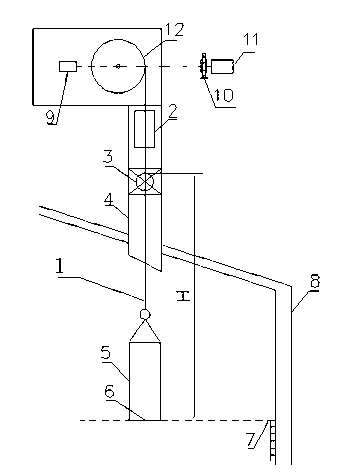

Patents

Literature

59 results about "Stock level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stock level refers to the different levels of stock which are required for an efficient and effective control of materials and to avoid over and under-stocking of materials.

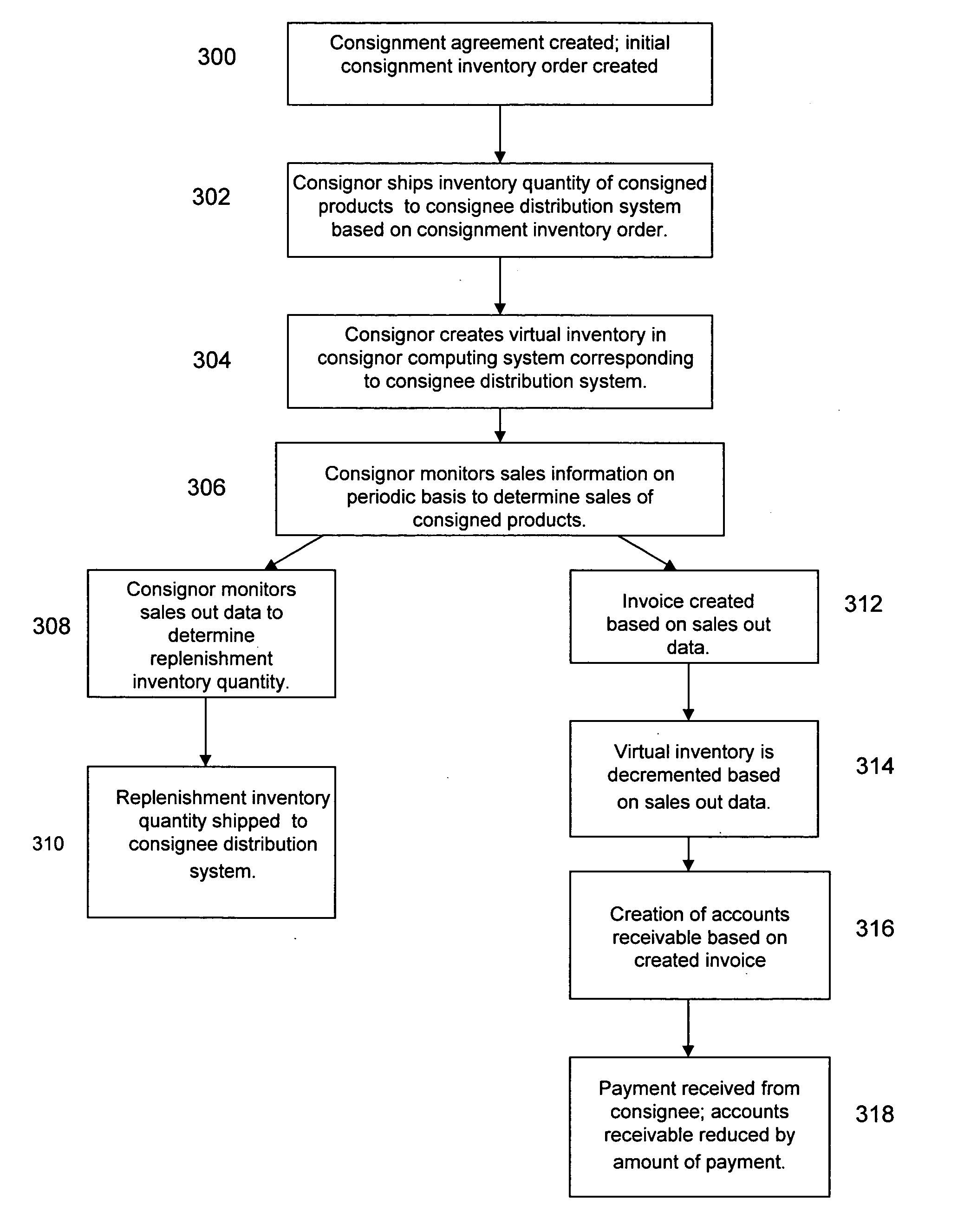

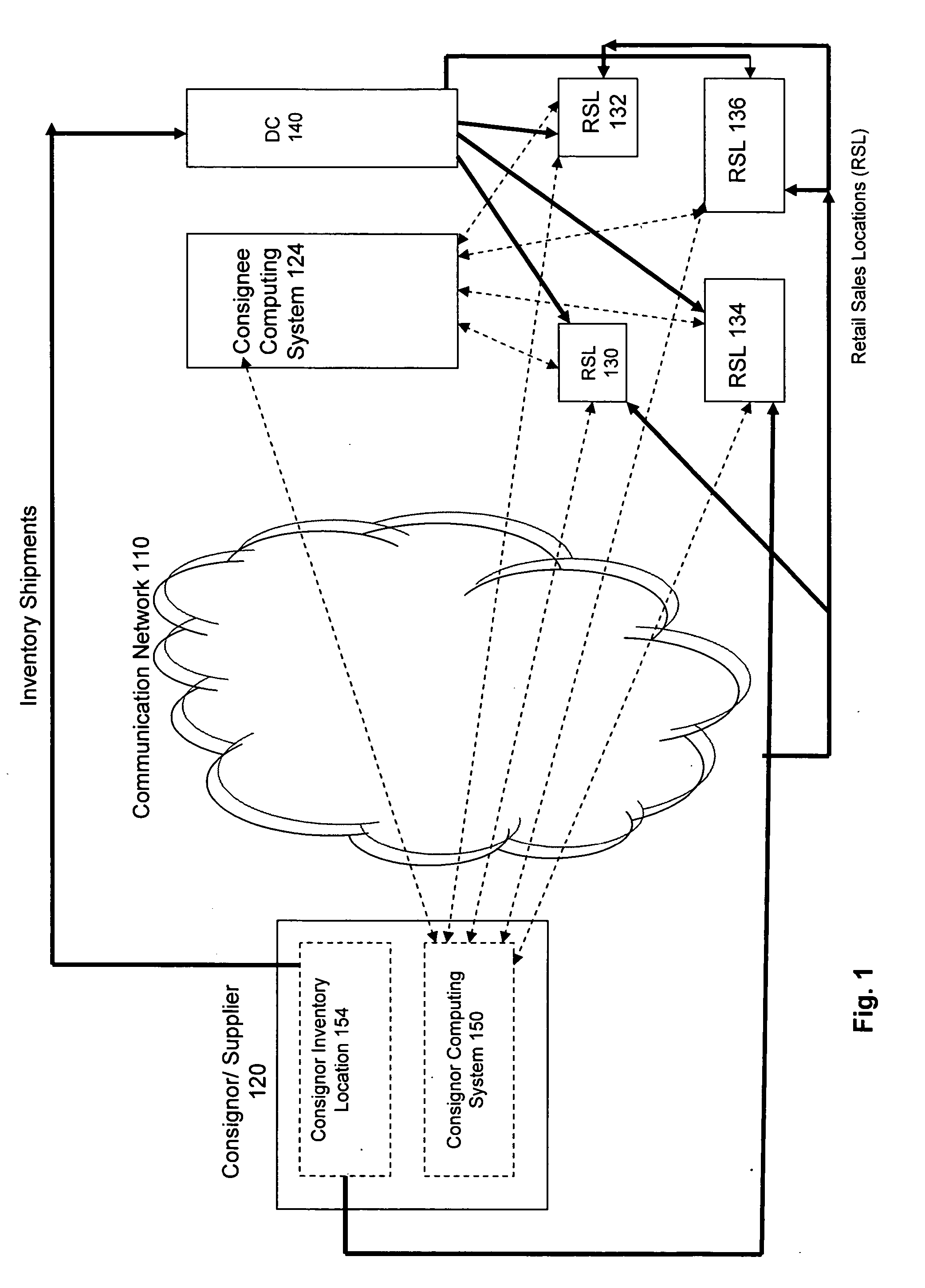

System, apparatus and process to provide, replenish, monitor, and invoice consignment inventory with retail customers

A consignor and a retailer develop a consignment agreement for a consigned product. An inventory order is generated for stocking levels of the consigned product in a retailer's distribution system. An inventory quantity of the consigned product based on the inventory order is shipped out to the retailer's distribution system. A virtual inventory is created in a consignor's computer system to match the inventory quantity shipped to the retailer's distribution system and also that identifies the inventory location. A consignor's computer system receives sales data for the consigned product. The retailer's distribution system is replenished based on the sales data. The virtual inventory in the consignor's computer system is decremented based on the sales data received.

Owner:IRBY SEAN +3

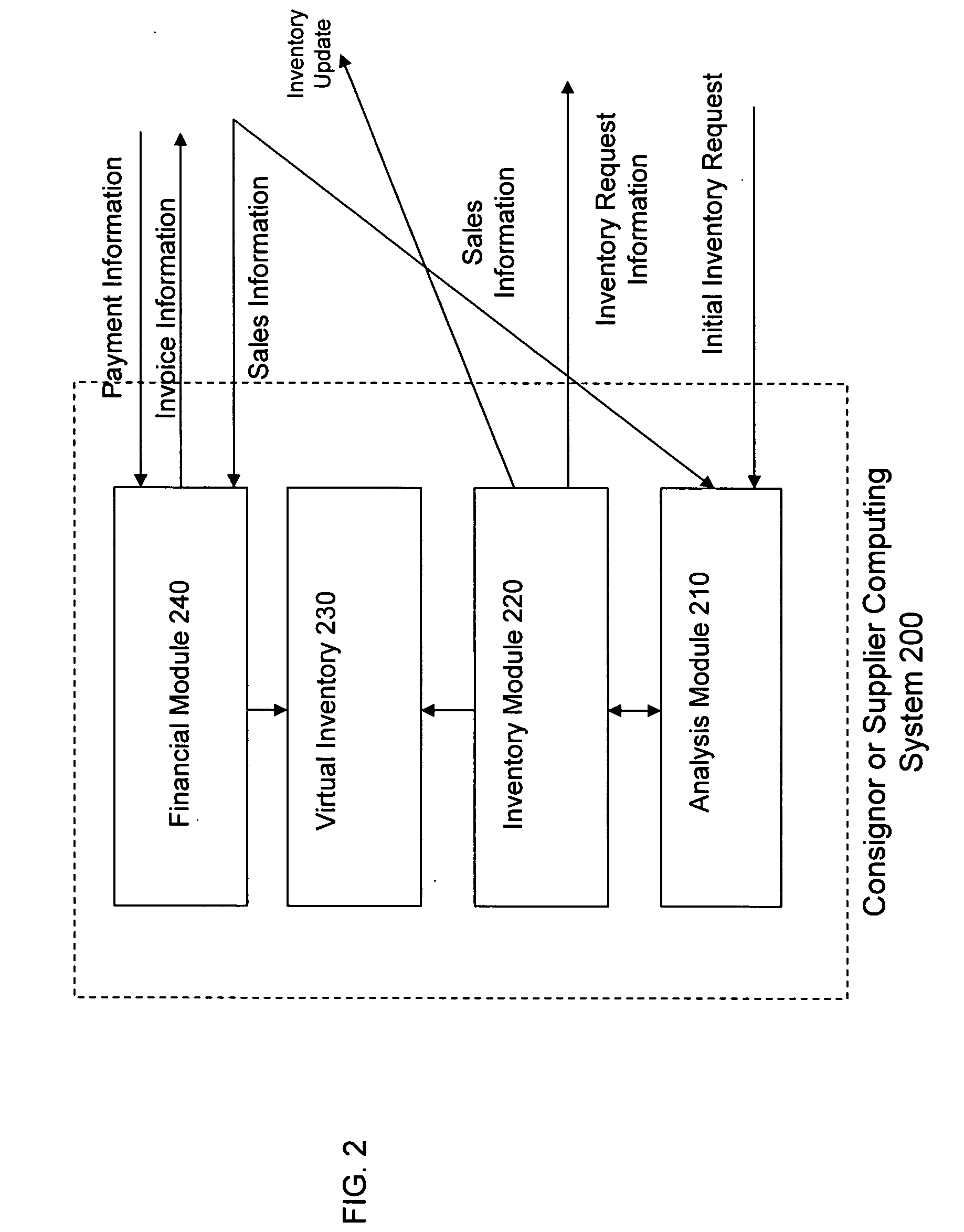

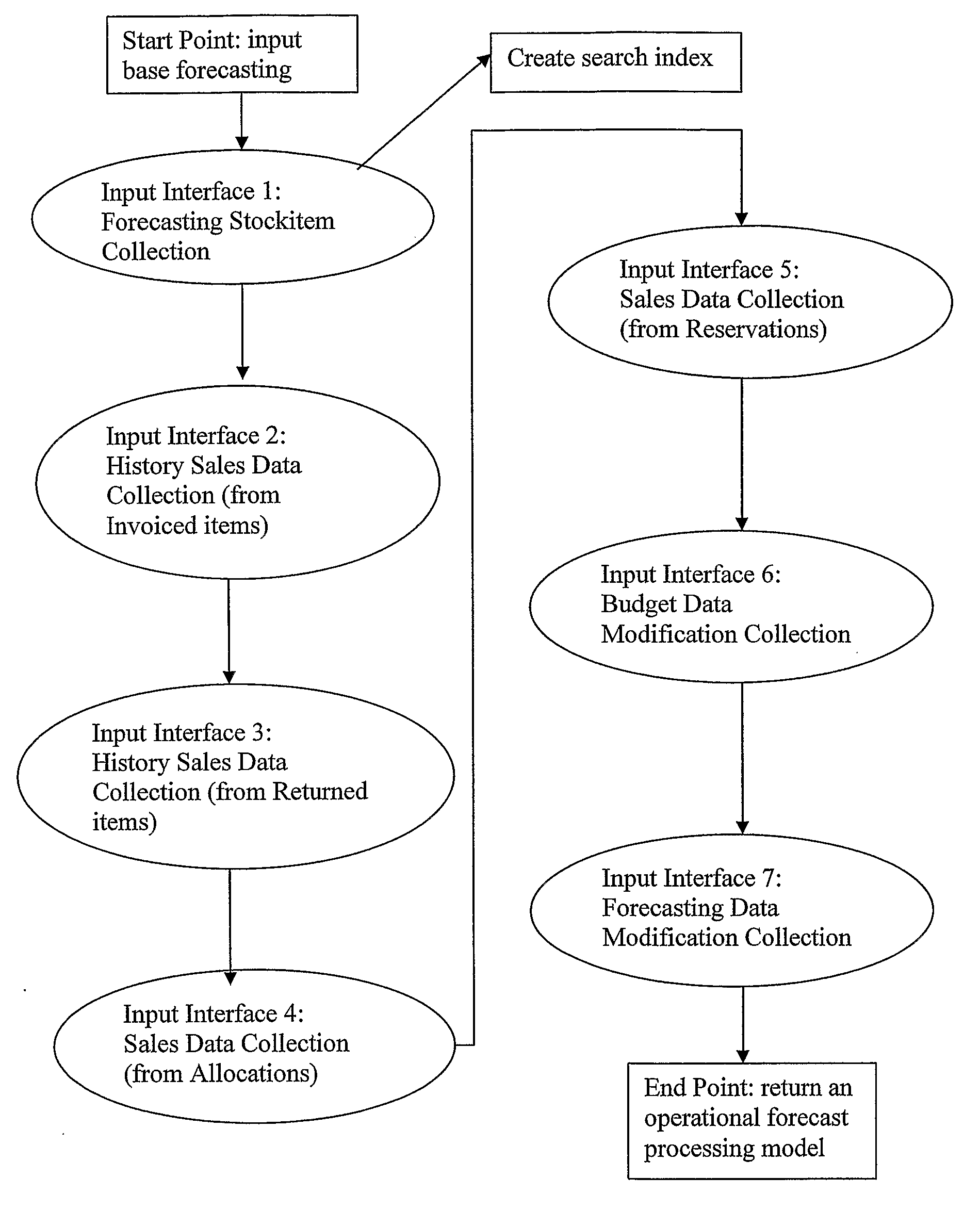

Dynamic business enhancement system

A computer enabled business system is disclosed which provides a business with the ability to be aware on a moment-to-moment basis of their historic, current and future operational states. The business system uses a dynamic data engine for the purposes of creating and displaying historic transactions, current stock levels and forecasted demand data in real-time. As the data is created and cast forward, the data retains attributes of the original transaction data. These attributes are configured and modified dynamically resulting in precise and managed demand forecast, budget and purchasing information. Any change in the raw data as a result of a business transaction is immediately reflected in the demand forecast; hence, the data is in a perpetual dynamic state.

