Patents

Literature

38results about How to "Large processing depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiple pressurizing fast consolidated compacting soft earth foundation treatment method

InactiveCN101016740AIncreased excess pore water pressureExpand the scope of processingSoil preservationSoil sciencePresent method

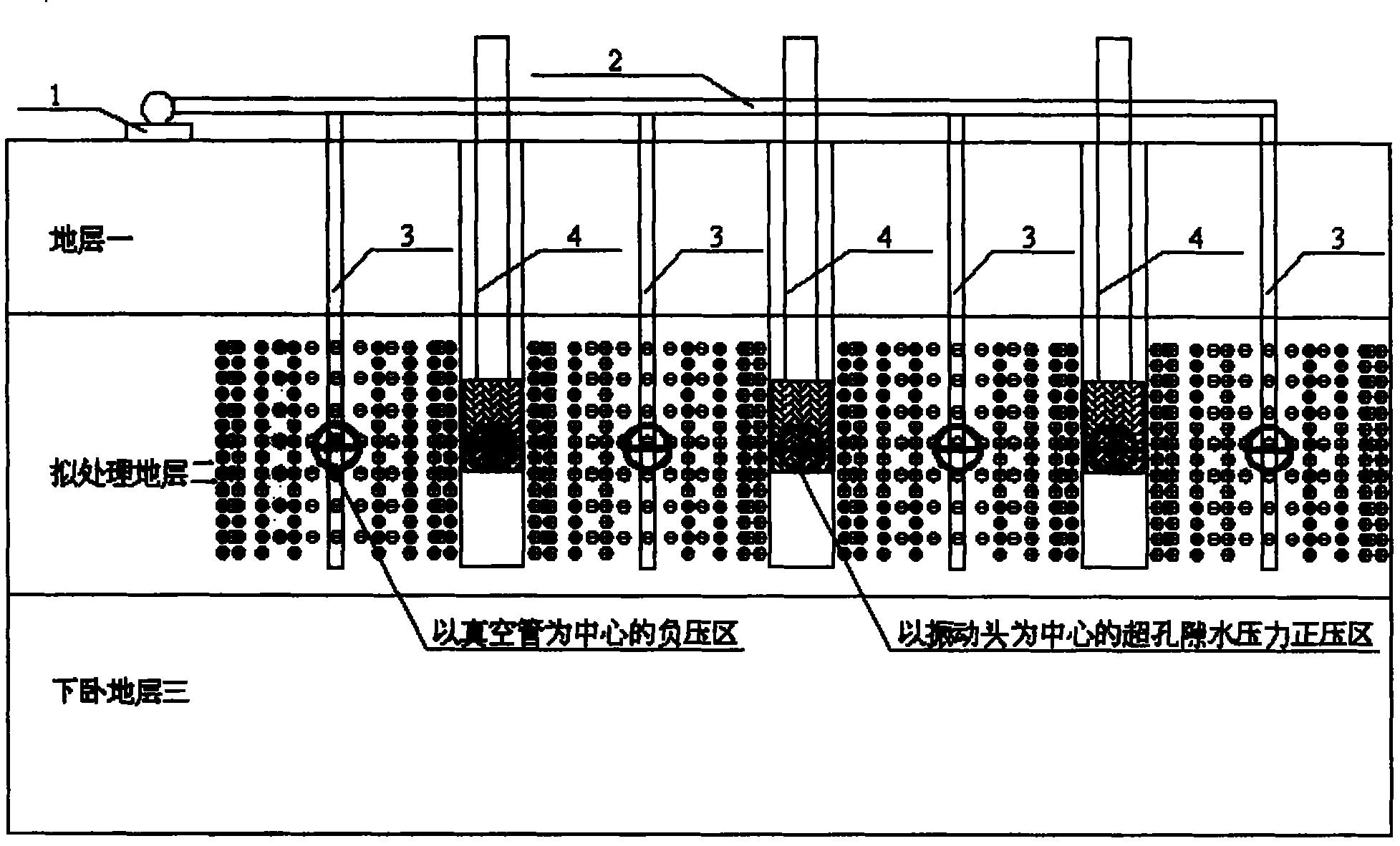

The invention in a technical sphere of soft soil ground treatment in geotechnical engineering relates to a soil ground treatment method in the areas along the sea, the river and the lake. The invention combines a vacuum drainage, a compaction via vibration supercharging, and a compaction via dynamic consolidation supercharging, wherein a higher kinetic head gradient which is consisted of a positive pressure of excess pore water by vibration excitation and a vacuum negative pressure firstly discharges the water in soil and increases the water content in the soil, thereby compacting the soil to a certain extend, and then the dynamic consolidation action is proceeded to improve the excess pore water pressure and form the higher kinetic head gradient thereby draining and compacting the soil. All the steps are proceeded many times to eliminate the settling of the worked deep layer soft soil and to improve surface consolidation degree, intensity, and stiffness until up the design requirement. Compared with the present method, the invention not only has a short time for a project, lower manufacturing cost and settling after work, and a good effect of consolidating and compacting, but also is extensive used in the soft soil ground treatment of various projects in the area along the sea, the river, or the like.

