Patents

Literature

33 results about "Annular fluidized bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluidisation is a phenomenon whereby solid particulate is placed under certain conditions to cause it to behave like a fluid. A fluidized bed is a system conceived to facilitate the fluidisation. Fluidized beds have a wide range of applications including but not limited to: assisting with chemical reactions, heat transfer, mixing and drying. A recent concept devised and patented by Outotec, "An annular fluidized bed consists of a large central nozzle surrounded be a stationary fluidized" .

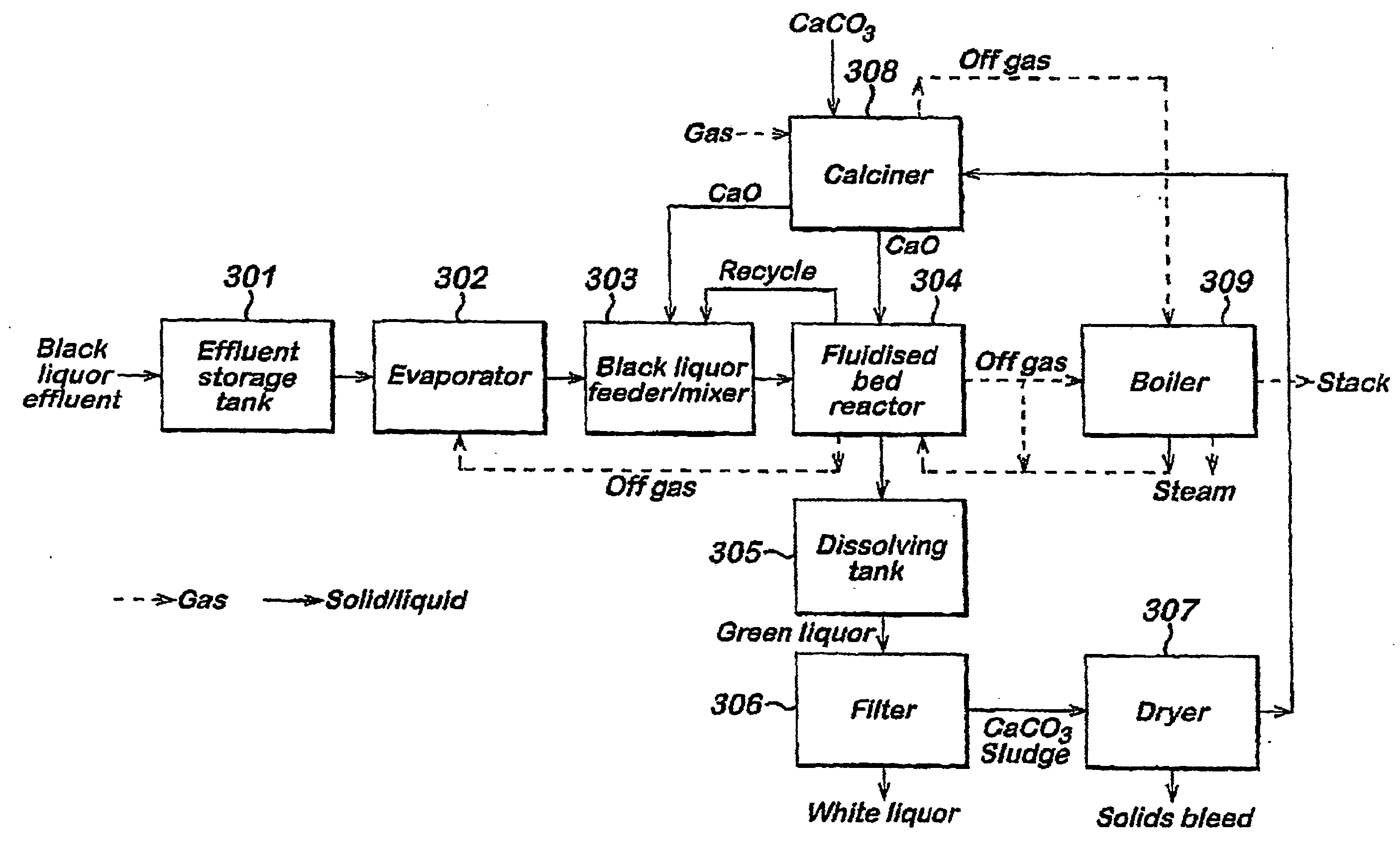

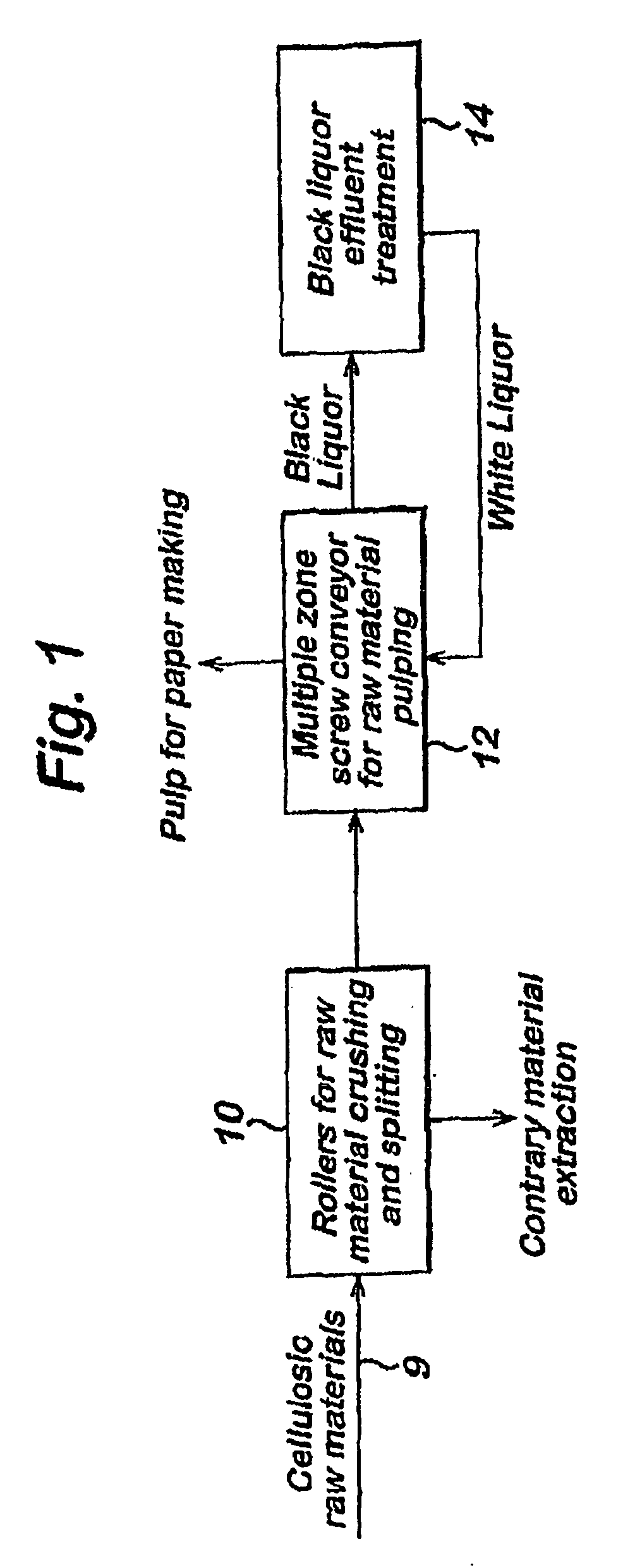

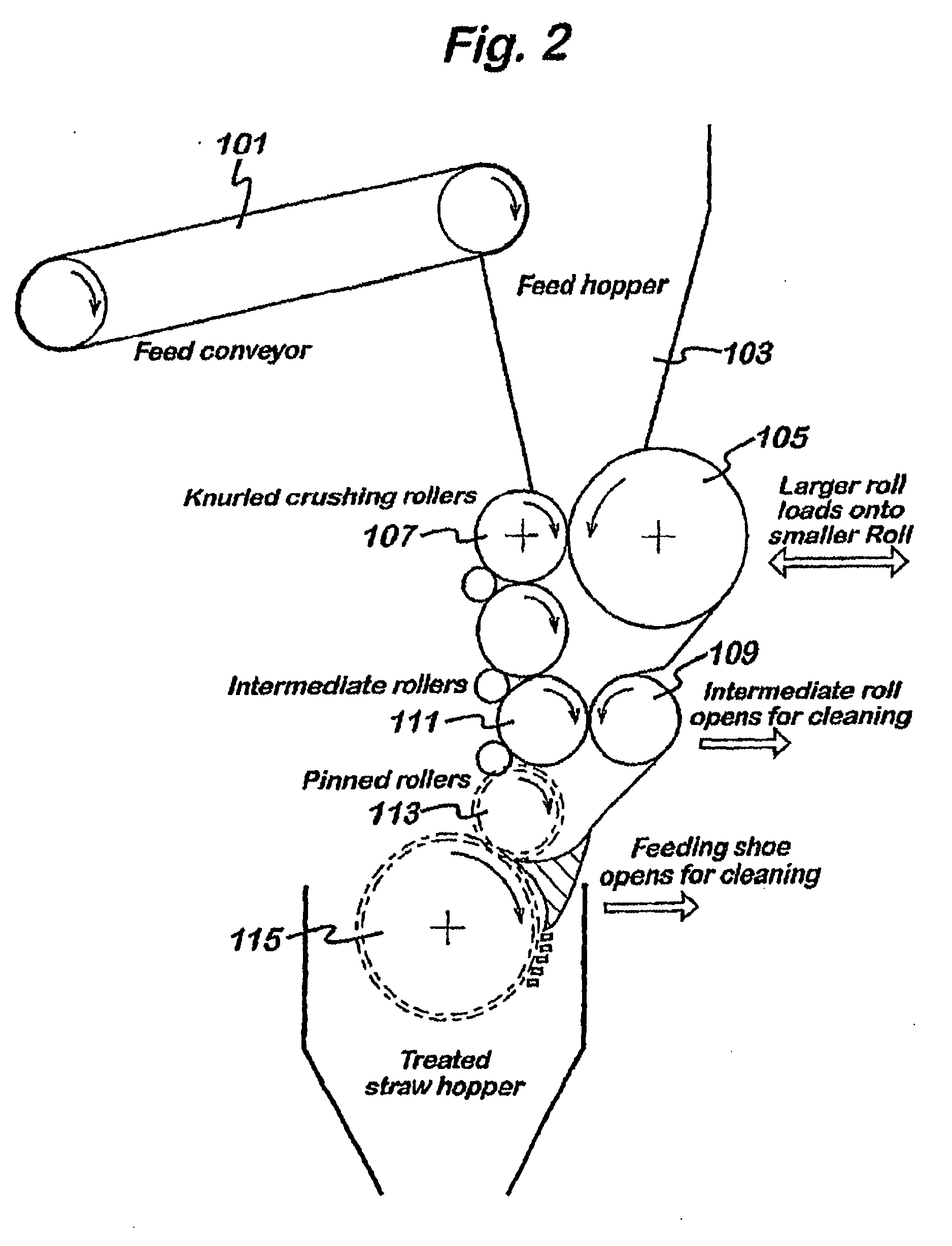

Methods for producing pulp and treating black liquor

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

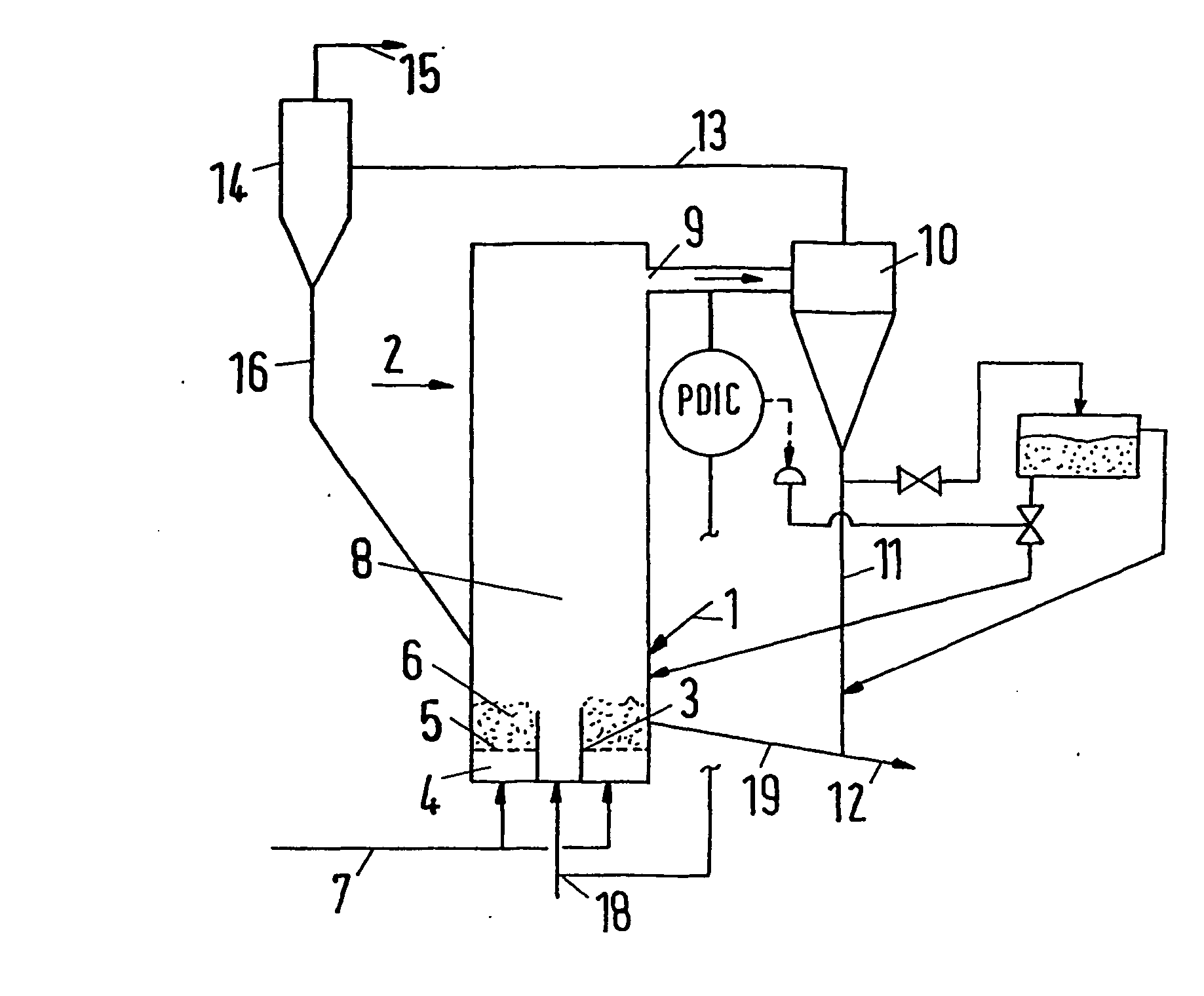

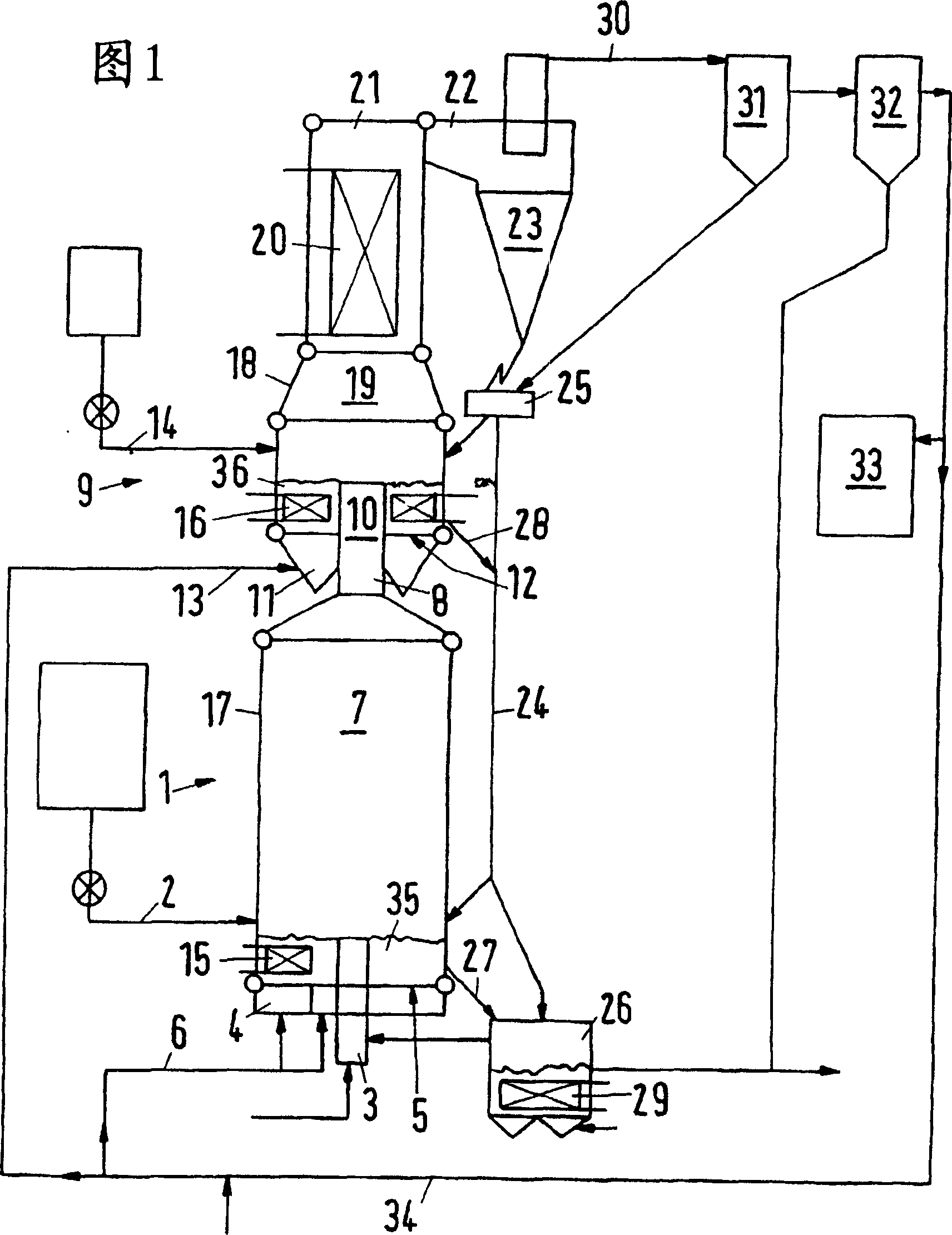

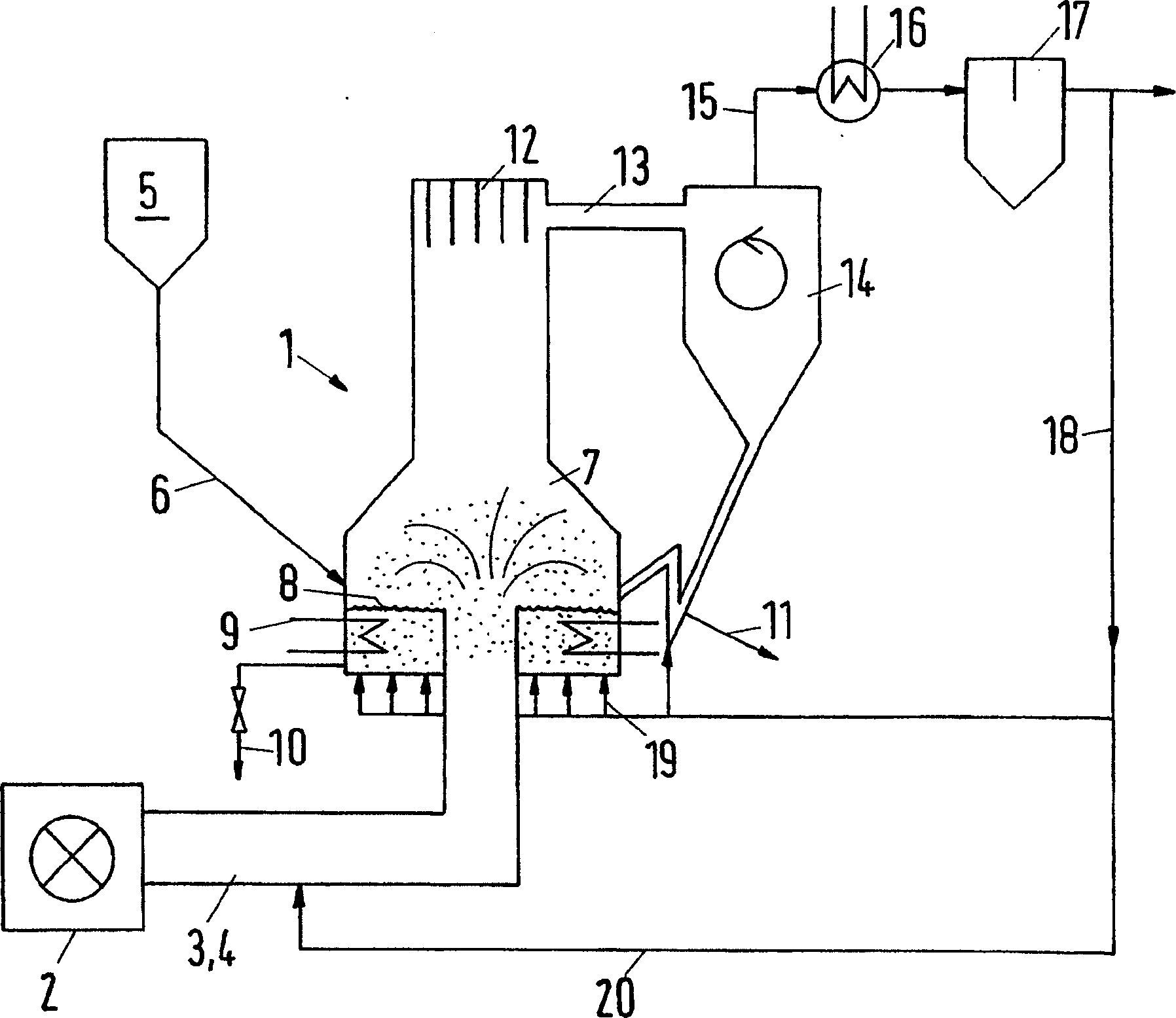

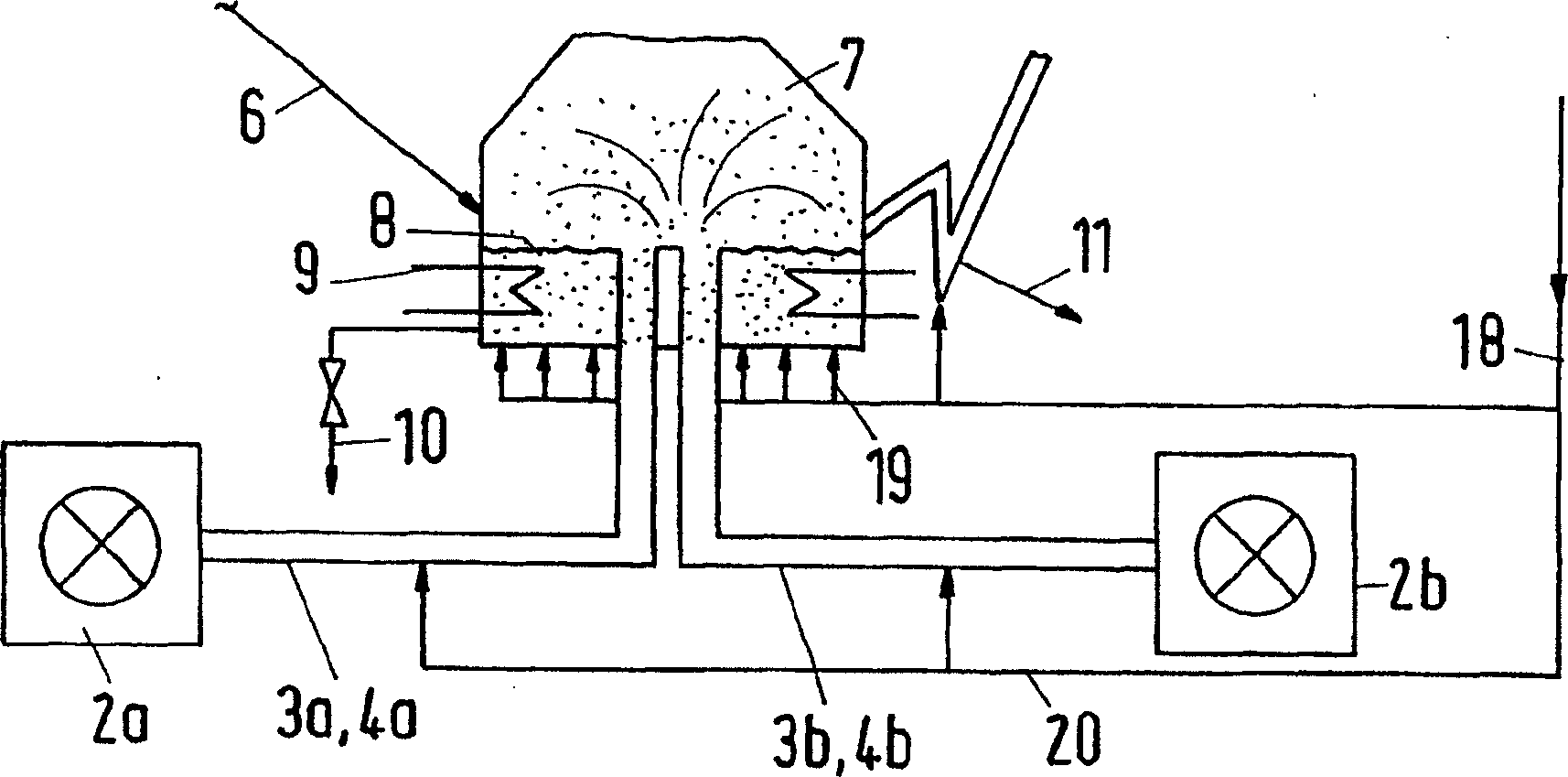

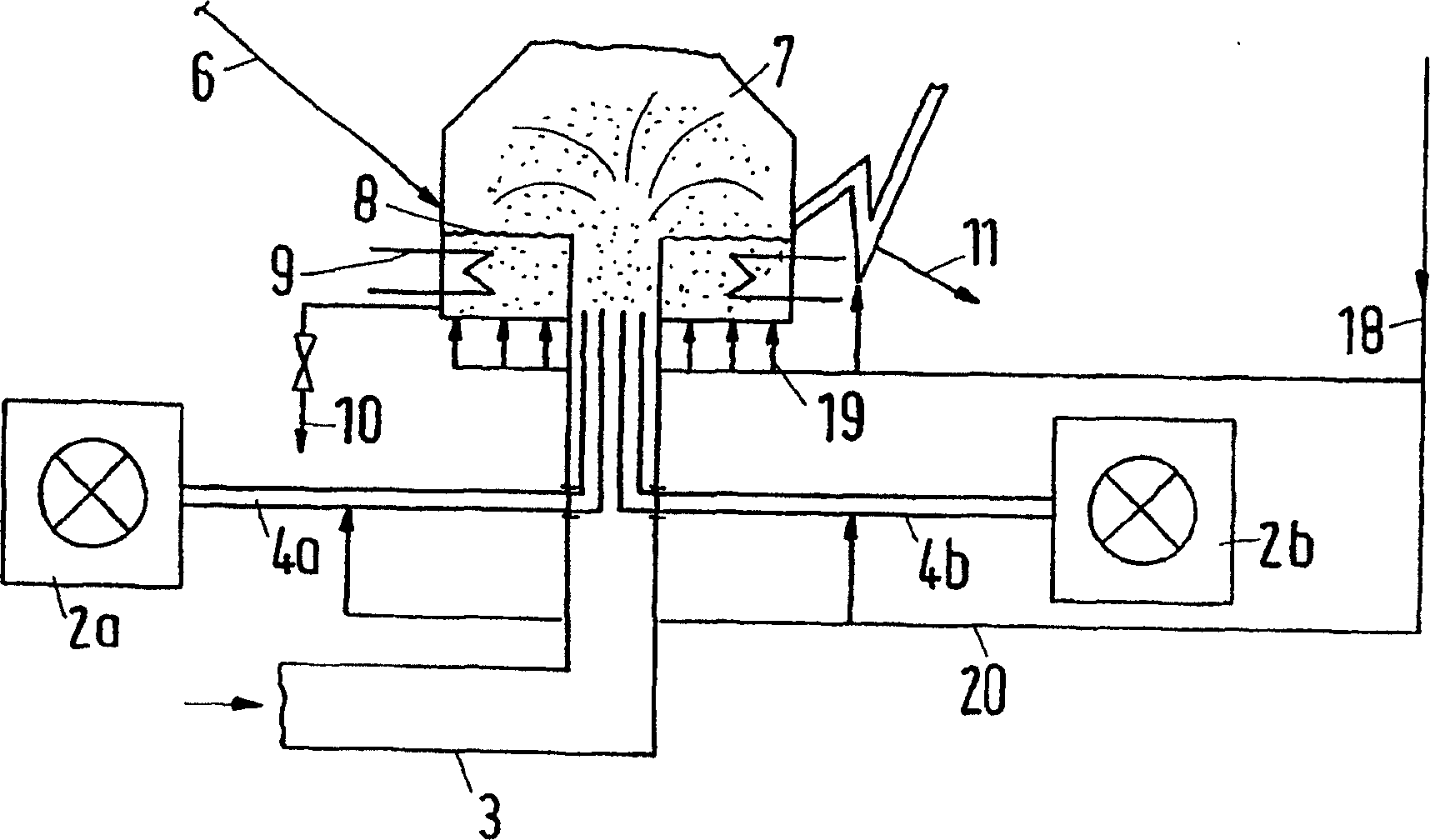

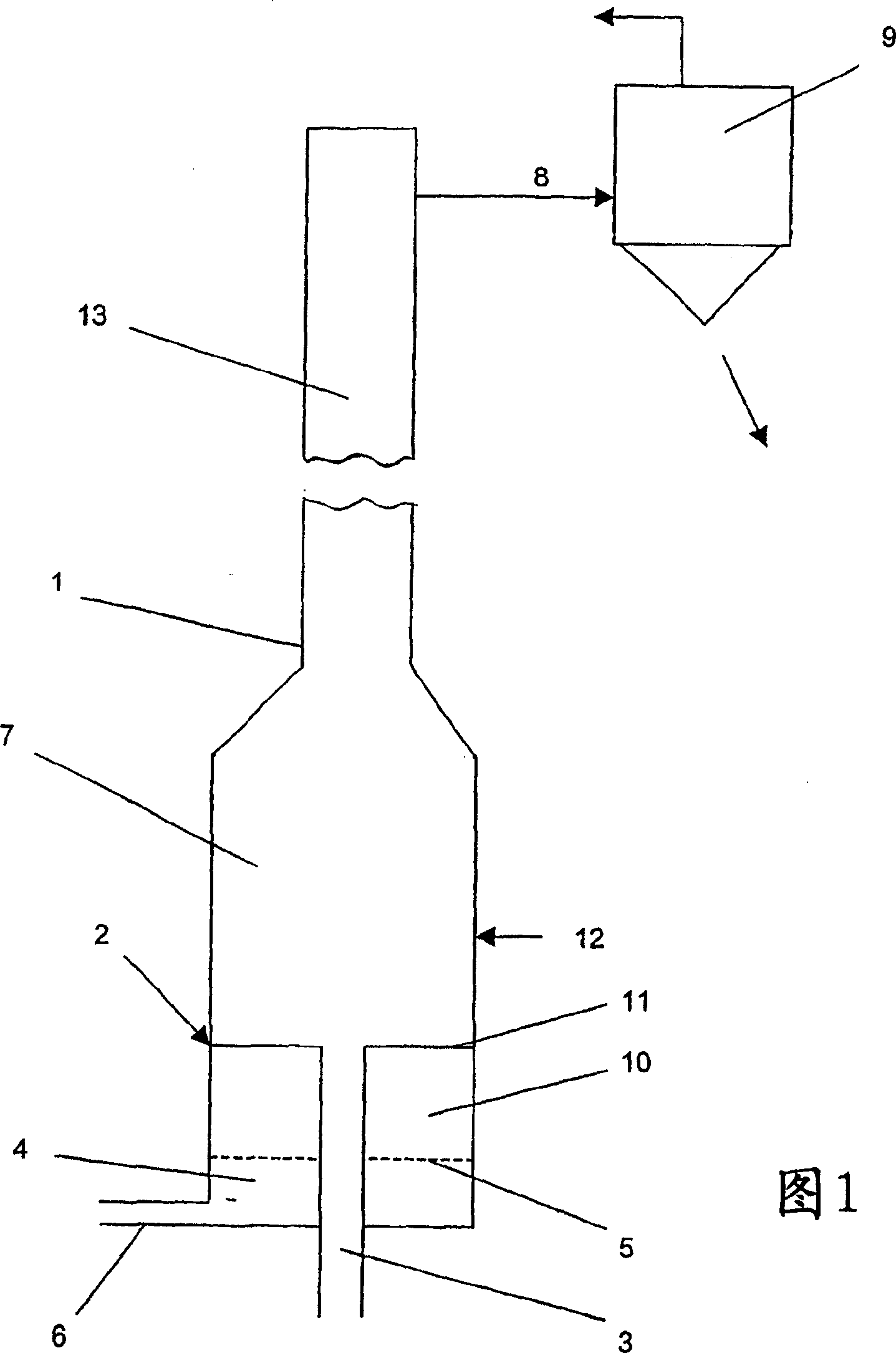

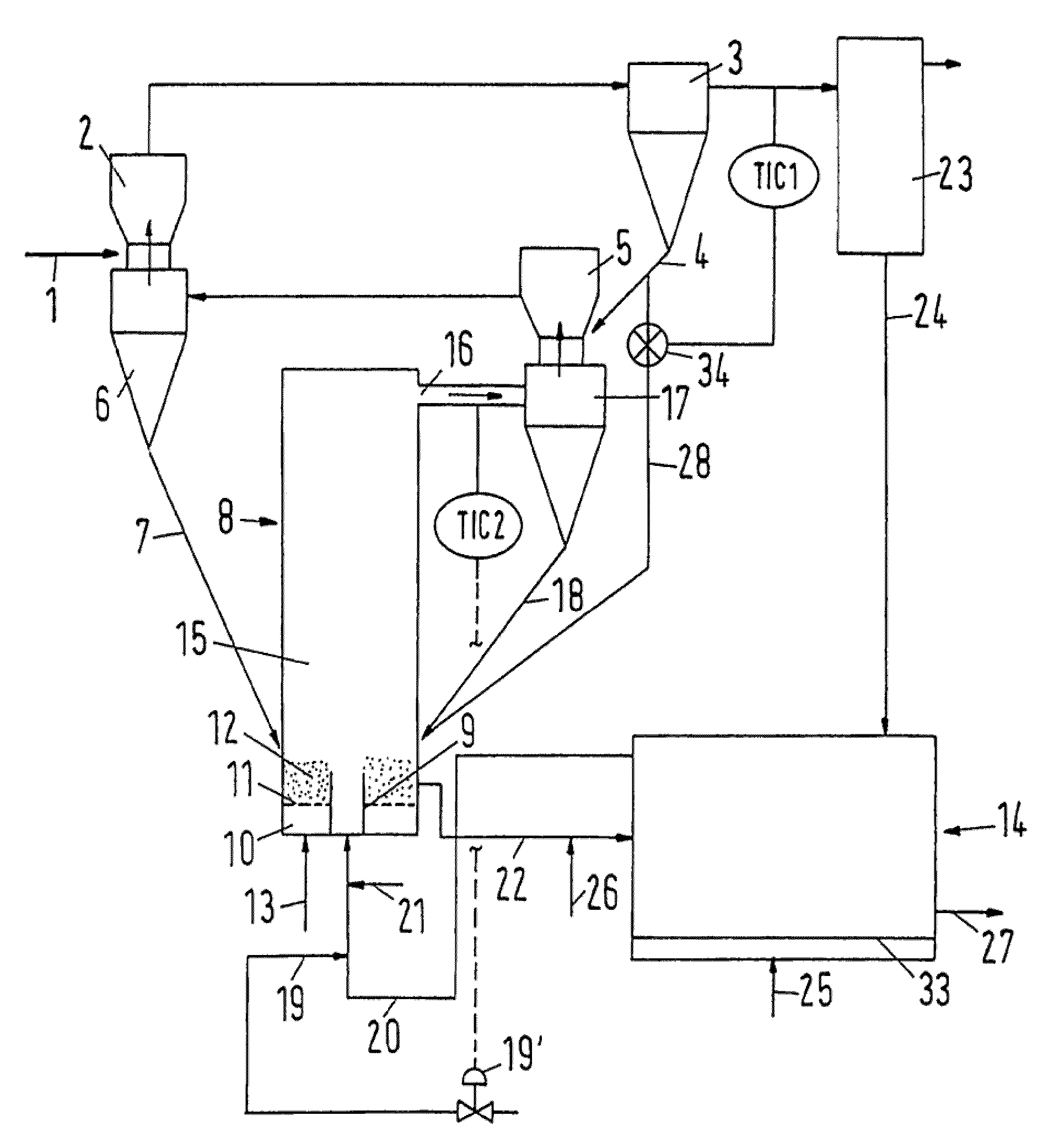

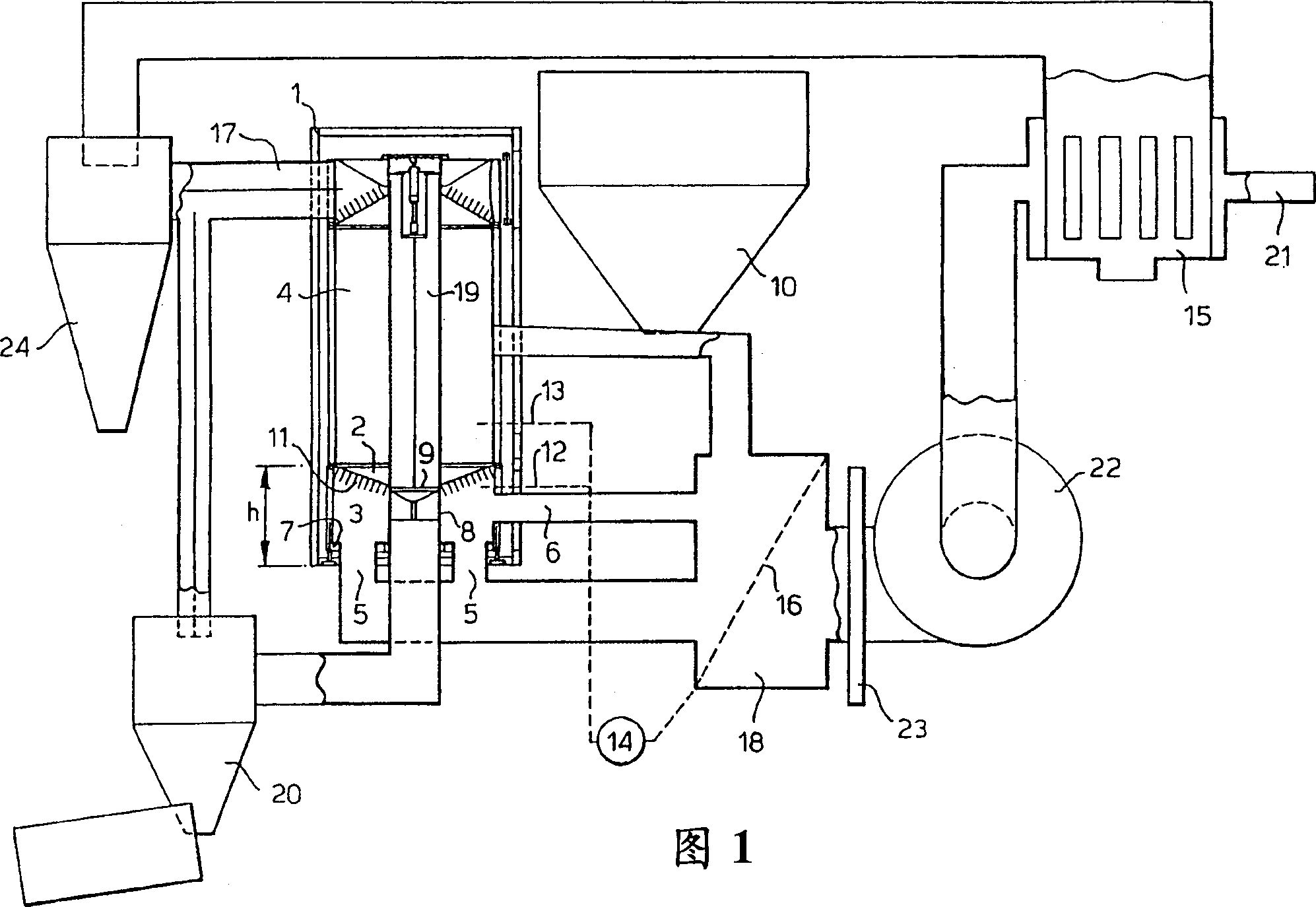

Method and plant for producing low-temperature coke

InactiveUS20060278566A1Optimize energy usageEfficient executionThermal non-catalytic crackingDirect heating destructive distillationFluidized bedProcess engineering

