Patents

Literature

297results about How to "Accurate and effective detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for detecting software plagiarism

InactiveCN103729580AAccurate detectionAccurate and effective detectionSoftware engineeringProgram/content distribution protectionRead-only memoryComputer equipment

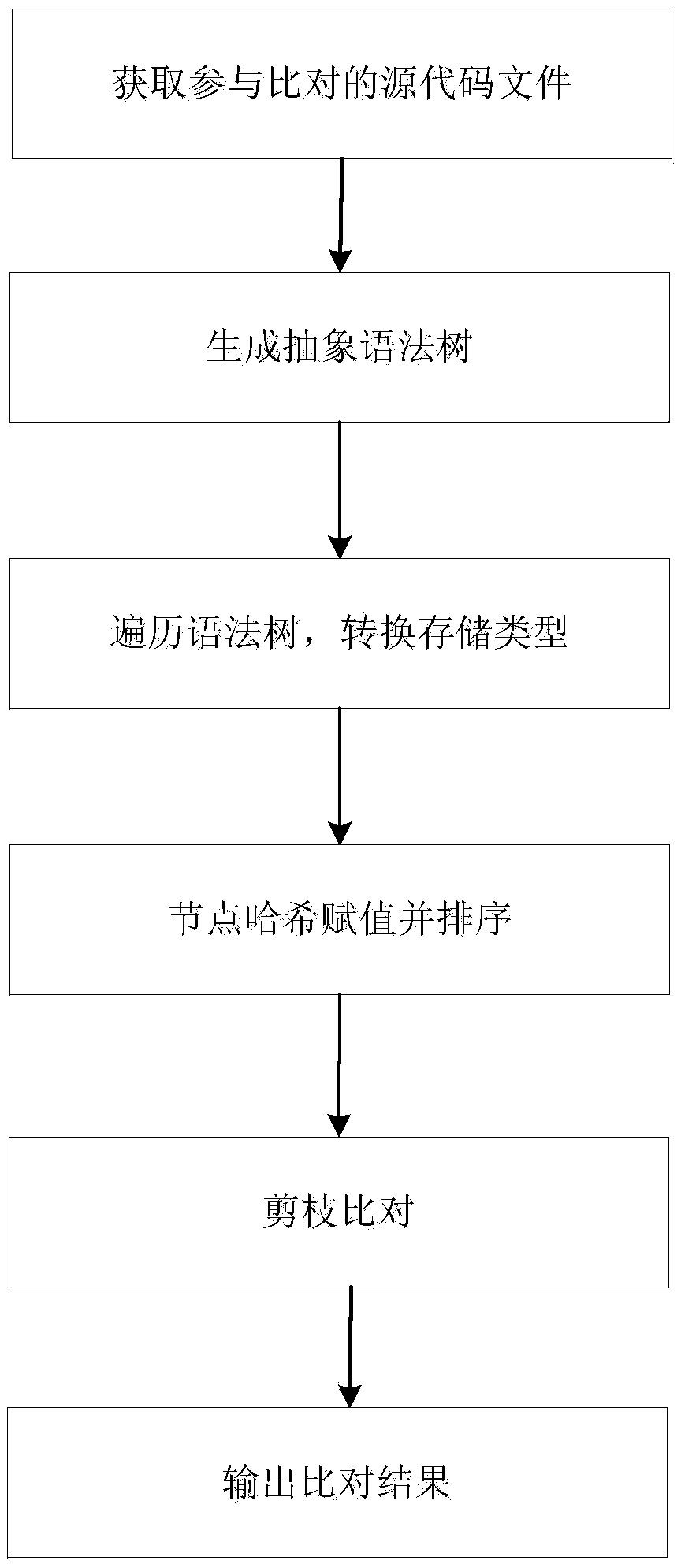

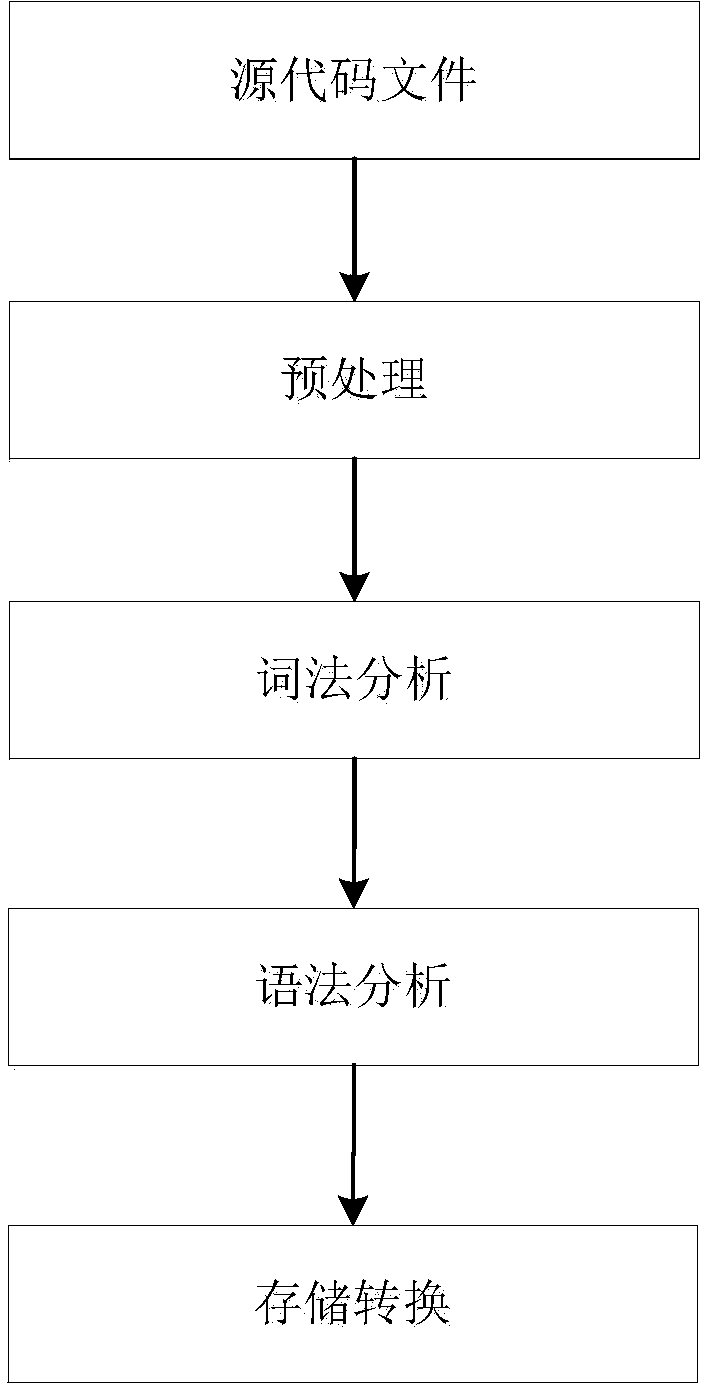

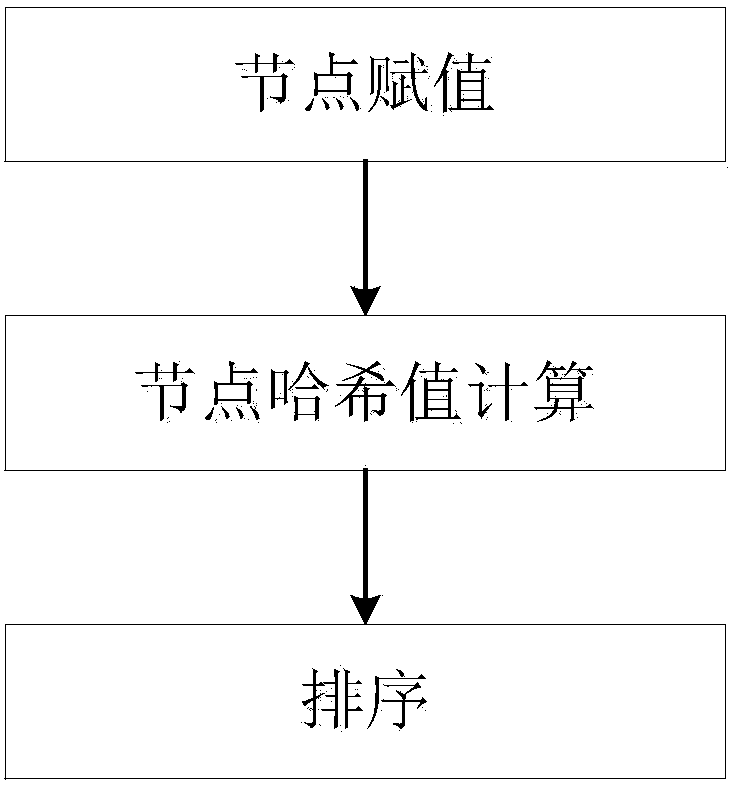

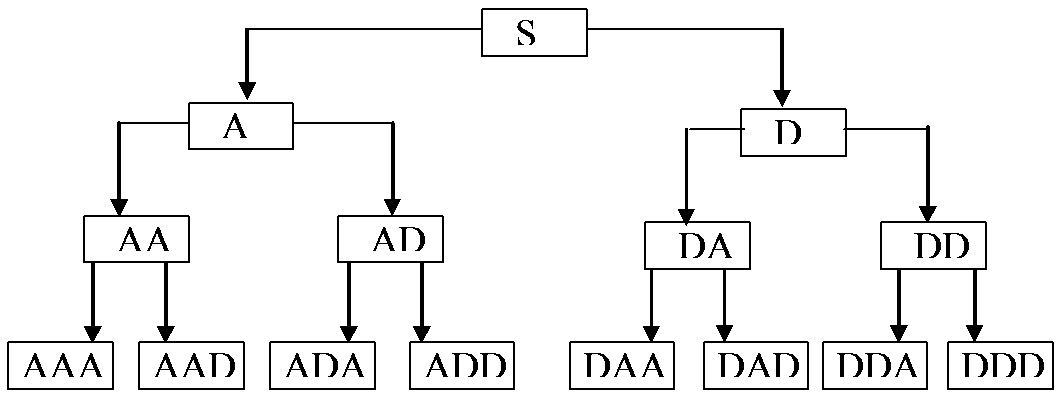

The invention provides a method and a device for detecting software plagiarism. The method is on the basis of an abstract syntax tree pruning comparison algorithm, and comprises the following steps: A, acquiring a source code file; B, generating an abstract syntax tree; C, traversing the abstract syntax tree, and converting the abstract syntax tree into a required storage type; D, assigning and sequencing the nodes of the abstract syntax tree; E, comparing the sequenced nodes; and F, outputting an result. According to the method and the device, the source code plagiarism is detected accurately on a syntax level, particularly the variable type change and the interference variable-added plagiarism which cannot be distinguished by the abstract syntax tree are detected accurately and effectively and can be embodied in the form of a software product; the computer software product can be stored in a storage medium, such as an ROM (read only memory) / an RAM (random access memory), a magnetic disc and a compact disc, which contains a plurality of commands so that a piece of computer equipment executes the method disclosed by the invention.

Owner:STATE GRID CORP OF CHINA +3

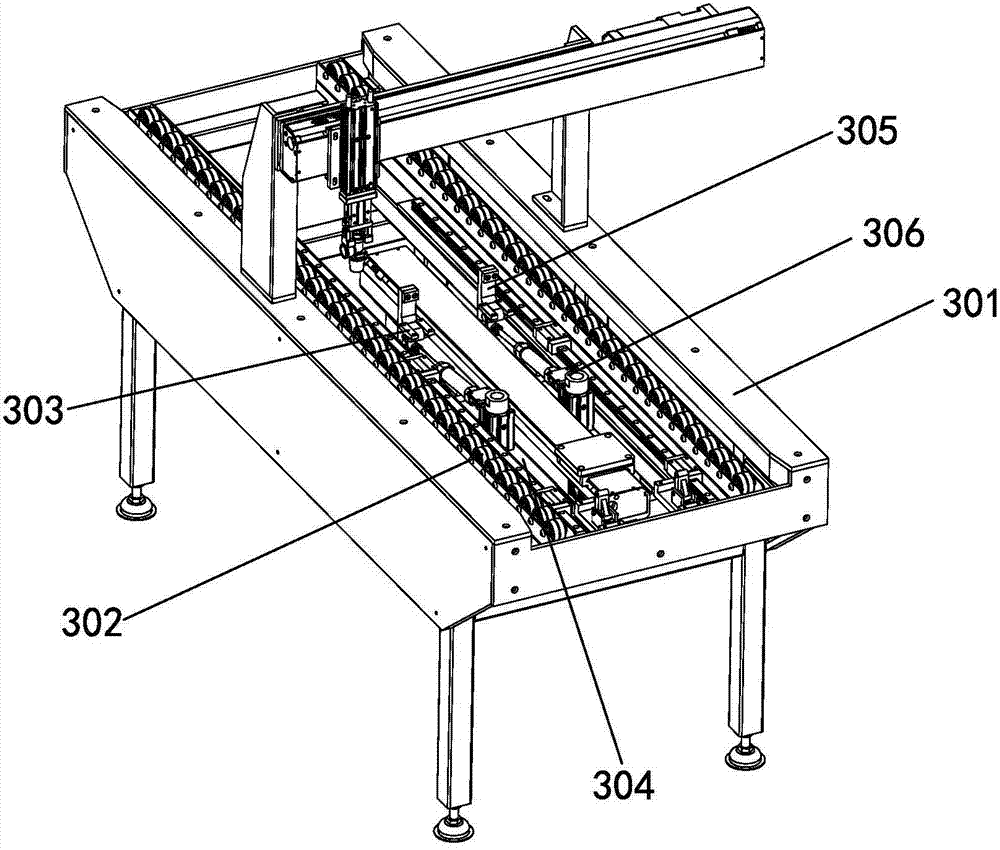

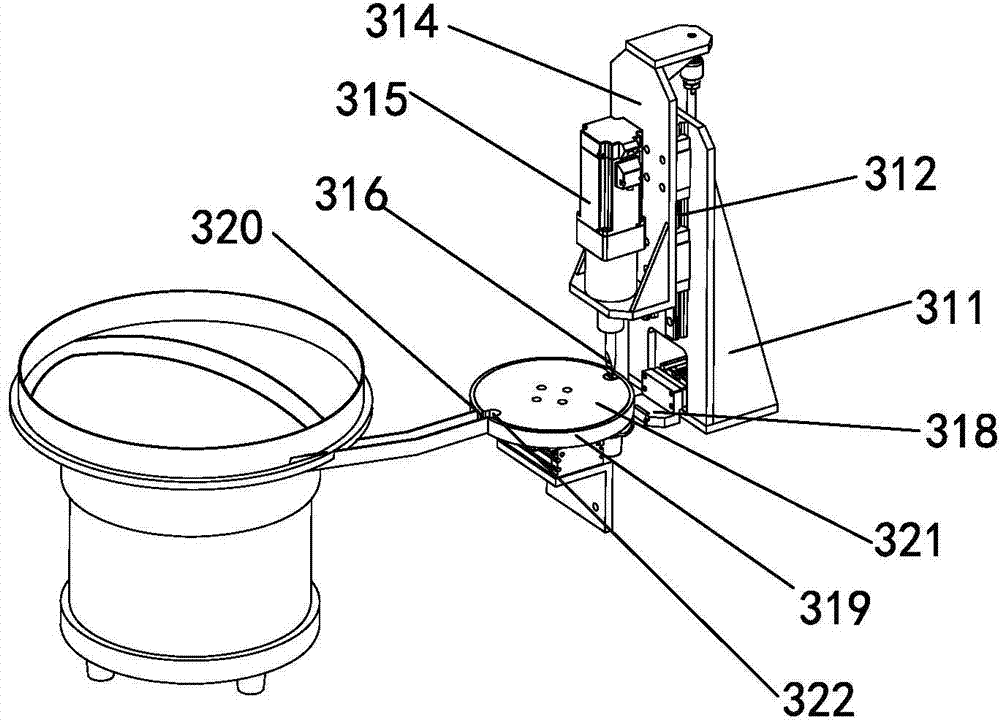

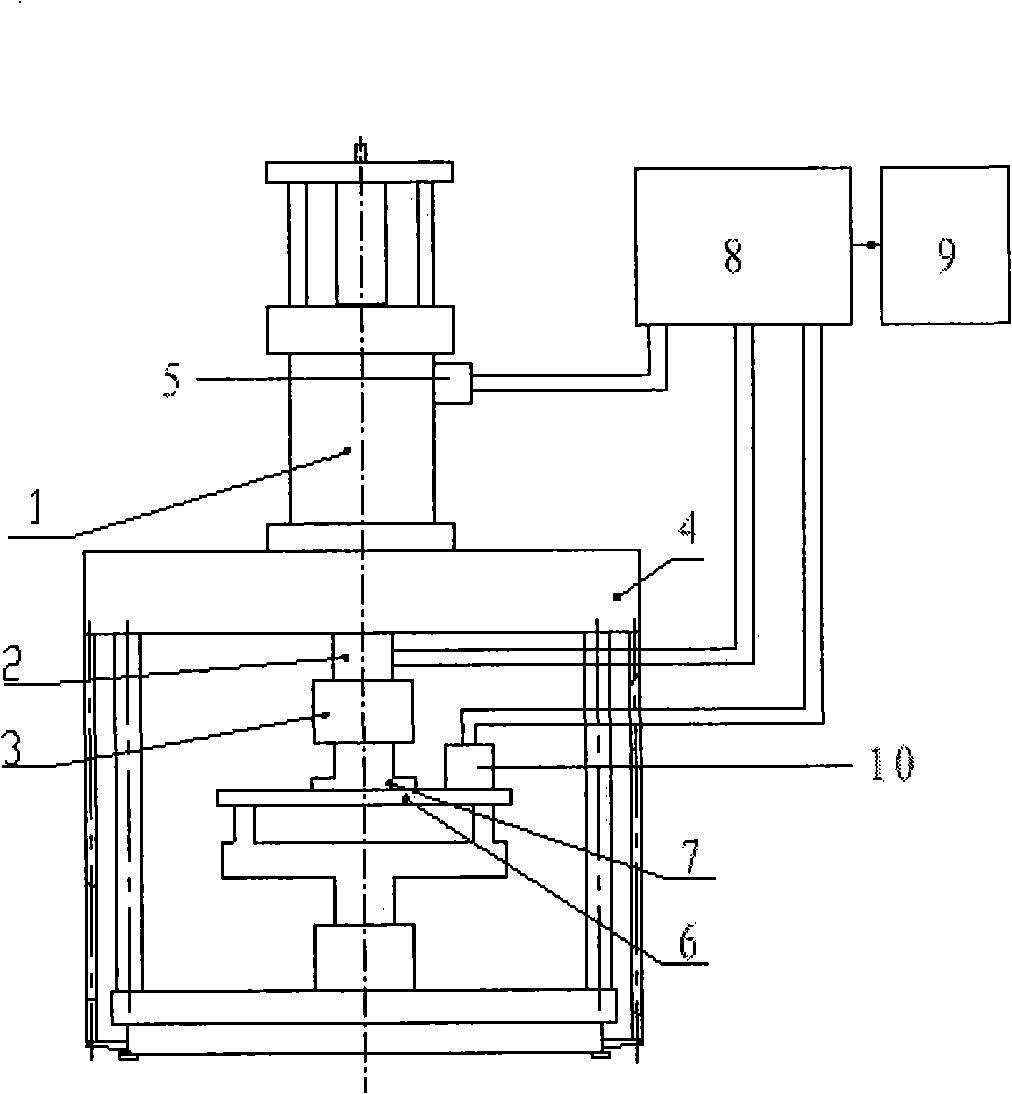

Valve assembling production line

ActiveCN103894823AImprove work efficiencyCooperate wellAssembly machinesMetal working apparatusProduction lineEngineering

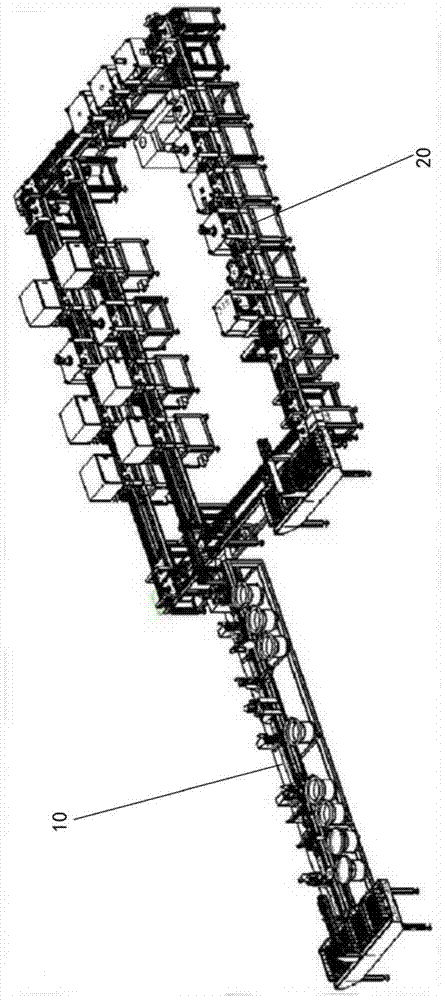

The invention relates to the technical field of valves, in particular to a valve assembling production line. The valve assembling production line comprises an assembling machine frame, a plug assembling device, a connection piece assembling device, a valve rod assembling device, a rubber pad assembling device, a rubber pad sealing performance detection device, a nut assembling device, a nut screwing device, a washer assembling device, a hand wheel assembling device, a spring assembling device and a spring nut assembling device, wherein the plug assembling device, the connection piece assembling device, the valve rod assembling device, the rubber pad assembling device, the rubber pad sealing performance detection device, the nut assembling device, the nut screwing device, the washer assembling device, the hand wheel assembling device, the spring assembling device and the spring nut assembling device are sequentially arranged on the assembling machine frame. A product which is assembled in one device among the preceding devices is conveyed to the next device to be assembled through an assembling conveying device, and one side of the plug assembling device, one side of the connection piece assembling device, one side of the valve rod assembling device, one side of the rubber pad assembling device, one side of the nut assembling device, one side of the hand wheel assembling device, one side of the spring assembling device and one side of the spring nut assembling device are respectively provided with a vibration feeding mechanism. The valve assembling production line has the advantages that valve assembling and detecting are finished fully automatically, time is saved, requirements for labor are reduced, assembling and detecting effects are improved, and assembling accuracy of the valves and detecting strictness are improved.

Owner:WENLING JINYUE AUTOMATION EQUIP

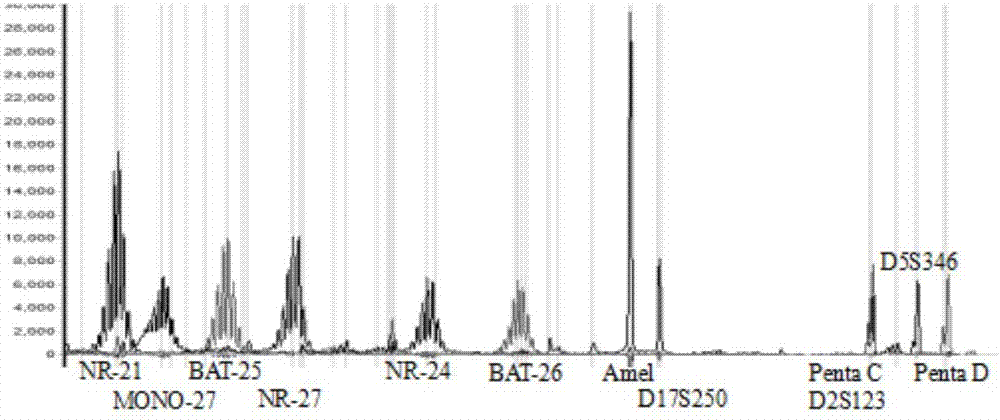

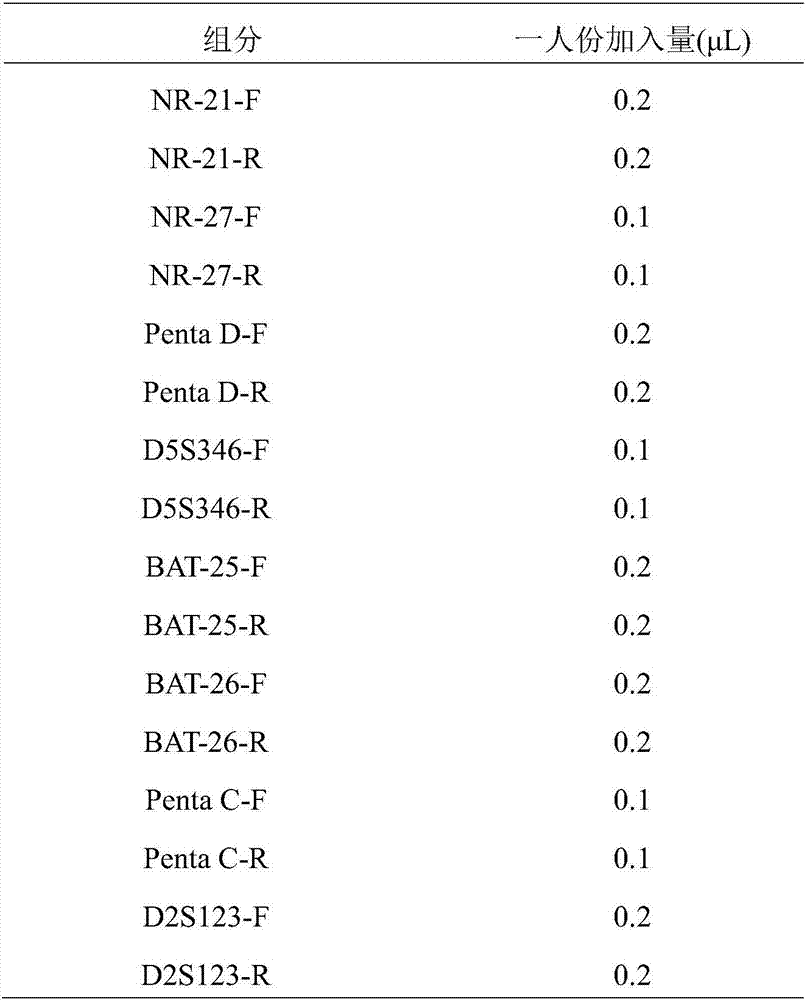

Composition for detecting instability of microsatellite and application of composition

ActiveCN107299139ASimple and fast operationEasy to readMicrobiological testing/measurementDNA/RNA fragmentationMicrochiropteraFluorescence

The invention discloses a composition for detecting the instability of a microsatellite and application of the composition. The composition comprises primer pairs respectively used for detecting specific target genes relevant with the instability of the microsatellite in a to-be-detected sample. A kit for detecting the instability of the microsatellite is used for detecting microsatellite distribution conditions of nine loci of Bat 26, Bat 25, NR-21, NR-24, NR-27, Mono-27, D5S346, D2S123 and D17S250 and three loci of Penta C, Penta D and Amel by virtue of a specific multi-fluorescence PCR fragment through an analysis capillary electrophoresis method and detecting whether the microsatellite is in a stable or instable state. By adjusting the proportion of 12 pairs of primers, the use amounts of Taq enzyme and magnesium ions, a PCR system and the like, and the sensitivity and specificity of the whole kit are improved.

