A process method for treating refinery wastewater combined with biological aerated filter

An aerated biological filter, refining and chemical sewage technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the impact of biochemical section, abnormal sewage treatment system, etc. Water quality instability and other problems, to achieve the effect of increasing the treatment depth and avoiding the impact of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

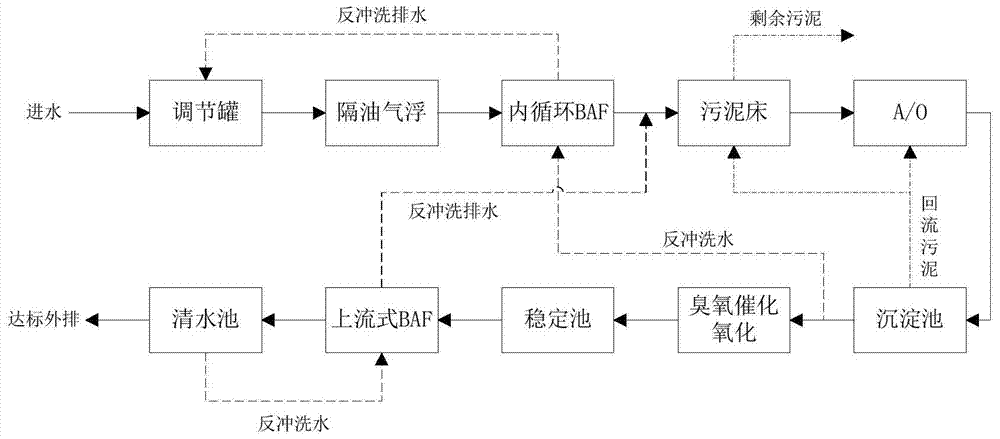

Method used

Image

Examples

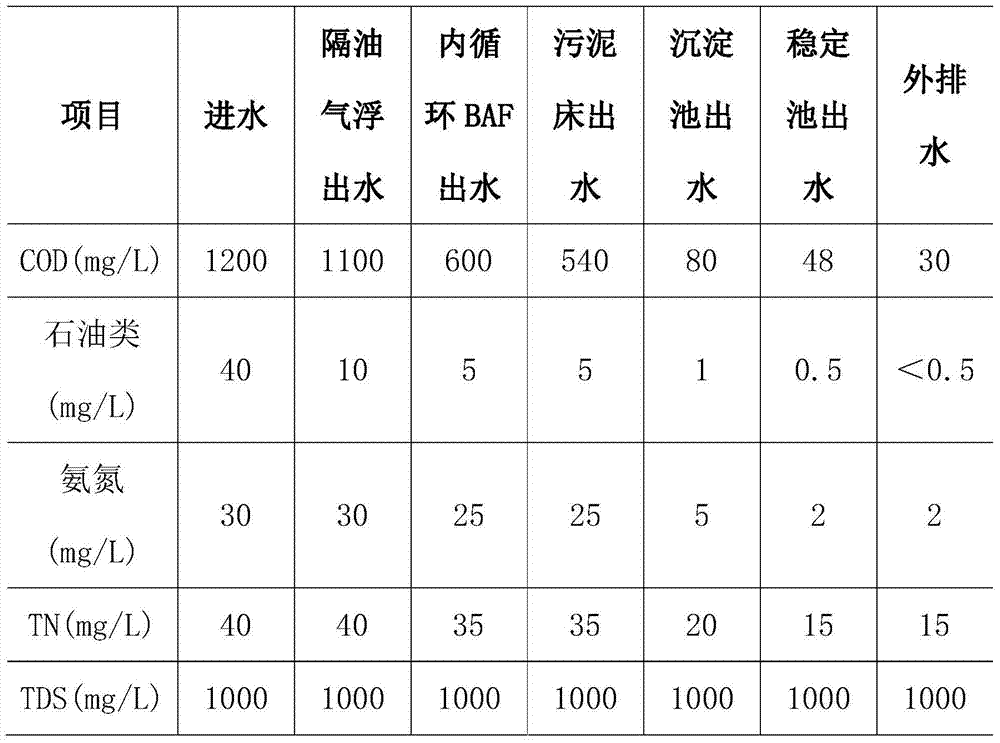

Embodiment 1

[0082] According to the above process to treat the sewage of a refinery, the process conditions of the main treatment unit are as follows:

[0083] The BAF filler in the internal circulation is anthracite, the filtration rate is 3m / h, the gas-water ratio is 3:1, the internal circulation ratio is 150%, and the backwash cycle is 48h;

[0084] The residence time of the sludge bed is 1.0h, the sludge concentration in the sludge bed is 10g / L, and the sludge return rate is 20%;

[0085] The COD volume load of the A / O pool is 0.8kg COD / m 3 d, the residence time is 12 / 48h, the internal reflux ratio is 300%, the sludge reflux ratio is 80%, the sludge concentration is 4g / L, and the aeration intensity is 8m 3 / m 2 h;

[0086] The catalyst used in the ozone catalytic oxidation system is modified ceramsite carrier loaded with 3.0% cerium element, the dosage of ozone is 40mg / L, and the oxidation time is 30min;

[0087] The upflow BAF adopts ceramsite filler, the filtration rate is 5m / h,...

