Patents

Literature

79 results about "Modular fixture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

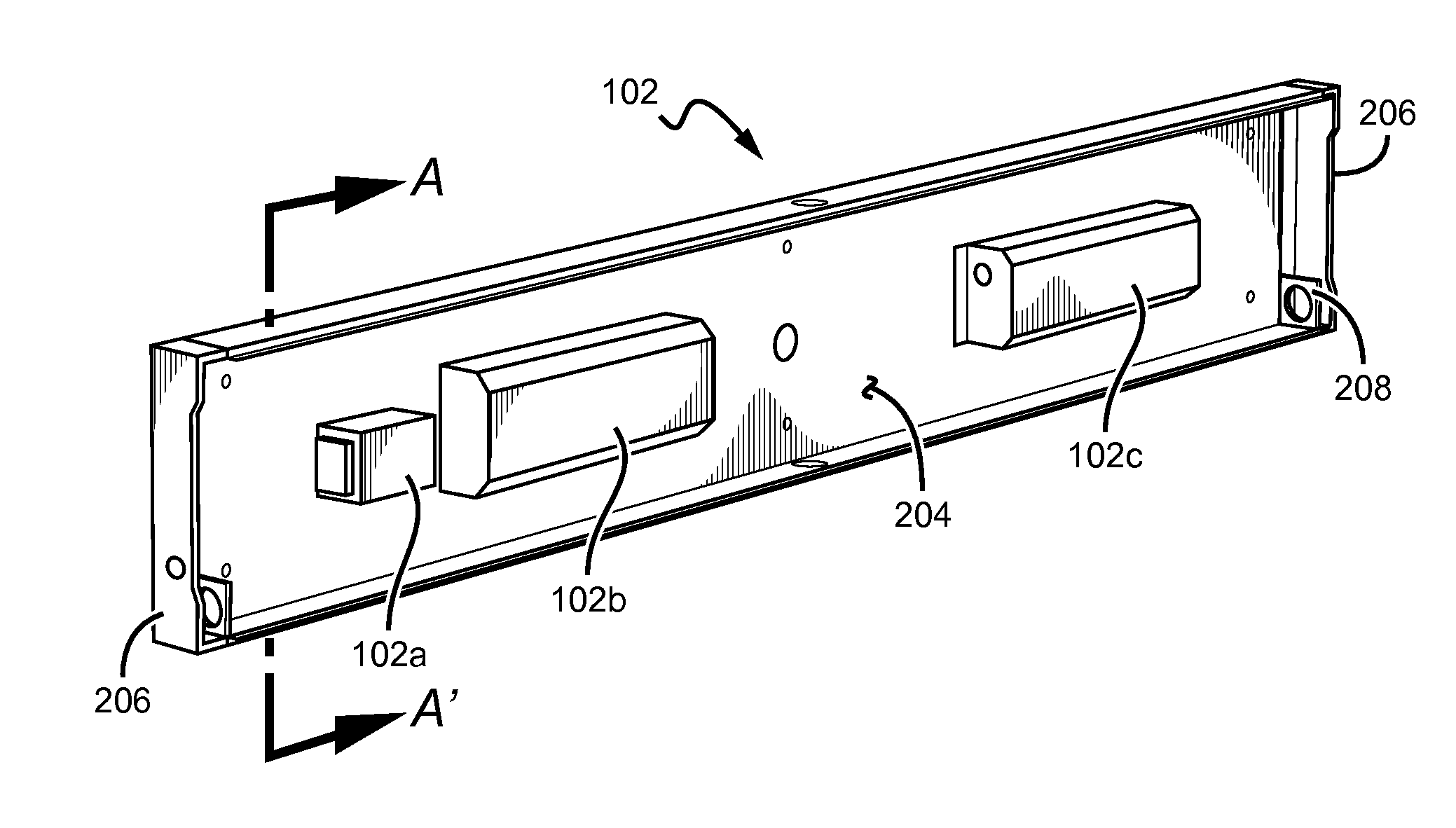

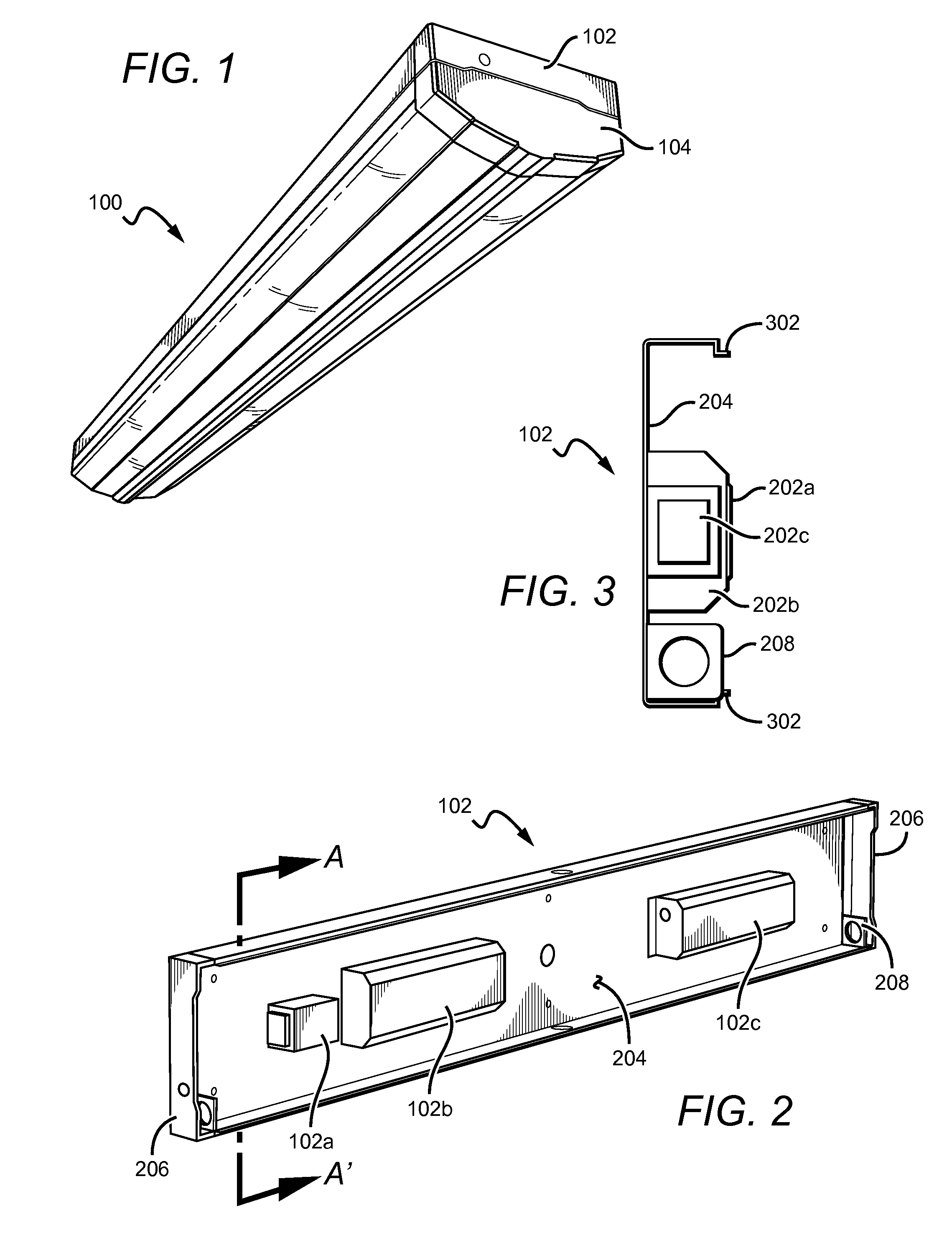

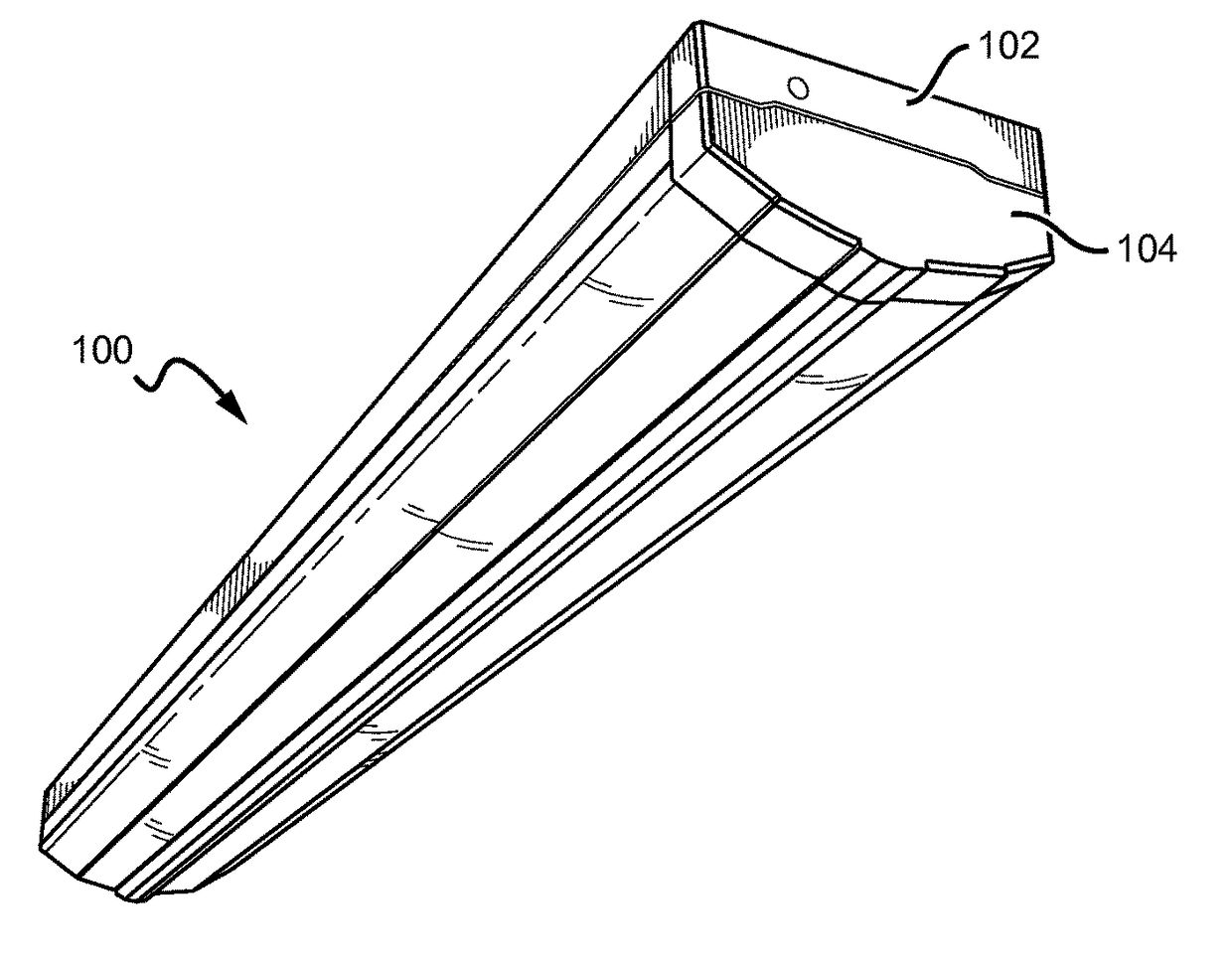

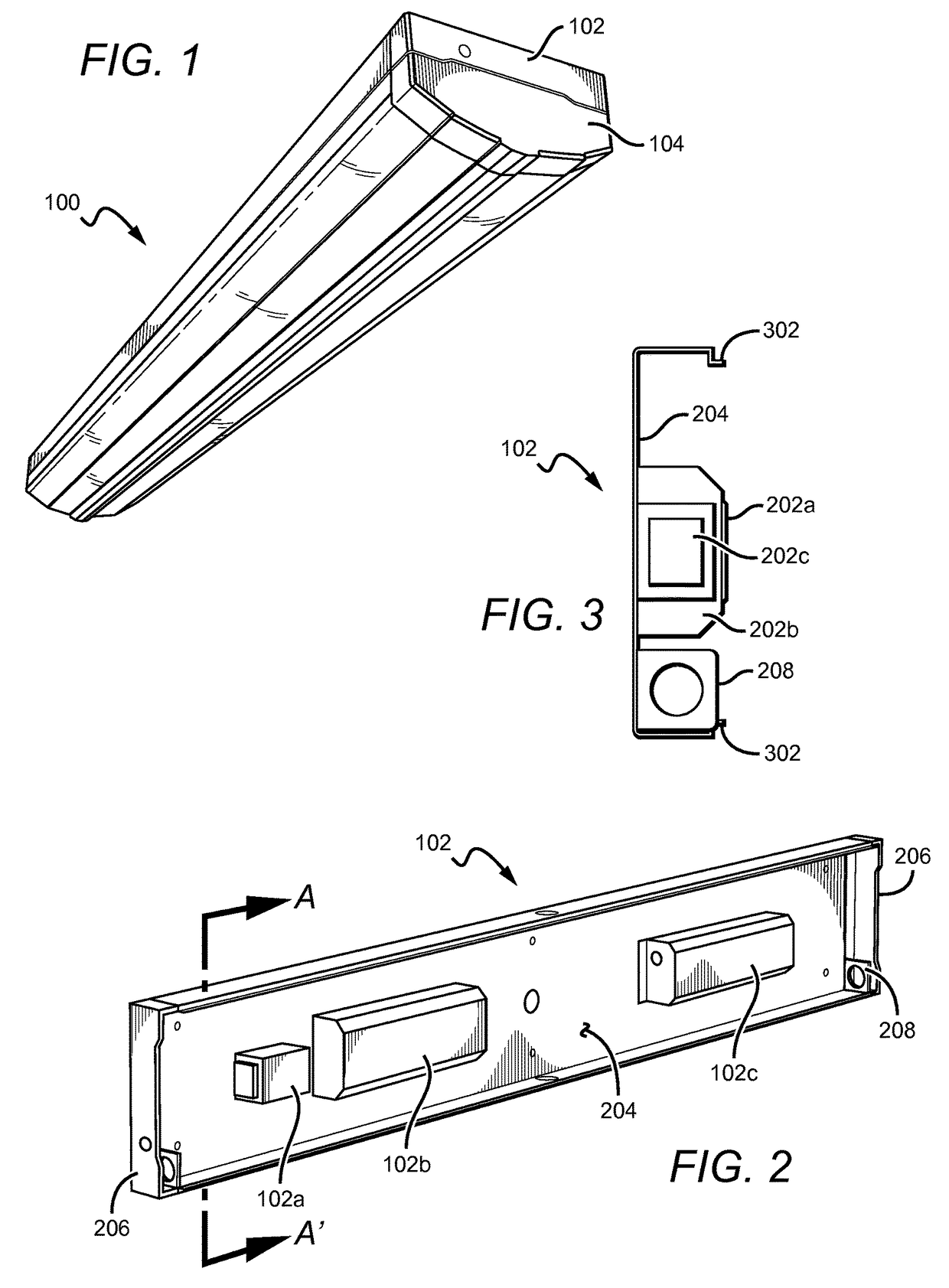

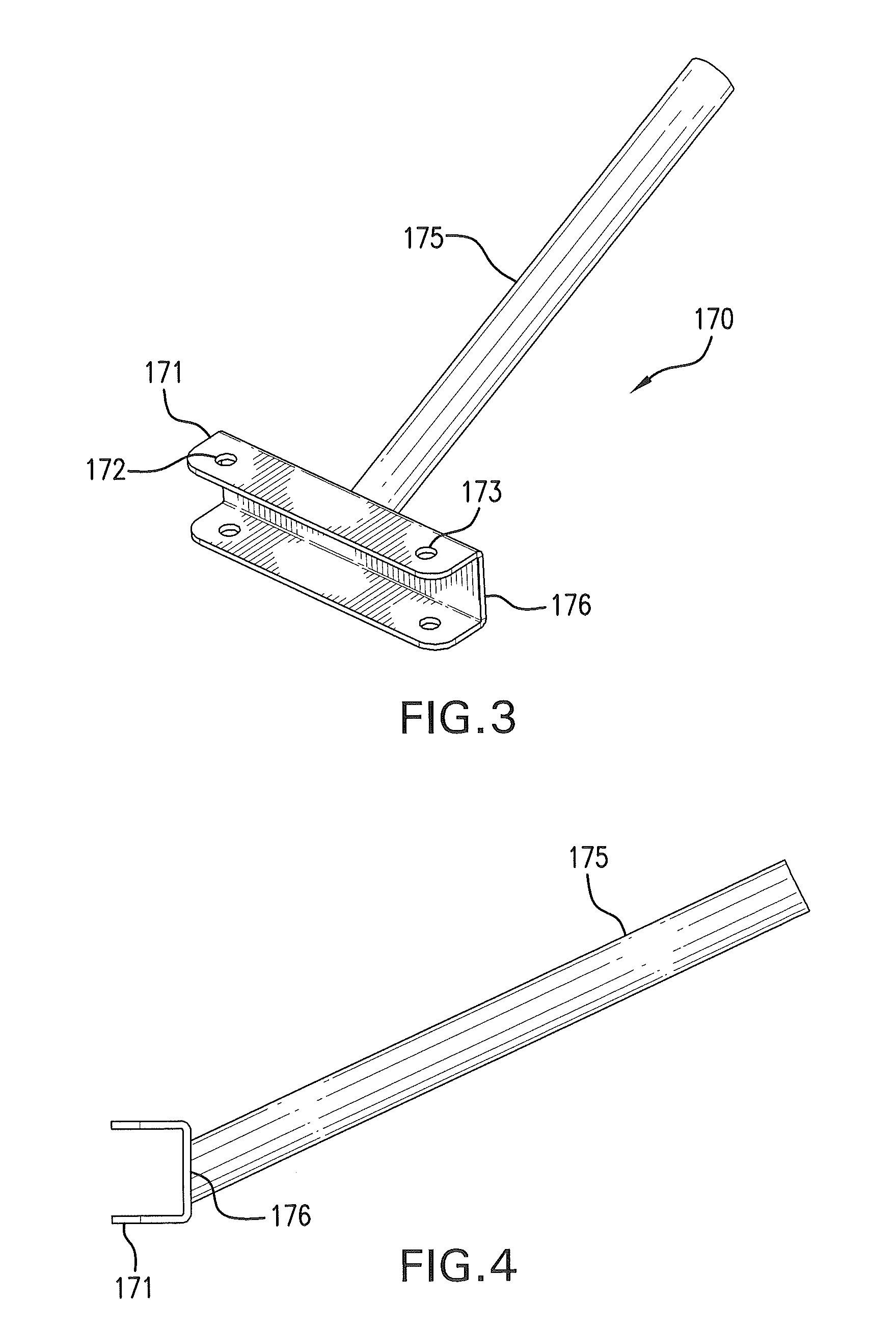

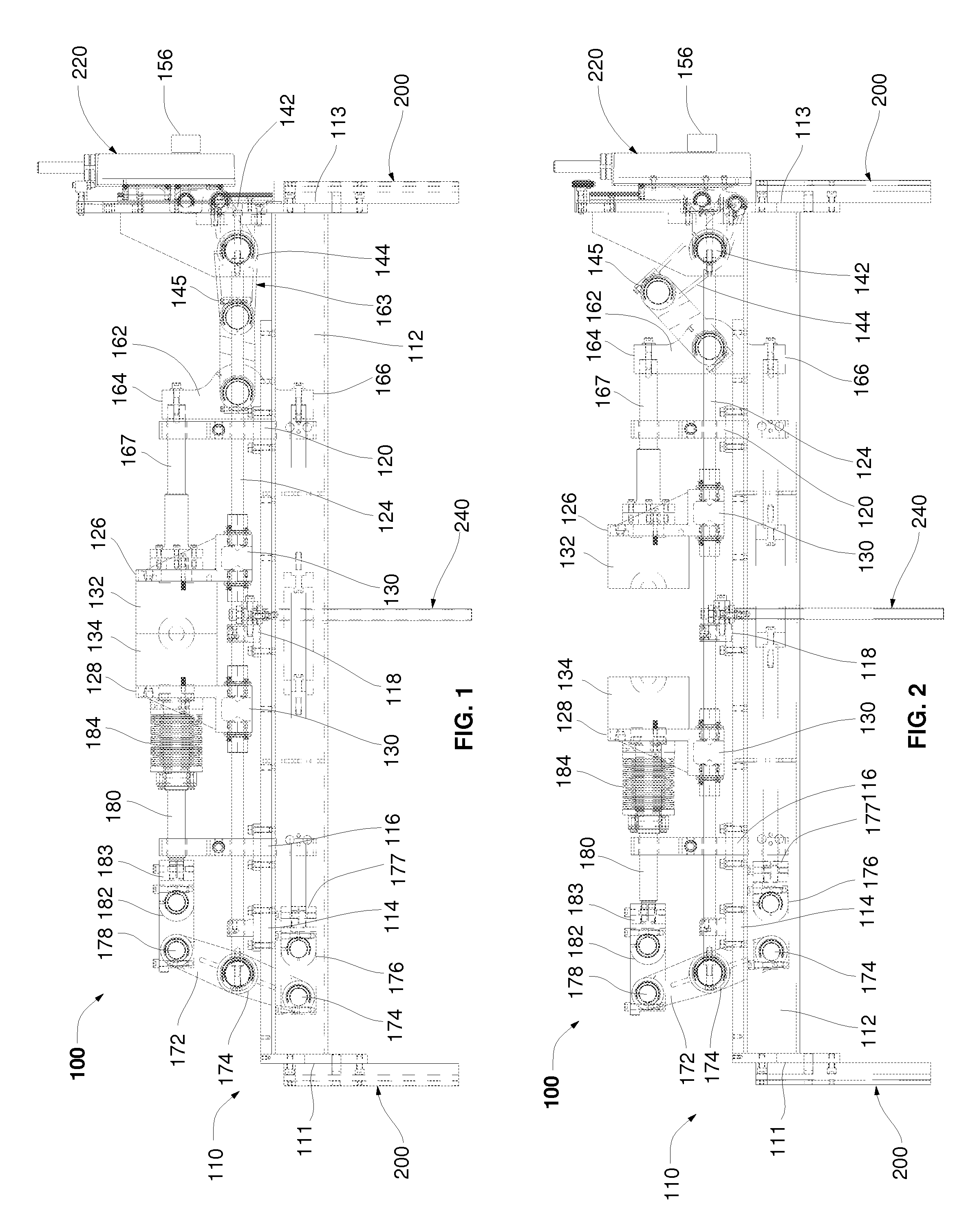

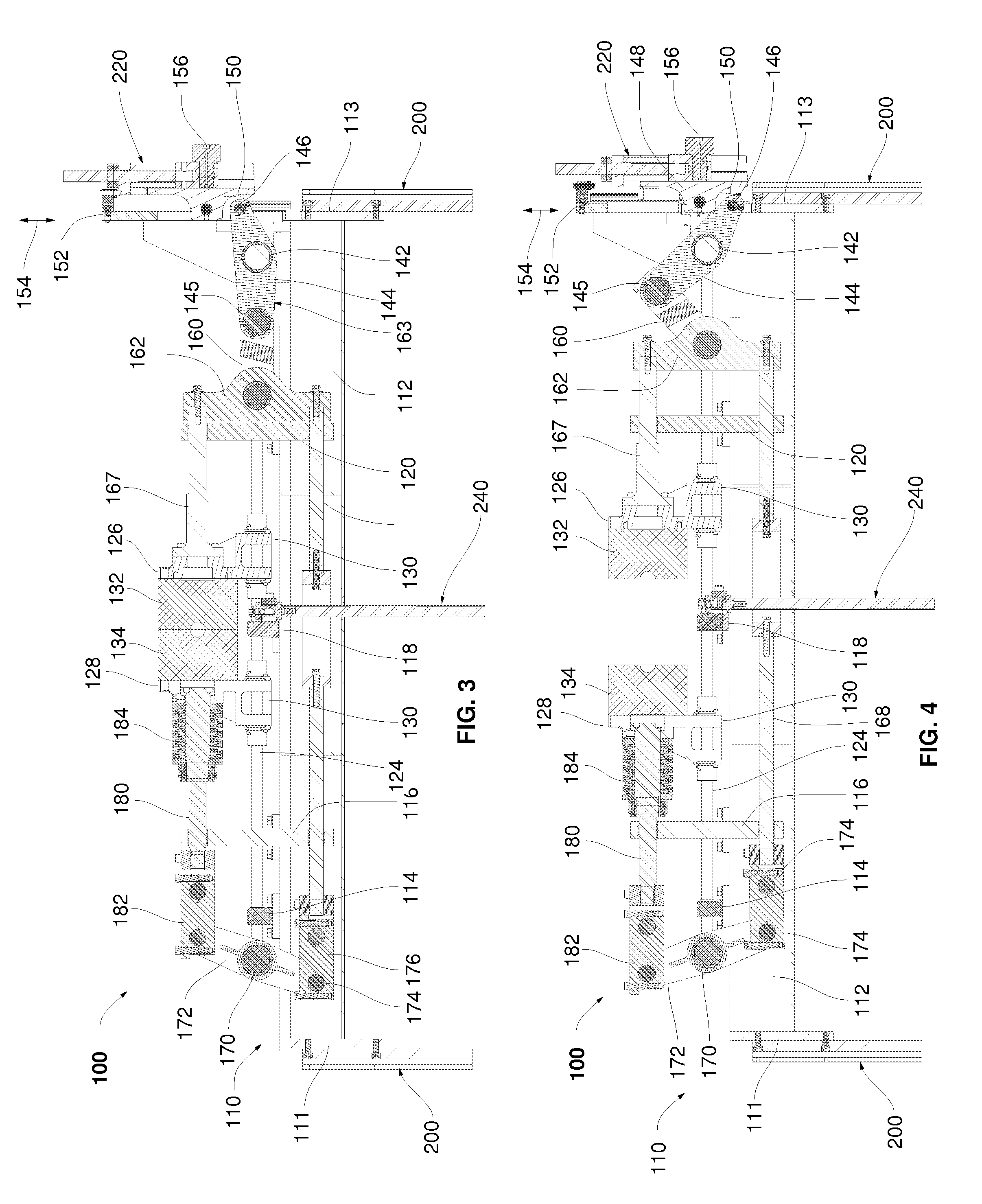

Surface ambient wrap light fixture

A modular fixture that is well-suited for use with solid state light sources, such as LEDs, to provide a surface ambient light (SAL). The fixture comprises two structural components: a housing subassembly and a lighting subassembly. These two subassemblies may be removably attached to operate as a singular fixture. Many different lighting subassemblies may be compatible with a single housing subassembly and vice versa. The housing subassembly comprises a frame that is mountable to an external structure. The lighting subassembly comprises the light sources and optical elements that tailor the light to achieve a particular profile. Electronics necessary to power and control the light sources may be disposed in the lighting subassembly. Various mount mechanisms may be used to attach the fixture to a surface such as a ceiling or a wall. Multiple fixtures can be connected serially to provide an extended linear fixture.

