Patents

Literature

80results about How to "Avoid teething" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

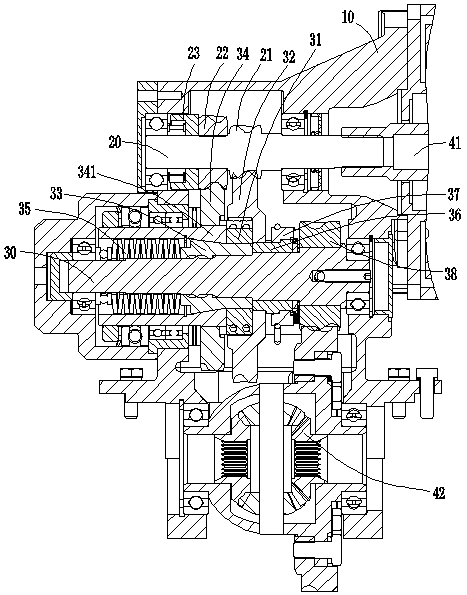

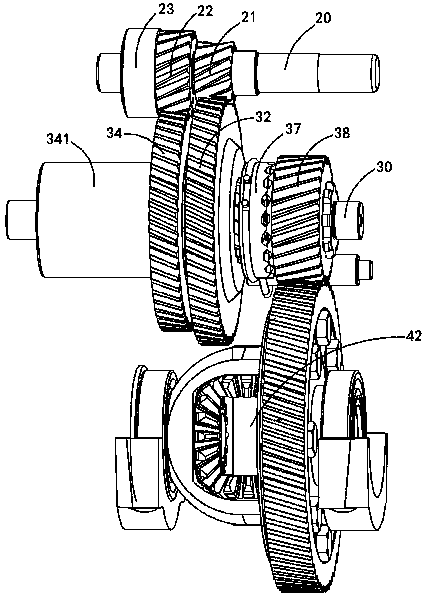

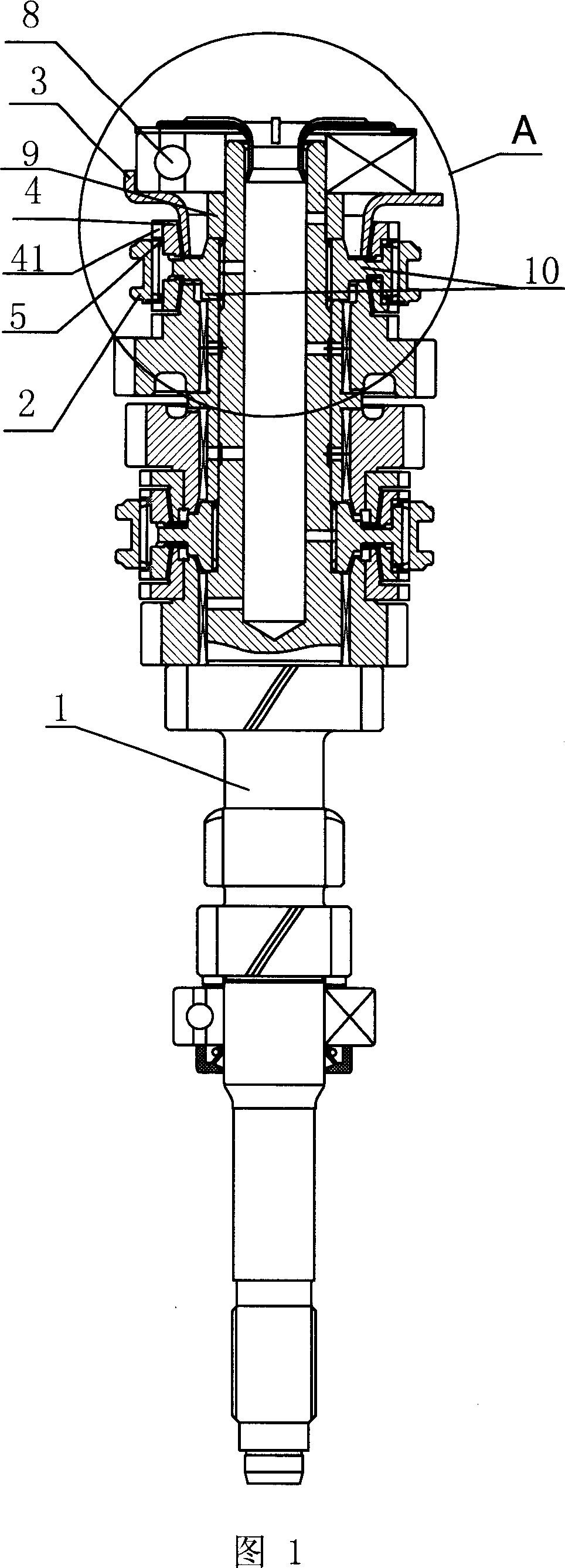

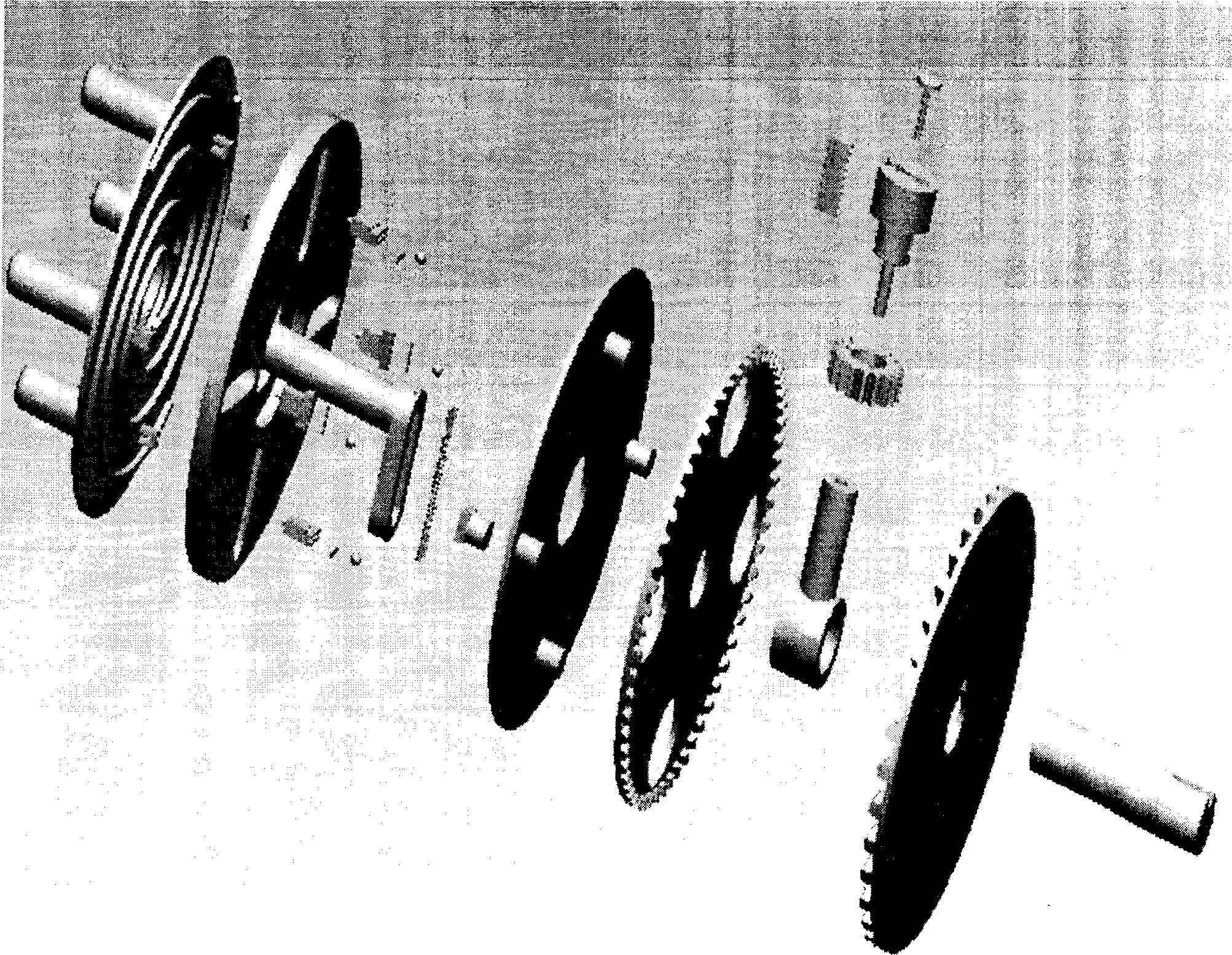

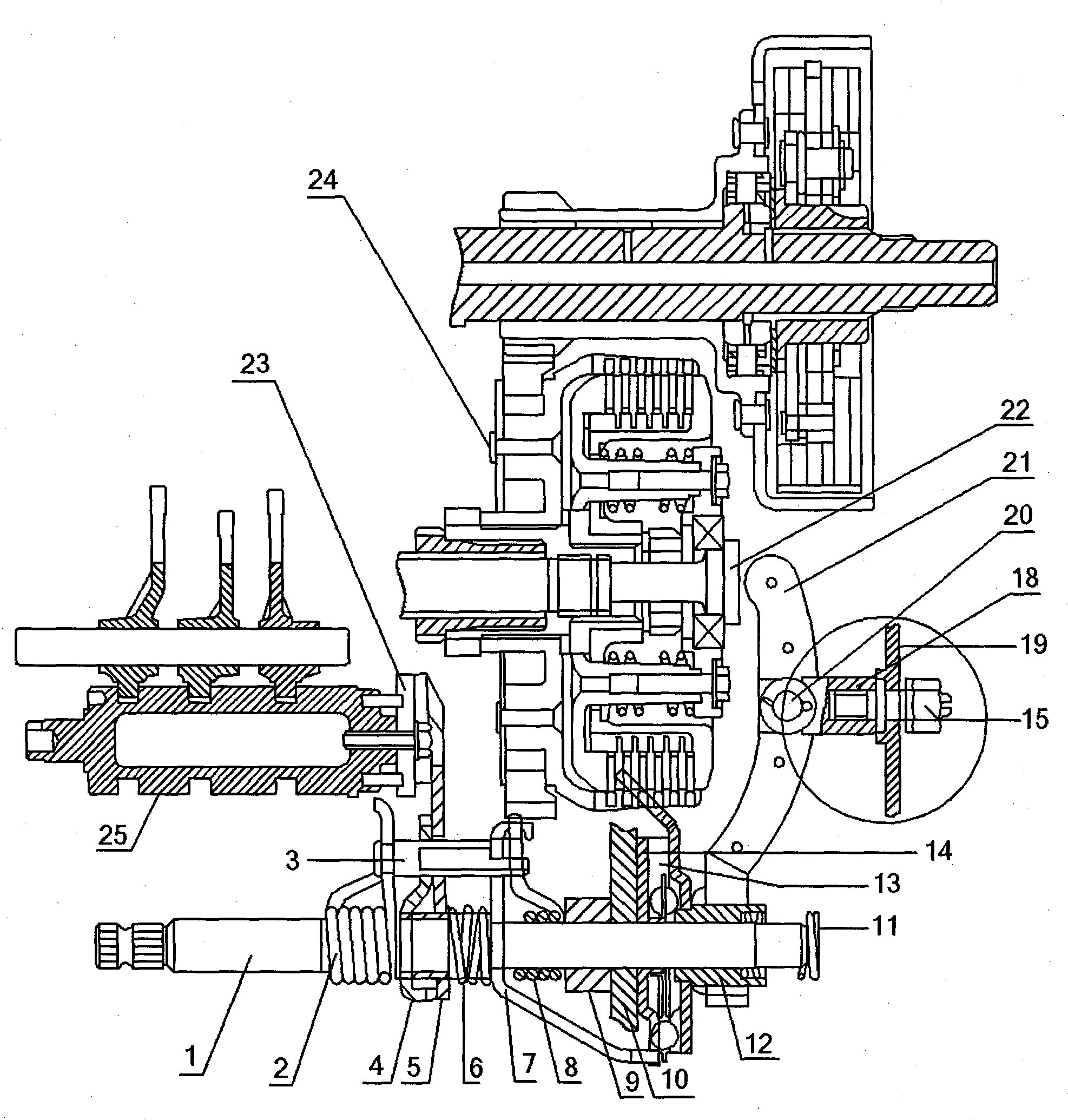

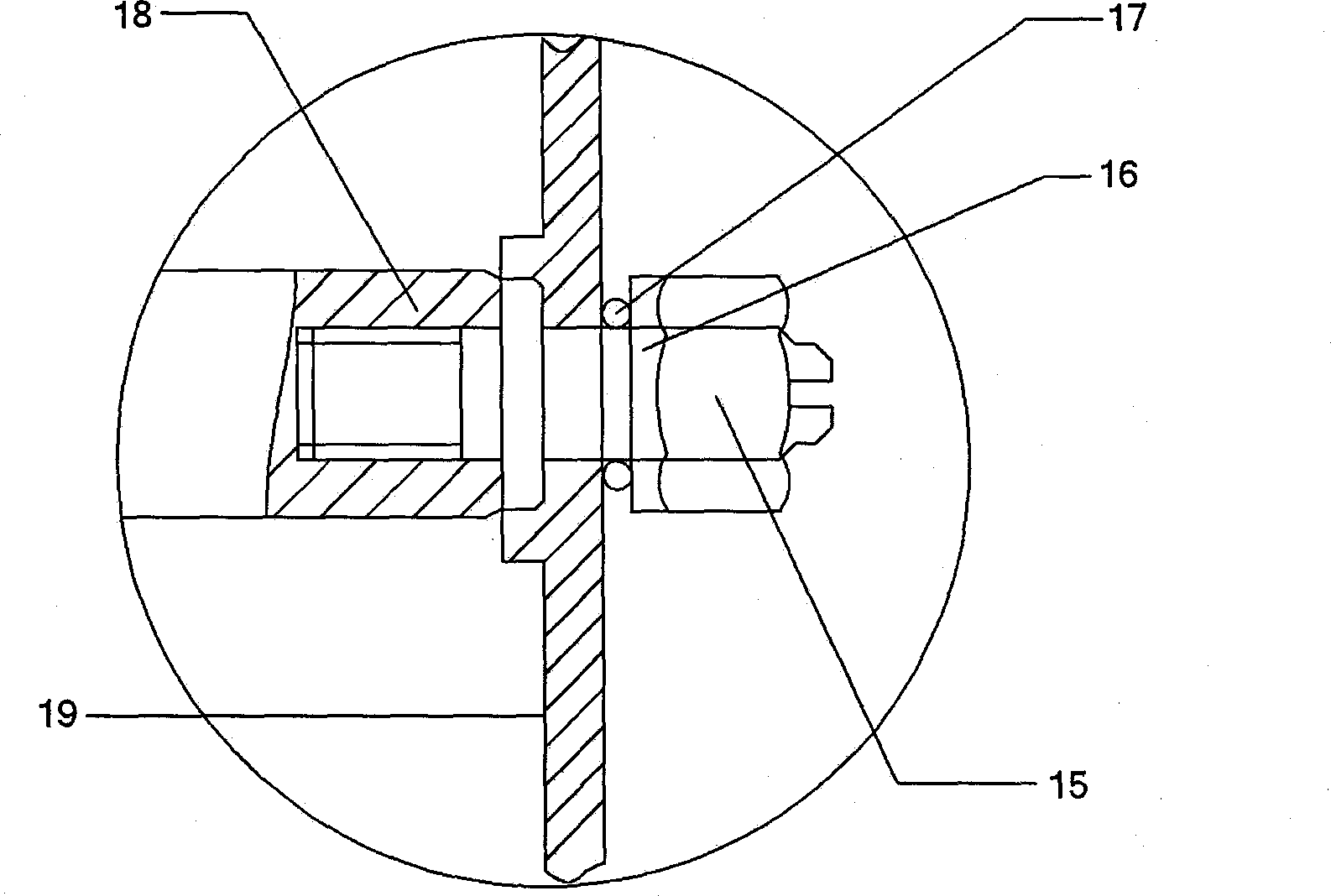

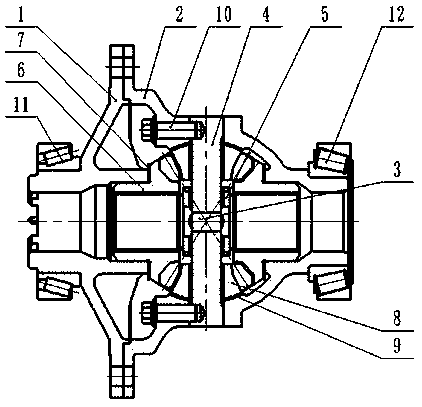

Speed changer

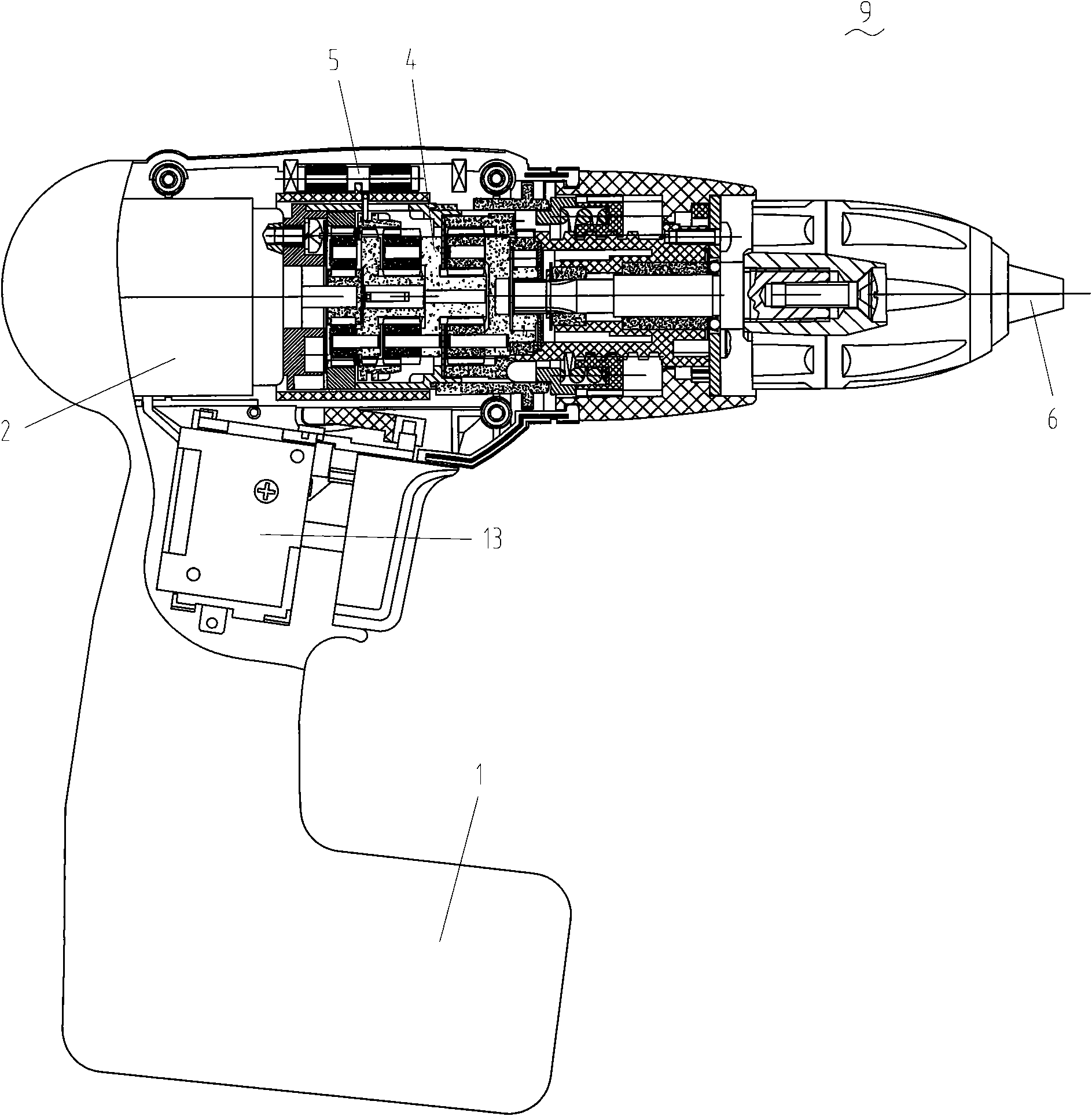

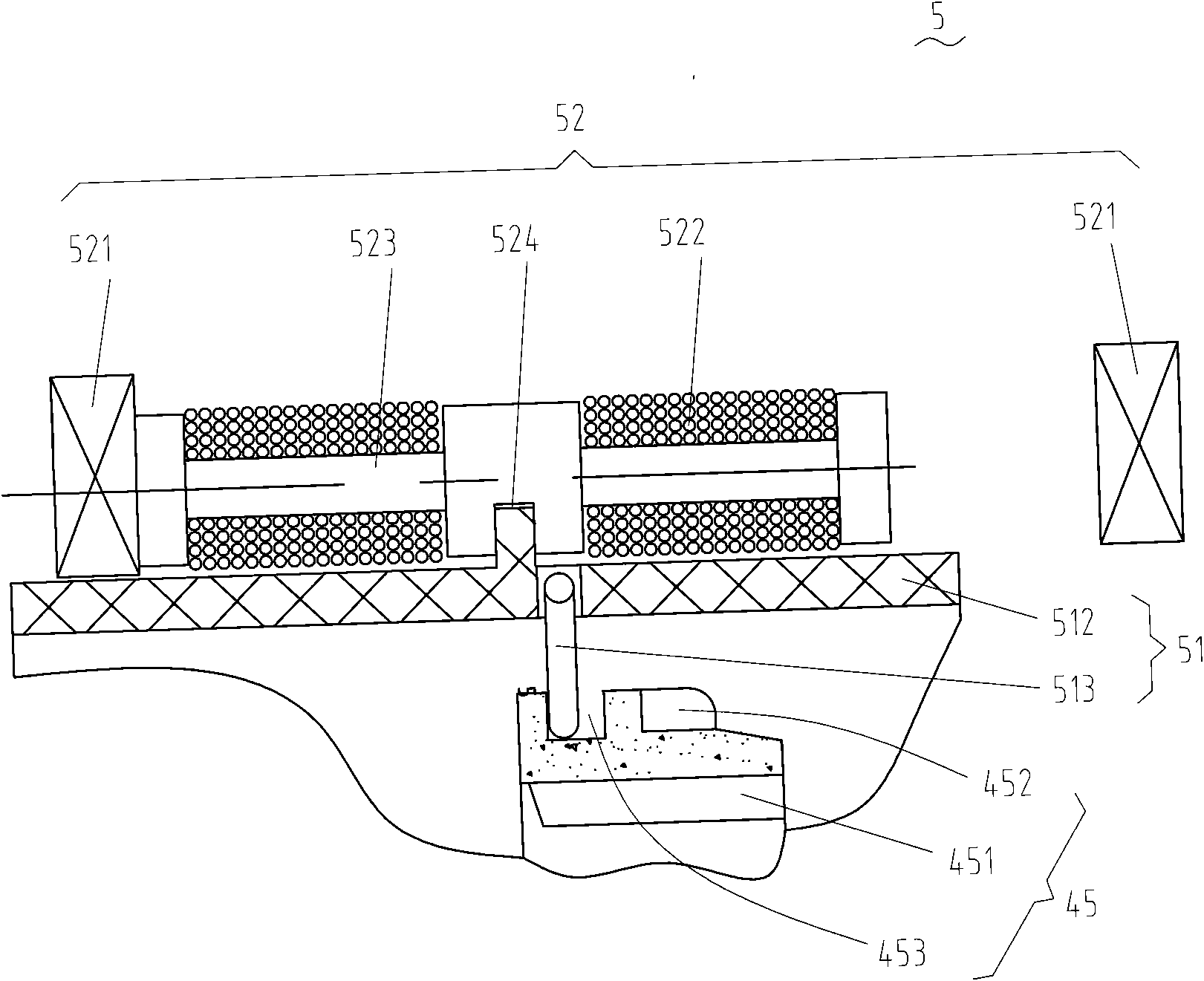

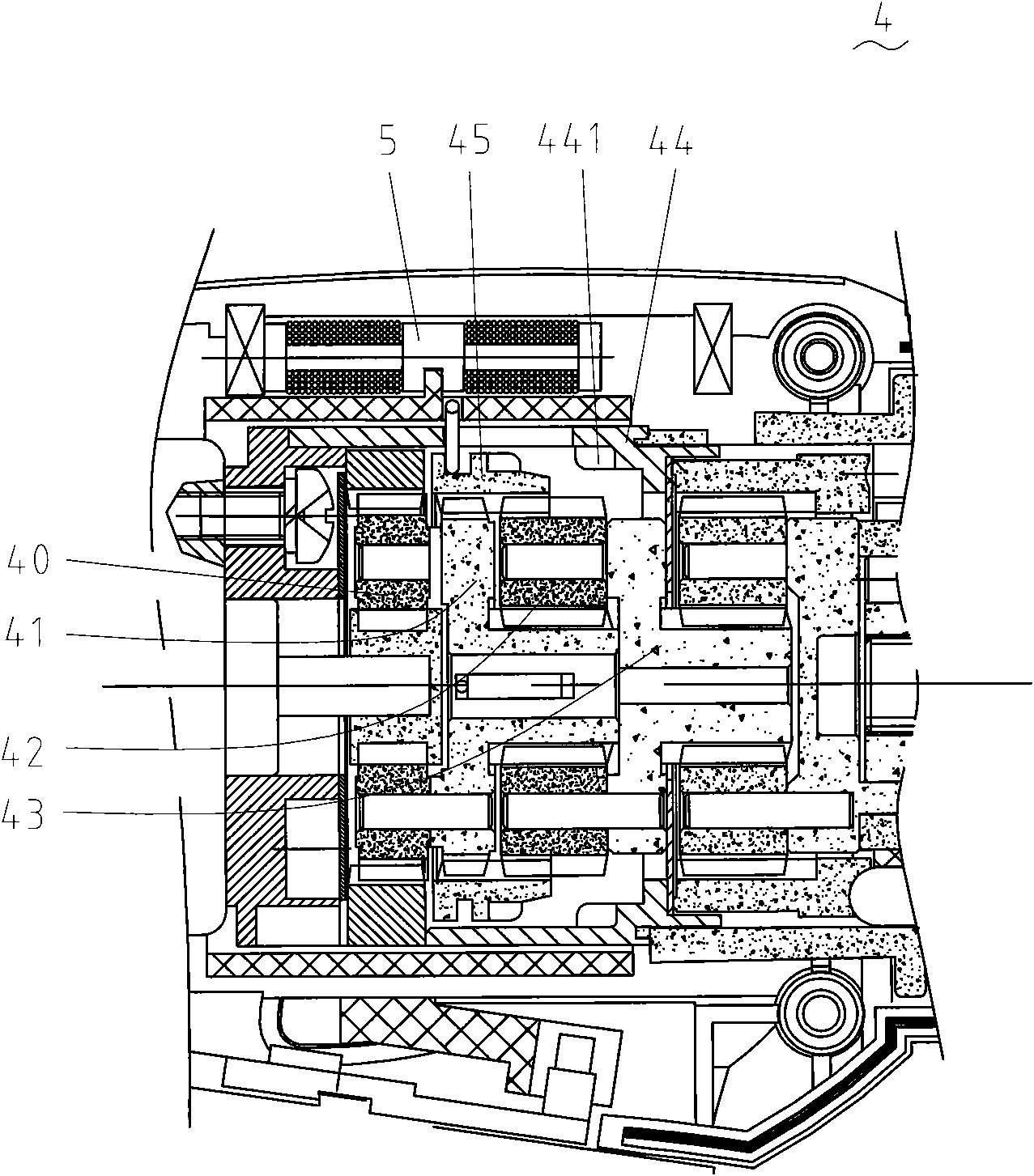

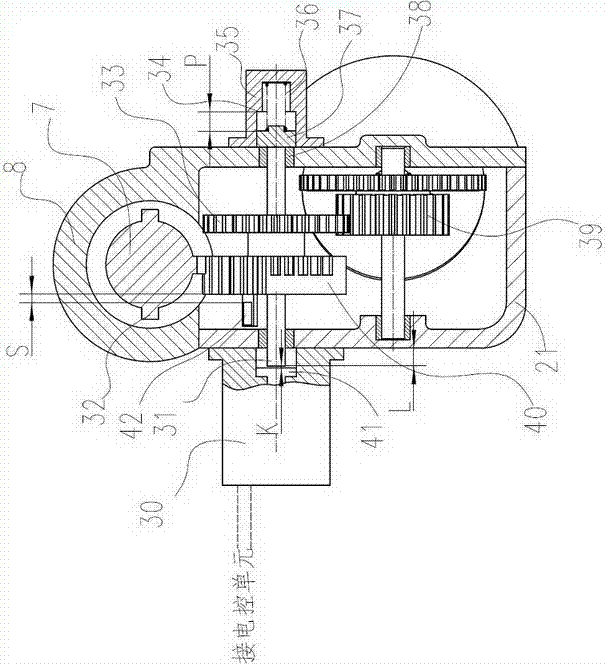

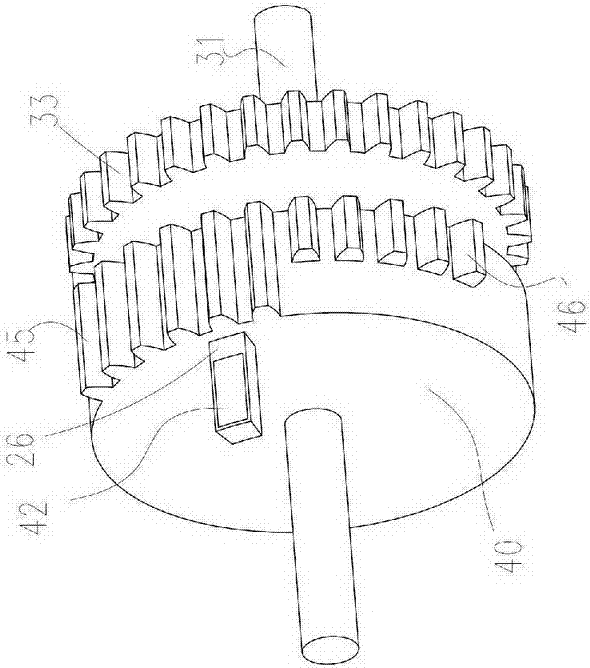

InactiveCN101637906AAvoid teethingExtended service lifeToothed gearingsPortable power-driven toolsGear transmissionControl system