Owner:武亚军

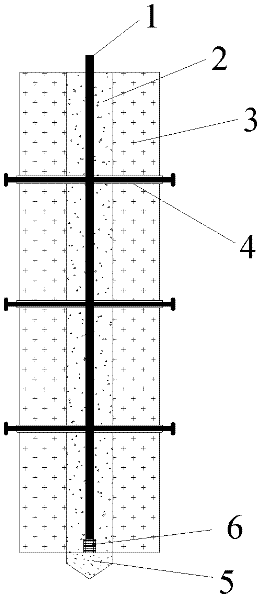

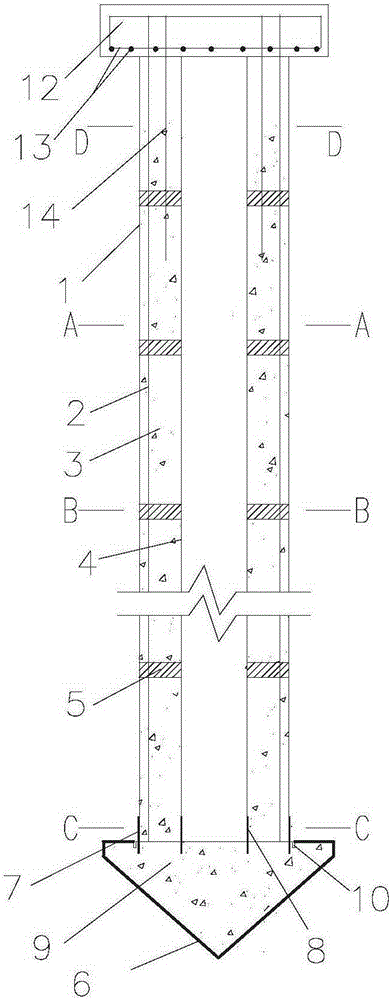

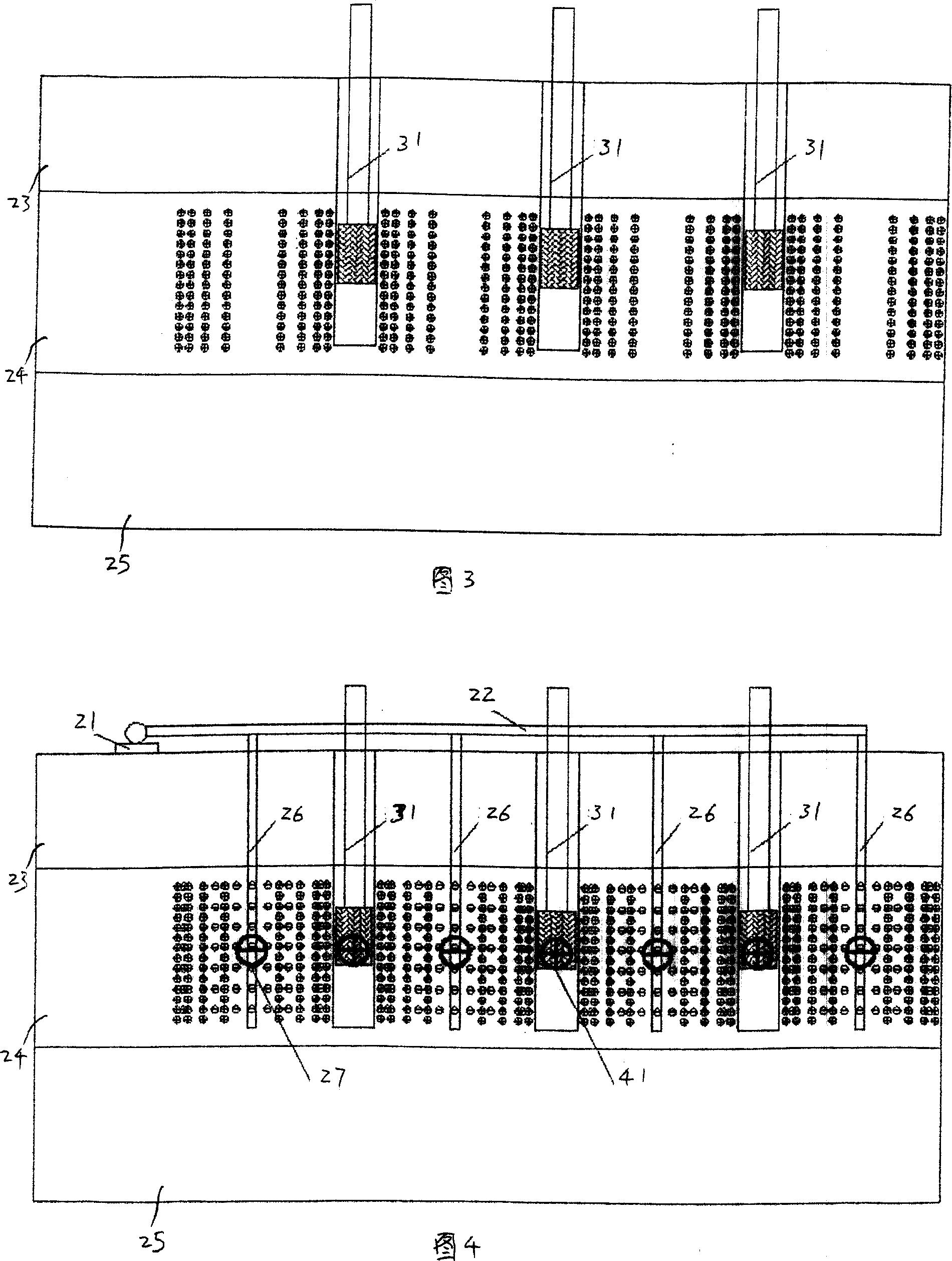

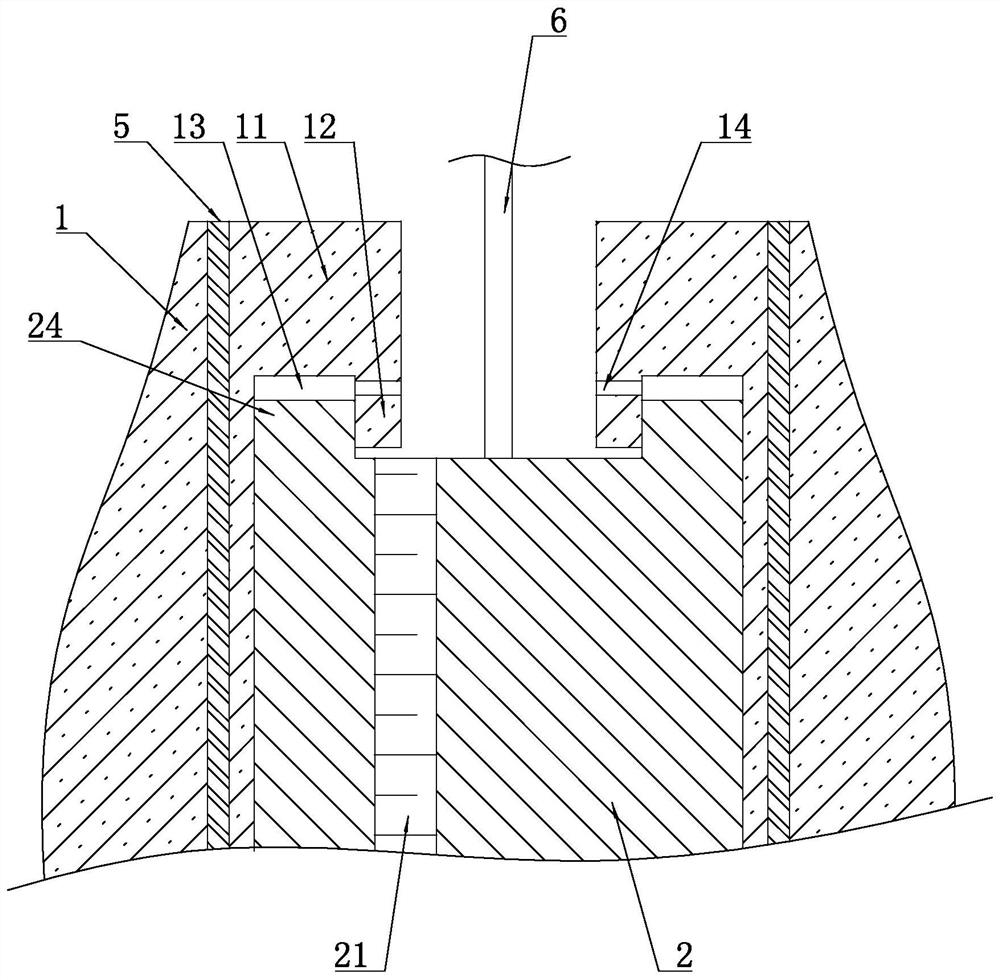

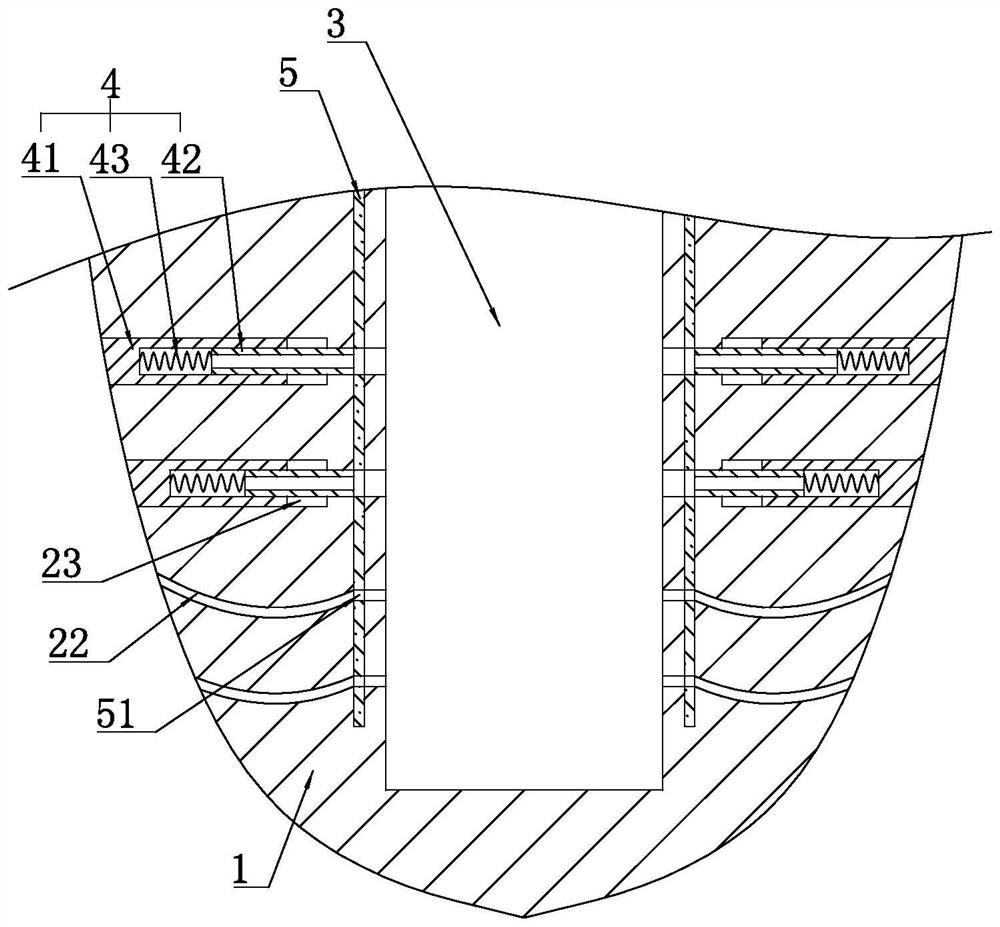

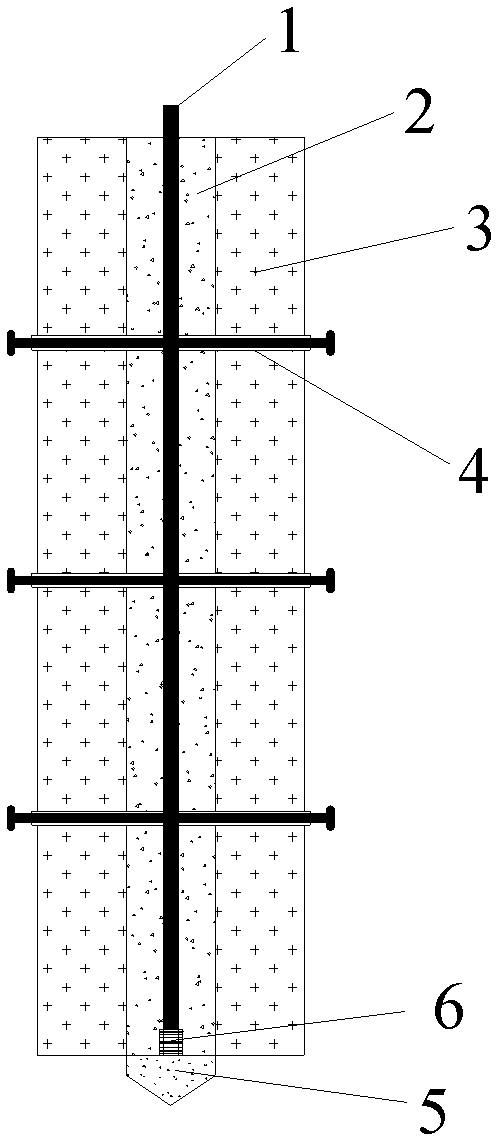

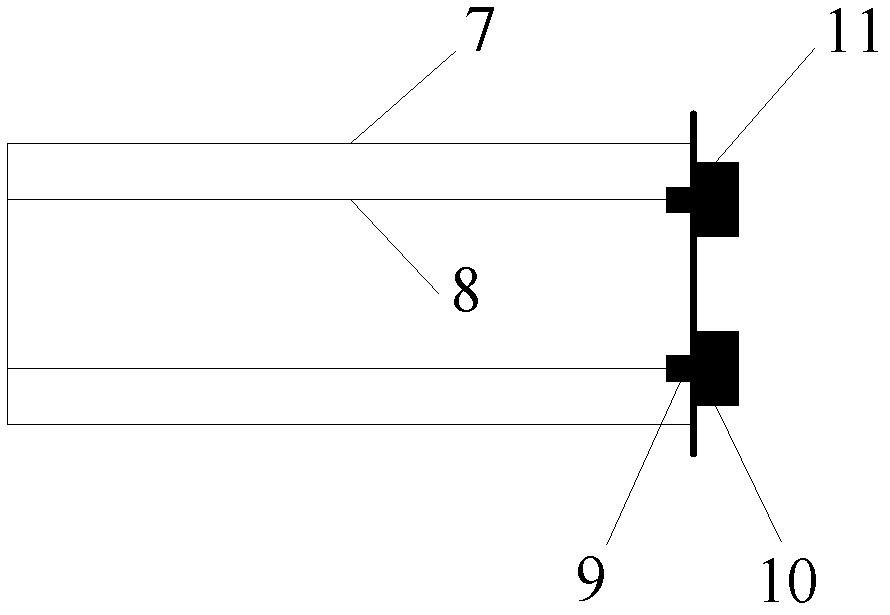

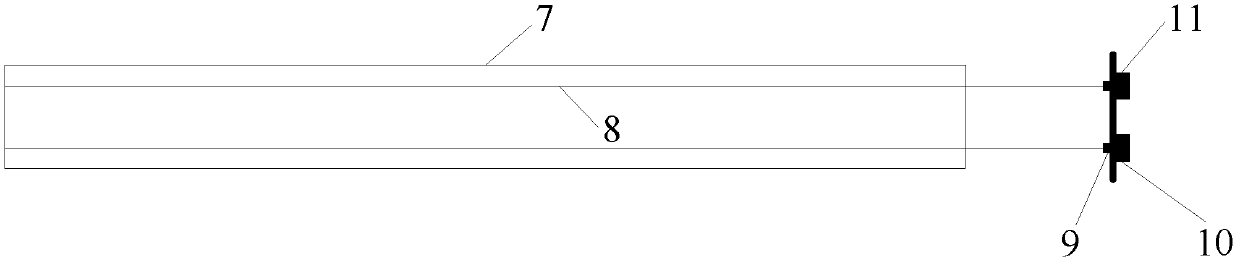

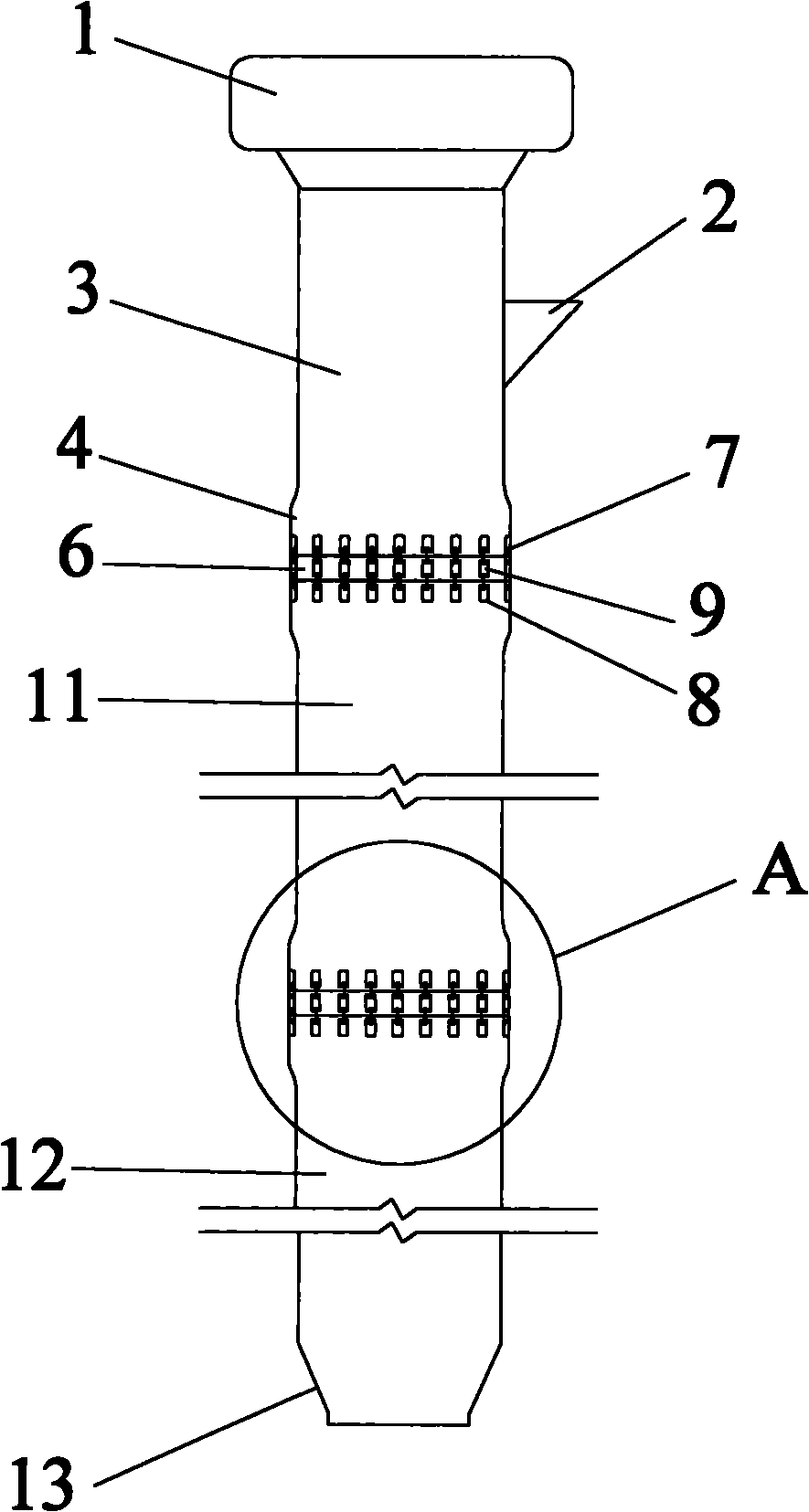

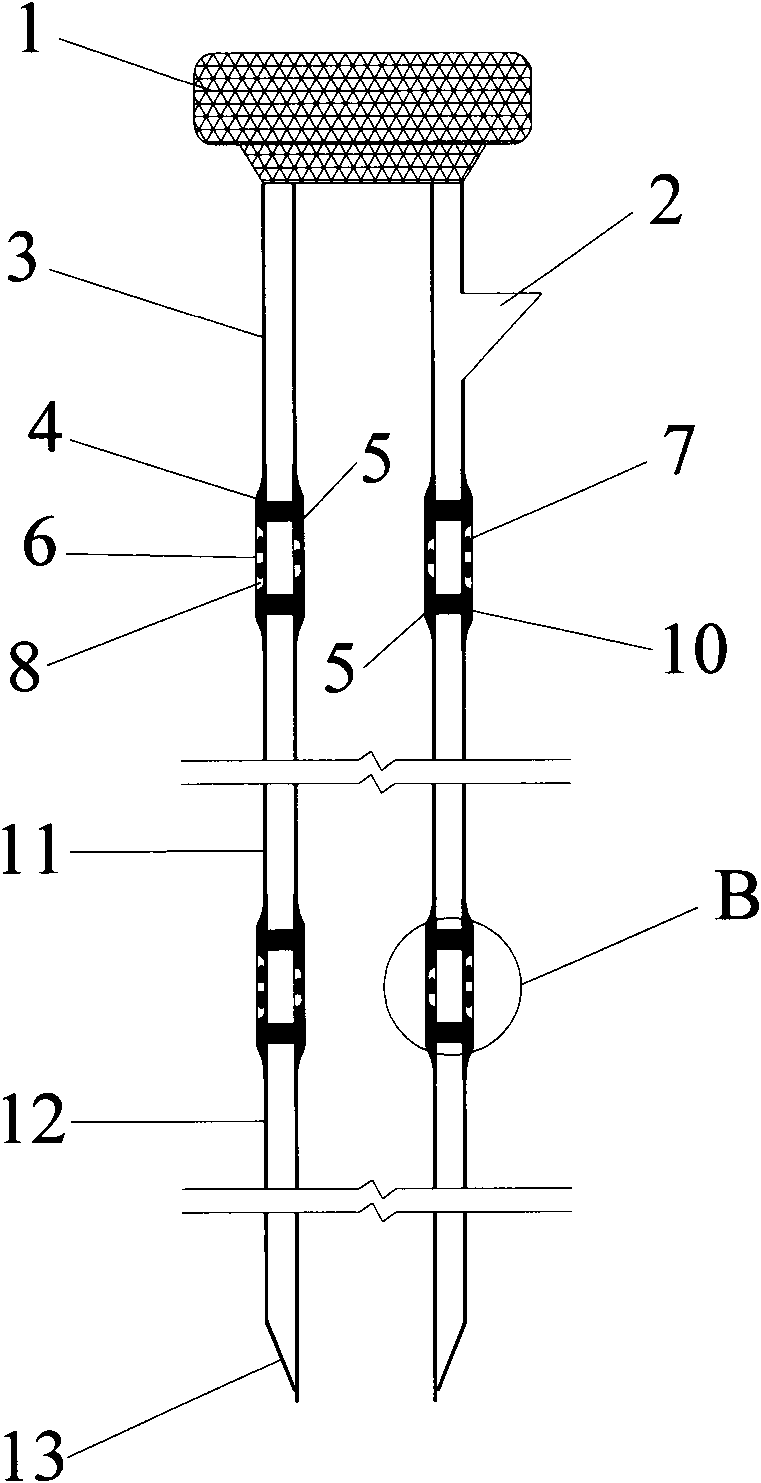

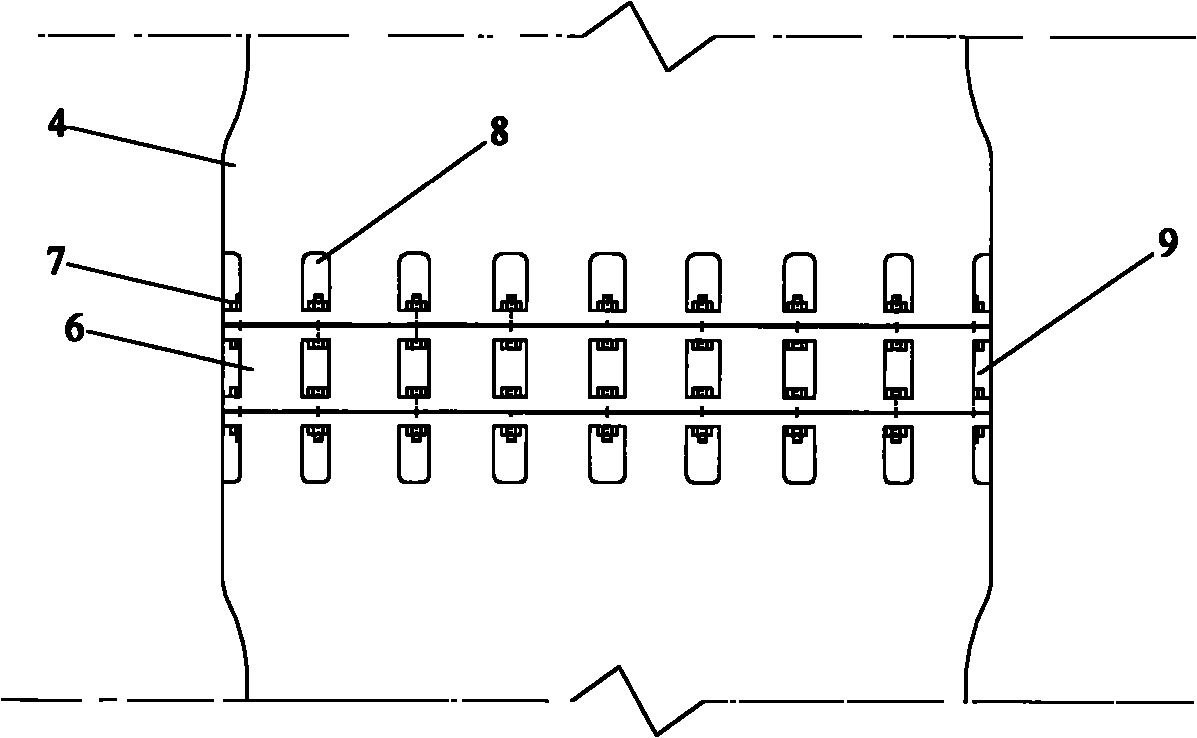

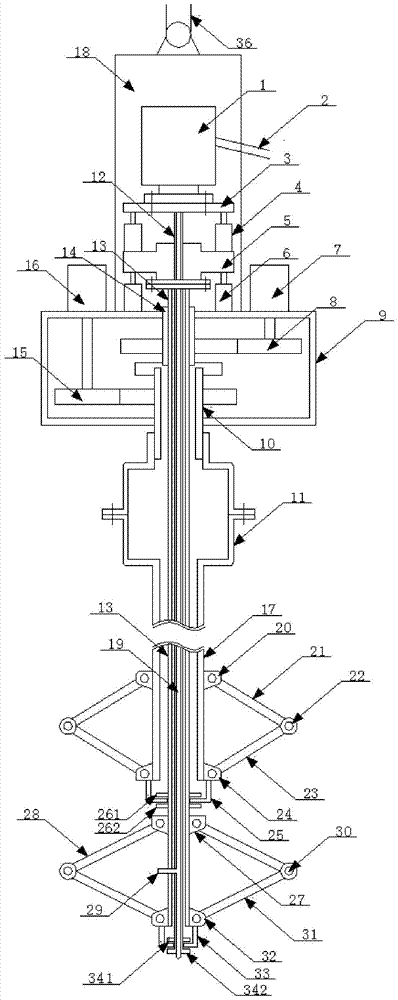

Cement mixing pile with stiffness core capable of draining and pre-pressing firstly and then grouting as well as construction method thereof

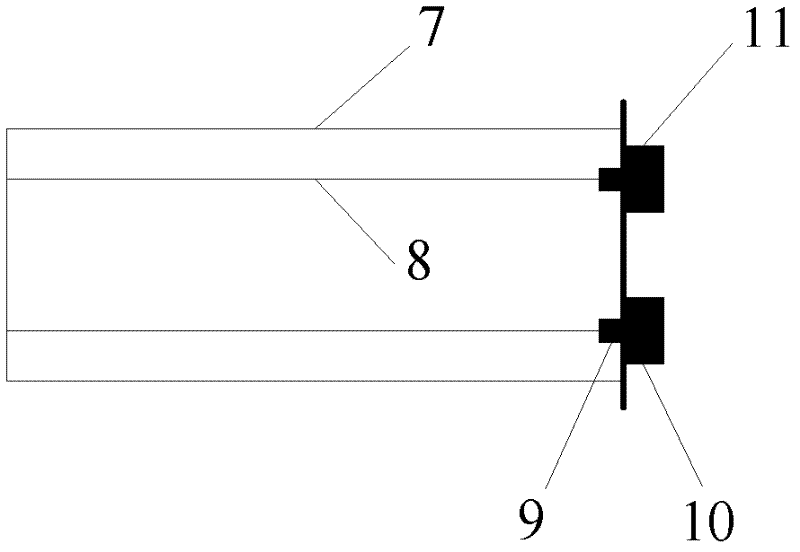

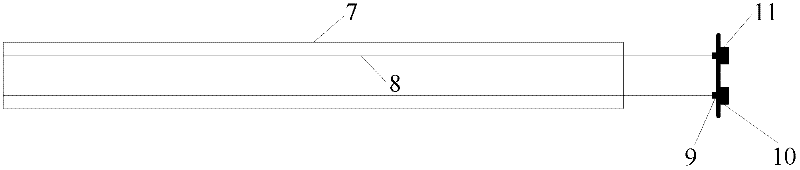

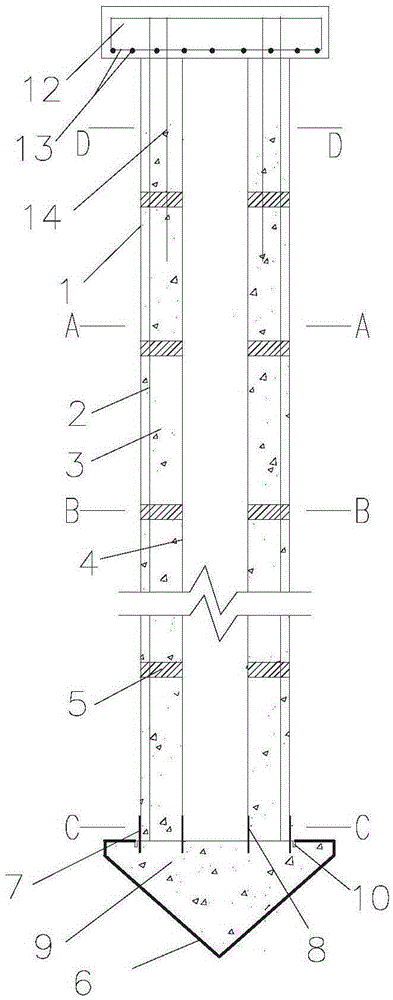

InactiveCN102650128AEasy to sinkConducive to uplift constructionBulkheads/pilesSoil preservationImmersed tubePipe

The invention relates to a cement mixing pile with a stiffness core capable of draining and pre-pressing firstly and then grouting as well as a construction method thereof. The cement mixing pile comprises a vertical draining and grouting pipe arranged in the cement mixing pile, and more than one dual-layer telescopic horizontal draining and grouting pipes arranged at intervals on the vertical draining and grouting pipe, wherein a bulk solid pile with the stiffness core is arranged in the cement mixing pile, and the length of a horizontal draining and grouting pipe in an outer layer is smaller than that of the horizontal draining and grouting pipe in an inner layer when the horizontal draining and grouting pipe is in a telescopic state. In a construction process, an upper drawn steel immersed tube is vibrated, and the horizontal draining and grouting pipe departs from the steel immersed tube and is stretched to form a horizontal draining body. According to the invention, the advantages of drainage consolidation and composite foundation methods are integrated, and foundations can be dynamically reinforced according to the construction period and the settlement requirements on the premise of lower construction cost while the bearing capacity and the processing depth of the cement mixing pile are increased.

Owner:ZHEJIANG UNIV CITY COLLEGE +2

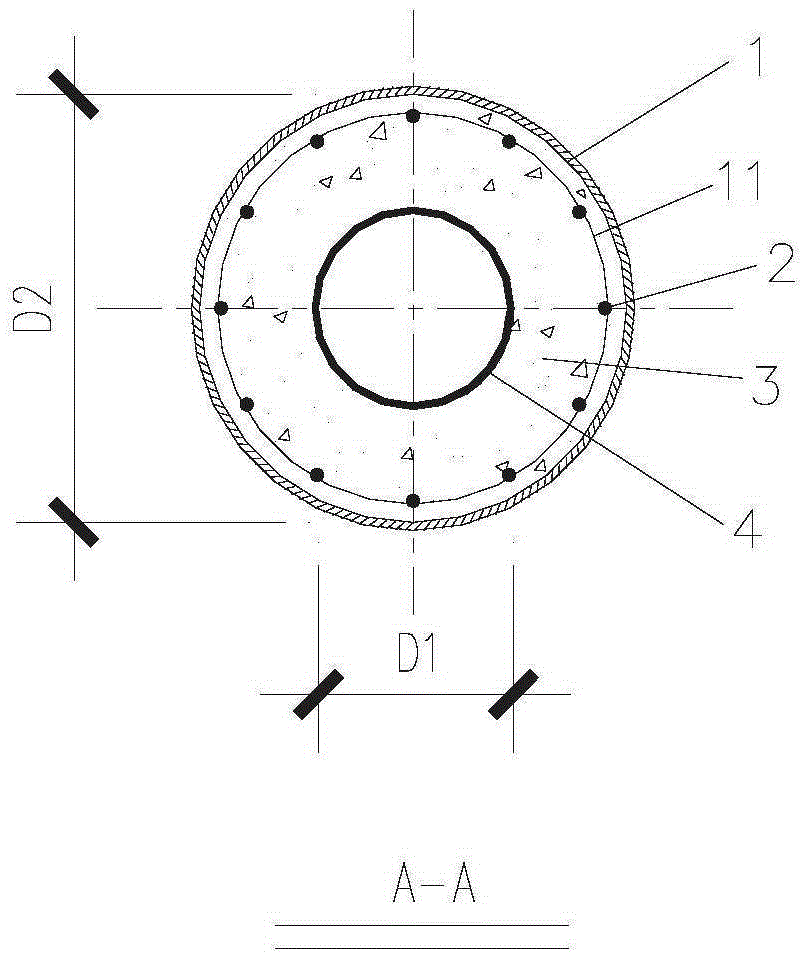

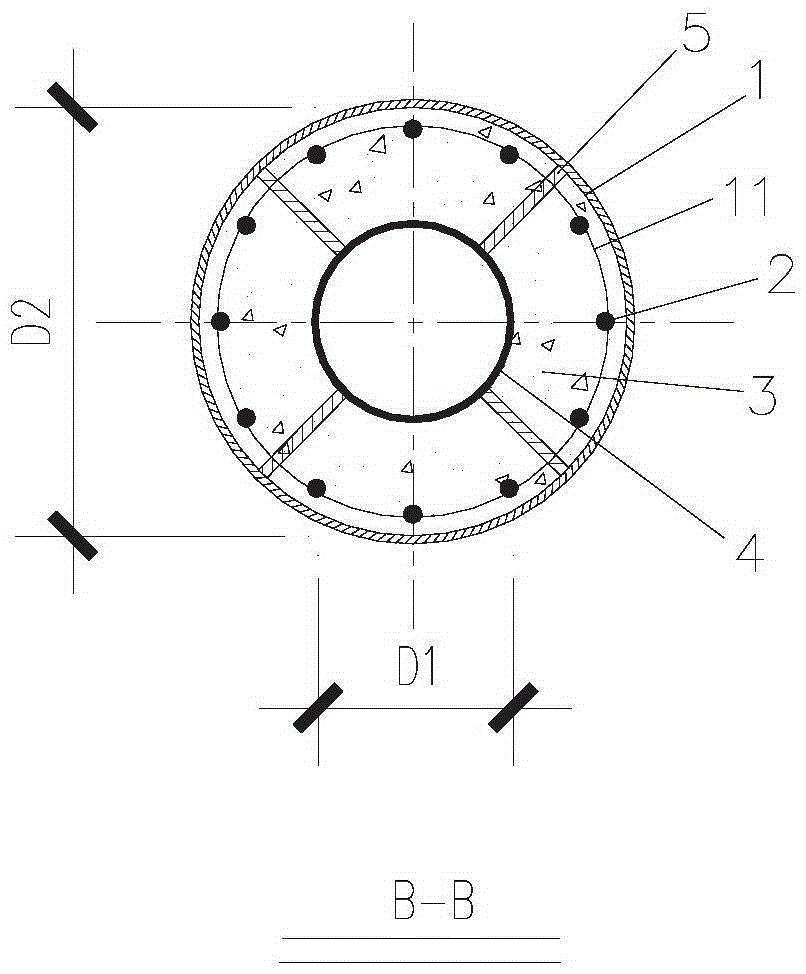

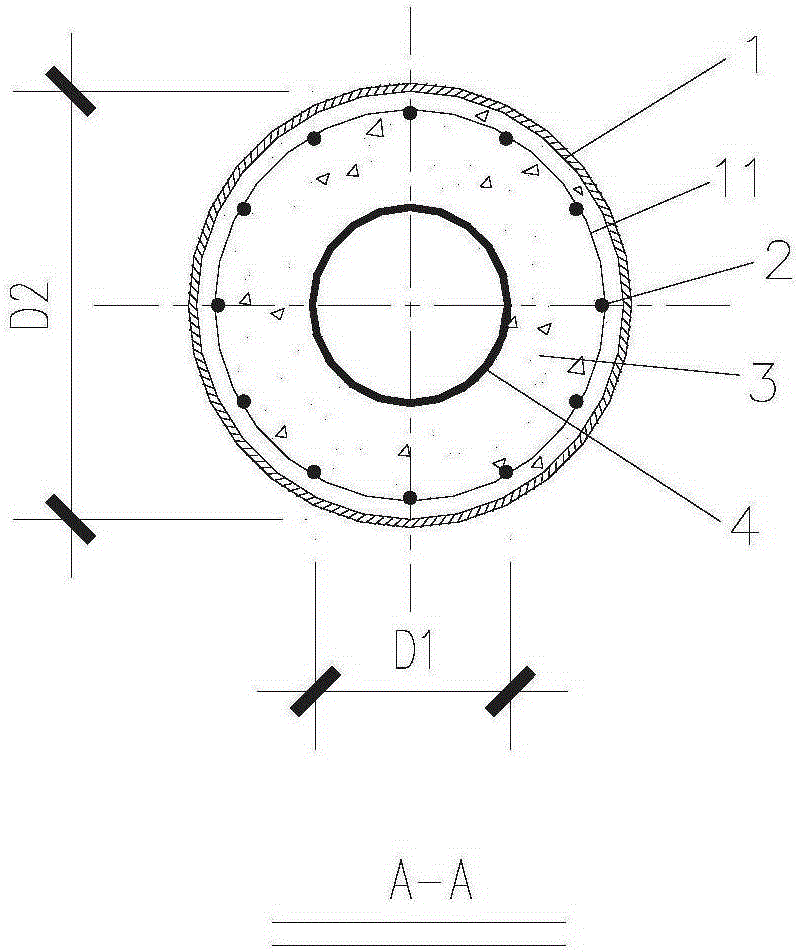

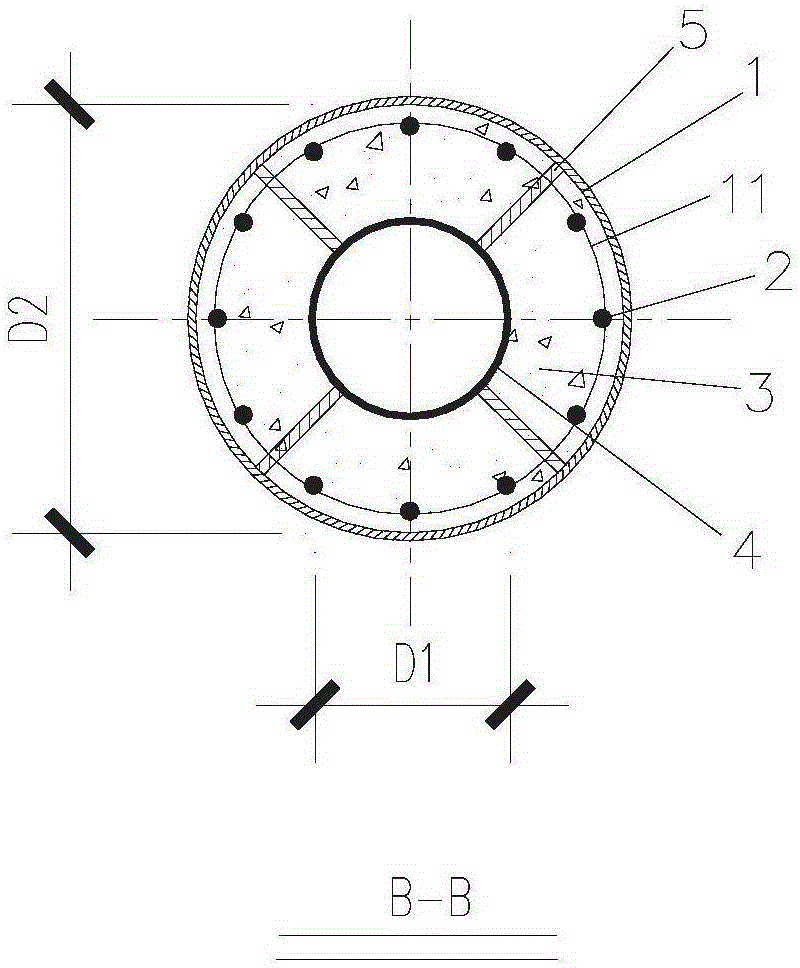

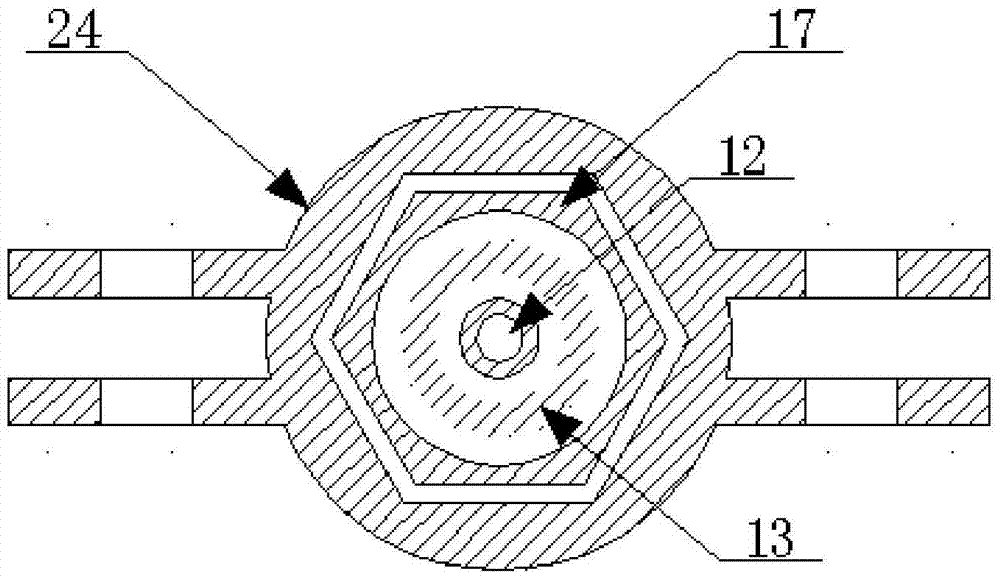

FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile

InactiveCN105386443AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses an FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile which is mainly formed by an FRP pipe, a round reinforcement cage framework, a thick-wall steel pipe and recycled concrete. The round reinforcement cage framework and the thick-wall steel pipe are arranged in the FRP pipe, and the round reinforcement cage framework, the thick-wall steel pipe and the FRP pipe are arranged concentrically. The recycled concrete is poured in annular space between the FRP pipe and the thick-wall steel pipe. The bearing capacity and deformation resisting capacity of the single pile can be greatly improved through the built-in thick-wall steel pipe. The wrapping FRP pipe can effectively prevent a pile body from being corroded, and the durability of the pile body is improved. Meanwhile, the FRP pipe and spiral stirrups are combined to restrain the inner recycled concrete, and the bearing force of the compounding pile is further improved. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated. In a word, the compounding hollow recycled concrete pile has the advantages of being good in pile forming quality, high in bearing force, good in deformation resisting capacity and durability, small in influence on the environment, high in construction speed and the like.

