Patents

Literature

111 results about "Light particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light as a Particle. Light behaves mainly like a wave but it can also be considered to consist of tiny packages of energy called photons. Photons carry a fixed amount of energy but have no mass.

Particles incorporating surfactants for pulmonary drug delivery

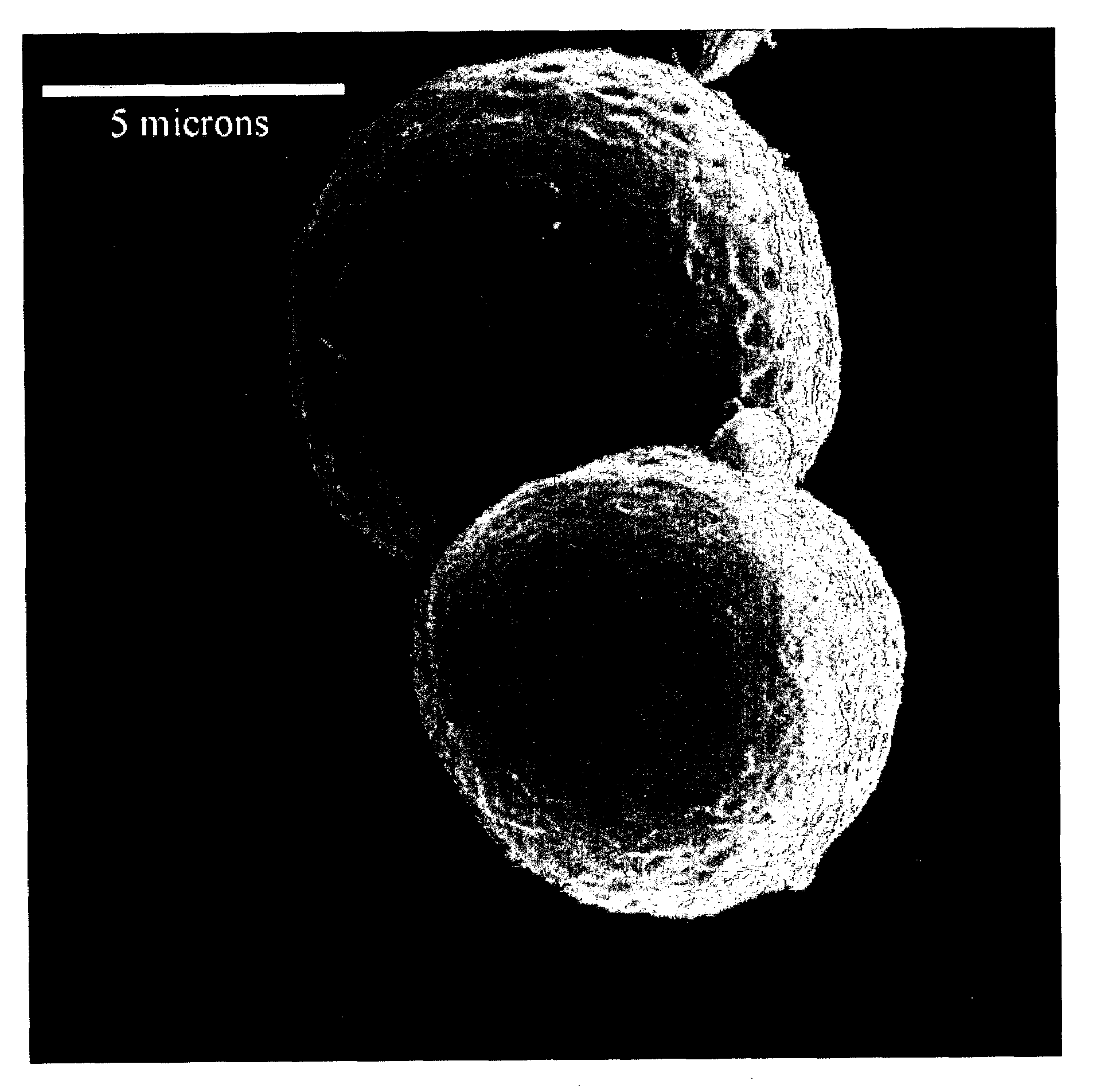

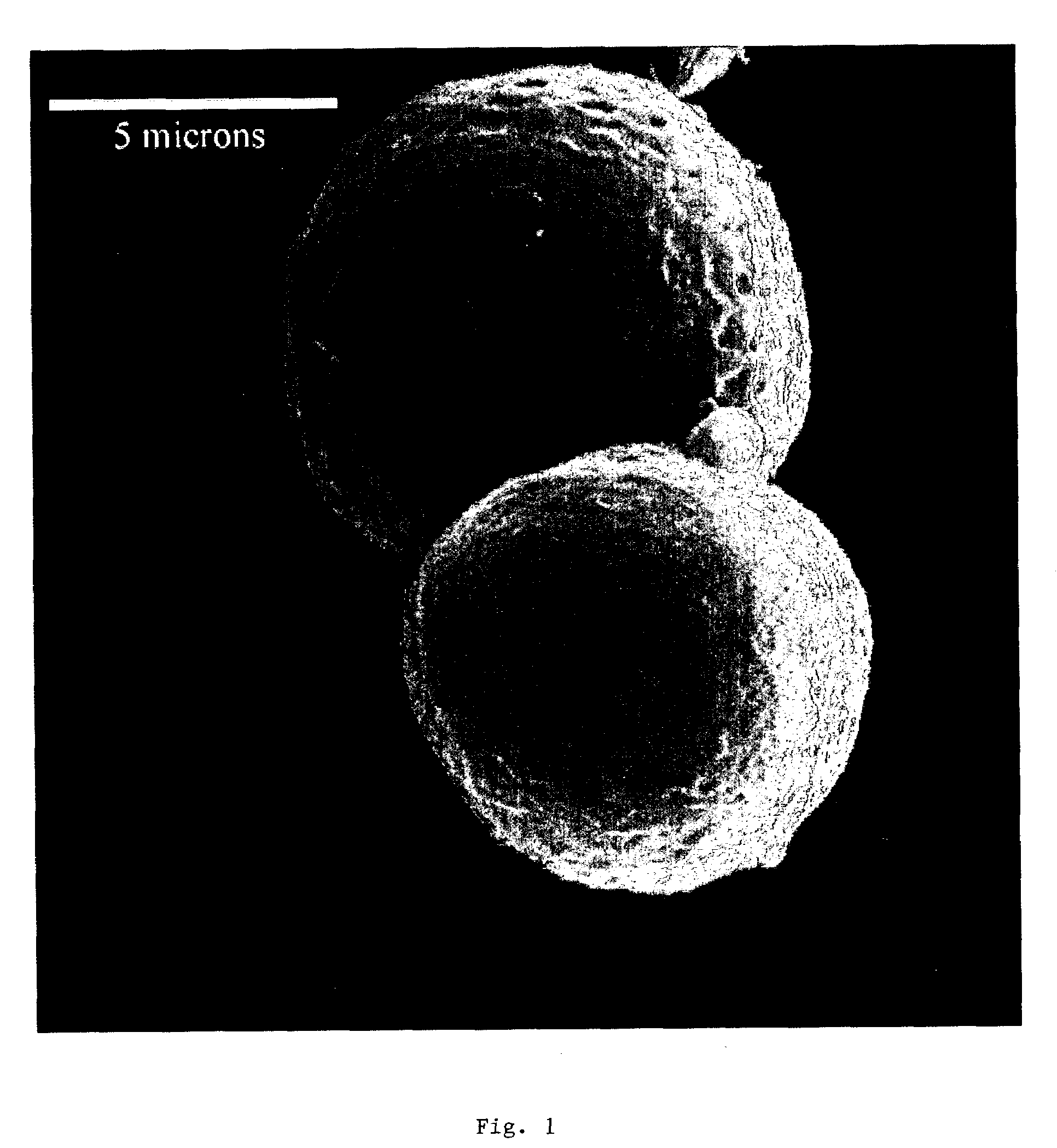

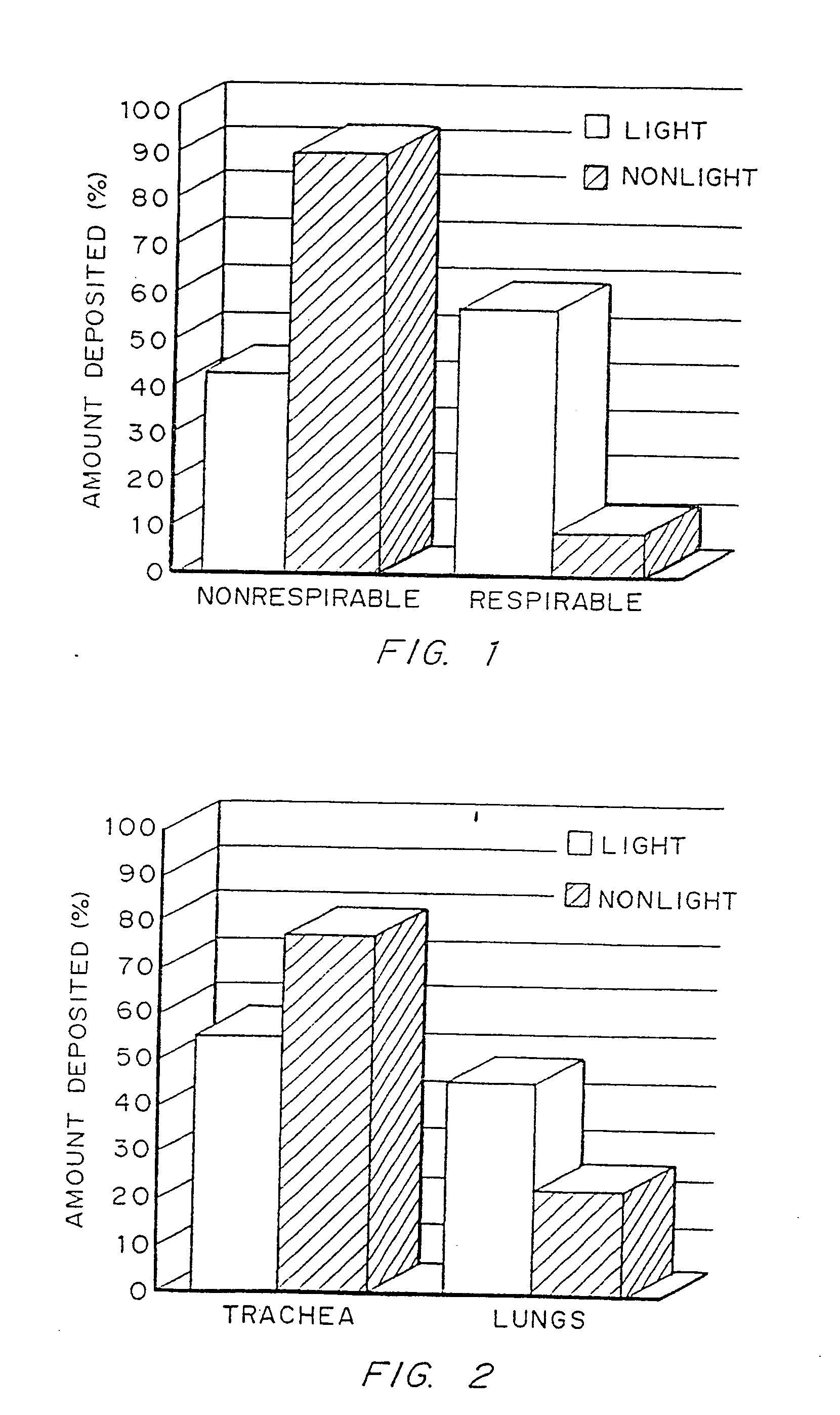

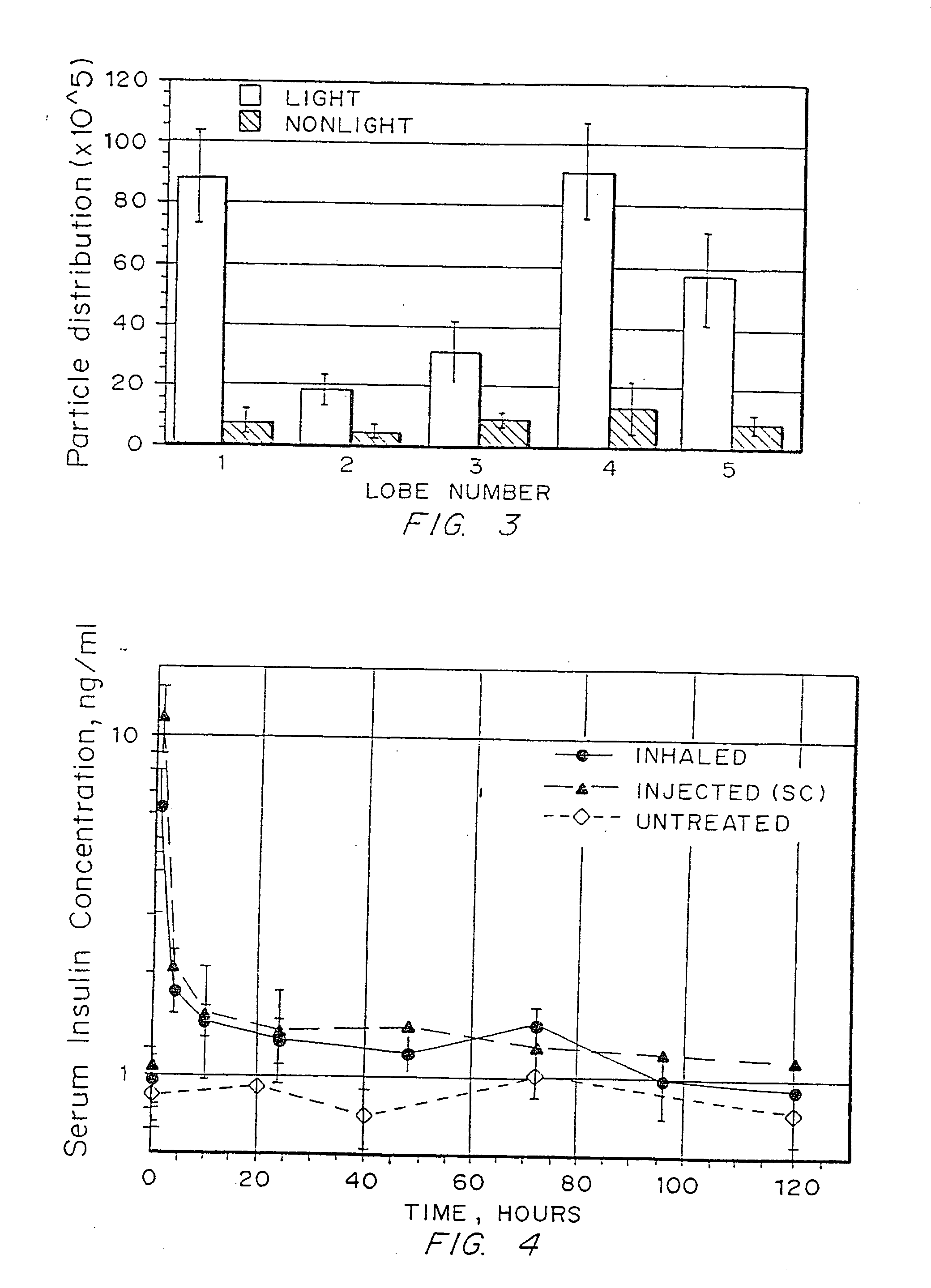

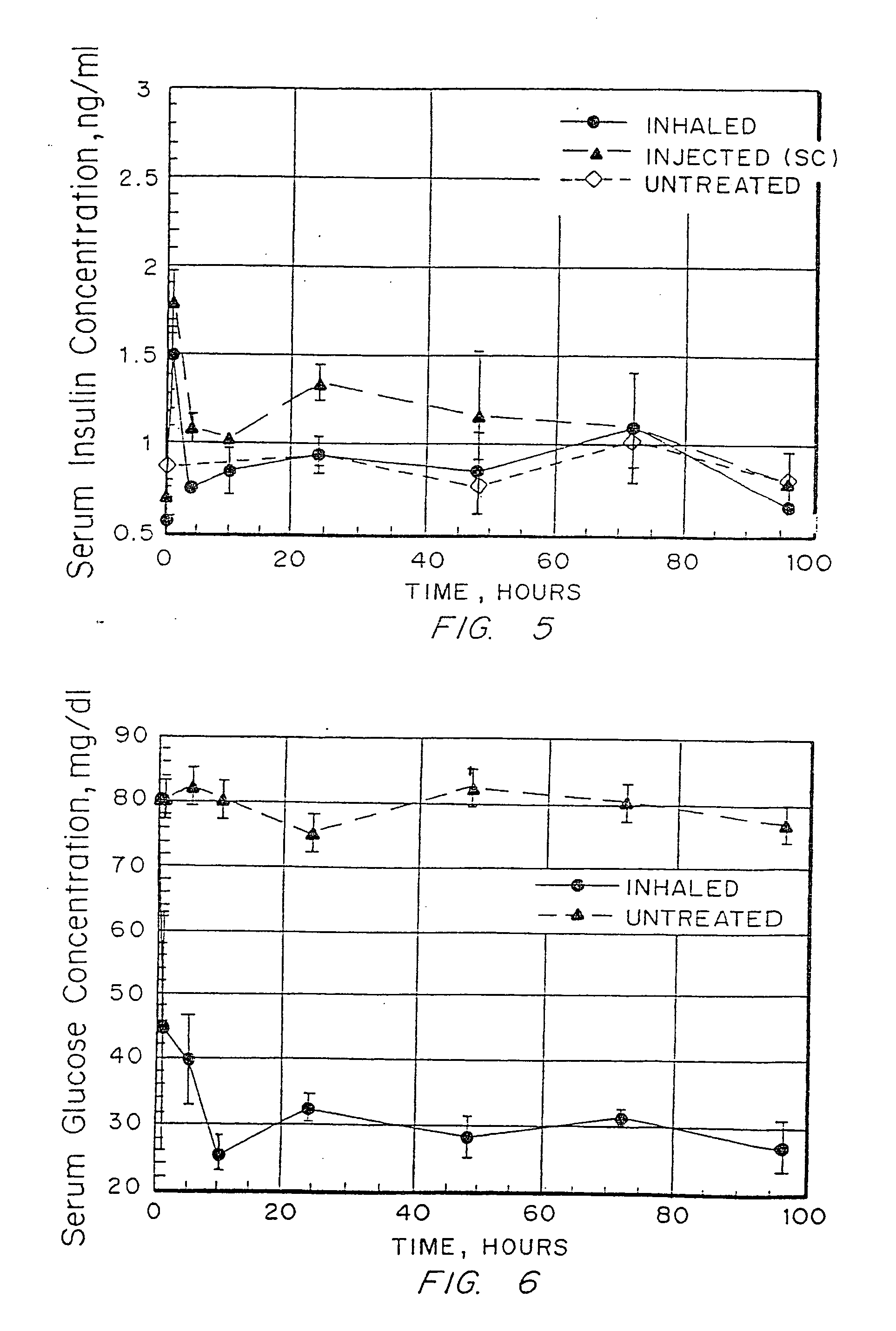

Improved aerodynamically light particles for drug delivery to the pulmonary system, and methods for their synthesis and administration are provided. In a preferred embodiment, the aerodynamically light particles are made of a biodegradable material and have a tap density less than 0.4 g / cm3 and a mass mean diameter between 5 mum and 30 mum. The particles may be formed of biodegradable materials such as biodegradable polymers. For example, the particles may be formed of a functionalized polyester graft copolymer consisting of a linear alpha-hydroxy-acid polyester backbone having at least one amino acid group incorporated therein and at least one poly(amino acid) side chain extending from an amino acid group in the polyester backbone. In one embodiment, aerodynamically light particles having a large mean diameter, for example greater than 5 mum, can be used for enhanced delivery of a therapeutic agent to the alveolar region of the lung. The aerodynamically light particles incorporating a therapeutic agent may be effectively aerosolized for administration to the respiratory tract to permit systemic or local delivery of wide variety of therapeutic agents.

Owner:MASSACHUSETTS INST OF TECH

Particulate compositions for pulmonary delivery

ActiveUS7182961B2Maximize drug deliveryWall thickness can be minimizedPowder deliveryPharmaceutical product form changeParticulatesMedicine

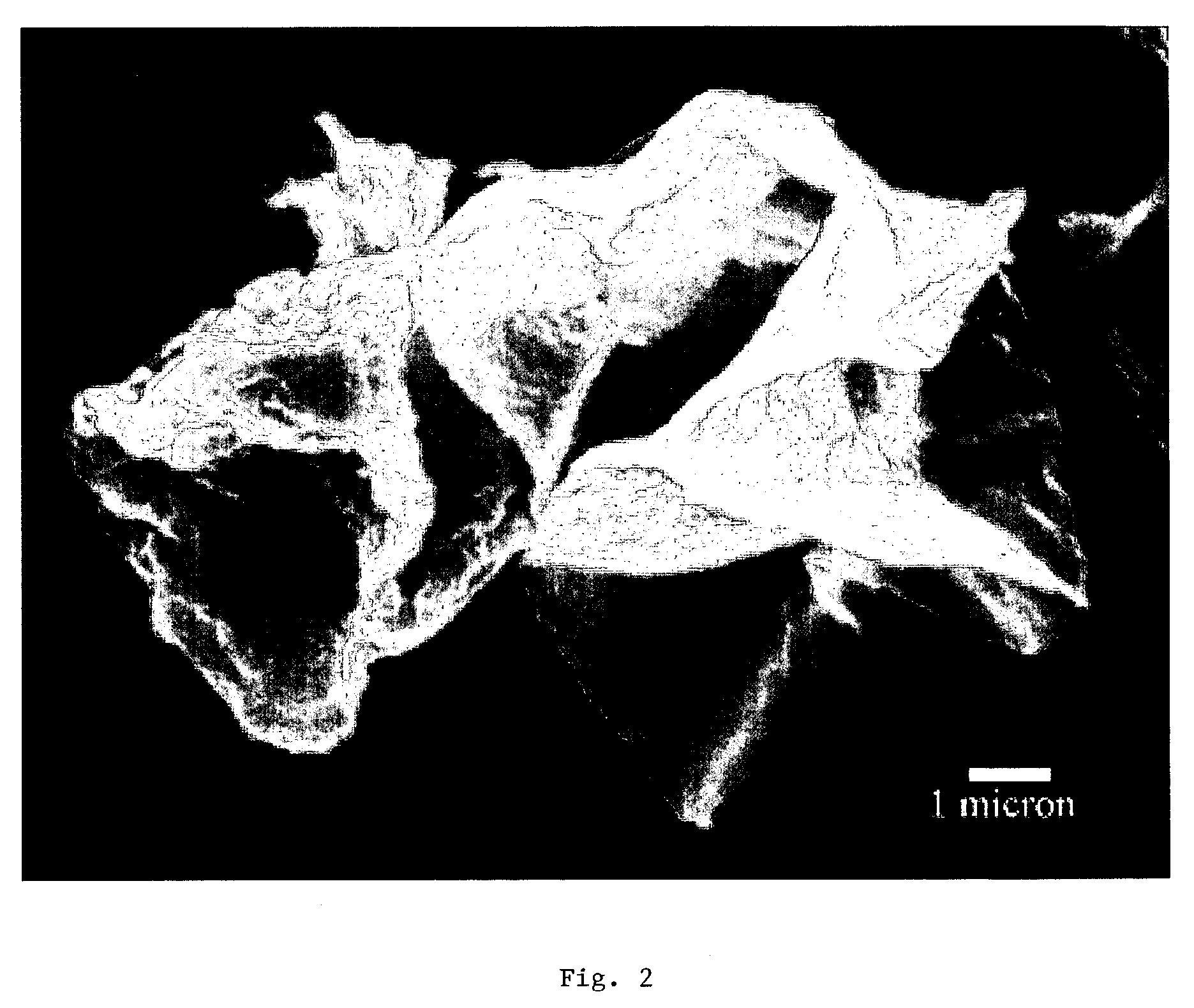

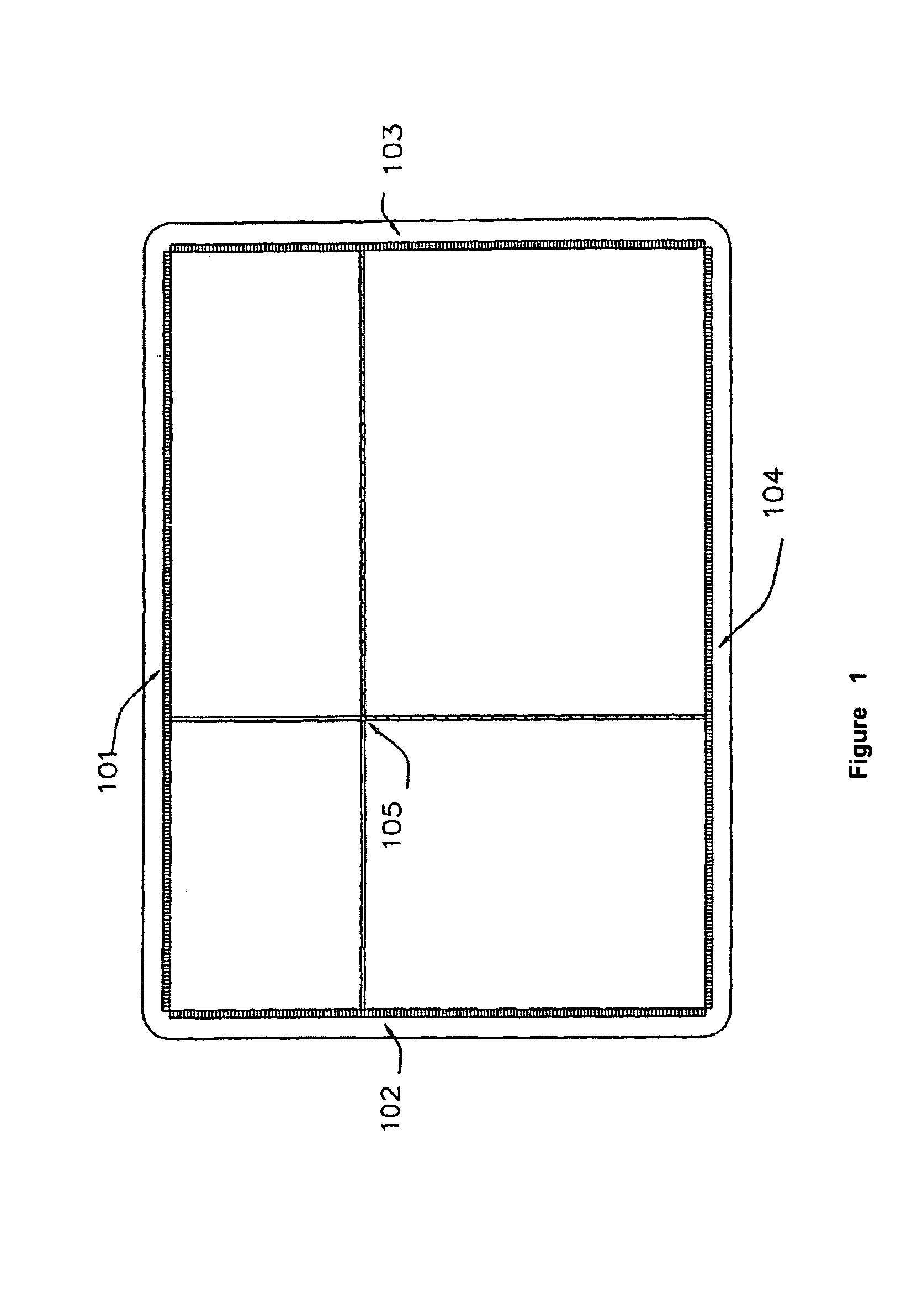

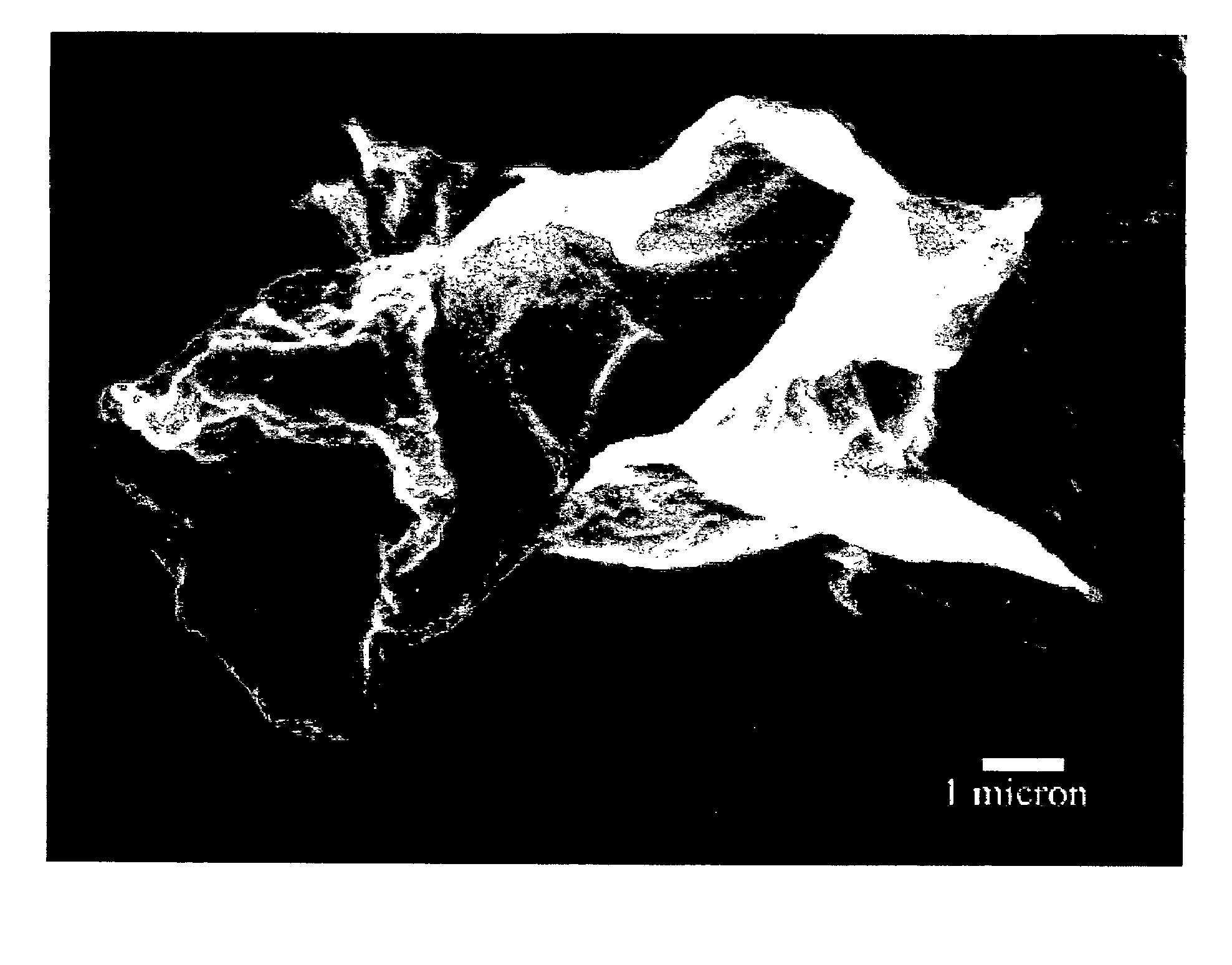

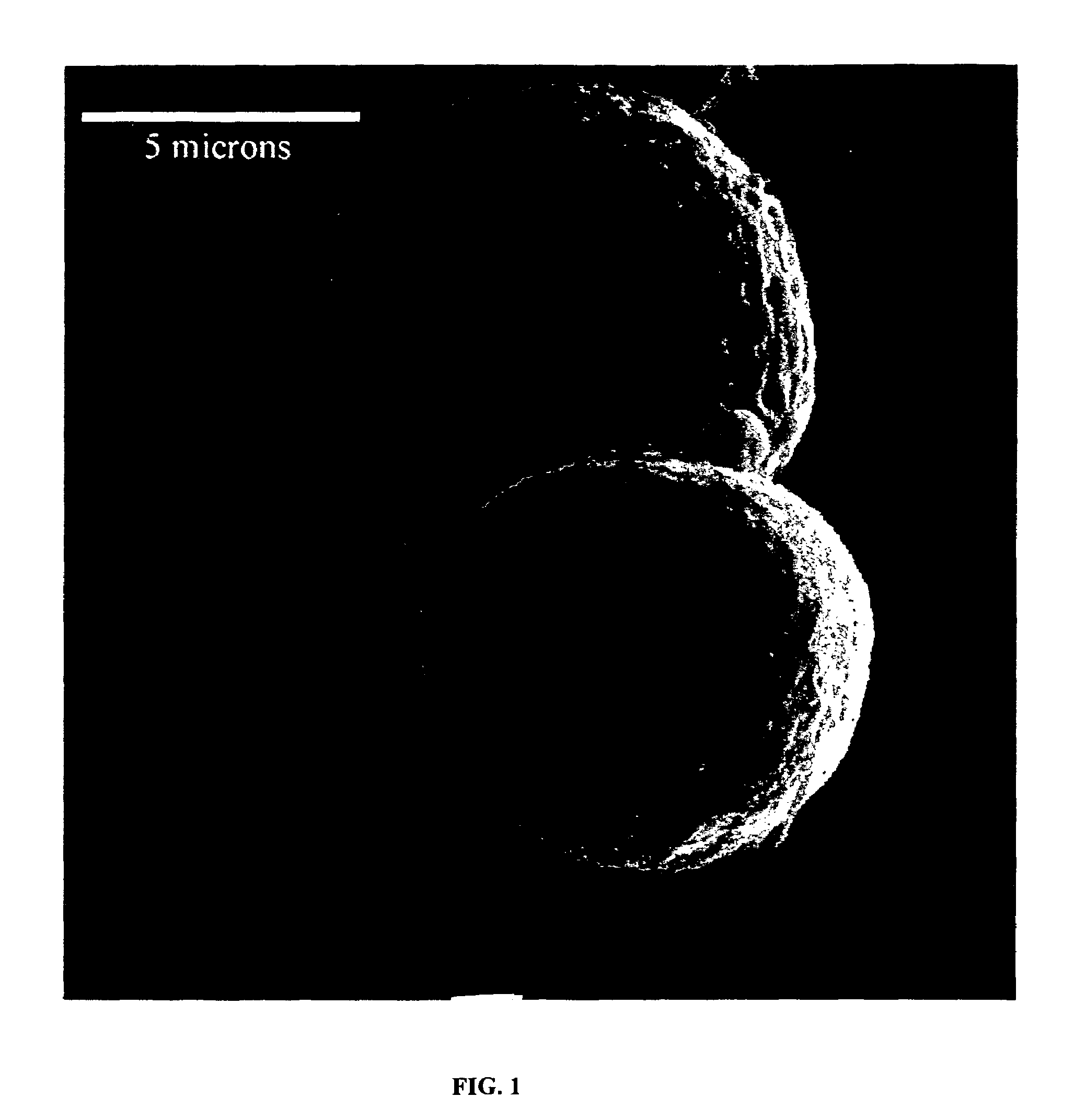

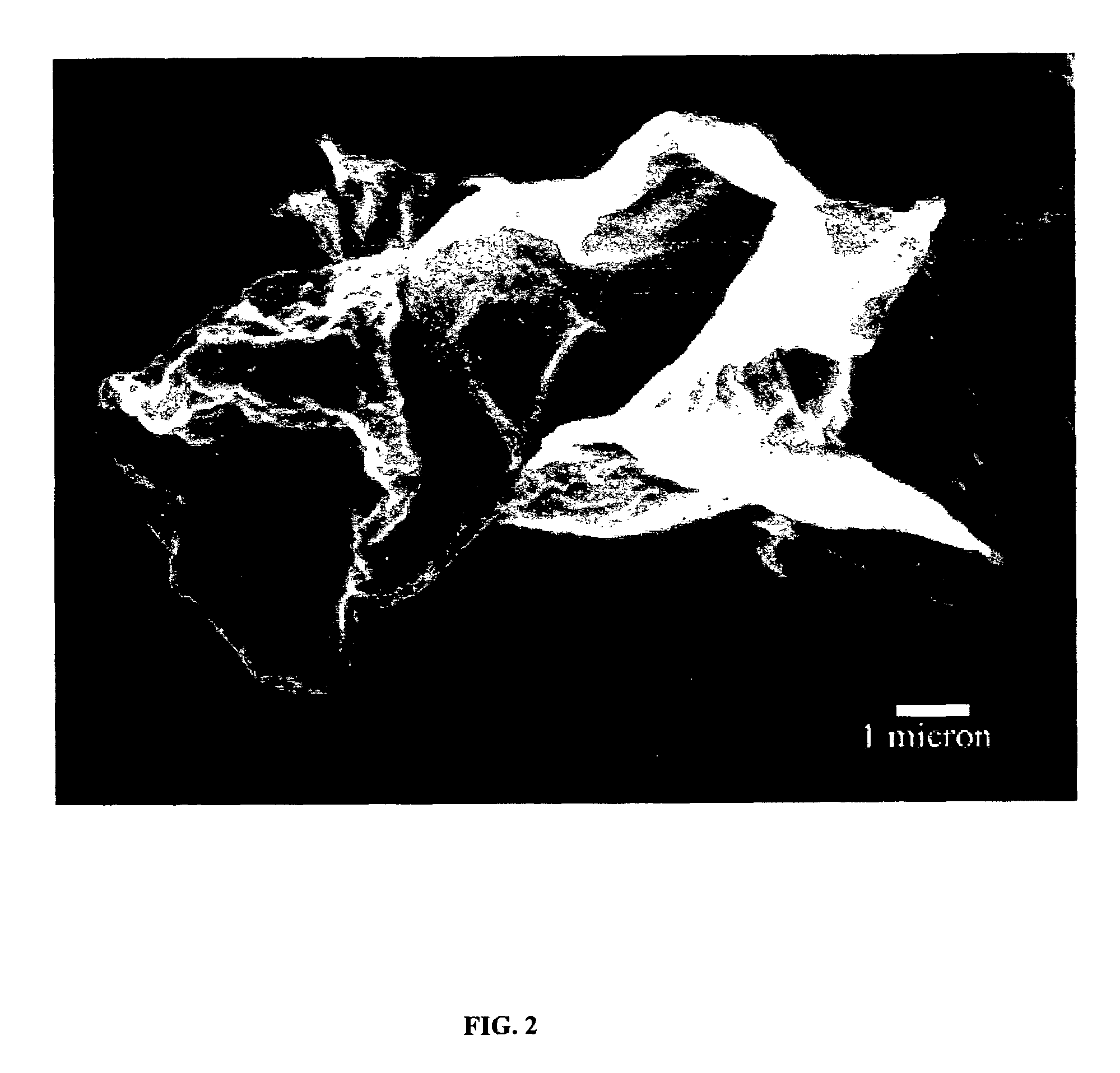

This invention concerns an improved particulate composition for delivering a drug to the pulmonary system. Applicants disclose a method of identifying an optimal form of aerodynamically light particles which are highly dispersible. The particles of the instant invention are made by creating hollow, spherical drug particles (i.e., progenitor particles) that collapse in the process of particle formation, leading to wrinkled, thin-walled drug particles of very low envelope density. Additionally, Applicants have found that such particles are especially optimal for inhaled aerosols when the surface area parameter (σ) is greater than 2, optimally greater than 3.

