Annular fluidized bed separator of particle mixture

An annular flow, fluidized bed technology, applied in solid separation, separation of solids from solids by gas flow, chemical instruments and methods, etc. problems, to achieve the effect of improving separation efficiency, optimizing structure size, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

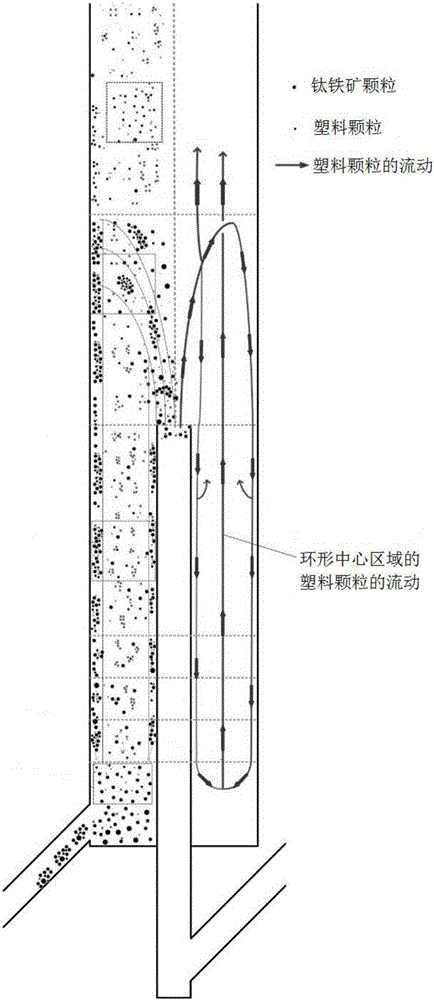

[0057] Ore enrichment and flotation: separation of ilmenite particles and light particles at room temperature.

