Patents

Literature

153results about How to "Continuous separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

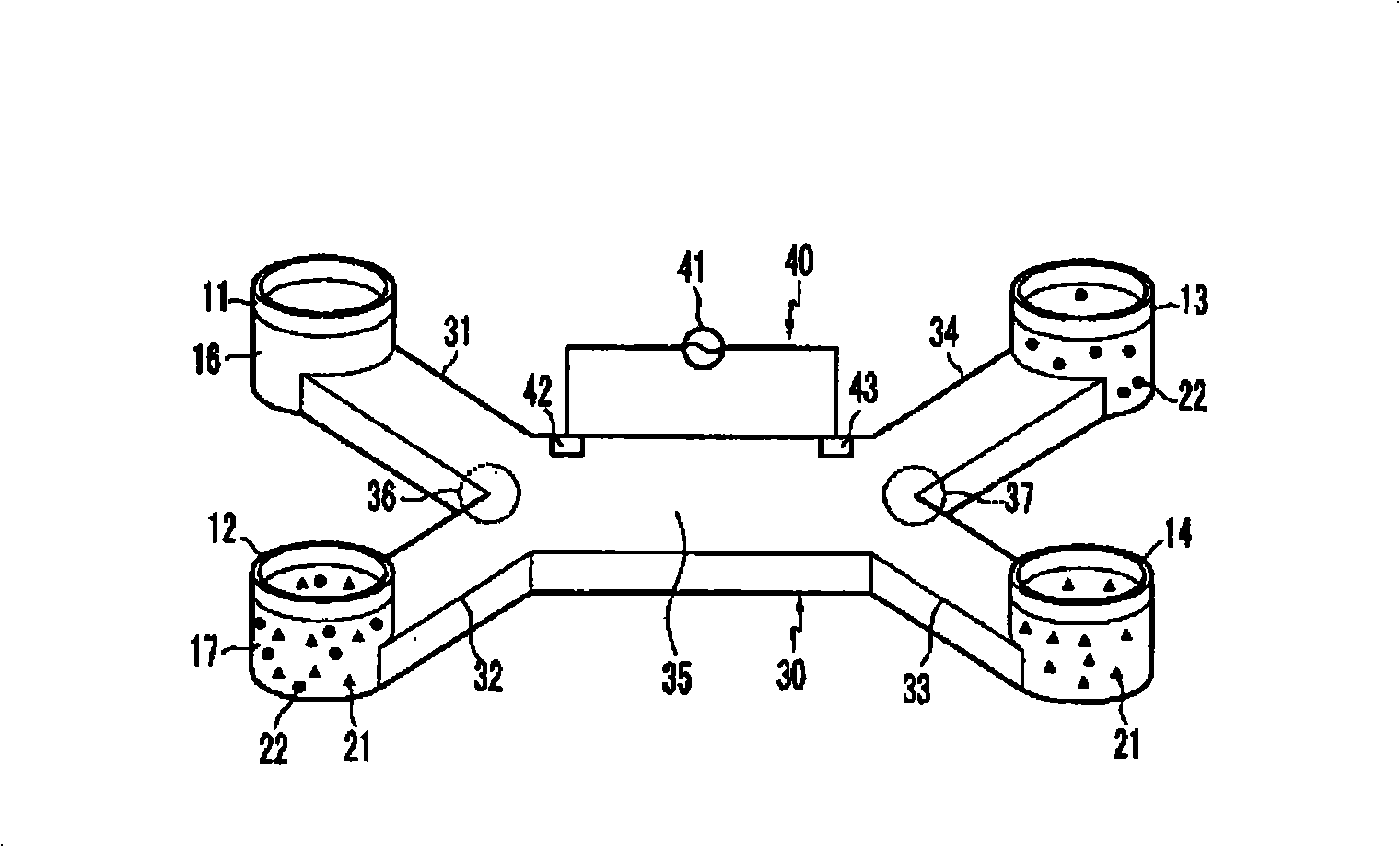

Method and apparatus for the continuous separation of biological fluids into components

ActiveUS20030181305A1Improve efficiencyTreat a patient more efficientlyOther blood circulation devicesDispersed particle separationDiseaseWhite blood cell