Owner:CIVITAS THERAPEUTICS

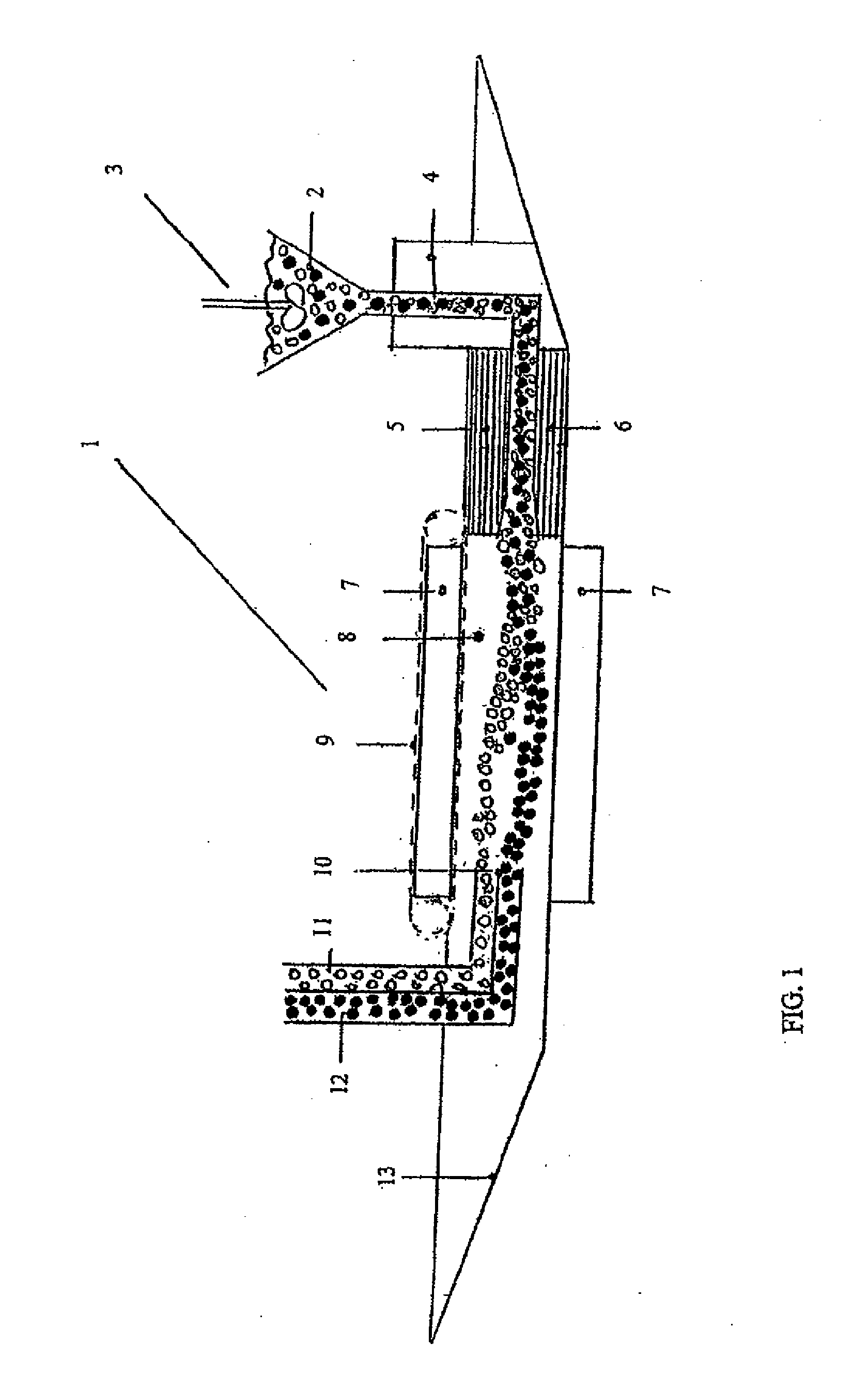

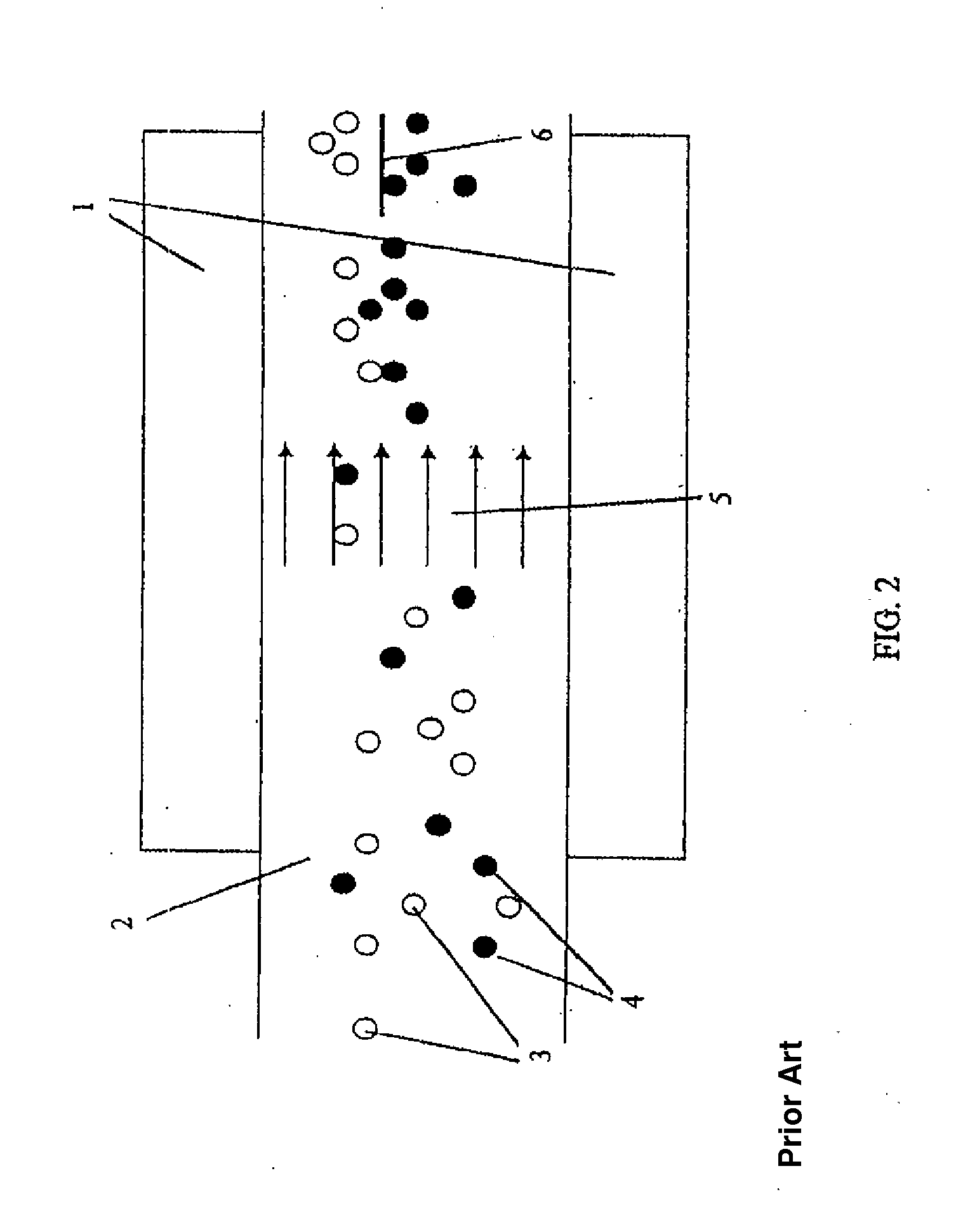

Method and Apparatus for Separation of Particles From a Flow of Gas

ActiveUS20090266231A1Increase capacityImprove efficiencyDispersed particle separationCentrifugesEngineeringCentrifugal force

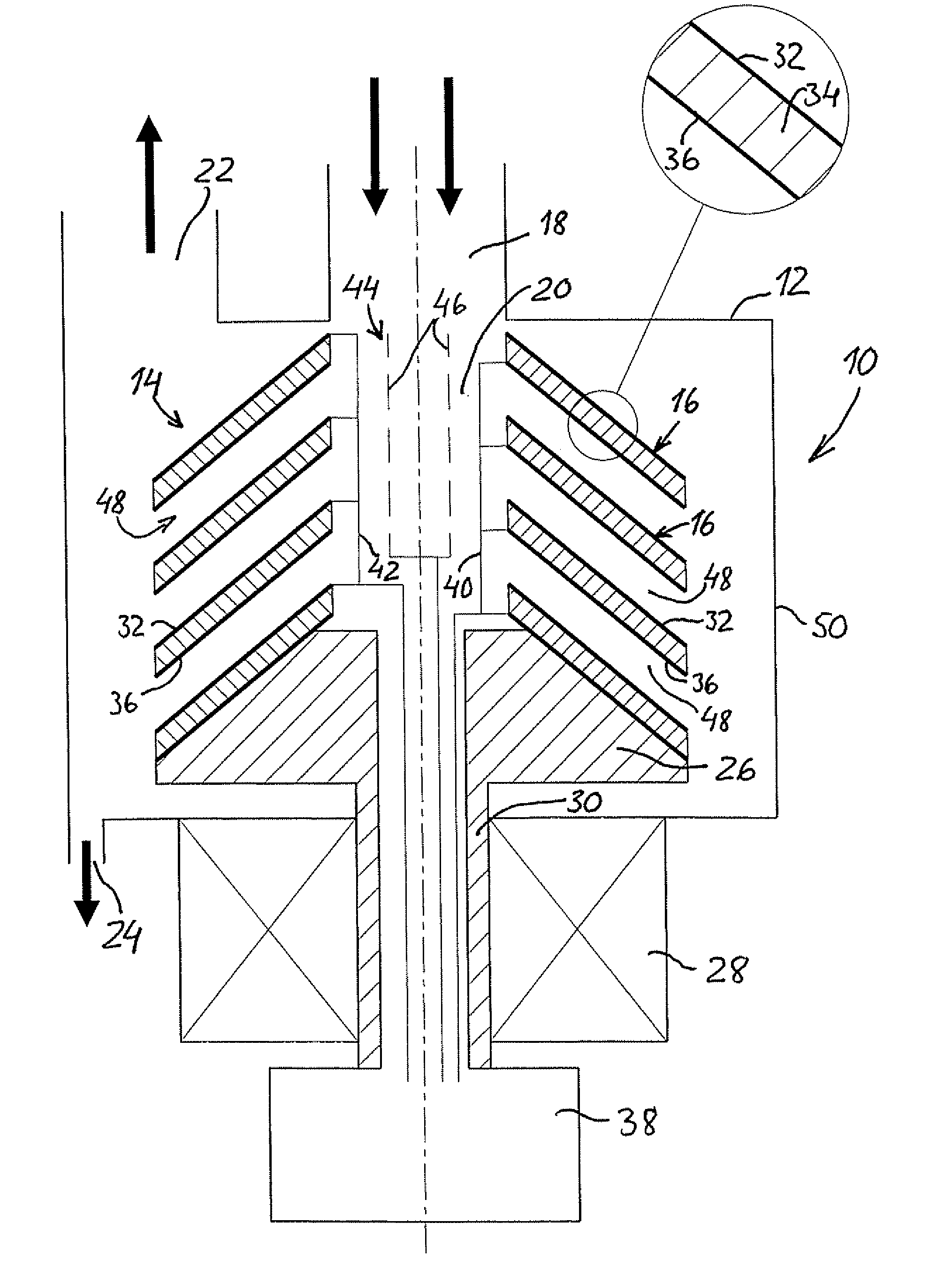

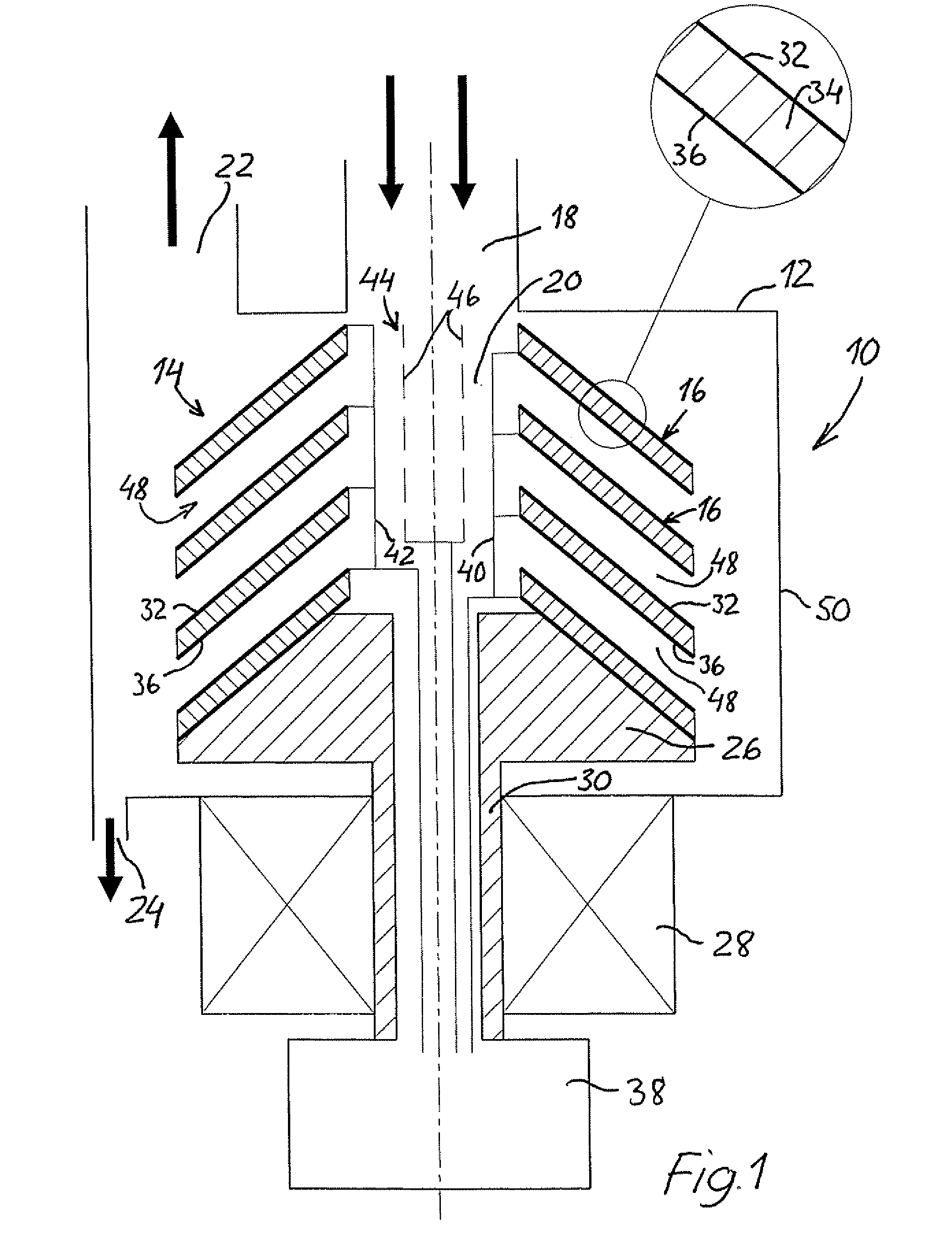

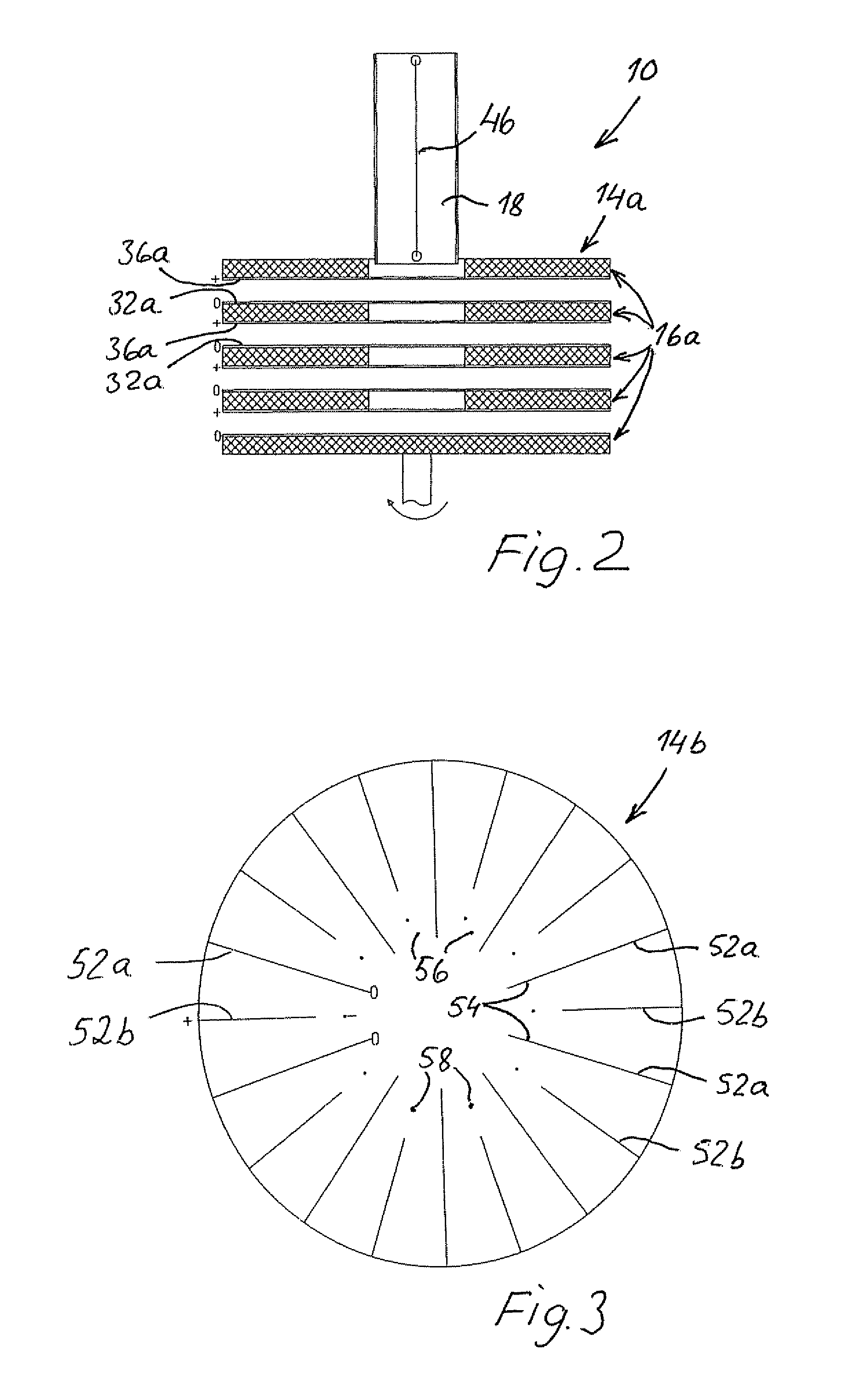

A method and apparatus for the separation of particles from a flow of gas, where both large, heavy and small, light particles can be separated off from the gas by means of the combined effect of an electrostatic attraction force and a centrifugal force in a centrifugal separator (10) of the type that comprises a rotor (14) that has a plurality of adjacent surface elements (16) with intermediate gas flow gaps (48) and that is mounted in such a way that it can rotate in a surrounding casing (12), which casing has an inlet (18) for unclean gas and an outlet (22) for clean gas and an outlet (24) for separated-of f particles. A charging unit (44) ionizes the particles upstream of the rotor (14). An electrical field is generated between adjacent surface elements (16) of the rotor in order to attract the ionized light particles towards a face of the surface elements by means of the electrostatic force. By means of the centrifugal force created by the rotor, the particles that have accumulated on the surface elements are thrown towards the inside of the casing and are led out through the outlet.