Owner:GUANGXI UNIV

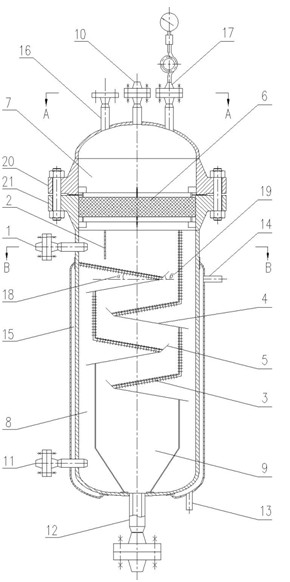

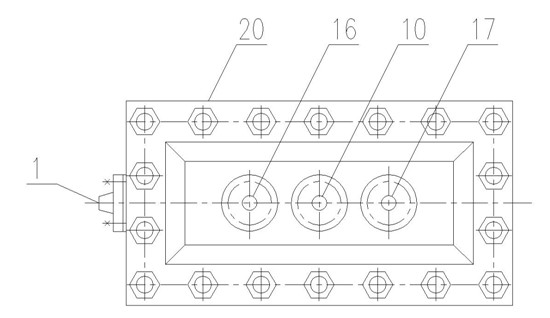

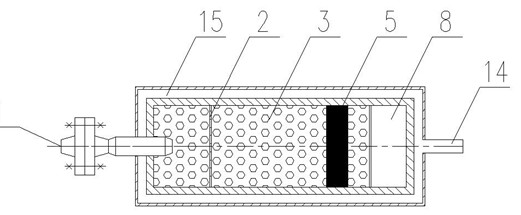

Device for continuously separating gas hydrate

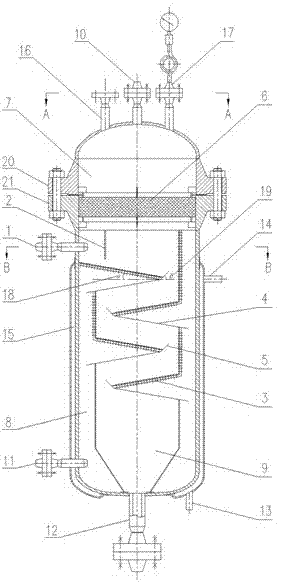

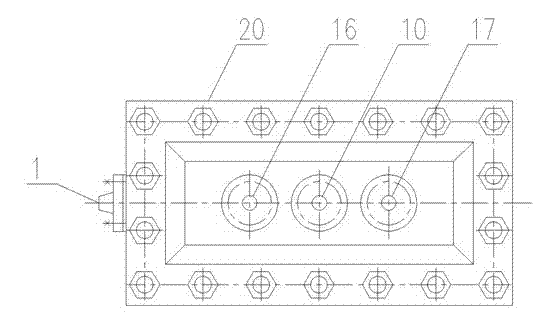

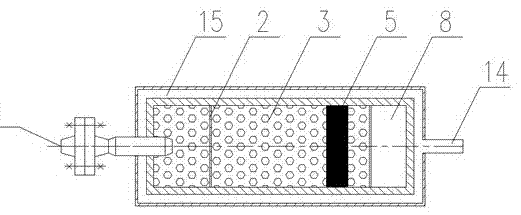

ActiveCN102120104ASimple structureSmall footprintPressurized chemical processLiquid degasificationSlurryEngineering

The invention discloses a device for continuously separating gas hydrate, which comprises an upper box body and a lower box body, wherein the upper box body is a gas collecting cavity (7), the upper end of the upper box body is provided with a separated gas outlet (10), a safety valve port (16) and a pressure meter port (17), and the lower part of the upper box body is provided with a silk screenmist eliminator (6); the lower box body is shaped as a cuboid, the upper part of the lower box body is provided with a hydrate slurry inlet (1), the tail end of the hydrate slurry inlet (1) is provided with a flow equalizing plate (2) in a vertical direction, the bottom end of the flow equalizing plate (2) is provided with a sieve plate (3), the sieve plate (3) is alternatively connected with a drainage plate (4) to form a separating channel; a water collecting cavity (8) is arranged between the separation channel and the lower box body, and the lower part of the separation channel is provided with a separated water outlet (11); and the lower end of the separation channel is connected with a hydrate storing cavity (9), and the bottom end of the hydrate storing cavity (9) is provided with a hydrate outlet. The invention has the advantages of simple structure, small occupation area and convenience for maintenance.

Owner:溧阳常大技术转移中心有限公司

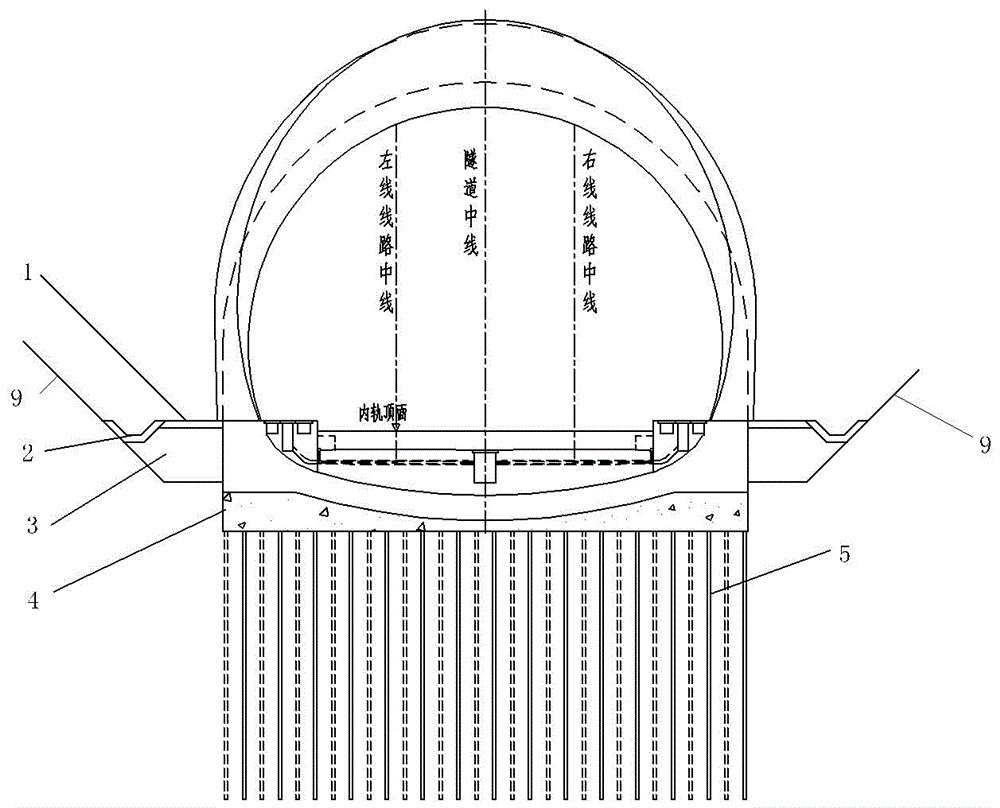

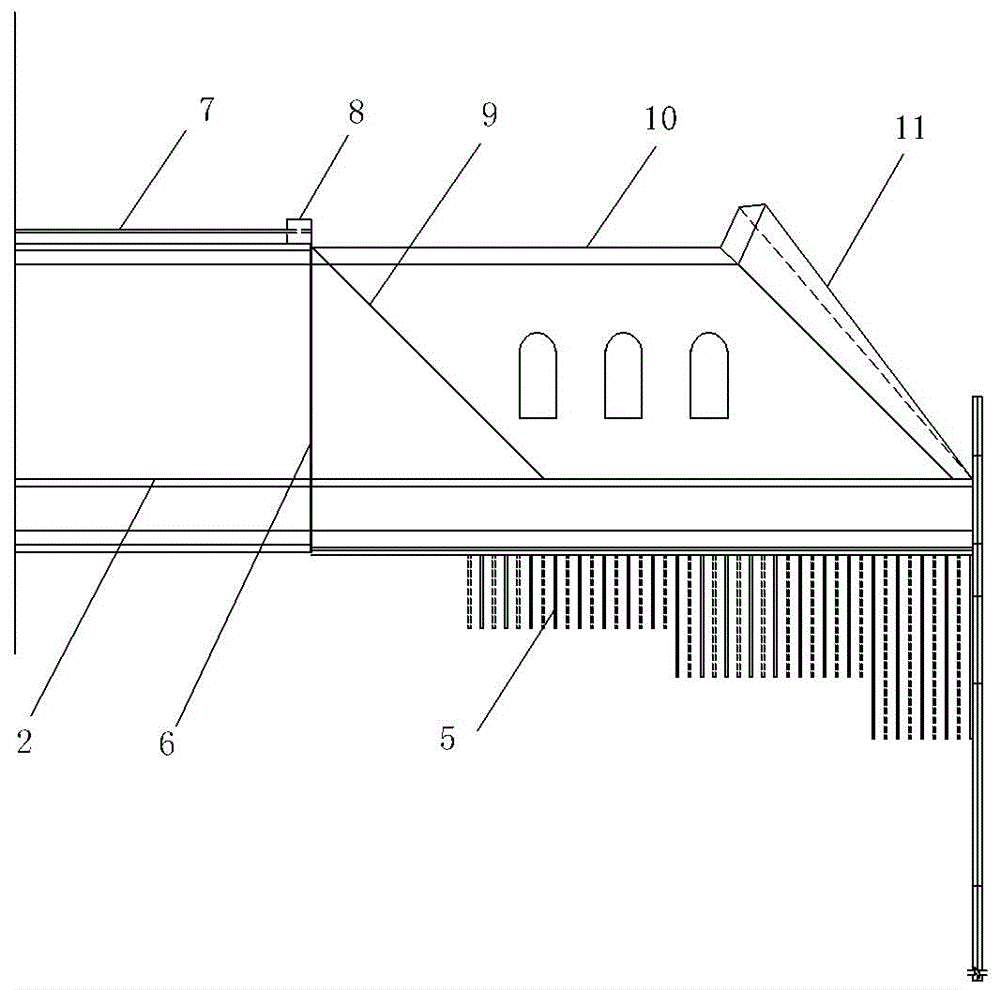

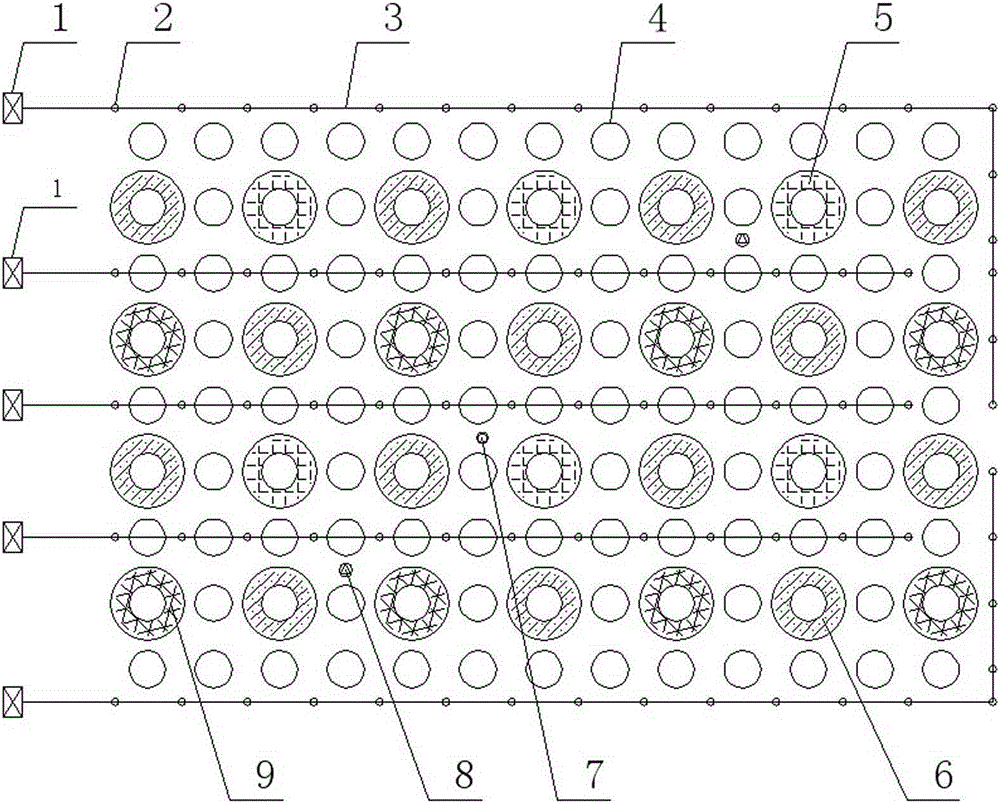

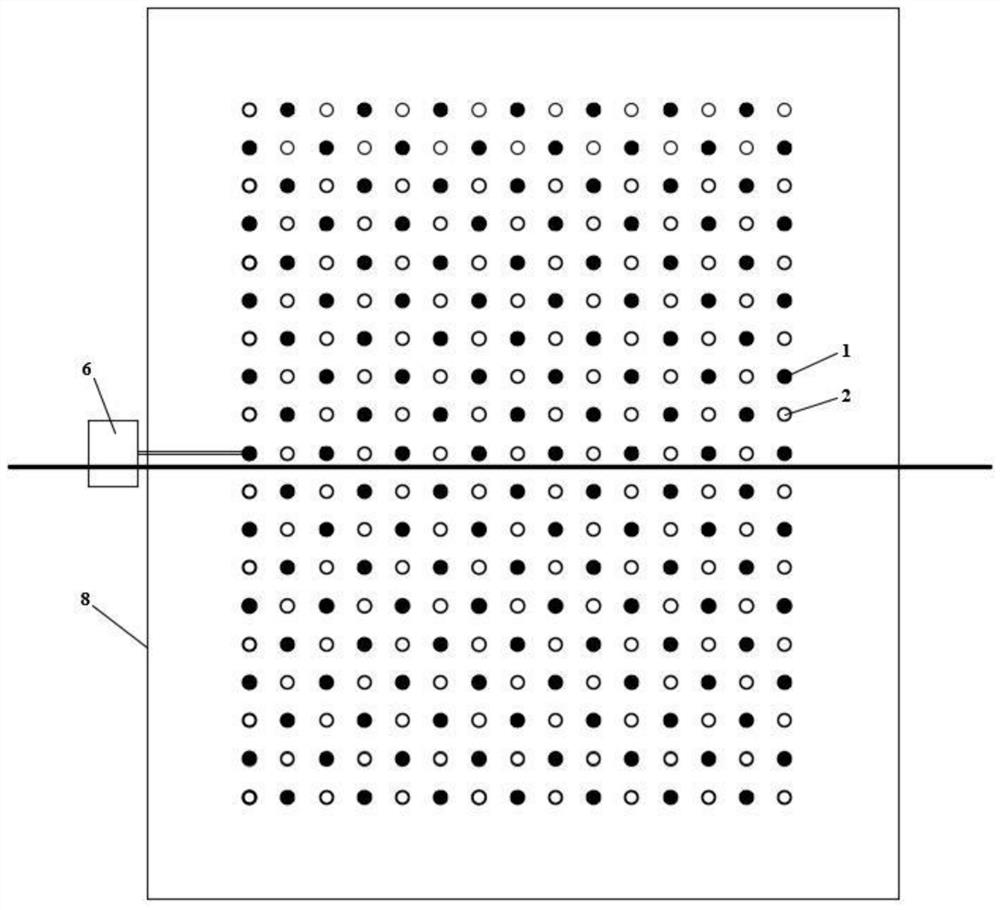

Small tubular pile reinforcement system for weak base of tunnel and method for constructing small tubular pile reinforcement system

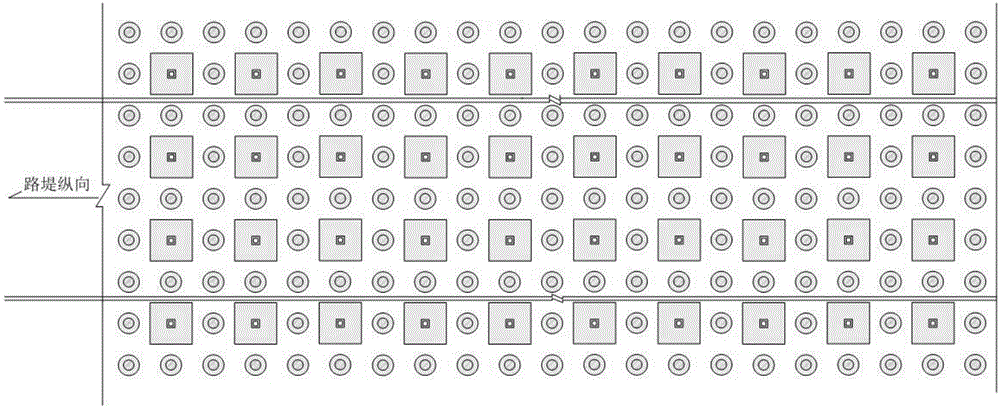

InactiveCN106246200ALarge processing depthControl uneven settlement deformationUnderground chambersFoundation engineeringTerrainIn plane

The invention relates to a small tubular pile reinforcement system for a weak base of a tunnel and a method for constructing the small tubular pile reinforcement system. Foundations of a tunnel portal at a bridge and tunnel joint directly extend into terrains such as deep valleys in a direct transition manner, the terrains correspond to a bridge, and treatment on the foundations of the soft base at the bridge and tunnel joint has important significance on the stability of integral construction structures at a bridge and tunnel transition position. The small tubular pile reinforcement system is characterized in that a concrete supporting plate is arranged below a tunnel inverted arch structure of the tunnel portal at the bridge and tunnel joint, and steel tubular piles which are arrayed are arranged in the foundations below the concrete supporting plate; the depths of the steel tubular piles are gradually inwardly reduced from the portal, and the steel tubular piles are stepped along the directions of lines and are arranged are arranged in a quincuncial manner in planes. The small tubular pile reinforcement system and the method have the advantages that the small tubular pile reinforcement system is large in foundation treatment depth and small in treatment area, the bearing capacity of the weak foundations can be obviously improved after the small tubular pile reinforcement system is constructed, settlement and deformation of the foundations can be controlled, and normal use of the structures can be guaranteed.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

