Patents

Literature

30 results about "Solid circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

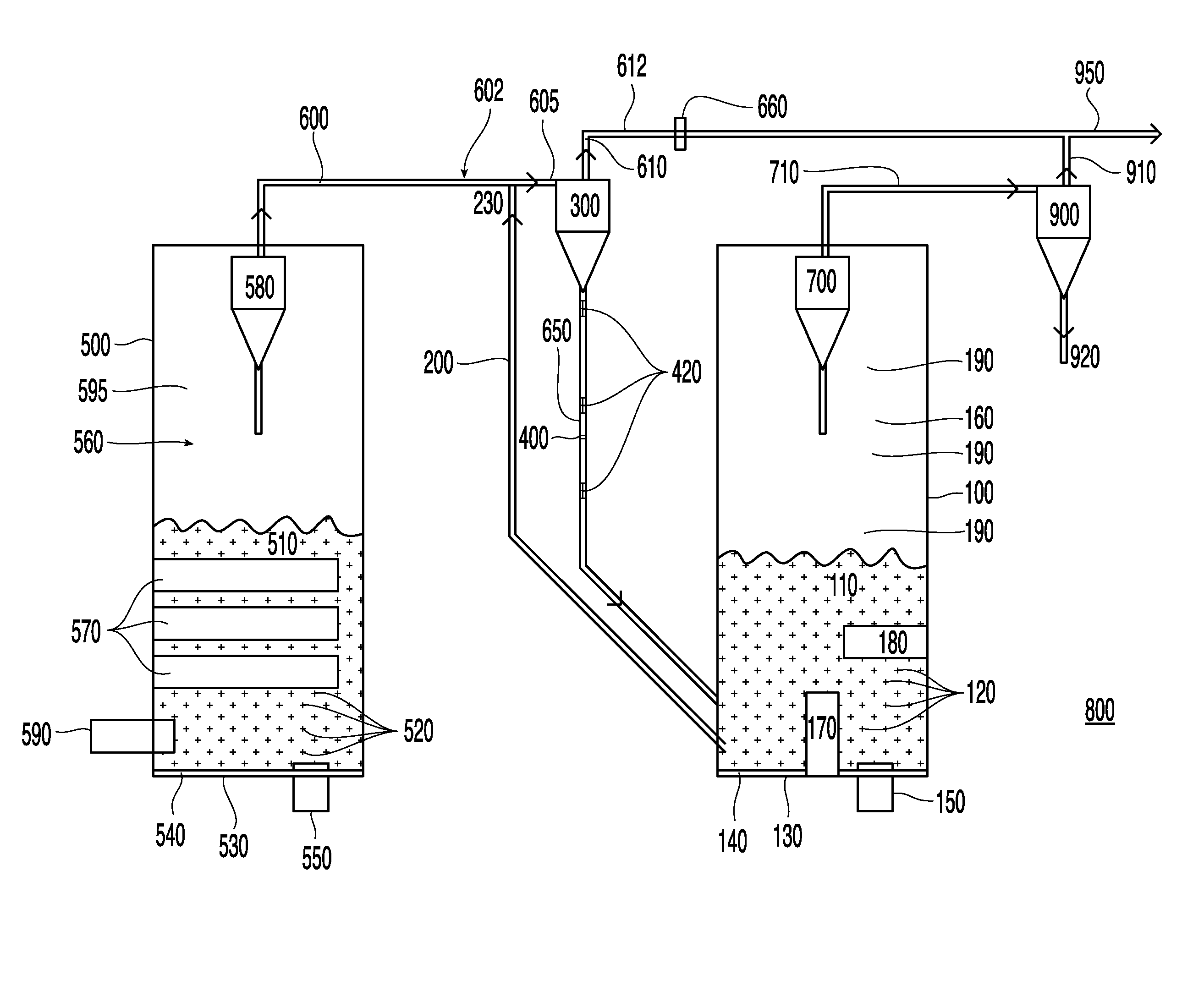

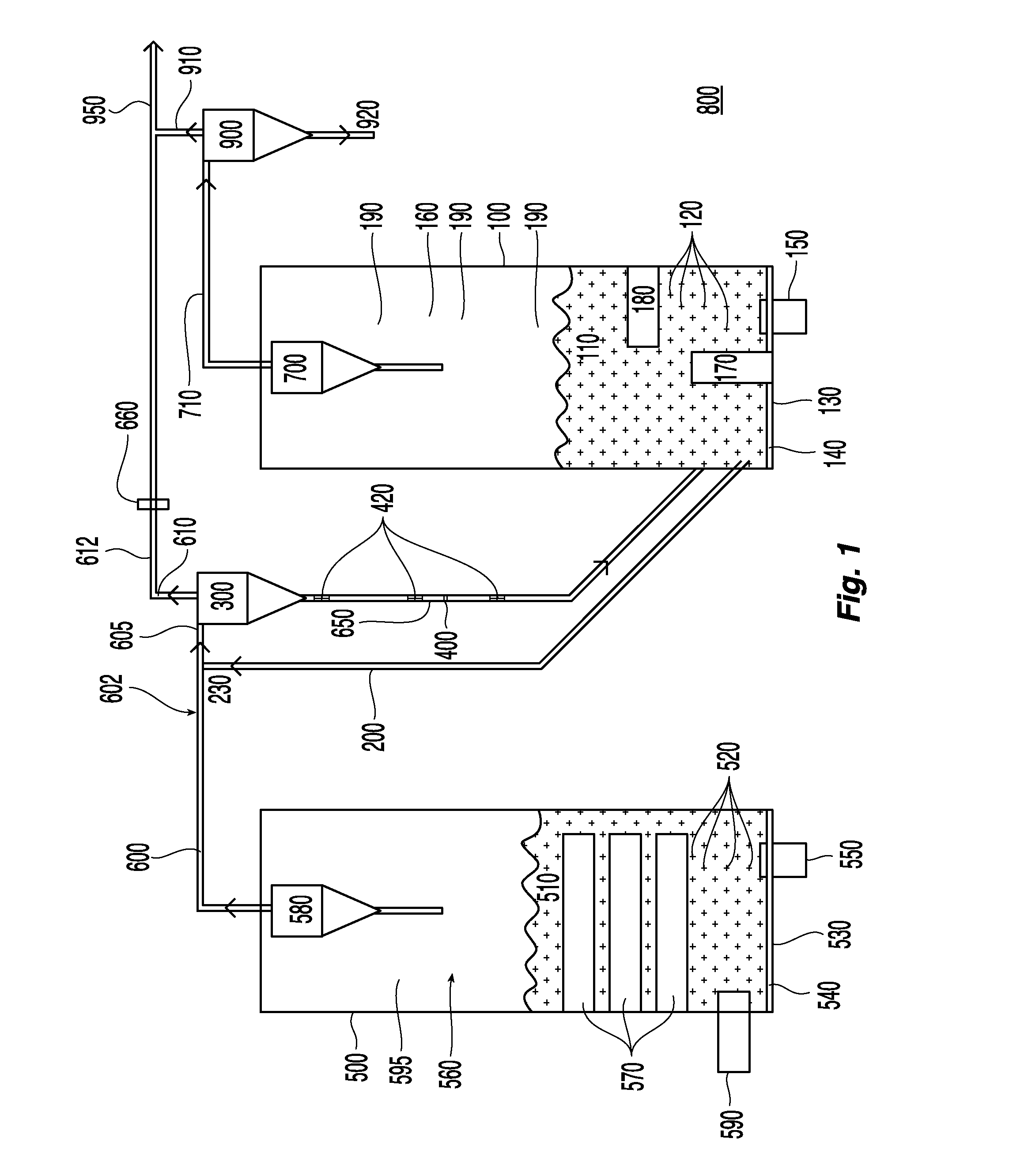

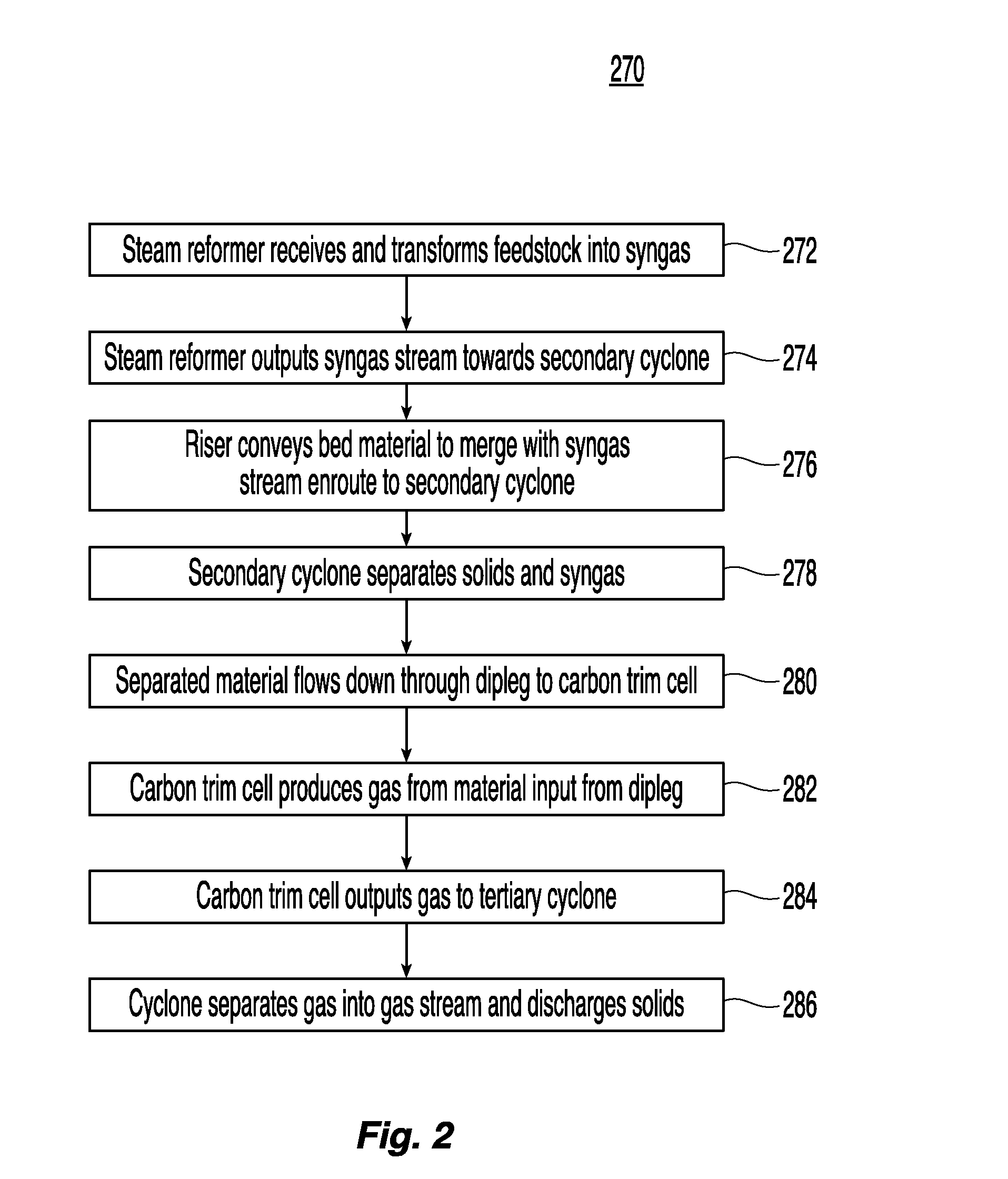

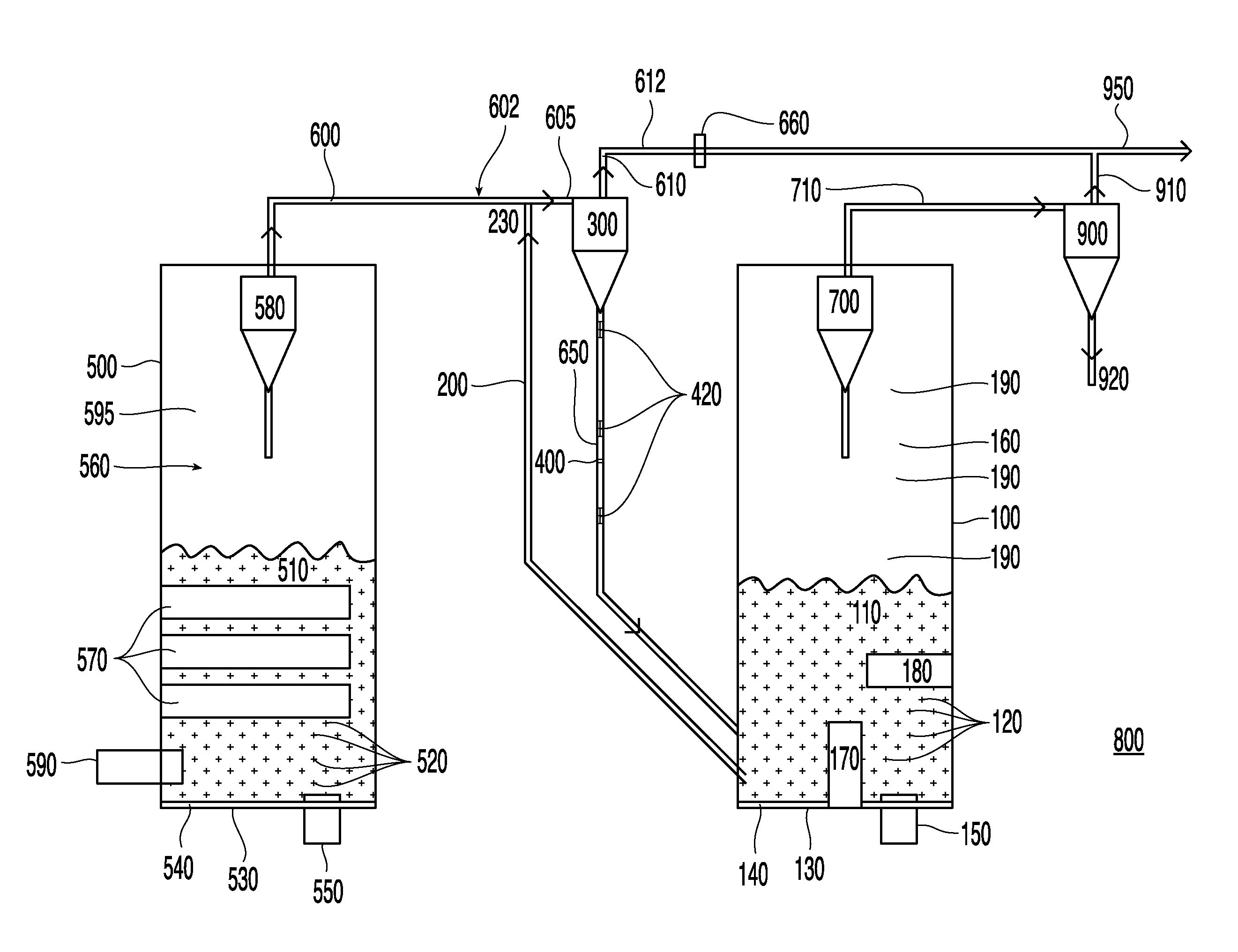

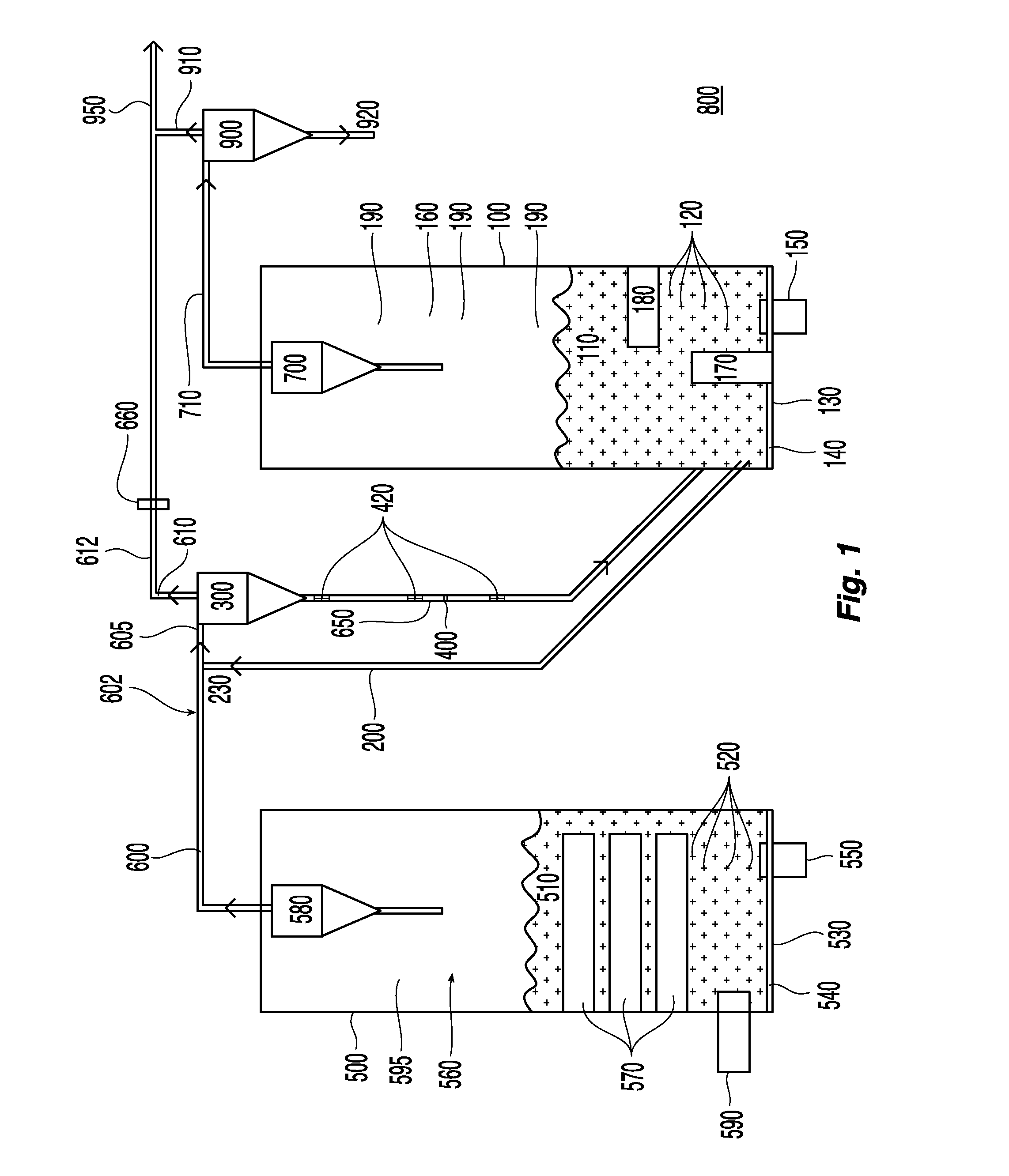

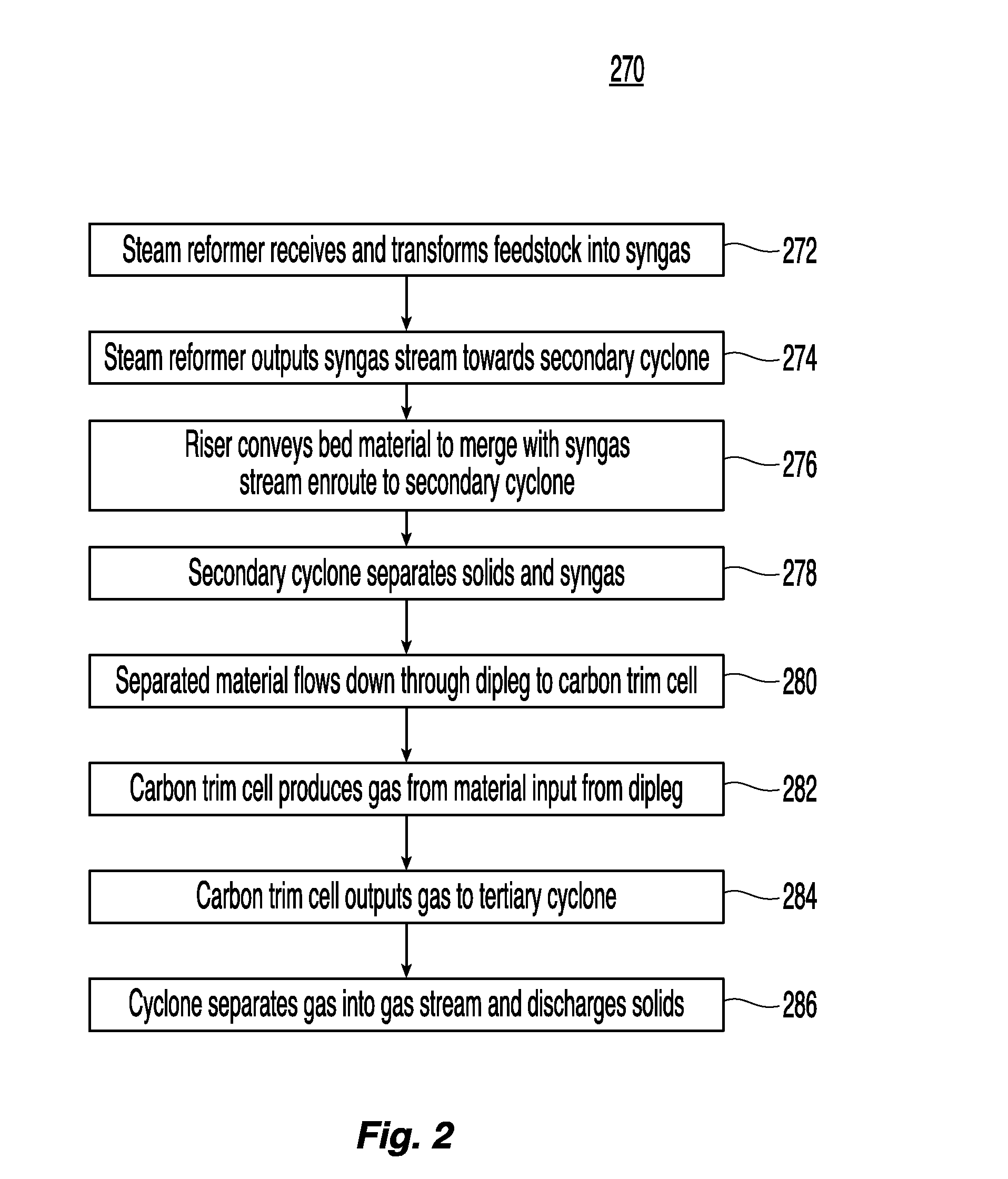

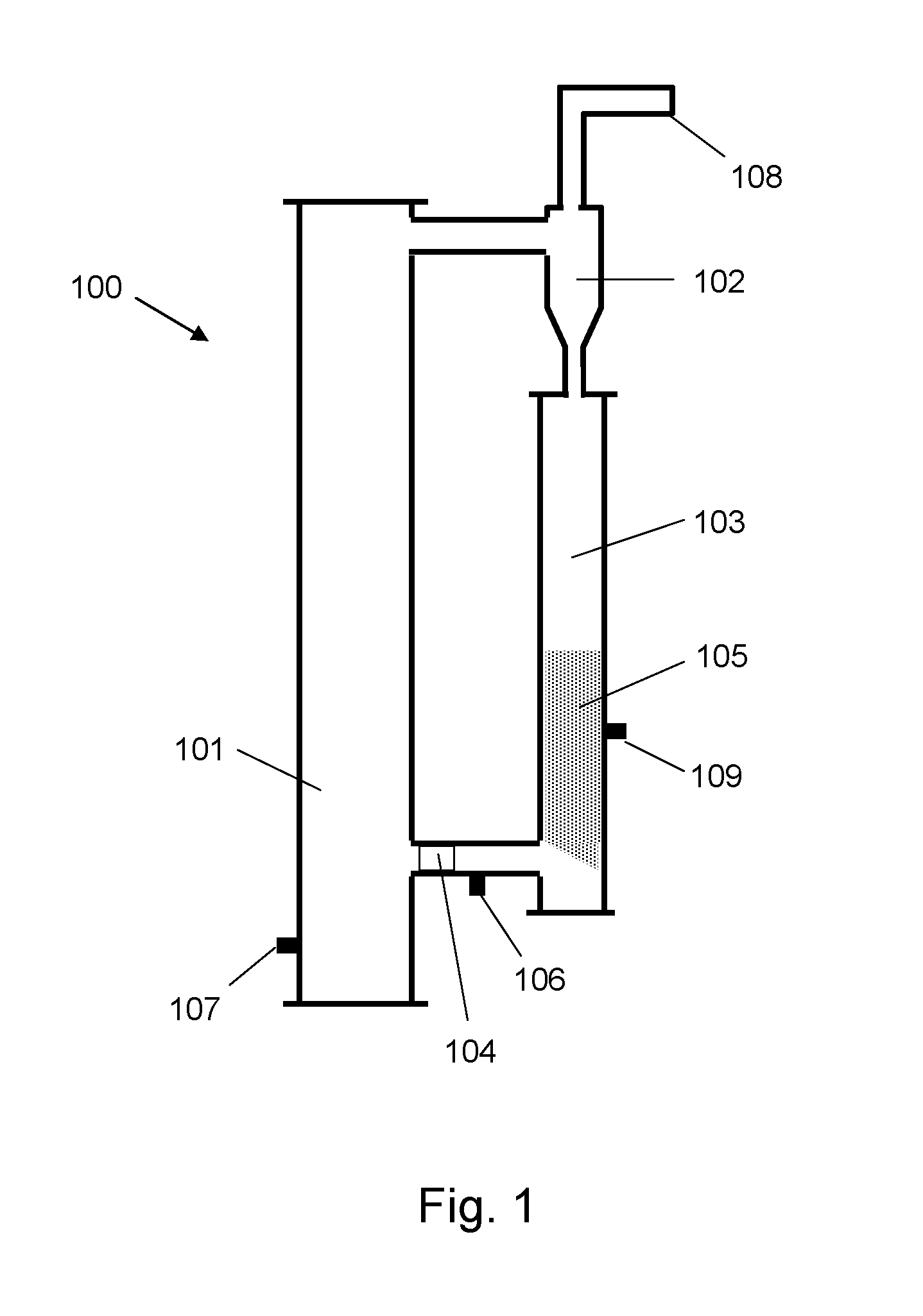

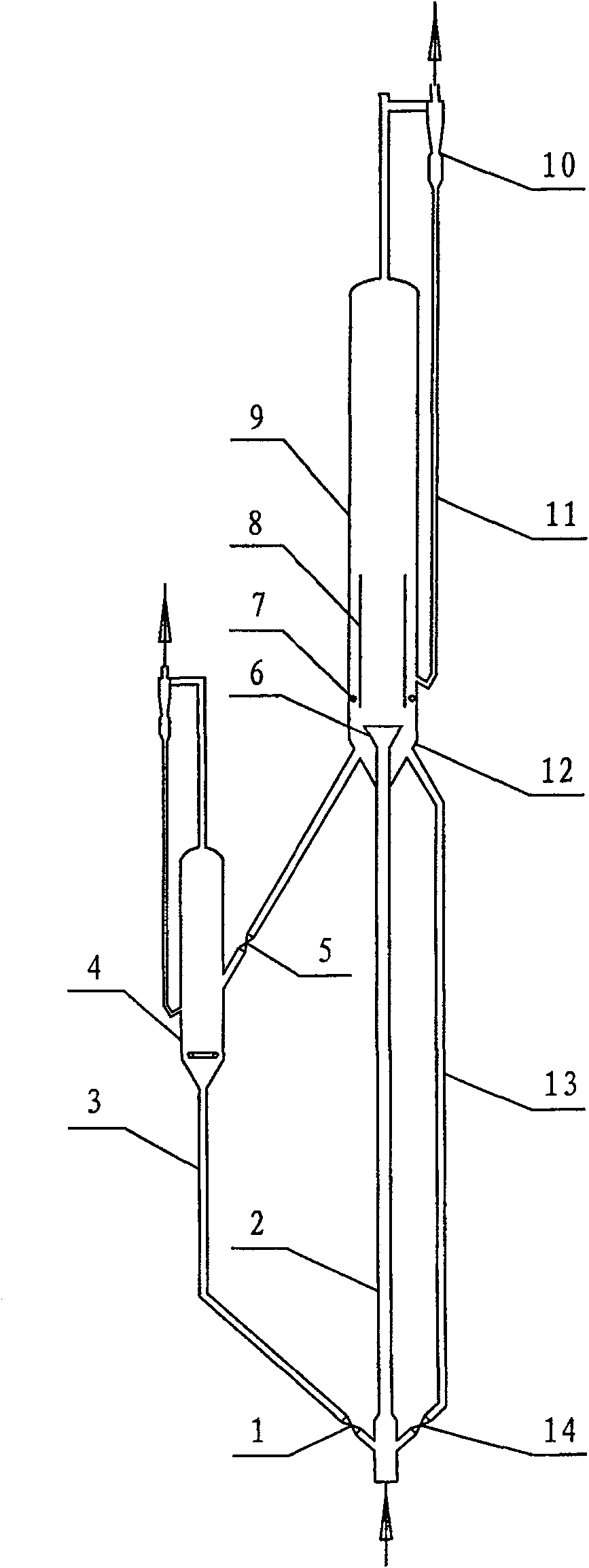

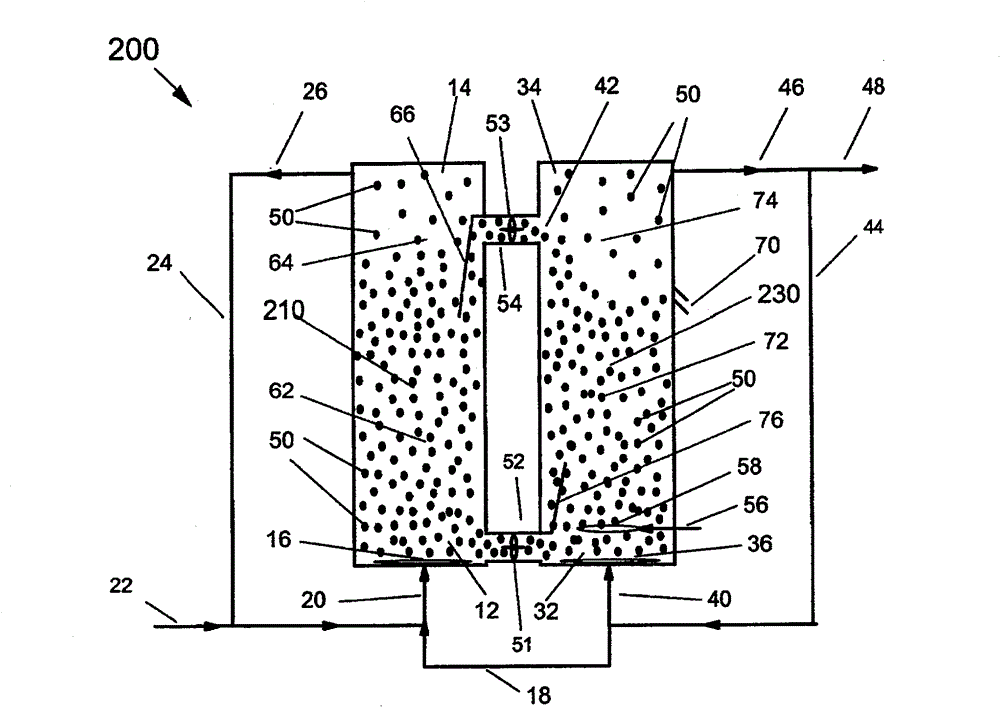

Solids Circulation System and Method for Capture and Conversion of Reactive Solids

ActiveUS20120111109A1Specific gravity by measuring pressure differencesGasifier mechanical detailsCycloneFluid transport

A solids circulation system receives a gas stream containing char or other reacting solids from a first reactor. The solids circulation system includes a cyclone configured to receive the gas stream from the first reactor, a dipleg from the cyclone to a second reactor, and a riser from the second reactor which merges with the gas stream received by the cyclone. The second reactor has a dense fluid bed and converts the received materials to gaseous products. A conveying fluid transports a portion of the bed media from the second reactor through the riser to mix with the gas stream prior to cyclone entry. The bed media helps manipulate the solids that is received by the cyclone to facilitate flow of solids down the dipleg into the second reactor. The second reactor provides additional residence time, mixing and gas-solid contact for efficient conversion of char or reacting solids.