Owner:GRIMALDI DEV AB

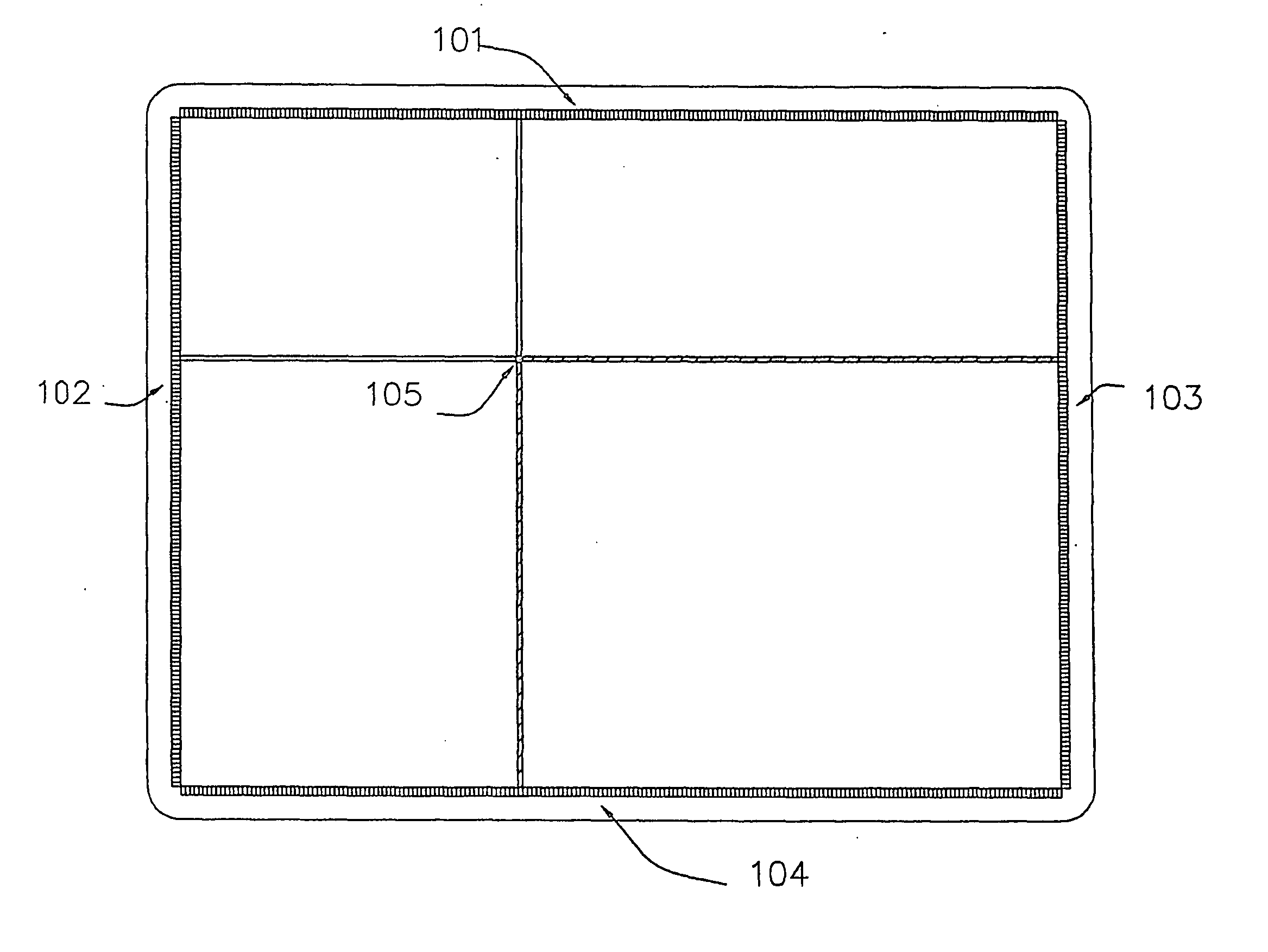

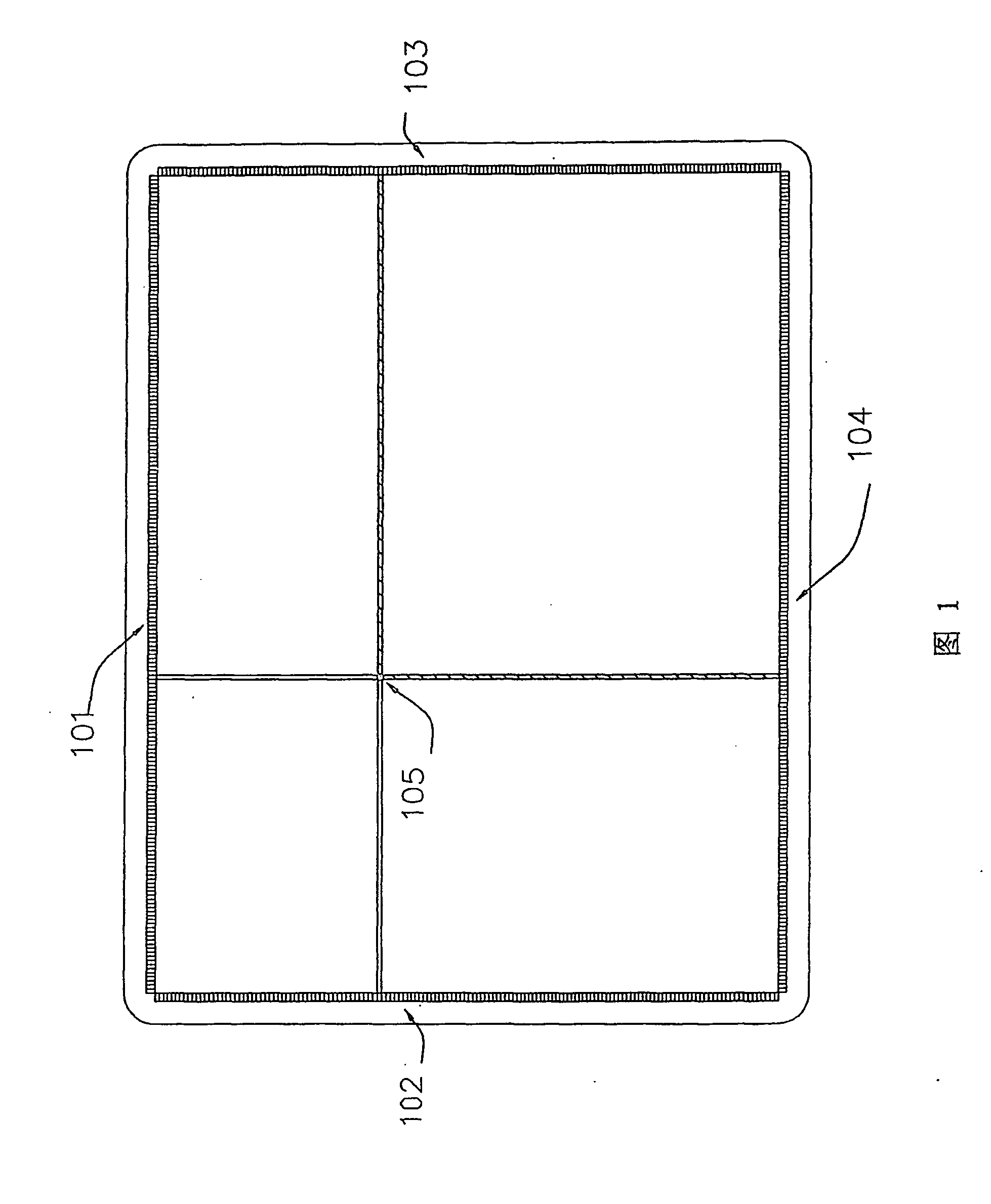

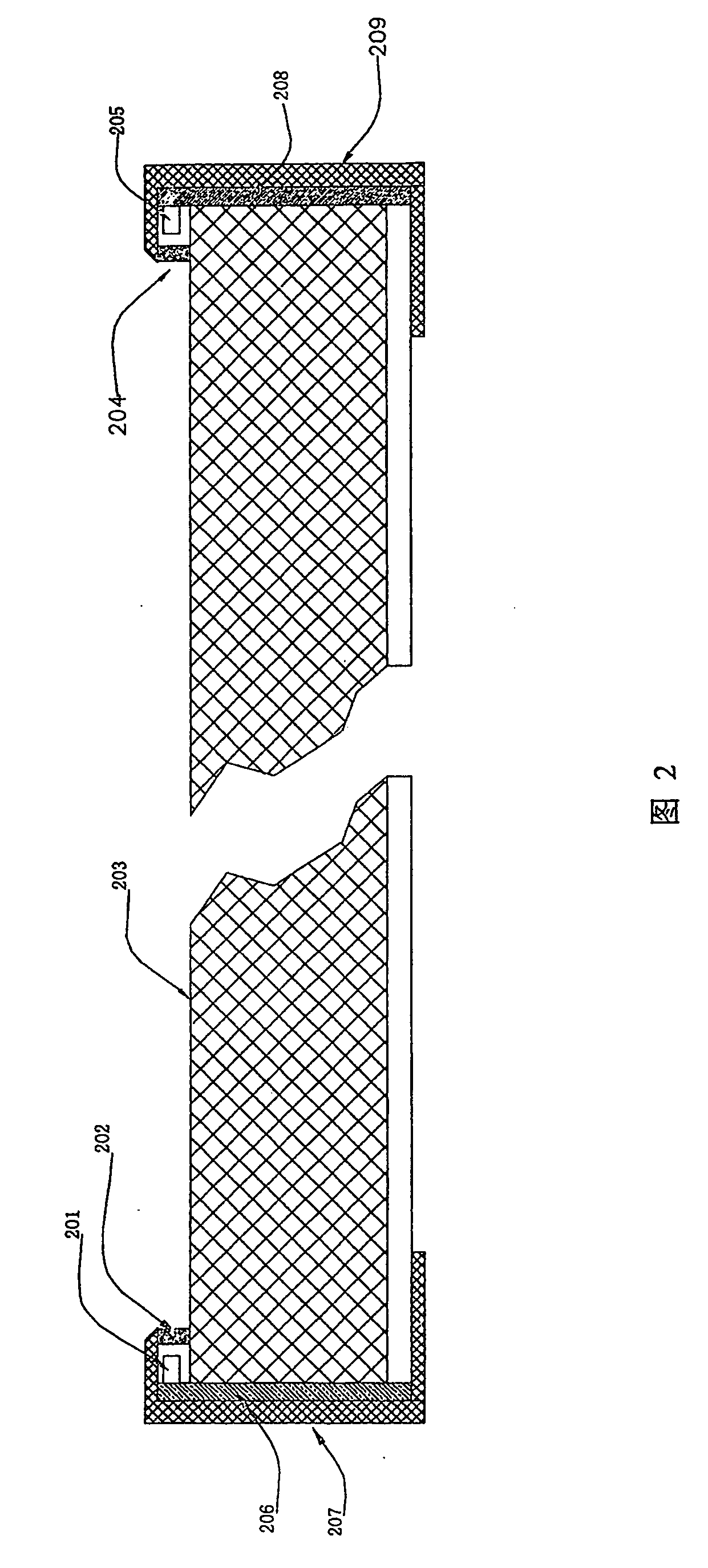

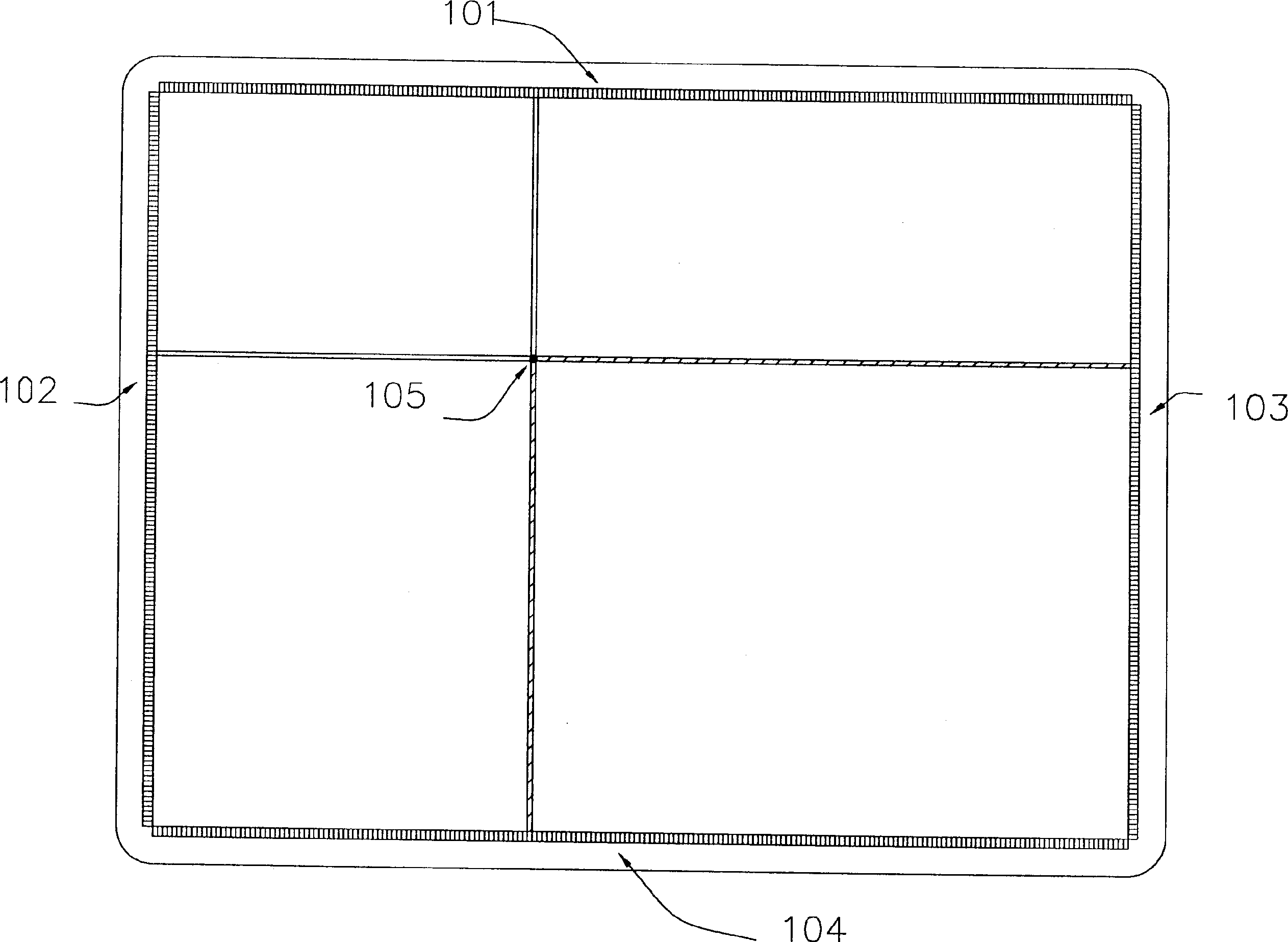

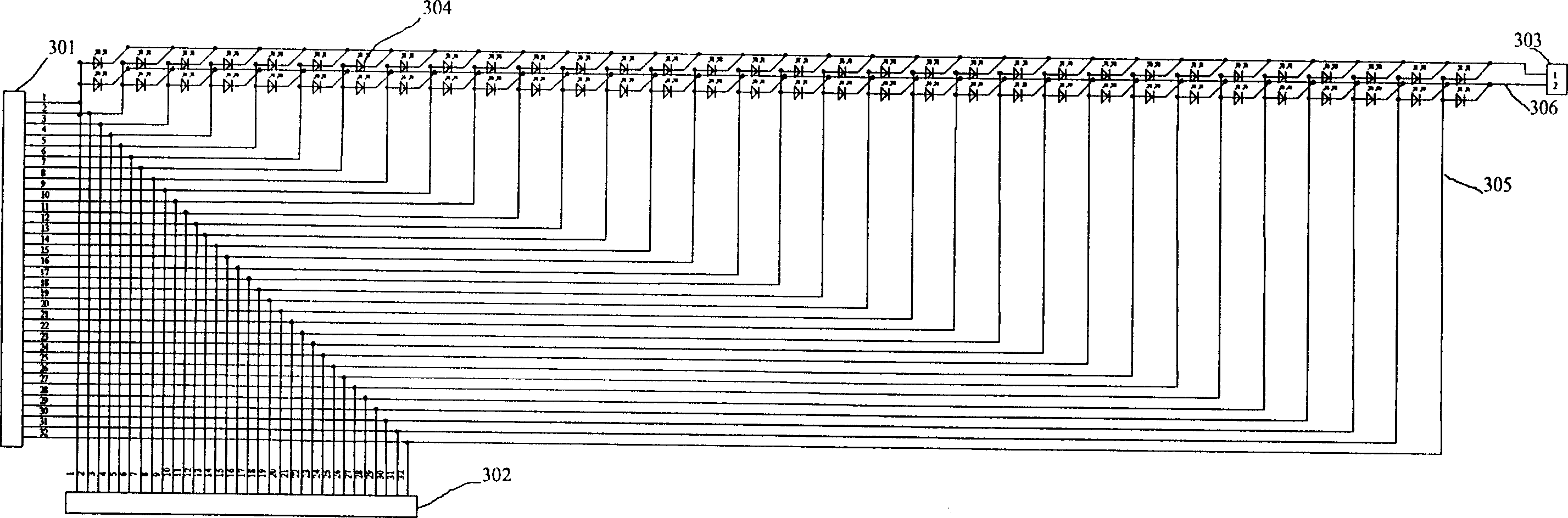

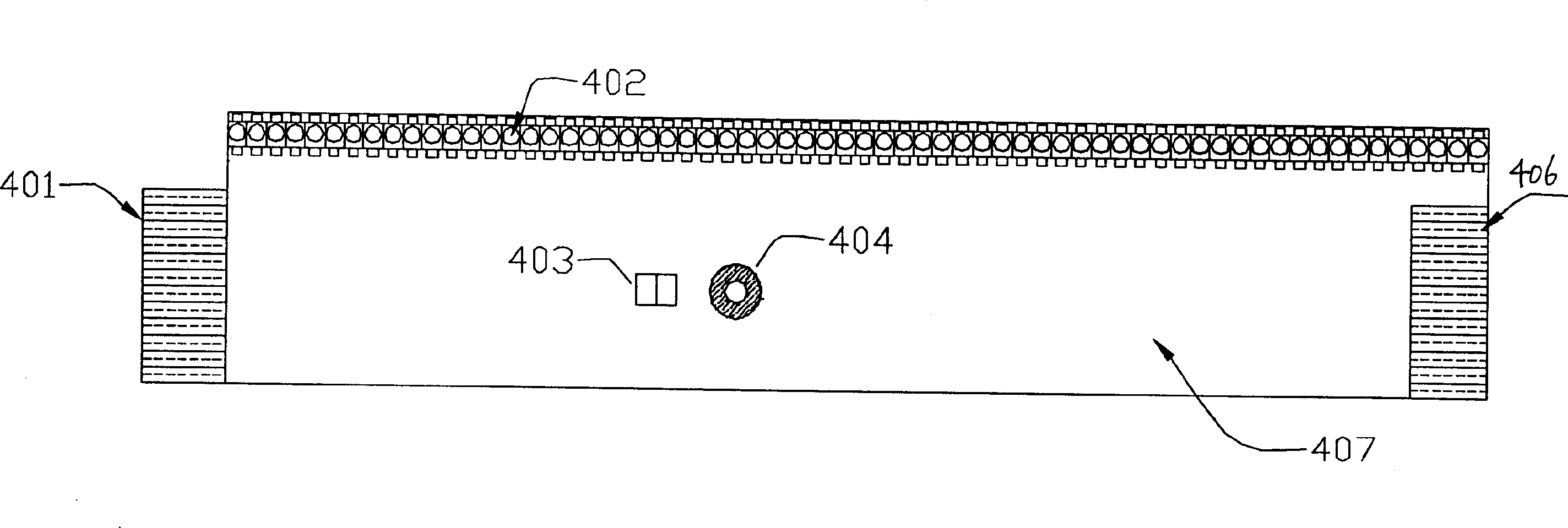

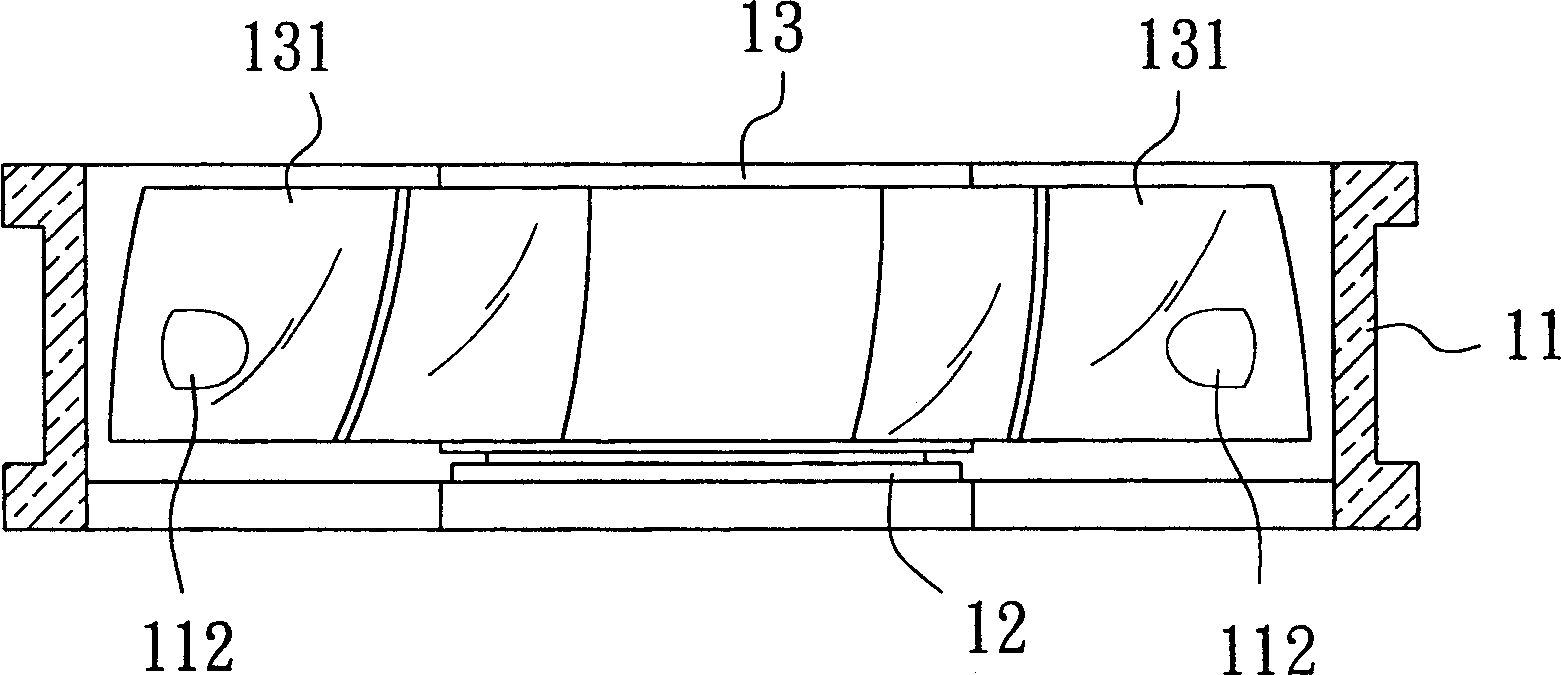

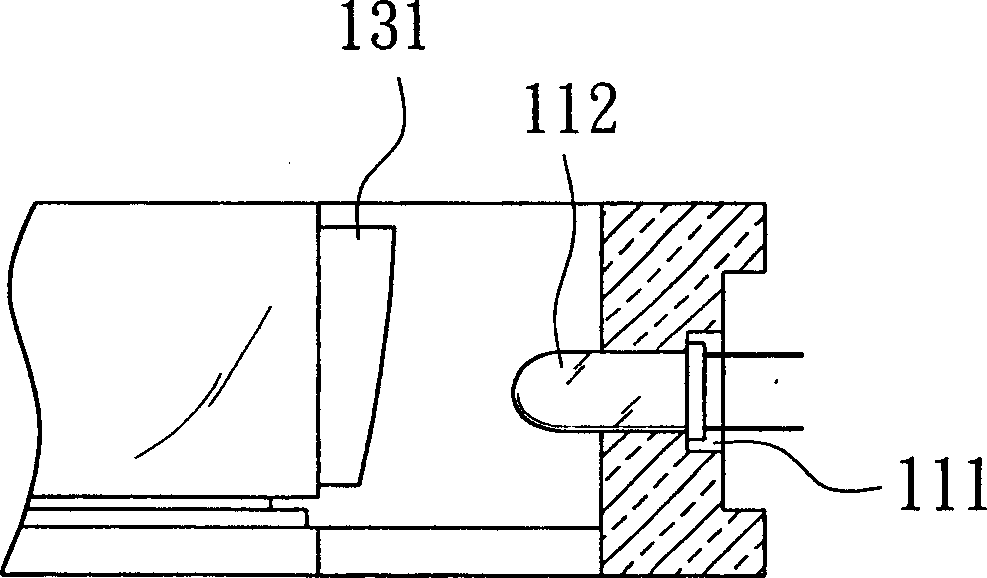

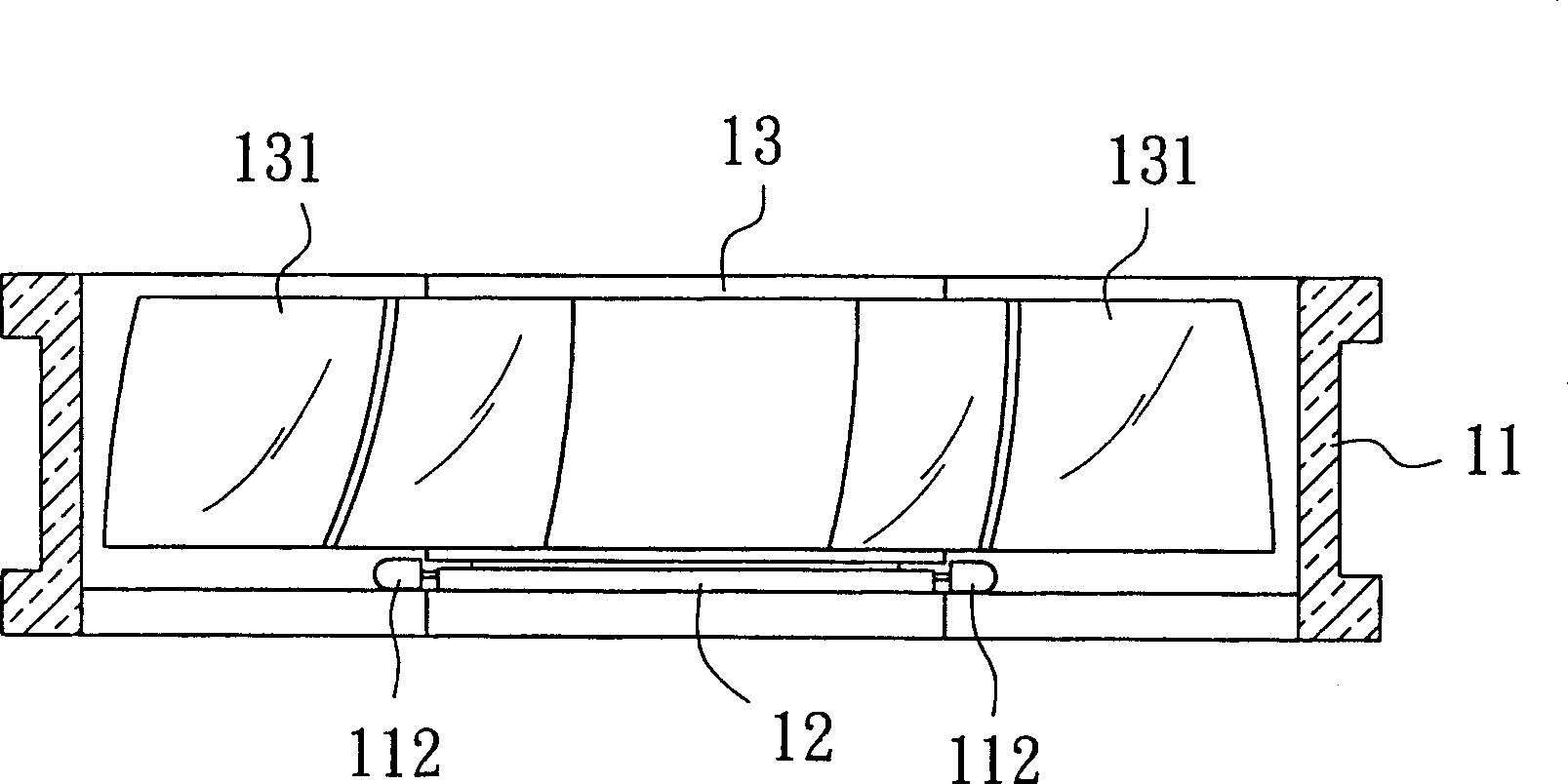

Interactive IR electronic white board

InactiveUS7429706B2Durable surfaceReduce complexityTransmission systemsGraph readingAddress busLinearity

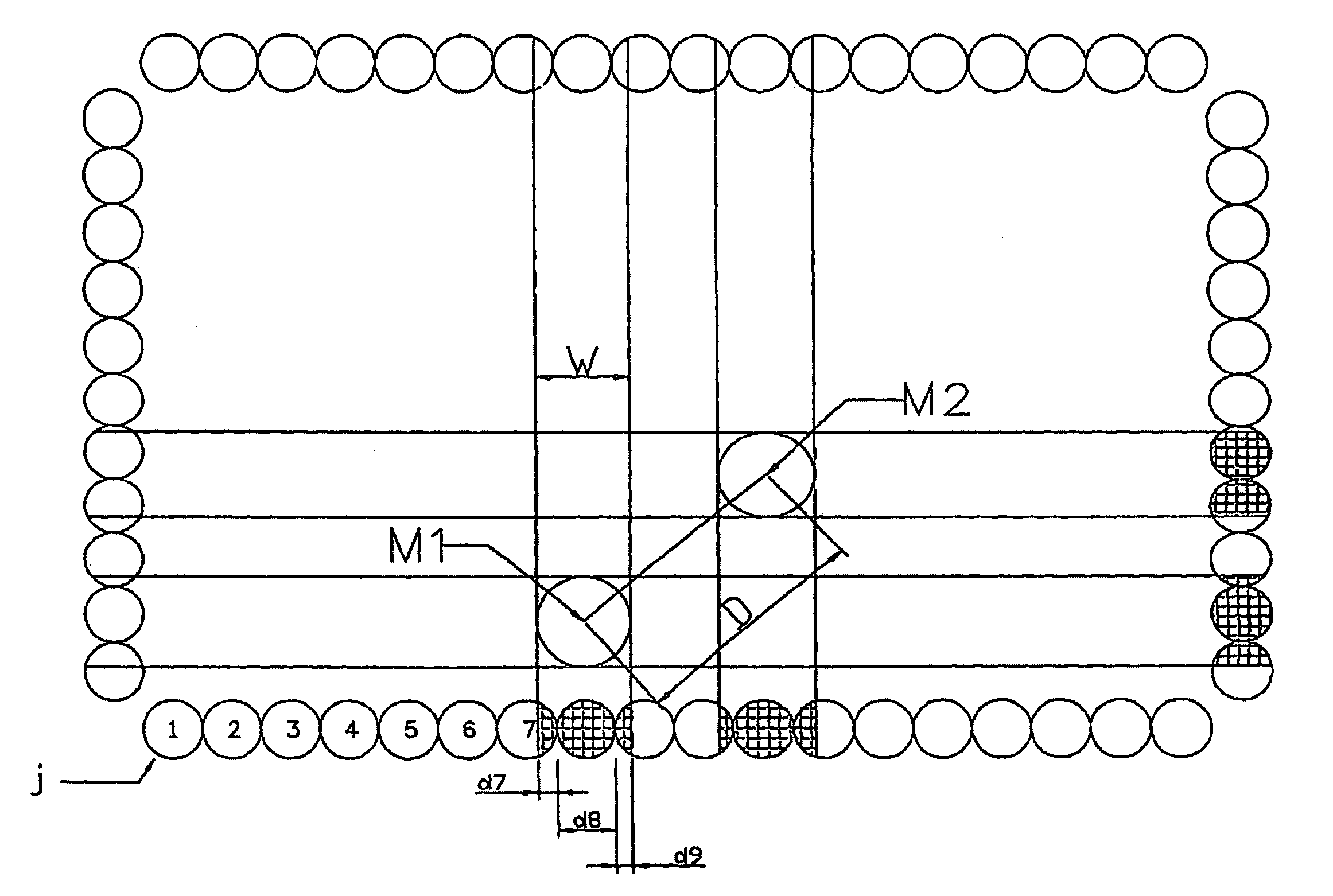

The present invention discloses an interactive IR electronic white board, around which is an infrared emitting and receiving array. An output port of a column driver of emitting array is connected to high frequency modulating signal generator, and an output port of a column driver of the receiving array is connected to a microprocessor through a signal receiving circuit and an analog-digital converter A / D. The emitting array and the receiving array are connected to emitting and the receiving driver through emitting and receiving driver lines, and the emitting driver and the receiving driver are connected with the microprocessor through address bus. The present invention utilizes the Inverse Square Law of optical theory and the linear direct ratio relation between the quantity change of light particles received by an infrared receiving diode and the output voltage of the receiving diode to associate the output voltage of the receiving diode with the interrupted width of the infrared light path, so that it can calculate the coordinate of interrupter accurately and improve the resolution of infrared scanning. The present invention can not only distribute pens or erase, but can be used by plurality of users at the same time as well.

Owner:HO WAI

Particulate compositions for pulmonary delivery

This invention concerns an improved particulate composition for delivering a drug to the pulmonary system. Applicants disclose a method of identifying an optimal form of aerodynamically light particles which are highly dispersible. The particles of the instant invention are made by creating hollow, spherical drug particles (i.e., progenitor particles) that collapse in the process of particle formation, leading to wrinkled, thin-walled drug particles of very low envelope density. Additionally, Applicants have found that such particles are especially optimal for inhaled aerosols when the surface area parameter (σ) is greater than 2, optimally greater than 3.

Owner:CIVITAS THERAPEUTICS

Interactive ir electronic white board

InactiveUS20060097989A1Durable surfaceReduce complexityCathode-ray tube indicatorsInput/output processes for data processingAddress busLinearity

The present invention discloses an interactive IR electronic white board, around which is an infrared emitting and receiving array. An output port of a column driver of emitting array is connected to high frequency modulating signal generator, and an output port of a column driver of the receiving array is connected to a microprocessor through a signal receiving circuit and an analog-digital converter A / D. The emitting array and the receiving array are connected to emitting and the receiving driver through emitting and receiving driver lines, and the emitting driver and the receiving driver are connected with the microprocessor through address bus. The present invention utilizes the Inverse Square Law of optical theory and the linear direct ratio relation between the quantity change of light particles received by an infrared receiving diode and the output voltage of the receiving diode to associate the output voltage of the receiving diode with the interrupted width of the infrared light path, so that it can calculate the coordinate of interrupter accurately and improve the resolution of infrared scanning. The present invention can not only distribute pens or erase, but can be used by plurality of users at the same time as well.