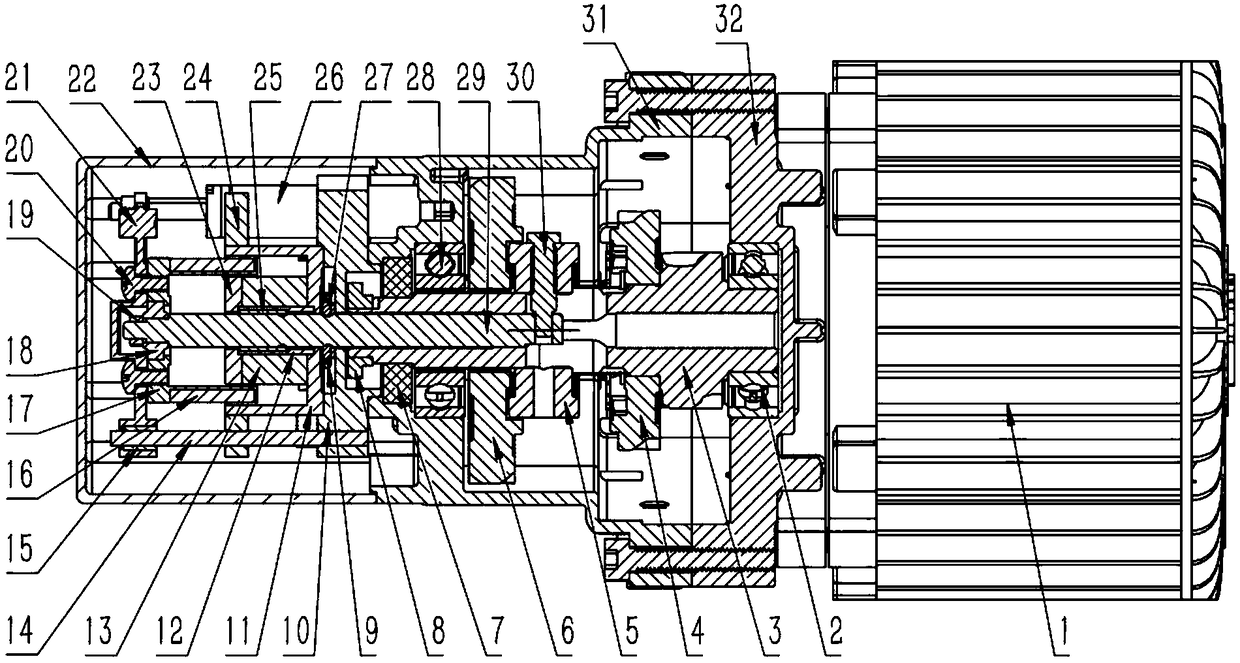

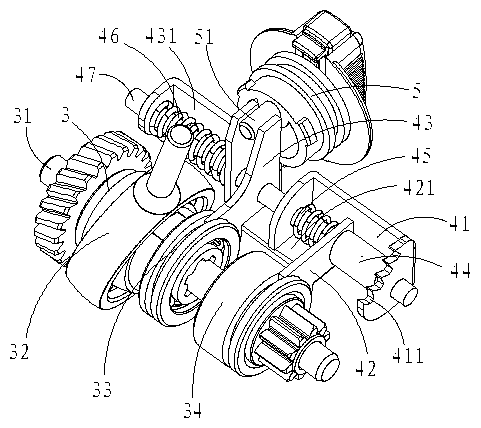

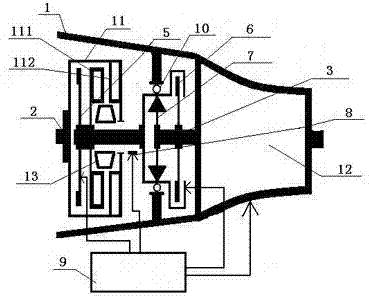

The invention discloses a speed changer, comprising a motor, an output shaft, a gear transmission mechanism and a control system, wherein the motor and the output shaft are connected by the gear transmission mechanism; the control system comprises a control unit and a driving device, the driving device is provided with a moving piece which can move between a first position and a second position inthe gear transmission mechanism, and when the moving piece is in the first position and the second position, the output shaft has different output characteristics. When load torque changes to a preset value, the control unit firstly adjusts the torque transferred by the motor to the gear transmission mechanism, and then controls the driving device to realize automatic gear shift. The speed changer of the invention can solve the problem of gear beating in the process of automatic gear shift, the electrical properties are improved, and the service life is also extended.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

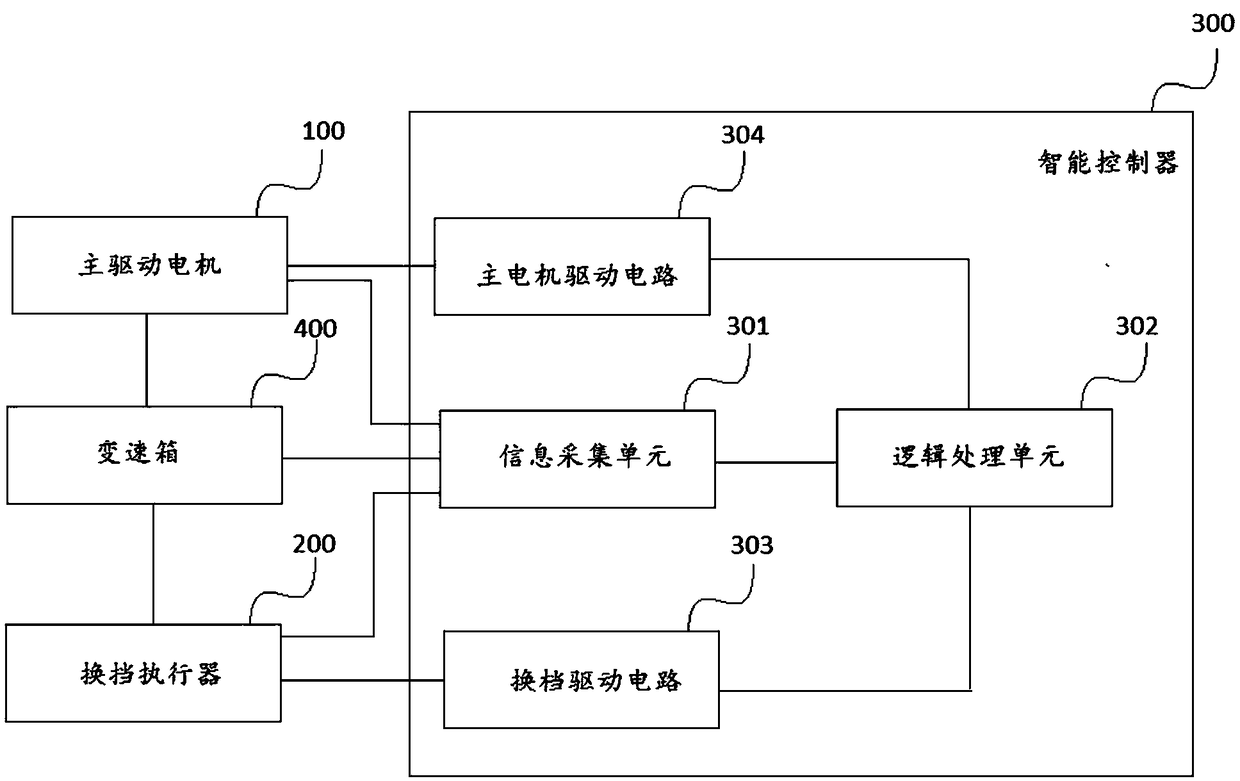

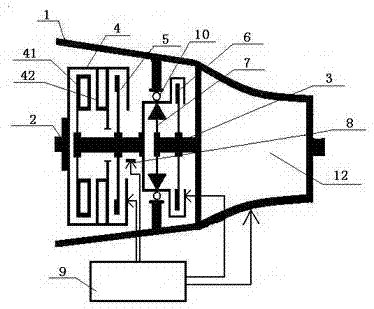

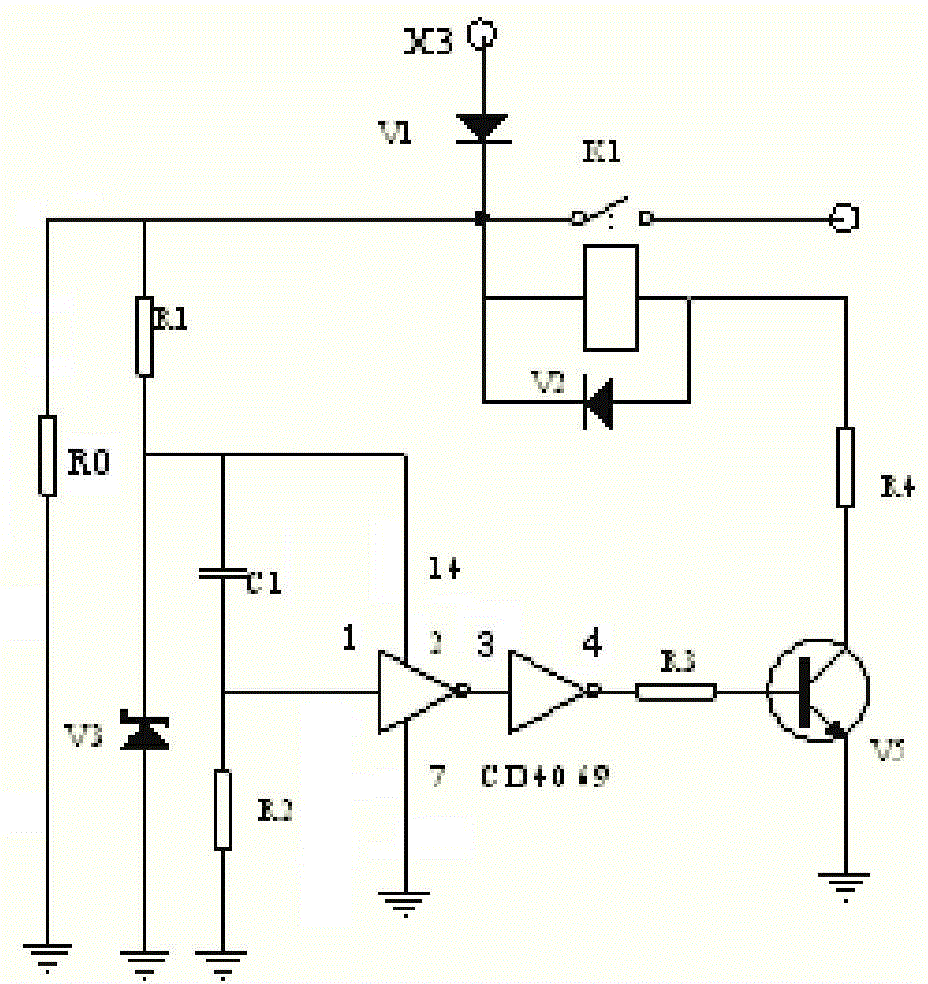

Adaptive automatic speed changing gearbox control system and control method thereof

ActiveCN108413025AImprove battery lifeExtended service lifeGearing controlMotor driveElectric machine

The invention provides an adaptive automatic speed changing and gear shifting intelligent control system. The adaptive automatic speed changing and gear shifting intelligent control system comprises amain driving motor, a gear shifting actuator, an intelligent controller and a gearbox, wherein the main driving motor and the gearbox are connected through splines, and the gear shifting operation ofthe gear shifting actuator is controlled by the intelligent controller; the intelligent controller comprises an information acquisition unit, a logical processing unit, a gear shifting driving circuit and a main motor driving circuit; vehicle driving data, power supply data and traffic data are input into the logical processing unit through the information acquisition unit, and information is processed by the logical processing unit so as to obtain a target gear suitable for the current main driving motor; the gear shifting driving circuit is connected with the gear shifting actuator, and a gear shifting associative ring in the gear shifting actuator is adaptively adjusted to move to the position of the target gear by the gear shifting driving circuit; and the main motor driving circuit is connected with the main driving motor, and the rotating speed of the main driving motor is adaptively controlled to match with the gear shifting associative ring to switch in the target gear by themain motor driving circuit according to the target gear.