Owner:IDEAL IND LIGHTING LLC

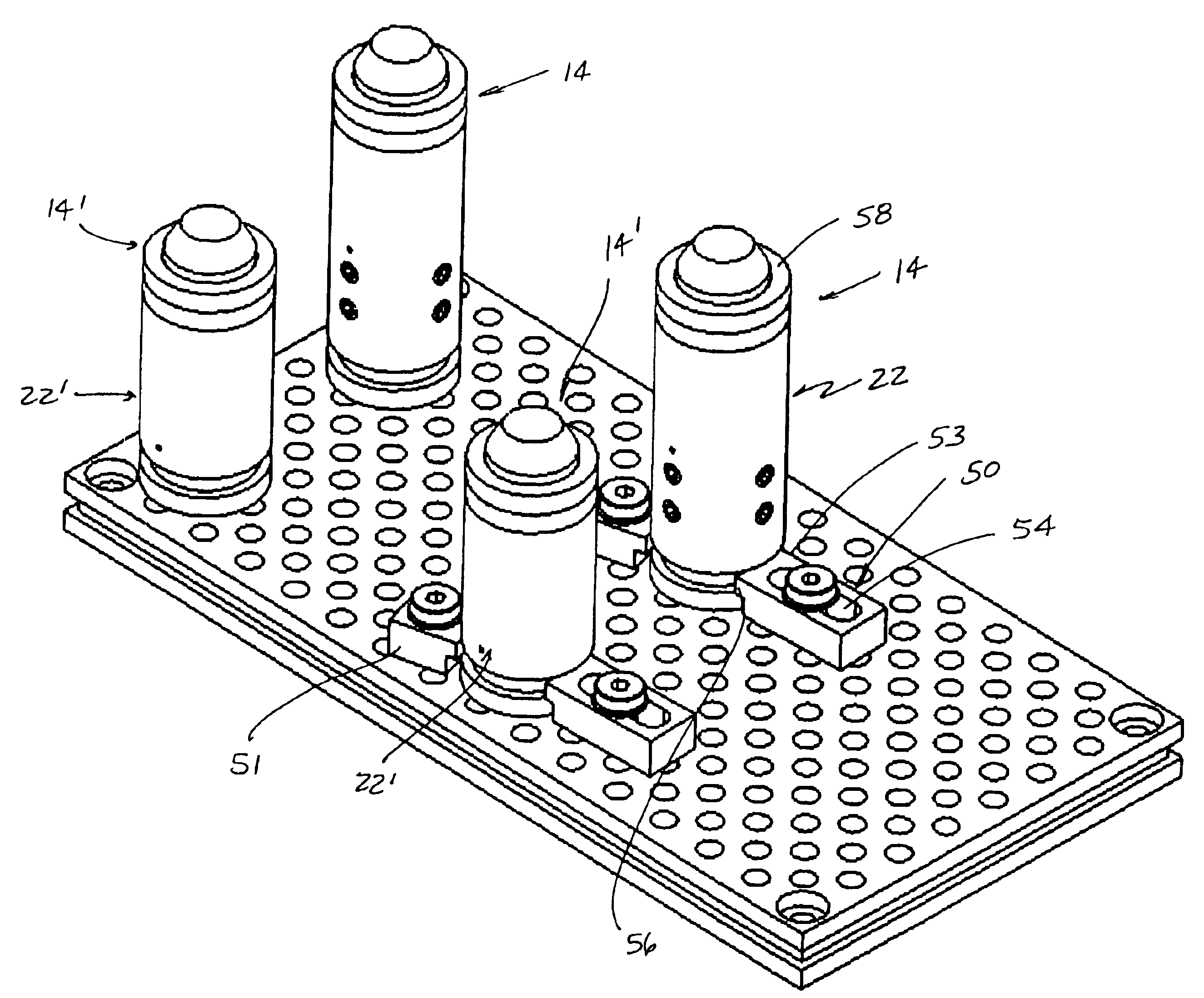

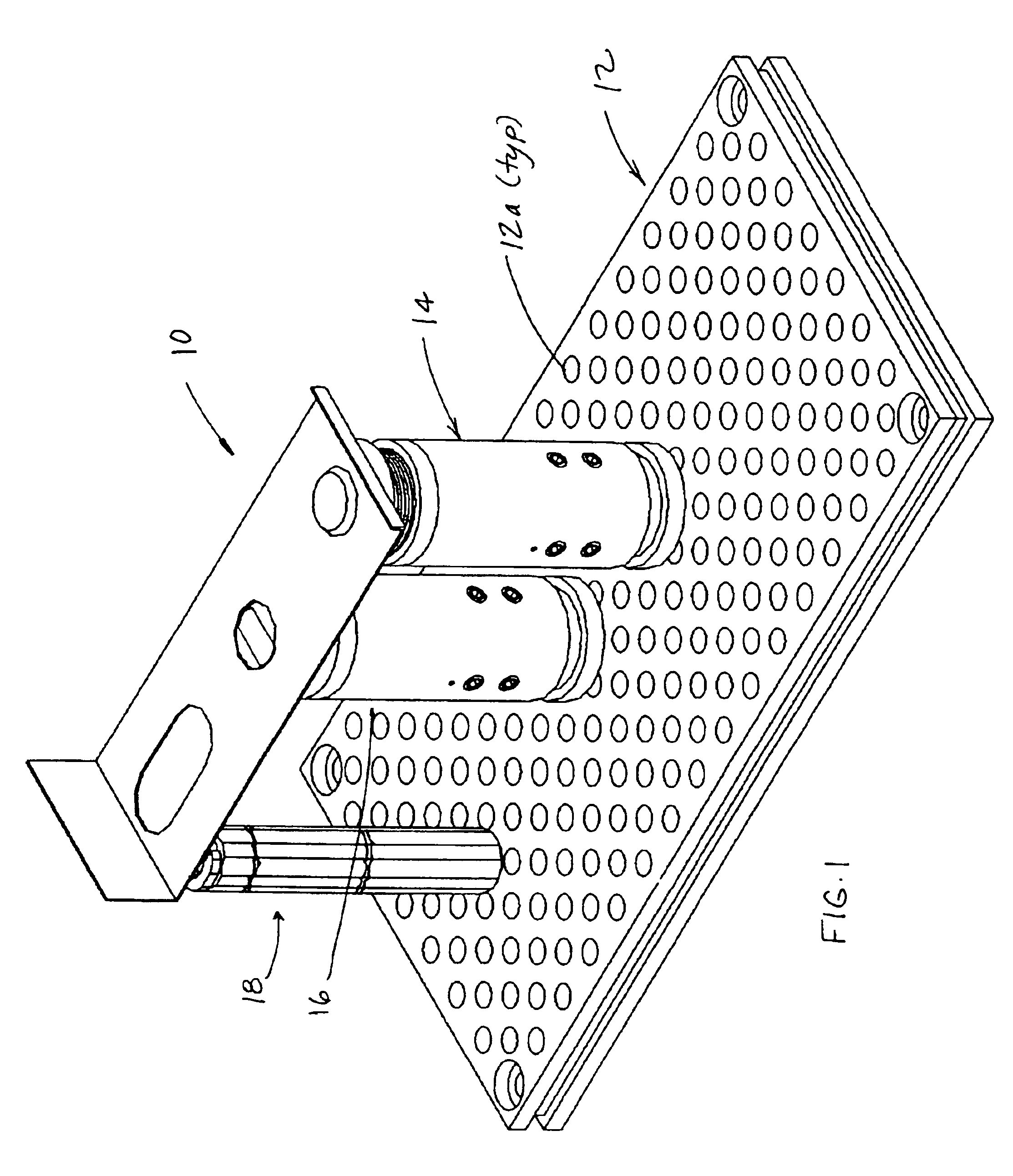

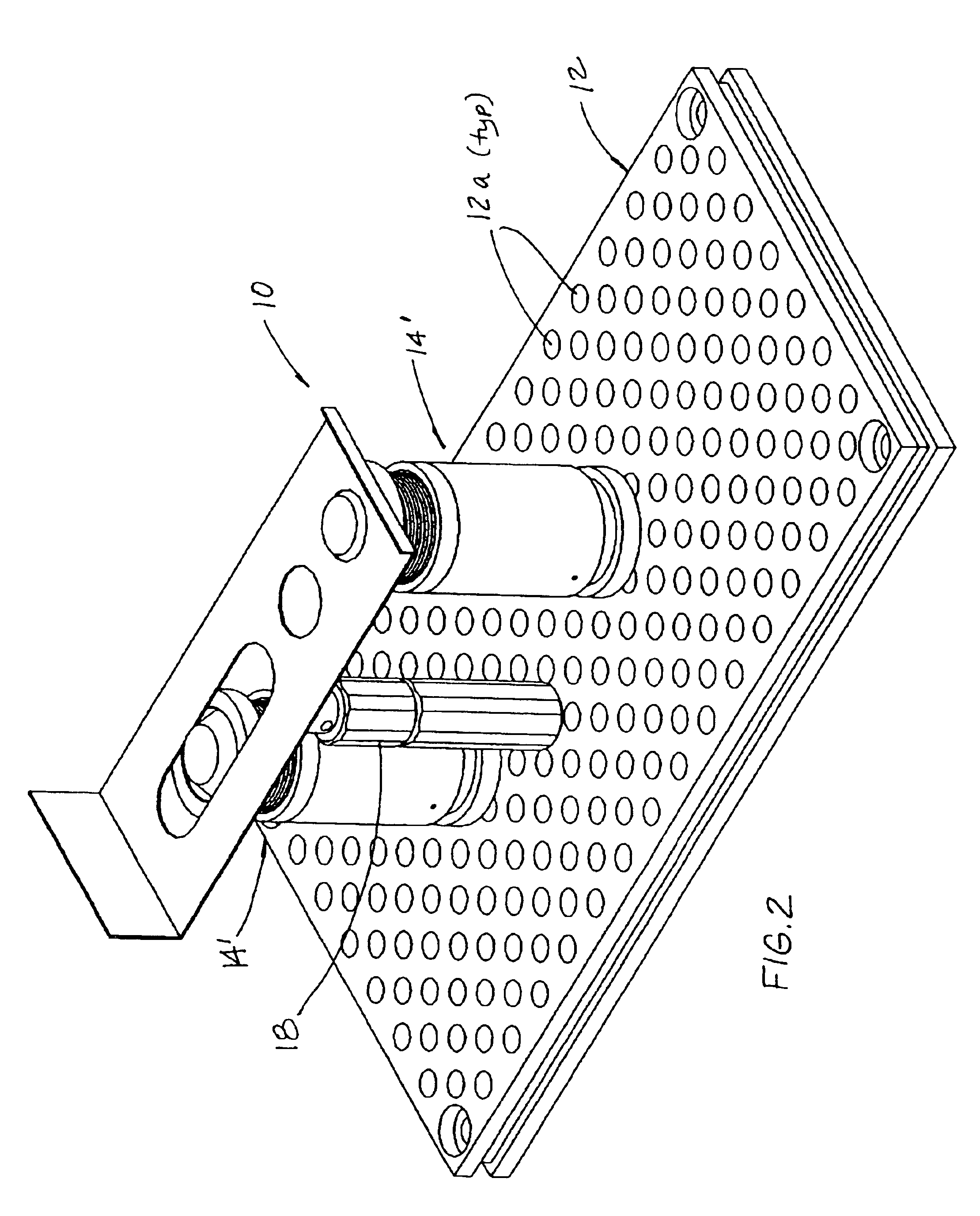

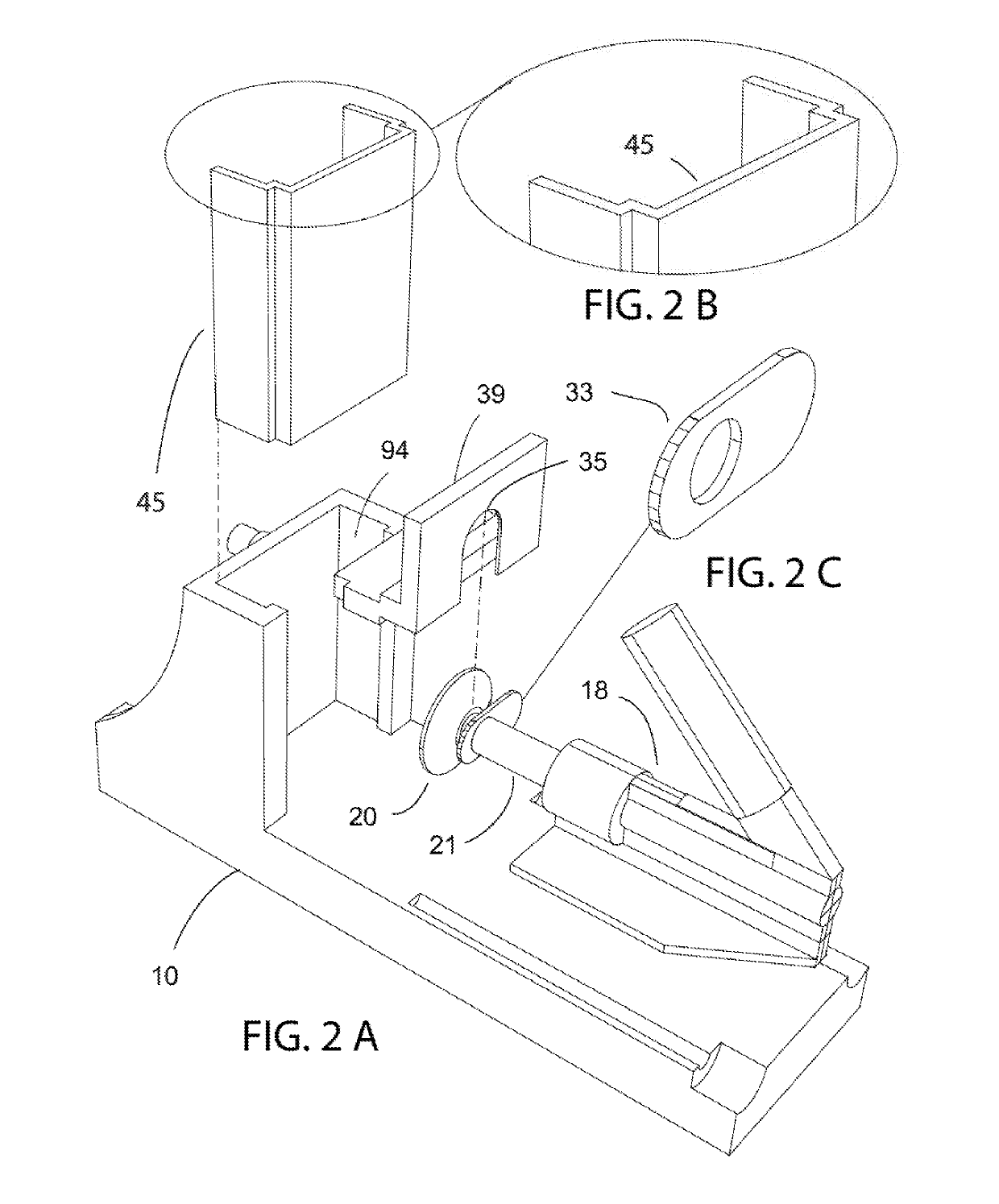

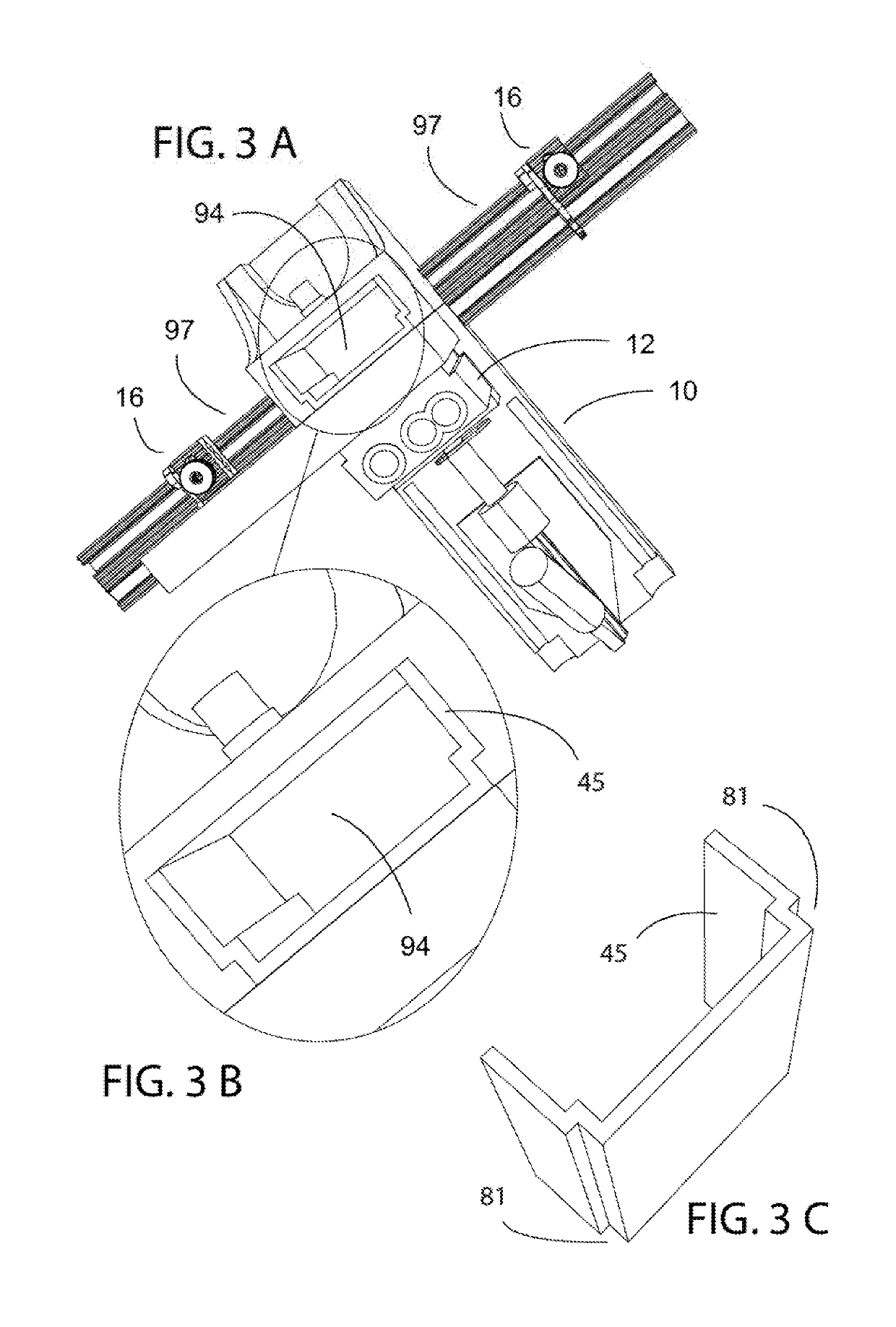

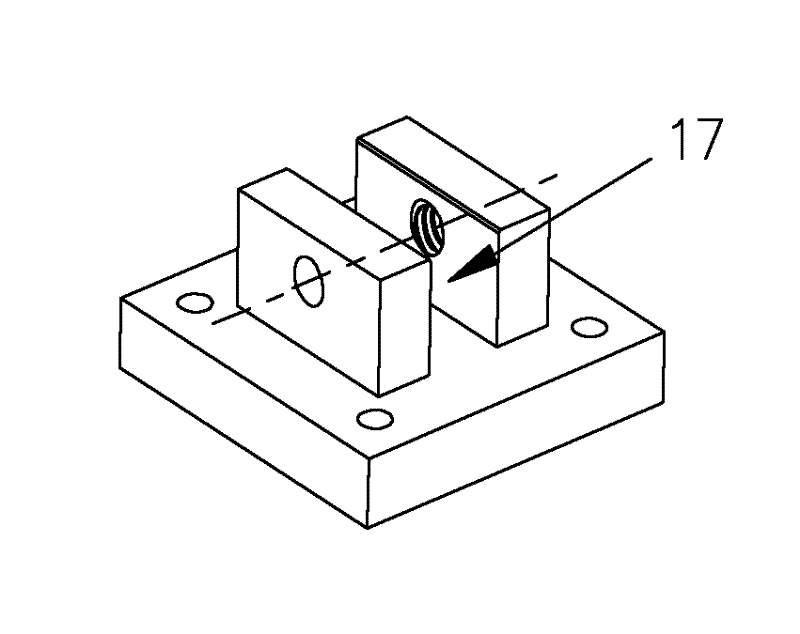

Modular tooling apparatus with tapered locater system

InactiveUS7036810B2Minimize the numberAvoid partialPrecision positioning equipmentLarge fixed membersModular fixtureEngineering

A modular fixturing apparatus component includes a body and a locator mechanism. The locator means is supported in the body for linear movement along the longitudinal axis of the body and for rotational movement about the longitudinal axis. The locator mechanism is provided to locate a center of an opening in an article undergoing inspection or the like. The modular fixturing apparatus component further includes a support surface that is provided at the body and that provides support for the article along the longitudinal axis. In this manner, when the component is mounted to a modular fixturing base plate, the fixturing apparatus component of the present invention provides a datum hole locator mechanism with a sliding action along the Z-axis and, further, provides Z-axis support for the article undergoing inspection or the like. Optionally, the locator mechanism may be rotationally locked to provide an additional, rotational restraint to the article undergoing inspection.

Owner:WAL III H JAMES VANDER

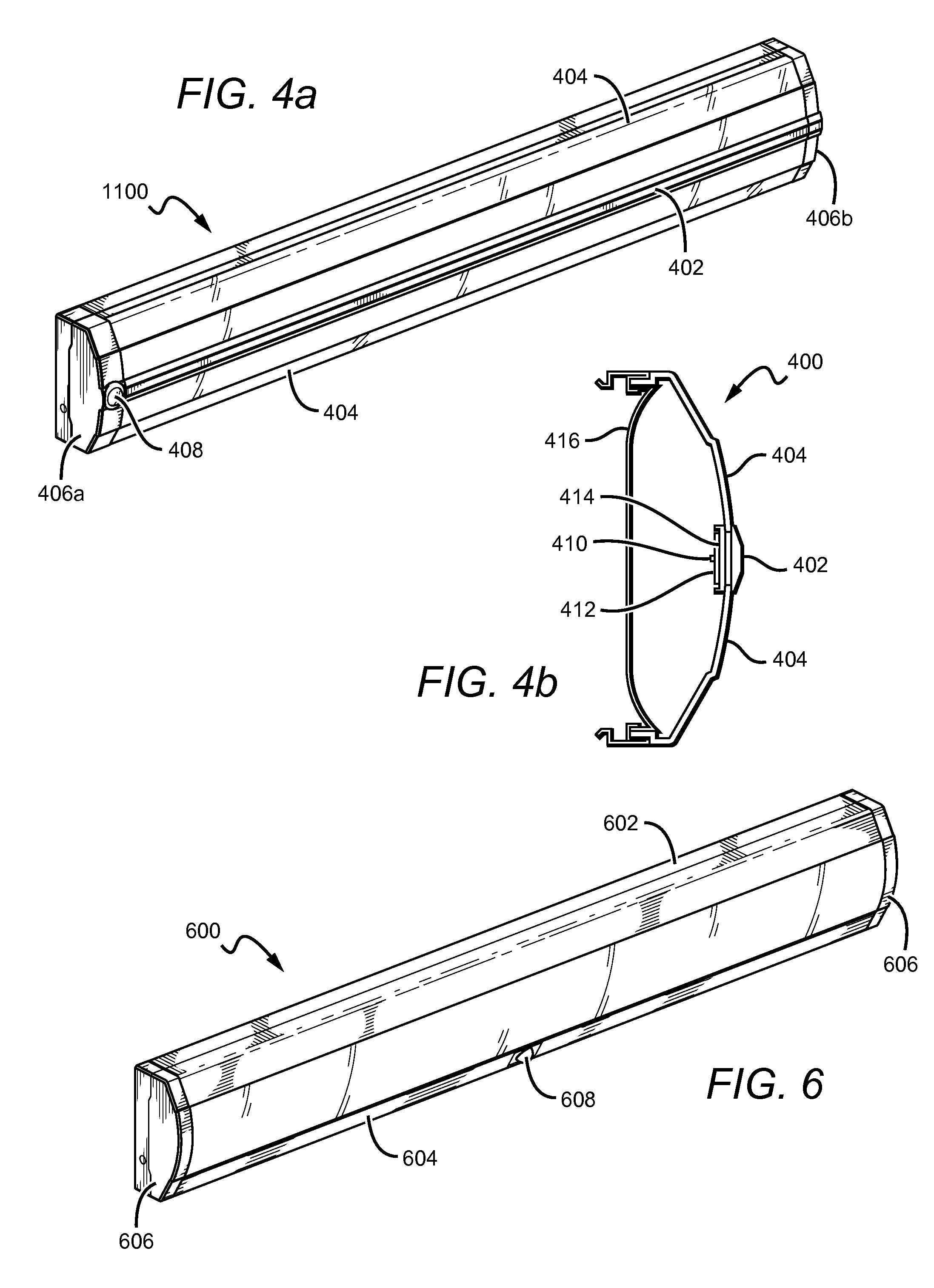

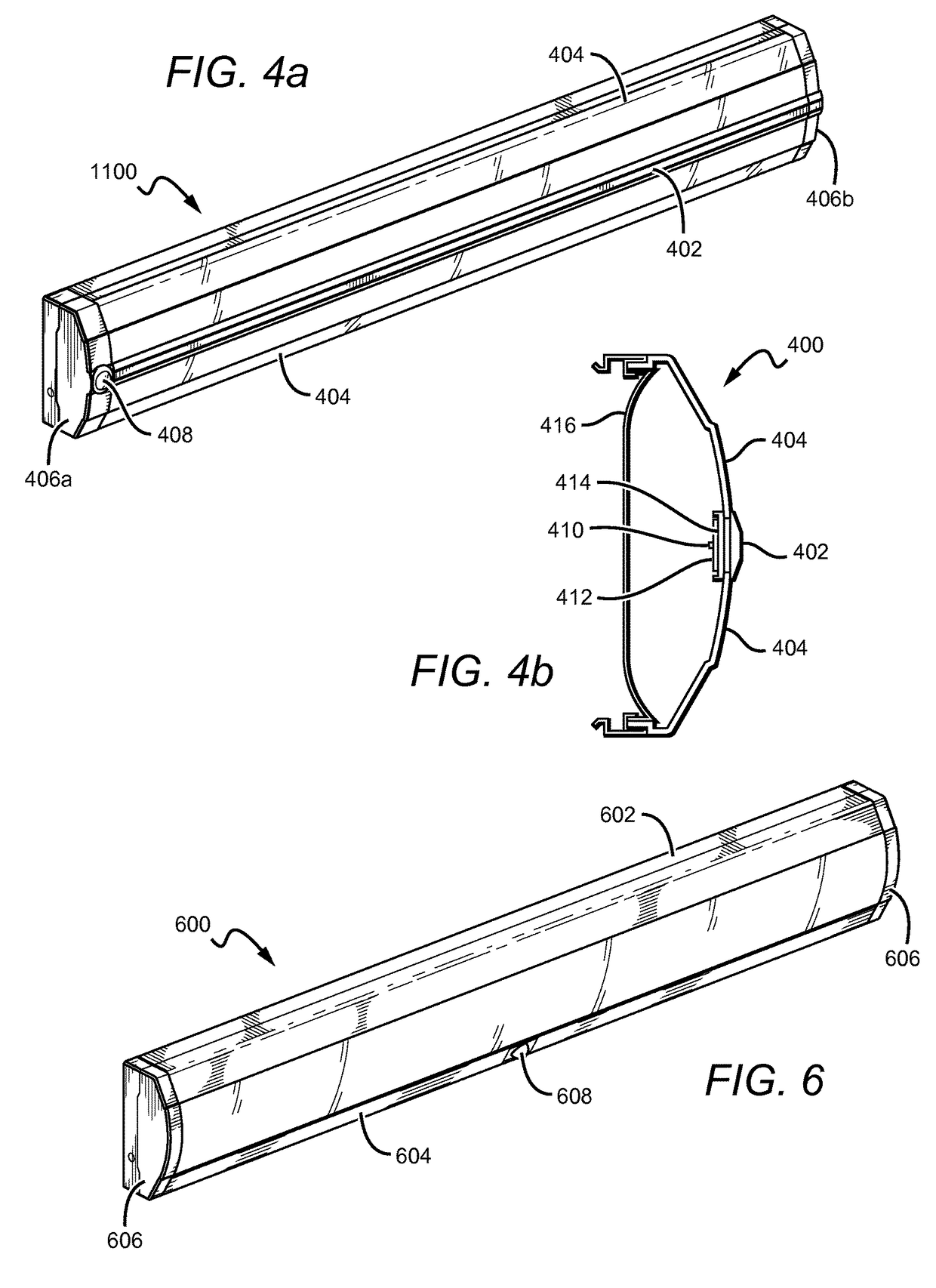

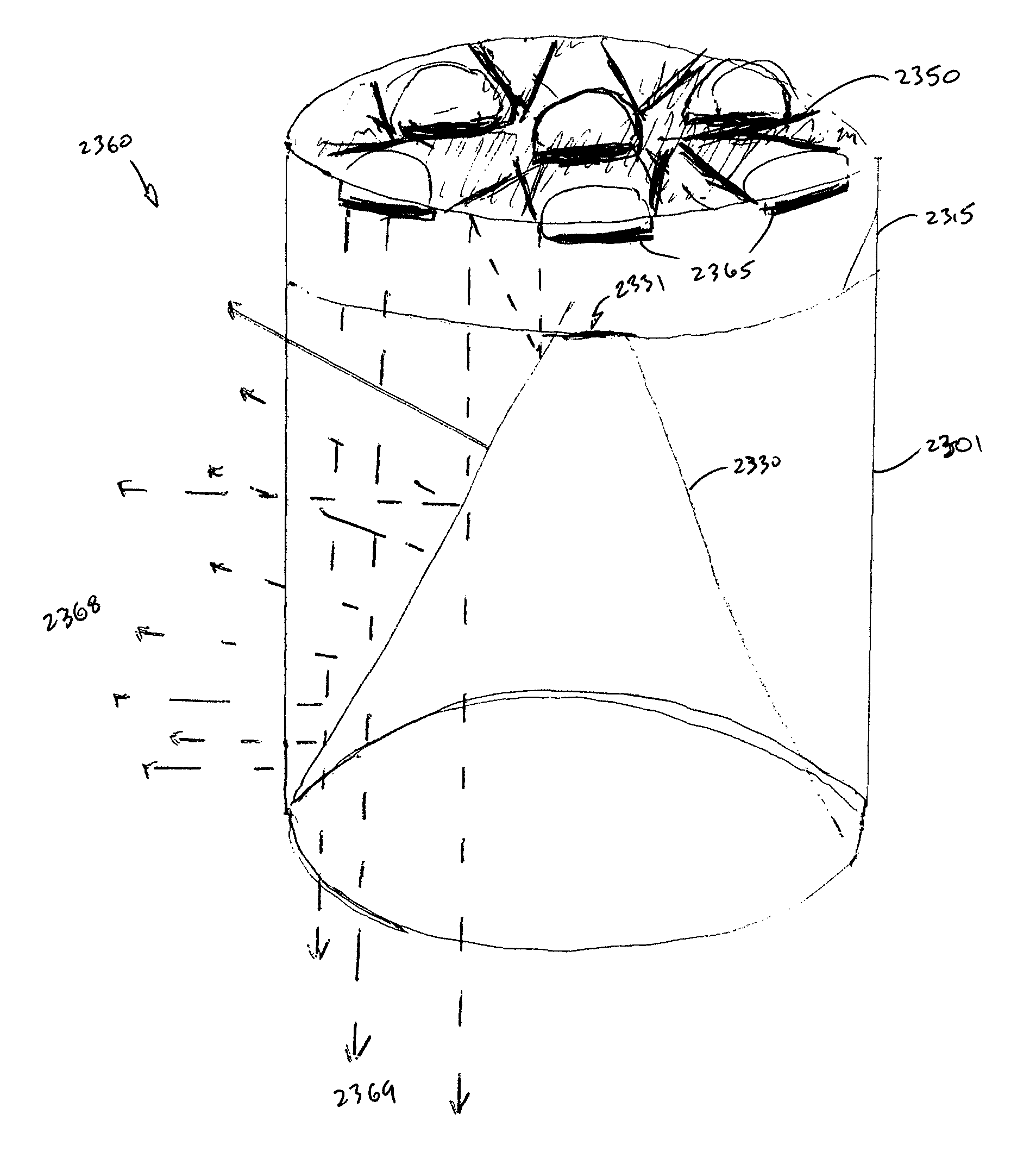

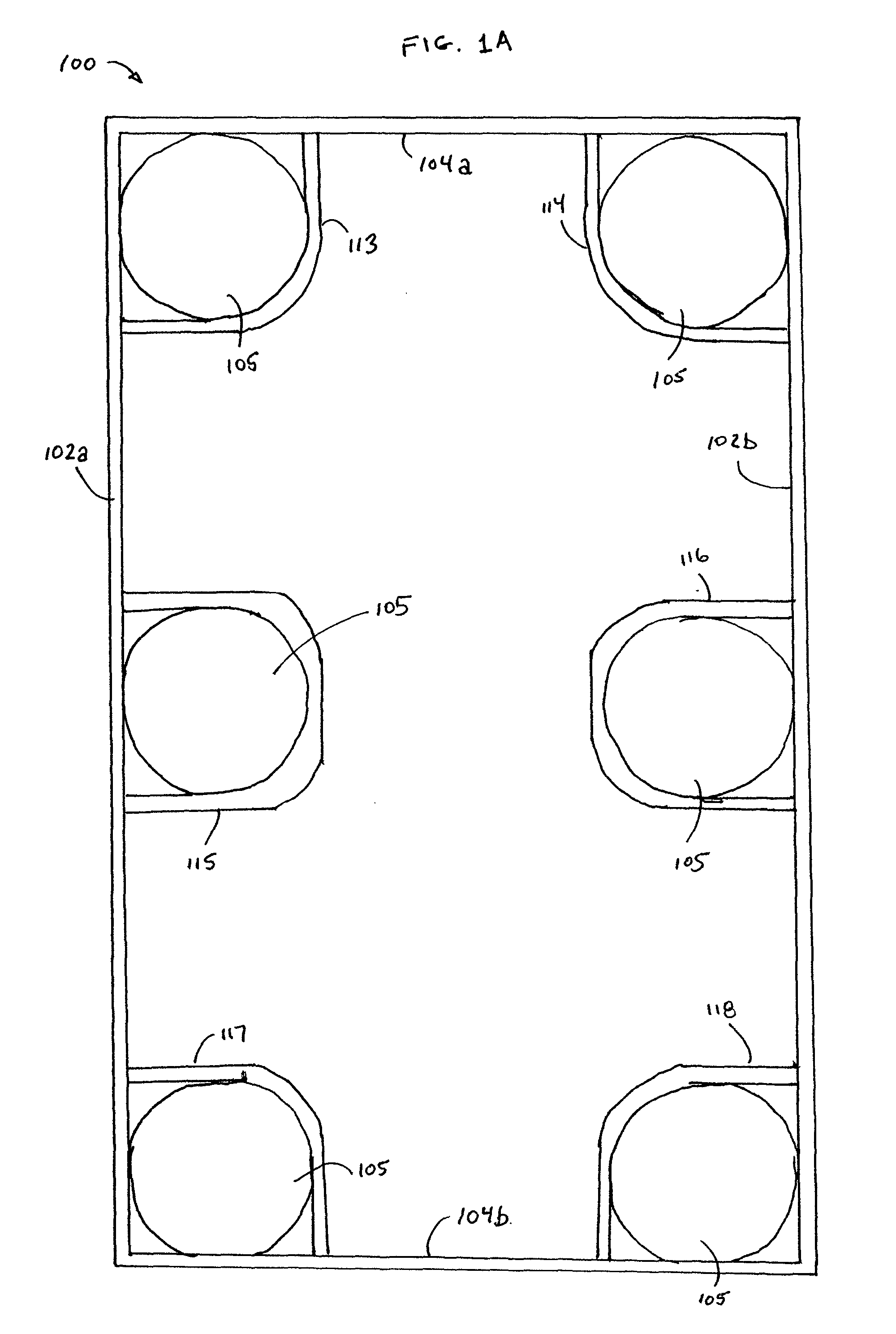

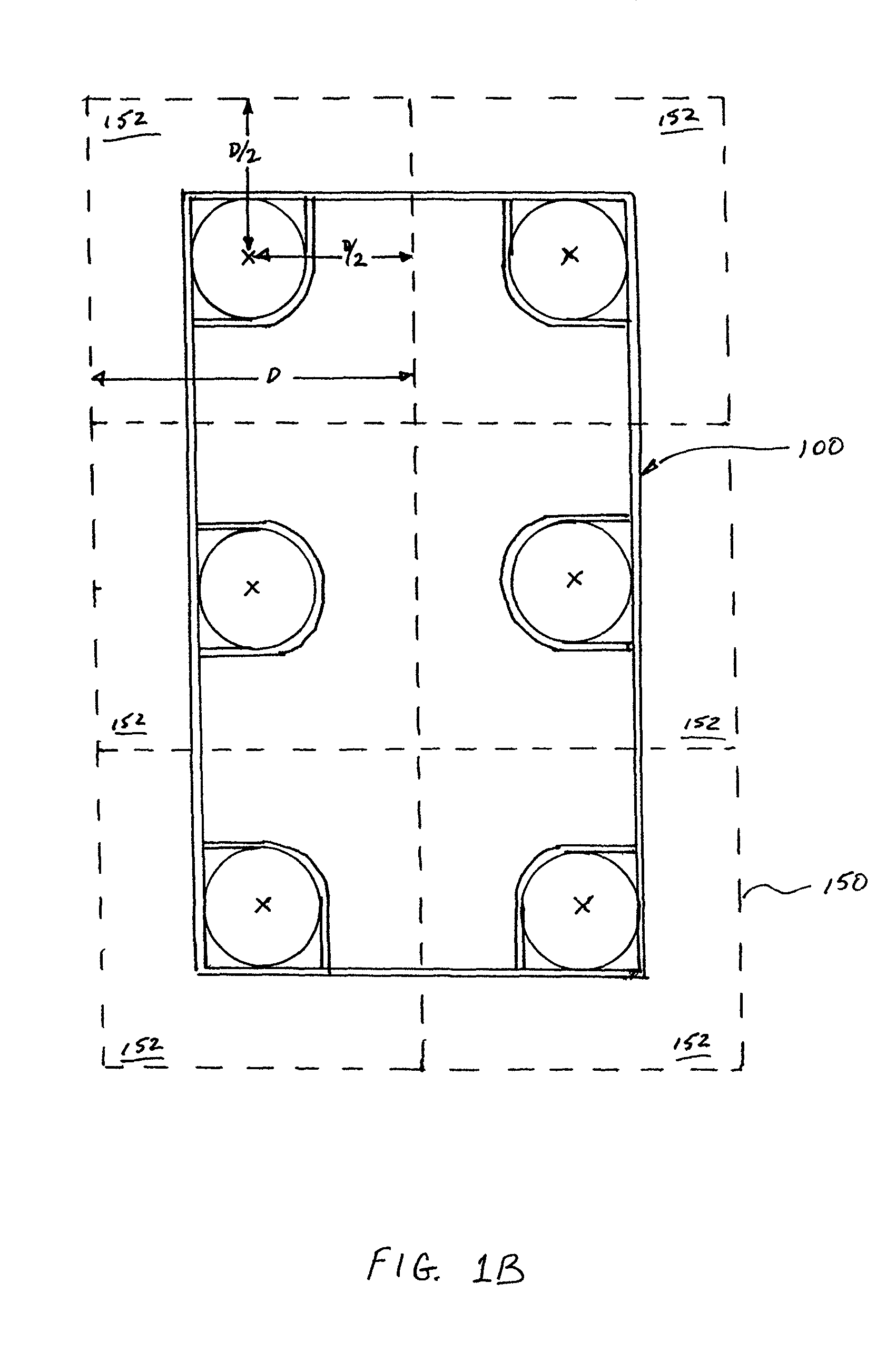

Versatile illumination system

InactiveUS20080079906A1Increase flexibilityImprove versatilityLighting applicationsMechanical apparatusModular fixtureEffect light

A lightweight, modular expandable multiple par lamp fixture configurable to form various sizes and intensities of high output area lighting or projected soft light. A high efficiency par lamp includes a high output globe and lightweight reflector, optional collar, and lens. Individual modular fixtures comprising high efficiency par lamps may be stacked to create larger units. The par lamps may be arranged in pods which can be assembled into larger units. A diffusion frame and fabric cover can be attached to the fixture in front of the par lamps to create a soft, deeply projected light. The diffusion frame may have an internal semi-translucent baffle to spread light through diffusive sidewalls.

