Parallel optical emission assembly based on 45-degree fiber array and manufacturing method thereof

A technology of optical fiber array and optical transmission, which is applied in the coupling of electromagnetic transmitters and optical waveguides, can solve the problems that hinder the development and production of parallel optical transceiver modules, and achieve the effects of small thermal expansion coefficient, good high-frequency characteristics, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

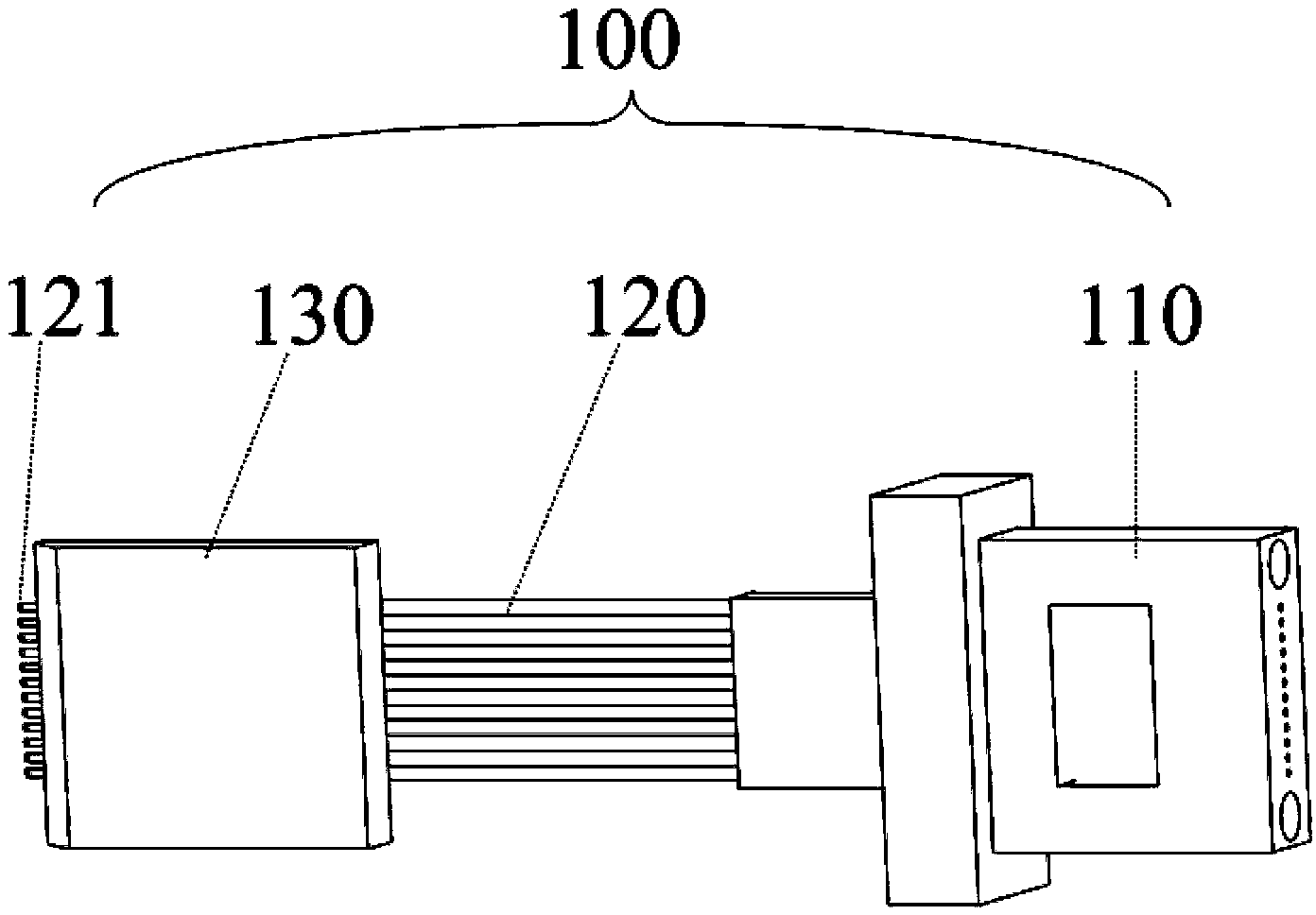

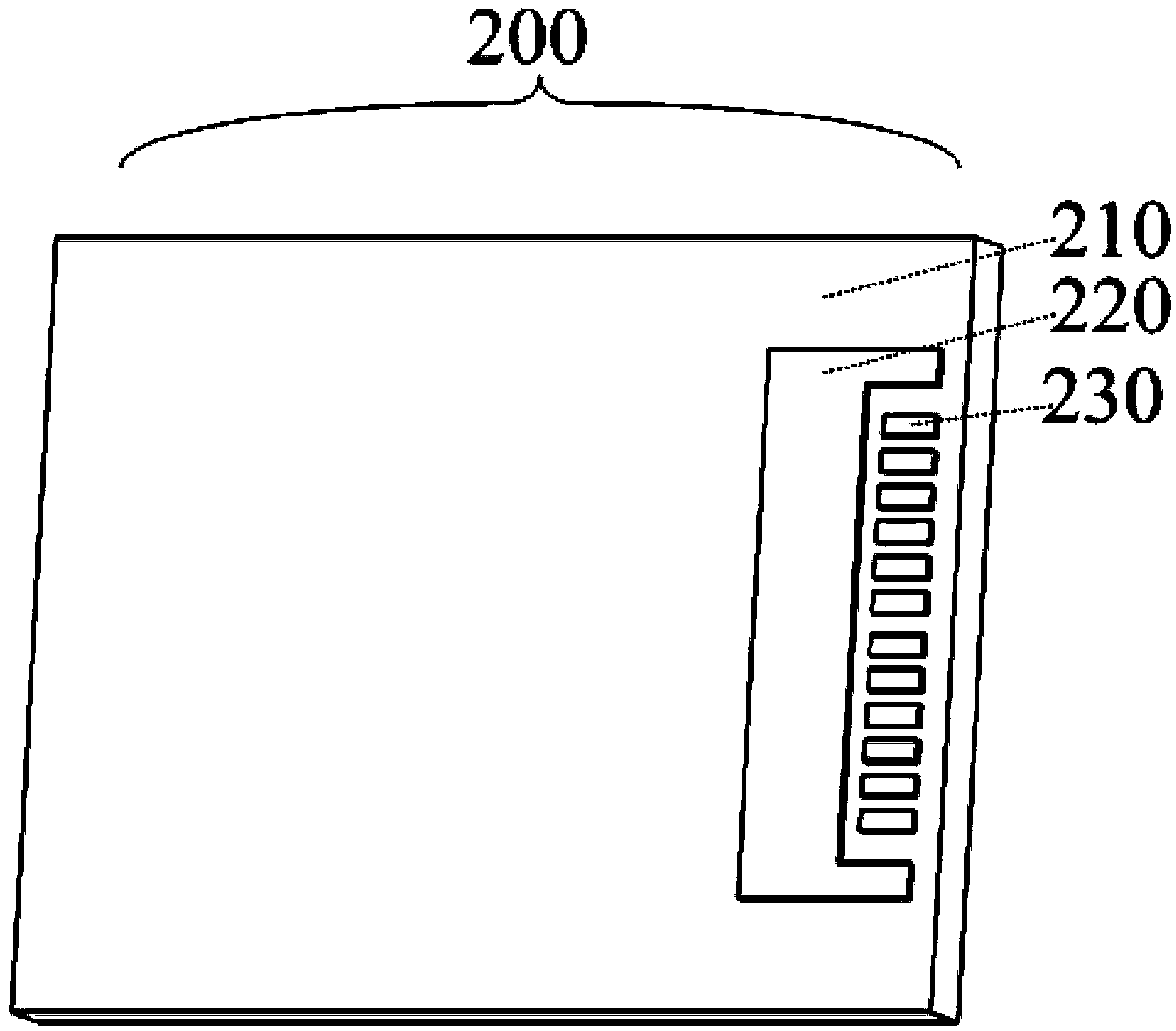

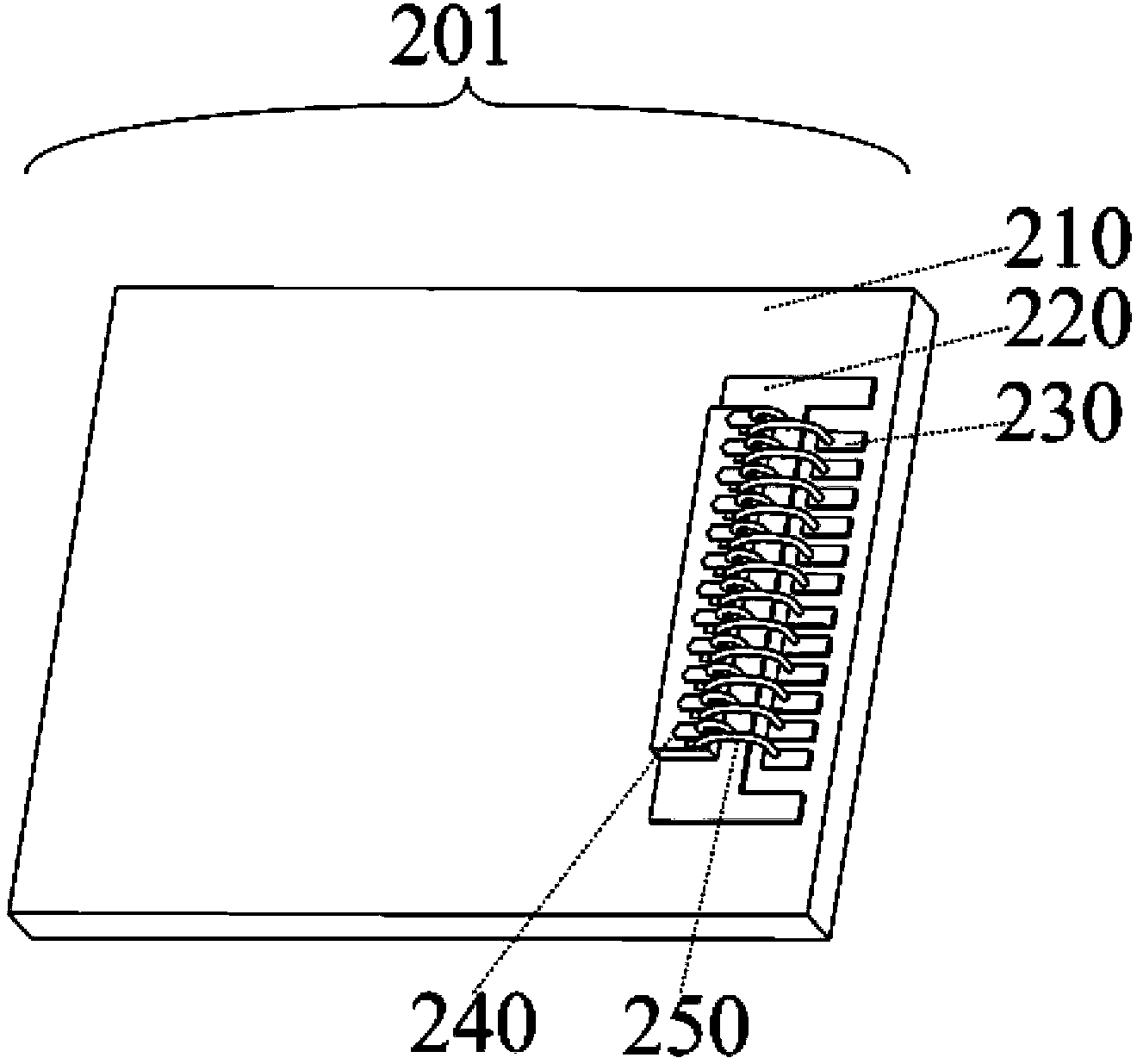

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, among them, Figure 4 It is a schematic structural view of an embodiment of a parallel optical launch assembly based on a 45° fiber array, figure 1 It is a schematic diagram of a 45° fiber array with an MT connector in a parallel optical launch assembly based on a 45° fiber array in the embodiment, figure 2 It is a schematic diagram of a ceramic substrate etched with electrodes and pads in a parallel optical emission component based on a 45° fiber array in the embodiment, image 3 It is a schematic diagram of a ceramic substrate bonded with a VCSEL laser array and bonded with gold wires in a parallel optical emission assembly based on a 45° f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com