Owner:上海质慧科技有限公司

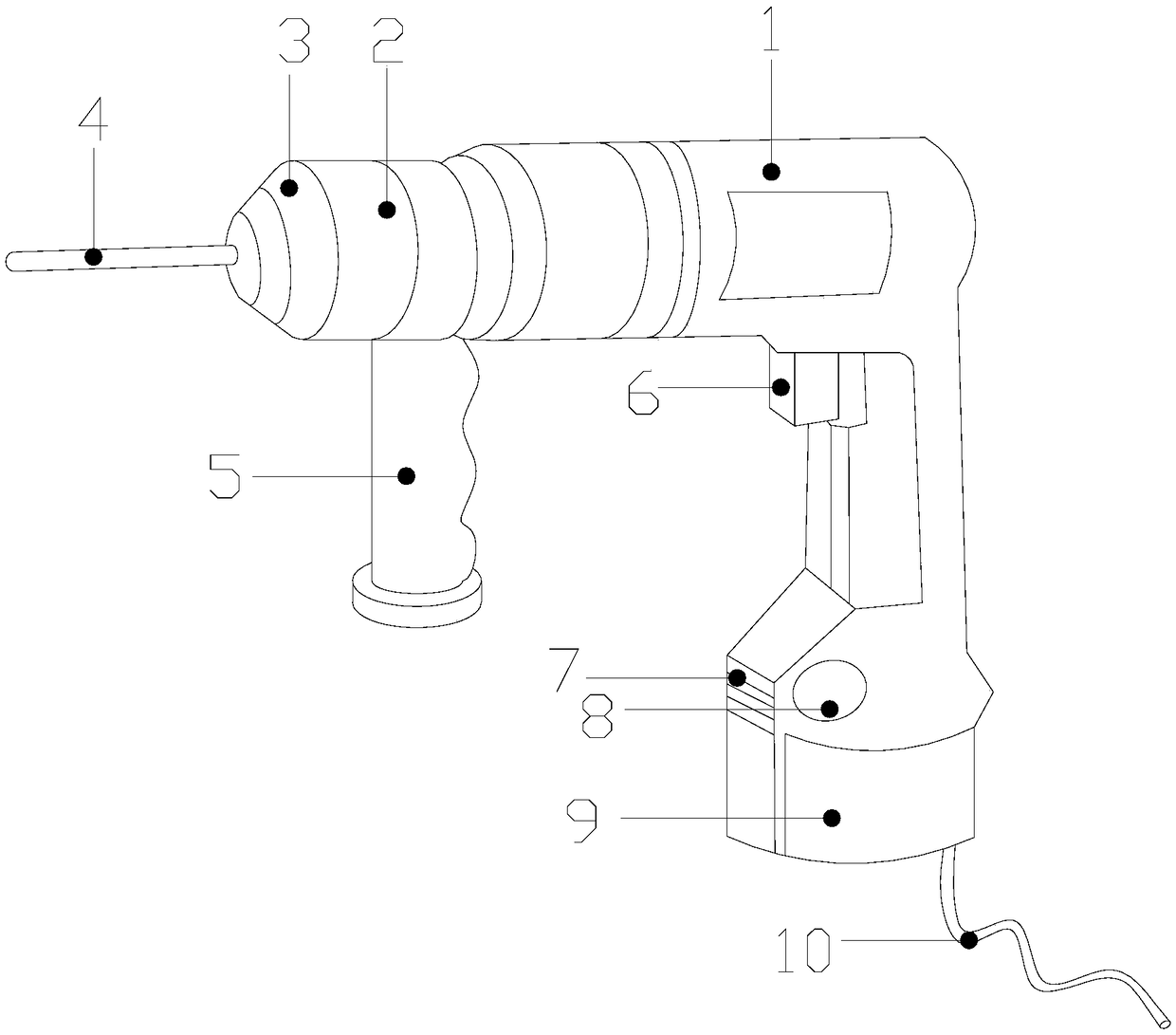

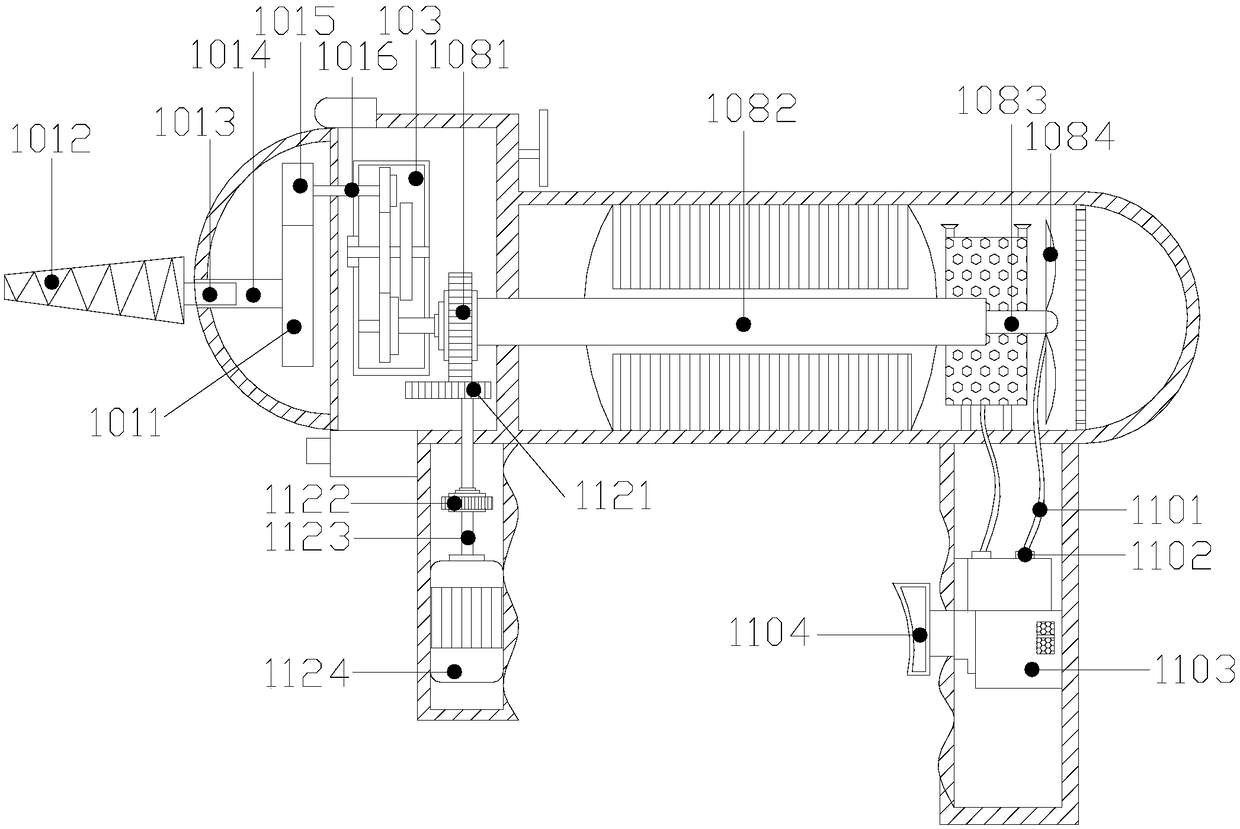

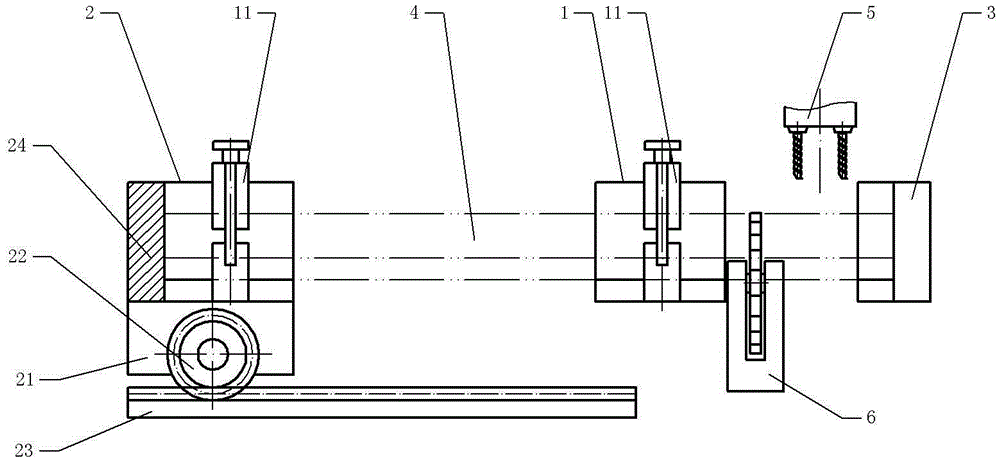

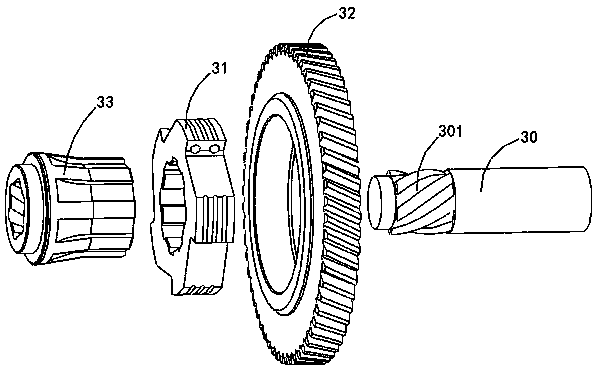

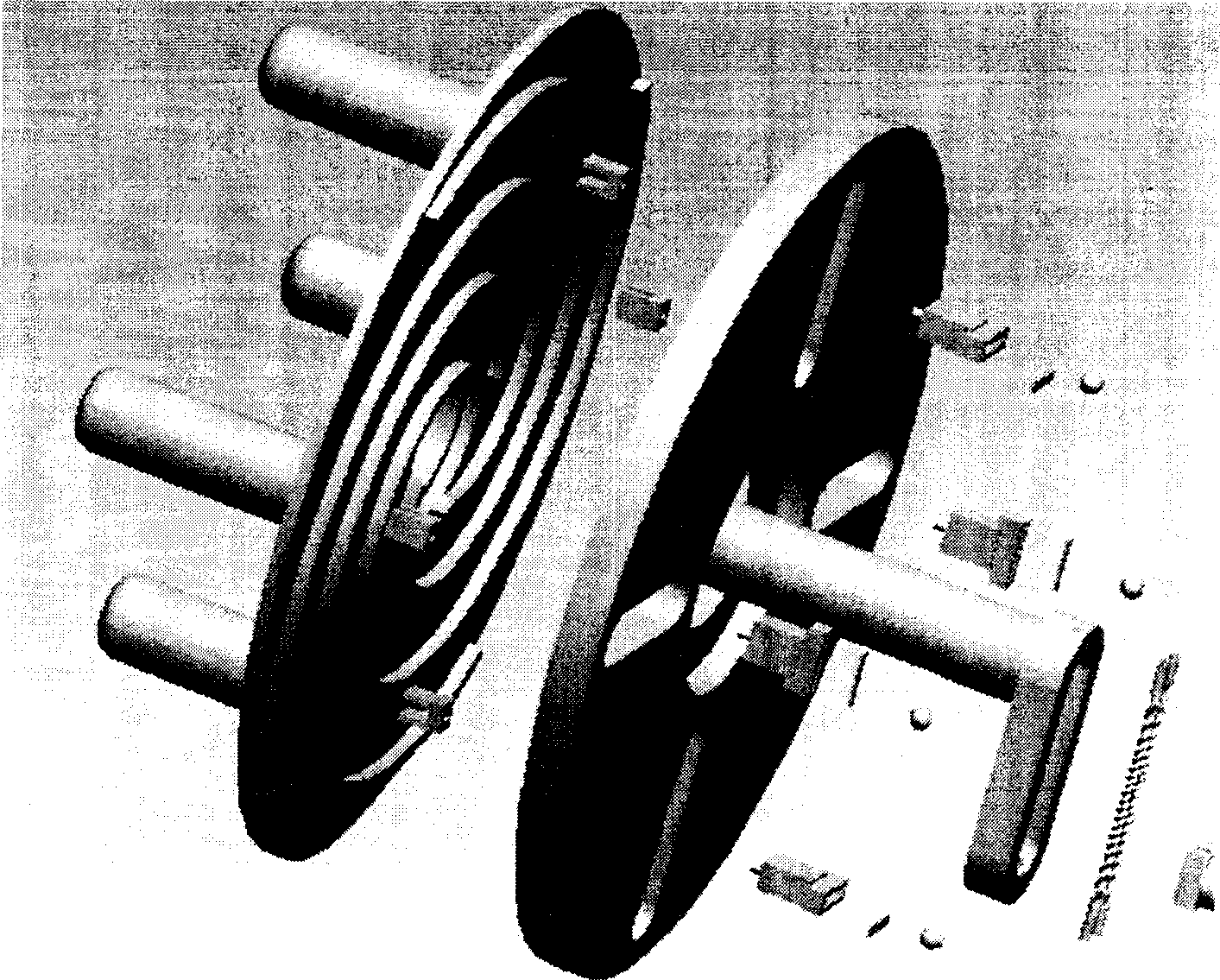

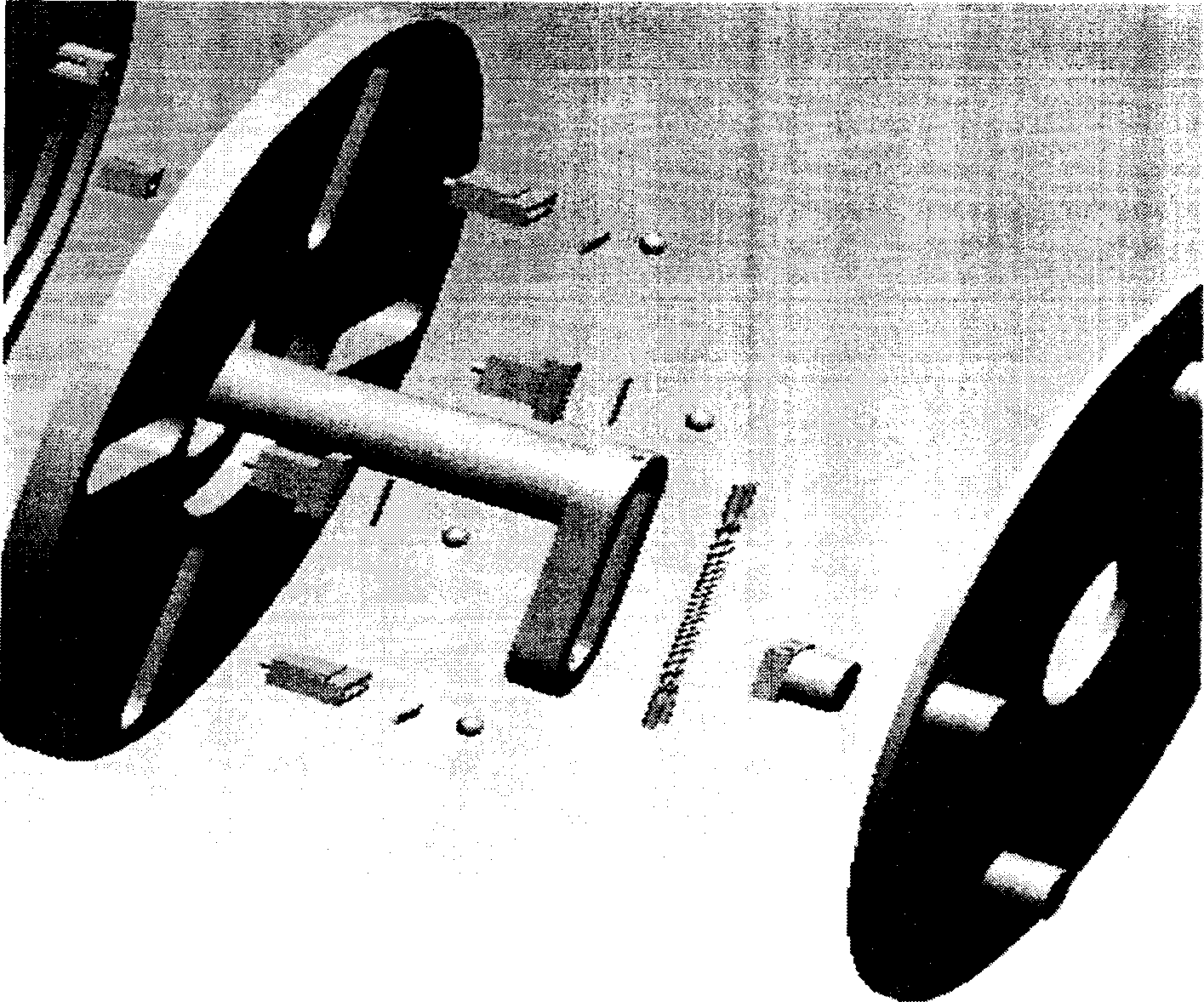

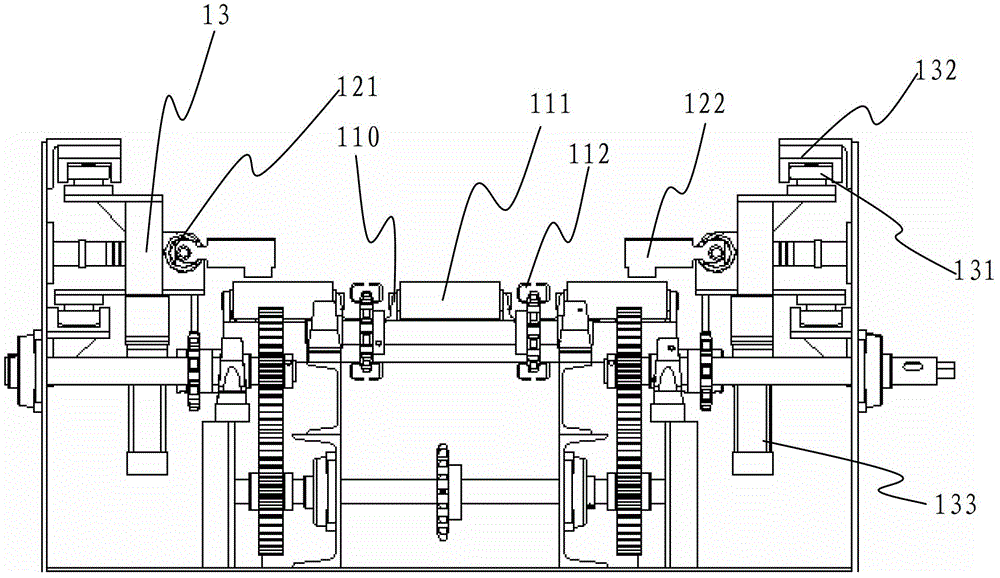

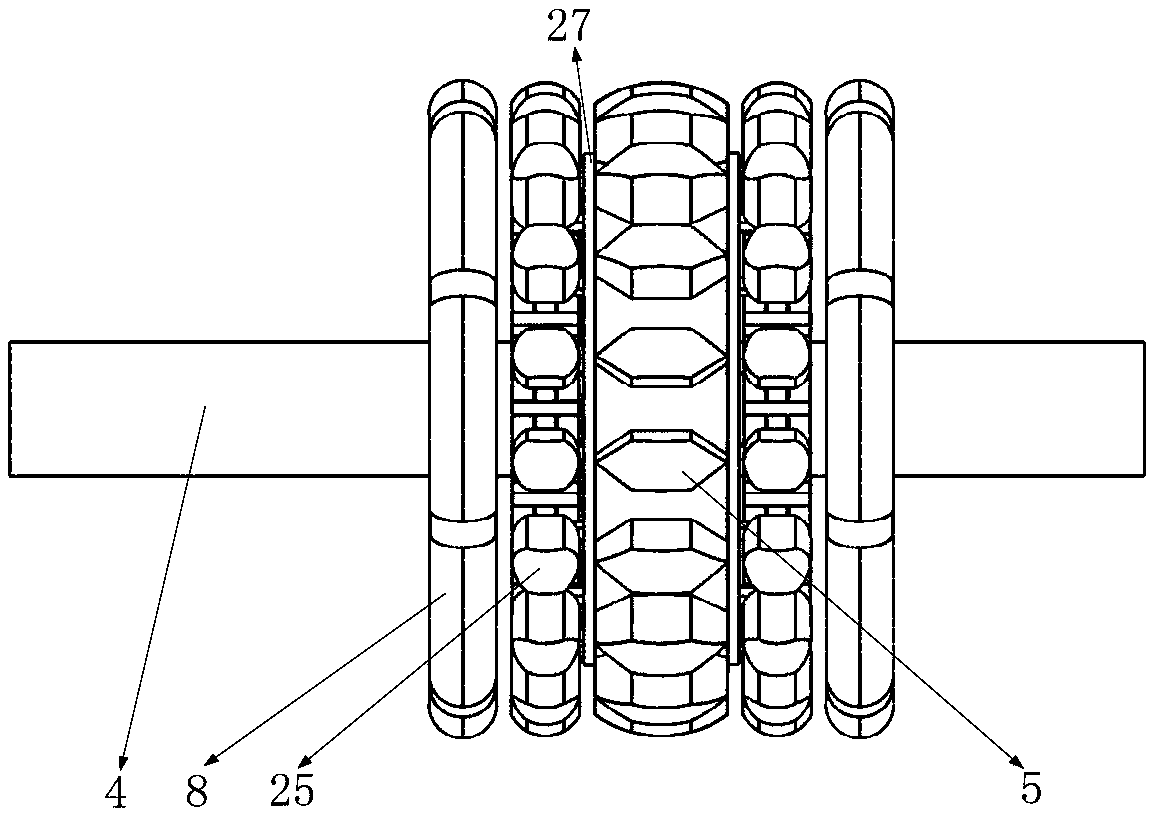

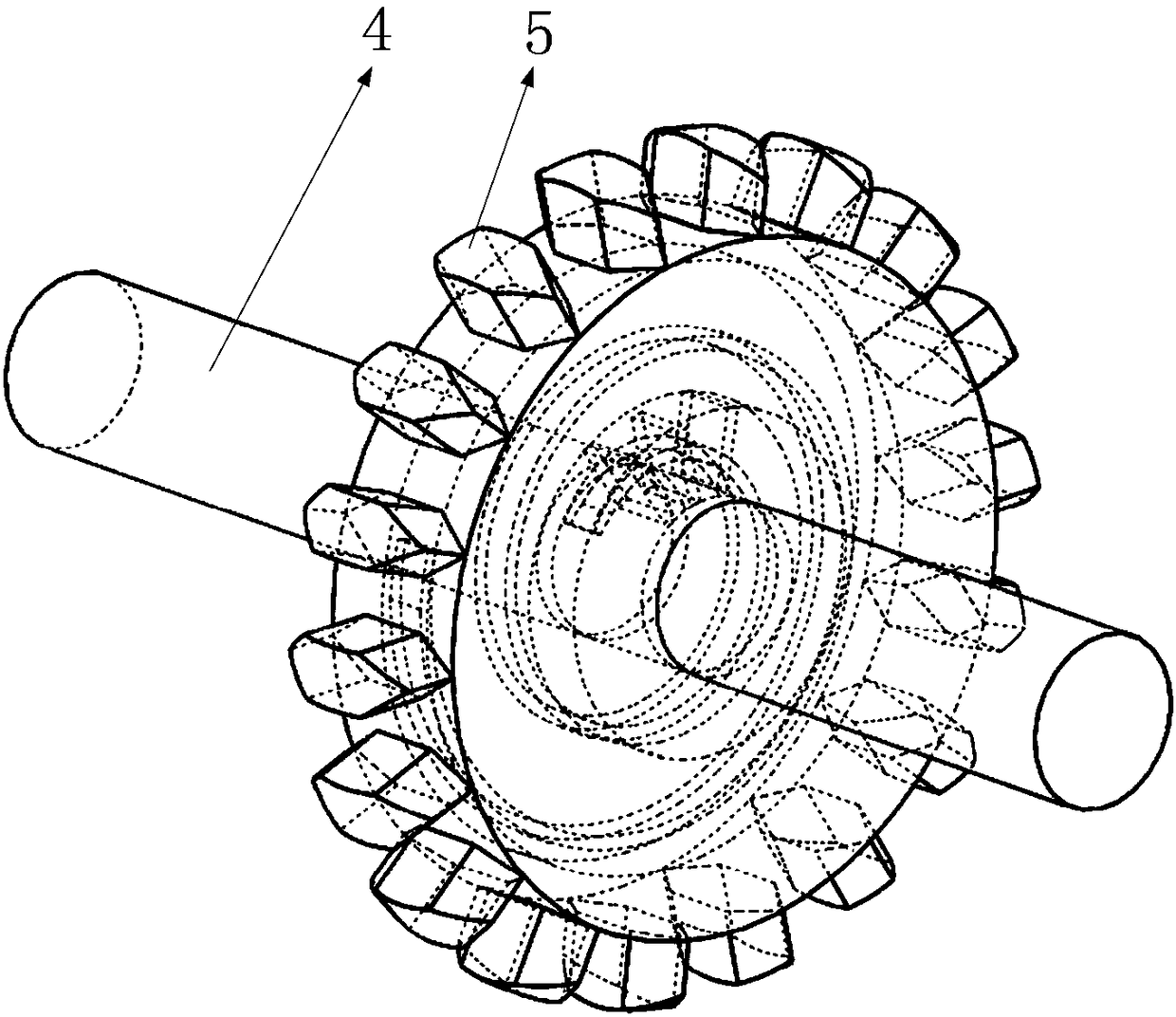

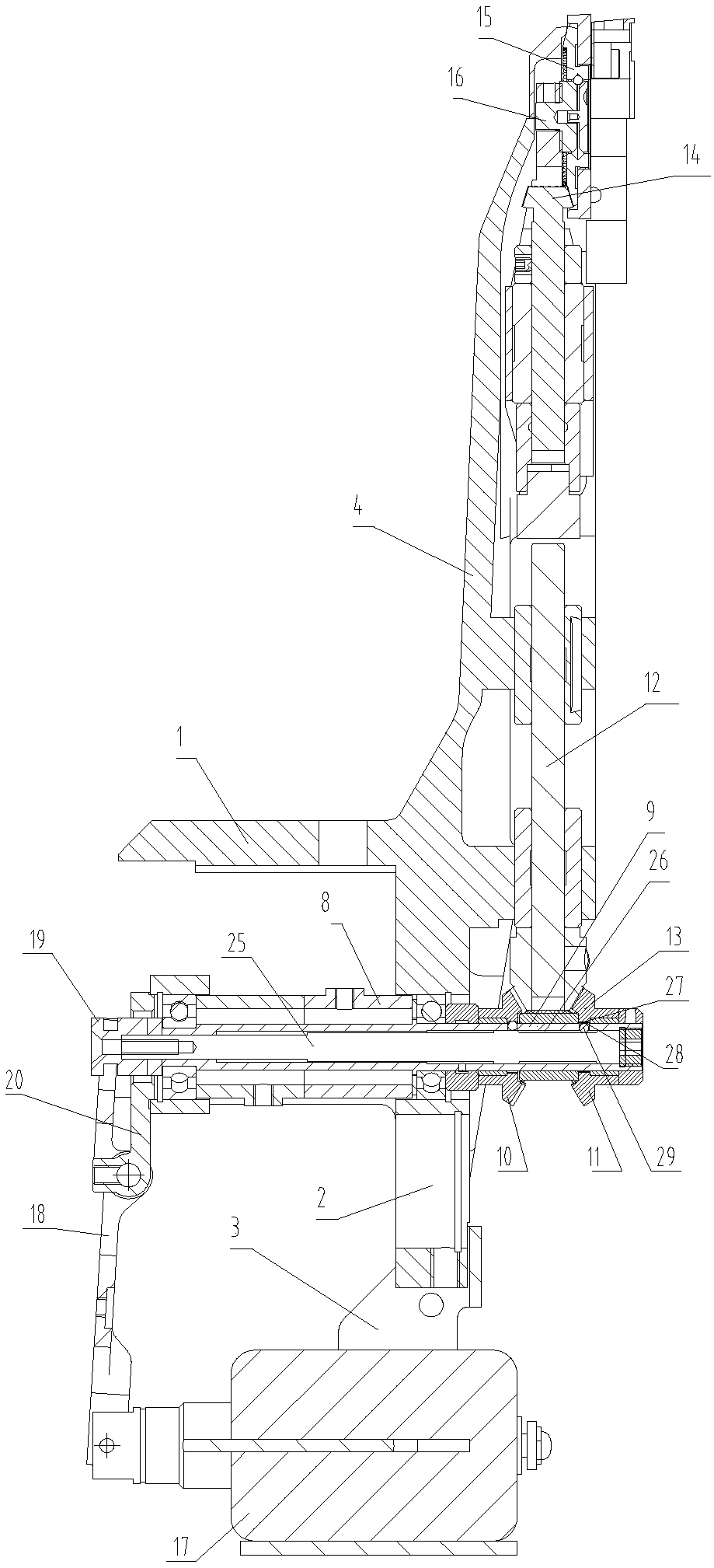

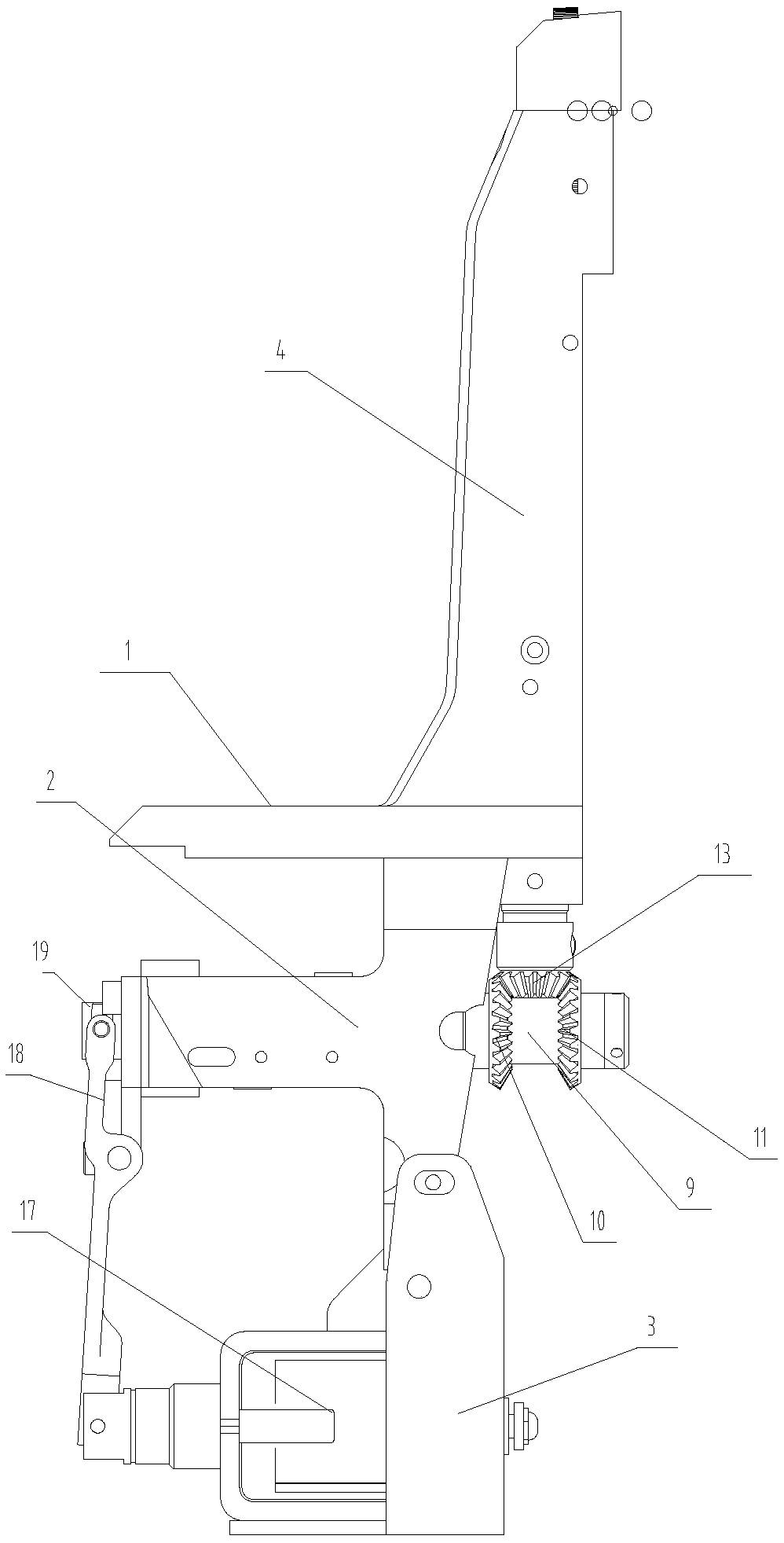

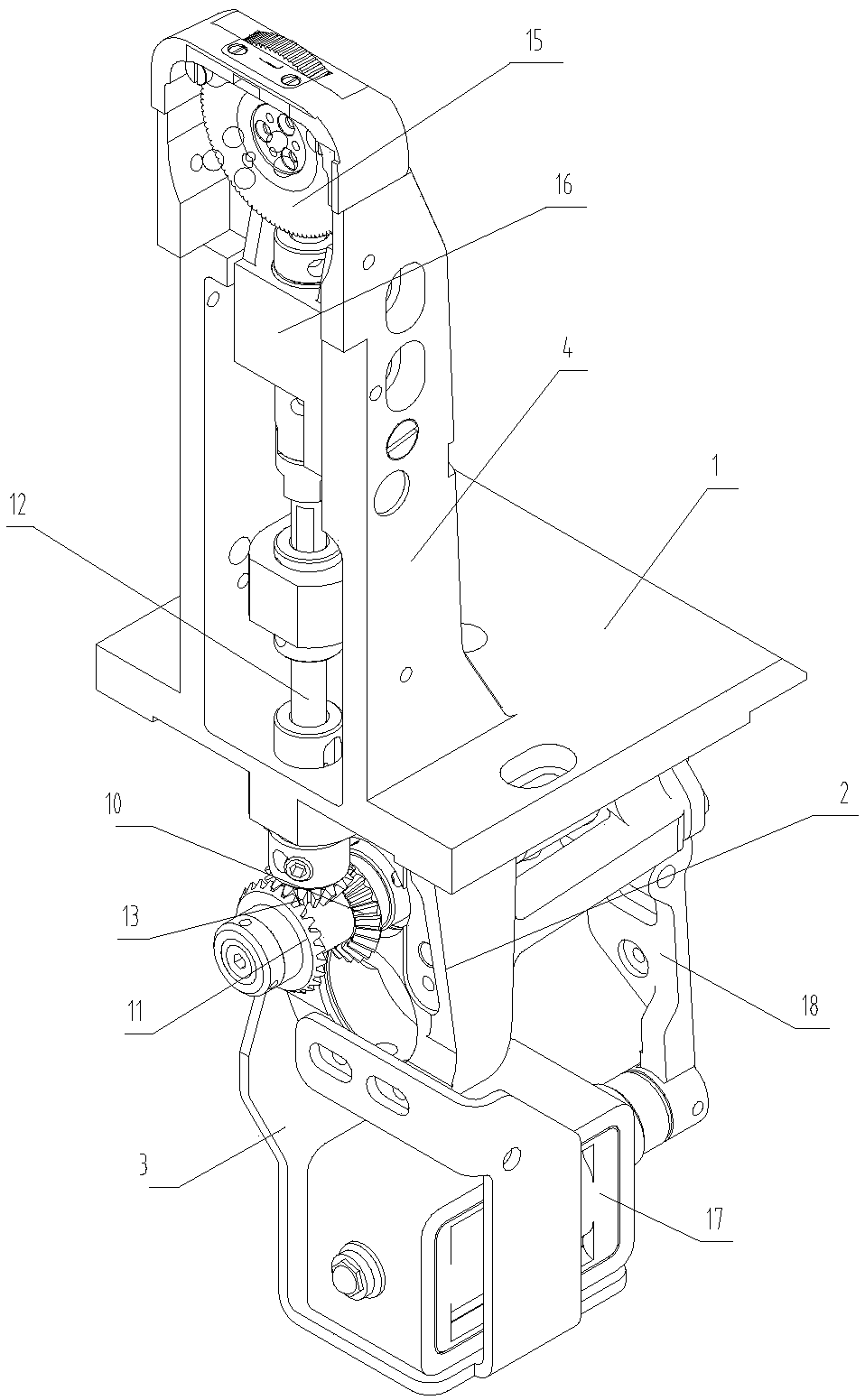

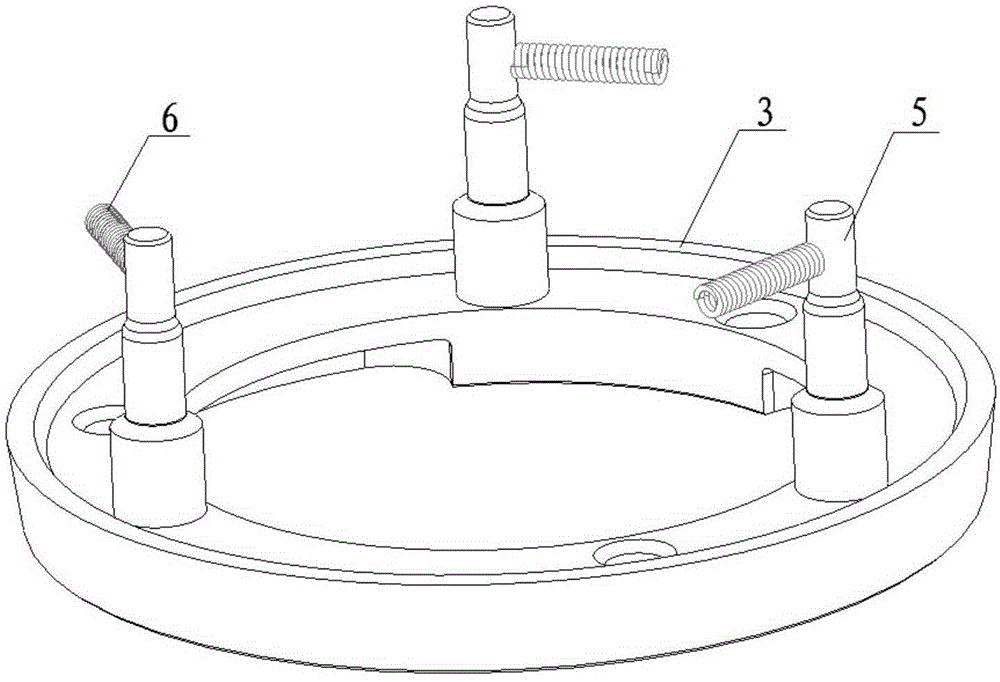

Shifting device of electric hammer

InactiveCN102837296ASimple structureReasonable designPortable percussive toolsQuality of workGear wheel

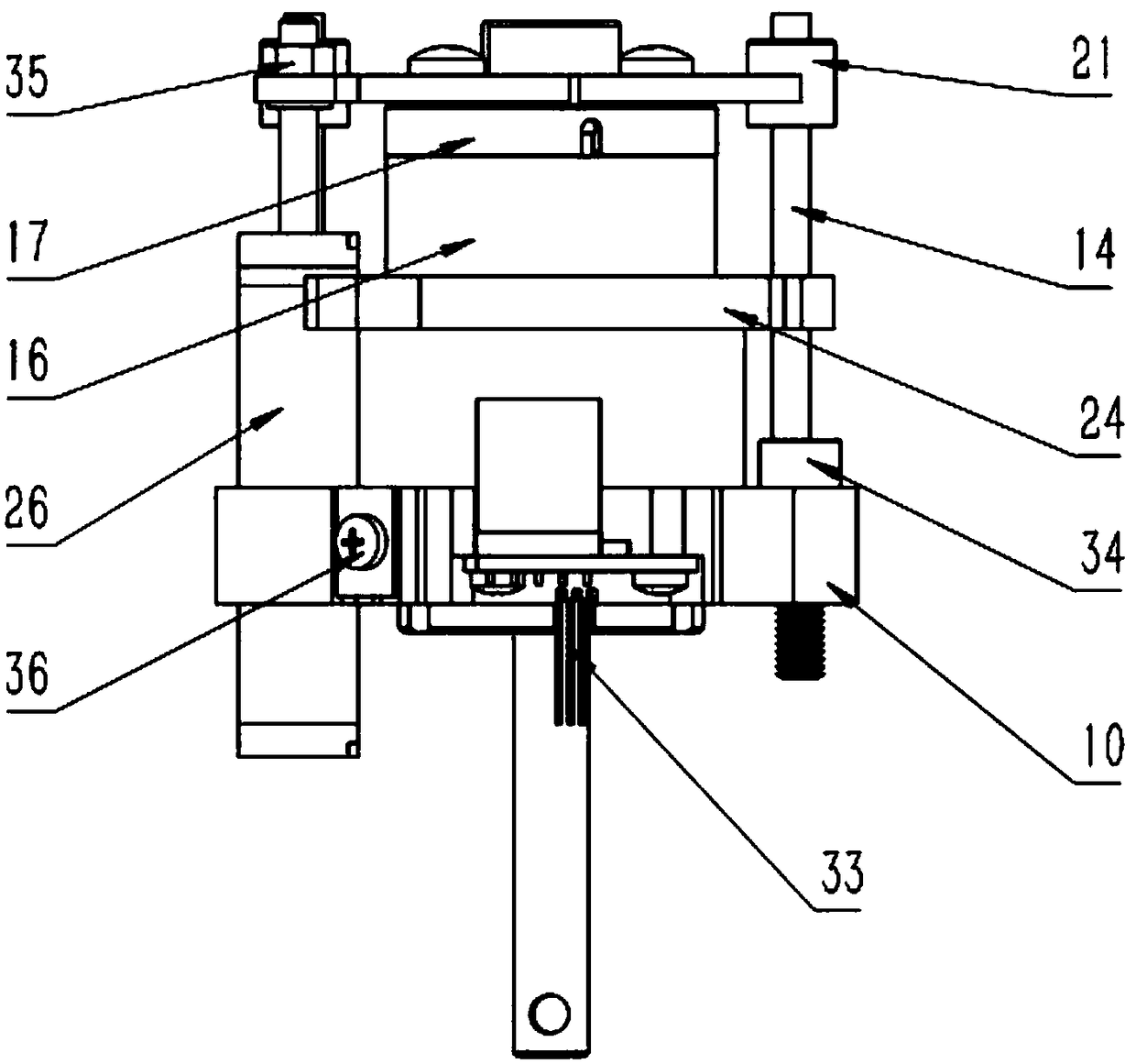

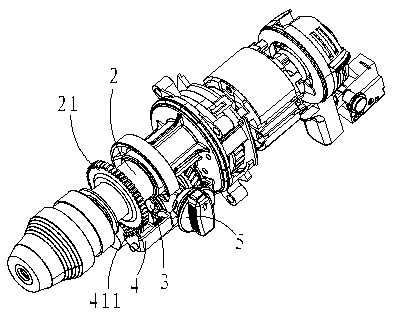

The invention discloses a shifting device of an electric hammer, and the electric hammer comprises a drive device, a gear shift device, a shifting device and a knob, wherein the gear shift device comprises an intermediate shaft, an intermediate shaft gear, a clutch and an oscillating rod bearing, a large gear is arranged inside the drive device, the large gear is engaged with the intermediate shaft gear, the oscillating rod bearing is connected with the drive device, the shifting device comprises a first shifting member and a second shifting member, one end of the first shifting member and one end of the second shifting member are respectively connected with a shifting rod on the knob, the other end of the first shifting member is connected with the intermediate shaft gear, the other end of the second shifting member is connected with the clutch, and the first shifting member and the second shifting member are respectively connected with a resetting mechanism. The shifting device is simple in structure, reasonable in design, convenient to manufacture, capable of realizing the shifting of the electric hammer without stopping the electric hammer, not only capable of avoiding the tooth seizing phenomenon, but also capable of guaranteeing the personal safety of the operation personnel, and capable of improving the labor productivity and the working quality.

