Patents

Literature

177results about How to "Sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

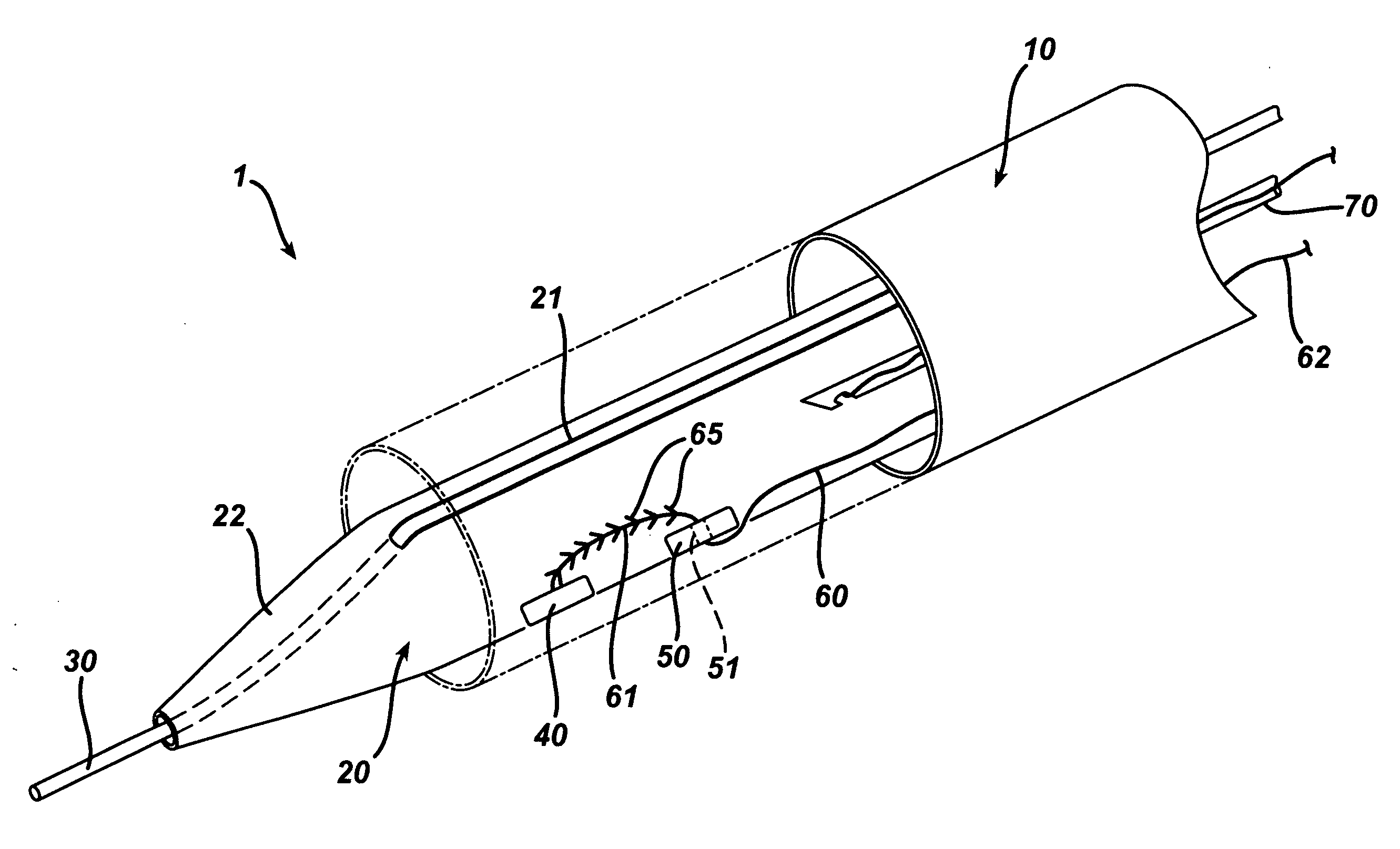

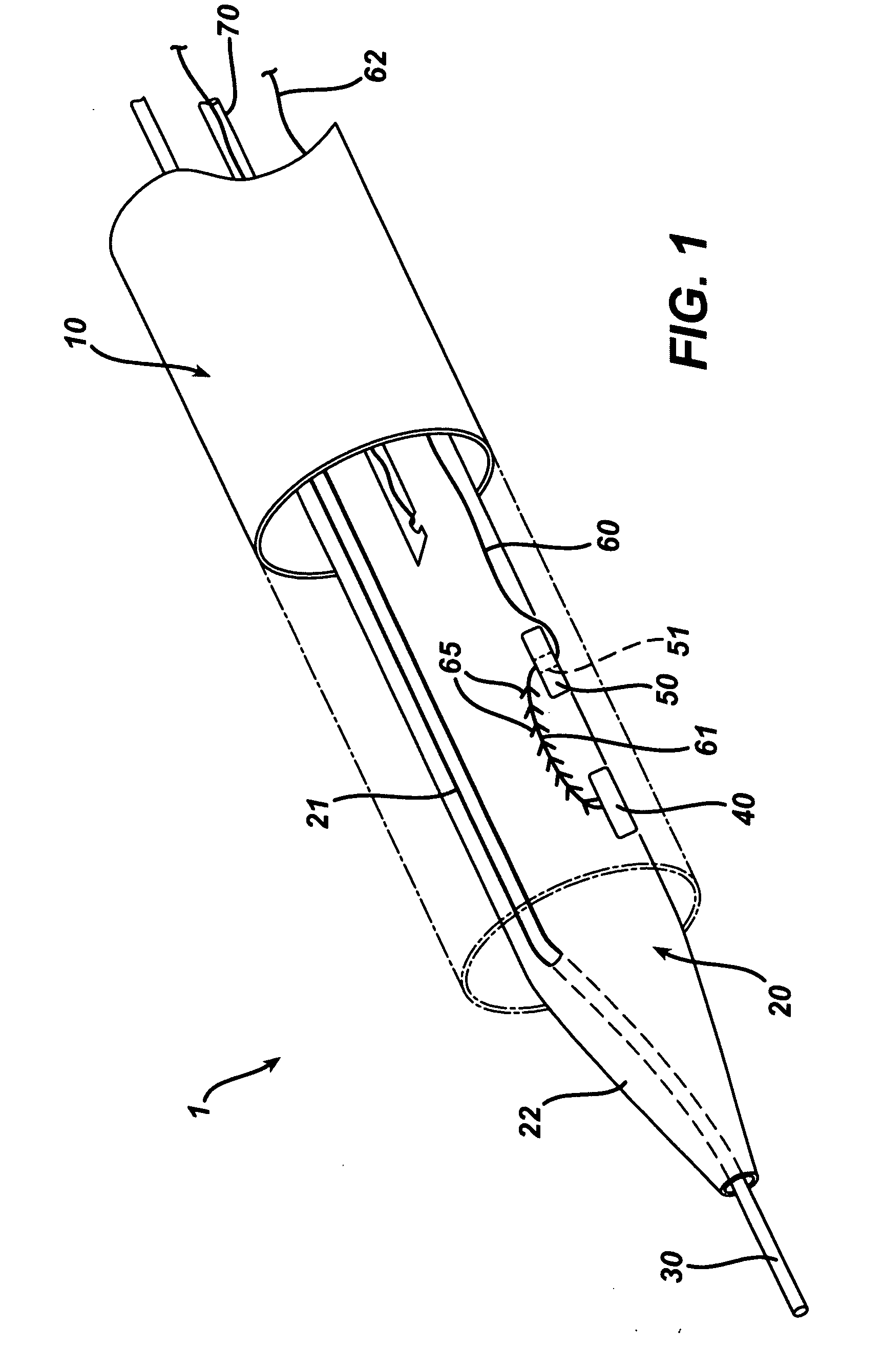

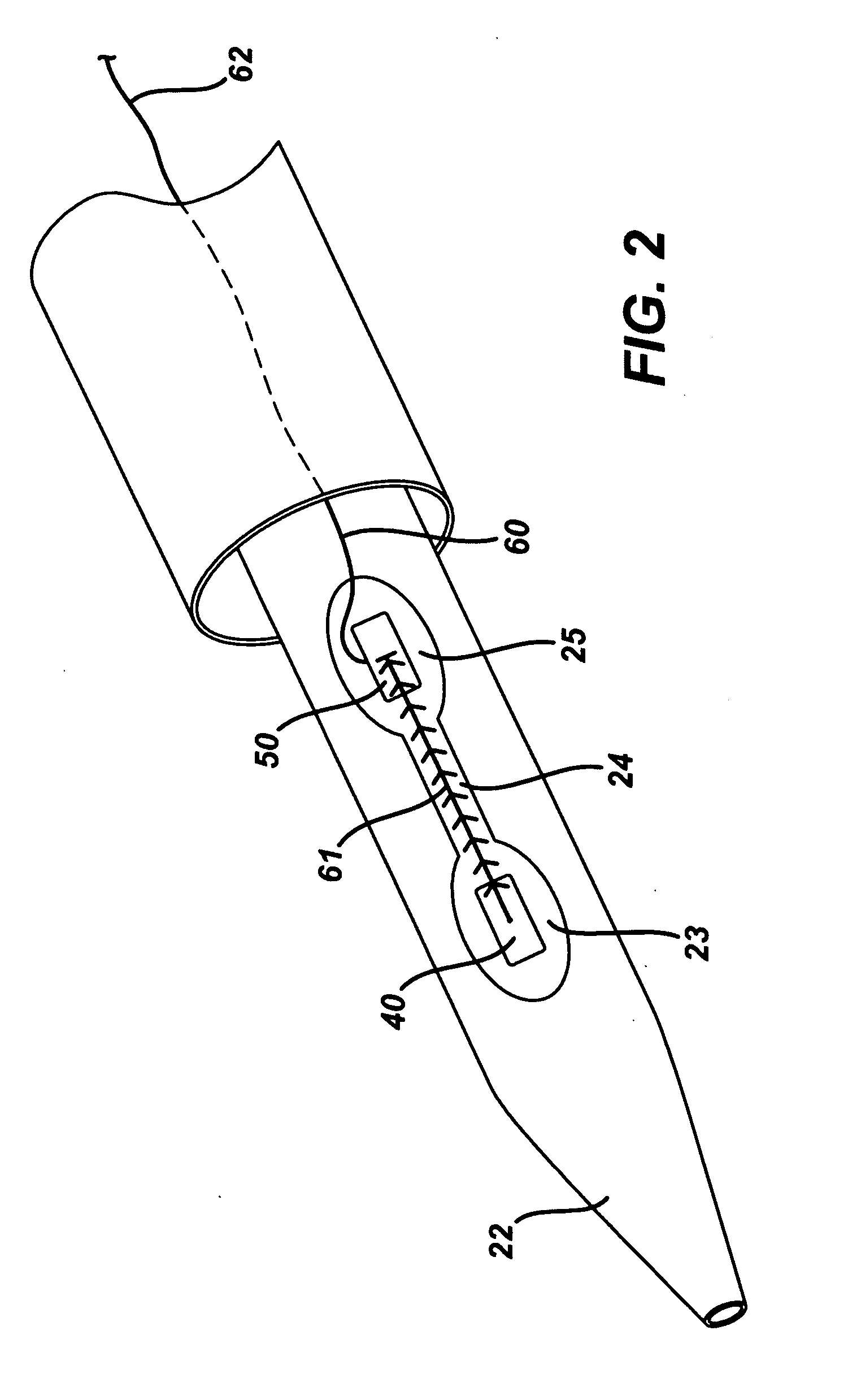

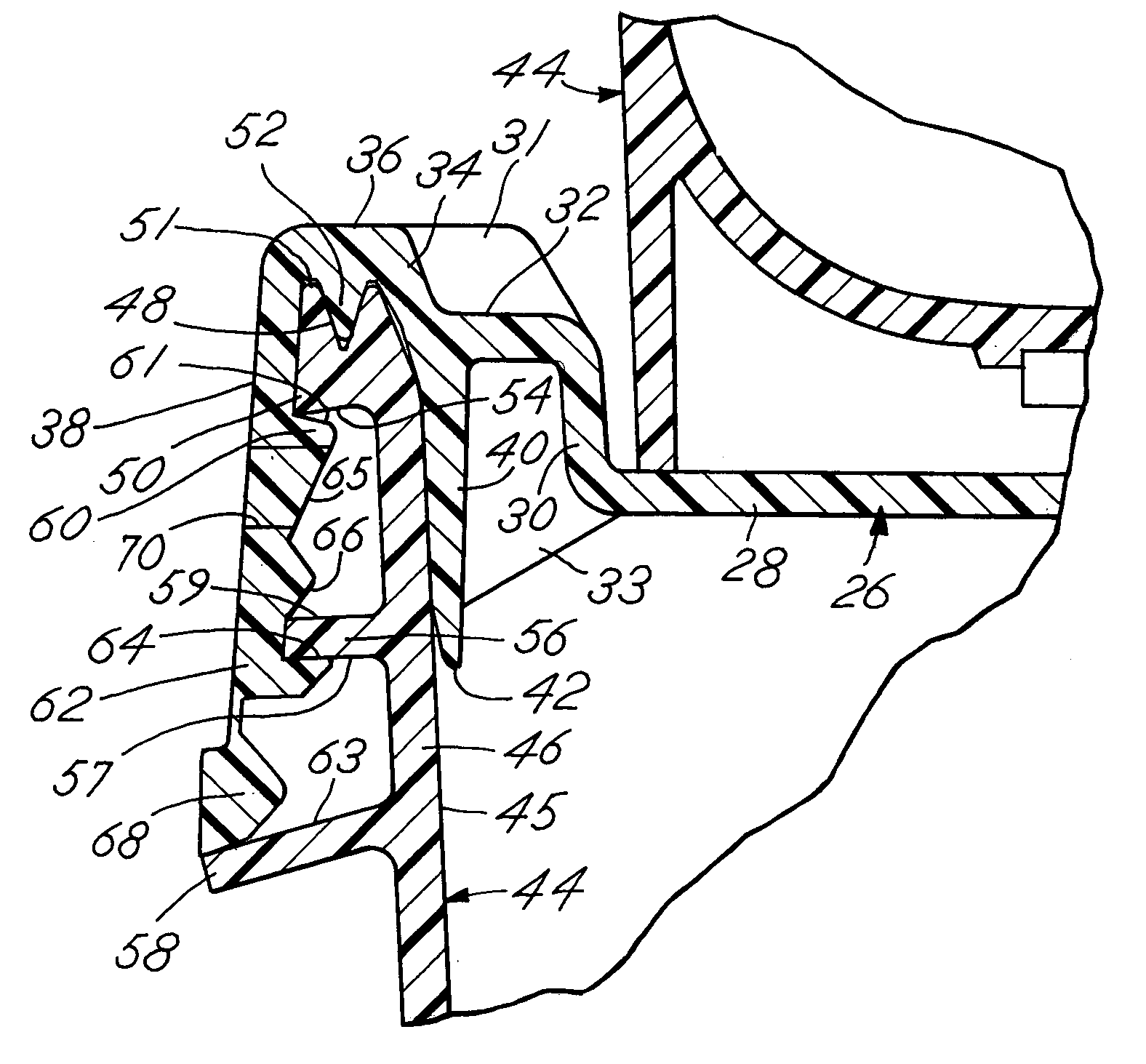

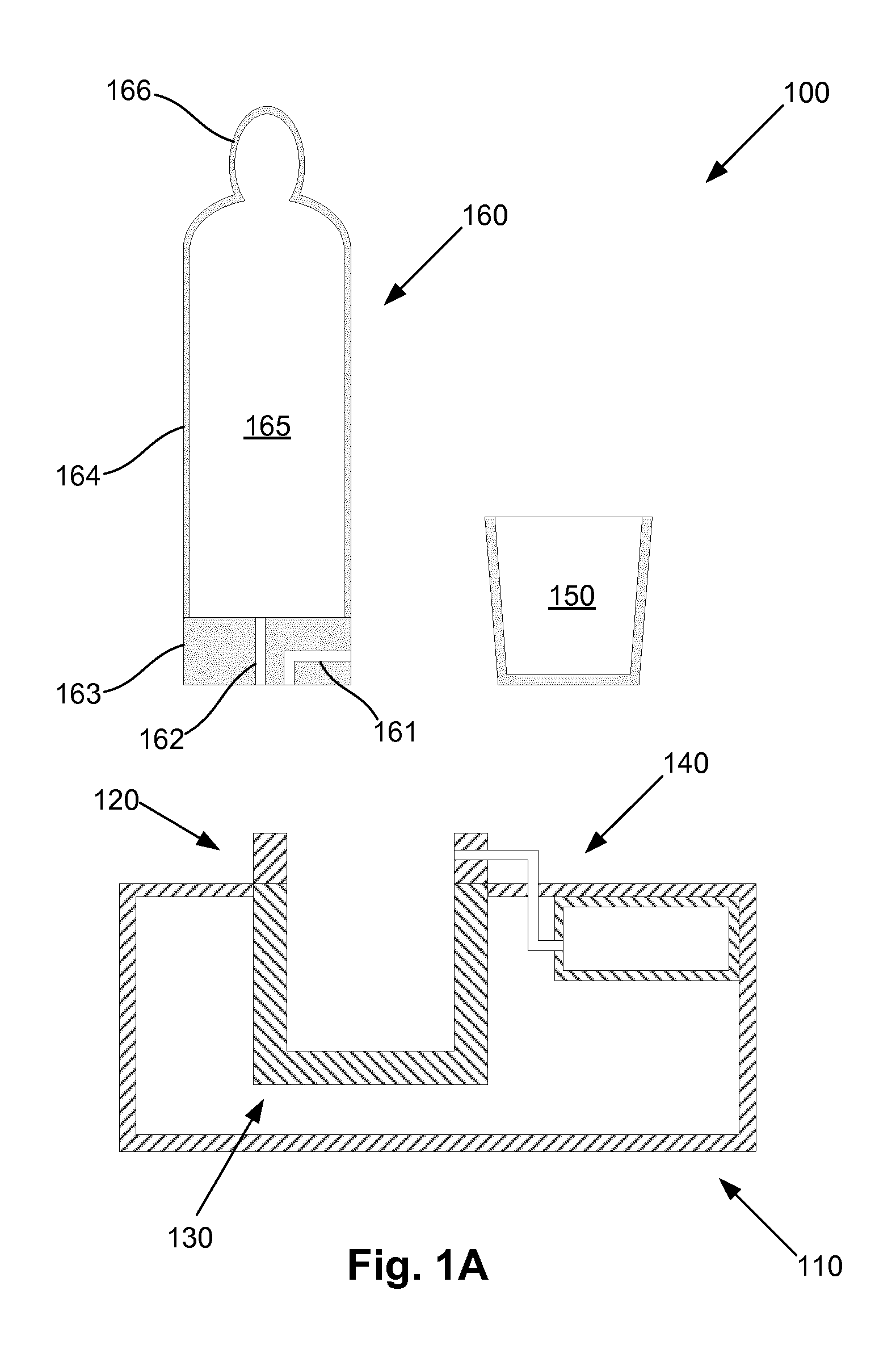

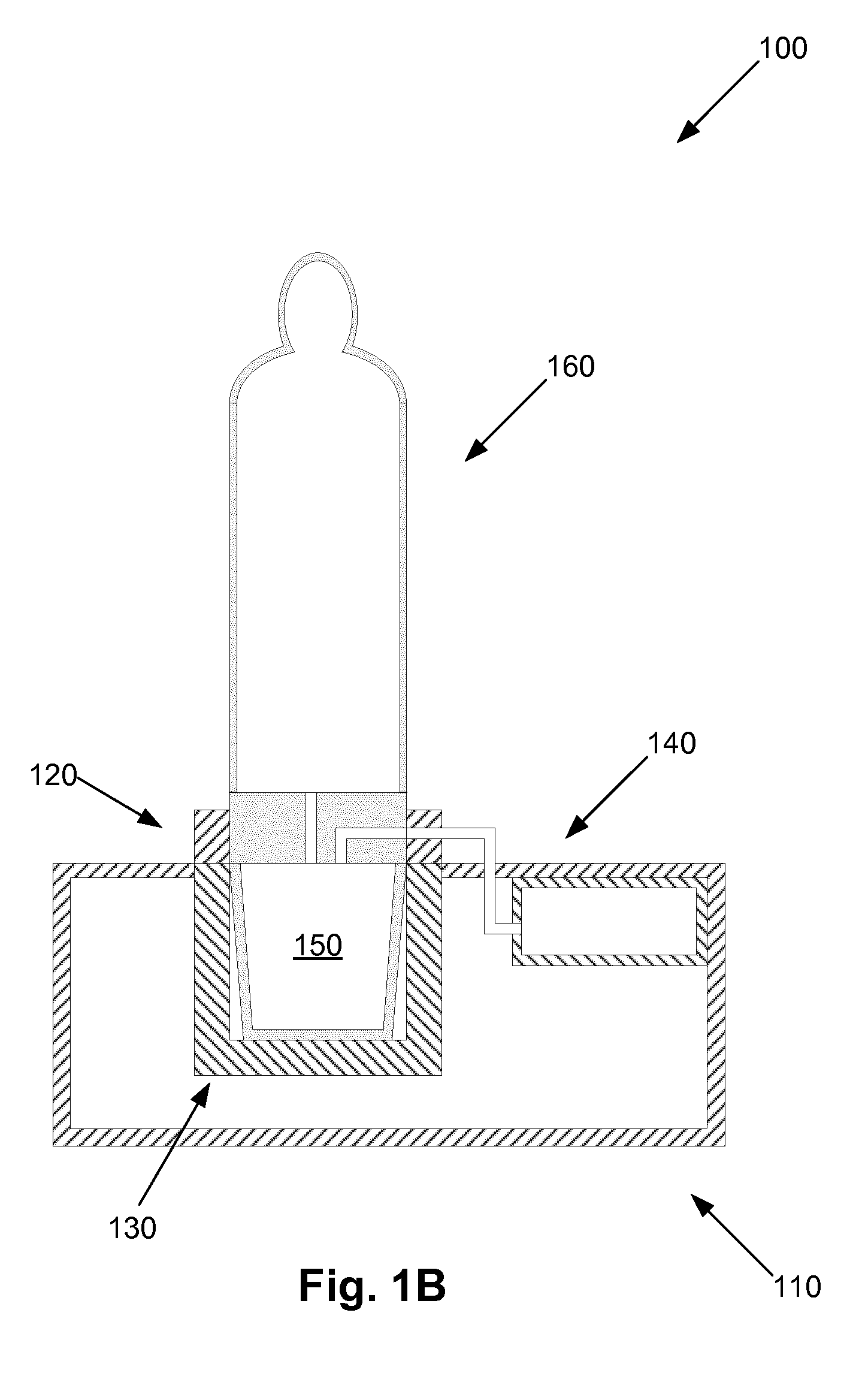

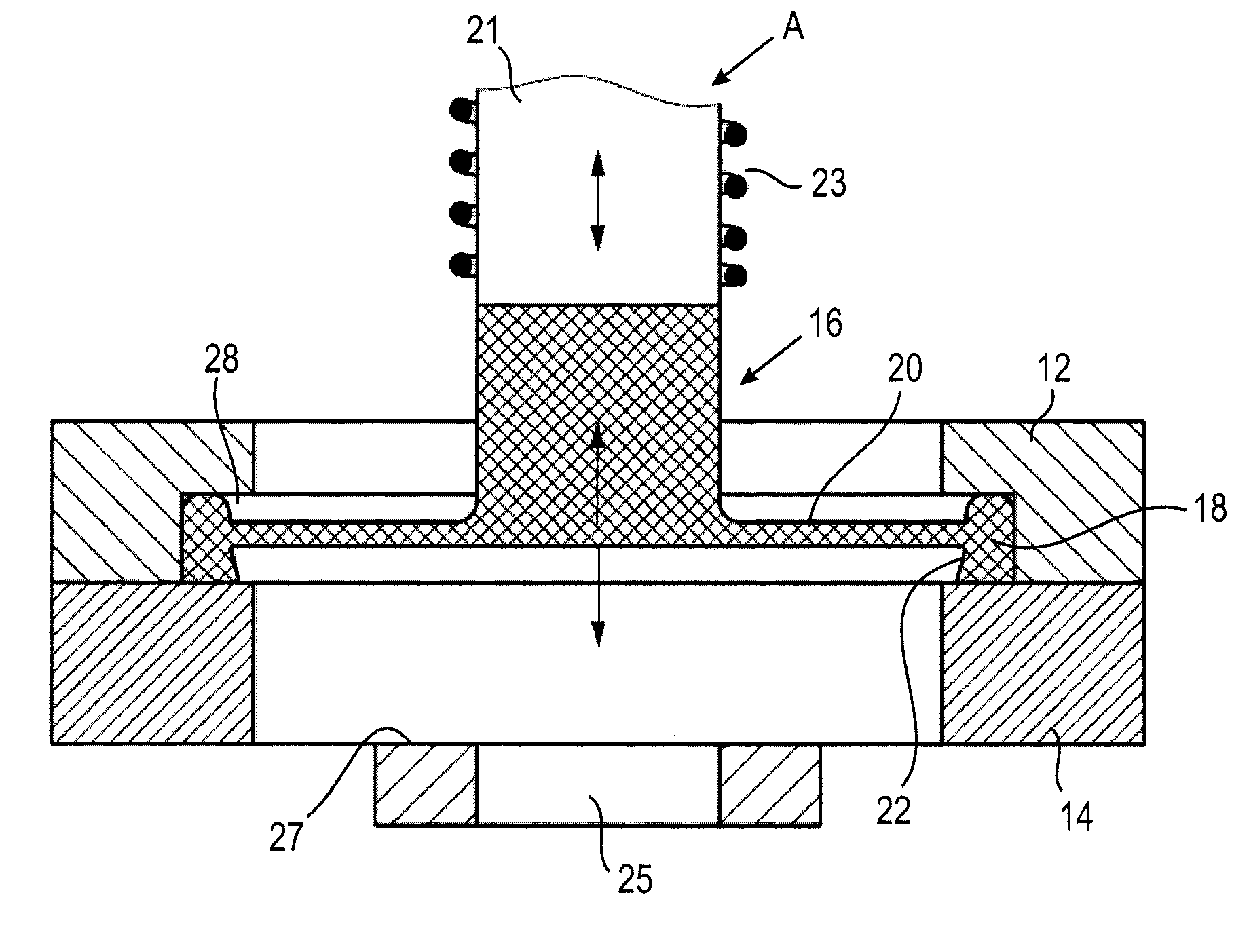

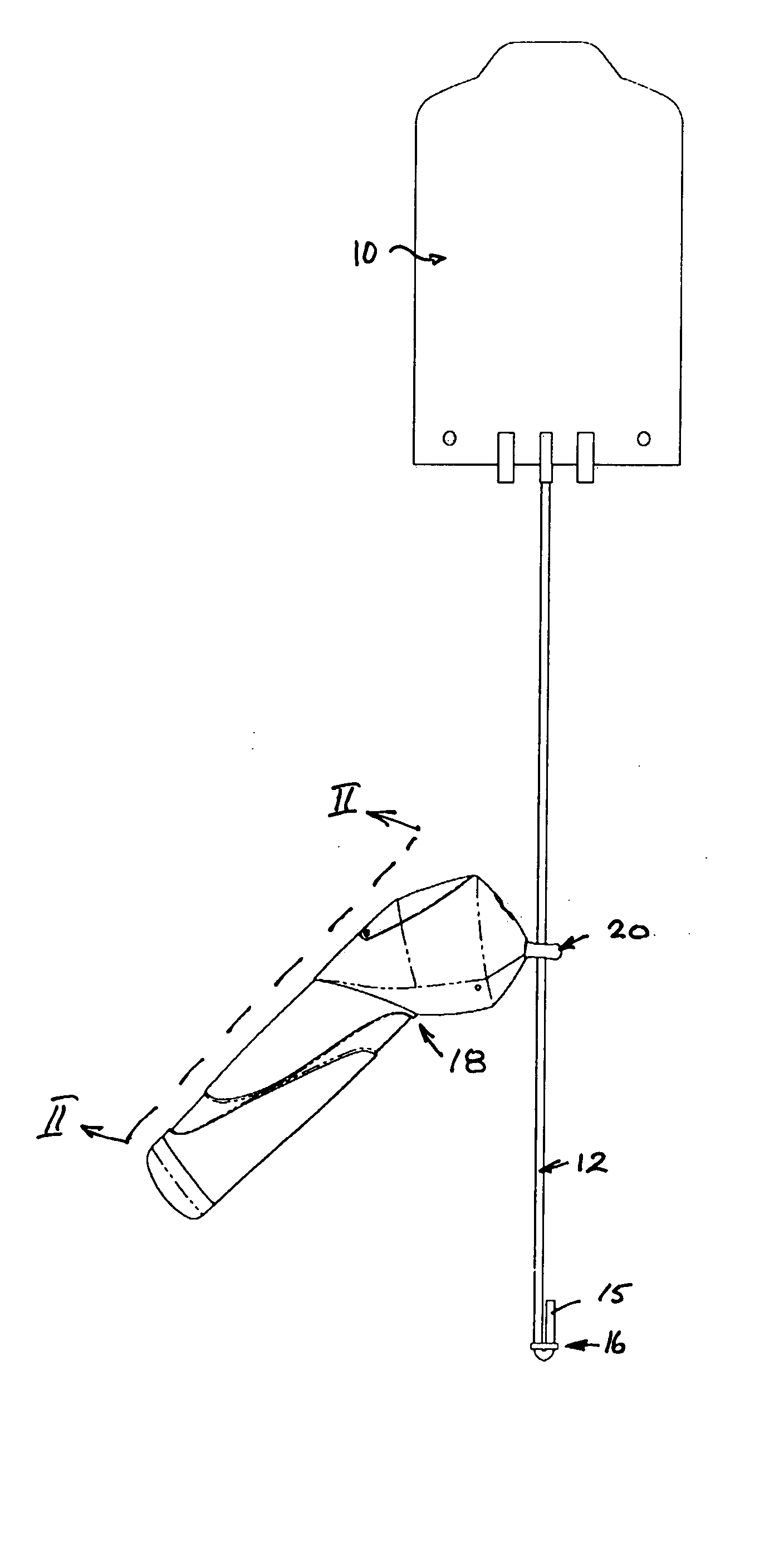

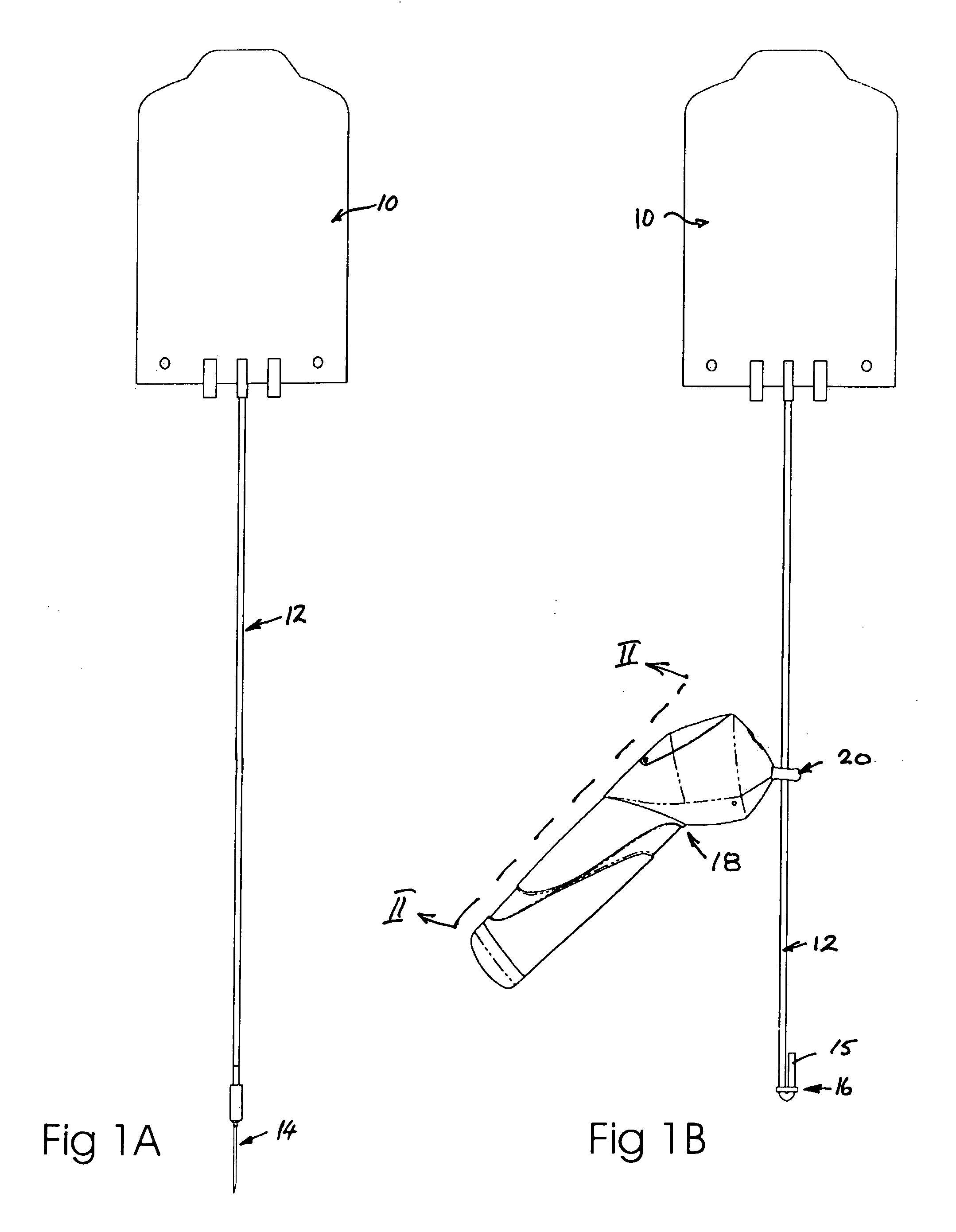

Systems and methods for closing a vessel wound

Vessel wound closure systems and method for sealing a puncture wound in a target vessel, such as those puncture wounds that occur from prior interventional procedures. A sealing member is deployed intravascularly into the target vessel, and an anchor member is deployed extravascularly of the target vessel. The sealing member and the anchor member are connected by a suture that may be drawn to tighten the sealing member and the anchor member relative to one another in order to effect the seal of the puncture wound. After tightening, the suture is secured to maintain the sealing member and the anchor member relative to one another in order to maintain the seal. Preferably, the anchor member, the suture and the sealing member are comprised of biocompatible, bioresorbable materials that are absorbed into the body after the sealing of the puncture wound has been achieved. The sealing member, suture and the anchor member are delivered by a delivery rod or other components over a guidewire or through an introducer already in place from the preceding interventional procedure.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

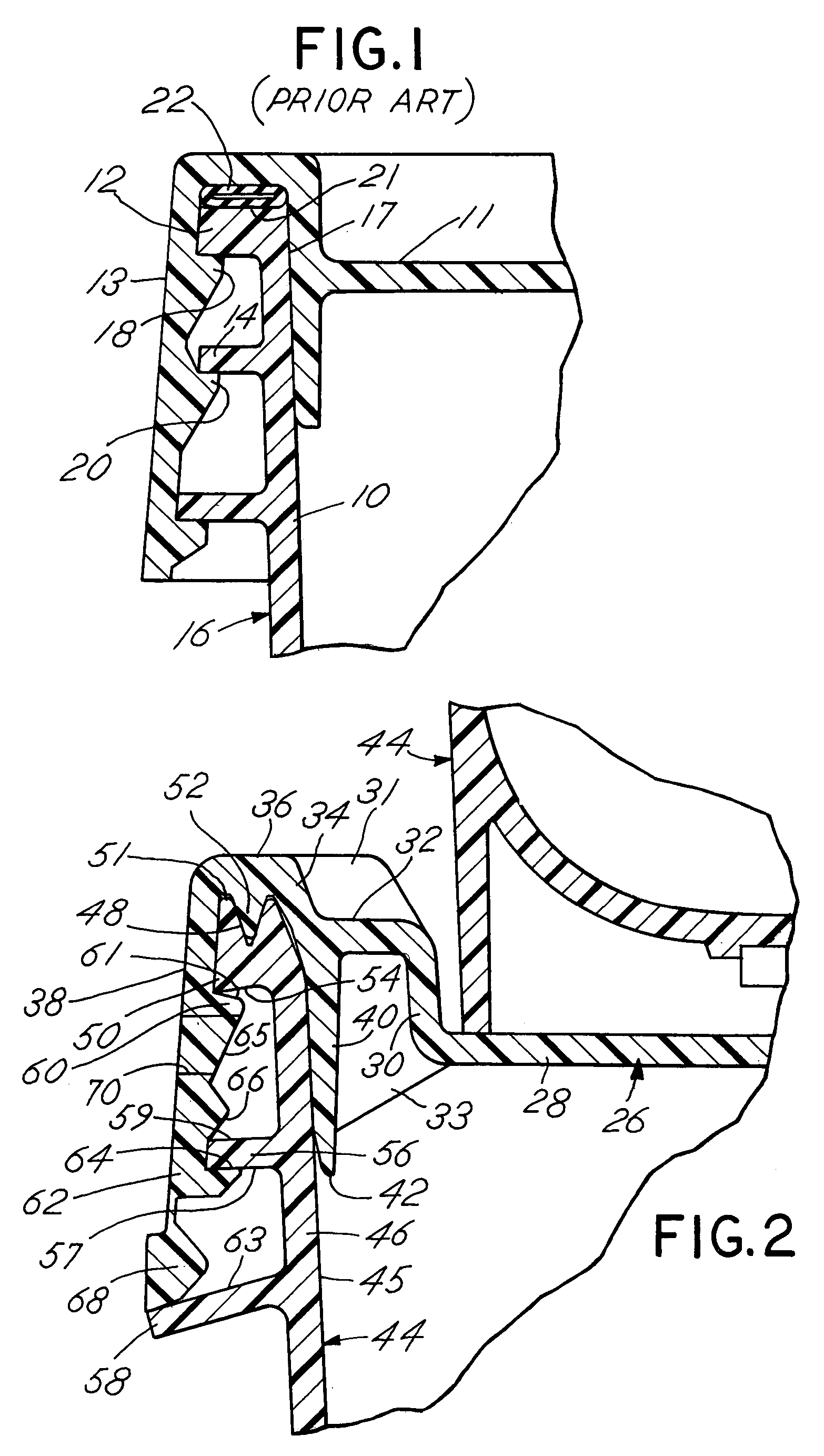

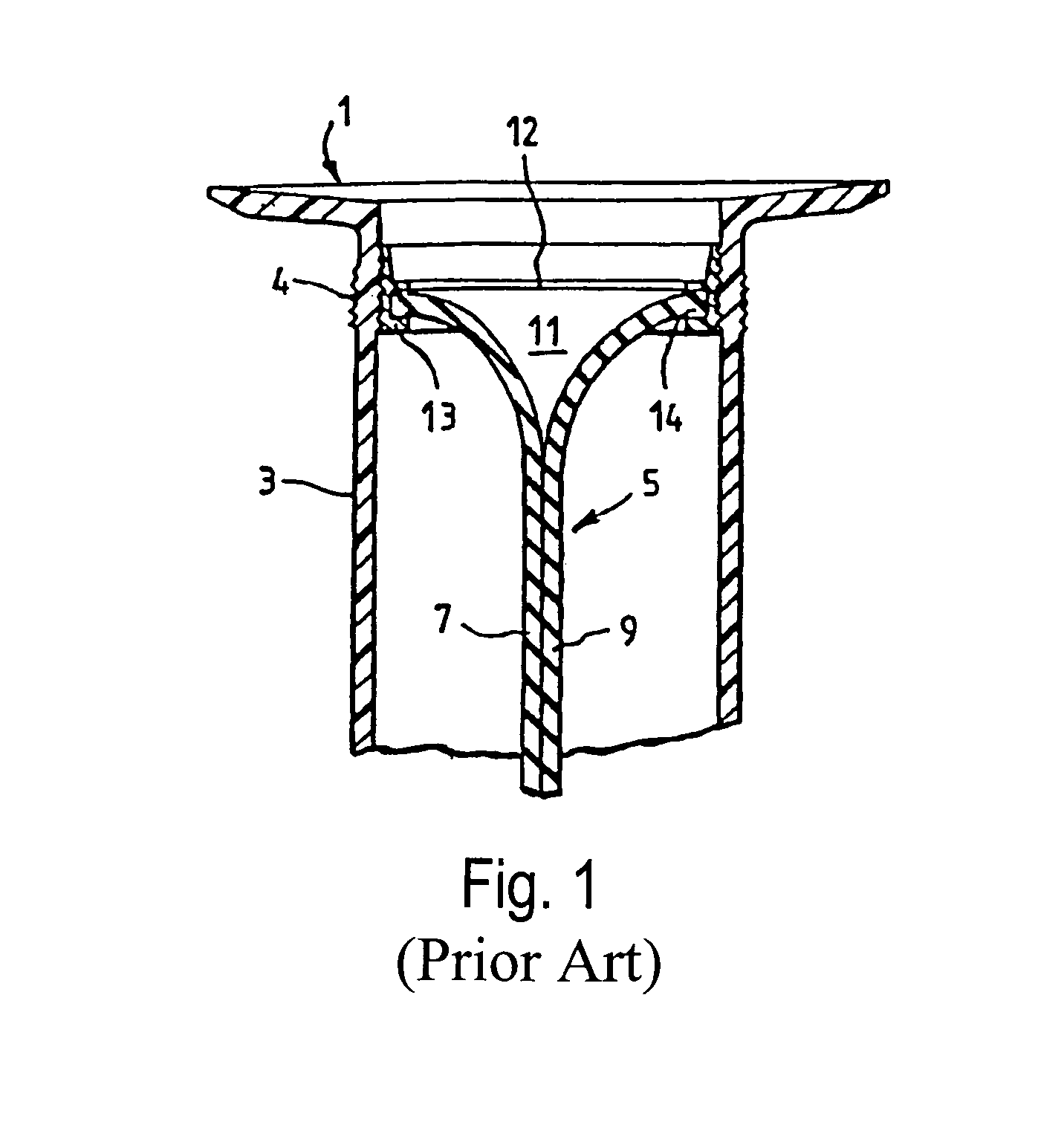

Plastic container and lid construction

A combination molded plastic bucket and lid includes a series of outwardly extending ribs on the top edge of the bucket and inwardly extending flanges on a depending outer skirt of the lid which engaged with the bucket ribs to provide a wedging action that holds the lid tightly in a sealing position on the top of the bucket. A zig-zag tear strip permits removal of a portion of the lowermost lid flange. The top of the bucket includes a groove adapted to receive a projection or tongue seal.