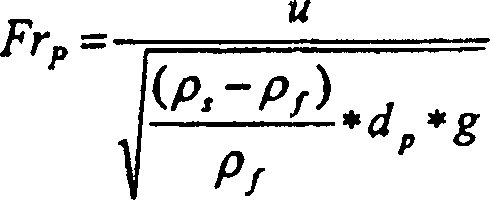

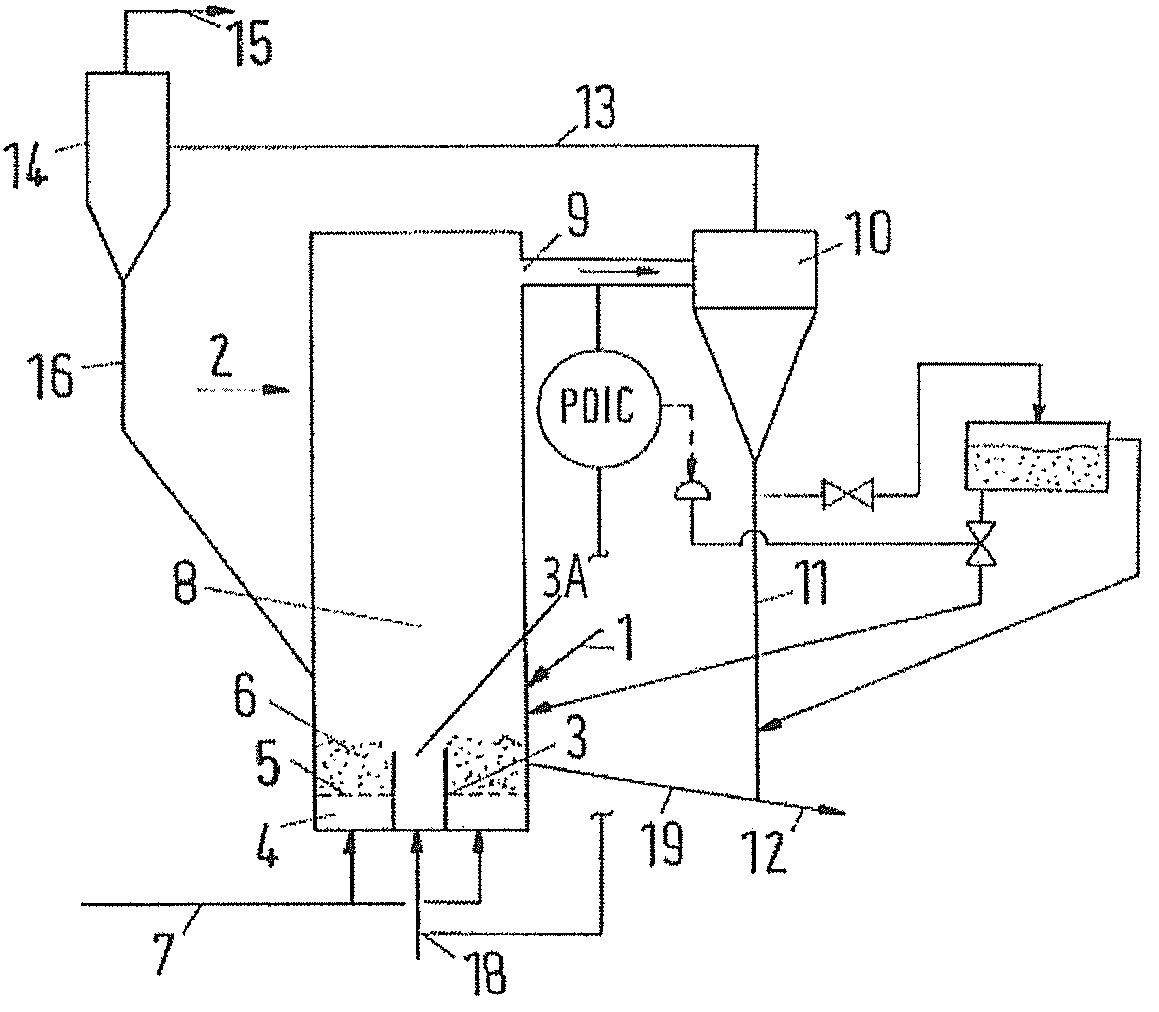

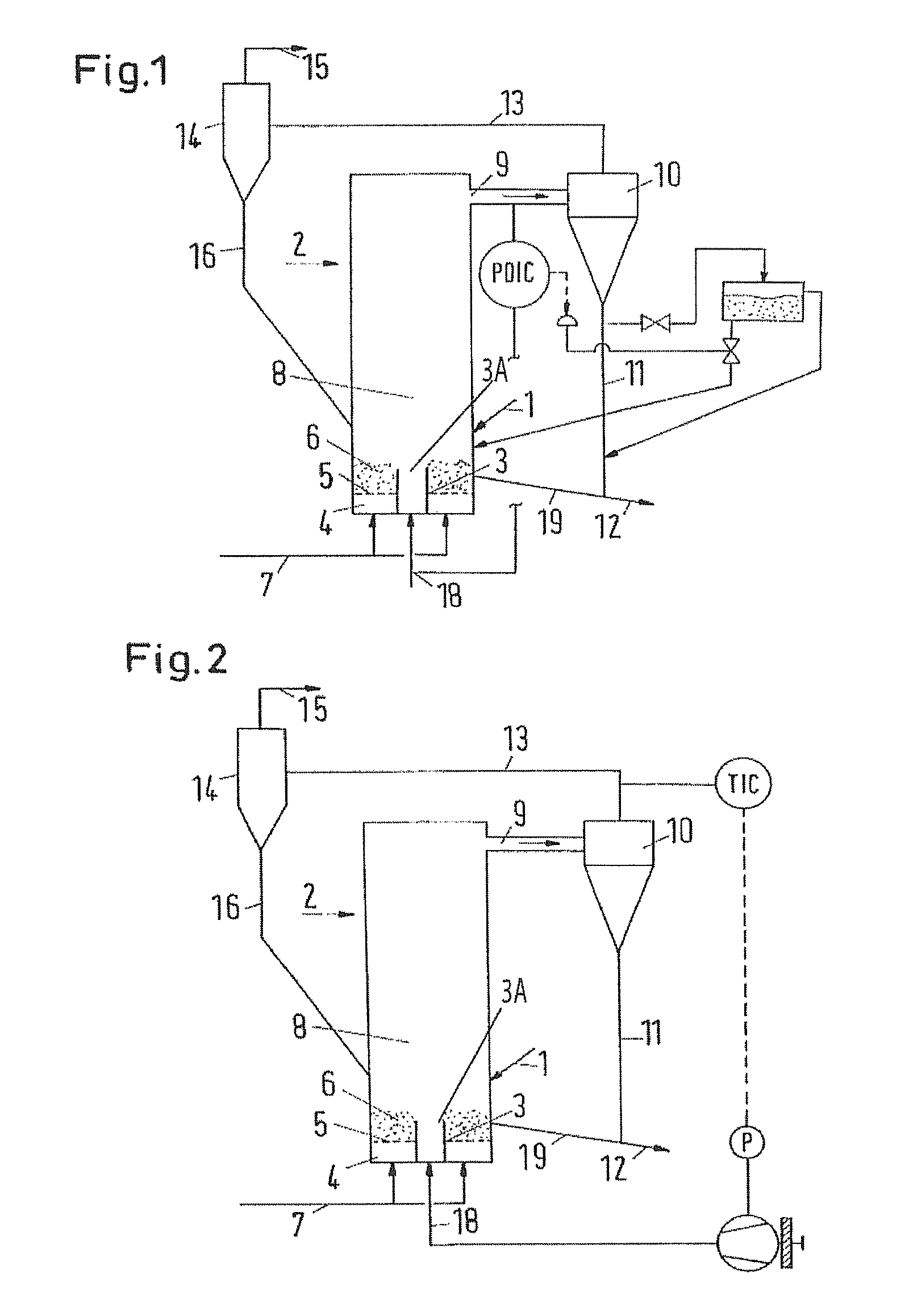

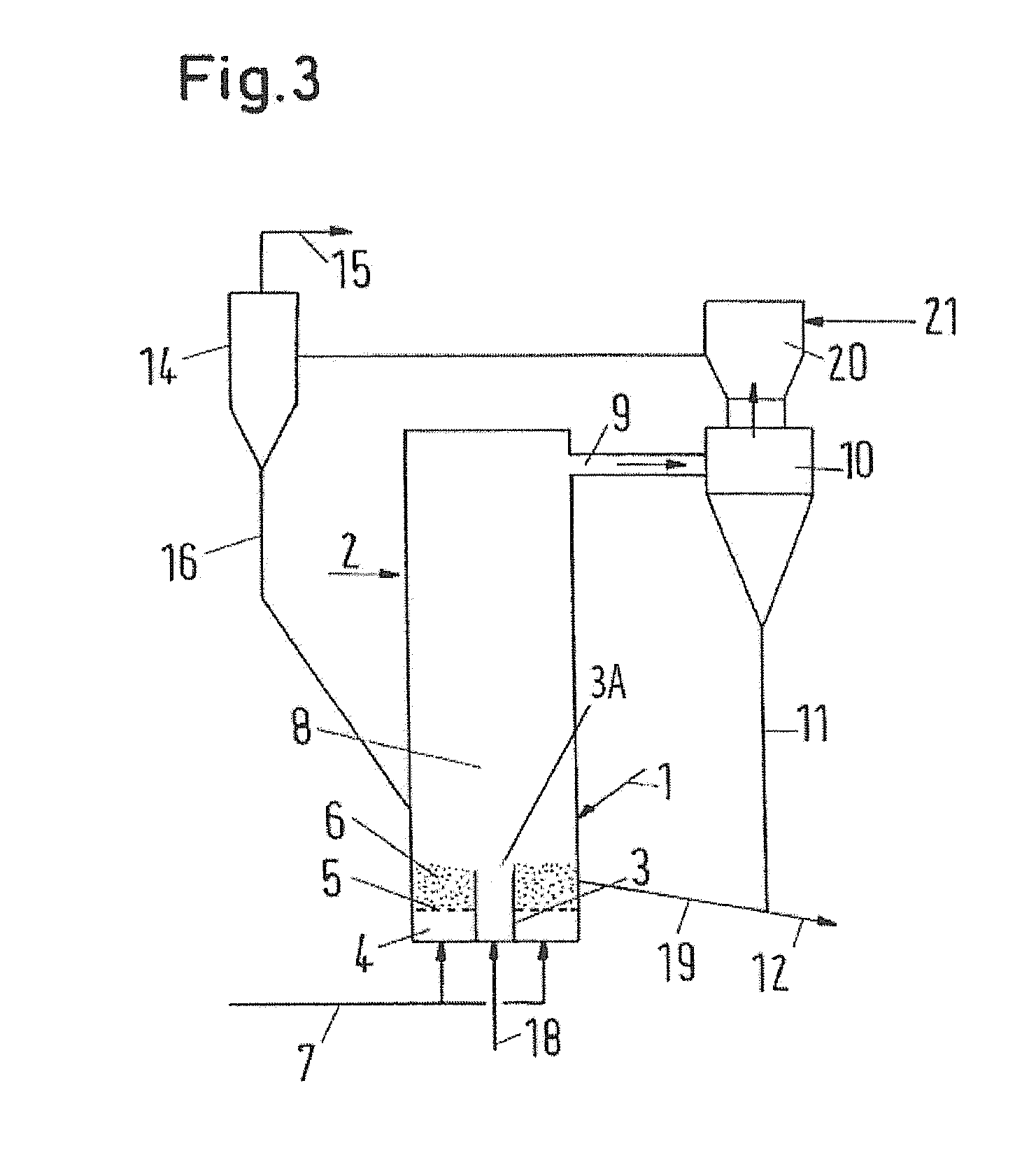

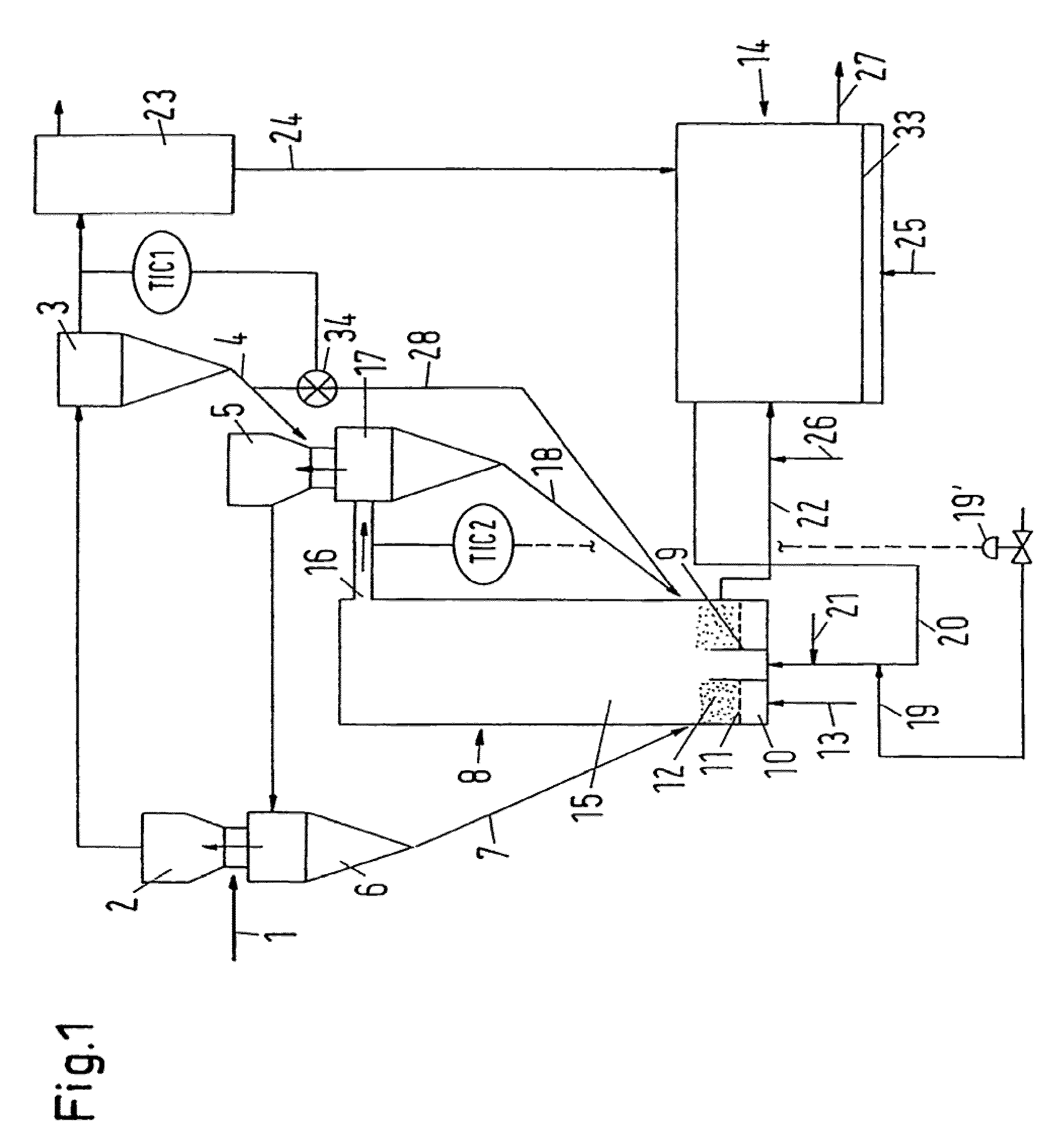

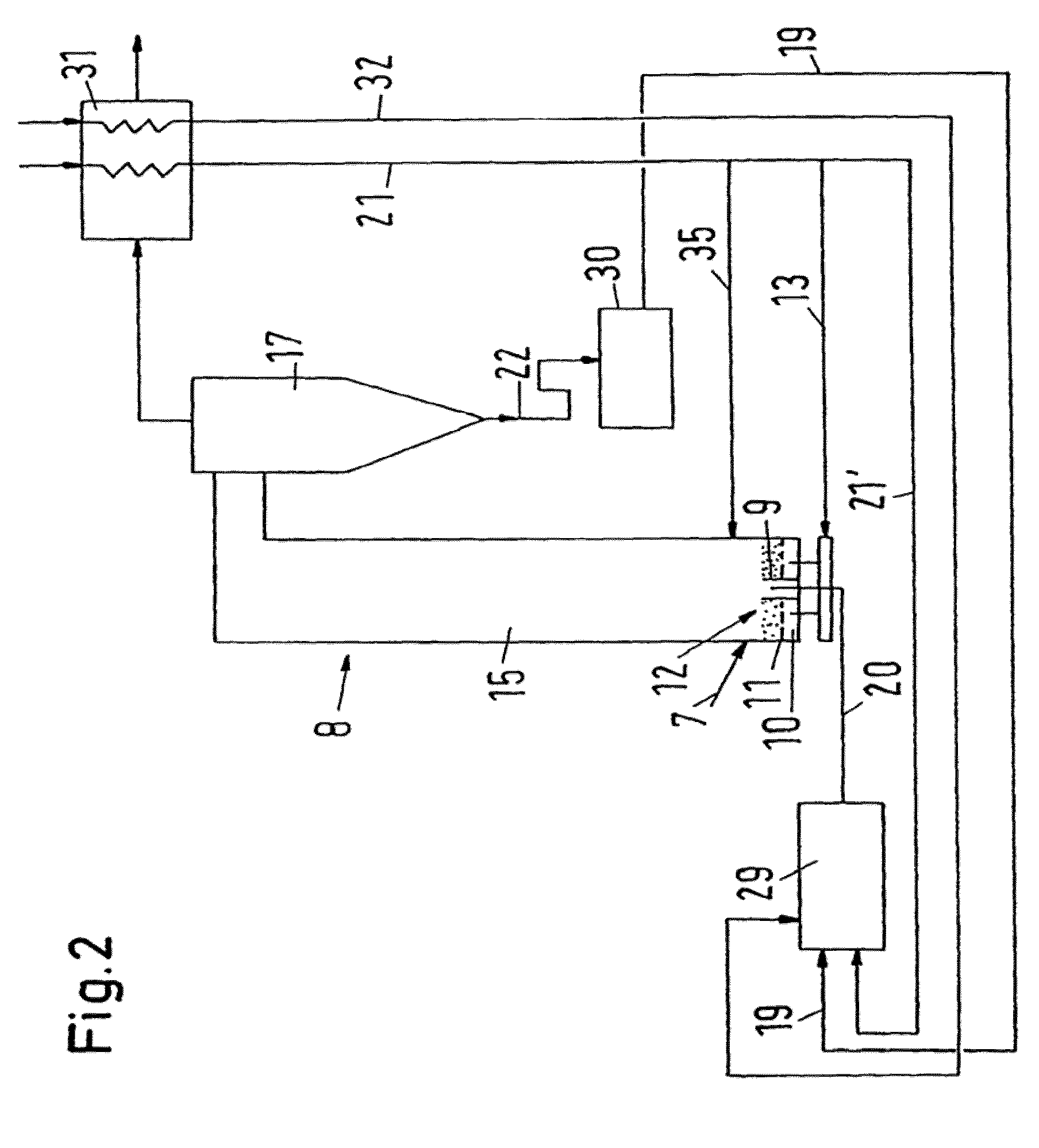

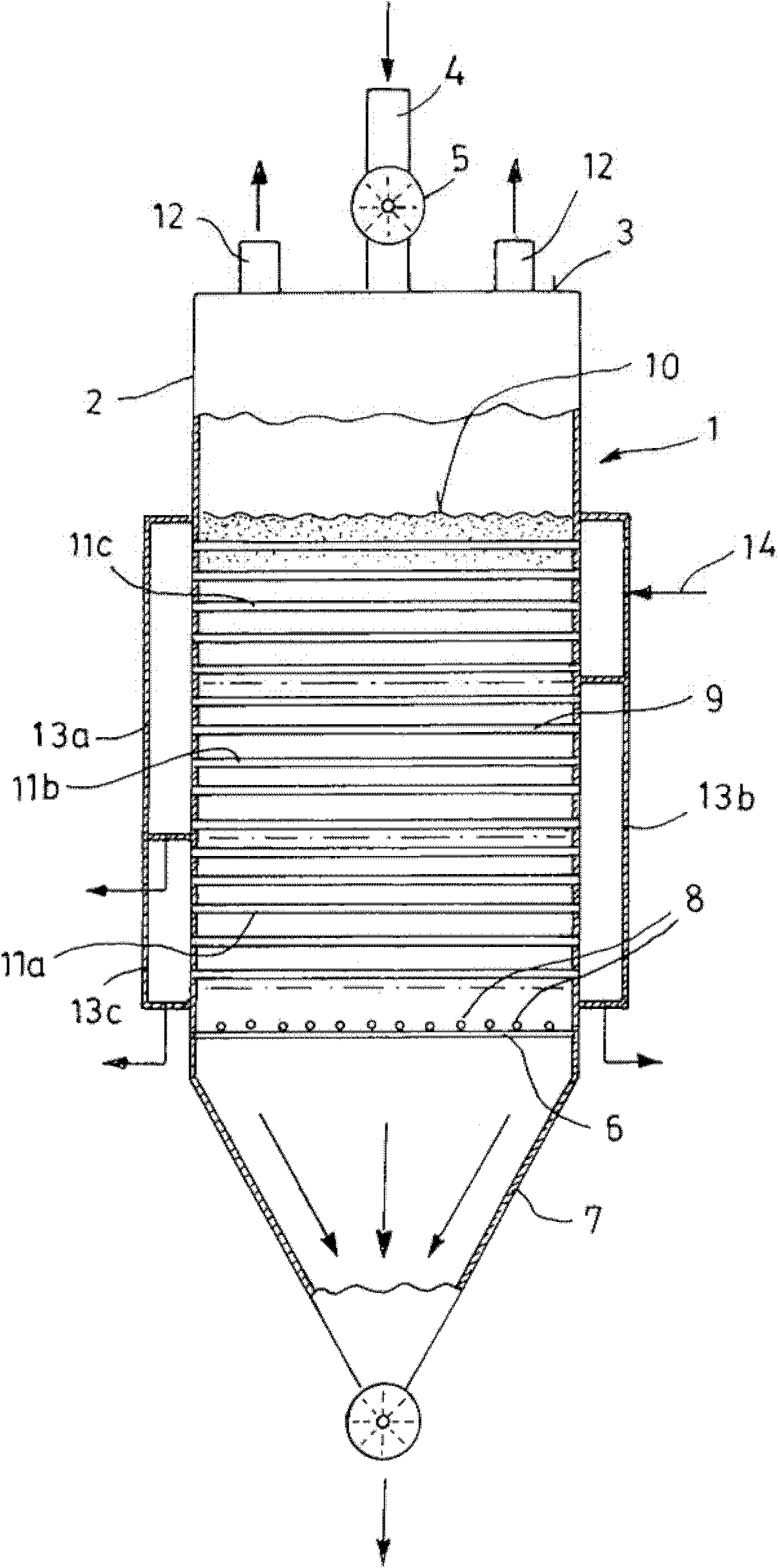

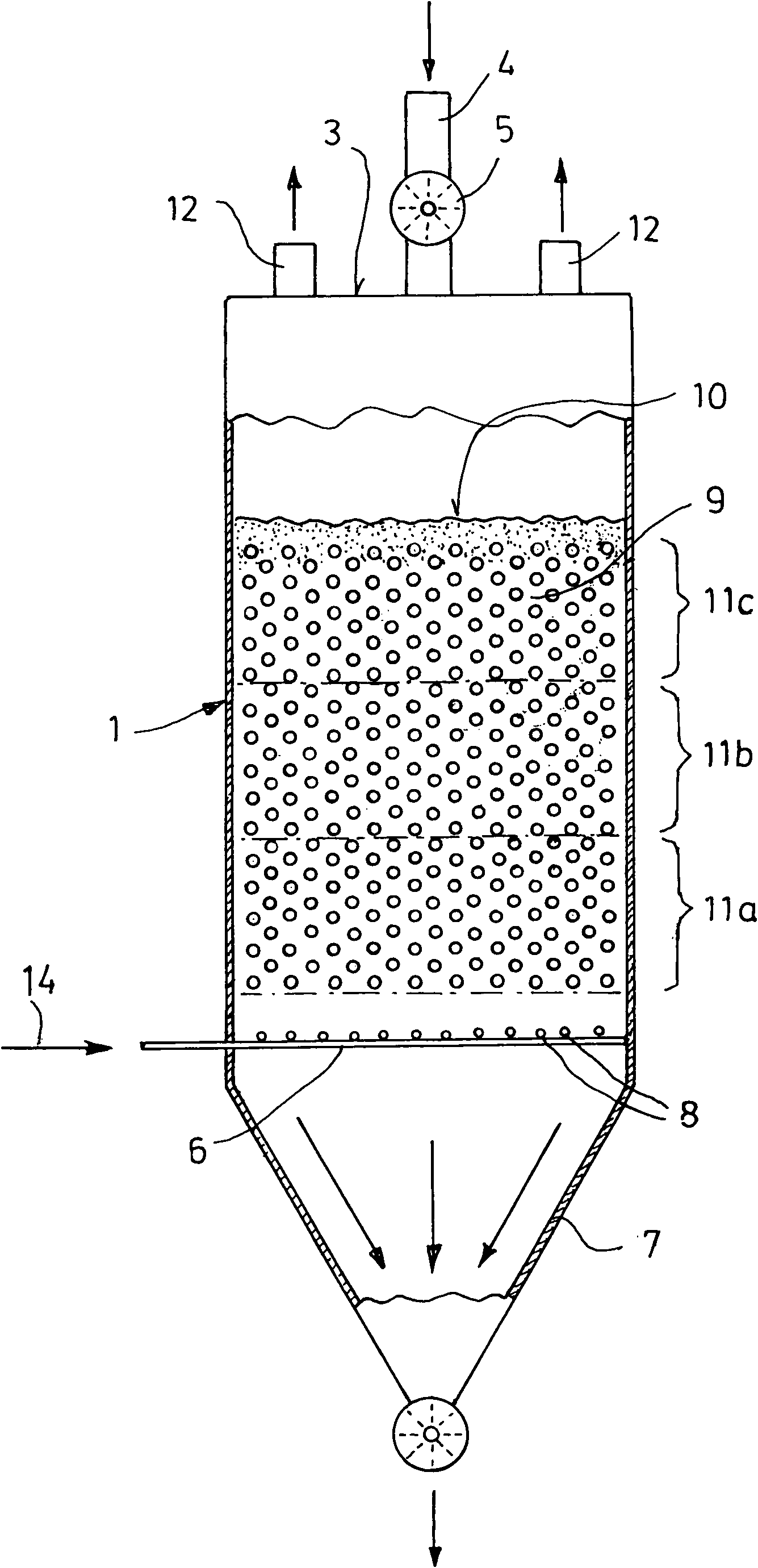

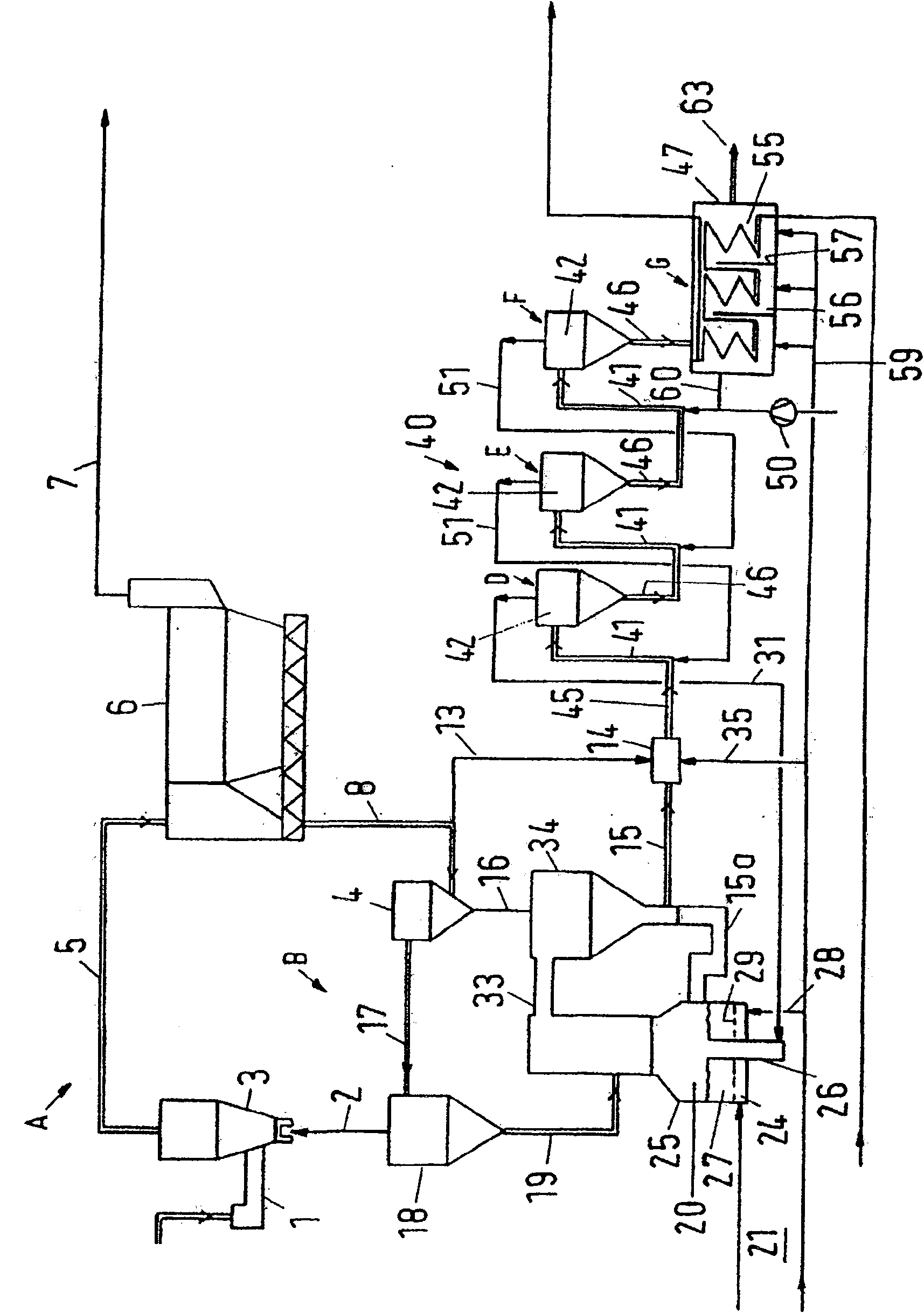

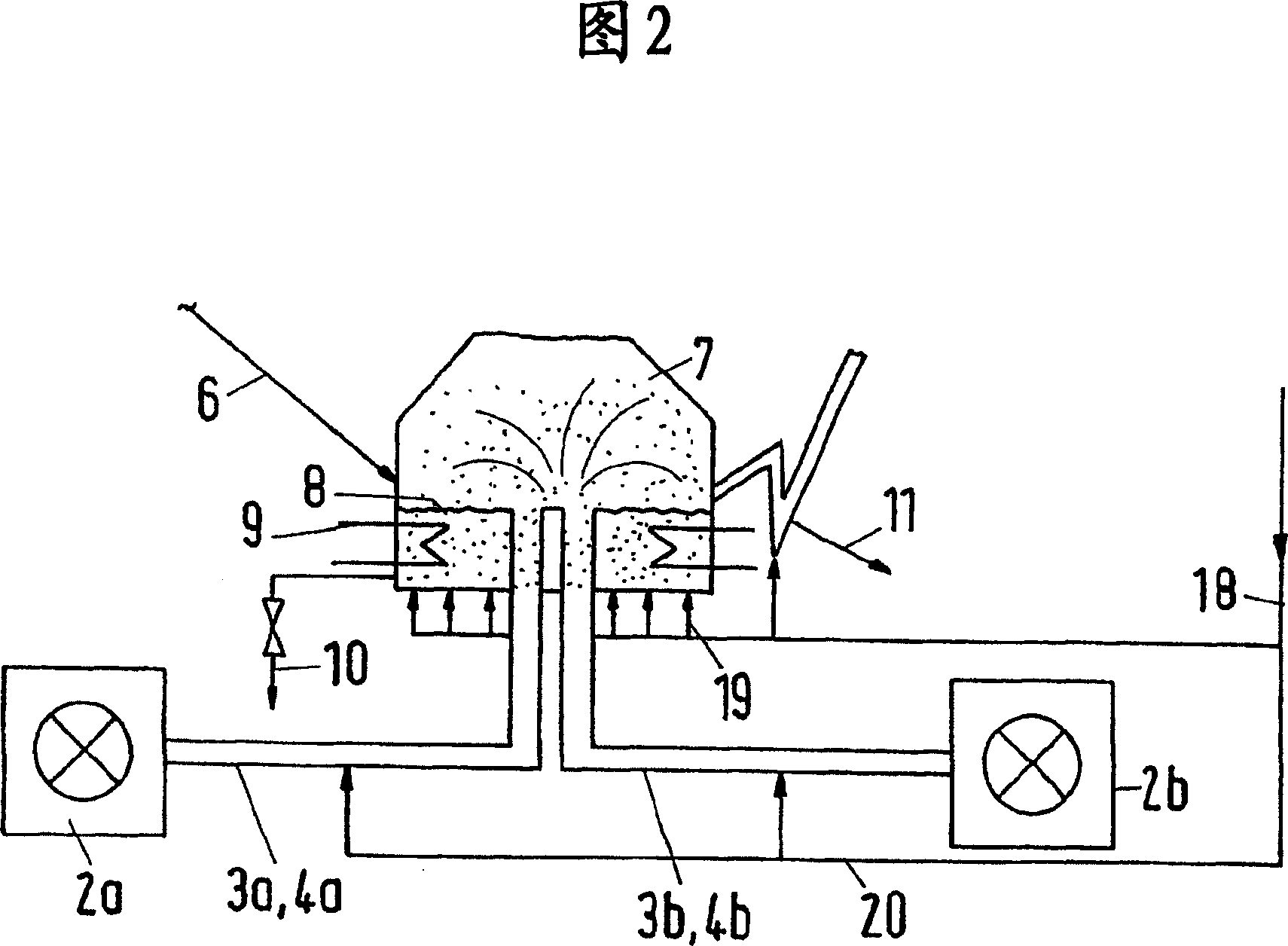

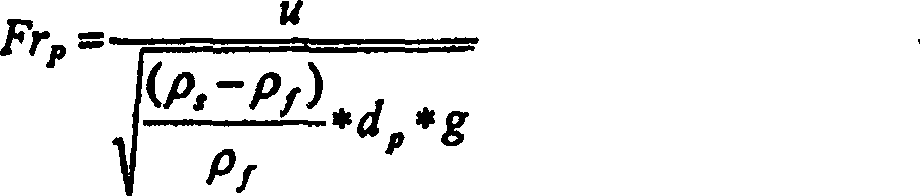

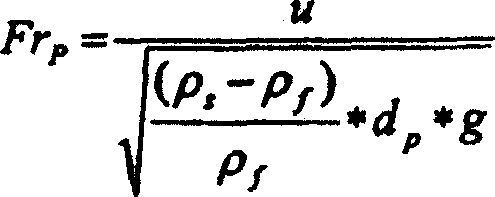

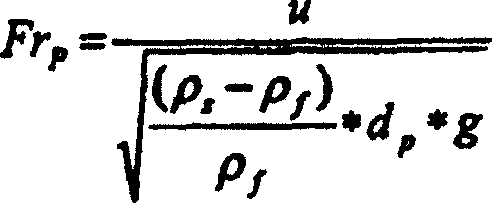

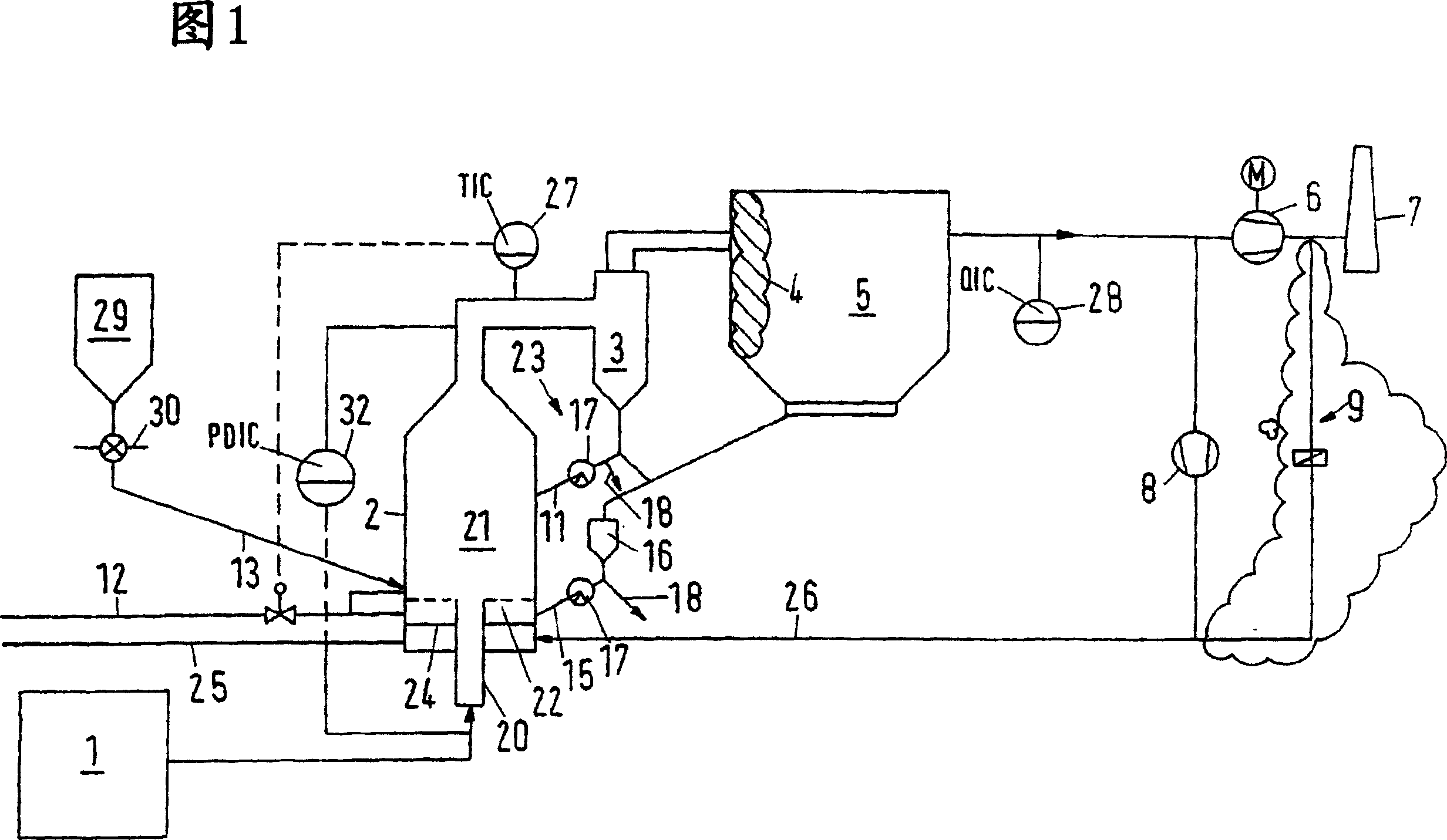

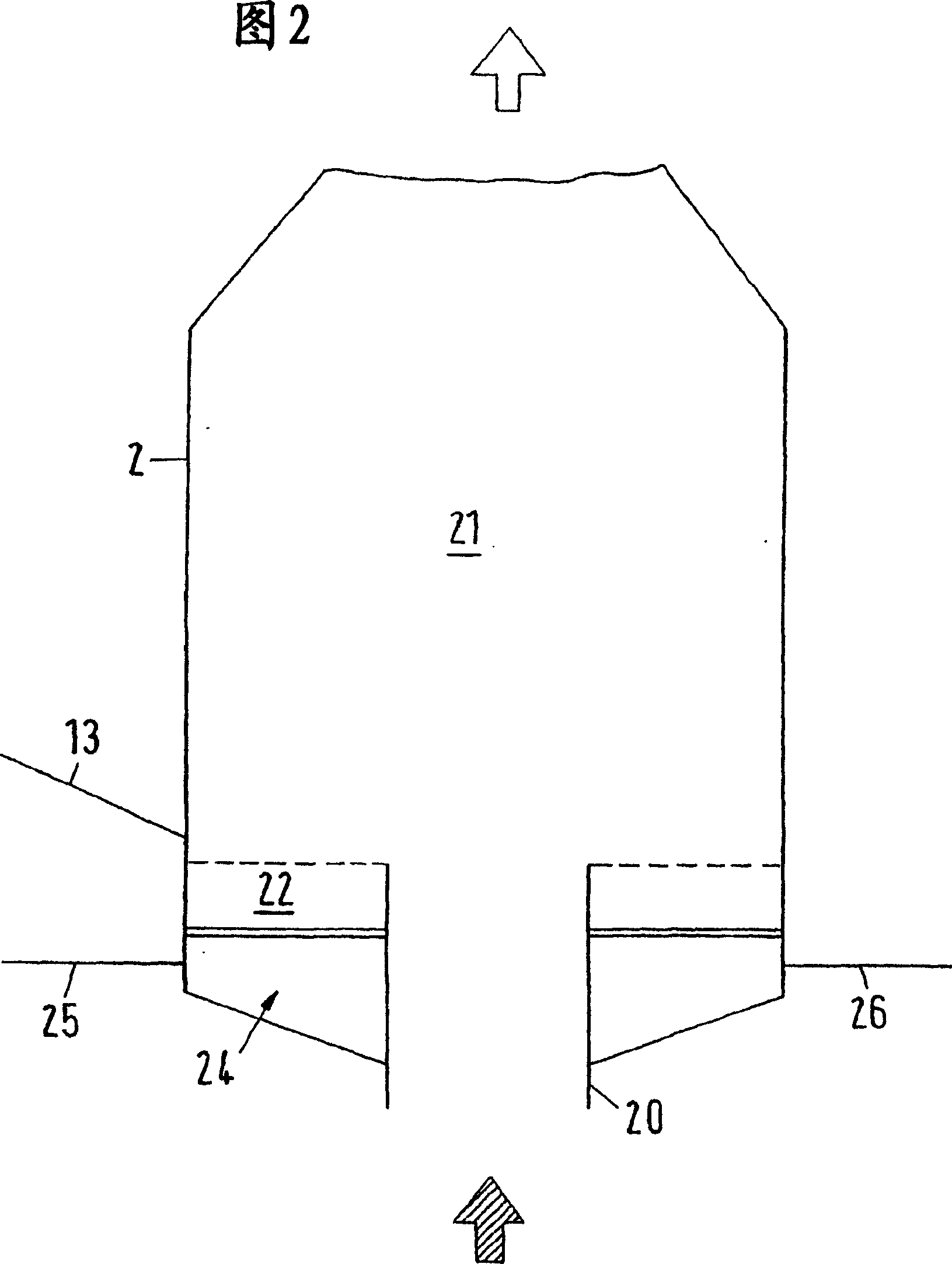

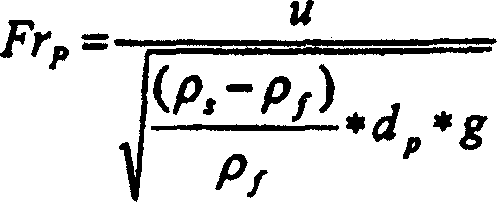

The present invention relates to a method and a plant for producing low 15 temperature coke, in which granular coal and possibly further solids are heated to a temperature of 700 to 1050° C. in a fluidized-bed reactor (2) by means of an oxygen-containing gas. To improve the utilization of energy it is proposed to introduce a first gas or gas mixture from below through at least one gas supply tube (3) into a mixing chamber region (8) of the reactor (2), the gas supply tube (3) being at least partly surrounded by a stationary annular fluidized bed (6) which is fluidized by supplying fluidizing gas. The gas velocities of the first gas or gas mixture and of the fluidizing gas for the annular fluidized bed (6) are adjusted such that the Particle-Froude-Numbers in the gas supply tube (3) are between 1 and 100, in the annular fluidized bed (6) between 0.02 and 2 and in the 25 mixing chamber (8) between 0.3 and 30.

Owner:OUTOTEC OYJ

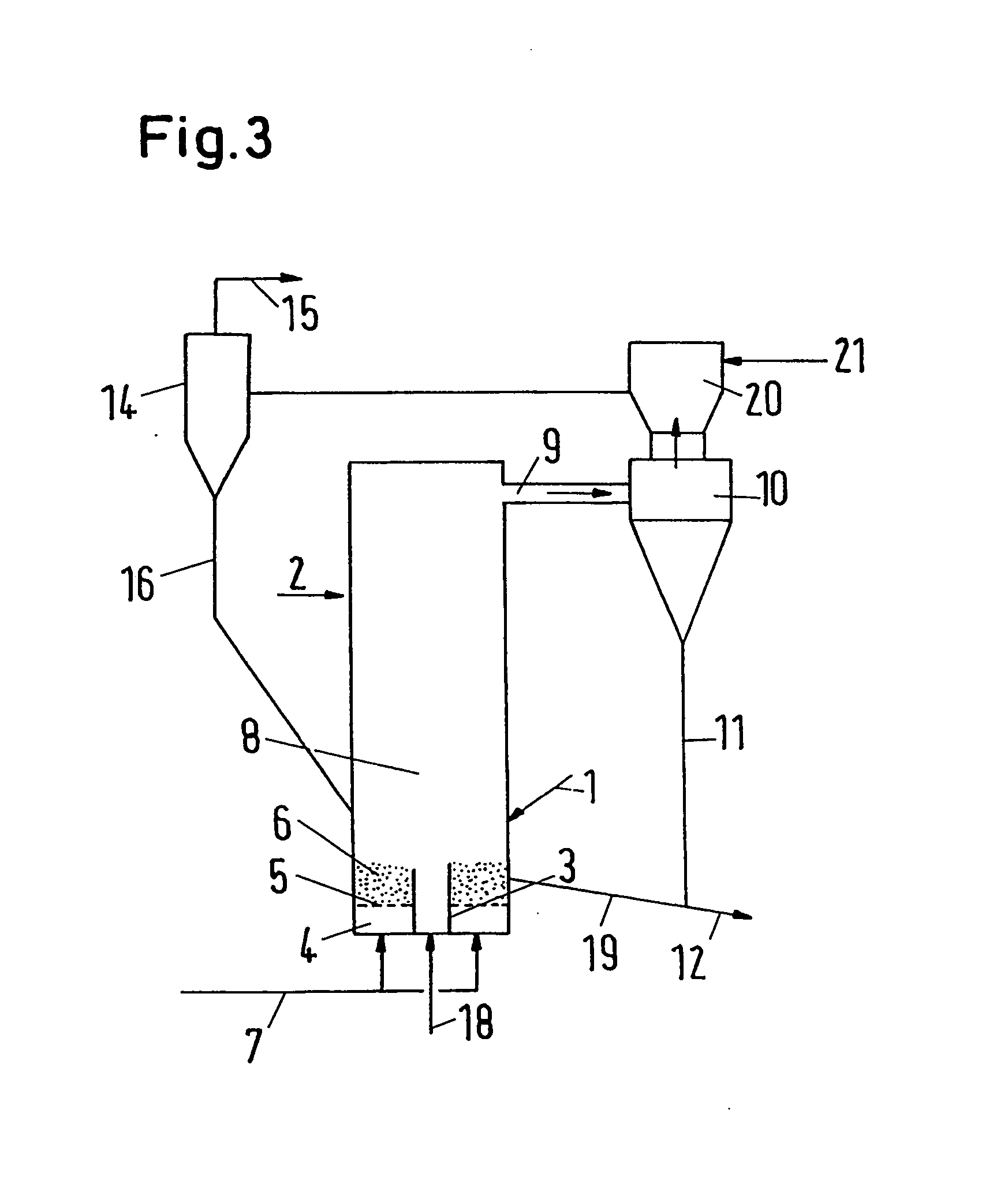

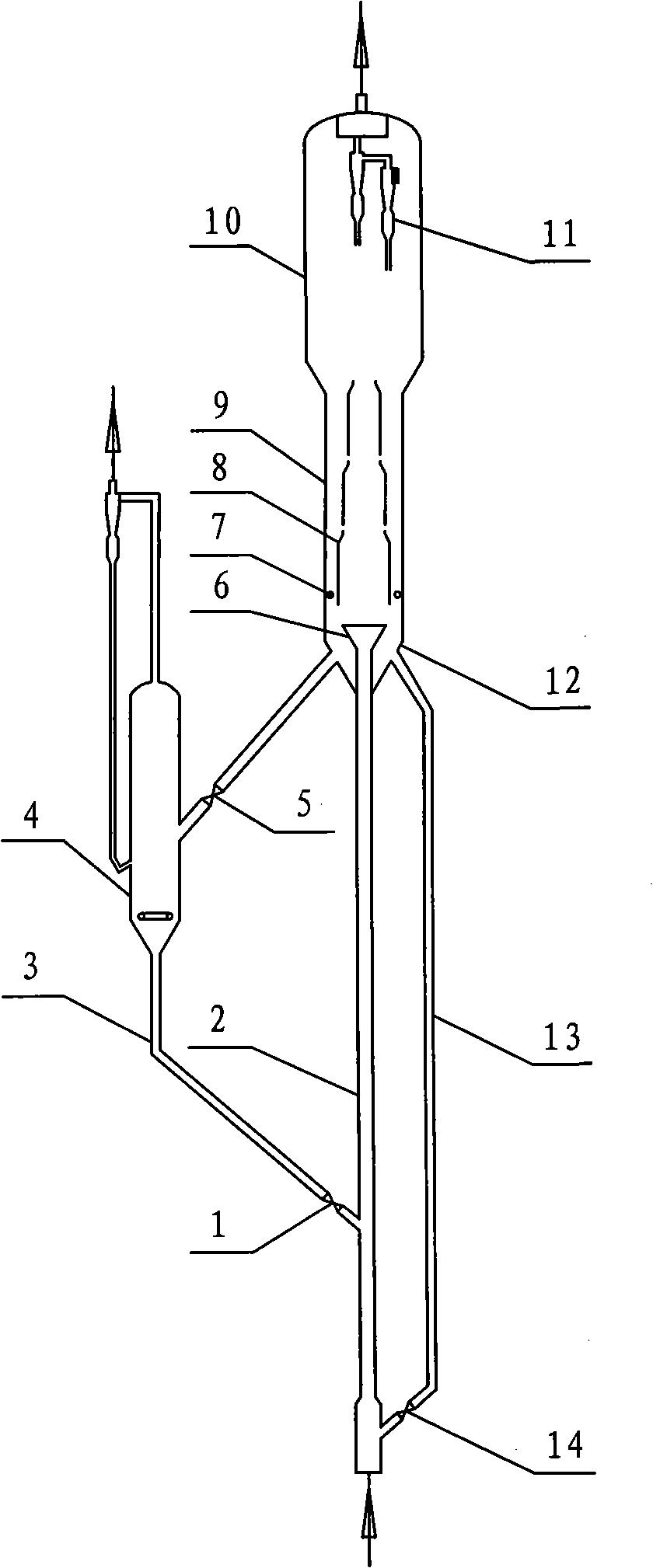

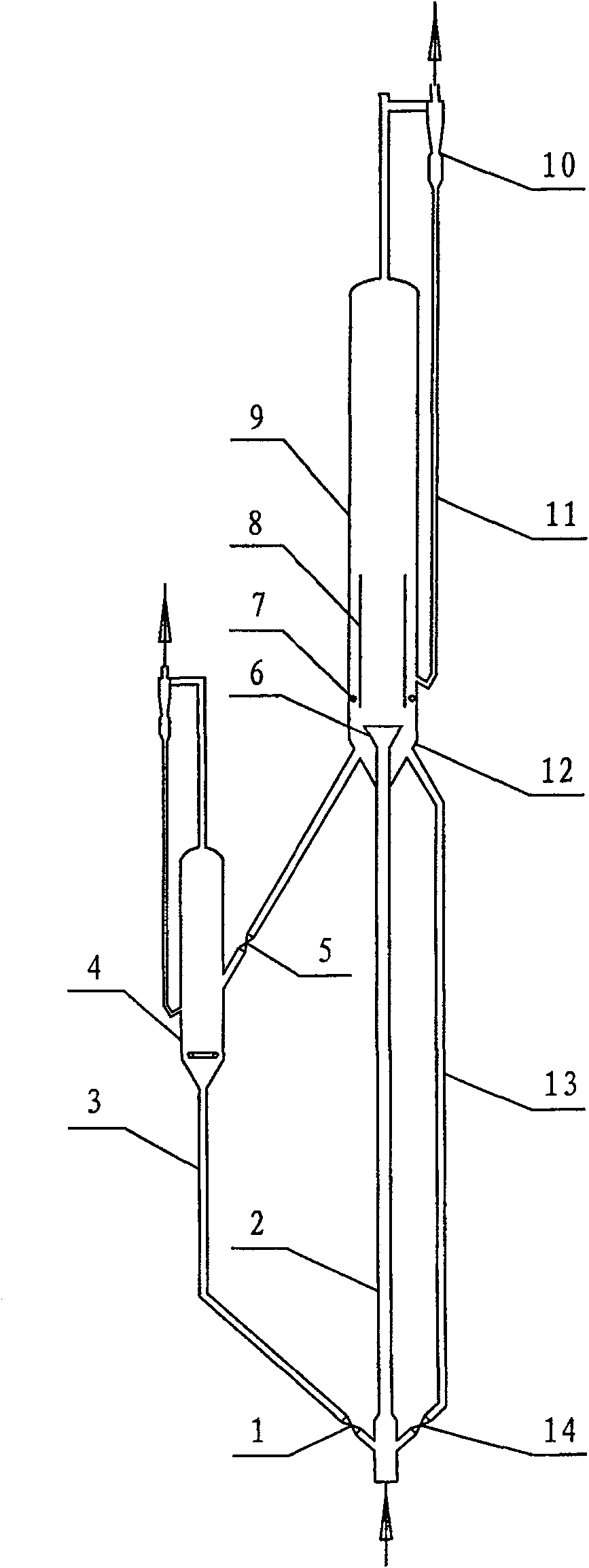

Device for improving pipe and gas-solid circumfluence bed coupling reaction