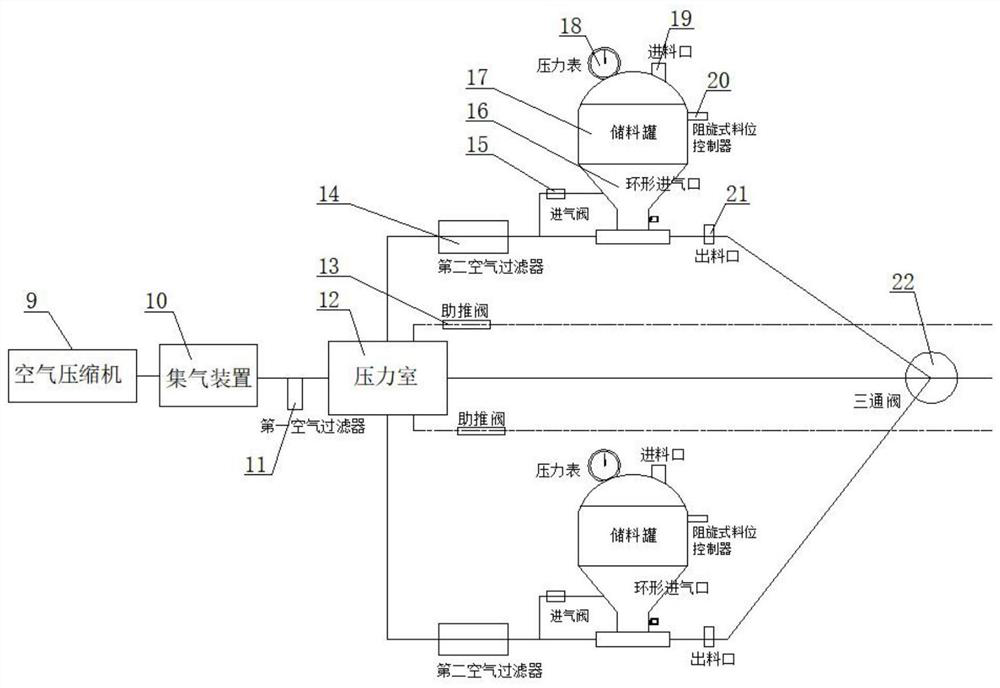

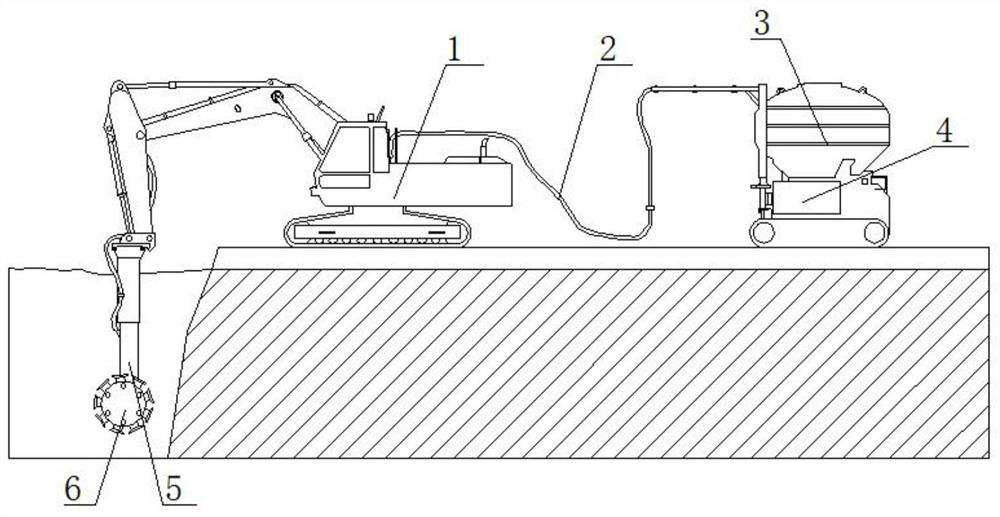

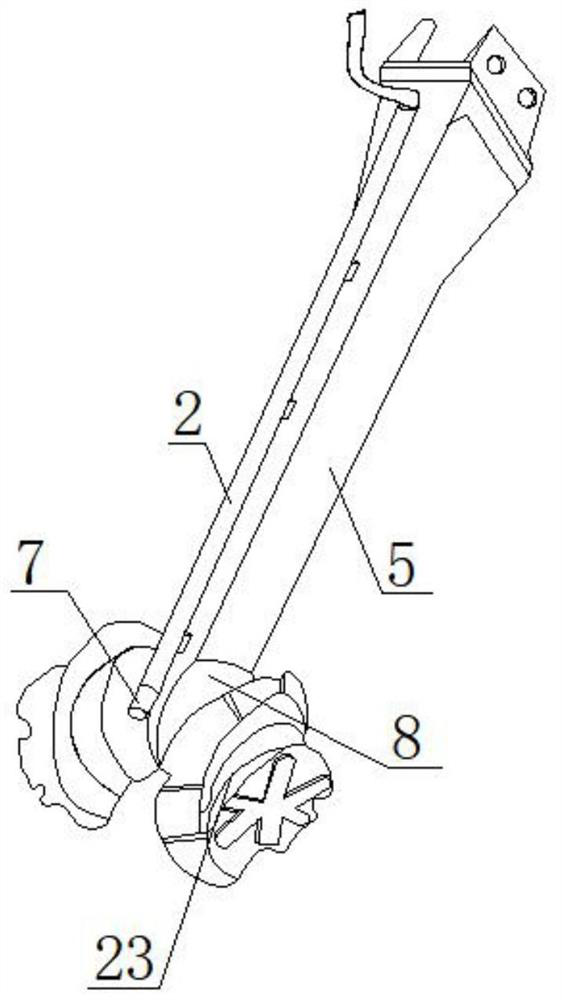

Soft soil stratum in-situ curing agent preparing and feeding equipment and curing process thereof

InactiveCN113699971AAchieve zero dischargeAchieve impactRoadwaysSoil-shifting machines/dredgersEnvironmental engineeringAir compressor

The invention discloses a soft soil stratum in-situ curing agent preparing and feeding equipment and curing process thereof, the soft soil stratum in-situ curing agent preparing and feeding equipment comprises an excavator and curing agent preparing equipment, a material conveying pipe is arranged between the excavator and the curing agent preparing equipment, the curing agent preparing equipment is provided with an automatic quantitative feeding system, the excavator is provided with a bucket arm, the tail end of the bucket arm is connected with a powerful stirring head, and the curing agent preparation equipment comprises a storage tank, a pressure chamber and an air compressor. The soft soil stratum in-situ curing agent preparing and feeding equipment and the curing process thereof replace a traditional replacement filling method for treating the soft soil stratum, zero discharge of engineering waste soil can be achieved, the influence degree of transportation and the waste soil on the environment is reduced, a large number of replacement materials do not need to be used, the use amount of gravel is reduced, and mountain cutting quarrying and river channel sand digging are reduced; the influence on surrounding buildings is reduced, the construction speed is increased, a hard shell layer can be quickly formed, cyclic utilization of resources is achieved, and energy conservation and environmental protection are achieved.

Owner:赵立财

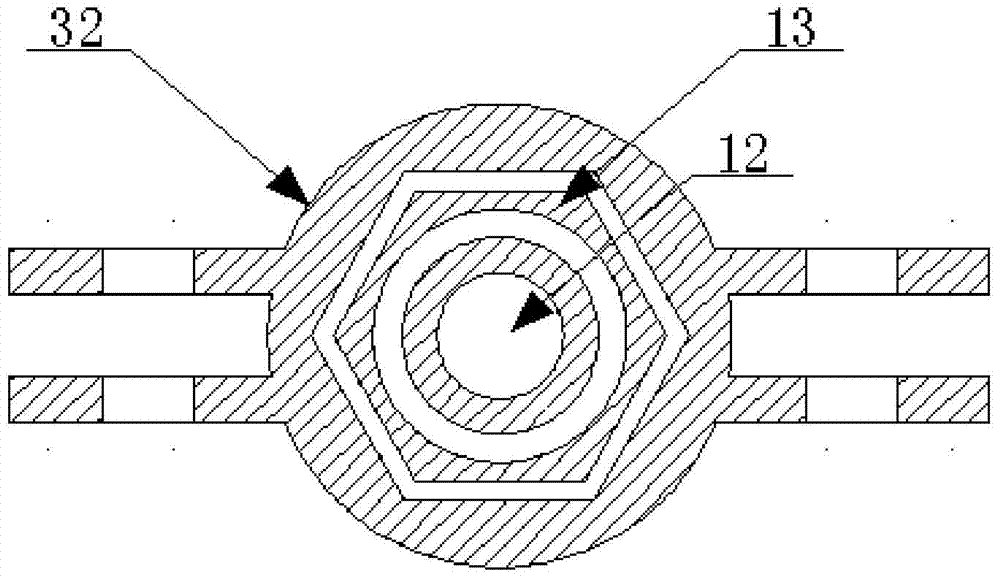

PVC pipe and thick wall steel tube composite hollow recycled concrete pile

InactiveCN105200983AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses a PVC pipe and thick wall steel tube composite hollow recycled concrete pile, which is mainly prepared from PVC pipes, a round reinforcement cage framework, thick wall steel tubes and recycled concrete, wherein the round reinforcement cage framework and the thick wall steel tubes are arranged in PVC pipes, and the three are concentrically arranged; recycled concrete is poured into the PVC pipes and the thick wall steel tubes; the built-in thick wall steel tubes are capable of improving single-pile bearing capacity and non-deformability by a large margin; the externally covered PVC pipes are capable of effectively preventing pile bodies from being corroded and improving pipe body durability; at the same time, the recycled concrete inside can be jointed restrained by the PVC pipes and spiral stirrups, thus further enhancing composite pile bearing capacity; and waste concrete can be used as recycled aggregate, thus being favor of popularization and application of recycled concrete in building foundation engineering. In short, the PVC pipe and thick wall steel tube composite hollow recycled concrete pile has the advantages of good pile formation quality, high bearing capability, good non-deformability, good durability, small environment influence, quick construction speed and the like.

Owner:GUANGXI UNIV

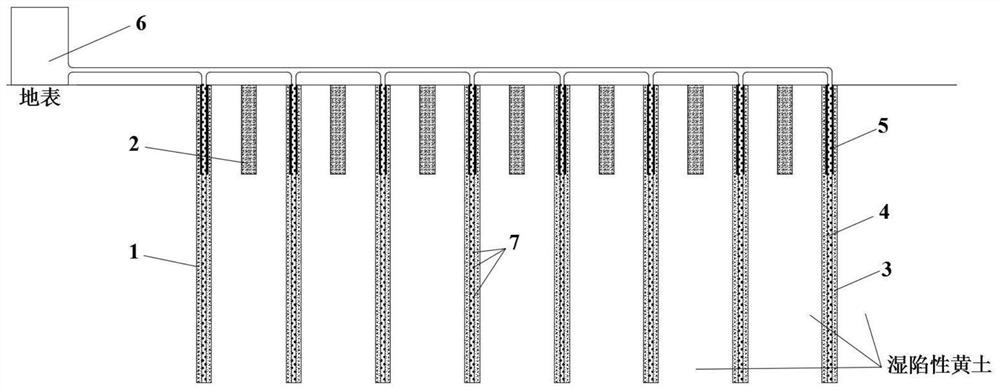

Combined treatment construction method for collapsible loess foundation

InactiveCN103790148ALarge processing depthLarge carrying potentialBulkheads/pilesSoil preservationLoad resistanceTherapeutic effect

The invention relates to a combined treatment construction method for a collapsible loess foundation. The method comprises the following steps of firstly, performing impacting and pretreatment on a collapsible loess land by using a conical pounder and treating the foundation; secondly, expanding lime-soil compaction piles by using a drilling ram and performing pile repairing and reinforcing; and finally, performing post grouting construction on cast-in-place piles. The combined treatment construction method for the collapsible loess foundation has the advantages that the method is economical and environment-friendly; the treatment depth is great; the treatment effect is high; the bearing potential is high; and the complicated load resistance is high. By using the method, various negative effects caused by collapsibility of a deep and thick collapsible loess land can be eliminated, and requirements of an upper high-rise building on the bearing capacity and the sedimentation of the foundation can be met.

