Patents

Literature

153 results about "Bearing fault detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibration measurement and analysis

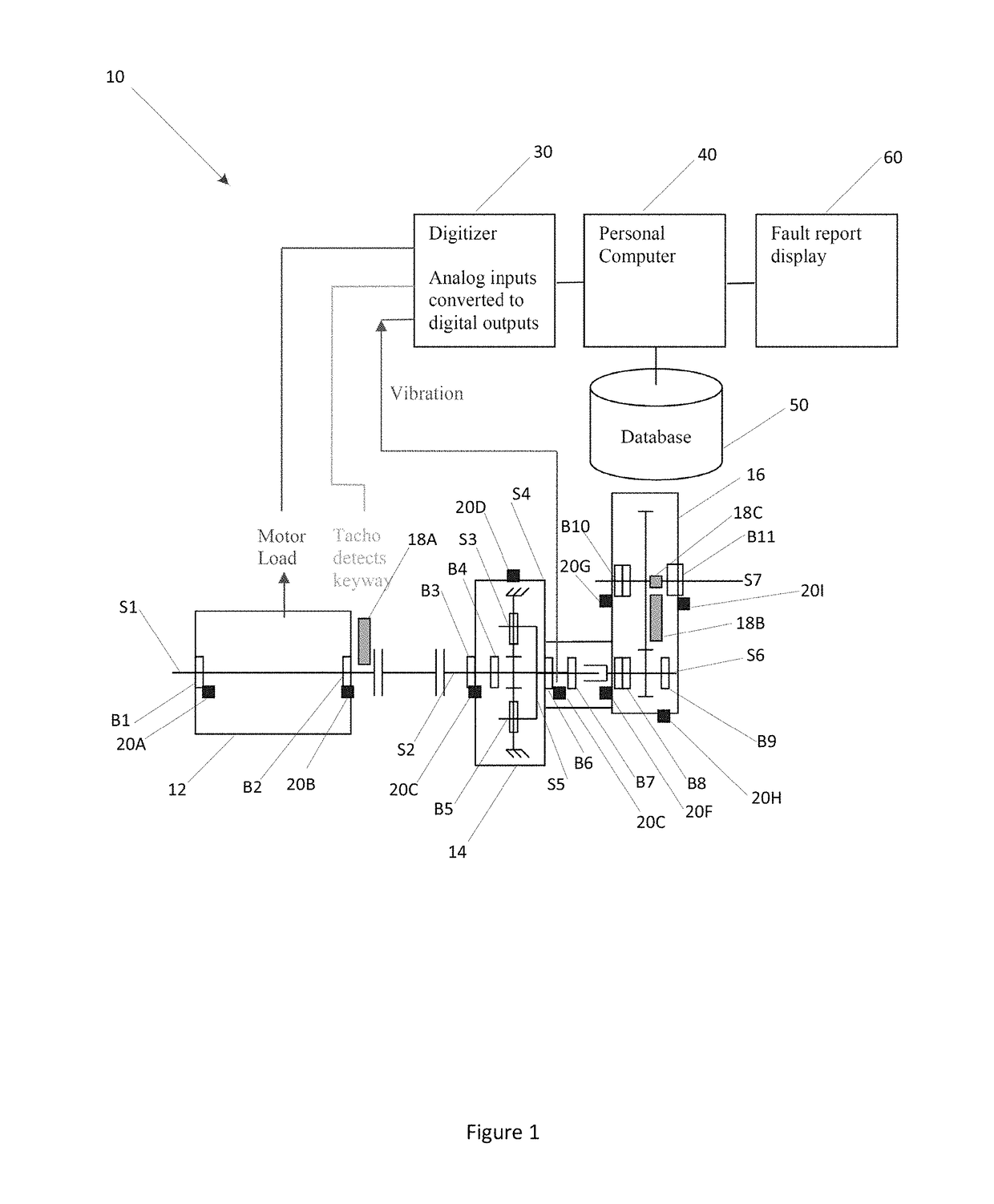

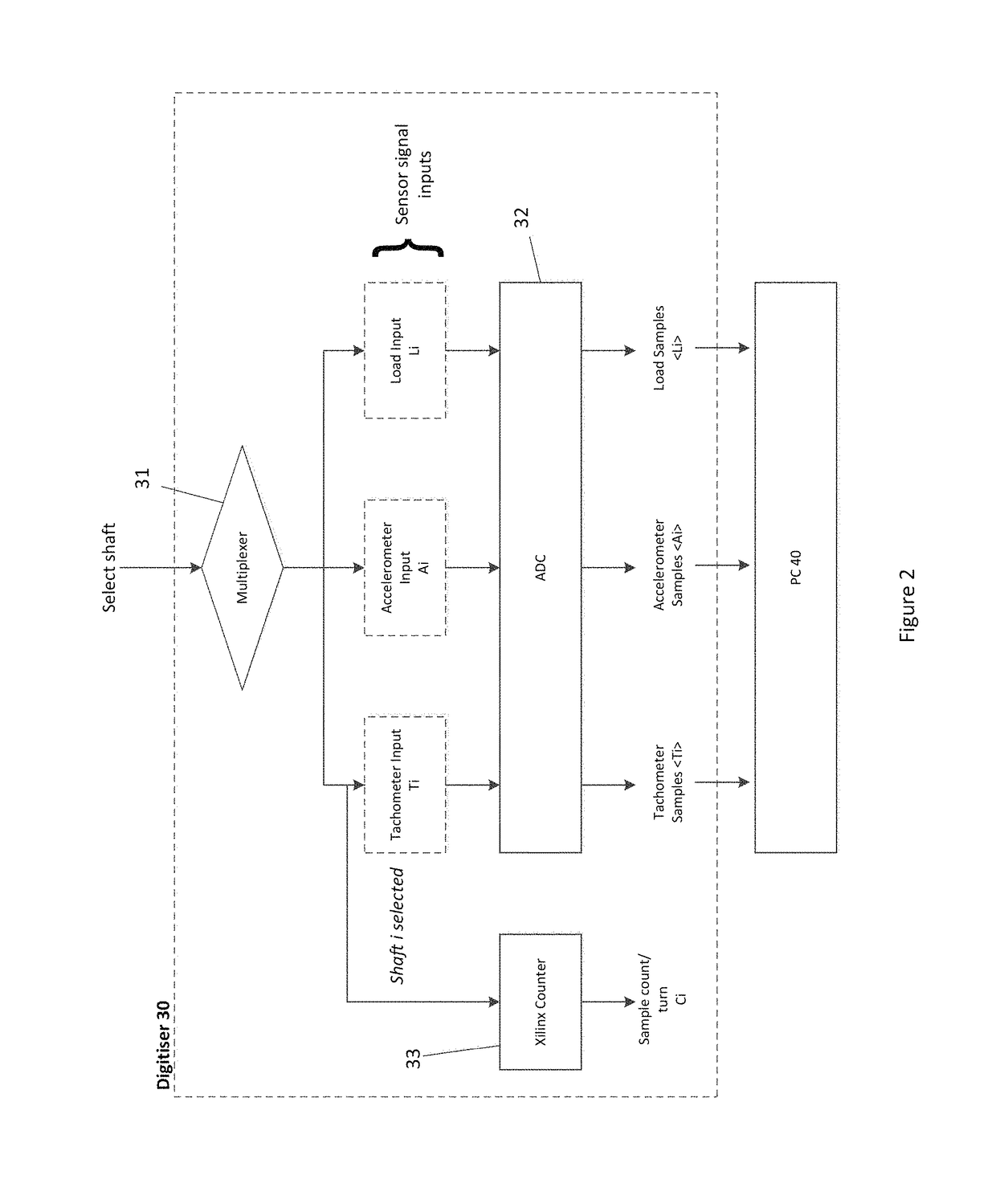

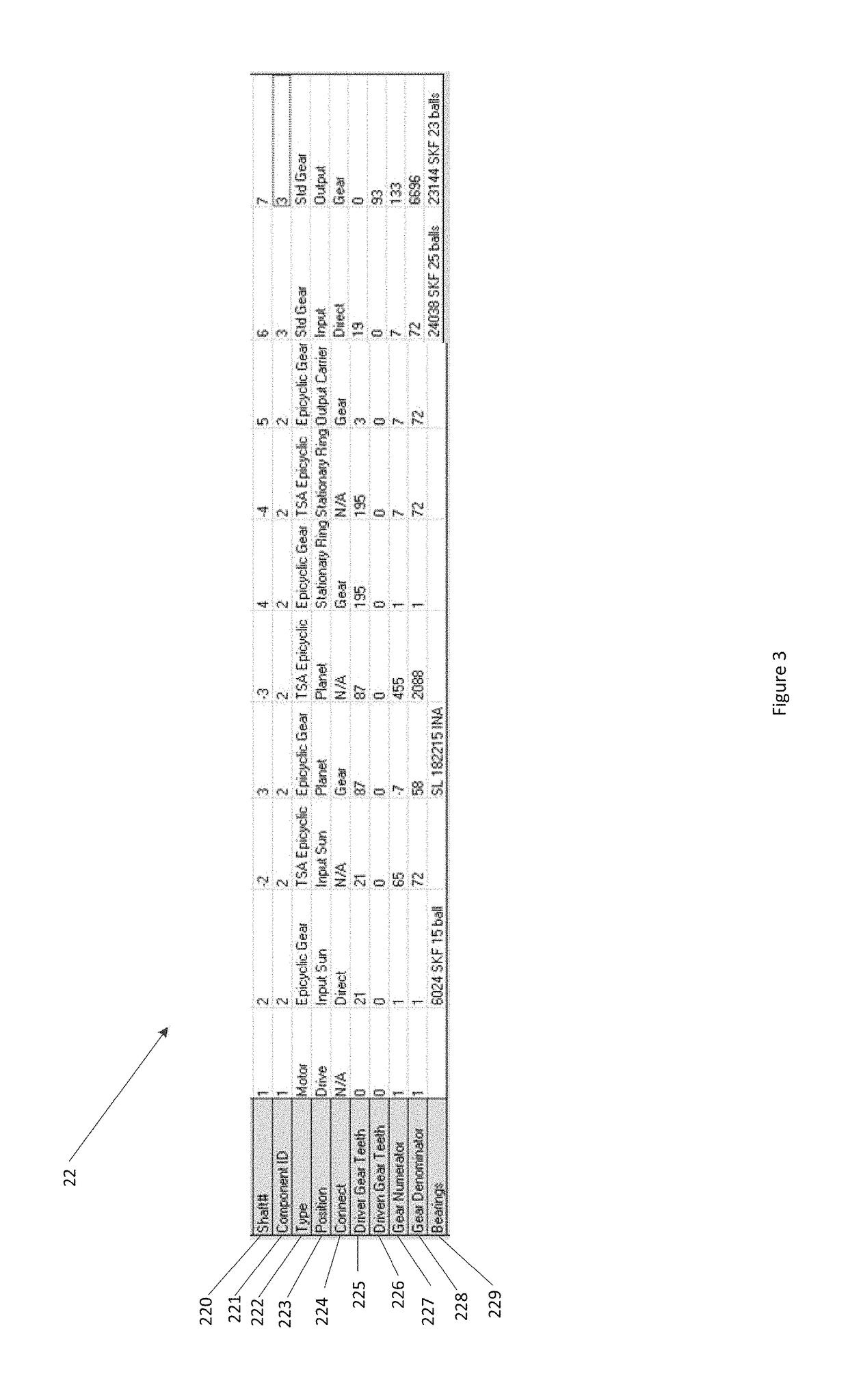

ActiveUS10168248B1Machine gearing/transmission testingMachine bearings testingVibration measurementEngineering

A method of measuring and analyzing vibrations of a mechanical system, e.g., for performing gear and bearing fault detection within a system having a reference shaft and a plurality of rotating components. The method may include the steps of tabulating gear ratios of the plurality of rotating components relative to the reference shaft in integer form, establishing a measurement specification and communicating the measurement specification to a digitizer, recording vibration data from the mechanical system during operation, and resampling the recorded vibration data using the tabulated gear ratios to obtain vibration data corresponding to the rotating components and a vibration signature for a component of interest at predetermined angular increments.

Owner:TENSOR SYST PTY LTD

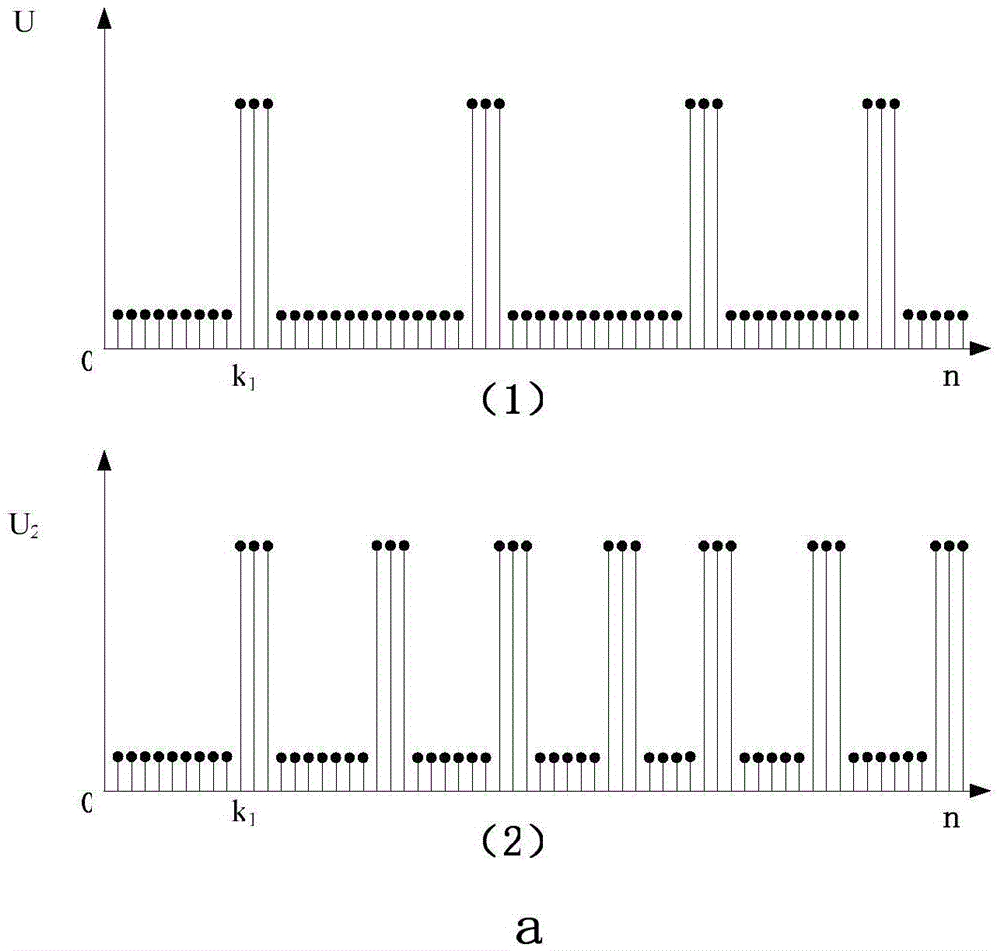

Bearing fault detection method based on manner of controlling stochastic resonance by external periodic signal

InactiveCN102226740AEnhanced spectral valueAccurate detectionMachine bearings testingControl signalEscape rate

The invention discloses a bearing fault detection method based on a manner of controlling stochastic resonance by an external periodic signal. According to the method provided in the invention, after a bearing fault signal is converted by a variable metric method, the converted signal is input in a bistable system; meanwhile, an external single frequency periodic signal is taken as a control signal to act directly on the system; contact barrier height of the bistable system and an escape rate of Kramers are changed by continuously adjusting an amplitude of the control signal. Therefore, stochastic resonance can be generated or increased artificially; a spectral value of an output power spectrum at the position of an input signal frequency can be effectively improved; and thus a characteristic signal of a bearing fault can be detected accurately at last. The detection method provided in the invention enables the effective control of the stochastic resonance to be realized, thereby providing a novel method for early detection of equipment faults.

Owner:CHINA JILIANG UNIV

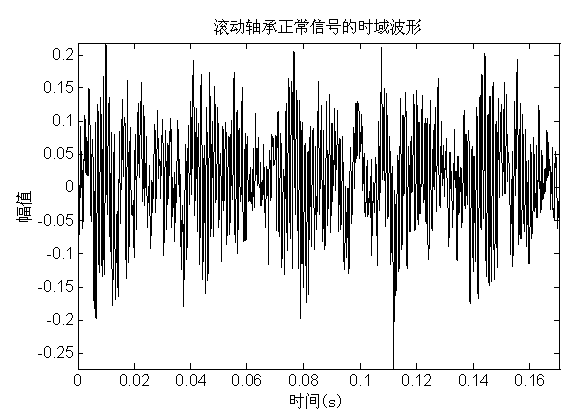

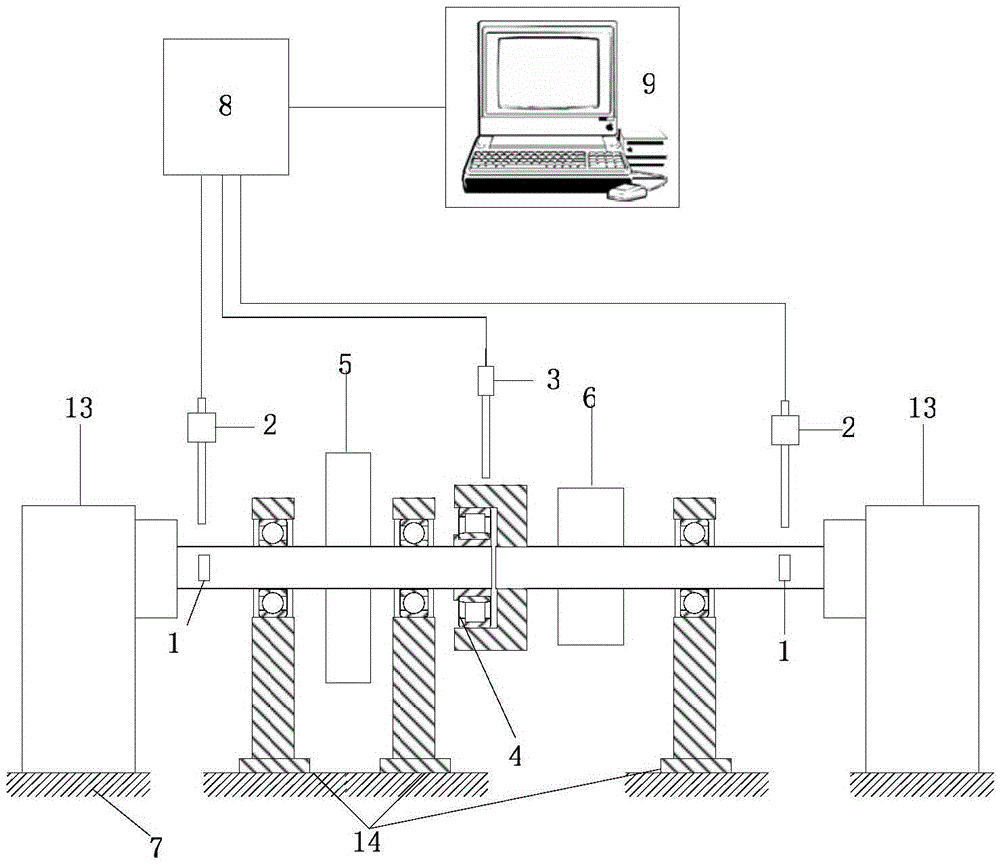

Rolling bearing fault detection method based on vibration detection

InactiveCN103076177AEliminate distractionsRich in detailsMachine bearings testingDiagnosis methodsFrequency characteristic

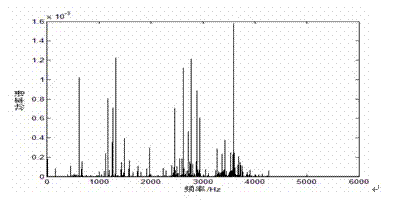

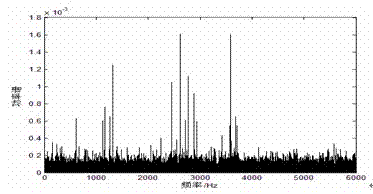

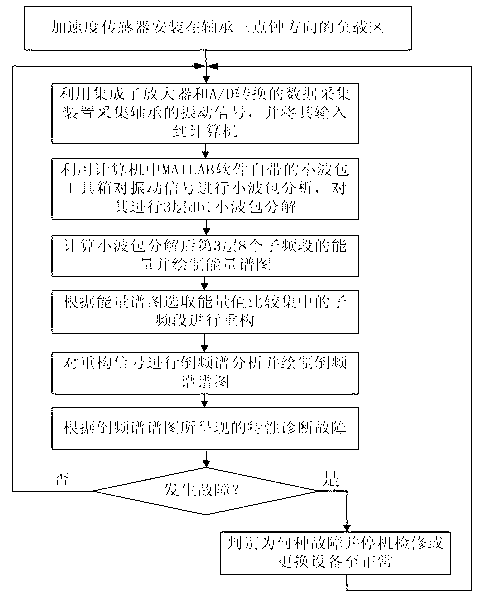

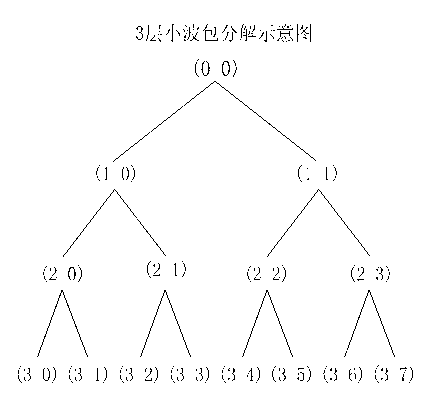

The invention relates to a fault diagnosis method, in particular to a rolling bearing fault diagnosis method based on the vibration detection. The method comprises the following steps of firstly decomposing the rolling bearing data collected by an acceleration sensor into three layers of wavelet packets, solving the energy of a third layer of wavelet packet coefficient rebuilding signals, selecting a frequency band with centralized energy to rebuild approximate evaluation of an original signal according to the variation of energy values of each frequency bands of the third layer; and utilizing a cepstrum to further analyze the rebuilt signal, and comparing the rebuilt signal with a theoretically-computed fault characteristic frequency and an edge frequency characteristic. By combining multiple resolutions of the wavelet packet and the cepstrum, the periodic component on a power spectrum, a separated-side frequency-band signal and the characteristics which are slightly subjected to the transmission route can be well detected. Meanwhile, the method is strong in manipulability and practicability.