Owner:FINN BRUCE L

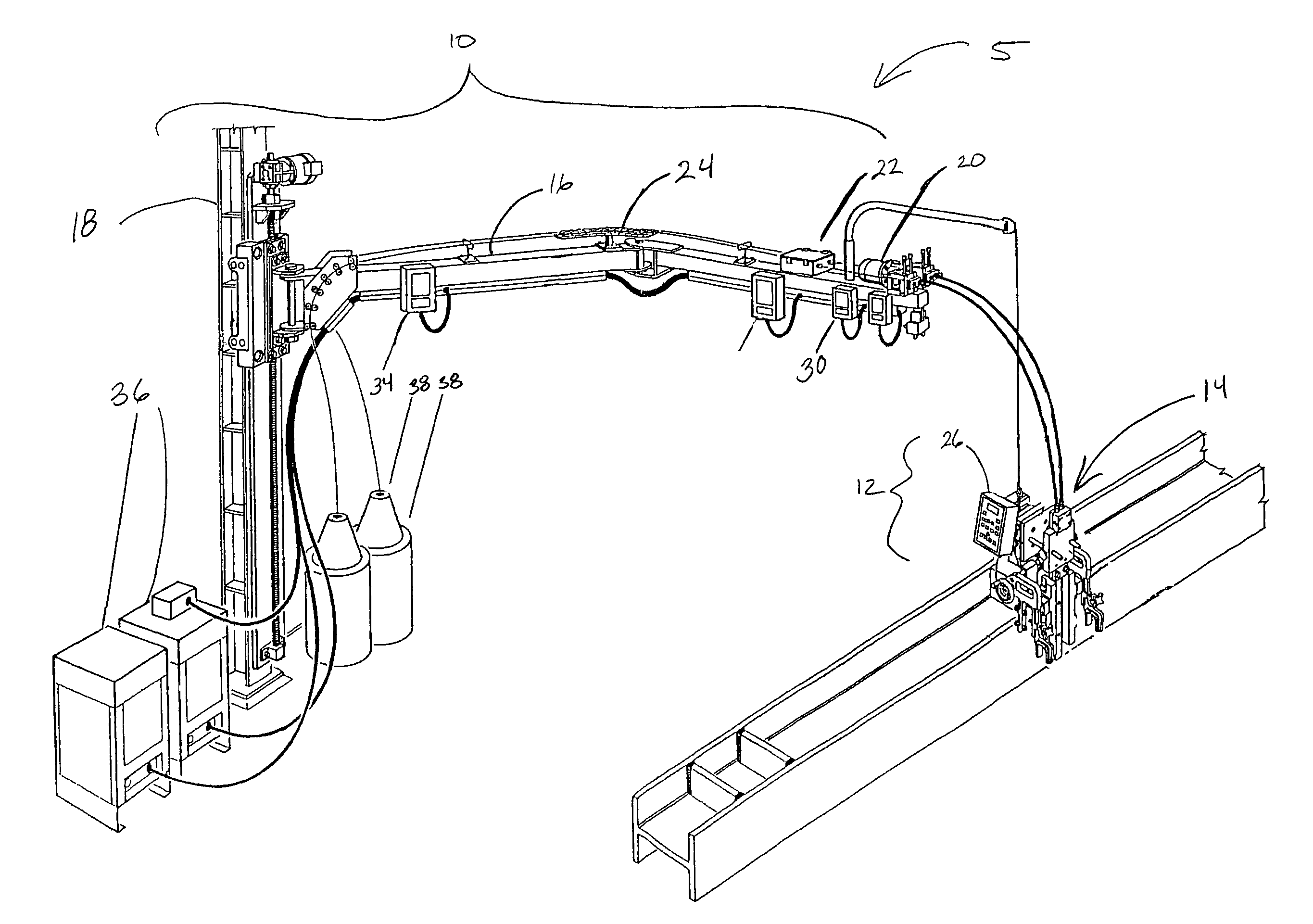

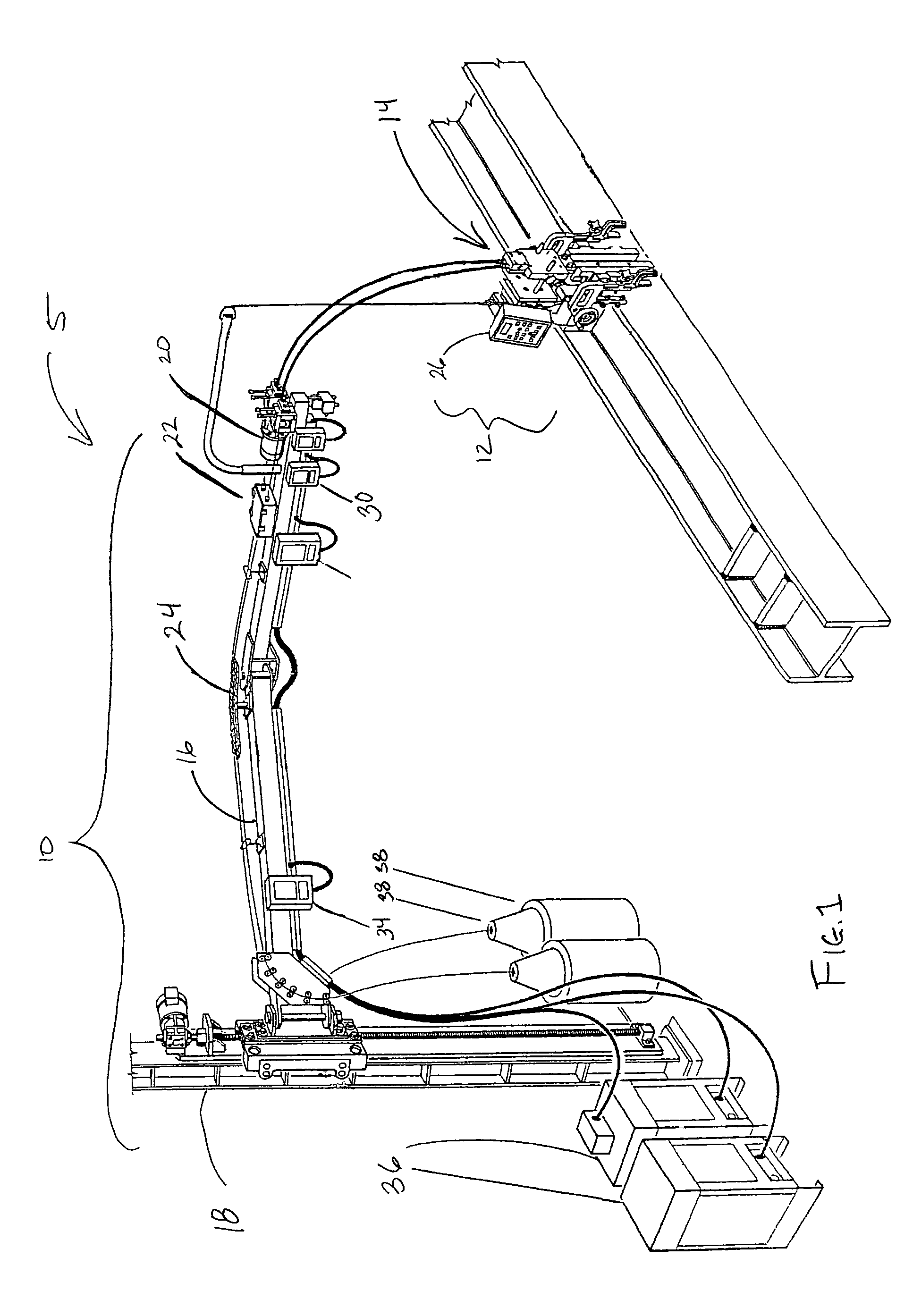

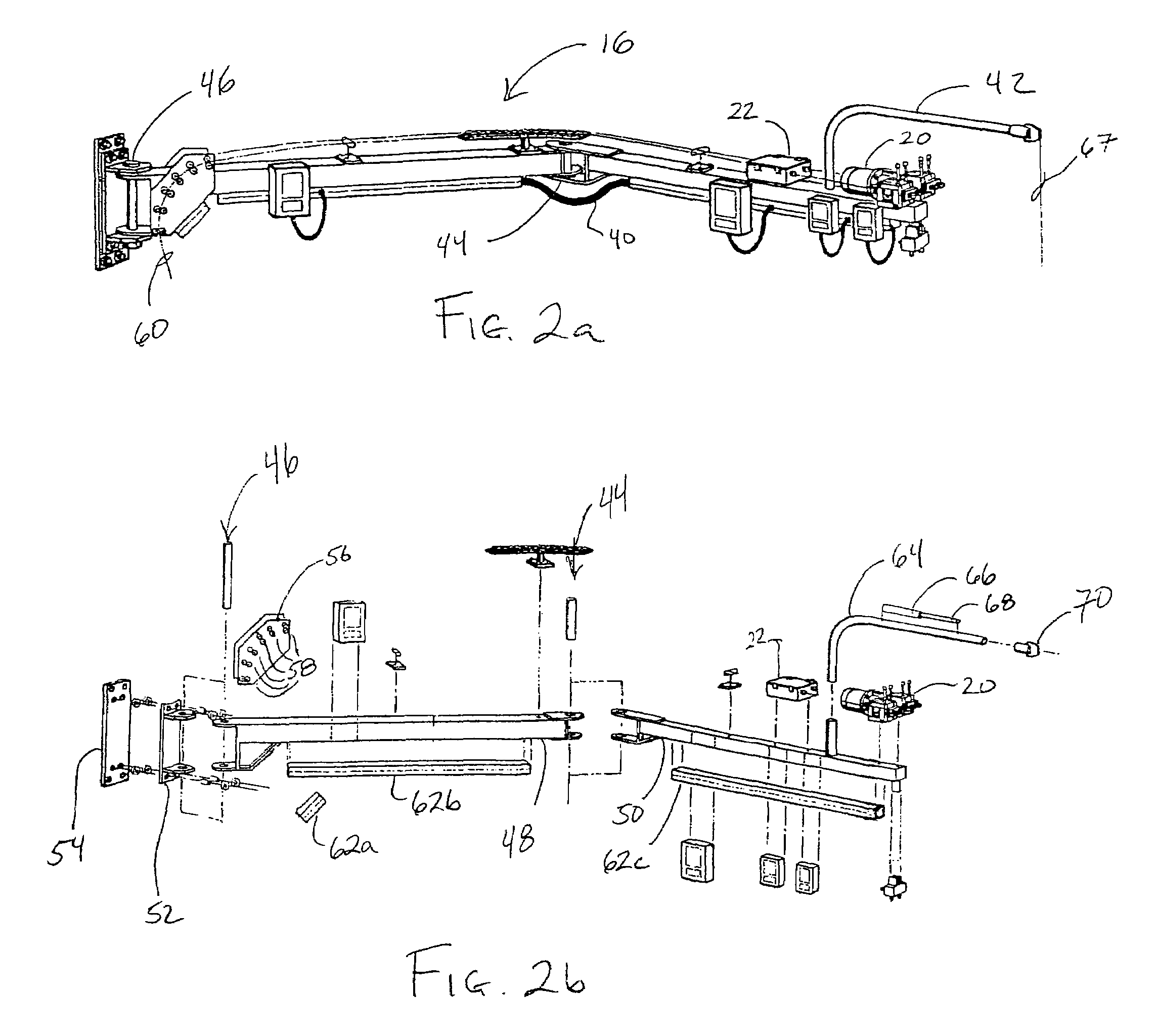

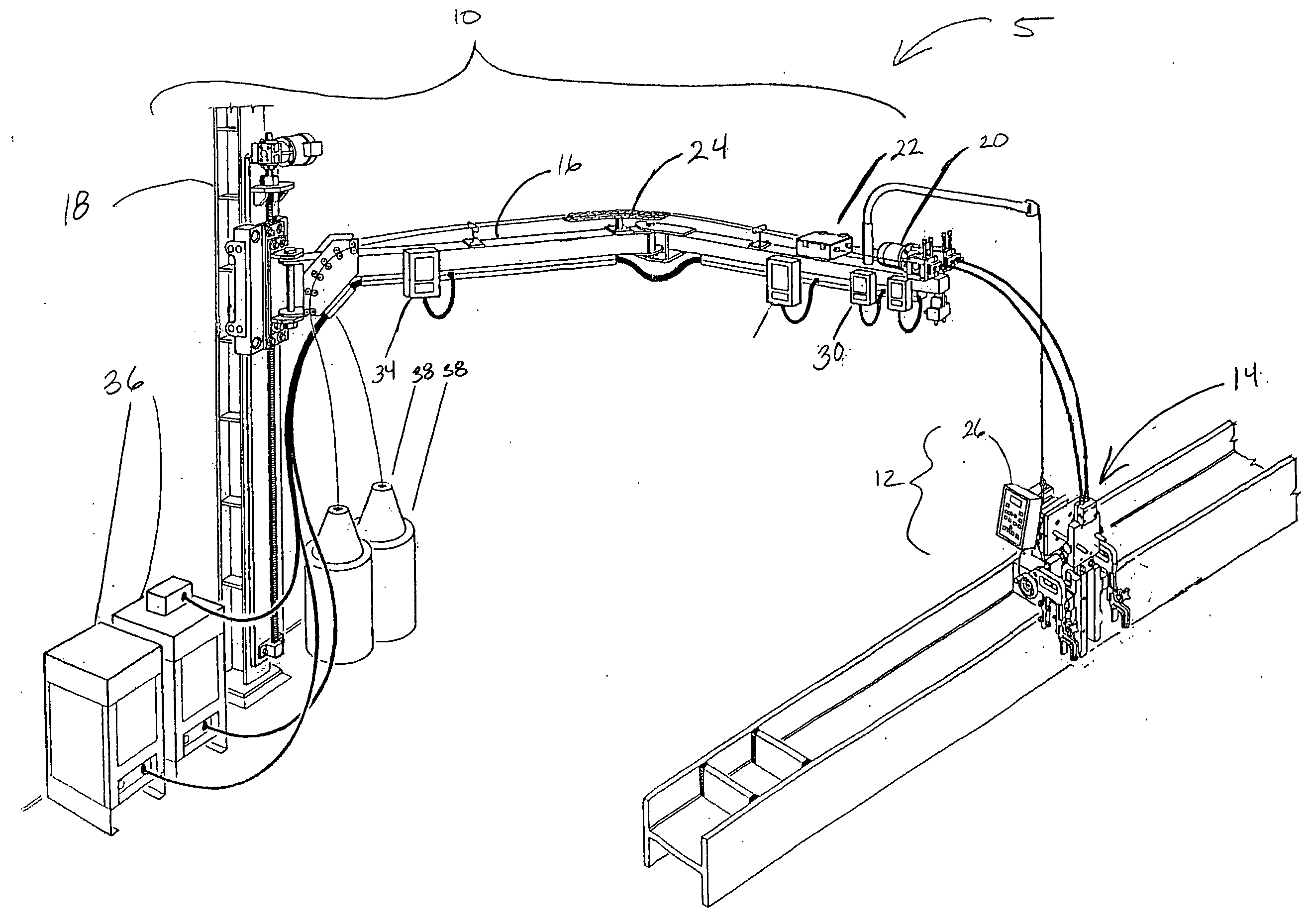

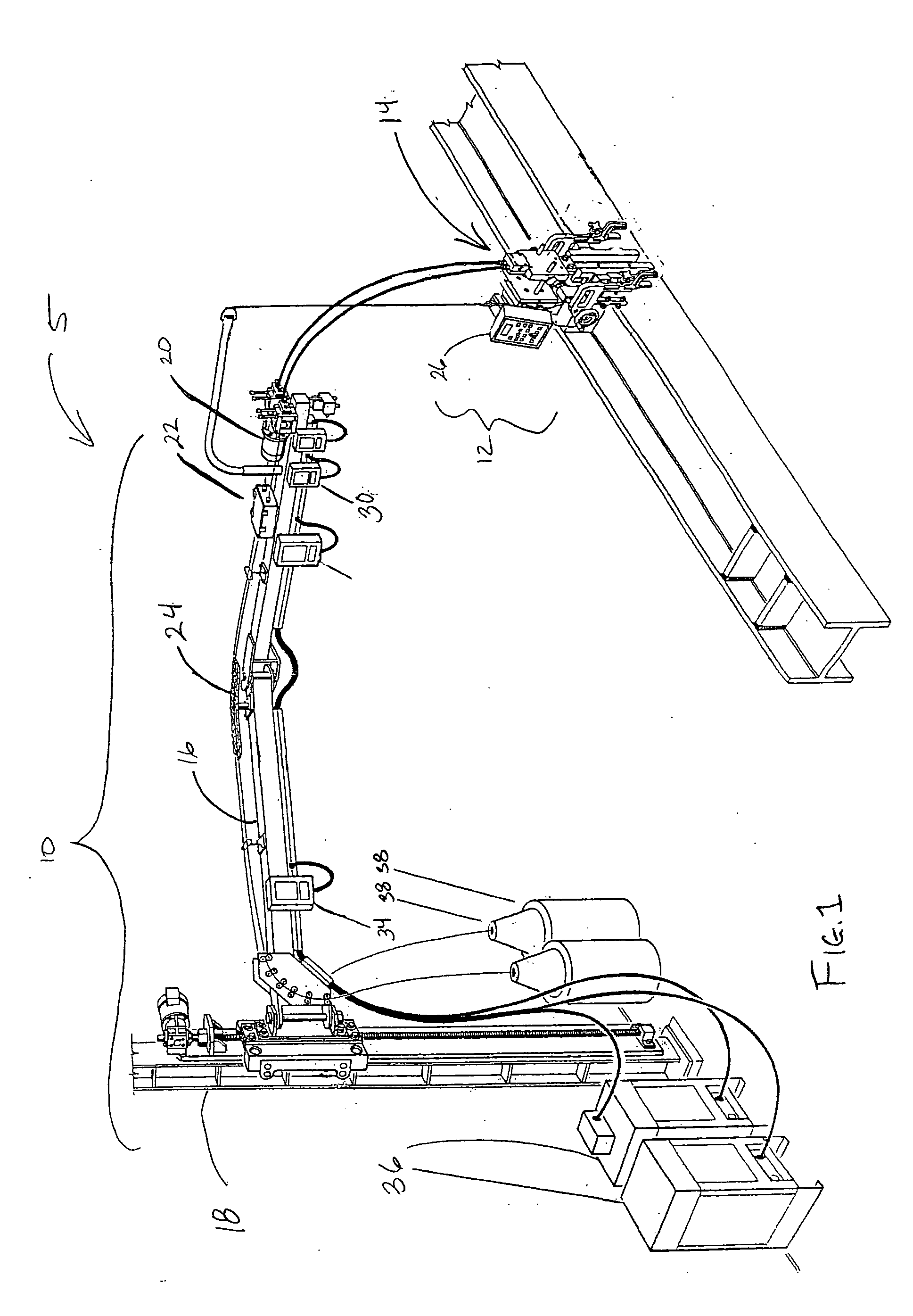

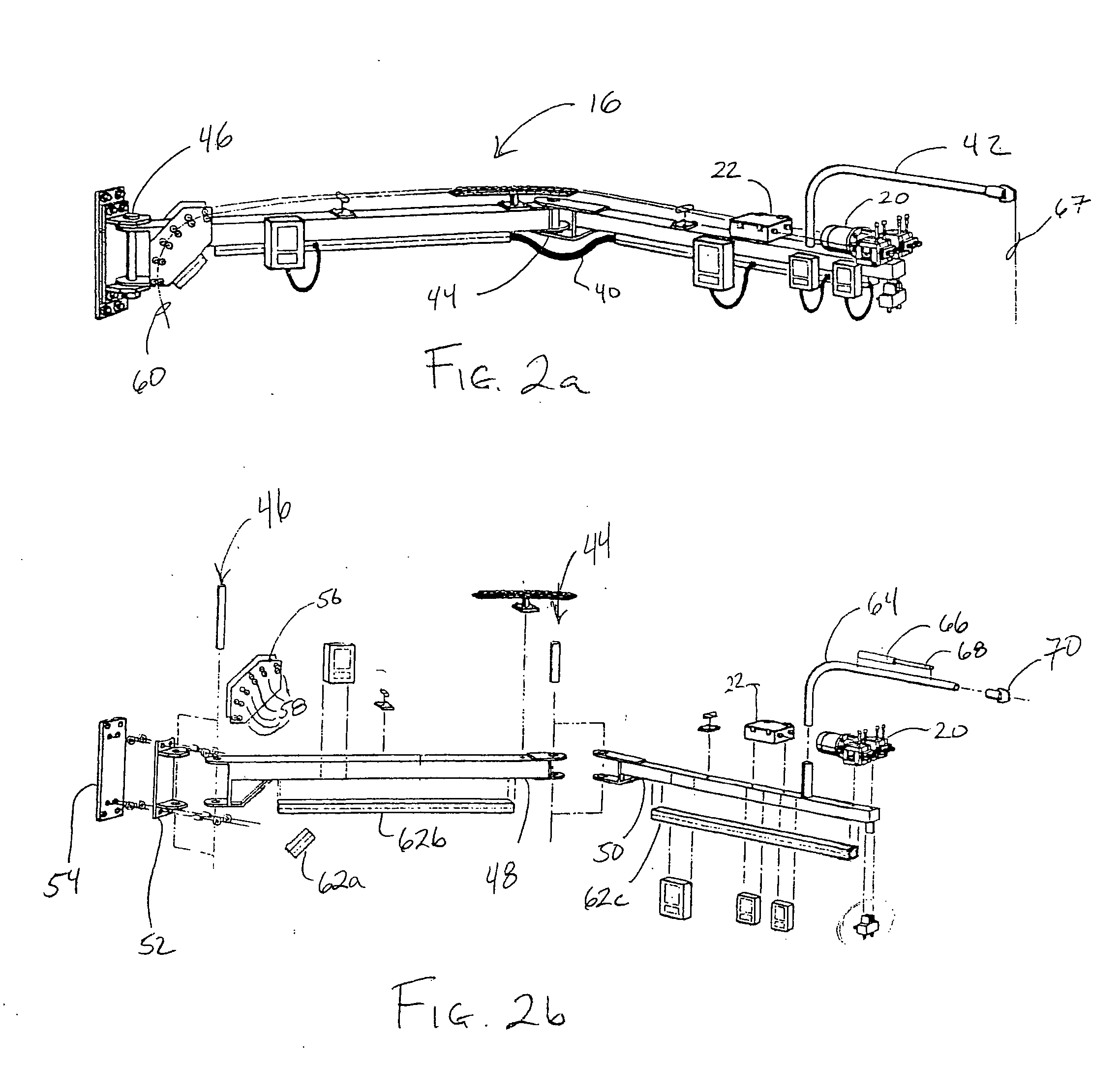

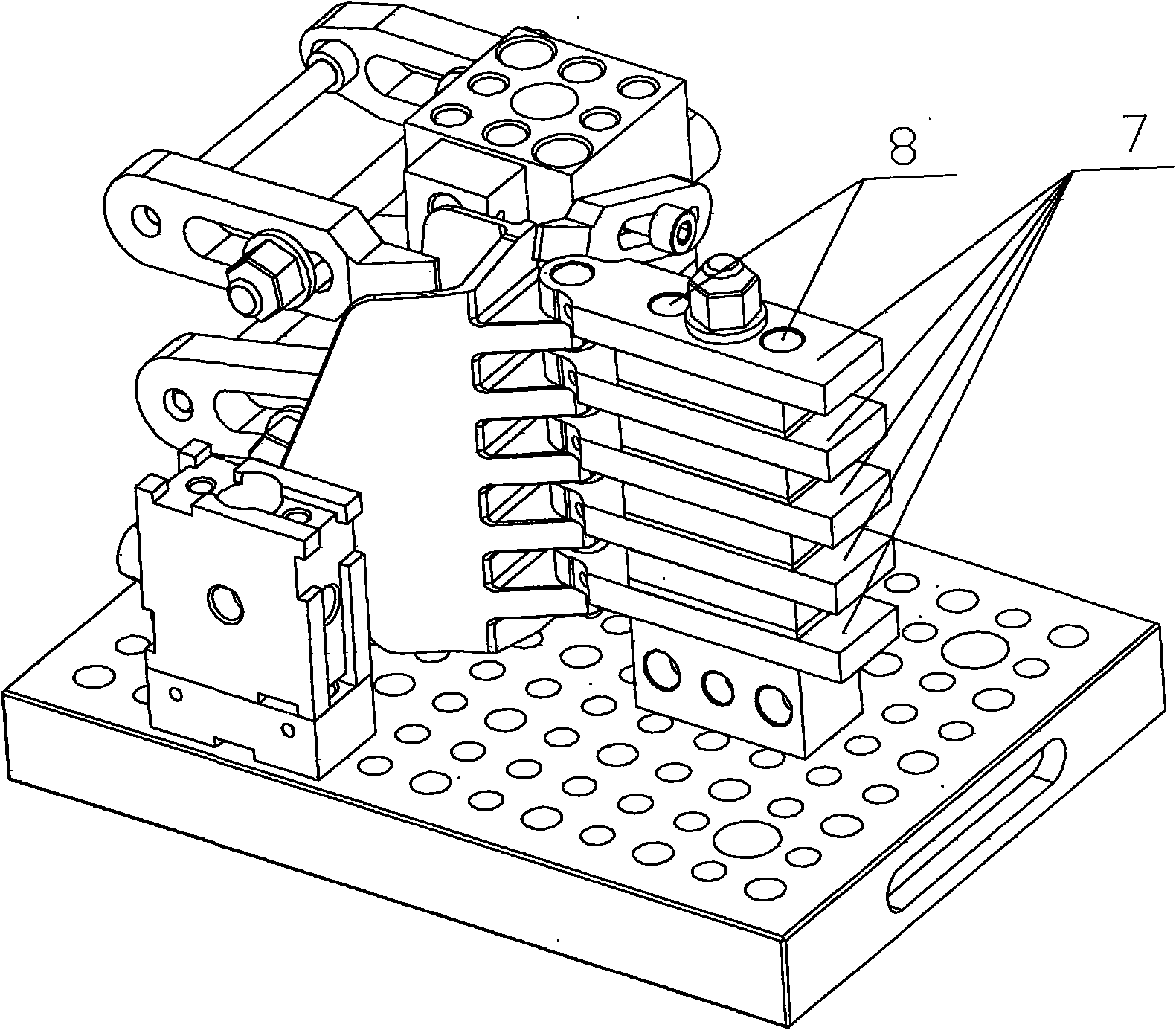

Modular welding system

InactiveUS7429716B2Quick and easy fabricationQuality improvementWelding/cutting auxillary devicesArc welding apparatusModular fixtureModularity

A modular welding system for performing quick, easy and high quality welds. The modular welding system comprises a basic component system and a modular fixture component system. The basic component system provides the basic components which are needed to perform a quality weld efficiently. The modular fixture component system interfaces with the basic component system and provides a particular welding fixture assembly that performs a particular type of weld. More particularly, a stiffener type modular fixture component system and a butt / tee type modular fixture system are described. However, any other particular fixture type system may be integrated with the basic component system of the present invention.