Owner:ZHEJIANG BENYU TOOLS

Drug breaking and grinding device

InactiveCN106733109AIncrease grinding rateImprove grinding effectFurnace typesGrain treatmentsDrugTransmission system

The invention relates to a drug breaking and grinding device which comprises a breaking system, a grinding system and a power and transmission system. Through the improvement and reasonable arrangement of the various components, breaking and grinding are separated, so that the working efficiency is improved. In addition, with the creative adoption of the grinding system in which grinding balls are matched with a grinding internal barrel and a grinding external barrel, the grinding efficiency and the product quality are improved.

Owner:王宝林

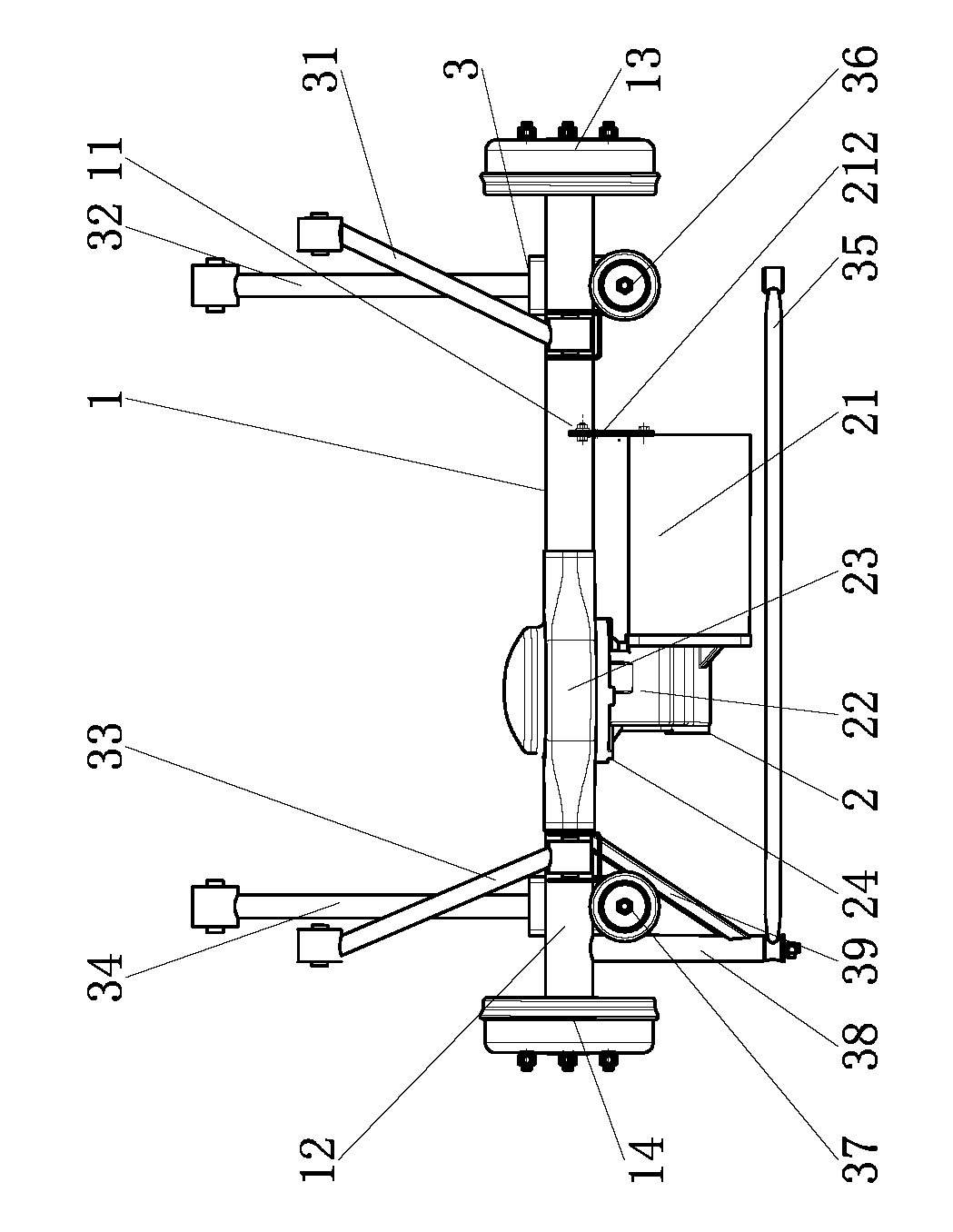

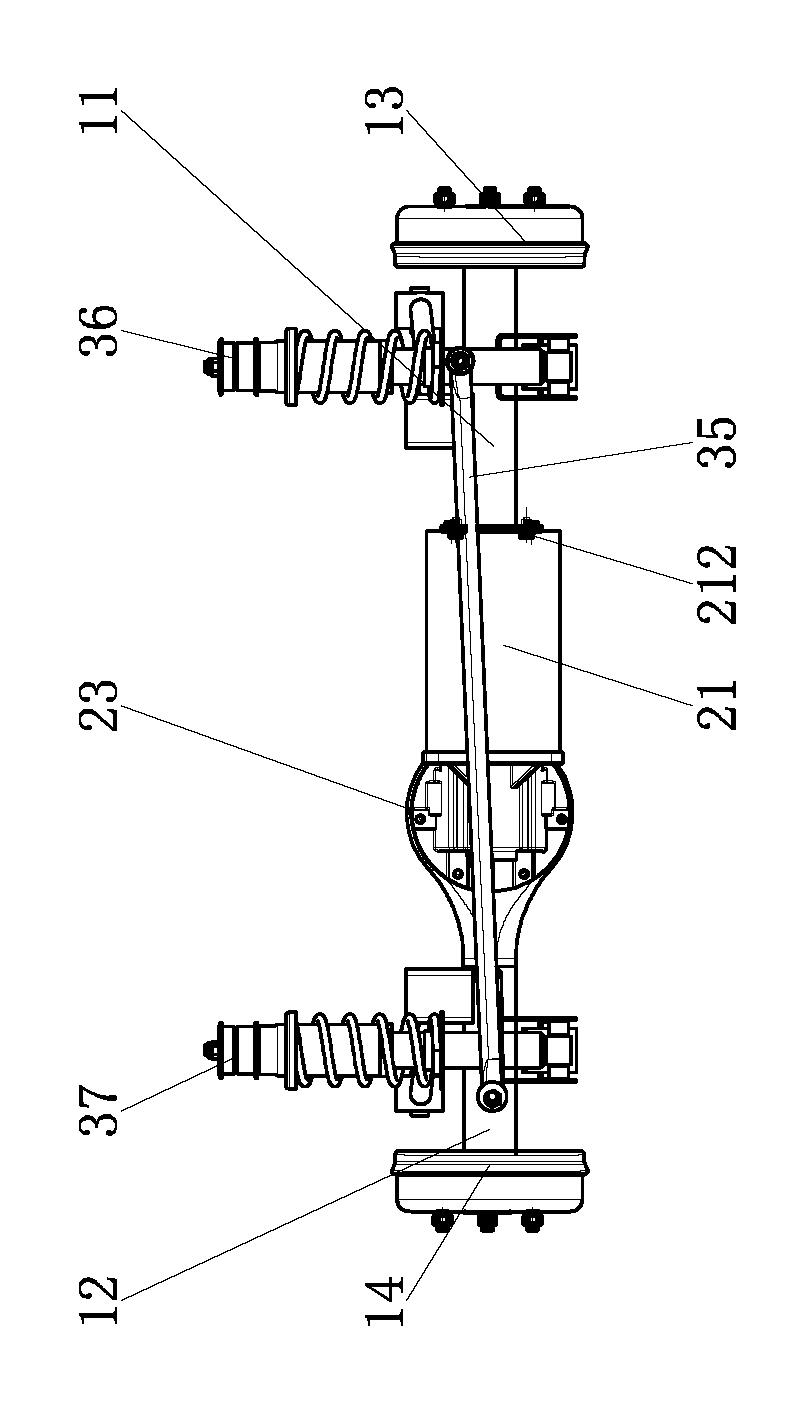

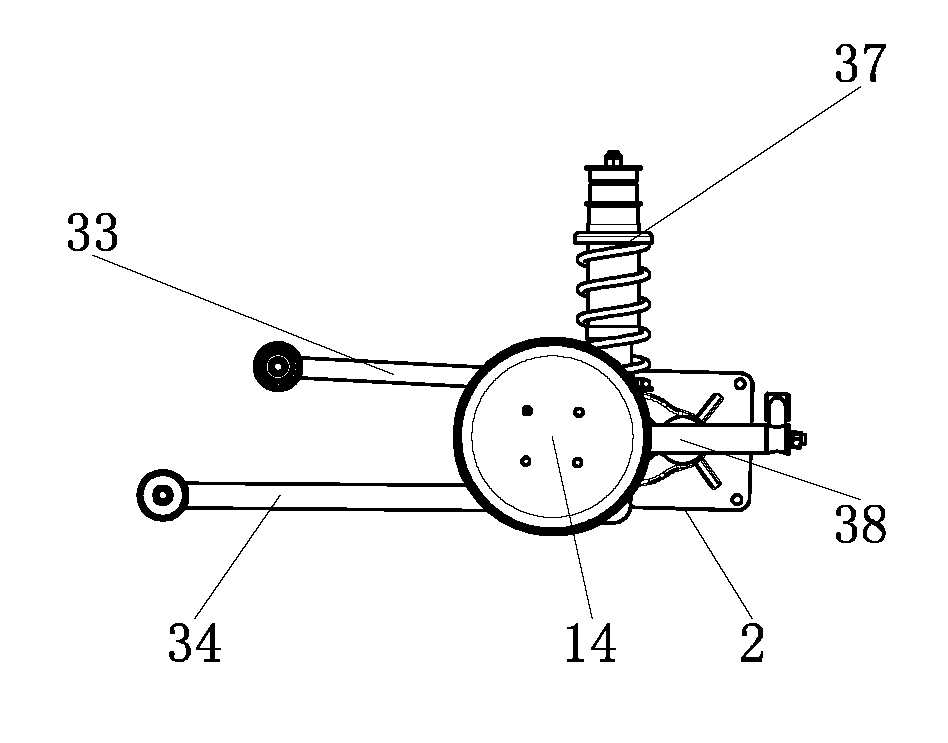

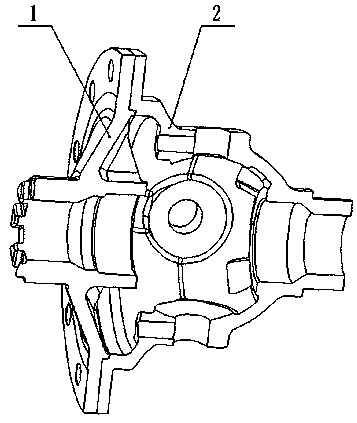

Integrated type motor rear-drive rear-suspension mechanism

ActiveCN103158542AReduce intermediate transmission linksImprove efficiencyInterconnection systemsControl devicesTrailing armControl theory

The invention discloses an integrated type motor rear-drive rear-suspension mechanism which comprises a rear axle, a driving mechanism and a rear suspension. A differential mechanism is a planetary gear differential mechanism. A cylindrical input gear is arranged on a planetary gear support in the planetary gear differential mechanism. The planetary gear differential mechanism and a reducer are installed in the same integrated shell body in an integrated mode. An output shaft of the reducer is connected with the cylindrical input gear in the planetary gear differential mechanism in an integrated and transmission mode through an output gear. The output shaft of the reducer is parallel to an output shaft of the planetary gear differential mechanism. An input shaft of the reducer is fixedly connected with an output shaft of an electromotor in an integrated and coaxial mode. The suspension comprises two upper trailing arms and two lower trailing arms. The integrated type motor rear-drive rear-suspension mechanism can reduce an intermediate transmission link and improve transmission efficiency, and the transmission efficiency can be improved to 92%. Meanwhile, occupied space near the rear axle can be reduced greatly so that other parts can be arranged conveniently, and comfort of a rider can be improved.

Owner:北京宏瑞汽车科技股份有限公司

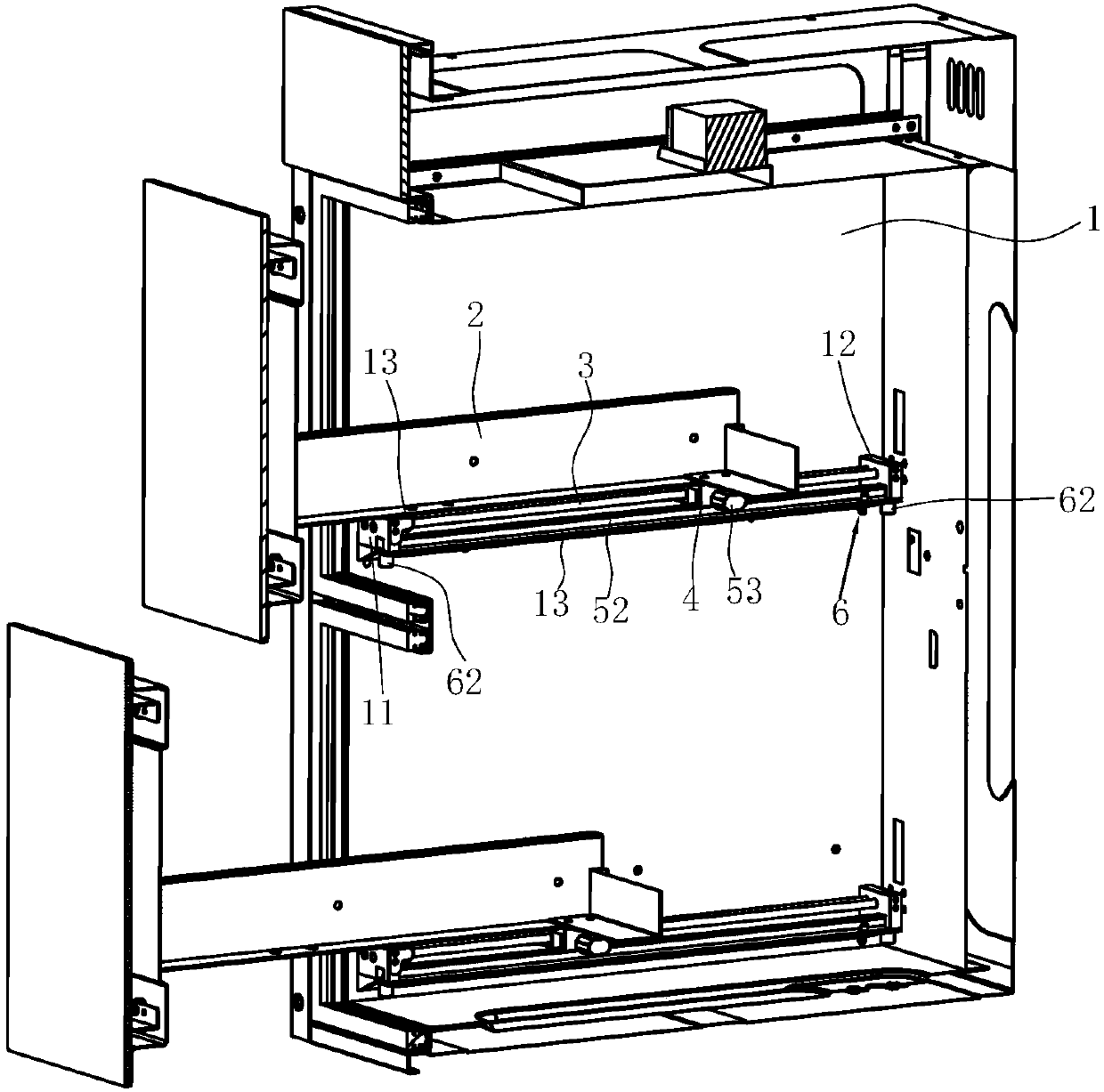

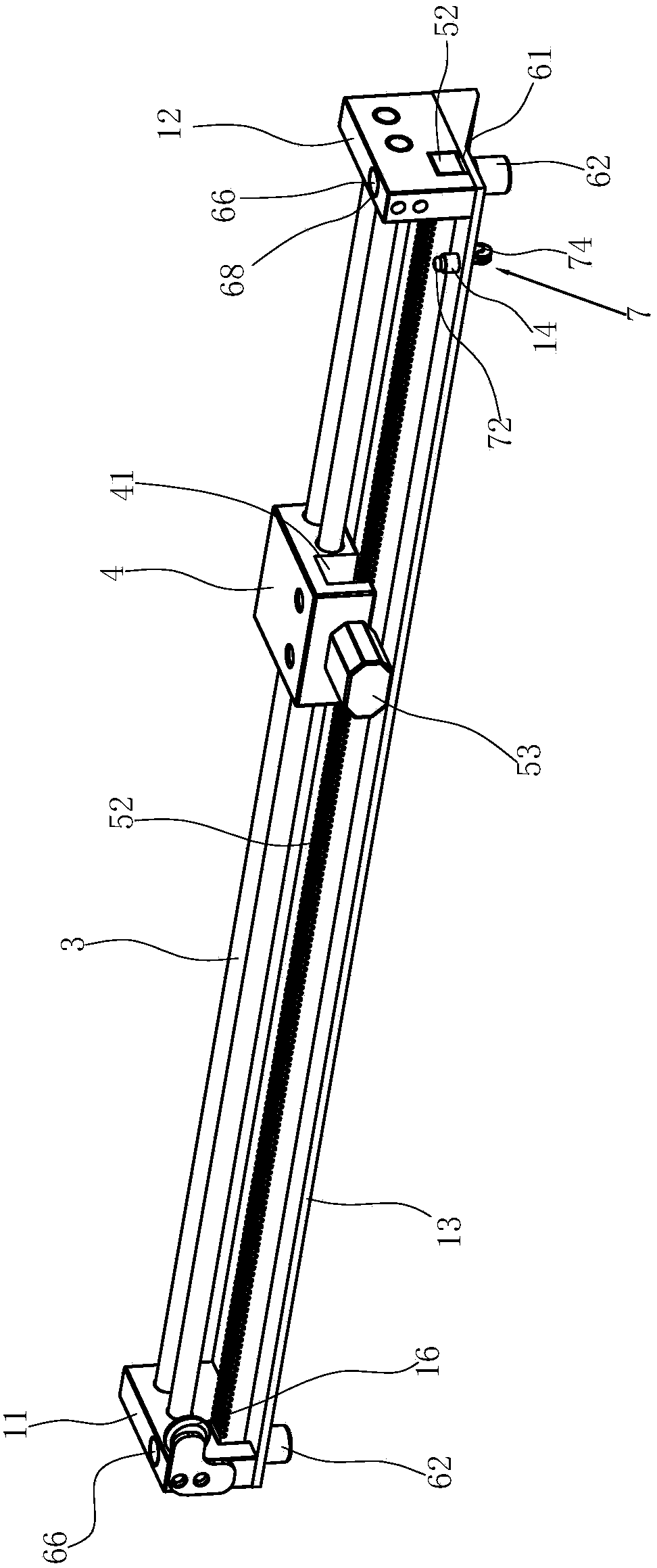

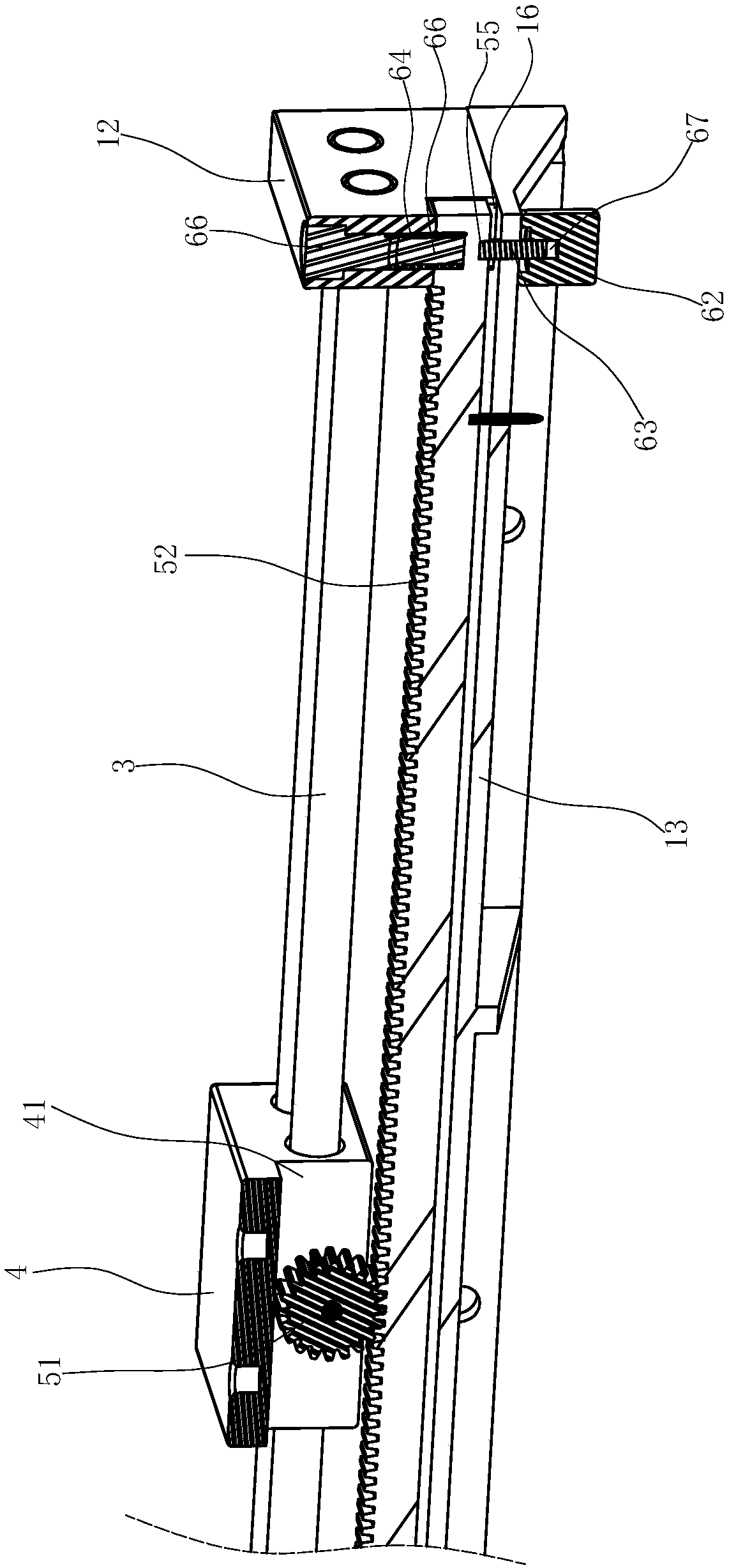

Drawer opening mechanism

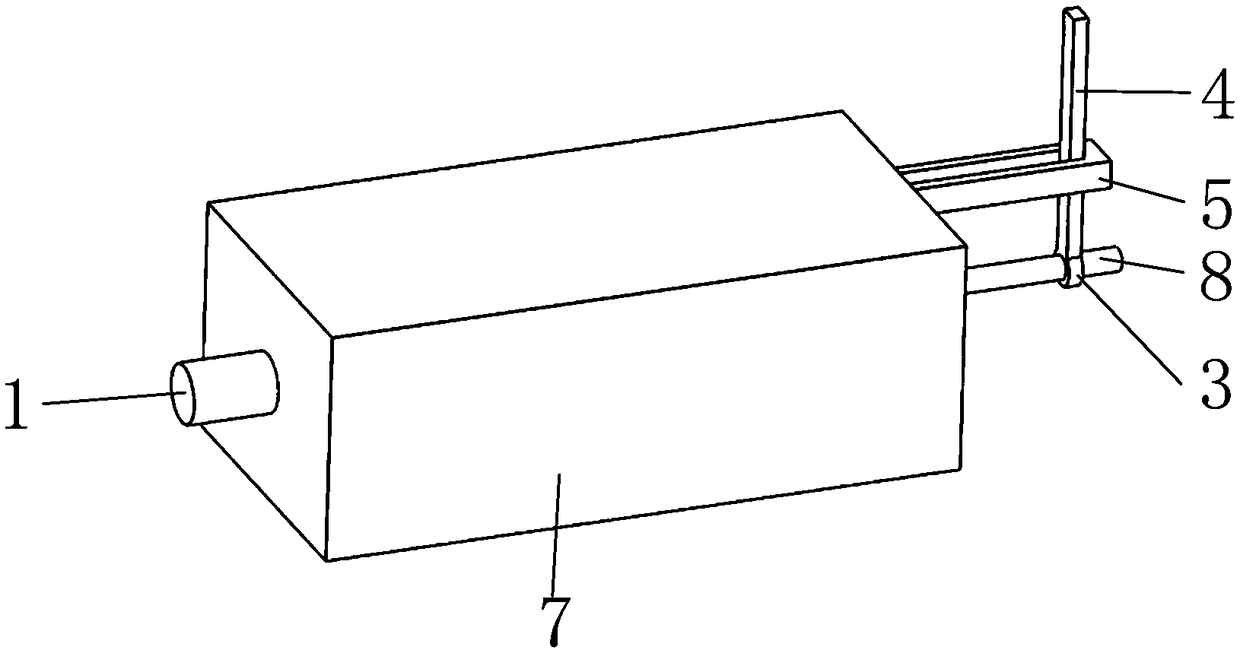

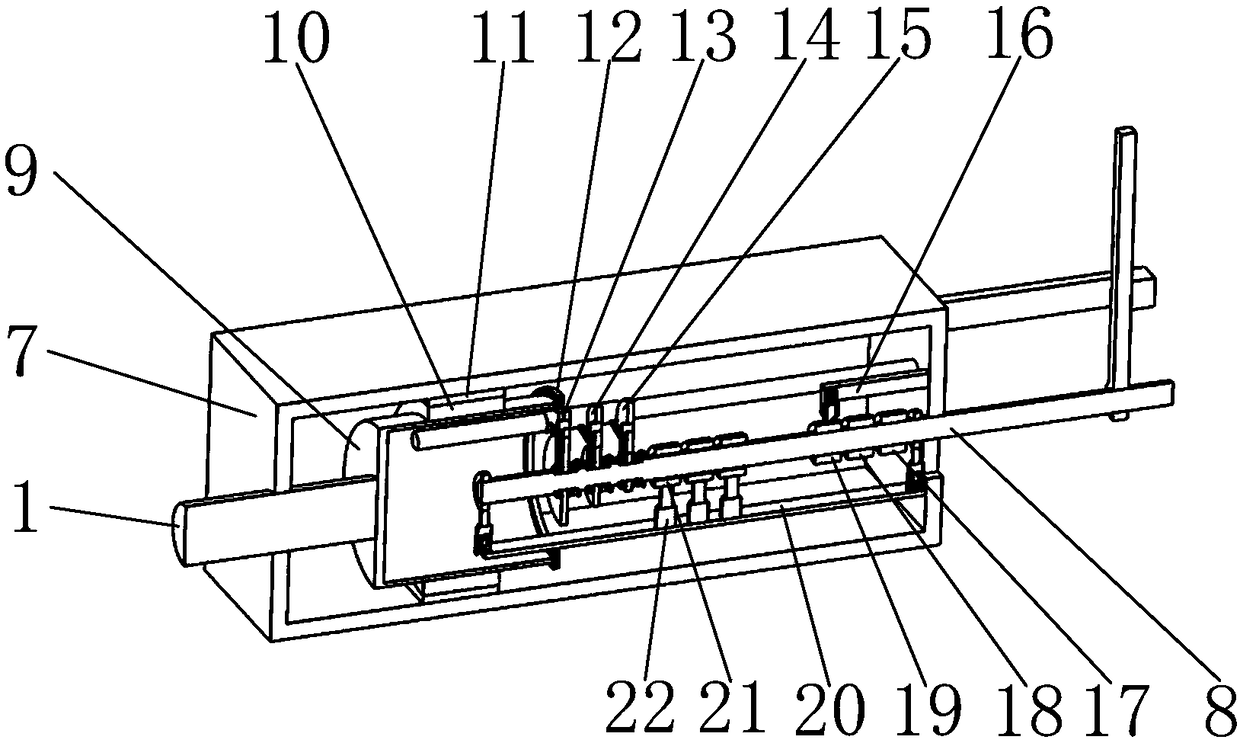

The invention relates to a drawer opening mechanism. The drawer opening mechanism is arranged between a cabinet body (1) of a disinfection cabinet and a drawer (2). The drawer opening mechanism is characterized in that a guide rod (3) and a rack (52) are located relative to the side walls of the cabinet body (1) and arranged in the pulling direction of the drawer (2); a sliding table (4) is in driving connection with the drawer (2) can be limited on the guide rod (3) in a sliding manner; the rack (52) and the guide rod (3) are arranged at intervals in an up-down manner; a clutch mechanism (6)is used for driving the rack (52) to move up and down, so that the rack is meshed with or de-meshed from a gear (51); a motor (53) is in driving connection with the sliding table (4); and an output shaft of the motor (53) is in driving connection with the gear (51). A manual mode and an automatic mode of the drawer opening mechanism can be freely switched; and the drawer opening mechanism is compact in structure and can be installed in a narrow and small space.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