Owner:PLAS TOOL

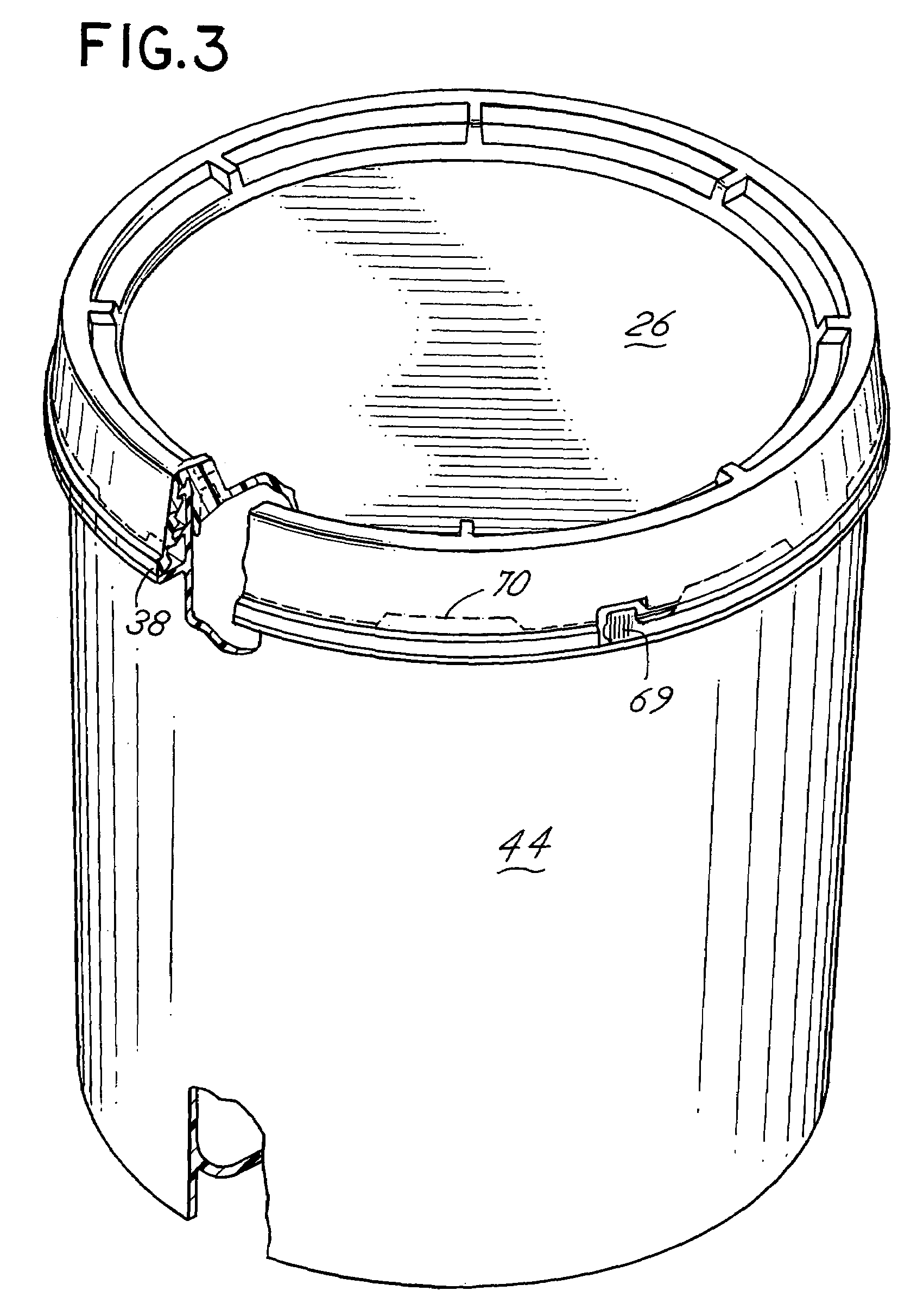

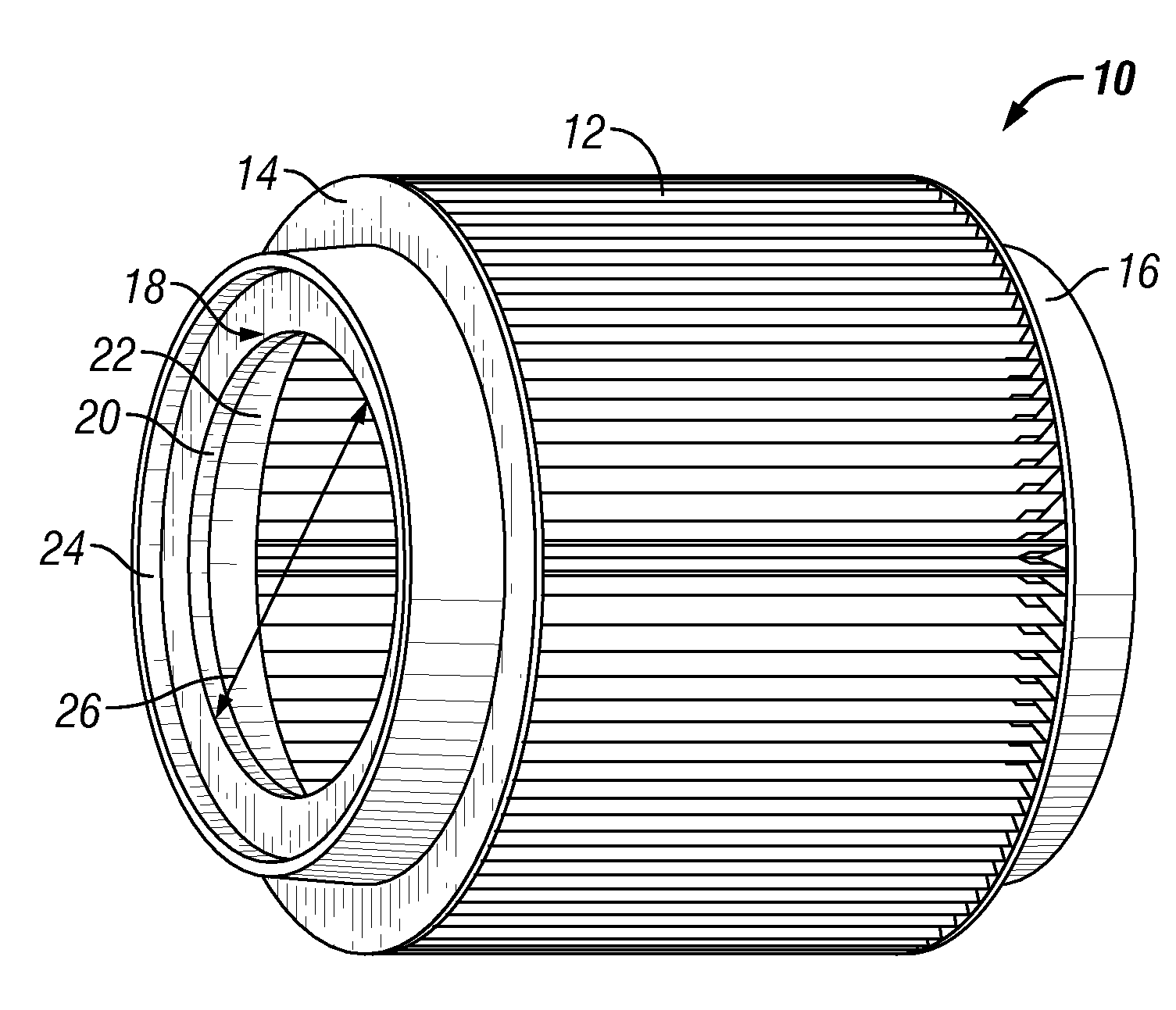

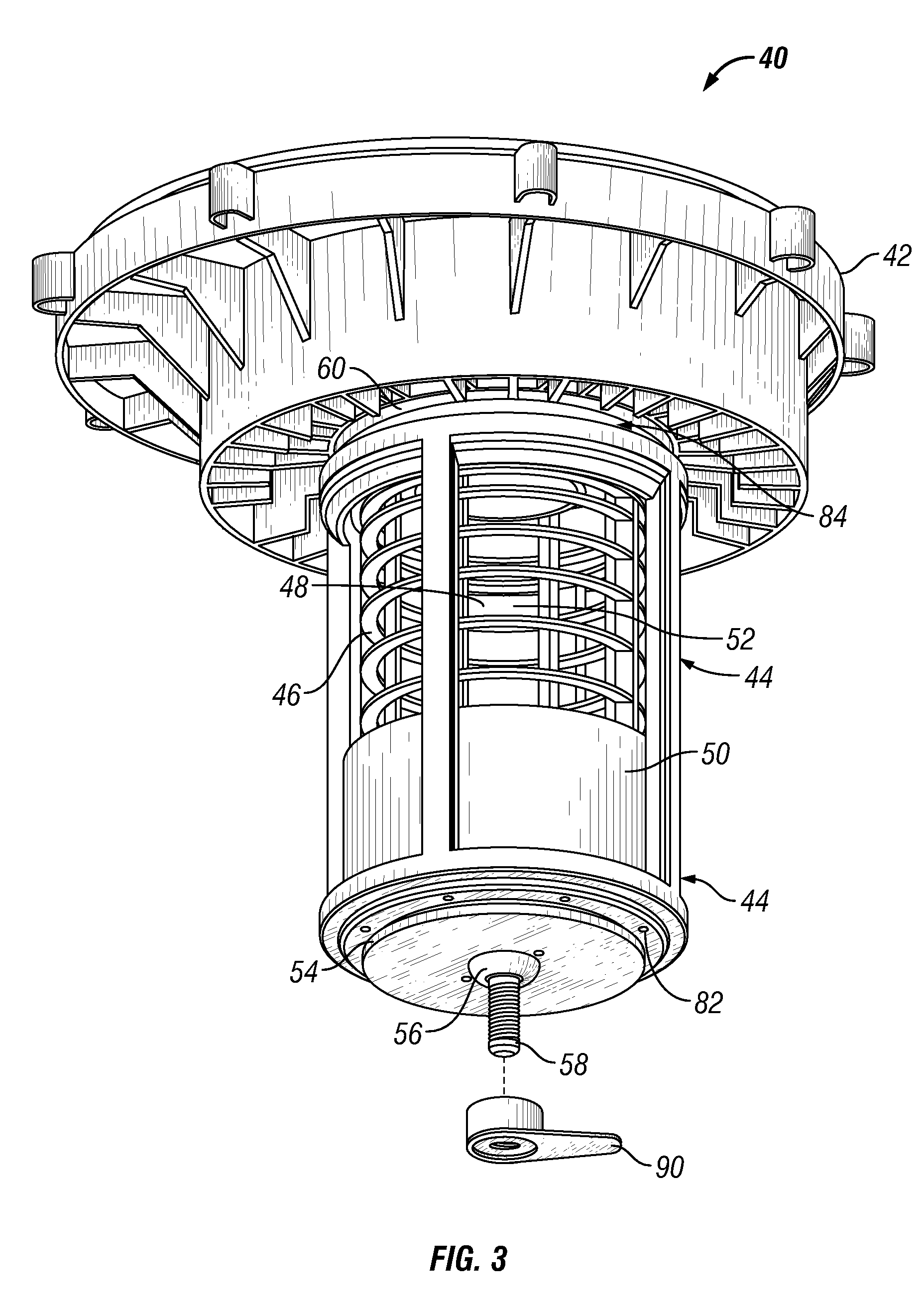

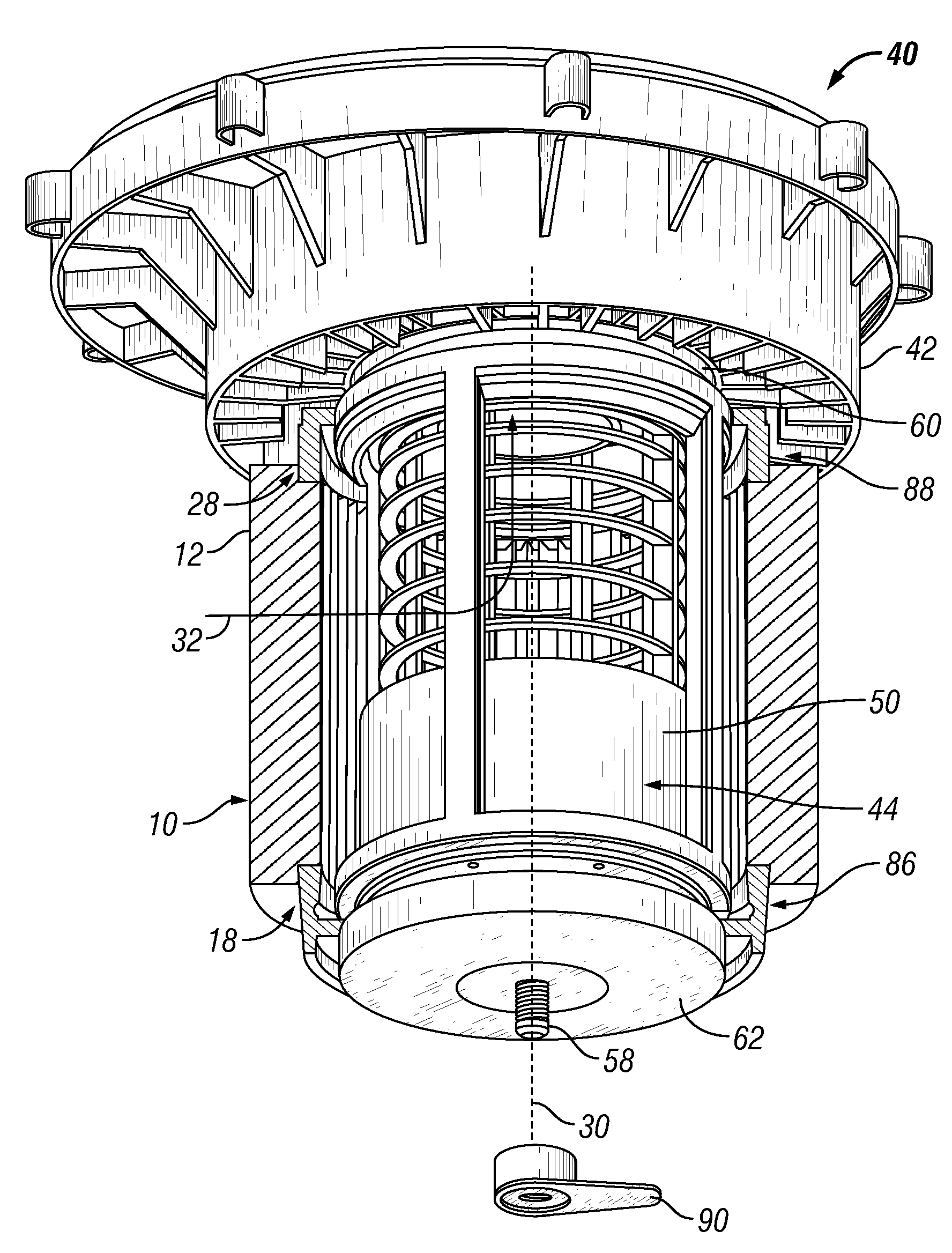

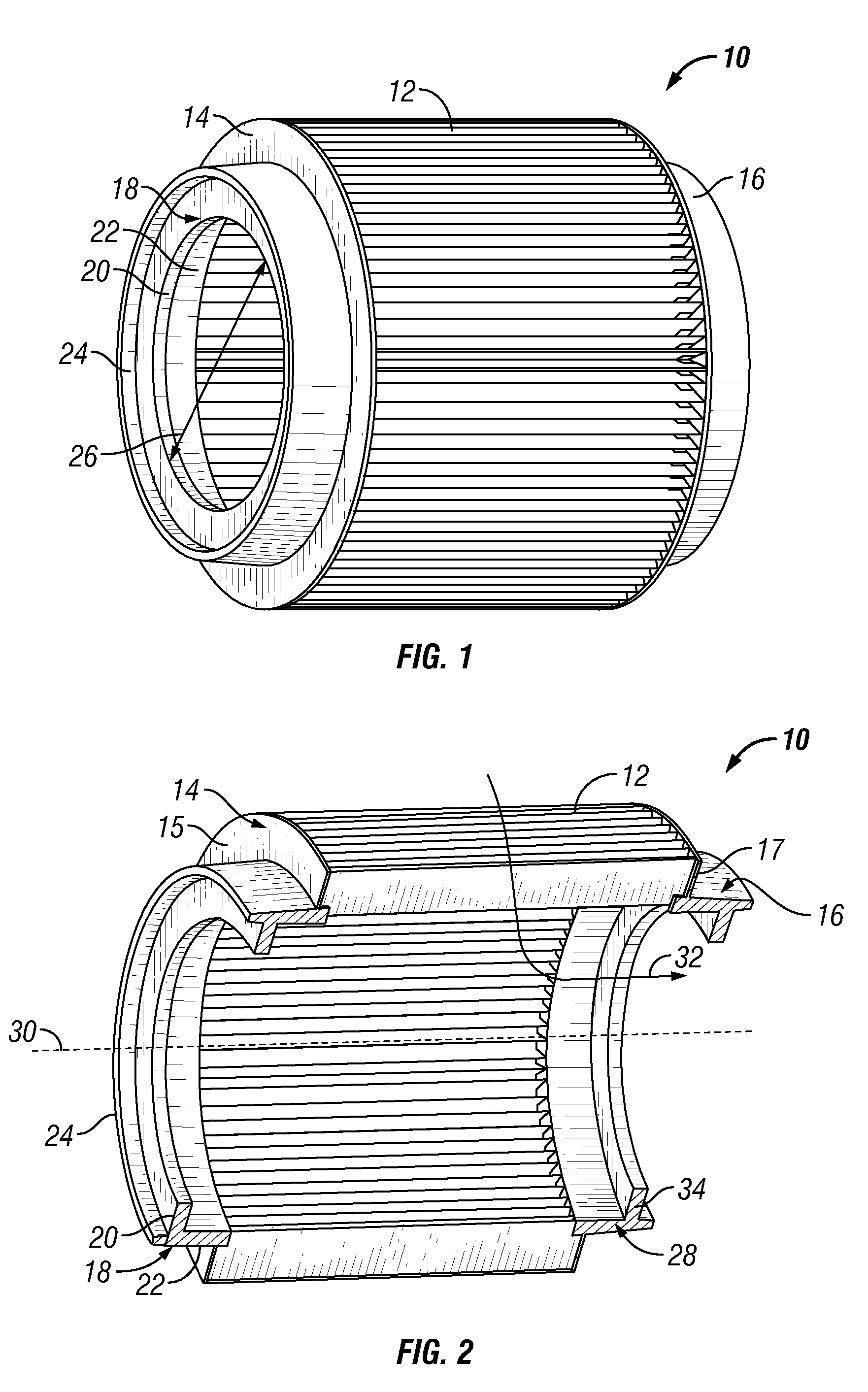

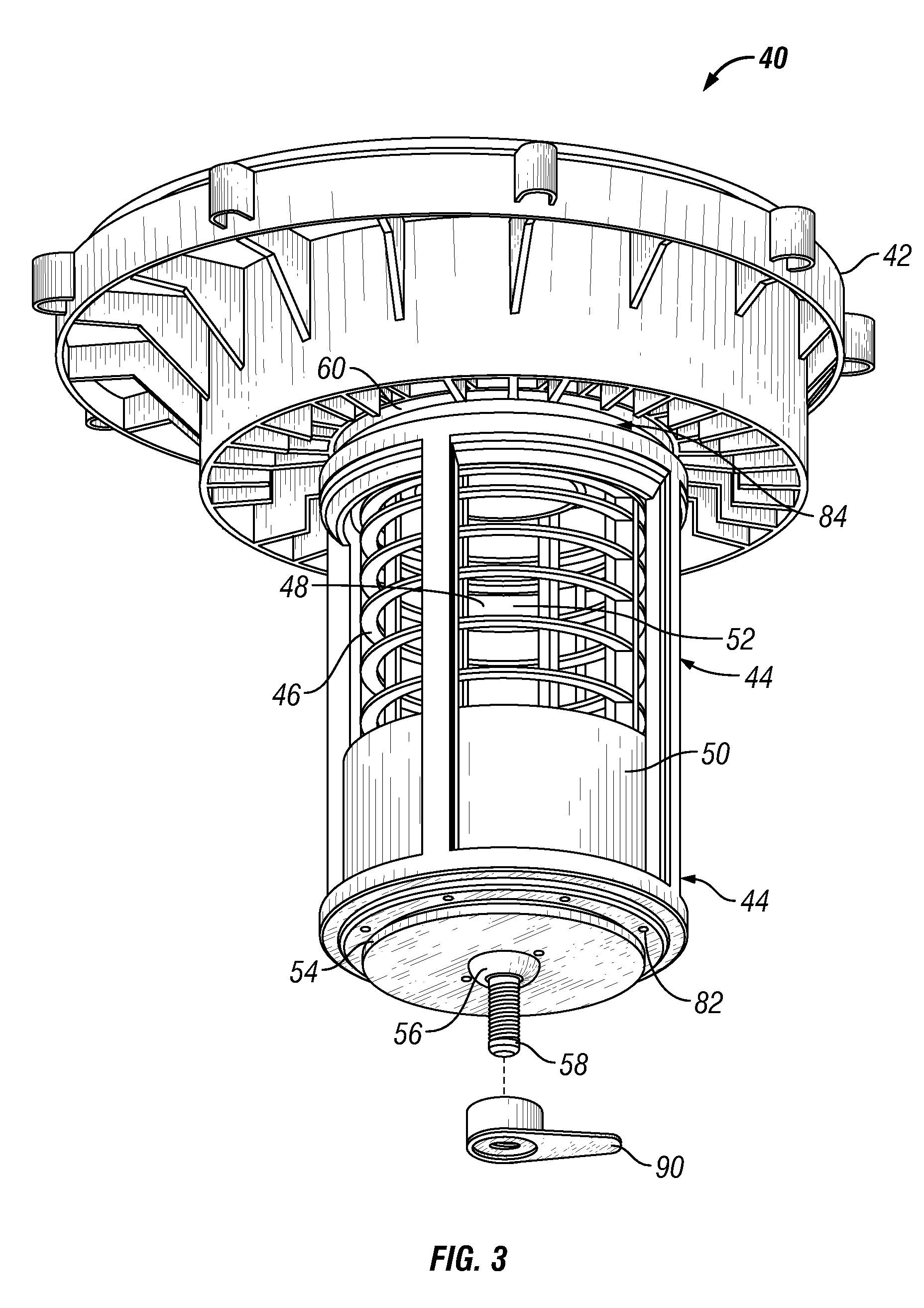

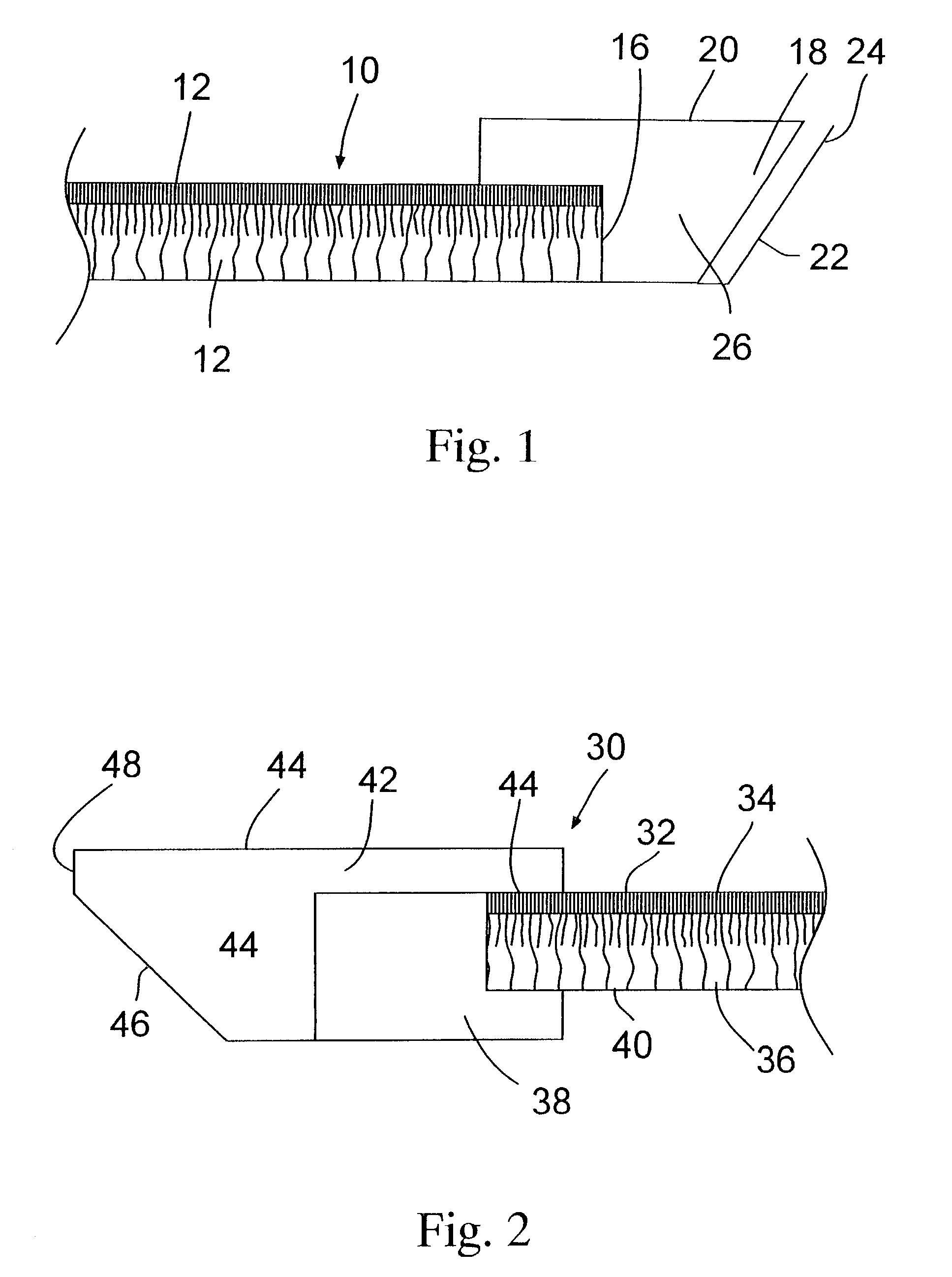

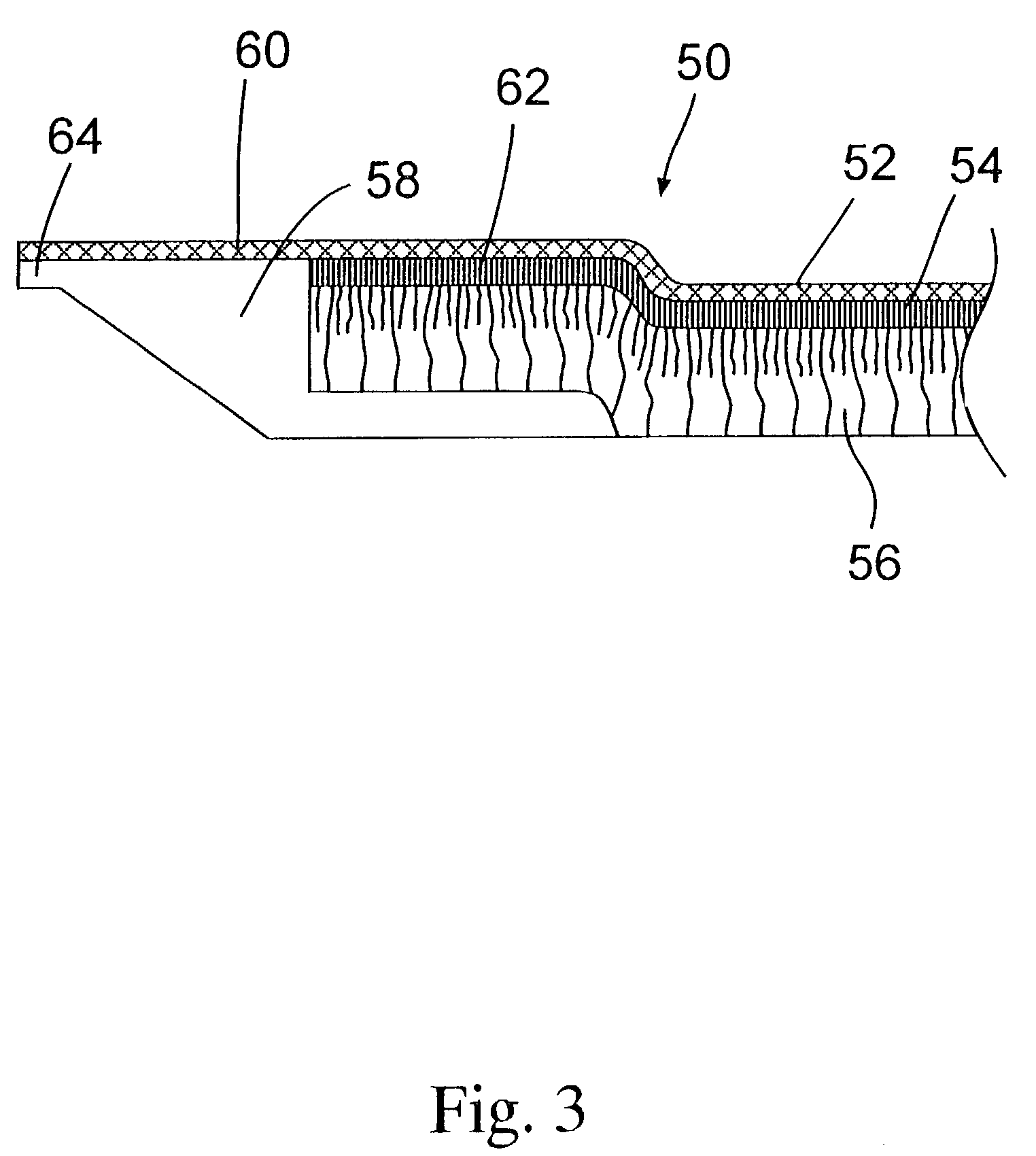

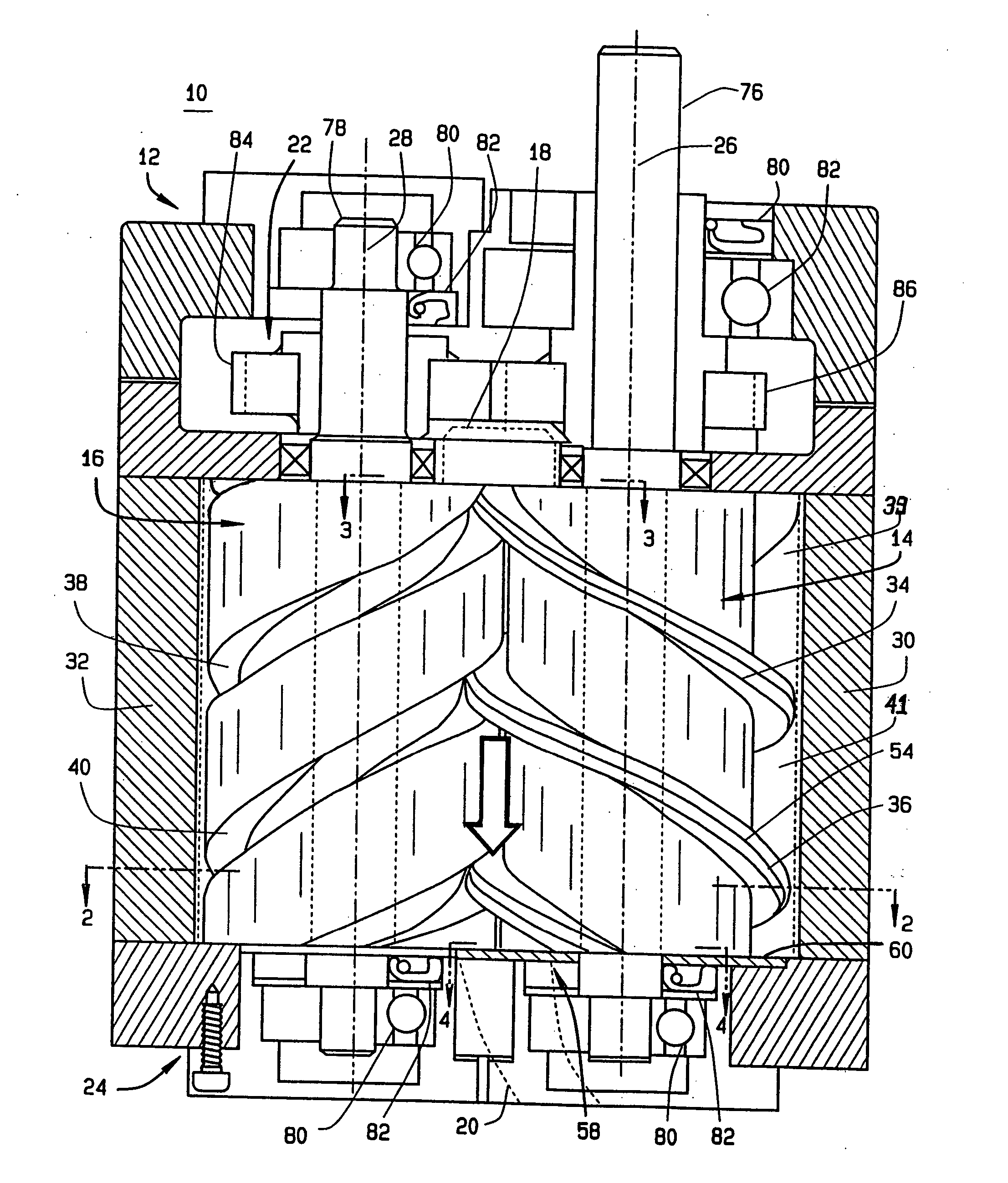

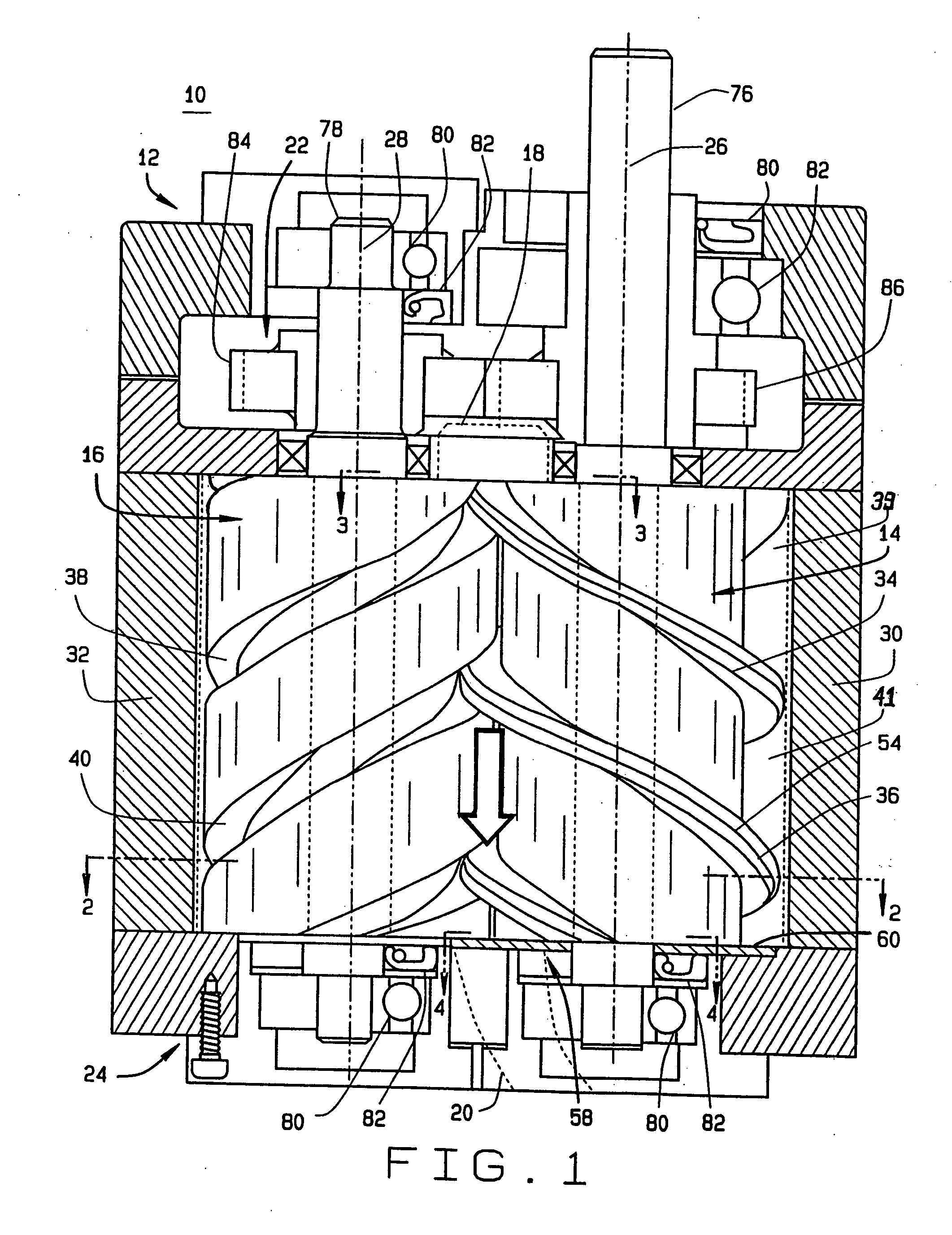

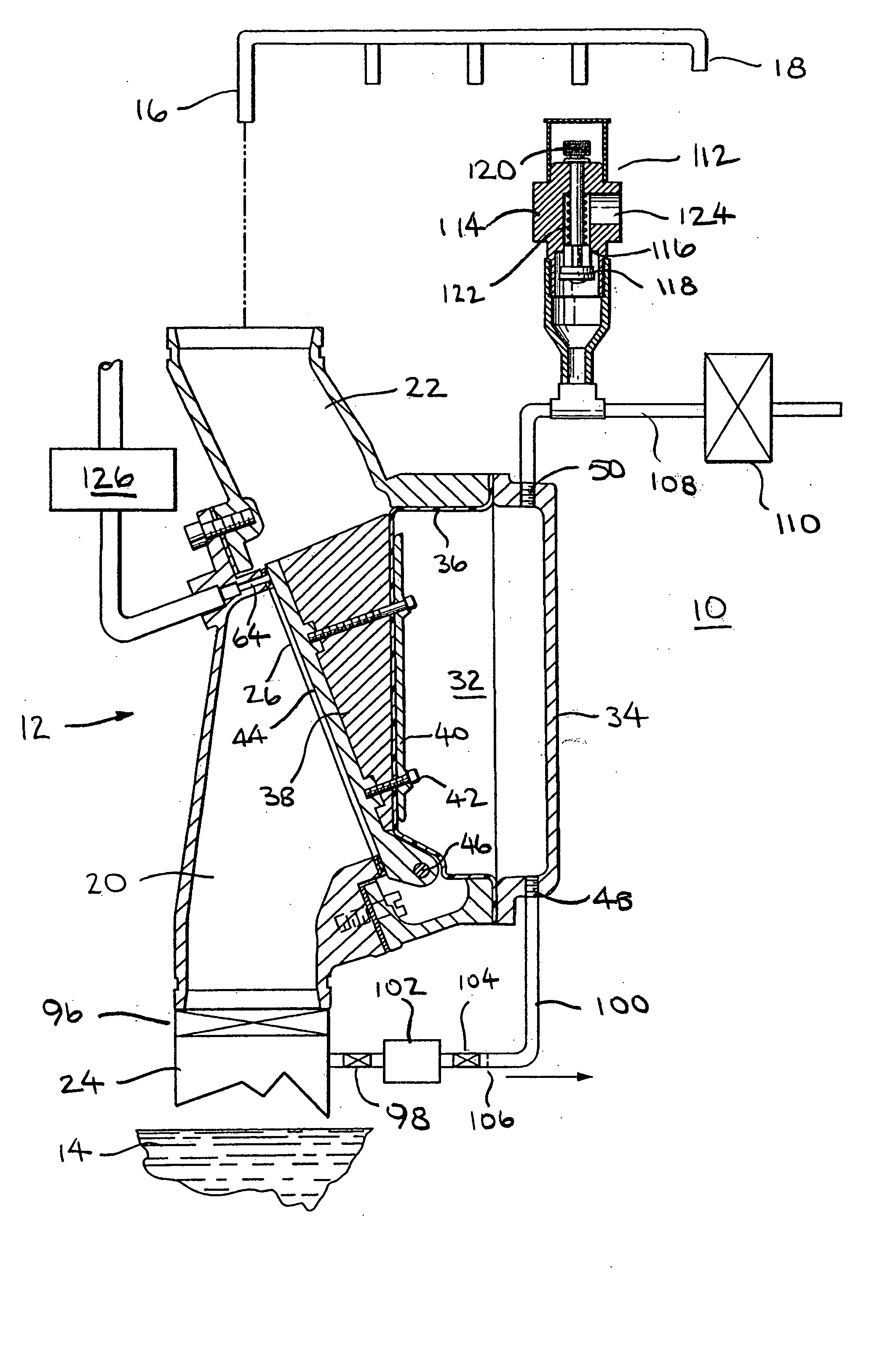

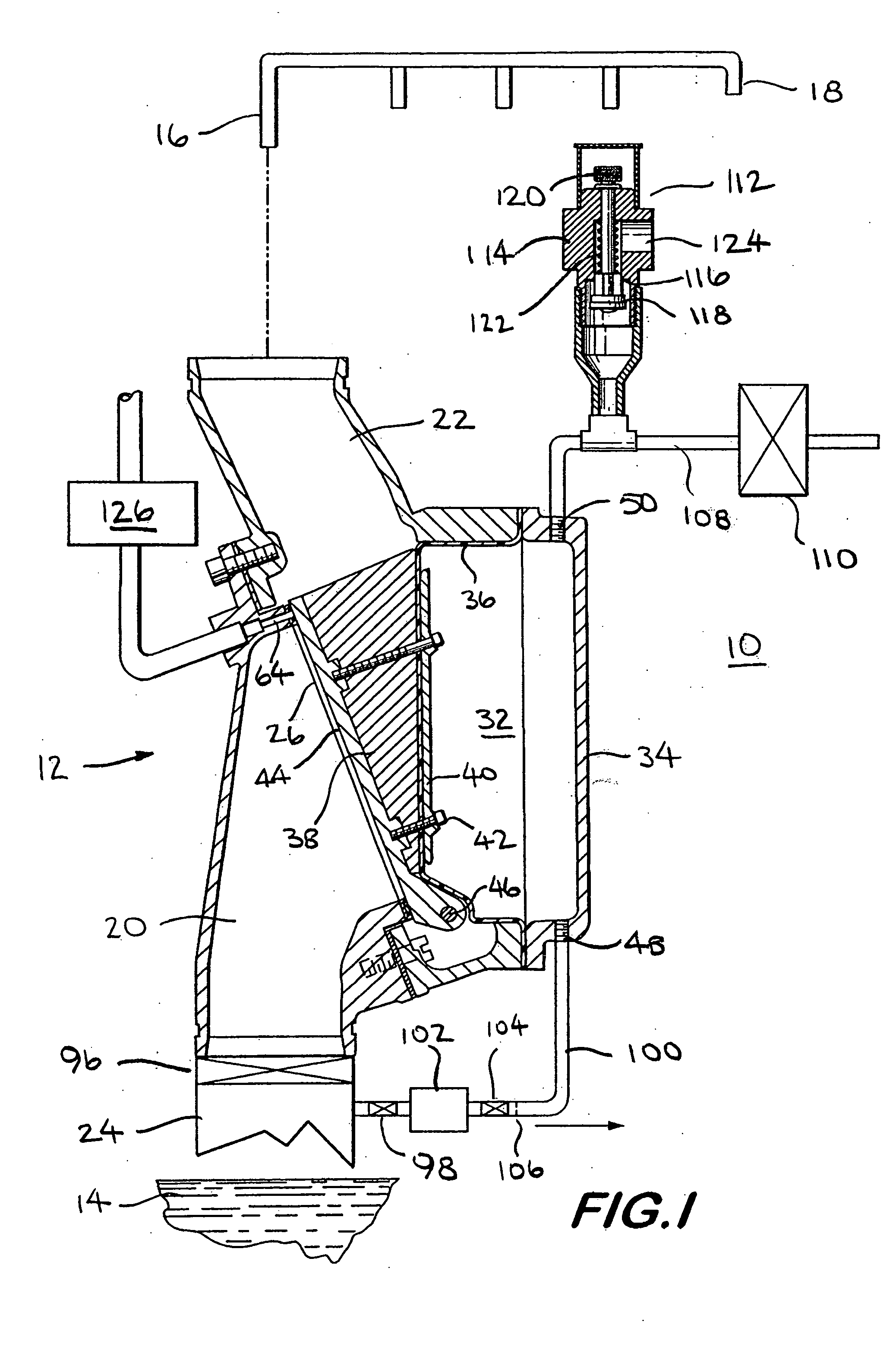

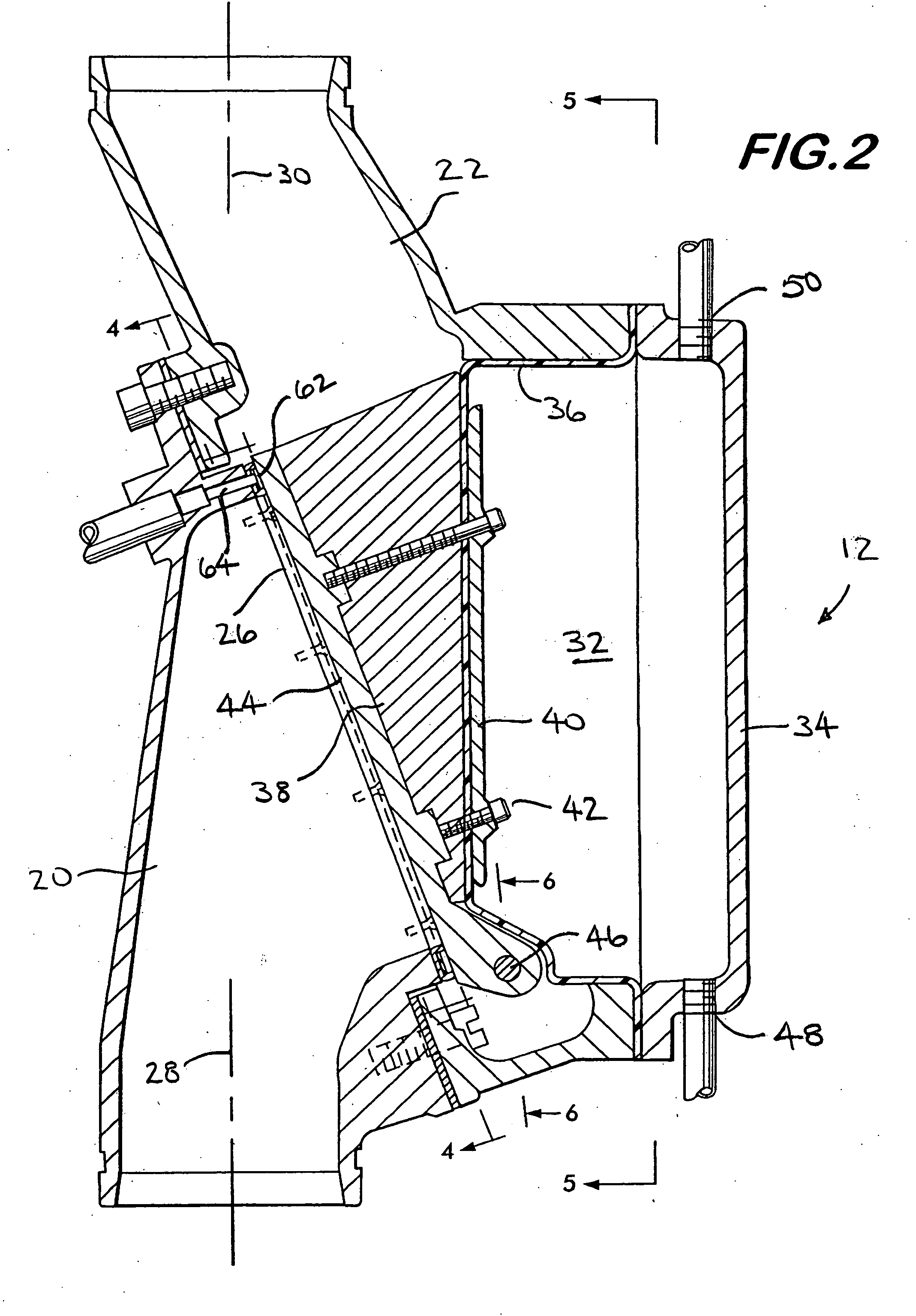

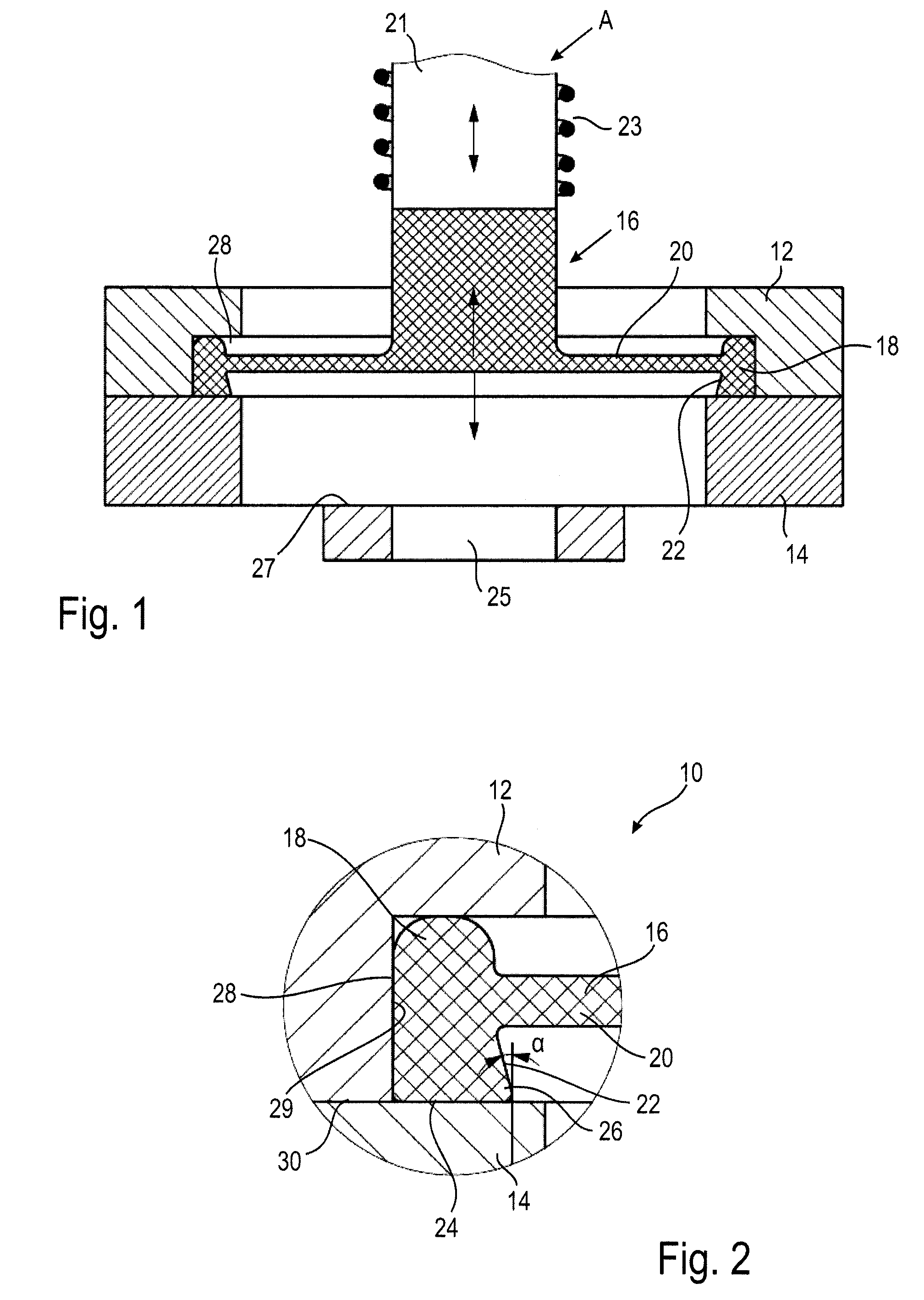

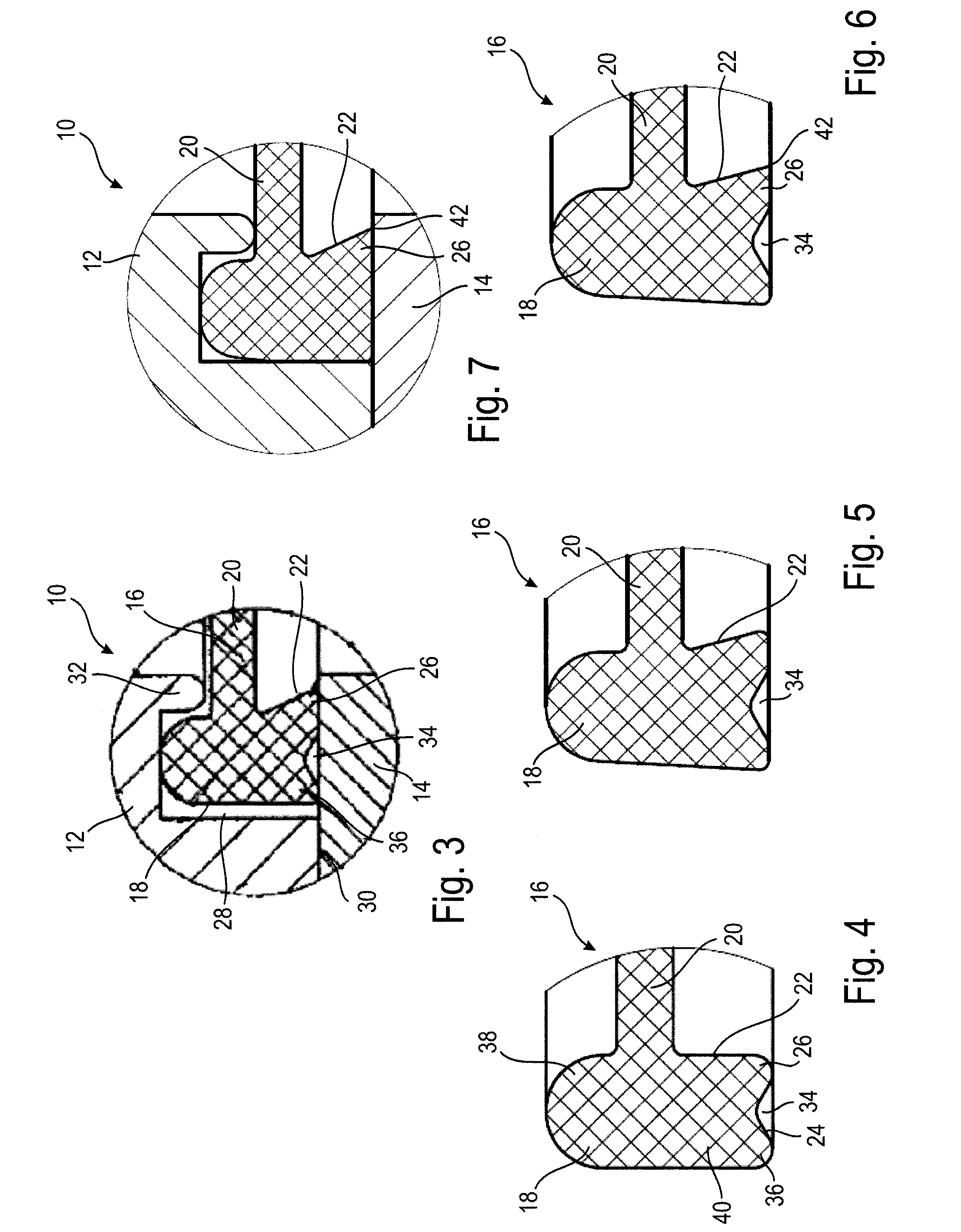

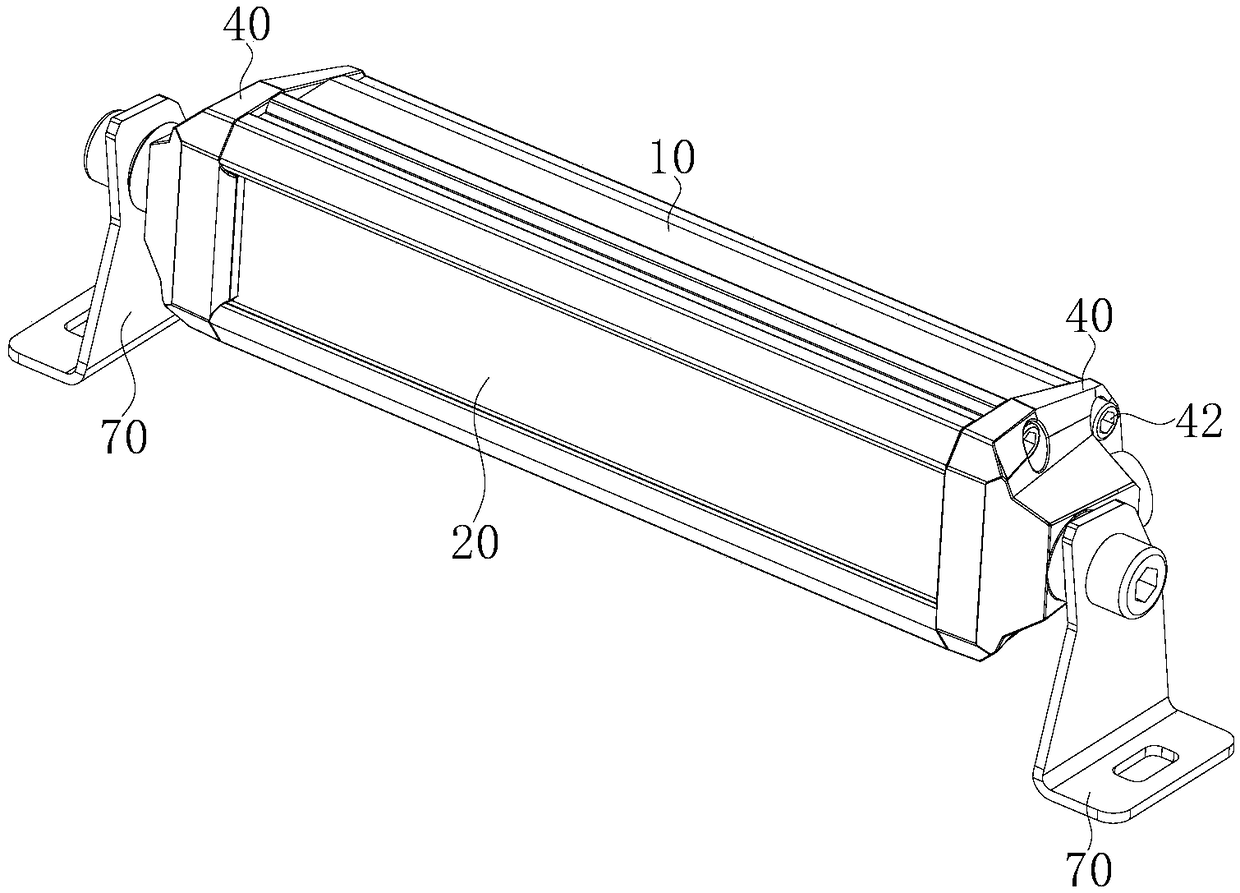

Filter and system for improved sealing on a vacuum cleaner

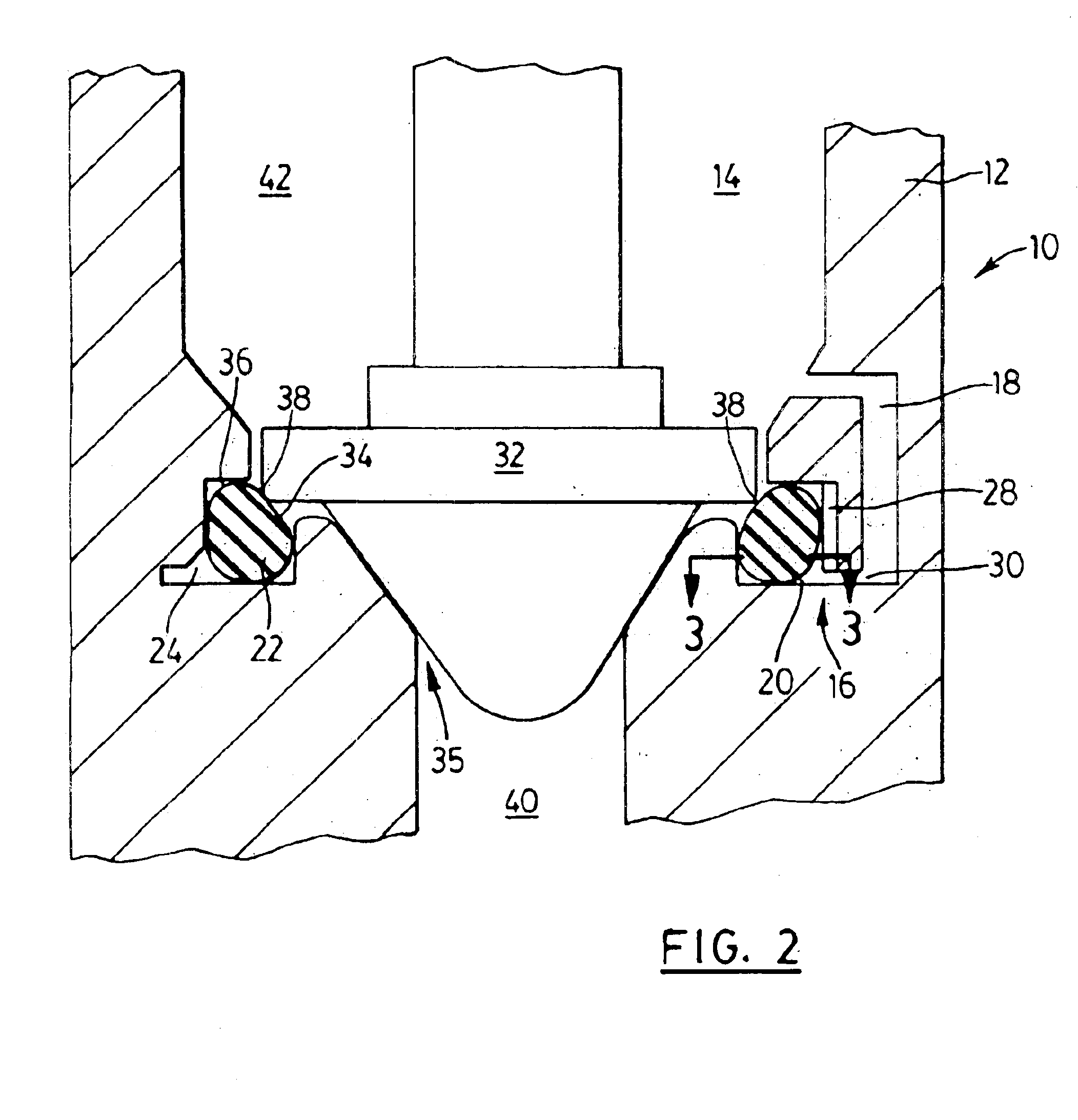

