Ceramic packaging structure and pressure sensitive apparatus shell of ceramic packaging structure

A technology of ceramic packaging and sensitive devices, applied in the direction of measuring fluid pressure, instruments, measuring force, etc., can solve the problems of oxidation, pressure sensitive device shell thermomechanical stress, easy corrosion, etc., to achieve improved stability and excellent thermal conductivity , Improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific implementation mode 1: A ceramic packaging structure in this implementation mode, using ceramic (AL 2 o 3 The coefficient of linear expansion (20-1000°C) 7.1-7.7) is used as an insulating material, and the metallized layer is sintered on the ceramic surface at high temperature, and nickel or Ag-Cu solder is used as a transition material to sinter with metal shells with different characteristics to form a sealed structure.

[0011] Ceramic materials include Al 2 o 3 , SiC, BeO, TiO 2 , ZrO 2 , M g O, AlN, Si 3 N 4 Or BN and mixtures of all the above materials.

[0012] Materials for the metallization layer include tungsten, molybdenum or manganese and mixtures of all of the above materials.

[0013] When Ag-Cu is selected as the solder, the sintering temperature is 790°C.

specific Embodiment approach 2

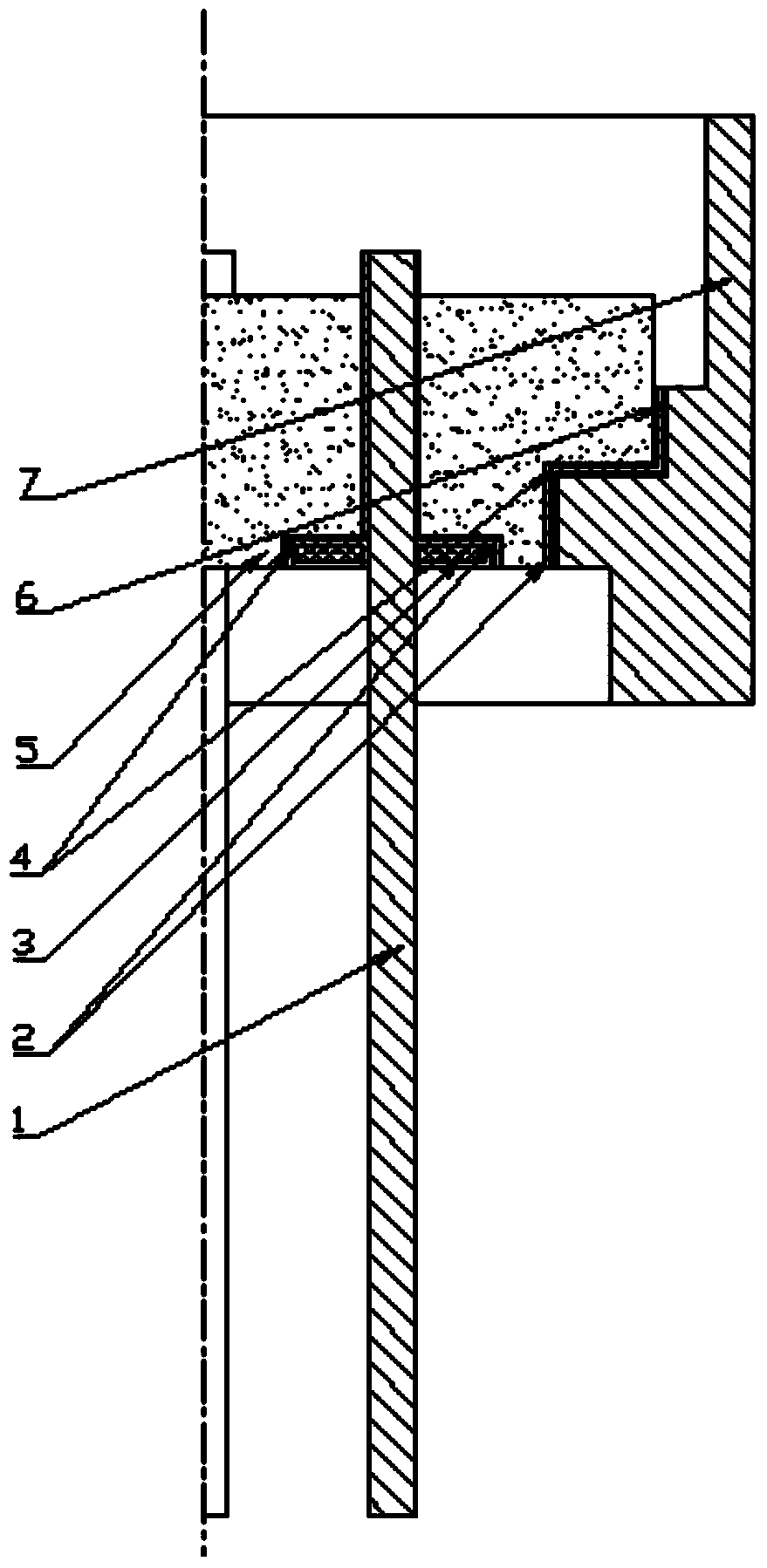