Owner:HO WAI

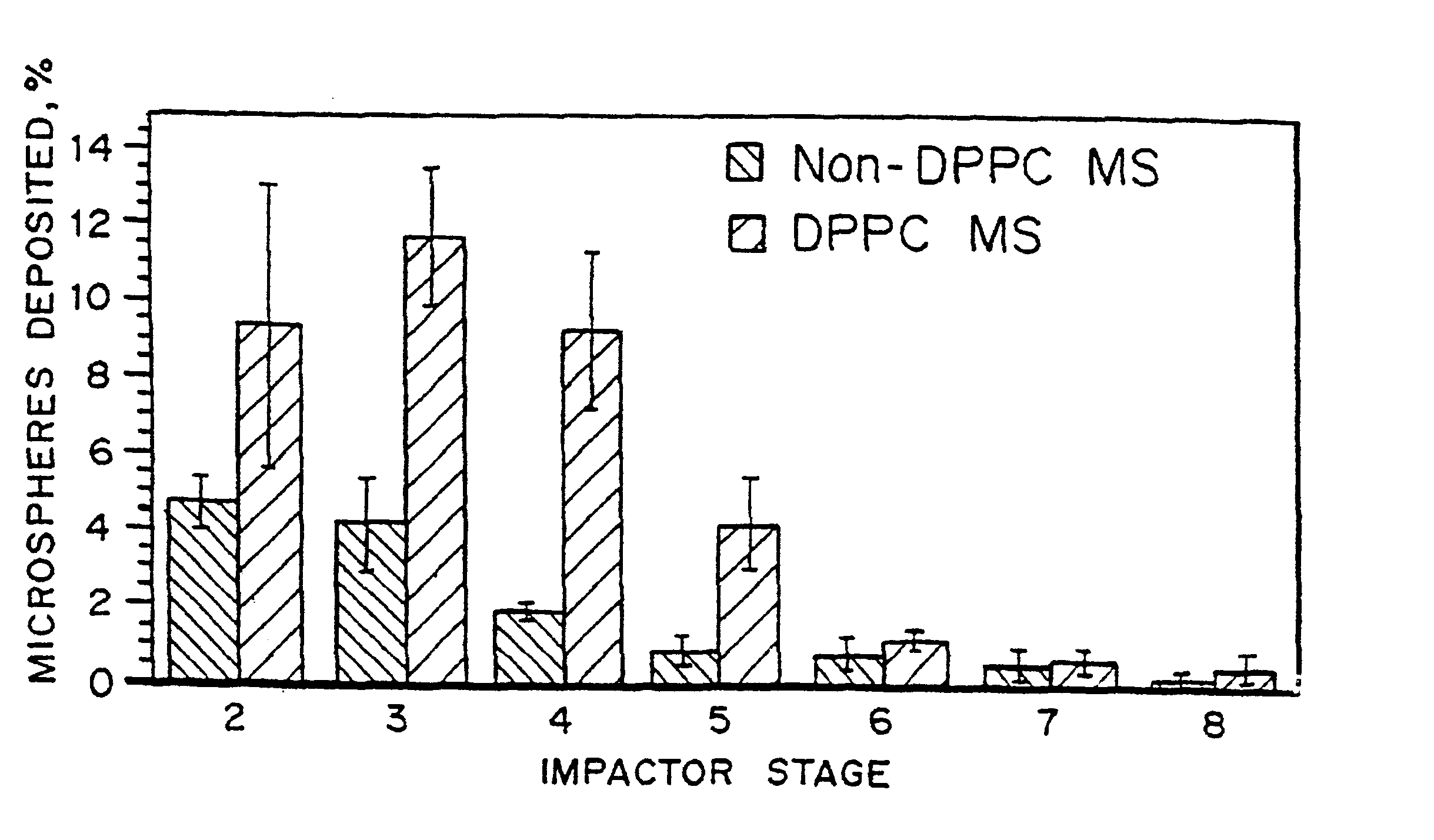

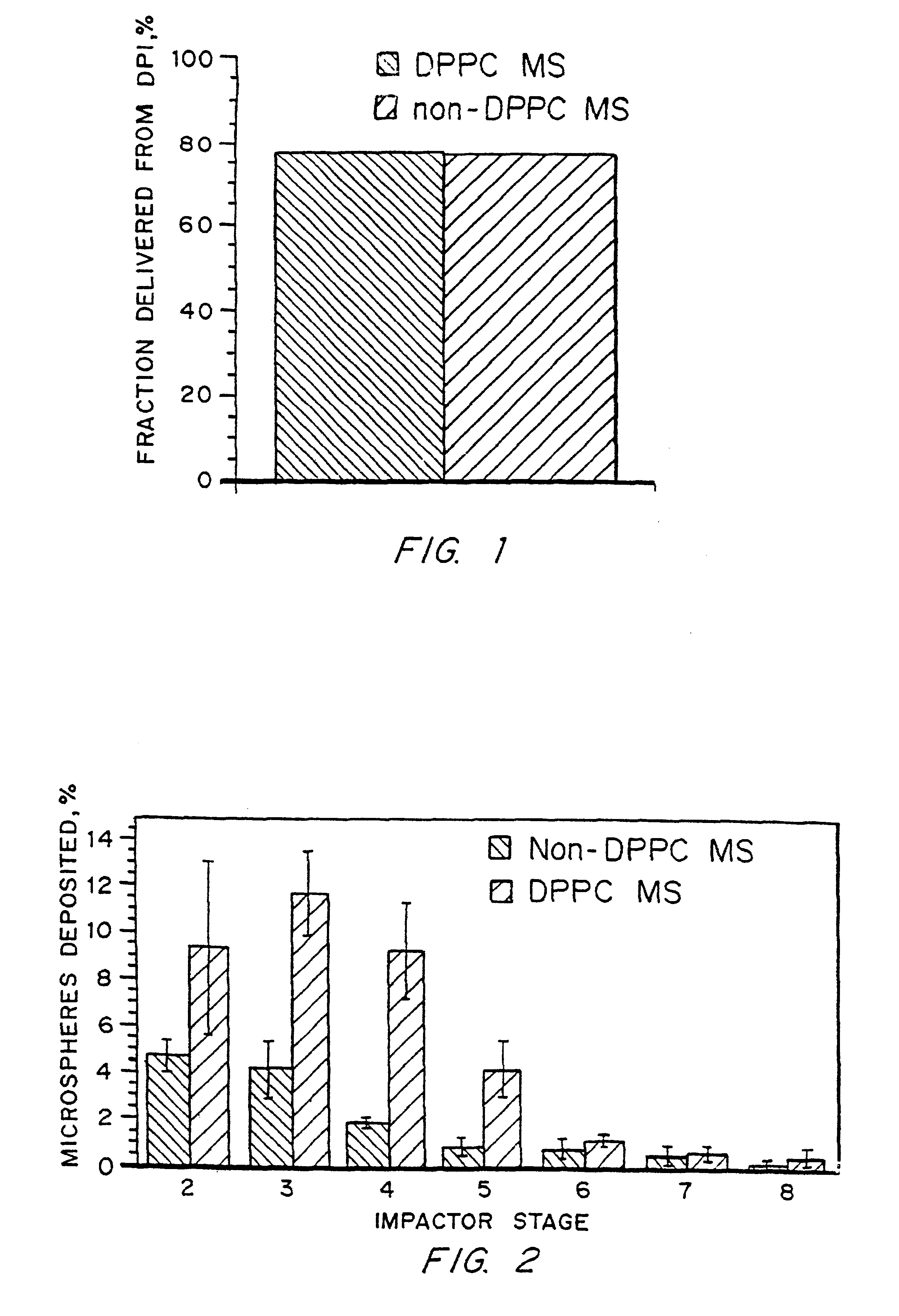

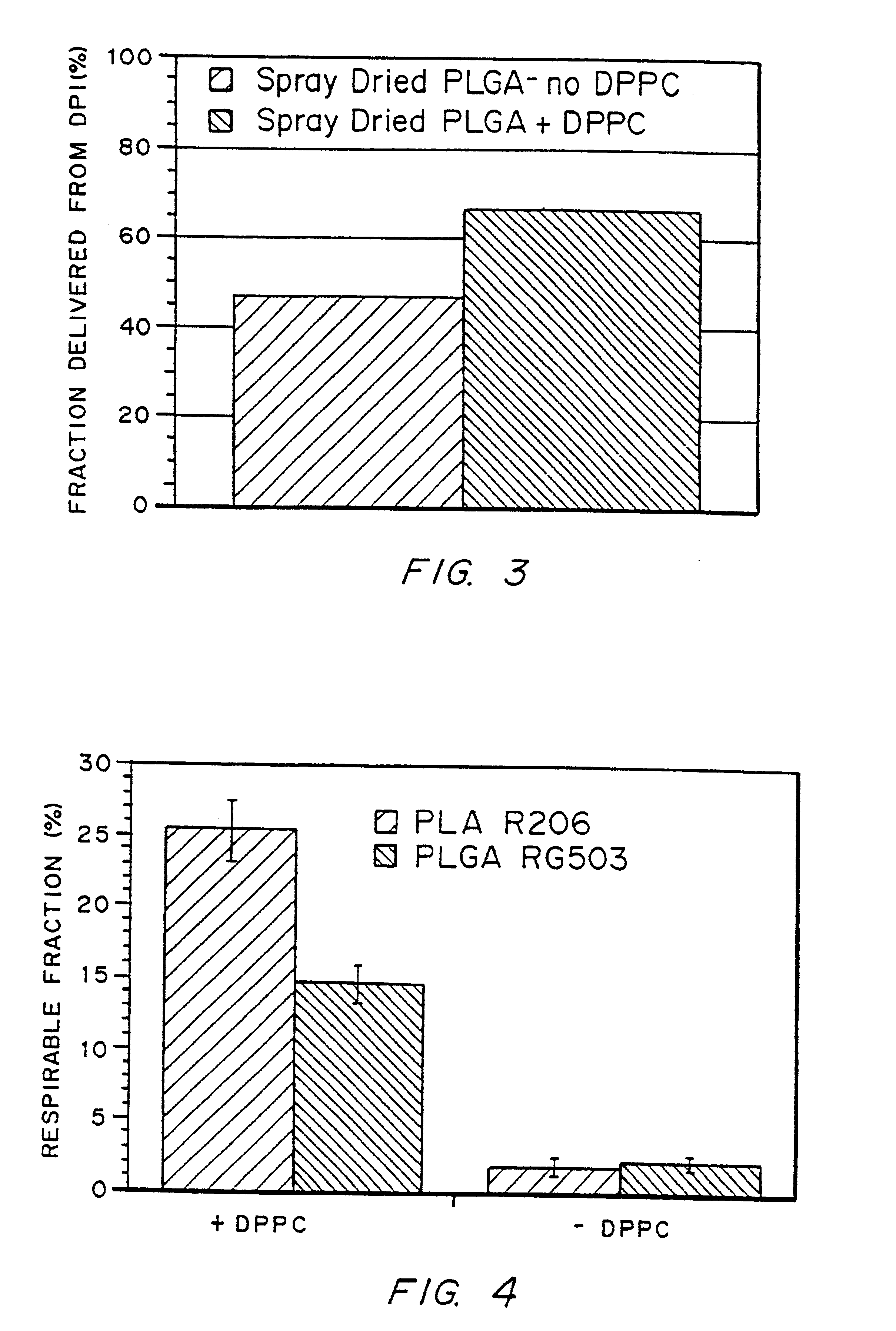

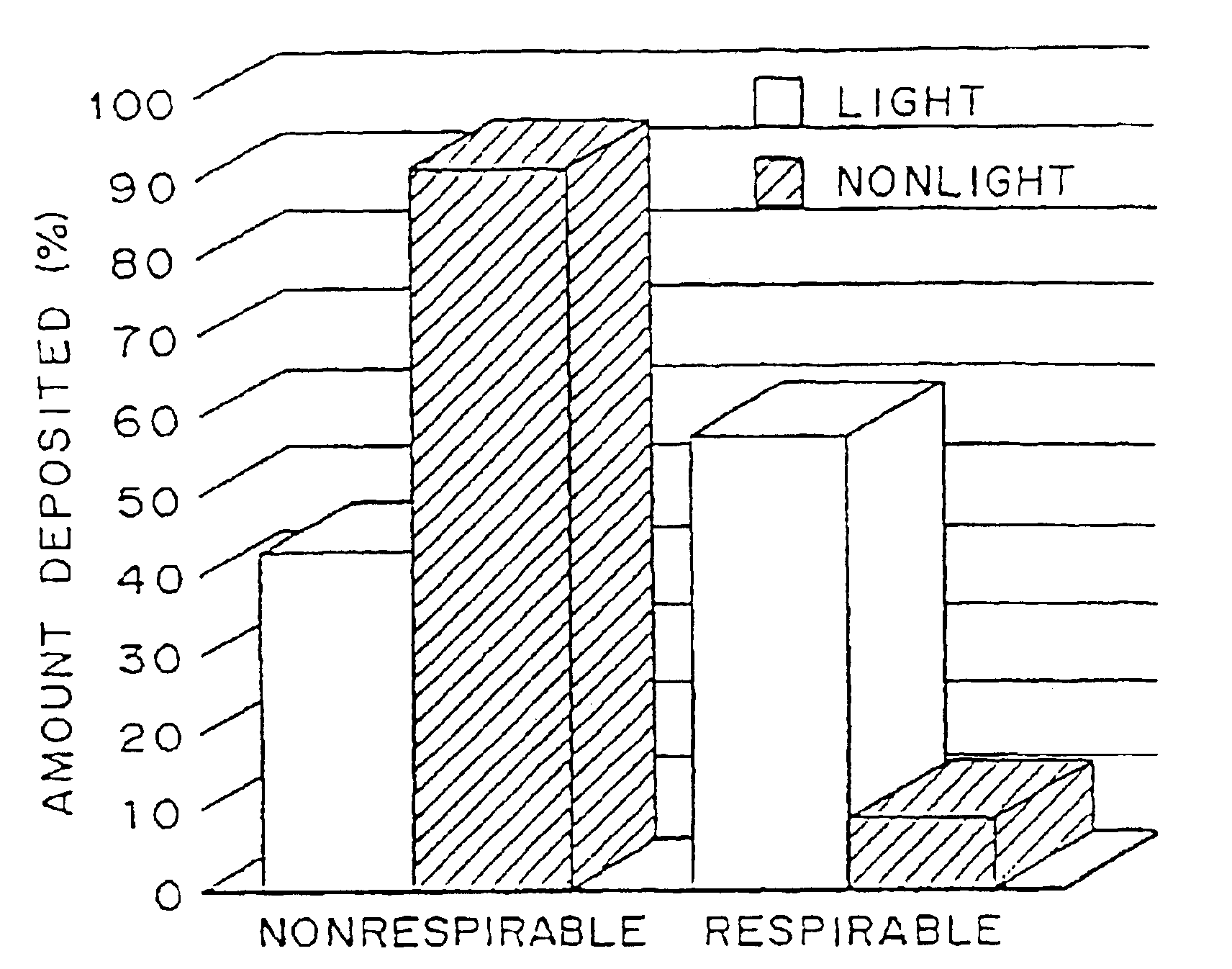

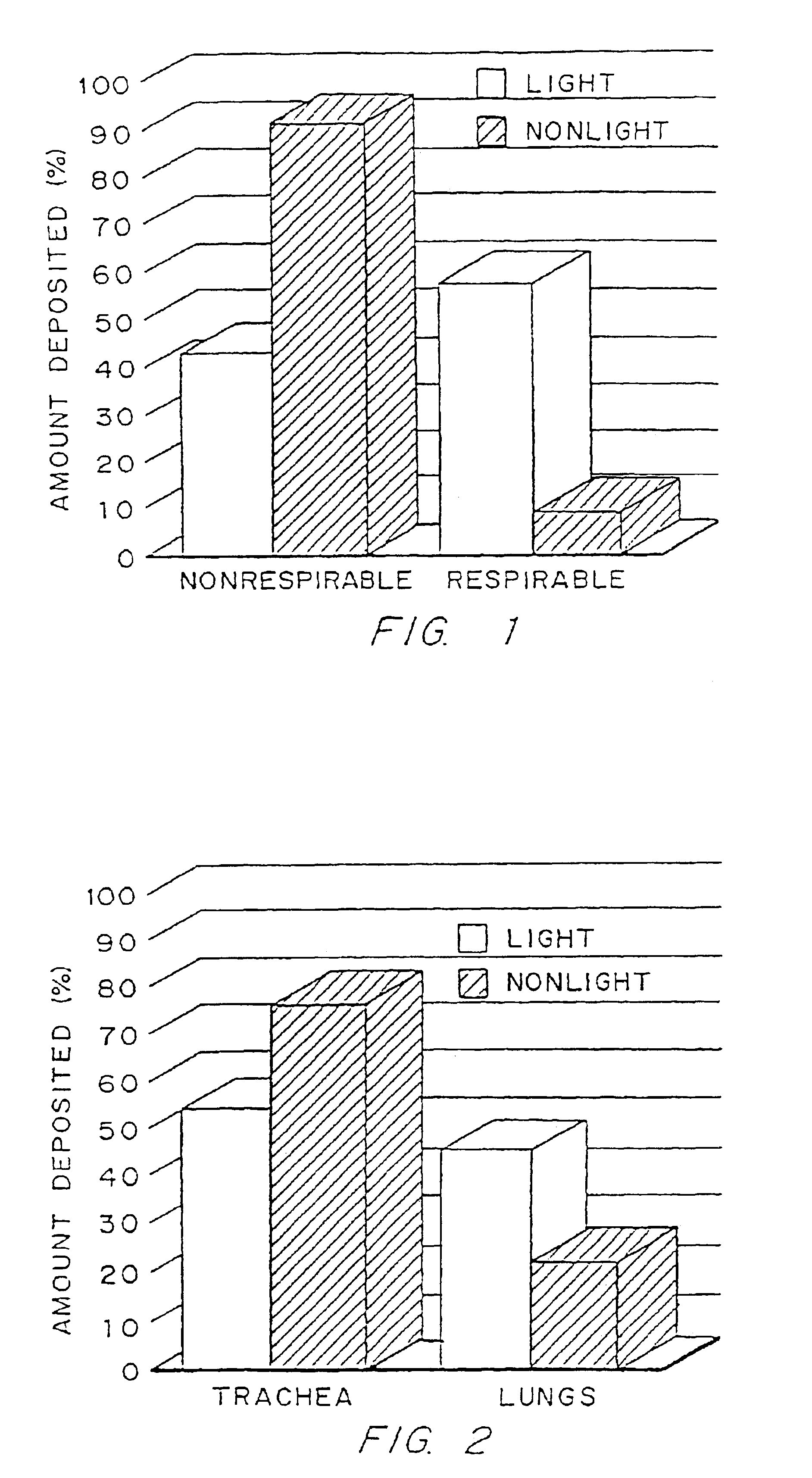

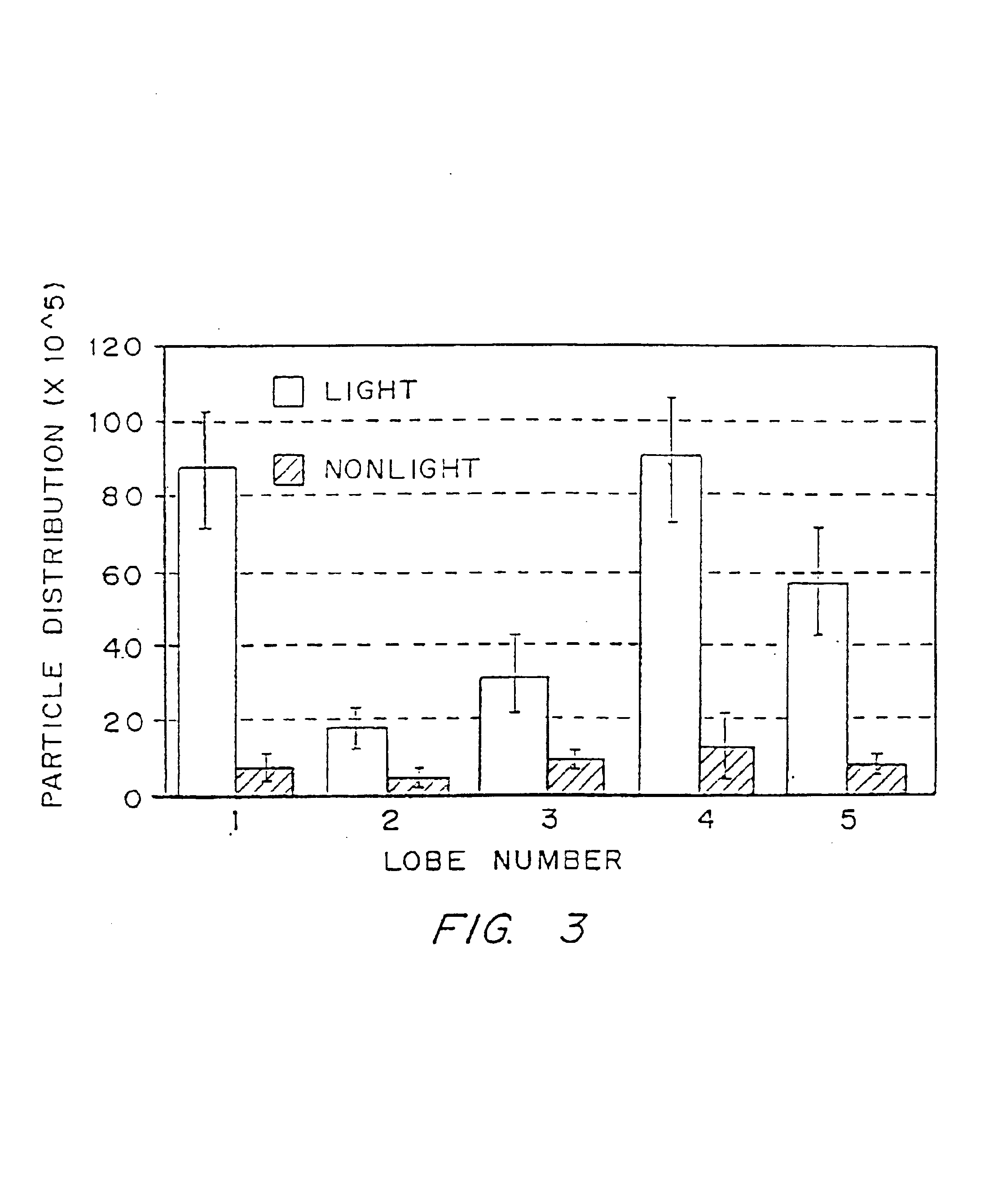

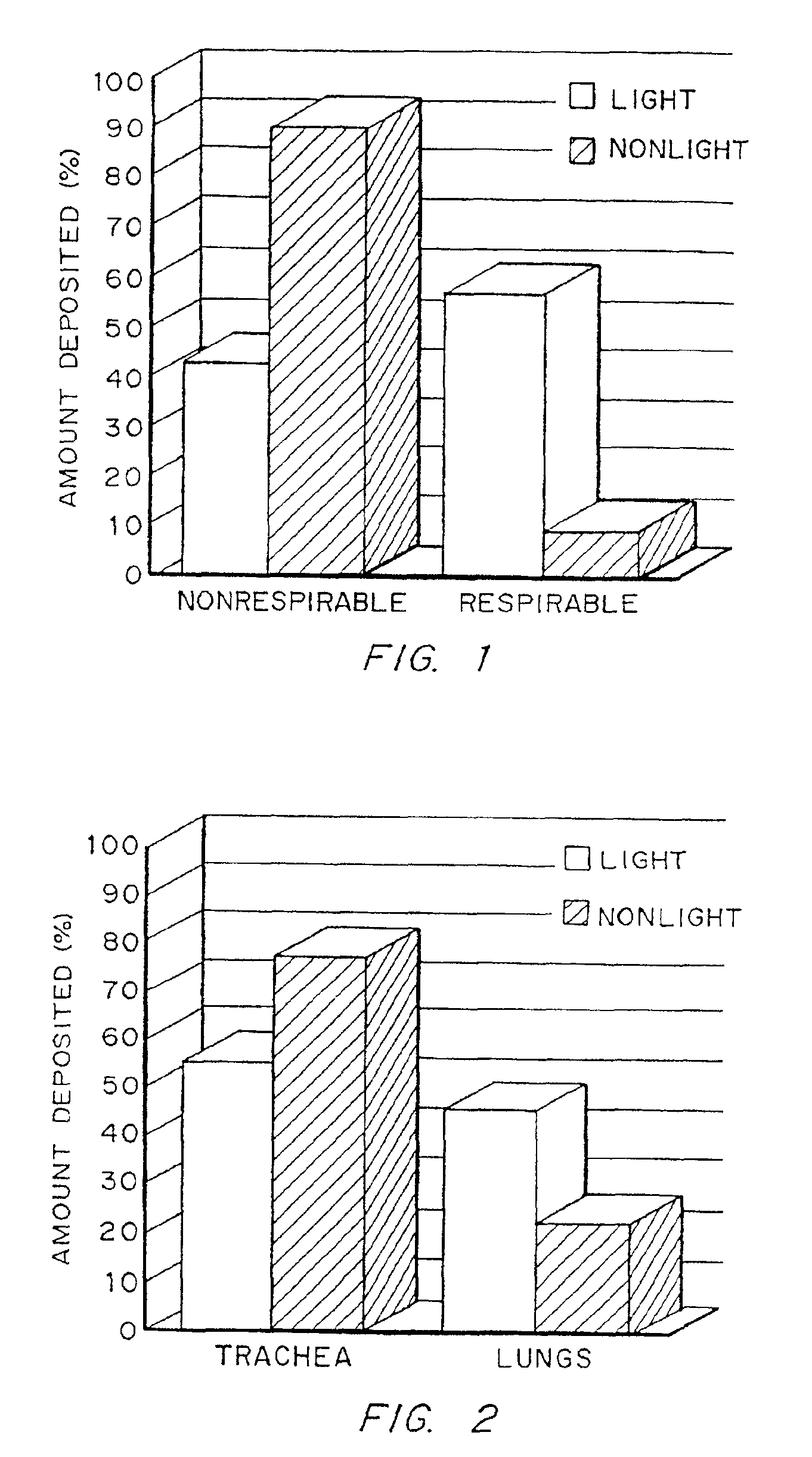

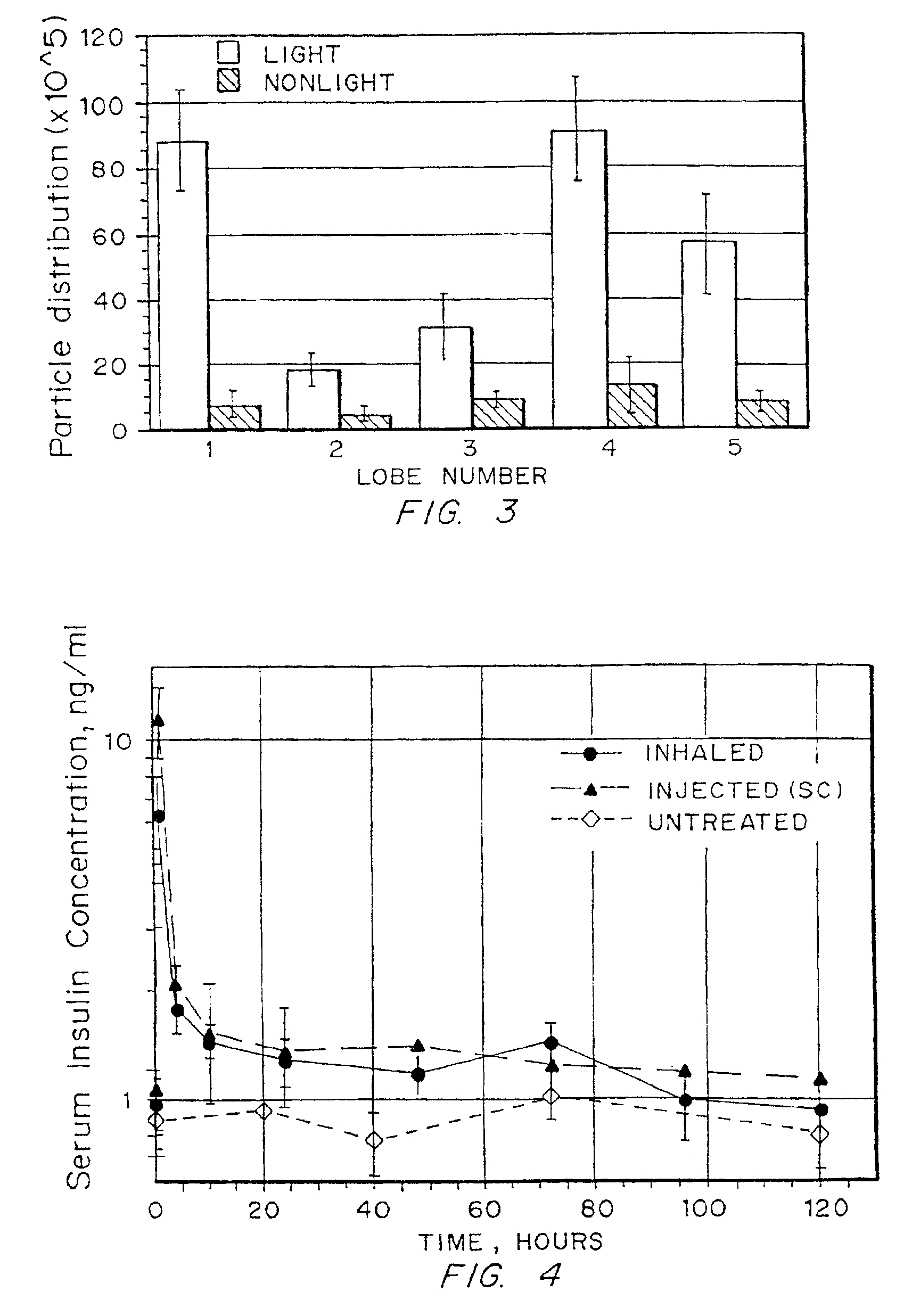

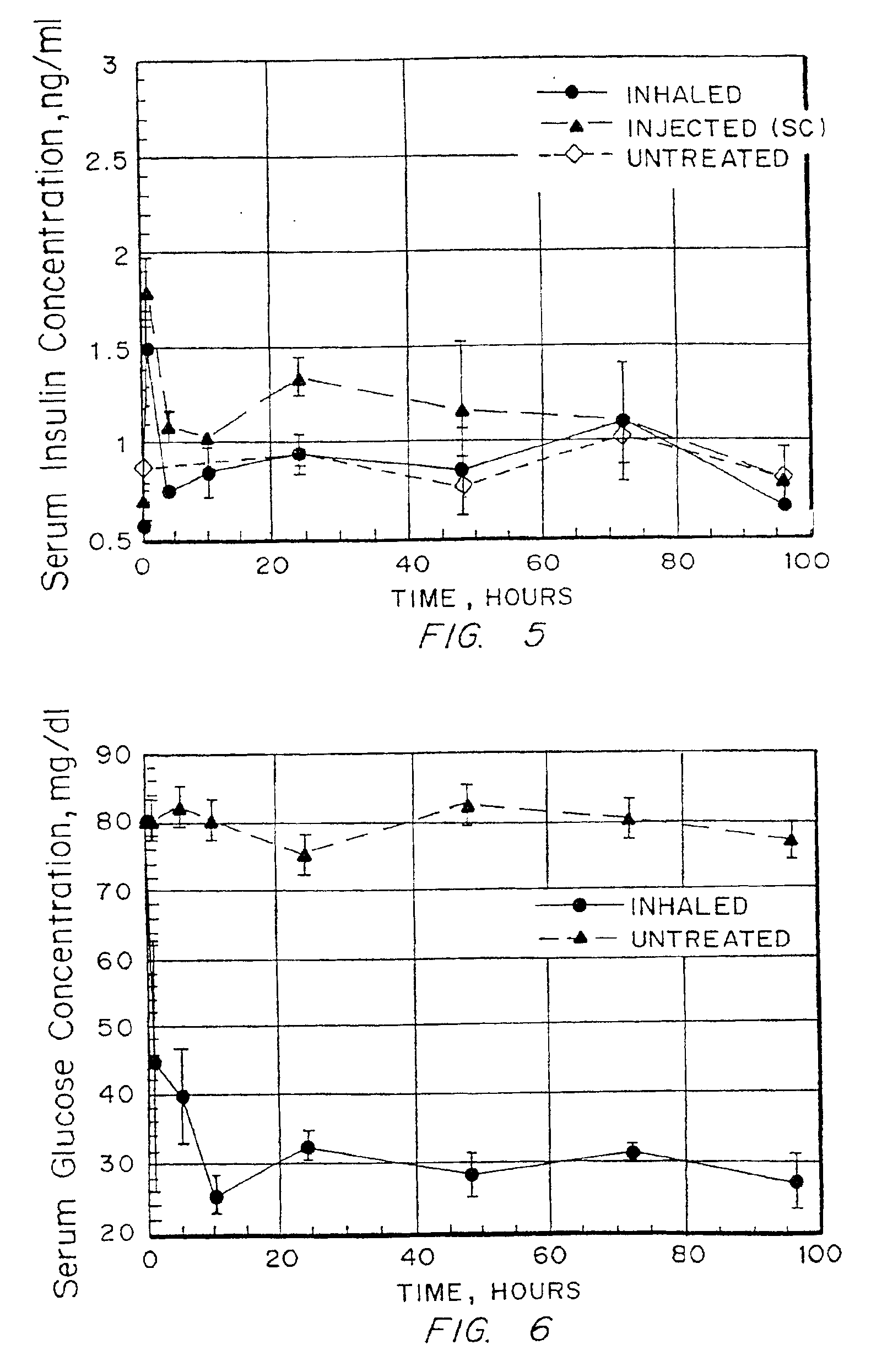

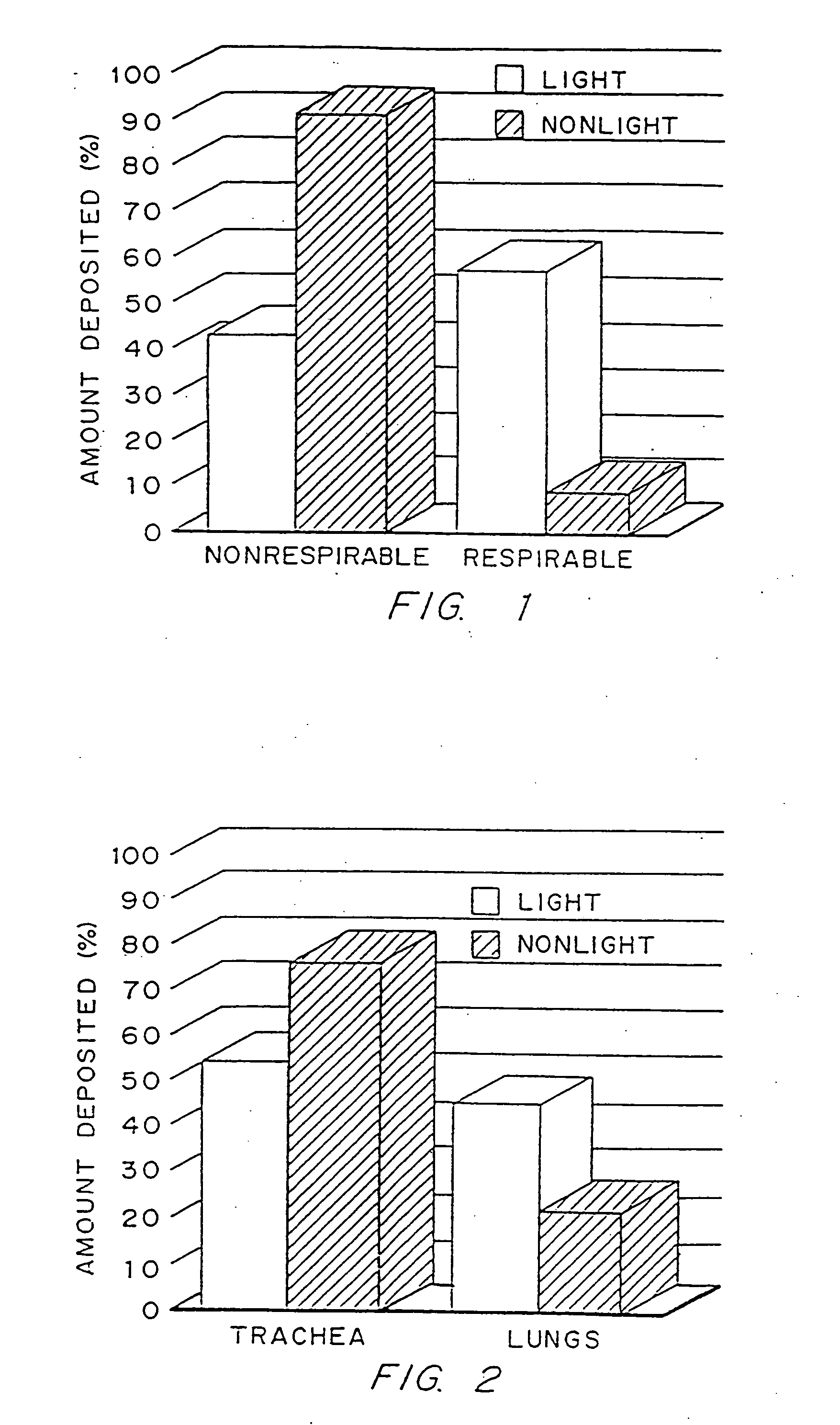

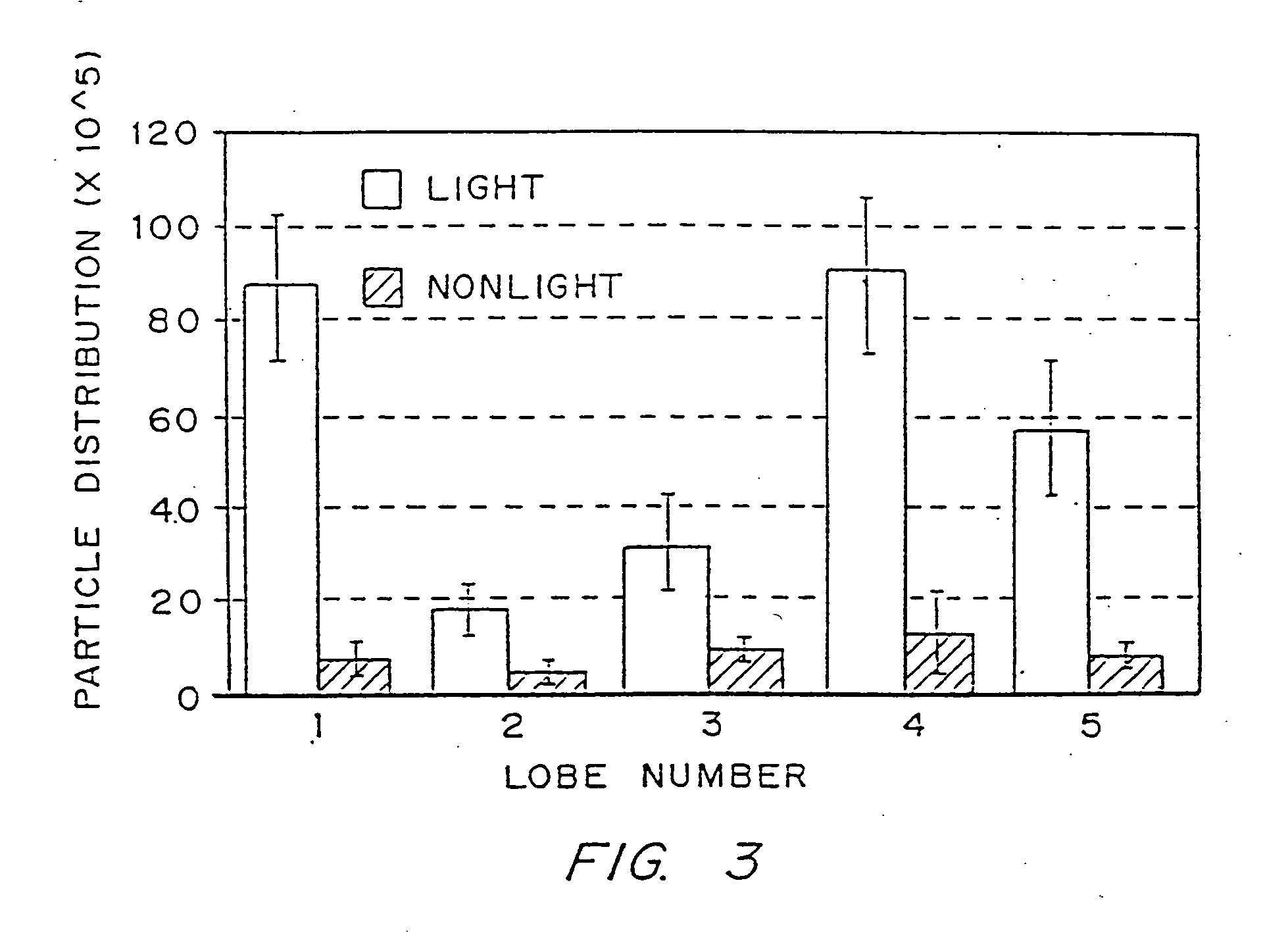

Aerodynamically light particles for pulmonary drug delivery

Improved aerodynamically light particles for drug delivery to the pulmonary system, and methods for their synthesis and administration are provided. In a preferred embodiment, the aerodynamically light particles are made of biodegradable material and have a tap density of less than 0.4 g / cm3 and a mass mean diameter between 5 μm and 30 μm. The particles may be formed of biodegradable materials such as biodegradable polymers. For example, the particles may be formed of a functionalized polyester graft copolymer consisting of a linear α-hydroxy-acid polyester backbone having at least one amino acid group incorporated therein and at least one poly(amino acid) side chain extending from an amino acid group in the polyester backbone. In one embodiment, aerodynamically light particles having a large mean diameter, for example greater than 5 μm, can be used for enhanced delivery of a therapeutic agent to the alveolar region of the lung. The aerodynamically light particles incorporating a therapeutic agent may be effectively aerosolized for administration to the respiratory tract to permit systemic or local delivery of wide variety of therapeutic agents.