Owner:KUNMING UNIV OF SCI & TECH

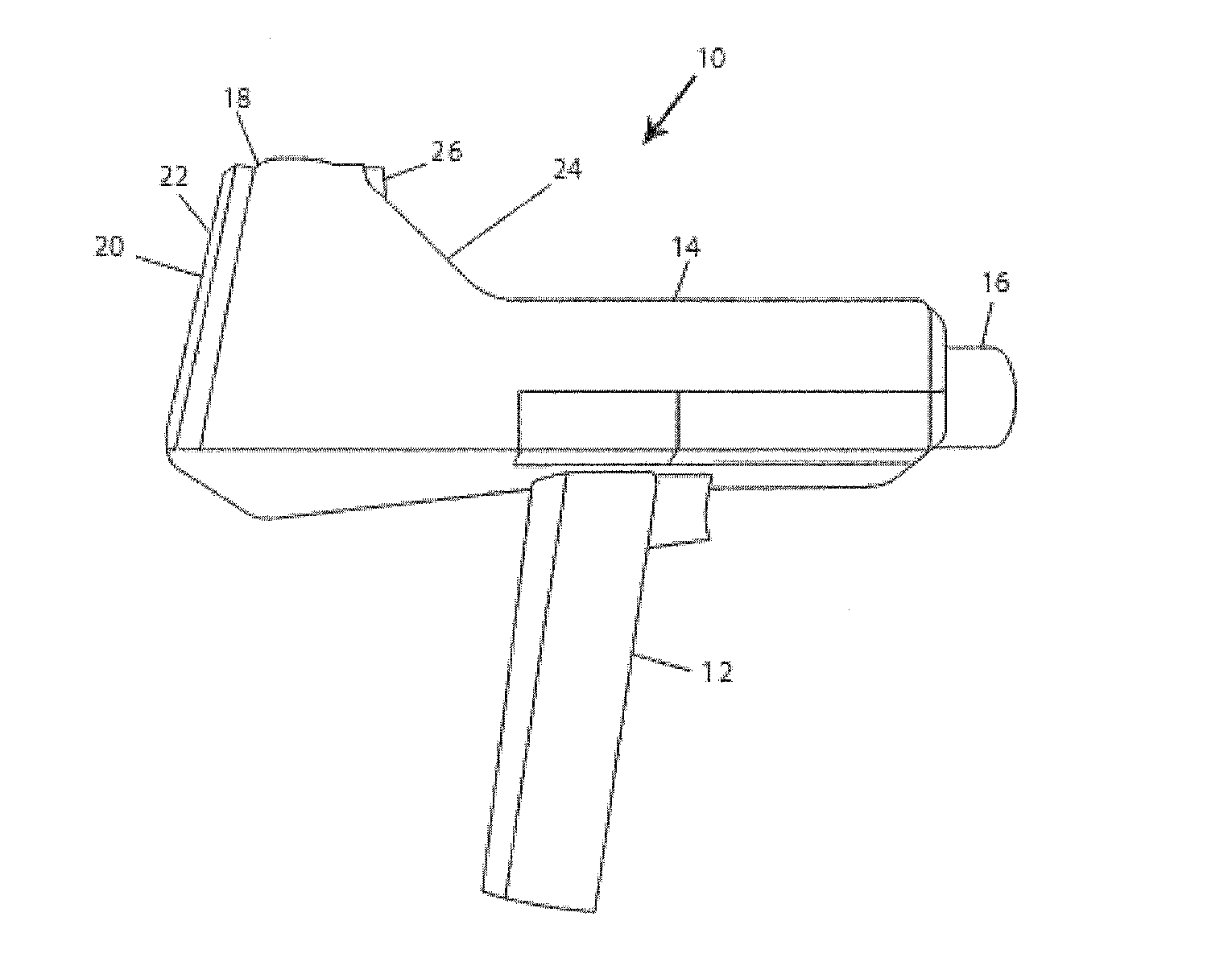

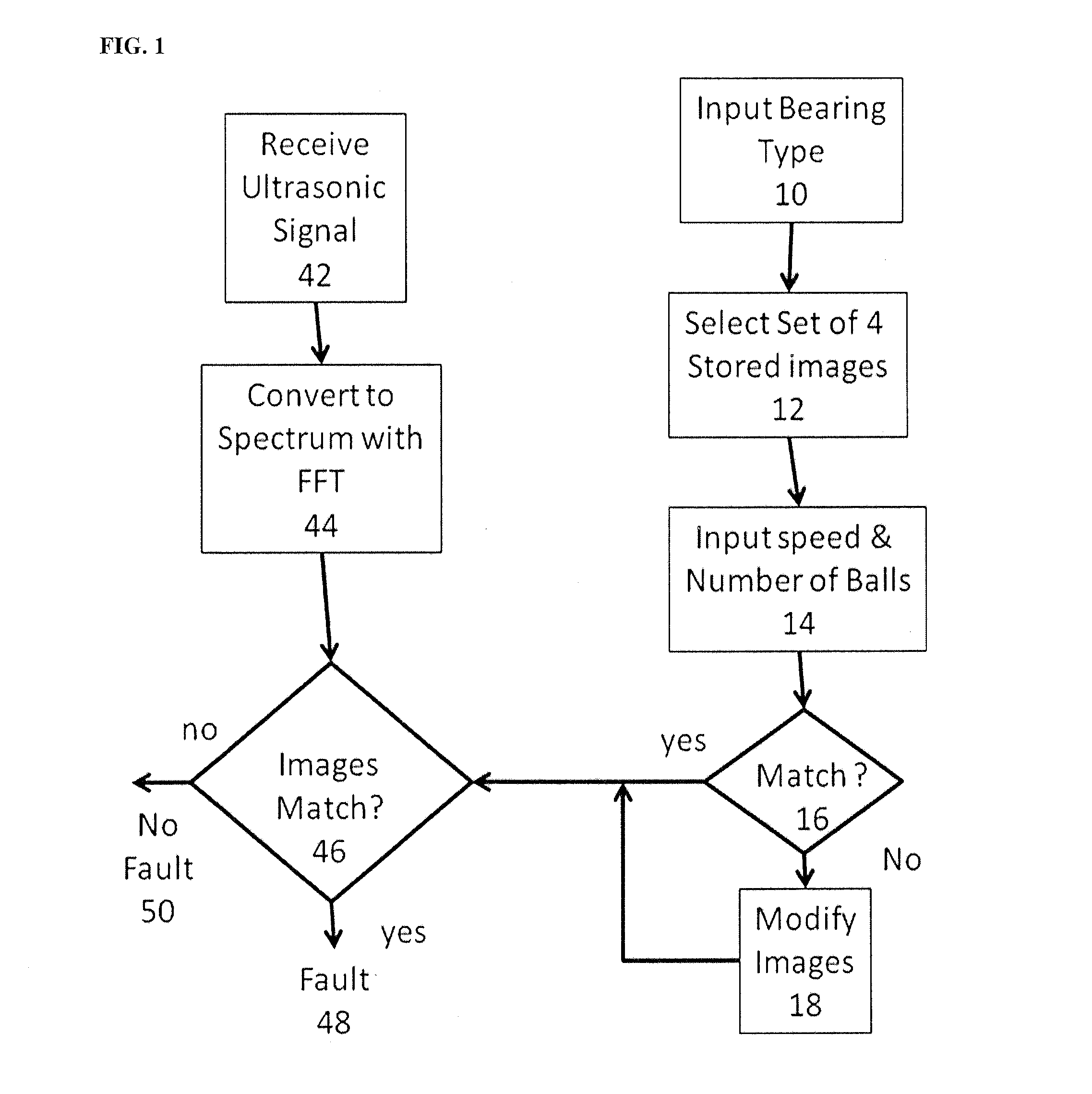

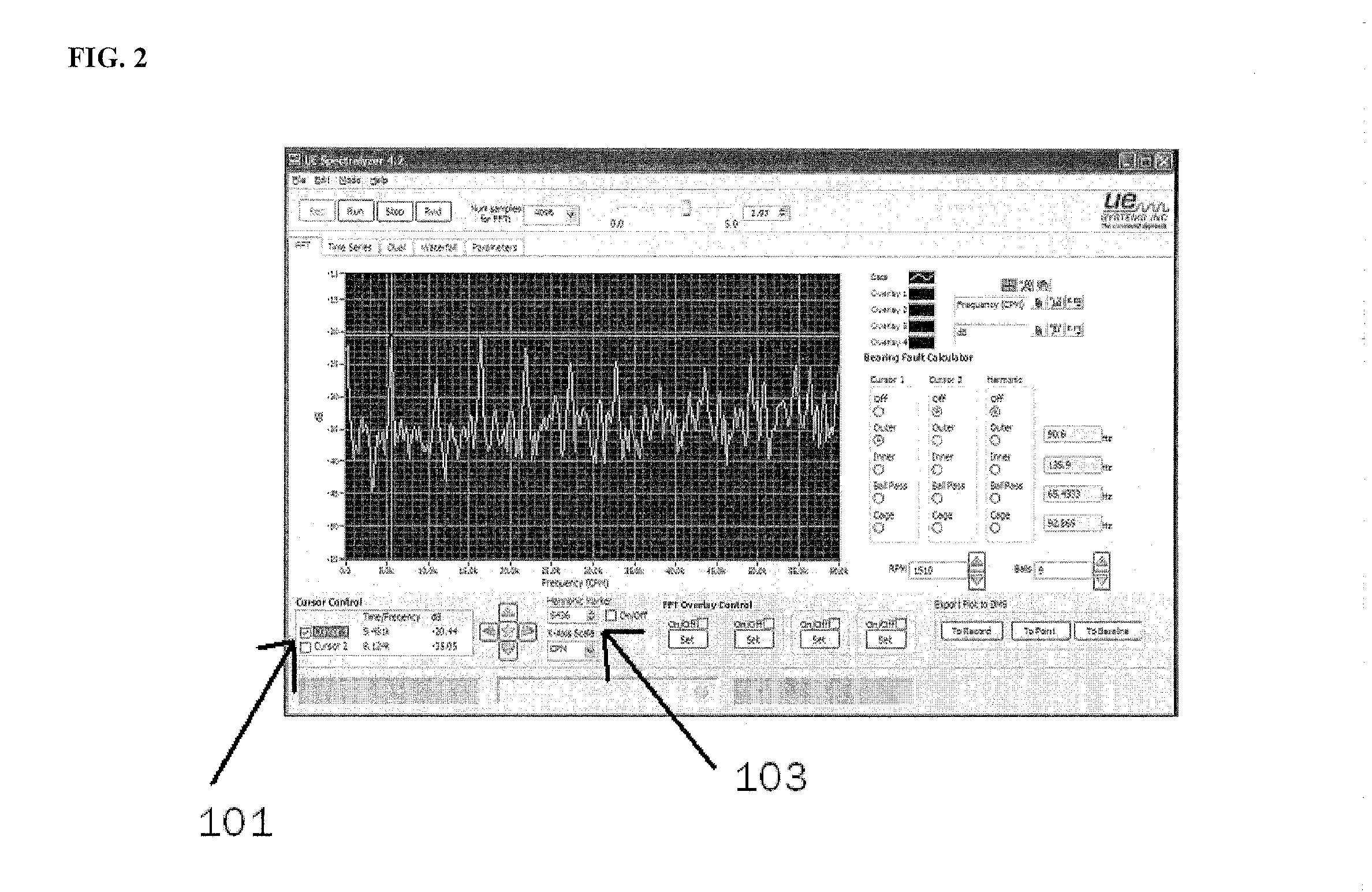

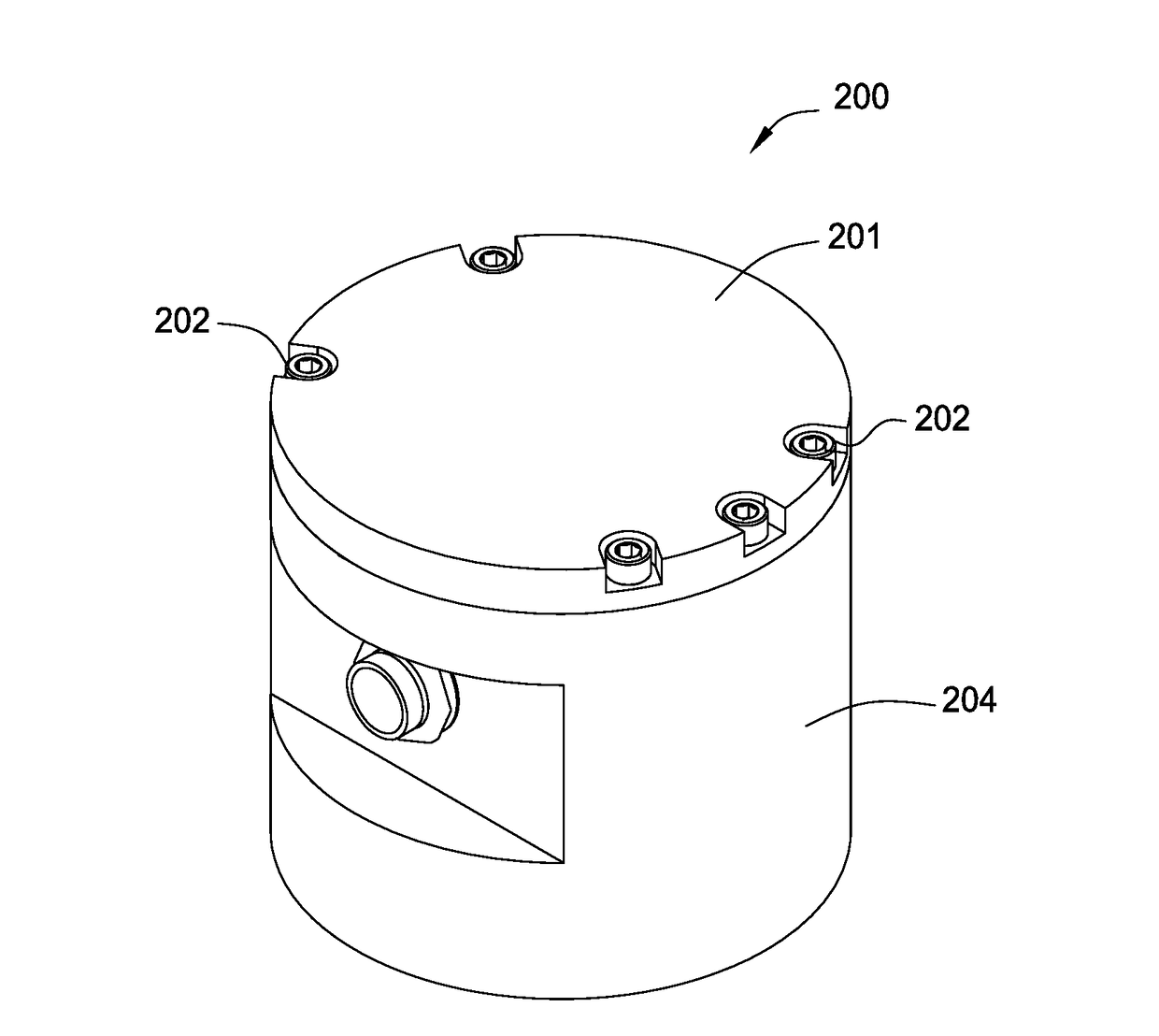

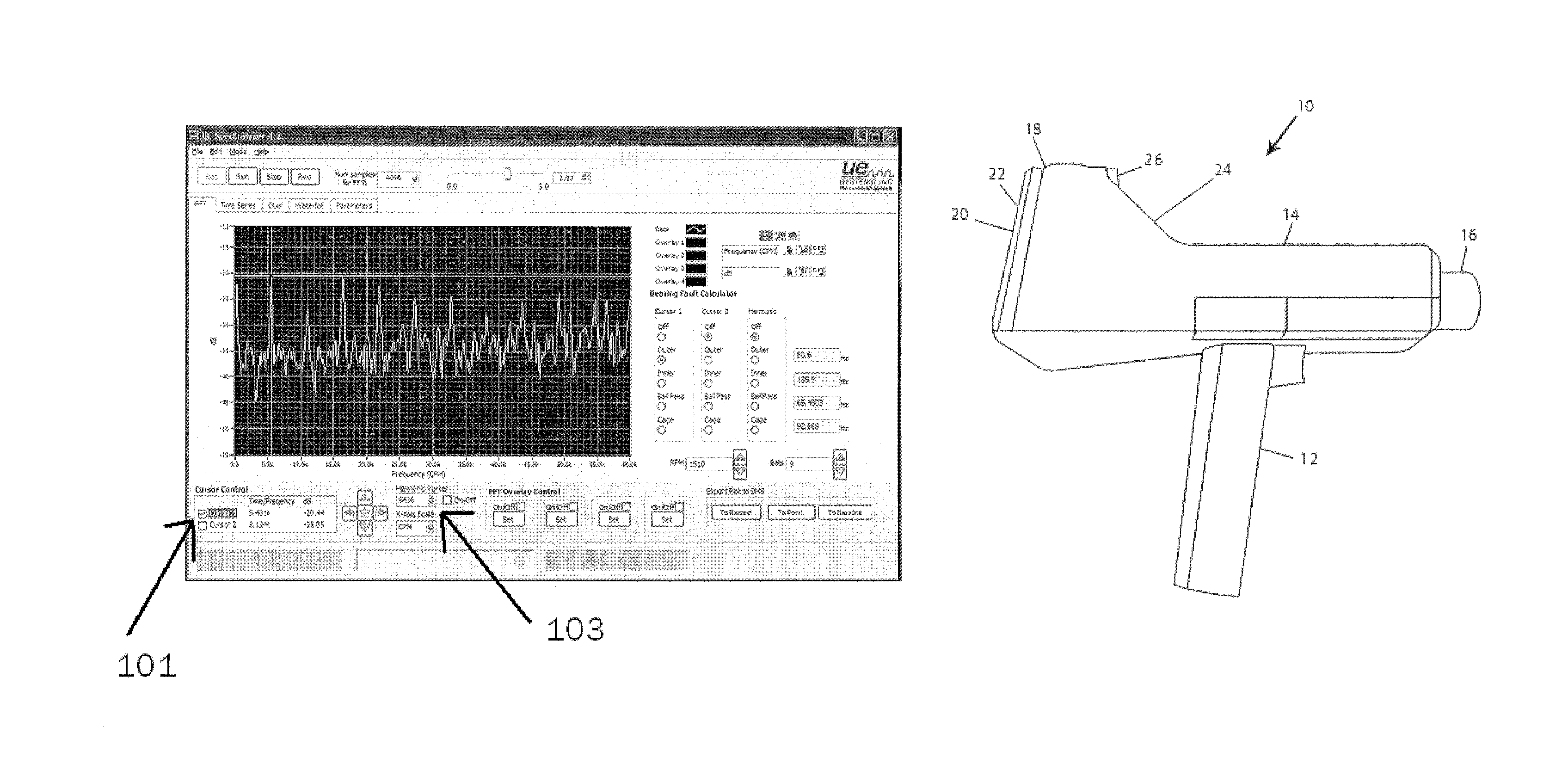

System for bearing fault detection

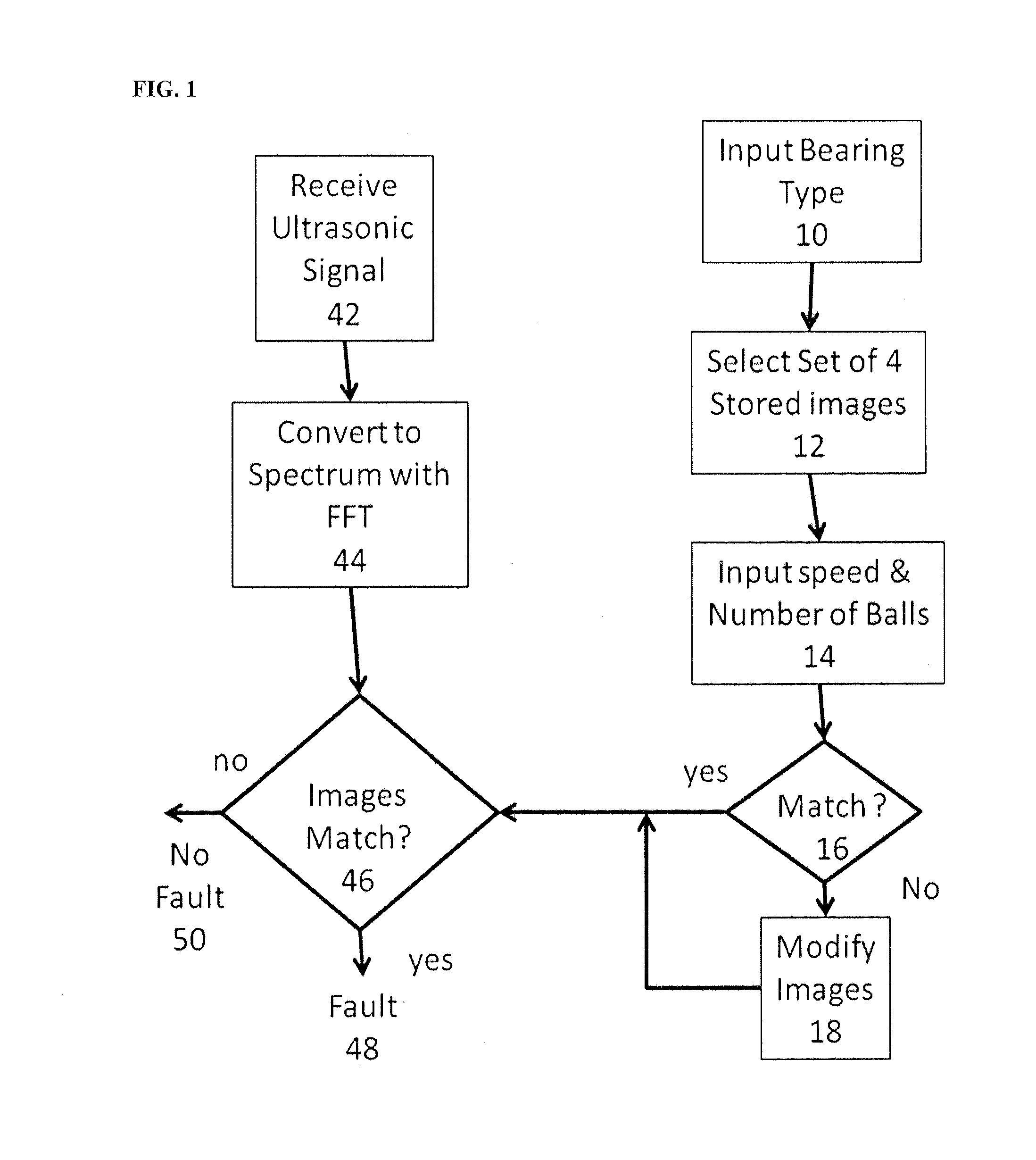

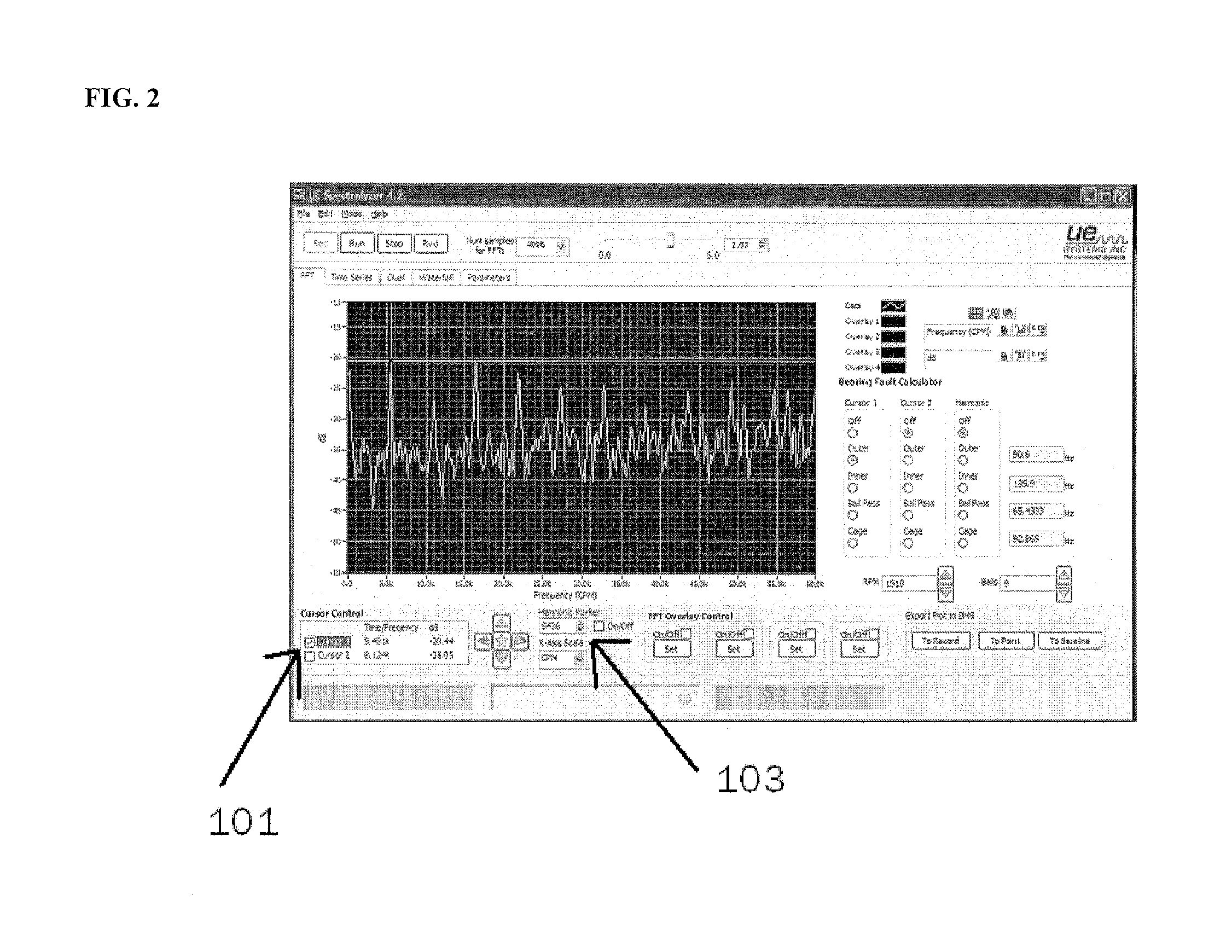

ActiveUS20120316796A1Accurate fault diagnosisAccurate diagnosisMachine part testingUsing subsonic/sonic/ultrasonic vibration meansFrequency spectrumEngineering

The present invention is directed an ultrasonic frequencies fault detecting apparatus. The present invention uses high frequency ultrasonic energy signals to analyze bearings and determine the presence of faults therein. The ultrasonic return signals are heterodyned (by amplitude demodulation) into the audio spectrum for purposes of audio detection. In addition, a FFT spectrum of the signal is displayed on a monitor for more accurate results. According to the present invention software is used to automatically analyze the FFT spectrum by comparing the current spectrum with stored spectrums of known bearing conditions as modified based on the rotary speed of the bearing and the number of balls. Once a defect in a bearing has been located in this manner using automated FFT analysis, an operator can then use a device, such as a calibrated lubricant dispenser, to effectuate maintenance and / or repair.

Owner:U E SYST

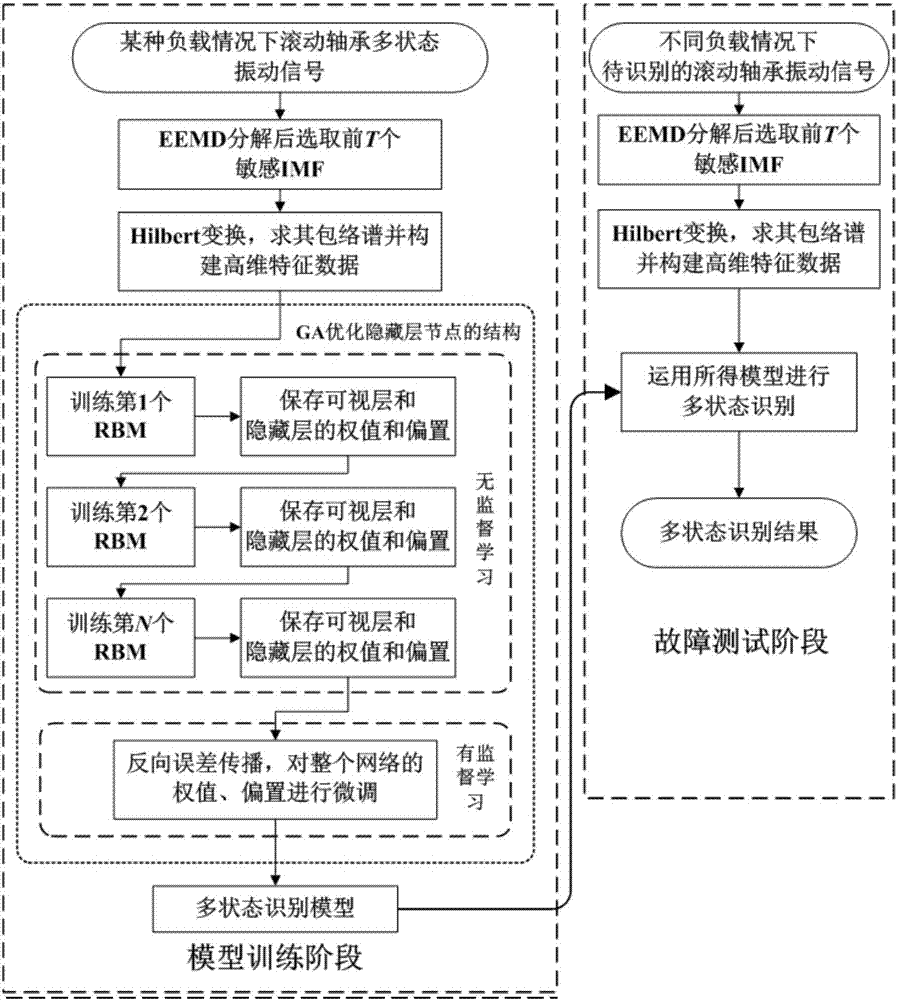

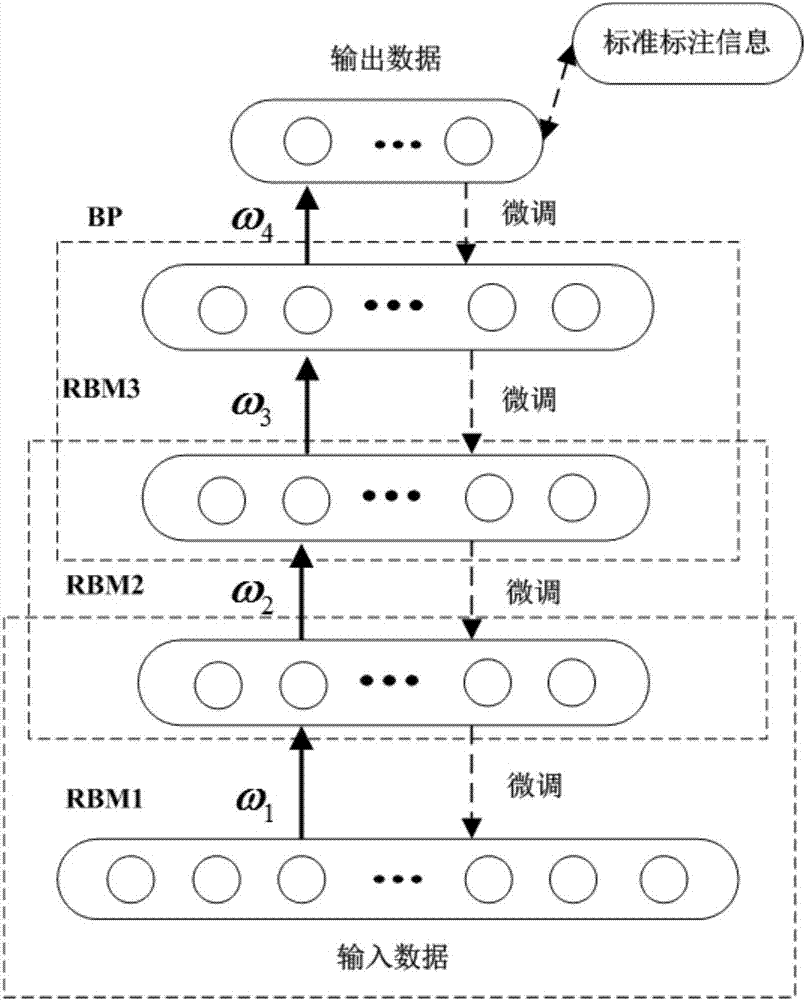

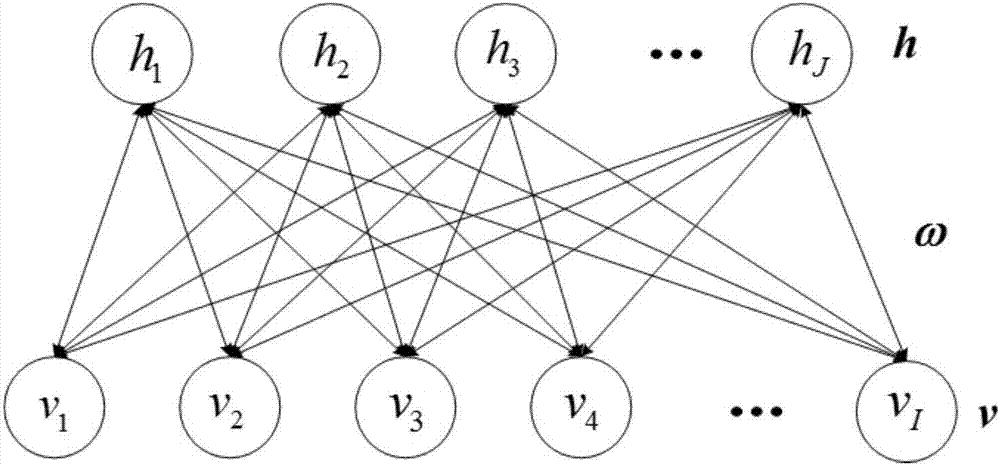

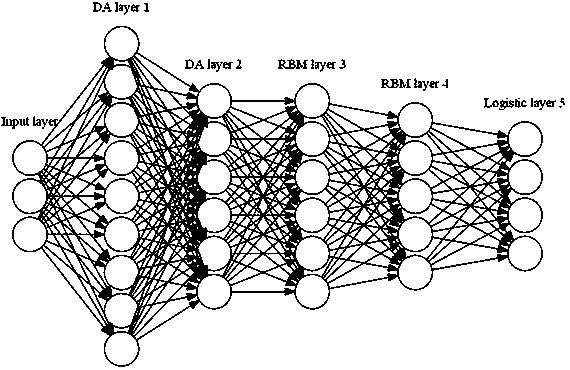

Identification method of rolling bearing state under variable load of EEMD-Hilbert envelope spectrum in combination with DBN

InactiveCN106886660AReduce distractionsMulti-state recognition implementationGeometric CADNeural learning methodsEngineeringHigh dimensional

The invention provides an identification method of rolling bearing state under variable load of EEMD-Hilbert envelope spectrum in combination with DBN, and belongs to the field of rolling bearing fault detection. The aim is to solve the problems that under the circumstance of training data using one load and test data using other loads, the rolling bearing fault state and the fault extent cannot be accurately identified. Firstly EEMD is conducted on the vibration signals of each status of the rolling bearing, then a sensitive eigenmode state function is selected, and Hilbert transformation is conducted to obtain the envelope spectrum. Finally, new high-dimensional data are built according to the order of the IMF envelope spectrum of the vibration signals of each status, then inputted into the DBN of each hidden layer node structure optimized by the genetic algorithm, and the multi-state recognition of rolling bearing under the variable load is achieved. In the process of 10 state recognition of rolling bearing using DBN, under the circumstance of the training data using one load and the test data using other loads, the EEMD-Hilbert envelope spectrum time domain or frequency-domain amplitude spectrum can better reflect the multiple state characteristics of rolling bearing under different loads, and has a higher recognition rate.

