Patents

Literature

99results about How to "Reasonable stress distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

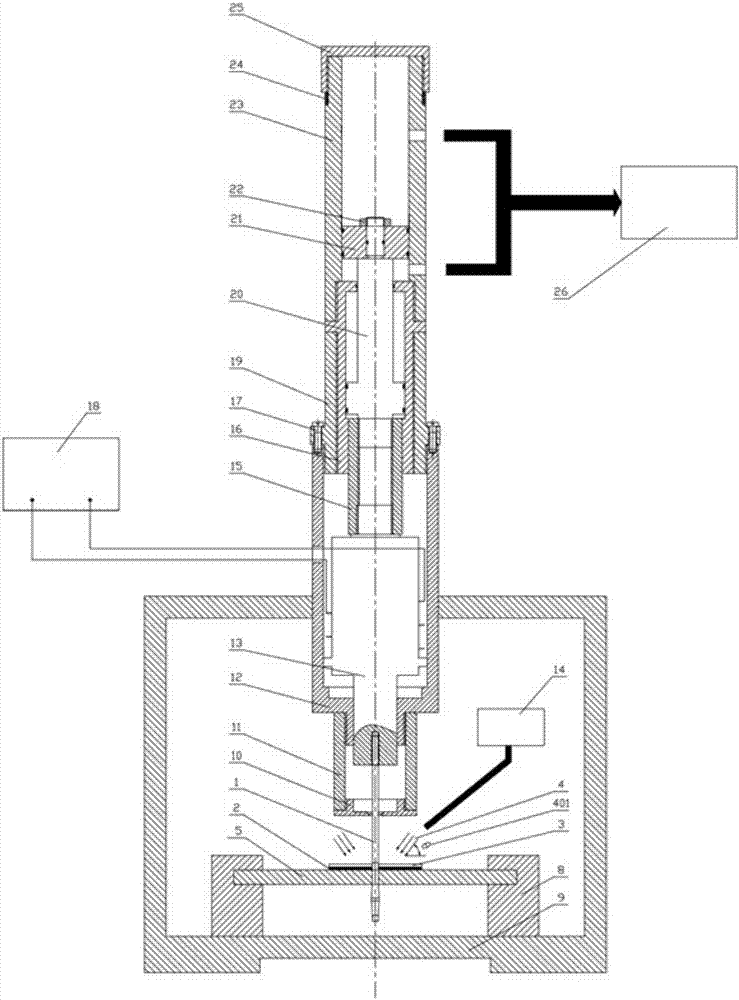

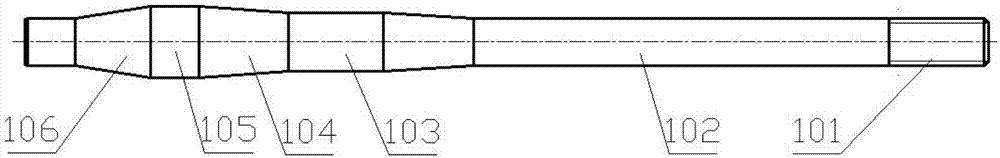

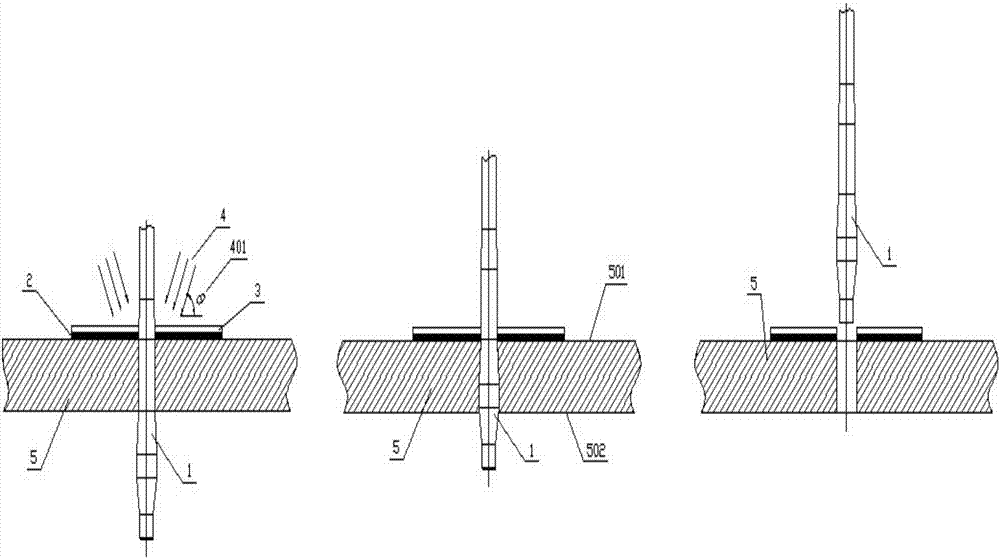

Laser shock and supersonic vibration extrusion co-strengthening device and method

ActiveCN107254581AImprove fatigue resistanceSmooth inner surfaceLaser beam welding apparatusShock waveUltrasonic vibration

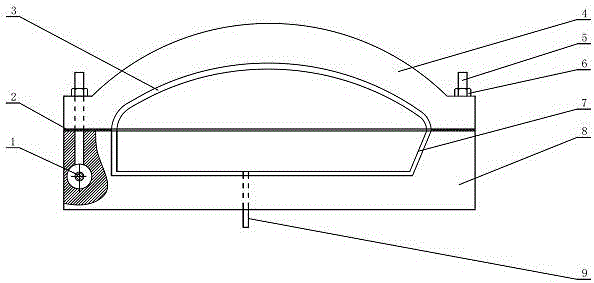

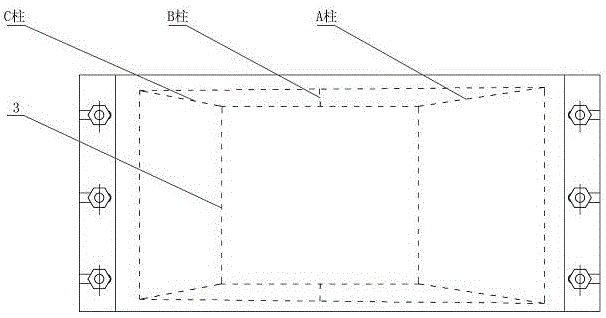

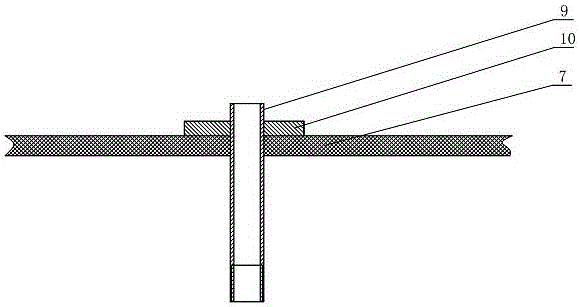

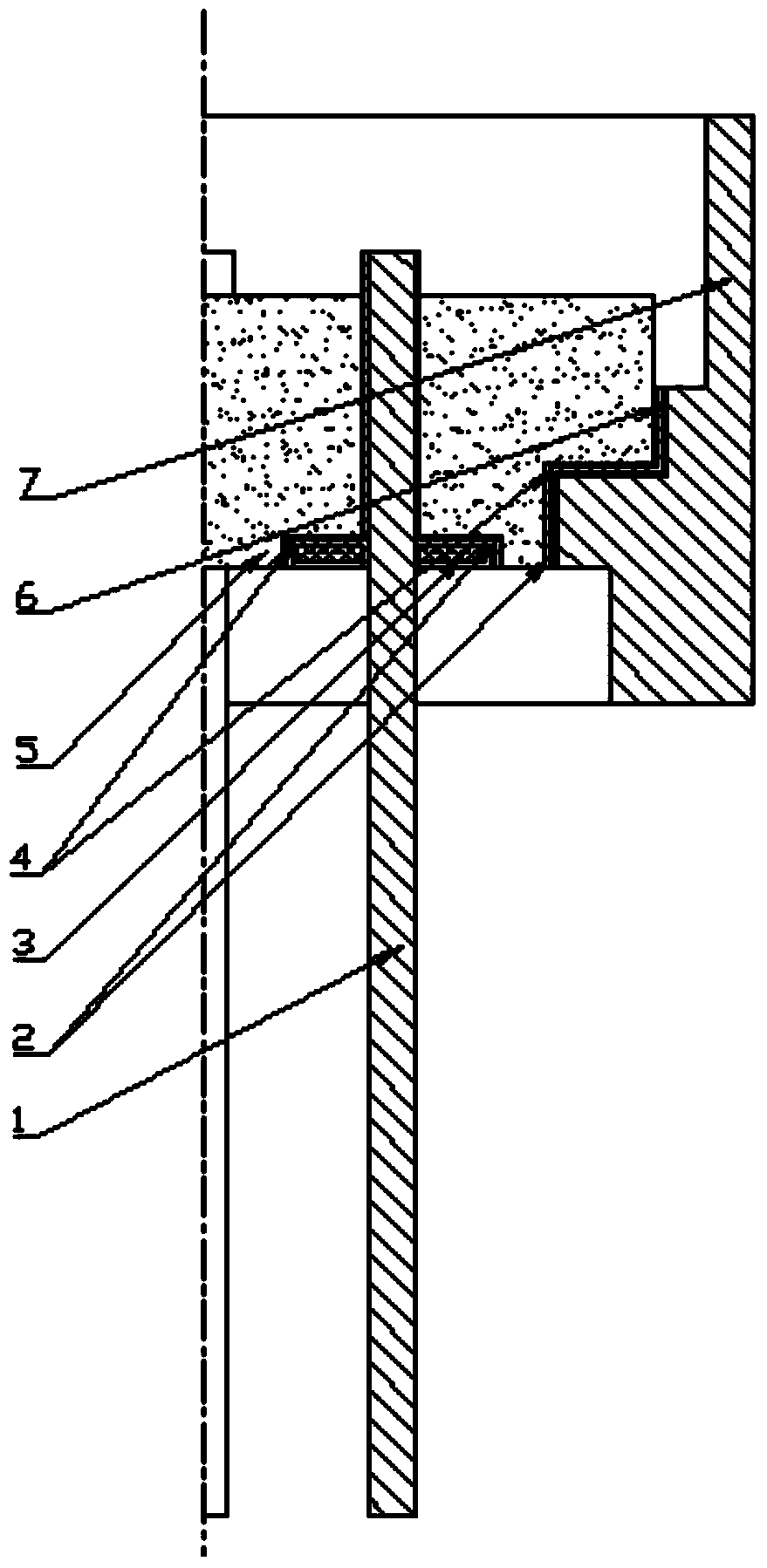

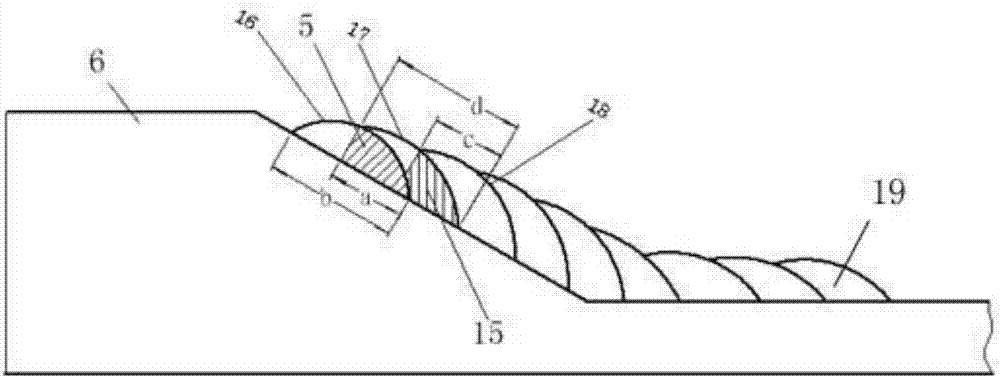

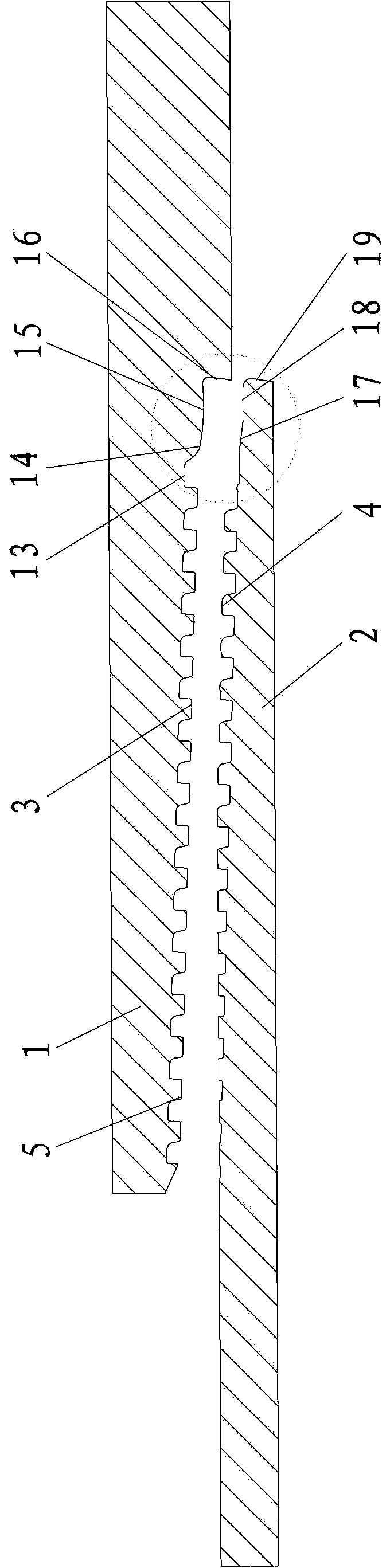

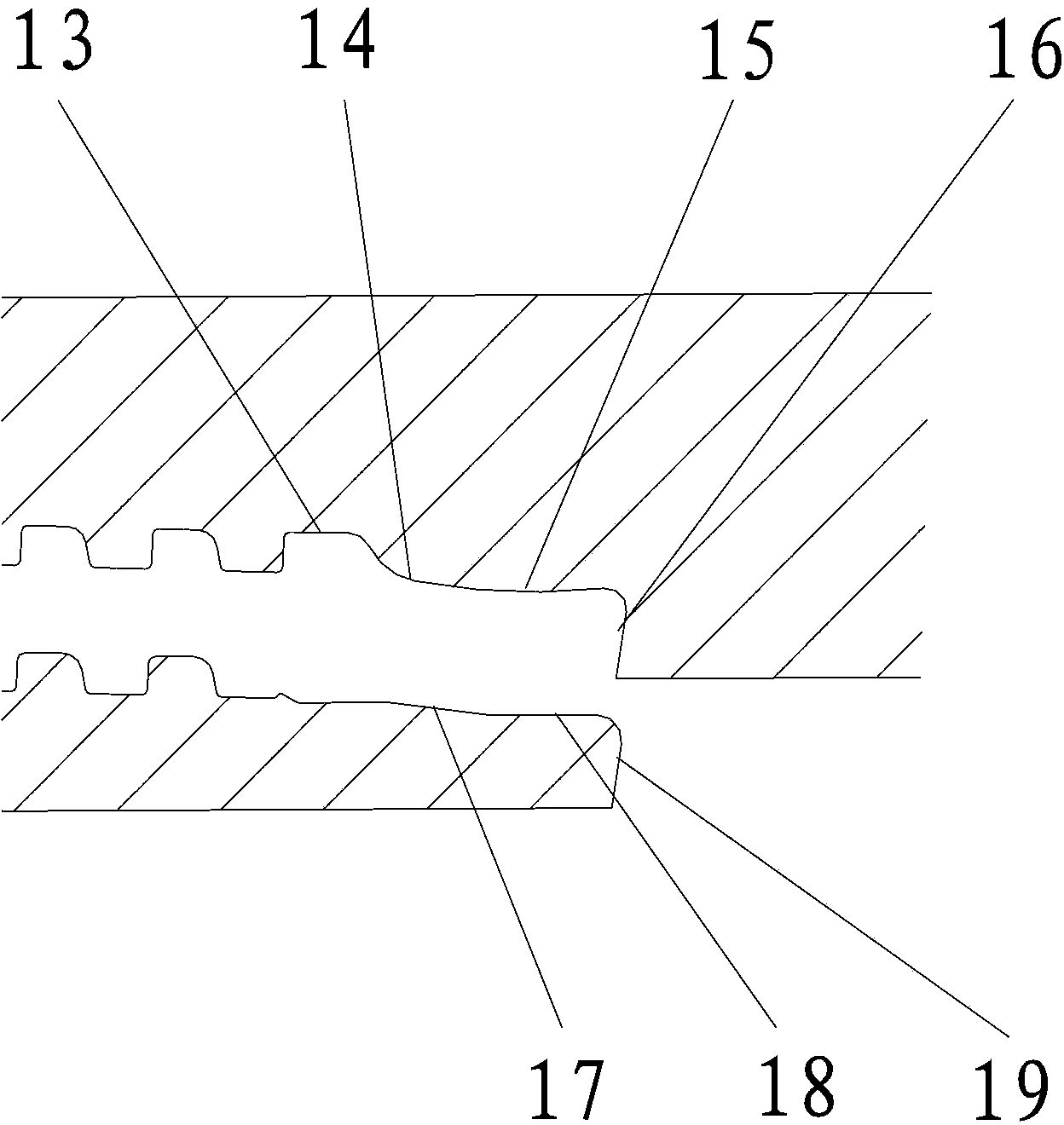

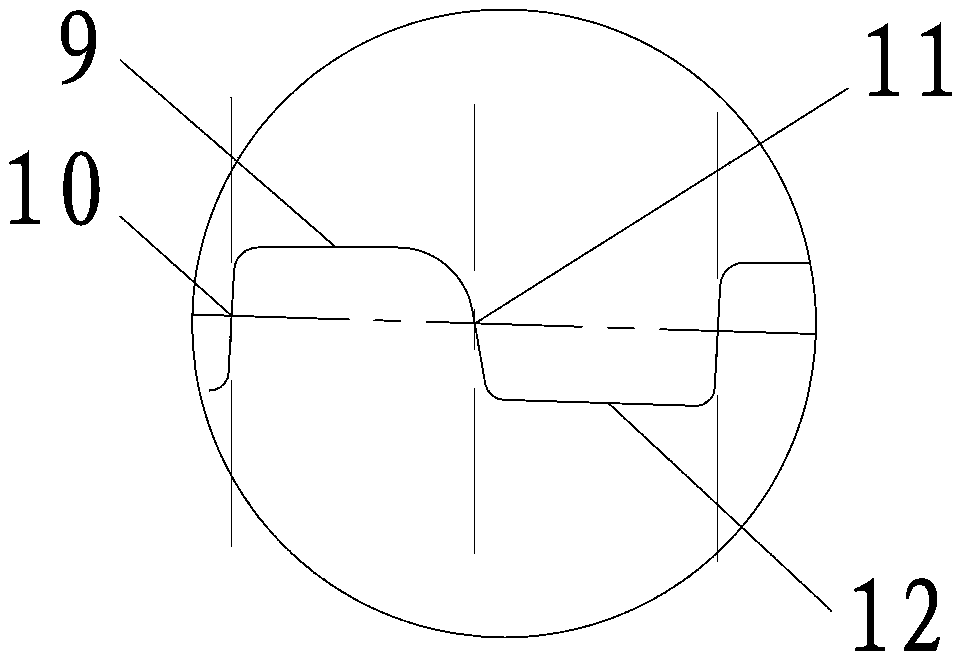

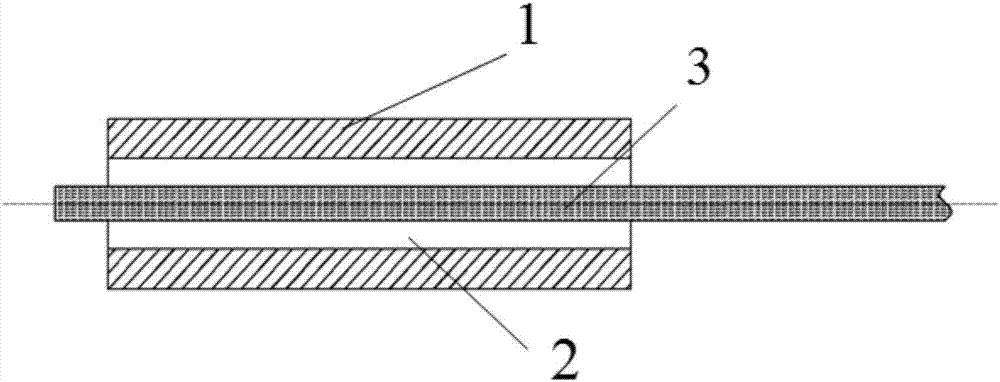

The invention provides a laser shock and supersonic vibration extrusion co-strengthening device and method. The device comprises a laser assembly, a vibration assembly, a hydraulic assembly and a connecting assembly. The method comprises steps as follows: a hole formed on sheet metal is strengthened while laser shock strengthening and supersonic vibration extrusion strengthening are adopted, a mandrel forms clearance fit with the hole to constrain the hole, so that distortion of hole and a hole angle when the laser shock is performed on the outer surface of a workpiece is prevented, and the strengthening effect of the hole wall is improved; when the laser shock is performed on the outer surface of the sheet metal, supersonic vibration is applied to the mandrel in the hole, three-dimensional pressure stress distribution is formed nearby the hole wall at certain depth under the interaction produced by laser shock waves and power ultrasound at certain frequency, amplitude and modal, and higher anti-fatigue performance and smoother inner surface of the hole are obtained. With the adoption of the device and the method, defects of a traditional strengthening technology are overcome, and the problem that the hole is strengthened through either single laser shock or single supersonic vibration extrusion is solved.