Owner:TOTAL COMM

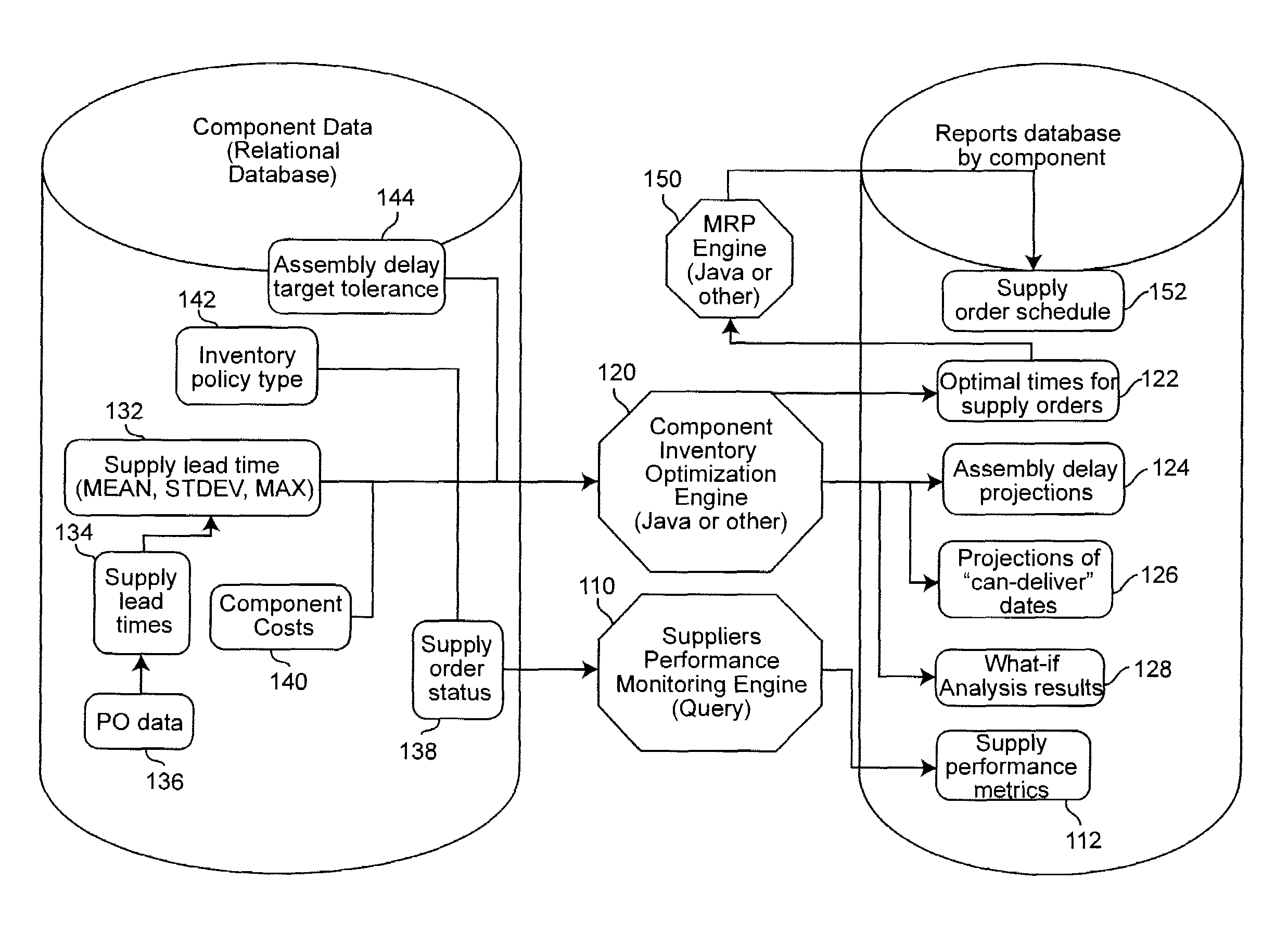

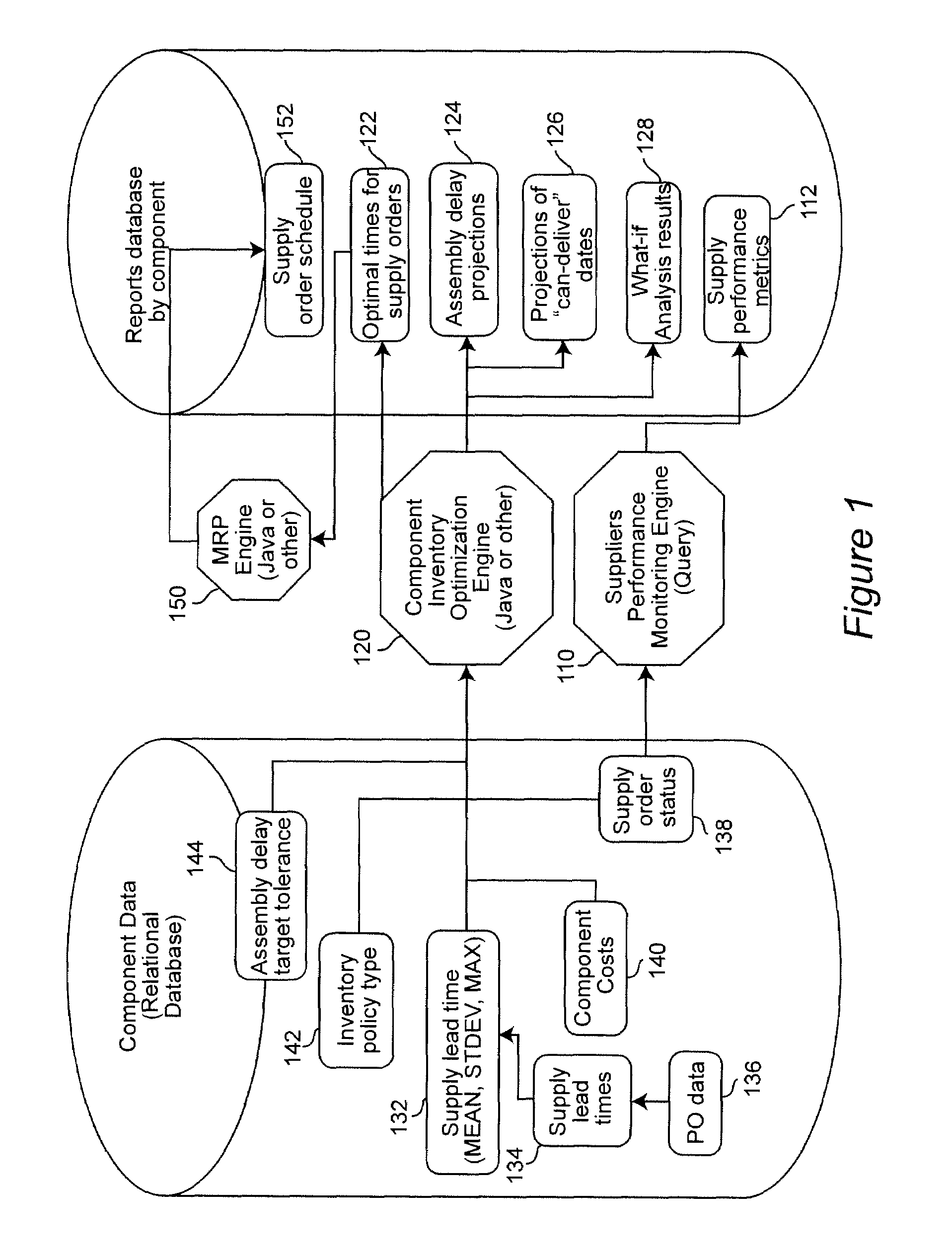

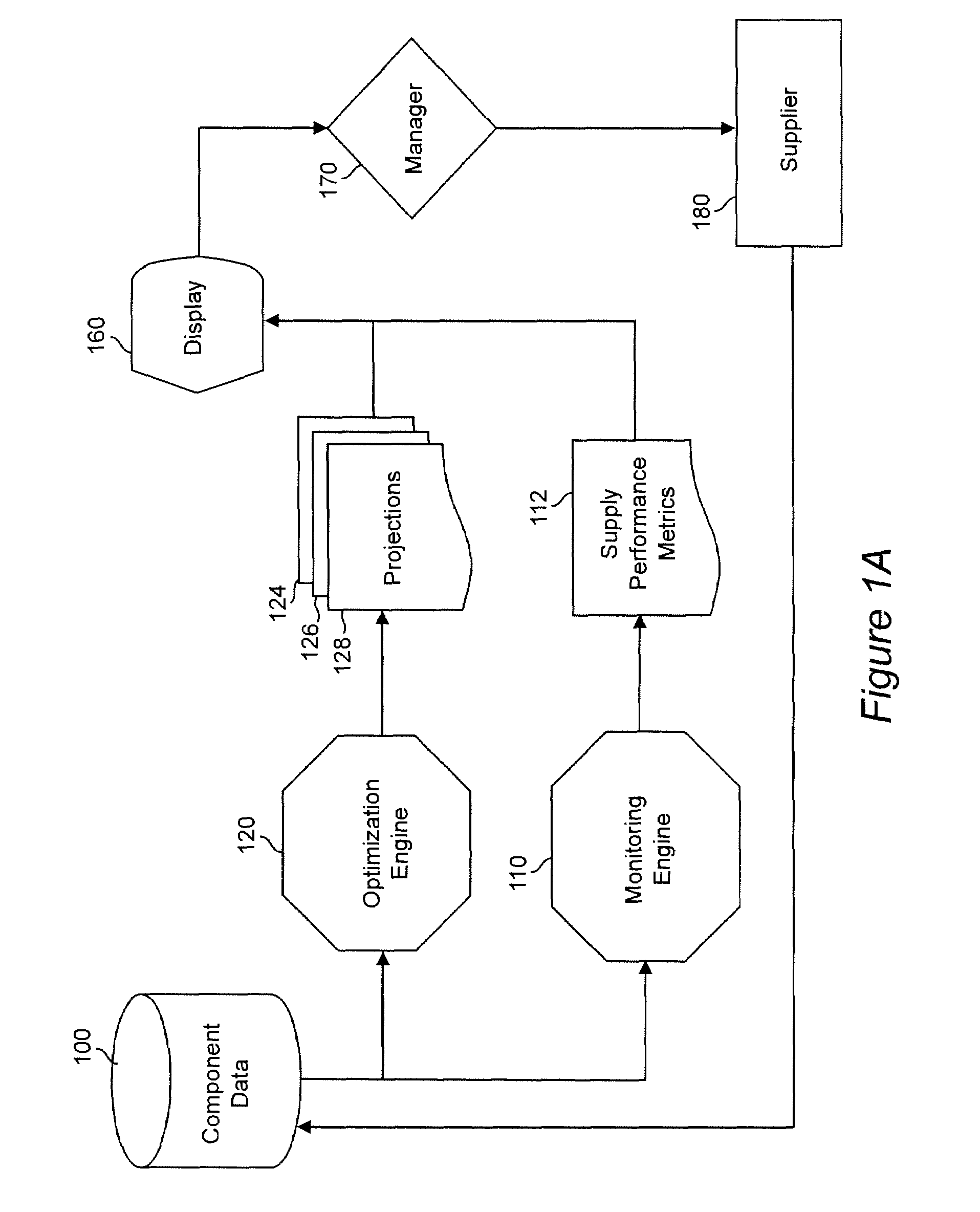

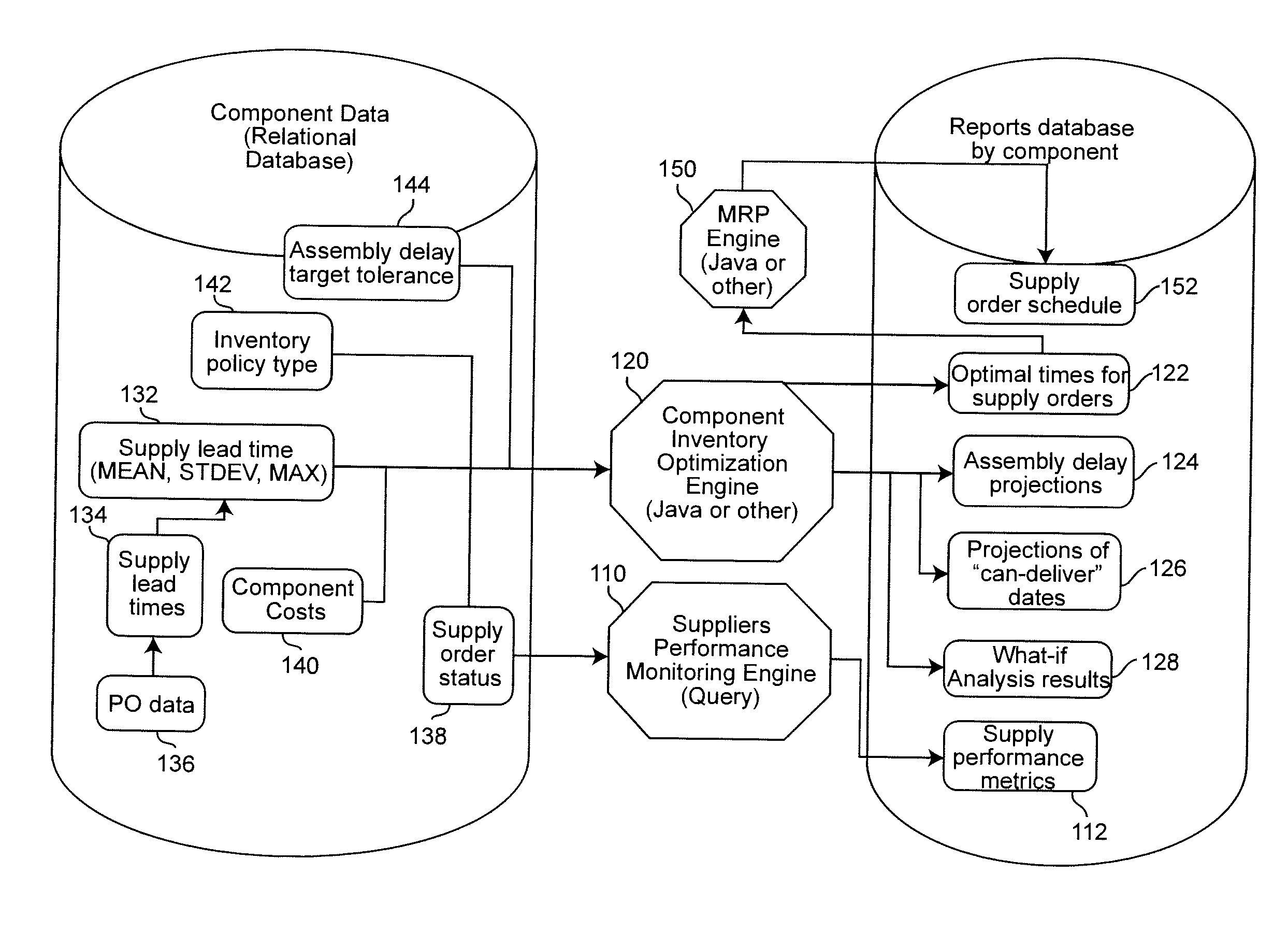

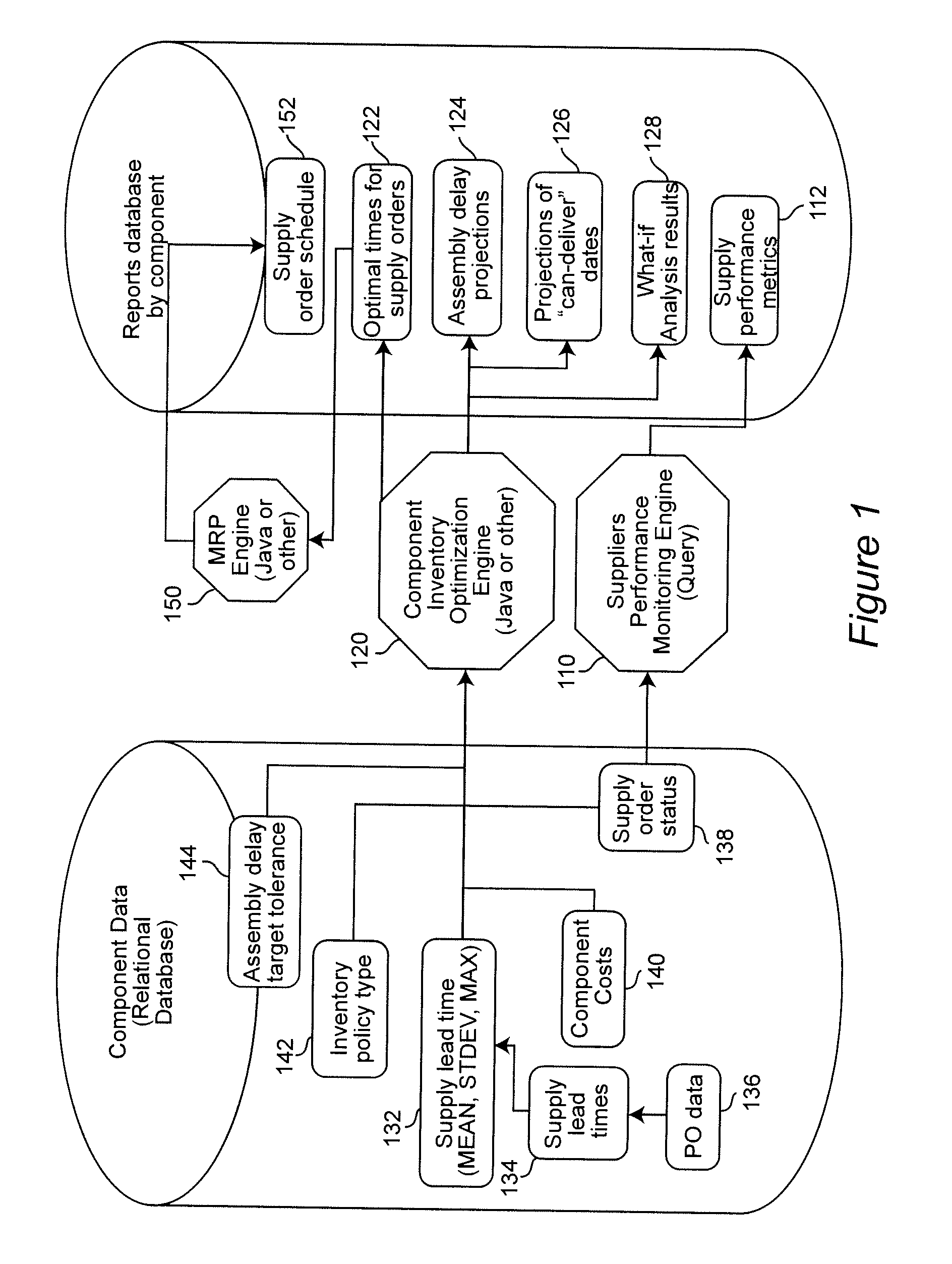

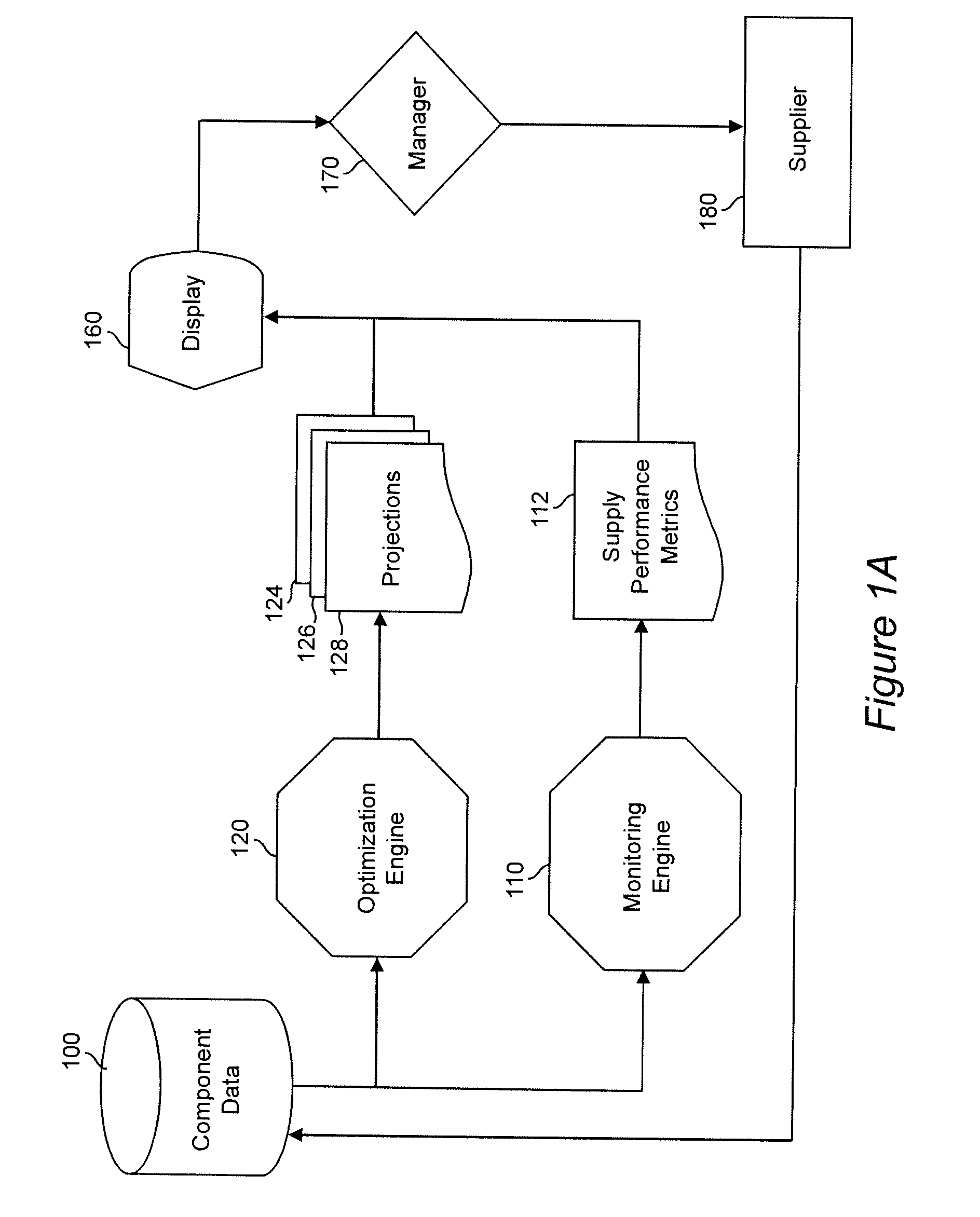

System and process for supply management for the assembly of expensive products

ActiveUS7418307B2Guaranteed uptimeHigh level confidenceResourcesSpecial data processing applicationsStock levelTime schedule

A Managing component supply for complex products is achieved by monitoring the delivery performance of component suppliers and optimizing the times at which orders are placed. Supply delivery performance targets are set for each supplier, and component order times are optimized by 1) optimizing safety stock for each component, 2) calculating optimal times to place supply orders in order to maintain the safety stock level, and then 3) iterating safety stock calculations in order to minimize overall inventory costs and maximize supply availability. The process takes into account supply lead times, component costs, and target tolerances for delays in the assembly of components. The effects of changes in supply lead time performance on assembly schedules are projected for planning purposes.

Owner:GLOBALFOUNDRIES US INC

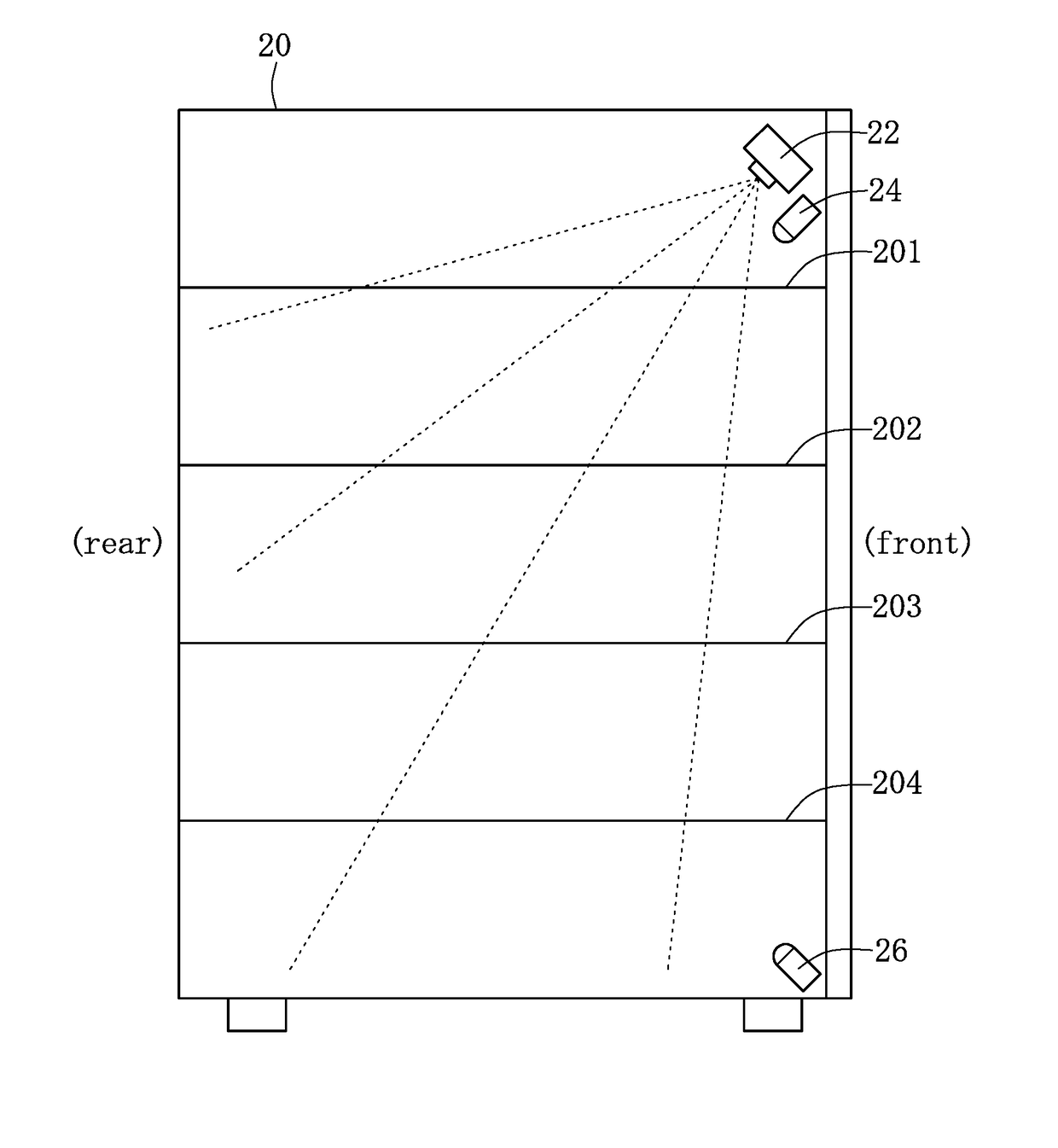

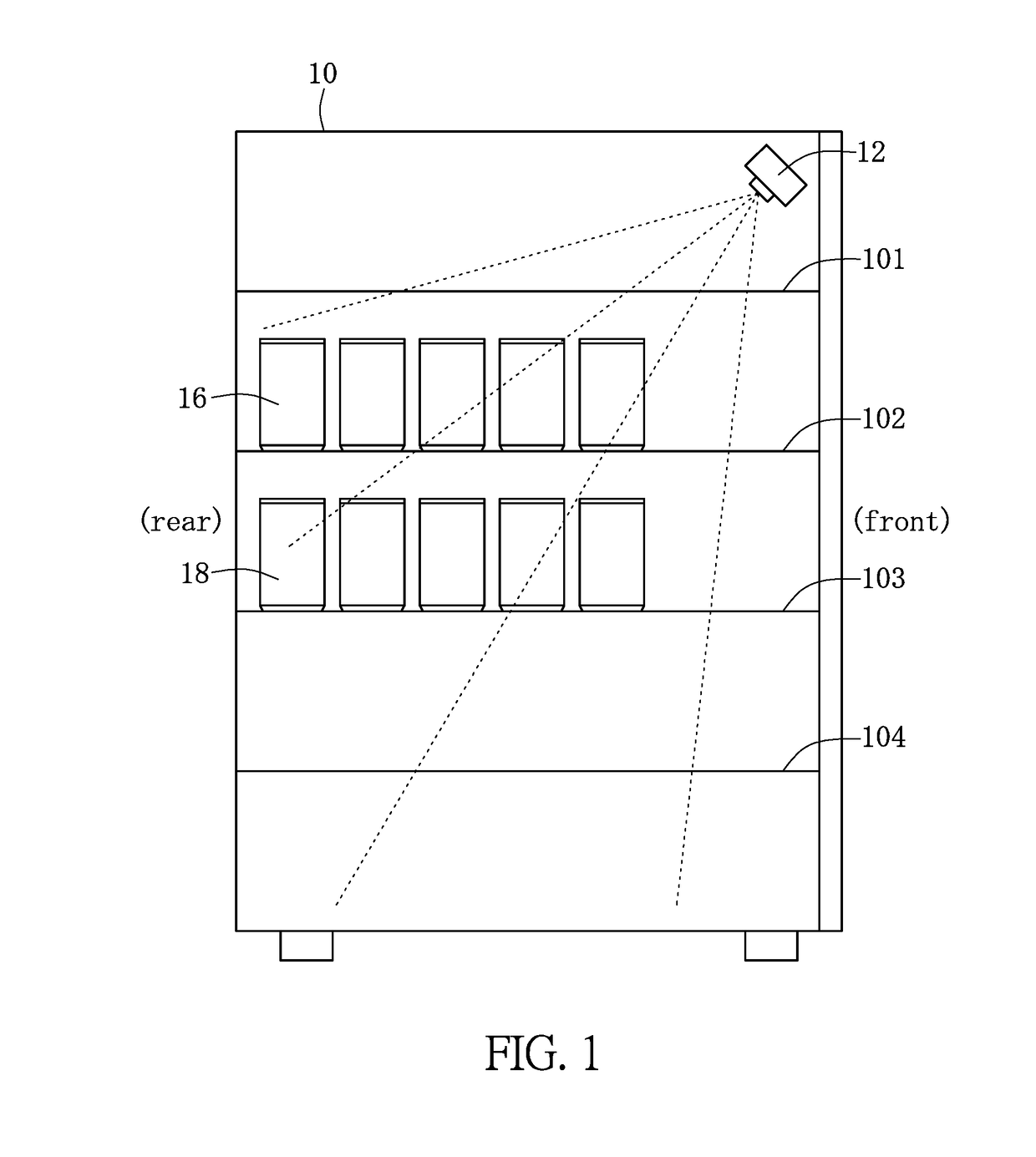

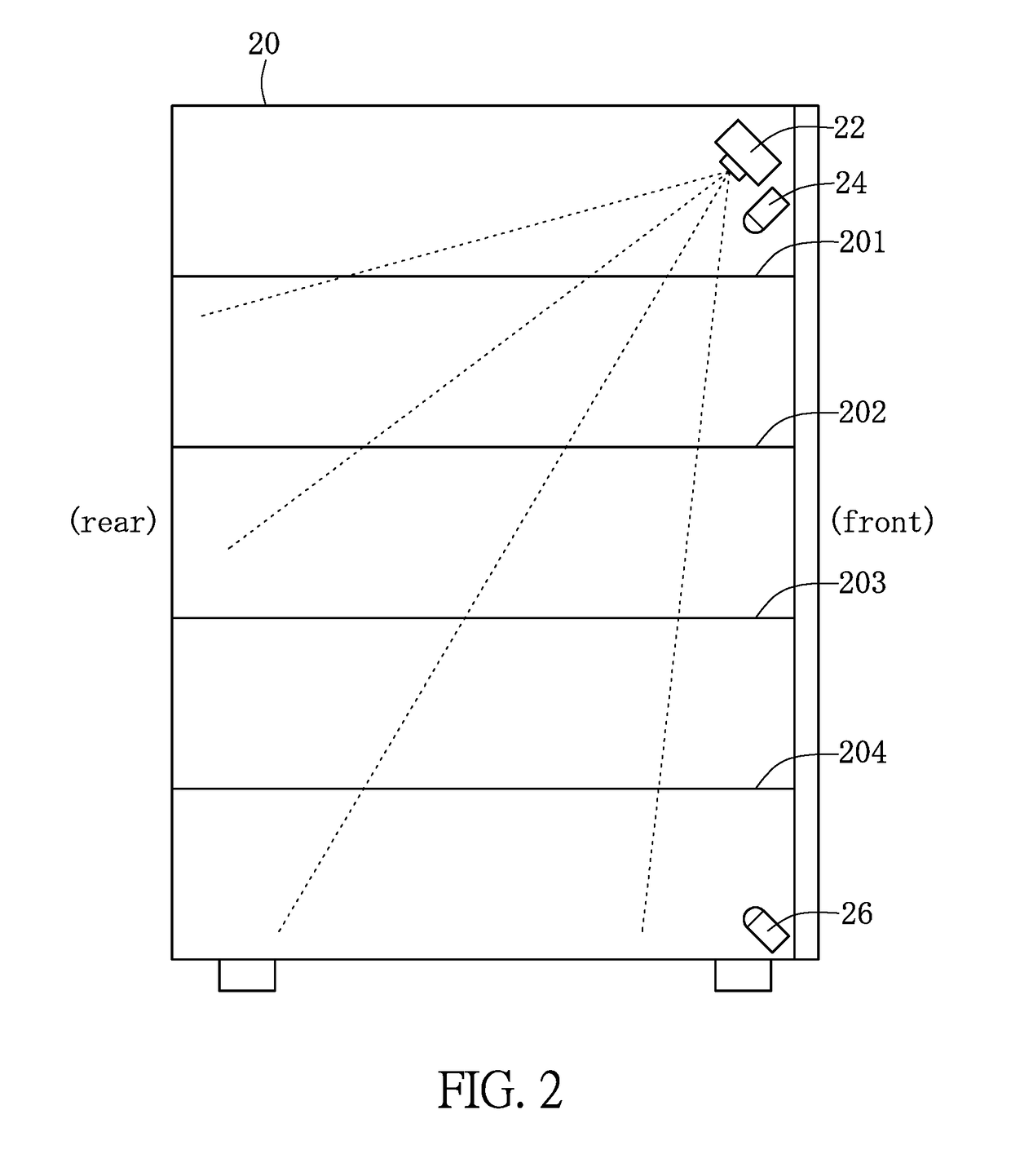

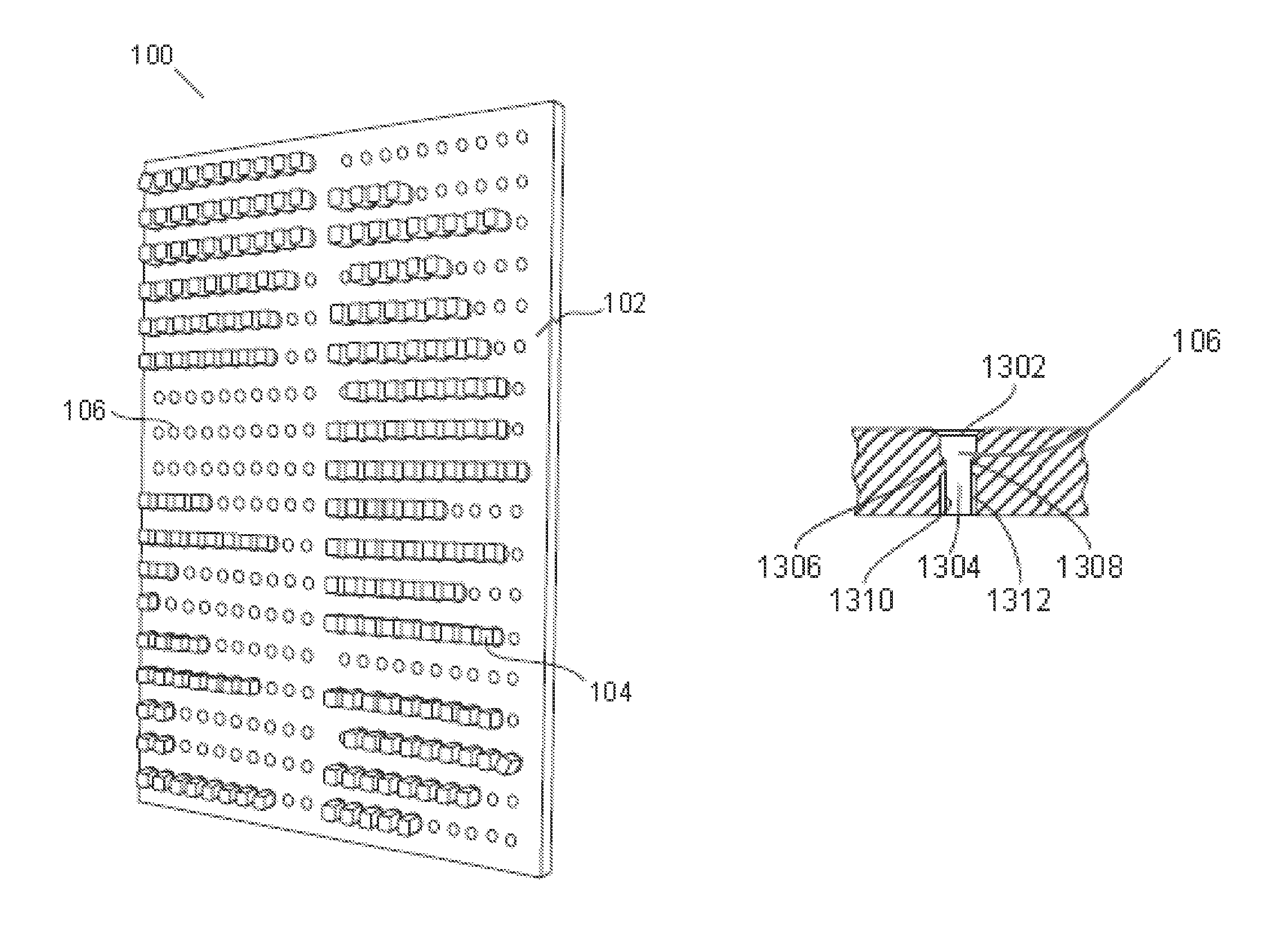

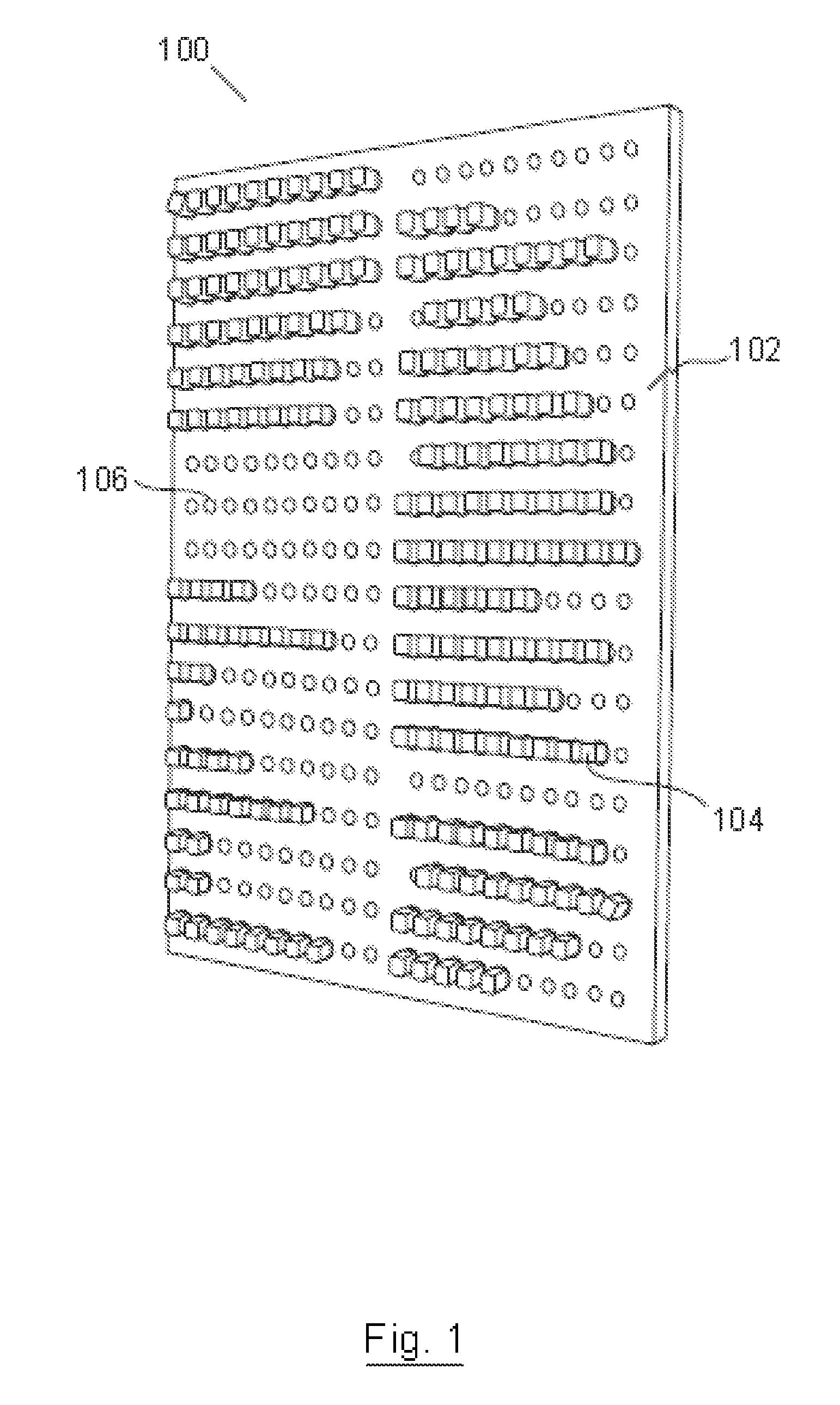

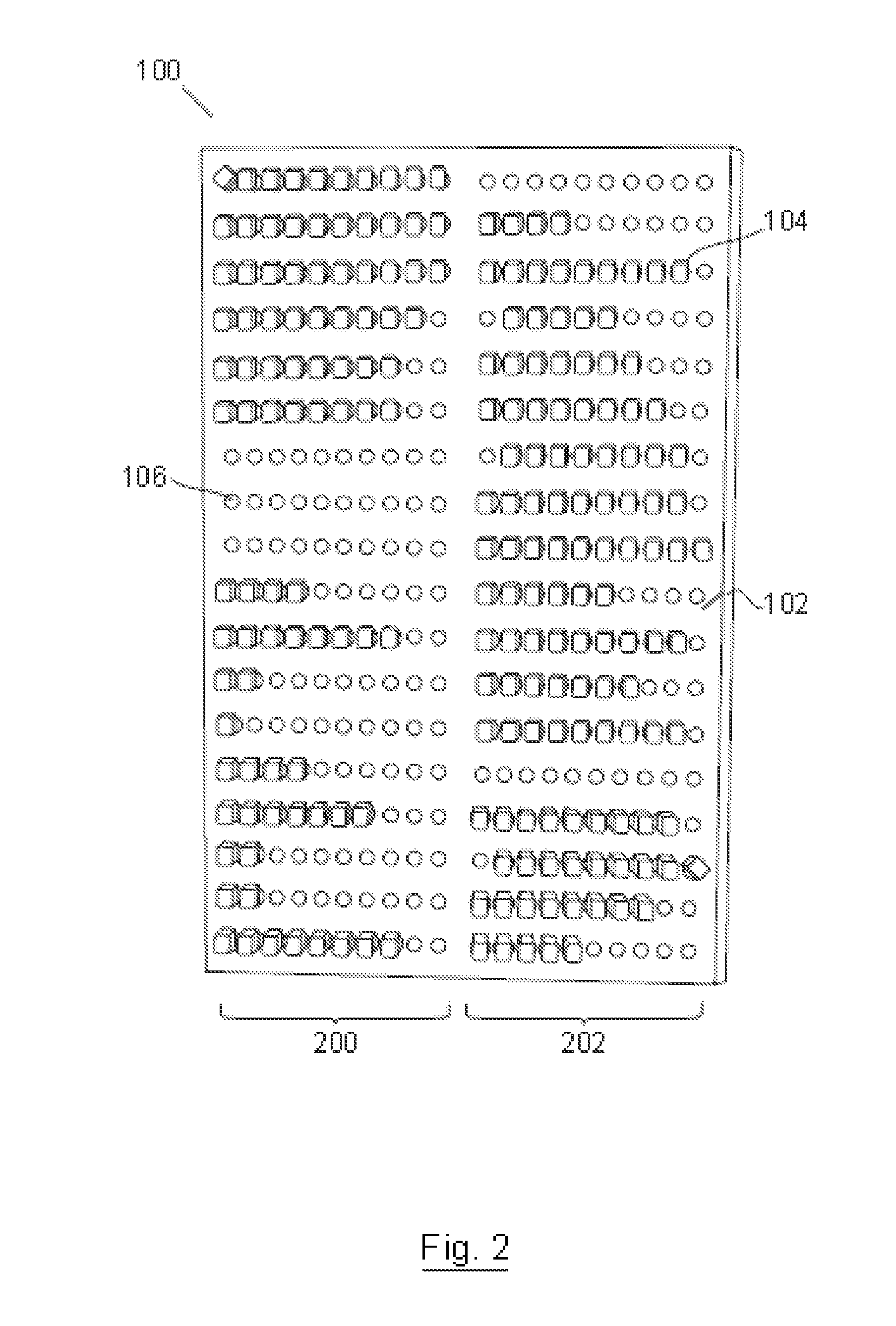

Method and system for estimating stock level of shelf

ActiveUS20180089613A1Efficiently and instantly obtainingImage enhancementImage analysisStock levelReference image

The disclosure is related to a method and a system for estimating a stock level of a shelf. An image processing technique is incorporated to conduct stock estimation that is used as a reference for replenishment decisions. In the method, a camera is used to capture a shelf image. The shelf image is divided into multiple sub-region images. Multiple binarized images with respect to the multiple sub-region images are obtained by applying a binarization method. A ratio of the binarization values with respect to the pixels within every sub-region is calculated. The method also includes comparing the ratio of the binarization values in at least two sub-regions with a reference ratio in the at least two sub-regions within a shelf reference image. The comparison is used to estimate the stock level, and also to determine whether the shelf is to be replenished.

