Shifting device of electric hammer

A technology of electric hammers and shifting parts, which is applied in the direction of striking tools, light impact tools, manufacturing tools, etc., which can solve the problems of lack of manpower control and response speed, reduce operating efficiency of operators, and injuries of operators, so as to improve labor efficiency. Productivity and work quality, avoiding tooth punching phenomenon, and improving the effect of work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

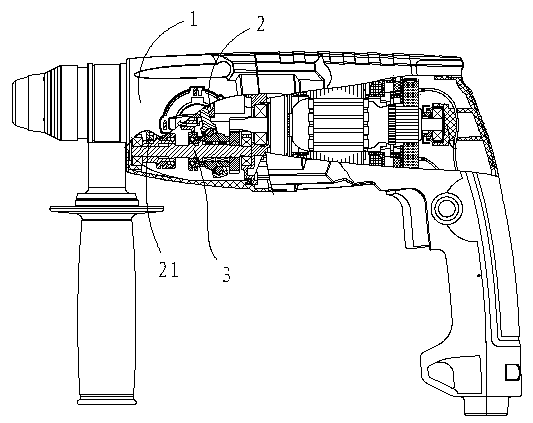

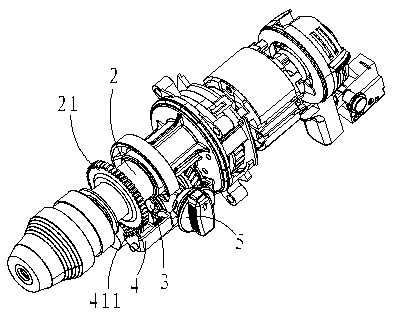

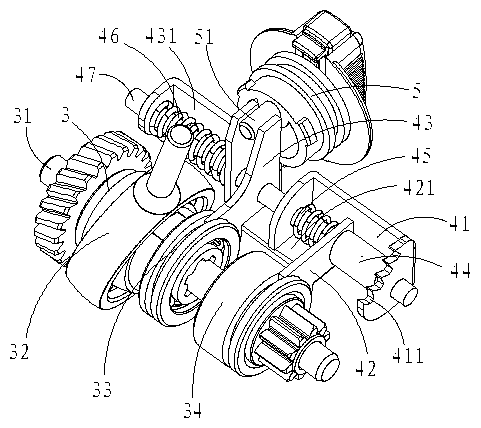

[0019] Embodiment: a gear shifting device of an electric hammer, such as figure 1 , figure 2 , image 3 As shown, the electric hammer 1 includes a transmission device 2, a shifting device 3, a shifting device 4, and a knob 5. The shifting device 3 includes an intermediate shaft 31, and an intermediate shaft gear that can be linked or disengaged from the intermediate shaft 31. 34. A clutch 33 that is linked with the intermediate shaft 31 in the circumferential direction and can move back and forth in the axial direction, and a swing rod bearing 32 that can be linked or disengaged by adjusting the position of the clutch 33 and the intermediate shaft 31. The transmission device 2 is provided with a large gear 21 , the large gear 21 meshes with the intermediate shaft gear 34 , the swing rod bearing 32 is connected with the transmission device 2 , and the driving rod 51 on the knob 5 is offset relative to the axial center of the knob 5 .

[0020] like image 3 , Figure 4 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com