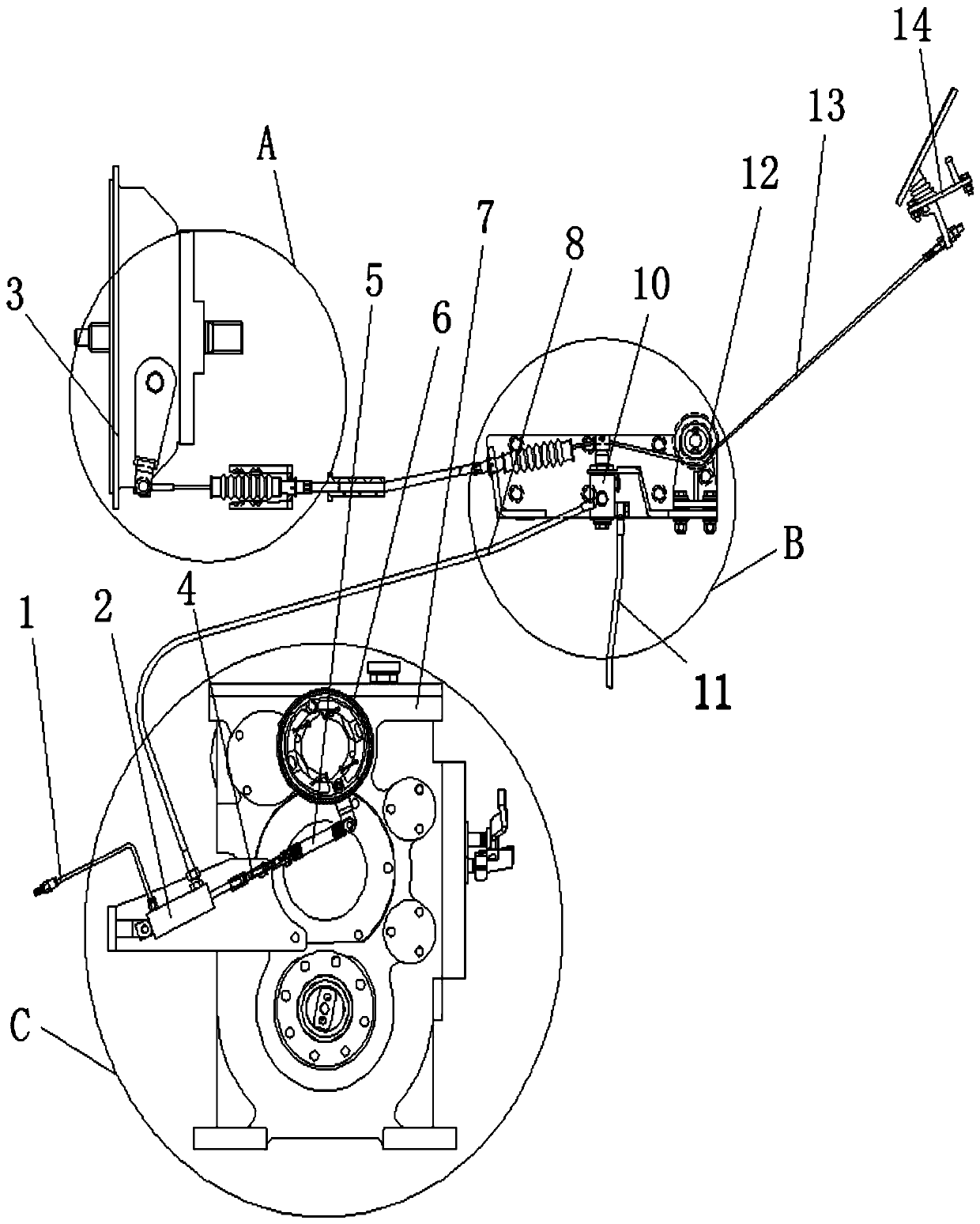

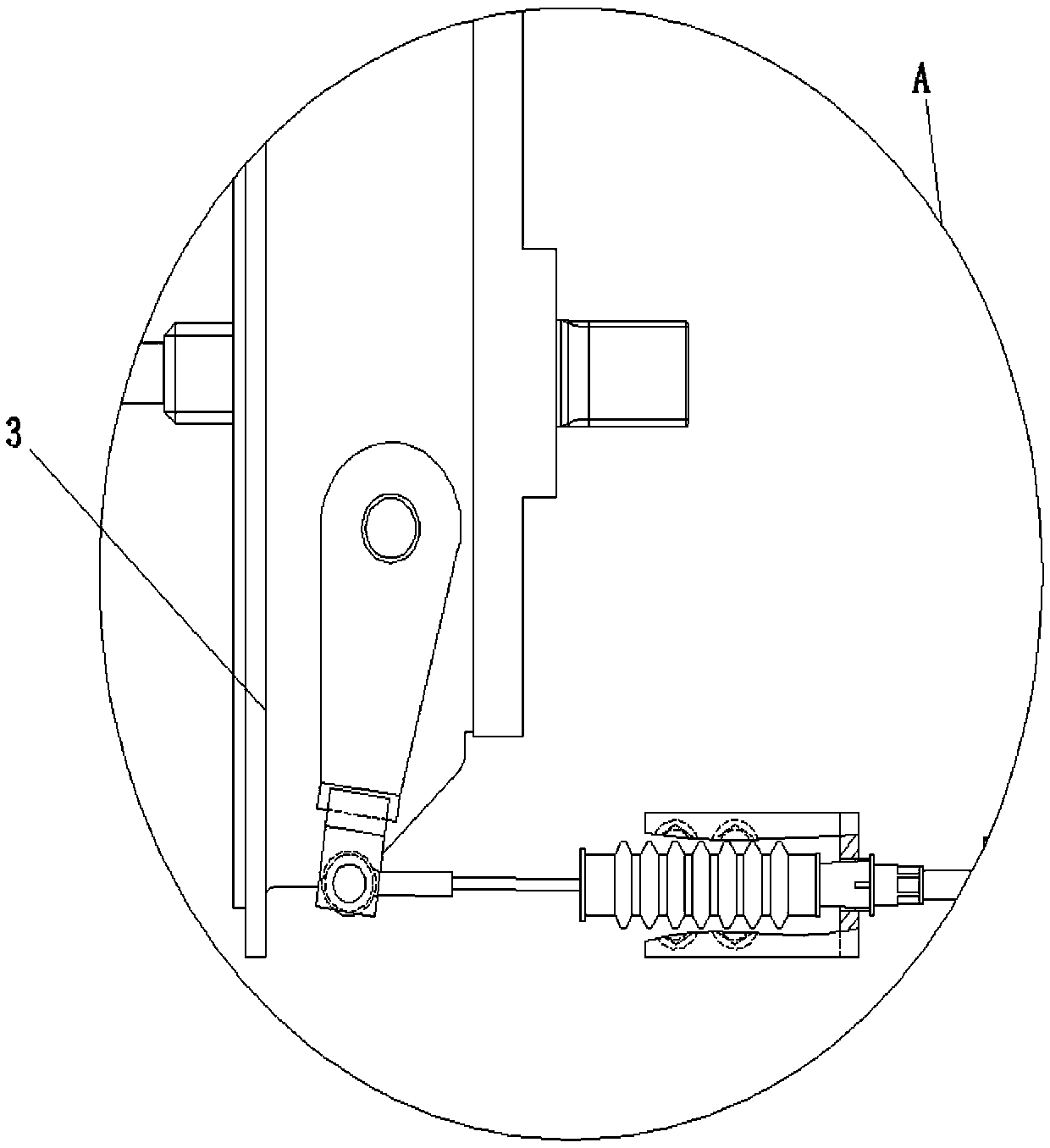

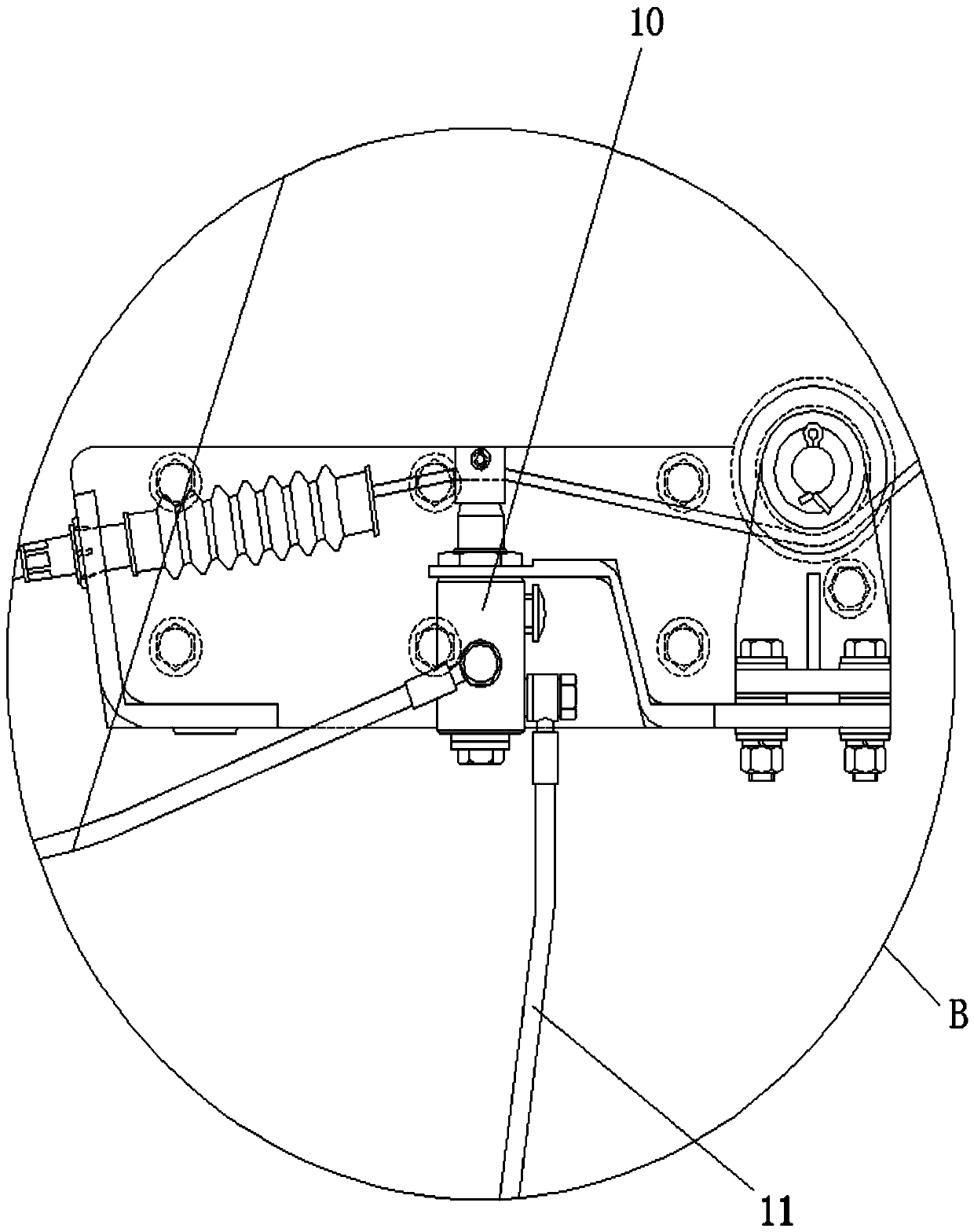

Auxiliary brake mechanism of gearbox

InactiveCN107825960AImprove reliabilitySimple structureBraking element arrangementsMechanical braking transmissionBlock and tackleEngineering

The invention discloses an auxiliary brake mechanism of a gearbox. The auxiliary brake mechanism comprises a clutch pedal, a muffler combined device with an exhaust pipe, a single-acting cylinder, a clutch and a drum brake, wherein the muffler combined device with the exhaust pipe is connected with the side edge of the single-acting cylinder in a penetrating manner, and the other side edge of thesingle-acting cylinder is connected with one end of a first hose in a penetrating manner; the other end of the first hose is connected with a button valve in a penetrating manner; one end of a secondhose is connected to the lower end of the button valve in a penetrating manner; the button valve is opened and closed through the pulling of one end of a first flexible shaft, and the other end of thefirst flexible shaft goes around guiding wheels of a pulley block and is connected to the clutch pedal; and the control comfortableness of a manipulator is improved, and the gear shifting is smoother. The auxiliary brake mechanism disclosed by the invention is applied to a mechanically-driven single-steel-wheel vibrating roller, so that time for gear shifting is shortened, the labor intensity ofthe manipulator is reduced, the gear shifting is smoother, the manipulation comfortableness of road rolling is improved, and besides, the reliability of a gearbox is improved.

Owner:YTO LUOYANG CONSTR MASCH CO LTD

Combined clutch of automotive AMT (Automated Mechanical Transmission)

The invention relates to a combined clutch of an automotive AMT (Automated Mechanical Transmission). The combined clutch of the automotive AMT comprises a housing, an engine power output shaft, a gear transmission input shaft, a hydraulic transmission device and a one-way clutch; the hydraulic transmission device is a hydraulic torque converter with a locking device or the hydraulic transmission device is a device which is formed by a hydraulic coupling and a friction clutch A; a pump wheel and a turbine of the hydraulic coupling can be locked into a whole through the friction clutch A; the engine power output shaft is connected with the hydraulic transmission device; the hydraulic transmission device is connected with the one-way clutch; the one-way clutch is connected with the gear transmission input shaft and provided with a friction clutch B; an inner ring and an outer ring of the one-way clutch can be locked into a whole through the friction clutch B. According to the combined clutch of the automotive AMT, an automobile can start smoothly, the problem that impact on shifting is caused by power interruption in the process of the shifting of the automobile is solved, the structure is simple, the cost is low, and the wide popularization and application can be convenient.

Owner:张耀新

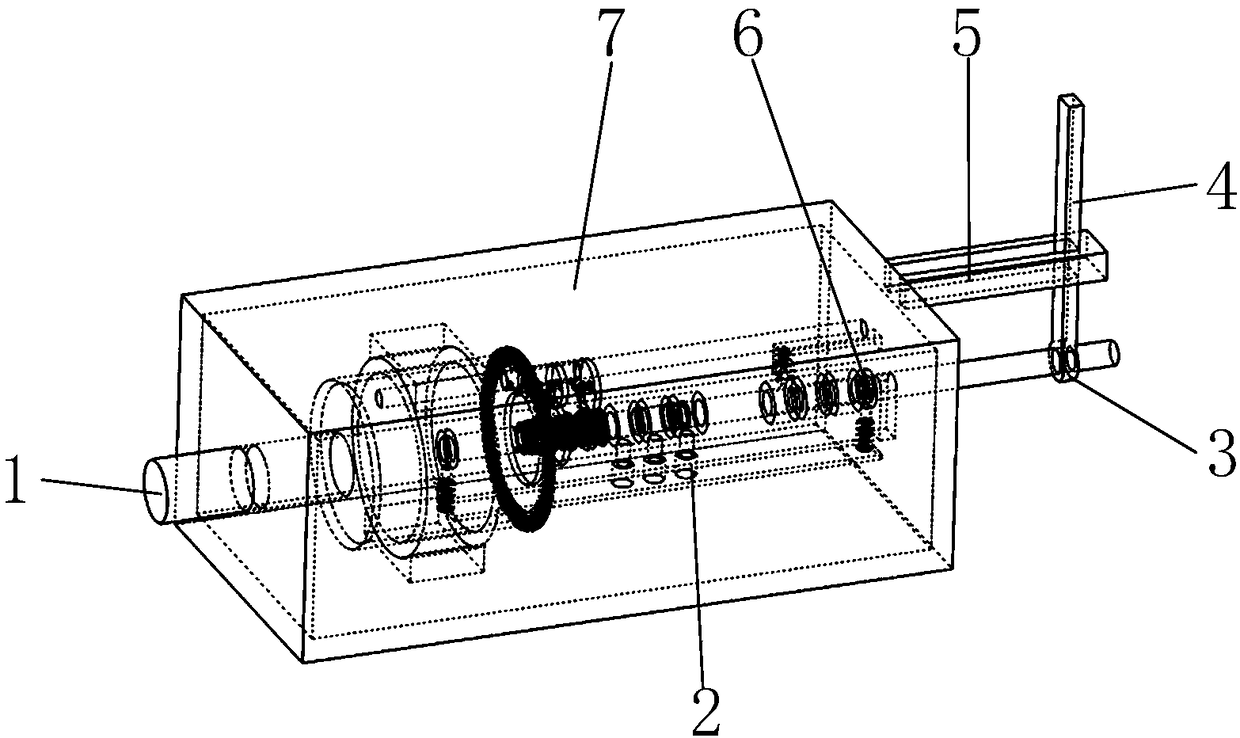

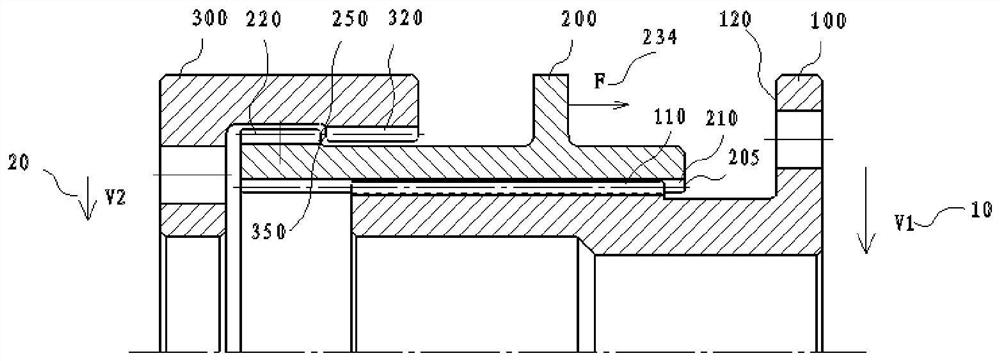

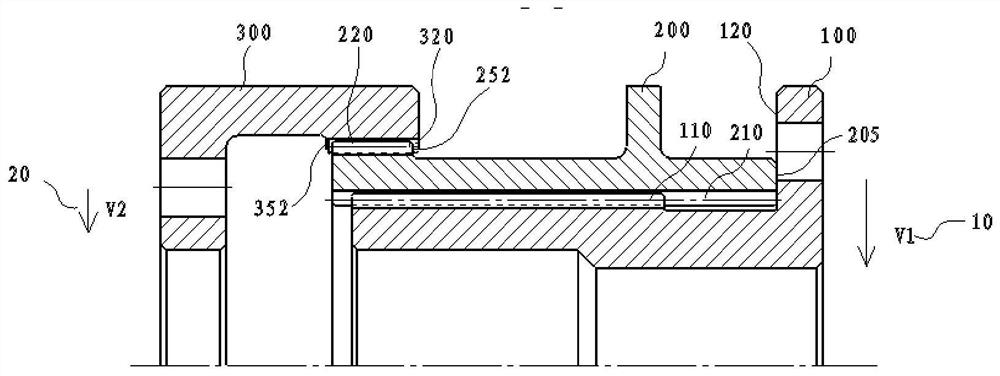

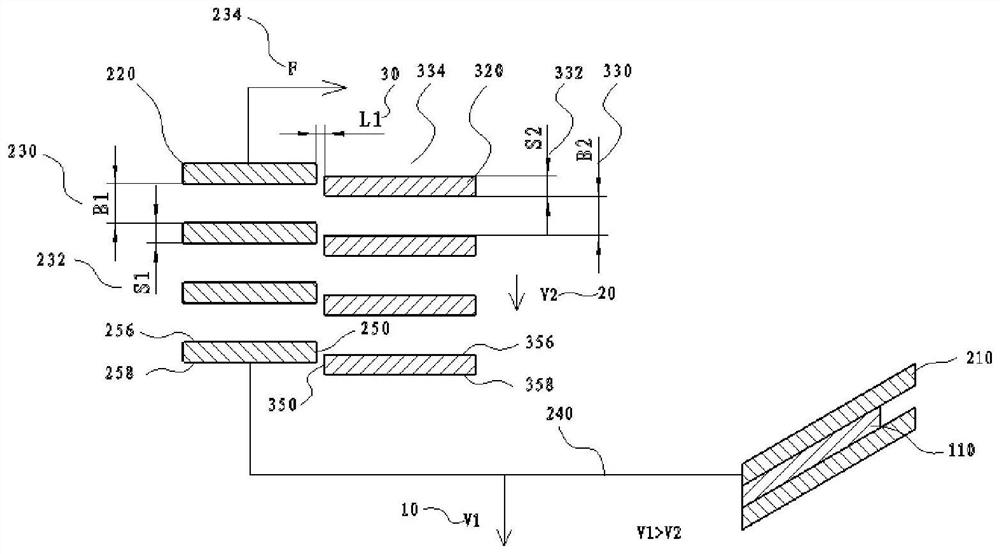

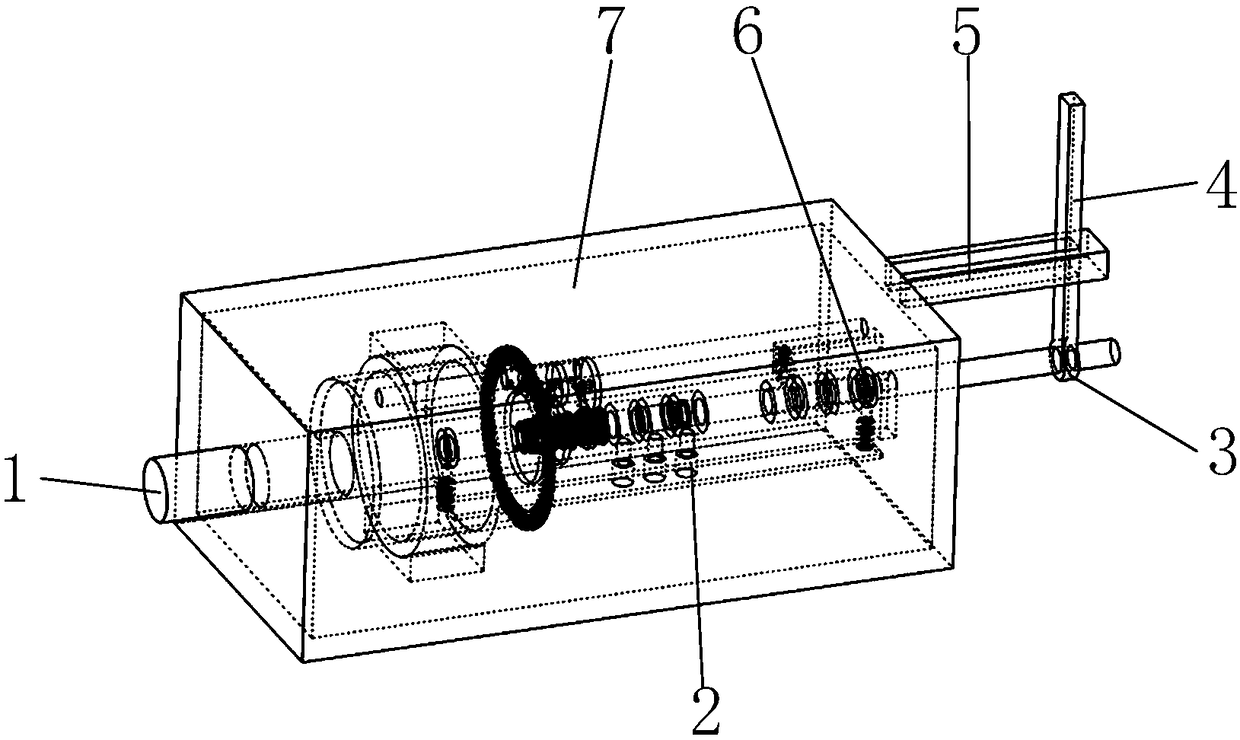

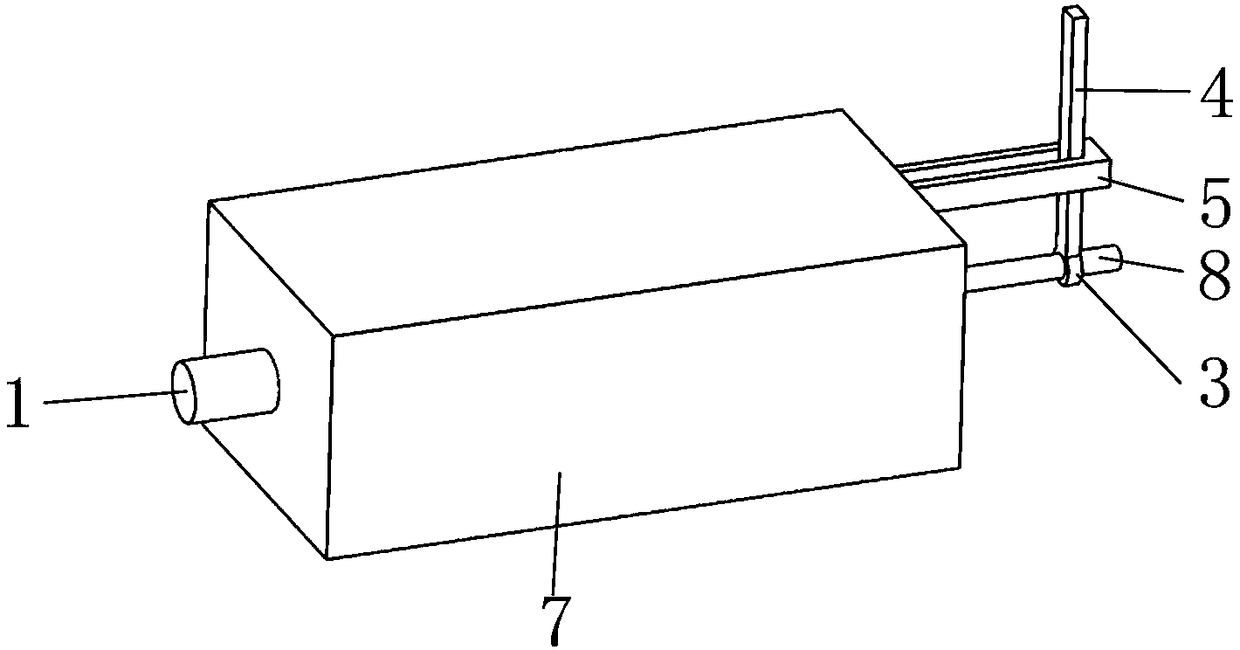

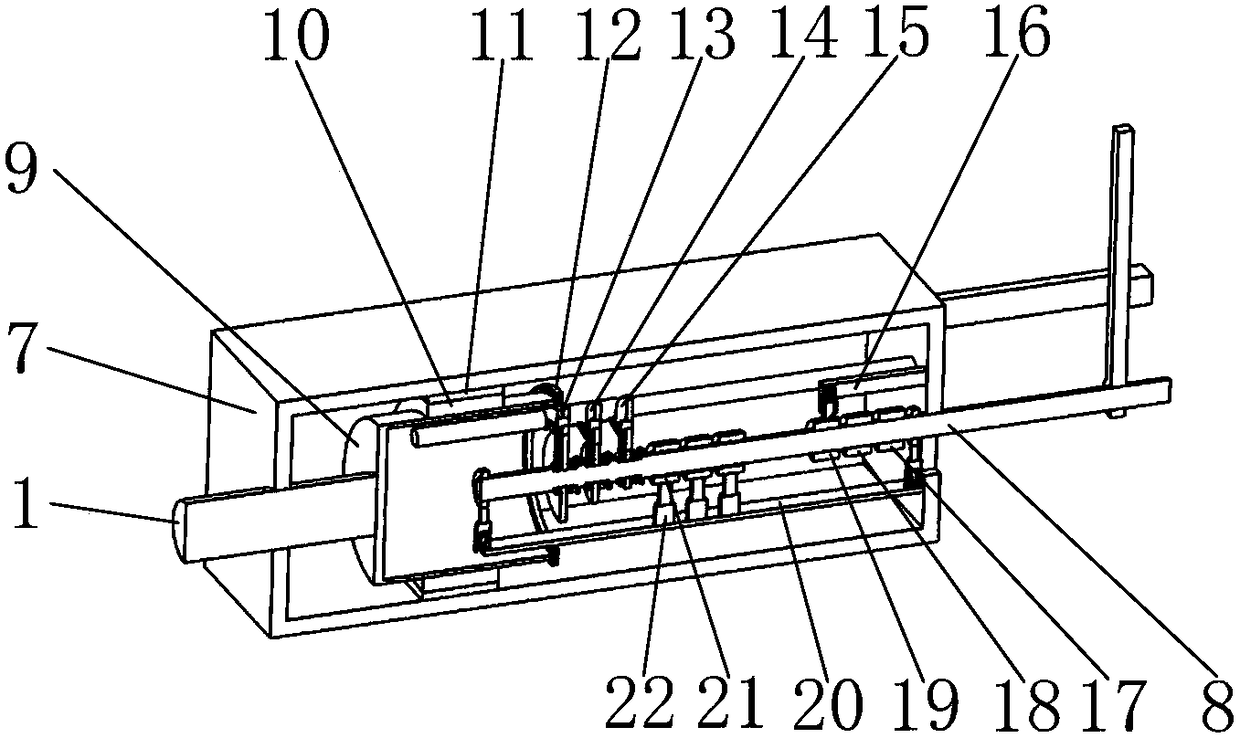

Speed shifting tool and speed shifting control method thereof

ActiveCN102562958AChange reduction ratioShorten pause timeToothed gearingsGearing controlFistPower flow