Owner:MASSACHUSETTS INST OF TECH +1

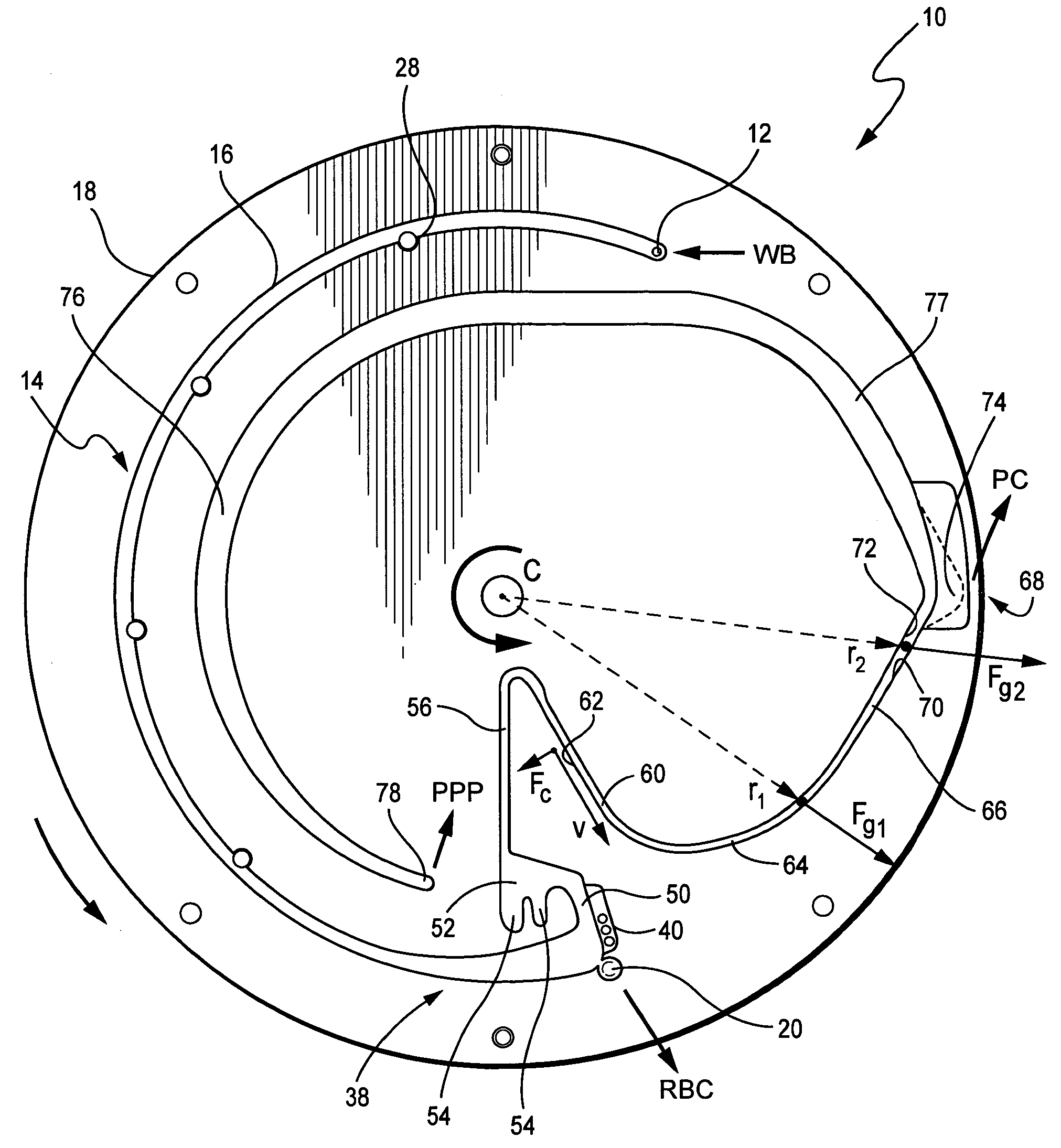

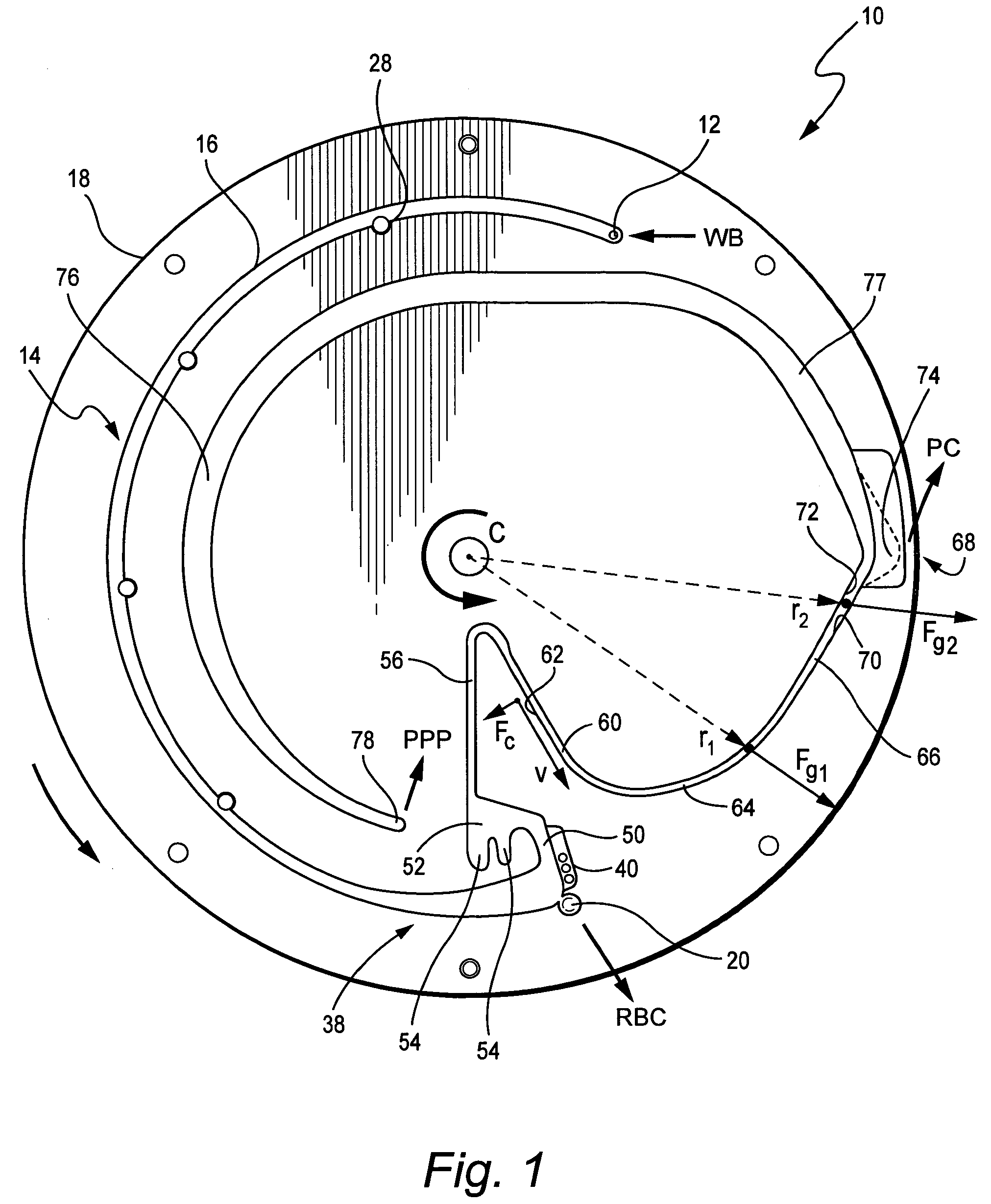

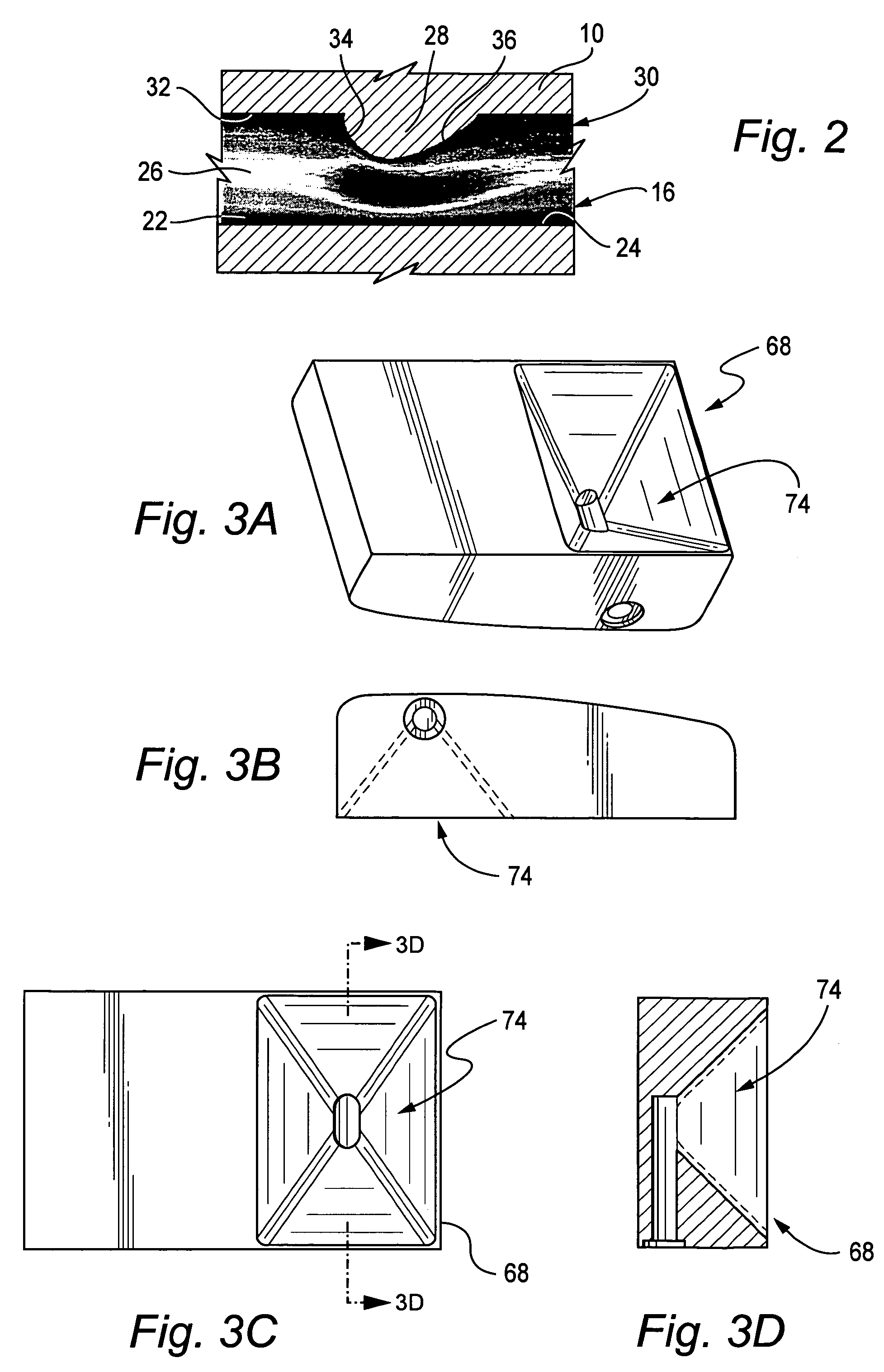

Apparatus for separation of a fluid with a separation channel having a mixer component

InactiveUS7473216B2Easy to separateMost efficientFlow mixersTransportation and packagingGravitational forceCoriolis force

For an effective separation of more than one kind of particle from a mixture, a plurality of separation stages are provided, arranged in series. Mixer elements may be disposed along the flow path to disturb the sedimenting particles, to release entrained lighter particles. Further, the separation channel may widen near the particle recovery port(s), to well suspend lighter particles in the fluid as denser particles are extracted and / or to allow gravitational forces to more effectively influence particle movement. In an example embodiment one stage utilizes Coriolis force in a narrow, radial passage for concentrating and agglomerating particles. The serial separation stages may be communicated with a radially inward extending passage to limit undesirable particle spill-over.

Owner:FRESENIUS HEMOCARE DEUTLAND

Aerodynamically light particles for pulmonary drug delivery

Improved aerodynamically light particles for delivery to the pulmonary system, and methods for their preparation and administration are provided. In a preferred embodiment, the aerodynamically light particles are made of a biodegradable material and have a tap density less than 0.4 g / cm3 and a mass mean diameter between 5 μm and 30 μm. The particles may be formed of biodegradable materials such as biodegradable polymers. For example, the particles may be formed of a functionalized polyester graft copolymer consisting of a linear α-hydroxy-acid polyester backbone having at least one amino acid group incorporated herein and at least on poly(amino acid) side chain extending from an amino acid group in the polyester backbone. In one embodiment, aerodynamically light particles having a large mean diameter, for example greater than 5 μm, can be used for enhanced delivery of a therapeutic or diagnostic agent to the alveolar region of the lung. The aerodynamically light particles optionally can incorporate a therapeutic or diagnostic agent, and may be effectively aerosolized for administration to the respiratory tract to permit systemic or local delivery of a wide variety of incorporated agents.

Owner:MASSACHUSETTS INST OF TECH +1

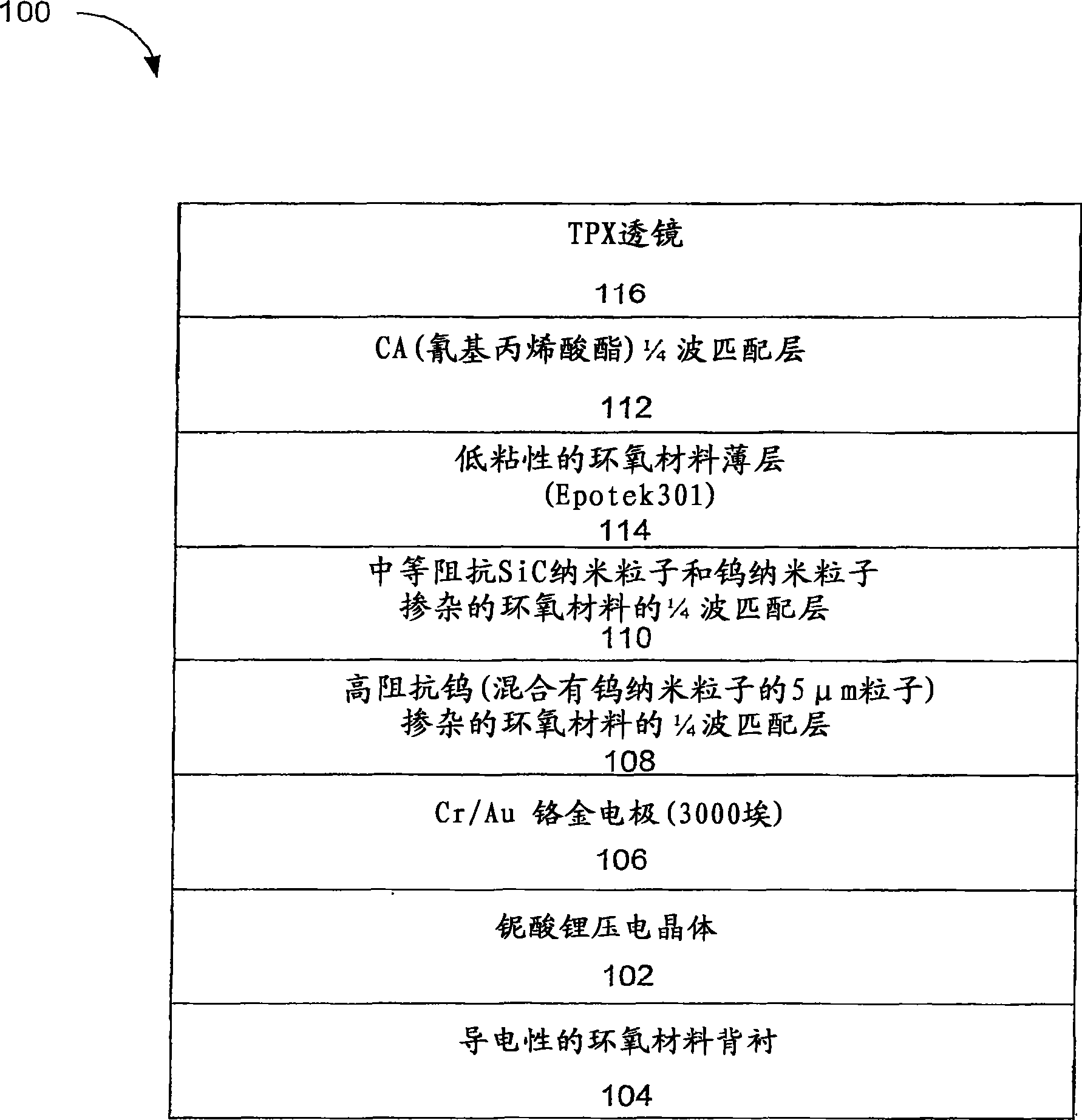

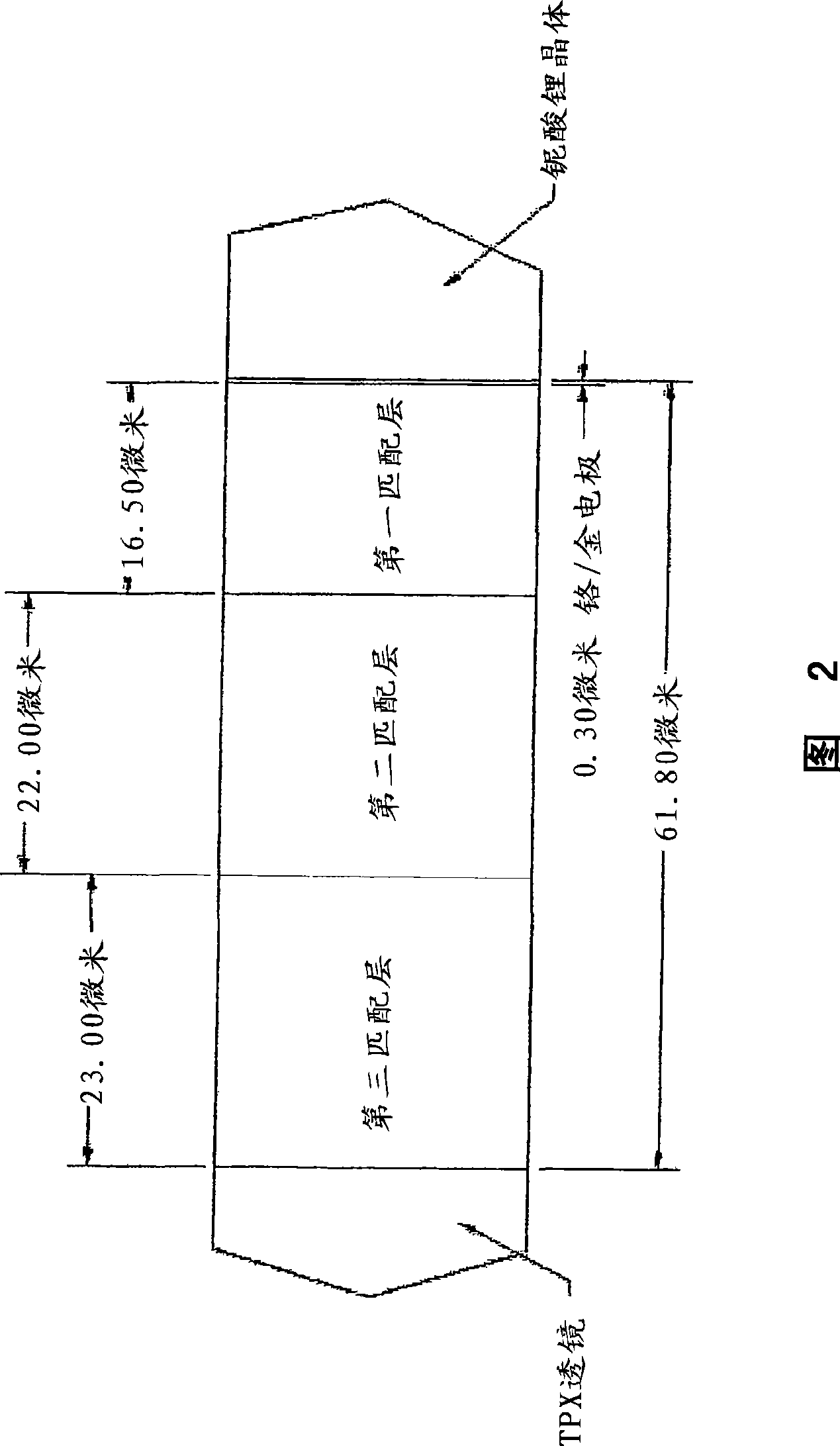

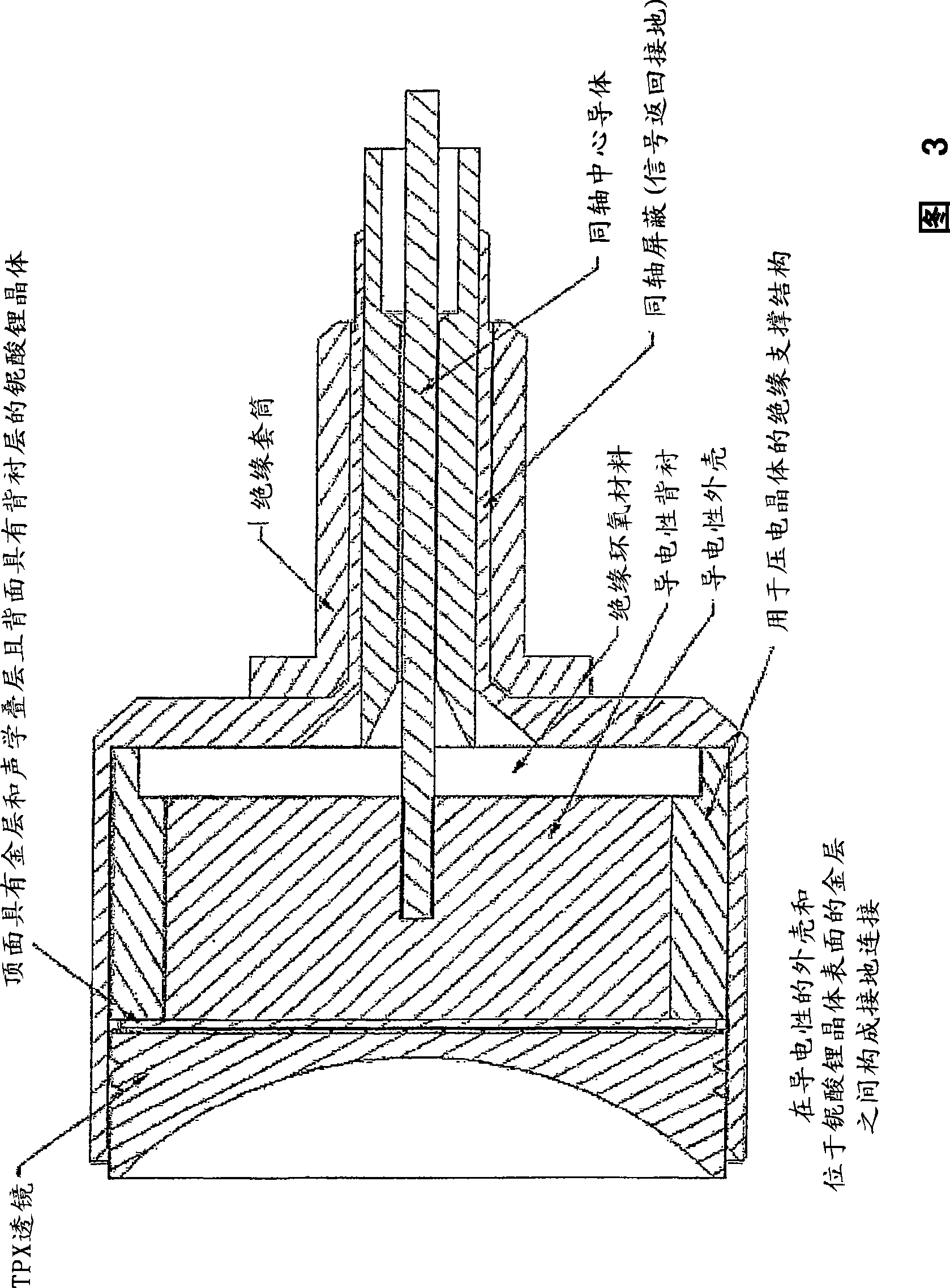

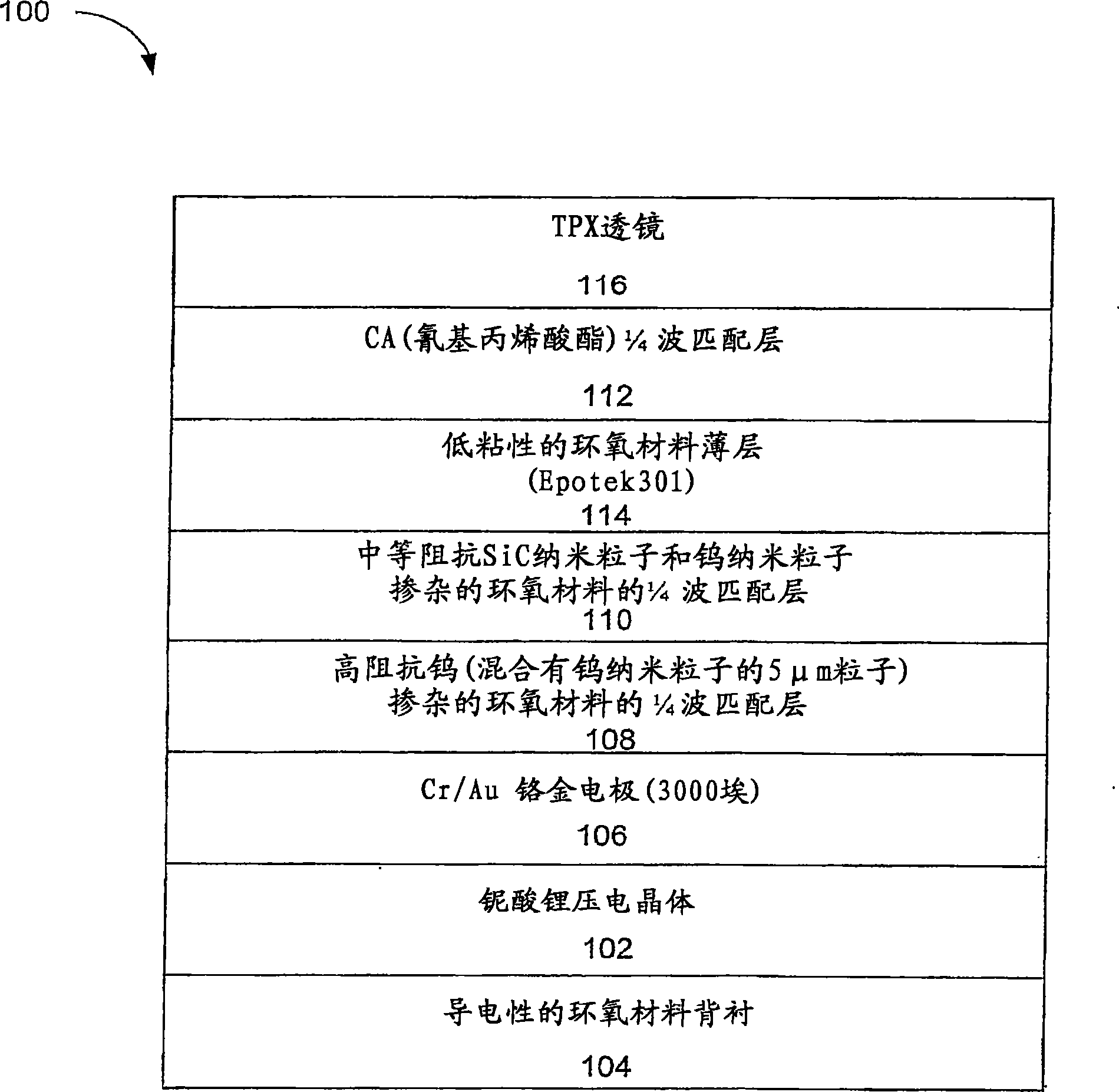

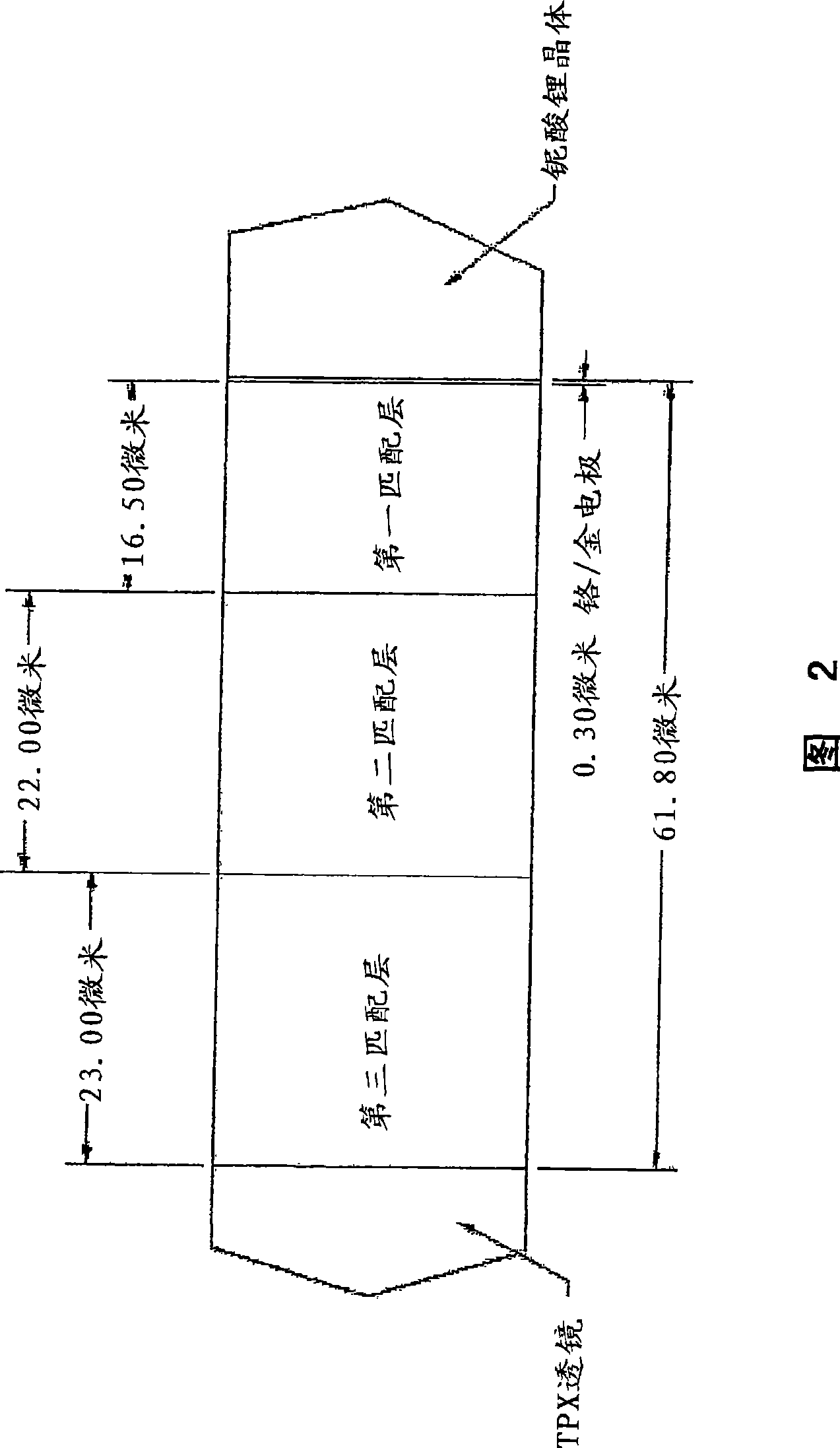

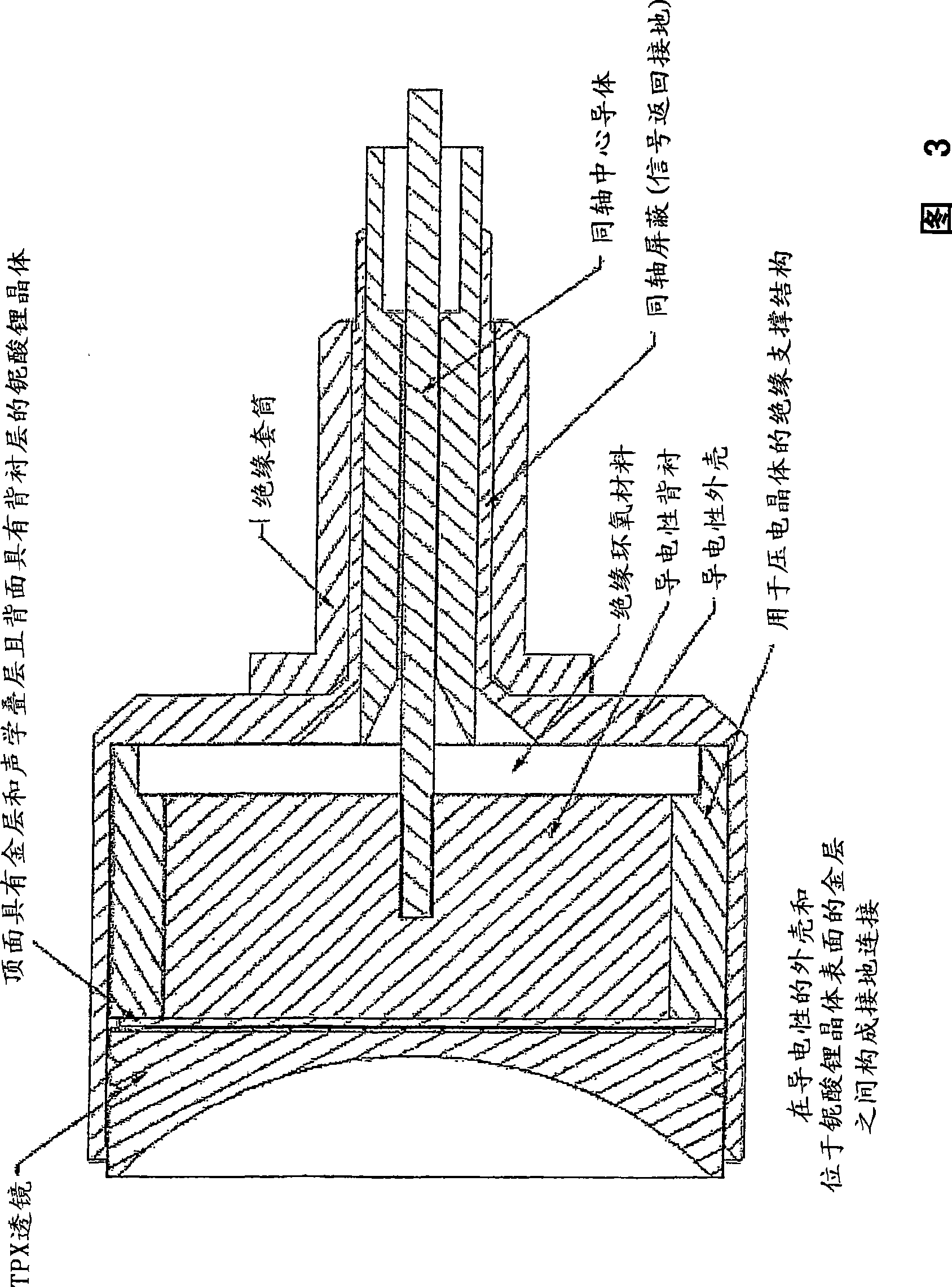

Ultrasonic matching layer and transducer

ActiveCN101442941AUltrasonic/sonic/infrasonic diagnosticsLayered productsCyanoacrylateUltrasonic sensor

In one aspect, matching layers for an ultrasonic transducer stack having a matching layer comprising a matrix material loaded with a plurality of micron-sized and nano-sized particles. In another aspect, the matrix material is loaded with a plurality of heavy and light particles. In another aspect, an ultrasound transducer stack comprises a piezoelectric layer and at least one matching layer. In one aspect, the matching layer comprises a composite material comprising a matrix material loaded with a plurality of micron-sized and nano-sized particles. In a further aspect, the composite material can also comprise a matrix material loaded with a plurality of heavy and light particles. In a further aspect, a matching layer can also comprise cyanoacrylate.

Owner:VISUALSONICS

12-degree soft-light porcelain glaze facing bricks

The invention belongs to the field of preparation of soft-light bricks, and particularly relates to 12-degree soft-light porcelain glaze facing bricks. Each 12-degree soft-light porcelain glaze facingbrick comprises a green body, a ground glaze and a facing glaze, wherein the facing glaze is prepared from potassium feldspar, burnt talc, barium carbonate, calcined alumina, calcined zinc oxide, calcined kaolin, kaolin, matte frit, transparent frit and forging light particles. The green body of the soft-light porcelain glaze facing brick is low in water absorption rate (0.05 to 0.1 percent); therupture modulus is large (40 to 45 MPa); a green brick is high in intensity, and is not easy to break; the edge bending curvature (-0.03 to +0.05 mm) and the central bending degree (-0.04 to +0.06 mm) are extremely small; the brick surface is flat, so that the bricks look tidy and attractive after being paved. The soft-light bricks promote a light pollution-free healthy atmosphere; according to the spatial optical refraction rule, light reflected by the bricks is controlled horizontally at 12-degree soft light, so that the spatial light sensation is moderate in brightness and darkness, the most comfortable light sensing state is created for eyes, and the potential fatigue hazard is avoided.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Light sand without burning and preparation method thereof

The invention discloses light sand without burning and a preparation method thereof. The light sand without burning is prepared by the following steps: crushing aerated concrete leftover material or waste aerated concrete into particles, stirring cement, finely ground silicon-contained material and water storage material uniformly so as to prepare powder body material with canned surface; and spraying a surface modifier solution on the surfaces of aerated concrete particles, then canning the aerated concrete particles and the powder body into a ball, standing for one hour so as to conduct secondary canning to a ball, standing the formed spherical particle for 2-10h, and then pressurizing and evaporating the particle under the conditions of 80-190 DEG C and 1atm-15atm, thereby obtaining light particles with particle size being not more than 5mm, stacking density being not more than 1200kg / m3, cylinder pressure being more than 3.5MPa and water absorbing rate being not more than 5%. On the basis of saving production raw materials, the strength of the light aggregate can be improved effectively, and the water absorbing rate is reduced.