Owner:HARBIN UNIV OF SCI & TECH

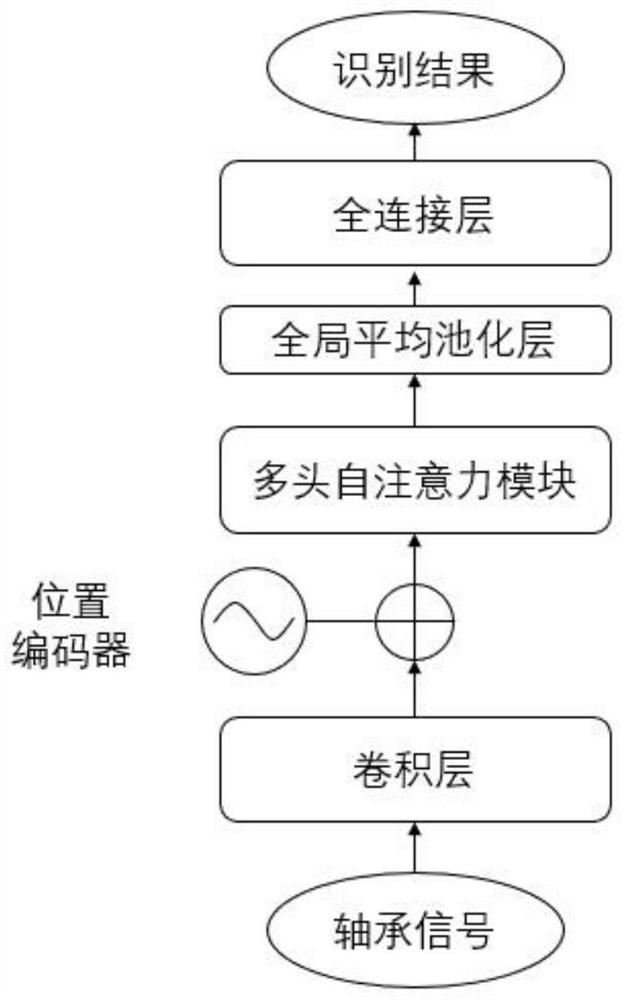

Bearing fault detection method based on convolution multi-head self-attention mechanism

ActiveCN111721535ARealize intelligent detectionAccurate identificationMachine part testingCharacter and pattern recognitionData setAlgorithm

The invention discloses a bearing fault detection method based on a convolution multi-head self-attention mechanism. The detection method comprises the following steps: acquiring and preprocessing a fault bearing vibration signal; generating a bearing fault data set; and constructing a convolutional multi-head self-attention mechanism network, and performing training to obtain a bearing fault detection result. The convolution multi-head self-attention mechanism network comprises a convolution layer, a position encoder, a multi-head self-attention module, a global average pooling layer and a full connection layer; the convolution layer extracts bearing signal initial features; the position encoder performs position encoding on the initial characteristics of the bearing; the multi-head self-attention module learns the initial features; the global average pooling layer regularizes the network to prevent overfitting; and the full connection layer outputs different fault types of the bearing. An efficient and accurate method is provided for bearing fault detection, so that normal operation of mechanical equipment is effectively maintained.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

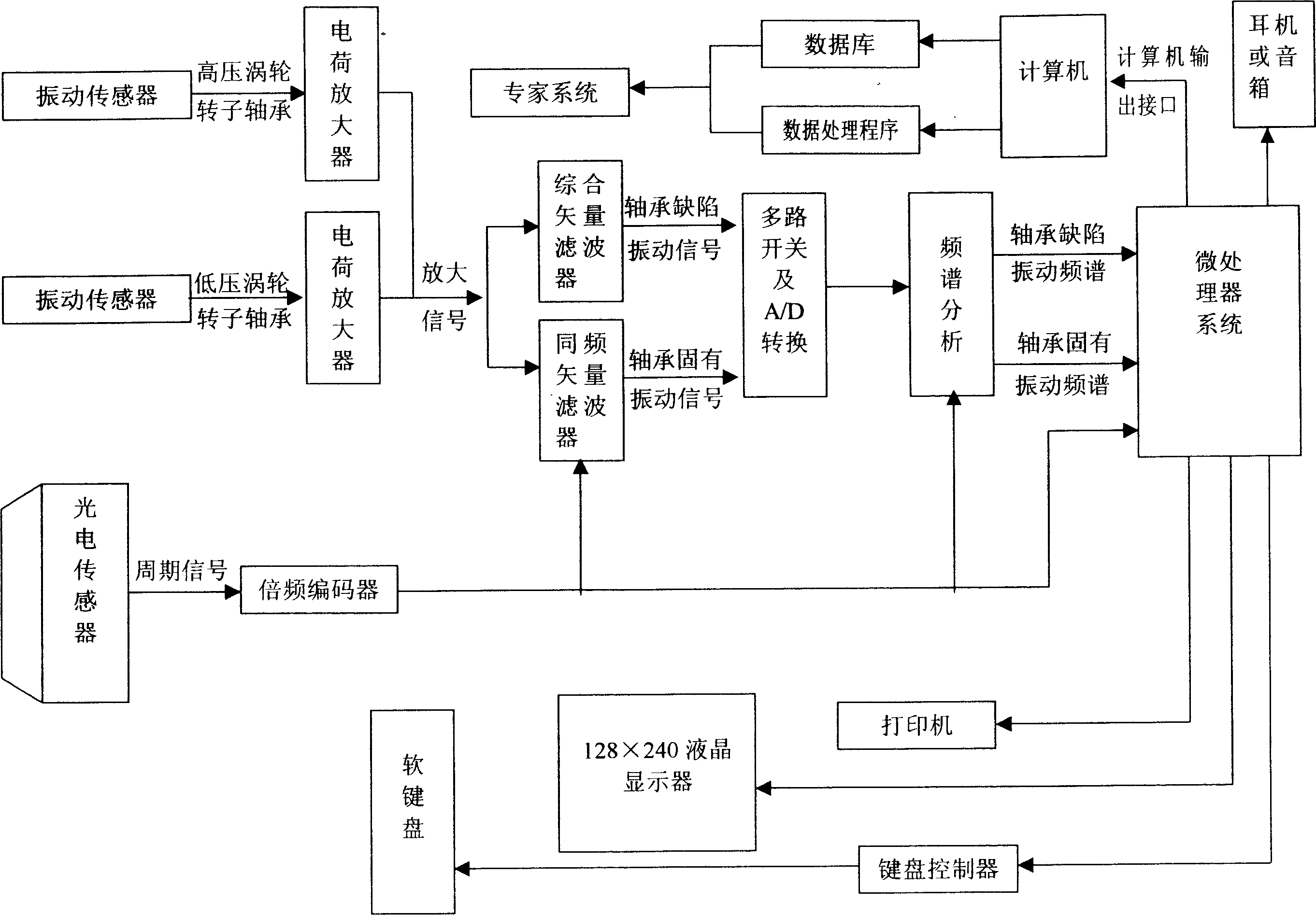

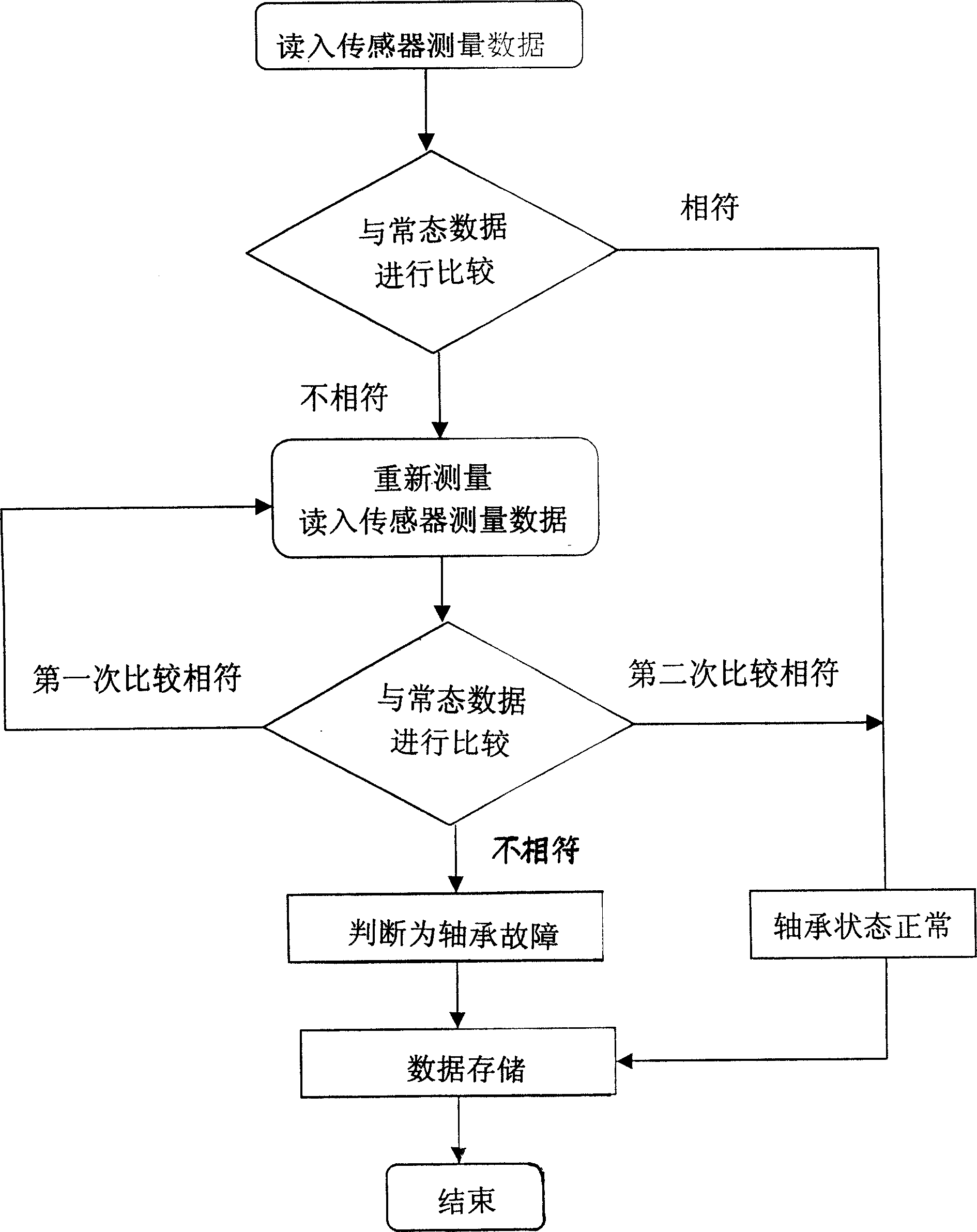

Engine bearing failure testing and diagnosing method and failure detecting instrument

InactiveCN1758042AAccurate judgmentAccurate diagnosisMachine bearings testingEngine testingAviationProcess systems

This invention puts forward a method for testing and diagnosing faults of generator bearings characterizing in collecting the vibration spectrum of a bearing and comparing it with its original vibration spectrum to diagnose the fault of the bearing. This invention also designs and manufactures a related test device characterizing in composed of a vibration signal amplifier, a vector filter, a multiple switch and an A / D converter, a spectrum analysis and microprocessor process system and the computer software for testing faults.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

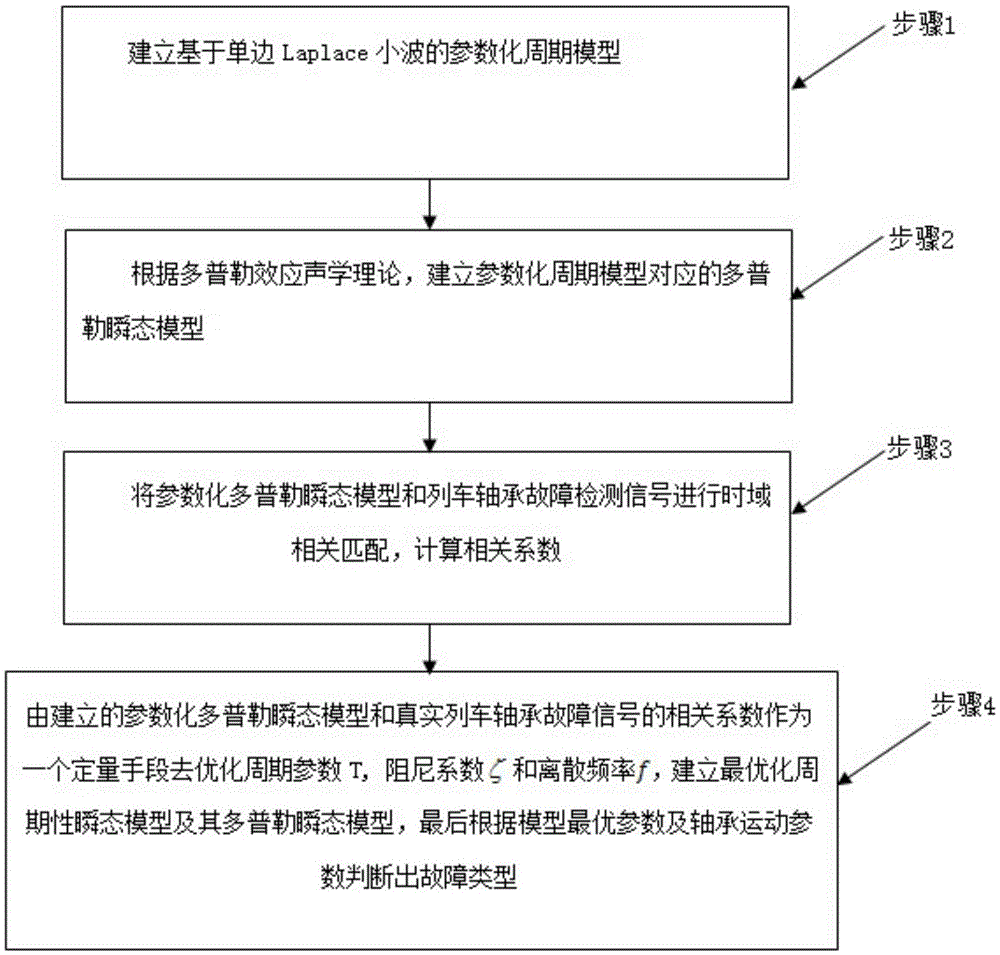

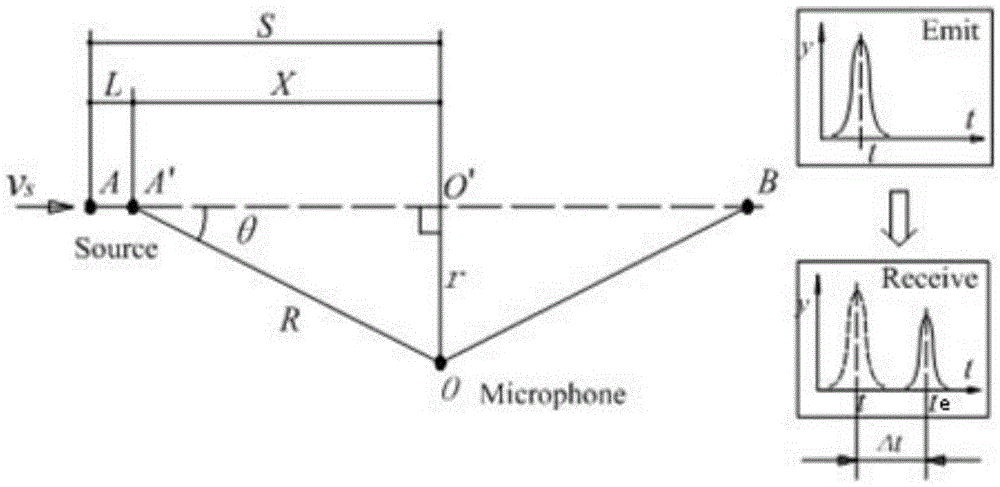

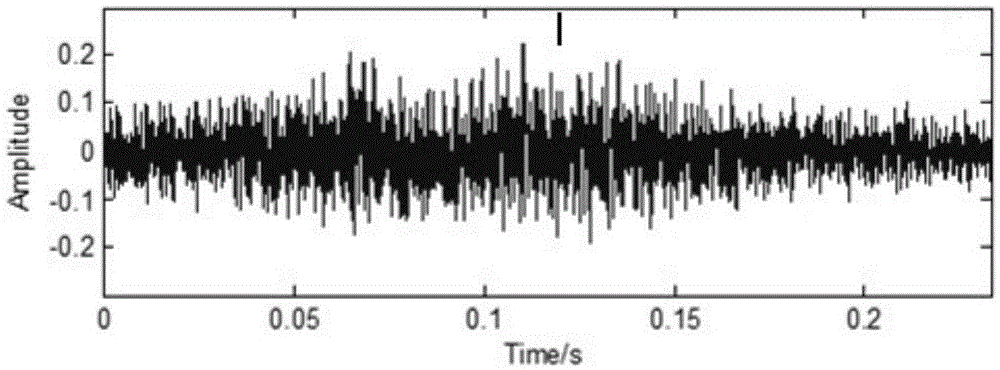

Train wheel set bearing fault transient characteristic detection method based on parametric Doppler transient model

ActiveCN105424388AMachine bearings testingRailway vehicle testingCorrelation coefficientDamping factor

The invention discloses a train wheel set bearing fault transient characteristic detection method based on a parametric Doppler transient model. The method comprises the following steps: building a parametric cycle model based on a unilateral Laplace wavelet; building a parametric Doppler transient model according to the Doppler effect; performing correlation matching between the parametric Doppler transient model and a train bearing fault detection signal, and calculating the correlation coefficient; optimizing the cycle parameter T, damping coefficient zeta and discrete frequency f by taking the correlation coefficient between the built parametric Doppler transient model and a real train bearing fault signal as a quantitative means, and building an optimal periodic transient model and a Doppler transient model thereof; and finally, judging the fault type based on the model optimal parameters and bearing motion parameters. By using the method, a train bearing signal under the influence of the Doppler effect can be processed, and the fault of the bearing can be diagnosed accurately.