Owner:WISTRON NEWEB

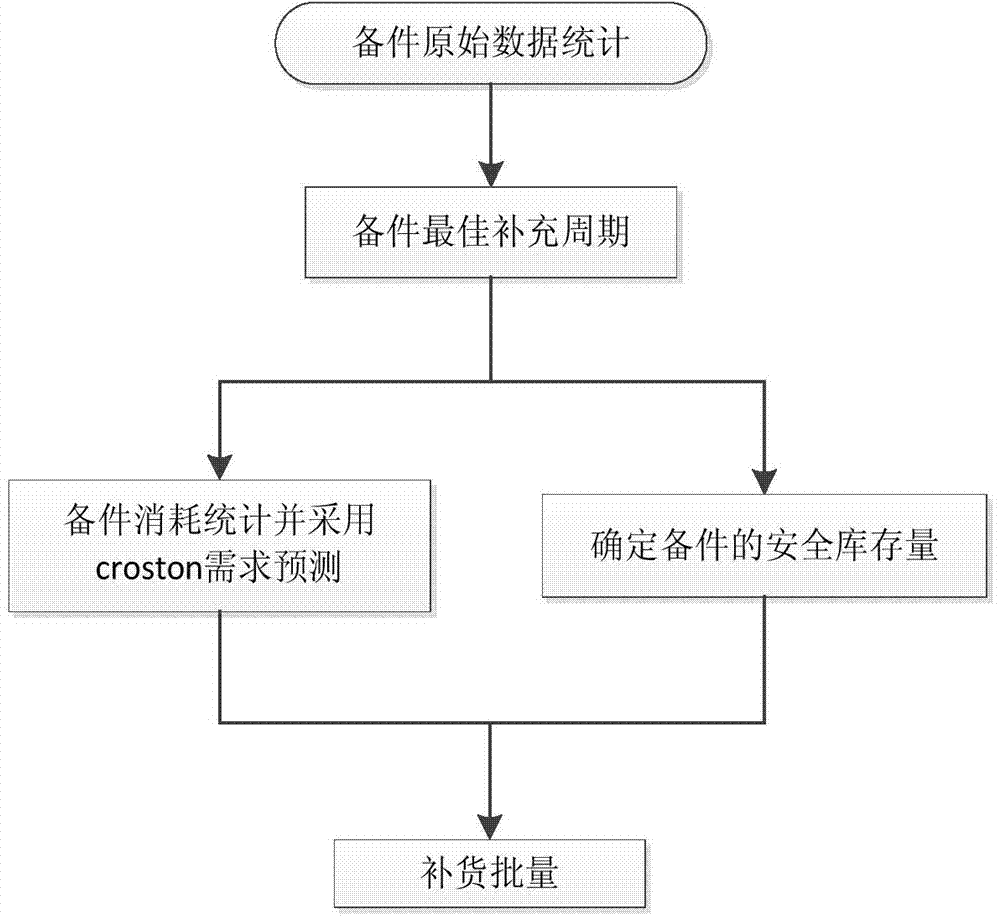

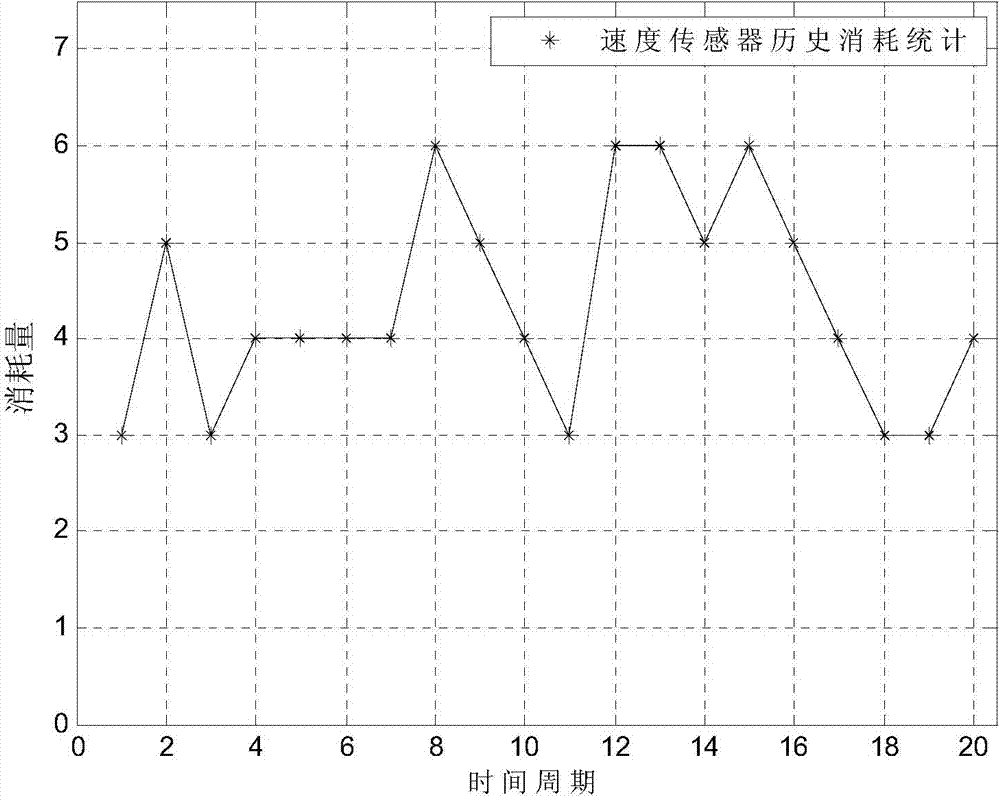

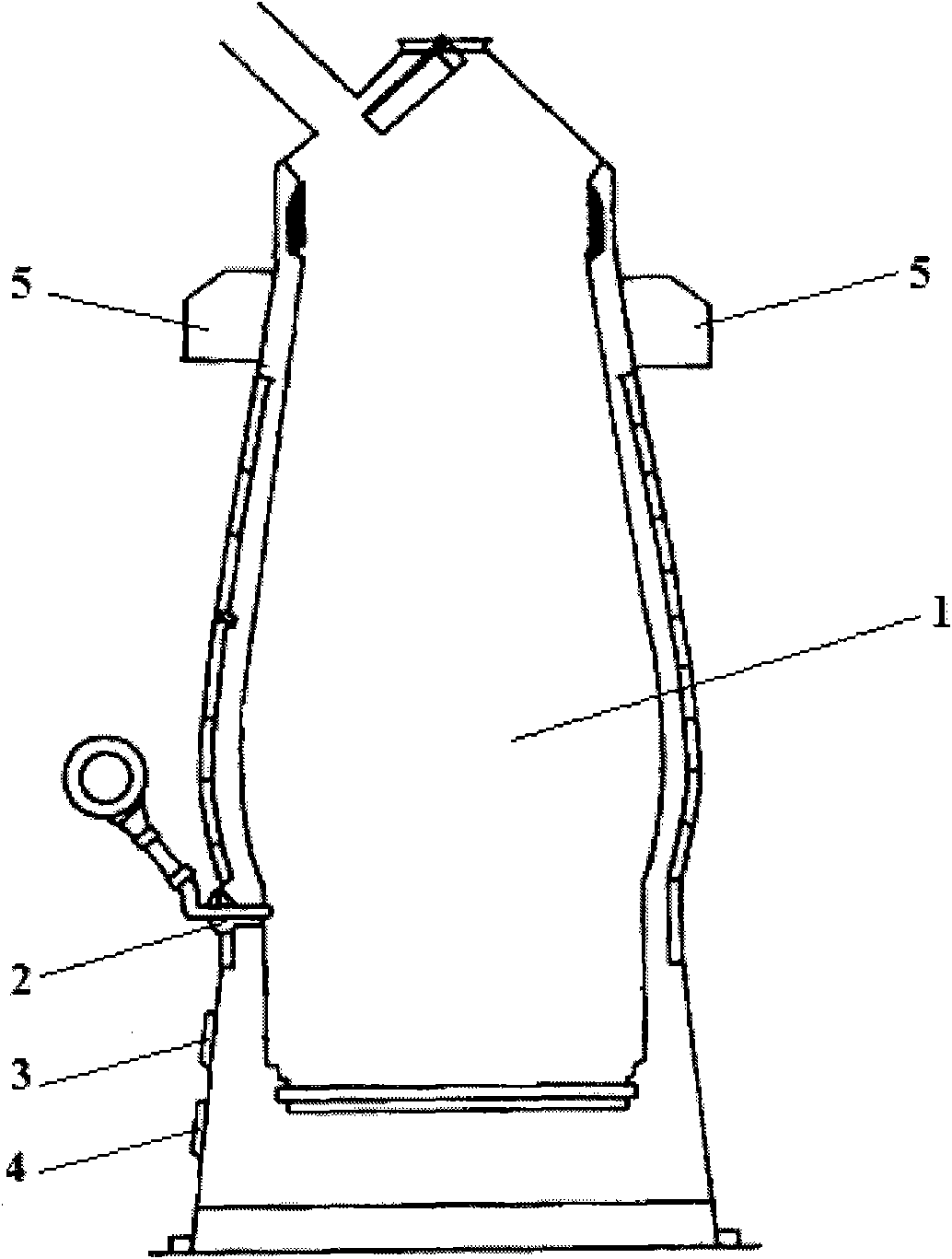

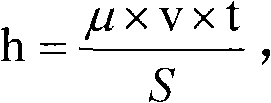

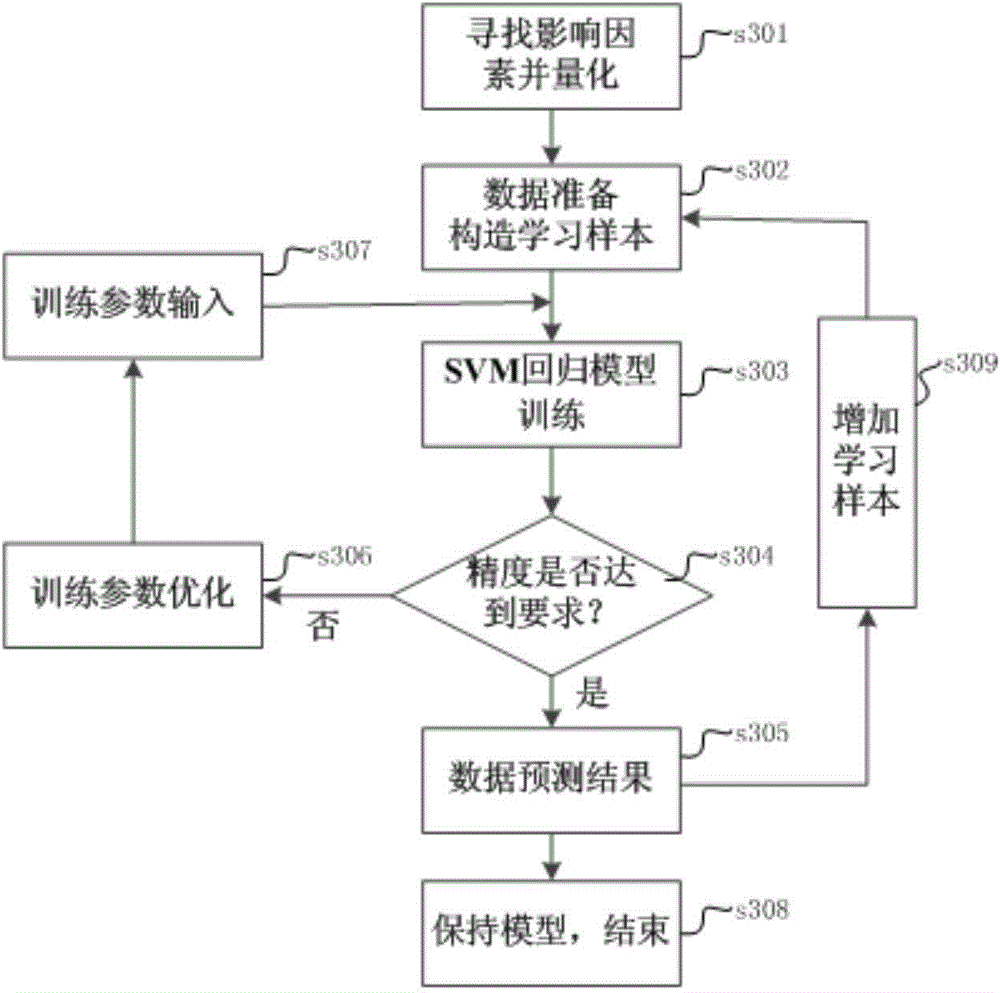

Stock control method based on optimum replenishment period of spare part

ActiveCN104732287AControl the average inventoryAchieve reasonable controlForecastingLogisticsStock levelEngineering

The invention provides a stock control method based on an optimum replenishment period of a spare part, and aims at lowering the cost of spare part stock of a company. By means of the influence of a replenishment period of the spare part on the stock level, a complete stock control module based on the optimum replenishment period of the spare part is provided, and the stock of the spare part of the company is optimized. By means of the history requirement characteristic of the spare part and costs such as spare part purchasing and storing, a spare part optimum replenishment time and the safety stock of the spare part storing of the spare part in one replenishment period are judged, and the replenishment sending time and the replenishment batch of the spare part are judged by combining the requirement predicted value of the spare part.

Owner:GUANGZHOU METRO GRP CO LTD

System and process for supply management for the assembly of expensive products

ActiveUS20070270990A1Guaranteed uptimeHigh level confidenceResourcesSpecial data processing applicationsStock levelDelivery Performance

A method and system are described for managing component supply for complex products by monitoring the delivery performance of component suppliers and optimizing the times at which orders are placed. Performance of component suppliers is monitored by setting supply delivery performance targets for each supplier, and then monitoring and managing supply delivery performance for each supplier. Component order times are optimized by 1) optimizing safety stock for each component, 2) calculating optimal times to place supply orders for each component in order to maintain the safety stock level, and then 3) iterating safety stock calculations in order to minimize overall inventory costs and maximize supply availability, taking into account supply lead times, component costs, and target tolerances for delays in the assembly of components. The method also provides projections of effects of changes in supply lead time performance on assembly schedules so that managers can seek delivery improvements from component suppliers.

