Rolling bearing fault detection method based on vibration detection

A rolling bearing and vibration detection technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as poor non-stationary signal processing effect, and achieve the effect of eliminating the interference of irrelevant information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Diagnosis of Outer Ring Fault

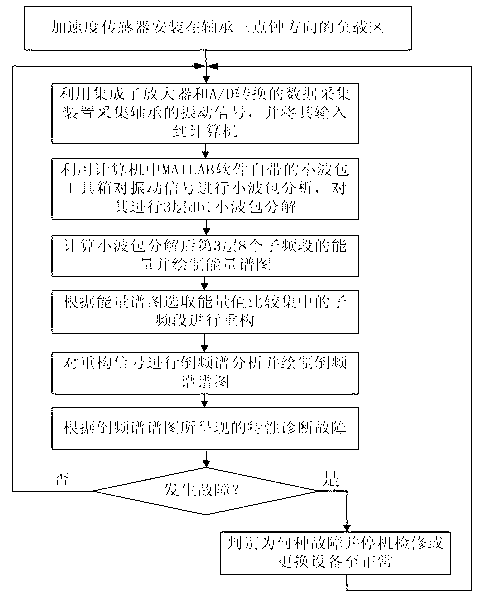

[0047] In specific implementation, a kind of rolling bearing fault diagnosis method based on vibration detection is carried out according to the following steps:

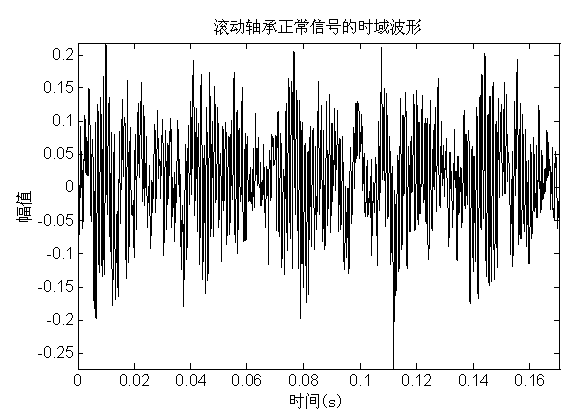

[0048] Step (1), respectively install the acceleration sensors in the 3 o'clock direction of the motor bearing load area, use the data acquisition device integrated with the amplifier to collect the original vibration signal of the rolling bearing, and input the amplified and A / D converted vibration signal into the computer , where the sampling frequency is 12KHZ, and the original vibration signal of the rolling bearing with no load of the motor and a rotational speed of 1797RPM is obtained by sampling.

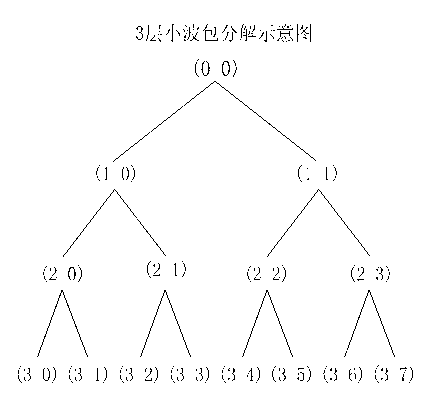

[0049] Step (2), such as figure 2 As shown, using the wavelet toolbox that comes with the MATLAB software in the computer to decompose the collected vibration signals into three layers of db1 wavelet packets;

[0050] Step (3), according to the energy calculat...

Embodiment 2

[0055] Example 2: Diagnosis of Inner Ring Faults

[0056] In specific implementation, a kind of rolling bearing fault diagnosis method based on vibration detection is carried out according to the following steps:

[0057] Step (1), respectively install the acceleration sensors in the 3 o'clock direction of the motor bearing load area, use the data acquisition device integrated with the amplifier to collect the original vibration signal of the rolling bearing, and input the amplified and A / D converted vibration signal into the computer , where the sampling frequency is 12KHZ, and the original vibration signal of the rolling bearing with no load of the motor and a rotational speed of 1797RPM is obtained by sampling.

[0058] Step (2), such as figure 2 As shown, using the wavelet toolbox that comes with the MATLAB software in the computer to decompose the collected vibration signals into three layers of db1 wavelet packets;

[0059] Step (3), according to the energy calculatio...

Embodiment 3

[0064] Example 3: Diagnosis of Rolling Element Faults

[0065] In specific implementation, a kind of rolling bearing fault diagnosis method based on vibration detection is carried out according to the following steps:

[0066] Step (1), respectively install the acceleration sensors in the 3 o'clock direction of the motor bearing load area, use the data acquisition device integrated with the amplifier to collect the original vibration signal of the rolling bearing, and input the amplified and A / D converted vibration signal into the computer . Among them, the sampling frequency is 12KHZ, and the original vibration signal of the rolling bearing with the motor no-load and the speed of 1797RPM is obtained by sampling.

[0067] Step (2), such as figure 2 As shown, using the wavelet toolbox that comes with the MATLAB software in the computer to decompose the collected vibration signals into three layers of db1 wavelet packets;

[0068] Step (3), according to the energy calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com