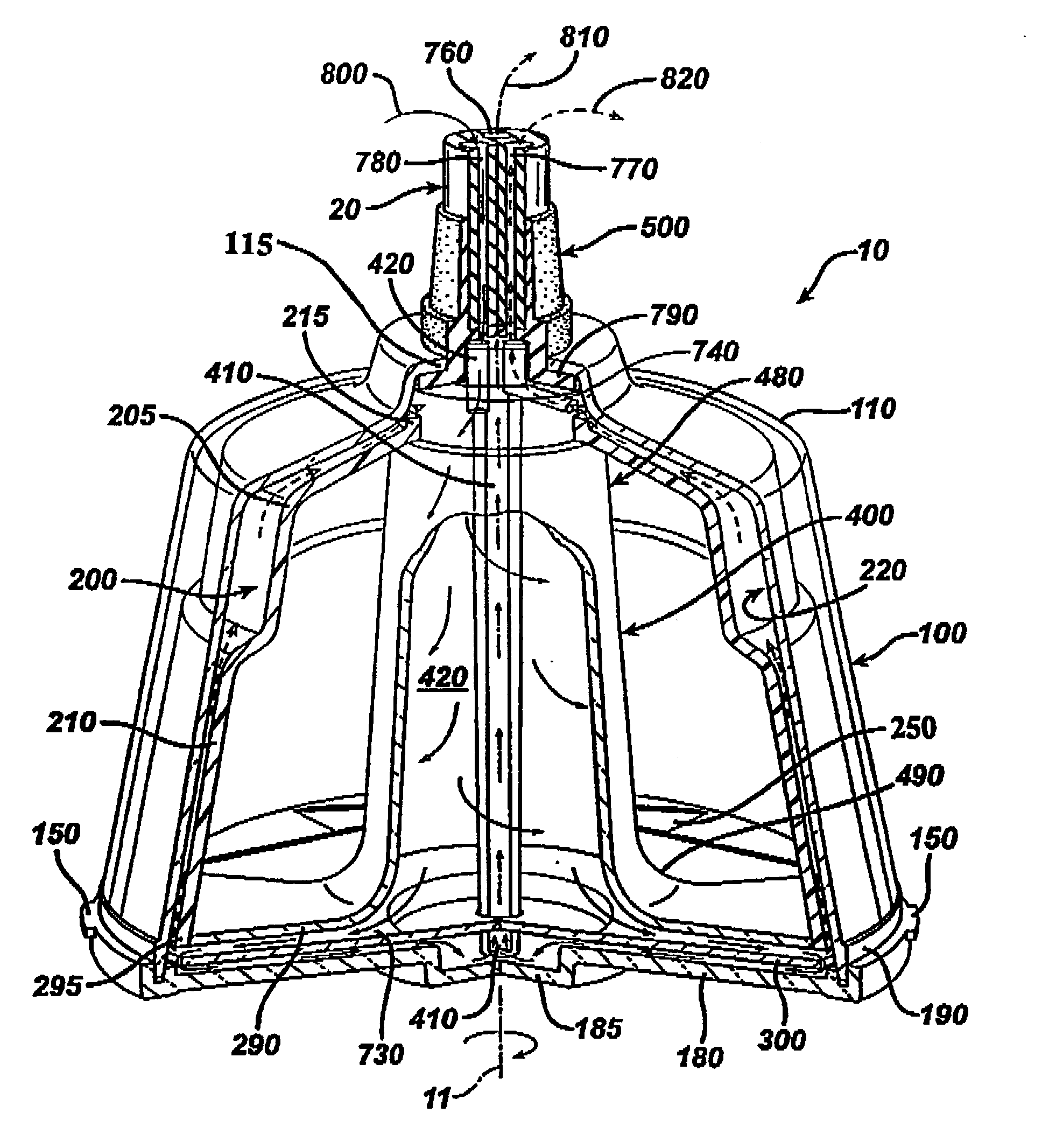

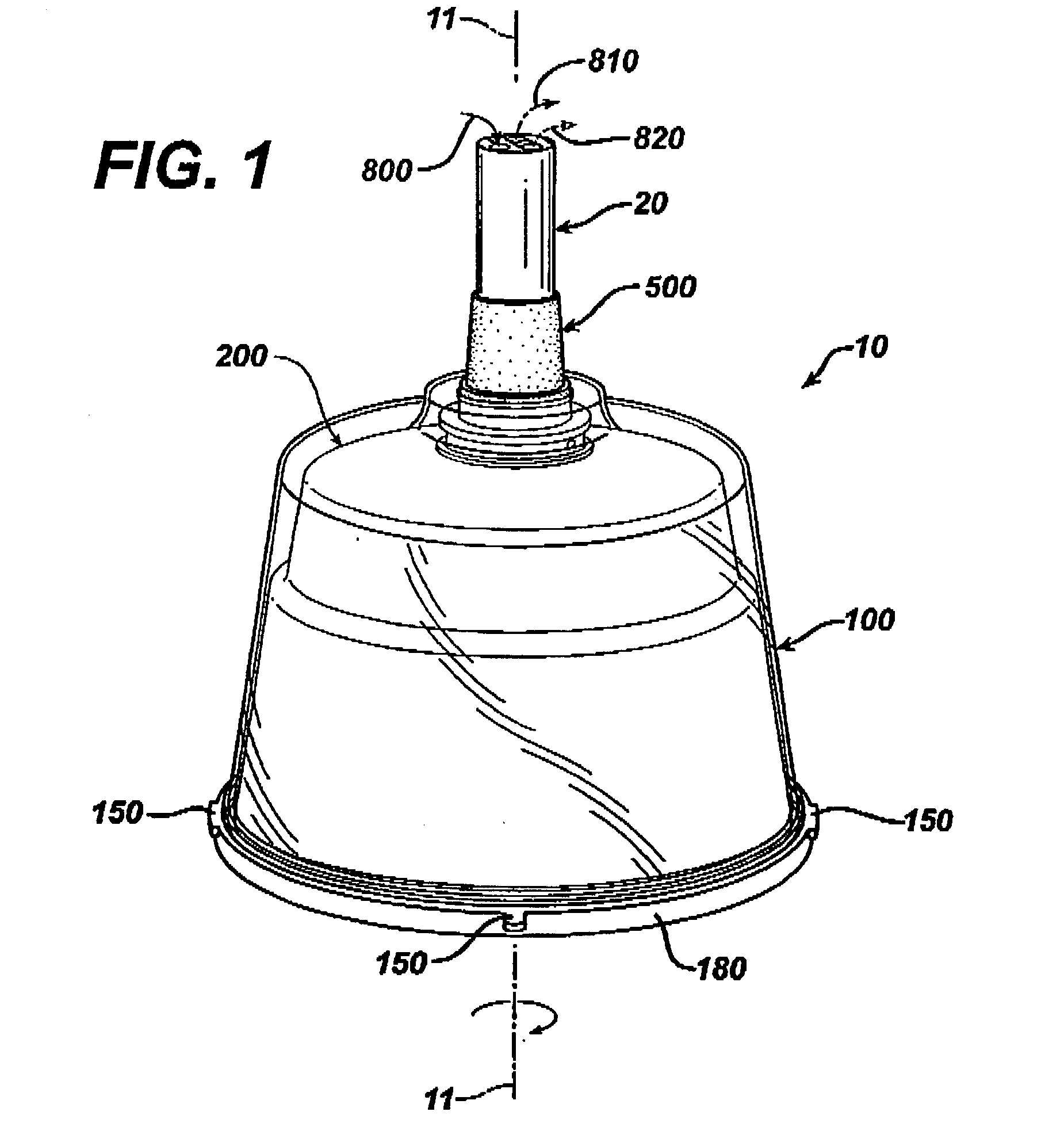

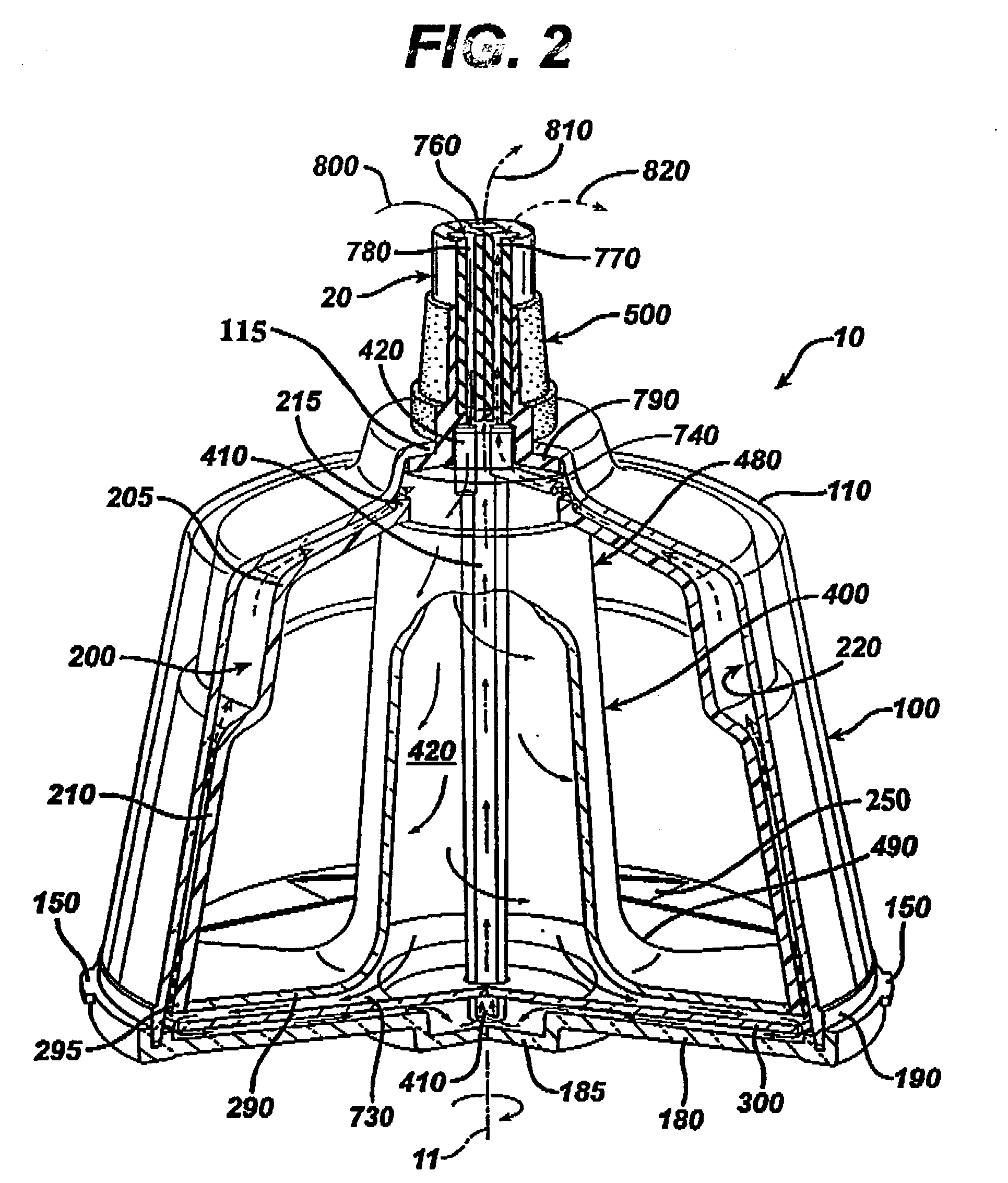

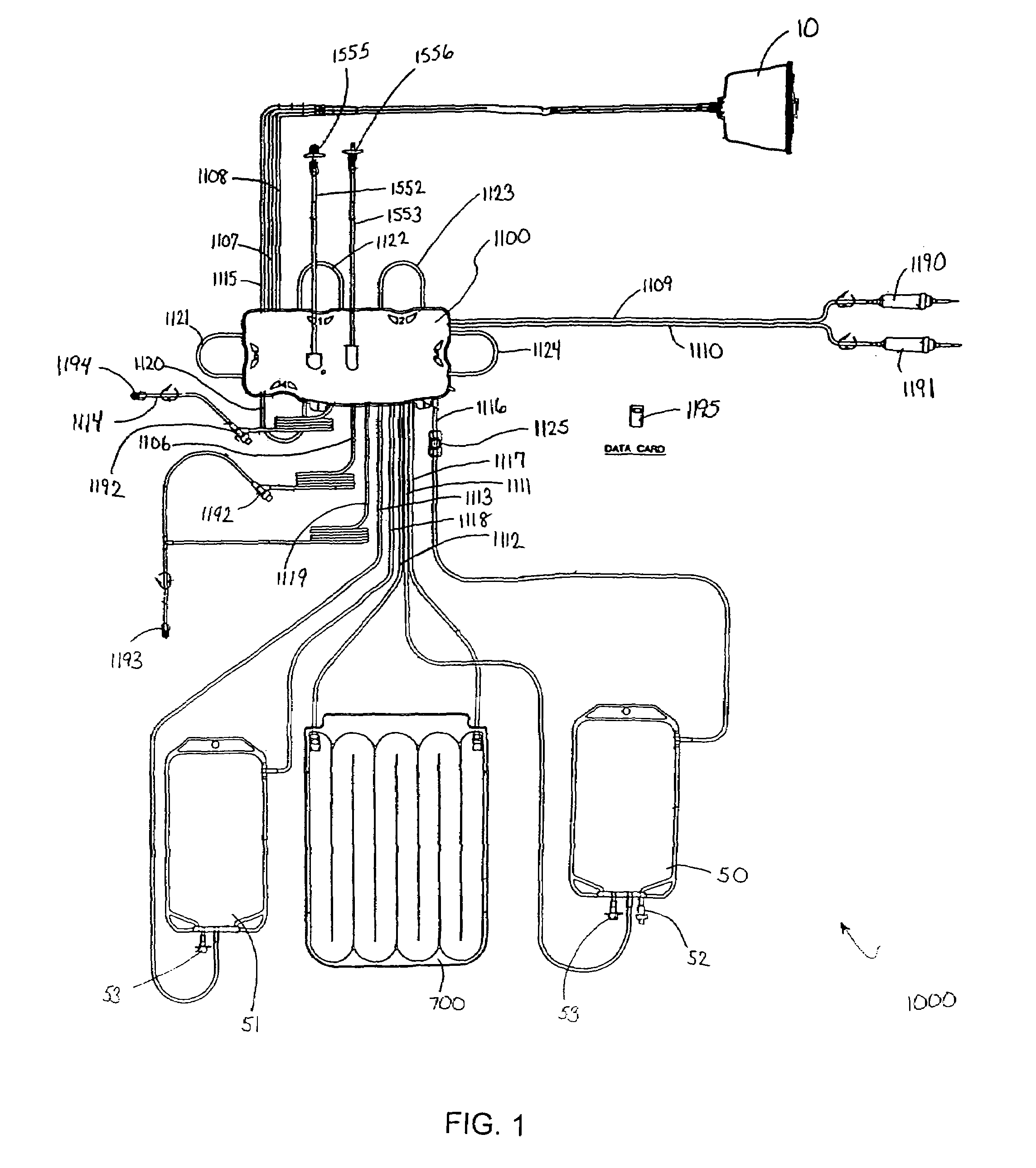

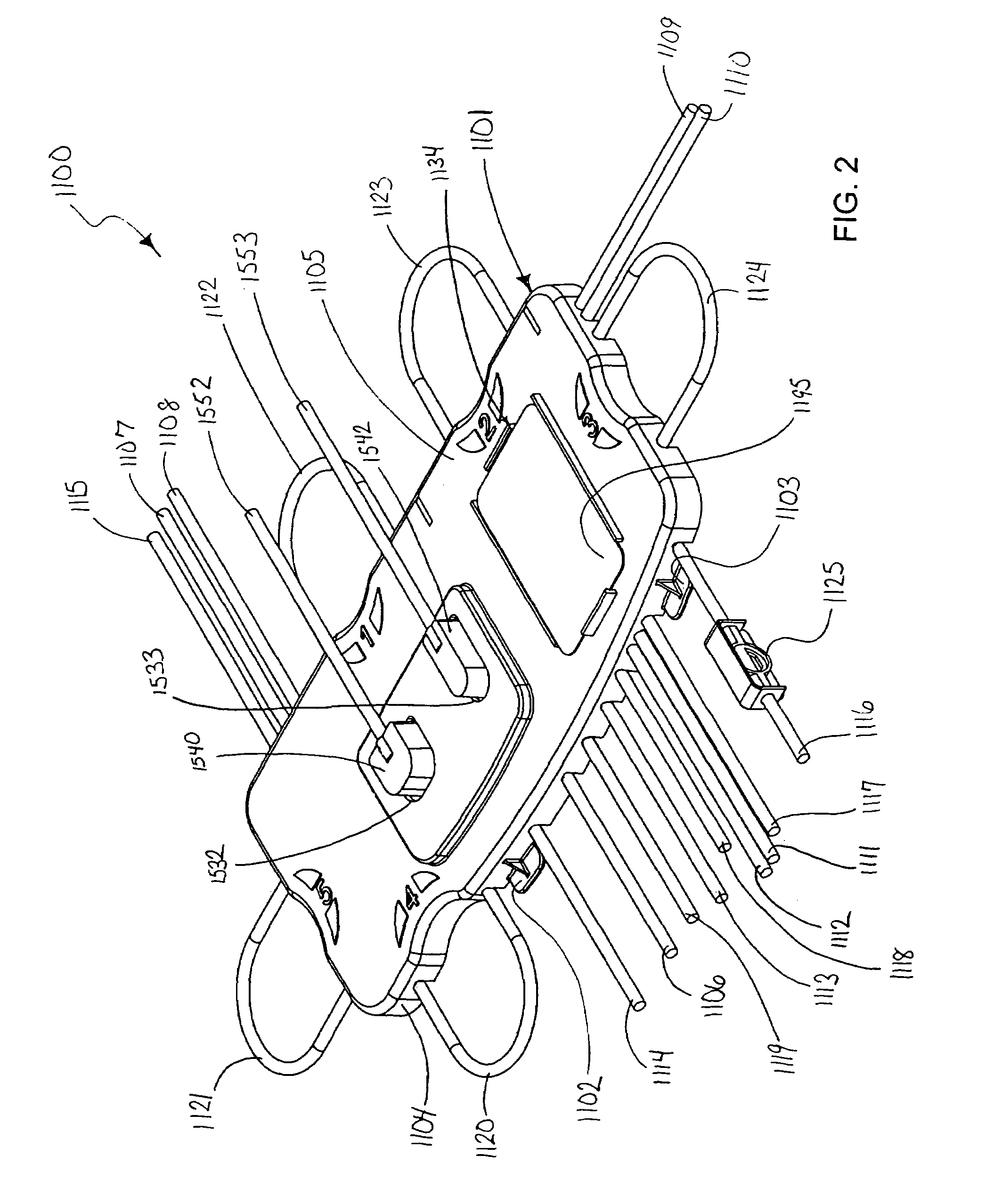

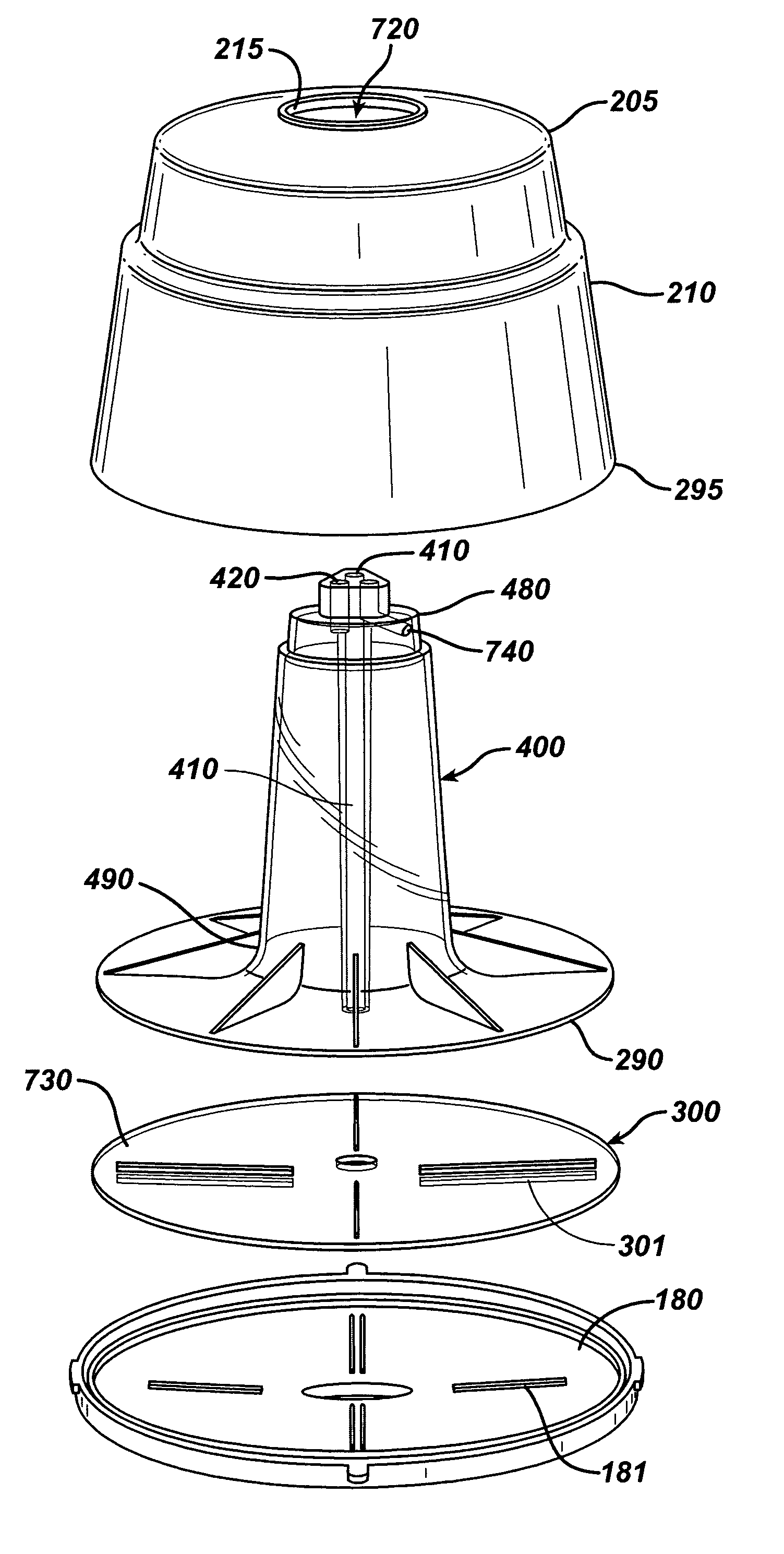

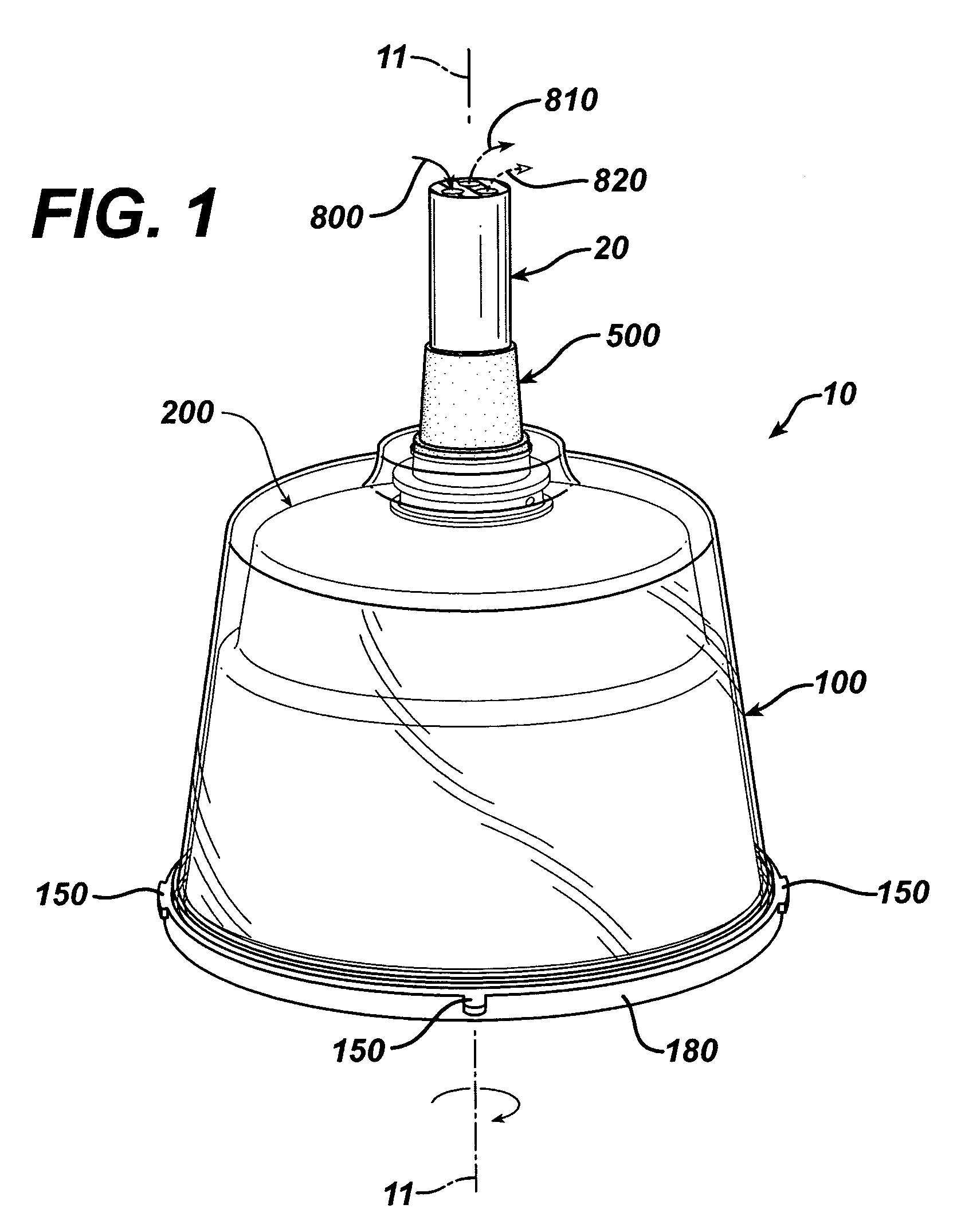

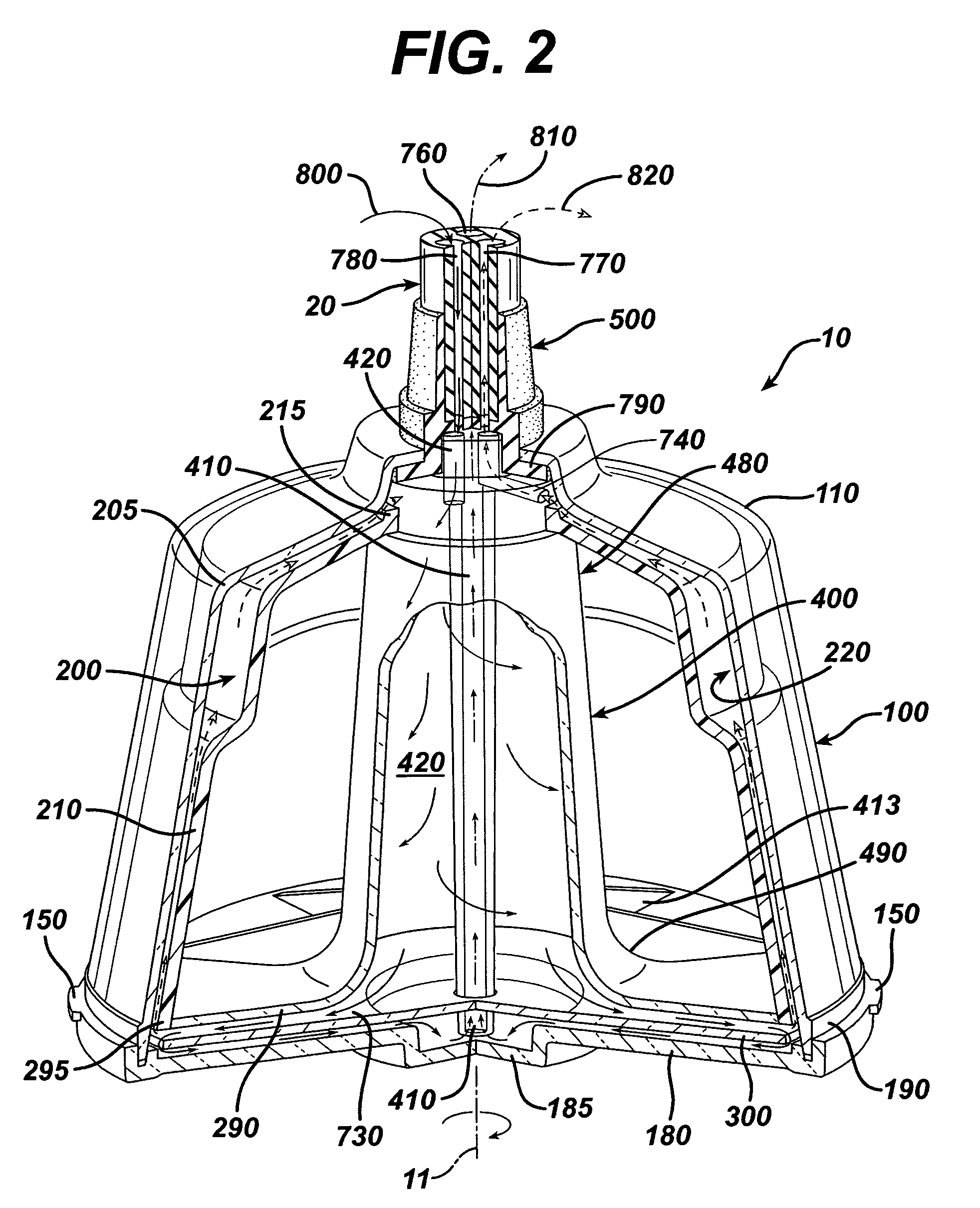

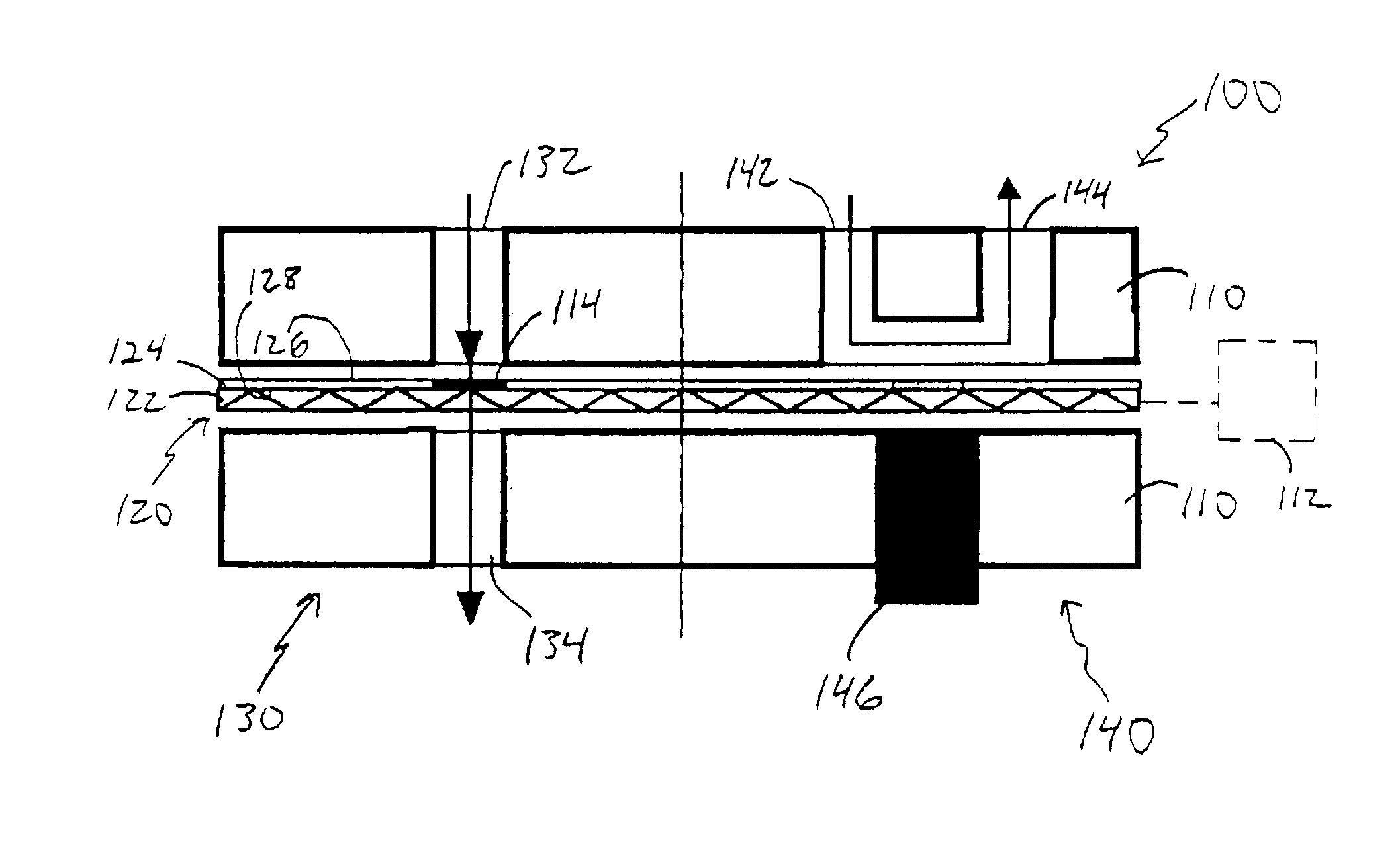

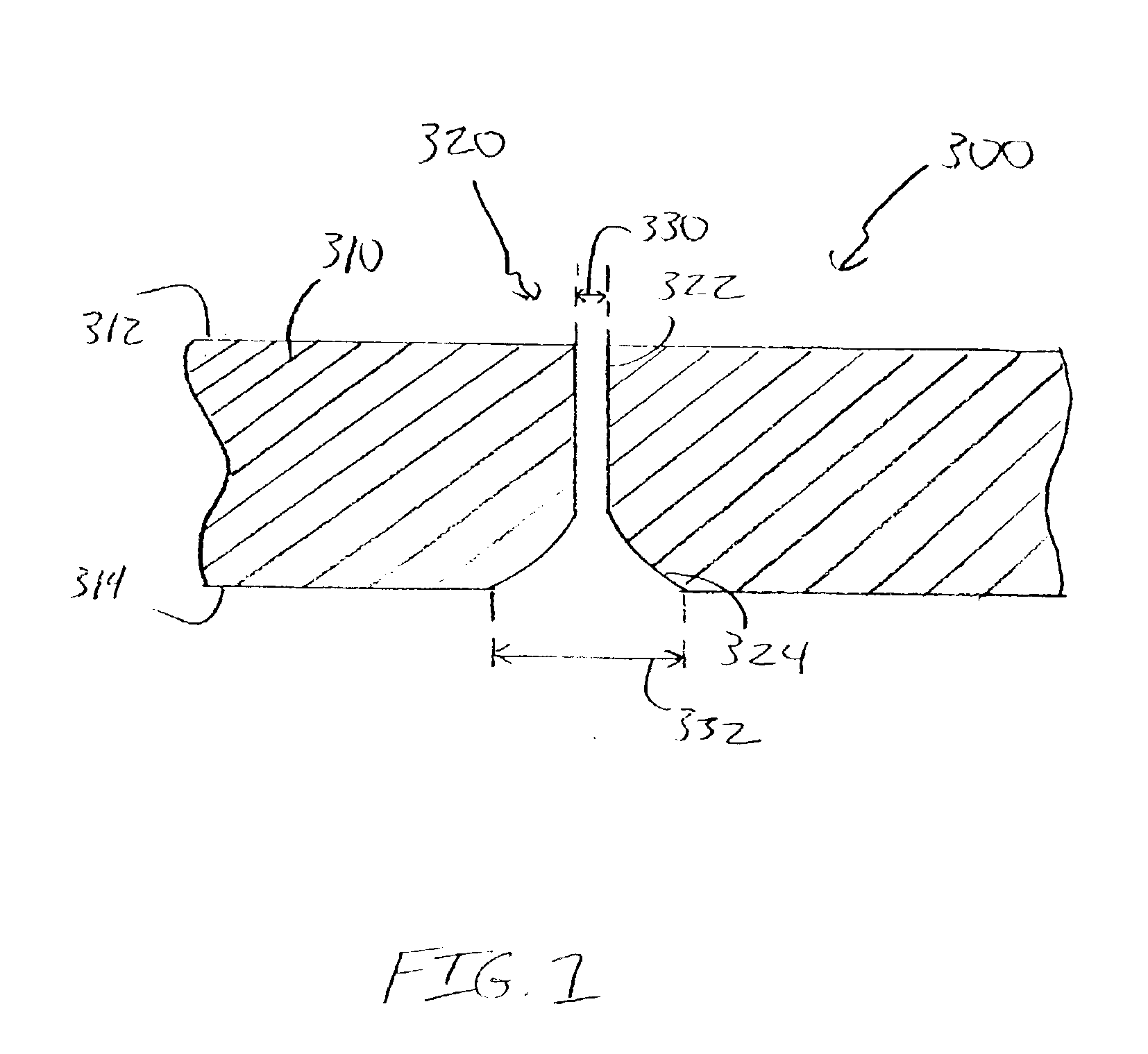

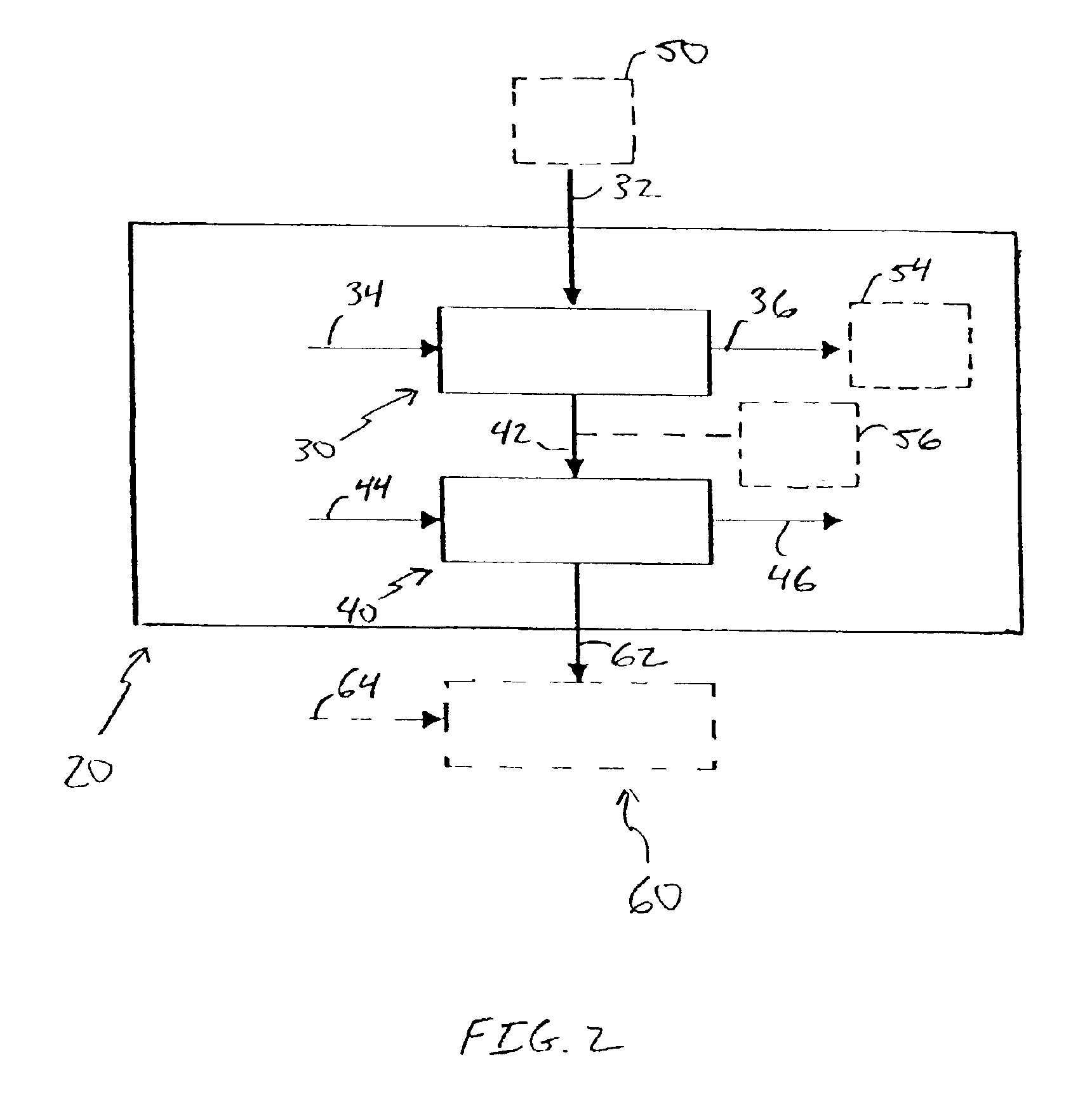

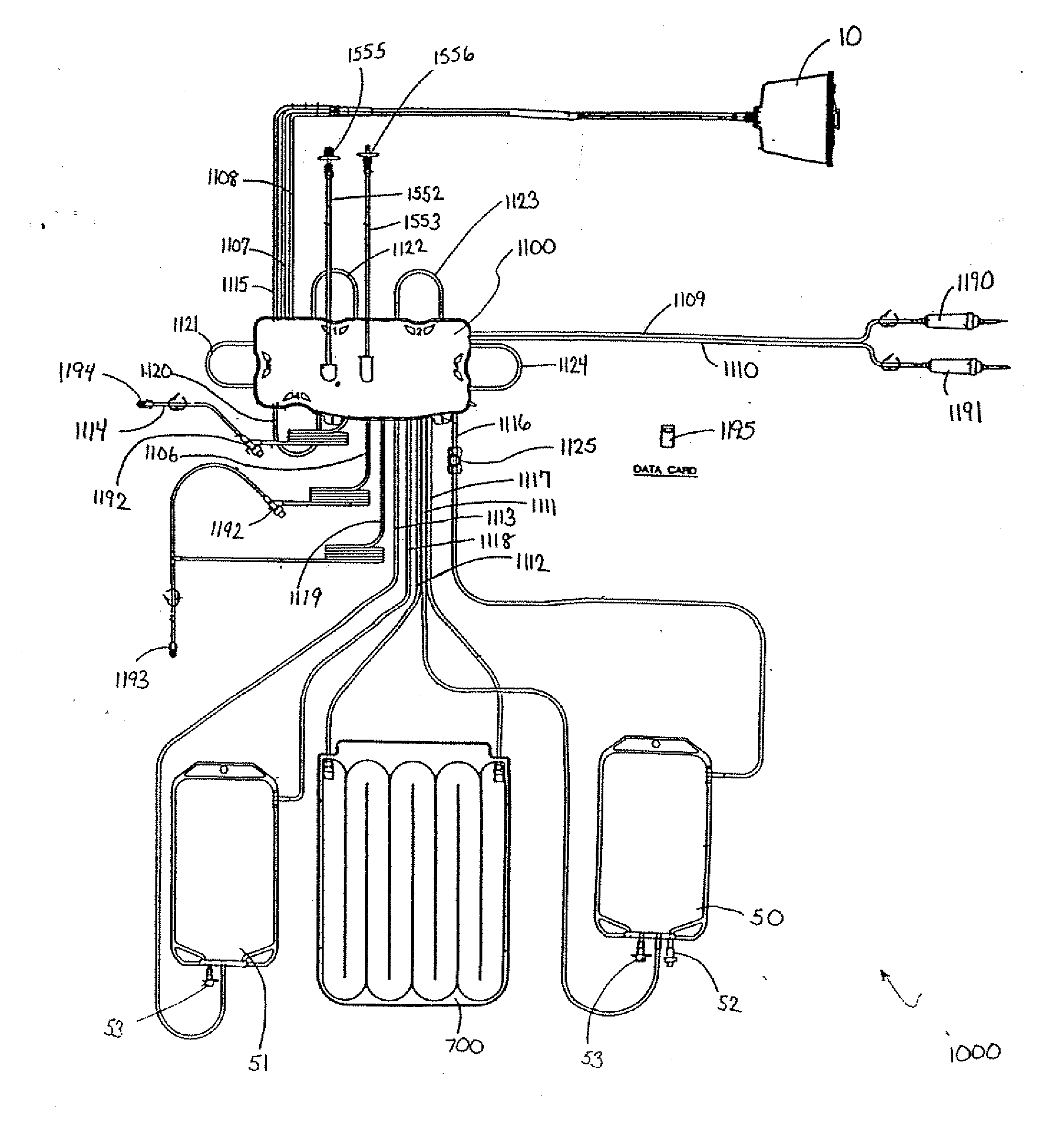

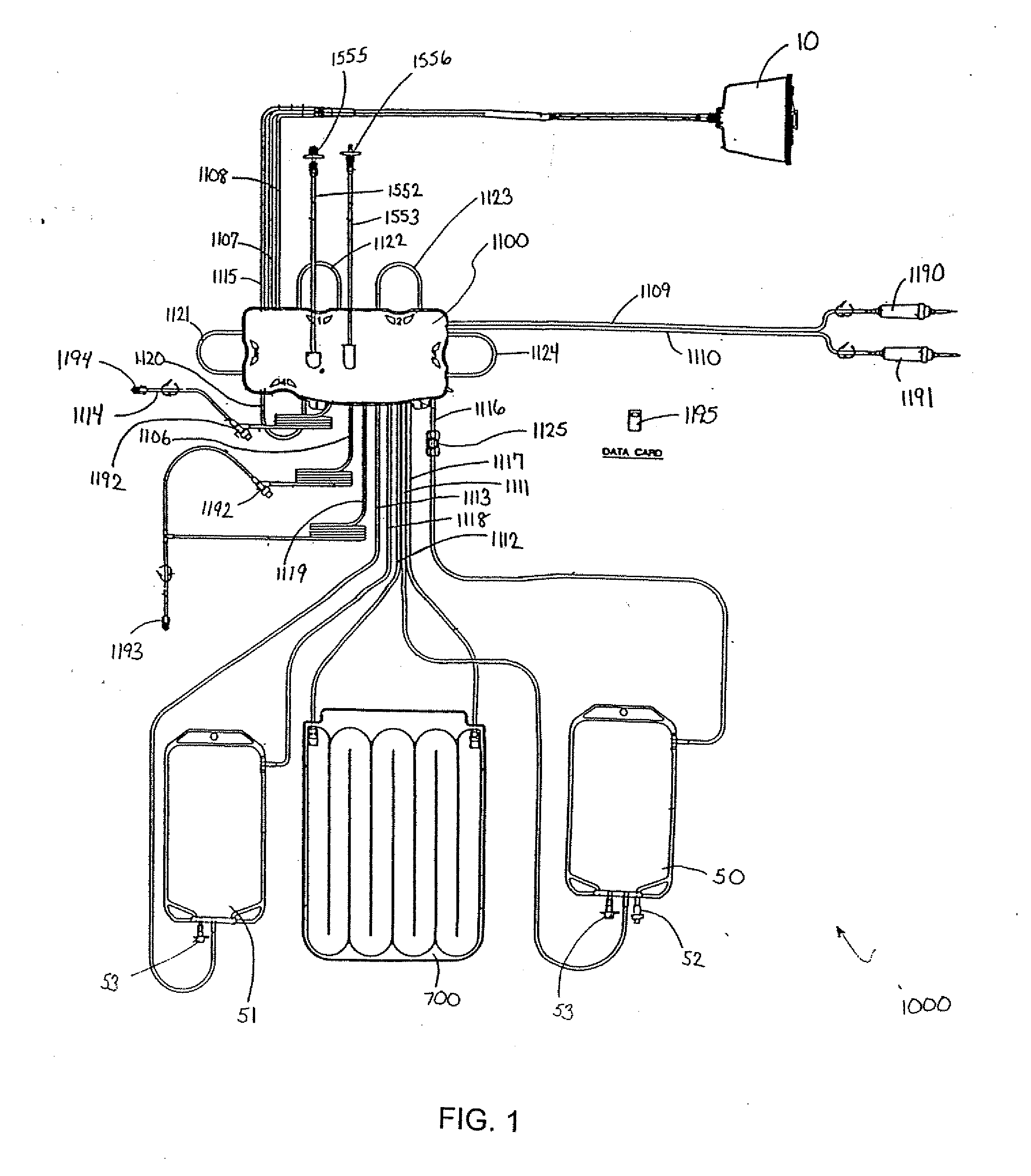

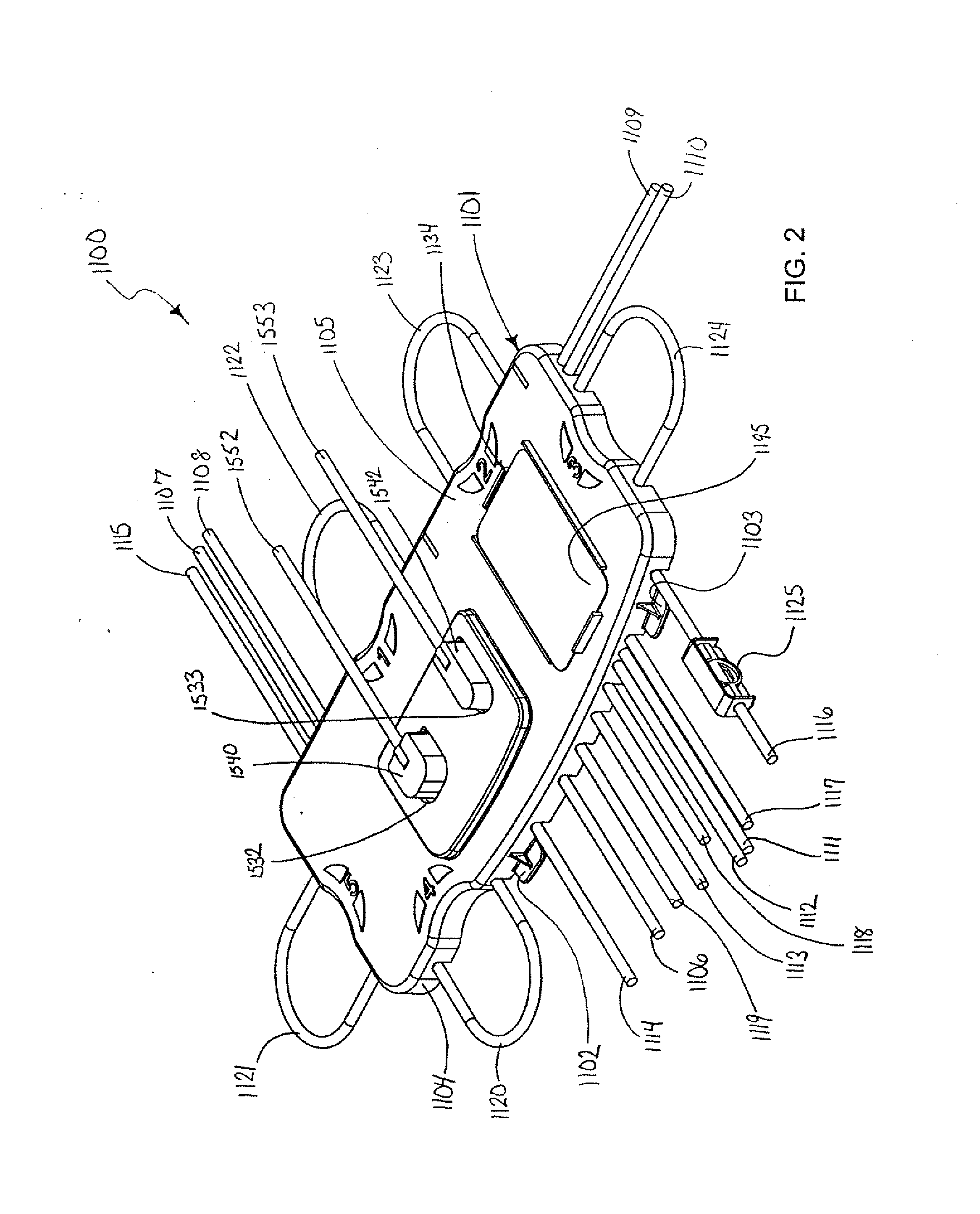

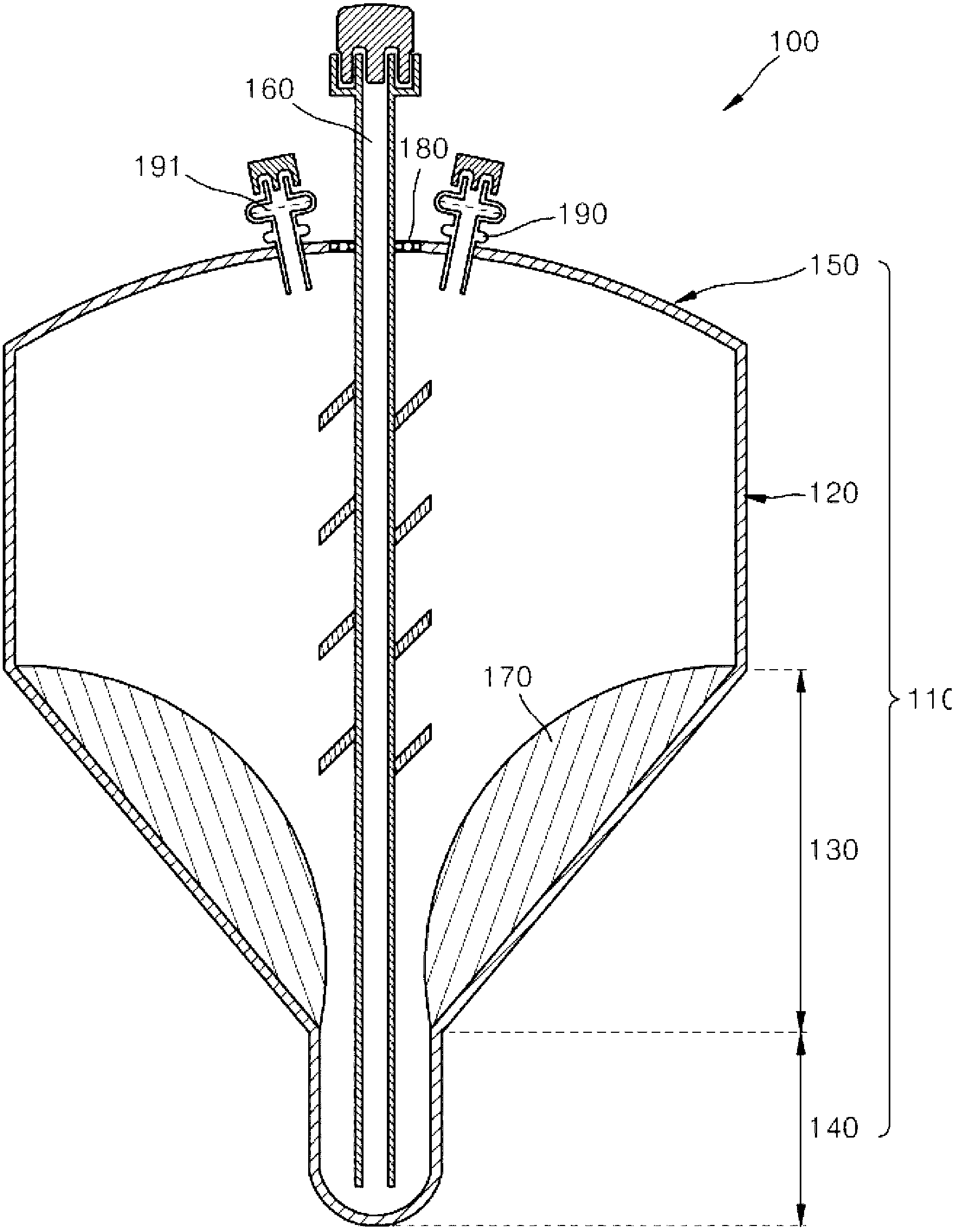

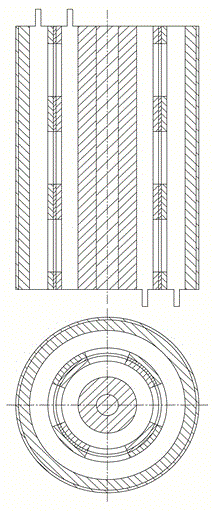

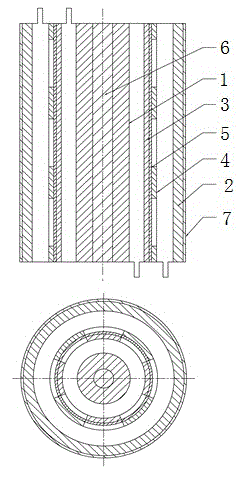

The present invention relates to systems, methods and apparatus for improving the yield for separating components of fluids, for example biological or sensitive fluids such as blood, and improving the component yield, for example, from donated whole blood by separating its components by density in a centrifuge bowl with a multi-axial lumen. The apparatus, system, and method eliminate the need to batch-type separate blood and can reduce the time needed to treat patients suffering from T-cell or white blood cell mediated diseases or conditions to less than 70 minutes. In one aspect, the invention is a centrifuge bowl (10) comprising an outer housing (100); a core (200); a lower plate (300); a lumen (400); a first bowl channel (420) within said lumen (400) for inflowing said fluid (800); a second bowl channel (410) for removing a first separated fluid component (810); and a third bowl channel (740) for removing a second separated fluid component (820).

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

Method for collecting a desired blood component and performing a photopheresis treatment

ActiveUS7479123B2Improve efficiencyHigh yieldOther blood circulation devicesFlexible member pumpsDiseasePhotopheresis

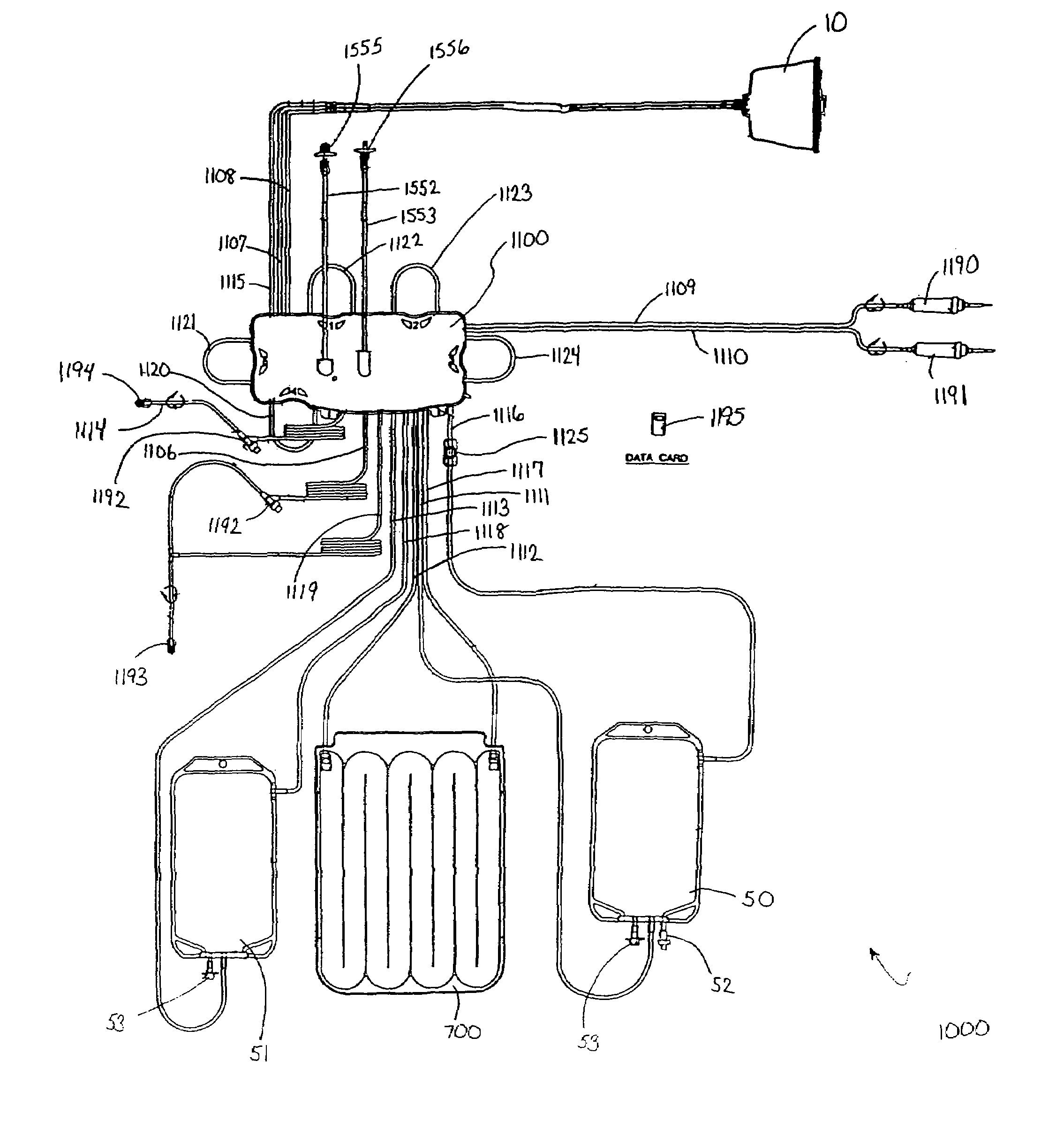

An improved method for separating whole blood into components and collecting a desired blood component. The method allows a desired blood component to be subjected to centrifugal forces within a separator for prolonged periods of time, yielding a cleaner cut and higher yield of the desired blood component. Whole blood is drawn from a source and pumped into a separator, the undesired blood components are removed from the separator at rates so as to build up the desired blood component in the separator. The desired blood component is only removed after a predetermined amount of the desired blood component has built up in the separator. It is preferred that the desired blood component be buffy coat and that the method be used to perform photopheresis treatments. In another aspect, the invention is a method of performing a full photopheresis treatment to treat diseases in a reduced time, preferably less than about 70 minutes, and more preferably less than about 45 minutes.

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

Method and apparatus for the continuous separation of biological fluids into components

ActiveUS7186230B2Improve efficiencyTreat a patient more efficientlyWater/sewage treatment by centrifugal separationOther blood circulation devicesWhite blood cellVolumetric Mass Density