Owner:GLOBALFOUNDRIES US INC

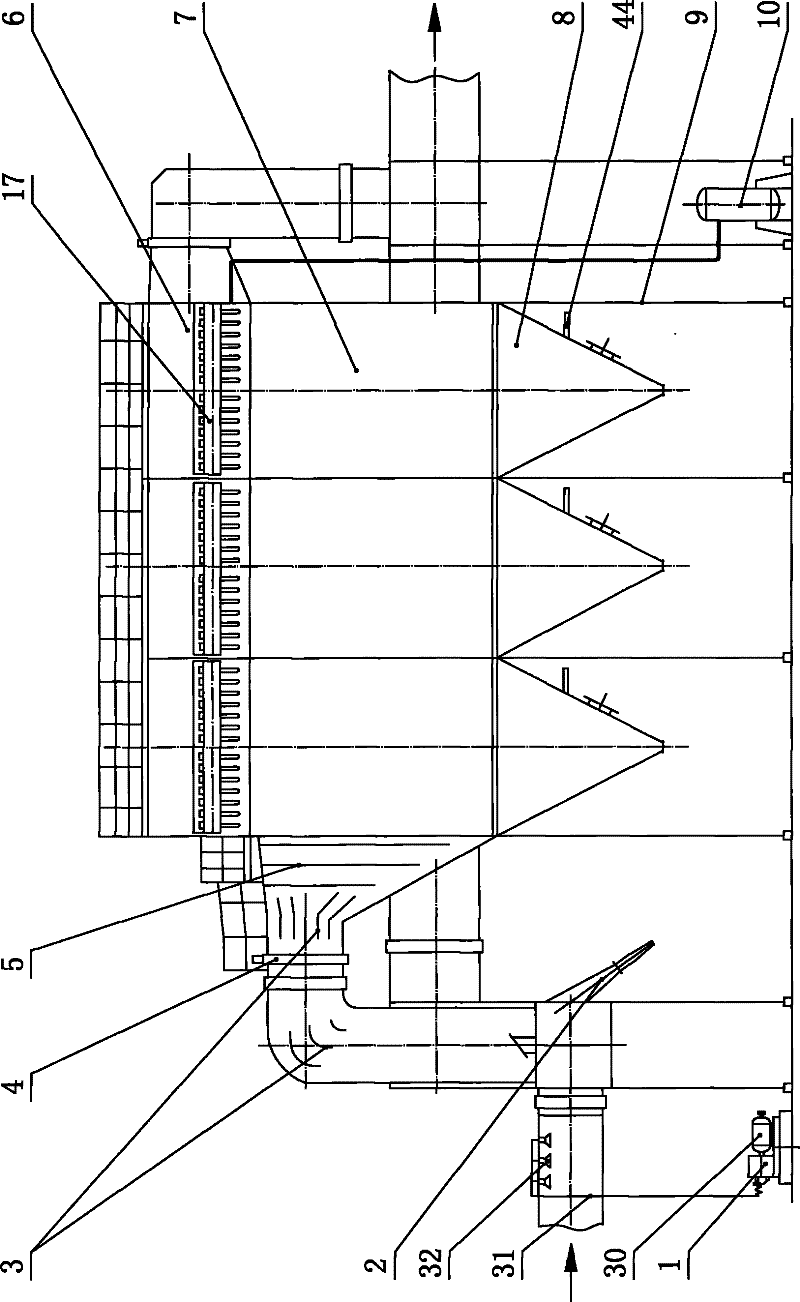

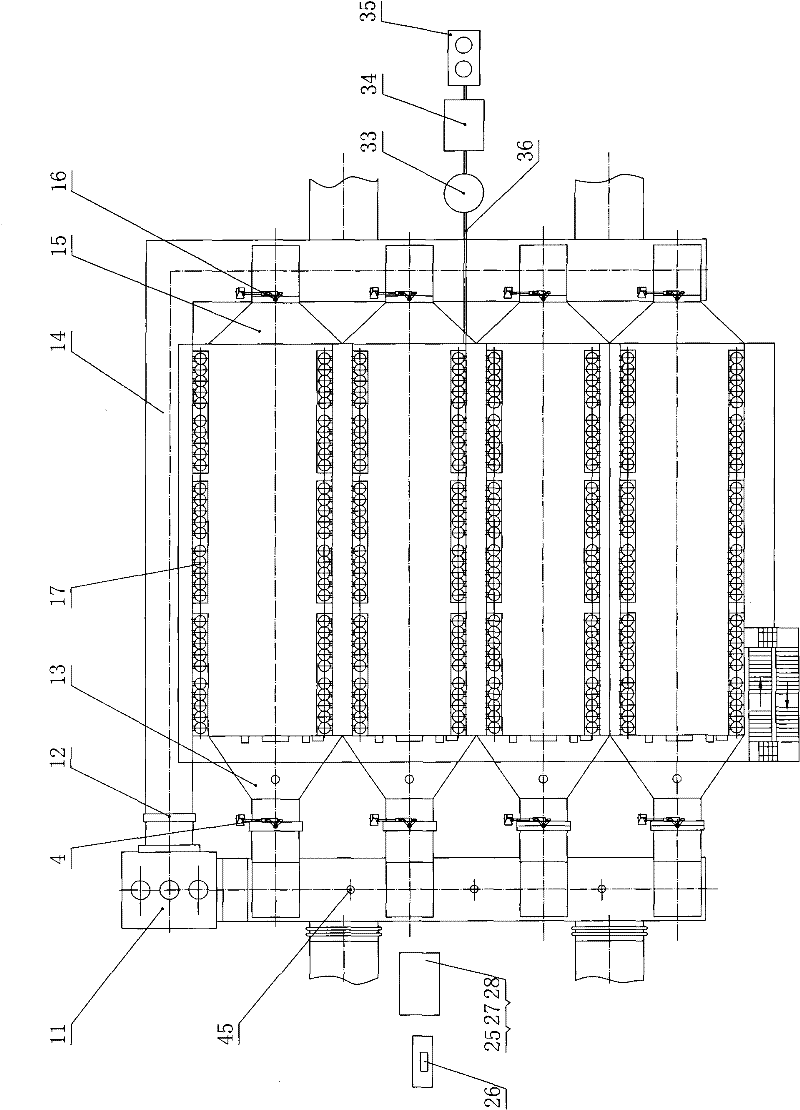

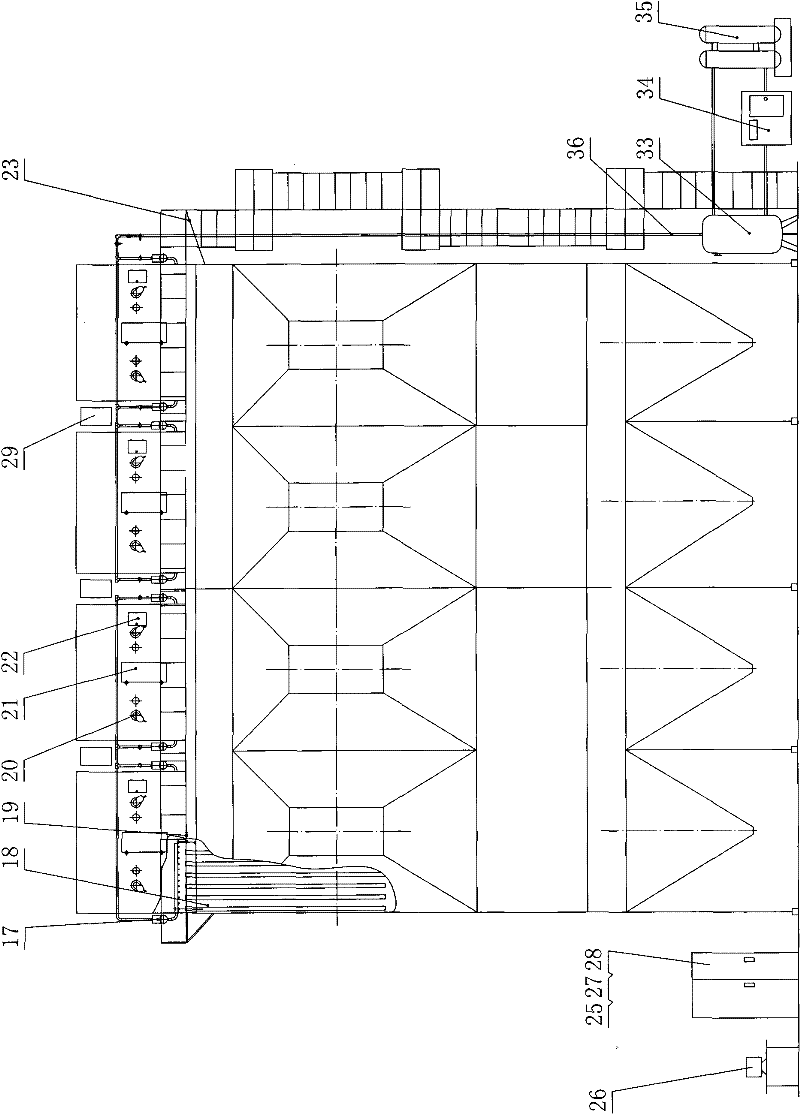

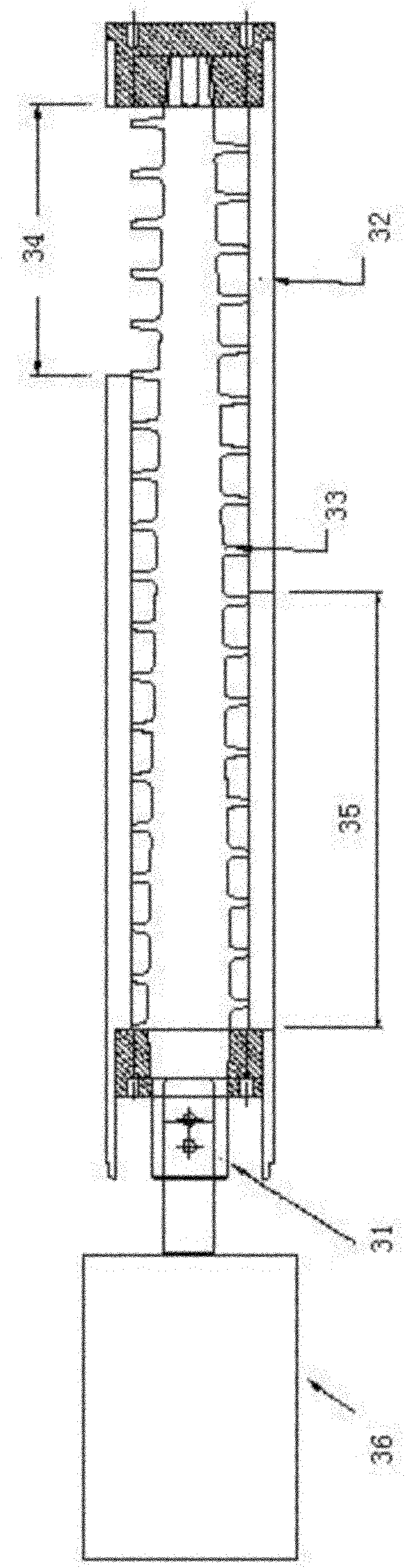

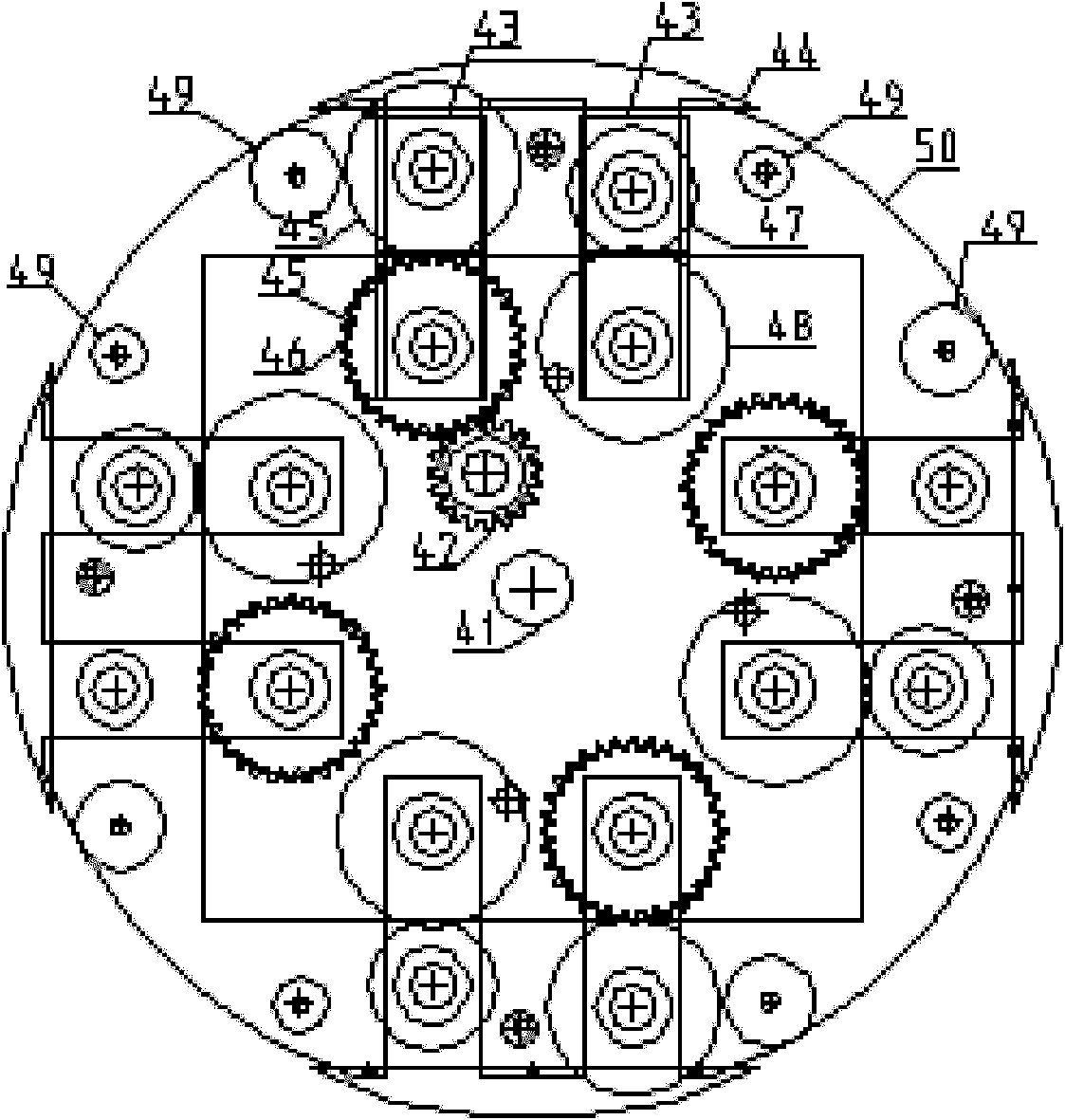

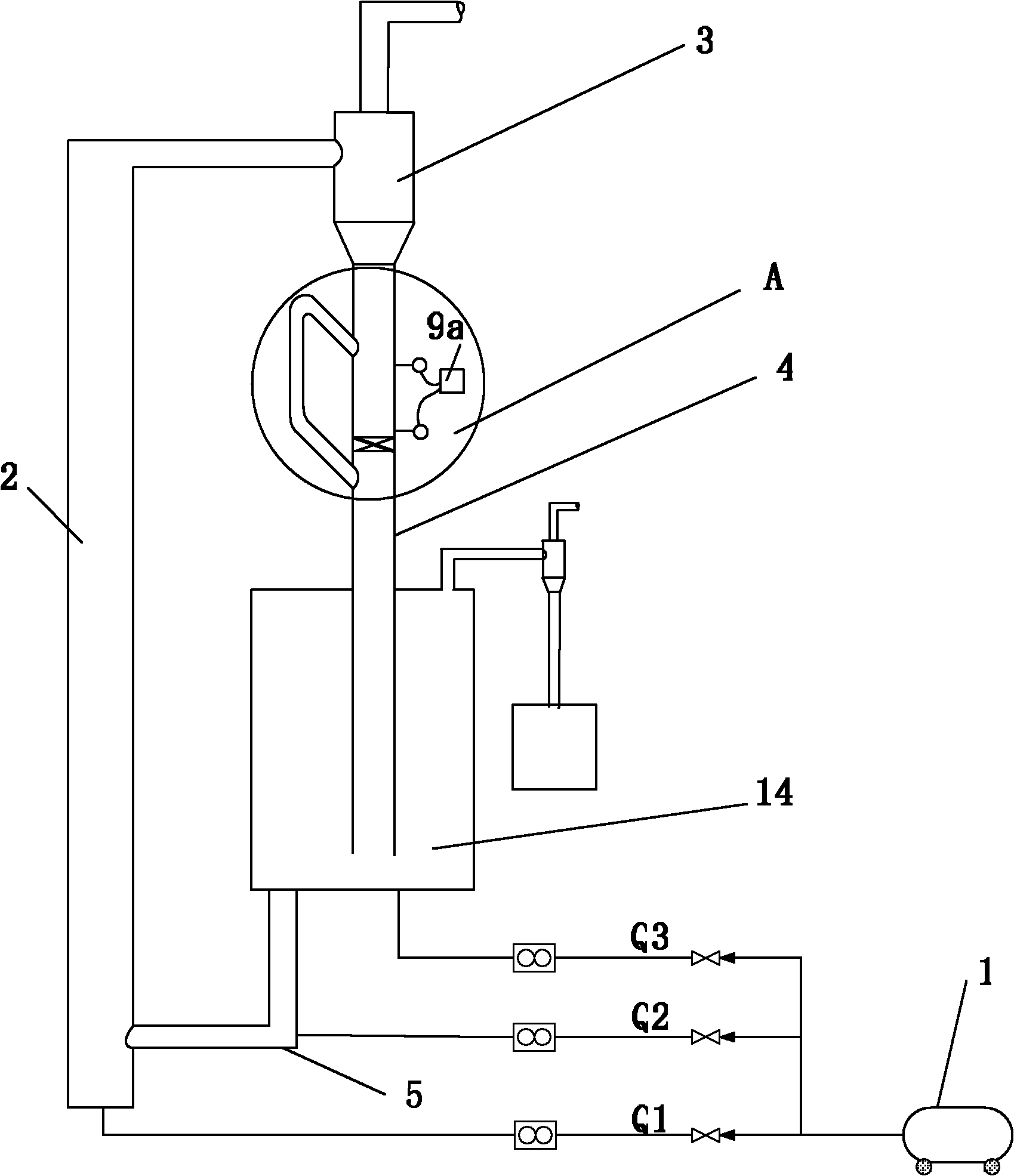

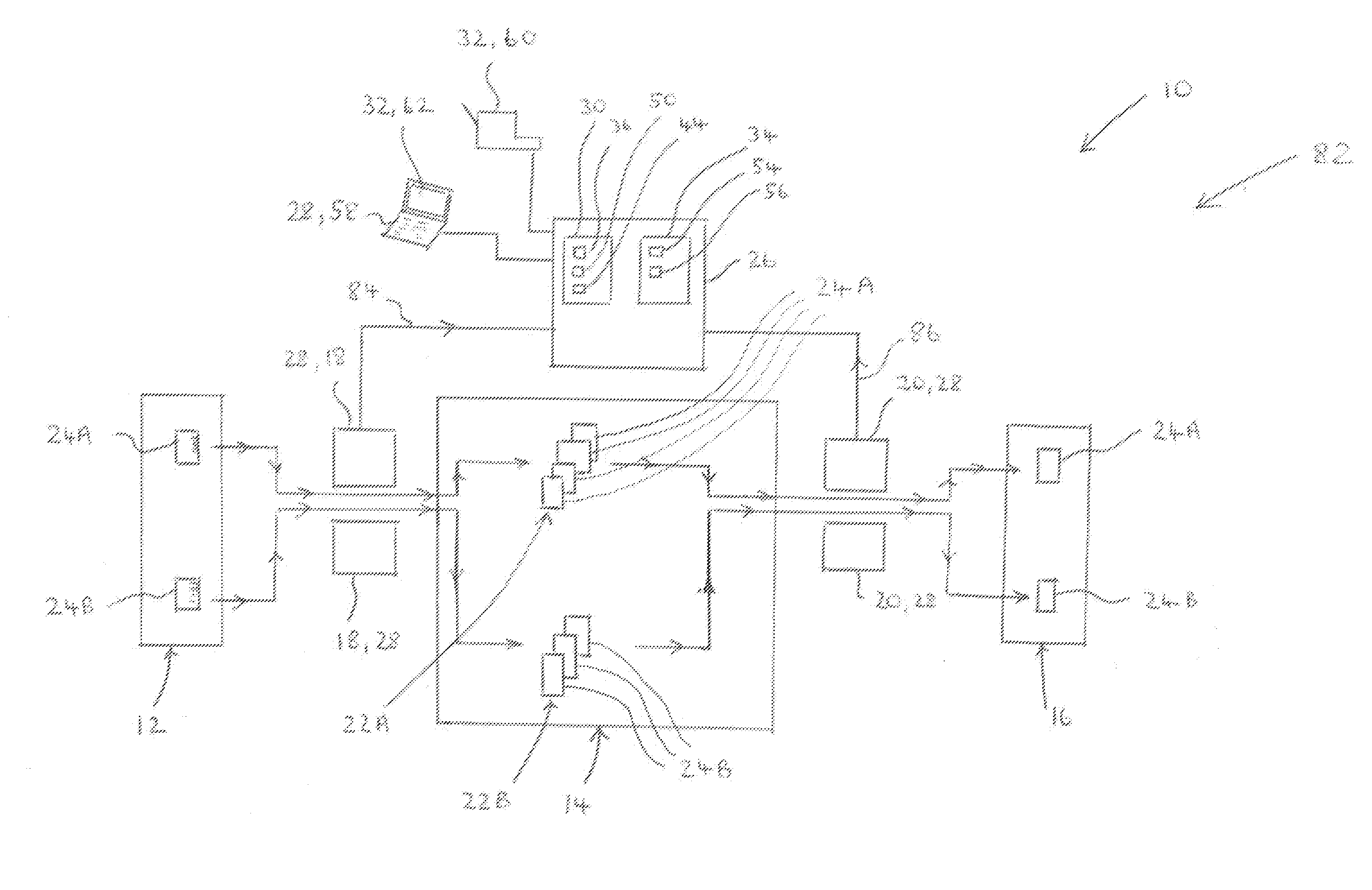

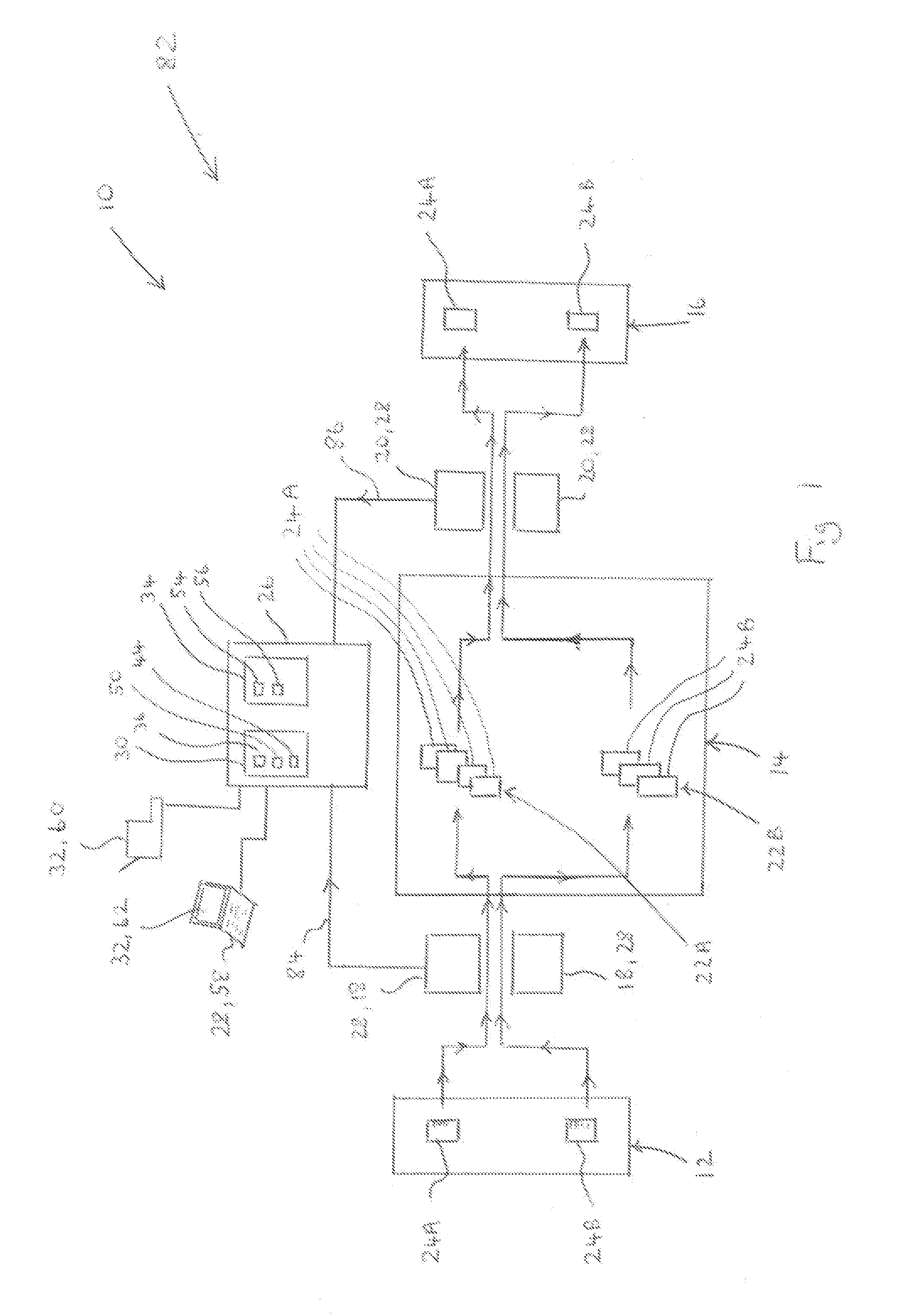

Runoff long-bag low-pressure pulse bag type dust collector

InactiveCN102125787AEasy to controlSolve the problem of poor sealingHuman health protectionDispersed particle filtrationDifferential pressureEngineering

The invention relates to a runoff long-bag low-pressure pulse bag type dust collector. At present, a blowing pulse dust collector has the defect that a filter bag has the troublesome process of check and replacement and is easy to interfere by weather factors, the defect that the service life of the filter bag is shortened due to the extraordinary strong scour of high-pressure airflow on the filter bag, the defect that a chimney flue is not closed completely due to expansion caused by heat and contraction caused by cold in equipment, and other defects. The bag type dust collector comprises a group of single bag type dust collectors and a controller thereof, wherein the controller comprises a personal computer (PC) cabinet (25); the PC cabinet is respectively connected with an industrial control computer (26), a programmed logic controller (27), a motor control center (28), a field control case (29), a temperature sensor (44) arranged on an inlet chimney flue of each single bag type dust collector, a stock-level sensor (45) arranged on a dust collecting hopper of each single bag type dust collector and a differential pressure sensor (22) arranged on an air-purifying chamber shell and a dust air chamber shell; and the single bag type dust collectors are arranged in a parallel connection structure. The runoff long-bag low-pressure pulse bag type dust collector is used for managing smoke dust in coal-fired boilers.

Owner:哈尔滨云水工大环保科技股份有限公司

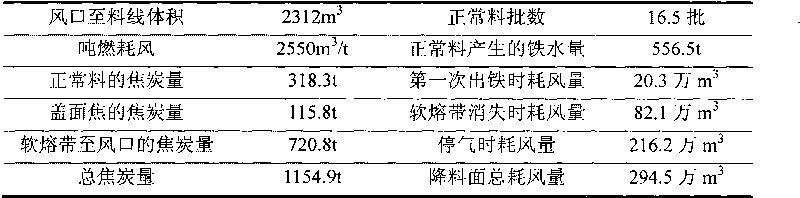

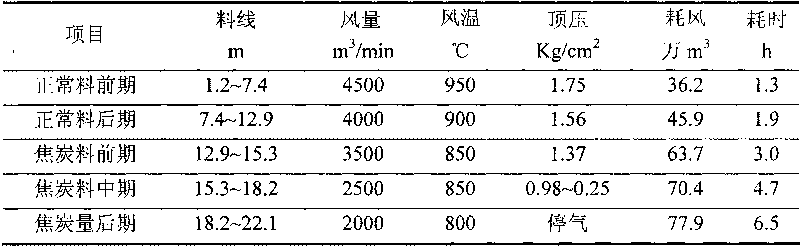

Method for quantitative stock level-lowering and blowing out of blast furnace

InactiveCN101696458AEliminate security threatsAvoid threatsBlast furnace detailsStock levelBlast furnace

The invention discloses a method for quantitative stock level-lowering and blowing out of a blast furnace and belongs to the technical field of blast furnace iron making. The process of blowing out comprises a normal material stage and a coke stage; the normal material stage further comprises an early period and a later period during which normal materials are in the furnace; the coke stage further comprises an early period during which there is only coke in the furnace and the stock level is at the lower part of the furnace stack, a middle period during which there is only coke in the furnace and the stock level is at the furnace belly, a later period during which there is only coke in the furnace and the stock level is at the upper part of the furnace bosh or the furnace crucible, so that key tasks and quantitative principles at stages of the process of stock level-lowering and blowing out can be made clear. The method is to focus on initiative control over air quantities at different stock level-lowering stages and also give consideration to specific conditions for the stock level-lowering and blowing out of the blast furnace so as to quantify the stock level-lowering and blowing-out technology and detail all the parameters in the stock level-lowering and blowing out processes. Practice proves that the actual parameters in the stock level-lowering and blowing out processes are as planed and the stock level-lowering process is safe, efficient and environmentally-friendly.

Owner:SHOUGANG CORPORATION

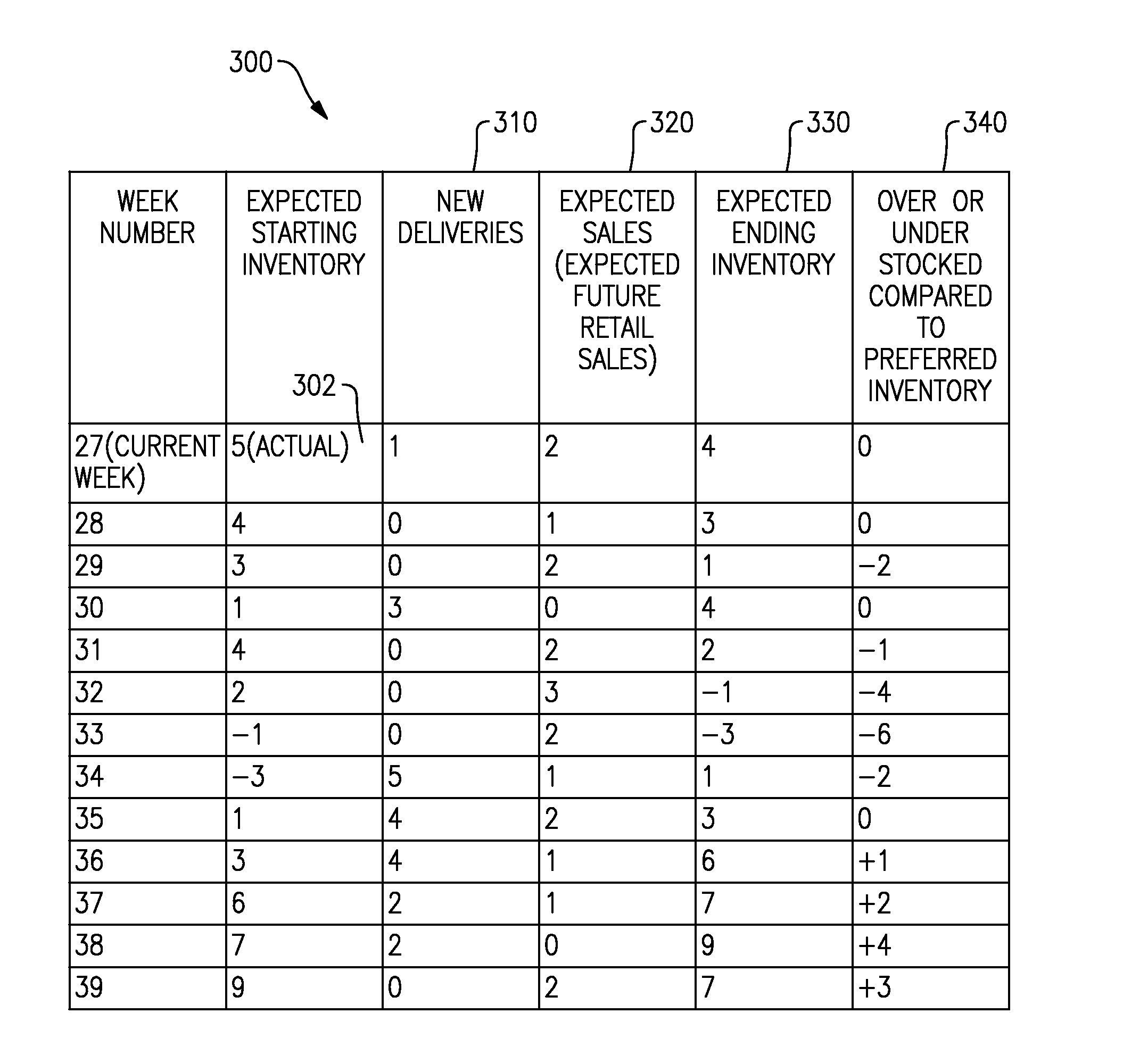

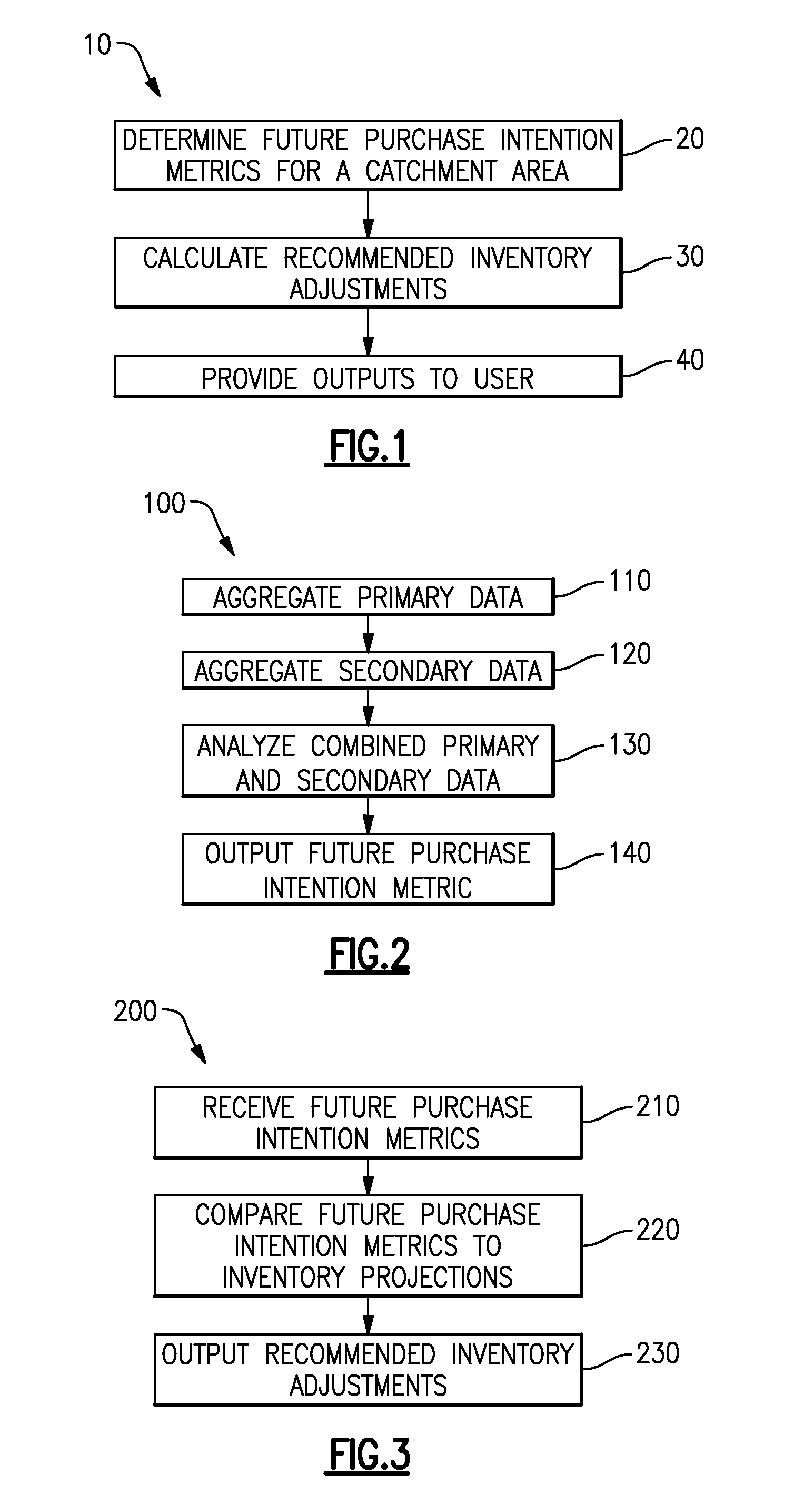

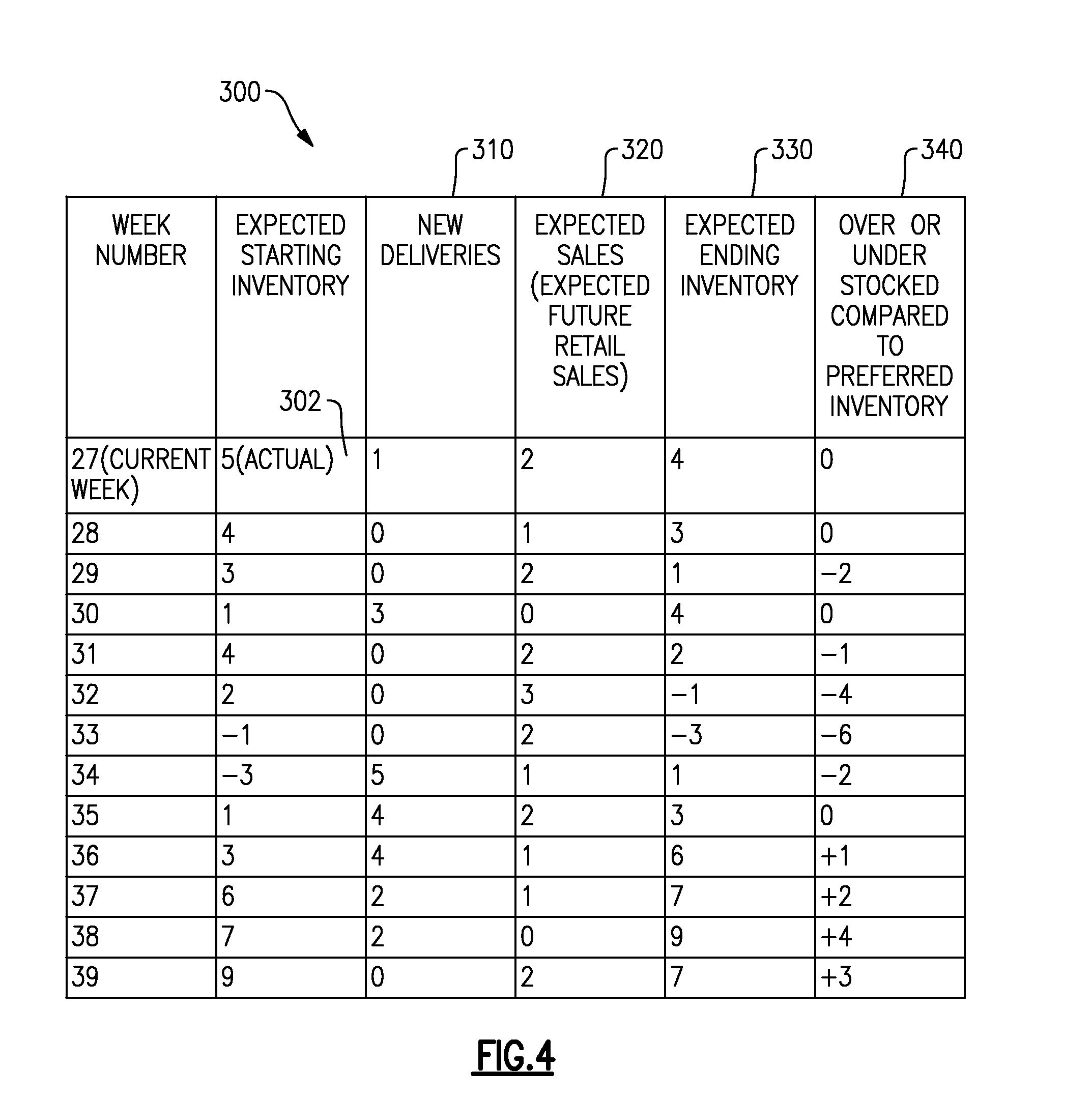

Method for optimizing new vehicle inventory for a car dealership

A computer implemented method for optimizing automobile dealer inventory includes determining at least one future purchase intention metric for a catchment area in which a dealer is located, determining expected future retail sales of a vehicle type based on the determined future purchase intention metric, comparing the expected future retail sales of the vehicle type to an expected inventory of the vehicle type for at least one time period, and outputting a recommended adjustment to at least one of a current inventory of the vehicle type and an on-order inventory of the vehicle type, thereby ensuring that a more desirable stock level is maintained for the at least one time period.

