Copper foil and manufacturing method therefor, copper foil with carrier and manufacturing method therefor, printed circuit board, and multilayer printed circuit board

A technology for printed circuit boards and carrier foils, which is applied in the manufacture of printed circuit precursors, printed circuits, and printed circuit manufacturing. It can solve the problems that the surface roughness of copper foil is not necessarily smooth and cannot meet the requirements of copper foil, and achieve excellent high-frequency characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

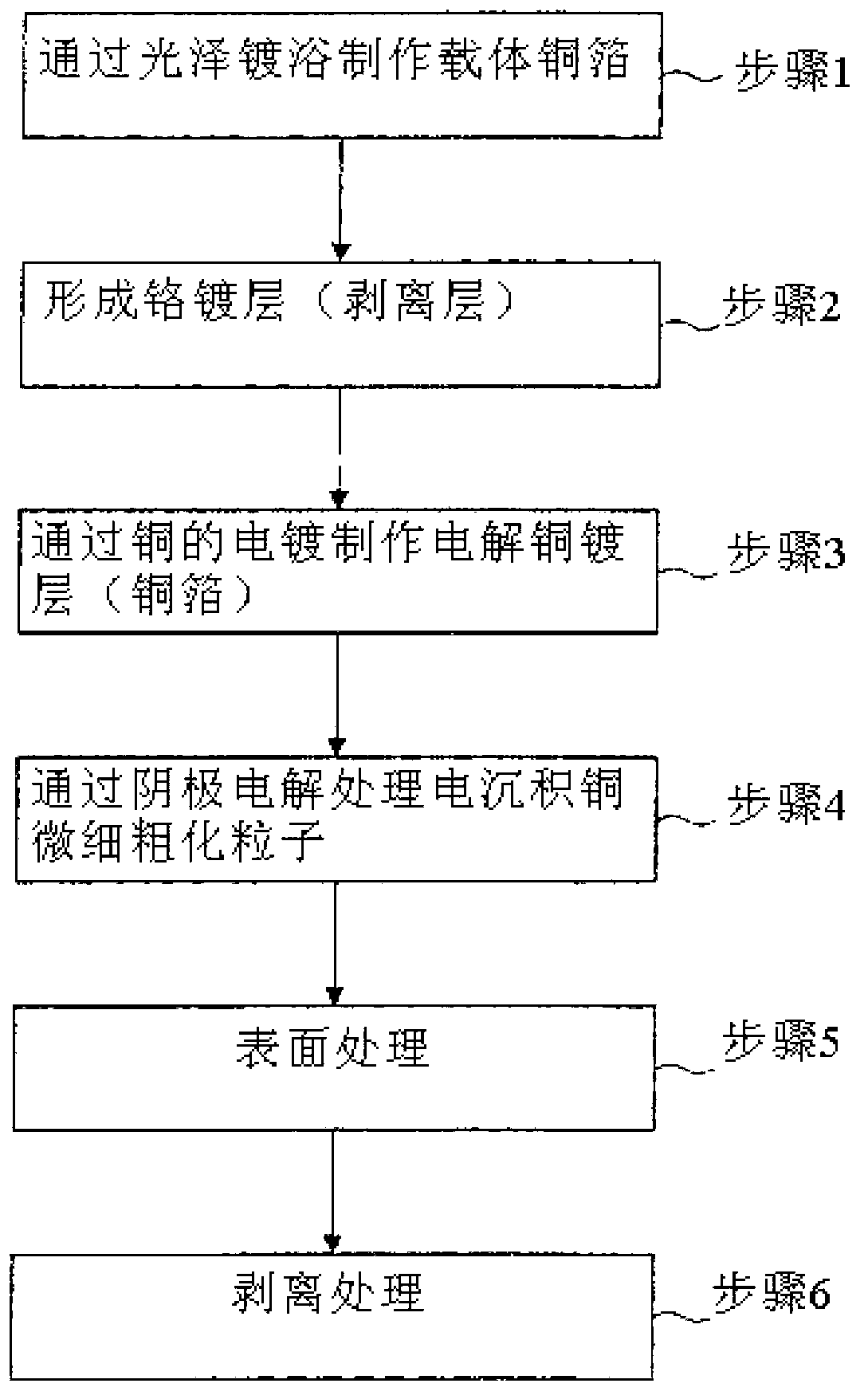

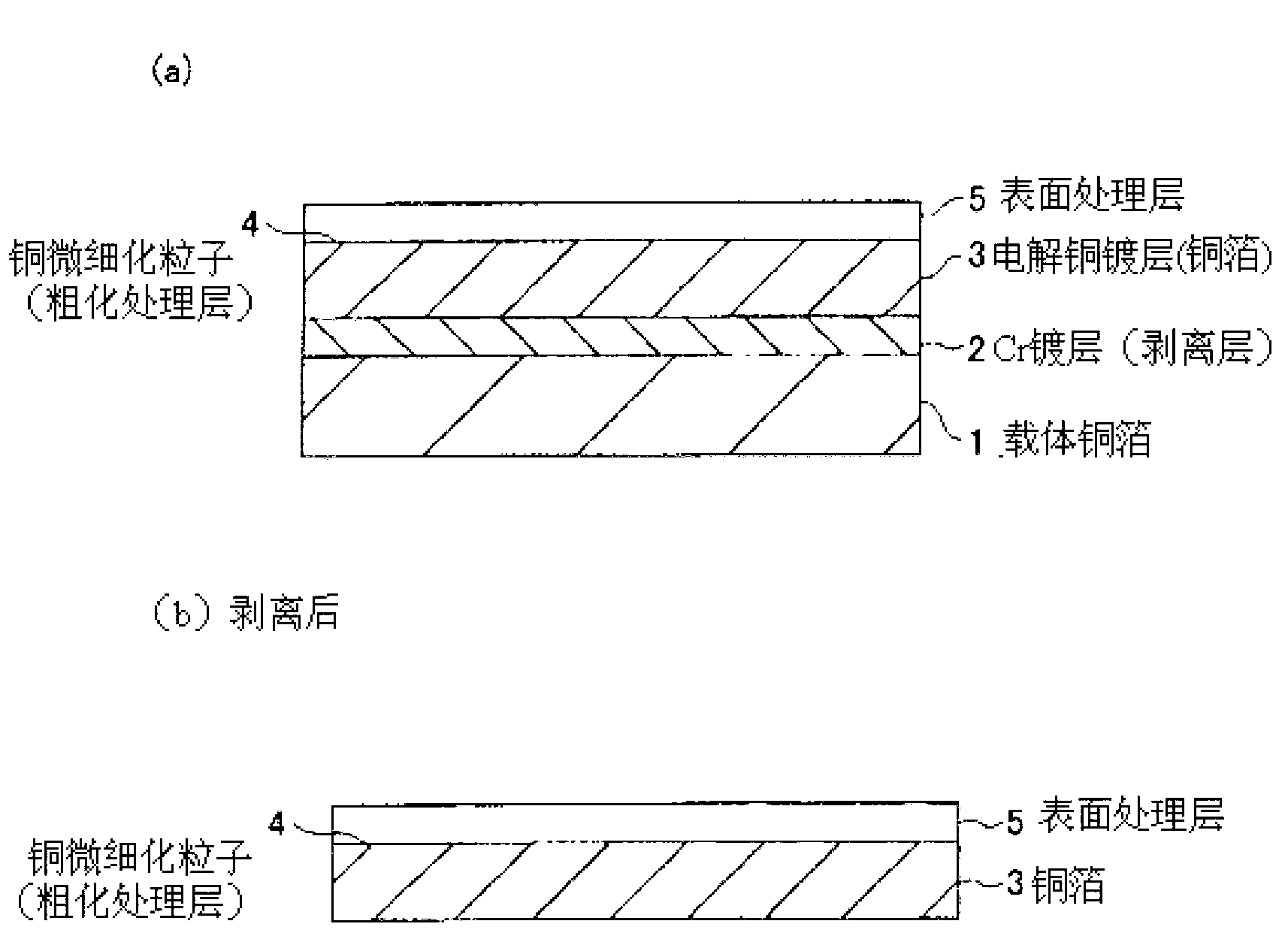

Method used