Owner:ESKANDARI AMIR

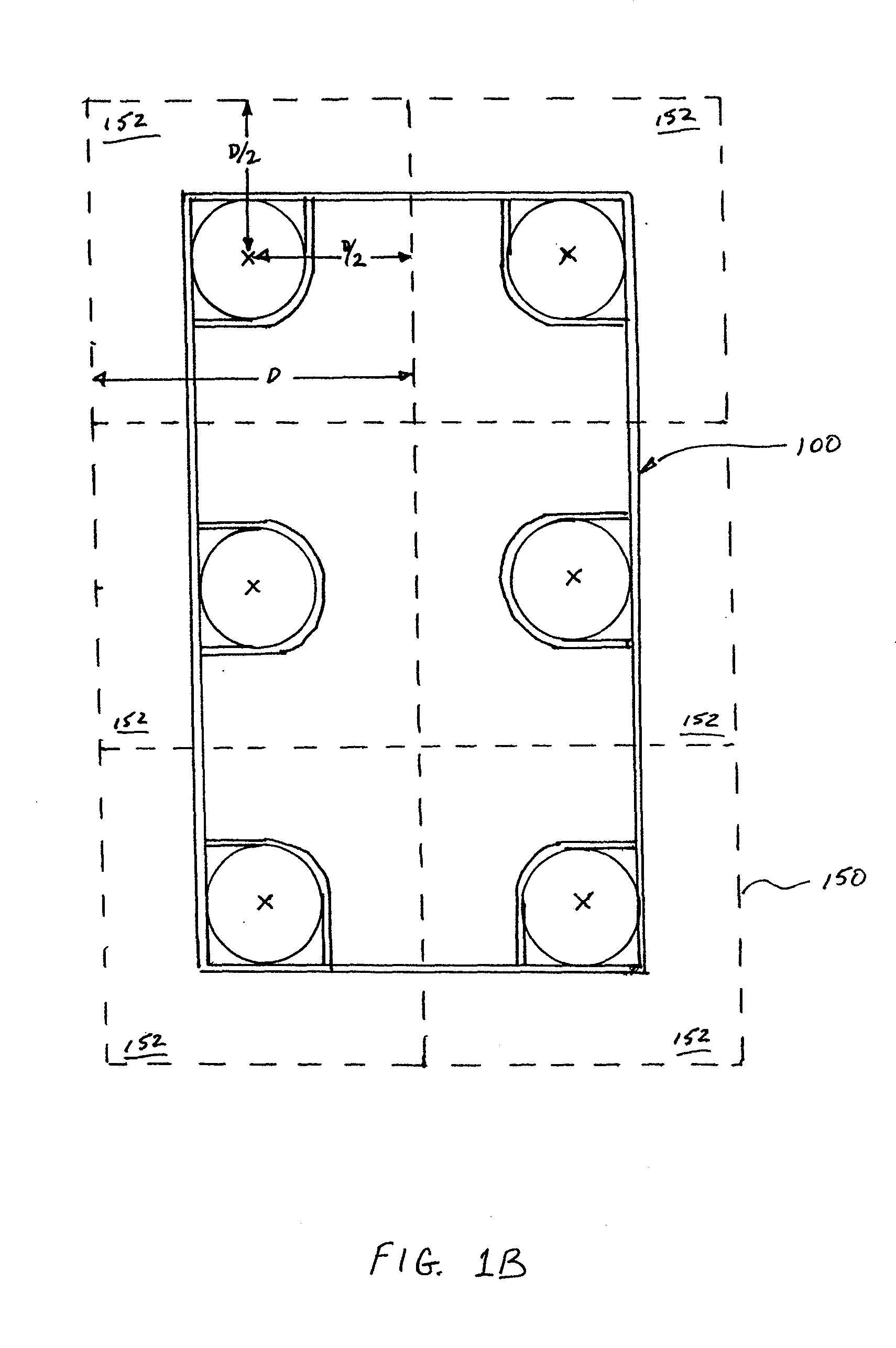

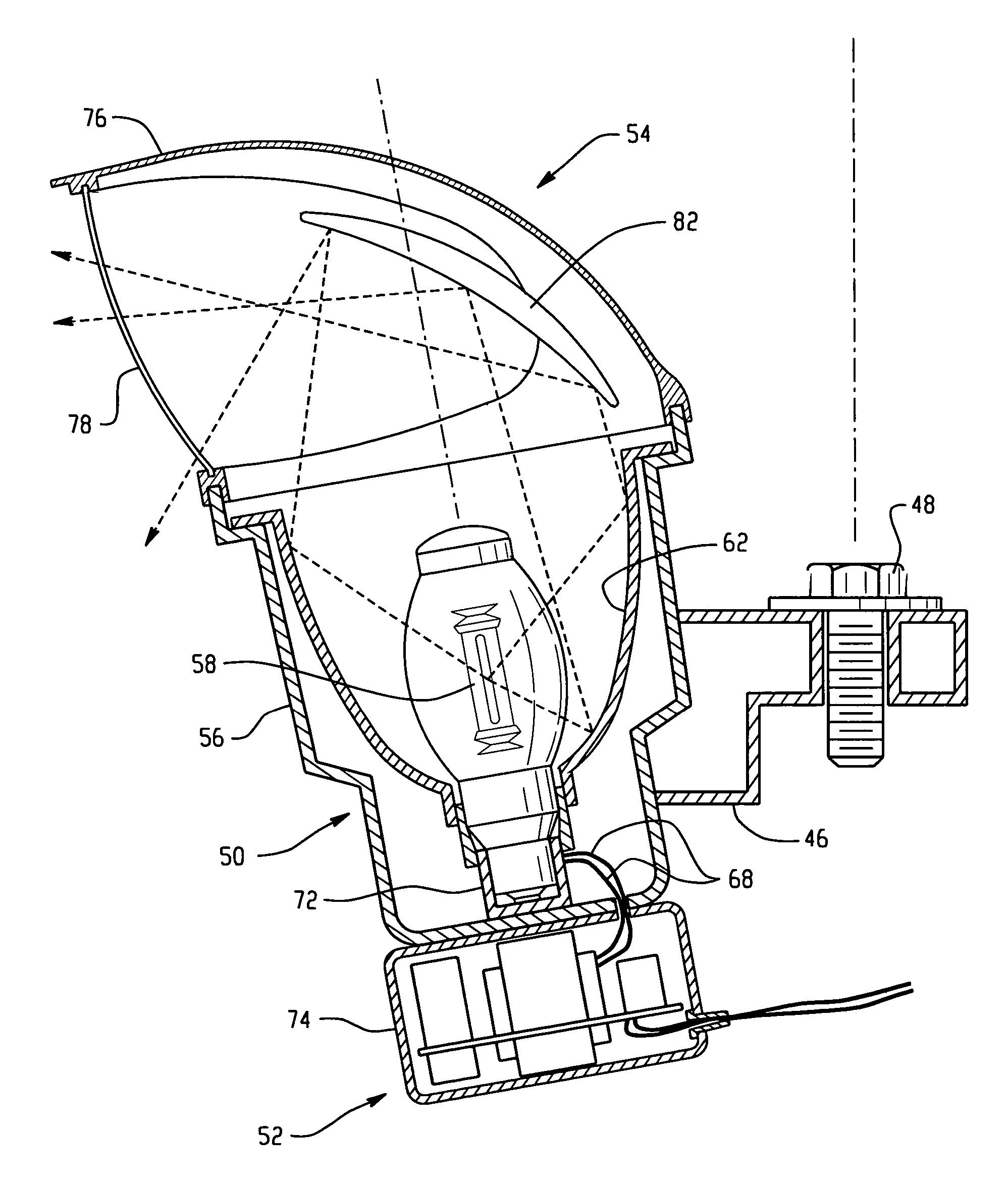

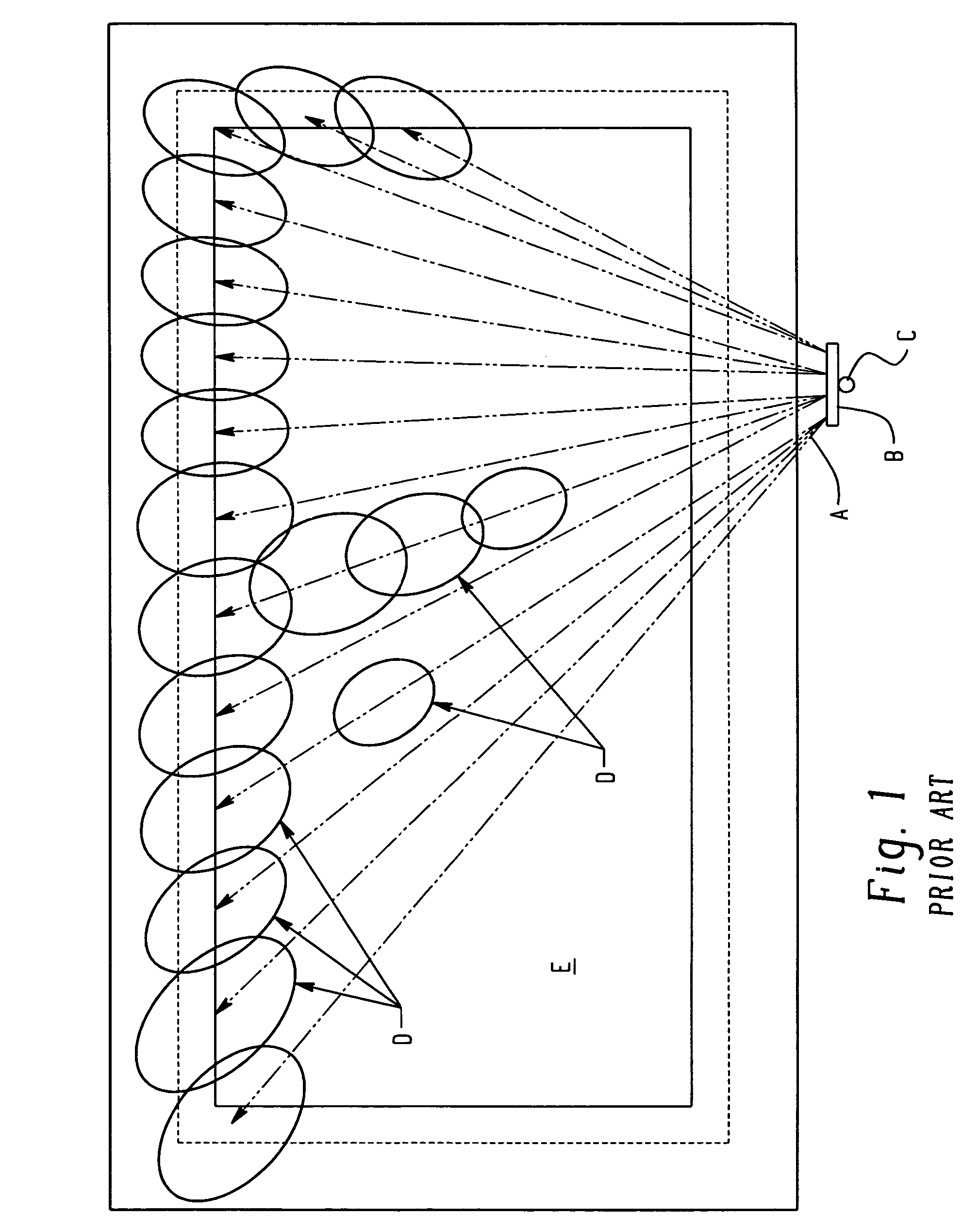

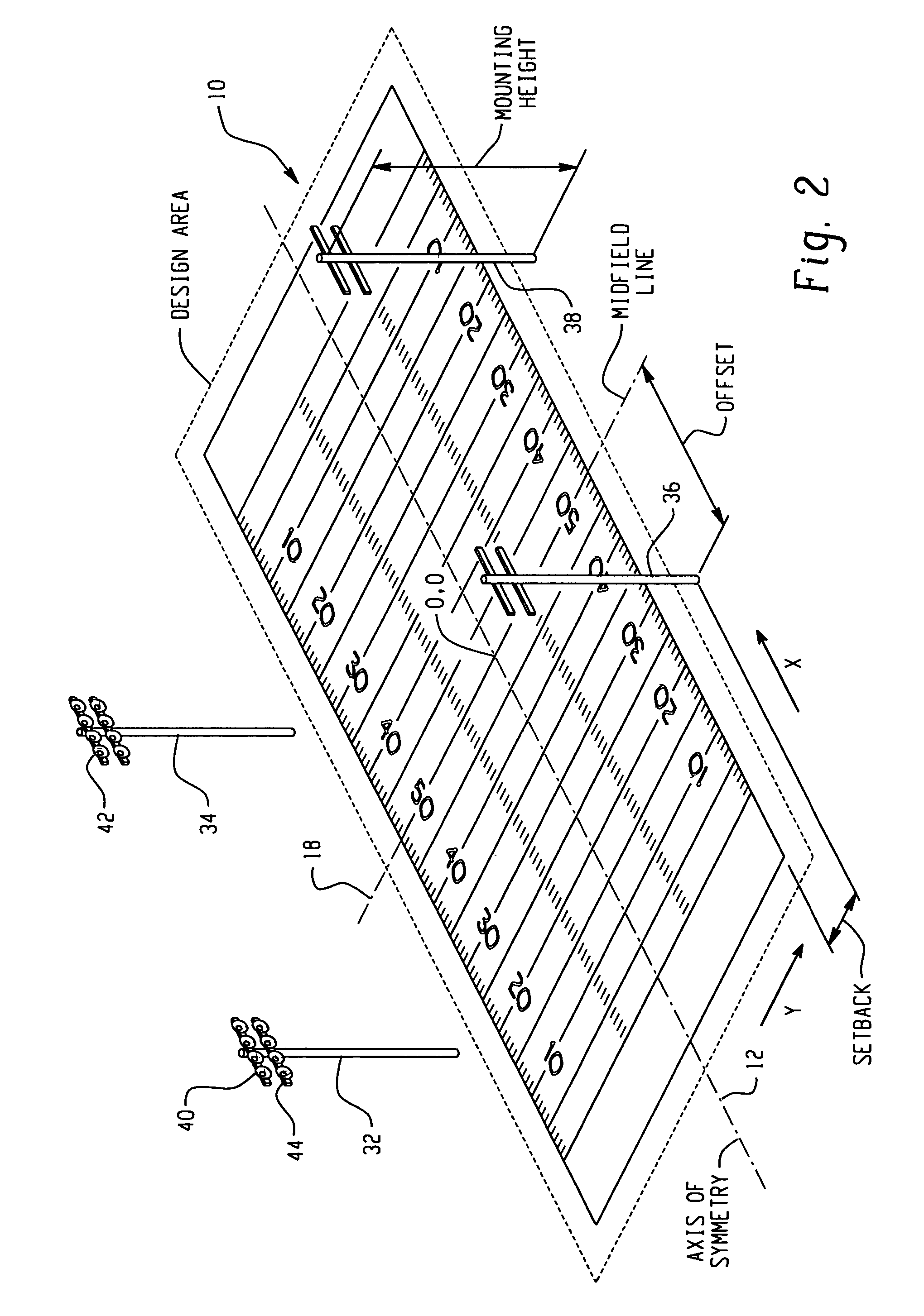

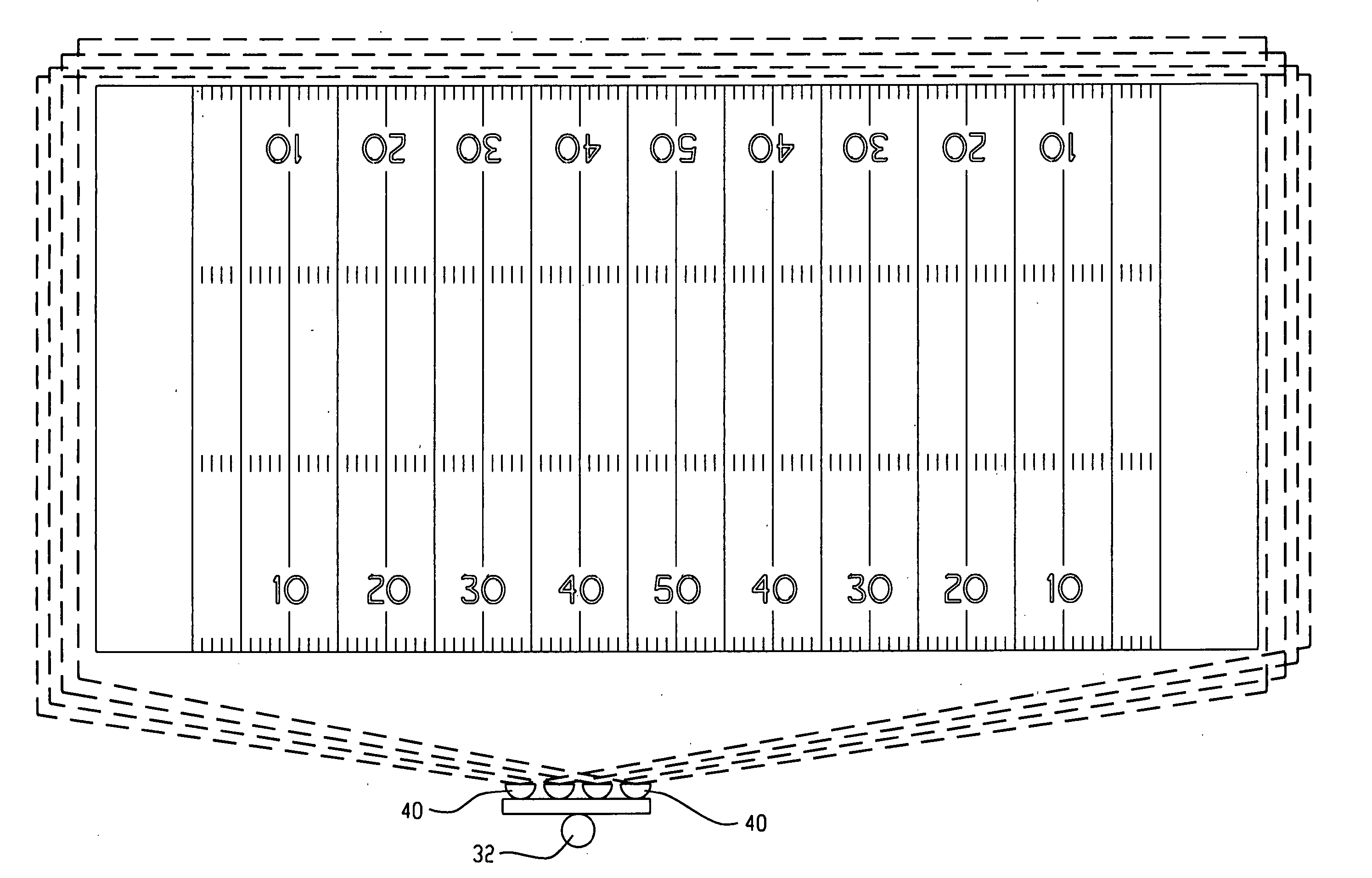

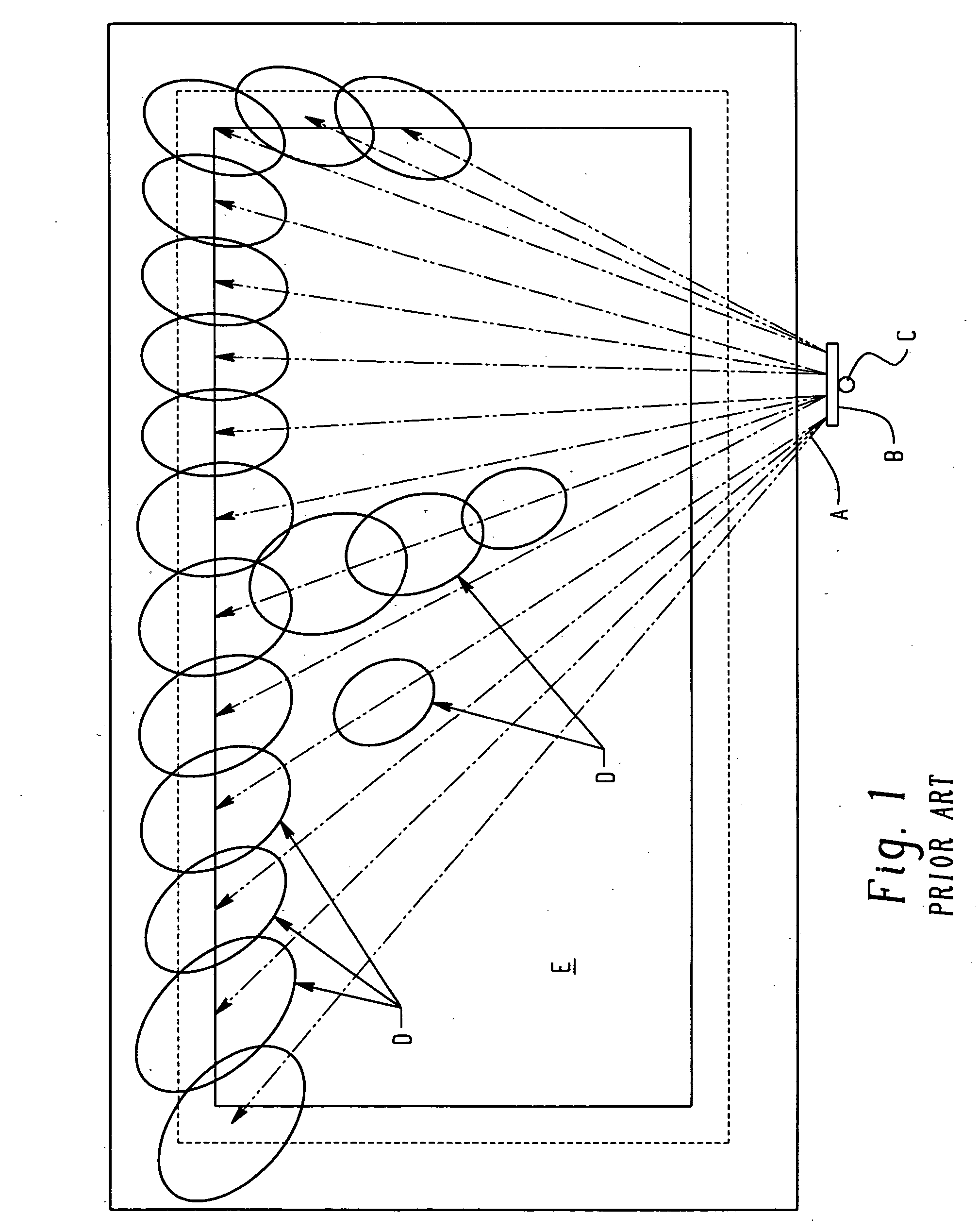

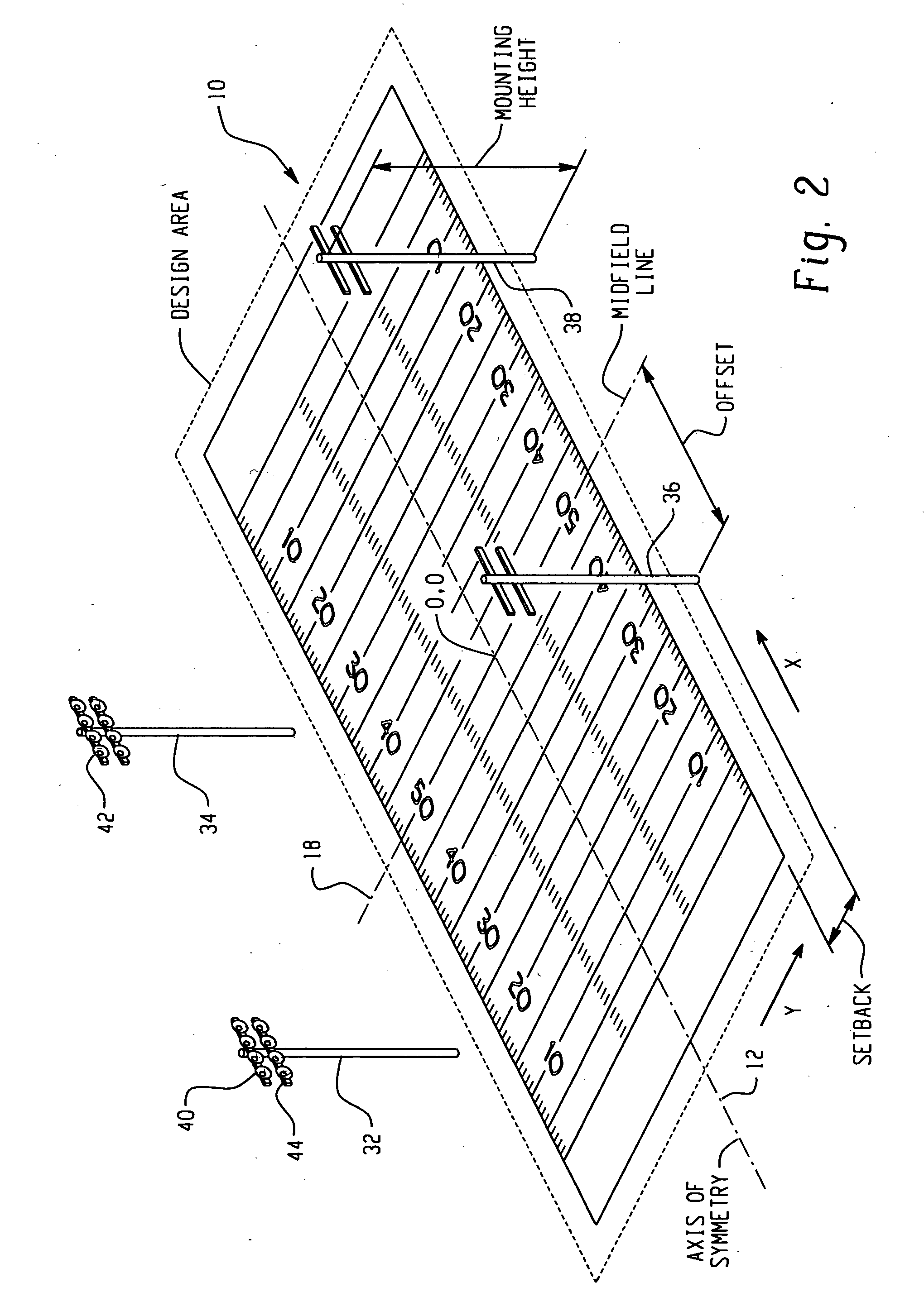

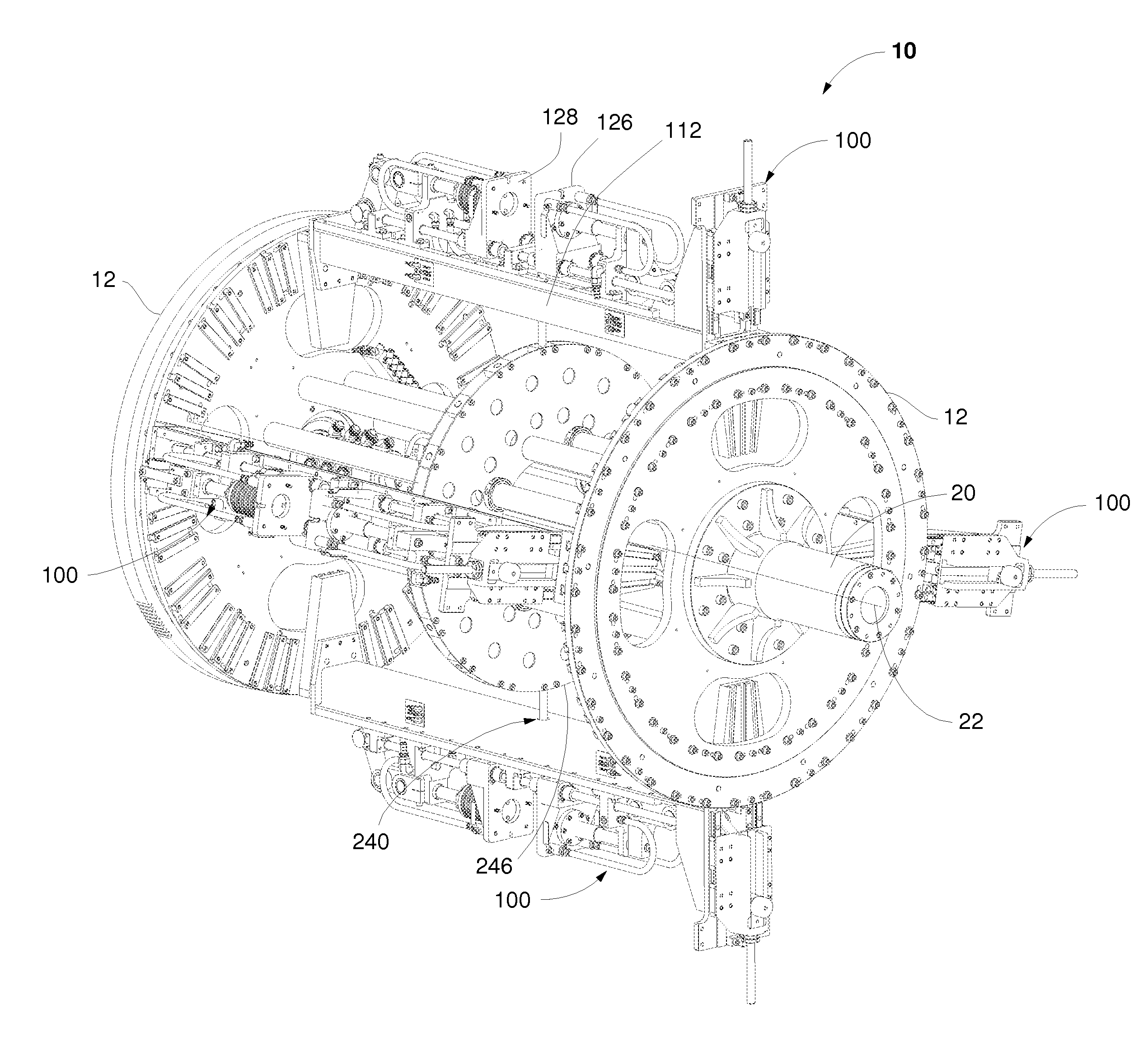

Modular fixture and sports lighting system

InactiveUS7540629B2Easy to assembleEasy to installLighting applicationsMechanical apparatusModular fixtureEffect light

A light fixture includes a lamp engine, an electronic module connected to the lamp engine and a photometric module mounted to the light engine. The electronic module is connected to the light source and an associated power source for providing power to the light source. The photometric module mounts to the light engine and creates a beam pattern that illuminates a substantial portion of an entire associated subject area. The method of illuminating a large area includes determining a subject area to be illuminated by a plurality of light sources and determining a desired lighting criteria for the subject area. A first light source is provided and light emitted from the first light source is directed to illuminate the subject area. Additional light sources are provided and directed to provide additional light to illuminate the same portion of the subject area until the desired lighting criteria are met.

Owner:GENERAL ELECTRIC CO

Surface ambient wrap light fixture

A modular fixture that is well-suited for use with solid state light sources, such as LEDs, to provide a surface ambient light (SAL). The fixture comprises two structural components: a housing subassembly and a lighting subassembly. These two subassemblies may be removably attached to operate as a singular fixture. Many different lighting subassemblies may be compatible with a single housing subassembly and vice versa. The housing subassembly comprises a frame that is mountable to an external structure. The lighting subassembly comprises the light sources and optical elements that tailor the light to achieve a particular profile. Electronics necessary to power and control the light sources may be disposed in the lighting subassembly. Various mount mechanisms may be used to attach the fixture to a surface such as a ceiling or a wall. Multiple fixtures can be connected serially to provide an extended linear fixture.

Owner:IDEAL IND LIGHTING LLC

Modular fixture and sports lighting system

InactiveUS20060139659A1Easy to assembleFacilitates lighting system installationLighting applicationsMechanical apparatusModular fixtureEffect light

A light fixture includes a lamp engine, an electronic module connected to the lamp engine and a photometric module mounted to the light engine. The electronic module is connected to the light source and an associated power source for providing power to the light source. The photometric module mounts to the light engine and creates a beam pattern that illuminates a substantial portion of an entire associated subject area. The method of illuminating a large area includes determining a subject area to be illuminated by a plurality of light sources and determining a desired lighting criteria for the subject area. A first light source is provided and light emitted from the first light source is directed to illuminate the subject area. Additional light sources are provided and directed to provide additional light to illuminate the same portion of the subject area until the desired lighting criteria are met.

Owner:GENERAL ELECTRIC CO

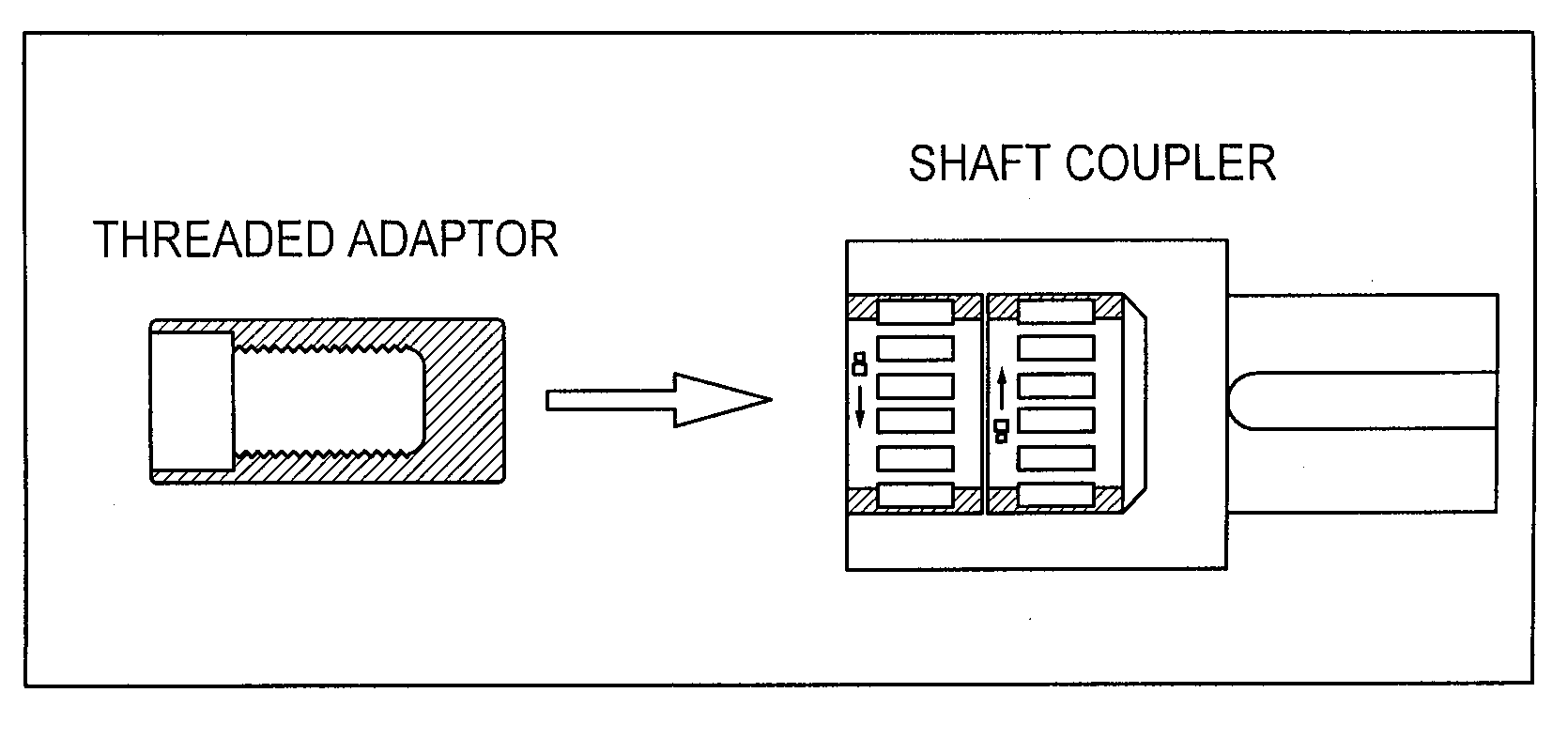

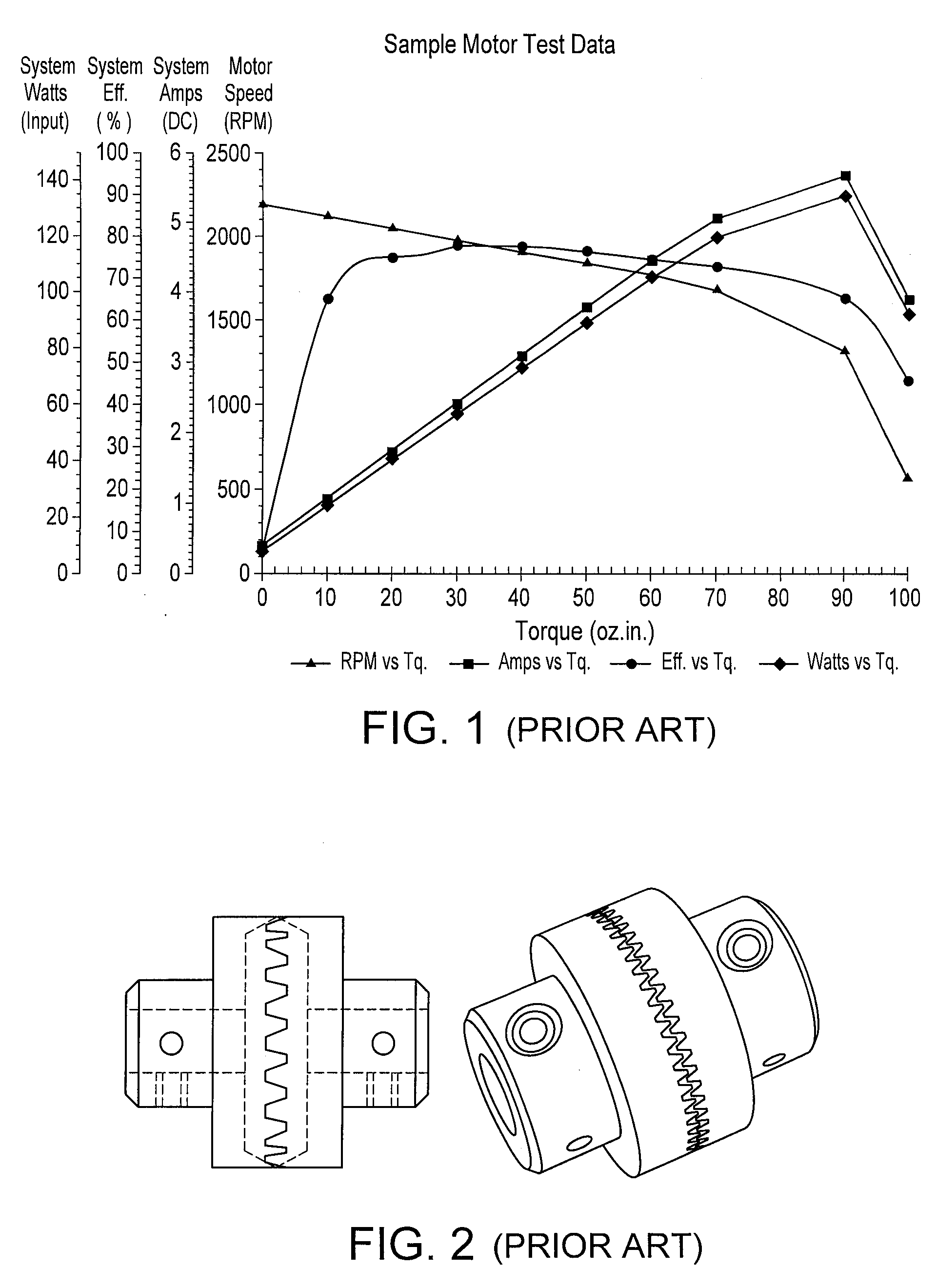

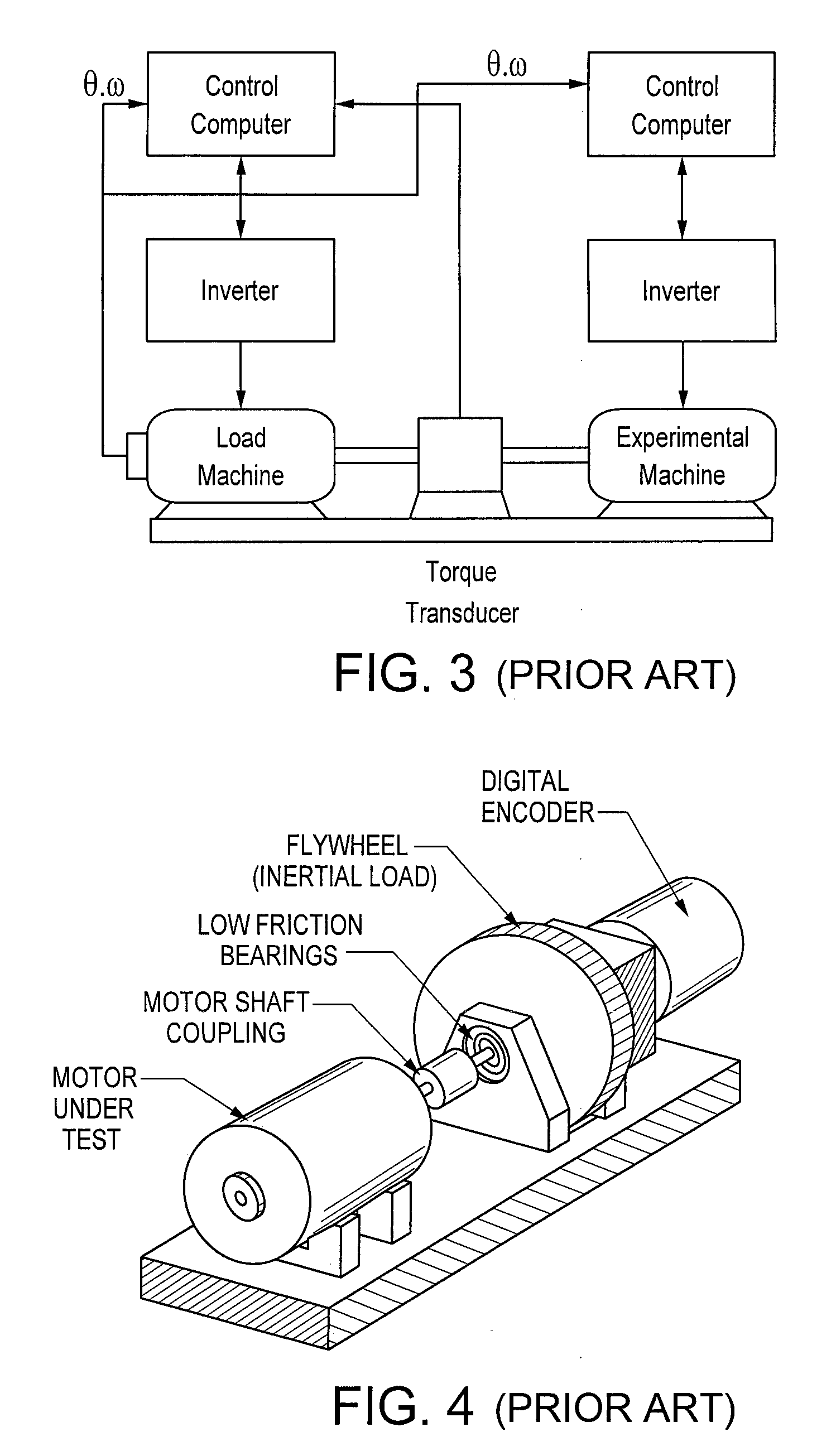

System, Method and Computer Program for Remotely Testing System Components Over A Network

The invention is a turn-key, modular platform, including software and hardware, for testing physical system components such as motors remotely over the Internet. The system allows remote customers to test multiple physical system components under the specific loading conditions of the real-world application. This will provide more detailed and accurate information than what is usually given in the data sheets for system component performance, enabling the user to make a more-reliable decision. With respect to motors, the hardware consists of a torque motor that moves autonomously in xy plane to couple to the individual test motors, through a unique coupling mechanism, and emulate various load profiles on them. Test motors are mounted onto modular fixtures that allow for one-time manual positioning in xyz space. The software, consisting of server and target applications, creates user accounts and profiles, controls user access by means of a scheduler, and enables each user to connect to the hardware via Internet and run a customized experiment.

Owner:EMAMI MOHAMMED REZA +1

Modular welding system

InactiveUS20050023262A1Quick and easy fabricationReducing extensive set up timeWelding/cutting auxillary devicesArc welding apparatusModular fixtureModularity

A modular welding system for performing quick, easy and high quality welds. The modular welding system comprises a basic component system and a modular fixture component system. The basic component system provides the basic components which are needed to perform a quality weld efficiently. The modular fixture component system interfaces with the basic component system and provides a particular welding fixture assembly that performs a particular type of weld. More particularly, a stiffener type modular fixture component system and a butt / tee type modular fixture system are described. However, any other particular fixture type system may be integrated with the basic component system of the present invention.