Owner:北京鑫诺美迪基因检测技术有限公司

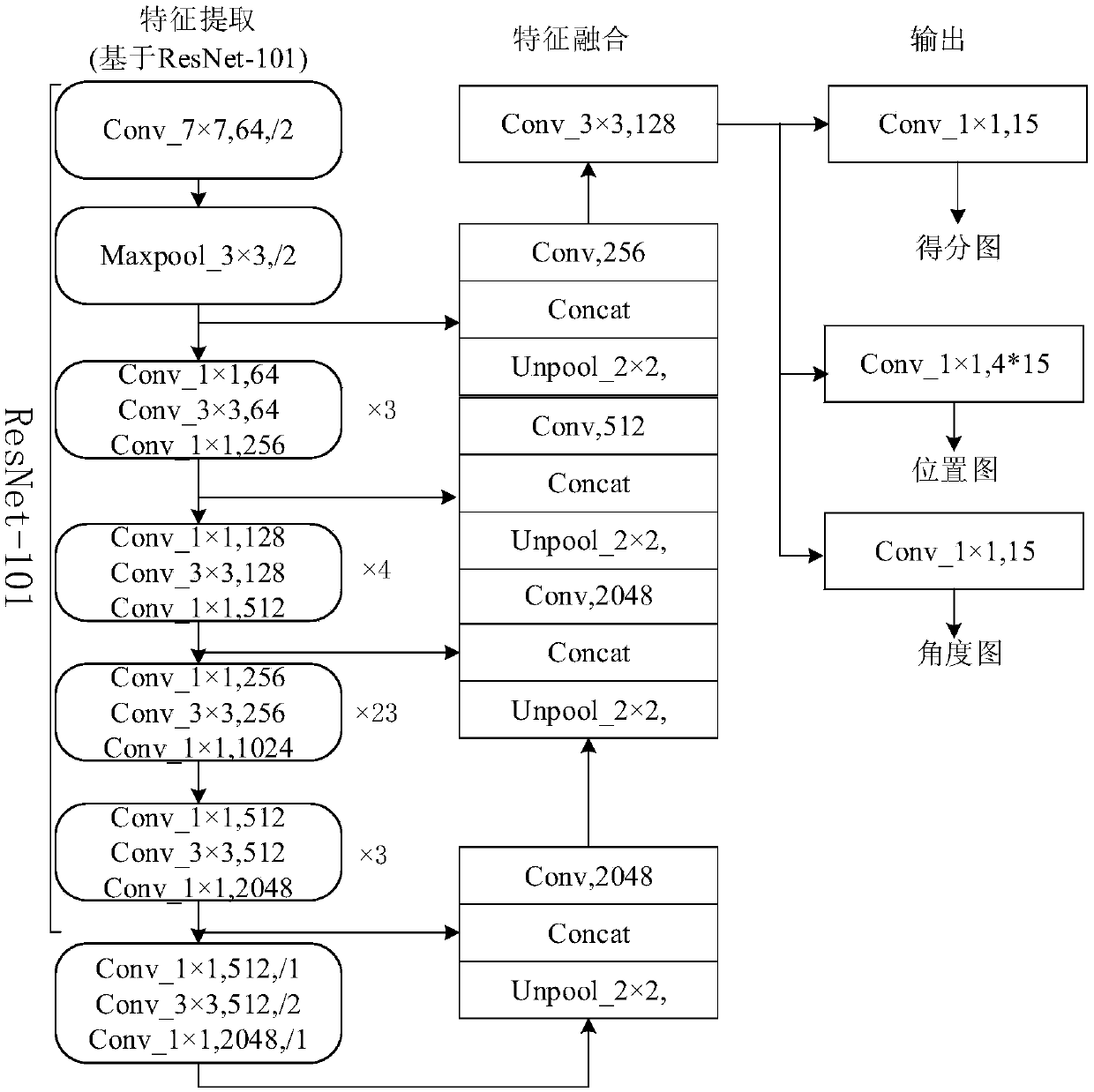

Accurate detection method for dense ship targets based on high-resolution remote sensing images

ActiveCN108960135AQuick checkEffective and accurate detectionScene recognitionNeural architecturesFeature fusionConvolution

The invention relates to an accurate detection method for dense ship targets based on high-resolution remote sensing images. First, the features of a remote sensing image are extracted through a convolution neural network, and then, the features are fused through up-sampling and the convolution features extracted by the convolution neural network. Target prediction is carried out independently ateach point on the feature map obtained by feature fusion. Specifically, the score of probability that each point on the feature map belongs to a target, the distance from the point to each of the foursides of a target frame where the point is located and the angle of the target frame where the point is located are predicted at the same time. When the score of probability that a point on the feature map belongs to a target is greater than a set threshold, a detected target frame can be calculated according to the distance from the point to each of the four sides of the target frame where the point is located and the angle of the target frame where the point is located. As target prediction is carried out independently and intensively at each point on the feature map, a final target detection result can be obtained through non-maximum suppression on the predicted target frame.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

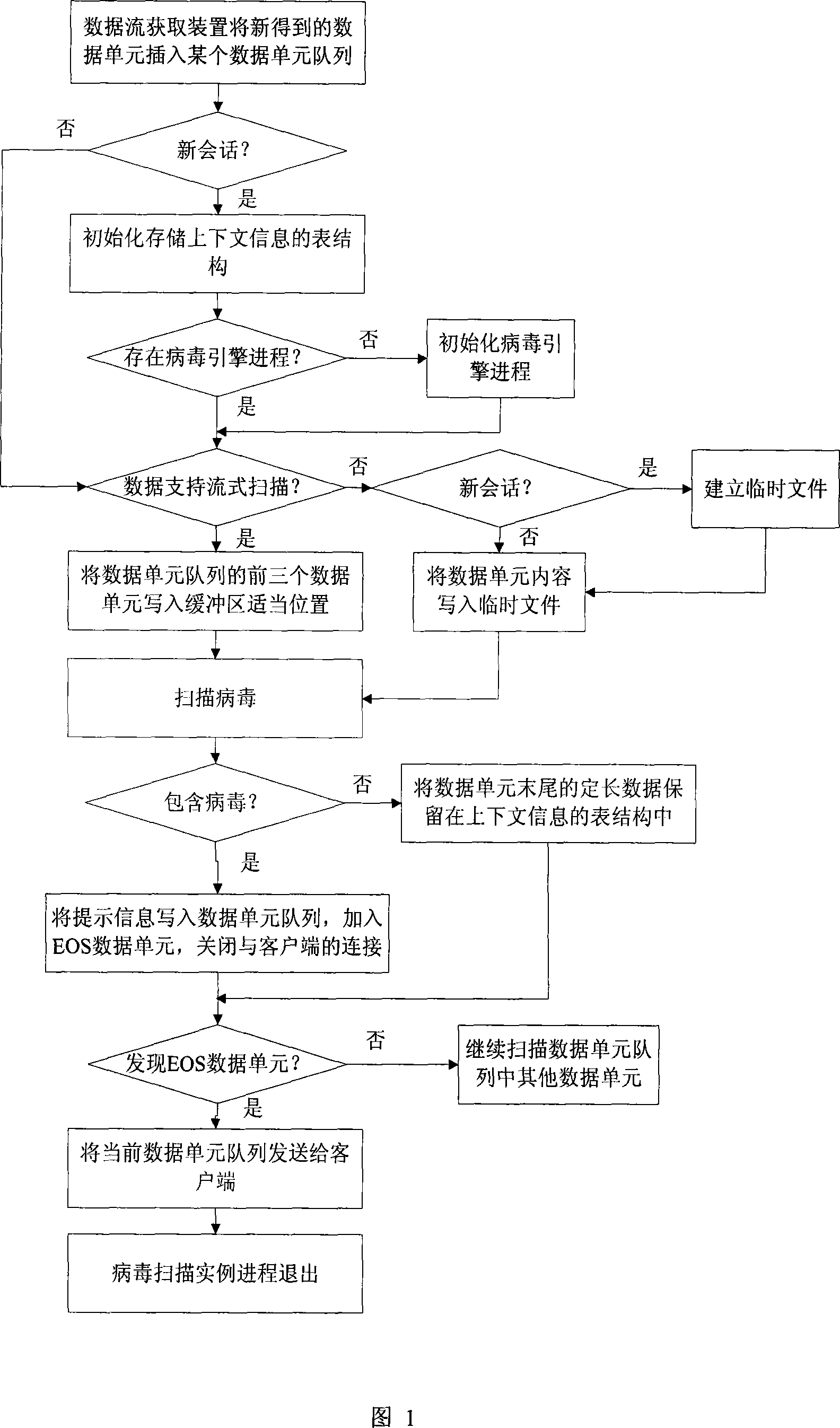

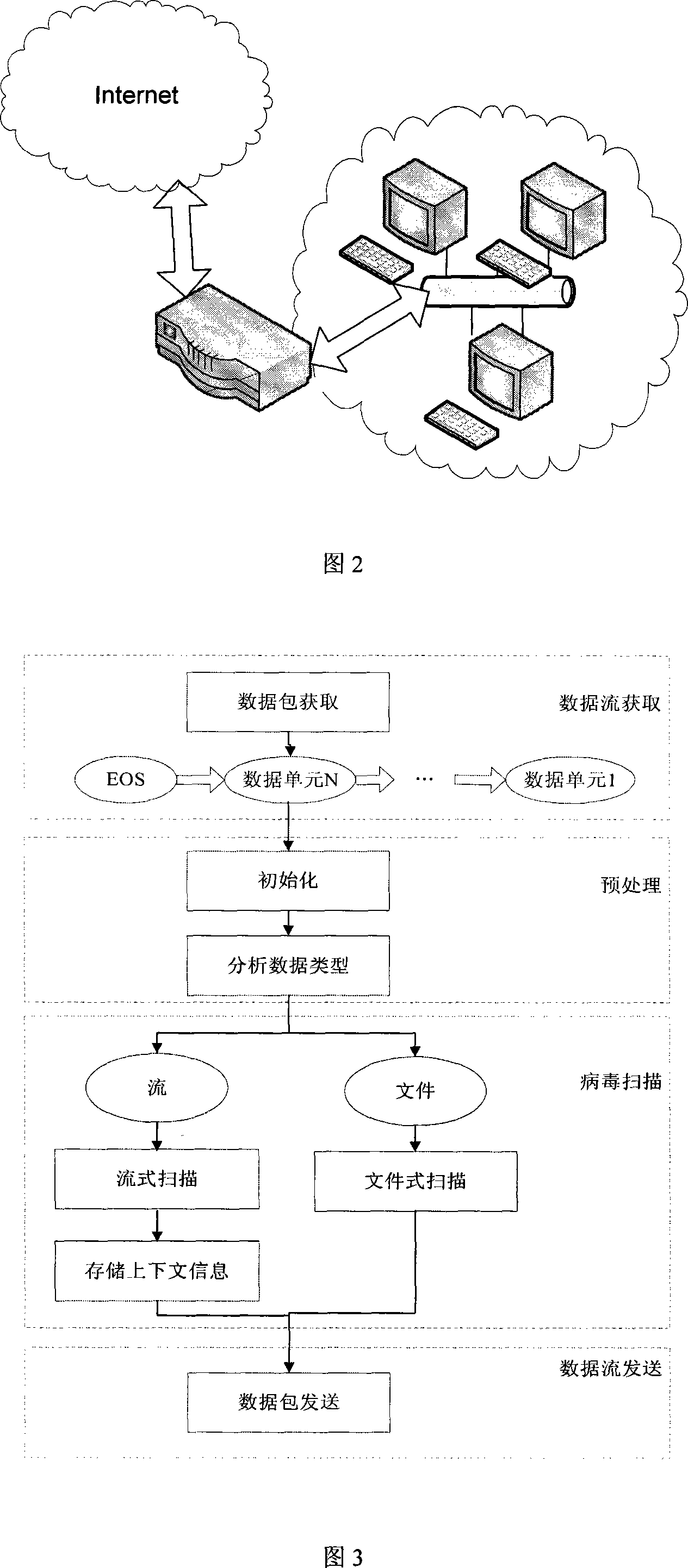

Gateway stream type virus scanning method and system

InactiveCN101119373AAccurate and effective detectionReduce transmission delayData switching networksClient-sideAnalysis data

The invention discloses a gateway level streaming virus scanning method and the system. The method is characterized in that a dialogue data packet is organized into a data unit array; analyzing whether the data types inside the data unit support the streaming scanning operation or not and carrying out text scanning and streaming scanning operations to the data. The system includes a data flow obtaining device, a preprocessing device, a virus scanning device and a meter device of memorized context information. The gateway level streaming virus scanning method and the system disclosed in the invention improves the responding speed of the gateway to the client terminal and conserves the memorized resources of the gateway under the circumstance of assuring of carrying out effective and accurate virus inspection of the data.

Owner:PEKING UNIV

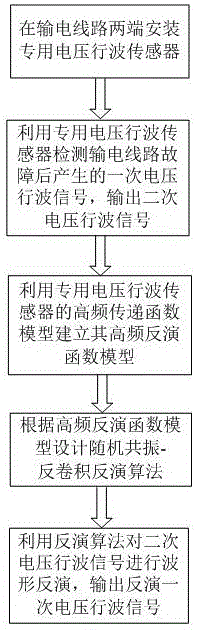

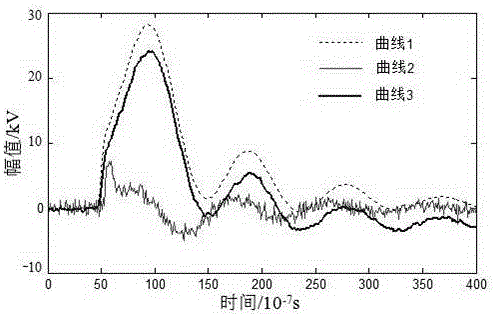

Accurate detection method for voltage travelling wave of transmission line fault based on waveform inversion

ActiveCN106019081AAccurate and effective extractionSolve the problem of waveform distortionFault location by conductor typesTransformerEngineering

The invention discloses an accurate detection method for the voltage travelling wave of a transmission line fault based on waveform inversion. According to the method, special voltage travelling wave sensors are mounted on grounding wires of capacitive equipment, as capacitive voltage transformers (CVT), of transformer stations at the two ends of a power transmission line; the special voltage travelling wave sensors are utilized to detect a primary voltage traveling wave signal after the transmission line fault and output a secondary voltage traveling wave signal; and a high-frequency transfer function model of the special voltage travelling wave sensors is used to establish a high-frequency inversion function model of the special voltage travelling wave sensors, according to the high-frequency inversion function model, a random resonance-deconvolution inversion algorithm is designed for waveform inversion, the primary voltage traveling wave signal is output and inversed, and accurate inversion from the second voltage traveling wave signal to the primary voltage traveling wave signal is realized. According to the invention, the problem of waveform distortion generated when the primary voltage traveling wave signals is transformed by the special voltage travelling wave sensors, and the primary voltage traveling wave signal can be detected accurately and effectively.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