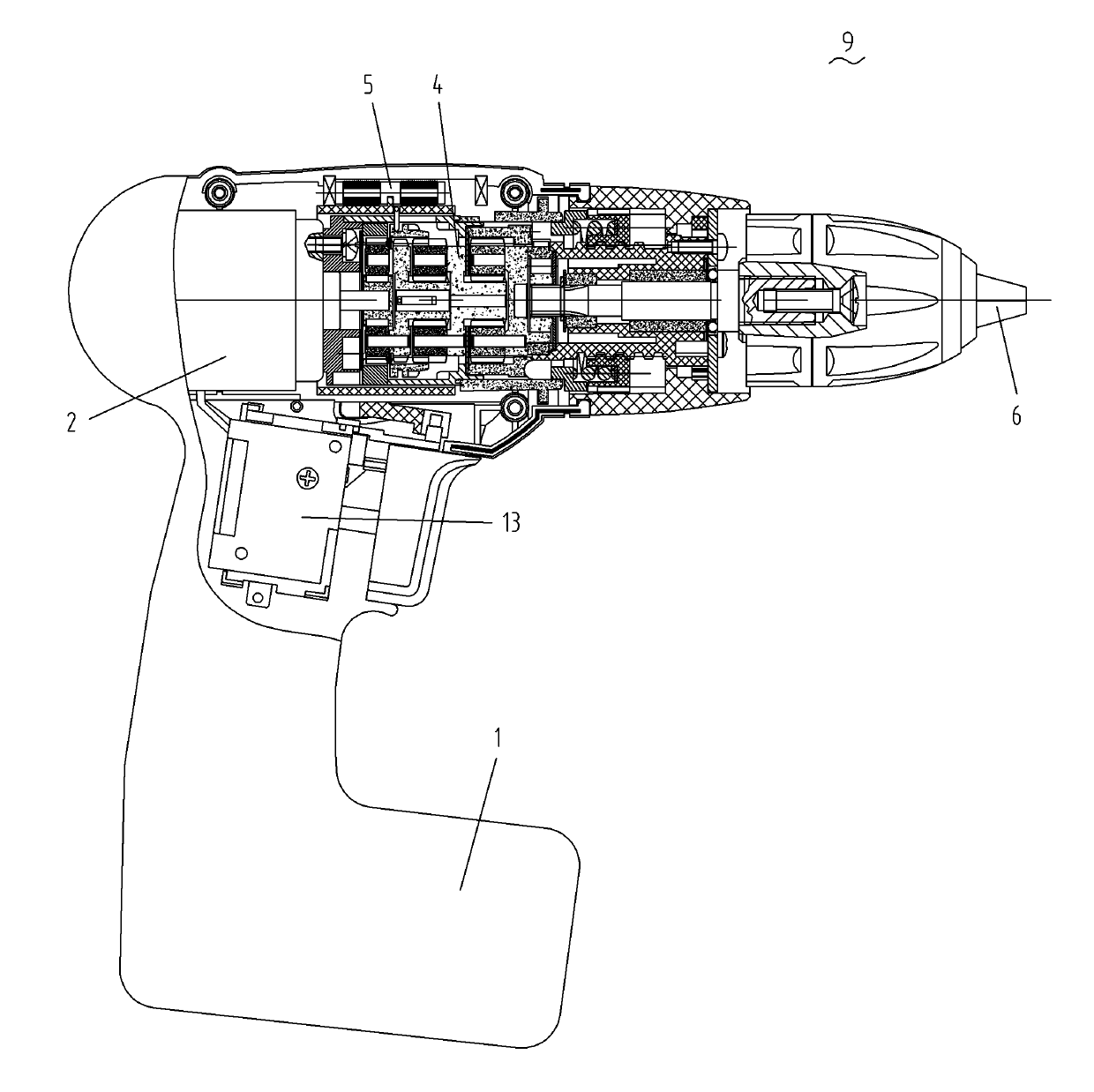

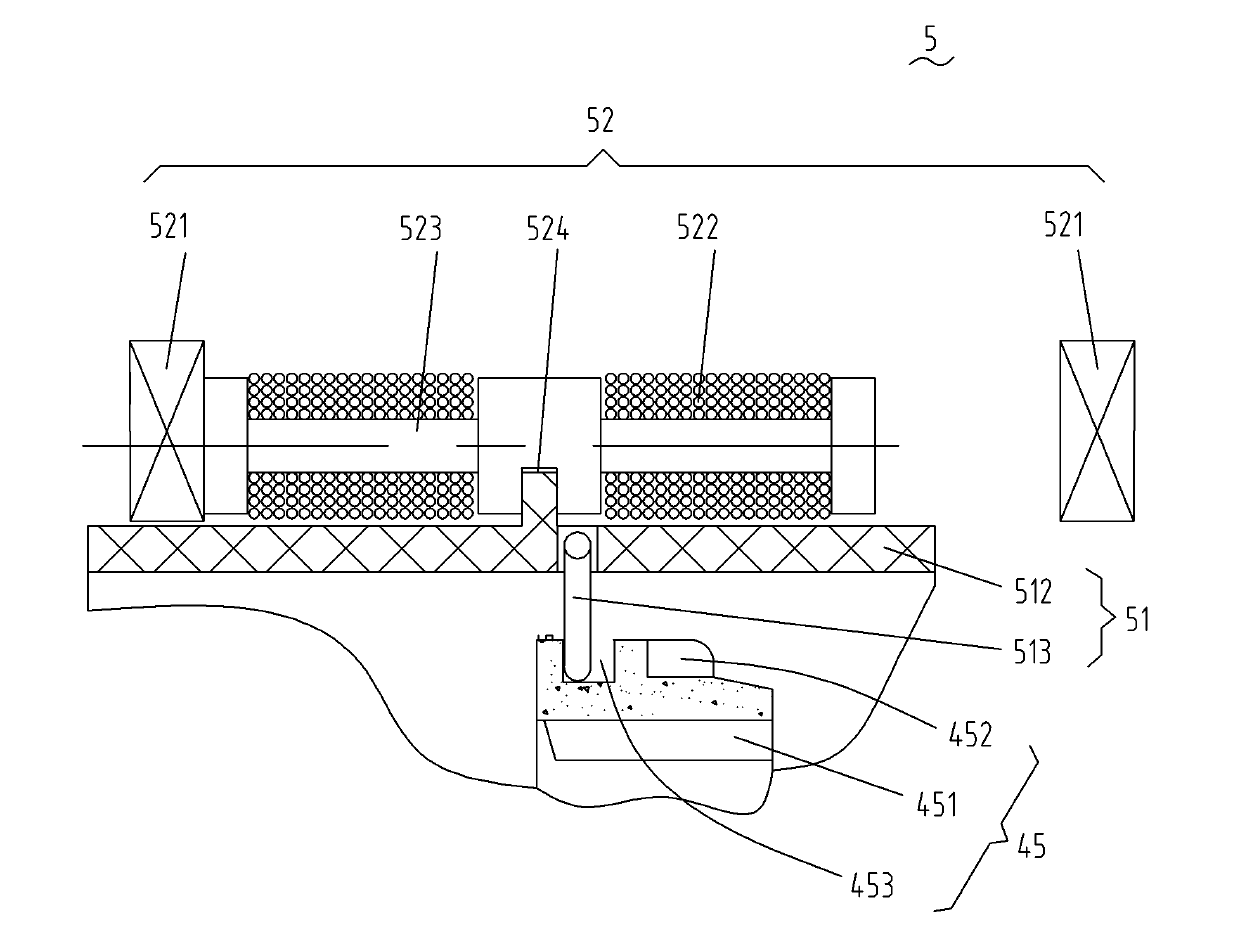

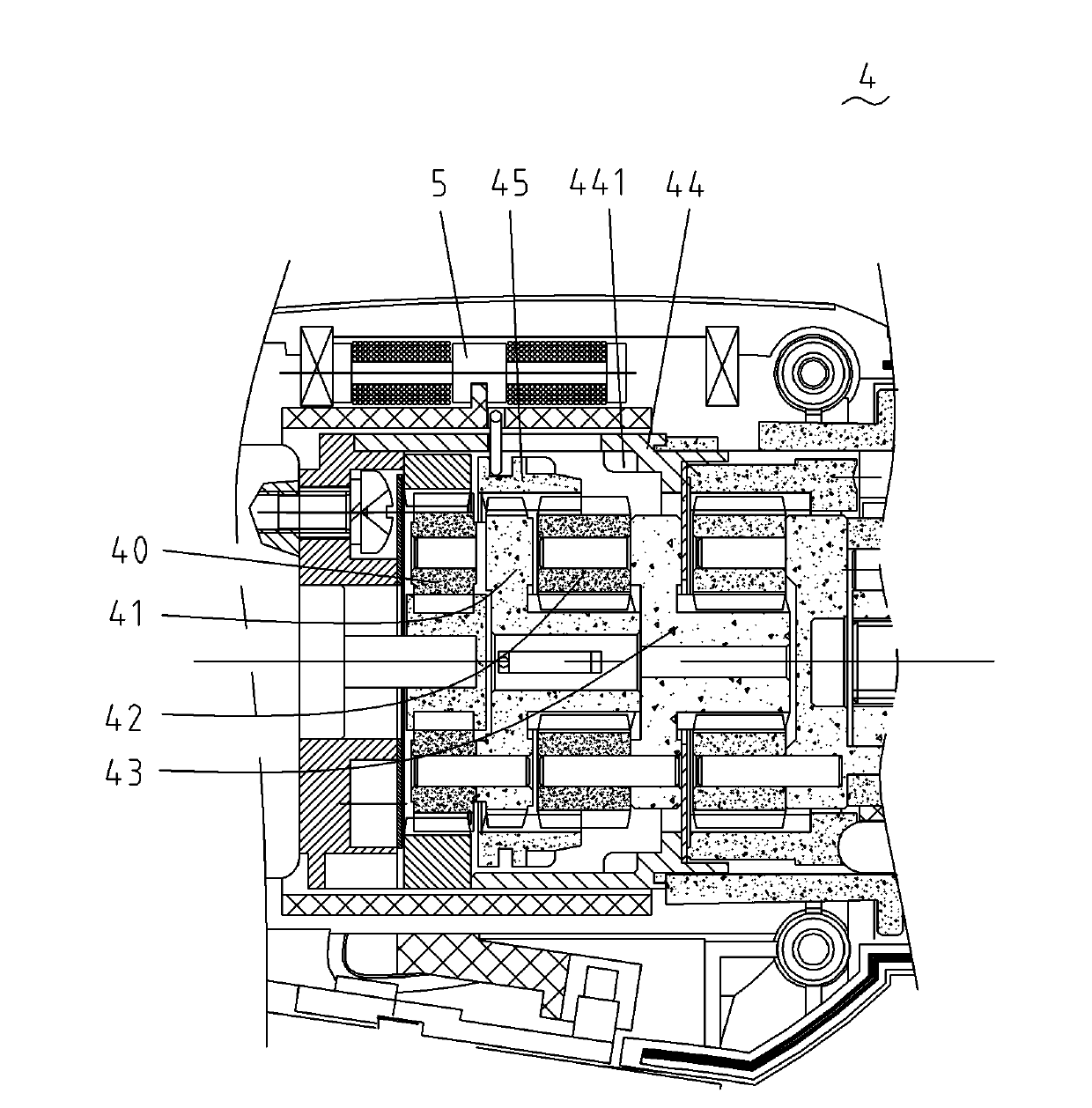

The invention discloses a speed shifting tool which comprises a case, a motor, an output shaft, a gear transmission mechanism and a control system, wherein the motor is arranged in the case and outputs rotary power; the gear transmission mechanism is arranged between the motor and the output shaft so as to transmit rotary output to the output shaft and comprises at least one gear train and a moving piece, the moving piece can move between the fist position and the second position, and the moving piece and the gear train are matched in different ways in the first position and the second position so that the gear transmission mechanism outputs the speed of the motor in different reduction ratios; and the control system comprises a driving device matched with the moving piece, the driving device is used for driving the moving piece to move between the first position and the second position, and the control system also comprises an electronic switch in parallel to the motor. When the reduction ratio of the gear transmission mechanism requires changing, the control system cuts off the current of the motor, connects the electronic switch and controls the driving device to drive the moving piece to move between the first position and the second position.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

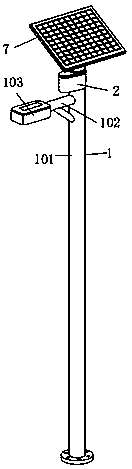

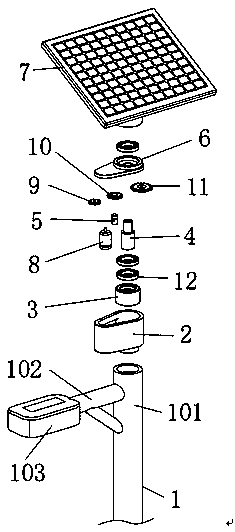

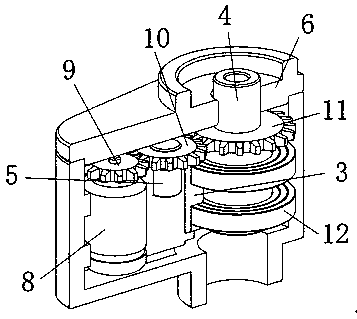

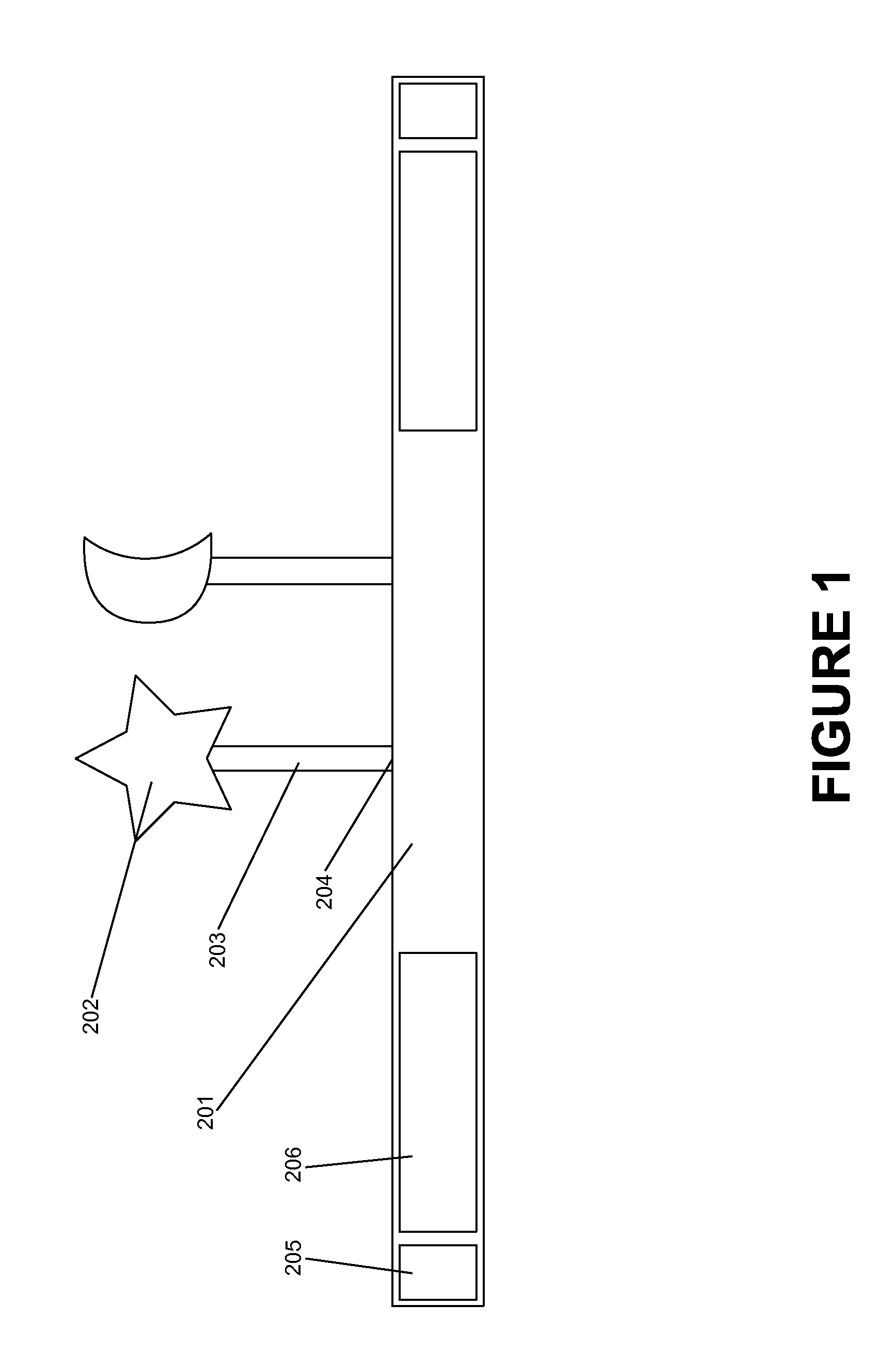

5G solar intelligent street lamp light station system

InactiveCN110440212AImprove conversion efficiencySmooth rotationPhotovoltaic supportsMechanical apparatusElectricityInterference fit

The invention discloses a 5G solar intelligent street lamp light station system. The system comprises a street lamp, the top end of the street lamp is fixedly connected with the bottom end of a shell,a connecting frame sleeves the right side of the inside of the shell, two bearings are mounted in the connecting frame, a second gear is meshed to the right side of a first gear, the second gear andthe top end of a connecting shaft are in interference fit, the right side of the second gear is meshed with a third gear, the third gear and a rotation shaft are in interference fit, a top cover attaches to the top end of the shell, the top cover and the rotation shaft are in clearance fit, the top end of the rotation shaft penetrates through the top cover to be in interference fit with the bottomend of a solar energy conversion mechanism, and the bottom end of the solar energy conversion mechanism is rotatably connected with the top cover through a bearing. Through the match among a connecting frame body, the bearings, the rotation shaft and the solar energy conversion mechanism, the rotation of a solar panel is realized, then that the solar panel is always opposite to the sun becomes possible, and further, the efficiency in converting the solar energy into electricity is improved.

Owner:芜湖乐知智能科技有限公司

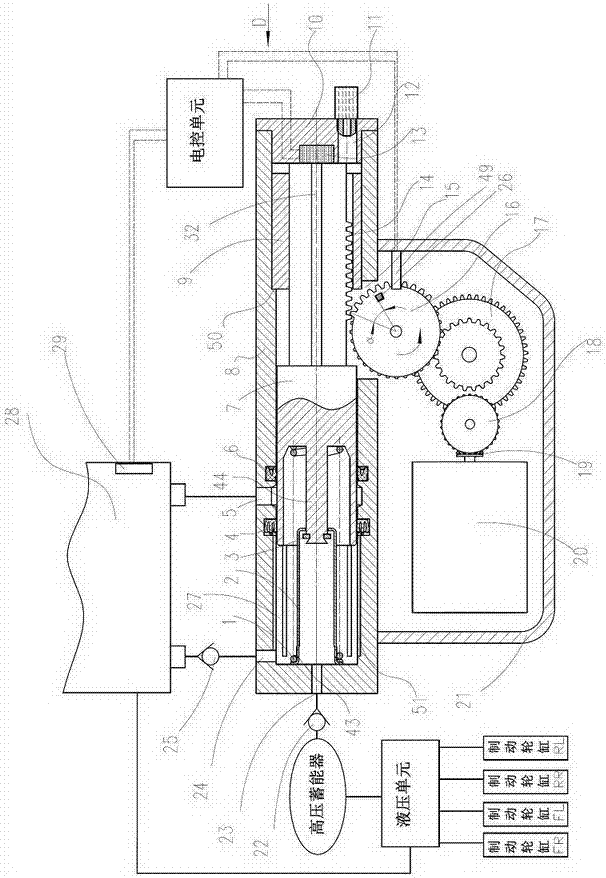

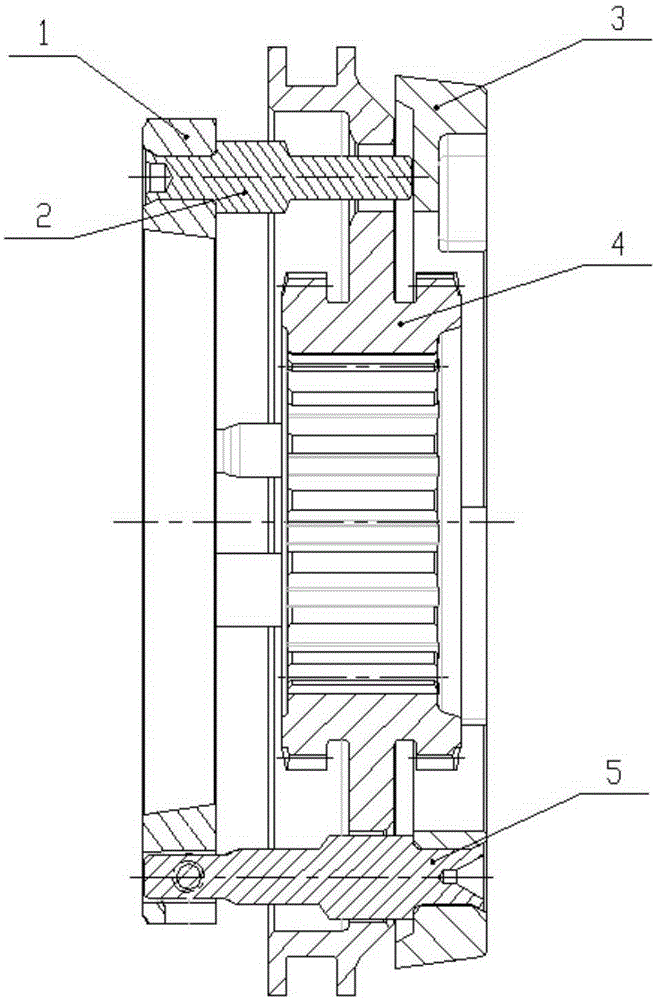

Electric pump for automobile drive-by-wire braking system

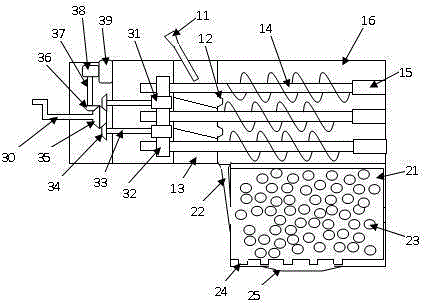

ActiveCN107117152ANovel structureReduce pressure building strokeBraking action transmissionAutomotive engineeringCylinder block

The invention relates to an electric pump for an automobile drive-by-wire braking system and belongs to automobile industries. The electric pump for the automobile drive-by-wire braking system is applied into the automobile drive-by-wire braking system. A guide sleeve is matched with a cylinder body inner hole in an interference mode, one axial end of the guide sleeve makes contact with a limiting step of the cylinder body inner hole, and the surface of a guide sleeve inner hole is a cylindrical surface; the two sides of the cylindrical surface are symmetrically provided with axial guide rail straight grooves, an axial rack straight groove is formed in the bottom of the cylindrical surface, and the diameter of a sealing cylindrical surface is larger than that of a guiding part; a secondary packing cup is sleeved with the sealing cylindrical surface of a piston, strip-shaped protruded guide rails are symmetrically arranged on the two axial sides of a cylindrical surface of the guiding part, and racks are arranged at the bottom of the cylindrical surface of the guiding part in the axial direction; and the sealing cylindrical surface of the piston is matched with a cylinder body primary hole in an interval mode, the guiding part is matched with the cylindrical surface of the guide sleeve inner hole in the interval mode, and the guide rail straight grooves are matched with the guide rails in the interval mode. The electric pump for the automobile drive-by-wire braking system has the advantages that the structure is novel, the number of teeth, engaged with the racks, of transposition gear drive wheels is automatically switched under a low-temperature state so that the pressure-building stroke of the piston can be reduced, return stroke time of the piston is increased, timely supplement of braking fluid at a low temperature is facilitated, and the reliable work of the electric pump under the low-temperature state is ensured.

Owner:JILIN DONGGUANG AOWEI AUTOMOBILE BRAKE SYST

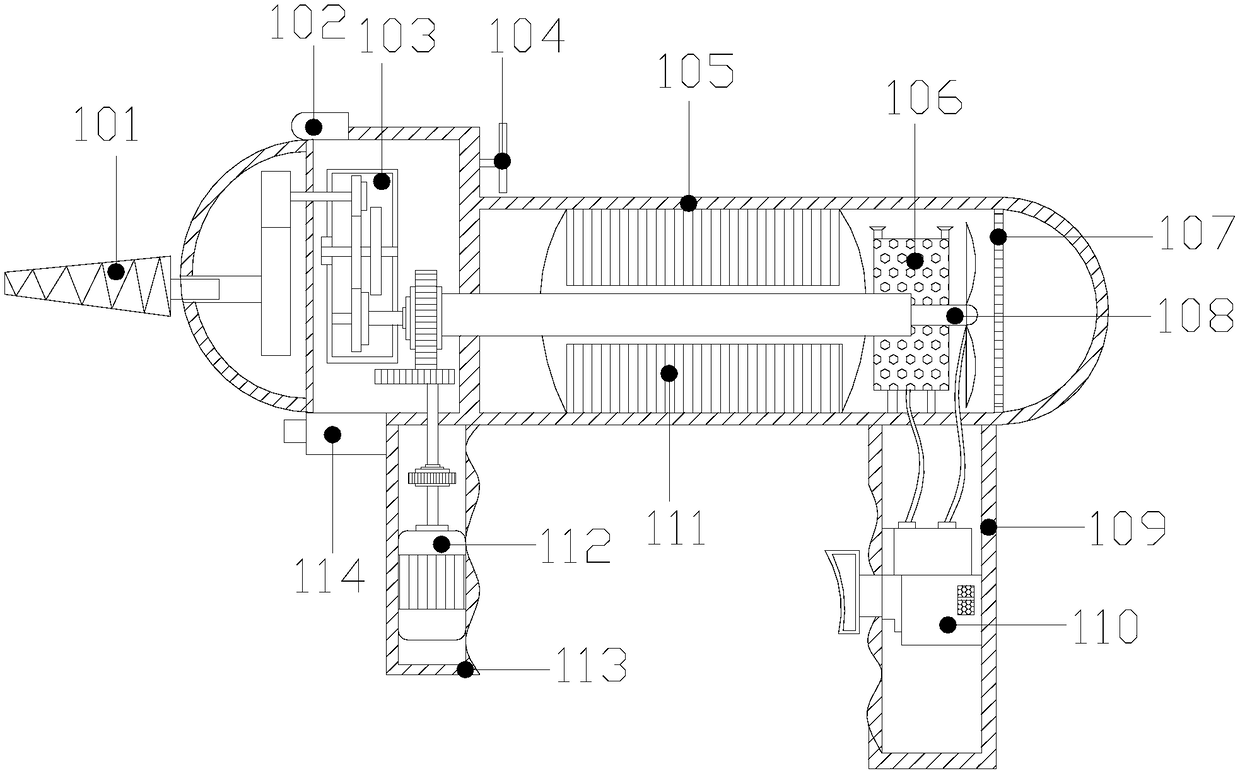

Electric drill device capable of measuring while drilling

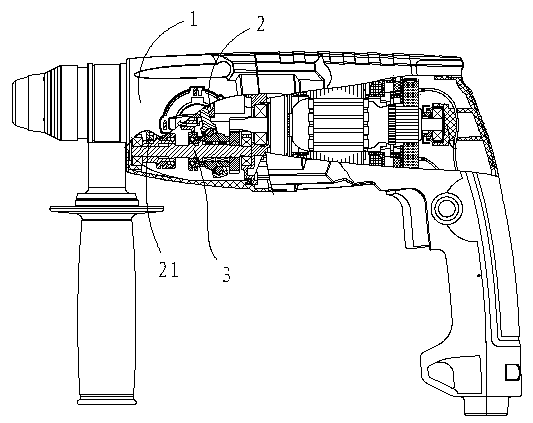

InactiveCN108422009ATimely evacuationAvoid meshingDrilling/boring measurement devicesPortable power-driven toolsPower flowCoupling

The invention discloses an electric drill device capable of measuring while drilling. The electric drill device structurally comprises a high-efficiency electronic mechanism, a dust suction pipe, a dust suction opening, a drill bit, a handle, a power switch, an exhaust outlet, a vacuum cleaner, a dust box and a power line, the right side of the dust suction pipe are fixedly welded to the left sideof the high-efficiency electronic mechanism, and the dust suction pipe and the high-efficiency electronic mechanism are embedded together; the right side of the dust suction opening is fixedly fastened to the left side of the dust suction pipe and the dust suction opening and the dust suction pipe are of an integrated molding structure. The electric drill device is capable of dispersing heat generated during work timely and effectively. When a propulsive force is excessively large, a spiral bit stops rotating, and at this time, the current of a motor rises instantaneously, which is likely tocause hidden danger. If the force is over large when the device is propelled, a fourth gear and a first coupler are disengaged, and then the device needs to be powered off and restarted, thereby preventing direct engagement between a rotating fourth gear and the stationary first coupler, avoiding the occurrence of tooth collision, and further avoiding damage to the device and potential safety hazard caused by excessive current.

