Device for continuously separating gas hydrate

A gas hydrate and hydrate technology, applied in solid separation devices, gas and liquid fields, can solve the problems of increased investment cost, operation management and maintenance costs, long processing time, poor separation effect, etc. The effect of large processing capacity and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

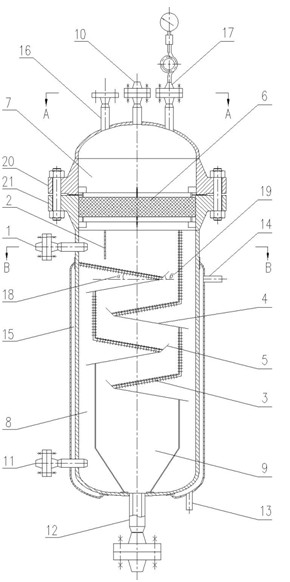

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

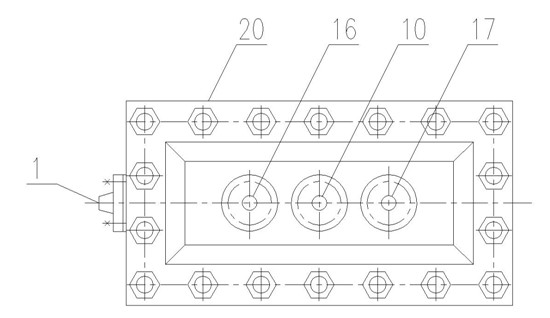

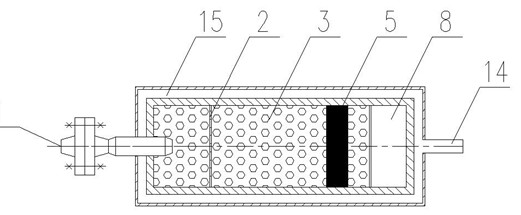

[0017] like figure 1 As shown, a device for continuous separation of gas hydrates consists of an upper box and a lower box, the box is connected by an upper flange 20 and a lower flange 21; the upper box is a gas collection chamber 7, and its The top is arched, the upper end is provided with a separation gas outlet 10, a safety valve port 16 and a pressure gauge port 17, and the lower part is provided with a wire mesh demister 6; the lower box is cuboid, and the upper part is provided with a hydrate slurry inlet 1, The cross-section of the hydrate slurry inlet 1 is circular, and the end is provided with a vertical flow equalizer 2. A sieve plate 3 is provided at a distance of 8 to 20 mm from the bottom of the flow equalizer 2. The three sides of the sieve plate 3 are connected to the lower box. The sieve plate 3 is alternately connected with the drainage pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com