Owner:JIANGSU UNIV

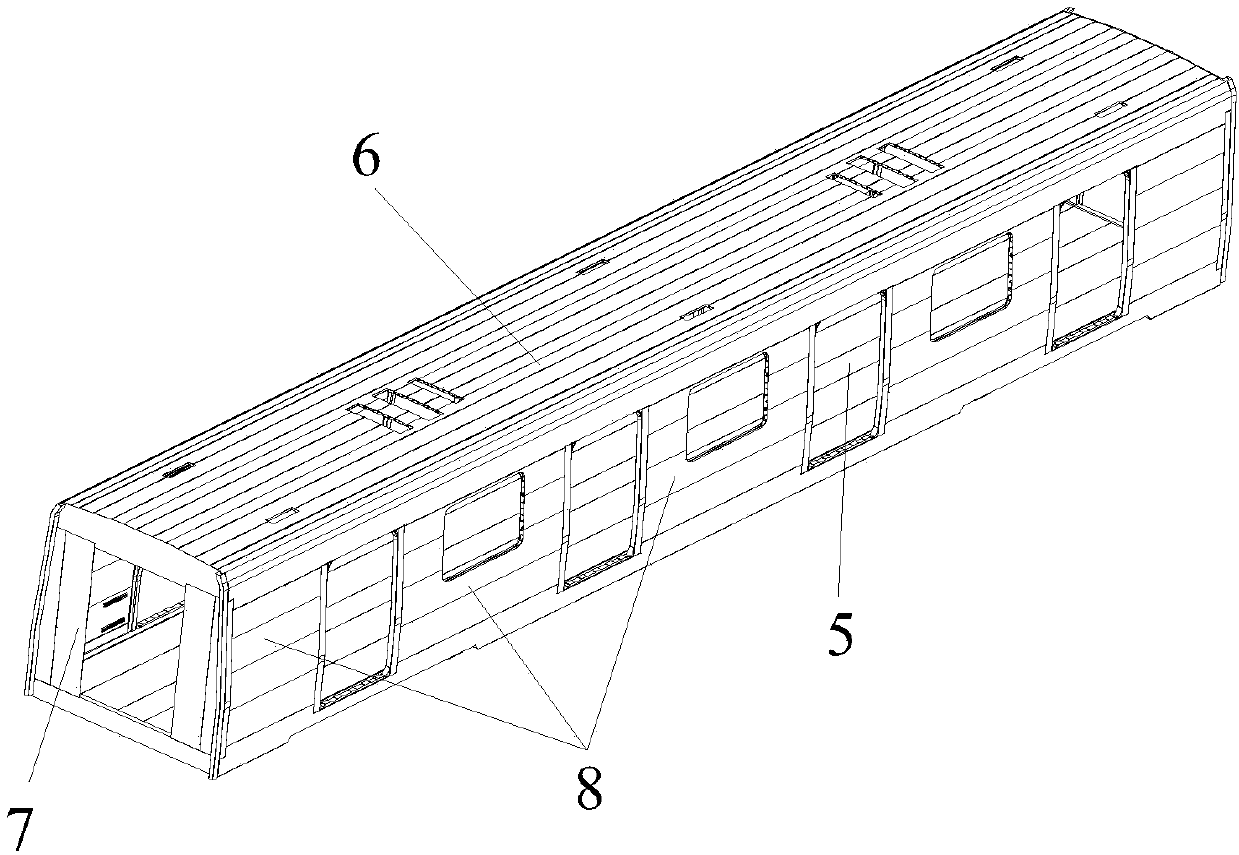

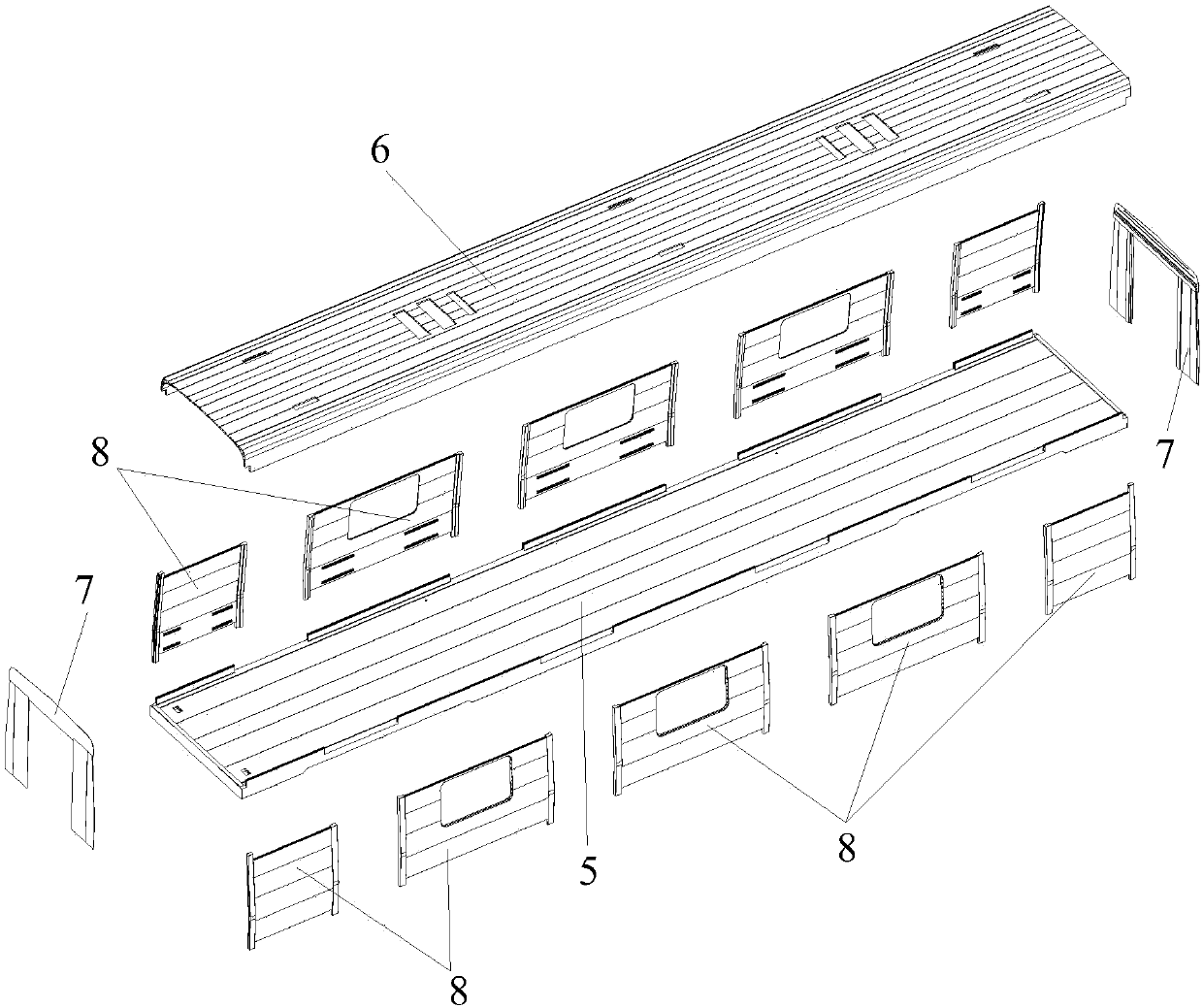

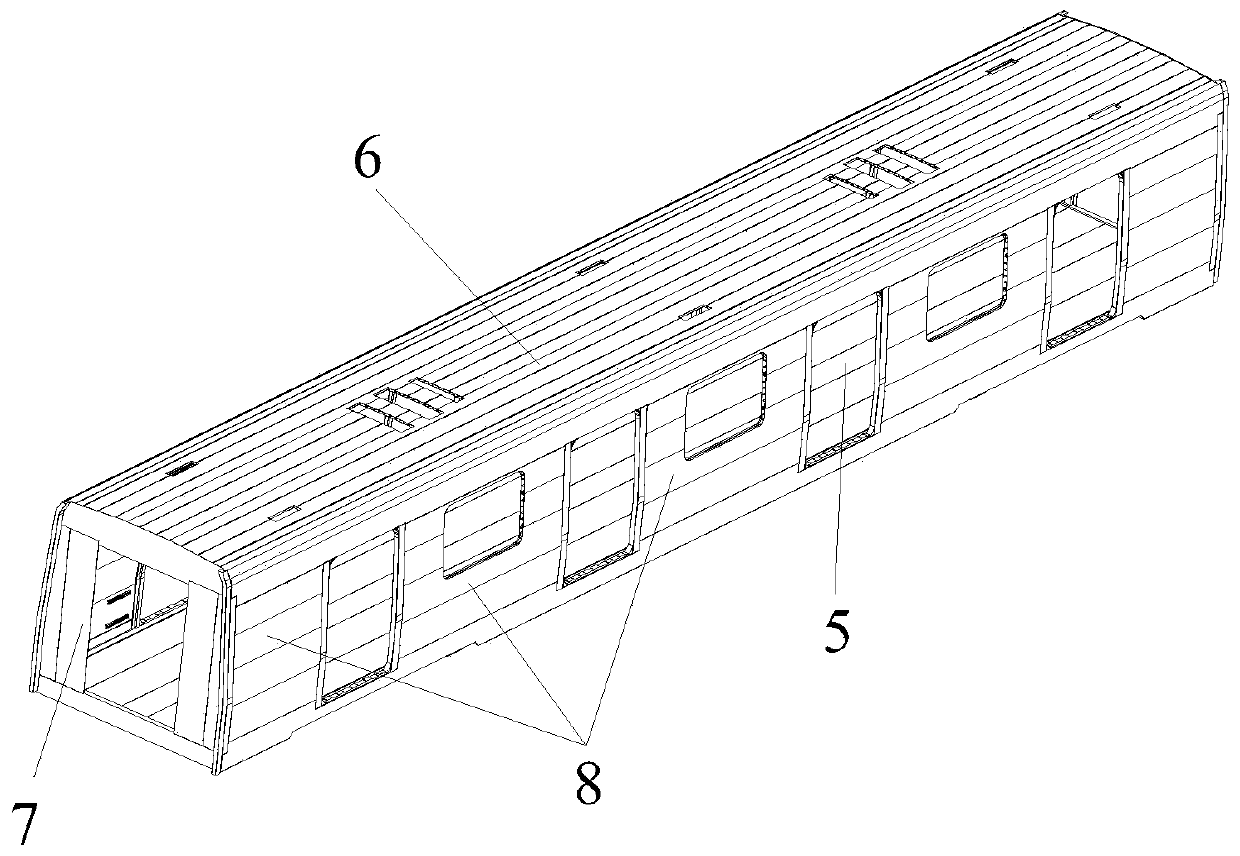

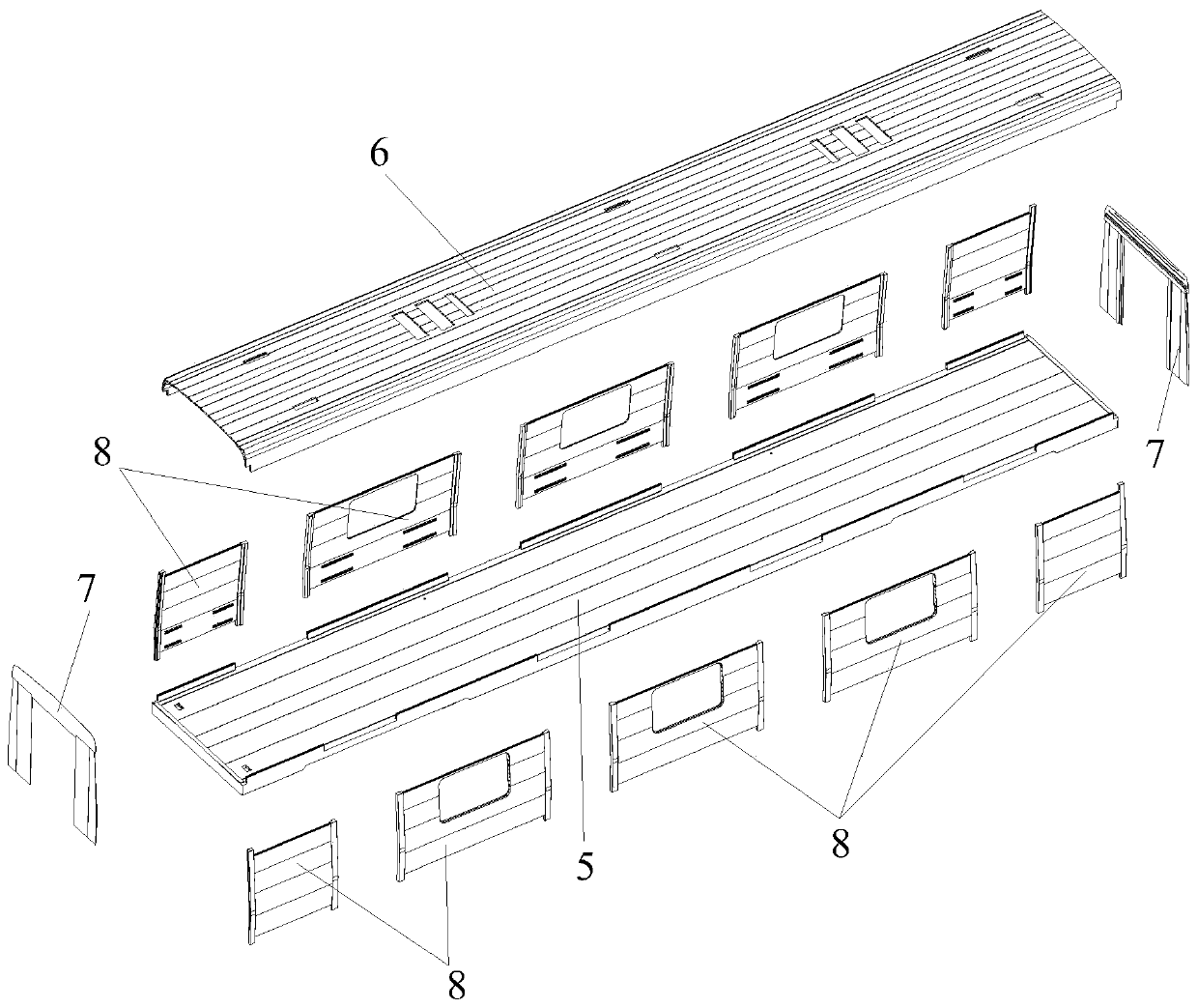

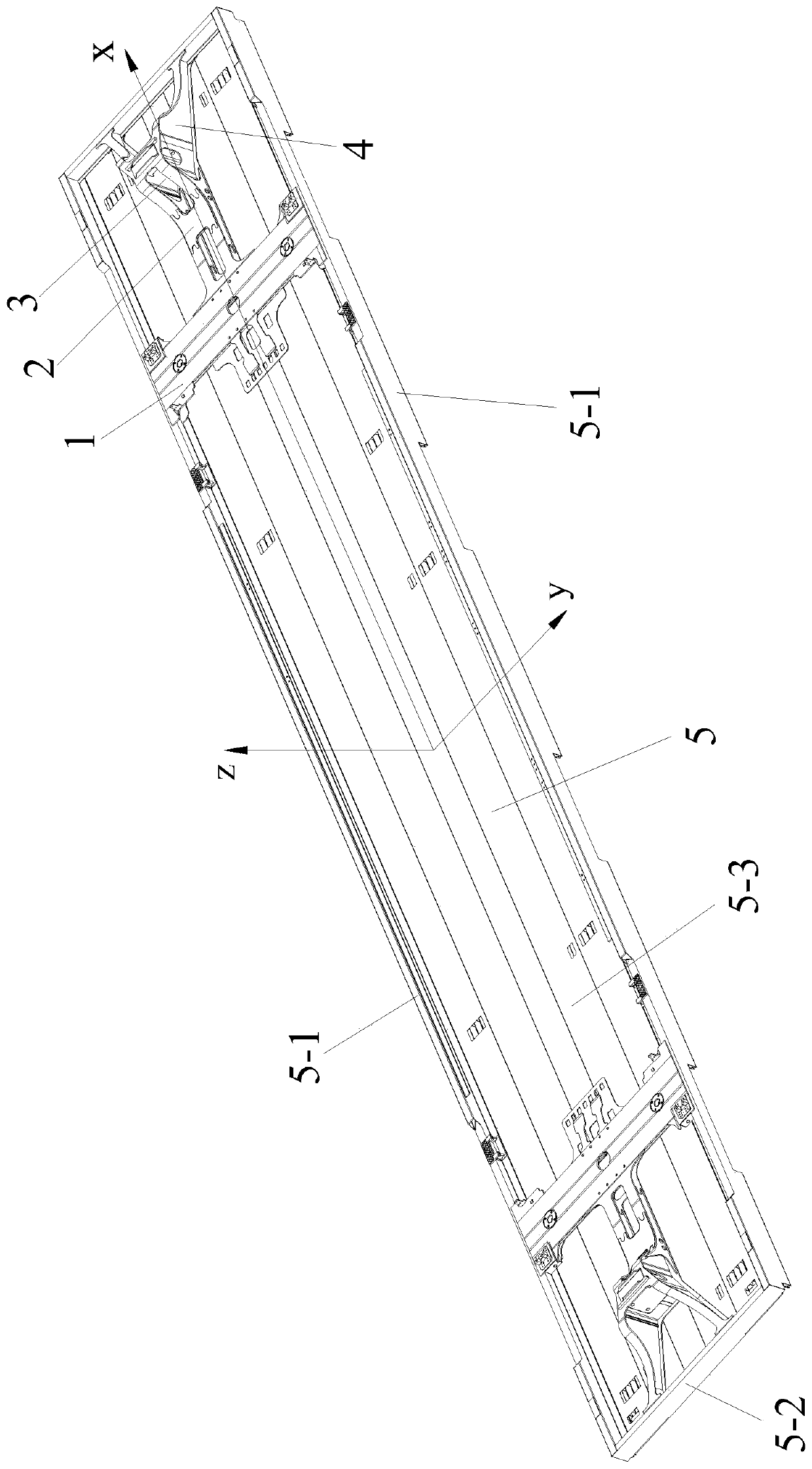

Light-weight metro vehicle body with novel traction sleeper buffer structure

ActiveCN107856688AImprove accessibilityImprove welding qualityRailway roofsUnderframesEngineeringUltimate tensile strength

The invention provides a light-weight metro vehicle body with a novel traction sleeper buffer structure and belongs to the field of full-aluminum product metro vehicle body devices. The light-weight metro vehicle body comprises a chassis, a vehicle roof, two end walls, multiple side wall boards and a full-aluminum product traction sleeper buffer device. The chassis comprises a rectangular floor frame jointly defined by two side beams and two end beams and a floor located in the floor frame. The traction sleeper buffer device comprises a sleeper beam, a traction beam, a draw gear installation seat and two buffer beams. A traction beam lower cover plate and a buffer beam lower cover plate of the full-aluminum product traction sleeper buffer device of the light-weight metro vehicle body are both made of a profile aluminum plate material which is low in density, light in weight and good in bending performance, the draw gear installation seat is made from aluminum plates high in yield stress, other straight plate structures are all made of an aluminum plate material high in yield stress, overall selected materials of the traction sleeper buffer device meet the strength standard, and theprocessing property of welding and manufacturing of the traction sleeper buffer device is the best; and all lightening holes can be simultaneously used as auxiliary holes in the inner cavity weldingoperation process, so that the accessibility and welding quality of inner cavity welding joints are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

