Patents

Literature

66results about How to "Reduce intermediate transmission links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

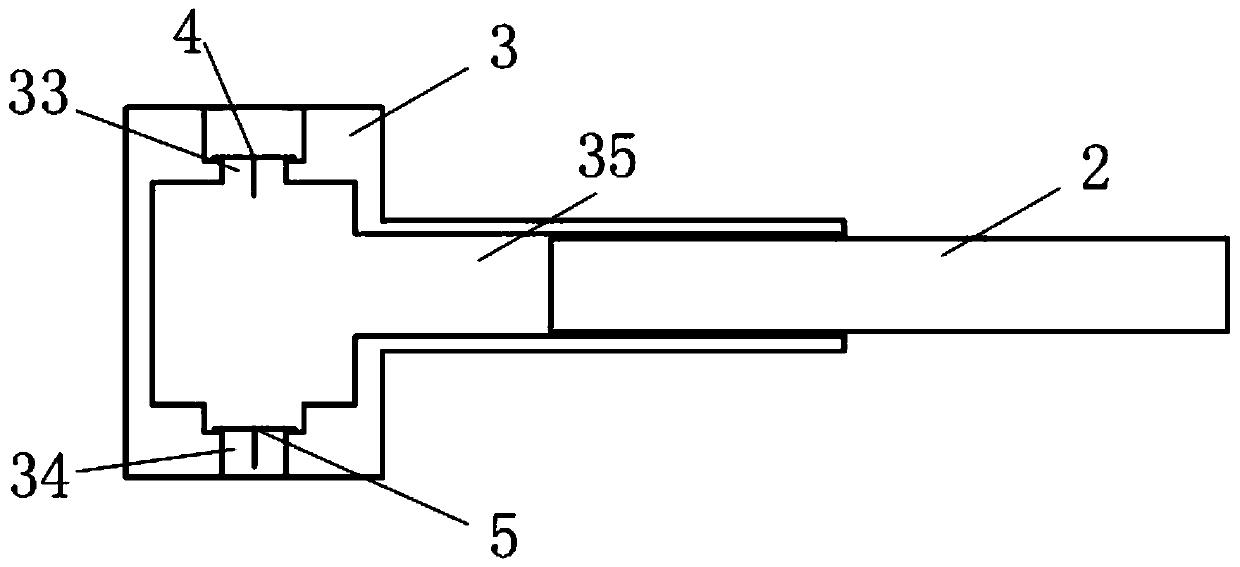

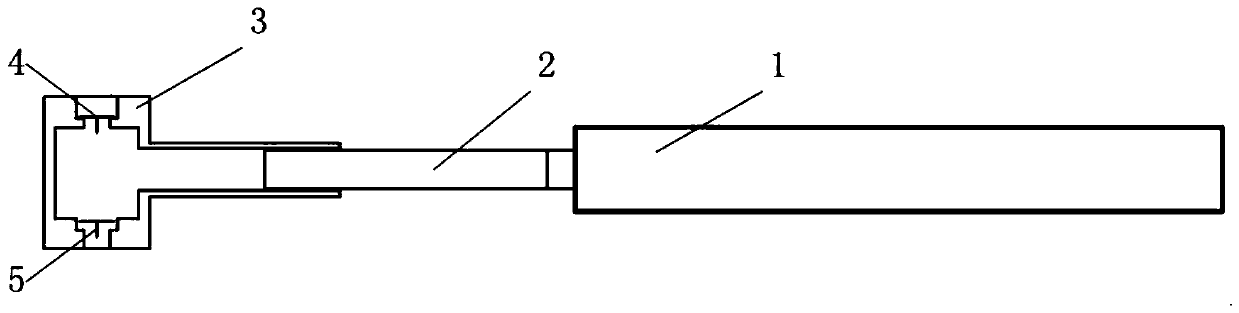

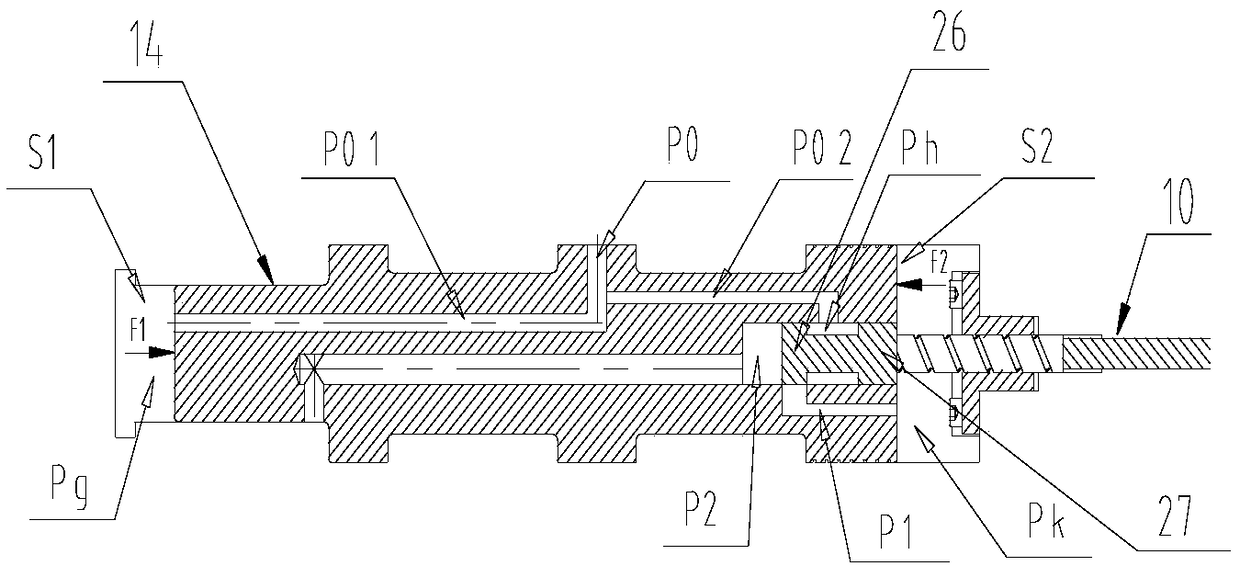

Plunger pump driven by linear motor

PendingCN110454352ASolve the real problemReduce intermediate transmission linksPositive displacement pump componentsPumpsLinear motorPlunger pump

The invention discloses a plunger pump driven by a linear motor. The plunger pump is characterized in that the plunger pump is driven by the linear motor, and the movement rule of an assembly is controlled by controlling the movement rule of the linear motor, so that the defects of an existing plunger pump are overcome, and the advantages of the plunger pump are exerted to the maximum extent.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

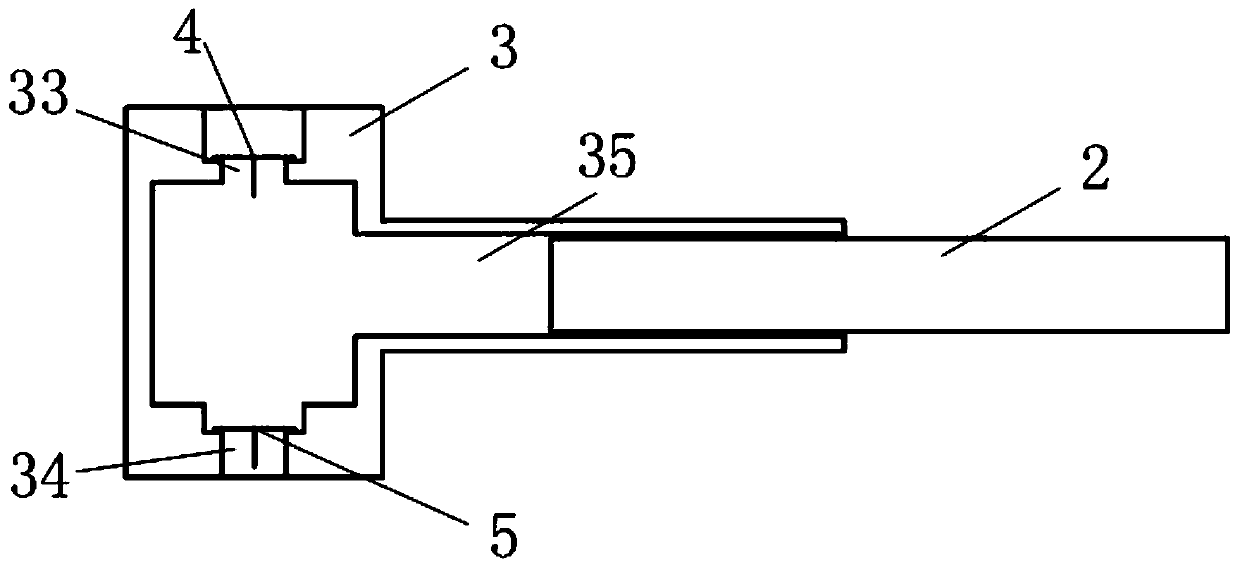

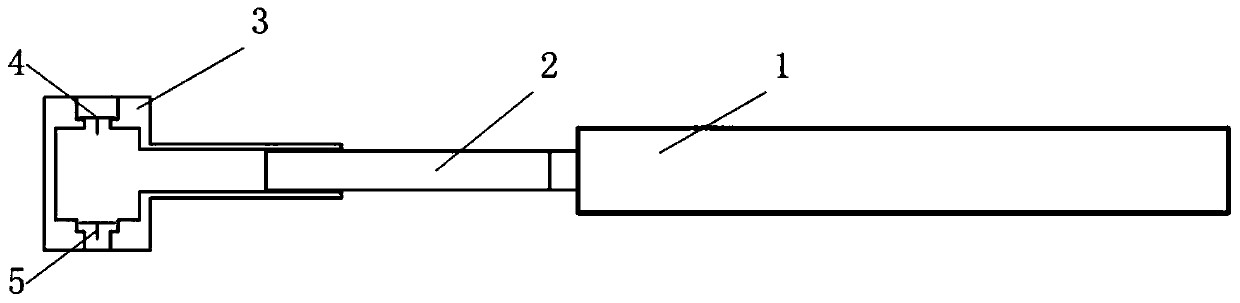

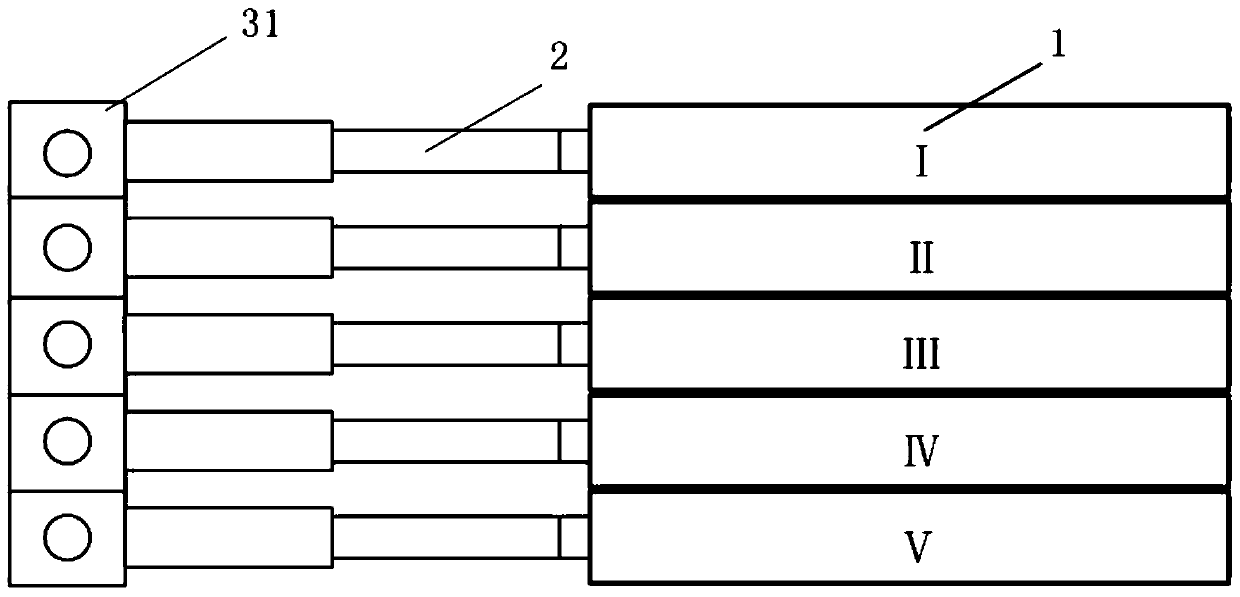

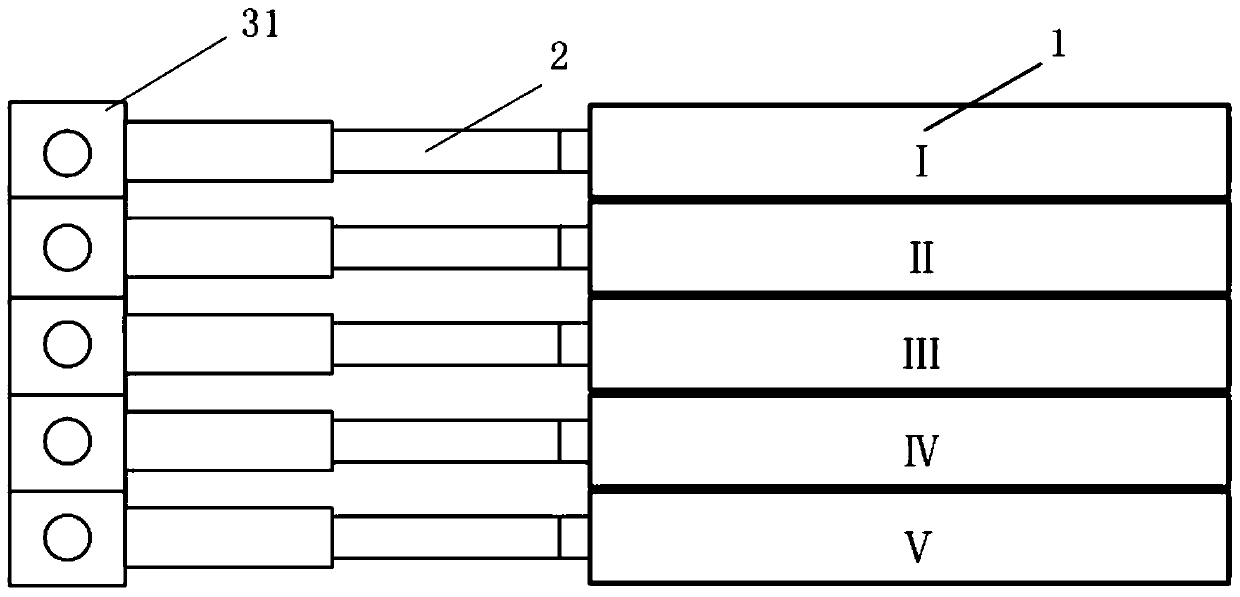

Linear motor plunger pump

PendingCN110425105ASolve the real problemReduce intermediate transmission linksPositive displacement pump componentsPumpsEngineeringLinear motor

The invention discloses a linear motor plunger pump. The plunger pump is driven through a linear motor, the movement rule of an assembly is controlled by controlling the movement rule of the linear motor, and therefore the defects of an existing plunger pump are overcome, and the advantages of the plunger pump are furthest developed.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

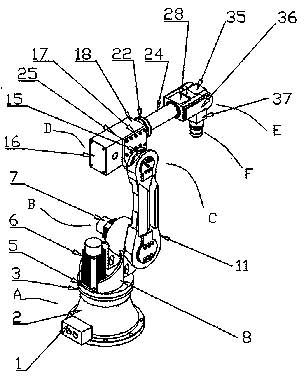

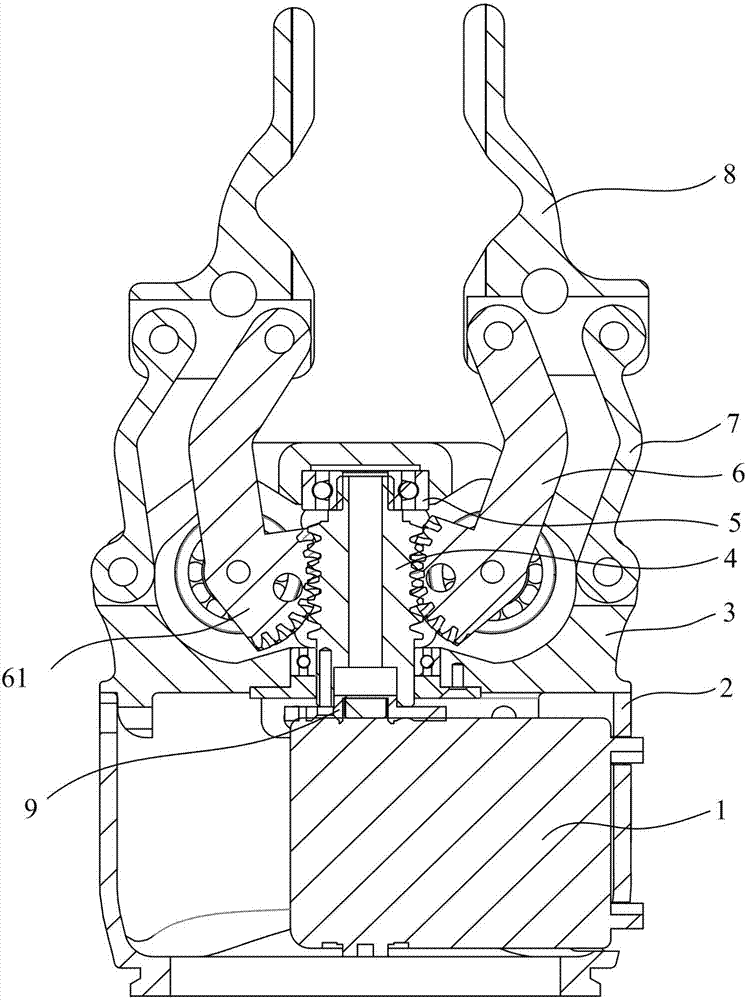

Six-axis degree-of-freedom manipulator

InactiveCN103568002AAvoid jitterCompact structureProgramme-controlled manipulatorControl systemDegrees of freedom

The invention discloses a six-axis degree-of-freedom manipulator. The six-axis degree-of-freedom manipulator comprises a base, wherein the base is in transmission connection with a first transmission mechanism, a second transmission mechanism, a third transmission mechanism, a fourth transmission mechanism, a fifth transmission mechanism and a sixth transmission mechanism in sequence, wherein the six transmission mechanism is in transmission connection with a mechanical palm part. A series of functions such as welding, spraying and handling are combined, the newest servo control system is adopted, and a series of new functions which can meet the industrial production of users are developed on the platform. The conventional complex transmission process is greatly simplified in the aspect of mechanical transmission, and the characteristic that bevel gear mesh type transmission is generally adopted by the conventional six axes is cancelled, so that the manipulator has a compacter structure and higher transmission efficiency, is more accurate in control and can effectively prevent the situation of jitter due to joint movement.