The present invention relates to systems, methods and apparatus for improving the yield for separating components of fluids, for example biological or sensitive fluids such as blood, and improving the component yield, for example, from donated whole blood by separating its components by density in a centrifuge bowl with a multi-axial lumen. The apparatus, system, and method eliminate the need to batch-type separate blood and can reduce the time needed to treat patients suffering from T-cell or white blood cell mediated diseases or conditions to less than 70 minutes. In one aspect, the invention is a centrifuge bowl (10) comprising an outer housing (100); a core (200); a lower plate (300); a lumen (400); a first bowl channel (420) within said lumen (400) for inflowing said fluid (800); a second bowl channel (410) for removing a first separated fluid component (810); and a third bowl channel (740) for removing a second separated fluid component (820).

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

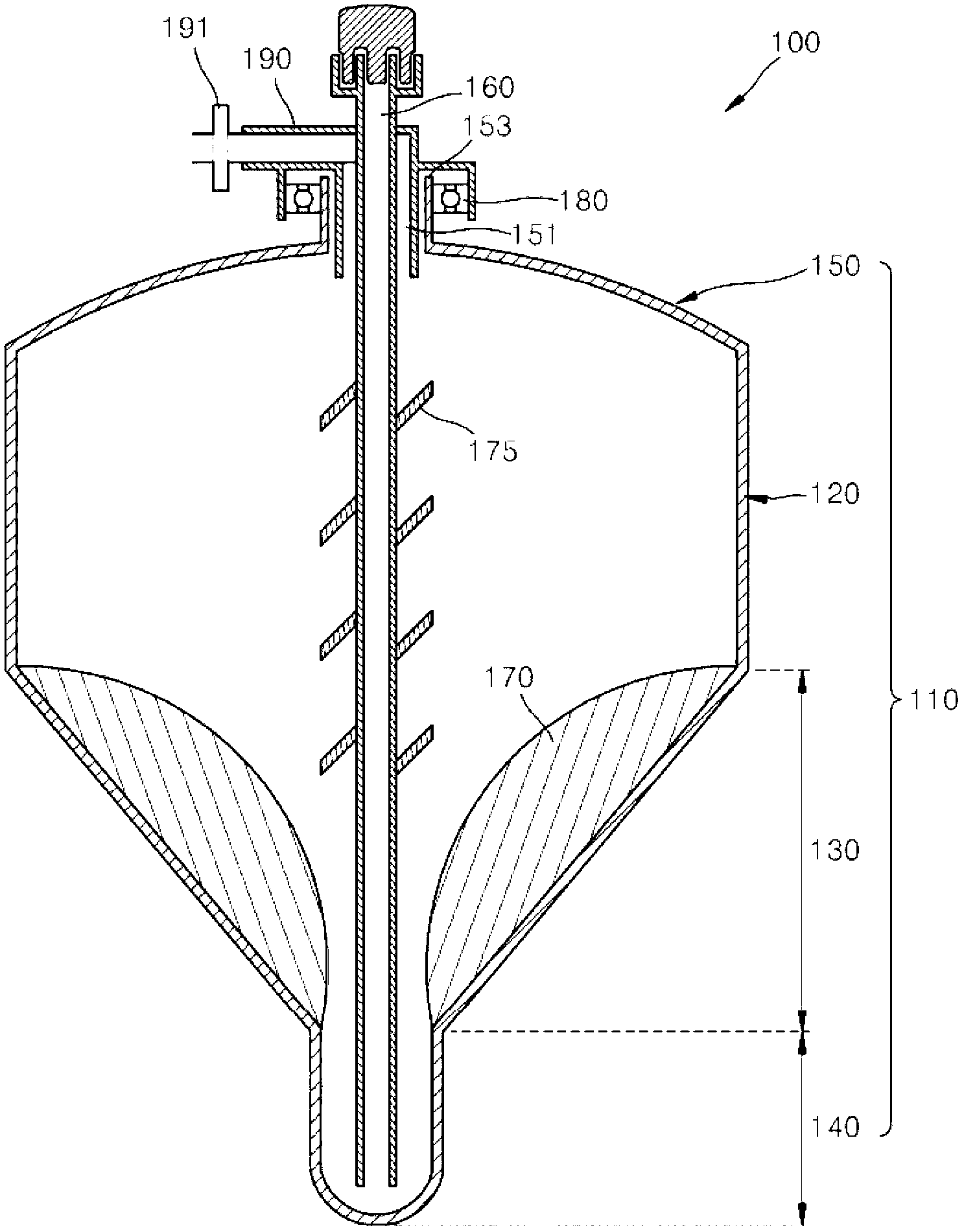

Disposable device for the continuous centrifugal separation of a physiological fluid

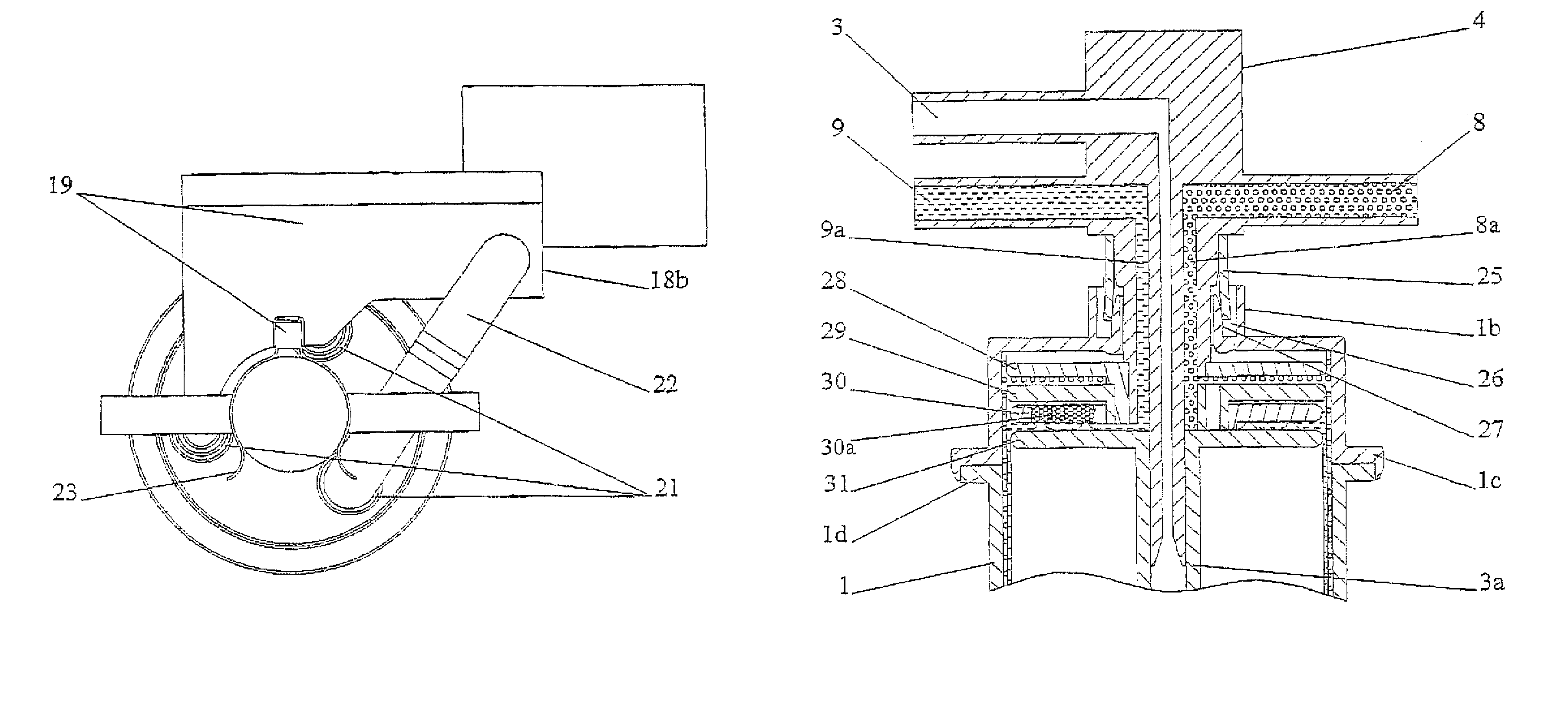

ActiveUS8070664B2Reduced Tolerance RequirementsReduce amount of shrinkageCentrifugesPhysiological fluidSingle-Use Device

The invention relates to disposable device for the continuous centrifugal separation of a physiological fluid. The inventive device comprises: a fixed axial element; a centrifugation chamber which is mounted such that it can rotate around the axis of said element; an inlet channel for the blood to be centrifuged, the dispensing port of which is located close to the base of the chamber; and an outlet passage for a separated constituent, the inlet port of which is located close to the other end of the chamber in a concentrated area of one of the separated constituents having the lowest mass density in order for same to be removed continuously. The above-mentioned chamber takes the form of a long tube. The fixed axial element comprises a second outlet passage for a second of the separated constituents, the inlet port of which is located close to the end of the chamber opposite the above-mentioned base in a concentrated area of said second separated constituent having the highest mass density in order for same to be removed continuously.

Owner:SORIN GRP ITAL SRL

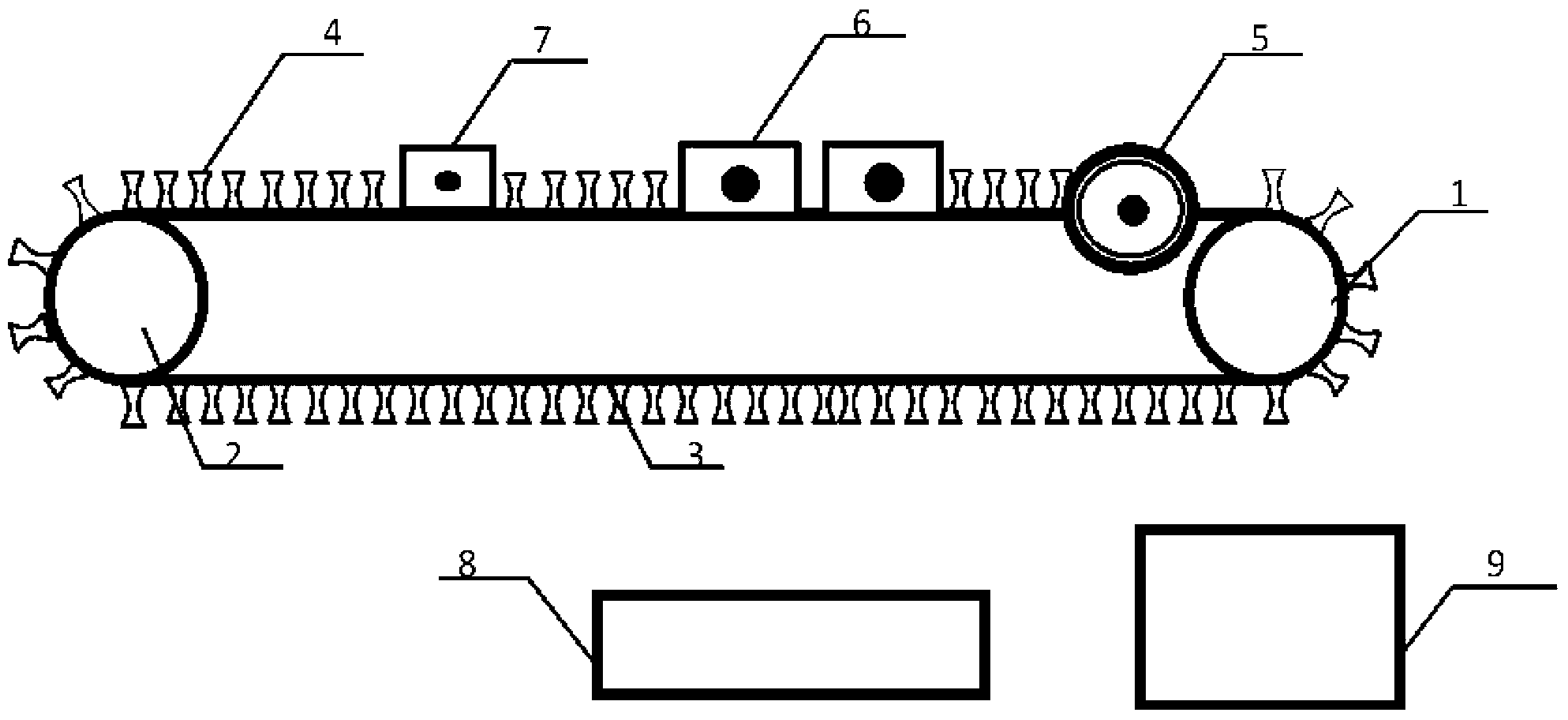

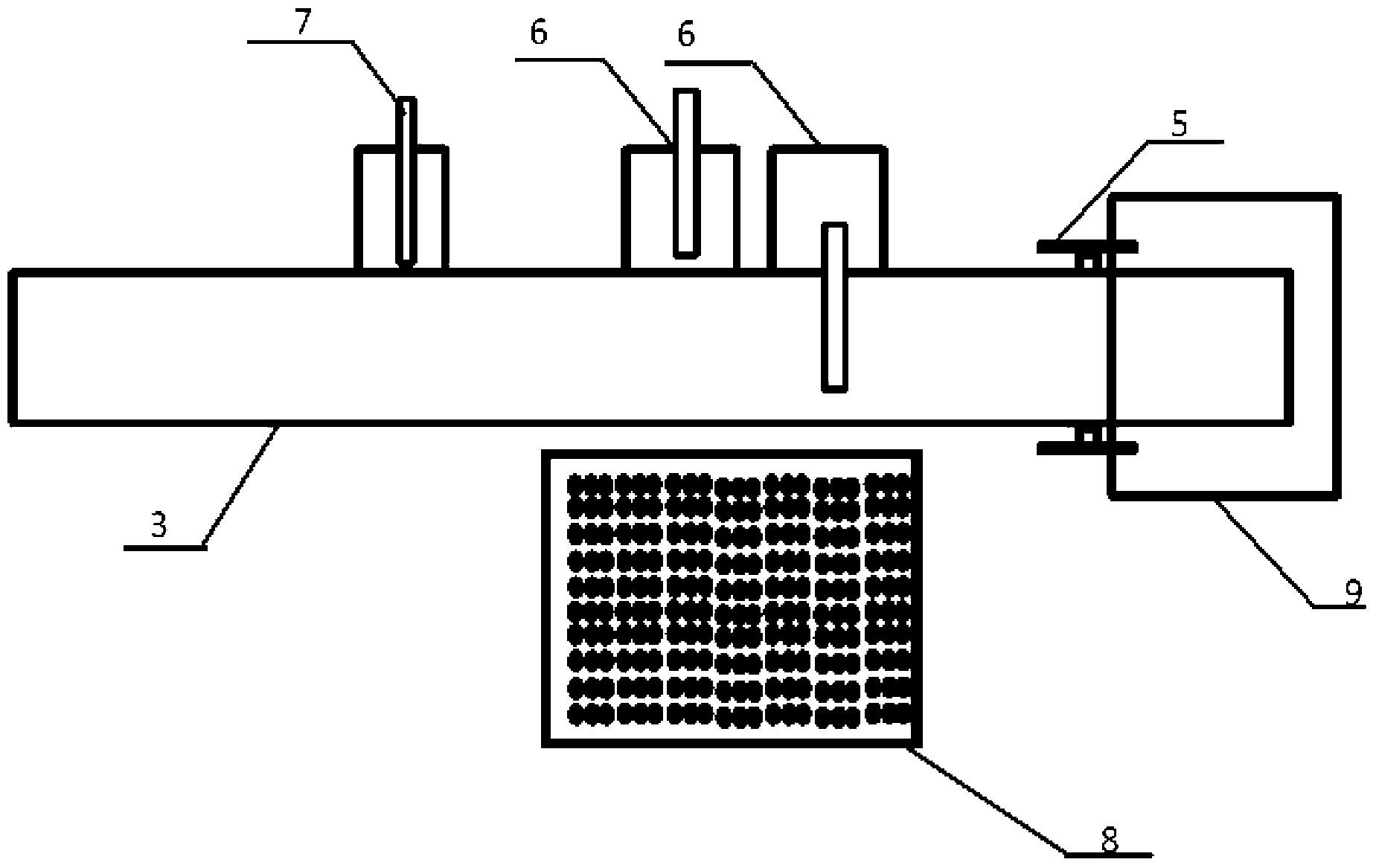

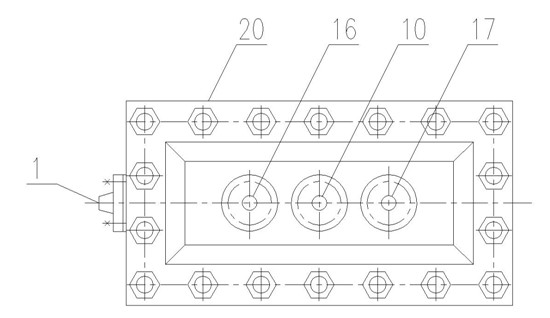

Automatic dismantling and separating device for waste dry cell and dismantling and separating method

InactiveCN103296294AAvoid processing inefficienciesSolve follow-up processing difficultiesSolid waste disposalReclaiming serviceable partsProcess engineeringConveyor belt

The invention discloses an automatic dismantling and separating device for a waste dry cell and a dismantling and separating method, The automatic dismantling and separating device comprises a roller, a belt, a grinding wheel group, a firing pin, a cutter and a vibrating screen, wherein the conveyor belt is provided with a plurality of rubber partition plates; the grinding wheel group is arranged on the conveyor belt; the first side of the conveyor belt is provided with the cutter and the firing pin; the second side of the conveyor belt is provided with the vibrating screen. A first roller, a grinding wheel, the cutter and the firing pin are powered on; the waste dry cells are fixedly arranged between two adjacent partition plates of the belt one by one. Along with the movement of the belt, two ends of each waste dry cell are cut off by the grinding wheel rotating at high speed, paste and a carbon bar of the dry cell are pushed out of a shell of the dry cell through the firing pin, and a zinc skin is separated from a plastic skin through the cutter. The automatic dismantling and separating device and dismantling and separating method for the waste dry cell have the advantages that a paste electrolyte, a zinc drum and the carbon bar can be comprehensively recycled, and the processing working efficiency and a separation effect of the waste dry cell can be improved.