ActiveCN101259398AExtended reaction timeReduce resistanceFluidized bed combustionChemical/physical processesChemical industryGas solid

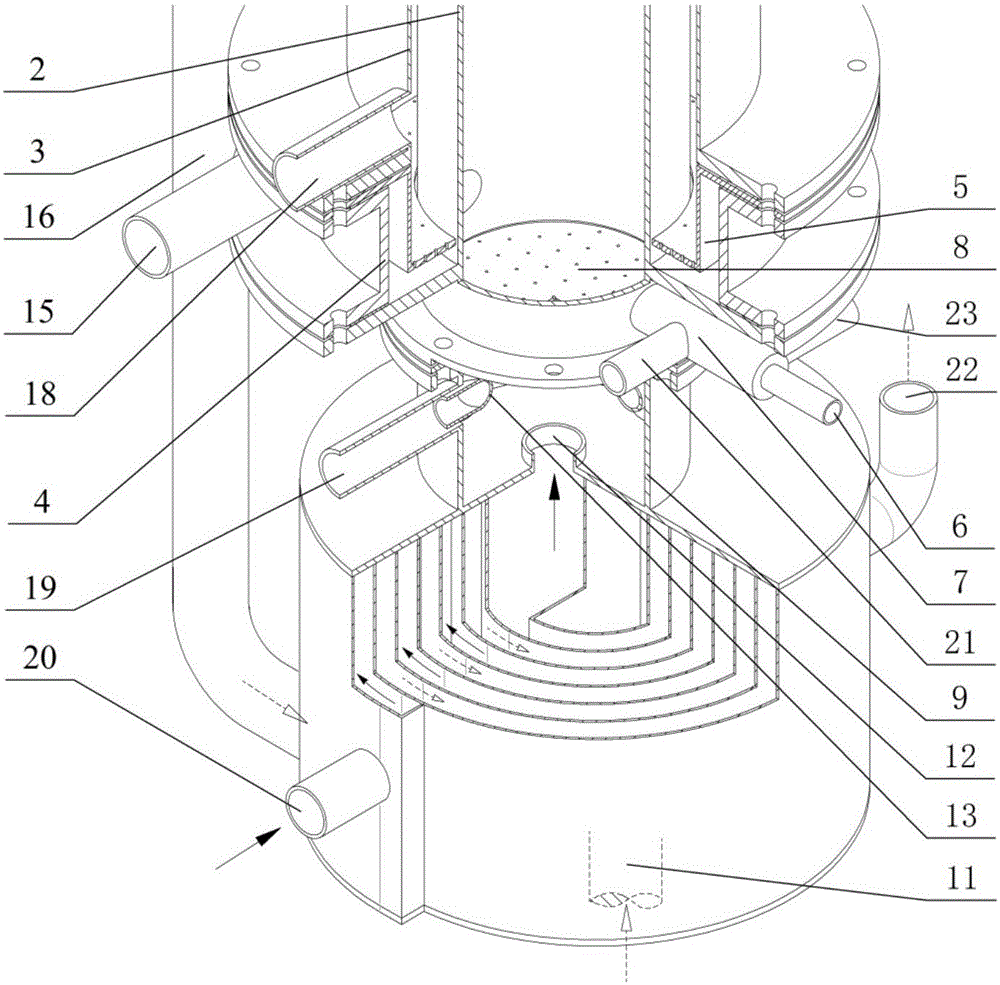

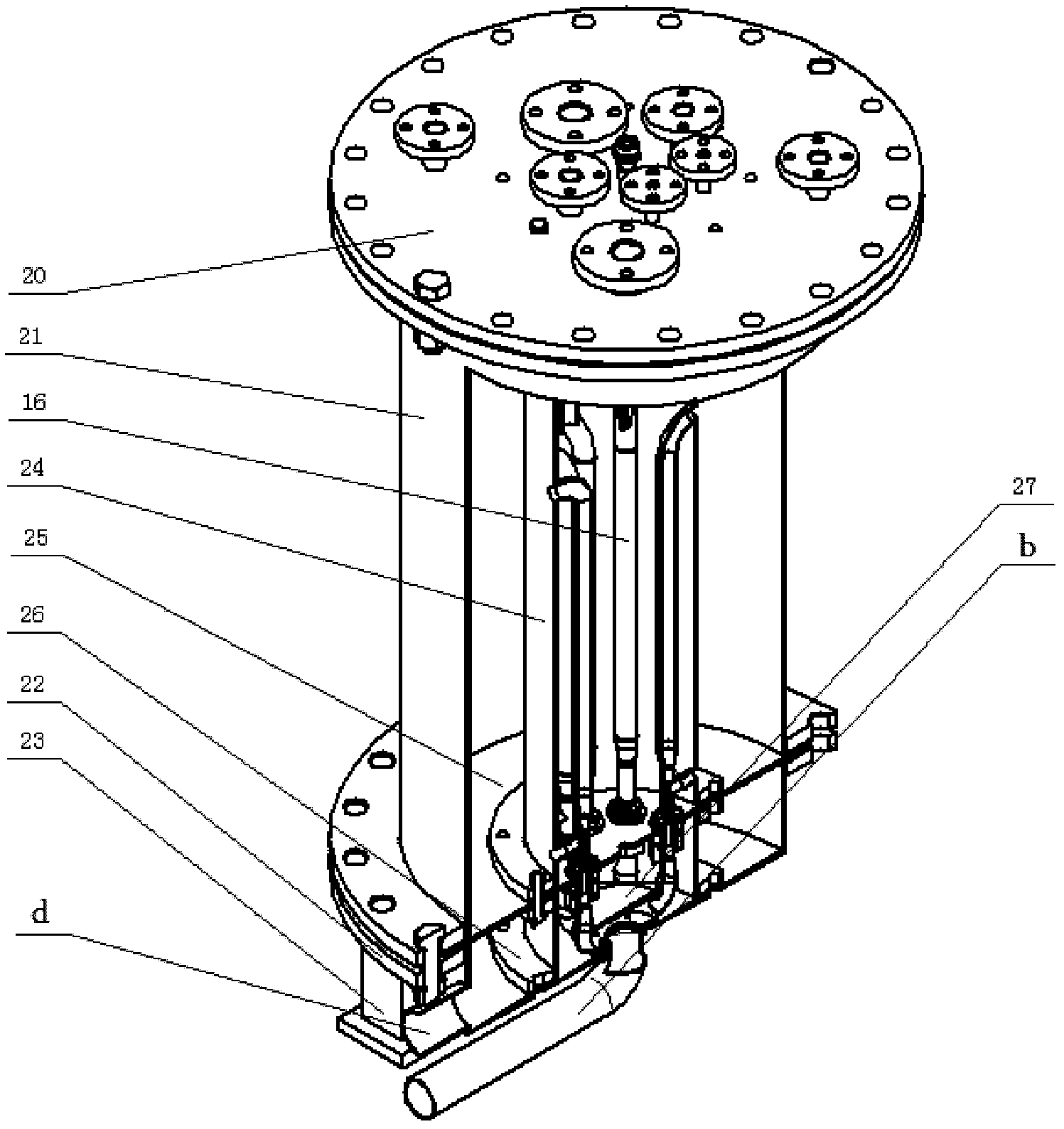

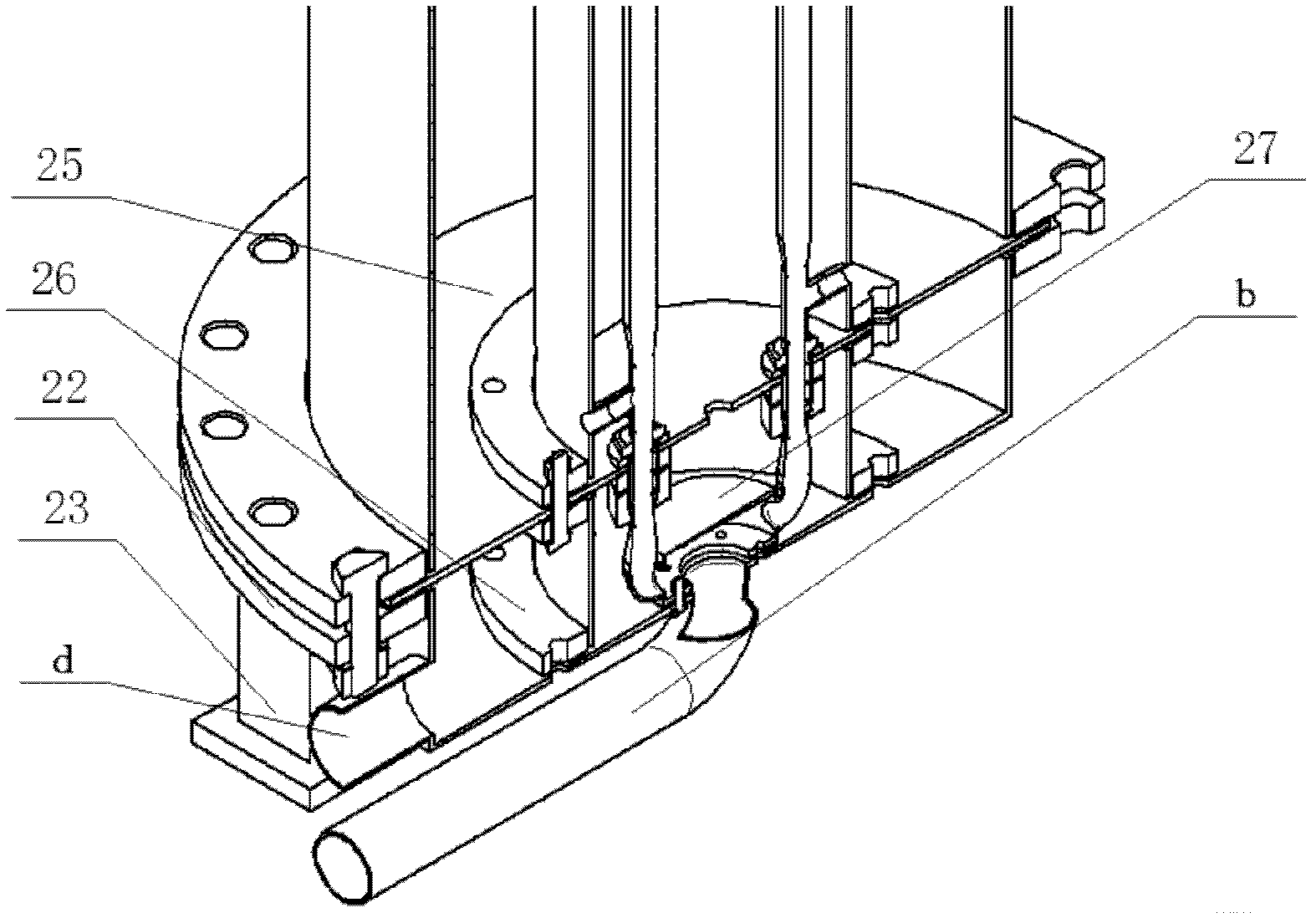

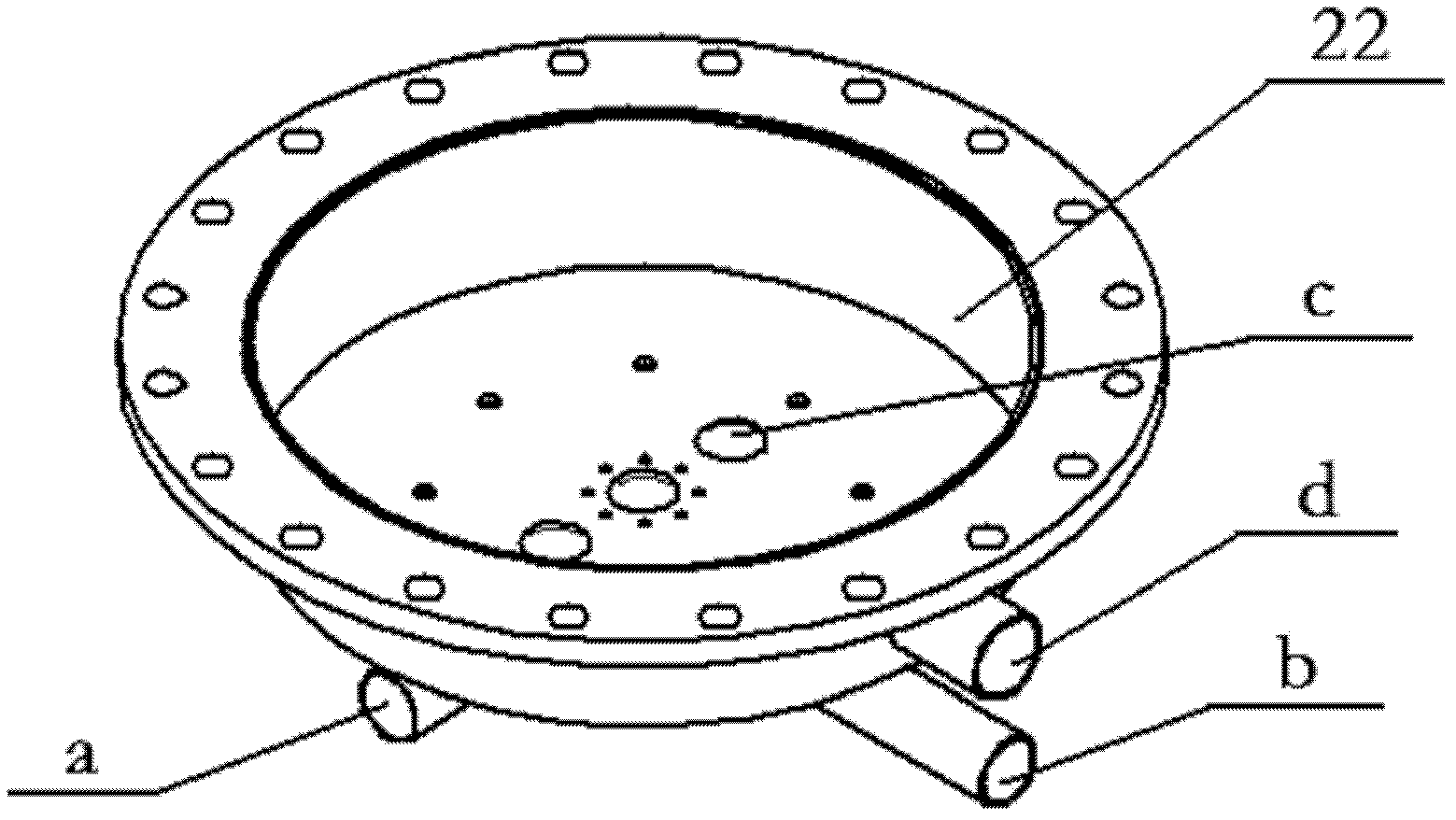

The invention provides a lift pipe and air-solid circulation bed coupling reaction device which at least includes a lift pipe, a shower head distributor, a guide cylinder, an annular space air distribution ring, an outer cylinder, an inner circulation pipe, an outer circulation fluidized bed, an outer circulation pipe and an air-solid separating system. Particles and air are transmitted upwards along the lift pipe, pass through the shower head distributor and enter the upper annular fluidized bed to form a central air lifting type circumfluence between the guide cylinder and the annular space. Part of the particles below the outer cylinder enters the lift pipe through the inner circulation pipe and another part enters the outer circulation fluidized bed to be mixed with the original particles in the outer circulation fluidized bed; the mixed particles enter the lift pipe through the outer circulation pipe; the positions where the inner circulation pipe and the outer circulation pipe enter the lift pipe can be flexibly arranged; the lift pipe and air-solid circulation bed coupling reaction device overcomes the limitations of system pressure balance and short reaction time and has the advantages that each area is flexible to be operated and controlled, the air-solid contact efficiency of the annular fluidized bed is high and the resistance above the distributor is small, etc. The device can be broadly applied to the fields of energy supply, chemical industries and particle combustion, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