Owner:RIZHAO POLYTECHNIC

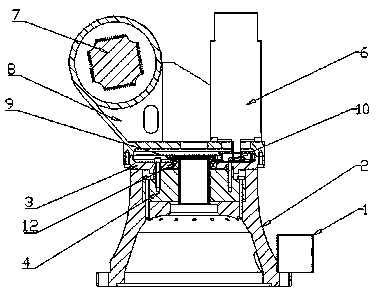

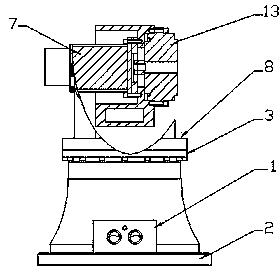

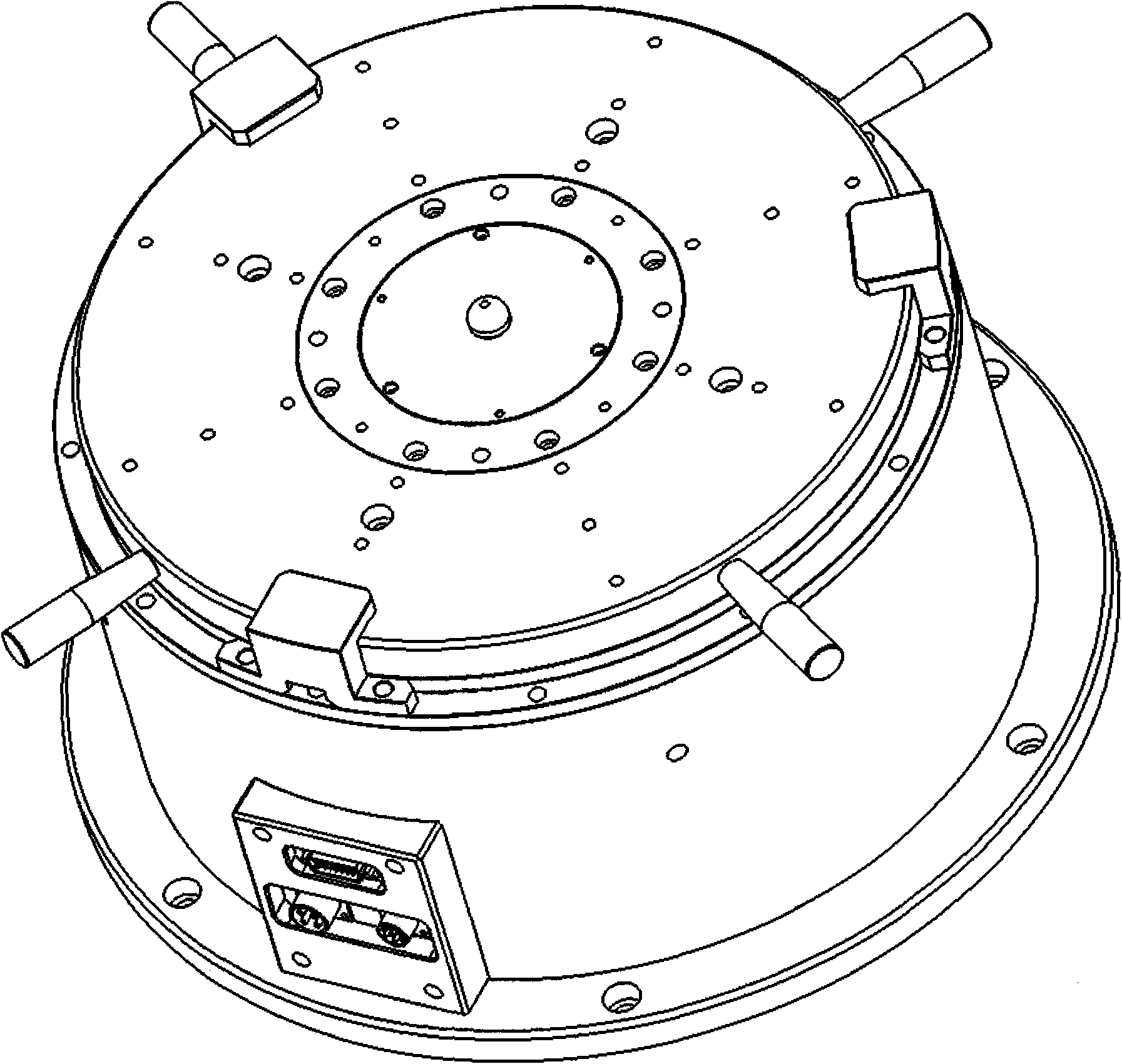

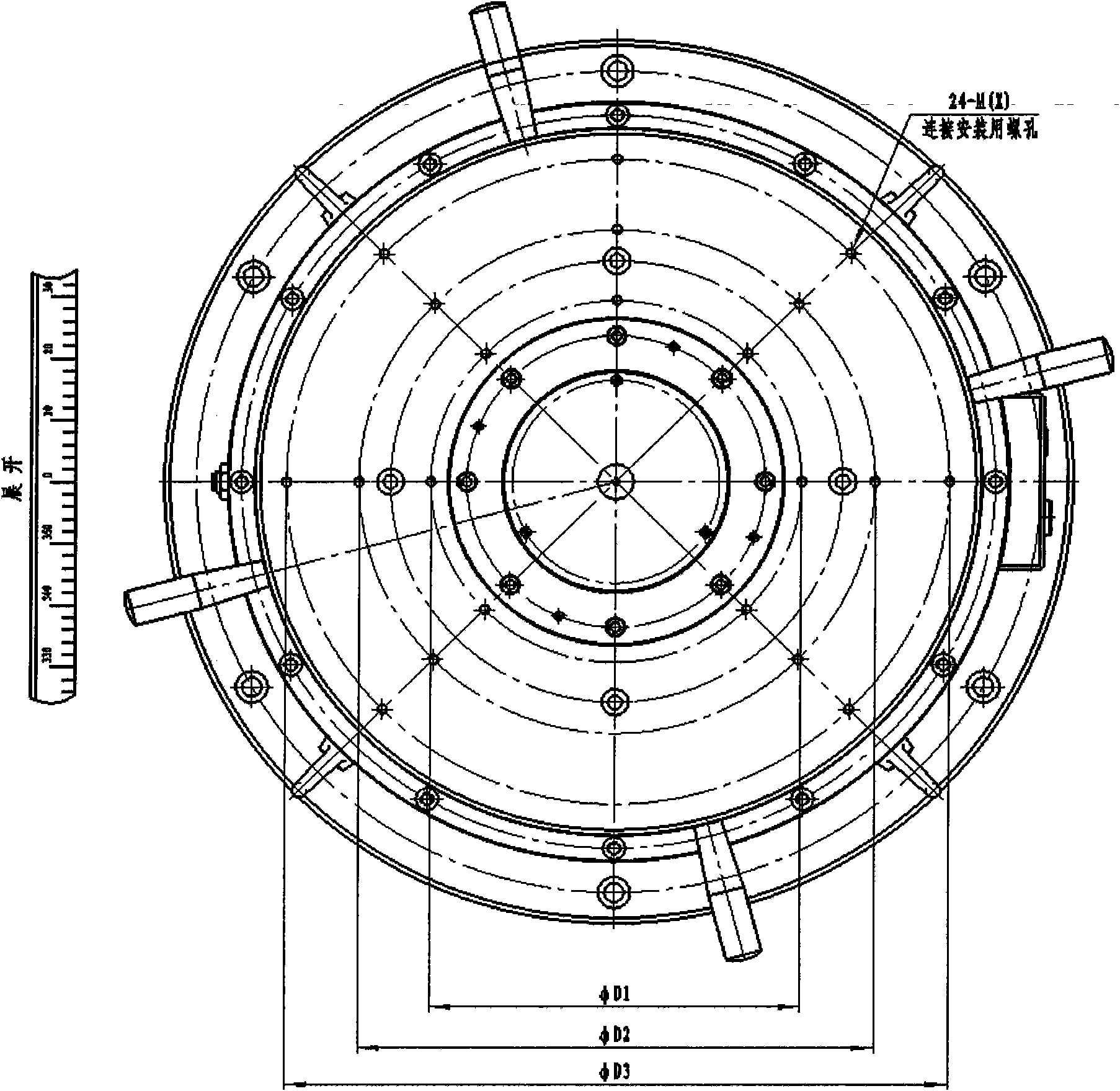

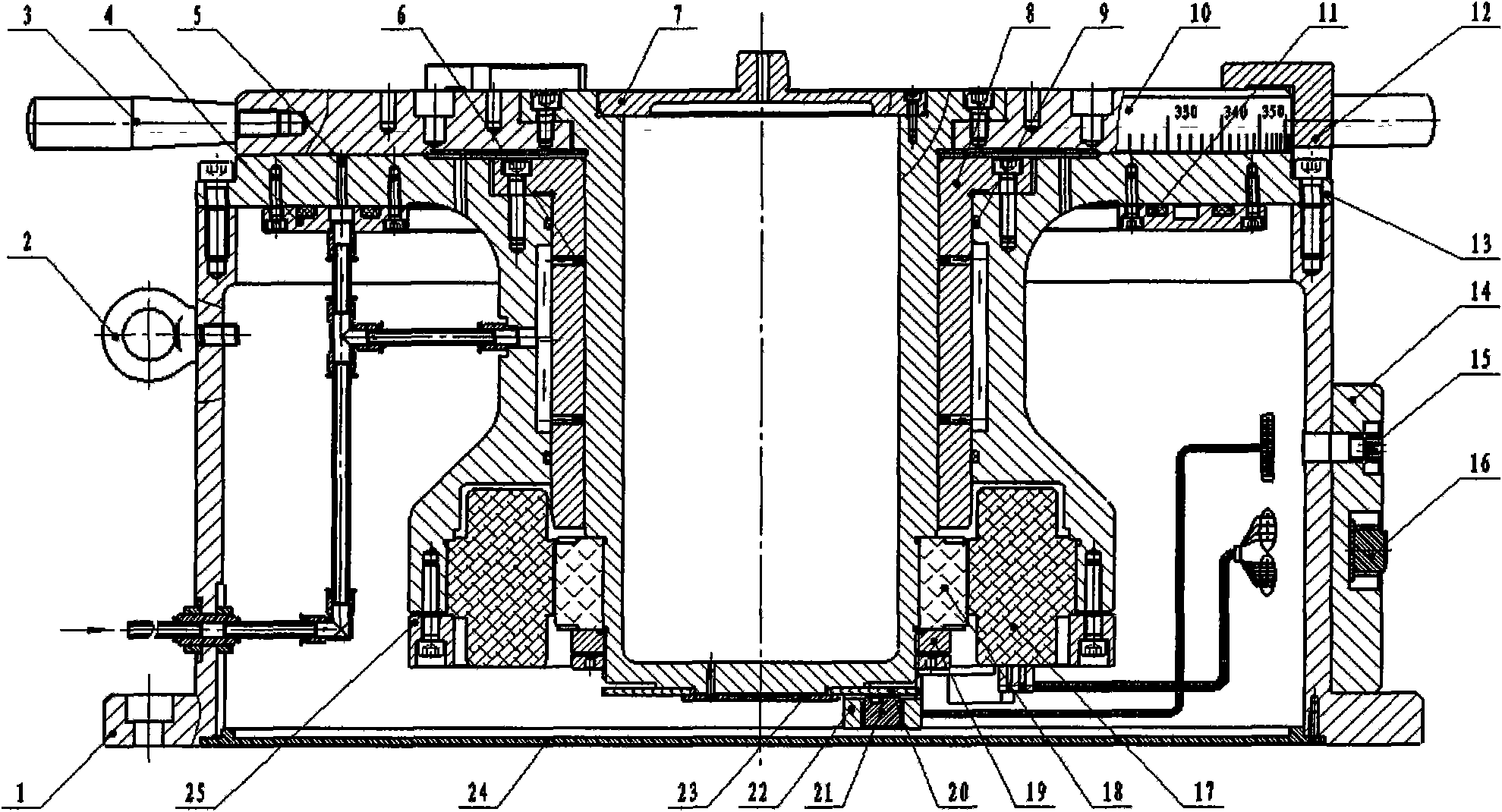

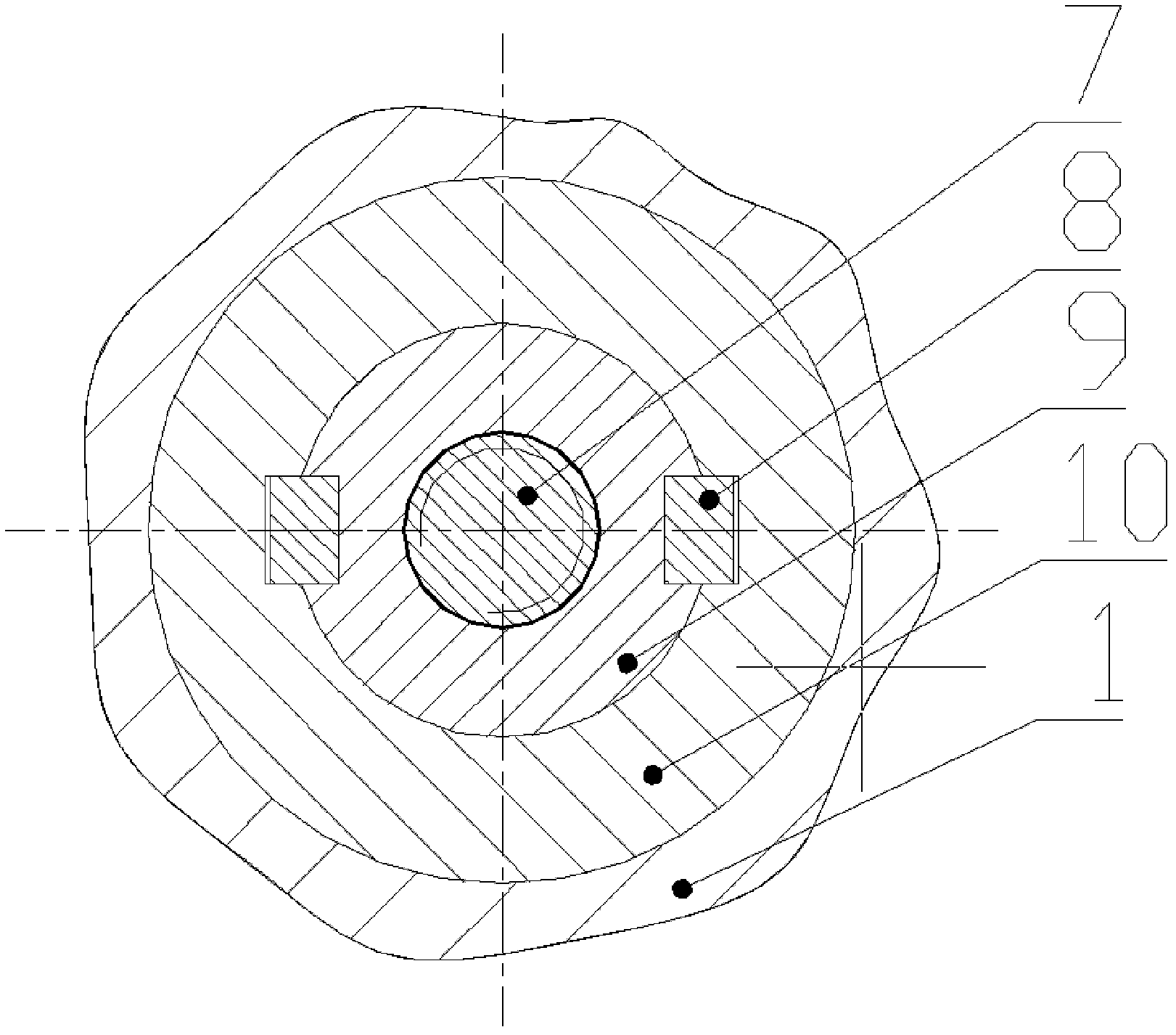

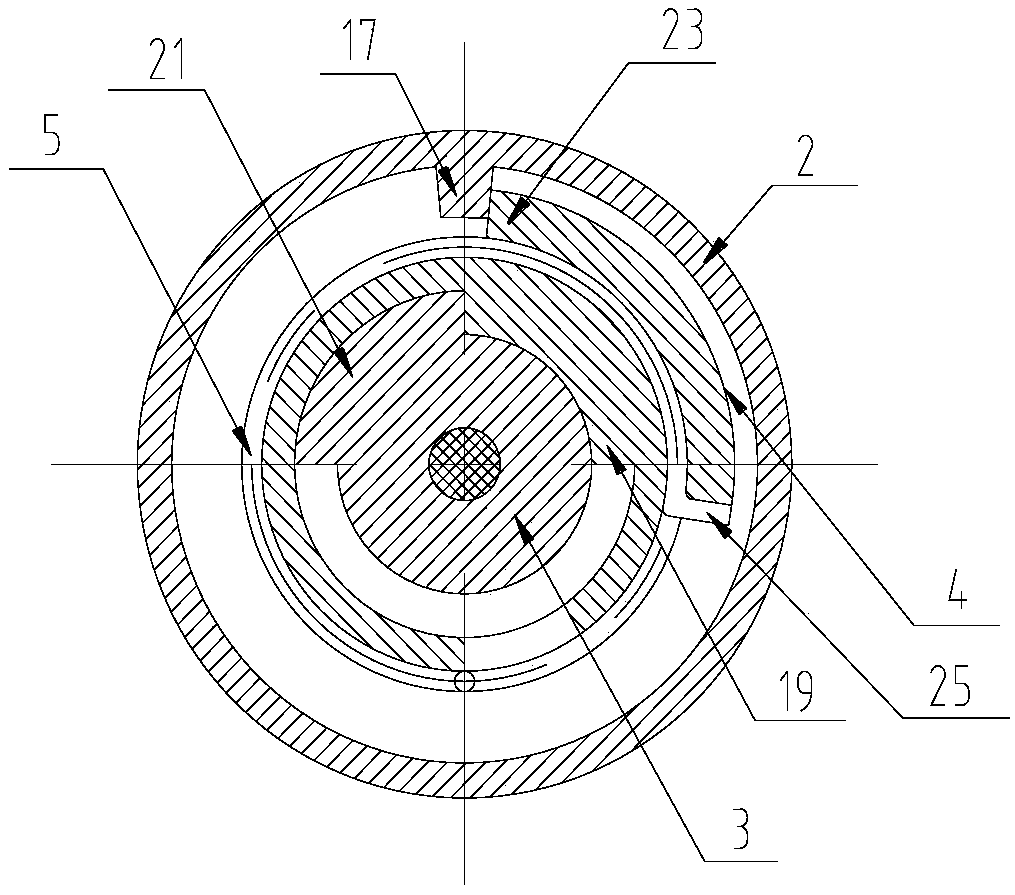

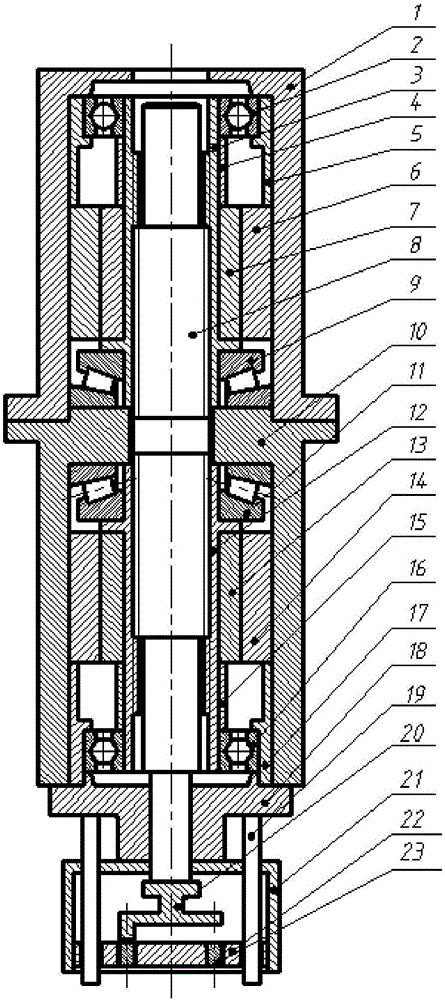

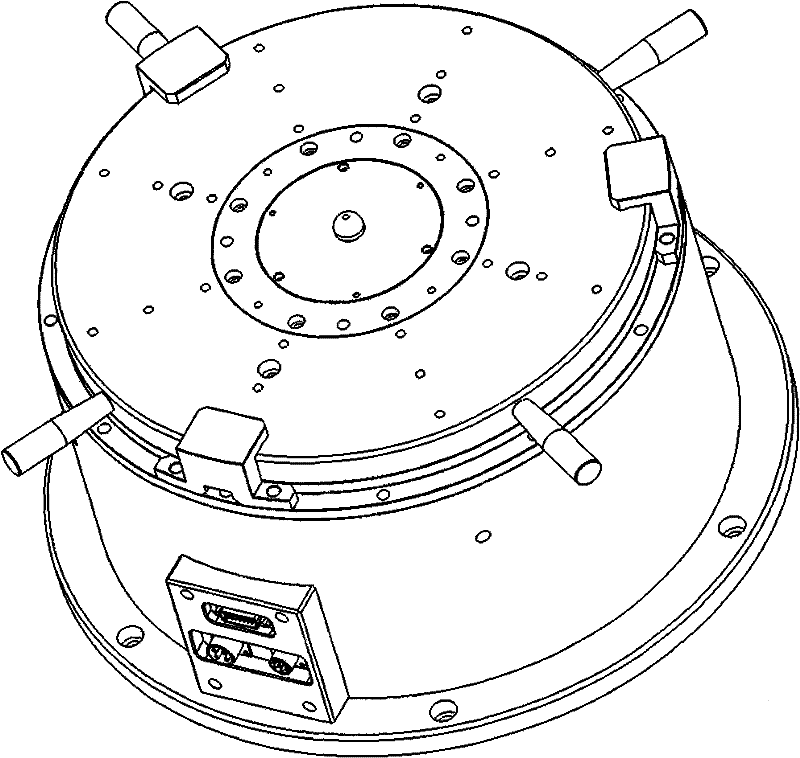

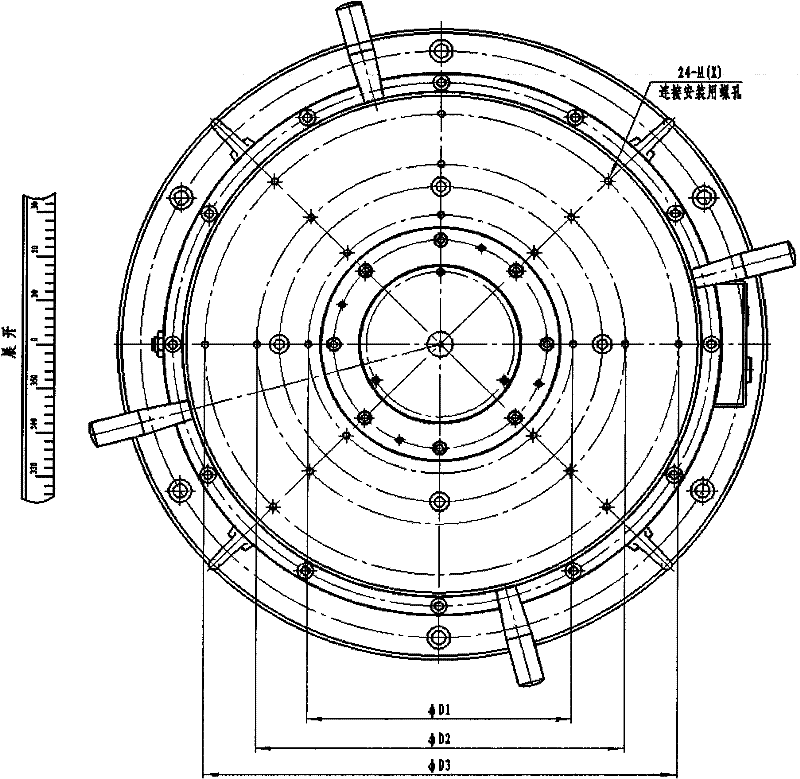

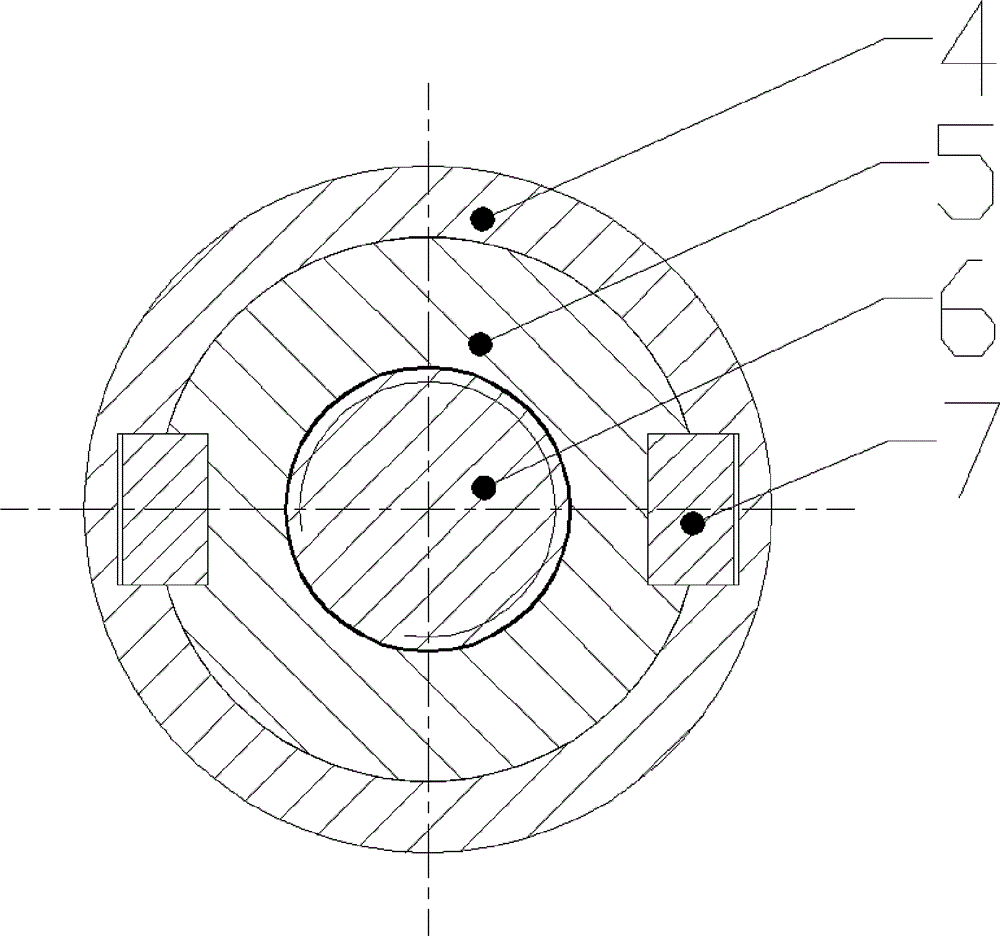

High-precision direct driven air flotation turntable

ActiveCN102011918AReduce intermediate transmission linksReduce the transmission linkStands/trestlesBearingsTorque motorEngineering

The invention discloses a high-precision direct driven air flotation turntable, which comprises a supporting seat (1), a hoisting ring screw (2), a handle (3), a sealing ring (4), an axial throttle (5), a radial throttle (6), a mounting pedestal (7), a radial bearing outer ring (8), an O-shaped rubber sealing ring I (9), an air flotation face assembly (10), an O-shaped rubber sealing ring II (11), a pressure block (12), a motor mounting seat (13), a socket (14), a plug I (15), a plug II (16), a torque motor stator (17), a torque motor rotator (18), a small pressure ring (19), a grating disc (20), a reading head (21), a reading head bracket (22), a gland (23), a sealing plate (24) and a large pressure ring (25). The turntable has high indexing precision and low end face run-out and radial run-out, and solves the precise indexing problem under the condition of high load.

Owner:BEIJING SATELLITE MFG FACTORY

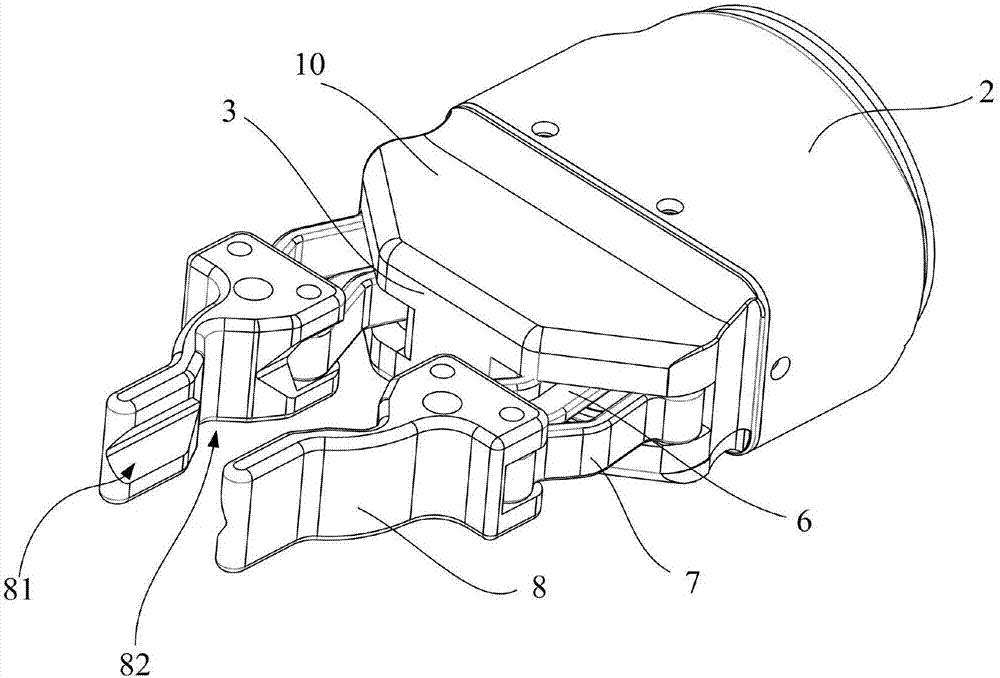

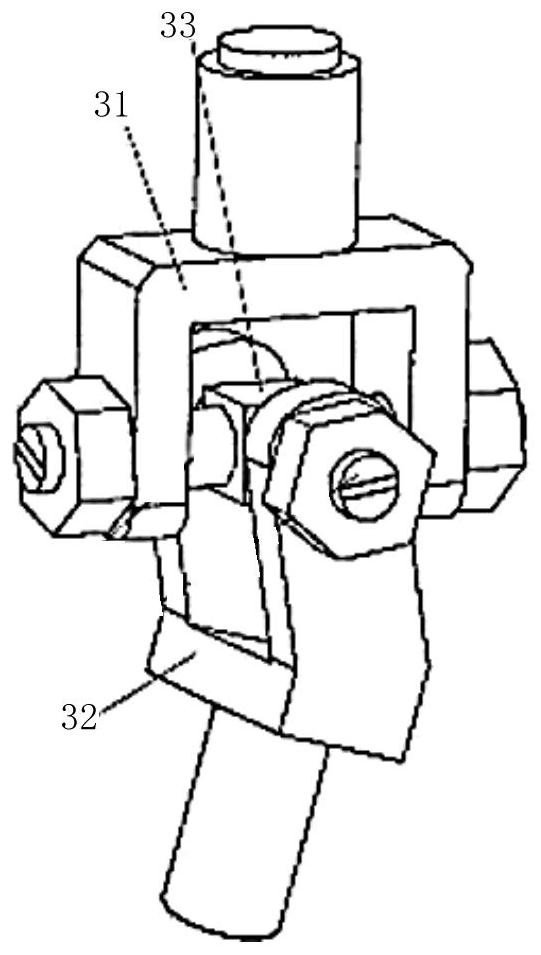

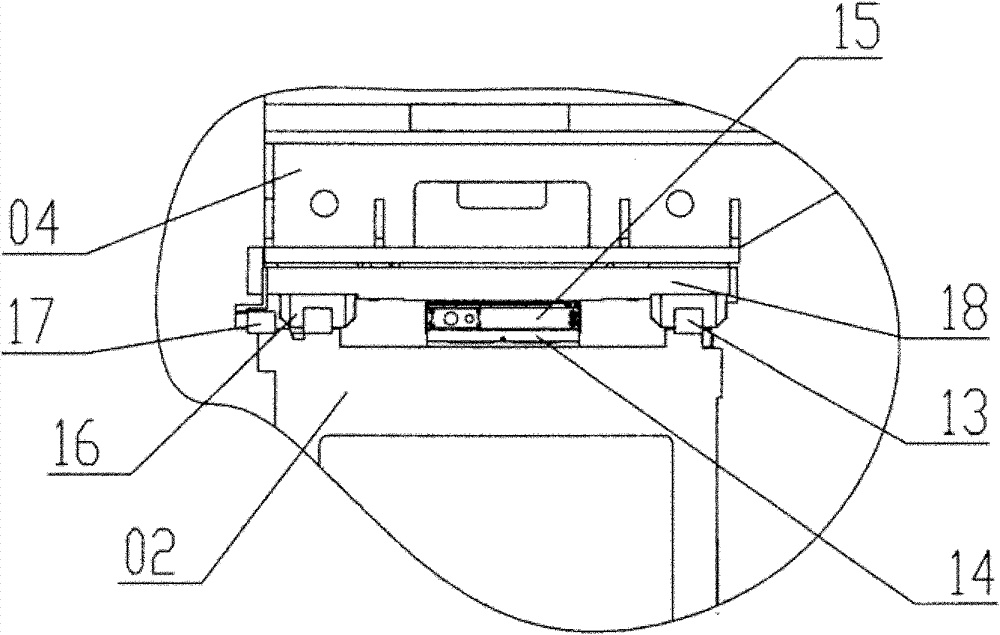

Robot end clamping module driven by steering engine

The invention discloses a robot end clamping module driven by a steering engine. The end clamping module comprises the drive steering engine capable of outputting power outwards. The power output end of the drive steering engine is connected with a steering engine output disc. The other end of the steering engine output disc is connected with one end of a worm arranged in an upper base and drives the worm to rotate forwards or backwards. A pair of drive clamping arms is further hinged into the upper base in a bilateral symmetry mode. The worm is in engaged transmission connection with the drive clamping arms, so that the drive clamping arms swing around the hinge center of the upper base. The clamping ends of the drive clamping arms can be reunited or separated. Compared with the prior art, the robot end clamping module driven by the steering engine has the advantages of being simple in structure, small in size, compact, flexible to operate and the like; control under conditions of various torque, speeds and positions can be achieved by controlling the steering engine motion mode; and a lower base is of a replaceable structure, and can cooperate with ends of different robots for operation quite conveniently, so that a work procedure needing to prevent workpieces from being damaged during clamping is efficiently completed.

