Soft soil stratum in-situ curing agent preparing and feeding equipment and curing process thereof

A technology of curing process and feeding equipment, which is applied in soil protection, infrastructure engineering, earth mover/shovel, etc. It can solve the problem of large amount of waste soil discharge and transportation of engineering, the impact of surrounding buildings, and the increase of sand and gravel consumption. and other problems, to achieve the effect of reducing the amount of sand and gravel, eliminating the need for excavation work, and reducing post-construction settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

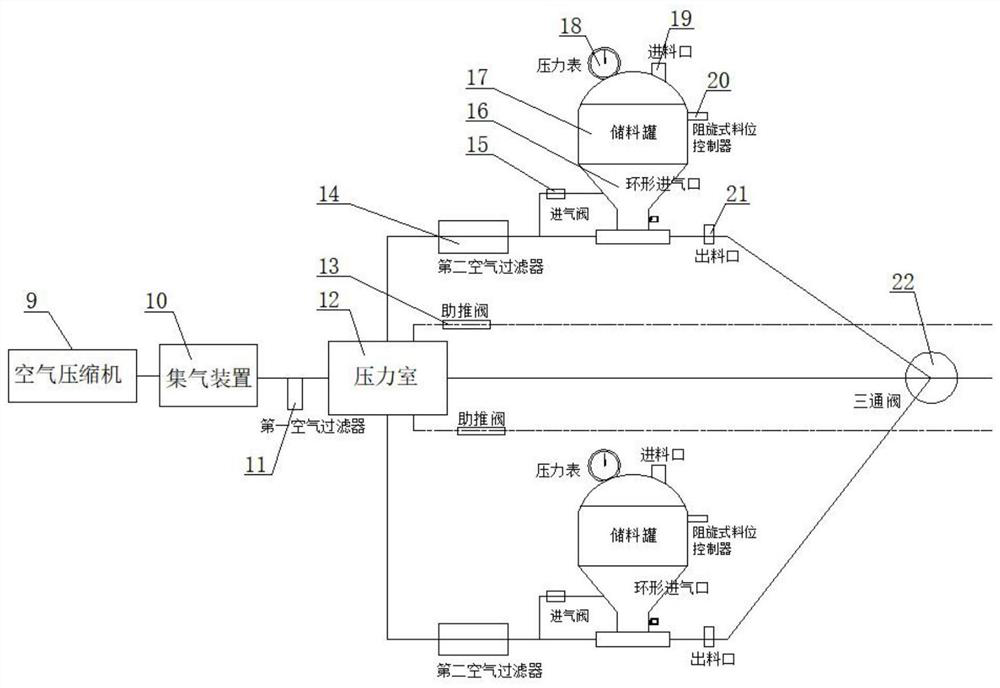

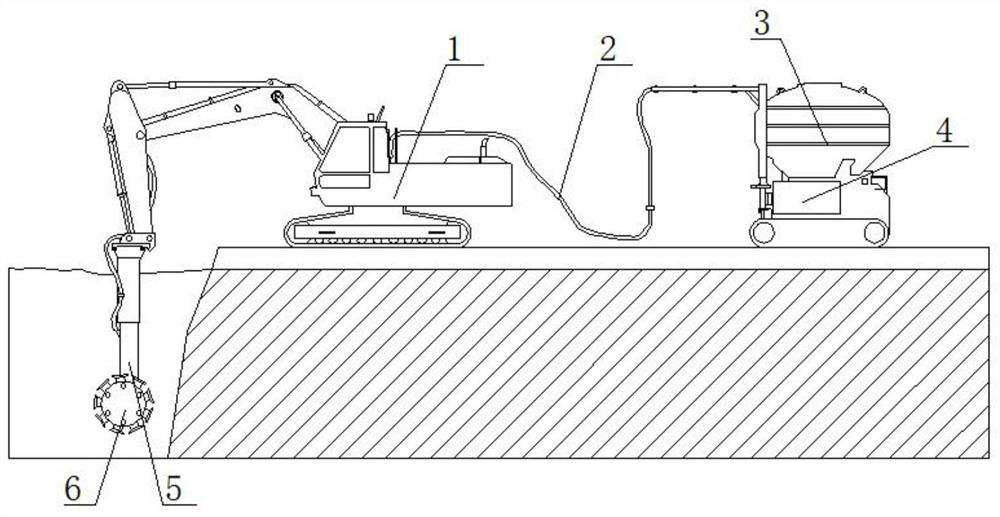

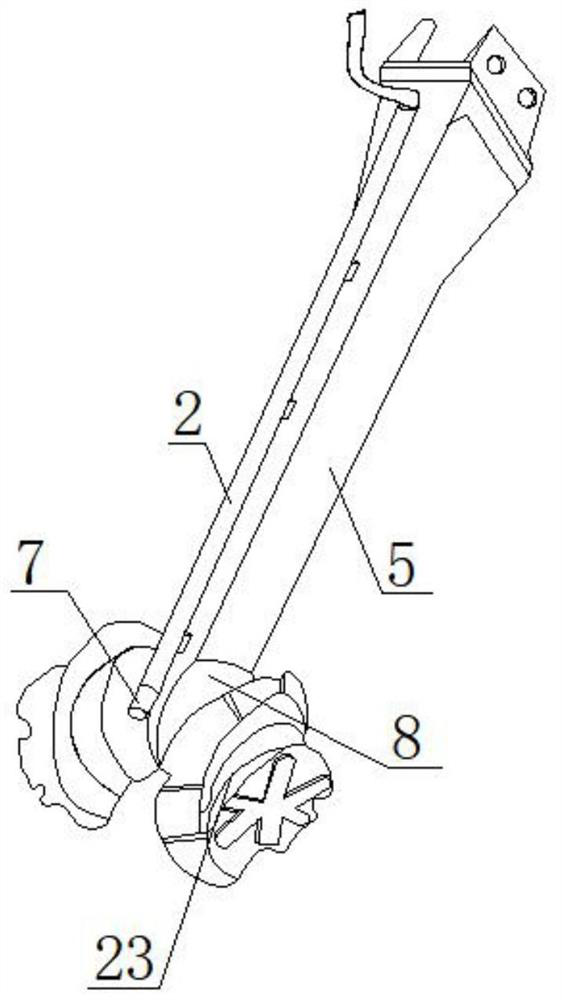

[0041] refer to Figure 1-7 , the in-situ curing agent curing process for soft soil formations comprises the following steps;

[0042] Step 1. Surface cleaning: first remove surface impurities and other sundries that affect sinking and mixing in the treatment area, level the site, and conduct on-site trial mixing before construction. If the mixing head itself is difficult to stir the sinking soil layer, you can first clean this Part of the soil layer shall be excavated as a whole or partially first, and after excavation, it shall be roughly leveled and then solidified. The elevation of the excavation surface shall be determined according to the design elevation of the pavement, the thickness of the pavement, the thickness of the roadbed and the thickness of the construction waste on site;

[0043] Step 2. Divide blocks: Stake out the area to be processed and divide it into blocks, and divide the processing blocks with a size of about 5m×6m. In case of areas with large cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com