A New Type of Hydraulic Jet Blocking Removal Device

A new type of hydraulic jet technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of easy blockage of pore channels, single physical action, and decreased water absorption in water wells, and achieves improved use flexibility, Simple construction process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

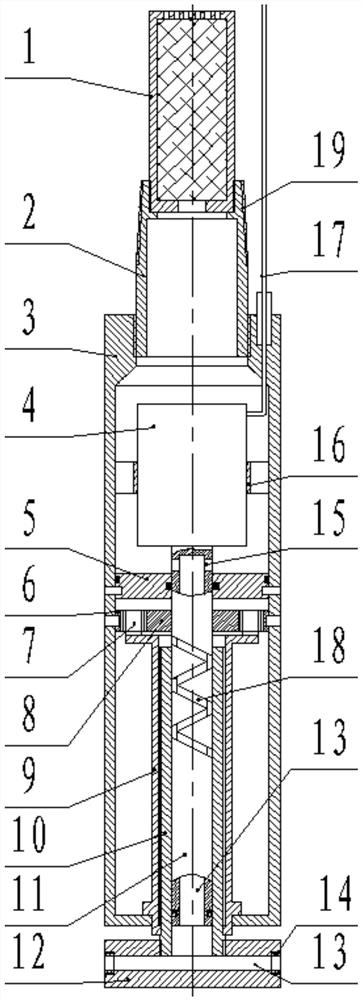

[0033] Such as figure 1 As shown, this embodiment includes a filter 1, a short tube 2, a cylinder 3, a motor 4, a reciprocating mechanism and a rotating disk 12, the filter 1 and the cylinder 3 are fixedly connected to the upper and lower ends of the short tube 2 respectively, and the motor 4 is fixedly installed in the barrel 3 through a motor bracket 16, the power input end of the reciprocating mechanism is connected with the output shaft of the motor 4, and the power output end of the reciprocating mechanism is fixedly connected with the rotating disk 12. The invention realizes blocking removal by spraying emulsifier downhole, and compared with the prior art, the construction process is simple, the construction cost is low, and the treatment depth is large. At the same time, by spraying the emulsifier by rotation, the jet of the emulsifier impacts the scale on the inner wall of the casing from radial and tangential directions, so that the scale is easier to remove and effec...

Embodiment 2

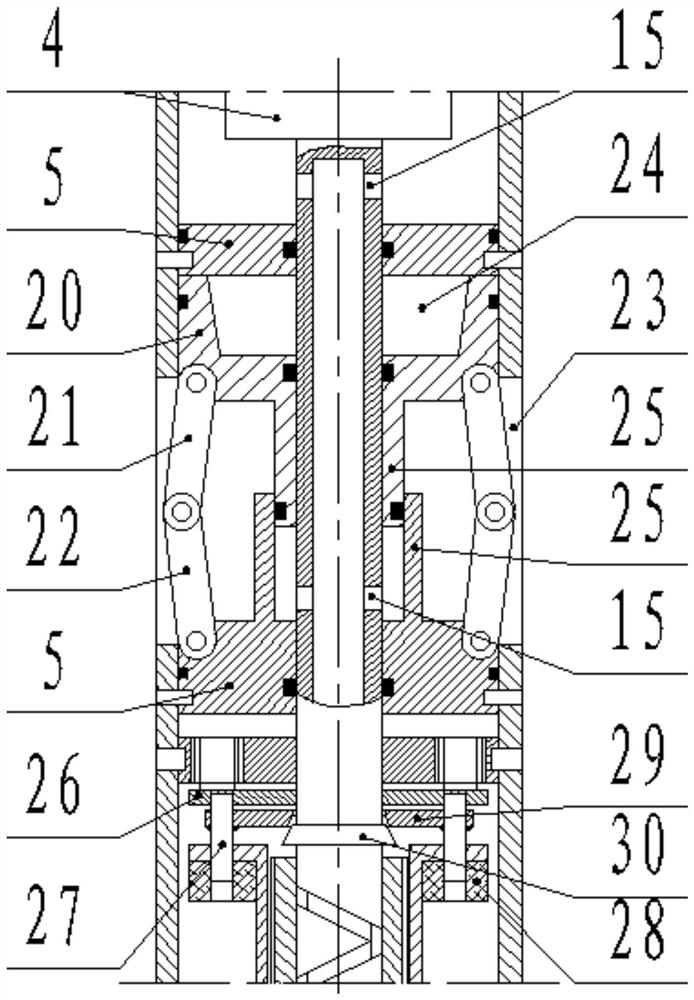

[0055] Such as figure 2 As shown, there are two main differences between this embodiment and Embodiment 1: one is that a supporting mechanism is added, and a partition plate 5 is added above the supporting mechanism; the other is that a clutch mechanism for cutting off reciprocating motion is added. In addition, as an adaptive improvement, the planetary gear 7 is no longer installed on the upper end of the outer tube 9 , but is installed on a newly added planetary gear carrier 26 .

[0056] The supporting mechanism is arranged on the upper end of the reciprocating lead screw 11 . Its structure comprises a piston 20, a first connecting rod 21, a second connecting rod 22, one end of the first connecting rod 21 and the second connecting rod 22 are movably linked, the other end of the first connecting rod 21 is hinged on the piston 20, the second The other end of the connecting rod 22 is hinged on the partition plate 5 above the planetary gear train, and the upper side of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com