Owner:GUANGDONG UNIV OF TECH

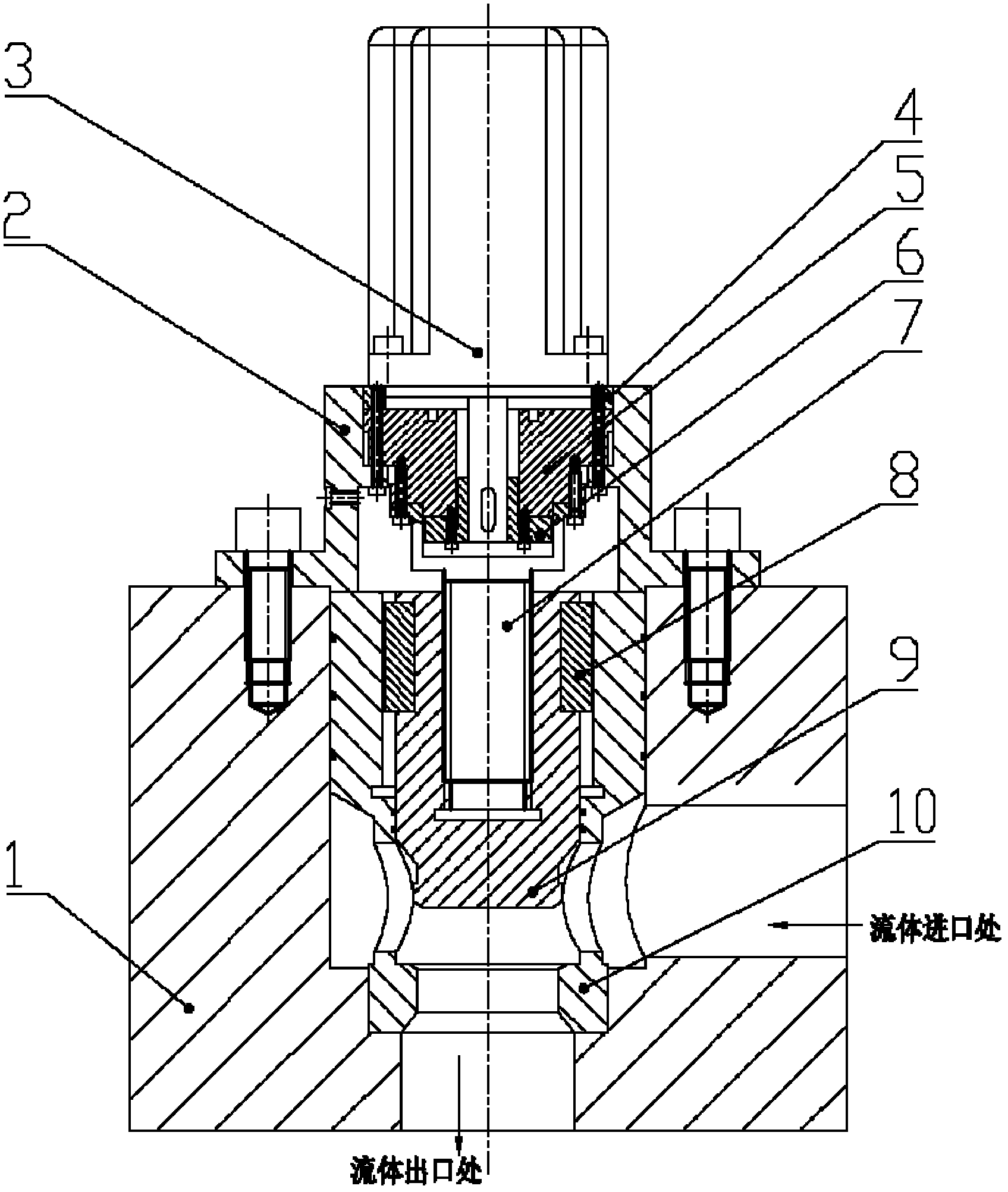

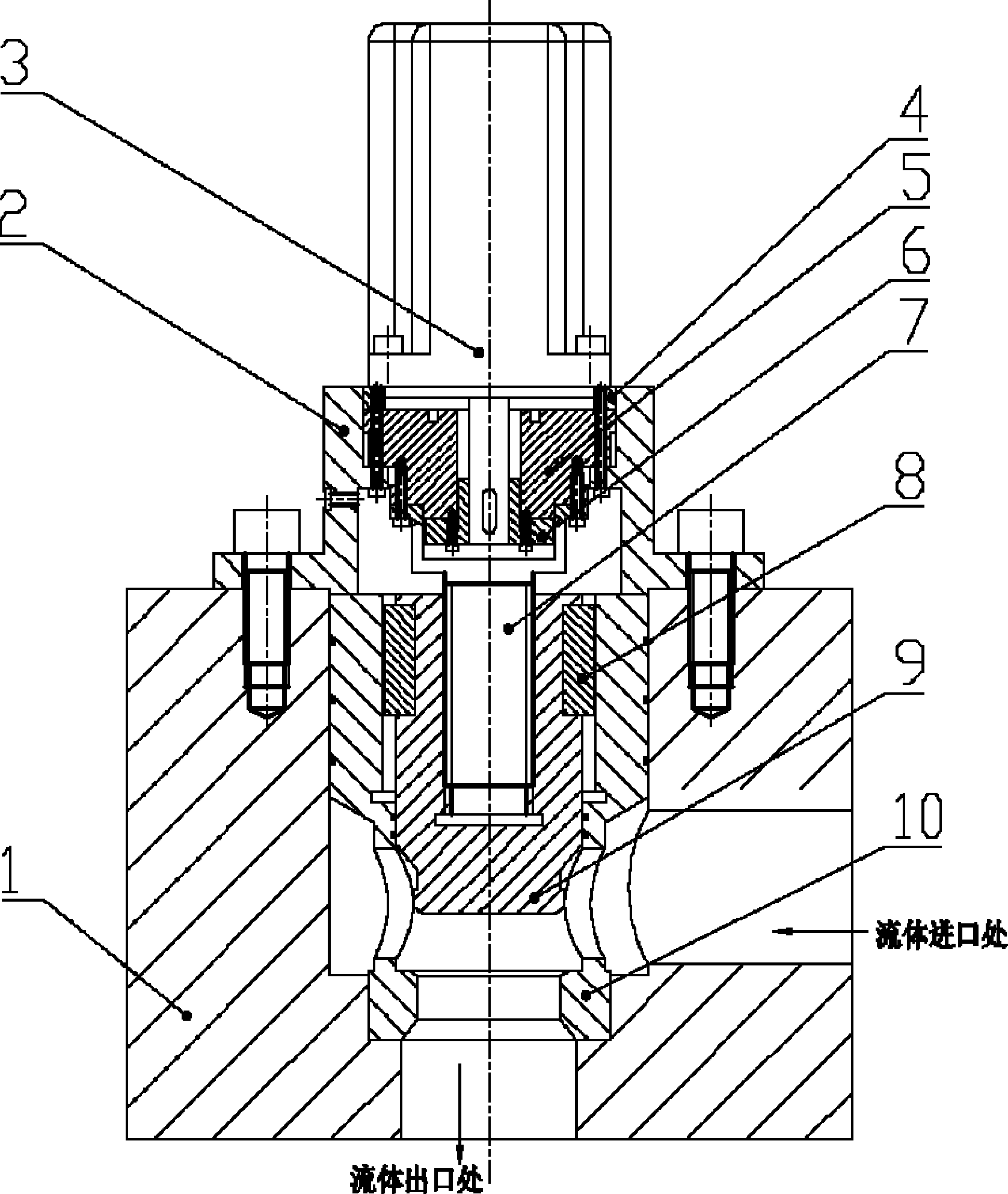

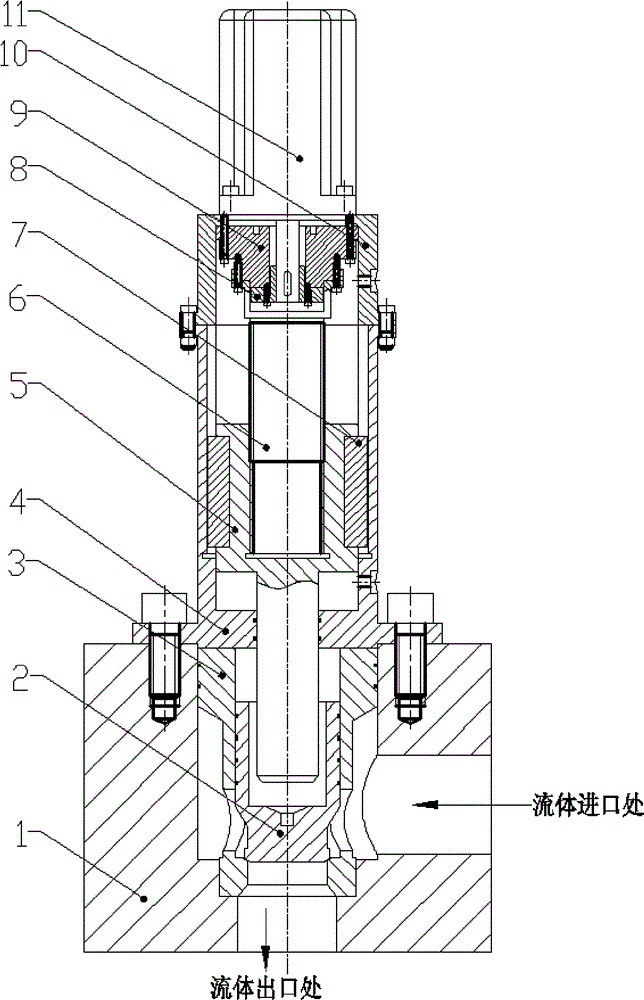

High-pressure high-flow alternating-current servo direct-driven threaded flow valve

InactiveCN102635582AOvercoming contamination sensitivityReduce manufacturing costsServomotor componentsElectricityWorking pressure

Disclosed is a high-pressure high-flow alternating-current servo direct-driven threaded flow valve. An alternating-current servo motor directly drives a valve spool to open and close by the aid of transmission of threads, and the threads only need to transmit driving force on a single side during integral operation of the valve due to hydraulic force, and are selectively one-way transmission saw-toothed threads. The valve is simple in structure, accurate in control and convenient in use, can be directly digitally controlled by a computer and has excellent buffering and positioning performances, the requirement on positioning at an optional point can be met, a closed-loop system with an electrical feedback function can be realized, particularly, the problem that an original servo valve is sensitive to oil pollution can be effectively solved, and shortcomings that the original servo valve is used difficultly in high-pressure and high-flow environments and the like are also overcome. In addition, the valve is wide in working pressure range and high in flow, and can also work under extremely low oil supply pressure, the dynamic performance of the valve is rarely affected by the oil supply pressure, and the efficiency of a system can be improved due to the fact that intermediate transmission links are few.

Owner:XI AN JIAOTONG UNIV

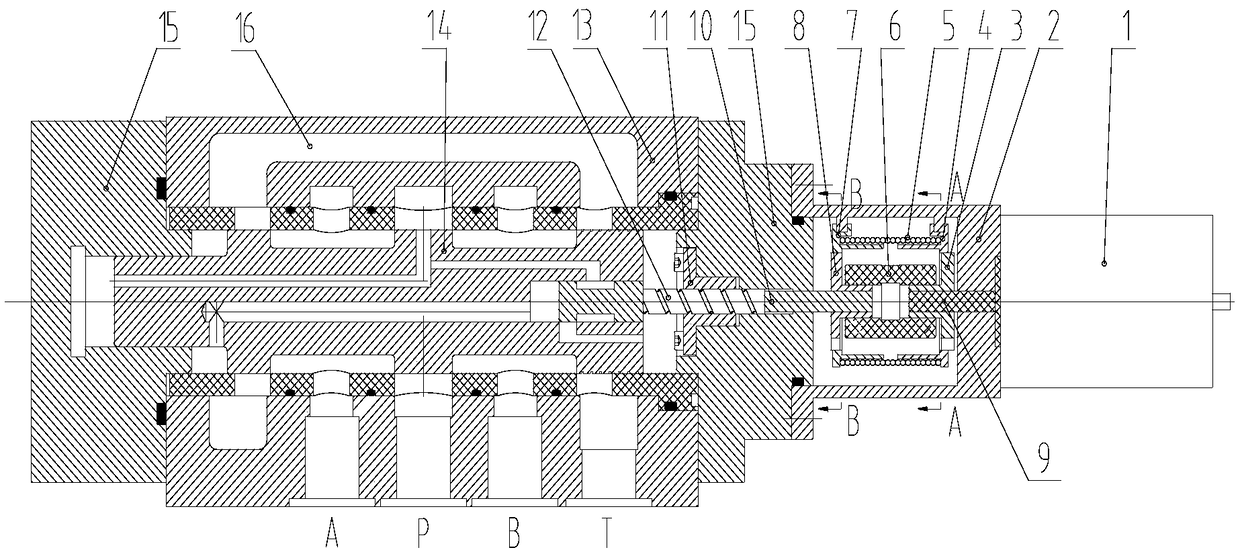

Indirect control type digital servo valve

PendingCN108757621ASimple structureImplementation driveServomotor componentsDifferential pressureEngineering

The invention provides an indirect control type digital servo valve. According to the technical scheme, digital quantity control is adopted, the driving force of a valve element is large, the valve element is not prone to jamming, the anti-pollution capability of the servo valve is improved, the control of a main valve element can be realized without arranging a sensor, so that the control loop issimplified. In order to achieve the aim, the indirect control type servo valve comprises a valve body, the main valve element and a pilot valve element, the main valve element is provided with an oilinlet passage, an oil return passage and a control oil passage, the area of the axial two ends of the main valve element is unequal, the valve body is provided with a control oil cavity communicatingwith the control oil passage at the end, which is large in area, of the main valve element, and is provided with a high-pressure oil cavity communicating with high-pressure oil at the end, which is small in area, of the main valve element, one end of the pilot valve element extends into the main valve element in an axial direction so as to enable the control oil passage and the oil inlet passageor the oil return passage to communicate through axial movement, so that the two ends of the main valve element form the differential pressure for axial movement, then the working positions of the valve are switched, and the continuous adjustment of the flow is realized.

Owner:三河沃达液压控制系统有限公司

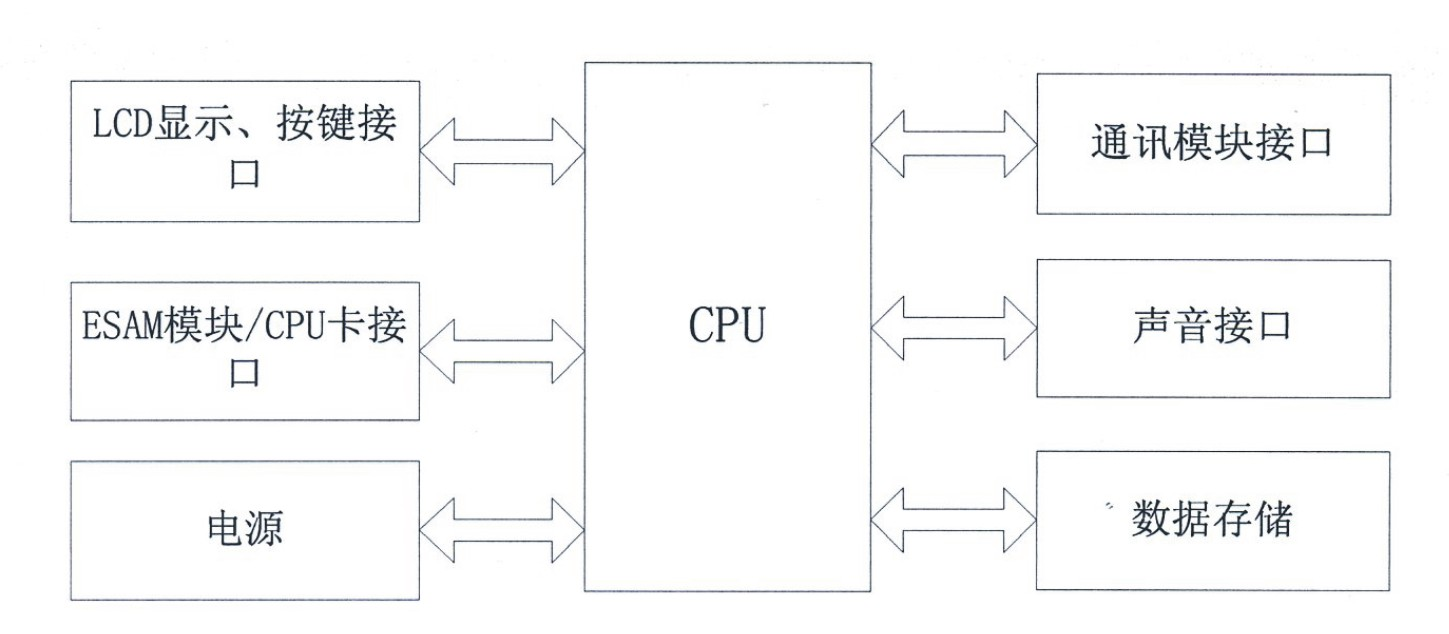

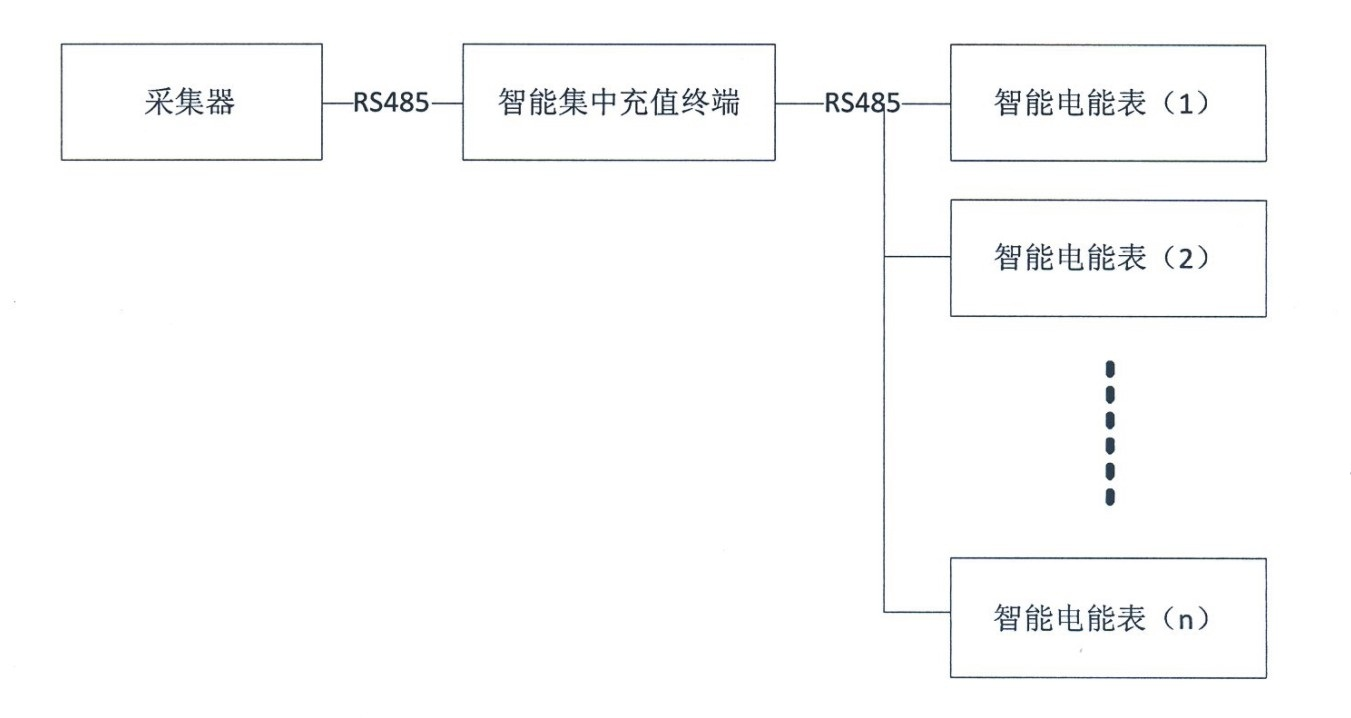

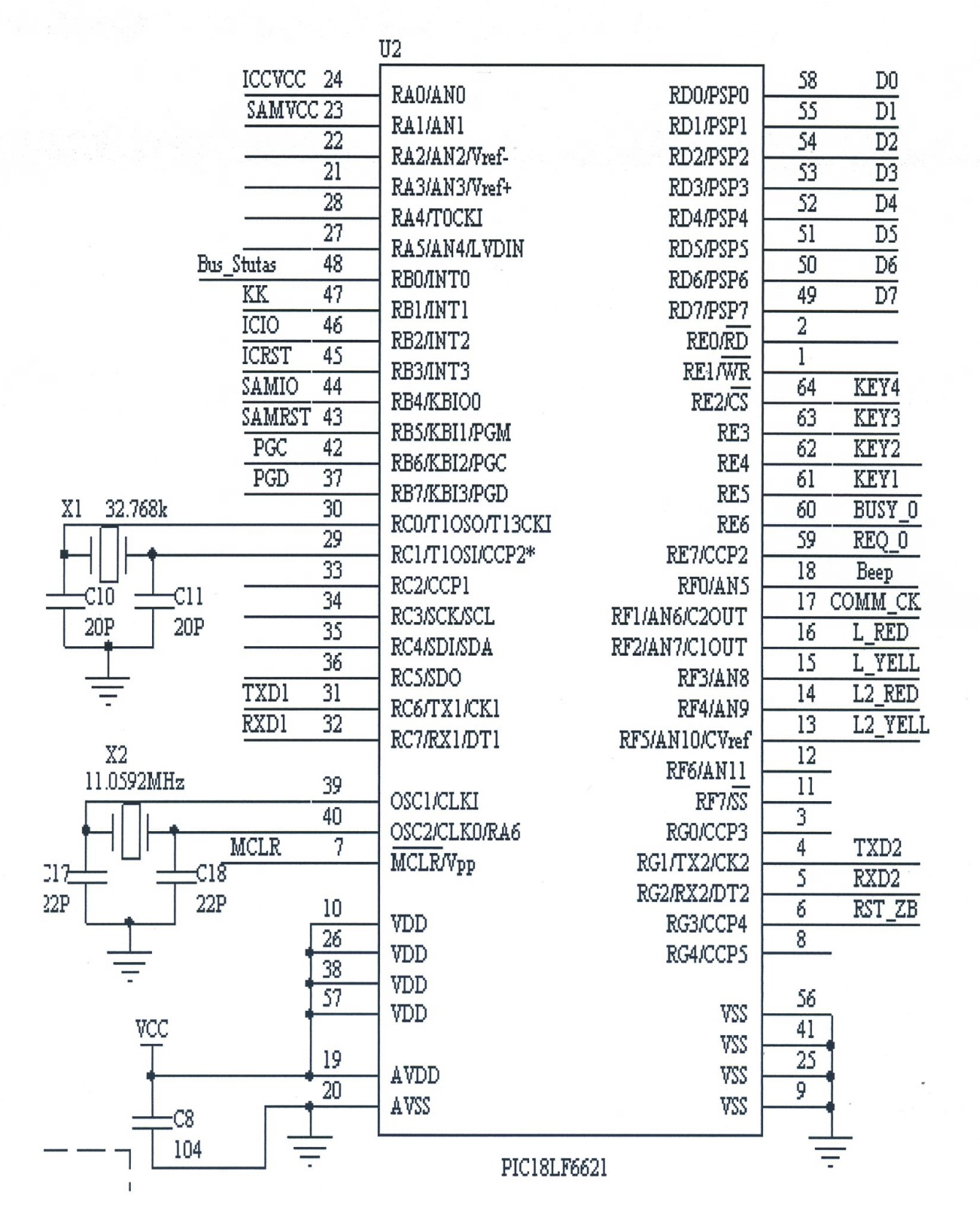

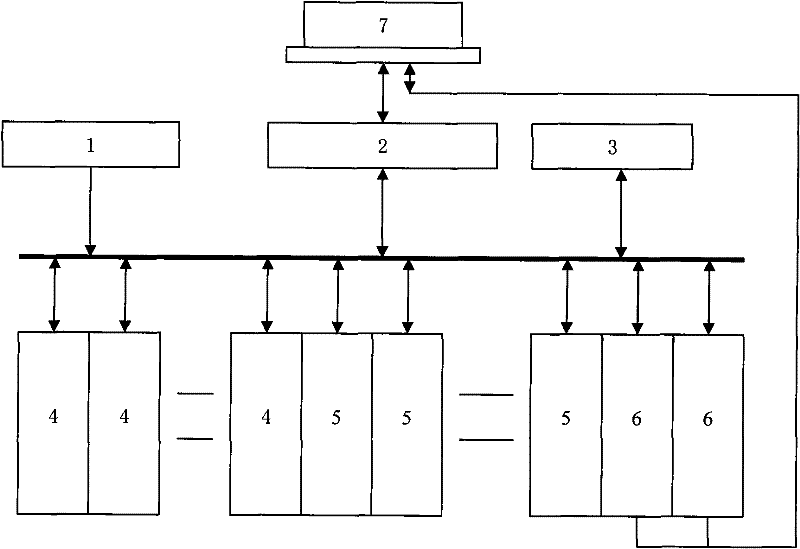

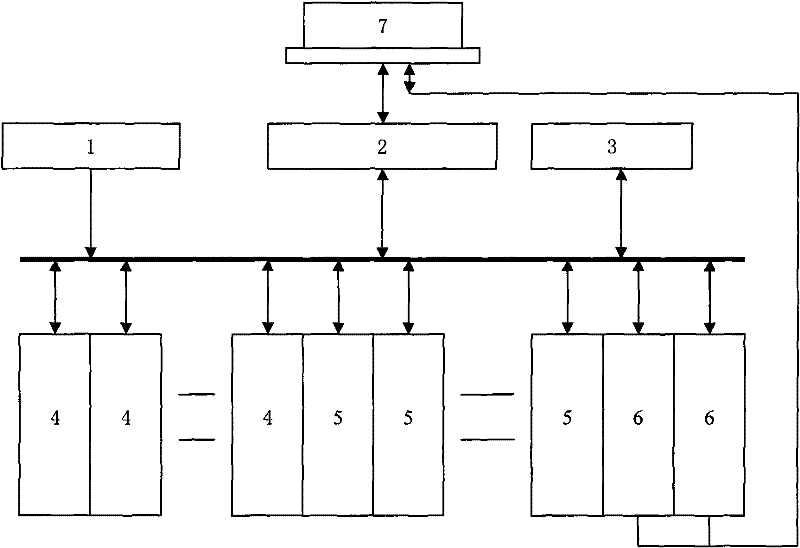

Intelligent electric meter centralized recharging terminal and control method thereof

