Hydraulic brake apparatus of haulage winch

A hydraulic brake and winch technology, applied in hoisting devices and other directions, can solve problems such as misoperation of working brakes and clutches, small braking force of electric hydraulic pushers, and high labor intensity of operators, so as to avoid gear grinding , avoid duplication of labor, reduce the effect of labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

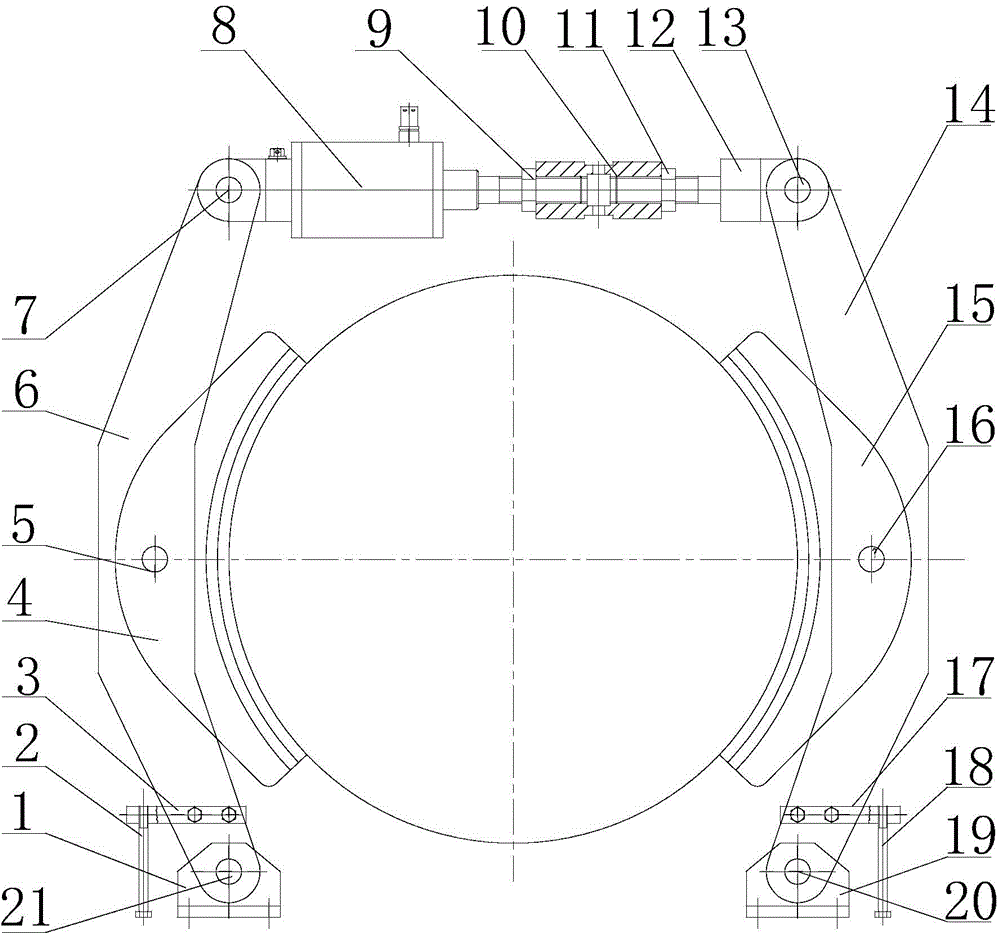

[0016] Such as figure 1 Shown: a transport winch hydraulic braking device, including the rear support 1 installed on the transport winch, the rear support 1 is connected with one end of the rear brake arm 6 through the pin shaft Ⅵ21, and is in contact with the rear support 1 A left anti-yaw block 3 is installed at one end of the rear brake arm 6, and the left anti-yaw block 3 can adjust the yaw amount of the rear brake arm 6 through the left adjustment screw 2, so that the rear brake arm 6 is in a reasonable position. position, the rear brake block 4 is installed on the rear brake arm 6 through the pin shaft I5, the other end of the rear brake arm 6 is connected to the brake hydraulic cylinder 8 through the pin shaft II7, and the piston rod of the brake hydraulic cylinder 8 is passed through the adjustment nut 10 is connected with one end of the connecting rod 12, the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com