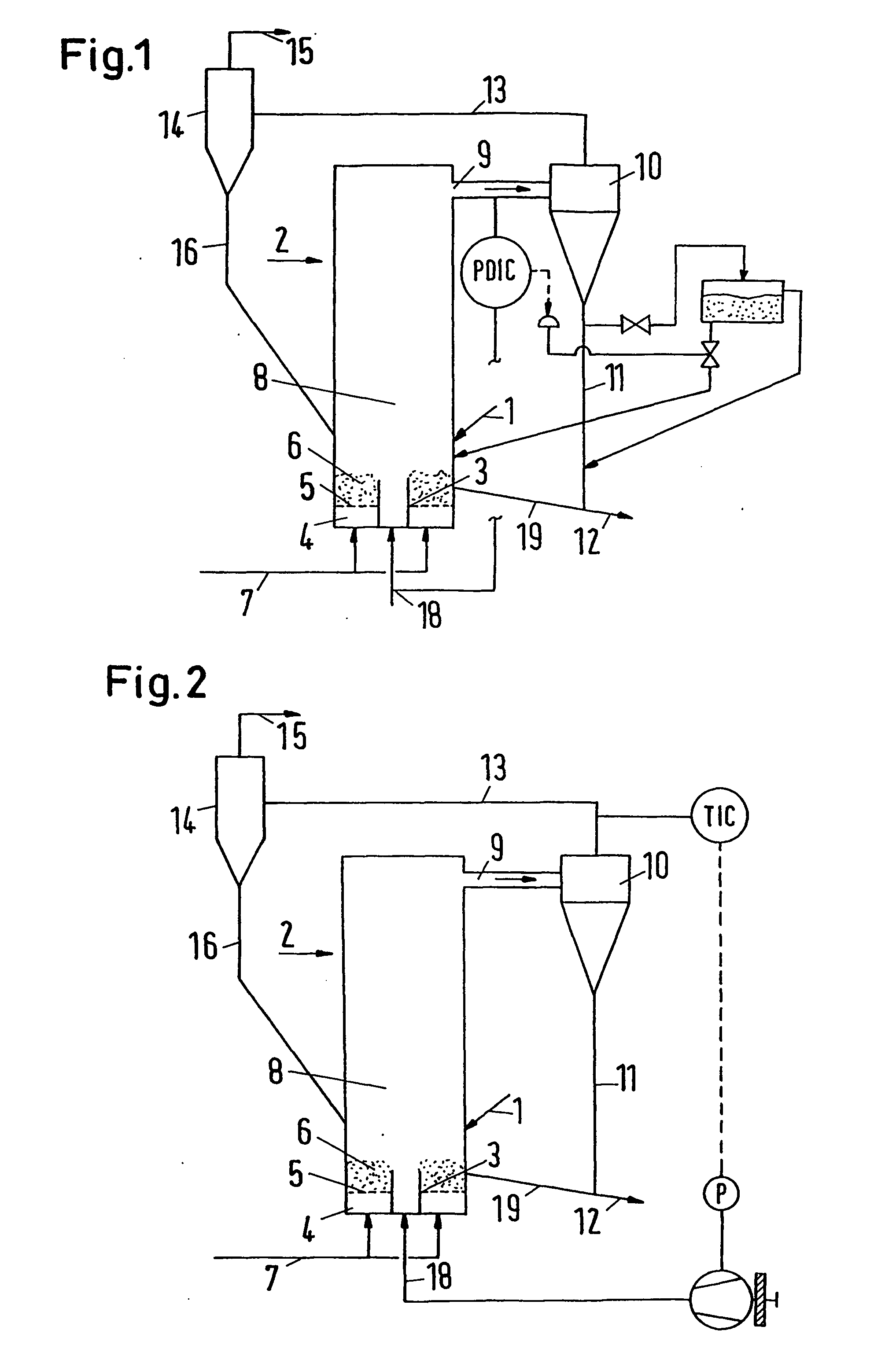

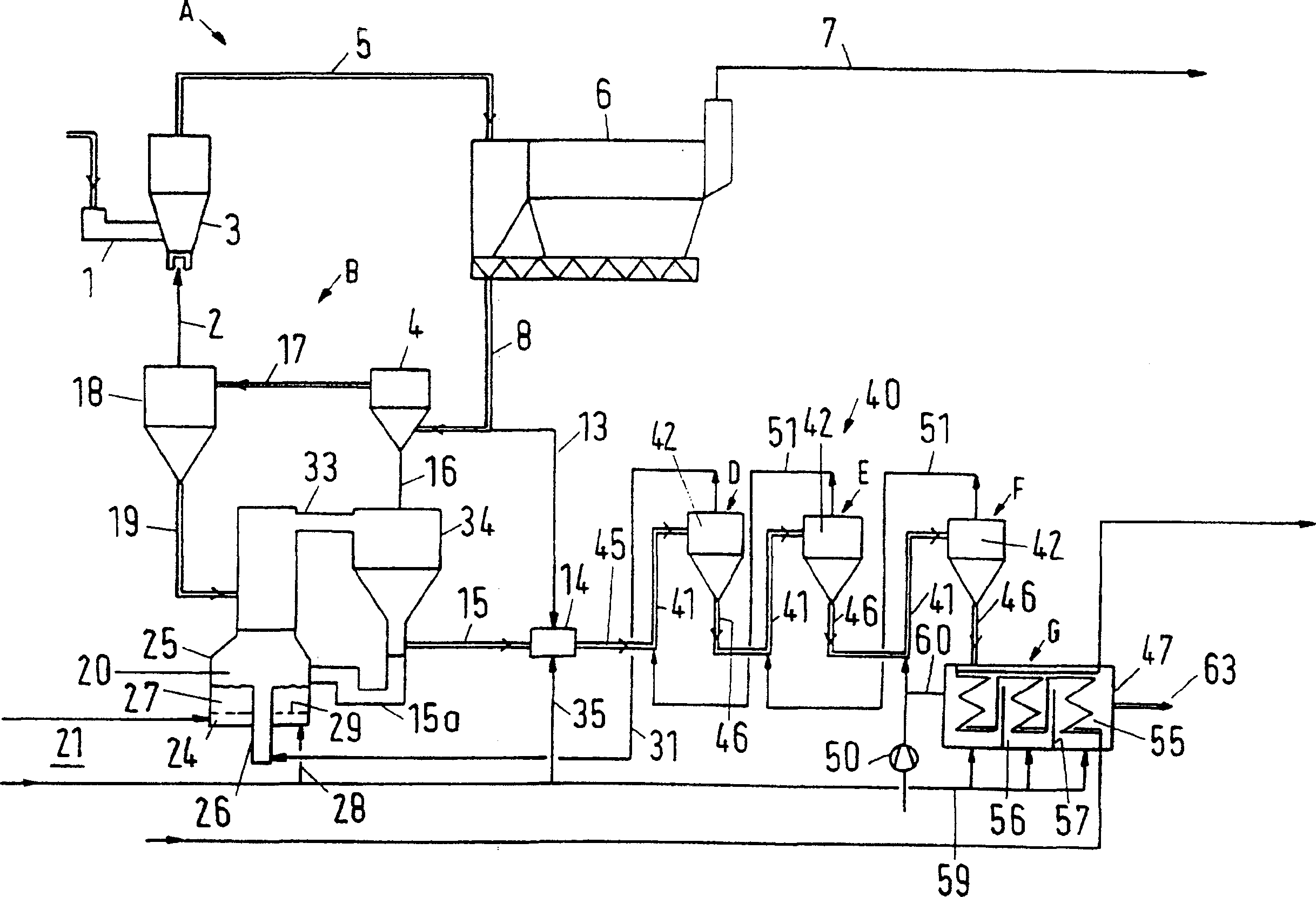

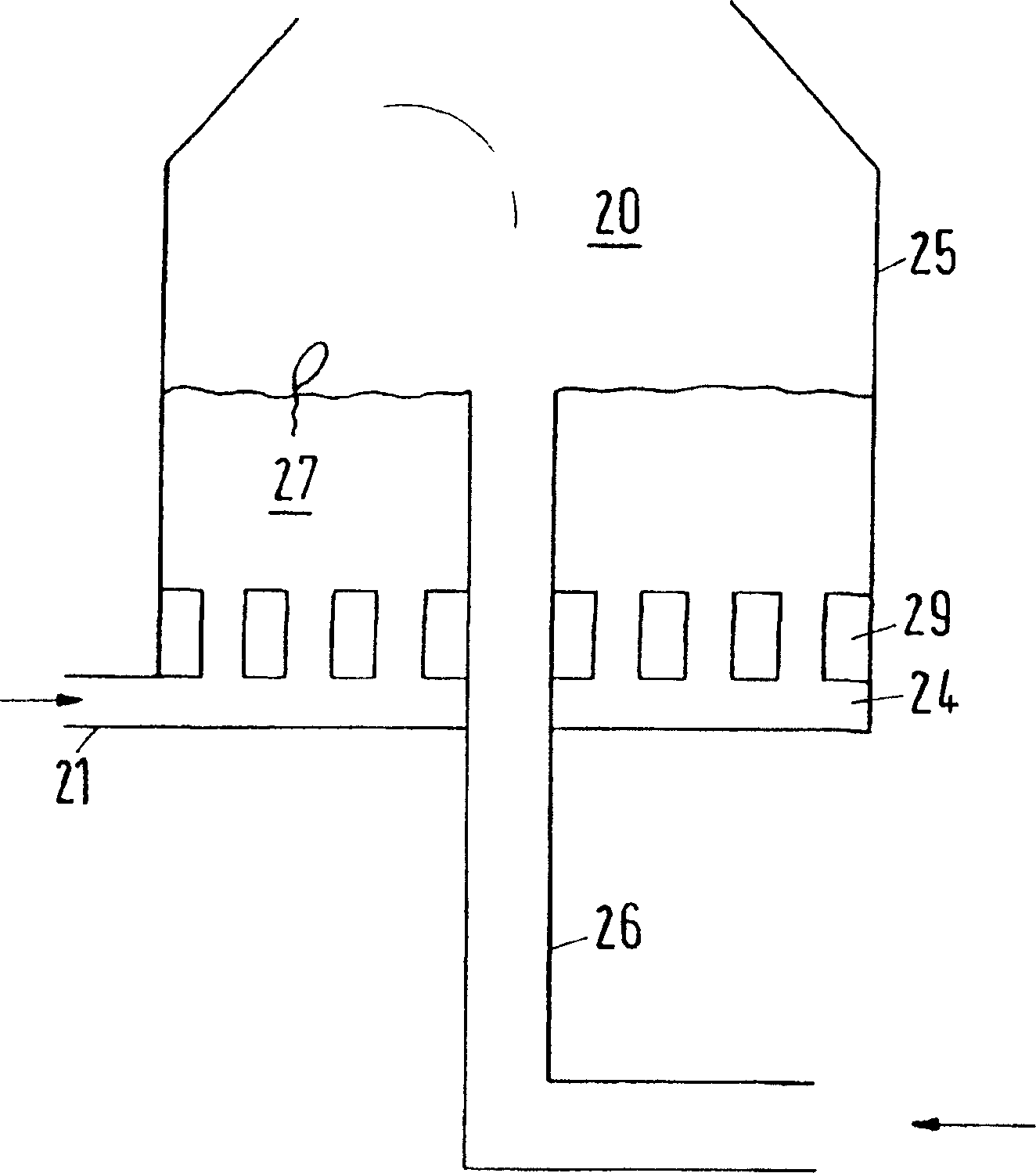

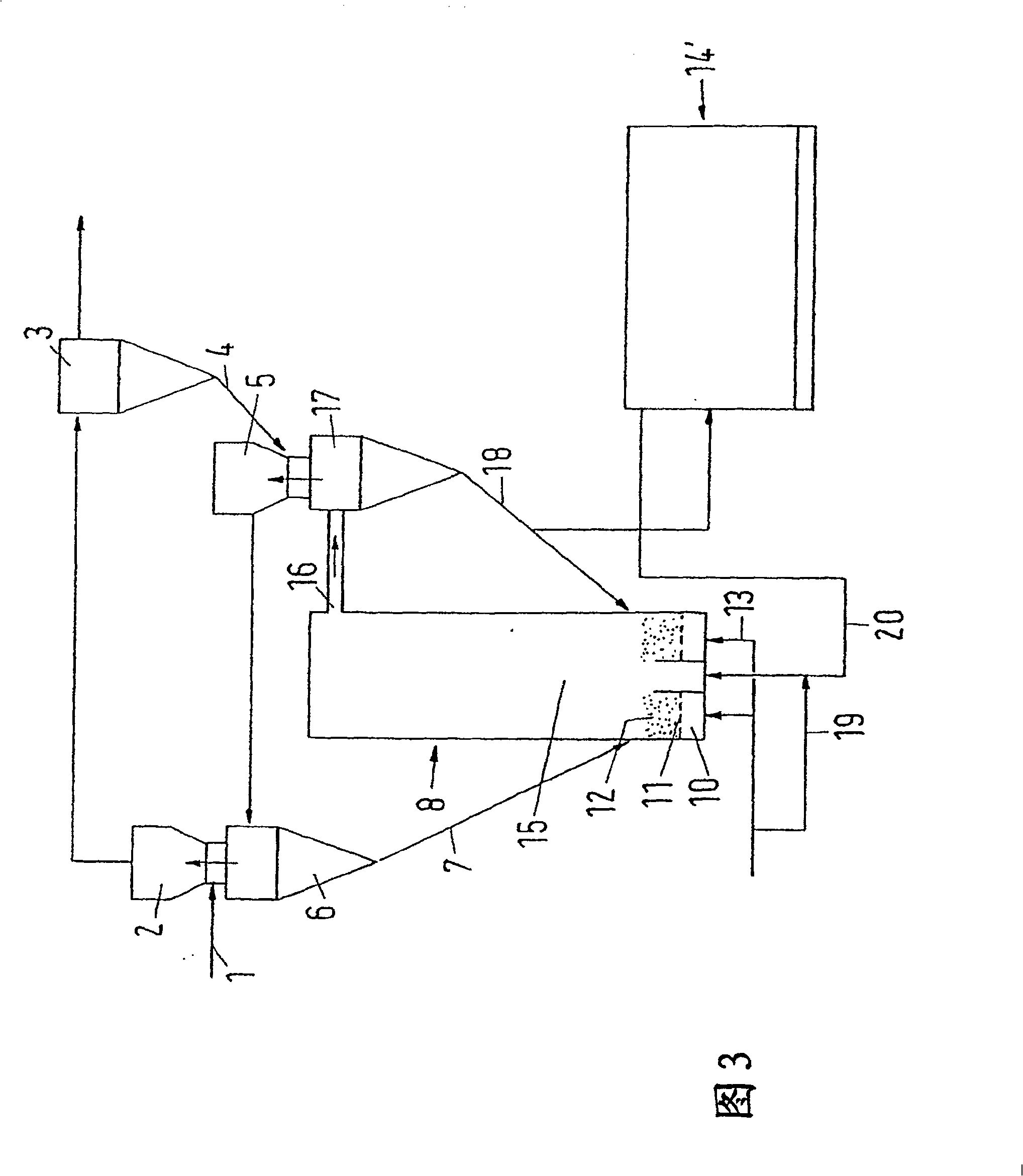

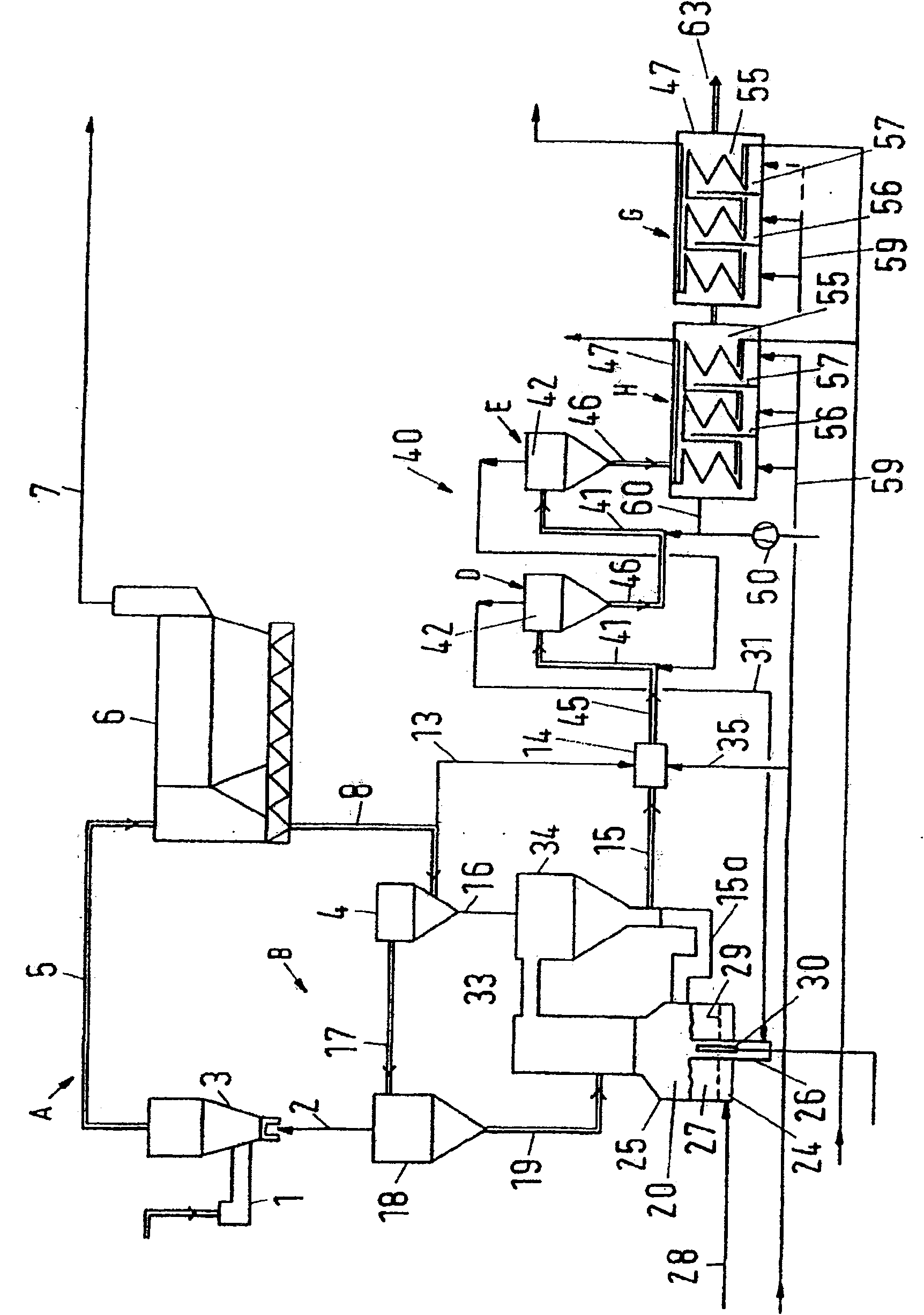

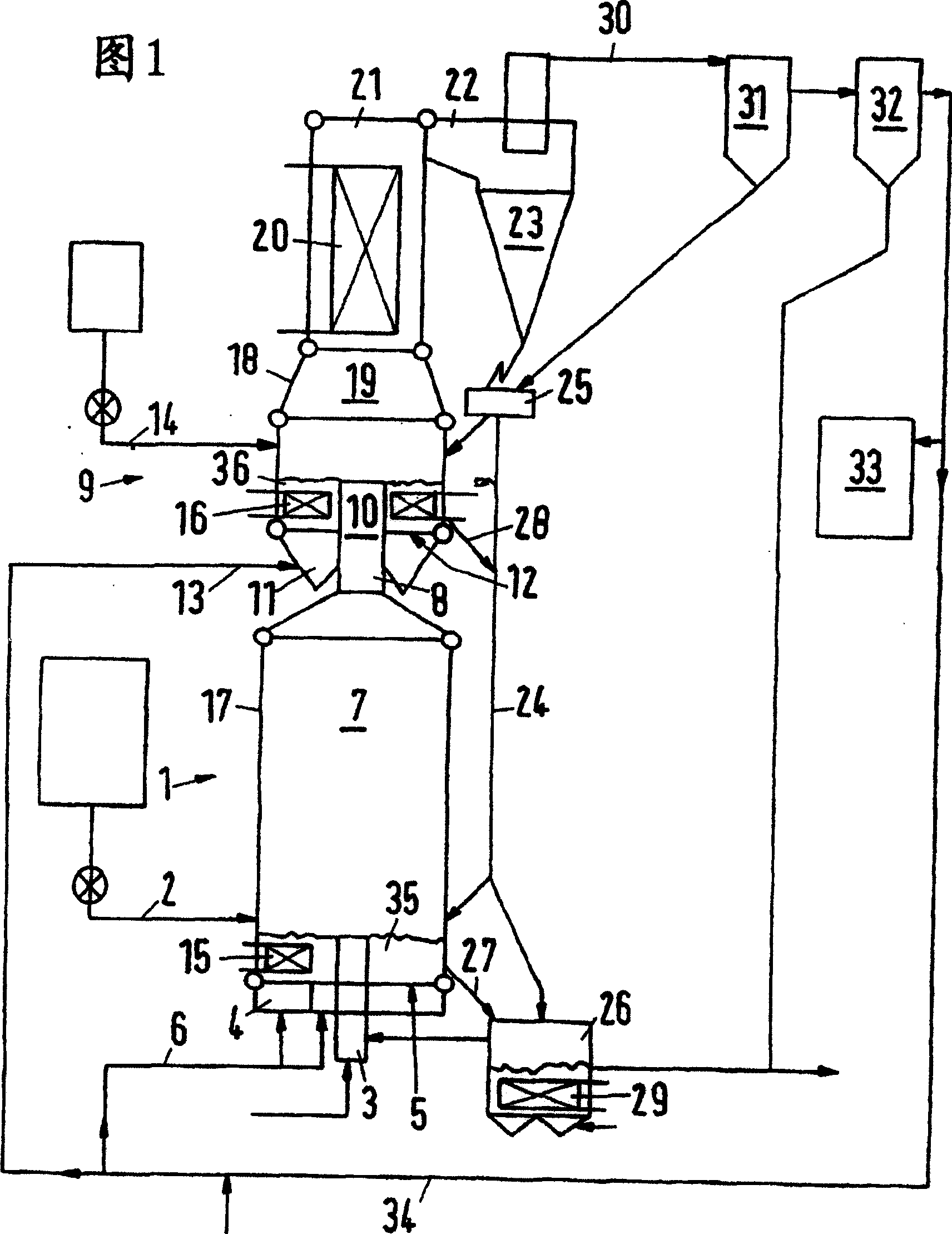

Method and plant for the heat treatment of sulfidic ores using annular fluidized

InactiveCN1732276AOptimizing Energy UtilizationFluidised-bed furnacesChemical/physical processesFluidized bedSulfide

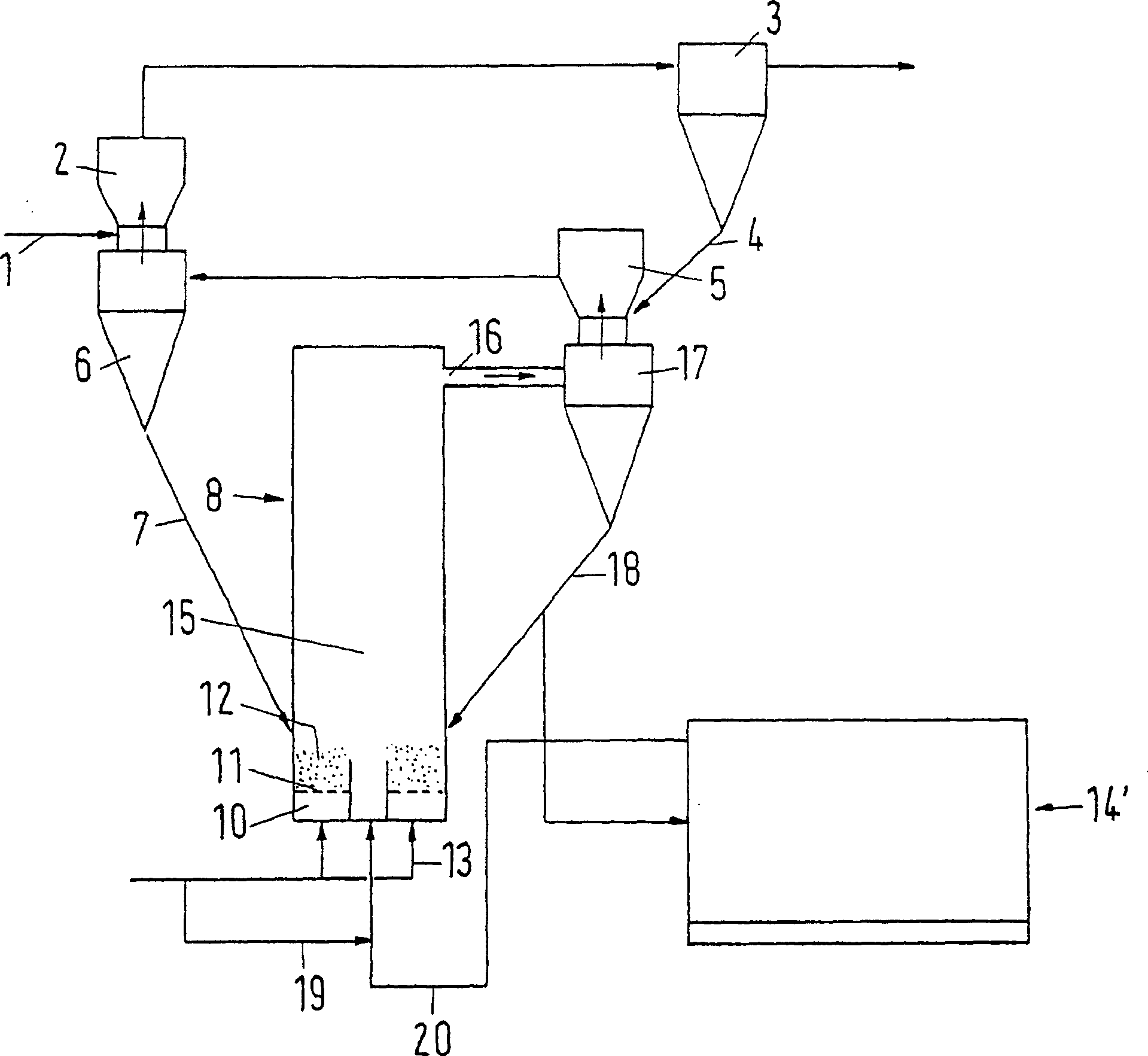

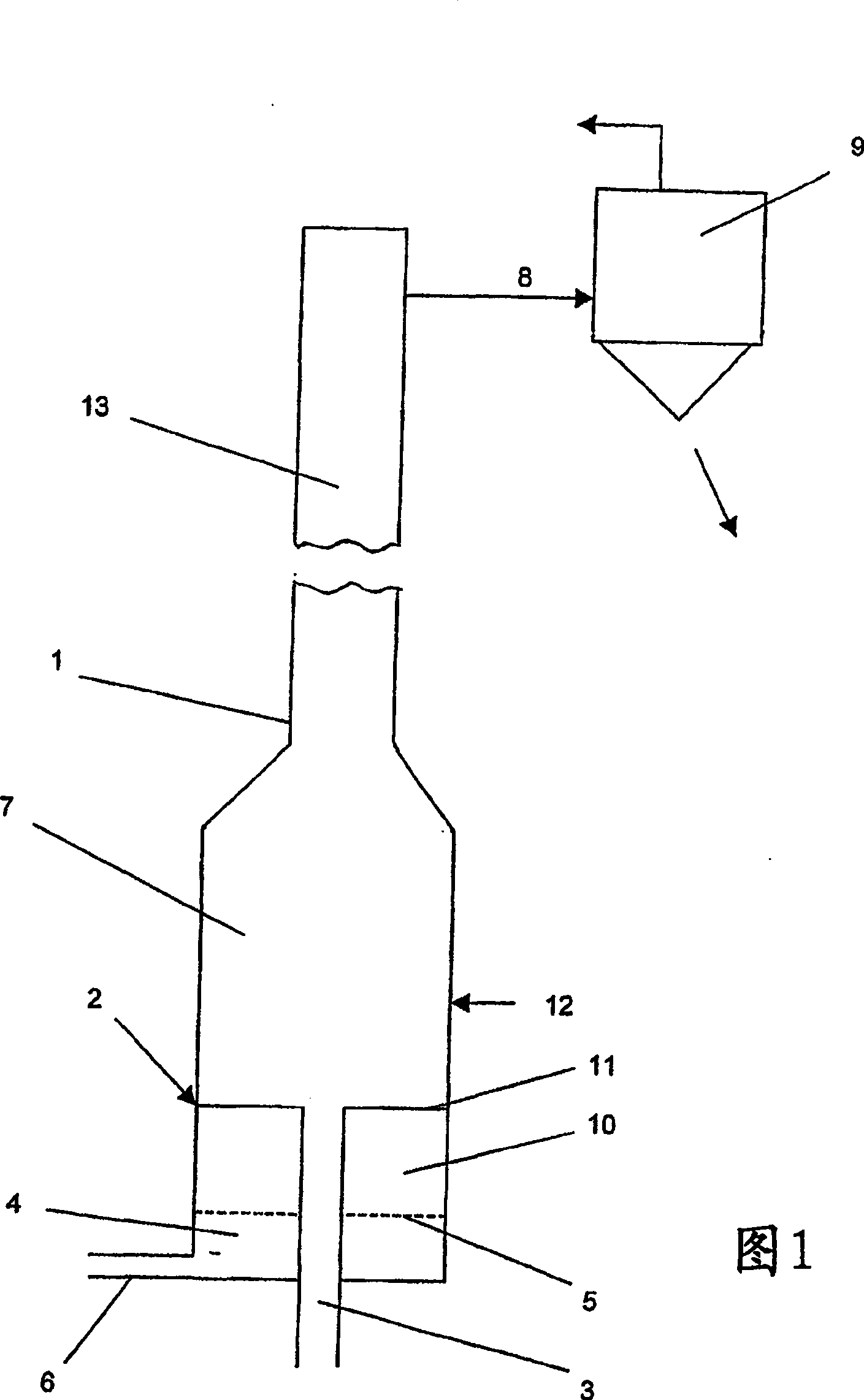

The invention relates to a method and a plant for the heat treatment of sulfidic ores, in which solids are heated to a temperature of approximately 450 to 1500 DEG C in a fluidized bed reactor (1). In order to improve the energy utilization, it is proposed to introduce a first gas or gas mixture from below through a gas supply tube (3) into a mixing chamber (7) of the reactor (1), the gas supply tube (3) being at least partly surrounded by a stationary annular fluidized bed (35) which is fluidized by supplying fluidizing gas. The gas velocities of the first gas or gas mixture as well as of the fluidizing gas for the annular fluidized bed (35) are adjusted such that the particle Froude numbers in the gas supply tube (3) are between 1 and 100, in the annular fluidized bed (35) between 0.02 and 2 and in the mixing chamber (7) between 0.3 and 30.