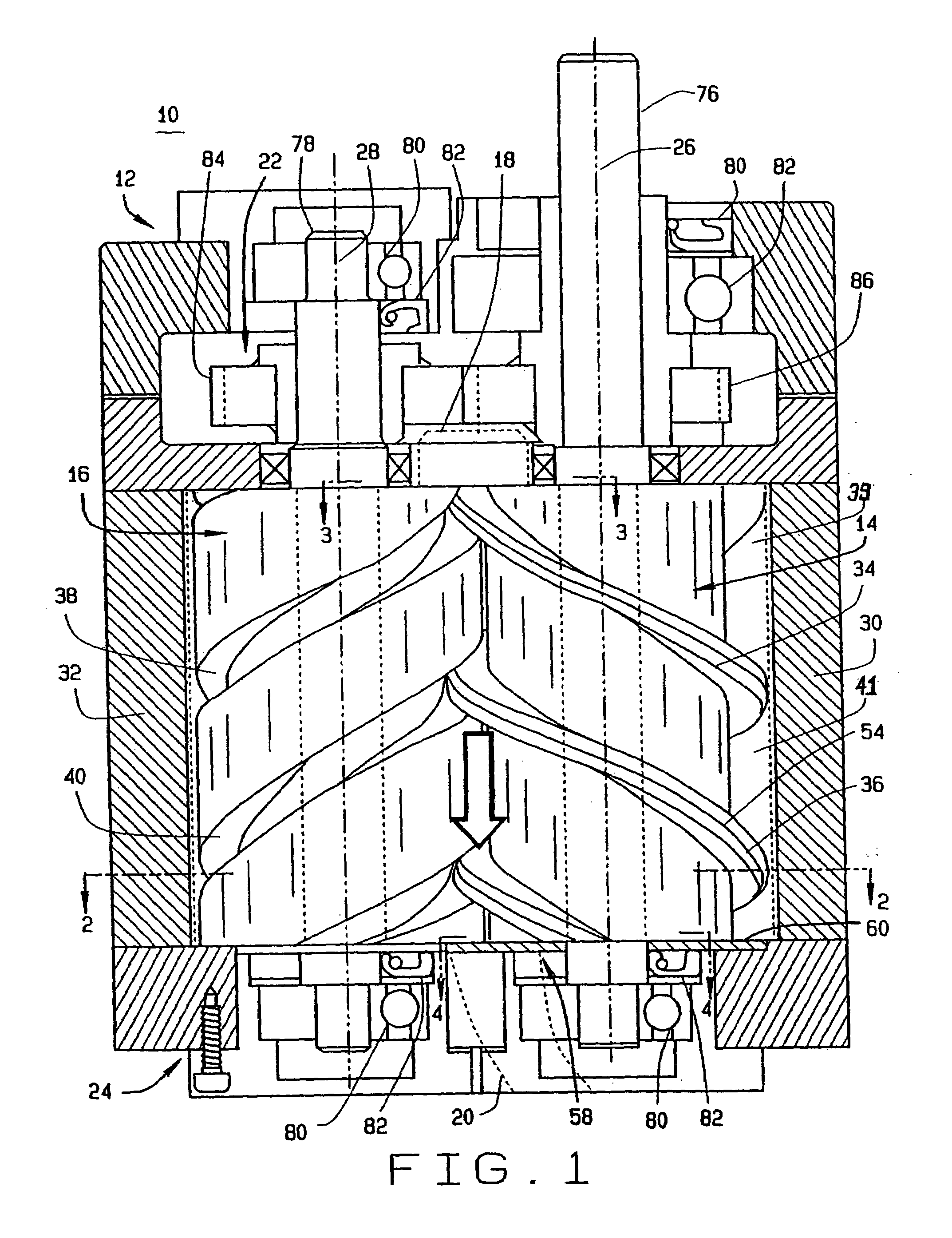

ActiveUS20070113529A1Sealing effectGas treatmentDispersed particle filtrationEngineeringMechanical engineering

The disclosure provides a filter for mounting in a vacuum cleaner, such as a wet and dry vacuum cleaner, having a seal at generally each end, and a corresponding mounting structure that focuses compressive sealing forces on specific seal components rather than the filter body as a whole. The sealing is directed primarily to portions of the seals on the filter ends that are compressed or “pinched” between adjacent surfaces. The concentrated compressive stress provides a well-defined region to consistently provide a sealing engagement. The compressive force can thereby remain relatively constant through multiple uses of the filter.