Owner:THERMOCHEM RECOVERY INT

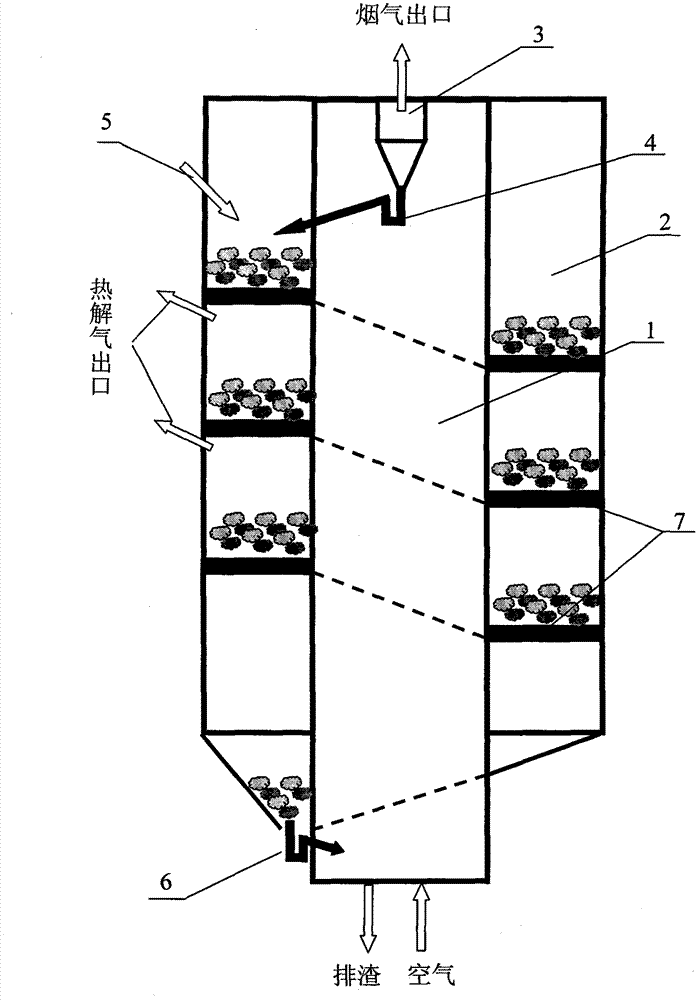

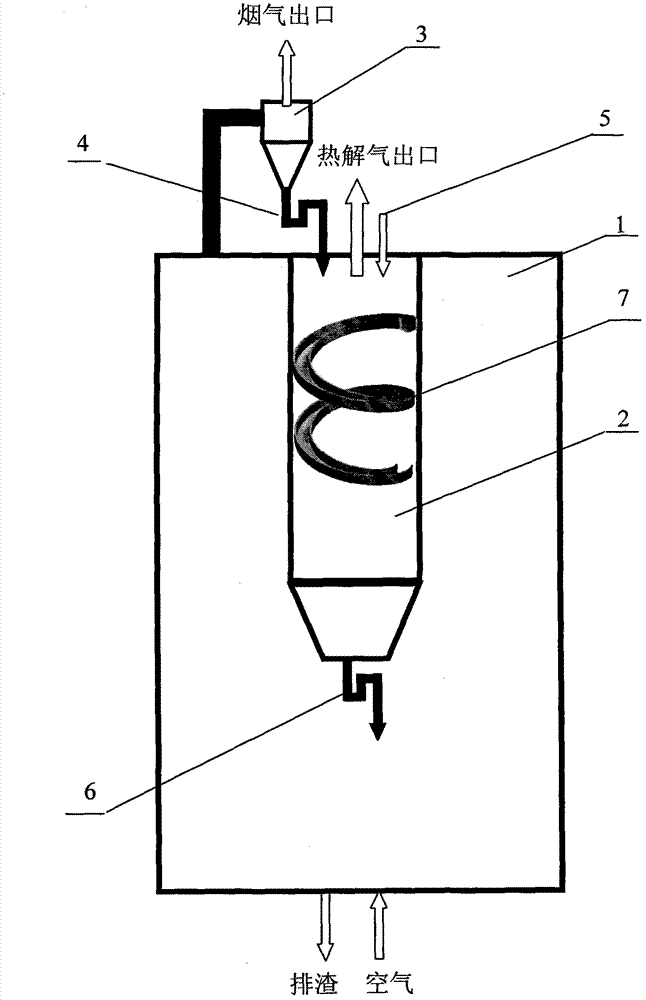

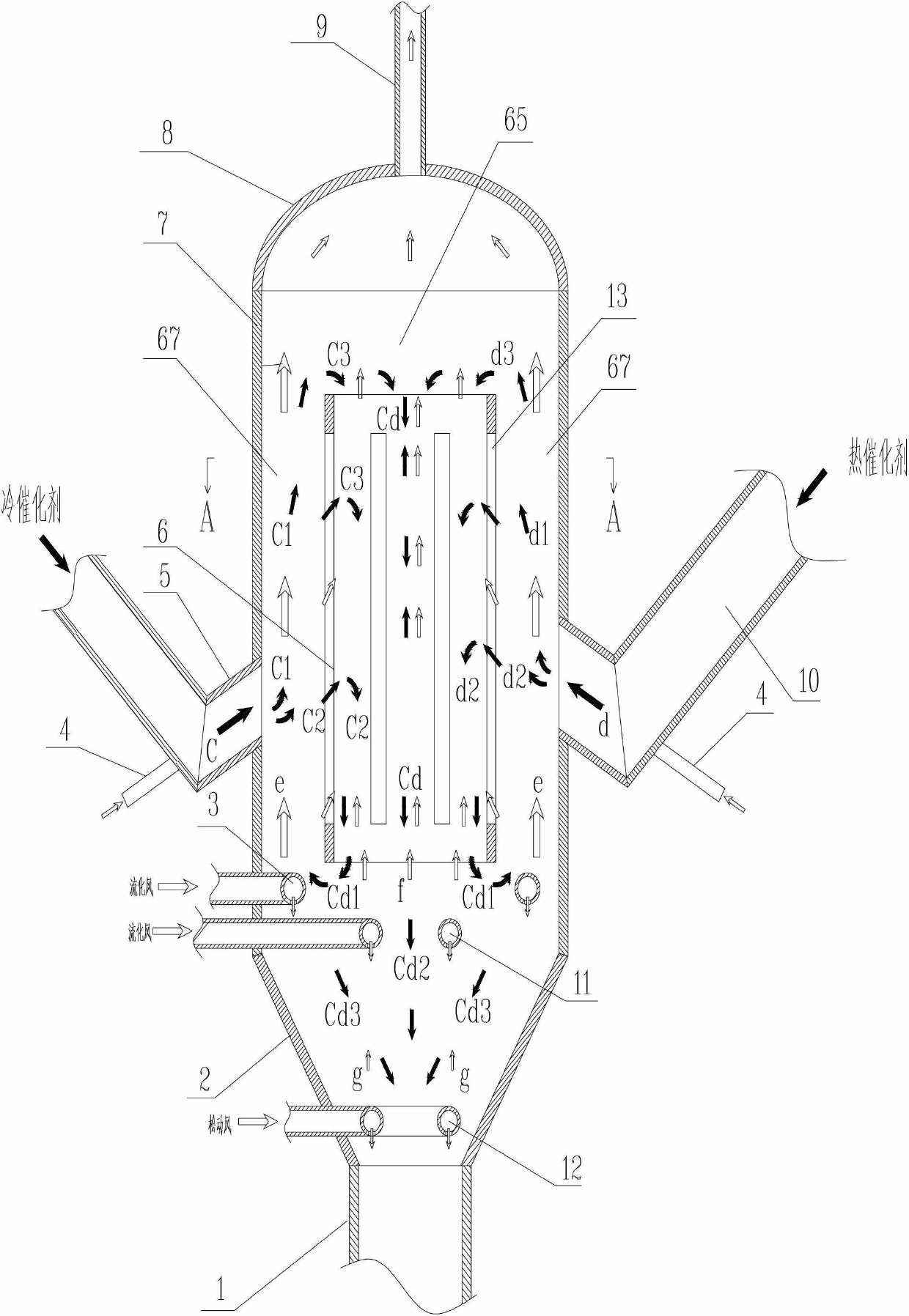

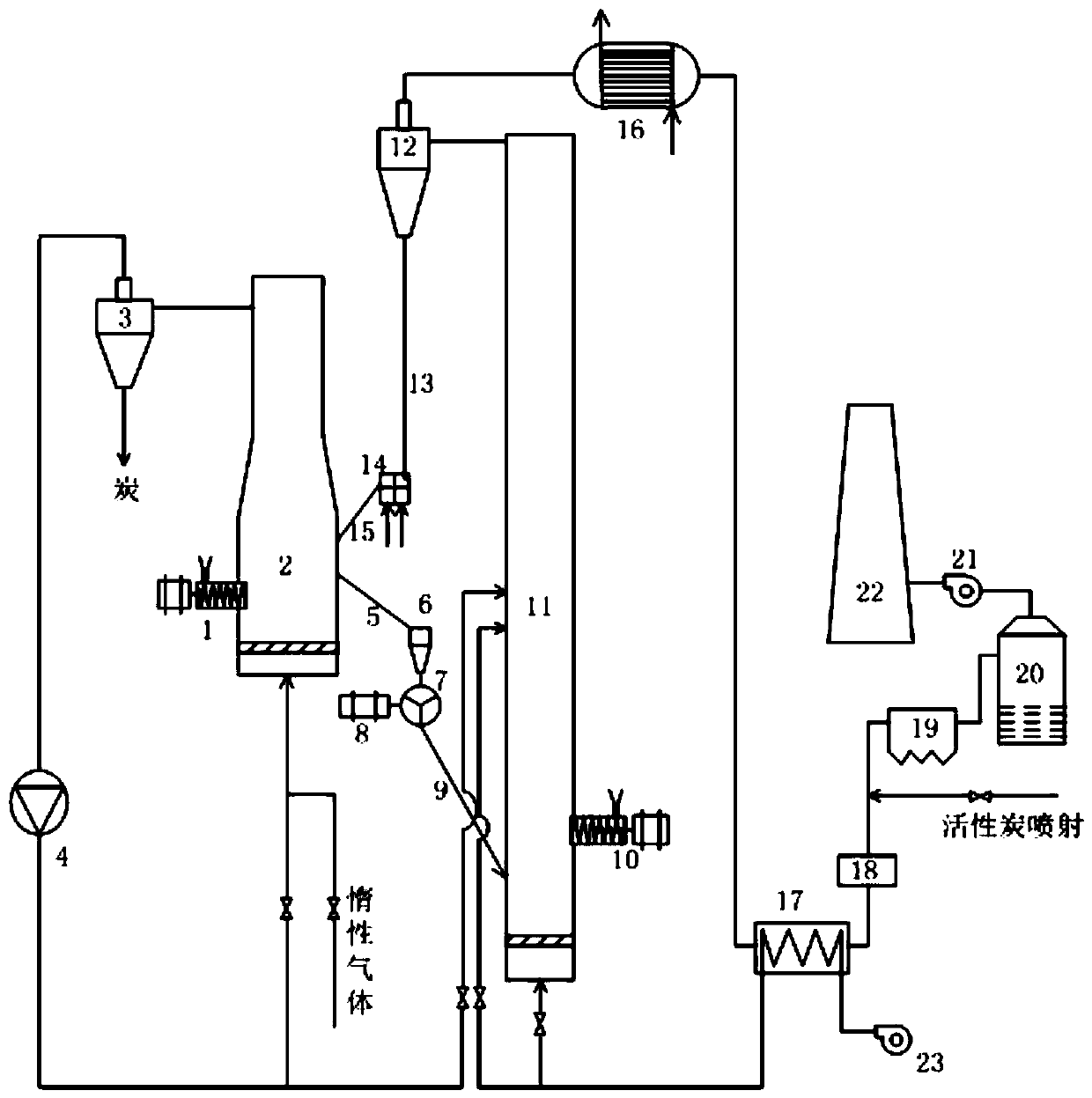

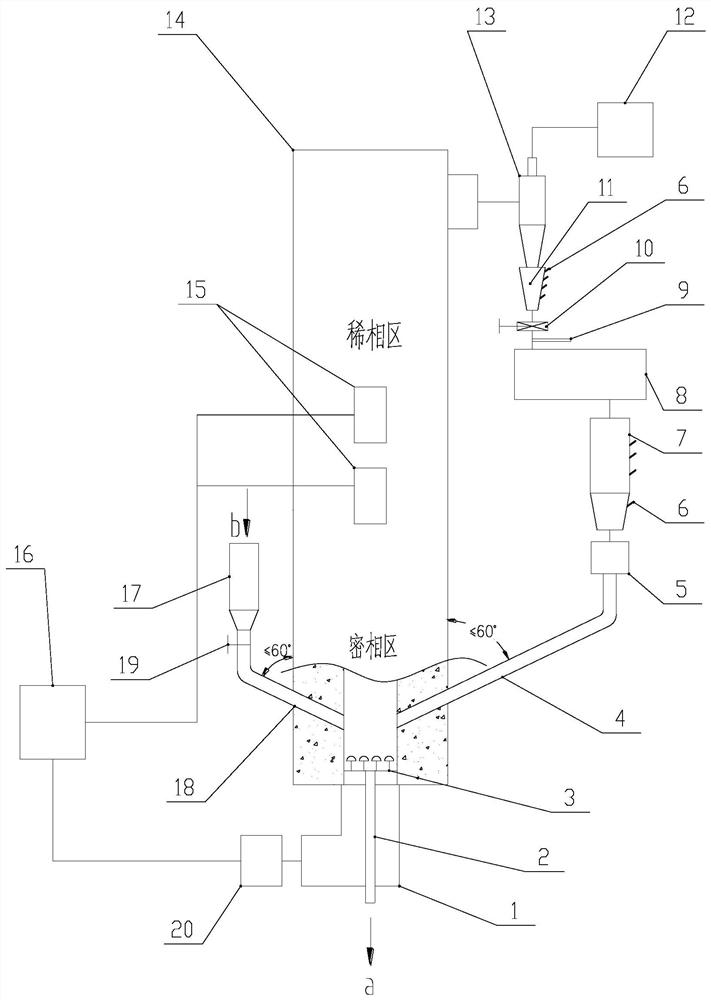

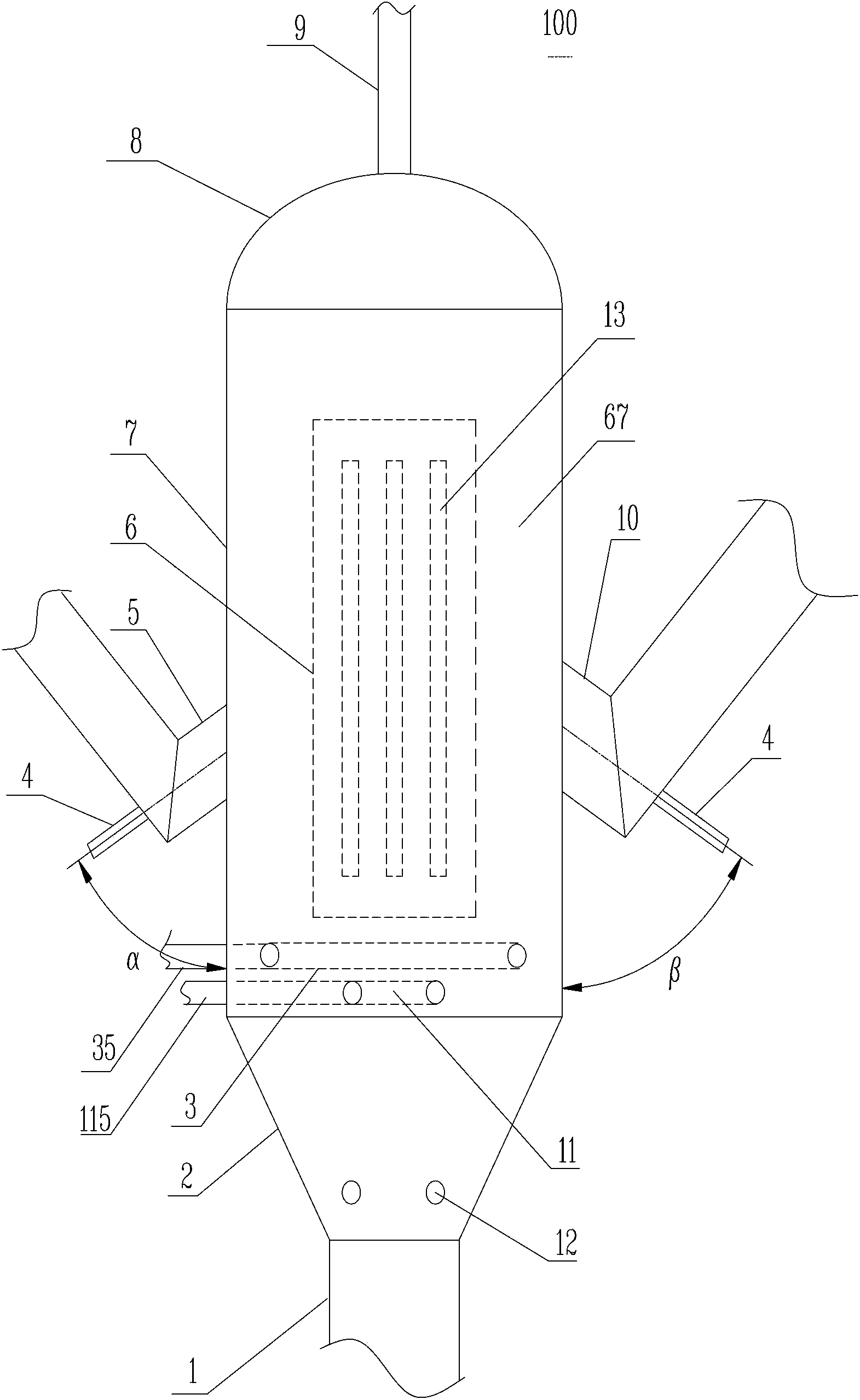

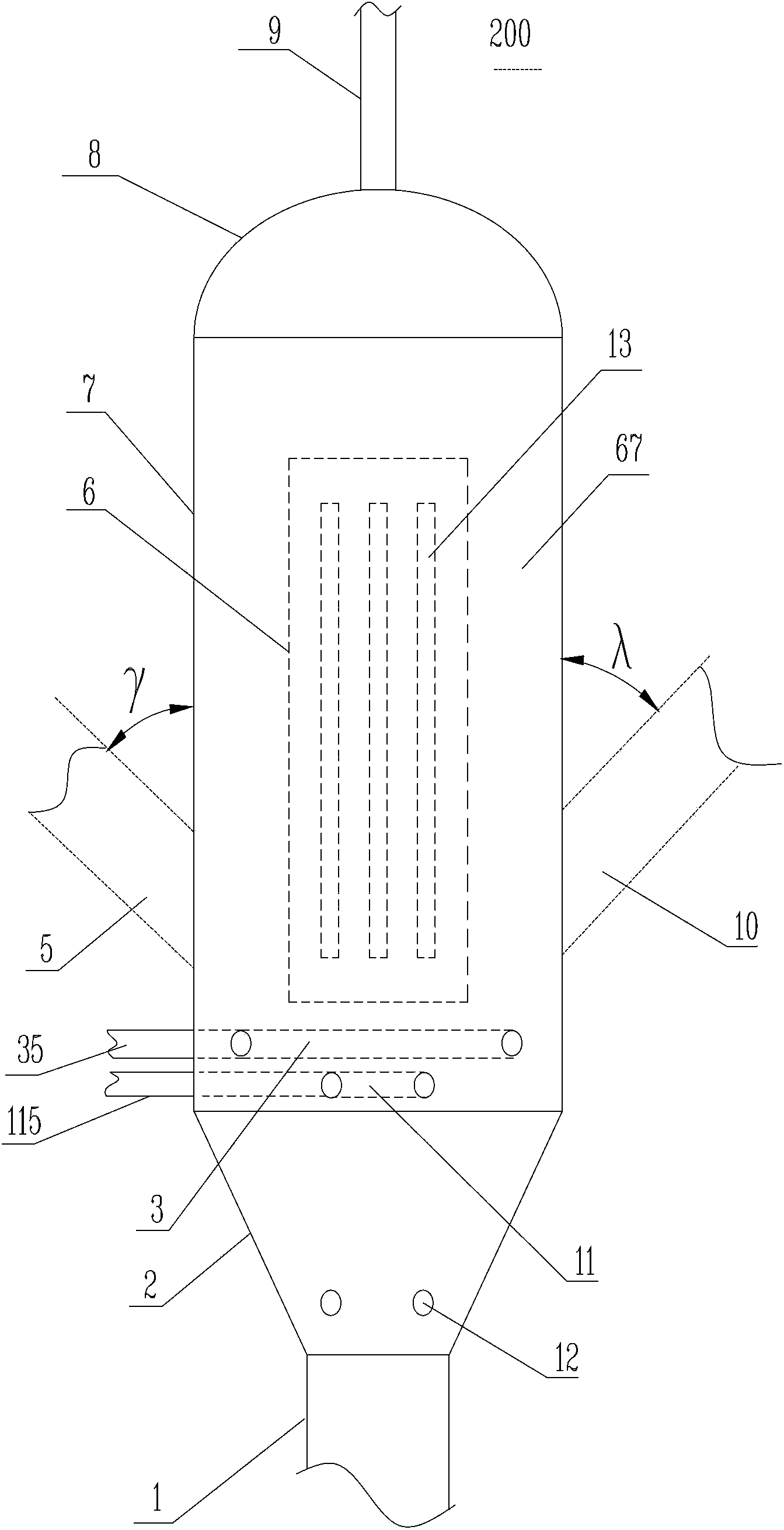

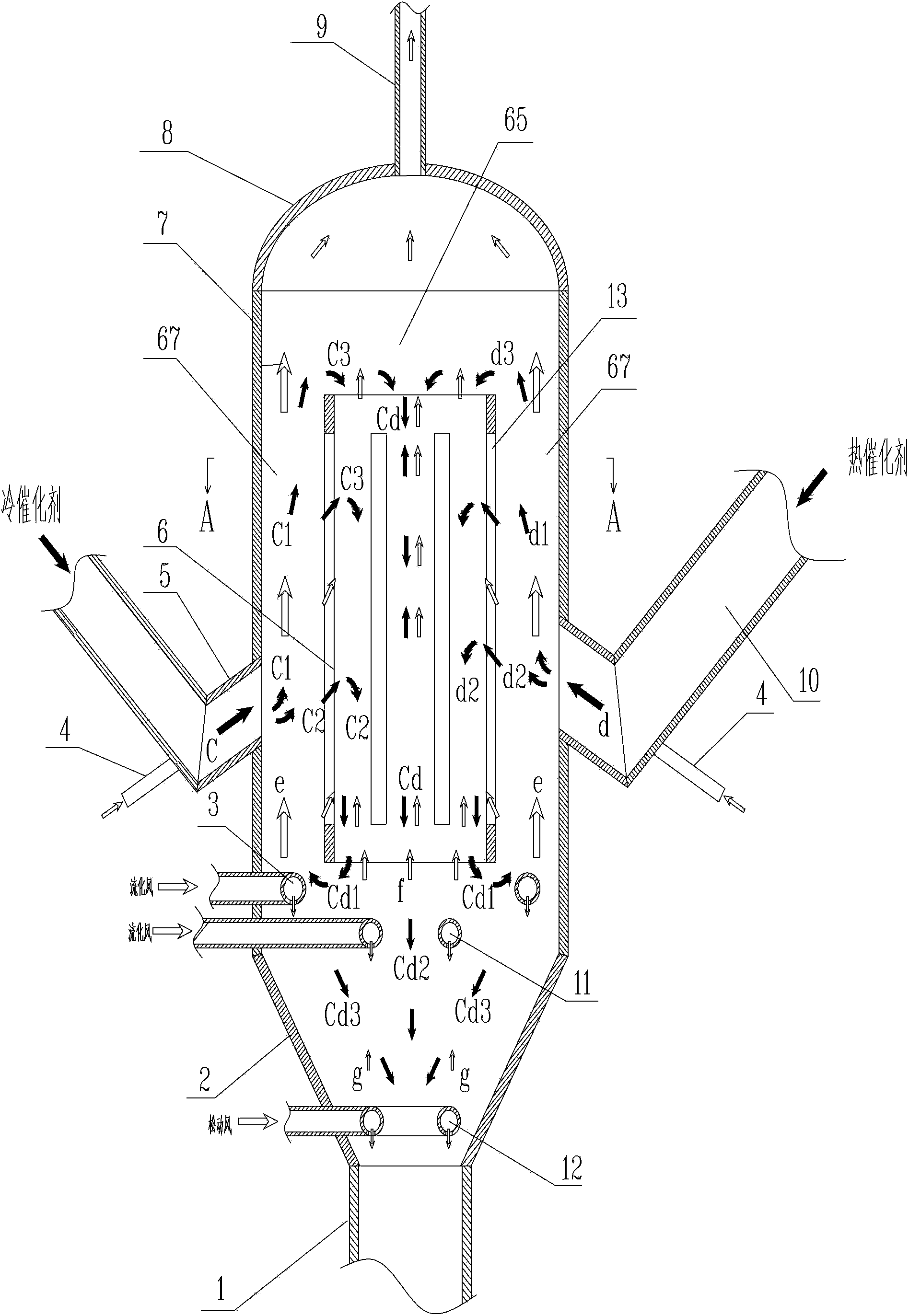

Pyrolysis and combustion coupled circular reaction method and device

InactiveCN103361087AReduce heat lossImprove thermal efficiencyDirect heating destructive distillationEnergy inputHeat carrierHeat conducting

The invention relates to a pyrolysis and combustion coupled circular reaction method and device. The method and the device are used for converting fine-grained carbon containing materials such as coal, biomasses and oil shale into oil, gas, heat and other products through fast pyrolysis and combustion. The device mainly comprises a fluidized-bed combustion chamber, a pyrolysis chamber and a solid circulation system. Compared with the prior art, the method has the advantages that the pyrolysis and combustion coupling process is shortened due to the integration of the structures and the functions of the pyrolysis and the combustion, and the device is compact in structure, has high degree of integration and high thermal efficiency and occupies a small floor area. The pyrolysis reaction can be carried out by both a high-temperature wall surface or heat-conducting component obtained by combusting semicoke in the fluidized-bed combustion chamber and a solid heat carrier, thus the pyrolysis capacity, the equipment production capacity and the oil, gas and heat recovery rate can be improved.

Owner:张荣光

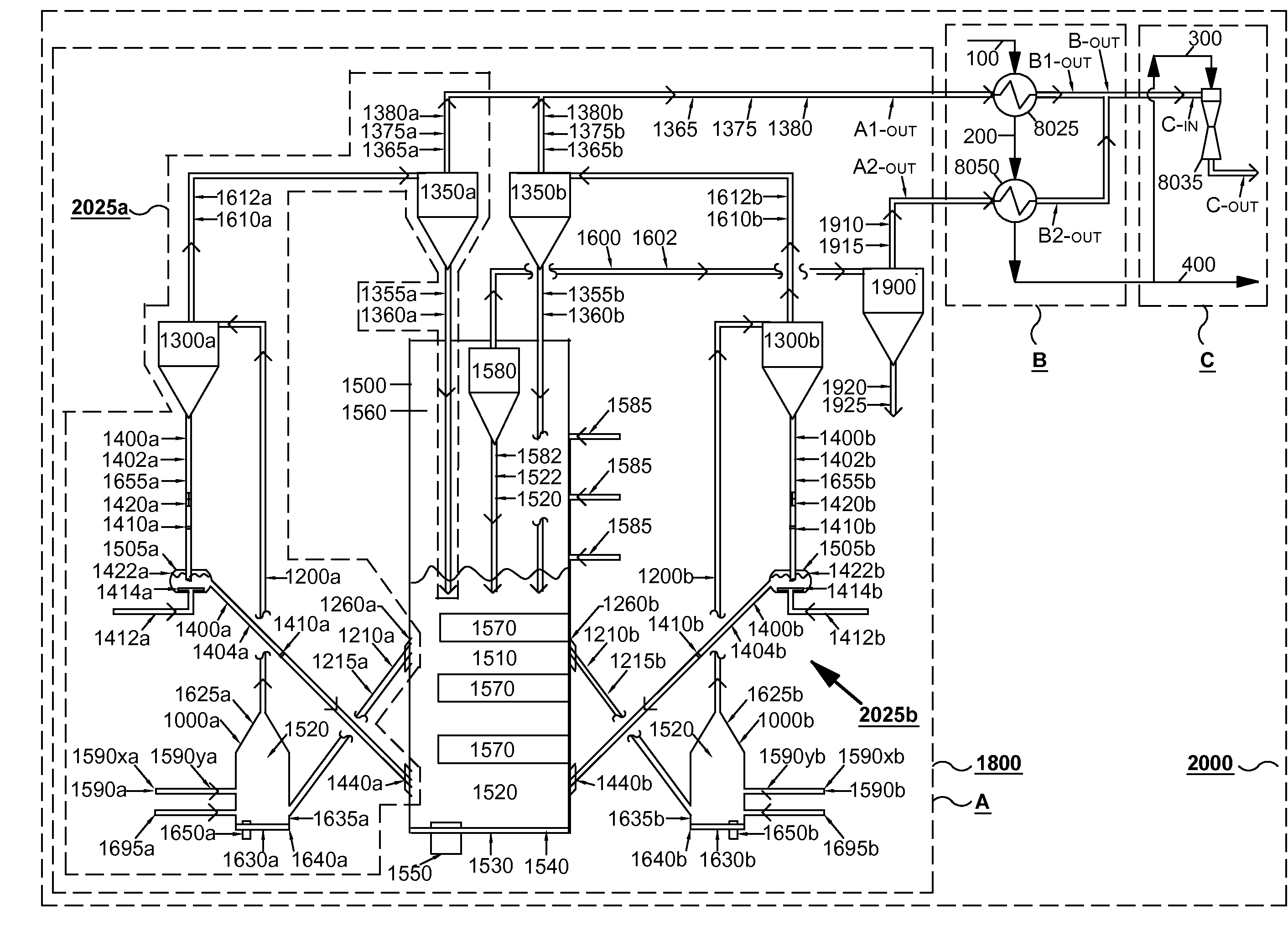

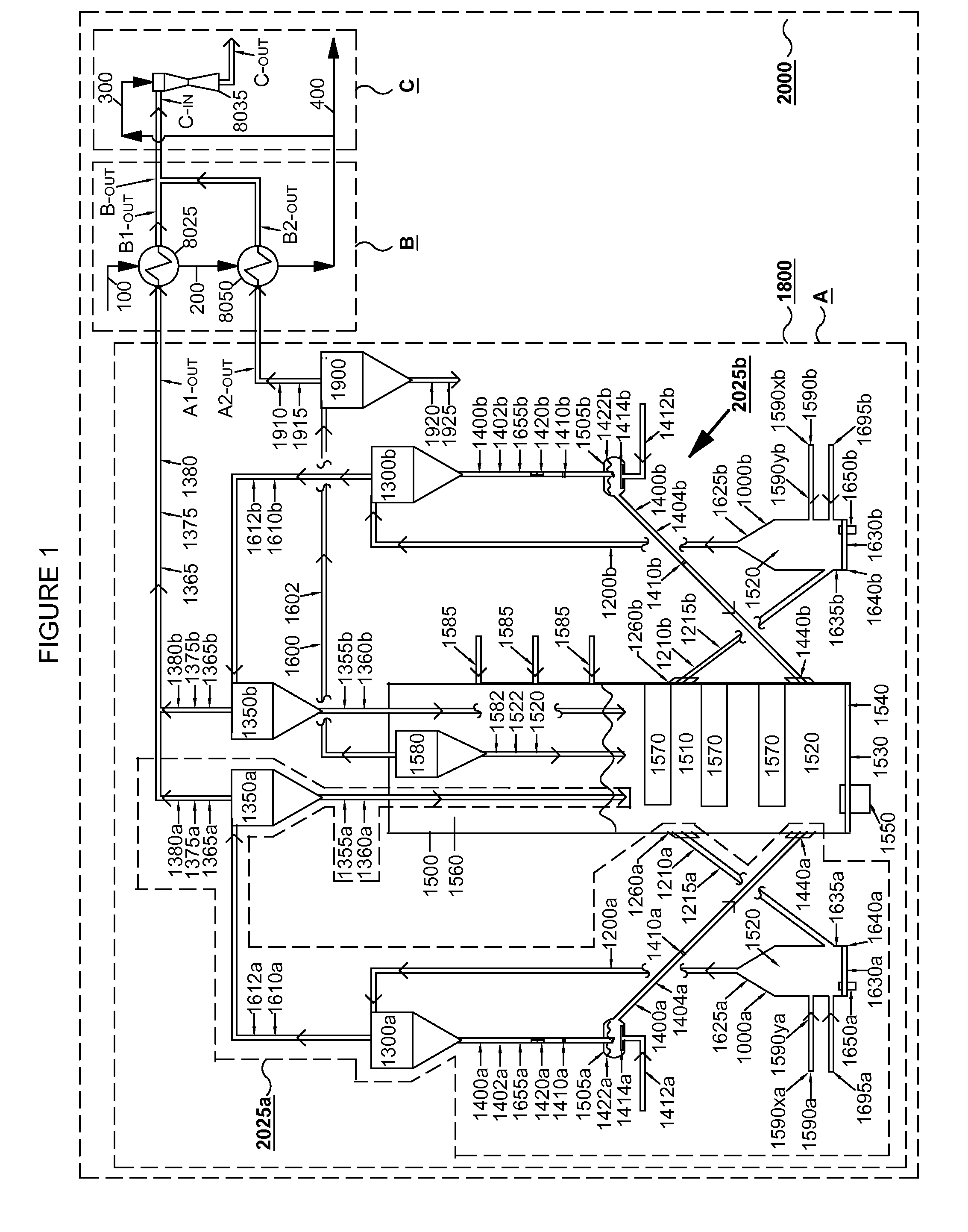

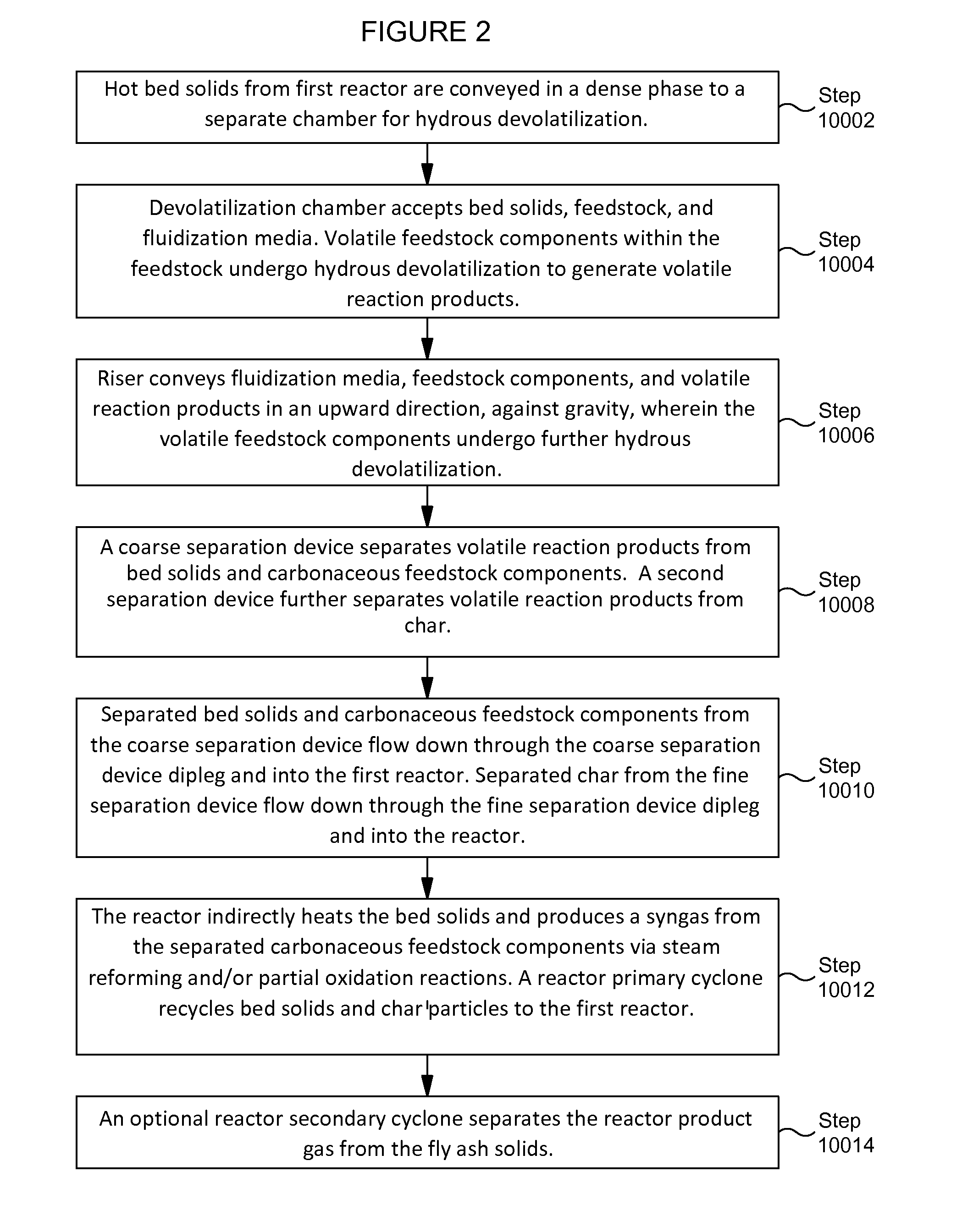

System and method for flexible conversion of feedstock to oil and gas

ActiveUS20140296586A1Minimize complexityLow costDirect heating destructive distillationBiofuelsChemical reactorProduct gas

A feedstock flexible process for converting feedstock into oil and gas includes (i) indirectly heated hydrous devolatilization of volatile feedstock components, (ii) indirectly heated thermochemical conversion of fixed carbon feedstock components, (iii) heat integration and recovery, (iv) vapor and gas pressurization, and (v) vapor and gas clean-up and product recovery. A system and method for feedstock conversion includes a thermochemical reactor integrated with one or more hydrous devolatilization and solids circulation subsystems configured to accept a feedstock mixture, comprised of volatile feedstock components and fixed carbon feedstock components, and continuously produce a volatile reaction product stream therefrom, while simultaneously and continuously capturing, transferring, and converting the fixed carbon feedstock components to syngas.