Owner:XIAN UNIV OF SCI & TECH

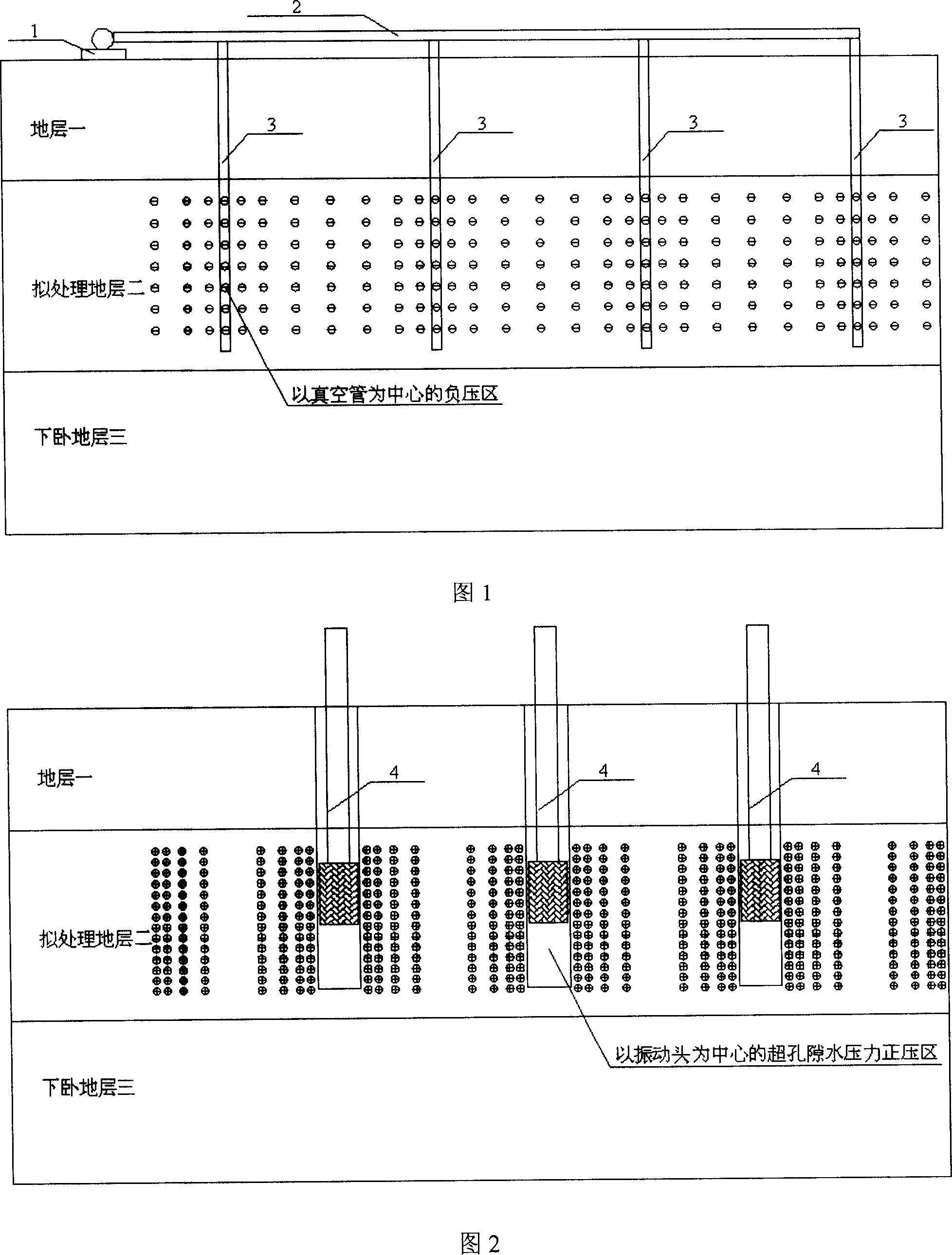

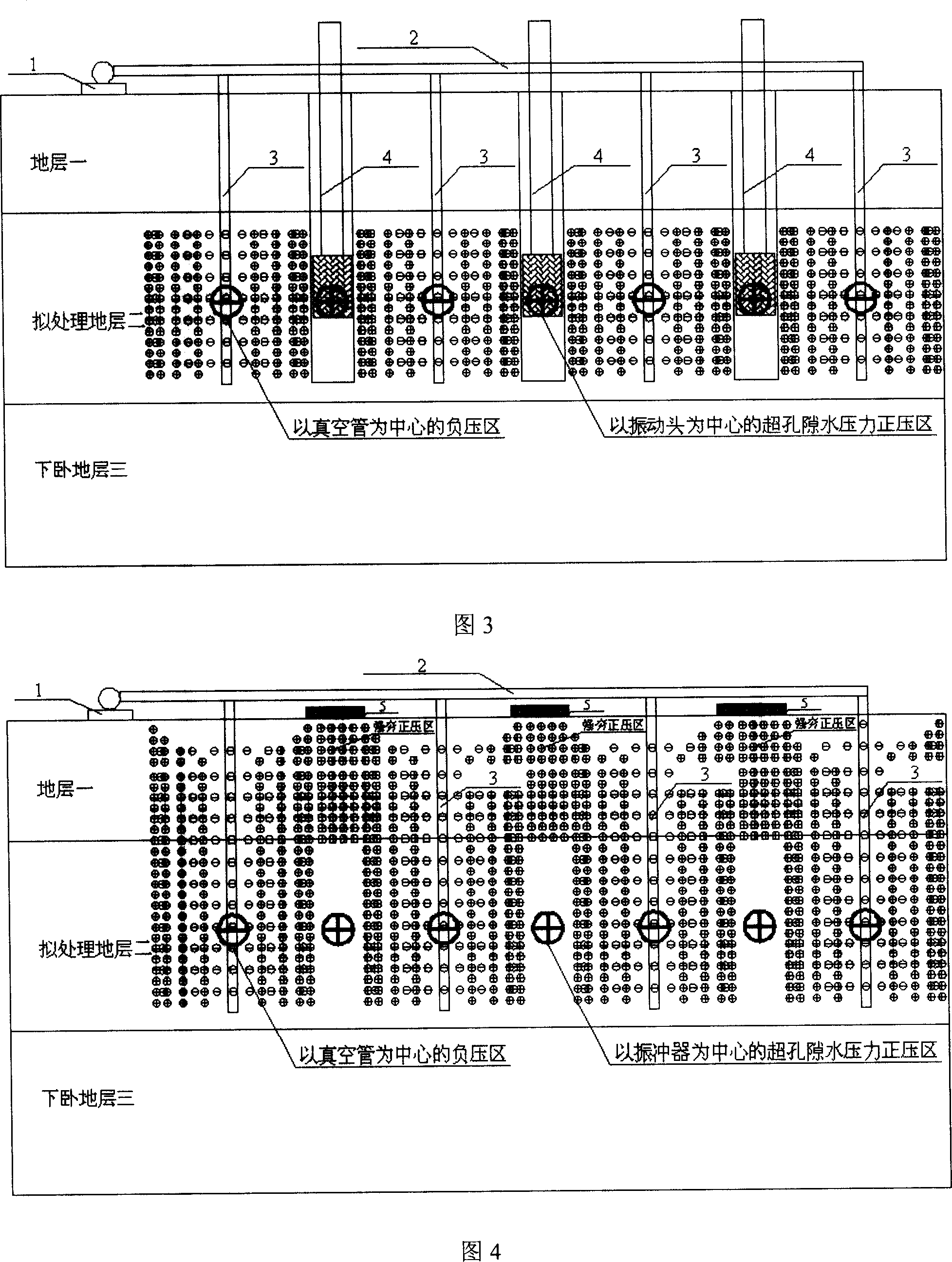

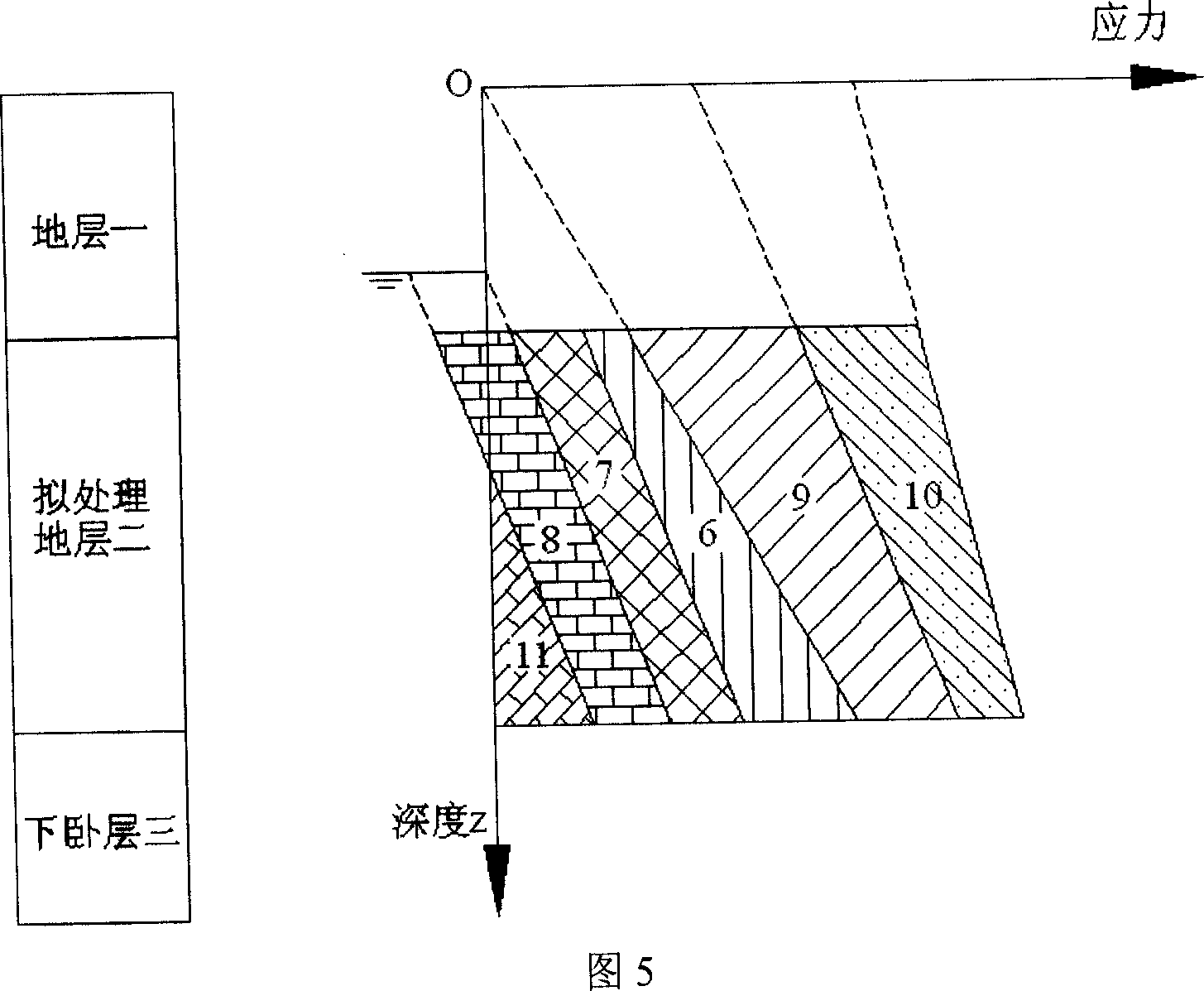

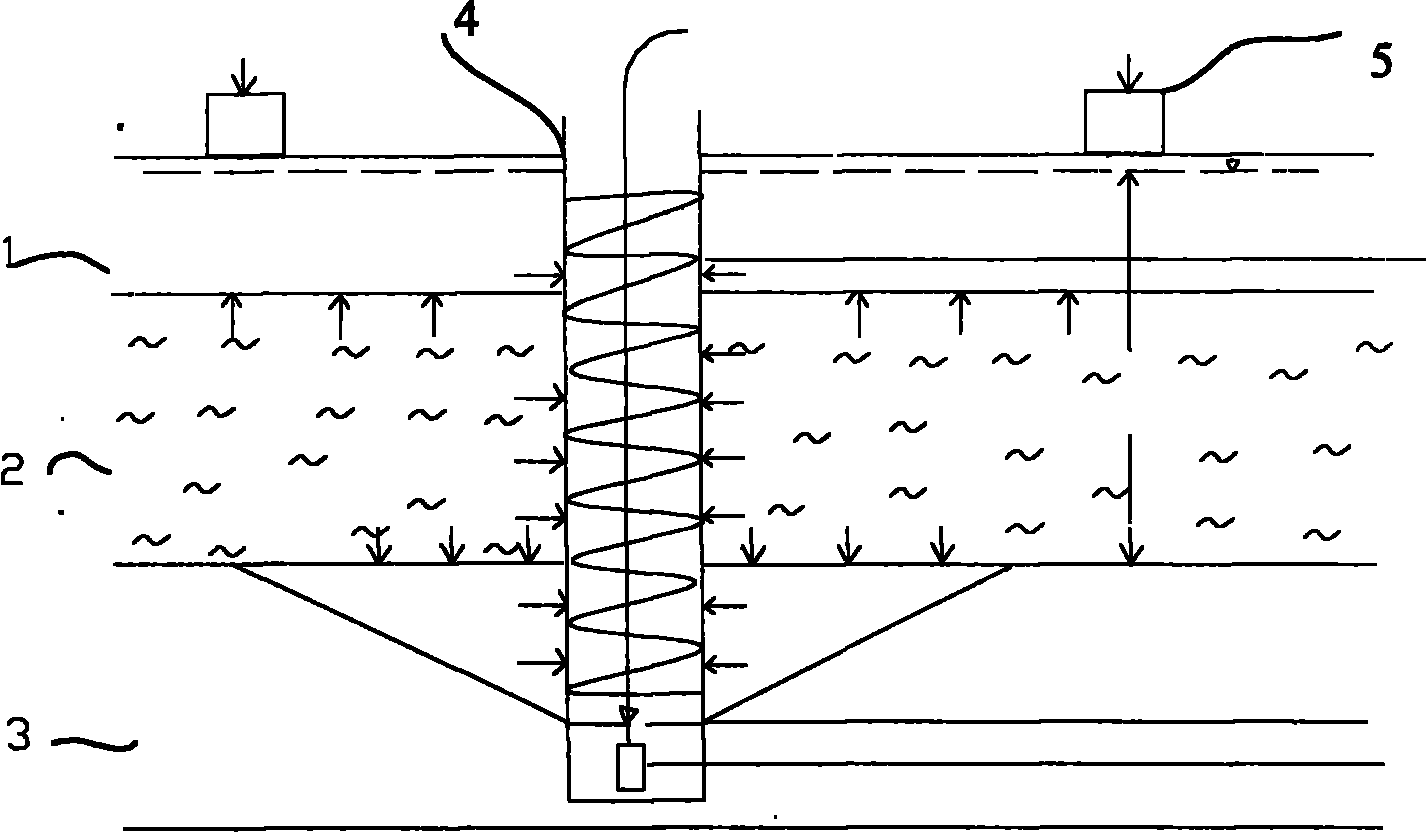

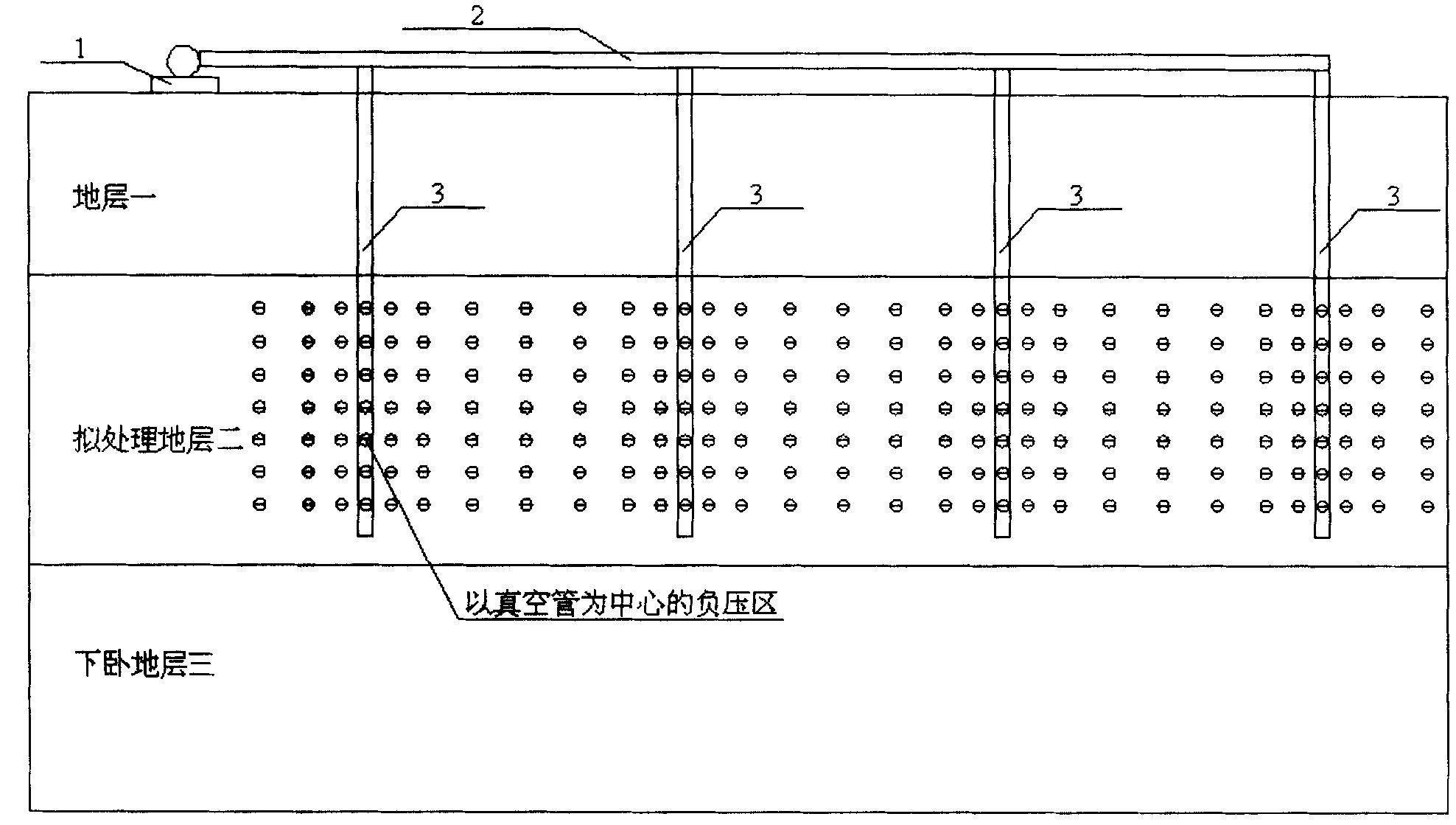

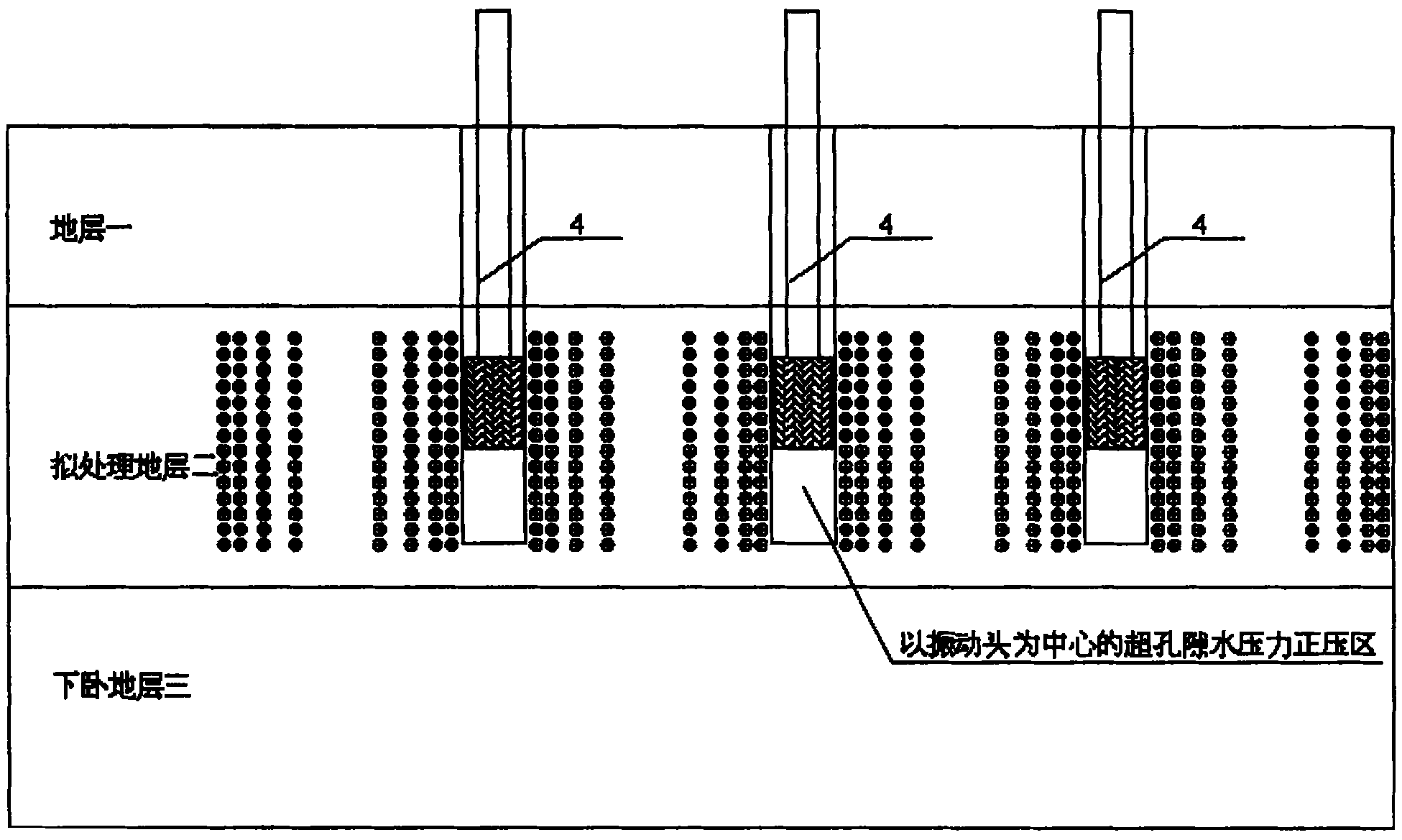

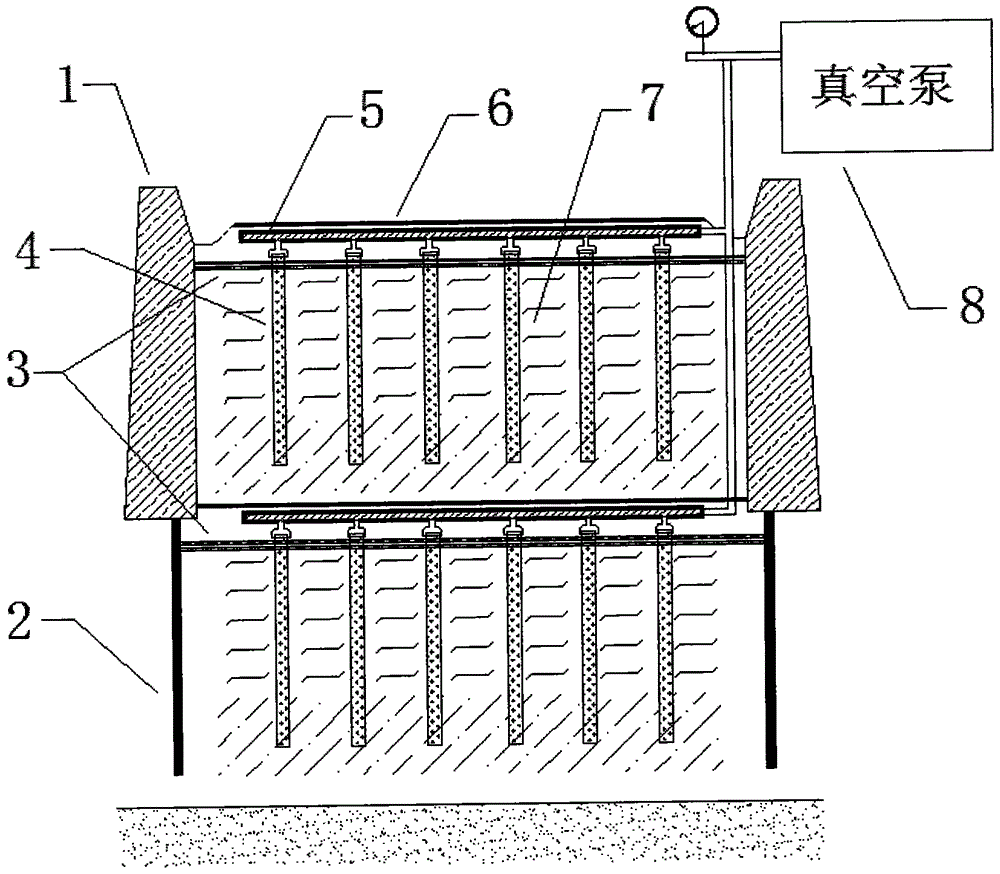

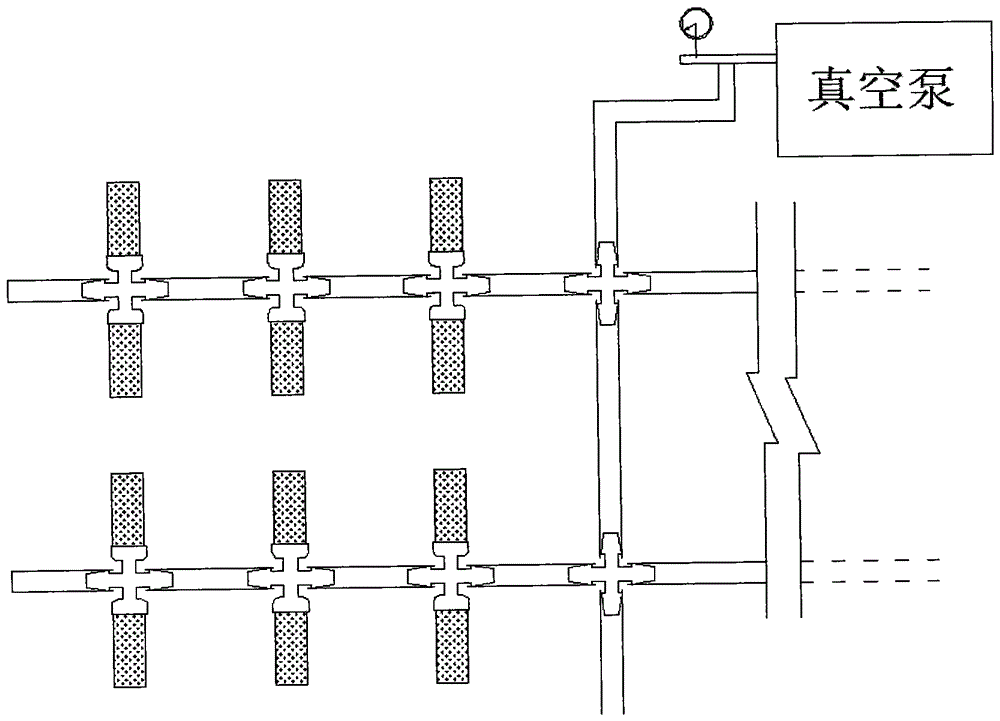

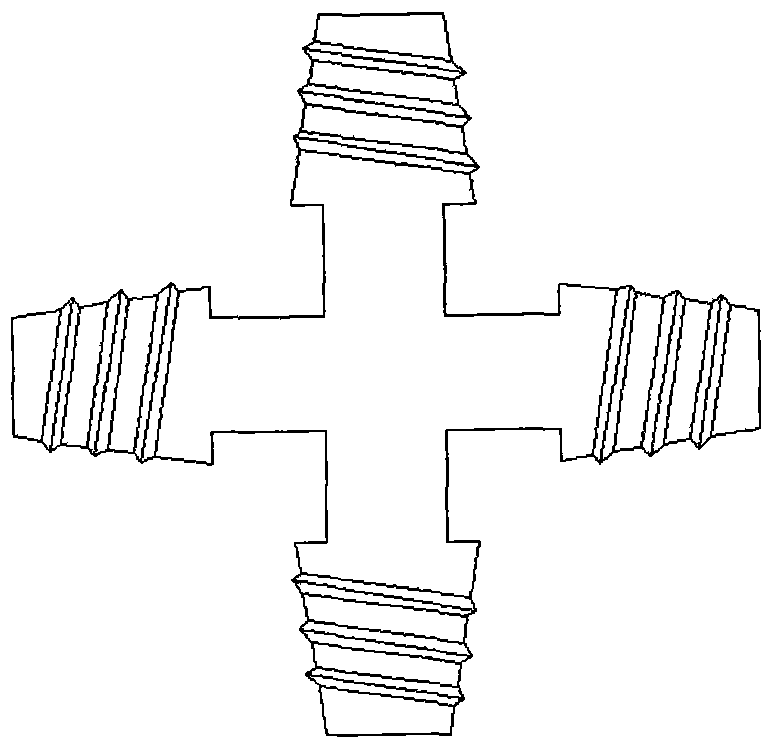

Vibration pressurizing quick solidification soft foundation processing method

ActiveCN101024949AShort construction periodLow costSoil preservationPositive pressureEconomic benefits

The invention discloses a processing method for quickly concreting soft groundsill by vibrating pressurization, characterized in: firstly deposing well sites according to the required clearances and depths and vacuumly pumping water in the to-be-processed stratum to form vacuum negative pressure; when making vibrate-impacting pressurization in the stratum according to the required clearances and depths, forming positive pressure; synchronously making vacuum water pumping and vibration above once and overlapping negative and positive regions and forming higher hydrodynamic force gradient, and finally finishing quick concretion of soft soil in short time. And its beneficial effects: having less deposition after processing, and having advantages of short processing time, better processing effect, lower manufacturing cost, etc, and having good economic benefits and wide application prospect.

Owner:CCCC ROAD & BRIDGE CONSULTANTS

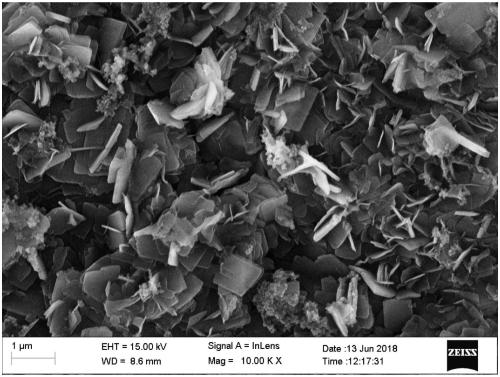

Organic-inorganic hybrid adsorbent with hierarchical structure, preparation method and application thereof

ActiveCN109046292AShort manufacturing timePromote polymerizationOther chemical processesWater contaminantsFerrous saltsSorbent

The invention relates to an organic-inorganic hybrid adsorbent with a hierarchical structure, a preparation method and application thereof. The preparation method comprises the steps of adding ion exchange resin, dopamine, copper sulfate and hydrogen peroxide into a Tris-HCl buffer solution, performing dark reaction at room temperature, separating the ion exchange resin having an adhesive polydopamine on the surface, then adding the resin into a ferrous salt solution, reacting at room temperature, separating the ion exchange resin carrying ion, adding thiol protease and the ion exchange resincarrying ion into a PBS buffer solution, reacting at room temperature, separating and naturally drying the solid material, thus obtaining the organic-inorganic hybrid adsorbent with a hierarchical structure. The prepared adsorbent can efficiently adsorb lead ions in water, solves the problem that the conventional powder nano-adsorbent is easy to agglomerate and lose and difficult to separate fromthe treated water body when lead-containing wastewater is treated, and is suitable for treating heavy metal sewage.

Owner:YANSHAN UNIV

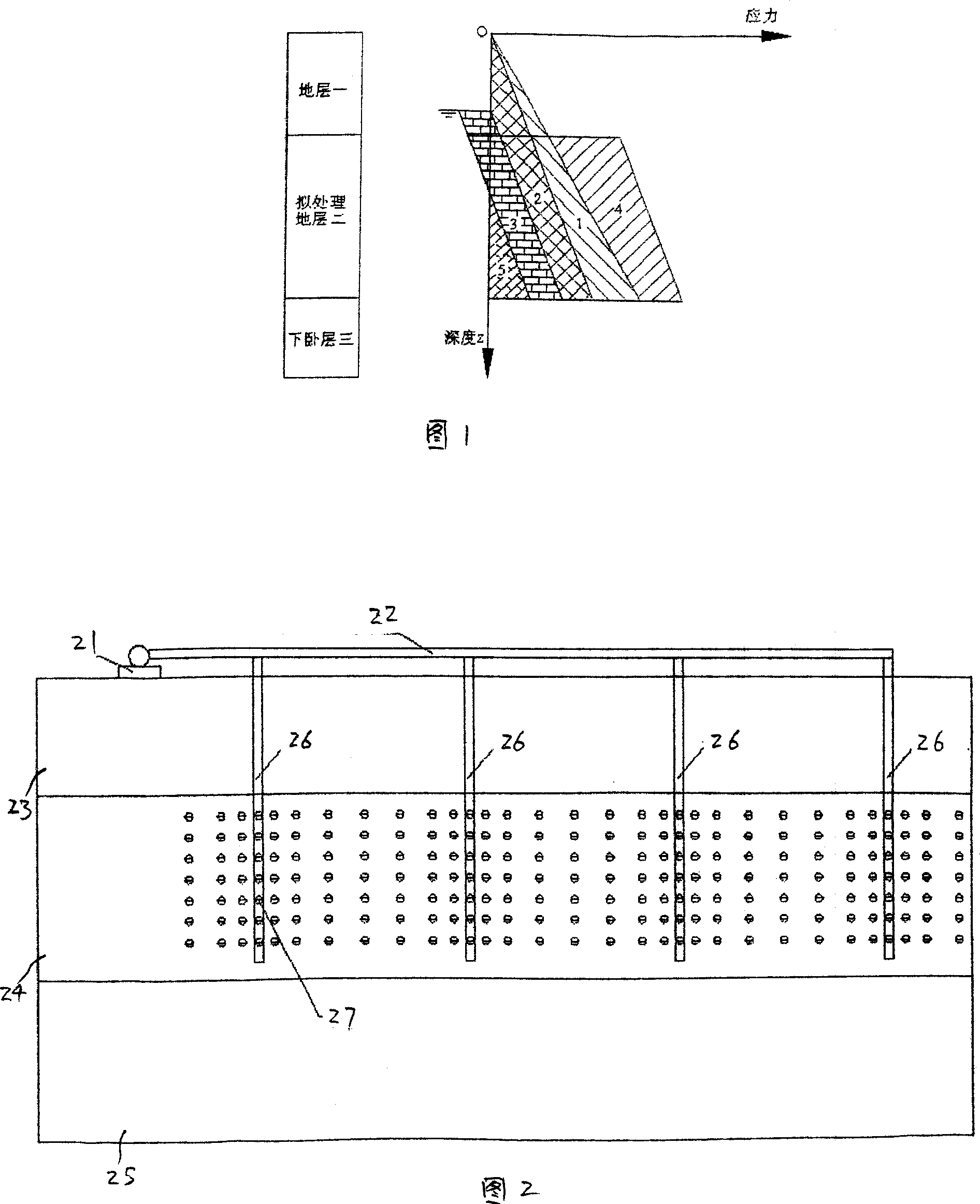

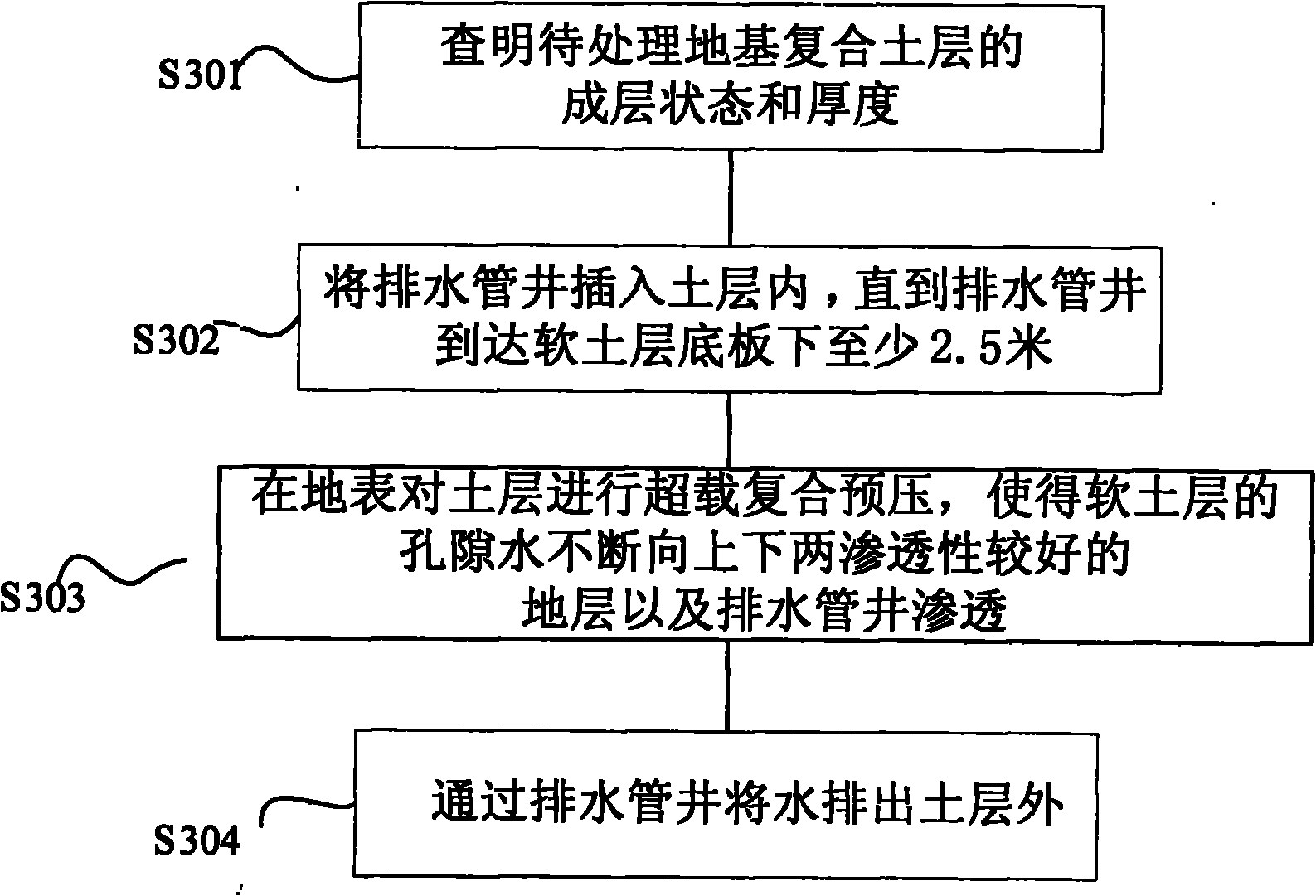

Soft soil foundation treatment method by three-dimensional drainage power pre-pressing consolidation