Owner:ESKANDARI AMIR

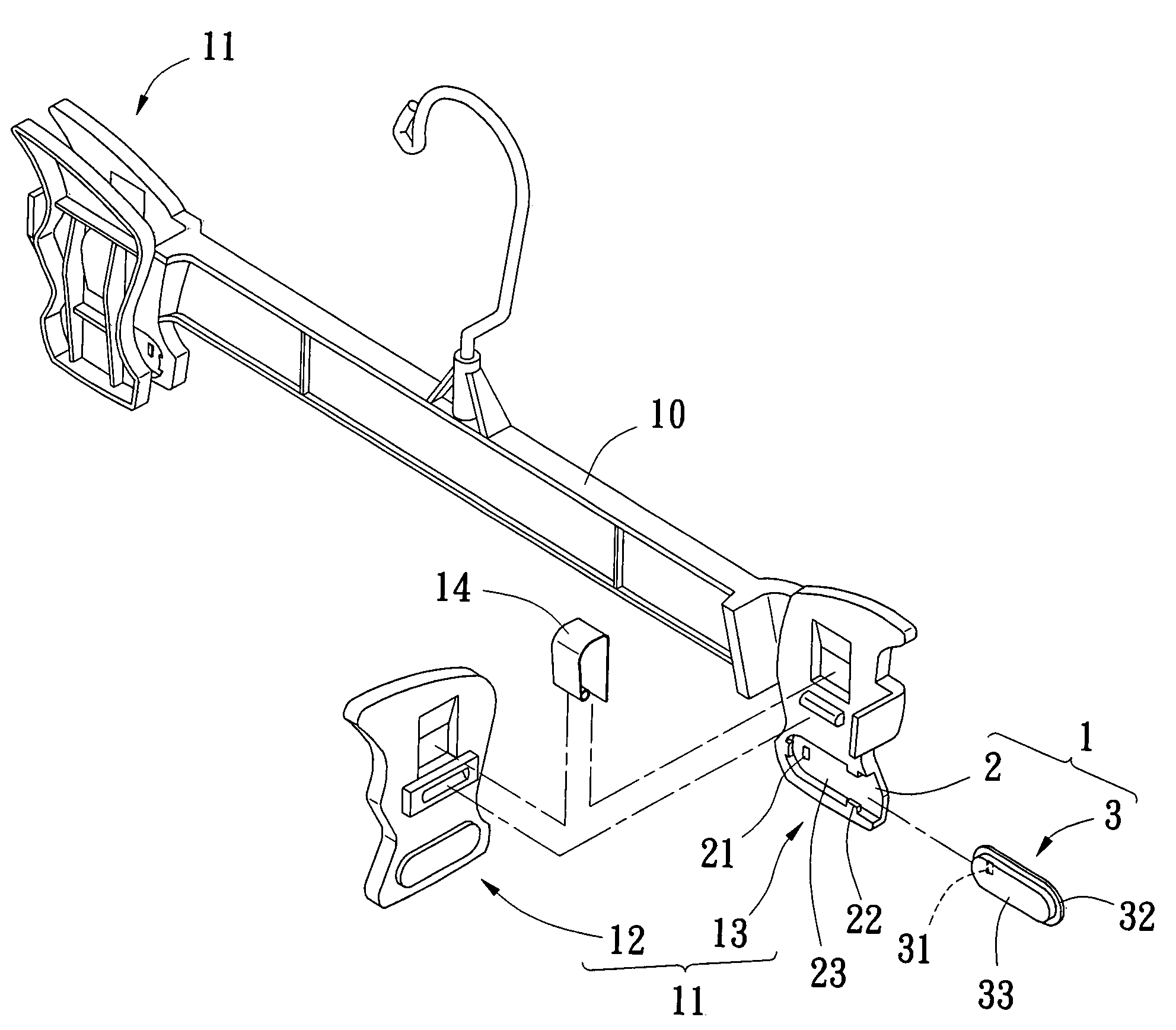

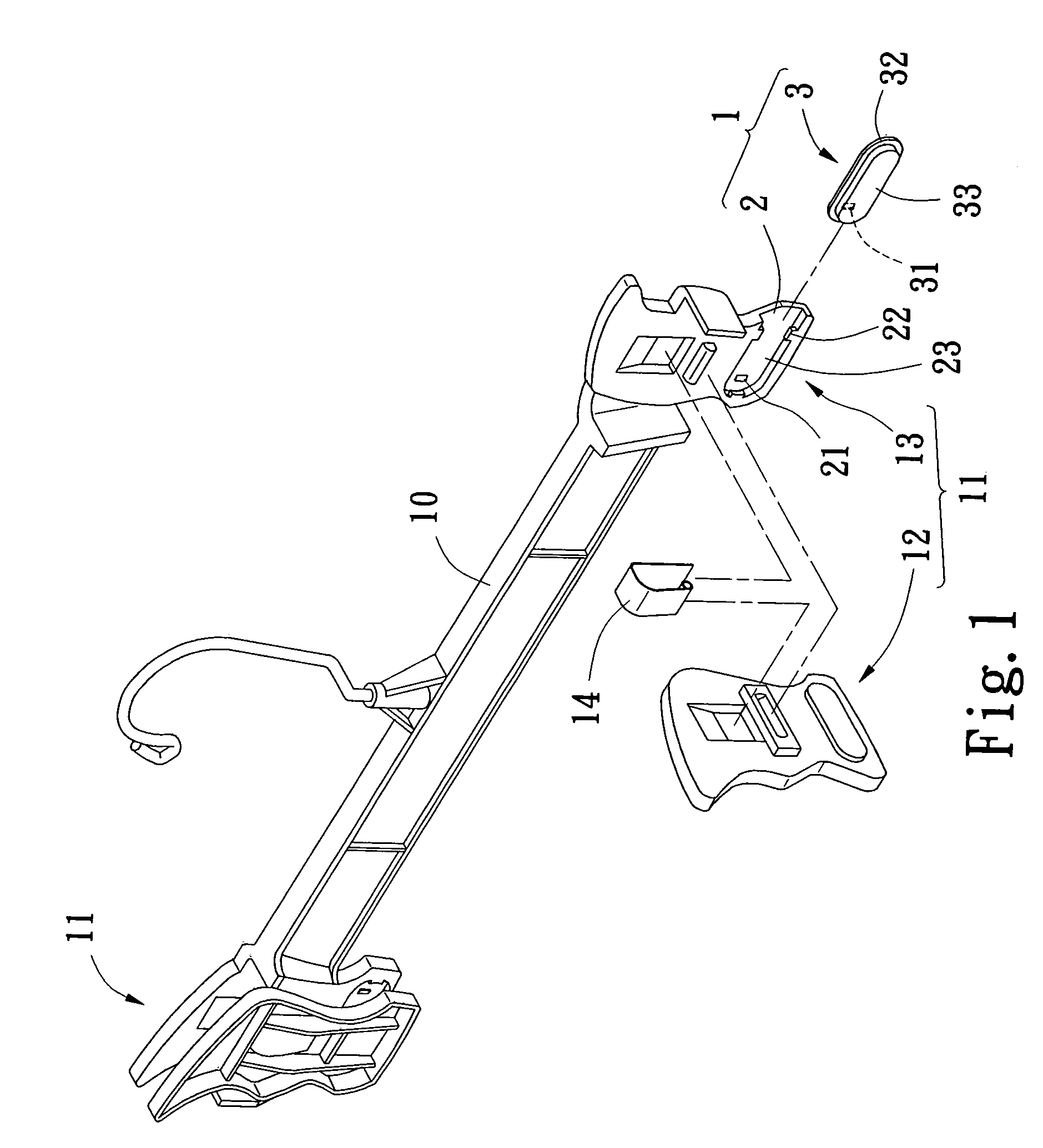

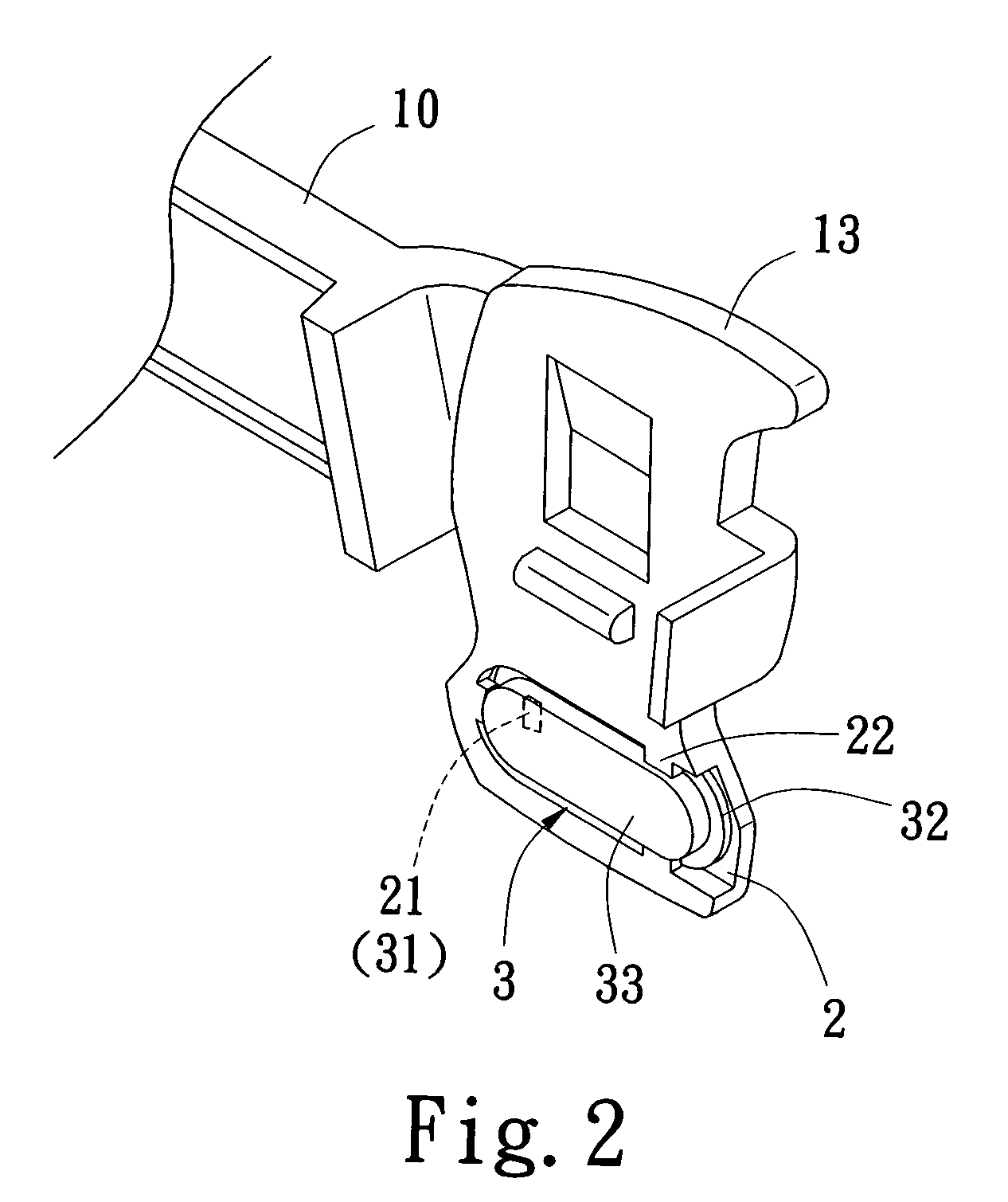

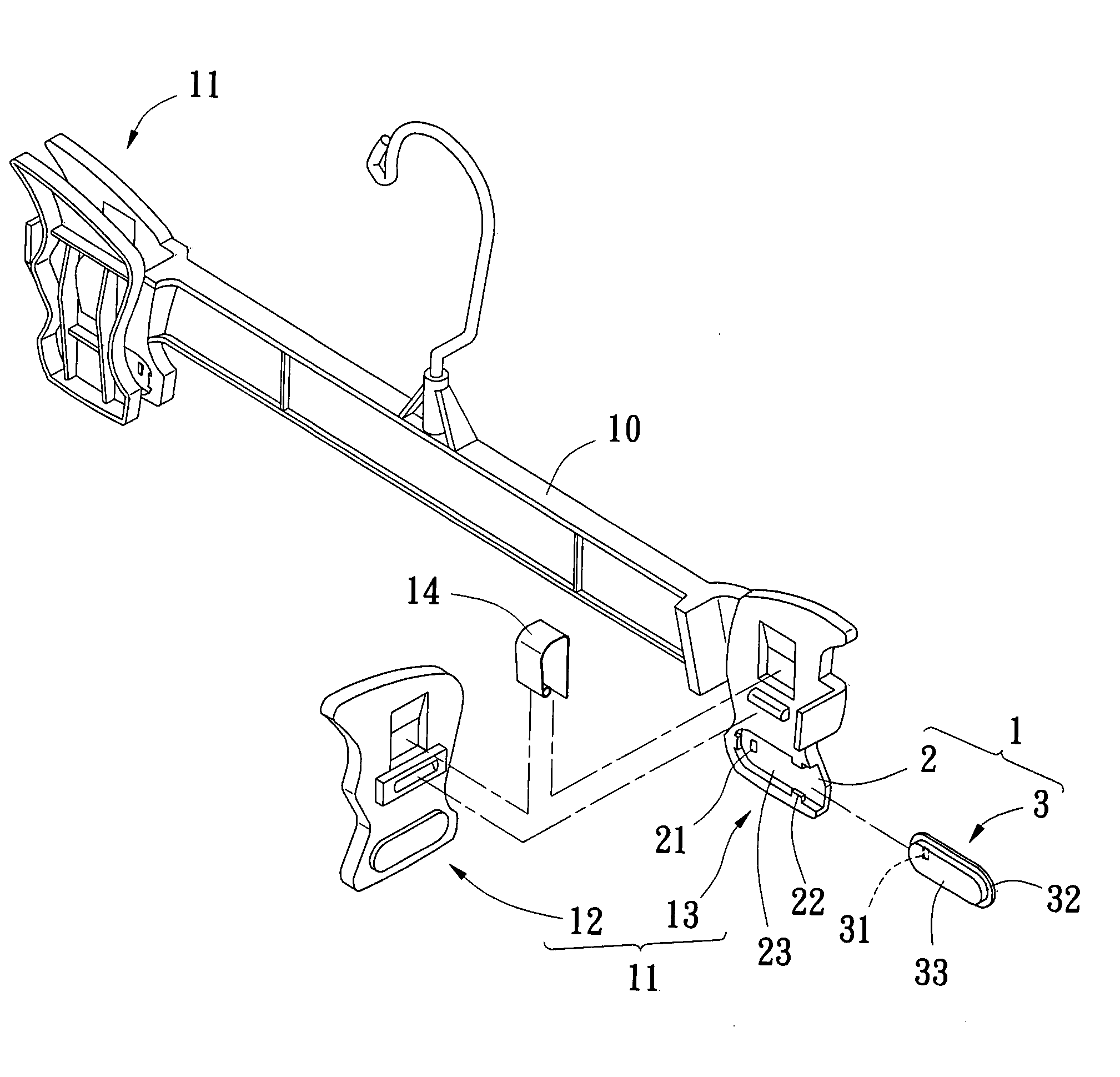

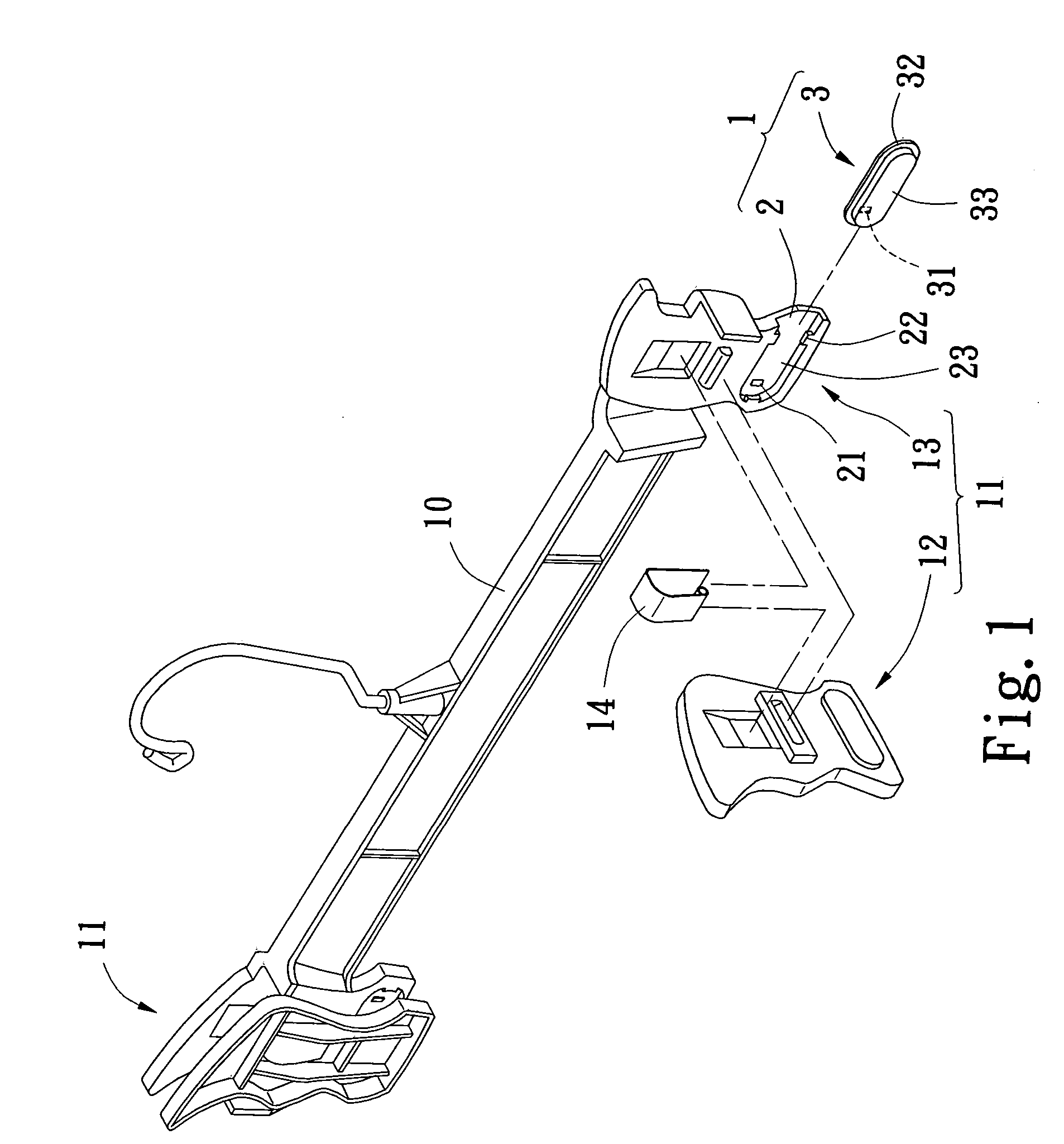

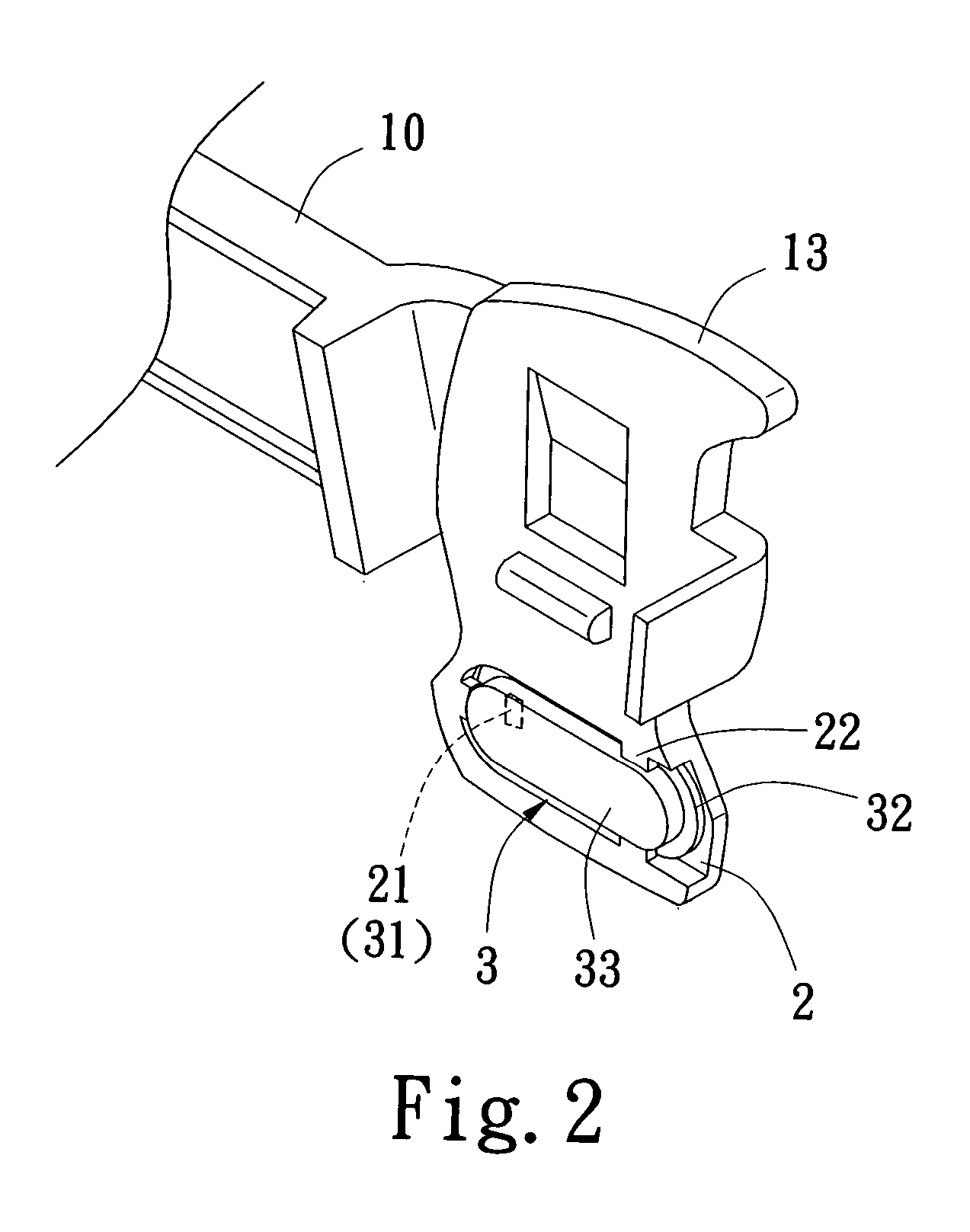

Combination method of a modularized clamp structure

A combination method of a modularized clamp structure, wherein mainly, two clamping portions of two clamps on the two ends of a suit hanger are provided thereon with two engaging channels, each engaging channel has therein a first positioning portion; two slide blocks are pushed into the engaging channels, the slide blocks each has a second positioning portion to be engaged with a corresponding one of the first positioning portions, so that the slide blocks are fixed in the engaging channels. Thereby, a user can change the two slide blocks in a flexible way, when in production, the slide blocks can be assembled and released in an energy saving mode. The clamp structure is applicable to a suit hanger for hanging paints or towels etc.

Owner:AMERICAN APPL ACCESSORIES

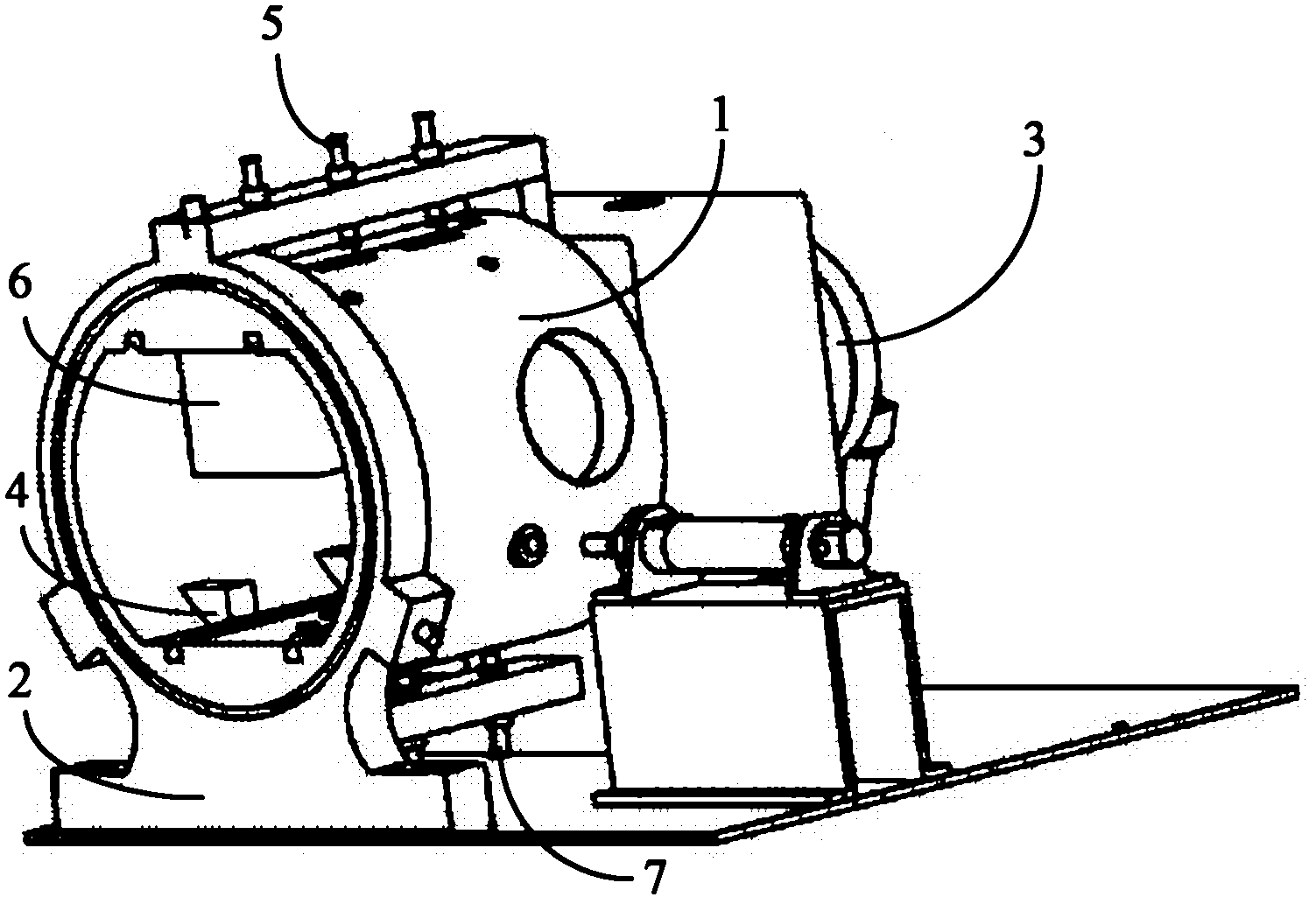

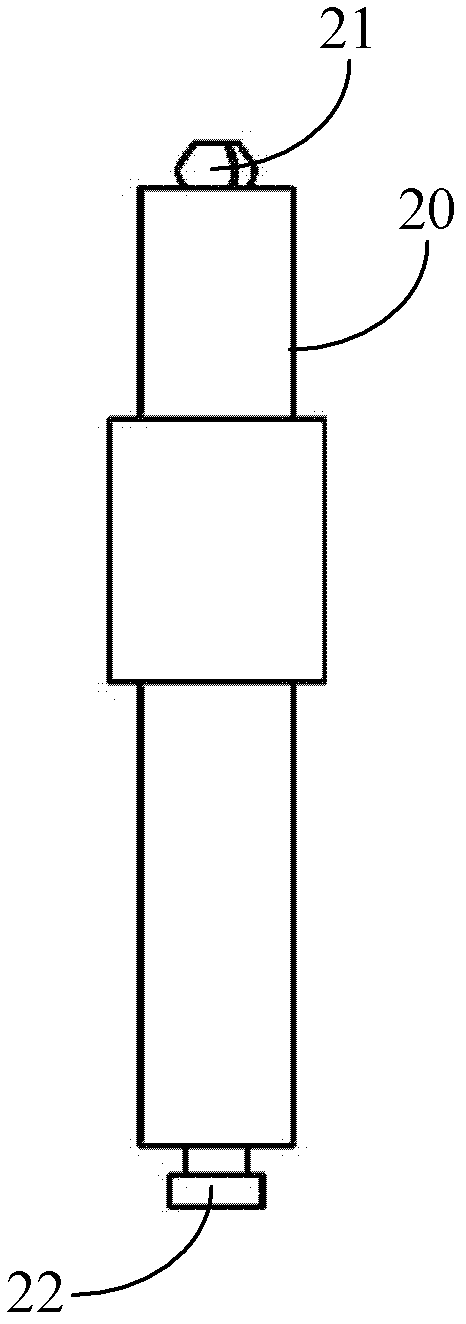

Microtubule inverting and reclamping device

ActiveCN102489932AConvenient and convenientReduce radiation doseWelding/cutting auxillary devicesAuxillary welding devicesModular fixtureEngineering

The invention discloses a microtubule inverting and reclamping device, belonging to the field of iodine (125I) sealing seed source preparation equipment. The device comprises a rotary drum support, a rotary drum, a swing cylinder, a positioning device and two chuck driving mechanisms, wherein the rotary drum is a round hollow structure with at least one open end, the rotary drum is movably arranged on the rotary drum support, the swing cylinder is connected with the rotary drum and can drive the rotary drum to rotate on the rotary drum support for at least 180 degrees; the rotary drum is internally provided with the positioning device which can mount and position two modular fixtures, the two chuck driving mechanisms are respectively oppositely arranged outside the rotary drum, and the front end of each chuck driving mechanism is corresponding to the bottom end of the modular fixture arranged on the positioning device in the rotary drum. The microtubule inverting and reclamping device disclosed by the invention has simple structure, is convenient to operate and can automatically complete inverting and reclamping of microtubules in the two modular fixtures; meanwhile, a transfer path of the microtubules during inverting is the shortest and transmission accuracy is high, preparation time is effectively shortened, and personnel can be protected by receiving less radioactive irradiation.

Owner:BEIJING ZHIBO BIO MEDICAL TECH

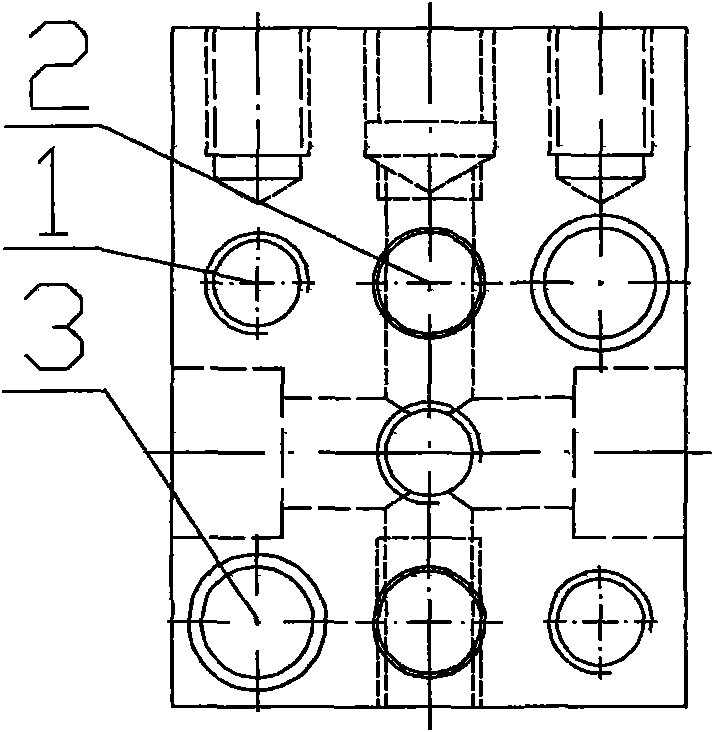

Modularization positioning fixture and positioning fixture assembly

ActiveCN105773024AExtended service lifeEasy to installWelding/cutting auxillary devicesAuxillary welding devicesModular fixtureModularity

The invention discloses a modularization positioning fixture and a positioning fixture assembly. The modularization positioning fixture comprises a pressure head, a first connecting plate, a first clamping air cylinder and a dustproof cover; one end of the pressure head is hinged to the front end of an extending rod of the first clamping air cylinder, and the middle portion of the pressure head is hinged to the first connecting plate; and the periphery of the extending rod of the first clamping air cylinder is surrounded by the dustproof cover. The modularization positioning fixture is simple in structure and small in size; moving parts are effectively protected, and the service life of the fixture is prolonged; the modularization positioning fixture is convenient to install, safe in use and high in efficiency; and standard modules are directly called, the machining period is short, the cost is low, and the opening angle of the fixture is large.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

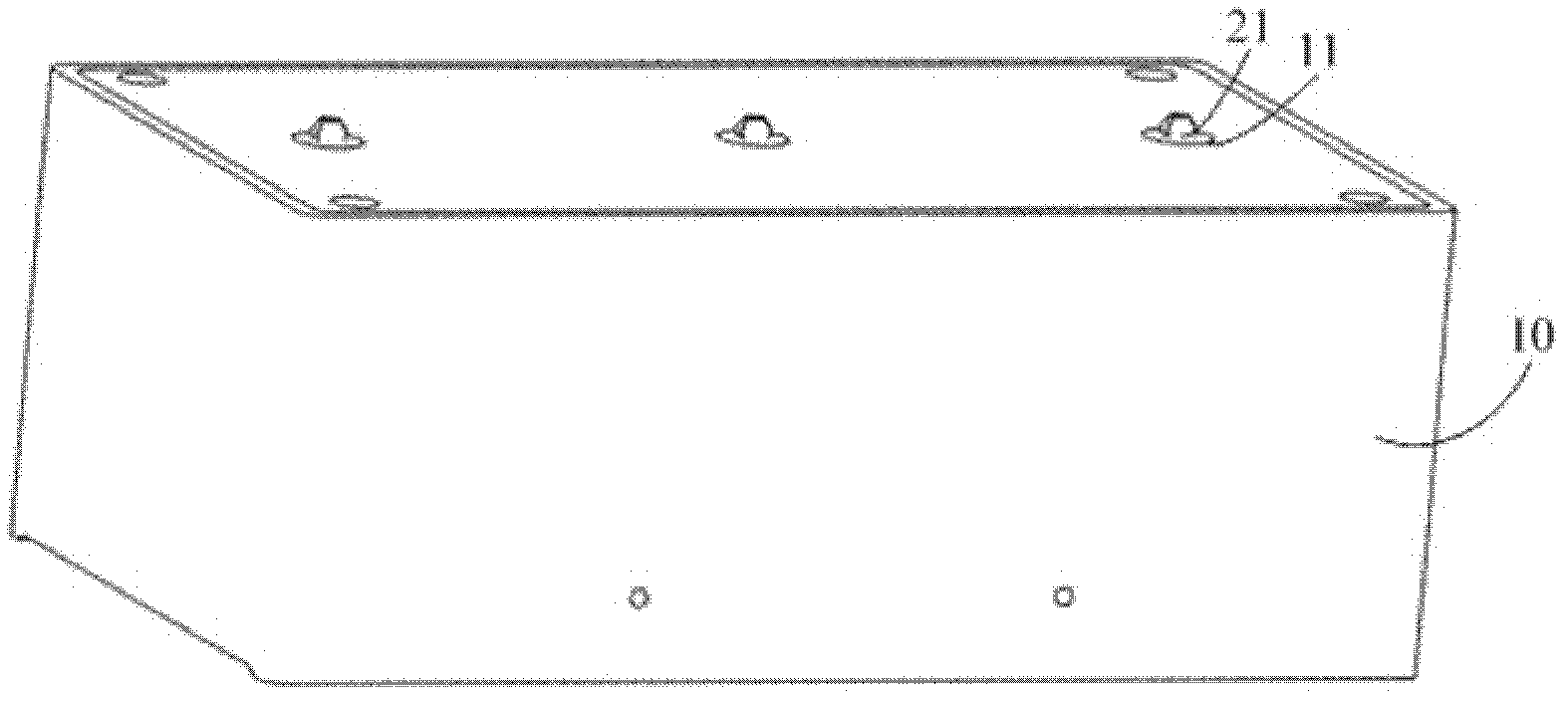

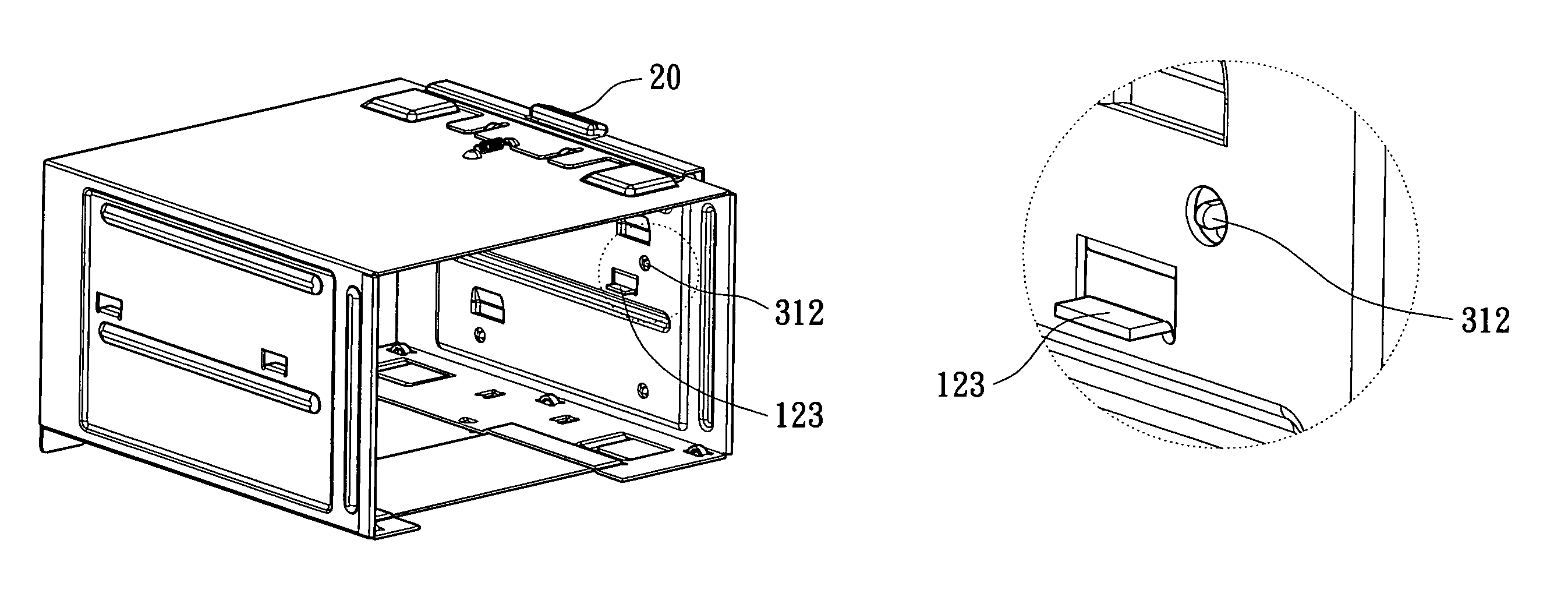

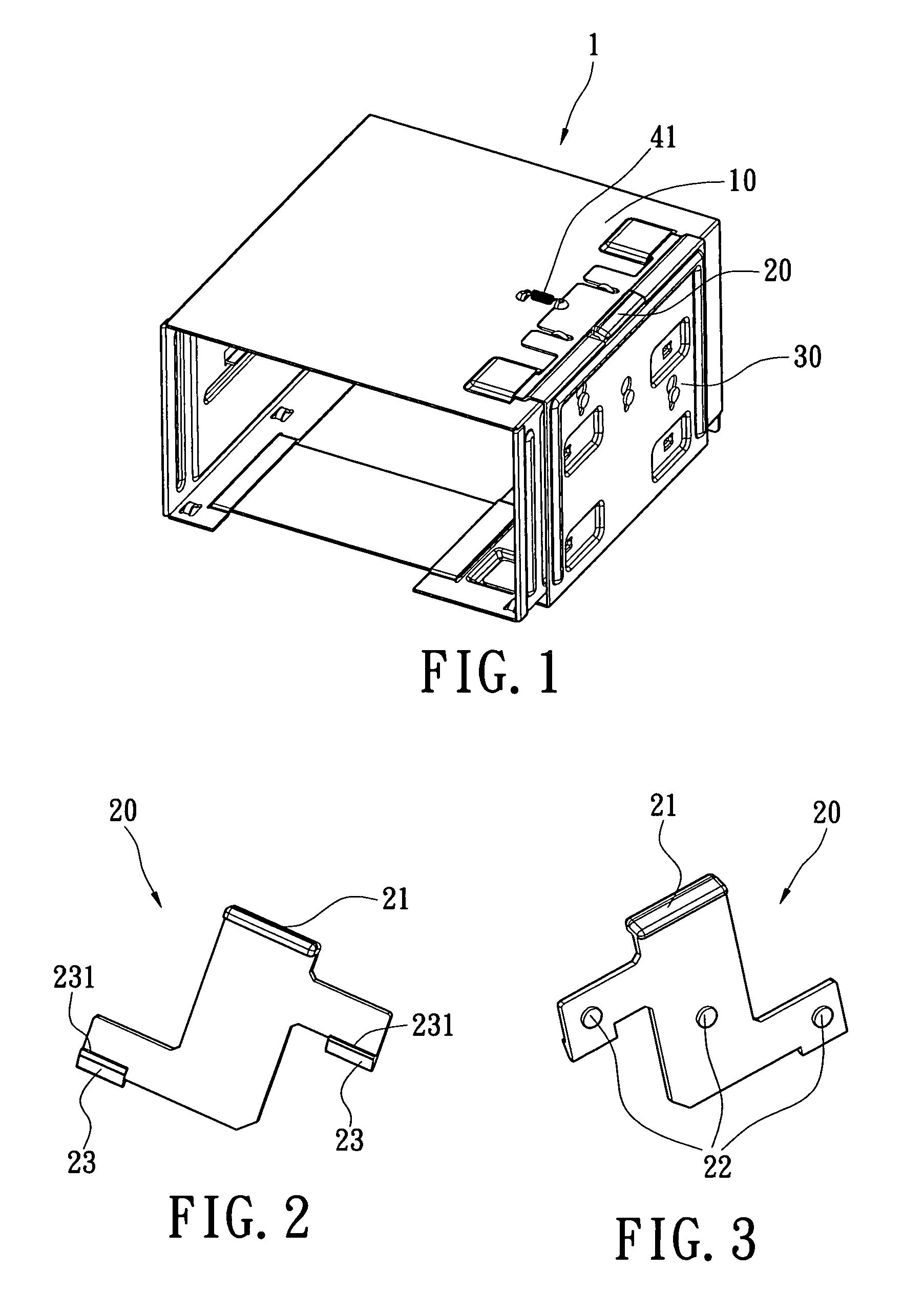

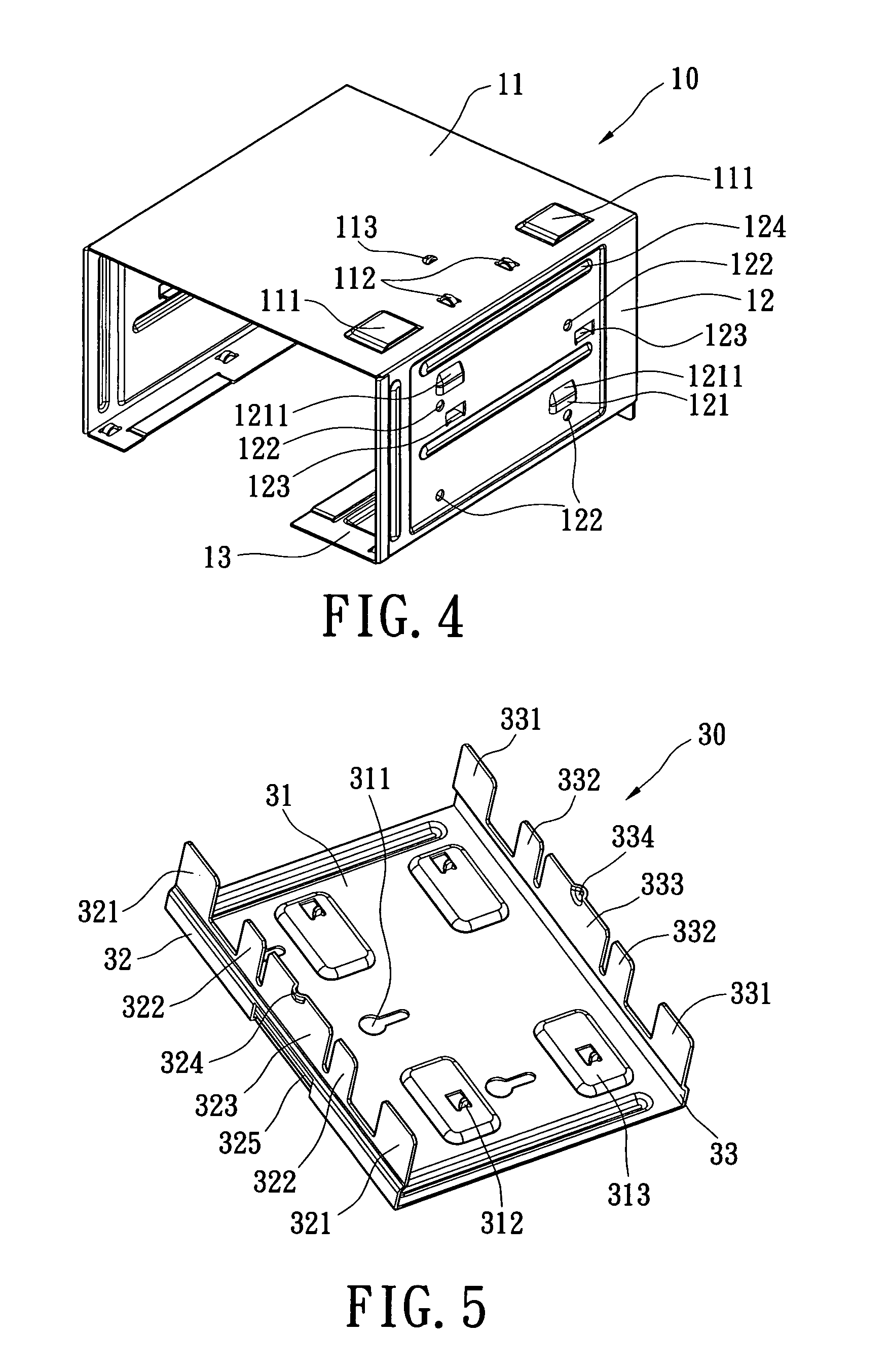

Modular fixture for a data storage unit inside a computer

InactiveUS7965501B2Rapidly fixed and removedRapidly fix and removeDigital data processing detailsComponent plug-in assemblagesModular fixtureStorage cell

