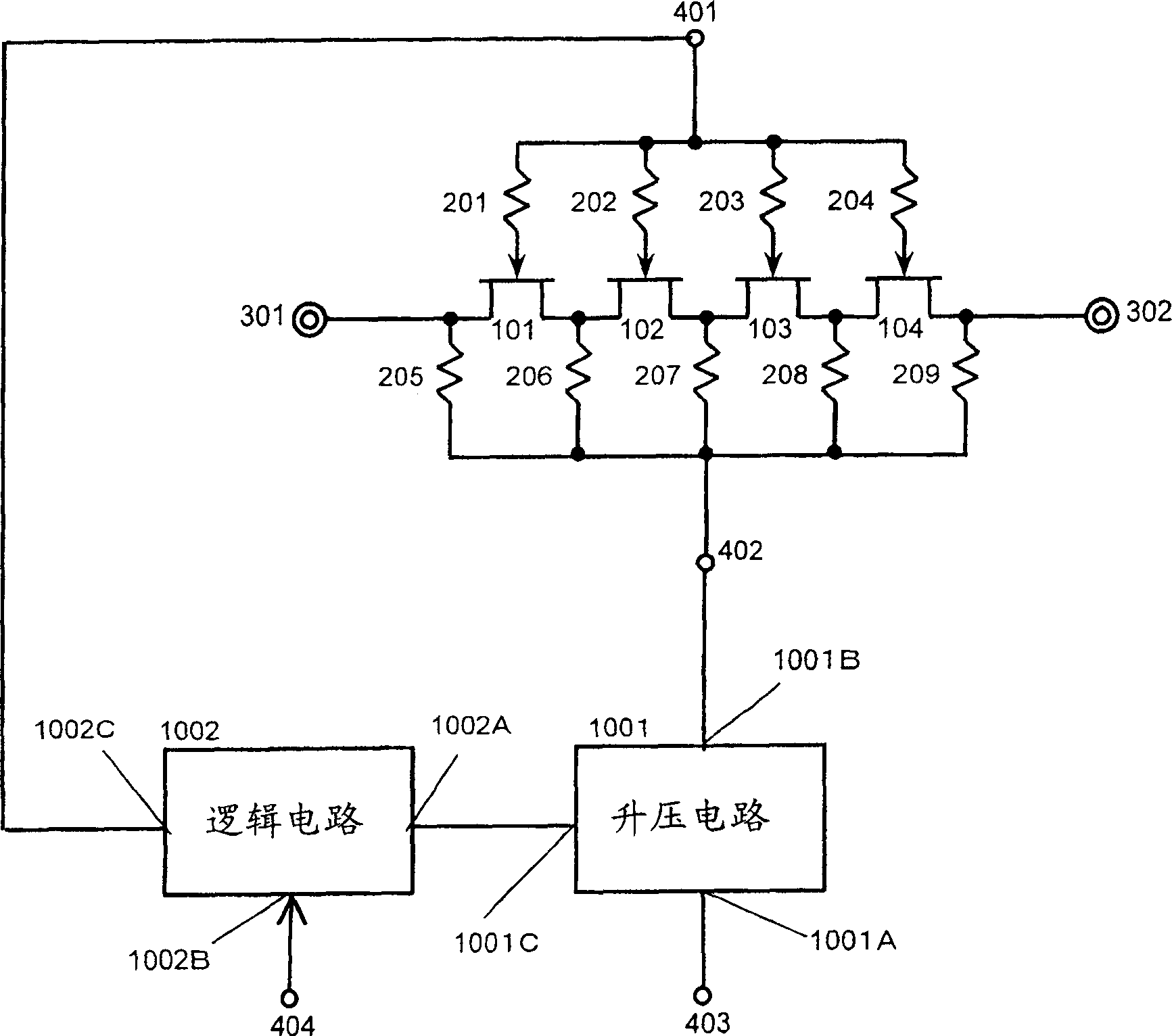

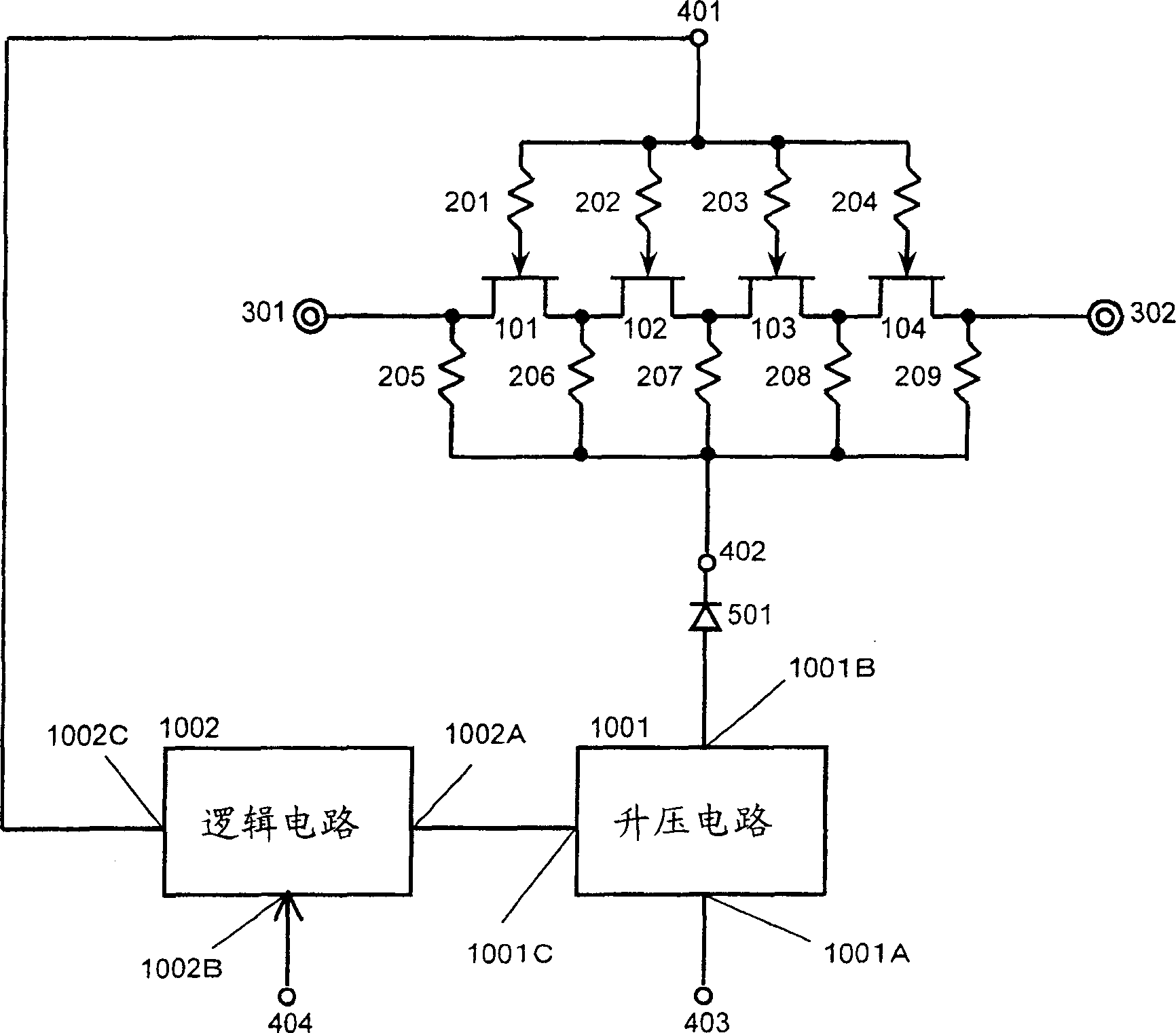

High-frequency switched circuit

ActiveCN1538621AGood resistance valuePrevent leakageResonant circuit tuningElectronic switchingEngineeringIntermediate point

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

High-performance carbon film resistor, and preparation method thereof

InactiveCN105355351AImprove performanceSmall negative temperature coefficientAdjustable resistorsCarbon filmSlurry