The invention provides a soft soil foundation treatment method by three-dimensional drainage power pre-pressing consolidation, comprising the following steps: (1) ascertaining the layering status and the thickness of a foundation compound soil layer to be processed; (2) inserting a drainage tube well into the soil layer until the drainage tube well reaches at about at least of 2.5m under the baseboard of the soft soil layer; (3) performing overload compound prepressing on the soil layer on earth surface so that pore water of the soft soil layer continuously permeates towards an upper layer and a lower layer with good permeability and the drainage tube well; and (4) discharging water outside the soil layer through a drainage pipe. The major innovation on the existing single-side drainage consolidation, vacuum well point dewatering and dynamic consolidation, and a dewatering prepressing method is a novel power drainage consolidation method with large, fast and effective processing depth; and the treatment method has good application prospect on soft soil foundation treatment of deltas, estuaries and coastal areas with similar sedimentary characteristics.

Owner:郭艳景 +1

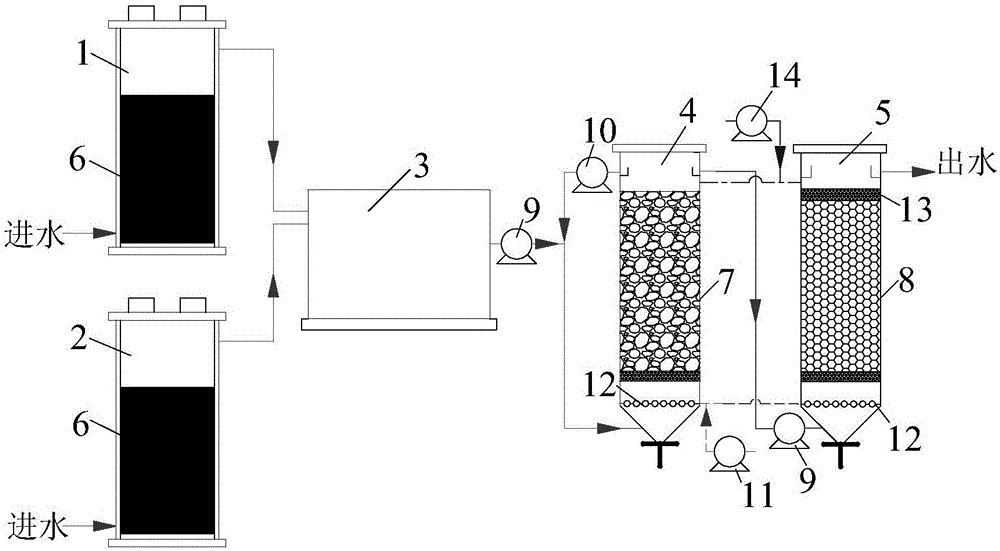

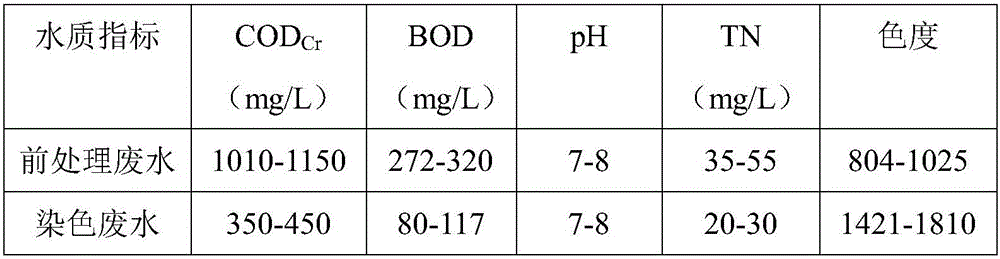

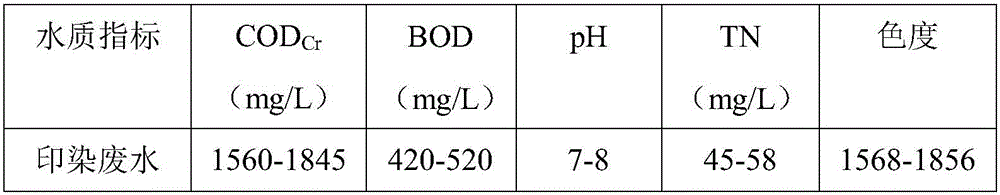

Treatment device and method for strengthening of removal effect on hardly degradable substances in printing and dyeing wastewater

ActiveCN106186306AGood removal effectHigh quality carbon sourceTreatment using aerobic processesSpecific water treatment objectivesMicroorganismSludge

The invention discloses a treatment device and method for strengthening of the removal effect on hardly degradable substances in printing and dyeing wastewater. The printing and dyeing wastewater to be treated sequentially passes through an anaerobic UASB tank, a mixing tank, an internal circulating BAF tank and an upward flowing type BAF tank, the anaerobic tank adopts anaerobic granular sludge dominated by mesophile microorganisms, the internal circulating BAF tank operates in an upward flowing mode, and the packing surface is acclimatized and enriched with shortcut denitrifying bacteria and microorganisms, and the upward flowing type BAF tank adopts an embedded and fixed denitrifying bacterium and microorganism PEG carrier as a packing. The treatment device combines with the anaerobic granular sludge, a biological membrane colonization packing and an embedded microbial carrier technology, makes full use of the characteristics of anaerobic UASB and BAF devices, can avoid the phenomenon that microorganisms are impacted by the water, and also increases the wastewater treatment depth. The treatment device strengthens the removal effect on the hardly degradable substances in the printing and dyeing wastewater, the wastewater chroma removal rate of a UASB reaches 80%, the COD and BOD removal rate of a BAF reaches 78%, and treatment device has the advantages of being stable in treatment effect, low in sludge production volume, simple in operation and management and the like and has a popularization value.

Owner:HOHAI UNIV

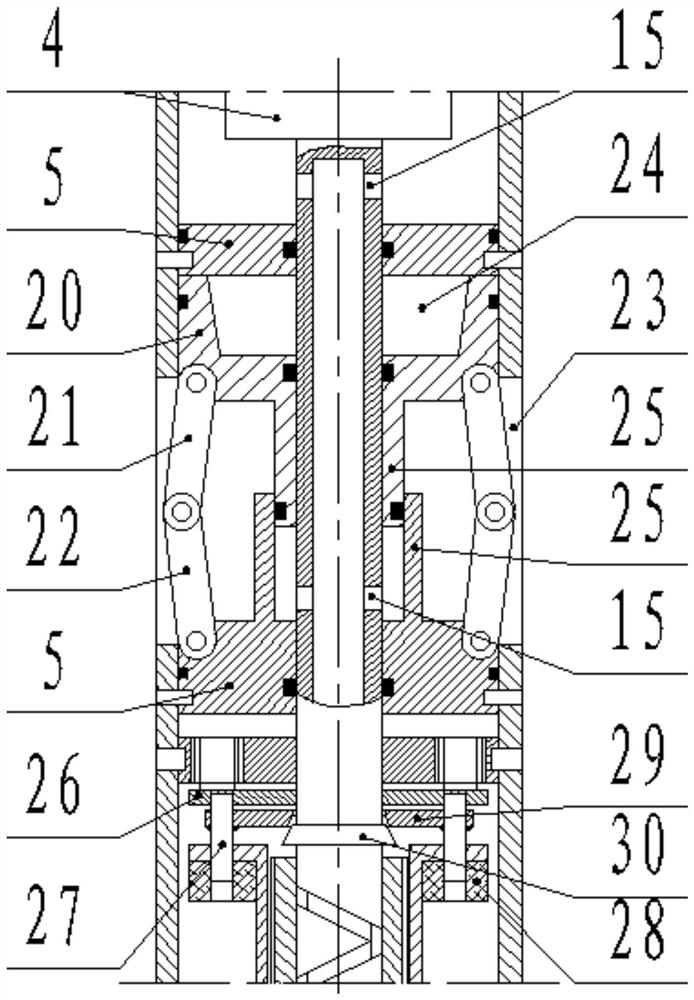

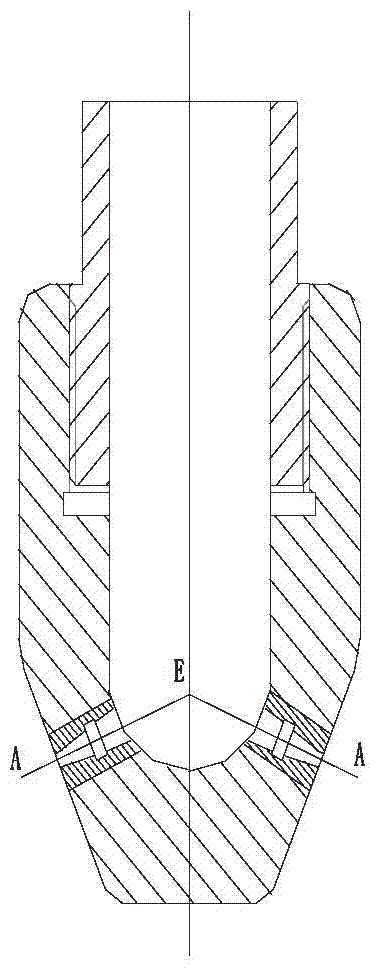

Hydraulic rotating jet flow blockage remover

ActiveCN104806182ANo dischargeNo pollution in the processDrilling rodsFlushingEngineeringScrew thread

The invention discloses a hydraulic rotating jet flow blockage remover, which comprises a screw rod, wherein the middle part of the screw rod is a threaded section, left-hand screw threads and right-hand screw threads are arranged on the threaded section, an upper centralizer is also arranged on the screw rod, the upper centralizer is positioned at the upper side of the threaded section, a case is arranged at the outer sides of the threaded section and the upper centralizer in a sleeving way, the upper end of the case is connected with a short joint, the lower end of the case is connected with a connecting pipe, the lower end of the connecting pipe is connected with a connecting end cover, a base is arranged in the connecting pipe, two pins are fixedly arranged on the base, and are respectively inserted into the left-hand screw threads and the right-hand screw threads, in addition, the position difference of the two pins is 1.5 thread pitches, the bottom of the screw rod is connected with a rotating spray head, and a lower centralizer is arranged between the rotating spray head and the connecting end cover. The hydraulic rotating jet flow blockage remover has the advantages that the structure is simple, in addition, the jet hole section of the whole oil layer can be thoroughly cleaned, the cleaning quality is high, no damage occurs, the cleaning speed is high, and the efficiency is high.

Owner:XI'AN PETROLEUM UNIVERSITY

Comprehensive treatment method of soft foundation

InactiveCN105200973ADiffuse Horizontal DrainageEnhance horizontal drainageSoil preservationTreatment effectEngineering

The invention discloses a comprehensive treatment method of a soft foundation. The comprehensive treatment method comprises the following steps of firstly, designing and constructing vibro-replacement stone columns; secondly, designing, distributing and precipitating a drainage system for vacuum well points among the columns; thirdly, designing and constructing a broken stone hardcore; fourthly, designing and constructing low-energy dynamic consolidation; fifthly, leveling the broken stone hardcore. The comprehensive treatment method disclosed by the invention is a novel comprehensive treatment method of the soft foundation, which is formed by organically combining four foundation treatment techniques of vibro-replacement stone column, vacuum well point precipitation, a hardcore method and dynamic consolidation on the basis of the characteristics of a soft soil layer, and is great in treatment depth and improvement amplitude of foundation bearing capacity, and has technical and economic advantages of great improvement amplitude of the foundation bearing capacity, low construction cost and good treatment effect.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

A New Type of Hydraulic Jet Blocking Removal Device

ActiveCN112240179BEasy to removeSimple construction processCleaning apparatusFluid removalJet flowReciprocating motion

Owner:大庆永铸石油技术开发有限公司

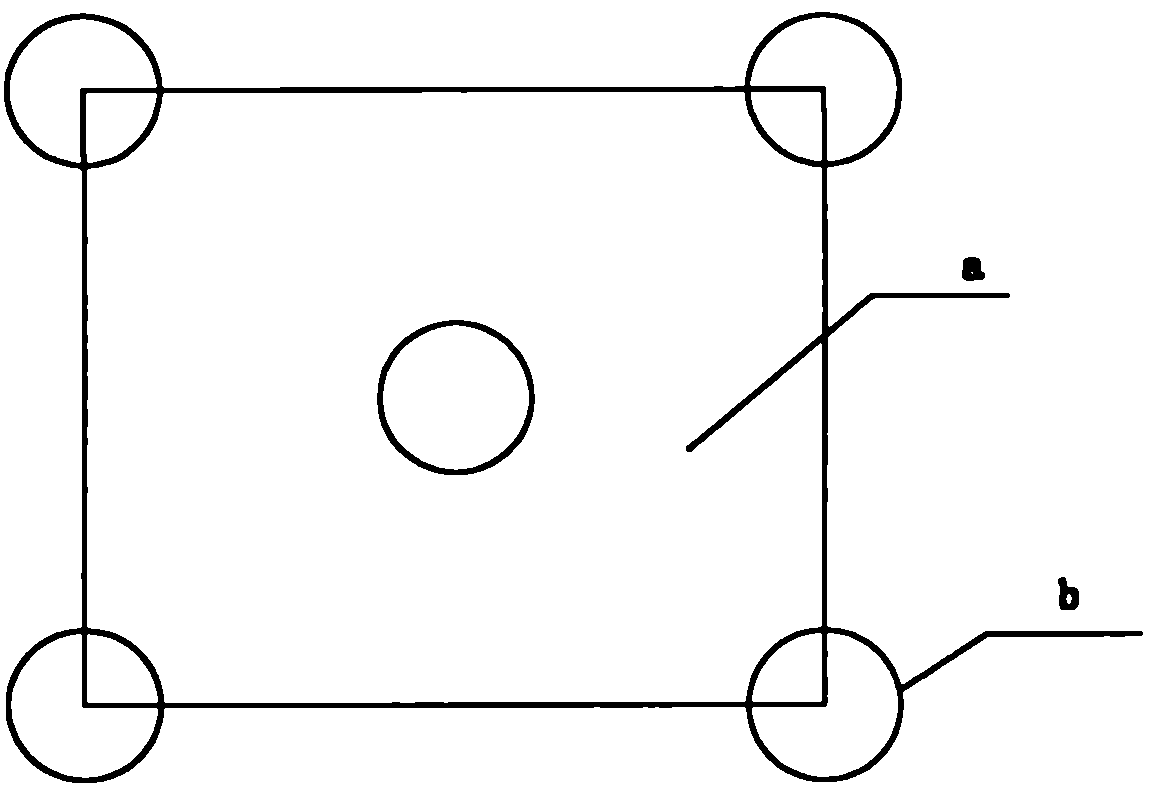

Composite pile structure suitable for coastal deep reclaimed soil foundation treatment and construction method

InactiveCN106245643ALarge processing depthImprove bearing capacityBulkheads/pilesSoil preservationReinforced concretePre stress

The invention discloses a composite pile structure suitable for coastal deep reclaimed soil foundation treatment and a construction method. The structure comprises prestressed concrete thin-walled hollow square piles, nail type bidirectional agitating mixing piles and an upper portion mattress layer. The prestressed concrete thin-walled hollow square piles are long rigid piles and penetrate through a reclaimed soil layer to a supporting layer for controlling settlement, and meanwhile reinforced concrete bearing platforms are arranged at the tops of the prestressed concrete thin-walled hollow square piles and used for adjusting the pile soil load sharing ratio, so that the high bearing capacity performance of the prestressed concrete thin-walled hollow square piles is brought into full play. The nail type bidirectional agitating mixing piles are flexible piles, based on the composite foundation stress transfer and bearing optimizing principle, the upper portion reclaimed soft soil layer with large additional stress is reinforced with more attention, and the upper pile body replacement rate is increased. The prestressed concrete thin-walled hollow square piles and the nail type bidirectional agitating mixing piles are arranged alternately, the requirement for the bearing capacity and post-construction settlement can be met, and the project construction cost can be reduced.

Owner:江苏筑港建设集团有限公司 +1

Medicine feeding device

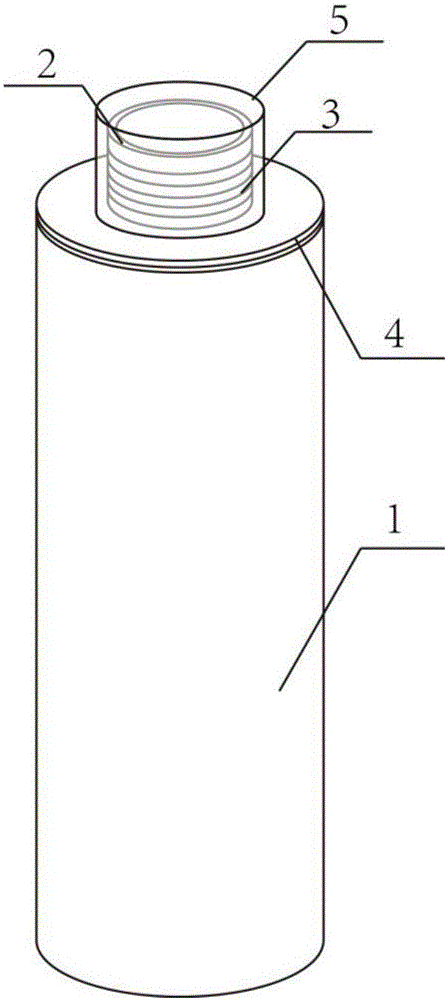

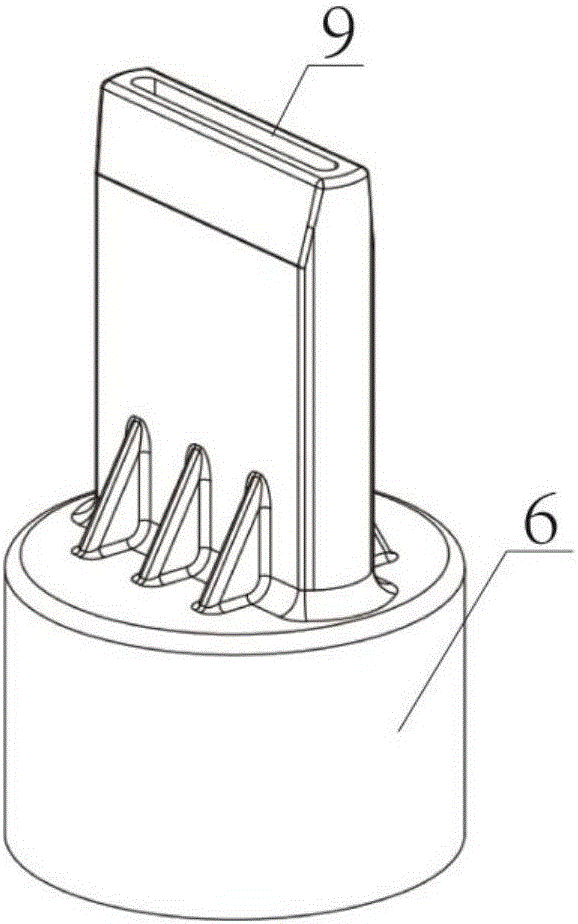

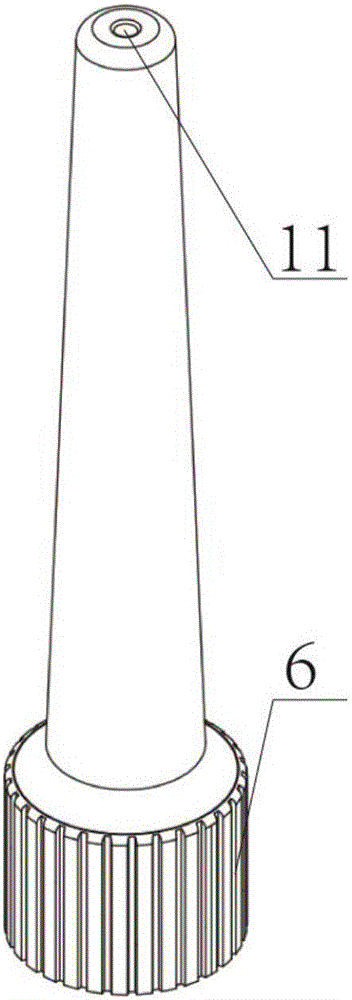

PendingCN106215313ARelieve painIncrease the smear area onceMedical devicesExchange timeCross infection

The invention discloses a medicine feeding device characterized in that the medicine feeding device is provided with a medicine storing cylinder; the medicine storing cylinder is in a cavity structure; the medicine storing cylinder is a soft housing; one end of the medicine storing cylinder is enclosed and the other end is provided with a projected round medicine discharging port; an external thread is formed on the outer wall of the medicine discharging port; an annular sealing pad is mounted under the medicine discharging port; a cover lid is mounted on the medicine discharging port; the medicine feeding device has a connection part and a medicine discharging nozzle; the medicine feeding device is in a cavity structure; an internal thread matching with the external thread is formed in the inner wall of the connection part; and the medicine discharging nozzle is flat and inclined and an inclined included angle (Alpha) is 0 to 40 degrees. The medicine feeding device is simply structured; medicine feeding devices of various structures can be suitable for various infected parts; cross infection can be prevented; and medicine exchanging time can be reduced and union of infected parts can be accelerated.

