Anti-bonding three-stage end surface metal sealing threaded connector for titanium alloy pipe

A metal sealing, titanium alloy pipe technology, applied in drilling pipes, casings, drilling equipment, etc., can solve problems such as low surface hardness, oil and gas leakage accidents, oil and gas safety, and threats to the surrounding ecological environment and people's life and property safety. The effect of reducing stress relief and stress concentration, reducing the possibility of damage, excellent anti-galling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

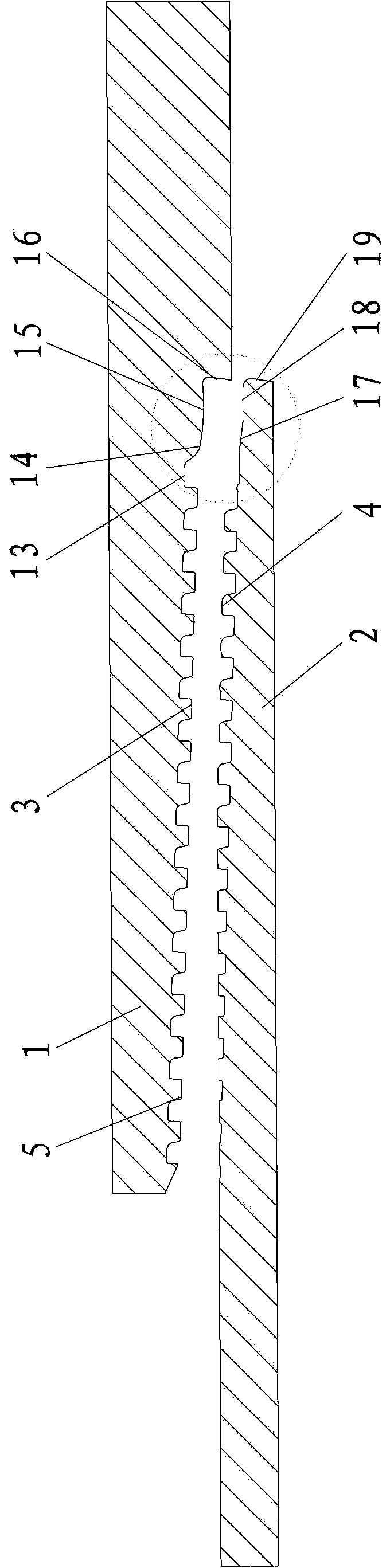

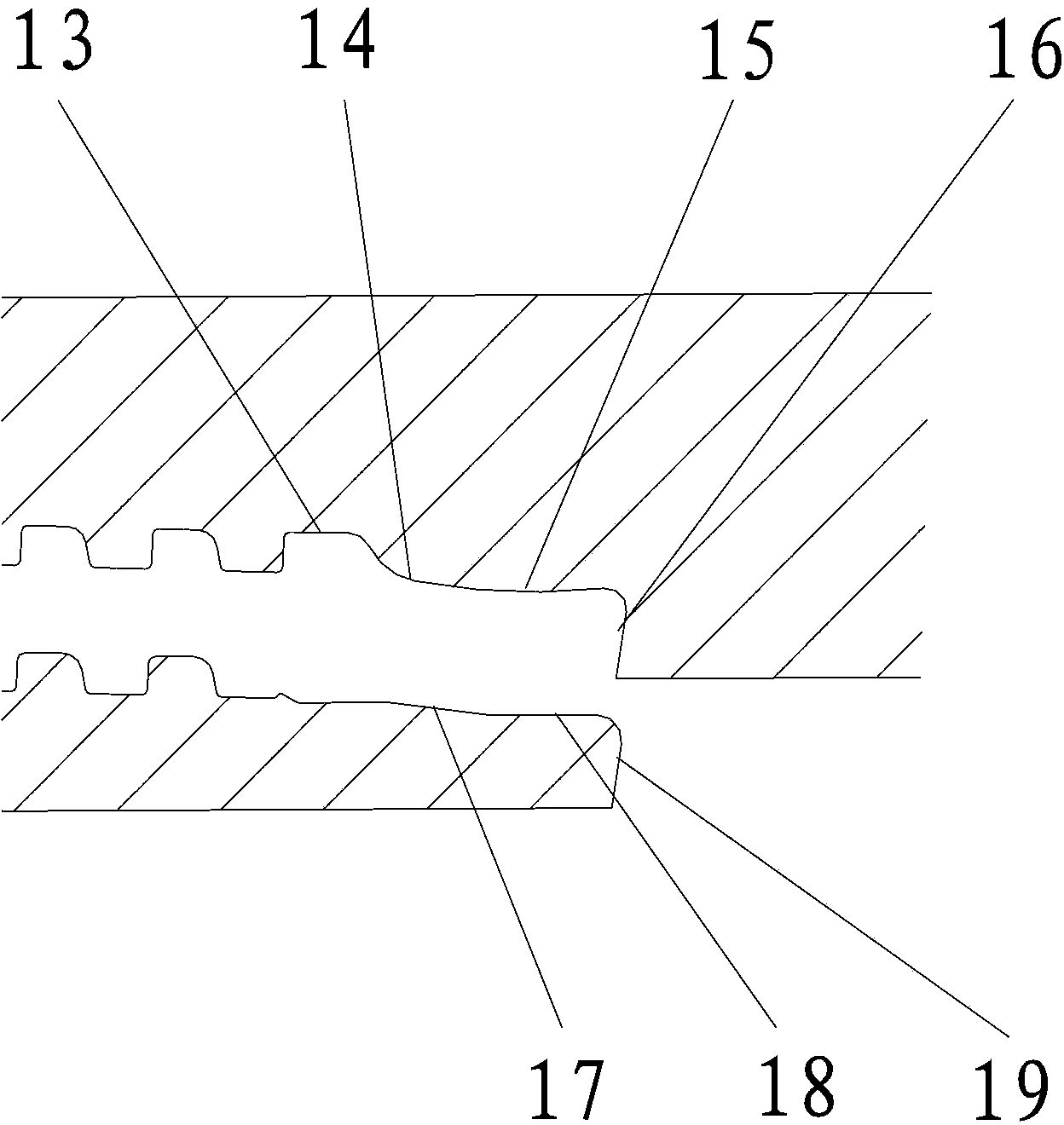

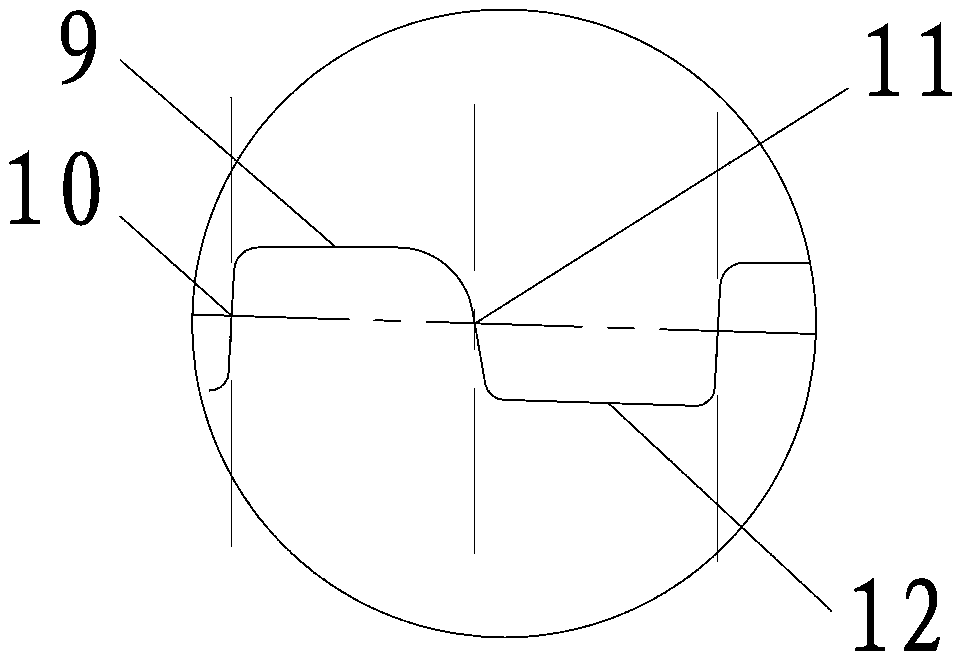

[0026] Example 1: Processing oil casing joints with an outer diameter of Φ88.9mm

[0027] The oil casing coupling 1 and oil casing body of the same steel grade are used, the inner thread is copper-plated with a thickness of 10um, and the surface of the outer thread is shot peened. When making up, apply API thread grease evenly on both ends, clamp the oil casing coupling 1, make up with the maximum torque at the factory end, and make up with the best torque at the field end.

[0028] Processing parameters:

[0029]

[0030]After processing, the outer diameter Φ88.9mm oil-casing threaded joint has been tested and verified, and there is no sticking phenomenon in 9 times of make-up and break-out, and no gas leakage occurs when the axial load is 890KN and the internal pressure load is 80MPa, which meets the structural integrity and sealing Integrity required.

Embodiment 2

[0031] Example 2: Processing oil-casing joints with an outer diameter of Φ117.8mm

[0032] The oil casing coupling 1 and oil casing body of the same steel grade are used, the internal thread is copper-plated 15um thick, and the surface of the external thread is shot peened. When making up, apply API thread grease evenly on both ends, clamp the oil casing coupling 1, make up with the maximum torque at the factory end, and make up with the best torque at the field end.

[0033] Processing parameters:

[0034]

[0035] The processed titanium alloy oil casing joint with an outer diameter of Φ177.8mm has been tested and verified, and there is no sticking phenomenon for three times of make-up and breakout, and no gas leakage occurs when the axial load is 1100KN and the internal pressure load is 65MPa, which meets the structural integrity, Seal integrity requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com