Owner:THERMOCHEM RECOVERY INT

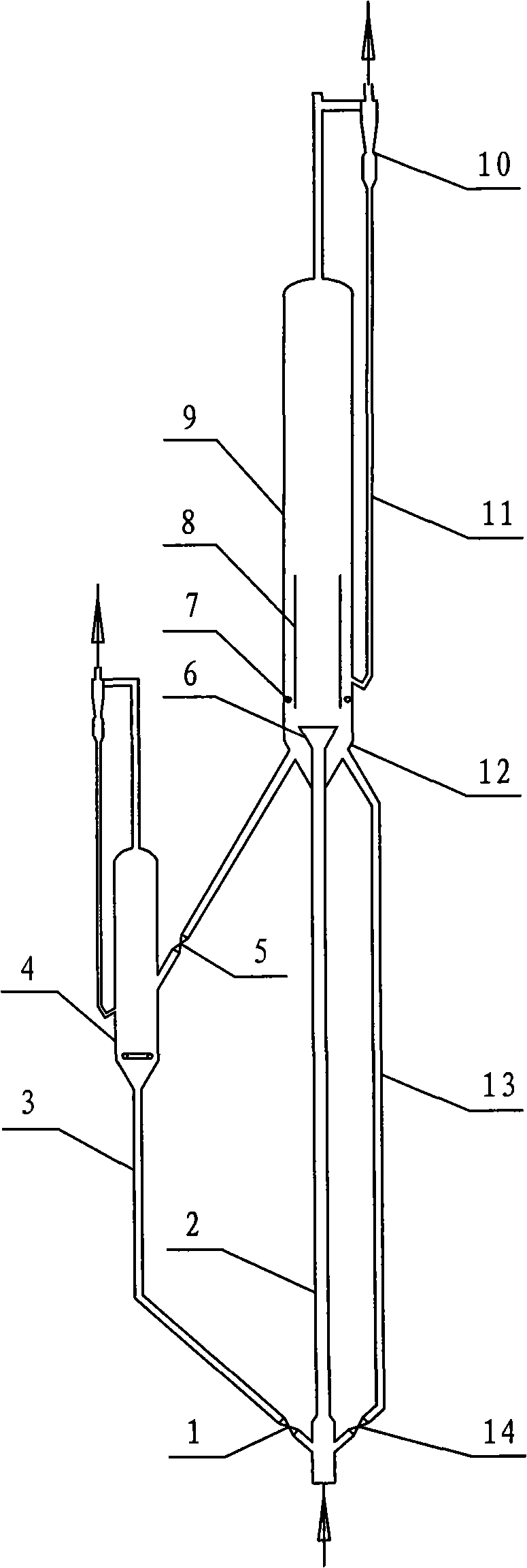

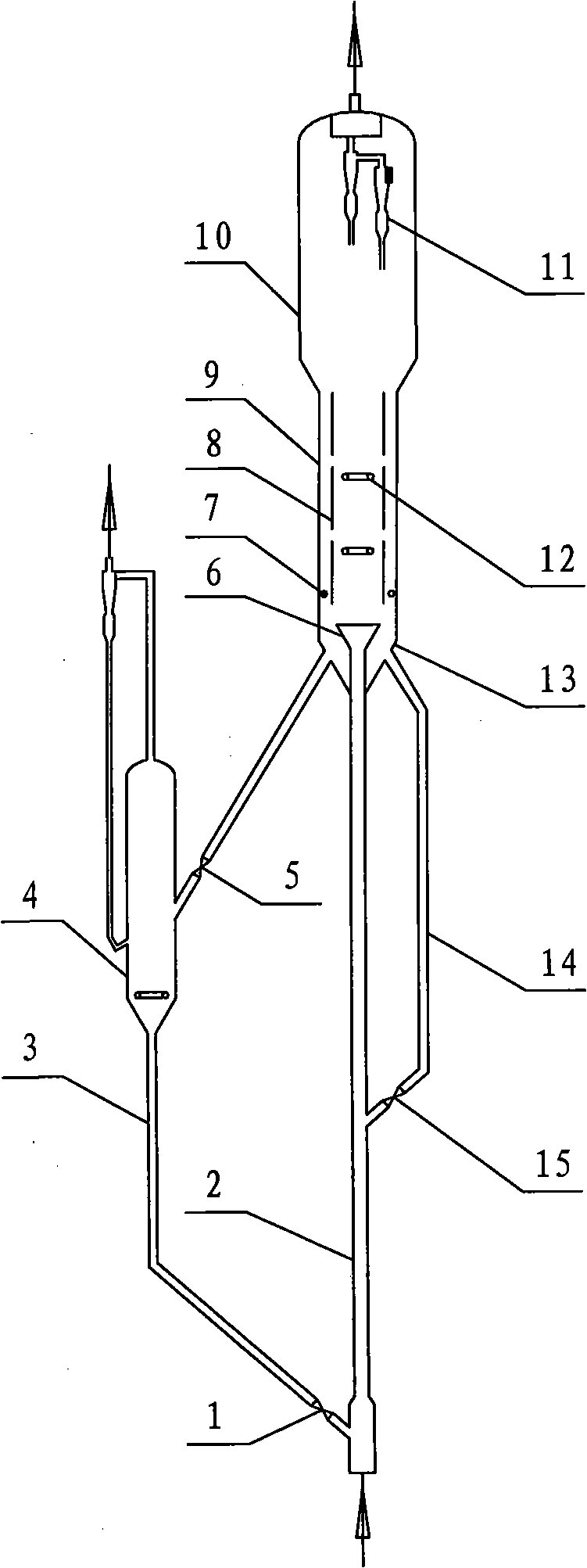

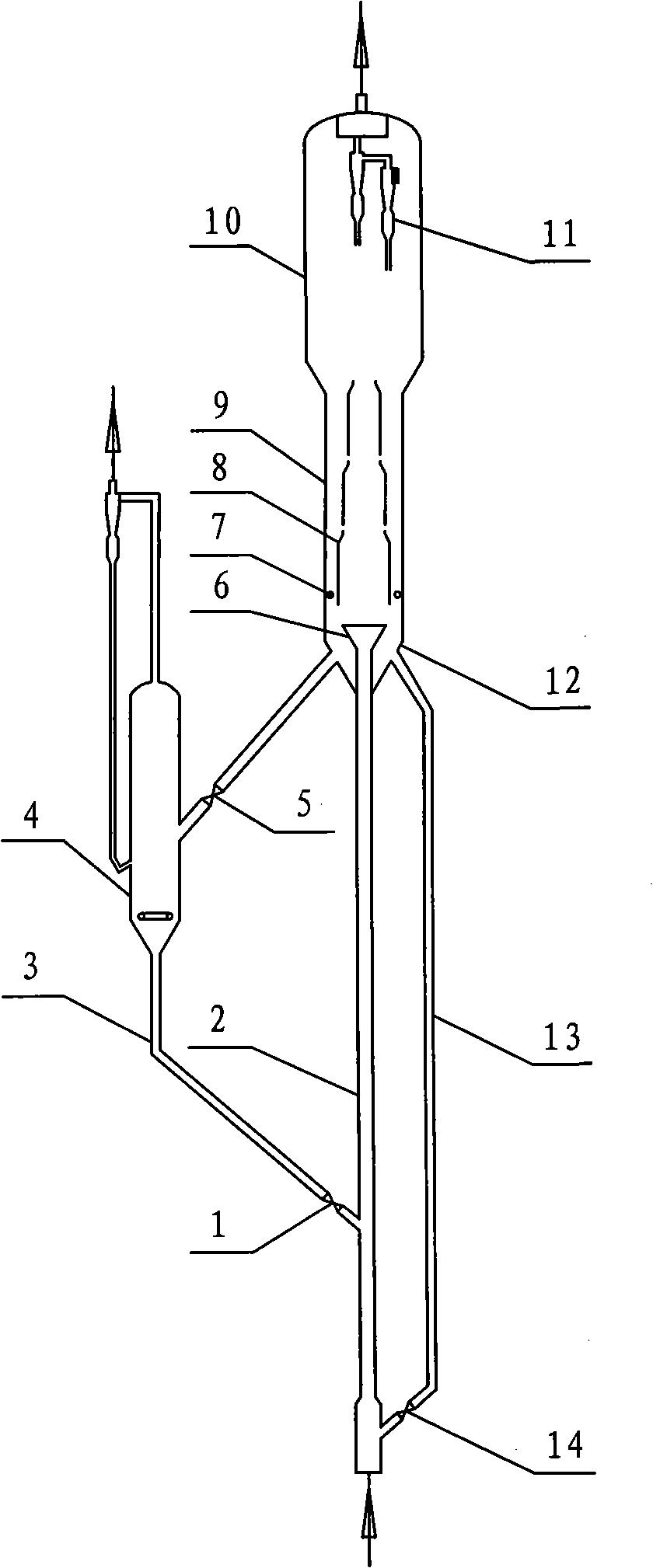

Device for improving pipe and gas-solid circumfluence bed coupling reaction

ActiveCN101259398AExtended reaction timeReduce resistanceFluidized bed combustionChemical/physical processesChemical industryGas solid

The invention provides a lift pipe and air-solid circulation bed coupling reaction device which at least includes a lift pipe, a shower head distributor, a guide cylinder, an annular space air distribution ring, an outer cylinder, an inner circulation pipe, an outer circulation fluidized bed, an outer circulation pipe and an air-solid separating system. Particles and air are transmitted upwards along the lift pipe, pass through the shower head distributor and enter the upper annular fluidized bed to form a central air lifting type circumfluence between the guide cylinder and the annular space. Part of the particles below the outer cylinder enters the lift pipe through the inner circulation pipe and another part enters the outer circulation fluidized bed to be mixed with the original particles in the outer circulation fluidized bed; the mixed particles enter the lift pipe through the outer circulation pipe; the positions where the inner circulation pipe and the outer circulation pipe enter the lift pipe can be flexibly arranged; the lift pipe and air-solid circulation bed coupling reaction device overcomes the limitations of system pressure balance and short reaction time and has the advantages that each area is flexible to be operated and controlled, the air-solid contact efficiency of the annular fluidized bed is high and the resistance above the distributor is small, etc. The device can be broadly applied to the fields of energy supply, chemical industries and particle combustion, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

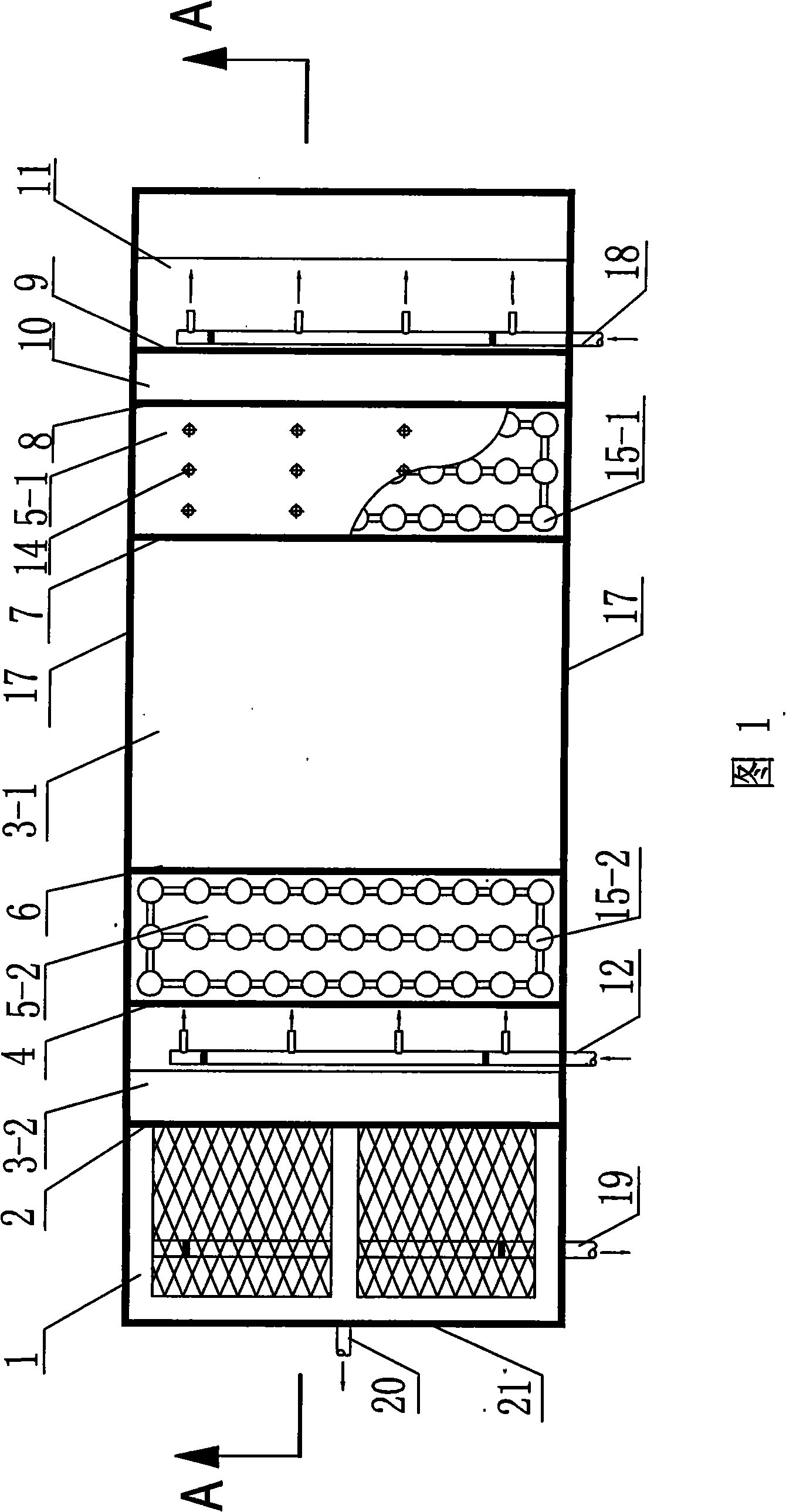

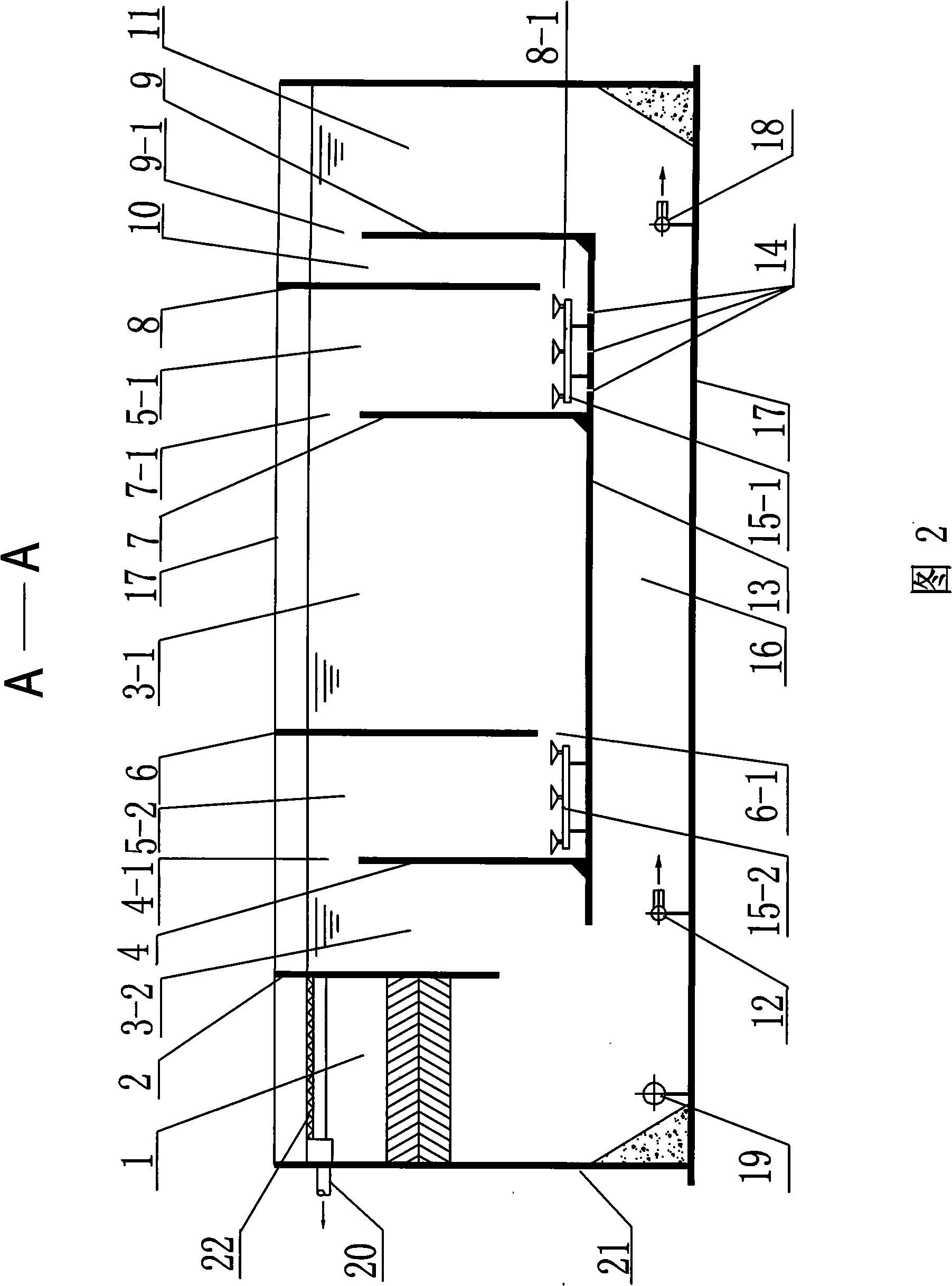

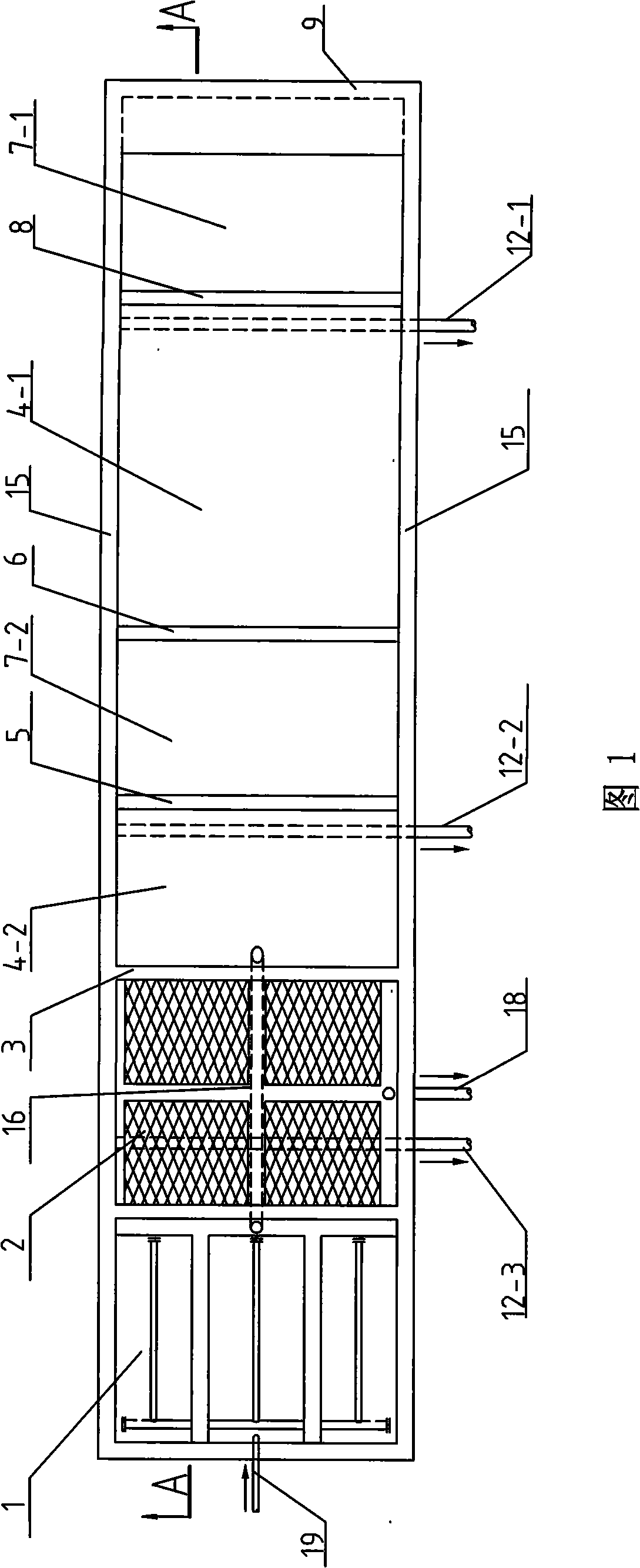

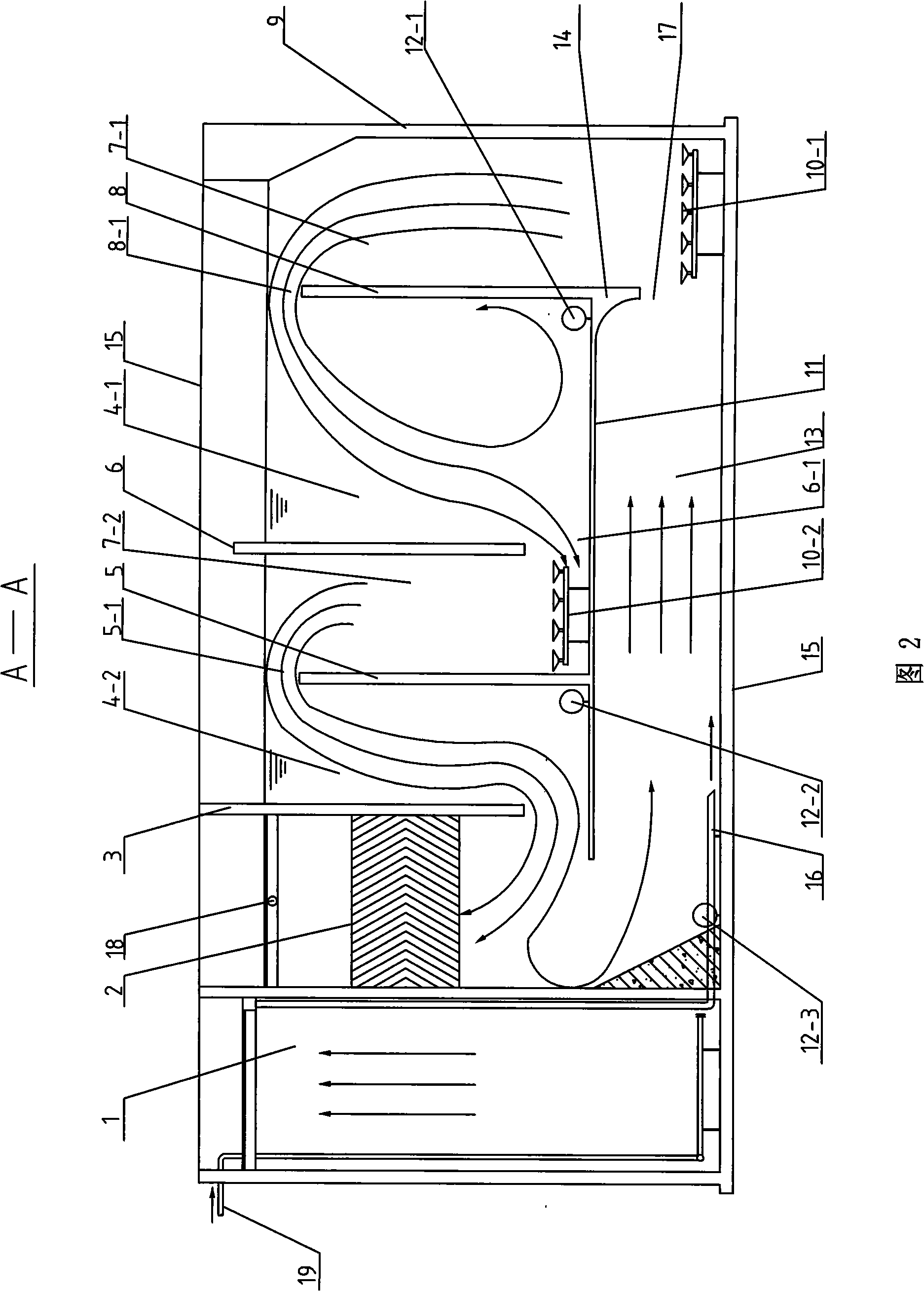

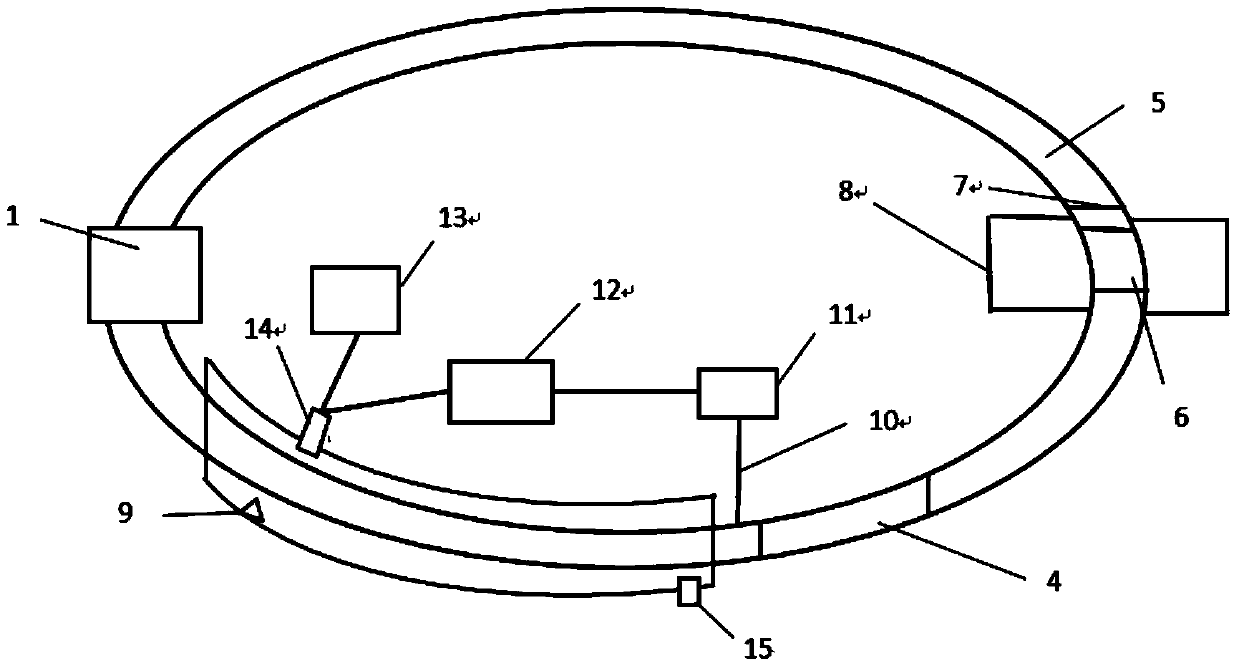

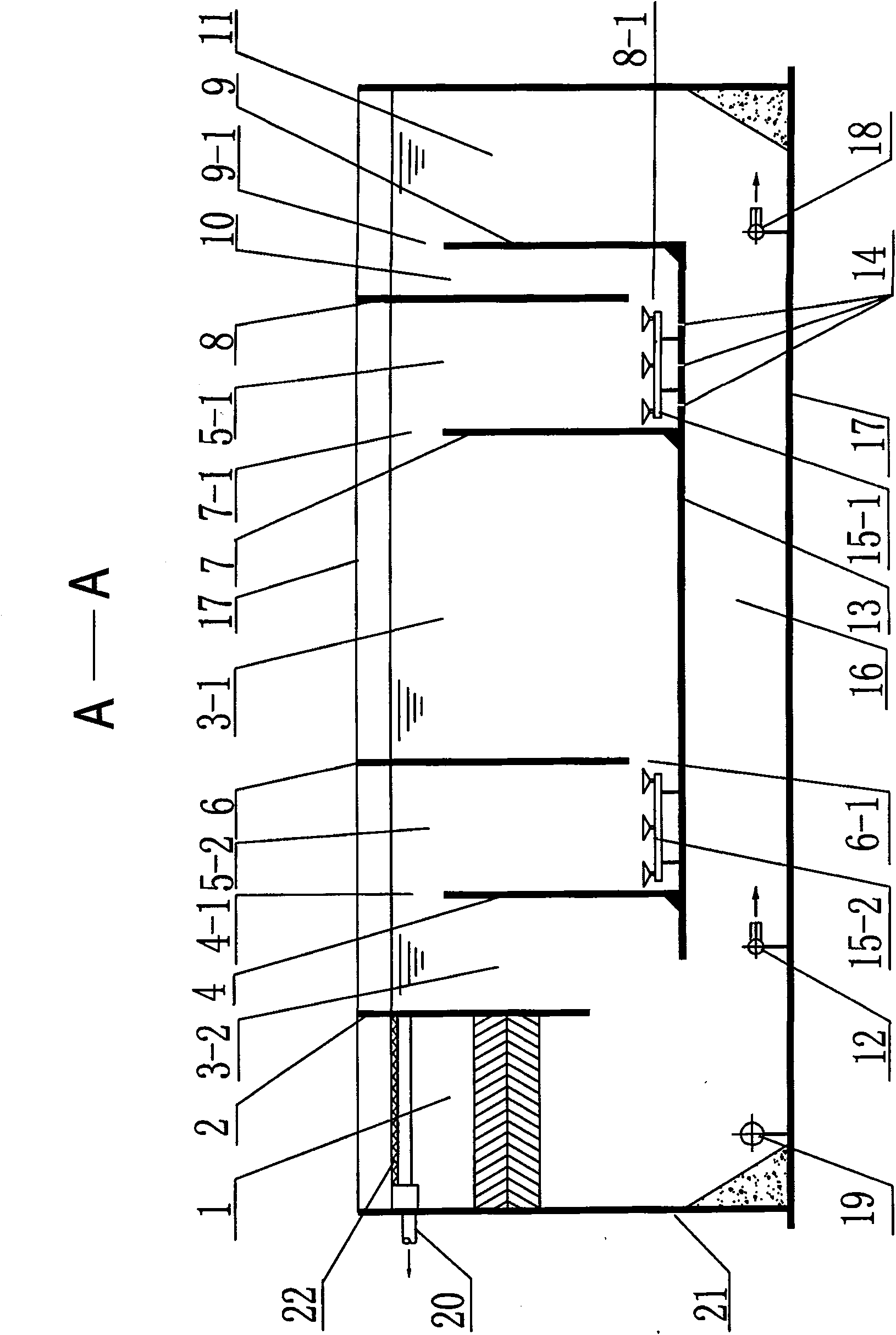

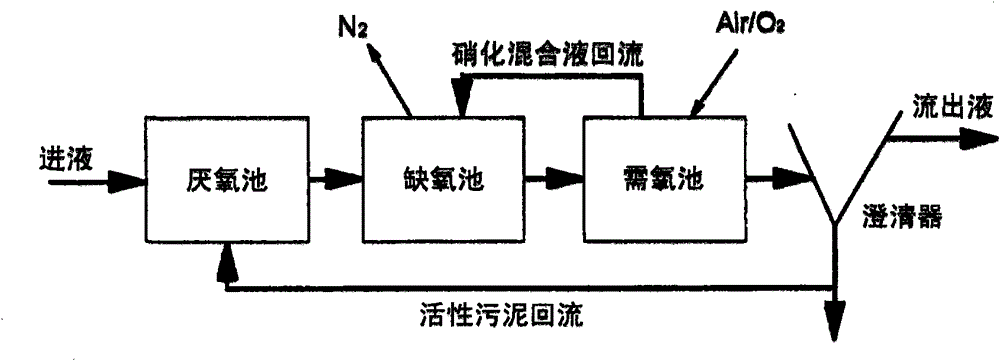

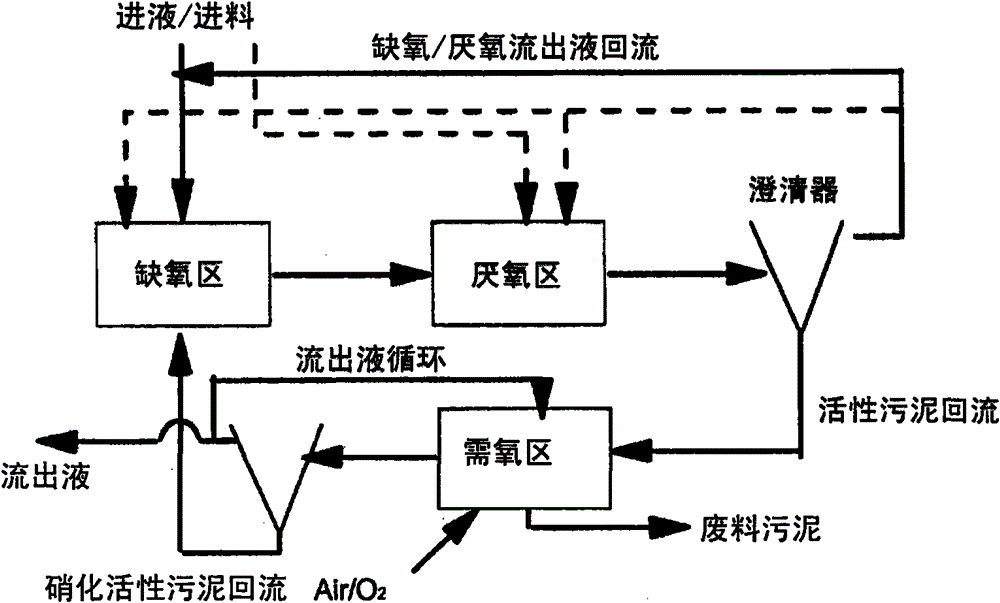

Zanjon type gas-lift stream-pull tridimensional circulation type inversion A<2>O integral co-construction oxidation ditch

ActiveCN101269879AIncrease water depthGood removal effectTreatment with aerobic and anaerobic processesWater qualityEnvironmental engineering

The invention relates to a zanjon air lifting pushing solid circulation inversion A<2>O integrated construction oxidation ditch, which comprises an anoxic zone, an anaerobic zone, an aerobic zone provided with a millipore aerator group and an inversion A<2>O integrated construction oxidation ditch of a solid and liquid separating zone. The solid and liquid separating zone is arranged at the front end of a main ditch, the anaerobic zone is arranged at the tail end of the main ditch, and water inlets are respectively arranged at the front ends of the aerobic zone and the anaerobic zone. The integrated construction oxidation ditch is characterized in that a horizontal partition board which divides the main ditch into an upper groove layer and a lower groove layer is arranged at the middle-lower part of the main ditch, the aerobic zone and the anaerobic zone are respectively arranged at the upper groove layer and the lower groove layer, the aerobic zone is internally provided with n (n is more than or equal to 1) aeration lifting zone (s) which is (are) composed of an inlet water-retaining wall, an outlet water-retaining wall and the millipore aerator group and is (are) provided with a lower water inlet and an upper water outlet, the horizontal partition board of a first grade aeration lifting zone is provided with a plurality of lifting holes, and the aerobic zone is internally divided into n aerobic reaction zone (s) corresponding to the aeration lifting zone (s).The integrated construction oxidation ditch has the advantages that: the yielding water quality, particularly the dephosphorization and denitrification effect, is better, the occupation area is reduced, the equipment is reduced, the operation is simplified, and the operation cost is lowered.