Owner:ANHUI UNIV OF SCI & TECH

Mesoporous membrane collector and separator for airborne pathogen detection

InactiveUS7037425B2Function increaseQuick checkBioreactor/fermenter combinationsMaterial nanotechnologyPorous substrateBiological materials

A process and apparatus for the collection of biological materials from air. Collection and separation devices utilize a novel membrane structure formed from a functionalized inorganic mesoporous membrane supported by porous substrate.

Owner:PURDUE RES FOUND INC

Method for collecting a desired blood component and performing a photopheresis treatment

ActiveUS20070100272A1BuildImprove efficiencyOther blood circulation devicesFlexible member pumpsPhotopheresisBlood component

An improved method for separating whole blood into components and collecting a desired blood component. The method allows a desired blood component to be subjected to centrifugal forces within a separator for prolonged periods of time, yielding a cleaner cut and higher yield of the desired blood component. Whole blood is drawn from a source and pumped into a separator, the undesired blood components are removed from the separator at rates so as to build up the desired blood component in the separator. The desired blood component is only removed after a predetermined amount of the desired blood component has built up in the separator. It is preferred that the desired blood component be buffy coat and that the method be used to perform photopheresis treatments. In another aspect, the invention is a method of performing a full photopheresis treatment to treat diseases in a reduced time, preferably less than about 70 minutes, and more preferably less than about 45 minutes.

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

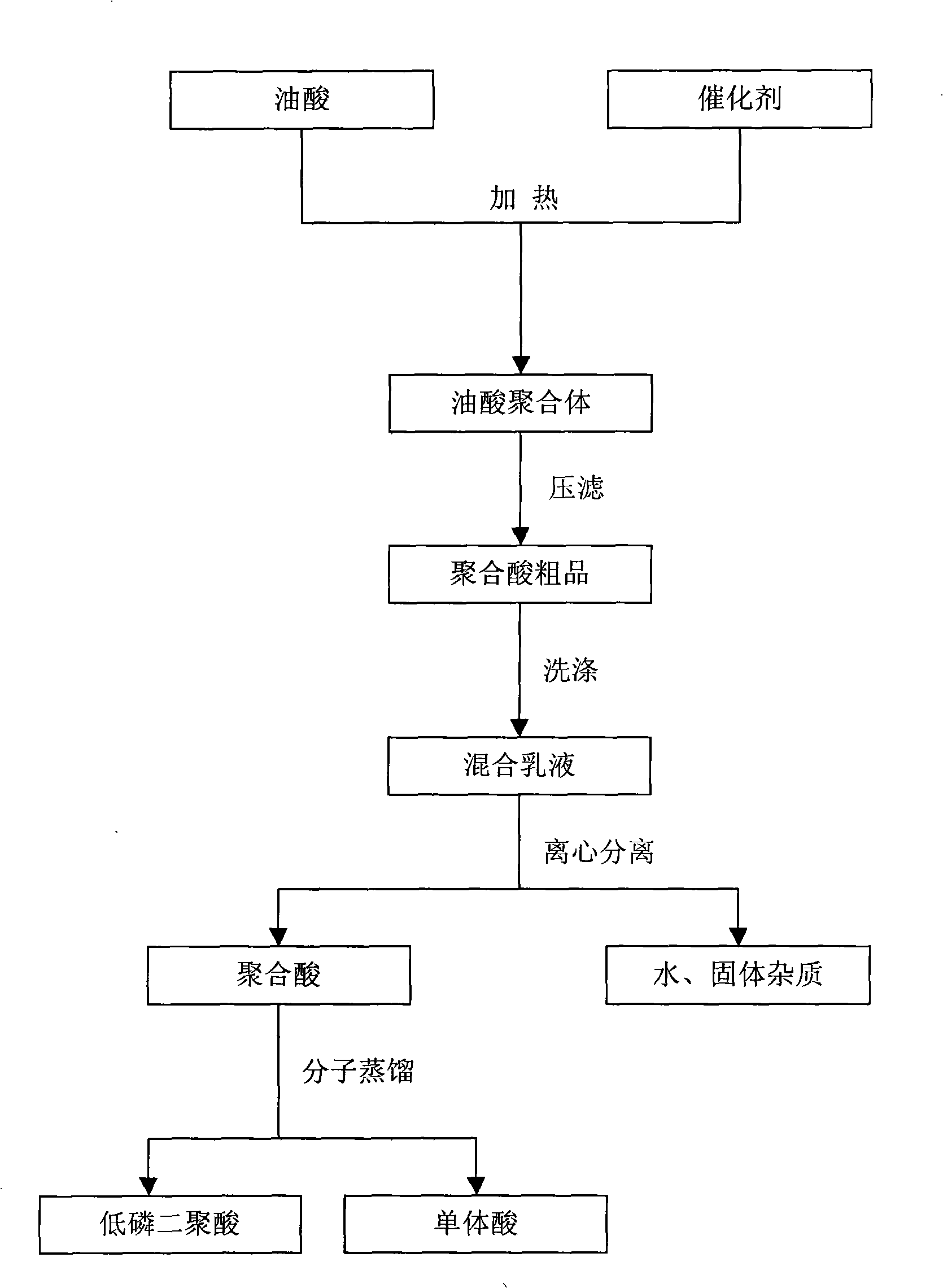

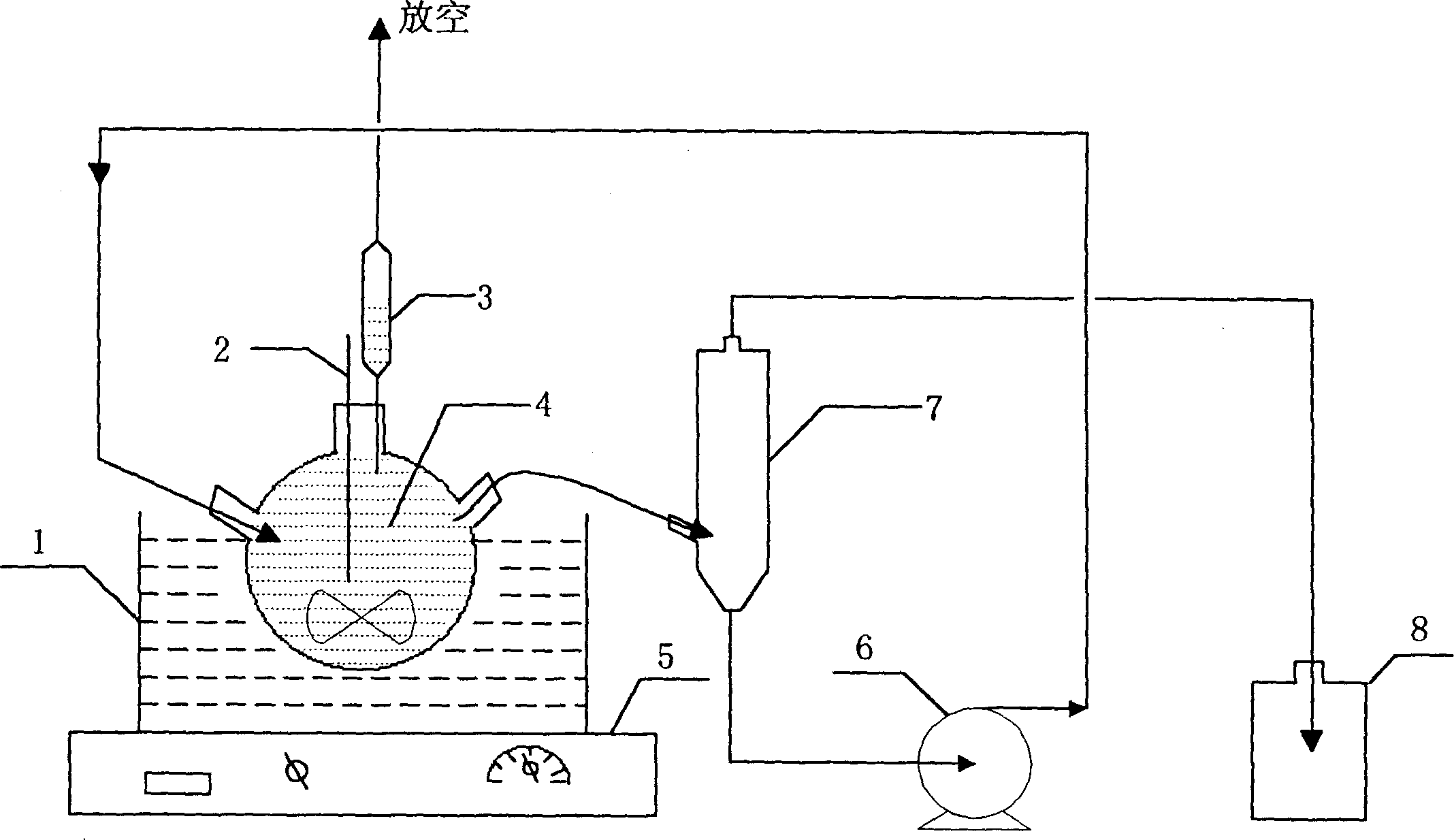

Method for producing low-phosphor dimer acid

ActiveCN101492358AImprove qualityContinuous separationOrganic compound preparationCarboxylic compound separation/purificationDistillationPhosphate

The invention relates to a method for producing low-phosphorous dimer acid and provides a method for producing dimer acid with low phosphor content. The method is characterized in that oleic acid is polymerized by catalysts of carclazyte, phosphoric acid and the like to obtain crude polymerized acid; the crude polymerized acid is washed by water; a centrifugal separation device is used for separating the polymerized acid from the water continuously to remove excessive phosphate and other filtered solid impurity to obtain low-phosphorous polymerized acid. The washing condition is as follows: the proportion of the polymerized acid and water (W / W) is 1: 0.1-10; the washing temperature is 10 DEG C to 100 DEG C; and the washing time is 0.1h to 3h. Molecular distillation is carried out on the low-phosphorous polymerized acid to obtain the low-phosphorous dimer acid and a side product of monomer acid. The invention increases the working procedures of washing and separating, thereby ensuring that the content of the phosphate of the dimer acid is reduced to be lower than 30mu g / g, reducing the content of the impurity in the dimer acid and improving the quality of the dimer acid and the downstream product.

Owner:YIHAI TIANCHENG LIANYUNGANG CHEM INDSCO

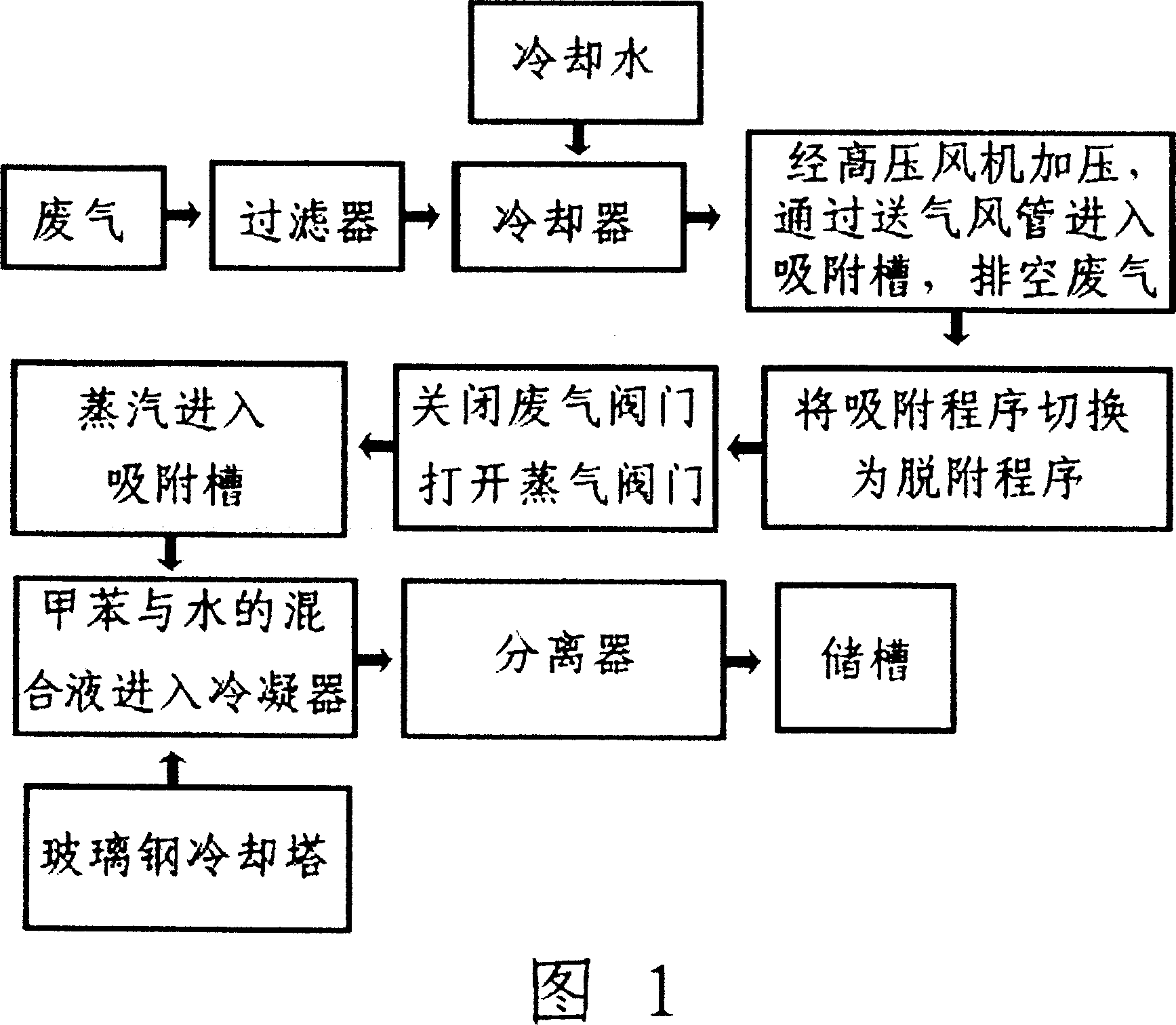

Method for recovering toluene

InactiveCN101077850AMassive absorptionInflow guaranteeAdsorption purification/separationDesorptionWater vapor

The recovery process includes the following steps: 1. making the produced waste gas pass through the control valve and filtering in the gas filter; 2. cooling waste gas including toluene in the cooler; 3. pressurizing with the high pressure blower and adsorbing with active carbon in three adsorbing tanks; 4. switching to desorption program through closing the waste gas valve and opening the steam valve for steam to enter the active carbon, with the toluene separated from the active carbon being exhausted together with the steam from the bottom of the adsorbing tanks; 5. condensing the steam with toluene gas to form mixture liquid of toluene and water; 6. separating the mixture liquid of light toluene and heavy water in a separator; and 7. storing toluene in a tank. The process has toluene recovering rate over 86 % and low cost.

Owner:王少平

Rainwater pollutant interception well adopting cyclone separation

InactiveCN105569181ASimple structureFew partsFatty/oily/floating substances removal devicesSewerage structuresPollutantPre treatment

The invention discloses a rainwater pollutant interception well adopting cyclone separation. The well comprises a shaft and is characterized in that a cyclone unit and a precipitation unit positioned under the cyclone unit are arranged in the shaft; the cyclone unit comprises a cyclone cylinder and an inner cylinder arranged in the cyclone cylinder; outer annular spaces for rainwater to pass through in a cyclone manner are reserved at intervals between the cyclone cylinder and the shaft; a water inlet pipe communicated with the outer annular spaces is connected to the shaft; inner annular spaces for the rainwater to pass through in the cyclone manner are reserved at intervals between the inner cylinder and the cyclone cylinder; a water outlet pipe communicated with the inner annular spaces is connected to the cyclone cylinder; and the precipitation unit comprises a funnel arranged below the inner cylinder and fixed with the inner wall of the shaft, and a storage tank positioned below the funnel. According to the well, the effect of separating pollutants in the rainwater is achieved through centrifugal force generated by a cyclone effect; and the well serving as a rainwater pretreatment device can greatly reduce the pollutants flowing into river channels to ensure the unobstruction of a downstream pipe network.

Owner:苏州市清泽环境技术有限公司

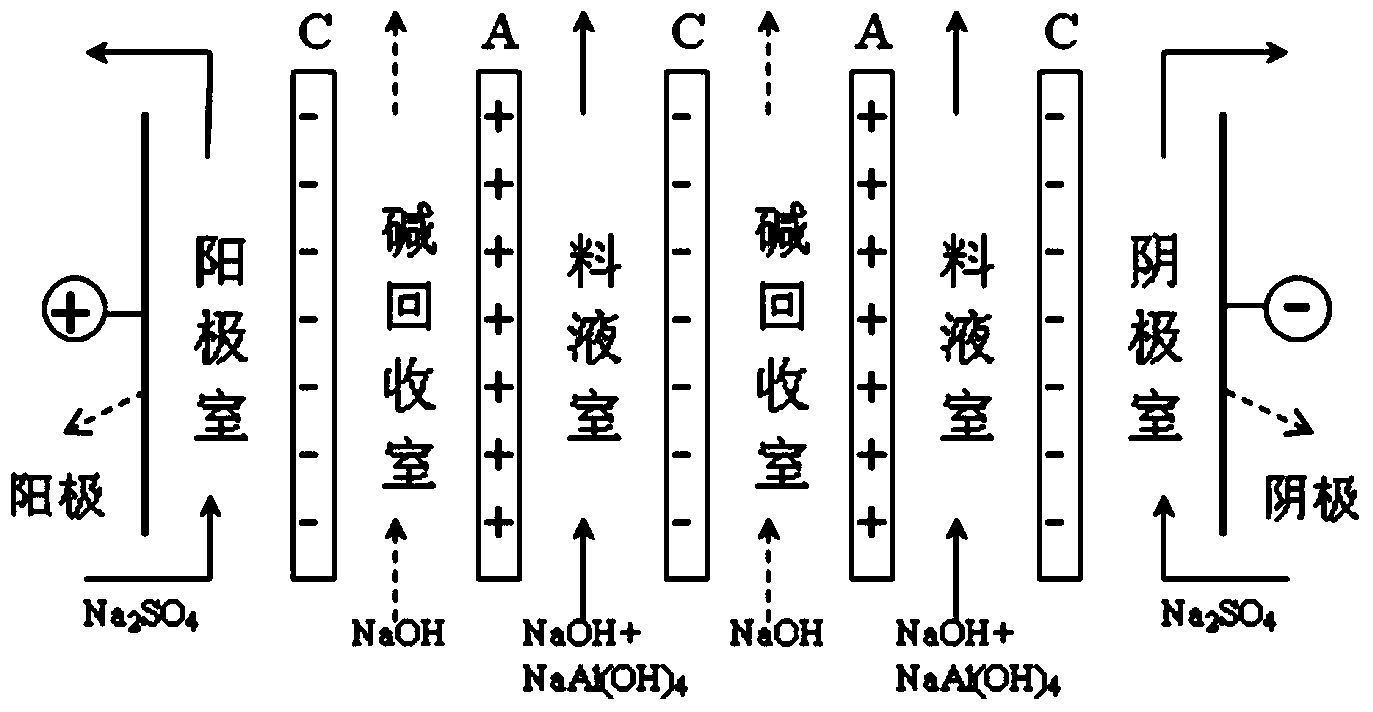

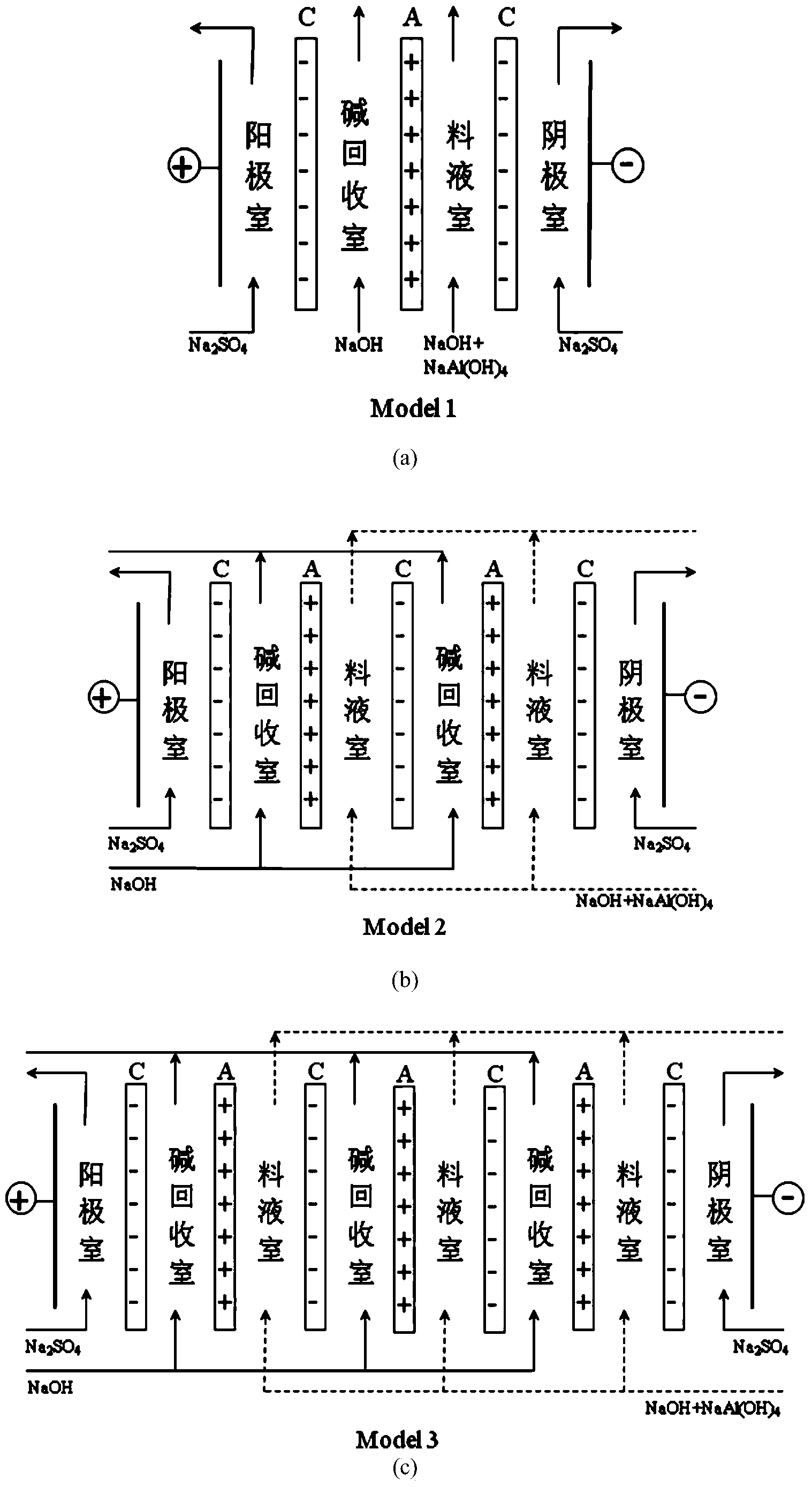

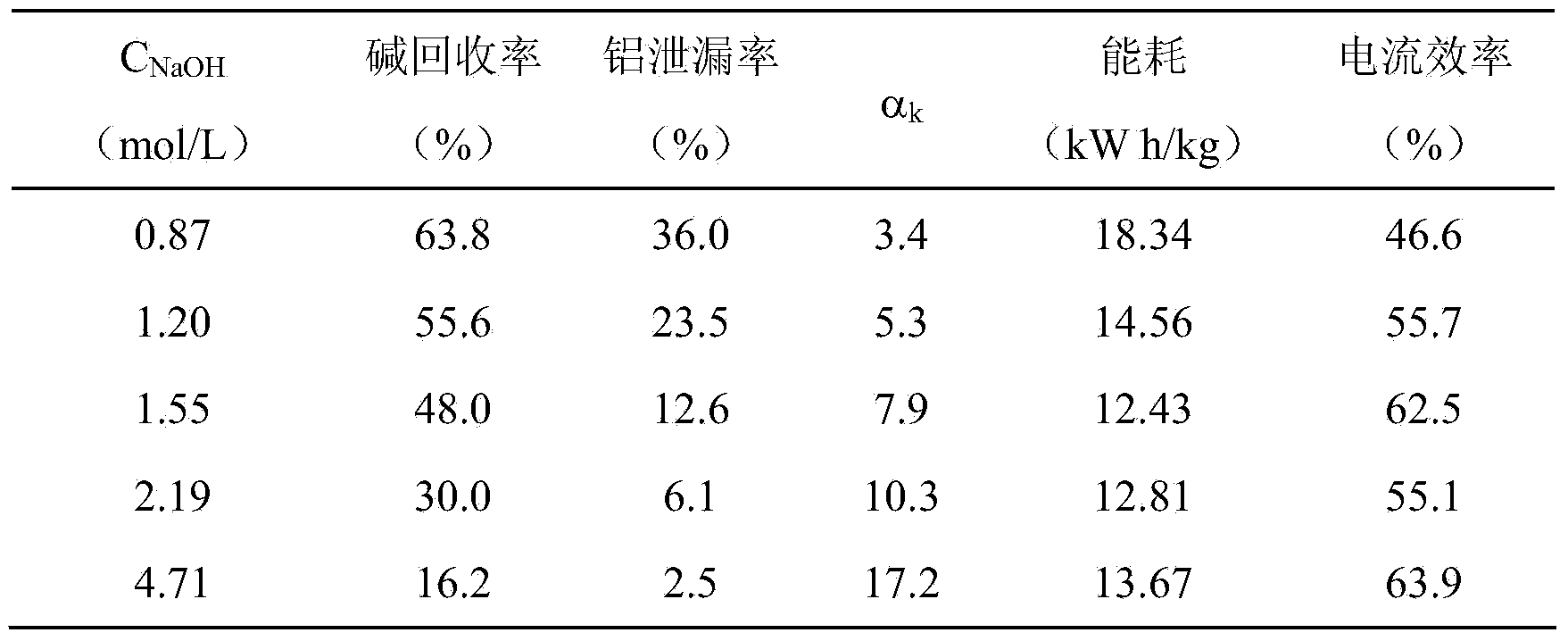

Separation method of alkaline liquid in production of alumina

InactiveCN104016388AHigh yieldHigh purityAluminium oxides/hydroxidesEnergy consumptionSodium hydroxide

The invention discloses a separation method of alkaline liquid in production of alumina. The separation method is characterized in that sodium hydroxide and sodium metaaluminate in alkaline liquid can be separated by an electroosmosis device. According to the separation method disclosed by the invention, the alumina production process is optimized, i.e., the sodium hydroxide and sodium metaaluminate in the alkaline liquid are subjected to membrane separation before crystal seeds are introduced, therefore, the energy consumption and time in the subsequent crystal seed precipitation process can be reduced and shortened, and the productivity of aluminum hydroxide is increased; in addition, the purity of alkali in mother liquor can be improved and recycling of alkali is facilitated.