A fixture for fixing a data storage unit is disclosed. The fixture includes: a body receives the computer components and defines a protrusion and a hole thereon; a separating piece includes a separating portion correspondingly to the protrusion; a fixing piece includes a lockpin correspondingly to the hole of the body, and the separating piece is set between the fixing piece and the body; and a controlling component fixes the fixing piece on the body. The fixture of the present invention can rapidly fix or remove a data storage unit inside a computer case without any screws. The assembly cost and the maintaining cost of the fixture are low, and the assembly and the disassembly of which is simple and timesaving.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

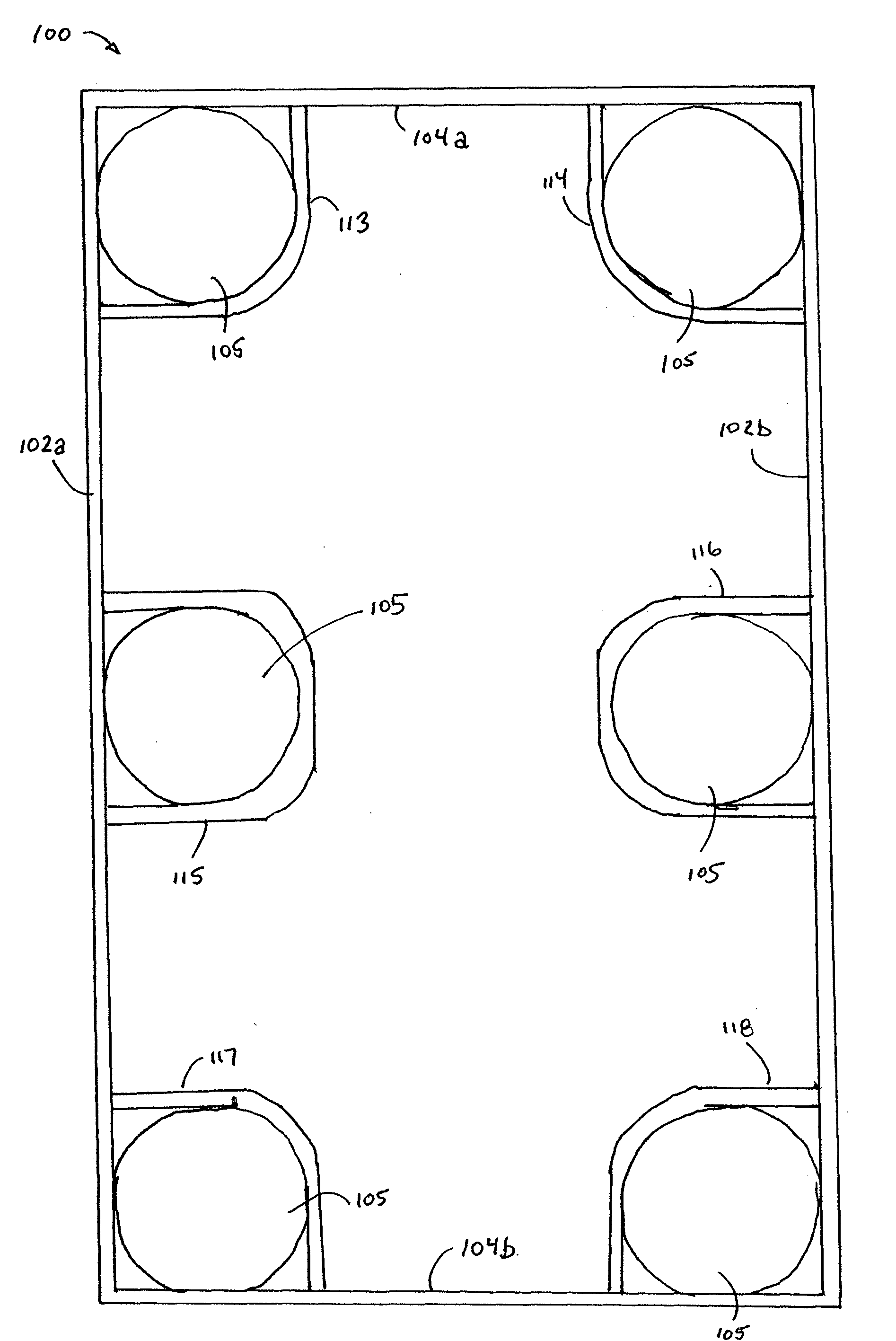

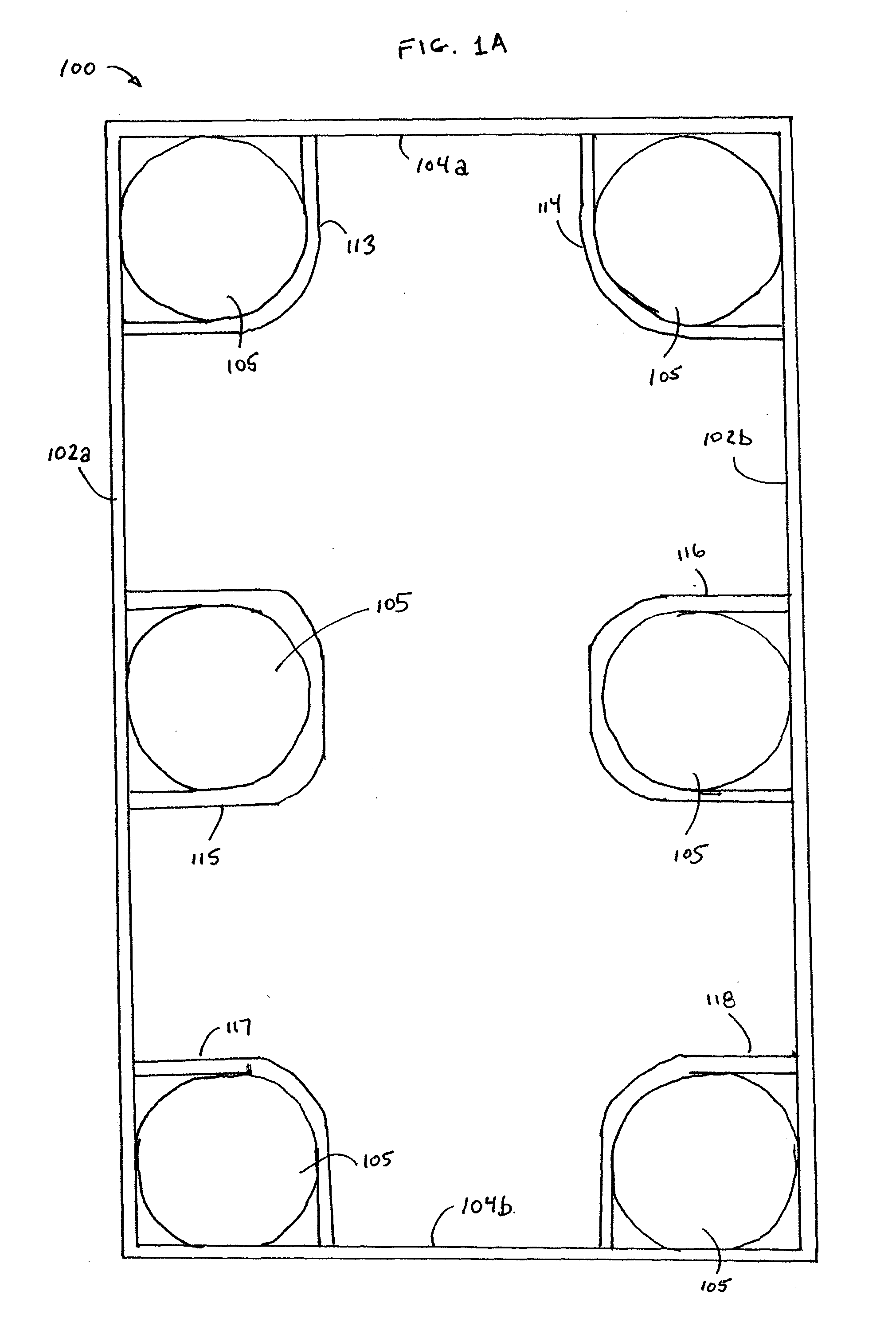

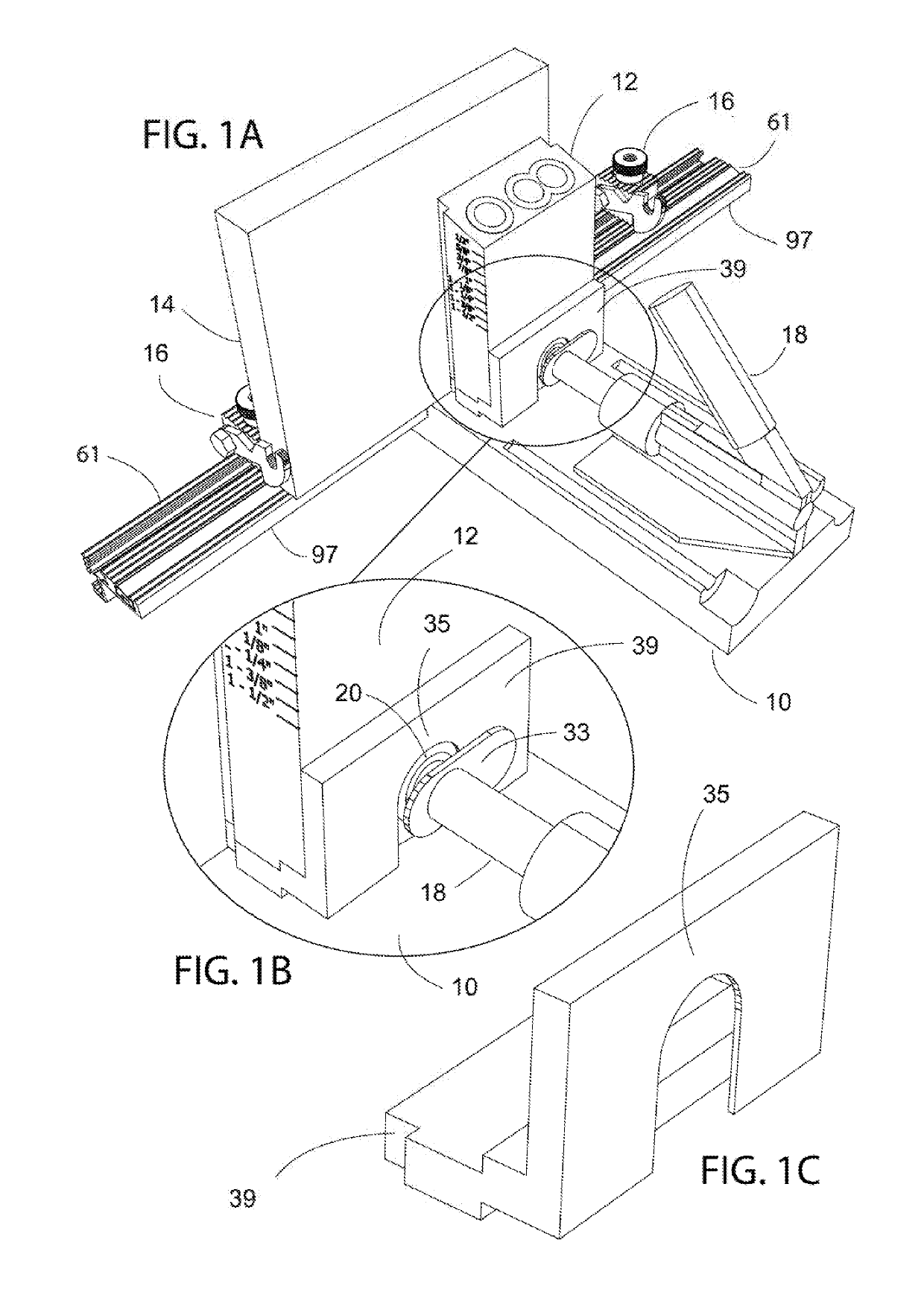

Modular Jig and Fixture Systems and Methods

ActiveUS20190270143A1Simple processGuide fencesMetal working apparatusModular fixtureWoodworking machinery

Jigs and fixtures for aligning, guiding, and / or holding a workpiece on woodworking machinery during a woodworking operation are described, as well as methods of making, modifying, and using jigs and fixtures.

Owner:DUGINSKE MARK A

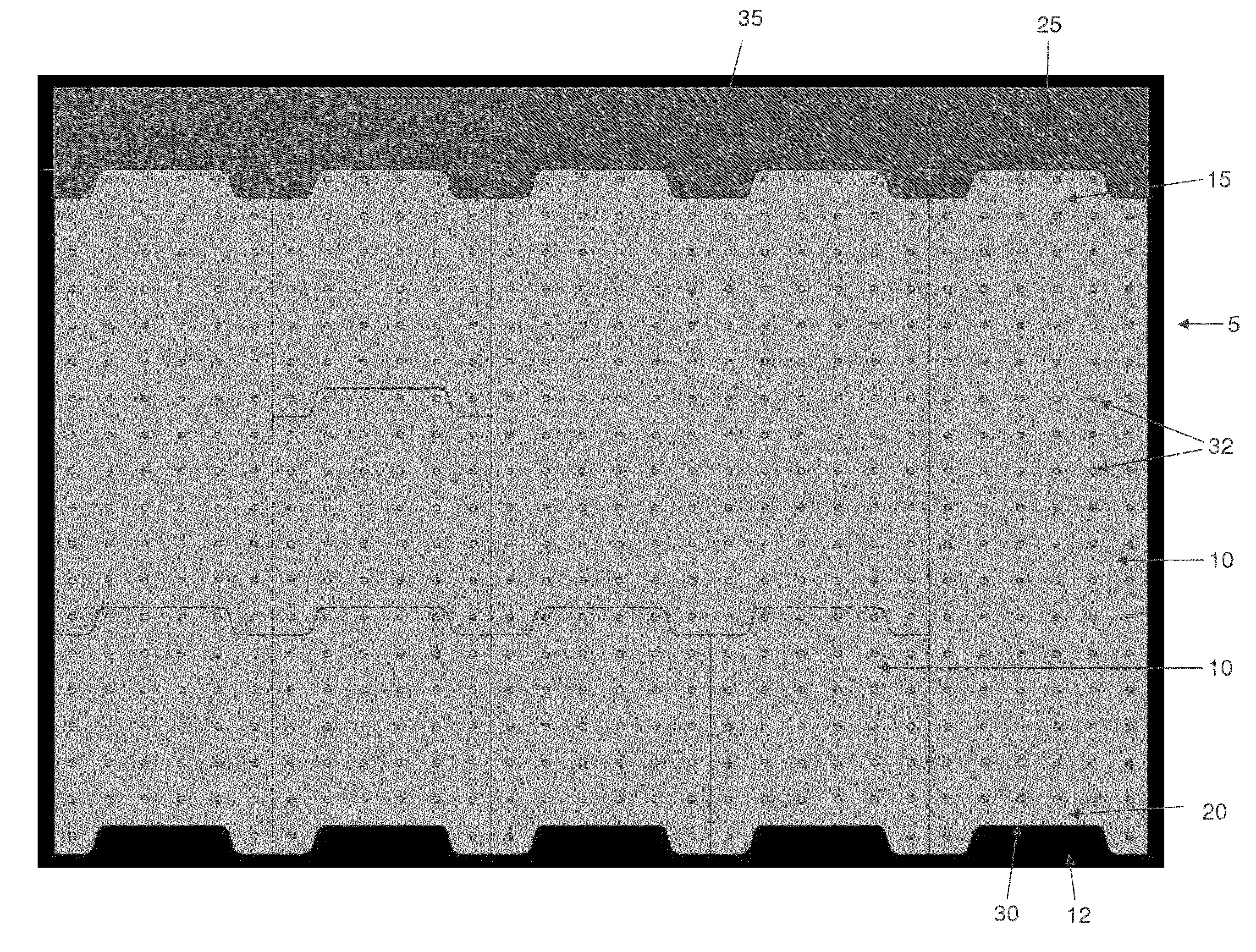

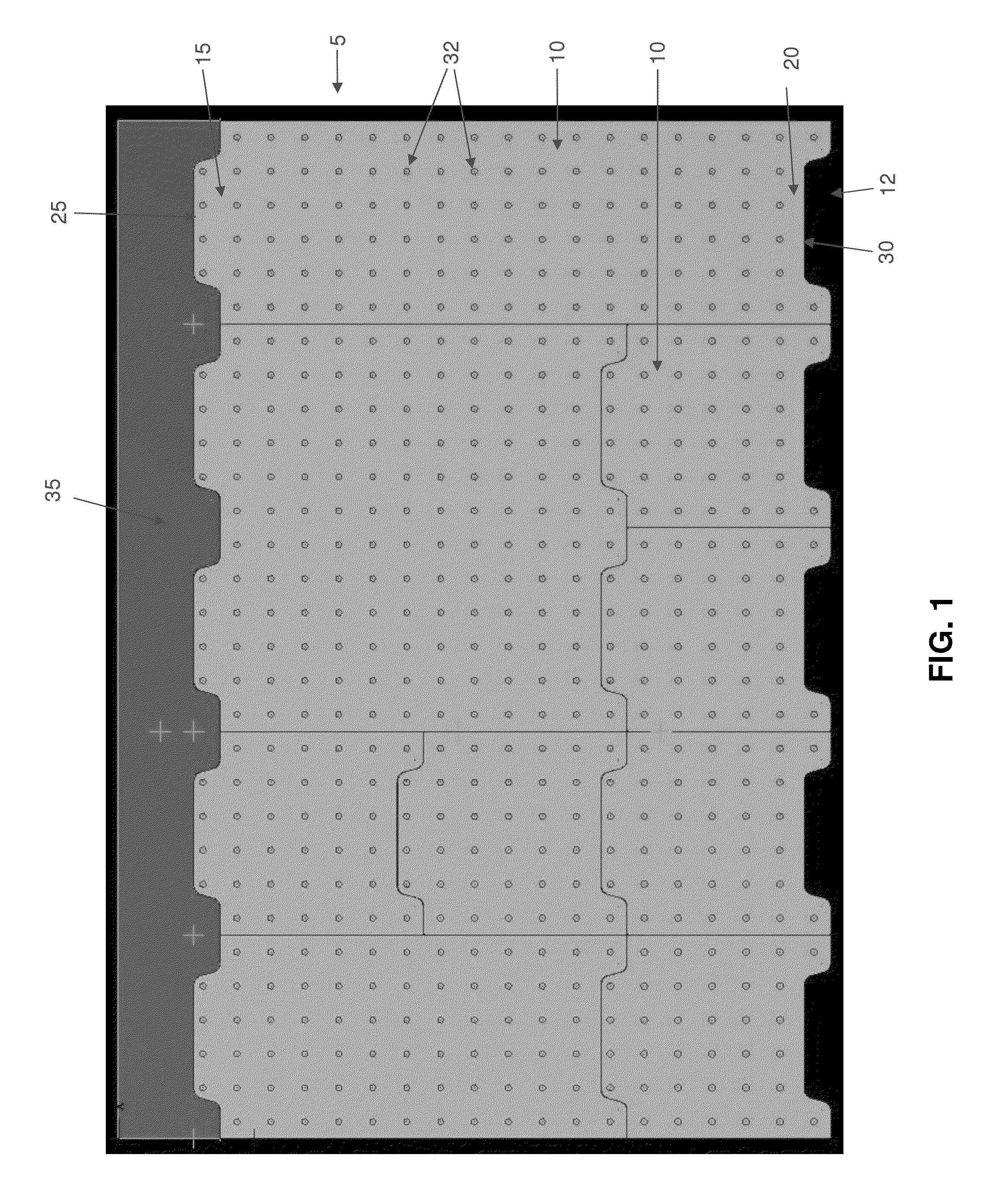

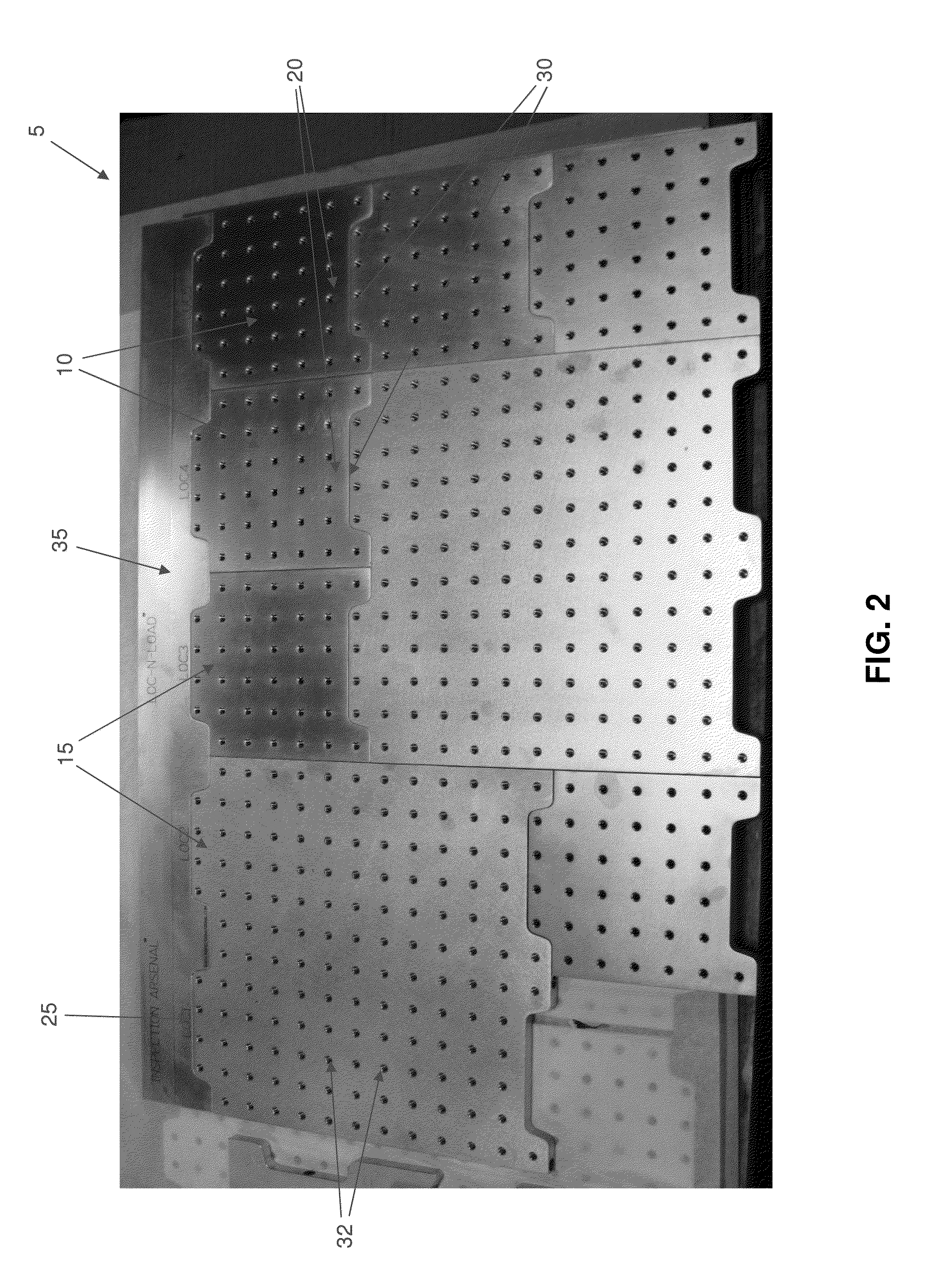

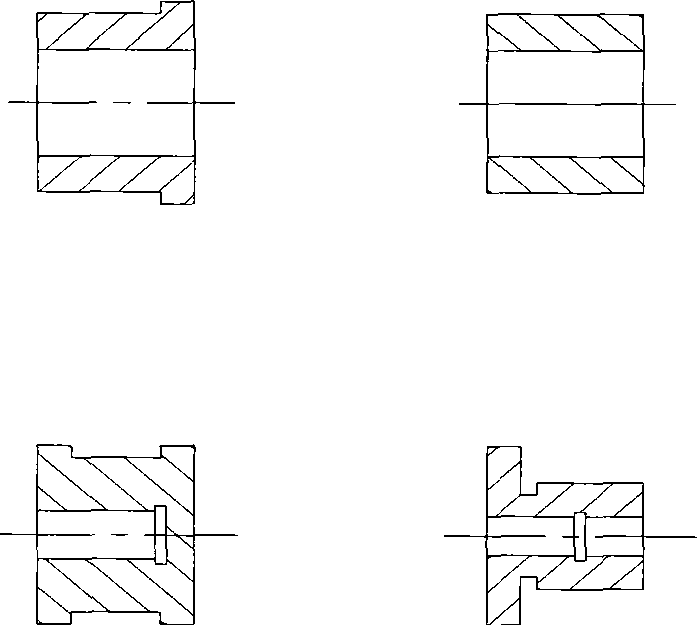

Modular fixture plate system for positioning a workpiece during a manufacturing and/or inspection process

ActiveUS20140248113A1Simple but effectiveFast and easy and repeatable setupSemiconductor/solid-state device manufacturingWork holdersModular fixtureEngineering

A modular fixture plate system comprising:at least one interlocking fixture plate comprising at least one of a male end and a female end, wherein the male end comprises at least one male projection and the female end comprises at least one female recess; anda docking plate comprising at least one of at least one male projection and at least one female recess;wherein at least one male projection or female recess of the at least one interlocking fixture plate is interlocked with a mating one of the at least one male projection or the at least one female recess of the docking plate.

Owner:PHILLIPS STEVEN E

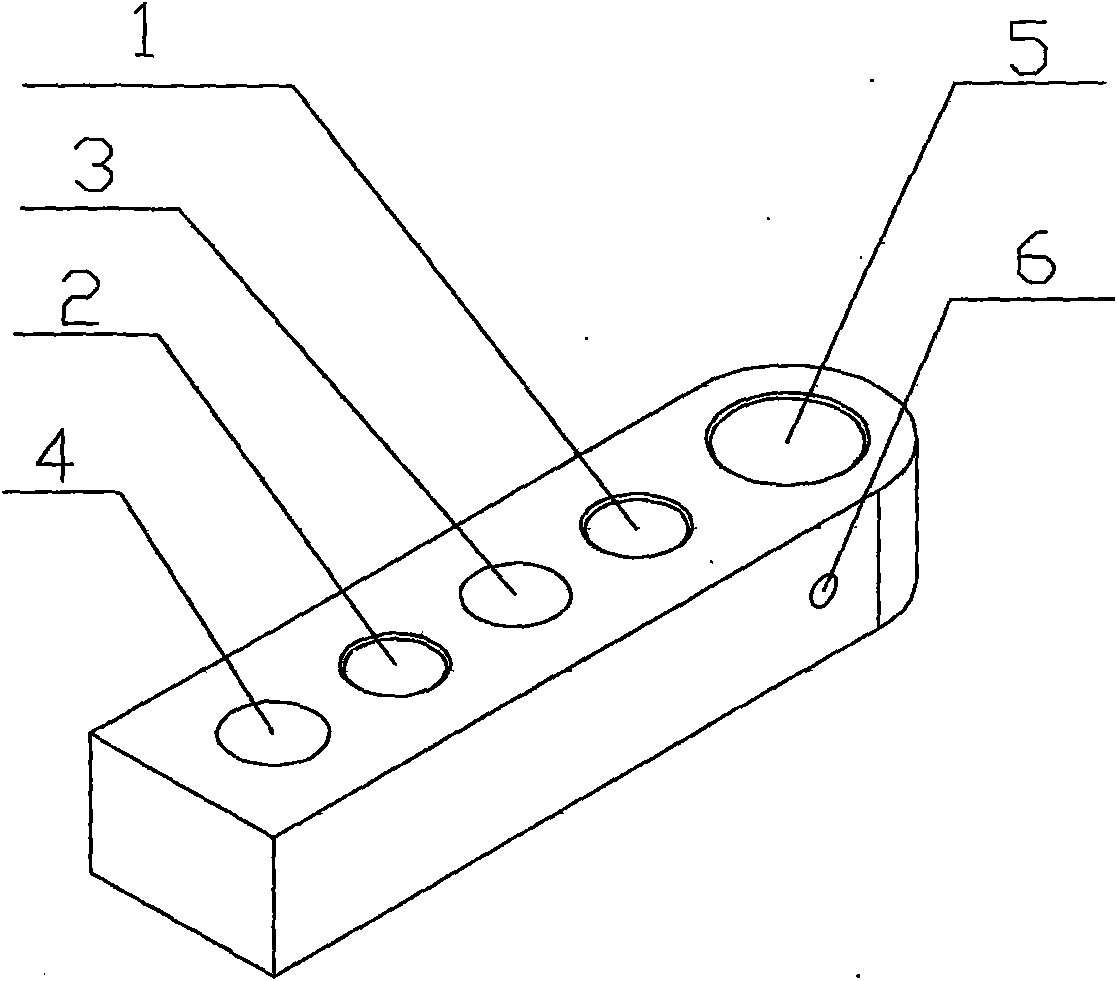

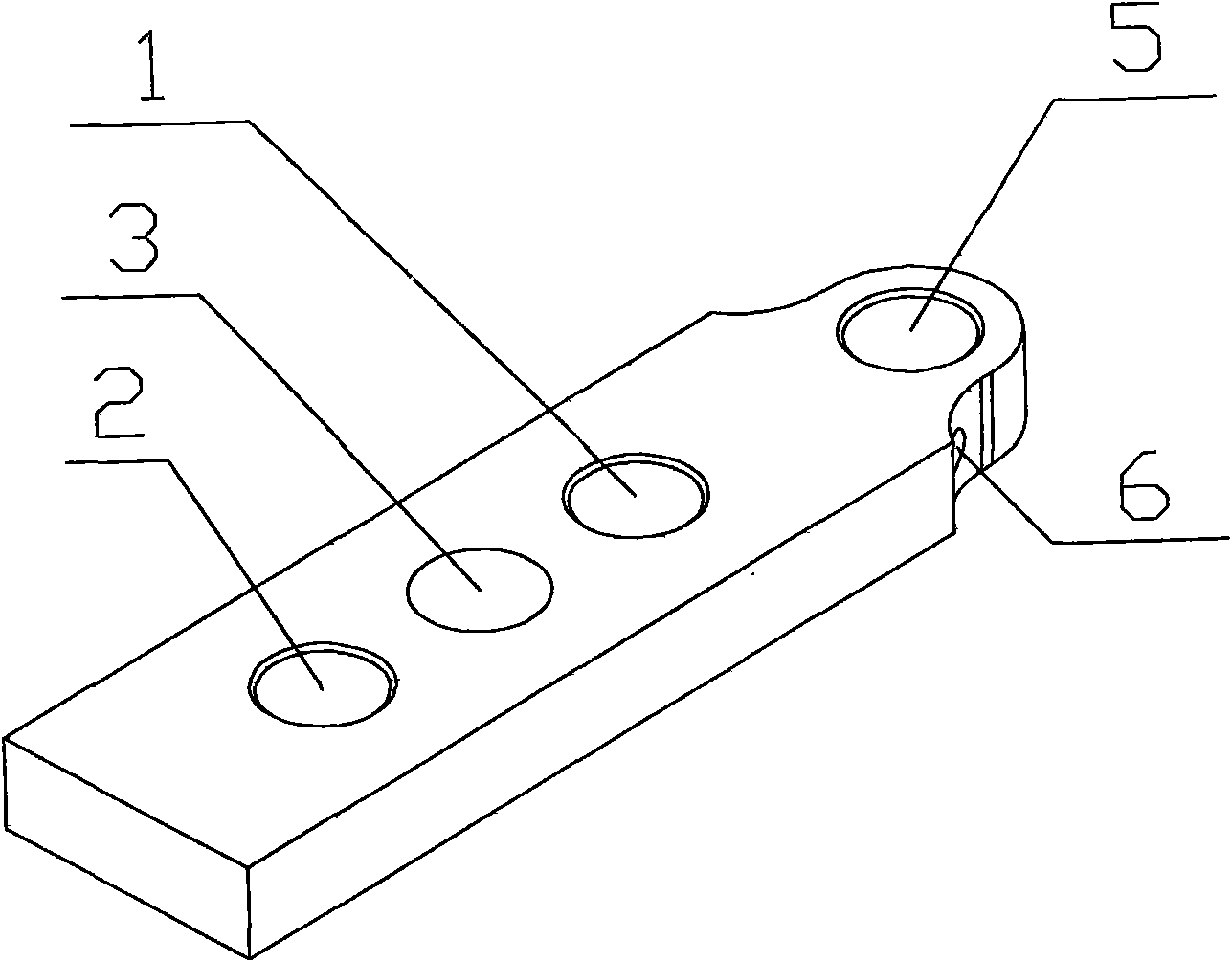

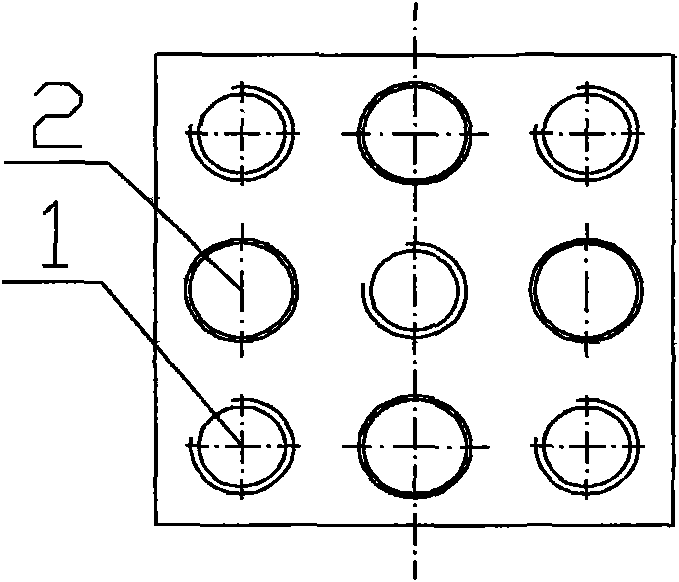

Straight panel type bushing plate

The invention discloses a straight panel type bushing plate which is used on a hole-series modular fixture and is an element used for ensuring the concentricity of a plurality of holes on a workpiece during processing, such as drilling, expanding or reaming and the like. The straight panel type bushing plate comprises a bushing plate body, a leading hole is manufactured on one end of the bushing plate body, and two positioning pin holes and one or two bolt passing holes are manufactured on the bushing plate body; the arrangement of two kinds of holes is as follows: a positioning pin hole, a bolt passing hole, a positioning pin hole and a bolt passing hole are arranged in order from the leading hole, a thread hole vertical to the leading hole is manufactured between the leading hole and the positioning pin hole, and the thread hole and the leading hole are tangent. The invention has the advantages that a plurality of straight panel type bushing plates can be simultaneously adopted for assembling multiple layers of leading structures to realize the functions of drilling, reaming, leading or stitching; a function simplifying and assembling step which can replace special pieces is used for shortening assembly time and ensuring product quality; the invention can be arbitrarily matched with supporting pieces, gaskets, guidance supporting pieces, displacement supporting pieces and the like in the combined fixture to realize the functions of positioning, orientation and integral displacement.

