Variable diameter rotary jet mixing pile

A technology of mixing piles and mixing blades, which is applied in the field of variable-diameter rotary spraying mixing piles, can solve the problems of uneven mixing at the lower part of the pile body and poor strength of the pile body, and achieve the effects of wide applicable stratum, large treatment depth and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

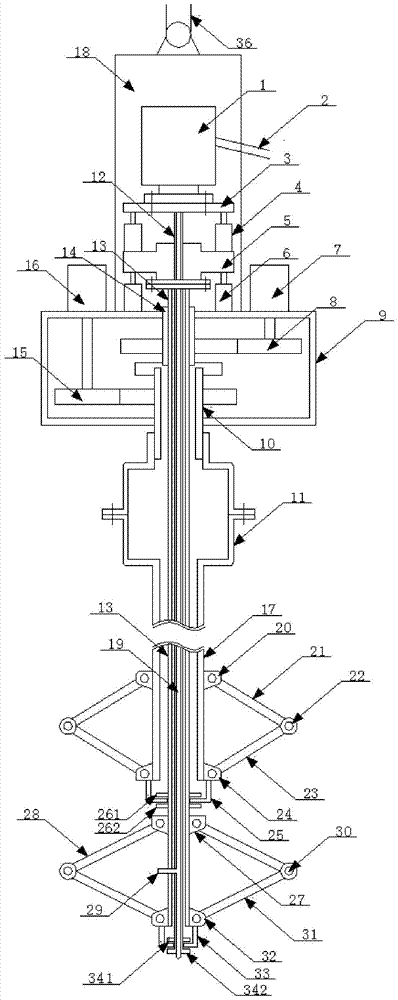

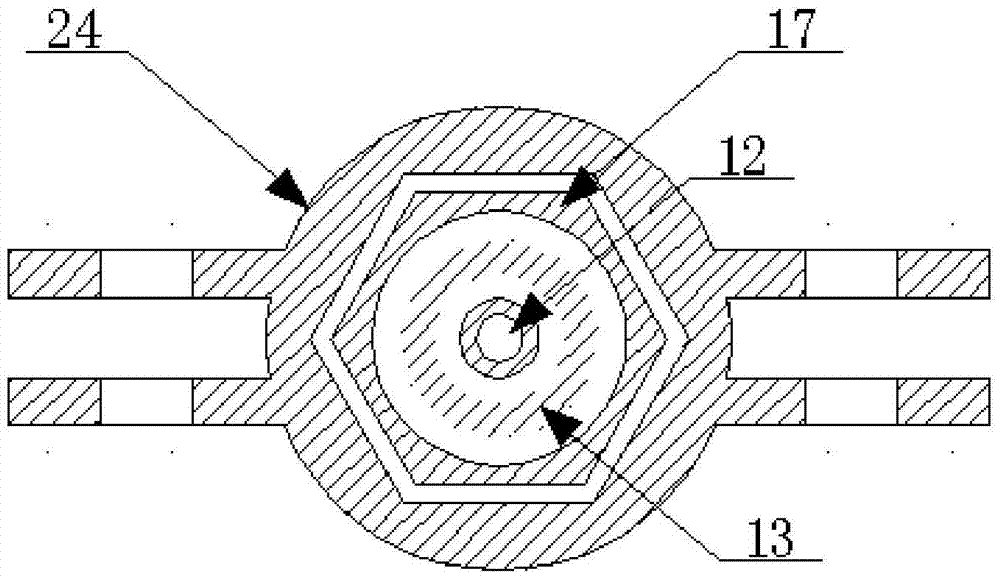

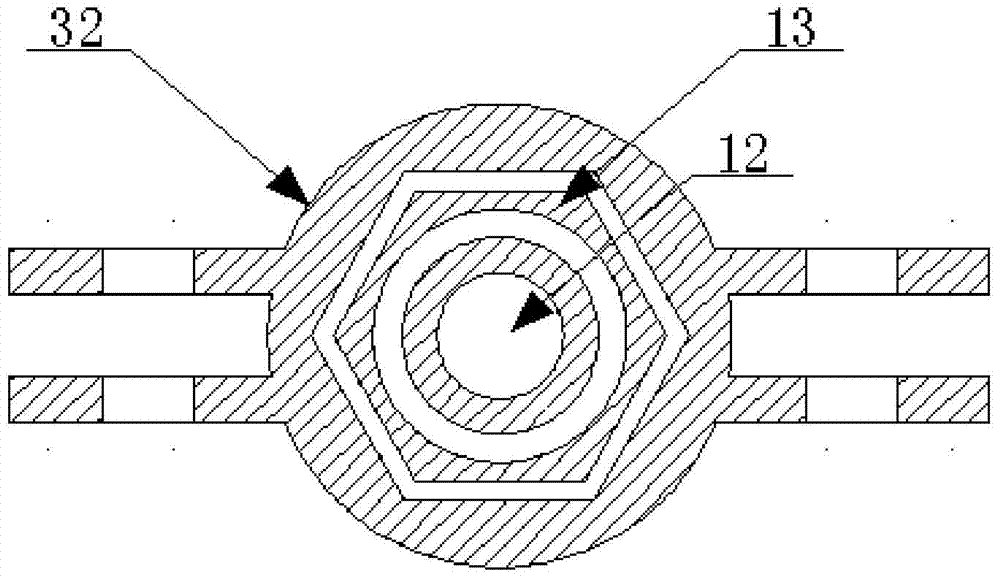

[0028] The invention discloses a variable-diameter rotary spraying mixing pile, which includes an outer drill rod and an inner drill rod, both of which are hollow structures, and the inner drill rod is arranged in the outer drill rod, and the same The shaft is arranged, and the lower part of the inner drill rod passes through the outer drill rod; the lower part of the inner drill rod and the lower part of the outer drill rod are respectively provided with variable-diameter stirring blades that can expand or contract; the inner drill rod and the outer drill rod The drill pipe can move relative to the axial direction, driving the expandable or shrinkable variable-diameter stirring blades to rotate relatively; there is a high-pressure grouting head at the lower part of the inner drill pipe and between the expandable or shrinkable variable-diameter stirring blades. The high-pressure grouting head is connected to the mud pump through the grouting steel pipe set in the inner drill pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com