Owner:HEFEI UNIV OF TECH

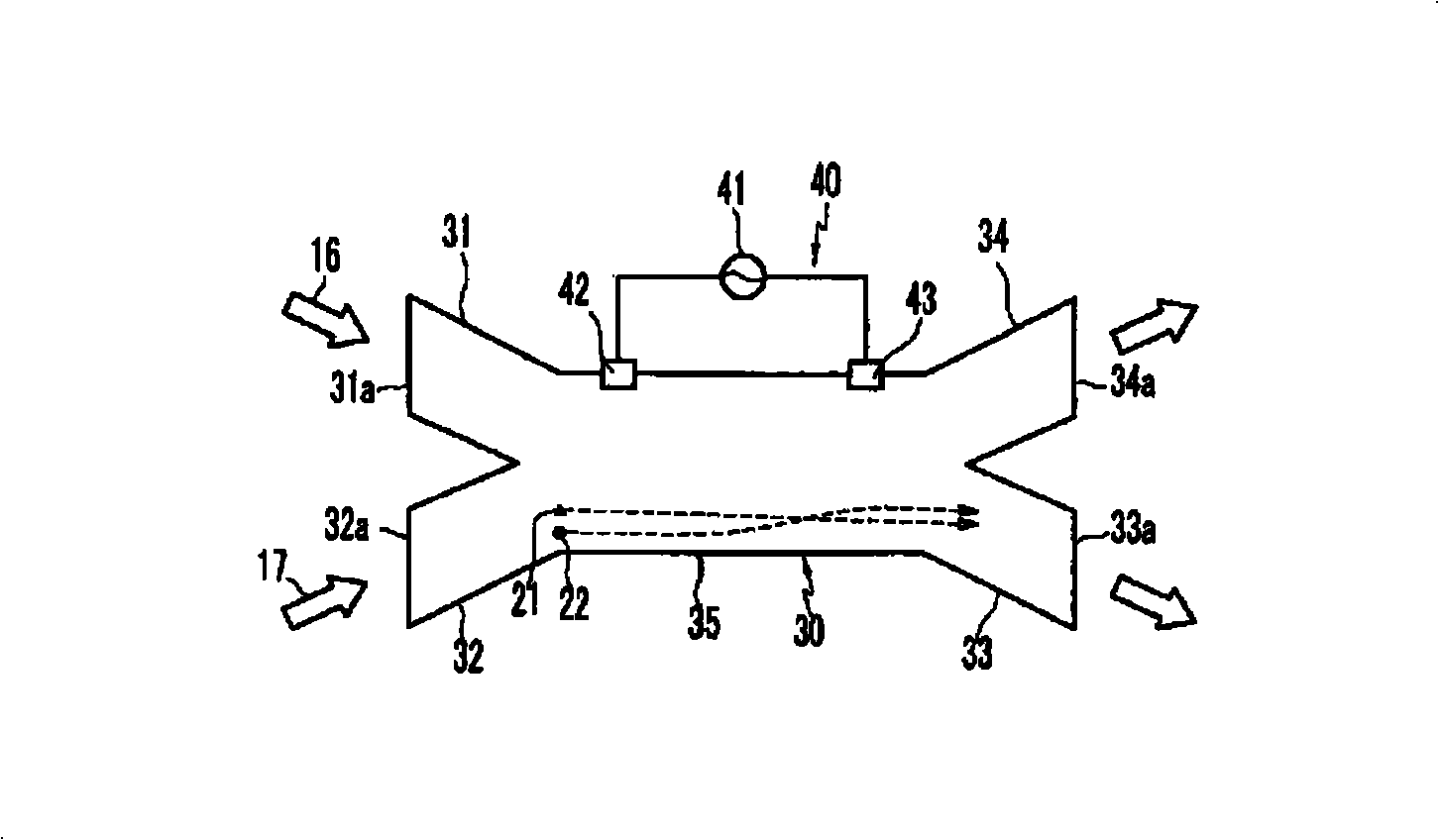

Apparatus and method for separating particles

ActiveCN101405085AEasy to separateFreely control the movement pathDielectrophoresisElectrostatic separatorsUniform fieldEngineering

Owner:INTELLECTUAL DISCOVERY CO LTD

Method for enriching and purifying aloe polysaccharides in aloe

ActiveCN102101893AContinuous separationEfficient separationUrinary disorderRespiratory disorderChromatographic separationLiquid liquid partition

The invention belongs to the field of natural organic chemistry, and relates to a method for purifying aloe polysaccharides, particularly a preparation method for enriching and purifying aloe polysaccharides in aloe by a high-speed countercurrent chromatography separation process. The method is characterized by purifying natural plant aloe leaching liquor twice by a high-speed countercurrent chromatography separation process to obtain aloe polysaccharides of which the purity is higher than 95%. The method is suitable for preparing high-purity aloe polysaccharides from natural plants containing aloe polysaccharides and extracts of the natural plants. The method is suitable for preparing aloe polysaccharides by separating with various types of countercurrent chromatographs, and the aloe polysaccharides prepared by the high-speed countercurrent chromatography process can be continuously, efficiently and quickly separated by liquid-liquid partition chromatography; and thus, the method has the characteristics of great separation amount, no sample loss, high recovery rate, mild separation environment, solvent saving and the like.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

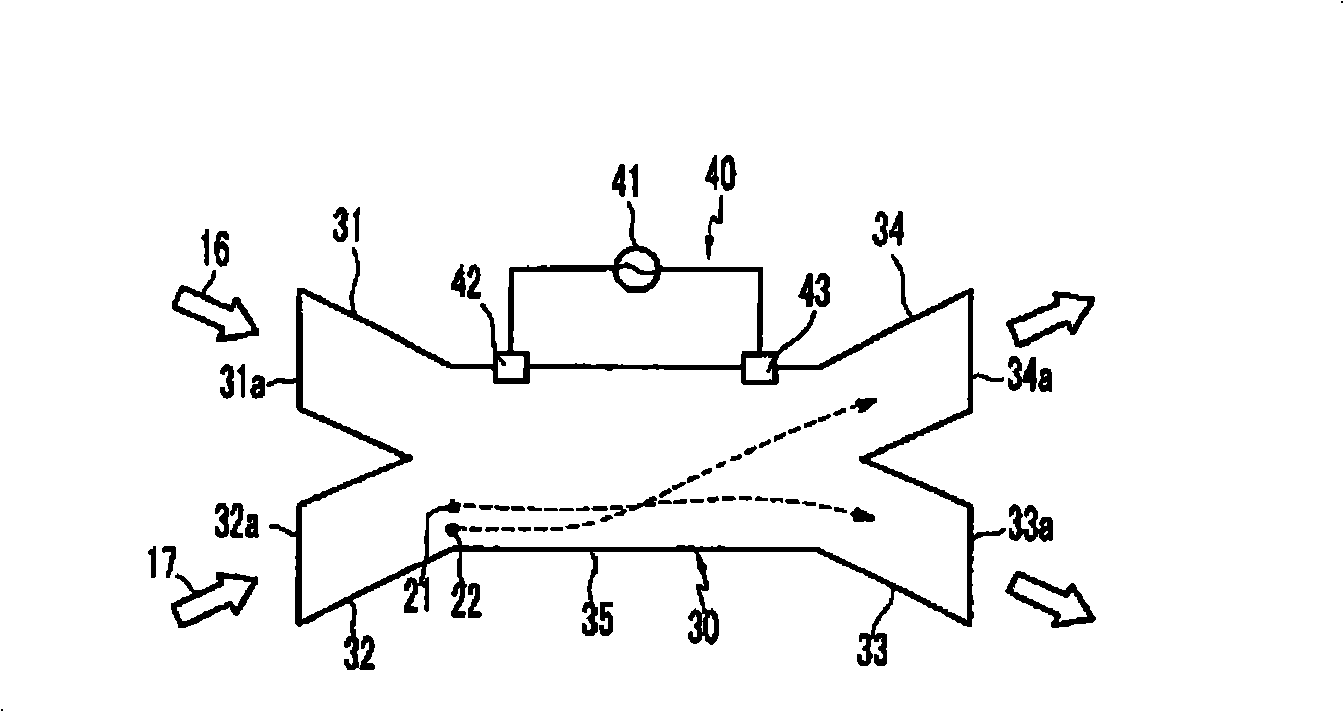

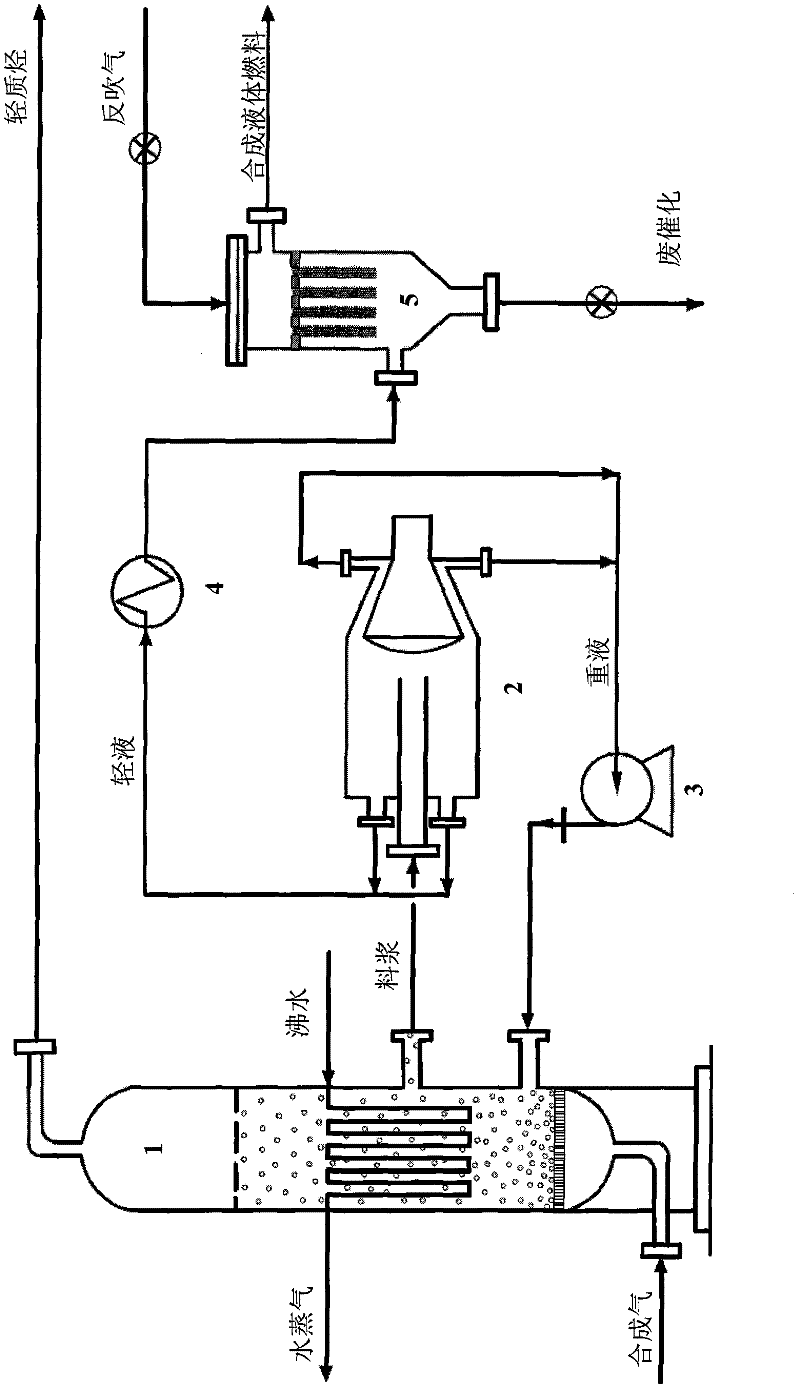

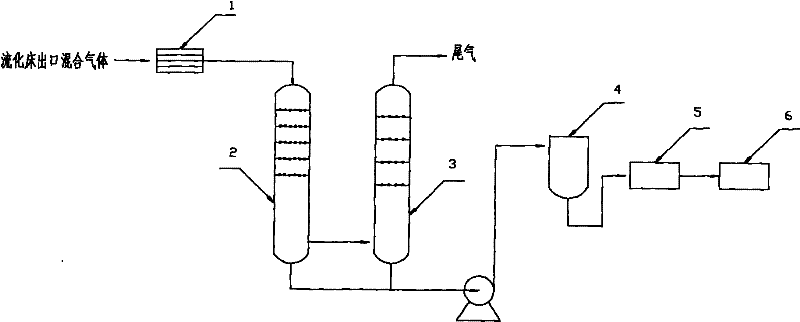

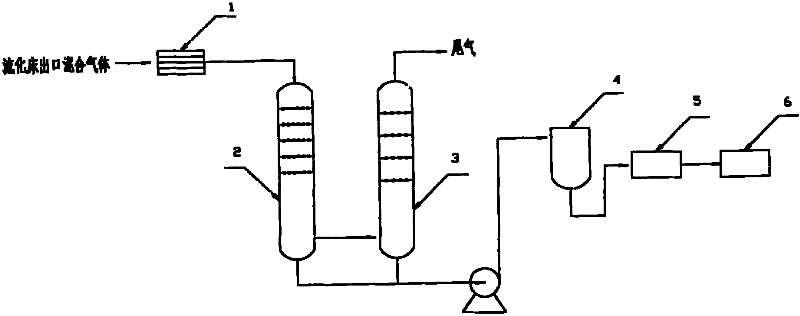

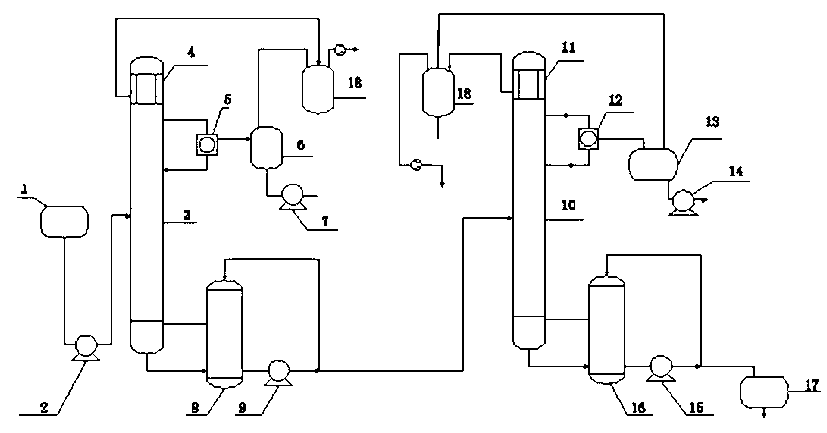

Method and device for continuously separating catalyst of synthetic fluid fuel in slurry bed from product

ActiveCN102553343AImprove continuityEfficient separationHydrocarbon from carbon oxidesLiquid carbonaceous fuelsSlurryEngineering

The invention relates to a method for continuously separating a catalyst of a synthetic fluid in a slurry bed from a product. The method comprises the following steps of: feeding a synthesis gas into a slurry bed reactor for carrying out catalytic synthesis reaction, leading obtained slurry to be subjected to the primary seperation of a 4000-6000 r / min high-speed centrifugal machine, and obtaining a light liquid component and a heavy liquid component, wherein the heavy liquid component is concentrated oil slurry being rich in more than 75% of catalyst, and the concentrated oil slurry is pressurized by using a centrifugal pump and returned to a reaction region of the slurry bed reactor to participate in reaction; heating the light liquid component to reach the temperature of 240-350 DEG C, leading the viscosity of light liquid to be less than 1mPa.S, leading the light liquid to enter into a multilayer metal sintering screen filter with the particle sizes of filtering meshes in the range of 0.5-20mum to be subjected to secondary seperation, and after seperation, treating filtrate containing the catalyst of less than 65.80mug.g as the product to be fed into a fraction seperation workshop section for deep processing; and carrying out back flushing on the sintering screen filter by using back flushing air when carrying out secondary seperation for 20-60 minutes by using the sintering screen filter so that the sintering screen filter is regenerated, and treating filter residues formed after back flushing as the waste catalyst to be processed. The method has the advantage that the catalyst of the synthetic fluid fuel in the slurry bed can be effectively and continuously separated from the product.

Owner:SEDIN ENG +1

Separation process of molecular sieve catalyst in ketone oxamidinating reaction system

InactiveCN1432432AContinuous separationGood separation effectMolecular sieve catalystsOximes preparationSal ammoniacWater content

In the ketone oxamidinating reaction system with water mutually soluble low-carbon alcohol of 30-50 wt% concentration and excessive ammonia water content, the material including titania-silica molecular sieve is deposited at 60-85 deg.c in deposition rate of 0.5-3 cm / min for at least 10 min. The present invention can realize the continuous separation of titania-silica molecular sieve from reaction liquid and is suitable for cyclohexanone oxamidinating reaction system with titania-silica molecular sieve catalyst of 0.1-0.3 micron size.

Owner:CHINA PETROLEUM & CHEM CORP +1

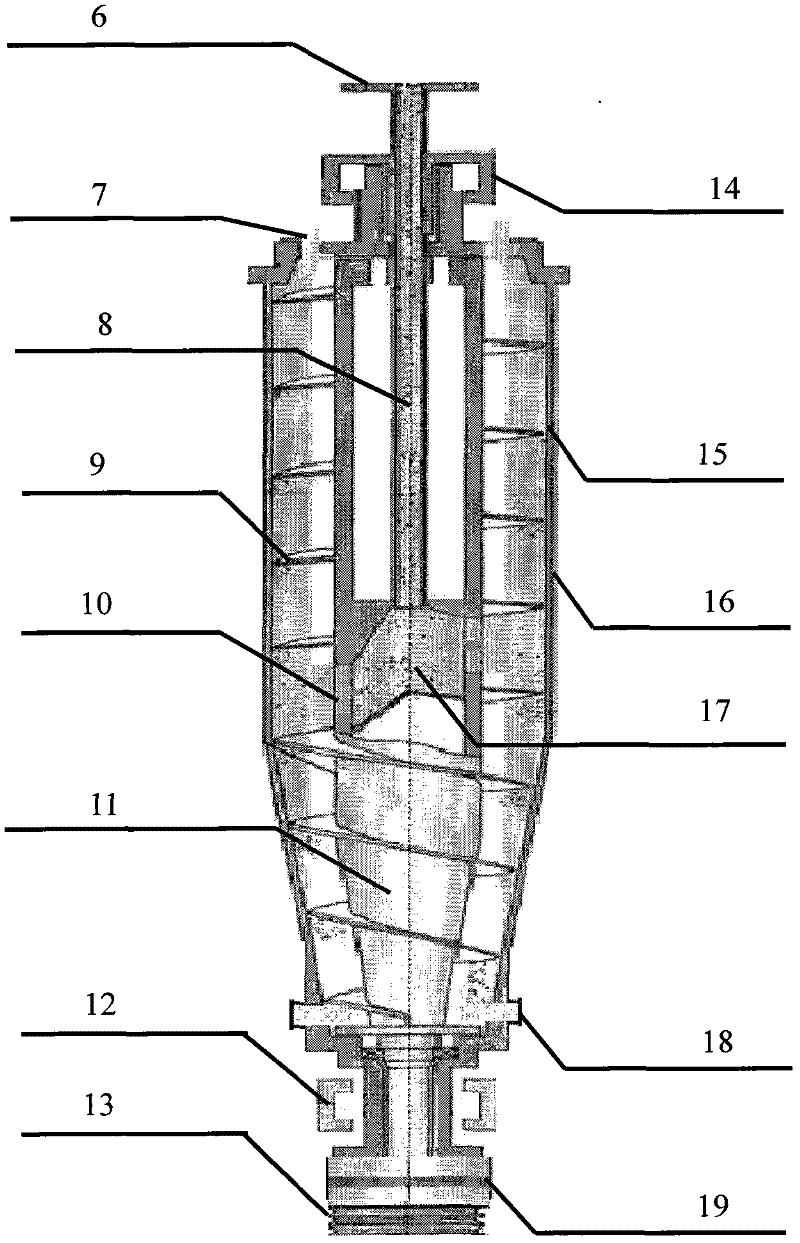

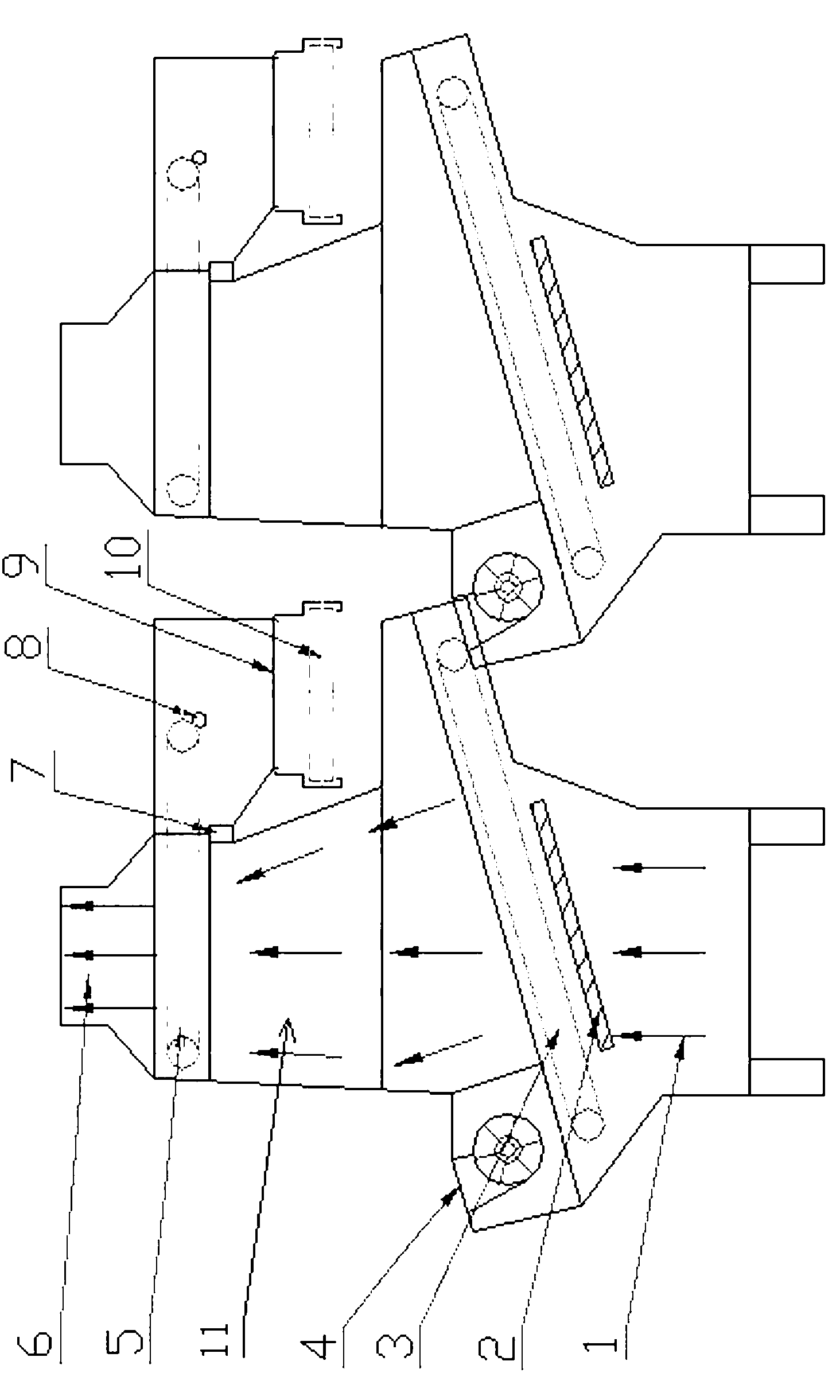

Air separator capable of separating tobacco stems from tobacco shreds in multi-level manner

ActiveCN103271432AContinuous separationEasy to separateTobacco treatmentGas current separationAir separationEquipment use

The invention relates to an air separator capable of separating tobacco stems from tobacco shreds in a multi-level manner, particularly relates to threshing and air separating equipment used in threshing and redrying procedures, and belongs to the technical field of tobacco processing equipment. The air separator capable of separating the tobacco stems from the tobacco shreds in the multi-level manner comprises a plurality of air separator bodies. The air separator bodies work independently and are serially connected with one another to form the air separator, and materials which do not meet requirements can be directly conveyed into a feed inlet of a next air separator body from a discharge outlet of a previous air separator body via a conveying mesh belt mounted in the previous air separator body, and then are subjected to secondary air separation; the materials can be continuously and repeatedly separated in different levels owing to separation bins in the different air separator bodies which work independently, separation air pressures with different air powers, different air speeds, different dimensions of the various separation bins, different material flow rates and different speeds of the conveying mesh belts. The air separator has the advantages of high efficiency, low energy consumption and simple structure, and material loss is low in a processing procedure.