The invention relates to a high-performance carbon film resistor, and a preparation method thereof, and belongs to the technical field of thin film resistor. A carbon film slurry comprises, by weight, 15 to 25 parts of graphite, 8 to 16 parts of carbon black, 1 to 3 parts of phenolic resin, 2 to 5 parts of silicon dioxide, 1 to 3 parts of a binder, 2 to 3 parts of silver oxide, 3 to 5 parts of copper oxide, and 30 to 40 parts of propyl alcohol. The preparation method comprises following steps: graphite and carbon black are mixed, an obtained mixture is subjected to ball milling for 30 to 40min, and is subjected to sintering for 20 to 28min under nitrogen protection at 170 to 180 DEG C; the other raw materials are added, an obtained mixed product is subjected to ultrasonic treatment for 30 to 45min, and is delivered through a filter membrane with filtration pore diameter of 130 to 160<mu>m so as to obtain the carbon film slurry; a ceramic substrate is coated with the carbon film slurry via magnetron sputtering so as to obtain finished products, wherein acceleration voltage is controlled to be 300 to 340V, magnetic field intensity is controlled to be 200 to 300G, electric current density is controlled to be 50 to 60mA / cm, power density is controlled to be 30 to 40W / cm, film thickness is controlled to be 0.2 to 0.8<mu>m. The high-performance carbon film resistor possesses excellent performance, low negative temperature coefficient, and excellent high frequency characteristics; influences caused by voltage and frequency are low; noise electrodynamic potential is low; pulse load is stable; resistance range is wide; and production cost is low.

Owner:陈桂兴

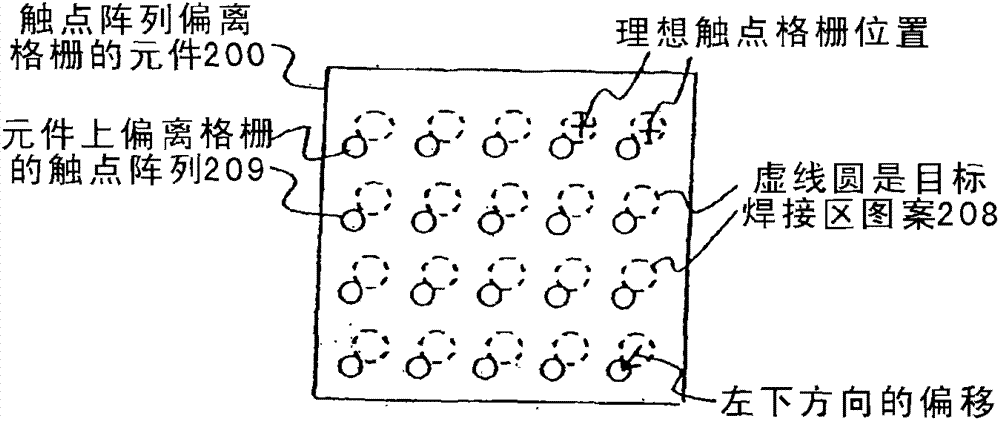

Device and method for placing predetermined element on target platform

InactiveCN102856239AHigh yieldReduce reworkSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringMulti sensor

The invention discloses a device and a method for placing a predetermined element on a target platform, and relates to an assembly technique. According to the device and the method, alignment and detection techniques for improving element placing accuracy in the assembly are described. Particularly, the device and the method include that the placing accuracy of the element on the target platform is detected and improved by combining alignment signs on the element and reference signs on the target platform in various detection techniques. A group of sensors which form an array to form multi-sensor probes can detect the offset of offset elements in the assembly.

Owner:温泰克工业有限公司

Non-reduced dielectric ceramics and ceramic electronic element using the same

InactiveCN1365121AReduce capacitanceLow costImpedence networksFixed capacitor dielectricAs elementRare-earth element

Owner:MURATA MFG CO LTD

Multi-channel antenna

InactiveCN1610182AGood high frequency characteristicsGood electromagnetic compatibilitySimultaneous aerial operationsResonant antennasImpedance matchingEngineering

The multi-waveband antenna includes tuner, earthing element, circuit shorter and feeding lines. The tuner provides the first resonant mode and the second resonant mode corresponding to the first waveband and the second waveband separately. The earthing element includes the main earthing surface, the first earthing regulator and the second earthing regulator. The main earthing surface includes the first earthing point corresponding to the first resonant mode and the second earthing point corresponding to the second resonant mode, the first earthing regulator is used in regulating impedance matching of the first resonant mode and the bandwidth of the first waveband and the second earthing regulator is used in regulating impedance matching of the second resonant mode and the bandwidth of the second waveband. The circuit shorter has one end connected to the tuner, the other end to the second earthing point and feeding points connected to the feeding lines.

Owner:QUANTA COMPUTER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com