Owner:HOHAI UNIV +1

Production method of light particle board

InactiveCN107671979AReduce usageReduce Density EffectsFlat articlesDomestic articlesAdhesiveParticle board

The invention belongs to the technical field of artificial boards, and relates to production of particle boards, in particular to a production method of a light particle board. The production method of the light particle board comprises the steps of: shaving preparation, drying, glue stirring, pavement, prepressing and hot pressing; a surface layer adopts common wood fine shavings; core layer shavings are corn straw shavings and pennisetum alopecuroides straw shavings; and the hot pressing process is to hot press a prepressed board blank at a temperature of 170-190 DEG C under a pressure of 2.5-3.5 MPa for 3-6 min. Light materials are used as raw materials; and a production process is improved to produce the light particle board. Based on a traditional particle board production process, the core layer shavings are changed from common wood shavings to the corn straw shavings and the pennisetum alopecuroides straw shavings with lower density and bulk density; MDI resins are added in a core layer; and the use level of MUF resins is reduced to reduce influence on the board density by adhesive and to improve overall board physical performances. The light particle board, whose density iswithin 0.38-0.50 g / cm3 and physical and chemical indexes both meet national standard requirements, can be manufactured by the production method.

Owner:DARE WOOD BASED PANEL GRP

Aerodynamically light particles for pulmonary drug delivery

InactiveUS20050158249A1Reduce deliveryConvenient lightingBiocidePowder deliveryPolyesterMean diameter

Improved aerodynamically light particles for drug delivery to the pulmonary system, and methods for their synthesis and administration are provided. In a preferred embodiment, the aerodynamically light particles are made of biodegradable material and have a tap density of less than 0.4 g / cm3 and a mass mean diameter between 5 μm and 30 μm. The particles may be formed of biodegradable materials such as biodegradable polymers. For example, the particles may be formed of a functionalized polyester graft copolymer consisting of a linear α-hydroxy-acid polyester backbone having at least one amino acid group incorporated therein and at least one poly(amino acid) side chain extending from an amino acid group in the polyester backbone. In one embodiment, aerodynamically light particles having a large mean diameter, for example greater than 5 μm, can be used for enhanced delivery of a therapeutic agent to the alveolar region of the lung. The aerodynamically light particles incorporating a therapeutic agent may be effectively aerosolized for administration to the respiratory tract to permit systemic or local delivery of wide variety of therapeutic agents.

Owner:EDWARDS DAVID A +6

Infrared ray touch device with high resolutions

Through building the model of light particle distribution density in the optical axis channel, using the relation between the reduction of the light particle density caused by shelter from the blocking object and the output voltage variety of the receiving tube, based on the voltage variety generated when the moving object passing through optical axis channel, the quadratic function curve or exponential, logarithmic curve equation are created. The specific position or coordinate lambda of the block object passing through optical axis channel can be obtained by the known voltage. By applying the method, the resolution of the infrared capture is increased greatly so as to realize the technique of capturing the handwriting script by using infrared accurately and smoothly.

Owner:贺伟

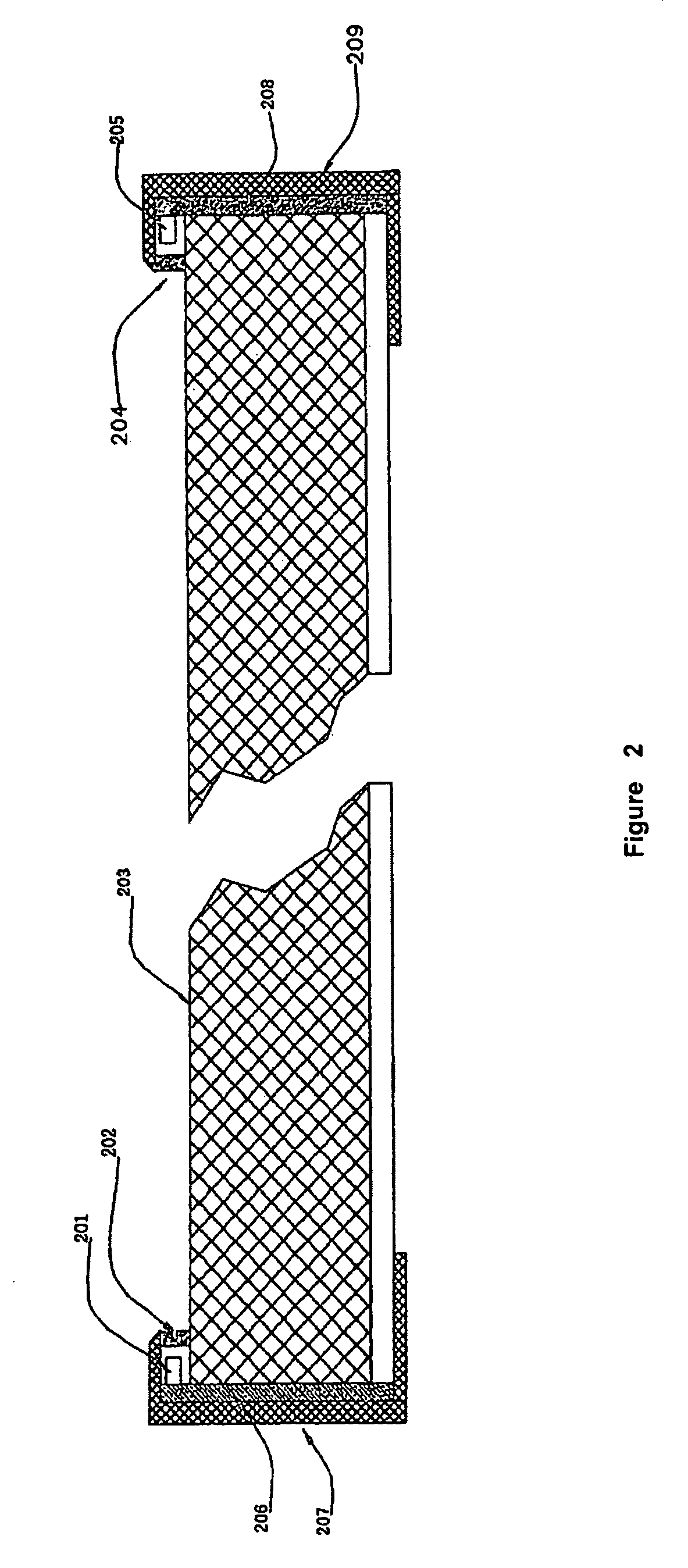

Method and Apparatus for the Separation of Solid Particles Having Different Densities

A method and apparatus for separating solid particles of different densities, using a magnetic process fluid. The solid particles are thoroughly mixed in a small partial flow of the process fluid. The small turbulent partial flow is added to a large laminar partial flow of the process fluid, after which the obtained mixture of the respective partial process fluids is conducted over, under, or through the middle of two magnet configurations, wherein the particles are separated into lighter particles at the top of the laminar process fluid and heavier particles at the bottom of the laminar process fluid, each of which are subsequently removed with the aid of a splitter. After that furthermore the particles of low density and the particles of high density are separated from the respective process streams, dried and stored. Finally, the process fluid from which the particles have been removed is returned to the original starting process stream. The method according to the invention is especially suitable, for example, for separating a mixture of polypropylene particles and polyethylene particles.

Owner:URBAN MINING CORP BV

Ultrasonic matching layer and transducer

ActiveCN101442940AUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationCyanoacrylateUltrasonic sensor

Owner:富士胶卷视声公司

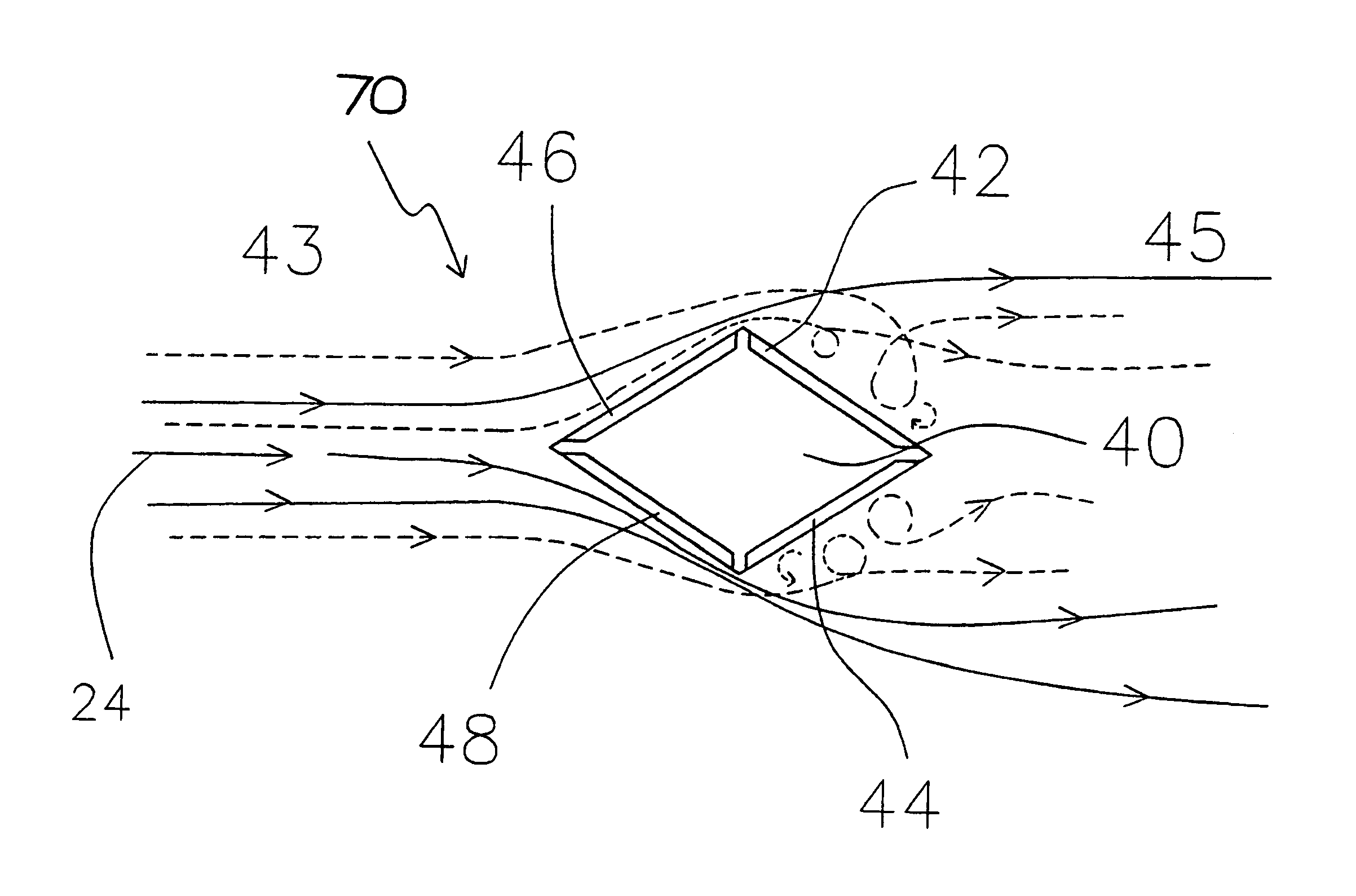

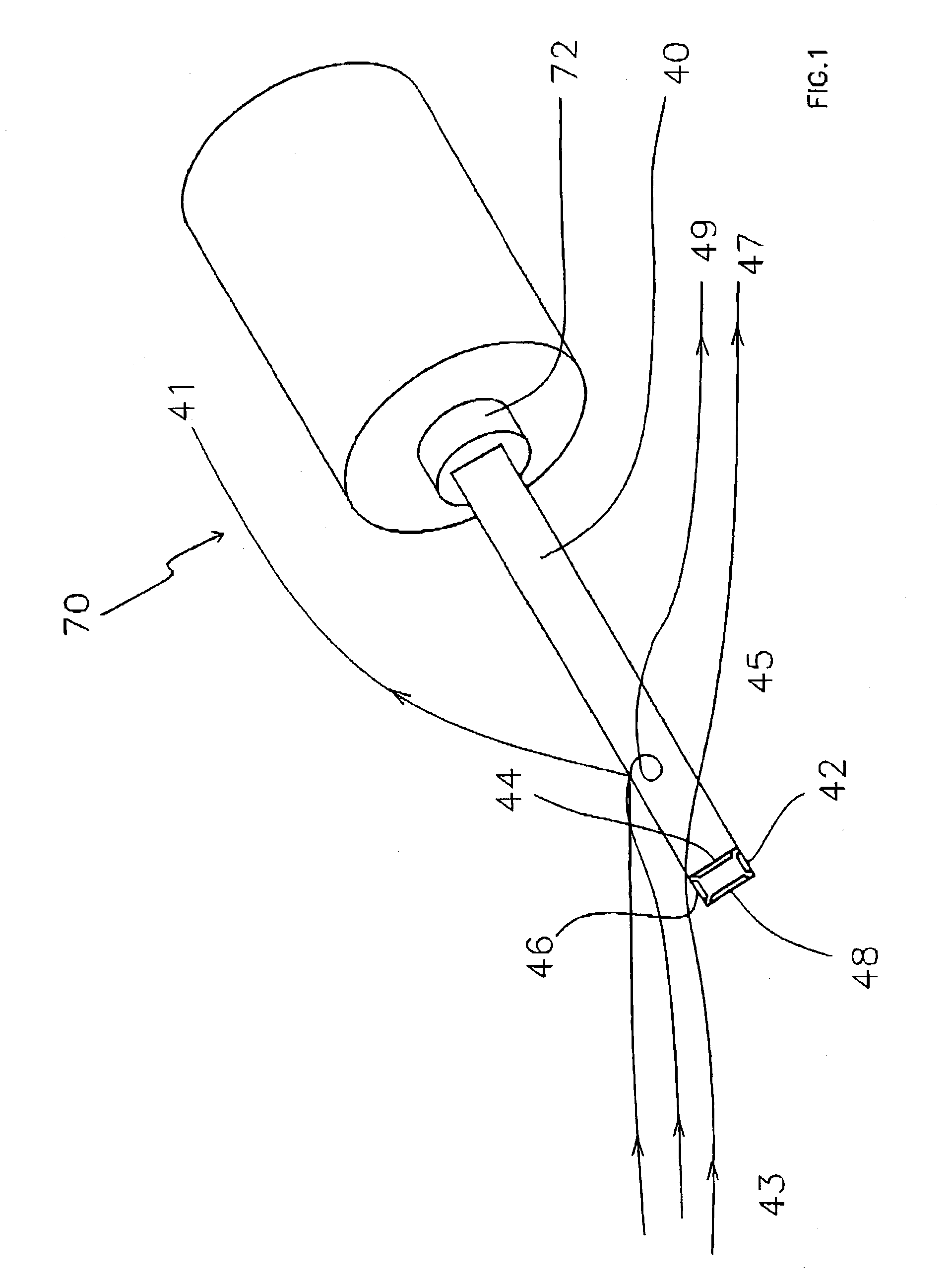

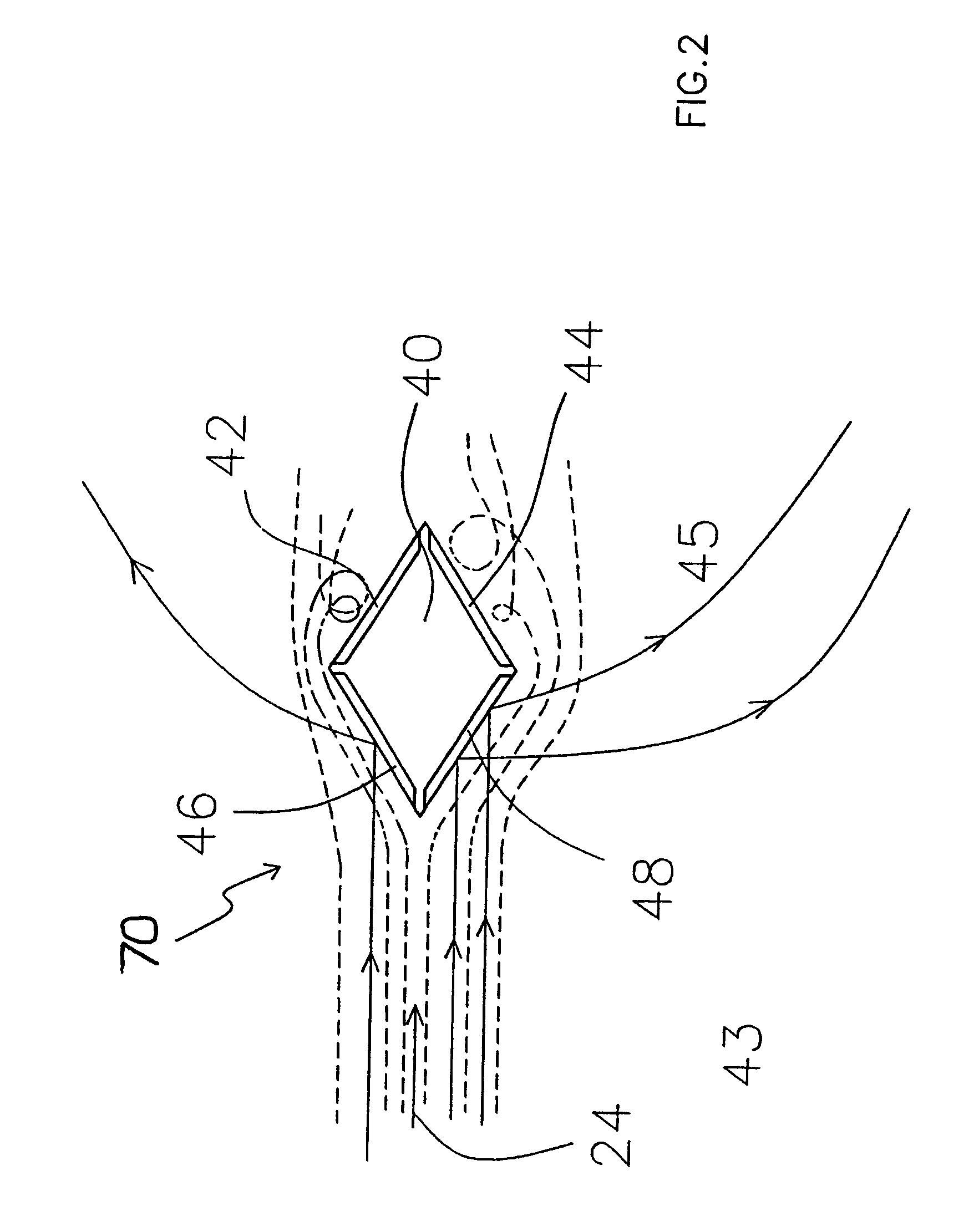

Method and apparatus for detecting particles in a gas flow

InactiveUS7063731B2Improve linearitySamplingMaterial analysis by electric/magnetic meansLinearityLarge particle

The application discloses several methods of detecting particles moving in a gas flow, a detection means (70), a method of improving the linearity of the signal produced by a triboelectric particle detector, a method to test a signal path of an emission monitor, an emission monitor for detecting particles, and a method of detecting faults in a triboelectric probe of system for detecting particles entrained in a gas flow. The particle detection means (70) includes a gas flow deflection means (40) having an upstream face (43) and a downstream face (45) and a detector (42, 44) associated exclusively with the downstream face (45). Deflecting the gas flow creates vortices that have little effect on the large particles, but cause the small particles to move close to the detectors on the downstream face. Therefore the downstream detectors (42, 44) are particularly sensitive to light particles. The method improves of small particles and provides accurate particle counts.

Owner:GOYEN CONTROLS CO PTY LTD

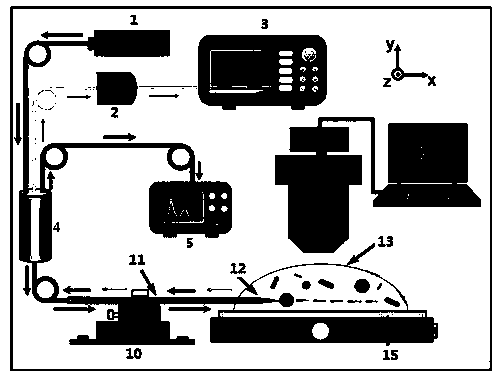

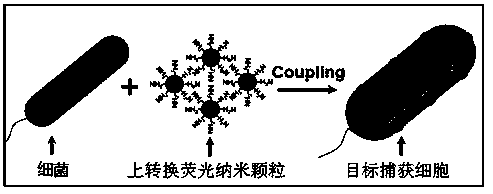

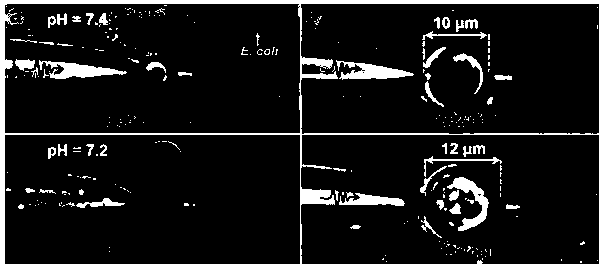

Cell capture and fluorescence enhancement device and method based on biological lens

InactiveCN109374588AReduce limitationsReduce volumeMaterial analysis using wave/particle radiationFluorescence/phosphorescenceFluorescenceSpectrograph

The invention discloses a cell capture and fluorescence enhancement device and method based on a biological lens. The device comprises a laser device, a photoelectric detector, an oscilloscope, an optical fiber coupler, a spectrograph, an optical coupling part, a microscope, an objective lens, a computer, an optical fiber adjusting rack, capillary glass tubes, an optical probe, a suspension, an objective table and a glass slide. The method includes following steps: S1, preparing the optical fiber probe for capturing an experimental object and a detection signal; S2, preparing a bacterial suspension; S3, preparing target capture cells; S4, preparing a biological lens suspension. Nano photon jet flow having stronger focusing property is utilized to excite stronger fluorescence of upconversion nano light particles, so that the light-emitting efficiency of the device is improved by two magnitude orders.

Owner:JINAN UNIVERSITY

Self-insulation material of light particle and fiber concrete series

The invention relates to a novel material, and belongs to the technical field of building materials. A self-insulation material of light particle and fiber concrete series is disclosed. Sealed waterproof light particles and fine short fibers are mixed into concrete. The invention effectively solves the problem that novel building materials such as aerated concrete and foam concrete are high in water absorption rate, low in strength and easy to crack. Because the self-insulation material of light particle and fiber concrete series contains sealed waterproof light particles and fine short fibers, the material has obvious effects of light weight, high strength, sound insulation, crack resistance, etc., can be prefabricated and cast into various blocks and plates, or cast to mould by shipping in a canned car on site, can be widely used as the materials for self-insulation outer walls, various walls with retaining filling structures and roofing, has a good energy saving effect, conforms to national industrial policies of low carbon and environmental protection, and helps to promote the improvement of energy conservation and environmental protection building materials.

Owner:杨卫平

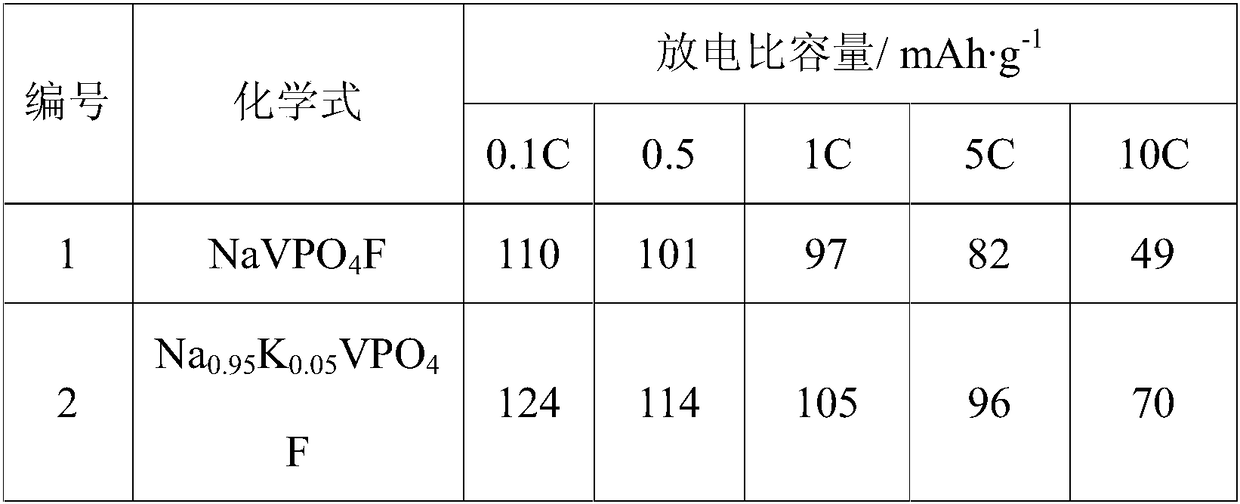

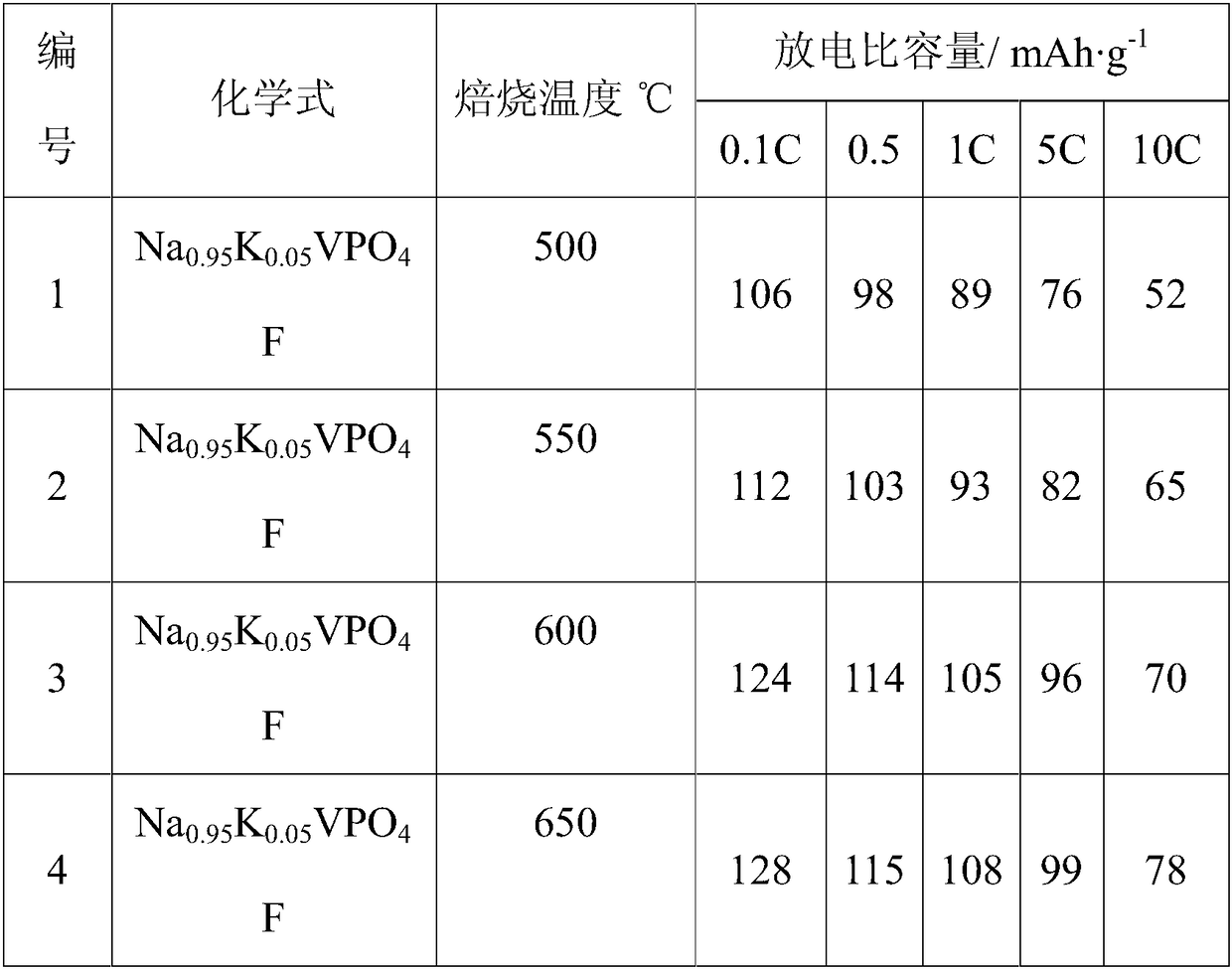

Doping modified sodium vanadium fluorophosphates positive electrode material and preparation method thereof

InactiveCN108899505AHigh purityImprove charge and discharge performanceCell electrodesSecondary cellsFreeze-dryingPotassium

The invention provides a doping modified sodium vanadium fluorophosphates positive electrode material and a preparation method thereof. The positive electrode material is represented by a general formula of Na(1-x)KxVPO4F, wherein x is more than or equal to 0 and less than or equal to 0.15. The preparation method disclosed by the invention comprises the following steps: mixing and dissolving various raw materials into deionized water to realize uniform mixing on a molecular level; freezing, and performing freeze-drying treatment to prepare a powdered material having the characteristics of excellent dispersion property, light particle aggregation and the like; and calcining twice at a medium temperature and a high temperature, thereby obtaining the doping modified sodium vanadium fluorophosphates positive electrode material with the advantages of being loose and porous, fine and uniformly distributed in particle system, high in purity and excellent in charge and discharge performance.

Owner:CENT SOUTH UNIV

Heat radiation fan with evenly luminous effect

InactiveCN1884843AUniform luminous effectUniform illumination effectPump componentsPump installationsEngineeringLight particle

The invention relates to a radiation fan with uniform lighting effect, which comprises a frame, a circuit board, a fan wheel, and a lighting unit, wherein said frame comprises one annular frame, one base plate at the center of annular frame and several ribs connecting the annular frame and base plate; the circuit board is arranged on the base plate; the fan wheel is rotationally mounted the circuit board while it comprises one fan hub and several transparent leaves on the circumference of fan hub; each leaf has several light particles, to form frog station in concave-convex shape; when the light of lighting unit is emitted to all leaves, it will generate uniform reflection.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Aerodynamically light particles for pulmonary drug delivery

Improved aerodynamically light particles for delivery to the pulmonary system, and methods for their preparation and administration are provided. In a preferred embodiment, the aerodynamically light particles are made of a biodegradable material and have a tap density less than 0.4 g / cm3 and a mass mean diameter between 5 μm and 30 μm. The particles may be formed of biodegradable materials such as biodegradable polymers. For example, the particles may be formed of a functionalized polyester graft copolymer consisting of a linear a-hydroxy-acid polyester backbone having at least one amino acid group incorporated herein and at least on poly(amino acid) side chain extending from an amino acid group in the polyester backbone. In one embodiment, aerodynamically light particles having a large mean diameter, for example greater than 5 μm, can be used for enhanced delivery of a therapeutic or diagnostic agent to the alveolar region of the lung. The aerodynamically light particles optionally can incorporate a therapeutic or diagnostic agent, and may be effectively aerosolized for administration to the respiratory tract to permit systemic or local delivery of a wide variety of incorporated agents.