Owner:OUTOKUMPU OY

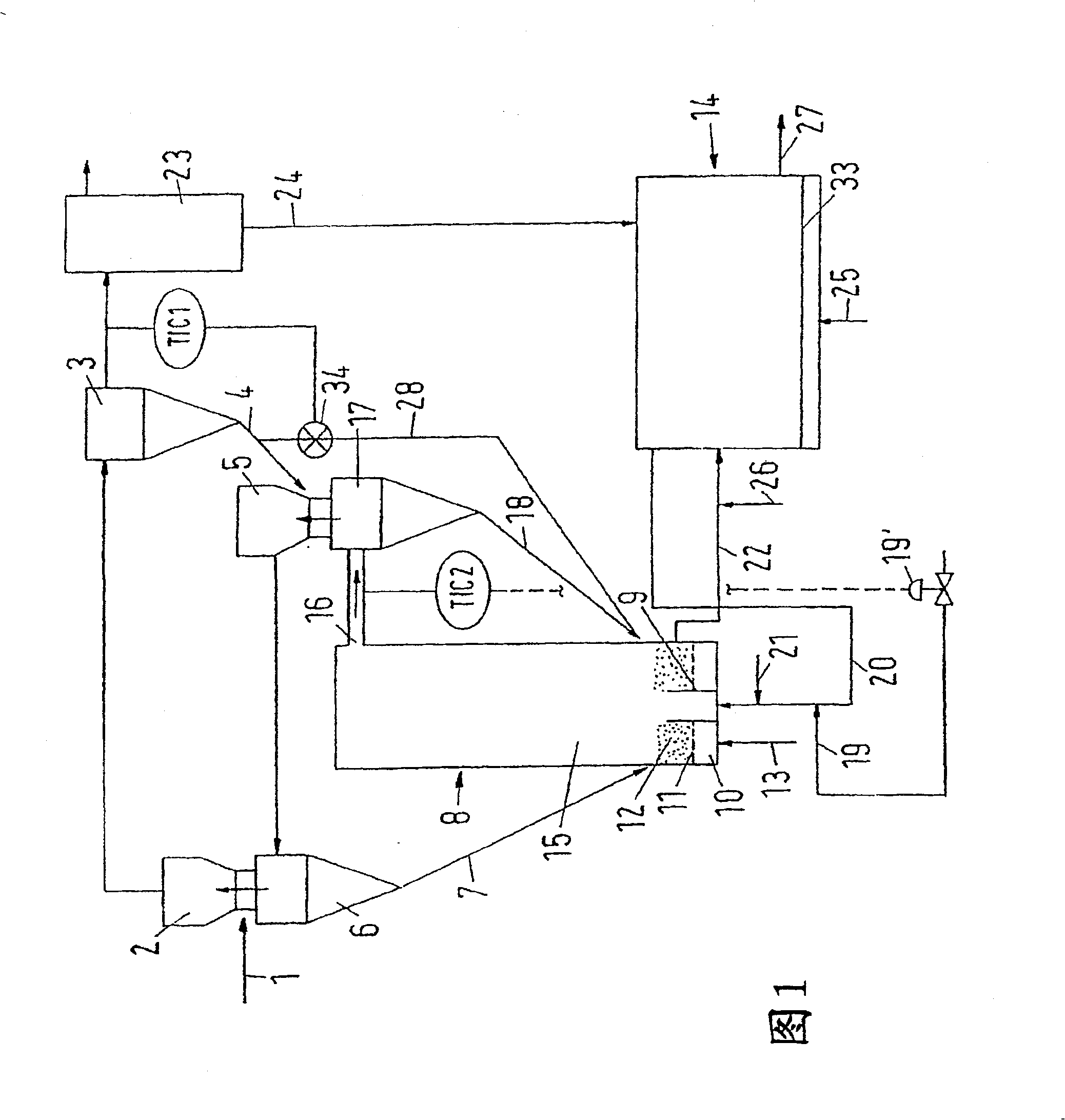

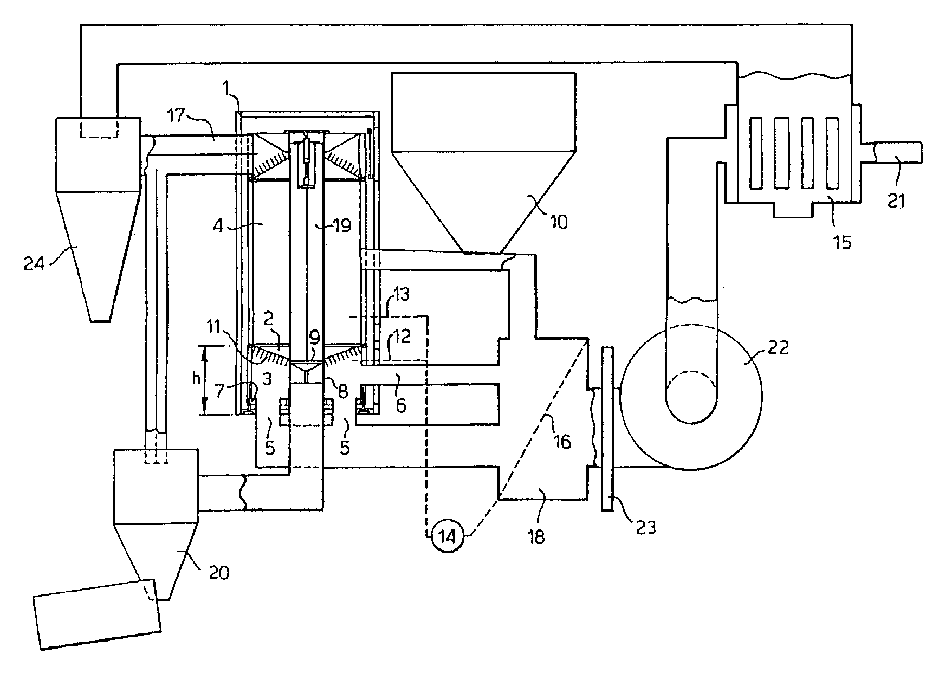

Method and plant for the heat treatment of solids containing iron oxide using a fluidized bed reactor

ActiveCN1756851AEnhanced mass transferImprove heat transfer performanceFluidised-bed furnacesChemical/physical processesFluidized bedPhysical chemistry

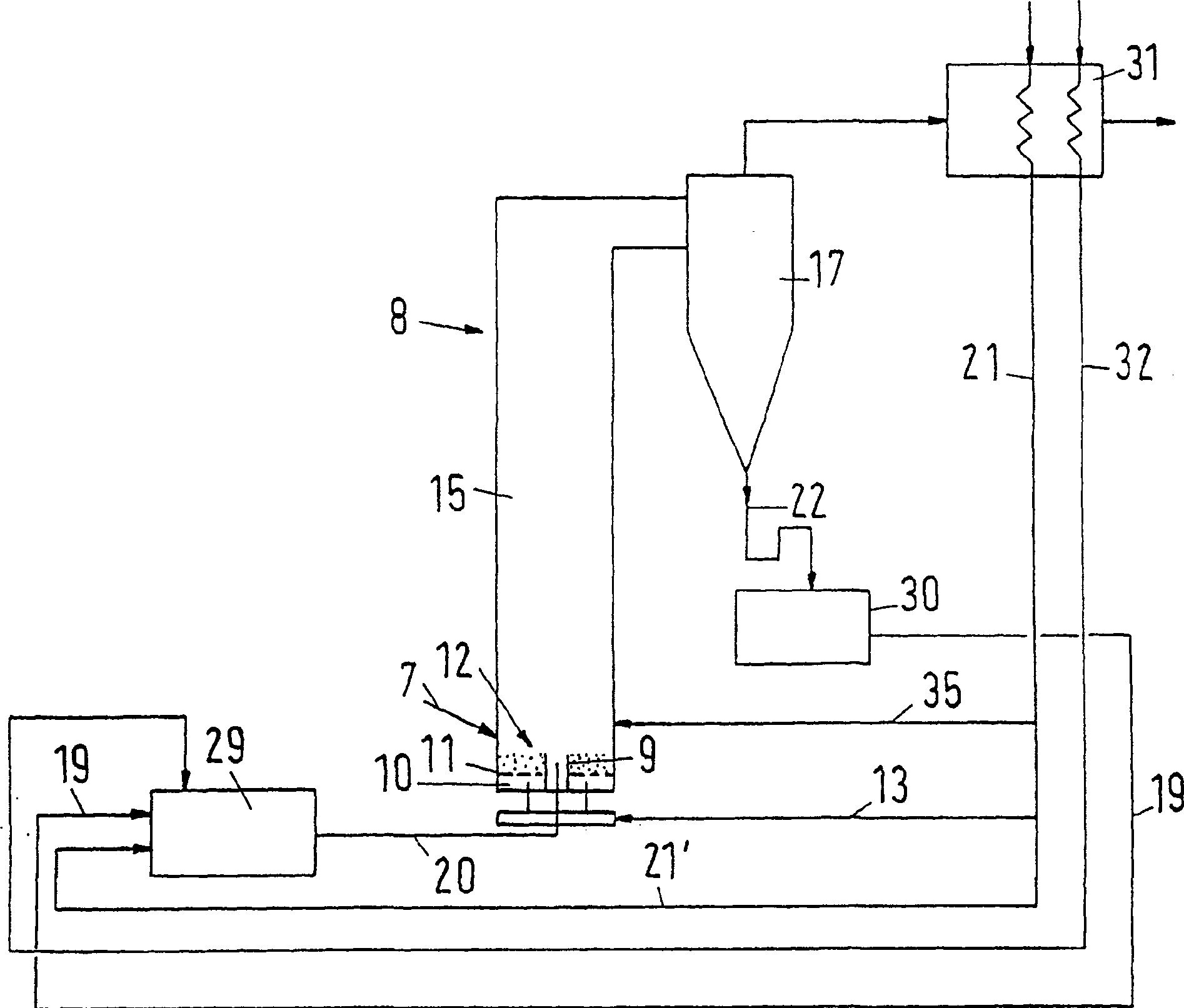

The present invention relates to a method and a plant for the heat treatment of solids containing iron oxide, in which fine-grained solids are heated to a temperature of 700 to 1150 DEG C in a fluidized bed reactor (8) . To improve the utilization of energy, it is proposed to introduce a first gas or gas mixture from below through at least one gas supply tube (9) into a mixing chamber region (15) of the reactor (8), the gas supply tube (9) being at least partly surrounded by a stationary annular fluidized bed (12) which is fluidized by supplying fluidizing gas. The gas velocities of the first gas or gas mixture and of the fluidizing gas for the annular fluidized bed (12) are adjusted such that the Particle-Froude-Numbers in the gas supply tube (9) are between 1 and 100, in the annular fluidized bed (12) between 0.02 and 2, and in the mixing chamber (15) between 0.3 and 30.

Owner:METSO OUTOTEC (FINLAND) OY

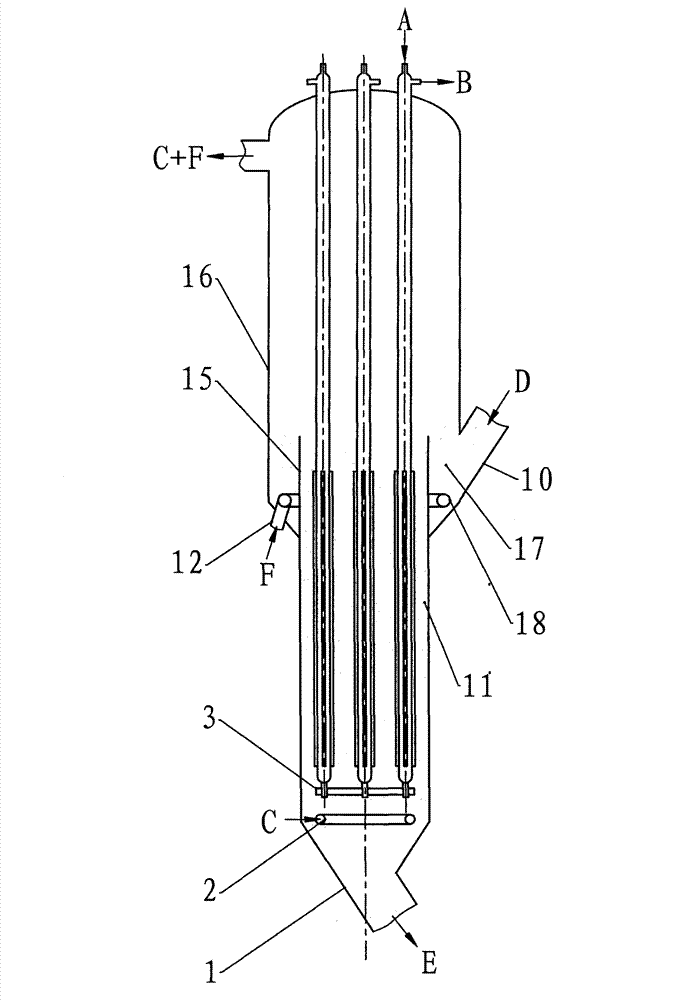

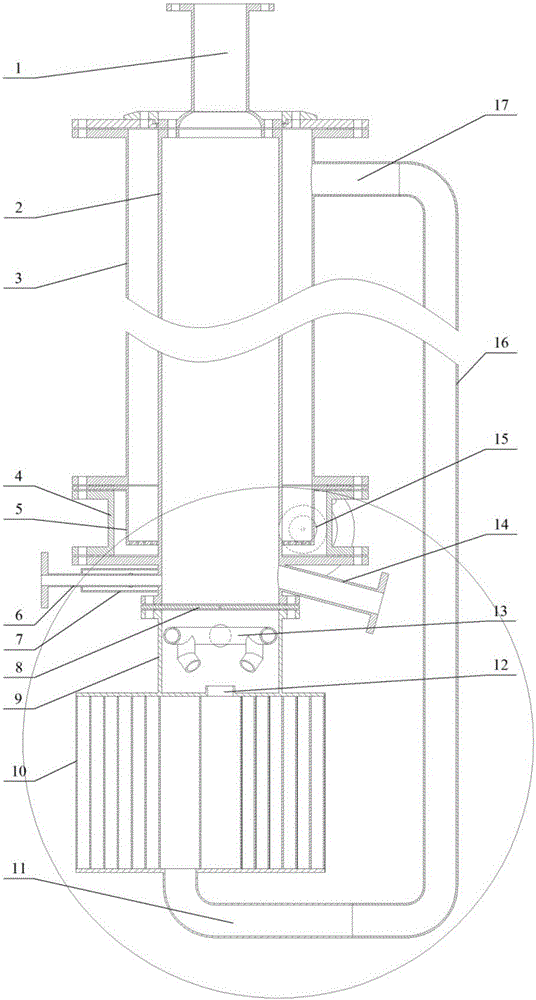

External catalytic cracking heater with pre-distributed particles

InactiveCN103113914AImprove reliabilityExtended service lifeCatalytic crackingFluidised bed heat exchangersFluidized bedEngineering

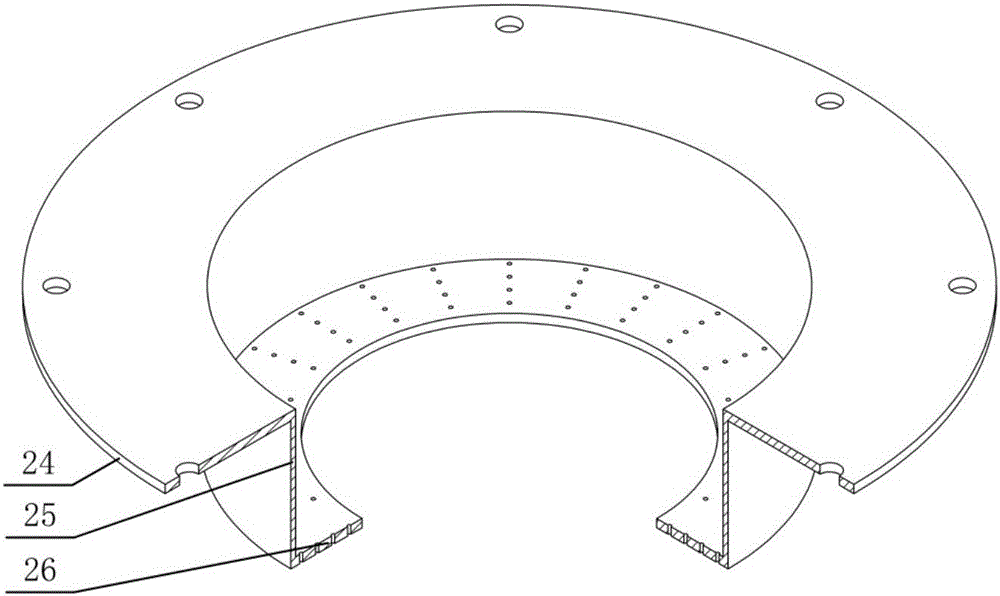

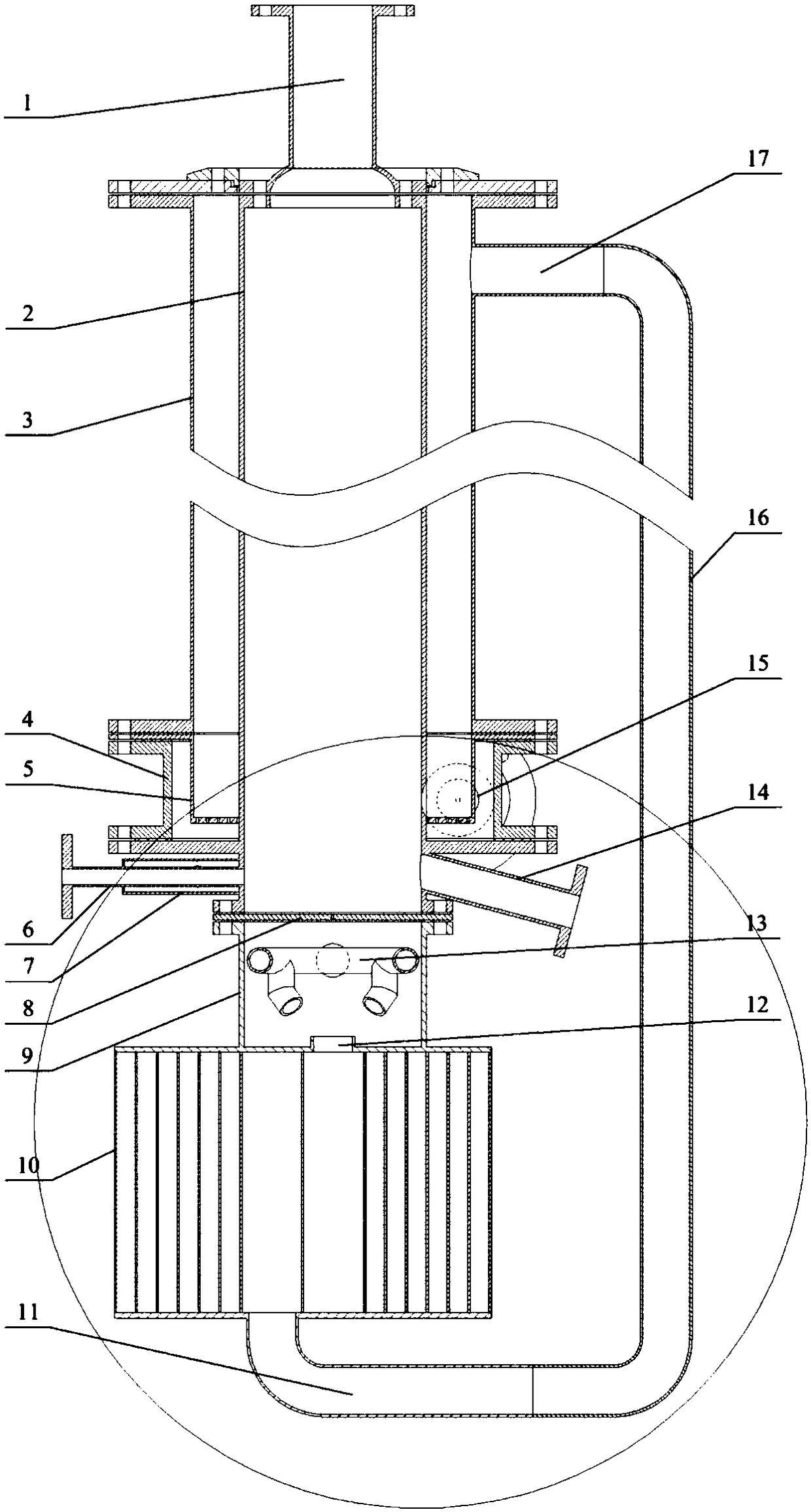

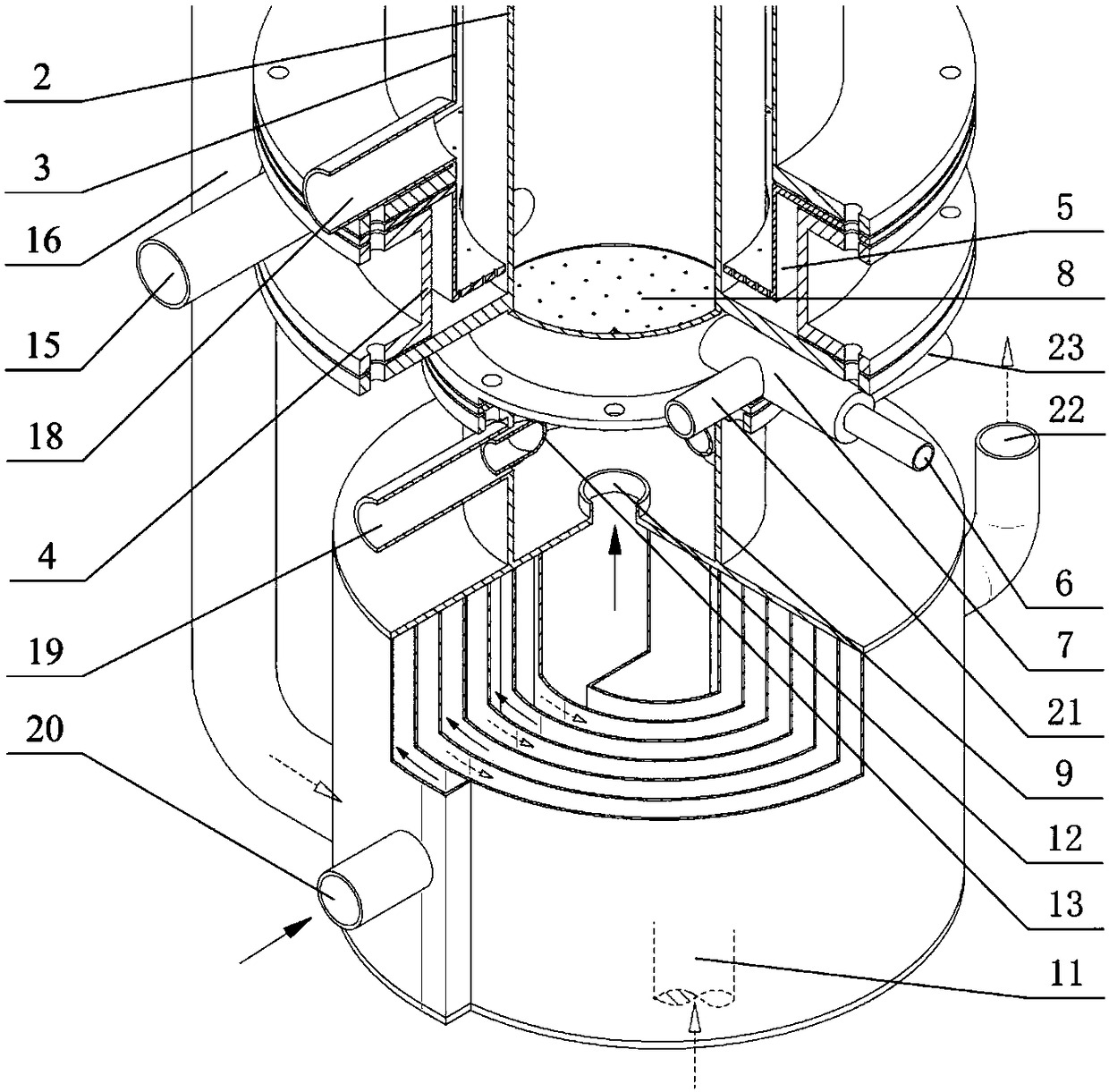

The invention discloses an external catalytic cracking heater with pre-distributed particles and is suitable for a catalytic cracking device in an oil refinery. The external catalytic cracking heater is characterized in that a plurality of unit type heat exchange tubes (6) with independent water inlets and water outlets are arranged inside an external heater (4); the heat exchange tubes (6) extend from the top to the bottom of the external heater (4), and the bottom of the external heater is provided with a guide bracket (2) which limits transverse swing of the heat exchange tubes (6); the lower parts of the heat exchange tubes (6) are immersed in a dense-phase fluidized bed (11) at the bottom of the external heater (4); hot catalyst particles entering from a catalyst inlet (10) in the middle of the external heater (4) enter an annular fluidized bed (17), and the hot particles uniformly flow into the dense-phase fluidized bed (11) from the upper edge of a side wall (15) on the inner side of the annular fluidized bed (17) or an overflow notch (19) formed in the side wall (15) on the inner side by utilizing the particle pre-distribution function of the annular fluidized bed (17); the hot particles are contacted and cooled with the side wall of the heat exchange tubes (6) and flow out of a catalyst outlet (1) at the bottom of the external heater (4) in the dense-phase fluidized bed (11); and fluidized gas in the dense-phase fluidized bed (11) is introduced from a bottom gas distributor (2), and the fluidized gas which passes through the dense-phase fluidized bed (11) and the fluidized gas in the annular fluidized bed (17) are mixed to enter a dilute phase space of a catalytic cracking device regenerator through a gas outlet (7) formed on the top of the external heater (4).

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

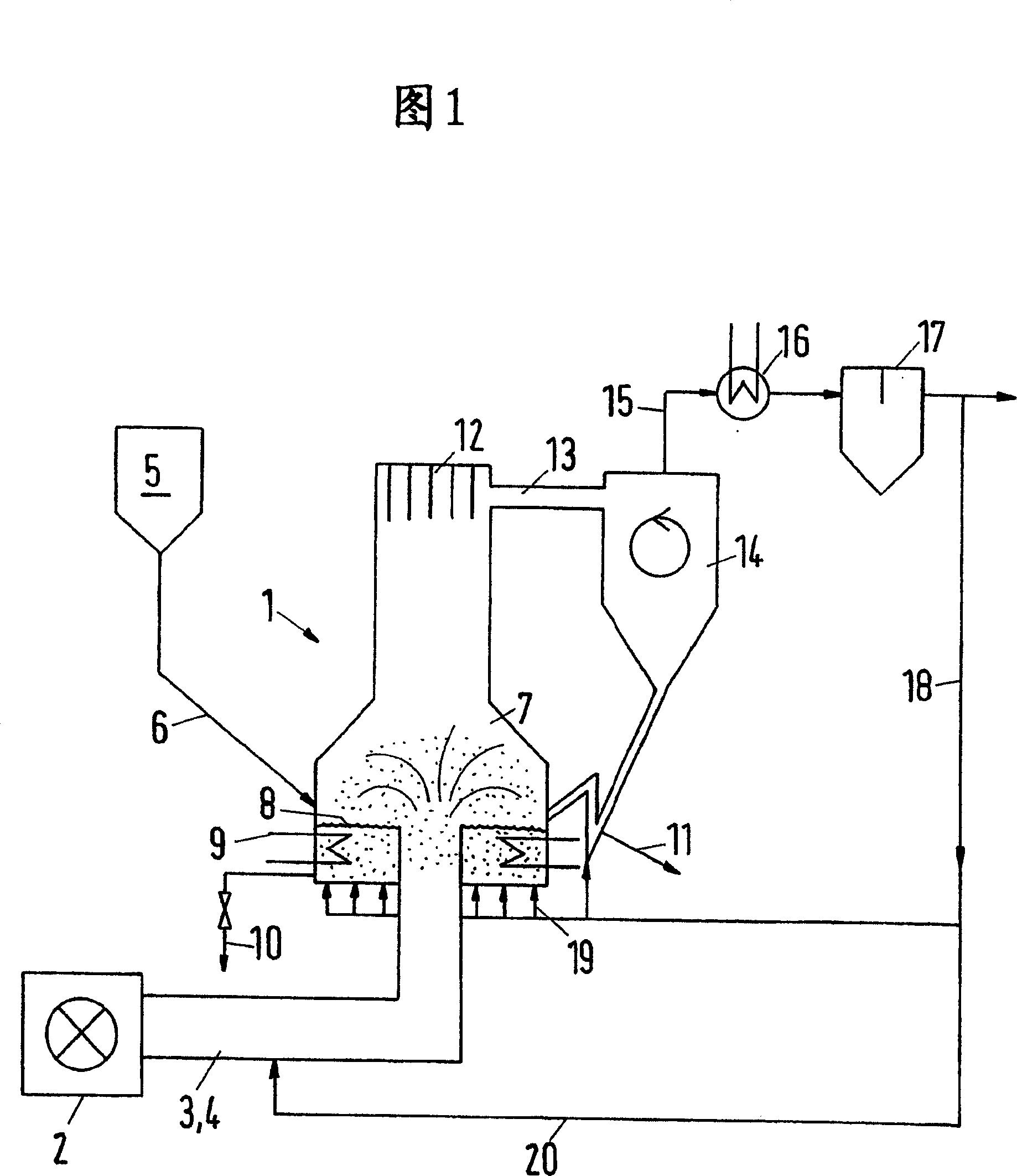

Treatment of granular solids in an annular fluidized bed with microwaves

InactiveCN1732042AEfficient use ofPromote absorptionDrying solid materials with heatMicrowave heatingFluidized bedProcess engineering

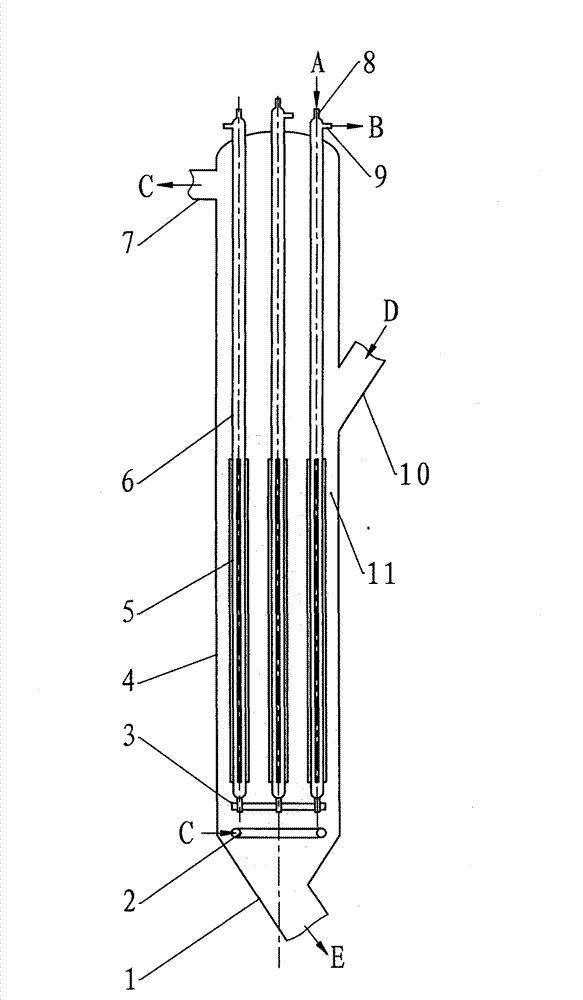

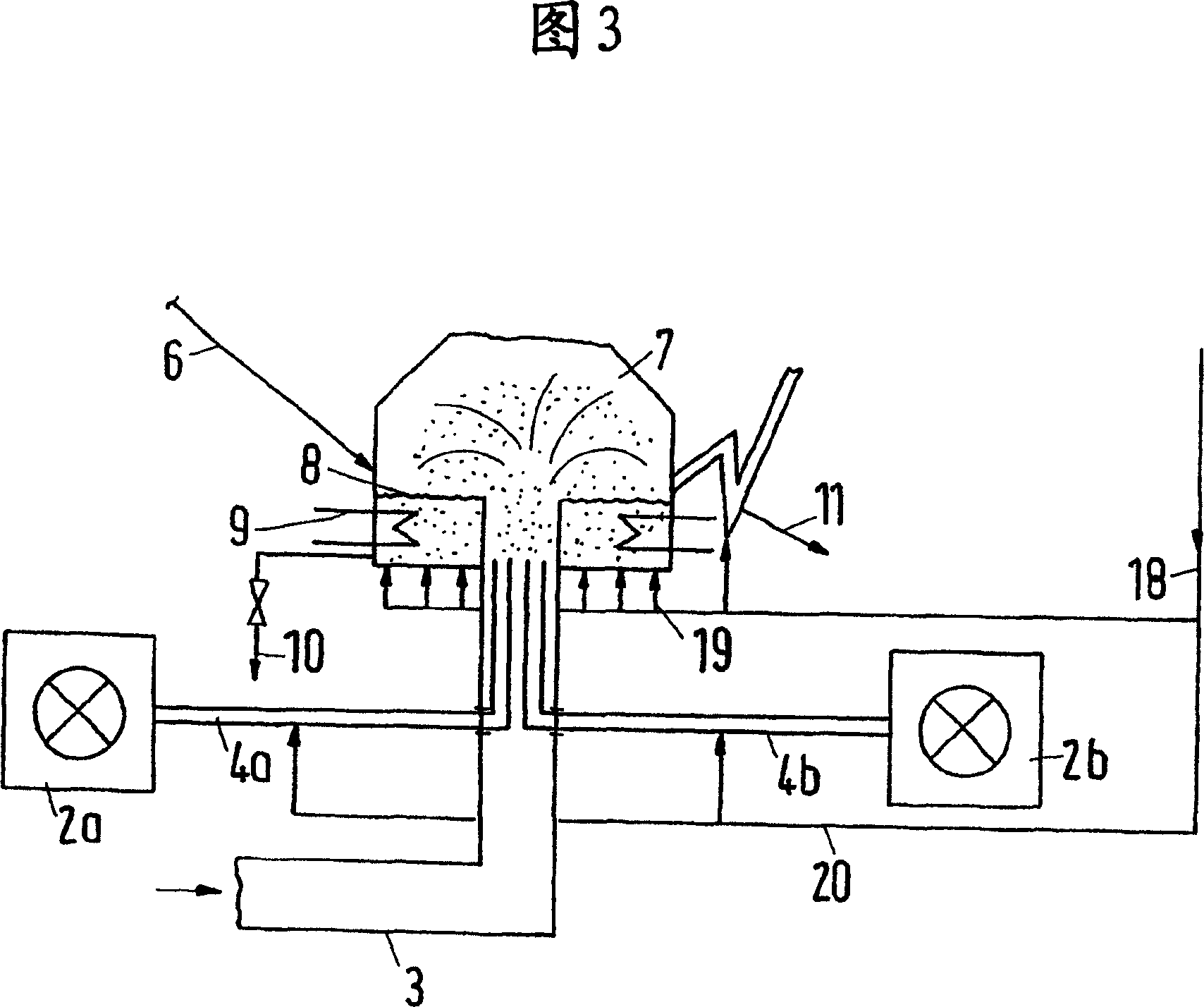

This invention relates to a method for the thermal treatment of granular solids in a fluidized-bed reactor ( 1 ), in which microwave radiation from a microwave source ( 2 ) is fed into the reactor ( 1 ), and to a corresponding plant. To improve the utilization of energy and the introduction of the microwave radiation, a first gas or gas mixture is introduced from below through a preferably central gas supply tube ( 3 ) into a mixing chamber ( 7 ) of the reactor, the gas supply tube ( 3 ) being at least partly surrounded by a stationary annular fluidized bed ( 8 ) which is fluidized by supplying fluidizing gas. The microwave radiation is supplied to the mixing chamber ( 7 ) through the same gas supply tube ( 3 ).