Owner:EMERSON ELECTRIC CO

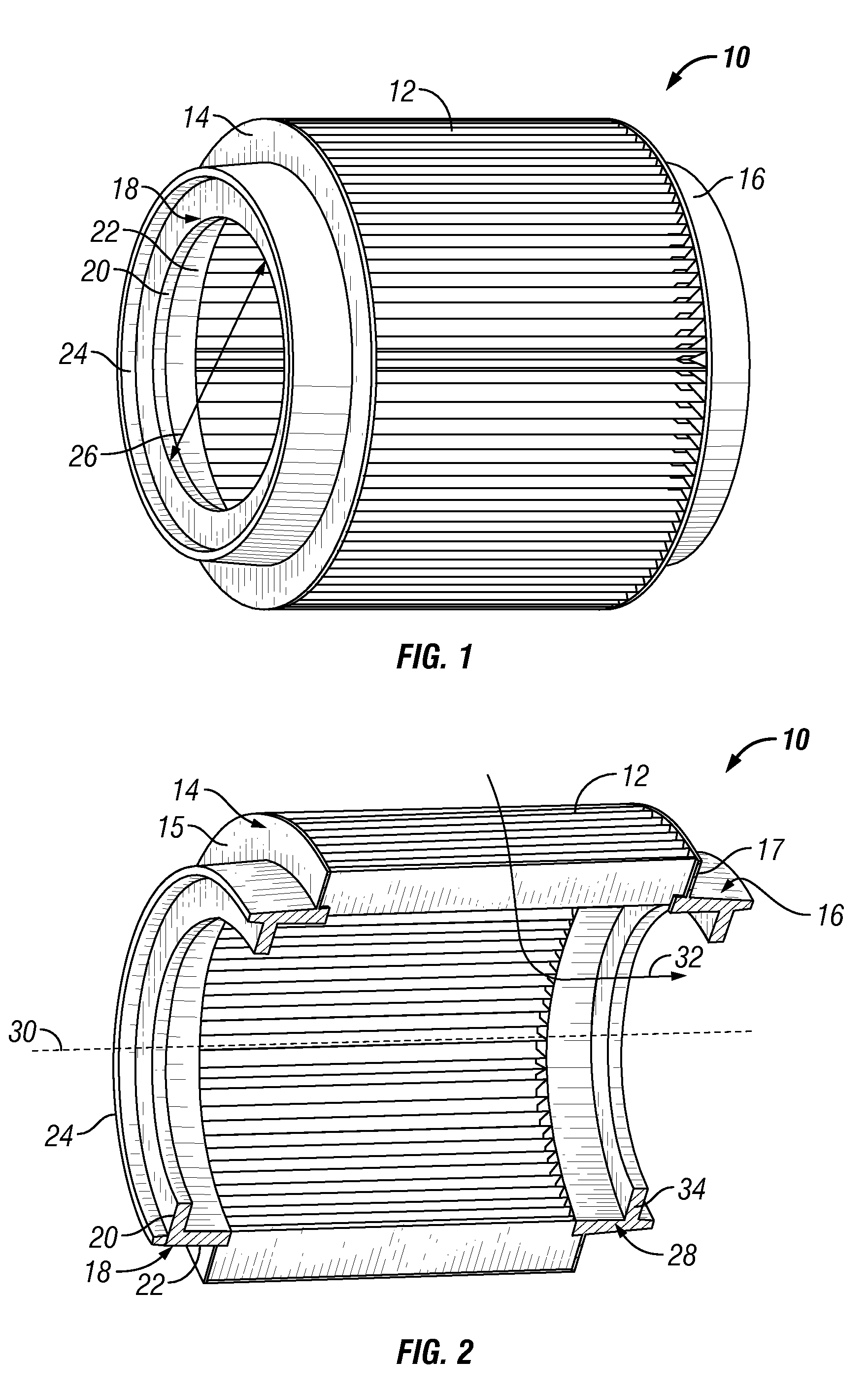

Filter and system for improved sealing on a vacuum cleaner

ActiveUS7374595B2Sealing effectGas treatmentDispersed particle filtrationMechanical engineeringVacuum cleaner

The disclosure provides a filter for mounting in a vacuum cleaner, such as a wet and dry vacuum cleaner, having a seal at generally each end, and a corresponding mounting structure that focuses compressive sealing forces on specific seal components rather than the filter body as a whole. The sealing is directed primarily to portions of the seals on the filter ends that are compressed or “pinched” between adjacent surfaces. The concentrated compressive stress provides a well-defined region to consistently provide a sealing engagement. The compressive force can thereby remain relatively constant through multiple uses of the filter.

Owner:EMERSON ELECTRIC CO

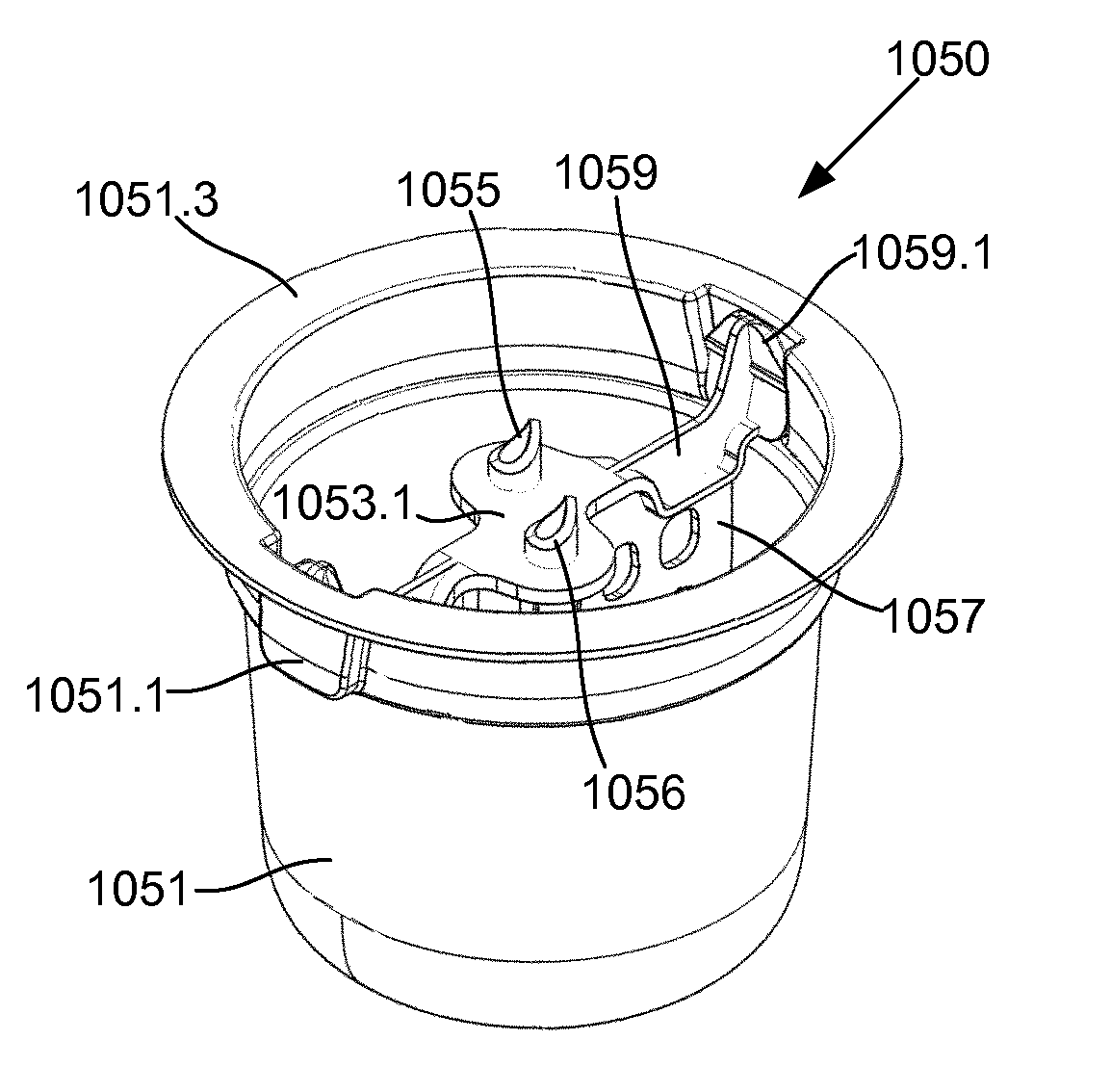

A capsule for beverage dispensing apparatus

InactiveUS20150368033A1Sealing effectGood removal effectReady-for-oven doughsBeverage vesselsBiomedical engineering

A capsule (550) for use in apparatus for dispensing liquid beverage, the capsule including at least one capsule side wall (551), a capsule base (552) and a capsule lid (553) defining a capsule cavity containing concentrated beverage and first (555) and second (556) capsule conduits wherein the first capsule conduit extends from proximate the lid and terminates remote from the capsule base allowing fluid to be supplied to the capsule away from the capsule base and the second capsule conduit extends substantially along a length of the capsule and terminates adjacent the capsule base allowing fluid to be dispensed from the capsule via the second capsule conduit.

Owner:NV NUTRICIA

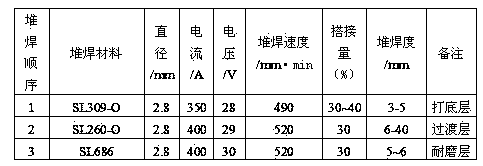

Novel full-automatic online cold welding repairing process for roll squeezers

ActiveCN103481010AReduce workloadSimplify your workflowArc welding apparatusWelding/cutting media/materialsPre treatmentEngineering

The invention discloses a novel full-automatic online cold welding repairing process for roll squeezers. The novel full-automatic online cold welding repairing process is characterized by comprising steps of (1), pre-treating roll surfaces of cement squeeze rolls to remove fatigue layers, welding check rings at two ends of each roll surface and enabling the corresponding check rings and each roll surface to be located on the same curved surface; (2), checking the roll surfaces to determine whether cracks are formed on the roll surfaces or not, grinding crack positions of the roll surfaces to remove the cracks, and performing repair welding on pits until the pits are filled; (3), performing buildup welding on the roll surfaces by means of automatic open arc welding; (4), removing the check rings and grinding and leveling the roll surfaces. The novel full-automatic online cold welding repairing process has the advantages that the buildup welding repairing quality can be guaranteed, the rolls of the roll squeezers do not need to be detached, stress relieving measures such as heating and heat insulation are omitted in buildup welding procedures, accordingly, working procedures can be greatly simplified, the construction cost can be greatly reduced, and energy can be saved.

Owner:柳州市三龙耐磨焊接科技有限公司

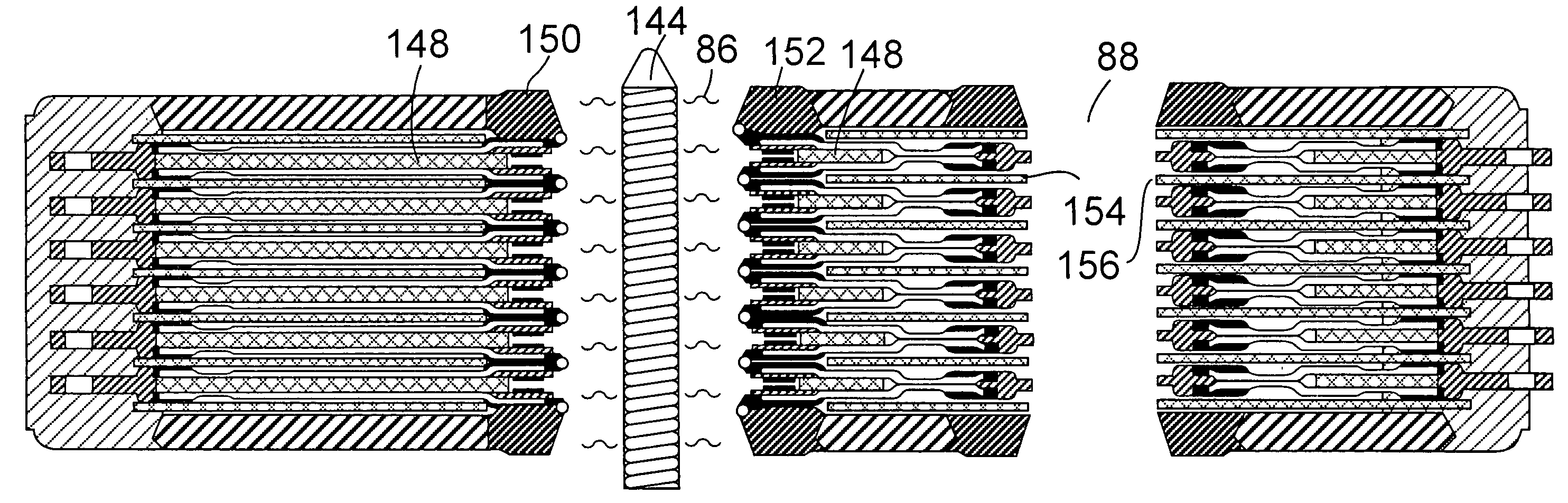

Process for making a fluid processing module

InactiveUS7097800B2Improve sealingAvoid degradation of mechanical propertiesSemi-permeable membranesOther chemical processesPorous layerFiltration

A process for making a fluid processing module is provided wherein a plurality of filtration elements is alternated with a fluid porous layer to form a stack. The filtration elements comprise a membrane sheet having a thermoplastic element bonded to a portion of an edge of the membrane. An opening is provided either through the membrane or through the thermoplastic element. A portion of the thermoplastic element extends into the opening and can be sealed to an adjacent positioned thermoplastic element to seal the porous sheet positioned between adjacently positioned membranes from fluid communication with the opening. Sealing can be effected by extending a heating element through the opening of the stack to effect simultaneous sealing of a plurality of thermoplastic elements.

Owner:MILLIPORE CORP

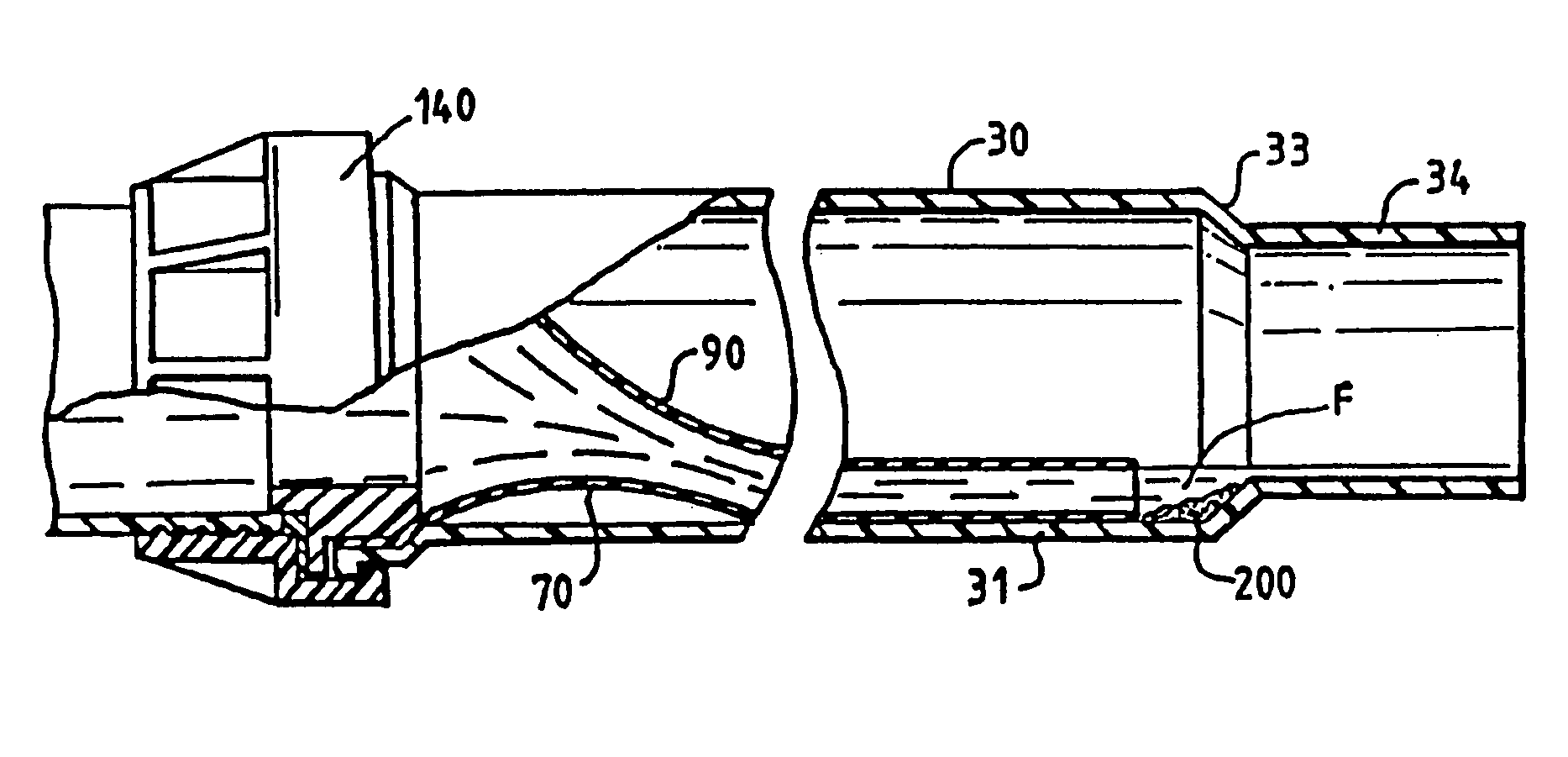

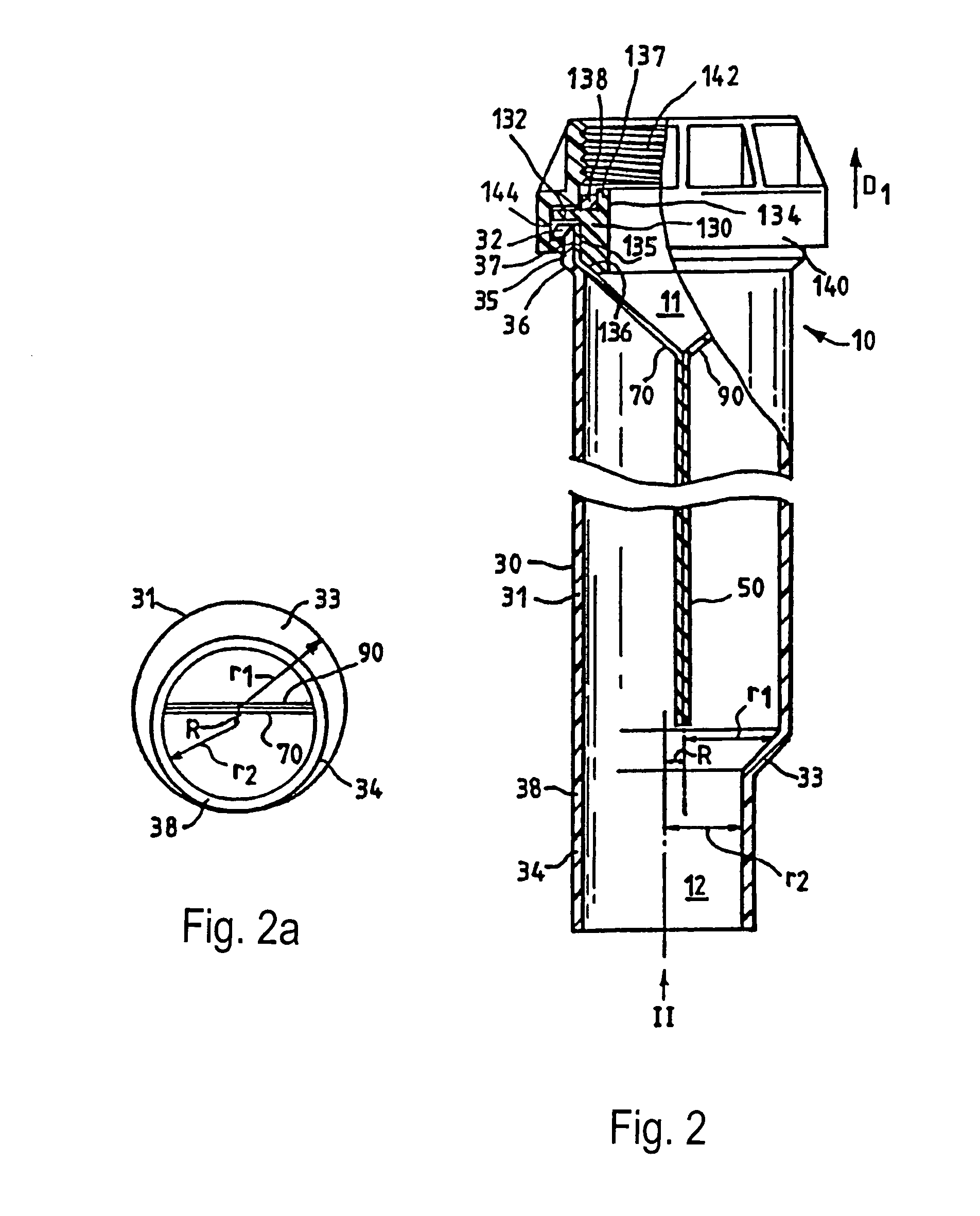

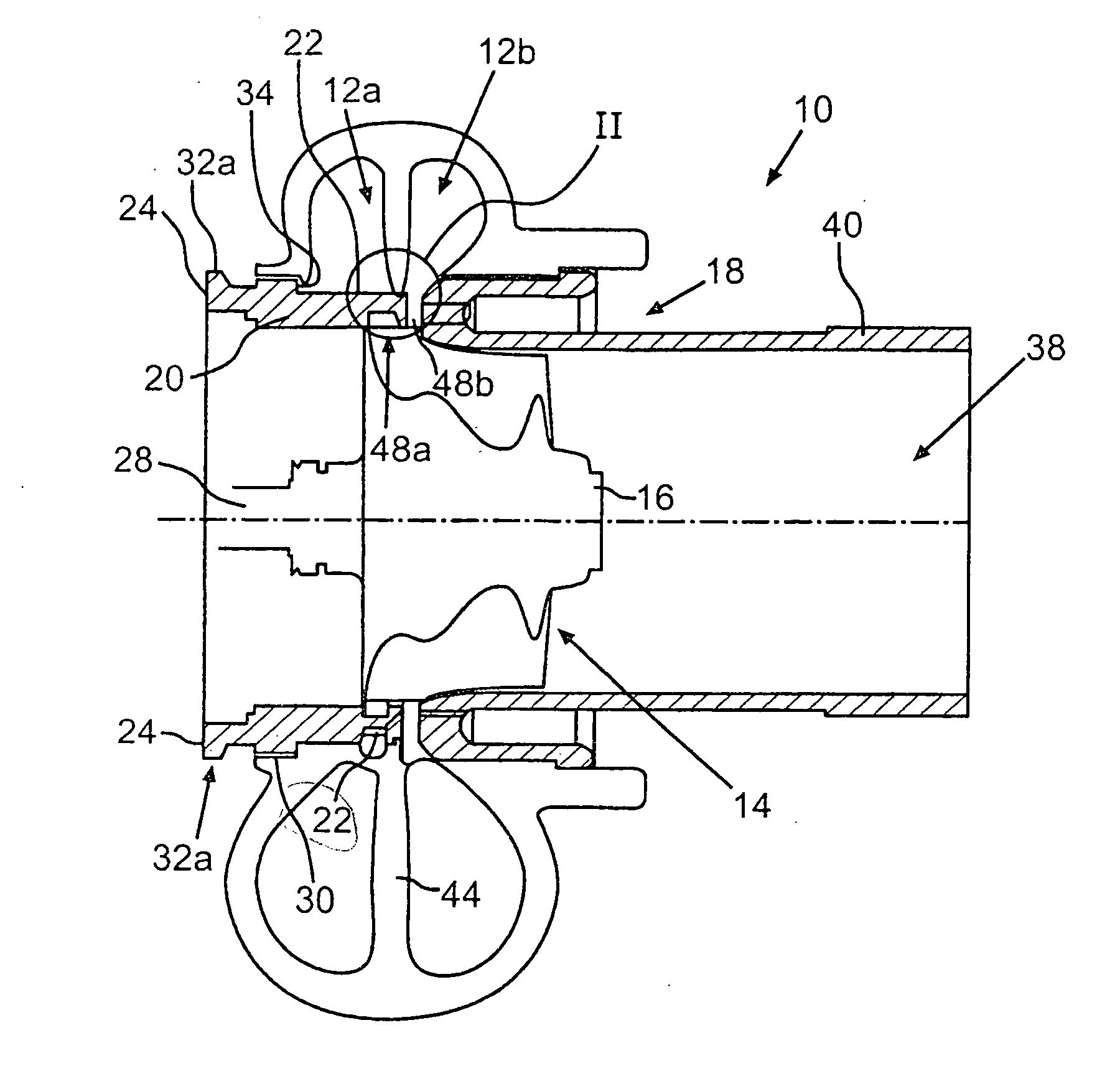

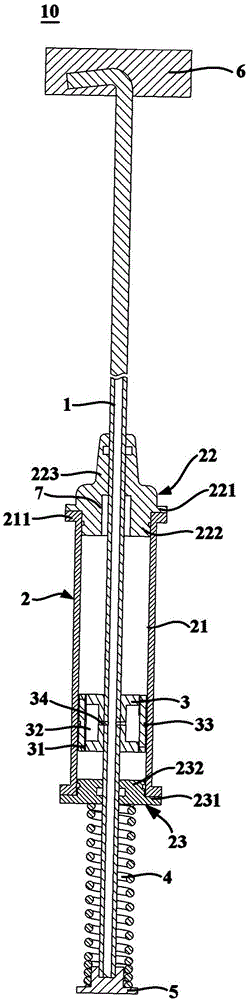

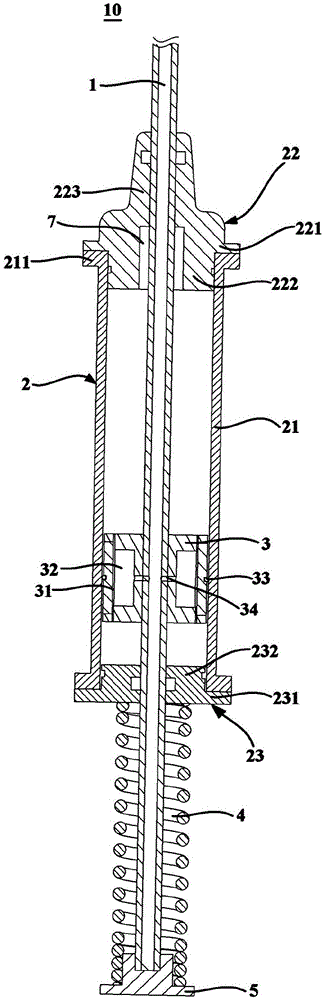

Non-return device

InactiveUS7509978B1Avoid collectingImprove flow characteristicsCheck valvesDomestic plumbingBiomedical engineeringSilicone rubber

A non-return device (10) comprises a flat silicone rubber tubing (50) defining a pair of walls (70, 90) which separate to admit fluid in a forward direction but remain together to block fluid flow in a reverse direction. A tubular body (30) surrounds the tubing (50) and comprises an off-set outlet (34) to provide an uninterrupted fluid flow surface for use in a non-vertical orientation. The tubing (50) is mounted on a cartridge (130) which moves axially within the tubular body and compresses the tubing against the tubular body to effect a seal when the device is mounted on an outlet. The tubing (50) provides good operational characteristics and sensitivity as a consequence of having a wall thickness which is 0.3% to 3% of its width.

Owner:HEPWORTH BUILDING PROD

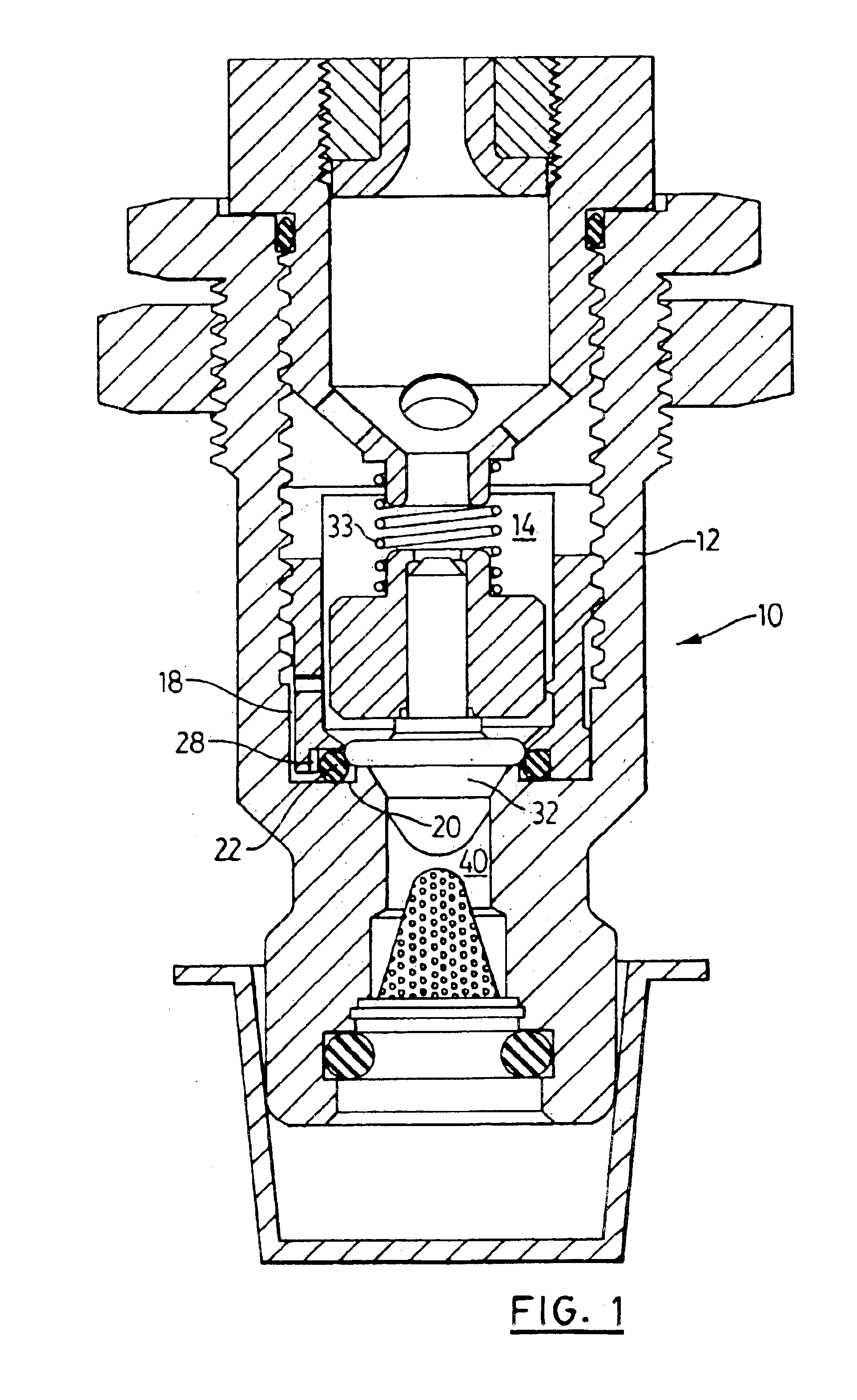

Pressurized valve seal

InactiveUS6845965B2Broaden applicationFluid pressure can be appliedEngine sealsLift valveSupport surfaceVALVE PORT

A valve for controlling flow of a fluid exerting a fluid pressure. The valve has a body including a fluid passage for the fluid, and a valve seat positioned adjacent to the fluid passage at an orifice coaxial with the fluid passage. The valve seat includes a sealing gland defining a cavity therein, and the sealing gland has a support surface adjacent to the cavity and a resilient valve seat member within the cavity. The valve seat member includes a first pressure responsive surface adjacent to the orifice and a second pressure responsive surface substantially opposed to the first pressure responsive surface. The support surface includes a notch for positioning a portion of the support surface a distance apart from the second pressure responsive surface.