Owner:HONGTA TOBACCO GRP +1

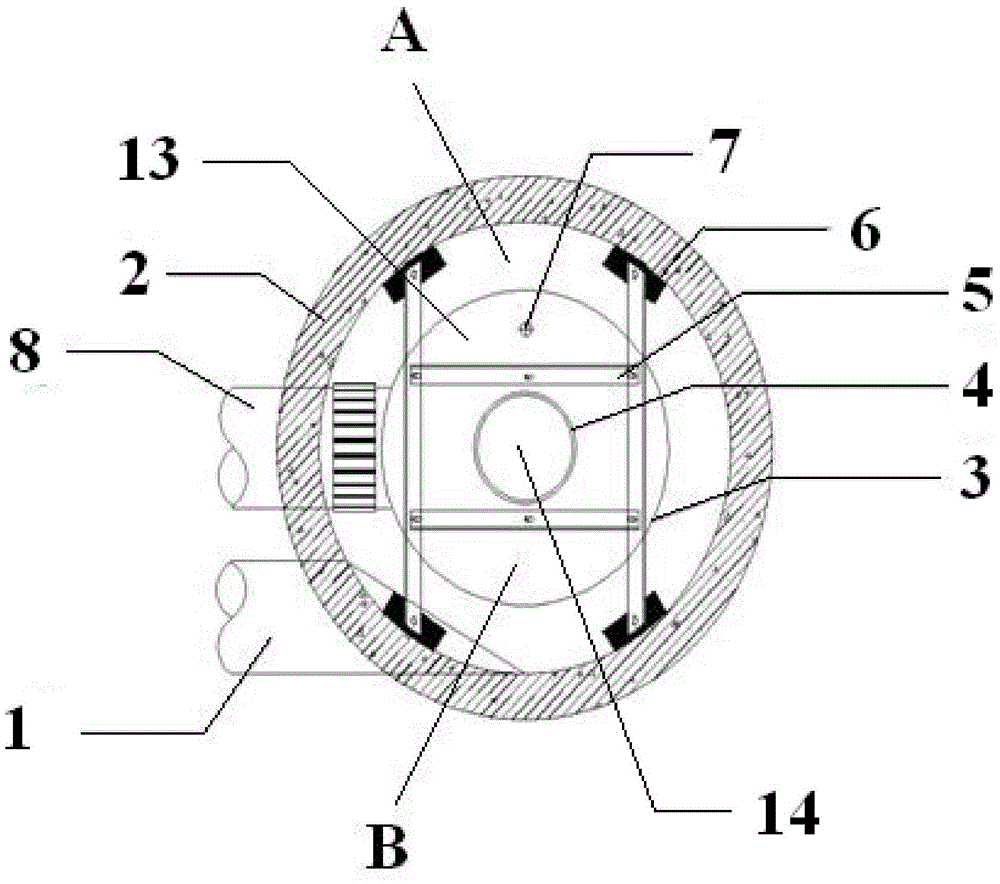

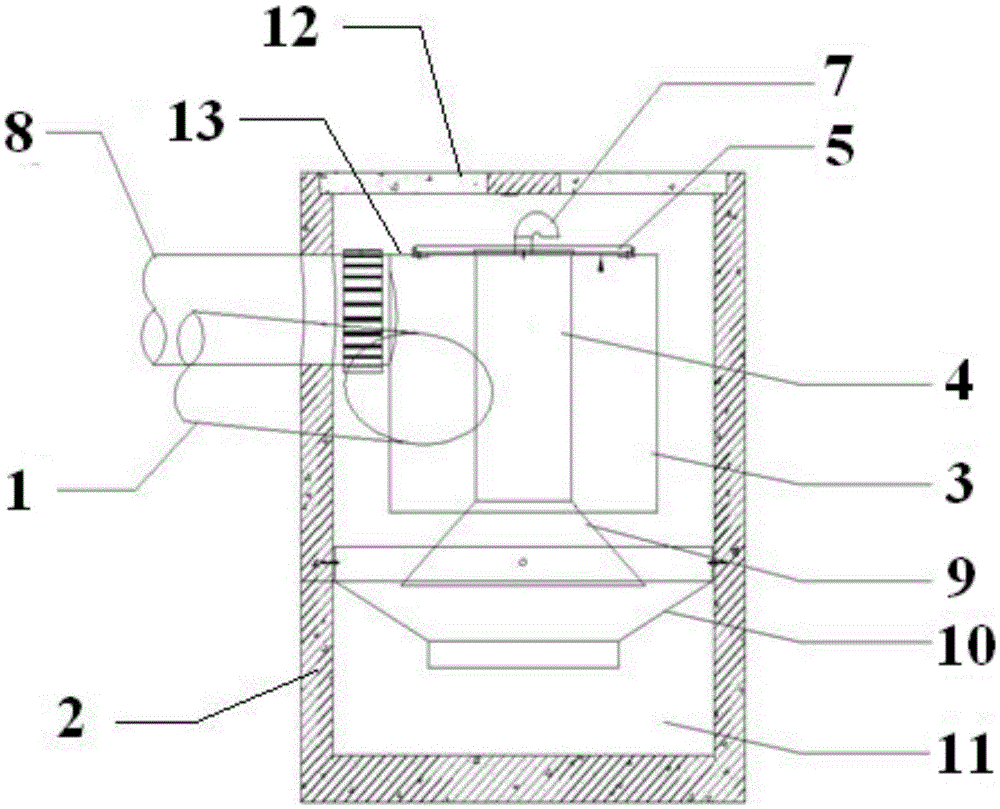

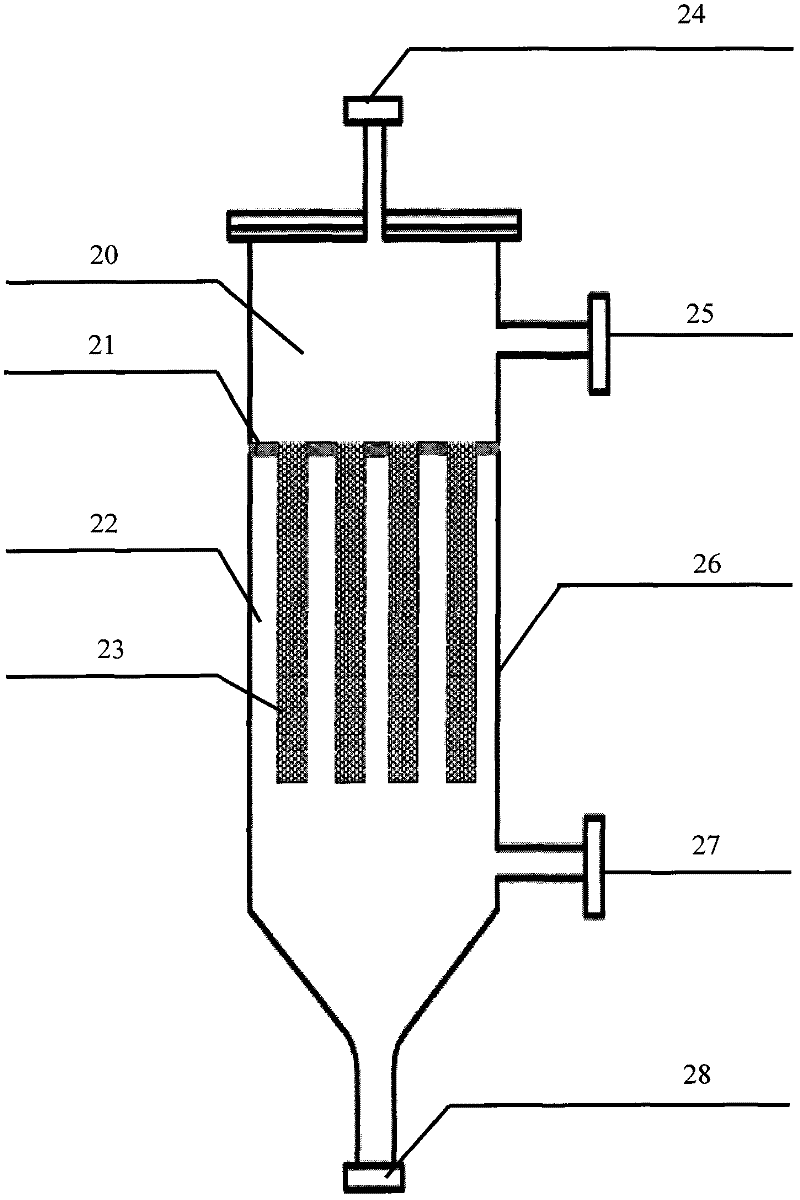

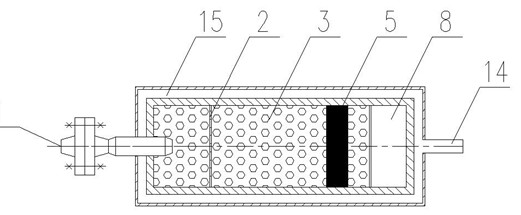

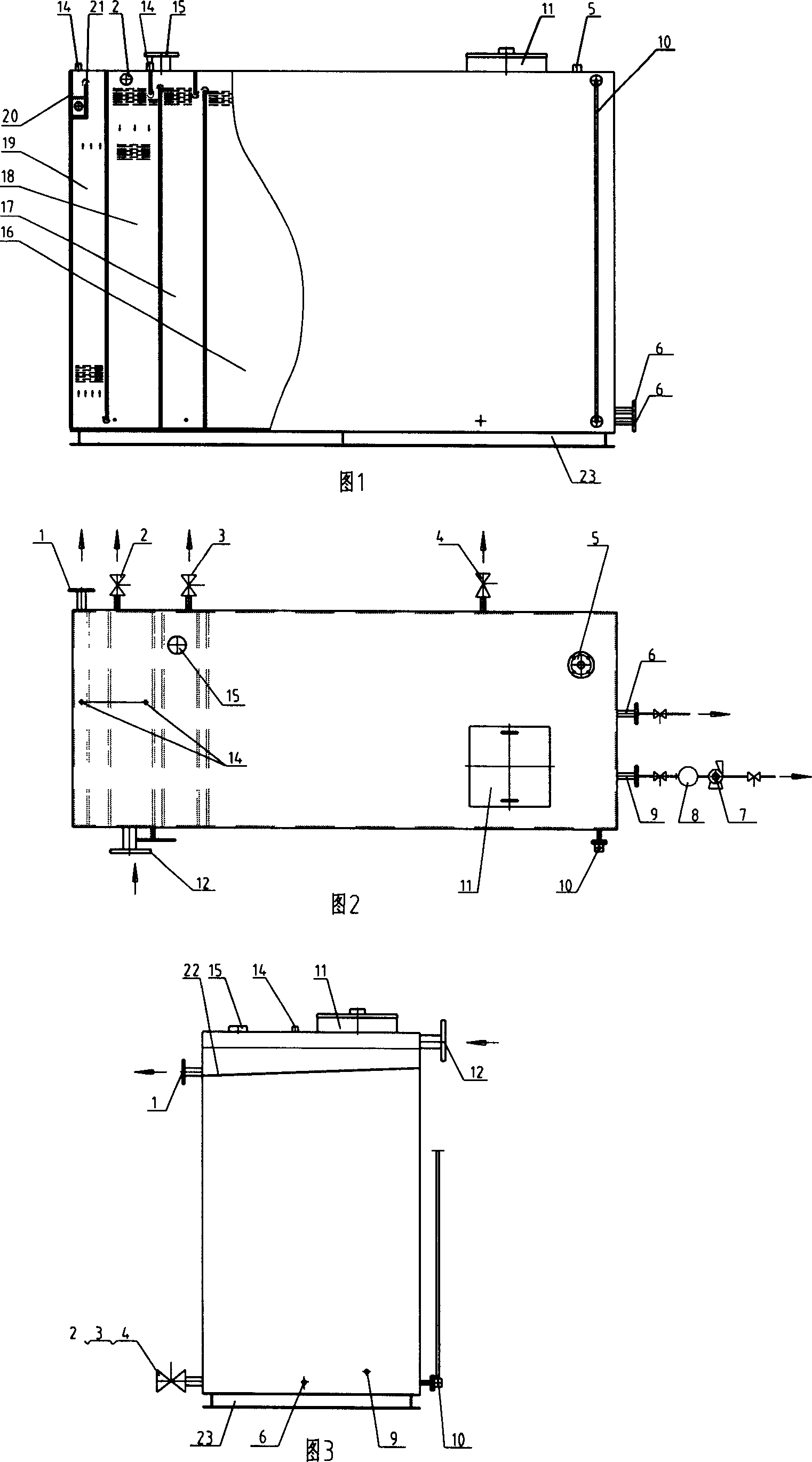

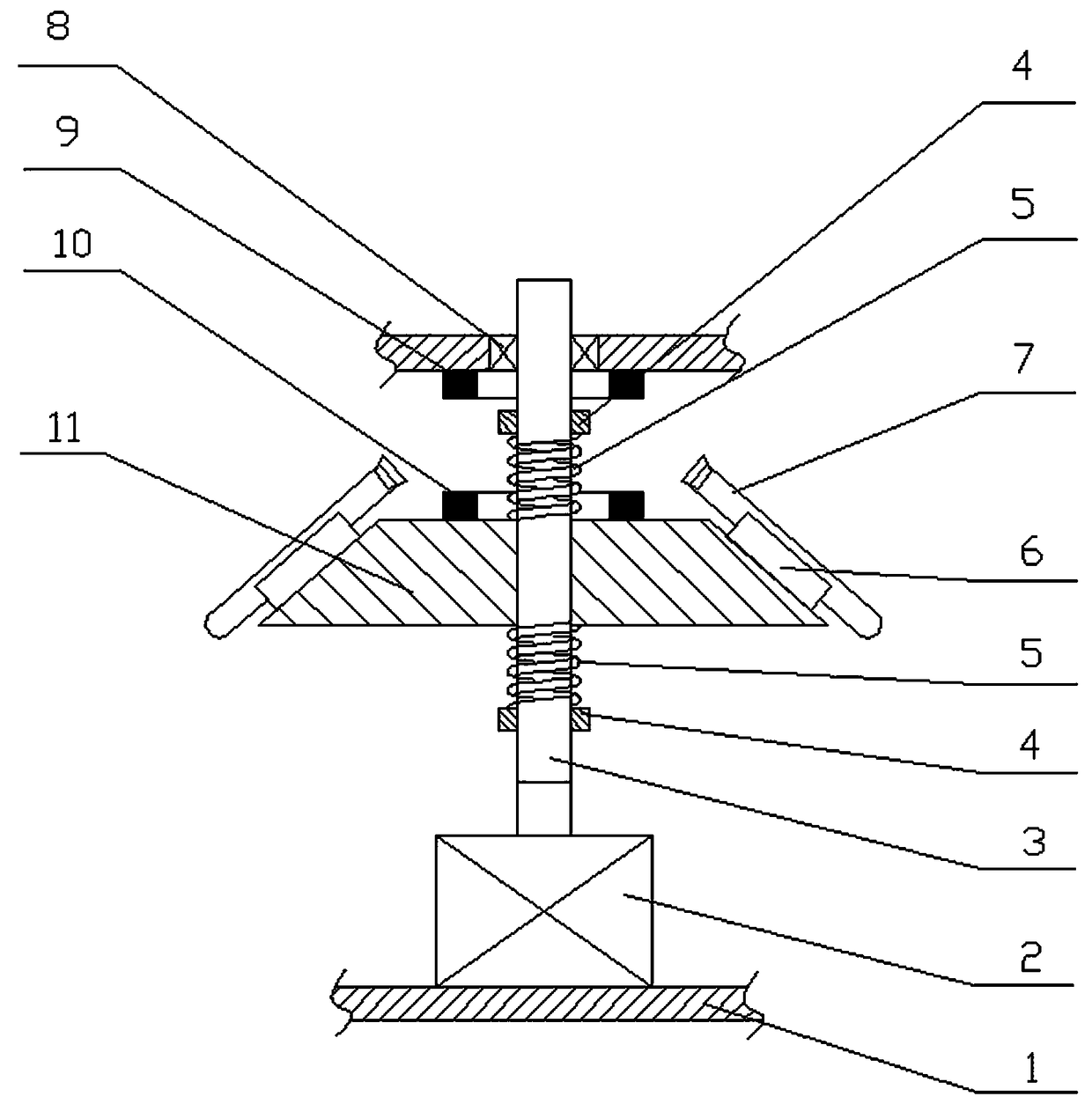

Device for continuously separating gas hydrate

ActiveCN102120104ASimple structureSmall footprintPressurized chemical processLiquid degasificationSlurryEngineering

The invention discloses a device for continuously separating gas hydrate, which comprises an upper box body and a lower box body, wherein the upper box body is a gas collecting cavity (7), the upper end of the upper box body is provided with a separated gas outlet (10), a safety valve port (16) and a pressure meter port (17), and the lower part of the upper box body is provided with a silk screenmist eliminator (6); the lower box body is shaped as a cuboid, the upper part of the lower box body is provided with a hydrate slurry inlet (1), the tail end of the hydrate slurry inlet (1) is provided with a flow equalizing plate (2) in a vertical direction, the bottom end of the flow equalizing plate (2) is provided with a sieve plate (3), the sieve plate (3) is alternatively connected with a drainage plate (4) to form a separating channel; a water collecting cavity (8) is arranged between the separation channel and the lower box body, and the lower part of the separation channel is provided with a separated water outlet (11); and the lower end of the separation channel is connected with a hydrate storing cavity (9), and the bottom end of the hydrate storing cavity (9) is provided with a hydrate outlet. The invention has the advantages of simple structure, small occupation area and convenience for maintenance.

Owner:溧阳常大技术转移中心有限公司

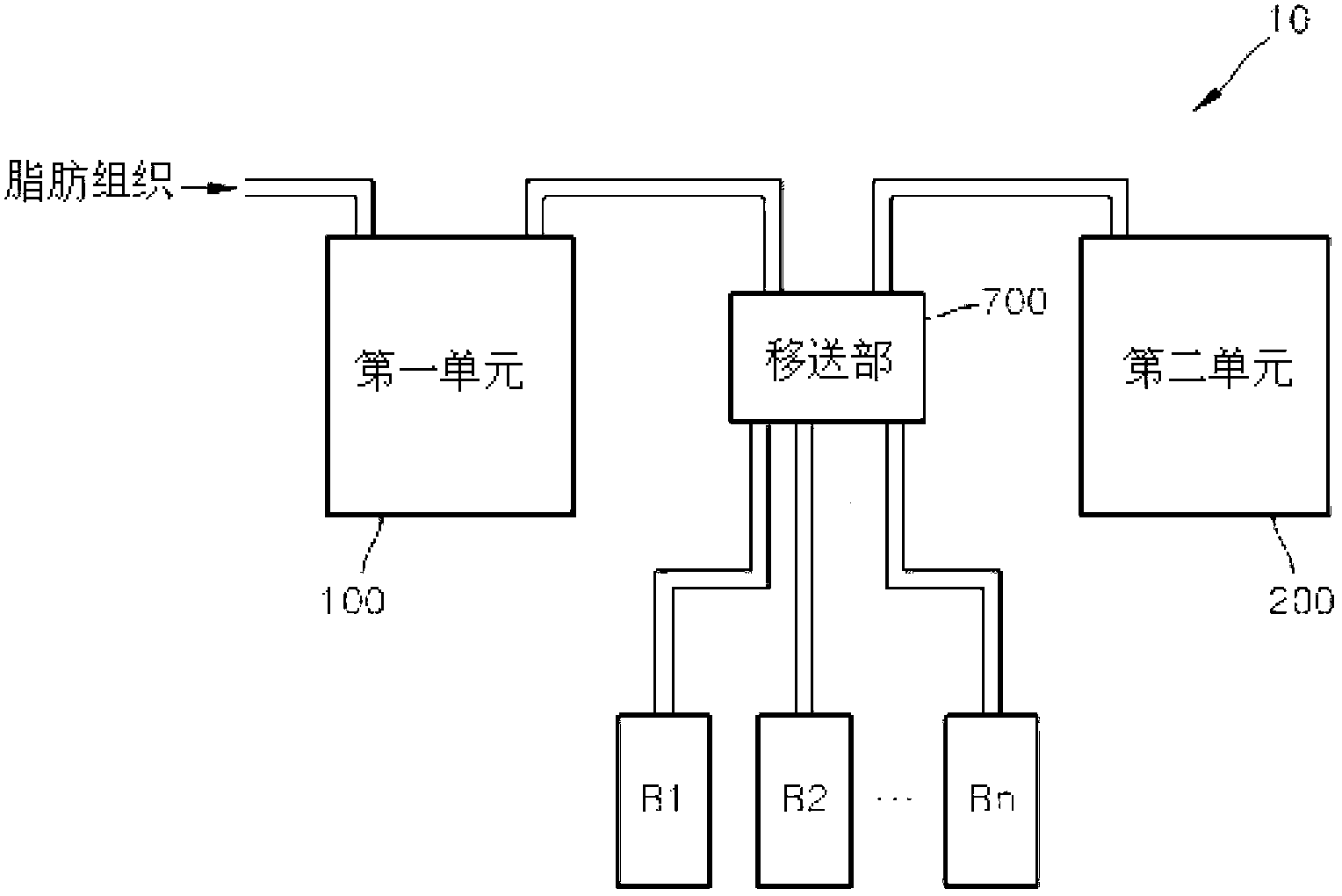

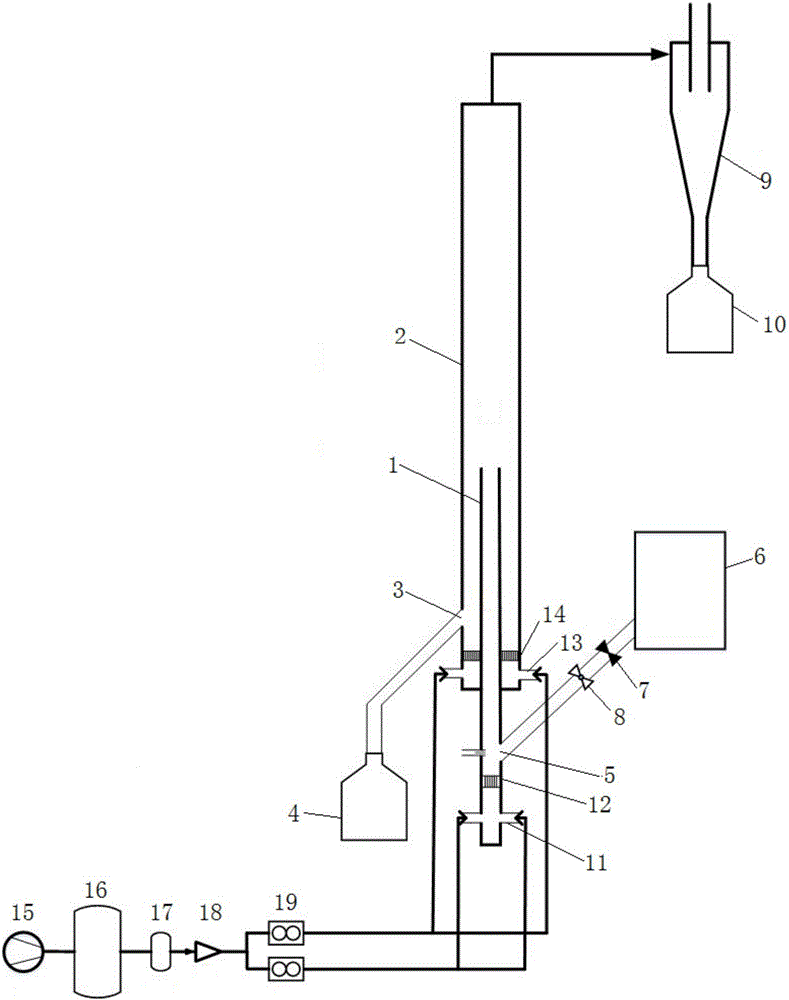

Regenerative cell extraction system

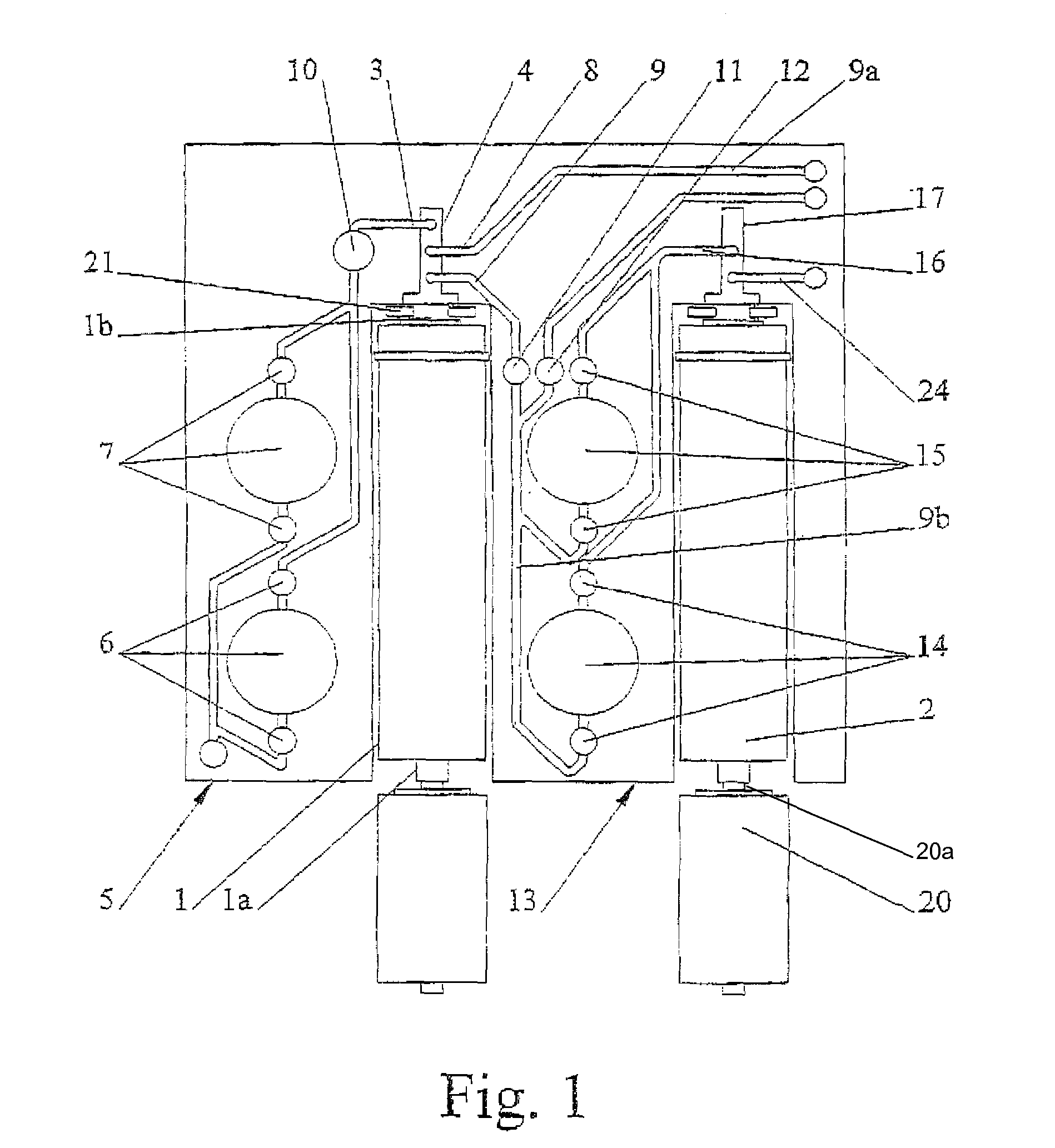

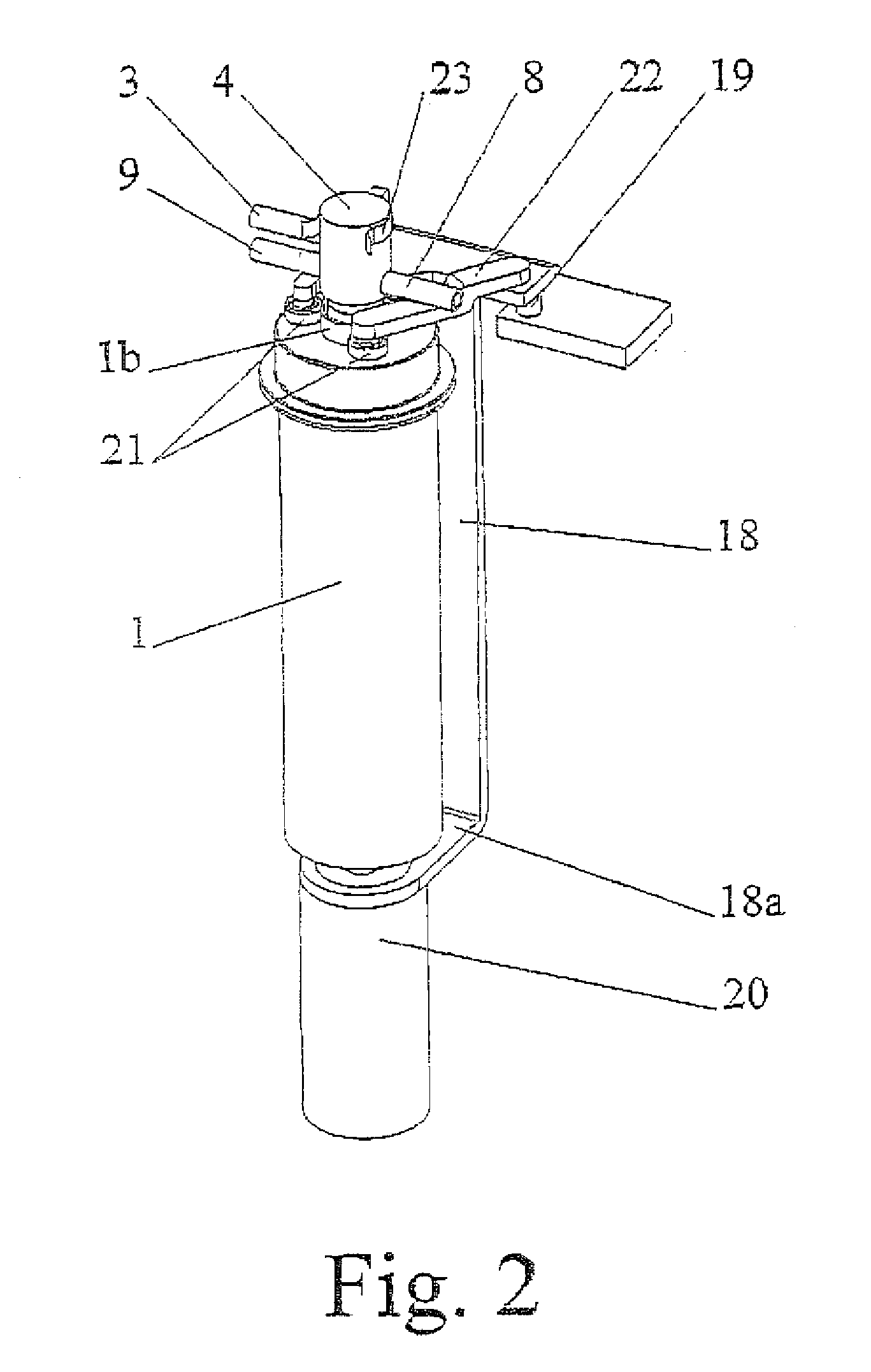

InactiveCN102869761AFully automatedContinuous separationBioreactor/fermenter combinationsBiological substance pretreatmentsCell extractionCentrifugation

Disclosed is a regenerative cell extraction system. The regenerative cell extraction system according to an embodiment of the present invention comprises a first unit, a second unit and a transfer unit. The first unit collects tissues by vacuum suction, separates blood contaminants from the collected tissues by agitation and centrifugation, and separates cells from the tissues from which blood contaminants have been separated to discharge the cells suspended in liquid. The cells suspended in liquid are inputted from the first unit into the second unit, regenerative cells are separated by centrifugation in the second unit, and the capacity of the second unit is smaller than that of the first unit.; The transfer unit is connected between the first unit and the second unit, injects cleaning water into the first unit and the second unit, delivers extracts from the first unit and the second unit to the corresponding bags, and inputs cells suspended in liquid extracted in the first unit into the second unit or transfers tissues and cell contaminants. The tissues are fat tissues and the regenerative cells are fat-derived stem cells.