ActiveCN102074076AEnsure safetyImprove reliabilityElectrical measurement instrument detailsApparatus for hiring articlesComputer moduleE communication

The invention provides an intelligent electric meter centralized recharging terminal and a control method thereof, relating to the technical field of combination of electrical equipment and computers. The terminal comprises an IC card interface circuit, an embedded secure access module (ESAM) circuit and two communication module interface circuits, wherein the IC card interface circuit is connected with a CPU via ICREST and ICIO pins; the ESAM circuit is connected with the CPU via data and reset pins SAMIO and SAMRST; the two communication module interface circuits are respectively connected with the CPU, realize communications with an intelligent electric meter and a collector and can monitor communication data between the collector and the electric meter in real time and forward the data; the IC card interface circuit completes communications with user card interfaces; and the ESAM circuit completes data exchange and reset operations and various safety certification operations such as encryption, decryption and operation. A program module for the intelligent electric meter centralized recharging terminal is also designed. The terminal has the following advantages and beneficial effects: normal communications of the system are ensured; and the operations are convenient, simple, safe and reliable.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

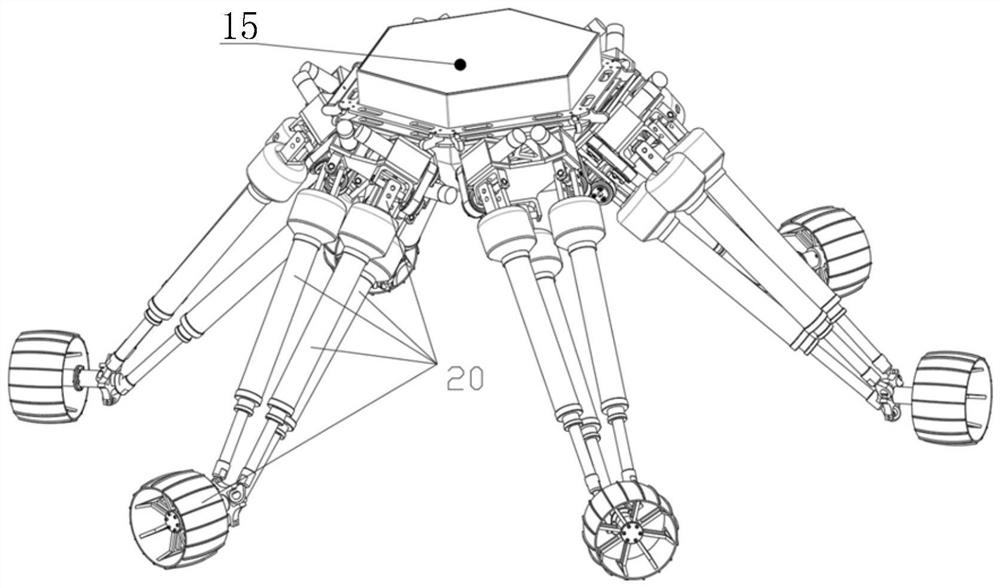

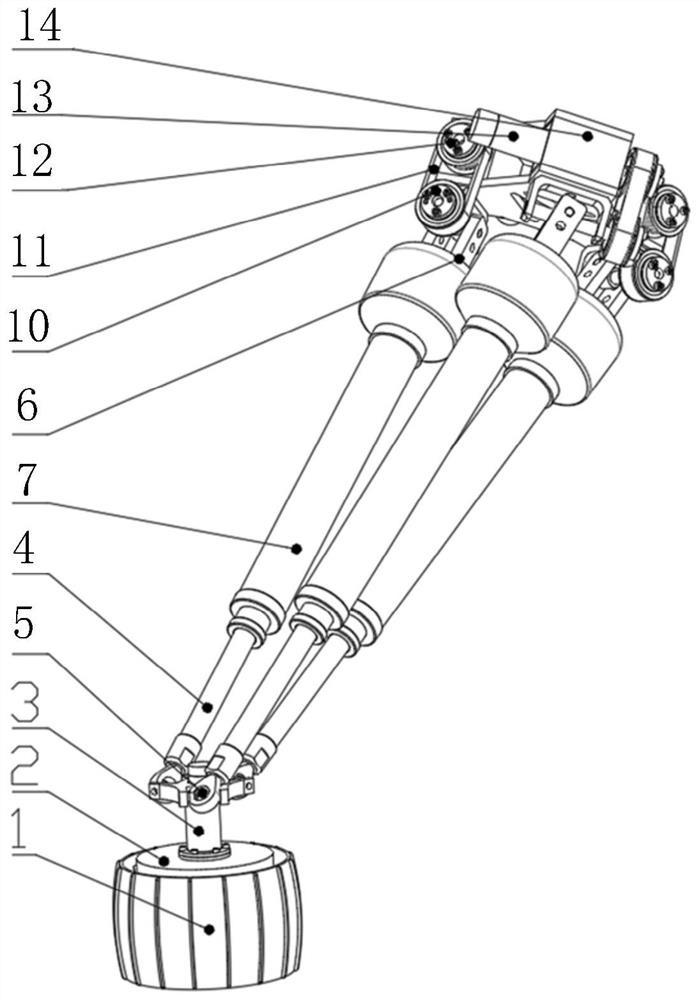

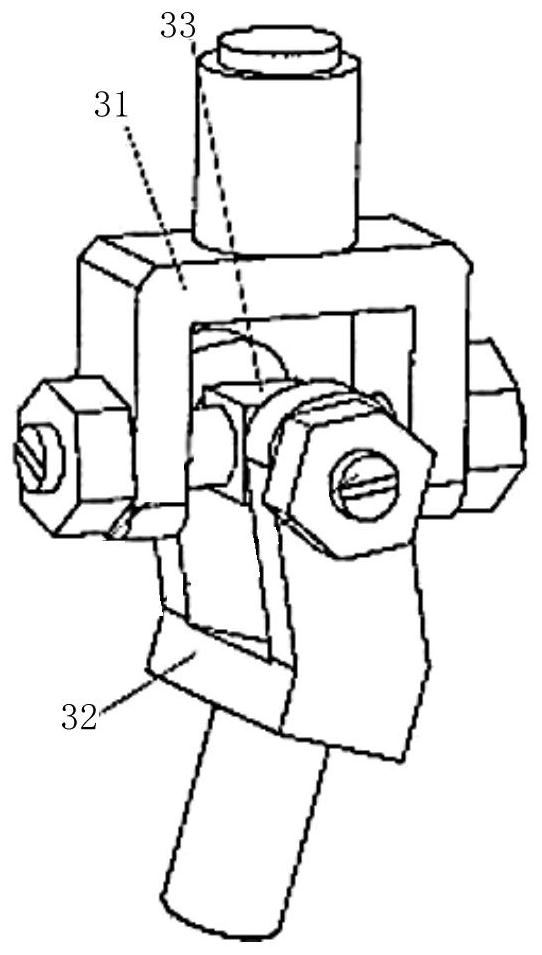

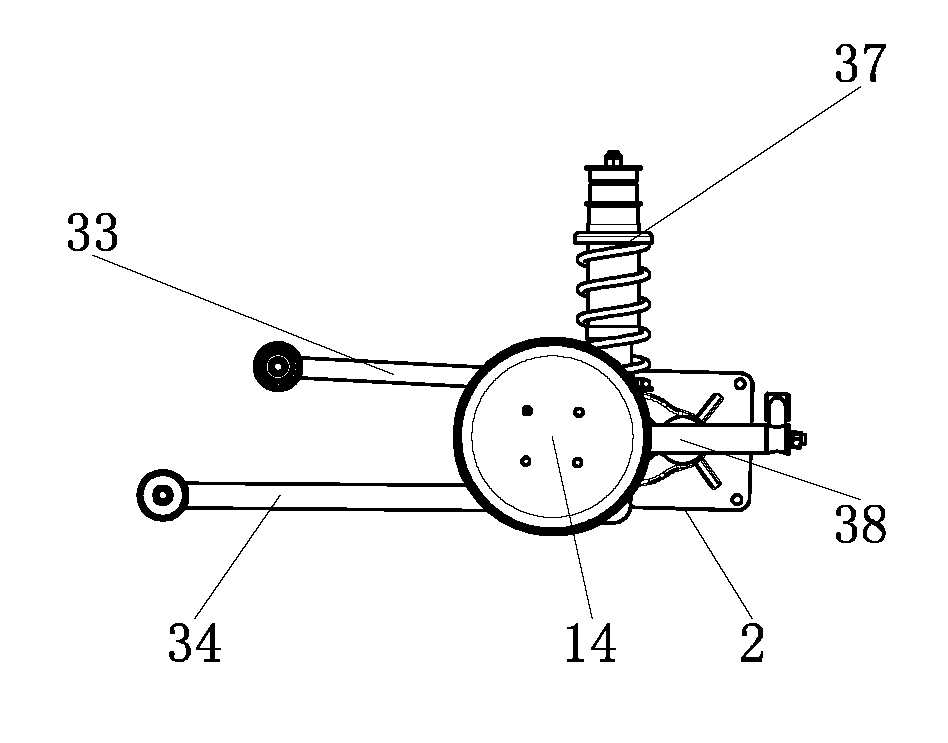

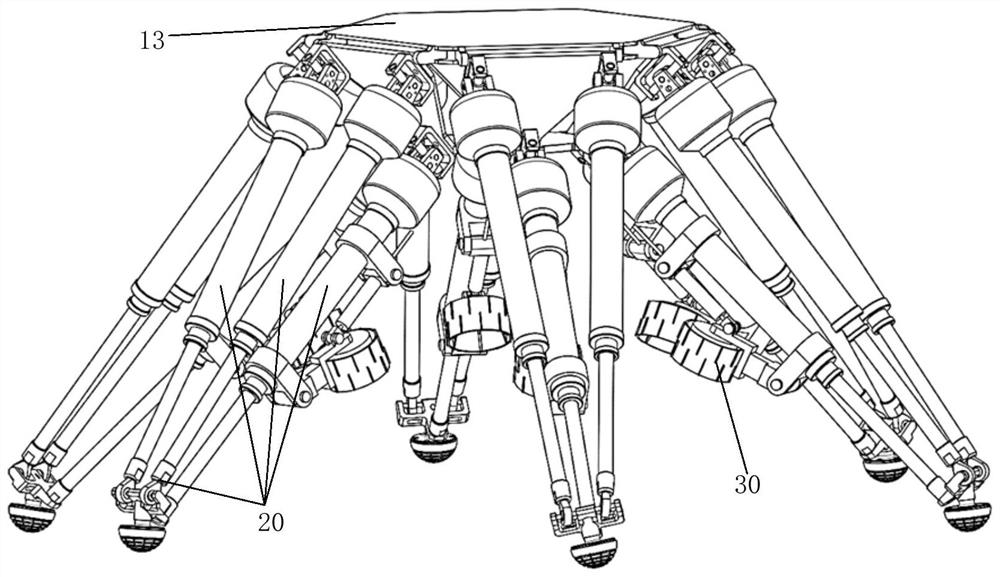

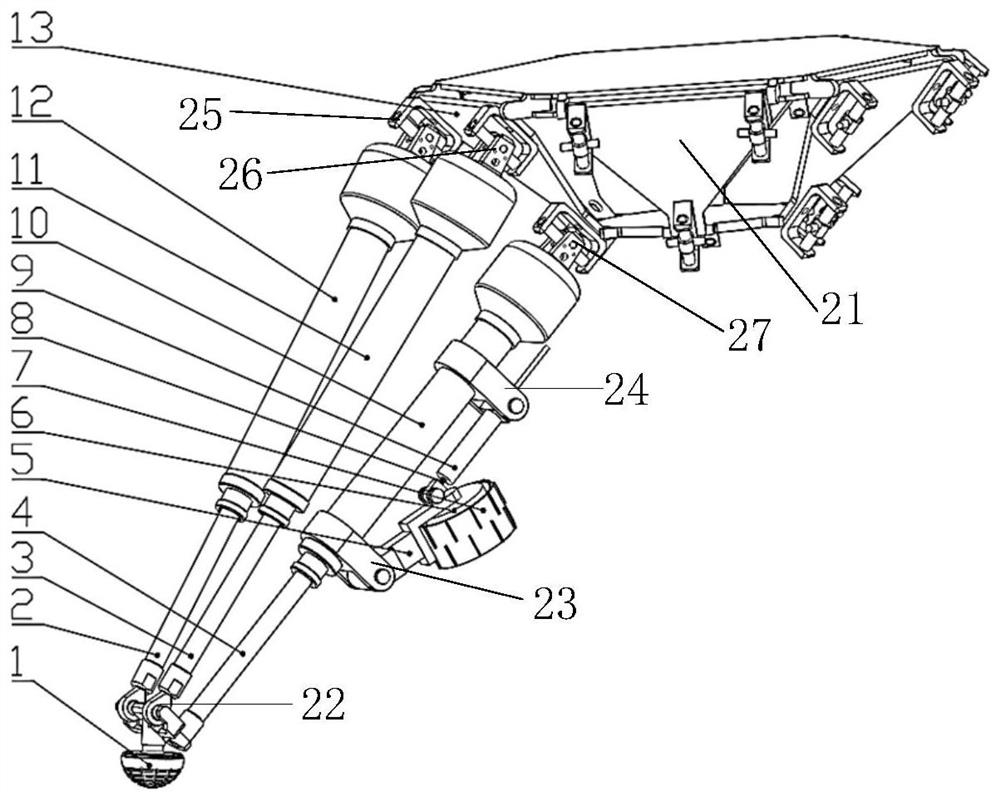

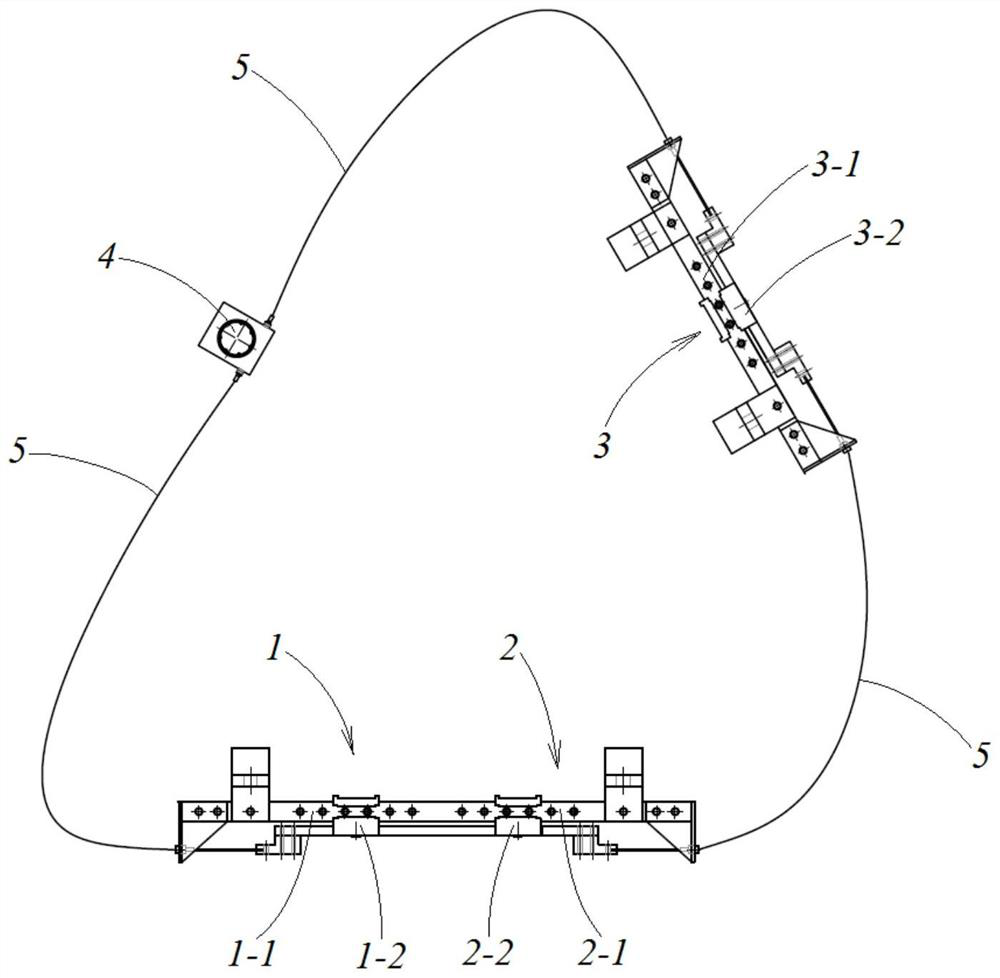

UPS-based parallel structure wheel-foot mobile robot

ActiveCN111976859AImprove carrying capacityIncrease flexibilityVehiclesControl engineeringMechanical engineering

The invention provides a UPS-based parallel structure wheel-foot mobile robot. The UPS-based parallel structure wheel-foot mobile robot comprises wheels, a support carrier and six mechanical leg assemblies, wherein one ends of the six mechanical leg assemblies are uniformly arranged in the circumferential direction of the lower side of the support carrier, the wheels are mounted at the other endsof the mechanical leg assemblies, the robot comprises a wheel type motion mode and a foot type motion mode and can be switched between the wheel type motion mode and the foot type motion mode according to different scenes, in the wheel type motion mode, the circumferential faces of the wheels touch the ground and move in a wheel rolling mode, and in the foot type movement mode, the side faces of the wheels touch the ground and move in a foot type walking mode. According to the UPS-based parallel structure wheel-foot mobile robot, a 3UPS parallel type six-degree-of-freedom mechanical arm structure is adopted, so that the flexibility is high, the bearing capacity is high, more sensors can be carried to execute more complex exploration tasks, the motion input corresponding to the pose of thefoot end relative to a rack can be determined and unique through calculation, the control precision is high, and the stability is high.

Owner:SHANGHAI JIAO TONG UNIV

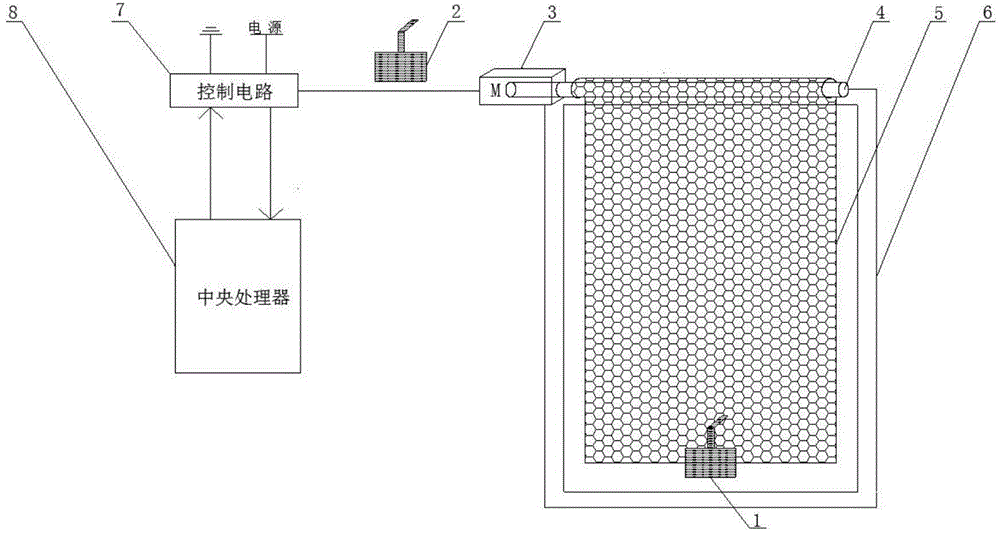

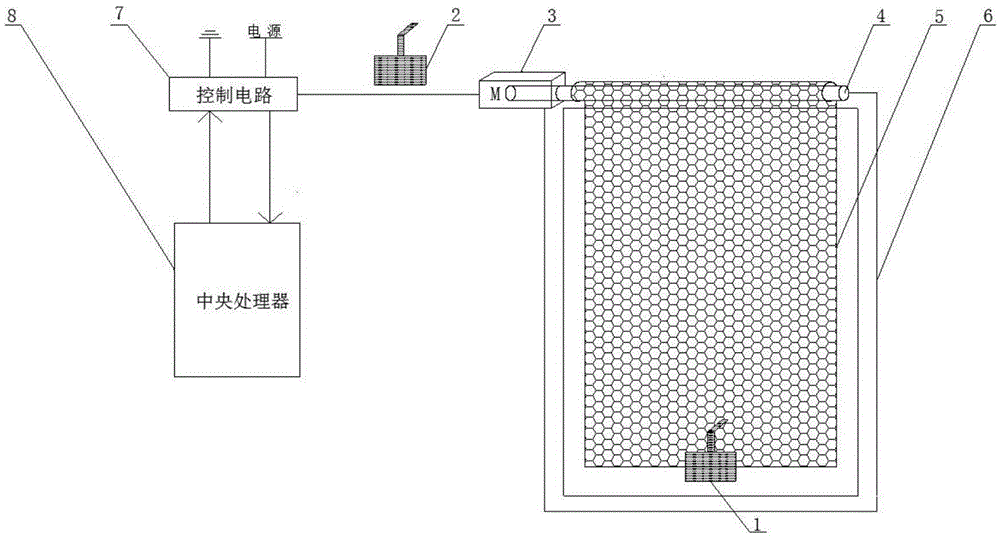

Intelligent light control sun-shading system

InactiveCN104563835AControl movementEasy to install and disassembleDoor/window protective devicesWireless transmissionControl system

The invention discloses an intelligent light control sun-shading system. The intelligent light control sun-shading system solves the problem that due to the fact that in daily life, a curtain can not be opened or closed in time, the indoor luminance is too high or too low. The intelligent light control sun-shading system can be automatically and manually controlled. A luminance sensor is arranged to collect luminance data, the data are transmitted to a central processing unit of an indoor control system with the help of a wireless transmission module, and whether the curtain opening and closing operation and other operation are conducted or not is analyzed according to set programs. By means of the system, under the no-man control condition, automatic opening and closing of the curtain can be controlled on the basis of the indoor light ray intensity, the good rest environment, the good reading environment, the good study environment, the good storage environment and other environments are created for indoor portions, and the more comfortable and user-friendly living experience is provided.

Owner:SHANGHAI OCEAN UNIV

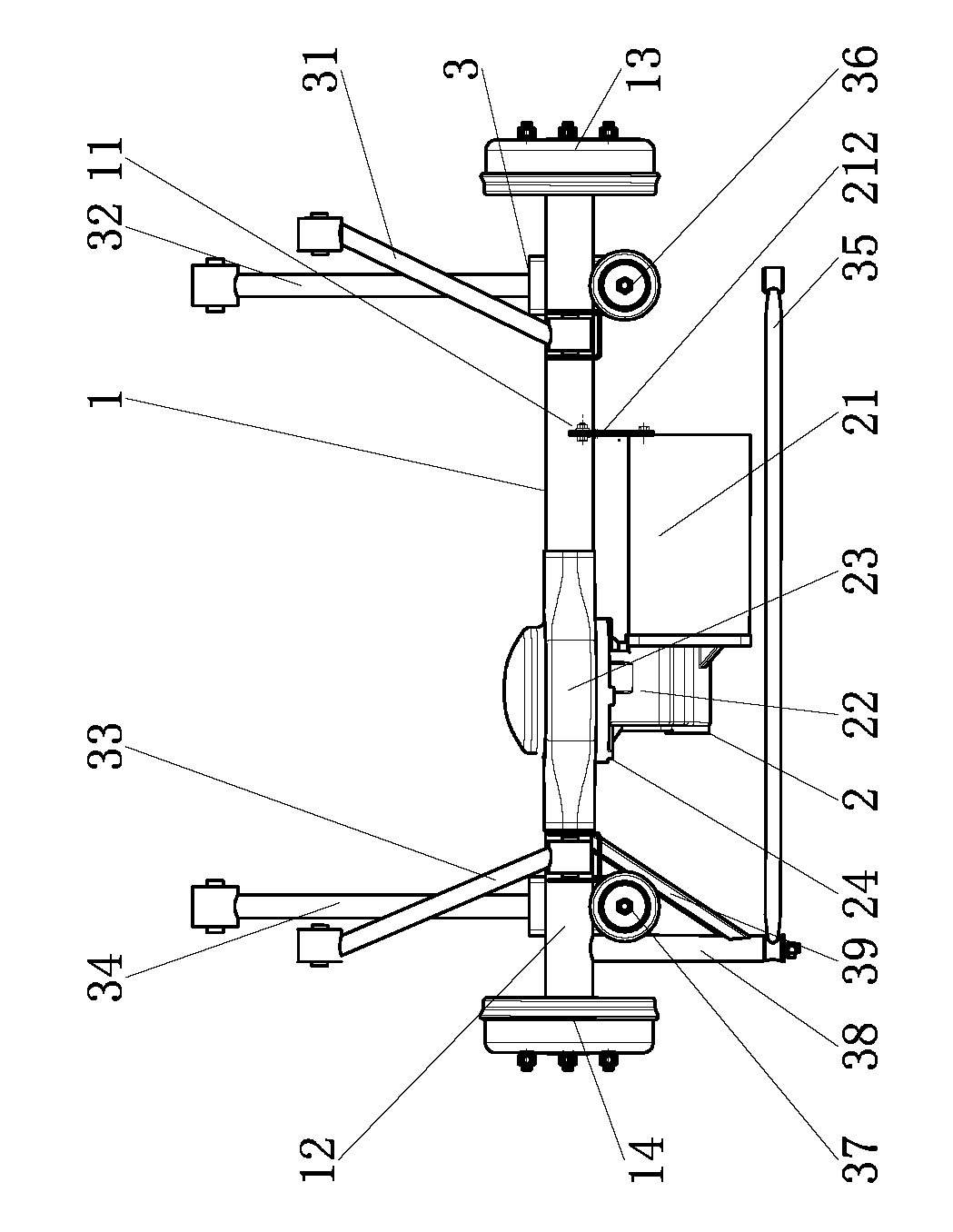

Integrated type motor rear-drive rear-suspension mechanism

ActiveCN103158542AReduce intermediate transmission linksImprove efficiencyInterconnection systemsControl devicesTrailing armControl theory

The invention discloses an integrated type motor rear-drive rear-suspension mechanism which comprises a rear axle, a driving mechanism and a rear suspension. A differential mechanism is a planetary gear differential mechanism. A cylindrical input gear is arranged on a planetary gear support in the planetary gear differential mechanism. The planetary gear differential mechanism and a reducer are installed in the same integrated shell body in an integrated mode. An output shaft of the reducer is connected with the cylindrical input gear in the planetary gear differential mechanism in an integrated and transmission mode through an output gear. The output shaft of the reducer is parallel to an output shaft of the planetary gear differential mechanism. An input shaft of the reducer is fixedly connected with an output shaft of an electromotor in an integrated and coaxial mode. The suspension comprises two upper trailing arms and two lower trailing arms. The integrated type motor rear-drive rear-suspension mechanism can reduce an intermediate transmission link and improve transmission efficiency, and the transmission efficiency can be improved to 92%. Meanwhile, occupied space near the rear axle can be reduced greatly so that other parts can be arranged conveniently, and comfort of a rider can be improved.