[0014] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. A pressure-sensitive device shell adopting a ceramic packaging structure in this embodiment includes a lead wire 1, a metallization layer 2, a sealing ring 3, solder 4, a ceramic body 5, a transition layer 6 and a socket 7, and the ceramic body 5 is fixed On the tube base 7, a metallized layer 2 is provided on the connection surface between the ceramic body 5 and the tube base 7, the ceramic body 5 and the metallized layer 2 are sintered into one at high temperature, and the solder 4 is passed between the metallized layer 2 and the tube base 7 The sintering effect forms the transition layer 6, the lead wire 1 runs through the ceramic body 5, and the outer surface of the ceramic body 5 in the direction where the lead wire 1 passes through the stem 7 is provided with a sealing ring 3, and the sealing ring 3 and the ceramic body 5 are sintered by solder 4 to...

specific Embodiment approach 3

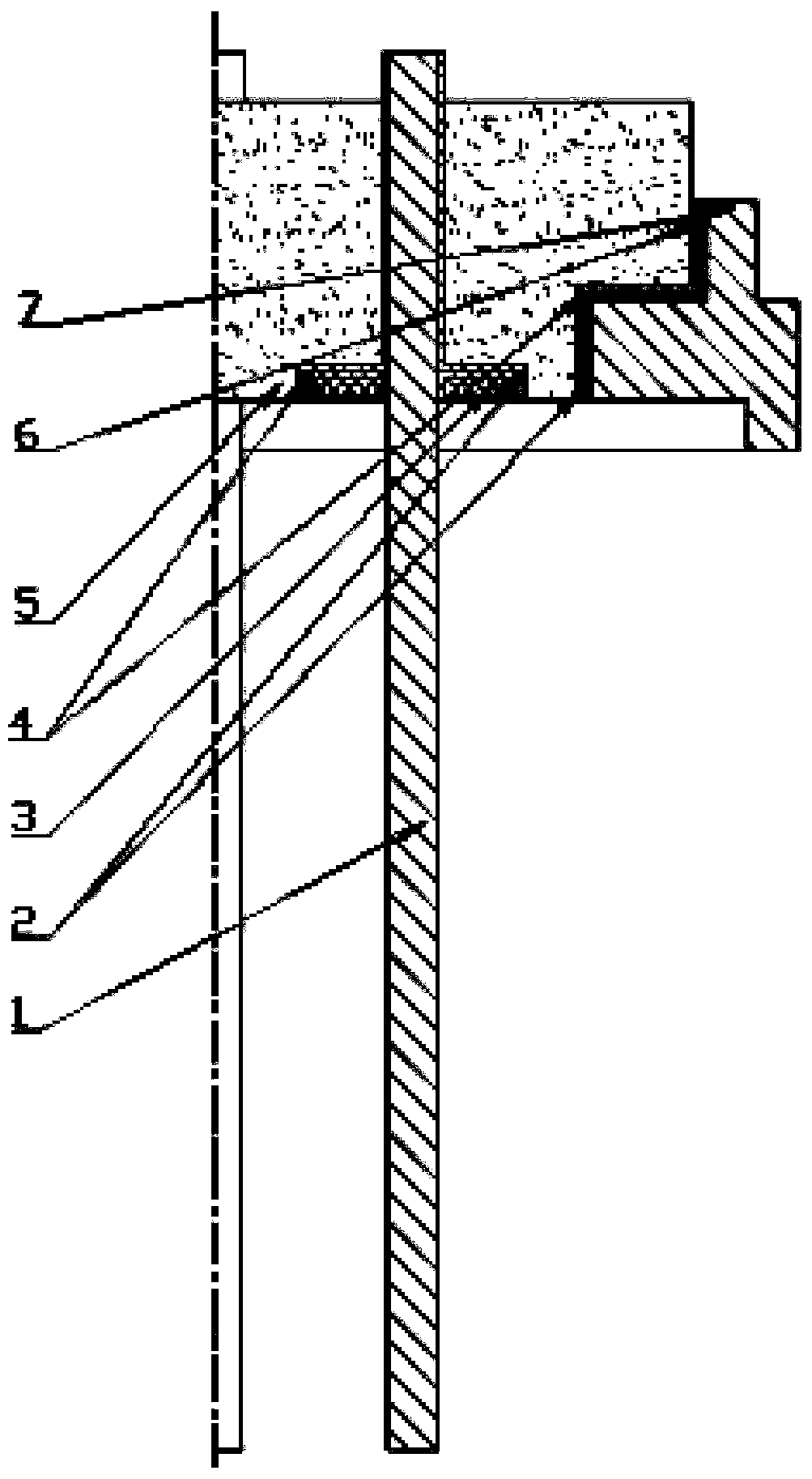

[0020] Specific implementation mode three: this implementation mode is as follows figure 2 Shown: alumina ceramic body 5 and metallized layer 2 are sintered at high temperature in a vacuum environment; lead wire 1, seal ring 3, and tube base 7 are electroplated with nickel at the joint; lead wire 1, seal ring 3, tube base 7 and alumina Ceramic 7 is sintered by Ag-Cu solder 4 under protective atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com