Image

Examples

Embodiment 1~8)

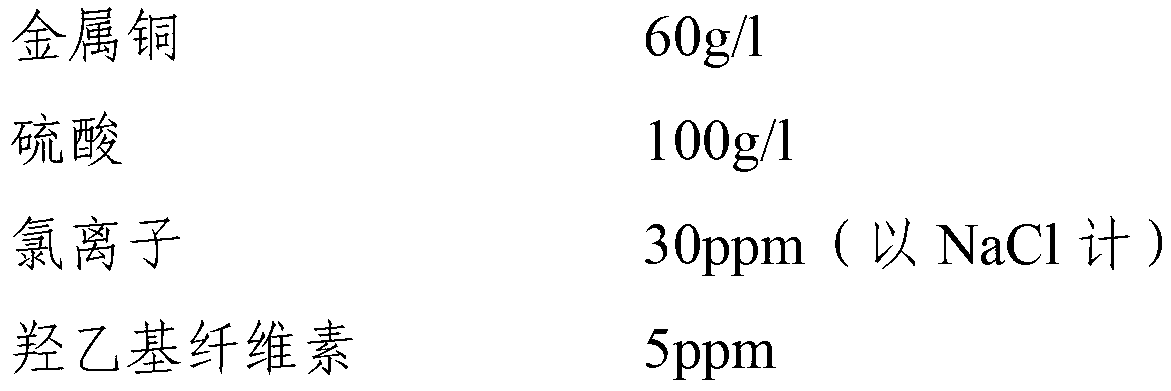

[0069] Plating solution

[0070] ·Bath composition:

[0071]

[0072] ·Bath temperature 58℃

[0073] ·Current density 5~50A / dm 2

[0074] Through the plating solution composed of the above plating bath, the current density and time were changed, and carrier copper foils (35 μm) with different average spacing Sm values were produced on the ground titanium drum (Examples 1-8).

[0075] Table 1 shows the average pitch Sm of the rough surface (portion in contact with the plating solution) of the electrolytic copper foils of Examples 1 to 8 measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com