Owner:莆田市荔城区秋妹电子商务有限公司

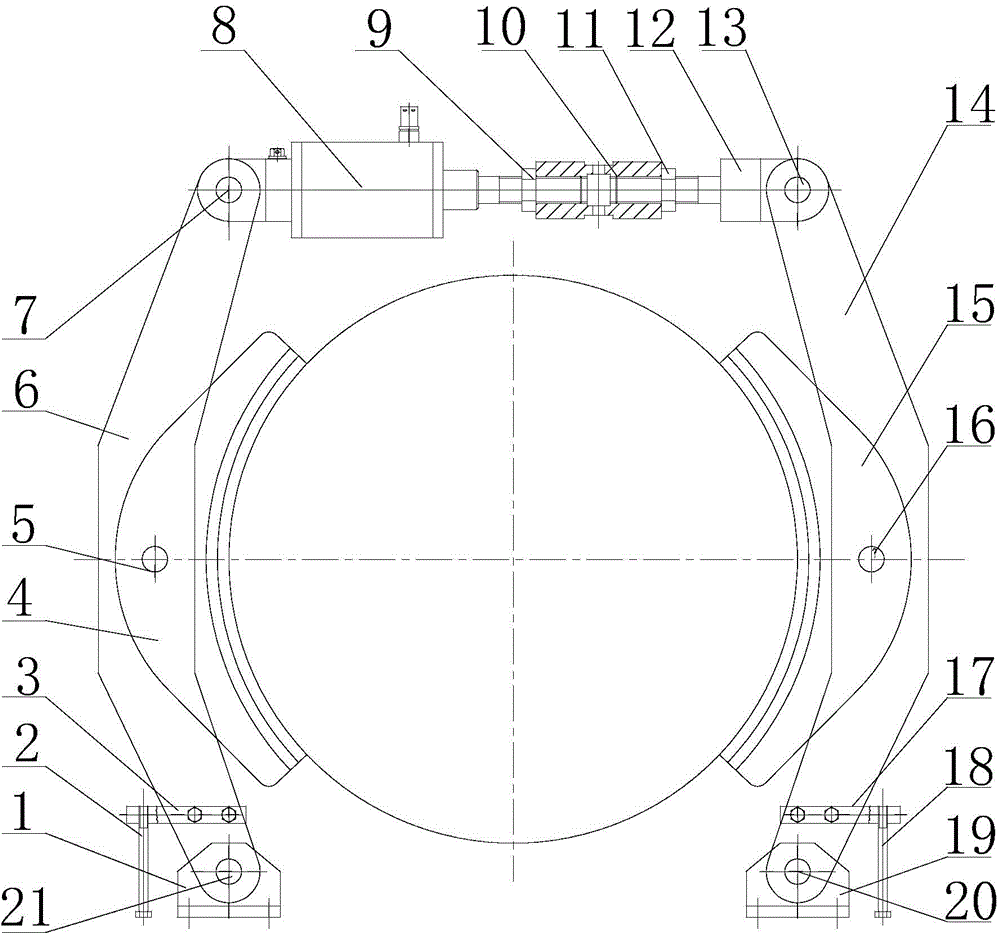

Hydraulic brake apparatus of haulage winch

InactiveCN105271040AAvoid close operationsAvoid duplication of effortHoisting equipmentsGear wheelHydraulic ram

The invention discloses a hydraulic brake apparatus of a haulage winch. The other end of a rear brake arm (6) is connected with a braking hydraulic ram (8) through a pin roll II (7). The piston rod of the braking hydraulic ram is connected with one end of a connecting rod through an adjusting nut (10). The other end of the connecting rod (12) is connected with the other end of a front brake arm (14) through a pin roll III (13). The brake apparatus uses the hydraulic ram to brake, so braking forces are larger, and brake is safe and reliable. The brake apparatus can be far away from a controlled winch, and labor intensity of workers is greatly reduced. The brake apparatus can prevent gear damage phenomenon in a winch, and ensures operation safety of winch.

Owner:XUZHOU ANDI MINING EQUIP CO LTD

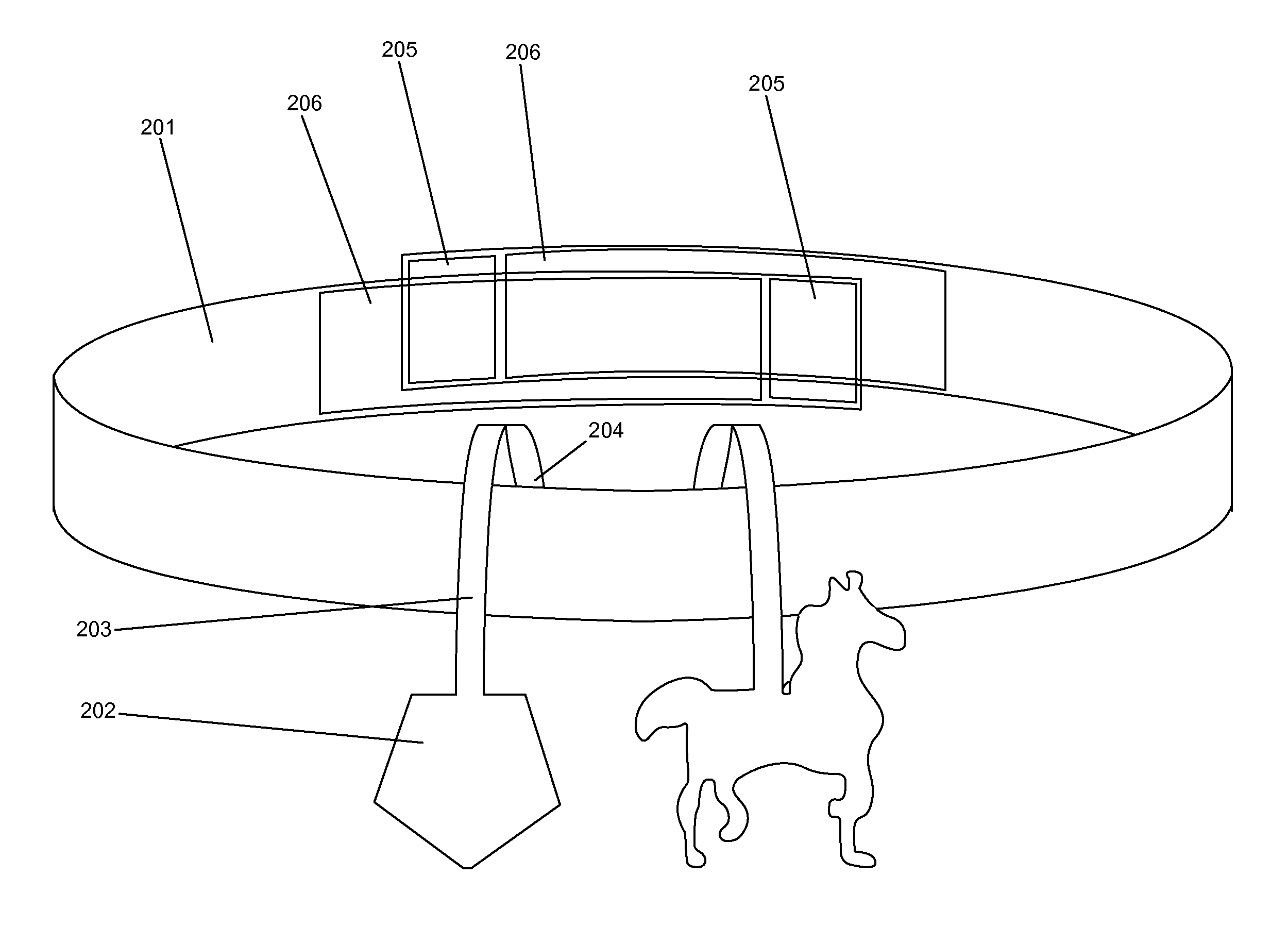

Baby Band

The Baby Band is a chest band with attached toys that are always reachable, in any natural infant position. The infant constantly rediscovers toys when returning hands to a natural resting position. The toy tethers are not long enough to wrap around the infant's neck or get tangled when the infant rolls over or crawls. The toys compress to flat or near flat to allow for normal movement and development, such as rolling or crawling. The flexible band is adjustable for comfort, can be reversible, and gives enough not to be binding, so the infant can wear it for prolonged periods of time without discomfort, but is securely fastened in the back with a variable fastener, such as hook and loop, to prevent it coming off. Also, the adjustable fastener of the chest band allows it to be worn in any state of dress or undress.

Owner:DEFOREST LYSANDRA

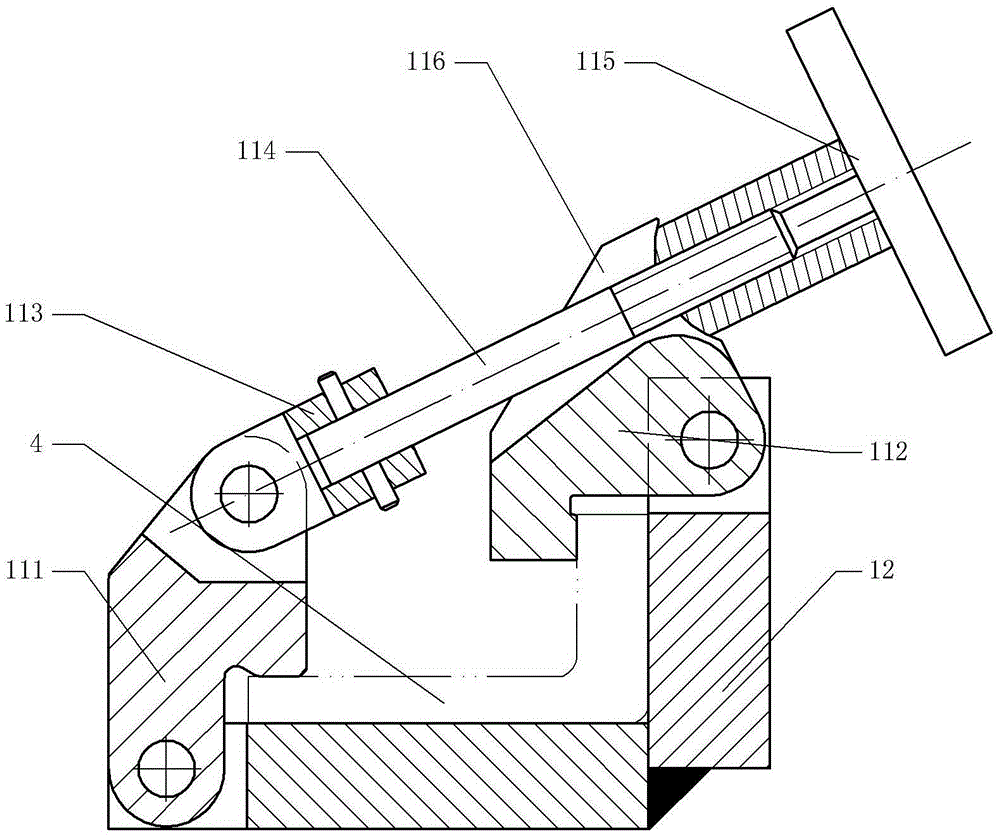

L-shaped connection piece machining equipment

InactiveCN105414970AIncrease productivityAvoid teethingOther manufacturing equipments/toolsPositioning apparatusGear wheelDrive motor

The invention discloses L-shaped connection piece machining equipment, and relates to the machining equipment. The L-shaped connection piece machining equipment comprises a machine frame, a drilling portion and a cutting portion and further comprises clamping portions and a push portion. Each clamping portion comprises a base and a clamping mechanism. The section of each base is in an L shape. Each clamping mechanism comprises a first clamping jaw and a second clamping jaw which are hinged to the corresponding base and further comprises a linkage rod and a handle. The bases are fixed to the machine frame. One end of each linkage rod is hinged to the corresponding first clamping jaw. A groove is formed in the corresponding second clamping jaw. The linkage rods are embedded into the corresponding grooves. A workpiece can be clamped and located in two directions by screwing the handles. The push portion comprises a mounting seat, a rack and a gear. The mounting seat is connected to the rack in a sliding manner. The gear is rotationally connected to the mounting seat. The rack is fixed to the machine frame. The gear is meshed with the rack and driven by a drive motor to rotate so that the push portion can push the workpiece to be jacked and pressed to a limiting seat, and the workpiece is located in the axial direction.

Owner:CHONGQING CHENGJISI MACHINERY MFG CO LTD

Gear transmission gearbox with gear collision preventing function

The invention belongs to the technical field of gear transmission gearboxes, and particularly relates to a gear transmission gearbox with a gear collision preventing function. The gear transmission gearbox comprises an output shaft, a position clamping mechanism, a first fixing ring, a stirring rod, a first fixing plate, a supporting mechanism, a first guide block, a second guide block, a third guide block, a fixing shell, an input shaft, a first connecting barrel, a second fixing ring, a fixing block, a third fixing ring and the like, wherein the fixing shell is provided with a containing cavity. A penetration fixing circular hole is formed in the side face of the containing cavity. The side face, opposite to the fixing circular hole, of the containing cavity is provided with a penetration motion groove. Two first guide grooves are symmetrically formed in the outer circle face of the input shaft. Two third guide grooves are symmetrically formed in the outer circle face of the input shaft. By means of the gear transmission gearbox, when a gear rotating at the low speed is forcibly plugged into a gear rotating at the high speed or the gear rotating at the high speed is forcibly plugged into the gear rotating at the low speed, the phenomenon of gear collisions in the gearbox can be avoided.

Owner:柳欢

Gearbox for automobile

PendingCN109538708AGuaranteed uptimeAvoid teethingToothed gearingsControl devicesDriver/operatorEngineering

The invention belongs to the technical field of gearboxes, and particularly relates to a gearbox for an automobile. The gearbox for the automobile comprises a connecting shaft, a first gear, a secondgear, a speed change shaft, a first one-way clutch, a third gear, a torsion sensing ring, a fourth gear and an elastic element; the first end of the connecting shaft is connected with an output shaftof a motor; the first gear and the second gear are arranged on the connecting shaft in a sleeved mode; a first thread section is arranged in the middle of the speed change shaft; the first one-way clutch is arranged on the speed change shaft in a sleeved mode; the third gear is arranged on the first one-way clutch in a sleeved mode and is meshed with the first gear; the torsion sensing ring is arranged on the speed change shaft in a sleeved mode, and is connected with the first threaded section in a threaded mode; the fourth gear is arranged on the torsion sensing ring in a sleeved mode and ismeshed with the second gear; and the first end of the elastic element is connected with a box body, and the second end of the elastic element is connected with the torsion sensing ring. The gearbox can sense the road resistance so as to achieve automatic gear shifting, so that the situation that the operation of the motor is unstable due to the fact that an improper gear which is adopted by the driver can be avoided.

Owner:辛集市宇泰机械有限公司

Vehicle reverse gear synchronous mechanism

A synchronizing mechanism for the reverse-gear shift or car is composed of a mainshaft, a reverse-gear shift synchronizing toothed sleeve installed radially onto mainshaft, a conic ring sleeving on mainshift in movable mode and fixed to box body, and a synchronizing ring sleeving on said conic ring in movable mode, fixed to mainshaft, and with radial tooth engaged with said toothed sleeve and synchronizng spring at the root of said radial tooth.

Owner:BYD CO LTD

Gear clutch with high meshing success probability

InactiveCN112696439AGuaranteed bending strengthGuaranteed shear strengthPortable liftingInterengaging clutchesGear wheelTorque transmission

The invention provides a gear clutch with the high meshing success probability. A section of inclined face is manufactured on the side, close to a non-torque-transmission gear face, of the gear tooth end face of a movable sleeve gear and the gear tooth end face of a static sleeve gear, a straight face is reserved on the side close to a torque-transmission gear face, and the width of the inclined face accounts for about 95% of the gear thickness. The inclination direction of the movable sleeve tooth end face slope is opposite to the moving direction of the movable sleeve teeth, the inclination direction of the static sleeve tooth end face slopes is the same as the moving direction of the movable sleeve teeth, and the inclination angles of the tooth end face slopes of the movable sleeve teeth and the static sleeve teeth are equal. During meshing, the movable sleeve teeth move downwards to the static sleeve teeth under the action of an external force, the inclined faces of the tooth end faces of the movable sleeve teeth and the inclined faces of the tooth end faces of the static sleeve teeth make contact with each other, and along with rotation of the movable sleeve teeth, due to the action of the inclined faces, the movable sleeve teeth generate an axial movement distance L relative to the static sleeve teeth; when the gear teeth of the movable sleeve gear rotate over the current static sleeve gear tooth in contact with the gear teeth and are in contact with the working tooth surface of the next static sleeve gear tooth, the distance L can avoid the tooth collision phenomenon, the probability of one-time meshing success of the sleeve gear is improved, and the torque transmission strength of the sleeve gear is kept not to be reduced.

Owner:中国船舶重工集团公司第七0三研究所

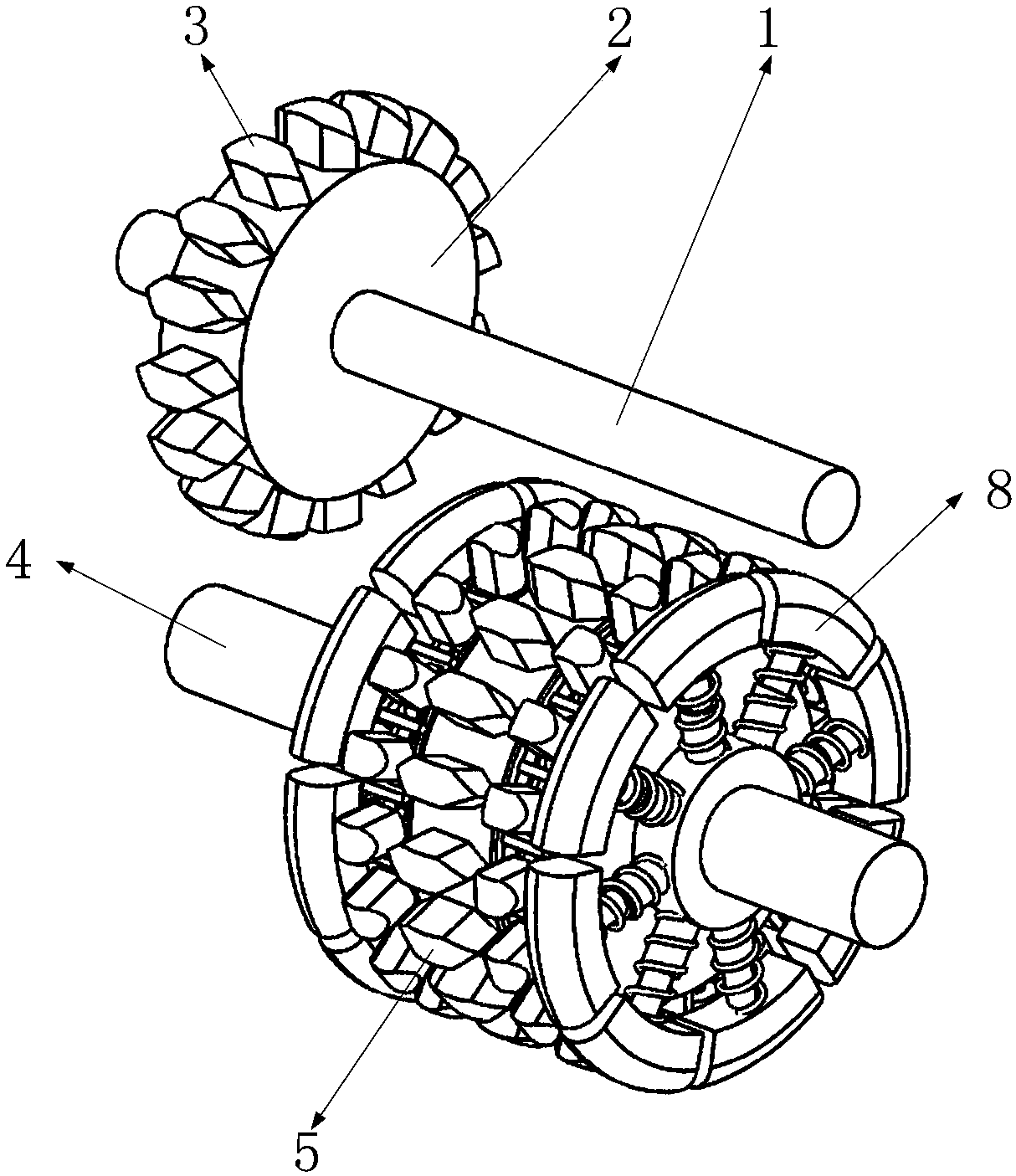

Clutch type stepless speed variator

Purpose of the invention is to solve a series of problems: large prestress, high thermal value, short service life, low efficiency, and rigorous requirement for materials brought by friction of general stepless gear. The disclosed mechanism realizes transmission by structure of steel balls and wedge slot. Speed changing procedure is not dependent on means of speed adjustment in liquid, friction, and electrical power. In the invention, input axis and output axis are coaxial. Rotating external rotatable disc unit can make speed changer obtain variable transmission ratio. In addition, the invention sets up controller for shift zone. Using the controller can obtain continuously variable shift zone in suitable range. No matter input rotation speed is in positive or negative, the intermediary mechanism outputs rotation in same direction. Unit for switching rotation direction provided by the invention is as an option. Pin type interposer is adopted in the control scheme.

Owner:穆树亮

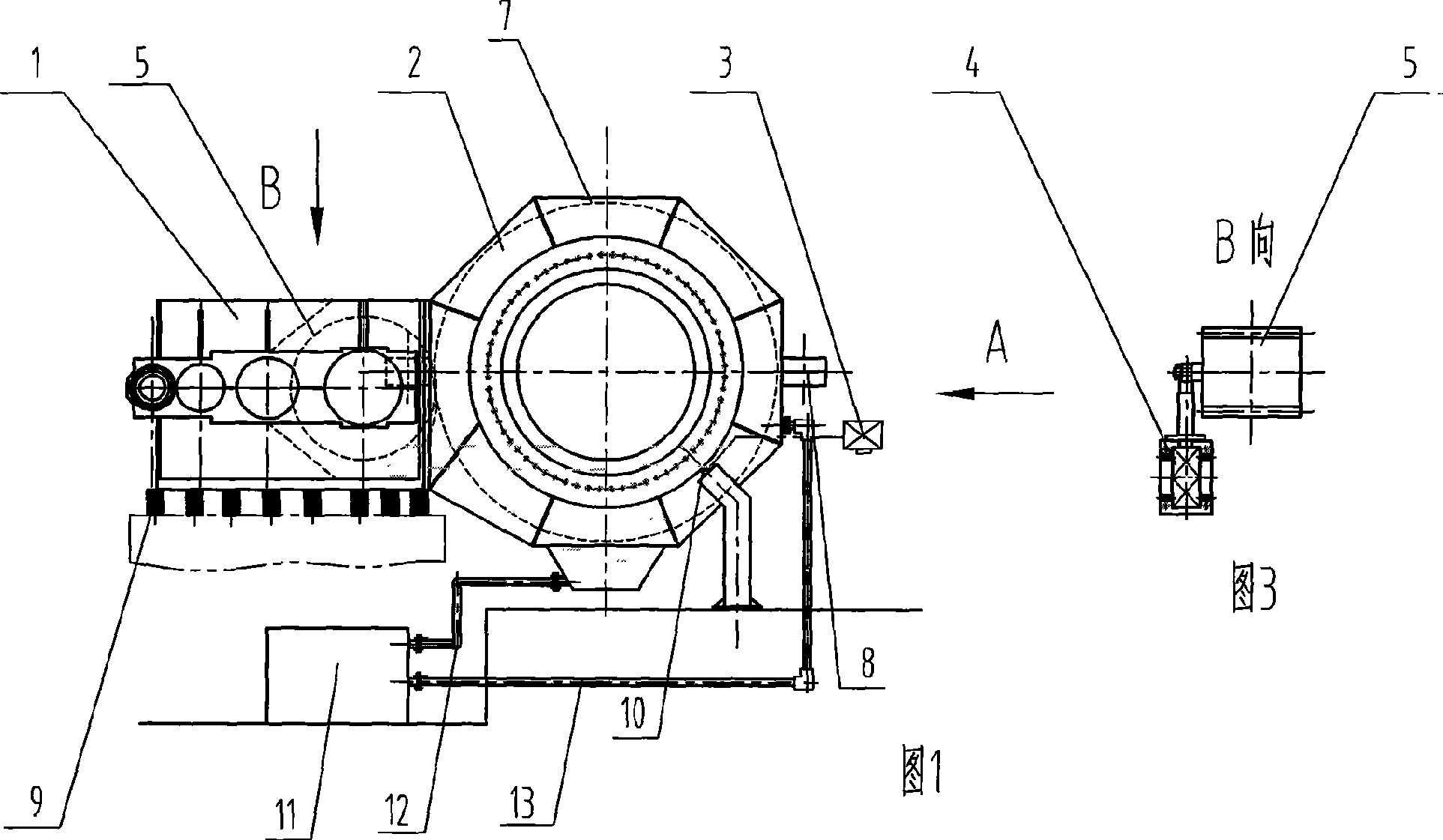

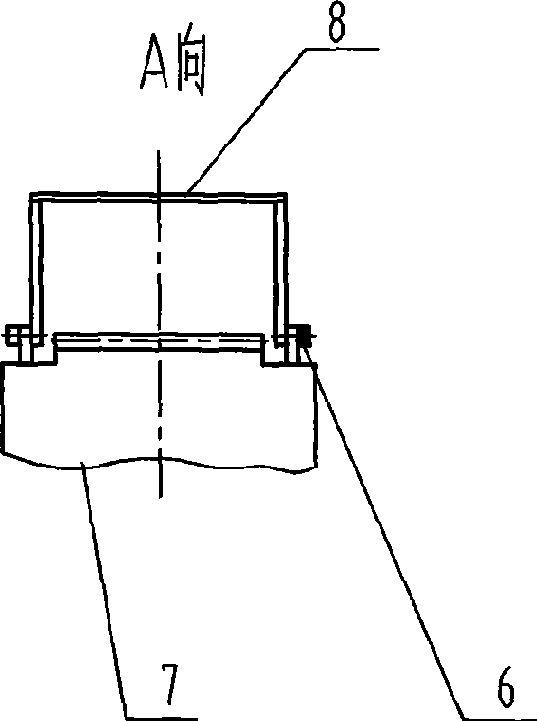

Gear box device for mixing machine

ActiveCN101497010AExtended service lifeFully lubricatedRotating receptacle mixersTransportation and packagingHydraulic cylinderGear wheel

The invention relates to a gear box device for a mixing machine. The structure comprises that: a gearwheel of a cylinder mixing machine is meshed with a pinion of the cylinder mixing machine; the pinion is connected with an output shaft of a gear box; the gear box is arranged on an elasticity-floating supporting seat; the side of the gear box is provided with a hydraulic cylinder following system; the gearwheel and the pinion which are driven by a roller of the cylinder mixing machine are arranged in a closed box; the bottom of the roller of the cylinder mixing machine and the side wall of the closed box are connected with an oil storing box through pipelines respectively; the closed box is sealed by a sealing ring; and the whole set of device is provided with a servo telegraphy coder. The device adopts the structure, avoids the phenomena that a cylinder body sinks or moves in the operation for a long time to cause uneven mesh of the gearwheel and the pinion, pitting corrosion and gear beating, and improves the service life of the gear. The device adopts thin oil to lubricate, can effectively save energy resources, reduce environment pollution, and improve the working efficiency.