Owner:EDWARDS DAVID A +6

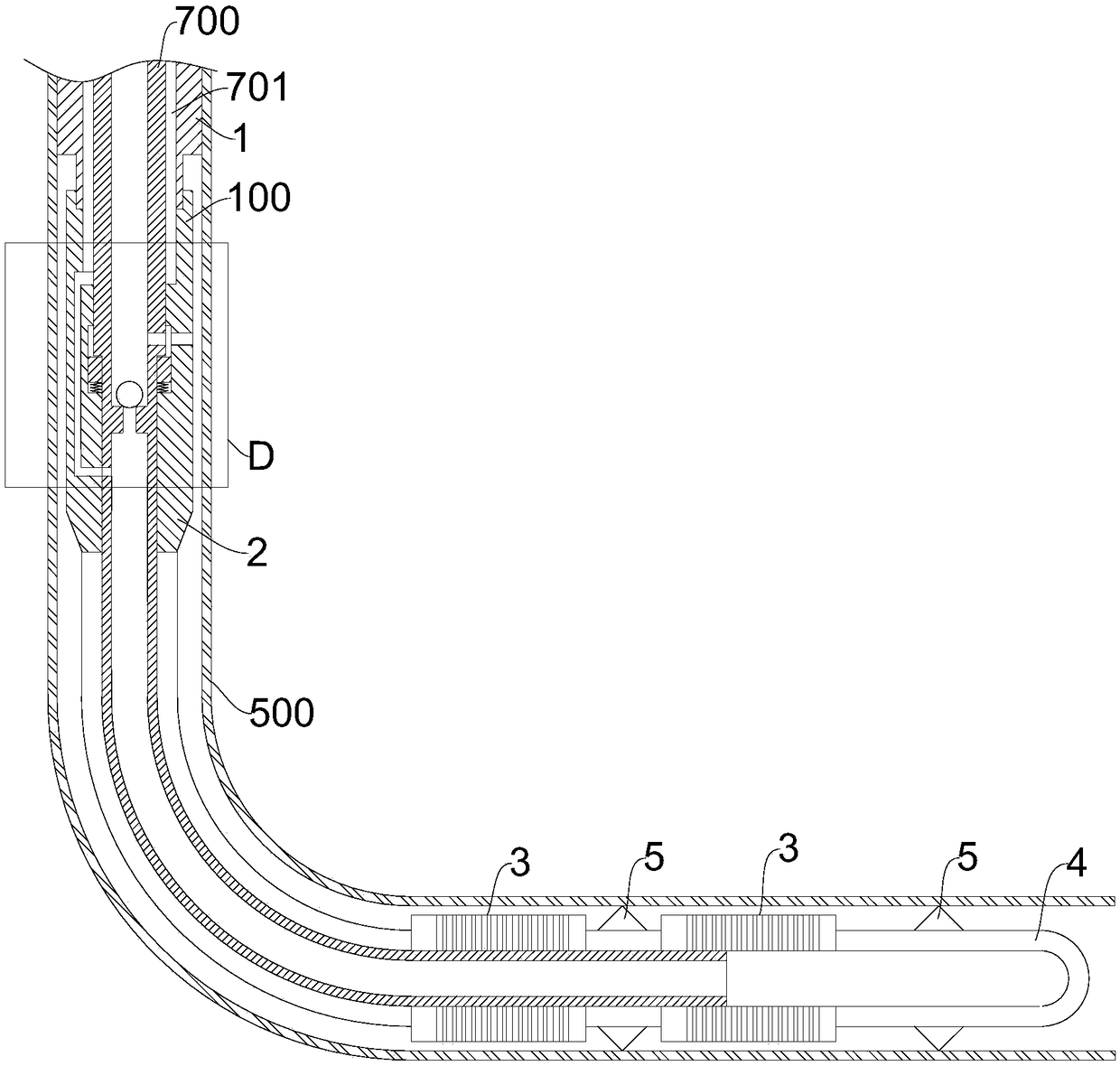

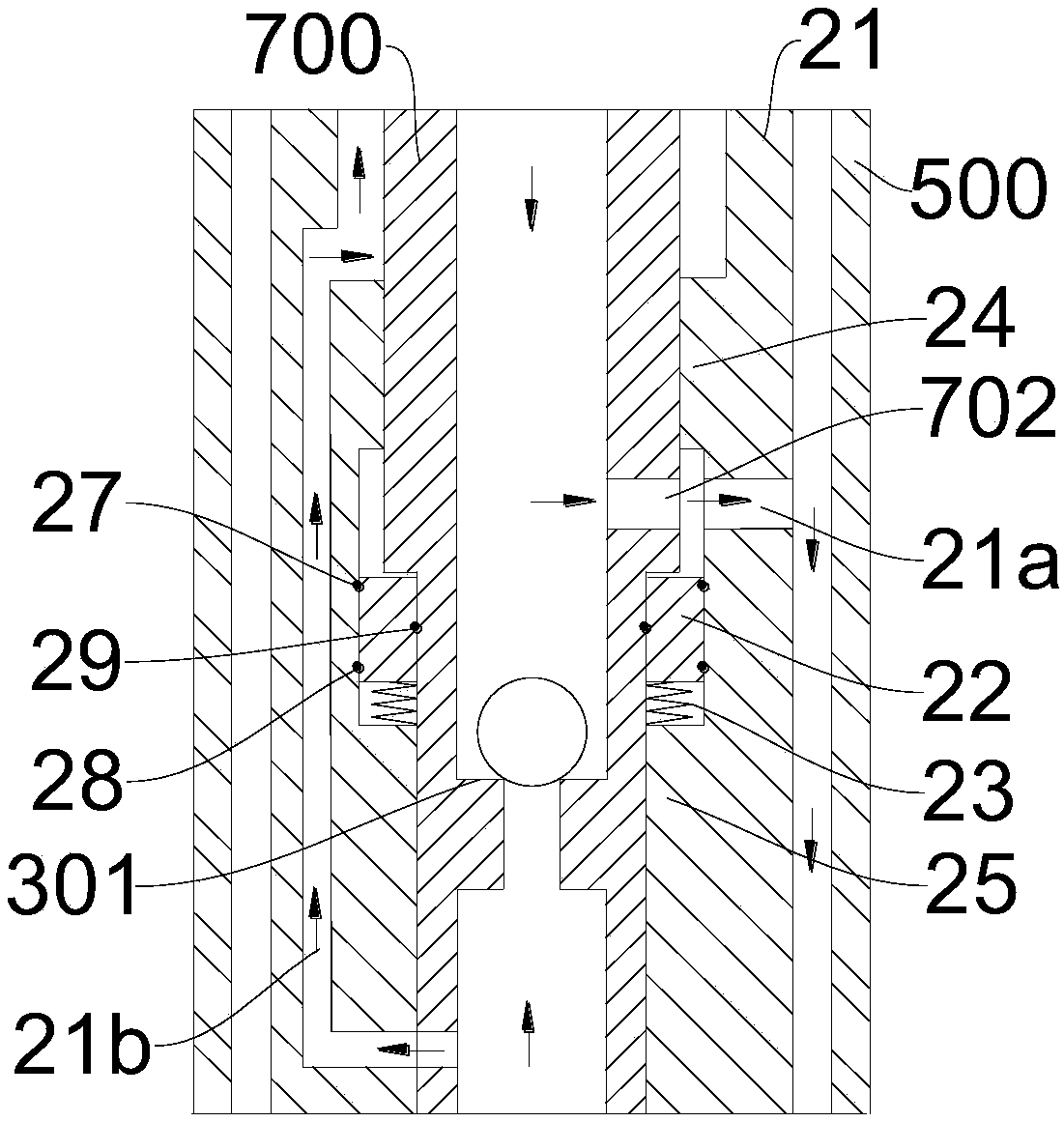

Oil and gas well structure facilitating pulling out downhole filter pipe column and method for pulling out downhole filter pipe

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

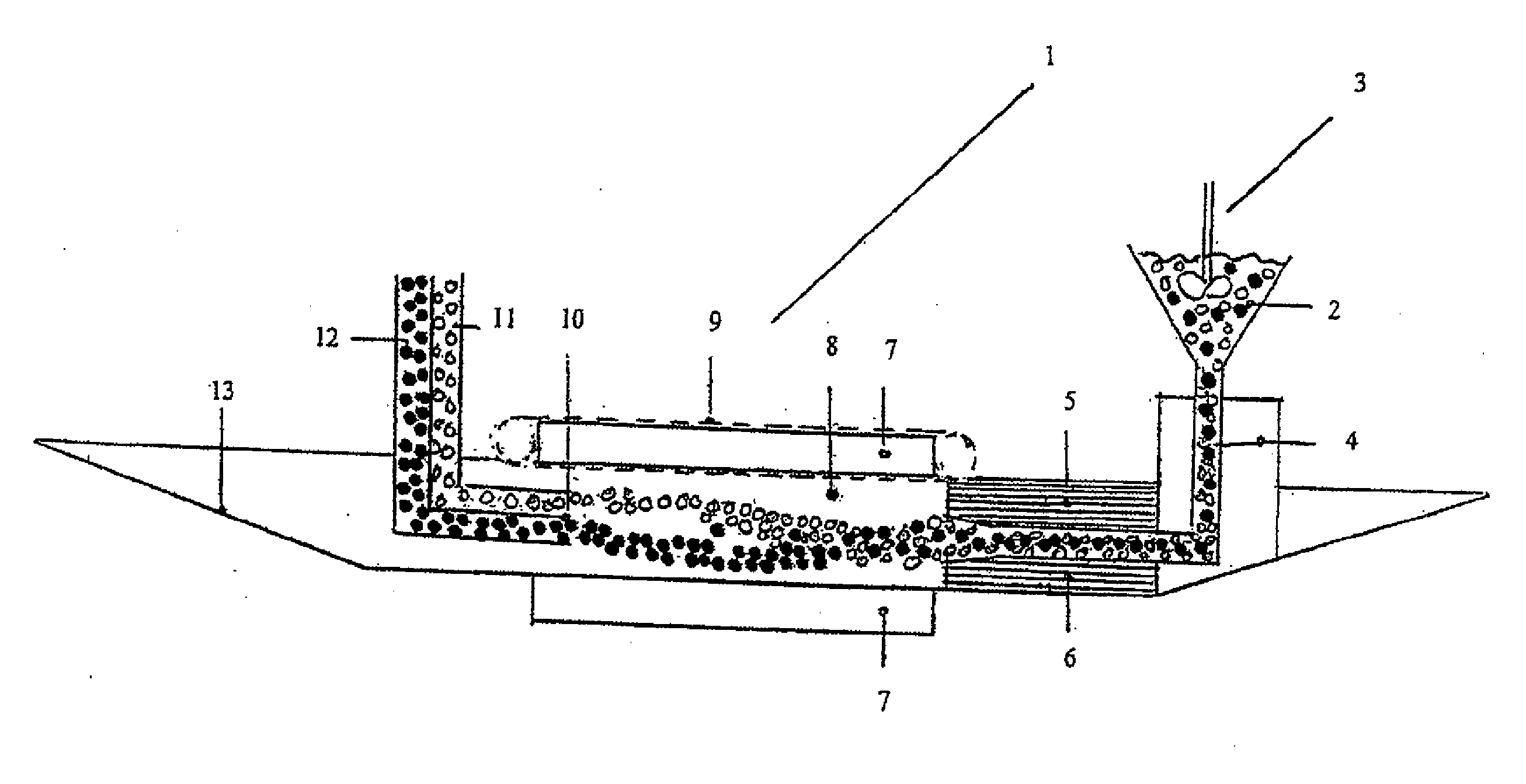

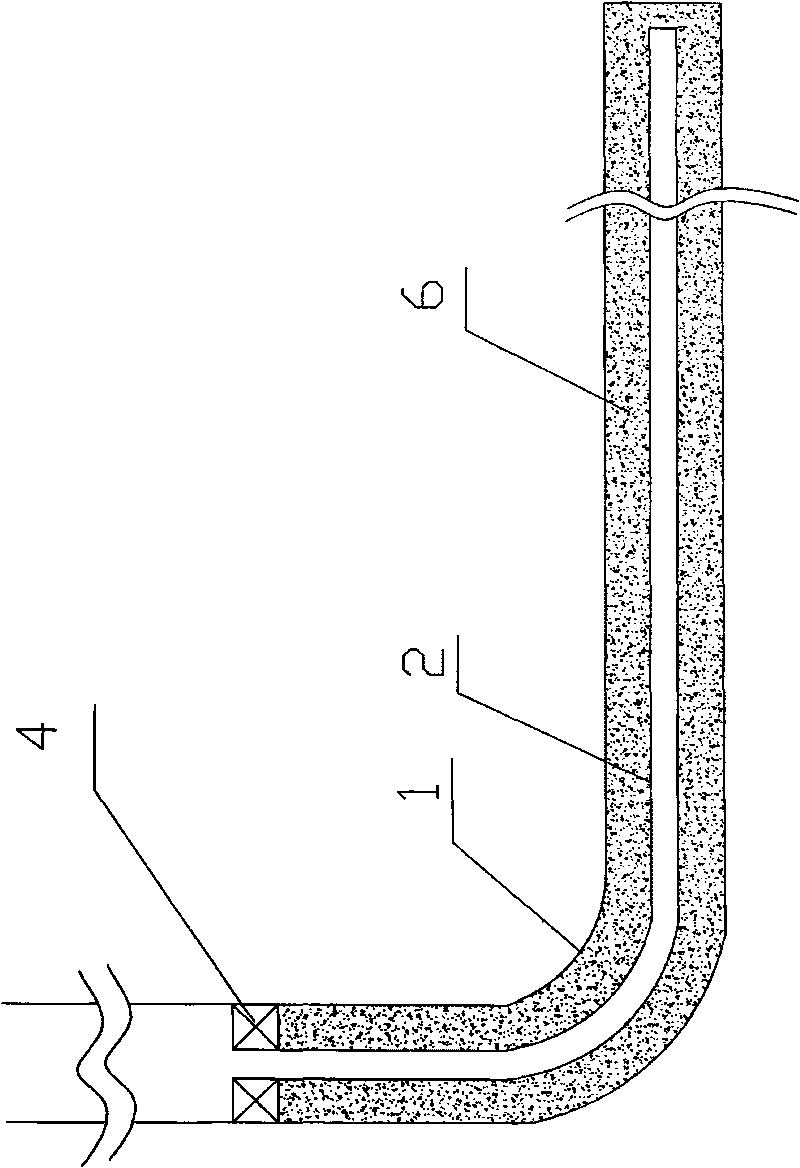

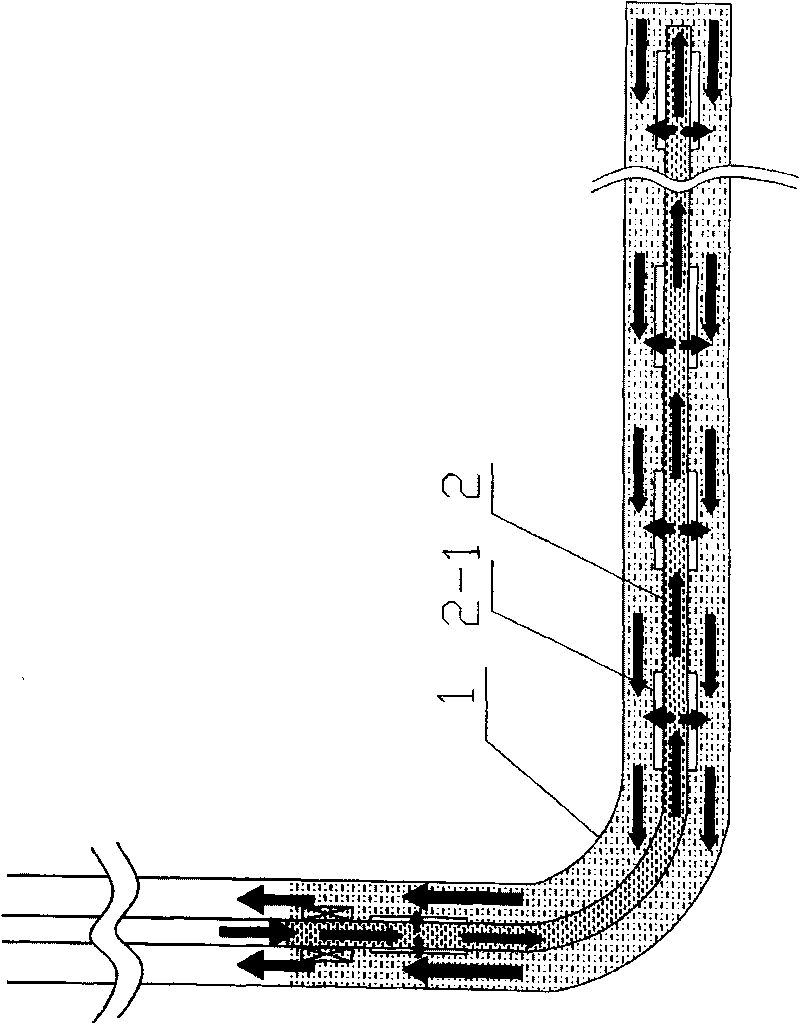

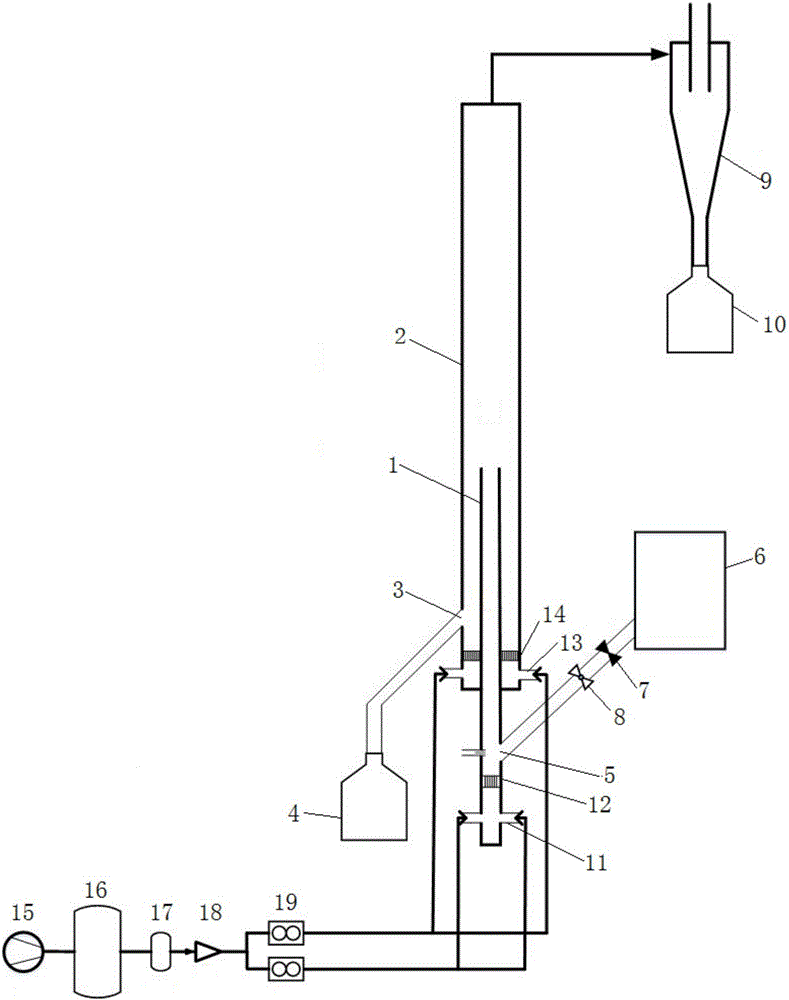

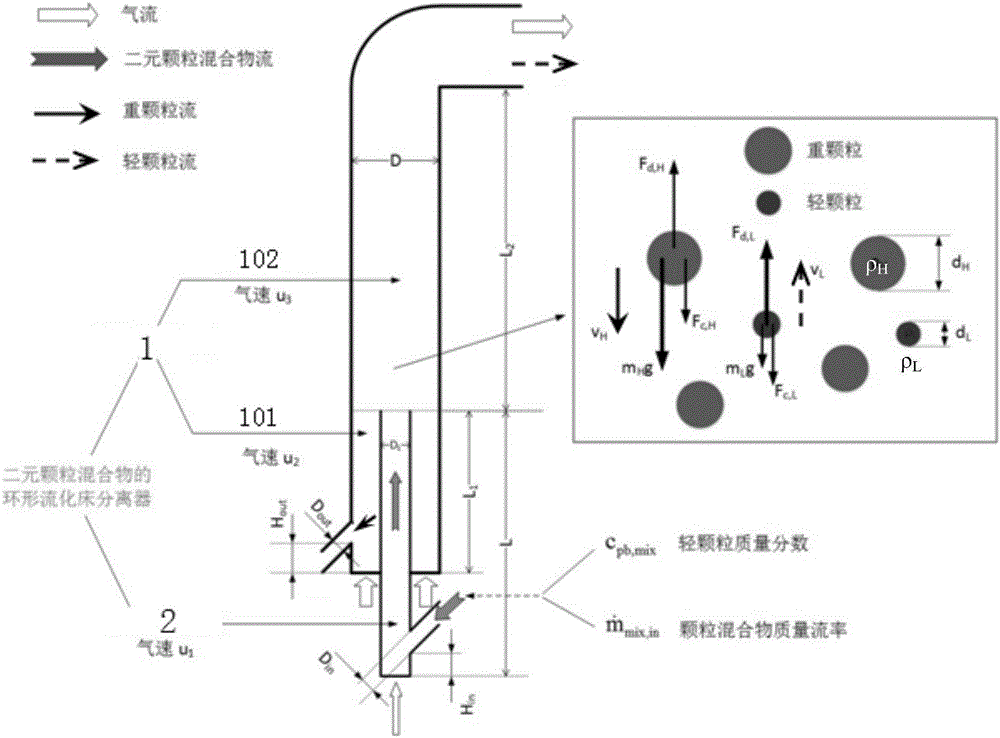

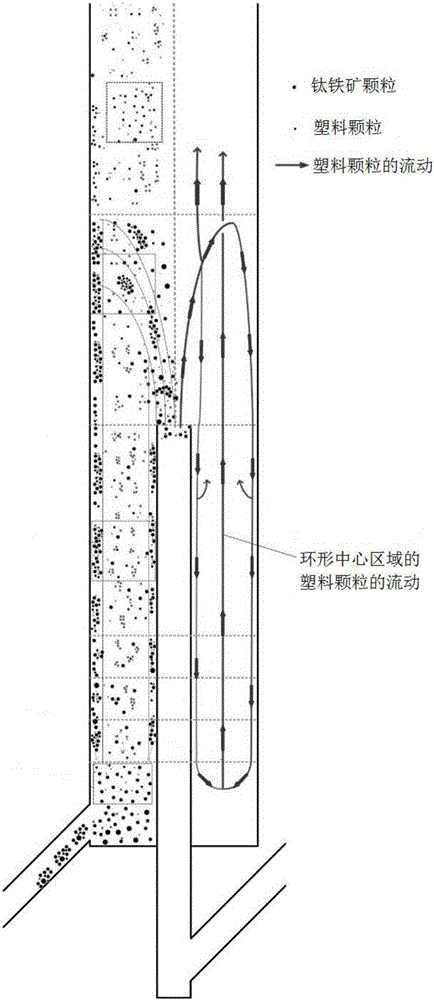

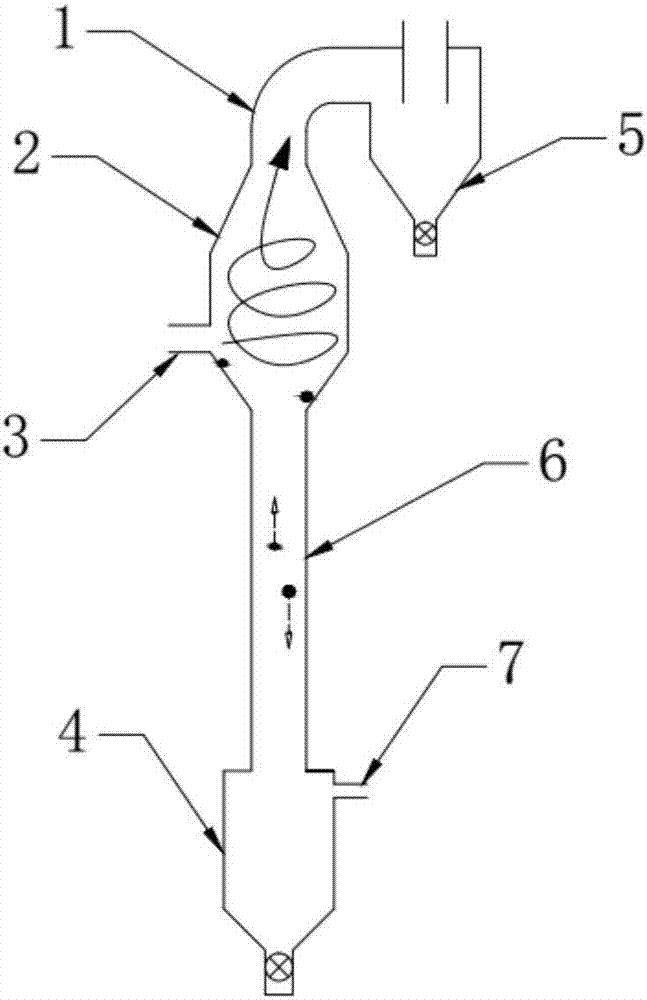

Annular fluidized bed separator of particle mixture

ActiveCN106269508AEfficient separationImprove dispersionGas current separationHeavy particleReactor system

The invention relates to an annular fluidized bed separator of a particle mixture. The upper end of a center lifting pipe extends into an annular fluidized bed by a certain height, so that the annular fluidized bed is divided into an annular area at the lower part and a cylindrical area at the upper part; an air inlet and a wind distribution plate are respectively arranged at the bottoms of the center lifting pipe and the annular fluidized bed; a feed port is formed in the bottom of the center lifting pipe; a heavy particle outlet is formed in the bottom of an annular area of the annular fluidized bed, and is connected with a heavy particle collecting tank; and an airflow outlet at the top of the annular fluidized bed is connected to a light particle collecting tank by a cyclone separator. The particle mixture is quickly fluidized in the center lifting pipe for primary dispersion, and is ascended along with air currents to enter the annular fluidized bed for secondary dispersion. The annular fluidized bed separator can continuously and quickly perform high-efficiency separation for light and heavy particle mixtures under the condition of normal temperature or high temperature. The annular fluidized bed separator can be coupled with a circulating fluidized bed reactor system, and can continuously and stably operate.

Owner:TSINGHUA UNIV

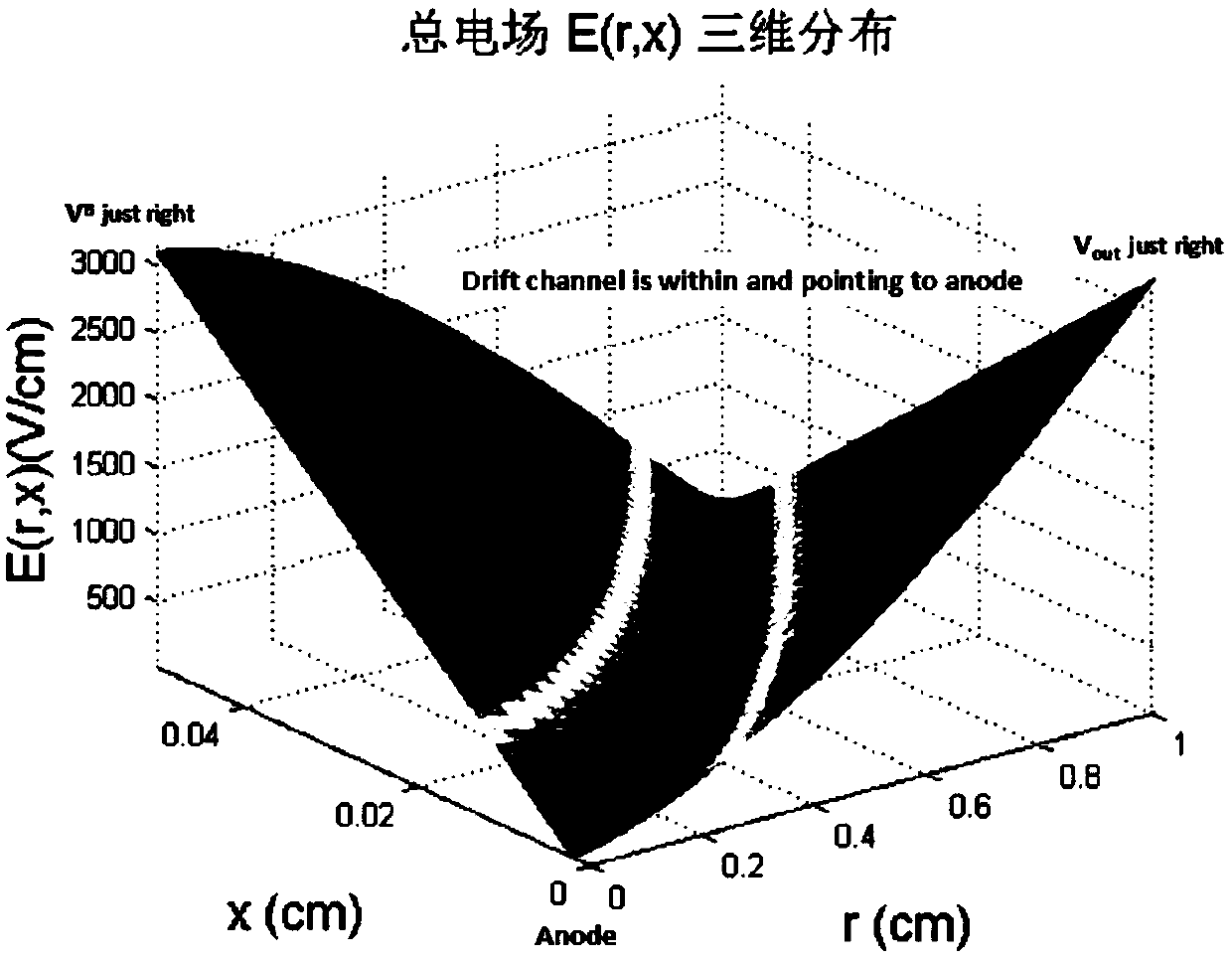

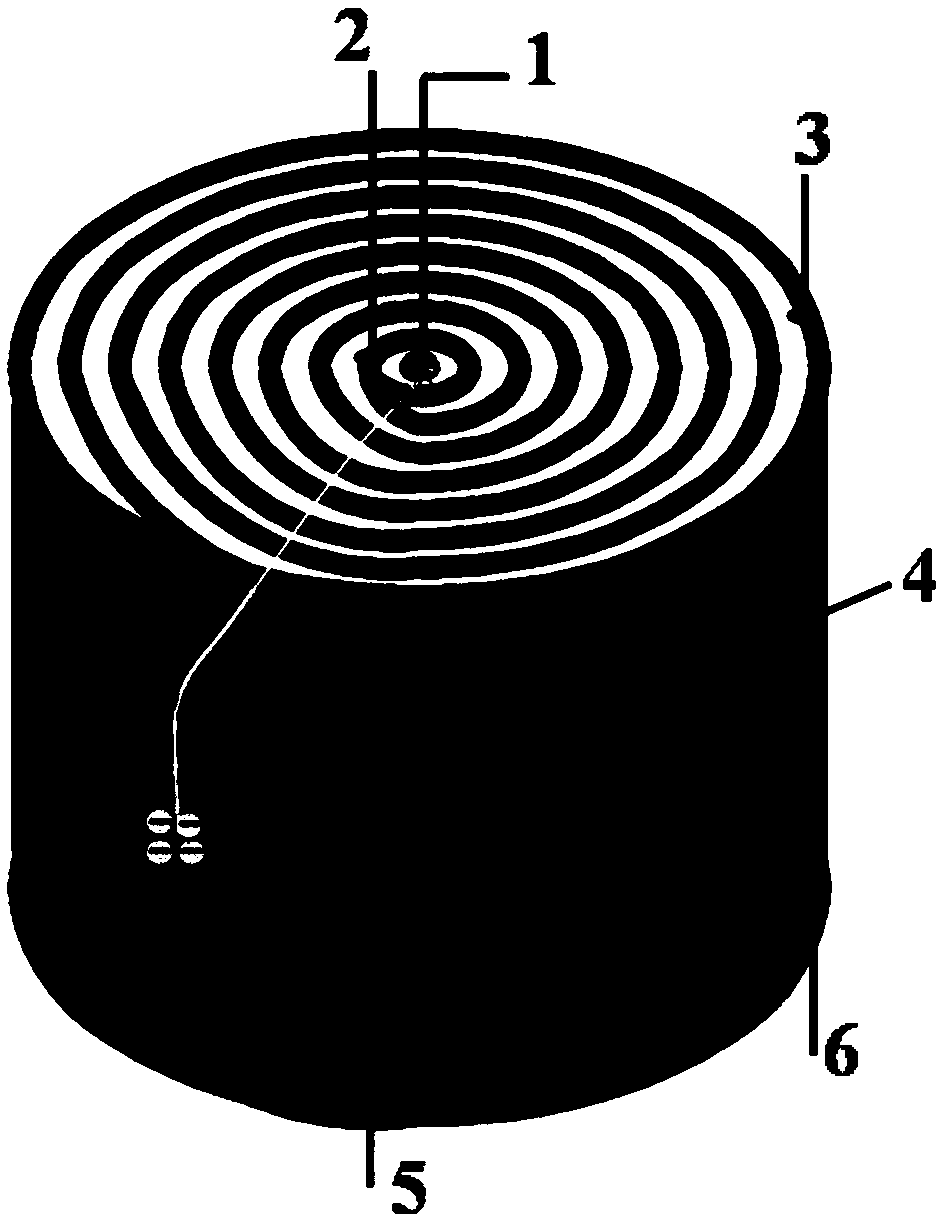

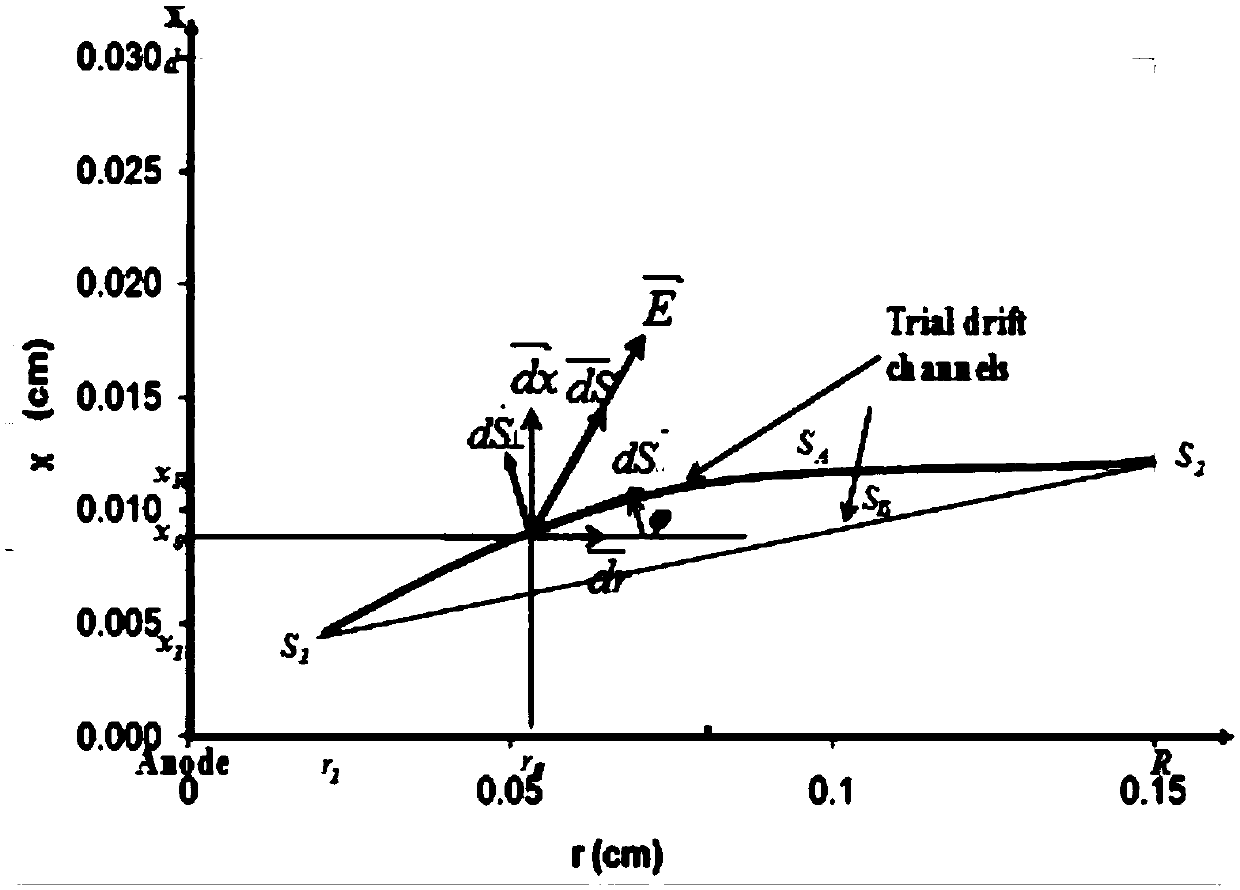

Large-area spiral cylindrical double-sided silicon drift detector and design method thereof

PendingCN108733953AOptimal drift pathOvercome the disadvantage of small areaDesign optimisation/simulationSpecial data processing applicationsElectron driftLight particle

The invention belongs to the technical field of deep space detection and discloses a large-area spiral cylindrical double-sided silicon drift detector and a design method thereof. The design method for the large-area spiral cylindrical double-sided silicon drift detector comprises the following steps of determining electric potentials of the front surface and the rear surface of the silicon driftdetector; calculating an optimal drift path from a point S1 to a point S2 for a carrier during drifting in the silicon drift detector by adopting a mathematical variation method; determining a constant drift electric field of the optimal drift path; and calculating width distribution of a spiral negative electrode of the silicon drift detector. According to the method, through analysis on a carrier drift behavior law and heavily doped electrode growth of the SSD, starting from a new structure, a novel process integration design and a light particle theory calculation method, a double-sided electrode having a double-sided correlation effect and capable of keeping an uniform electron drift electric field and providing a smooth drift trajectory is designed, and an innovative design and manufacturing mode of the efficient collection SDD with high energy resolution of soft X-ray particles with the intensity of 0.5-15keV is established.

