Combined treatment construction method for collapsible loess foundation

A collapsible loess, combined treatment technology, applied in soil protection, infrastructure engineering, sheet pile wall and other directions, can solve the problems of unsatisfactory soil compaction effect between piles, affecting building safety, single filling and other problems, achieving Satisfy the foundation bearing capacity and settlement requirements, strong resistance to complex loads, and the effect of eliminating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

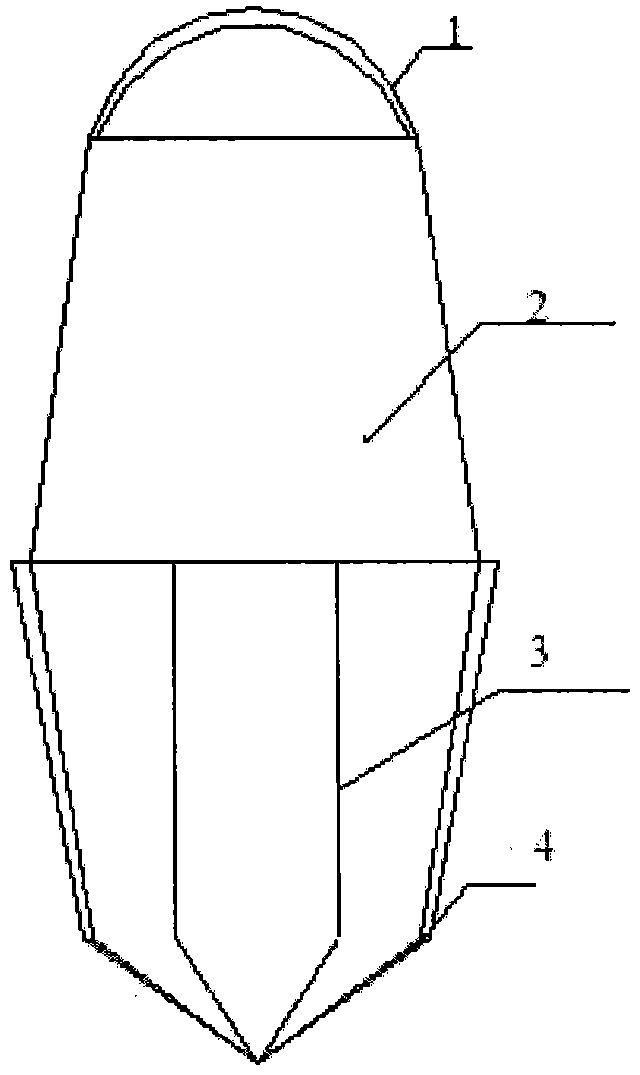

[0047] The joint treatment method of the collapsible loess foundation of the present invention, the method first adopts conical rammer to impact the pretreatment collapsible loess field to carry out foundation treatment; then, adopts borehole ramming and expanding lime-soil compaction piles to carry out supplementary pile reinforcement; finally , Carry out grouting construction after pouring piles.

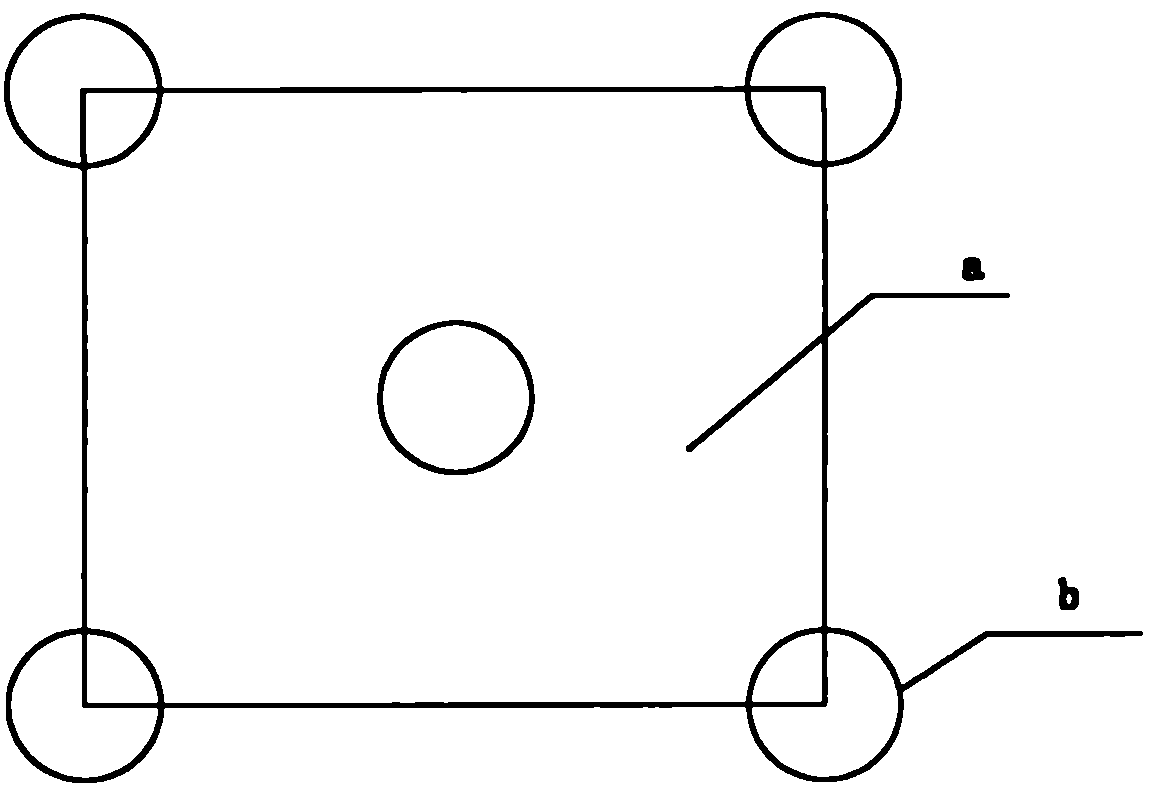

[0048] see figure 1 As shown, it is a structural schematic diagram of the pile patch of the present invention, in which a is the conical rammer treatment area, and b is the drilled and rammed lime-soil compaction pile, which is arranged on the conical rammer treatment area. at the four corners and at the center.

[0049] Specifically include the following steps:

[0050]Step 1, use a conical tamper to impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com