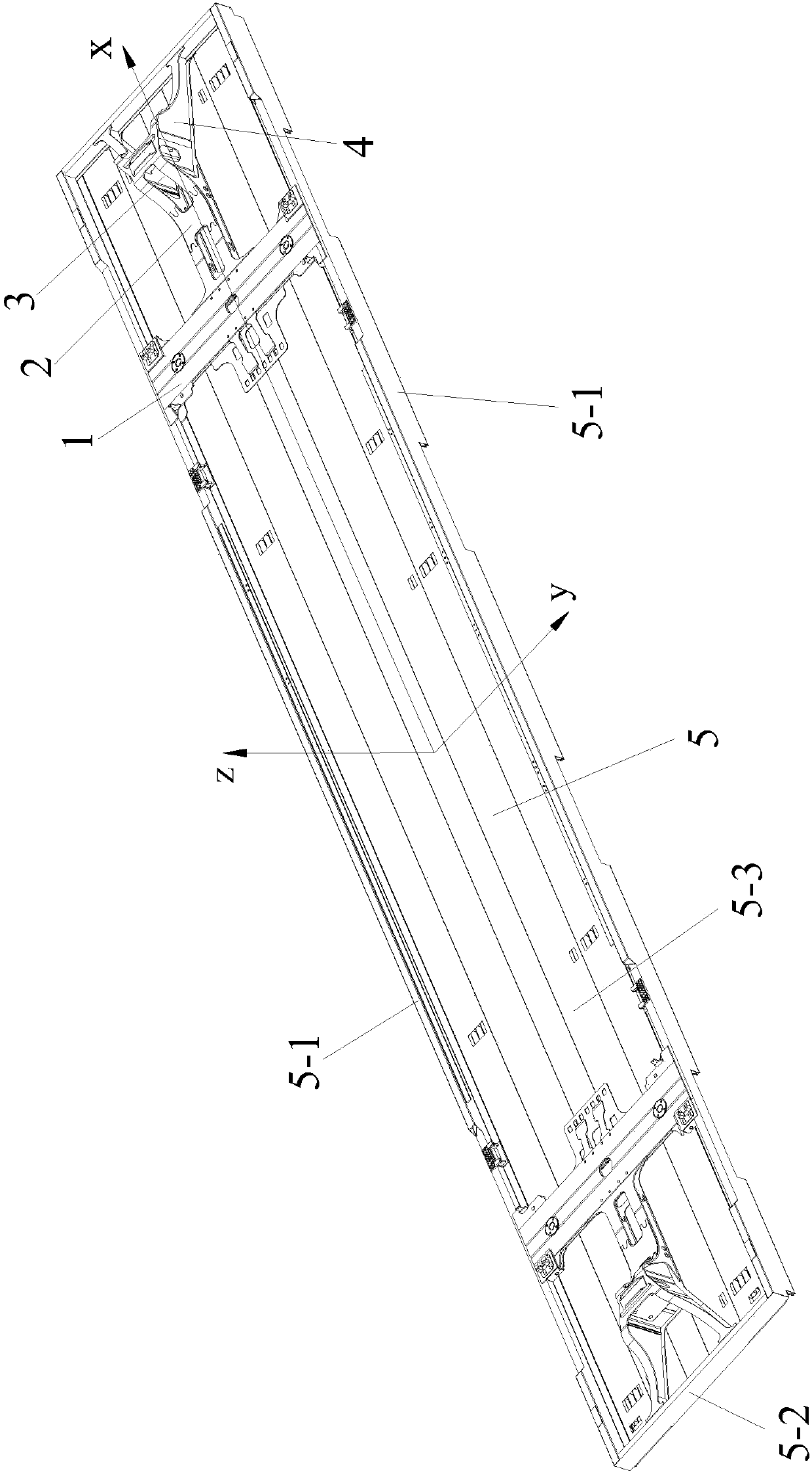

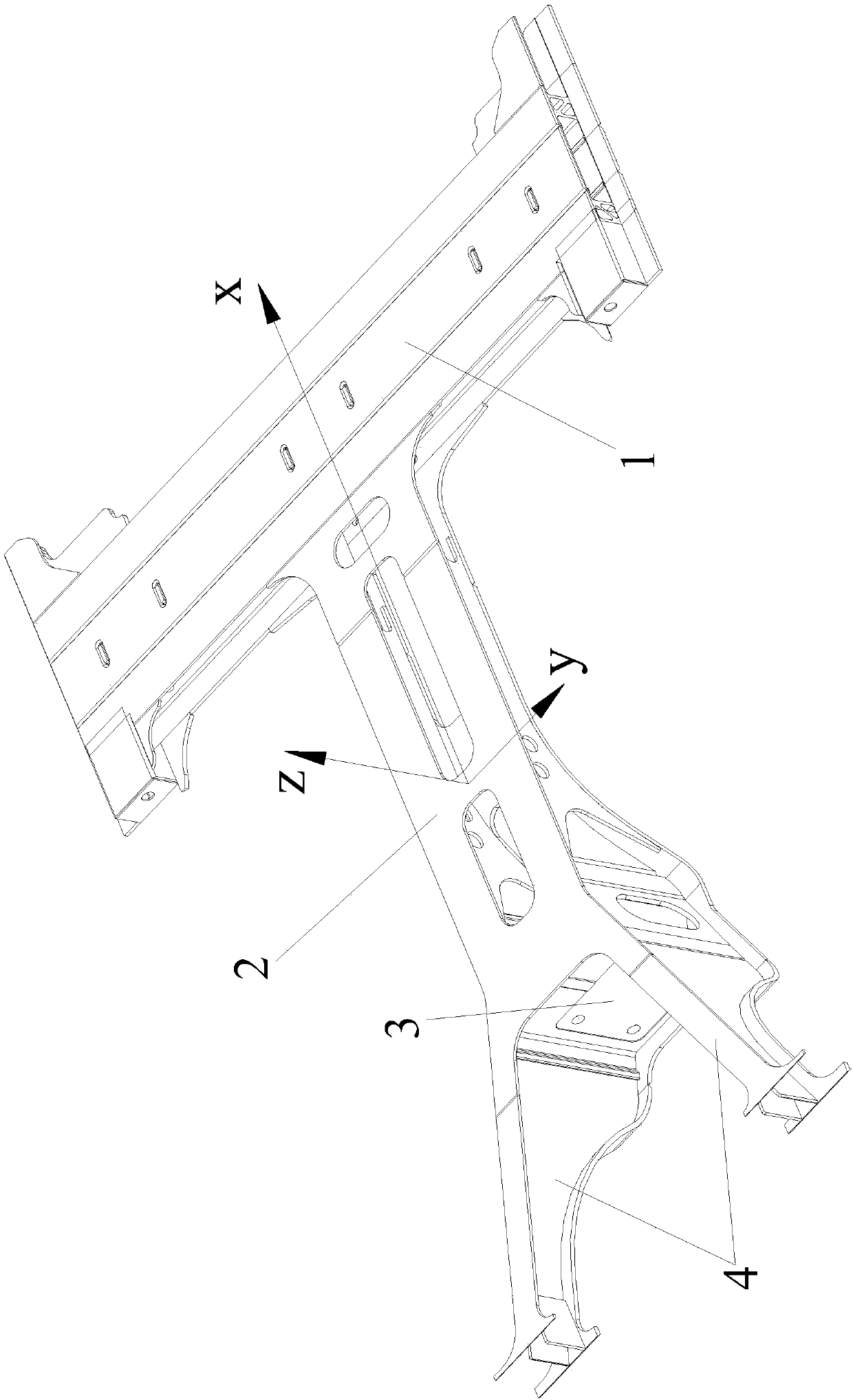

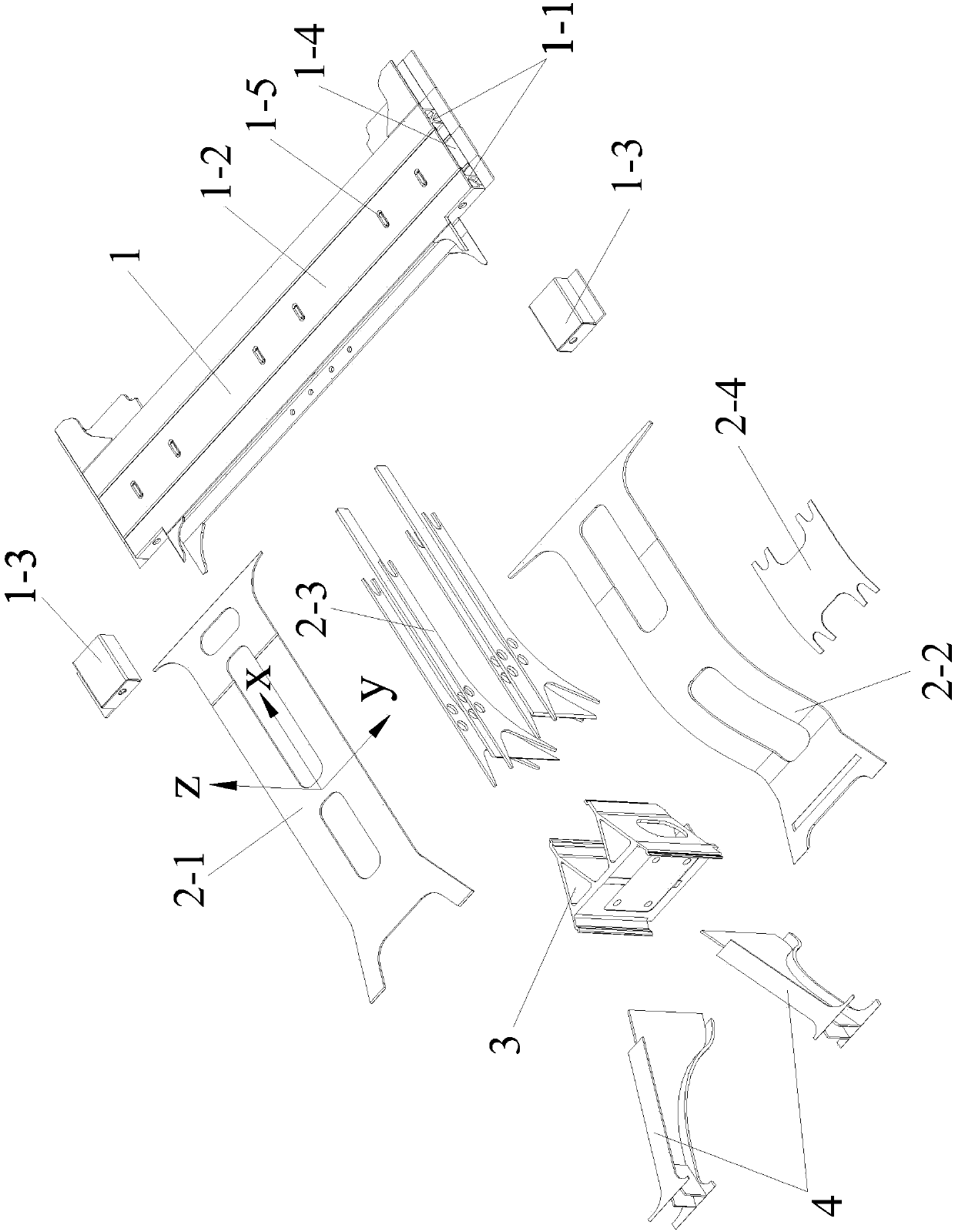

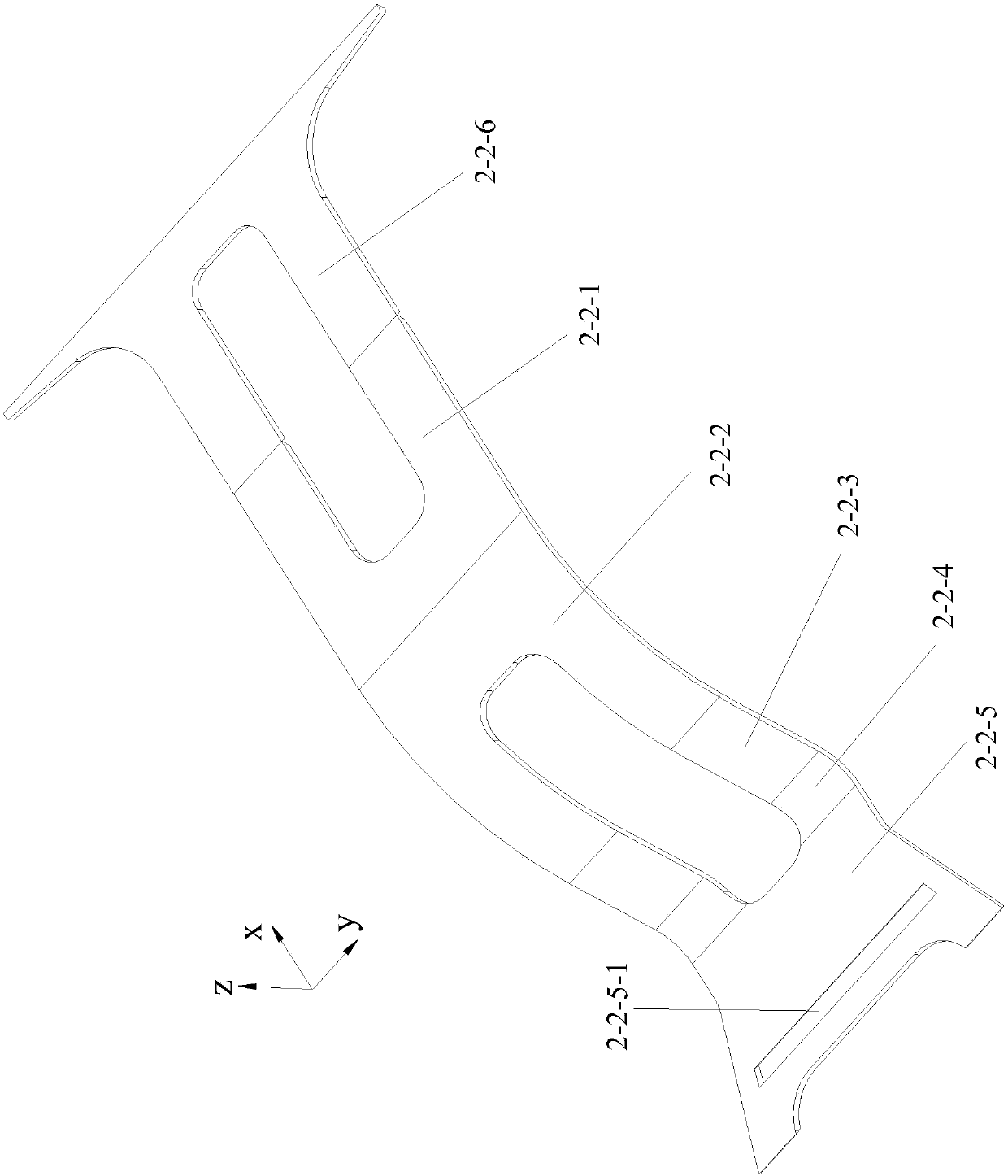

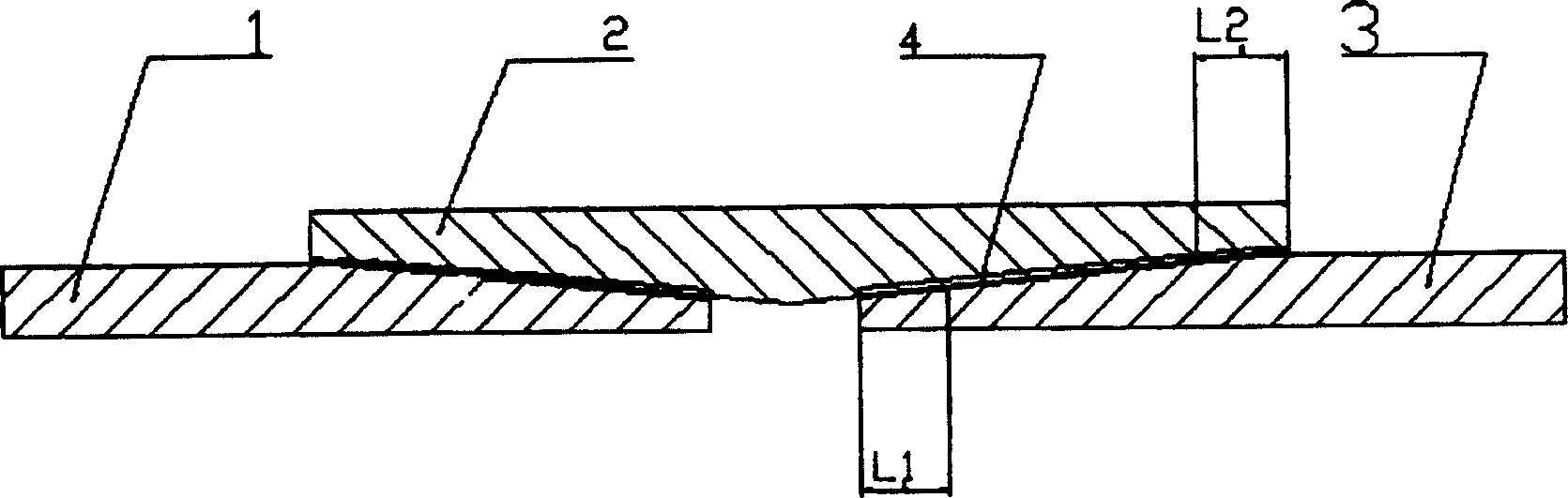

Traction sleeper buffer device of all-aluminum railway vehicle

ActiveCN107901938AImprove accessibilityImprove welding qualityUnderframesEngineeringUltimate tensile strength

The invention provides a traction sleeper buffer device of an all-aluminum railway vehicle and belongs to the field of traction sleeper buffer devices for railway vehicles. The traction sleeper bufferdevice comprises a sleeper beam, a traction beam, a drag gear installation seat and two buffer beams. A lower traction beam cover board and lower buffer beam cover boards of the traction sleeper buffer device are all made of an EN AW 5083 type aluminum plate material which is low in density, low in weight and good in bending performance, the drag gear installation seat is made from EN AW 6005A aluminum plates high in yield stress, other straight plate structures are all made of an EN AW 6082 type aluminum plate material high in yield stress, so that the overall selected materials of the traction sleeper buffer device meet the strength standard, and the welding and manufacturing processing property of the traction sleeper buffer device is the best. All lightening holes can be used as auxiliary holes at the same time in the inner cavity welding operation process, and therefore the accessibility and welding quality of an inner cavity welding joint are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

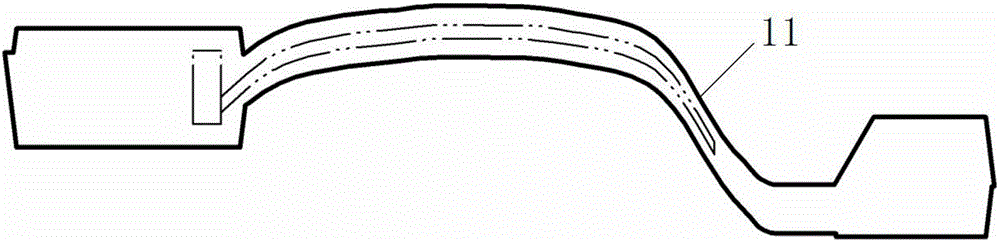

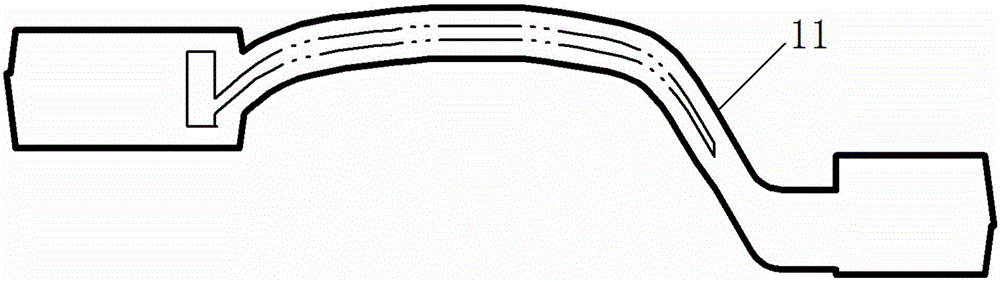

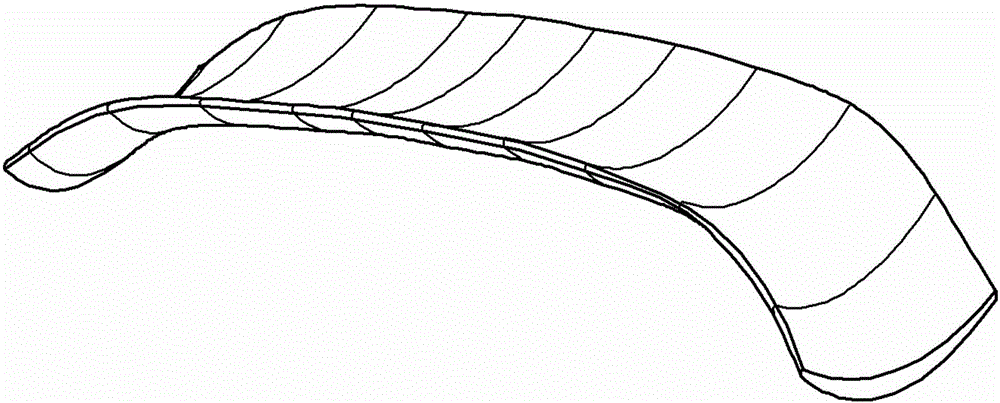

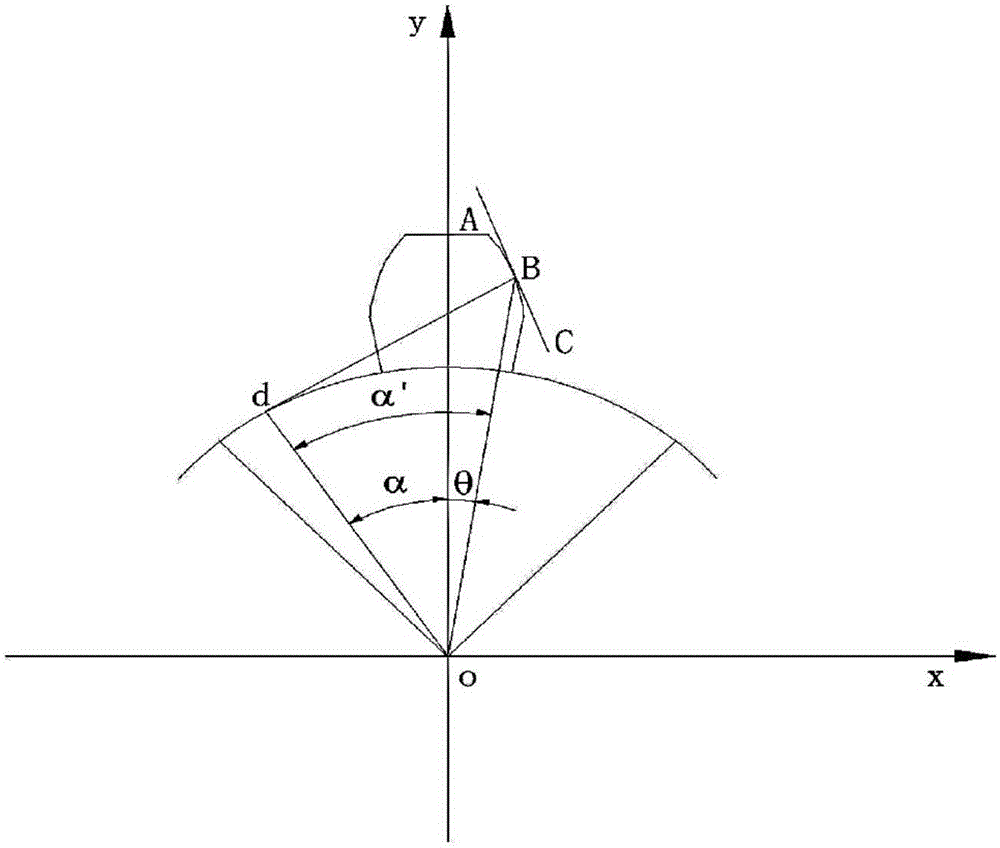

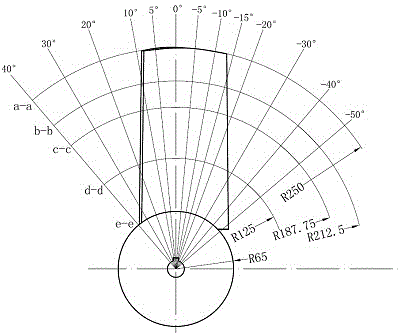

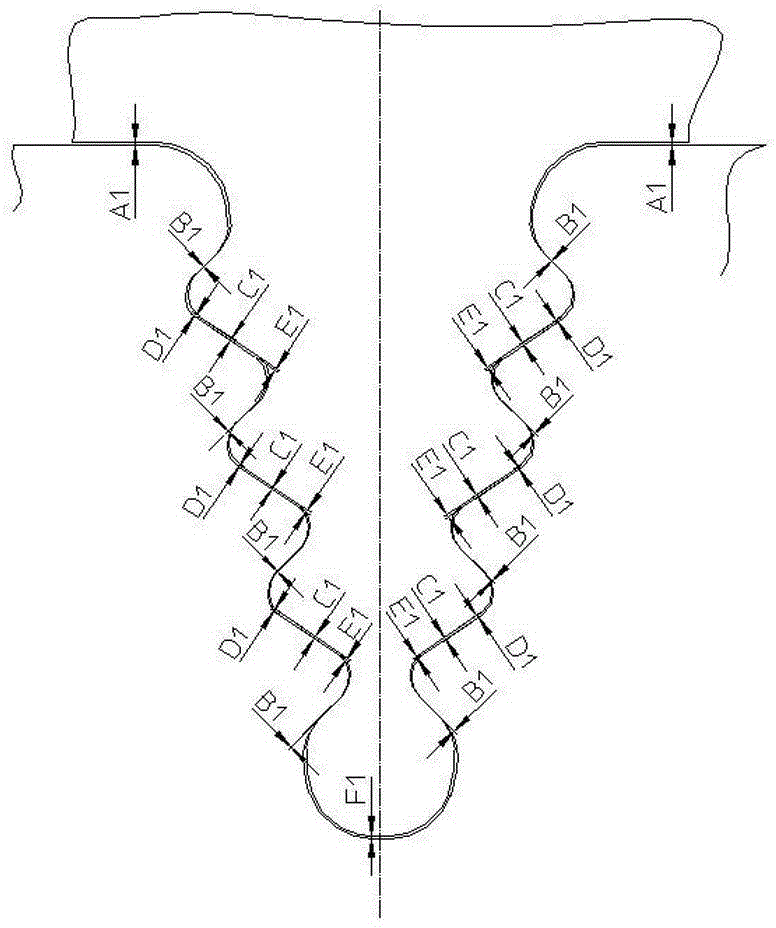

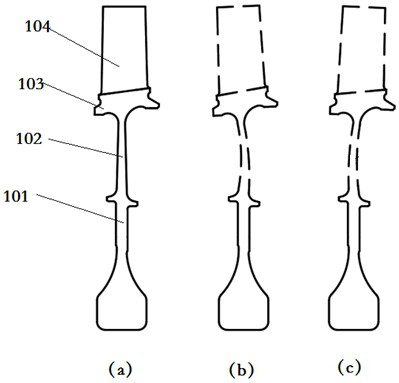

Method for designing blade body margin of over-bent blade forge piece

ActiveCN106529069AEvenly distributed machining allowanceReasonable stress distributionGeometric CADSpecial data processing applicationsEngineeringForge

