Method and device for controlling induced draft temperature of grate cooler of cement afterheat generation system

A technology of waste heat power generation and grate cooler, which is applied in the direction of temperature control, temperature control, non-electric variable control, etc. by using electric mode, and can solve the problems of temperature fluctuation of the waste heat of the cooler, which is not conducive to system operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

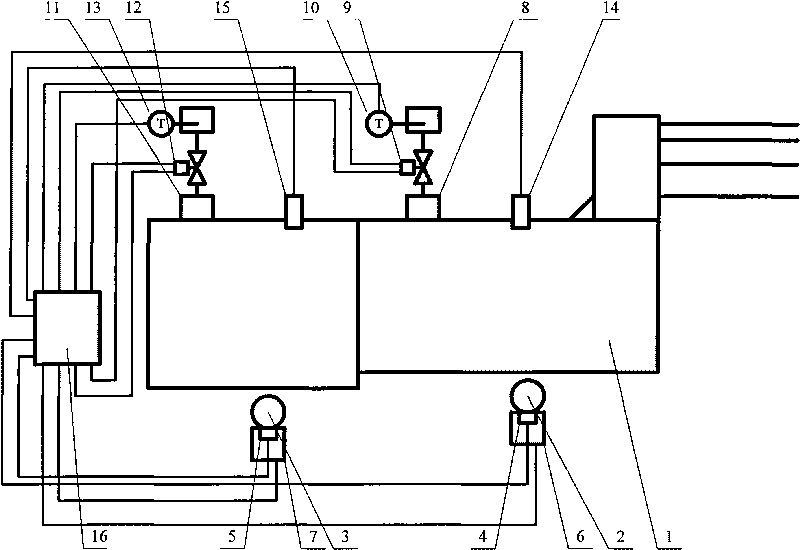

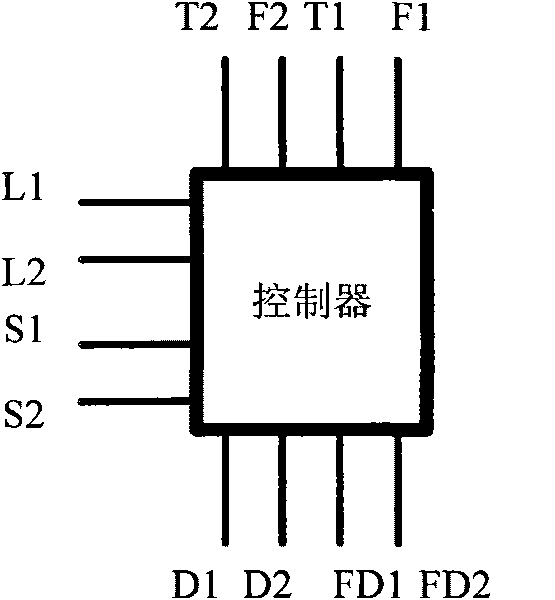

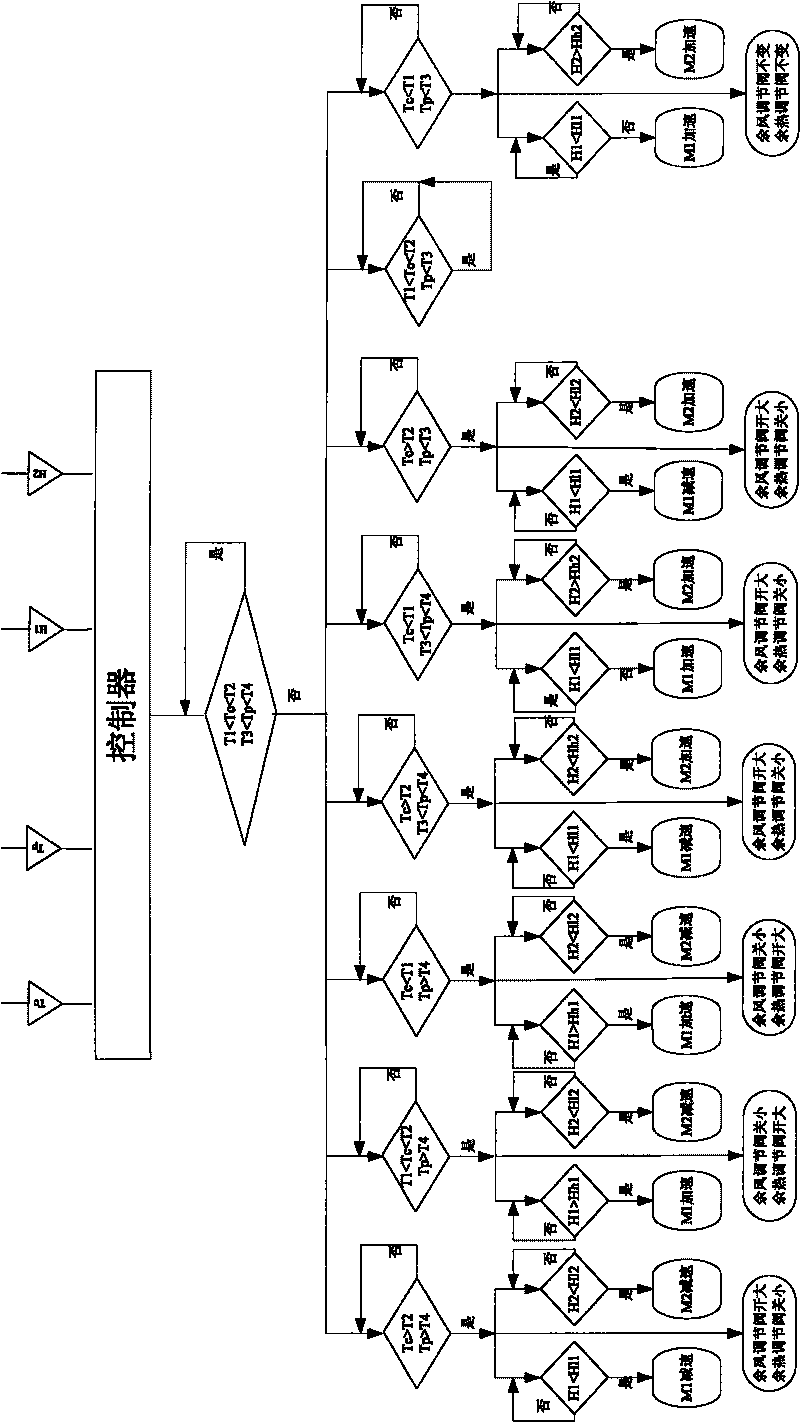

[0044] This embodiment is a grate cooler exhaust temperature control method used in a cement waste heat power generation system. The controller realizes the opening of the waste heat utilization damper in the grate cooler, the opening of the residual air damper, and the rotational speed of a section of the main transmission shaft. and the speed of the second-stage main transmission shaft are controlled, such as Figure 4 As shown, it specifically includes the following steps:

[0045] (1) In the controller 16, the set value ranges of waste heat utilization exhaust temperature, residual air temperature, the first stage material level of the grate cooler and the second stage material level of the grate cooler are respectively set;

[0046] (2) Waste heat utilizes the exhaust air temperature detector 10 and the residual air temperature detector 13 to detect the real-time wind temperature in the waste heat exhaust pipe 8 and the waste air exhaust pipe 11 respectively, and the obta...

Embodiment 2

[0075] This embodiment is used in the grate cooler exhaust temperature control method and device of the cement waste heat power generation system. Compared with the first embodiment, the difference lies in the analysis and calculation of the data by the signal analysis and processing unit of the controller in the control method Adopt fuzzy control.

[0076] Fuzzy control divides the input parameters and output parameters into several levels, and then summarizes the fuzzy correspondence between input and output according to theoretical analysis and experimental experience, and formulates control rules. In this embodiment, the method for analyzing and calculating using fuzzy control is as follows:

[0077] (1) Set fuzzy variables

[0078] a. Waste heat utilization exhaust temperature (YCW): basic domain [250°C, 450°C], quantitative grade range [-5, +5]. Preset fuzzy subset: {too high, slightly high, normal, slightly low, too low}, abbreviated as: {TH, SH, OK, SL, TL};

[0079...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com