Owner:北京创未环境工程技术有限公司

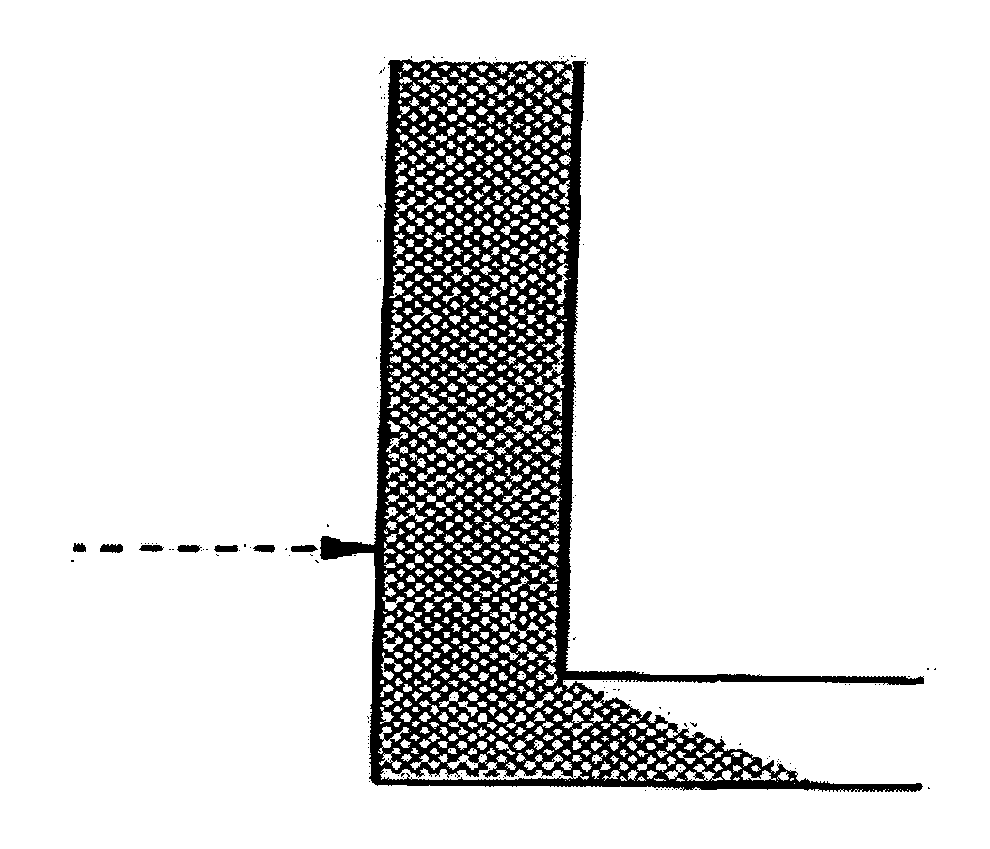

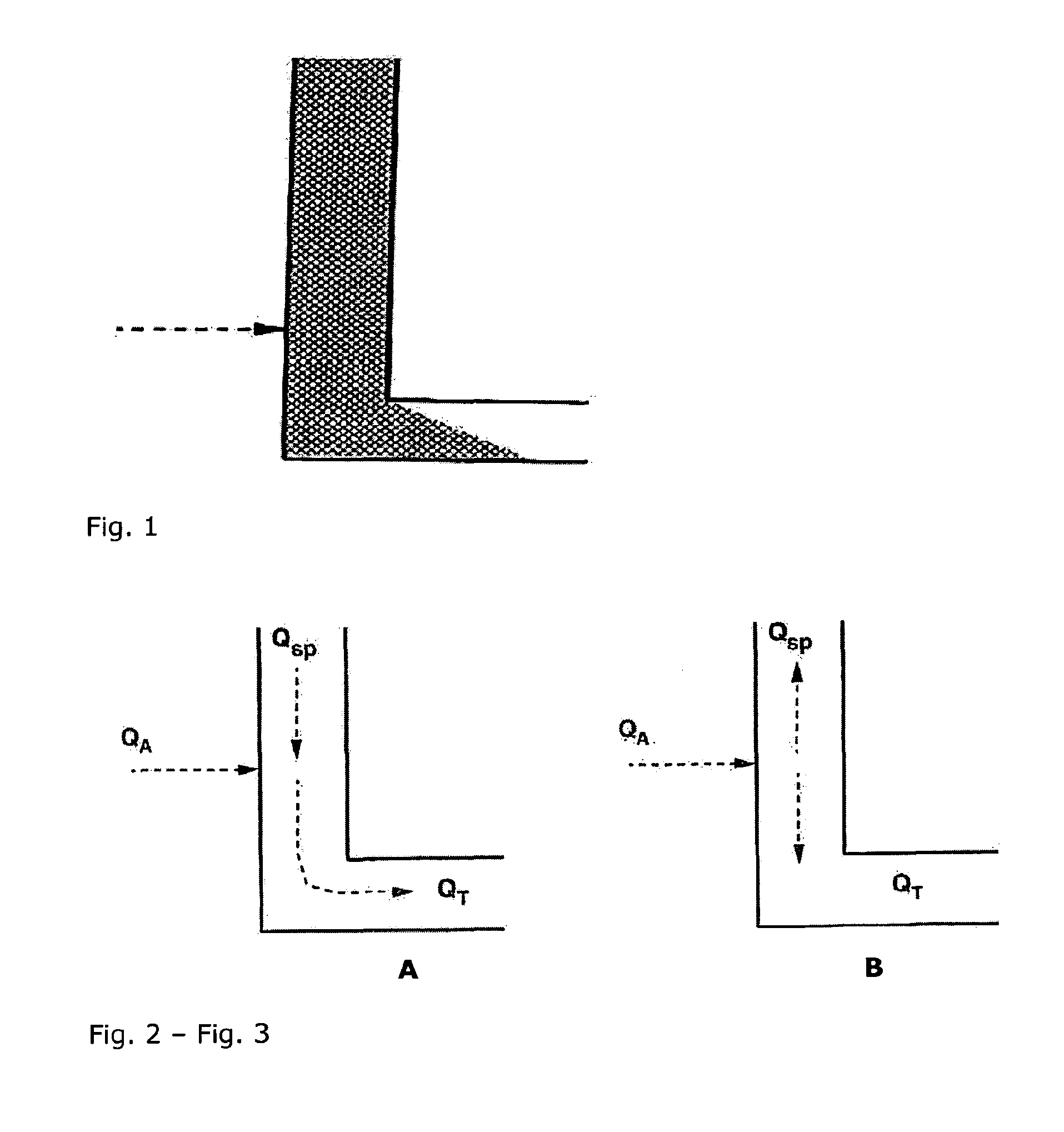

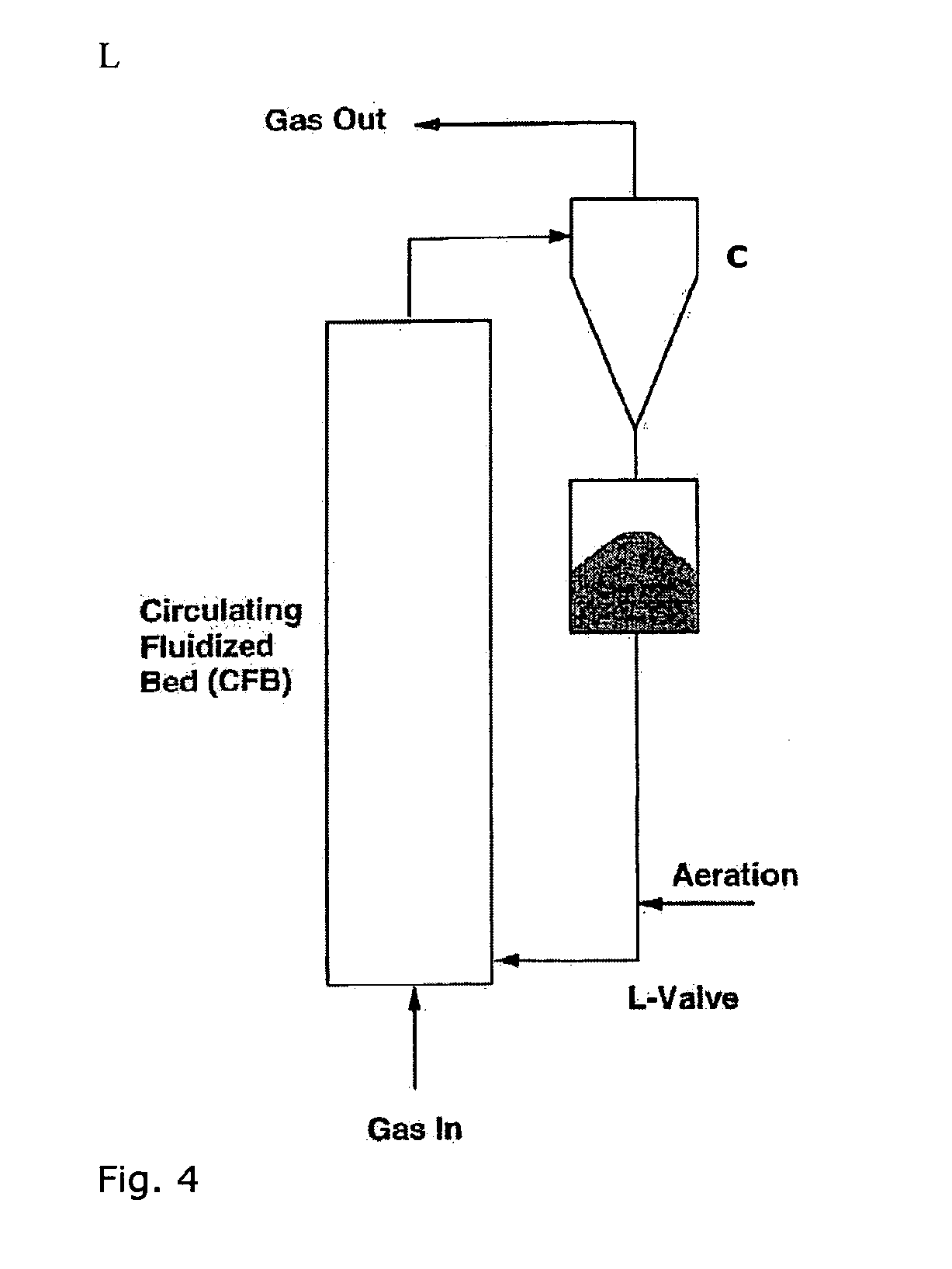

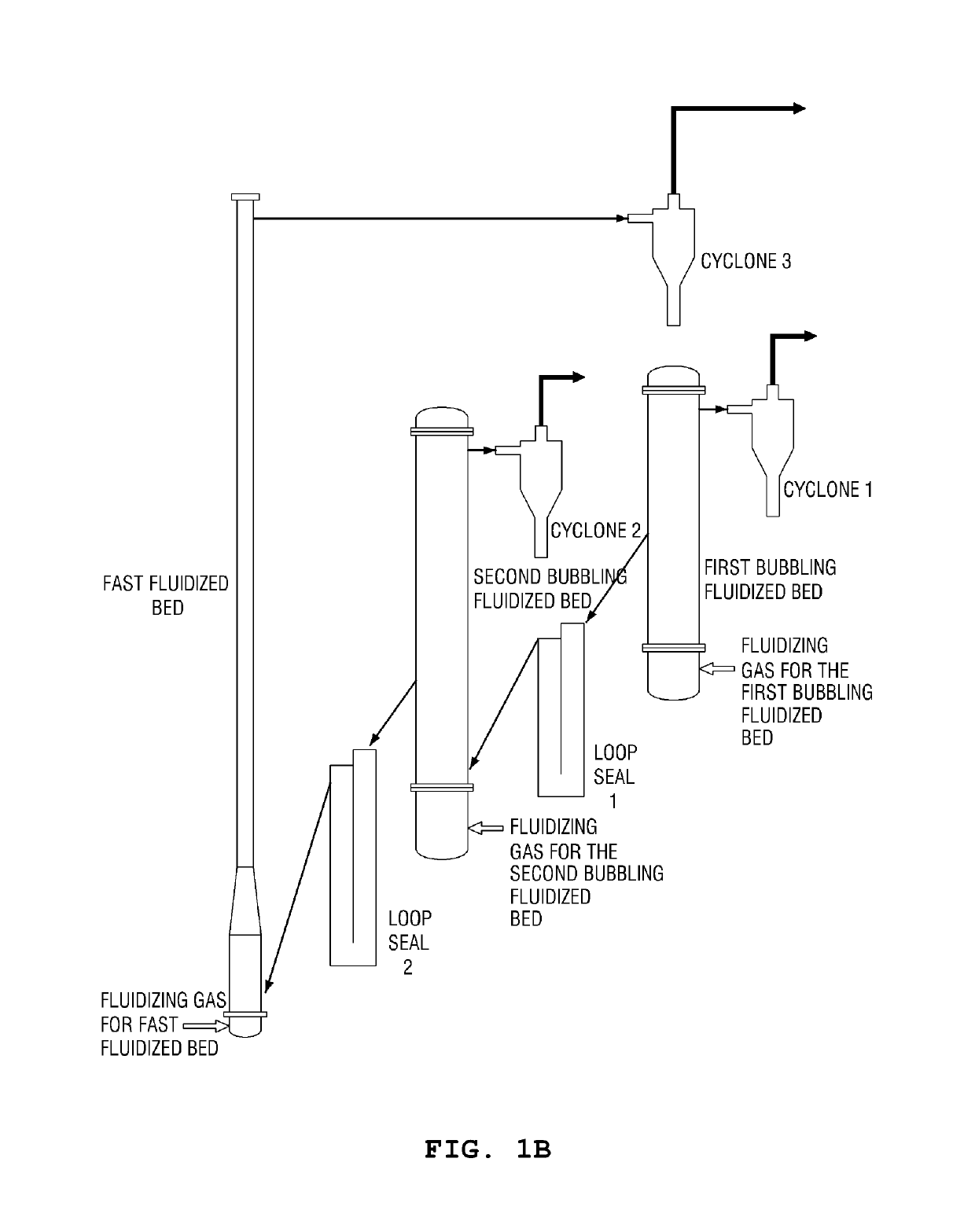

Chemical looping combustion method and plant with independent solid circulation control

ActiveUS20120148484A1Gasification processes detailsHydrogen productionReaction zoneProcess engineering

The invention relates to an improved plant and method for chemical looping combustion of at least one hydrocarbon feed with independent control of the circulation of the solid active mass particles between the fluidized bed reaction zones, by means of one or more non-mechanical valves of L-valve type.

Owner:INST FR DU PETROLE +1

Zanjon type gas-lift stream-pull tridimensional circulation type integral co-construction oxidation ditch

ActiveCN101269880AIncrease water depthImprove overall oxygen transfer coefficientTreatment with aerobic and anaerobic processesWater qualityEnvironmental engineering

The invention relates to a zanjon air lifting pushing solid circulation integrated construction oxidation ditch, which comprises an anoxic zone, an anaerobic zone, an aerobic zone provided with a millipore aerator group and an integrated construction oxidation ditch of a solid and liquid separating zone, wherein, the anoxic zone is arranged at the front end of a main ditch. The integrated construction oxidation ditch is characterized in that a horizontal partition board which divides the main ditch into an upper groove layer and a lower groove layer as well as is left with channels at the front and the back is arranged at the middle-lower part of the ditch body between the ditch walls at the tail ends of the anoxic zone and the main ditch, the aerobic zone is arranged at the upper groove layer and the tail end of the main ditch and is provided with n (n is more than or equal to 1) aeration lifting zone (s) which is (are) composed of an inlet water-retaining wall, an outlet water-retaining wall and the millipore aerator group and is (are) provided with a lower water inlet and an upper water outlet. The aerobic zone is internally provided with n aerobic reaction zone (s), and the solid and the liquid separating zone is arranged between the anaerobic zone and the nth aerobic reaction zone. The lower groove layer is the anoxic zone. The integrated construction oxidation ditch has the advantages that: better anoxic, anaerobic, aerobic, and solid and liquid separating environments are created, the total dephosphorization and the total denitrification effects are improved, the yielding water quality is better, the occupation area is reduced, and the construction and the operation costs are lowered.

Owner:北京创未环境工程技术有限公司

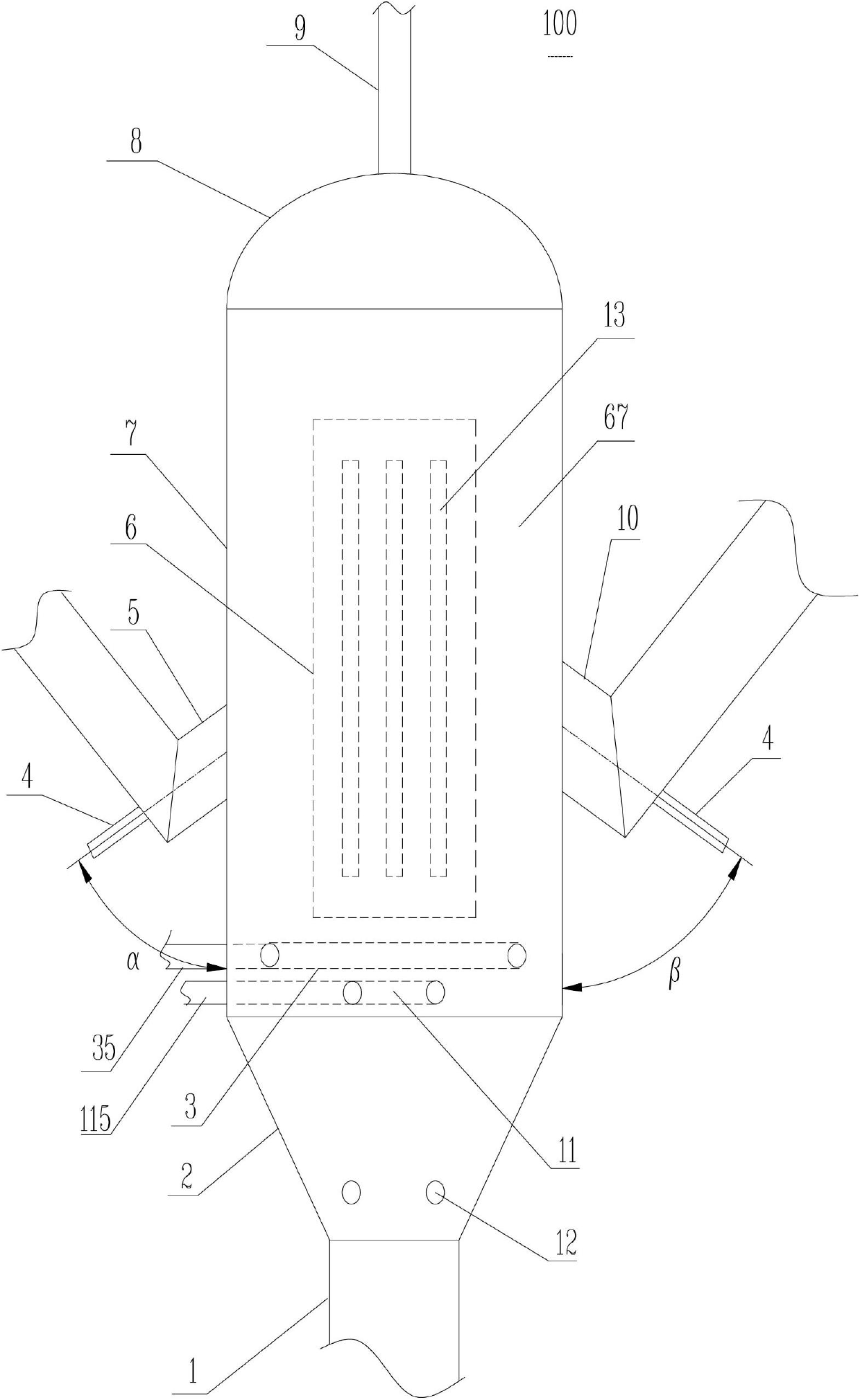

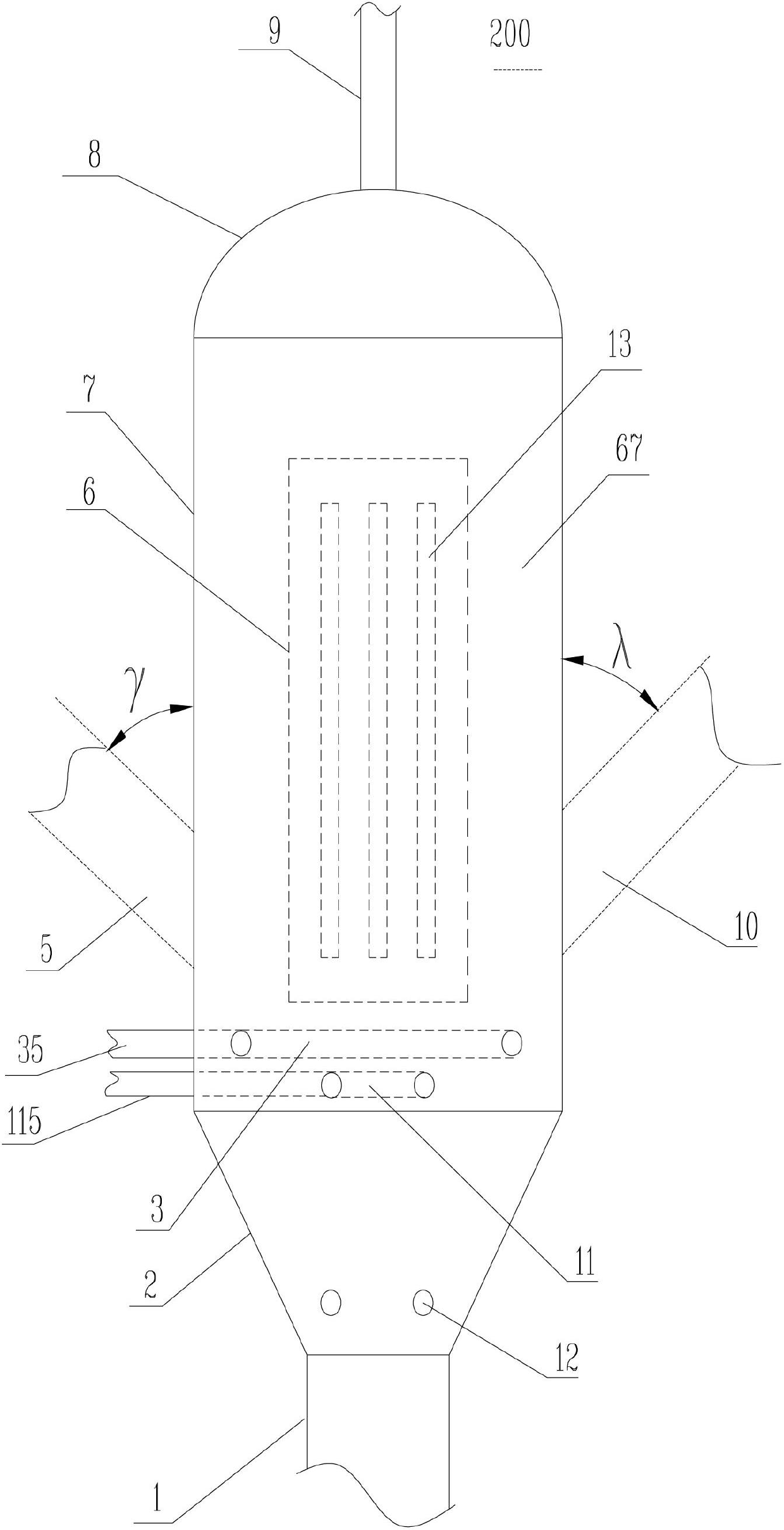

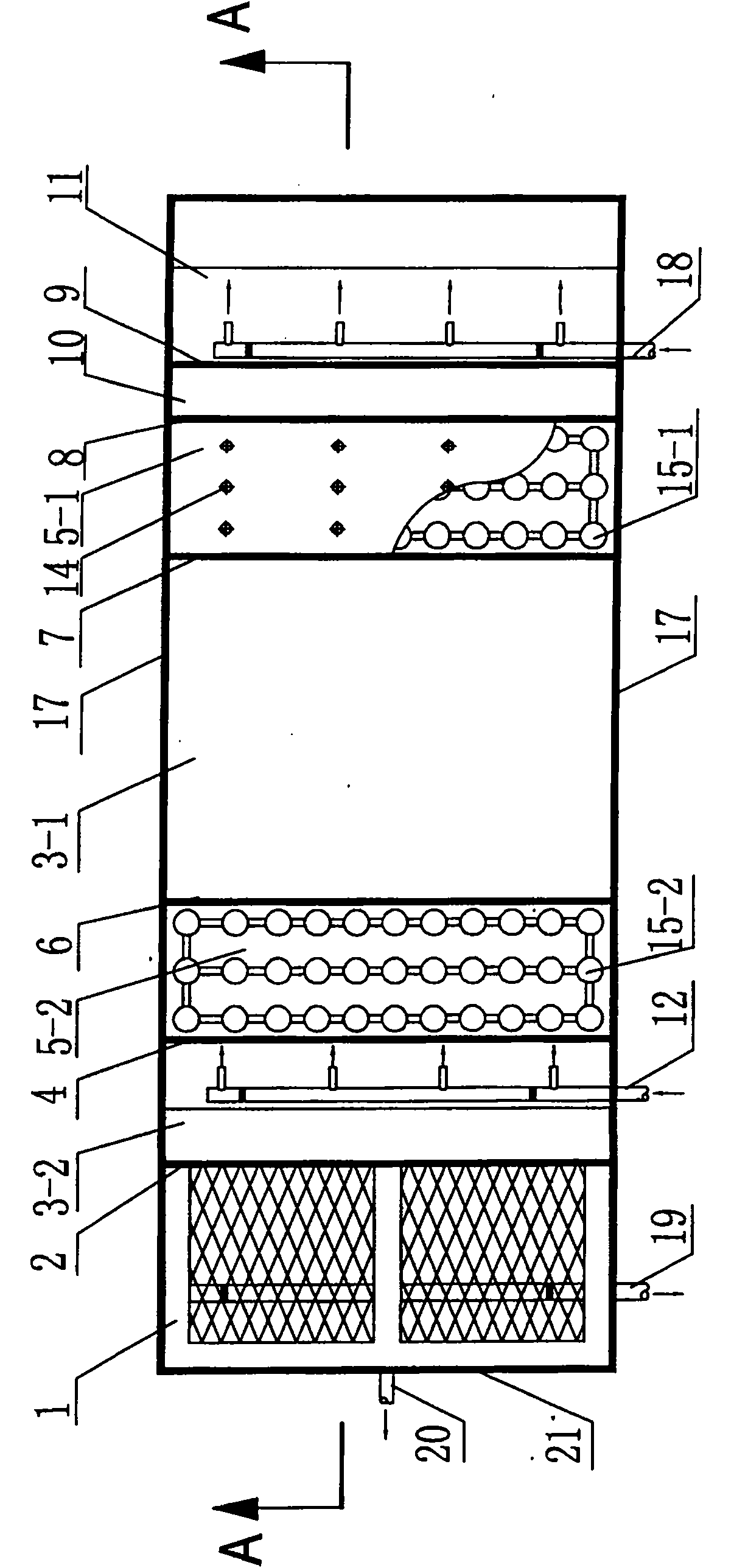

Gas/solid circulation mixing steam stripper and mixing and steam stripping method of solid particles

ActiveCN102676206AStrong shearImprove contact efficiencyCatalytic crackingCatalyst regeneration/reactivationEngineeringProduct gas

The invention provides a gas / solid circulation mixing steam stripper and a mixing and steam stripping method of solid particles. The gas / solid circulation mixing steam stripper comprises a cylinder body (7) with an inner cavity, a flow guide cylinder (6), a ring-gap gas distributor (3), a gas distributor (11) of the flow guide cylinder, a gas outlet extending into the inside of the cylinder body (7), a cone (2) connected with the lower end of the cylinder body (7), a mixed solid particle outlet (1) arranged below the cone (2), a loose steam ring (12) which is positioned at the bottom of the cone (2) and is also positioned above the mixed solid particle outlet (1), a first solid particle inlet passage and a second solid particle inlet passage, wherein the first solid particle inlet passage and the second solid particle inlet passage are respectively connected to the inside of the cylinder body. The gas / solid circulation mixing steam stripper is adopted by the mixing and steam stripping method of the solid particles.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Solids circulation system and method for capture and conversion of reactive solids

A solids circulation system receives a gas stream containing char or other reacting solids from a first reactor. The solids circulation system includes a cyclone configured to receive the gas stream from the first reactor, a dipleg from the cyclone to a second reactor, and a riser from the second reactor which merges with the gas stream received by the cyclone. The second reactor has a dense fluid bed and converts the received materials to gaseous products. A conveying fluid transports a portion of the bed media from the second reactor through the riser to mix with the gas stream prior to cyclone entry. The bed media helps manipulate the solids that is received by the cyclone to facilitate flow of solids down the dipleg into the second reactor. The second reactor provides additional residence time, mixing and gas-solid contact for efficient conversion of char or reacting solids.

