Gallium arsenide PIN diode and preparation method thereof

A manufacturing method and diode technology, applied in the field of diodes, can solve problems such as easy collapse or breakage of the bridge surface, increase process difficulty, and reduce yield rate, etc., and achieve the effects of easy monolithic integration, simple process, and reduced parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

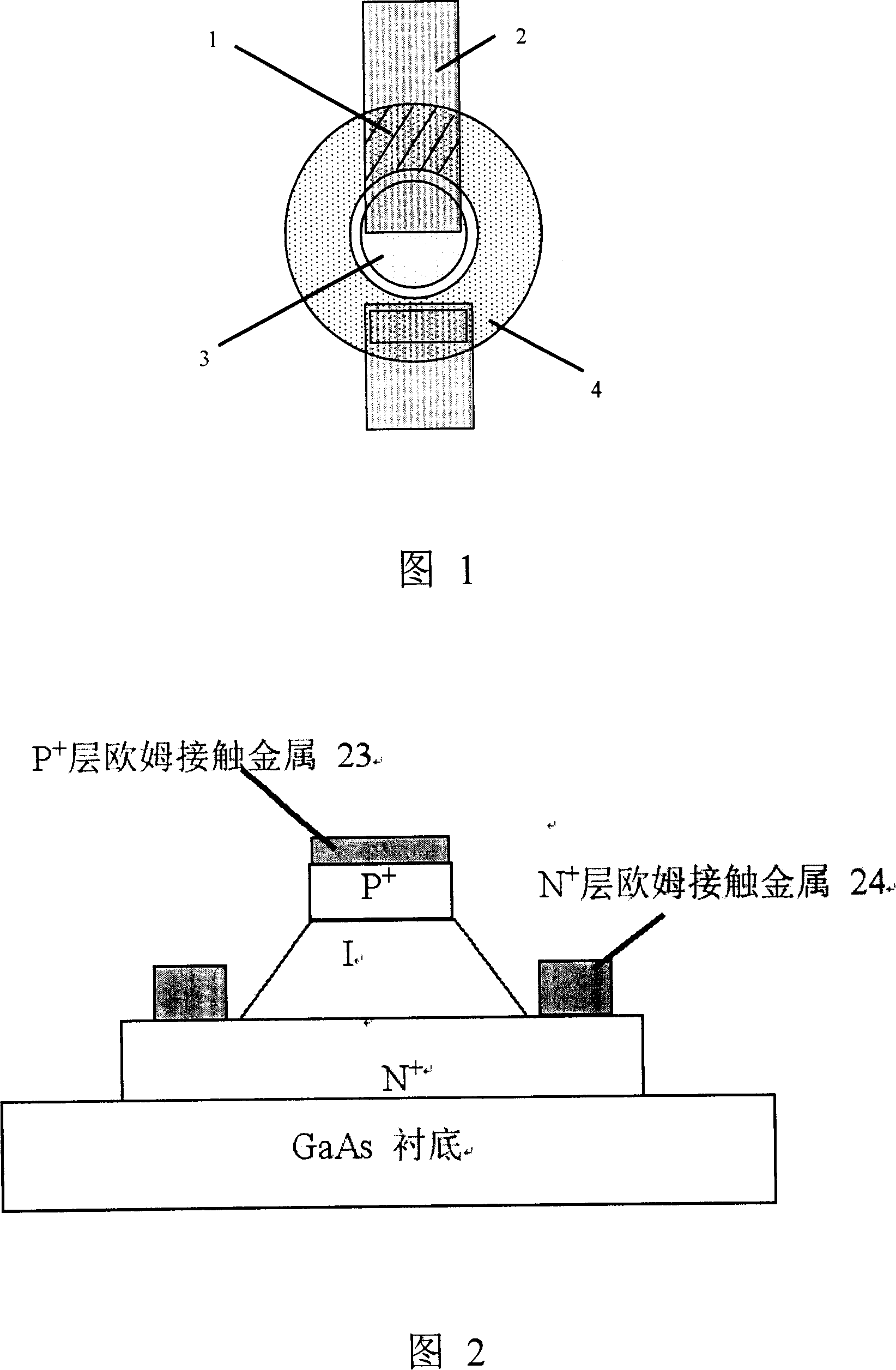

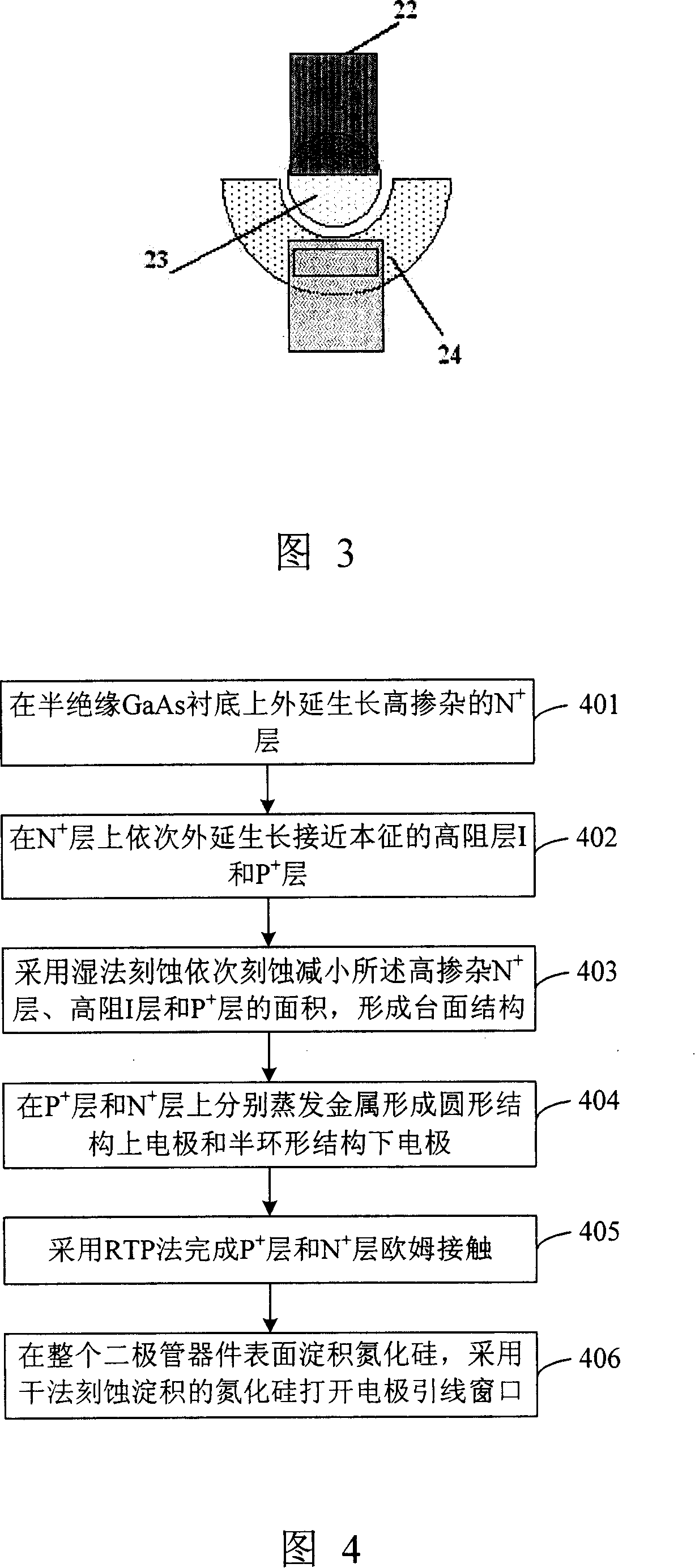

[0041] As shown in Figure 2, Figure 2 is a cross-sectional view of the GaAs PIN diode provided by the present invention. The cross-sectional view is a cross-sectional view perpendicular to the substrate along the two ends of the lower electrode half ring of the GaAs PIN diode. The GaAs PIN diode includes:

[0042] Semi-insulating GaAs substrate used to support the entire GaAs PIN diode;

[0043] Highly doped N epitaxially grown on semi-insulating GaAs substrate + Layer, in highly doped N + The high-resistance I layer and P layer that are close to intrinsic and epitaxially grown on the layer + Layer; by using wet etching, the highly doped N + Layer, high resistance I layer and P + The area of the layer is successively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com