Owner:SUZHOU UNIV

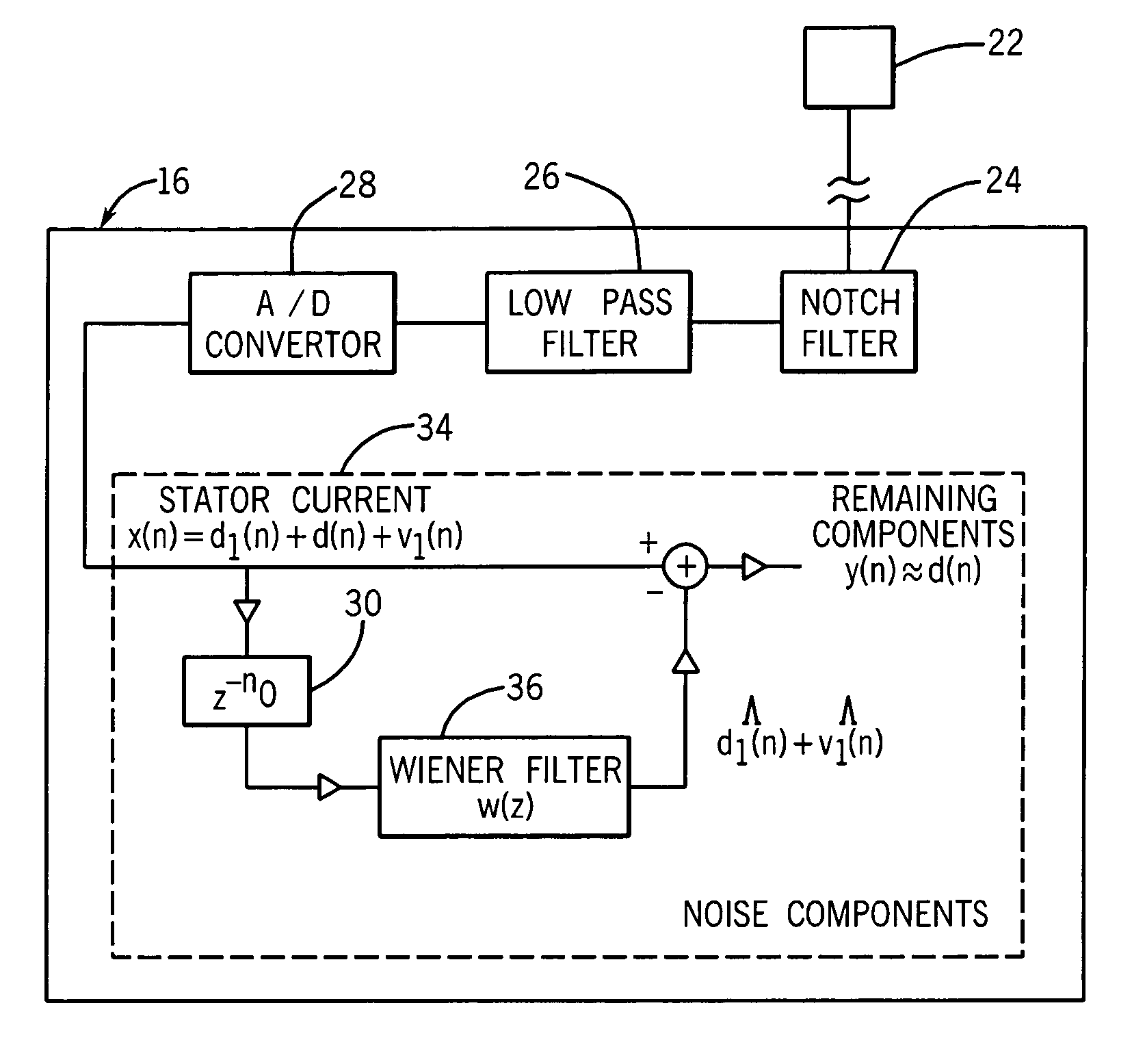

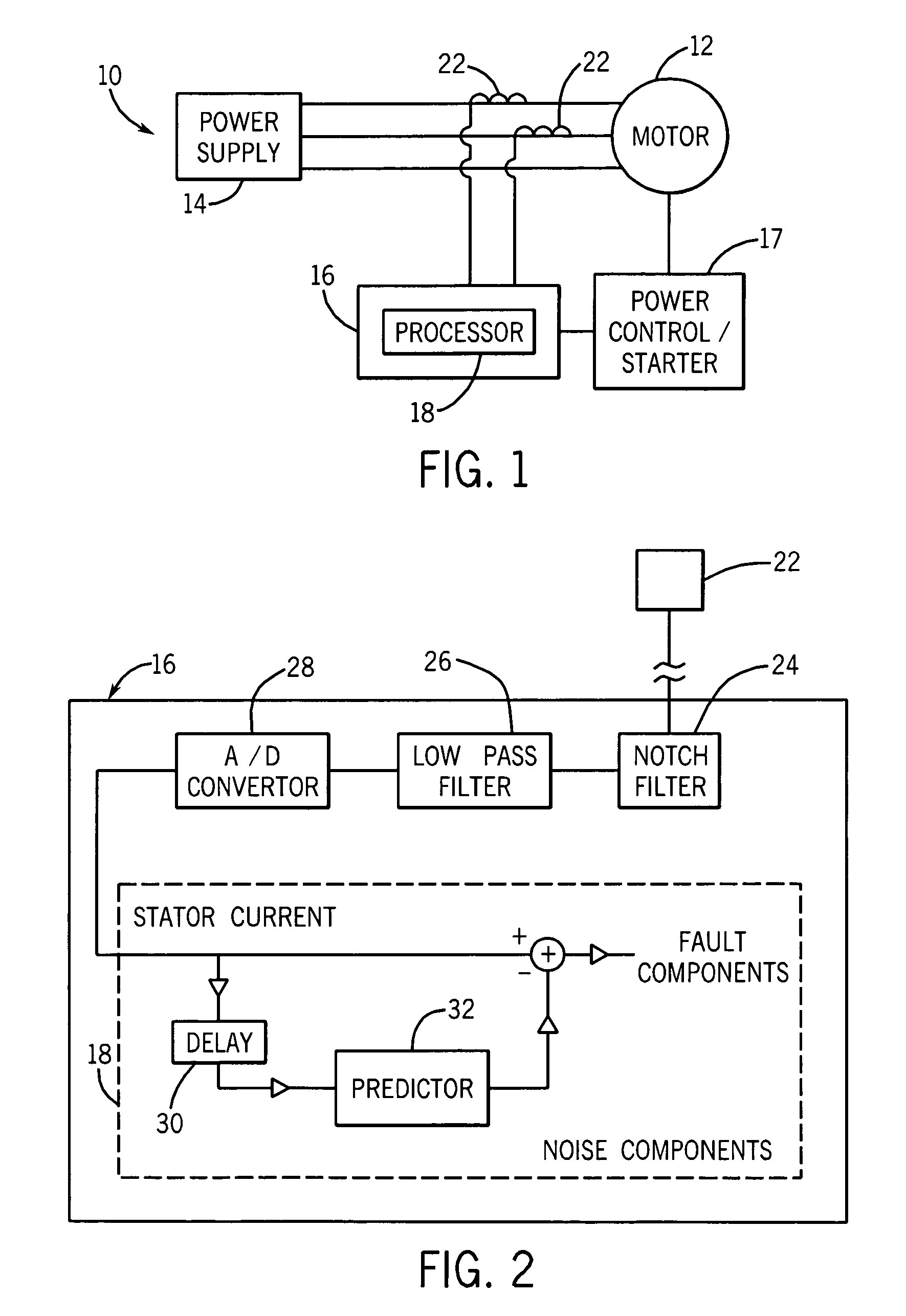

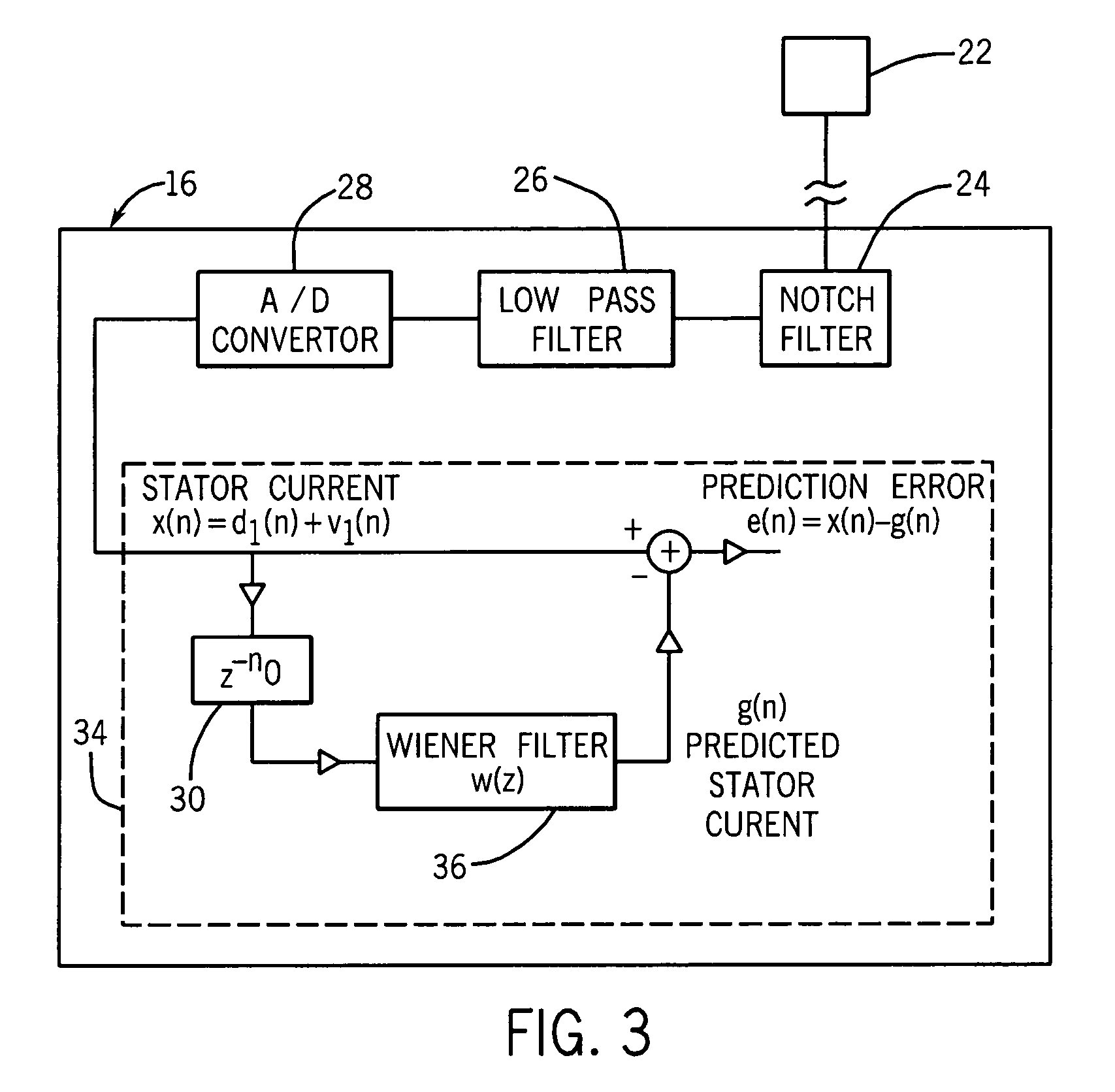

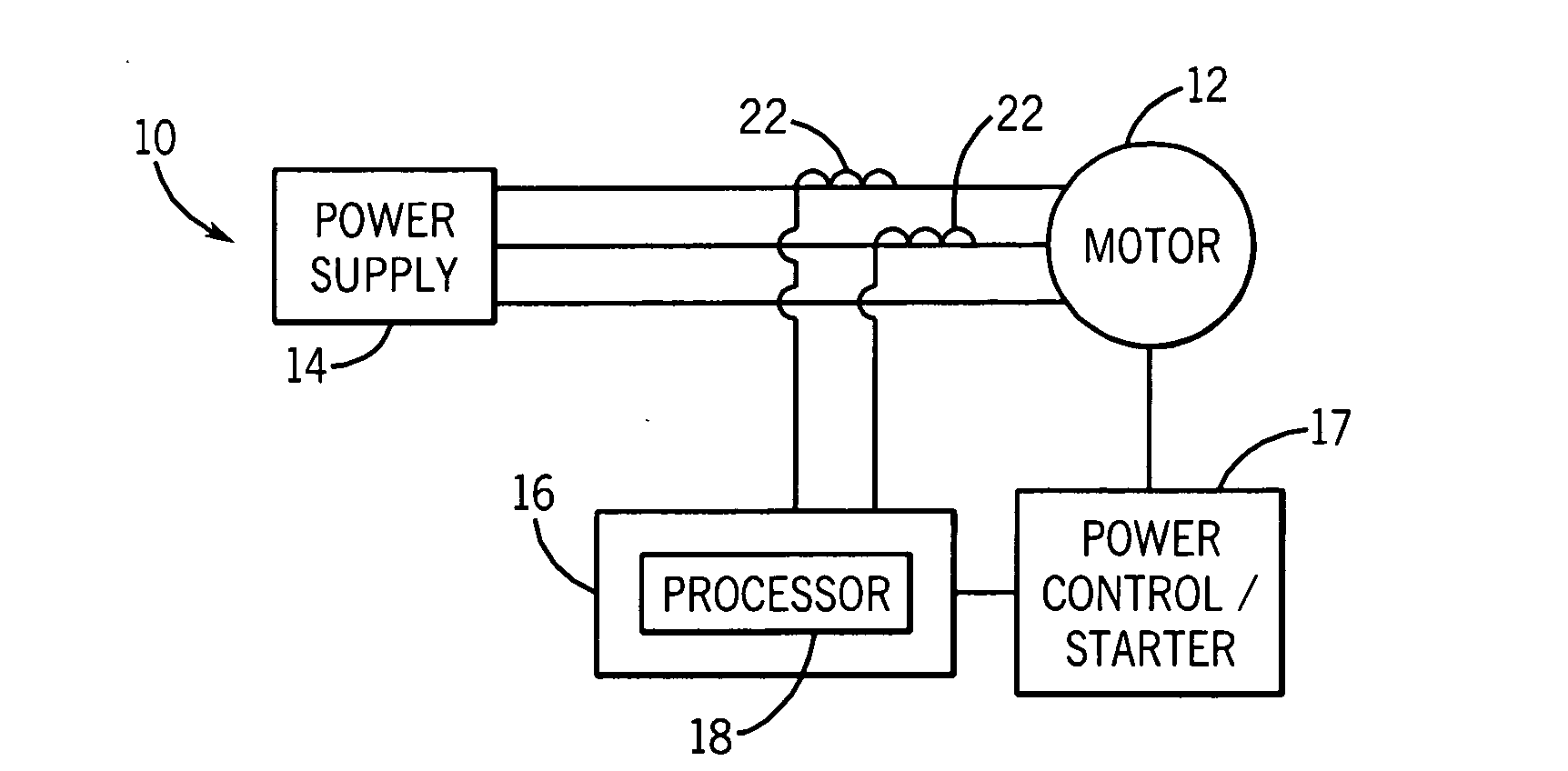

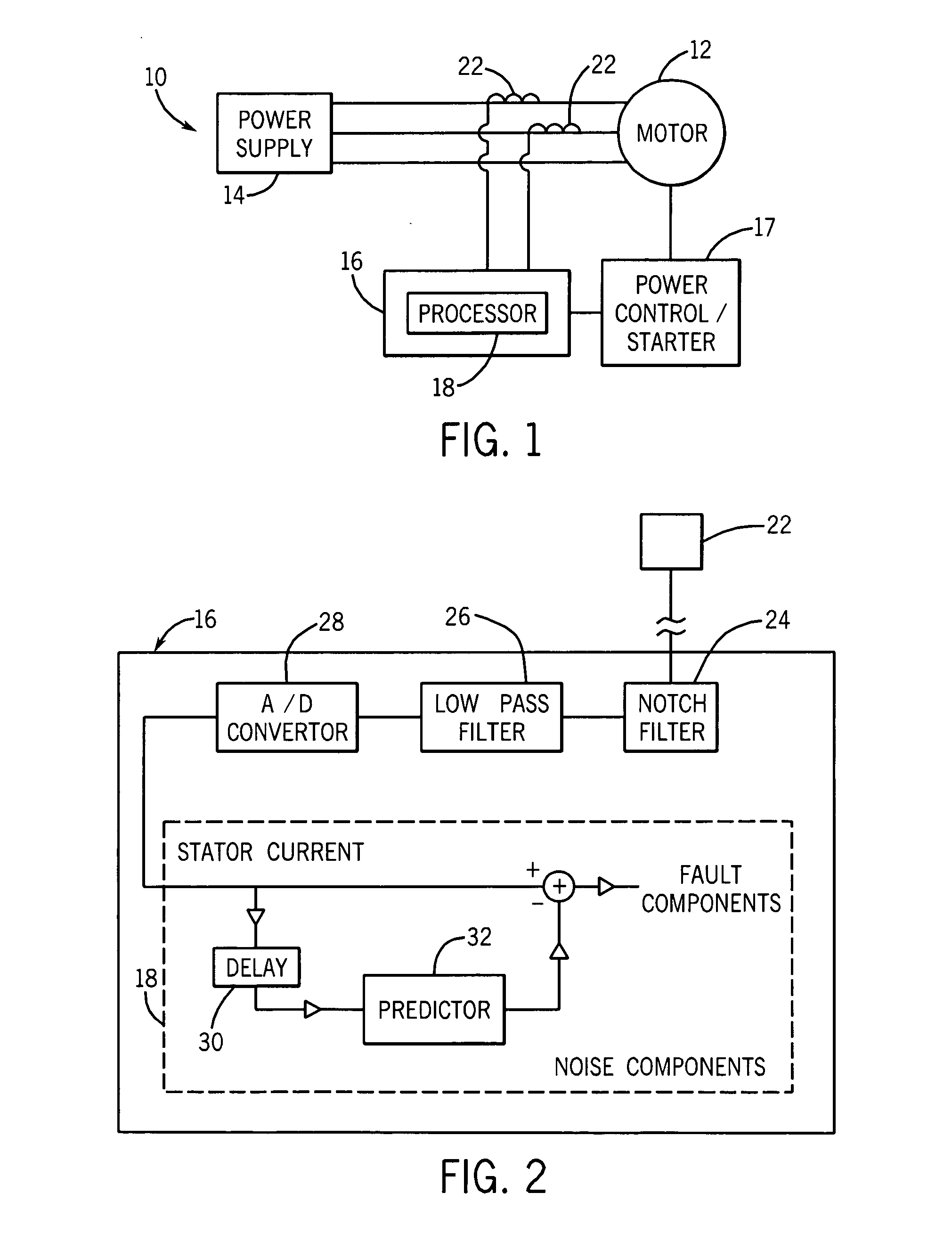

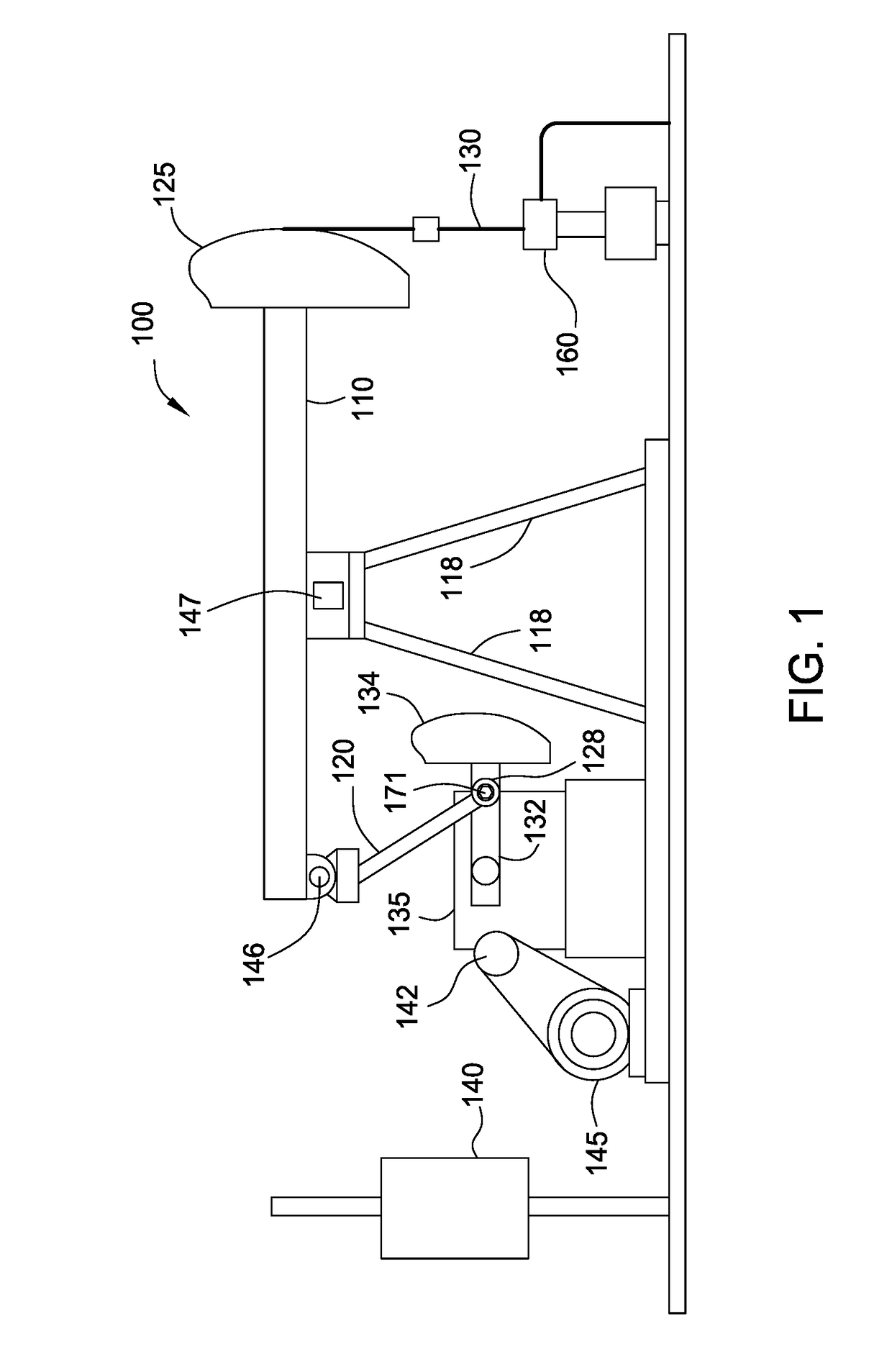

System and method for bearing fault detection using stator current noise cancellation

A system and method for detecting incipient mechanical motor faults by way of current noise cancellation is disclosed. The system includes a controller configured to detect indicia of incipient mechanical motor faults. The controller further includes a processor programmed to receive a baseline set of current data from an operating motor and define a noise component in the baseline set of current data. The processor is also programmed to repeatedly receive real-time operating current data from the operating motor and remove the noise component from the operating current data in real-time to isolate any fault components present in the operating current data. The processor is then programmed to generate a fault index for the operating current data based on any isolated fault components.

Owner:EATON INTELLIGENT POWER LTD

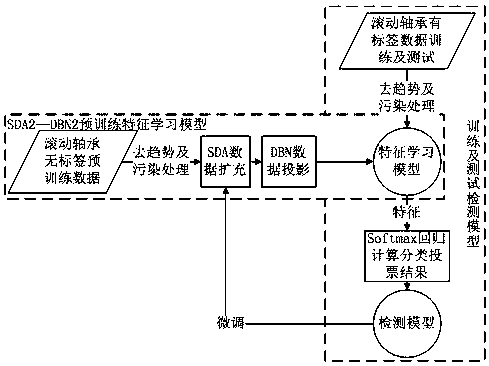

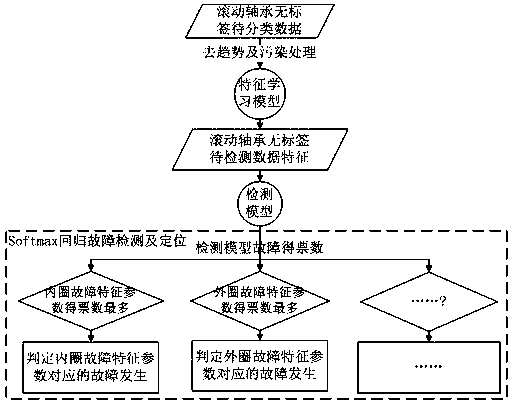

Bearing fault detecting and locating method and detecting and locating model implementation system and method

ActiveCN107657250AImprove abstract abilityAchieve self-expressionMachine bearings testingCharacter and pattern recognitionData expansionFeature extraction

The invention provides a bearing fault detecting and locating method and a detecting and locating model implementation system and method. Data preprocessing is performed on the no-tag classification data of a rolling bearing and then the data are inputted to a trained feature learning and detection model so that the fast detecting and locating problem of the rolling bearing under multiple fault modes can be solved, and statistics of the probability of each type of classification result is performed through voting by the minimization loss function; and the certain fault feature of the most votes is determined as the currently estimated fault mode and the fault part is located. The whole feature learning process does not require any manual feature extraction process, the original data act asthe input of the feature learning algorithm, the unsupervised feature learning process is used in the learning process, and the extracted bearing fault features can be efficiently self-expressed through deep data expansion and projection so that the problem of acquisition difficulty of the tag data can be solved, and the method has the characteristic of high detecting and locating accuracy.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

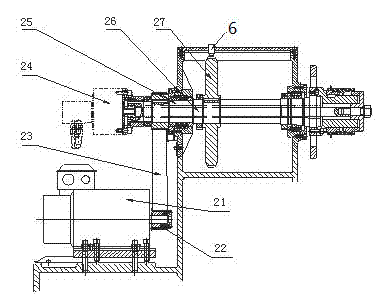

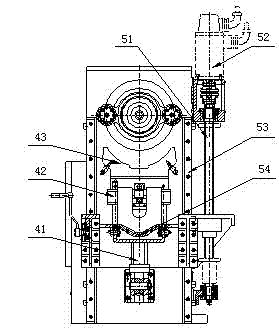

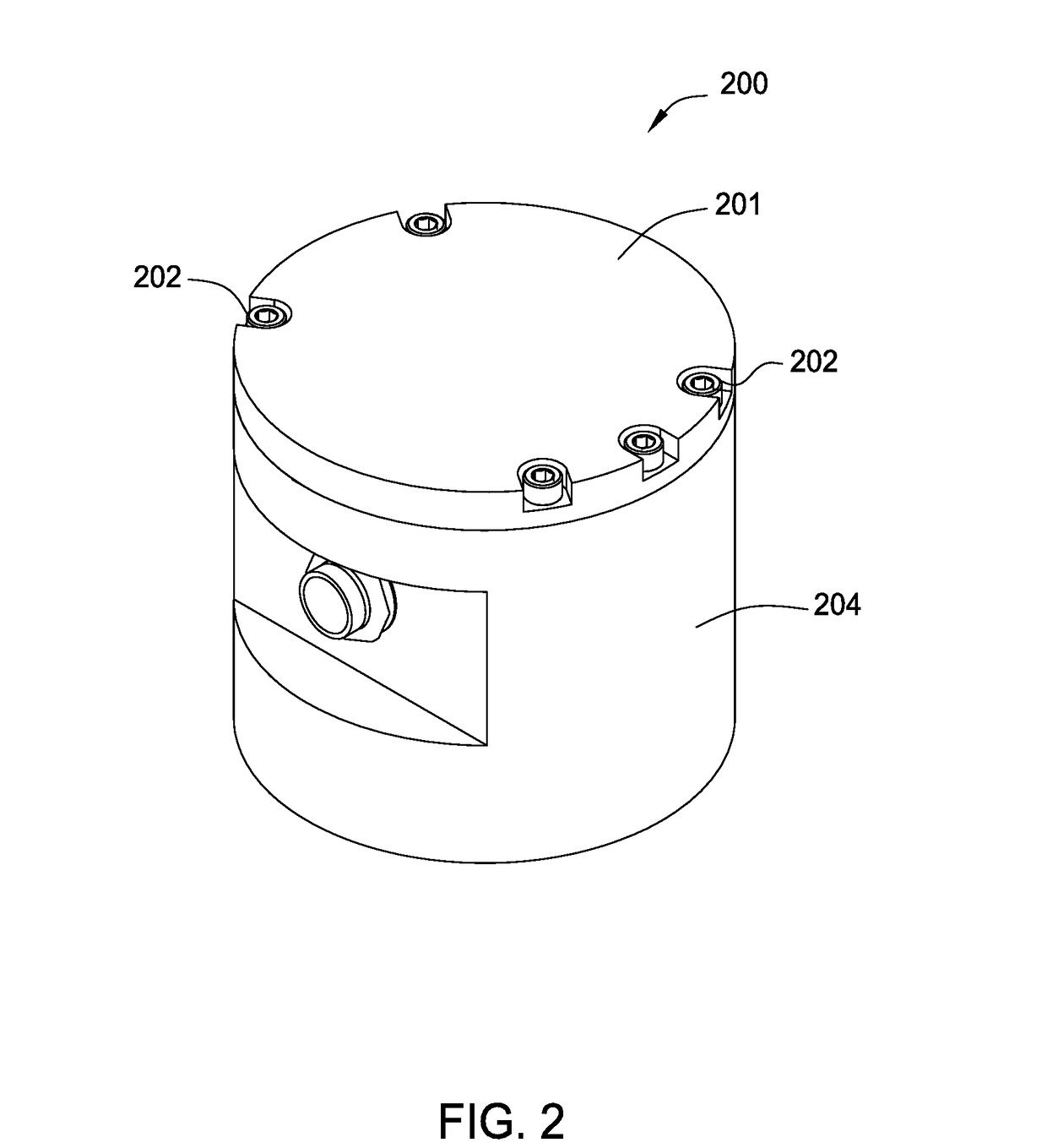

Rolling bearing fault detection device

InactiveCN103076173AWide range of specificationsImprove accuracyMachine bearings testingRolling-element bearingEngineering

The invention discloses a rolling bearing fault detection device, which comprises an engine base and a host machine fixed on the engine base, wherein the host machine comprises a main shaft system, an expanding-sleeve elastic chuck component, a loading component and a lifting platform; the expanding-sleeve elastic chuck component is arranged at one end of a main shaft of the main shaft system; the loading component is fixed just below the expanding-sleeve elastic chuck component and is contacted with a bearing; the lifting platform is arranged at one side of the engine base; and when the bearing is loaded, the bearing is driven to move up, and the bearing is loaded to the expanding-sleeve elastic chuck component. With the adoption of the rolling bearing fault detection device, the detection accuracy can be improved, the specification range of the detected rolling bearing is increased, and the automatic diagnosis of the bearing is realized.

Owner:唐德尧

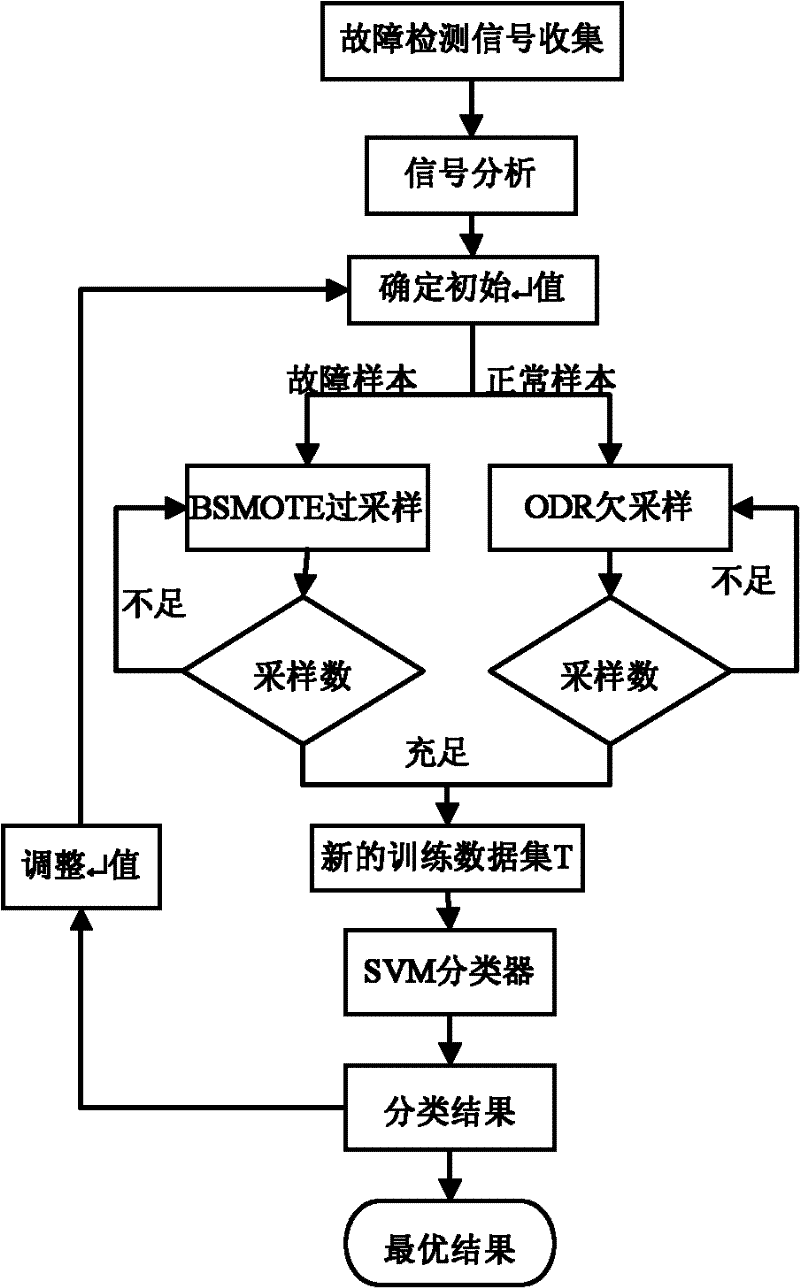

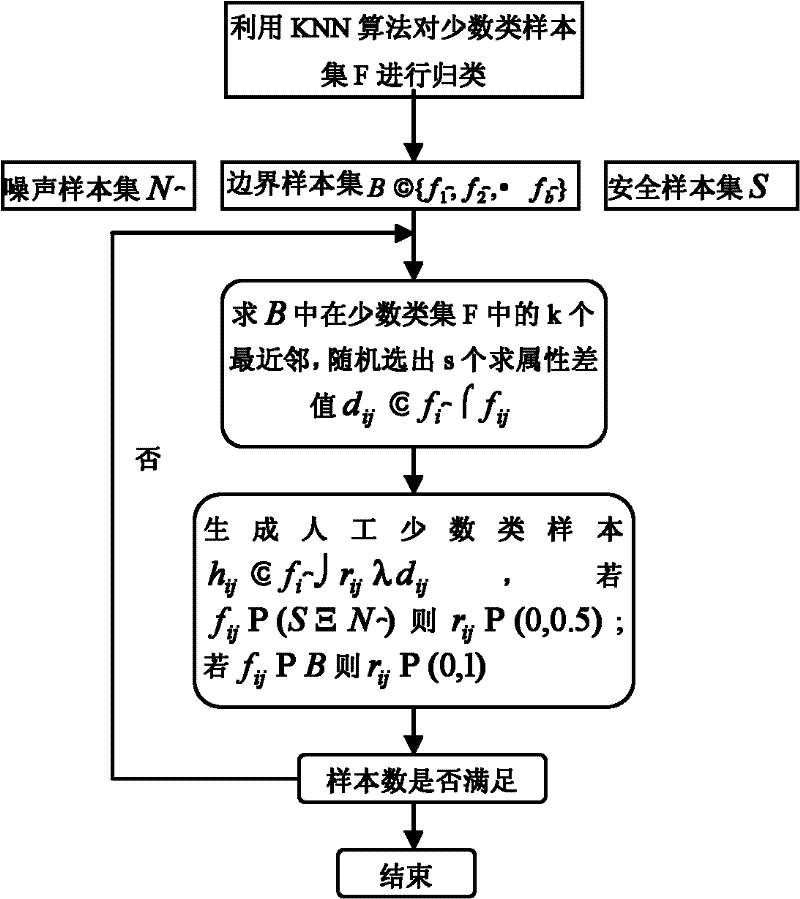

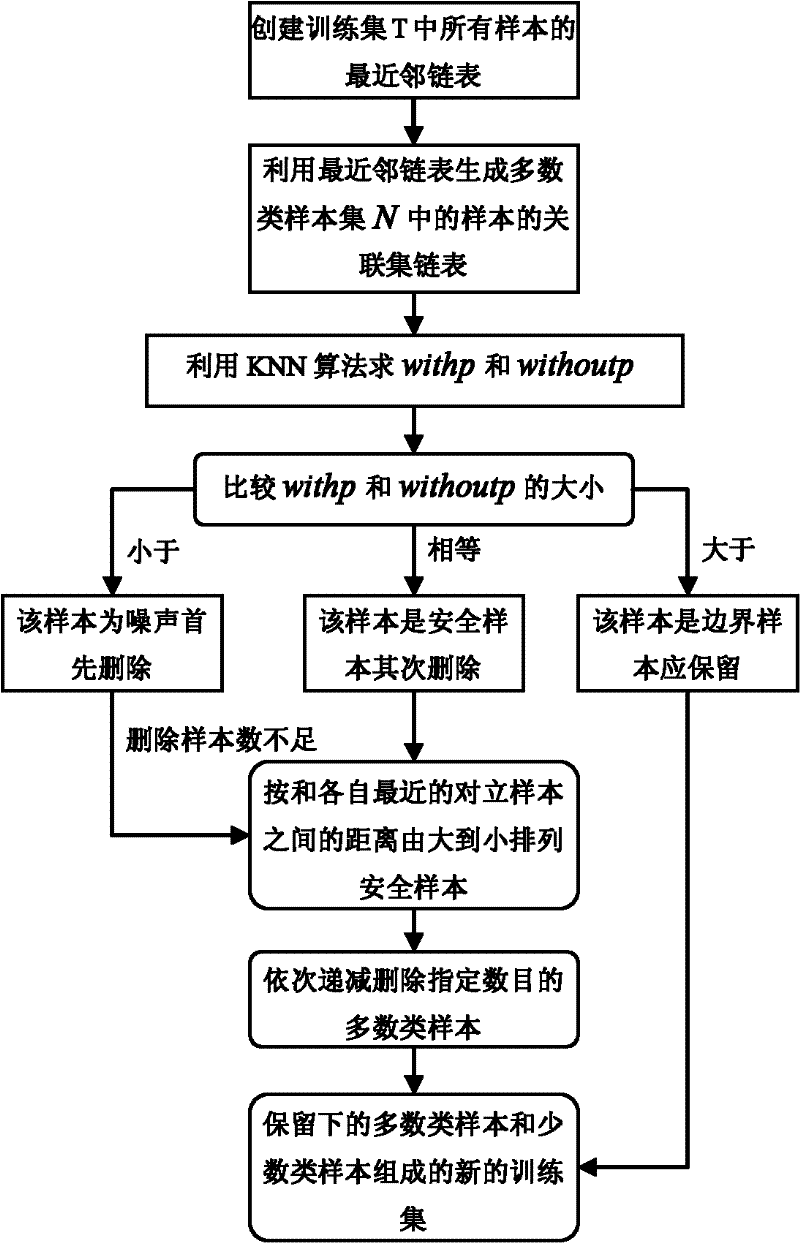

Bearing fault detection method for unbalanced data SVM (support vector machine)

InactiveCN102254177AGood removal effectEasy to detectSubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionSupport vector machinePhase space

The invention aims at providing a bearing fault detection method for an unbalanced data SVM (support vector machine), and the method comprises the following steps of: collecting a vibration signal; determining a time interval of embedding dimension and delay; reconfiguring a normal sample phase space; determining the quantity of samples required to be deleted and increased; respectively utilizingan ODR (optimization of decreasing reduction) algorithm and a BSNOTE (border synthetic minority over-sample technique) algorithm to delete the normal samples and increase artificial fault samples; training an SVM detector; adjusting the specific value between the quantity of the normal samples required to be deleted and the difference value between the normal sample quantity and the fault sample quantity; and then putting into the SVM detector for training until the detected performance index reaches 0.6; inputting bearing data samples to be tested in the SVM detector to realize rolling bearing fault detection. The method can be used for improving the data sample sampling, thus, the method has strong capability of removing redundant information and noise in the normal state sample, and further can be used for improving the detection performance of the unbalanced data SVM bearing fault detector.

Owner:HARBIN ENG UNIV

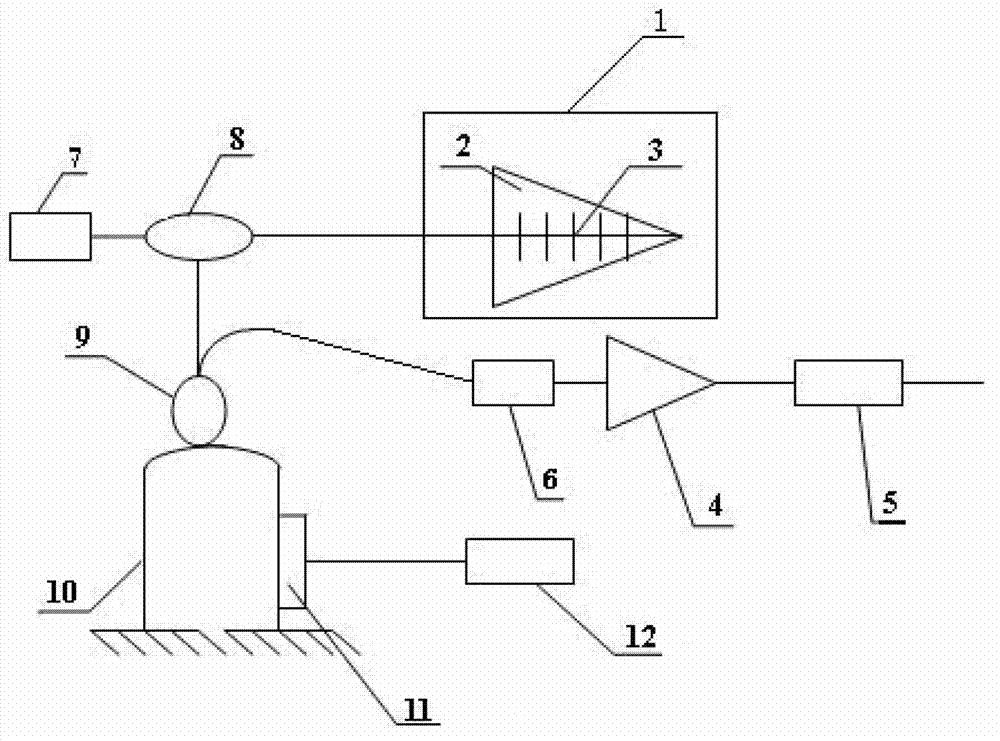

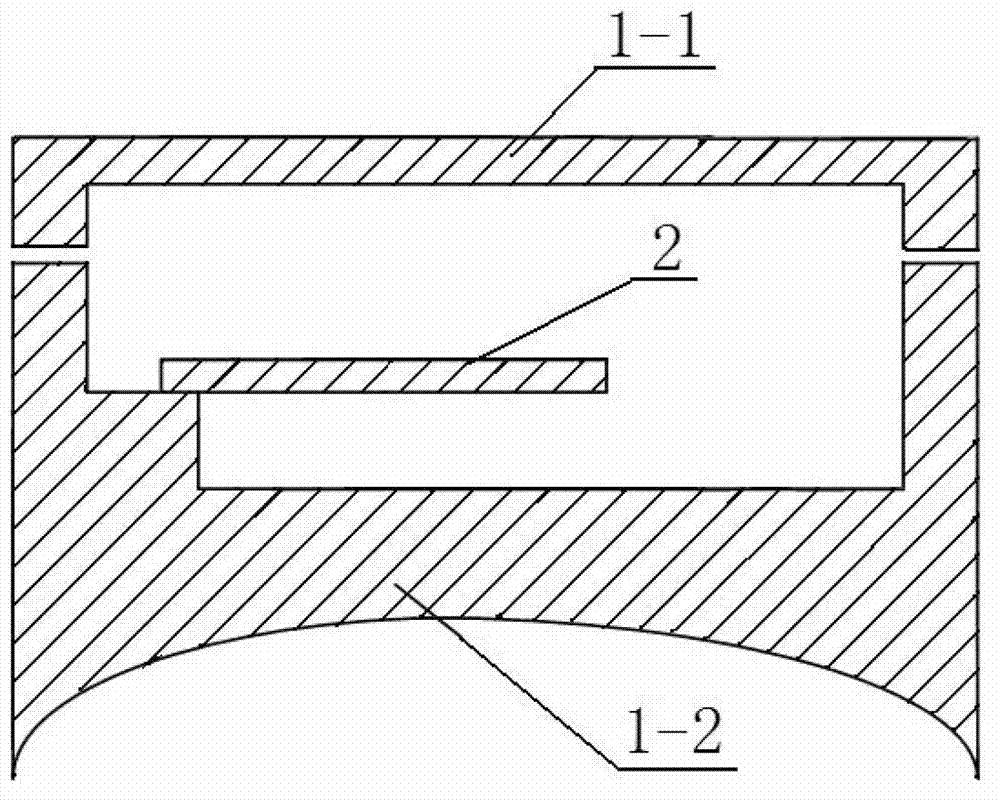

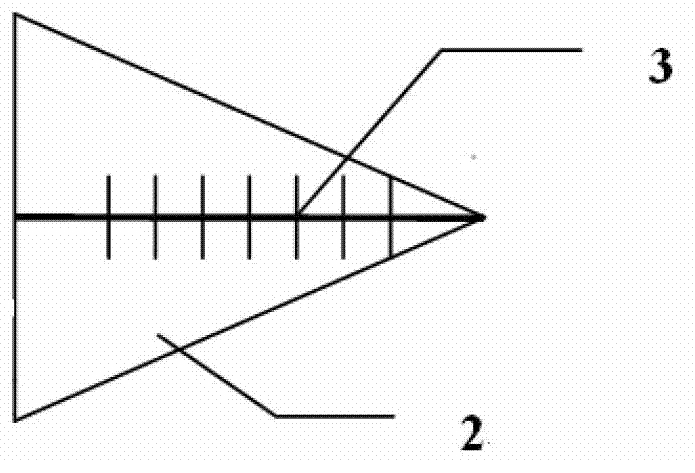

Optical fiber on-line vehicle bearing fault detection device

ActiveCN103175849ARealize high-precision detectionLow crosstalkOptically investigating flaws/contaminationEngineeringVIT signals

The invention relates to an on-line vehicle bearing fault detection device, and in particular relates to an optical fiber on-line vehicle bearing fault detection device, aiming at solving the problems that an existing vehicle bearing fault detection device is easily interfered by vehicle equipment such as a motor as well as communication signals of a power grid, and real-time health monitoring accuracy of a heavy rail is low. The optical fiber on-line vehicle bearing fault detection device comprises a sensor, an analog to digital (A / D) converter, a signal processing system, a photoelectric detector, a broadband light source, a wavelength division multiplexer, a coupling, a scanning interferometer and a signal generator, wherein the output end of the sensor is communicated with the input end of the wavelength division multiplexer; the broadband light source is communicated with the input end of the wavelength division multiplexer; the wavelength division multiplexer is communicated with one signal end of the coupling; the coupling is communicated with the scanning interferometer; the signal generator is communicated with the scanning interferometer; thr signal output end of the coupling is communicated with the photoelectric detector; the photoelectric detector is communicated with the A / D converter; and the output end of the A / D converter is communicated with the signal processing system. The device is used for detecting the fault of an on-line vehicle bearing.