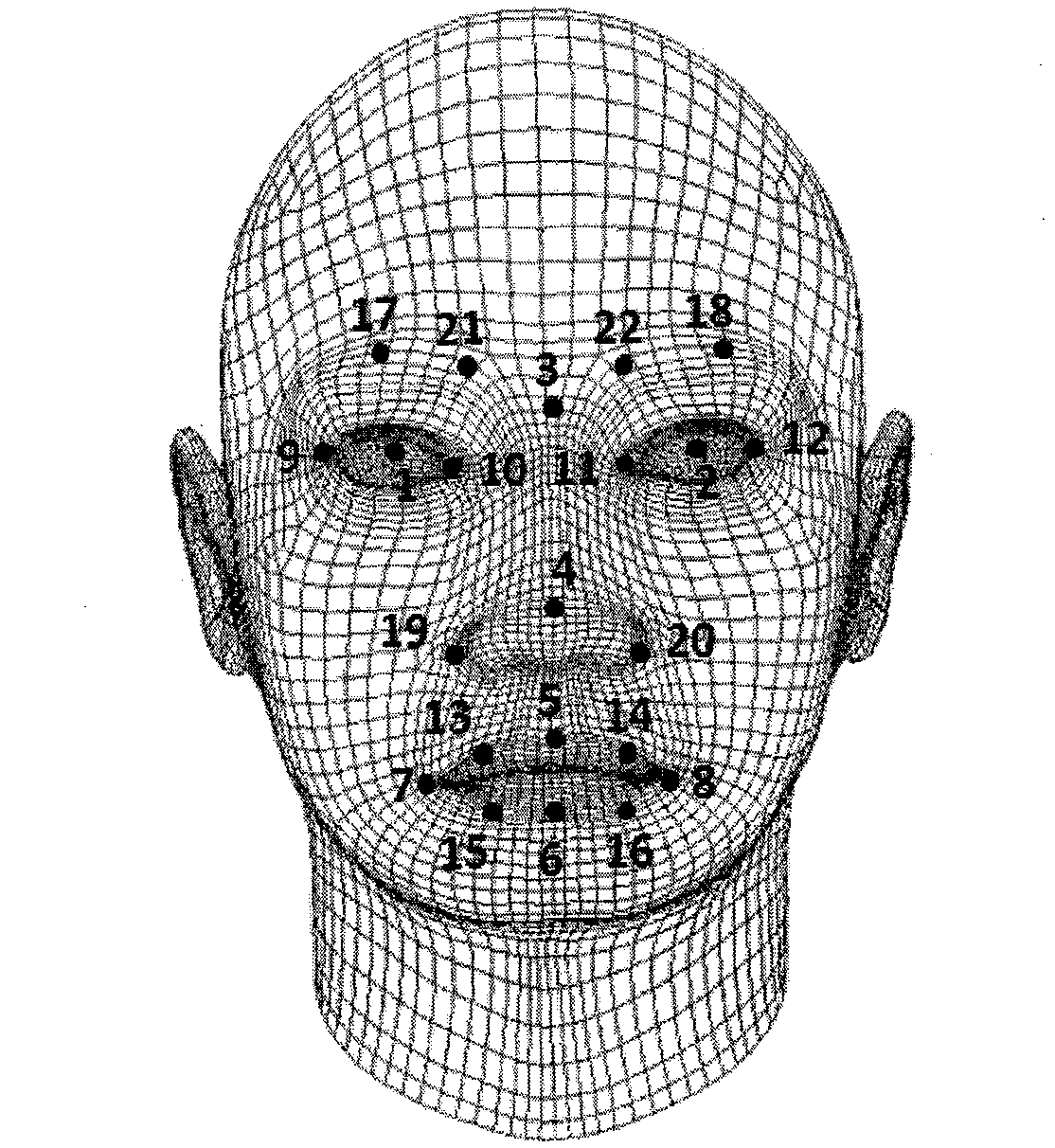

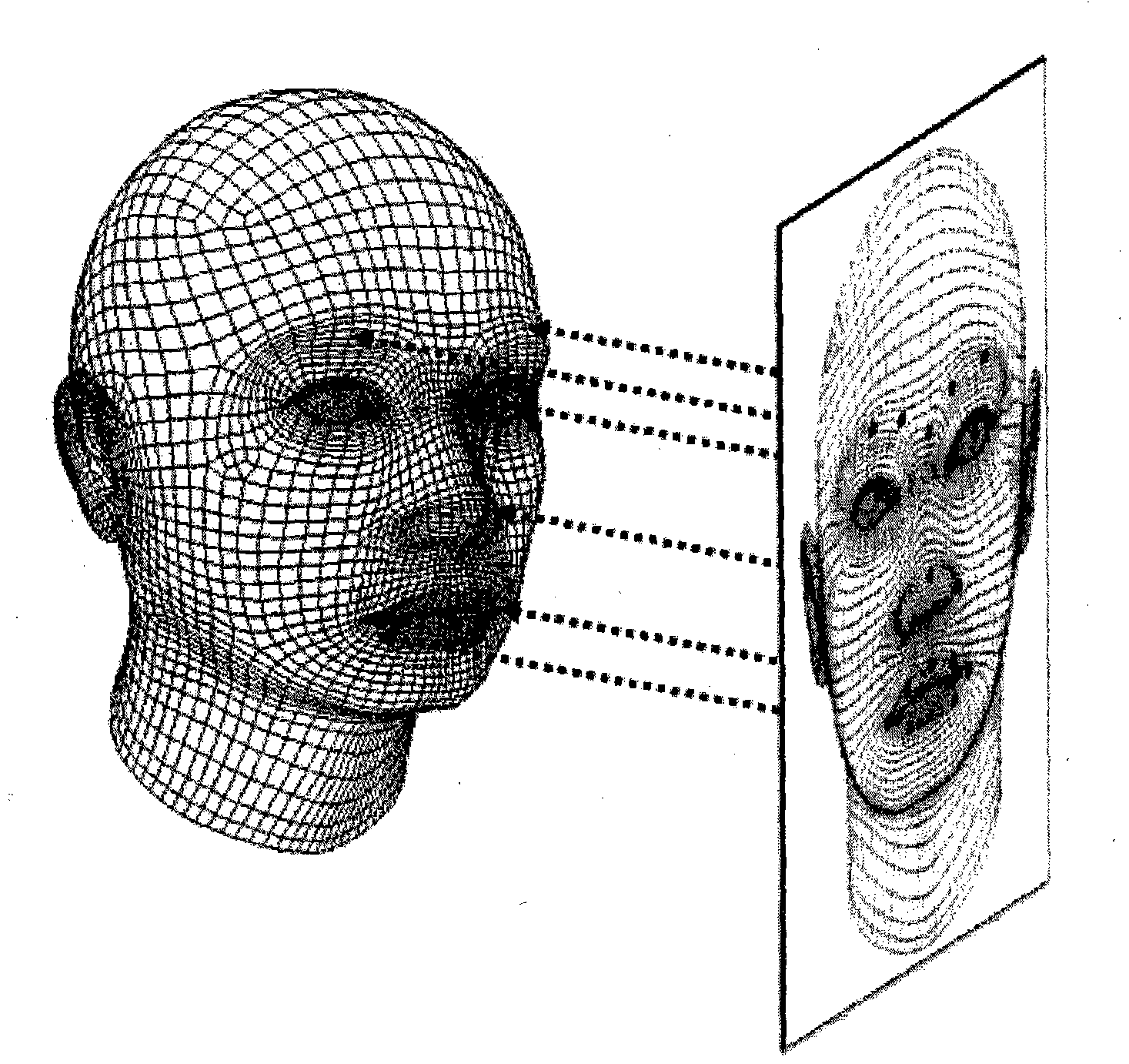

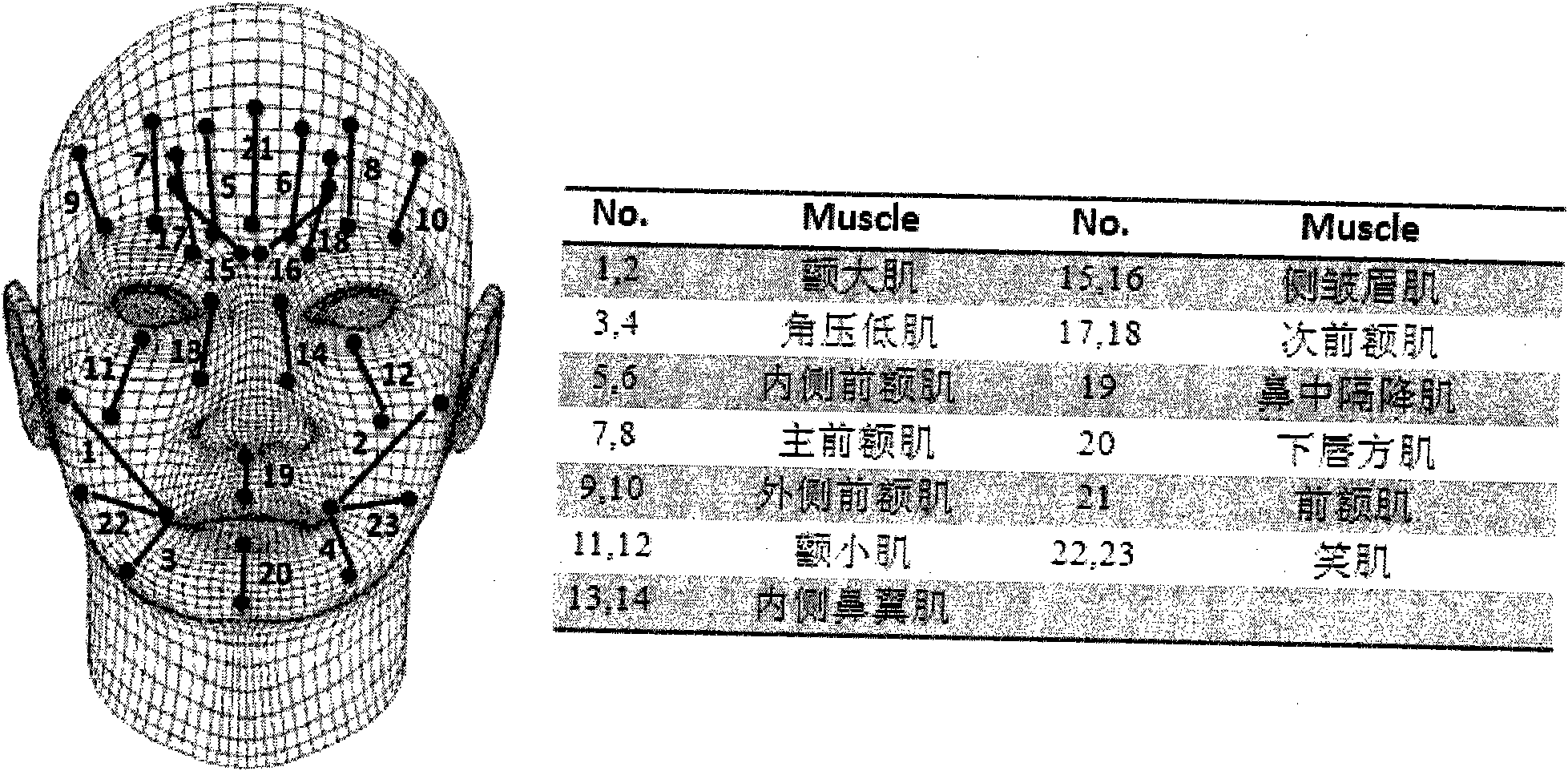

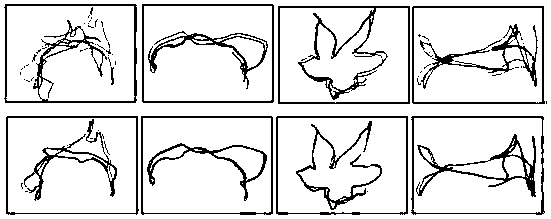

Method for automatically constructing three-dimensional face muscle model

InactiveCN101783026AAccurate locationRealize the assembly3D-image rendering3D modellingMuscle contractionAnimation

The invention provides a method for automatically constructing a three-dimensional face muscle model. The muscle model is the most commonly used facial animation drive model at present, three-dimensional facial expression changes are driven by simulating contraction of the facial muscle; however, an artist spends much time in performing fine adjusting on the construction of the conventional face muscle model, and after the face muscle model is changed at a time, all the construction even needs to do again. Based on the problems, the invention provides the novel method for constructing the face muscle model; the method realizes the automatic construction and the assembly of the face muscle by researching a space position mapping relationship between the three-dimensional face characteristic points and the face muscle; and an experimental result proves that the method makes the artist be free from fussy hand debugging, and enables a normal user to customize a three-dimensional image with various expressions required per se.

Owner:BEIHANG UNIV

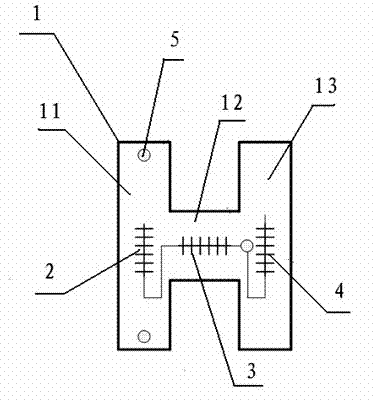

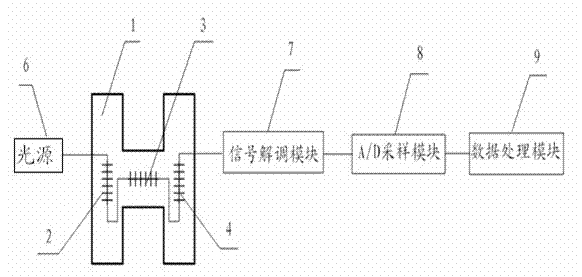

Long period fiber grating strain gauge for micro strain detection of high-temperature pipes

ActiveCN102564334AAccurate and effective detectionWith temperature compensation functionUsing optical meansFiberGrating

The invention belongs to the field of micro strain detection technology of high-temperature pipes, and particularly relates to a long period fiber grating strain gauge for micro strain detection of high-temperature pipes, which comprises an H-shaped metal substrate; the metal substrate comprises a first vertical beam, a second vertical beam and a crossbeam; an LPFG (Long Period Fiber Grating)1 is vertically fixed on the first vertical beam; an LPFG2 is horizontally fixed on the crossbeam; two ends of an LPFG3 are freely and vertically fixed on the second vertical beam; the LPFG1, LPFG 2 and LPFG3 are optically connected with one another; and the three high-temperature long period fiber gratings have different characteristic wavelengths. The long period fiber grating strain gauge for micro strain detection of high-temperature pipes has the advantages as follows: as the three high-temperature long period fiber gratings which are distributed in an H shape are adopted, the horizontal and vertical strains of high-temperature pipes can be detected at the same time; a temperature compensation function is provided so that the high-temperature pipes above 200 DEG C can be detected; the structure is simple and the mounting is convenient; and correct and effective detection can be carried out on the two-dimensional strain states of outer walls of the high-temperature pipes.

Owner:ZHEJIANG ZHONGGONG PETROCHEMICAL EQUIP CO LTD +1

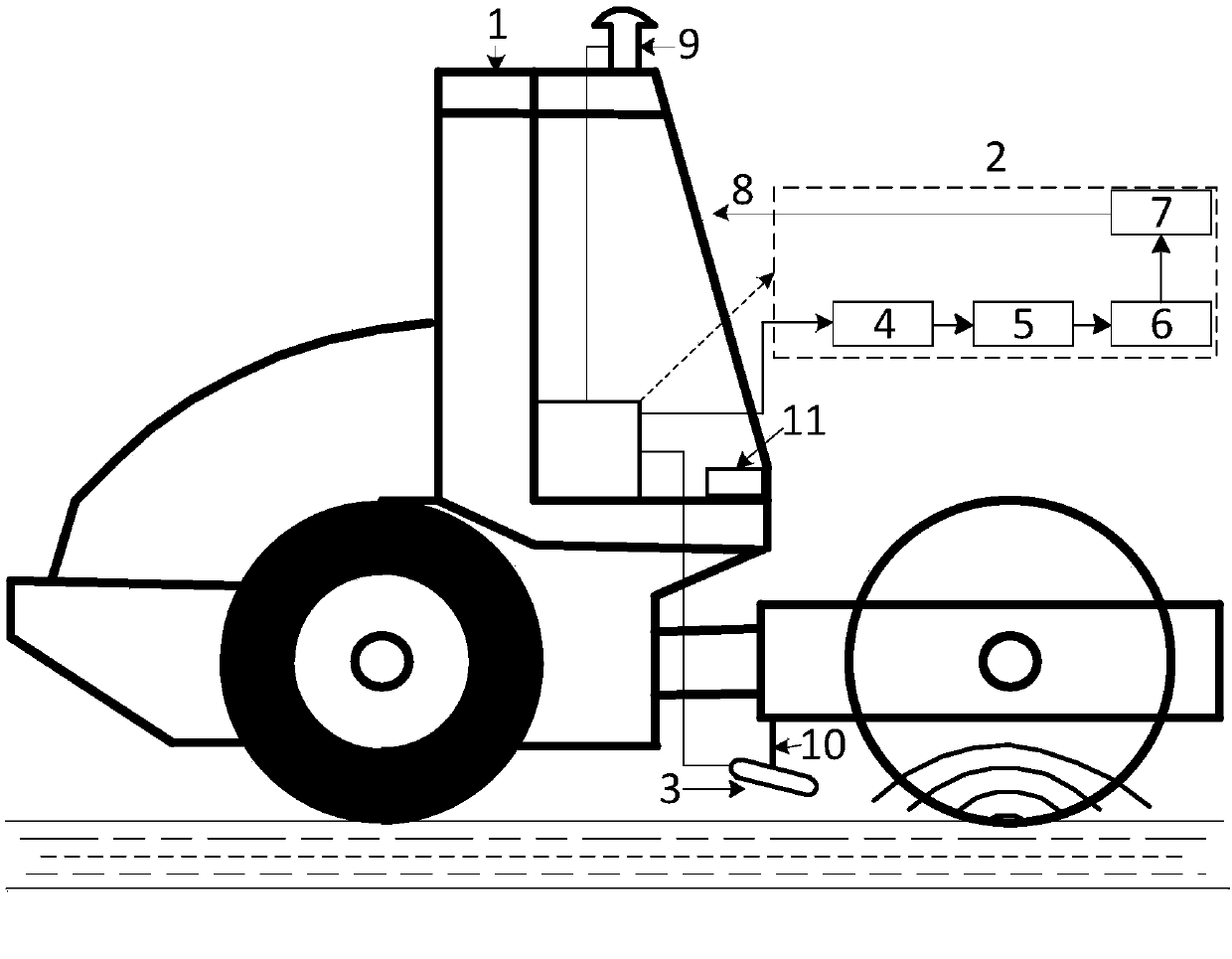

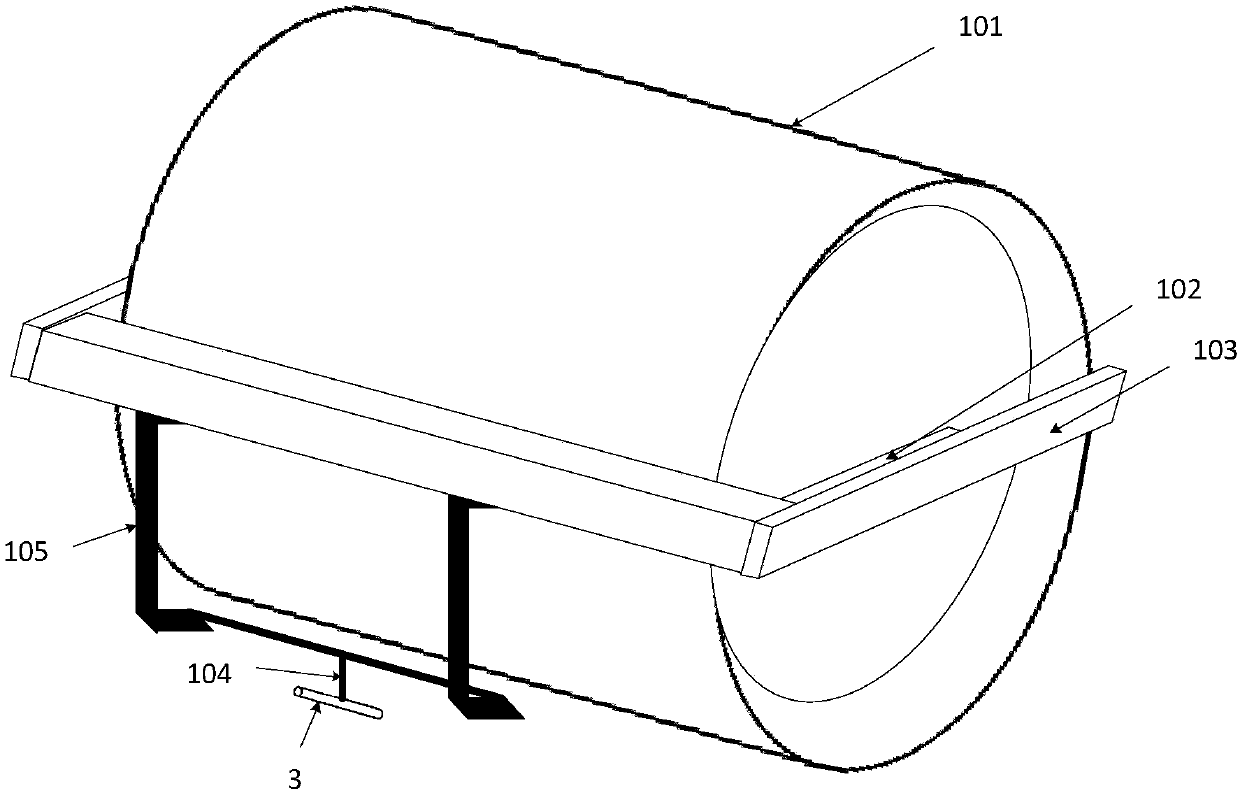

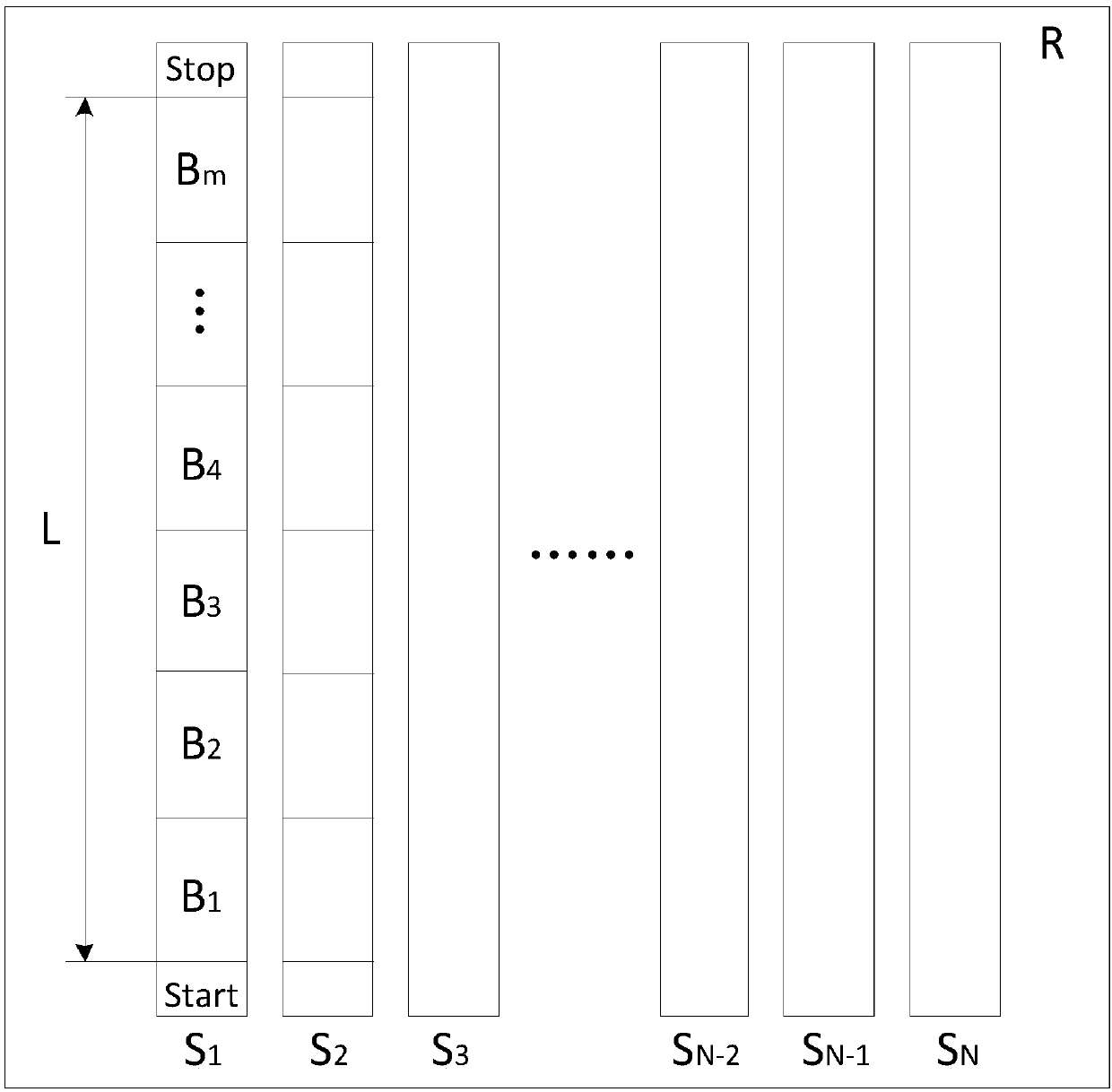

Filling continuous compaction acoustic wave detection system and method

InactiveCN107831217AAccurate and effective detectionDetection is accurate, effective, fast and non-destructiveAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFrequency spectrumWave field

The invention discloses a filling continuous compaction acoustic wave detection system. Based on a rolling machine, detection equipment comprises a sound field pickup, an analyzing and processing module, a displayer, a GPS receiver and the like. When a filling layer is rolled, an acoustic wave field time domain signals generated near a rolling layer are received by the sound field pickup which isarranged on an eternal machine frame of a vibrating drum of a road roller and are sampled to form acoustic wave field digital signals; meanwhile, the GPS receiver provides spatial signals related to the rolled position, the sampled acoustic wave signals are filtered and spectrally analyzed to obtain secondary harmonic amplitudes of the effective acoustic signals, a continuous compaction degree index value is established according to the relevance between the secondary harmonic amplitudes and an earth-rock material compaction degree, and combined with GPS spatial position information, a time-space compaction degree distribution diagram of a rolled area is shown on the machine-mounted displayer. The filling continuous compaction acoustic wave detection system disclosed by the invention has the characteristics of non contact, continuity, real timeliness, suitable for filling engineering continuous compaction quality control and the like. A vibrating frequency and a vibrating amplitude ofthe vibrating drum of the road roller are controlled by compaction feedback, so that an intelligent continuous compaction function can be easily achieved.

Owner:TSINGHUA UNIV +1

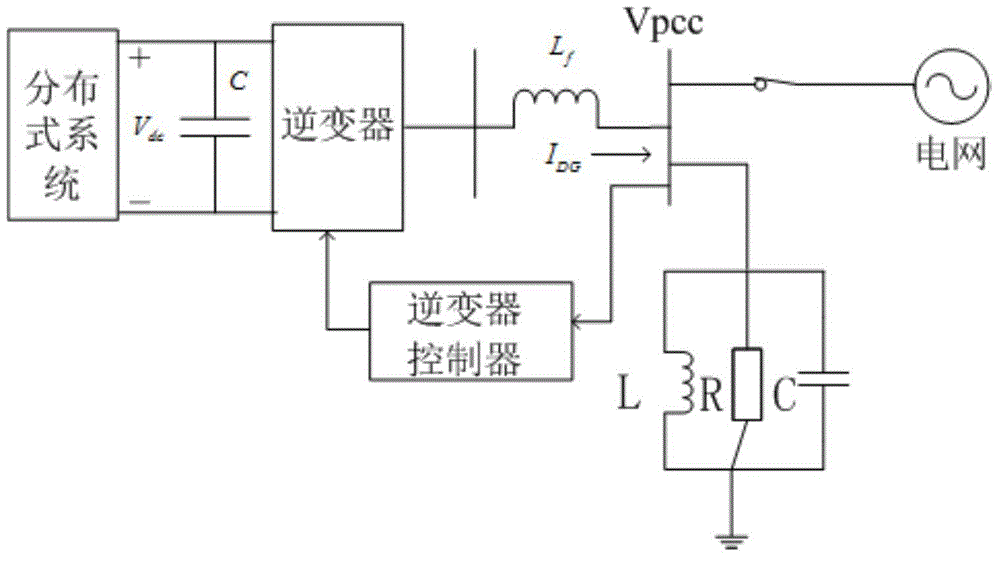

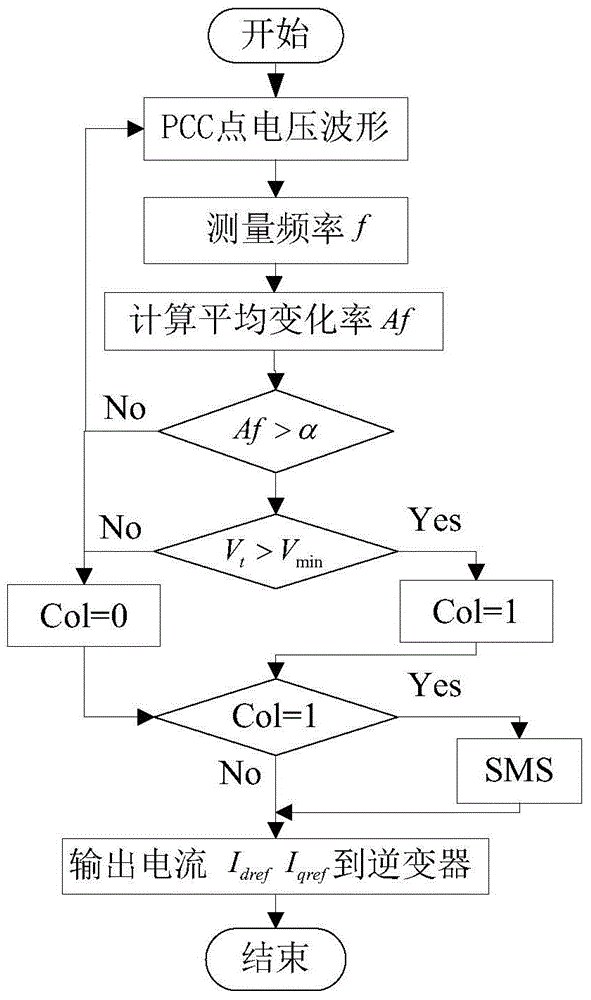

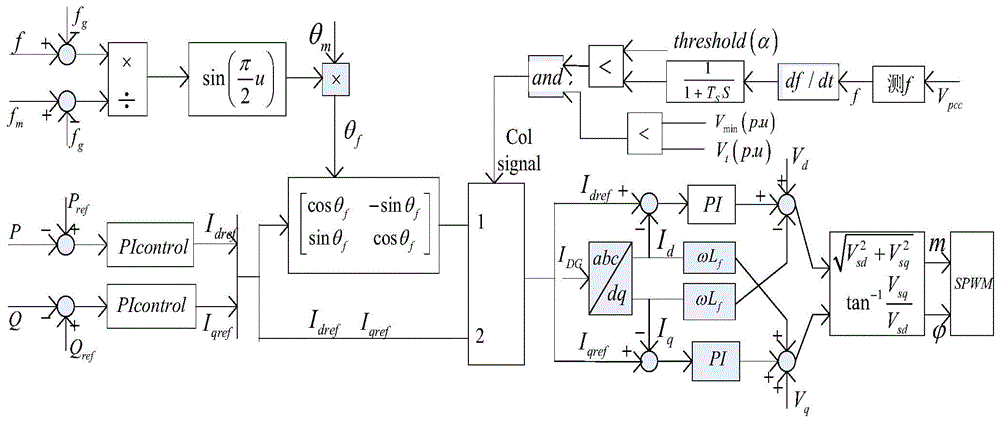

Islanding detecting method

ActiveCN104865479AAccurate and effective detectionMeet the standard requirements of testingElectrical testingBlind zoneIslanding

The invention discloses an islanding detecting method which comprises the following steps: acquiring a voltage waveform of a common coupling point and measuring a frequency value, calculating the average change rate in a certain period to obtain a judging signal, comparing the judging signal with the preset change rate threshold value, outputting a control signal, selecting an outputted reference signal of an inverter by the control signal, introducing reference current after phase deviation under the condition that islanding possibly exists by a frequency change rate detection method, realizing further detection according to a sliding mode frequency deviation method, otherwise, introducing non-deviation reference current, and achieving normal operation of the system. The islanding detecting method has the advantages of reducing detection blind zones and impact on the system power quality and increasing the detection speed.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