Owner:TIANJIN ZHONGJIAN AIHE MEDICAL TECH +1

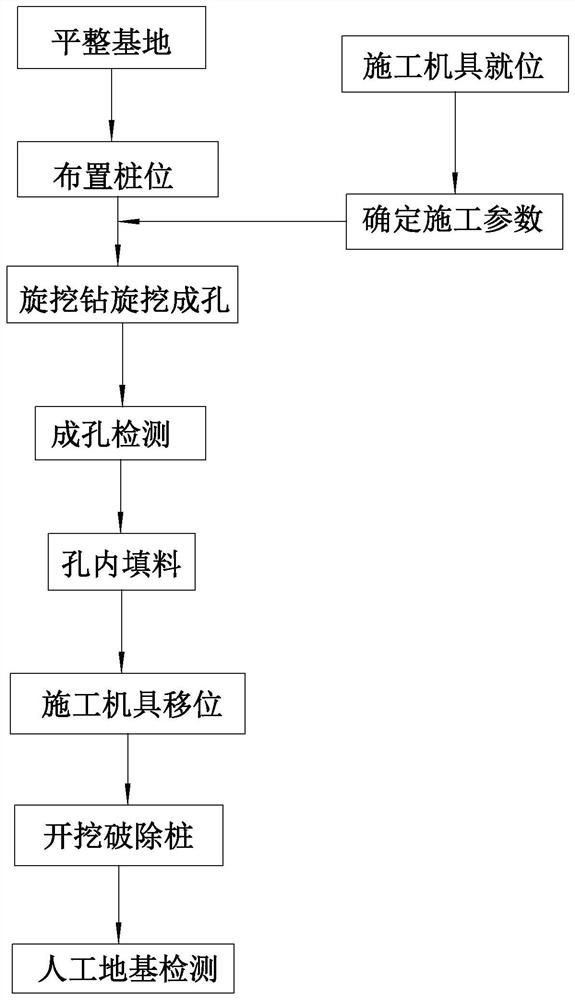

SDDC pile ground structure construction method

InactiveCN111648354AUniform stiffnessImprove bearing capacityBulkheads/pilesSoil preservationArchitectural engineeringHigh kinetic energy

The invention relates to an SDDC pile ground structure construction method. A rammer carries out layered tamping and compacting on the deep layer of a foundation from bottom to top, backfill is forcedto be extruded through tamping work with high kinetic energy, super pressure intensity and strong compaction, and dense pile bodies are formed. Meanwhile, the side face of the rammer generates extremely high dynamic passive earth pressure, and earth among piles is strongly compacted and reinforced. Earth around the piles is compacted to form a forced compacted area, a compacted area and a compacted influence area, so that a foundation bears high compressive pre-press, no obvious compressive deformation is generated when the treated foundation is soaked with water or loaded, and the mechanicalproperty of the foundation is improved. Under the tamping action of high kinetic energy, super pressure intensity and strong compaction on the SDDC piles, the earth stress is slowly released, and lateral restraints are generated on the earth around the piles. The lateral stress borne by the earth around the piles is slowly released after the piles are formed, the piles and the earth among the piles form a compact whole, and the treatment depth is large. The treated composite foundation is uniform in rigidity, and the bearing capacity is remarkably improved.

Owner:河南省第八建设集团有限公司

Method for treating collapsible loess foundation through combination of deep pre-soaking method and shallow compaction method

InactiveCN112942304ALarge processing depthShorten the construction periodBulkheads/pilesSoil preservationRebarGeotechnical engineering

The invention relates to the field of foundation treatment, in particular to a method for treating a collapsible loess foundation by combining a deep pre-soaking method with a shallow compaction method, and effectively solves the problems of limited treatment depth, longer construction period, lower bearing capacity after treatment and the like of the pre-soaking method. The method includes the specific operation steps that the treatment depth and the treatment range for eliminating the loess foundation collapsibility are determined; an arrangement form and hole positions of piles in the processing range are determined to form pile holes; the pile holes are used for sequentially carrying out deep-layer water soaking and drainage consolidation procedures; cement paste is injected into the pile holes, steel bars are inserted, and rigid piles are formed; within the treatment range, construction is conducted through the shallow soil body compaction method, and flexible piles are formed; and a mattress layer is laid on the upper portion of the foundation, and the rigid piles and the flexible piles are combined to form a multi-pile type composite foundation. According to the method for treating the collapsible loess foundation by combining the deep pre-soaking method with the shallow compaction method, the deep pre-soaking method is combined with the shallow compaction method, so that the deep collapsible loess foundation can be effectively and comprehensively treated, and the bearing capacity of the foundation is improved.

Owner:甘肃中建市政工程勘察设计研究院有限公司

Cement mixing pile with stiffness core capable of draining and pre-pressing firstly and then grouting as well as construction method thereof

InactiveCN102650128BEasy to sinkGuarantee the pile qualityBulkheads/pilesSoil preservationImmersed tubeDual layer

The invention relates to a cement mixing pile with a stiffness core capable of draining and pre-pressing firstly and then grouting as well as a construction method thereof. The cement mixing pile comprises a vertical draining and grouting pipe arranged in the cement mixing pile, and more than one dual-layer telescopic horizontal draining and grouting pipes arranged at intervals on the vertical draining and grouting pipe, wherein a bulk solid pile with the stiffness core is arranged in the cement mixing pile, and the length of a horizontal draining and grouting pipe in an outer layer is smaller than that of the horizontal draining and grouting pipe in an inner layer when the horizontal draining and grouting pipe is in a telescopic state. In a construction process, an upper drawn steel immersed tube is vibrated, and the horizontal draining and grouting pipe departs from the steel immersed tube and is stretched to form a horizontal draining body. According to the invention, the advantages of drainage consolidation and composite foundation methods are integrated, and foundations can be dynamically reinforced according to the construction period and the settlement requirements on the premise of lower construction cost while the bearing capacity and the processing depth of the cement mixing pile are increased.

Owner:ZHEJIANG UNIV CITY COLLEGE +2

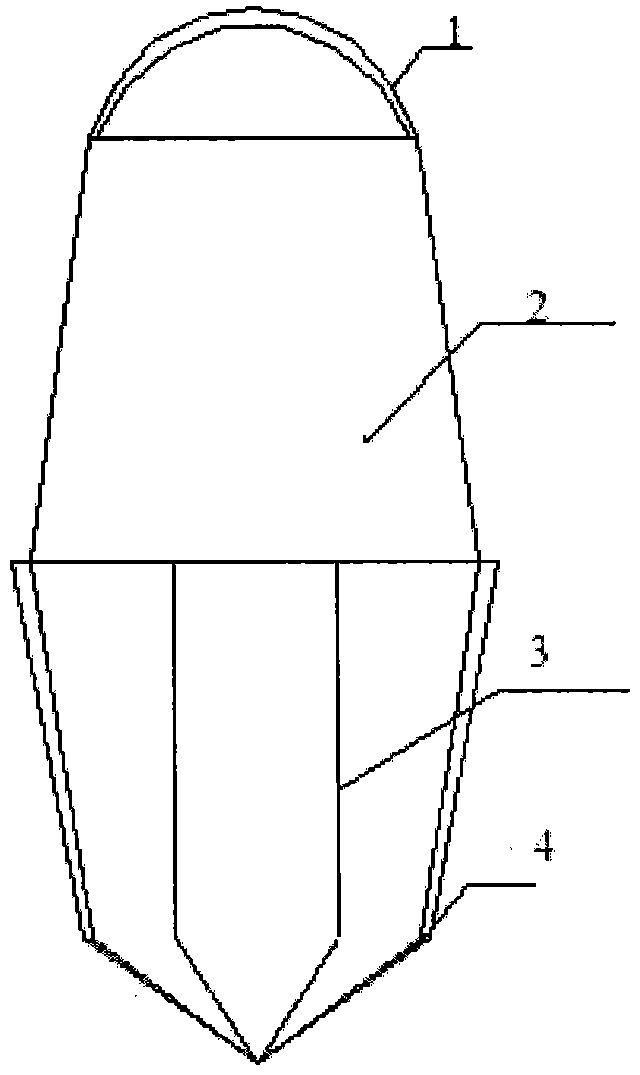

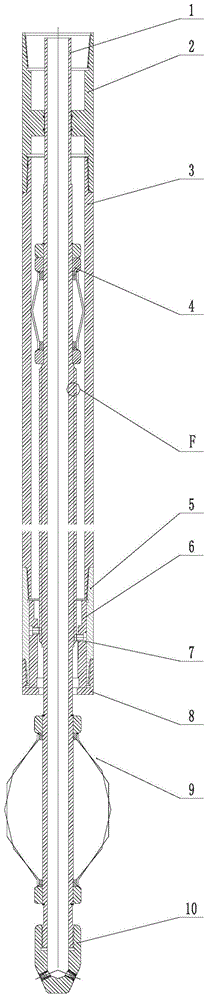

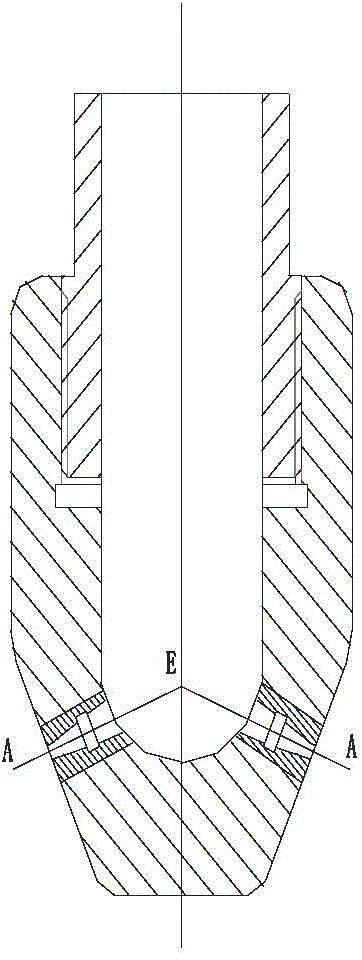

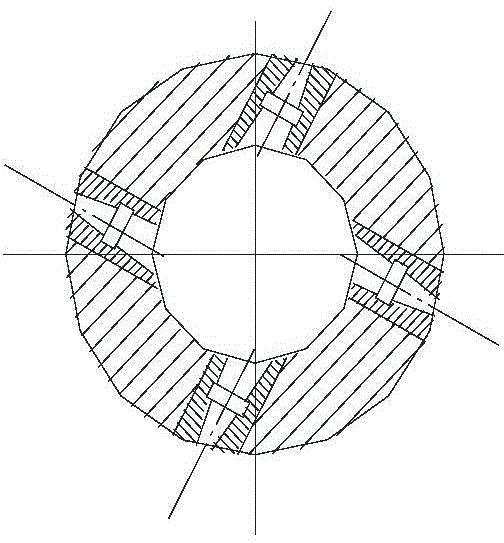

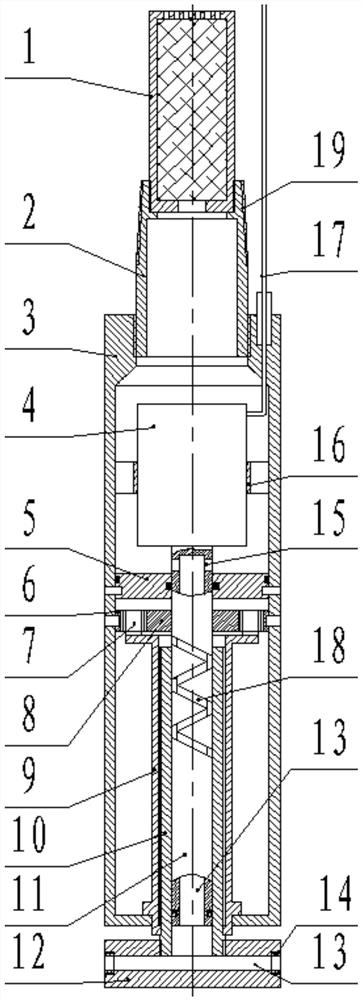

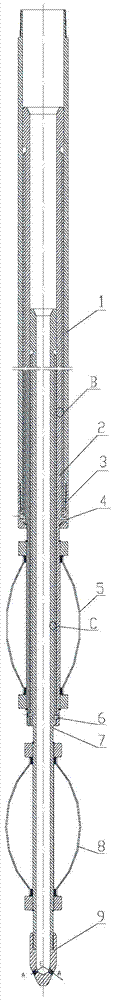

Pile mould for PCC pile and construction method for overlong PCC pile

ActiveCN101691753BImprove the bearing capacity of single pileImprove processing depthBulkheads/pilesBuilding construction

The invention discloses a pile mould for a PCC pile and a construction method for an overlong PCC pile. The pile mould consists of a feeding section, one or more segments of intermediate sections and a pile tip section which are connected sequentially; the connection among the sections can be disassembled; and inner pipes of the sections at connecting ends are longer than outer pipes, the inner pipes are connected directly at a connecting position, and the outer pipes are connected by outer pipe connecting sections. The construction method for the overlong PCC pile comprises the following steps: firstly, sinking the pile tip section of the pile mould in foundation soil, and then sinking one or more segments of intermediate sections in the foundation soil until the sunk pile mould reaches a designed pile length; and after concrete is poured, pulling out the pile mould in a subsection mode. The construction method overcomes the restriction to the length of the PCC pile, and the pile length of the PCC pile for construction is increased greatly through the connection of the pile mould of each section so as to implement the construction of the overlong PCC pile. The pile mould can adapt to requirements of different pile lengths due to the detachable pile mould, and is convenient to transport; and the sections of the pile mould are simple in connection and convenient in operation.