The invention provides a method for designing a blade body margin of an over-bent blade forge piece. The method comprises the following steps: drawing a three-dimensional model of a part blade body; executing an offset command according to machining margin to obtain a three-dimensional model of the part blade body with the margin increased; extracting section lines of the part and the forge piece according to a sectional distance on a part drawing; importing the section lines in two-dimensional drawing software; drawing two continuous inscribed circles on the exhaust edge of the section line of the part, and drawing an extension line of a connecting line of circle centers; drawing a normal of the extension line on a cross point of the extension line and the section line of the part; offsetting both sides of the extension line to obtain two symmetrical first offset lines, wherein the offset is a half of the thickness of a deckle edge of the exhaust edge of the section line at an over-bent site; offsetting a single side of the normal to obtain a second offset line, wherein the offset is the margin of the exhaust edge at the over-bent site, and the cross points of the first offset lines and the second offset line are respectively marked as first and second edge control points; moving two outer end points of the section line of the forge piece to the first and second edge control points; and inquiring all control points of the section line of the forge piece, and importing the same into a three-dimensional drawing software to generate a three-dimensional model of the blade body of the forge piece.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for manufacturing automobile body through carbon fiber composite

InactiveCN105666892AReasonable stress distributionReduce weightDomestic articlesFiberEnergy absorption

The invention discloses a method for manufacturing an automobile body through a carbon fiber composite. The method comprises the following steps that a flexible inner mold matched with the automobile body and used for manufacturing the automobile body is inflated to be in an automobile body shape, the outer surface of the flexible inner mold is coated with the pre-glued carbon fiber composite according to the requirement for the design angle and the number of layers, and then the automobile body is formed; the flexible inner mold coated with the carbon fiber composite is placed in an outer mold to be fixed, inflated and pressurized, and then the outer mold is placed in a curing furnace to be cured; and after the carbon fiber composite is cured, natural cooling is carried out, the flexible inner mold is deflated to reduce pressure, the outer mold is opened, and the cure-molded composite automobile body is taken out. Due to the fact that the automobile body made of the carbon fiber resin composite is adopted, compared with a traditional metal material automobile body, the weight is reduced by 60% or above, the corrosion resisting performance is improved, energy absorption of the automobile body is better, and running energy consumption is reduced.

Owner:ZHEJIANG UNIV

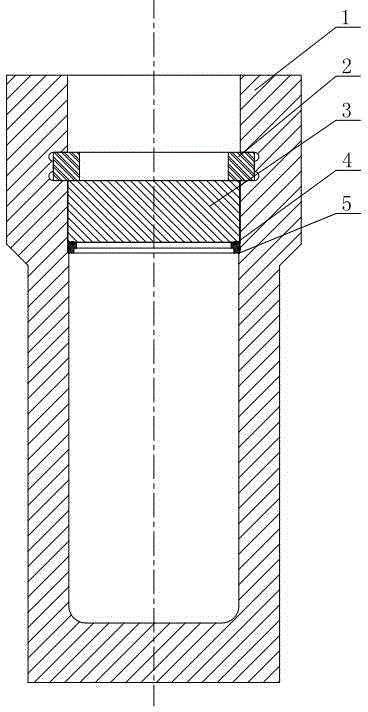

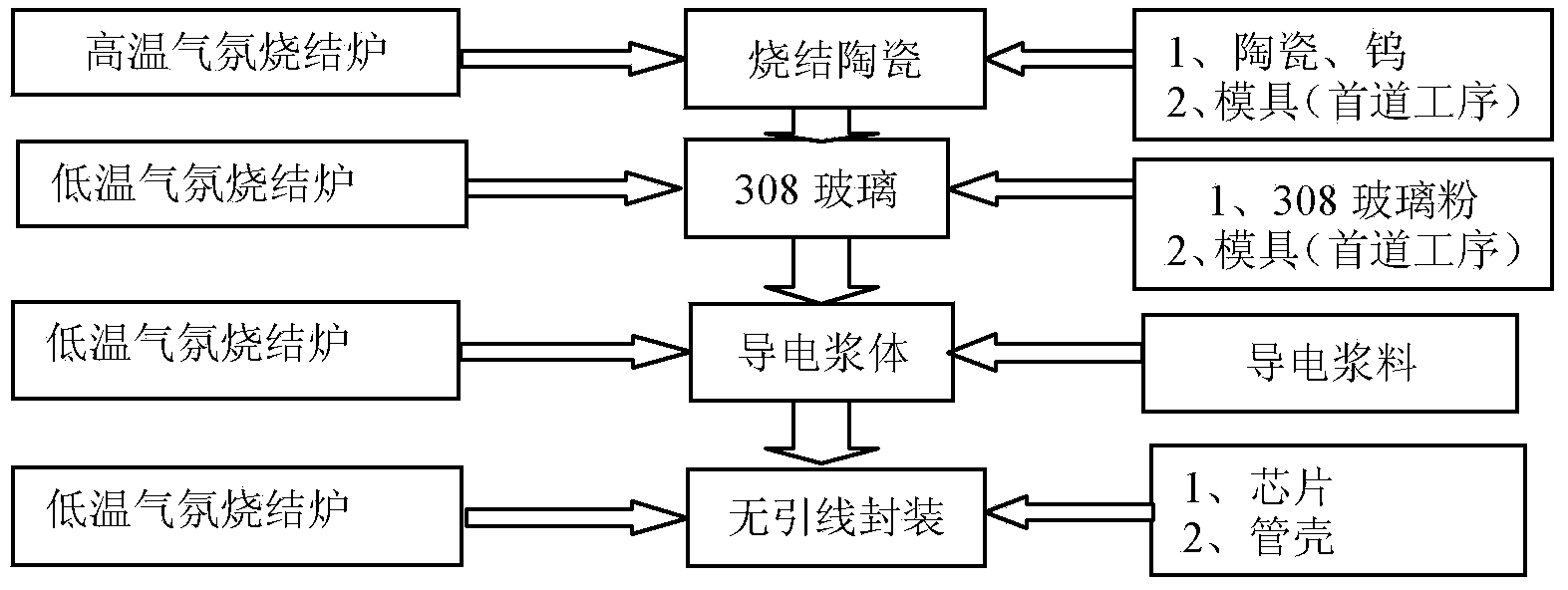

Ceramic packaging structure and pressure sensitive apparatus shell of ceramic packaging structure

InactiveCN103759864ALow dielectric constantReasonable stress distributionForce measurementFluid pressure measurementTransition layerCeramic

The invention provides a ceramic packaging structure and a pressure sensitive apparatus shell of the ceramic packaging structure, and relates to a packaging structure of the pressure sensitive apparatus shell, in particular to the pressure sensitive apparatus shell of the ceramic packaging structure. Accordingly, the problem that in the prior art, the pressure sensitive apparatus shell is prone to corrosion and oxidation when used at a high temperature or the pressure sensitive apparatus shell is influenced by thermal mechanical stress is solved. Ceramic is adopted to serve as an insulating material of the ceramic packaging structure, a metallization layer is sintered on the surface of the ceramic at a high temperature, and the metallization layer and a metal shell are sintered through solder, such as nickel or gold or Ag-Cu, serving as a transition material to form a sealing structure. The pressure sensitive apparatus shell comprises a lead, the metallization layer, a seal ring, the solder, a ceramic body, a transition layer and a tube base, wherein the metallization layer is arranged on the junction surface of the ceramic body and the tube base, the ceramic body and the metallization layer are sintered to form a whole under a high temperature, the transition layer is formed between the metallization layer and the tube base through the sintering effect of the solder, and the lead and the surface of an inner hole of the seal ring are sintered to form a whole through the solder.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

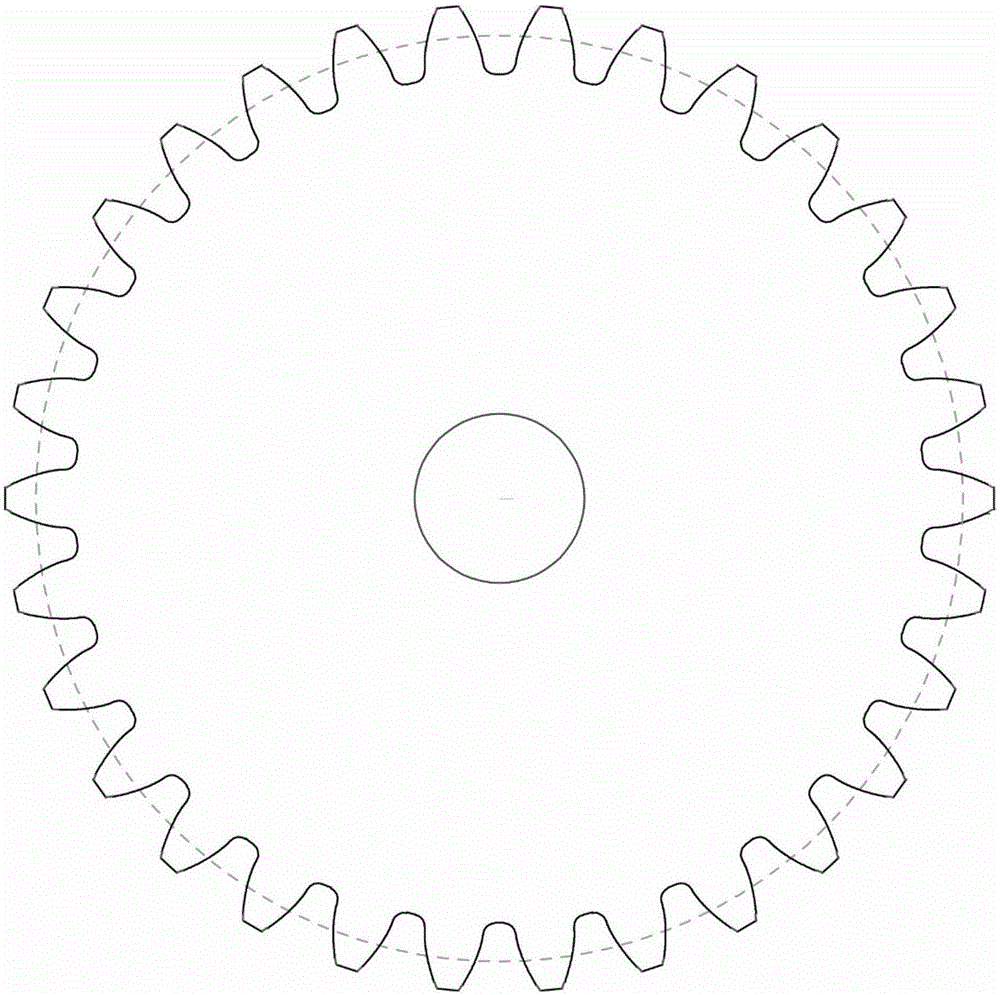

Involute straight tooth gear modification optimization method

InactiveCN105156634AImprove optimization accuracyImprove efficiencyPortable liftingGearing elementsNumerical controlProcess optimization

The invention provides an involute straight tooth gear modification optimization method; and the method comprises the steps of: building engaged three-dimensional gear pair models; primarily selecting modification optimization parameters; respectively performing the primary modification processing for the three-dimensional gear pair models; performing the primary modification optimization analysis to obtain optimal primary analysis optimization parameters; obtaining more precise optimization samples in finite element analysis software according to the optimization parameters; and screening the samples. After screening, the secondary modification processing is performed for a pair of standard three-dimensional involute gears to obtain multiple sets of secondarily processed optimization parameters, optimal modification optimization gear parameters, one set of parabola modification and one set of arc modification; the three-dimensional diagram drawing is performed for gears optimized by the secondarily processed optimization parameters; and optimally modified three-dimensional diagrams are leaded in a numerical control machine tool to machine blanks to finished products. The method is more precise in modification, is more obvious in optimization effect, can preferably reduce the engagement noise and vibration, and reduces such adverse effects as load concentration.

Owner:梅文杰

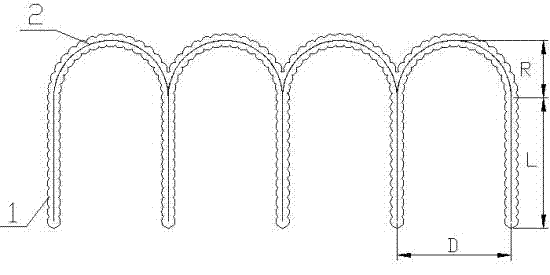

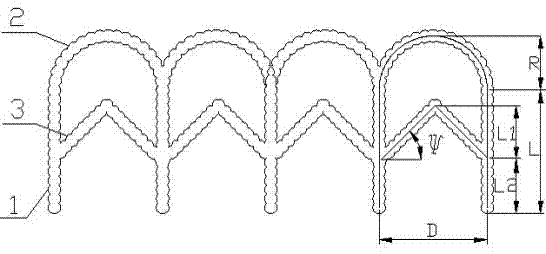

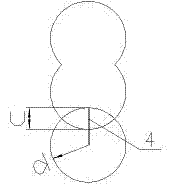

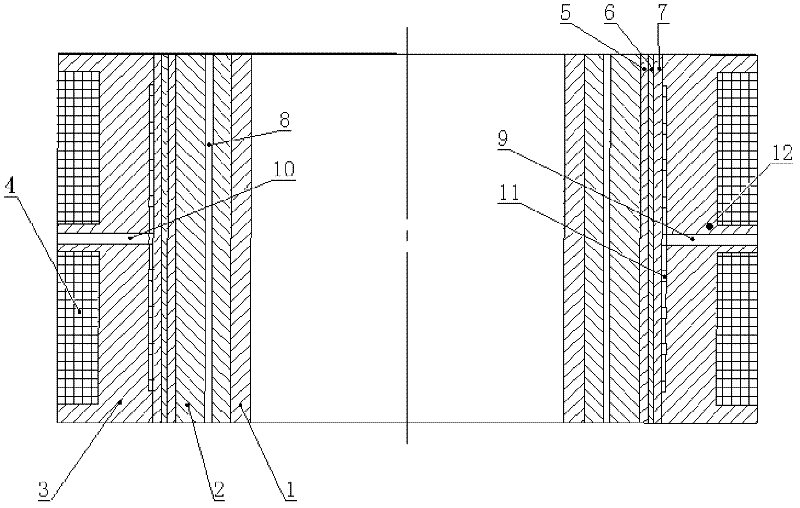

Soil cement long wall continuous arch structure for slope reinforcement

InactiveCN102444133AStrong anti-seepageImprove skid resistanceExcavationsBulkheads/pilesSoil cementStructural engineering

The invention discloses a soil cement long wall continuous arch structure for slope reinforcement. The structural form has high slip-resisting capacity and high economic efficiency, and is very suitable for slip-resisting reinforcement treatment in soft soil slopes and soft foundation filling engineering in the engineering fields of buildings, traffic, water conservancy, mines and the like. The long wall continuous arch structure comprises an arc-shaped wall and a slip-resisting wall, wherein both the slip-resisting wall and the arc-shaped wall are formed by engaging dry spray stirring piles or wet spray stirring piles. In the working mechanism, a long wall continuous arch embedded into a slope body or a soft soil foundation passes through a most dangerous slip surface, soil is retained by using a stirring pile arc-shaped wall, the stirring pile arc-shaped wall is used for transferring horizontal push force to a stirring pile slip-resisting wall, and the stirring pile slip-resisting wall is used for finally transferring horizontal push force to a lower soil layer. By adopting the structure, the compression resistance and shearing resistance of soil cement can be brought into full play, and pile body tensile stress is avoided.