Owner:KNIGHT BARNABY ST JOHN +1

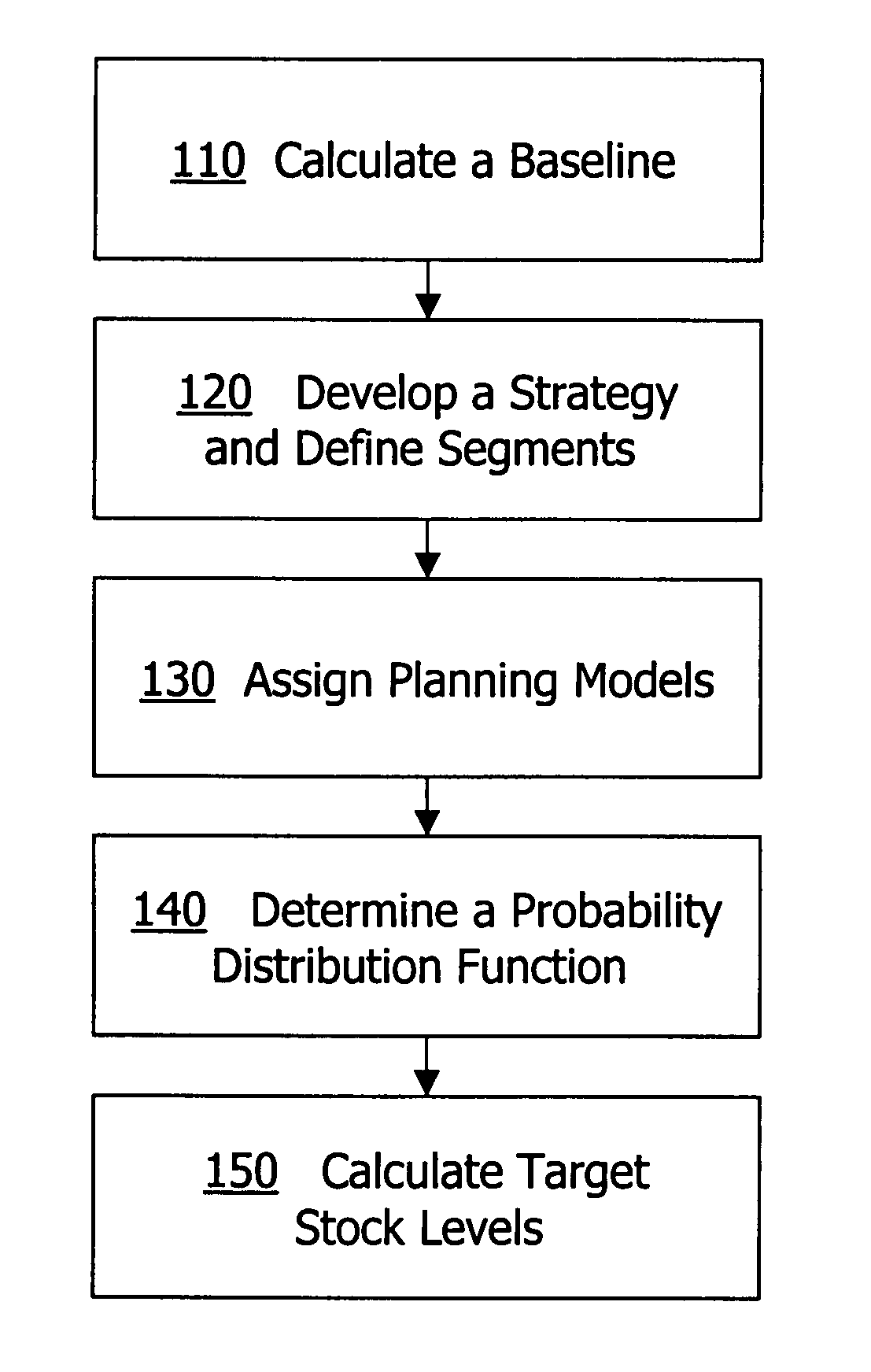

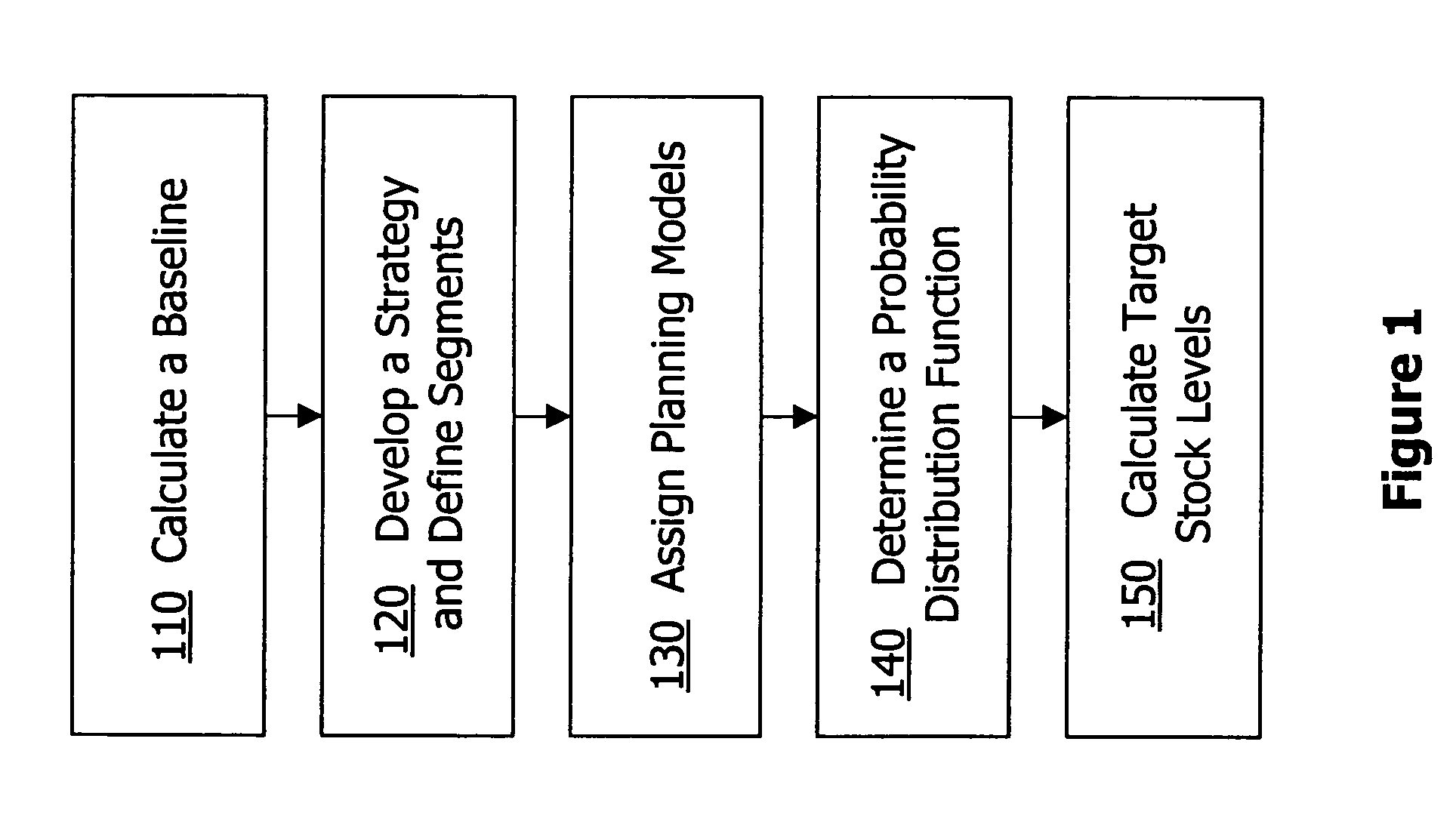

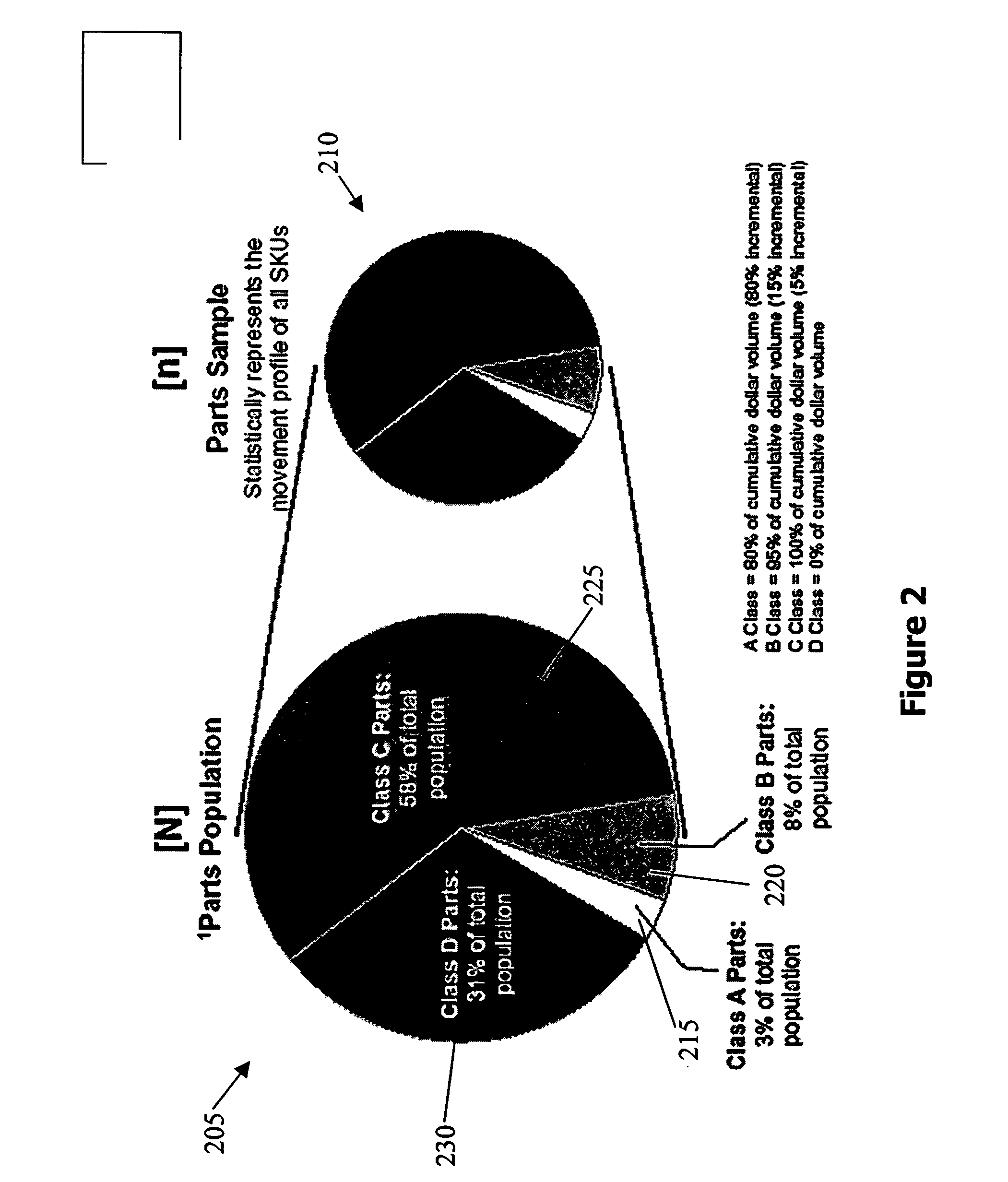

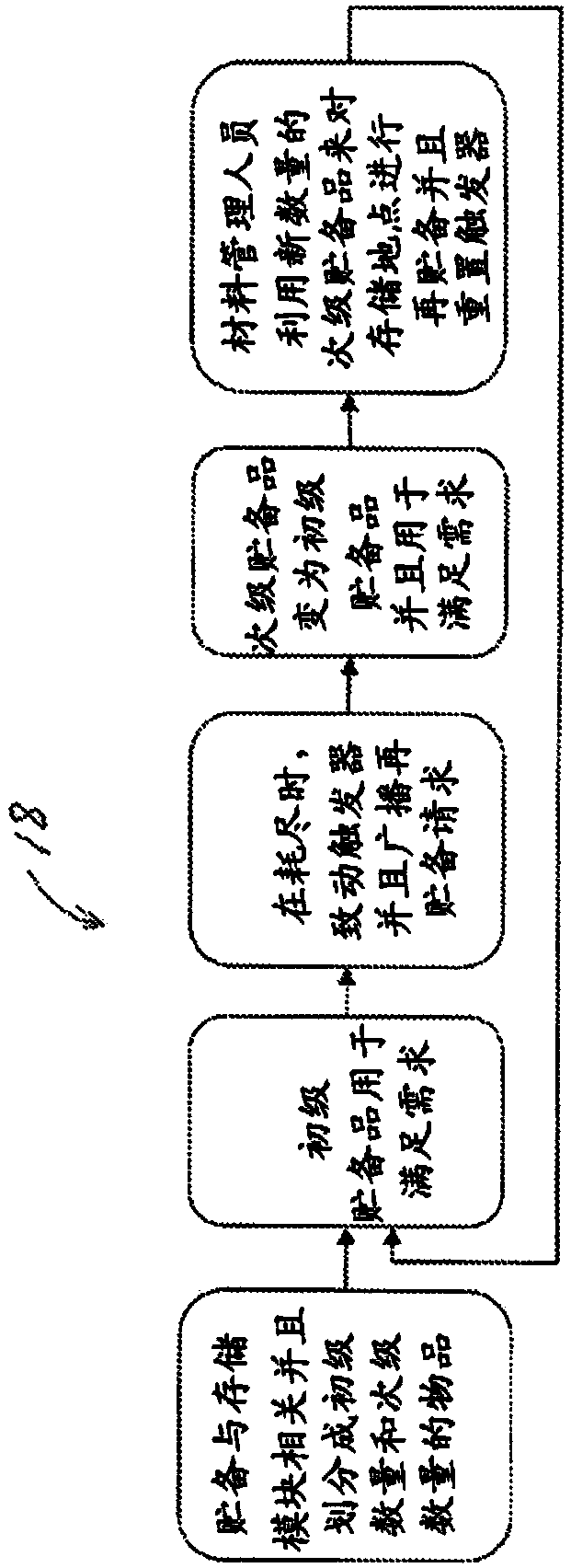

Managing an inventory of service parts

An inventory of service parts may be managed by assessing a company's capability, optimizing the inventory and implementing a management program based on the assessment and optimization. Optimizing target stock levels for the inventory of parts may be accomplished by calculating an inventory baseline for understanding information about the currently held inventory; developing a service strategy for a set of segments; quantifying a service level for each of the segments; analyzing the segments and their service levels for identifying at least one logistically distinct business; assigning each of the segments to a “best-fit” planning model for indicating each segment's deployment, replenishment, forecasting and review characteristics; identifying a probability distribution function for estimating a demand process of each of the segments; and calculating a target stock level for each segment.

Owner:ACCENTURE GLOBAL SERVICES LTD

Method for blowing out blast furnace

The invention relates to a method for blowing out a blast furnace. The method comprises the following steps of: continuously adding iron ore and a solid carbonaceous substance into a blast furnace before blown out so that the height from a stock level to the horizontal plane of an iron notch is 86-93 percent of total eight of the blast furnace; when the adding volume of mixed materials is 65-75 percent of the total volume in the blast furnace, stopping adding the mixed materials; then leading the height from the stock level to the horizontal plane of the iron notch to be 45-65 percent of the total eight of the blast furnace by an empty stock level, spraying water into the blast furnace and predamping down; then continuously spraying water into the blast furnace and blowing air the blast furnace so that the stock level is reduced; when at least one of the following three conditions is met, opening the iron notch for tapping and then opening a residual iron notch for discharging slag iron; (1) calculating that the stock level depth reaches the horizontal plane of an air opening by the air blowing amount; (2) generating a second peak value of CO2 content in a change curve of the CO2 content; and (3) turning the combustion flame of the air opening to be yellow green. By adopting the method for blowing out a blast furnace, the probability for reducing the stock level in the blast furnace below the horizontal plane of the air opening after blowing out is as high as more than 90 percent.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

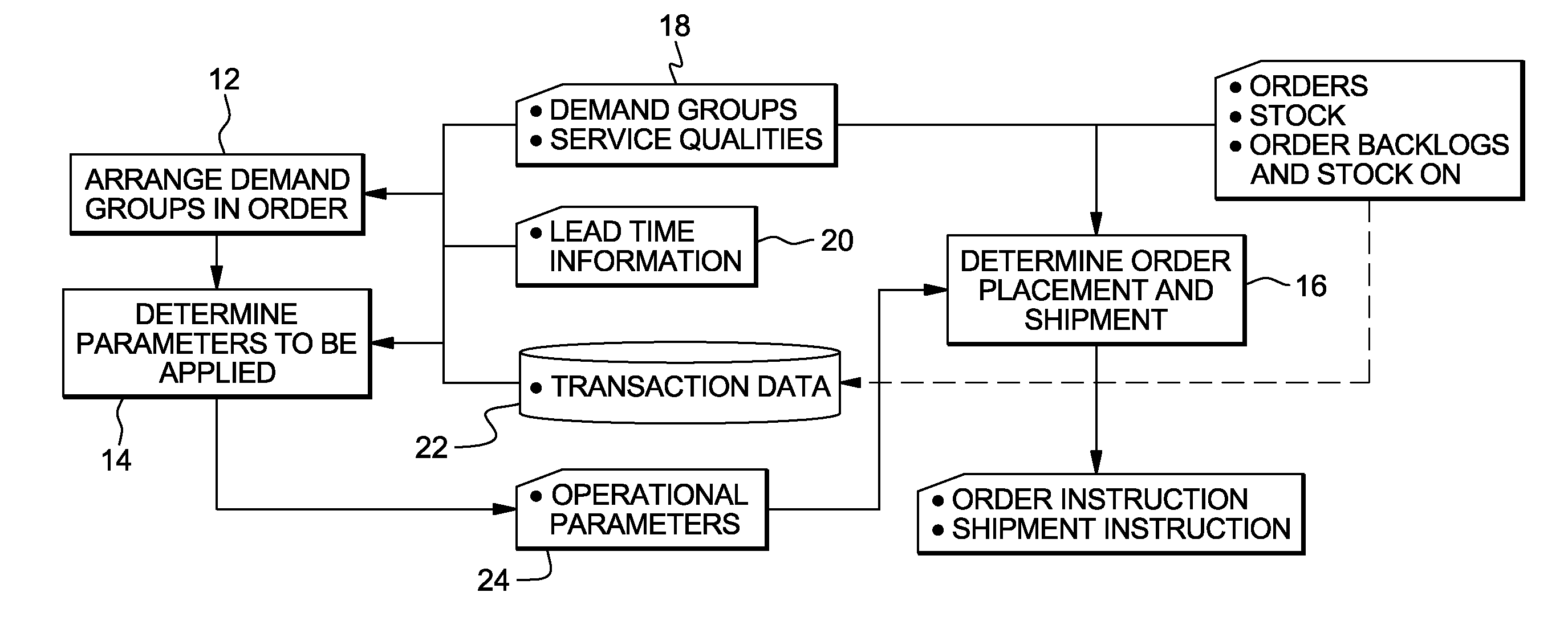

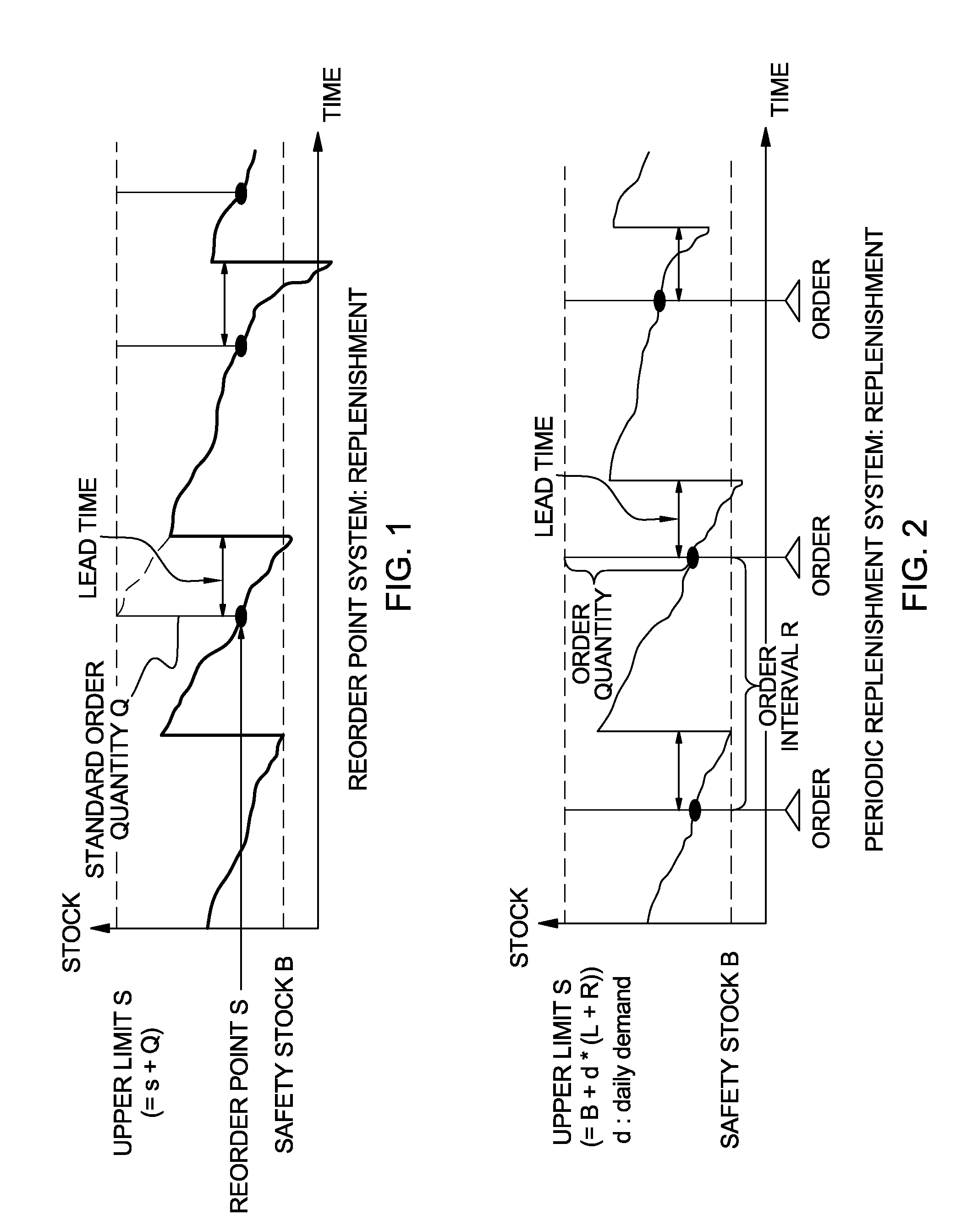

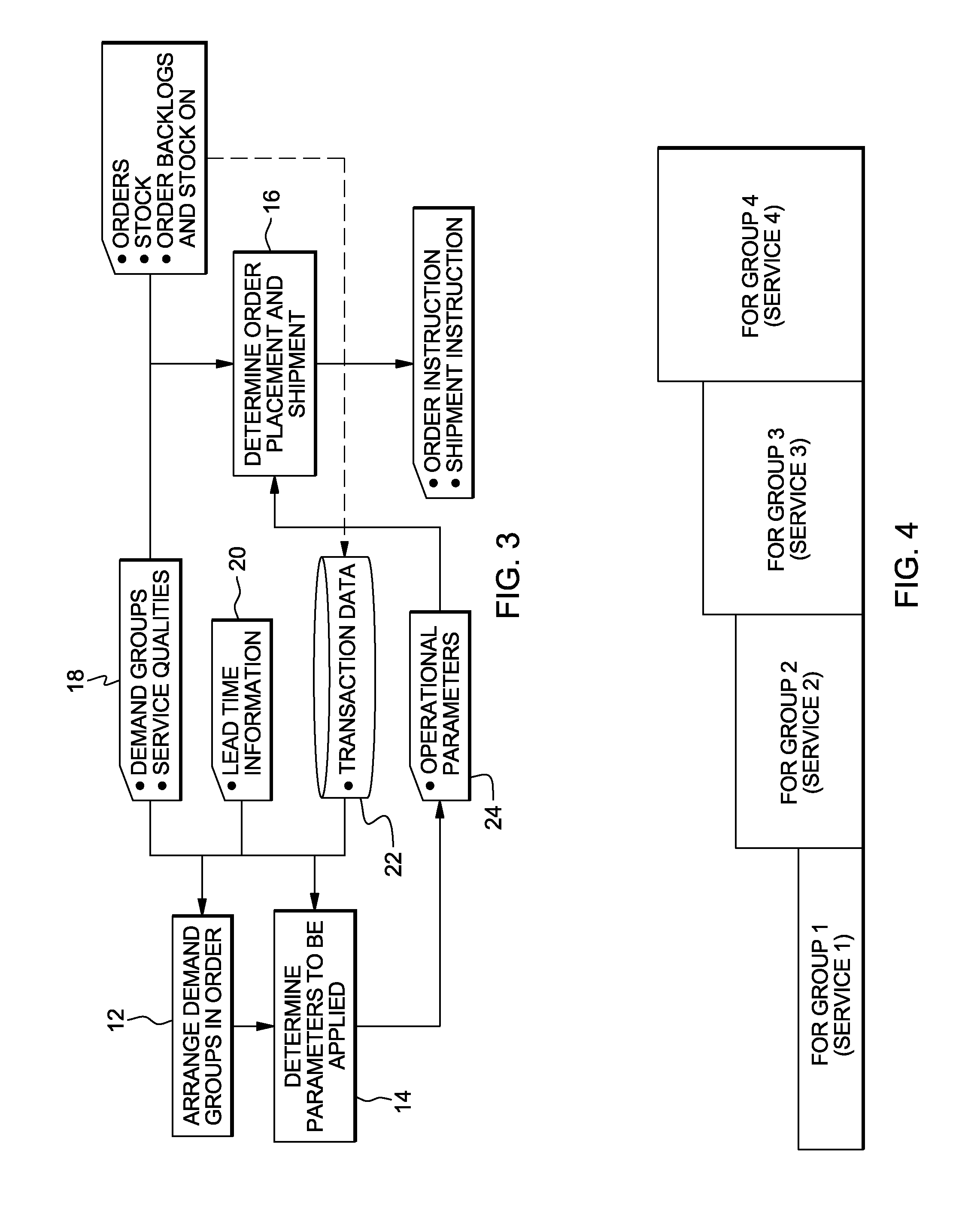

Efficient inventory management for providing distinct service qualities for multiple demand groups

An inventory management method for managing an inventory of goods for a plurality of demand groups with each demand group having at least one service quality, the method includes determining a total safety stock level for the plurality of demand groups that satisfies the distinct service quality of each demand group, determining a shipment limit Zi for each demand group Gi, wherein goods are shipped for a demand group Gi only if the inventory of goods for the demand group Gi exceeds the shipment limit Zi. Also disclosed is a computer program product and a method for an inventory management service.

Owner:IBM CORP

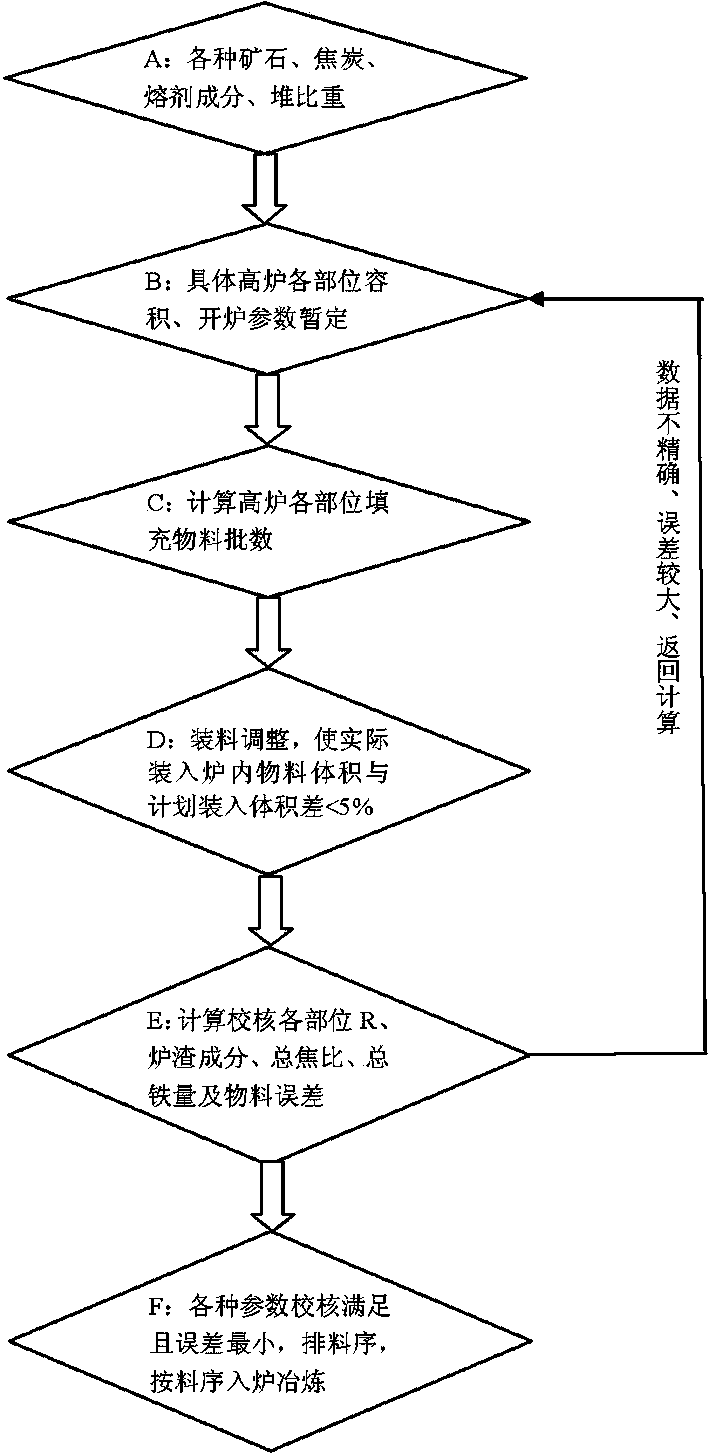

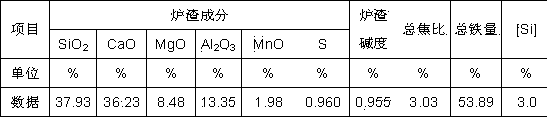

Quantitative modularized method for accurately controlling blow-in, banking and blow-out of blast furnace

ActiveCN104313214AIncreased iron [Si] contentAddressing Temporary Change RequestsBlast furnace detailsStock levelAlkalinity

The invention discloses a quantitative modularized method for accurately controlling blow-in, banking and blow-out of a blast furnace. The blow-in method comprises the following steps: burdening, feeding calculation, charging for the blast furnace, adjustment of charging, feed-in calculation and blow-in control. The banking method comprises the following steps: canceling limestone, dolomite and silica in claims 1 to 6, adjusting a total coke ratio and a total alkalinity according to the banking time, stably descending furnace burden, and when the calculated furnace burden is fed into the furnace, and the burden line is about 6 cm of the stock level, damping down so as to finish banking. The blow-out method comprises the following steps: after furnace burden feeding is stopped, calculating the burning coke quantity based on feed-in air quantity of the blast furnace, when the volume vacated in the furnace is up to the predetermined cleared amount, combining with outer furnace observation and determination, and damping down so as to finish blow-out. The quantitative modularized method is based on the principles of local material balance of each part in the blast furnace, full-furnace material balance and thermal balance, solves the problems that the associated data such as the total coke ratio, the alkalinity balance at the filled part, final slag constituents, cast iron composition control, empty burden batches and normal burden batches are processed in an interacted manner, and has the characteristics of simplicity in method, and quickness and accuracy in control.

Owner:红河钢铁有限公司

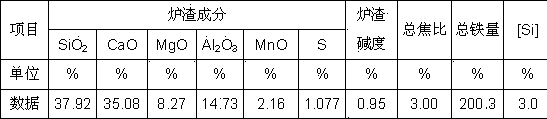

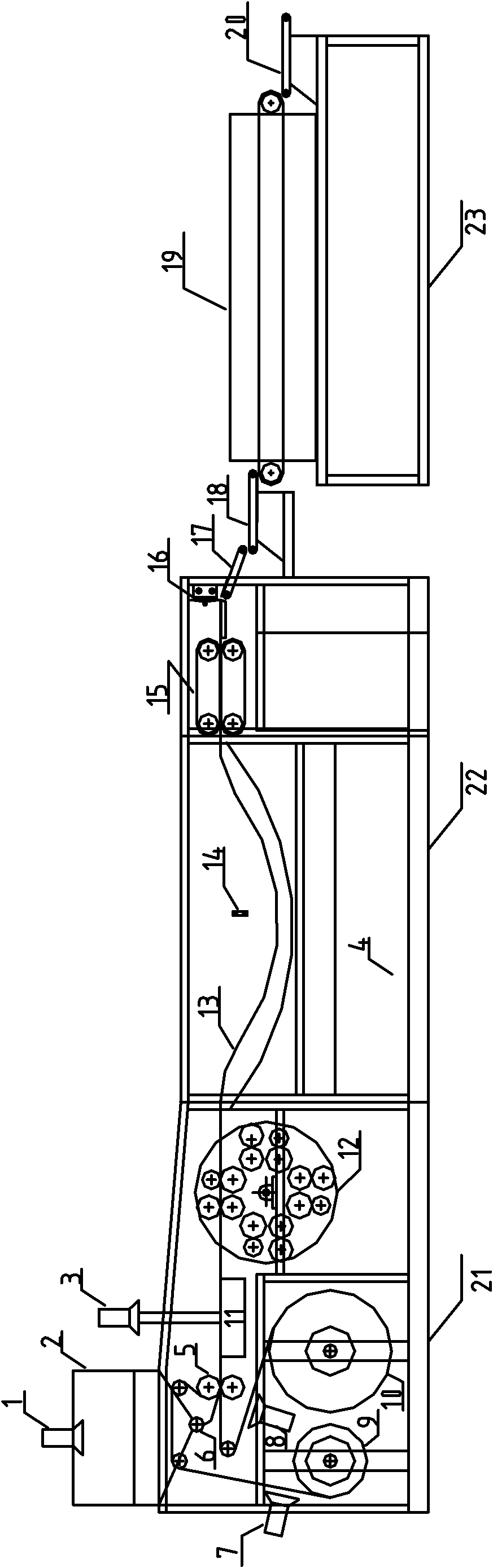

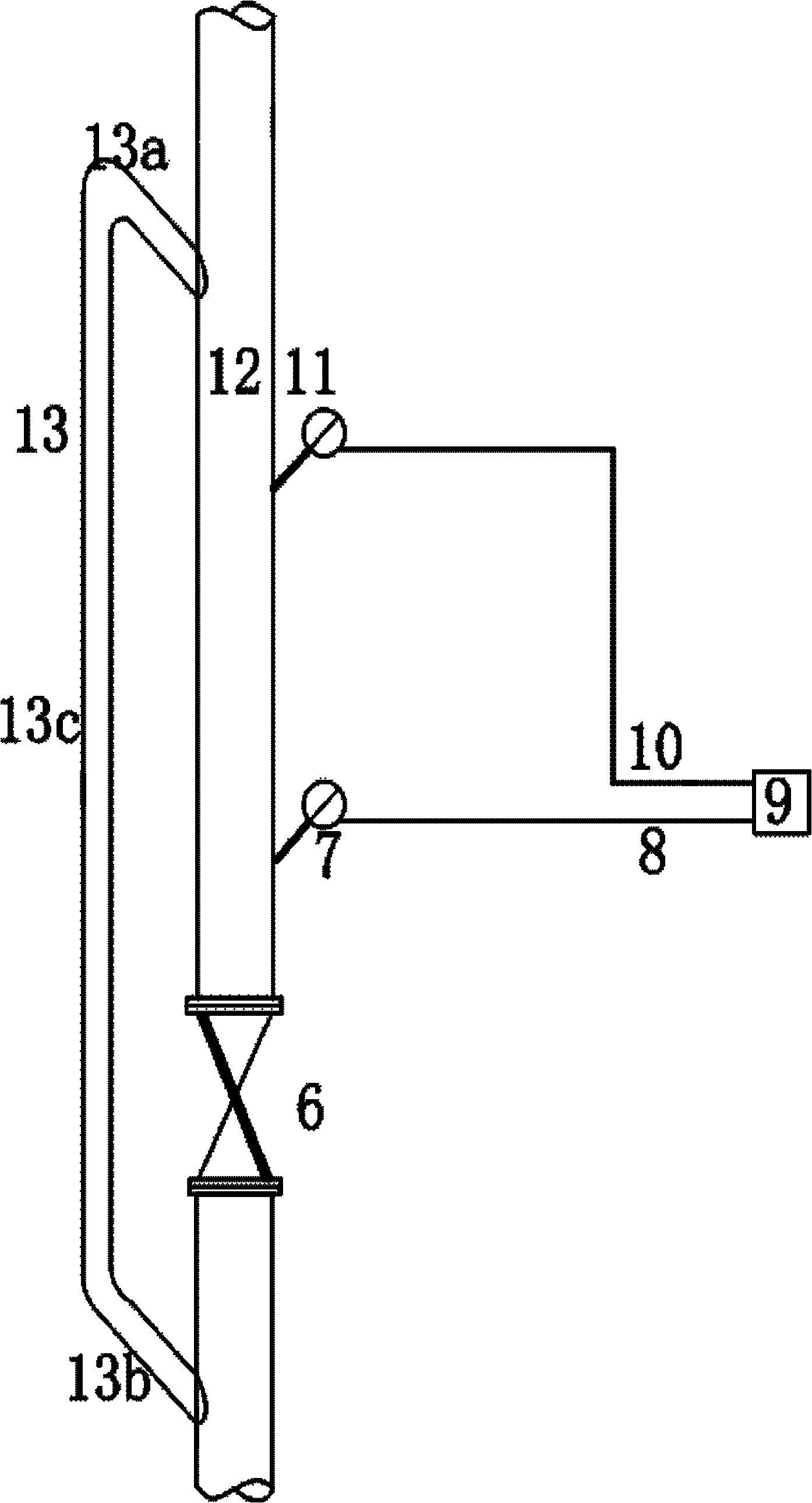

Sounding rod debugging device for determining datum point of blast-furnace charge level and debugging and positioning method of device

The invention relates to a sounding rod debugging device for determining a datum point of a blast-furnace charge level and a debugging and positioning method of the device and belongs to the technical field of blast-furnace sounding rod measurement. According to the technical scheme, the sounding rod debugging device comprises a sounding rod head (5), absolute value encoders (9), a motor (11), a roller (12), a mooring rope (1), a ball valve (3) and a blast-furnace pipeline (4), wherein the ball valve is arranged on the blast-furnace pipeline; the output of the motor is connected with the roller; one end of the mooring rope is wound on the roller, and the other end of the mooring rope penetrates through the blast-furnace pipeline and the ball valve to enter the blast furnace and is connected with the sounding rod head; the absolute value encoders are arranged on the motor and the roller shaft. The sounding rod debugging device has the positive effects that the datum point of a sounding rod does not required to be corrected during blast-furnace blowing-down, the sounding rod can be debugged during normal production, manual visual inspection is not required during determining and debugging, the stock level is accurately detected, the datum point of the charge level can be corrected when the stock level cannot be determined in a production process, the blowing-down is not required in the process of replacing the sounding rod head, the debugging is convenient and simple and is not limited by the blanking time, and the labor intensity is reduced.