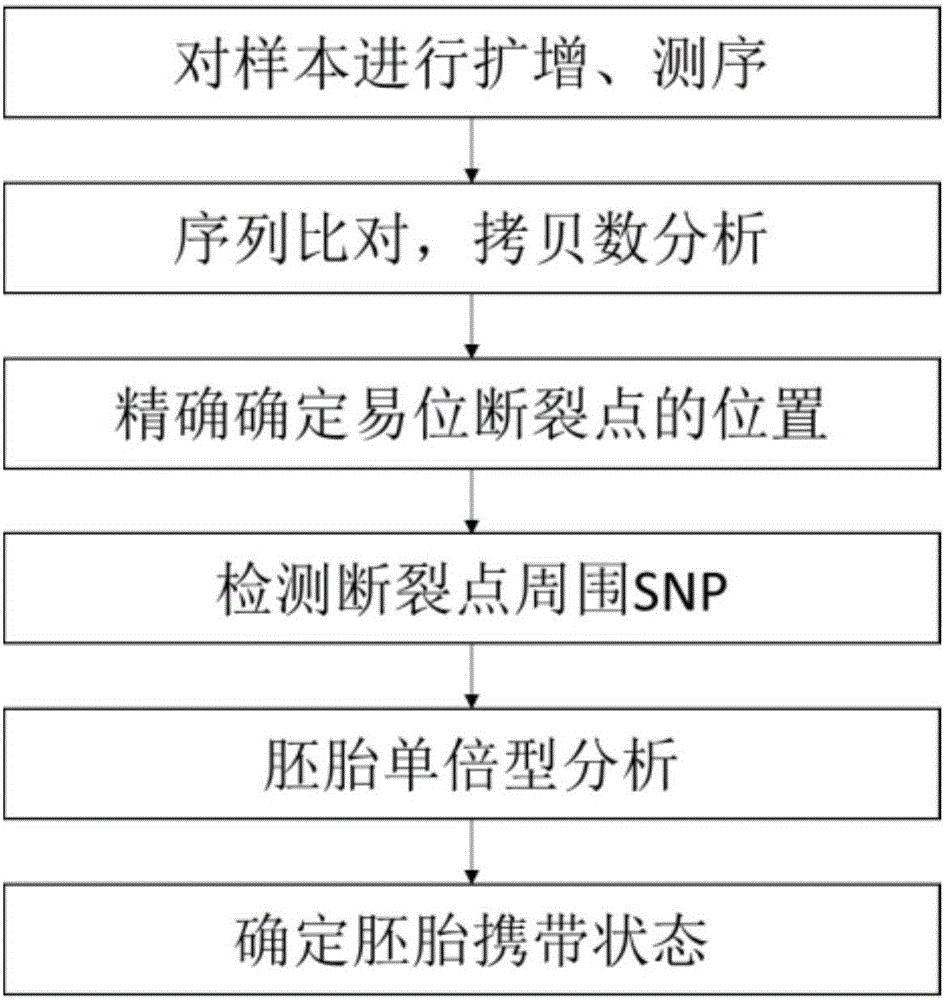

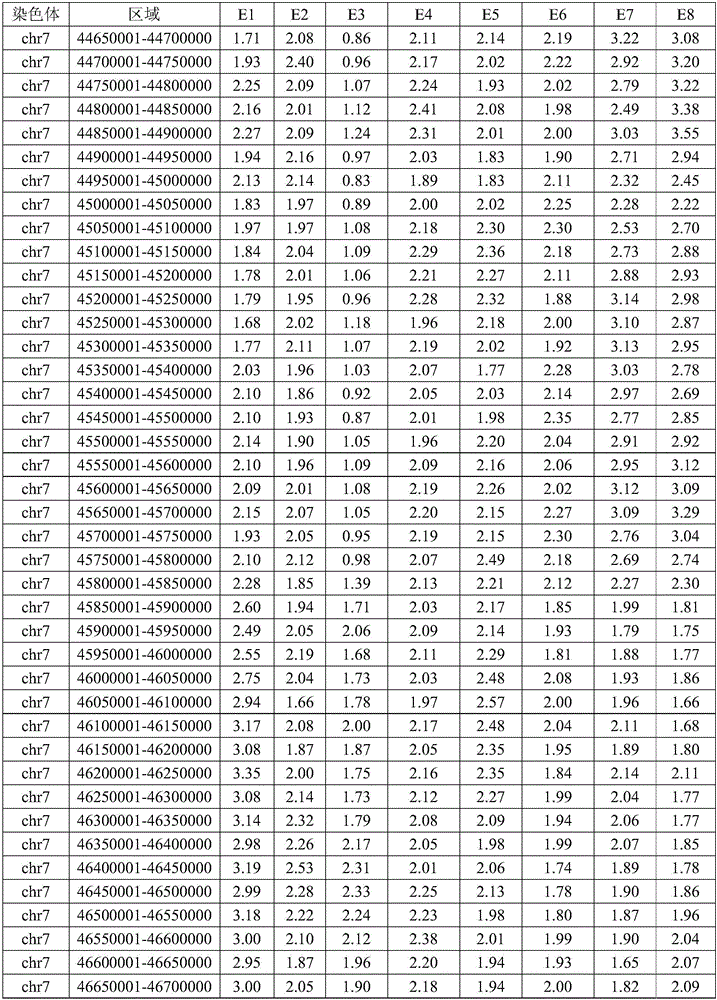

Method for identifying balanced translocation breaking point and balanced translocation carrying state of embryo

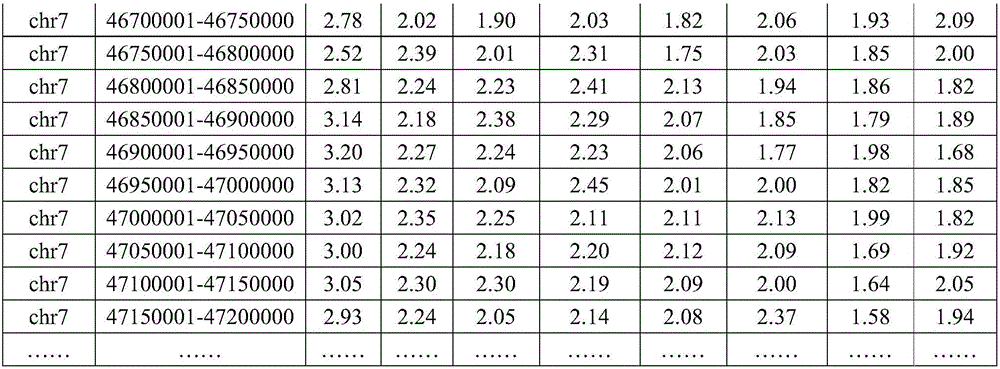

ActiveCN106834490AAccurate and effective detectionJudgment resolution improvedMicrobiological testing/measurementBiostatisticsSequence analysisCopy number analysis

The invention relates to the technical field of biotechnology and relates to the field of genome sequence analysis, and particularly relates a method for identifying a balanced translocation breaking point and a balanced translocation carrying state of an embryo. The method comprises the following steps: amplifying and sequencing a sample; comparing a sequencing sequence to a reference genome and analyzing a copy number; accurately determining a position of a translocation breaking point; detecting SNP (Single Nucleotide Polymorphism) at the periphery of the breaking point; carrying out SNP genotyping; carrying out embryo haplotype analysis; comprehensively judging a regular chromosome and a translocation chromosome haplotype; determining an embryo carrying state; and selecting an embryo without balanced translocation according to a haplotype. According to the method provided by the invention, the position of the balanced translocation breaking point can be accurately determined, and a few of SNP sites can also be used for accurately judging and typing; and the embryo without the balanced translocation is identified.

Owner:YIKON GENOMICS SHANGHAI CO LTD

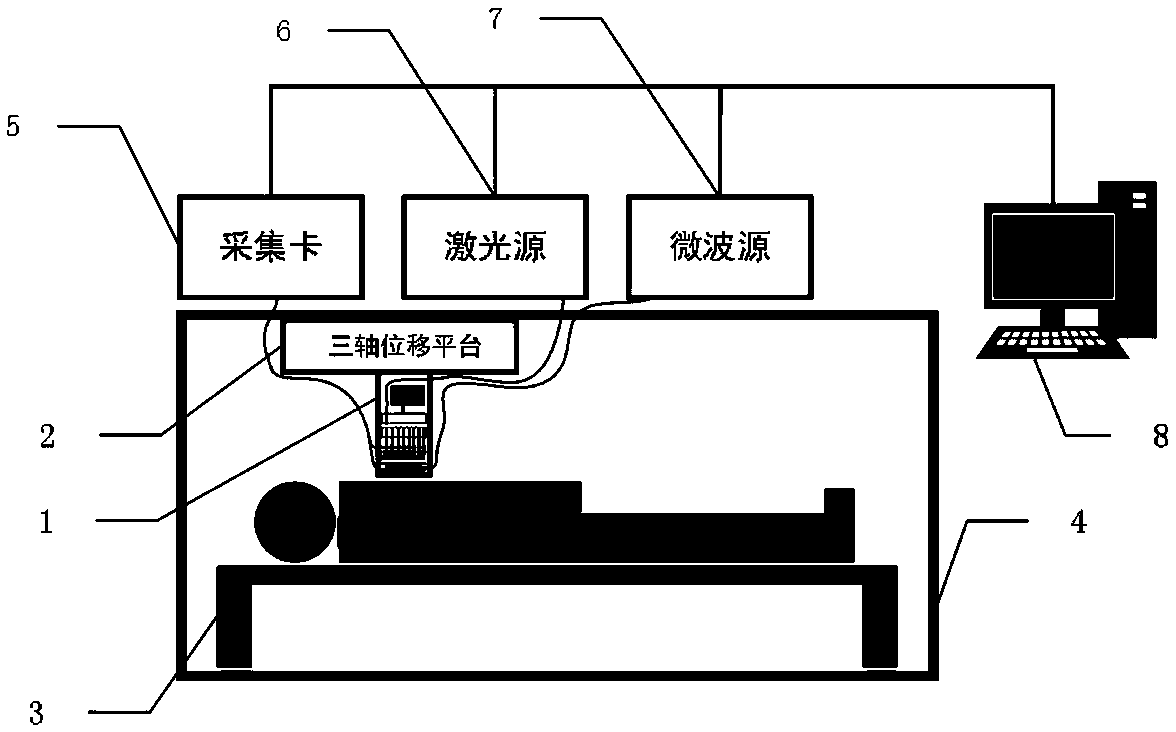

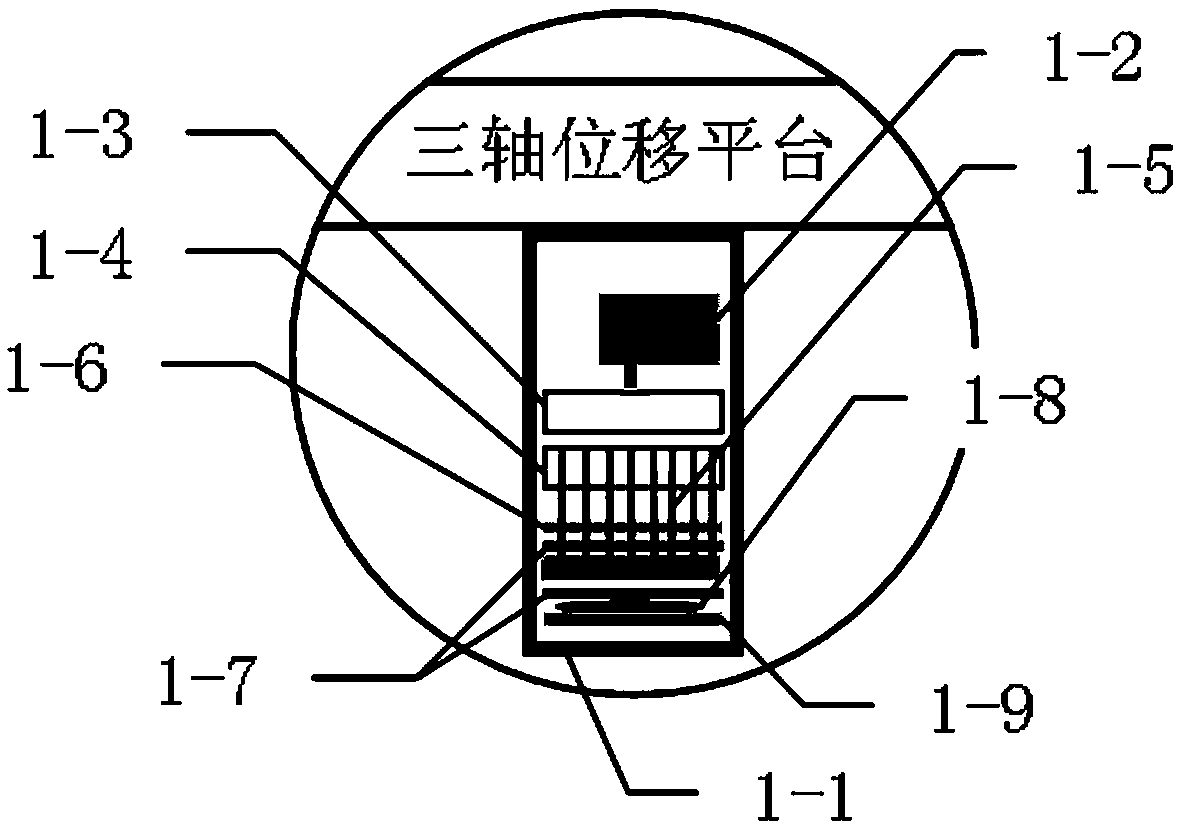

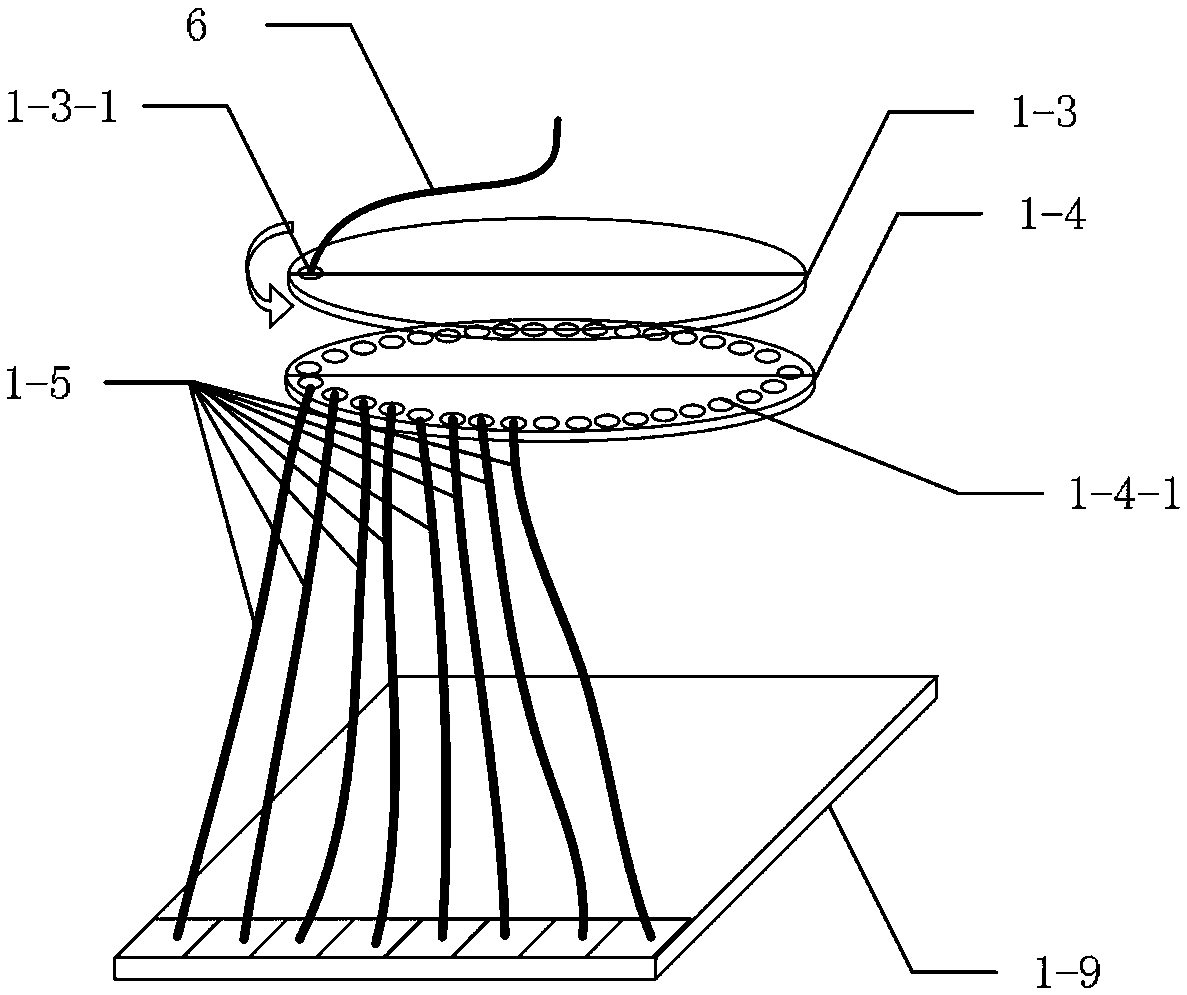

Magnetometer and magnetocardiograph system for magnetocardiograph based on diamond nitrogen-vacancy center

ActiveCN111568418ALow costGood precisionMedical imagingMaterial analysis by optical meansPhotodetectorFluorescence

The invention relates to a rectangular hyper-fluorescence-collecting-efficiency magnetometer and magnetocardiograph system for magnetocardiograph based on diamond nitrogen-vacancy center. The magnetometer consists of a magnetic shielding room, a nonmagnetic bed, a magnetocardiograph array probe, a triaxial displacement platform, a high speed data acquiring card, a fiber laser source, a microwave source and a computer, wherein the magnetocardiograph array probe consists of a nonmagnetic housing, a stepping motor, a porous rotary fiber coupling device, a fiber bundle beam, a specially made photodetector (PD), a filter, a loop antenna and a specially made diamond.The rectangular hyper-fluorescence-collecting-efficiency magnetometer has the characteristics of being low in maintenance cost, high in sensitivity and high in adjustability, and is a new-generation high-precision high-efficiency low-cost magnetocardiogram instrument system.

Owner:ZHONGBEI UNIV

Test method for detecting cytotoxicity of buccal tobacco products

ActiveCN104789633AEasy to handleAccurate and effective detectionMicrobiological testing/measurementFiberPretreatment method

The invention provides a test method for detecting cytotoxicity of buccal tobacco products. The test method comprises the following steps: sample pretreatment, single-cell suspension preparation, cell concentration calculation, cell inoculation, test substance addition, test substance incubation, dye incubation, light absorption value measurement, cell inhibition rate calculation and cell half lethal dose calculation. According to the test method provided by the invention, the exposure means and action manners of the buccal tobacco products are comprehensively surveyed, a sample pretreatment method of the buccal tobacco products is established, human oral mucosa fibroblasts hoMF are selected as the cells for cytotoxicity test of the buccal tobacco products according to the acting target cells, the sample detection dosage is determined and a cytotoxicity test method suitable for the buccal tobacco products is formed.

Owner:CHINA TOBACCO YUNNAN IND

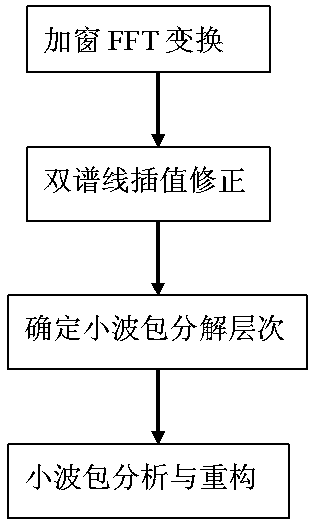

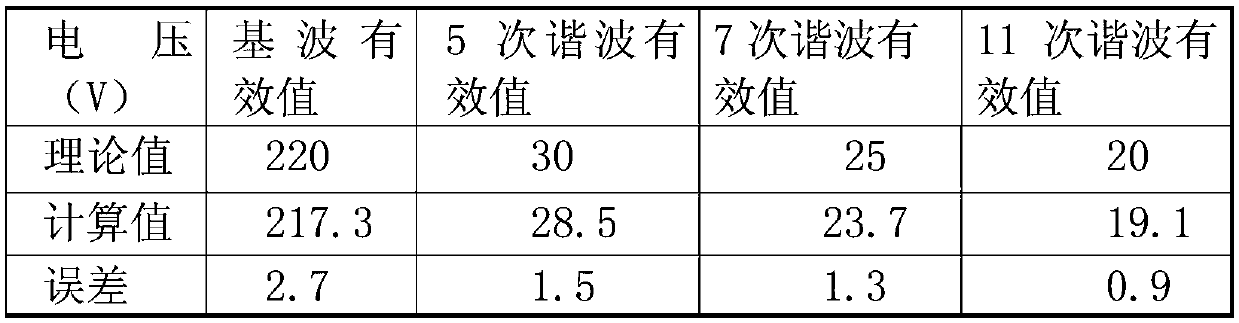

Charging pile harmonic wave detection algorithm based on windowing interpolation FFT and wavelet packet

InactiveCN105512469AQuick identificationAccurate and effective identificationSpectral/fourier analysisInformaticsStart stopWave detection

The invention discloses a charging pile harmonic wave detection algorithm based on a windowing interpolation FFT and a wavelet packet; the algorithm comprises the following steps: windowing interpolation FFT transformation, using a Blair window and double-spectral line interpolation to carry out FFT transformation for an obtained signal, thus obtaining various harmonic waves in the signal; selecting a to-be analyzed frequency range, extracting harmonic waves having big influence on power grid characteristics, and neglecting harmonic waves with almost no influence, thus improving detection instantaneity; using the wavelet packet to decompose and reconstruct the selected frequency range , applying DB3 wavelet packet transformation on the signal, thus obtaining start-stop times of various generated harmonic waves. The algorithm can fast and accurately detect each harmonic wave of the electric vehicle charging pile, and can determine harmonic wave generation start-stop times.

Owner:HUAIAN OF JIANGSU ELECTRIC POWER COMPANY POWER SUPPLY +1

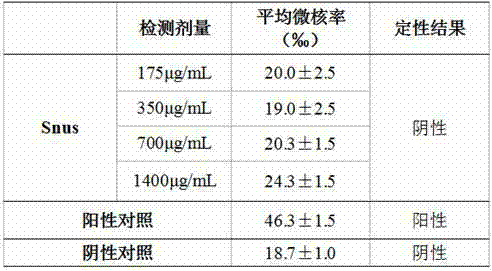

Method for detecting influence of buccal tobacco product on micronucleus rates of cells

ActiveCN104749353AAccurate and effective detectionCells are used for detection, and the sample detection is confirmed to be accurate and effectiveBiological testingPretreatment methodSingle cell suspension

The invention provides a method for detecting influence of a buccal tobacco product on micronucleus rates of cells. The method comprises the following steps of performing a sample pretreatment method, performing preparation of single-cell suspension, calculating cell concentration, performing cell inoculation, adding a test object, incubating the test object, harvesting the cells, performing hypotension, dropping to a slider, dyeing, performing micronucleus calculation, performing result determination and the like. According to the method provided by the invention, by comprehensively surveying the exposure way and the action mode of the buccal tobacco product, the sample pretreatment method for the buccal tobacco product is established; moreover, human oral mucosal fibroblasts hOMF are selected according to action target cells of the buccal tobacco product to serve as cells for in vitro micronucleus test detection on the buccal tobacco product, and the sample detection dosage is determined, and therefore an in vitro micronucleus test detection method suitable for the buccal tobacco product is formed.