Owner:HOHAI UNIV

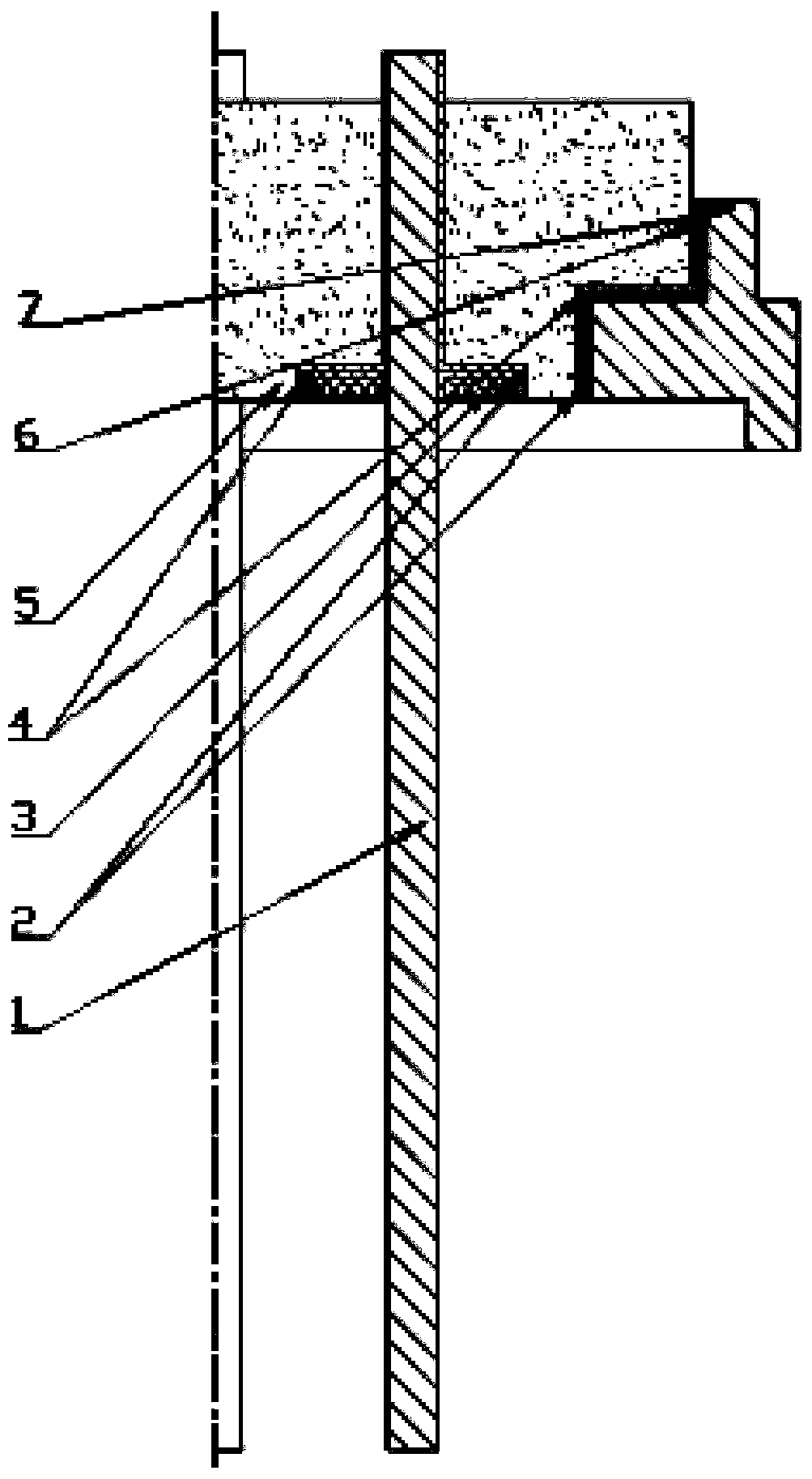

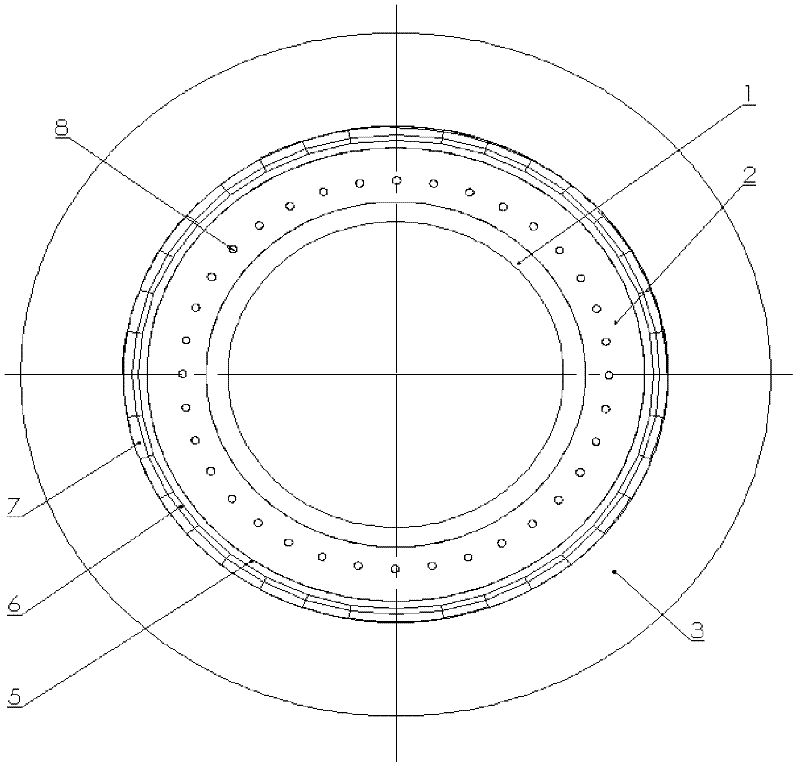

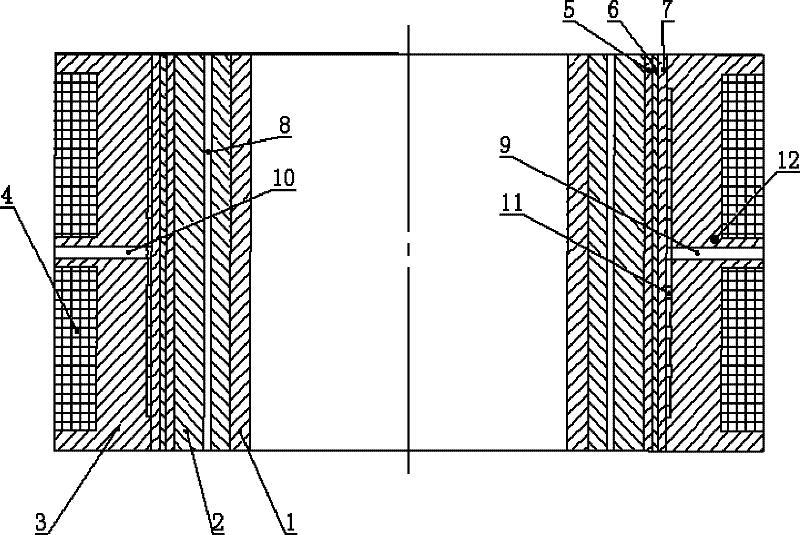

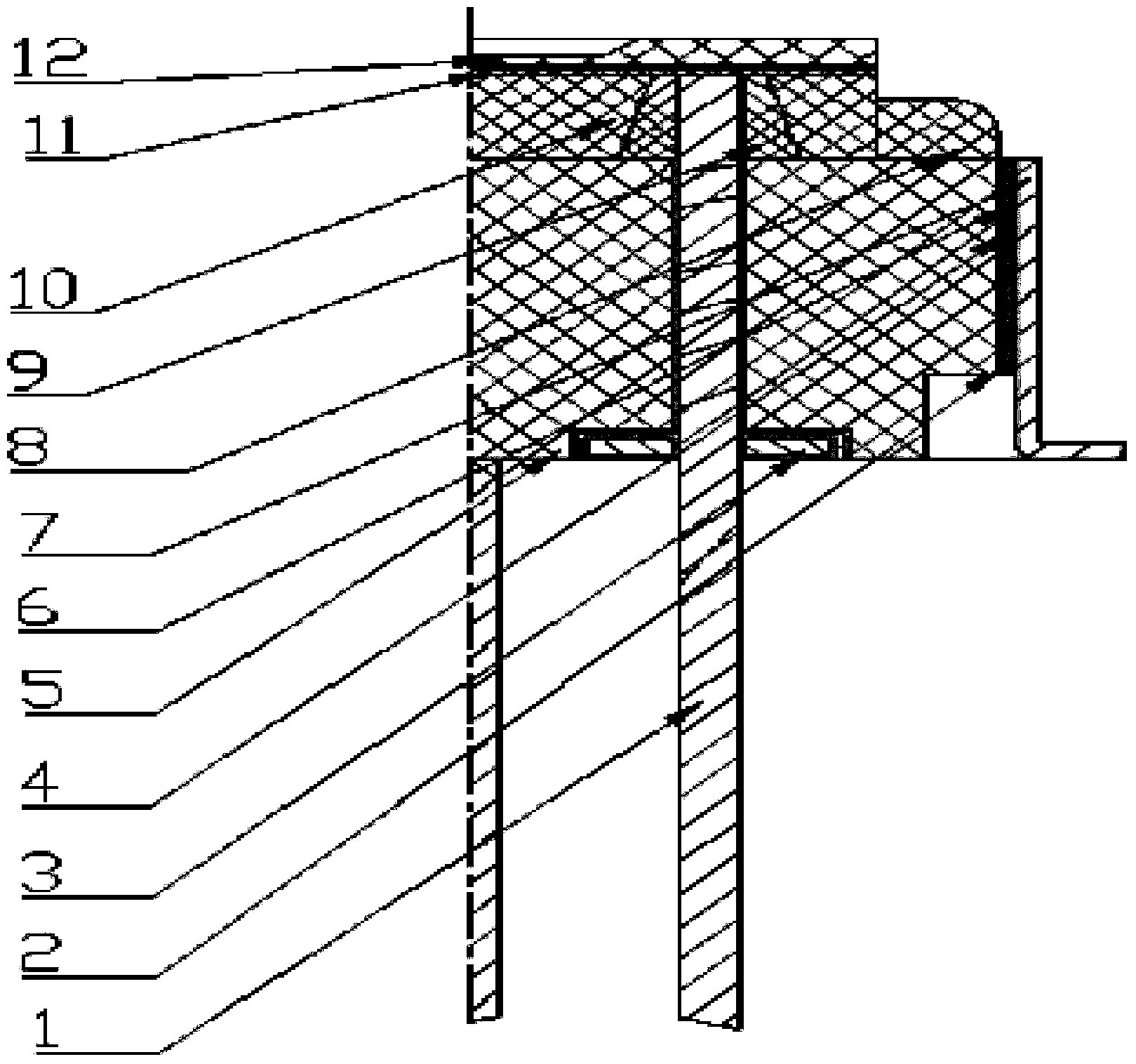

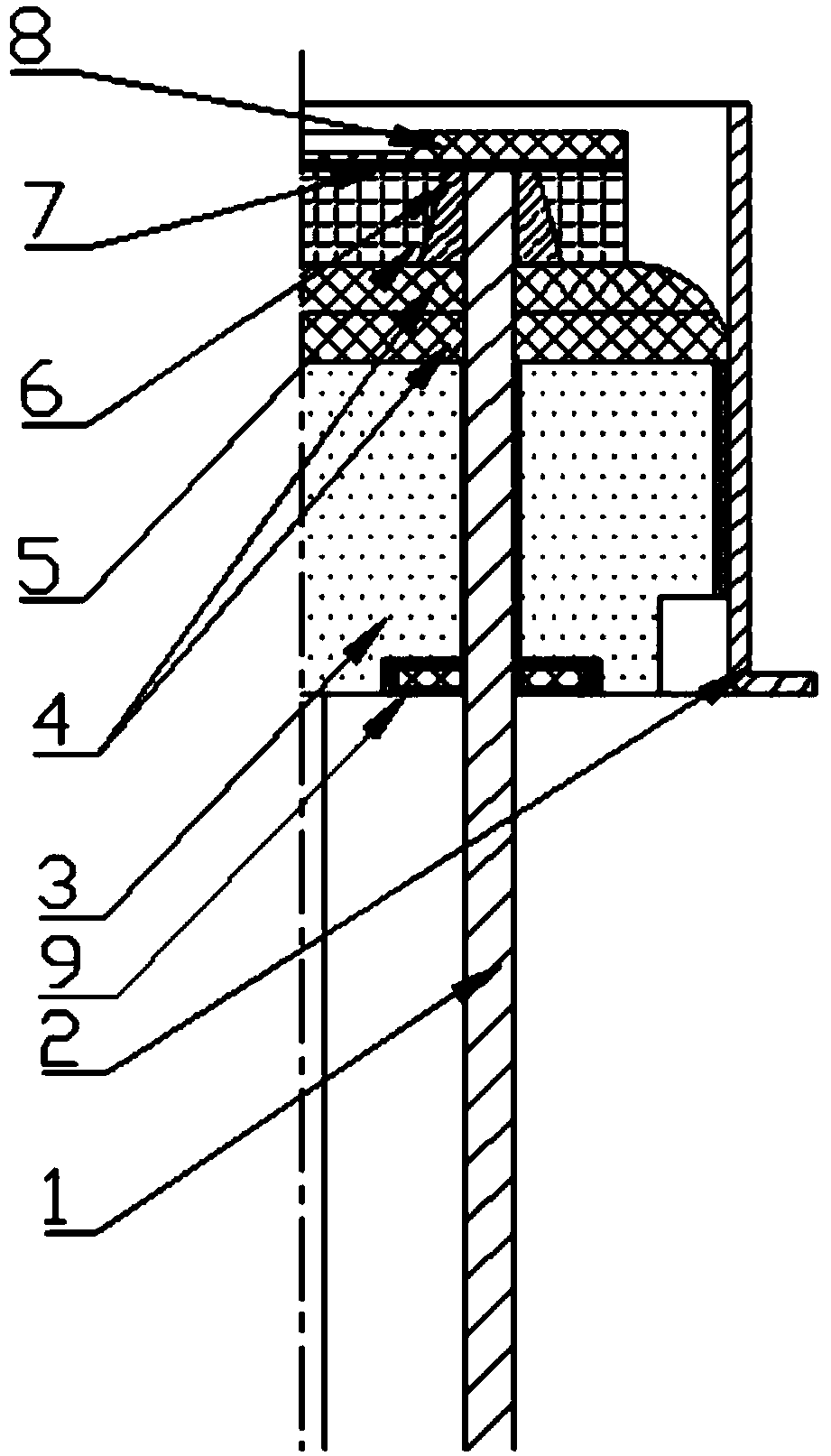

Prestressed wire winding recipient

ActiveCN102389906AImprove fatigue lifeEnsure safetyExtrusion profiling toolsStress distributionThermal insulation

A prestressed wire winding recipient can be applied to hot metal extruding technology, and particularly can be applied to the hot extrusion of seamless steel tubes with large caliber and thick walls. The recipient comprises an inner liner, a middle liner, a thermal insulation layer, an outer liner and a steel wire layer, wherein a hearing rod hole is arranged in the middle liner, and a heating element is arranged in the hole and is used for preheating the recipient; the thermal insulation layer is arranged between the middle liner and the outer liner, consists of an inner protective plate od the thermal insulation layer, a thermal insulation material and an outer protective plate of the thermal insulation layer, and is used for preventing heat from being transmitted to the outer liner and the steel wire layer from the inner liner and the middle liner which are in high temperature; an annular cooling groove is arranged on the inner surface of the outer liner and is used for cooling the outer liner by leading cooling media in; and the temperature near a contact interface between the steel wire layer and the outer liner is detected in real time by a temperature sensor. As the middle liner is provided with a preheating hole to preheat the recipient, a preheating temperature field which is more uniform on the radial and circumference directions can be obtained by the recipient, and the reasonable stress distribution in the recipient can be realized, so that the fatigue life of the recipient can be prolonged greatly.

Owner:TSINGHUA UNIV +1

Leadless packaging structure and SOI absolute pressure sensitive device of leadless packaging structure

ActiveCN103759880AReasonable stress distributionImprove high temperature resistanceFluid pressure measurement using ohmic-resistance variationSemiconductor/solid-state device detailsPressure sensitiveBiomedical engineering

The invention relates to a leadless packaging structure and an SOI absolute pressure sensitive device of the leadless packaging structure. The leadless packaging structure and the SOI absolute pressure sensitive device solve the problems that in the prior art, silicone oil is prone to leaking under high-temperature and high-pressure conditions, a metal lead easily breaks, an electrode system disconnects from a key and fails, and influences of thermal stress exist. According to the leadless packaging structure, a metallization layer is sintered on the surface of a solid insulating material, and the metallization layer and a metal tube shell are sintered to form a sealing structure through solder. According to the SOI absolute pressure sensitive device of the leadless packaging structure, the solid insulating material is fixed to a tube base through the metallization layer and the solder, a seal ring is arranged on the outer surface, which the lead penetrates out downwards in the tube base direction, of the solid insulating material, a multi-layer composite material, a glass-metal composite material and a borosilicate glass base are arranged on the outer surface, which the lead penetrates out upwards in the tube base direction, of the solid insulating material, a metal electrode is arranged at the top end of the lead, and a chip is arranged at the other end of the metal electrode.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

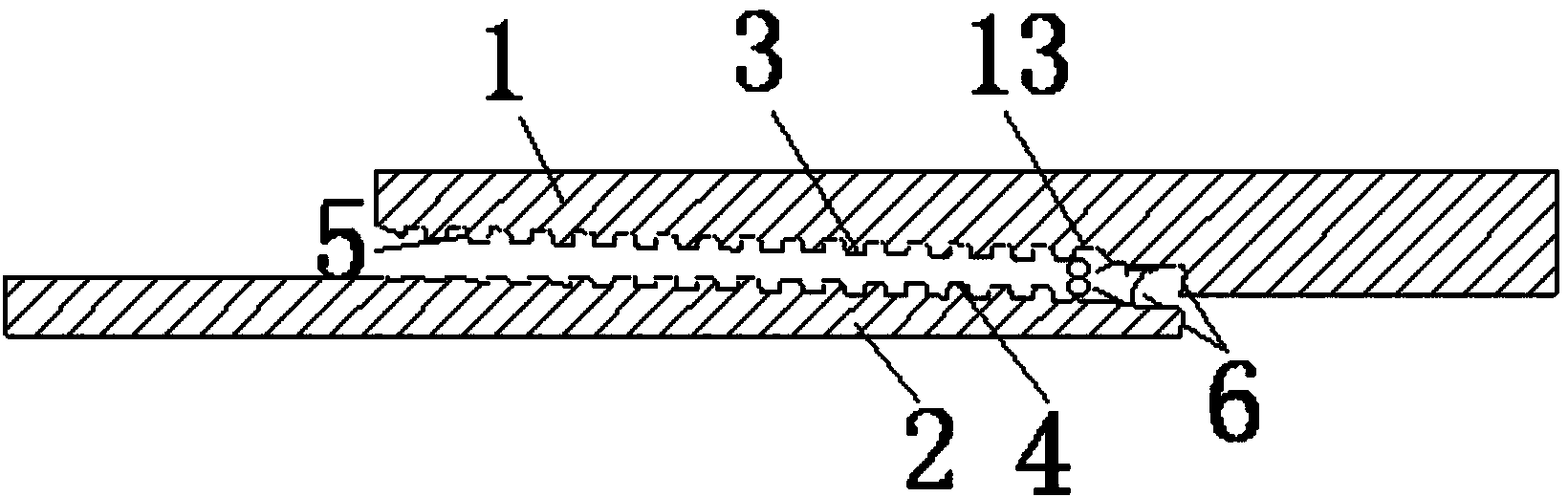

Multistage sealing anti-sticky buckle type thread for titanium alloy oil casing

InactiveCN103527110AImprove airtight reliability performanceReduced stress stateDrilling rodsDrilling casingsButtressCoupling

The invention relates to a multistage sealing anti-sticky buckle type thread for a titanium alloy oil casing. The multistage sealing anti-sticky buckle type thread comprises an oil casing coupling and an oil casing tube end, the oil casing coupling is provided with a standard API buttress internal thread which is sequentially connected with a tool withdrawal groove, a cone surface to cone surface first stage sealing structure, a cylinder surface to cylinder surface second stage sealing structure and a negative angle torque circular bead, wherein the cone surface to cone surface first stage sealing structure and the cylinder surface to cylinder surface second stage sealing structure are in transition through chambering, and the negative angle torque circular bead is connected with the standard API buttress internal thread through a transitional angle. The multistage sealing anti-sticky buckle type thread for the titanium alloy oil casing has the advantages that two stages of metal sealing and one negative angle torque circular bead sealing are added based on the improved buttress thread, the reliability of the air tightness of a thread connector is improved through the design of multistage sealing, meanwhile, the stress state of the thread connector is reduced by changing a thread parameter, the performance of an anti-sticky buckle is improved, and machining and detecting are convenient.

Owner:XIAN SANHUAN TECH DEV GENERAL

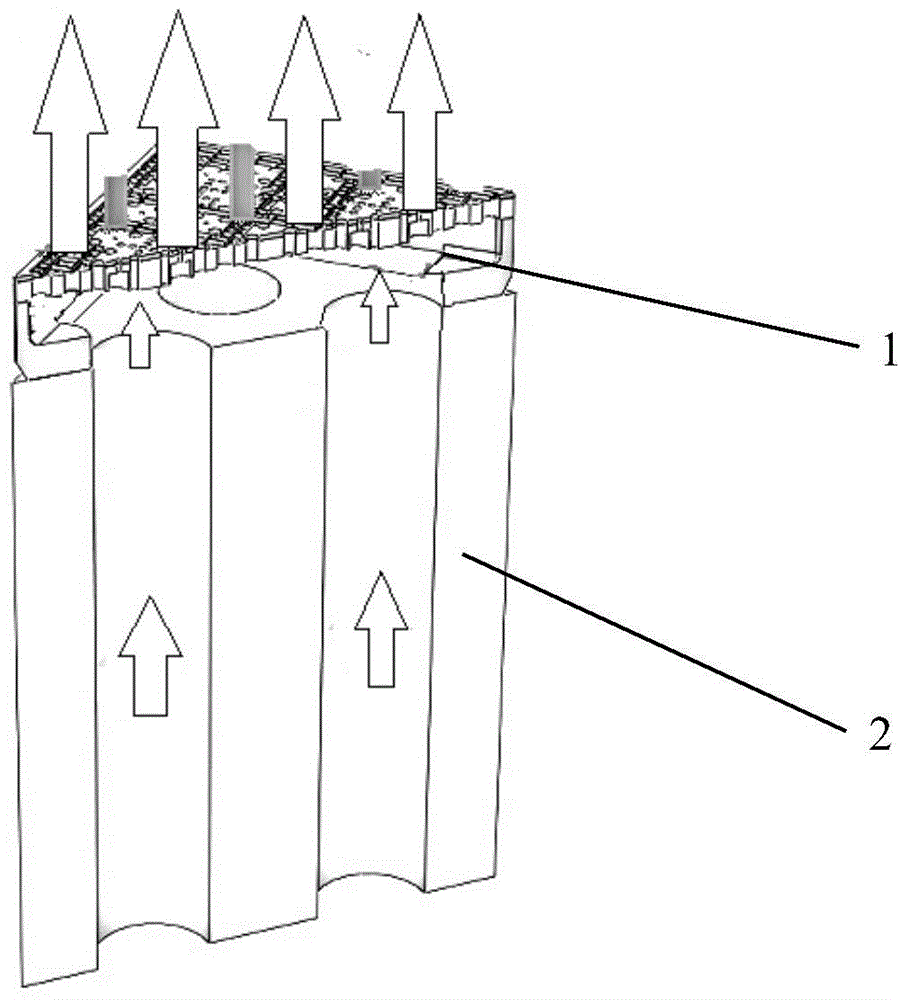

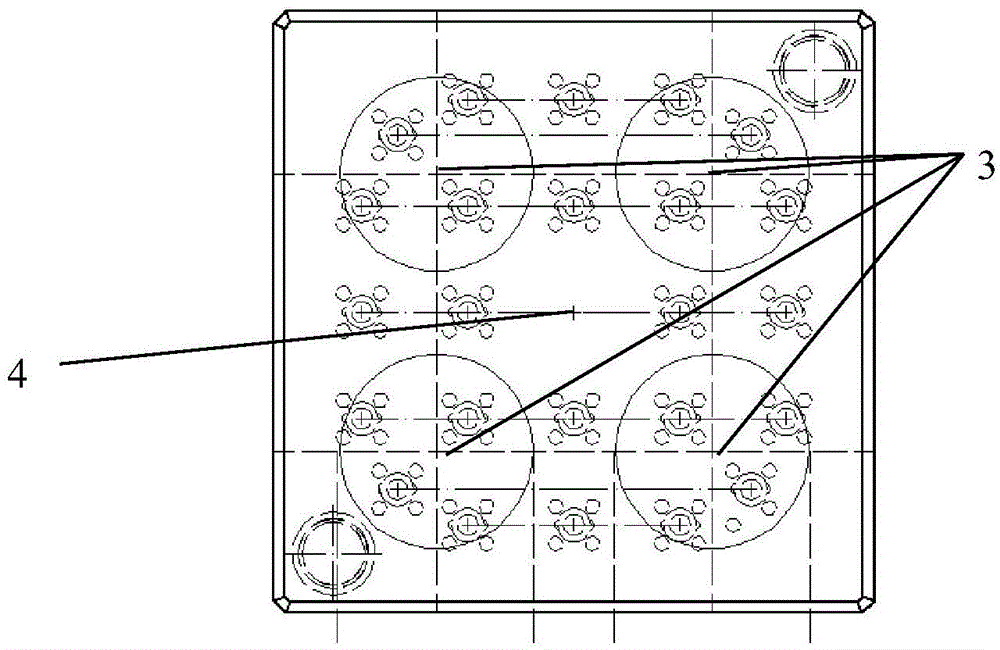

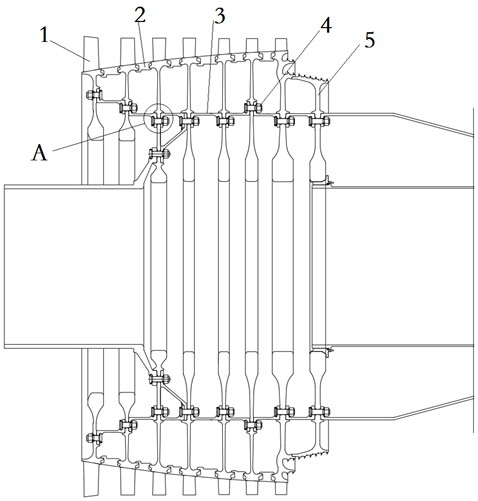

Fuel assembly lower pipe seat for balancing flow rate of coolant at reactor core inlet

ActiveCN104538064AWeaken vibration excitation sourceReduced risk of vibration abrasionNuclear energy generationReactor fuel elementsNuclear reactorJet flow

The invention discloses a fuel assembly lower pipe seat for balancing flow rate of a coolant at a reactor core inlet, and relates to the design field of pressurized water nuclear reactors. The fuel assembly lower pipe seat for balancing flow rate of the coolant at the reactor core inlet disclosed by the invention comprises a lower grating, a supporting framework and a filtering structure, wherein the lower grating is located at the upper part of the supporting framework, the filtering structure is located at the upper part or the lower part of the lower grating, a guide pipe hole used for mounting a fuel assembly guide pipe, an instrument pipe hole used for mounting a fuel assembly instrument pipe and a water flow hole group used for flowing the coolant and re-distributing the flow rate are formed on the lower grating in a penetration manner; aiming at the phenomenon of non-uniform flow rate distribution on the contour section of the lower part area of the reactor core caused by jet flow of a large water flow hole in a lower plate of the reactor core, the structural design is optimized to obtain more uniform flow of the coolant at the lower part of the reactor core.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

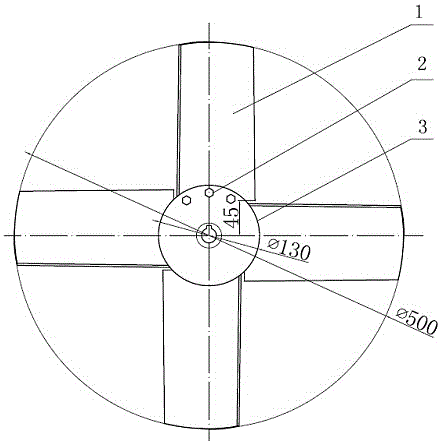

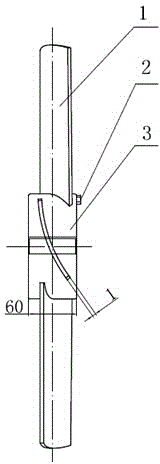

Carbon fiber composite material axial flow fan impeller

InactiveCN104929968AReasonable stress distributionReduce weightPump componentsPumpsImpellerCarbon fiber composite

The invention discloses a carbon fiber composite material axial flow fan impeller. Two or more carbon fiber composite material vanes arranged on the outer surface of a cylindrical metal impeller hub, a carbon fiber composite material vane and a metal impeller hub are connected in an equally-dividing mode. The cylindrical metal impeller hub is arranged on an output shaft of a motor through a center hole thereof. An impeller rotates at high speed under driving of the motor. Air is pushed to enter one end of an impeller rotating center shaft and be output from the other end of the impeller rotating center shaft, and axial wind is generated. According to the bending stress and the stretching stress on the vanes, the designability of composite material intensity is used, through the optimized combination design of the carbon fiber laying angle and the composite layer number, stress distribution on the vanes is reasonable, weight is low, multiple materials are saved, the carbon fiber resin composite material impeller is used, compared with the background technology, weight is lowered by at least 60%, noise is lowered, corrosion resistance is improved, impeller service life is prolonged, and operation energy loss is lowered.