Owner:OUTOKUMPU OY

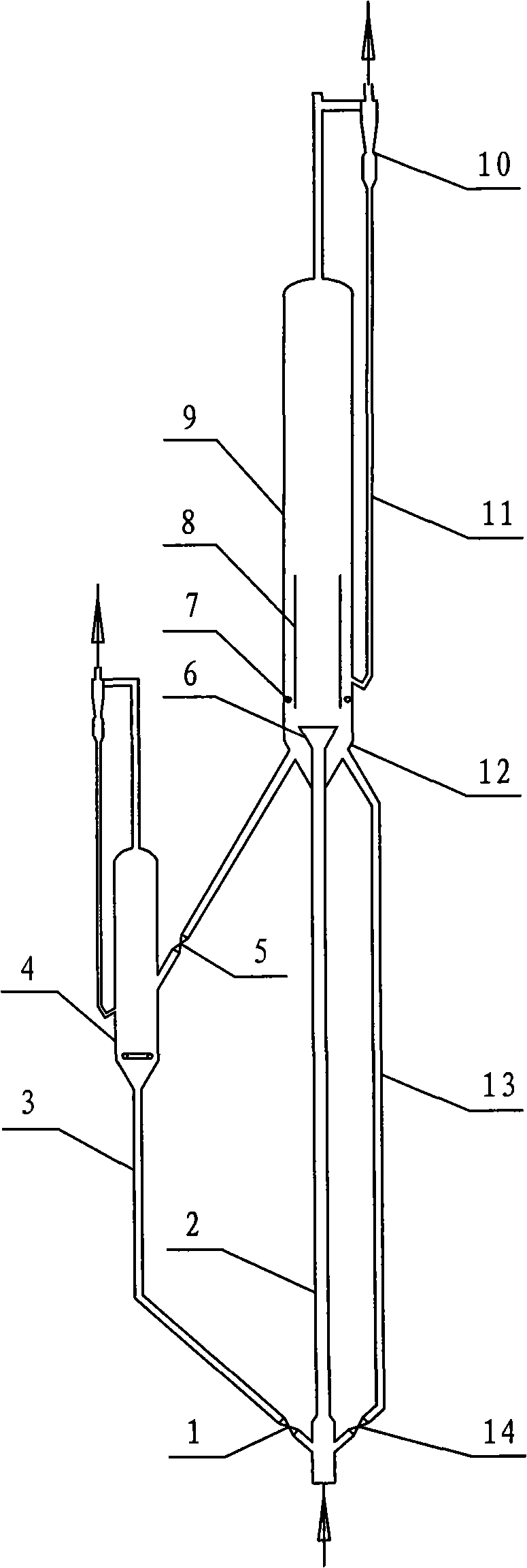

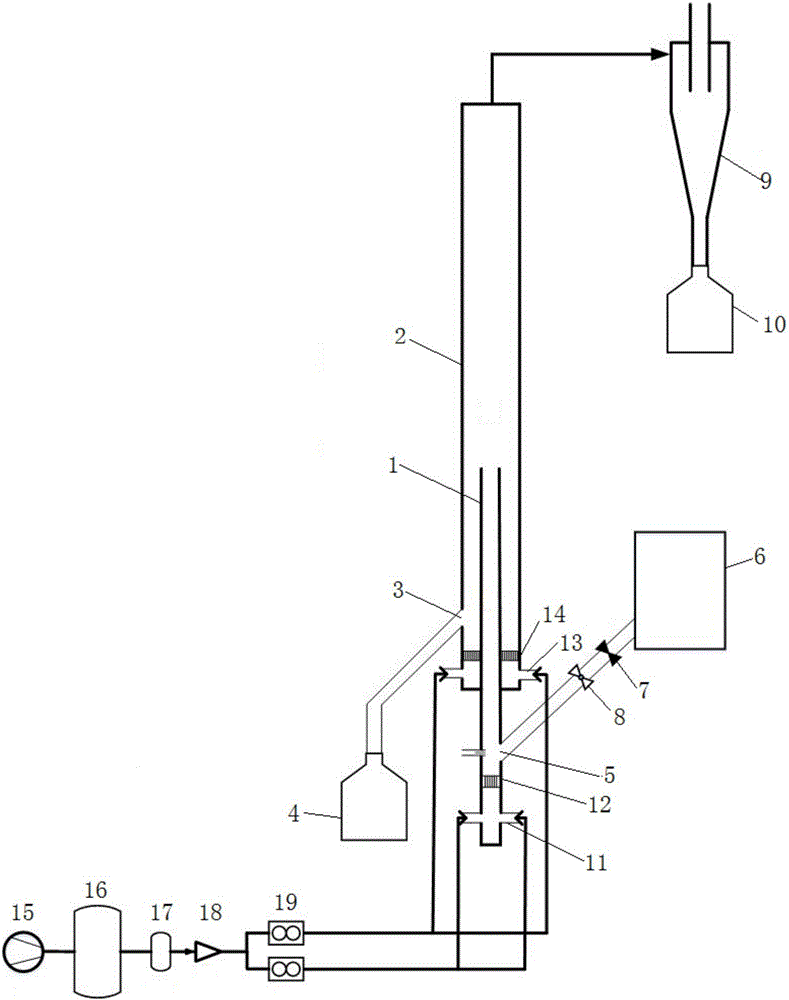

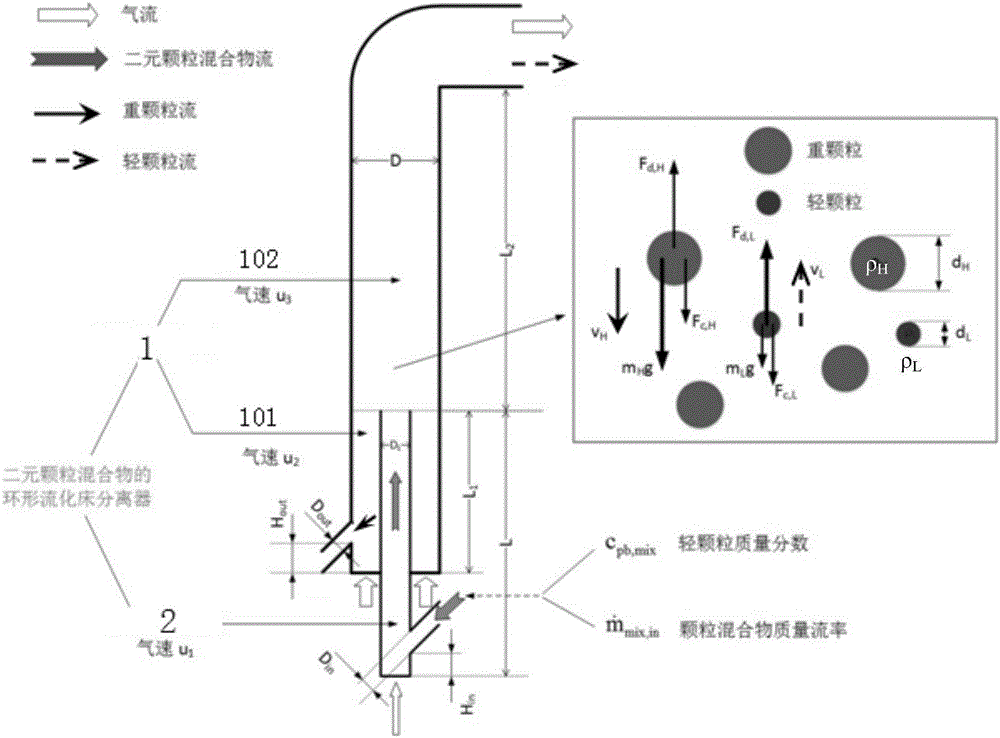

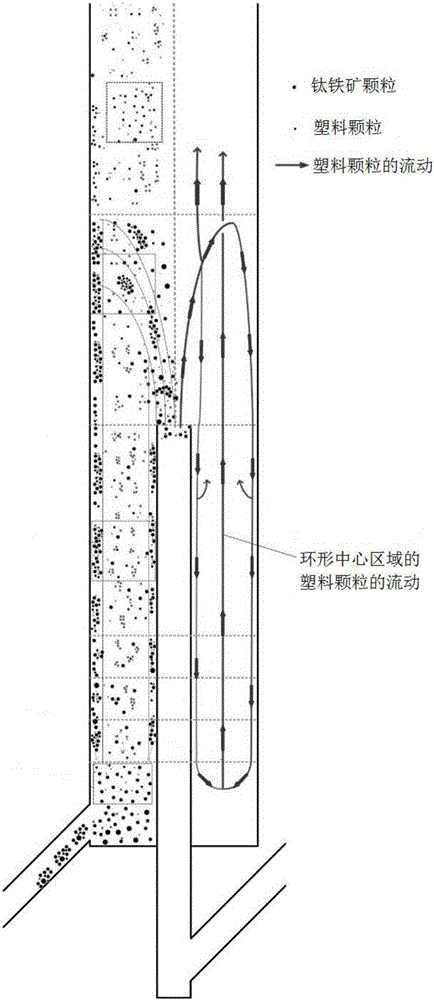

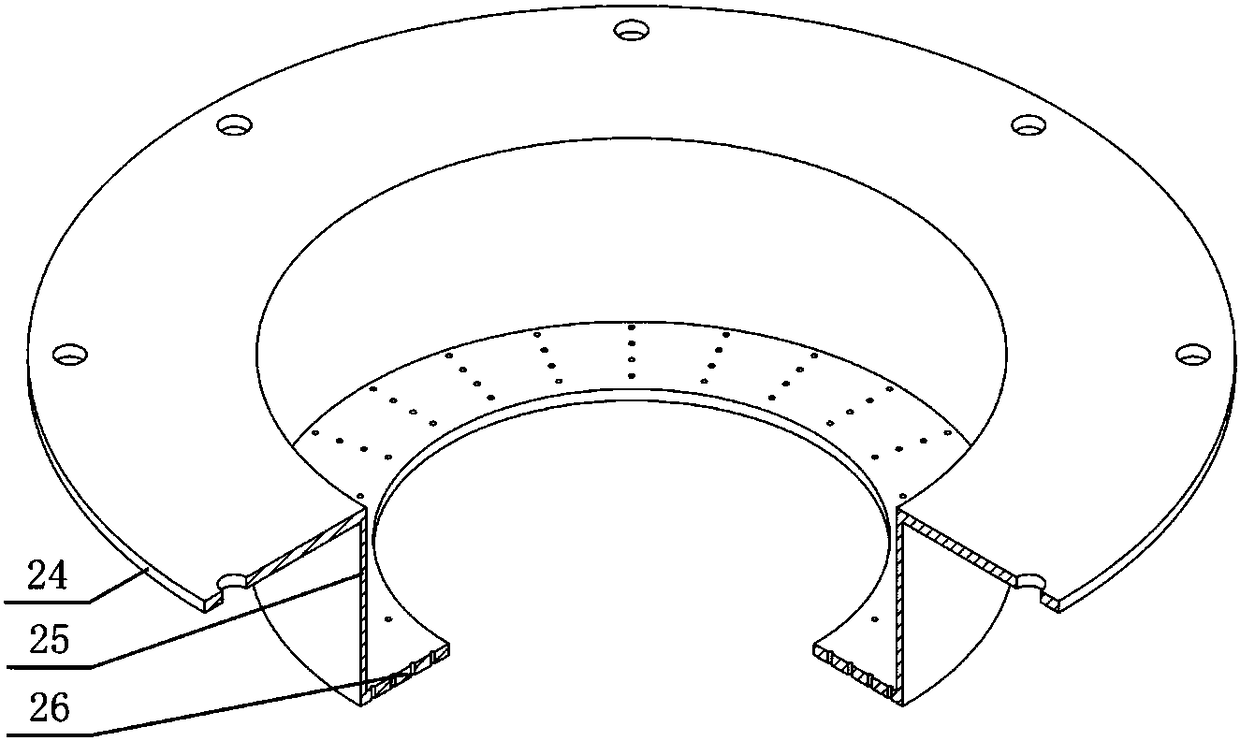

Annular fluidized bed separator of particle mixture

ActiveCN106269508AEfficient separationImprove dispersionGas current separationHeavy particleReactor system

The invention relates to an annular fluidized bed separator of a particle mixture. The upper end of a center lifting pipe extends into an annular fluidized bed by a certain height, so that the annular fluidized bed is divided into an annular area at the lower part and a cylindrical area at the upper part; an air inlet and a wind distribution plate are respectively arranged at the bottoms of the center lifting pipe and the annular fluidized bed; a feed port is formed in the bottom of the center lifting pipe; a heavy particle outlet is formed in the bottom of an annular area of the annular fluidized bed, and is connected with a heavy particle collecting tank; and an airflow outlet at the top of the annular fluidized bed is connected to a light particle collecting tank by a cyclone separator. The particle mixture is quickly fluidized in the center lifting pipe for primary dispersion, and is ascended along with air currents to enter the annular fluidized bed for secondary dispersion. The annular fluidized bed separator can continuously and quickly perform high-efficiency separation for light and heavy particle mixtures under the condition of normal temperature or high temperature. The annular fluidized bed separator can be coupled with a circulating fluidized bed reactor system, and can continuously and stably operate.

Owner:TSINGHUA UNIV

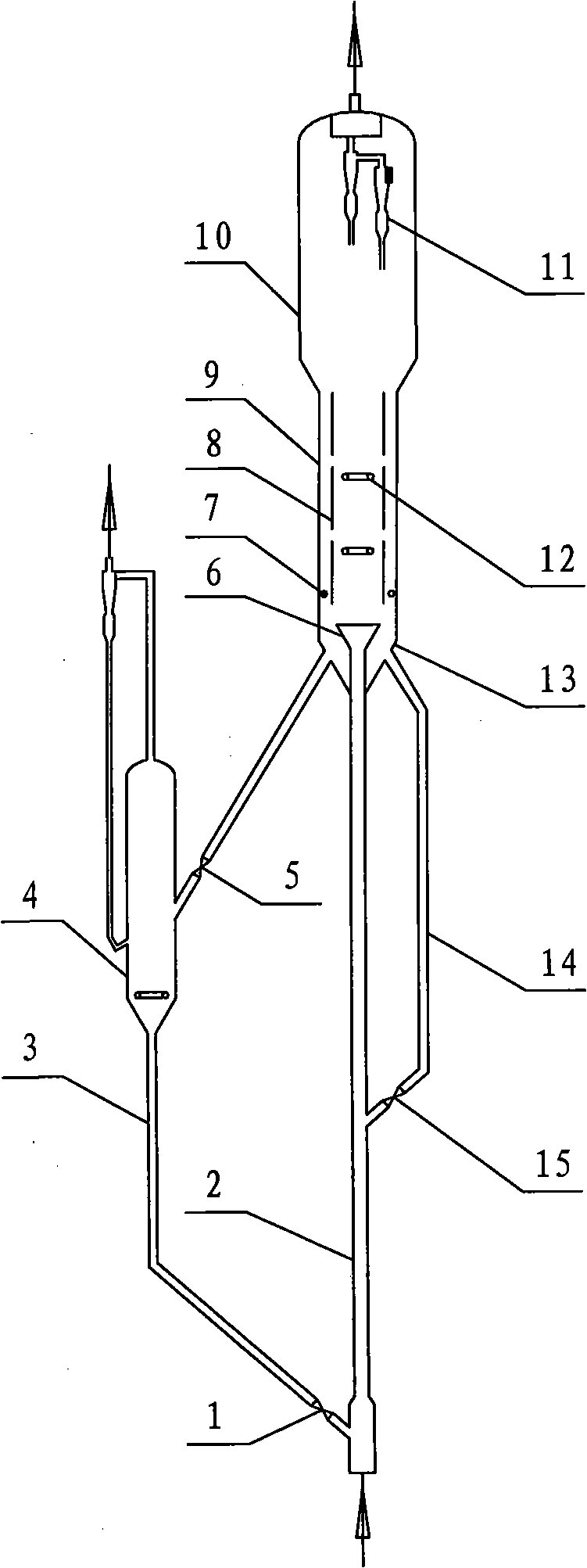

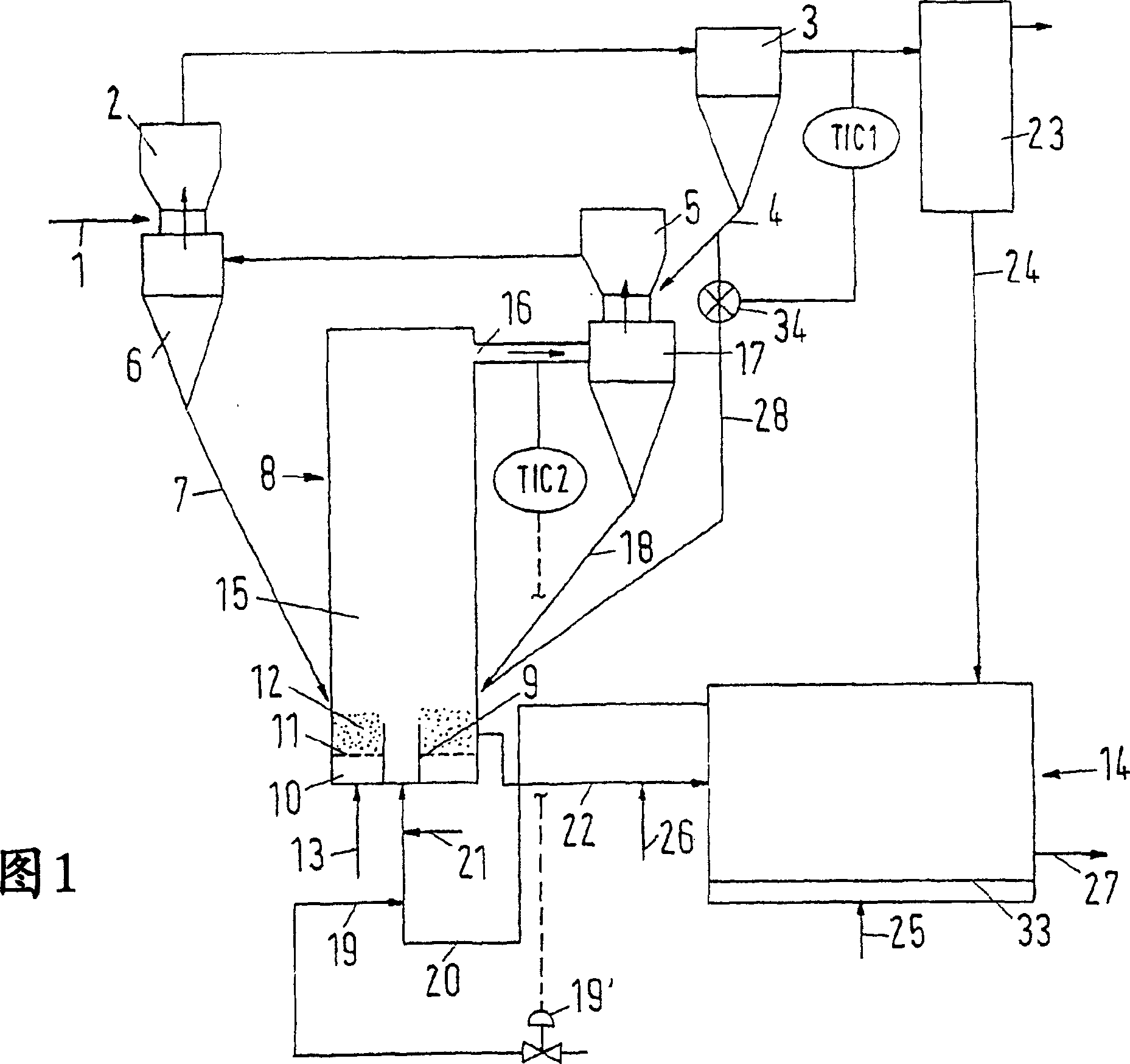

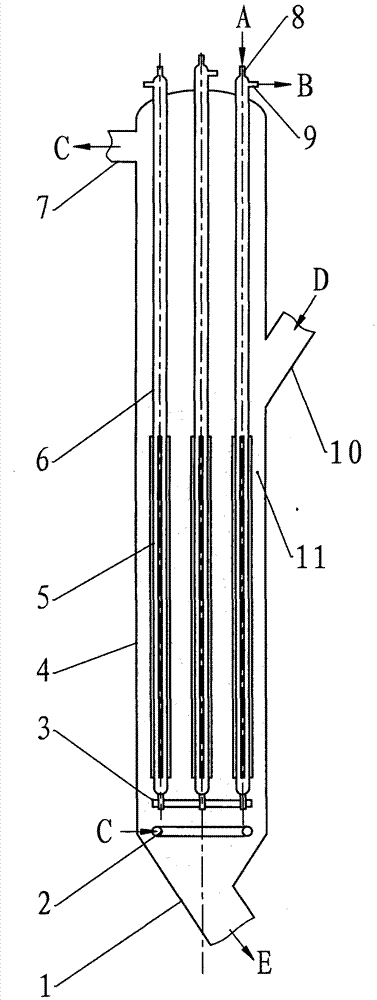

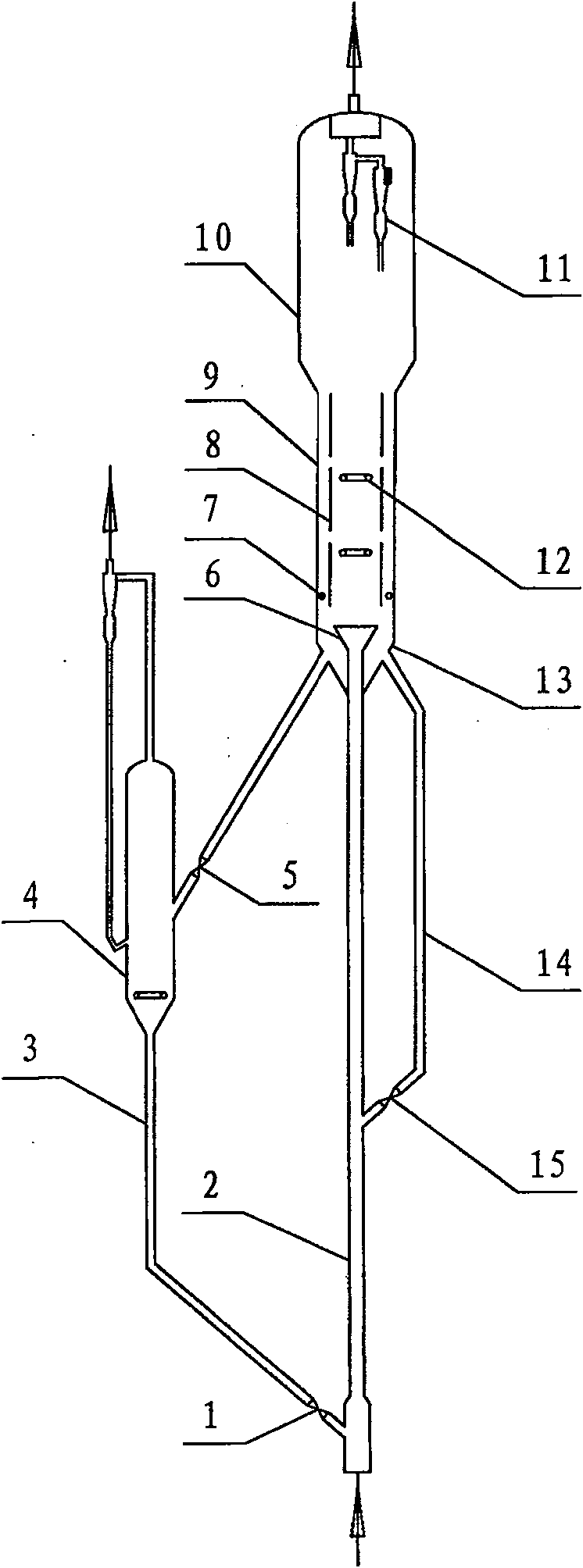

Tubular bilateral fluidized bed rapid pyrolysis device

ActiveCN106010604AIncrease temperature differenceImprove heat transfer performanceDirect heating destructive distillationBiofuelsCounter flowEngineering

The invention relates to a tubular bilateral fluidized bed rapid pyrolysis device, and belongs to the technical field of utilization of renewable energy sources. The rapid pyrolysis device comprises an inner pipe, an outer pipe, a supporting sleeve, an annular air distribution plate, a round air distribution plate, a buffer sleeve, a carrier gas uniform distributor and a spiral plate heat exchanger which are coaxially arranged from top to bottom. According to the rapid pyrolysis device disclosed by the invention, the characteristic of high heat transfer efficiency of the fluidized bed and the wall surface of a container is utilized, the fluidized bed in the inner pipe is used as a reaction zone, an annular fluidized bed is additionally at the periphery as a heating zone, and high-temperature flue gas after combustion is used as fluidized carrier gas, so that the comprehensive heat transfer of a reactor is increased, heat absorbed by biomass pyrolysis can be supplemented, and the whole structure is more compact; meanwhile, the counter-flow type spiral plate heat exchanger is added, so that combustion flue gas waste heat can be fully utilized. By changing the flow of two branches in the rapid pyrolysis device, temperature regulation can be realized on the premise that the unchanged fluidizing gas speed of the reaction zone is ensured, and biomass pyrolysis reactions under different technological conditions can be adapted.

Owner:BEIJING FORESTRY UNIVERSITY

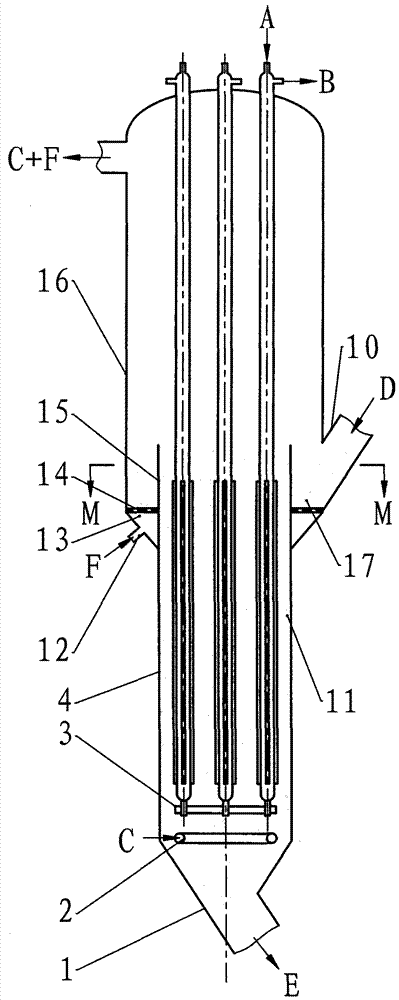

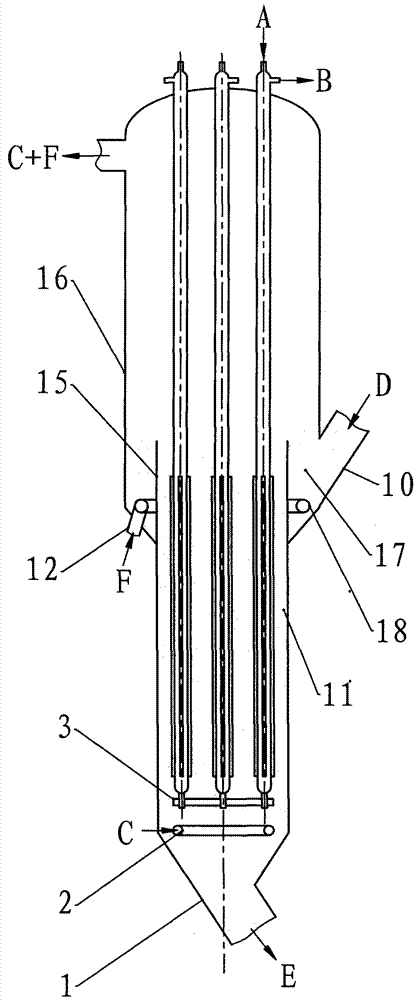

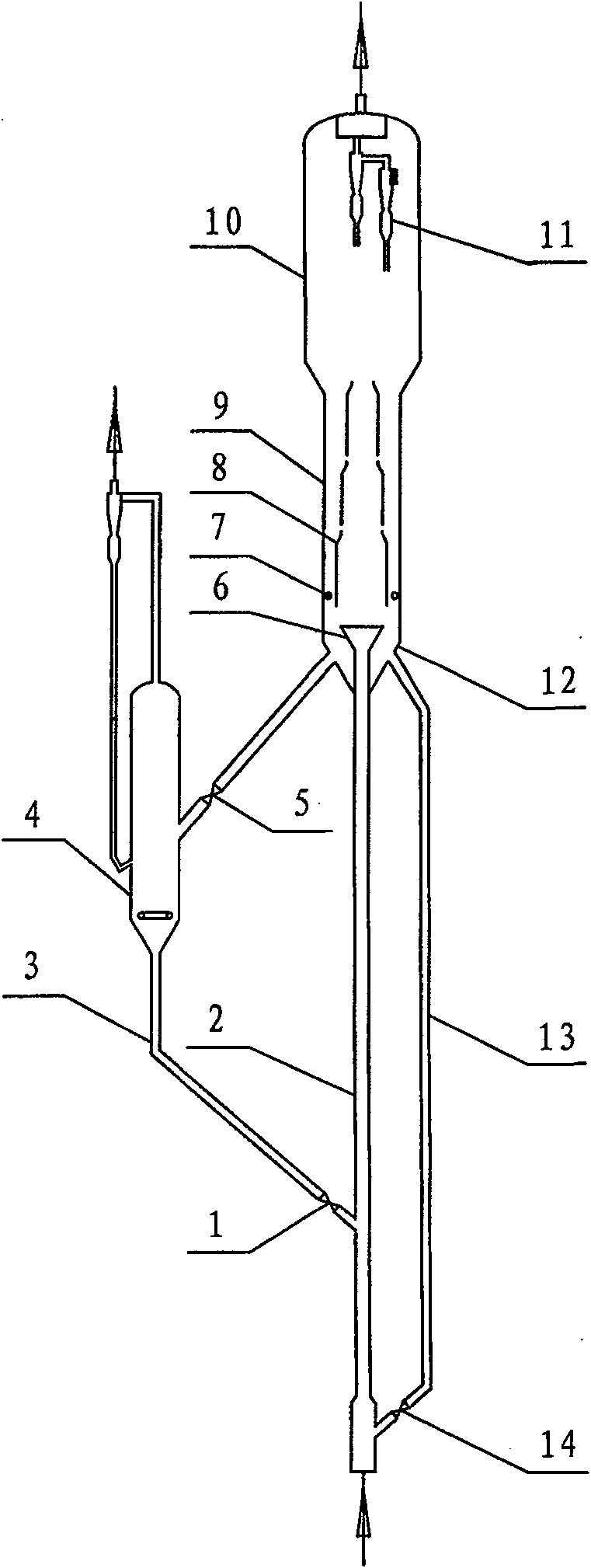

Ring-shaped fluidized bed reactor

InactiveCN102658067AImprove heat transfer efficiencyHigh reaction conversion rateChemical/physical processesCombustion chamberFluidized bed

The invention provides a ring-shaped fluidized bed reactor, belonging to the technical field of fluidized bed reactors. The ring-shaped fluidized bed reactor comprises a top cover, a reactor outer shell, a bottom shell, a support, a combustion chamber, an air distributing plate and an air distributing cabin partition and also comprises circulatory speed increasing pipes and an air distributing cabin, wherein peripheral equipment comprises a cyclone separator and a fan; the lower end of the reactor outer shell is provided with the air distributing plate and then is fixedly connected with the bottom shell; the combustion chamber is sheathed in the reactor outer shell; the axis of the reactor outer shell and the axis of the combustion chamber are consistent, and a ring-shaped reaction area is formed between the reactor outer shell and the combustion chamber; the circulatory speed increasing pipes are uniformly distributed in the combustion chamber, the upper ends of the circulatory speed increasing pipes are communicated with the ring-shaped reaction area, and the lower ends of the circulatory speed increasing pipes penetrate through the air distributing plate; the bottom shell is internally provided with the air distributing cabin partition which is internally provided with the air distributing cabin; and bending pipes on the circumferential surface of the air distributing cabin are communicated with the lower ends of the circulatory speed increasing pipes. The ring-shaped fluidized bed reactor provided by the invention has the advantages that the combustion chamber is arranged in the reactor outer shell and is internally provided with the circulatory speed increasing pipes, so that the space can be saved, the heat loss can be reduced, meanwhile the internal circulation of fluid is enhanced, and the heat transferring efficiency and the reaction conversion rate of the reactor are increased.

Owner:BEIJING FORESTRY UNIVERSITY

Method and plant for producing low-temperature coke

InactiveUS7803268B2Optimize energy usageEfficient executionThermal non-catalytic crackingFluidized bed combustionFluidized bedCoke

The present invention relates to a method and a plant for producing low 15 temperature coke, in which granular coal and possibly further solids are heated to a temperature of 700 to 1050° C. in a fluidized-bed reactor (2) by means of an oxygen-containing gas. To improve the utilization of energy it is proposed to introduce a first gas or gas mixture from below through at least one gas supply tube (3) into a mixing chamber region (8) of the reactor (2), the gas supply tube (3) being at least partly surrounded by a stationary annular fluidized bed (6) which is fluidized by supplying fluidizing gas. The gas velocities of the first gas or gas mixture and of the fluidizing gas for the annular fluidized bed (6) are adjusted such that the Particle-Froude-Numbers in the gas supply tube (3) are between 1 and 100, in the annular fluidized bed (6) between 0.02 and 2 and in the 25 mixing chamber (8) between 0.3 and 30.

Owner:OUTOTEC OYJ

Process and plant for producing metal oxide from metal compounds

InactiveCN1759066AConstant process conditionsExtended dwell timeFluidized bed combustionAluminium compoundsParticulatesChemical compound

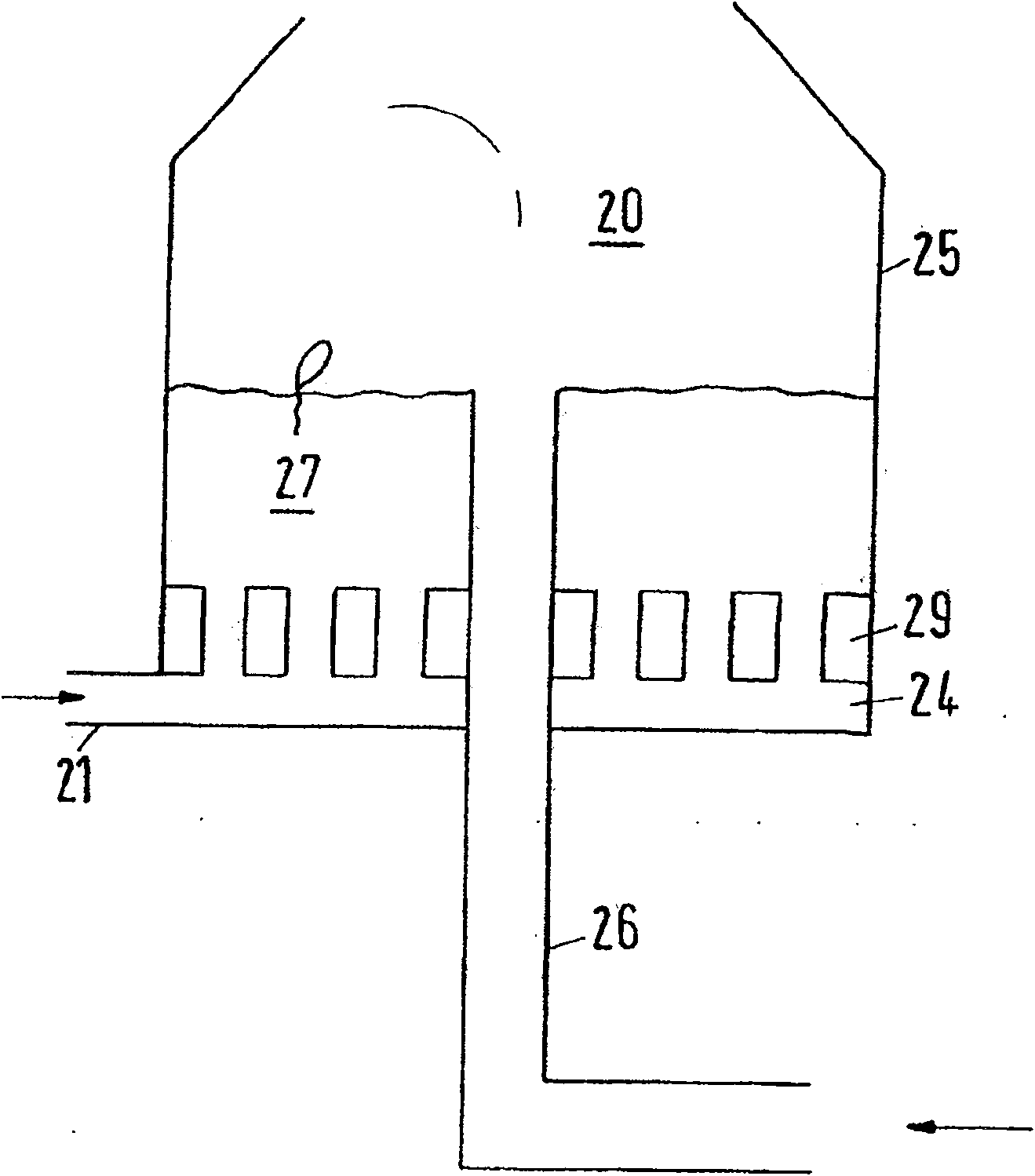

The invention relates to a process for the production of metal oxides from metal compounds, in particular metal hydroxides or metal carbonates, in which the metal compounds are fed into a reactor (25) with a fluidized bed, where they are combusted by fuel It is heated to a temperature of 650-1150° C. to generate metal oxides, and the invention also relates to a corresponding device. In order to improve energy utilization, it is proposed to introduce the first gas or gas mixture from below into the mixing chamber (20) of the reactor (25) through the gas supply pipe (26), which is at least partially fixed by supplying fluidized gas The annular fluidized bed (27) is surrounded by adjusting the gas velocity of the first gas or gas mixture and the fluidizing gas for the annular fluidized bed (27), so that the particle Froude number in the gas supply pipe (26) is 1- 100, the Froude number of particles in the annular fluidized bed (27) is 0.02-2, and the Froude number of particles in the mixing chamber (20) is 0.3-30.