Owner:SHENYANG AIRCRAFT CORP

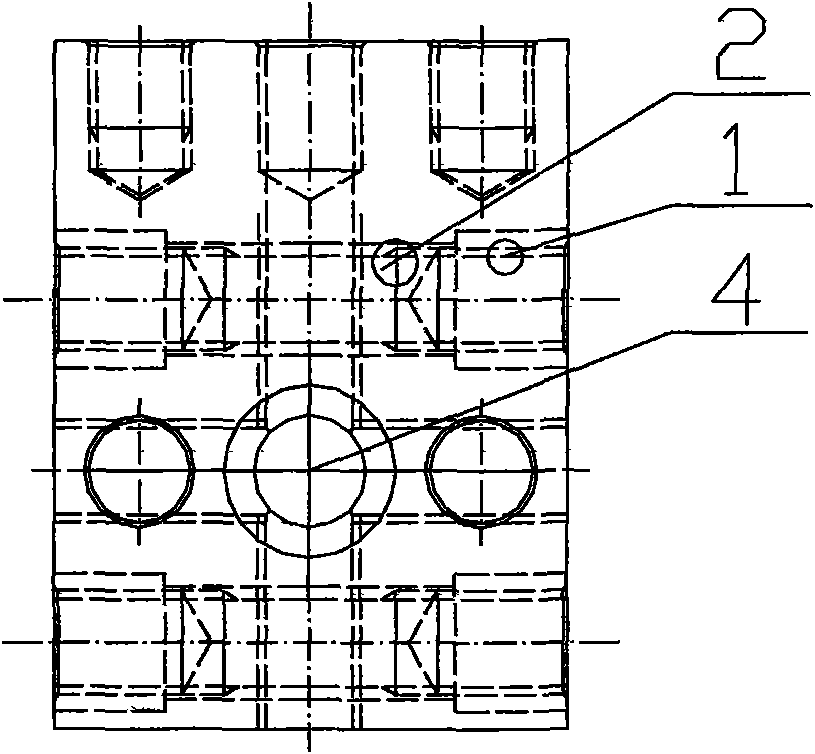

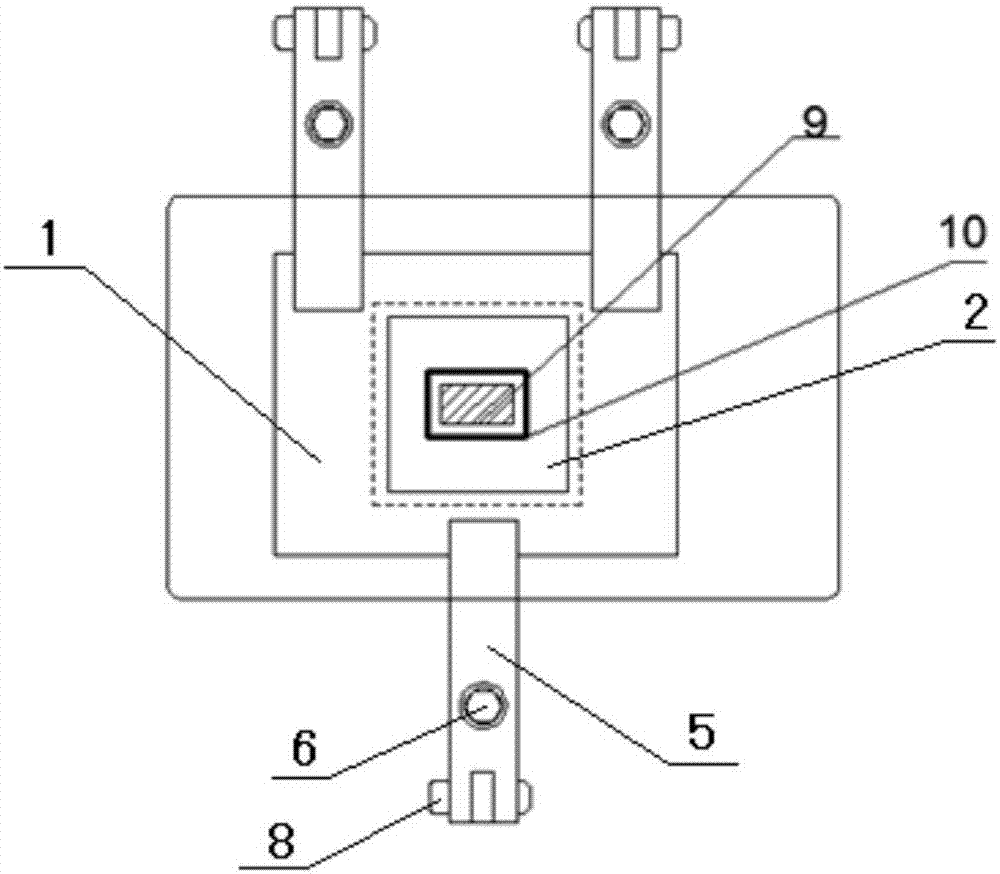

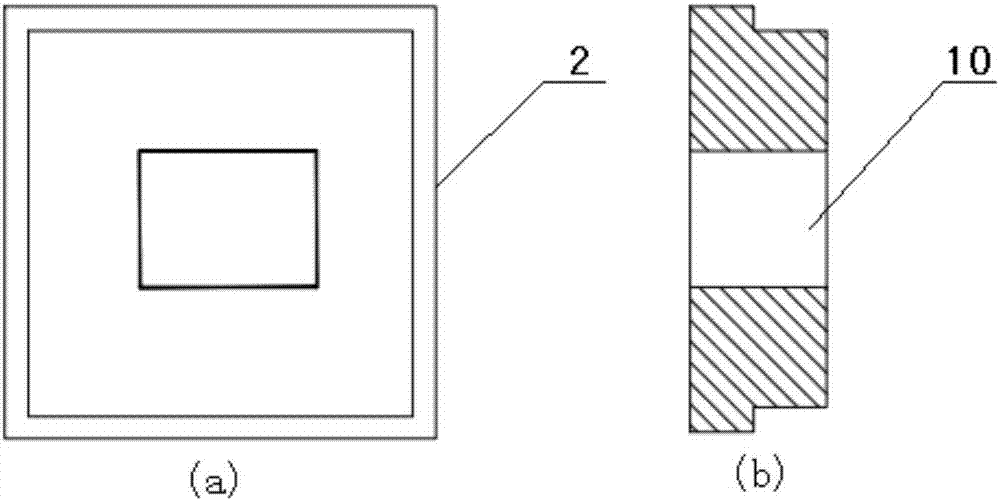

Modular fixture for microfluidic chip

ActiveCN107321403ASimple structureEasy to assemble and disassembleLaboratory glasswaresSupporting apparatusModular fixtureComputer module

A modular fixture for a microfluidic chip comprises upper plate assemblies and lower plate assemblies and further comprises movable clamps, wherein a space for accommodating the microfluidic chip is formed between the upper plate assemblies and the lower plate assemblies; each upper plate assembly comprises a fixture cover plate and a liquid feed module which is detachably connected to the fixture cover plate, and a liquid feed pipe communicated with the space is arranged on the liquid feed module; each lower plate assembly is provided with support rods, through holes allowing the support rods to penetrate out are formed in the corresponding upper plate assembly, the support rods penetrate the corresponding upper plate assembly through the through holes, and the movable clamps are fixed on the support rods at the upper part of the upper plate assembly and propped against or loosened from the upper plate assembly by rotating in different directions, so that the upper plate assembly and the lower plate assembly are in a locking state or unlocking state. The modular fixture for the microfluidic chip is simple in structure and easy to assemble and dismount.

Owner:PEKING UNIV

Milling modular fixture

InactiveCN101786238AImprove machining accuracySolve the problem that the accuracy of multiple machining cannot be guaranteedMilling equipment detailsPositioning apparatusModular fixtureEngineering

The invention discloses a milling modular fixture, which comprises a centre connecting plate, a four-axis connecting plate and a positioning plate. A center shaft of the centre connecting plate is contacted with a centre on a tailstock; a center shaft of the four-axis connecting plate is connected with a four-axis rotary table of a machine tool; and the positioning plate is provided with a positioning hole and an elastic deformation hole. The milling modular fixture has the advantages that: the milling modular fixture has reasonable design, simple structure, low manufacturing cost, simple and convenient operation, difficult mixed assembly during installation and the like, improves the machining precision of shaft parts, solves the problems of unwarrantable precision of the conventional shaft parts machined for multiple times, high manufacturing cost, inconvenient operation and the like in the multi-time machining process, solves the problem that holes in an axial direction and a radial direction of the shaft parts are not machined simultaneously, improves the machining efficiency, namely multiple parts can be machined once, avoids the phenomenon of machining omission of the holes in the machining process, and has a function of error protection.

Owner:WUXI YINGBEI PRECISION BEARING

Power cable strength testing machine with modular fixture

ActiveCN105954096AAvoid pinchingAvoid damageMaterial strength using tensile/compressive forcesModular fixturePower cable

The invention discloses a power cable strength testing machine with a modular fixture. The power cable strength testing machine with the modular fixture adopts two fixtures to implement tension or compression strength tests; a claw fixture adopts moving claws to slide and fix a cable; a limiting mechanism can swing leftwards or rightwards in a limited manner when the moving claws move, so that the moving claws can be well prevented from moving randomly, firm and stable clamping can be ensured, and the moving claws can be prevented from being folded to jam hands of a user by accident because of mal-operation when being reset; a cable is inserted from the middle part of the disc-shaped structure of a disc fixture; the cable can be clamped and fixed by clamping ring structures layer by layer; the layered structures are restricted by one another without being loosened or displaced; clamping rings can be tightened or released so as to achieve fastening when the arc-shaped wall of an external rotary table is rotated; the rotation stroke is relatively long, so that the cable can be slowly fastened without being damaged, the clamping firmness of the cable can be prevented from being affected by a damaged cable, and thus test data errors can be prevented.

Owner:HUNAN JIADA WIRE & CABLE

Multifunctional connecting support

InactiveCN101623825ARealize limitRealize functionPositioning apparatusMetal-working holdersModular fixtureDiagonal

The invention discloses a multifunctional connecting support which is a multifunctional element used in a hole-series modular fixture. A supporting body is made into a cubiod, and a thread through hole is made on the center of the surface formed by two short edges, the axis of the surface formed by other two short edges is manufactured with four pin shaft blind holes, and four thread blind holes are manufactured on the diagonal; two pin shaft through holes are respectively manufactured on the axis of the symmetrical surfaces of the two short edges and long edges; an inner hexagon screw passing hole is respectively manufactured above the right side of the axis and below the left side of the axis, and the thread blind hole is respectively manufactured above the left side of the axis, below the right side of the axis and on the center; a bolt sinking through hole is manufactured on the axis crossing point of the symmetrical surface of the other two short edges and long edges, and a pin shaft blind hole is respectively manufactured on two ends of a horizontal axis. The invention has the advantages: due to adoption of hexagonal support, the invention is capable of extending to multiple directions to be combined with other hole system elements and realize the functions of orientation, positioning, limiting and locking; and space for converting and adjusting to each angel with 90 degrees can be added.

Owner:SHENYANG AIRCRAFT CORP

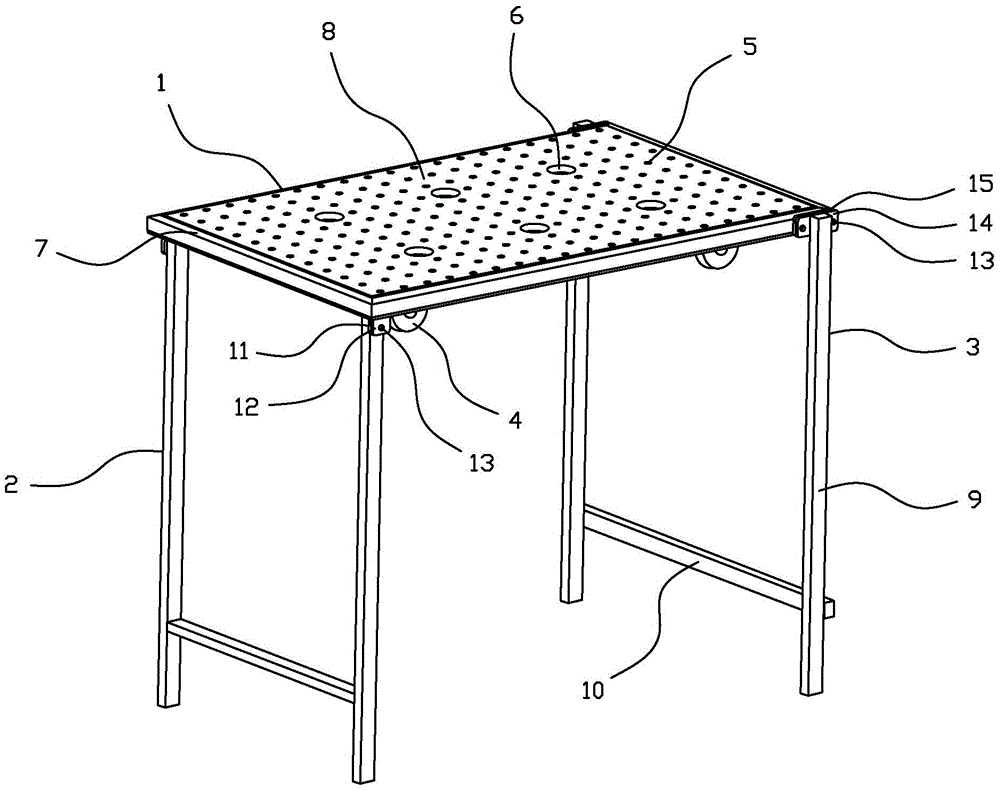

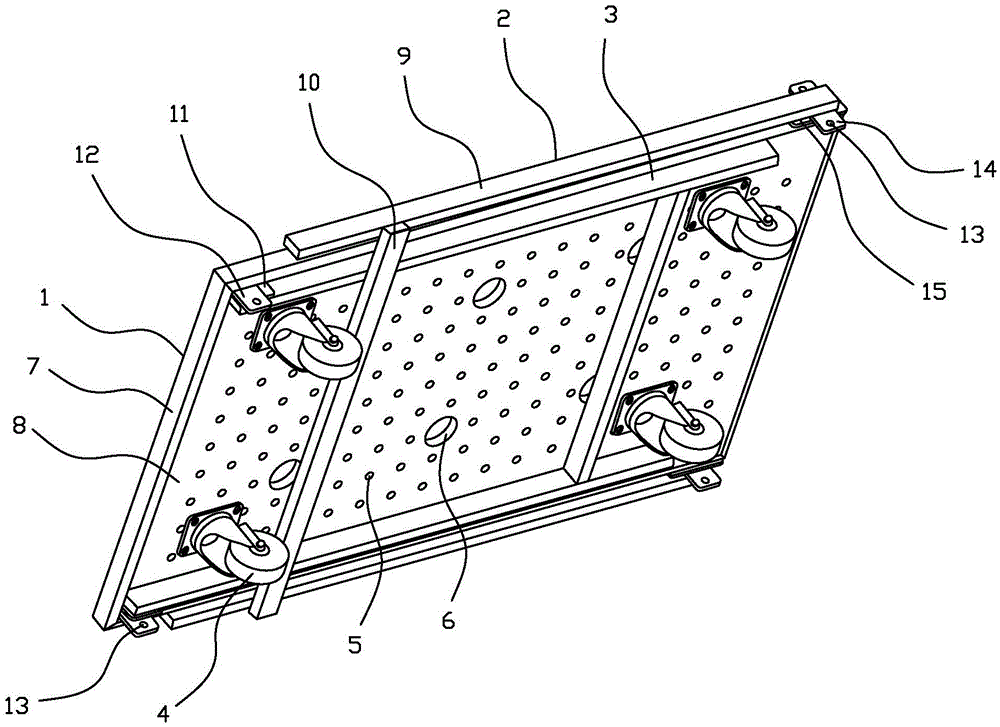

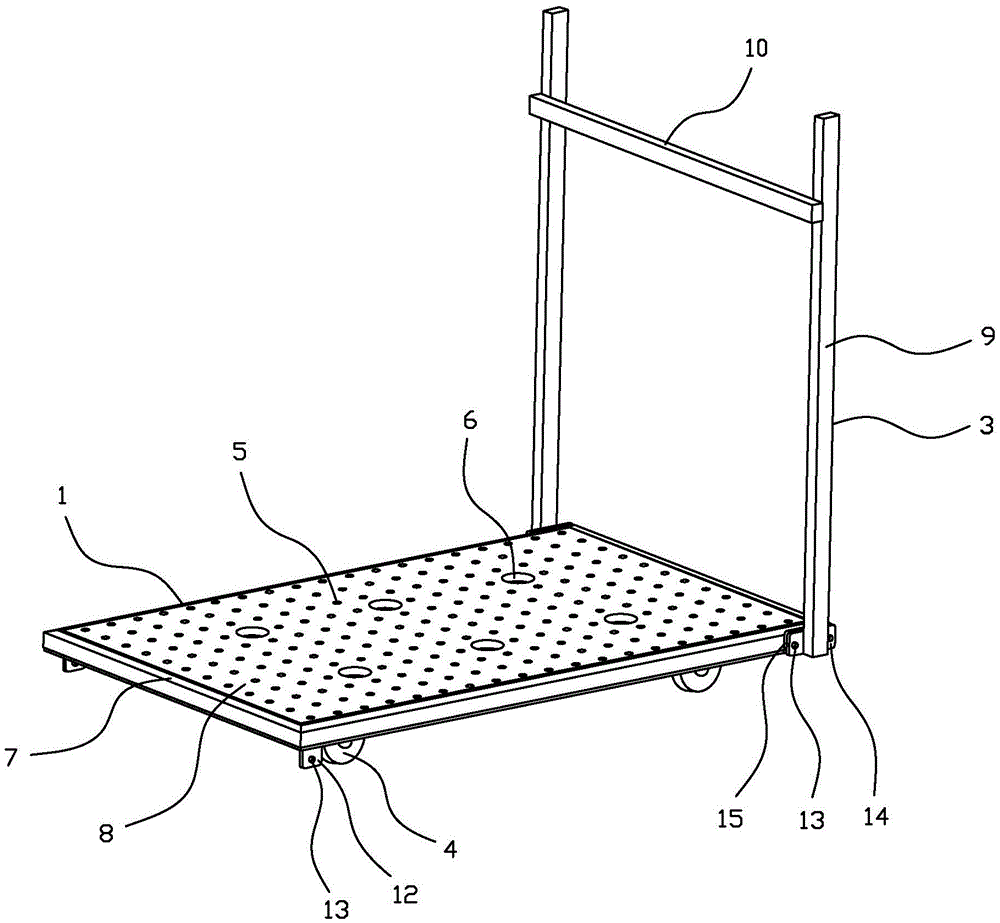

Multipurpose portable high-voltage isolating switch overhaul worktable and using method thereof

ActiveCN105552761AReduce space consumptionEasy to carryWork benchesSwitchgearModular fixtureProcess quality

The invention discloses a multipurpose portable high-voltage isolating switch overhaul worktable. The multipurpose portable high-voltage isolating switch overhaul worktable comprises a worktable board and multiple foldable support legs which are hinged to the worktable board and are used for supporting the worktable board; rolling wheels are arranged at the bottom of the worktable board; and at least one foldable support leg can be turned to the upside of the worktable board. The overhaul worktable can be folded, so that relatively small space is occupied; a platform plate which is made from a polyformaldehyde resin material is light in weight and convenient to carry; the rolling wheels are arranged at the bottom of the worktable board, and the multipurpose portable high-voltage isolating switch overhaul worktable can be used as a trailer by folding one foldable support leg at the bottom of the worktable board and turning another foldable support leg to the upside of the worktable board, so that the high-voltage isolating switch overhaul worktable can be used for multiple purposes, is convenient to carry tools and various modular fixtures and is convenient to use, the work efficiency can be improved greatly, and the labor intensity can be reduced; meanwhile, a series-hole modular fixture structure is formed on the worktable board and via holes are formed in the worktable board, so that more convenience is brought to assembly and disassembly of the isolating switch overhaul fixtures, the work precision can be ensured, and the work efficiency as well as the process quality can be improved.

Owner:QUANZHOU POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +1

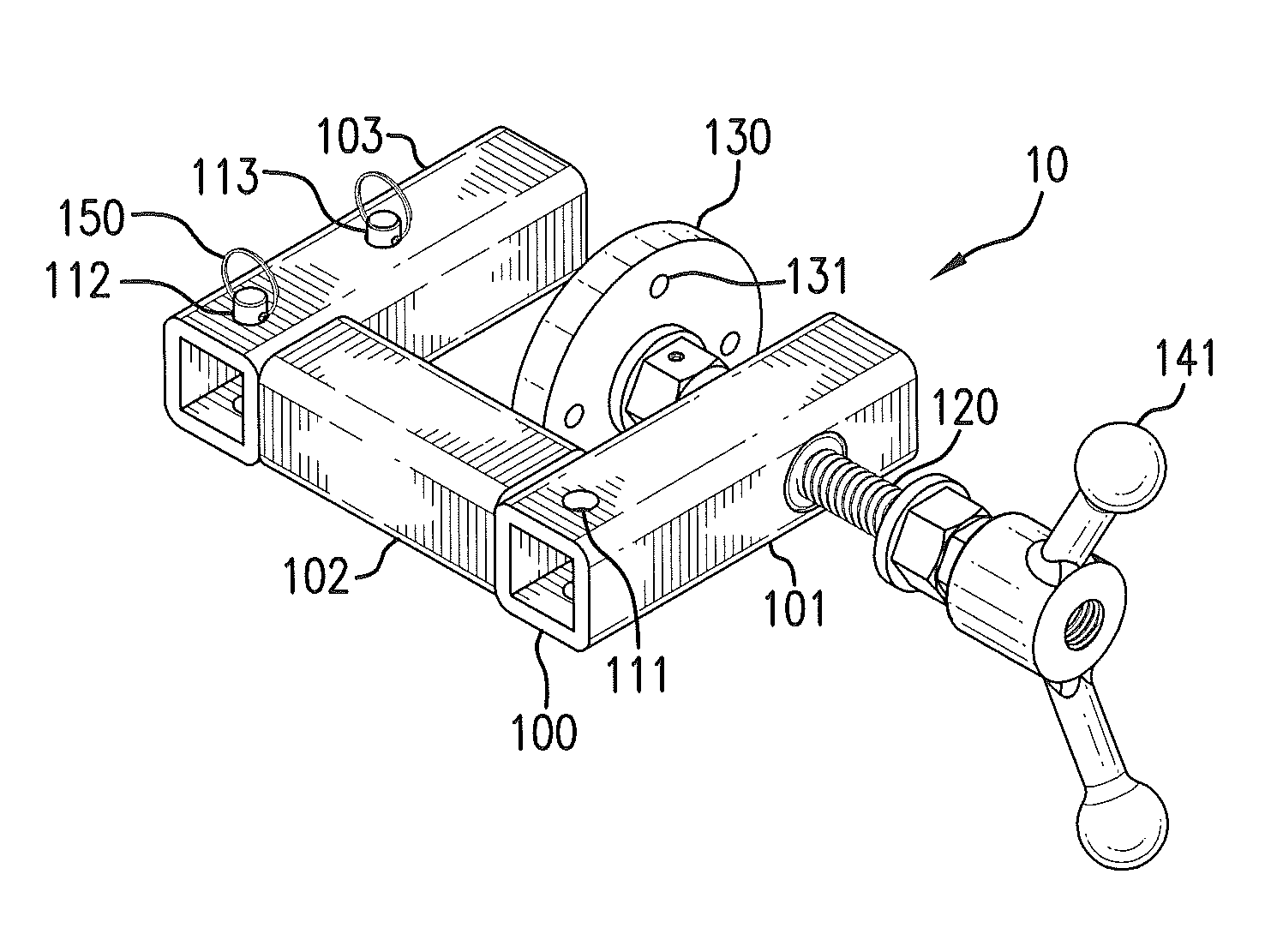

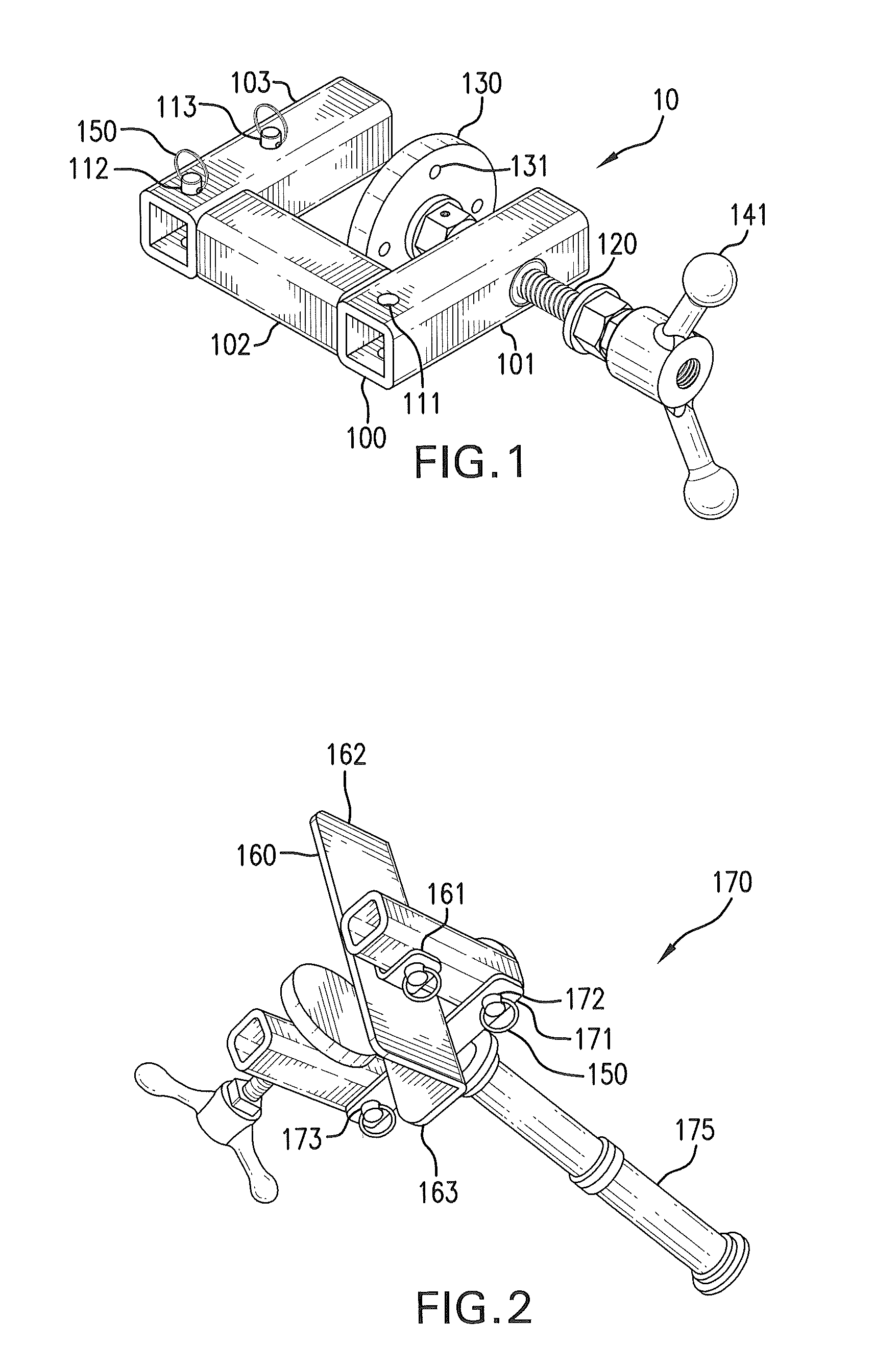

Modular clamp assembly with multiple tool attachments

A clamp assembly including: a clamp frame including a first portion including a first opening which accepts a fastener, and a second portion interposed between the first portion and a third portion, wherein the third portion includes a second opening and a third opening, each of which accepts a fastener, a threaded rod disposed through the first portion of the clamp frame; and a clamp pad on an inner end of the clamp rod.

Owner:ON THE LEVEL BILLIARDS

Combination method of a modularized clamp structure

A combination method of a modularized clamp structure, wherein mainly, two clamping portions of two clamps on the two ends of a suit hanger are provided thereon with two engaging channels, each engaging channel has therein a first positioning portion; two slide blocks are pushed into the engaging channels, the slide blocks each has a second positioning portion to be engaged with a corresponding one of the first positioning portions, so that the slide blocks are fixed in the engaging channels. Thereby, a user can change the two slide blocks in a flexible way, when in production, the slide blocks can be assembled and released in an energy saving mode. The clamp structure is applicable to a suit hanger for hanging paints or towels etc.

Owner:AMERICAN APPL ACCESSORIES

Versatile illumination system

InactiveUS7963673B2Increase in sizeIncrease flexibilityLighting applicationsMechanical apparatusModular fixtureModularity

A lightweight, modular expandable multiple par lamp fixture configurable to form various sizes and intensities of high output area lighting or projected soft light. A high efficiency par lamp includes a high output globe and lightweight reflector, optional collar, and lens. Individual modular fixtures comprising high efficiency par lamps may be stacked to create larger units. The par lamps may be arranged in pods which can be assembled into larger units. A diffusion frame and fabric cover can be attached to the fixture in front of the par lamps to create a soft, deeply projected light. The diffusion frame may have an internal semi-translucent baffle to spread light through diffusive sidewalls.

Owner:FINN BRUCE L

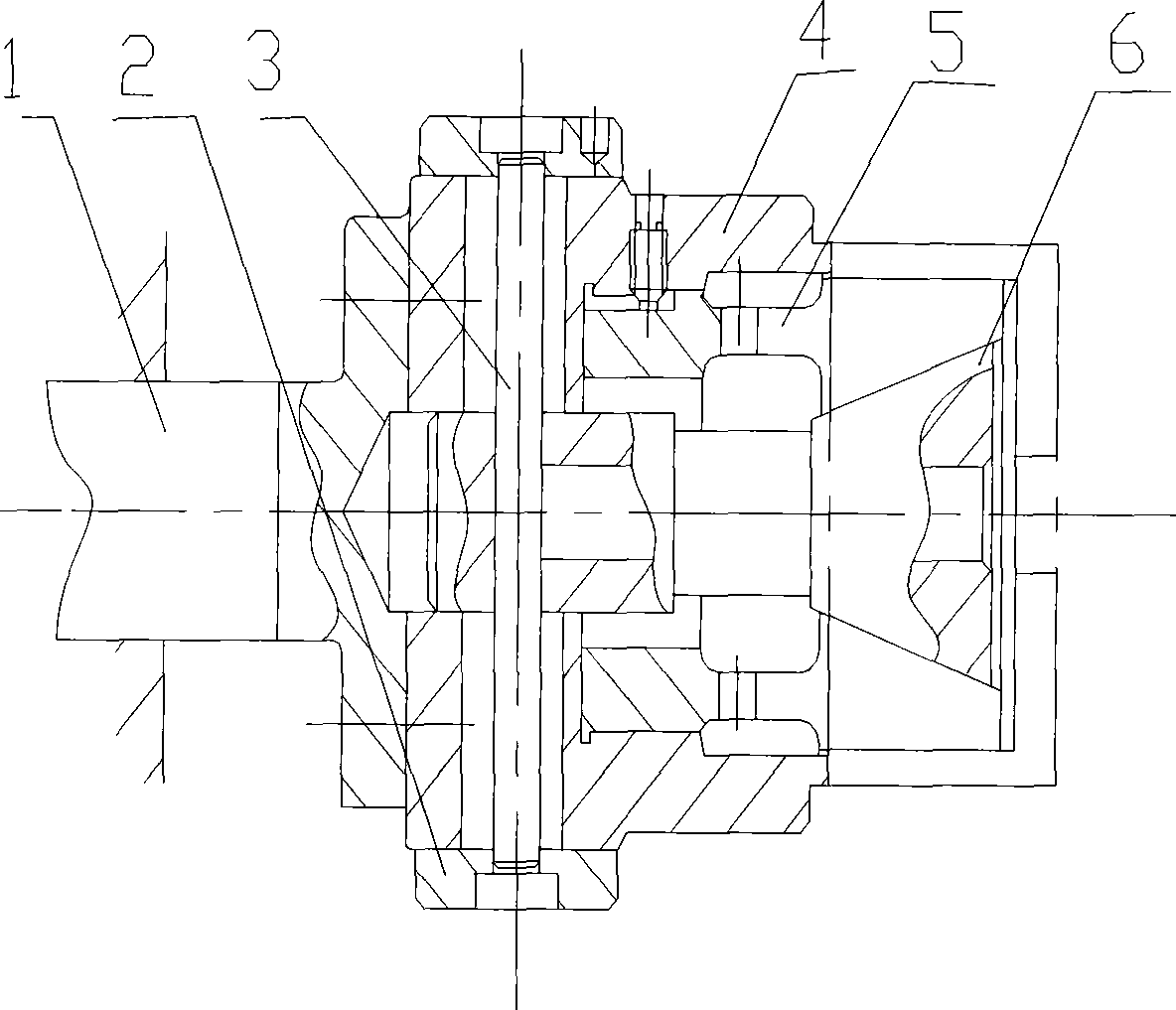

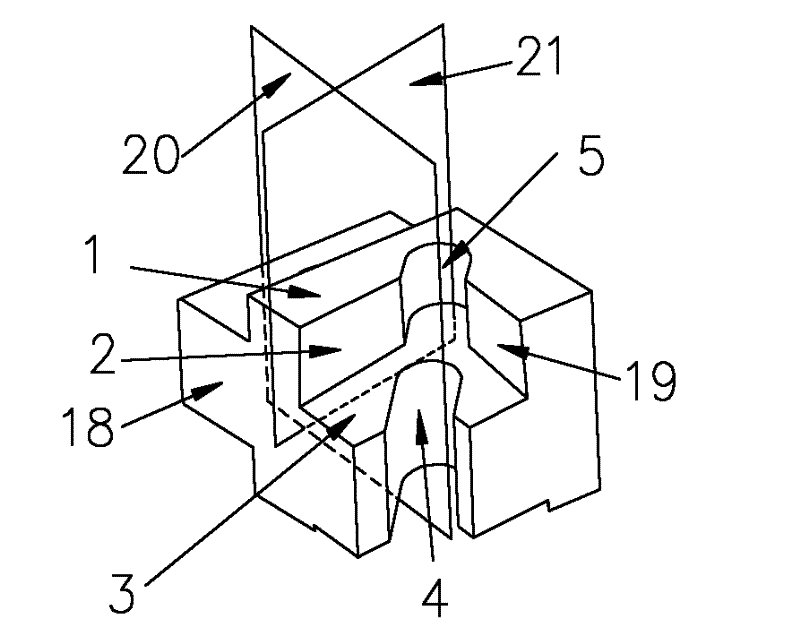

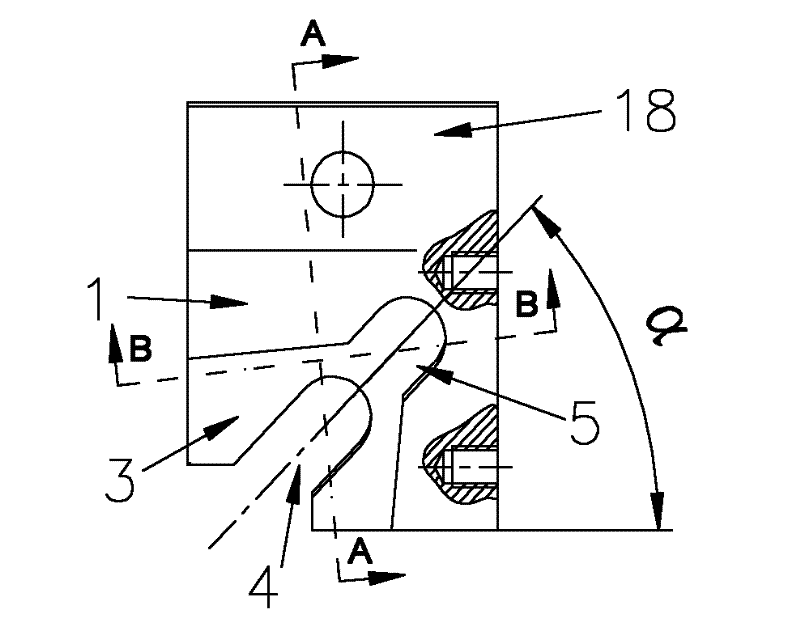

High-efficient modular fixture for processing part

InactiveCN101372083AReduce design man-hoursReduce production man-hoursPositioning apparatusMetal-working holdersModular fixtureEngineering

The invention relates to a group of clamps used for part processing, mainly consisting of a basic part and an adjustable part; wherein, the basic part comprises a clamping body (1) and transmission clamping parts (2, 3); the adjustable part consists of replaceable parts (4, 6) and an elastic expanding part (5); during the part processing, each dimension group of the part is provided with a group of corresponding replaceable parts. When parts of different dimension groups are processed, replaceable parts (4, 6) are all needed to be replaced; but in the same dimension group, only elastic expanding part (5) of corresponding dimension is needed to be replaced for the workpiece of difference positioning aperture; the clamp can shorten the design and manufacture time of normal clamp, saves the material and reduces the production cost.