Owner:WESTPORT FUEL SYST CANADA INC

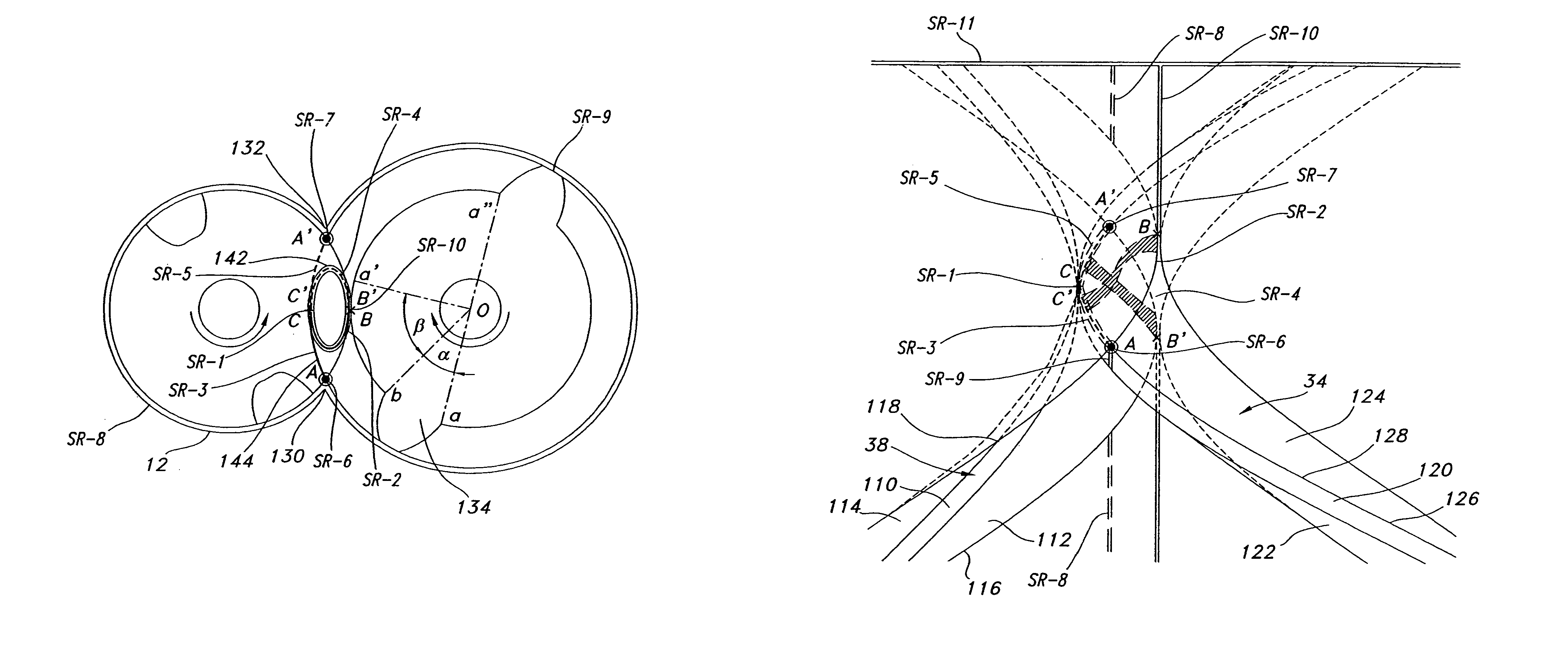

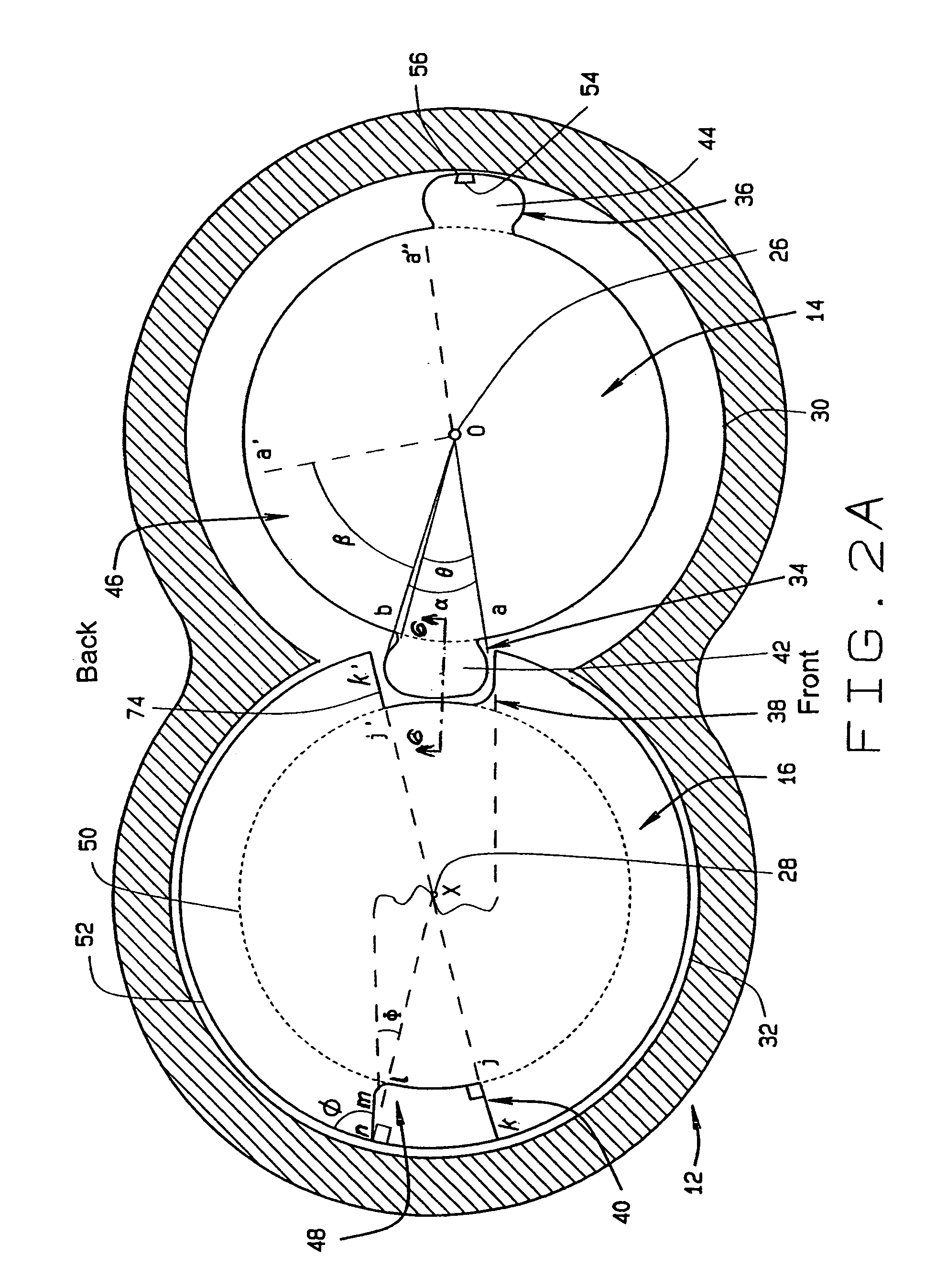

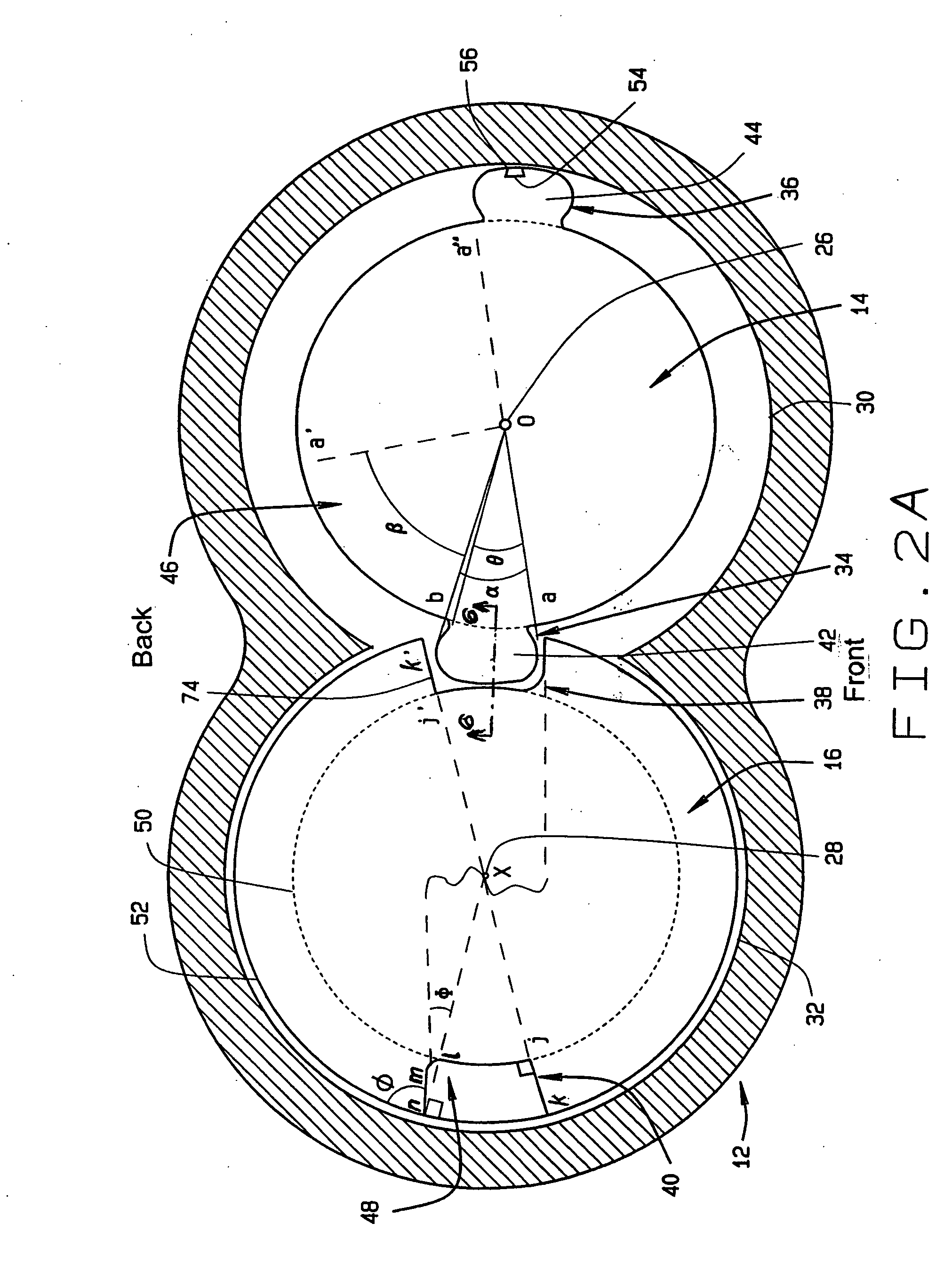

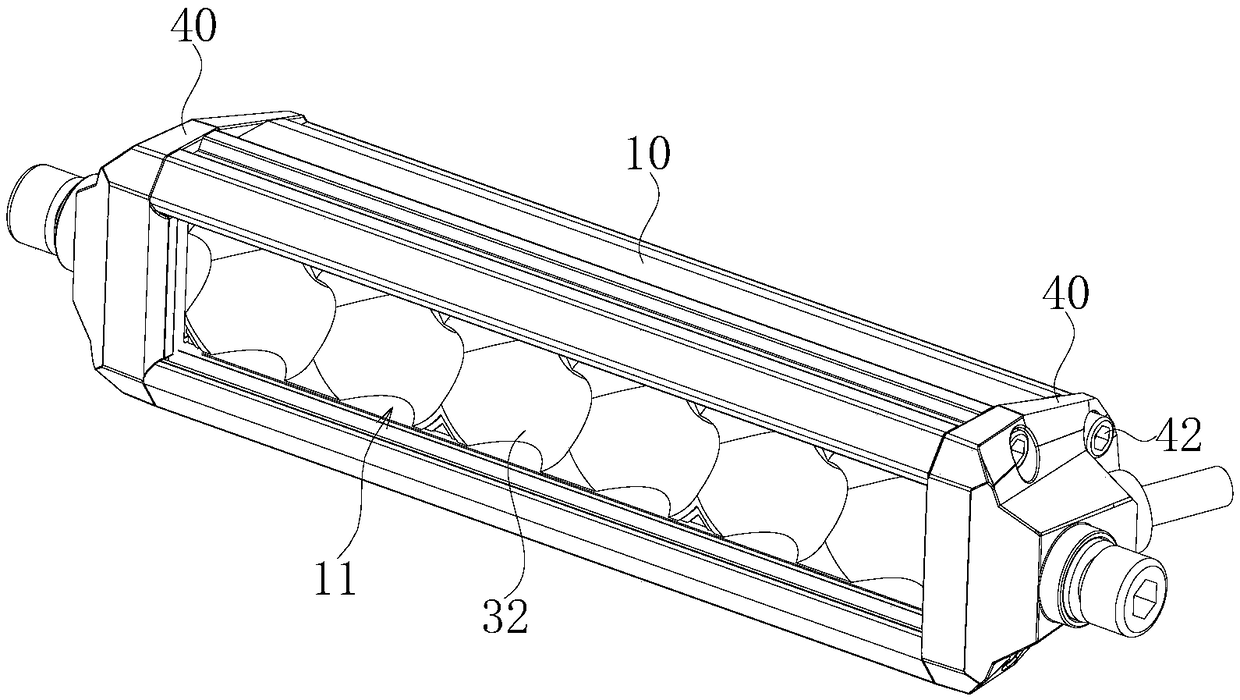

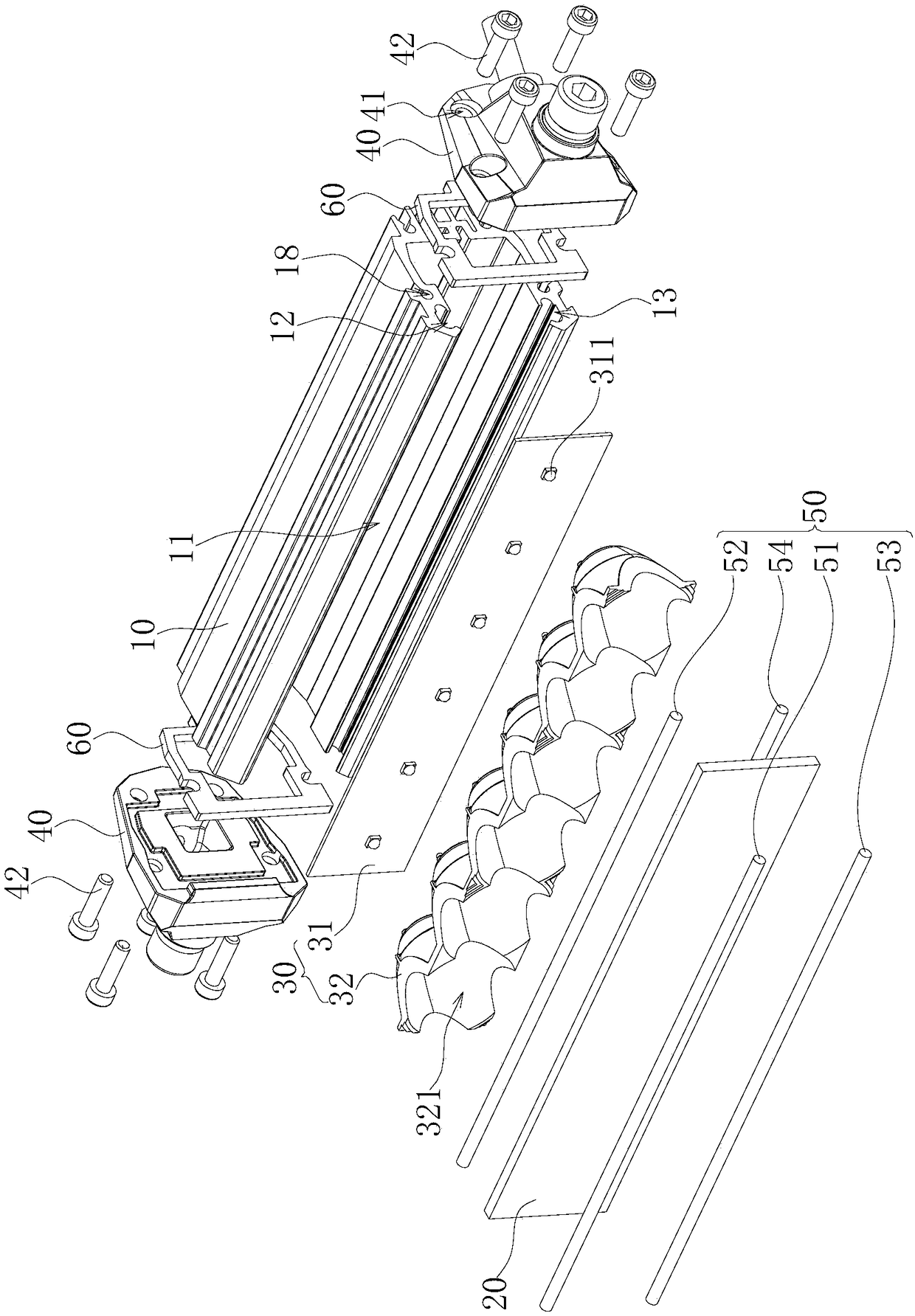

Gapless screw rotor device

InactiveUS7008201B2Maximize thermodynamic efficiency and volumetric efficiencyReduce manufacturing costOscillating piston enginesSealing arrangement for pumpsScrew threadHelix

A screw rotor device has a housing with an inlet port and an outlet port, a male rotor with helical threads, and a female rotor with helical grooves. The helical threads and helical grooves are designed to eliminate the blow hole leak pathway for multiple-pitch screw rotor devices as well as single-pitch screw rotor devices. The male rotor has a pair of helical threads with a phase-offset aspect, and the female rotor has a corresponding pair of helical grooves. The female rotor counter-rotates with respect to the male rotor and each of the helical grooves respectively intermeshes in phase with each of the helical threads. The phase-offset aspect of the helical threads is formed by a pair of teeth bounding a toothless sector.

Owner:IMPERIAL RES

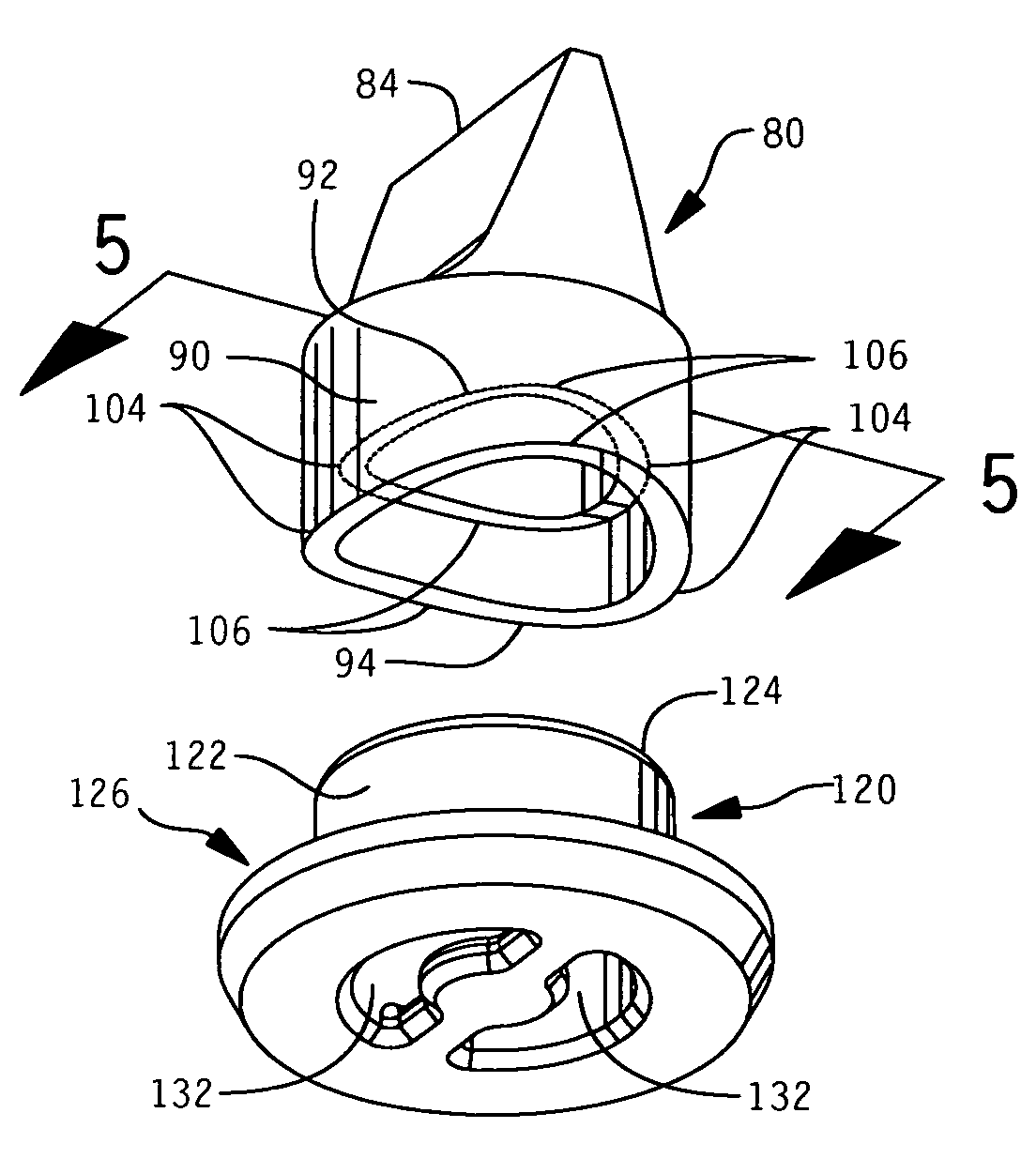

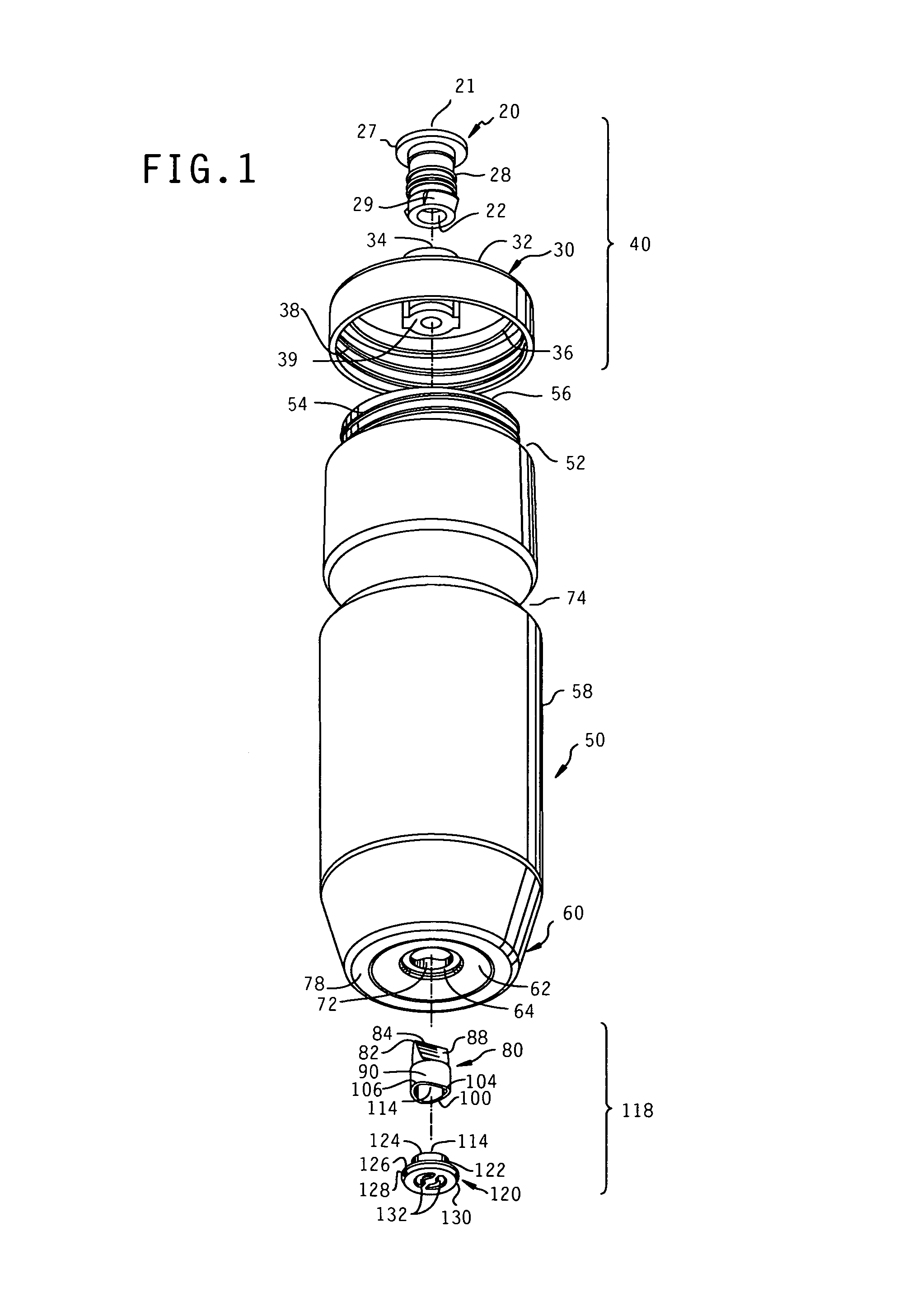

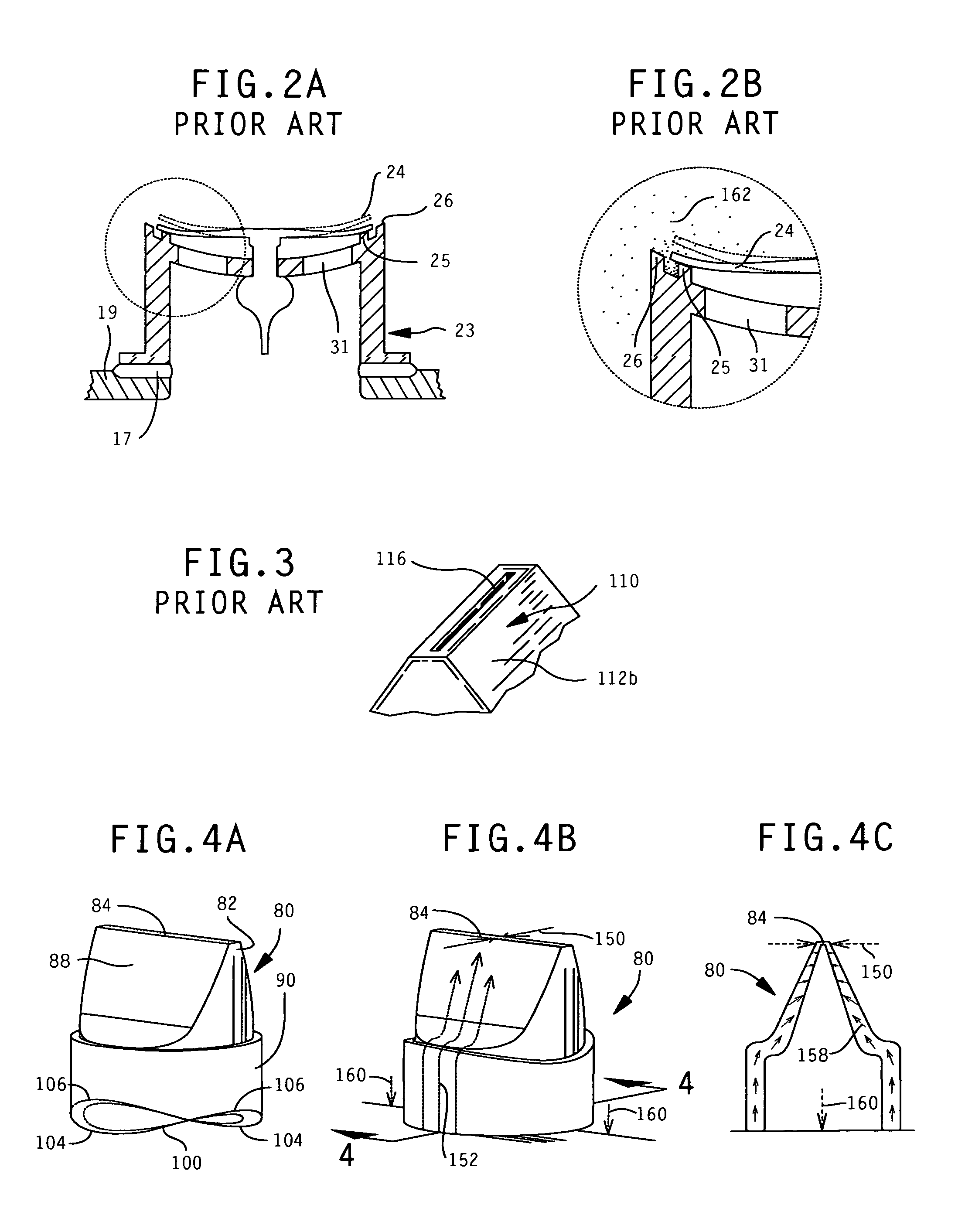

Sports bottle with preloaded valve and methods

InactiveUS8561851B1Particular resistanceResistant to leakageCheck valvesEqualizing valvesEngineeringWater bottle

A beverage bottle for storing and dispensing water and impure sports beverages having a container and a dispensing opening on a top wall movable between an open position and a closed position and a unitary valve disposed within the container bottom wall having a vertically sinuous contour, and laterally opposed, laterally actuating, compliant slit faces and a substantially rigid annular flat surface. As the vertically sinuous contour is flattened upon the annular flat surface, the slit faces are laterally urged together establishing a preloaded seal, for leak resistant valve operation, and reduced restriction dispensing of water and impure sports beverages.

Owner:LEONOFF CHRISTOPHER A

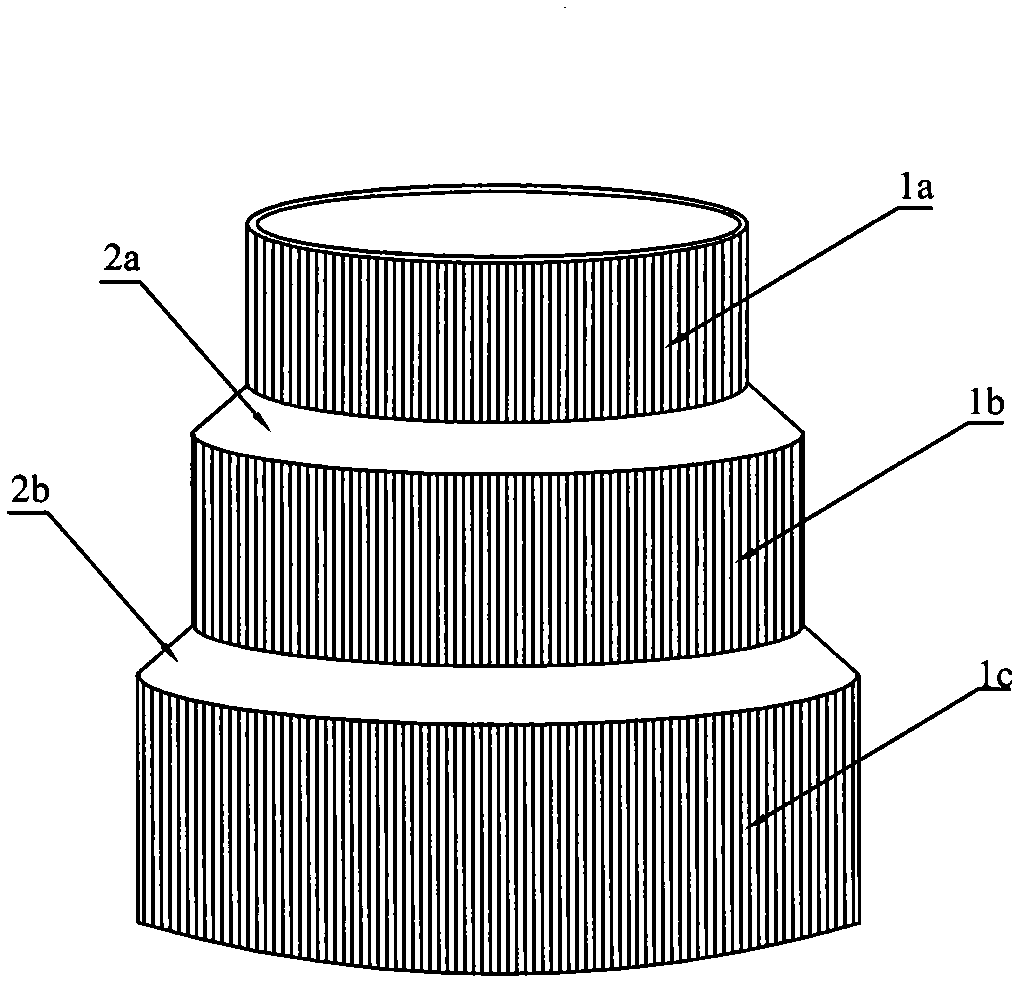

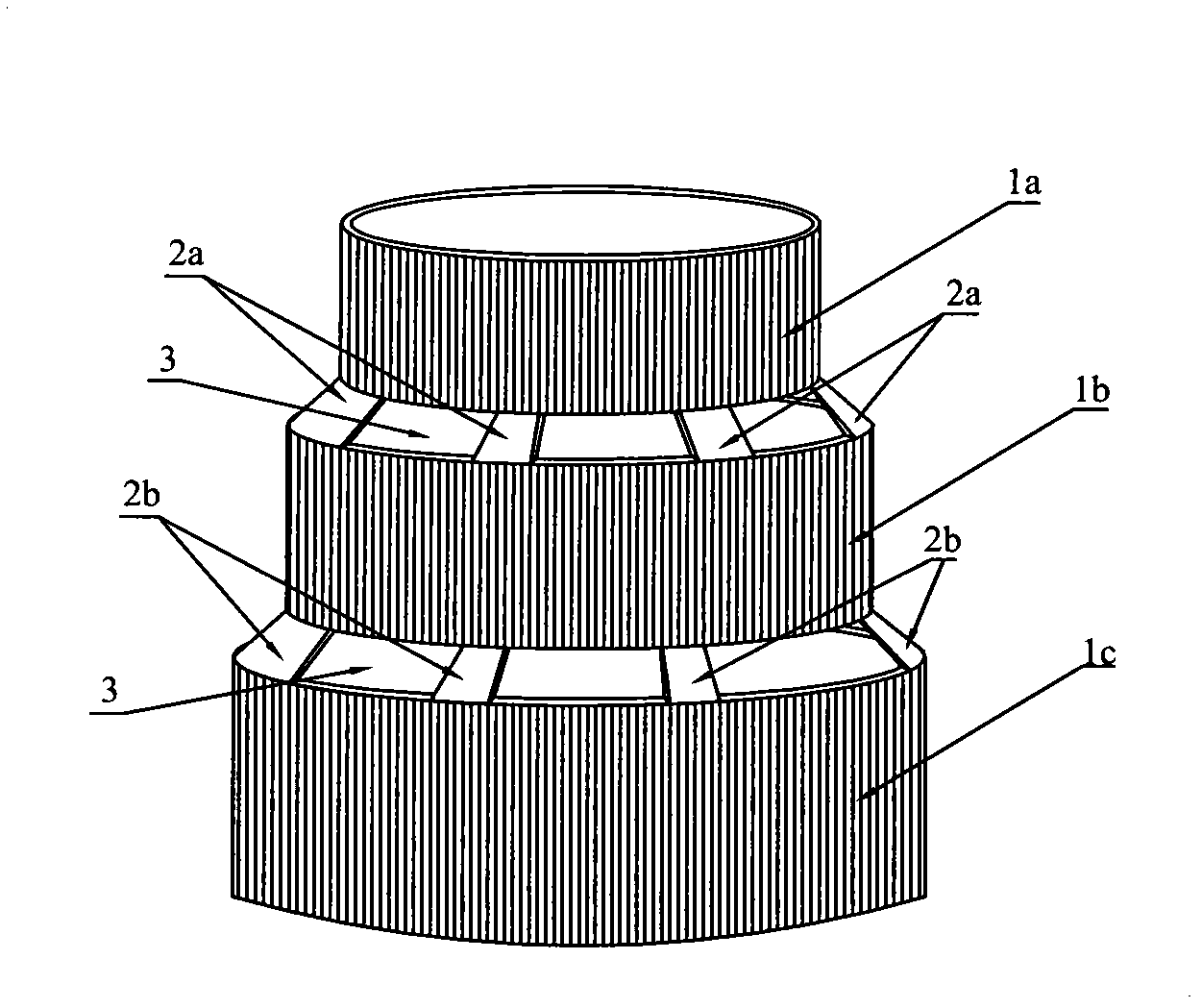

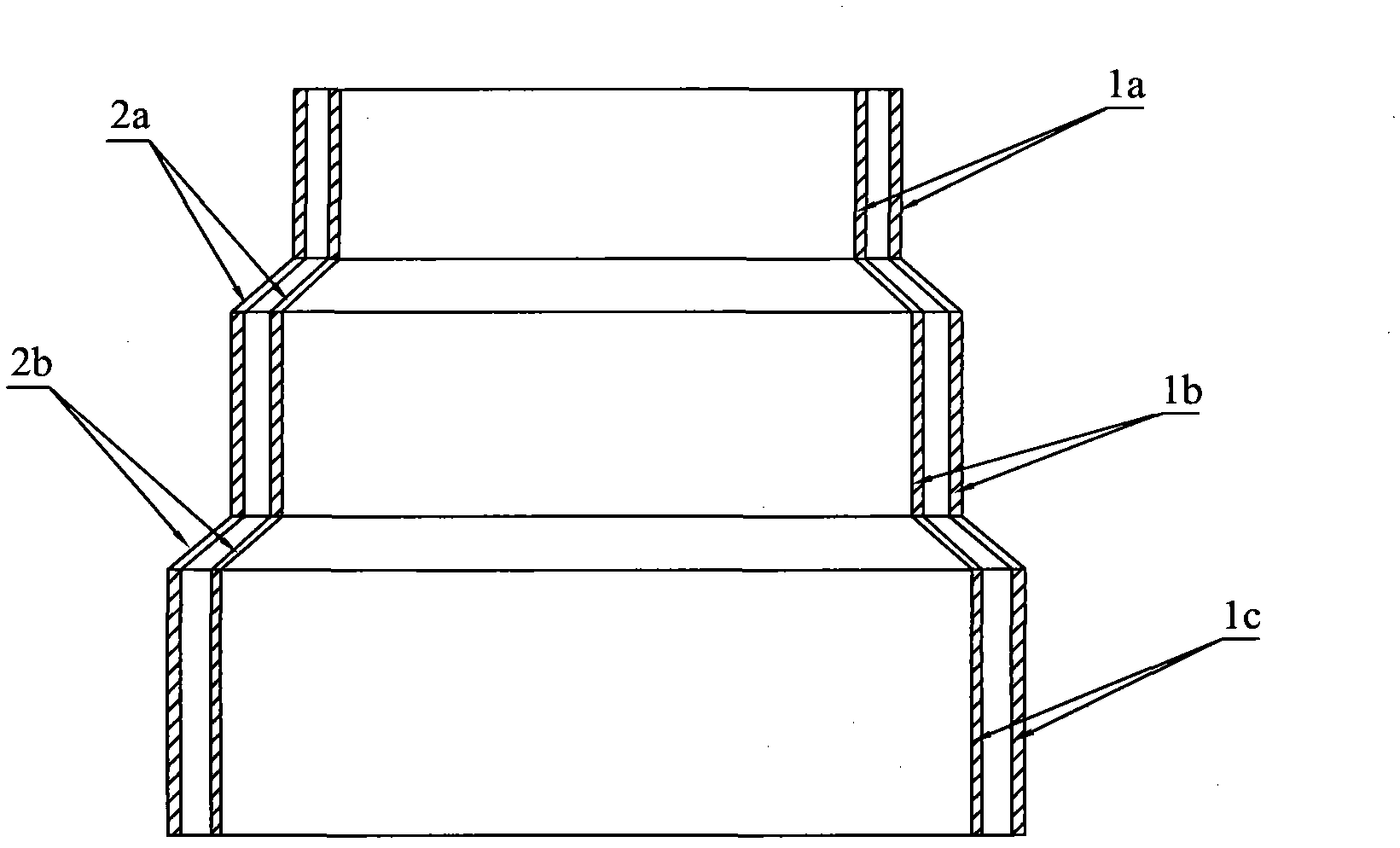

Screen cylinder and multistage pulp pressure screen with same

ActiveCN102051837AEasy to disassemble and washEasy maintenancePaper material treatmentPulp and paper industryComplex problems

The invention provides a composite type screen cylinder and a multistage pressure screen with the same. The screen cylinder comprises at least two screen cylinder units which are sequentially arranged along the axial direction, wherein axial center lines of various screen cylinder units are coincident with each other; the inside diameters of the screen cylinder units are progressively increased along the axial direction; bottom ends of the previous stage of screen cylinder units are connected with top ends of the next stage of screen cylinder units through connectors; various screen cylinders connected with the connectors can realize the overall movement relative to a pressure screen shell; and liquid flow channels are arranged between two stages of screen cylinders. The screen cylinder has the advantages of simple structure and convenience in disassembly, washing and maintenance when applied to the multistage screen. Moreover, the composite type screen cylinder can be assembled and disassembled as a whole, so that the problem of complex operation of assembly and disassembly in the prior art when the screen cylinders on the lower layer are washed or maintained is solved.

Owner:山东惠祥专利造纸机械有限公司

Gapless screw rotor device

InactiveUS20050129561A1Reduce manufacturing costReduce gapOscillating piston enginesSealing arrangement for pumpsEngineeringScrew thread

A screw rotor device has a housing with an inlet port and an outlet port, a male rotor with helical threads, and a female rotor with helical grooves. The helical threads and helical grooves are designed to eliminate the blow hole leak pathway for multiple-pitch screw rotor devices as well as single-pitch screw rotor devices. The male rotor has a pair of helical threads with a phase-offset aspect, and the female rotor has a corresponding pair of helical grooves. The female rotor counter-rotates with respect to the male rotor and each of the helical grooves respectively intermeshes in phase with each of the helical threads. The phase-offset aspect of the helical threads is formed by a pair of teeth bounding a toothless sector.