Owner:THERMOCHEM RECOVERY INT

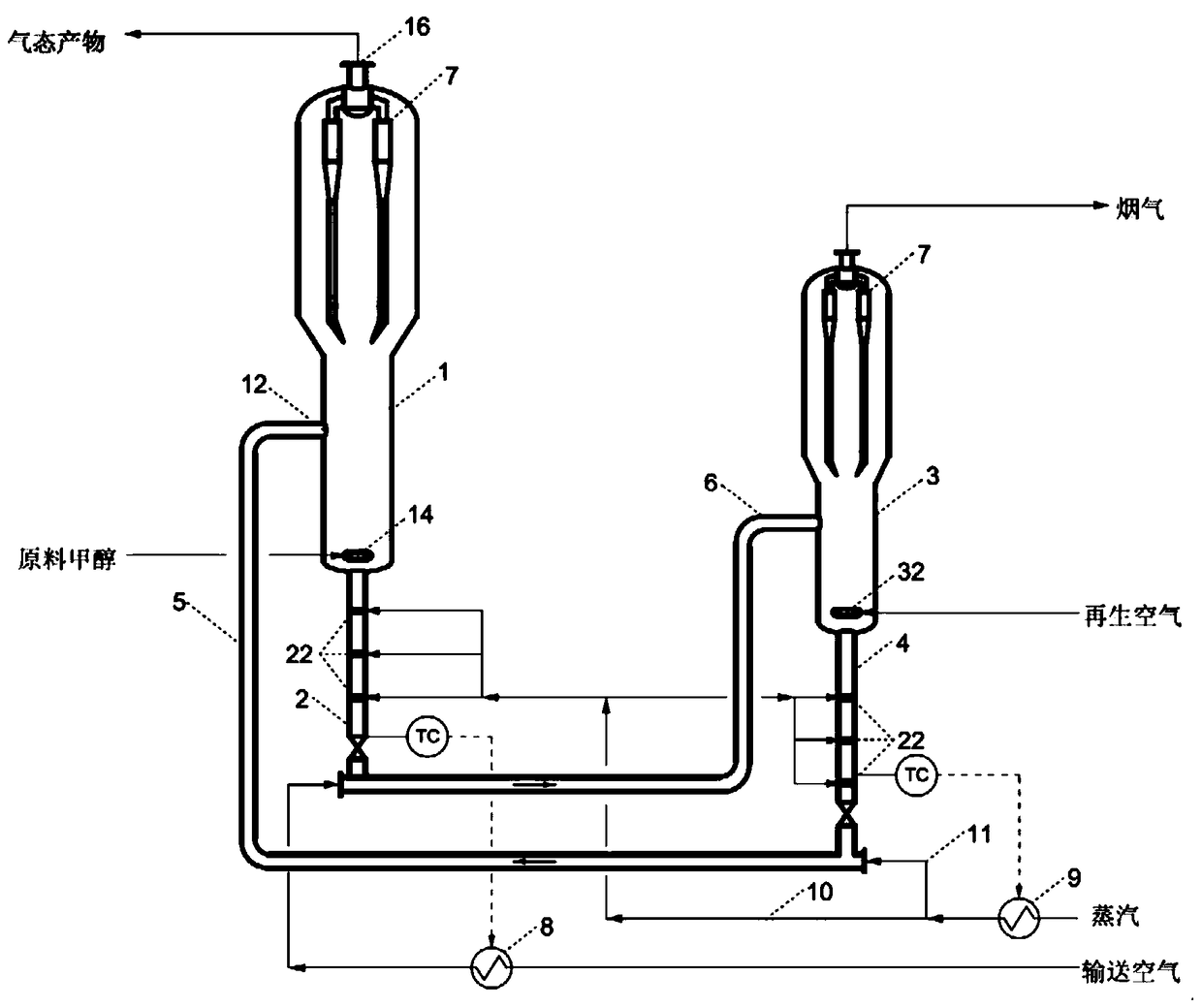

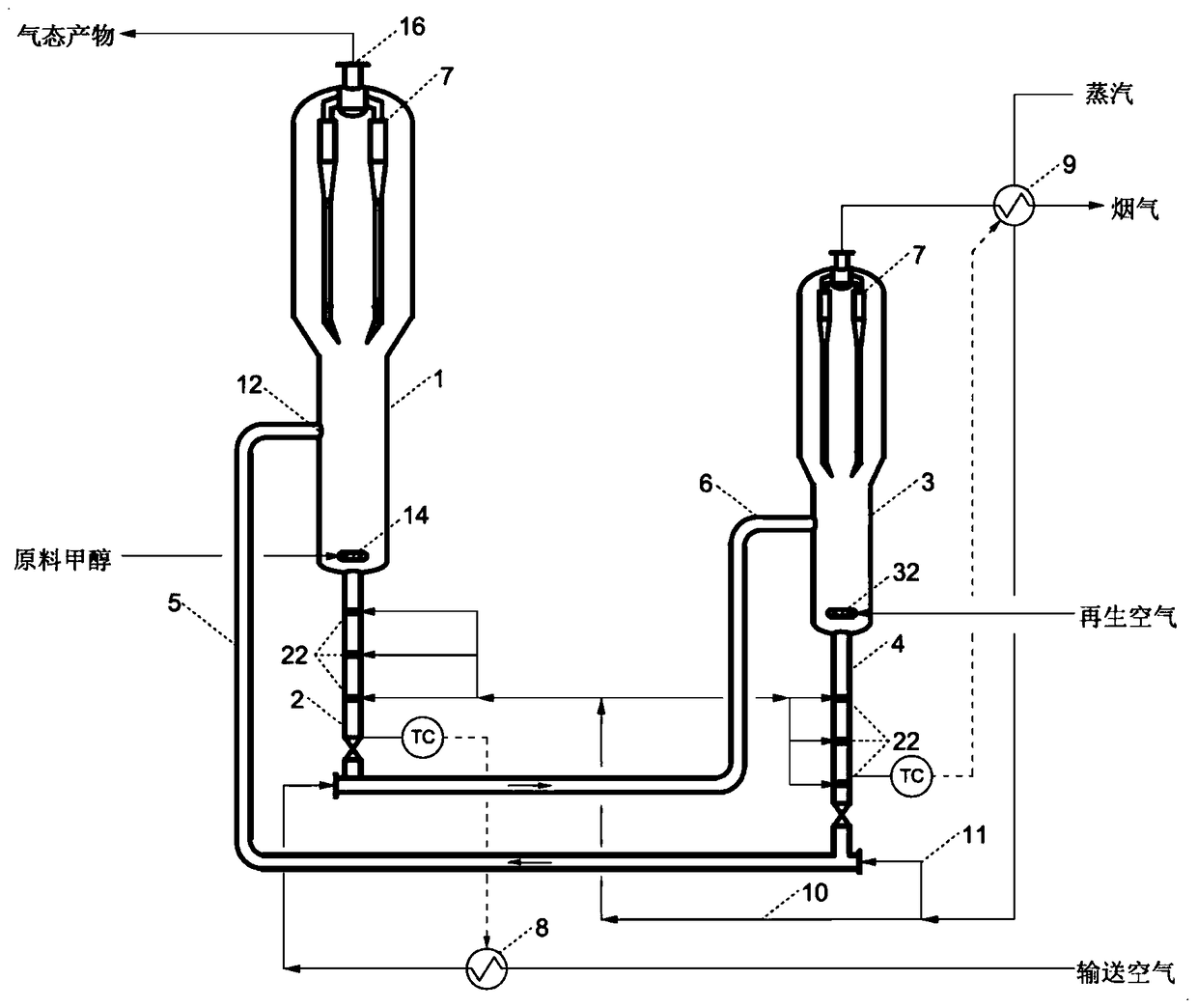

Method for carrying out gas-solid fluidized bed reaction

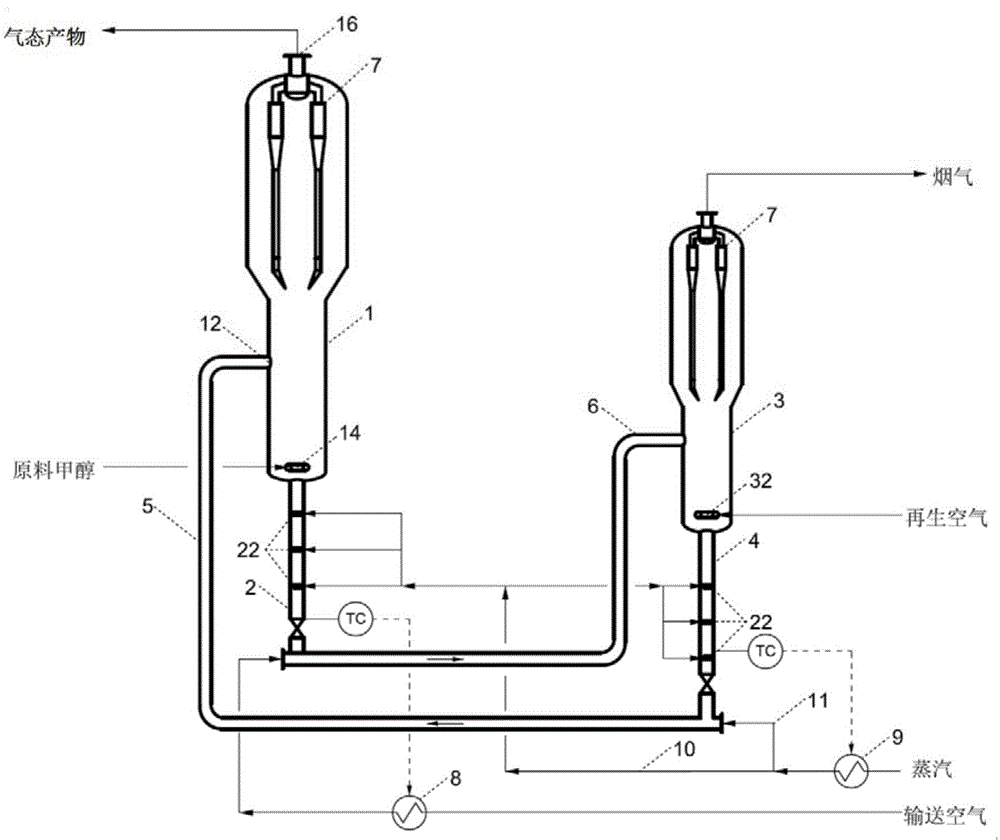

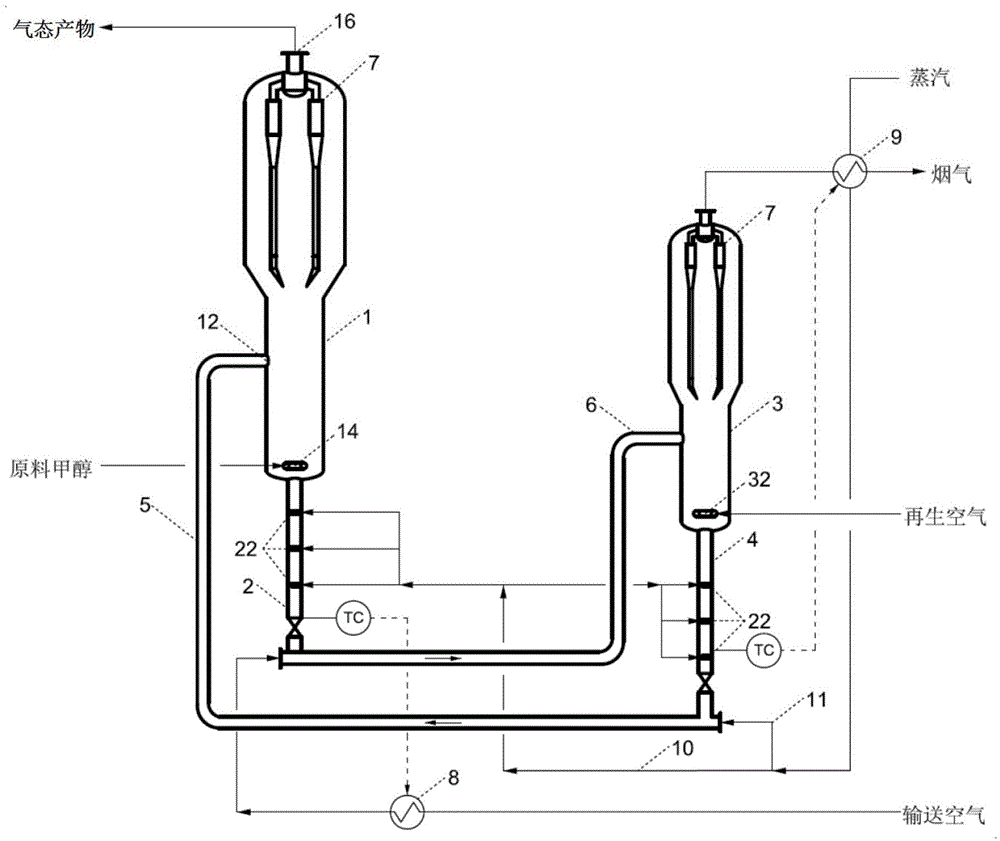

ActiveCN105771818AReduce wearHydrocarbon from oxygen organic compoundsChemical recyclingGas solidFlue gas

The invention relates to a method for carrying out a gas-solid circulation fluidized bed reaction. The method comprises the following steps: (1) in a fluidized bed reactor, an exothermic reaction is carried out under a condition that a gaseous raw material contacts a solid catalyst, such that a mixed product comprising a gaseous product and the solid catalyst is produced; (2) gas-solid separation is carried out in the upper part of the reactor; a part of the catalyst with charcoal deposit is delivered to a catalyst regenerator; (3) in the catalyst regenerator, the catalyst with charcoal deposit contacts regeneration air, such that a charcoal burning reaction is carried out; catalyst activity is recovered, and flue gas is generated; (4) the regenerated catalyst is delivered to the fluidized bed reactor through a regenerated catalyst delivery pipe; (5) the absolute value of the difference between the temperature of steam used for delivery and stripping and the temperature of the solid catalyst in a regenerated catalyst stripping section is 0-100 DEG C; and the absolute value of the difference between the temperature of delivery air used for delivering and the temperature of the solid catalyst in a spent catalyst stripping section is 0-100 DEG C. With the method, catalyst powdering damage caused by thermal expansion and contraction is effectively reduced.

Owner:SHANGHAI BI KE CLEAN ENERGY TECH +1

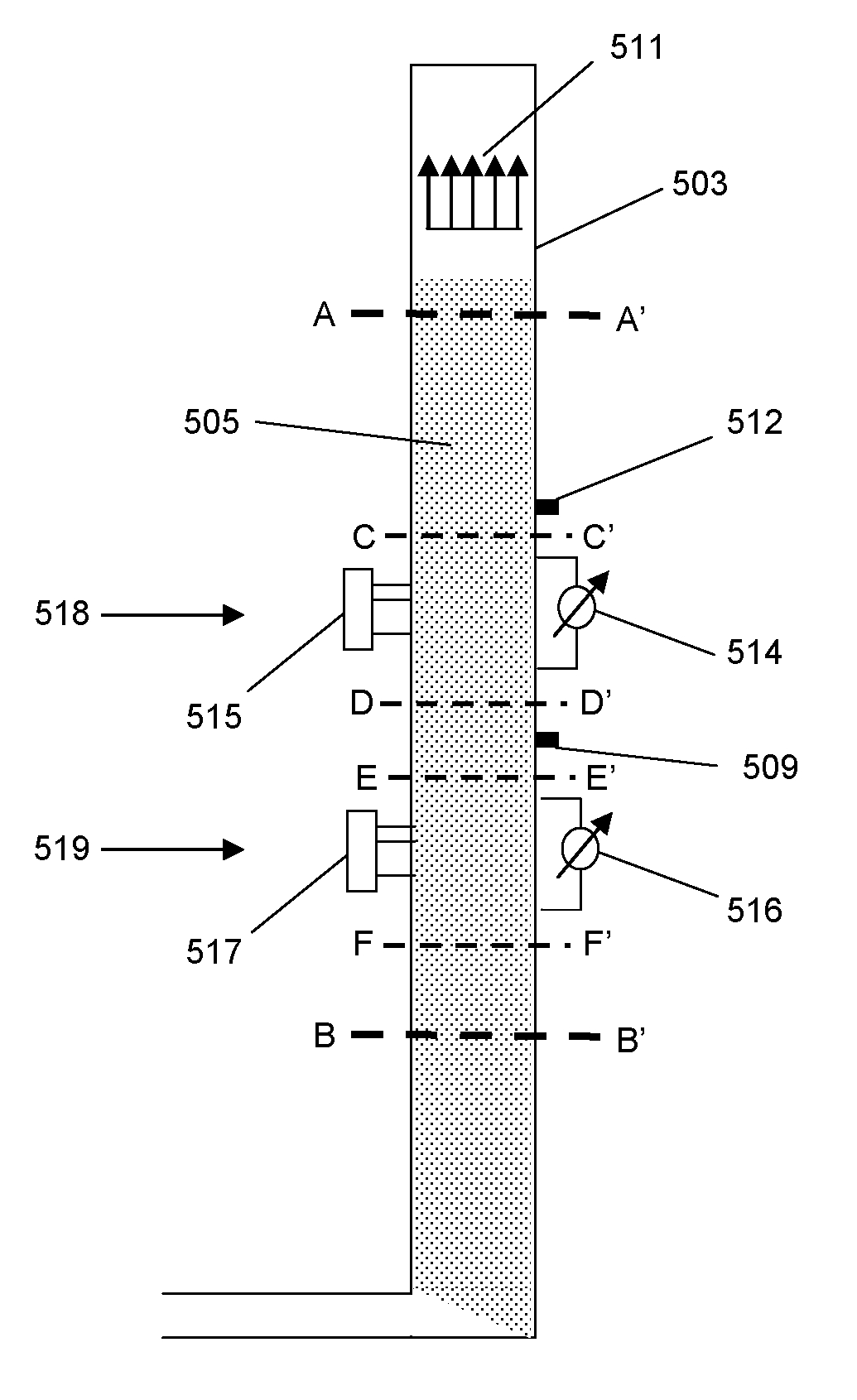

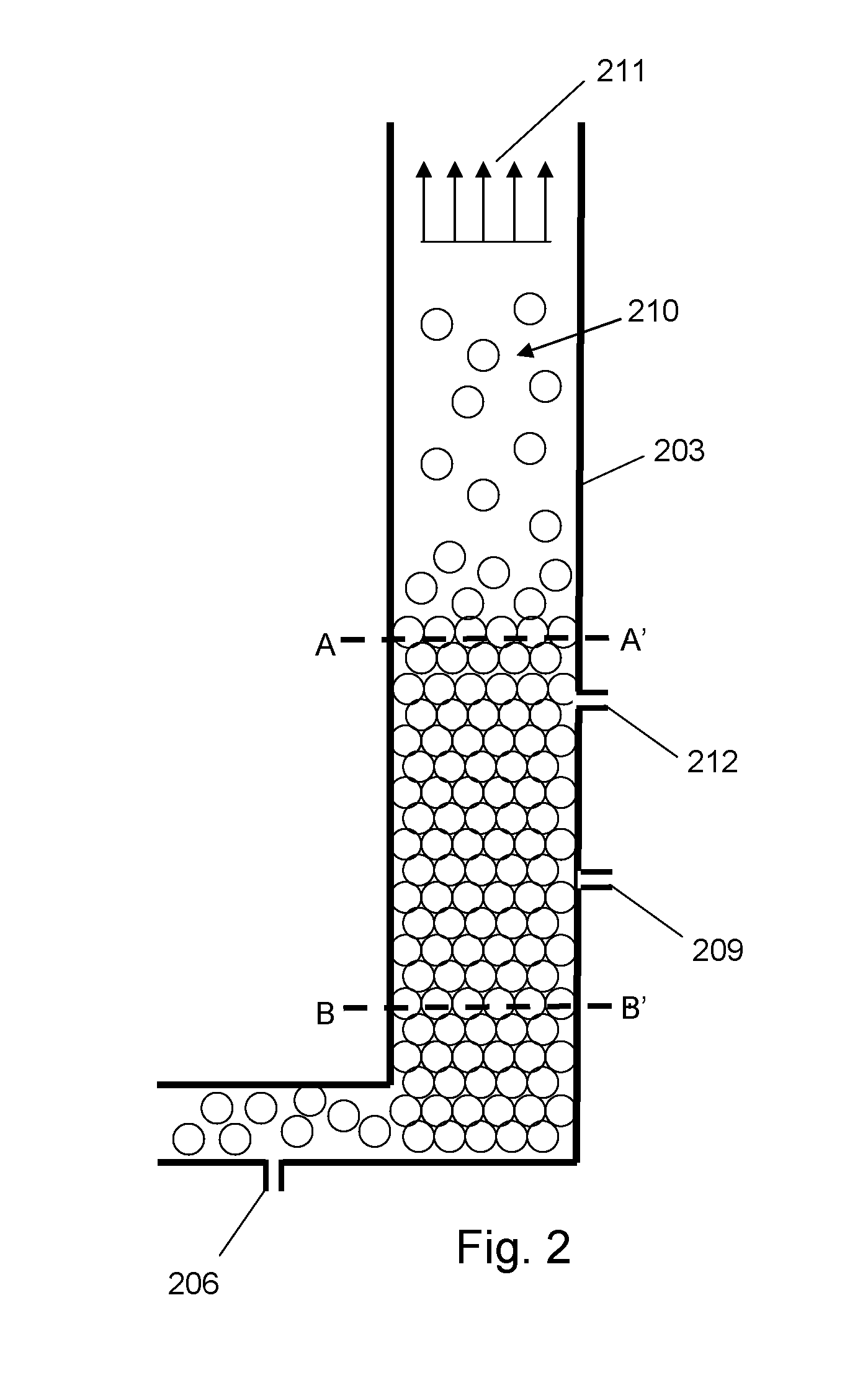

Apparatus and method for determining solids circulation rate

ActiveUS8116992B1Mitigate aggressive impact of high-temperaturesError changeFluidized bed combustionFluidised-bed furnacesDifferential pressureEngineering

The invention relates to a method of determining bed velocity and solids circulation rate in a standpipe experiencing a moving packed bed flow, such as the in the standpipe section of a circulating bed fluidized reactor The method utilizes in-situ measurement of differential pressure over known axial lengths of the standpipe in conjunction with in-situ gas velocity measurement for a novel application of Ergun equations allowing determination of standpipe void fraction and moving packed bed velocity. The method takes advantage of the moving packed bed property of constant void fraction in order to integrate measured parameters into simultaneous solution of Ergun-based equations and conservation of mass equations across multiple sections of the standpipe.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