Owner:CHINA TOBACCO YUNNAN IND

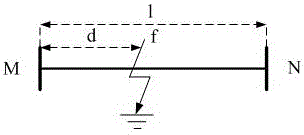

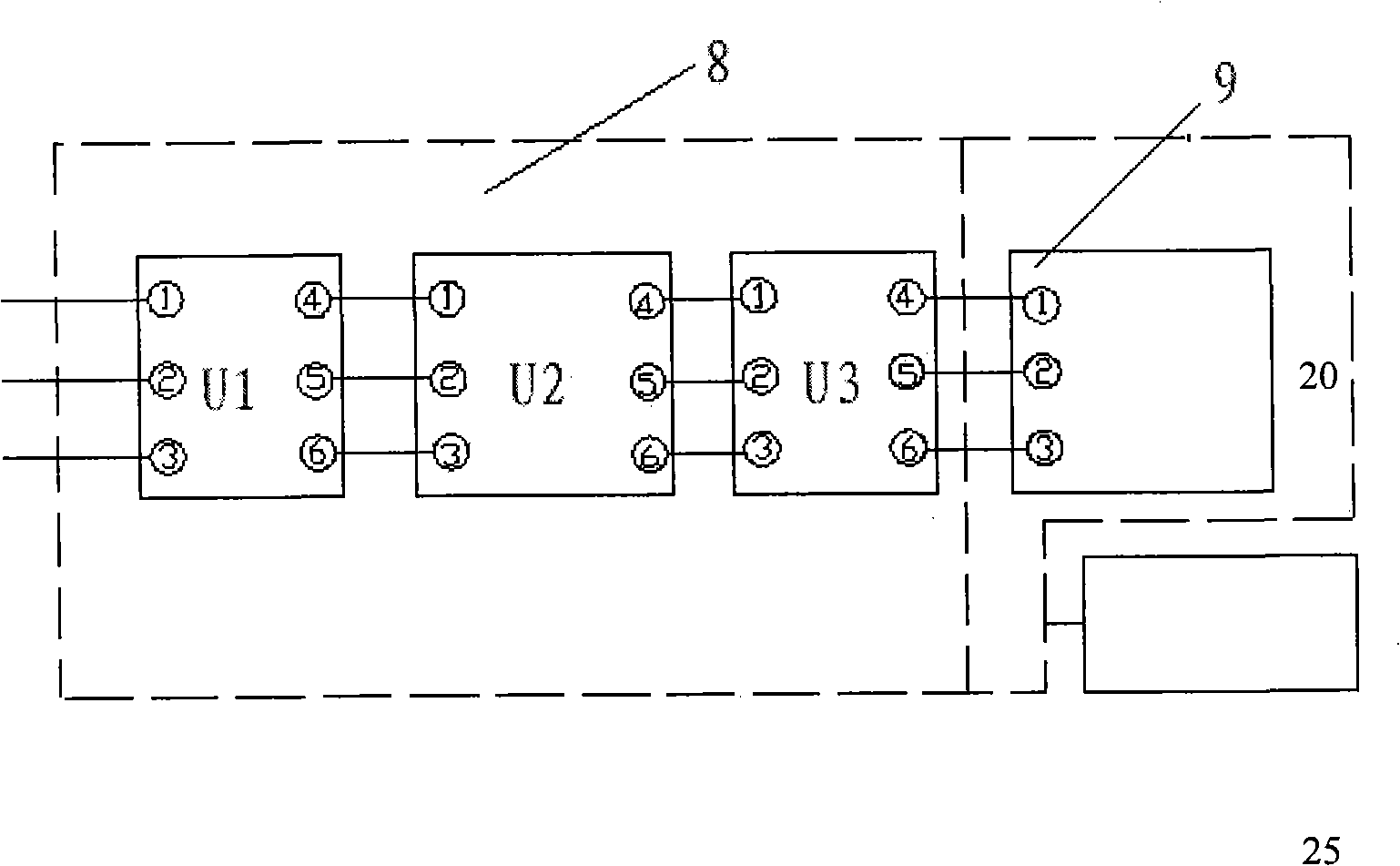

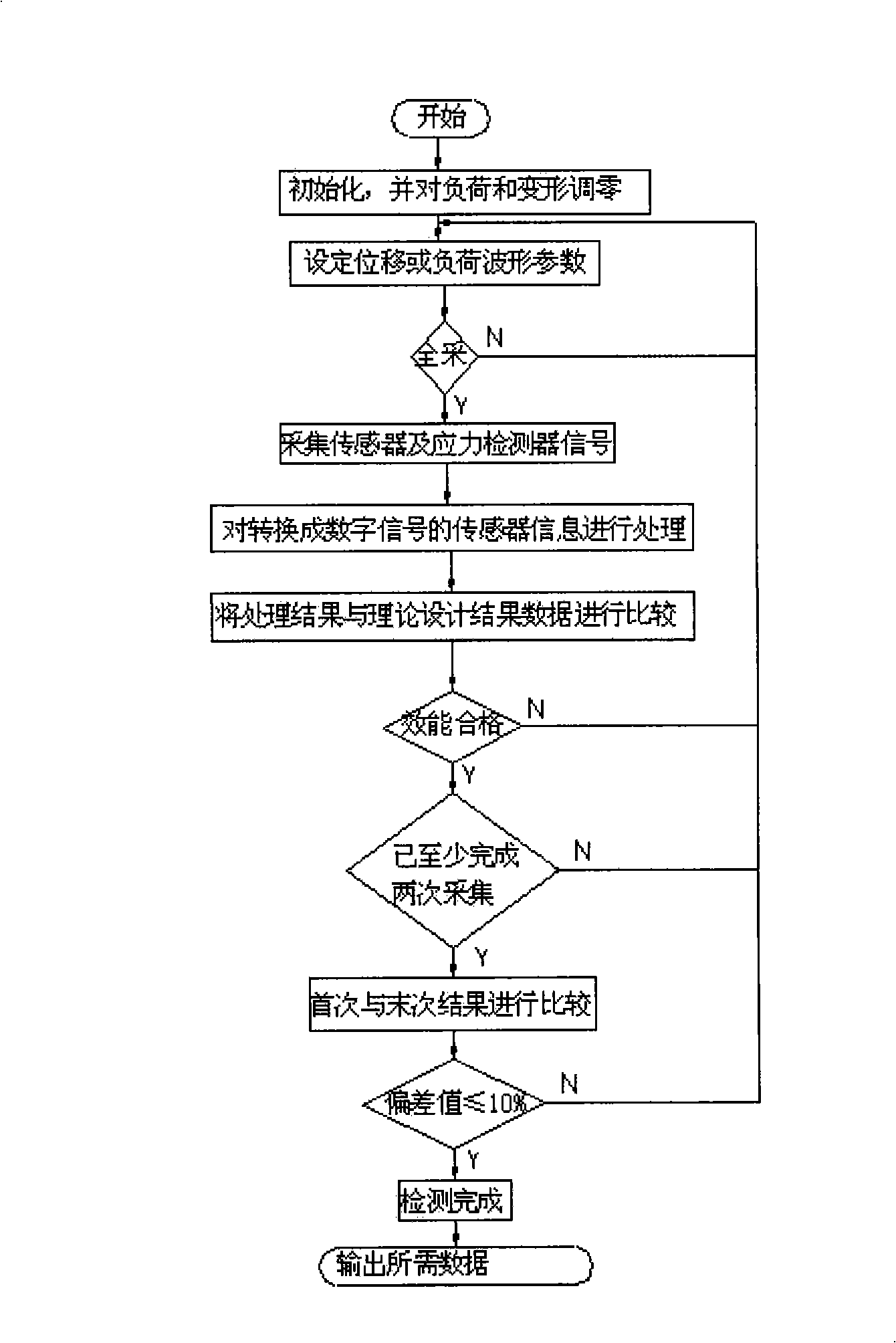

Flexible plate assembly axial fatigue test method

InactiveCN101324497AAccurate and effective detectionMaterial strength using repeated/pulsating forcesMicrocomputerMicrocontroller

The invention relates to a method for testing the axial fatigue of a flexible plate assembly, which can effectively test the axial fatigue resistance capability of the flexible plate assembly. The method adopts the technical proposal that the method for testing the axial fatigue of the flexible plate assembly is characterized in that a microcomputer is adopted in the test to control an electro-hydraulic servo fatigue testing machine; a displacement sensor, a load sensor and a stress detector are arranged on the electro-hydraulic servo fatigue testing machine controlled by the microcomputer; signals output through the displacement sensor, the load sensor and the stress detector are transferred to a single-chip microcomputer; the signals are output through the single-chip microcomputer, so that an externally connected display displays a load-time curve, a displacement-time curve and a stress-time curve.

Owner:CHERY AUTOMOBILE CO LTD

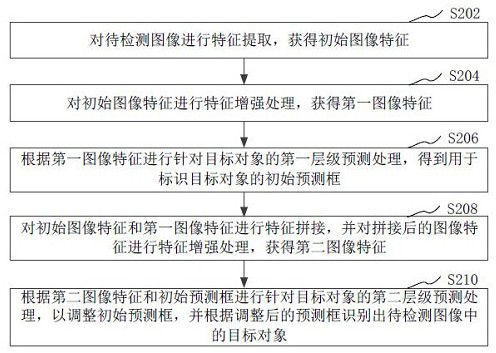

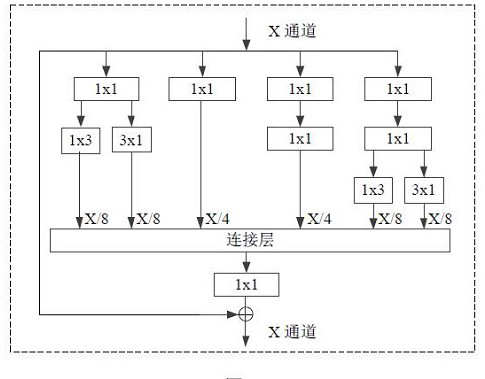

Target object detection method and device, computer equipment and storage medium

ActiveCN111738231AImprove detection accuracyAccurate and effective detectionBiometric pattern recognitionNeural architecturesFeature extractionEngineering

The invention relates to a target object detection method and device, computer equipment and a storage medium. The method comprises the steps of performing feature extraction on a to-be-detected imageto obtain initial image features; performing feature enhancement processing on the initial image feature to obtain a first image feature; performing first-level prediction processing for a target object according to the first image feature to obtain an initial prediction box for identifying the target object; performing feature splicing on the initial image features and the first image features,and performing feature enhancement processing on the spliced image features to obtain second image features; and performing second-level prediction processing for the target object according to the second image feature and the initial prediction box so as to adjust the initial prediction box, and identifying the target object in the to-be-detected image according to the adjusted prediction box. Byadopting the method, the detection accuracy of the target object can be effectively improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

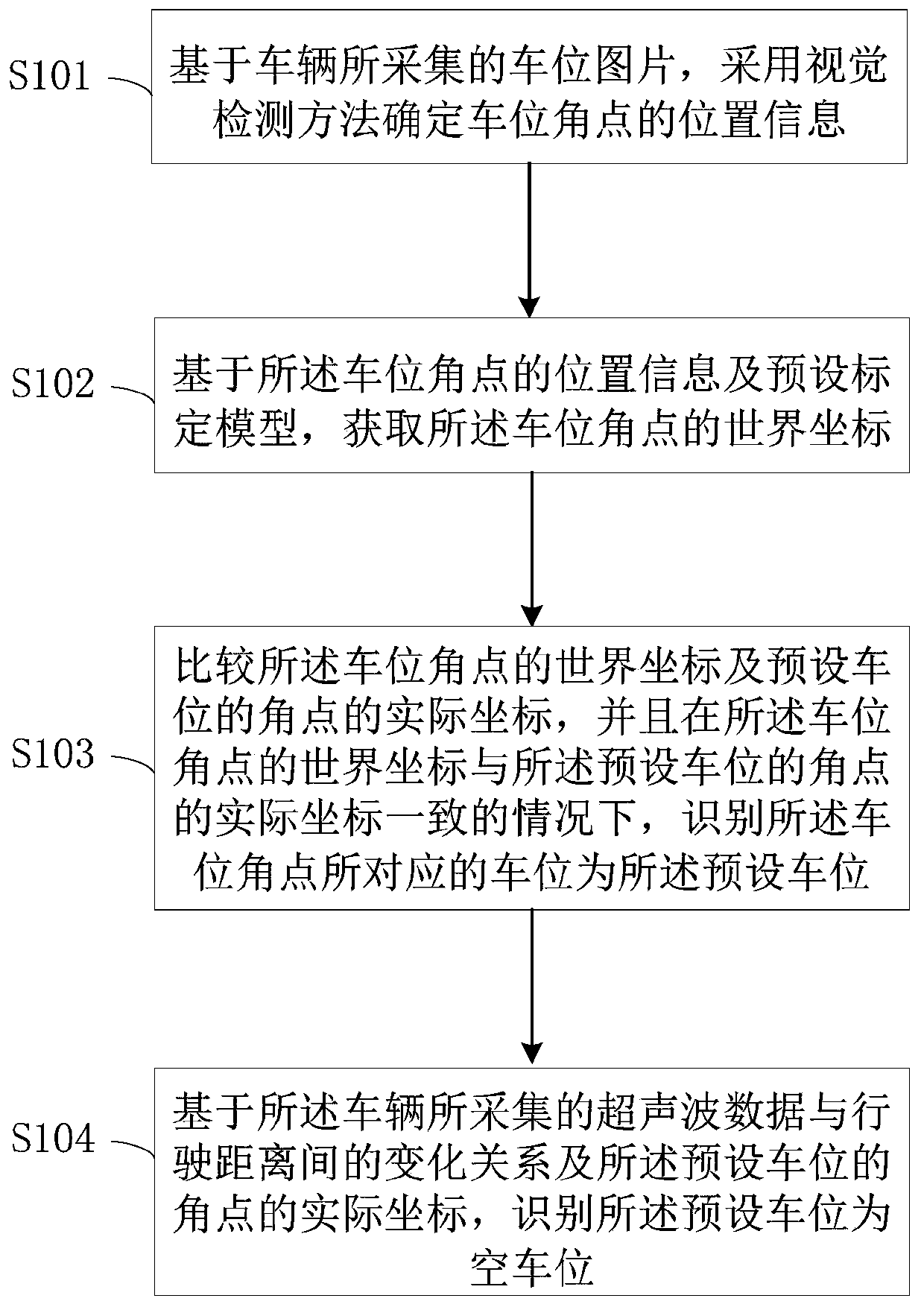

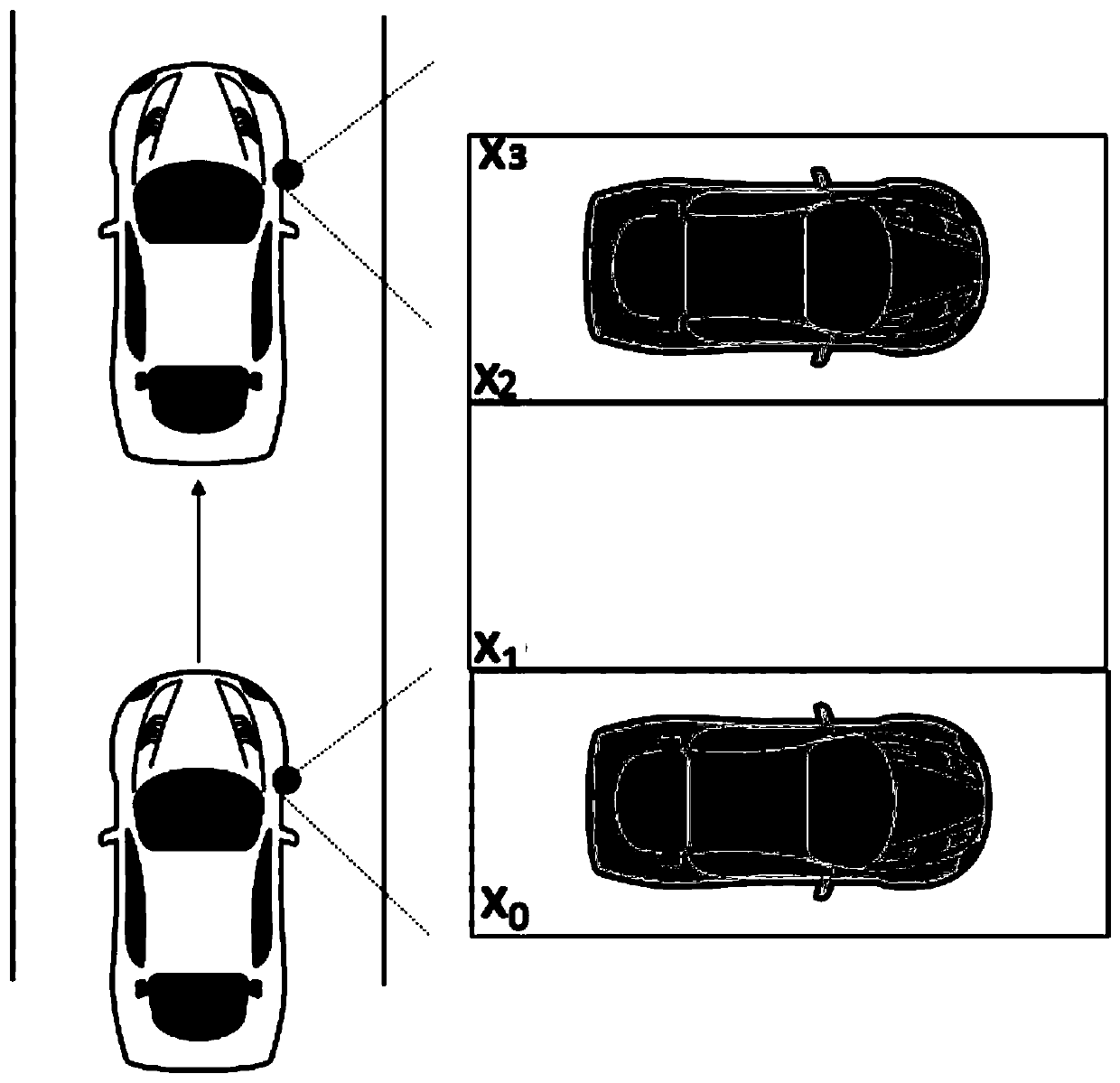

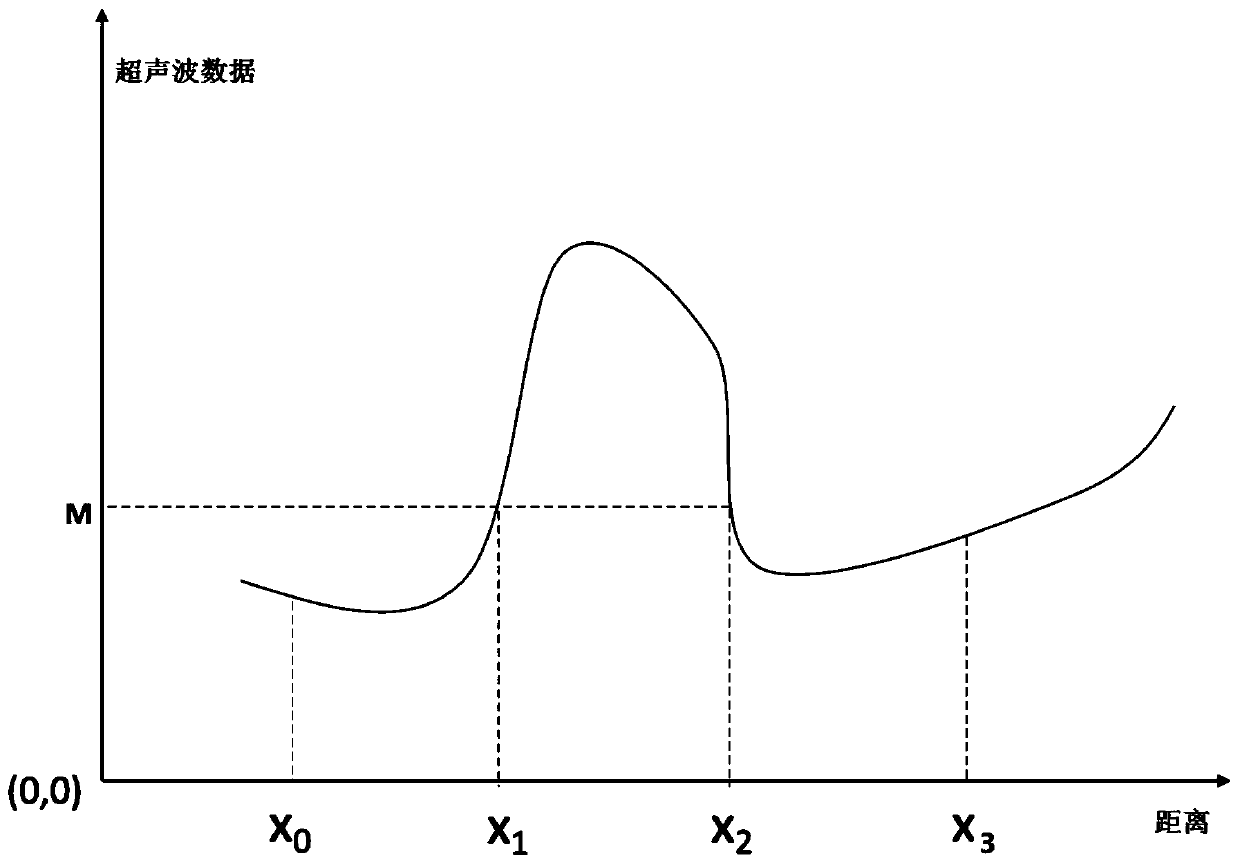

Method and system for identifying empty parking space and vehicle

ActiveCN109871745AAccurate and effective detectionRealize intelligent detectionPicture taking arrangementsCharacter and pattern recognitionParking spaceVisual perception

The embodiment of the invention provides a method and system for identifying an empty parking space and a vehicle, and belongs to the technical field of parking space monitoring. The method comprisesthe steps of determining position information of a parking space corner point by adopting a visual detection method based on a parking space picture collected by a vehicle; Based on the position information of the parking space corner points and a preset calibration model, obtaining world coordinates of the parking space corner points; Comparing the world coordinates of the parking space corner points with the actual coordinates of the preset parking space corner points, and under the condition that the world coordinates of the parking space corner points are consistent with the actual coordinates of the preset parking space corner points, identifying the parking space corresponding to the parking space corner points as a preset parking space; And identifying the preset parking space as anempty parking space based on the change relationship between the ultrasonic data and the driving distance and the actual coordinates of the corner point of the preset parking space. According to themethod, the empty parking space in the preset parking space can be accurately and effectively detected in automatic parking or passenger-replacing parking, intelligent detection of the empty parking space is achieved, and therefore a vehicle can be accurately parked on the preset parking space.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

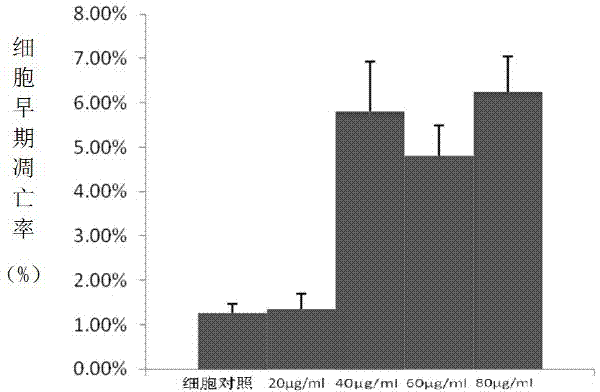

Method of detecting effect of oral tobacco products upon early apoptosis

InactiveCN104726532AEarly apoptotic effects are accurate and effectiveAccurate and efficient flow cytometric detection of early apoptotic effectsMicrobiological testing/measurementTest sampleSingle cell suspension

The invention discloses a method of detecting effect of oral tobacco products upon early apoptosis. The method includes: pretreating a sample, preparing single-cell suspension, calculating cell concentration of the single-cell suspension, inoculating cells, setting groups, setting dosage, adding a test sample, incubating the test sample, collecting cells, washing the cells, adding resuspended cells, mixing Annexin V-FITC and PI (propidium iodide) dye, allowing reaction, adding binding buffer, detecting the test sample after mixing, and performing detecting with a flow cytometer in one hour to obtain an early apoptosis influence rate. Through effective treatment of the sample, optimal setting of detection dosage and correct selection of target cells, the invention allows the effect of the oral tobacco products upon early apoptosis to be accurately and effectively detected.