Owner:IMPERIAL RES

Diaphragm valve with pivoting closure member

ActiveUS20050155777A1Reduce total pressure lossEnhanced closing forceOperating means/releasing devices for valvesCheck valvesDiaphragm valveVALVE PORT

A valve is disclosed having an inlet duct aligned with an outlet duct and an angularly oriented elliptical seat positioned between them. A pressure chamber faces the seat. A pivoting valve closure member is positioned between the pressure chamber and the seat. An asymmetrical rolling diaphragm is attached to the closure member and defines part of the pressure chamber. A seat engaging surface on the side of the closure member opposite the pressure chamber is sealingly engageable with the seat to close the valve. The valve closure member is pivoted into the closed positioned by pressurizing the pressure chamber. The valve remains closed against hydraulic pressure in the inlet duct. The valve is permitted to open by de-pressurizing the pressure chamber, allowing the closure member to pivot out of engagement with the seat. Fluid may then flow from the inlet duct to the outlet duct.

Owner:VICTAULIC

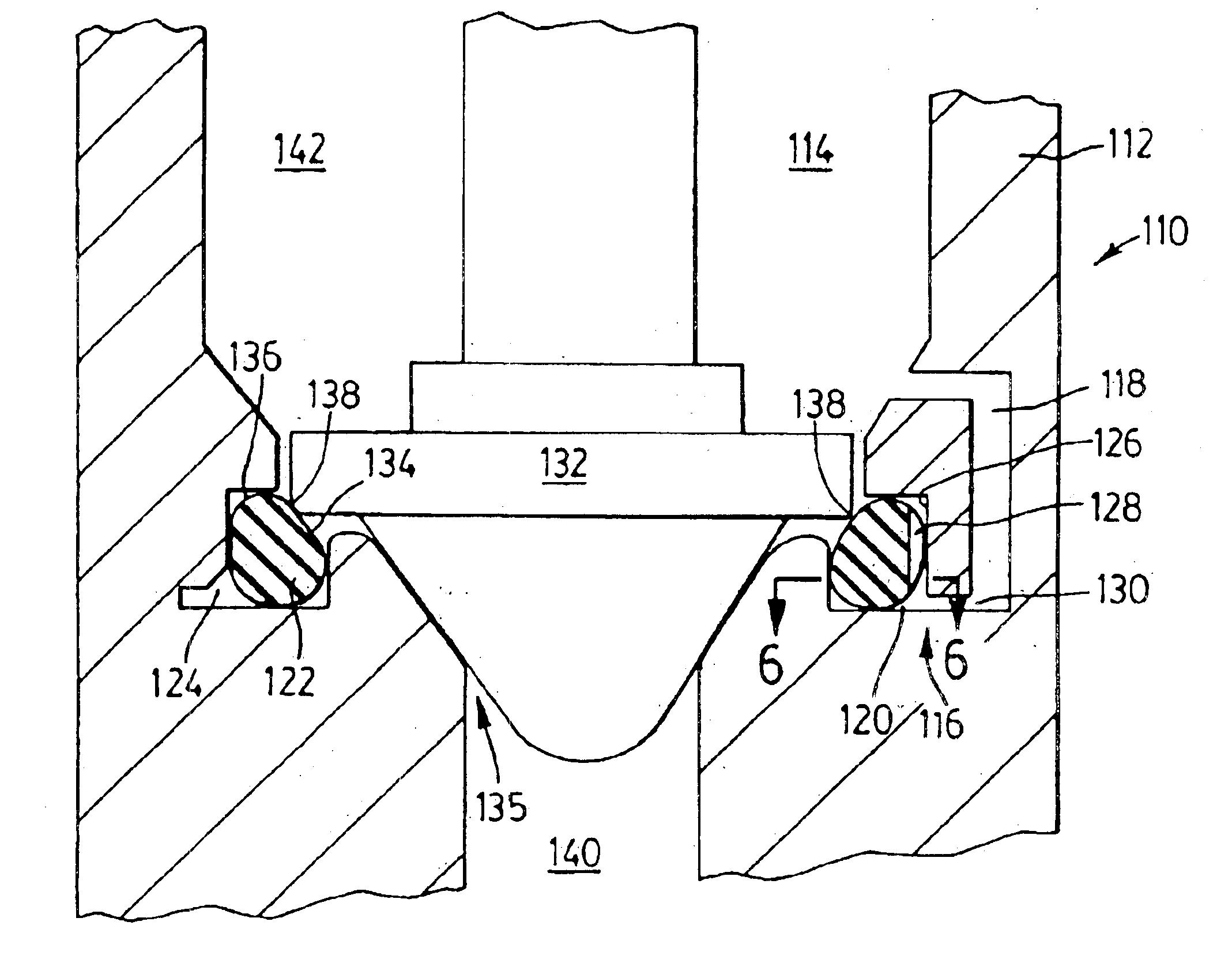

Turbine housing for an exhaust gas turbocharger of an internal combustion engine

InactiveUS20110091318A1Optimal flow influencingImprove air tightnessPump componentsGas turbine plantsImpellerTurbine wheel

In a turbine housing for an exhaust gas turbocharger of an internal combustion engine with at least one spiral channel, which can be coupled into an exhaust gas flow of an exhaust tract of the internal combustion engine, and a receiving space for a turbine wheel which is disposed downstream of the at least one spiral channel and can be acted upon by the exhaust gas of the internal combustion engine passing through the at least one spiral channel of the turbine housing, there is at least one partial housing including the at least one spiral channel, and a housing module which is fastened to the partial housing and has a vane structure disposed upstream of the receiving space which also includes an attachment surface for a bearing section of the exhaust gas turbocharger. The invention also resides in an exhaust gas turbocharger with such a turbine housing as well as to a method for producing such a turbine housing.

Owner:DAIMLER AG

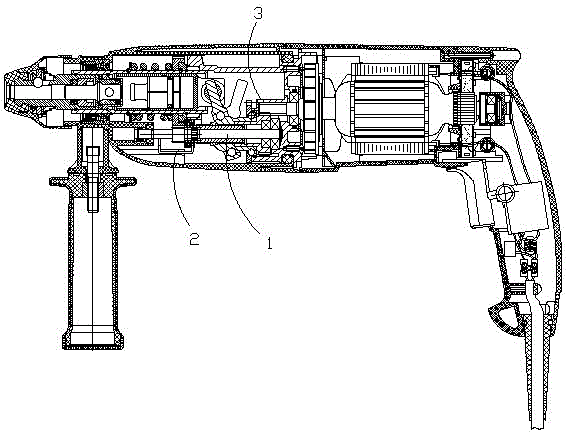

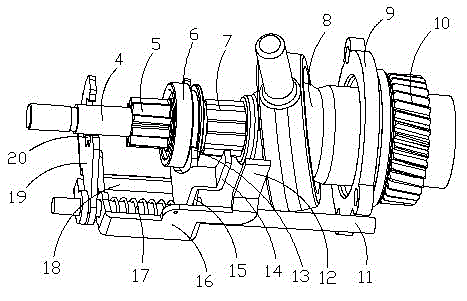

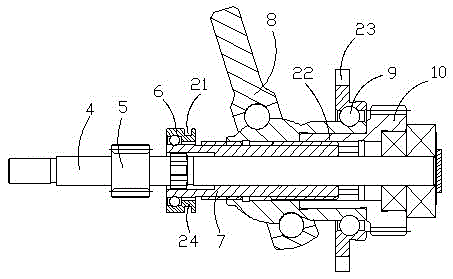

Transmission switching device of electric hammer

ActiveCN102975174AReduce frictional heatNot easy to get hotGearing controlPortable percussive toolsEngineeringElectrical and Electronics engineering

The invention discloses a transmission switching device of an electric hammer, and the device comprises an intermediate shaft; an intermediate shaft gear, a transmission gear, swing rod bearings and an intermediate shaft sleeve are arranged on the intermediate shaft; a connecting part extends outwards from the transmission gear; the connecting part is sleeved on one end of the intermediate shaft sleeve; the swing rod bearings are respectively sleeved on the connecting part and the intermediate shaft sleeve; keyway matching structures are arranged between the other end of the intermediate shaft sleeve and the intermediate shaft, the connecting part and the swing rod bearings; a shift bearing is arranged on the peripheral side of the intermediate shaft sleeve; the inner ring of the shift bearing is the intermediate shaft sleeve, and a groove is arranged on the outer ring of the shift bearing; and a shifting mechanism is connected into the groove. The transmission switching device of the electric hammer has the beneficial effects that a transmission mechanism and the shifting mechanism stay still relatively, no friction, wear, heating or oil leakage occurs, the service life is long, the maintenance amount is small, the gear friction phenomenon is overcome, and the working efficiency is high.

Owner:ZHEJIANG BENYU TOOLS

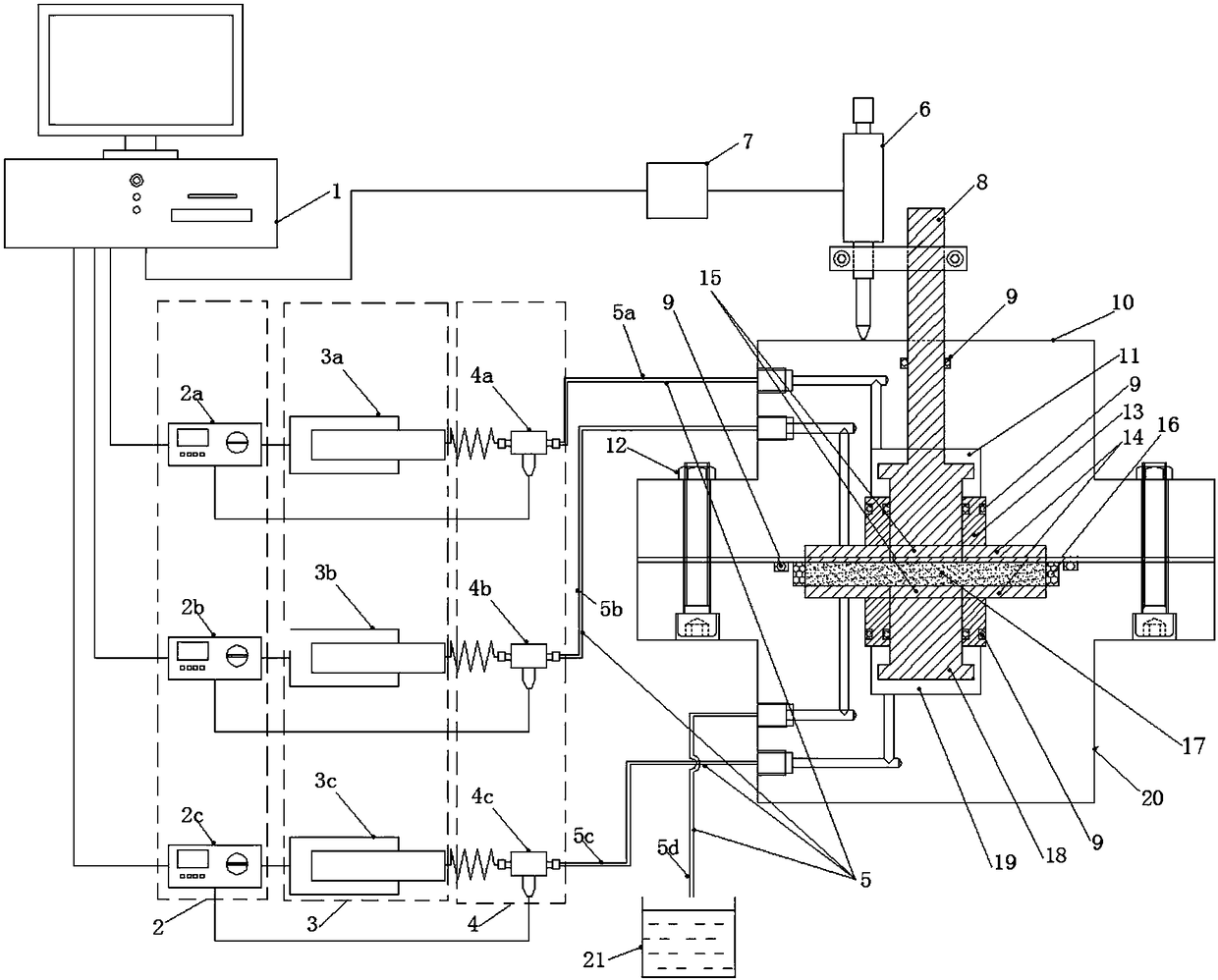

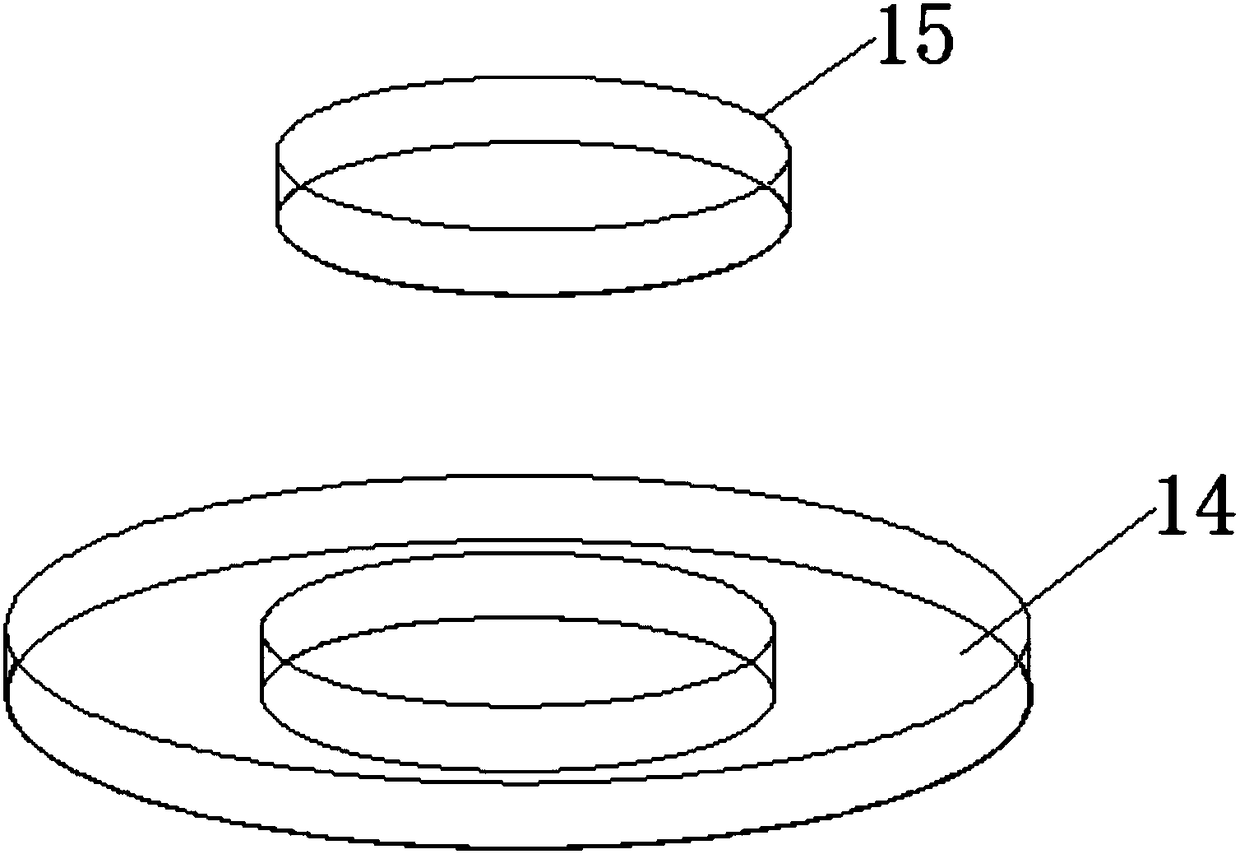

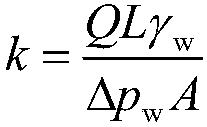

Tester for measuring evolution of clay rock shear crack permeability coefficients according to steady-state method

PendingCN108333060AShear displacement controllableEasy to testMaterial strength using steady shearing forcesPermeability/surface area analysisLinear variable differential transformerStructure of the Earth

The invention relates to a tester for measuring evolution of clay rock shear crack permeability coefficients according to a steady-state method. The tester comprises a shearing box, a water pressure servo loader, a water pressure sensor and an LVDT (linear variable differential transformer) displacement sensor. A clay rock sample is of a flat cylindrical structure with the thickness of 1-2cm. Thewater pressure servo loader is communicated to the upper side of the clay rock sample through a pipeline, provides pore water to the clay rock sample and applies pore water pressure to the clay rock sample. The lower side of the clay rock sample is communicated to the air through a pipeline. The shearing direction of the clay rock sample is parallel to the permeation path of the pore water in theclay rock sample. During shear displacement, the pore water pressure is applied to the upper side of the clay rock sample of the flat cylindrical structure with the thickness of 1-2cm, the lower sideof the clay rock sample is communicated to the air through the pipeline, and a constant water head difference between the upper side and the lower side of the sheared clay rock sample can be formed, so that steady-state seepage is generated, and the permeability coefficients of low-permeability clay rock can be measured accurately according to the steady-state method.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

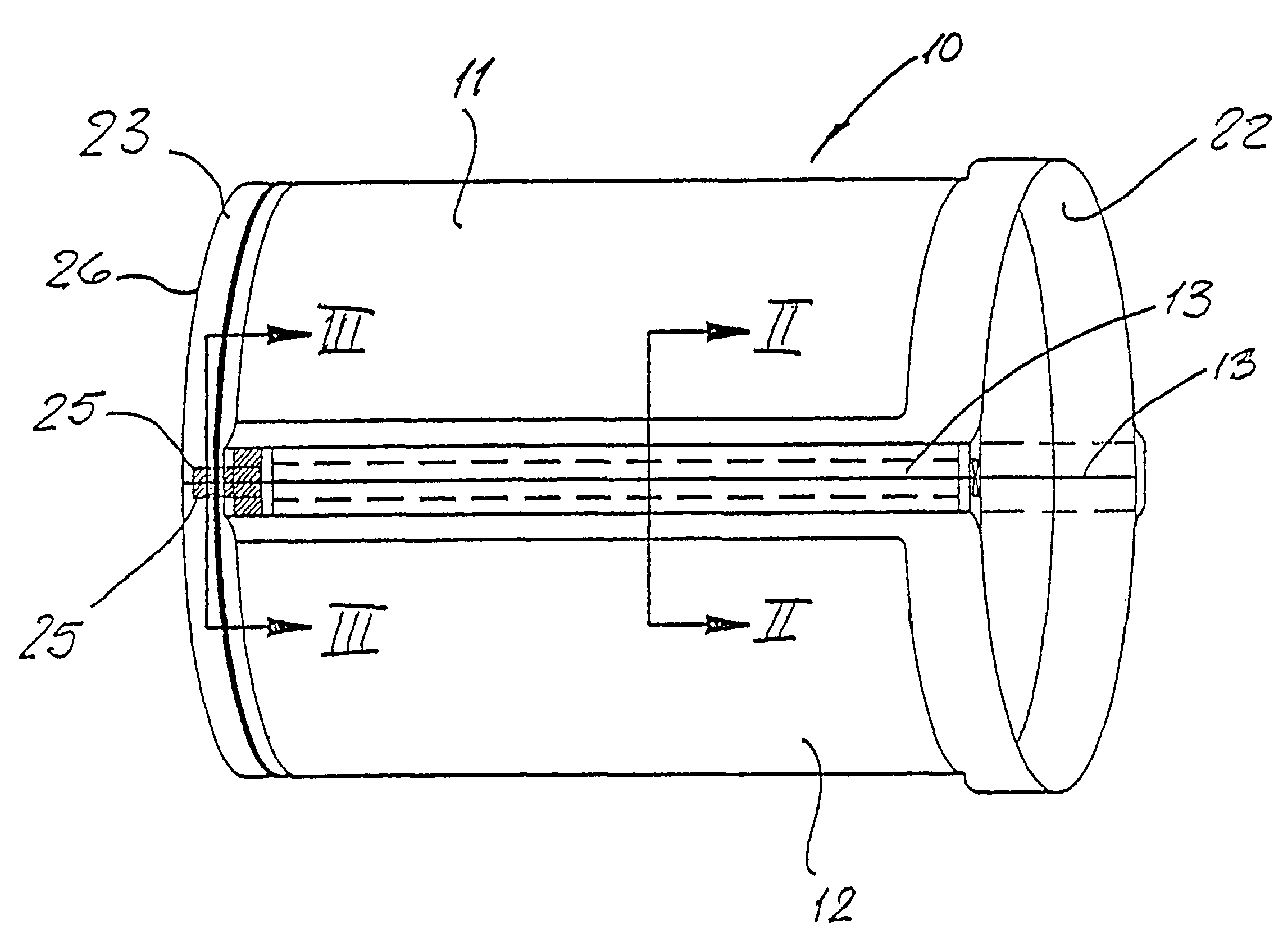

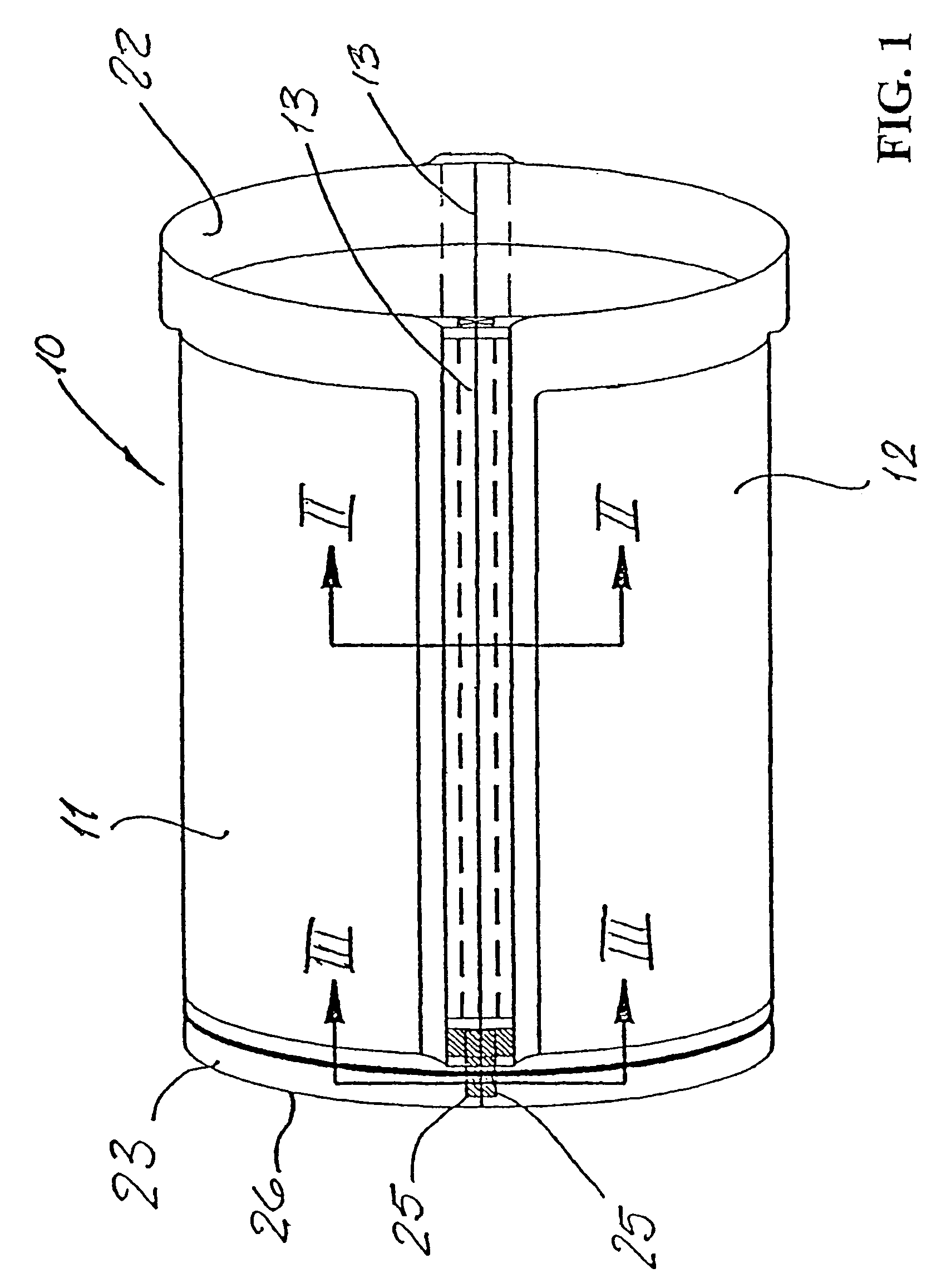

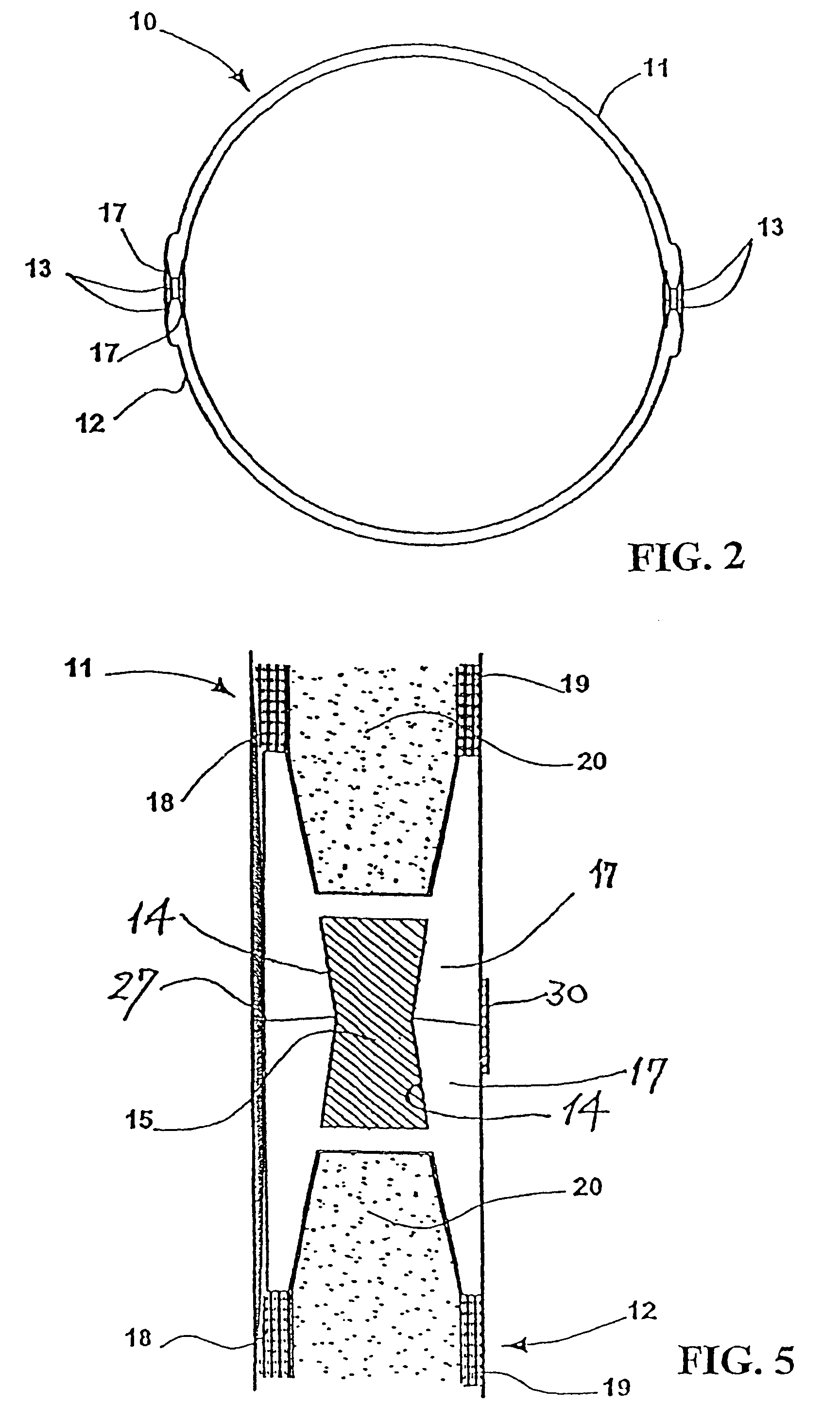

Pipe construction system

InactiveUS7238256B2Mitigate disadvantageIncrease radial thicknessLaminationLamination apparatusEngineeringSealant

A pipe construction system which utilizes a multiplicity of arcuate pipe segments 11, 12 to form a pipe section 10 and which sections are assembled together to form a length of pipe. Each segment 11, 12 has two longitudinal edges 13 of increased radial thickness and having a groove 14 formed in the circumferential direction whereby an interlocking and sealing member 15 may be located in the aligned grooves 14 of two adjacent segments 11, 12. One end of a pipe section 10 assembled from the segments defines a socket 22 for receiving a spigot 23 defined at the other end of a like section. The spigot end of each segment has a pocket 25 formed along said edge 13 but within the thickness of the major area of the segment, which pocket 25 mates with a corresponding pocket 25 of an adjacent segment whereby sealant may be disposed in the mating pockets.