Owner:北京宏瑞汽车科技股份有限公司

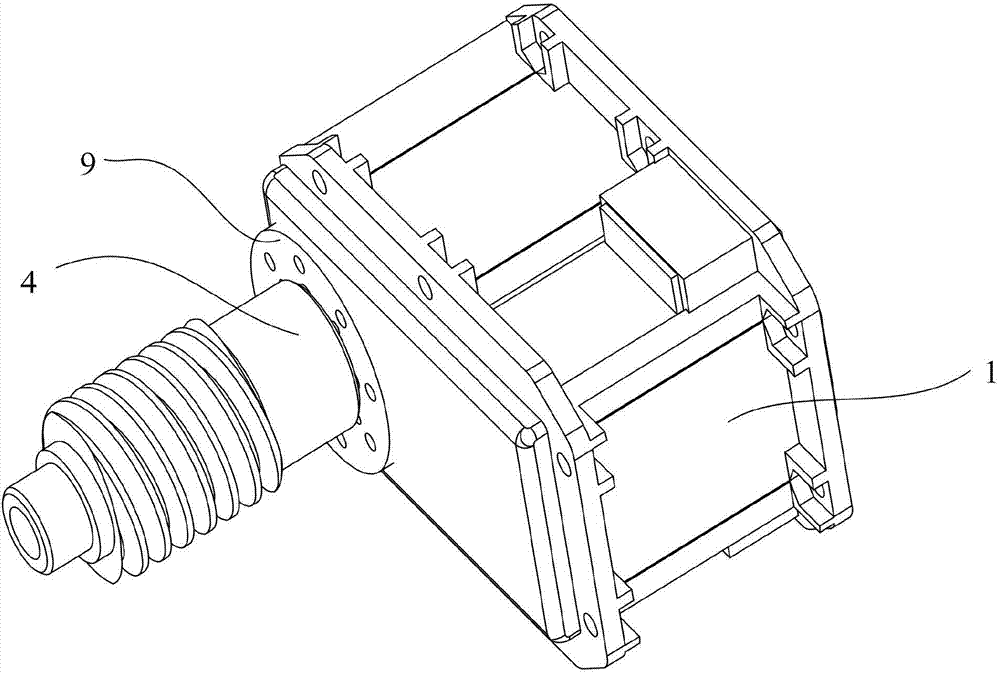

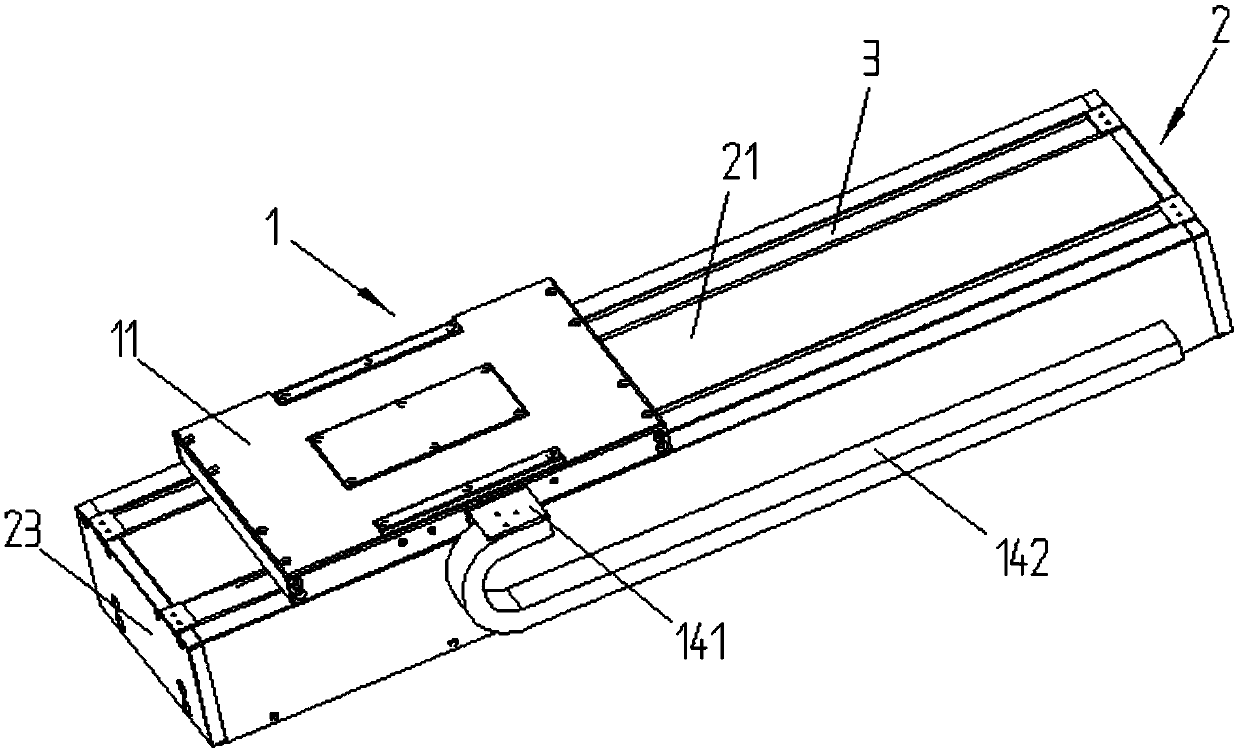

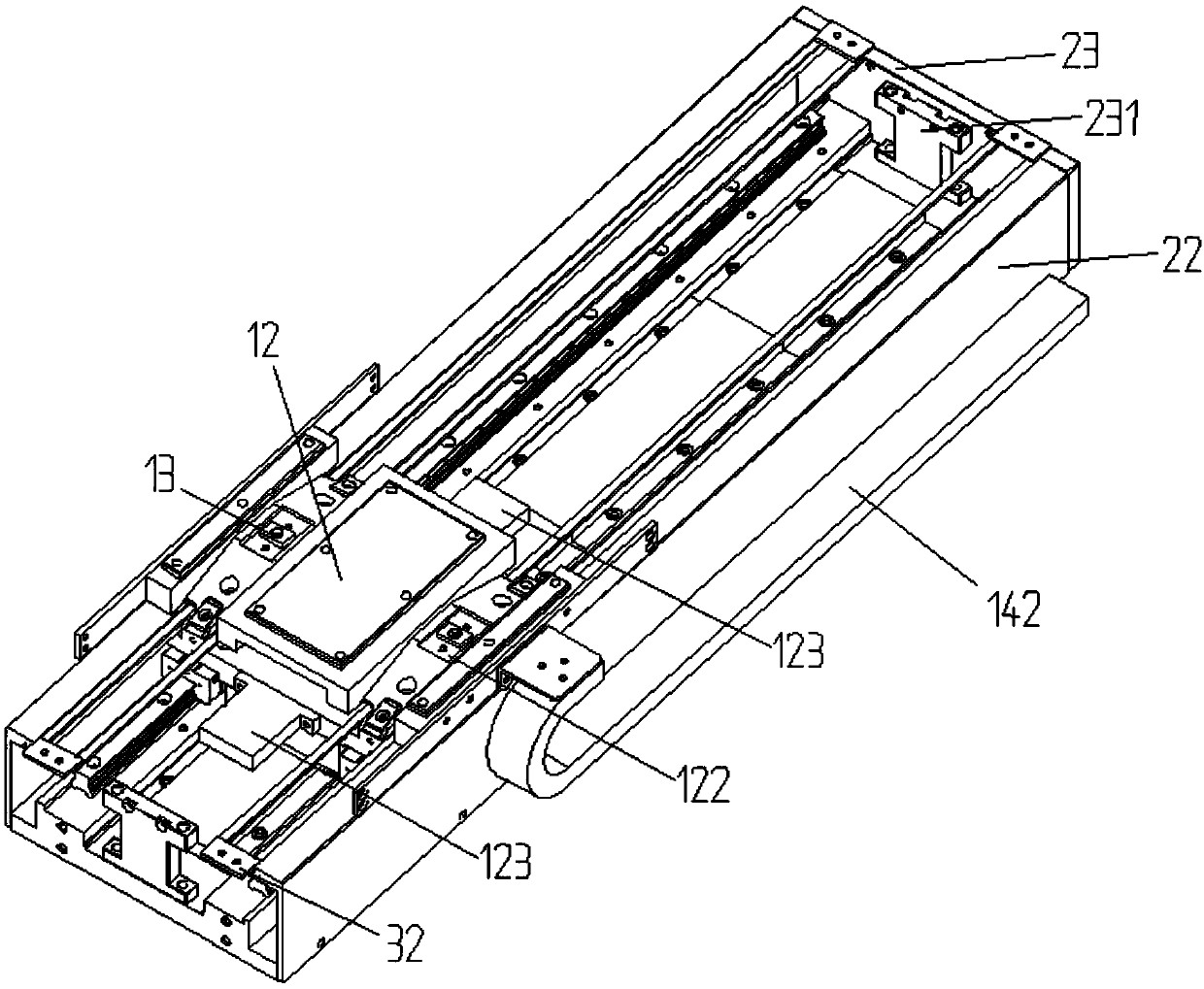

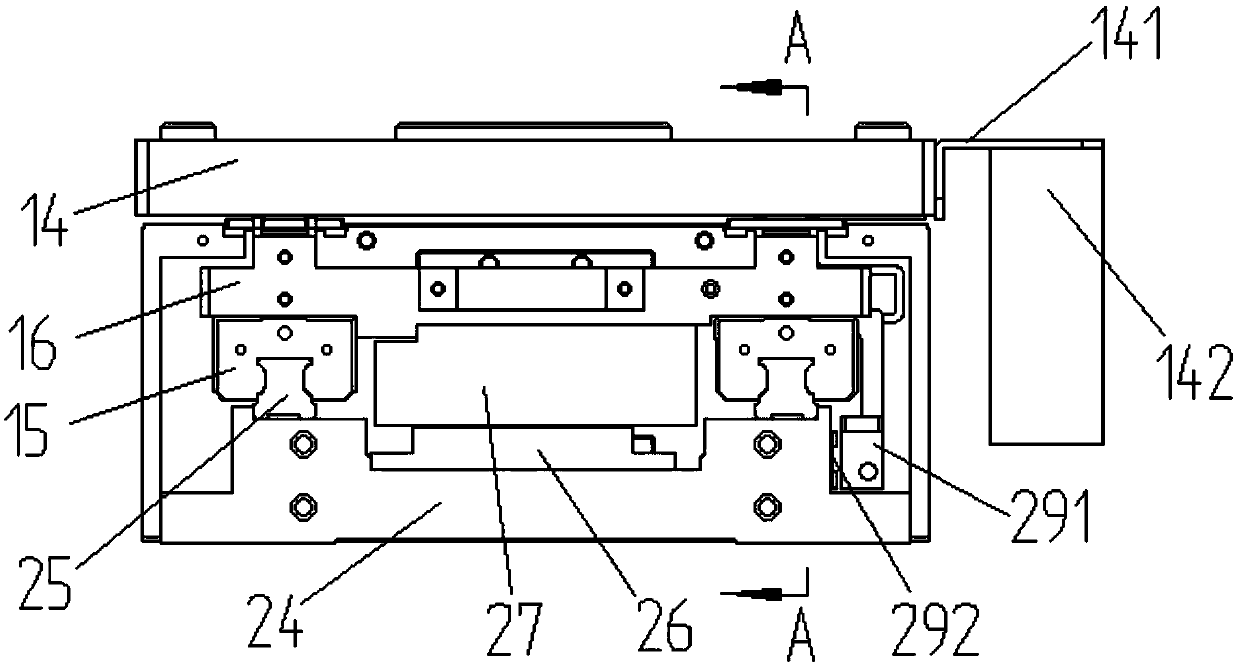

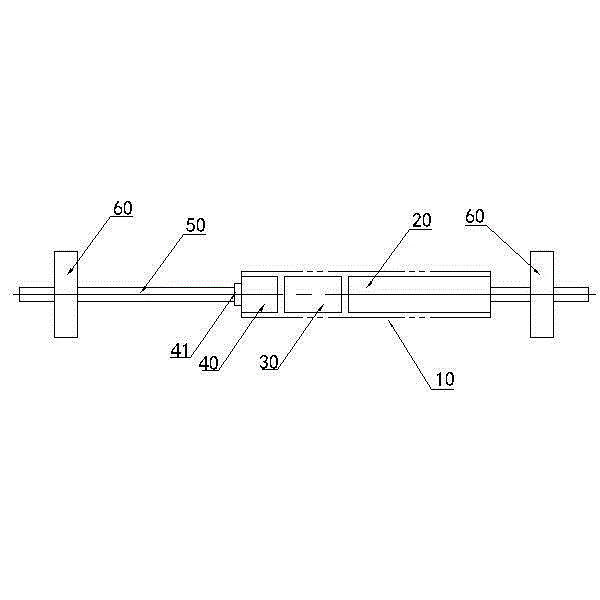

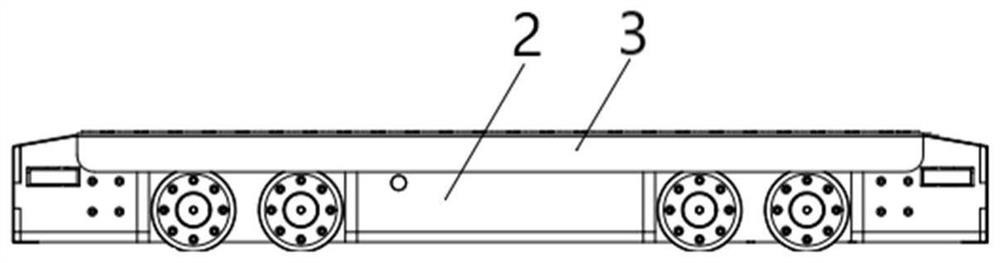

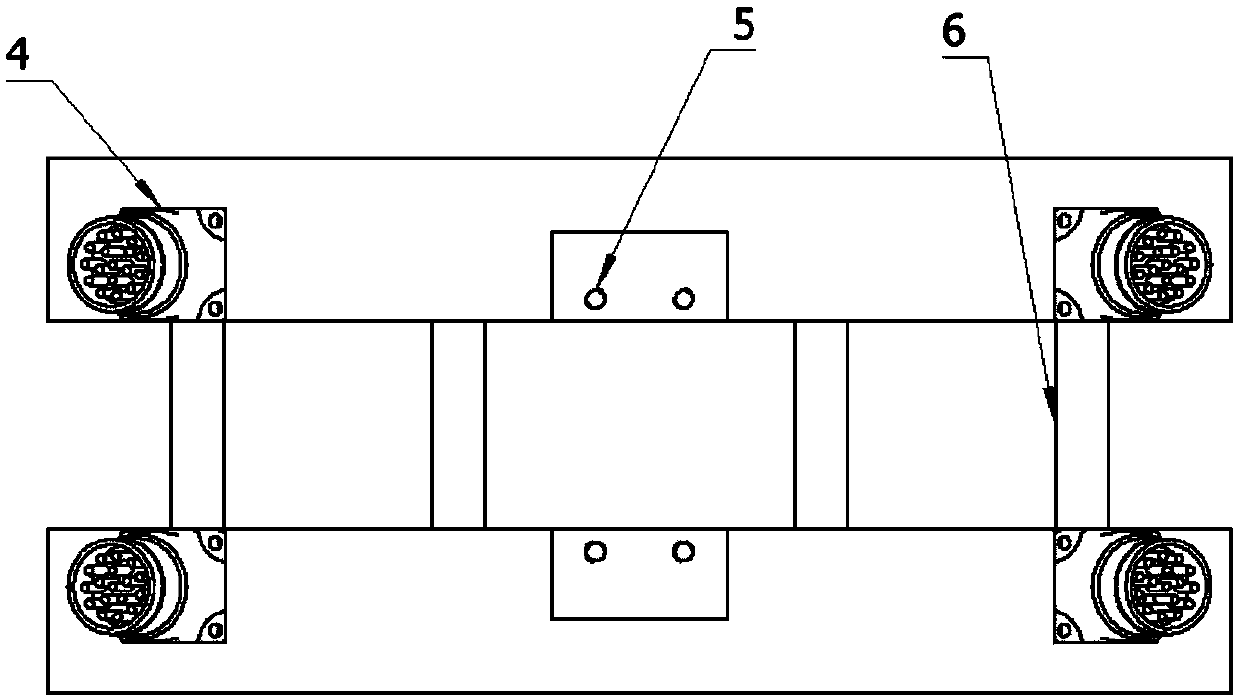

Fully sealed compact dustproof linear motor moving platform

Owner:SUZHOU LINGHOU ROBOT

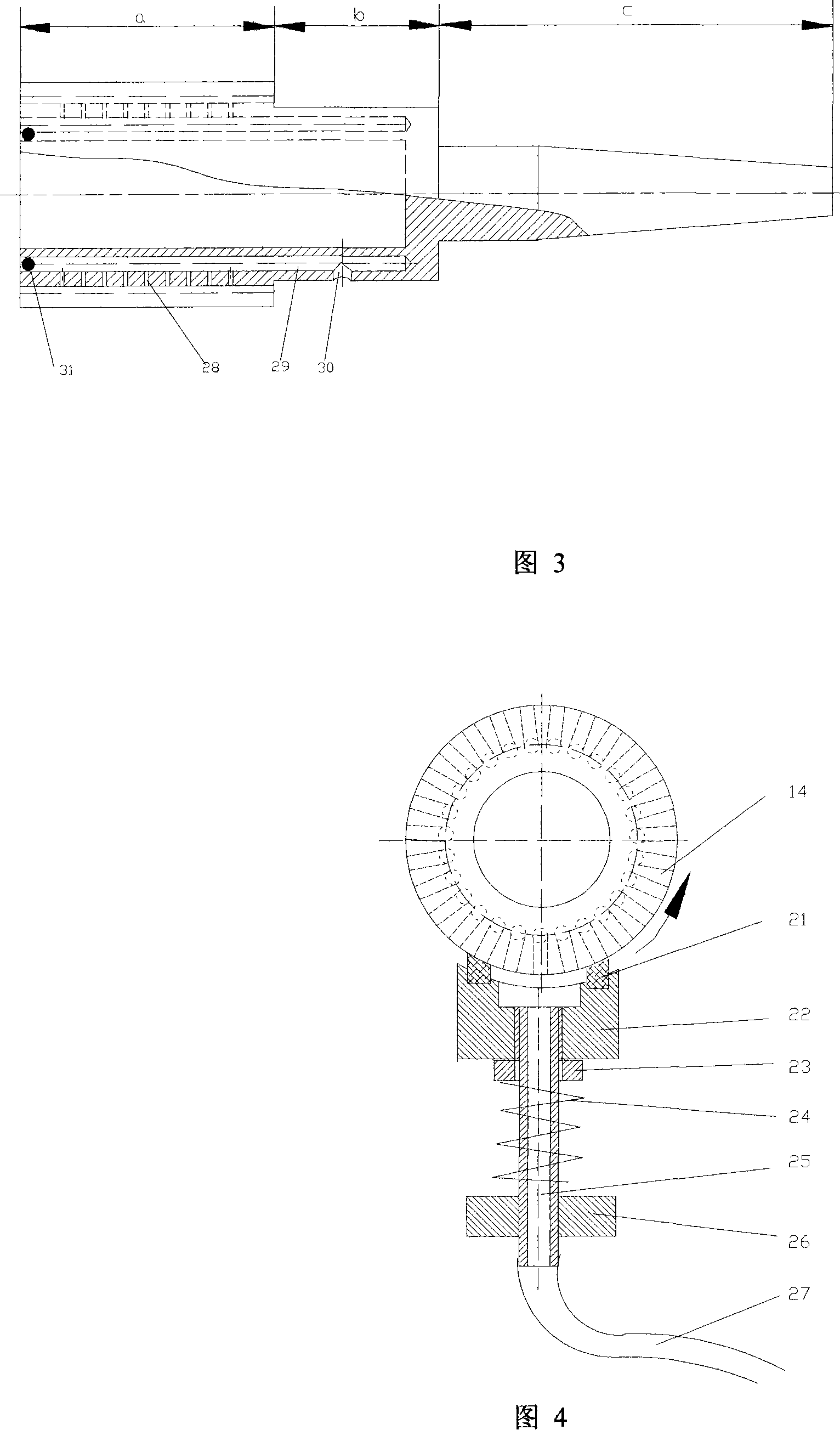

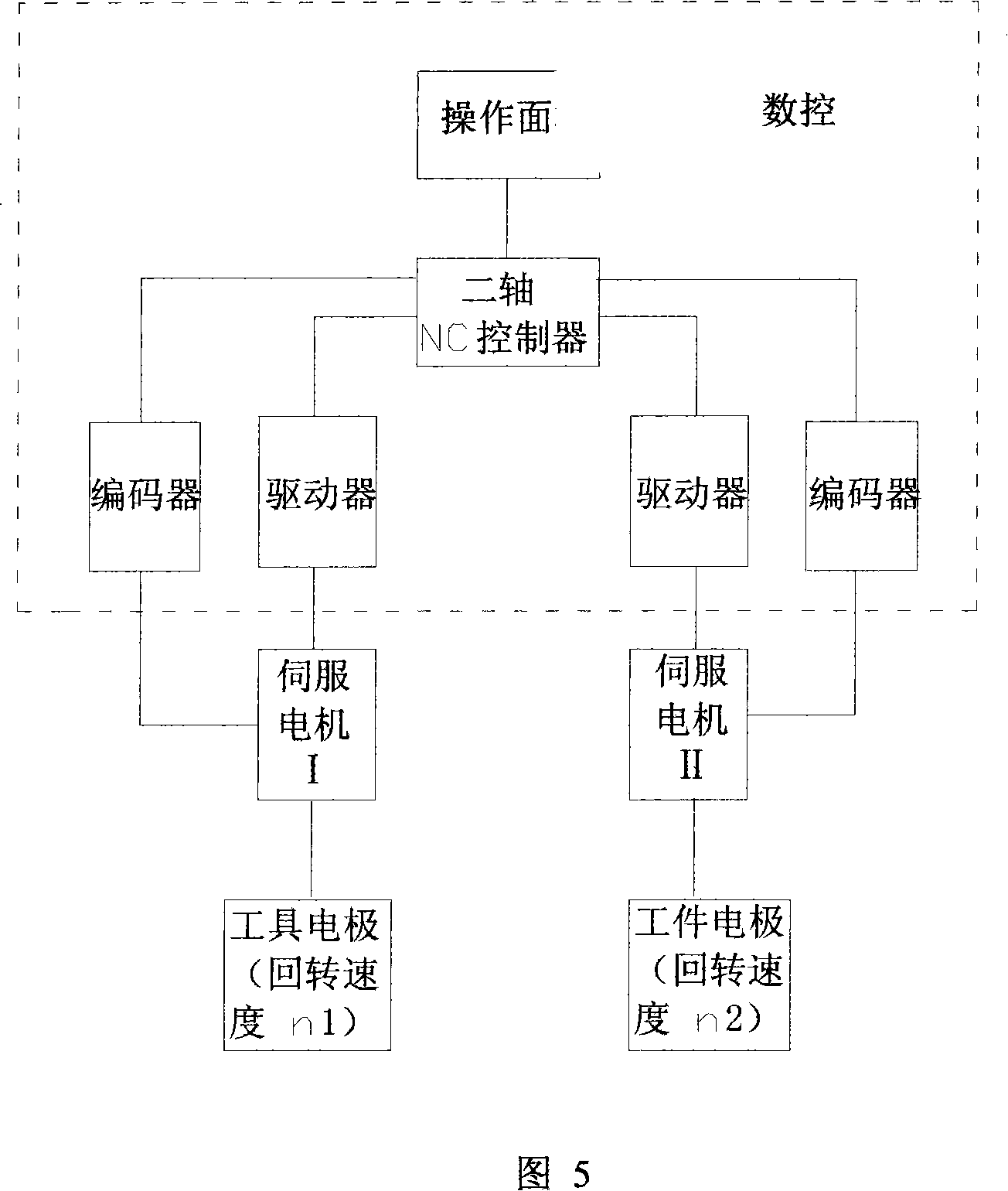

Large deep/dameter ratio dentiform female die numerically-controlled electric spark expanding and processing device and processing method thereof

InactiveCN101147992AImprove efficiencyHigh precisionElectrical-based machining electrodesDiameter ratioSurface roughness

The present invention discloses numerically controlled electric spark machining apparatus and process for great depth / diameter ratio toothed female die. The horizontal machining apparatus includes one biaxial numerically controlling device, two servo motors, one tool electrode, one fixture with three claws, one rotary inner sleeve for workpiece, one local directional liquid leading unit and one tool electrode holding casing. The present invention has combination of electric spark generating technology and numerically controlling technology to expand the machining range, and is especially suitable for machining hard-to-machine materials.