Owner:ZHEJIANG UNIV

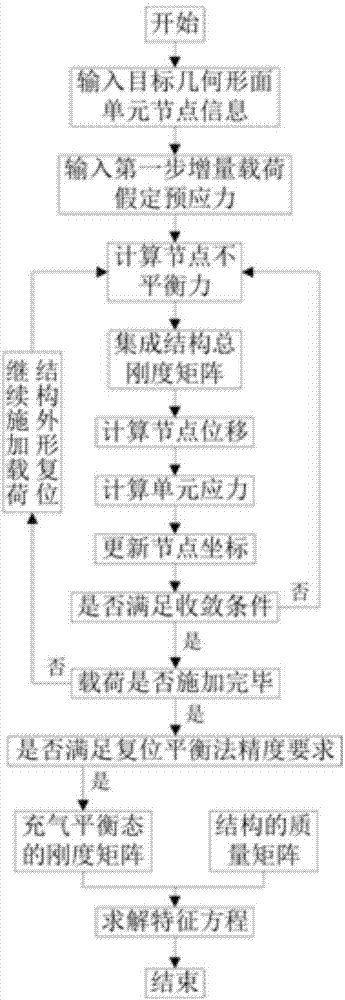

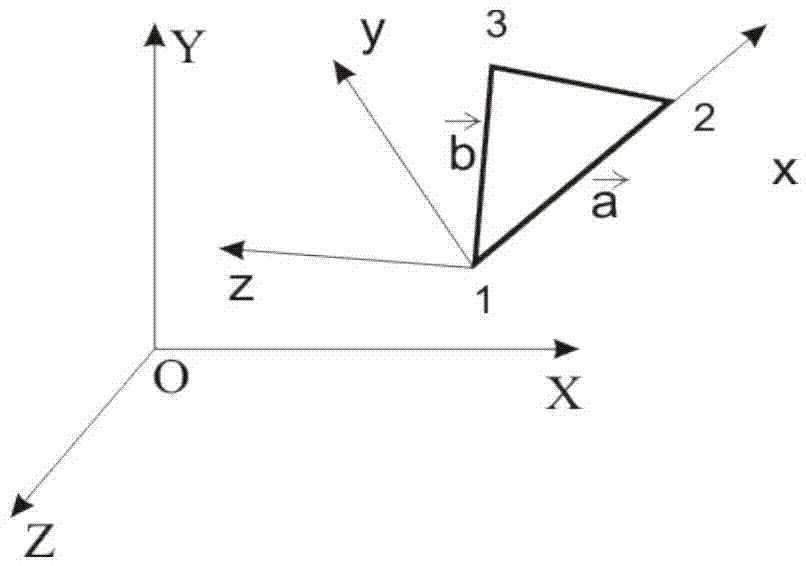

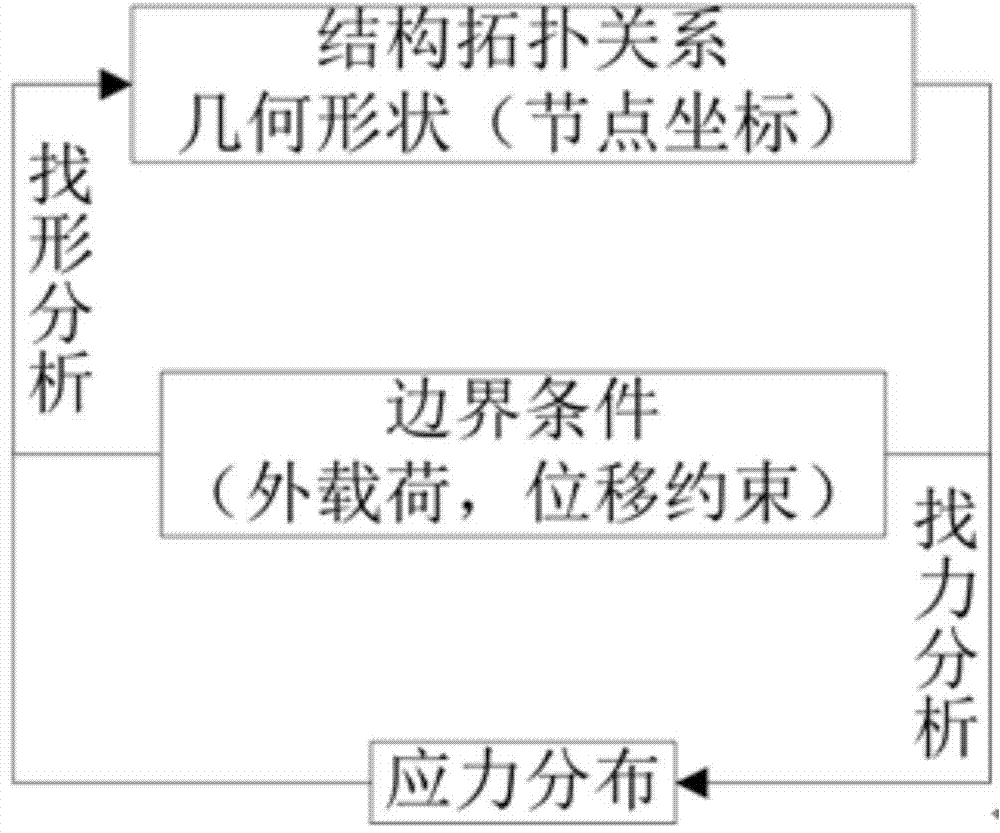

Inflation flexible structure inherent characteristic solving method

ActiveCN104732030AReasonable stress distributionThe force characteristics conform toComplex mathematical operationsForm analysisFilm structure

The invention discloses an inflation flexible structure inherent characteristic solving method. The method comprises the steps that firstly, according to the stress characteristic of an inflation film structure, the geometric nonlinearity factors such as large deformation and initial prestress are taken into consideration, a reset balancing method is introduced to conduct force finding analysis, and the stress distribution corresponding to a given target form and inflation pressure is obtained; secondly, a stiffness matrix of an inflation balancing state is inherited, and a ritz vector direct superposition method is adopted for conducting numerical value calculation on the mode of the inflation film structure. By means of the inflation flexible structure inherent characteristic solving method, the balancing state is easier to obtain when the form analysis of the inflation film structure is conducted, the stress distribution of the balancing state is more real, and thus the obtained inherent characteristic is more reasonable.

Owner:BEIHANG UNIV +2

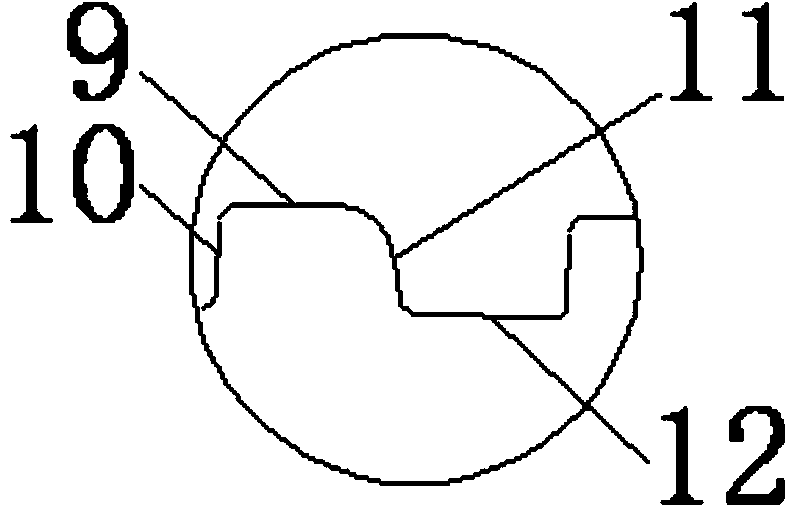

Detachable ultrahigh pressure waterproof sealing ring

The invention discloses a detachable ultrahigh pressure waterproof sealing ring, including a waterproof sealing ring which is of annular axisymmetric structure, the cross section of the waterproof sealing ring is shaped that a radial groove and a longitudinal groove are respectively formed in the top part and side part of the waterproof sealing ring, a radial O-shaped sealing ring is installed in the radial groove, and a longitudinal O-shaped sealing ring is installed in the longitudinal groove; the top surface of the waterproof sealing ring is a top radial sealing surface, the bottom part of the waterproof sealing ring is a bottom surface, one side of the waterproof sealing ring is an outer-side longitudinal sealing surface while the other side of the same serves as an inner press acting surface, and the bottom part of the inner press acting surface extends to form an arc surface. The detachable ultrahigh pressure waterproof sealing ring is compact and reasonable in structure, convenient to arrange and dismount, and capable of being used repeatedly; the waterproof sealing ring is an independent module, thus avoiding the complication or welding problem of an end part structure of a pressure barrel. The waterproof sealing ring is reasonable in structural stress distribution, is not high in requirement on material strength of manufacturing material, simple in processing technique, and can achieve reliable ultrahigh pressure sealing performance with lower project cost.

Owner:中国船舶重工集团公司第七〇二研究所

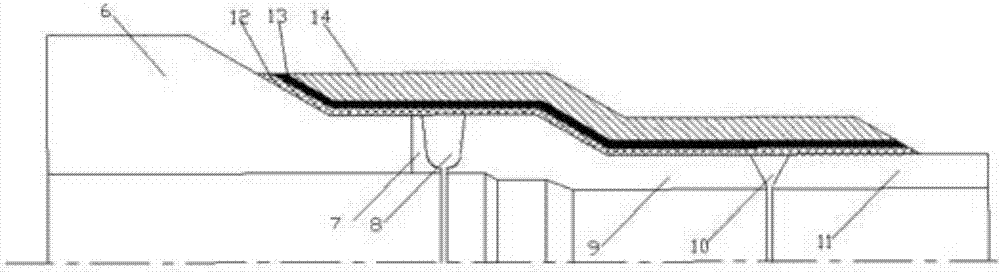

Automatic tempering surfacing welding method for pipeline maintenance

ActiveCN107186317AImprove organizationImprove performanceArc welding apparatusTubular articlesHeat-affected zoneNuclear power

The invention discloses an automatic tempering surfacing welding method for pipeline maintenance. The method comprises the steps of 1, tempering surfacing welding layer welding, wherein a tempering surfacing welding layer is welded to the ring surface of a to-be-maintained pipeline of a dissimilar metal joint, and in the tempering surfacing welding layer welding process, welding is conducted in a layer welding manner, and then a bead overlapping manner is adopted for welding; 2, transition surfacing welding layer welding, wherein a transition surfacing welding layer is welded to the tempering surfacing welding layer in a surfacing welding manner; 3, reinforcing tempering welding bead welding, wherein tempering welding is conducted on the two ends of the tempering surfacing welding layer and the two ends of the transition surfacing welding layer; and 4, polishing, wherein after welding is completed, reinforcing welding seams are polished to required sizes. On the one hand, structure and performance of a heat-affected zone on the low alloy steel side of the dissimilar metal joint of a nuclear power device can be effectively improved, and postweld heat treatment is not conducted after surfacing welding maintenance is conducted; on the other hand, according to the designed reinforcing welding seam structure form, not only can the tempering effect of the two ends of a workpiece be improved, but also the polishing working load of completed welding seams is effectively reduced.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Anti-bonding three-stage end surface metal sealing threaded connector for titanium alloy pipe

ActiveCN103628827AImproves sealing reliabilityLow contact pressureDrilling rodsDrilling casingsButtressThree stage

The invention relates to a threaded structure for connection of a well completion production tubular column of the petroleum and gas industry, in particular to an anti-bonding three-stage end surface metal sealing threaded connector for a titanium alloy pipe. The anti-bonding three-stage end surface metal sealing threaded connector for the titanium alloy pipe comprises an oil casing collar and an oil casing end, wherein the oil casing collar is provided with an API buttress inner thread, the oil casing end is provided with a buttress outer thread matched with the API buttress inner thread, a tool withdrawal groove is formed in one end of the API buttress inner thread and is sequentially connected with an arc surface I and an arc surface II through chamfer transition, the arc surface II is connected with a negative angle torque lifting shoulder I through chamfer transition, a conical surface, a cylindrical surface and a negative angle torque lifting shoulder II are arranged at one end of the buttress outer thread, the conical surface and the cylindrical surface sequentially correspond to the arc surface I and the arc surface II, the negative angle torque lifting shoulder II corresponds to the negative angle torque lifting shoulder I, and after the oil casing collar is matched with the oil casing end in a threaded mode, interference sealing is carried out on metal through a first-stage sealing structure of the arc surface I on the conical surface, a second-stage sealing structure of the arc surface II on the cylindrical surface and third-stage metal of the sealing structure of the negative angle torque lifting shoulders. The anti-bonding three-stage end surface metal sealing threaded connector for the titanium alloy pipe improves the air sealing reliability, and has good anti-bonding performance.

Owner:忠世高新材料股份有限公司

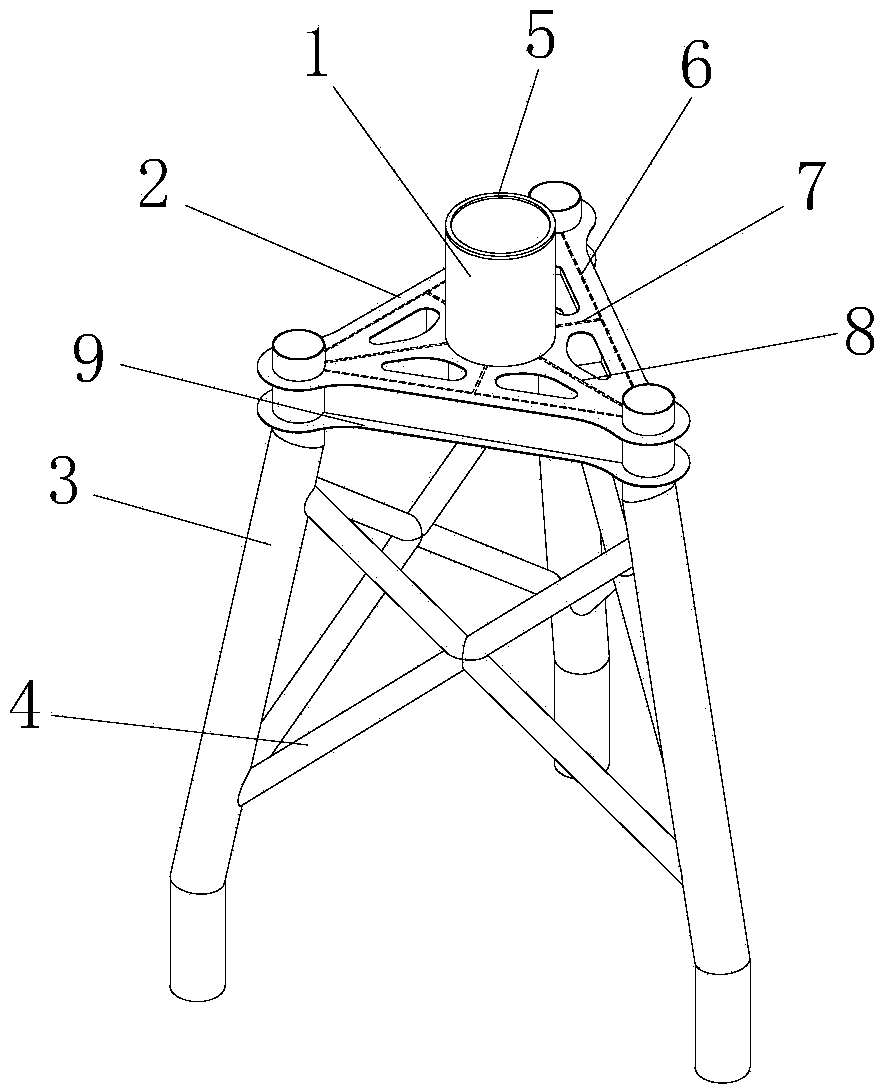

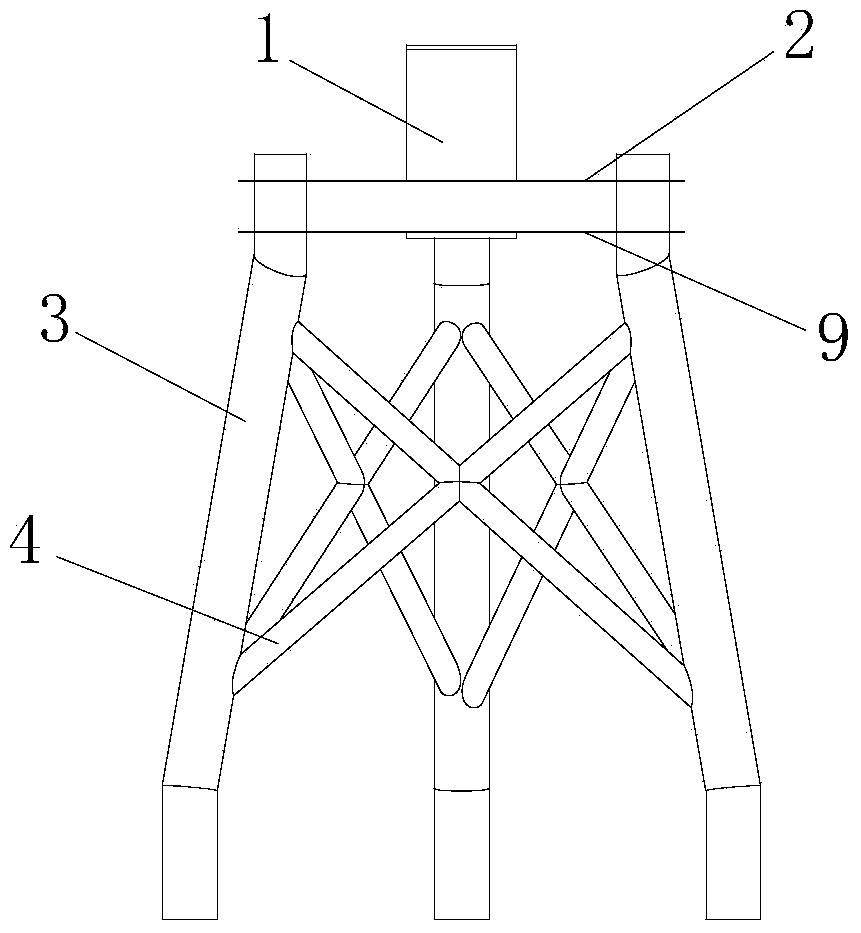

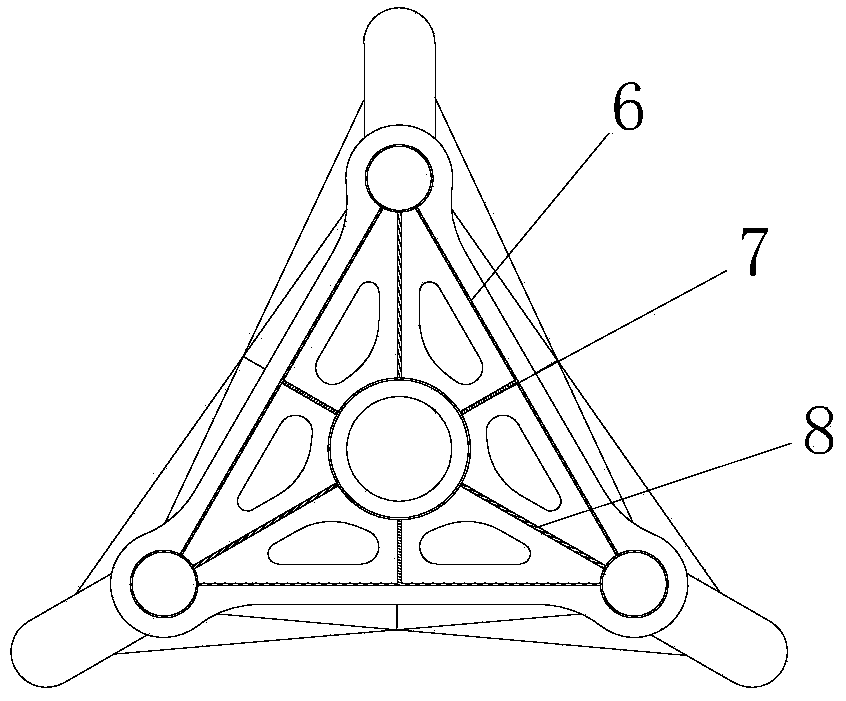

Sea wind power guiding pipe frame foundation structure

ActiveCN103953061ASimple structureReasonable stress distributionFoundation engineeringEngineeringStress distribution