Owner:SABAS LIMITED

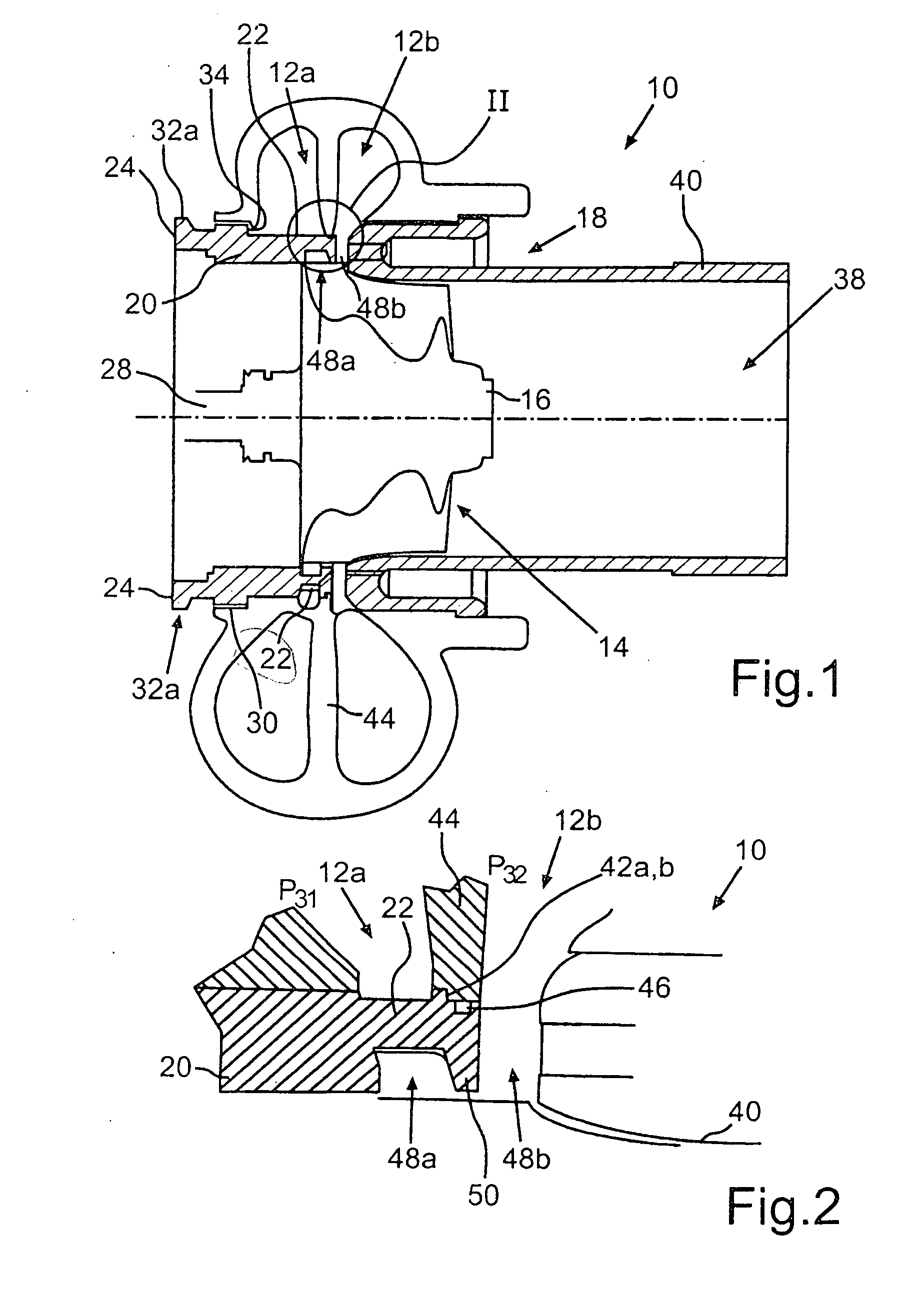

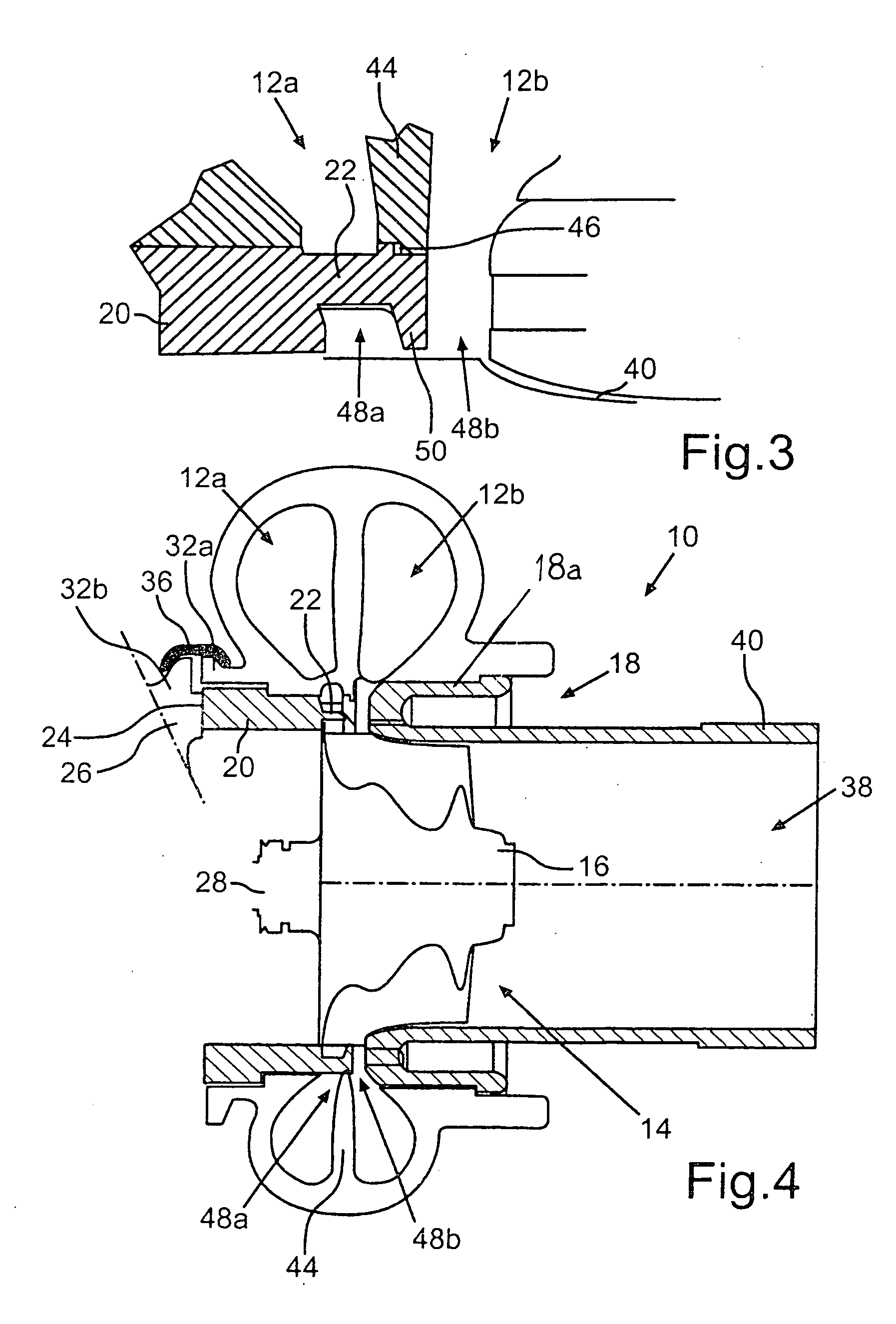

Membrane valve

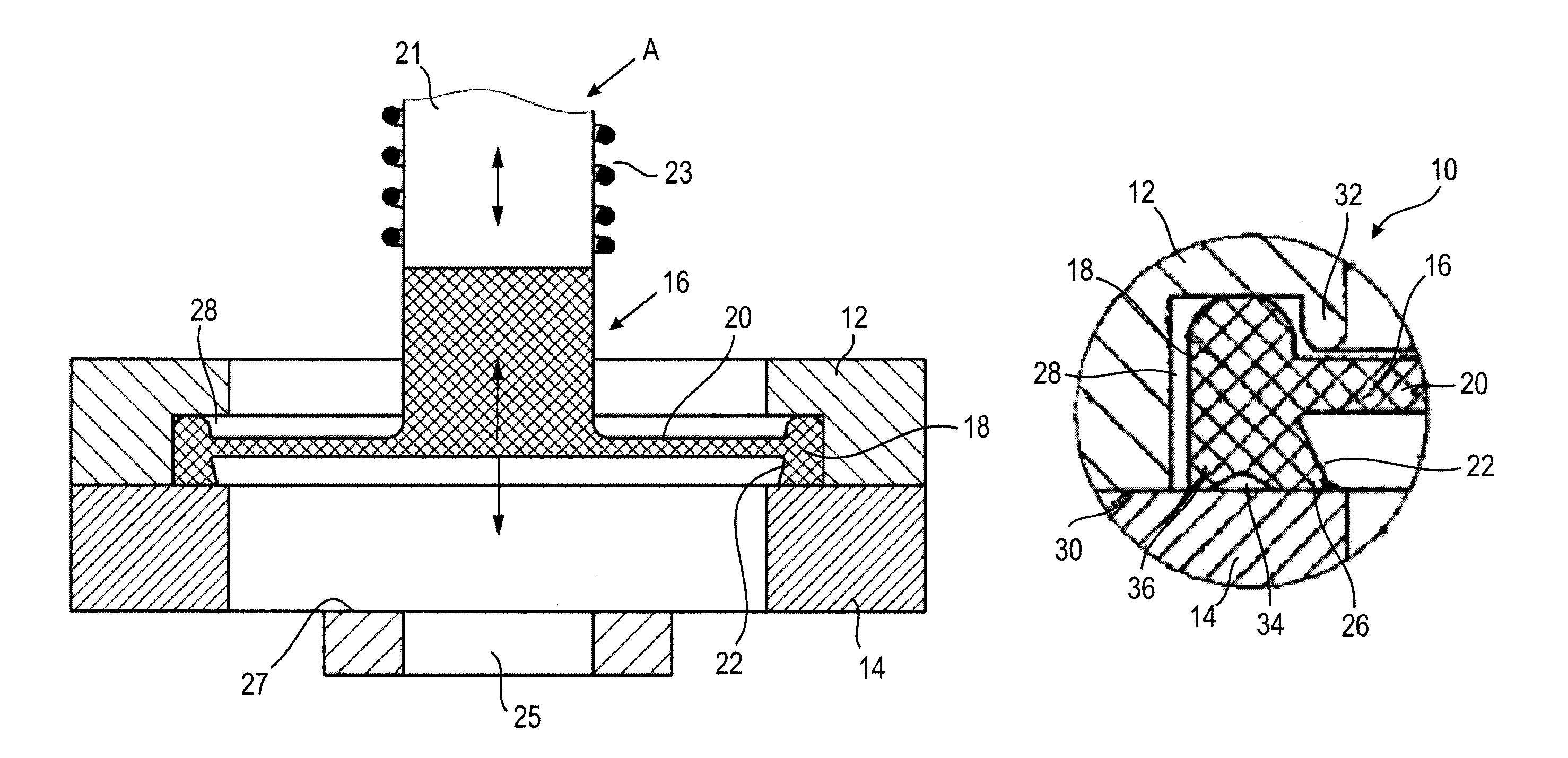

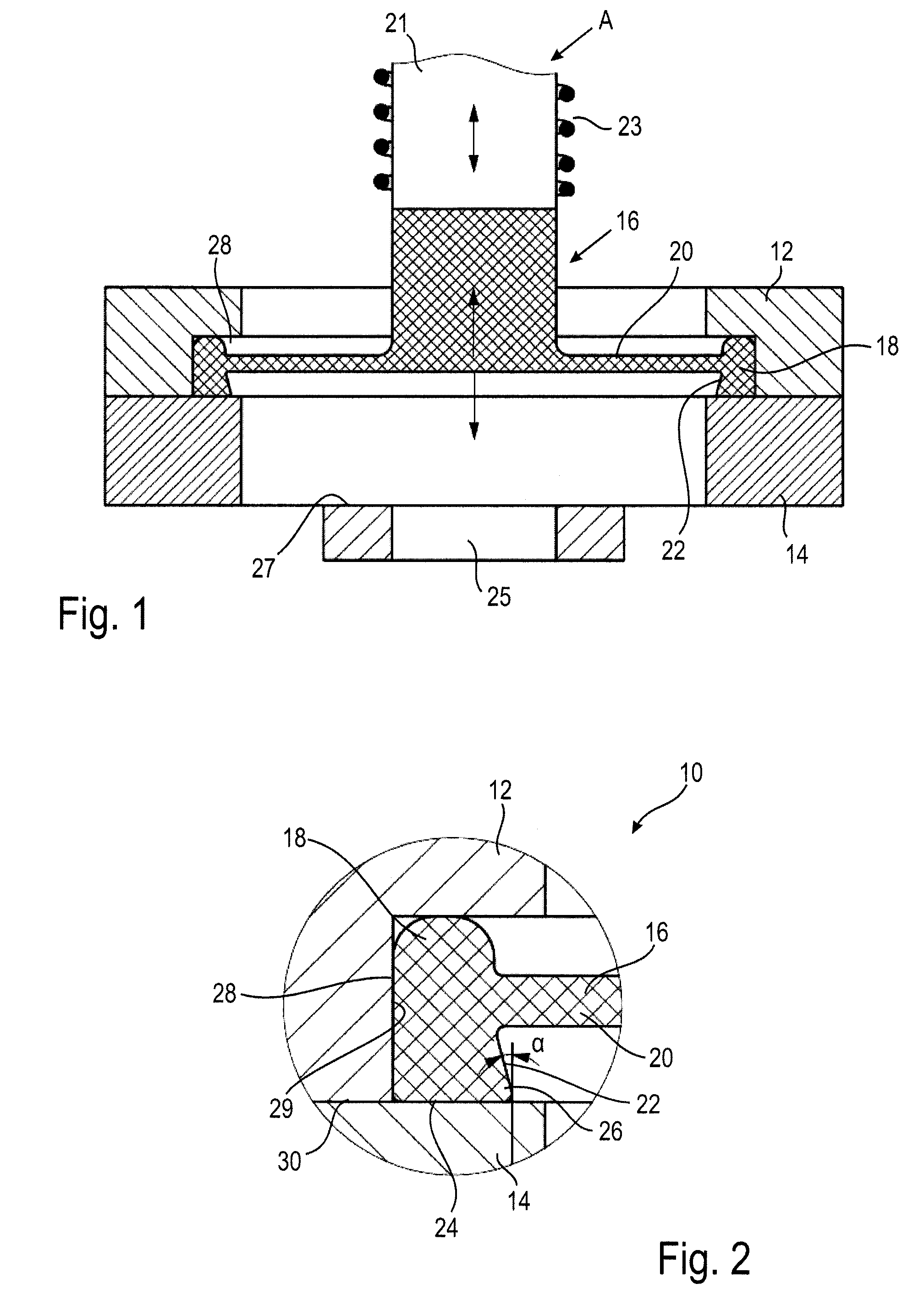

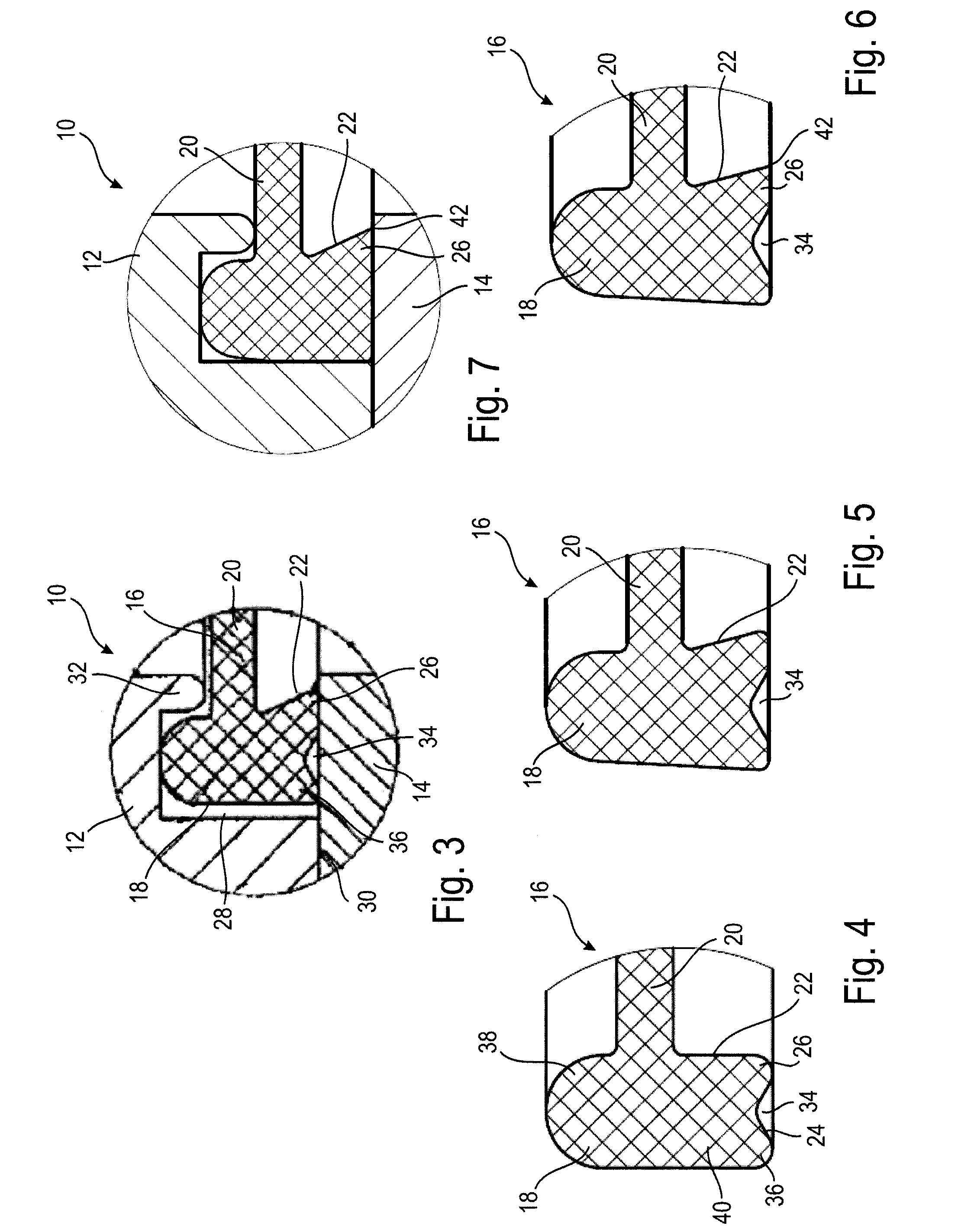

ActiveUS20120248364A1Improve sealingSelf-enhancement of sealing effectSpindle sealingsDiaphragm valvesBiomedical engineeringMembrane configuration

A membrane valve comprising a first and a second valve housing part and a membrane clamped between the valve housing parts comprises a peripherally surrounding bead on the membrane and a thin, axially movable membrane portion adjacent thereto. The bead is supported by the two valve housing parts and is provided with an undercut at a radial inner side. Further, a membrane for installation in a membrane valve is provided.

Owner:BURKERT WERKE

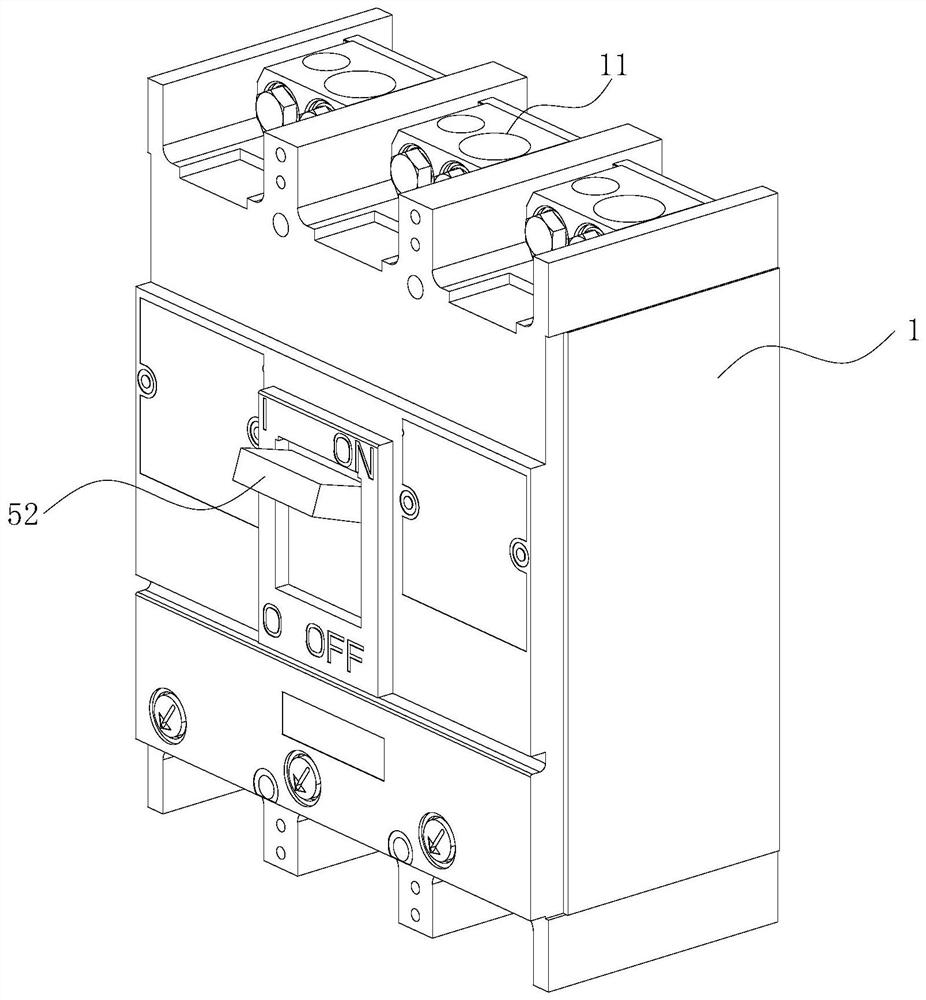

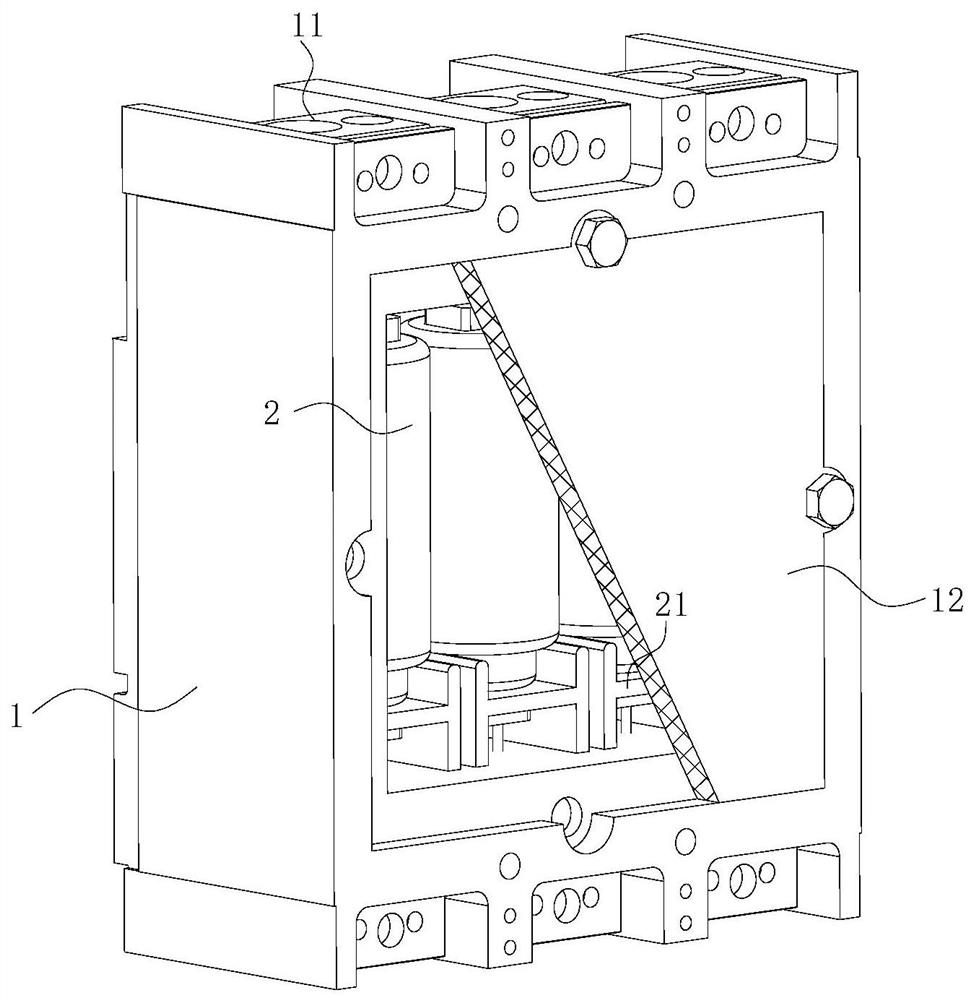

Low-voltage vacuum circuit breaker based on Internet of Things

InactiveCN111952107AExtended service lifeImprove insulation performanceHigh-tension/heavy-dress switchesAir-break switchesPlastic materialsElectric power equipment

The invention belongs to the technical field of power equipment, and particularly relates to a low-voltage vacuum circuit breaker based on the Internet of Things, which comprises a flat cable shell, awiring terminal and a vacuum valve, the flat cable shell is made of an insulating plastic material; the wiring terminals are fixedly connected to the upper end and the lower end of the flat cable shell and used for being communicated with wires in a circuit. A first groove is formed in the flat cable shell; the first groove is formed in an opening in one side of the flat cable shell; the openingof the first groove is fixedly connected with a sealing plate through a fastening bolt; the bottom of the first groove is fixedly connected with supporting seats which are uniformly distributed; the supporting base is designed to be in an H shape. The vacuum valve is mounted on the upper surface of the supporting seat; and the lower surface of the supporting seat is fixedly connected with a lowerwiring seat. According to the vacuum circuit breaker, the vacuum arc-extinguishing chamber shell and the vacuum valve are in double sleeve connection, and the vacuum valve is filled with the high-voltage insulating gas, so that the insulating property between the vacuum circuit breaker and the outside can be effectively enhanced, and the safety of the device is further enhanced.

Owner:淮南生橘网络科技有限公司

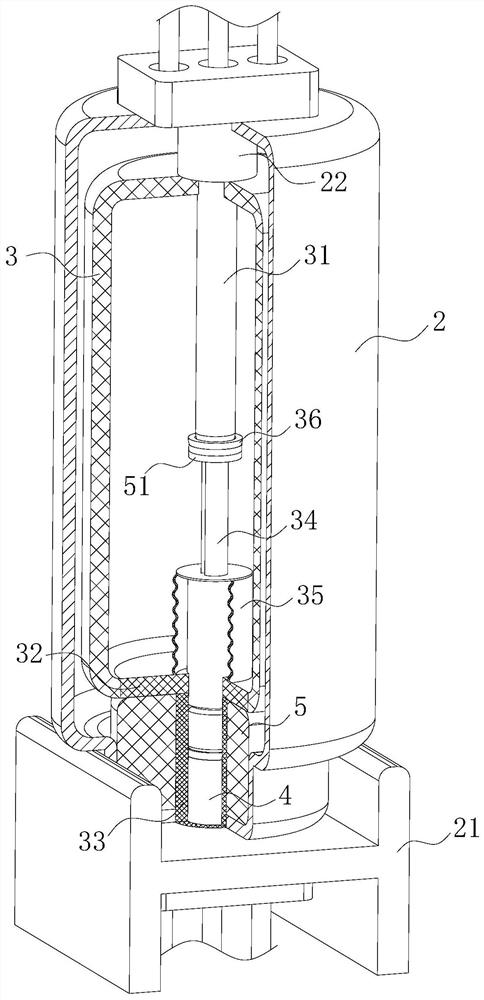

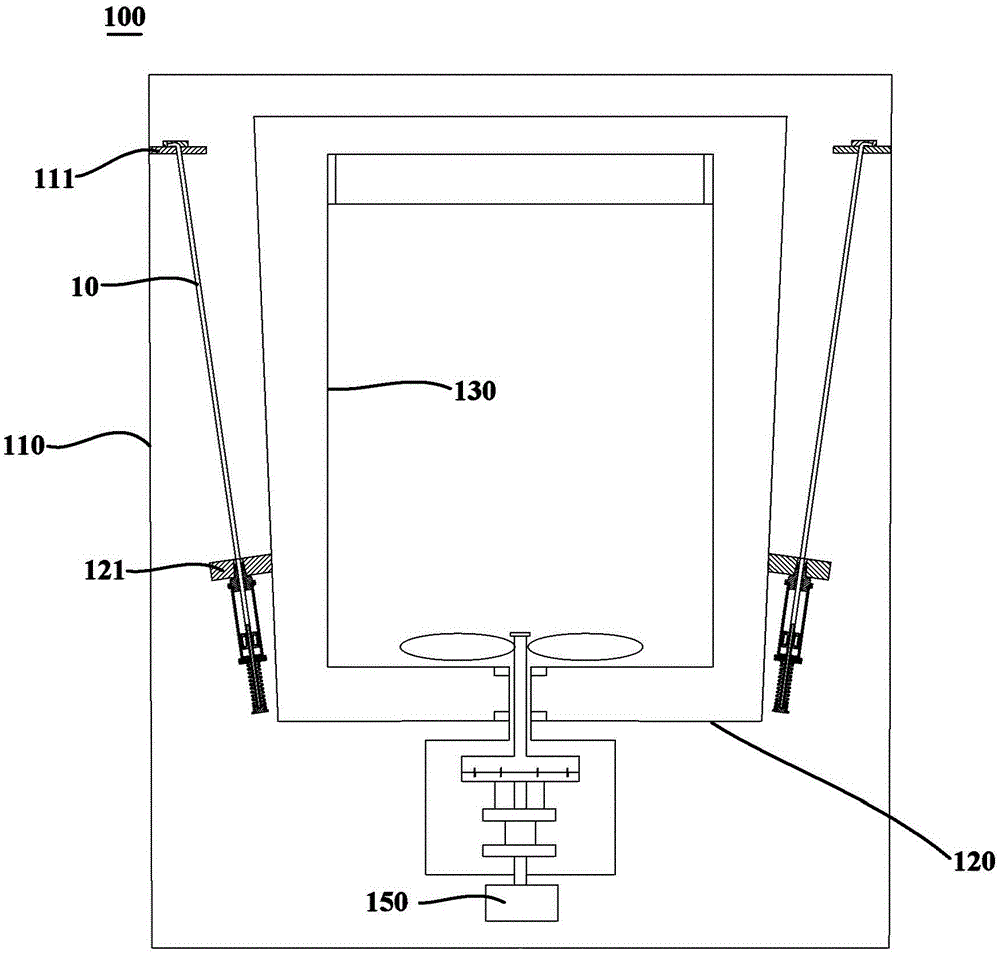

Adjustable damping hanger rod applied to pulsator washing machine and pulsator washing machine provided with adjustable damping hanger rod

ActiveCN106481723ADamping controlSimple structureSpringsNon-rotating vibration suppressionReciprocating motionMagnetorheological fluid

The invention provides an adjustable damping hanger rod applied to a pulsator washing machine and the pulsator washing machine provided with the adjustable damping hanger rod. The adjustable damping hanger rod comprises a cylinder body, a long hanger rod, a piston and a top mounting seat, wherein the long hanger rod penetrates through the cylinder body along the axial direction and can do reciprocating motion relative to the cylinder body and along the axial direction; the piston is fixedly arranged on the long hanger rod inside the cylinder body in a sleeved mode; the piston is provided with a coil and a liquid flowing passage, wherein the coil is used for generating a magnetic field when power is on, and the liquid flowing passage penetrates through the piston along the axial direction so that the fluidity of magnetorheological fluid in the liquid flowing passage can be changed by changing the value of the current in the coil; and the top mounting seat is arranged at the top end of the long hanger rod in order to hang the adjustable damping hanger rod on a hanging holder arranged at the top of a shell of the pulsator washing machine, wherein a positioning part extending upwards is formed at the upper end of the cylinder body and is matched with a shock absorbing seat arranged at the circumferential wall of the lower part of a washing outer cylinder of the pulsator washing machine so that the washing outer cylinder can be hung on the adjustable damping hanger rod under the effect of the gravity. The adjustable damping hanger rod provided by the invention is especially applicable to the pulsator washing machine.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

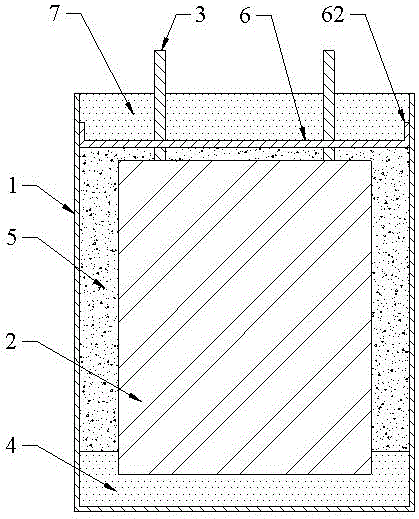

High-voltage pulse capacitor

ActiveCN106298241ASimple preparation processImprove securityThin/thick film capacitorStacked capacitorsEpoxyEngineering

The invention relates to a high-voltage pulse capacitor. The high-voltage pulse capacitor comprises a shell, a capacitor core group and an electrode, wherein a lower epoxy resin layer, an insulating layer which completely covers the capacitor core group, a fixing sleeve and an upper epoxy resin layer are successively arranged in the shell from bottom to top; the bottom of the capacitor core group is fixedly connected with the bottom of the shell through the lower epoxy resin layer; a mounting hole which is matched with the electrode is formed in the fixing sleeve; the top of the upper epoxy resin layer is parallel and level to the top of the shell; and the upper epoxy resin layer is fixedly connected with the shell. The high-voltage pulse capacitor is simple in manufacturing process, on the premise of guaranteeing voltage resistance and penetration resistance of the capacitor, airtightness of sealing of the shell is remarkably improved, sealing cost is low, and safety is high. The high-voltage pulse capacitor is good in heat dissipation property, heat generated by the capacitor core group can be dissipated outwards in time through the insulating layer, airtightness of sealing is prevented from being affected by heat, the implementing effect is good, and application value is high.

Owner:安徽四新电子有限责任公司

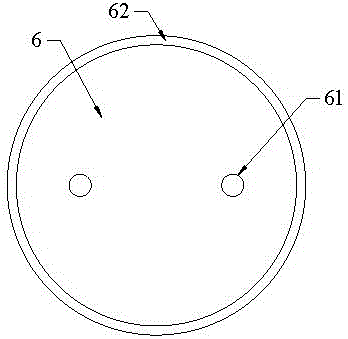

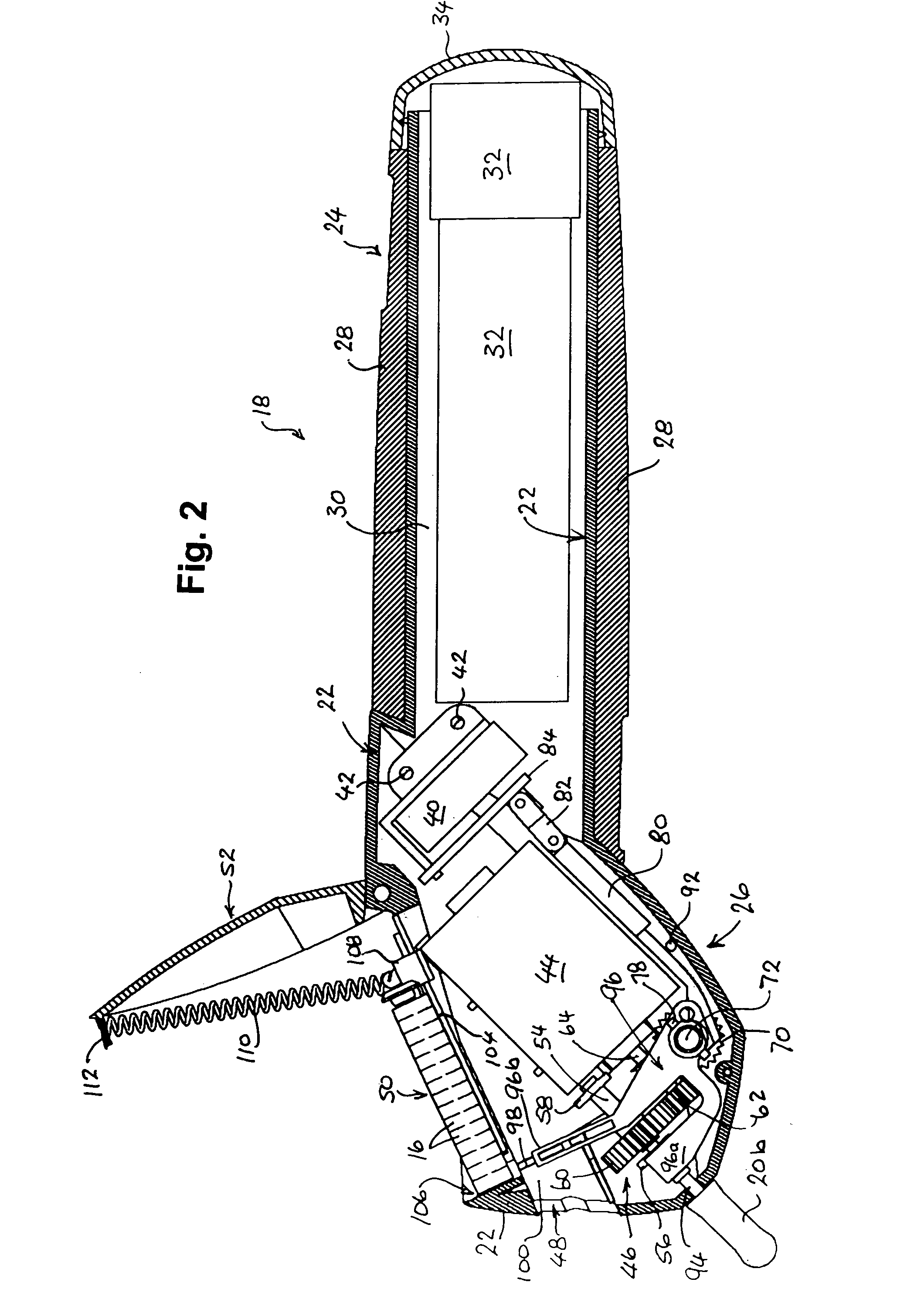

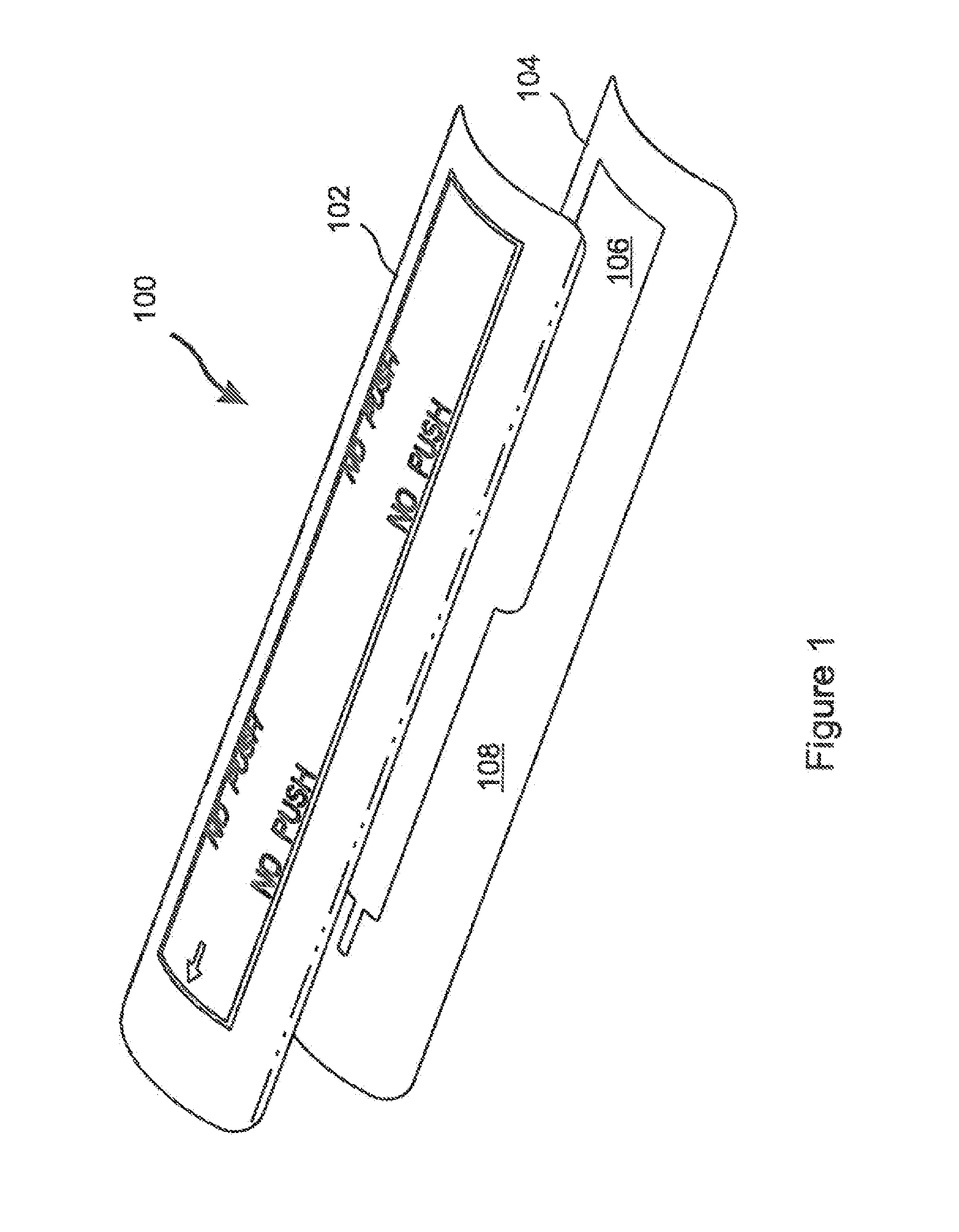

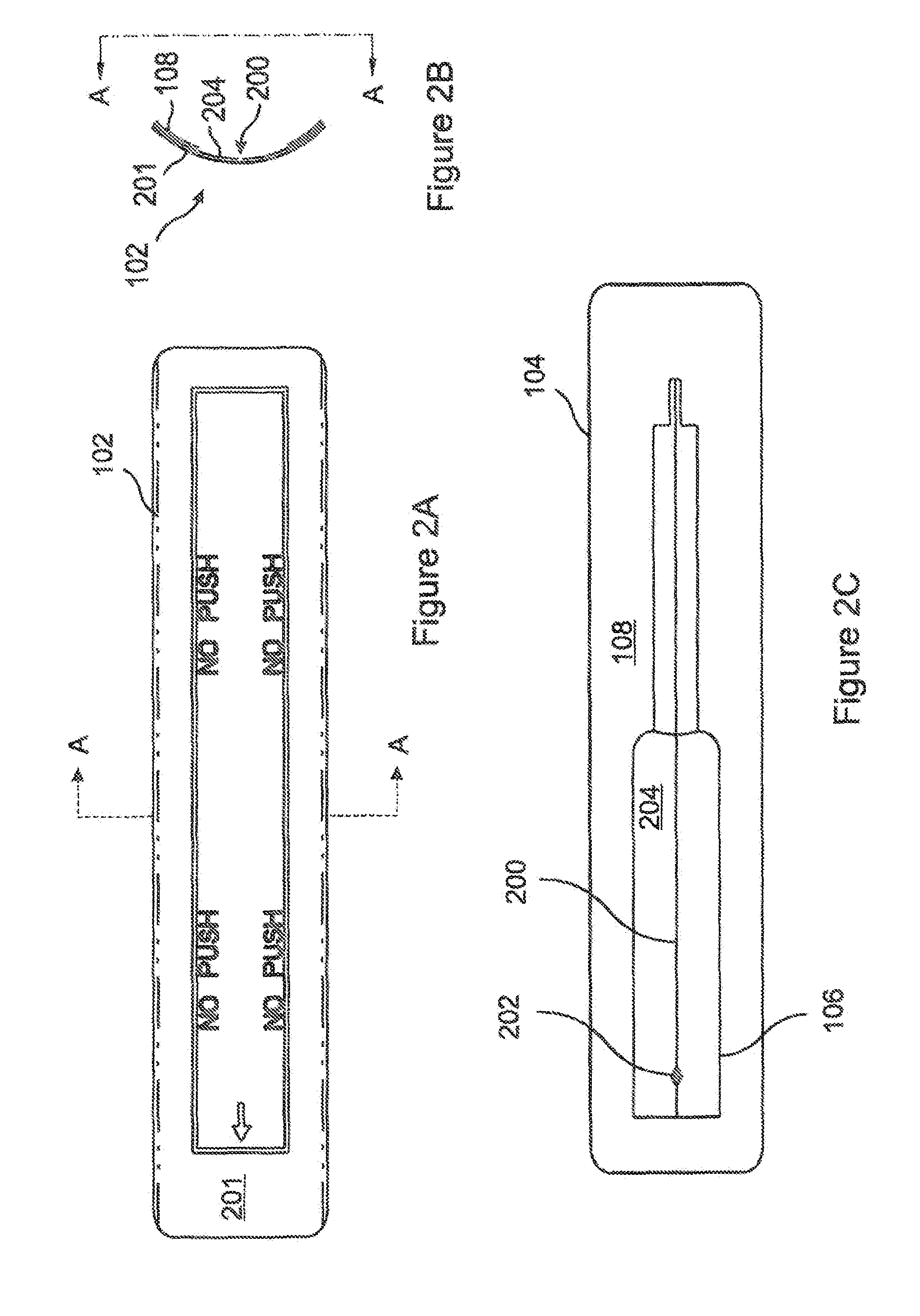

Means for stripping blood-lines

InactiveUS20040102716A1Sealing effectEasy to useSurgeryIntravenous devicesHand held devicesEngineering

A powered hand-held device (200) for use in stripping blood-lines is disclosed comprising a body (202) housing a battery (206) in a handle portion (204) thereof and housing a first motor (210) in a head portion (208) thereof. A pair of rollers extends from the head at an angle to the handle and is drivingly connected to the motor (210) by a drive mechanism (212). One of the rollers (220) is an idler and is mounted on a support member (222) adapted for lateral movement in the head (208) so that it can be moved toward and away from the other roller (not shown). Support member (222) is driven by an actuator including a second motor (214) that rotates a gear (218) which engages a toothed rack (226) on support member (222).