Owner:GUANGDONG IND TECHN COLLEGE +1

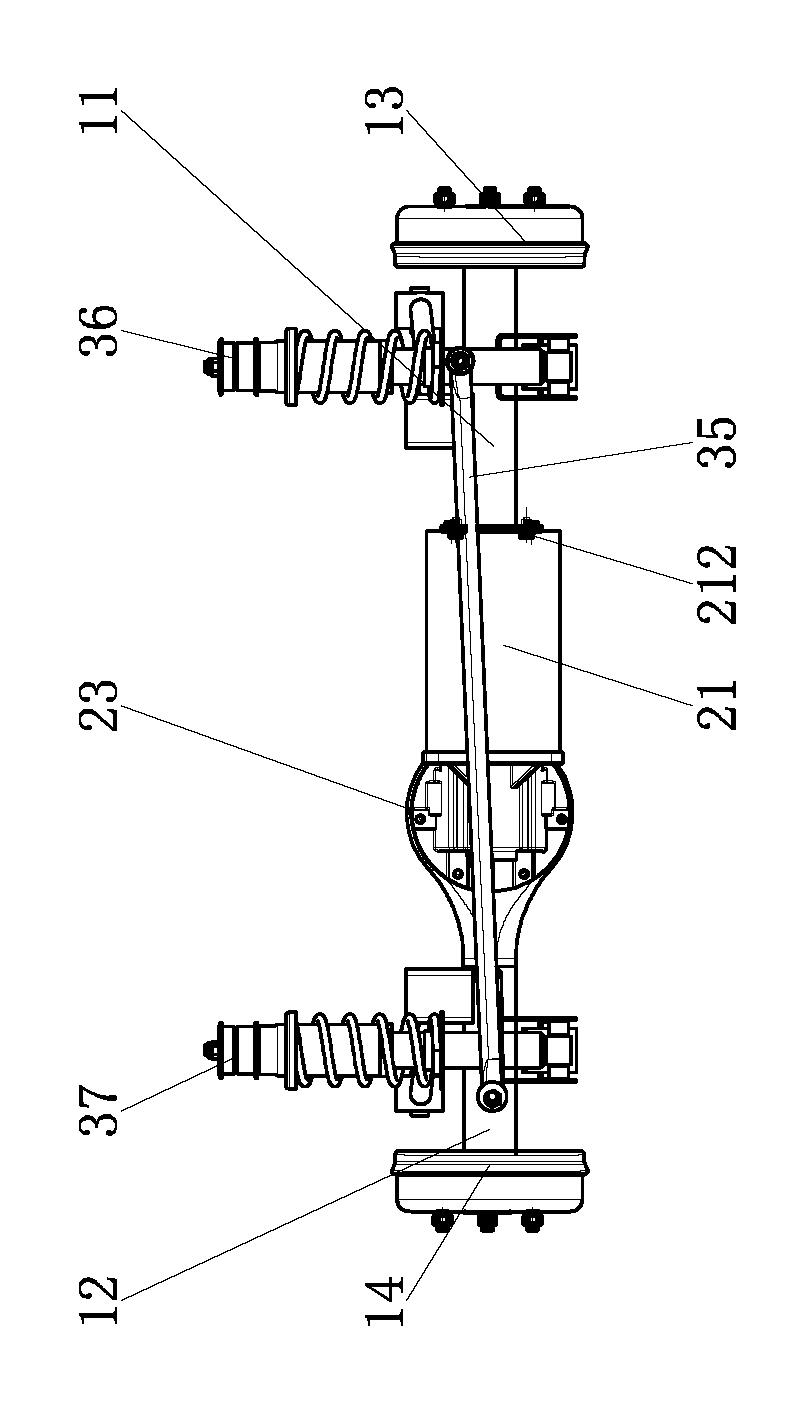

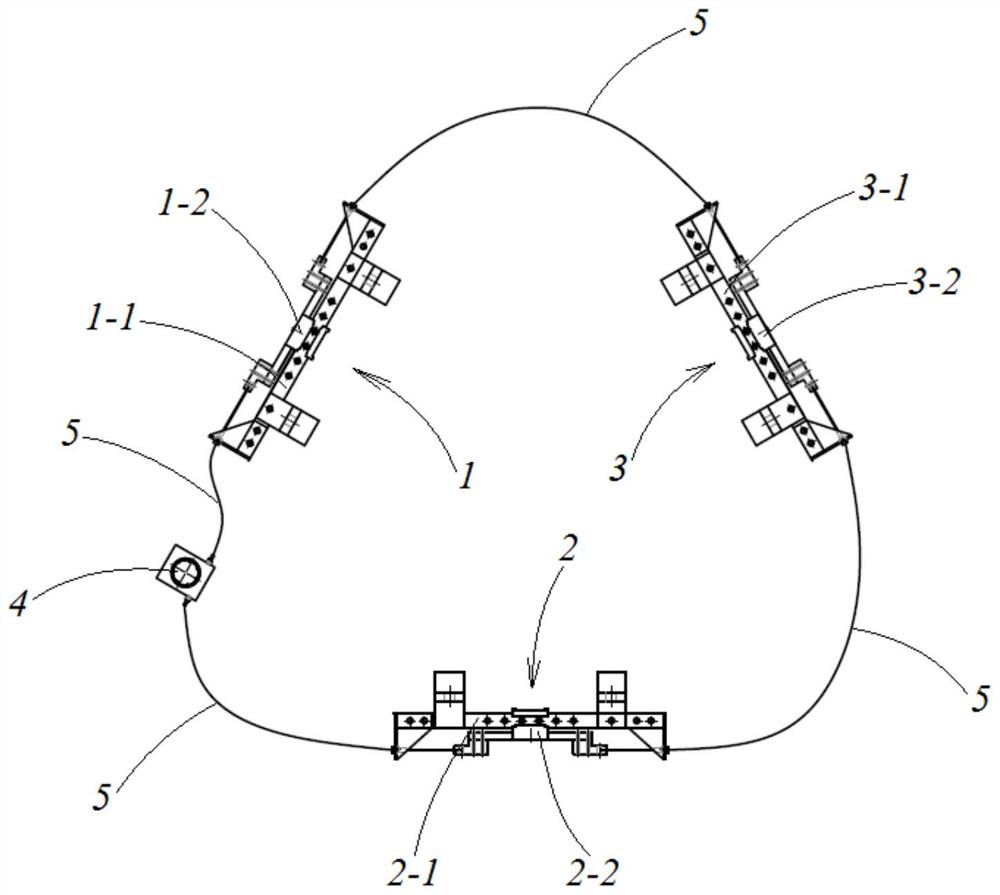

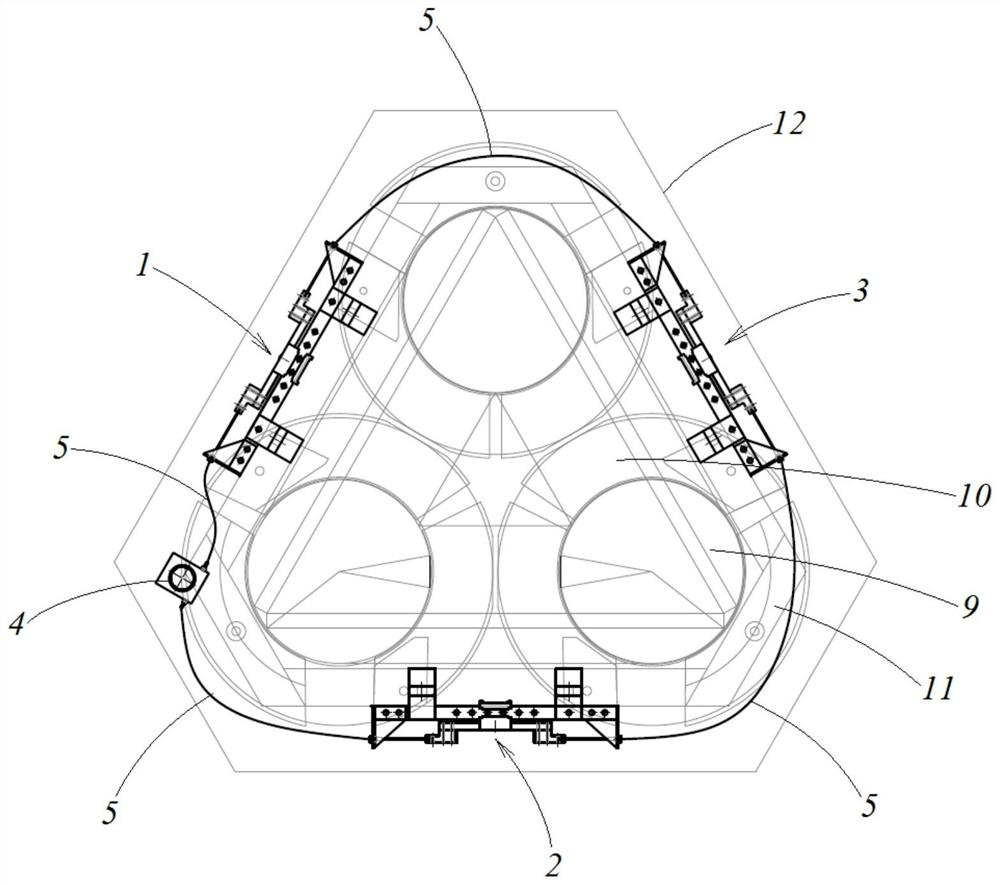

UP and UPS-based parallel structure wheel foot mobile robot

ActiveCN111942491AAvoid Position Error Cumulative DefectsHigh mechanical rigidityVehiclesControl theoryMotion Mode

The invention provides a UP and UPS-based parallel structure wheel foot mobile robot which comprises a rack and six mechanical leg assemblies, a supporting plate is arranged on the rack, each mechanical leg assembly comprises a power telescopic device and a walking foot end, a wheel retracting and releasing device is mounted on each power telescopic device. Wheels are arranged on the wheel retracting and releasing device, one end of the power telescopic device is movably matched with the walking foot end, and the other end of the power telescopic device is installed on the supporting plate. The robot comprises a wheel type motion mode and a foot type motion mode, the robot can be switched between the wheel type motion mode and the foot type motion mode according to different scenes, a parallel mechanical structure is adopted, the mechanical rigidity is large, and the large-bearing requirement can be met; and the expansion amount, corresponding to the pose of the rack, of the semispherical walking foot end can be determined through calculation and unique, the control precision is high, and the stability is high.

Owner:SHANGHAI JIAO TONG UNIV

Low-voltage motor restarting device

InactiveCN102237835APerfect electrical and safety isolationEasy maintenance of equipmentMultiple dynamo-motor startersModularityData transmission

The invention discloses a low-voltage motor restarting device, which comprises a master central processing unit (CPU) control unit, a power unit, analogue quantity units, input units, output units and a display unit. Each unit adopts a modular design and independent detection and control ways. The power unit is connected with the other units, and supplies working power to the other units. A low-voltage motor restarting function and data transmission among the master CPU control unit, the analogue quantity units, the input units, the output units and the display unit are realized by a controller area network (CAN) bus. The device has the characteristics of high reliability, high real-time performance, wide application range, low cost and flexibility and convenience of operation and maintenance.

Owner:SHANGHAI HUAJIAN ELECTRICAL EQUIP

Compact frame dedicated motor

ActiveCN104037977AReduce horizontal dimension spaceImprove drive transmission efficiencyMechanical energy handlingDrive wheelReduction drive

The invention discloses a compact frame dedicated motor comprising a motor, a speed reducer and a clutch. The motor, the speed reducer and the clutch are combined together in a transmission way so that a tubular compact frame dedicated motor integrated structure is formed. In the tubular compact frame dedicated motor, the motor is directly connected with the clutch via a planetary gear speed reducing mechanism of the speed reducer. Transmission is outputted to a transmission shaft by the clutch so that compact frame driving wheels arranged at the two ends of the transmission shaft are driven, and thus a compact frame body is driven to move. The driving structure is integrally simpler, production installation operation is simpler, convenient and rapid, and production efficiency is high without using transmission of a transmission chain for driving the compact frame by the motor so that an intermediate transmission link of the transmission chain is saved, and space occupied by installation of the whole driving device of the electric compact frame is reduced to a larger extent. Convenient and rapid performance of production installation, disassembling maintenance and repairing operation are enhanced, and fault identification judgment is more accurate, rapid and effective.

Owner:宁波八益智能存储系统有限公司

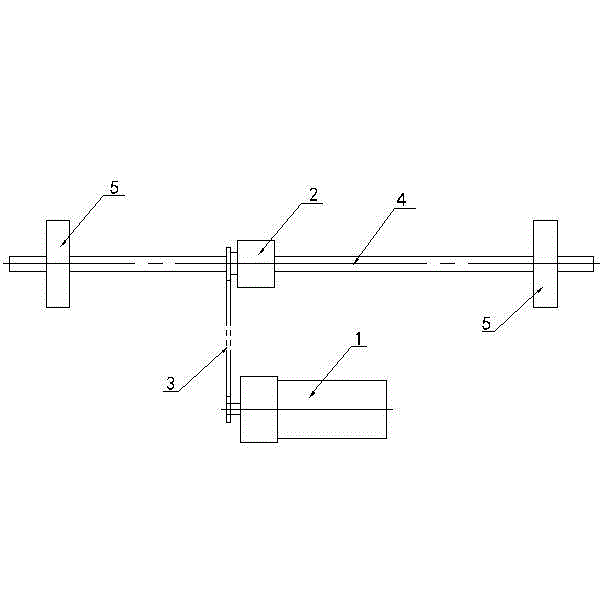

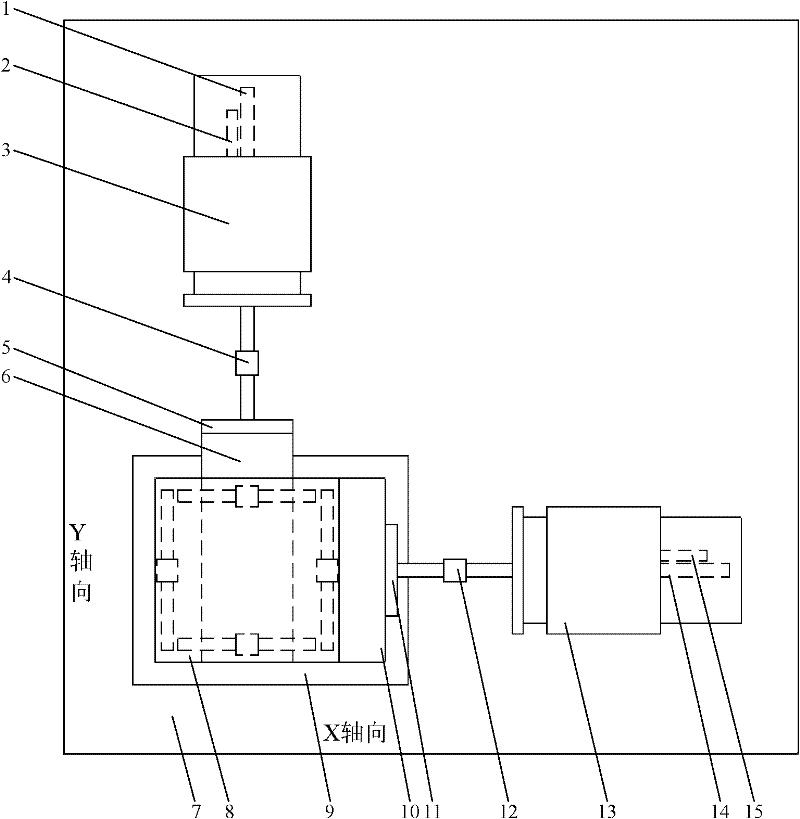

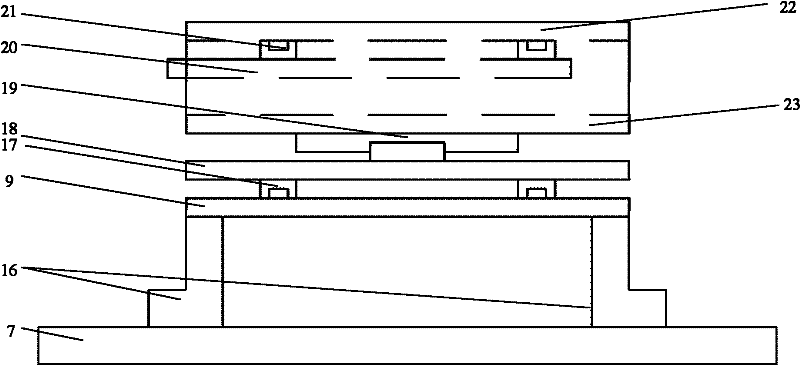

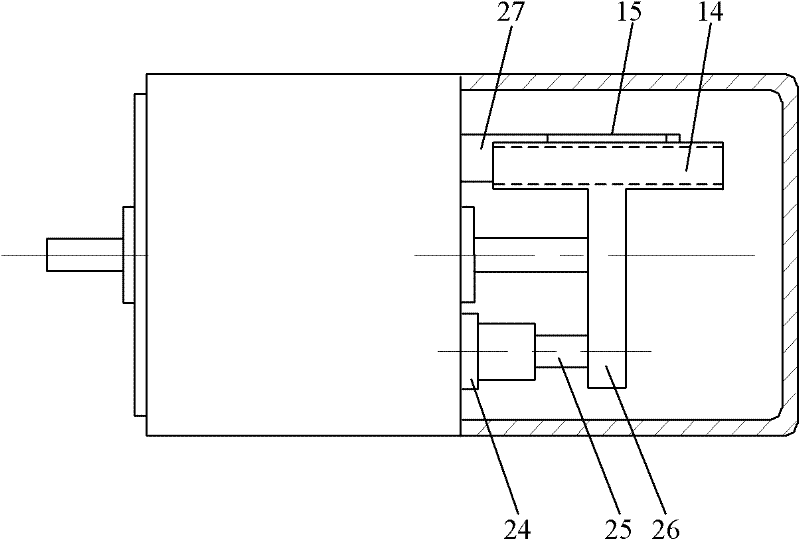

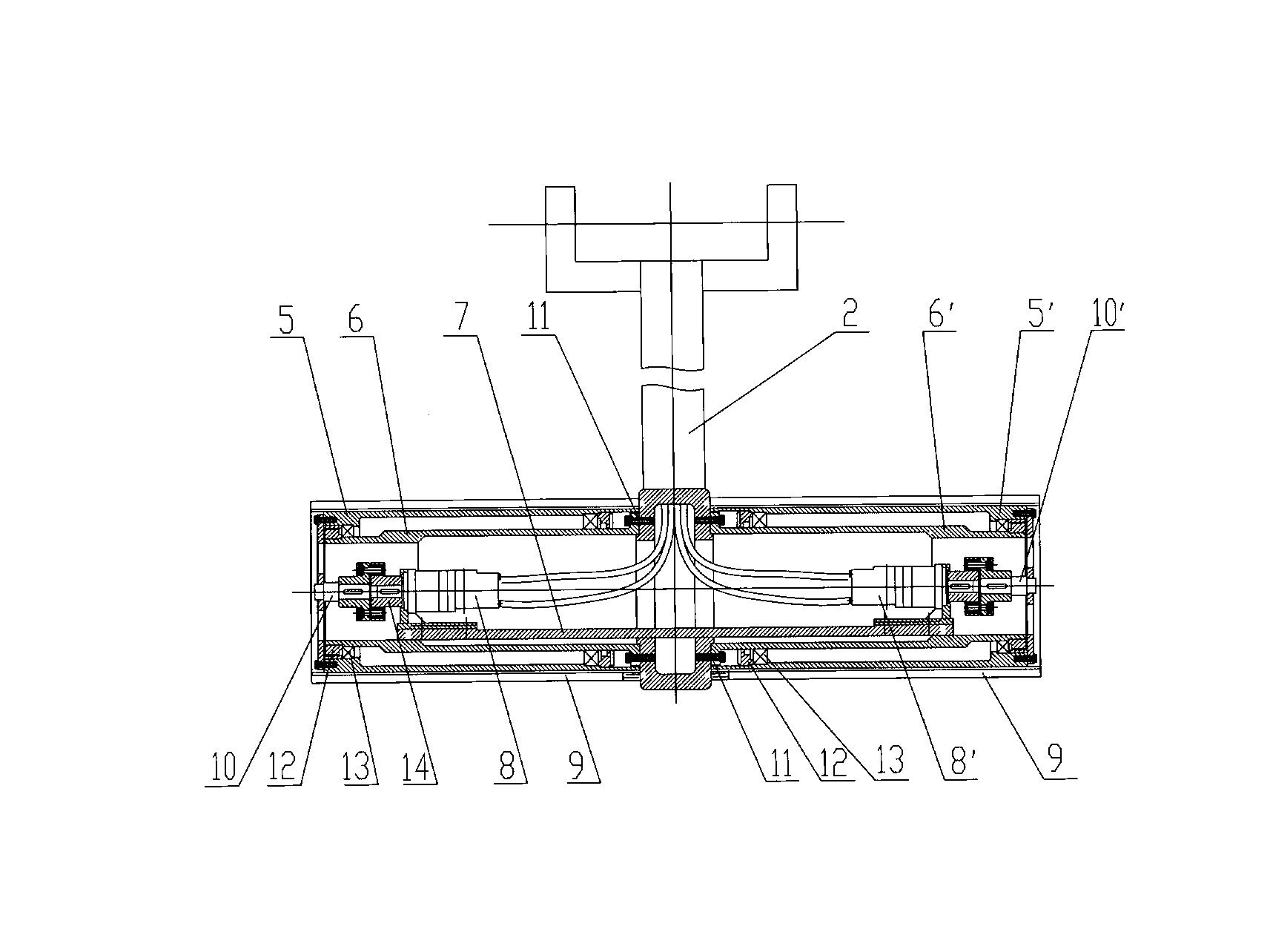

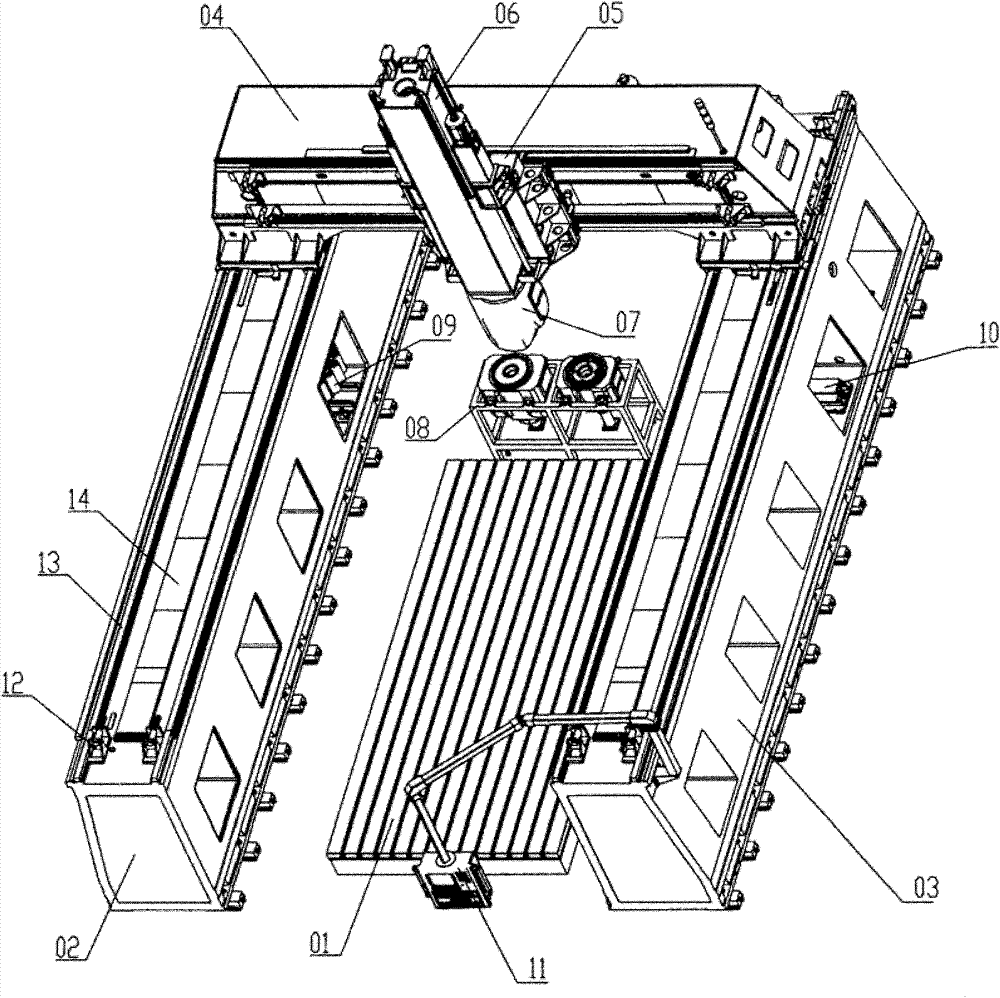

Fixed voice coil motor direct drive type X-Y micro-vibration platform

InactiveCN101924450BSimple structureSmall moment of inertiaDynamo-electric machinesEngineeringSemiconductor

The invention relates to a linear motor direct drive two-dimensional micro-vibration platform, in particular to a fixed voice coil motor direct drive type X-Y micro-vibration platform. The fixed voice coil motor direct drive type X-Y micro-vibration platform comprises a base, voice coil linear motors, an X-direction motion platform, a Y-direction motion platform, a decoupling component, a gratingruler and the like, wherein the voice coil linear motors directly drive the X-Y two-dimensional micro-vibration platform; both the X-direction and Y-direction voice coil linear motors are fixed on the base, and the X-direction and X-direction motions are realized by the decoupling component; and the grating ruler is used for detecting the position of the motors. In order to increase the motion speed and enhance the motion accuracy, the invention eliminates the traditional rotating motor transmission mechanism and adopts the linear motor to direct drive; in order to reduce the motion inertia, the invention designs the decoupling component, and both the X-direction and Y-direction linear motors are fixed to realize the X-Y two-dimensional motion; and in order to realize high-accuracy high-stability motion, the invention uses the grating ruler as the feedback element. The invention has the advantages of high speed, high acceleration, high accuracy and high stability, and can be used in the fields of high-speed automation equipments, electronic and semiconductor processing equipments, laser processing equipments and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

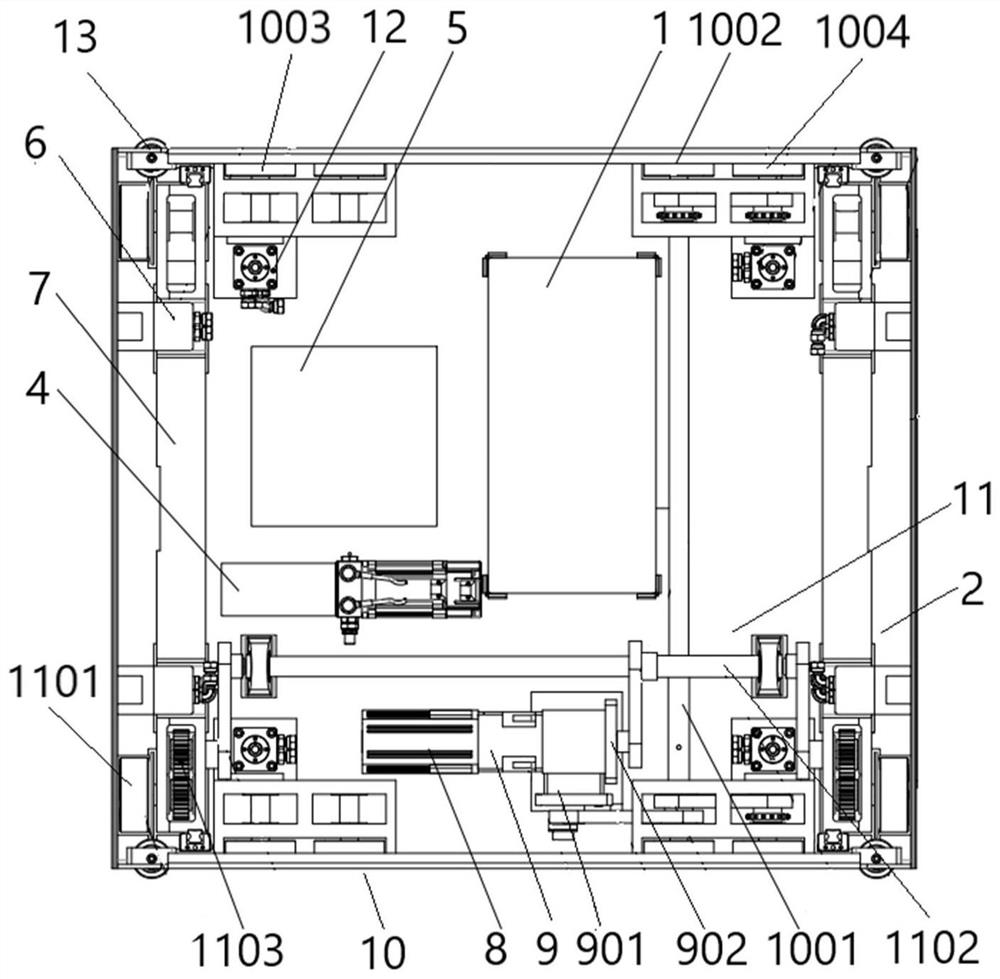

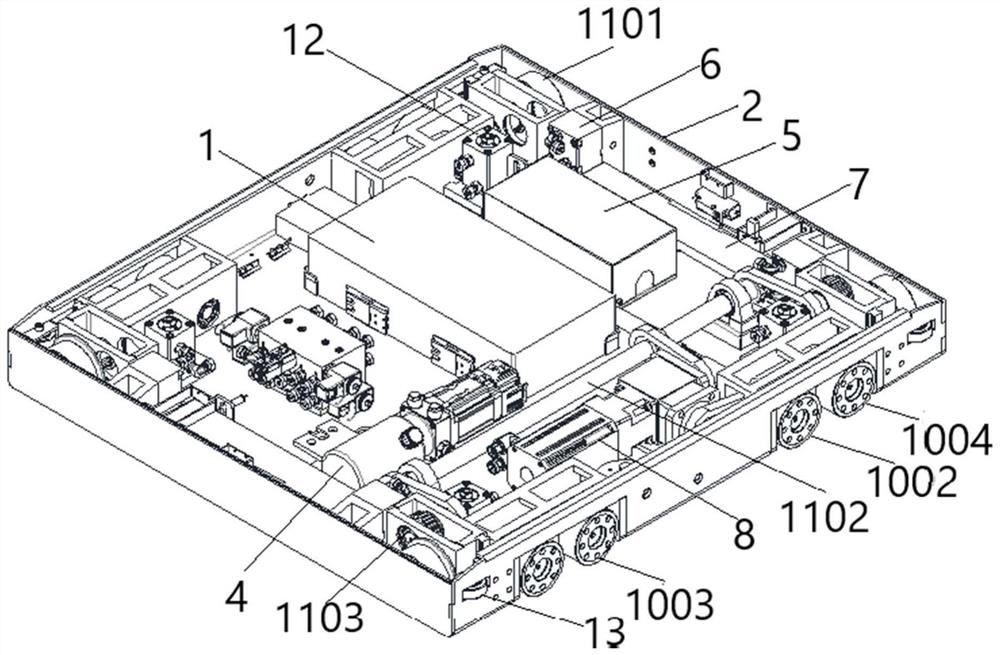

Four-way shuttle vehicle

PendingCN112978181AReduce running noiseGood lift synchronizationStorage devicesHydraulic cylinderHydraulic pump

The invention provides a four-way shuttle vehicle. The four-way shuttle vehicle comprises a controller, a sensor, a hydraulic pump assembly, a hydraulic valve assembly, a reversing hydraulic cylinder, a reversing bracket, a walking driving motor, a speed reducer, a child vehicle direction walking driving component and a mother vehicle direction walking driving component, wherein the sensor is electrically connected with the controller; the hydraulic pump assembly comprises a hydraulic pump driving motor electrically connected with the controller; the hydraulic valve assembly is connected with the hydraulic pump assembly; the reversing hydraulic cylinder is connected with the hydraulic valve assembly; the reversing bracket is mechanically connected with a plunger rod of the reversing hydraulic cylinder; the walking driving motor is electrically connected with the controller; the speed reducer is mechanically connected with the walking driving motor and is provided with a first driving part and a second driving part; the child vehicle direction walking driving component is mechanically connected with the first driving part; and the mother vehicle direction walking driving component is mechanically connected with the second driving part. According to the four-way shuttle vehicle, a hydraulic reversing device and a jacking device are arranged, so that intermediate transmission links are reduced, the fault rate is lower, mounting and maintenance are more convenient, and the running noise of the four-way shuttle vehicle is greatly reduced.

