Circulating accelerating pipe used in annular fluidized bed reactor

A technology of fluidized bed reactor and bed reactor, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of improving conversion rate, accelerating cycle, and adjustable working state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and embodiments.

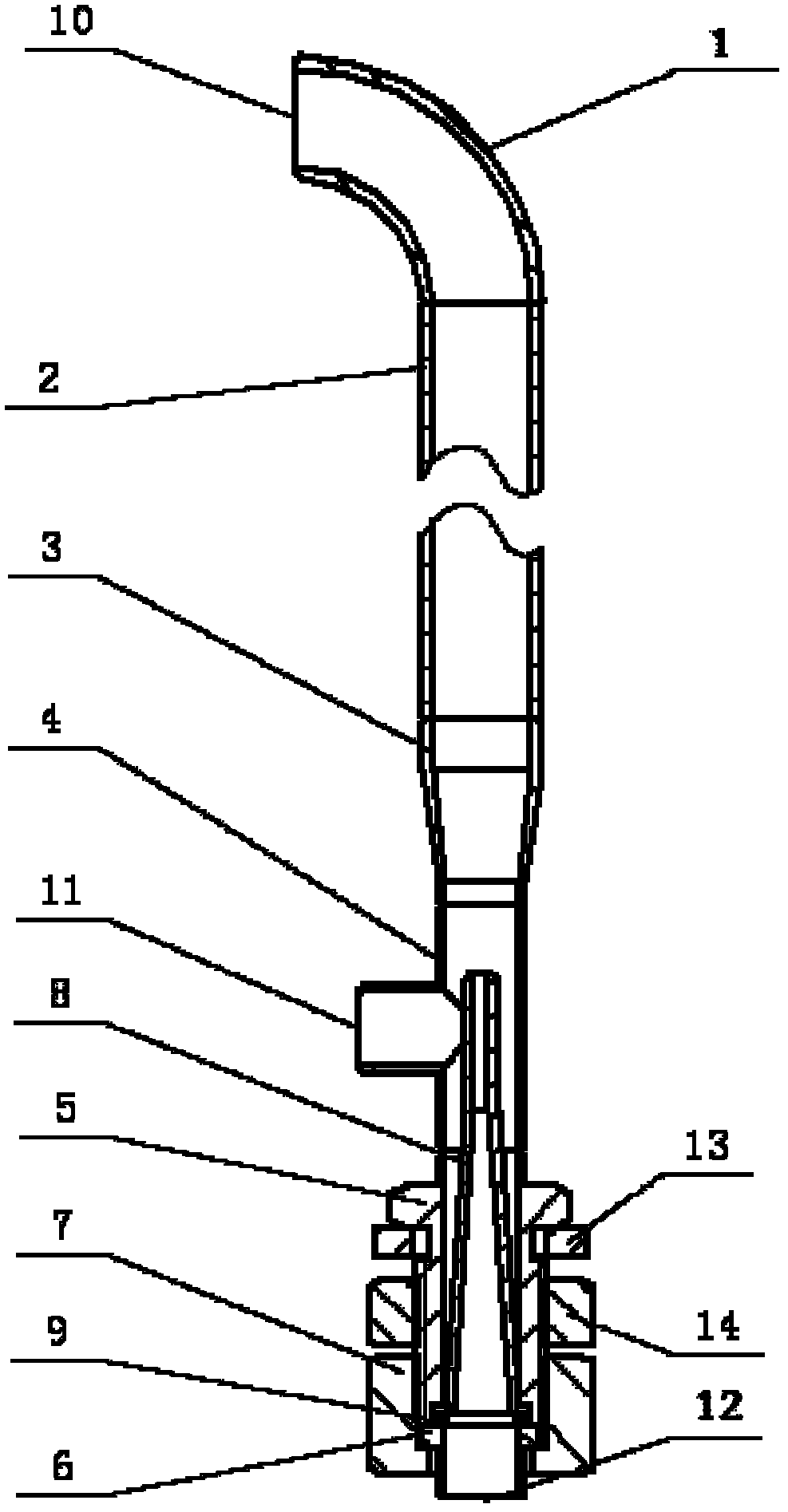

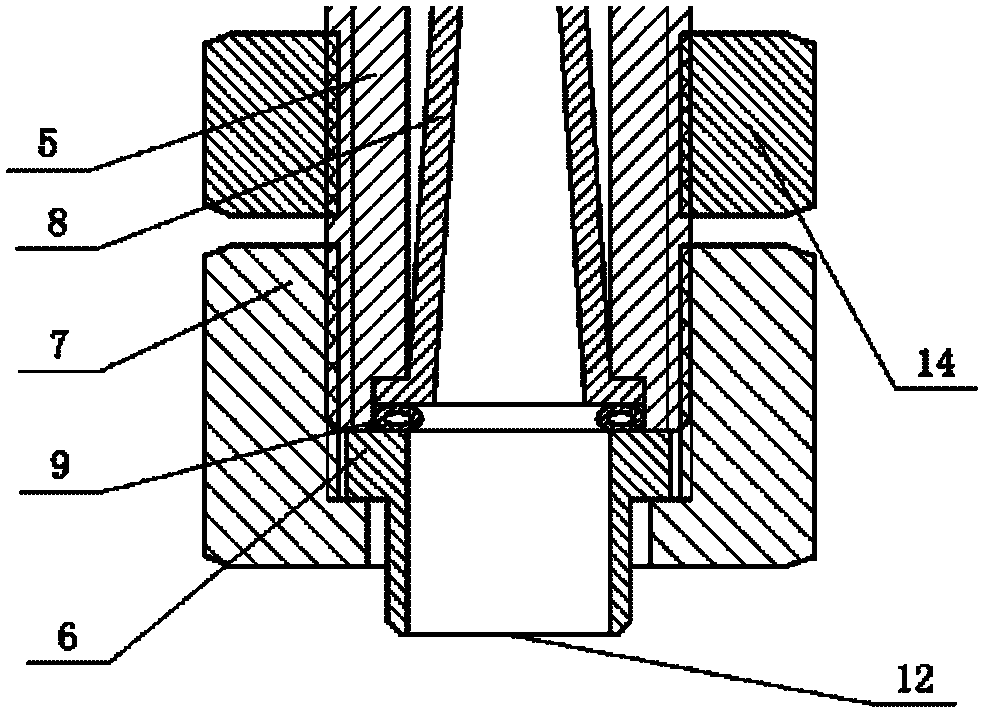

[0015] As attached figure 1 And attached figure 2 As shown, the present invention provides a circulating speed-increasing pipe used in an annular fluidized bed reactor. The circulating speed-increasing pipe includes a 90° elbow 1, a riser 2, a reducing joint 3, a three-way pipe 4, Straight pipe joint 5, connection pipe 6, first nut 7, tapered pipe 8, O-ring 9, gasket 13 and second nut 14, the peripheral equipment is a fan; the center of the straight pipe joint 5 is provided with a through hole, The lower end of the hole is machined with a sinker, and the middle circumferential surface is machined with a card slot, and the lower end circumferential surface is machined with two threads; the inner cavity of the tapered tube 8 is divided into two upper and lower sections, the upper cavity is cylindrical, and the lower section The cavity is conical, the cone angle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com