Owner:HEBEI IRON AND STEEL

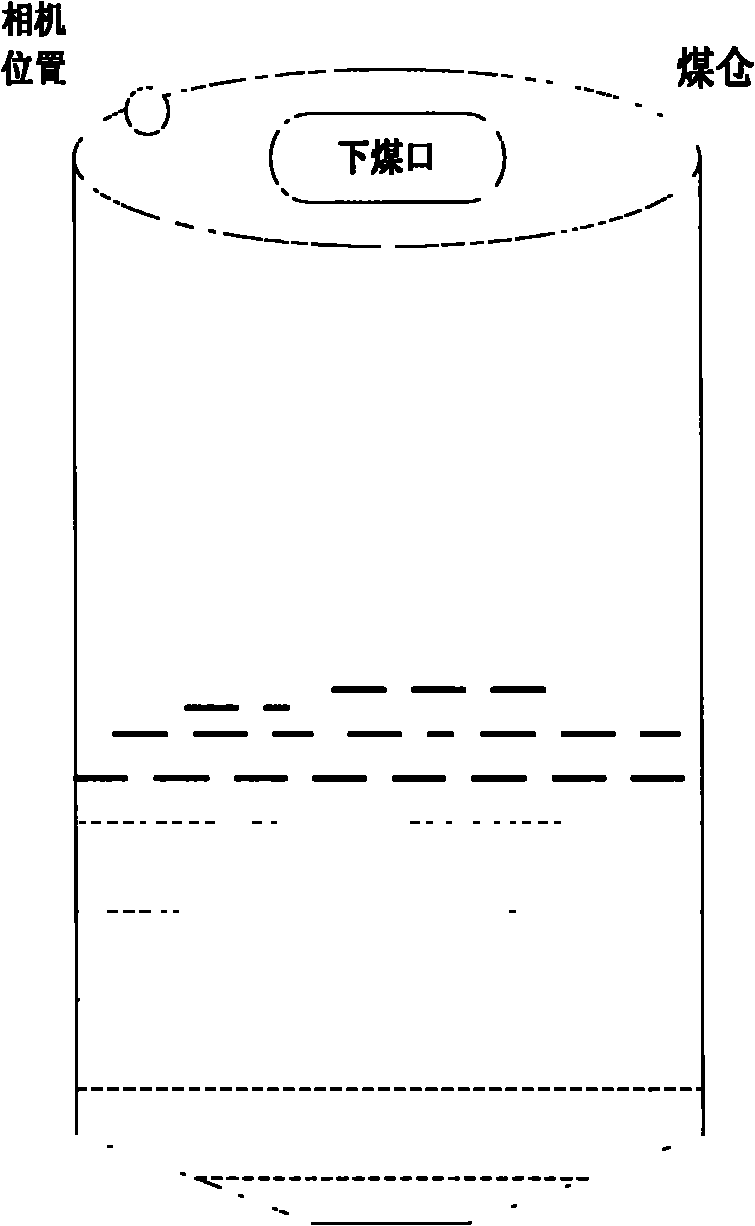

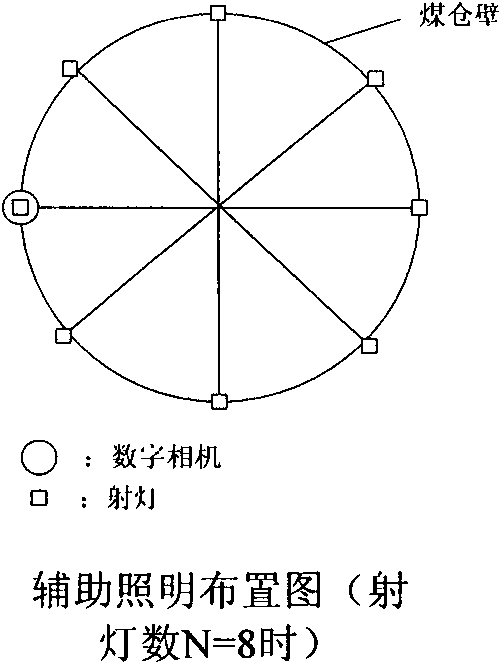

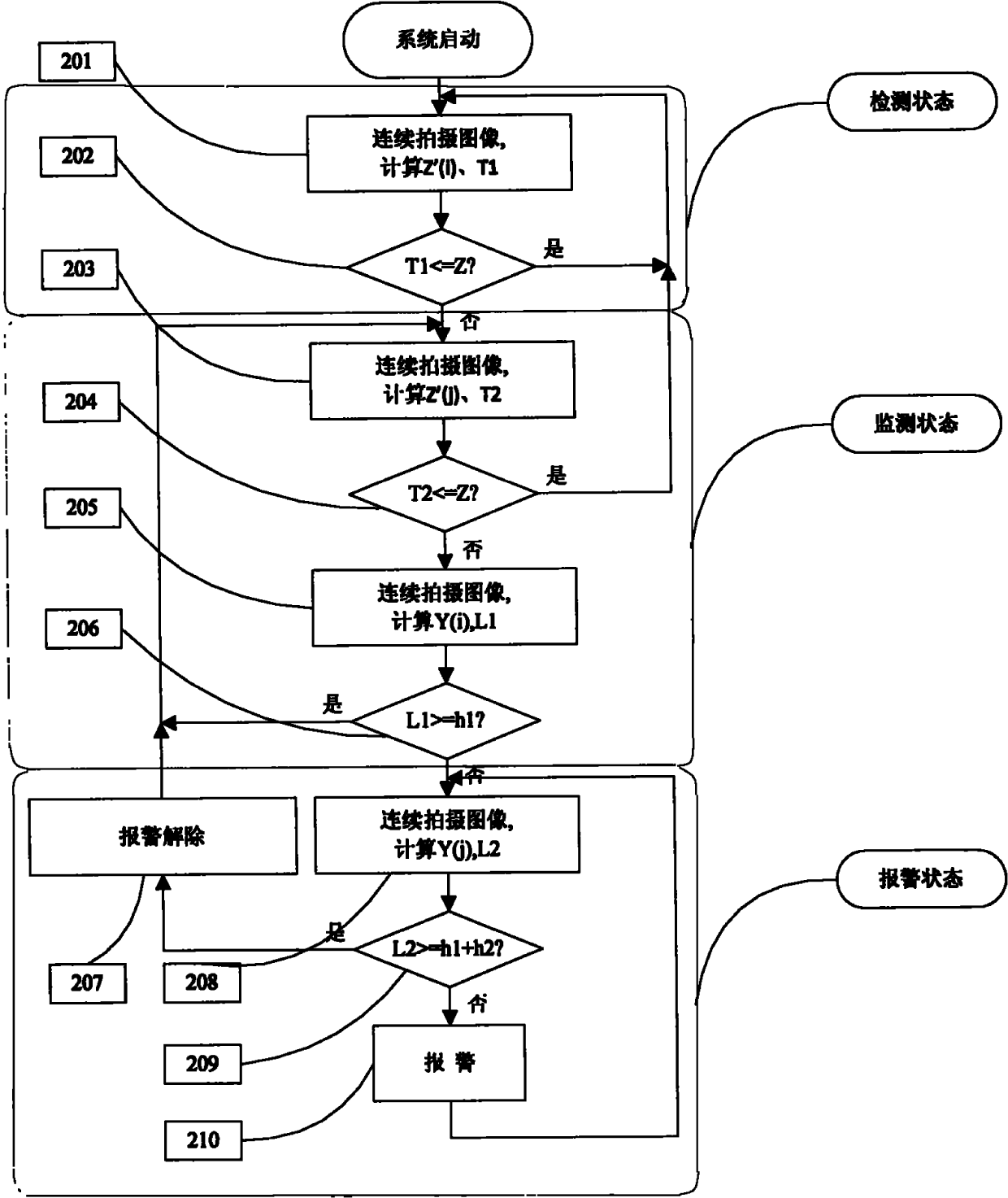

Method for detecting dynamic stock level in stock bin limit position based on machine vision

ActiveCN102116661ATelevision system detailsLevel indicators by dip membersStock levelLight equipment

The invention relates to a method for detecting the dynamic stock level in a stock bin limit position in an image processing manner based on a digital camera and an auxiliary lighting device. By shooting images of a stock bin and processing the images in real time, the real time monitoring of the dynamic stock level is completed, and an ultralimit alarm for the stock level is realized. By analyzing the characteristics of the stock bin limit position images and adopting the characteristics of particular images extracted in the image processing manner as a basis, the dynamic stock level near the stock bin limit position corresponds to three working states including a detection state, a monitoring state and an alarm state, the ultralimit alarm for the stock level is realized, and the method has the characteristics of good real time performance and high reliability. The method is especially applicable to occasions having safety enforcement requirements for the stock level in the stock bin limit position, such as underground coal bins in coal mines.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Traditional Chinese medicine cataplasma forming device with automatic detection function

InactiveCN102178605AOvercome uneven thicknessLower the altitudeLiquid surface applicatorsPharmaceutical product form changeStock levelProgrammable logic device

The invention discloses a traditional Chinese medicine cataplasma forming device with automatic detection function. The device comprises: a storage silo, a transverse feeding medicine film forming pump, a patch composite molding device, a patch longitudinal trimming device, a patch transverse cutting device, a patch dehumidifying device, a weighing device and an automatic online detection device based on FPGA (Field Programmable Gate Array) fuzzy pattern recognition, wherein the patch longitudinal trimming device is formed by a combined cutting tool magazine; the patch transverse cutting device adopts an electrostatic adsorption quantitative feeding structure; and the automatic online detection device based on FPGA comprises a plurality of cameras respectively used for stock level detection, coating film detection and cloth substrate detection, a camera and a backlight used for detection of uniformity degree, a photoelectric detector used for transverse feeding detection, a video A / D (Analog to Digital) converter ADV7181B, an SDRAM (Synchronous Dynamic random access memory) cache with the capacity of 16M, and a programmable logic device FPGA. The traditional Chinese medicine cataplasma forming device can monitor the humiture of materials and the indexes such as uniformity, size, dehumidification, weight and the like of auxiliary materials and patches.

Owner:TIANJIN UNIV

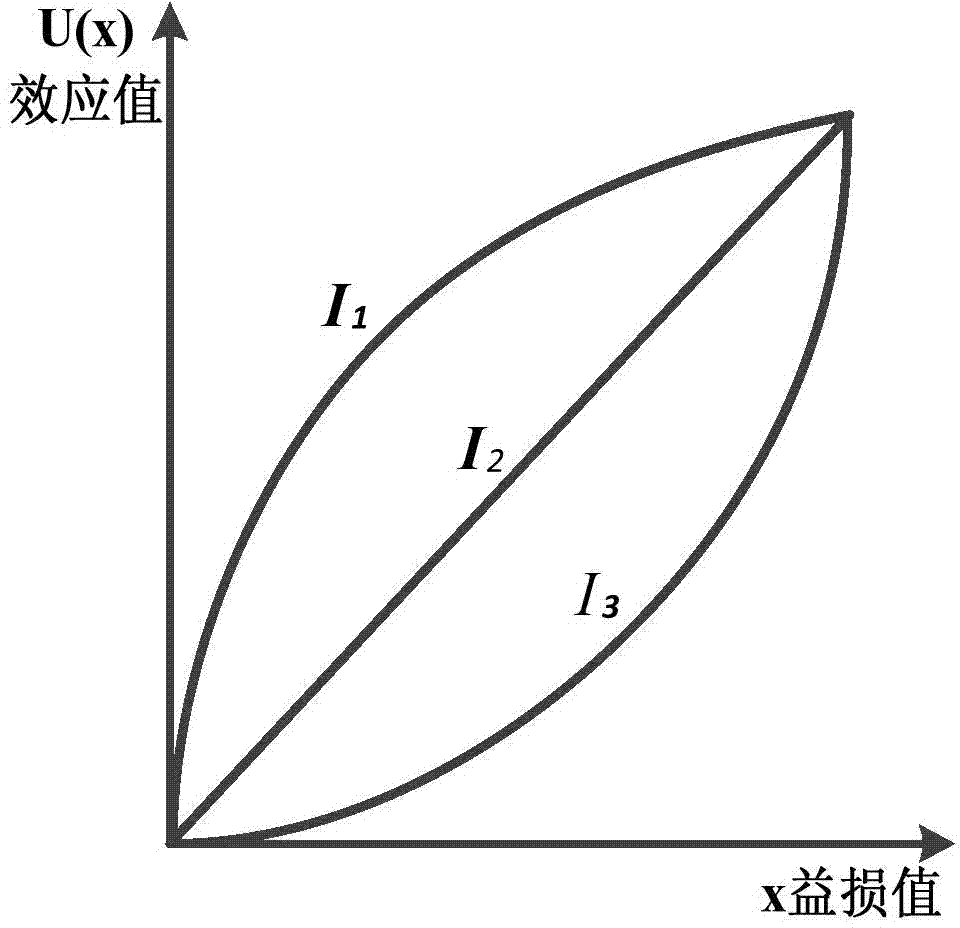

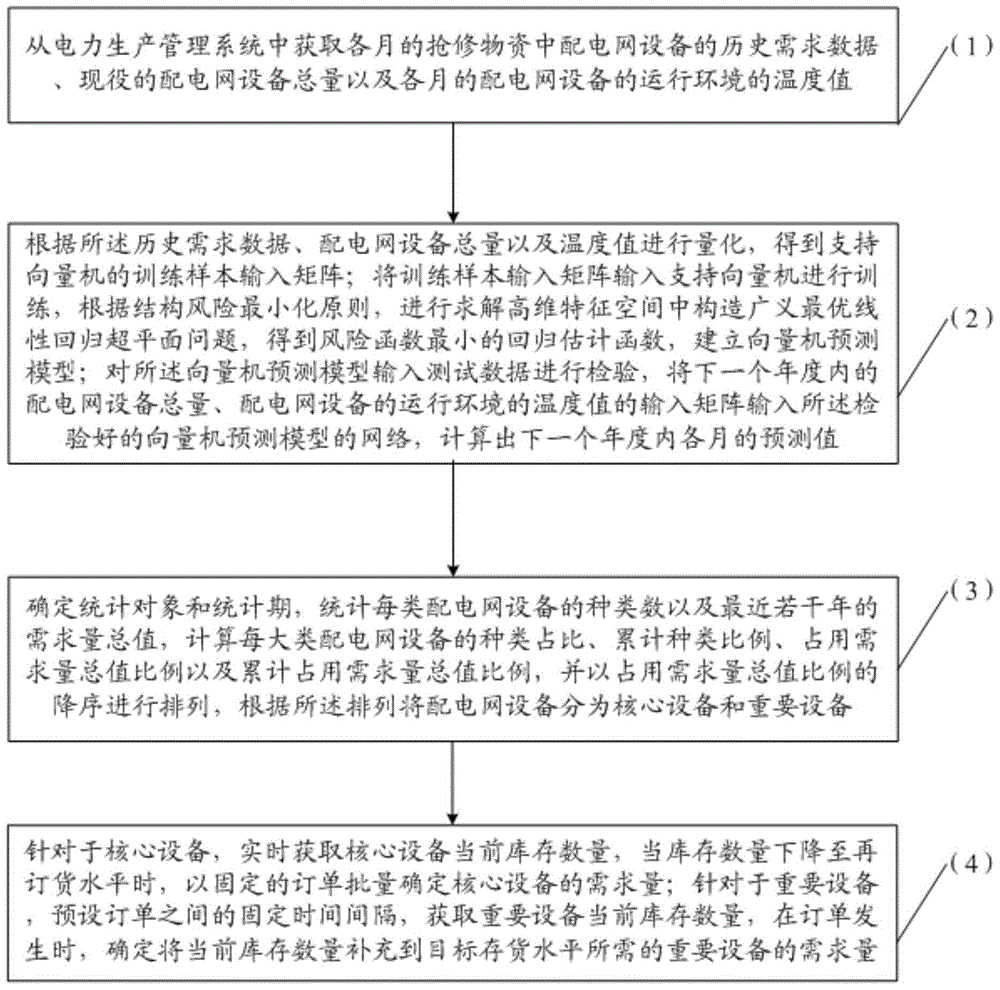

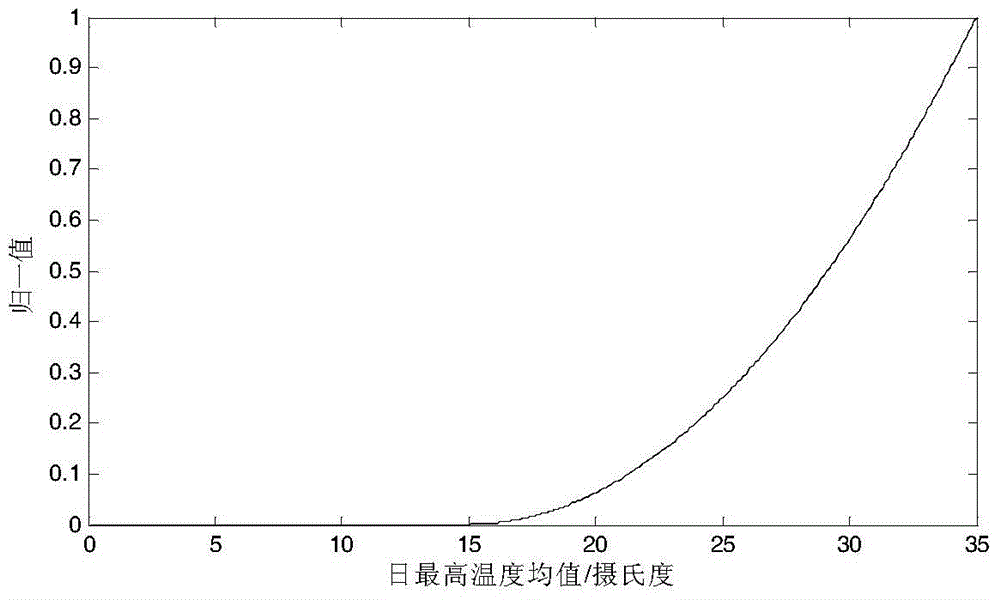

Power distribution network equipment demand prediction and quantitative method and system

InactiveCN104573877AEnsure safetyGuaranteed economyForecastingInformation technology support systemStock levelSupport vector machine

The invention provides a power distribution network equipment demand prediction and quantitative method and system. Based on history demand condition, current equipment amount, equipment reliability and equipment running climatic environment factor quantized data of the power distribution network equipment, demand per month of distribution network repair materials is predicted by an SVM (support vector machine). According to fund occupation condition of the power distribution network to the equipment, the power distribution network equipment is divided into core equipment and important equipment by the aid of the primary and secondary analytic method, and spare part safe stock and target stock levels of the power distribution network equipment are determined in the phase review way and the fixed order batch way, thus the power distribution network equipment is quantified. The quantitative data is more accurate and reliable and applicable to power distribution network material reserve quantity determination process, in this way, overstocked products are reduced, and material reserve efficiency and duration is improved, so that safety and economy of the power grid production are guaranteed, and utilization rate is enhanced.

Owner:GUANGZHOU POWER SUPPLY CO LTD +1

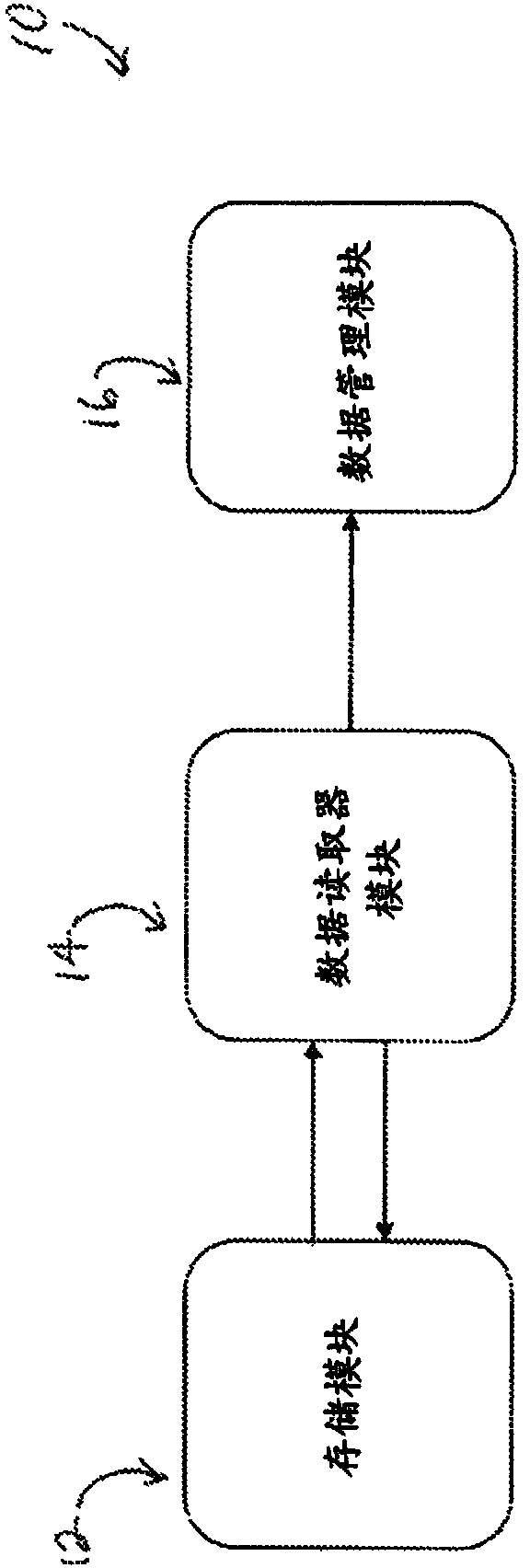

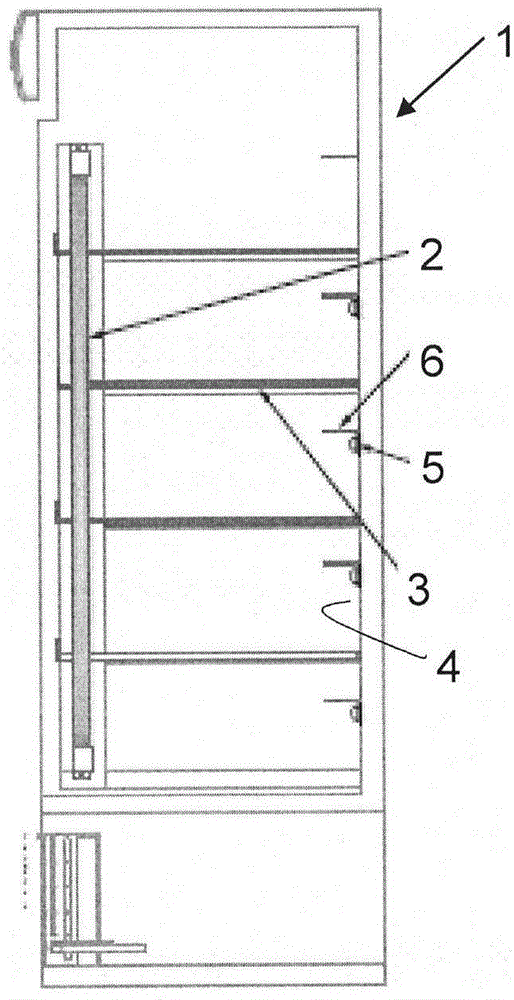

Inventory management system

InactiveCN103703476AContribute to high confidence levelsLower levelCoin-freed apparatus detailsApparatus for meter-controlled dispensingStock levelVisibility

The present disclosure provides an inventory management system that offers significant improvement over existing systems by automating requests to restock inventory. The present disclosure details an inventory management system that provides real time visibility to stock levels and streamlines materials management activities, while addressing the issues of human resource misallocations, inaccurate inventory data management and related out of stock conditions. Moreover, the system of the present disclosure promotes a high level of confidence in inventory data that enables on-hand inventory levels to be reduced, thereby reducing costs and waste.

Owner:INTERMETRO IND CORP

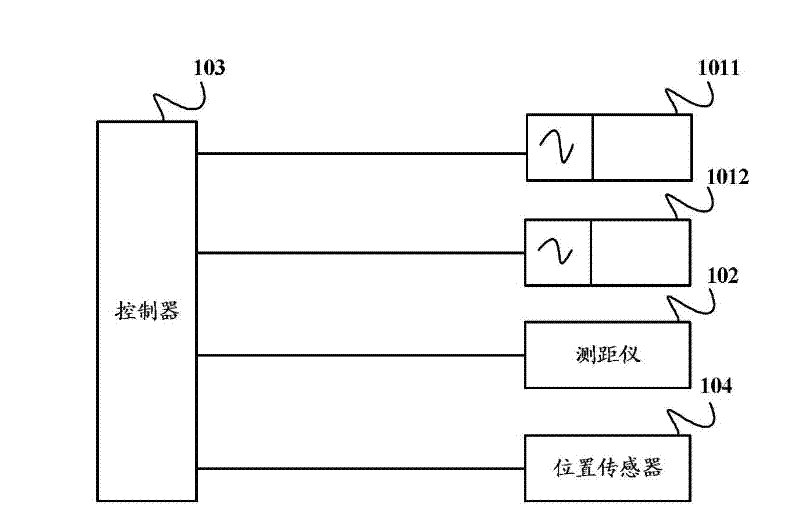

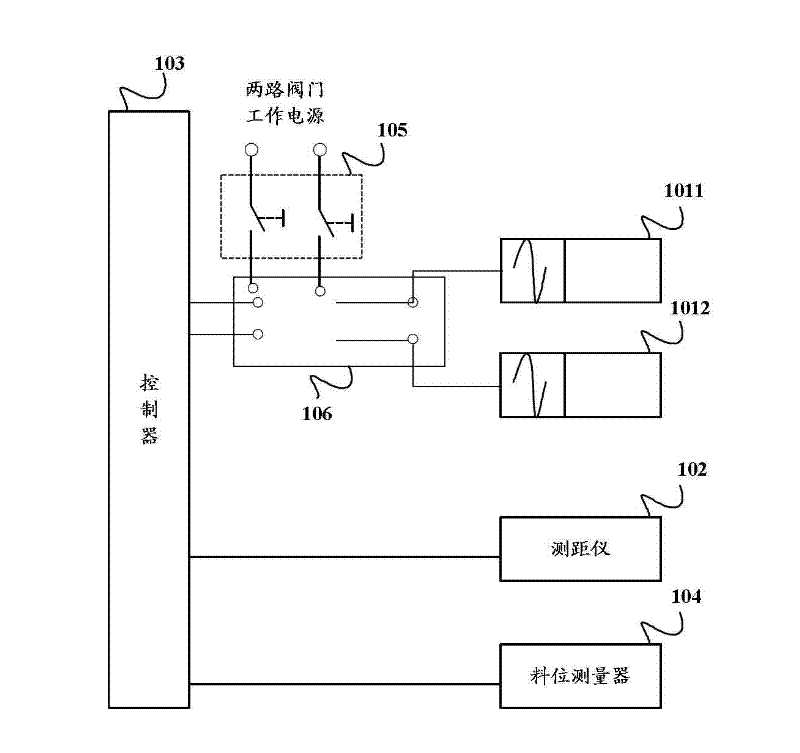

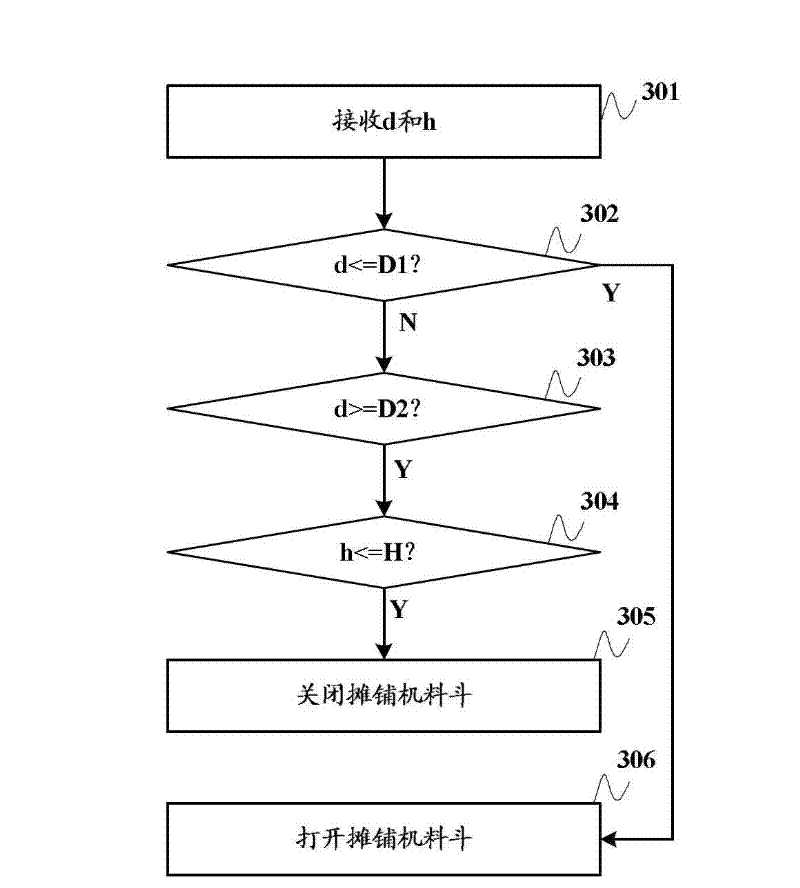

Control system, method and device of spreading machine hopper

The invention relates to the field of engineering machinery, provides a control technique of a spreading machine hopper, and is used for automatically controlling the spreading machine hopper. The embodiment of the invention provides the following technical schemes: a control system of the spreading machine hopper comprises a valve used for controlling the hopper to open and another valve used for controlling the hopper to close, as well as a range finder and a controller, wherein the range finder is arranged on a spreading machine and is used for measuring the distance between a skip car and the setting position of the spreading machine; and the controller is connected with control loops of the two valves and the range finder respectively, and is used for controlling the valve for opening to have electric action to open the spreading machine hopper when determining that the distance between the skip car and the setting position of the spreading machine is gradually reduced and is smaller than or equal to a set first distance threshold value according to the measured result of the range finder, or controlling the valve for closing to have electric action to close the spreading machine hopper when determining that the distance between the skip car and the setting position of the spreading machine is gradually increased and is larger than or equal to a set second distance threshold value, and the stock level is smaller than or equal to a set height threshold value.