Owner:沈阳乾鼎机械制造有限公司

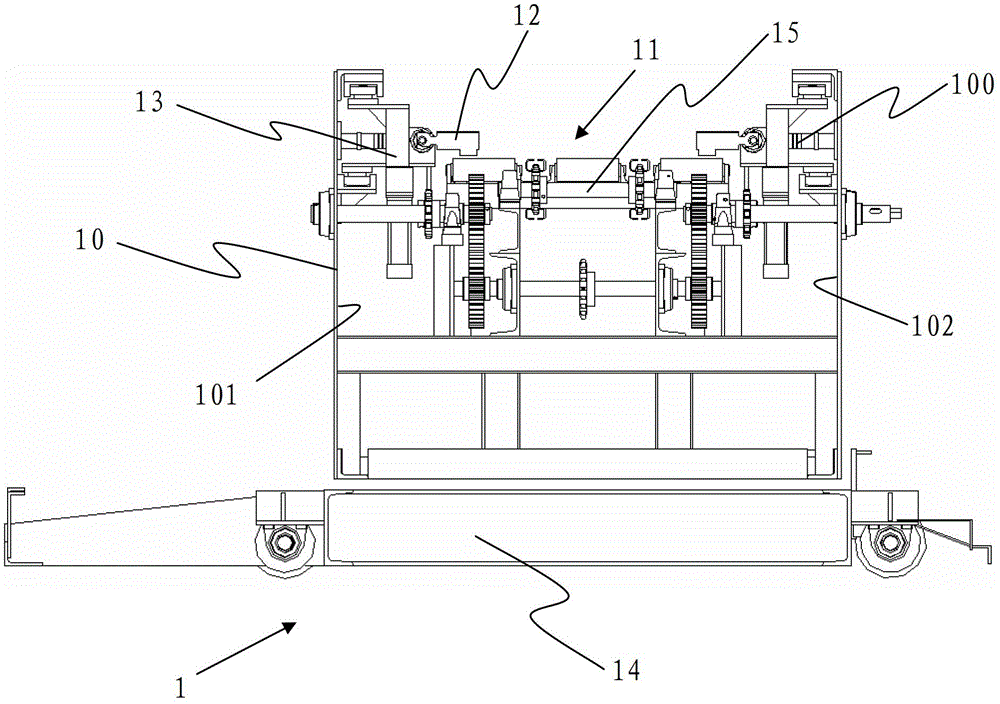

Bi-directional skip car

The invention discloses a bi-directional skip car. The bi-directional skip car mainly comprises a skip car framework, a roller table driving device, two push rods and two geared-up pulleys. The roller table driving device is used as a driving device of the bi-directional skip car, and a reducing motor is adopted as a starting motor to drive a loop chain to load materials. Each the push rod comprises a cylindrical rack and two push rod hook heads, wherein the two push rod hook heads are respectively arranged at two ends of the cylindrical rack. In the process of moving, the cylindrical rack of the push rod is meshed with a speed increasing gear of the geared-up pulley all the time. The geared-up pulley is connected with a guide sleeve of the push rod. Moving of the geared-up pulleys drives the push rods to move. In the moving process of the push rods, the problems of tooth breaking and being stuck are avoided. The bi-directional skip car has the advantages of being safe and reliable, strong in flexibility and uneasy to abrade.

Owner:SHANGHAI HUISEN MTH INDAL FURNACES

Synchronous tooth collision prevention gear transmission mechanism

ActiveCN108591367AExtended service lifeWeaken Rigid CollisionPortable liftingToothed gearingsDrive shaftGear wheel

The invention belongs to the technical field of gear transmission and particularly relates to a synchronous tooth collision prevention gear transmission mechanism. The gear transmission mechanism comprises a driven shaft, a driven gear, driven teeth, a driving shaft, driving teeth, a driving gear and the like, wherein a driving mechanism is matched with the driven gear to make the rotational speedof the driven gear close to the rotational speed of the driving gear, and rigid collision between the driving gear and the driven gear during engagement of the driving gear and the driven gear is reduced; a synchronization mechanism is matched with the driven gear to make the driven gear and the driving gear rotate synchronously, and rigid collision of the driving gear and the driven gear duringengagement of the driving gear and the driven gear is avoided; besides, when slight rigid collision happens during engagement of the driving teeth and the driven teeth, a volute spiral spring can achieve a certain rigid collision buffering effect. Through the design, the tooth collision phenomenon caused by rigid collision during gear engagement is avoided, and the service life of the gears is prolonged. The synchronous tooth collision prevention gear transmission mechanism is simple in structure and has a good using effect.

Owner:HAIMEN MAOFA ART DESIGN CO LTD

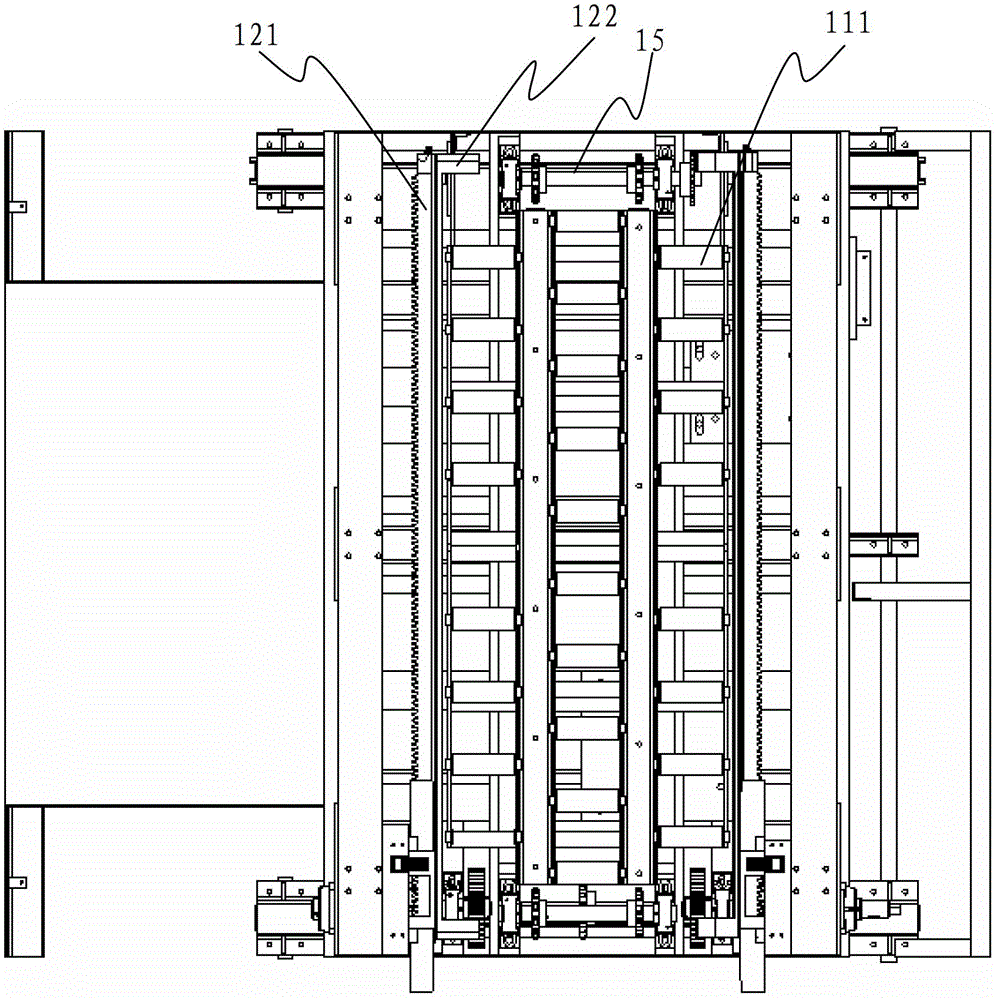

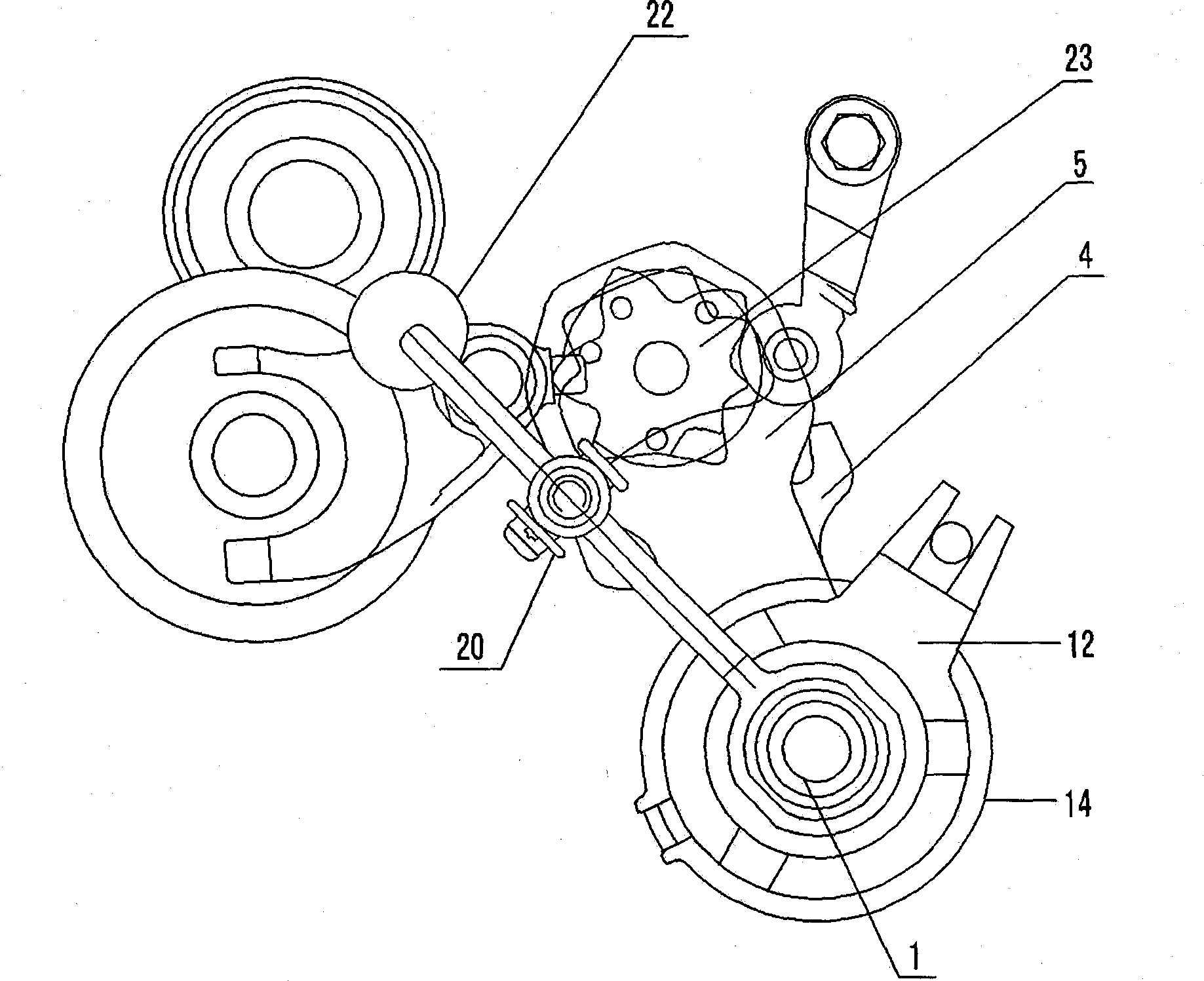

Backstitching mechanism below sewing machine

The invention discloses a backstitching mechanism below a sewing machine. A driving shaft performs forward and backward motion to drive a clamping piece to swing; a pulling rod on the clamping piece pulls a one-way bearing to perform one-way rotation so as to drive a first driven shaft to rotate; the teeth on the first driven shaft drive a gear to rotate; the gear drives a second driven shaft to rotate; a feeding mechanism is arranged at the upper end of the second driven shaft; in this case, the feeding mechanism feeds forwards; a backstitching electromagnet is opened; the lower end of an overturning plate is pulled and overturned by the backstitching electromagnet; the overturning plate overturns around a point which is hinged to a vertical plate; the upper end of the overturning plate pulls an inner shaft; the position of an annular groove of the inner shaft moves therewith, so that the positions of two steel balls in the inner shaft and the annular groove are changed; the steel ball which is positioned out of the annular groove falls into the annular groove, and the steel ball which is positioned in the annular groove rises out of the annular groove to complete the alternationof a first bevel gear and a second bevel gear; and the second driven shaft rotates backwards so as to drive the feeding mechanism to rotate backwards to complete backstitch. Therefore, the situation of tooth breaking is avoided.

Owner:ANHUI JIEYU SHOEMAKING MACHINERY TECH CO LTD

Motorcycle gear shift mechanism

The invention provides a motorcycle gear shift mechanism, and the structure of the motorcycle gear shift mechanism comprises a stop plate, an movable switch plate, a locating plate, a connection plate and a separation device which are respectively connected on a gear shift shaft; a five-star plate is top-supported on the movable switch plate; the front end of the movable switch plate is provided with the stop plate and a reset torsion spring; a compression spring for the movable switch plate is clamped at the back end of the movable switch plate; the upper end and the lower end of the locating plate are respectively and fixedly abutted with a stop pin and the separation device; the locating plate passes through the gear shift shaft and is installed on the compression spring for the movable switch plate; a torsion spring for the locating plate is installed at the inner side of the locating plate; the top end of the torsion spring for the locating plate is clamped on the stop pin; a lining top-supporting the connection plate is installed on the torsion spring for the locating plate in a pressing manner; and a rocker is installed on the separation device. During the speed change and gear shift process, the invention has no abortive phenomenon, reasonable design, simple components and strong practicability, ensures easier and freer driving of a motorcycle, and has the technical advantages of high technical aggregative degree, simple and easy installation and maintenance, convenient and simple operation and flexible use.

Owner:耿军

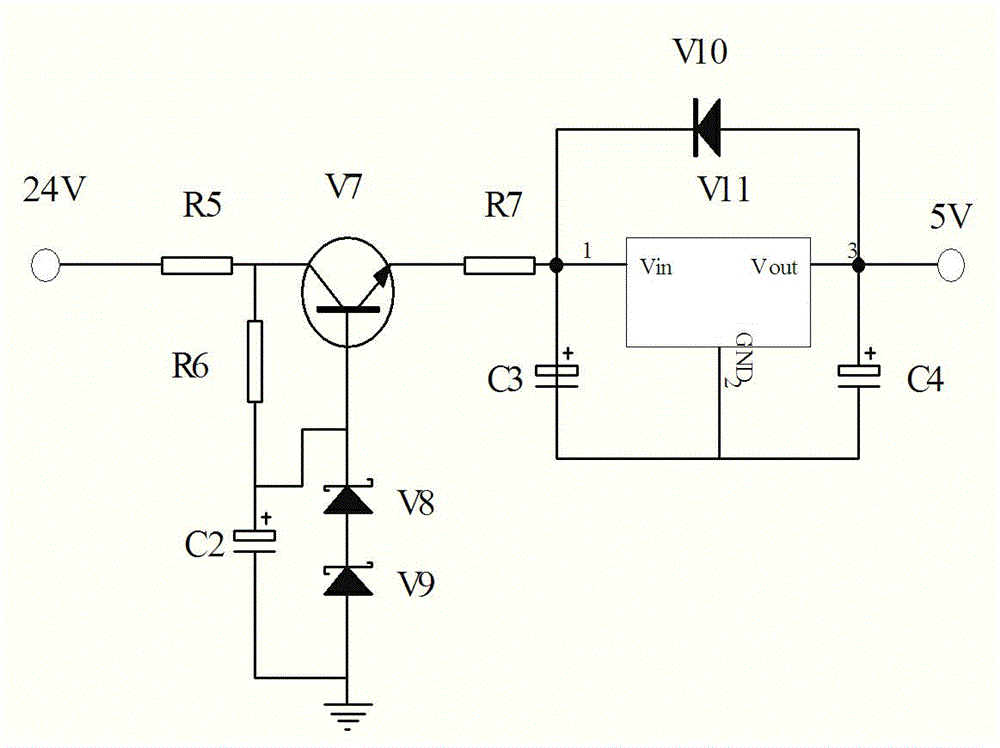

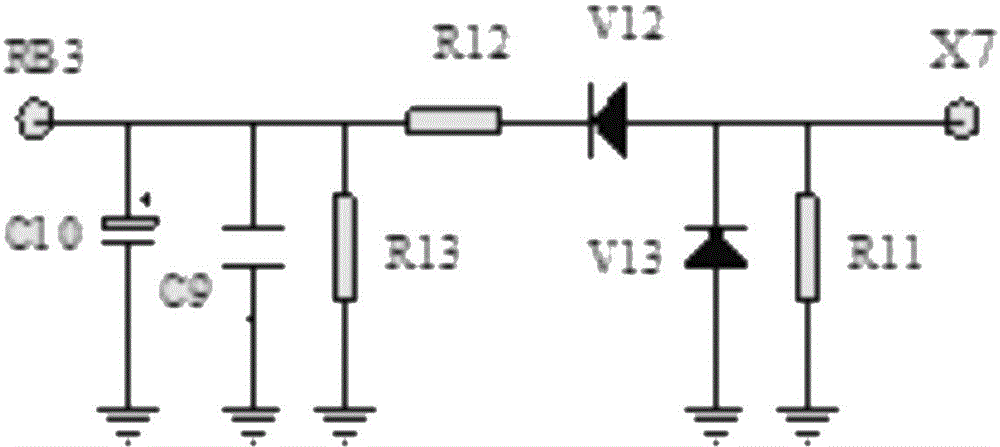

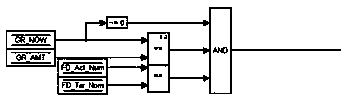

Starter starting protection logic controller

InactiveCN103821653ALittle chance of interferenceNo damageElectric motor startersMachines/enginesInterference resistanceControl engineering

The invention discloses a starter starting protection logic controller comprising a single-chip computer, a delay power-off protection circuit, a two-level voltage stabilizing circuit, a clutch signal sampling circuit, a neutral signal sampling circuit, an output control circuit, a START signal sampling circuit and a D+ signal sampling circuit. The starter starting protecting logic controller has the advantages that anti-interference capacity is high; the rate of the single-chip computer being influenced is low through the use of the delay power-off protection circuit; a time interval is arranged between two starts, and a starter can be protected from damage by tooth breakage and other problems.

Owner:王智军

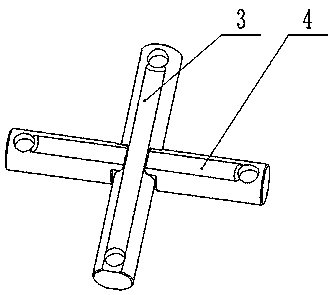

Firm supporting and smooth lubricating type differential mechanism assembly

InactiveCN109578558AOutstanding FeaturesHighlight significant progressDifferential gearingsGearing detailsBlind holeGasket

The invention discloses a firm supporting and smooth lubricating type differential mechanism assembly which comprises a differential mechanism left shell (1), a differential mechanism right shell (2),cross shaft long shafts (3), long shaft short shafts (4), half shaft wheels (6), half shaft wheel gaskets (7), planet gears (8), planet gear gaskets (9), a differential mechanism left bearing (11) and a differential mechanism right bearing (12). The firm supporting and smooth lubricating type differential mechanism assembly is characterized in that milling flat planes are arranged on the cross shaft long shafts (3) and the long shaft short shafts (4) correspondingly; a cross shaft fixed sleeve is fixed to a cross shaft assembly formed by the cross shaft long shafts (3) and the long shaft short shafts (4); and anti-loose bolts (10) are fixedly mounted in the differential mechanism right shell (2) through a mounting plane, and the anti-loose bolts (10) penetrate into blind holes of the cross shaft long shafts (3) and the long shaft short shafts (4). By means of the differential mechanism assembly, the rigidity of a split cross shaft is greatly enhanced, the position precision of work ofhalf shafts and the planet gears is guaranteed, outer component damage brought by the situation that the cross shaft moves out of a differential mechanism is avoided, and work and operation of innercomponents of the differential mechanism assembly under the good lubricating condition are facilitated.

Owner:SHANDONG PENGXIANG AUTOMOBILE

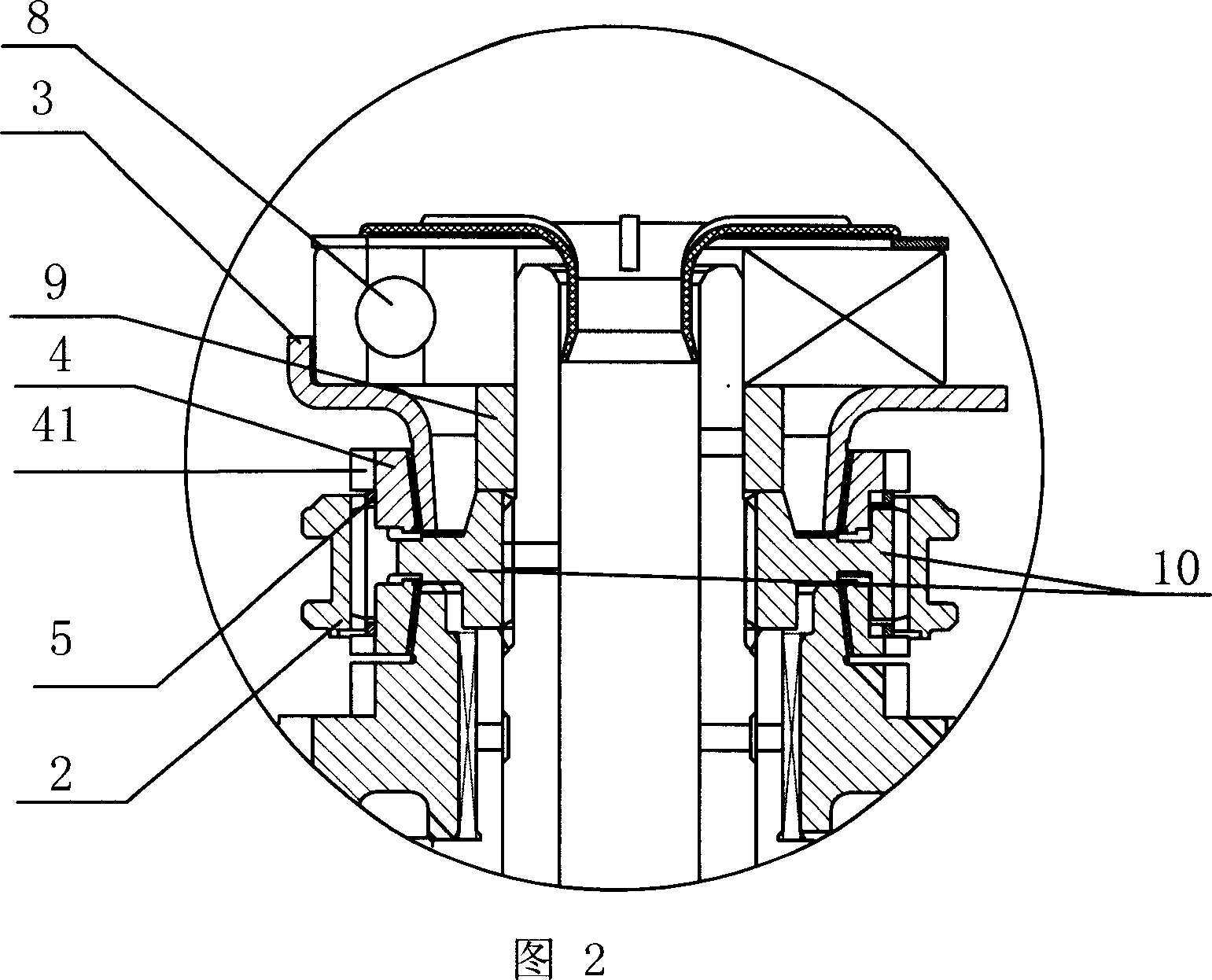

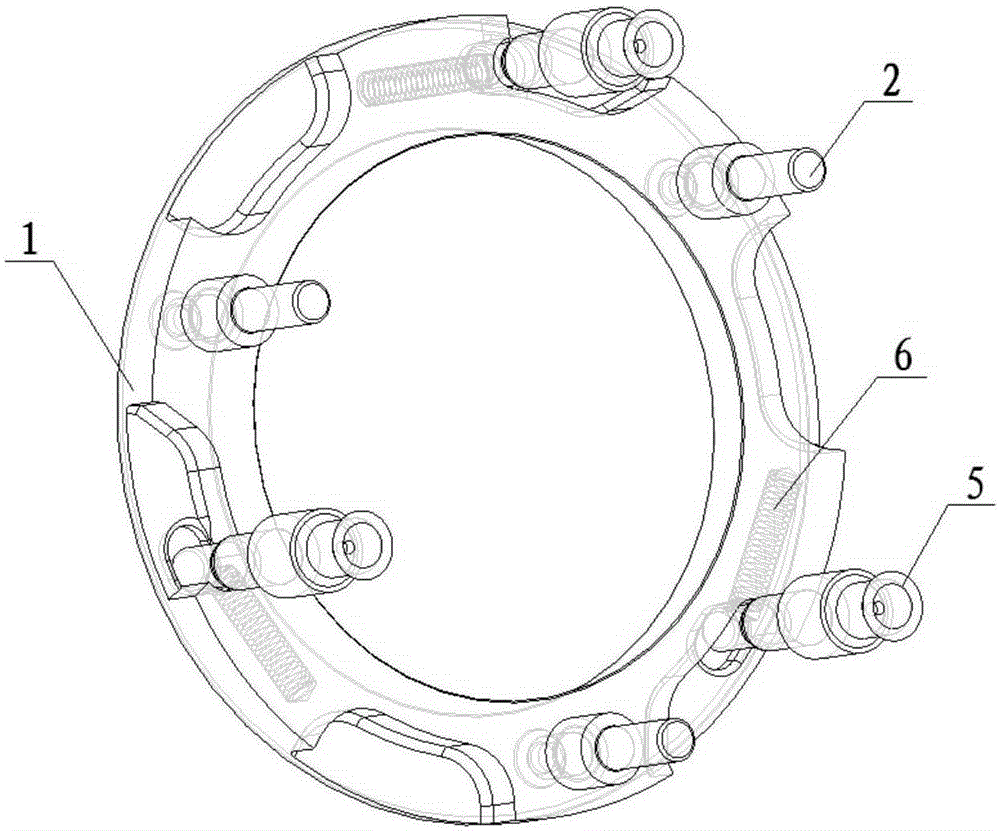

Self-locking mechanism of synchronizer

InactiveCN105179510AAvoid teethingAvoid damageMechanical actuated clutchesLocking mechanismSelf locking

The invention discloses a self-locking mechanism of a synchronizer. The self-locking mechanism comprises a high-gear conical ring and a low-gear conical ring. High-gear locking pins are inserted in the high-gear conical ring in a penetrating manner. Low-gear locking pins are inserted in the low-gear conical ring in a penetrating manner. A sliding gear sleeve is arranged between the high-gear conical ring and the low-gear conical ring and provided with two sets of holes. The two sets of holes are distributed in a non-equal manner, and the high-gear locking pins and the low-gear locking pins are sleeved with the two sets of holes respectively. Springs matched with the low-gear locking pins are arranged in the circumferential direction of the high-gear conical ring. The springs are embedded springs or disc springs with cylinders, wherein the force transmission area of the springs and the low-gear locking pins can be increased, and one ends of the springs are closely folded. Or, ejector pins capable of increasing the force transmission area of the springs and the low-gear locking pins are arranged between the springs and the low-gear locking pins. The phenomenon that gear colliding happens in the process that the synchronizer loses synchronization due to unreliable self-locking can be avoided, and the synchronizer is prevented from being damaged.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Three-speed gear transmission gearbox with gear striking preventing function

The invention belongs to the technical field of gear transmission gearboxes, and particularly relates to a three-speed gear transmission gearbox with a gear striking preventing function. The three-speed gear transmission gearbox with the gear striking preventing function comprises an output shaft, a clamping mechanism, a first fixing ring, a shifting rod, a first fixing plate, a supporting mechanism, a first guide block, a second guide block, a third guide block, a fixing housing, an input shaft, a first connecting barrel, a second fixing ring, a fixing block, a third fixing ring, etc., wherein a storing chamber is formed in the fixing housing; a through fixing circular hole is formed in the side surface of the storing chamber; a through moving groove is formed in the side surface, opposite to the fixing circular hole, of the storing chamber; two first guide grooves are symmetrically formed in the outer circle surface of the input shaft; and two third guide grooves are symmetrically formed in the outer circle surface of the input shaft. According to the gear transmission gearbox, when a gear which rotates at a slow speed is forcibly embedded into a gear which rotates at a high speed, or when the gear which rotates at the high speed is forcibly embedded into the gear which rotates at a slow speed, the problem of gear striking in the gearbox can be avoided.

Owner:柳欢

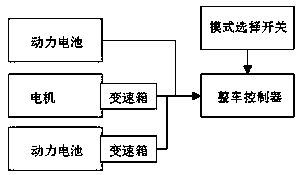

Control method of hybrid power system switching

The invention discloses a control method of hybrid power system switching. The method includes judgment of a user driving mode, gear control of gearboxes of two driving systems, processing of vehiclespeed and acceleration pedal signals, receiving of input signals of an external power system, and judgment of external conditions. According to the scheme, an engine can work under the condition thata motor cannot satisfy driving force and the motor can drive an automobile to drive in urban areas or at low speed so as to better improve the economy of the automobile, meet low speed of the automobile in urban areas and reduce oil consumption during frequent braking and staring. The engine and the motor can be smooth switched so as to avoid mis-engagement due to idle running of the gearboxes after the gearboxes and the clutches are separated.

Owner:HANTENG AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com