Owner:OUTOKUMPU OY

An external heat extractor for catalytic cracking with particle predistribution

InactiveCN103113914BImprove reliabilityExtended service lifeFluidised bed heat exchangersParticulatesFluidized bed

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

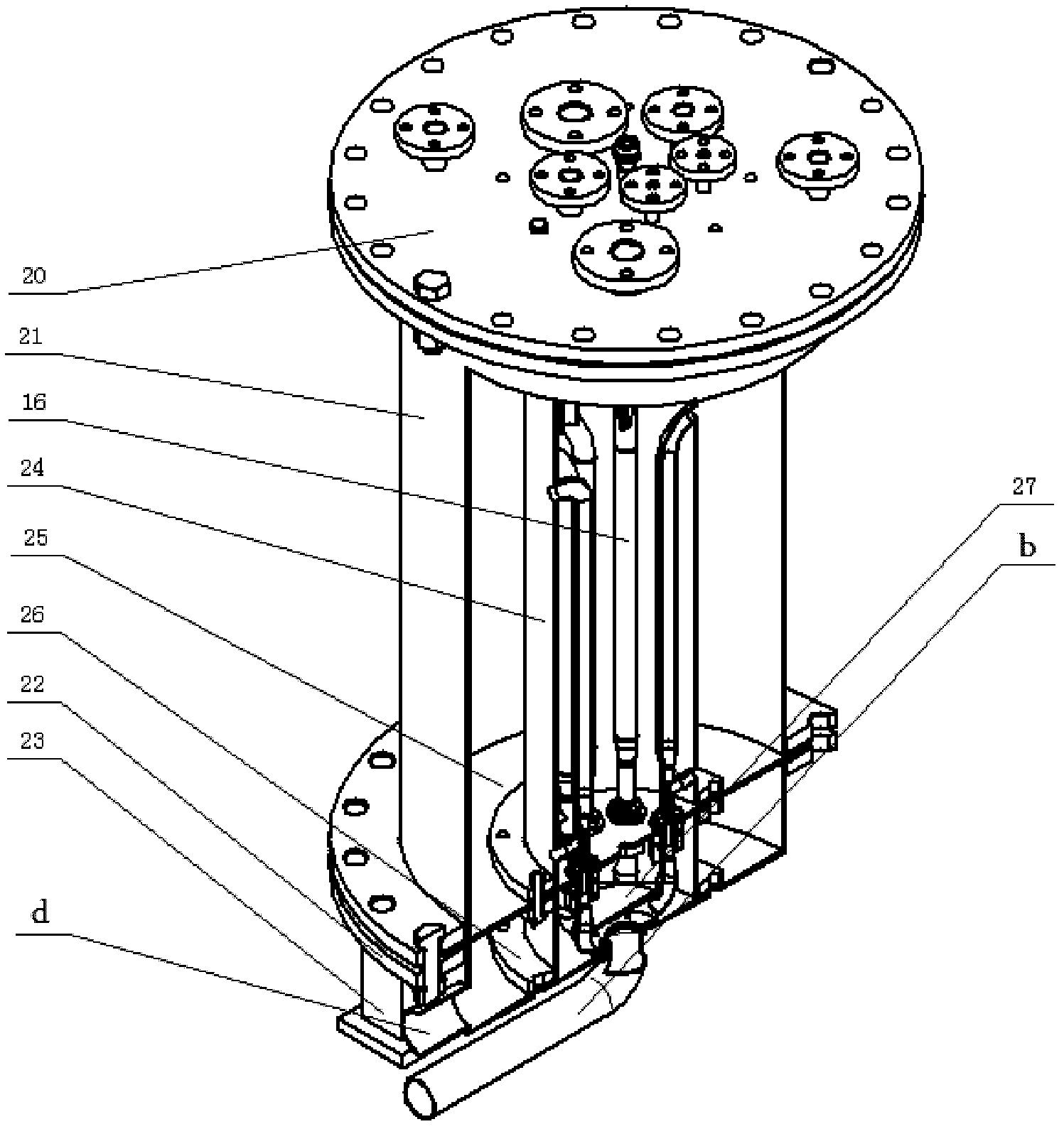

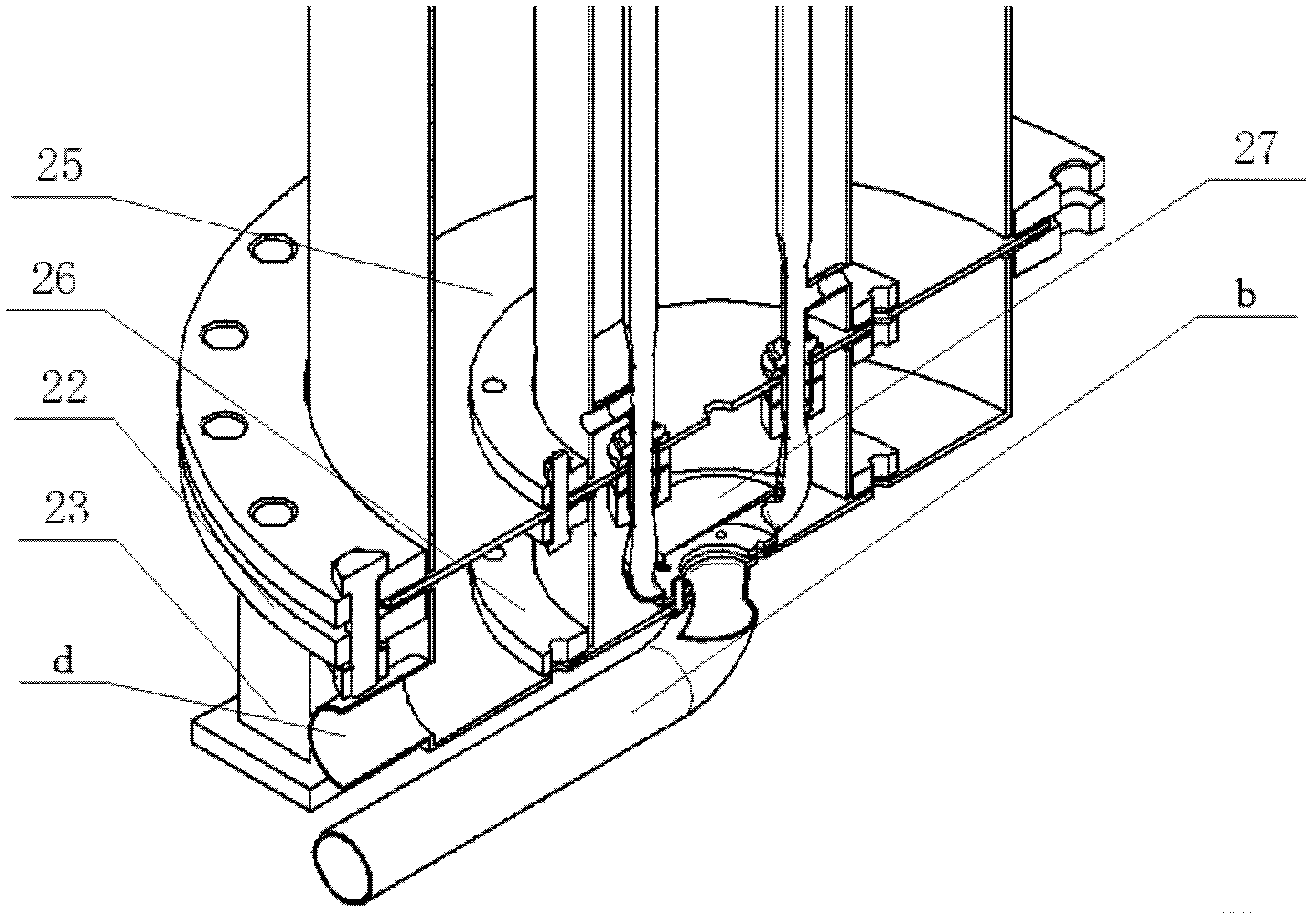

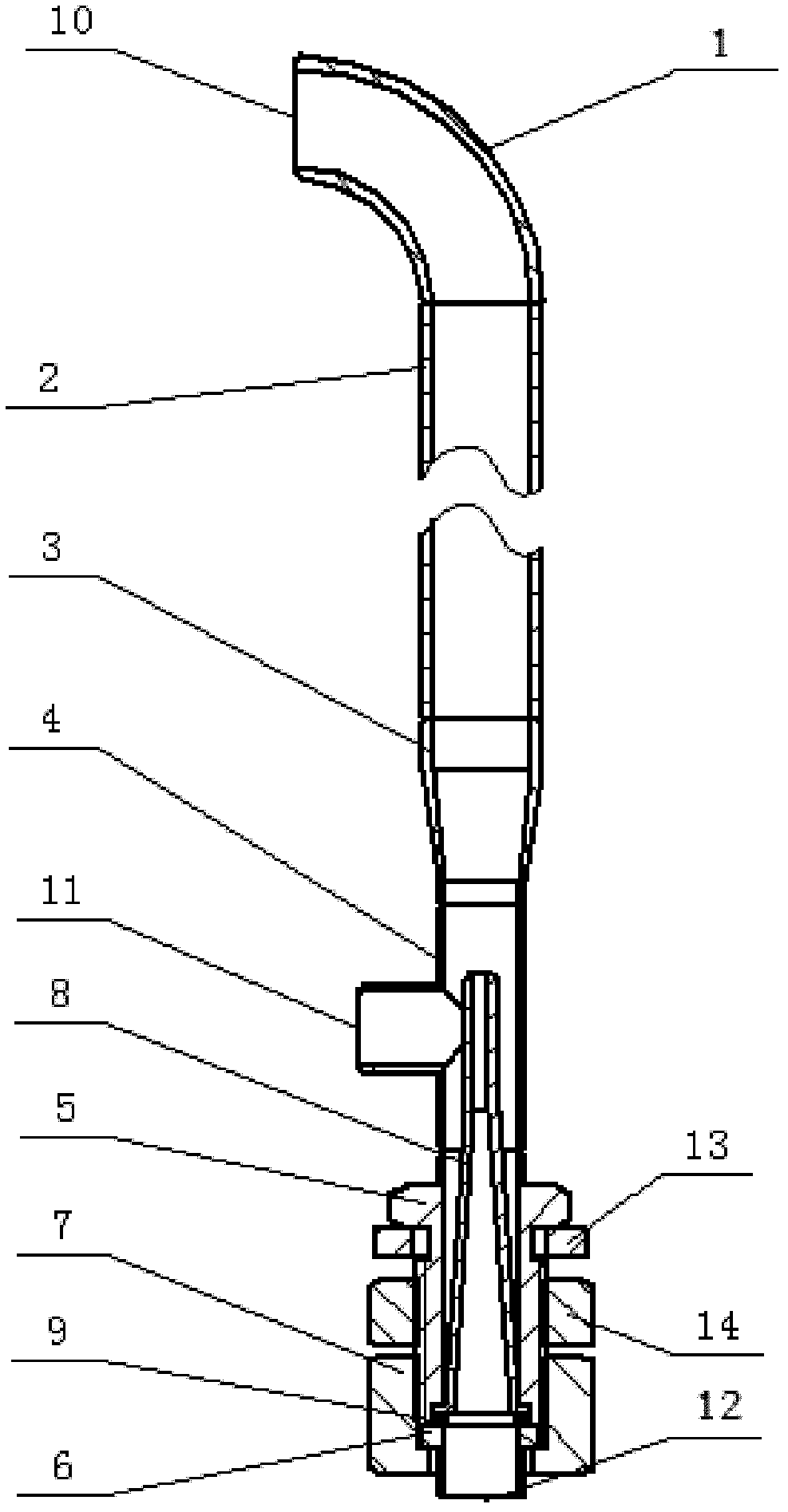

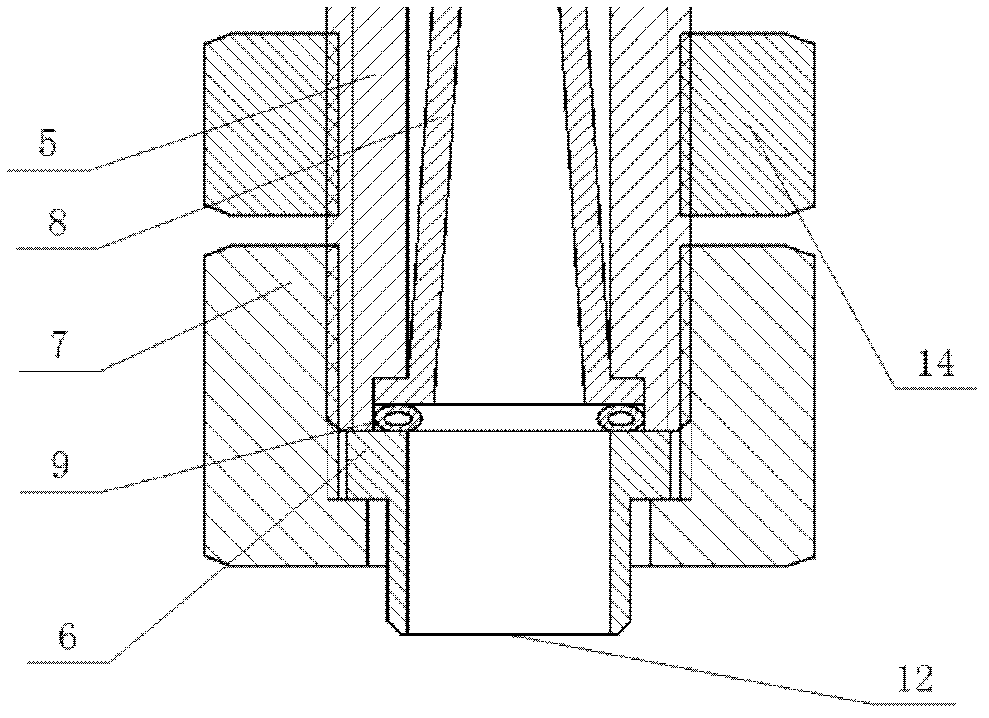

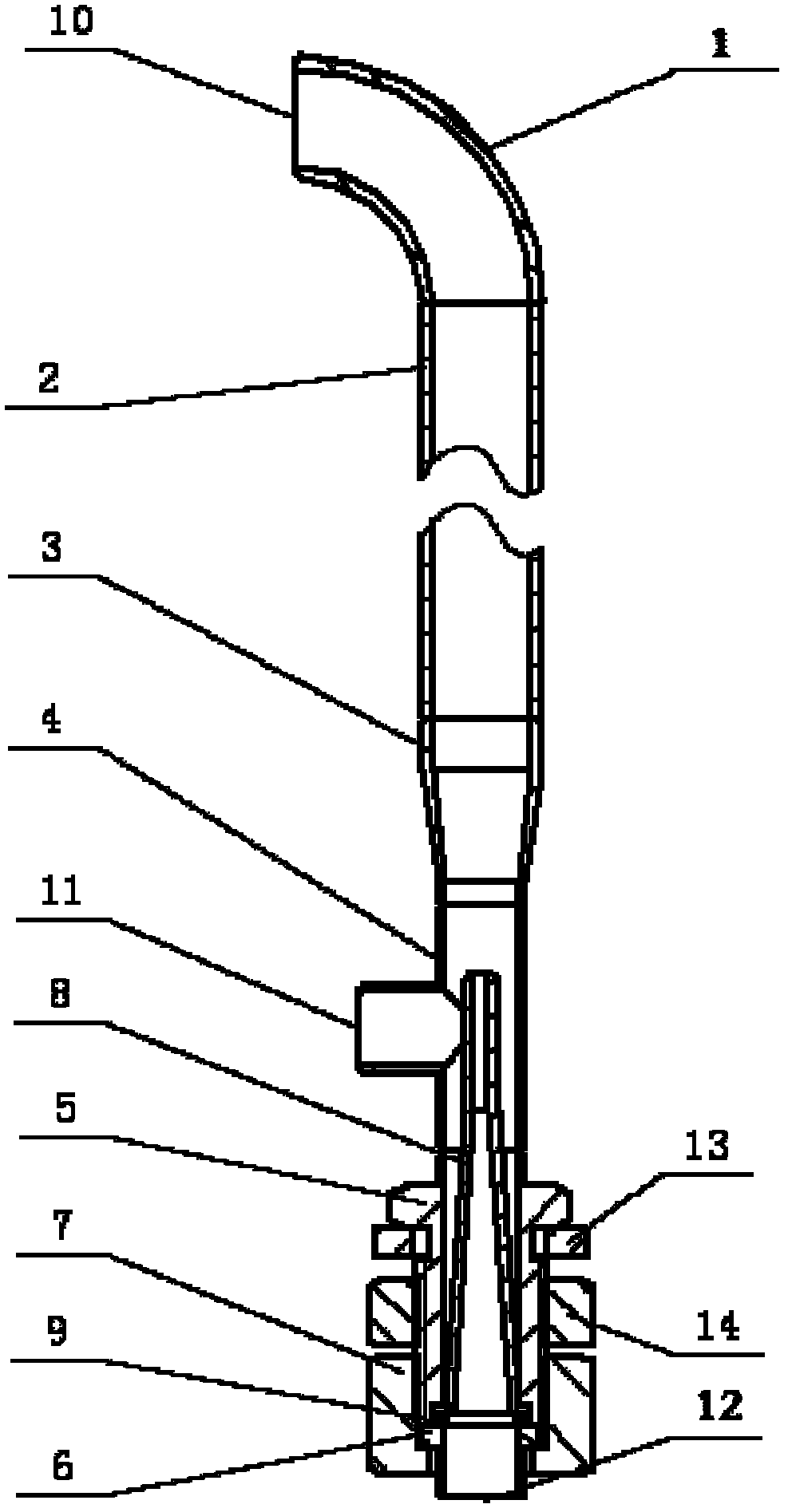

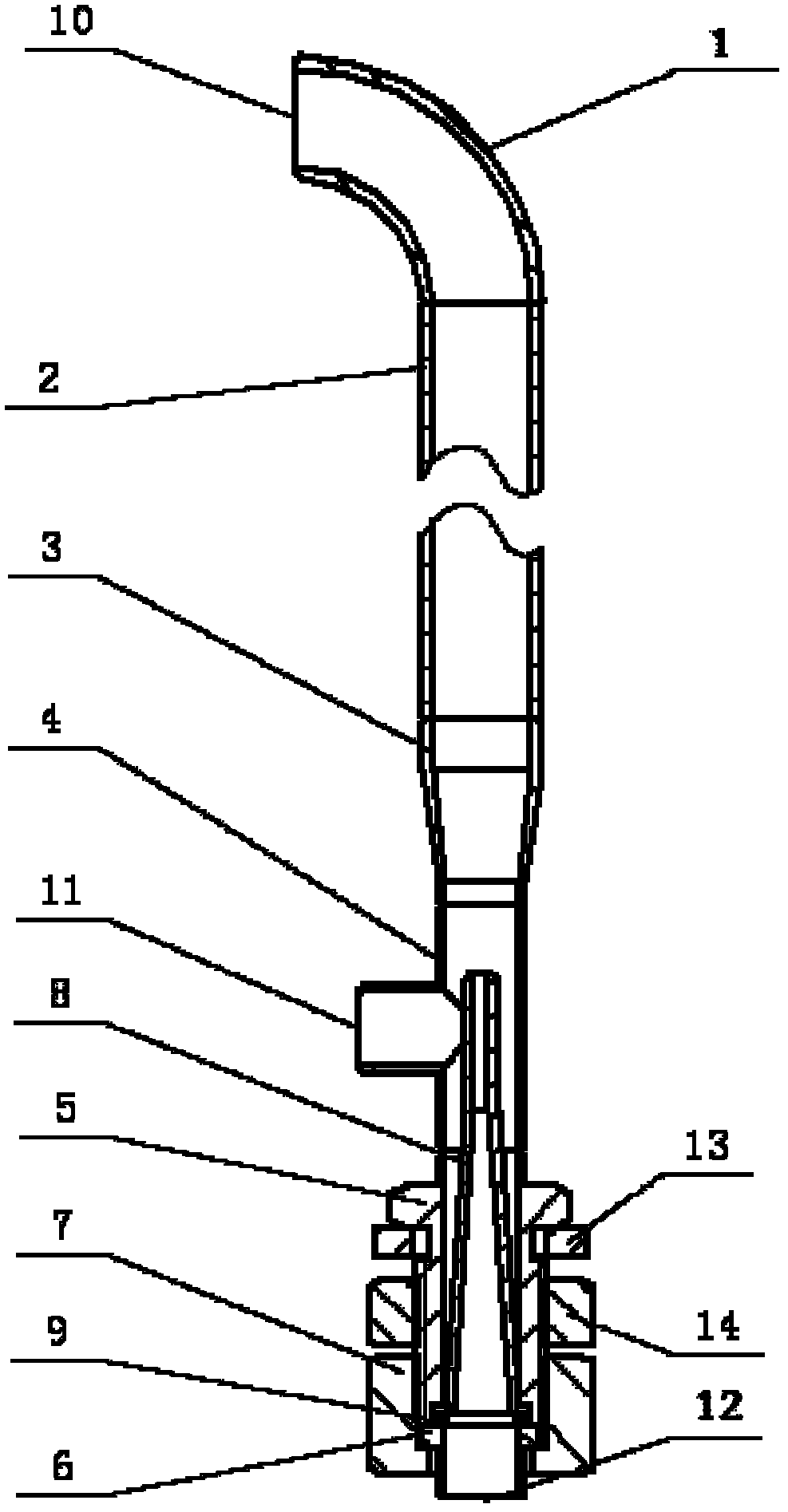

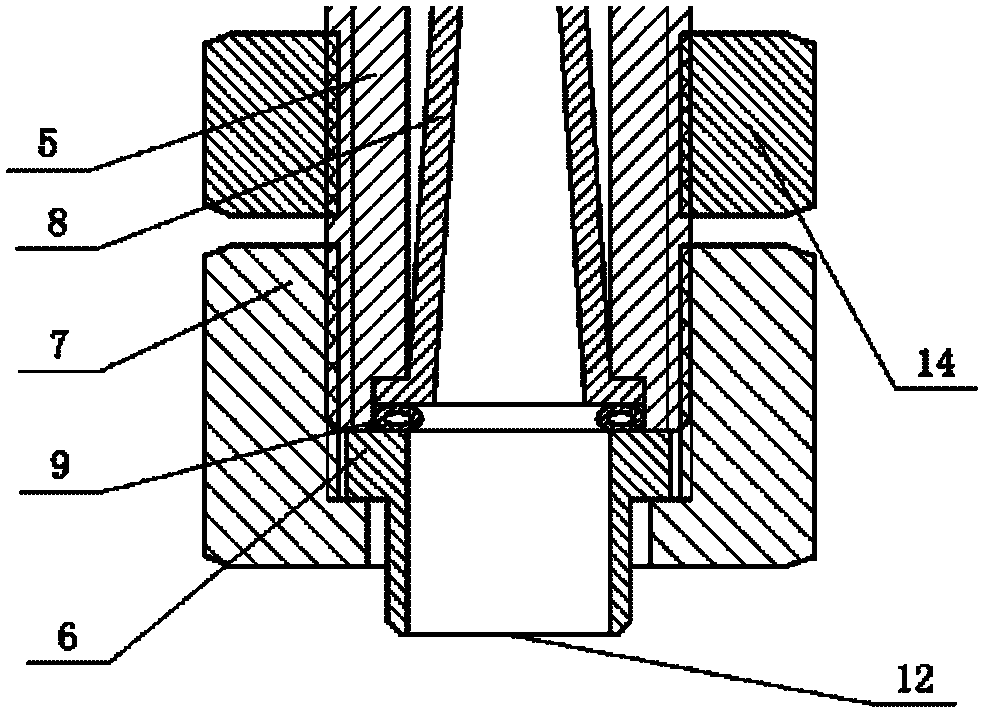

Circulating accelerating pipe used in annular fluidized bed reactor

InactiveCN102641695APromote circulationIncrease the number ofChemical/physical processesSpray nozzleAnnular fluidized bed

The invention provides a circulating accelerating pipe used in an annular fluidized bed reactor, which comprises a 90-degree elbow pipe, a riser pipe, a reducing joint, a three-way pipe, a straight-through pipe joint, a connecting pipe, a first nut, a conical pipe, an O-shaped ring, a gasket and a second nut. The upper end of a main pipe of the three-way pipe is vertically successively connected with the reducing joint, the riser pipe and the 90-degree elbow pipe, the lower end of the main pipe of the three-way pipe is vertically successively connected with the straight-through pipe joint and the connecting pipe, the straight-through pipe joint is fixedly connected with the connecting pipe via the first nut, the conical pipe is mounted in the straight-through pipe joint, the lower end of the conical pipe is clamped in a sunken table at the lower end of a center through hole of the straight-through pipe joint, the top end of the conical pipe is higher than the axis of a side branch pipe of the three-way pipe, the O-shaped ring is disposed between the lower end surface of the conical pipe and the upper end surface of the connecting pipe, the lower end of the connecting pipe is a spraying nozzle, and the side branch pipe of the three-way pipe is an air inlet of the circulating accelerating pipe. The conical pipe is added in the circulating accelerating pipe, so that fluid circulation can be accelerated, and the conversion rate of objective products is improved.

Owner:BEIJING FORESTRY UNIVERSITY

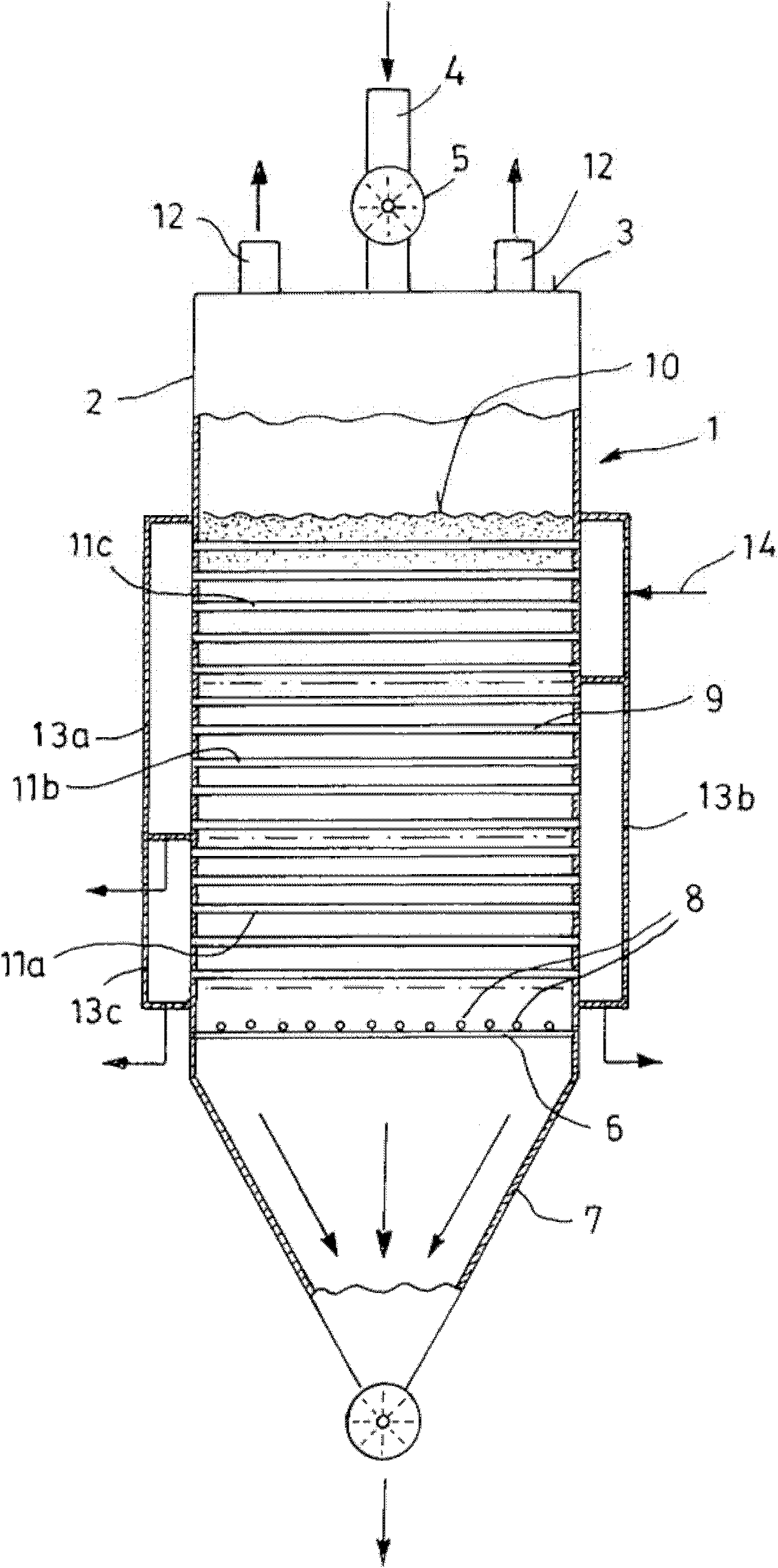

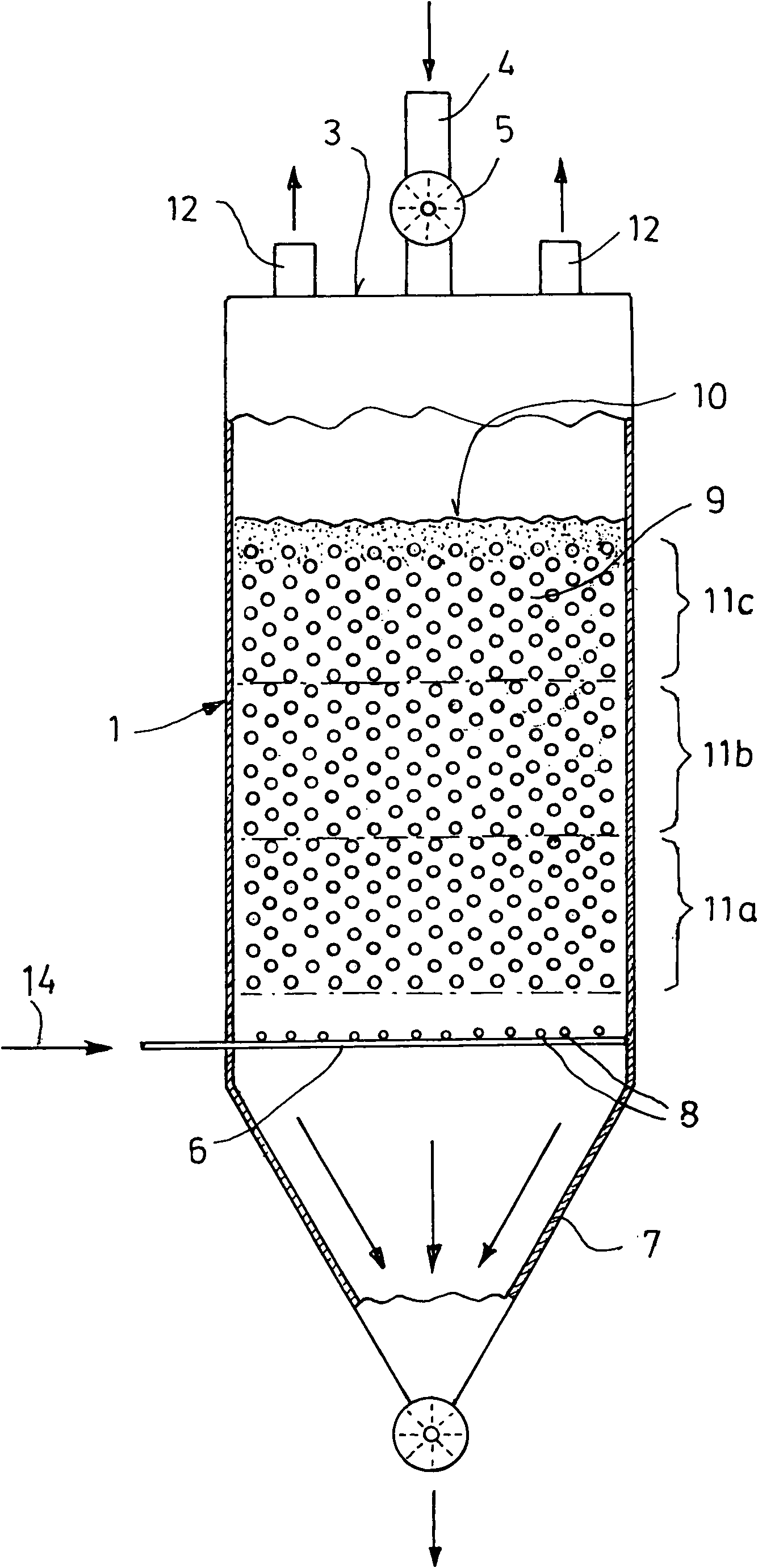

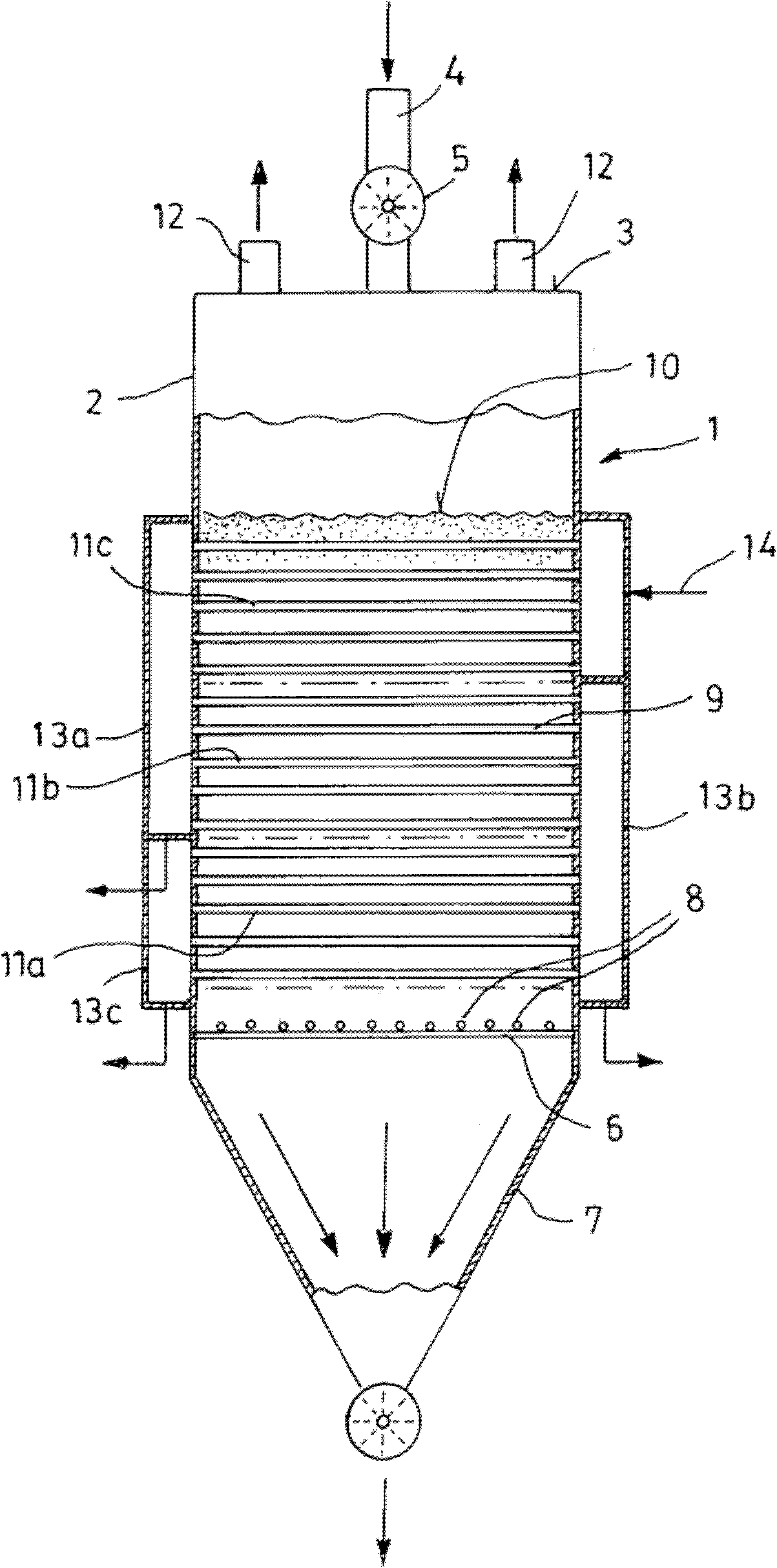

Indirectly heated fluidized bed dryer

InactiveCN102224388AIncreased flow cross sectionShorten speedDrying solid materials with heatFluidised bed heat exchangersFluidized bed dryingProcess engineering

The invention relates to an indirectly heated fluidized bed dryer (1) for drying wet, fine-grained bulk materials. The fluidized bed dryer (1) comprises a housing (2) having a gassing floor (6) having heat exchanger fixtures extending above the gassing floor (6) and at least one discharge device below the gassing floor (6) for the dried bulk material. The fluidized bed dryer (1) according to the invention is characterized in that the usable flow cross section of the housing (2) in the area of the heat exchanger fixtures decreases over the height of the heat exchanger fixtures in the flow direction of the fluidizing material, as the cross-sectional area of the housing remains the same. In this manner, an unallowable expansion of the stationary fluidized bed is reliably prevented.