Owner:MOBBS WILLIAM LEONARD +1

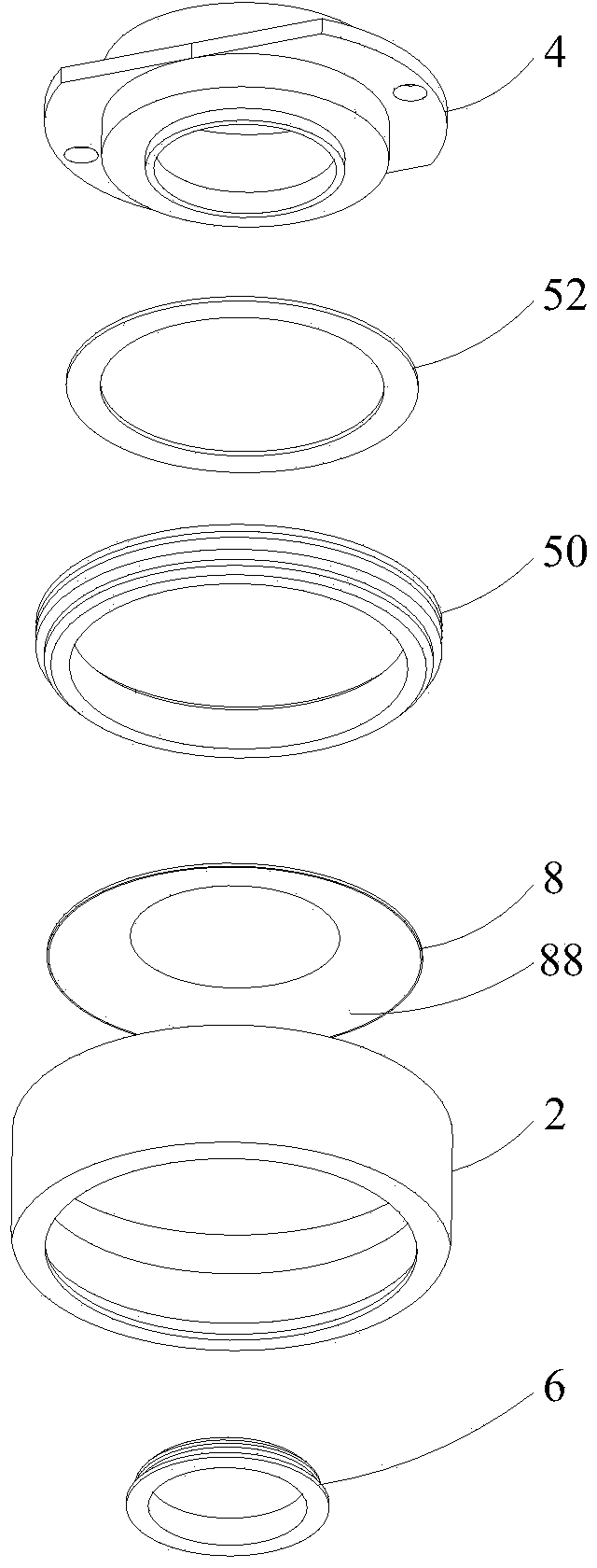

Ultrasonic focusing transducer and ultrasonic focusing treatment head

ActiveCN104225811ASealing effectImprove sealingUltrasound therapySurgical instruments for heatingTransducerMaterials science

The invention discloses an ultrasonic focusing transducer. The ultrasonic focusing transducer comprises a shell, a piezoelectric ceramic wafer, a fixed sealing part and a support, wherein the piezoelectric ceramic wafer, the fixed sealing part and the support are contained in the shell. The piezoelectric ceramic wafer is of a spherical segment shape and is provided with a spherical-segment-shaped through hole, the spherical-segment-shaped through hole is provided with a first side opening and a second side opening, the hole diameter of the first side opening is smaller than that of the second side opening, one end of the second side opening of the piezoelectric ceramic wafer abuts against one end of the shell, and one end of the first side opening of the piezoelectric ceramic wafer faces the other end of the shell. The fixed sealing part is annular, is installed on the inner surface of the shell, abuts against the piezoelectric ceramic wafer and is used for being connected with the support in a sealing mode. The support is provided with a clamping part, and the clamping part is used for extruding and clamping the periphery of the first side opening of the piezoelectric ceramic wafer. The fixed sealing part, the support and the piezoelectric ceramic wafer define a closed air cavity. The invention further discloses an ultrasonic focusing treatment head. The sealing performance of the air cavity of the ultrasonic focusing transducer is good.

Owner:SHENZHEN PRO HIFU MEDICAL TECH

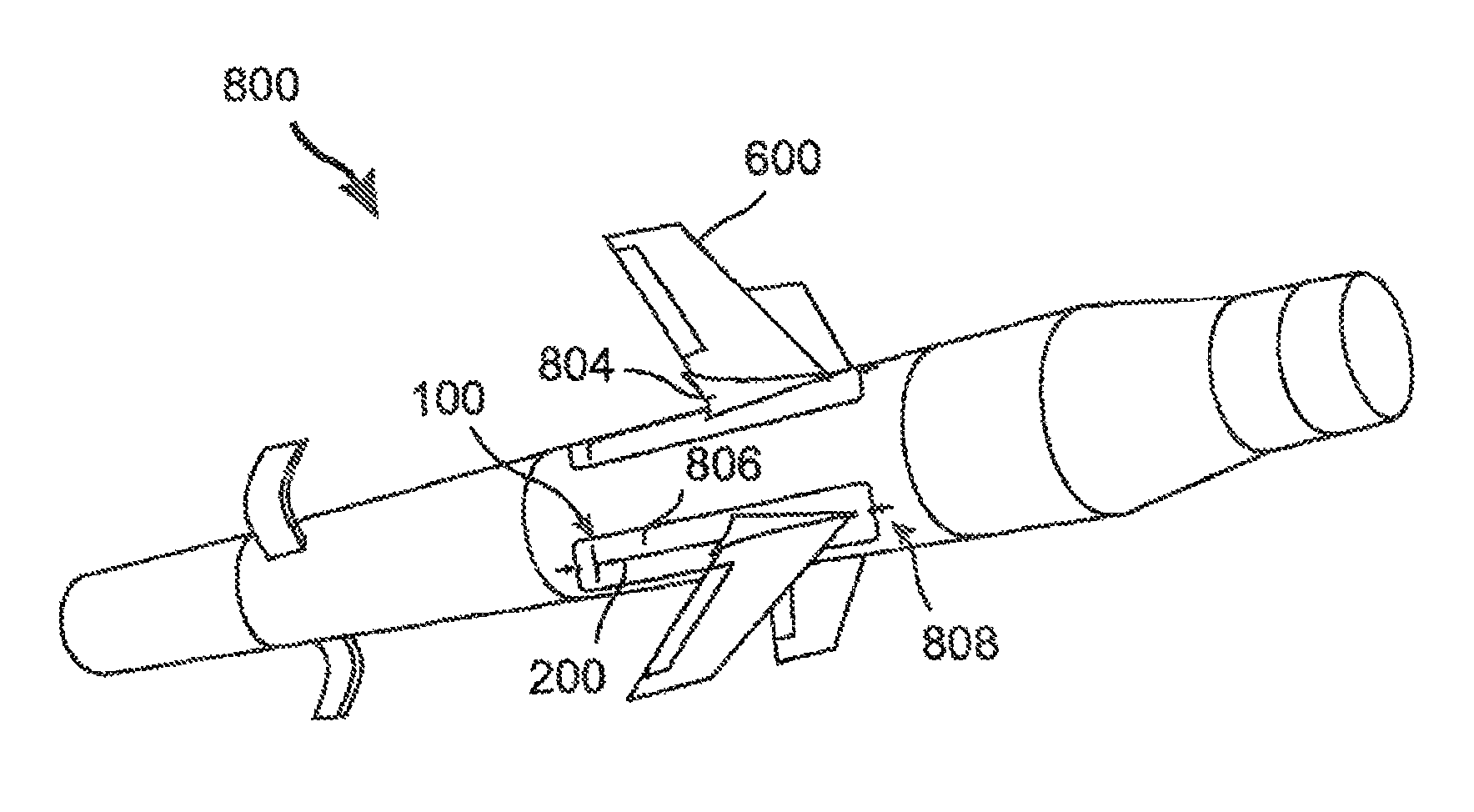

Wing slot seal

ActiveUS8895908B2Resist ruptureResist dislodgementDirection controllersAircraft stabilisationLeading edgeRocket

A low cost, lightweight frangible wing slot seal can be applied to a guidance wing slot of a folding fin aerial rocket or missile, providing a barrier against exposure of internal missile components to external contaminants, while allowing unhindered deployment of missile guidance wings simply by bursting through the seals. The simple design is nearly foolproof, and has no impact the likelihood of weapon failure. The seal is a flexible sheet which is sufficiently thin so as not to exceed the required volume envelope of the missile. The sheet includes a burst seam, which is breached when impacted by the leading edge of a deploying wing. No additional wing deployment force is required, and after deployment the seal has minimal impact on the aerodynamic performance of the wing.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTEGRATION INC

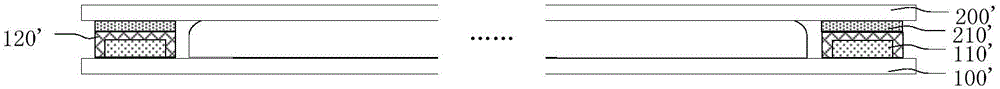

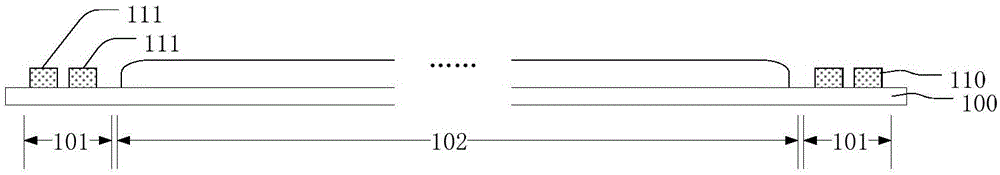

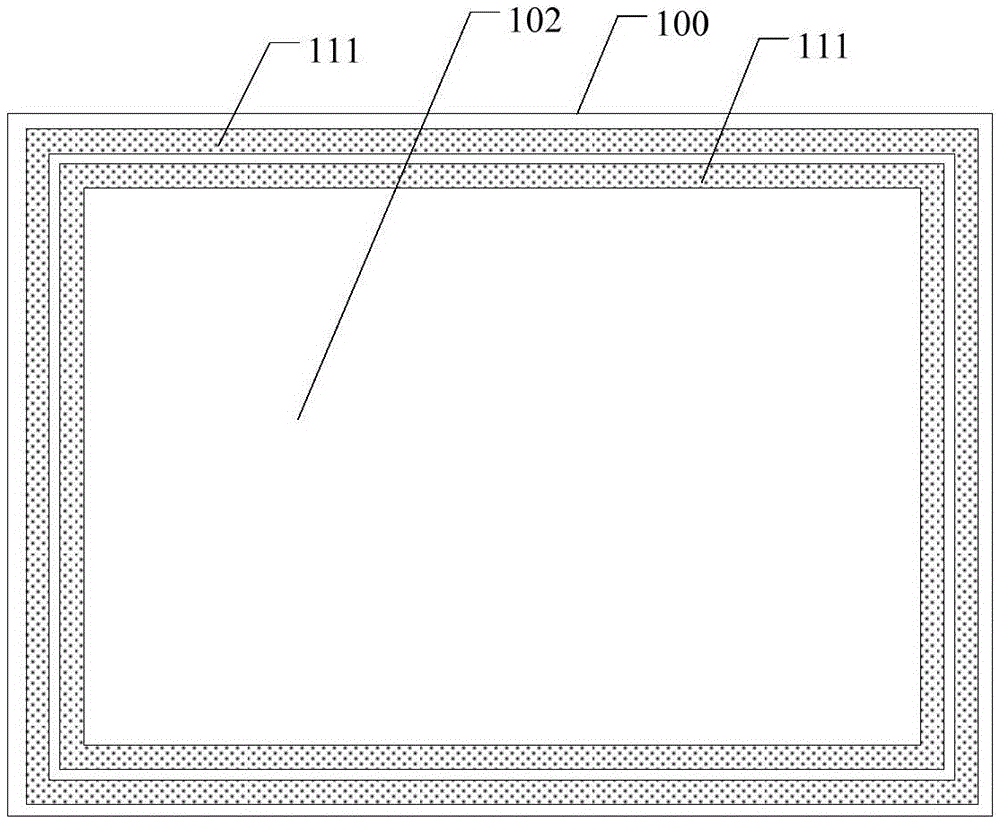

Array substrate, production method thereof, display panel and display device

ActiveCN105070743AImprove yieldImprove toughnessStatic indicating devicesSolid-state devicesDisplay deviceUnit structure

The invention provides an array substrate, a production method thereof, a display panel and a display device. The array substrate includes a display area and a packaging area surrounding the display area; the packaging area is provided with a packaging flat layer; the packaging flat layer comprises a plurality of packaging flat units; and each packaging flat unit forms an annular pattern on the packaging area and surrounds the display area. With the array substrate of the invention adopted, the contact area of a formed normal-temperature bonding layer and the packaging flat layer can be increased, and the strength of a bonding force between the normal-temperature bonding layer and the packaging flat layer can be improved; the packaging flat layer is divided into a plurality of unit structures which are independent from each other, even if dust or other defects exist on the surface of one unit structure, the sealing performance of the other unit structures and the normal-temperature bonding layer has little possibility of being adversely affected, and therefore, the yield of a packaging process can be improved.

Owner:BOE TECH GRP CO LTD

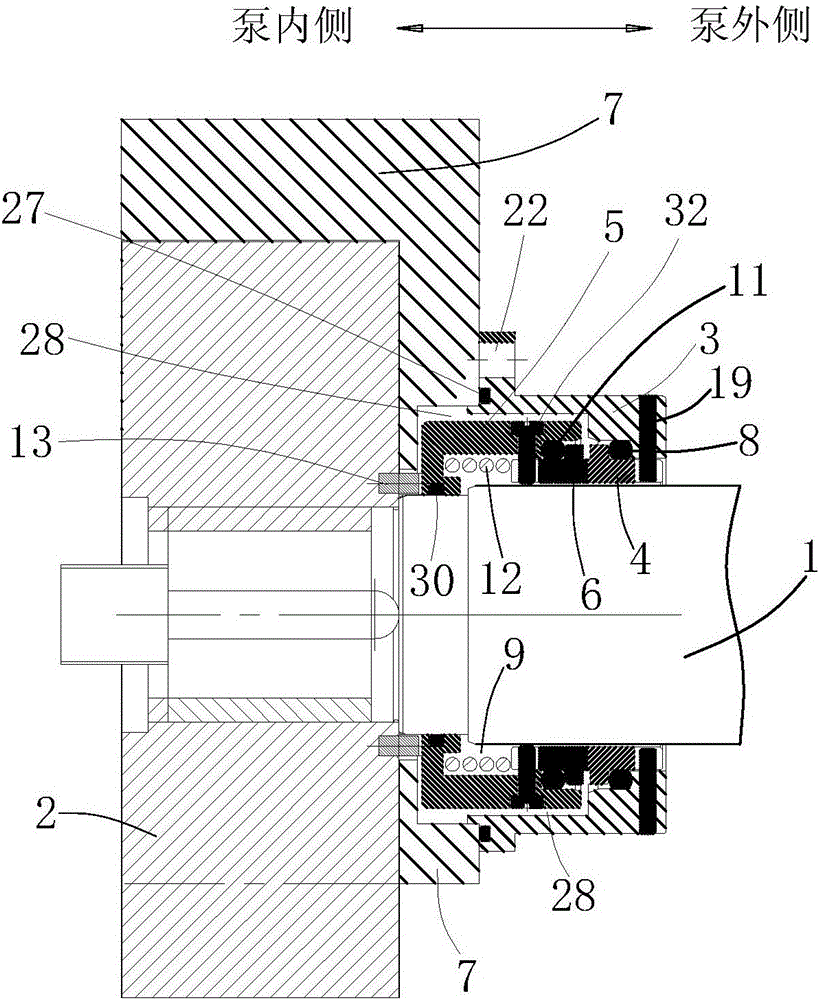

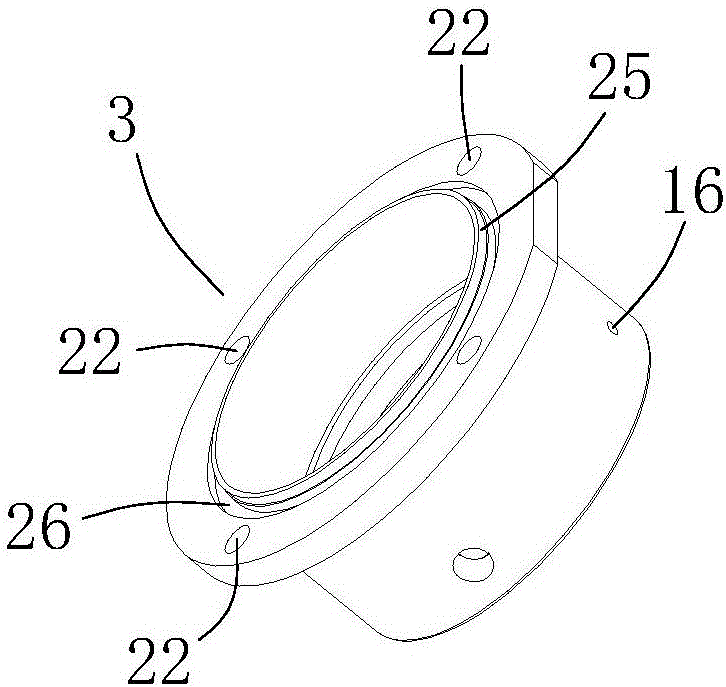

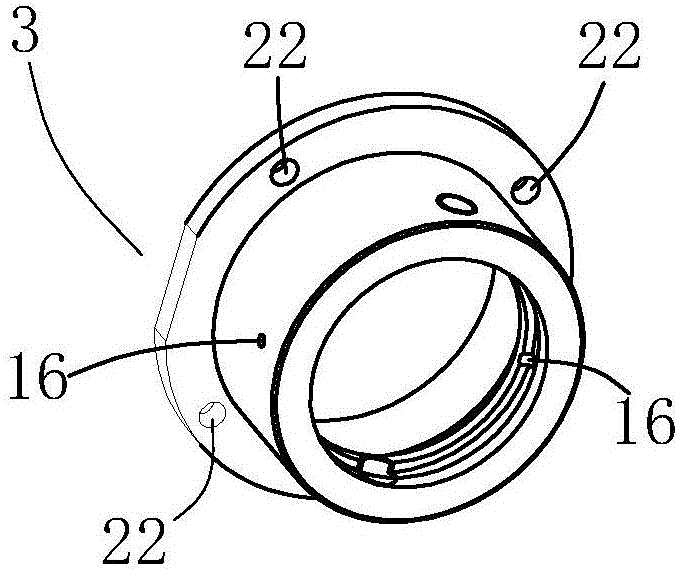

Shaft seal device of rotor pump

ActiveCN106286290AExtended service lifeAvoid continuous heatingMachines/enginesRotary/oscillating piston pump componentsImpellerClose contact

Provided is a shaft seal device of a rotor pump. The shaft seal device comprises a mechanical seal base (3), a fixed ring (4), a moving ring base (5) and a moving ring (6) driven by the moving ring base (5). A first O-shaped ring (8) is arranged in a slit between the fixed ring (4) and the mechanical seal base (3). A tube body of the moving ring base (5) extends into the inner cavity of the mechanical seal base (3), an inner cavity (9) of the moving ring base, which is closed, is formed between the tube body of the moving ring base (5) and a shaft (1), a second O-shaped ring (11) is arranged in a slit between the moving ring (6) and the moving ring base (5). A compressive spring (12) is arranged between a connected end of the moving ring base (5) and the moving ring (6), and the moving ring (6) is in close contact with the fixed ring (4). A third O-shaped ring (30) is arranged between a connected end of the moving ring base (5) and the shaft (1). The moving ring base (5) is connected with an impeller (2) through at least one drive pin (13); one end of each drive pin (13) is in close-fit connection and the other end thereof is in floating insertion. By the shaft seal device of the rotor pump, performance of the rotor pump is improved and service life thereof is prolonged effectively. The shaft seal device is particularly applicable to shaft sealing of hygiene-grade rotor pumps.

Owner:宁波邦威泵业有限公司

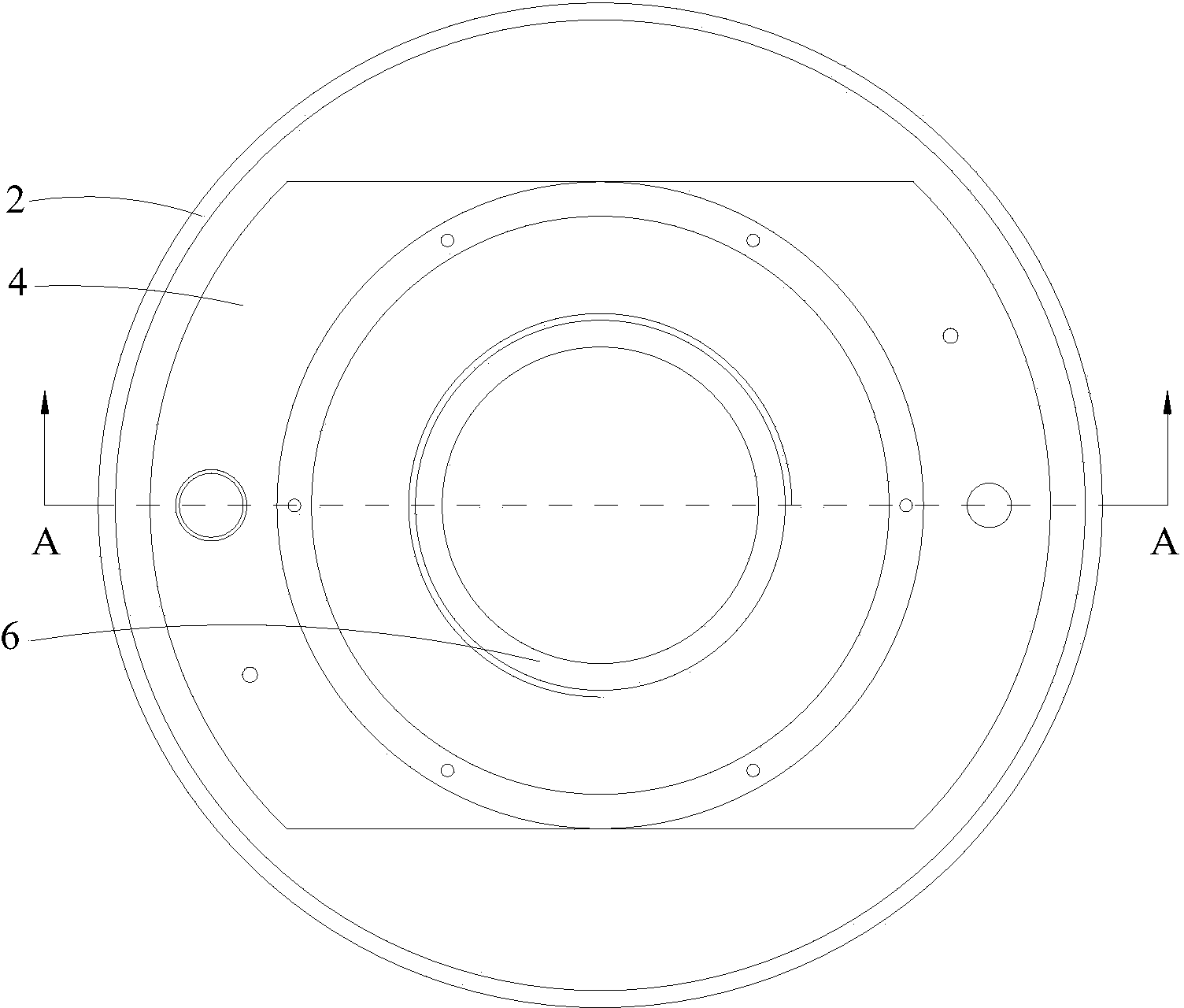

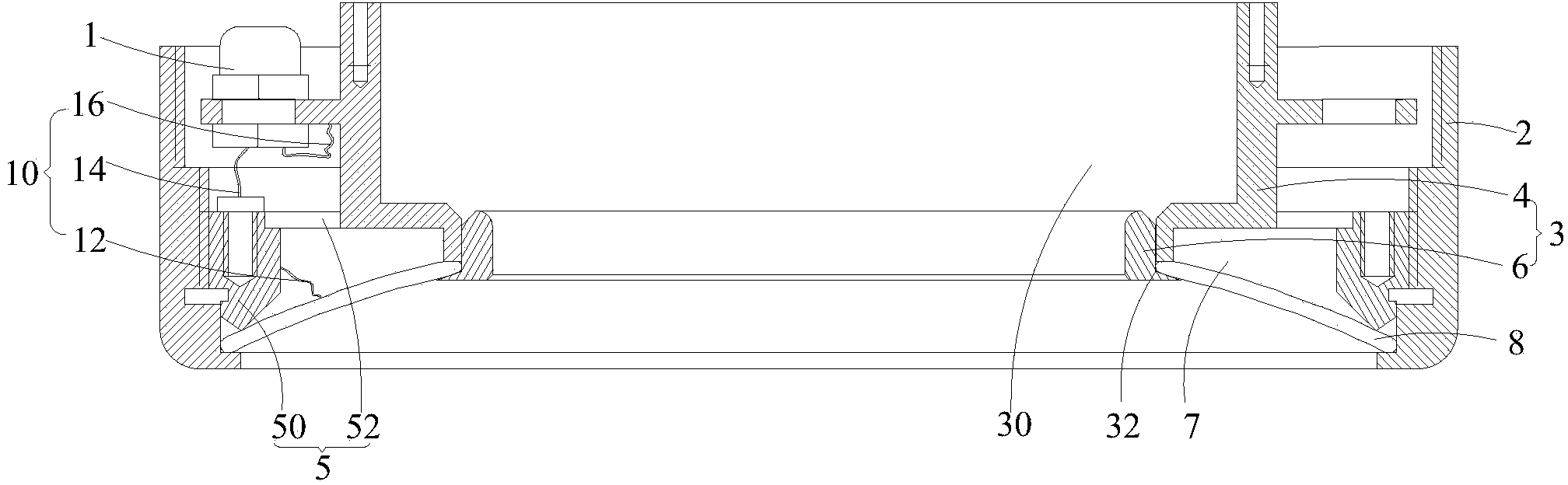

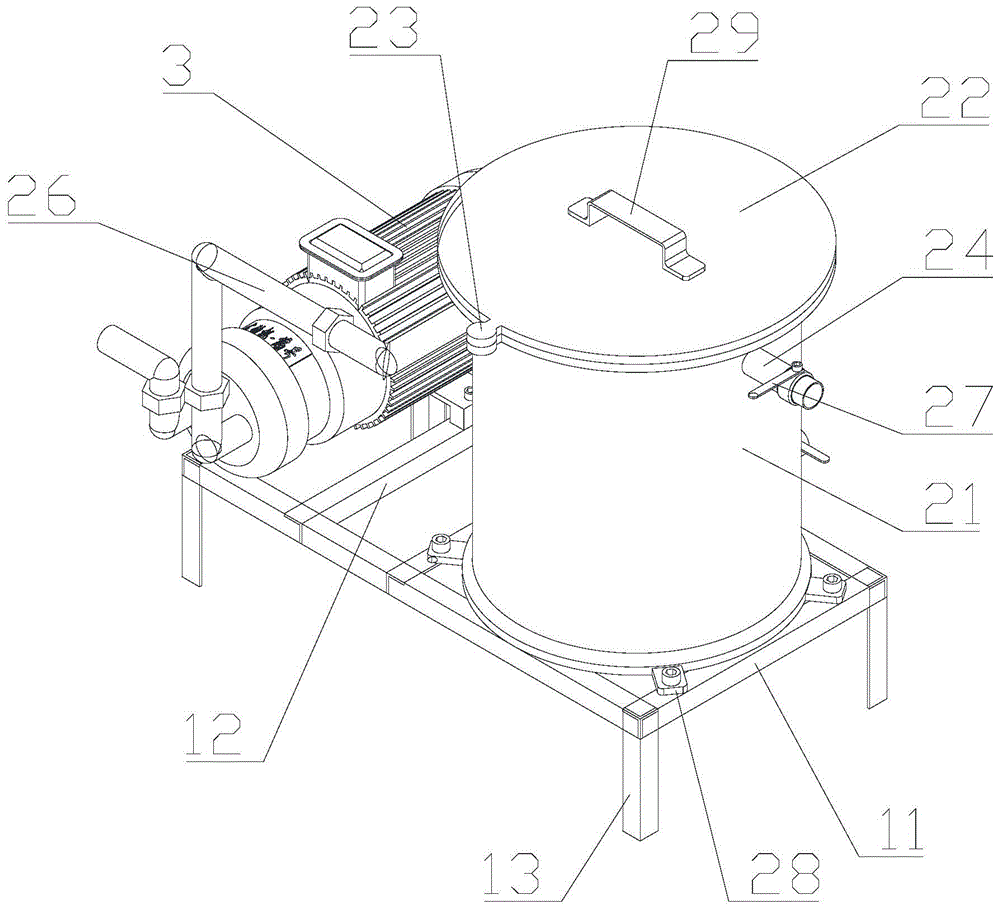

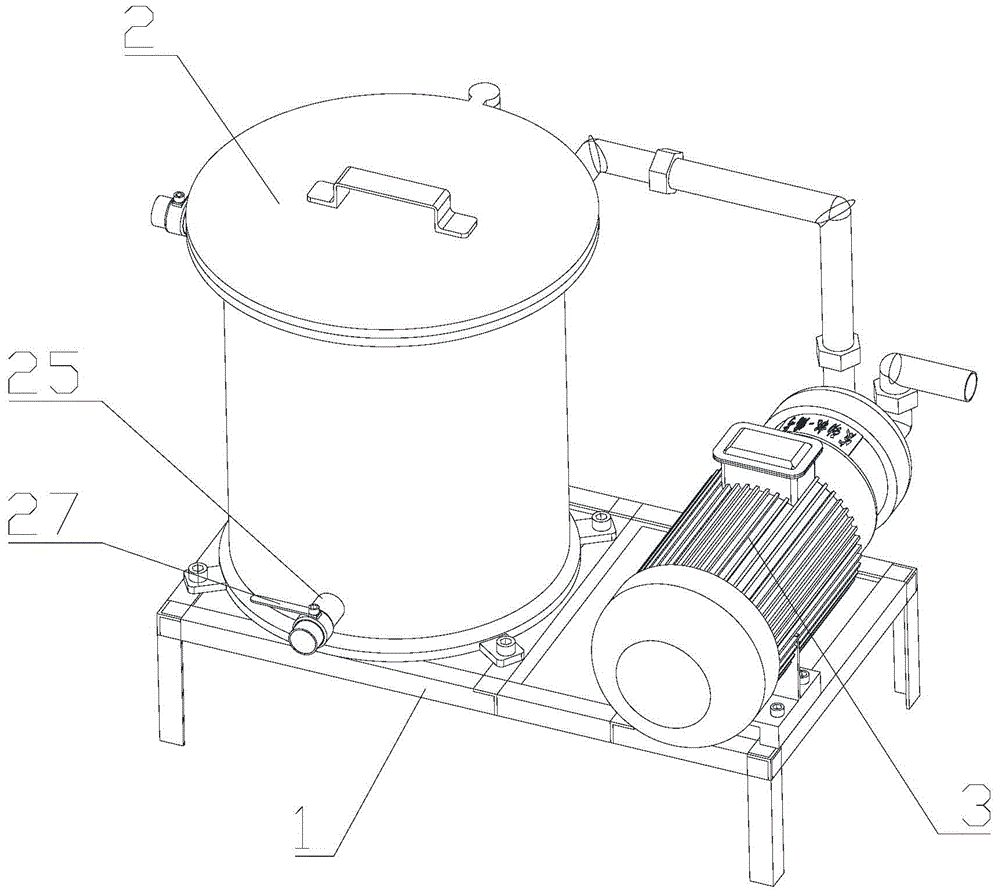

Vacuumizing device

InactiveCN104595156AAvoid affecting the tightnessSealing effectPositive displacement pump componentsPackaging under vacuum/special atmosphereBiochemical engineeringVacuum tube

The invention discloses a vacuumizing device. The vacuumizing device comprises a vacuumizing tank and a vacuumizing pump, wherein the vacuumizing tank comprises a tank body and a cover body, wherein calibration parts are respectively arranged on the tank body and the cover body; when the cover body and the tank body are tightly screwed until the two calibration parts are thoroughly overlapped, the cover body is in sealing fit with the tank body; a feeding pipe, a discharging pipe and a vacuumizing pipe are arranged on the tank body; valves are respectively arranged at parts, on the outer side of the tank body, of the feeding pipe and the discharging pipe; the vacuumizing tank is communicated with the vacuumizing pump through the vacuumizing pipe. When the cover body is rotated until the cover body is tightly screwed and the calibration part of the cover body is thoroughly overlapped with the calibration part of the tank body, the cover body is in thorough sealing fit with the tank body; the gas in the vacuumizing tank is extracted by the vacuumizing pump; then the valve on the discharging pipe is switched off for outputting the material; the cover body can be screwed out for washing the vacuumizing tank after being used; the vacuumizing device is convenient and effective; the vacuumizing tank does not need to be replaced regularly; the cost is reduced; due to the arrangement of the calibration parts, the excessive rotation or insufficient rotation of the cover body can be avoided.

Owner:CHANGXING TIANCHEN MOLD

Membrane valve

ActiveUS9010729B2Improve sealingSealing effectSpindle sealingsDiaphragm valvesBiomedical engineeringMembrane configuration

A membrane valve comprising a first and a second valve housing part and a membrane clamped between the valve housing parts comprises a peripherally surrounding bead on the membrane and a thin, axially movable membrane portion adjacent thereto. The bead is supported by the two valve housing parts and is provided with an undercut at a radial inner side. Further, a membrane for installation in a membrane valve is provided.

Owner:BURKERT WERKE

Lamp

InactiveCN109000178ASealing effectLighting heating/cooling arrangementsProtective devices for lightingWater vaporEngineering

The invention belongs to the technical field of photo equipment, and particularly relates to a lamp. The lamp comprises a lamp housing, a light transmitting plate, a light source assembly, two end covers and a sealing strip assembly. The lamp housing is provided with a mounting cavity with the front side being provided with an opening. The light source assembly is arranged in the mounting cavity.An upper embedding groove and a lower embedding groove which correspond to each other up and down are formed in the position, close to the opening, of the inner wall of the mounting cavity. The upperend and the lower end of the light transmitting plate are embedded into the upper embedding groove and the lower embedding groove correspondingly and further abut against the inner wall of the upper embedding groove and the inner wall of the lower embedding groove through the sealing strip assembly. The two end covers are fixed to the two opposite ends of the lamp housing separately and further limit the light source assembly, the light transmitting plate and the sealing strip assembly from being disengaged from the two sides of the mounting cavity together. The gap between the light transmitting plate and the mounting cavity can be sealed and fixed in the butting mode by the sealing strip assembly. Therefore, the light transmitting plate can be fixed without fasteners, and the phenomenonthat the sealing property of the light transmitting plate can be influenced by water vapor in the long-term using process does not need to be worried.

Owner:SHENZHEN AURORA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com