Owner:CHINA TOBACCO YUNNAN IND

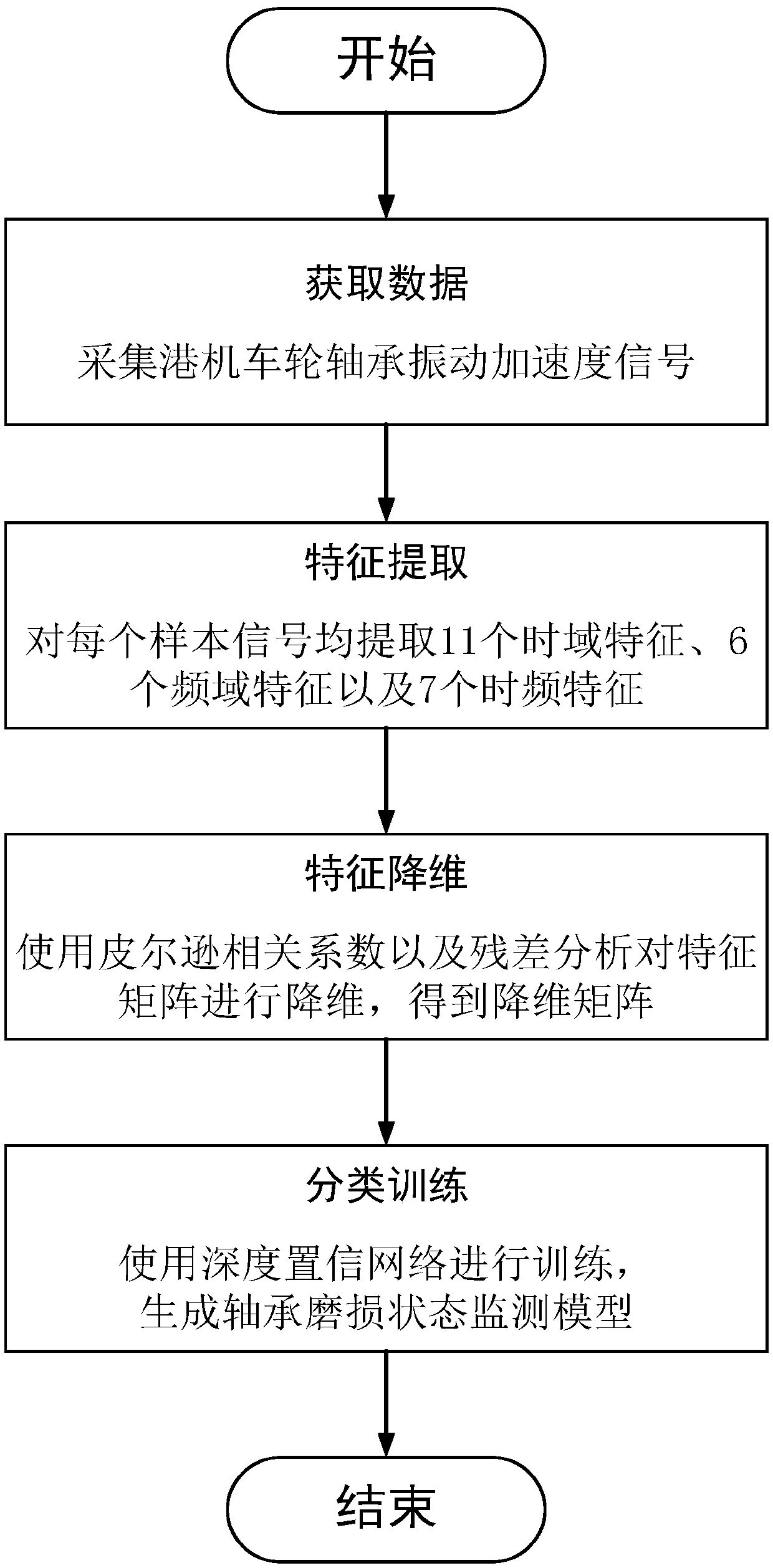

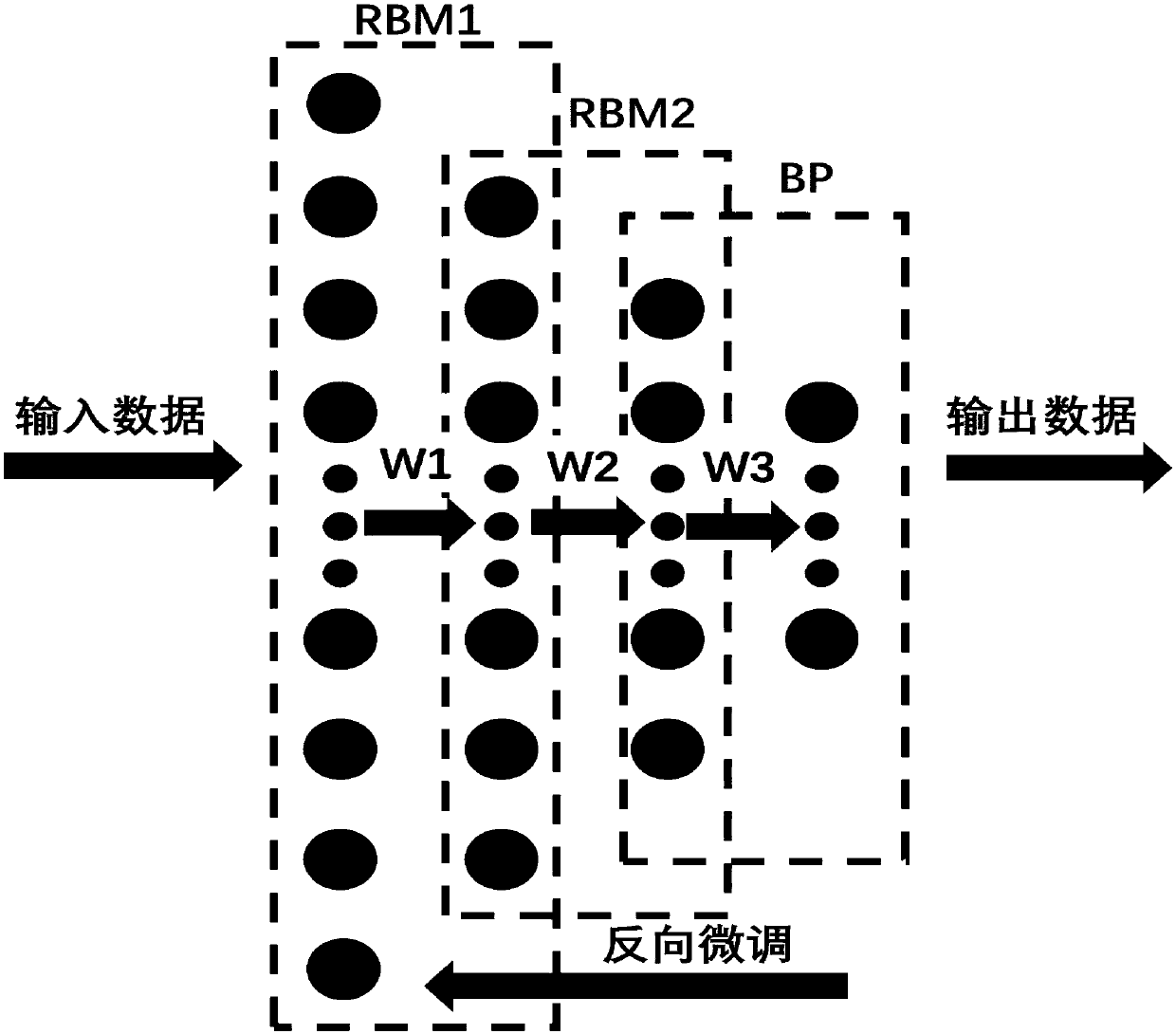

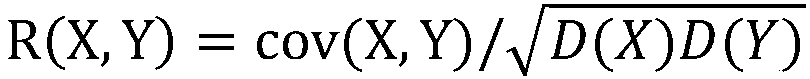

Fault state recognition method for port machine wheel bearing

PendingCN109612729AAccurate and effective detectionImprove accuracyMachine part testingDeep belief networkData set

The invention discloses a fault state recognition method for a port machine wheel bearing. The fault state recognition method comprises the steps that collected vibration signal data of the port machine wheel bearing in different fault states are evenly divided into a plurality of samples, and classified label matrixes are constructed and formed; time domain characteristic extraction, frequency domain characteristic extraction and time-frequency domain characteristic extraction are conducted on all the samples to obtain the characteristic number, and a high-dimensional original characteristicdata set matrix with the sample total number as the line number and the characteristic number as the column number is established; a Pearson correlation coefficient and residual analysis combined method is adopted to conduct correlation analysis on obtained characteristic parameters, distinguishing characteristics are extracted to reduce the dimension of the high-dimensional original characteristic data set matrix, and thus a sample characteristic matrix is obtained; and the dimension-reduced sample characteristic matrix and the corresponding label matrix are led into a deep belief network algorithm for classified training, and thus a bearing fault state classifying model is obtained. The bearing fault can be detected accurately and effectively, and the defects of a traditional method in bearing fault recognition are overcome.

Owner:TIANJIN JINAN HEAVY IND

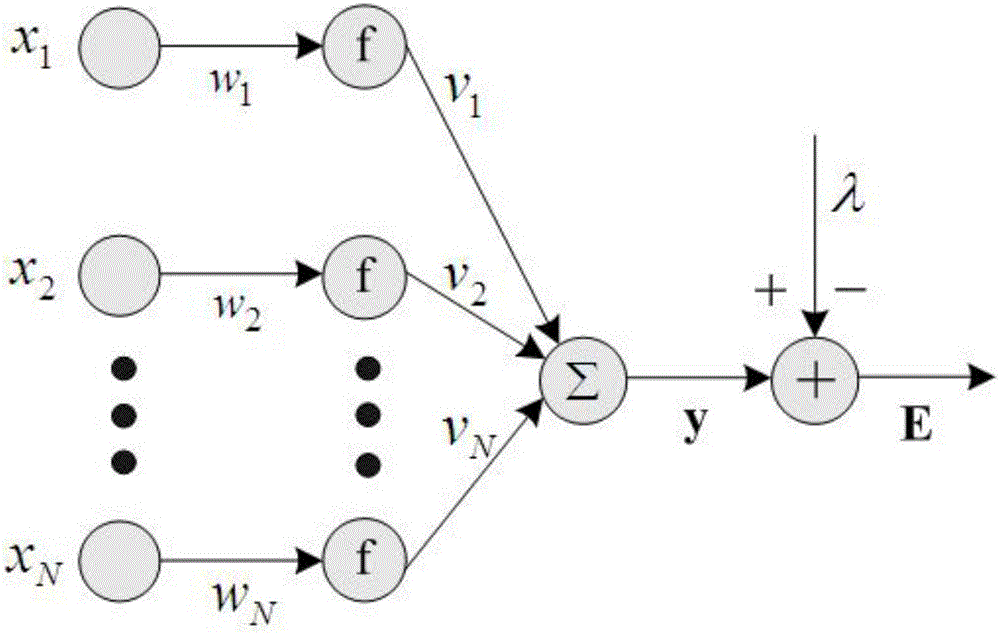

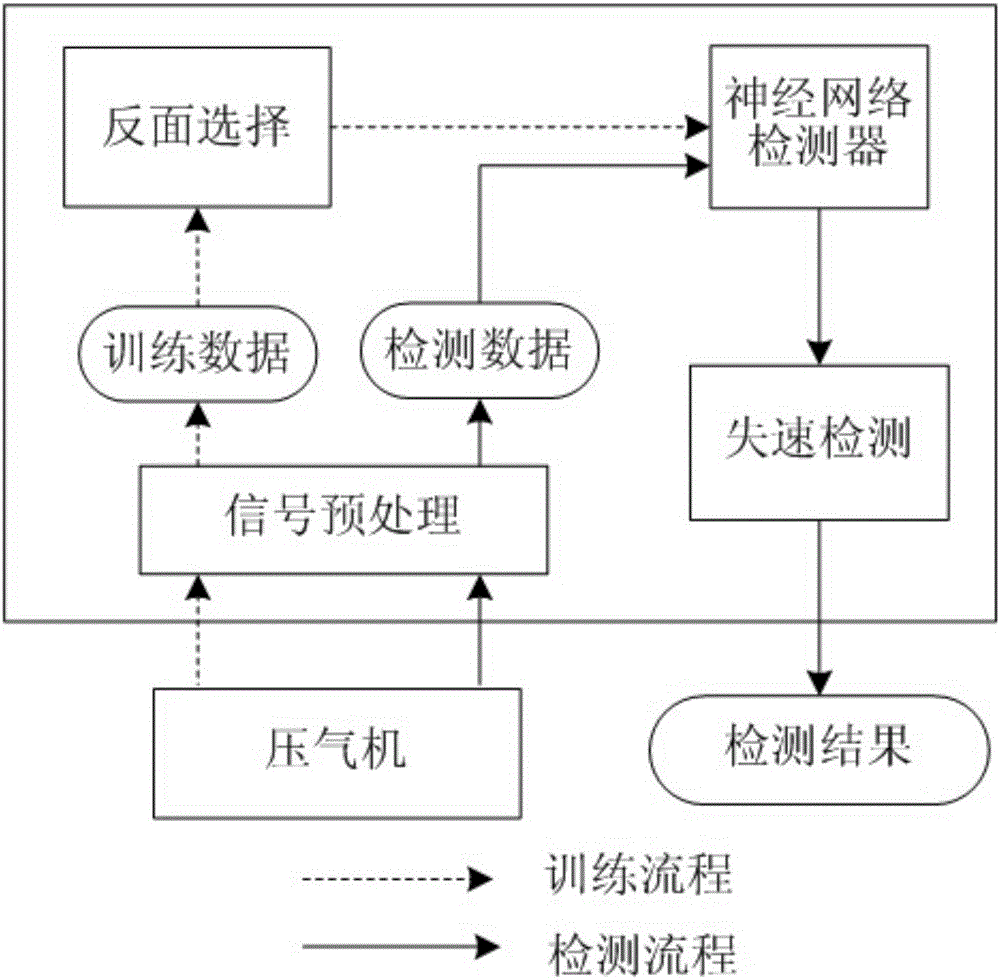

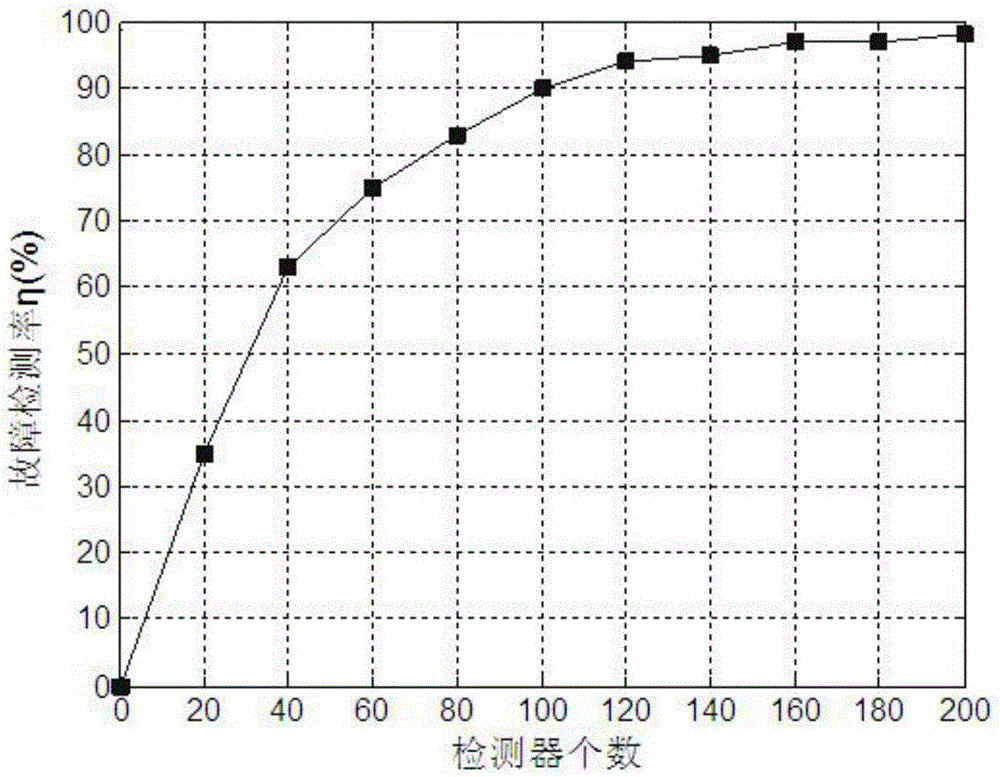

Airplane engine air compressor stall detection method

InactiveCN105094118AAccurate and effective detectionEasy fault detectionElectric testing/monitoringAxial compressorArtificial immune system

The invention discloses an airplane engine air compressor stall detection method. The method comprises steps: a sensor is firstly used for collecting pressure signals when the air compressor is in a normal working condition or in a stall condition, and pretreatment is carried out; a negative selection principle in an artificial immune system is then used for building a neural network detector, and the fault detection ability of the detector is improved through training; and finally, stall detection is carried out on the acquired airplane engine air compressor pressure fluctuation signals with a fault label. The negative selection principle in the artificial immune system is used for building the neural network detector, abnormal mode information of the air compressor is stored in the distributed detector through training, fault is found out according to activation of the detector, stall signals can be detected instantly when stall happens, and the detection speed is improved; existing historical data are fully used through training, and the detection rate is improved; and stall of the airplane engine air compressor can be accurately and effectively detected.

Owner:中国人民解放军空军勤务学院

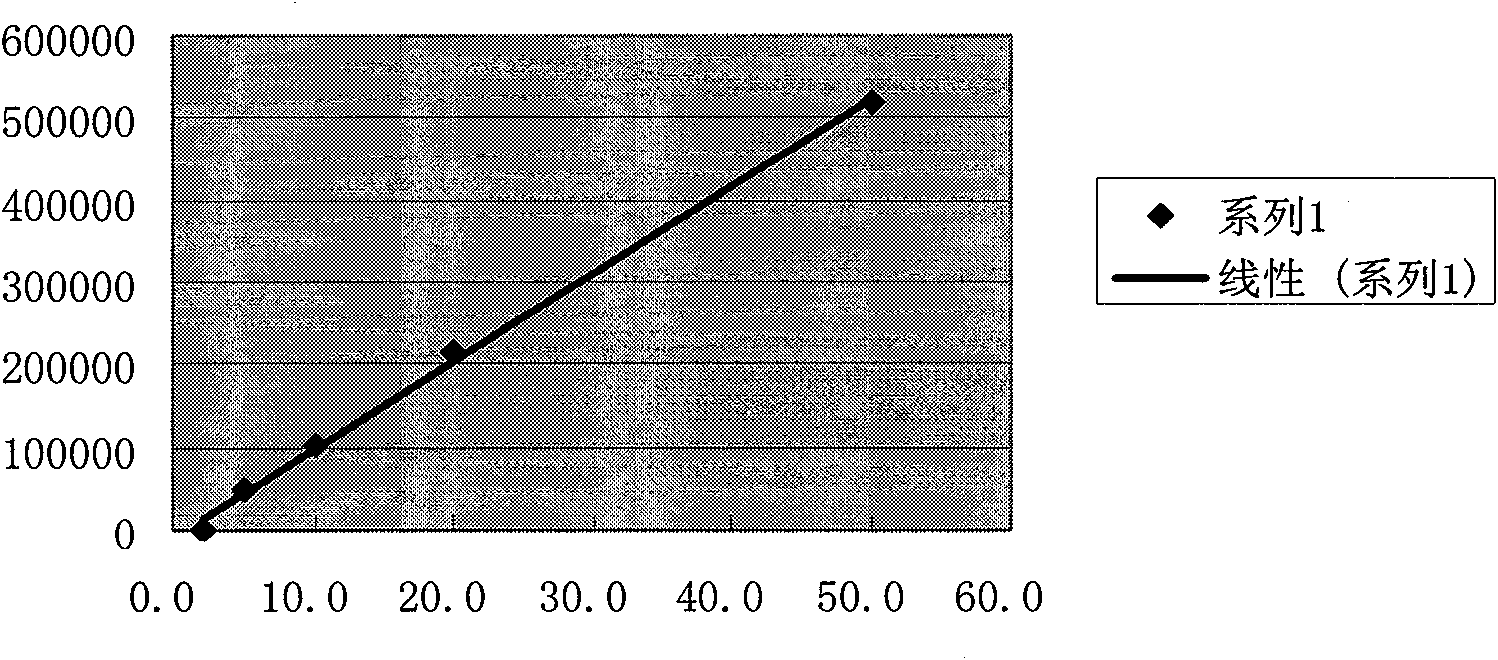

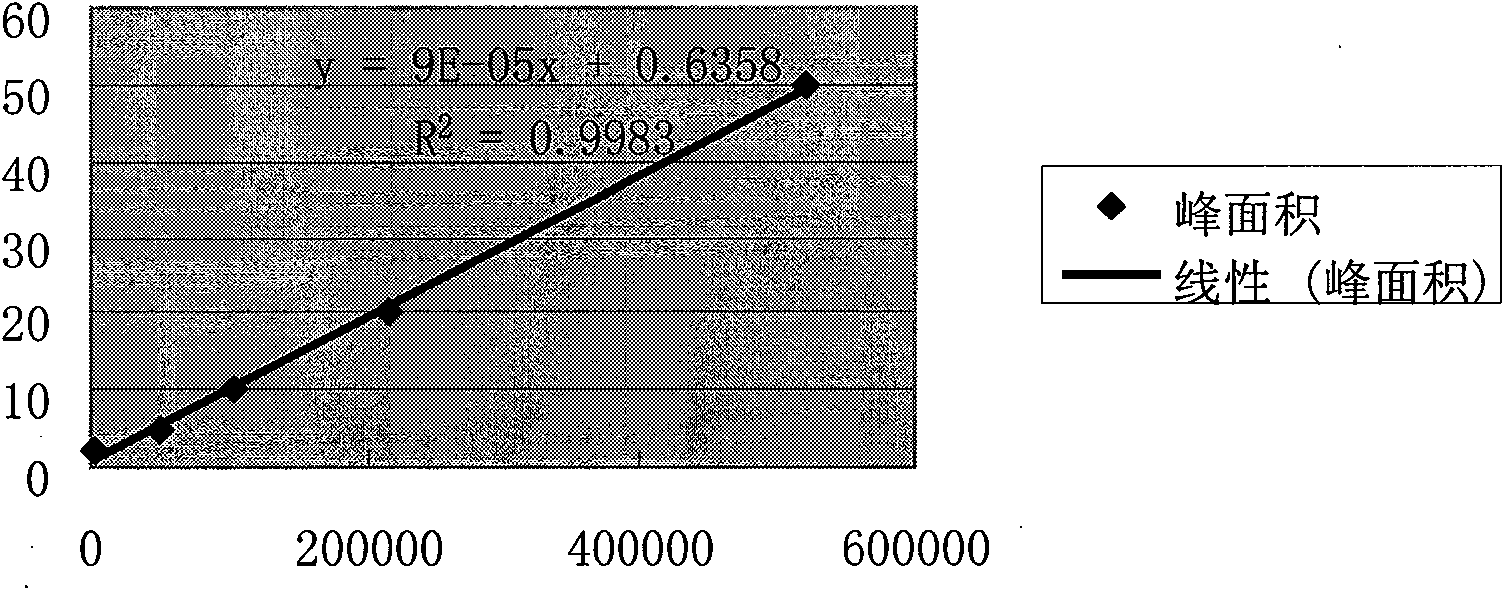

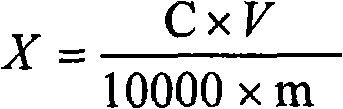

Detection method of IPBC in cosmetics

InactiveCN101644697AReliable implementationEasy to implementComponent separationChemistrySODIUM SULFATE ANHYDROUS

The invention relates to a detection method of IPBC (3-iodo-2-propymyl btycarbamate) in cosmetics by quantitative determination with a gas chromatography and confirmation with a gas chromatograph-massspectrometer. The method comprises the following steps: distilling a volatile organic solvent in a specimen to be tested, extracting the specimen by methanol, adding anhydrous sodium sulfate for frozen centrifugation, purifying the obtained supernatant through a SPE-C18 column to obtain filtrate, and filtering the filtrate to obtain specimen treating fluid; accurately weighing, dissolving by using methanol and allowing an IPBC standard product to be a constant volume as stock solution, and further diluting the IPBC standard product with methanol into standard working solution with a concentration gradient; and carrying out quantitative determination with the gas chromatography and confirmation with the gas chromatograph-mass spectrometer. The detection method of the IPBC in the cosmeticscan help quickly and accurately achieve the purpose of quantitative and qualitative detection, and relative mean deviation is less than 5.0%, thus the method provides a reliable and enforceable schemefor IPBC detection in the cosmetics, and can meet the requirements of research and market detection.