The invention discloses a sea wind power guiding pipe frame foundation structure which comprises three guiding pipes, wherein the cross sections of the three guiding pipes are triangular, a triangular supporting platform is connected onto the upper parts of the guiding pipes, the supporting platform comprises an upper sealing board, a lower sealing board, a side beam, an auxiliary beam and a main beam, the upper sealing board and the lower sealing board are welded with a main cylinder body and the guiding pipes, the upper sides and the lower sides of the side beam, the auxiliary beam and the main beam are respectively welded on the upper sealing board and the lower sealing board, the main beam is distributed in 120 degrees, the two ends of the main beam are welded with the main cylinder body and the guiding pipes, the side beam is distributed along the edge line of the supporting platform, the two ends of the side beam are respectively welded with the upper ends of the guiding pipes, the auxiliary beam is perpendicular to the side beam, and the two ends of the auxiliary beam are respectively welded with the main cylinder body and the side beam. The sea wind power guiding pipe frame foundation structure has the advantages of being simple in structure, reasonable in stress distribution, light in weight, few in high dynamic stress areas, low in cost and the like.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

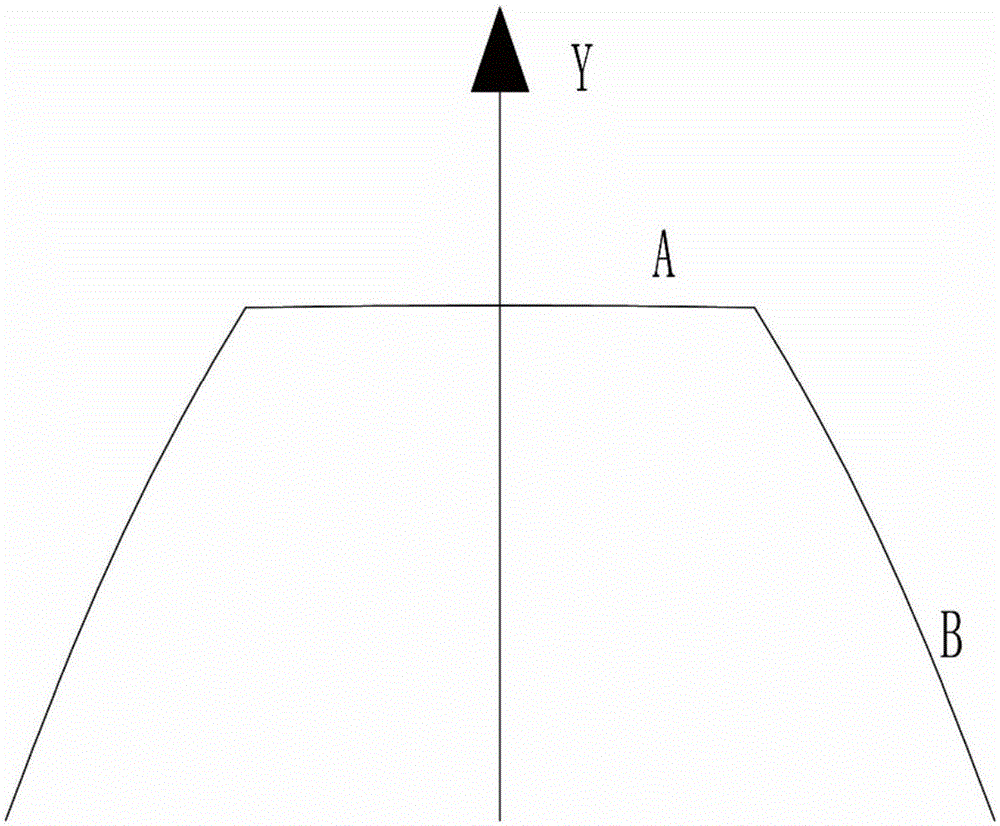

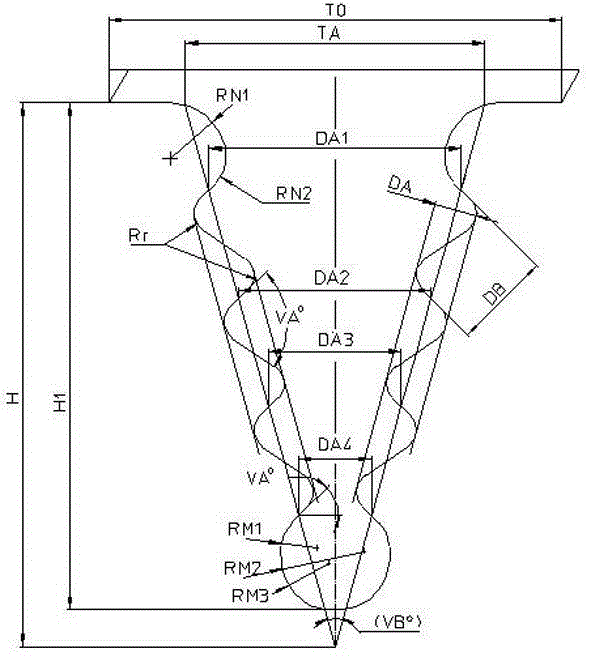

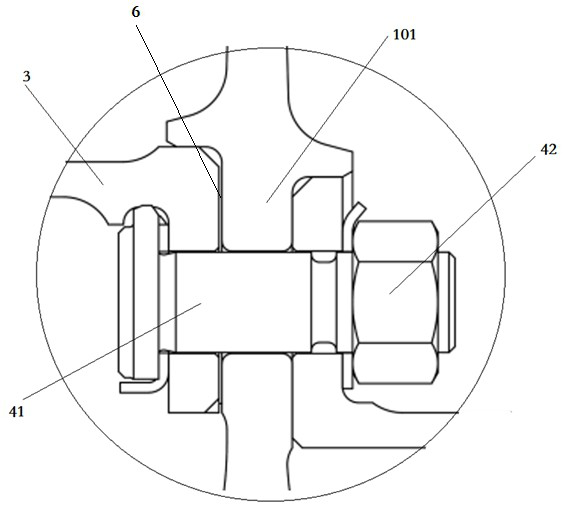

Blade root and wheel groove structure of turbine moving blade

InactiveCN104832220AImprove carrying capacityReasonable stress distributionBlade accessoriesMachines/enginesImpellerEngineering

A blade root and wheel groove structure of a turbine moving blade is disclosed. A blade root of the blade is assembled in a wheel groove of an impeller, and the contours of the blade root and the wheel groove are fir-shaped. The fir-shaped blade root has four teeth, and the contour of the transition position between the first tooth of the blade root and a blade root platform is formed by smoothly connecting through a linear section and two arc sections in different radius, wherein the connection points are tangential points. A linear line is a portion of bottom projection line of the blade root platform and is arranged in the upper side. The arc section with a large radius is arranged in the middle, and the arc section with a small radius is arranged in the lower side, wherein the large radius RN1 is 1.75 times of the small radius RN2. The fillet contour of a fourth tooth is formed by connecting of three arc sections with different radiuses in tangential manner. From top to bottom, the radius RM1 of a first arc section is 1.13 times of the RN2, the radius RM2 of a second arc section is 2.63 times of the RN2, and the radius RM3 of a third arc section is 1.44 times of the RN2. The blade root bearing capacity reaches over 1000 tons. The blade root and wheel groove structure is suitable for final-stage moving blades of super-large power turbines.

Owner:DONGFANG TURBINE CO LTD

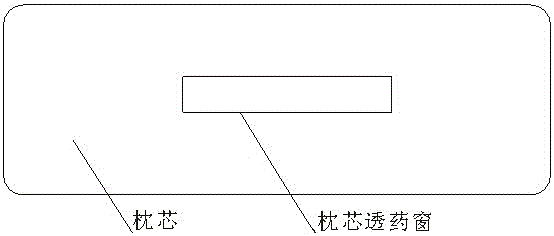

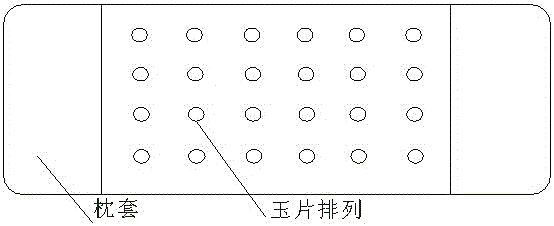

Blumea balsamifera-jade warming moxibustion pillow

InactiveCN106213916AReasonable stress distributionImprove physical conditionPillowsDevices for heating/cooling reflex pointsFiberHuman body

The invention discloses a blumea balsamifera-jade warming moxibustion pillow which comprises a pillow interior and a pillow cover, wherein blumea balsamifera branch and leaf fluffy materials, cinnamon and radix angelicae pubescentis are put in the pillow interior; a heating element and jade sheets are arranged on one side of the pillow cover; a zipper and a power interface are arranged on the other side of the pillow cover. The special magical plant blumea balsamifera from south area of Guizhou province, cinnamon and radix angelicae pubescentis are compounded in the blumea balsamifera jade moxibustion pillow, the volatilizing components can slowly release, penetrate skin and enter into human body under the mild heating effect of carbon fibers and the polyvinyl alcohol functional material can limit the volatilization of invalid drugs. The healthcare pillow adopts carbon fiber cloth for low-voltage electro-heating, so that the pillow is safe and the heat energy is uniformly distributed; a thermostatic controller is arranged for maintaining the required suitable temperature; the jade sheets are distributed on the surface; the jade sheets have the heat-gathering effect and act on the acupuncture points of neck, so as to achieve the moxibustion curative effect; the shape of the blumea balsamifera-jade warming moxibustion pillow is designed according to ergonomics; after long-term use, the physiological curvature of cervical vertebra can be corrected; the drugs have the effects of warming channels and activating blood circulation, relieving cramps and eliminating pain; the jade can massage the acupuncture points of the neck; the three materials cooperate with each other for keeping the neck healthy and maintaining human health.

Owner:贵州道地中药材工程研究中心

Pressure-sensitive device with axial sintering of ceramic metal tube shell adopted

InactiveCN103940536ARealize a rigid connectionCorrosion resistanceFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsCeramic metalMetal electrodes

The invention discloses a pressure-sensitive device with axial sintering of a ceramic metal tube shell adopted, and relates to a pressure-sensitive device. The pressure-sensitive device solves the problem that the axial size and the radial size of an existing pressure-sensitive device are large. The pressure-sensitive device comprises a lead, a tube base, a ceramic insulating material, a multi-layer composite material, a borosilicate glass base, a glass-metal composite material, a metal electrode, a chip and a seal ring. The upper surface of the borosilicate glass base and the lower surface of the chip are in static connection to form a seal structure. The method of axial low-temperature sintering is used for sintering the lower surface of the borosilicate glass base and the upper surface of the ceramic insulating material into a whole through the multi-layer composite material, the multi-layer composite material is of a wafer structure, the lower surface of the borosilicate glass base is square and the diameter of the multi-layer composite material is larger than or equal to the diagonal line of a square of the lower surface of the borosilicate glass base. The pressure-sensitive device with axial sintering of the ceramic metal tube shell adopted is used in the field of pressure-sensitive devices.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

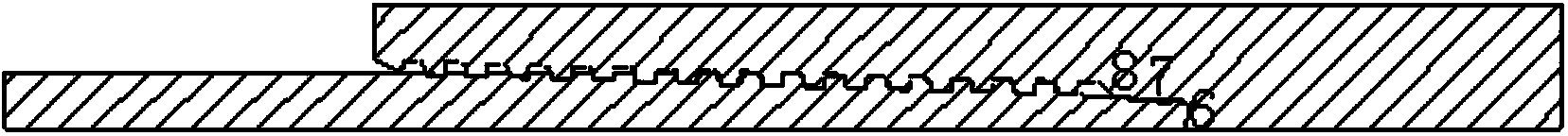

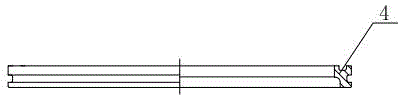

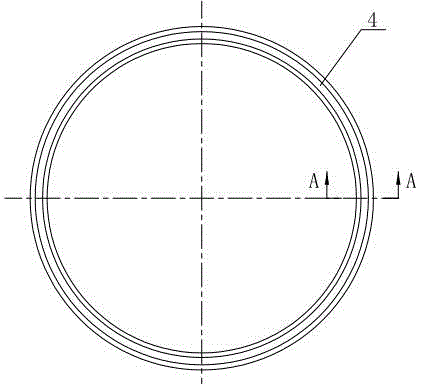

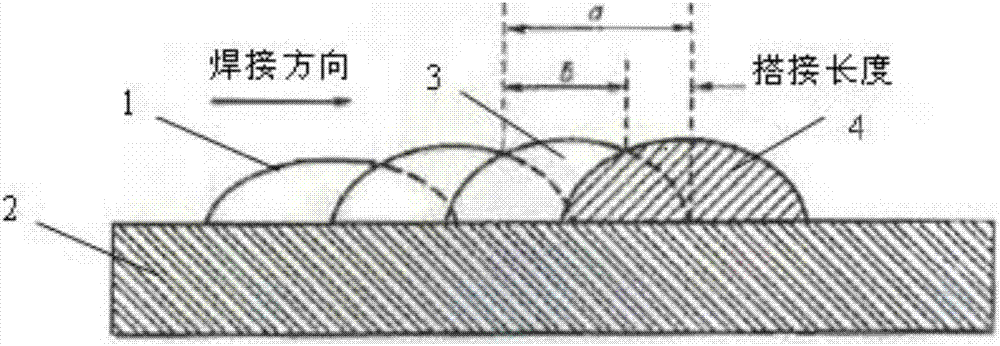

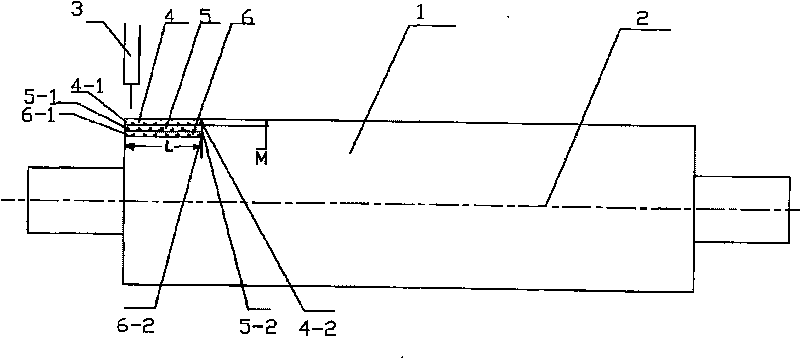

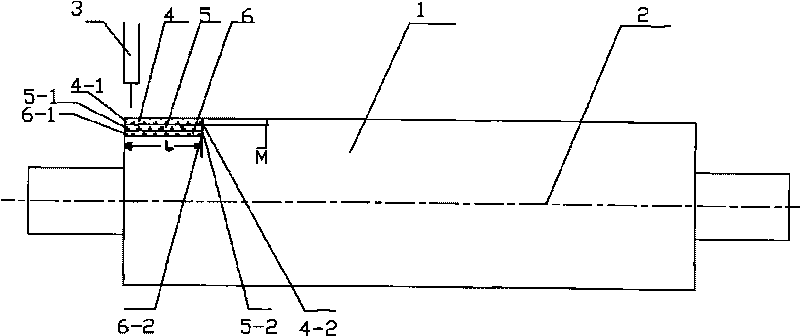

Novel continuous casting roller surfacing technology

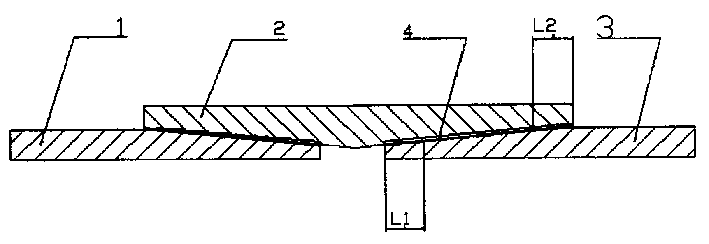

InactiveCN101733510AReasonable stress distributionAvoid residual shear stressArc welding apparatusMetallurgyReciprocating motion

The invention provides a novel continuous casting roller surfacing technology, solving the technical problems of surfacing blind area and poor surfacing stress state which exist in a swing spiral surfacing in the prior art. The novel continuous casting roller surfacing technology mainly comprises the following steps: a continuous casting roller (1) rotates step by step, a welding torch (3) moves back and forth for surfacing, that is, the continuous casting roller (1) does not rotate, the welding torch (3) moves to (4-2) surfacing from (4-1) surfacing along the direction of an axes (2), the continuous casting roller (1) rotates with a welding bead width M, and the welding torch (3) moves to (5-1) surfacing from (5-2) surfacing along the direction of the axes (2), the continuous casting roller (1) rotates and the welding torch (3) moves in cycles, thereby realizing the surfacing of whole continuous casting roller surface after finishing a cycle of surfacing of the roller surface. The novel continuous casting roller surfacing technology is mainly used for repairing the continuous casting roller (1).

Owner:HARBIN WELDING INST LTD

Manufacturing method for scale breaking tension leveler working roll

ActiveCN103589850AImprove toughnessIncreasing the thicknessFurnace typesHeat treatment furnacesStress distributionMedium frequency

The invention discloses a manufacturing method for a scale breaking tension leveler working roll. By adopting Cr12MoVCo die steel as the material, the manufacturing method includes the steps of: rough turning, hardening and tempering, semi-finish turning, shaping treatment, coarse grinding of roll surface, preheating, medium frequency spray quenching, isothermal treatment, tempering, and finish machining, thus obtaining a finished product. Specifically, the preheating temperature is 400-450DEG C, the medium frequency spray quenching temperature is 1100-1200DEG C, the isothermal temperature is 200-250DEG C, and the tempering temperature is 500-550DEG C. In the invention, by changing the thermal treatment process, under the circumstance of obtaining quenched martensite on the surface, a transition layer is mainly based on bainite, high hardness and high wear resistance of the surface are retained, toughness of the transition layer and the core is increased, the occurrence of microcracking is reduced, and the fracture risk in use is avoided. The thickness of the transition layer is increased, the overall strength of the roll is increased, the stress distribution is more reasonable, and the grinding performance of the roll is improved.

Owner:宜兴市鑫源辊业有限公司

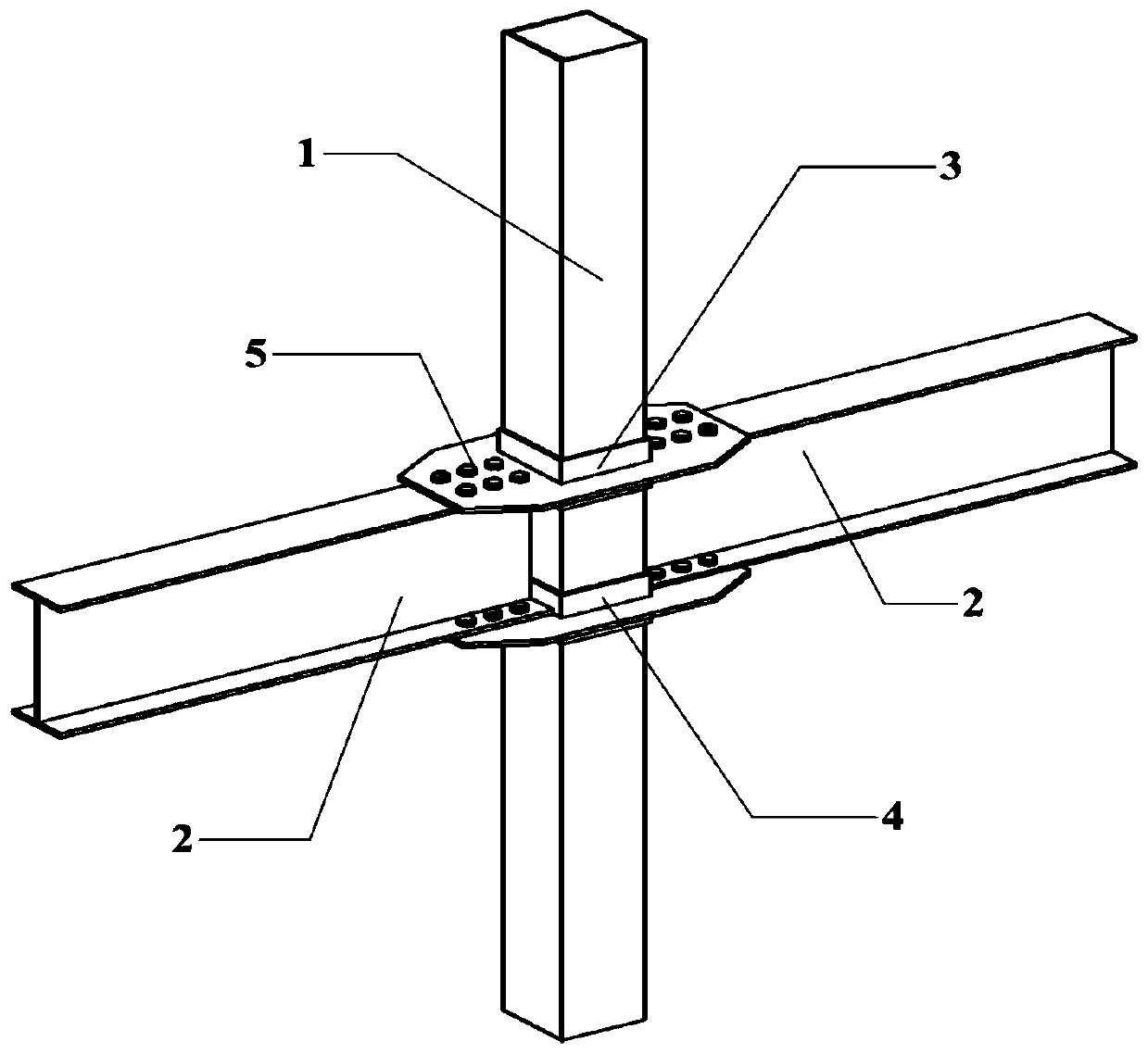

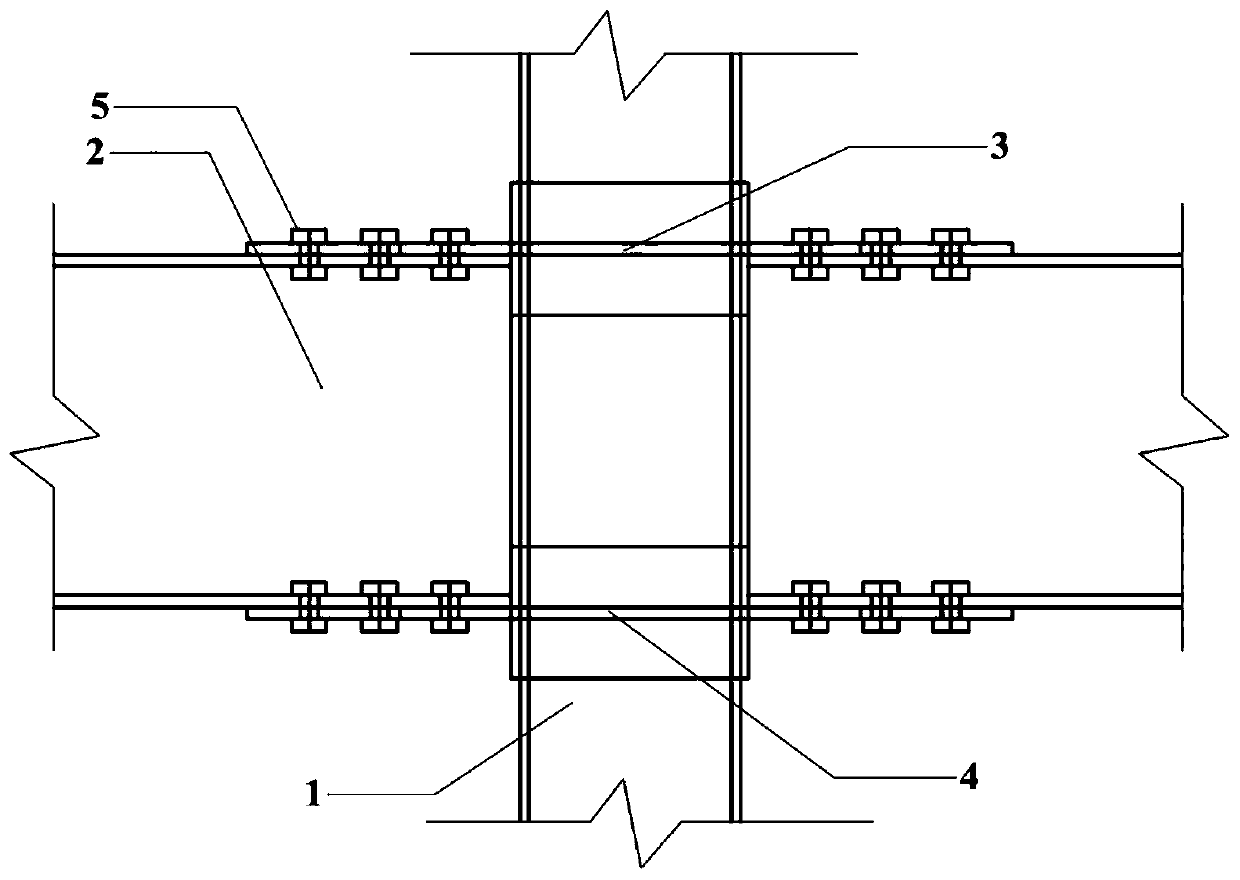

Square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint

InactiveCN111456235AIncrease the direct contact areaImprove distributionBuilding constructionsBoard structureSteel tube