Owner:HEILONGJIANG UNIV

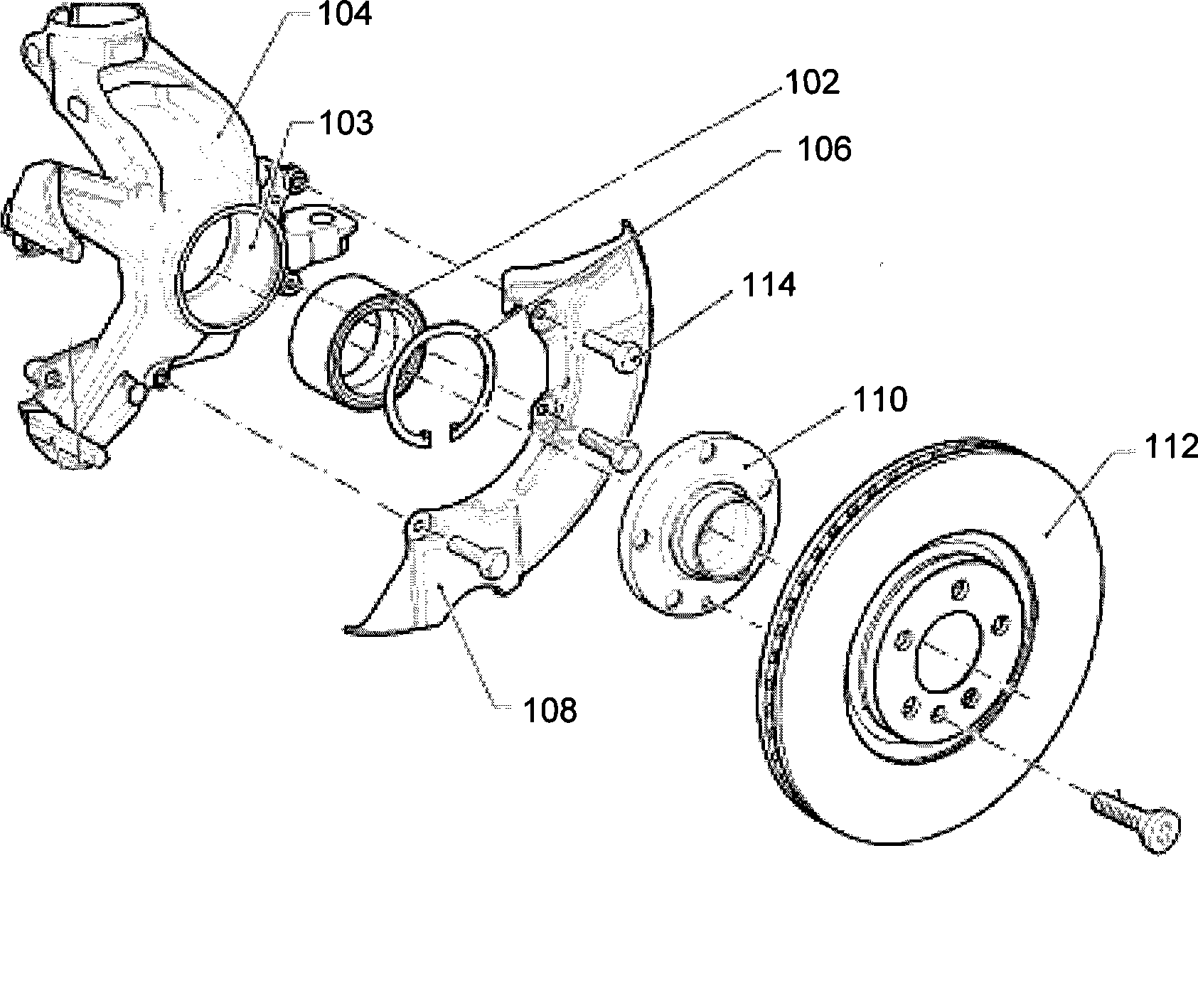

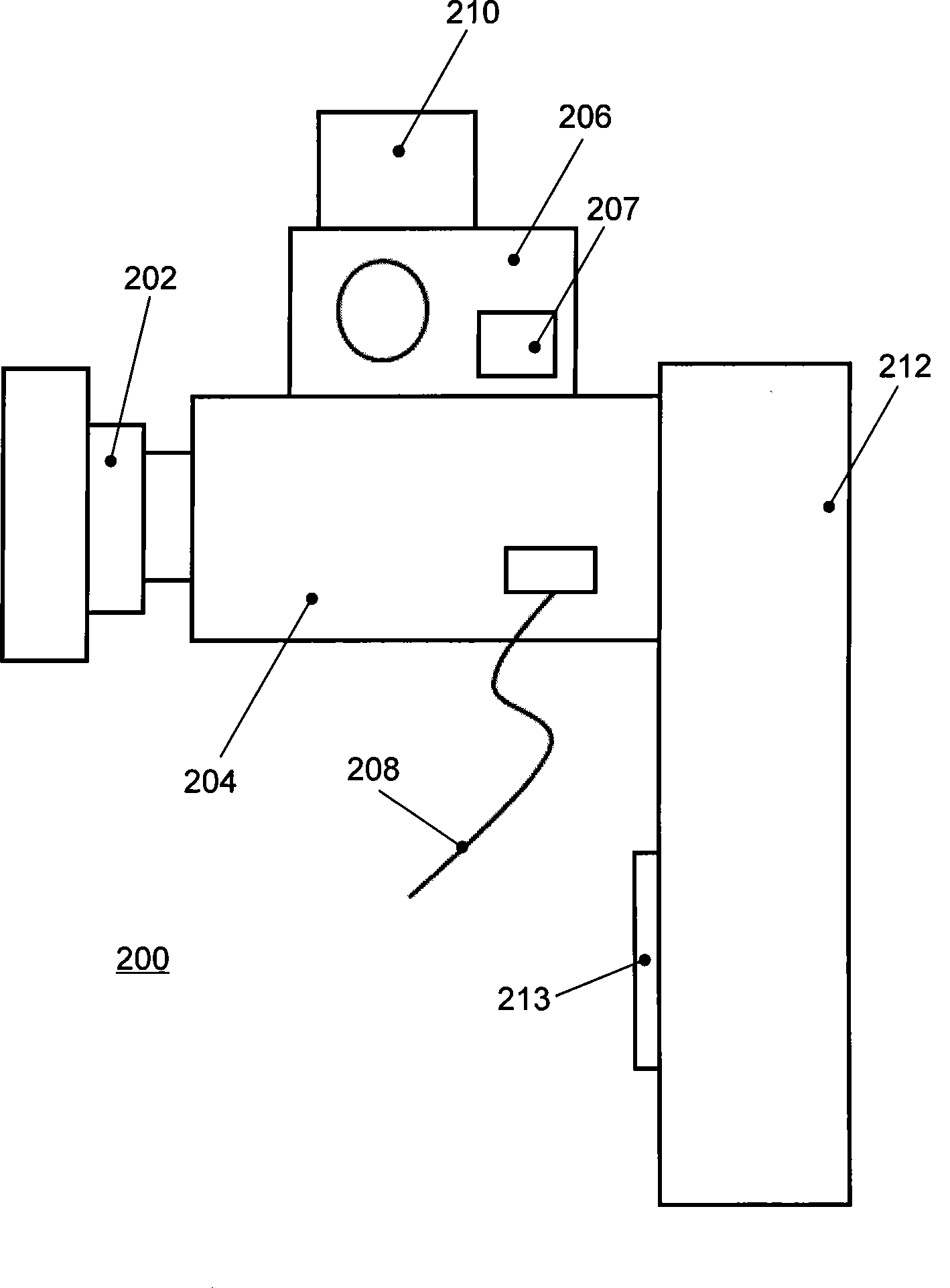

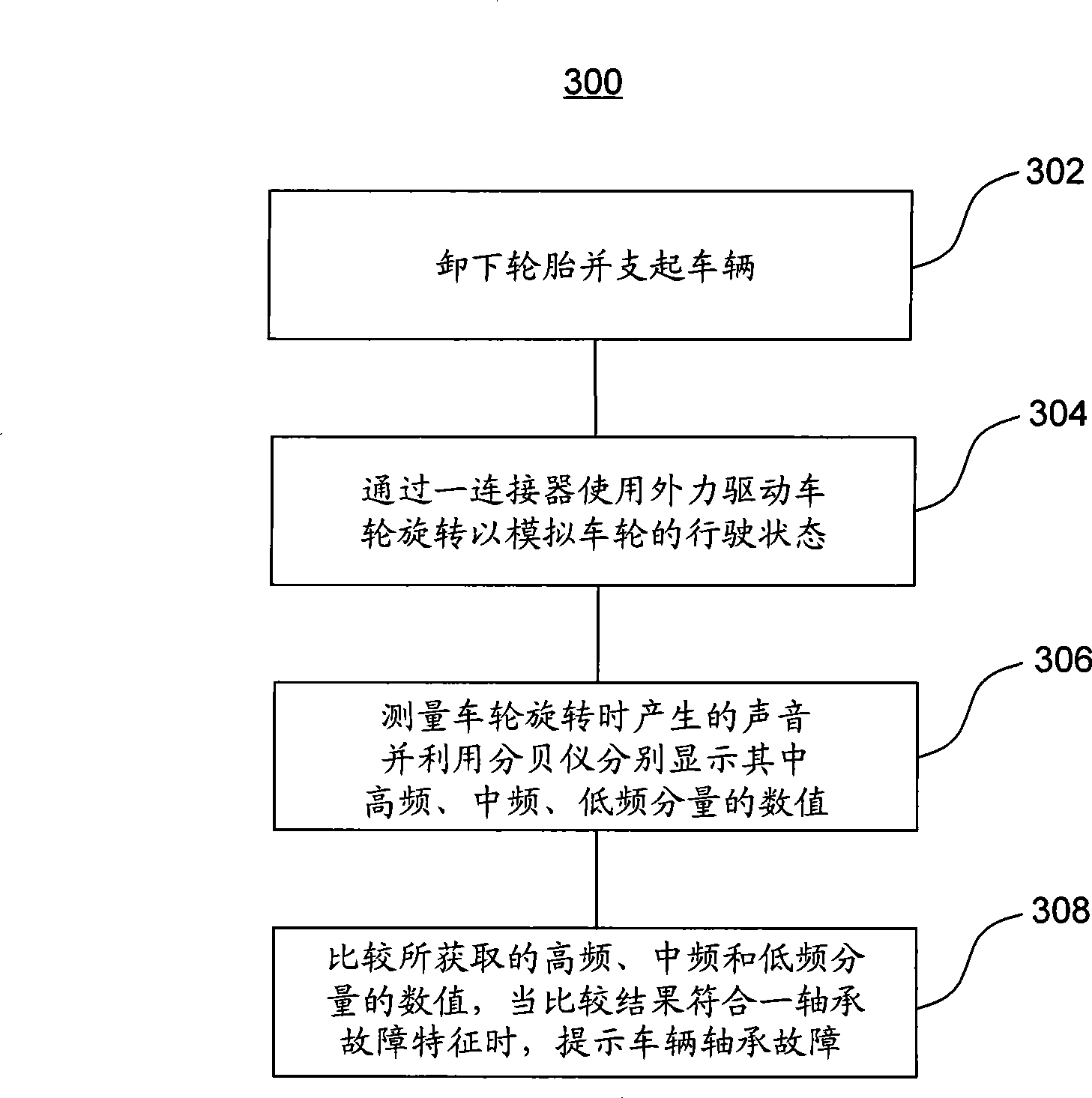

Vehicle bearing failure testing instrument and failure testing method

ActiveCN101419122AAvoid uncertaintyImprove accuracyVehicle testingSubsonic/sonic/ultrasonic wave measurementMedium frequencyDecibel meter

The invention provides a fault detector for a vehicle bearing, which judges by utilization of sound features of the bearing under the condition of fault. The detector comprises a connector, a driver, a decibel meter and a power module, wherein the connector is provided with a fixed component which is matched with a wheel axle hole of a wheel, and connected and fixed on the wheel; the driver drives the connector, drives the wheel to rotate, and simulates the running state of the wheel; the decibel meter measures the sound generated when the wheel is rotated, and respectively display values of high frequency components, medium frequency components and low frequency components; and the power module supplies power. The invention also discloses a method for detecting fault of the vehicle bearing. The fault detector for the vehicle bearing is importantly characterized in that the fault detector for the vehicle bearing quantizes the acquired sound according to high frequency, medium frequency and low frequency, takes quantized indexes as criterions, and avoids nondeterminacy caused by judgment in virtue of subjective experience.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

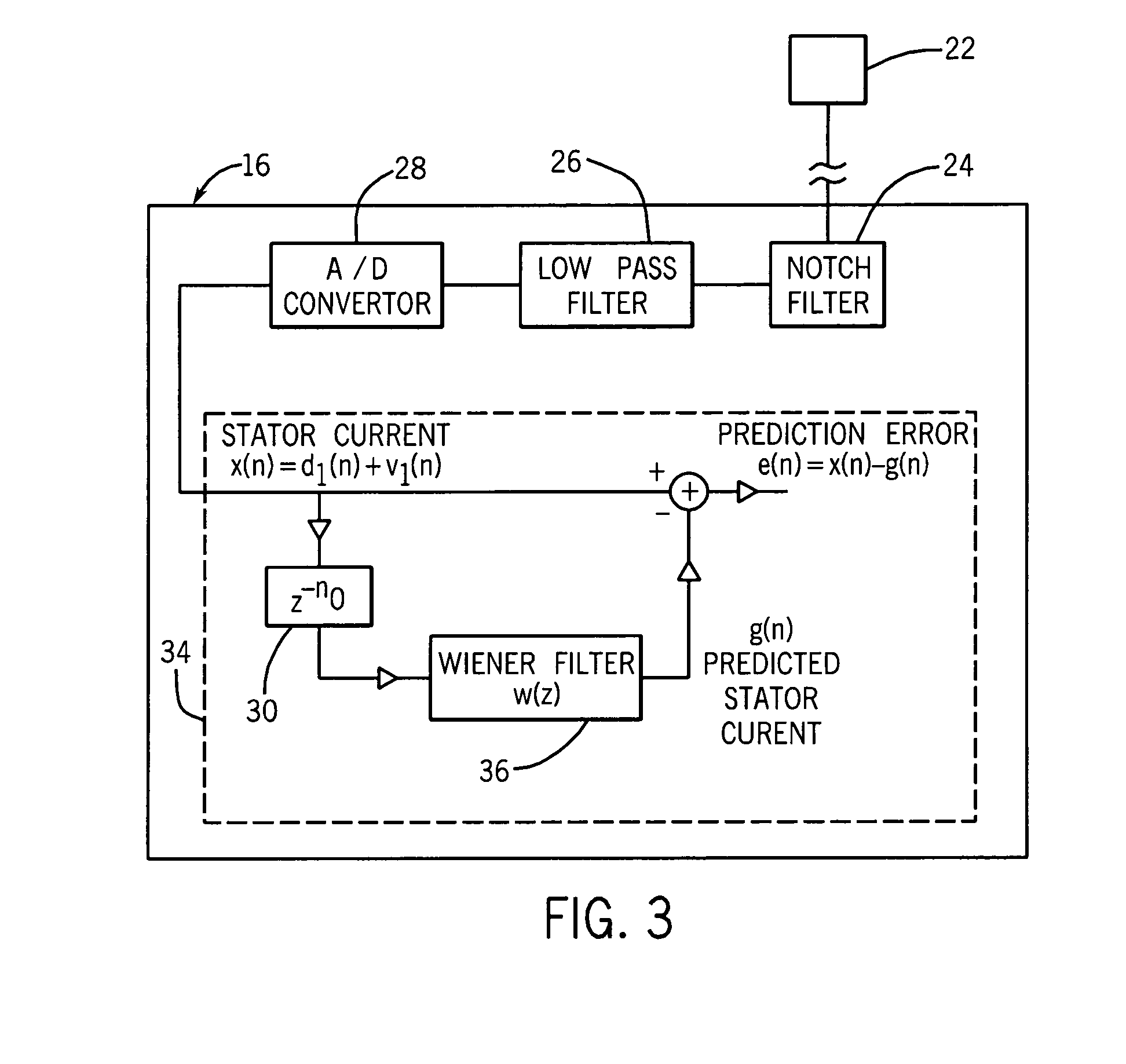

System and method for bearing fault detection using stator current noise cancellation

ActiveUS20080309366A1Overcomes drawbackEarly detectionMachine bearings testingDynamo-electric machine testingCurrent noiseEngineering

A system and method for detecting incipient mechanical motor faults by way of current noise cancellation is disclosed. The system includes a controller configured to detect indicia of incipient mechanical motor faults. The controller further includes a processor programmed to receive a baseline set of current data from an operating motor and define a noise component in the baseline set of current data. The processor is also programmed to repeatedly receive real-time operating current data from the operating motor and remove the noise component from the operating current data in real-time to isolate any fault components present in the operating current data. The processor is then programmed to generate a fault index for the operating current data based on any isolated fault components.

Owner:EATON INTELLIGENT POWER LIMITED

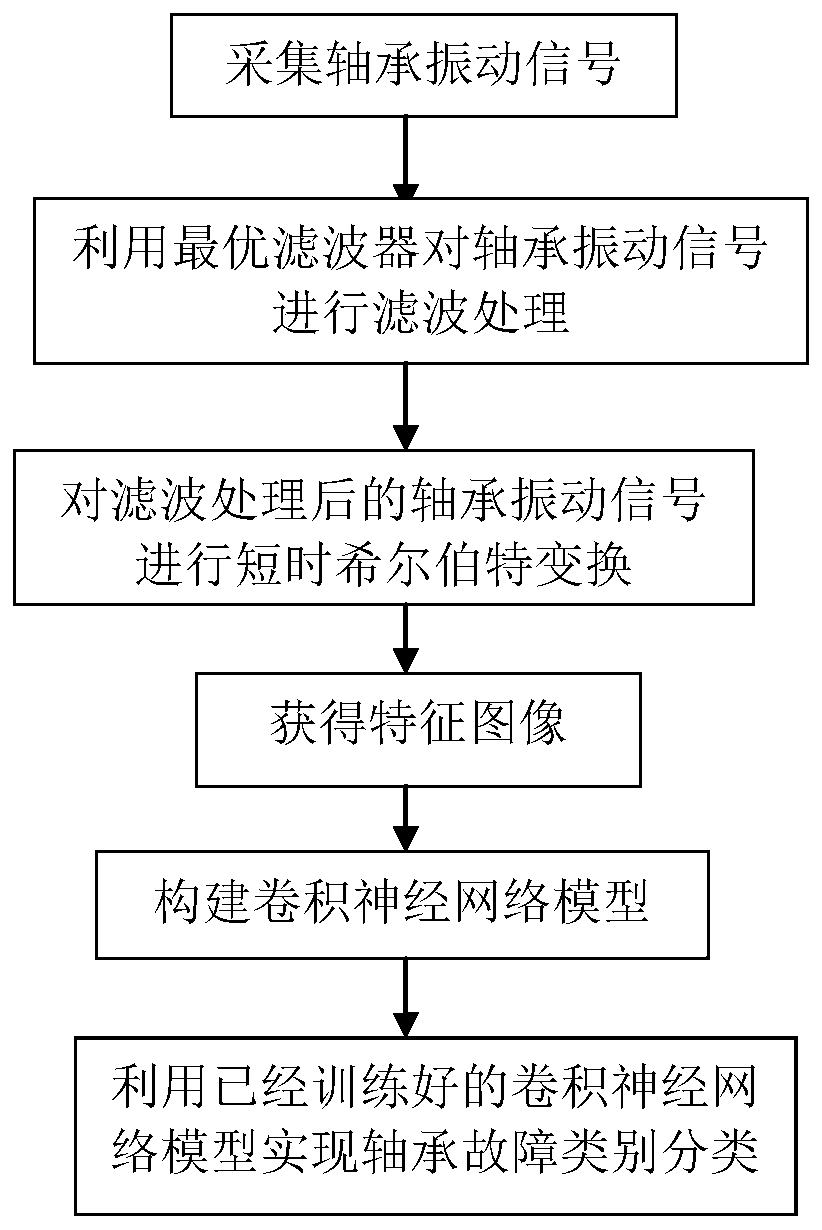

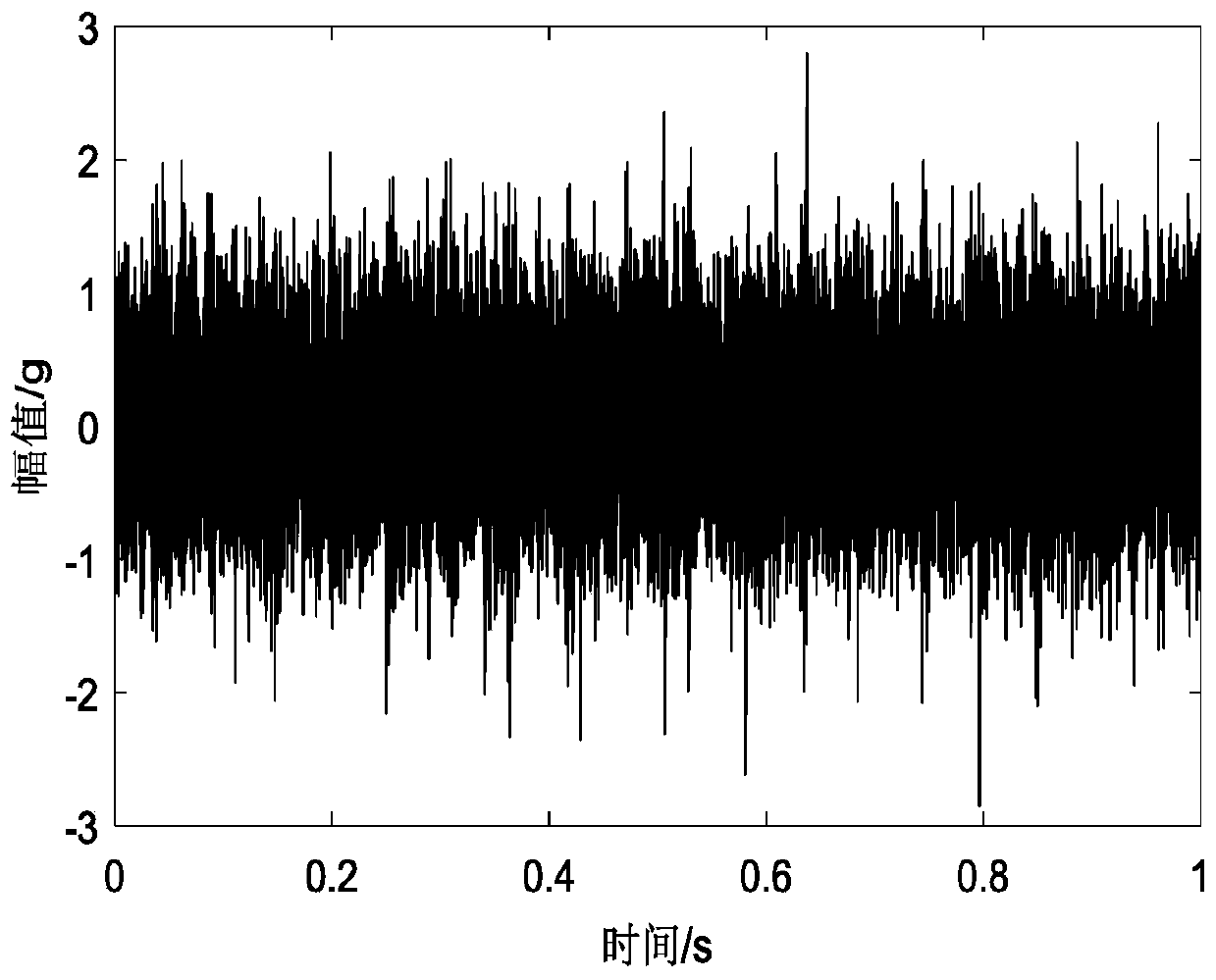

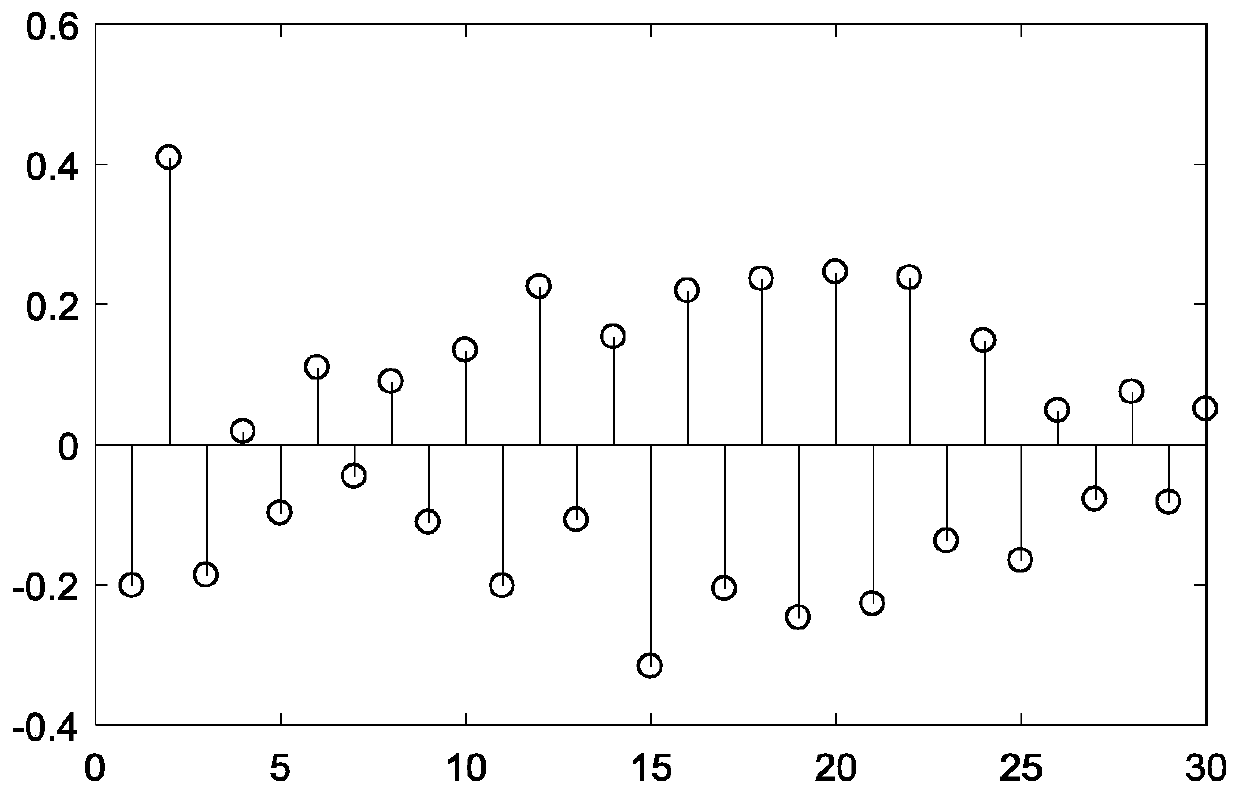

Rolling bearing fault diagnosis method based on short-time Hilbert transform

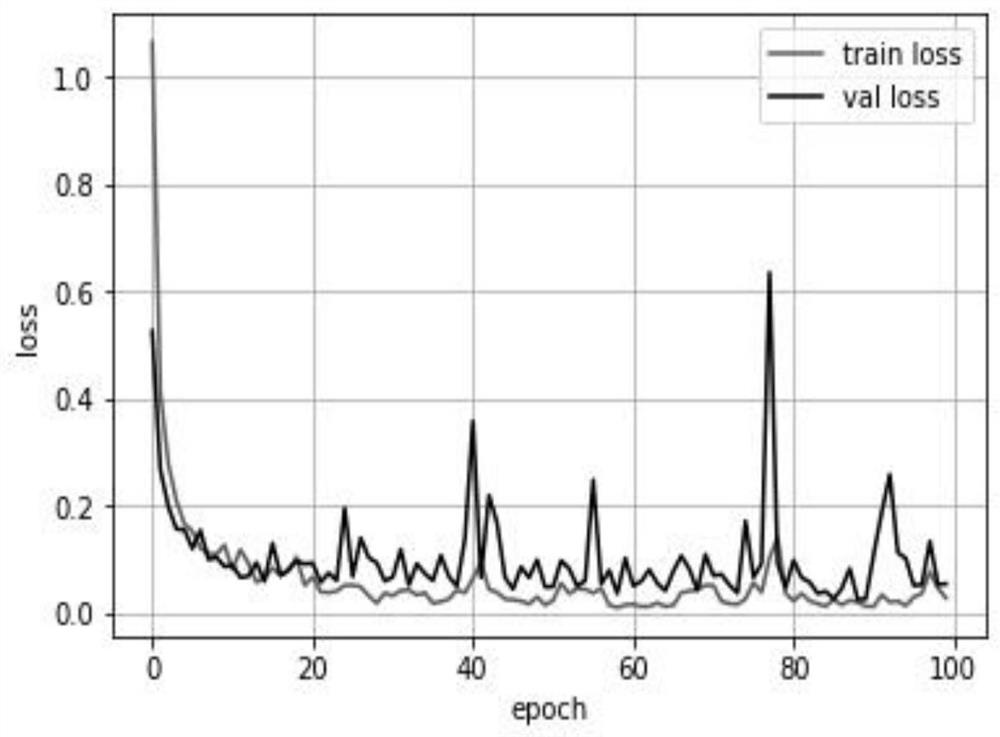

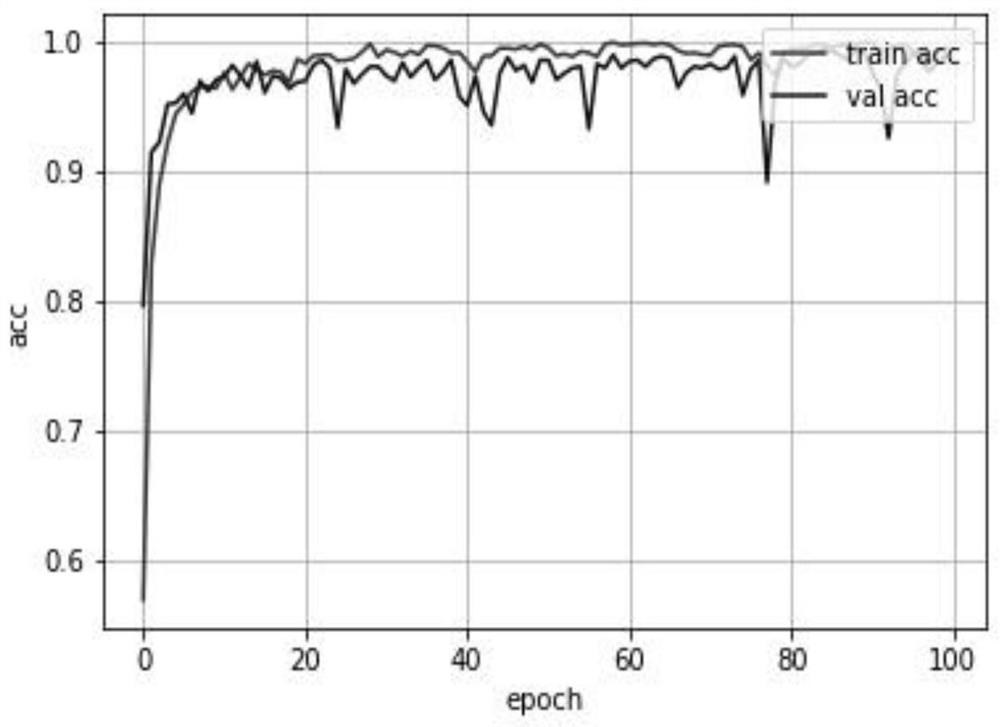

ActiveCN111238814AEfficient extractionPreserve vibration signal characteristicsMachine part testingNeural architecturesMinimum entropyEngineering

The invention relates to the technical field of bearing fault detection, and discloses a rolling bearing fault diagnosis method based on short-time Hilbert transform, and the method comprises the steps: A) collecting a bearing vibration signal, and designing an optimal filter through employing minimum entropy deconvolution; B) carrying out filtering processing on the bearing vibration signal by using the optimal filter; C) performing short-time Hilbert transform on the filtered bearing vibration signal to obtain a feature image; D) constructing a convolutional neural network model; and E) utilizing the trained convolutional neural network model to realize bearing fault category classification. The minimum entropy deconvolution is utilized to carry out filtering processing on the collectedsignals, and then the short-time Hilbert transform method is utilized to acquire the feature images so that the vibration signal features can be retained to the maximum extent, the classification of the bearing fault types and the fault severity is realized through the convolutional neural network and the accuracy of fault classification is improved.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

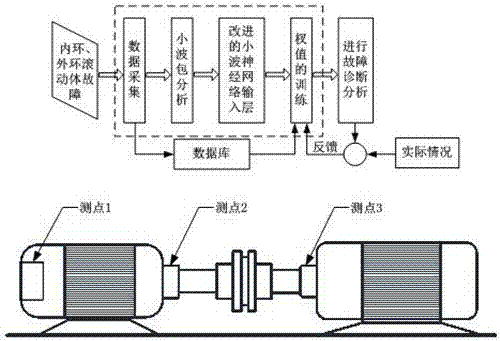

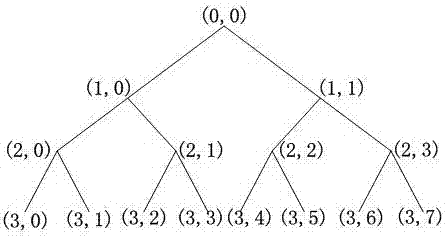

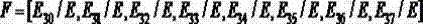

Rolling bearing fault detection method based on improved wavelet neural network

InactiveCN107122802AAccurate diagnosisImprove generalization abilityGeometric CADMachine bearings testingFeature vectorNerve network

The invention relates to a rolling bearing fault detection method based on the improved wavelet neural network. Energy distribution of each frequency band after wavelet packet decomposition is taken as a characteristic vector to input to the neural network, and the improved wavelet neural network is utilized to accomplish identification of rolling bearing fault modes. The method is advantaged in that a training speed of the wavelet neural network can be accelerated through extracting fault characteristics, and faults of the rolling bearing can be rapidly detected and positioned.

