Fault state recognition method for port machine wheel bearing

A fault state, wheel bearing technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as lack of generalization, and achieve the effect of accurate and effective detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

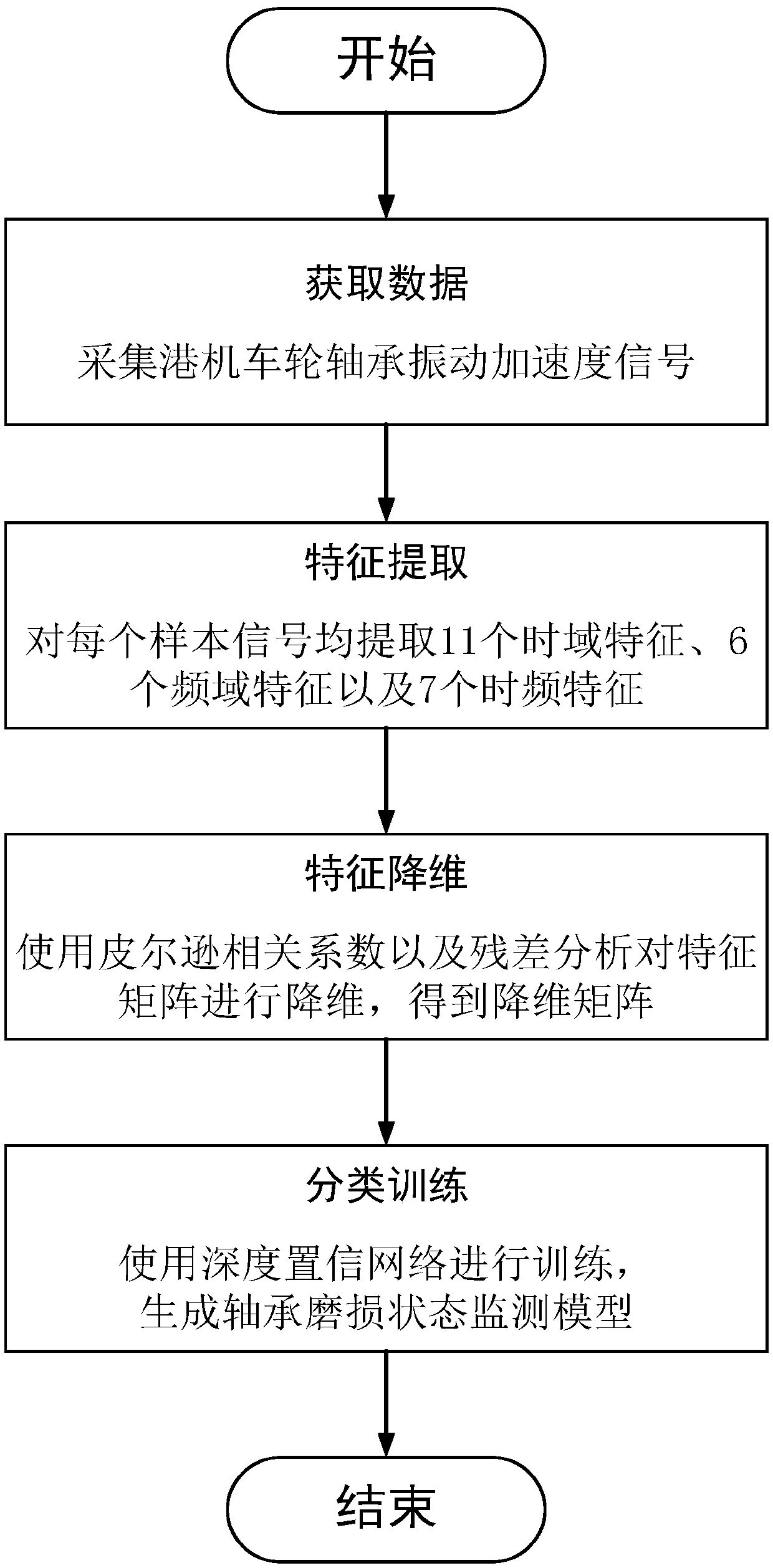

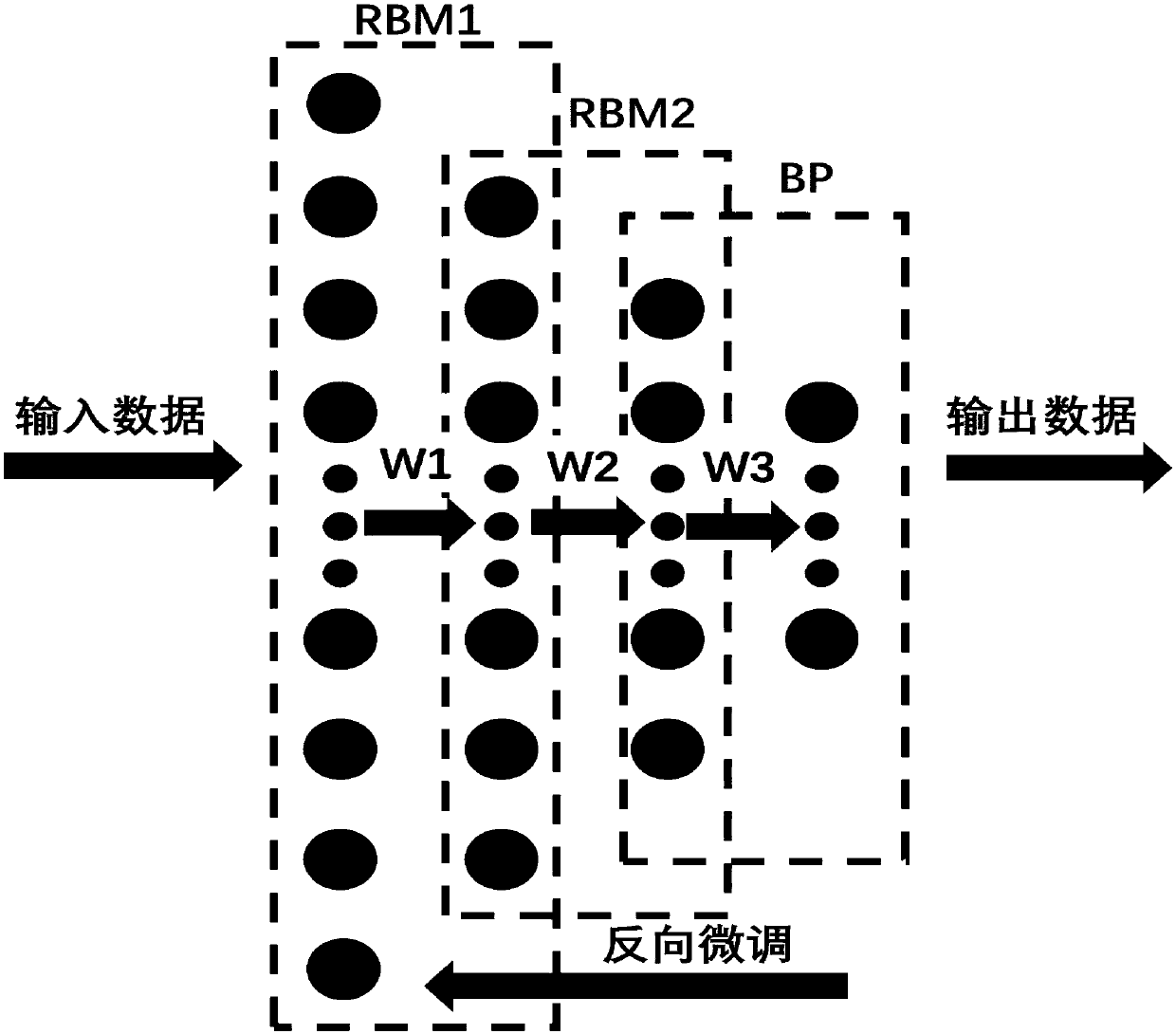

Method used

Image

Examples

Embodiment approach

[0027] As an embodiment of the present invention, the time domain features include: mean value, root mean square value, peak value, variance, peak-to-peak value, signal energy, crest factor, kurtosis, pulse index, skewness and margin coefficient.

[0028] Frequency domain features include: power spectrum sum, power spectrum mean, power spectrum variance, power spectrum skewness, power spectrum kurtosis, and power spectrum peak.

[0029] Time-frequency domain features include: time-frequency total energy, time-frequency energy distribution variance over time, time-frequency energy distribution skewness over time, time-frequency energy distribution kurtosis over time, time-frequency energy distribution variance over frequency, time-frequency energy over frequency Distribution skewness, time-frequency energy distribution kurtosis with frequency.

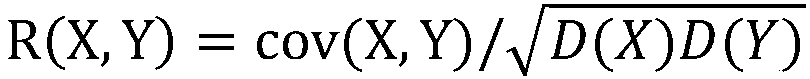

[0030] Step 4: Using the combination method of Pearson correlation coefficient and residual analysis, carry out correlation analysis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com