The invention discloses a square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint. The square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint comprises a square steel tube, the square steel tube is sleeved with an upper outer ring sleeve plate and a lower outer ring sleeve plate, the upper outer ring sleeve plate comprises an upper short sleeve, an inner surface of the upper short sleeve is connected with the square steel tube, an outer surface of the upper short sleeve is connected with an upper outer ring plate, the lowerouter ring sleeve plate and the upper outer ring sleeve plate are of the same structure, the lower outer ring sleeve plate comprises a lower short sleeve and a lower outer ring plate, and a steel beam is connected between the upper outer ring sleeve plate and the lower outer ring sleeve plate. The distribution of a column wall yield line is expanded, the column wall rigidity of a joint domain isimproved, and the contribution of an outer ring plate to the joint bearing capacity under the action of external load is increased; the defect that the rigidity at the joint is insufficient due to thefact that an inner ring plate is not arranged is overcome; by adopting the method, the field operation amount is small, the steel structure construction efficiency is improved, the material utilization rate is increased, and good economic benefits and social benefits are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

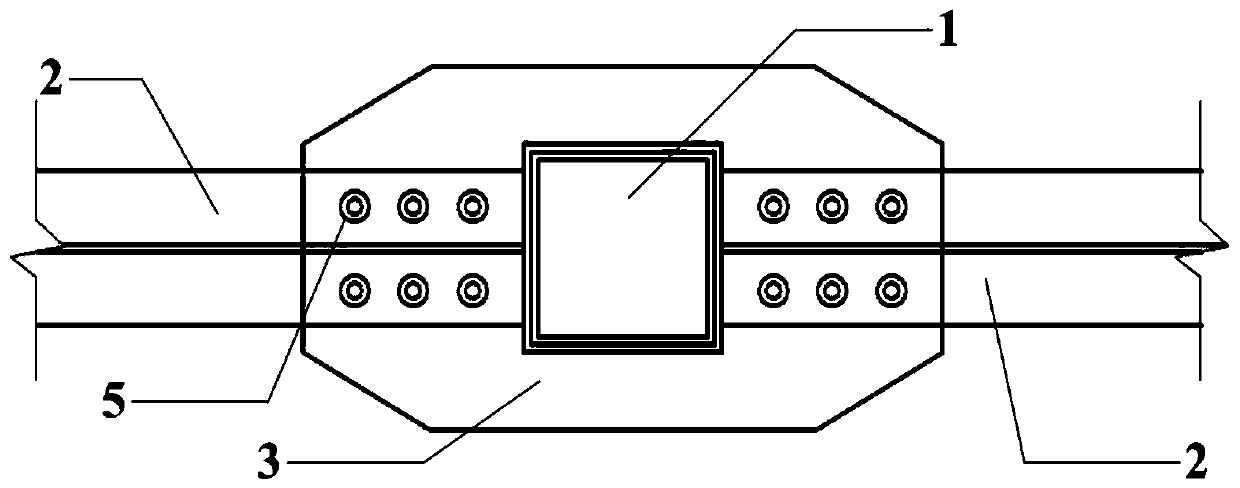

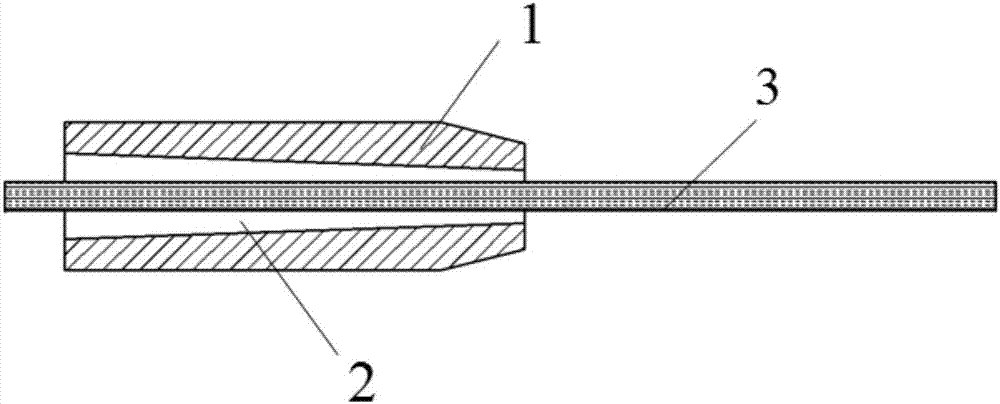

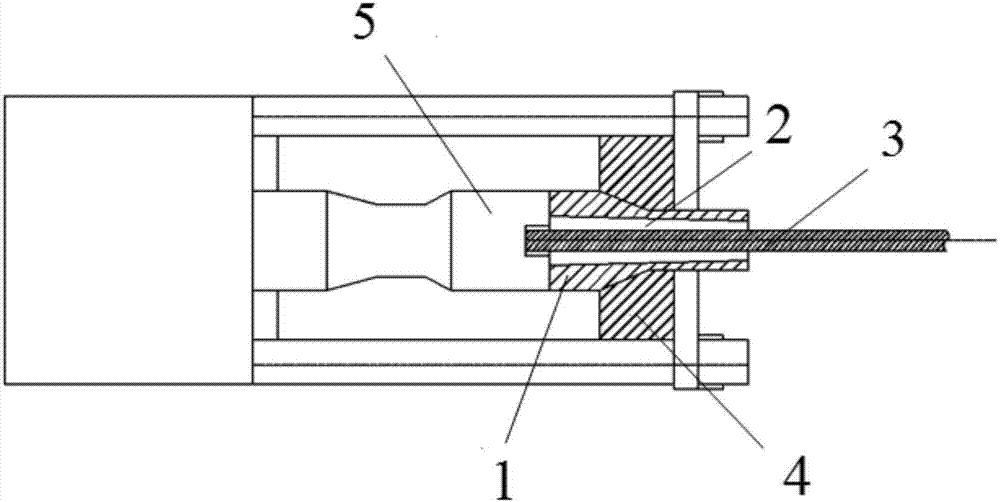

Extruded type anchorage device for FRP rib and anchoring method

ActiveCN107447757AThe amount of extrusion deformation is controllableReduce extrusion deformationBridge structural detailsBuilding reinforcementsBiomedical engineeringConstant speed

The invention discloses an extruded type anchorage device for an FRP rib and an anchoring method. The extruded type anchorage device comprises an anchor barrel, a sleeve, FRP rib, an extrusion die and an extruder, a chamfer is arranged at one end of the anchor barrel, a conical through hole extending in the center line of the anchor barrel is formed in the middle of the anchor barrel, the sleeve matched with the conical through hole is nested in the conical through hole, the outer surface of the sleeve is a wedge surface, a cylindrical center through hole matched with the FRP rib is formed in the middle of the sleeve, and the center lines of the conical through hole, the center through hole and the FRP rib are coincident. The anchoring method comprises the steps that the sleeve penetrates in the anchor barrel, and the wedge surface of the sleeve is attached to the conical through hole of the anchor barrel; the tail end of the FRP rib penetrates through the center hole of the sleeve and extends out of the end surfaces of the anchor barrel and the sleeve; an assembling piece is put in the extruder, and grease is evenly smeared on the outer surface of the anchor barrel; and the assembling piece of the anchor barrel, the sleeve and the FRP rib is jacked into the extrusion die by operating the extruder at a constant speed. The extruded type anchorage device for the FRP rib is safe and reliable, convenient to assemble and reasonable in inner stress and is a new anchorage device capable of exerting advantages of the FRP rib.

Owner:DALIAN UNIV OF TECH

Double-layer drum reinforced rotor structure of gas compressor of gas turbine

The invention belongs to the technical field of gas compressor rotors of gas turbines, and particularly relates to a double-layer drum reinforced rotor structure of a gas compressor of a gas turbine. An inner drum and an outer drum are arranged between adjacent stages of working impellers; and the inner drum can tension the working impellers so as to balance the stress of a web in the axial direction. According to the reinforced rotor structure in the scheme, the original shape change amount of a hybrid rotor is small while the performance of structural strength, rigidity, stability and the like is reinforced, rotor parts and connection of the rotor parts are stable and reliable, and the rigidity of the rotor structure can be remarkably improved; due to the fact that the structure of the inner drum and the outer drum is adopted, the shock resistance of the rotor can be improved, stable operation of the rotor can be guaranteed under the action of impact force of natural wind or impact force transmitted by natural factors such as sea wave jolting through an outer casing, the rotor has higher rigidity and more reasonable stress distribution in the radial direction and the axial direction, and the service life of the rotor structure is prolonged.

Owner:成都中科翼能科技有限公司

Lightweight subway car body with new tension pillow structure

ActiveCN107856688BGood workmanshipImprove accessibilityRailway roofsUnderframesEngineeringUltimate tensile strength

The invention provides a light-weight metro vehicle body with a novel traction sleeper buffer structure and belongs to the field of full-aluminum product metro vehicle body devices. The light-weight metro vehicle body comprises a chassis, a vehicle roof, two end walls, multiple side wall boards and a full-aluminum product traction sleeper buffer device. The chassis comprises a rectangular floor frame jointly defined by two side beams and two end beams and a floor located in the floor frame. The traction sleeper buffer device comprises a sleeper beam, a traction beam, a draw gear installation seat and two buffer beams. A traction beam lower cover plate and a buffer beam lower cover plate of the full-aluminum product traction sleeper buffer device of the light-weight metro vehicle body are both made of a profile aluminum plate material which is low in density, light in weight and good in bending performance, the draw gear installation seat is made from aluminum plates high in yield stress, other straight plate structures are all made of an aluminum plate material high in yield stress, overall selected materials of the traction sleeper buffer device meet the strength standard, and theprocessing property of welding and manufacturing of the traction sleeper buffer device is the best; and all lightening holes can be simultaneously used as auxiliary holes in the inner cavity weldingoperation process, so that the accessibility and welding quality of inner cavity welding joints are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Screw joint for oil pipe or casing

InactiveCN1182317CReasonable stress distributionUniform deformationDrilling rodsDrilling casingsNumerical controlScrew thread

A screw joint for oil pipe or casing is composed of pipe bodies and pipe collar, and is characterized by that said pipe collar has spiral thread whose pitch is segmentally changed. After the pipe collar is jointed with pipe, the axial gaps between internal and external threads are sequentially decreased from outside to inside. Its advantages are uniformly distributed load to spiral thread, high joint strength, and high power to resist stress corrosion.

Owner:SHANGHAI JIAO TONG UNIV

A kind of manufacturing process of bimetallic band saw blade

InactiveCN103962644BExtend your lifeIncrease the cryogenic treatment processMetal sawing tool makingMachiningIndustrial engineering

The invention provides a process for manufacturing a bimetal strip band saw blade, and belongs to the technical field of band saw blade manufacturing. The process solves the problems that band saw blades manufactured through an existing band saw blade manufacturing process are low in fatigue strength and short in service life. The process for manufacturing the bimetal strip band saw blade includes the first step of selecting materials, wherein the M42 high-speed steel serves as the materials of saw teeth, and Rm80 steel serves as the materials of a saw back; the second step of welding, wherein the materials of the saw teeth and the materials of the saw back are welded together according to the size of the bimetal strip band saw blade so that a first-level semi-finished product can be obtained; the third step of primary machining, wherein the first-level semi-finished product is straightened, the edge of the materials of the saw teeth of the first-level semi-finished product is milled to form the saw teeth according to the designed tooth shape so that a second-level semi-finished product can be obtained; the fourth step of conducting heat treatment, wherein heat treatment is conducted on the obtained second-level semi-finished product so that a third-level semi-finished product can be obtained; the fifth step of conducing surface finishing, wherein rolling is conducted on the third-level semi-finished product. The machined band saw blade has the advantages of being high in fatigue strength and long in service life.

Owner:温岭市工量刃具行业协会 +2

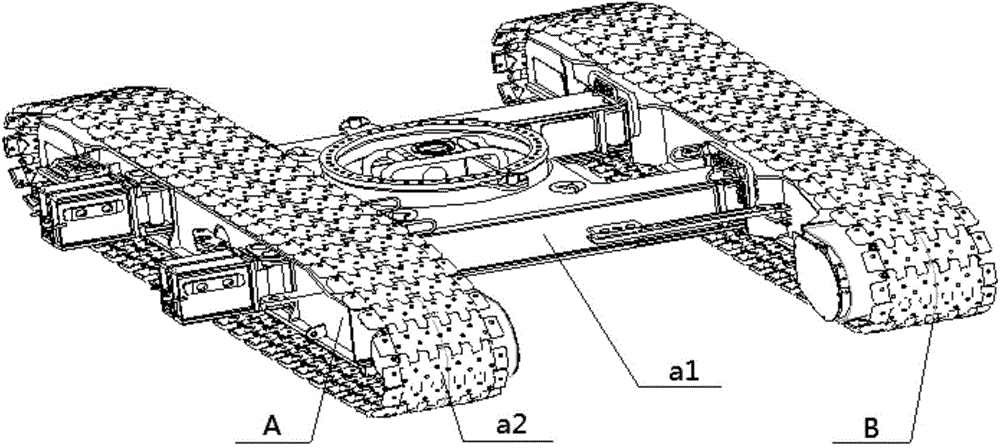

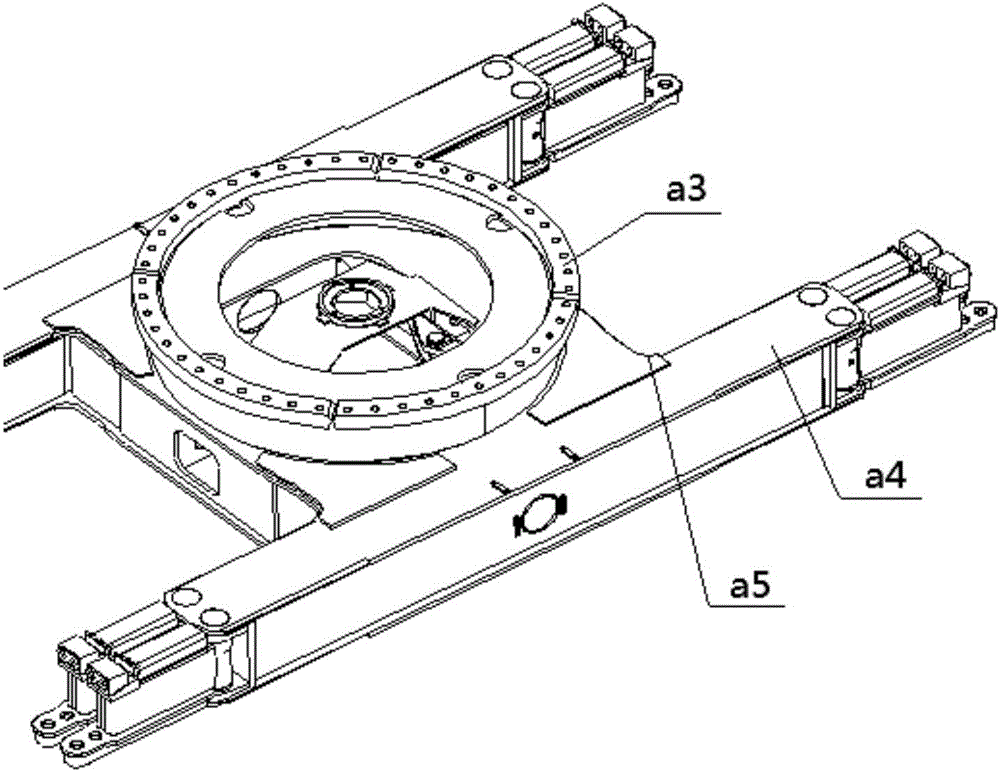

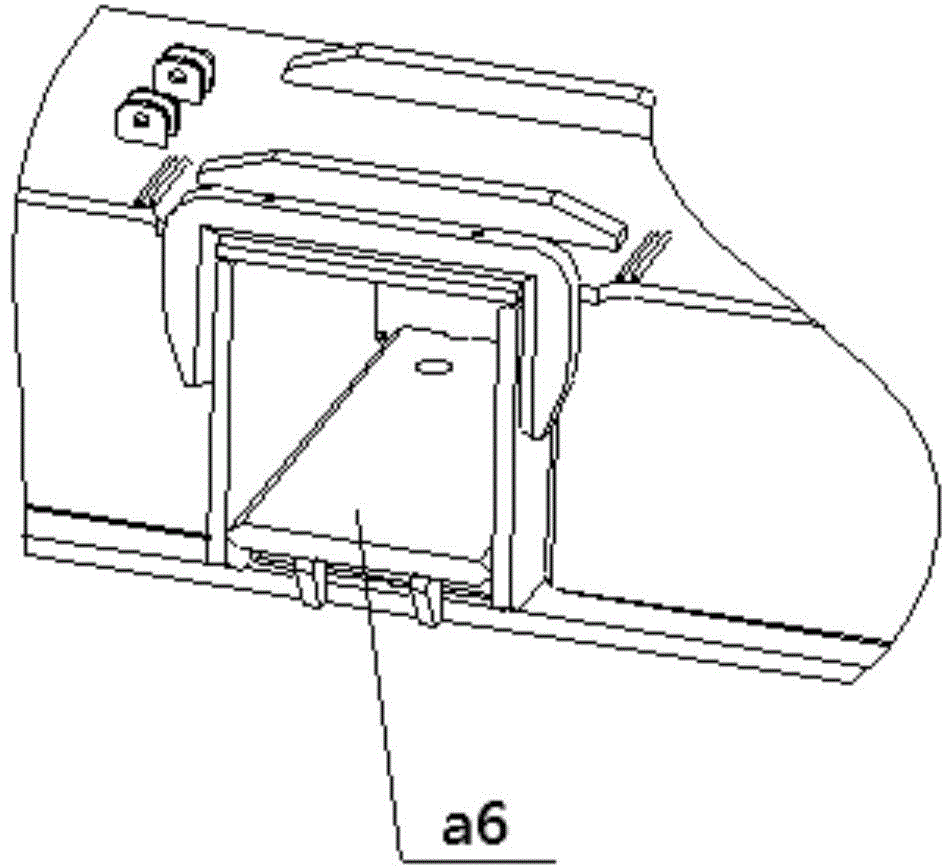

Plug-in tracked chassis structure

ActiveCN104627261AReduce manufacturing costReduce manufacturing difficultyEndless track vehiclesStress concentrationStress distribution

The invention relates to a plug-in tracked chassis structure comprising a frame and a track carrier. The frame comprises overhanging beams and a middle structure connected with the same. The track carrier comprises a square hole and inner vertical plates; the overhanging beams can be inserted into the square hole; the sectional areas of the roots, in connection with the middle structure, of the overhanging beams and the middle structure decrease from the middle structure to positions far away from the middle structure; The sections of the overhanging beams are designed in a variable form, namely, the sectional areas decrease from the middle structure to the positions far away from the middle structure, the middle structure is made transitional to the overhanging beams, sectional width of the roots of the overhanging beams is increased, stress area is enlarged, stress concentration of the roots is effectively decreased, stress distribution is more reasonable, the thickness of upper and lower cover plates need not be increased, the upper and lower cover plates need not be locally reinforced, strength level of material need not be increased either, manufacturing cost of the frame is decreased, and the frame is easier to manufacture.

Owner:XCMG CONSTR MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com