Owner:HARBIN UNIV OF SCI & TECH

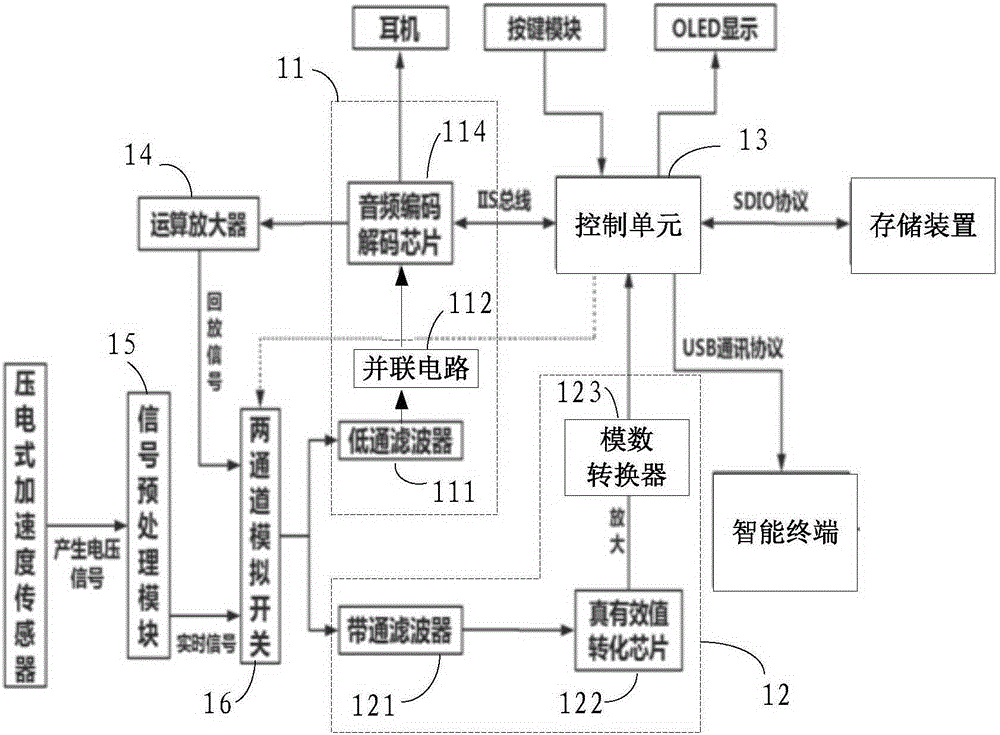

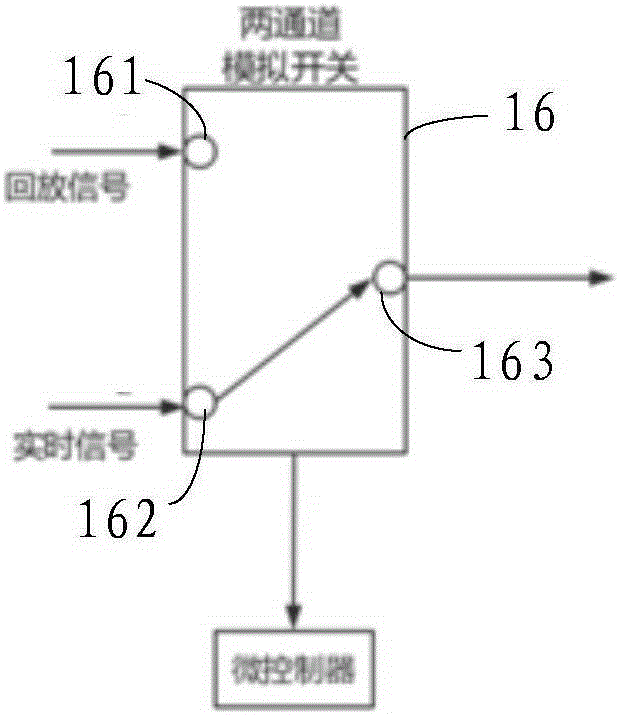

Detection signal processing device and method

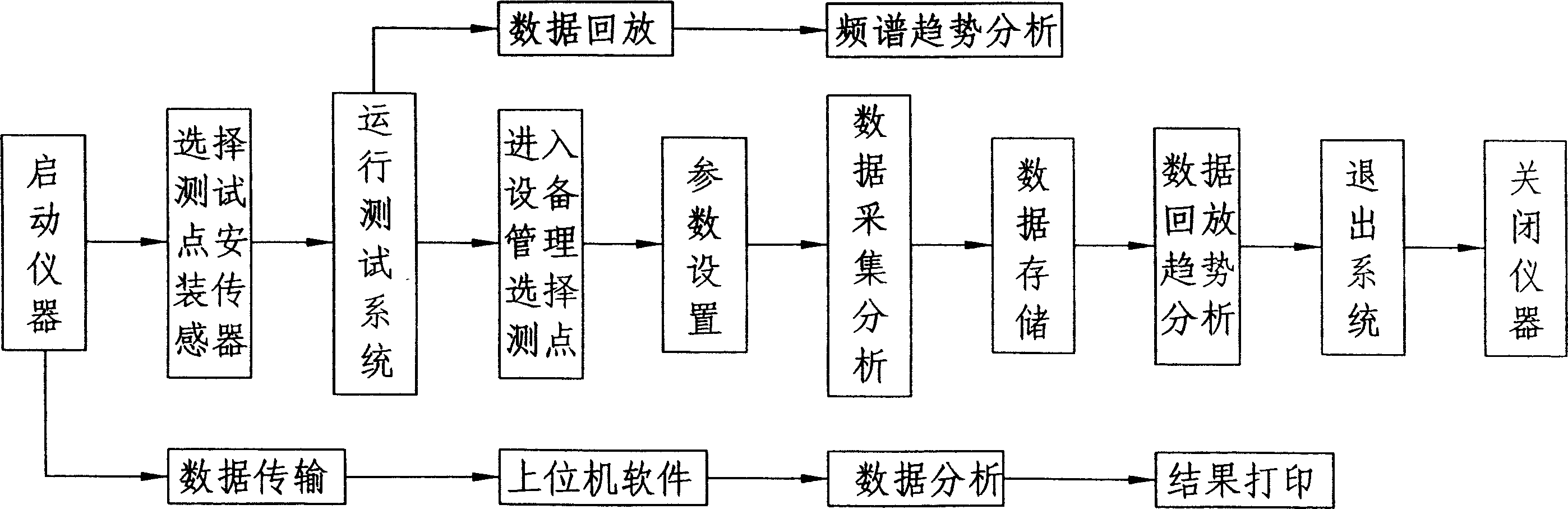

ActiveCN105353996AAchieve traceabilityAchieve experience accumulationInput/output to record carriersSubsonic/sonic/ultrasonic wave measurementExternal storageData acquisition

The invention relates to the technical field of bearing fault detection, in particular to a detection signal processing device and method. The method comprises the following steps: an audio processing line receives a first sensor signal; after the first sensor signal is processed, the processed first sensor signal is output to an earphone; and if a recording instruction sent from a control unit is received, the first sensor signal is sampled, and the sampled first sensor signal is converted into a digital signal, and the digital signal is sent to a control unit to be stored. When a detection device carries out real-time auscultation on a mechanical device, detection data is converted into the digital signal so as to store the digital signal by a lossless audio format, so that the digital signal can be stored in external storage devices, including an SD (Secure Digital Memory) card, a data acquisition card with large volume and high price does not need to be used, cost is lowered, and circuit design is simplified.

Owner:SHENZHEN YATEKS OPTICAL ELECTRONICS TECH CO LTD

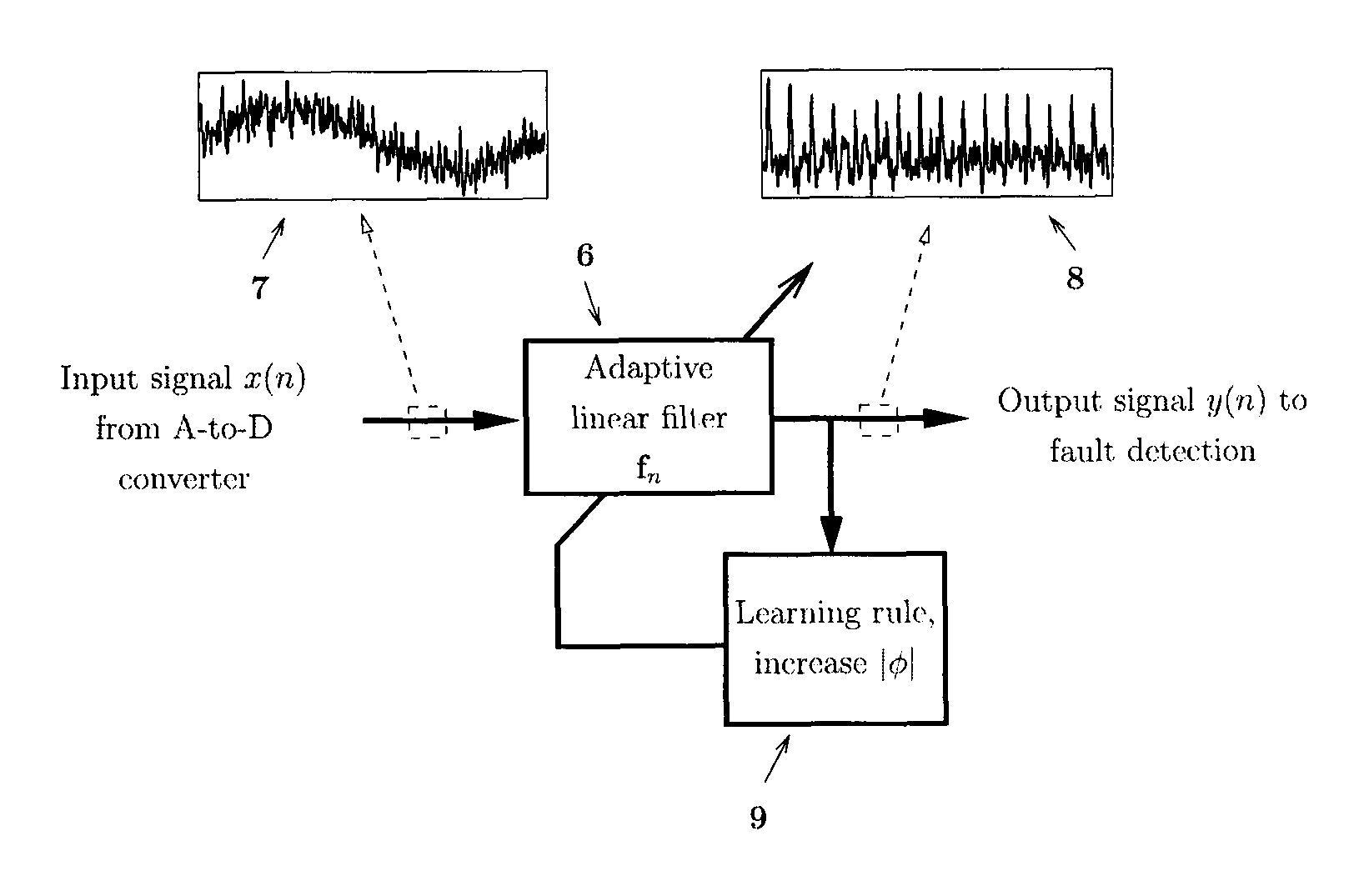

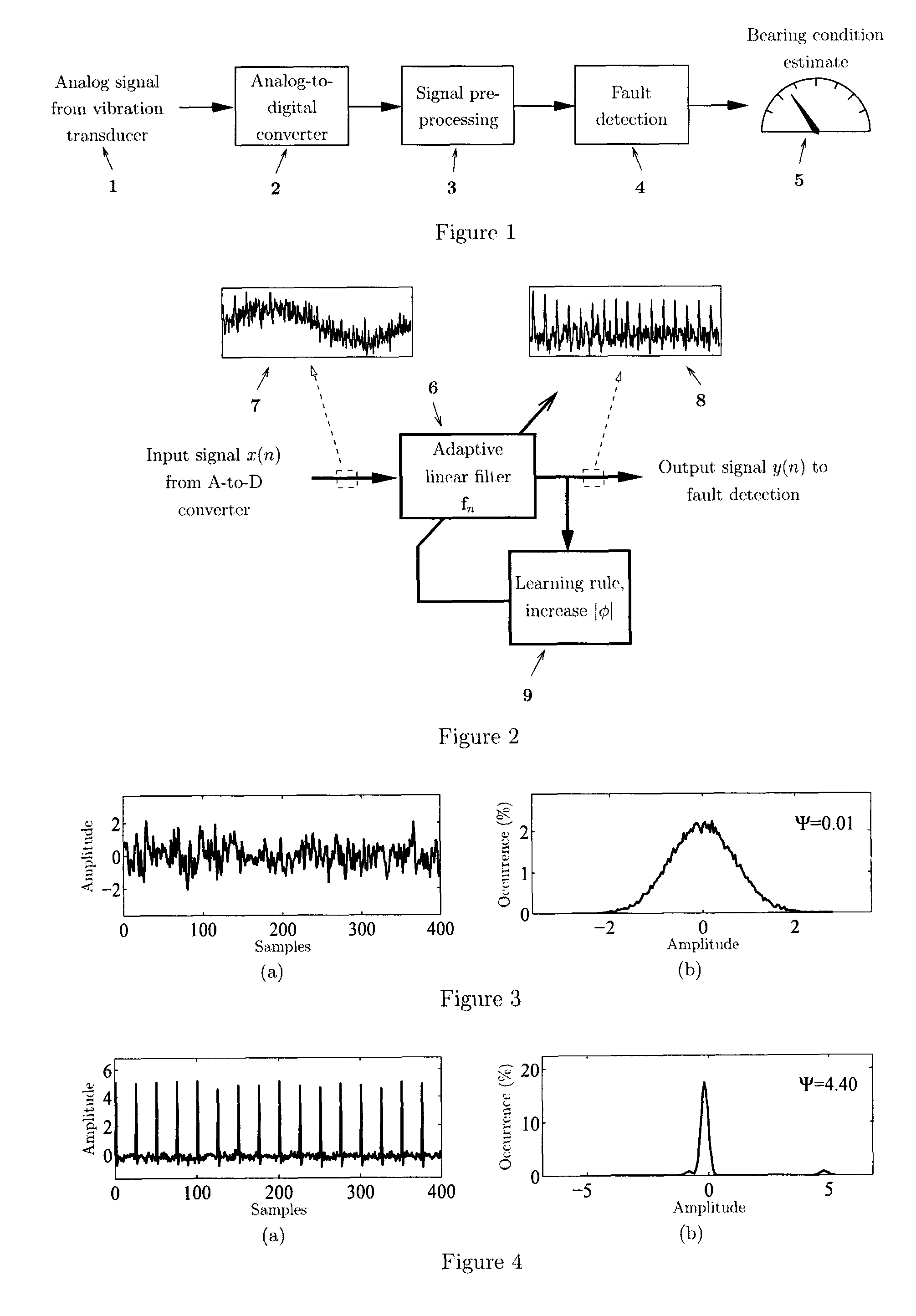

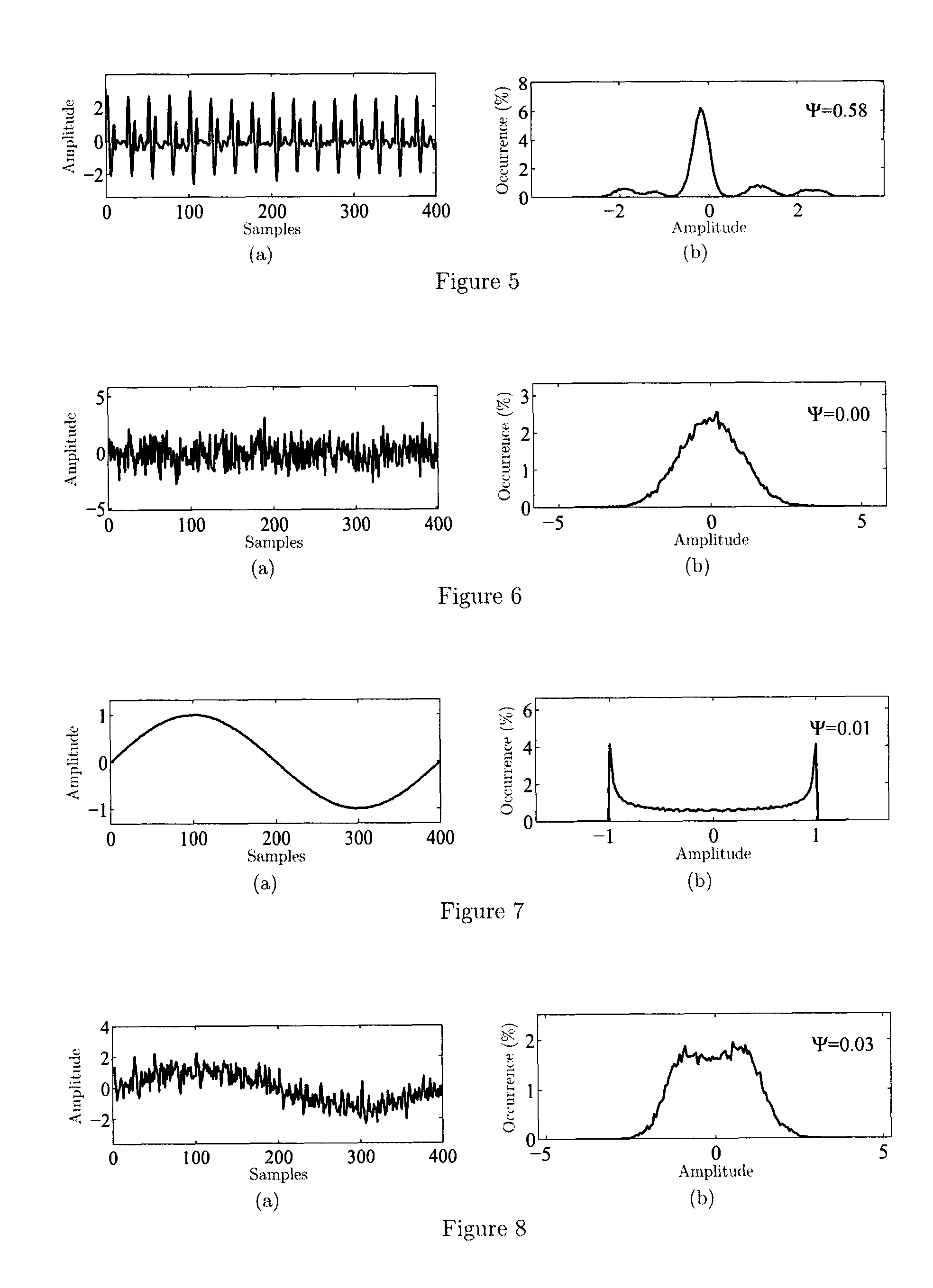

Method for rolling bearing fault detection based on enhancing statistical asymmetry

ActiveUS20130024164A1Increasing statistical asymmetrySmall amount of calculationMachine part testingAmplifier modifications to reduce noise influenceAmplitude distortionAdaptive filter

A method for digital processing of vibration signals from rolling bearings in rotating machines is presented, allowing subsequent fault detection with high reliability. A linear, adaptive filter is applied to the acquired vibration signal and iteratively tuned to increase the statistical asymmetry of its output. In this process, the filter removes phase- and amplitude distortion from underlying fault impulses. Furthermore, suppression of sinusoidal disturbances is simultaneously achieved with high robustness to measurement noise. The result is a processed signal from which rolling bearing defects are more easily detected.

Owner:AB SKF

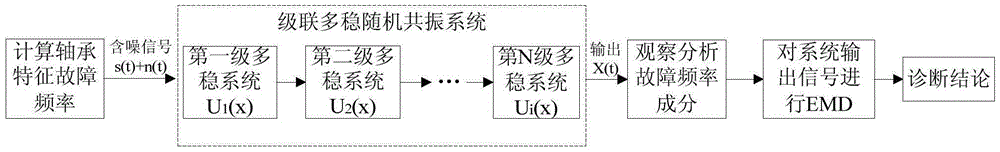

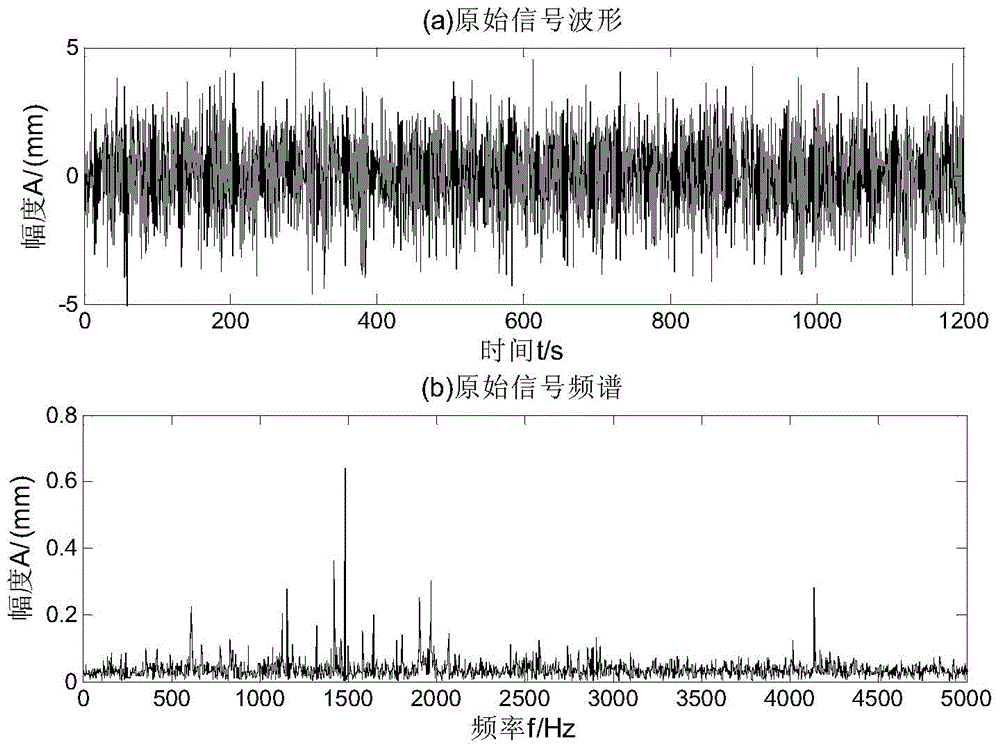

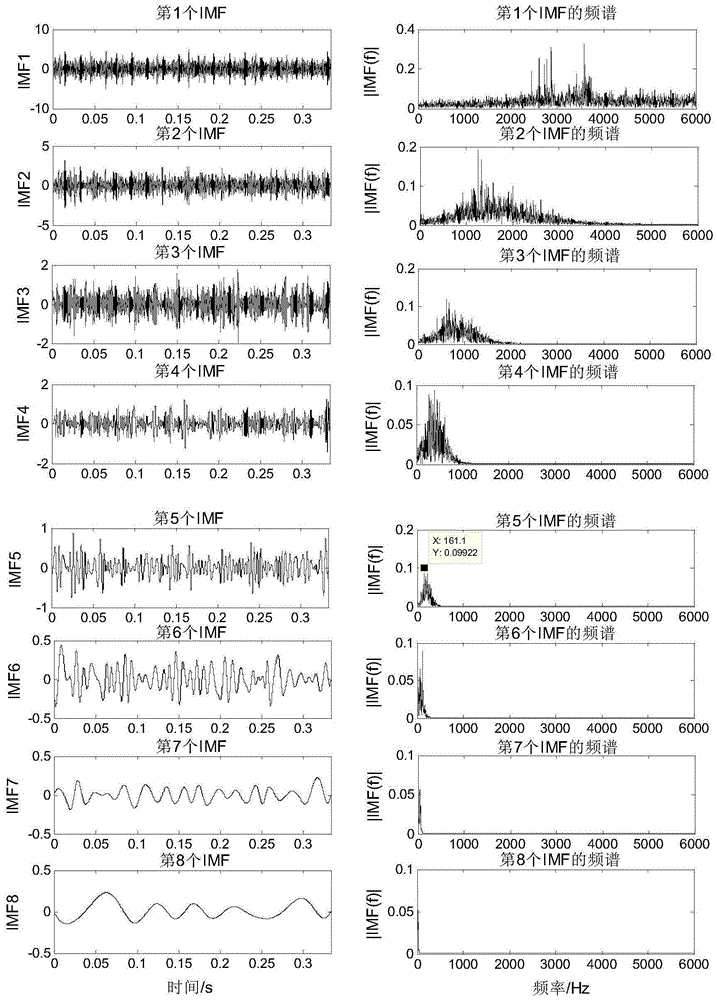

Rolling bearing fault detection method based on cascade multistable stochastic resonance and empirical mode decomposition (EMD)

InactiveCN105181334AEnable effective diagnosisOvercome the difficult problem of weak signal extractionMachine bearings testingFrequency spectrumDecomposition

The present invention relates to a rolling bearing fault detection method based on cascade multistable stochastic resonance and EMD. The method comprises the steps of calculating the fault characteristic frequency of a to-be-diagnosed mechanical device, extracting the vibration data of the to-be-diagnosed mechanical device as the input of a cascade multistable stochastic resonance system, wherein the output of the cascade multistable stochastic resonance system is used as a vibration data result corresponding to the vibration data; carrying out the Fourier transform on the extracted vibration data result to obtain the frequency spectrum of an original signal, and determining the frequency components contained in the frequency spectrum; optimally selecting the parameters of the multistable stochastic resonance system, and introducing a vibration signal in the cascade multistable stochastic resonance system; taking the output of the last-level of the cascade multistable stochastic resonance system as the output of the cascade multistable stochastic resonance system, carrying out the EMD on the output of the system, extracting the frequency components contained in the signals and according with the prescient fault characteristic frequency, and determining whether the rolling is faulted and the faulted parts according to an EMD result.