Owner:RWE POWER AKTIENGESELSCHAFT

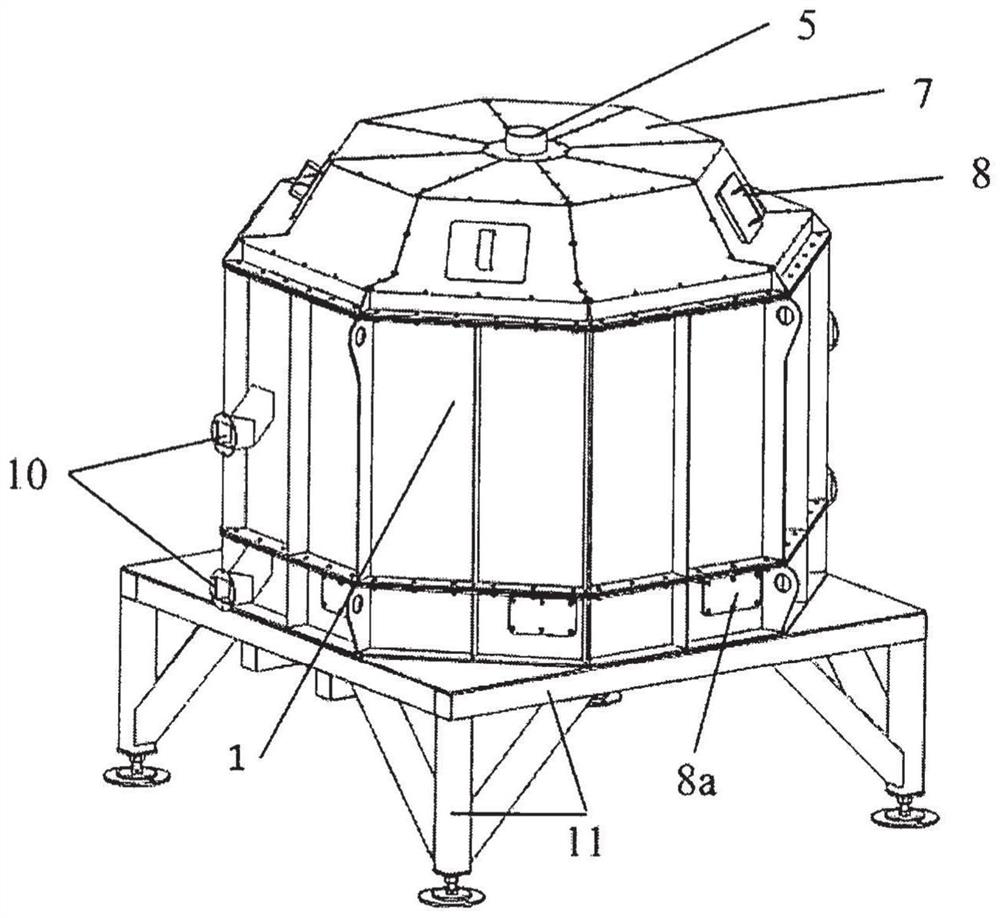

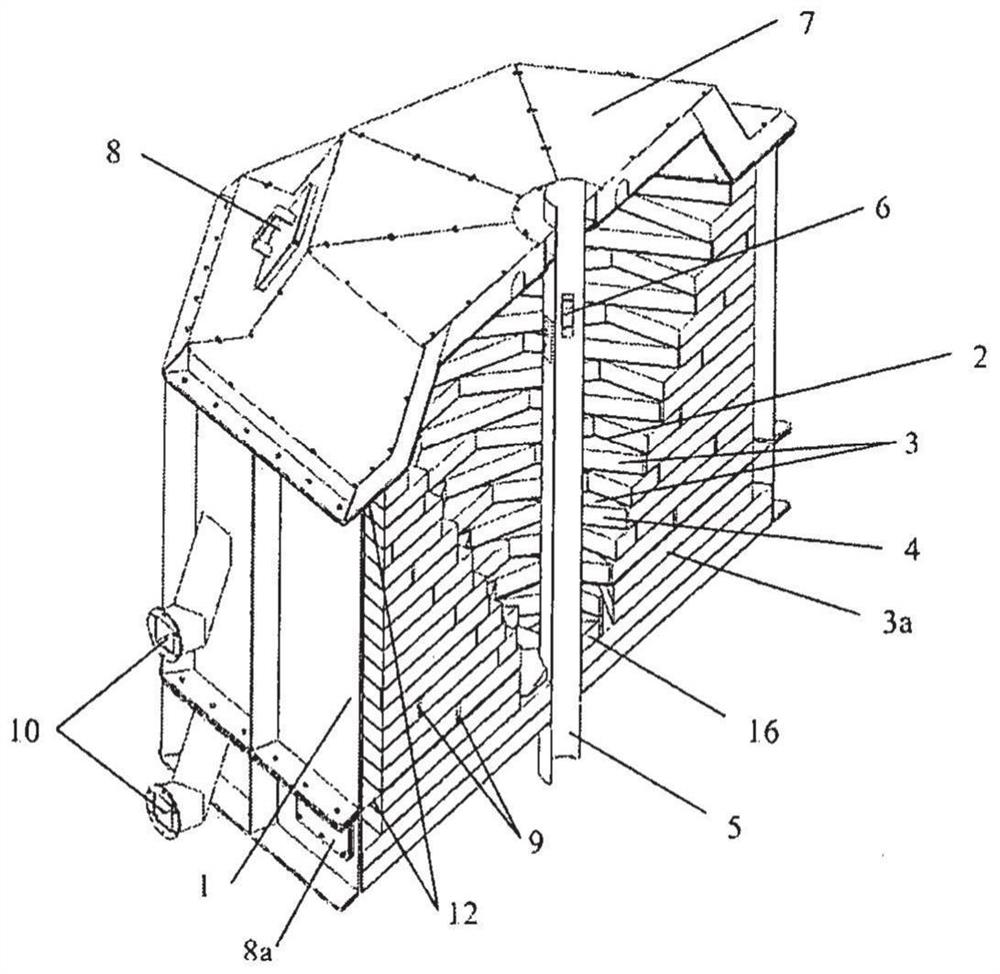

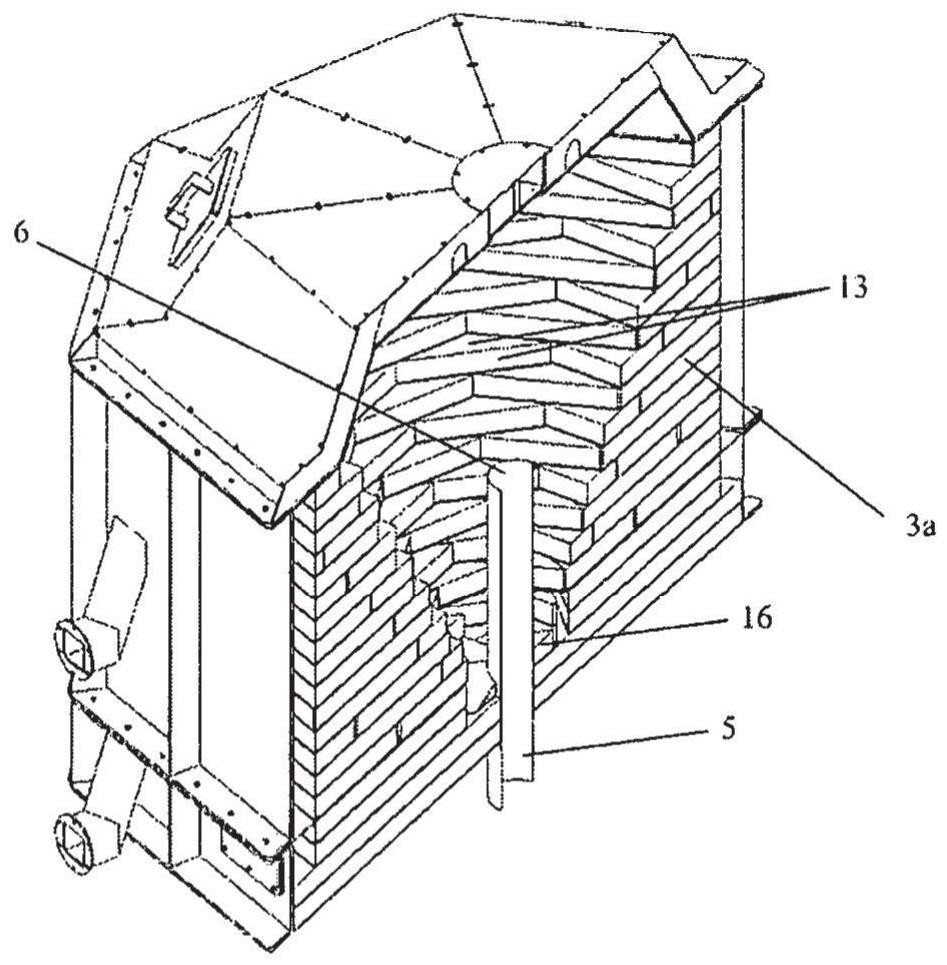

Device with an annular spouted fluidized bed and operating method therefor

PendingCN111655364AFluidized bed combustionDrying solid materials with heatChemical reactionEngineering

A device with an annular spouted fluidized bed and an operating method therefor are claimed. The device according to the invention can be used for carrying out the majority of technical processes carried out in fluidized bed devices, inter alia for purifying gas mixtures, drying materials, pyrolysis, gasification, and combusting solid fuels such as industrial waste, agricultural waste, MSW, coal,sewage sludge, and aerobic and anaerobic digestion reactor waste, and also for carrying out other chemical reactions carried out in a fluidized bed. A reaction chamber of the present device with a rotating annular spouted fluidized bed has, throughout at least a part of its height, a downwardly tapering funnel shape with a stepped interior surface. The shape of the reaction chamber, together withthe tangential admission thereto of fluidized and other gases, makes it possible to create, in the reaction chamber, an adjustable toroidal fluidized bed, in which the rate of rotation of the particles of the material undergoing treatment can be adjusted in both the horizontal and vertical planes, and also makes it possible to control the dwell time of particles of different sizes in the reactionzone, the intensity with which materials are treated, and other process parameters.

Owner:埃姆皮瑞欧有限公司

Method and plant for the conveyance of fine-grained solids

ActiveCN1767893AEasy to operateDirect contact heat exchangersChemical/physical processesFluidized bedProcess engineering

The invention relates to a method and a corresponding device for conveying fine-grained solids in a fluidized bed reactor. It is proposed to introduce the first gas or gas mixture from below into the mixing chamber (7) of the reactor (1) through a central tube (3) which is at least partially fluidized by a fixed annular fluidized bed ( 10) Surrounded. Adjust the gas velocity of the first gas or gas mixture and the fluidizing gas for the annular fluidized bed (10) so that the particle Froude number in the central tube (3) is 1-100, the annular fluidized bed (10) The particle Froude number in the mixing chamber (7) is 0.02-2, and the particle Froude number in the mixing chamber (7) is 0.3-30.

Owner:METSO OUTOTEC (FINLAND) OY

Method and plant for the heat treatment of solids containing iron oxide using a fluidized bed reactor

InactiveCN100529118CEnhanced mass transferImprove heat transfer performanceFluidised-bed furnacesChemical/physical processesPhysical chemistryThermal treatment

The invention relates to a method and an apparatus for the thermal treatment of iron oxide-containing solids, wherein the fine-grained solids are heated to a temperature of 700-1150° C. in a fluidized bed reactor (8). In order to improve energy utilization, it is proposed to introduce the first gas or gas mixture from below into the mixing chamber region (15) of the reactor (8) via at least one gas supply pipe (9) which is at least partially fed with a fluidizing gas flow Surrounded by a fixed annular fluidized bed (12). Adjust the gas velocity of the first gas or gas mixture and the fluidization gas used for the annular fluidized bed (12), so that the particle Froude number in the gas supply pipe (9) is 1-100, the annular fluidized bed (12) The particle Froude number in the mixing chamber (15) is 0.02-2, and the particle Froude number in the mixing chamber (15) is 0.3-30.

Owner:METSO OUTOTEC (FINLAND) OY

Method and plant for the heat treatment of solids containing iron oxide

ActiveUS8021600B2Improve the situationFluidised-bed furnacesChemical/physical processesFluidized bedProcess engineering

A plant for the heat treatment of solids containing iron oxide. The plant includes a reactor including a fluidized bed reactor. The reactor includes a gas supply system disposed in the reactor, a stationary annular fluidized bed which at least partly surrounds the gas supply system, and a mixing chamber. The gas supply system is configured so that gas flowing through the gas supply system entrains solids from the stationary annular fluidized bed into the mixing chamber.

Owner:OUTOTEC OYJ

A casing type double-sided fluidized bed rapid pyrolysis device

ActiveCN106010604BIncrease temperature differenceImprove heat transfer performanceDirect heating destructive distillationBiofuelsCounter flowEngineering

The invention relates to a tubular bilateral fluidized bed rapid pyrolysis device, and belongs to the technical field of utilization of renewable energy sources. The rapid pyrolysis device comprises an inner pipe, an outer pipe, a supporting sleeve, an annular air distribution plate, a round air distribution plate, a buffer sleeve, a carrier gas uniform distributor and a spiral plate heat exchanger which are coaxially arranged from top to bottom. According to the rapid pyrolysis device disclosed by the invention, the characteristic of high heat transfer efficiency of the fluidized bed and the wall surface of a container is utilized, the fluidized bed in the inner pipe is used as a reaction zone, an annular fluidized bed is additionally at the periphery as a heating zone, and high-temperature flue gas after combustion is used as fluidized carrier gas, so that the comprehensive heat transfer of a reactor is increased, heat absorbed by biomass pyrolysis can be supplemented, and the whole structure is more compact; meanwhile, the counter-flow type spiral plate heat exchanger is added, so that combustion flue gas waste heat can be fully utilized. By changing the flow of two branches in the rapid pyrolysis device, temperature regulation can be realized on the premise that the unchanged fluidizing gas speed of the reaction zone is ensured, and biomass pyrolysis reactions under different technological conditions can be adapted.

Owner:BEIJING FORESTRY UNIVERSITY

Device for improving pipe and gas-solid circumfluence bed coupling reaction

ActiveCN100577276CExtended reaction timeReduce resistanceFluidized bed combustionChemical/physical processesChemical industrySystem pressure

The invention provides a lift pipe and air-solid circulation bed coupling reaction device which at least includes a lift pipe, a shower head distributor, a guide cylinder, an annular space air distribution ring, an outer cylinder, an inner circulation pipe, an outer circulation fluidized bed, an outer circulation pipe and an air-solid separating system. Particles and air are transmitted upwards along the lift pipe, pass through the shower head distributor and enter the upper annular fluidized bed to form a central air lifting type circumfluence between the guide cylinder and the annular space. Part of the particles below the outer cylinder enters the lift pipe through the inner circulation pipe and another part enters the outer circulation fluidized bed to be mixed with the original particles in the outer circulation fluidized bed; the mixed particles enter the lift pipe through the outer circulation pipe; the positions where the inner circulation pipe and the outer circulation pipe enter the lift pipe can be flexibly arranged; the lift pipe and air-solid circulation bed coupling reaction device overcomes the limitations of system pressure balance and short reaction time and has the advantages that each area is flexible to be operated and controlled, the air-solid contact efficiency of the annular fluidized bed is high and the resistance above the distributor is small, etc. The device can be broadly applied to the fields of energy supply, chemical industries and particle combustion, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Indirectly heated fluidized bed dryer

InactiveCN102224388BSpeed up the flowReduce dustDrying solid materials with heatFluidised bed heat exchangersFluidized bed dryingProcess engineering

The invention relates to an indirectly heated fluidized bed dryer (1) for drying moist fine-grained bulk material. The fluidized bed dryer (1) comprises a housing (2) with an aerated bottom (6), heat exchanger inners extending above the aerated bottom (6) and at least one (6) The lower discharge device for the dried loose material. The fluidized bed dryer (1) according to the invention is characterized in that the available flow cross section of the housing (2) in the region of the heat exchanger inserts is constant over the entire height of the heat exchanger inserts in the cross section of the housing The case increases in the flow direction of the fluidized medium. Inadmissible expansion of the steady-state fluidized bed is reliably prevented in this way.

Owner:RWE POWER AKTIENGESELSCHAFT

Process and plant for producing metal oxide from metal compounds

InactiveCN1759066BLong solid residence timeEnhanced mass transferFluidized bed combustionOxygen/ozone/oxide/hydroxideCombustionChemical compound

Owner:OUTOKUMPU OY

Appts. for removing fluid component from particulized solid materials

The invention concerns an apparatus for the removal of moisture from particulized, solid food products, comprising; a housing (<HIL><PDAT>9< / BOLD><PDAT>); a perforated plate (<HIL><PDAT>2< / BOLD><PDAT>), creating two chambers (<HIL><PDAT>3, 4< / BOLD><PDAT>) in the housing (<HIL><PDAT>1< / BOLD><PDAT>), gas-inlets (<HIL><PDAT>5, 6< / BOLD><PDAT>), present below the perforated plate (<HIL><PDAT>2< / BOLD><PDAT>); an outlet (<HIL><PDAT>8< / BOLD><PDAT>) in the perforated plate (<HIL><PDAT>2< / BOLD><PDAT>), provided with a removable plug (<HIL><PDAT>9< / BOLD><PDAT>); heating means (<HIL><PDAT>15, 18< / BOLD><PDAT>) for the gases. The invention further concerns a process for the removal of moisture from solid, small particles, by subjecting these particles, while in an annular, fluidized bed to a heat treatment for a specific time.< / PTEXT>

Owner:UNILEVER NV

Treatment of granular solids in an annular fluidized bed with microwaves

InactiveCN100372602CEfficient use ofPromote absorptionDrying solid materials with heatMicrowave heatingFluidized bedProcess engineering

This invention relates to a method for the thermal treatment of granular solids in a fluidized-bed reactor ( 1 ), in which microwave radiation from a microwave source ( 2 ) is fed into the reactor ( 1 ), and to a corresponding plant. To improve the utilization of energy and the introduction of the microwave radiation, a first gas or gas mixture is introduced from below through a preferably central gas supply tube ( 3 ) into a mixing chamber ( 7 ) of the reactor, the gas supply tube ( 3 ) being at least partly surrounded by a stationary annular fluidized bed ( 8 ) which is fluidized by supplying fluidizing gas. The microwave radiation is supplied to the mixing chamber ( 7 ) through the same gas supply tube ( 3 ).

Owner:OUTOKUMPU OY

Method and apparatus for the conveyance of fine-grained solids

InactiveCN100473452CEasy to operateDirect contact heat exchangersChemical/physical processesFluidized bedEngineering

The present invention relates to a method for the conveyance of fine-grained solids in a fluidized bed reactor and also to a corresponding plant. It is proposed to introduce a first gas or gas mixture from below through a central tube ( 3 ) into a mixing chamber ( 7 ) of the reactor ( 1 ), the central tube ( 3 ) being at least partly surrounded by a stationary annular fluidized bed ( 10 ) which is fluidized by supplying fluidizing gas. The gas velocities of the first gas or gas mixture as well as of the fluidizing gas for the annular fluidized bed ( 10 ) are adjusted such that the particle Froude numbers in the central tube ( 3 ) are between 1 and 100, in the annular fluidizied bed ( 10 ) between 0.02 and 2 in the mixing chamber ( 7 ) between 0.3 and 30.

Owner:METSO OUTOTEC (FINLAND) OY

Circulating accelerating pipe used in annular fluidized bed reactor

InactiveCN102641695BPromote circulationIncrease the number ofChemical/physical processesSpray nozzleEngineering

Owner:BEIJING FORESTRY UNIVERSITY

Method and plant for the heat treatment of sulfidic ores using annular fluidized

InactiveCN100467630COptimizing Energy UtilizationFluidised-bed furnacesChemical/physical processesFluidized bedPhysical chemistry

The present invention relates to a method and apparatus for thermal treatment of sulfide ores, in which the solids are heated in a fluidized bed reactor (1) to a temperature of about 450-1500°C. In order to improve the energy utilization, it is proposed to introduce the first gas or gas mixture from below into the mixing chamber (7) of the reactor (1) through a gas supply pipe (3) which is at least partially fluidized by the supply fluidizing gas Surrounded by a fixed annular fluidized bed (35). Adjust the gas velocity of the first gas or gas mixture and the fluidizing gas for the annular fluidized bed (35) so that the particle Froude number in the gas supply pipe (3) is 1-100, and the annular fluidized bed (35) The Froude number of the particles in the mixing chamber (7) is 0.02-2, and the Froude number of the particles in the mixing chamber (7) is 0.3-30.

Owner:OUTOKUMPU OY

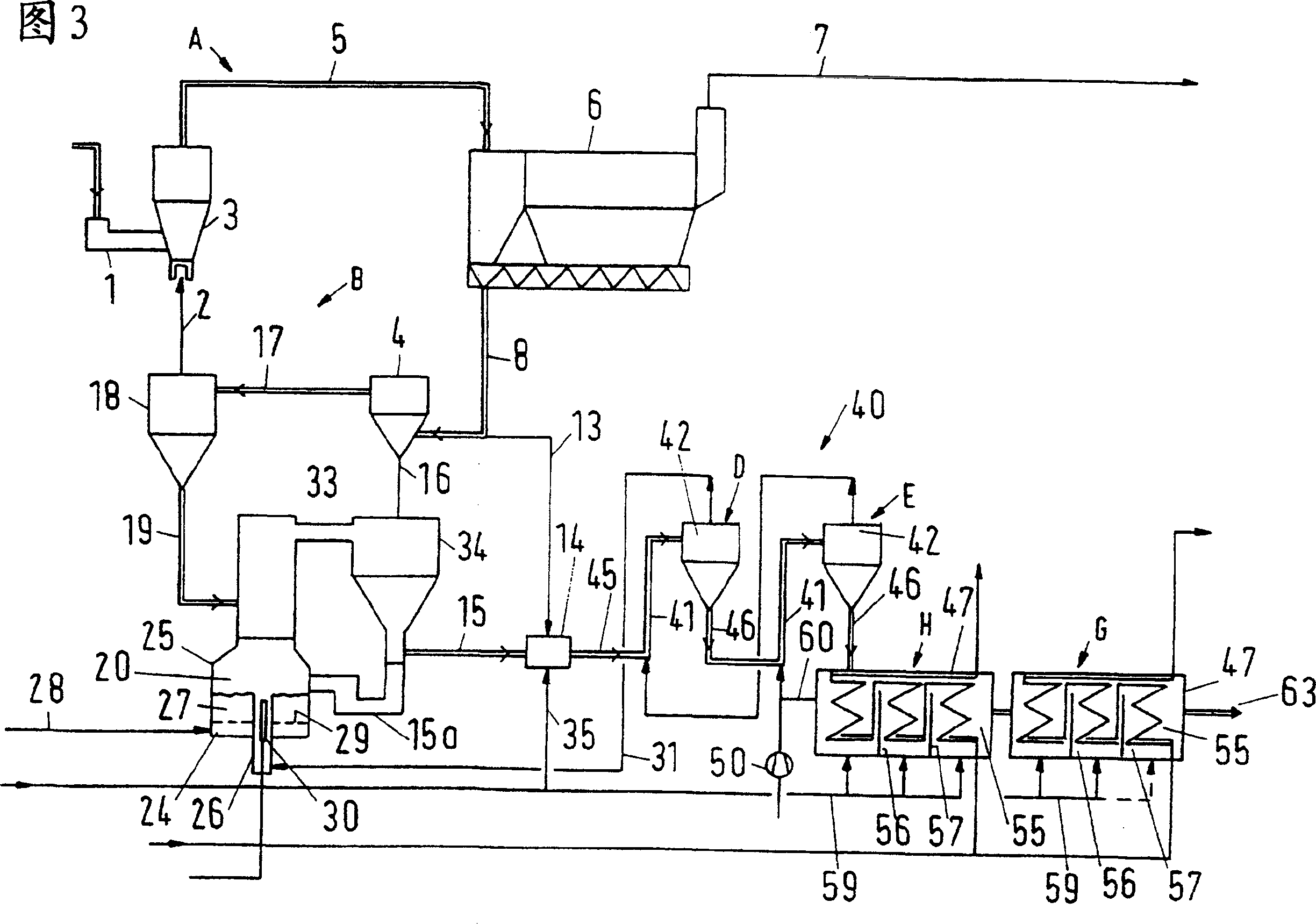

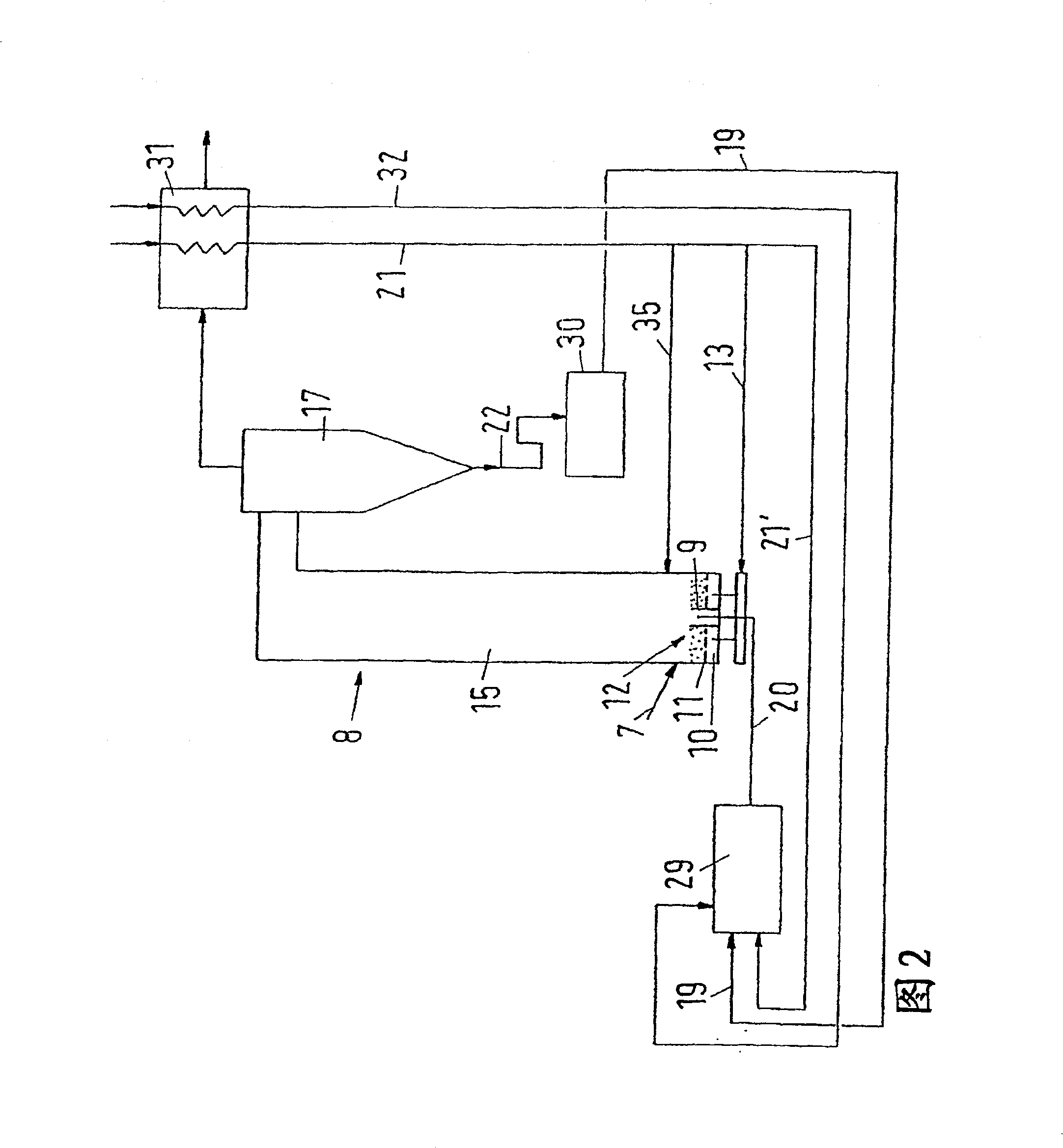

Method and device for removing gaseous pollutants from exhaust gases

InactiveCN100372593CExtended stayEnhanced mass transferDispersed particle separationChemical/physical processesFluidized bedExhaust fumes

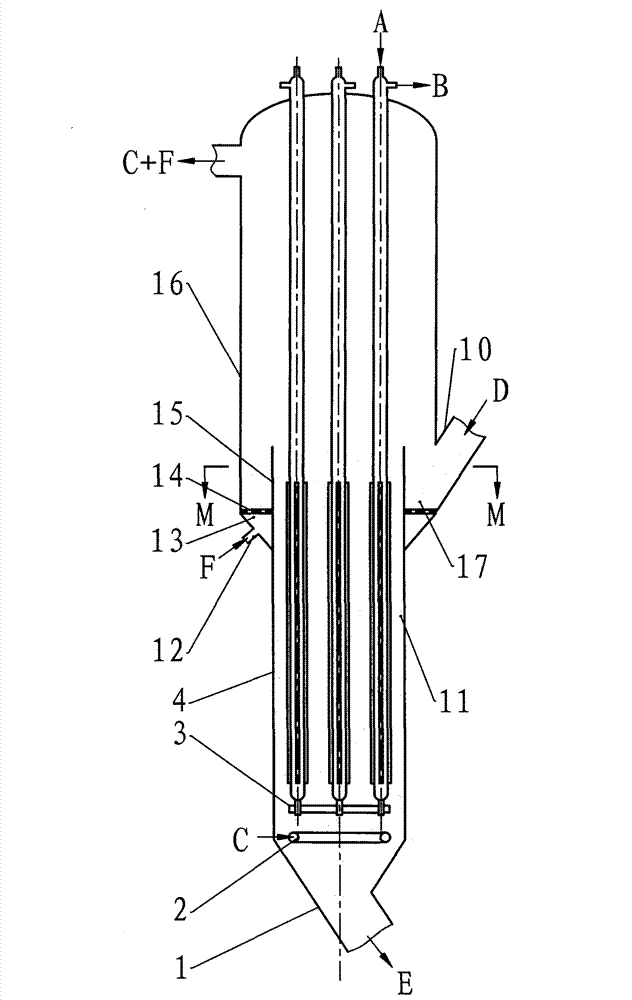

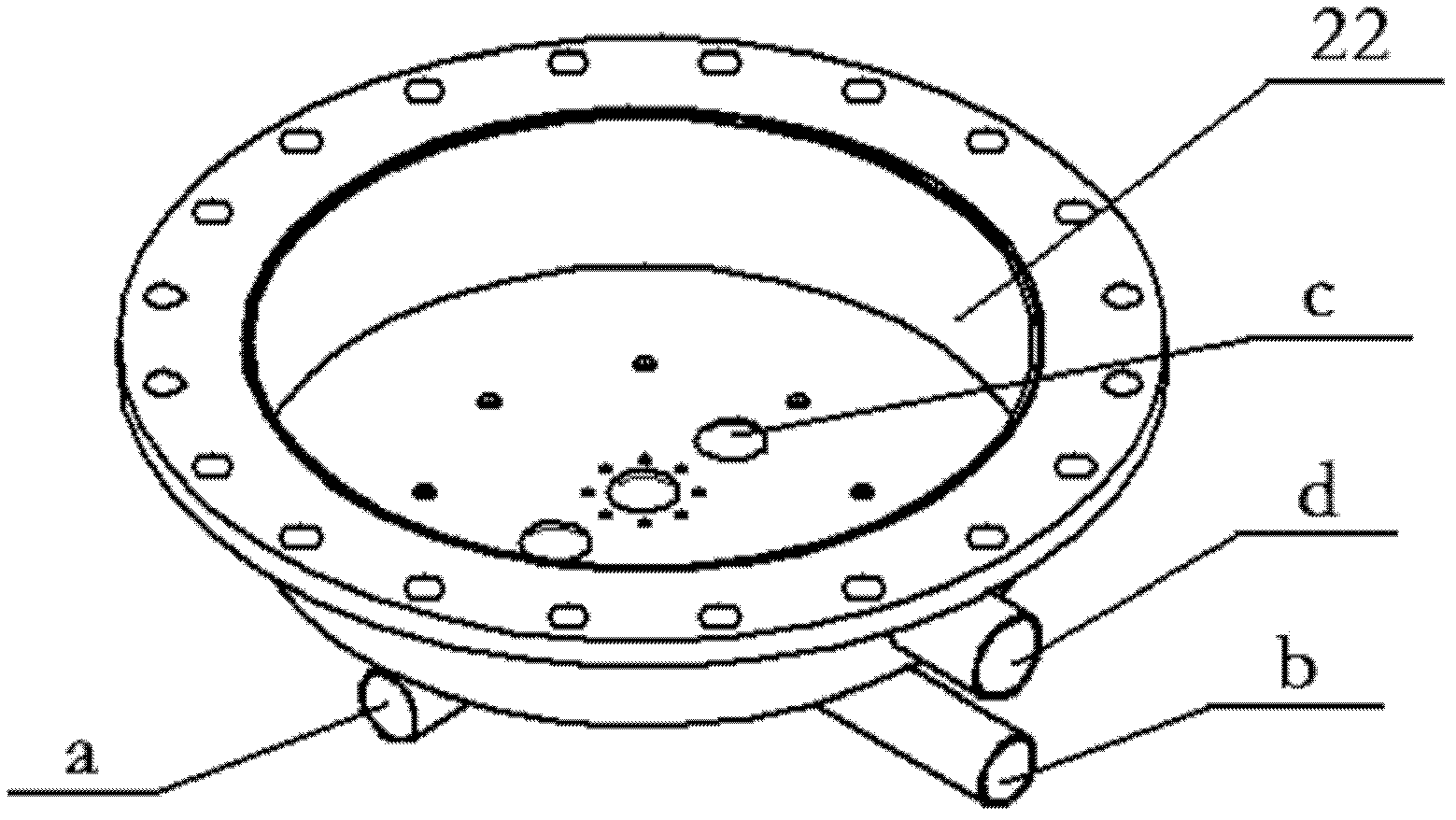

The present invention relates to a method for removing gaseous pollutants from exhaust gases, in which the gaseous pollutants react with a fine-grained reactant by forming solids in a fluidized-bed reactor (2), and to a corresponding plant. To achieve low pollutant concentrations in the clean gas with an almost stoichiometric consumption of reactant, it is proposed to introduce the exhaust gas from below through a preferably central gas supply tube (20) into a mixing chamber (21) of the reactor (2), the gas supply tube (20) being at least partly surrounded by a stationary annular fluidized bed (22) of reactant, which bed is fluidized by supplying fluidizing gas, and to adjust the the gas velocities of the exhaust gas and of the fluidizing gas for the annular fluidized bed (22) such that the Particle-Froude-Numbers in the gas supply tube (20) are between 1 and 100, in the annular fluidized bed (22) between 0.02 and 2, and in the mixing chamber (21) between 0.3 and 30.

Owner:OUTOKUMPU OY

Ring-shaped fluidized bed reactor

InactiveCN102658067BImprove heat transfer efficiencyHigh reaction conversion rateChemical/physical processesCombustion chamberFluidized bed

The invention provides a ring-shaped fluidized bed reactor, belonging to the technical field of fluidized bed reactors. The ring-shaped fluidized bed reactor comprises a top cover, a reactor outer shell, a bottom shell, a support, a combustion chamber, an air distributing plate and an air distributing cabin partition and also comprises circulatory speed increasing pipes and an air distributing cabin, wherein peripheral equipment comprises a cyclone separator and a fan; the lower end of the reactor outer shell is provided with the air distributing plate and then is fixedly connected with the bottom shell; the combustion chamber is sheathed in the reactor outer shell; the axis of the reactor outer shell and the axis of the combustion chamber are consistent, and a ring-shaped reaction area is formed between the reactor outer shell and the combustion chamber; the circulatory speed increasing pipes are uniformly distributed in the combustion chamber, the upper ends of the circulatory speed increasing pipes are communicated with the ring-shaped reaction area, and the lower ends of the circulatory speed increasing pipes penetrate through the air distributing plate; the bottom shell is internally provided with the air distributing cabin partition which is internally provided with the air distributing cabin; and bending pipes on the circumferential surface of the air distributing cabin are communicated with the lower ends of the circulatory speed increasing pipes. The ring-shaped fluidized bed reactor provided by the invention has the advantages that the combustion chamber is arranged in the reactor outer shell and is internally provided with the circulatory speed increasing pipes, so that the space can be saved, the heat loss can be reduced, meanwhile the internal circulation of fluid is enhanced, and the heat transferring efficiency and the reaction conversion rate of the reactor are increased.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com