Owner:ZOOMLION HEAVY IND CO LTD

Castable for gun patching of blast furnace lining and preparation method for castable

The invention discloses castable for gun patching of a blast furnace lining and a preparation method for the castable. The castable is prepared from raw materials, i.e., 10wt% to 15wt% of bauxite particles, 40wt% to 50wt% of brown fused alumina particles, 10wt% to 20wt% of silicon carbide fine powder, 15wt% to 25wt% of corundum fine powder, 0.5wt% to 2wt% of metal silicon powder, 0.5wt% to 2wt% of pelleted pitch, 2wt% to 7wt% of alpha-Al2O3 micropowder and 0.2wt% to 2wt% of silica micropowder, and silica sol, of which the weight percentage is 8% to 15% that of the raw materials, wherein the silica sol serves as a binder. The method comprises the steps of proportionally preparing the raw materials, adding the raw materials in a stirrer, carrying out uniform stirring and mixing, and then, adding the silica sol as a gun patching wetting medium and the binder, thereby obtaining the castable for gun patching of the blast furnace lining. The castable is superior in slag resistance, high in strength, good in bonding performance and quick in construction and can be integrated with a patched face of the blast furnace lining through binding; and the preparation method is simple in operation, exposed furnace wall linings can be subjected to gun-patching lining forming under the circumstances that a stock level of a blast furnace is lowered, and the blast furnace lining is rapidly patched in a large area.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

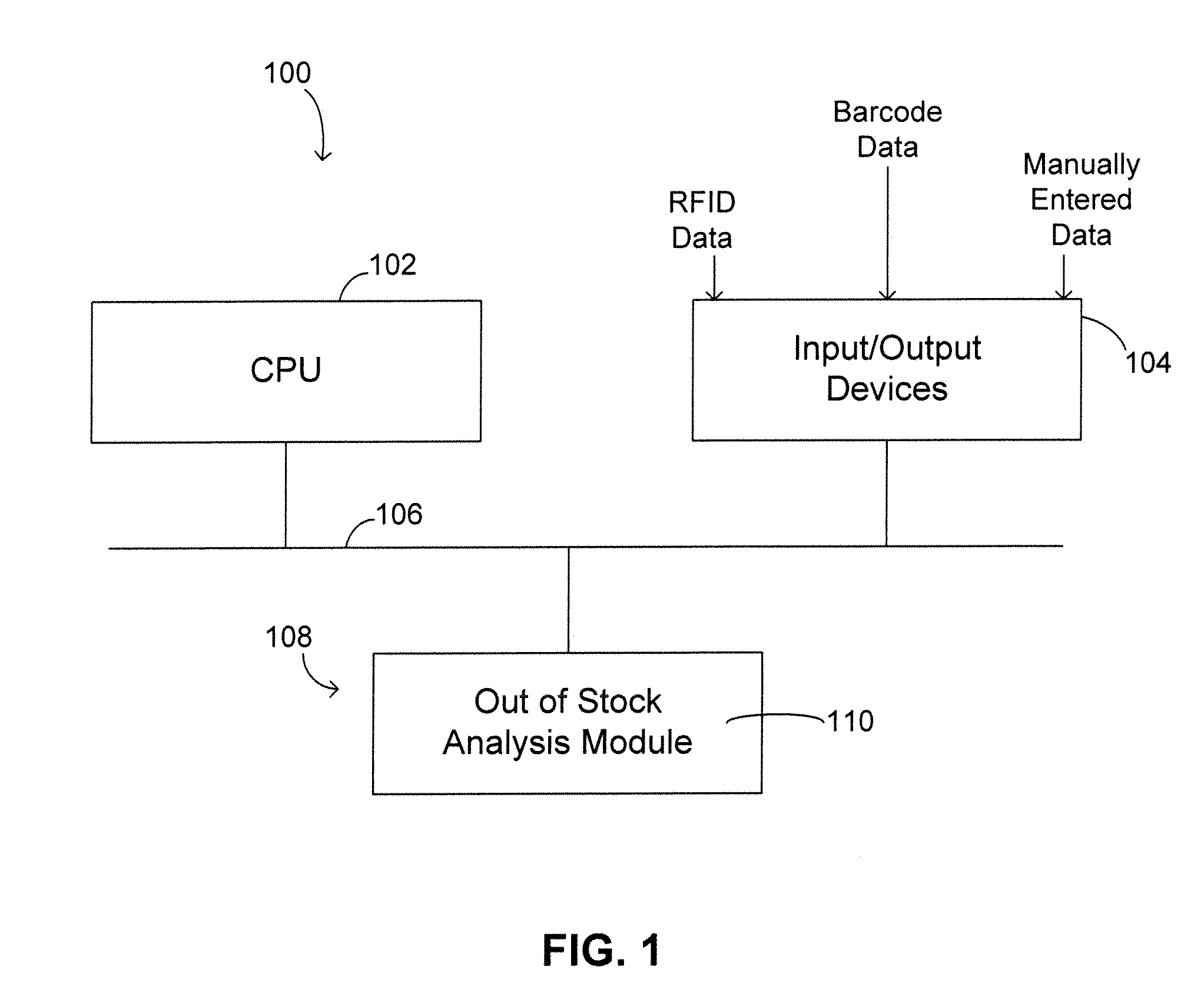

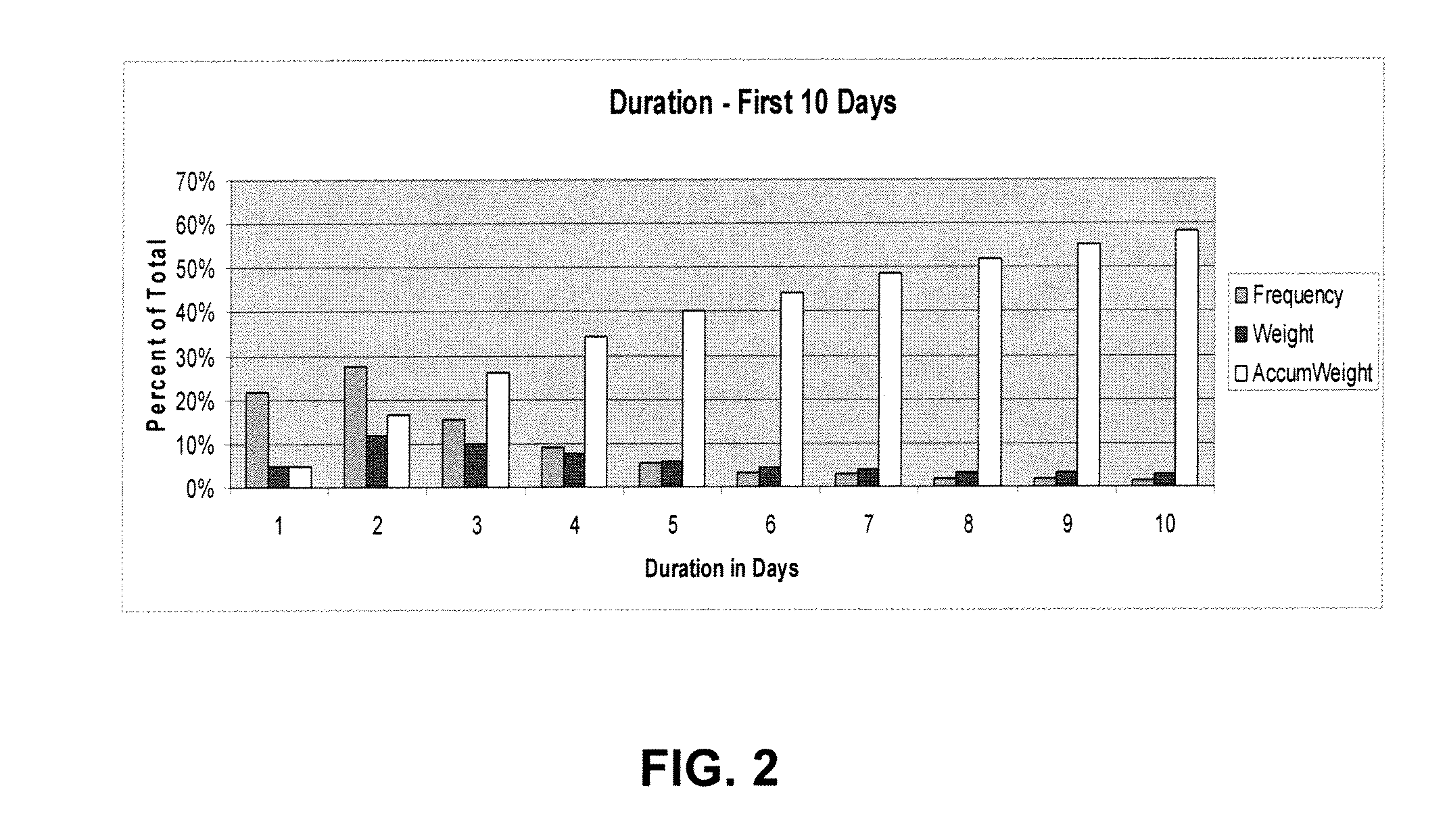

Apparatus and method for analyzing out of stock conditions

A method of evaluating out of stock conditions includes determining a minimum provable stock level relying upon RFID and non-RFID information sources.

Owner:T3C

Method for rapidly recovering furnace condition after long-time blowing-down of blast furnace

The invention discloses a method for rapidly recovering the furnace condition after long-time blowing-down of a blast furnace. The method comprises steps as follows: 1), blowing-down is started when a blowing-down material downwards reaches the lower edge of a furnace bosh, the stock level is 1.2m-1.5m during blowing down, and reblowing is performed after blowing-down is performed for 8-36 hours; 2), all tuyeres are opened for reblowing, coal gas is introduced for 8-10 minutes, then, the blowing rate reaches 3,200-4,000 m<3> / min, the ore batch before blowing-down is kept unchanged in the reblowing process; 3), coke load is started to be increased after the blowing rate reaches 3,200-4,000 m<3> / min, and the smelting level is adjusted to be normal after 8 hours; and 4), the iron opening time is firstly calculated according to the blast consumption of per ton of iron at 1,300 m<3> / t*Fe after reblowing, opening for iron discharging is performed after the air volume is added up to 260,000m<3>, iron slag can be firstly pelletized, and fire slag is not discharged. According to the method, the air adding speed is high, and the time is only 6.25% of original time; the load adjustment period is short, and time is shortened by 2 / 3; and the labor intensity of workers is greatly reduced, and occupational hazards such as high temperature, noise and the like are avoided.

Owner:SHANDONG IRON & STEEL CO LTD

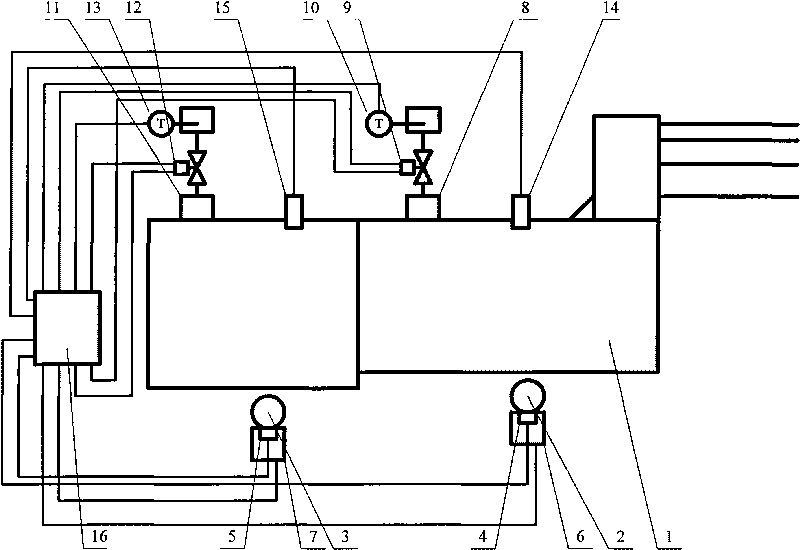

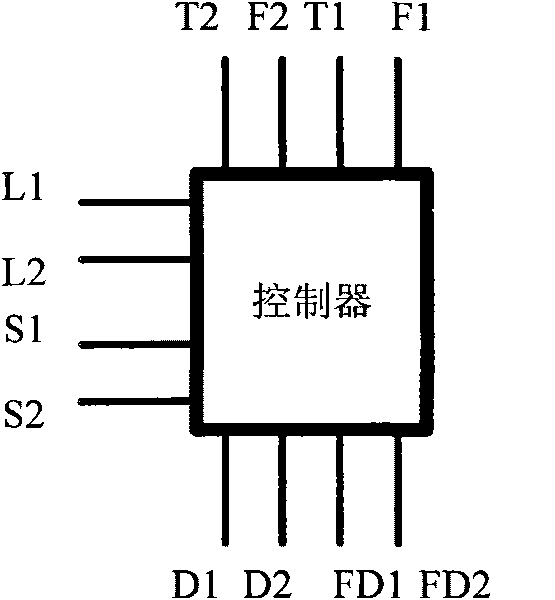

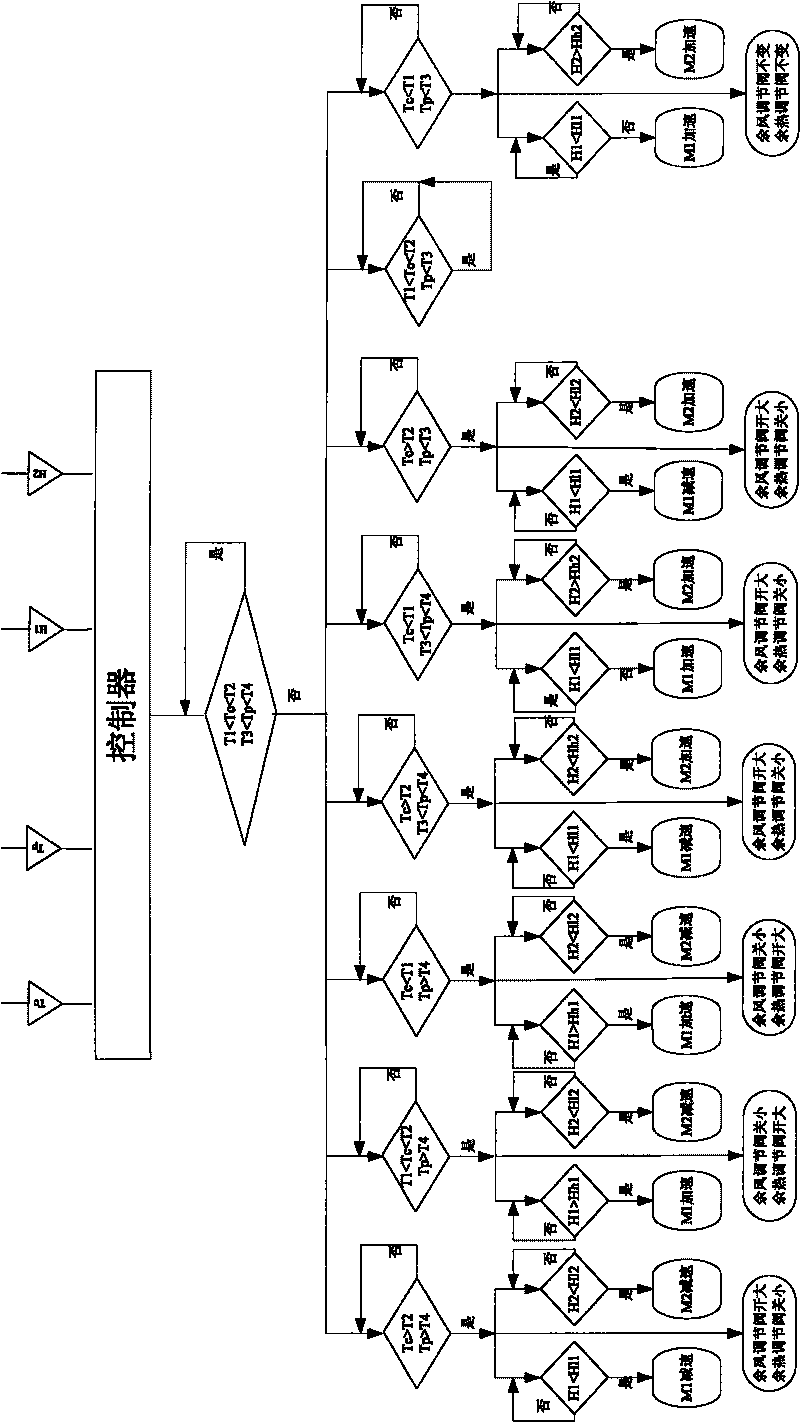

Method and device for controlling induced draft temperature of grate cooler of cement afterheat generation system

InactiveCN101706668ASuction temperature is stableSmall fluctuationTemperature control using electric meansClinker productionStock levelTemperature control

The invention provides a method and a device for controlling an induced draft temperature of a grate cooler of a cement afterheat generation system. The method comprises the step of controlling afterheat using air valve opening, the afterwind valve opening, a rotating speed of a first main transmission shaft and a rotating speed of a second main transmission shaft in the grate cooler by using a controller. The device comprises the grate cooler, a first drive mechanism and a second drive mechanism which are connected with the grate cooler, an afterheat using mechanism and an afterwind emission mechanism, wherein the grate cooler, the afterheat using mechanism and the afterwind emission mechanism are arranged on the grate cooler. The grate cooler is provided with at least two stock level detectors; the first drive mechanism, the second drive mechanism, the afterheat using mechanism, the afterwind emission mechanism and the stock level detectors detector are respectively connected with the controller; and the controller is provided with a signal input end, a signal analysis processing unit and a signal output end, which are sequentially connected. The control device can effectively reduce the fluctuation of the induced draft temperature of grate cooler afterheat, and the induced draft temperature is ensured to keep within a certain range, so that the induced draft temperature of the cement afterheat generating system is maintained at a higher level.

Owner:SOUTH CHINA UNIV OF TECH +1

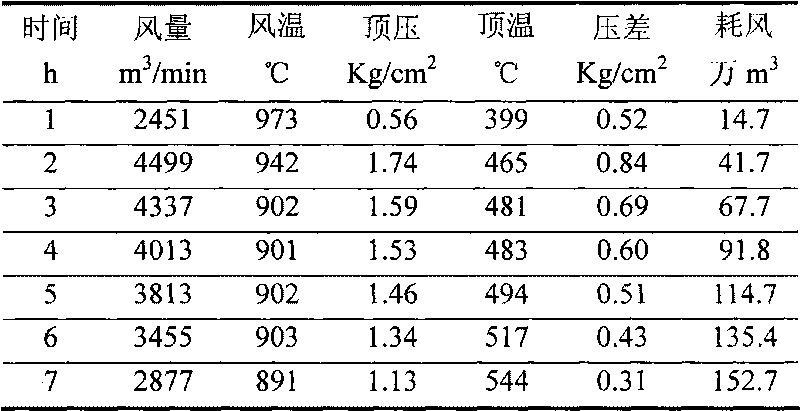

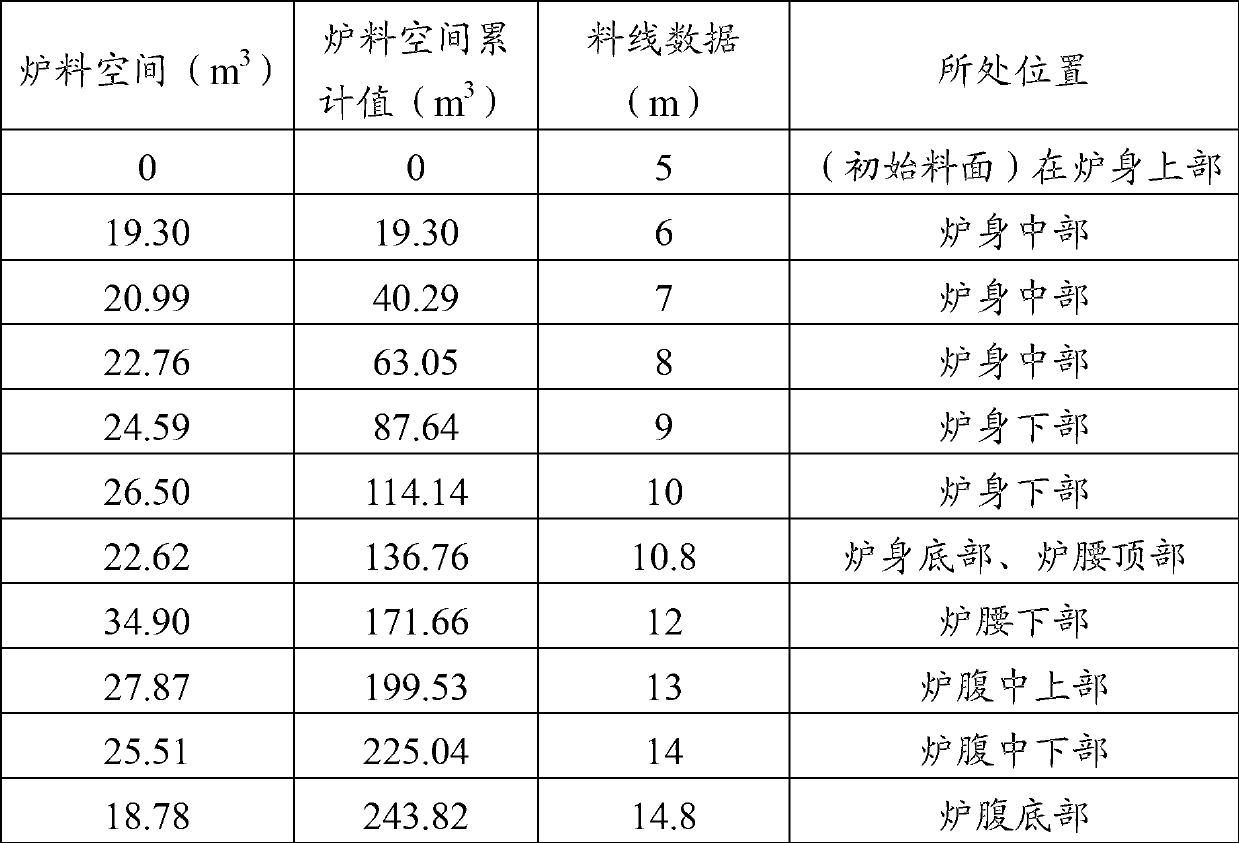

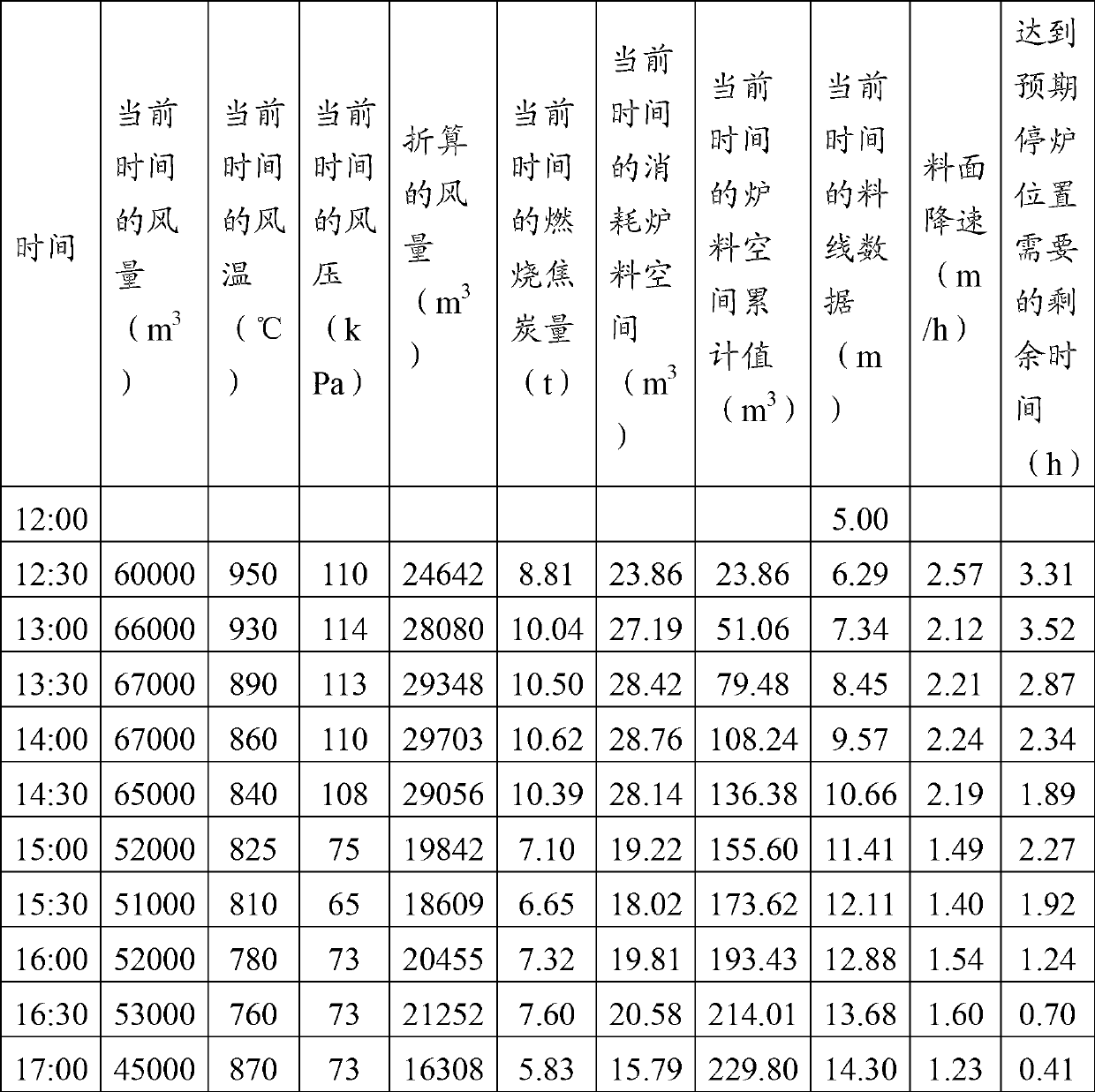

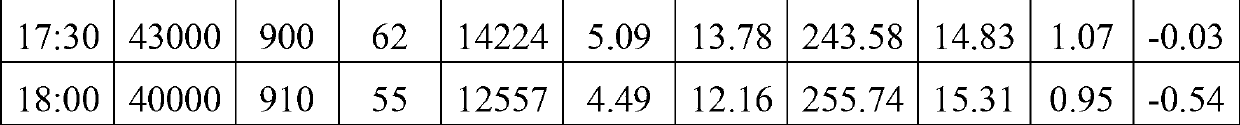

Forecasting method for descending depth of material surface of blast furnace during furnace shutting down

The invention provides a forecasting method for the descending depth of a material surface of a blast furnace during furnace shutting down. The method comprises the following steps of: forecasting the material surface depth at a regular preset time unit during the descending operation of the material surface of the blast furnace, in particular, computing the ton coke air loss according to the cold air blast flow and the coke consumption quantity on the latest normal smelting day before the blast furnace is shut down, taking the ton coke air loss as the ton coke air loss during descending operation of the material surface of the blast furnace, computing the air quantity at the current time according to the ton coke air loss, and carrying out the amortized computation on the air quantity at the current time based on the air pressure P0 and the air temperature T0 at the latest normal smelting day before the blast furnace is shut down; computing the coke burning quantity and the furnace burden consuming space at the current time; computing the accumulated value of the furnace burden space at the current time; computing the stock level data at the current time through the accumulated value of the furnace burden space at the current time by utilizing the linear relationship between the accumulated value of the furnace burden space and the stock level data; computing the descending speed of the material surface; and computing the required remaining time when an expected furnace shutting down time is reached.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

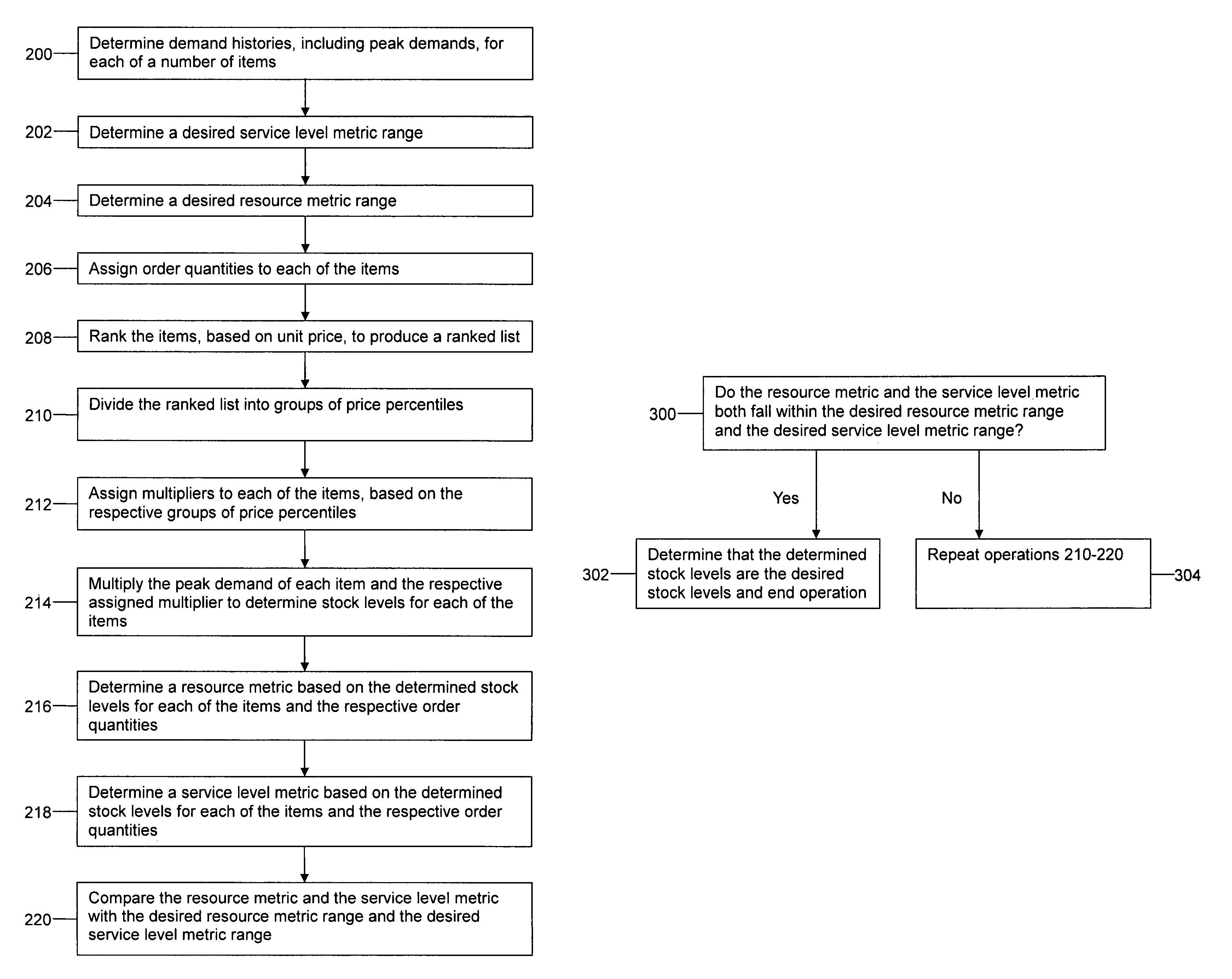

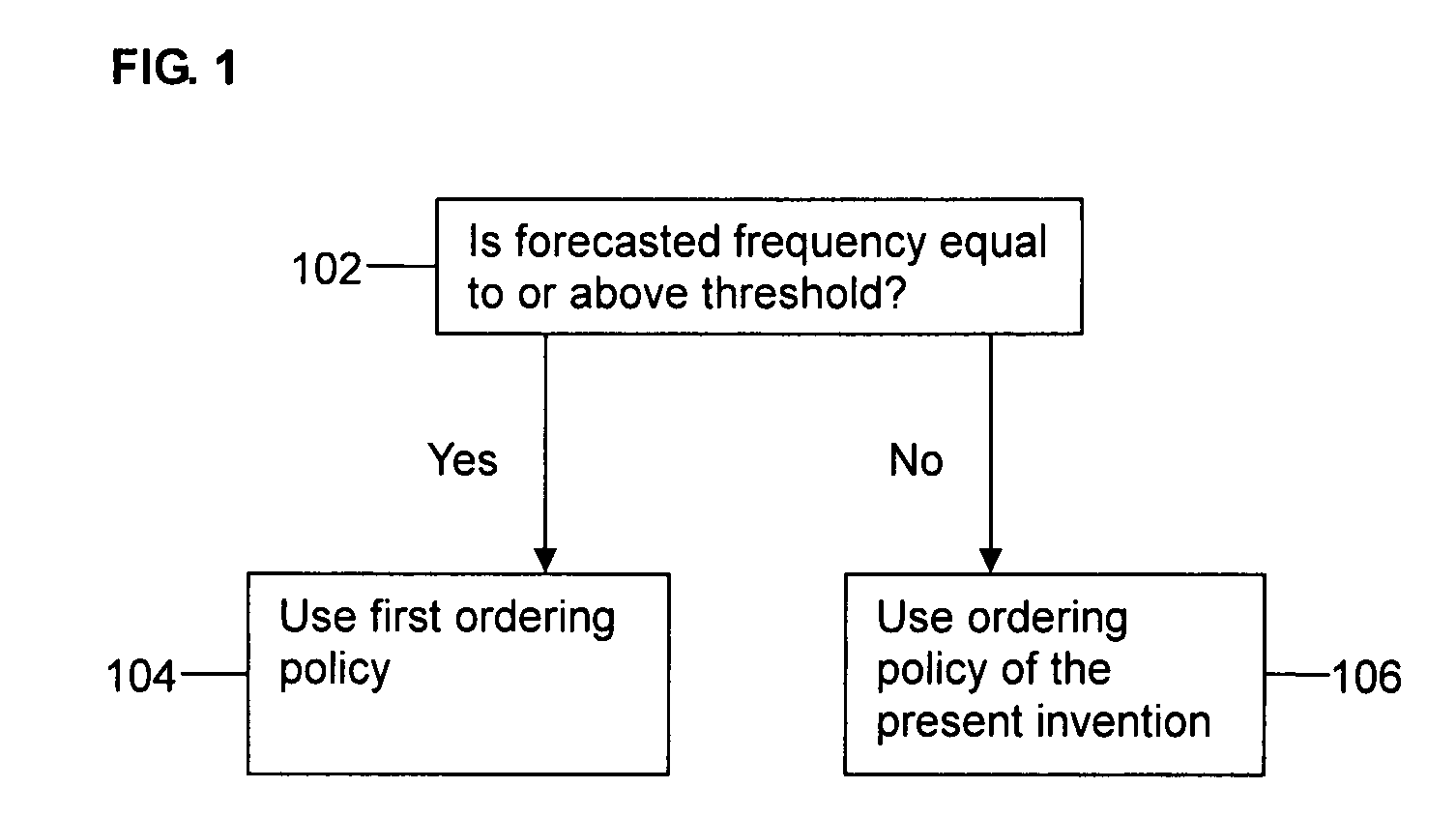

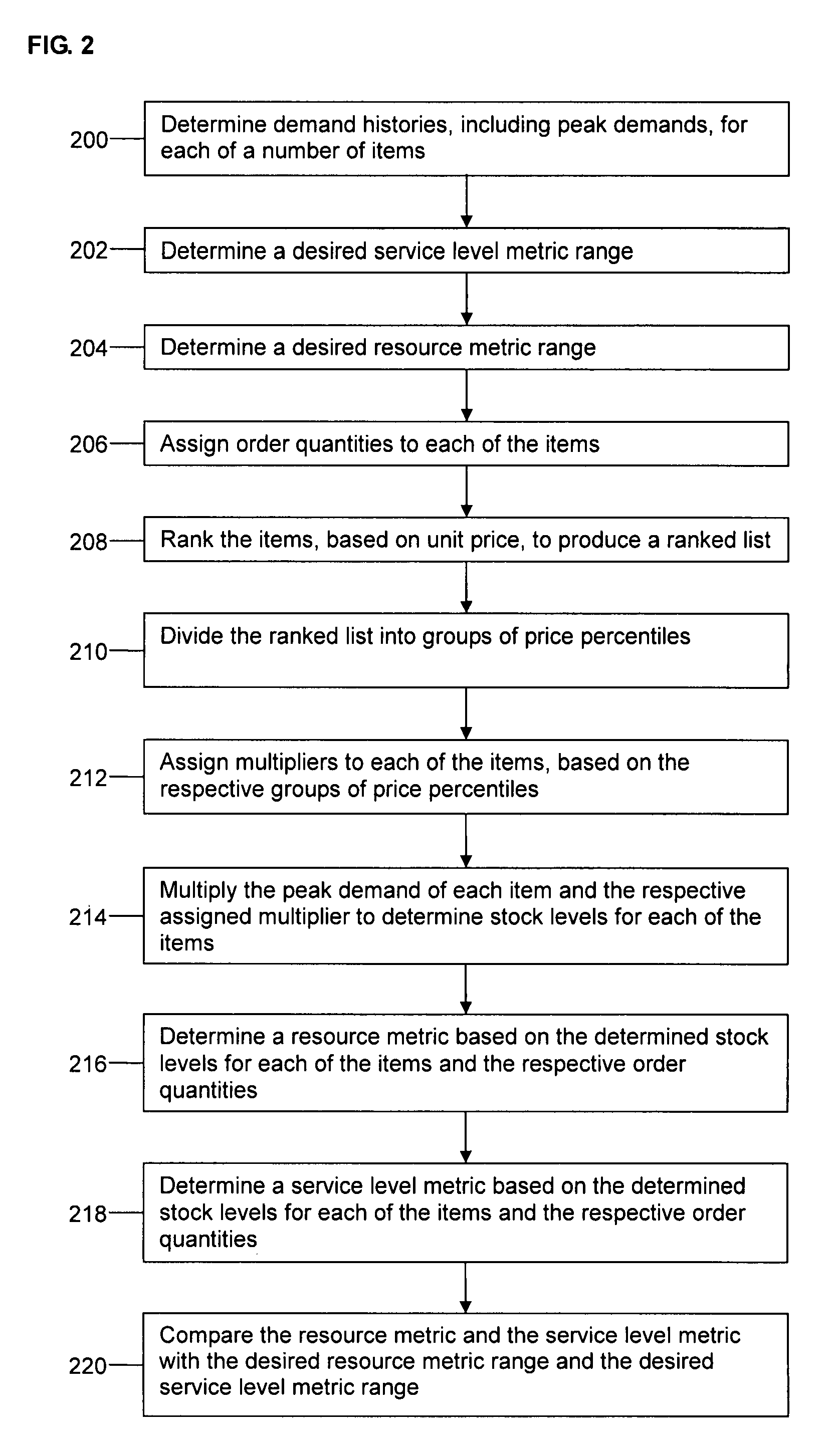

Method of determining inventory levels

ActiveUS8165914B2Increasing inventory investmentReducing customer wait-timeResourcesMarket data gatheringStock levelComputer science

A computer-readable medium executing a method of determining desired stock levels is provided. Demand histories, including peak demands, for each of a plurality of items are determined. The items are ranked, based on unit price, to produce a ranked list, which is divided into price percentiles. Multipliers are assigned to each of the items, based on the respective price percentiles, and stock levels are determined for each of the items by multiplying the peak demand of each item and the respective assigned multiplier. Order quantities are assigned to each of the items based on price percentiles. A service level metric and a resource metric are determined based on the stock levels and the respective order quantities, and the service level metric and resource metric are compared with a desired service level range and a desired resource metric range to determine whether the determined stock levels are the desired stock levels.