Owner:YANSHAN UNIV

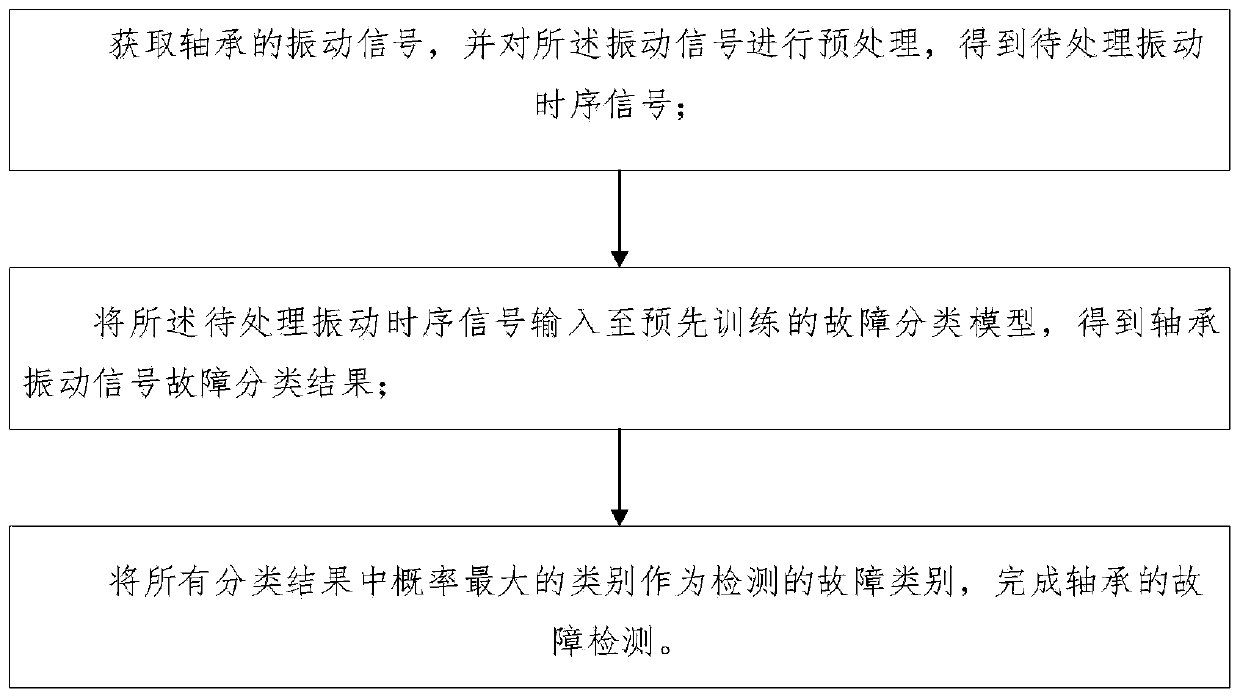

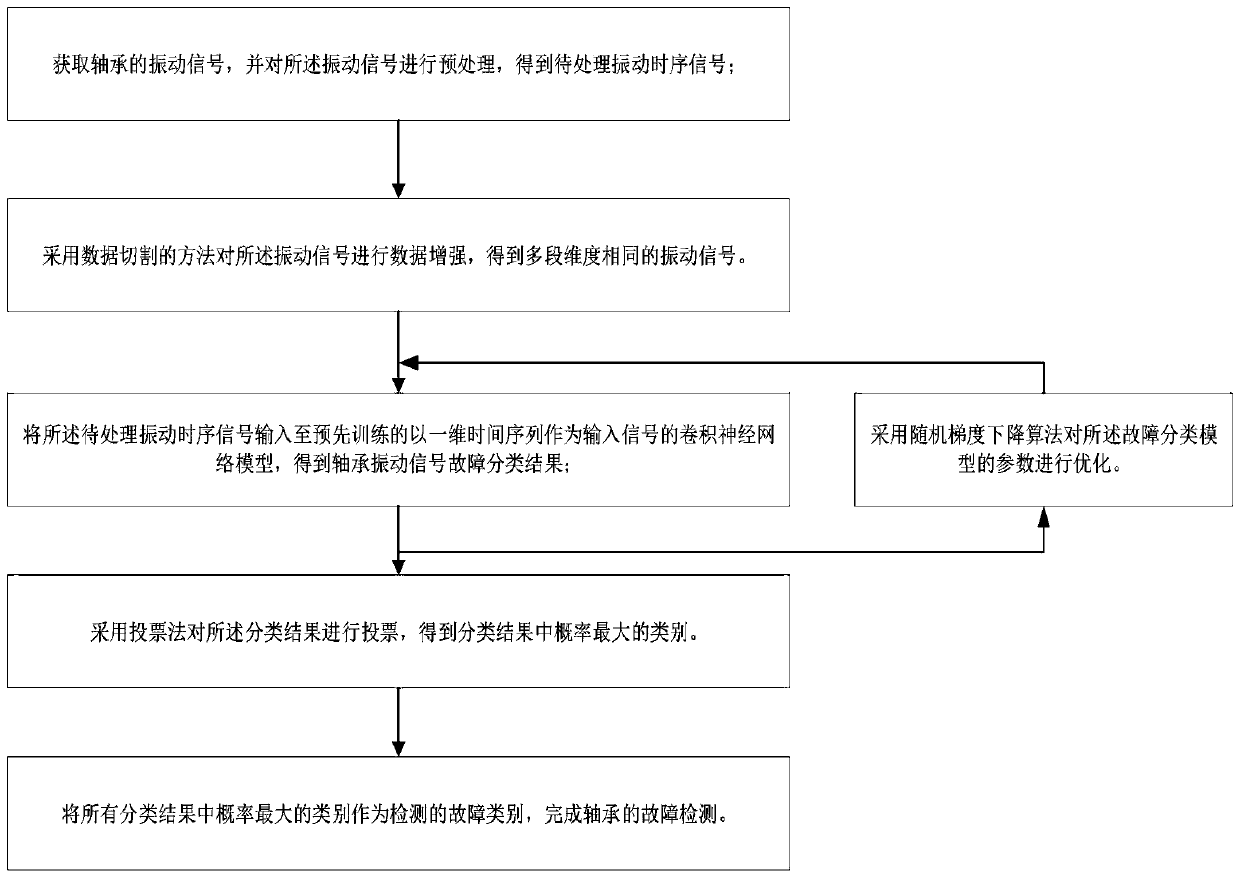

Bearing fault detection method and device

InactiveCN110261116AAccurate fault detectionAvoid problems such as difficult conversionMachine part testingCharacter and pattern recognitionFeature extractionVibratory signal

The invention discloses a bearing fault detection method and device. The method comprises that a vibration signal of a bearing is obtained, and preprocessed to obtain a vibration sequential signal to be processed; the vibration sequential signal to be processed is input to a pre-trained fault classification model to obtain a fault classification result of the bearing vibration signal; and the type of highest probability among all the classification results is the detected fault type, and bearing fault detection is completed. According to the method, vibration signal values sampled continuously according to the time sequence is used as a training sample for convolutional neural network directly, a signal feature extraction step in traditional fault recognition is not needed, influence of feature extraction on accuracy of a fault identification result is reduced, parameter training is carried out the whole network in a monitored way by combining labels, and thus, accurate bearing fault detection is realized.

Owner:SOUTH CHINA UNIV OF TECH

Bearing fault detection for surface pumping units

Methods and apparatus for operating a rod pumping unit for a wellbore are provided. One example method includes measuring vibration data in the time domain using at least one sensor coupled to a housing for a moving component of the rod pumping unit; converting the vibration data in the time domain to vibration data in the frequency domain; determining that: (1) at least one frequency component of the frequency-domain vibration data in a first frequency band has a power above a first threshold; or (2) a number of frequency components of the frequency-domain vibration data in a second frequency band having power above a second threshold is above a third threshold; and outputting an indication based on the determination.

Owner:WEATHERFORD TECH HLDG LLC

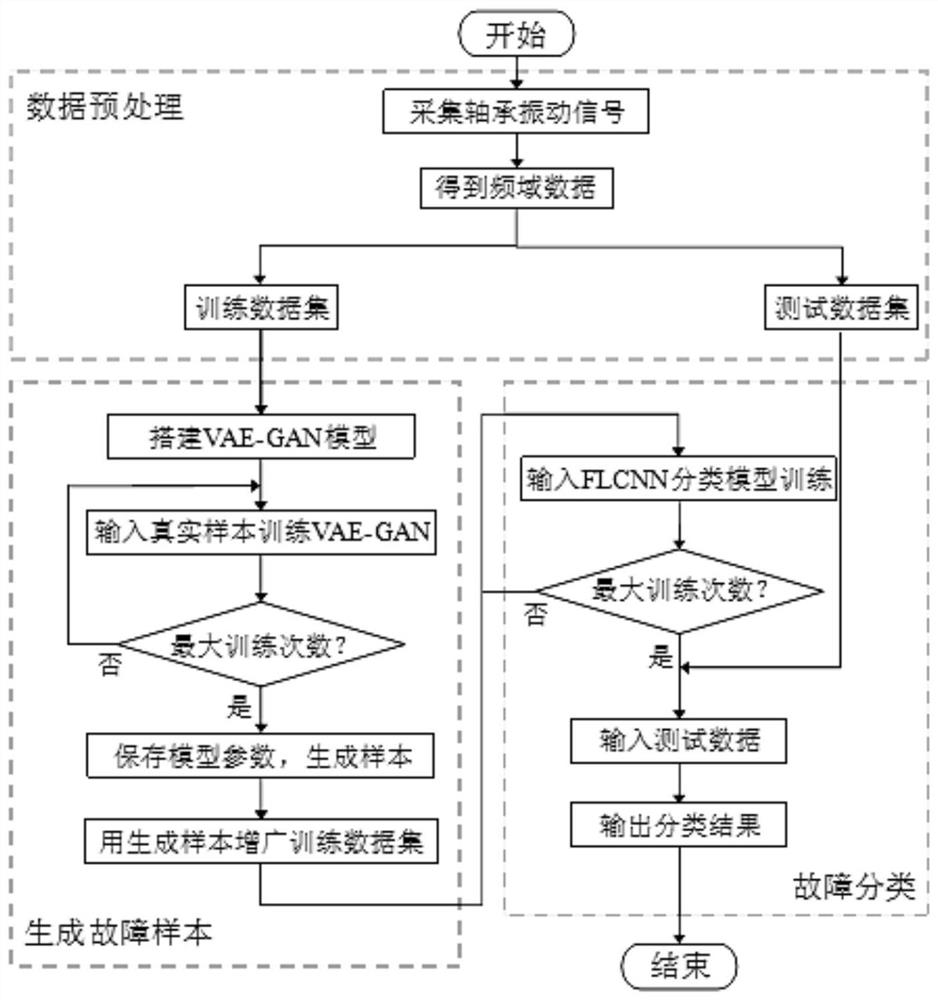

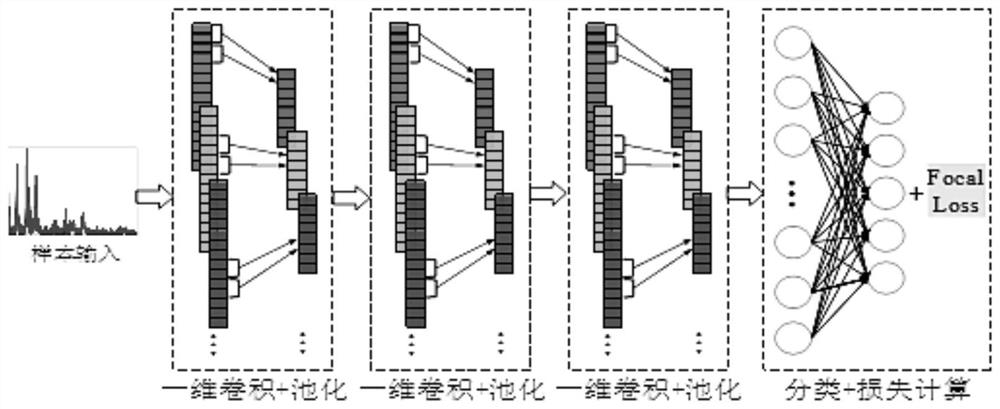

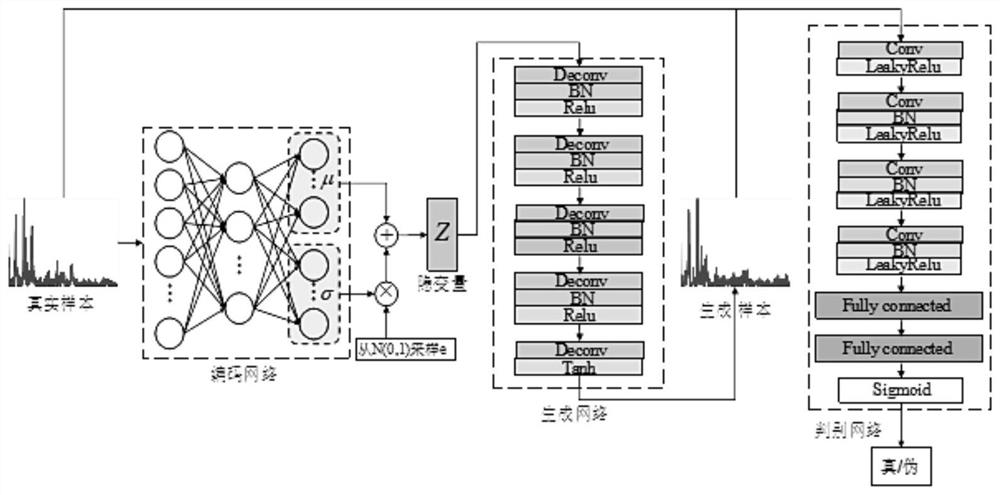

Bearing fault detection method and device under sample imbalance condition

PendingCN113255078AGenerate good effectImplement expansionGeometric CADCharacter and pattern recognitionLearning machineData set

The invention discloses a bearing fault diagnosis method and device under a sample imbalance condition, and relates to the field of bearing fault diagnosis, and the method comprises the steps: collecting time domain vibration signals of a bearing fault through equipment, and classifying the collected signals; segmenting the fault signals into a plurality of samples, then performing fast Fourier transform to obtain frequency domain data, and making a training set and a test set according to a proportion; building a VAE-GAN fault sample generation model, respectively inputting minority classes of fault samples in the training set into the model, and balancing the training data set; building an FLCNN fault classification model, and inputting the balance training set obtained in the step S3 into the model for training; and analyzing an experiment result. According to the bearing fault diagnosis method and device, the VAE network and the GAN network are combined, meanwhile, the feature coding capacity of the VAE for training data and the adversarial learning mechanism of the GAN are used for reference, and compared with other methods, the fault diagnosis precision can be effectively improved under different unbalanced proportions.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Fault detection for bearings

ActiveUS20160327452A1Machine bearings testingConverting sensor output electrically/magneticallyEngineeringFrequency profile

A fault detection system is disclosed for predicting bearing failure in a system with a bearing-supported shaft. A position sensor may sense a position of the shaft as the shaft rotates. A controller may receive, from the position sensor, position data indicating a plurality of sensed positions of the shaft. The controller may determine a position or velocity profile for the shaft based upon the received position data and may determine a frequency profile based upon the position or velocity profile. The controller may identify a characteristic of the frequency profile, and identify an expected bearing failure based upon the identified characteristic.

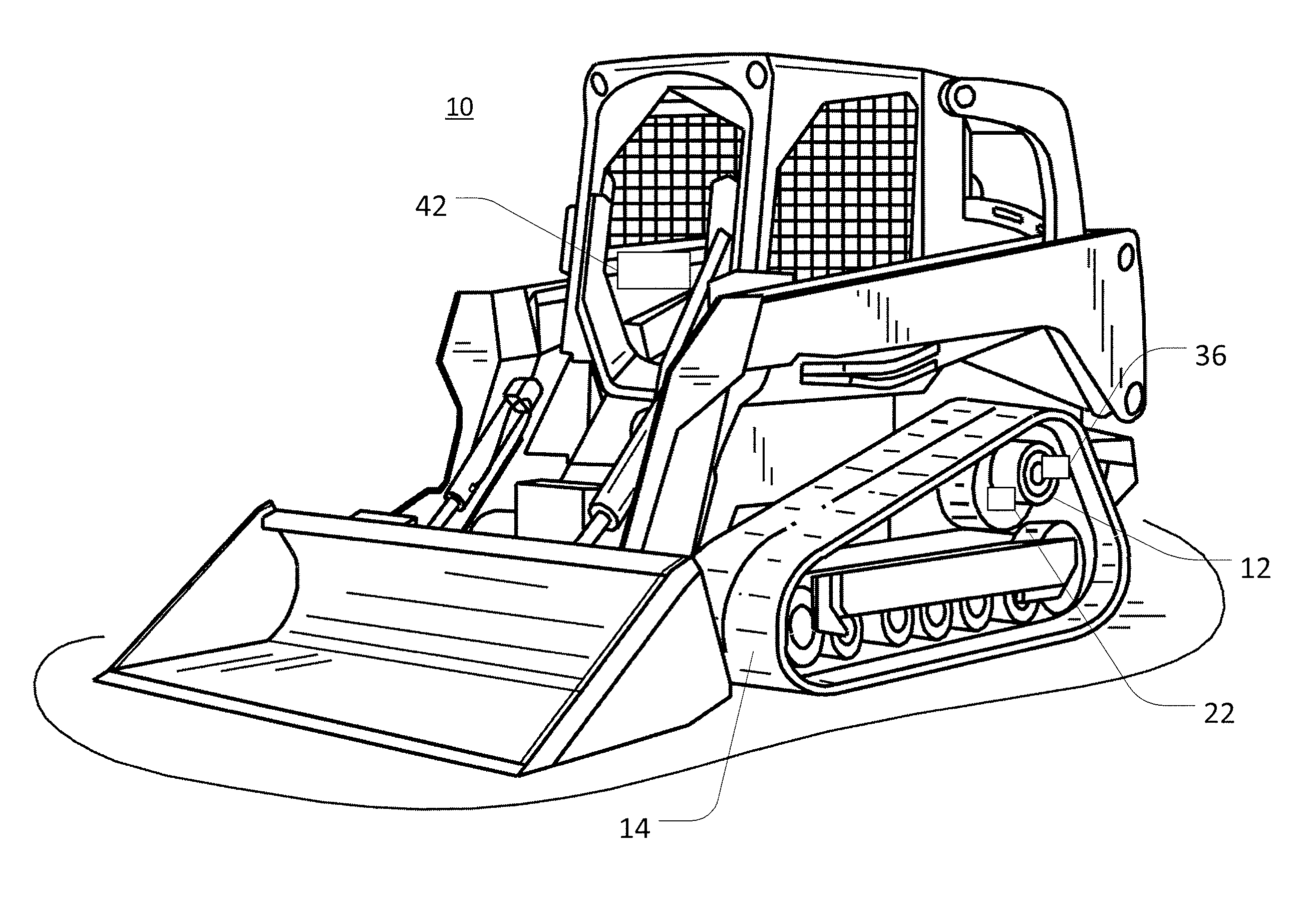

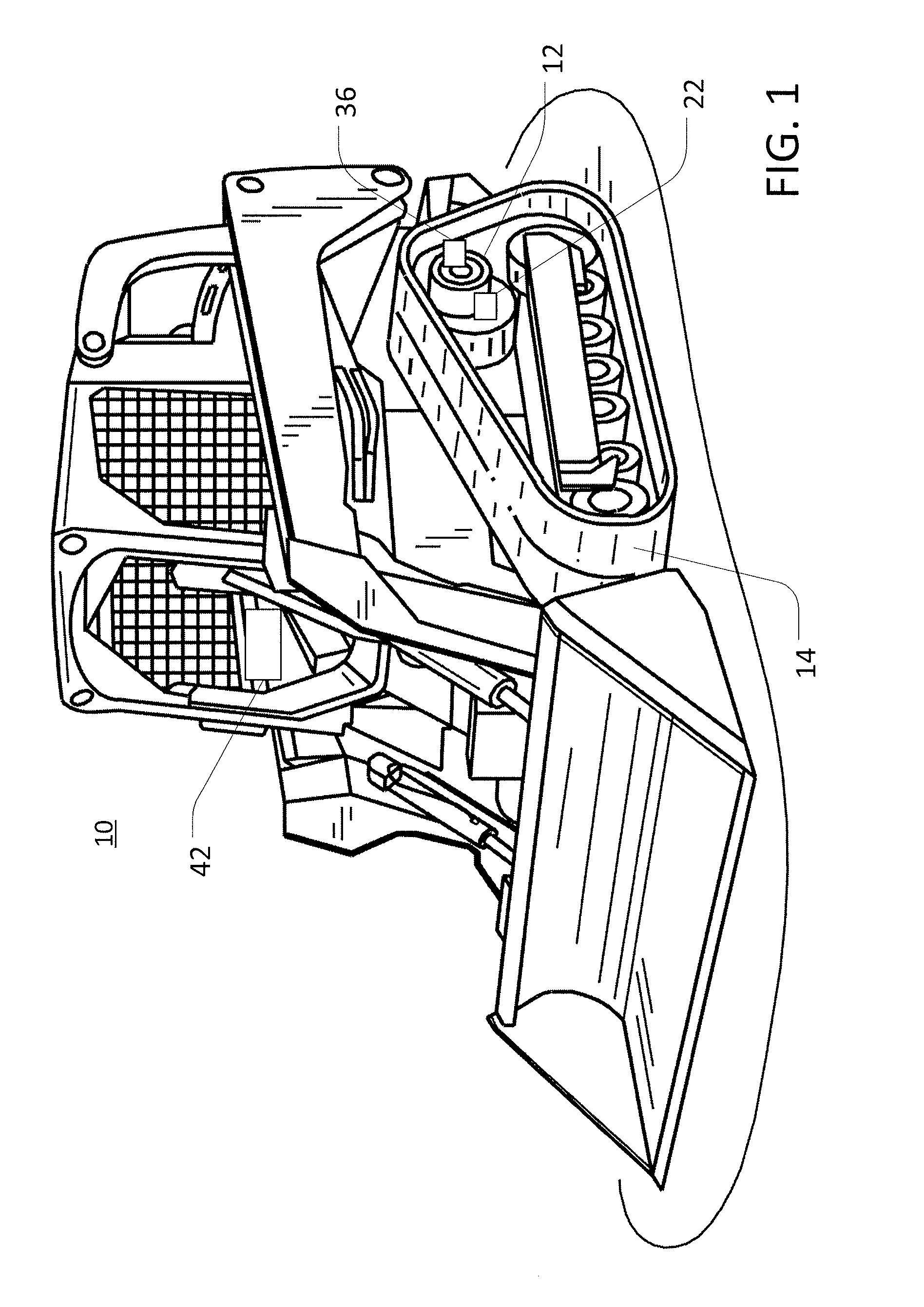

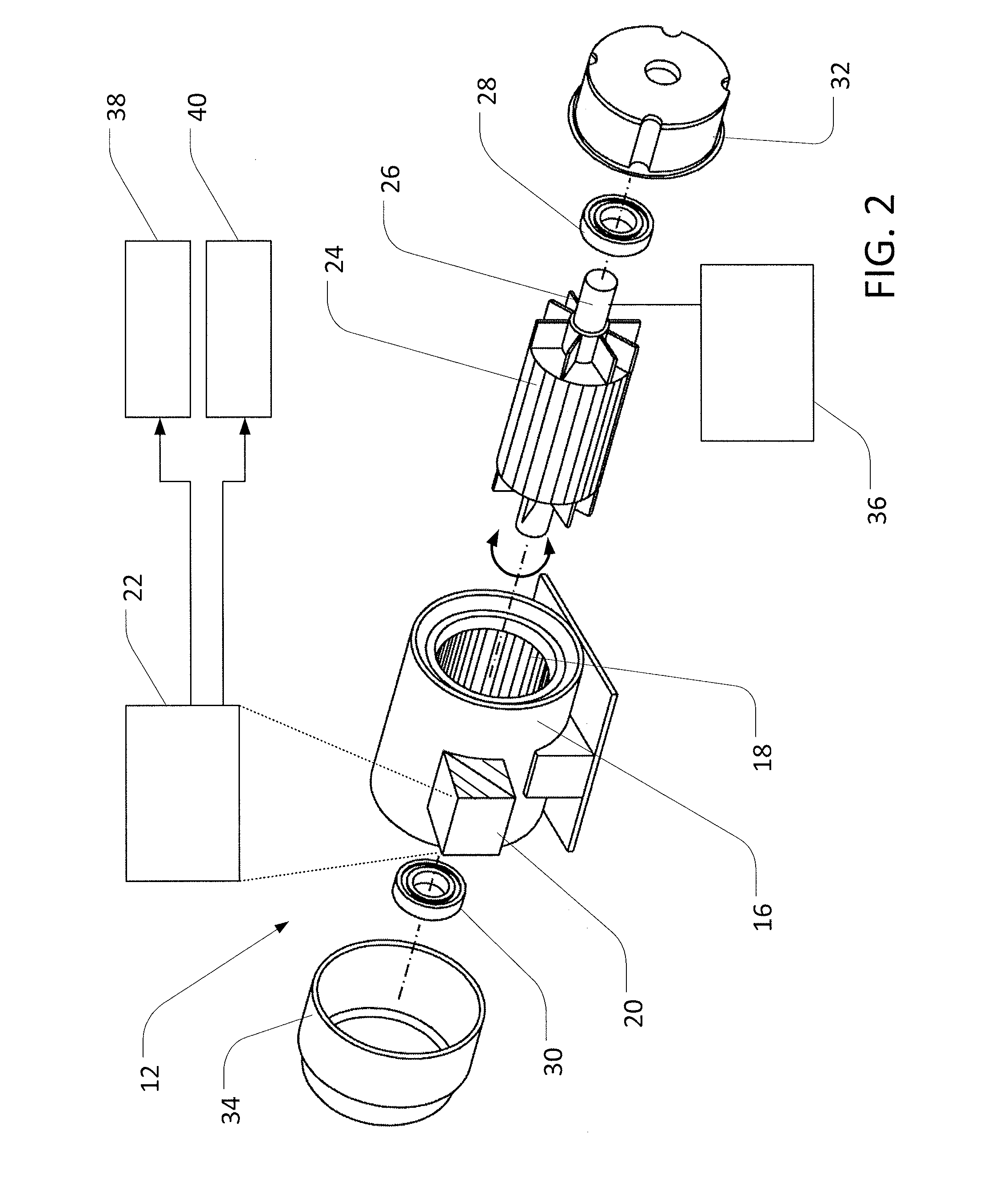

Owner:DEERE & CO

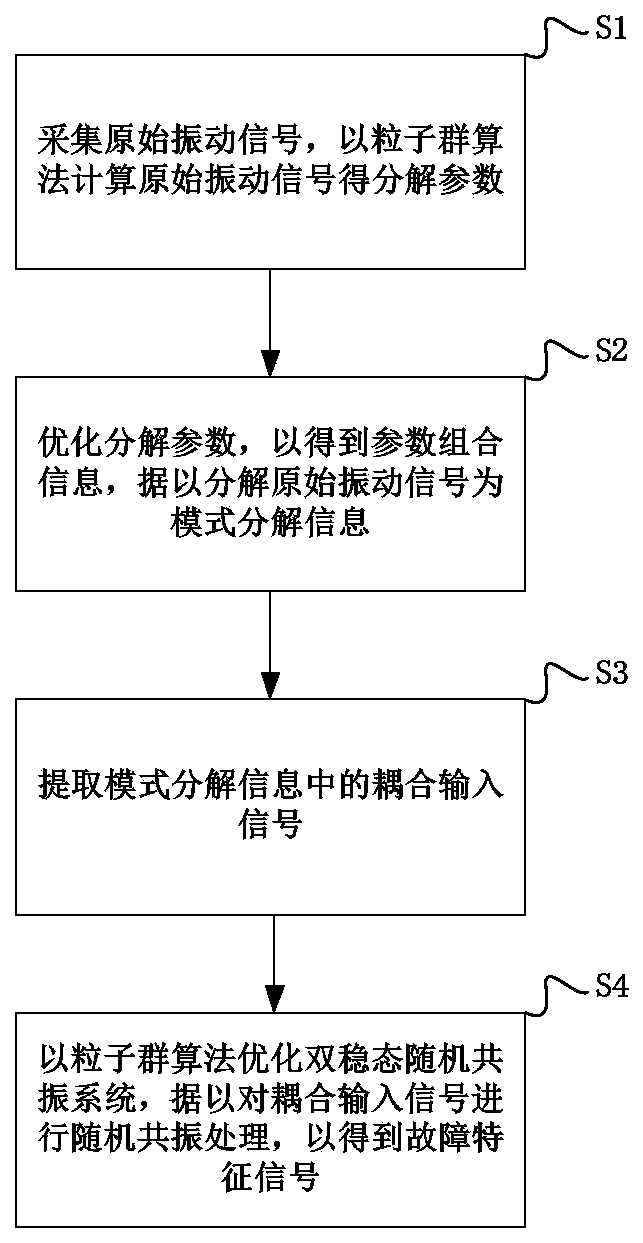

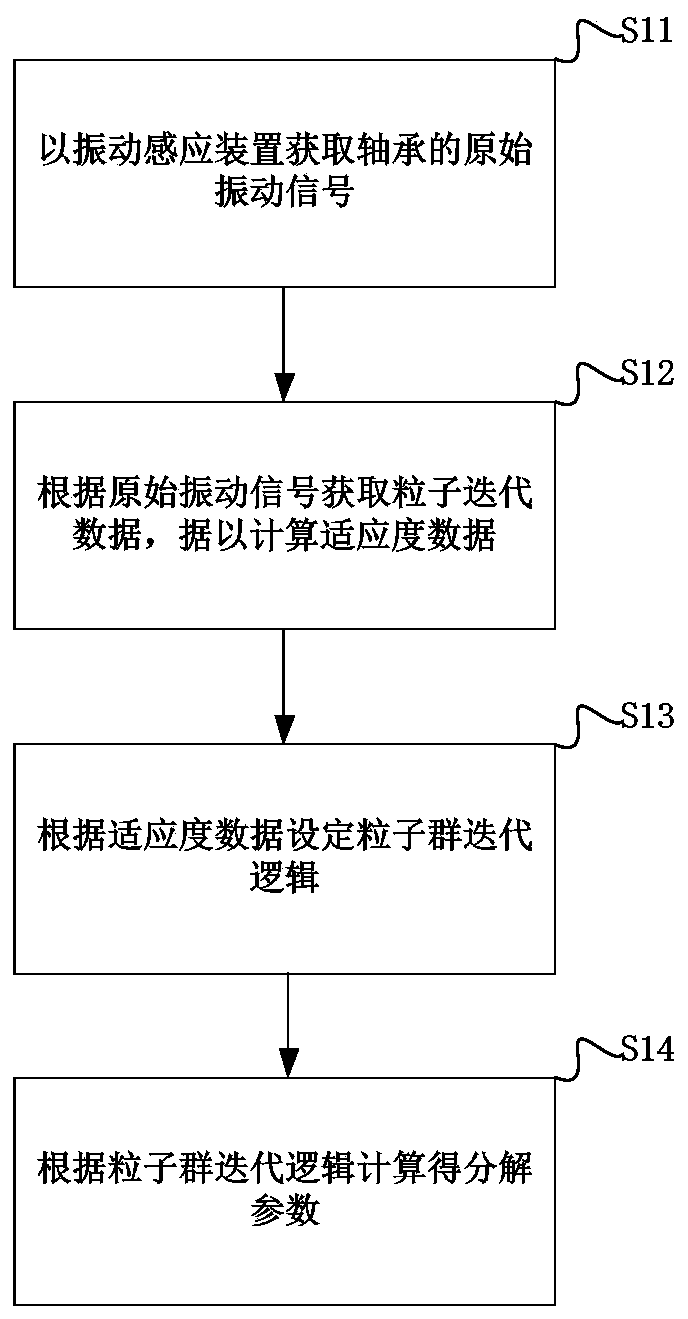

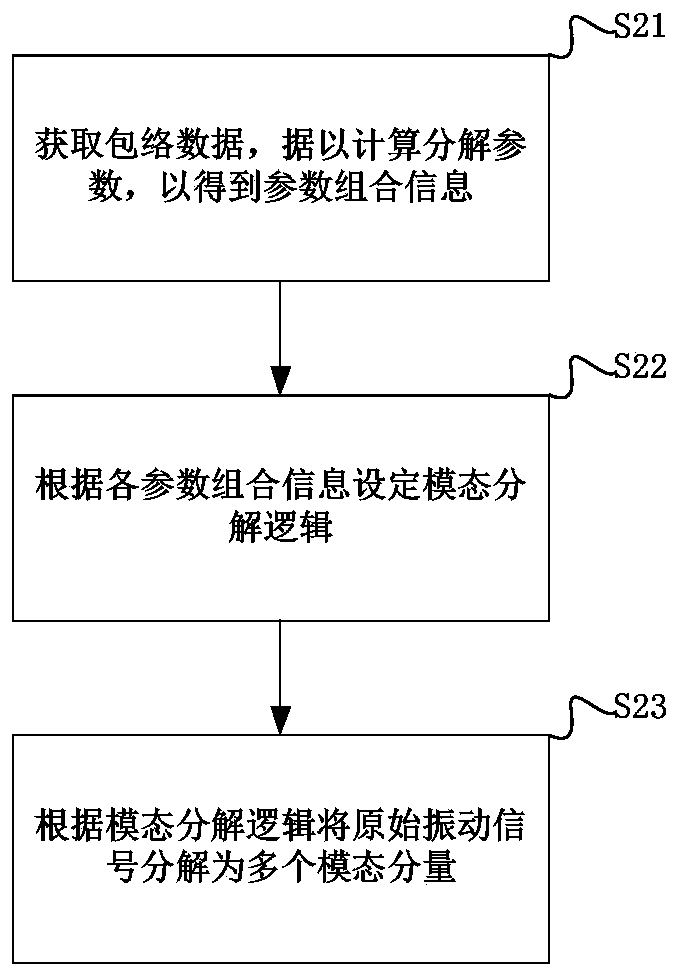

Bearing fault detection method and system

PendingCN109827776AImprove signal-to-noise ratioReduce the penalized function alphaMachine part testingAlgorithmDecomposition

The invention relates to a bearing fault detection method and system. The method includes the following steps that: original vibration signals are collected, the original vibration signals are calculated with a particle swarm algorithm, so that decomposition parameters can be obtained; the decomposition parameters are optimized, so that parameter combination information can be obtained, and the original vibration signals are decomposed into mode decomposition information according to the parameter combination information; coupled input signals in the mode decomposition information are extracted; and a bistable stochastic resonance system is optimized with the particle swarm algorithm, and stochastic resonance processing is performed on the coupled input signals, so that fault characteristic signals can be obtained. With the bearing fault detection method and system of the invention adopted, the technical problems of poor signal processing effect and low detection precision of weak fault signals in the prior art can be solved.