Owner:PUREBIO & TECH +2

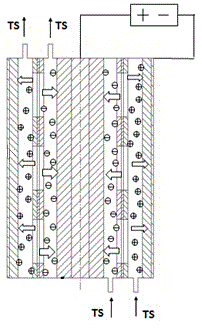

Device and method for separating and recycling negative and positive ions in weak solution continuously, synchronously and selectively

ActiveCN104587835ASimple structureEasy to operateDispersed particle separationElectrodialysisChemical physicsElectric machine

The invention discloses an electric control ion exchange device and an electric control ion exchange method which are capable of separating and recycling negative and positive ions in a weak solution continuously, synchronously and selectively. The ion separating and recycling device consists of an electroactivity ion exchange function membrane electrode, a controllable rotary closed concentric double-layer sleeve inert electrode, an external power source and a motor system, wherein the electroactivity ion exchange function membrane electrode consists of concentric cylinders and concentric drums which are provided with selective adsorption / desorption negative and positive ions under oxidation / reduction potential; oxidation / reduction potential is alternatively applied to membrane electrodes by an external power supply; meanwhile, the concentric double-layer sleeve inert electrode between the two membrane electrodes is controlled to be opened and closed; negative and positive ions in the weak solution are continuously separated and recycled by being combined with an external liquid path supplying system. An ion exchange membrane or a diaphragm electrode is not required for the device provided by the invention, the structure is simple, and the operation is convenient; ions in the solution are directly adsorbed / desorbed on / from the surface of the membrane electrodes; the ion dispersion and transmitting speed is high, and the separation efficiency is high; the membrane electrode can run continuously.

Owner:TAIYUAN UNIV OF TECH

Process for preparing high-purity rhodioloside

InactiveCN1365980AContinuous separationEfficient separationSugar derivativesSugar derivatives preparationCountercurrent chromatographySolvent

A process for preparing high-purity rhodioloside from natural rhodiola rosea by high-speed counter-current chromatography includes extracting by high-speed counter-current chromatography and purifying twice to obtain high-purity product. Its advantages are high purity (98%), and high output rate, and saving solvent.

Owner:北京天纯维通生物技术有限公司

Solid-liquid separation process for preparing isophthalodinitrile

The invention discloses a solid-liquid separation process for preparing isophthalodinitrile. The process comprises the following steps that: after being cooled by an oil cooler, a mixed gas at the outlet of a fluidized bed reactor enters from a first-grade water sprayer, and the mixed gas at the outlet of the first-grade water sprayer enters from the bottom of a second-grade water sprayer and then is discharged from the top of the second-grade water sprayer; and solid-liquid mixtures in the first-grade water sprayer and the second-grade water sprayer enter a settling tank to be settled, the slurry of isophthalodinitrile at the relatively high concentration at the bottom of the settling tank enters a centrifuge, and the material at the outlet of the centrifuge enters drying equipment to bedried finally. The solid-liquid separation process reduces working environment of workers, improves the working efficiency and increases the quality and yield of phthalodinitrile.

Owner:CAC NANTONG CHEM

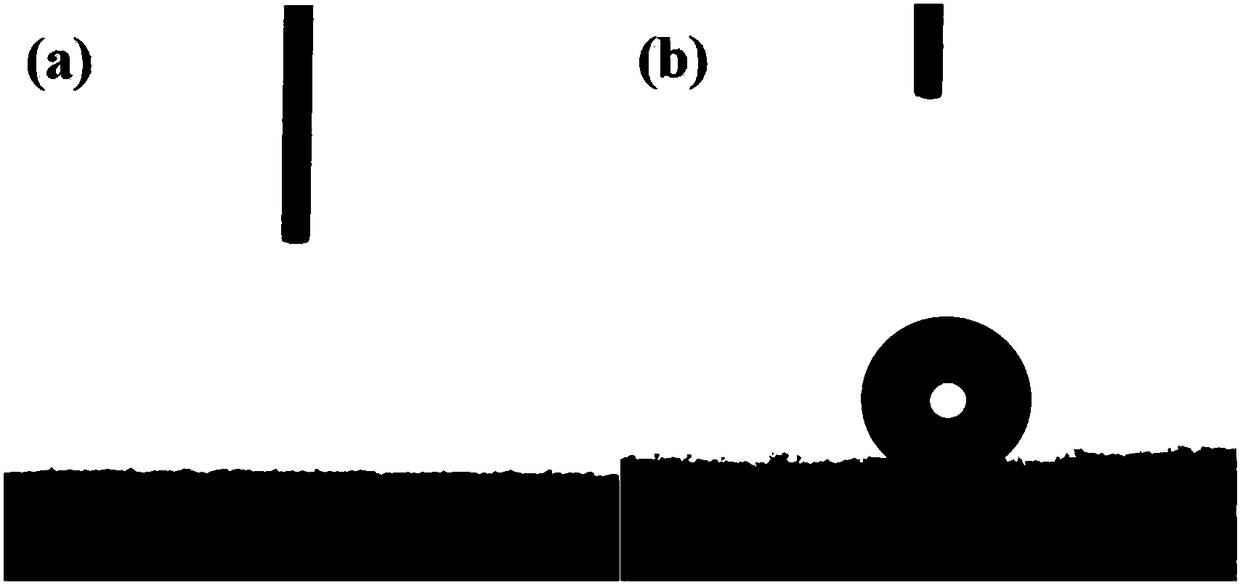

Preparation method of super-hydrophobic sponge adsorbing material

InactiveCN108465460ARich sourcesLow priceOther chemical processesAlkali metal oxides/hydroxidesAlcoholSilicic acid

The invention belongs to the technical field of preparation of environmental functional materials, and specifically relates to a preparation method of a super-hydrophobic sponge adsorbing material. The method specifically comprises the following steps: preparing a dopamine coated sponge base body; dissolving hexadecyltrimethoxysilane, tetraethyl orthosilicate and ammonia water into ethyl alcohol to obtain a mixed solution; adding the opamine coated sponge base body; transferring into a water bath pot; stirring under constant temperature; and oscillating through water bath; washing; and dryingto obtain the super-hydrophobic sponge adsorbing material. The prepared super-hydrophobic sponge adsorbing material is high acid, alkali and salt resistant super-hydrophobic oleophylic material whichis simple, environmentally friendly, low in cost, and small in investment and can realize mass production; and the material is applicable to oil and water separation in a complex industrial environment, and is stable in structure, and high in adsorbing capacity.

Owner:JIANGSU UNIV

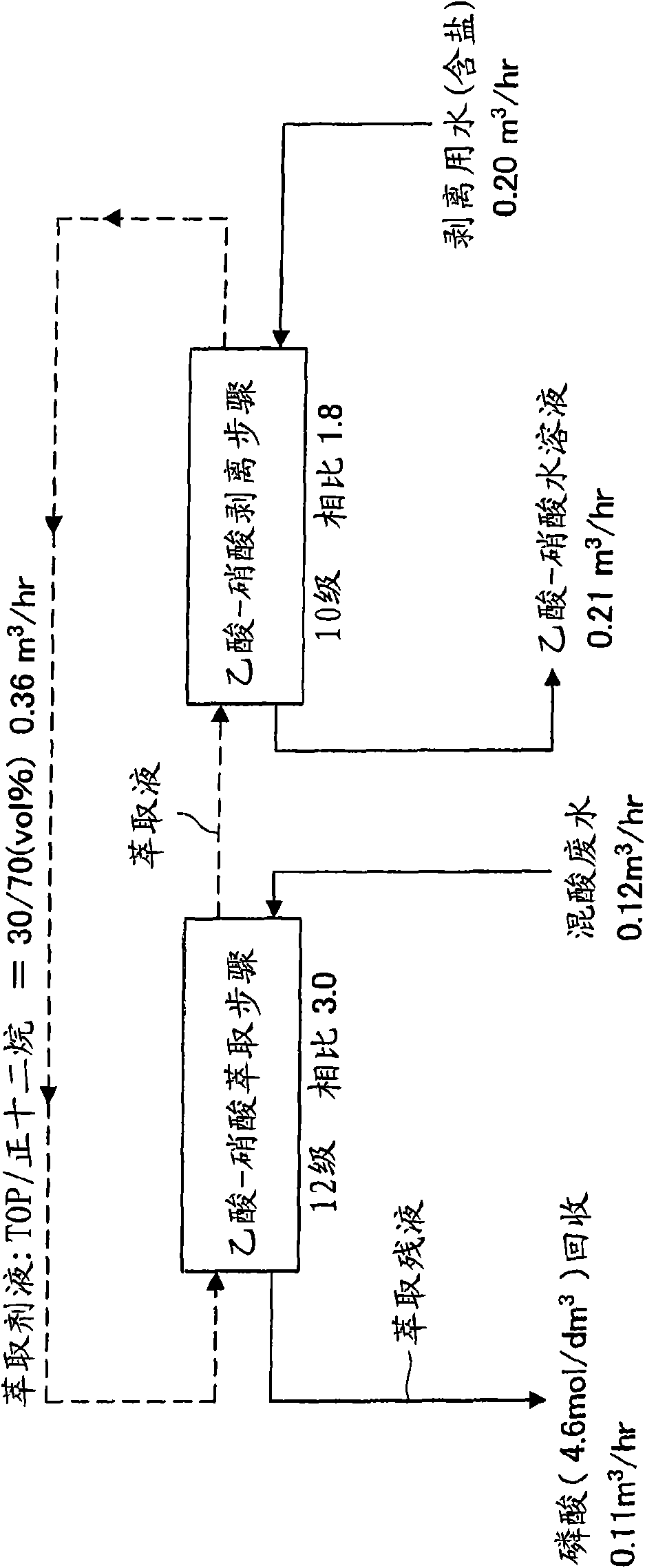

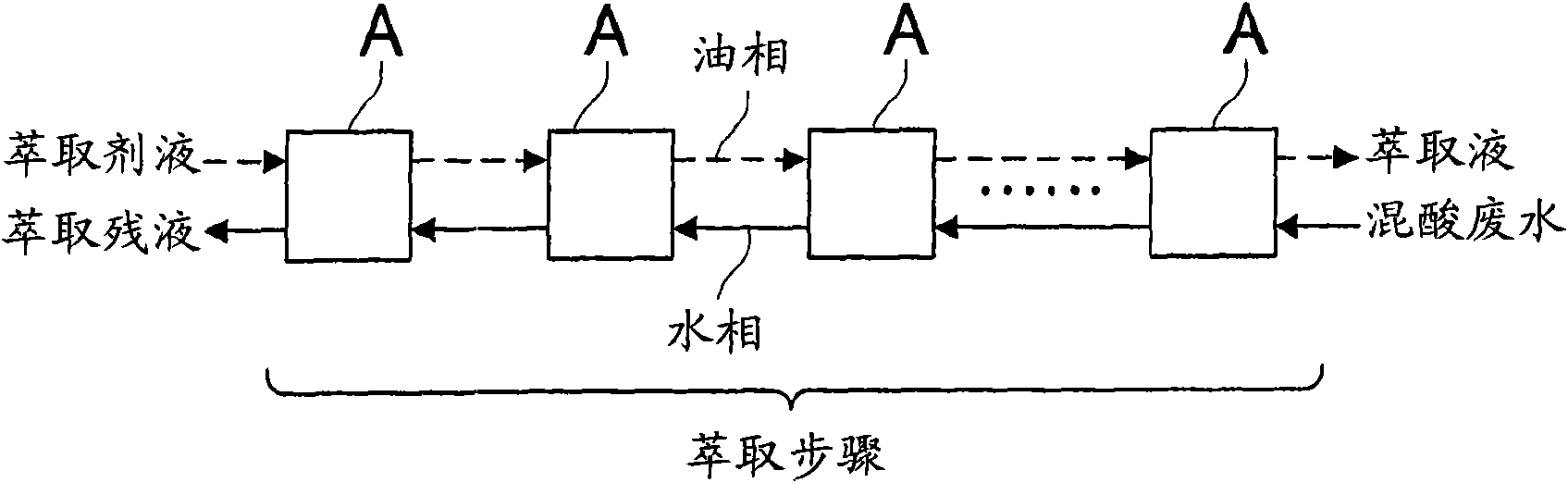

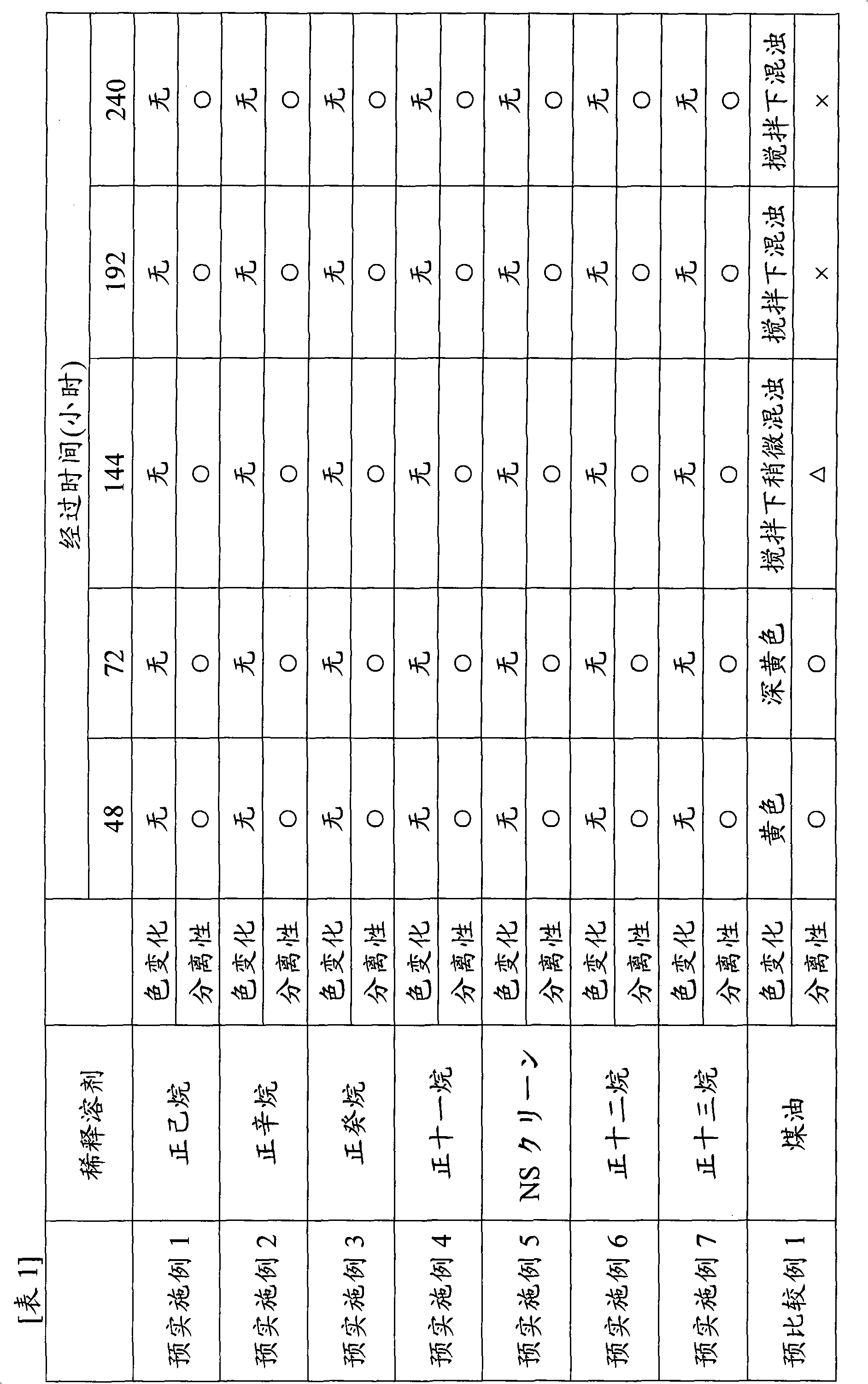

Method for separating and recovering phosphoric acid from acetic acid-nitric acid-phosphoric acid series mixed acid waste liquor

ActiveCN102167415AImprove peelabilityImprove separationWater/sewage treatment by extractionPhosphoric acidPhosphoric acidChemistry

The invention relates to a method for separating and recovering phosphoric acid from acetic acid-nitric acid-phosphoric acid series mixed acid waste liquor. The method disclosed by the invention is characterized by comprising the following steps of: an acetic acid-nitric acid extracting step: mixing waste liquor containing acetic acid, nitric acid and phosphoric acid with an extracting agent solution of aliphatic series straight-chain saturated hydrocarbon which contains phosphoric trialkyl ester and 6-13 carbon atoms and selectively dissolving and extracting acetic acid and nitric acid from the extracting agent solution; a phosphoric acid recovering step: recovering the phosphoric acid from extracting waste liquor obtained in the extraction step; and an acetic acid-nitric acid stripping step: enabling the extracting agent solution containing the acetic acid and the nitric acid, obtained in the acetic acid-nitric acid extracting step, to be in contact with stripping water so that the acetic acid and the nitric acid are dissolved and transferred to the stripping water. The extracting agent solution is recycled by feeding the oil-phase extracting agent solution obtained in the acetic acid-nitric acid stripping step to the acetic acid-nitric acid extracting step. By means of the invention, the favorable separability of oil phase and aqueous phase in the stripping step can be maintained for a long time, and the phosphoric acid can be selectively and favorably separated and recovered from the acetic acid-nitric acid-phosphoric acid series mixed acid waste liquor for a long time with high efficiency.

Owner:SANWA YUKA INDS

Method for continuously purifying and refining ortho toludiamine

ActiveCN102757351AContinuous separationAmino compound purification/separationProcess engineeringToluenediamine

The invention relates to method for continuously purifying and refining ortho toludiamine. The method comprises the steps of: carrying out rectification by two towers connected in series, removing a front fraction of an ortho toludiamine crude product through a light component removing tower, and rectifying and separating out ortho toludiamine and meta-toluenediamine through a product tower. The method has the advantages that rectification is carried out by the two towers connected in series; and the ortho toludiamine, the meta-toluenediamine, monamine and other impurities can be continuously separated, and the purity of the ortho toludiamine can be up to over 99.5%.

Owner:NANTONG BOTAO CHEM

Solvent recovery-separation apparatus

InactiveCN101011635ASeparation delay continuousContinuous separationDispersed particle separationLiquid separationWater storageOrganic solvent

The invention relates to a solvent recovery and separation device. This device can separate and recover the solvent 100% in a continuous process, which has seal container with five separated solvent chamber, mixed solvent inlet on the No.1 bumping chamber, organic solvent outlet and dreg release opening on the No.1 oil reservation chamber, water exhaust of the No.1 and No.2 oil reservation chamber and No.1 bumping chamber, water outlet for No.2 bumping chamber, gear oil pump at the outlet of the solvent, magnetic floating ball liquid level switch at the top of the No.1 oil storage chamber. The bottom of the No.1 bumping chamber connects with the water reservation chamber, top of the No.1 bumping chamber connects with the No.2 oil reservation chamber, bottom of the No.2 bumping chamber connects with the water storage chamber through passages with the water storage chamber having water blocks allowing water coming into No.1 bumping chamber from the top of the block. Top of the water reservation chamber connects with the No.2 bumping chamber. The No.2 oil reservation chamber connects with the No.1 oil reservation chamber through its top. The outlet of solvent for No.1 oil reservation connects to the organic solvent storage can through gear oil pump.