Owner:TIANJIN MASTER LOGISTICS EQUIP CO LTD

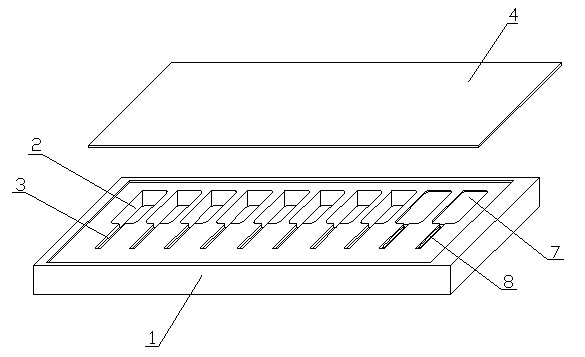

Disposable counting brain cotton aseptic package tray

InactiveCN102551896AReduce cumbersome operationsEasy accessSurgical furnitureDiagnosticsCounting efficiencyEngineering

The invention relates to a disposable counting brain cotton aseptic package tray. A plurality of brain cotton storage grooves for storing new brain cotton or recovering used brain cotton, the size of the brain cotton storage groove can accommodate one brain cotton, a leading wire groove is arranged on one side of each brain cotton storage groove and is used for placing a pull wire of the brain cotton, the leading wire grooves are communicated with the brain cotton storage grooves, a supporting rack or a bonding strip for vertically or obliquely placing the tray is arranged on the back surfaceof the tray, and when the tray is vertically or obliquely placed, the leading wire grooves are positioned below the brain cotton storage grooves. The pull wires are distinguished with the brain cotton, so as to facilitate taking and use; the tray is directly placed or bonded beside a physician operation region, and the brain cotton can be directly picked up in use, so as to reduce intermediate transfer links and shorten operation time; the used brain cotton is placed back the empty brain cotton storage grooves so as to avoid cross contamination, and the amount of the brain cotton is clear so as to improve counting efficiency.

Owner:HENAN UNIV OF SCI & TECH

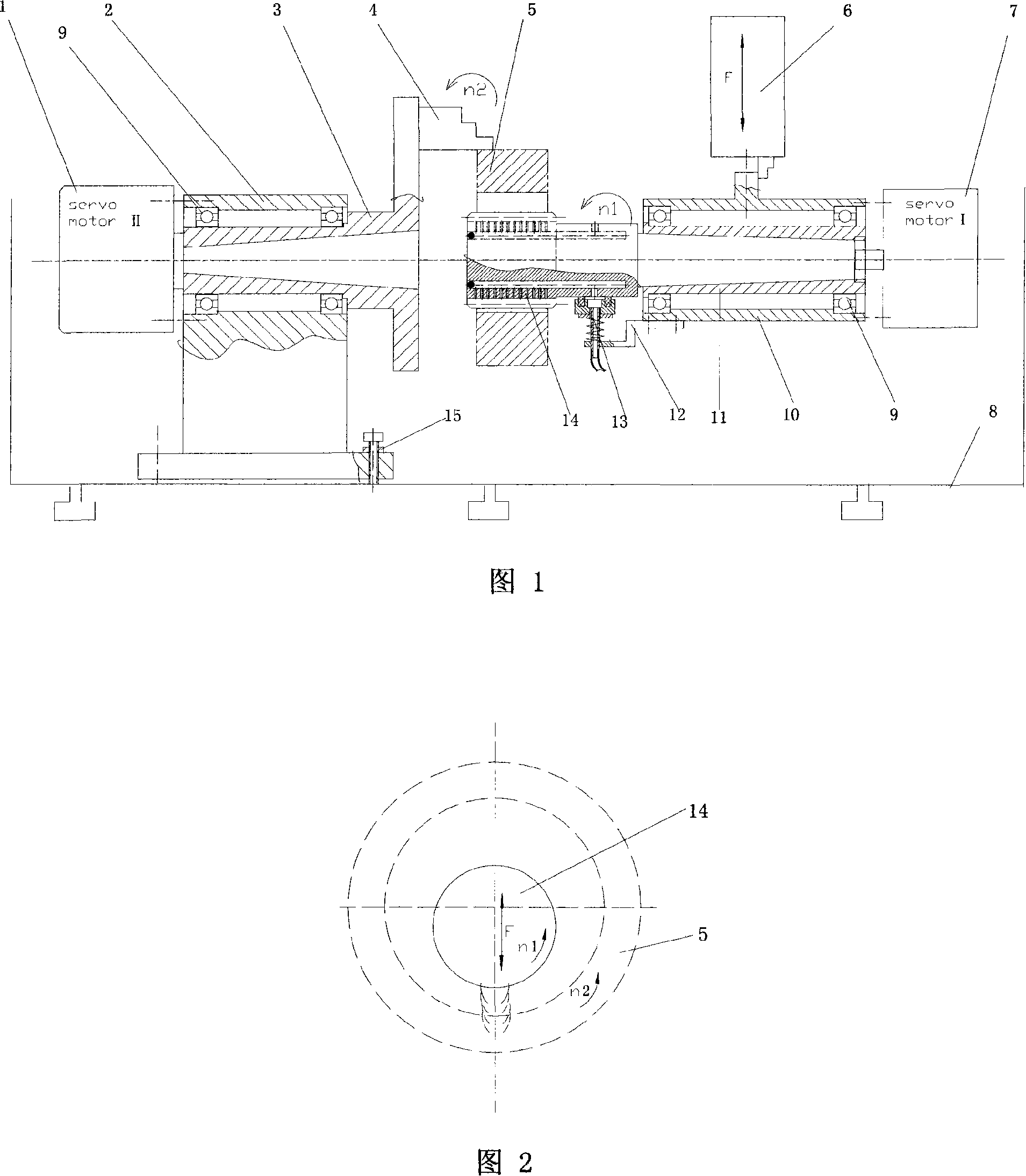

Dual-motor screw pair direct drive type turret punch press

ActiveCN106273608AImprove static and dynamic performanceReduce complexityPress ramEngineeringScrew thread

The invention relates to a dual-motor screw pair direct drive type turret punch press comprising a punch. A screw is arranged in the punch, two threads different in rotation direction are formed in the upper portion and the lower portion of the screw respectively, the upper thread is matched with a first screw nut, and the lower thread is matched with a second screw nut. The first screw nut is fixedly connected with a rotor of a first servo motor, and the rotor of the first servo motor and a stator thereof are mounted on an upper box body in a matched manner. The second screw nut is fixedly connected with a rotor of a second servo motor, and the rotor of the second servo motor and a stator thereof are mounted on a lower box body in a matched manner. The bottom of the screw passes through a bearing end cover to be connected with a punch body. The dual-motor screw pair direct drive type turret punch press has the advantages of safety, stability, reliability, high cost performance and improvement in static and dynamic performance.

Owner:XIAN SIYUAN UNIV

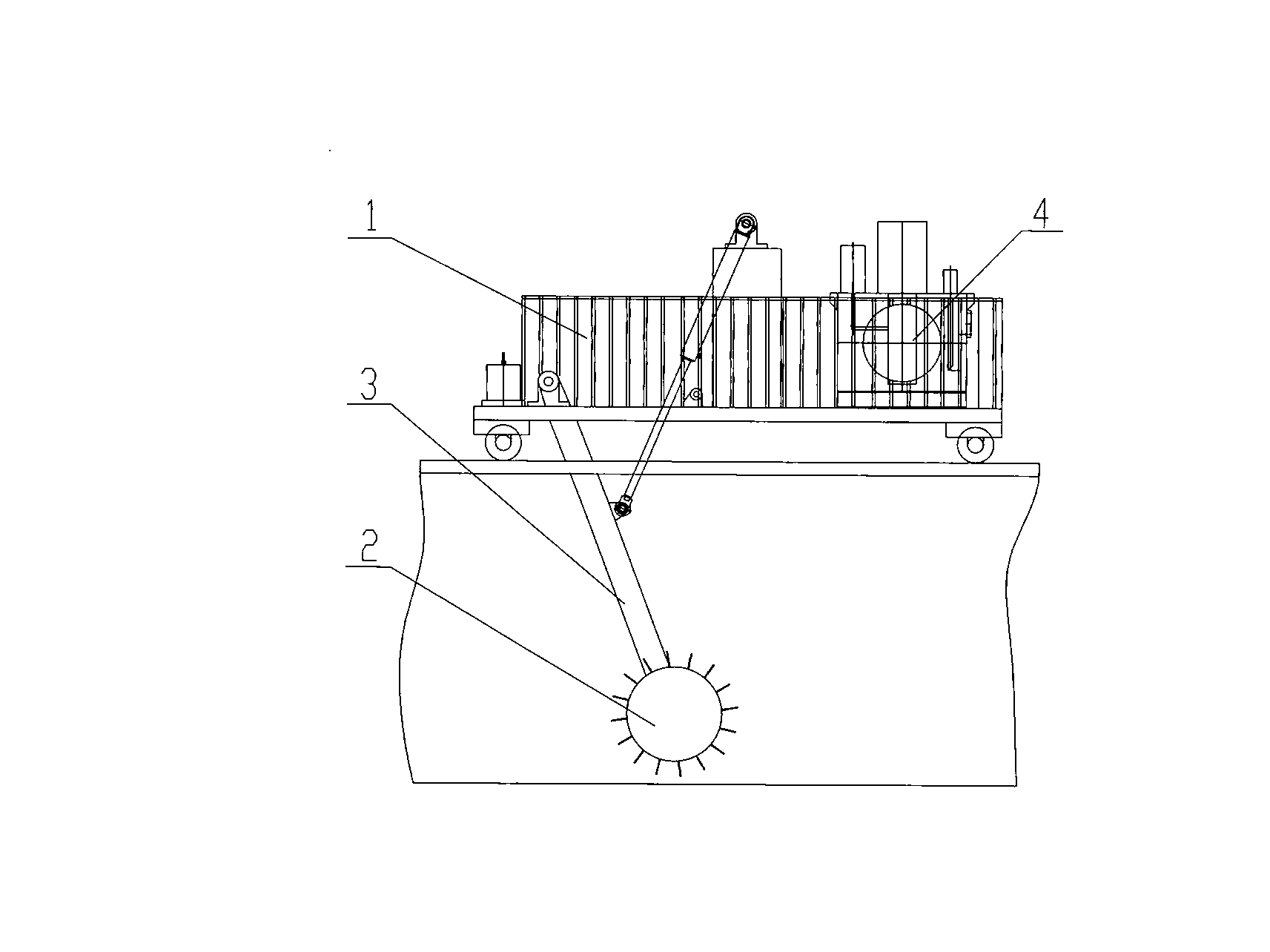

Drum-type hydraulic turner

InactiveCN103011926ASimple structureReduce intermediate transmission linksBio-organic fraction processingOrganic fertiliser preparationEngineeringPower transmission

The invention discloses a drum-type hydraulic turner, relating to environment-friendly equipment of treating solid waste. The drum-type hydraulic turner comprises a stand, a large arm, a drum device and a hydraulic device, wherein the middle part of the drum device is welded with the lower part of the large arm; left and right hydraulic motors drive left and right sets of drum in the drum device; and rectangular plane blades which are axially and symmetrically distributed are arranged at the outer side of the surface of the drums. According to the drum-type hydraulic turner, the hydraulic motors directly transfer the power to the drums, and a middle transmission link is saved, thus greatly improving the power transmission efficiency and the working reliability; a blade structure is improved, so the drum-type hydraulic turner has the advantages of small noise, low energy consumption and high production efficiency; and in addition, the blade structure is reasonable, so that the sludge turning throw efficiency is better.

Owner:安徽华龙环保技术工程有限公司

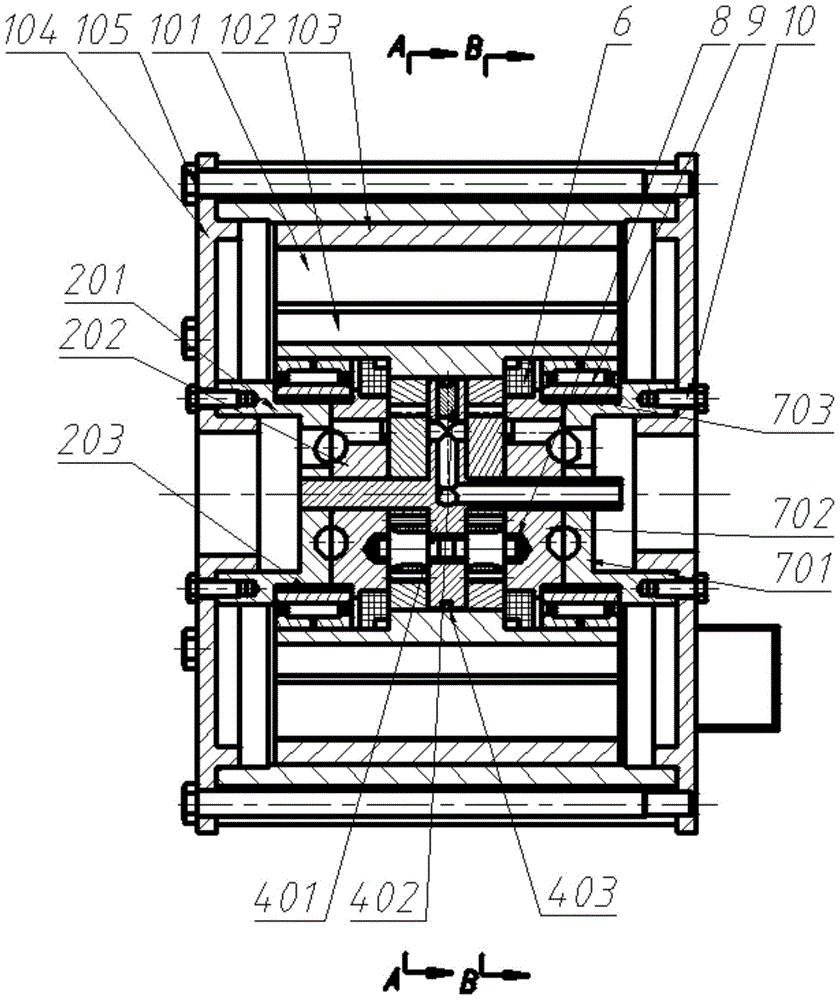

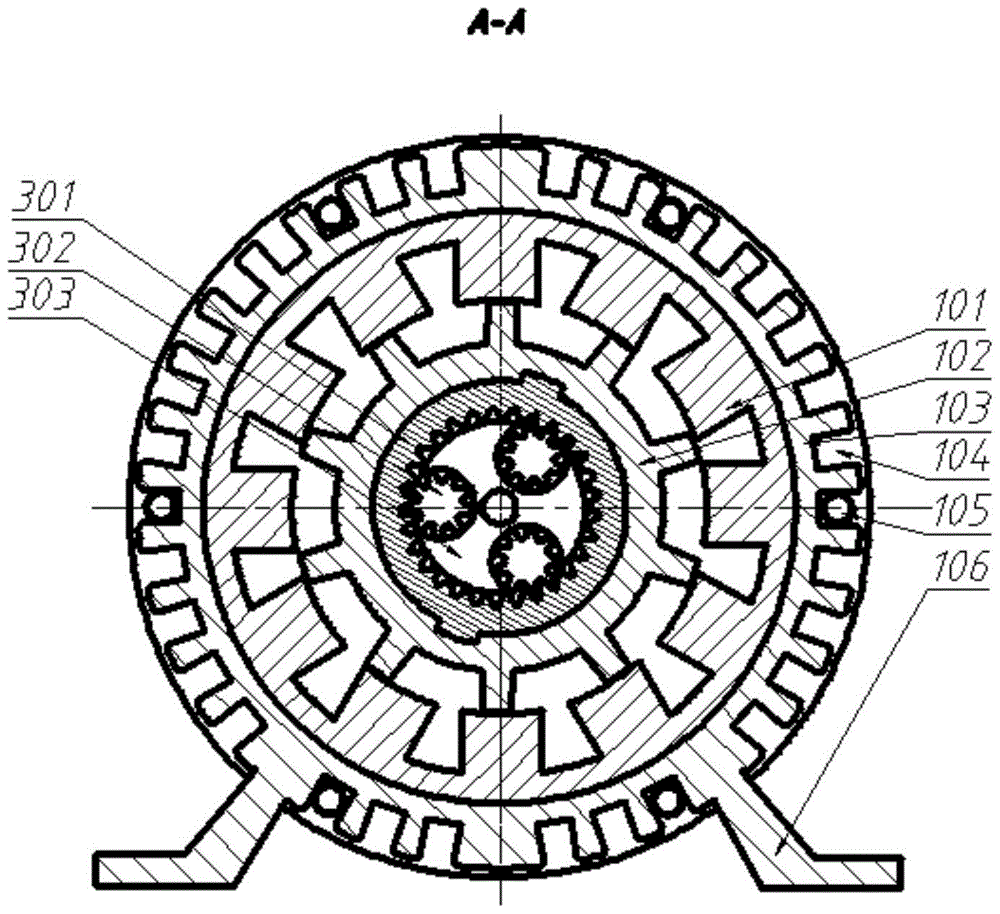

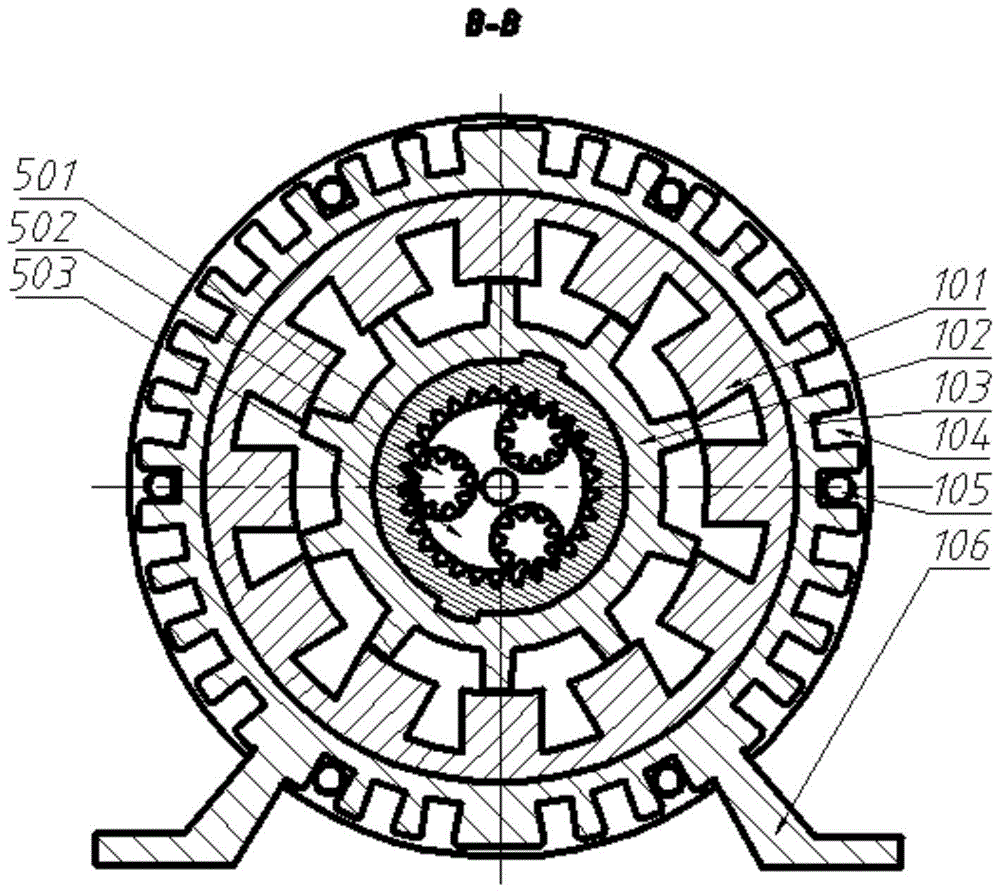

A double-connected three-gear internal meshing compound motor pump driven by a switched flux motor

InactiveCN103967780BImprove cooling effectEasy to useRotary piston pumpsRotary piston liquid enginesWork performanceGear pump

The invention discloses a duplex three-gear inner gearing compound motor pump driven by a switch flux motor. A motor rotor adopts a hollow structure; a first pump body composed of a first outer gear ring, a first pinion and a first partition board and a second pump body composed of a second outer gear ring, a second pinion and a second partition board are embedded in the motor rotor; the first pump body and the second pump body adopt inner gearing compound gear pumps and are connected in parallel to form a double-pump structure; the double-pump structure adopts the manner of oil feeding at two ends and oil discharging at one end; one side of each pump body is provided with an oil feeding oil distribution disc and an oil feeding end cover; an oil discharging oil distribution disc is arranged between two pump bodies. According to the invention, the pump bodies are embedded in the switch flux motor, so that the pumping capacity is increased, the pump flow pulsation is reduced, and the characteristic of high-pressure mass flow is easy to realize to enable the working performance to be safe and stable.

Owner:XI AN JIAOTONG UNIV

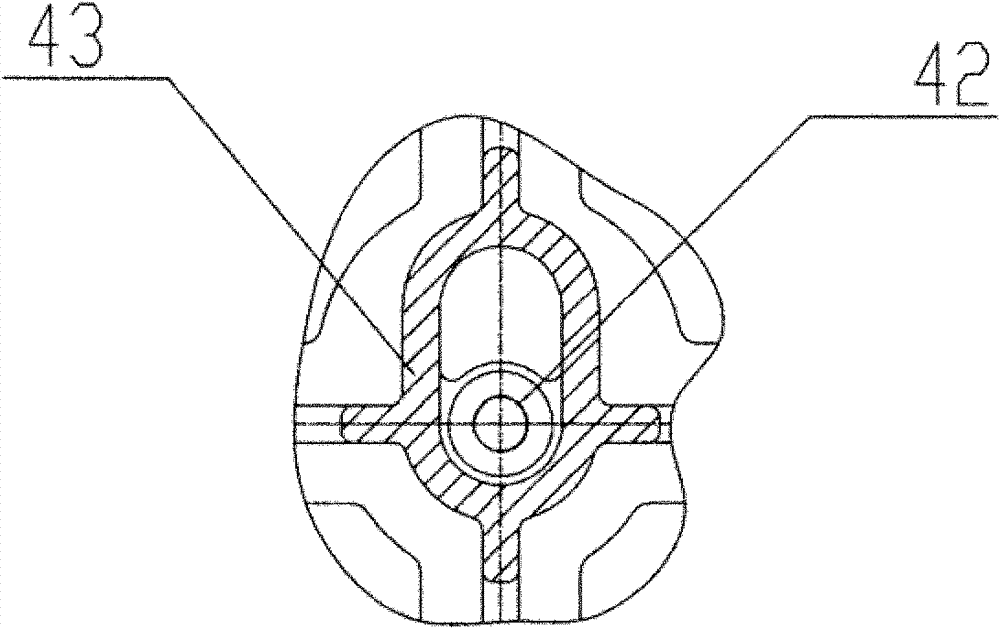

Transformer tap switch flexible to install and transformer applying same

PendingCN114373643AFlexible installation positionCompact structureTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerControl theory

The invention discloses a transformer tap switch flexible to install and a transformer applying the same, and belongs to the field of transformers. According to the invention, three groups of split-connection mechanisms of the transformer tap switch are divided into at least two independent switch parts, and the switch parts are in transmission connection with the switch operation mechanism through the transmission sleeve pipeline. According to the closed-loop tap switch, the switch operation mechanism synchronously controls the moving contact assemblies in the three groups of split-connection mechanisms to slide relative to the corresponding static contact assemblies so as to change the connection position of the moving contact and the static contact, so that the installation positions of the three groups of split-connection mechanisms in the transformer are more flexible; the wiring position of each tapping mechanism can be closer to the lead outgoing position of the corresponding coil winding of the transformer, so that the lead length of the coil winding is reduced, and the installation and operation of the tapping switch are facilitated; and the occupied space of the tap switch in the transformer can be reduced, so that the structure of the transformer is more compact, and the transformer can be suitable for the existing triangular three-dimensional transformer and planar rectangular transformer.

