Low-voltage motor restarting device

A low-voltage motor, restarting technology, applied in the direction of motor generator/starter, motor starter, etc., can solve the problems of unsuitable management, high cost, poor efficiency, etc., to achieve perfect electrical and safety isolation, easy equipment maintenance , the effect of convenient function throwing and withdrawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

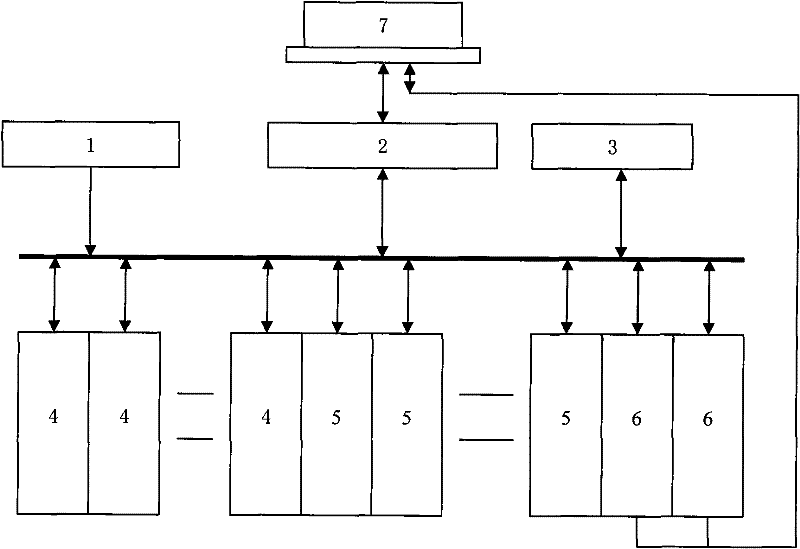

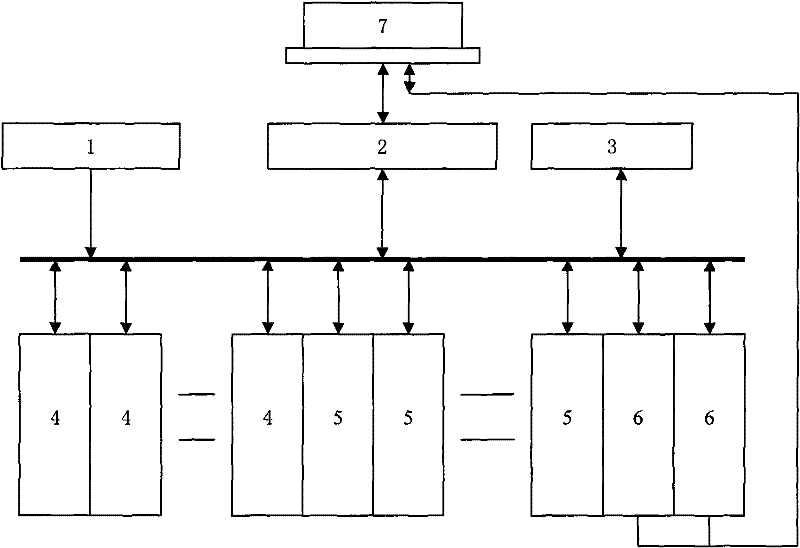

[0015] The present invention is further described below in conjunction with accompanying drawing:

[0016] See attached figure 1 , the connection of the low-voltage motor restart device is to use the power supply unit (1) and the main CPU control unit (2), display unit (3), input unit (4), output unit (5), analog unit (6) direct connection. The main CPU control unit (2), the display unit (3), the input unit (4), the output unit (5), and the analog unit (6) communicate through the CAN bus according to a certain protocol.

[0017] See attached figure 1 , in the low-voltage system of 380V (690V) and below, for the continuous operation of the motor circuit, when the system loses power for a short time, in order to restore the process as soon as possible, the motor needs to be able to restart automatically when the power is restored, the three-phase voltage and current Connect to the analog unit (6), convert it into a voltage signal within the AD sampling range, and upload the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com