Owner:HEFEI UNIV OF TECH

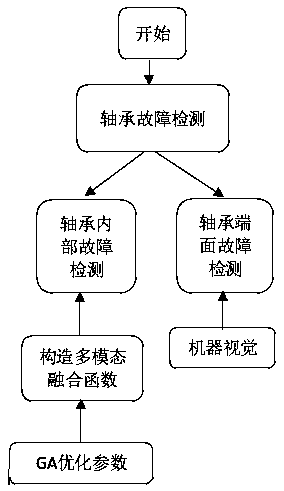

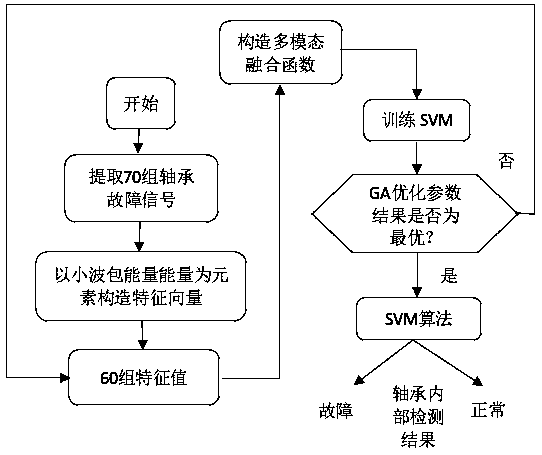

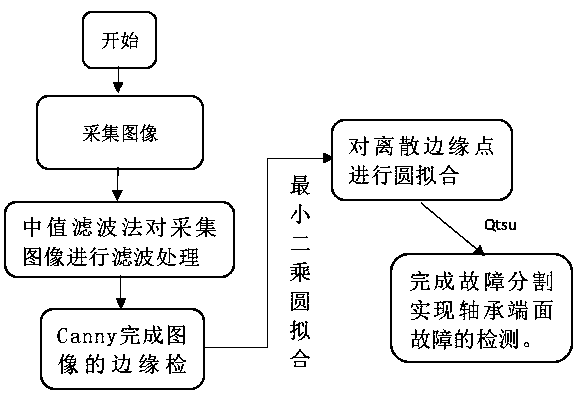

Bearing fault detection algorithm combining genetic algorithm optimization parameters and machine vision

InactiveCN109029993AFaint features are clearThe classification result is accurateMachine bearings testingGenetic algorithmsSupport vector machineFault detection algorithm

The invention provides a bearing interior and end face fault detection algorithm combining genetic algorithm optimization parameters and machine vision, and belongs to the technical field of analysisand measurement control. The bearing interior and end face fault detection algorithm comprises bearing interior fault detection and bearing end face fault detection. Firstly, the energy of each sub-band after vibration signal wavelet packet decomposition is used as a fault detection feature, and multi-modal fusion parameters are optimized in a training process of a support vector machine (SVM) byusing a genetic algorithm (GA) to achieve the bearing interior fault detection; and image collection is performed on an end face of a bearing, filtering processing is performed on a collected image byusing the machine vision technology, edge detection is completed by using a Canny operator, an optimal threshold value of a circular ring area is calculated by an Otsu algorithm to realize defect segmentation, and finally the bearing end face fault detection is realized. The accuracy of bearing fault detection is improved to a certain extent.

Owner:CHINA JILIANG UNIV

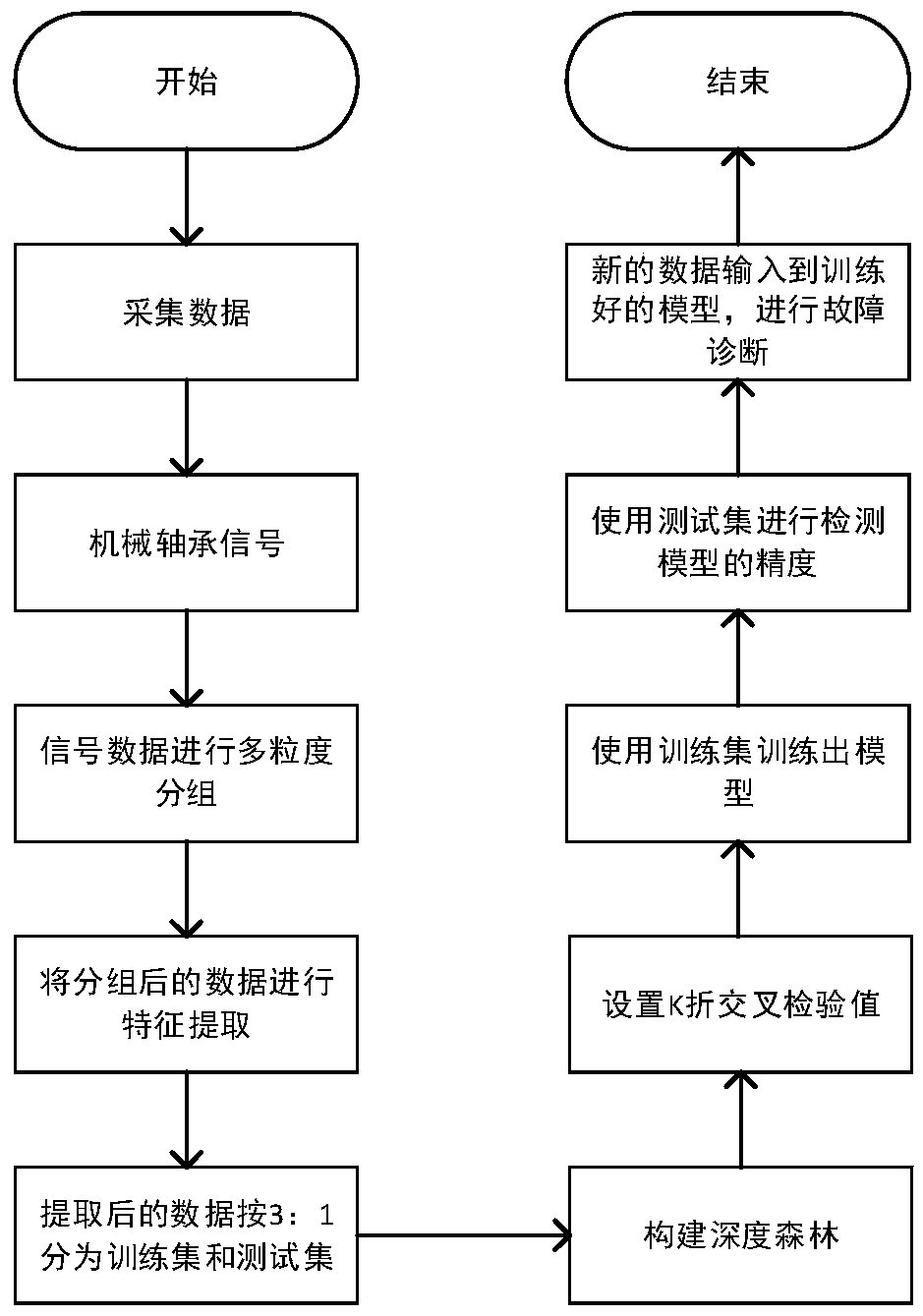

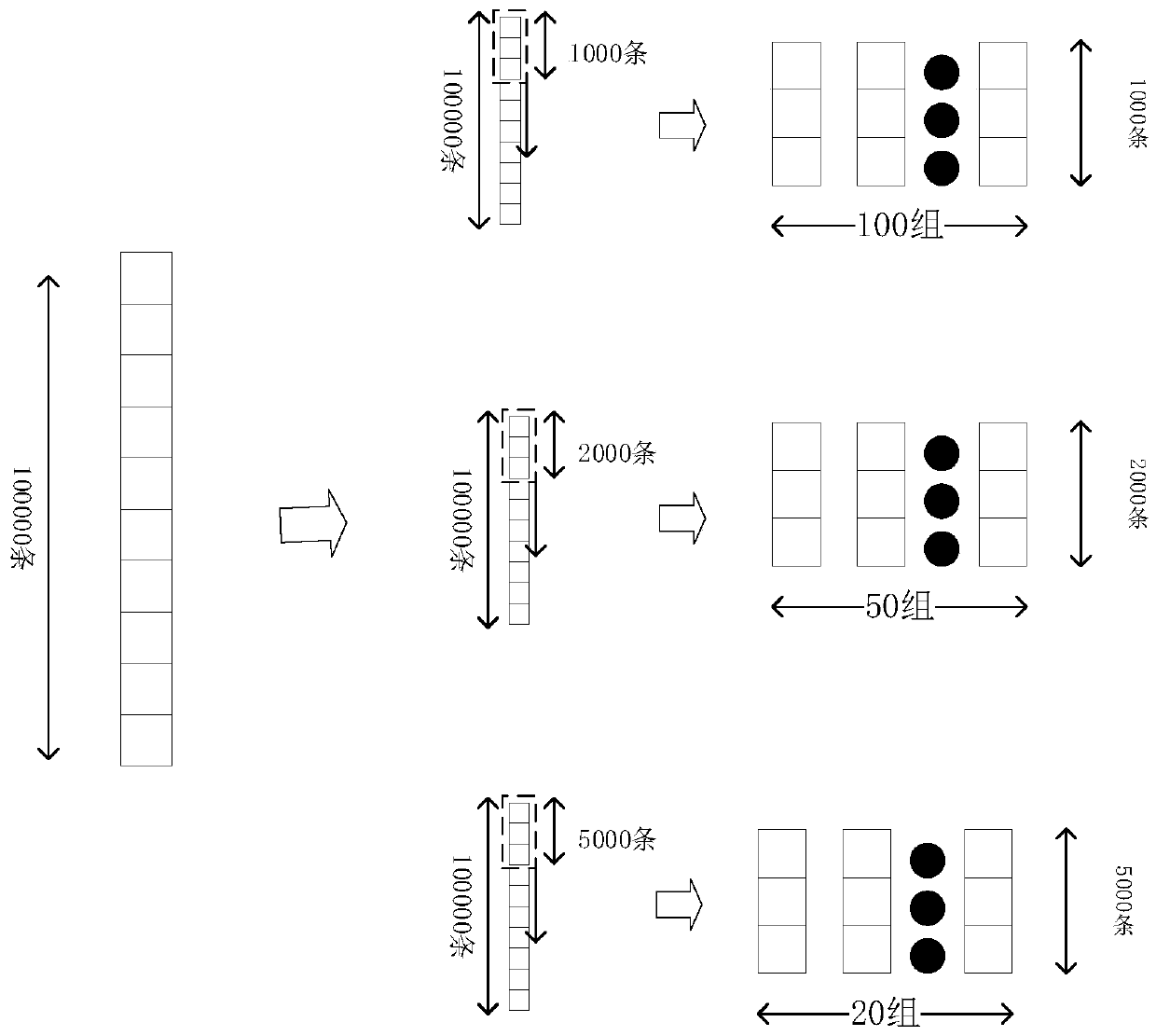

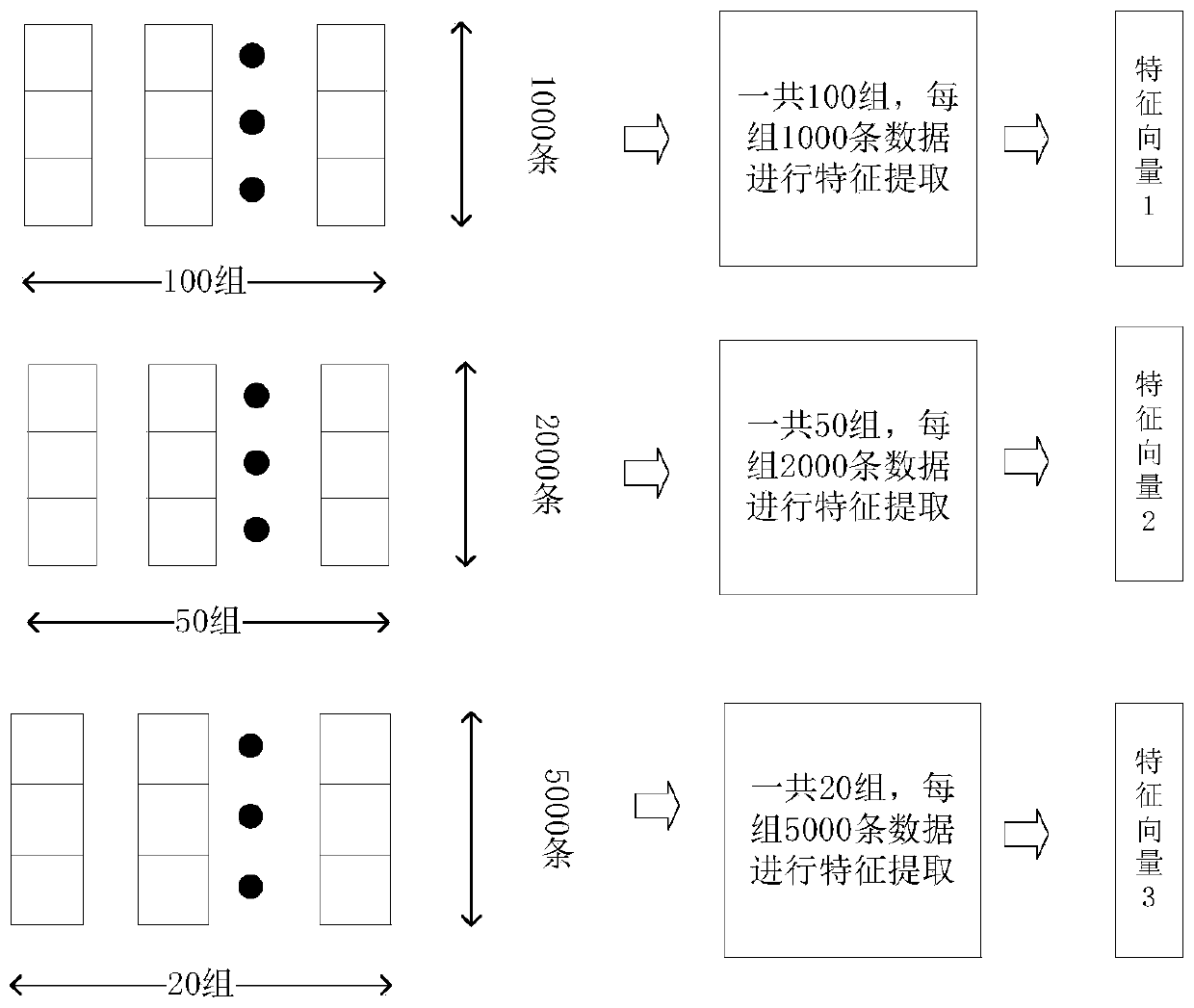

Deep-forest-based mechanical bearing fault detection method

The invention relates to a deep-forest-based mechanical bearing fault detection method, and belongs to the technical field of fault detection. The method comprises the following steps: firstly, performing a multi-granularity sampling strategy on acquired normal bearing data and various fault bearing data according to a vibration frequency f, grouping the data to obtain N groups of sampling data, performing feature extraction on the N groups of sampling data respectively to obtain an N groups of feature vectors Xs, labeling the N groups of feature vectors Xs respectively, integrating the N groups of feature vectors to obtain a feature vector X of the whole data, and finally, inputting the feature vector X into a deep forest to construct a cascaded structure to obtain a training model. The invention provides a multi-granularity grouping and feature extraction method based on the deep forest model, so that a training data set is effectively expanded; the phenomenon of loss of informationduring feature extraction is prevented; and the method is relatively high in applicability to mechanical bearing faults, and can be also applied to diagnosis of other types of mechanical faults.

Owner:KUNMING UNIV OF SCI & TECH

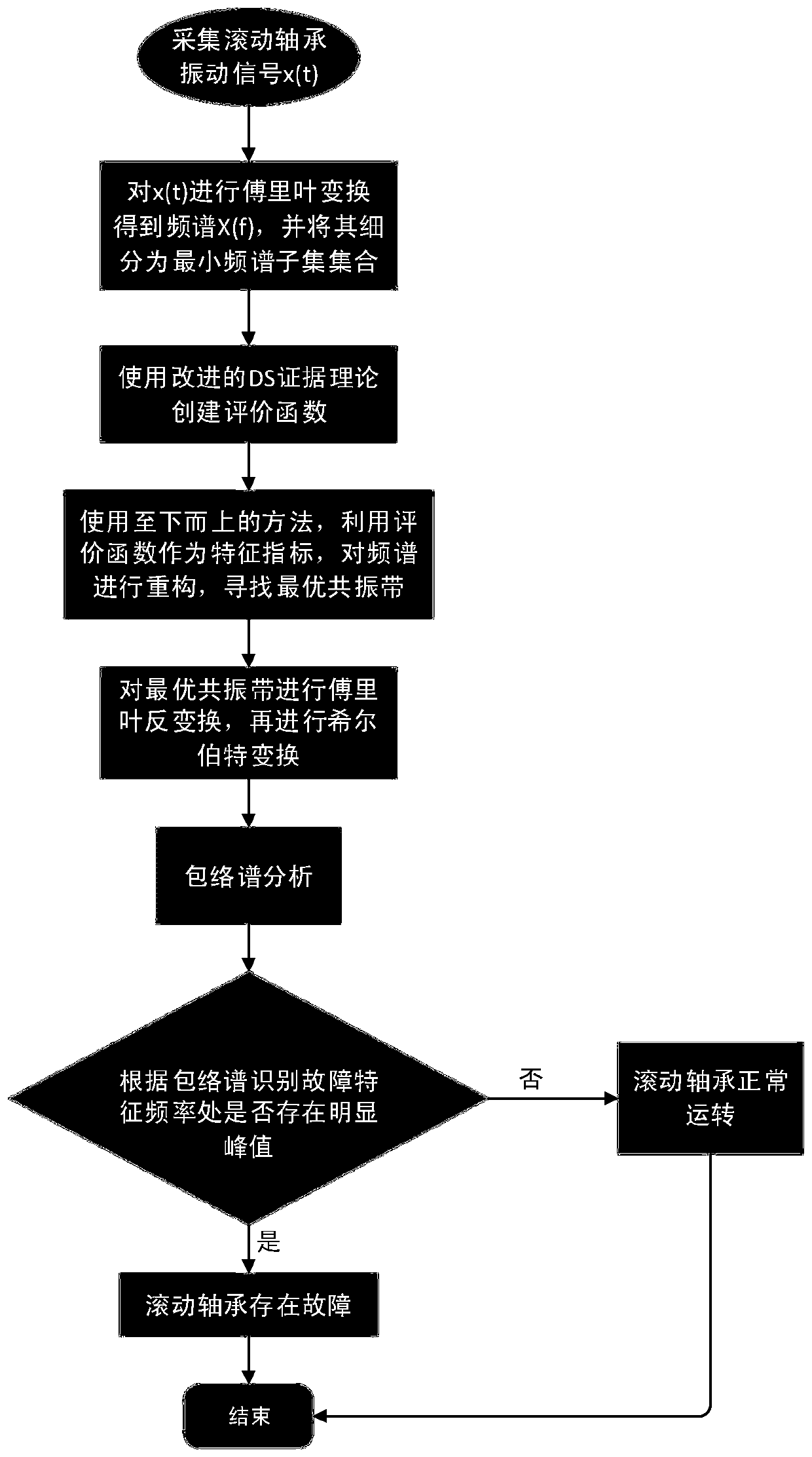

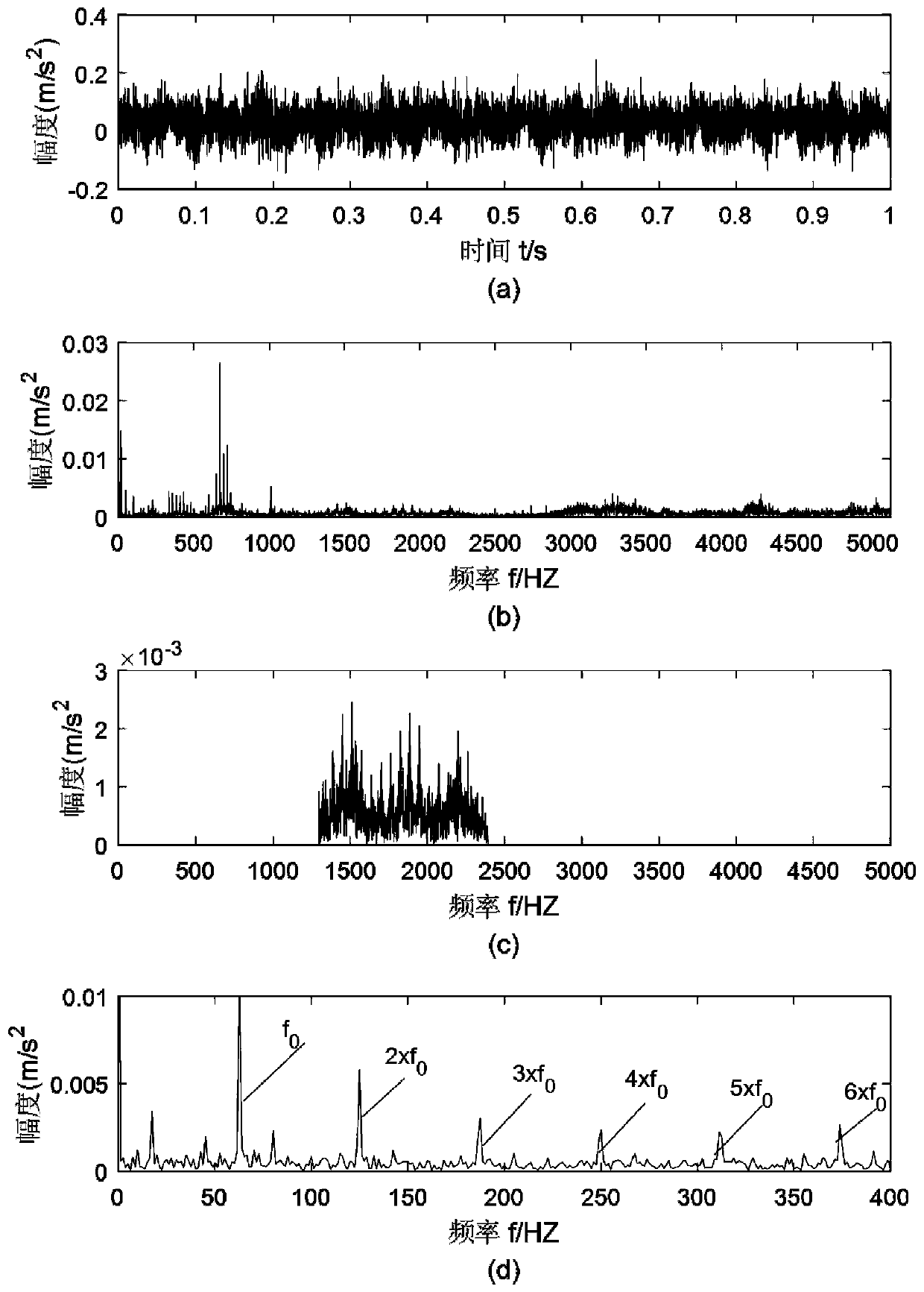

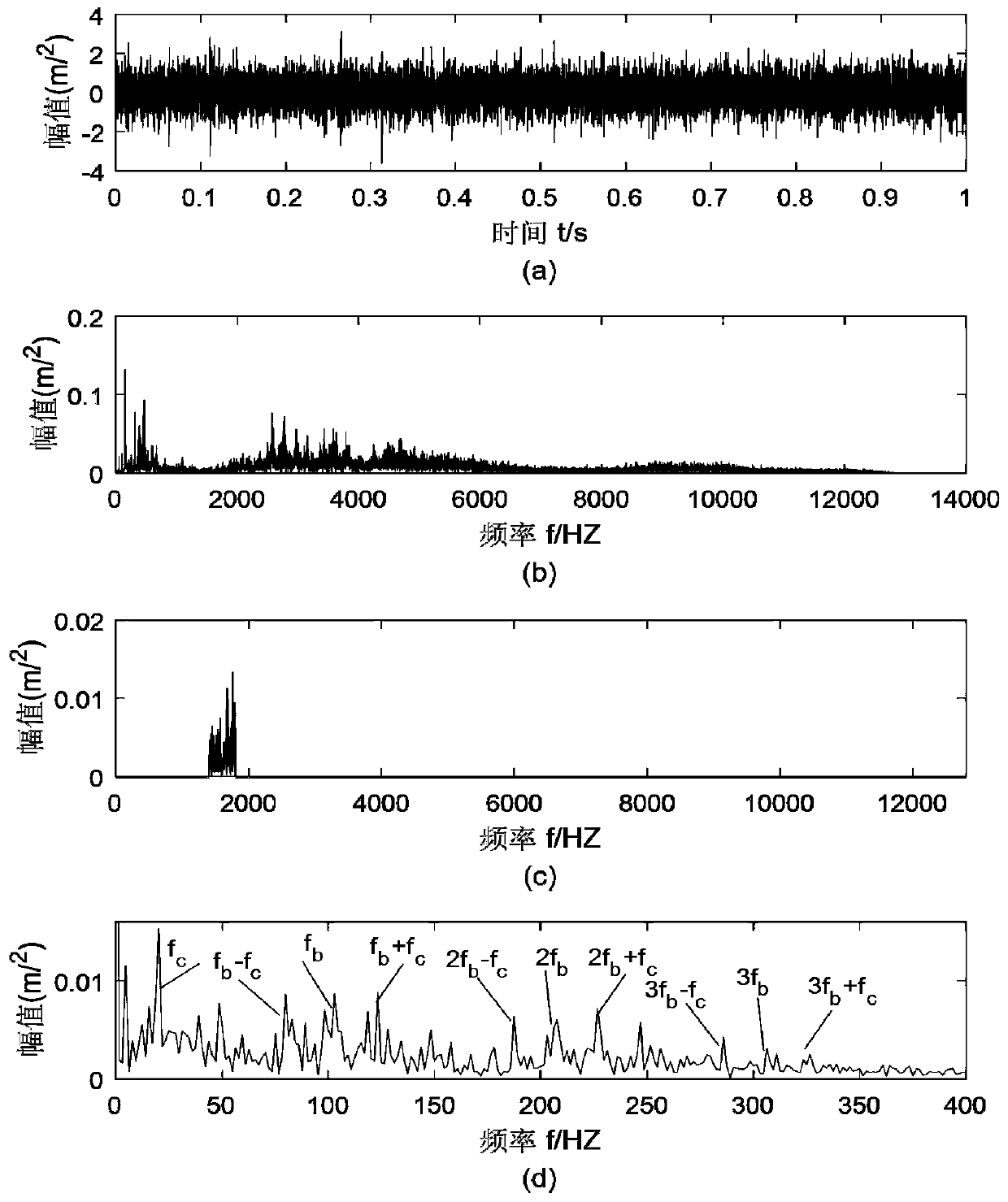

Rolling bearing fault detection method based on DS adaptive spectrum reconstruction

ActiveCN109932179AAchieving Failure Mode RecognitionReal-time monitoring of running statusMachine part testingFeature vectorFrequency spectrum

The invention discloses a rolling bearing fault detection method based on DS adaptive spectrum reconstruction. The method comprises the steps of: acquiring a vibration time signal x(t) as a source signal; defining the Fourier transform of the bearing vibration time signal x(t) as X (f), and subdividing the X (f) into a minimum spectrum subset set; creating an evaluation subset function by using animproved DS evidence theory; reconstructing the spectrum by using a bottom-up method and by using the evaluation function as a feature index in order to search for the optimal resonance band; performing the inverse Fourier transform on the optimal resonance band, and then performing Hilbert transform; performing envelope spectrum analysis; identifying whether the fault feature has an obvious peakaccording to the envelope spectrum; if not, determining that the bearing operates normally; and if so, determining that the bearing has a fault and needs to be stopped. The rolling bearing fault detection method based on DS adaptive spectrum reconstruction is a feature vector extraction method for timely and accurately realizing the rolling bearing fault pattern recognition and state monitoring.

Owner:SOUTHEAST UNIV

System for bearing fault detection

ActiveUS9200979B2Easy to detectEliminate needMaterial analysis using sonic/ultrasonic/infrasonic wavesMachine gearing/transmission testingSonificationFrequency spectrum

The present invention is directed an ultrasonic frequencies fault detecting apparatus. The present invention uses high frequency ultrasonic energy signals to analyze bearings and determine the presence of faults therein. The ultrasonic return signals are heterodyned (by amplitude demodulation) into the audio spectrum for purposes of audio detection. In addition, a FFT spectrum of the signal is displayed on a monitor for more accurate results. According to the present invention software is used to automatically analyze the FFT spectrum by comparing the current spectrum with stored spectrums of known bearing conditions as modified based on the rotary speed of the bearing and the number of balls. Once a defect in a bearing has been located in this manner using automated FFT analysis, an operator can then use a device, such as a calibrated lubricant dispenser, to effectuate maintenance and / or repair.

Owner:U E SYST

Fault detection method and device for aircraft engine intermediate bearing

The invention provides a fault detection method and device for an aircraft engine intermediate bearing. A low-voltage rotor and a high-voltage rotor in the detection device are mounted among three supporting frames; reflective paper patches are attached to a rotor shaft of the low-voltage rotor close to one end of a motor and a rotor shaft of the high-voltage rotor respectively. Two photoelectric sensors are utilized to collect rotational speed pulse signals, and an eddy current displacement sensor is utilized to collect vibration signals of the intermediate bearing; the problems that bearing fault characteristic frequency is poor in drift on a frequency spectrum and leptokurtosis can be well solved by determining fault characteristic frequency doubling, collecting the rotational speed pulse signals and original time domain vibration signals, obtaining zero phase position of an intermediate bearing slip domain, calculating a rotational speed-time function, converting original time-domain signals into intersection-angle-domain vibration signals and detecting the bearing fault through an envelope spectrum.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com