Transmission switching device of electric hammer

A technology of switching device and electric hammer, which is used in transmission control, components with teeth, light impact tools, etc., can solve the sealing effect of Jingxiang electric tools, affect the sensitivity of the shifting mechanism, and the surface of the electric hammer is easily dirty, etc. problems, to improve labor productivity and work quality, avoid tooth punching, and ensure the effect of work agility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

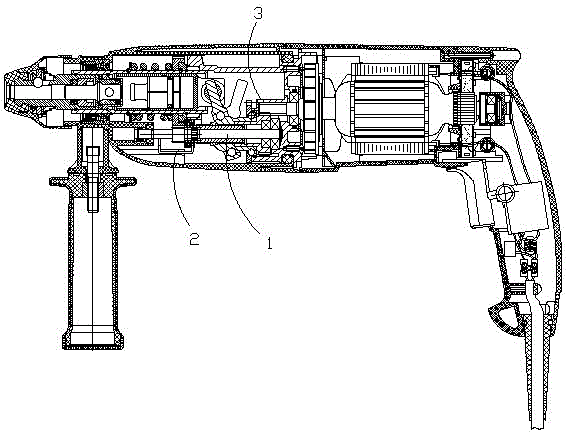

[0021] Example: such as figure 1 As shown, the transmission switching device of the electric hammer of the present invention is arranged in the electric hammer, including a transmission mechanism 1, a shift mechanism 2 and a knob (not shown in the figure) connected with the shift mechanism 2 .

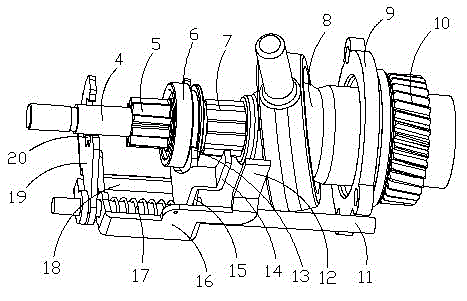

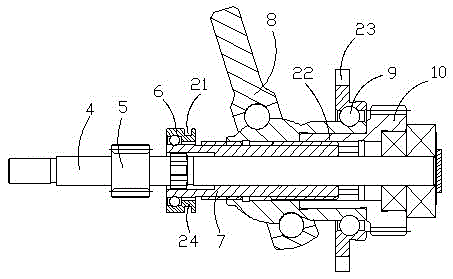

[0022] Such as figure 2 , image 3As shown, the transmission mechanism 1 includes an intermediate shaft 4, the intermediate shaft 4 is provided with an intermediate shaft gear 5 integrated with the intermediate shaft 4, one end of the intermediate shaft 4 is provided with a transmission gear 10, and the intermediate shaft 4 is between the transmission gear 10 and the intermediate shaft 4. A swing rod bearing 8 is arranged between the shaft gears 5, and the intermediate shaft 4 is sleeved with an intermediate shaft sleeve 7 between the transmission gear 10 and the intermediate shaft gear 5, and the side of the transmission gear 10 close to the intermediate shaft gear 5 faces outward. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com