Owner:谱尼测试集团股份有限公司

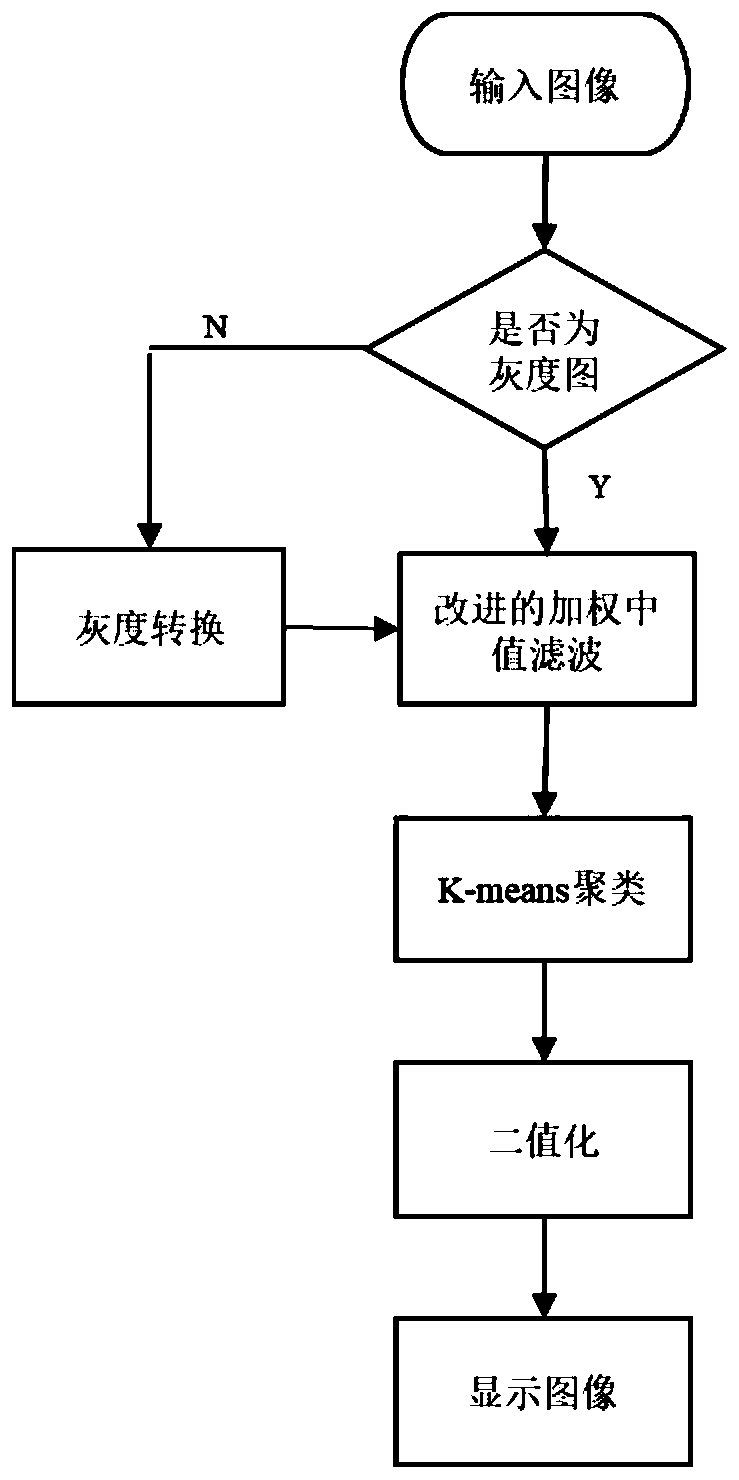

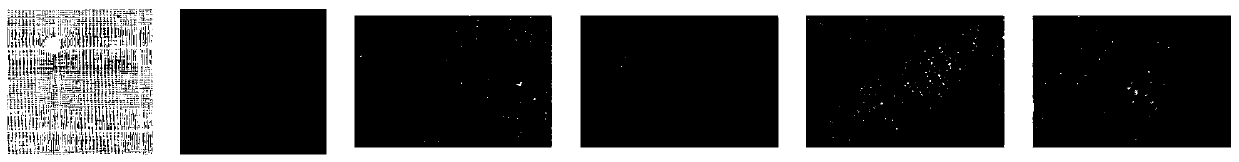

Fabric defect detection method

InactiveCN109978830AAccurate and effective detectionImprove adaptabilityImage enhancementImage analysisComputer visionGrayscale

The invention discloses a fabric defect detection method which specifically comprises the following steps: firstly, zooming a fabric defect image to be detected to 256 * 256 pixels, and then converting the fabric defect image into a gray level image; carrying out improved weighted median filtering processing on the fabric defect image obtained in the step 1; finally, using a K-means clustering tosegment the fabric defects. The filtering speed can be remarkably increased while the background textures of the fabric image are inhibited, and the defects of the fabric with different texture backgrounds can be effectively and accurately detected.

Owner:XI'AN POLYTECHNIC UNIVERSITY

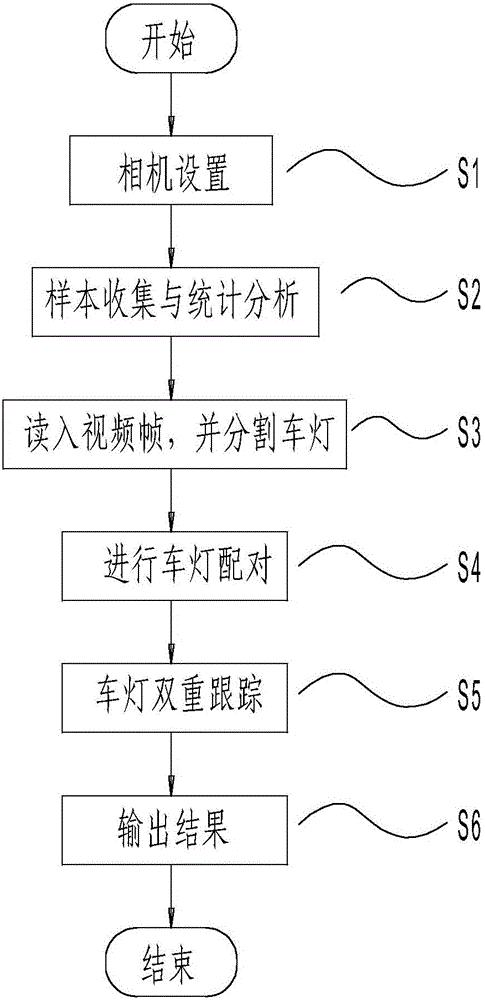

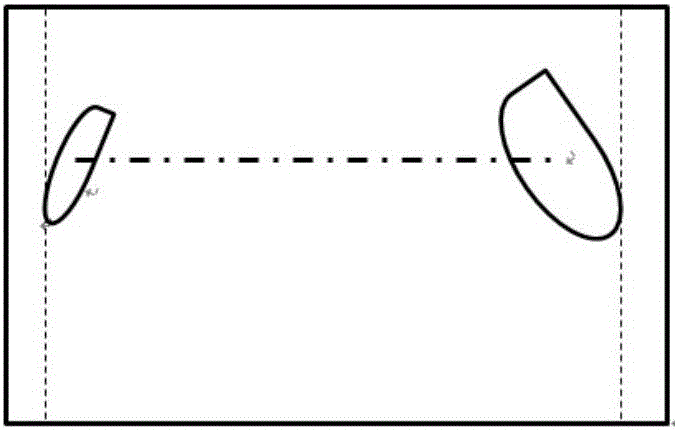

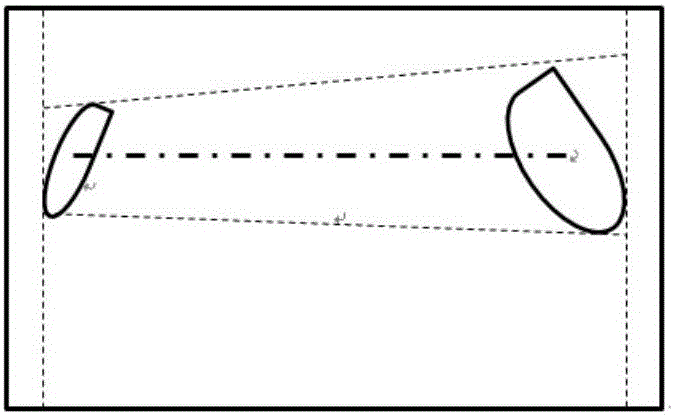

Preceding vehicle detection method based on vehicle-mounted camera under night-vision environment

InactiveCN105740835AReduce distractionsReduce reflective intensityImage enhancementImage analysisColor imageNight vision

The invention discloses a preceding vehicle detection method based on a vehicle-mounted camera under night-vision environment, relates to a method for detecting the preceding vehicle. According to the method, firstly, exposure control and polarized light elimination are performed on the vehicle-mounted camera used for detecting and tracking vehicle lights, then a region growing method combining with canny edge detection and a color image threshold segmentation method based on Mahalanobis distance are respectively used for segmenting headlights and taillights; on this base, the vehicle lights are paired, and the computing accuracy of the related coefficient is improved by using primary filtering and projection distortion compensation; and at last the target is tracked and confirmed based on Kalman filtering and state machine conversion. The method has the advantages of being capable of reducing the interference of complex background, reducing the intensity of light reflection of wet roadside, detecting the taillights, maintaining the appearance shapes of the headlights and improving the computing accuracy of the related coefficient, being simple in computing and solving process, and also being capable of accelerating the detection speed and maintaining the accuracy of vehicle detection, and can achieve the accurate detection and stable tracking on the preceding vehicle under the night-vision environment.

Owner:广西超宏科技有限公司

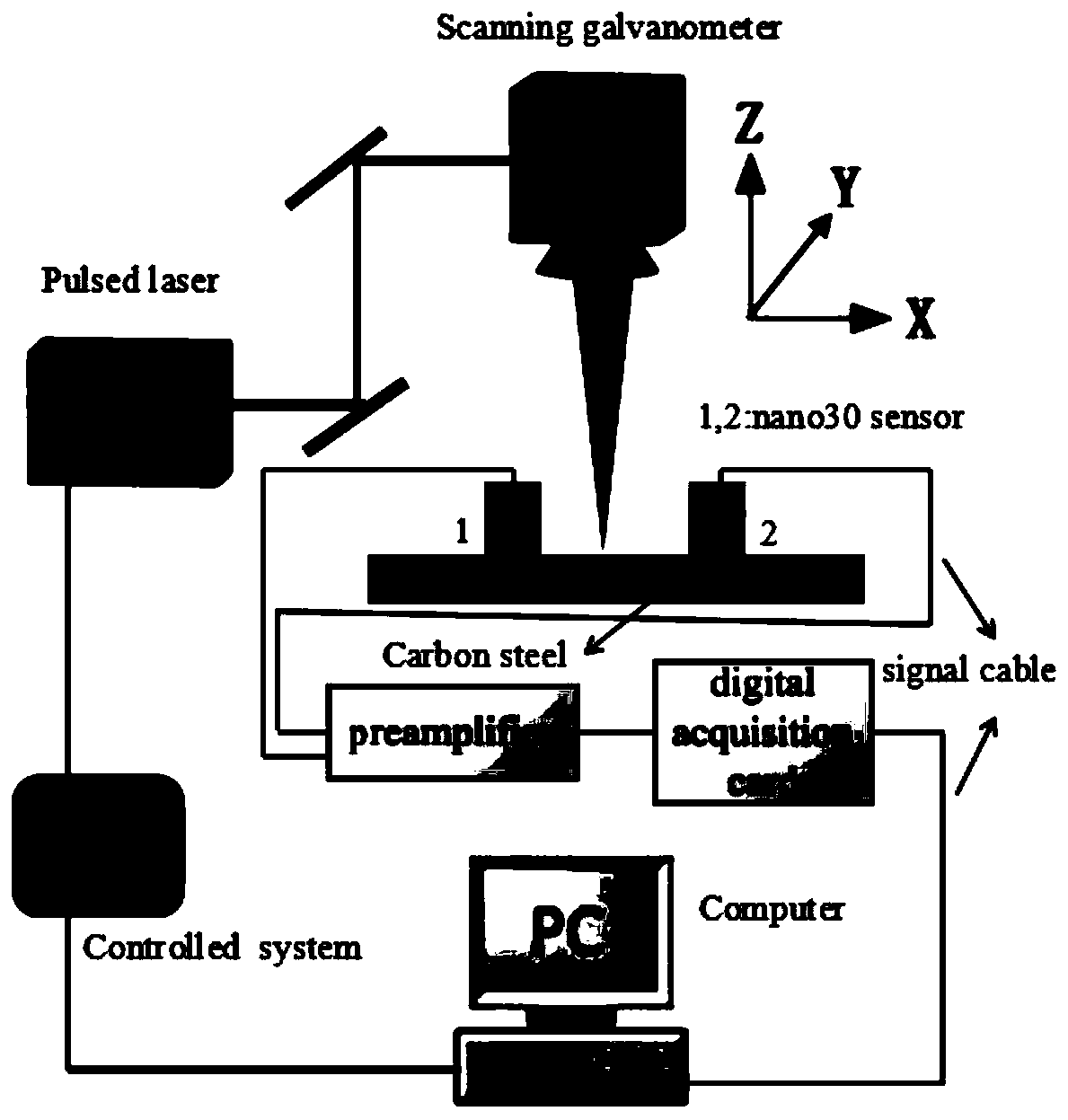

A loop detection method based on word bag model

ActiveCN109409418AAccurate and effective detectionImprove recallCharacter and pattern recognitionComputation complexityBag-of-words model

The invention relates to a loop detection method based on a word bag model. The lexical bag model adopts binary visual features ORB with rotation invariance and scale perception. This visual feature has the same performance as SIFT feature and SURF feature and the same computational efficiency as the visual feature composed of FAST key points and BRIEF descriptor. It is a visual feature with low computational complexity and high feature salience. The present invention employs a bag-of-words model that relies on the visual features, so that loop detection can be efficiently performed in a scenewith plane rotation and scale scaling. At the same time, the normalization method of similarity score is improved by calculating and maintaining the mean value of a normalization factor and replacingthe normalization factor when the normalization factor is abnormal. This normalization method enables the system to effectively detect loops in the event that the main body moves too fast or too slowly and steers.

Owner:SUN YAT SEN UNIV

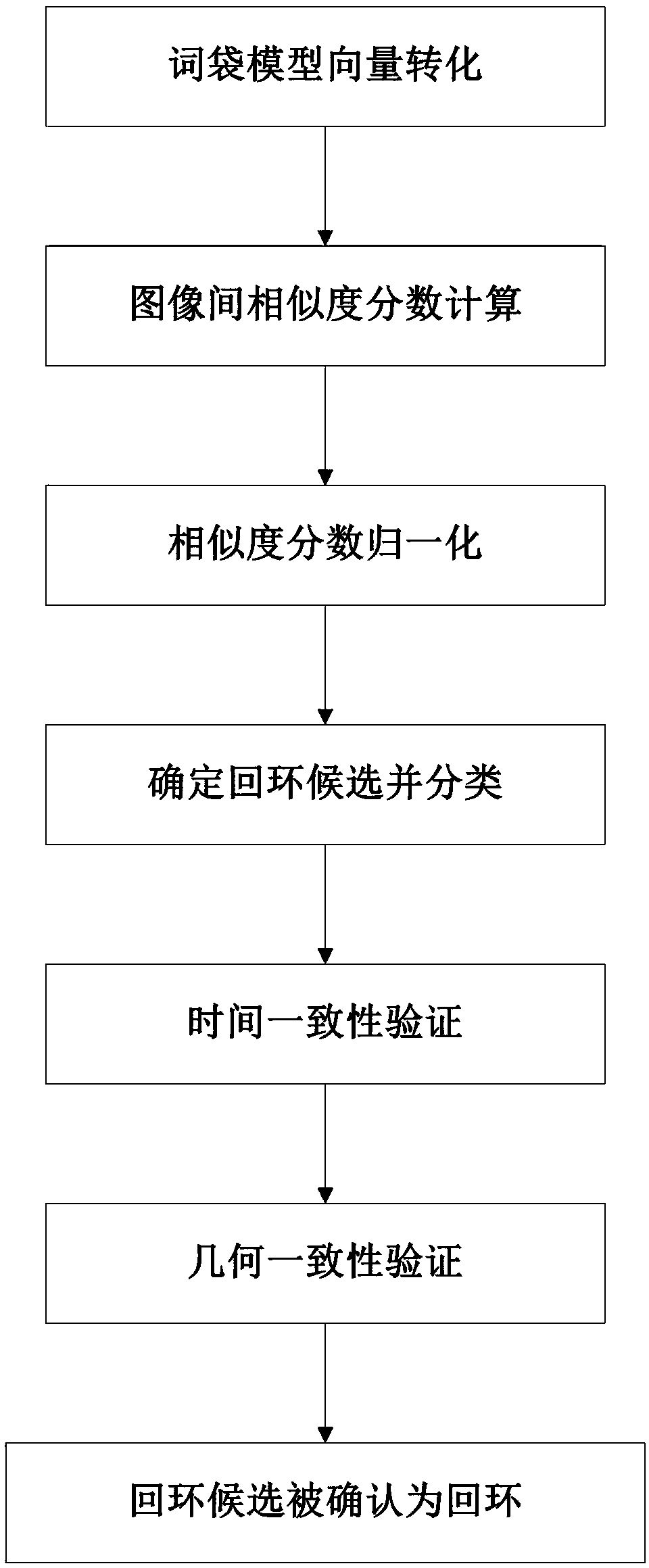

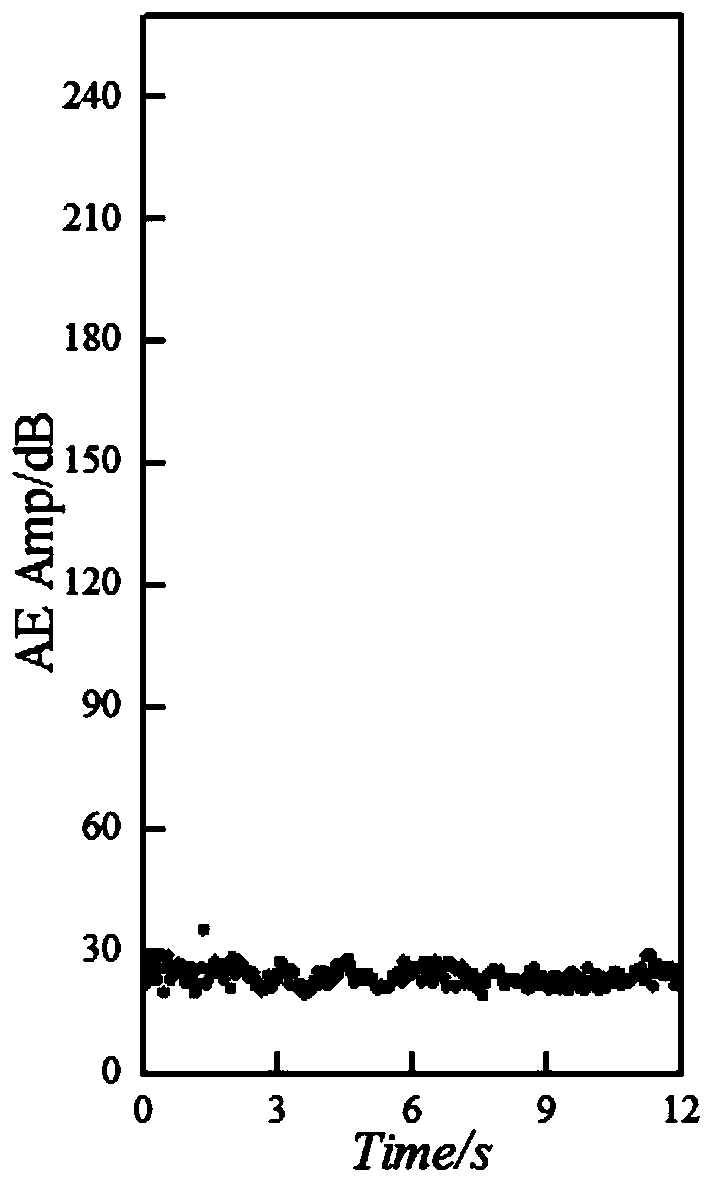

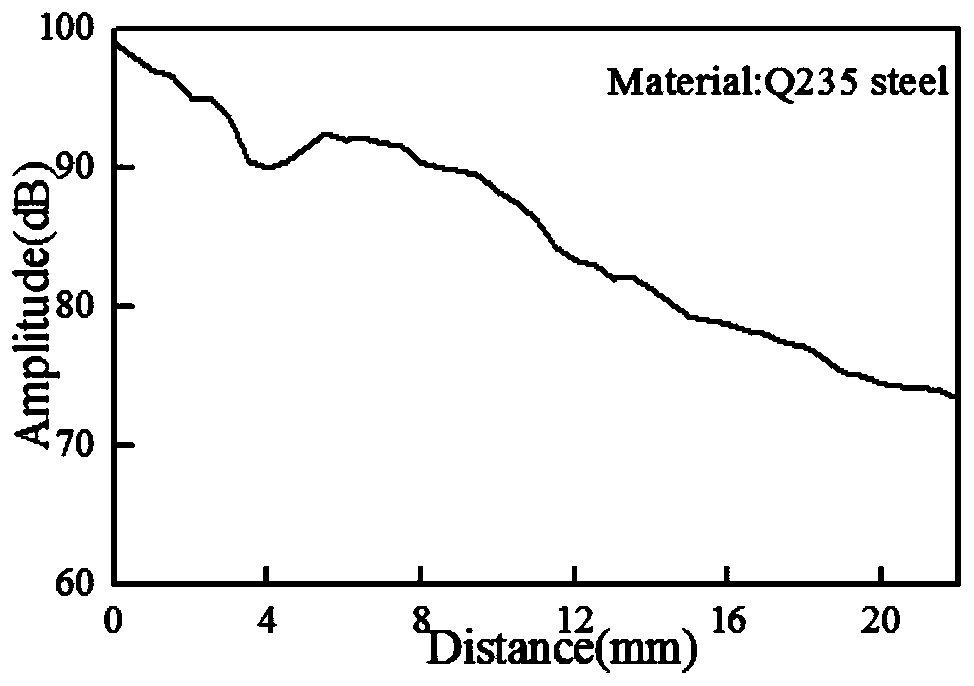

Laser cleaning process monitoring method based on acoustic emission technology

ActiveCN109813805AImprove reliabilityReduce distractionsAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesNon destructiveLaser processing

The invention discloses a laser cleaning process monitoring method based on an acoustic emission technology. A monitoring system is composed of a near-infrared nanosecond optical fiber laser processing system, a data acquisition card, preamplifiers, a signal cable and acoustic emission sensors. According to the principle of the laser cleaning process monitoring method, the cleaning effect is subjected to real-time and non-destructive monitoring based on the laser cleaning process of the acoustic emission technology; a mutual mathematical relation between the cleaning effect (the quantity of residual rust materials on the surfaces of workpieces) and the amplitude of acoustic emission signals is obtained, setting of laser processing parameters is controlled in real time, and thus laser cleaning is subjected to online and non-destructive monitoring; besides, the acoustic emission sensors are directly arranged on the surfaces of rust layers of the workpieces, the interference of other signals is reduced, and the reliability of the collected acoustic emission signals is improved. According to the monitoring system and method, the structure and use are very simple and reasonable, the precision is high, the performance is stable, the problem that an existing laser cleaning technology does not have a real-time detection function is solved, and the cleaning quality and efficiency are improved.