Owner:LMI CONSULTING LLC

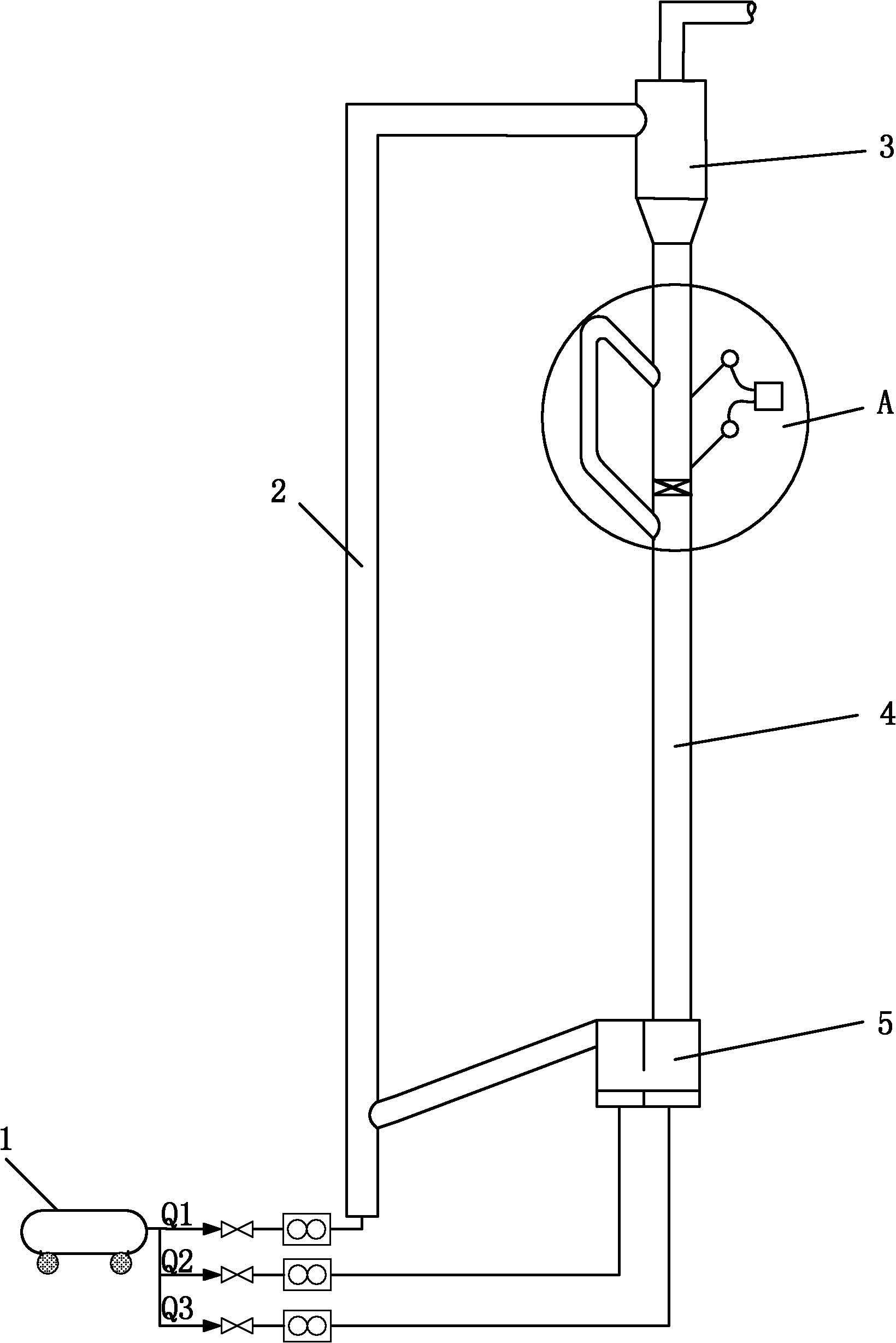

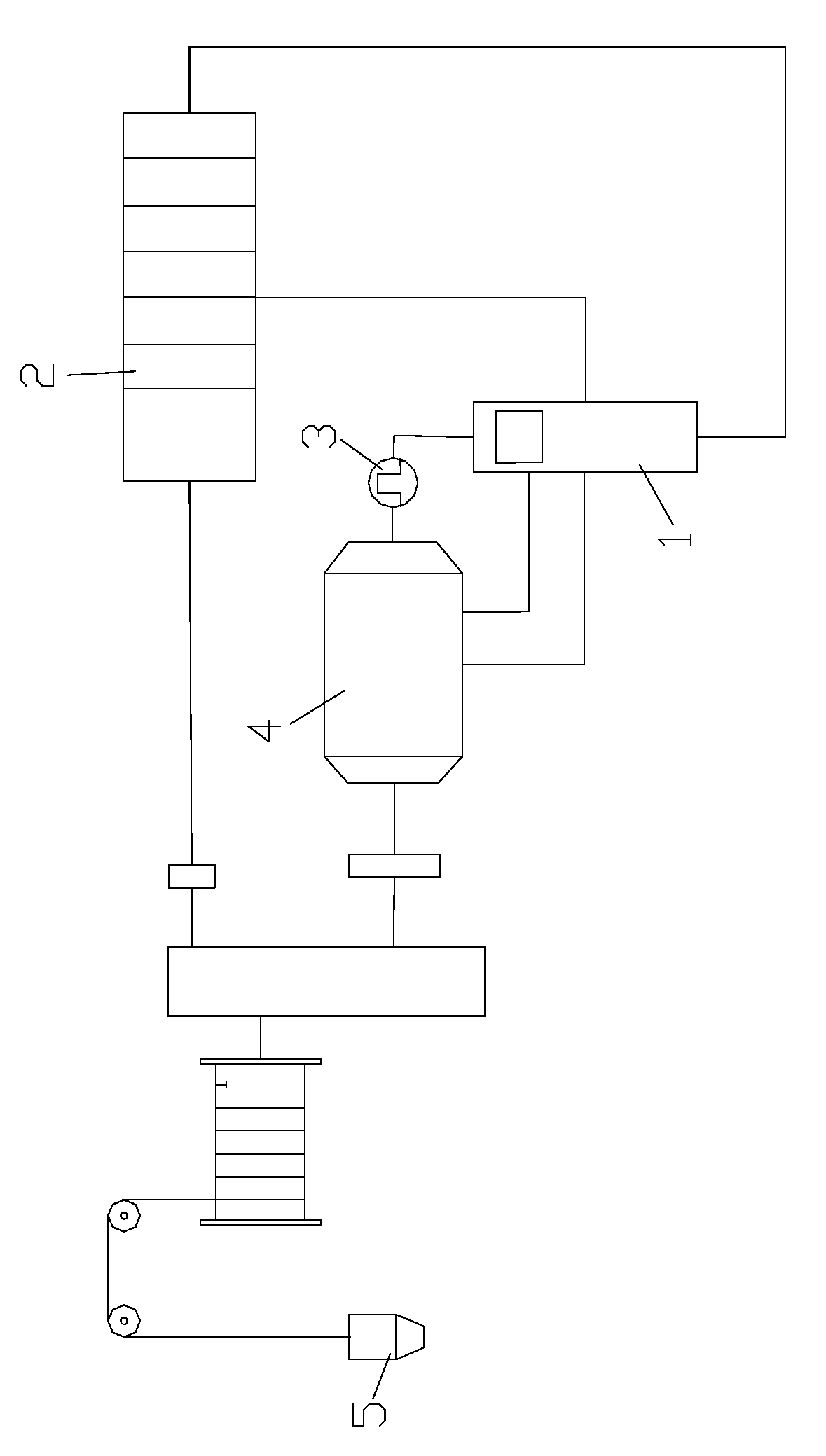

Device and method for measuring solid circulation flow rate

ActiveCN102759382AAdvantages Measuring DeviceAdvantage methodMass flow measurement devicesStock levelTransmission technology

The invention discloses a device and a method for measuring solid circulation flow rate, which relate to the solid transmission technology. The device for measuring solid circulation flow rate is composed of components, such as a valve, a high-low stock level switch, a timing device, a material measuring section, a balance pipe and the like. The position of the material is detected through the high-low stock level switch, a signal is transmitted to the timing device, and the material accumulation time is displayed, so that manual timing error is avoided, and measurement accuracy is improved greatly. The material measuring section of the device provided by the invention can be obtained by directly selecting one section of a dip leg, and the device is simple in structure and convenient to operate. With the balance pipe, the interference of the measuring process on the system operation can be reduced, and the device for measuring solid circulation flow rate is especially suitable for measuring the solid circulation flow rate of the devices with high solid circulation flow rate, and also can be used for measuring the solid circulation flow rate under a pressurization condition.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

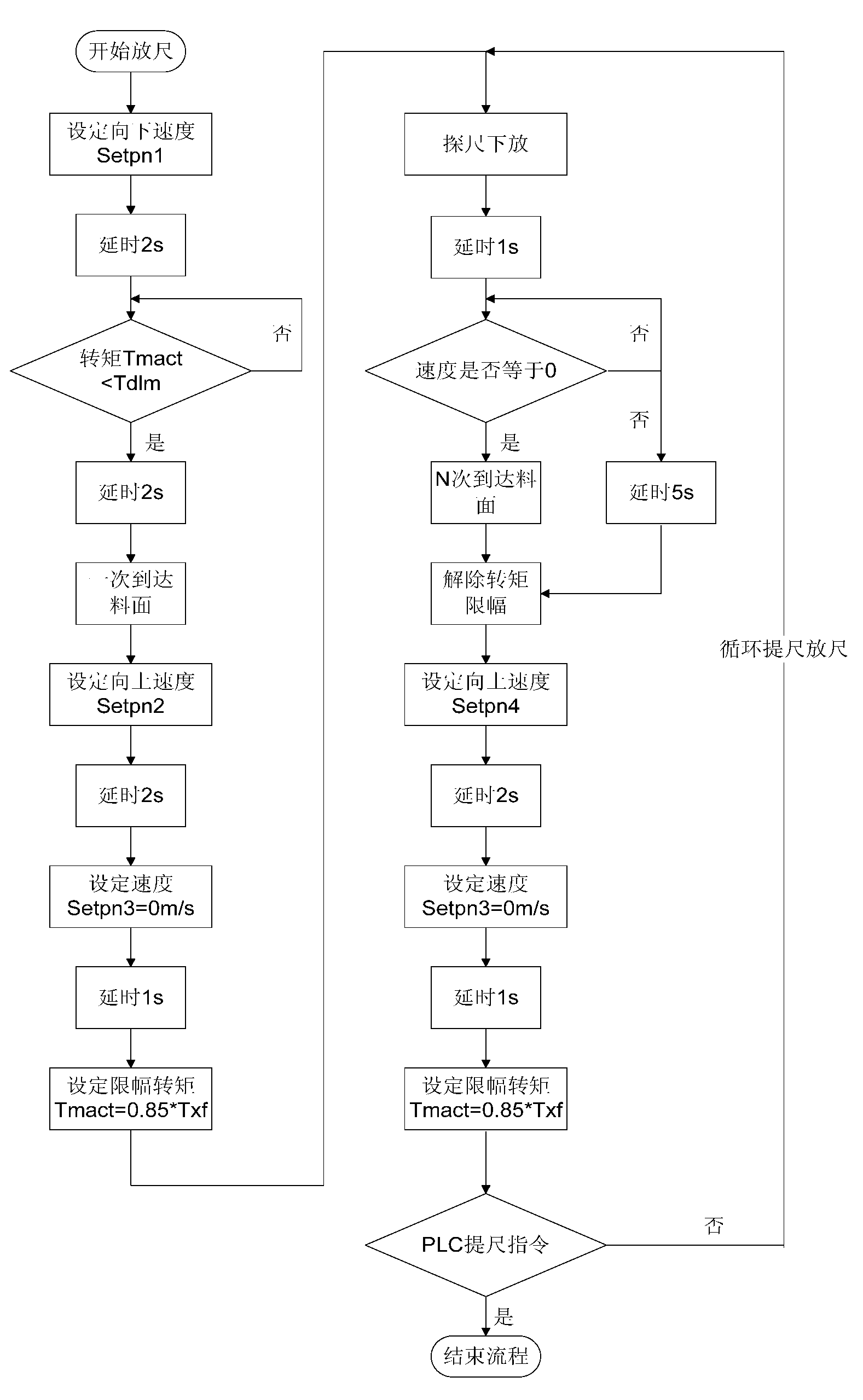

Control method of sounding rod to follow up charge level

InactiveCN102796834AStay tightAvoid diggingBlast furnace detailsChecking devicesFrequency changerStock level

The invention relates to a control method of a sounding rod to follow up a charge level. An AC (alternating current) frequency converter is controlled to complete the discharge of the sounding rod, follow up the charge level and lift up the sounding rod, and a PLC (programmable logic controller) makes an instruction, and is communicated with a frequency converter to send out a measurement starting command to the frequency converter, and the actual rotation speed of an increment type encoder measuring motor. The method comprises the following steps that (1) when the material is distributed on the top of a furnace, the PLC controller sends out the start command to the frequency converter; (2) the frequency converter runs, the sounding rod is opened, and the sounding rod lifts down at a constant control mode; and (3) the frequency converter monitors the motor torque and the torque mutation, the frequency converter judges that the sounding rod has reached the charge level, the sounding rod is slightly and upwards lift up, and the sounding rod is discharged till reaching to a stock level. According to the technical scheme, the passive follow-up mode is changed into an active mode, the sounding rod carries out the spot measurement of the charge level at a tinny amplitude after reaching the charge level, the running status of the sounding rod is completely controlled by the frequency converter, the tightness of a chain can be kept, and the burying of the sounding rod caused by the collapsed material can be avoided.

Owner:WISDRI ENG & RES INC LTD

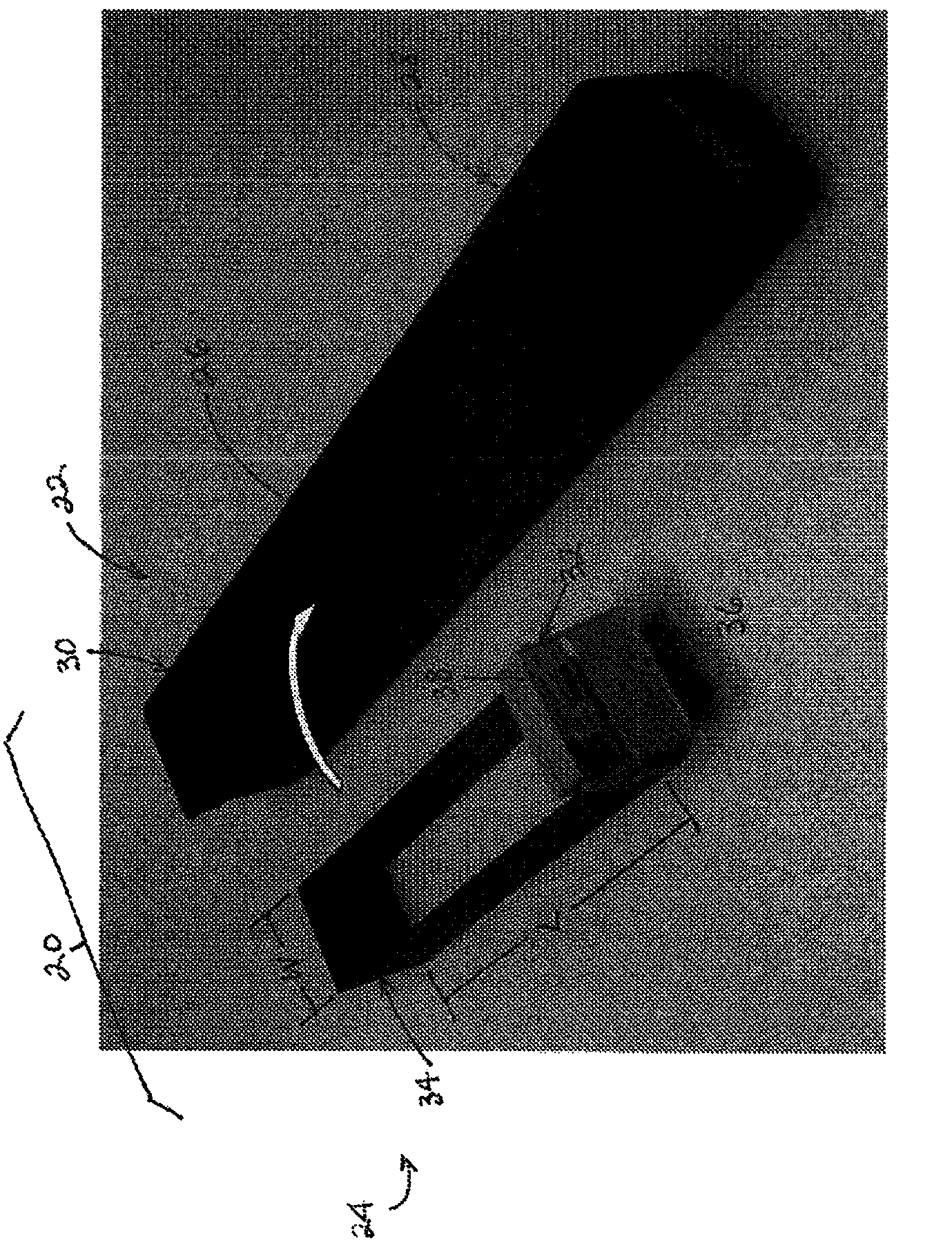

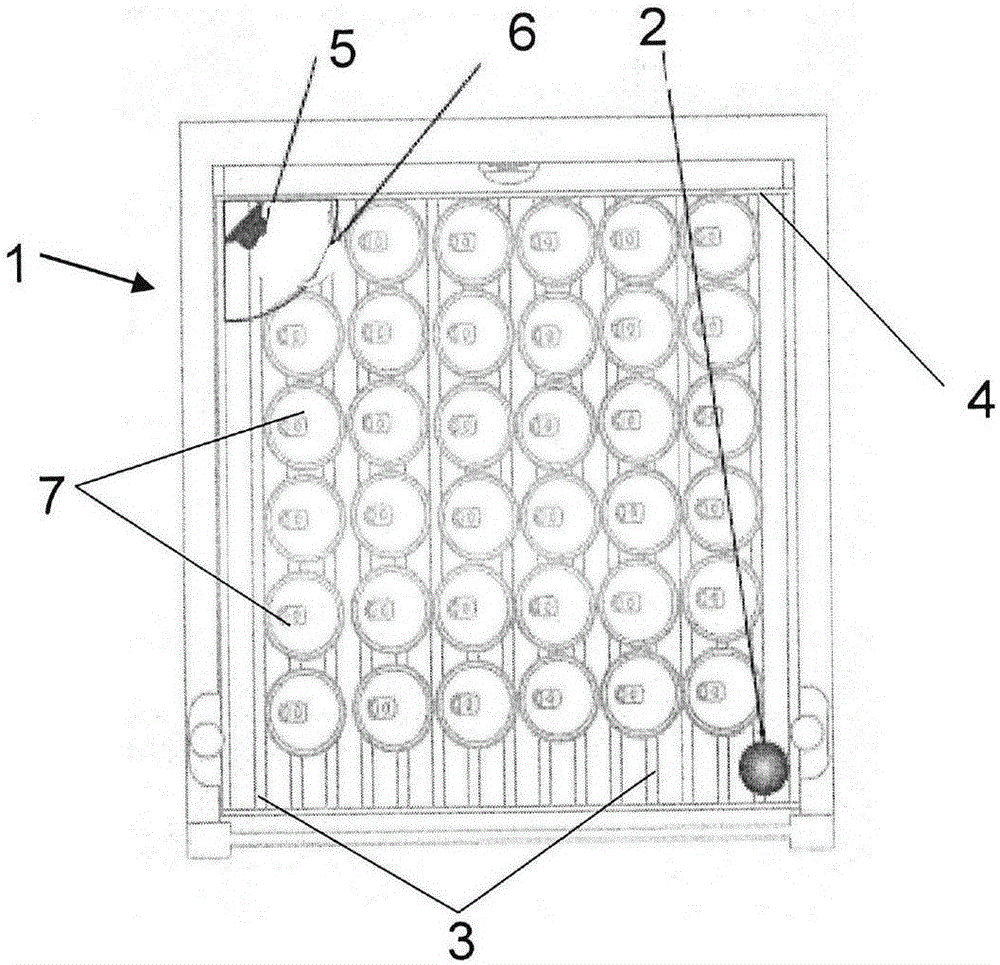

Mount for dental ceramic blocks

The present invention is directed to a dental mount for receiving and retaining a plurality of different dental ceramic blocks used in dental restoration treatments, wherein the dental mount comprises a substantially flat front face having a plurality of dental ceramic block receiving holes located thereon; each of the dental ceramic block receiving holes being dimensioned to form a retaining fit with any one of the different dental ceramic blocks. The advantage of providing a dental mount with dedicated holes for retaining any one of the dental ceramic blocks is that the dental mount can be used to comparatively present all the different types of dental ceramic blocks next to one another in an organized and graded manner so that a dentist may make quick and accurate comparisons between the different types of dental ceramic blocks. Furthermore, the dentist can quickly assess their stock levels by glancing at the dental mount. A further advantage is that the dental ceramic blocks are securely held apart from one another on the dental mount and therefore cannot damage one another when they are moved or transported.

Owner:GATE DENTAL SERVICES

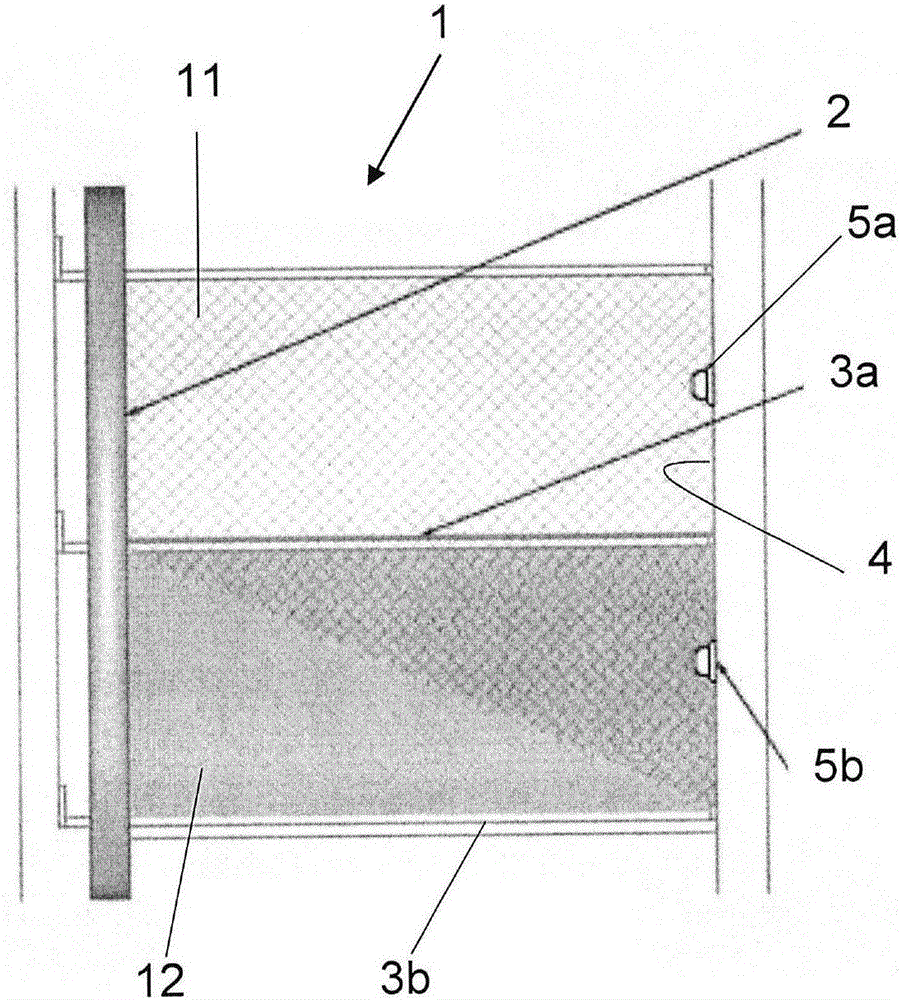

Light shield

Disclosed is a sensor shield (6, 6a, 6b) for use in a multi-shelf merchandise display unit (1) including a plurality of sensors (5, 5a, 5b) mounted on a wall (4) of the unit (1) and opposite a source of illumination (2), in which each sensor (5, 5a, 5b) corresponds to a single shelf (3, 3a, 3b) and in which the shelves (3, 3a, 3b) are at least semi-porous to the illumination. The shield (6, 6a, 6b) comprises i) a plate having a length that is sufficient substantially to reduce or prevent incident illumination from the shelf (3, 3a, 3b) above reaching the sensor (5, 5a, 5b); and ii) means (26) n to attach the plate to casing of or around the sensor (5, 5a, 5b) or the wall (4) of the unit (1). The plate is opaque to the illumination detected by the sensor (5, 5a, 5b). Also disclosed is a method to reduce the interference of light in a multi-shelf merchandise display unit (1) from shelves (3, 3a, 3b) above a shelf (3, 3a, 3b) on which stock levels are being measured and a method for monitoring stock levels in a retail display cabinet by measuring light entering the retail display cabinet.

Owner:ELSTAT ELECTRONICS

Stock system

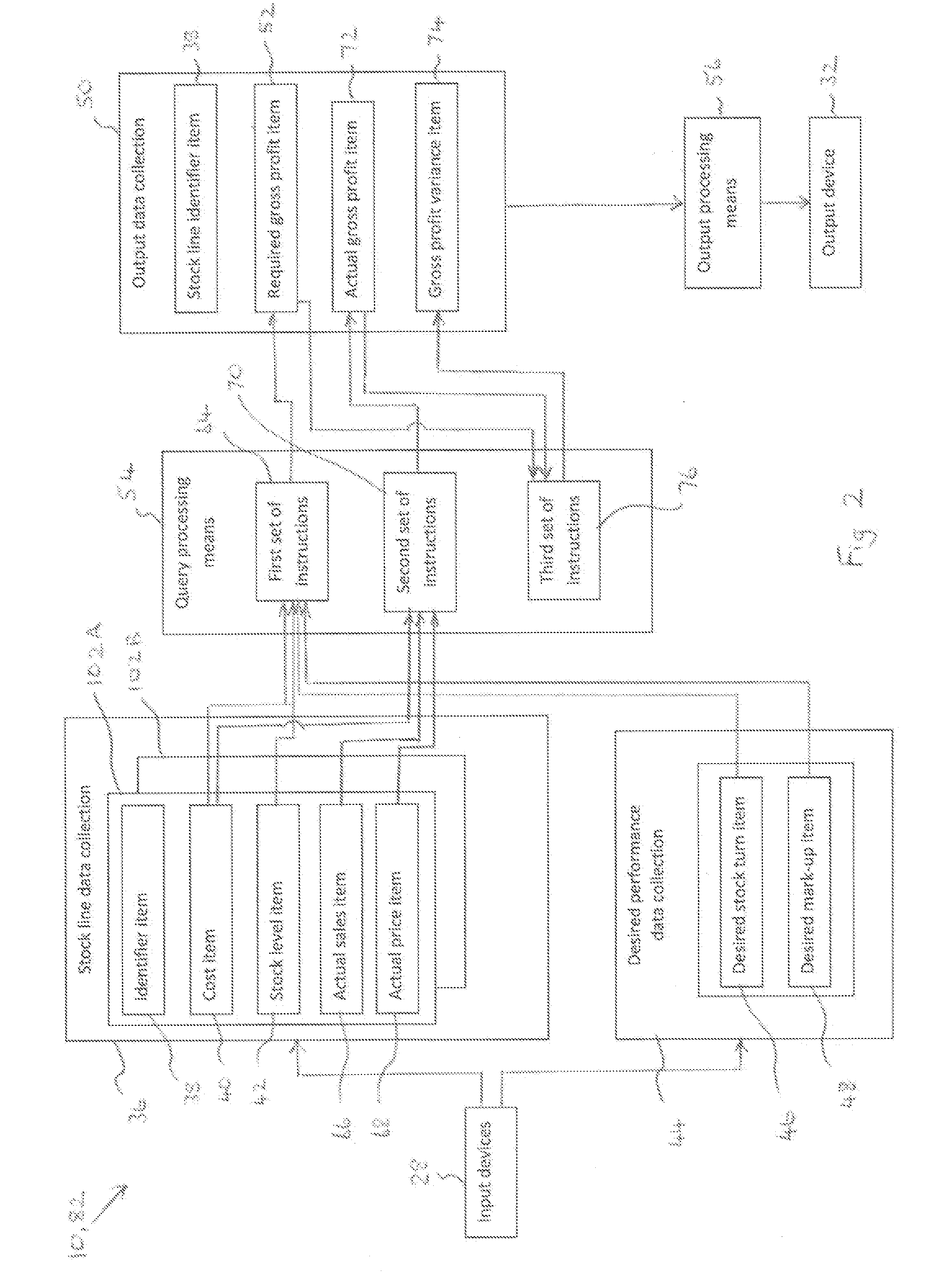

A stock system which includes a stock management apparatus. The apparatus has an input device, a memory, an output device and a processor. The memory device includes a stock line data collection which relates to a stock line and has an identifier unique to the stock line, a cost item relating to the cost incurred per stock item and a stock level item. The processor has query processing means for generating the required gross profit item for the stock line from a desired stockturn item, the desired mark-up item, the cost item and the stock level item for the stock line.

Owner:PORAY PSTROKONSKI MATTHEW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com