Owner:BEIJING UNION UNIVERSITY

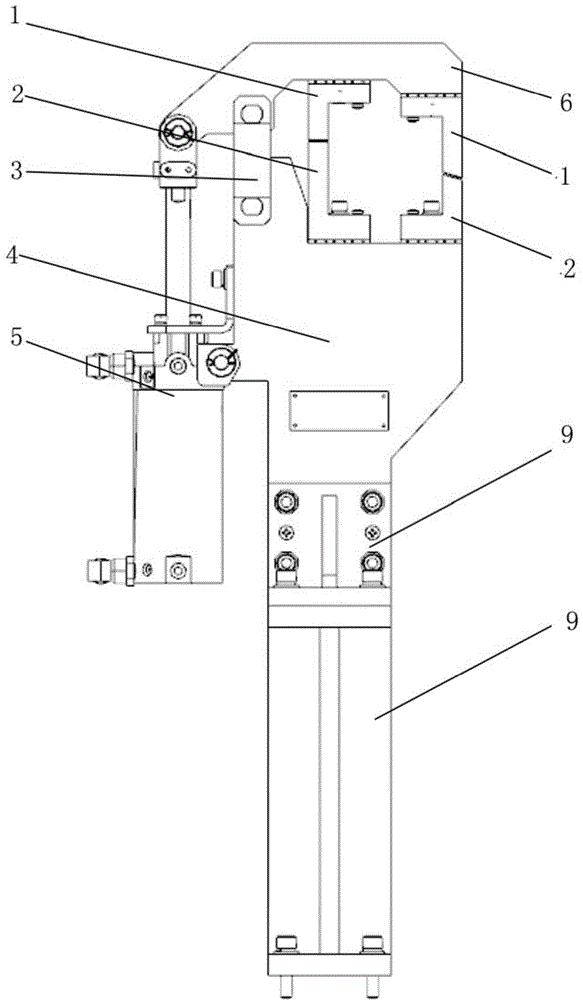

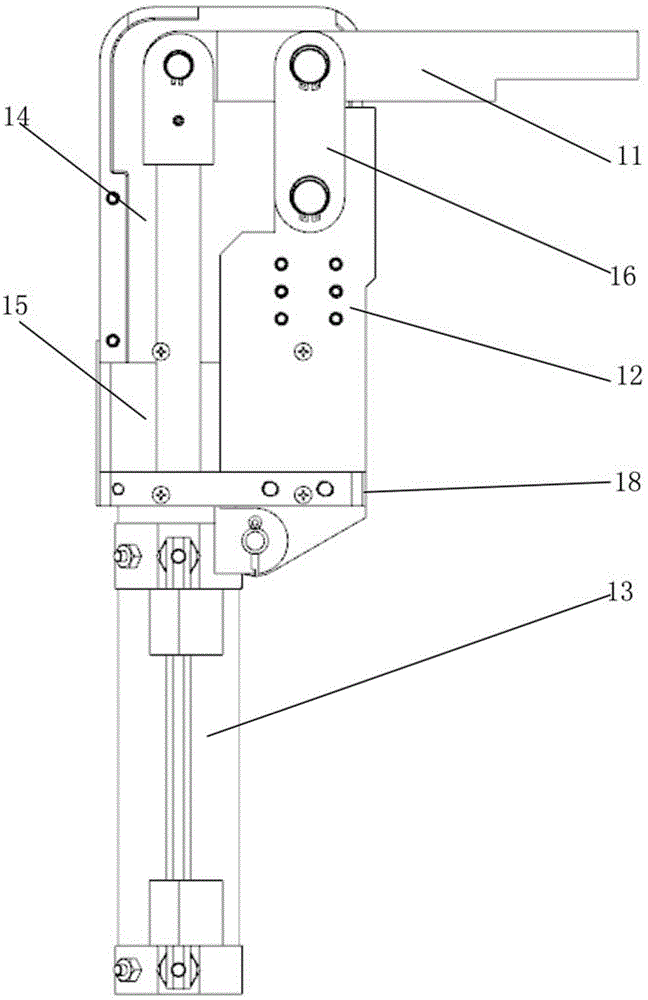

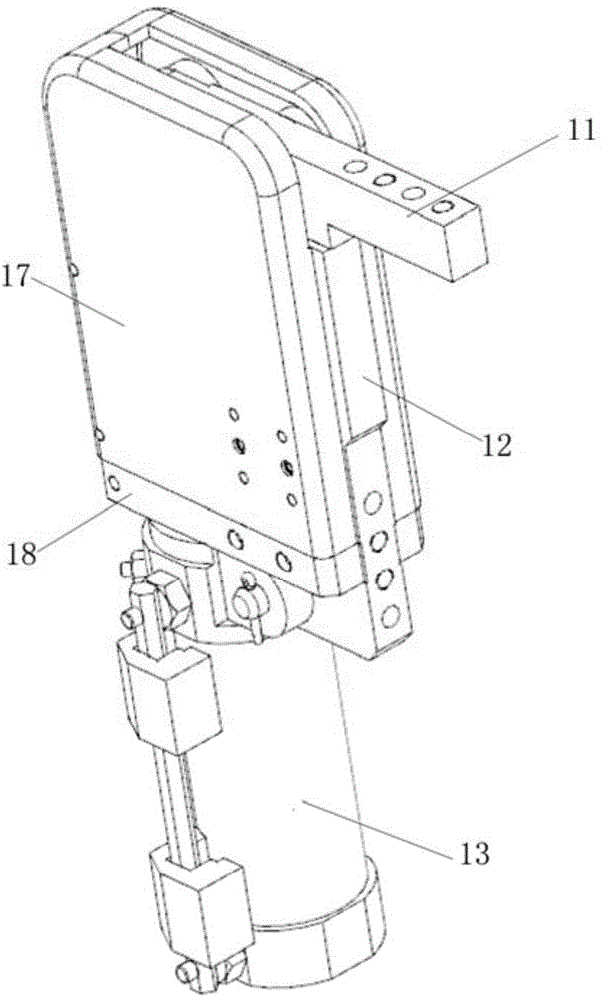

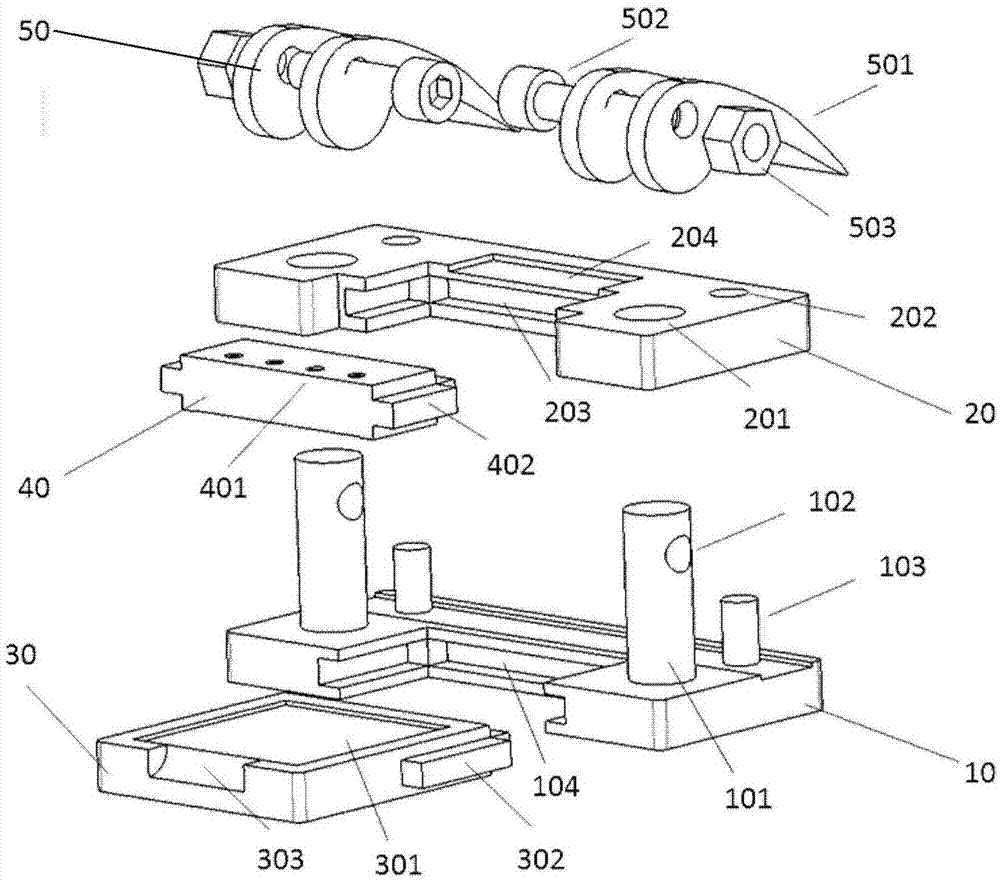

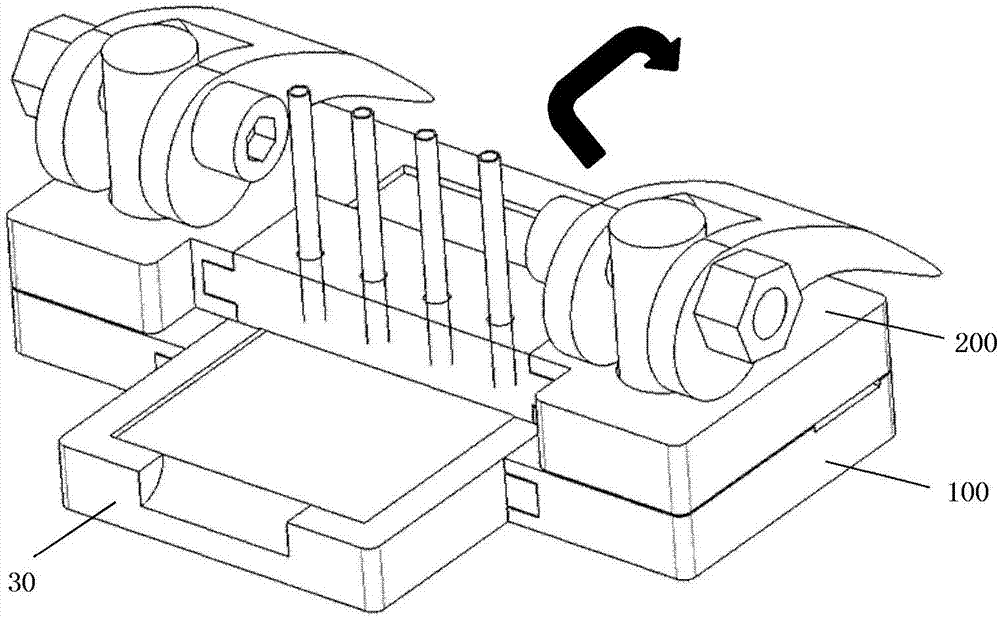

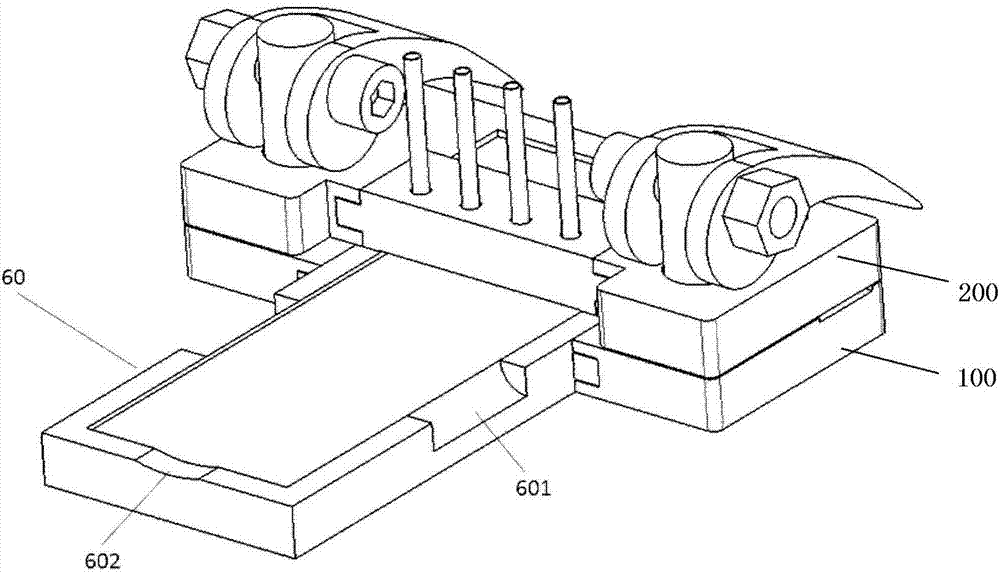

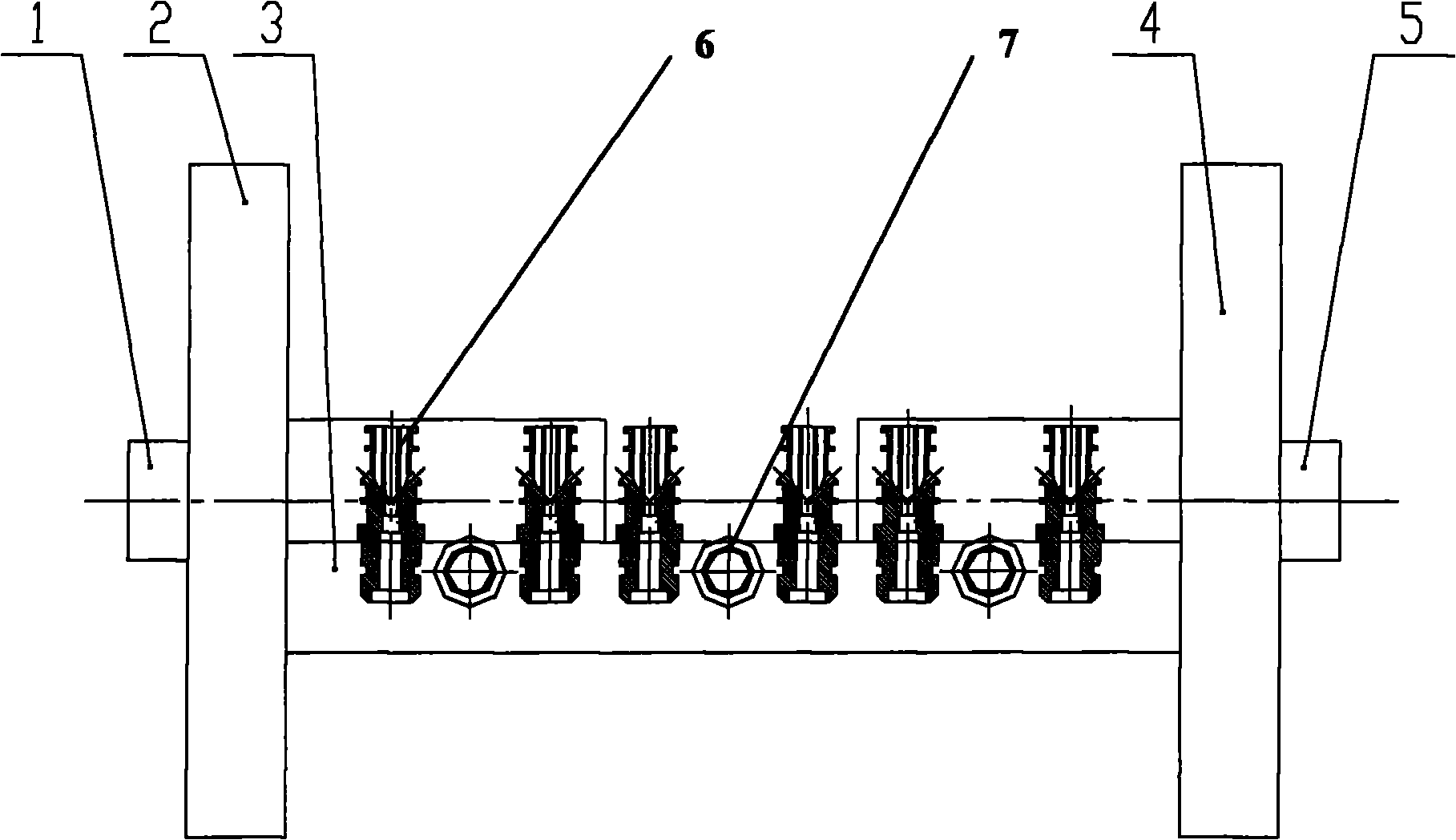

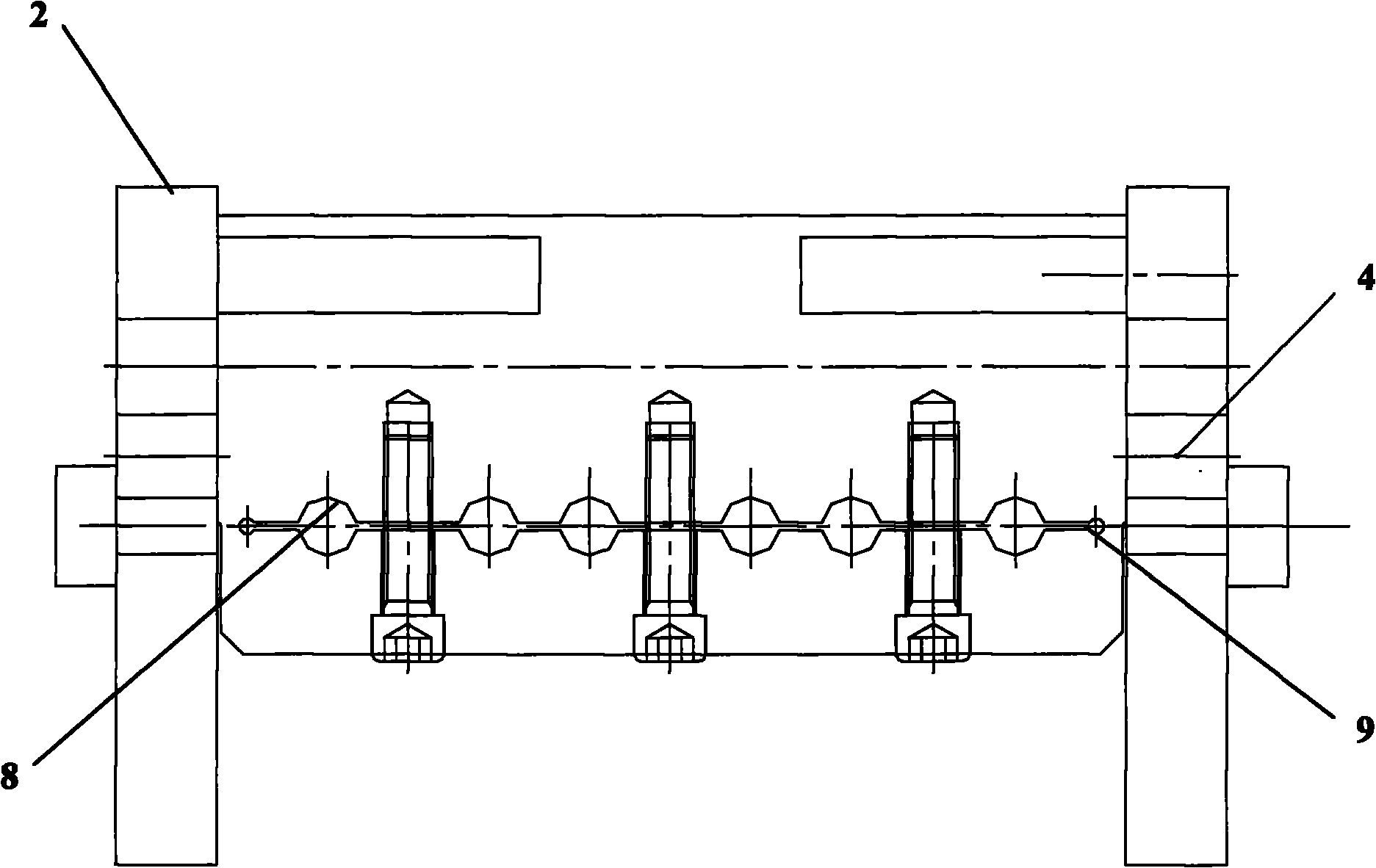

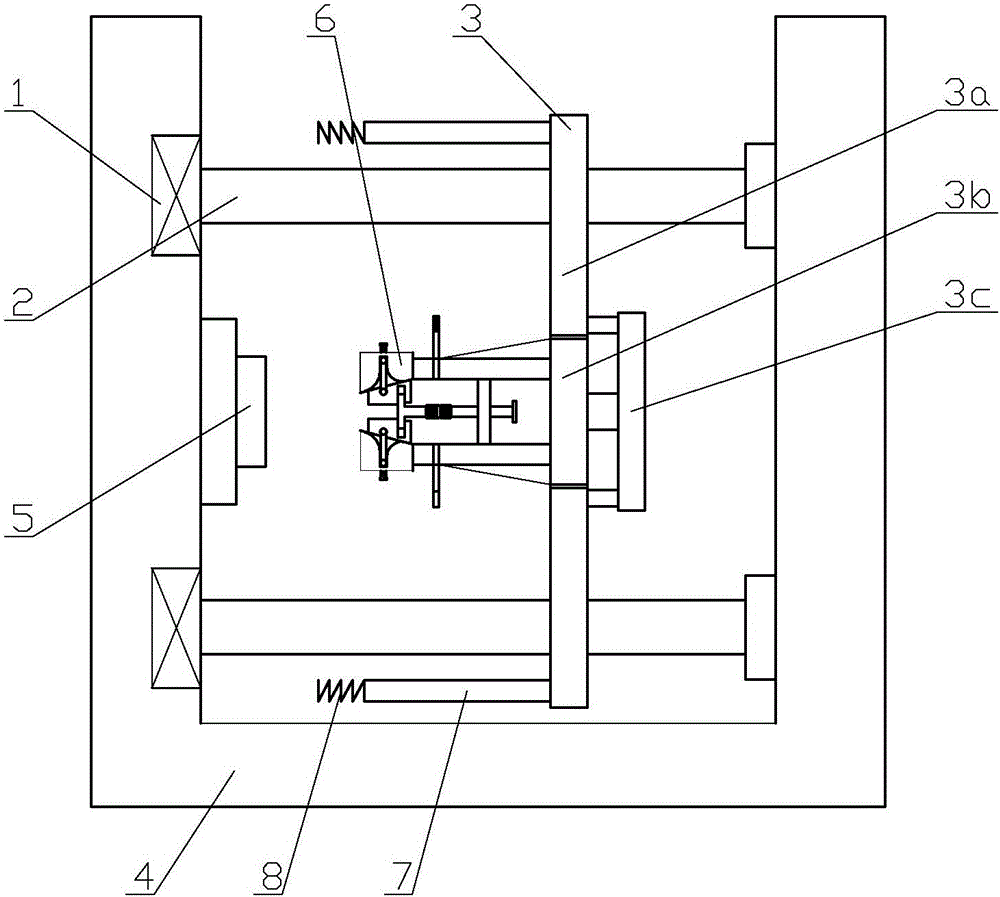

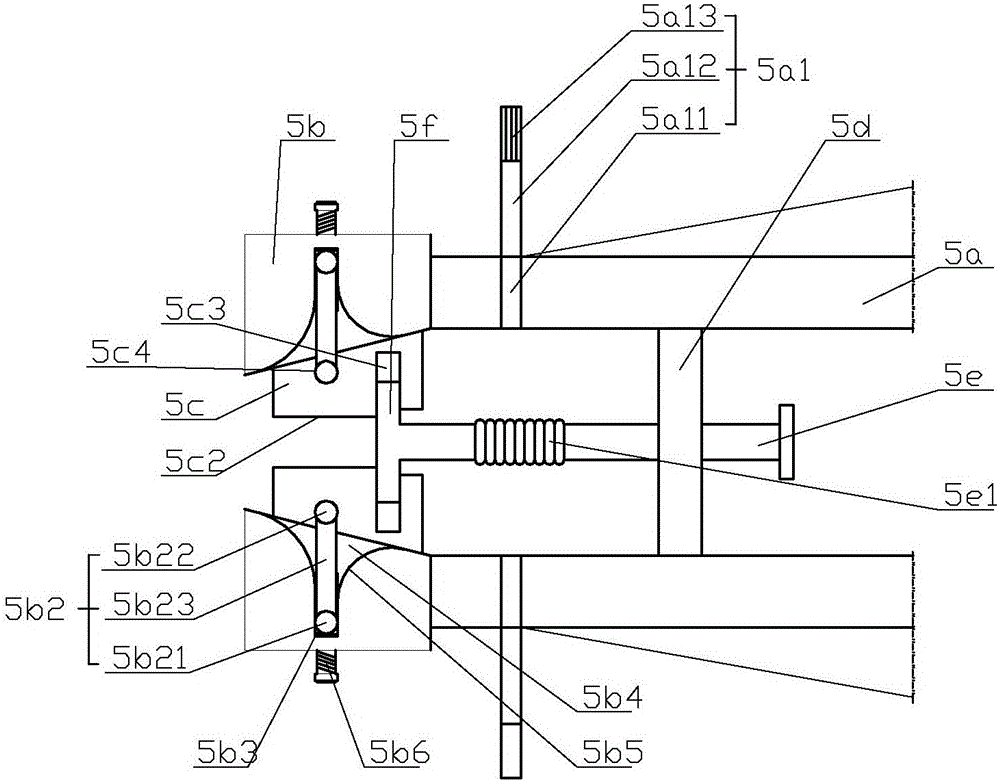

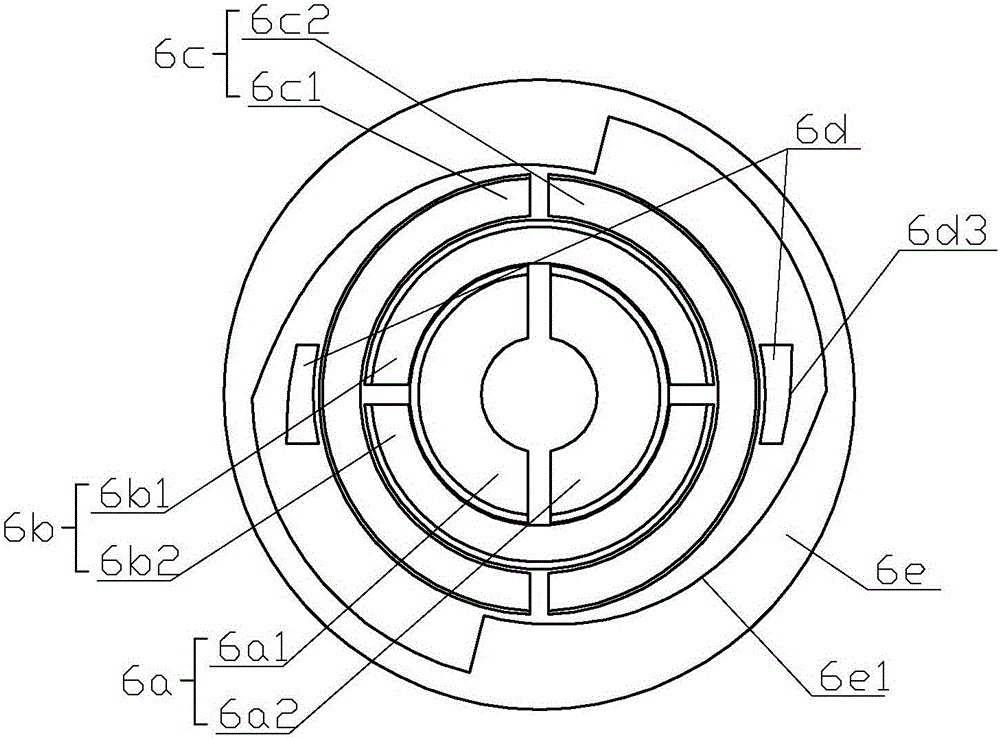

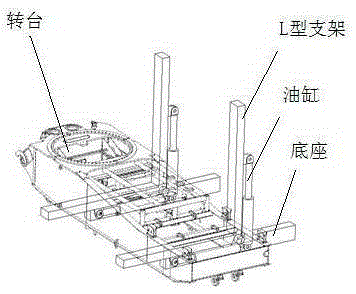

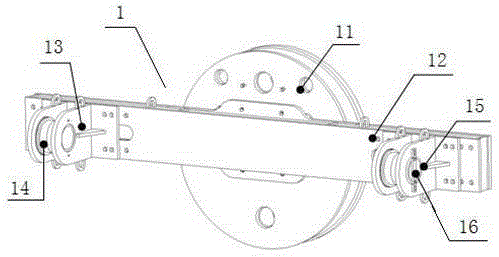

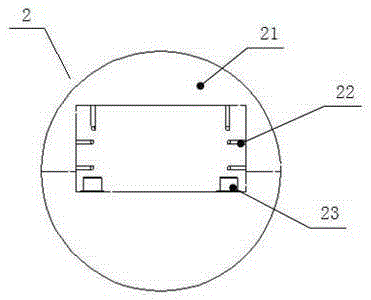

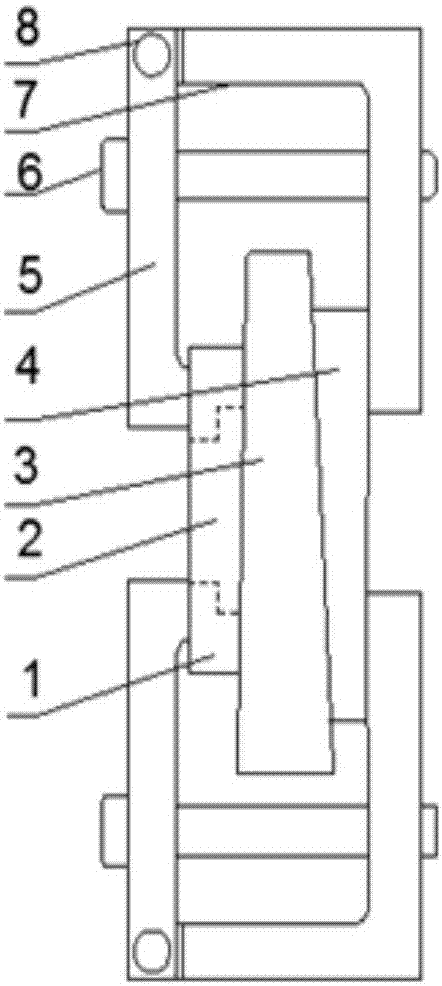

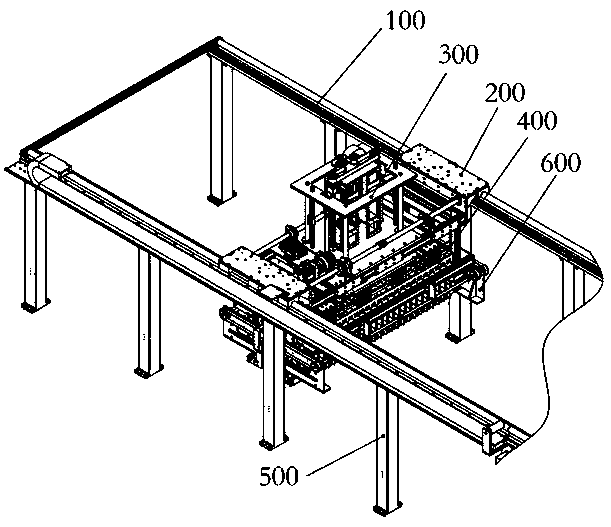

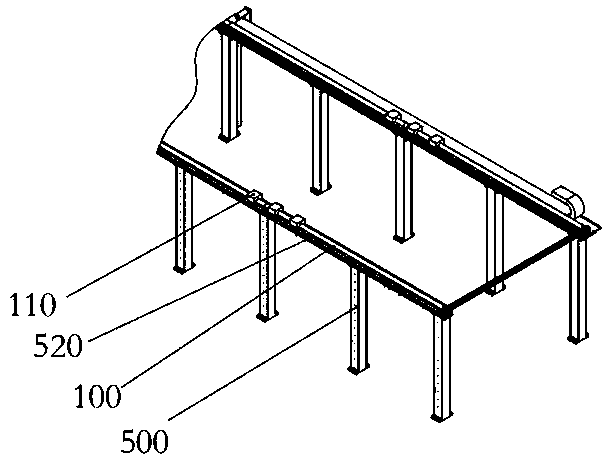

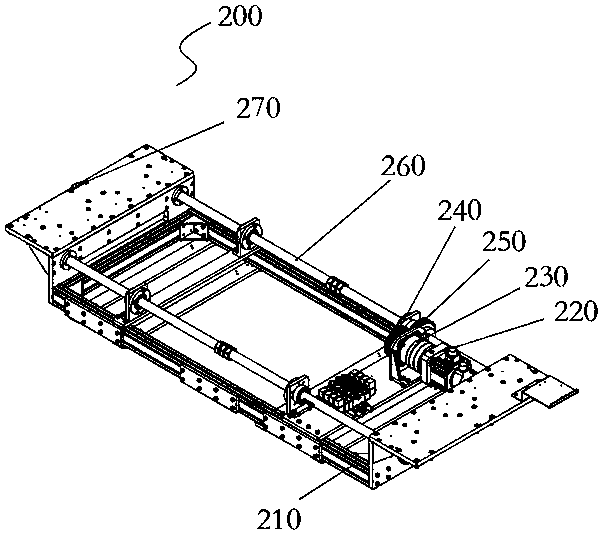

End-to-end type modular fixture and reversing machine comprising same

InactiveCN105415245AReduce investmentGuaranteed structural strengthWork holdersWork benchesModular fixtureControl system

The invention discloses an end-to-end type modular fixture and a reversing machine comprising the same. The end-to-end type modular fixture comprises a front clamping device and a tail clamping device, wherein the front clamping device consists of a rotary connecting disc, a crossbeam and supporting lugs; the rotary connecting disc is connected with the middle part of the crossbeam; two groups of supporting lugs are provided and are symmetrically arranged at the two ends of the crossbeam; the tail clamping device consists of a wheel type frame, regulating screws and a pedestal; the pedestal is arranged at the bottom of the wheel type frame; the regulating screws are arranged on the rest three surfaces of the wheel type frame; the reversing machine comprises a driving device, a driven device and a control system; the driving device consists of the tail clamping device, an anti-tipping wheel, supporting idler wheels, a driving motor and a supporting base; the driven device consists of the front clamping device, a rotary support, a mobile base and a driving screw. The end-to-end type modular fixture disclosed by the invention has the beneficial effects of realizing reversal replacement of a large part and being high in work efficiency, simple to operate, hard to roll over, high in safety efficiency and low in dependence on other auxiliary equipment.

Owner:XCMG CONSTR MACHINERY

Modular fixture for partial heat treatment of induction heating and using method thereof

InactiveCN107254570AReasonable control of deformationCompact structureFurnace typesIncreasing energy efficiencyModular fixtureEngineering

The invention provides a modular fixture for partial heat treatment of induction heating and a using method thereof. The modular fixture comprises a heat conduction fixture body, a heat insulation fixture body, a press plate and pressing mechanisms; the heat conduction fixture body, through inner steps therein, is assembled with outer steps of the heat insulation fixture body, and is attached to the surfaces of to-be-heat-treated components, and a through hole used for showing the to-be-heated area is formed in the interior of the heat conduction fixture body; and the pressing mechanisms comprise support blocks in hinged connection and pressing blocks, the support blocks support the bottom of the pressing plate, and the pressing blocks press the top surface of the heat insulation fixture body tightly so as to press the to-be-heat-treated components tightly. When in use, the specifications of the heat conduction fixture body and the heat insulation fixture body are selected according to the area size of the to-be-heated area. According to the modular fixture for the partial heat treatment of induction heating and the using method thereof, the accurate control over the heating area and the heating temperature of the repair area of the to-be-heat-treated components can be achieved, the problem of extremely-poor deformation generated in the heating process is solved, the operation is simple, the cost is low, and the universality is good.

Owner:SHENYANG AEROSPACE UNIVERSITY

Modular clamp station with variable pitch

ActiveUS20120228790A1Unwanted movementMinimizing the scrap generatedMouldsAuxillary shaping apparatusModular fixtureMolding machine

A method and modular mold clamp assembly for use in a molding machine. The assembly has a frame with a base member. The base member has end members provided thereon. Radial adjustment mechanisms are mounted on the end members, with the radial adjustment members configured to cooperate with turntables of the molding machine. At least one support bracket extends from the frame. The support bracket is configured to cooperate with at least one support fixture of the molding machine. The radial adjustment mechanisms and the at least one support bracket allow the modular mold clamp assembly to be moved toward and away from the center of a wheel of the molding machine.

Owner:GRAHAM ENG CO LLC

Convertible modular fixture of multifunctional frictional wear testing machine

ActiveCN102539232APrecise Tribological PropertiesAccurate and effective detectionStrength propertiesModular fixtureWear testing

The invention provides a convertible modular fixture of a multifunctional frictional wear testing machine, relating to an indexable numeric control turning blade fixture. The primary structure of a convertible fixture of the convertible modular fixture provided by the invention is a stepped slot, the stepped slot is provided with an upper base surface, a slot side and a slot bottom surface, the slot side and the slot bottom surface are mutually vertical, the lower part of the stepped slot is provided with a U-shaped opening cutter feeding slotted hole, the upper part of the stepped slot is provided with a U-shaped opening cutter retracting slotted hole which is consist with the direction of the cutter feeding slotted hole, a slot included angle, a tool cutting edge angle, an oblique angle, tool cutting edge inclination and a front angle related angle are formed, and a calculation formula which can design and calculate an included angle-inclined angle between a center line of a slot and the horizontal line is provided, namely the tool cutting edge angle Kr is equal to 90 degrees plus or minus (oblique angle alpha-1 / 2. the slot included angle theta), thus the primary structure of the convertible fixture which can be comprehensively and accurately adaptive to a diversity indexable numeric control turning blade, and an accurate, high-efficiency and practical innovative tool is provided for detecting and evaluating tribological properties and cutting capacity of the indexable numeric control turning blade.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Lithium battery modular clamp device

ActiveCN108890622ALow costAvoid taking up spaceProgramme-controlled manipulatorGripping headsModular fixtureEngineering

The invention discloses a lithium battery modular fixture device. A lateral moving mechanism arranged on the transfer rail and connected with the transfer rail through a slider for transporting a lithium battery on the modular fixture device to a designated position; A vertical moving mechanism fixedly connected with the transverse moving mechanism and used for making the modular fixture device have a vertical moving function; A fixture mechanism arranged on the vertical moving mechanism and connected with the vertical moving mechanism through a slider; The fixture mechanism is composed of a plurality of fixtures, and each fixture is provided with a plurality of jaws for clamping the lithium battery. The lithium battery modular fixture device of the invention can dispose of a plurality oflithium batteries, and can transport the lithium batteries to a designated chemical forming unit through lateral movement and vertical movement, thereby effectively saving cost and avoiding the problem that space is occupied by using a plurality of groups of manipulators.

Owner:广东恒翼能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com