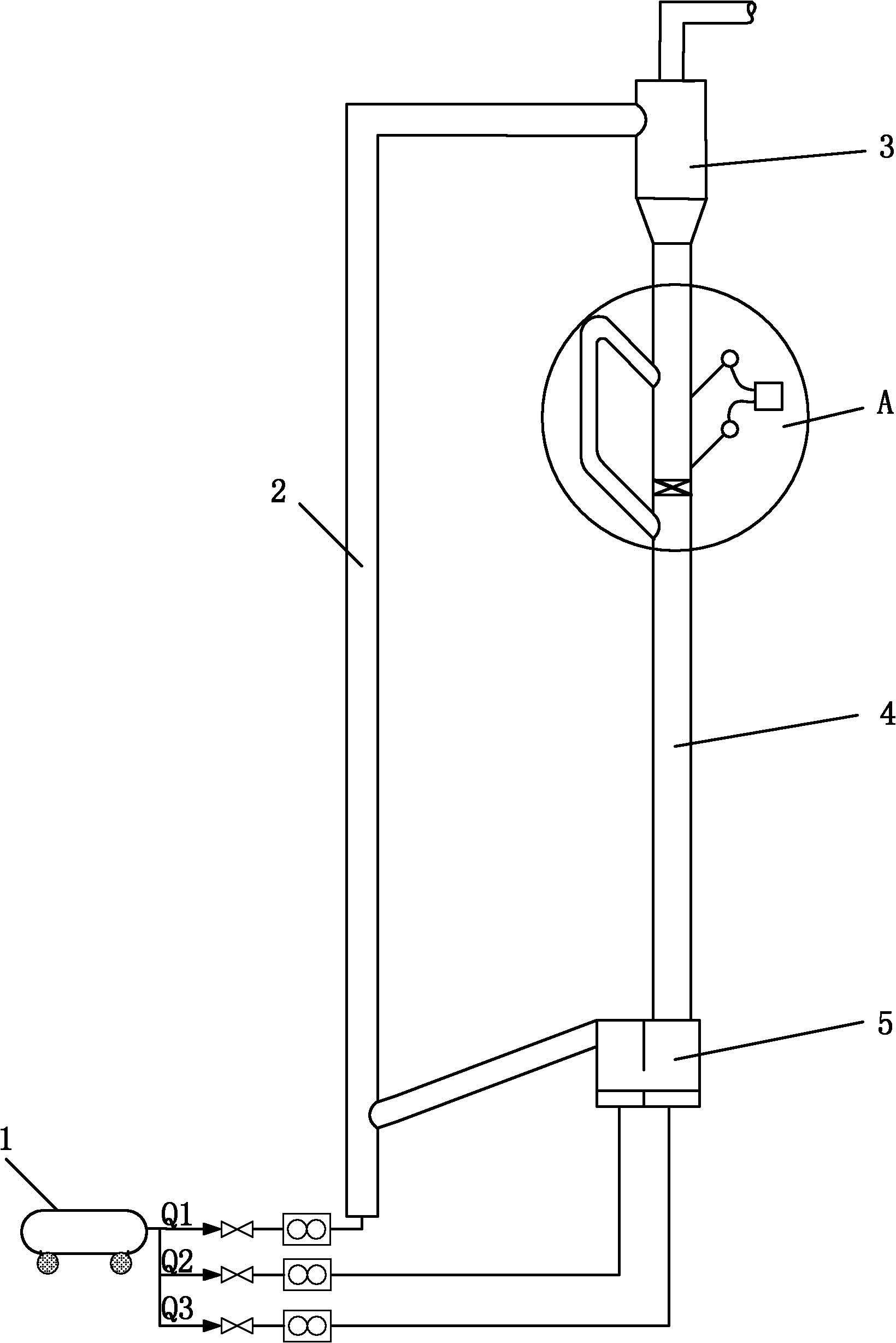

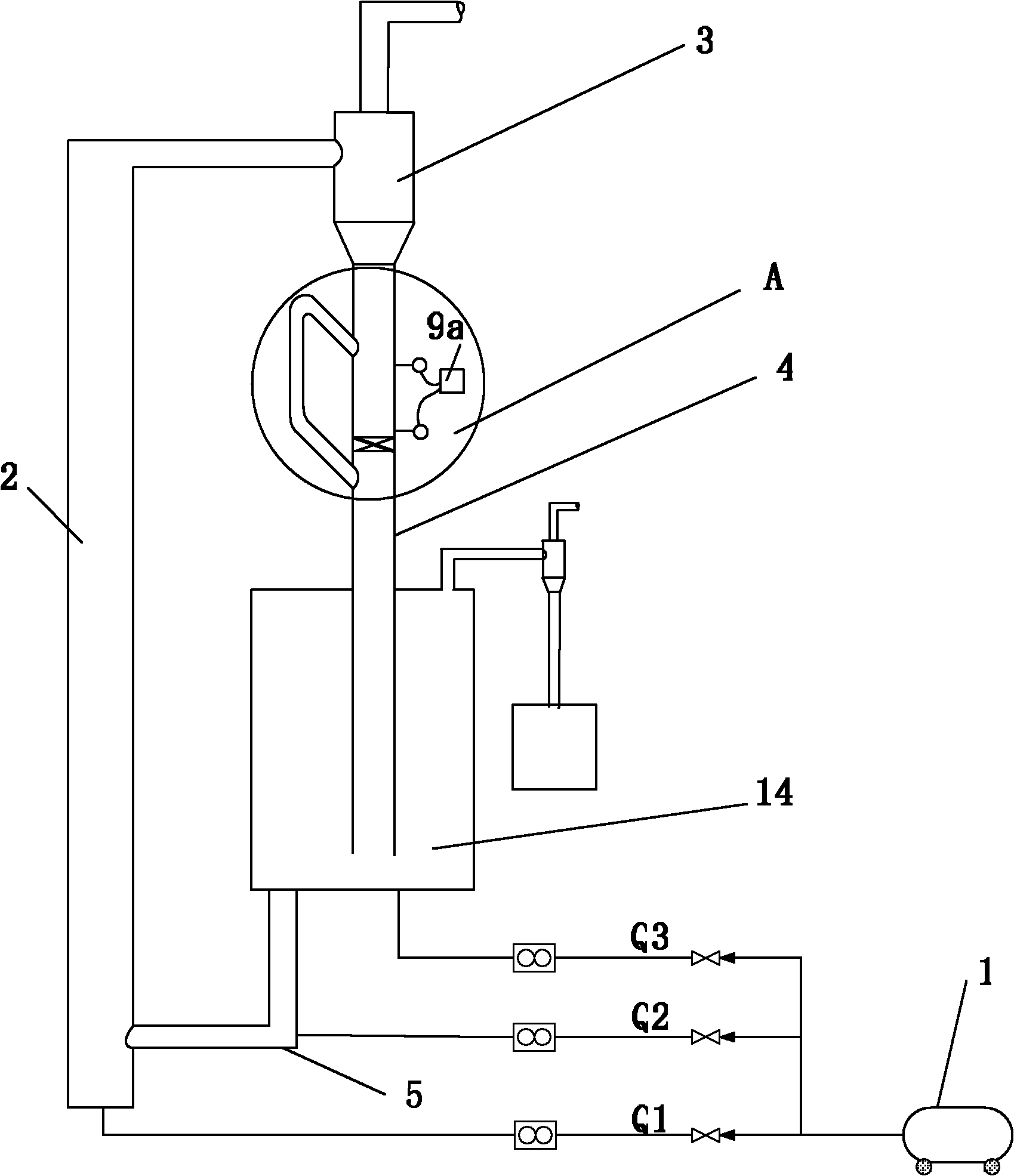

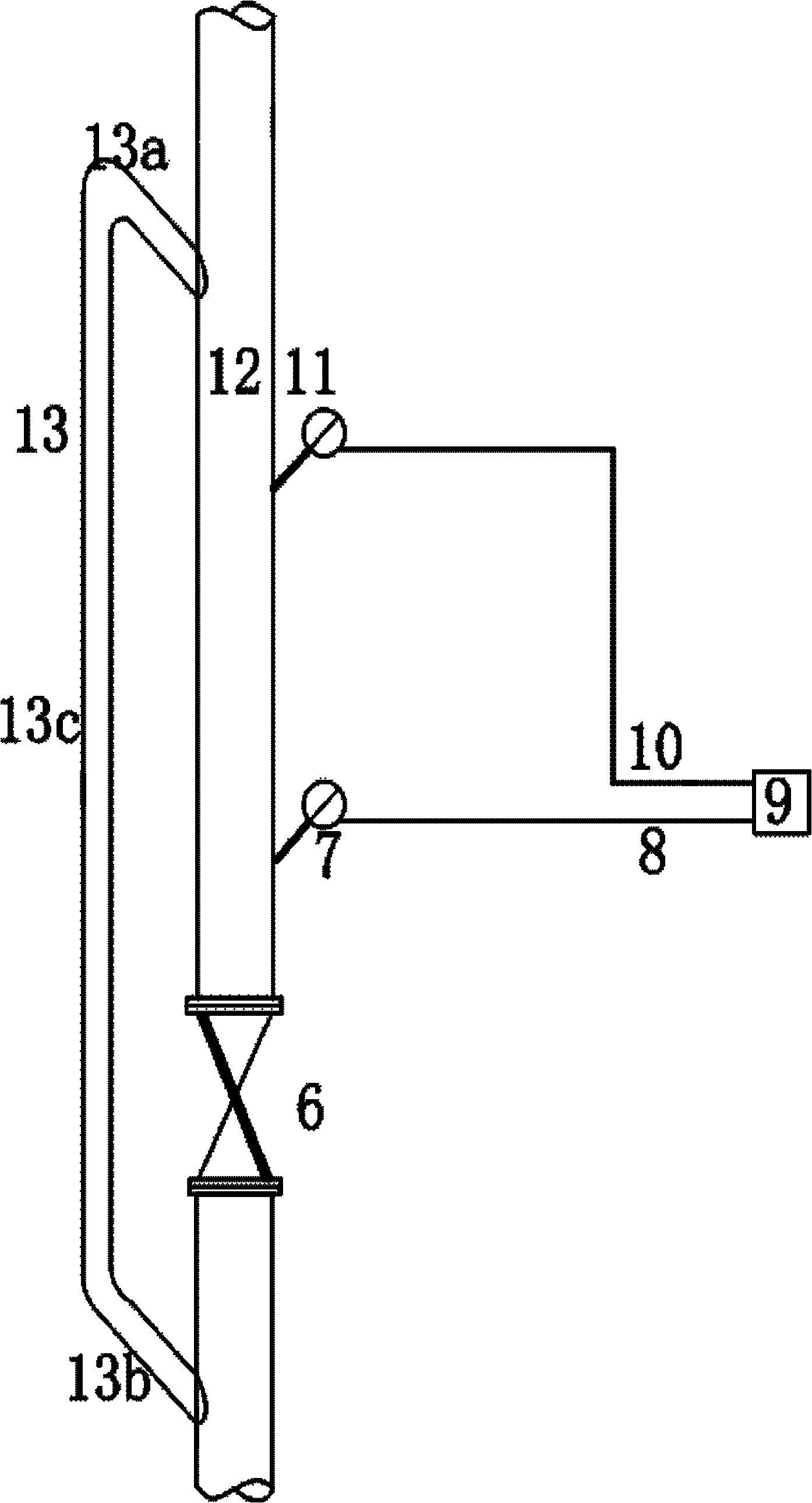

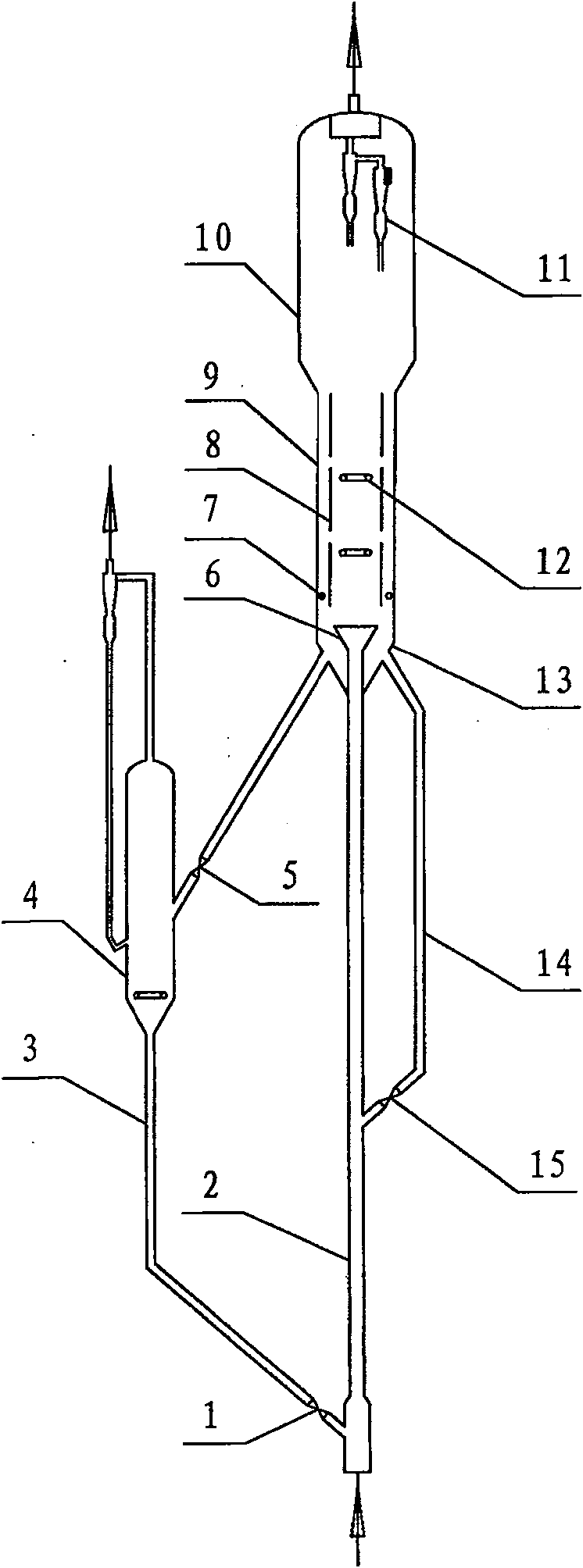

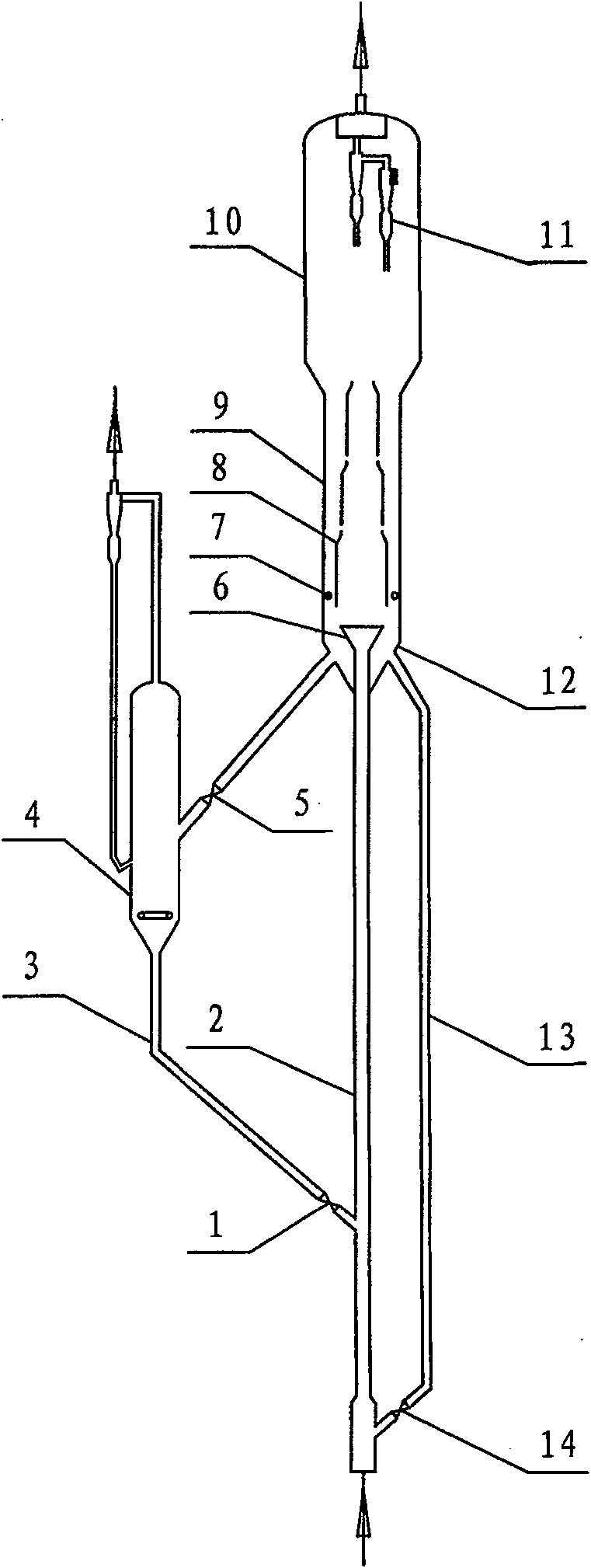

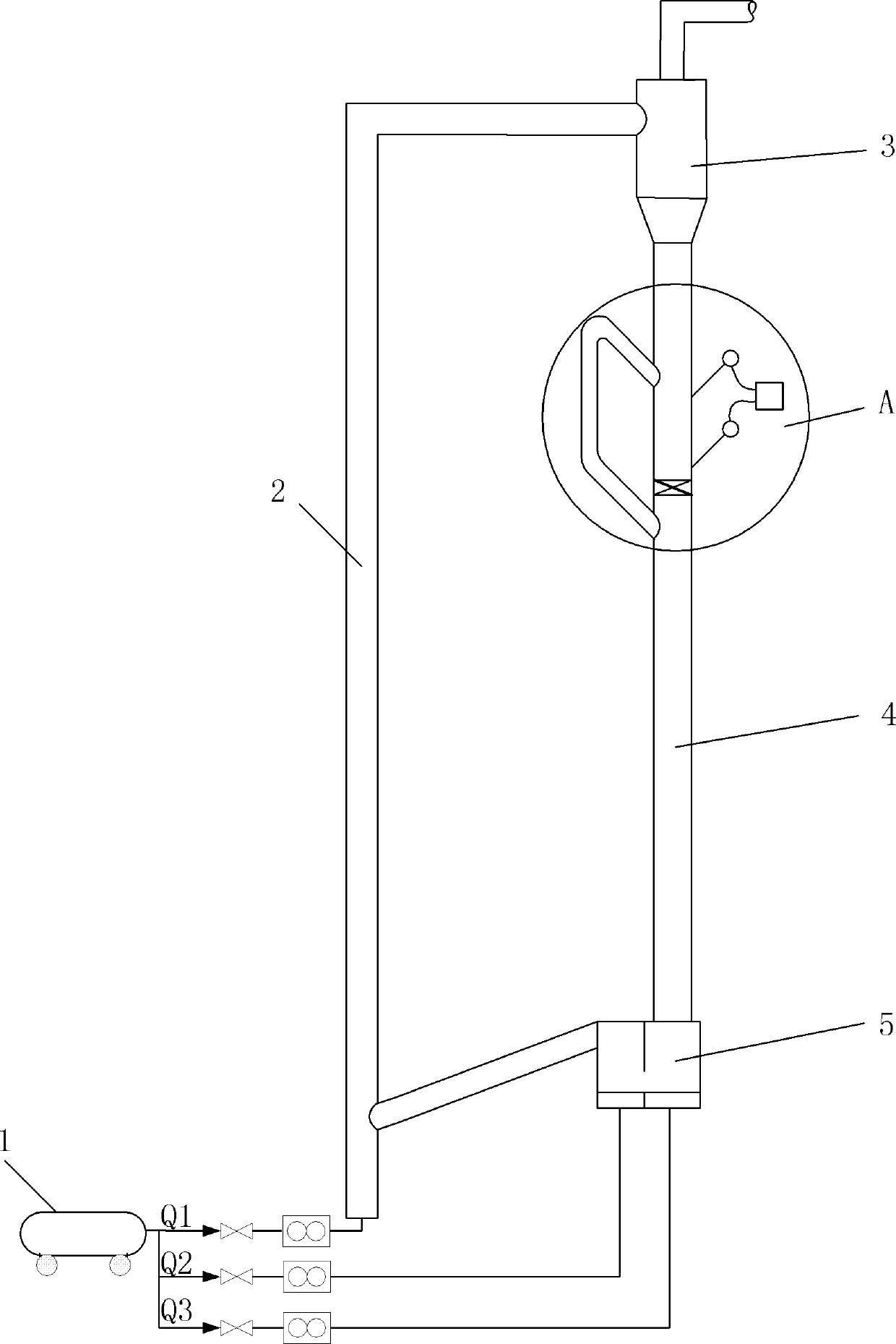

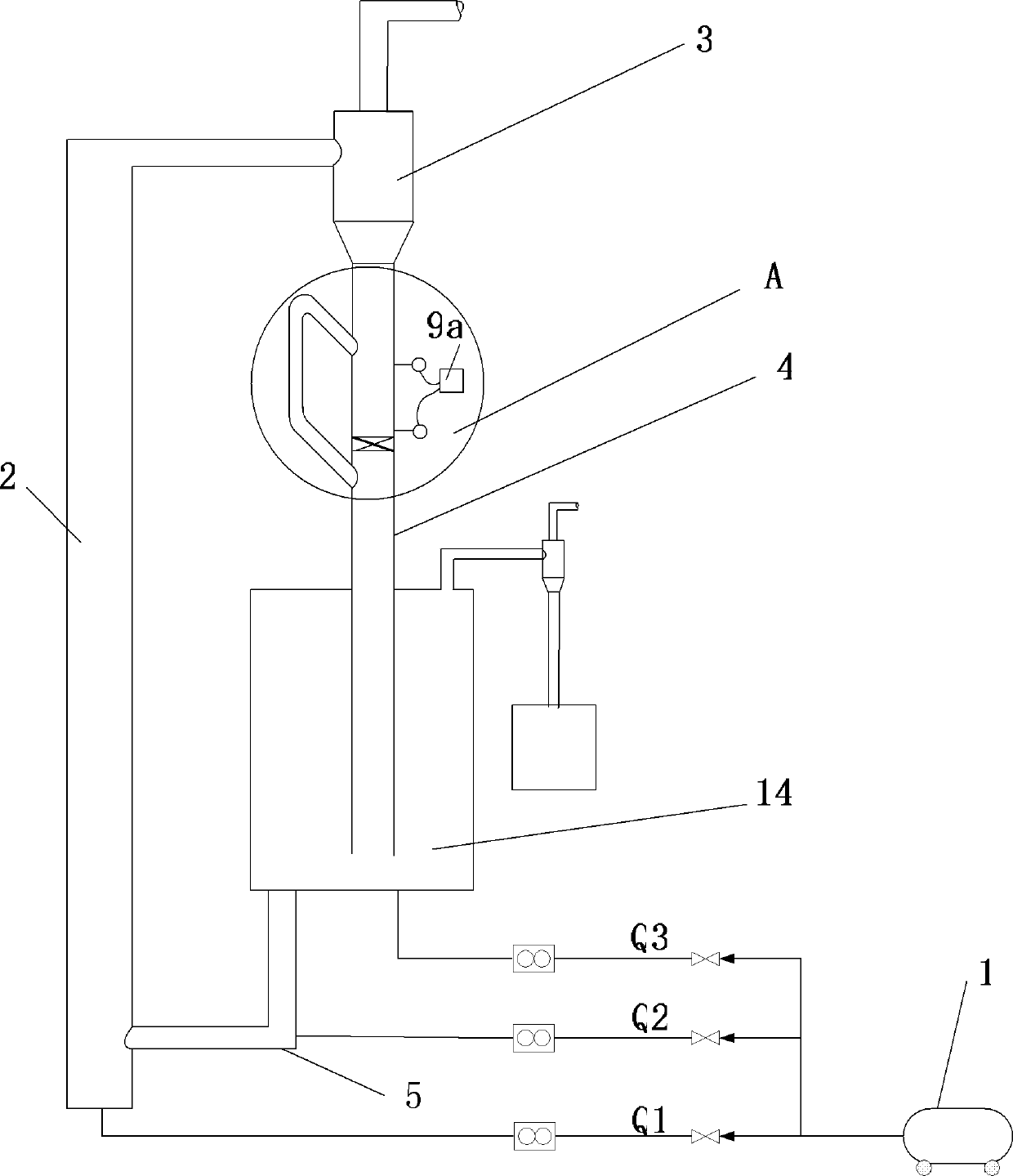

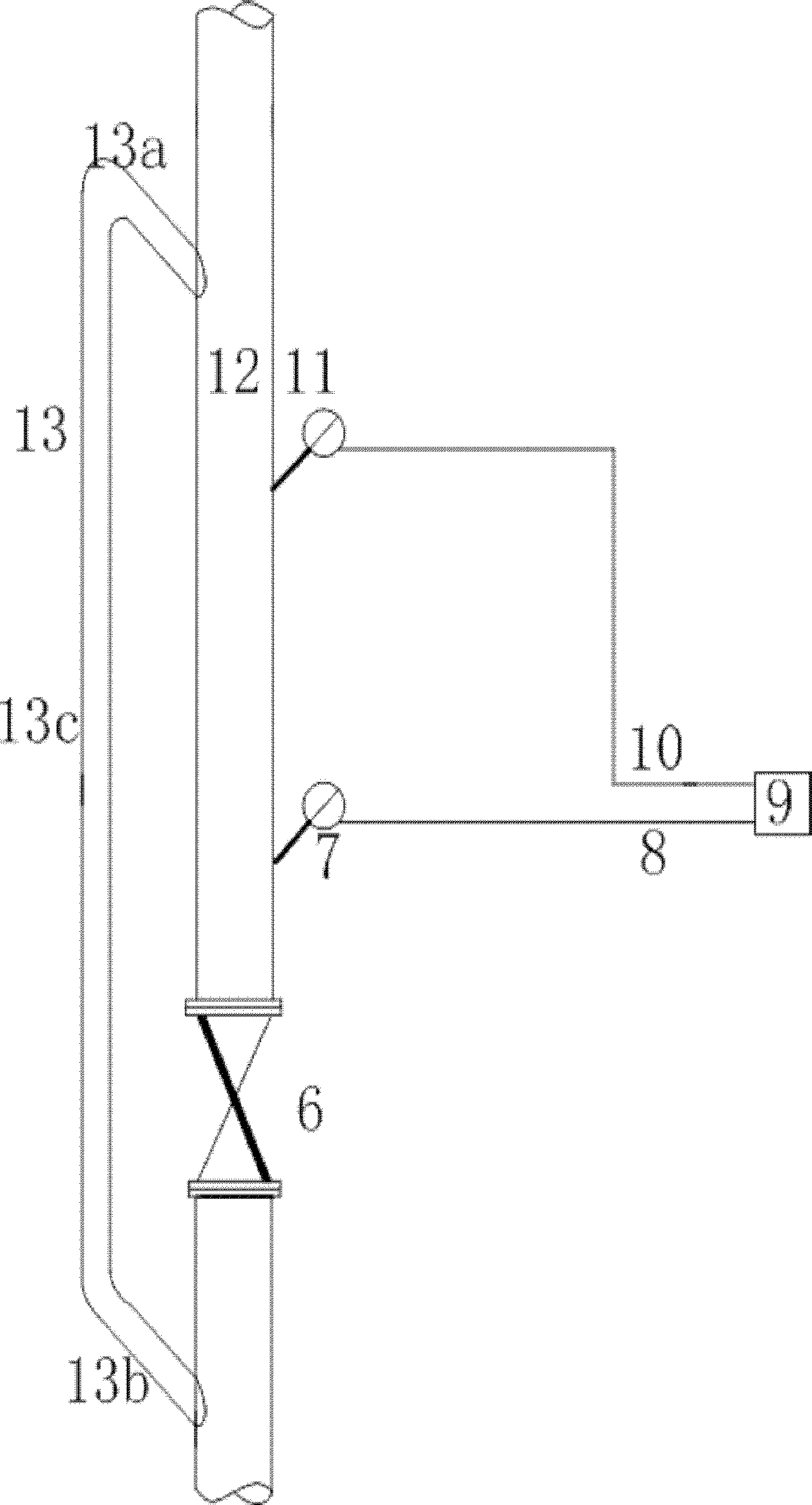

Device and method for measuring solid circulation flow rate

ActiveCN102759382AAdvantages Measuring DeviceAdvantage methodMass flow measurement devicesStock levelTransmission technology

The invention discloses a device and a method for measuring solid circulation flow rate, which relate to the solid transmission technology. The device for measuring solid circulation flow rate is composed of components, such as a valve, a high-low stock level switch, a timing device, a material measuring section, a balance pipe and the like. The position of the material is detected through the high-low stock level switch, a signal is transmitted to the timing device, and the material accumulation time is displayed, so that manual timing error is avoided, and measurement accuracy is improved greatly. The material measuring section of the device provided by the invention can be obtained by directly selecting one section of a dip leg, and the device is simple in structure and convenient to operate. With the balance pipe, the interference of the measuring process on the system operation can be reduced, and the device for measuring solid circulation flow rate is especially suitable for measuring the solid circulation flow rate of the devices with high solid circulation flow rate, and also can be used for measuring the solid circulation flow rate under a pressurization condition.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

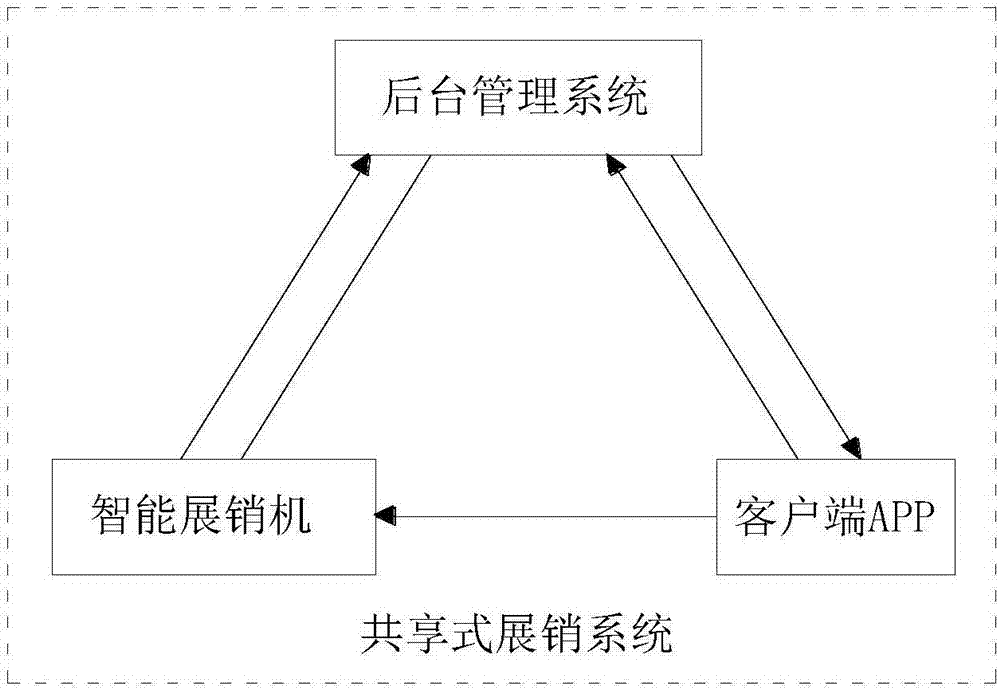

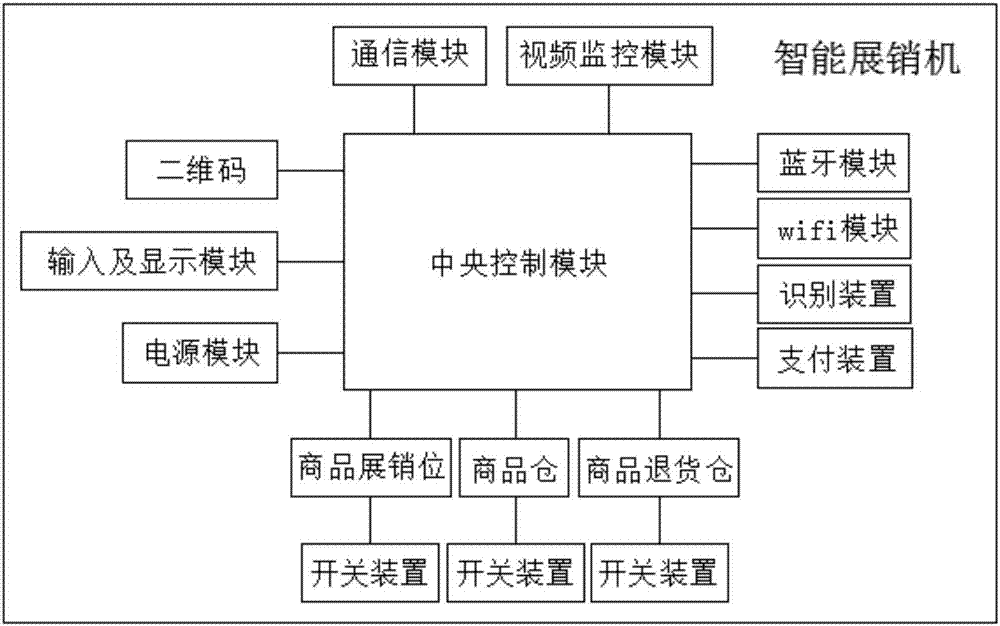

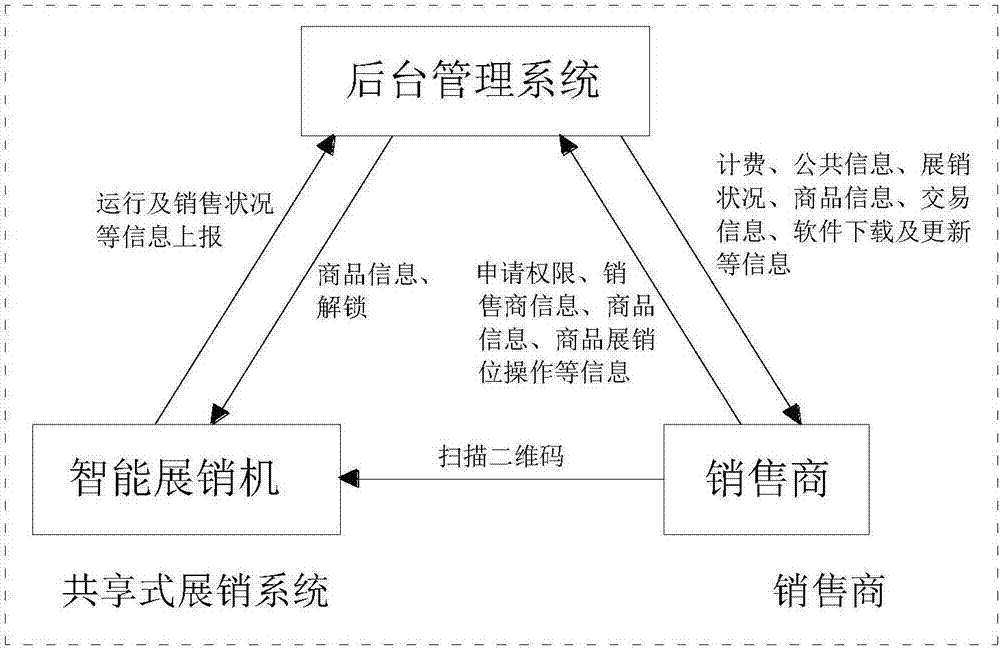

Sharing type exhibition system based on Internet of Things

PendingCN106934953AImprove experienceLower the thresholdApparatus for meter-controlled dispensingControl systemComputer science

The invention discloses a sharing type exhibition system based on Internet of Things. The sharing type exhibition system comprises an intelligent exhibition machine, a client APP and a background management system, wherein the intelligent exhibition machine integrates a communication module, a commodity exhibition position, a QR (Quick Response) code, a central control module and a power supply module; the communication module and the commodity exhibition position are respectively connected with the central control module; the client APP is in communication connection with the background management system; the central control module is connected with the background management system through the communication module; the background management system is arranged as a central control system arranged under a cloud computing environment; the client APP can recognize and show the commodity information of the intelligent exhibition machine in the manner of scanning the QR code on the intelligent exhibition machine. According to the invention, the channel for the company or personal commodity to enter into the field of social marketing circulation is widened, the threshold for the product to enter into the field of solid circulation is reduced, the retailer can sell the products without investment in shop, the development of consumption economy is boosted, convenience is brought to the user and the user experience is promoted.

Owner:SHENZHEN BEIZEER ELECTRONICS CO LTD

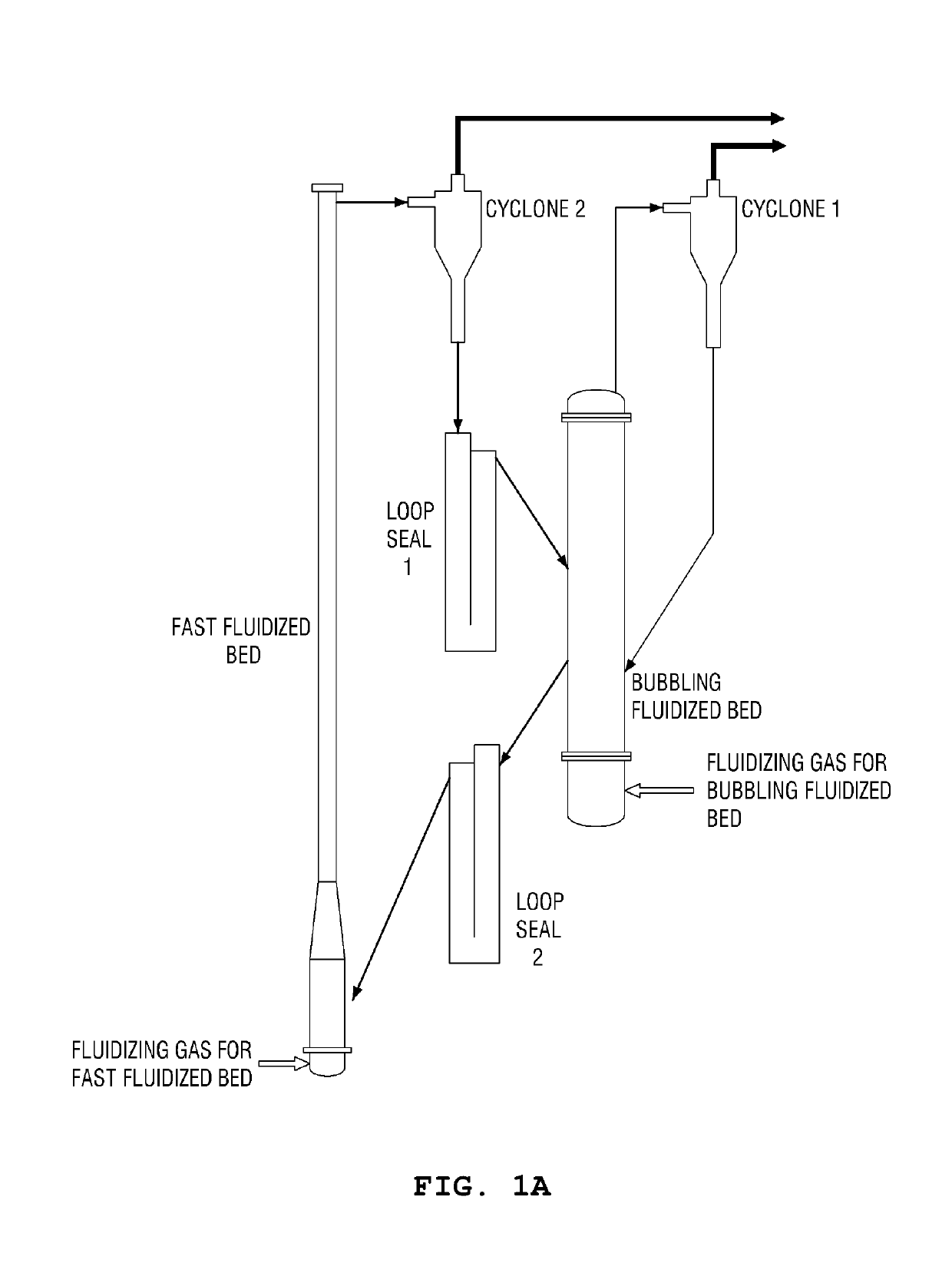

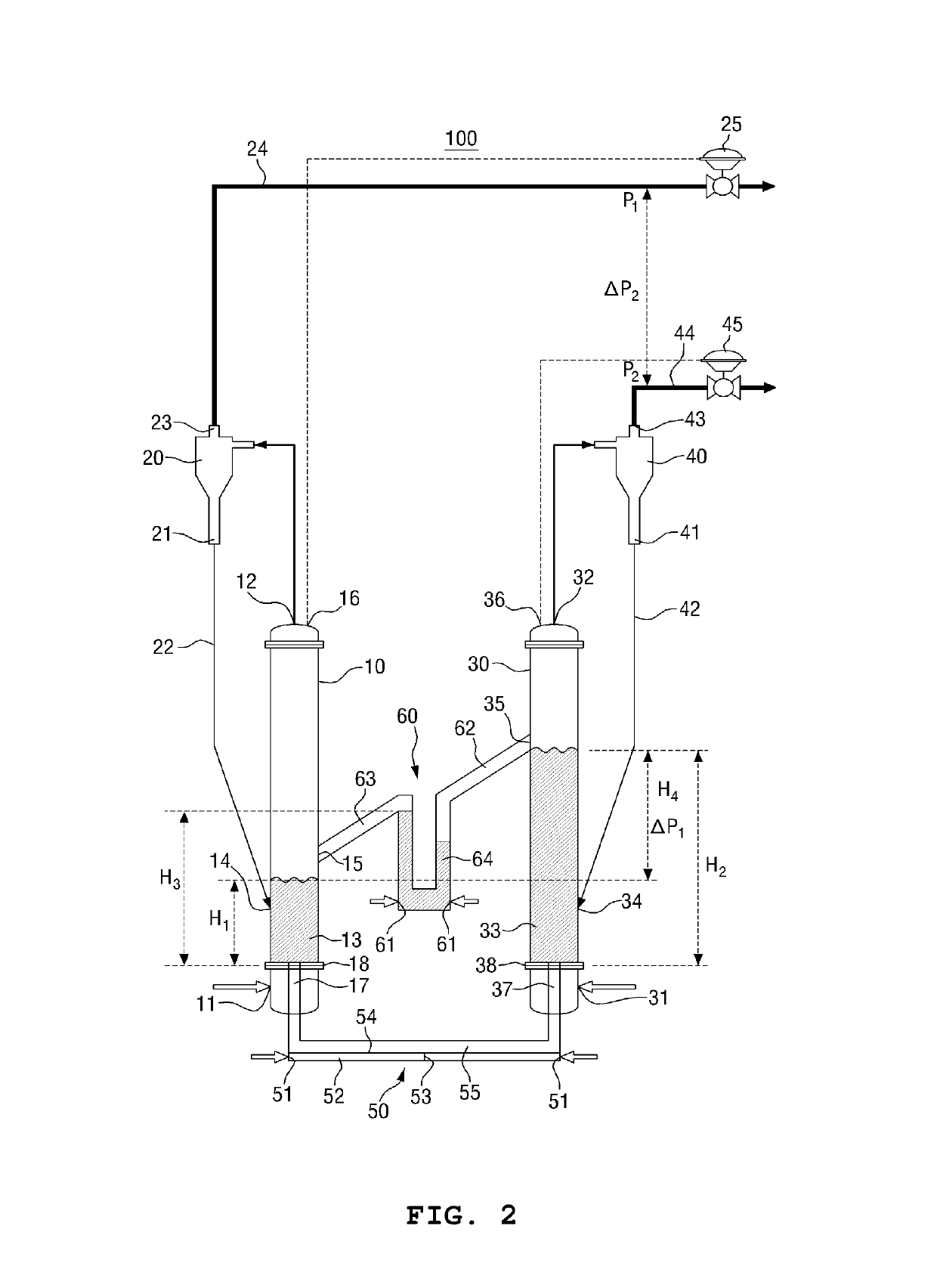

Fluidized bed solid circulation system using pressure and density difference, fluidized bed reaction system having the same and solid circulation method

ActiveUS10272408B1Increasing density of solidLow densityProcess control/regulationSingle direction vortexCycloneFluidized bed

Disclosed is provided to overcome problems of conventional methods using each of a solid discharge nozzle and a screw conveyer. According to one exemplary embodiment of the present invention, a fluidized bed system is provided to circulate solids using pressure and density difference. More particularly, a fluidized solid circulation system using pressure and density difference is characterized by comprising: a first fluidized bed reactor; a second fluidized bed reactor; a first cyclone; a second cyclone; a first pressure control valve; a second pressure control valve; a lower loop seal; an upper loop seal; and a control part, thereby circulating the solids between the first fluidized bed reactor and the second fluidized bed reactor.