Embodiment 2

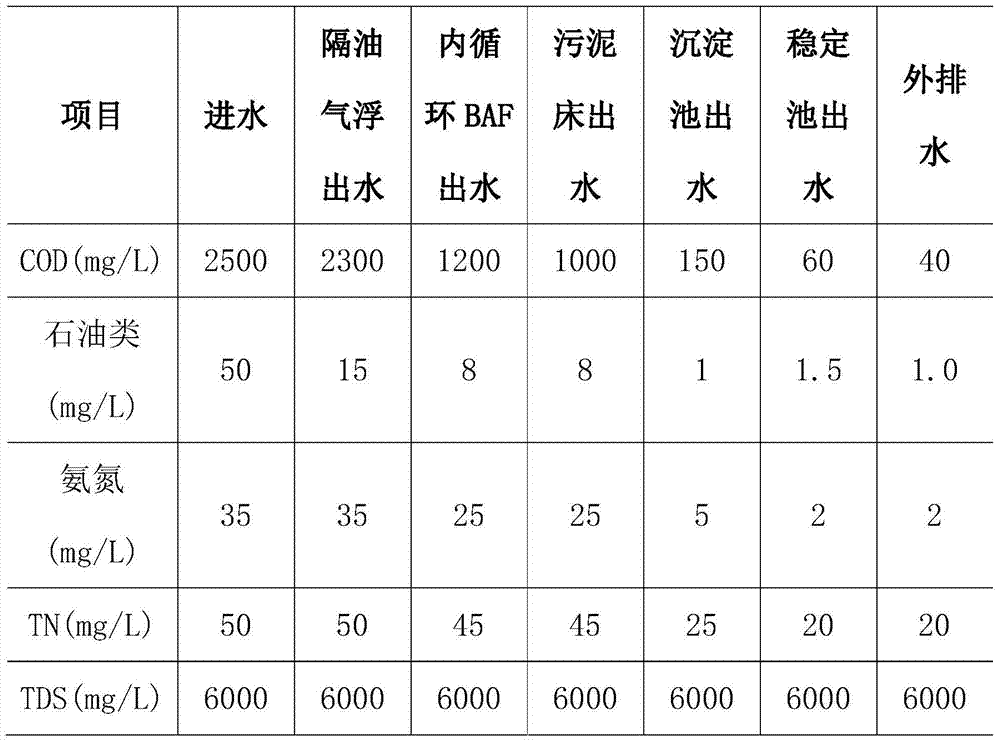

[0091] According to the above process, the saline sewage of a refinery is treated, and the process conditions of the main treatment units are as follows:

[0092] The BAF filler in the internal circulation is medical stone, the filtration rate is 2m / h, the air-water ratio is 3:1, the internal circulation ratio is 150%, and the backwash cycle is 36h;

[0093] The residence time of the sludge bed is 1.5h, the sludge concentration in the sludge bed is 13g / L, and the sludge return rate is 20%;

[0094] The COD volume load of the A / O pool is 1.2kg COD / m 3 d, the residence time is 16 / 56h, the internal reflux ratio is 300%, the sludge reflux ratio is 80%, the sludge concentration is 5g / L, and the aeration intensity is 10m 3 / m 2 h;

[0095] The catalyst used in the ozone catalytic oxidation system is a modified columnar activated carbon carrier loaded with 3.0% copper and 2.0% cerium element, the dosage of ozone is 50mg / L, and the oxidation time is 30min;

[0096] The upflow BAF ...

Embodiment 3

[0100] According to the above process, the saline sewage of a refinery is treated, and the process conditions of the main treatment units are as follows:

[0101] The BAF filler in the internal circulation is fiber balls, the filtration rate is 5m / h, the air-water ratio is 3:1, the internal circulation ratio is 150%, and the backwash cycle is 48h;

[0102] The residence time of the sludge bed is 1.5h, the sludge concentration in the sludge bed is 10g / L, and the sludge return rate is 10%;

[0103] The COD volume load of the A / O pool is 1.0kg COD / m 3 d, the residence time is 14 / 48h, the internal reflux ratio is 300%, the sludge reflux ratio is 90%, the sludge concentration is 5g / L, and the aeration intensity is 10m 3 / m 2 h;

[0104] The catalyst used in the ozone catalytic oxidation system is a modified alumina carrier loaded with 3.0% manganese and 3.0% copper, the ozone dosage is 40mg / L, and the oxidation time is 50min;

[0105] The upflow BAF adopts anthracite filler, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com