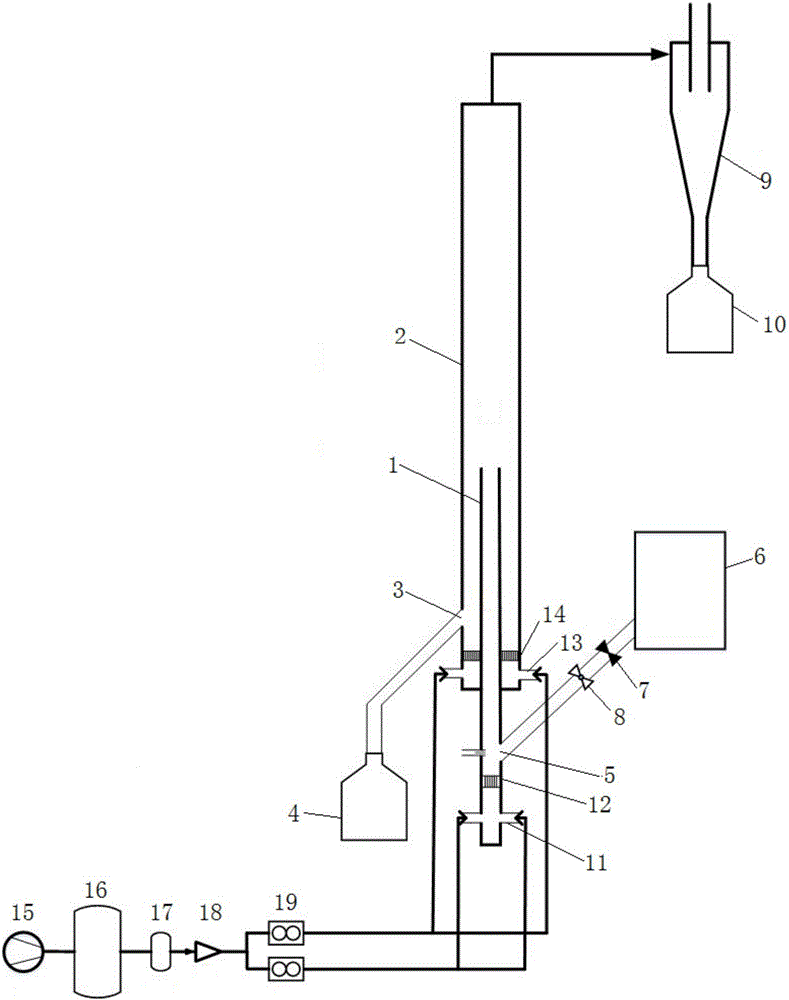

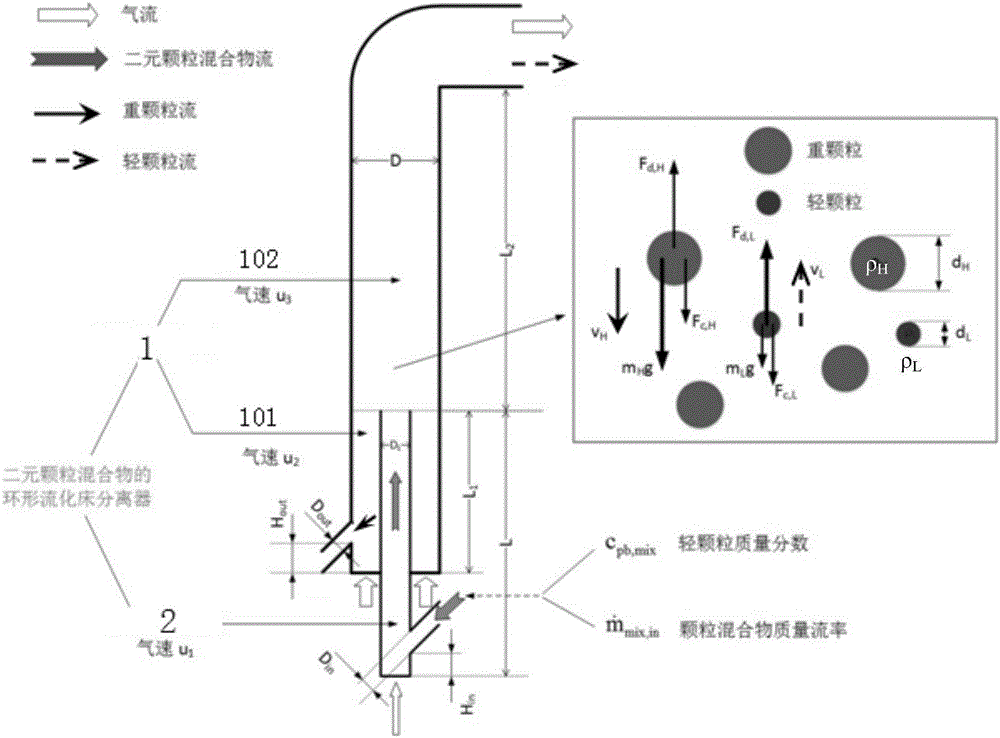

[0058] figure 1 Shown is an annular fluidized bed separator for particle mixture, the upper end of the central riser 1 extends from the bottom surface of the annular fluidized bed 2 to a certain height inside the annular fluidized bed 2, so that the annular fluidized bed 2 is divided into the lower part Annular area 101 and upper cylindrical area 102; the bottom of central riser 1 and annular fluidized bed 2 are respectively provided with central riser air inlet 11 and annular fluidized bed air inlet 13, and in central riser 1 and annular fluidized bed Inside the fluidized bed 2, a central riser air distribution plate 12 and an annular fluidized bed air distribution plate 14 are respectively arranged above the respective air inlets.

[0059] At the bottom of the central riser 1, at a certain height above the air distribution plate 12 of the central riser, there is ...

Embodiment 2

[0073] Gas-solid reaction process involving two kinds of particles: continuous and rapid separation at high temperature.

[0074] Reactor system such as Figure 4 As shown, the upper end of the central riser 1 extends vertically into the annular fluidized bed 2 to a certain height, so that the annular fluidized bed 2 is divided into a lower annular area 101 and an upper cylindrical area 102 . The lower end of the central riser 1 is connected to a buffer tank 21, and the feed port of the buffer tank 21 communicates with the solid phase outlet of the reactor 20 through a connecting pipe. The gas outlet at the top of the annular fluidized bed 2 is connected to the top of the reactor 20, and the gas outlet at the upper side wall of the reactor 20 is connected to the first cyclone separator 9, and the particle outlet of the cyclone separator 9 passes through a U-shaped return valve 23 The light particle return port connected to the side wall of the reactor 20.

[0075] At the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com