Owner:江苏金诺电气科技有限公司

Direct-drive high-speed five-axis gantry machining center with replaceable milling head

ActiveCN102049705BImprove machining accuracyQuick responseFeeding apparatusLarge fixed membersAviationEngineering

The invention relates to the field of five-axis gantry machining center tools, in particular to a direct-drive high-speed five-axis gantry machining center with a replaceable milling head, which solves the problems in the prior art, such as low precision and the like. Two linear guide rails are arranged on a left bridge and a right bridge respectively; a slide plate is in slide fit with a guide rail on a crossbeam through a slide block; a ram is in transmission fit with the slide plate through double lead screws, a double-pendulum head with A and C shafts is mounted at the bottom of the ram, and a head magazine is arranged on one side of a worktable; two ends of the crossbeam are mounted on the left bridge and the right bridge through slide seats; linear motors are adopted on the X direction and Y direction of the five-axis machining center for direct driving, the crossbeam moves horizontally along the left bridge and the right bridge in the X direction, and the slide plate moves horizontally along the crossbeam in the Y direction, double motors in the Z direction of the five-axis machining center drive the ram through gravity centers, and the ram moves vertically on the slide plate in the Z direction. The machining center has stable running and performance, and is suitable for precision finishing of dies in the industries of aviation, spaceflight, automobiles, and the like.

Owner:沈阳机床中捷友谊厂有限公司

High-precision direct driven air flotation turntable

ActiveCN102011918BReduce intermediate transmission linksReduce the transmission linkStands/trestlesBearingsTorque motorHigh load

The invention discloses a high-precision direct driven air flotation turntable, which comprises a supporting seat (1), a hoisting ring screw (2), a handle (3), a sealing ring (4), an axial throttle (5), a radial throttle (6), a mounting pedestal (7), a radial bearing outer ring (8), an O-shaped rubber sealing ring I (9), an air flotation face assembly (10), an O-shaped rubber sealing ring II (11), a pressure block (12), a motor mounting seat (13), a socket (14), a plug I (15), a plug II (16), a torque motor stator (17), a torque motor rotator (18), a small pressure ring (19), a grating disc (20), a reading head (21), a reading head bracket (22), a gland (23), a sealing plate (24) and a large pressure ring (25). The turntable has high indexing precision and low end face run-out and radial run-out, and solves the precise indexing problem under the condition of high load.

Owner:BEIJING SATELLITE MFG FACTORY

Combined type flow valve for liquid of high-pressure large-flow alternating current servo direct-drive machine

InactiveCN102635583BOvercoming contamination sensitivityReduce manufacturing costsServomotor componentsElectricityMotor drive

The invention provides a combined type flow valve for liquid of a high-pressure large-flow alternating current servo direct-drive machine. An alternating current servo motor drives a push rod through the transmission of a thread and the push rod acts on a hydraulic transmission cavity which is sealed with hydraulic oil; when the push rod moves, the inner volume of the hydraulic transmission cavity is changed and a valve core moves to the same side to compensate the change of the volume, so that the movement of the valve core is controlled through controlling the movement of the push rod. The valve has the advantages of simple structure, accurate control and convenience for use, can directly use a computer to carry out digital control, has good buffering and positioning performances, can meet the requirements of positioning any point, can realize a closed ring system of electric feedback, and especially can be used for better solving the problem that the previous servo valve is sensitive to oil liquid pollution. The valve is wide in working pressure range and large in flow and can work under a very low oil supply pressure, and the dynamic performance is not greatly influenced by the low oil supply pressure; and the valve has fewer middle transmission links so that the efficiency of the system can be improved.

Owner:XI AN JIAOTONG UNIV

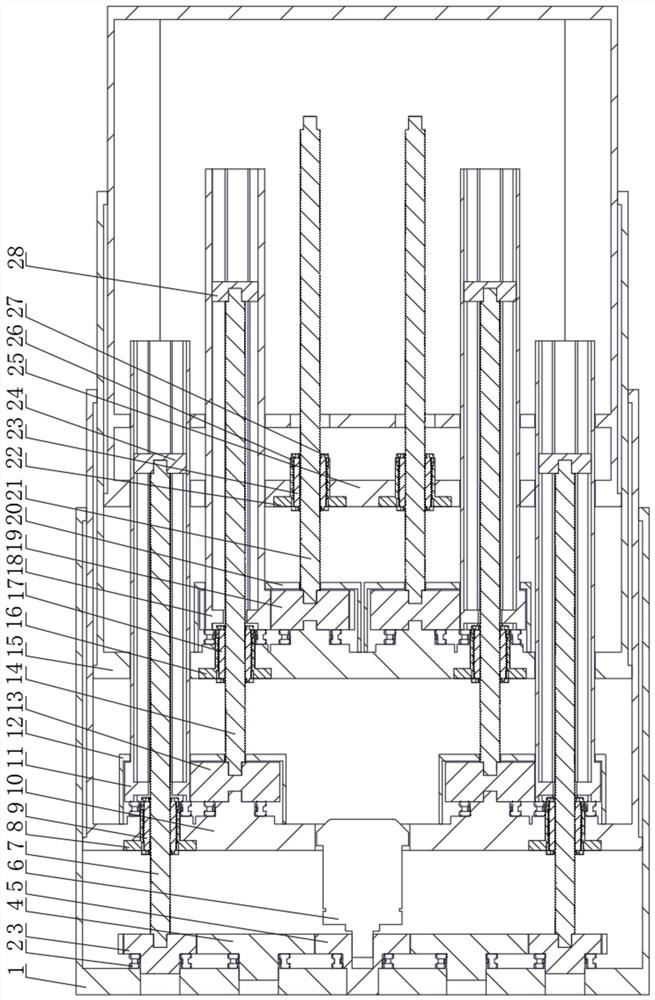

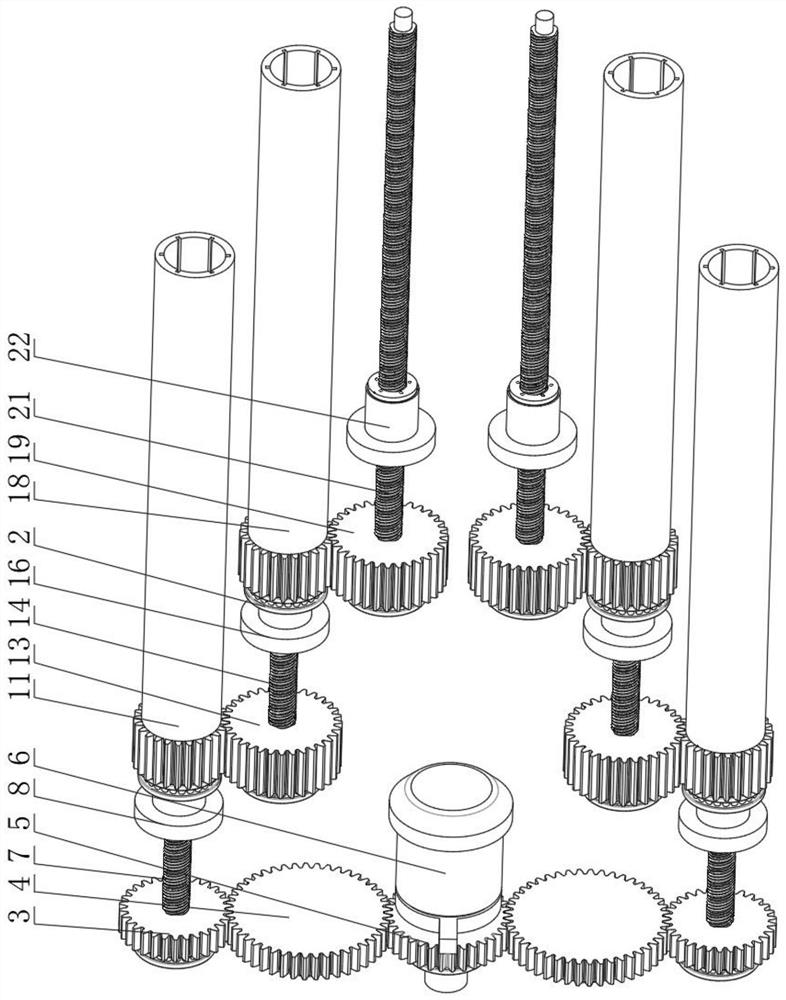

Multistage parallel heavy-load electric cylinder

ActiveCN113685526AAchieving Synchronized LiftingRealize synchronous axial movementGearingMechanical energy handlingRoller screwGear wheel

The invention provides a multi-stage parallel heavy-load electric cylinder, and belongs to the technical field of electric cylinders. The electric cylinder comprises planetary roller lead screw shafts, nuts, rollers, cylinder barrels, input gears, a servo motor, a reduction gear, splines and transmission barrels. The servo motor is fixedly connected with a base cylinder barrel, the servo motor is connected with the reduction gear, one end of the first-stage planetary roller screw shaft is fixedly connected with the first-stage input gear, the other end of the first-stage planetary roller screw shaft is connected with the spline A, the first-stage nut and the rollers surround the first-stage planetary roller screw shaft to form a whole, and one end of the second-stage planetary roller screw shaft is fixedly connected with the second-stage input gear; and the other end of the second-stage planetary roller lead screw shaft is connected with the spline B, the second-stage nut and the rollers surround the second-stage planetary roller lead screw shaft to form a whole, and the third-stage nut and the rollers surround the third-stage planetary roller lead screw shaft to form a whole. According to the electric cylinder, the space volume is reduced, the bearing capacity is enhanced, the bending resistance and the torsion resistance are high, and the transmission speed and the transmission efficiency are improved.

Owner:UNIV OF SCI & TECH BEIJING

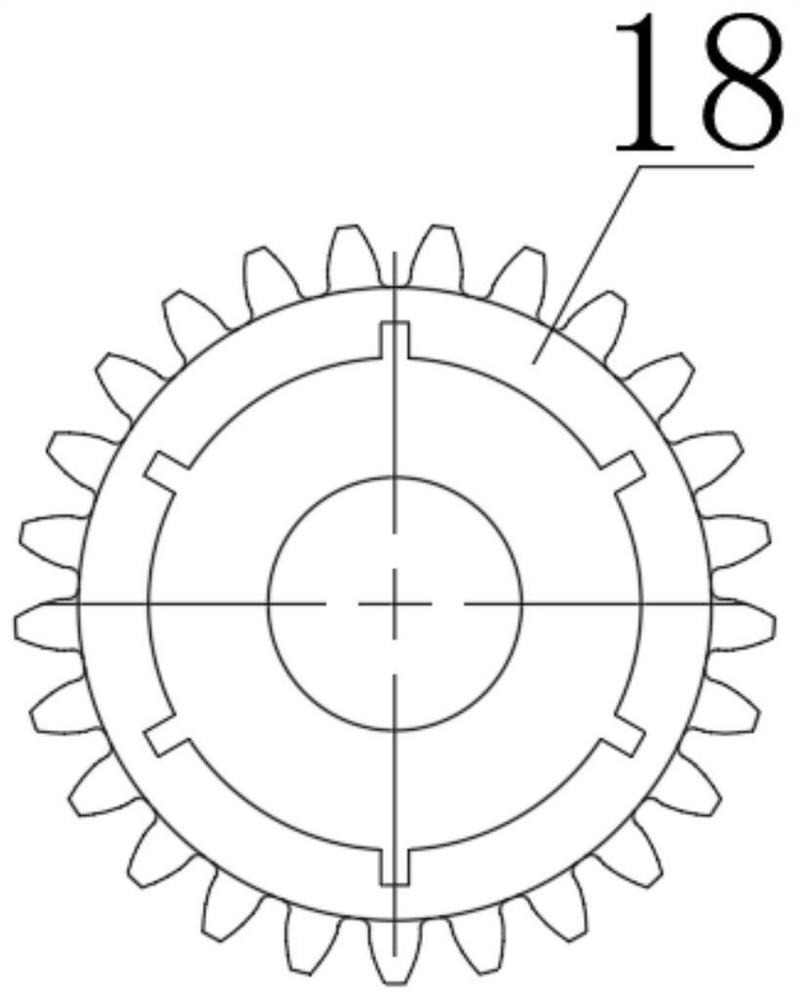

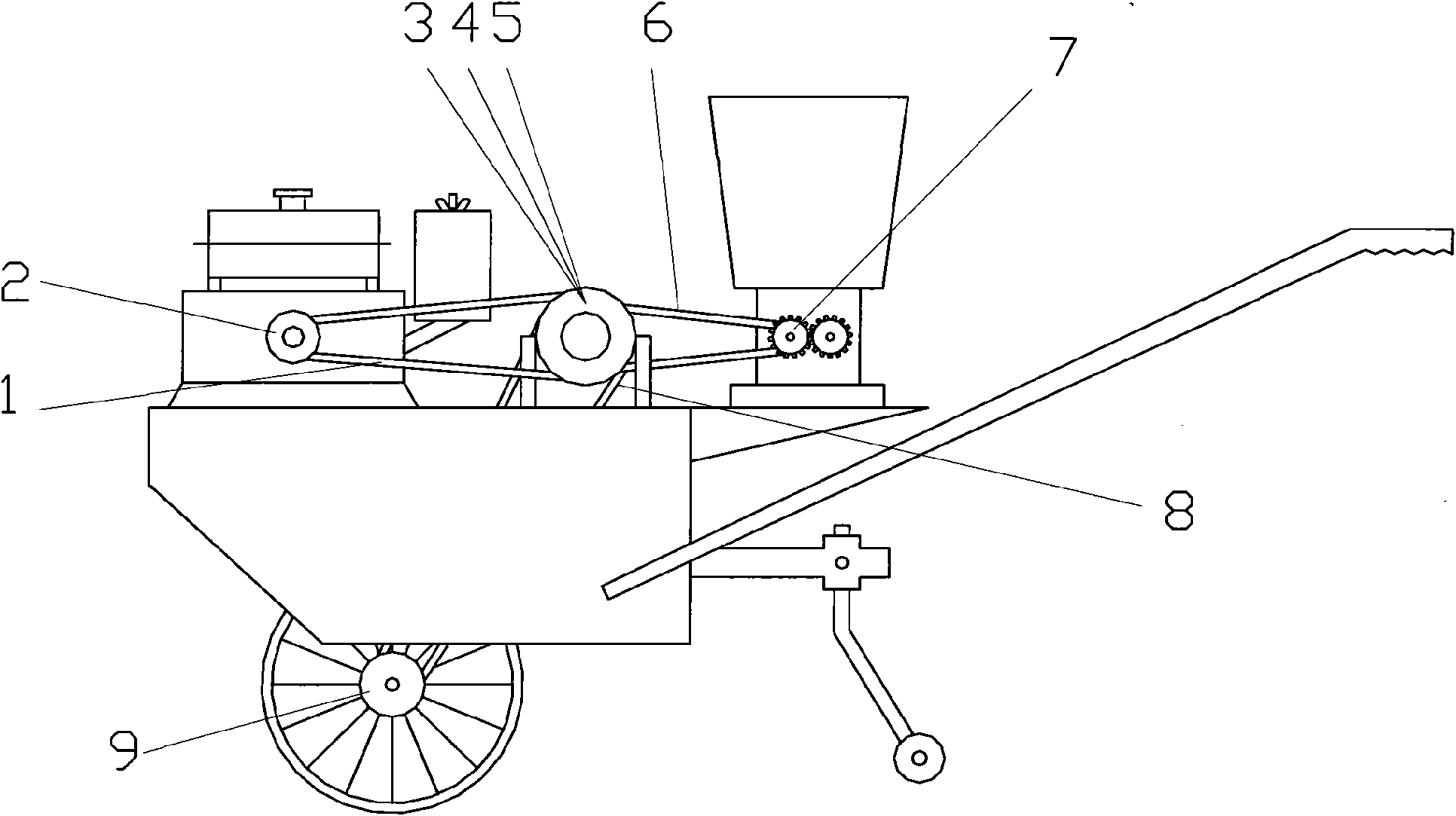

Seeder

The invention discloses a seeder with advancing and seeding noninterference and smoother clutch, comprising an output shaft chain wheel, a land wheel chain wheel, a speed changer chain wheel group, a seeding wheel chain wheel and a chain, wherein the output shaft chain wheel is linked with a first chain wheel in the speed changer chain wheel group, a second chain wheel in the speed changer chain wheel group is linked with the land wheel chain wheel, a clutch chain wheel arranged on a clutch is linked with the seeding wheel chain wheel, and the clutch is coaxially and movably matched with a speed changer. A speed reducer divides power into two paths and transmits the power to the land wheel chain wheel and the seeding wheel chain wheel, intermediate transmission links are reduced, and the transmission resistance is reduced; the clutch is modified on the speed changer, and the clutch is arranged in the upper level of the seeding wheel in transitive relation, therefore, when the clutch acts, the impact suffered by the seeding wheel is reduced, and the seeding operation and the seeder walking can more smoothly clutch.

Owner:姚惠敏

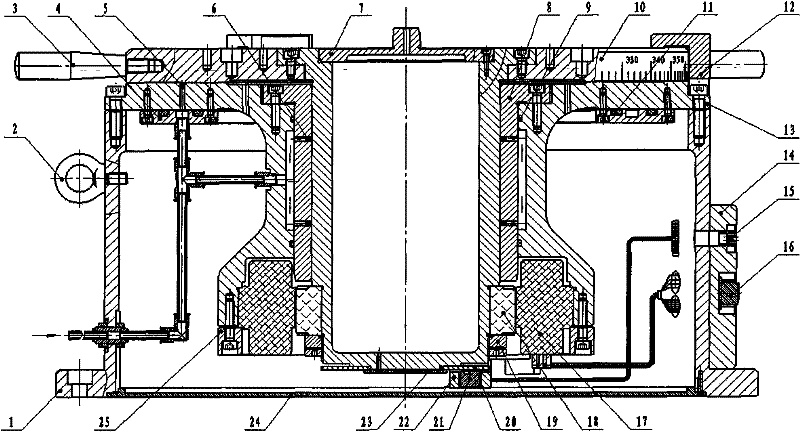

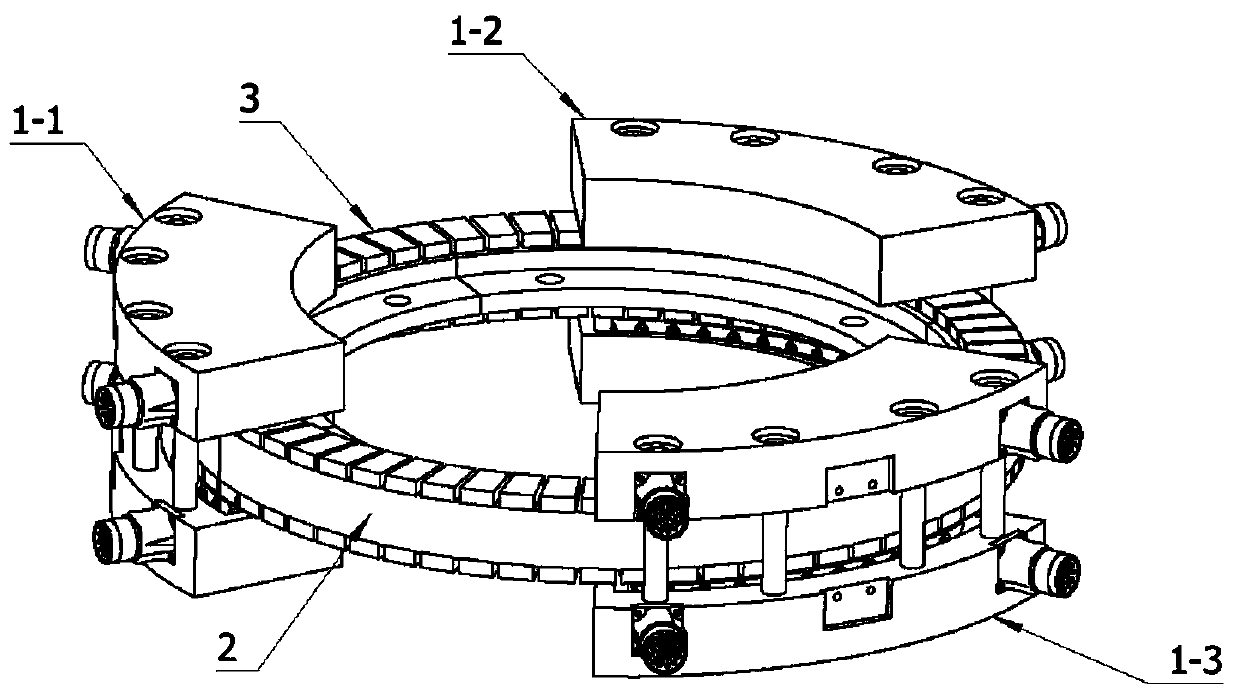

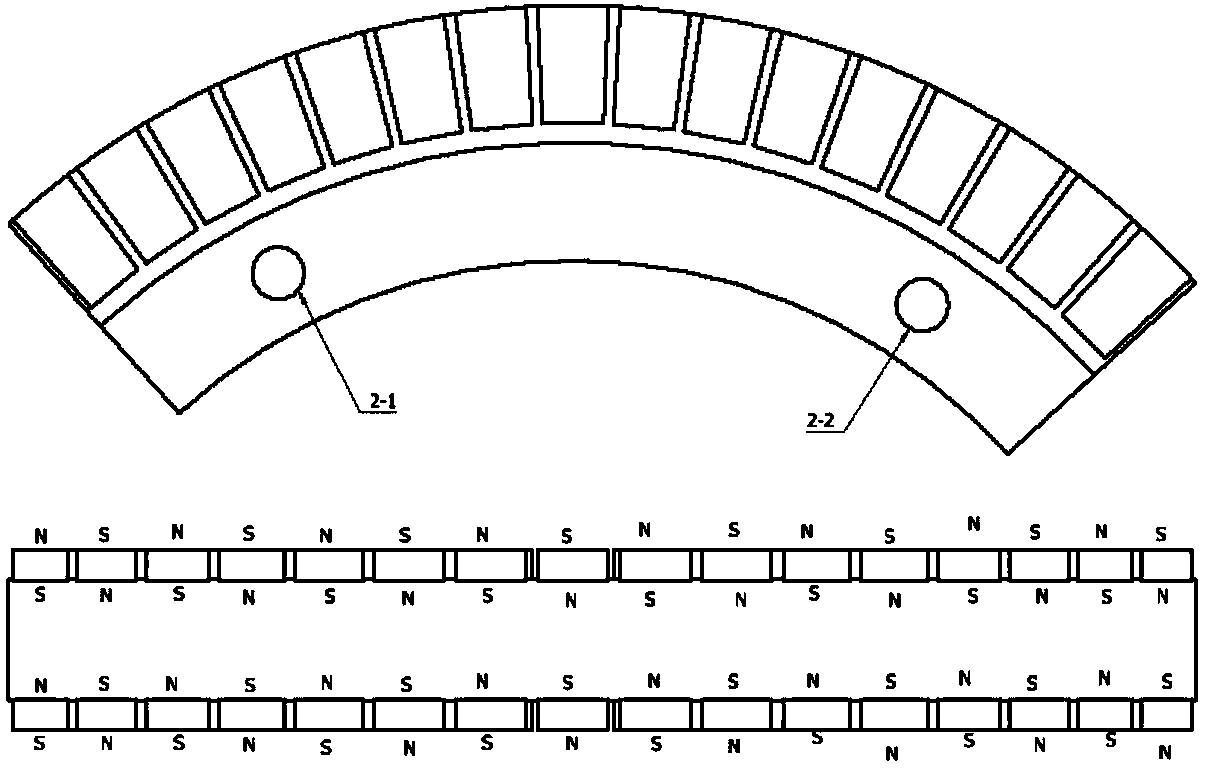

Double-edge arc-shaped permanent magnet synchronous motor used for large turntable

InactiveCN104052222AReduce intermediate transmission linksReduce local deformationMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsStator

A double-edge arc-shaped permanent magnet synchronous motor used for a large turntable is composed of a plurality of stator sets and a rotor, wherein each stator set is formed by two same upper stator piece and lower stator piece, upper iron core unit and lower iron core unit, upper iron core positioning piece and lower iron core positioning piece, upper coil winding and lower coil winding, upper stator casing and lower stator casing and upper connecting piece and lower connecting piece. The upper stator piece and the lower stator piece are connected and positioned through the connecting pieces. The iron core units are wound with the coil windings, and the iron core units and the coil windings are connected and positioned through the iron core positioning pieces and are fixed to the stator casings in an epoxy pouring mode. Each whole stator set is fixed to a fixed table face of a turntable device with screws through screw holes in the stator casings. The rotor is formed by splicing four same arc-shaped fan-area mechanisms, and each fan-area mechanism is formed by a permanent magnet and a magnet yoke. The upper surface and the lower surface of the magnet yoke are bonded with the permanent magnets respectively. The whole rotor is fixed to the rotating parts of the turntable devices through through-holes in the magnet yokes with screws. The stators are arranged and installed in a staggered mode.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

An intelligent light control shading system

InactiveCN104563835BEasy to moveControl movementDoor/window protective devicesWireless transmissionControl system

The invention discloses an intelligent light control sun-shading system. The intelligent light control sun-shading system solves the problem that due to the fact that in daily life, a curtain can not be opened or closed in time, the indoor luminance is too high or too low. The intelligent light control sun-shading system can be automatically and manually controlled. A luminance sensor is arranged to collect luminance data, the data are transmitted to a central processing unit of an indoor control system with the help of a wireless transmission module, and whether the curtain opening and closing operation and other operation are conducted or not is analyzed according to set programs. By means of the system, under the no-man control condition, automatic opening and closing of the curtain can be controlled on the basis of the indoor light ray intensity, the good rest environment, the good reading environment, the good study environment, the good storage environment and other environments are created for indoor portions, and the more comfortable and user-friendly living experience is provided.

Owner:SHANGHAI OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com