Owner:GUANGDONG UNIV OF TECH

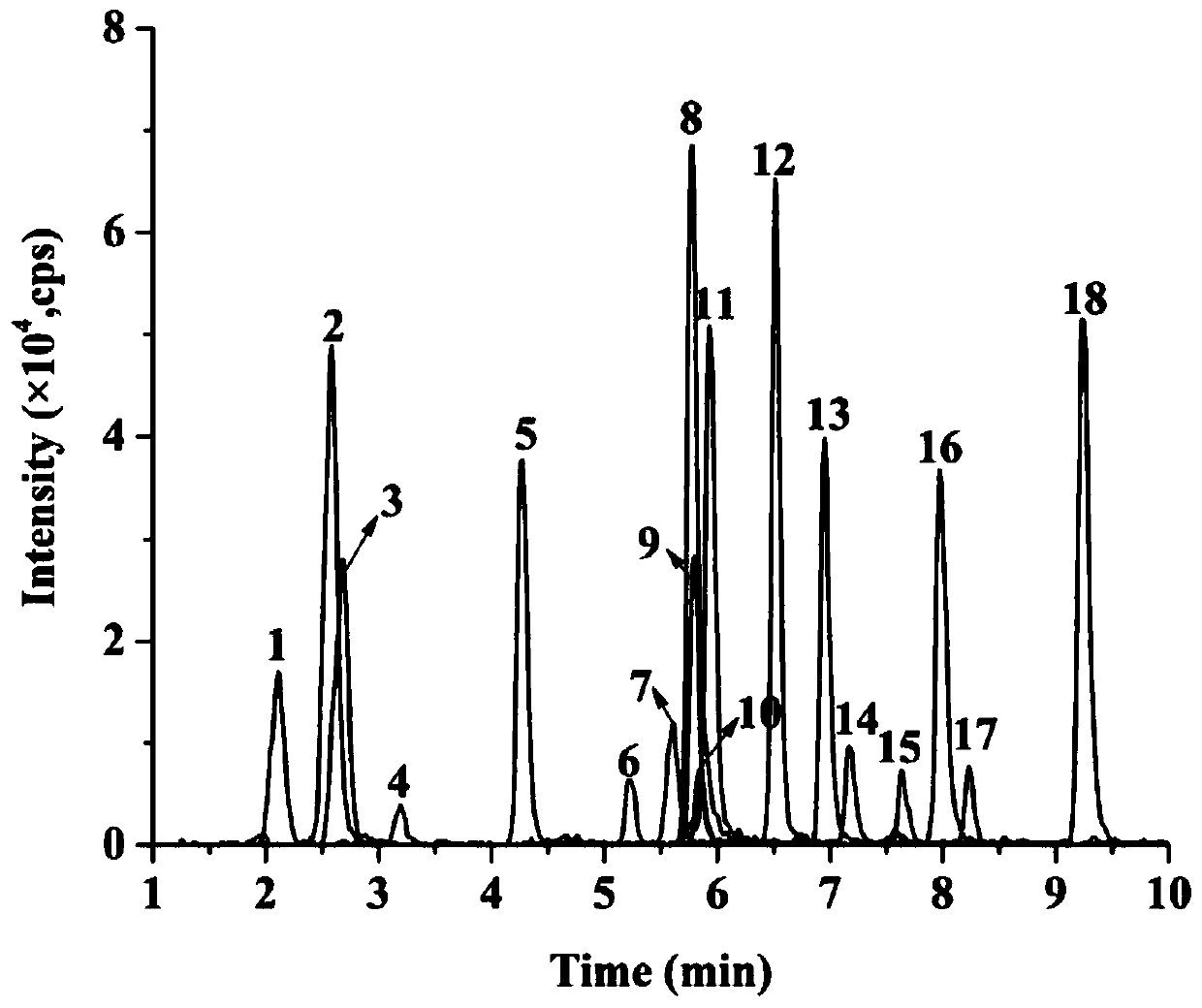

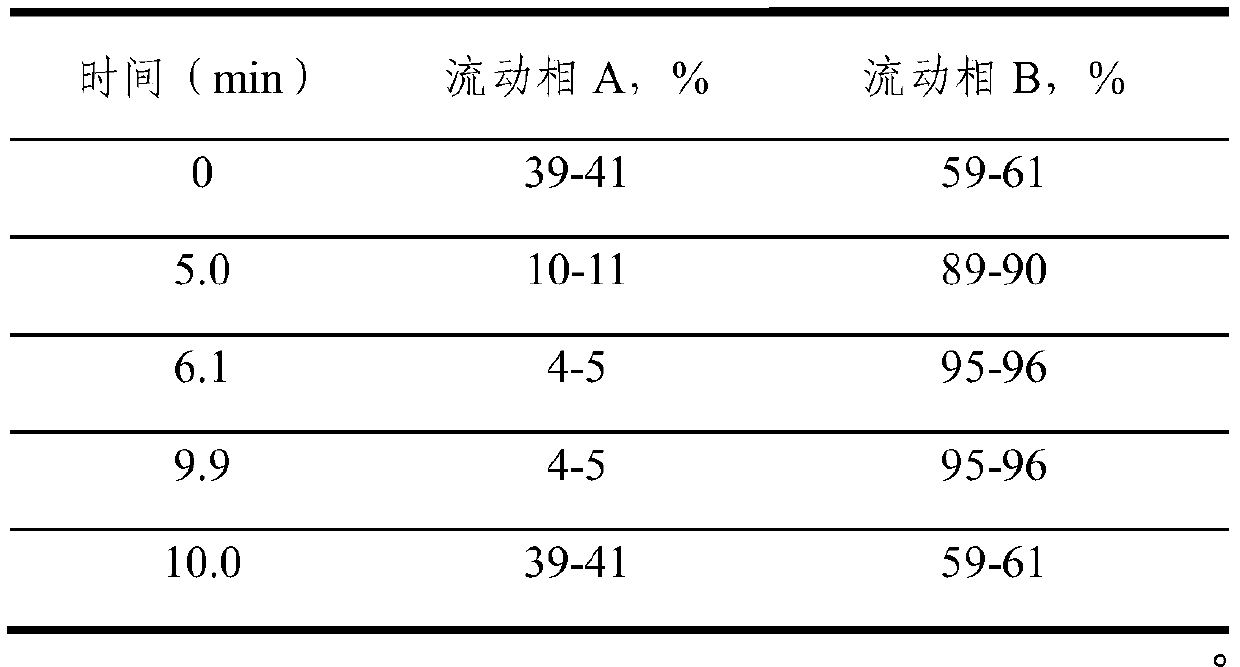

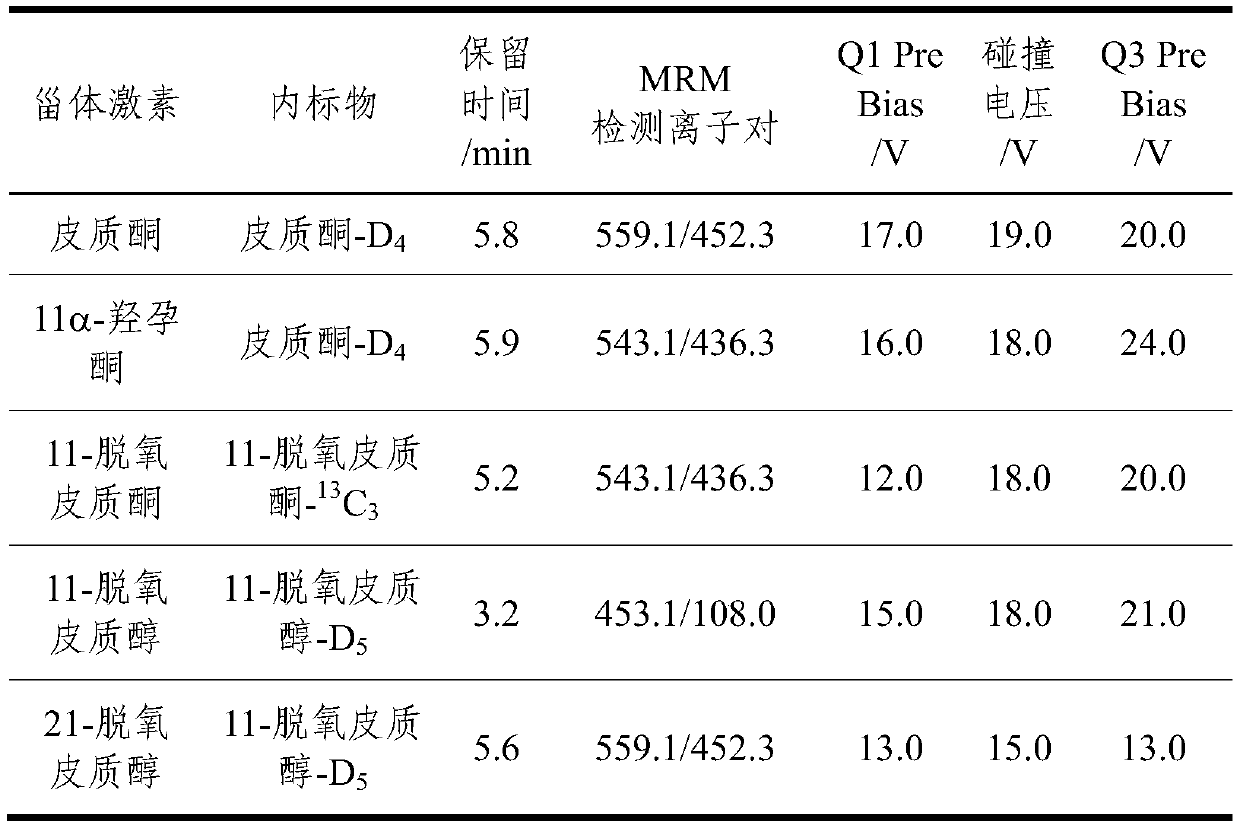

Chemical derivatization-ultra-high performance liquid chromatography-tandem mass spectrometry method for simultaneously detecting 18 steroid hormones in serum

ActiveCN111366671AEasy to separateHigh detection sensitivityComponent separationSteroidal hormonesDerivatization

The invention provides a chemical derivatization-ultra-high performance liquid chromatography-tandem mass spectrometry method for simultaneously detecting 18 steroid hormones in serum, which is characterized in that a novel derivatization reagent 3-pyridylmethoxylamine is adopted for derivatization and then ultra-high performance liquid chromatography-tandem mass spectrometry is used for detection. According to the method, only 10 minutes are needed for detecting 18 steroid hormones at the same time, the hydrophobicity index logP is greatly improved after derivatization, the peak shape and theseparation degree in a high performance liquid phase reversed phase chromatographic column are improved, and the ionization efficiency is better, so that the mass spectrum detection sensitivity is improved. The method has the characteristics of simplicity and convenience in operation, good accuracy, strong specificity, wide detection range and the like.

Owner:谱络(武汉)医学生物科技有限公司

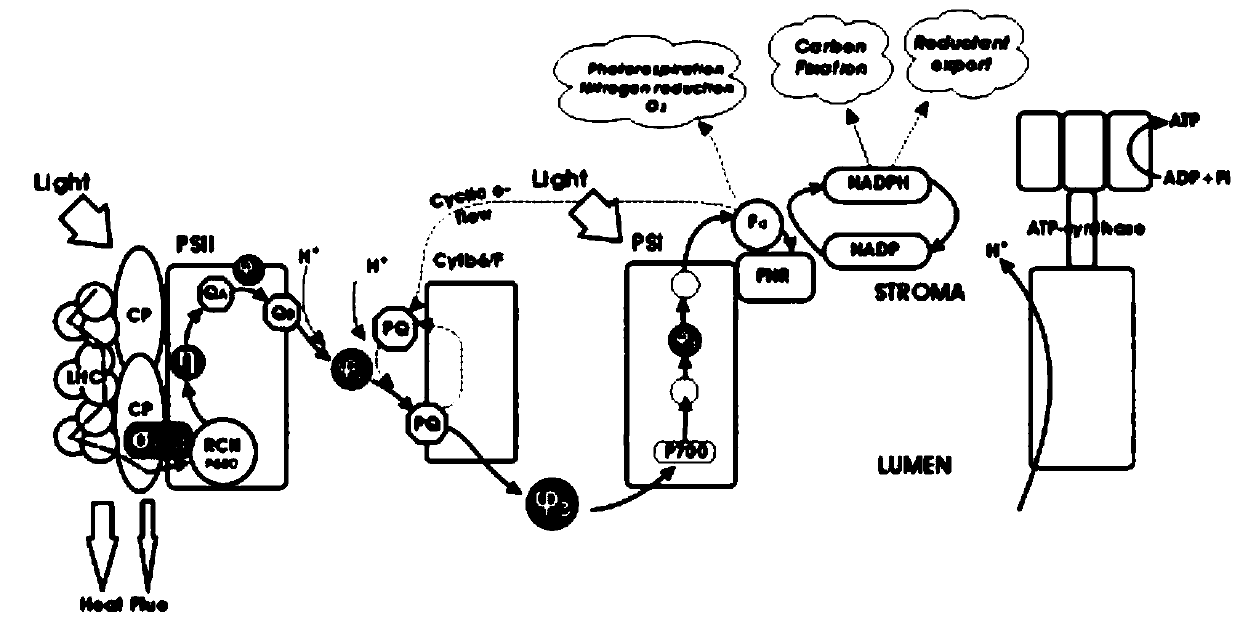

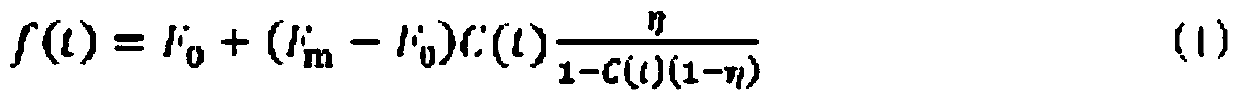

Method for rapidly detecting photosynthetic rate of phytoplankton based on chlorophyll fluorescence

ActiveCN104215616AReal-time detectionQuick analysisFluorescence/phosphorescenceThermodynamicsArbitrary Fluorescence Unit

The invention discloses a method for rapidly detecting a photosynthetic rate of phytoplankton based on chlorophyll fluorescence. According to the invention, from the view of energy flow angle of photosynthesis, the chlorophyll fluorescence serves as a probe of photosynthesis, a variable light pulse induction method for phytoplankton chlorophyll fluorescence is provided, the complex photosynthetic energy flow process is segmented, and photosynthetic parameters for leading the photosynthetic energy flow efficiency are obtained in a sectional mode by analyzing the chlorophyll fluorescence kinetic curves under different induction modes. On the basis, according to the biological film energy flow process, a quantitative analysis method for the photosynthetic rate of phytoplankton based on chlorophyll fluorescence is established, the state and growth potential of the photosynthesis of the phytoplankton are rapidly detected in real time, and a method basis is provided for developing an in-situ field measurement technology.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

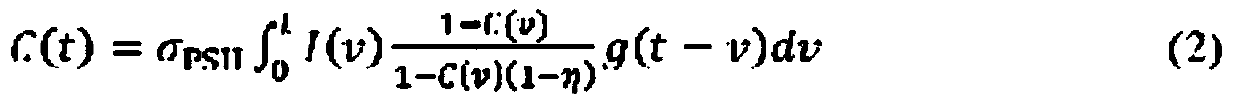

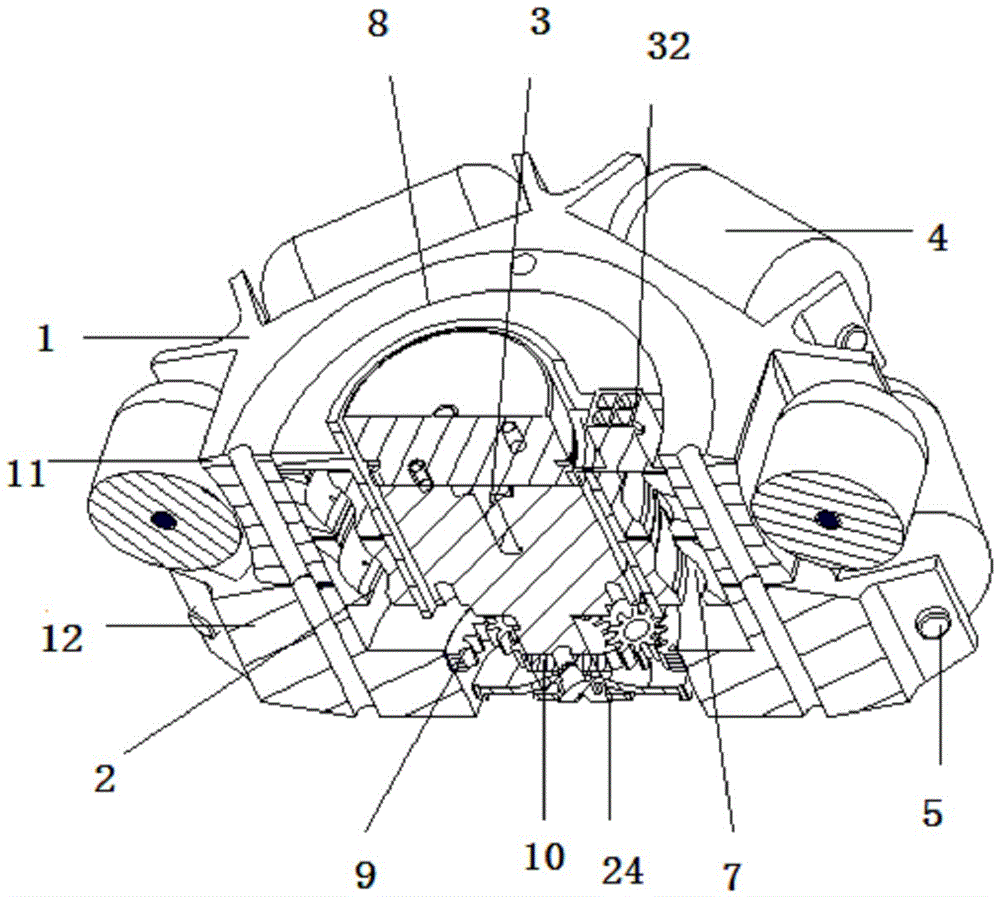

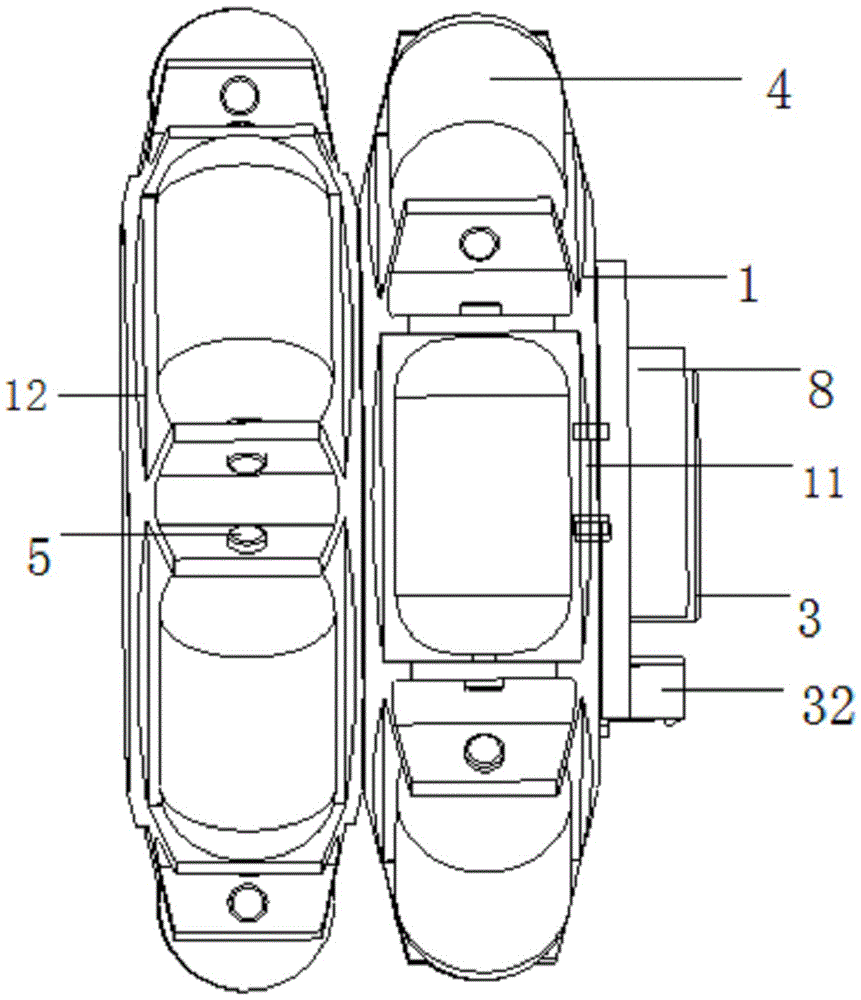

Integrated universal wheel and control method thereof

InactiveCN105730216AImprove work efficiencyImprove omnidirectionalityMotor depositionWheelsEngineeringMechanical engineering

An integrated universal wheel comprises a universal wheel body, a transmission and a brushless EU disc type motor. The brushless EU disc type motor and the transmission of the universal wheel are placed in the universal wheel body. The brushless EU disc type motor is connected with the transmission. A gear at the output end of the transmission serves as a sun gear to be engaged with a planet gear in the universal wheel body to drive the universal wheel body to move. By the adoption of the integrated universal wheel, the brushless EU disc type motor is fixed into the universal wheel body, and the working efficiency of the brushless EU disc type motor is improved.

Owner:SHENYANG POLYTECHNIC UNIV

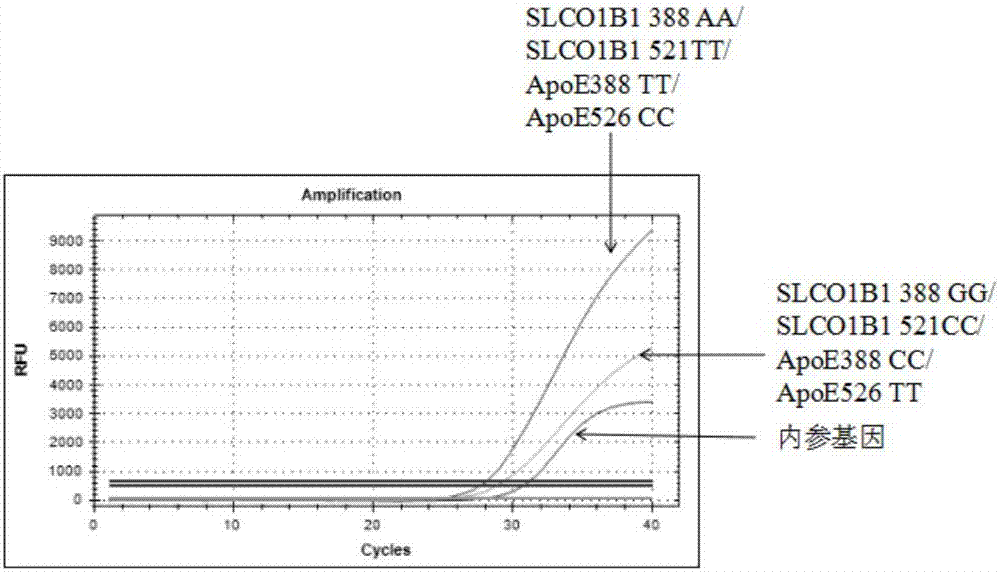

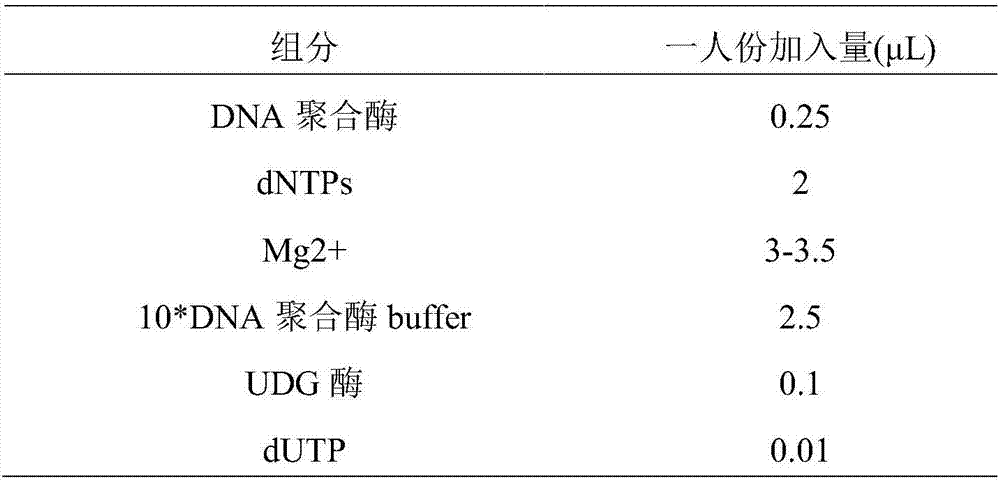

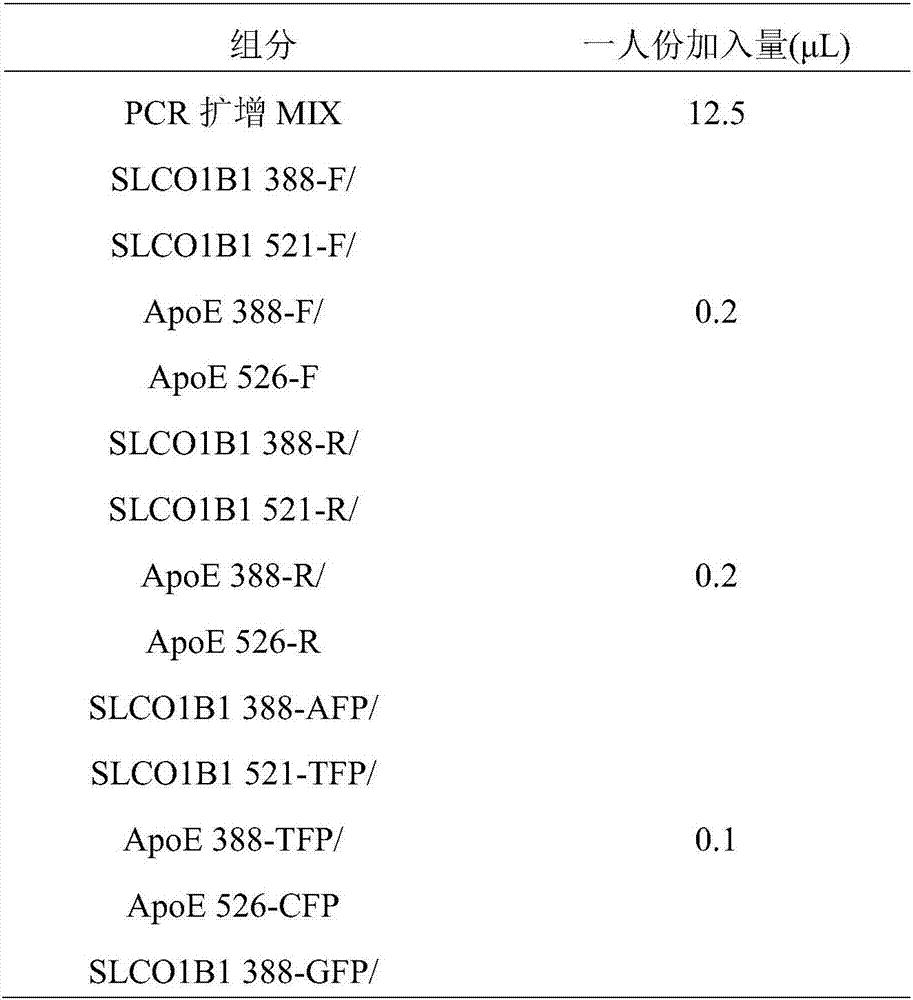

Composition for detecting gene polymorphism of SLCO1B1 and ApoE as well as application thereof

ActiveCN107541548ASimple and fast operationEasy to readMicrobiological testing/measurementDNA/RNA fragmentationProbe typeMultiplex pcrs

The invention discloses a composition for detecting gene polymorphism of SLCO1B1 and ApoE as well as an application thereof. An FAM, HEX, ROX (modified) three-channel multiple PCR reaction is used fordetecting single nucleotide polymorphism sites in SLCO1B1 and ApoE genes. In order to improve simplicity and specificity of detection, a probe typing technological means is used for realize one-tubetyping detection, and the whole operation and reaction process are simplified; on the basis, locked nucleic acid modification and secondary structure modification are carried out for the probe, Tm value of the product is added, in order to further improve specificity of probe combination; and finally proportioning of primer pairs, amount of Taq enzyme, amount of magnesium ions and the like are adjusted, in order to improve lowest detection limit, accuracy and specificity of the whole kit, lowest detection concentration of the kit reaches 1ng / [mu]L, and accuracy and specificity can reach 100%.

Owner:北京鑫诺美迪基因检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com