Owner:KOREA INST OF ENERGY RES

Method for obtaining sludge pyrolytic oil with different uses in circulating fluidized bed reactor

InactiveCN103571514AImprove gas-solid heat transfer effectSolve the problem that it is difficult to obtain high-value productsSludge treatment by pyrolysisDirect heating destructive distillationFluidized bedSludge

The invention discloses a method for obtaining sludge pyrolytic oil with different uses in a circulating fluidized bed reactor. A ratio-adjustable circulating fluidized bed is adopted as a reactor to pyrolyzing sludge, a high solid circulation ratio is kept at 30-50, and low and intermediate solid circulation ratios are kept at 1-29. The solid circulation ratios of the circulating fluidized bed are controlled by regulating the start frequency and the start time of a slag discharge valve of the ratio-adjustable circulating fluidized bed. The low and intermediate solid circulation ratios are adopted to obtain the pyrolytic oil used as fuel oil, and the high solid circulation ratio is adopted to obtain the pyrolytic oil used for extracting industrial chemicals. The method adopts a mode of circulating fluidized bed so as to increase the gas-solid heat transfer effect and realize that the sludge pyrolytic oil with different uses is obtained in the same circulating fluidized bed reactor.

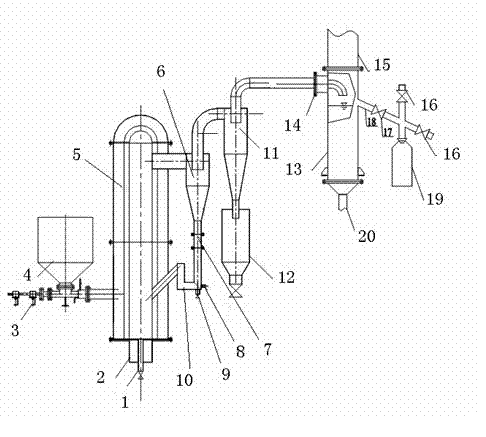

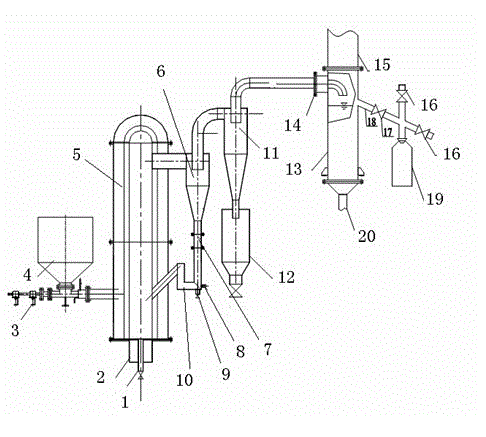

Device for obtaining sludge pyrolysis oil of different purposes in circulating fluidized bed reactor

InactiveCN103555355AImprove gas-solid heat transfer effectSolve the problem that it is difficult to obtain high-value productsSludge treatment by pyrolysisByproduct vaporizationSludgeFluidized bed

The invention discloses a device for obtaining sludge pyrolysis oil of different purposes in a circulating fluidized bed reactor. A sludge storage bin is connected to the lower end of a circulating fluidized bed body through a feeding spiral; a primary cyclone separator is connected to the upper part of the circulating fluidized bed body; the lower end of the primary cyclone separator is connected to the lower part of the circulating fluidized bed body through a return feeder; a return feeder slag discharge valve for controlling a solid circulation rate of the circulating fluidized bed is arranged on the return feeder; the top end of the primary cyclone separator is connected with a secondary cyclone separator; the top end of the secondary cyclone separator is connected with a spray tower main body; a carbon residue storage tank is arranged at the bottom of the secondary cyclone separator; the spray tower main body is connected with an upper oil recovery bottle; a lower oil discharge opening is formed in the bottom of the spray tower main body. A circulating fluidized bed mode is adopted, so that a gas-solid heat transfer effect is improved. Moreover, high-ash sludge pyrolysis oil of different purposes is obtained in one circulating fluidized bed reactor.

Owner:JIANGSU ZHONGRONG ENVIRONMENTAL PROTECTION +1

Combustible solid waste pyrolysis device and pyrolysis method

InactiveCN110484284ASimple structureEase of large-scale continuous productionDirect heating destructive distillationSpecial form destructive distillationHeat carrierProcess engineering

The invention discloses a combustible solid waste pyrolysis device and a pyrolysis method. The pyrolysis device comprises a fluidized bed pyrolysis reactor and a fluidized bed combustion reactor whichadopt heat carrier bed material interactive circulation. Combustible solid waste fuel is pyrolyzed in the fluidized bed pyrolysis reactor, and a heat carrier bed material overflows and is sent to thecombustion reactor through a star-shaped return feeder; the heat carrier bed material is heated again by utilizing heat released by pyrolysis oil gas combustion in the combustion reactor; and the heated heat carrier bed material enters the pyrolysis reactor again through a fluidized bed return feeder. Heat generated by combustion is transmitted to a pyrolysis process by utilizing interactive circulation of the heat carrier bed material between the two reactors, so that the problem of non-uniform temperature in reactors caused by heat transfer of conventional reactors is solved; the star-shaped return feeder for pyrolysis material returning achieves a good sealing effect, the fluidized bed material return feeder for combustion material returning avoids high oxidation and deformation of mechanical moving parts, and meanwhile the solid circulation flux can be controlled.

Owner:SOUTHEAST UNIV

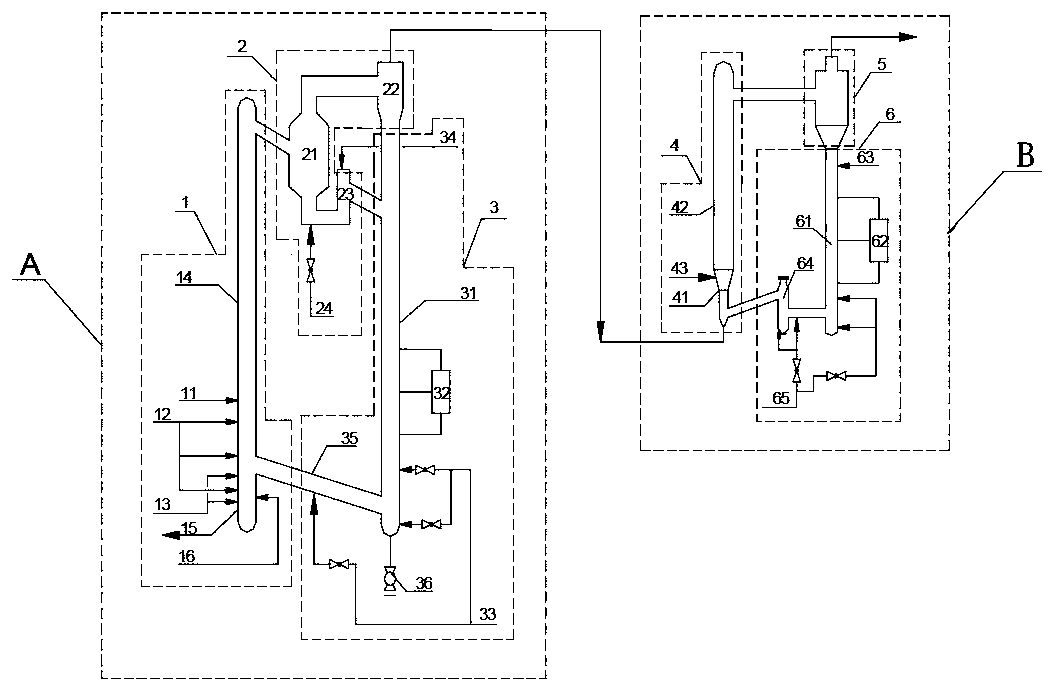

Double-circulation fluidized bed two-section coupled powdered coal pressure gasification device and method

PendingCN107937035ASufficient heat exchangeSmall temperature differenceGasification processes detailsGasification apparatus detailsSyngasFluidized bed

The invention discloses a double-circulation fluidized bed two-section coupled powdered coal pressure gasification device and method and belongs to the technical field of coal gasification. The deviceis characterized by comprising two parts, namely a first section reactor and a second section reactor, wherein the first section reactor comprises a reaction system, a carbon-containing material recycling system and a returned material conveying system which are connected in a head to end manner; the second section reactor comprises a secondary reaction system, a fine ash capturing device and a returned material conveying system which are connected in the head to end manner; the first section reactor is connected with the second section reactor through a pipeline. The improved device is rapidin solid circulation velocity and gas circulation speed, large in treatment capacity, sufficient in reaction medium heat exchange, high in heat exchange efficiency, small in overall temperature difference of fluidized beds and large in coal type application range, that is, from low-rank coal to medium / high-rank coal which is rich in reserve in China, the contents of effective gas components and the carbon conversion rate in coal gases are increased, a generated synthesis gas is free of tar, and later gas purification can be relatively simple.

Owner:SHAANXI YANCHANG PETROLEUM GRP

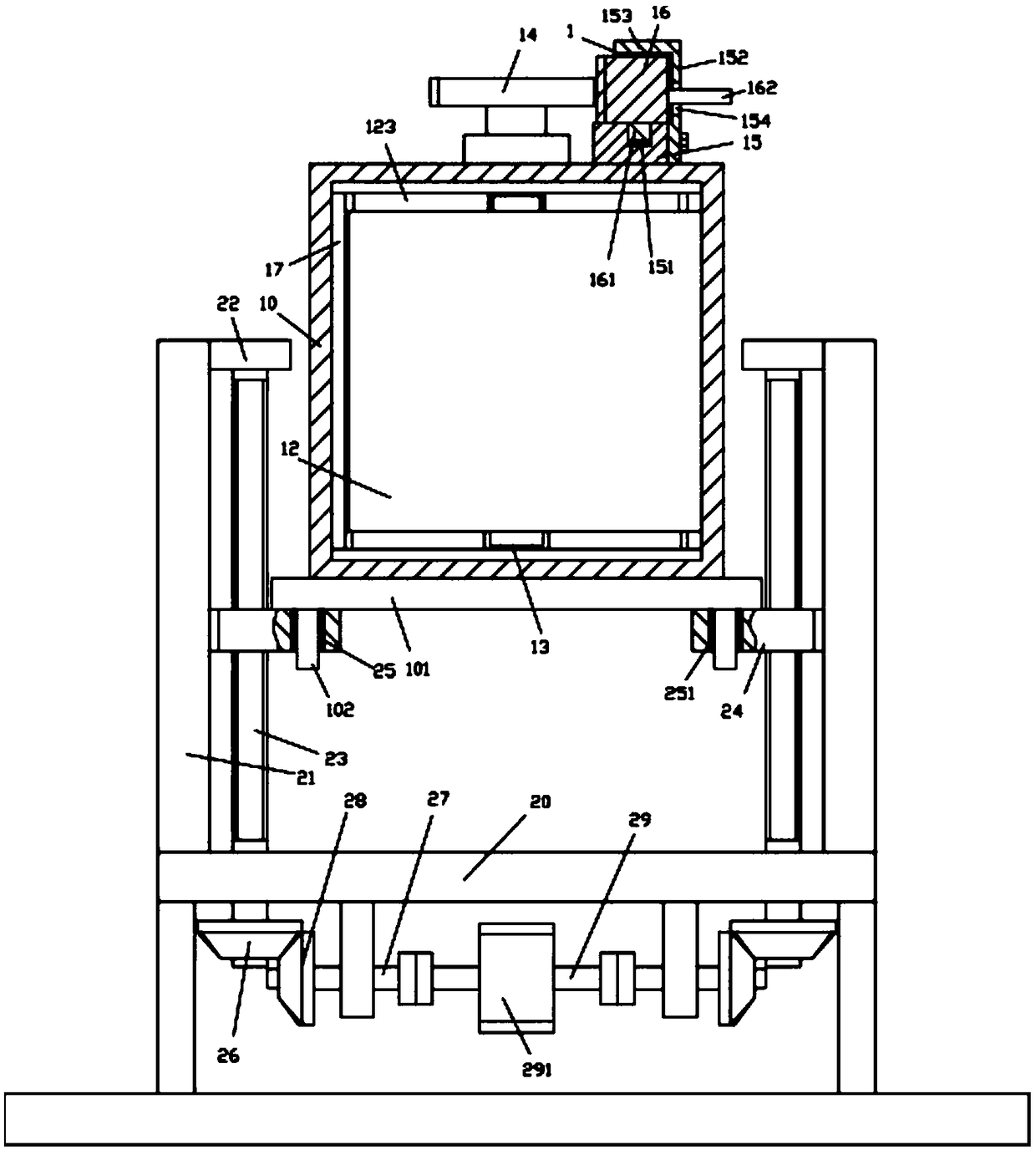

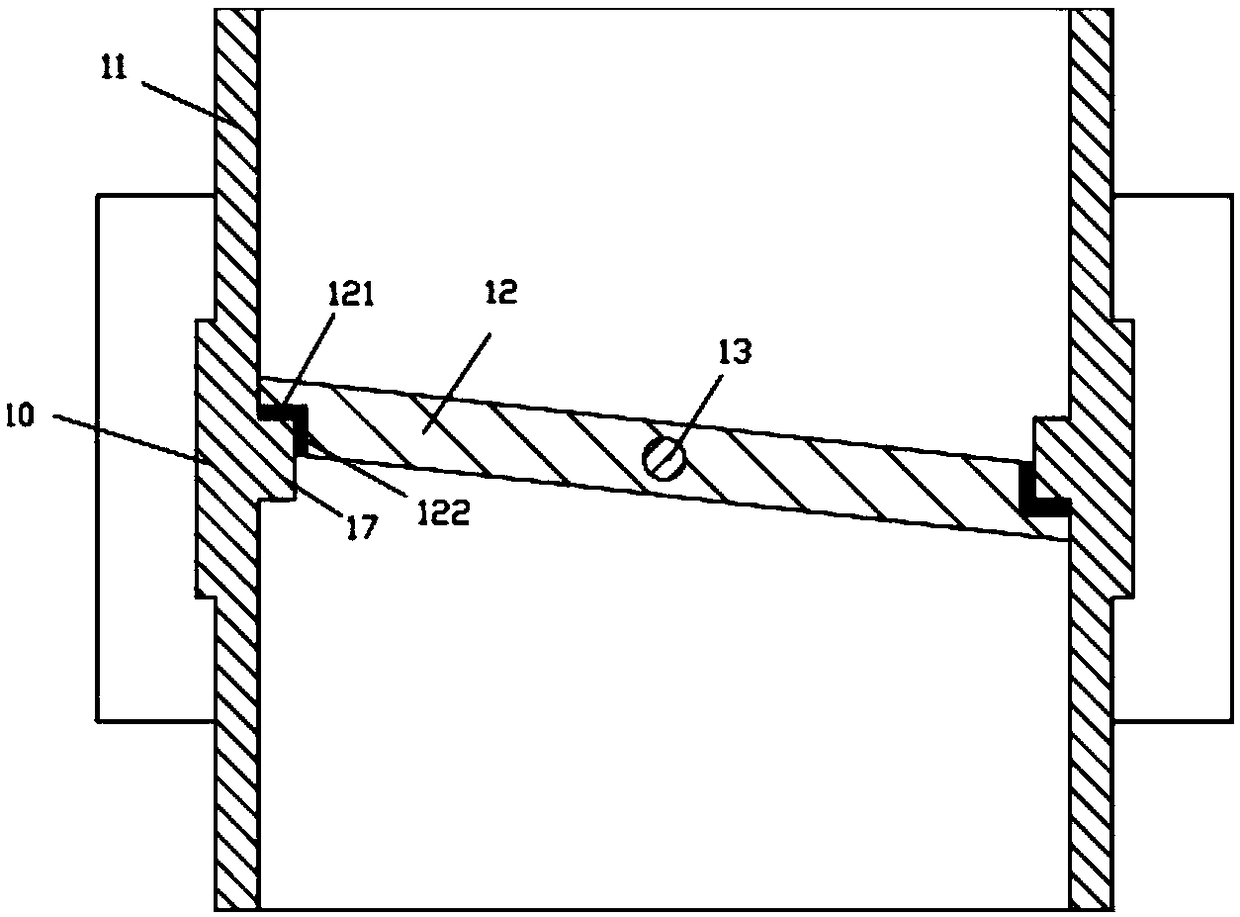

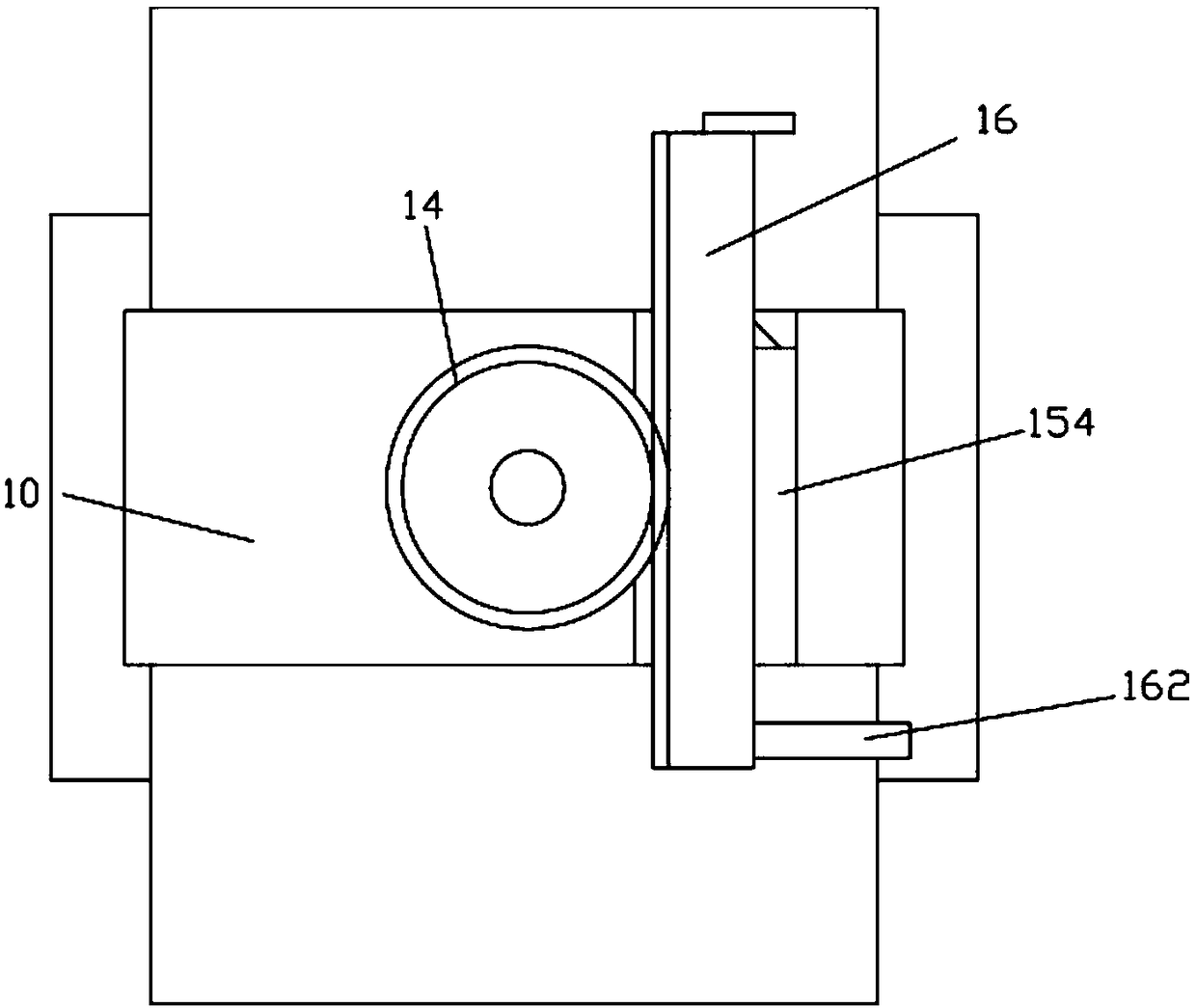

Movable type rectangular rack pulling type valve mechanism for large-particle solid circulation

InactiveCN108869771AEasy to makeEasy to installOperating means/releasing devices for valvesSlide valveTransportation capacityMovable type

The invention discloses a movable type rectangular rack pulling type valve mechanism for large-particle solid circulation. The valve mechanism comprises a rectangular valve body and an underbed. Rectangular extension connection sleeve bodies are formed on two end faces of the rectangular valve body. A main base plate is fixed to the bottom face of a base plate of the rectangular valve body. Vertical guide columns are fixed to the left side and the right side of the bottom face of the main base plate. Vertical supporting plates are fixed to the left side and the right side of a top plate of theunderbed. Transverse plates are fixed to the inner side walls of the top ends of the two vertical supporting plates. Two vertical screws are located on the left side and the right side of the top plate of the underbed. The movable type rectangular rack pulling type valve mechanism for large-particle solid circulation can be mounted in large-particle solid substance transportation mechanisms for temporary use; the rectangular valve body is adopted; manufacturing is simple; large-particle solid substance transportation control is satisfied; mounting is convenient to conduct; the position can beadjusted higher or lower; plugging connection of the valve mechanism with an interface of transportation equipment can be guaranteed; in addition, valve plate rotation is achieved through pulling ofracks, and the transportation capacity is adjusted through the valve plate rotation; and adjustment is convenient to conduct, and control precision is high.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Solid heat carrier furnace with controllable solid circulation amount in anaerobic pyrolysis environment

PendingCN113136233APrecise control of circulation volumeAchieve anaerobic environmentDirect heating destructive distillationSpecial form destructive distillationHeat carrierSlag

A solid heat carrier furnace with the controllable solid circulation amount in the anaerobic pyrolysis environment comprises a furnace body, and a slag discharge pipe and an air distribution device are arranged at the bottom of the furnace body; and heat carrier feeding equipment is arranged on the rear wall of the furnace body, a feeding control valve and a feeding inclined pipe are arranged on the lower portion of the heat carrier feeding equipment, and the feeding inclined pipe is connected with the furnace body. The top front wall of the furnace body is connected with the cyclone separator; and the lower part of the cyclone separator is sequentially connected with a surge bin, a blanking controller, a solid flowmeter, a reactor, a middle bin, material returning equipment and a material returning pipe, and the material returning pipe is connected with the furnace body to form a circulating channel of a solid heat carrier path.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Method for carrying out gas-solid fluidized bed reaction

ActiveCN105771818BReduce wearHydrocarbon from oxygen organic compoundsChemical recyclingPtru catalystFlue gas

The invention relates to a method for carrying out a gas-solid circulation fluidized bed reaction. The method comprises the following steps: (1) in a fluidized bed reactor, an exothermic reaction is carried out under a condition that a gaseous raw material contacts a solid catalyst, such that a mixed product comprising a gaseous product and the solid catalyst is produced; (2) gas-solid separation is carried out in the upper part of the reactor; a part of the catalyst with charcoal deposit is delivered to a catalyst regenerator; (3) in the catalyst regenerator, the catalyst with charcoal deposit contacts regeneration air, such that a charcoal burning reaction is carried out; catalyst activity is recovered, and flue gas is generated; (4) the regenerated catalyst is delivered to the fluidized bed reactor through a regenerated catalyst delivery pipe; (5) the absolute value of the difference between the temperature of steam used for delivery and stripping and the temperature of the solid catalyst in a regenerated catalyst stripping section is 0-100 DEG C; and the absolute value of the difference between the temperature of delivery air used for delivering and the temperature of the solid catalyst in a spent catalyst stripping section is 0-100 DEG C. With the method, catalyst powdering damage caused by thermal expansion and contraction is effectively reduced.

Owner:SHANGHAI BI KE CLEAN ENERGY TECH +1

Gas/solid circulation mixing steam stripper and mixing and steam stripping method of solid particles

ActiveCN102676206BStrong shearImprove contact efficiencyCatalytic crackingCatalyst regeneration/reactivationEngineeringProduct gas

The invention provides a gas / solid circulation mixing steam stripper and a mixing and steam stripping method of solid particles. The gas / solid circulation mixing steam stripper comprises a cylinder body (7) with an inner cavity, a flow guide cylinder (6), a ring-gap gas distributor (3), a gas distributor (11) of the flow guide cylinder, a gas outlet extending into the inside of the cylinder body (7), a cone (2) connected with the lower end of the cylinder body (7), a mixed solid particle outlet (1) arranged below the cone (2), a loose steam ring (12) which is positioned at the bottom of the cone (2) and is also positioned above the mixed solid particle outlet (1), a first solid particle inlet passage and a second solid particle inlet passage, wherein the first solid particle inlet passage and the second solid particle inlet passage are respectively connected to the inside of the cylinder body. The gas / solid circulation mixing steam stripper is adopted by the mixing and steam stripping method of the solid particles.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Device for improving pipe and gas-solid circumfluence bed coupling reaction

ActiveCN100577276CExtended reaction timeReduce resistanceFluidized bed combustionChemical/physical processesChemical industrySystem pressure

The invention provides a lift pipe and air-solid circulation bed coupling reaction device which at least includes a lift pipe, a shower head distributor, a guide cylinder, an annular space air distribution ring, an outer cylinder, an inner circulation pipe, an outer circulation fluidized bed, an outer circulation pipe and an air-solid separating system. Particles and air are transmitted upwards along the lift pipe, pass through the shower head distributor and enter the upper annular fluidized bed to form a central air lifting type circumfluence between the guide cylinder and the annular space. Part of the particles below the outer cylinder enters the lift pipe through the inner circulation pipe and another part enters the outer circulation fluidized bed to be mixed with the original particles in the outer circulation fluidized bed; the mixed particles enter the lift pipe through the outer circulation pipe; the positions where the inner circulation pipe and the outer circulation pipe enter the lift pipe can be flexibly arranged; the lift pipe and air-solid circulation bed coupling reaction device overcomes the limitations of system pressure balance and short reaction time and has the advantages that each area is flexible to be operated and controlled, the air-solid contact efficiency of the annular fluidized bed is high and the resistance above the distributor is small, etc. The device can be broadly applied to the fields of energy supply, chemical industries and particle combustion, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

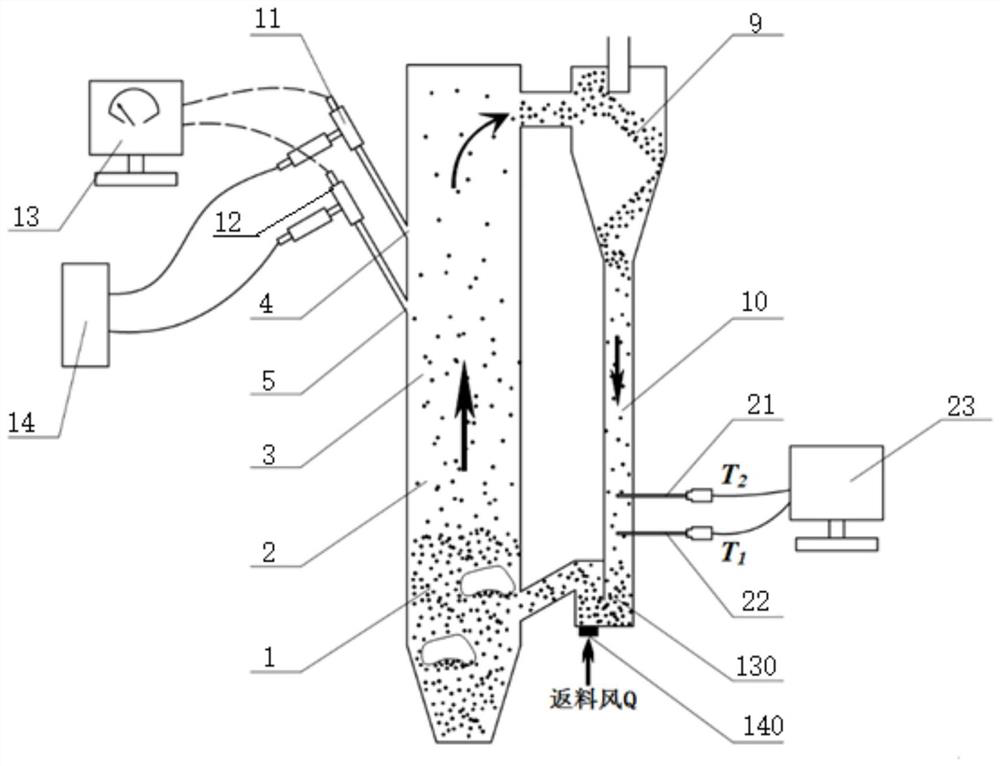

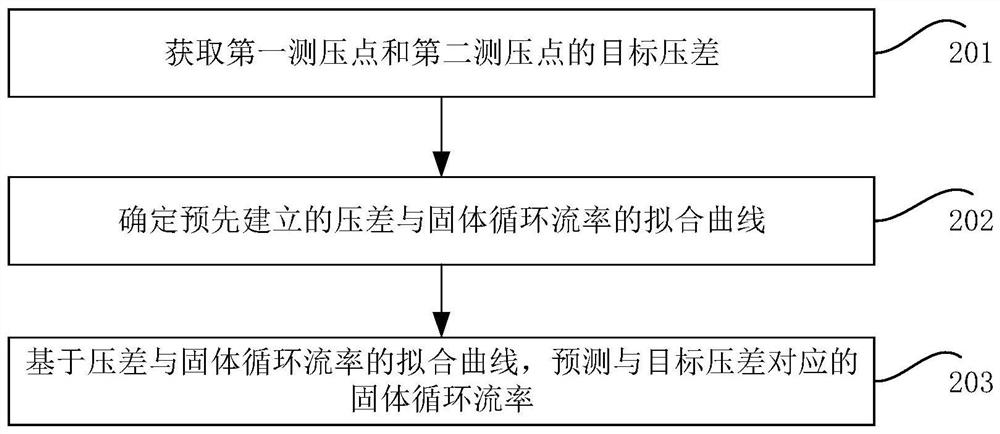

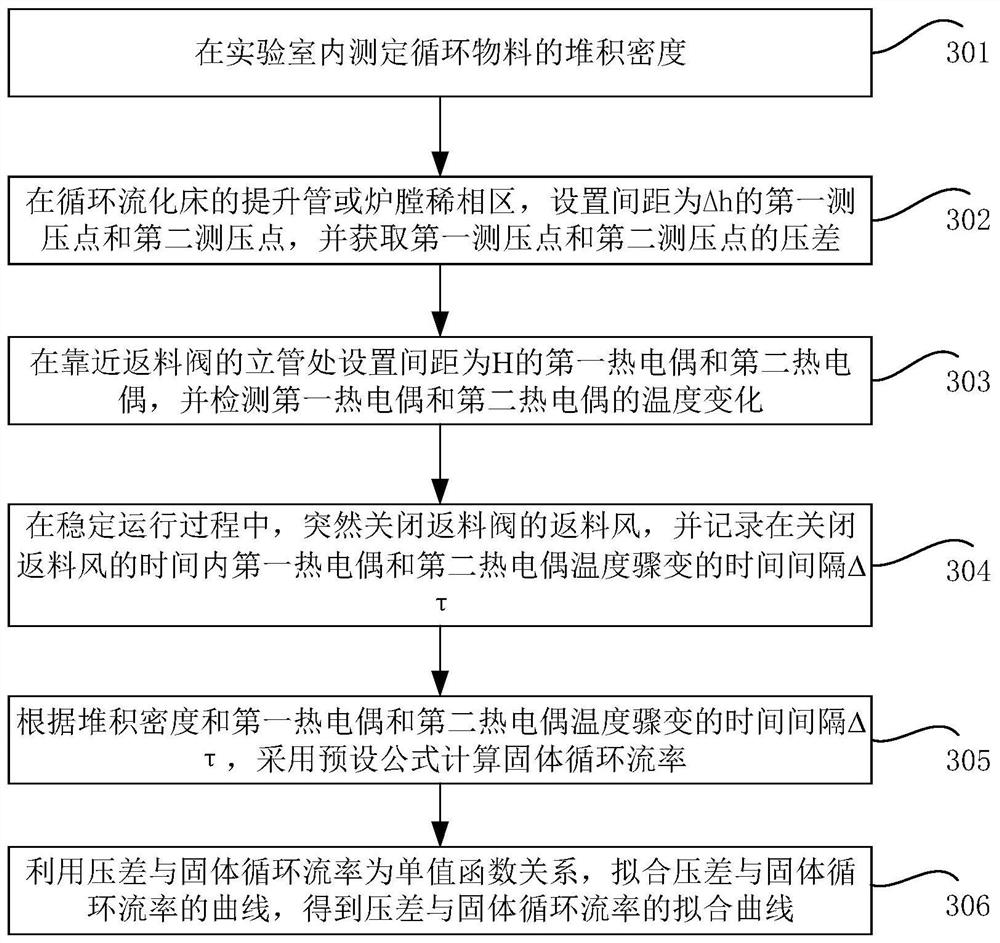

Method and system for measuring solid circulation flow rate of thermal-state circulating fluidized bed

ActiveCN113155217ARealize measurementDoes not interfere with normal operating conditionsIndirect mass flowmetersThermal stateFluidized bed

The invention provides a method and a system for measuring the solid circulation flow rate of a thermal-state circulating fluidized bed. The measuring method comprises the following steps that: a target pressure difference between a first pressure measuring point and a second pressure measuring point is acquired, wherein the first pressure measuring point and the second pressure measuring point are arranged in a lifting pipe or a hearth lean-phase region of a circulating fluidized bed, and the distance between the first pressure measuring point and the second pressure measuring point is delta h; a pre-established fitting curve of the pressure difference and the solid circulation flow rate is determined; and the solid circulation flow rate corresponding to the target pressure difference is predicted based on the fitting curve of the pressure difference and the solid circulation flow rate. The solid circulation flow rate of the thermal-state circulating fluidized bed can be reliably measured, measurement facilities are simple, a material measurement section does not need to be additionally arranged, the cost is low, the solid circulation flow rate is represented by directly utilizing the pressure difference, and the normal operation state of the circulating fluidized bed is not interfered.