Owner:HOHAI UNIV

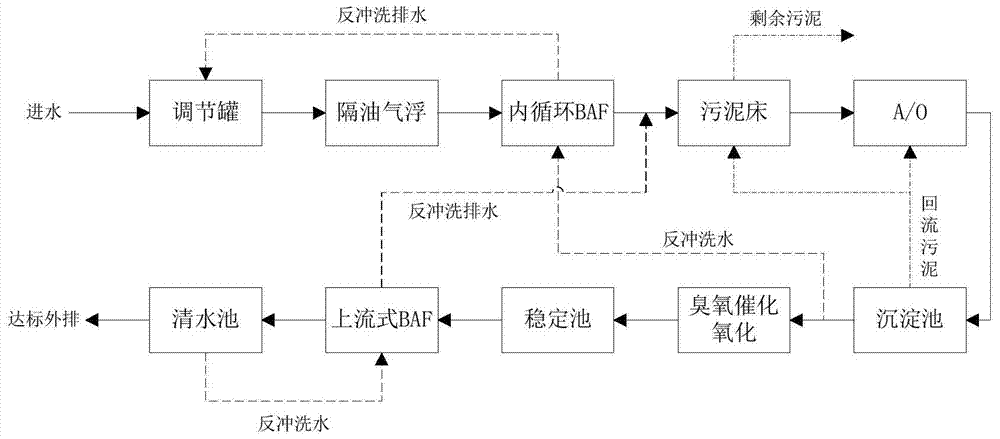

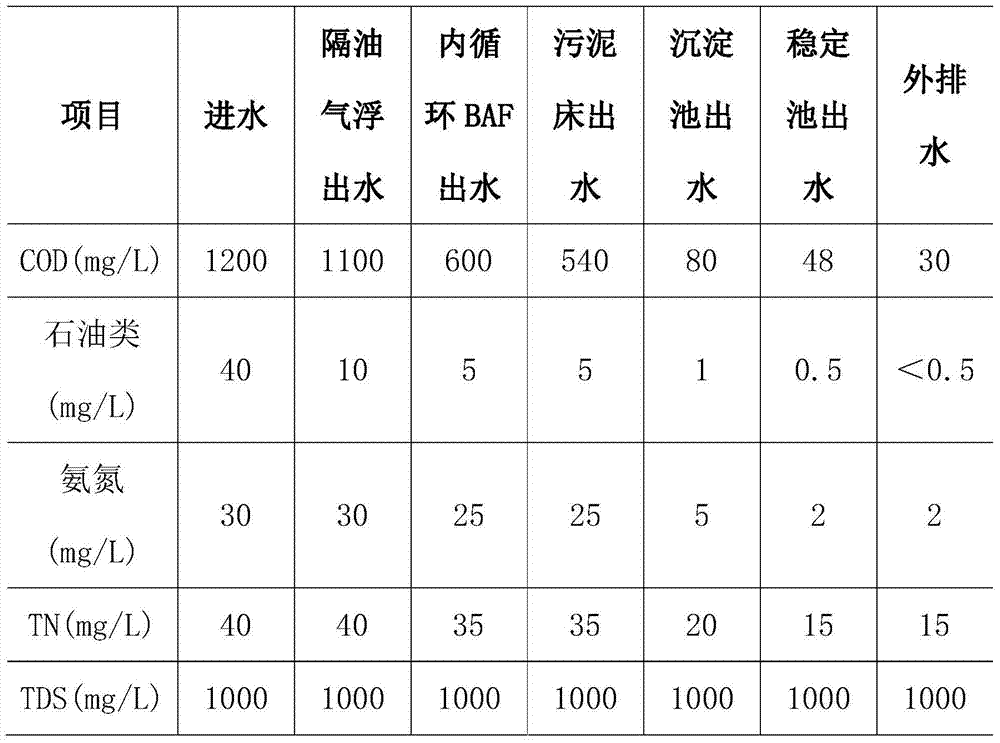

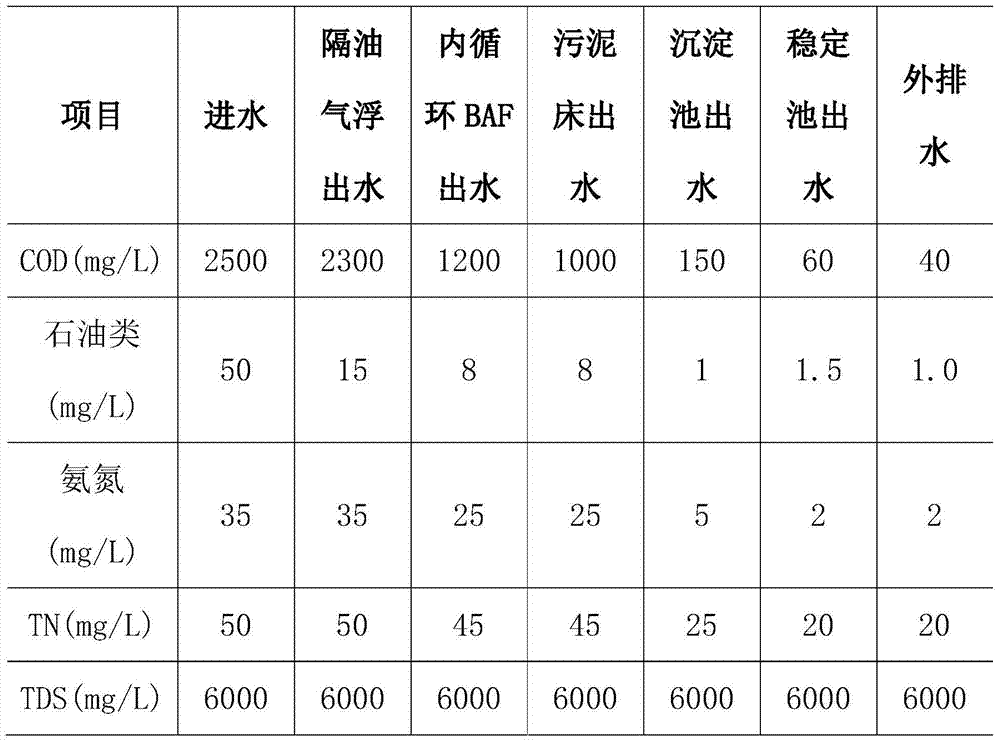

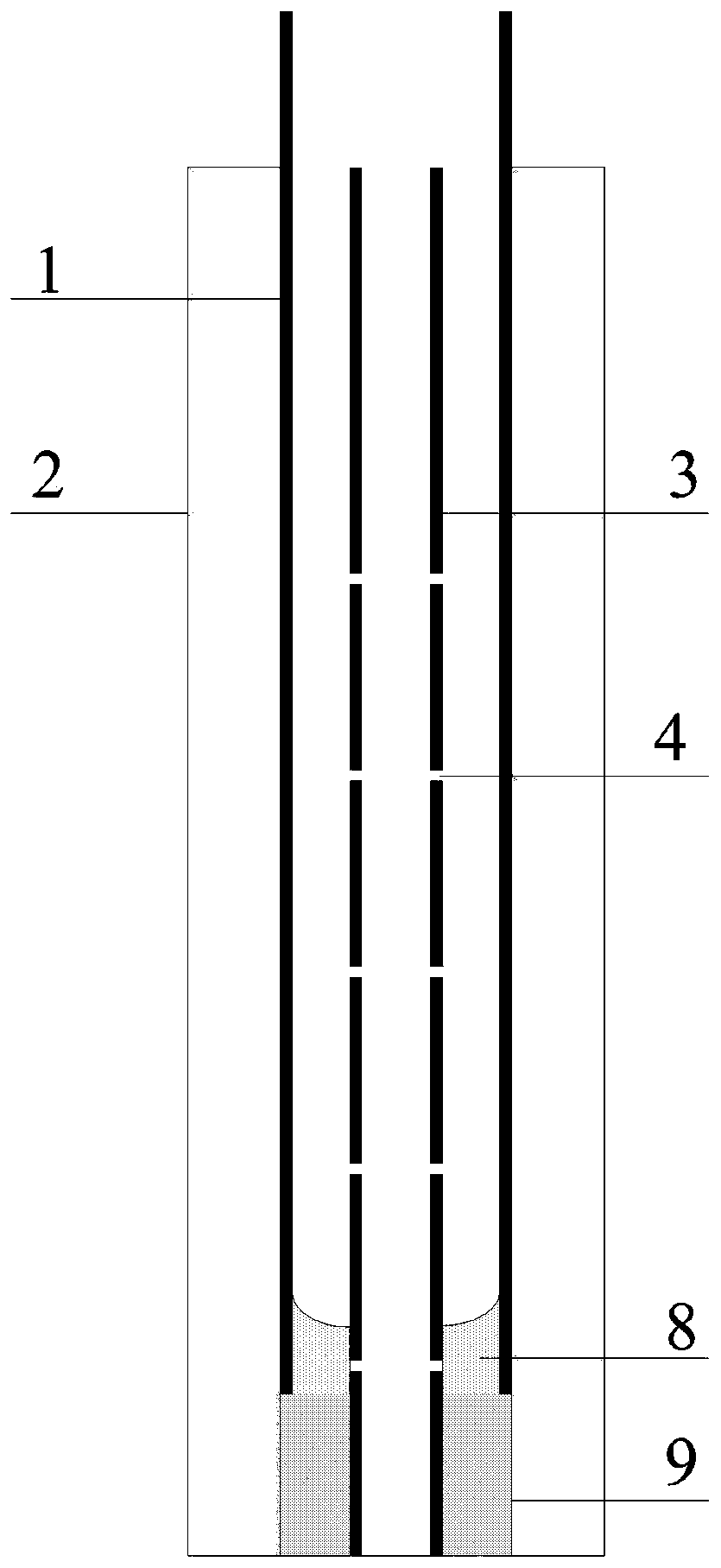

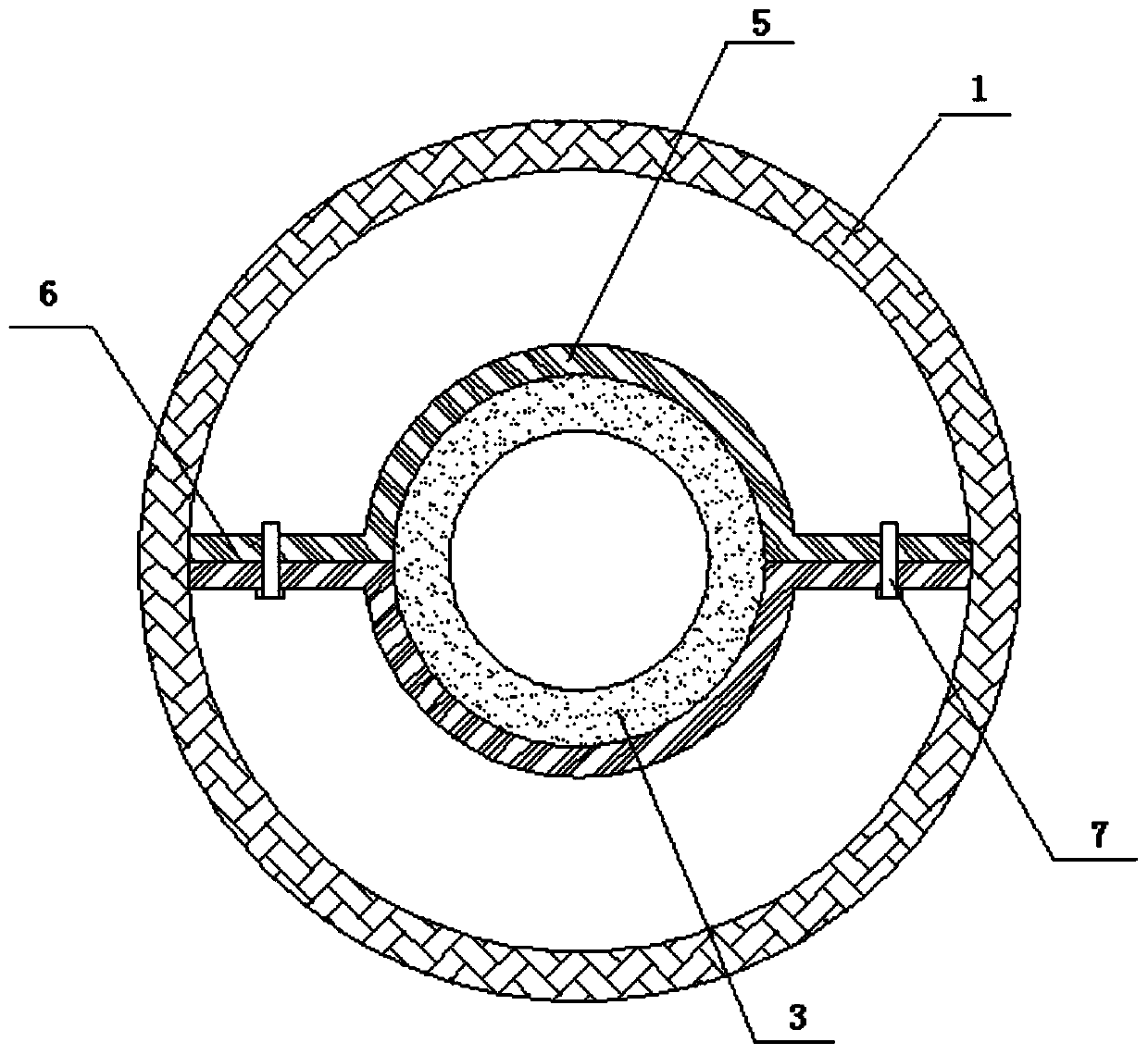

A process method for treating refinery wastewater combined with biological aerated filter

ActiveCN105439370BLarge processing depthMultistage water/sewage treatmentActivated sludgeCatalytic oxidation

The present invention relates to the technical field of industrial water treatment, and specifically relates to a process method for treating refinery sewage in combination with a biological aerated filter. The specific steps are: step 1, homogeneous adjustment; step 2, oil separation and air flotation; Circulating BAF; step 4, sludge bed adsorption; step 5, A / O + sedimentation system; step 6, ozone catalytic oxidation; step 7, upflow BAF; the final treated sewage meets the discharge standard for discharge. The process of treating refinery sewage in combination with the biological aerated filter of the present invention fully utilizes the characteristics of the BAF device, which can avoid the impact of water quality in the activated sludge tank and increase the treatment depth of sewage, which can be used for low-quality sewage , especially in the treatment of heavy crude oil refinery wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

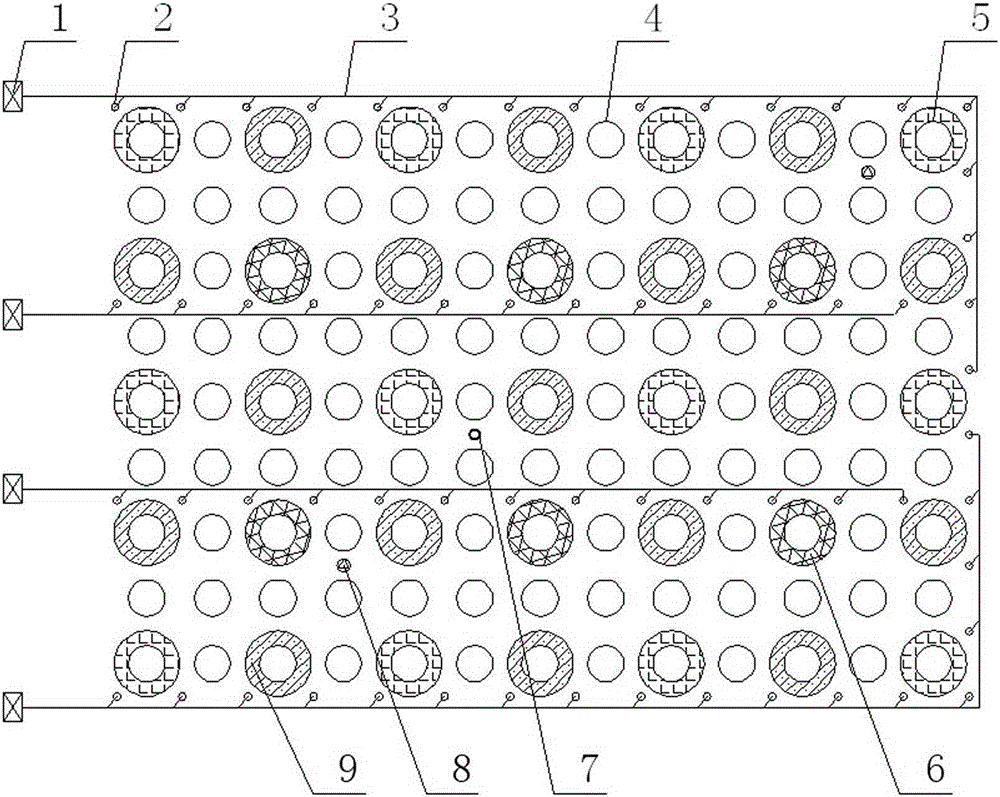

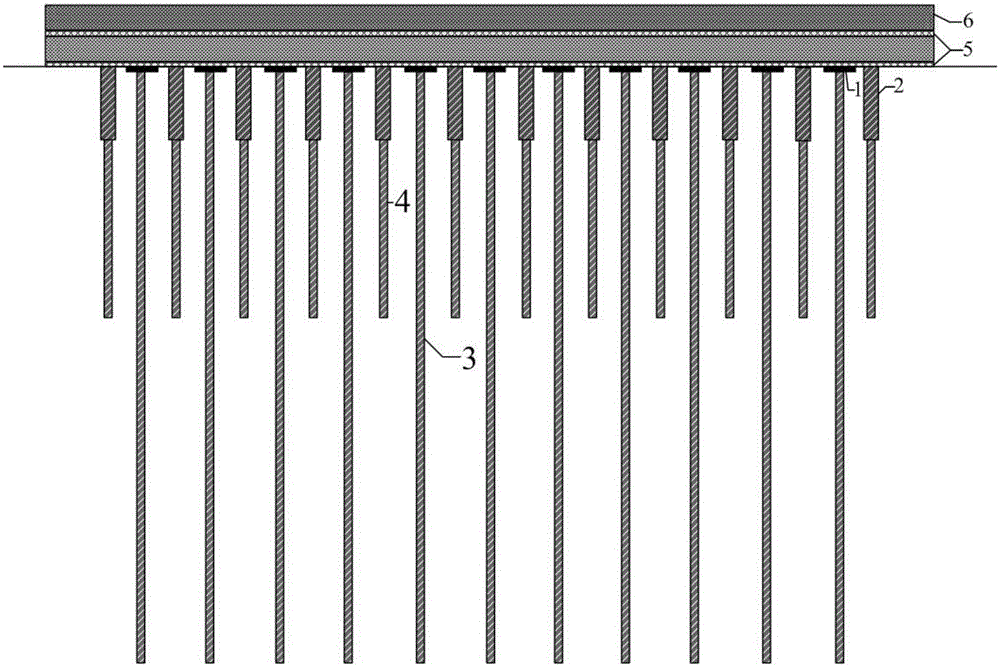

Micro steel pipe pile-sinking pipe sand gravel pile combined foundation reinforcement construction method and structure

InactiveCN110004907AImprove bearing capacityLarge processing depthBulkheads/pilesSoil preservationEngineeringCement mortar

The invention discloses a micro steel pipe pile-sinking pipe sand gravel pile combined foundation reinforcement construction method and structure. The combined foundation reinforcement structure comprises a plurality of reinforcement holes. Each of the reinforcement holes is internally provided with a micro steel pipe, and the micro steel pipes and the reinforcement holes are coaxially arranged. Annular sand gravel piles are arranged between the inner walls of the reinforcement holes and the outer walls of the micro steel pipes. A plurality of mortar outlet holes are formed in the pipe wall ofeach micro steel pipe. After cement mortar is injected into the micro steel pipes through grouting pipes, the cement mortar can penetrate into gaps of the annular sand gravel piles through the mortaroutlet holes. The micro steel pipes and the cement mortar therein solidify to form steel pipe piles, and the sand gravel piles outside the micro steel pipes are solidified into cement sand gravel piles through the cement mortar penetrating into the sand gravel gaps. The cement sand gravel piles and the steel pipe piles wrapped with the cement sand gravel piles jointly form combined reinforcementpiles. It can be seen that a combined reinforcement body of rigid piles and flexible piles can be formed, foundation soil can be compacted so that the characters of the foundation soil are significantly improved, the bearing capacity of the reinforcement body can be significantly improved, and the reinforcement effect is enhanced.

Owner:HOHAI UNIV

Ozone oxidization-precipitation-sand filtering-iron powder filtering treatment process for alkali-minimization wastewater in printing and dyeing industry

InactiveCN106348497ALow costSimple processTreatment involving filtrationMultistage water/sewage treatmentChemical oxygen demandKetone

The invention discloses an ozone oxidization-precipitation-sand filtering-iron powder filtering treatment process for alkali-minimization wastewater in the printing and dyeing industry. The treatment process comprises the following steps: (1) pretreating the alkali-minimization wastewater, and recovering terephthalic acid and a salt thereof; (2)introducing ozone into the pretreated wastewater to perform oxidization treatment; (3) adding a soluble ferric salt into sewage treated by ozone oxidization to perform precipitation treatment; (4) introducing the precipitated wastewater into sand filtering equipment to perform filtering treatment; (5) introducing the sand-filtered wastewater into iron powder filtering equipment to obtain purified water. By adopting the treatment process, ketones, alcohols, organic amine, benzene series, thiophene and a part of organic esters in water can be removed effectively. After continuous running for half a year, the COD (Chemical Oxygen Demand) removal rate is kept at 96 to 99 percent, the chromaticity removal rate is 97 to 99.9 percent, and the amine-nitrogen removal rate is kept at 93 to 98 percent.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

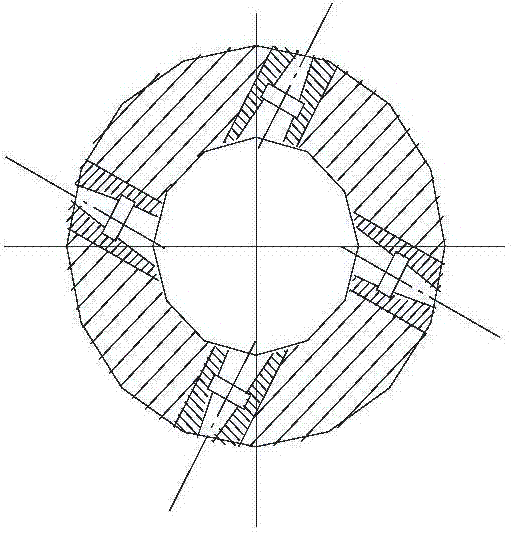

A two-stage hydraulic rotary jet block cleaner

The invention discloses a double-stage hydraulic power rotation jet flow blockage cleaning device which includes an outer barrel, a first stage screw, a connecting end cover, a first stage dowel, a first stage centralizer, a second stage dowel, a second stage screw, a second stage centralizer and a rotary sprayer, wherein the first stage screw sleeves the outer side at the upper part of the second stage screw; the outer barrel sleeves the outer side at the upper part of the first stage screw, and the matching relation of the first stage screw, the second stage screw and the outer barrel are all in clearance fit; the connecting end cover is connected with the lower end of the outer barrel; the outer barrel is in threaded connection with the connecting end cover with the taper ratio of 1:16; the rotary sprayer is connected to the bottom of the second stage screw; four nozzles are uniformly distributed on the rotary sprayer; the included angle of the centre line of the heads of the nozzles and the axial direction of the rotary sprayer is 10-30 degrees and the included angle of the centre line of the heads of the nozzles and the radial direction of the rotary sprayer is 20-45 degrees. The double-stage hydraulic power rotation jet flow blockage cleaning device is simple in structure, can be used for completely cleaning the entire oil layer perforation section quickly and efficiently with high quality and without damage.

Owner:XI'AN PETROLEUM UNIVERSITY

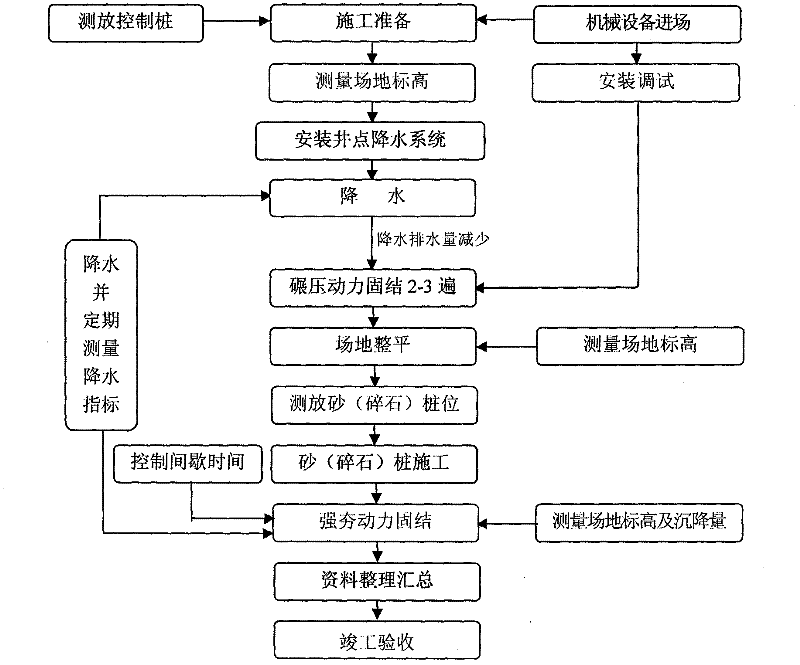

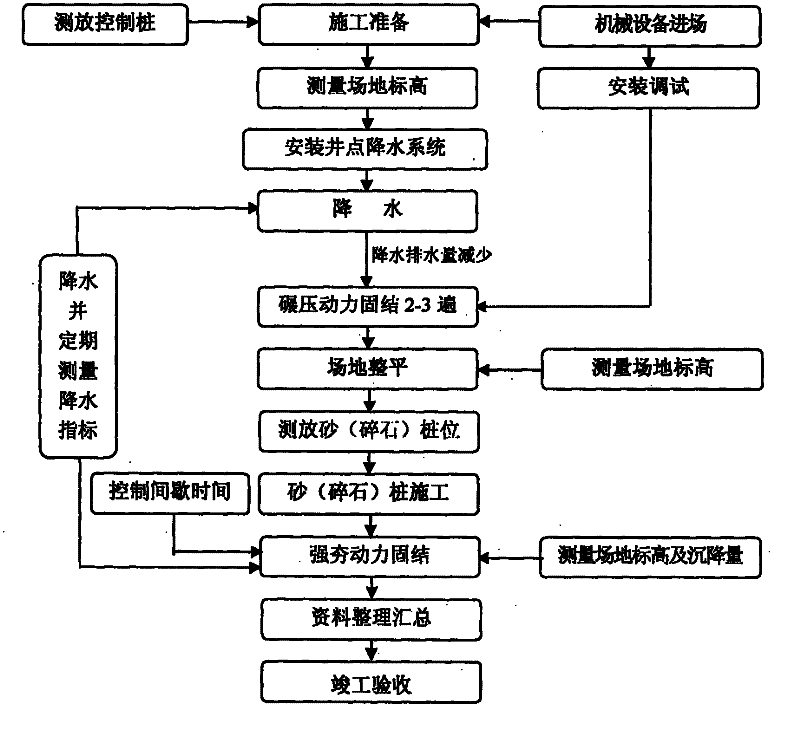

Reinforcement processing method of soft foundation

ActiveCN102011391BSolve processing problemsHigh strengthSoil preservationCrushed stoneEconomic advantage

The invention discloses a reinforcement processing method of a soft foundation, comprising the following steps: (1) well-point dewatering system installation and drainage; (2) rolling-compaction dynamic consolidation; (3) sand pile or gravel pile arrangement; and (4) forced ramming dynamic consolidation. In the invention, sand piles or gravel pile s, drainage and dynamic consolidations are organically combined based on the engineering properties of freshly dredger soft soil, thereby reaching implementation and processing effects on a freshly dredger soft soil foundation; the method has technical and economic advantages of short construction period, low construction cost, more than 8m of processing depth and good processing effect; and the method is suitable for freshly dredger soft soil, lake salinizedsoil and the like. The processed foundation can meet the requirement of general engineering construction.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

Multi-pressurized rapid consolidation compact soft soil foundation treatment method

InactiveCN101016740BShort construction periodLow costSoil preservationDynamic compactionPore water pressure

The invention belongs to the technical field of soft soil foundation treatment in geotechnical engineering, and in particular relates to a method for treating soft soil foundation along rivers, rivers and lakes. Combining vacuum drainage, vibration pressurized compaction and dynamic tamping pressurized compaction, first of all, the high dynamic head rate produced by the superposition of the excess pore water positive pressure excited by the vibration and the vacuum negative pressure is used in a short period of time. Drain the water in the soil within a short time to quickly reduce the water content of the soil and compact the soil to a certain extent; then carry out dynamic compaction to further increase the excess pore water pressure to form a higher dynamic head gradient to drain and compact the soil. Repeatedly for many times to eliminate the post-construction settlement of the deep soft soil to the greatest extent, improve the surface consolidation, strength and stiffness, until the design requirements are met. Compared with the existing method, the method of the invention has the characteristics of short construction period, low cost, small post-construction settlement, good consolidation and compaction effect, etc., and can be widely used in the treatment of soft soil foundations of various projects in coastal areas, along rivers and other areas.

Owner:武亚军

Device for continuously separating gas hydrate

ActiveCN102120104BSimple structureSmall footprintPressurized chemical processLiquid degasificationEngineeringProduct gas

The invention discloses a device for continuously separating gas hydrate, which comprises an upper box body and a lower box body, wherein the upper box body is a gas collecting cavity (7), the upper end of the upper box body is provided with a separated gas outlet (10), a safety valve port (16) and a pressure meter port (17), and the lower part of the upper box body is provided with a silk screen mist eliminator (6); the lower box body is shaped as a cuboid, the upper part of the lower box body is provided with a hydrate slurry inlet (1), the tail end of the hydrate slurry inlet (1) is provided with a flow equalizing plate (2) in a vertical direction, the bottom end of the flow equalizing plate (2) is provided with a sieve plate (3), the sieve plate (3) is alternatively connected with a drainage plate (4) to form a separating channel; a water collecting cavity (8) is arranged between the separation channel and the lower box body, and the lower part of the separation channel is provided with a separated water outlet (11); and the lower end of the separation channel is connected with a hydrate storing cavity (9), and the bottom end of the hydrate storing cavity (9) is provided with a hydrate outlet. The invention has the advantages of simple structure, small occupation area and convenience for maintenance.

Owner:溧阳常大技术转移中心有限公司

Treatment method of double-layer composite vacuum preloading and filling soft soil foundation

ActiveCN103806437BLarge processing depthEnsure vacuum transferSoil preservationSoil treatmentEngineering

The invention relates to a processing technology for hydraulic reclamation to soft foundation, particularly relates to a double-layer vacuum preloading and hydraulic reclamation soft foundation processing method, and belongs to the field of geotechnical engineering. According to the method, double-layer soft soil treatment is used, so as to overcome the defects of insufficient treatment depth and submucosal vacuum degree degression with depth in a single vacuum preloading technology, the energy transmission efficiency of vacuum degree along depth is increased, and a sealed drainage system designed ensures that the loss of the submucosal vacuum degree is reduced, so that soft foundation processing depth is enabled to be increased greatly, vacuum preloading treatment way is performed on upper half shallow soft soil, meanwhile a vacuum and overload combined preloading treatment way is performed on lower half deep soft soil, so that the phenomenon of bad solidification effect of a deep layer caused by difficulty water drainage in a traditional way is avoided.

Owner:WENZHOU UNIVERSITY

Variable diameter rotary jet mixing pile

The invention relates to a variable-diameter rotary spraying mixing pile. The mixed cement slurry is pressed into the cement slurry pipe by the mud pump, enters the faucet through the cement slurry pipe interface, and then enters the grouting steel pipe, and is sprayed out through the high-pressure spray head to realize high-pressure cutting of the soil. While the high-pressure cement slurry is cutting the soil, the variable-diameter stirring blades arranged on the outer drill pipe and the inner drill pipe realize the stirring of the soil synchronously. When the high-pressure grouting is cutting the soil while the inner and outer drill pipe stirring blades are rotating and stirring the soil, the whole high-pressure grouting mixing system, under the action of the lifting system, sinks while grouting while stirring or goes up while stirring according to the design requirements. carry. This series of actions just can complete the cement-soil cylindrical mixing pile with certain diameter. On the basis of inheriting the advantages of simple construction machinery and fast speed of the deep mixing method, the present invention combines the comprehensive advantages of high-pressure rotary spraying method with high grouting pressure, wide applicable strata and large power of three-axis stirring piles, and has a wide range of applications specialty.

Owner:南京路鼎搅拌桩特种技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com