Owner:XIANGTAN UNIV

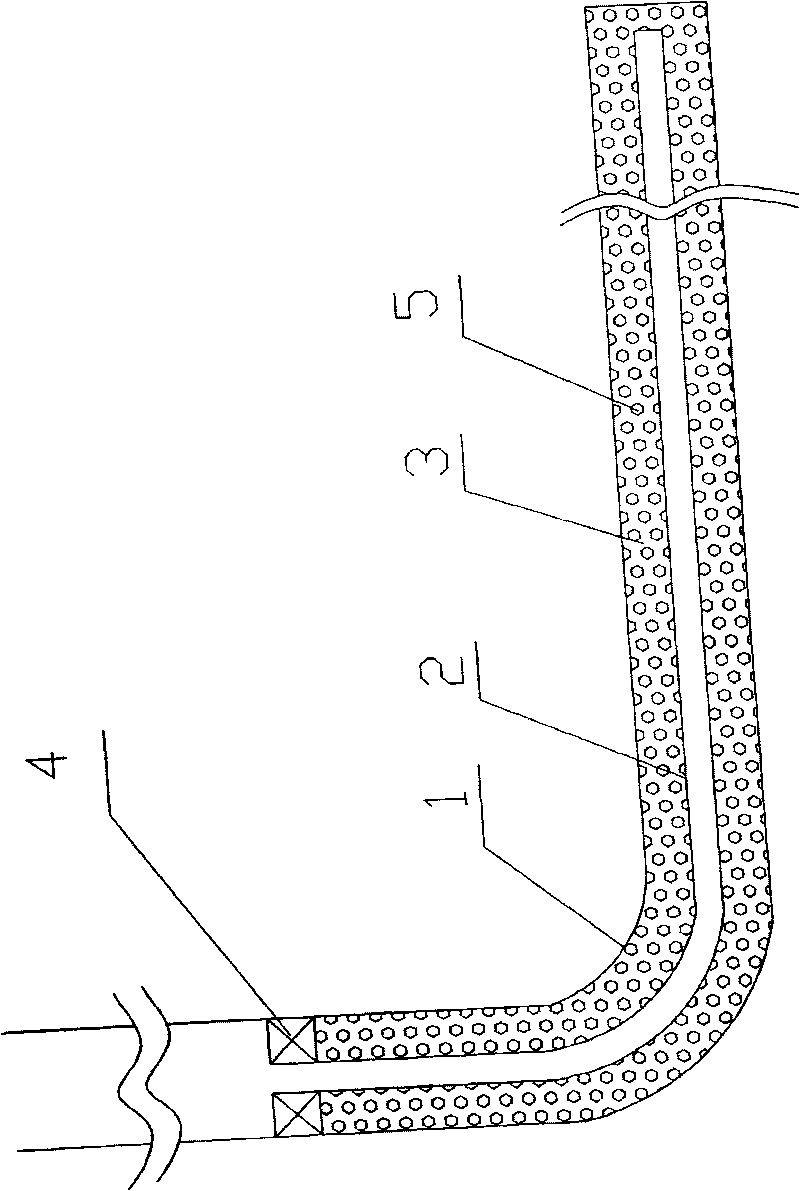

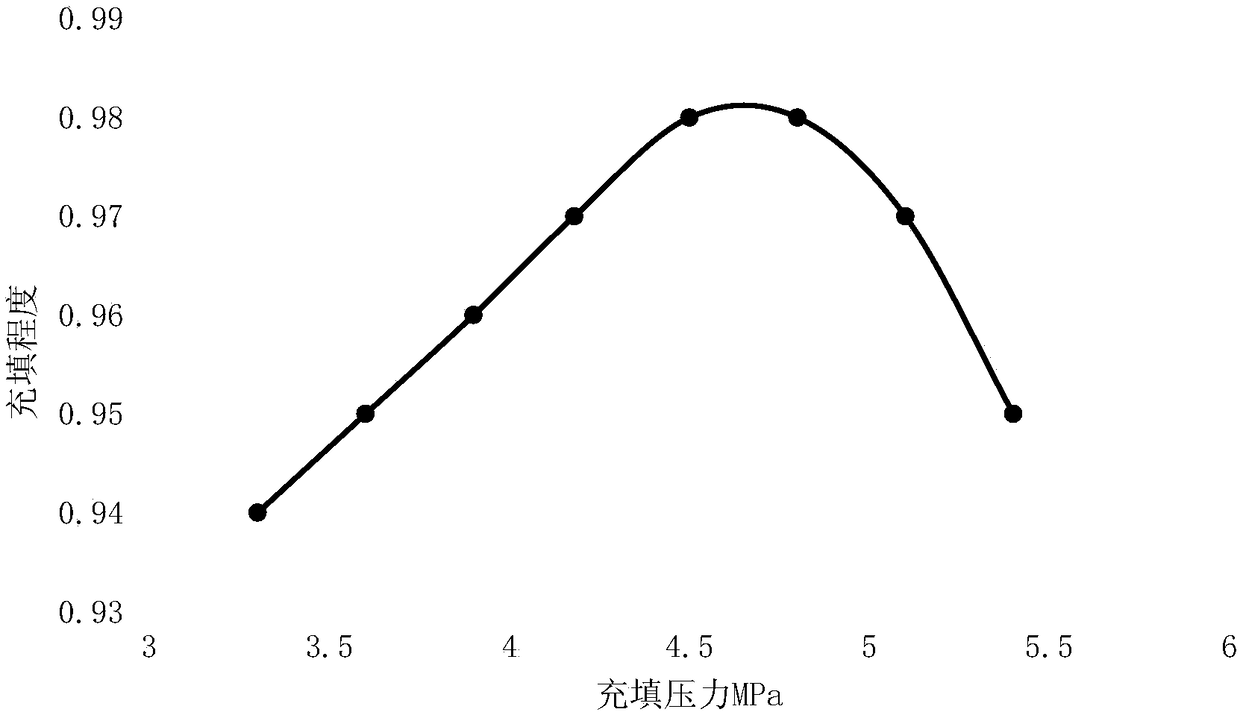

Pipe string capable of carrying out light particle filling and sand prevention and water control production

PendingCN108533236AImprove oil recovery efficiencySolve the problem of difficult flowbackDrilling rodsFluid removalParticle flowEngineering

The invention relates to a pipe string capable of carrying out light particle filling and sand prevention and water control production. The pipe string comprises a filling packer, a filling conversiondevice, self-adaptive flow adjustment water controlling screen pipes and a pipe plug. When a filling tool is inserted into the filling conversion device and open the filling conversion device, filling liquid carrying light particles in the filling tool can enter the annular space between the self-adaptive flow adjustment water controlling screen pipes and a casing pipe under the guidance of the filling tool, wherein the annular space is filled with the light particles, and the filling liquid penetrates into the self-adaptive flow adjustment water controlling screen pipes and enters the annular space between the filling tool and the casing pipe under the guidance of the filling conversion device through a backflow gap between the filling tool and the filling packer. The pipe string can fill the annular space between the self-adaptive flow adjustment water controlling screen pipes and the casing pipe with the light particles to solve the difficulty of particle flow back in the later stage, and can realize sand prevention and water control with outstanding effect in the later stage of oil production and the oil production efficiency of the pipe string is improved.

Owner:CHINA PETROLEUM & CHEM CORP

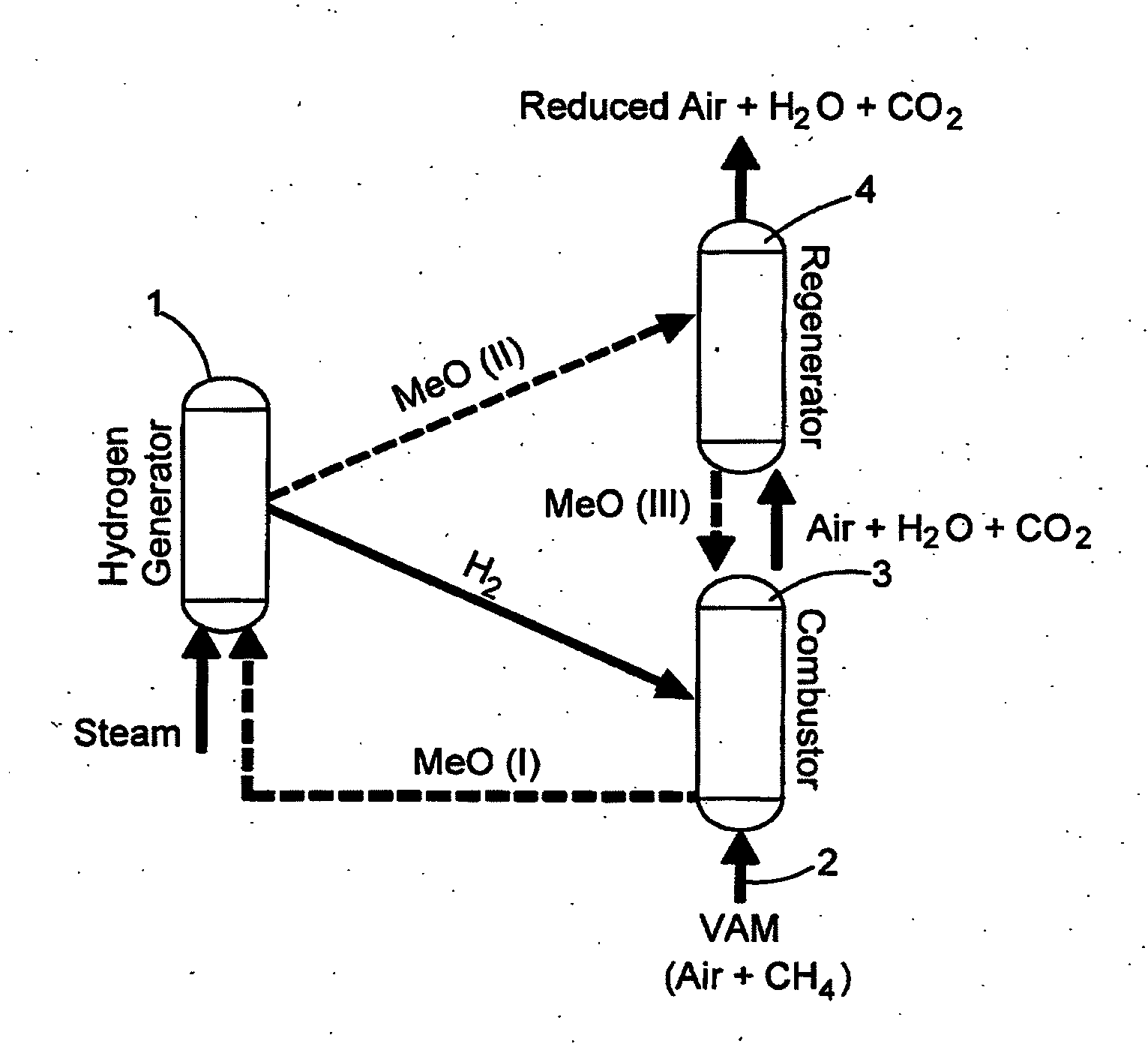

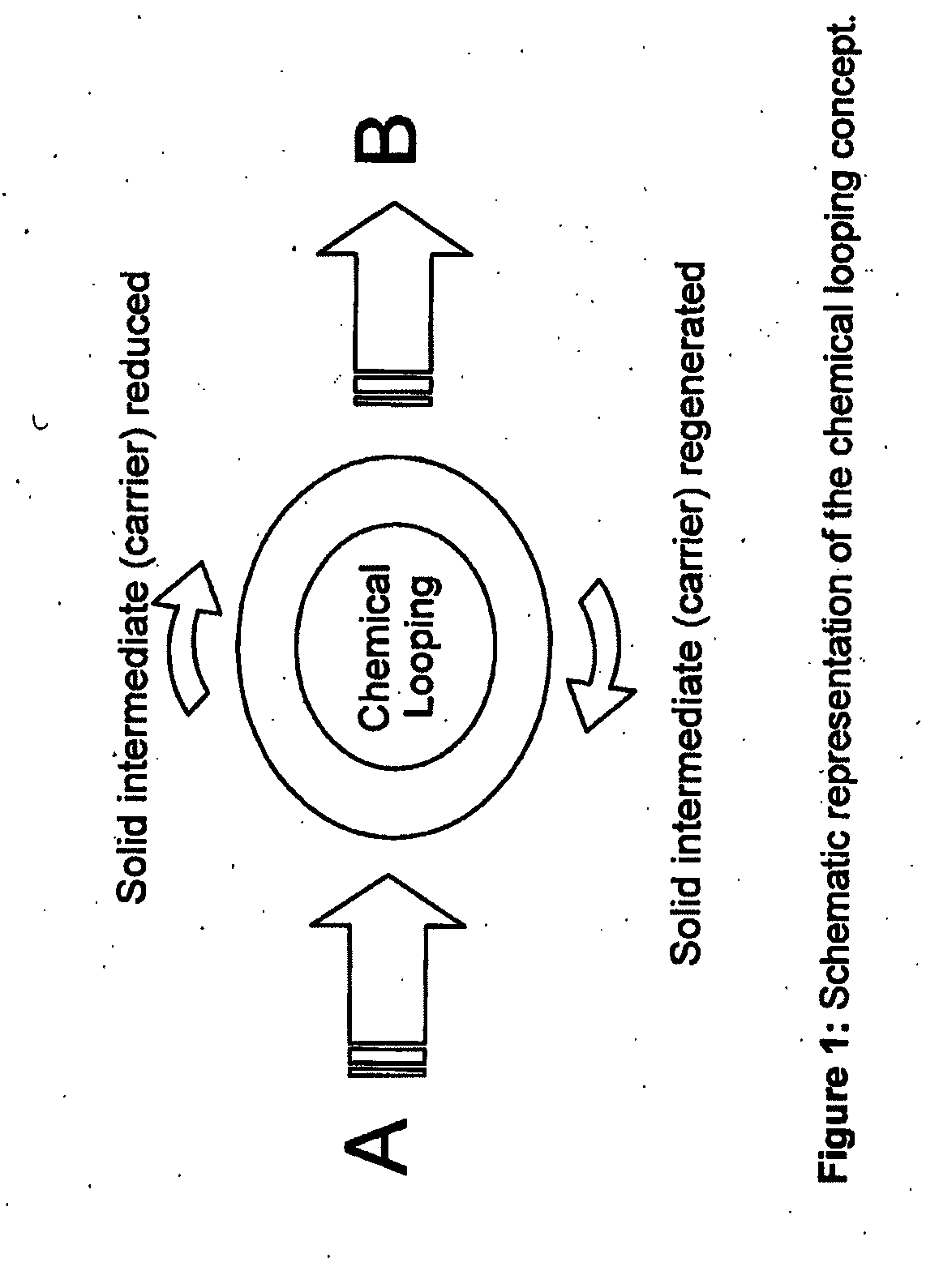

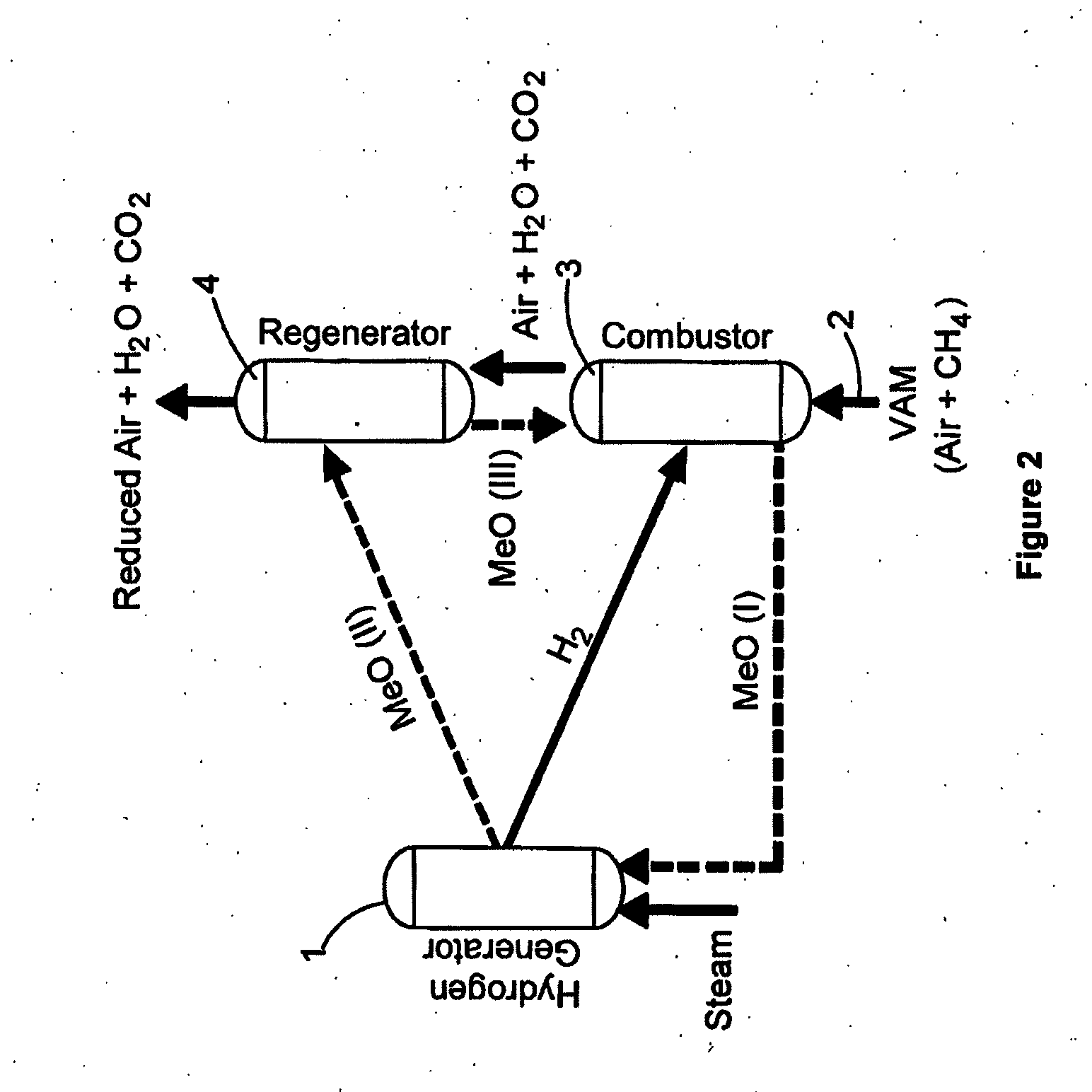

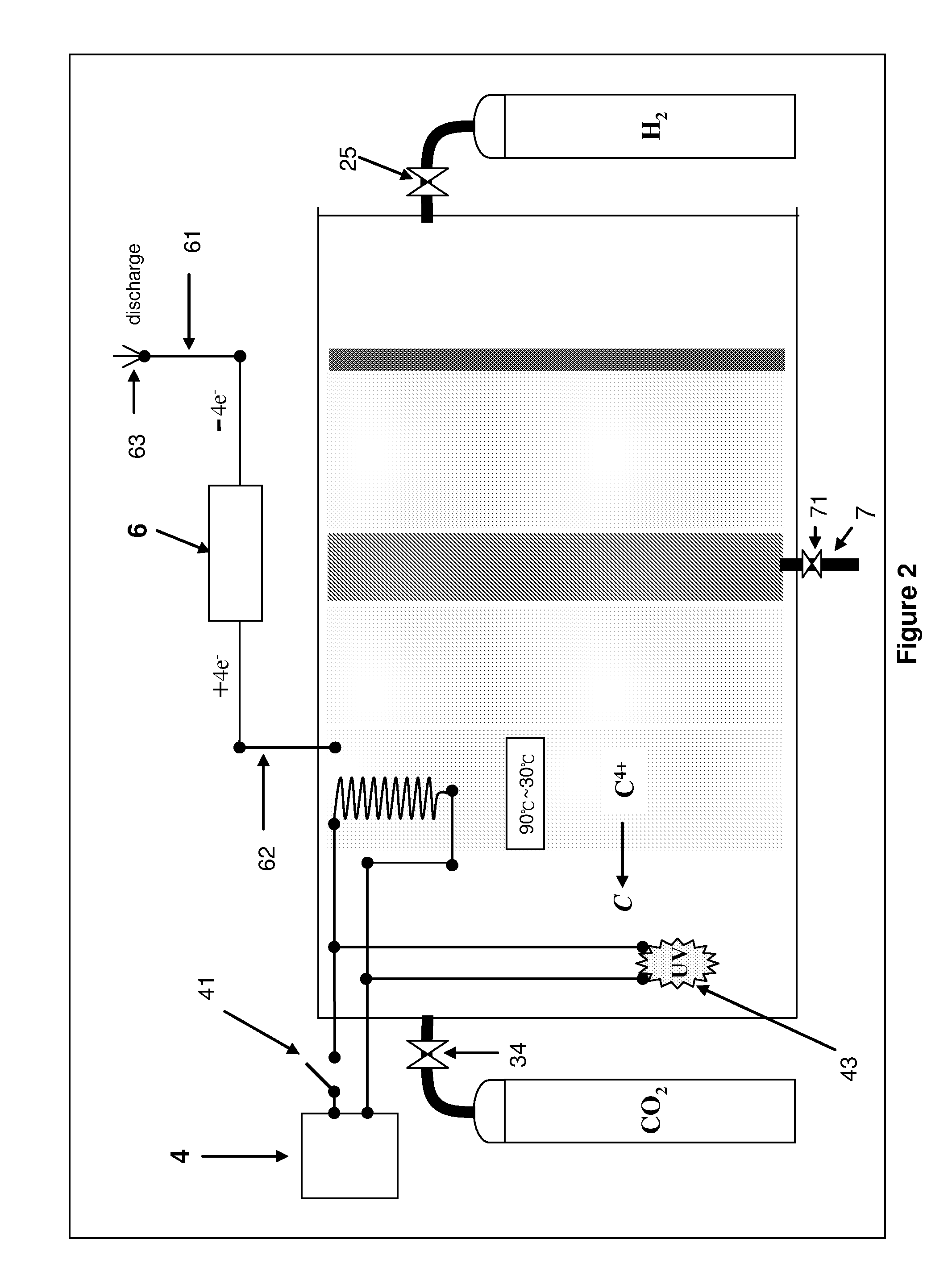

Chemical looping removal of ventilation air methane

Methane is removed from ventilation air by cycling metal or metal oxide particles in a chemical looping process in one or more reactors where the metal particles are alternately reduced and oxidised, and passing ventilation air through one or more of said reactors to convert the air plus methane into reduced air plus water plus carbon dioxide. In one variation, ventilation air methane (VAM) is removed from ventilation air in coal mines using a chemical looping process to move metal or metal oxide particles between reactors such as a hydrogen generator (5) and a regenerator (7) to alternatively reduce and oxidise the particles such that VAM introduced into a combustor (6) provided with hydrogen from the hydrogen generator (5) can be processed in the regenerator (7) to produce air plus water plus carbon dioxide. Other variations involve the use of three reactors in the chemical looping process, or the use of an array of parallel inclined plates forming lamellas between upper and lower reactors to keep lighter particles in the upper oxidiser reactor and heavier particles in the lower reducer reactor.

Owner:UNIVERSITY OF NEWCASTLE

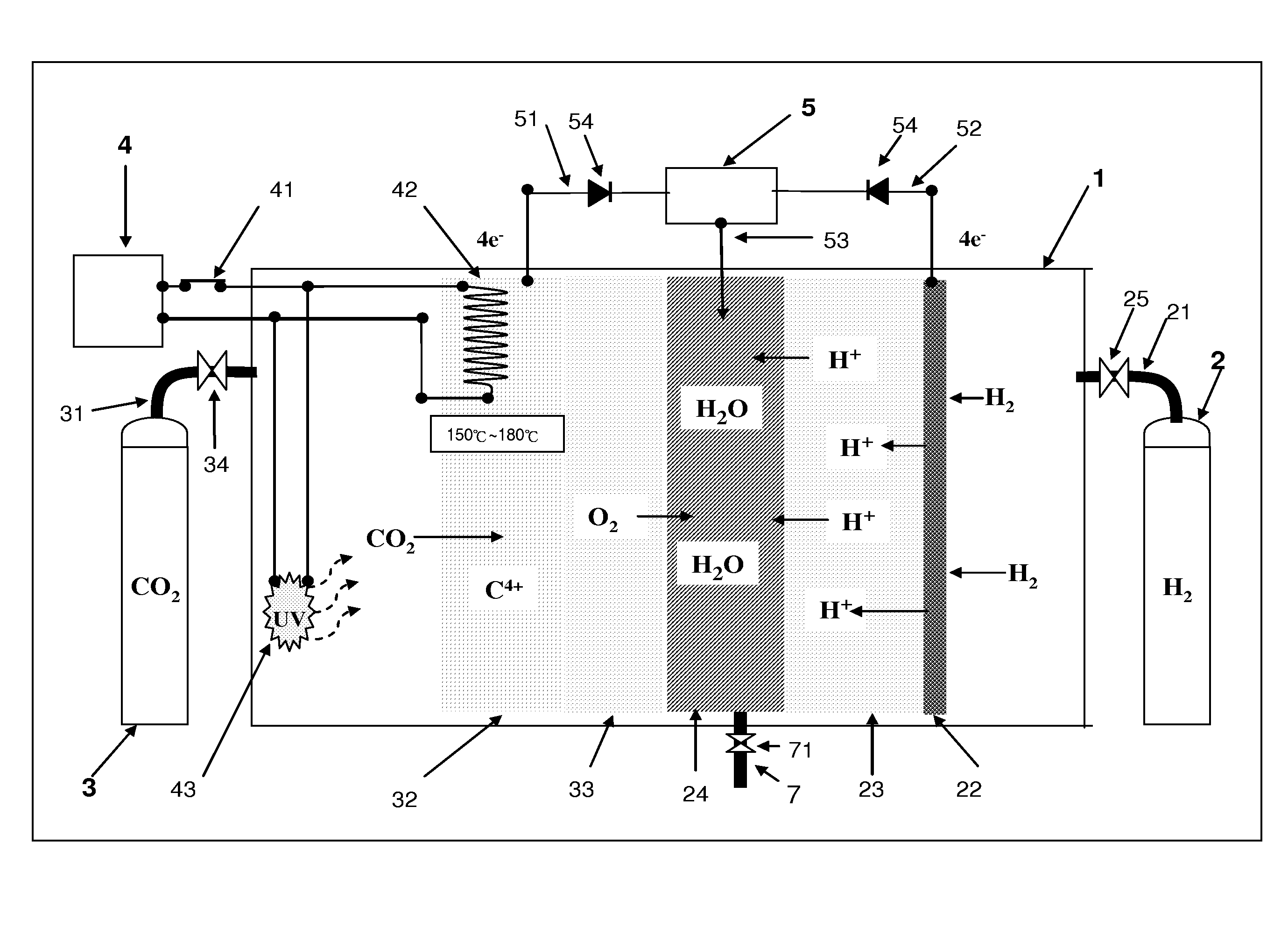

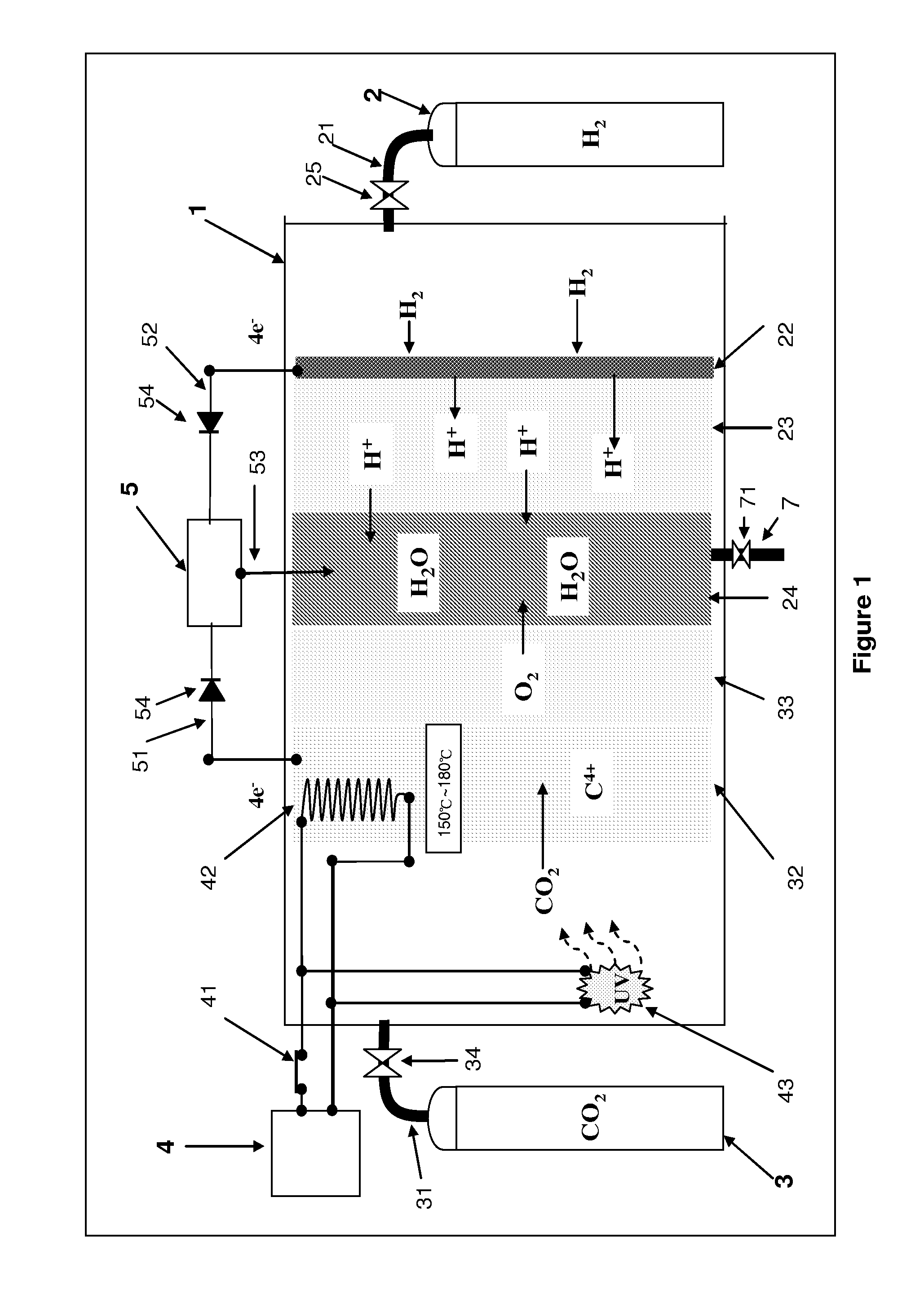

CARBON DIOXIDE DISSOLUTION AND C4+nM STATE CARBON RECYCLING DEVICE AND METHOD

With this technology, we build a nano-material which is structured as a tree with the branches and leaves being tentacles. When the temperature is between 150° C. and 180° C., those tentacles will shape themselves into nanometer holes to catch ion.The chemical equation: uv+CO2+ΔnM+2H2+4e−↑→C+2H2O+∇nM+4e−↓.Those two chemical equations have one common subject, that's they both take high energy light particles to break the electron bond between carbon and oxygen, thus, the invertor can reduce the greenhouse gases (CO2) in the atmosphere or recycle carbon from industrial emissions.

Owner:CHEN SHU CHIN +2

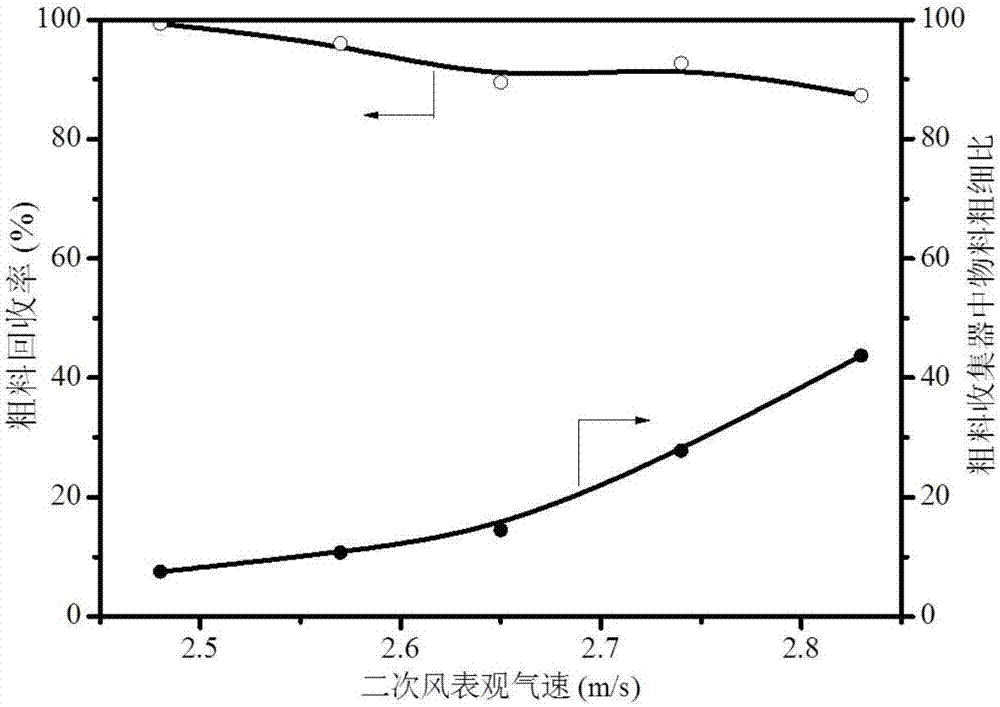

Particle classification device and method thereof

InactiveCN107185837AReinforcement brought outShort stayGas current separationHeavy particleEngineering

The invention belongs to the technical field of powder processing and utilizing and provides a particle classification device and a method thereof. The middle of the top of a barrel body of a cyclone separator is connected with the inlet end of a tail air outlet pipe, and the inlet end does not stretch into the cyclone separator; the outlet end of the tail air outlet pipe is connected with a fine / light particle set collector; the lower middle portion of the barrel body of the cyclone separator is provided with a primary air inlet pipe; the bottom of the barrel body of the cyclone separator is of a conical structure, and is connected with the top of a sedimentation classifier; the bottom of the sedimentation classifier is connected with a coarse / heavy particle set collector; and the lower portion of the sedimentation classifier or the coarse / heavy particle set collector is provided with a secondary air inlet pipe. Based on the differences of the centrifugal forces and the terminal speeds of coarse / heavy particles and fine / light particles in mixed particle size / density particle materials, the air speeds of primary air and secondary air are adjusted, it can be achieved that the cutting particle size is flexibly adjusted and changed, and the classification precision is high; and operation is easy and convenient, the structure is simple, and the particle classification device and the method thereof can be applied to the normal temperature / high temperature particle classification environment.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com