Owner:TSINGHUA UNIV

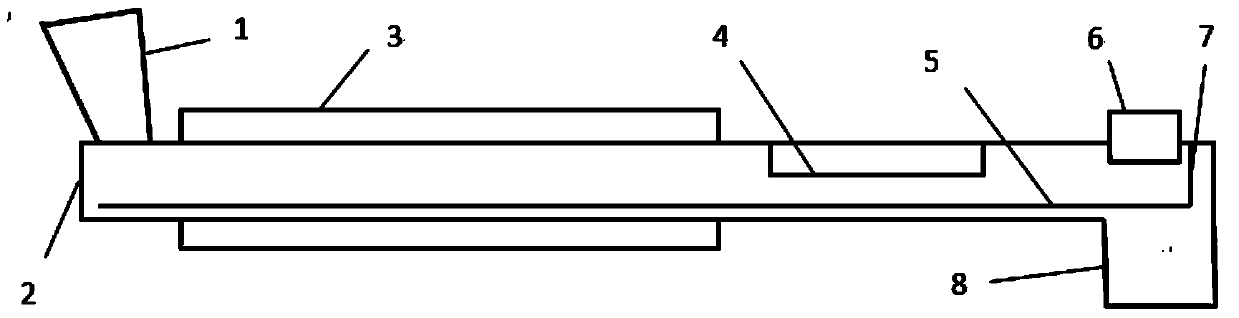

Magnetic type recycling pyrolyzer for preparing biomass activated carbon

InactiveCN104211060ASave energyContinuously workingChemical recyclingActivated carbonCombustion chamber

The invention discloses a magnetic type recycling pyrolyzer for preparing biomass activated carbon. A circular pipeline with a rectangular cross section is utilized as a pyrolysis pipeline, a conveyor belt is paved on the bottom of the circular pipeline for transmitting biomass rice husks doped with an iron-based catalyst; the rice husks pass through a combustion chamber on the exterior of the pipeline so as to be pyrolyzed in a transmitting process, and then, gases in a pyrolysis product are pumped away by an aspirator pump, and then pass through a cyclone separator; the rest gases are mixed with air so as to be injected into the combustion chamber, and combusted in the combustion chamber, so that recycling of energy resources is realized. Solid products pass through a part with a magnet at the top end, so that the iron-based catalyst is recycled by virtue of the magnet, and the rest solids are baffled by virtue of a baffle plate, and then blown and dropped into a lower ash slot by virtue of a fan at the top end. The magnetic type recycling pyrolyzer for preparing biomass activated carbon is simple in structure and convenient to operate; the rice husk processing efficiency is improved by virtue of a solid circulating path, and the utilization efficiency of the energy resources is improved by virtue of a gas circulating path. And moreover, the cost is greatly lowered by recycling the catalyst.

Owner:NANJING UNIV OF SCI & TECH

Zanjon type gas-lift stream-pull tridimensional circulation type inversion A<2>O integral co-construction oxidation ditch

ActiveCN101269879BIncrease water depthGood removal effectTreatment with aerobic and anaerobic processesWater qualityEnvironmental engineering

The invention relates to a zanjon air lifting pushing solid circulation inversion A<2>O integrated construction oxidation ditch, which comprises an anoxic zone, an anaerobic zone, an aerobic zone provided with a millipore aerator group and an inversion A<2>O integrated construction oxidation ditch of a solid and liquid separating zone. The solid and liquid separating zone is arranged at the frontend of a main ditch, the anaerobic zone is arranged at the tail end of the main ditch, and water inlets are respectively arranged at the front ends of the aerobic zone and the anaerobic zone. The integrated construction oxidation ditch is characterized in that a horizontal partition board which divides the main ditch into an upper groove layer and a lower groove layer is arranged at the middle-lower part of the main ditch, the aerobic zone and the anaerobic zone are respectively arranged at the upper groove layer and the lower groove layer, the aerobic zone is internally provided with n (n ismore than or equal to 1) aeration lifting zone (s) which is (are) composed of an inlet water-retaining wall, an outlet water-retaining wall and the millipore aerator group and is (are) provided with a lower water inlet and an upper water outlet, the horizontal partition board of a first grade aeration lifting zone is provided with a plurality of lifting holes, and the aerobic zone is internally divided into n aerobic reaction zone (s) corresponding to the aeration lifting zone (s).The integrated construction oxidation ditch has the advantages that: the yielding water quality, particularly thedephosphorization and denitrification effect, is better, the occupation area is reduced, the equipment is reduced, the operation is simplified, and the operation cost is lowered.

Owner:北京创未环境工程技术有限公司

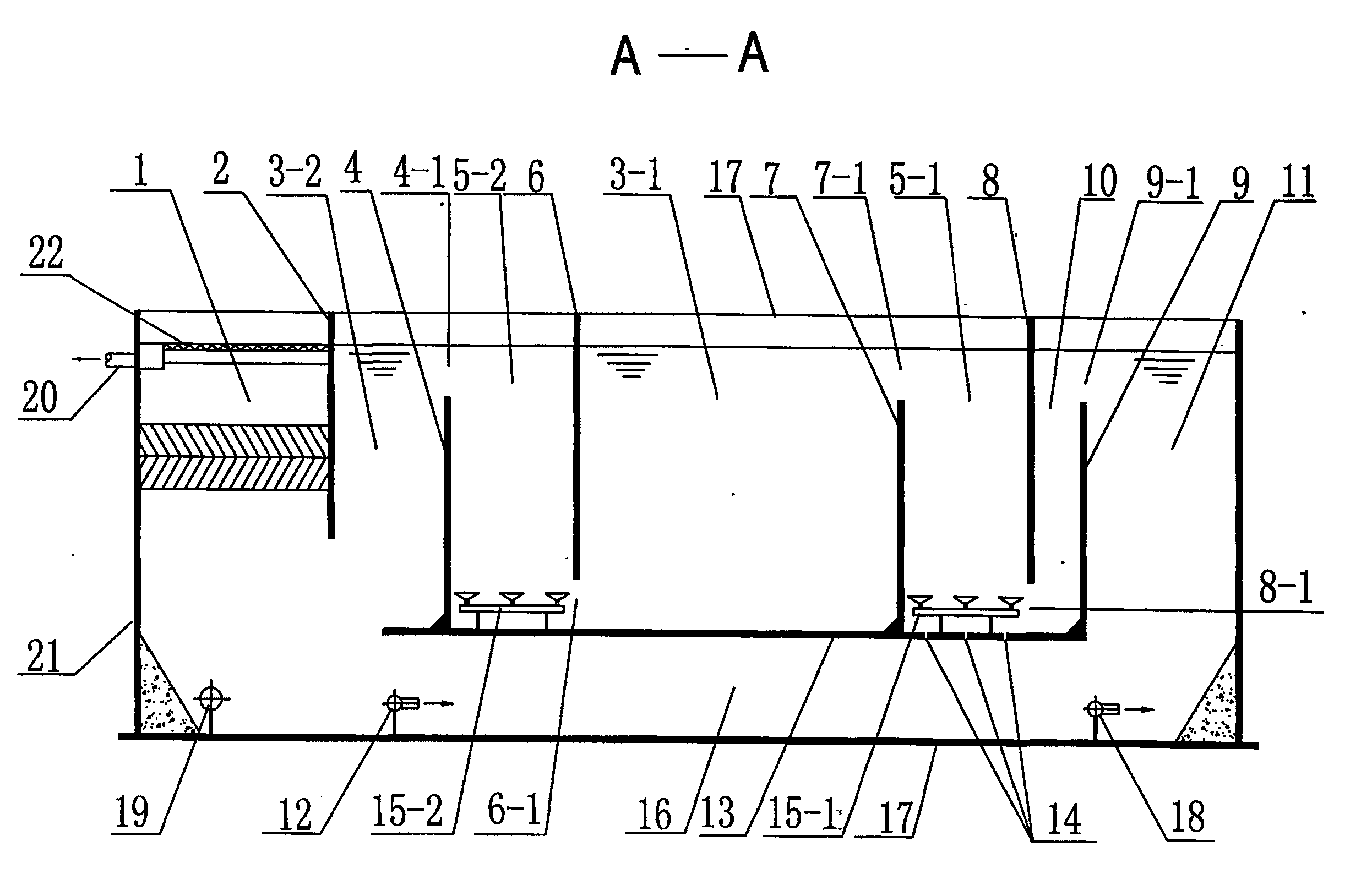

Liquid-solid fluidized bed waste water treatment system for simultaneous carbon, nitrogen and phosphorus removal

InactiveCN101842323BTreatment using aerobic processesSeparation devicesActivated sludgeWater treatment system

Biological nutrient removal (BNR) in wastewater treatment to remove carbonaceous substrates, nutrients and phosphorus, has recently become increasingly popular worldwide due to increasingly stringent regulations. Biological fluidized bed (BFB) technology, which could be potentially used for BNR processes, can provide some advantages such as high efficiency and compact structure. This present invention incorporates the fixed-film biological fluidized bed technology with the biological nutrient removal in a twin liquid-solid fluidized bed, which has achieved the simultaneous elimination of organic carbon, nitrogen and phosphorus, in a very efficient manner and with very compact space requirements. The BNR-LSFB has two fluidized beds, running as anoxic / anaerobic and aerobic processes to accomplish simultaneous nitrification and denitrification and to remove carbonaceous substrates, nutrients and phosphorus, with continuous liquid and solids recirculation through the anoxic / anaerobic bed and the aerobic bed. The new BNR-LSFB system is not only an excellent alternative for conventional activated sludge type BNR technologies but is also capable of processing much higher loadings and suitable for industrial applications.

Owner:UNIV OF WESTERN ONTARIO

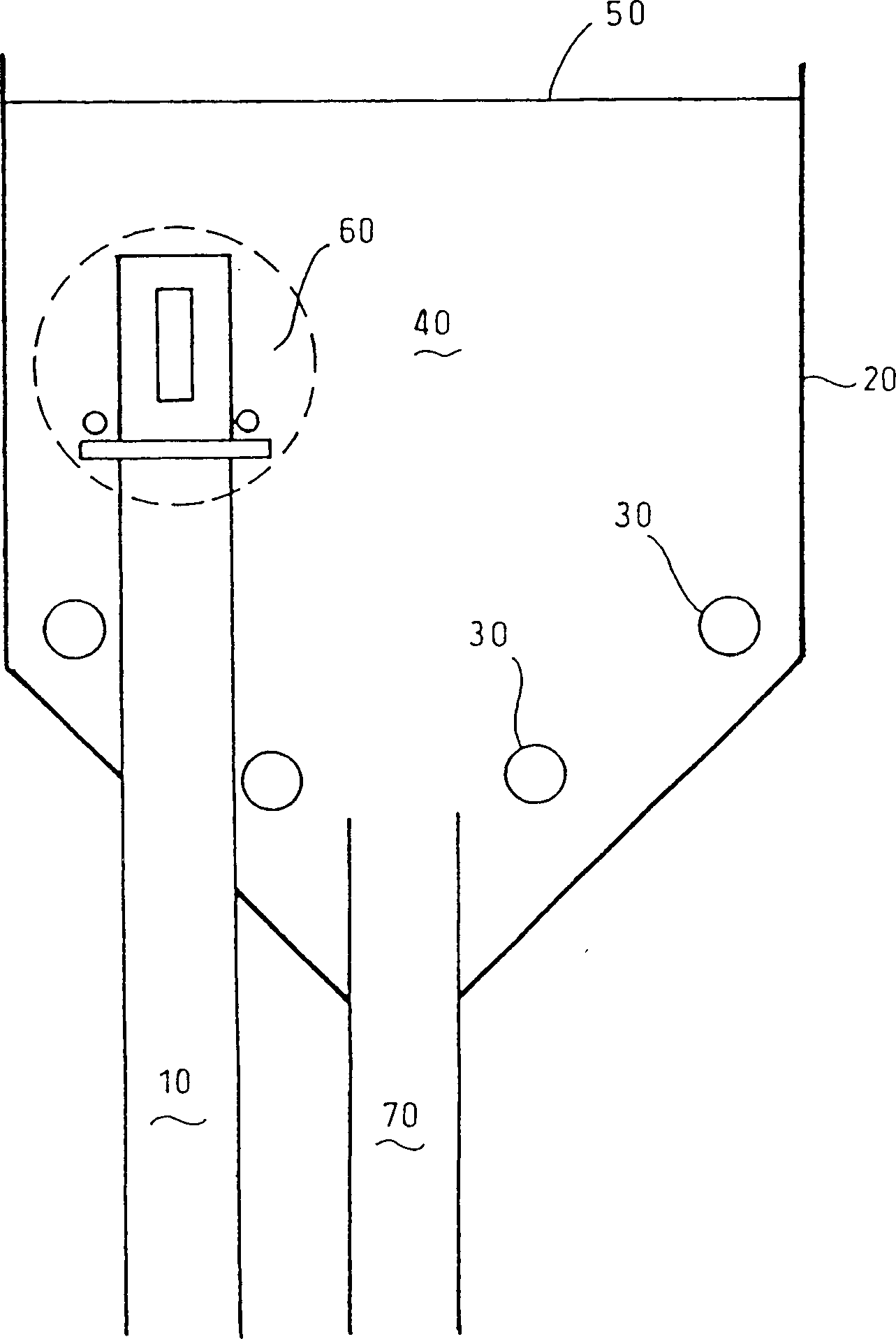

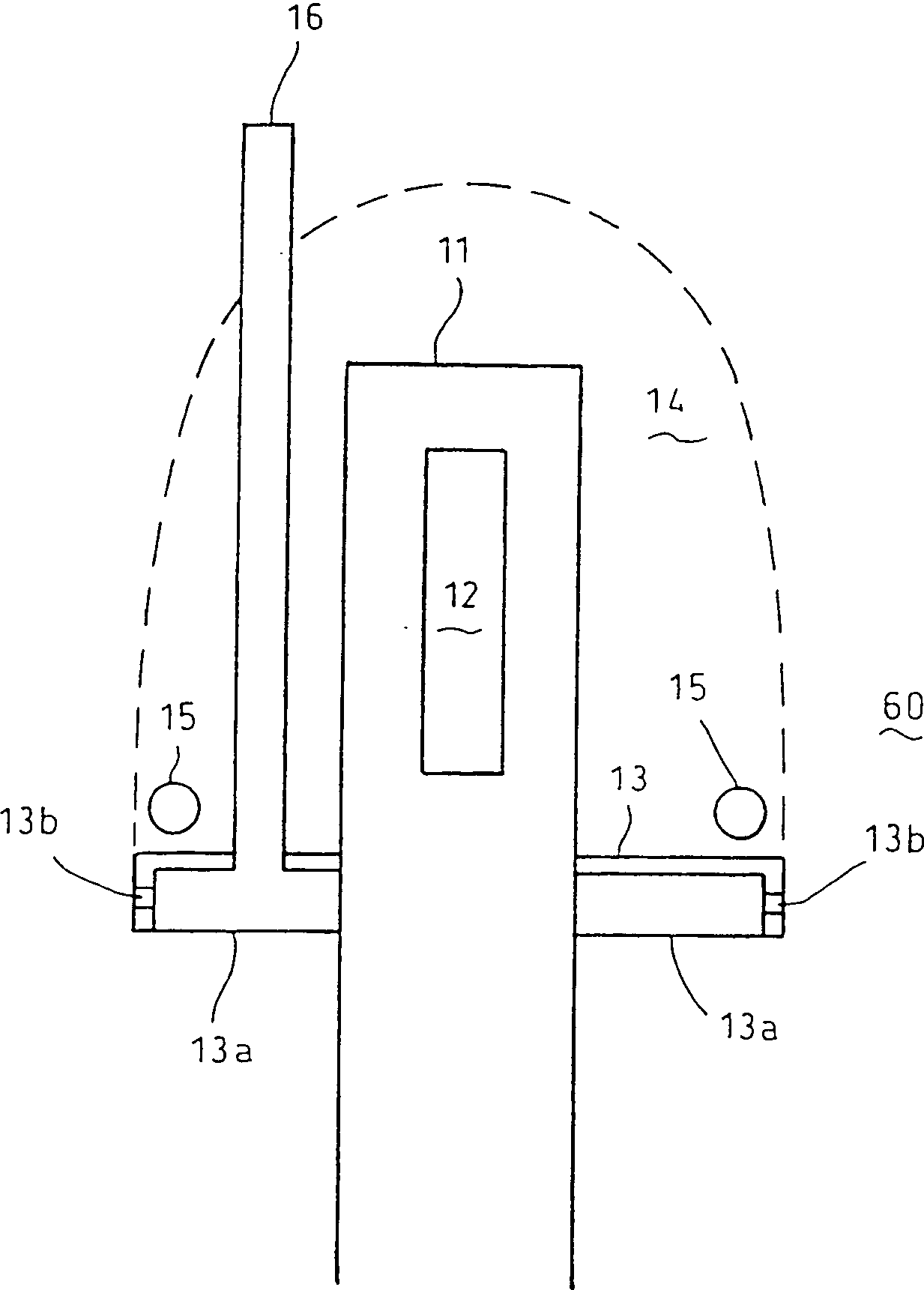

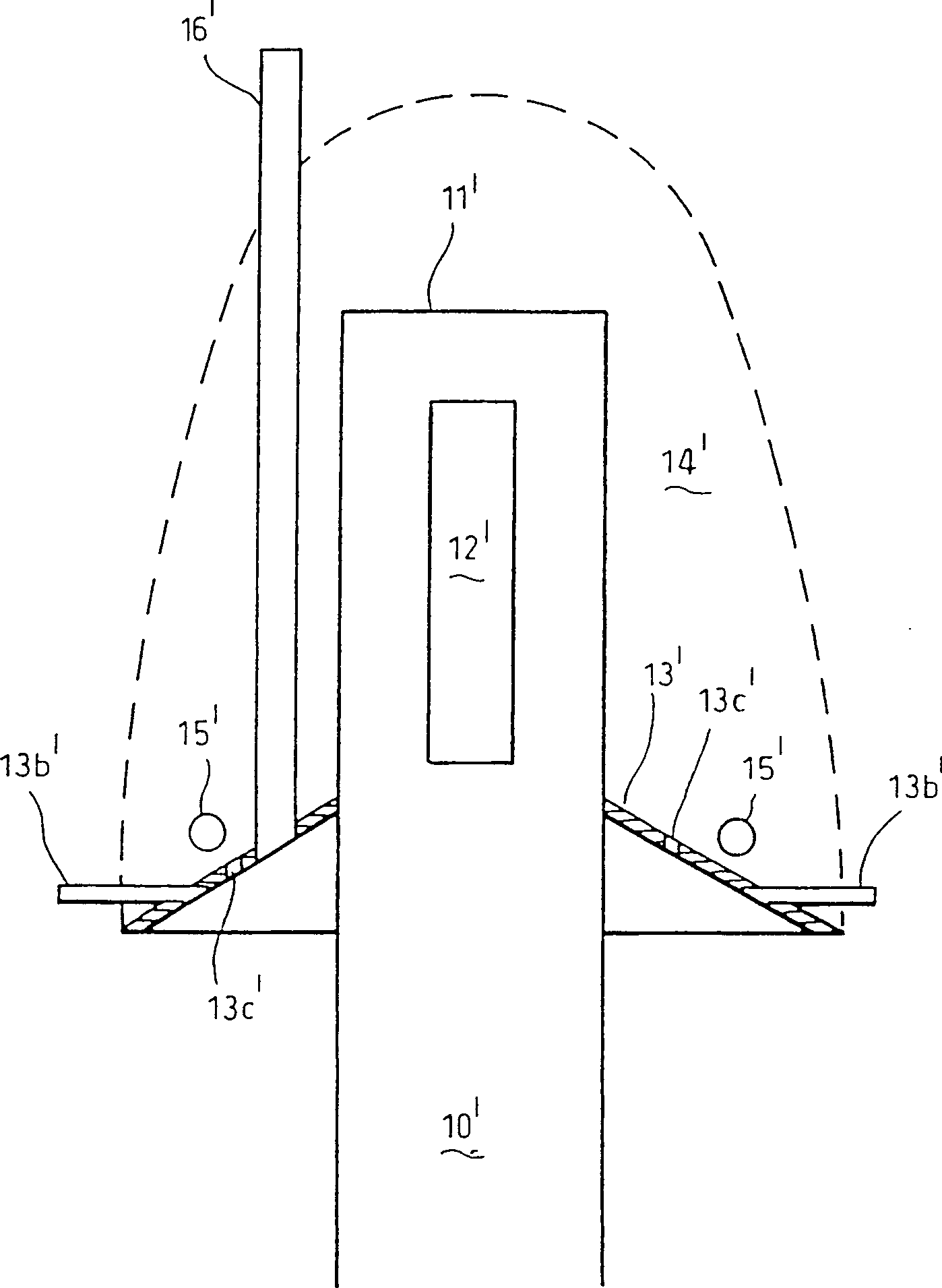

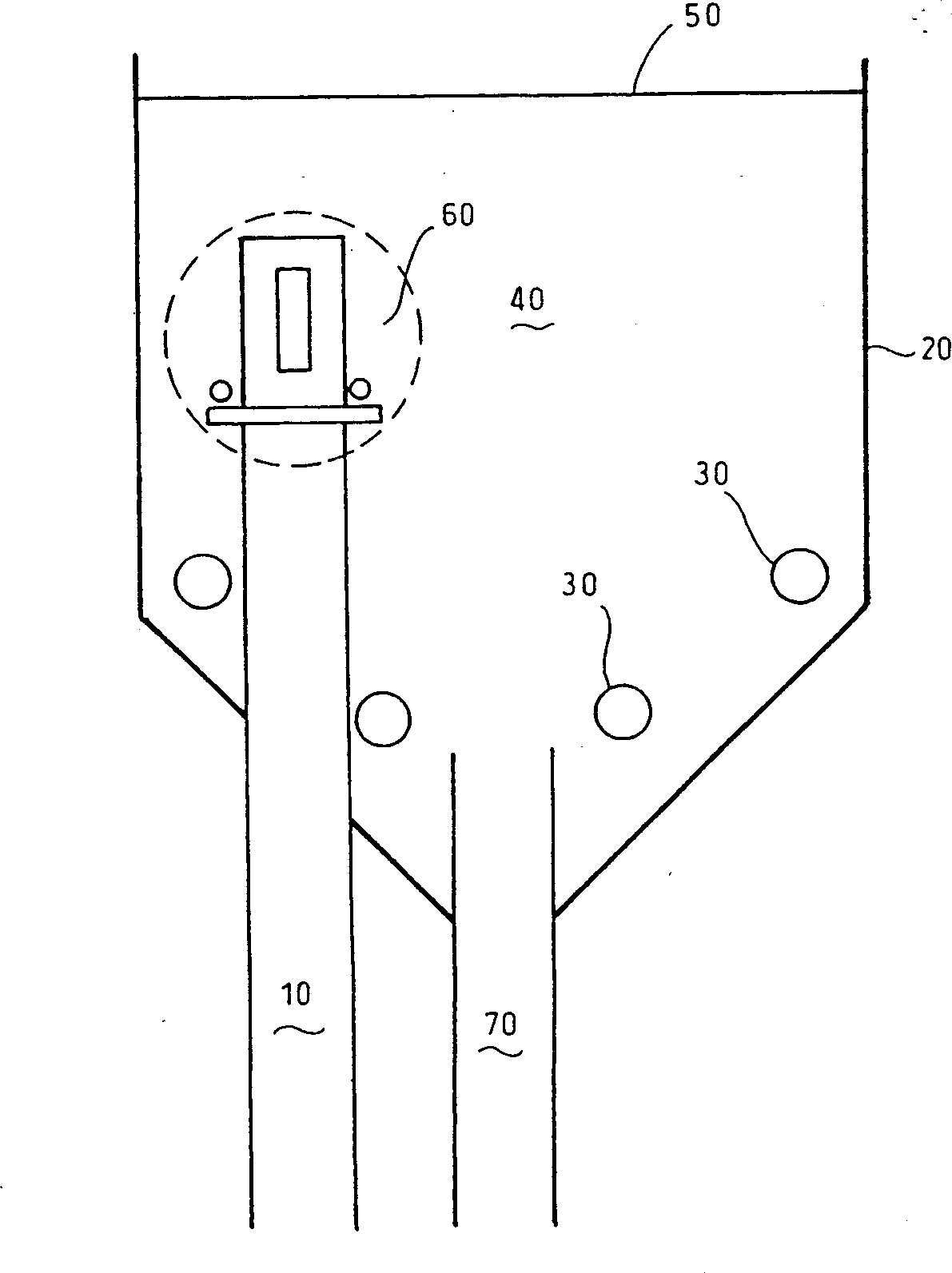

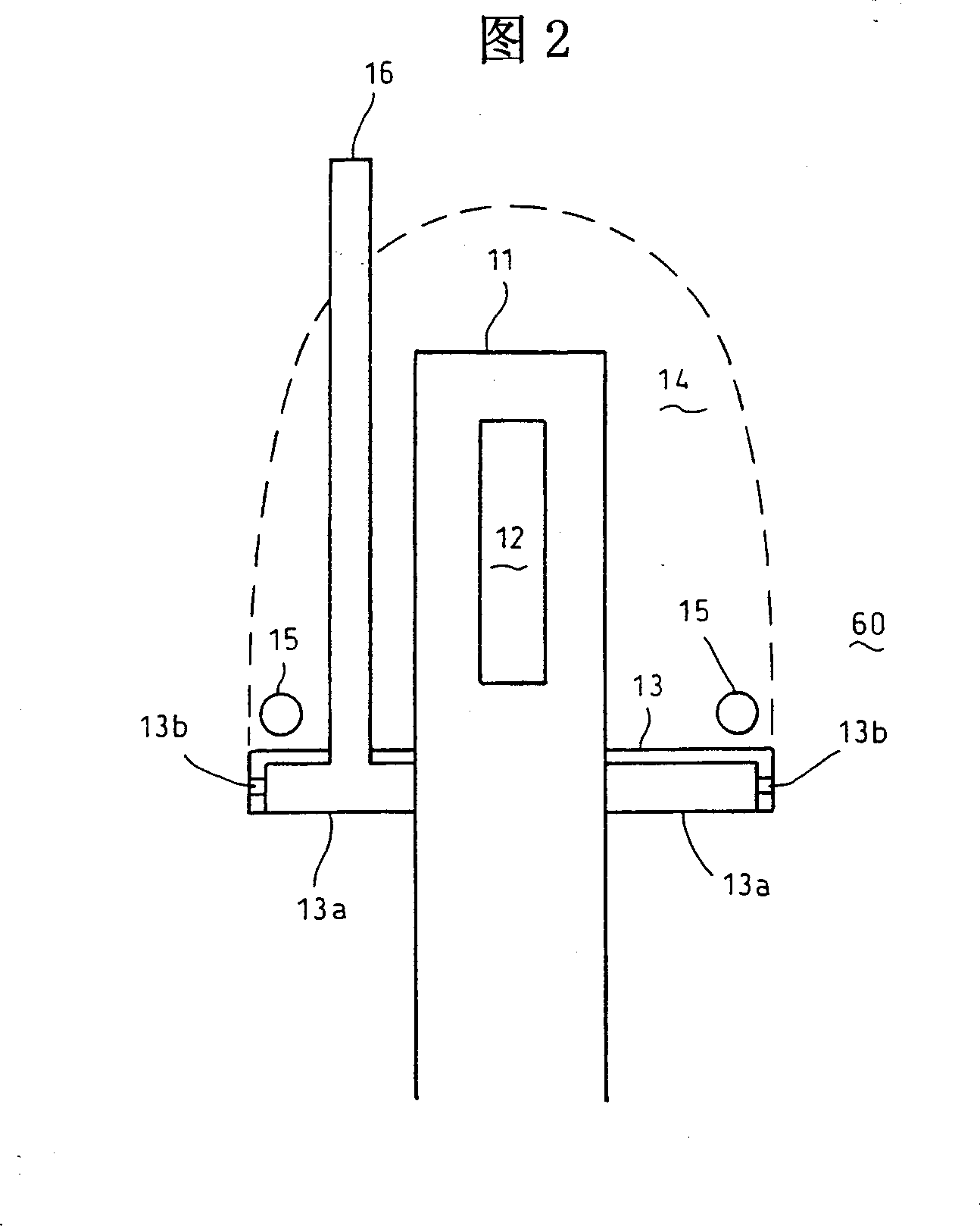

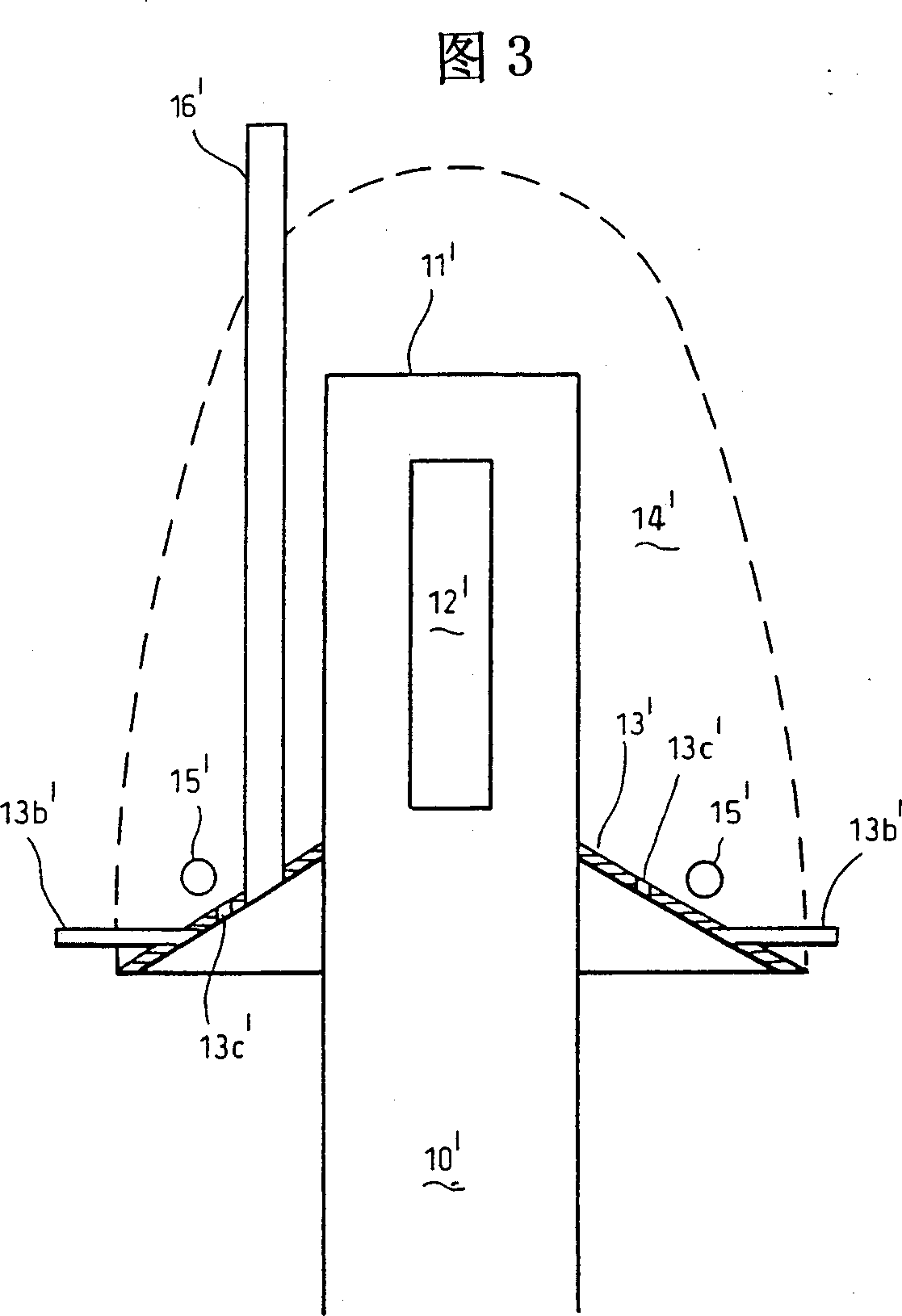

Standpipe inlet for enhancing particulate solids circulation for petrochemical and other processes

InactiveCN1227060CSmooth inflowAllow inflowFluidized bed combustionCatalytic crackingParticulatesFluidized bed

Apparatus comprising means for keeping a bed of particulate solids in a fluidized bed mode in a vessel, a conduit for transferring said particulate solids into the resulting fluidized bed and a standpipe, protruding into said fluidized bed, for transferring particulate solids out of the fluidized bed, wherein a disk surrounding the standpipe is present below the upper part of the standpipe, which upper part the standpipe comprises an inlet for receiving solids from the fluidized bed.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Device and method for measuring solid circulation flow rate

ActiveCN102759382BSimple structureMeet the measurement requirementsMass flow measurement devicesStock levelMeasurement device

The invention discloses a device and a method for measuring solid circulation flow rate, which relate to the solid transmission technology. The device for measuring solid circulation flow rate is composed of components, such as a valve, a high-low stock level switch, a timing device, a material measuring section, a balance pipe and the like. The position of the material is detected through the high-low stock level switch, a signal is transmitted to the timing device, and the material accumulation time is displayed, so that manual timing error is avoided, and measurement accuracy is improved greatly. The material measuring section of the device provided by the invention can be obtained by directly selecting one section of a dip leg, and the device is simple in structure and convenient to operate. With the balance pipe, the interference of the measuring process on the system operation can be reduced, and the device for measuring solid circulation flow rate is especially suitable for measuring the solid circulation flow rate of the devices with high solid circulation flow rate, and also can be used for measuring the solid circulation flow rate under a pressurization condition.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Standpipe inlet for enhancing particulate solids circulation for petrochemical and other processes

InactiveCN1341040ASmooth inflowAllow inflowFluidized bed combustionCatalytic crackingParticulatesFluidized bed

Apparatus comprising means for keeping a bed of particulate solids in a fluidized bed mode in a vessel, a conduit for transferring said particulate solids into the resulting fluidized bed and a standpipe, protruding into said fluidized bed, for transferring particulate solids out of the fluidized bed, wherein a disk surrounding the standpipe is present below the upper part of the standpipe, which upper part the standpipe comprises an inlet for receiving solids from the fluidized bed.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com