Owner:傅太平

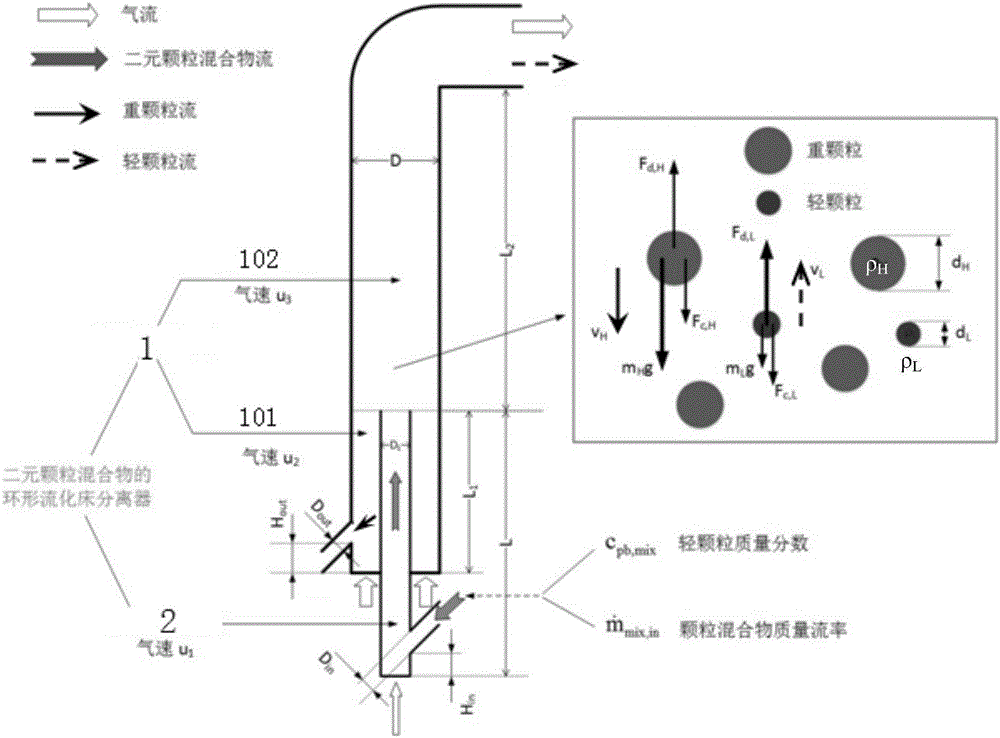

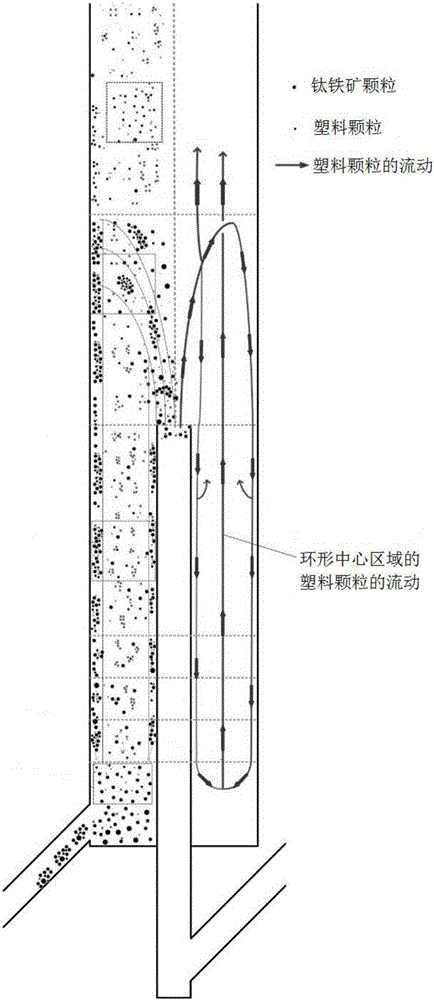

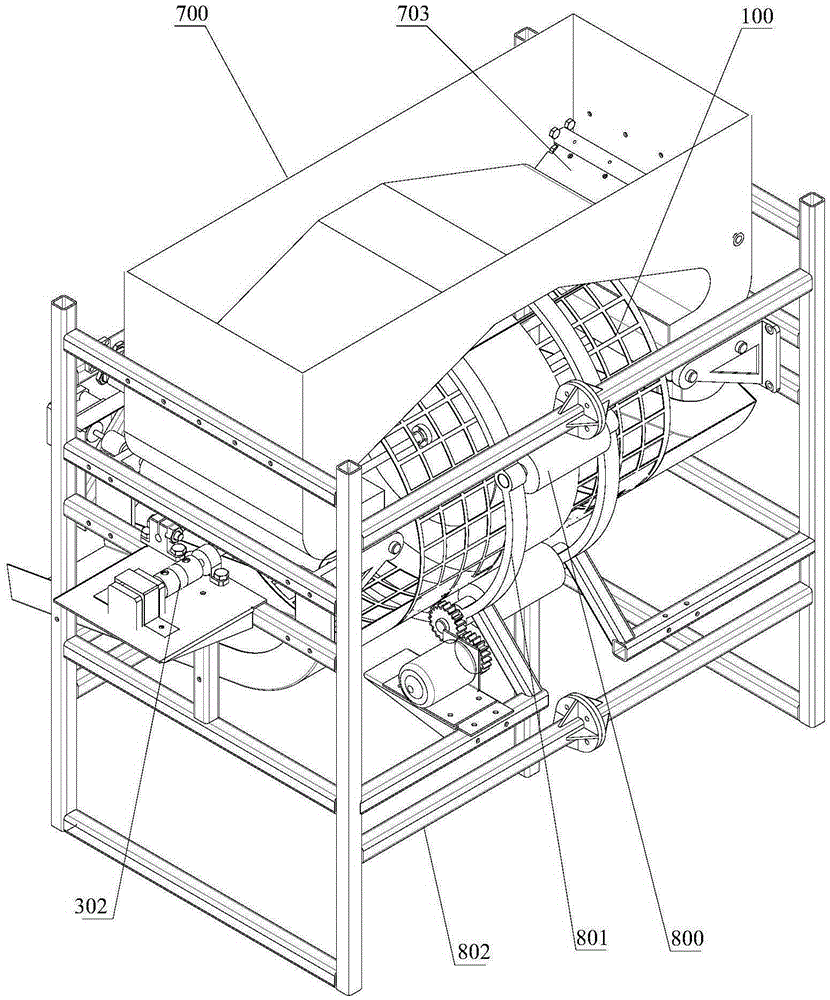

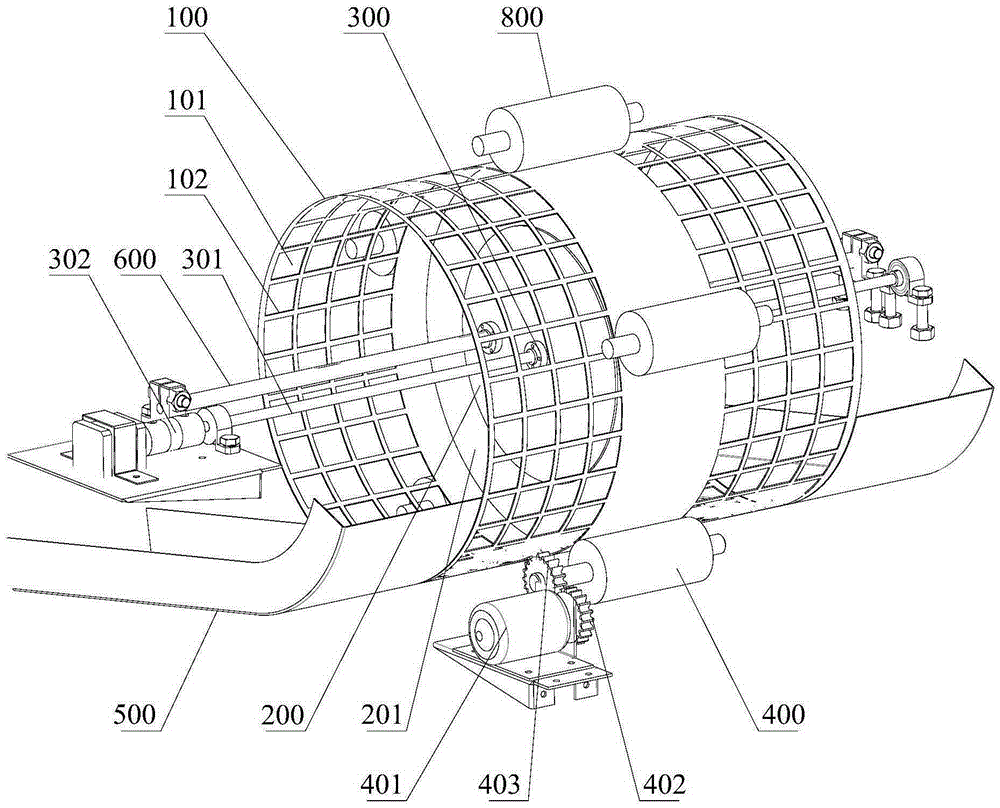

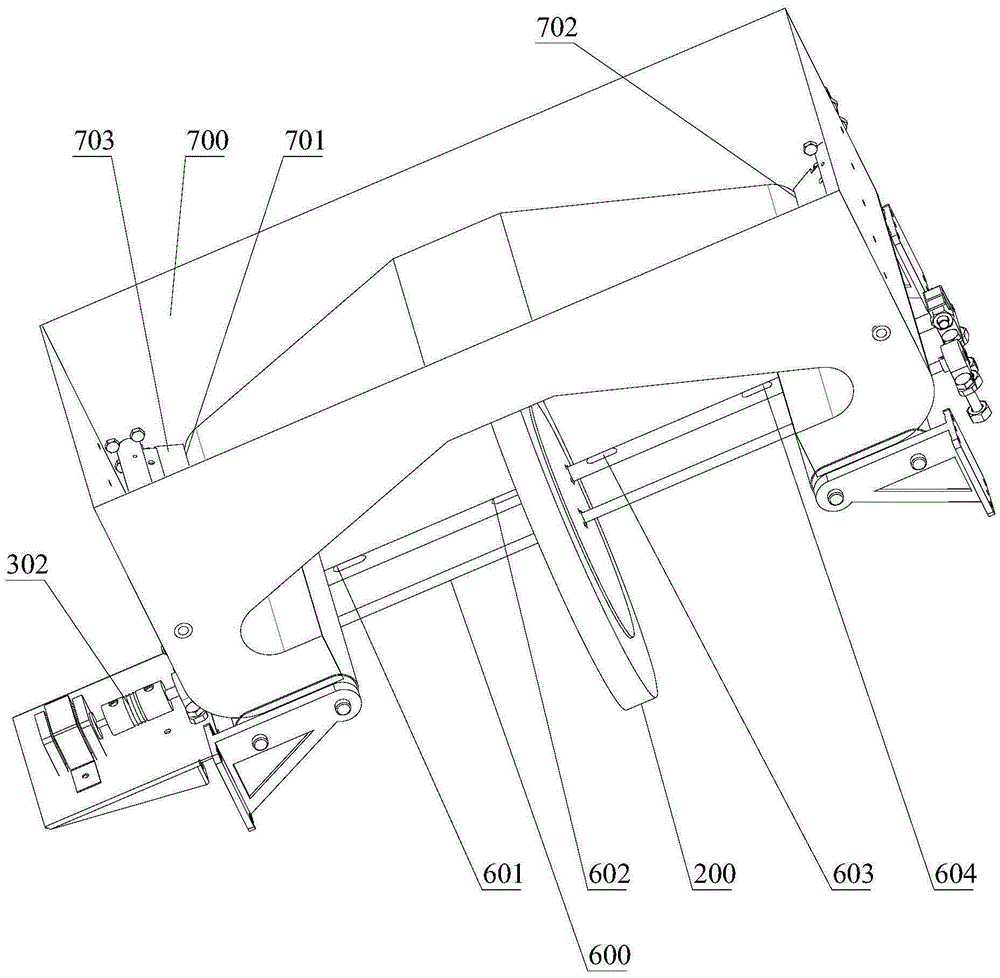

Annular fluidized bed separator of particle mixture

ActiveCN106269508AEfficient separationImprove dispersionGas current separationHeavy particleReactor system

The invention relates to an annular fluidized bed separator of a particle mixture. The upper end of a center lifting pipe extends into an annular fluidized bed by a certain height, so that the annular fluidized bed is divided into an annular area at the lower part and a cylindrical area at the upper part; an air inlet and a wind distribution plate are respectively arranged at the bottoms of the center lifting pipe and the annular fluidized bed; a feed port is formed in the bottom of the center lifting pipe; a heavy particle outlet is formed in the bottom of an annular area of the annular fluidized bed, and is connected with a heavy particle collecting tank; and an airflow outlet at the top of the annular fluidized bed is connected to a light particle collecting tank by a cyclone separator. The particle mixture is quickly fluidized in the center lifting pipe for primary dispersion, and is ascended along with air currents to enter the annular fluidized bed for secondary dispersion. The annular fluidized bed separator can continuously and quickly perform high-efficiency separation for light and heavy particle mixtures under the condition of normal temperature or high temperature. The annular fluidized bed separator can be coupled with a circulating fluidized bed reactor system, and can continuously and stably operate.

Owner:TSINGHUA UNIV

Banknote and coin separating mechanism

InactiveCN105389887AImprove uniformityNot easy to damageCoin/paper handlersReciprocating motionEngineering

The invention discloses a banknote and coin separating mechanism which comprises an accommodation cylinder, a piston, a first driving device and a second driving device, wherein at least one end of the accommodation cylinder is an open end, and the accommodation cylinder is provided with a plurality of holes for allowing coins to drop; the piston is matched with the inner surface of the accommodation cylinder, and a separation space is formed between the piston and the open end; the first driving device drives the accommodation cylinder to rotate around the axis of the accommodation cylinder; the second driving device drives the piston to reciprocate in the accommodation cylinder to change the volume size of the separation space; and the separation space is used for receiving banknotes and coins in the volume-enlarging process, and used for pushing out the banknotes in the separation space from the open end in the volume-reducing process. When banknote and coin separating mechanism separates the banknotes and coins, the banknotes are not easy to damage, the noise is small, the separation efficiency is high, and the banknotes can be collected easily.

Owner:GUANGDONG UNIV OF TECH

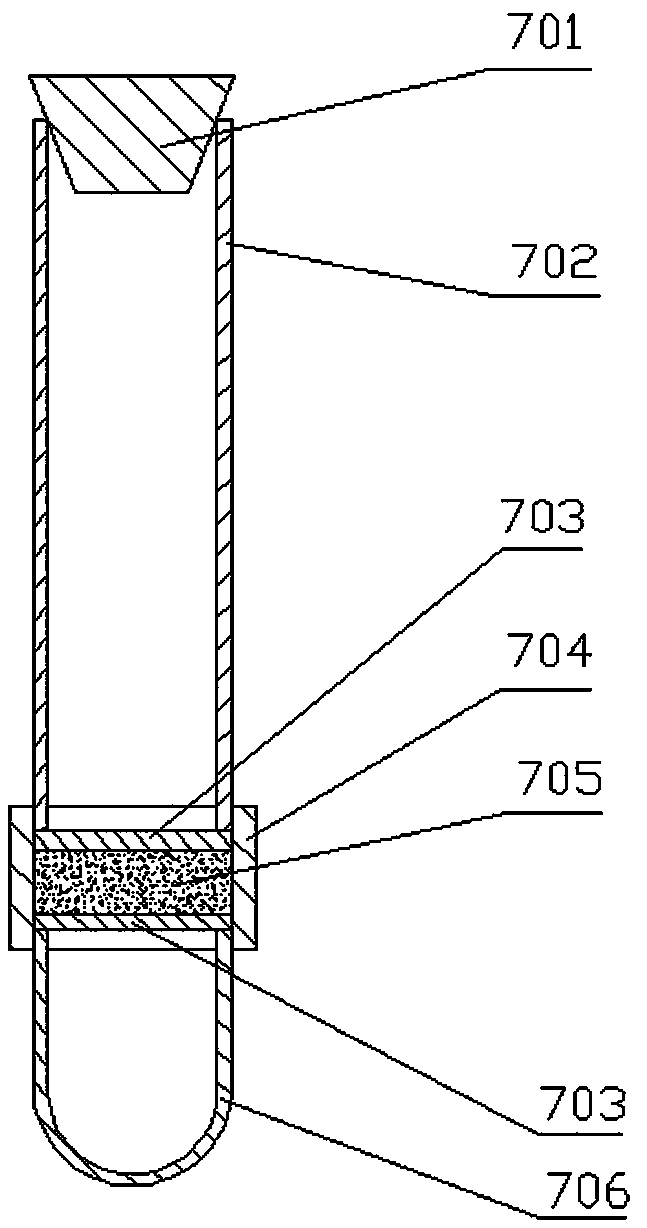

Blood platelet separation device

ActiveCN108479121AHigh purityEasy to separateNon-miscible liquid separationBiomedical engineeringMedical treatment

The invention relates to the field of medical instrument experiment equipment and in particular relates to a blood platelet separation device which comprises a shell, a motor, a spline shaft, a rotating disc and a vibration mechanism, wherein the motor is arranged inside the inner cavity of the shell; the spline shaft is connected with a motor output shaft; the rotating disc is mounted on the spline shaft in match; the vibration mechanism is used for controlling the rotating disc to vibrate intermittently in an axial direction of the spline shaft; the rotating disc takes the shape of a conicalplatform; a plurality of test tube clamps are arranged at intervals on the conical surface of the rotating disc; a centrifuge tube is fixedly arranged in any one test tube clamp; each centrifuge tubecomprises a fist tube body of which two ends are opened, and a second tube body of which one end is sealed and the other end is opened; one opened end of the first tube body is connected with the opened end of the second tube body through a connecting tube; a bovine serum agarose gel filtering layer is arranged inside the connecting tube; the other opened end of the first tube body is sealed through a test tube plug. The blood platelet separation device is high in separation efficiency, simple to operate and capable of thoroughly separating blood platelet from substances such as other blood cells and plasma proteins in whole blood.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

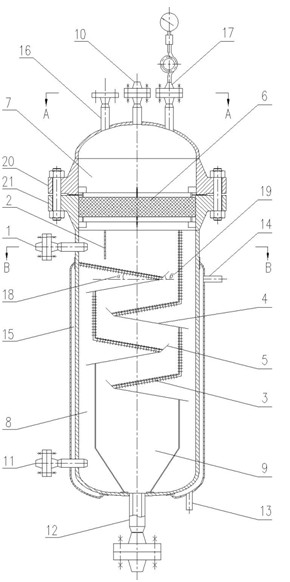

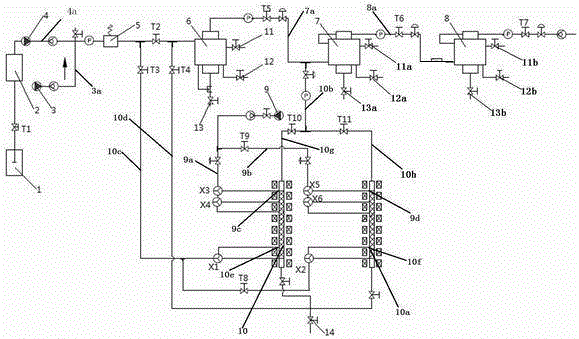

Supercritical fluid extraction, rectification and chromatography preparation device and control method thereof

ActiveCN105727589AEasy to separateSimplify the complex process of separationDistillation regulation/controlSolid sorbent liquid separationAutomatic controlChromatography column

The invention discloses a supercritical fluid extraction, rectification and chromatography preparation device and belongs to the technical field of chromatography devices. The supercritical fluid extraction part of the device comprises an extraction kettle, a first separation kettle, a second separation kettle, a CO2 conveying pump and a feeding pump; the supercritical fluid rectification part of the device comprises a rectification tower, the first separation kettle, the second separation kettle, the CO2 conveying pump and the feeding pump; the supercritical fluid chromatography part of the device comprises a chromatography column, the first separation kettle, the second separation kettle, the CO2 conveying pump and the feeding pump. The three parts control and monitor various indexes of the device through programmable logic controllers (PLCs), and an automatic control system capable of separating natural products is formed. The device has the advantages that operating manners of the device are regulated by changing the opening and closing states of valves and flow path directions, and the device is efficient and continuous in process, low in manpower and time costs, low in labor intensity of workers, capable of continuously, intelligently and efficiently separating the natural products, free of waste generation in the whole process, and environmental friendly.

Owner:DALIAN POLYTECHNIC UNIVERSITY

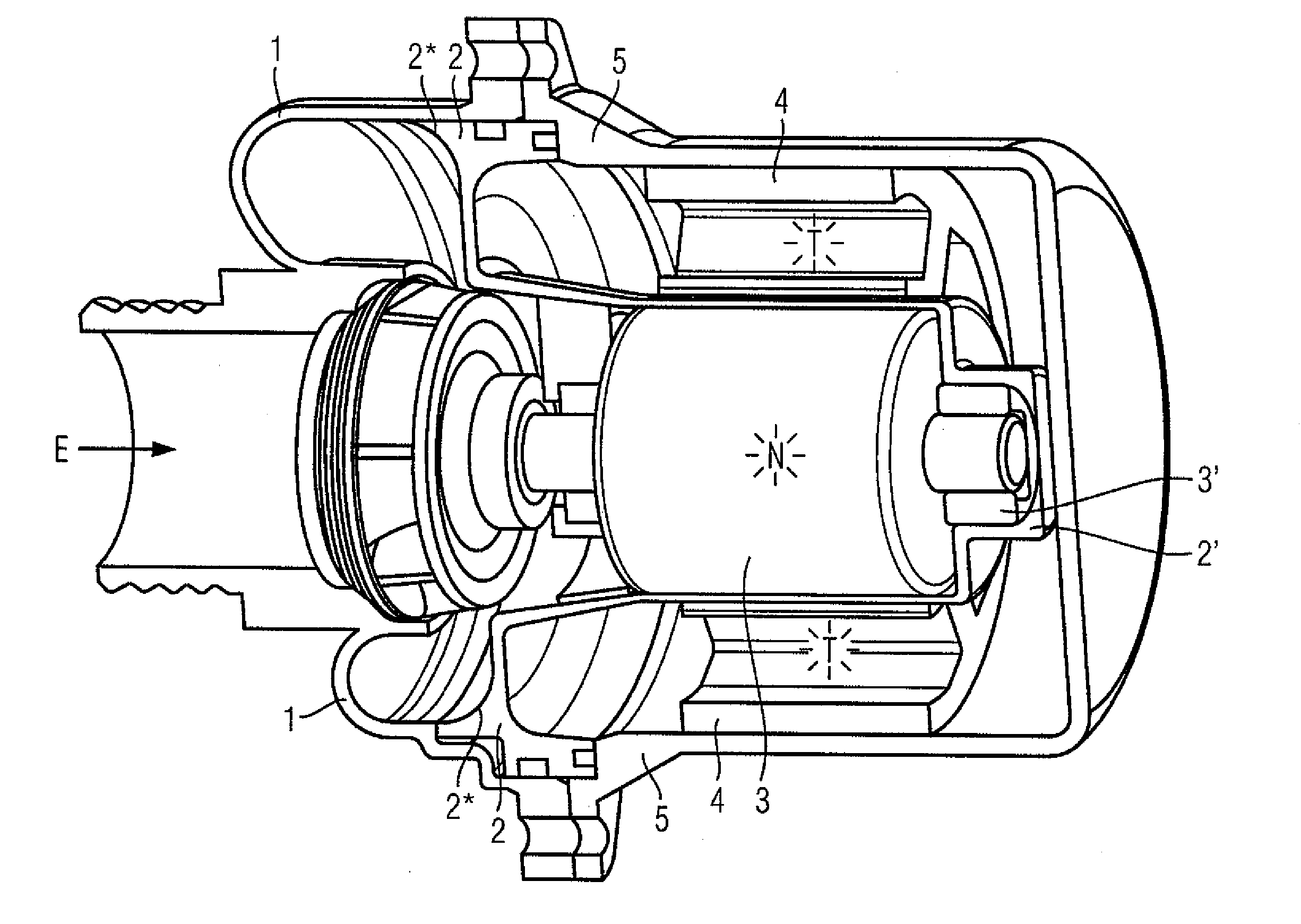

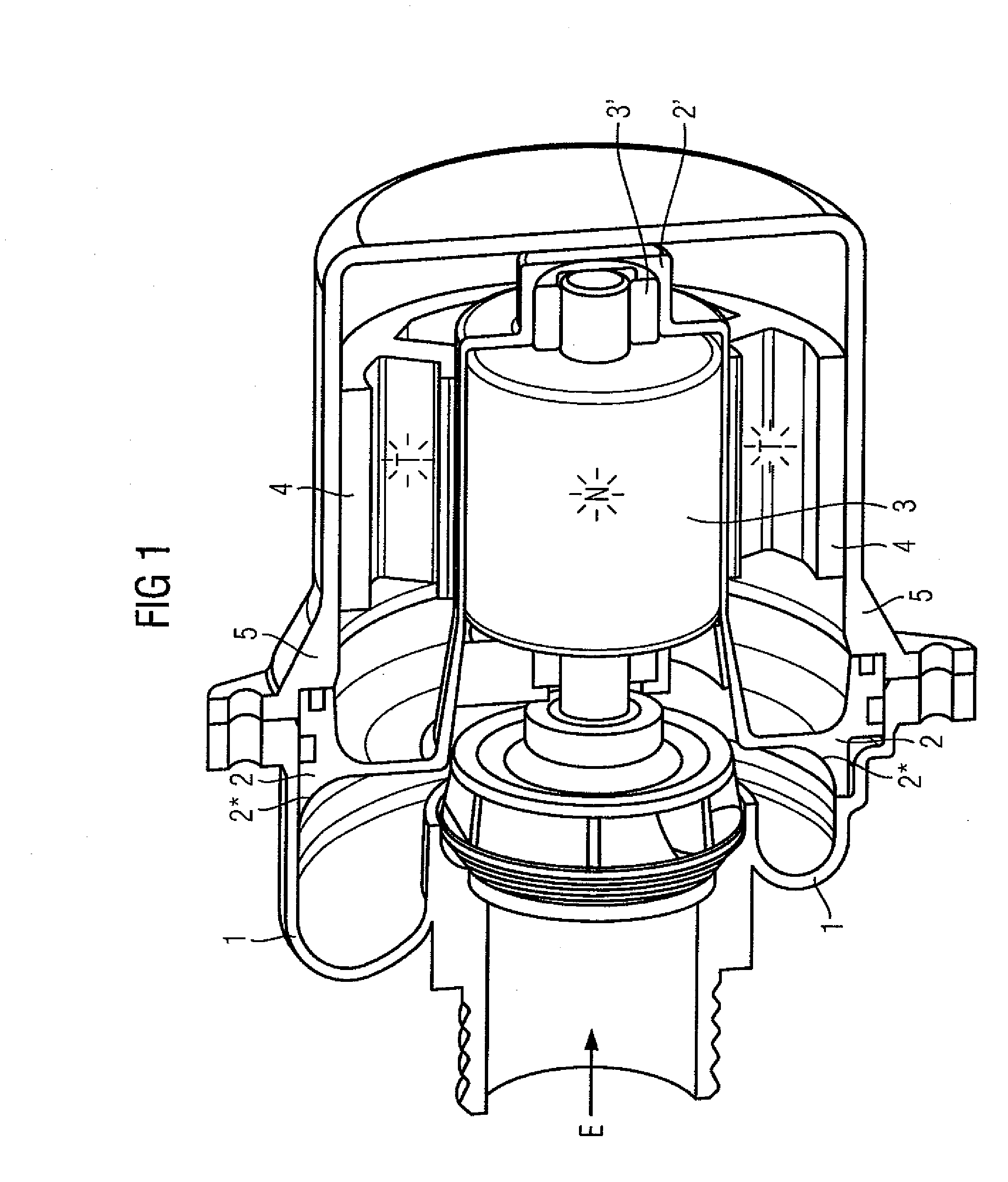

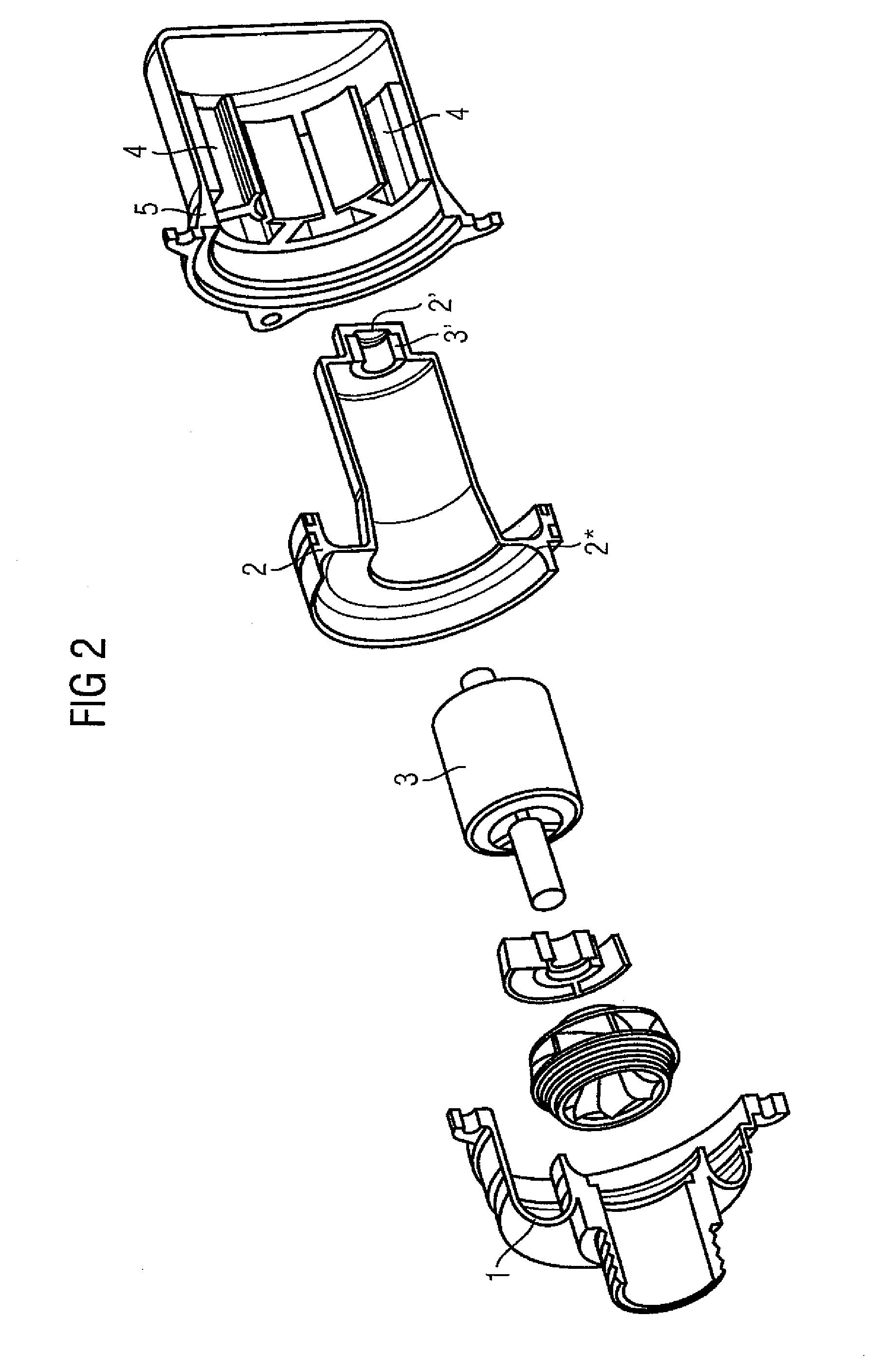

Centrifugal Pump Comprising a Spiral Housing

InactiveUS20100111687A1Continuous separationReduced space requirementsPump componentsStatorsEngineeringMechanical engineering

A centrifugal pump includes a spiral housing with a first housing part and a second housing part. The central region of the second housing part is cup-shaped in order to receive the rotor situated in a wet chamber and forms a bearing at the base of the cup-shaped region rotatably mounting the rotor. A stator surrounds the second housing part and is situated in a dry chamber in the vicinity of the exterior of the rotor.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com